Patents

Literature

755results about How to "Improve casting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lost foam casting coating and preparation method thereof

The invention discloses a lost foam casting coating, which comprises fire-proof powder, phenolic resin, white latex, calcium bentonite and isopropyl alcohol, wherein the fire-proof powder includes bauxite and quartz powder. The bauxite is formed by uniformly mixing the following components: 80% of particles with the granularity ranging from -280 to -310, 14% of particles with the granularity ranging from -280 mesh to -190 mesh and 6% of particles with the granularity ranging from -90 mesh to -190 mesh. The preparation method of the lost foam casting coating is as follows: calcining selected bauxite ore at the temperature of 1510-1550 DEG C; grinding calcined clinkers to acquire the granularity particles with the granularities respectively; evenly mixing the particles according to the composition proportion; and mixing the mixed bauxite with quartz powder, phenolic resin, white latex, calcium bentonite and isopropyl alcohol. According to the invention, bauxite is distributed according to particle sizes, and bauxite particles of different sizes are alternately arranged after even mixing. As a result, the compactness is changed, the air permeability is strengthened, the cold shut phenomenon occurring between liquid metal and the coating is avoided, and finally the quality of the casting produced through lost foam casting is improved.

Owner:ANYUE COUNTY JINLONG MACHINERY MFG

Aluminum alloy welding wire and preparation method thereof

The invention relates to an aluminum alloy welding wire and a preparation method thereof. The aluminum alloy welding wire is characterized by comprising the following chemical components in percentage by weight: 4-6 percent of Mg, 0.1-0.3 percent of Cr, not more than 0.1 percent of Fe and Si, 0.05-0.08 percent of Cu, 0.04-0.07 percent of Zn, 0.12-0.16 percent of Mn and the balance of Al. The preparation method of the aluminum alloy welding wire comprises the steps of: melting and refining, casting, homogenizing, thermally extruding, annealing, drawing, skiving and brightening, packaging and storing. The aluminum alloy welding wire provided by the invention is few in impurities, stable in performance, and small in texture grains, and has the characteristics of fatigue resistance, crack resistance, welding property and the like.

Owner:GUANGXI DOCTOR HAIYI INFORMATION TECH

Vacuum negative-pressure los mould casting technique

InactiveCN101332501AHigh precisionImprove casting qualityFoundry mouldsFoundry coresLost-foam castingMaterials science

The invention relates to a vacuum negative pressure lost foam casting process, which belongs to the technical field of casting. The process comprises the following steps: an integral mold of a screw is obtained by using resin bonded sand with a nut which has the same inner surface geometric parameters as that of or a little bigger internal diameter than that of a screw hole to be processed; the mold of the screw is taken out, coated with a coating and baked dry; then a hole is cut at the position of the screw hole to be processed on the integrally cast overall mold; finally the screw mold is inserted into the cutting hole and assembled to form the final mold; that is, the vacuum negative pressure lost foam casting process can be directly used for casting a casting with the screw hole, which creates a precedent of directly casting small-aperture screw holes without reprocessing in the casting field. The screw hole processed by the process can ensure precision and needs no reprocessing. The vacuum negative pressure lost foam casting process is especially applicable to the vacuum negative pressure lost foam casting of the casting with a plurality of screw holes, small size and high precision.

