Cold-type special molding sand for integral casting of large cast steel roller and manufacturing method of cold-type special molding sand

A cast steel roll and integral casting technology, applied in casting molding equipment, manufacturing tools, casting molds, etc., can solve the problems of product scrap, sand inclusion, sand sticking, etc., to reduce usage, improve quality, and improve economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A Φ1200×2800 cast steel rough roll integral casting cold casting special sand, which is composed of the following components in weight percentage: 79% quartz sand, 14.5% clay, 1.5% bentonite, and 5% water.

[0015] The quartz sand is composed of the following components in weight percentage, 55% of 6-12 mesh quartz sand, 35% of 20-40 mesh quartz sand, and 10% of 70-140 mesh quartz sand.

[0016] A method for manufacturing special molding sand, weighing 6-12 mesh quartz sand, 20-40 mesh quartz sand, 70-140 mesh quartz sand, clay, and bentonite into a hopper according to the above ratio, and then pouring it into a sand mixer to dry Mix for 3 minutes, then add water and mix for 10-15 minutes. The molding sand made with this ratio has an air permeability greater than 750, a wet compressive strength greater than 0.08MPa, and a dry compressive strength greater than 0.65MPa.

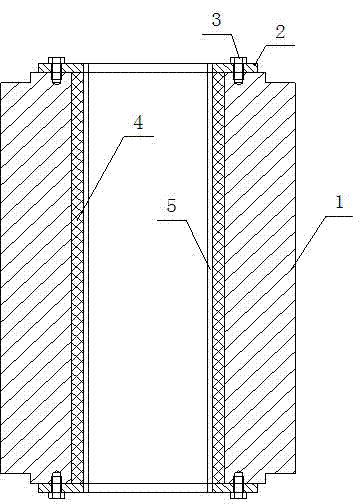

[0017] Such as figure 1 As shown, when using the special molding sand molding of the present invent...

Embodiment 2

[0021] A Φ1000×2600 cast steel rough roll integral casting cold casting special sand, which is composed of the following components in weight percentage, 76% of quartz sand, 15% of clay, 2% of bentonite, and 7% of water.

[0022] The quartz sand is composed of the following components in weight percentage, 50% of 6-12 mesh quartz sand, 38% of 20-40 mesh quartz sand, and 12% of 70-140 mesh quartz sand.

[0023] The manufacture method of special-purpose molding sand is identical with embodiment one.

Embodiment 3

[0025] A Φ1260×1200 special molding sand used for integral casting of cast steel back-up rolls, which is composed of the following components in weight percentage, 80% of quartz sand, 13% of clay, 1% of bentonite, and 6% of water.

[0026] The quartz sand is composed of the following components in weight percentage, 58% of 6-12 mesh quartz sand, 31.5% of 20-40 mesh quartz sand, and 10.5% of 70-140 mesh quartz sand.

[0027] The manufacture method of special-purpose molding sand is identical with embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com