Owner:泰州市永昌冶金设备有限公司

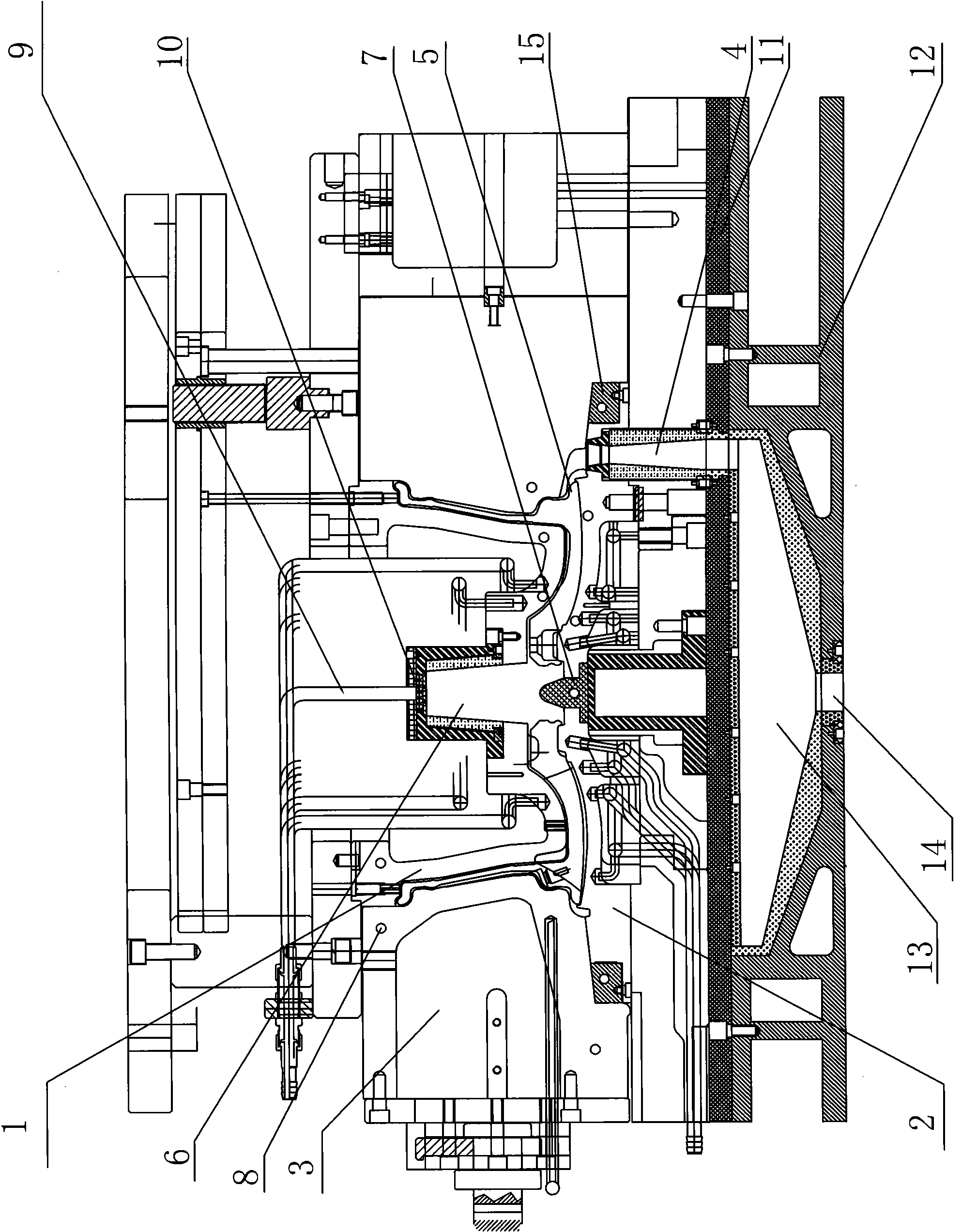

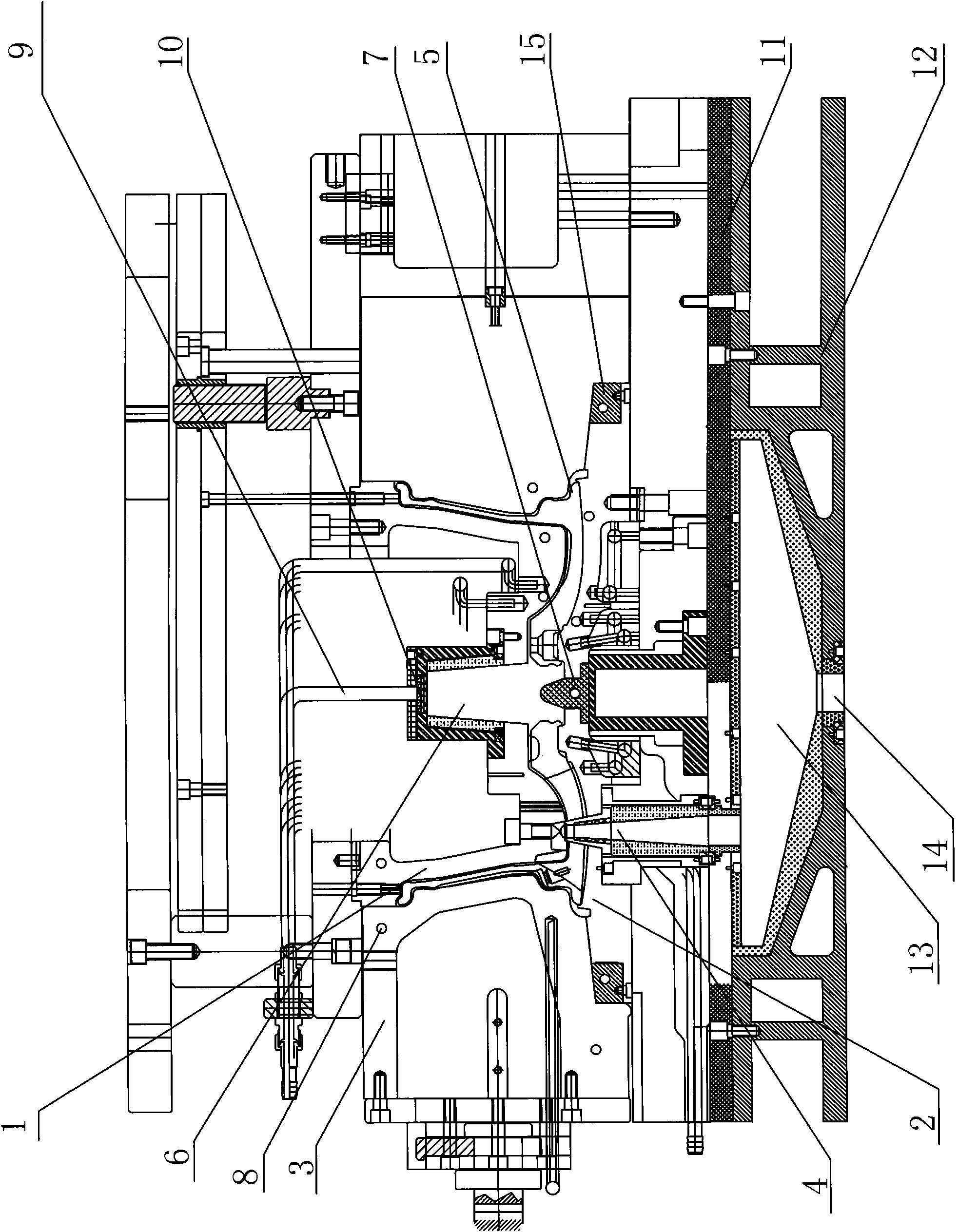

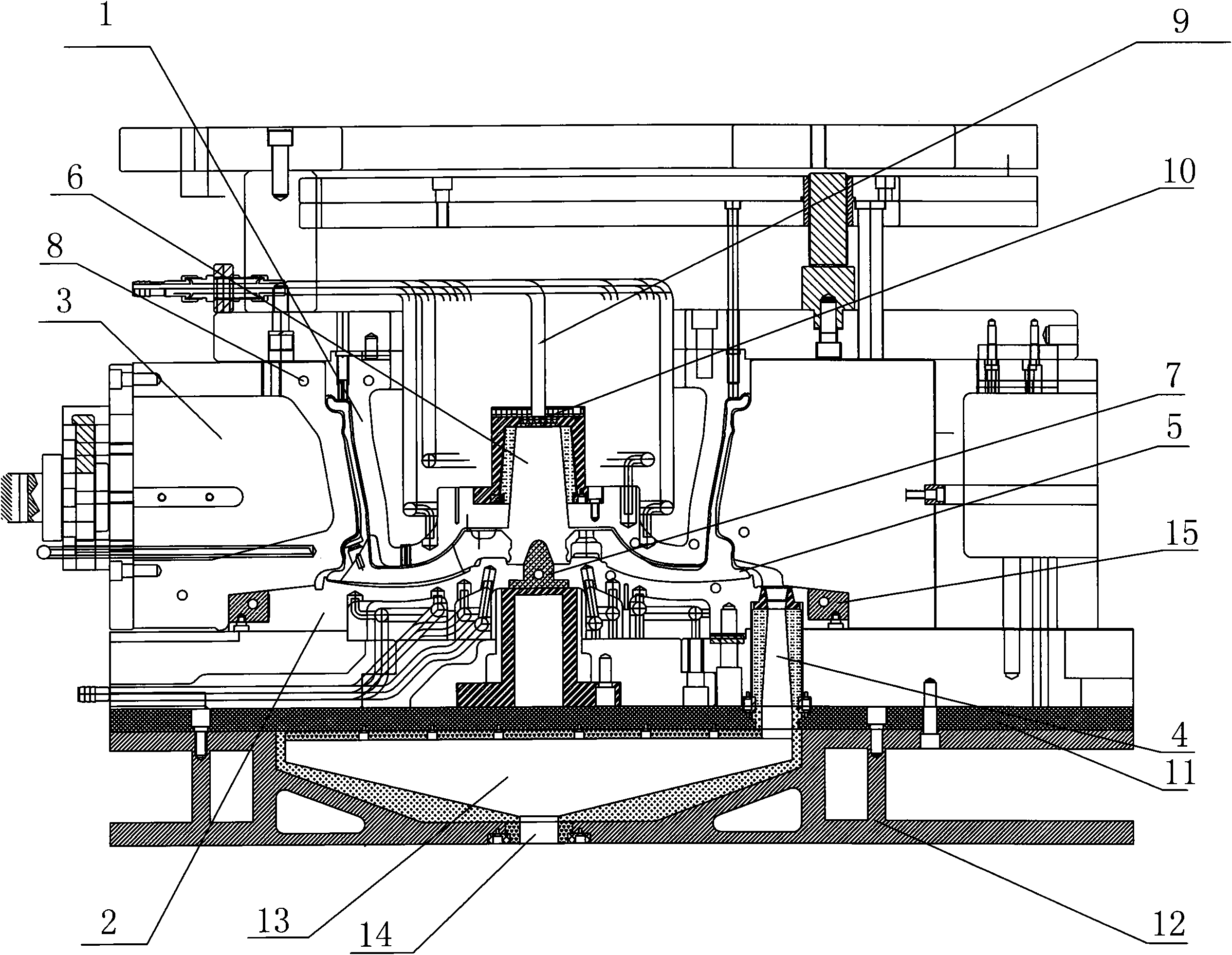

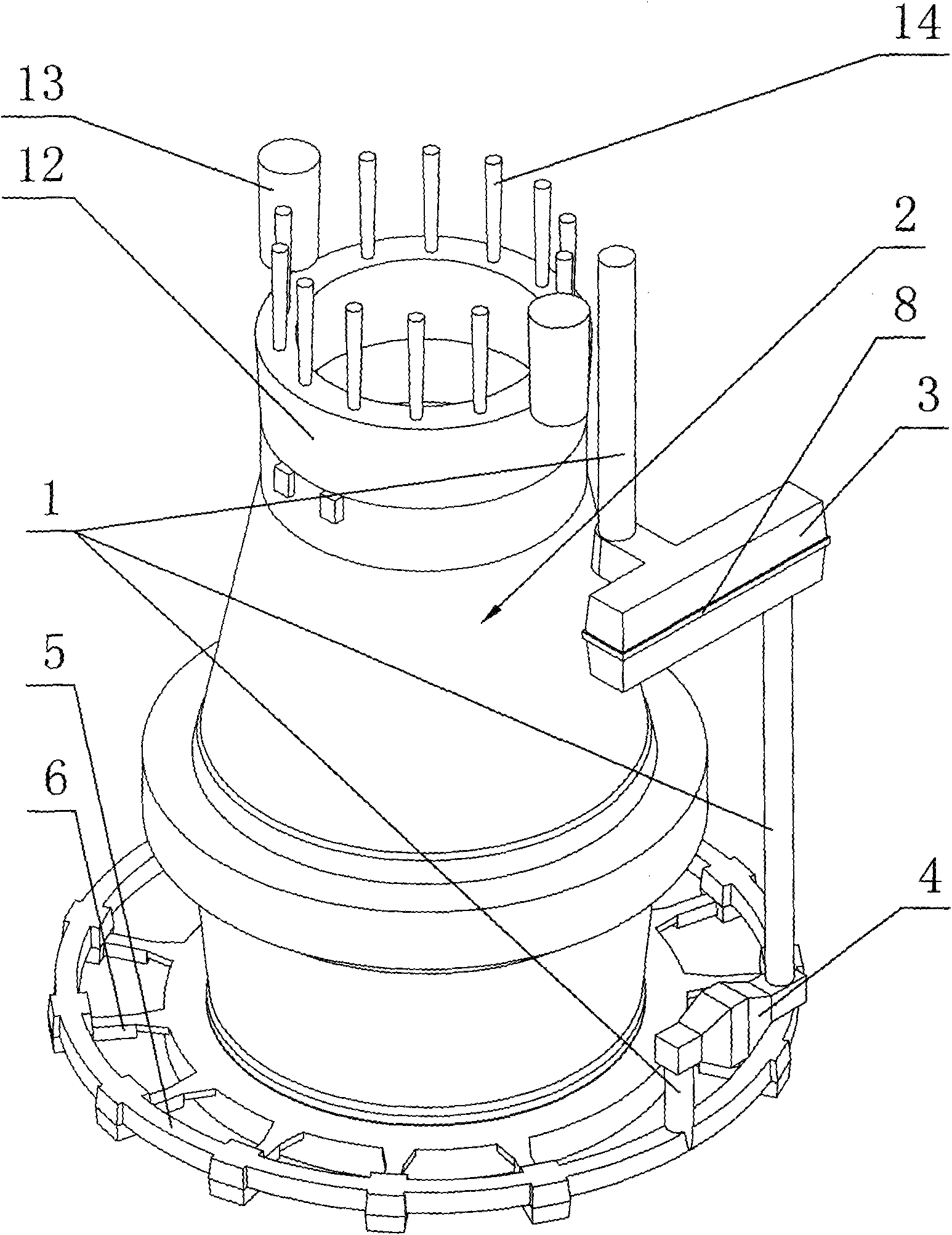

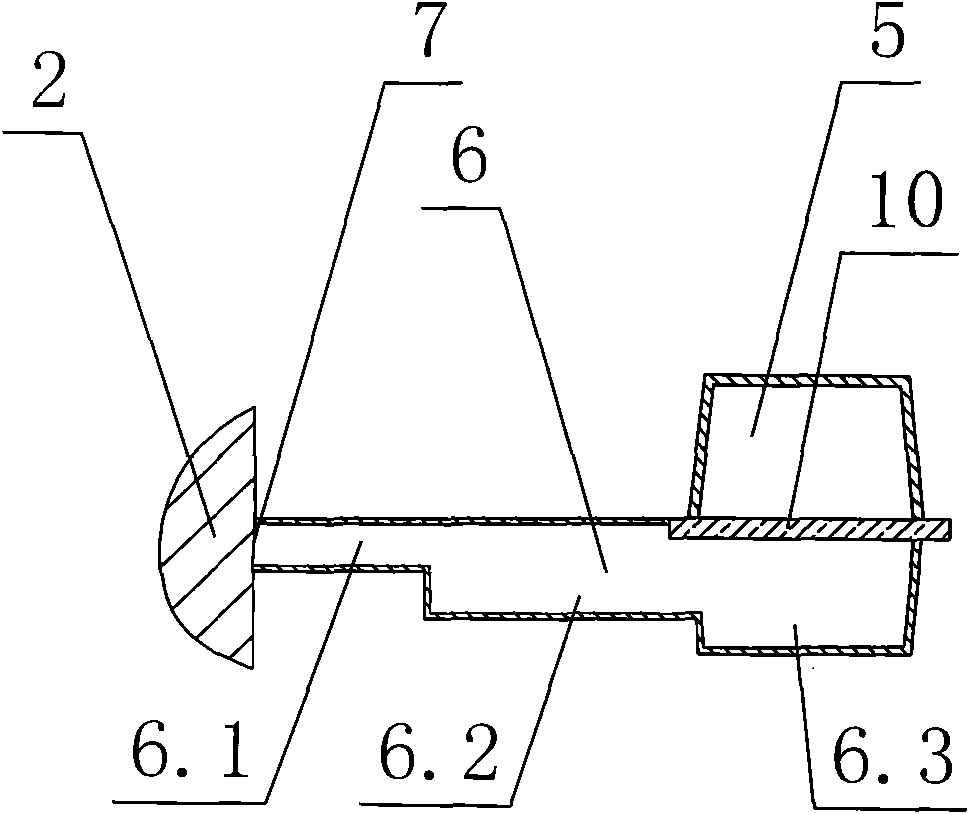

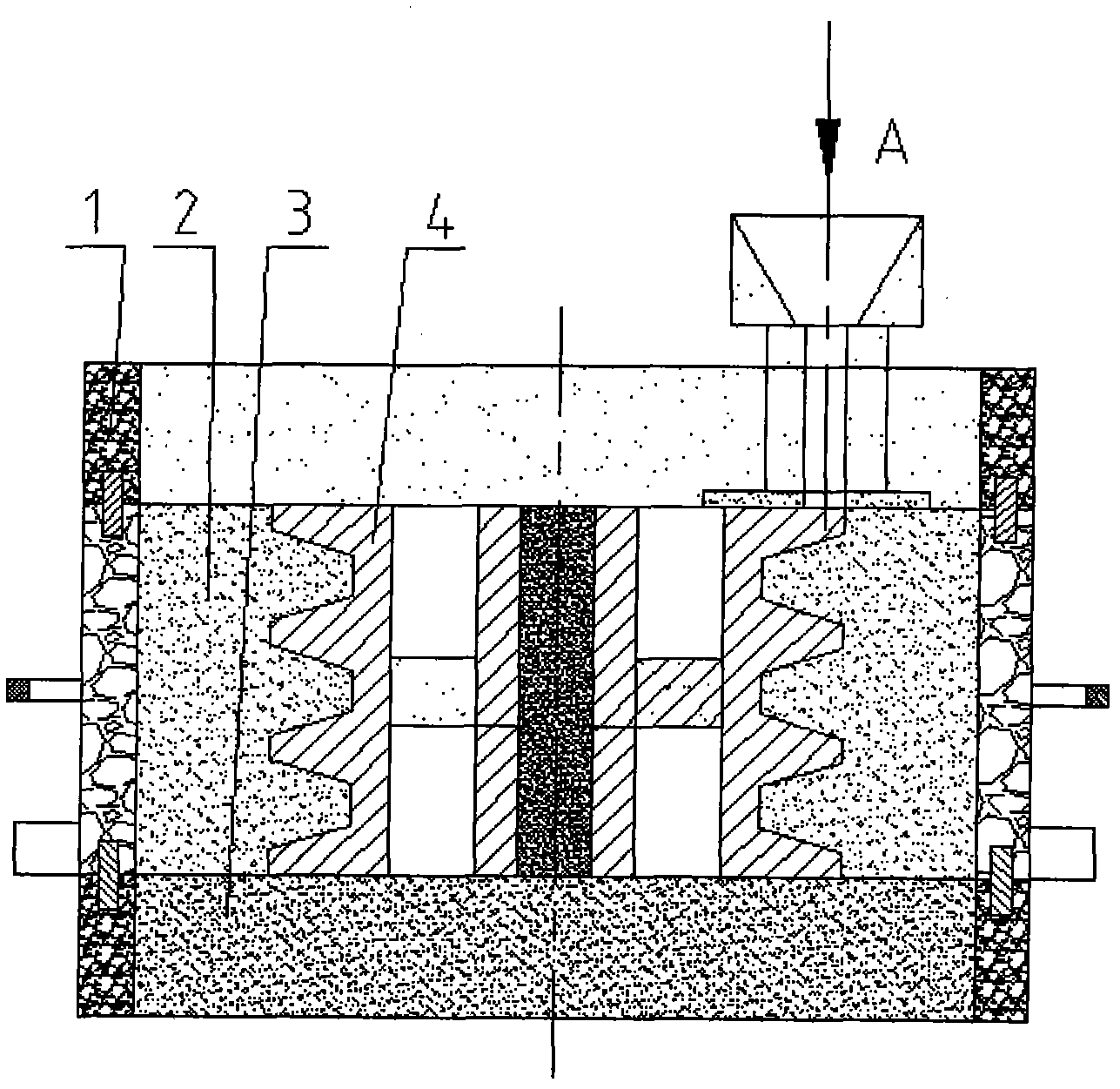

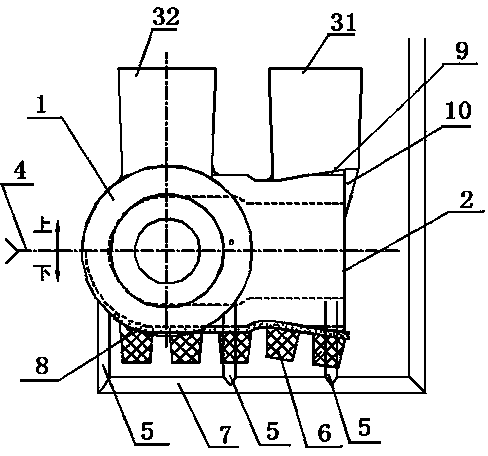

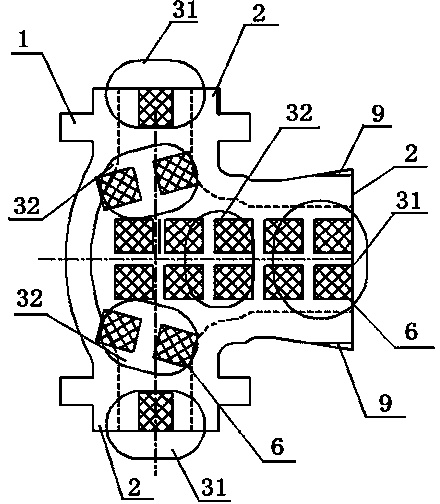

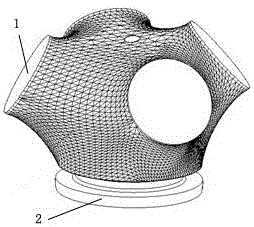

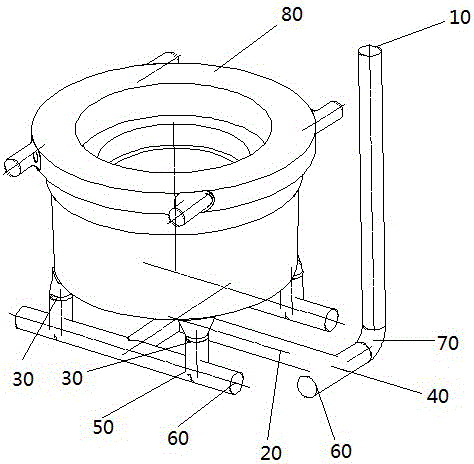

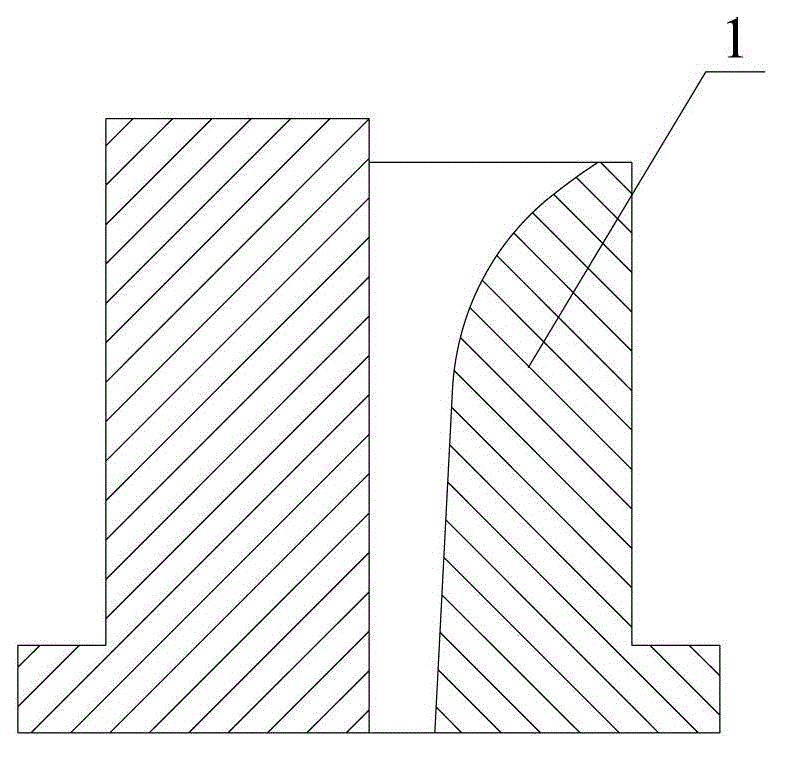

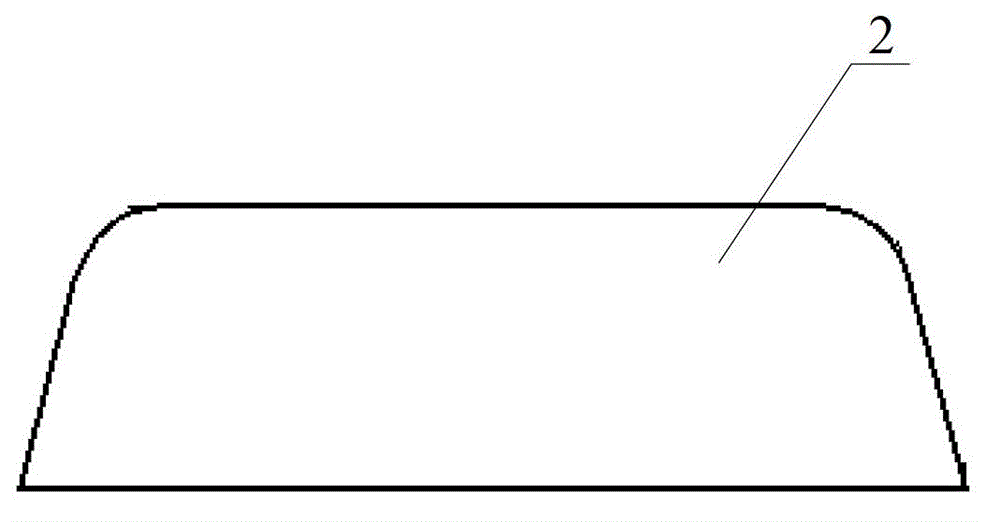

Low-pressure casting die of aluminium alloy wheel and casting method thereof

The invention discloses a low-pressure casting die of an aluminium alloy wheel and a casting method thereof. The low-pressure casting die comprises a top die (1), a bottom die (2) and a side die (3), wherein a plurality of gates (4) are arranged on the bottom die (2); the center of the top die is provided with a central riser (6) which is used for feeding; the center of the bottom die is provided with a shunt cone (7) which is used for forming the center of a wheel disc, and the gates are arranged at the outer side of the lower wheel lip of the bottom die or at the window of the bottom die. The casting method comprises the following steps of mold filling, exhausting, pressurization, cooling, feeding, aluminium liquid reflux and the like. By using the invention, the quality of casting parts is increased, the mechanical property index of produced vehicle wheel spokes and wheel centers is good, and pinholes do not easily appear on products. The invention can be suitable for occasions with high requirements for product quality, is beneficial to achieving the light weight of the products, improves production efficiency, and reduces die erosion.

Owner:何丙军 +1

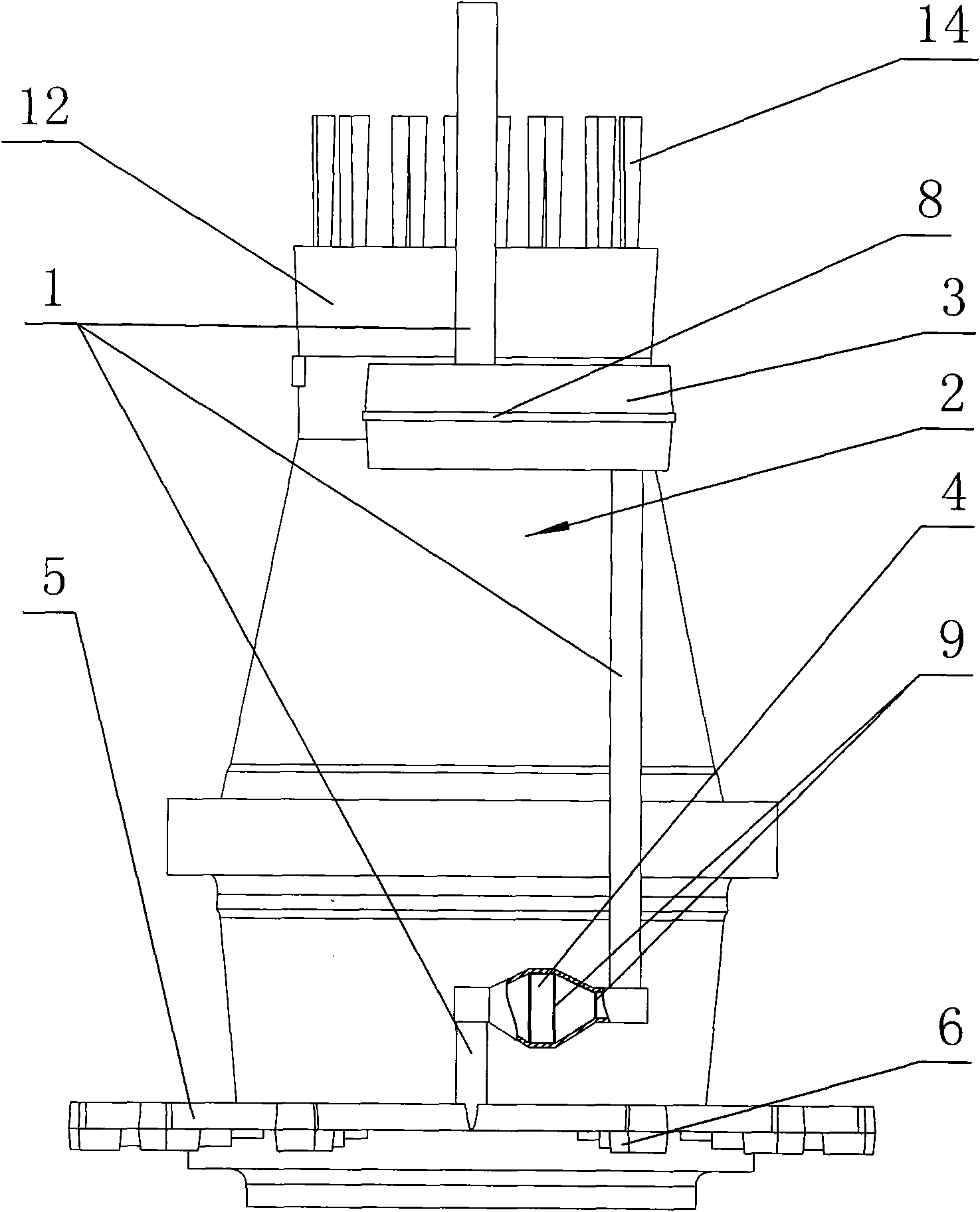

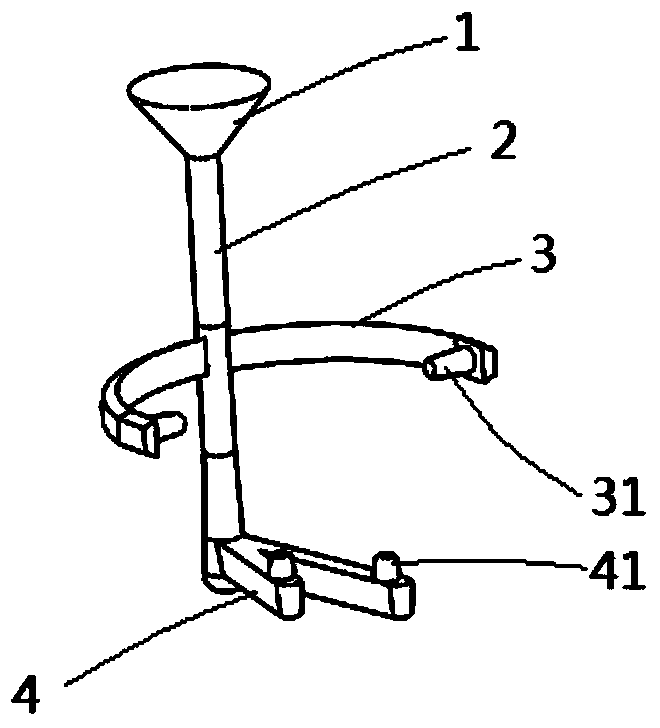

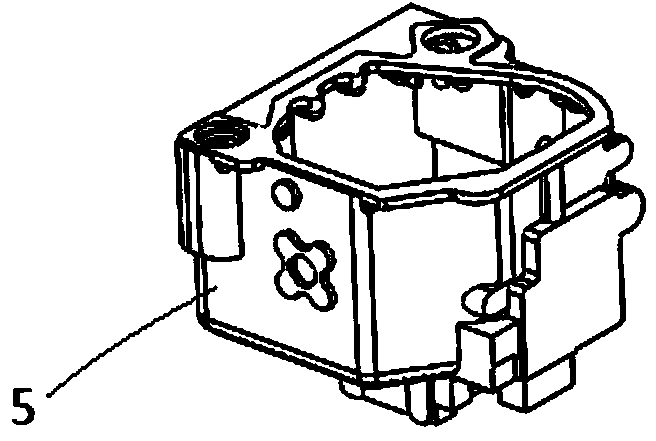

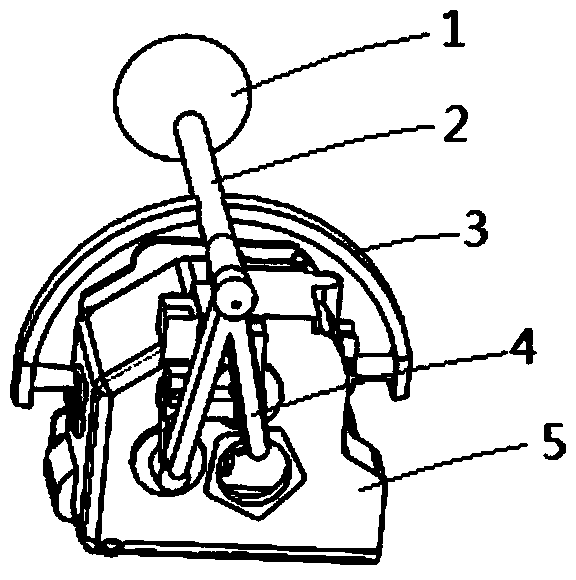

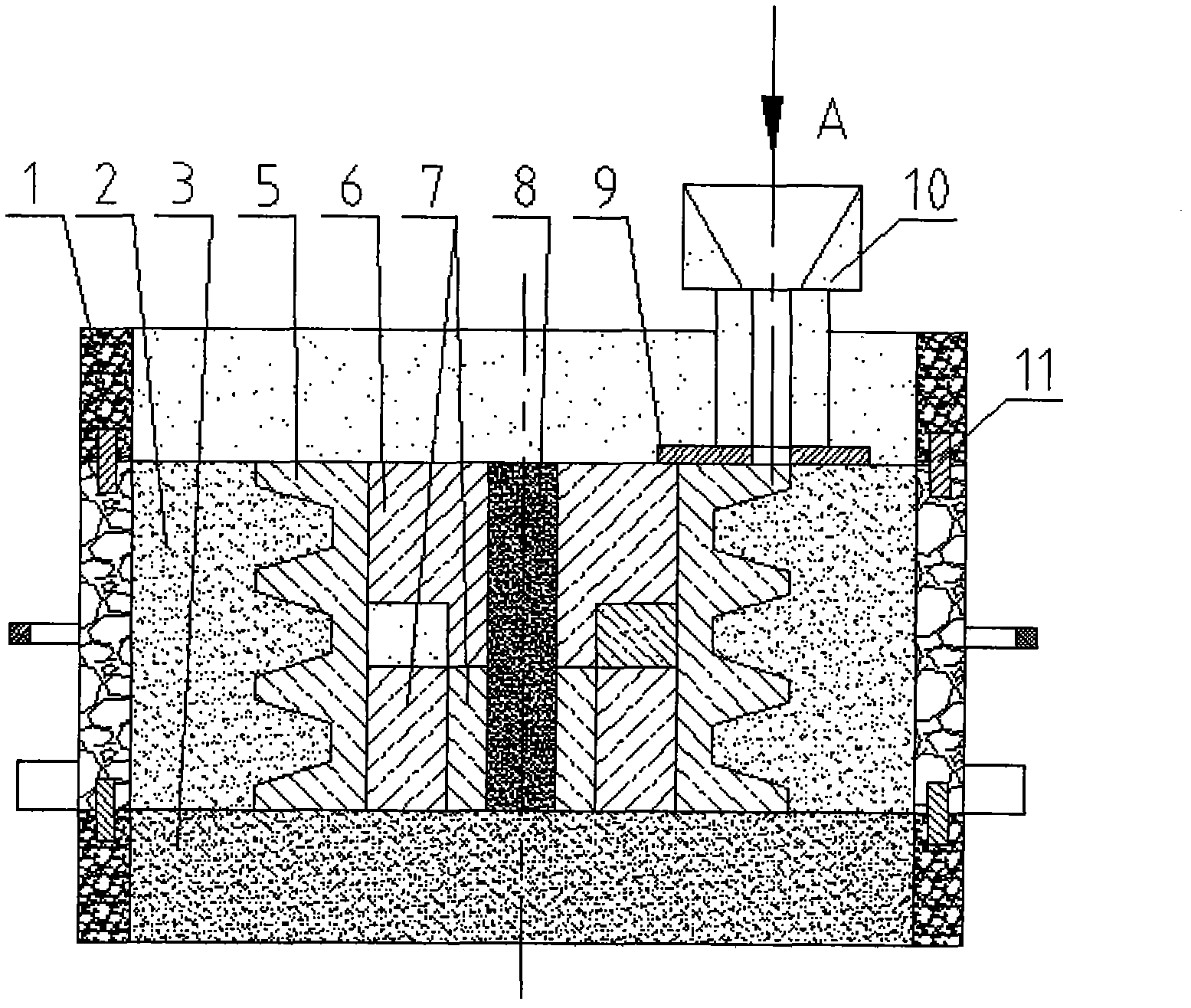

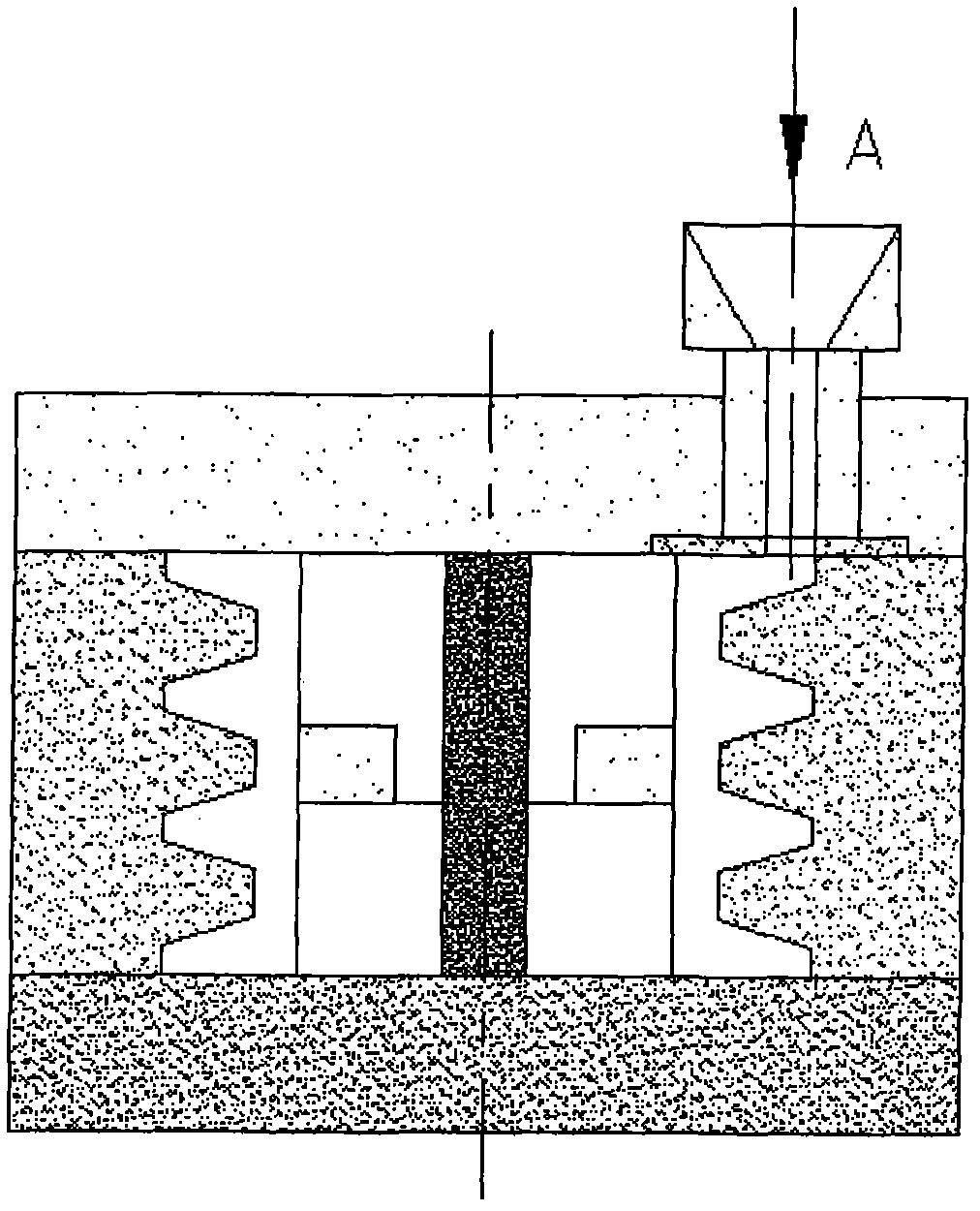

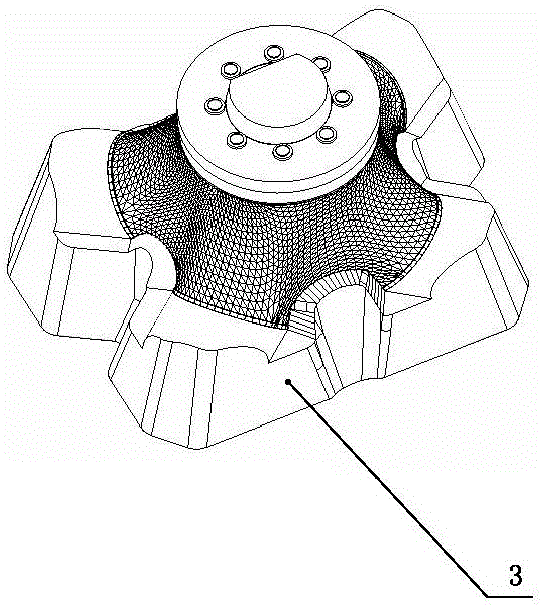

Method for casting rotary axis casts of aerogenerators

The invention discloses a method for casting rotary axis casts of aerogenerators, which comprises the steps of mould manufacture, the manufacture of sand moulds and moulding by casting. In the step b of the manufacture of sand moulds, a top sprue (1) is used as an inlet of iron liquor, and is alternately communicated with runners; a bottom runner is communicated with an ingate communicated with a cast mould cavity; the runners are designed into a first runner (3), a second runner (4) and a circular runner (5); the ingate is designed into a plurality of radial runners (6) for communicating the circular runner (5) and the cast mould cavity; filtering apparatuses are arranged on the first runner (3) and the second runner (4), and are also arranged between each radial runner (6) and the circular runner (5); and in the step c of moulding by casting, the casting temperature is controlled from 1310 DEG C to 1350DEG C; and finally, a cast (2) is obtained. The method for casting rotary axis cast of aerogenerator has the advantages of good residue blocking effect and low production cost.

Owner:RIYUE HEAVY IND

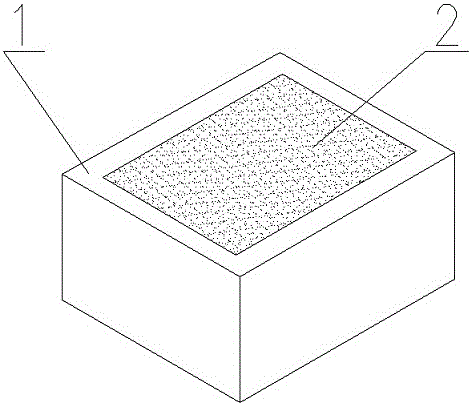

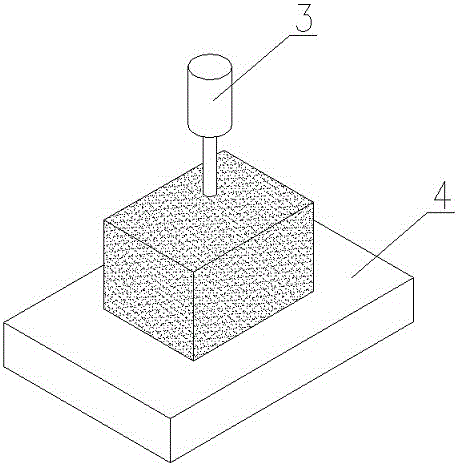

Containerless casting molding method of frozen sand mold

ActiveCN105665637ANothing producedIn line with the concept of green environmental protectionFoundry mouldsFoundry coresCasting moldMaterials science

The invention discloses a containerless casting molding method of a frozen sand mold, and belongs to the technical field of casting rapid molding. The method includes the steps that according to the characteristics of a casting, proper molding sand is selected and used and is evenly mixed with liquid, and a filling mold is placed in the frozen environment; after the molding sand is frozen and cured, a sand blank is obtained and placed on a machining platform to be fixed; the sand blank is directly cut and machined on machining equipment, and a casting mold is obtained; and finally, under the frozen environment, casting is carried out, and a final casting is obtained. According to the method, water or a solution is adopted to serve as a binding element, the source is wide, the price is low, organic resin and other binding elements are not used, and the problems that in the pouring process, the gas-forming amount is large, and waste sand is difficult to recycle are solved. The containerless casting molding method is an environment-friendly green casting method and is suitable for part rapid development trial production and small-batch production.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Evanescent mode pouring system of speed changing box body

The invention discloses an evanescent mode pouring system of a speed changing box body. The evanescent mode pouring system is provided with a sprue, wherein the sprue is sequentially communicated with a pouring cup, a first cross gate and a second cross gate from top to bottom, and the first cross gate and the second cross gate are respectively communicated onto the sprue along the radial direction of the sprue; the end part, away from of the sprue, of each of the first cross gate and the second cross gate is respectively provided with a first inner gate pouring port and a second inner gate pouring port. The pouring system is adopted for pouring a casting, so that the mold filling time is shortened, and the heat loss is reduced; moreover, the shrinkage porosity and cavity weakness can be greatly reduced, and the casting quality can be effectively improved.

Owner:HEFEI UNIV OF TECH

Ceramsite sand for casting and preparation method thereof

ActiveCN107298584AImprove thermal conductivityHigh thermal expansionFoundry mouldsFoundry coresExpanded clay aggregateSilicon dioxide

The invention relates to a ceramsite sand for casting and a preparation method thereof. The ceramsite sand comprises the following chemical components in parts by weight: 35-65 parts of silicon dioxide, 30-50 parts of aluminum oxide, 1-10 parts of iron oxide, 1-4 parts of manganese dioxide and 2-8 parts of chromic oxide. The method comprises the following steps: performing grinding, and detecting the chemical composition and contents of the raw materials; and sequentially performing proportioning, ball making, screening, sintering and grading to obtain the finished product. The ceramsite sand prepared by the invention is high in thermal conductivity and refractoriness, conforms to the requirements for casting sand, can be used for casting and casting mold production instead of silica sand, chromite sand and the like, reduces the discharge amount of solid waste in the casting industry, and improves the quality of cast products.

Owner:NINGXIA KOCEL MOLD

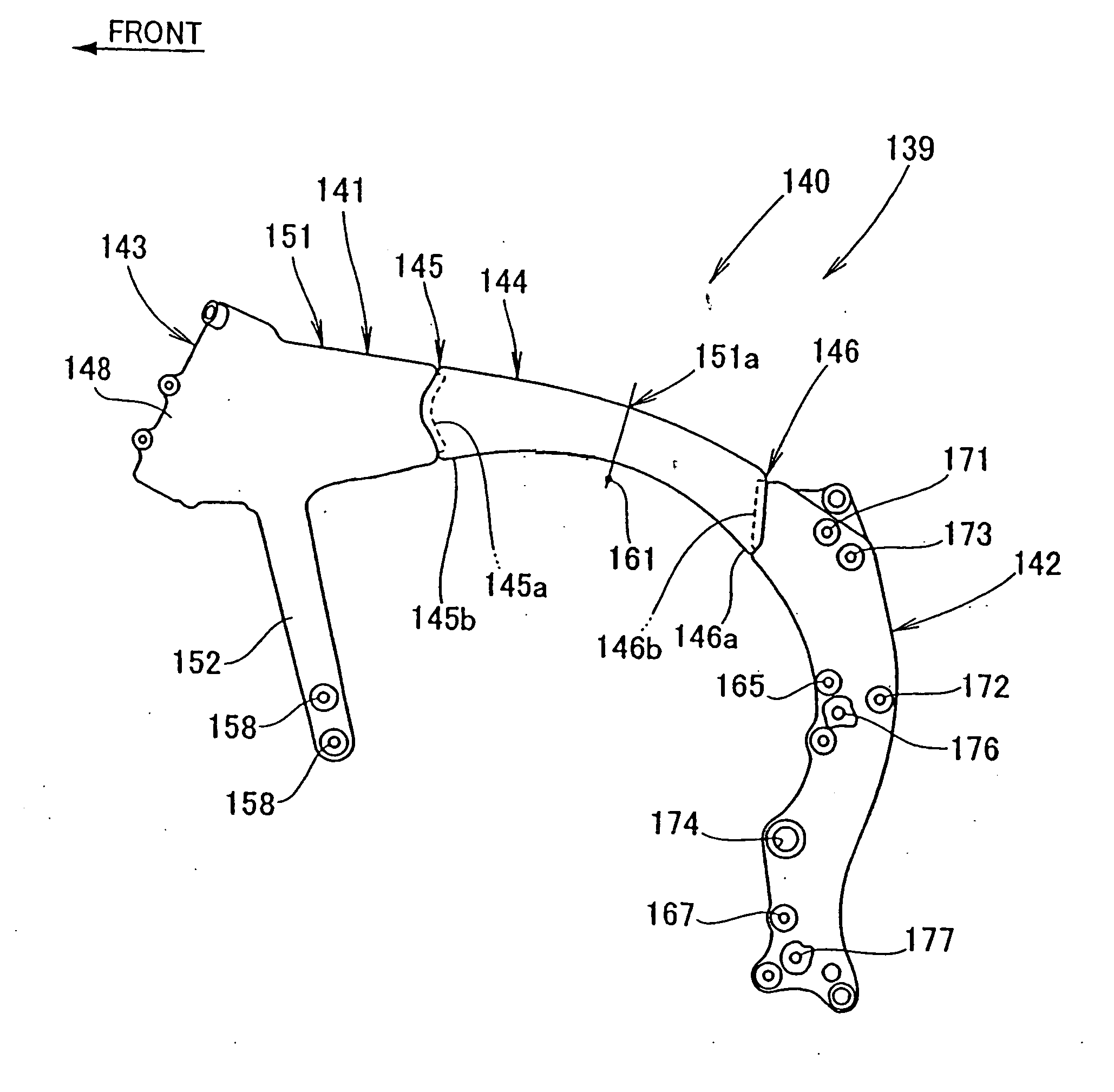

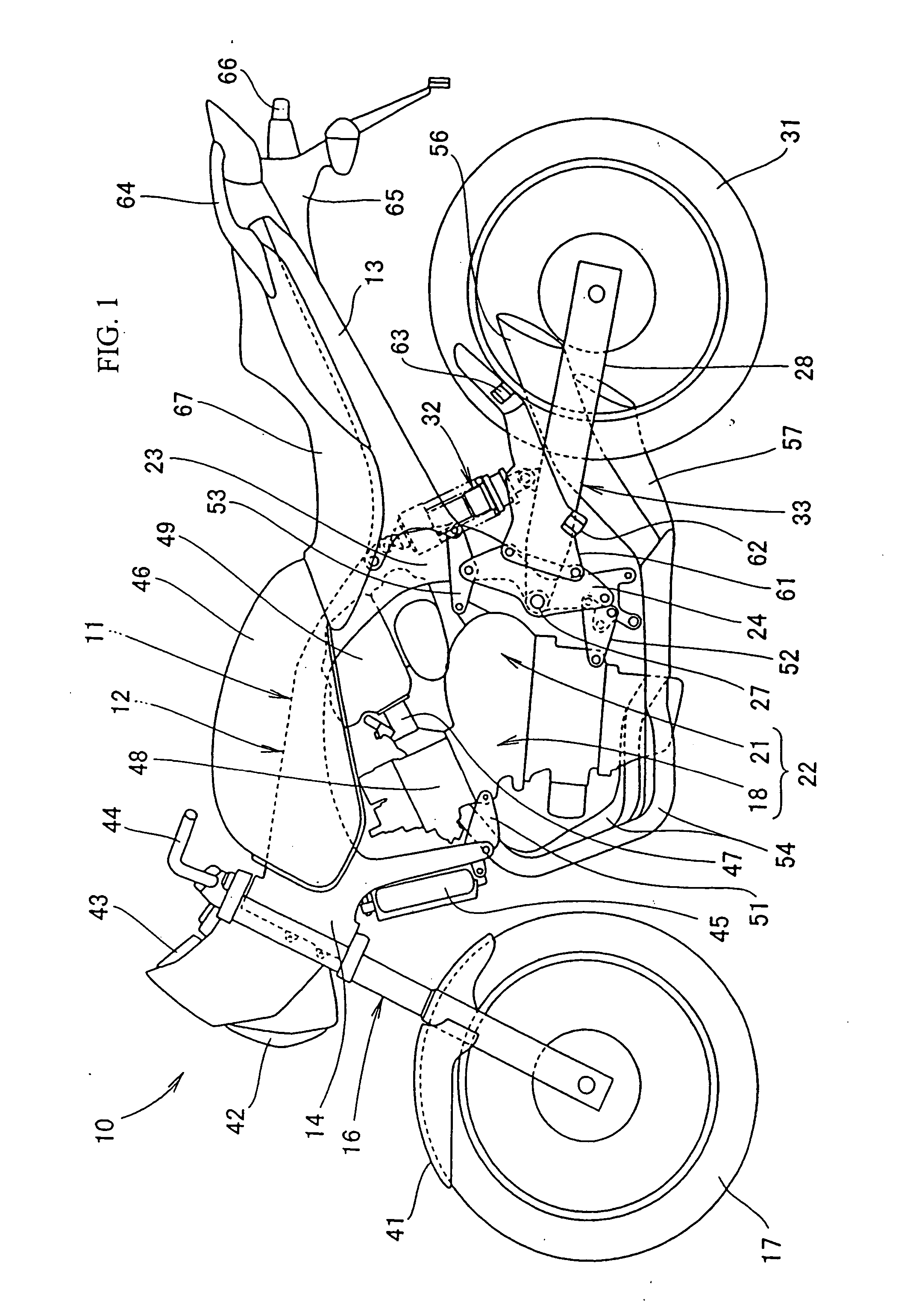

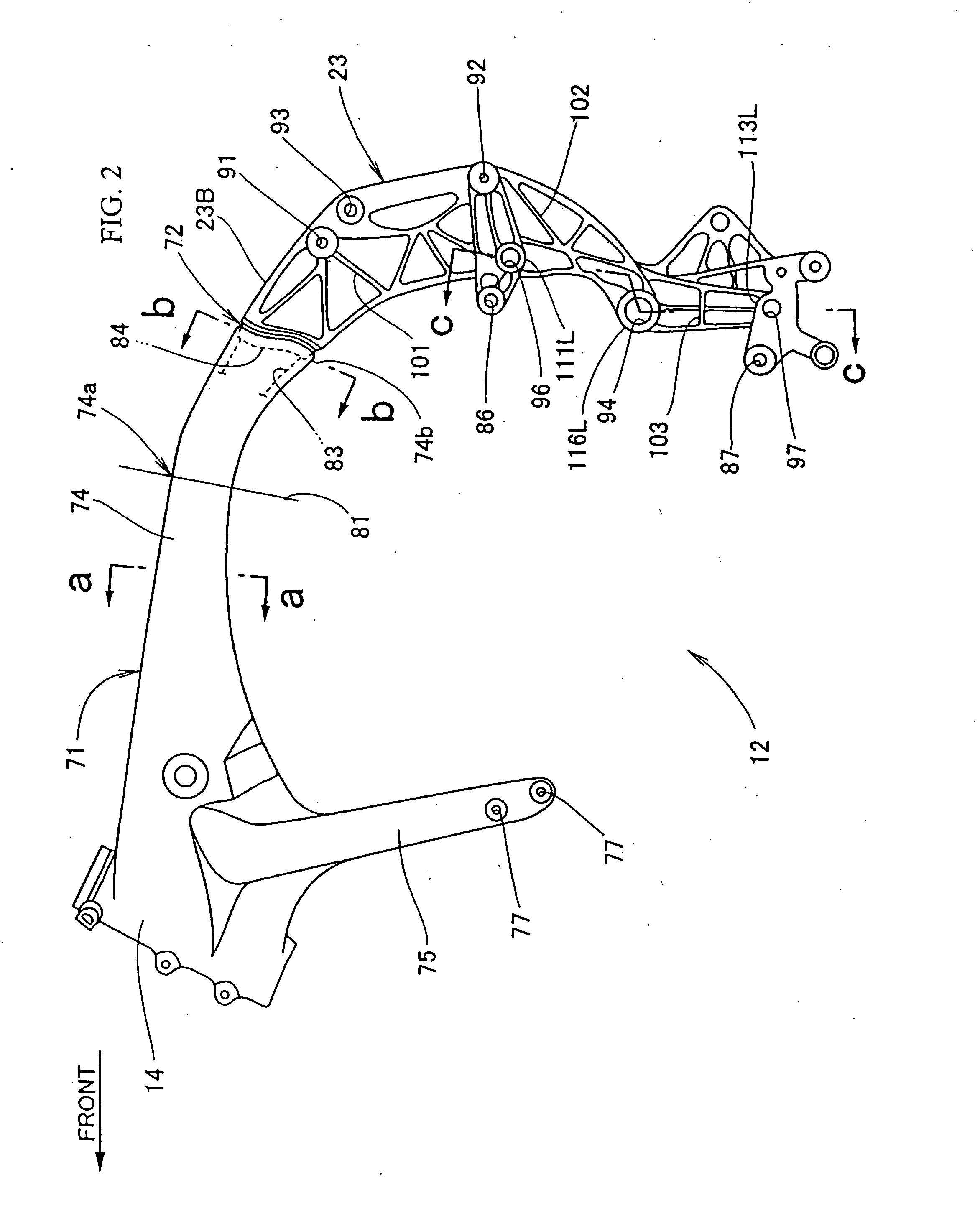

Frame assembly for a motorcycle

ActiveUS20060197304A1Improve manufacturing productivityReduce weld lengthPassenger cyclesChildren cyclesVehicle frameCoupling

A motorcycle body frame includes a main frame including a head pipe for supporting a front suspension at the front end thereof, a single leading frame portion extending rearwardly from the head pipe, and a rear frame portion for supporting a rear wheel suspension. The rear frame portion extends substantially downwardly from a rear part of the leading frame portion. The main frame, cast from an aluminum alloy, includes two component parts arranged front-to-rear. For example, a front frame portion is provided, and a rear frame portion is fixed to the rear side of the front frame portion. The leading frame portion has a small section portion, where the main frame is smallest in sectional area, disposed substantially centrally in the longitudinal direction thereof. The two component parts of the frame are joined at a coupling portion of the main frame situated in back of the small section portion.

Owner:HONDA MOTOR CO LTD

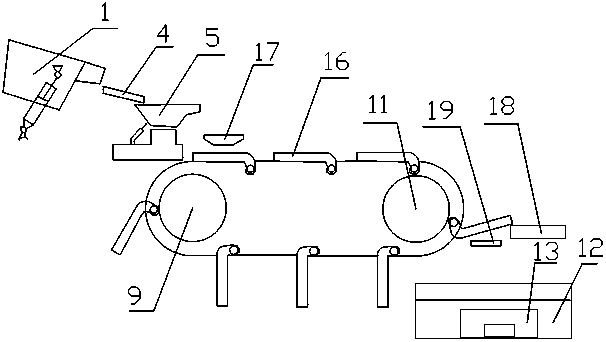

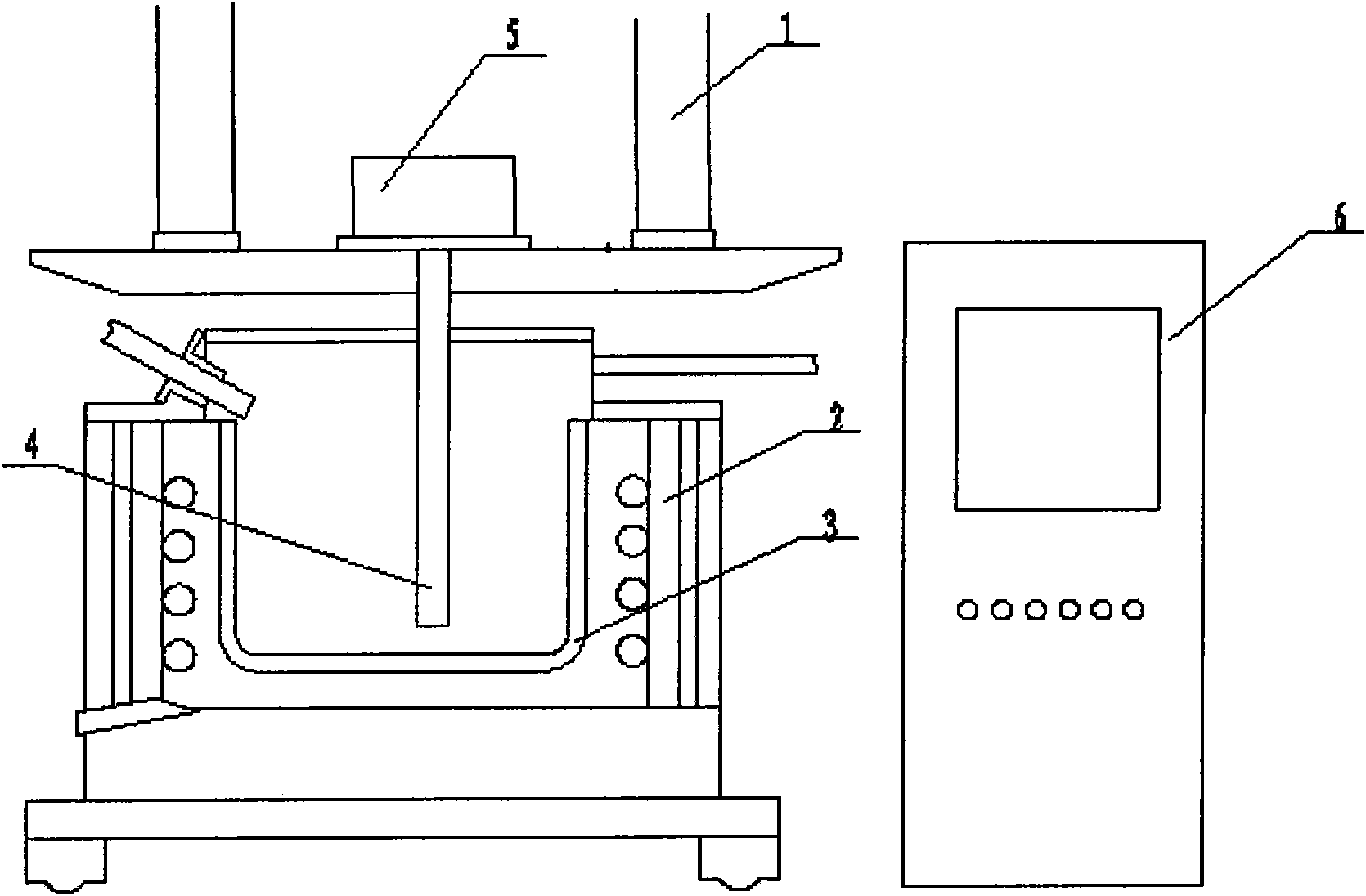

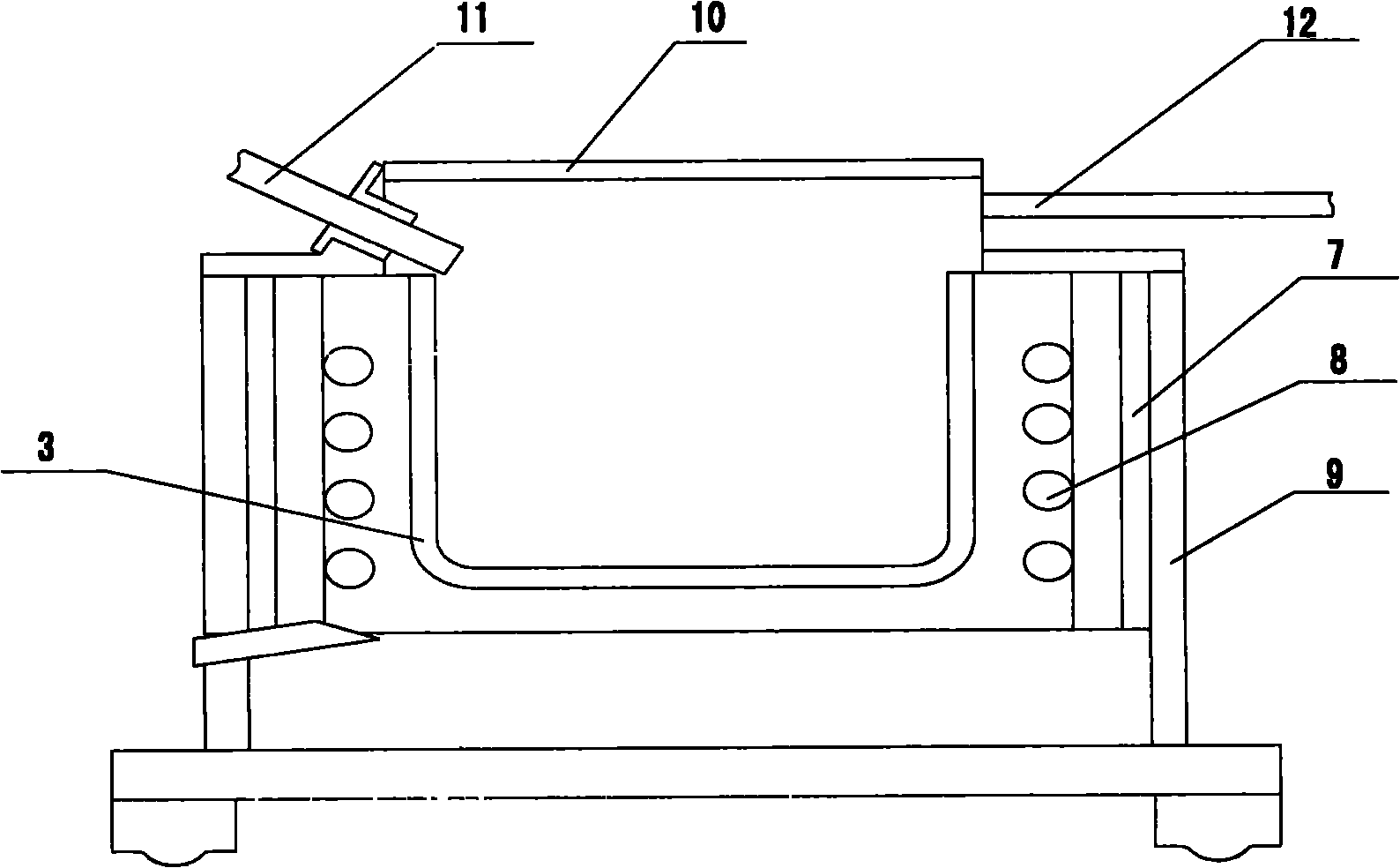

Double-row chain type automatic quantitative casting machine

ActiveCN103447482AQuantitatively accurateHigh degree of automationPig casting plantsMolten metal supplying equipmentsMedium frequencyChain type

The invention discloses a double-row chain type automatic quantitative casting machine. The double-row chain type automatic quantitative casting machine comprises a medium-frequency electric furnace, an electronic quantitative casting device, a conveyor and a fixed collision block, wherein the medium-frequency electric furnace is arranged at the front end of the conveyor and is used for accommodating molten metal; the electronic quantitative casting device is arranged between the medium-frequency electric furnace and the conveyor and is used for weighing the molten metal; a plurality of molds which are used for molding the molten metal are arranged on the conveyor at intervals; a power device which is used for driving the molds to cyclically move on the conveyor is arranged on the conveyor; the fixed collision block is arranged at the tail end of the conveyor and is used for removing and de-molding molded anodes in the molds when the molds on the conveyor move to the position of the fixed collision block.

Owner:YUNNAN COPPER CO LTD +1

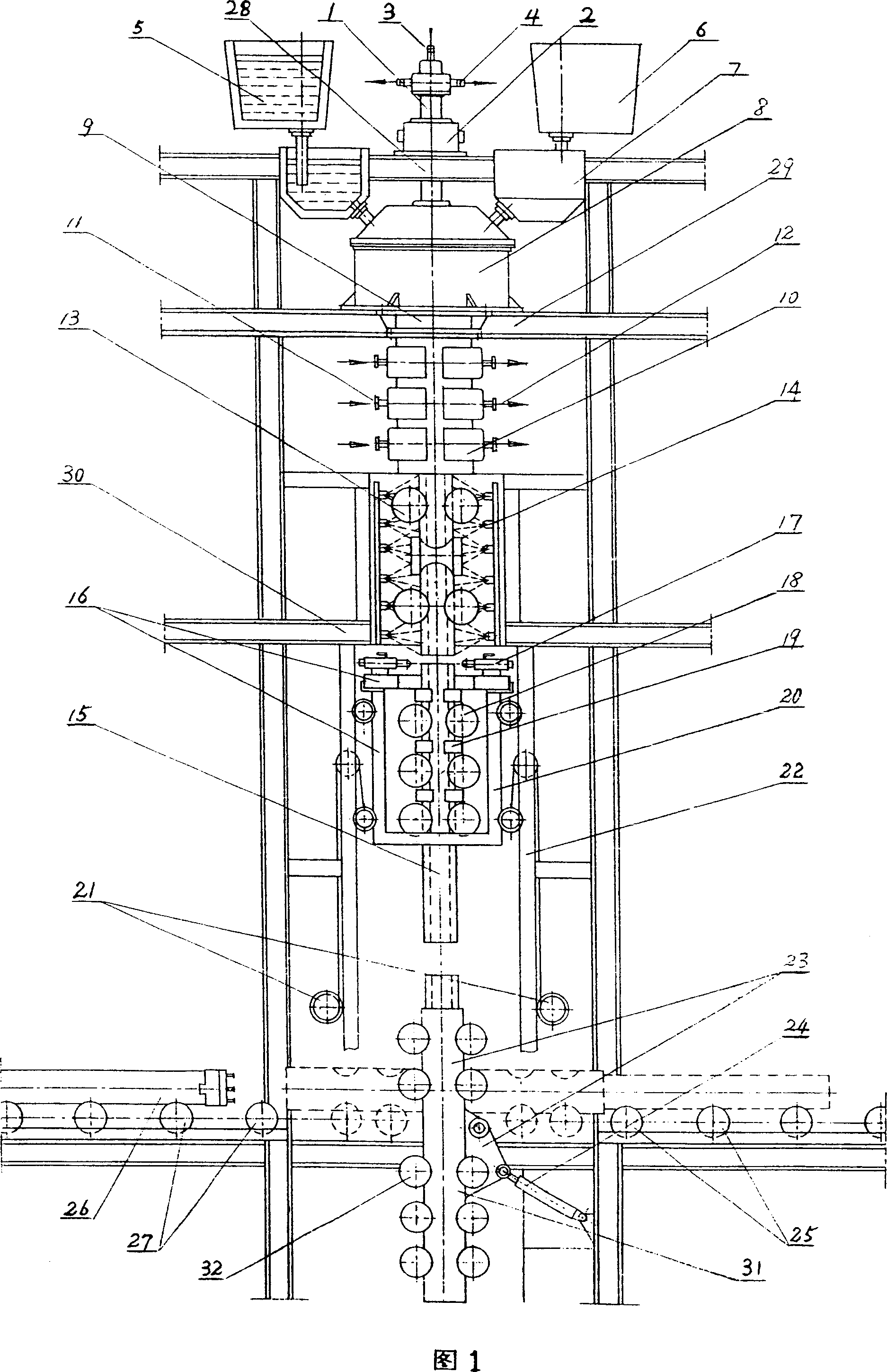

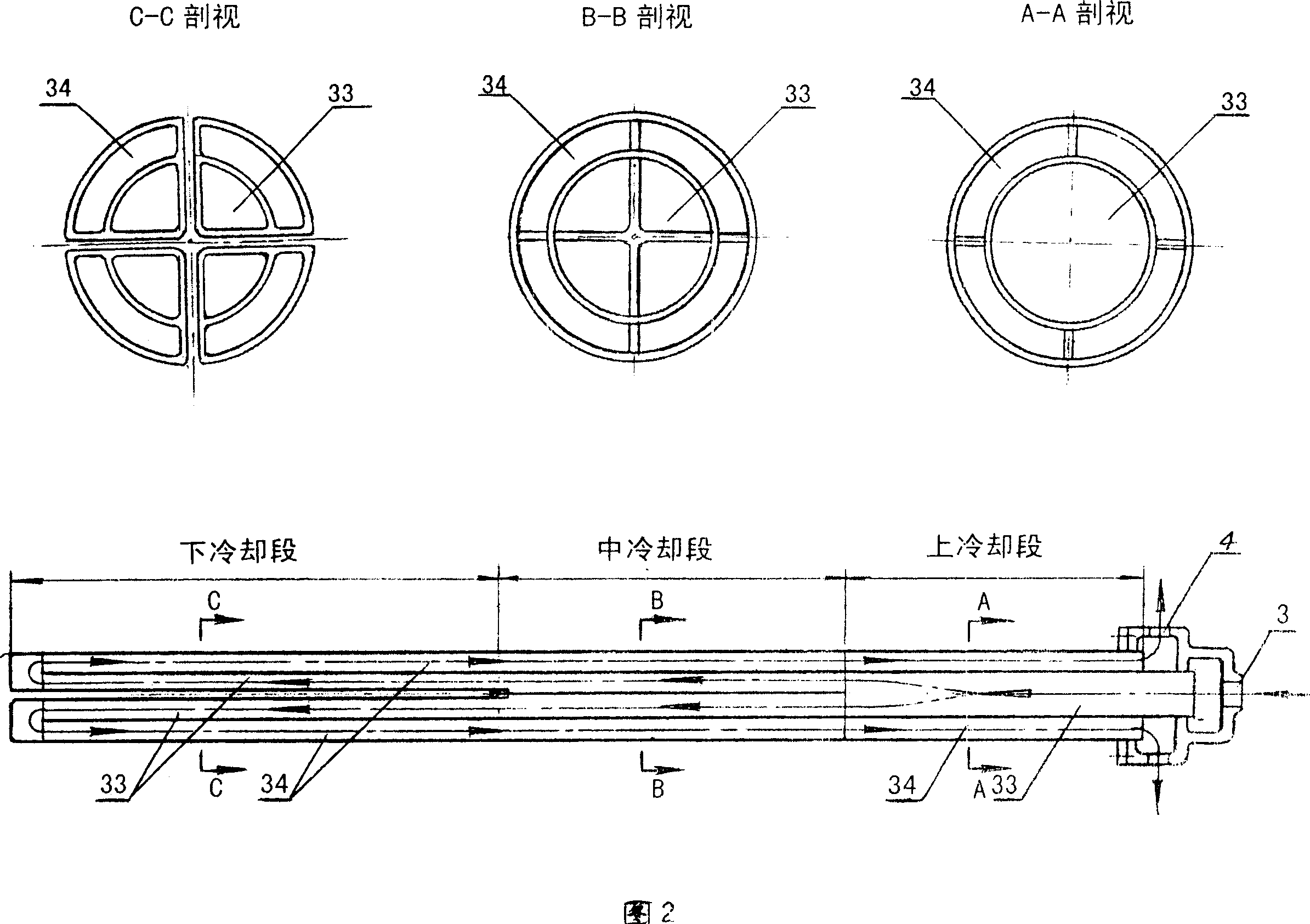

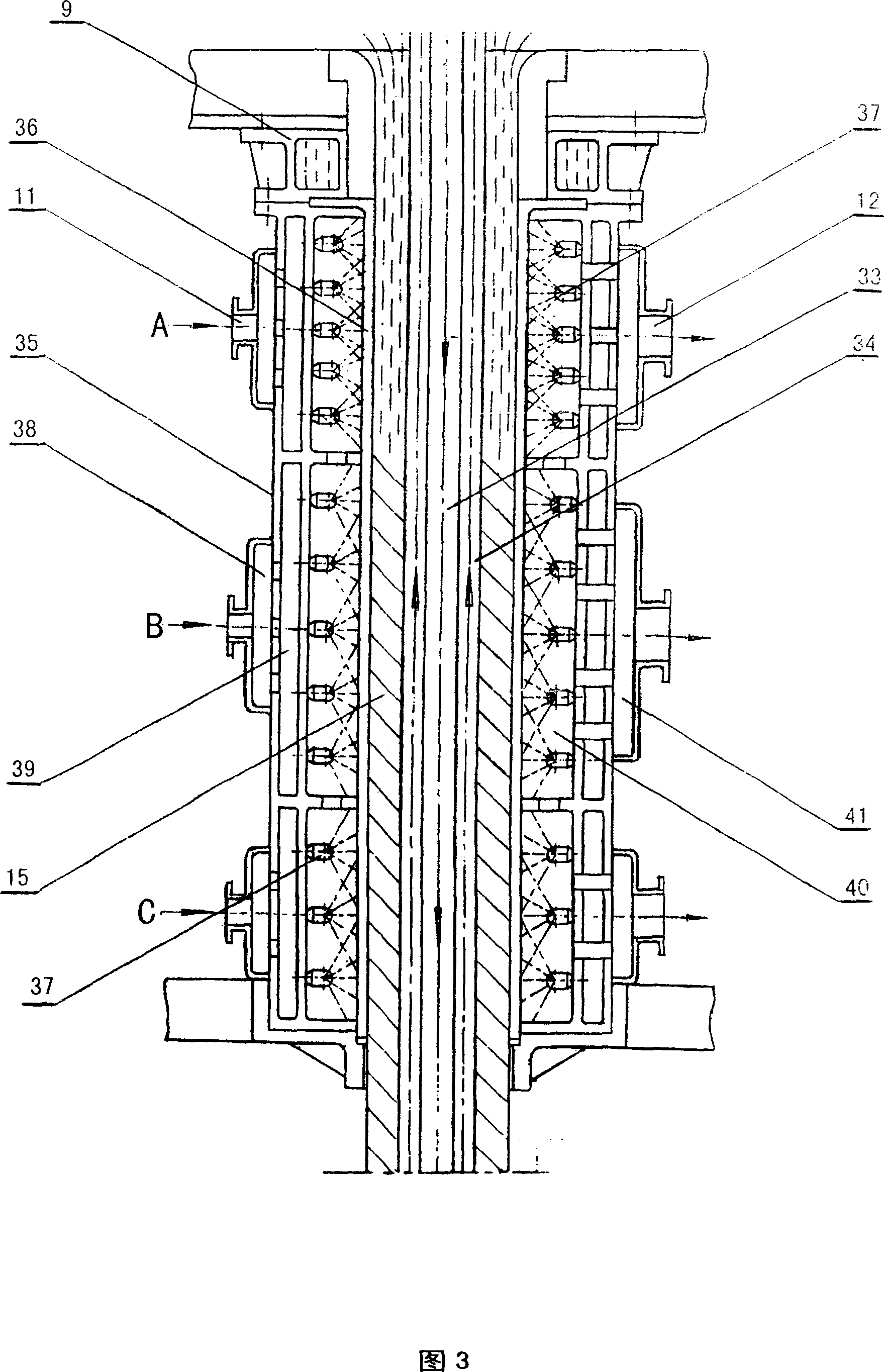

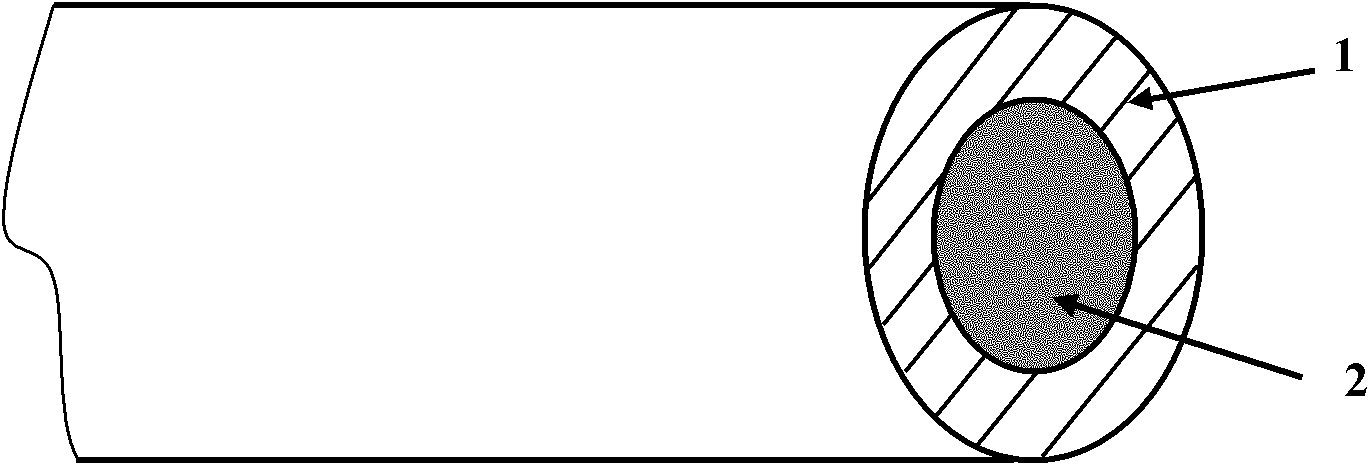

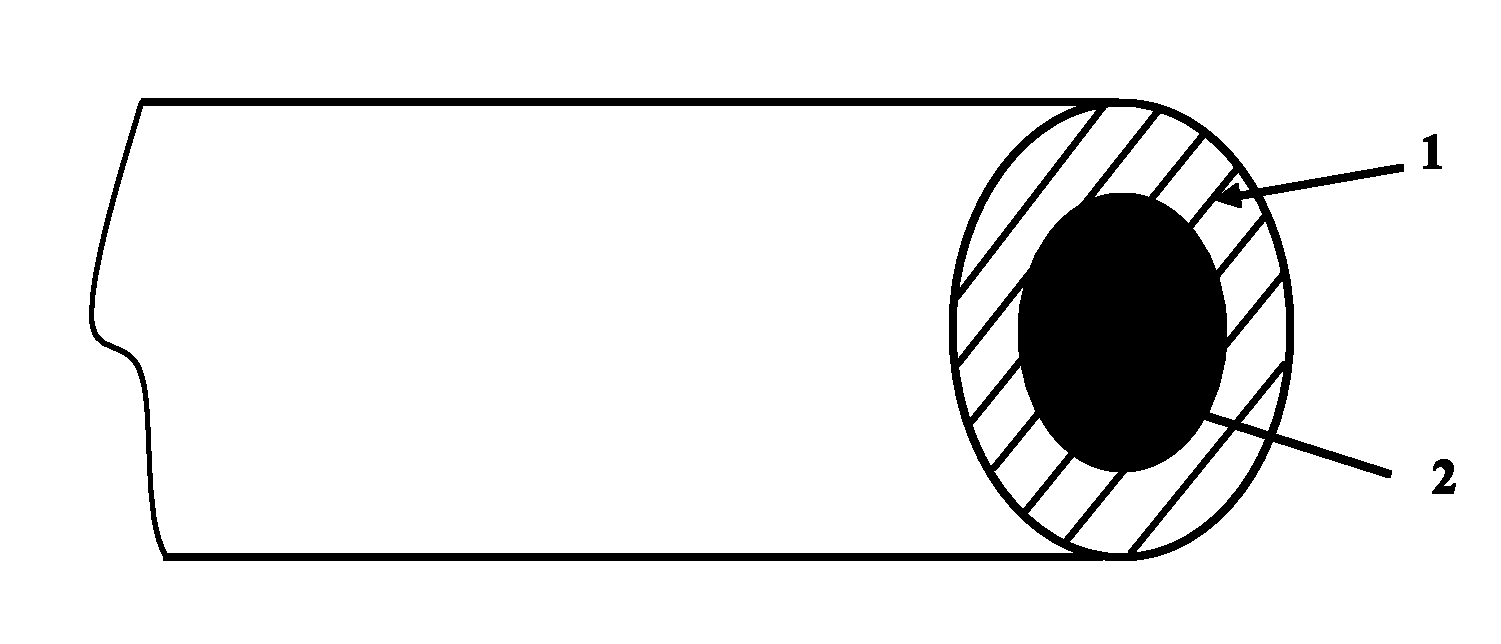

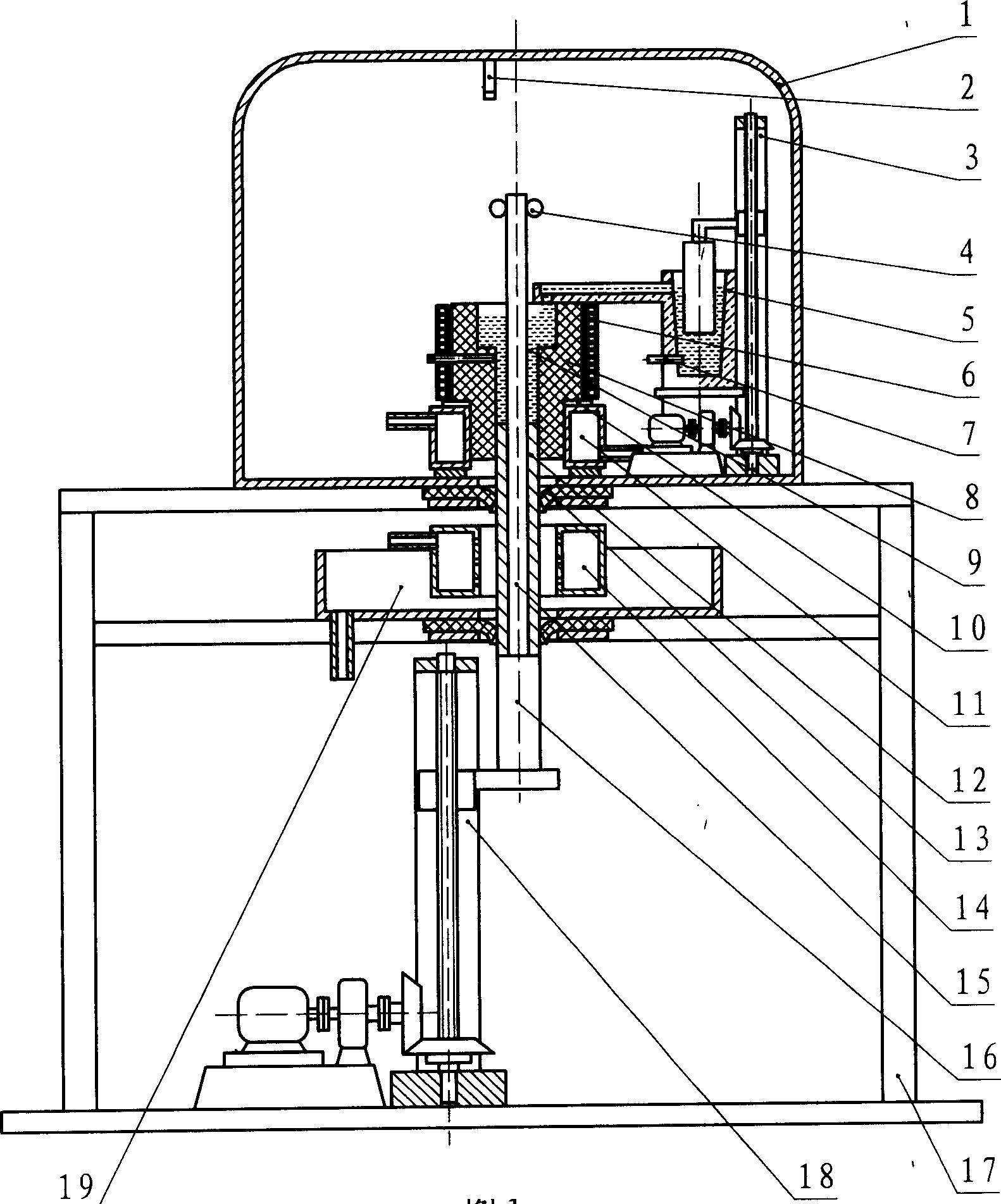

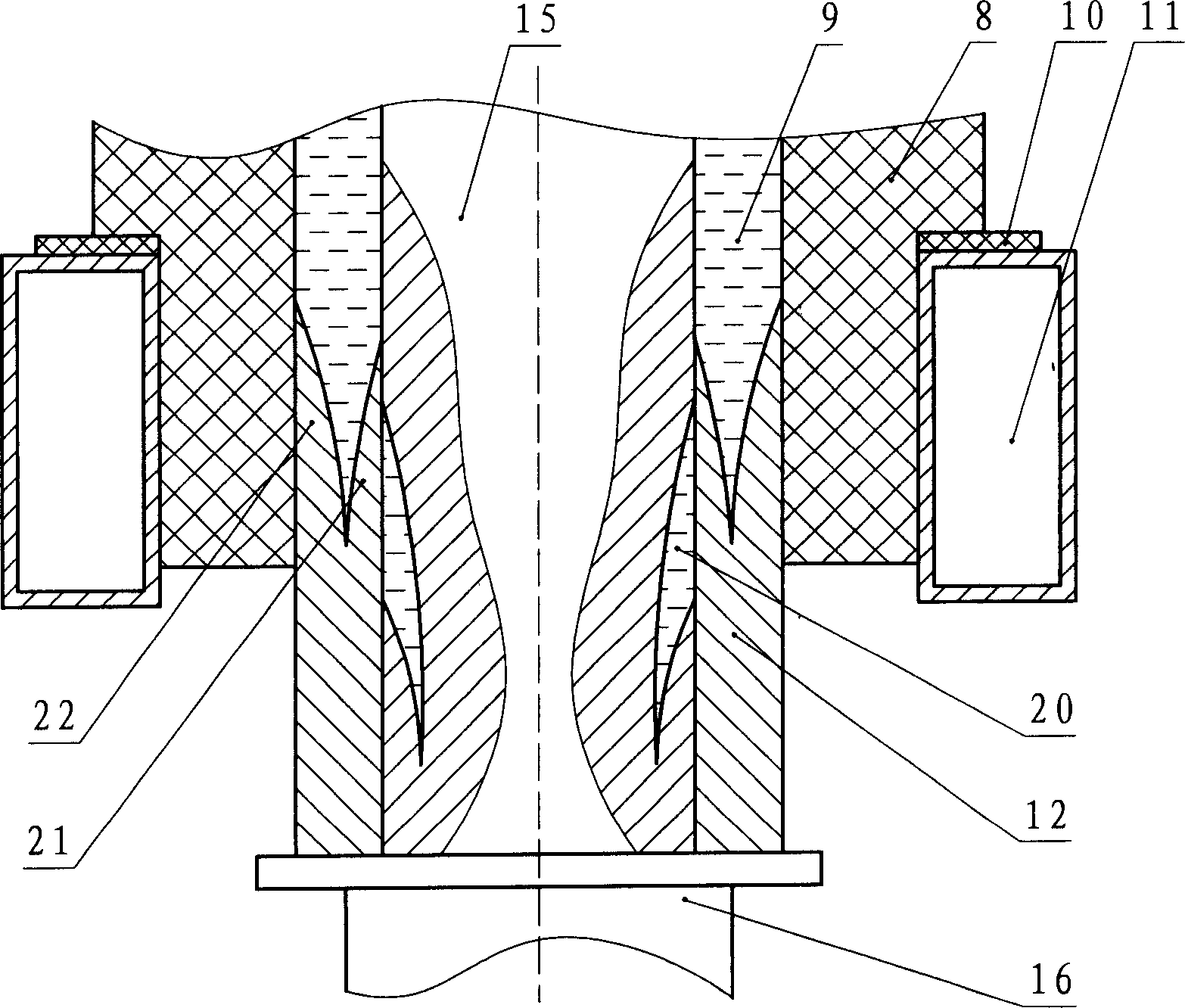

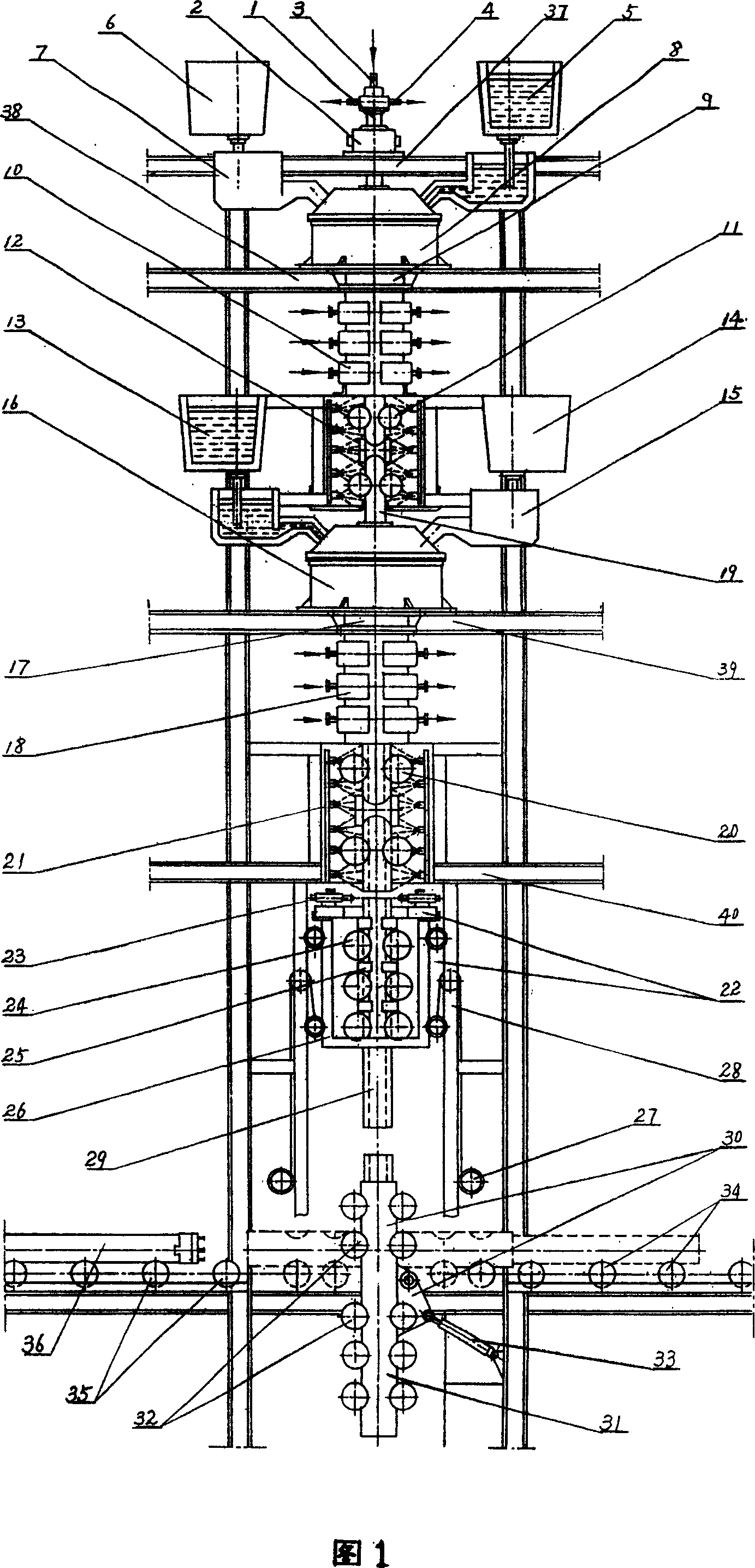

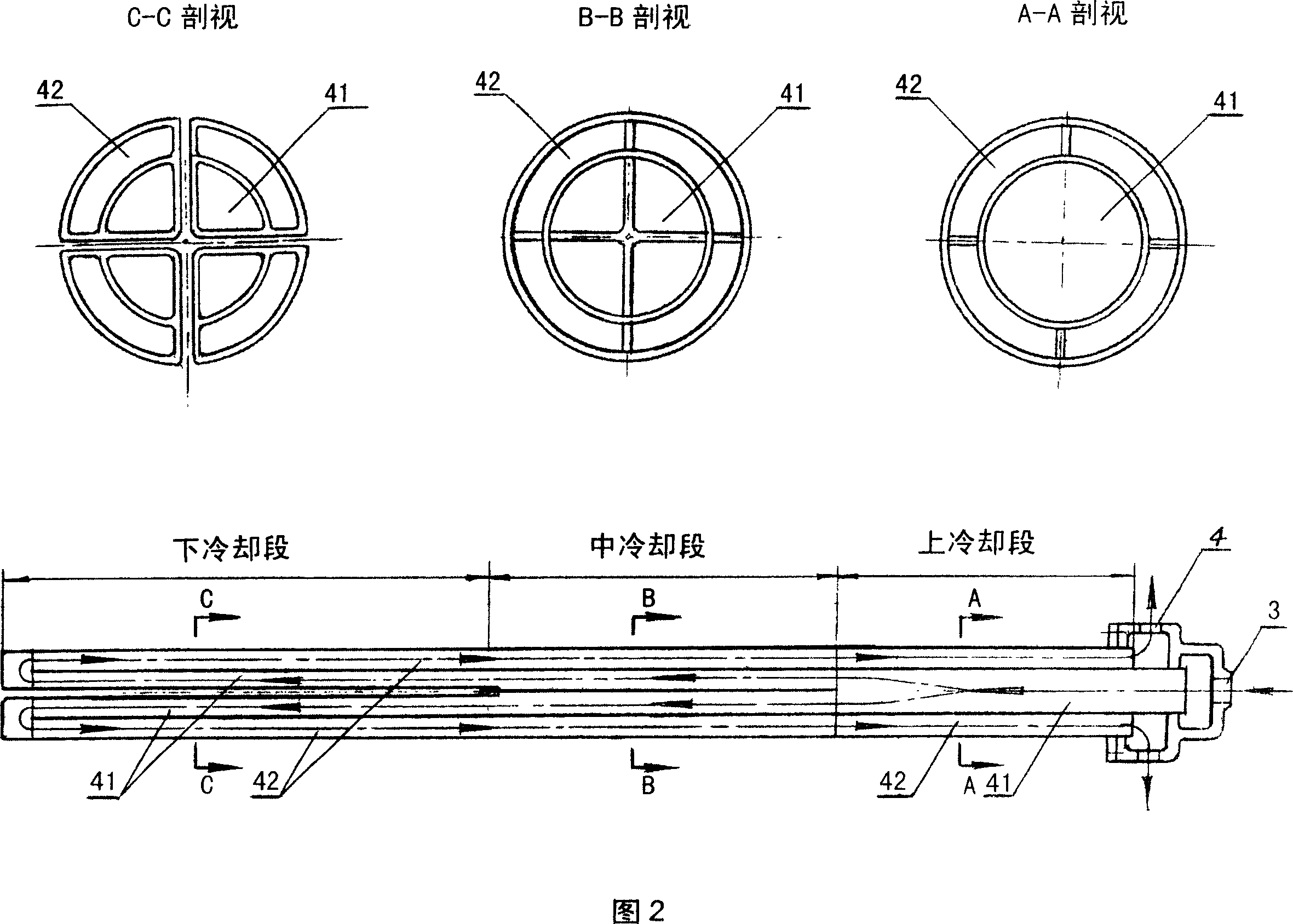

Vertical continuous casting machine for seamless steel pipe blank

The present invention relates to a vertical seamless steel pipe hollow pipe billet continuous casting machine. It is characterized by that it utilizes combination of internal crystallizer and external crystallizer to produce hollow pipe billets with various specification. Said continuous casting machine consists of internal crystallizer, external crystallizer, carryover pinch roll, dummy ingot cutting car and turnover roller way equipment. Said invention also provides their connection mode and concrete operation method of said continuous casting machine.

Owner:李铁铎

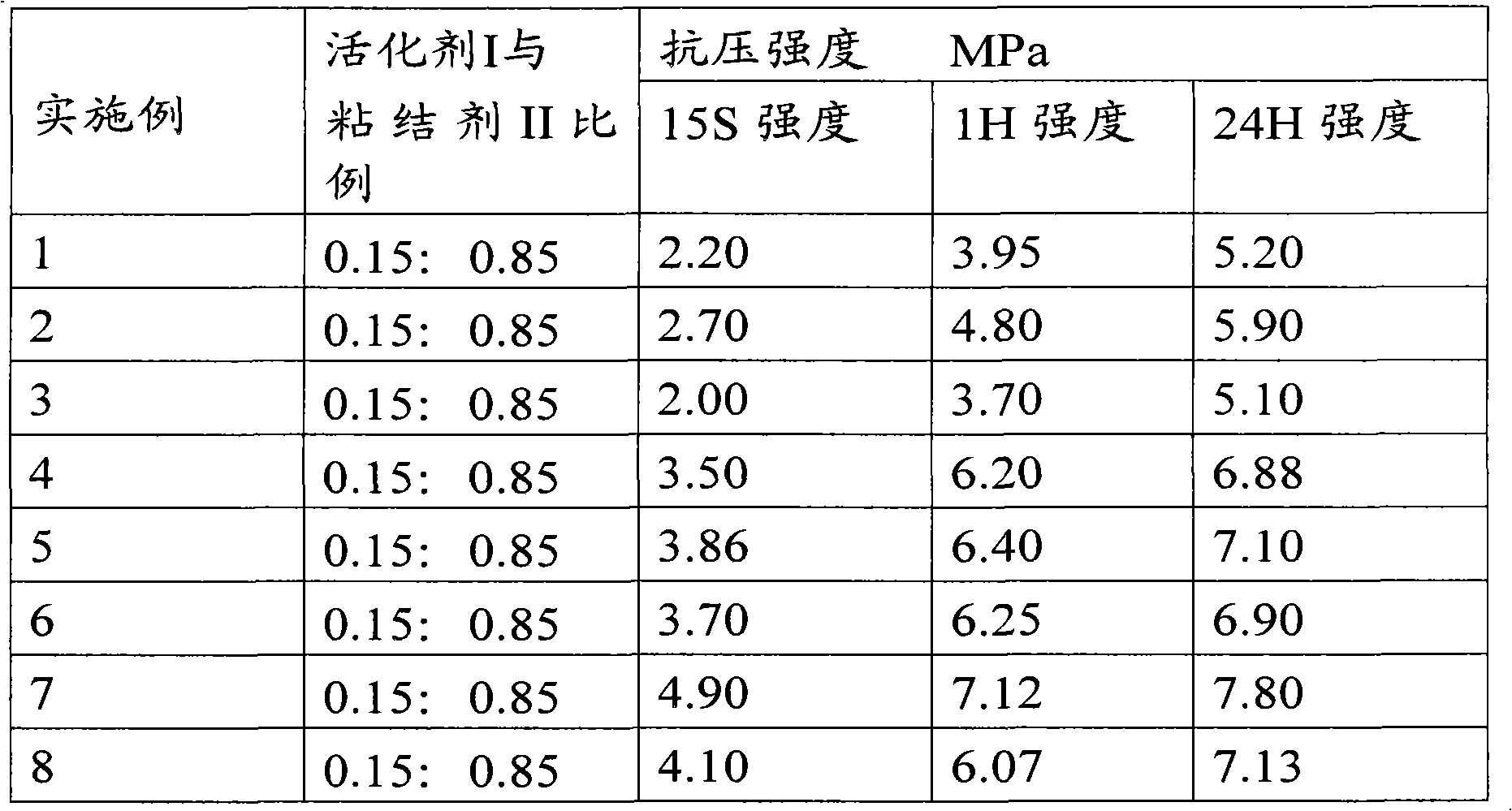

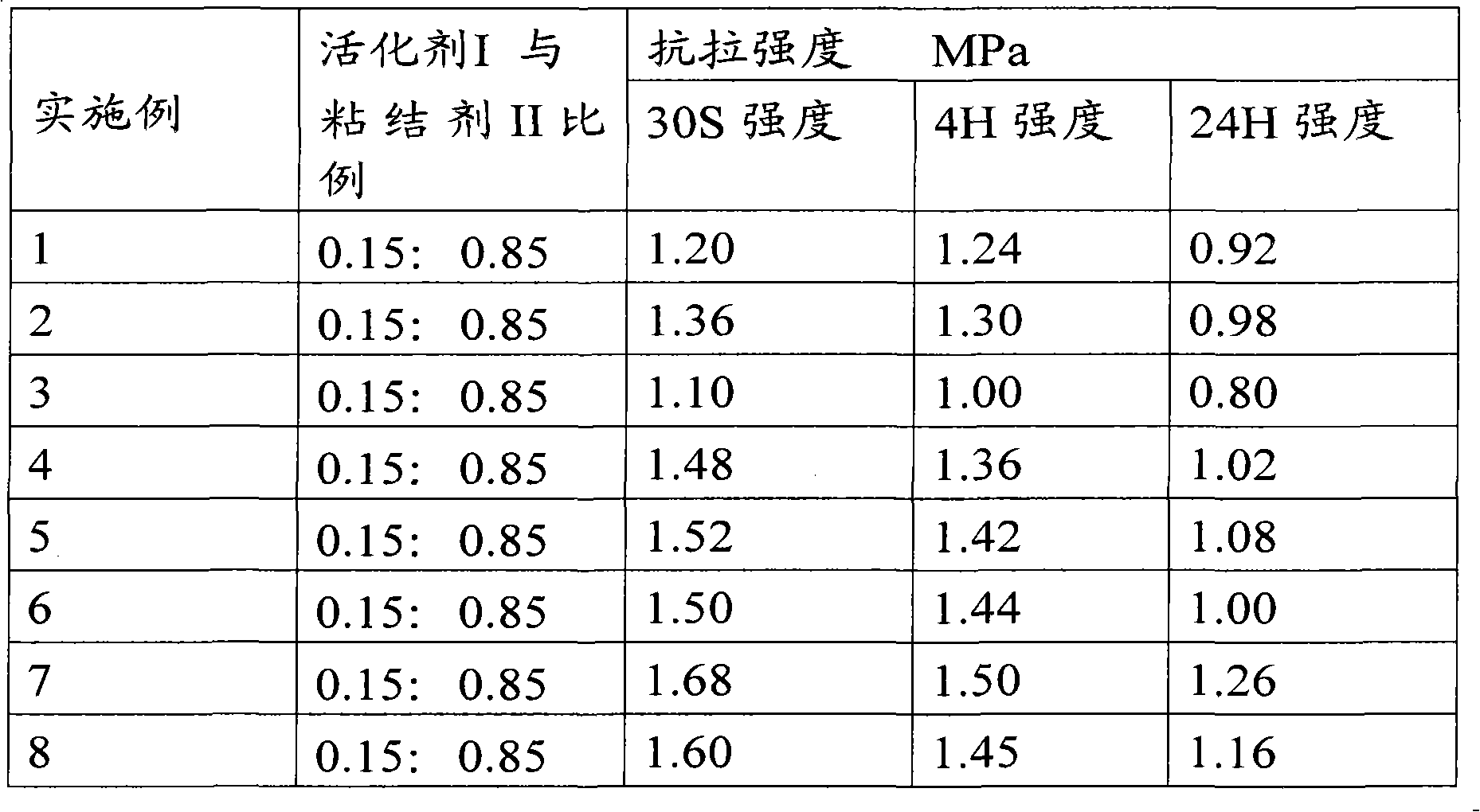

Binder for casting core mould

ActiveCN102069141AImprove casting qualityReduce scrap rateFoundry mouldsFoundry coresEpoxyMaterials science

The invention discloses a binder for hardening by sulphur dioxide blowing, and the binder is used for curing by sulphur dioxide blowing in the presence of an organic peroxide activator. The binder disclosed by the invention comprises the following compositions in parts by weight: (a) 1-40 parts of benzylidenehydrazine, (b) 0.1-10 parts of polyisocyanate, (c) 40-80 parts of epoxy resin, (d) 20-30 parts of acrylic ester, and (e) 1-30 parts of high-boiling esters and / or hydrocarbon diluents. The binder disclosed by the invention can be used for overcoming the defects that the brittleness and resistance to heat and humidity of the binder for hardening by sulphur dioxide blowing in the prior art are poor, thereby improving the strength of a core sand mould when the binder is used in the process of casting, reducing the rejection ratio, and improving the quality of castings.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Casting mould of belt pulley with groove

The invention discloses a casting mould of a belt pulley with a groove, comprising an upper die, a lower die, die cores, mud cores and a sprue. The casting mould is characterized in that a middle die is arranged between the upper die and the lower die; positioning connections between the upper dies and the lower die as well as between the middle die and the lower die are both realized through pins or tenons; the die cores and the mud cores are positioned in the cavities of the upper die, the lower die and the middle die; the sprue is fixed in the upper die; and the die cores are a plurality of removable middle dies cores, upper dies cores and lower die cores in a shape of a grooved belt pulley, each die core is made of a metal material, and the die cores utilize an integral structure or a split structure. The casting mould has the characteristics of simple structure, low cost, high durability of the die cores, good quality of casting pieces, high casting efficiency, wide adaptability and the like.

Owner:张玉峰

Mold core and preparation method thereof and method for producing casting inner cavity by using mold core

InactiveCN102059321AImprove structural strengthStress reliefFoundry mouldsFoundry coresUltimate tensile strengthLow melting point

The invention provides a mold, a preparation method thereof and a method for producing a casting inner cavity by using the mold core. The mold core is made of hollow material; and an alloy is arranged in the hollow structure of the mold core. The mold core made of brass replaces the traditional sand core, has higher structural strength and is suitable for complex fine hole inner cavities of an aluminum alloy casing to form. In the method for producing the mold core, the characteristic of low melting point aluminum alloy is used and the mold core is filled into a hollow brass tube to relieve the stress generated by bending the brass tube with favorable bending effect; in addition, the hollow brass section is prevented from being deformed due to external action in the bending process.

Owner:XIAN AERO ENGINE CONTROLS

Precisely cast low-temperature modulated wax and preparation method thereof

InactiveCN104592765AReduced linear shrinkageReduce the probability of subsidenceFoundry moulding apparatusParaffin waxProduction rate

The invention discloses a precisely cast low-temperature modulated wax and a preparation method thereof. The precisely cast low-temperature modulated wax comprises the following raw materials in parts by weight: 44-46 parts of microcrystalline wax, 2.5-3.5 parts of lignite wax, 34-36 parts of rosin resin, 3.5-4.5 parts of an ethylene-vinyl acetate copolymer and 12-14 parts of pure monomer resin. The wax disclosed by the invention is applied to a precision casting industry, has stability, hardly deforms due to high strength and hardly pollutes the metal cast due to low gray scale, is easy to demold, can be melted together with a wax mold to flow out of a shell during demolding; and the production rate can be effectively improved in the precision casting process.

Owner:青岛新诺科铸造材料科技有限公司

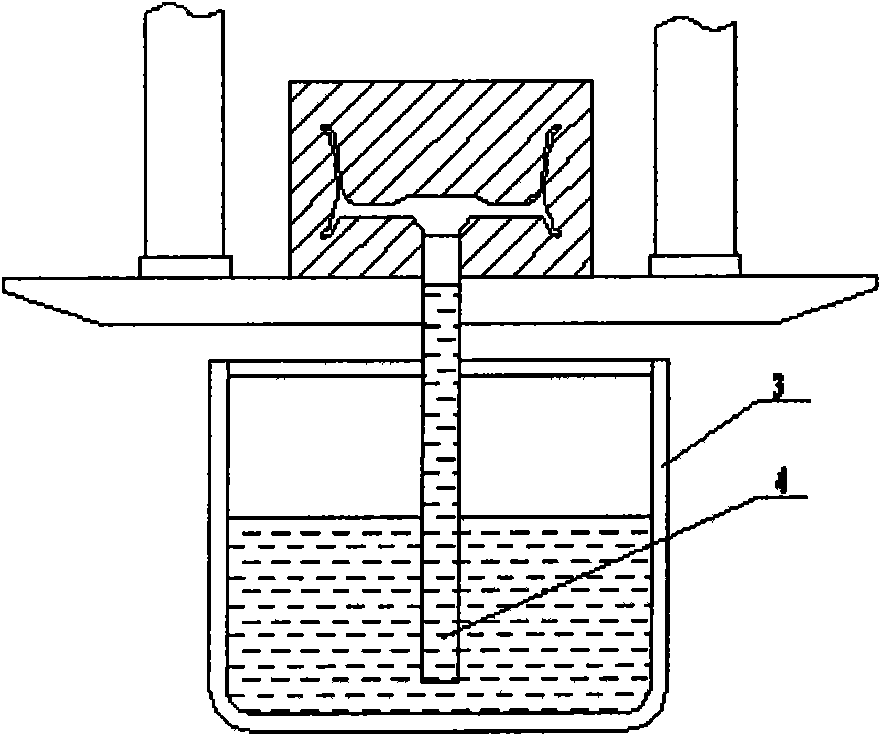

Composite ingot set for continuous casting of Cu-Al bimetal in down-pulling reverse solidification process

The continuous Cu-Al bimetal composite ingot casting set operating on down-pulling reverse solidification process has improved including effect and may be used in industrial production. The present invention includes one melting and maintaining furnace and one ingot drawing unit, and features that there are a crucible below the liquid outlet of the melting and maintaining furnace, a heating and temperature regulating unit outside the crucible, a crystallizer below the crucible, a ingot drawing unit below the crucible, a metal aluminum core mounted onto the dummy bar of the ingot drawing unit and located inside the crucible, a casting speed controller, and a vacuum chamber for all the melting and maintaining furnace, the crucible, the heating and temperature regulating unit, the crystallizer and the casting speed controller to be set inside. Copper as the coating material is smelted in the melting and maintaining furnace and coated to the aluminum core with the crucible and the crystallizer while the composite ingot is drawn out with the ingot drawing unit.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

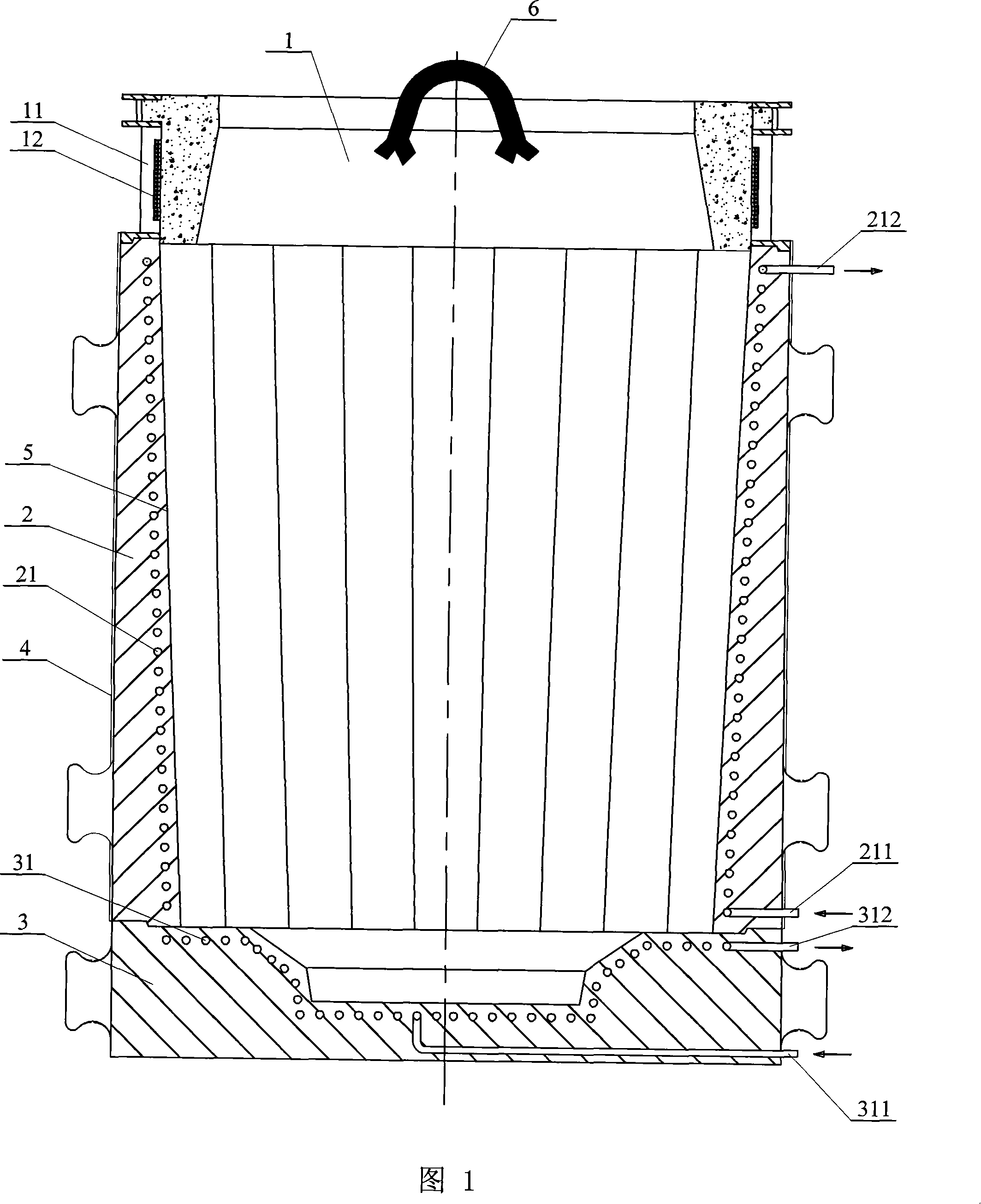

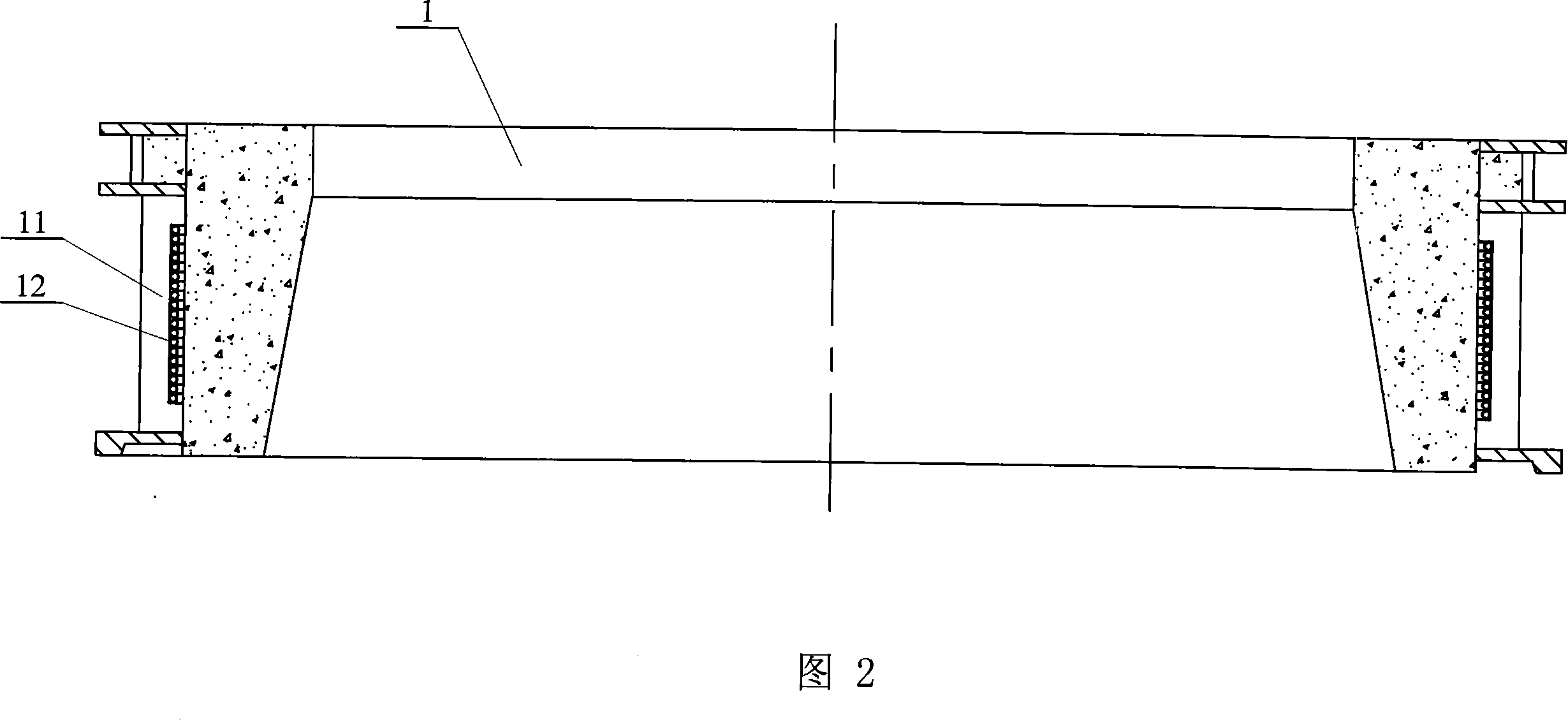

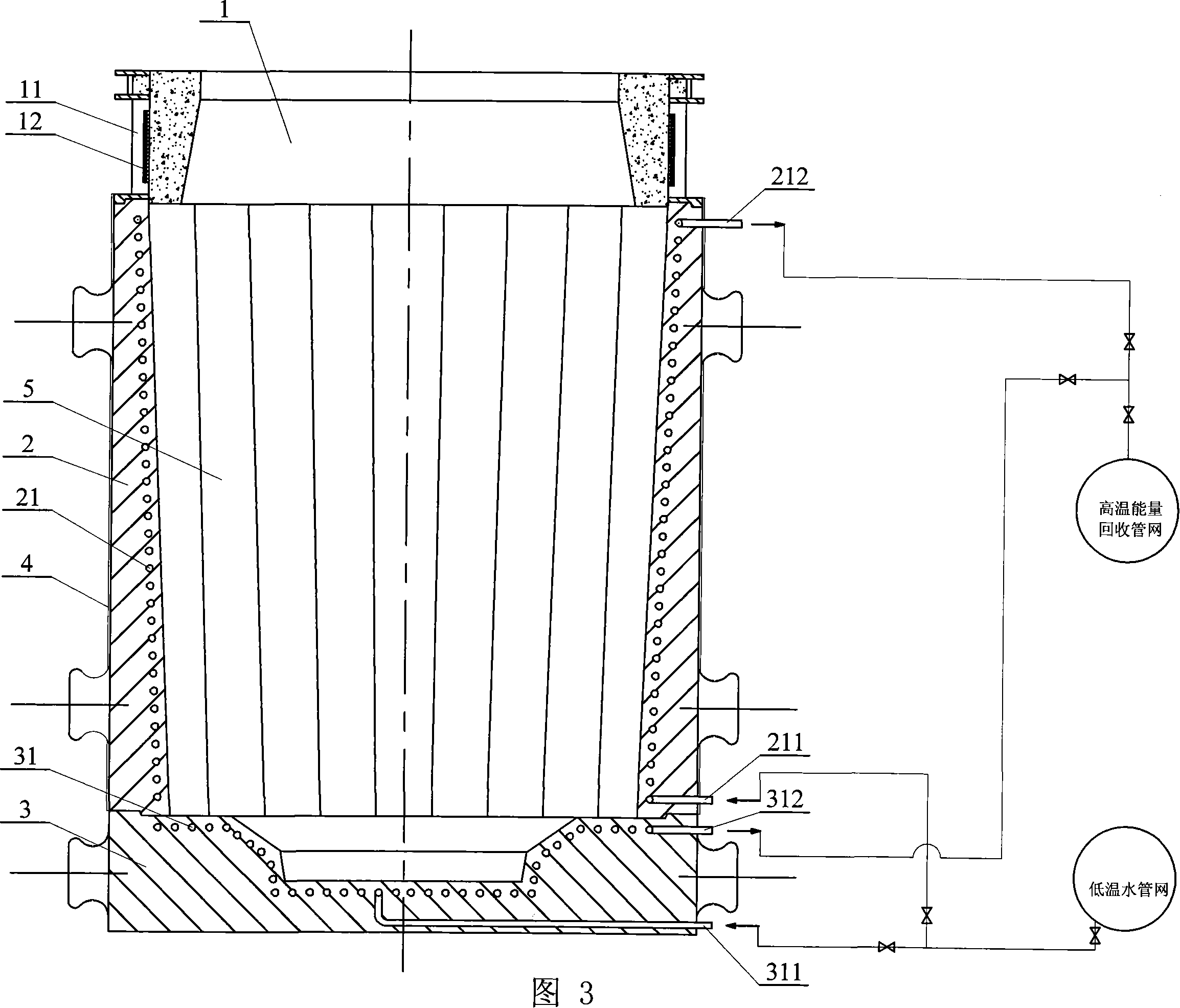

Macrotype metal mold system for recovering thermal energy by cooling water

The invention discloses a large water cooling heat recovery metal pattern system, belonging to the field of water cooling heat recovery in the casting technology of a plurality of castings such as large steel ingots and rollers. The invention adopts the technical proposal in comprising a metal pattern, the upper part of which are fixed with an electric heating riser and a metal pattern chassis; a cooling pipe is arranged inside the metal pattern, and a water inlet tube head and a water outlet tube head respectively communicated with the water inlet and outlet of the cooling pipe are arranged on the external surface of the metal pattern; a cooling pipe is arranged inside the metal pattern chassis, and a water inlet tube head and a water outlet tube head respectively communicated with the water inlet and outlet of the cooling pipe are arranged on an external surface of the metal pattern chassis. The invention has the advantages of long service life, high quality of casting pieces, good heat recovery and environment protection, and wide application prospect.

Owner:中国冶金科工股份有限公司

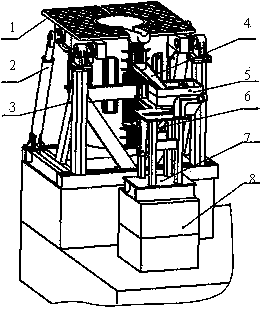

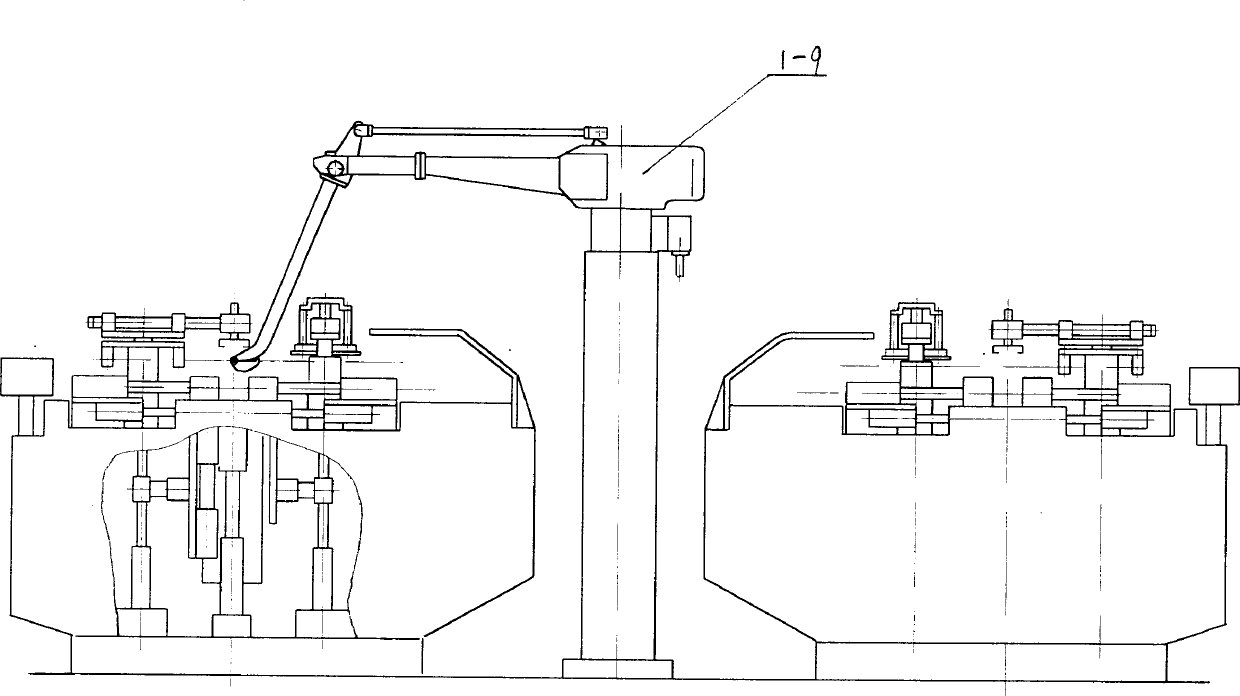

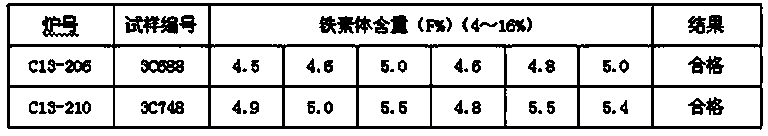

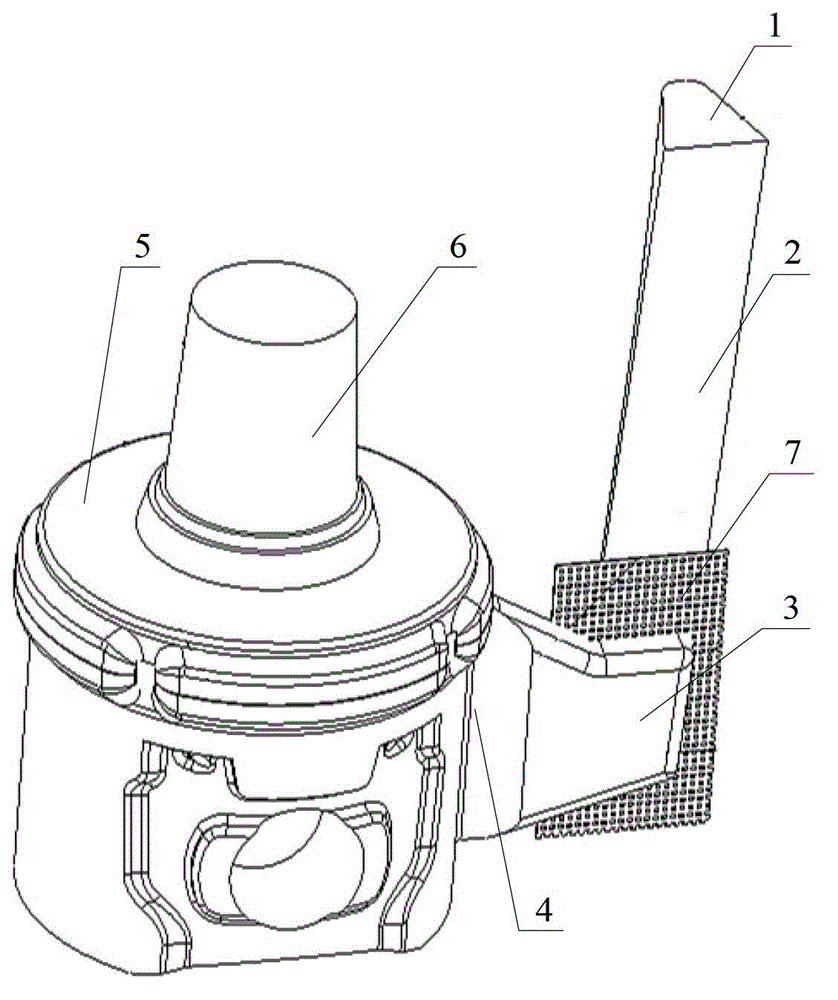

Automatic aluminium piston casting machines

InactiveCN1406690AImprove casting qualityComply with sequential solidification conditionsCasting plantsManipulatorMachining

A full-automatic casting machine for aluminium piston is composed of main body, external mould and edge core unit, mould pushing unit, manipulator for taking cast part, central core unit, rotating unit, manpulator for inlaying steel plates, steel plate chamber, filter net installing unit, and casting robot. Its advantages are high autoamtic level, productivity, and quality of castings.

Owner:SHANDONG BINZHOU BOHAI PISTON

High-temperature high-pressure ultralow sulfur-and-phosphorus valve body casting forming process

ActiveCN104190874AImprove relative dimensional accuracyImprove surface qualityFoundry mouldsFoundry coresSulfurEconomic benefits

The invention relates to the technical field of valve body casting and discloses a high-temperature high-pressure ultralow sulfur-and-phosphorus valve body casting forming process. A plane in which the centers of three pipe openings of a high-temperature high-pressure ultralow sulfur-and-phosphorus valve body casting part are located is used as a parting surface, first dead heads are arranged right above the three pipe opening respectively, second dead heads are arranged above the intersected positions of all pipes of the valve body casting part respectively, a plurality of chilling blocks are arranged under the intersected positions of all the pipes of the valve body casting part respectively, the chilling blocks are separated from the casting part by chromium ores, a bottom-returning type pouring system is adopted for pouring, a cross gate is positioned under the valve body casting part and is connected with a plurality of inner gates on the same horizontal plane, and an outlet in the top end of each inner gate is formed in the wall, close to the end surface, of the corresponding pipe opening. The valve body produced by adopting the casting forming process has the good casting forming quality, the formed matrix structure is compact, the CAE (Computer Aided Engineering) simulation technique is adopted, the production period of the casting part is shortened, the casting part manufacturing process is reasonably optimized, models and molding materials can be saved, the casting part production cost is reduced and the high economic benefit is achieved.

Owner:LANZHOU LS GRP

Method for casting automobile axle housing by V method

InactiveCN103722125AImprove casting qualityImprove yieldFoundry mouldsFoundry coresMechanical engineeringSurface film

The invention relates to a casting method and in particular relates to a method for casting an automobile axle housing by a V method. The method comprises the steps of (1) covering a model with a film; (2) adhering a casting head; (3) spraying coating on the surface film of the model; (4) drying the coating; (5) performing sand compaction; (6) rotating a sand box after the sand box is lifted out, and putting a loam core and cold iron into the sand box; (7) combining an upper box and a lower box; (8) preparing furnace burdens; (9) performing pouring. According to the method disclosed by the invention, a casting is high in casting quality, high in yield and low in casting cost.

Owner:LIUZHOU JINTE NEW WEAR RESISTANT MATERIAL CO LTD

Casting technique of supporting frame for building

InactiveCN106363129AGuarantee the pouring qualityReduce sticky sandFoundry mouldsFoundry coresModel sampleChiller

The invention relates to the technical field of casting, in particular to a casting technique of a supporting frame for building. The casting technique comprises the following processes that an outer cavity real sample model is adopted to be combined with an inner cavity sand core to form a cavity of a casting; the outer cavity real sample comprises a casting model sample and a supporting bed mould wholly covering the upper side of the supporting end of the casting model sample, and the top plane of the supporting bed mould serves as a model parting surface; the inner cavity sand core comprises a first sand core body for forming an inner cavity and a second sand core body for forming a small top hole, the second sand core body is inserted into the first sand core in a matched manner, and the bottom of the first sand core extends to the lower side of a flange hole and is fixed to a lower sand mould through an arbor; an open riser is arranged at the supporting end of the casting, a riser neck is arranged between the open riser and the end face of the supporting end, and a blind riser is arranged in the flange hole of the casting; the inner cavity of the casting, the normal direction of the end face of the flange end and the periphery of the flange end are each provided with a direct cooling chiller; and an open type gating system is adopted, a flow gate of an ingate is located below the blind riser of the inner cavity and is directly communicated with the blind riser, and a filter is arranged at the tail end of the flow gate.

Owner:KOCEL STEEL

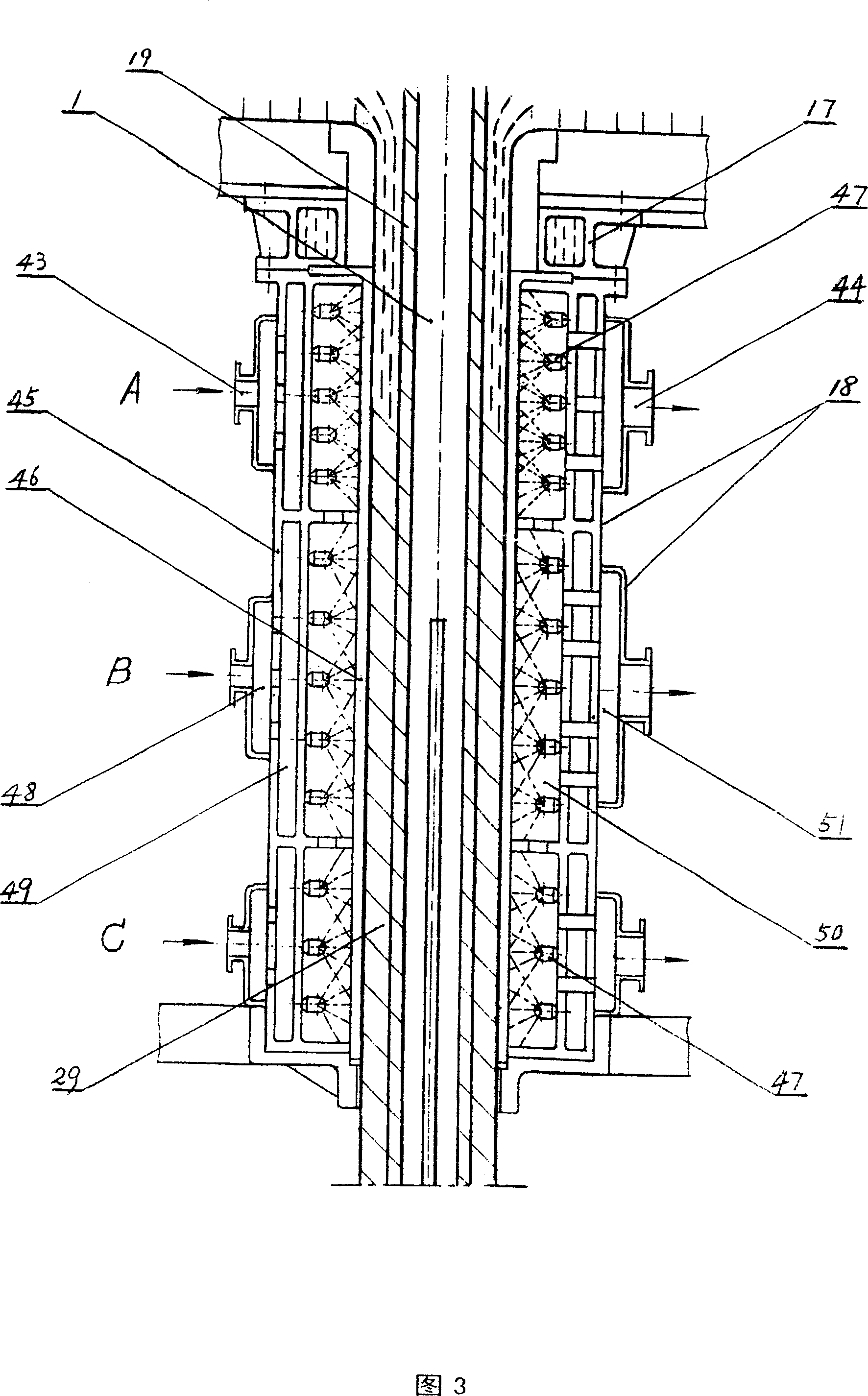

Continuous casting machine for stainless steel seamless composite hollow pipe blank

The present invention relates to a stainless steel seamless composite hollow pipe billet continuous casting machine. Said continuous casting machine consists of the following five portions: internal crystallizer, upper crystallizer, lower crystallizer, dummy ingot cutting car and turnover roller way. Said invention also provides the connection mode of all the above-mentioned five portion, and provides the working principle of said continuous casting machine and its concrete operation method.

Owner:李铁铎

High-thermostability water-based paint containing nanometer wollastonite for lost foam casting and manufacturing method of water-based paint

InactiveCN105057571AImprove breathabilityImprove thermal stabilityFoundry mouldsFoundry coresWater basedAluminum magnesium silicate

The invention relates to the technical field of lost form casting and in particular to high-thermostability water-based paint containing nanometer wallastonite for lost foam casting and a manufacturing method of the water-based paint. According to the paint, high-alumina bauxite and violet lime stone powder with the different grain sizes are used as refractory aggregates, so that the permeability of a coating is good, the thermostability is better, and the high heat resistance and impact resistance are good; a nanometer wollastonite, aluminum-magnesium silicate and sodium carboxymethylcellulose mixed sizing agent is used as a suspending agent, so that the paint has the good suspension property and thixotropy, a polyethylene wax emulsion is dispersed into the coating, then the flatness of the surface of the coating can be improved, the sand prevention stickiness is improved, rapid melting is performed in the pouring process, and the permeability of the coating is further improved; and the obtained paint is good in stickiness, the coating strength is uniform, the permeability is good, the thermostability is good, the size is stable, molten metal is not polluted, stripping is easy after casting is finished, and the quality of castings is effectively improved.

Owner:MINGGUANG CITY LIUXIANG PUMP IND

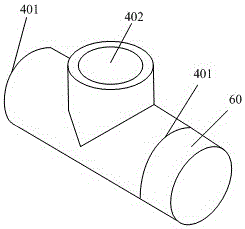

Bottom gating system and paving method thereof

ActiveCN105108065ASolve the shortcomings of poor qualityPure qualityFoundry mouldsFoundry coresBottom gateEngineering

The invention discloses a bottom gating system. The bottom gating system comprises a straight pouring gate, a transverse pouring gate and an inner pouring gate, wherein the inlet end of the straight pouring gate is connected with the outlet end of the transverse pouring gate through a first T-shaped pouring gate. The first T-shaped pouring gate adopted by the bottom gating system is similar to a conventional three-way porcelain tube; one transverse end is sealed by a metal plugging plate; the function of the metal plugging plate is characterized in that a first strand of molten steel mixed with a large quantity of impurities enters the T-shaped porcelain tube and can be quickly chilled and coagulated to form a shell when being in contact with the metal plugging plate, so that the impurities are fixed to one side with the metal plugging plate of the T-shaped pouring gate, thereby ensuring that the subsequent clean molten steel is incapable of carrying the impurities into the cavity during flowing; the defects of low quality of the first strand of molten steel and the impurities generated by flushing of the molten steel in the gating system can be effectively solved; the purity of the molten steel flowing into the cavity is ensured, so that the quality of castings is improved. The invention also provides a paving method of the bottom gating system.

Owner:KOCEL STEEL

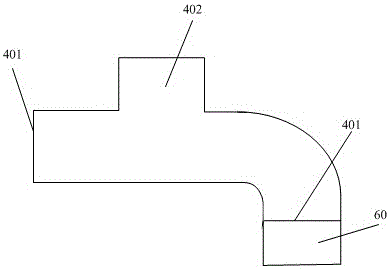

Pouring system for permanent mold gravity casting aluminum piston

InactiveCN102744370AReduce filling speedThe filling process is stableFoundry mouldsFoundry coresSlagPiston

The invention provides a pouring system for a permanent mold gravity casting aluminum piston, comprising a pouring cup, a vertical pouring gate, a horizontal pouring gate and an internal pouring gate, wherein a top end of the vertical pouring gate is communicated with an outlet of the pouring cup and the vertical pouring gate extends vertically; the horizontal pouring gate is communicated with a bottom end of the vertical pouring gate and extends horizontally; an inlet of the internal pouring gate is communicated with an outlet of the horizontal pouring gate and an outlet of the internal pouring gate is communicatied with a mold cavity of a piston mold; and cross sectional areas of the vertical pouring gate, the horizontal pouring gate and the internal pouring gate are increased in order. The minimum cross sectional areas of the vertical pouring gate, the horizontal pouring gate and the internal pouring gate in the pouring system are increased in order, so the pouring gate proportion of the vertical pouring gate, the horizontal pouring gate and the internal pouring gate is controlled strictly, and the pouring system becomes an open pouring system. Therefore, the mold filling speed of metal liquids at the outlet of the internal pouring gate can be reduced sufficiently to stabilize the mold filling process and the casting quality of an aluminum piston blank and decrease the defects of pinholes, slag inclusion, shrinkage porosity and the like of the piston blank, so that the process product yield of the piston blank can be improvd.

Owner:湖南江滨机器(集团)有限责任公司

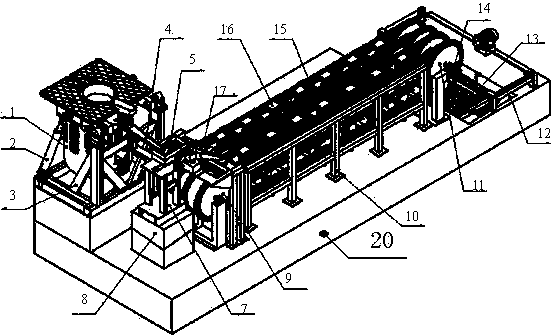

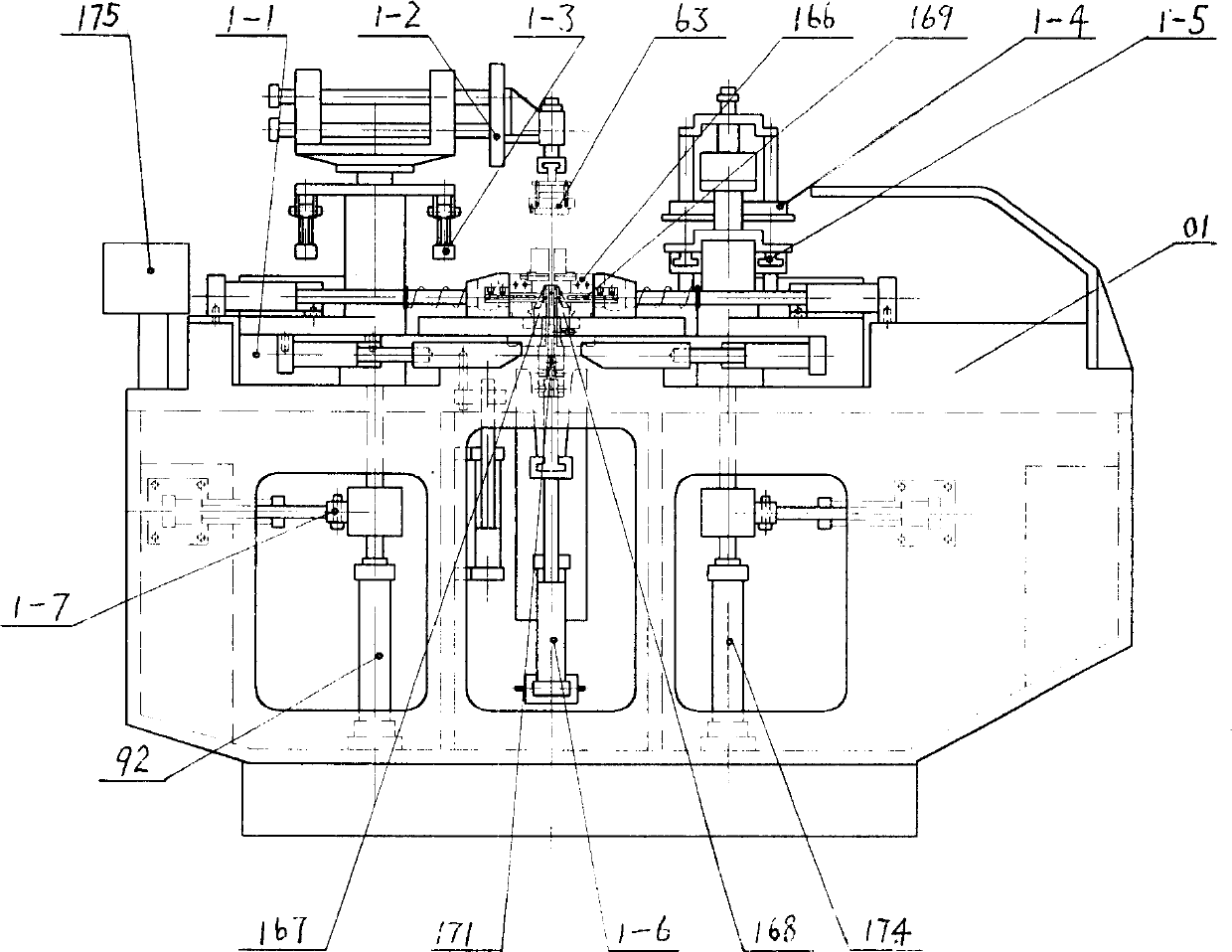

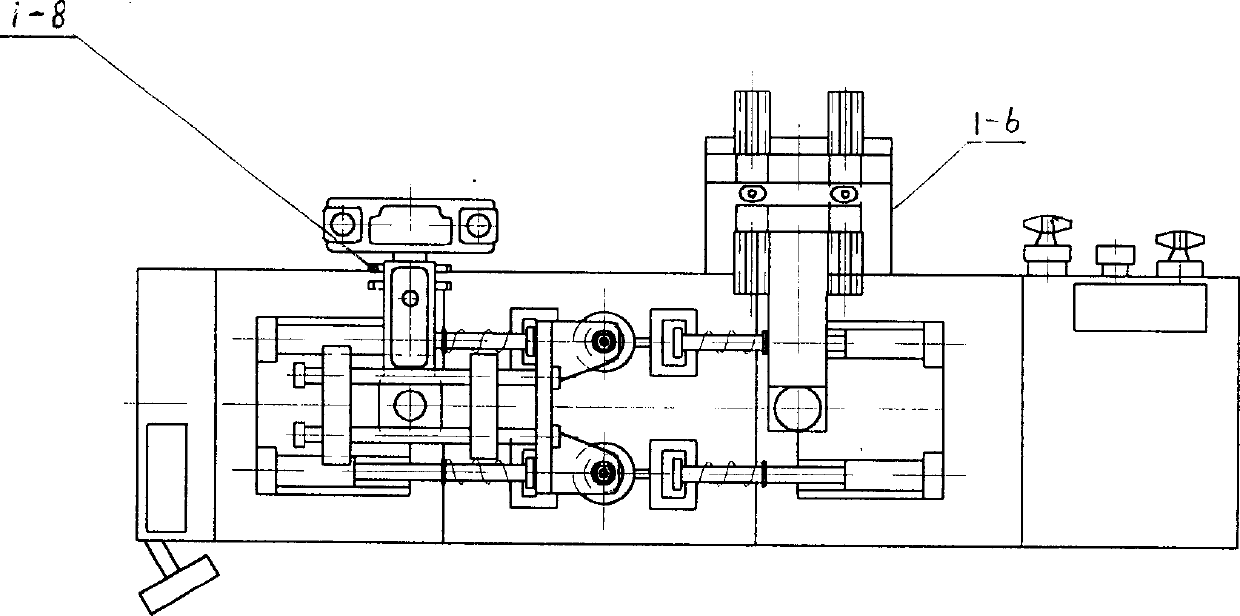

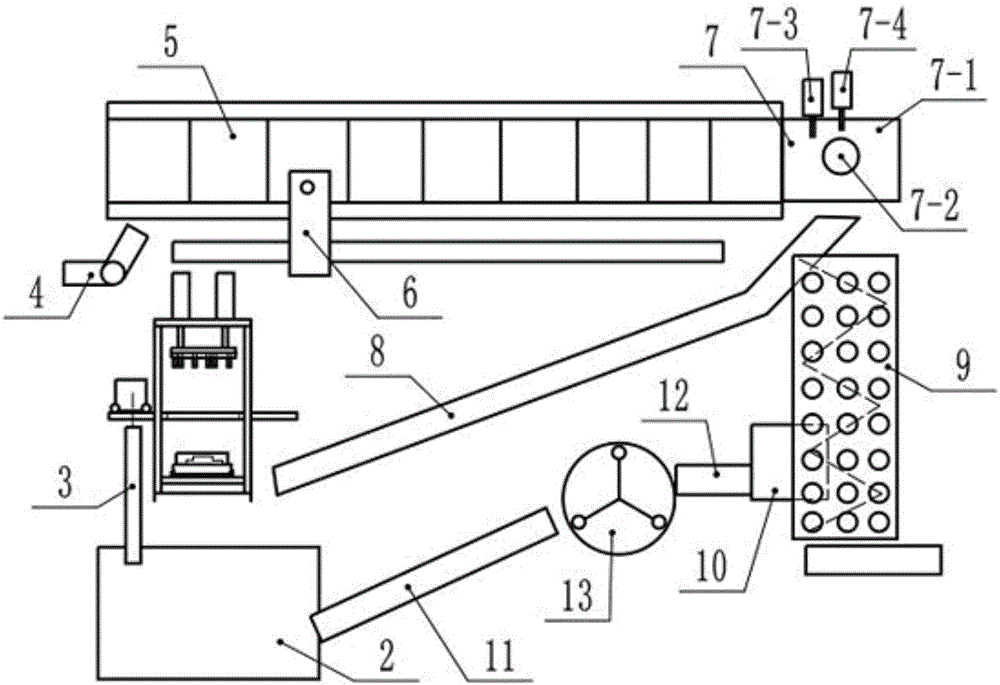

Casting production line

InactiveCN105798283AFully automatedCompact structureCasting plantsMoulding machinesManufacturing lineIndustrial engineering

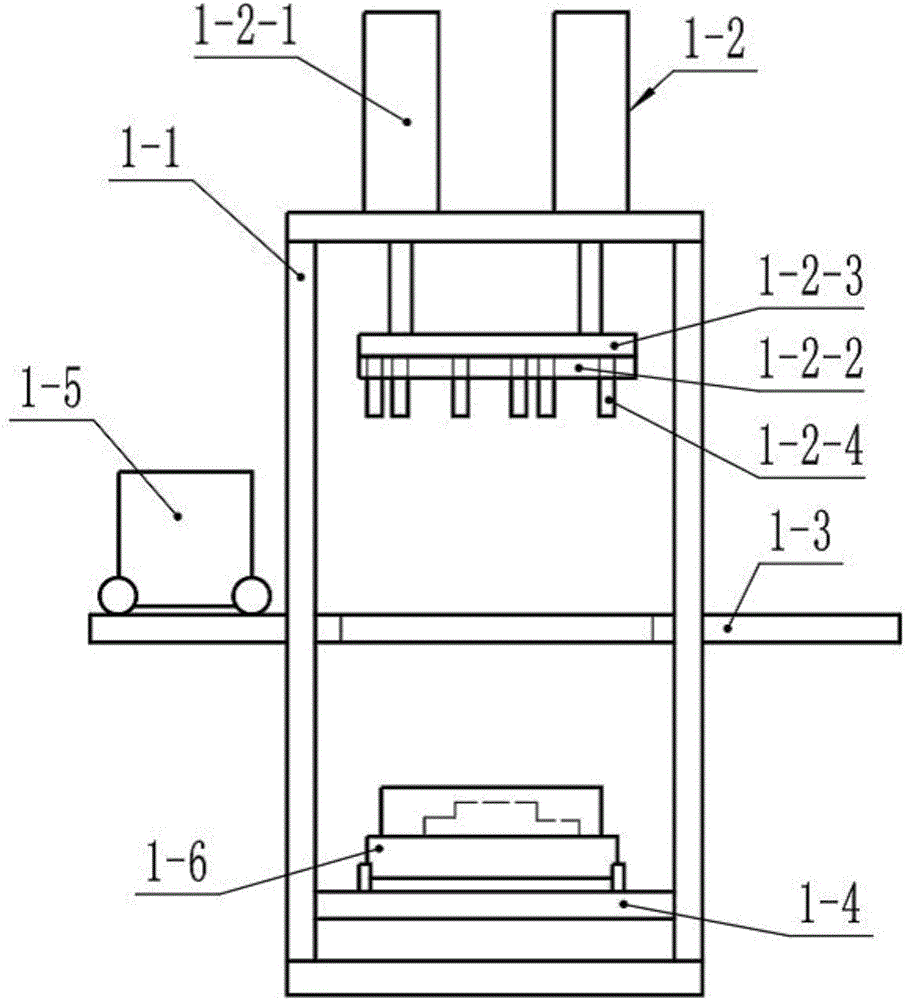

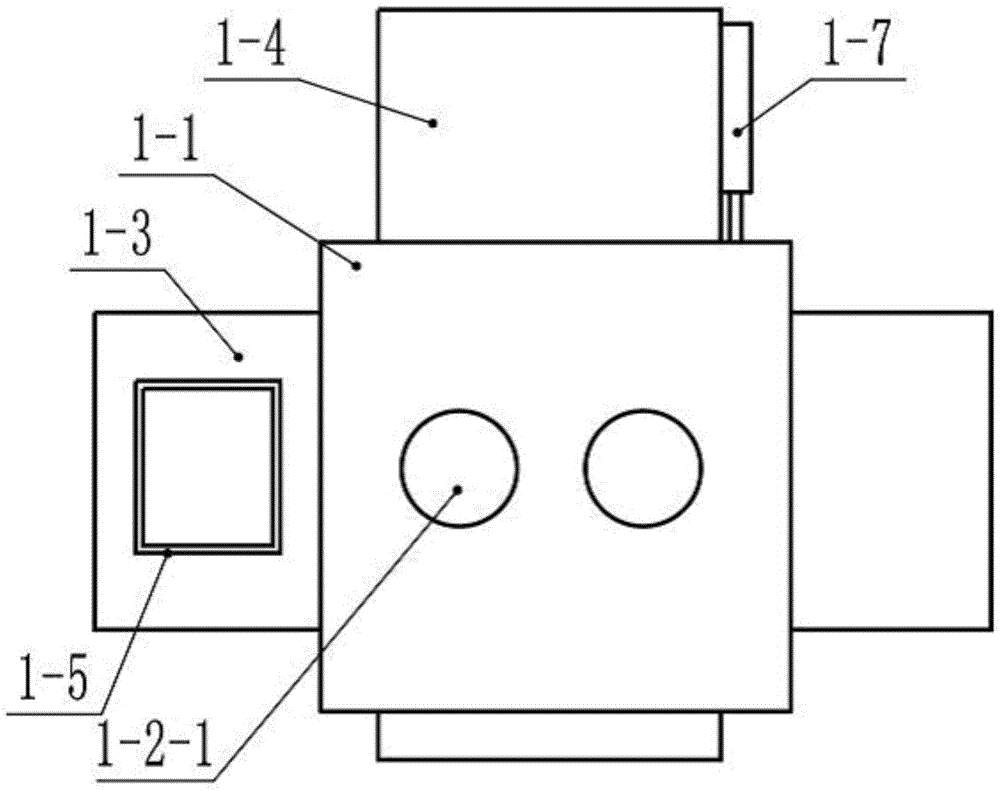

The invention provides a casting production line. A full-automatic sand box molding device is provided with a frame (1-1) and a sand smashing device (1-2). A sand adding track (1-3) horizontally arranged is installed in the middle portion of the frame (1-1). A die track (1-4) horizontally arranged is installed at the bottom of the frame (1-1). The full-automatic sand box molding device further comprises a control box. The sand adding track (1-3) is provided with a sand frame (1-5) controlled by the control box to horizontally move along the sand adding track (1-3). The top and the bottom of the sand frame (1-5) are both provided with openings. A sand falling port is further formed in the sand adding track (1-3), located under the sand smashing device (1-2) and located over the die track (1-4). According to the casting production line, automatic casting production can be achieved, repeated utilization of casting sand is achieved, and the casting production line has the beneficial effects of being good in casting quality, high in efficiency, low in labor cost, capable of saving energy and environment-friendly.

Owner:徐明

Novel process for producing super high manganese steel casting

InactiveCN102230054AImprove casting qualityImprove mechanical propertiesFoundry mouldsProcess efficiency improvementSmelting processElectric arc furnace

The invention belongs to the technical field of high manganese steel smelting process in iron and steel metallurgy, in particular relates to a novel process for producing a super high manganese steel casting. The novel process comprises an electric arc furnace smelting process, a steel casting process and a heat treatment process. An oxidation method used in the smelting process comprises the following steps of: blowing oxygen to support smelting when 18 to 22% of waste steel in a furnace is melted, slagging twice, adding chromium (Cr) iron and manganese (Mn) iron, tapping after all components meet the standards, modifying molten steel and finally performing argon purification. In the steel casting process, a casting head is arranged at the thickest position of the steel casting and designed into a side casting head, preferably a heating and heat-insulating casting head, the temperature of a casting box is under control so that the temperature of the casting is below 300 DEG C, and the casting is cooled with natural air during sand removal to prevent the cracking of the casting. The heat treatment process comprises the following steps of: performing water toughening treatment and tempering at 250 DEG C instantly after quenching. By the adoption of the novel process disclosed by the invention, the quality and mechanical properties of the casting are greatly improved, the casting can be prevented from being broken in use, and the wear resistance of the casting is increased. Besides, the novel process makes full use of resource materials and increases the economic benefit.

Owner:ANSTEEL GRP MINING CO LTD

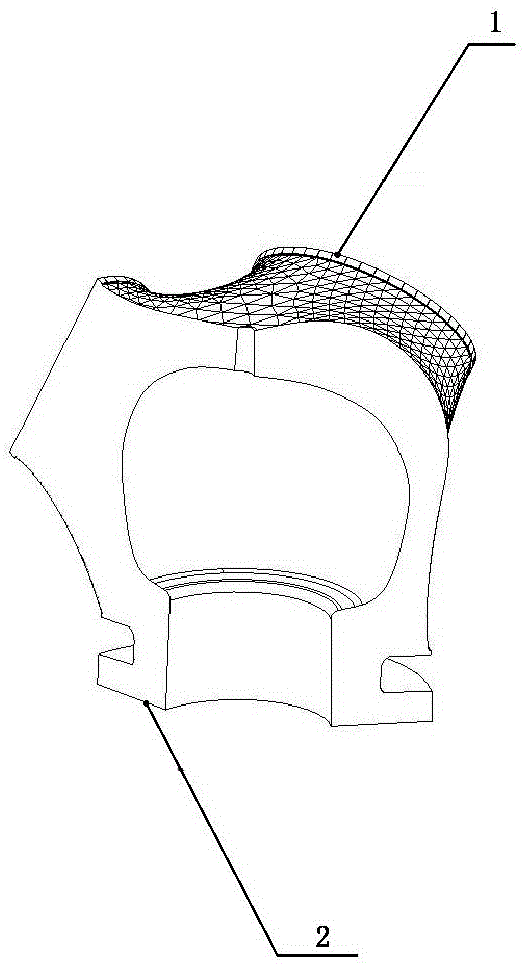

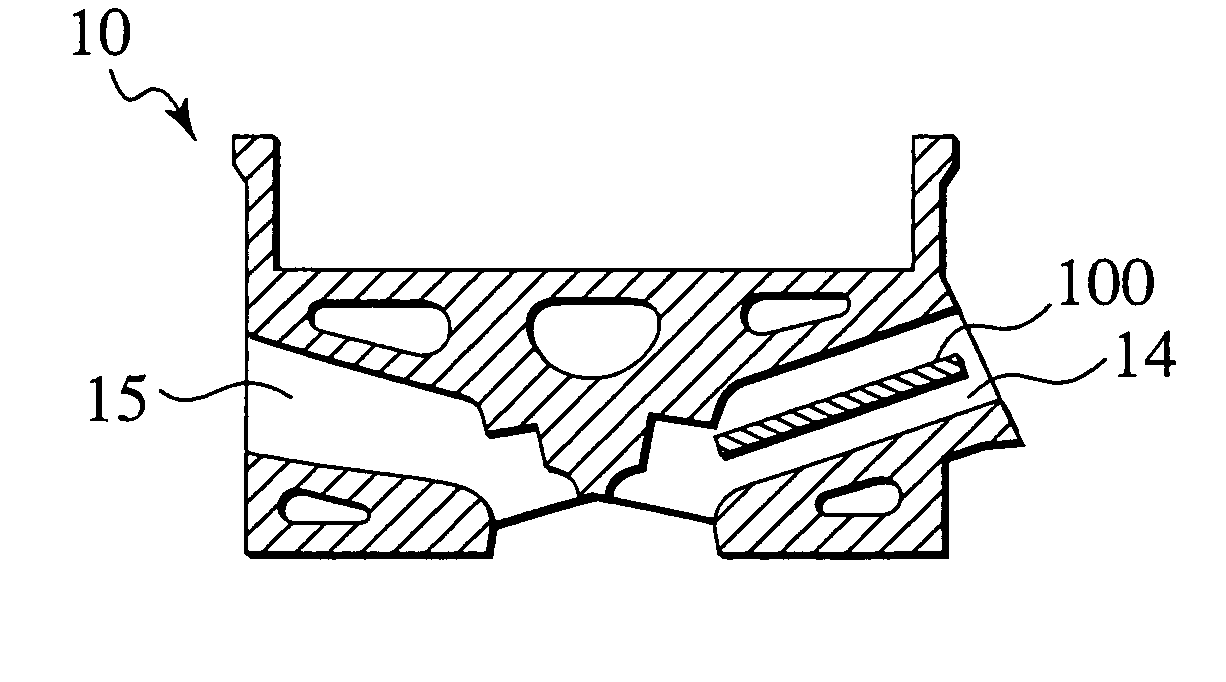

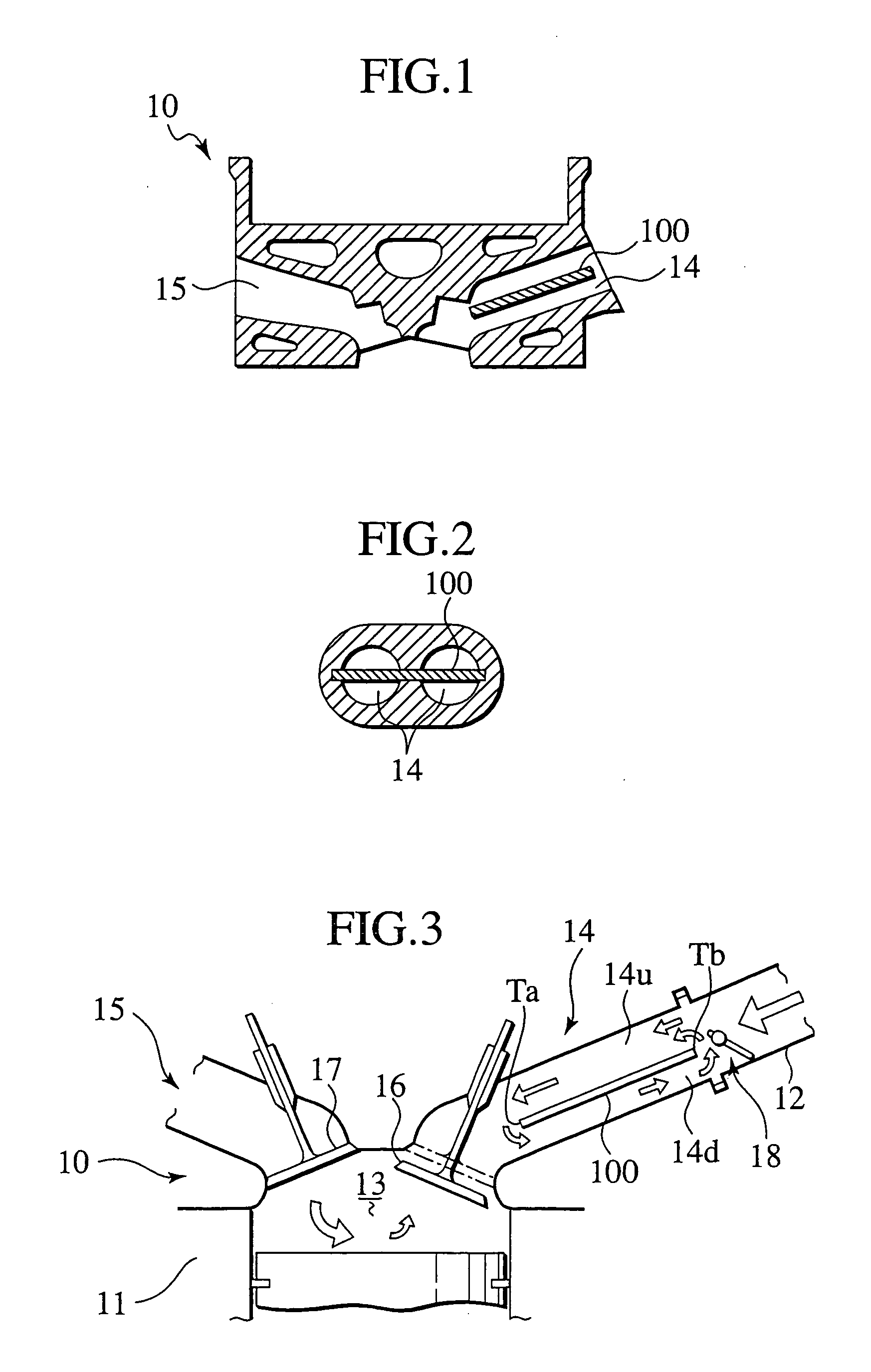

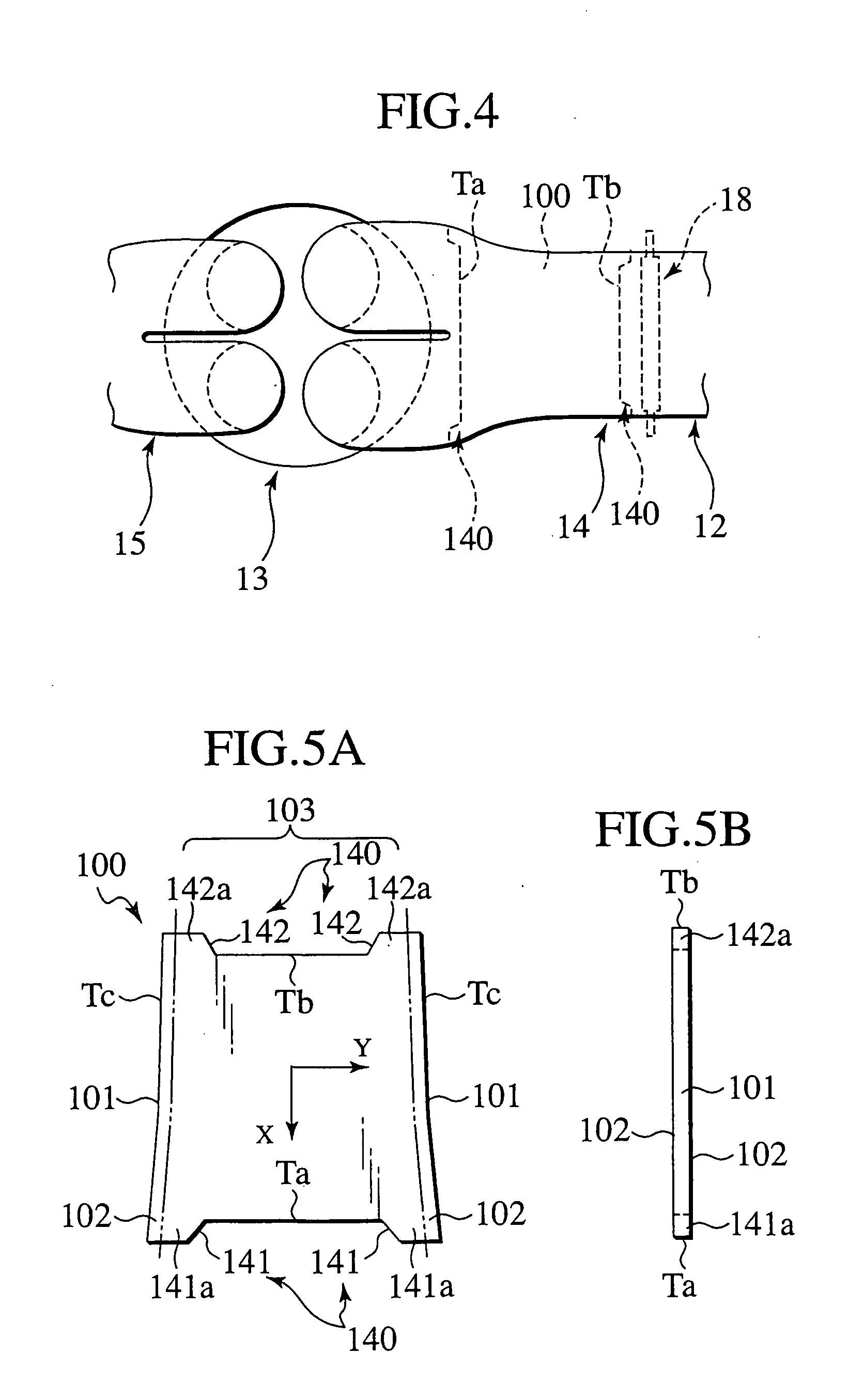

Partition plate for intake port, intake port molding sand core and cylinder head

InactiveUS20050081822A1Improve position offsetImprove casting qualityInternal combustion piston enginesCylinder headsCylinder headCasting mold

A partition plate (tumble plate) for an intake port is previously placed in an intake port molding sand core (port core) for forming an intake port of a cylinder head, and cast-in as the cylinder head is cast-molded, to partition the intake port into a plurality of ports. The partition plate is provided with shift preventing portion that prevent positional shift relative to the intake port molding sand core.

Owner:NISSAN MOTOR CO LTD +1

Low-pressure die casting machine for magnesium alloy automobile wheels

The invention discloses a low-pressure die casting machine for magnesium alloy automobile wheels. The low-pressure die casting machine comprises a main casting machine, a holding furnace, a die, a real-time casting monitoring console and a liquid lifting tube, wherein, the die and the holding furnace which are arranged above the main casting machine are communicated with each other through the liquid lifting tube; the holding furnace comprises a furnace lining, an electrical heating wire, a furnace shell, a crucible, a furnace cover, a fully enclosed liquid filler and a protective gas access device; the furnace shell is internally equipped with the crucible; the furnace lining is arranged between the furnace shell and the crucible, and the inner side of the furnace lining is equipped with the annular electrical heating wire for heating the crucible; and the furnace cover is arranged above the furnace shell, the furnace cover and the furnace shell are sealed by a high-temperature resistant seal ring, and the furnace cover is equipped with the fully enclosed liquid filler, the protective gas access device and the liquid lifting tube. In the invention, a die temperature gradient field conforming to the requirement is established, the furnace temperature can be monitored in real time and the casting quality of the magnesium alloy product is improved.

Owner:江苏圆通汽车零部件有限责任公司

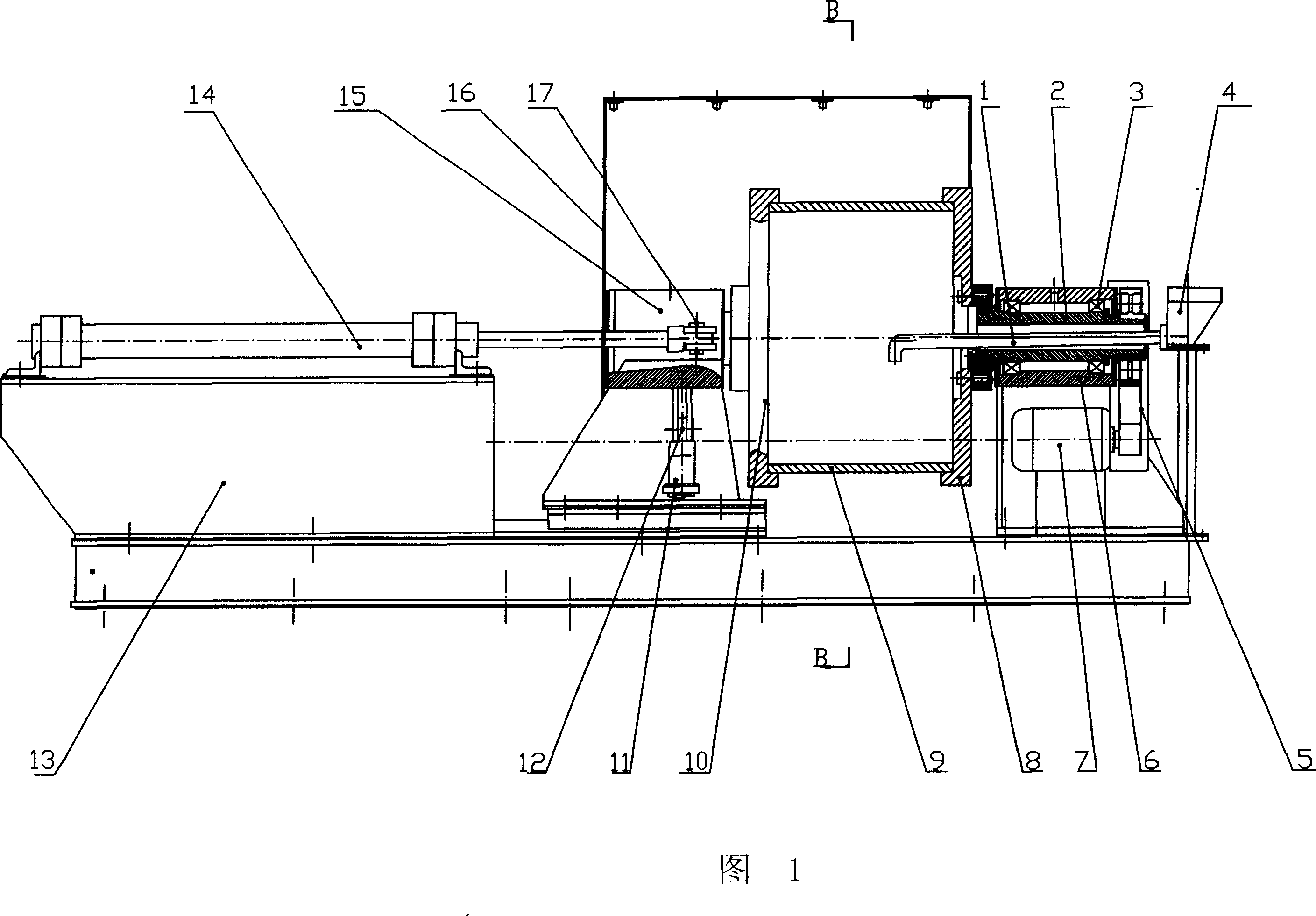

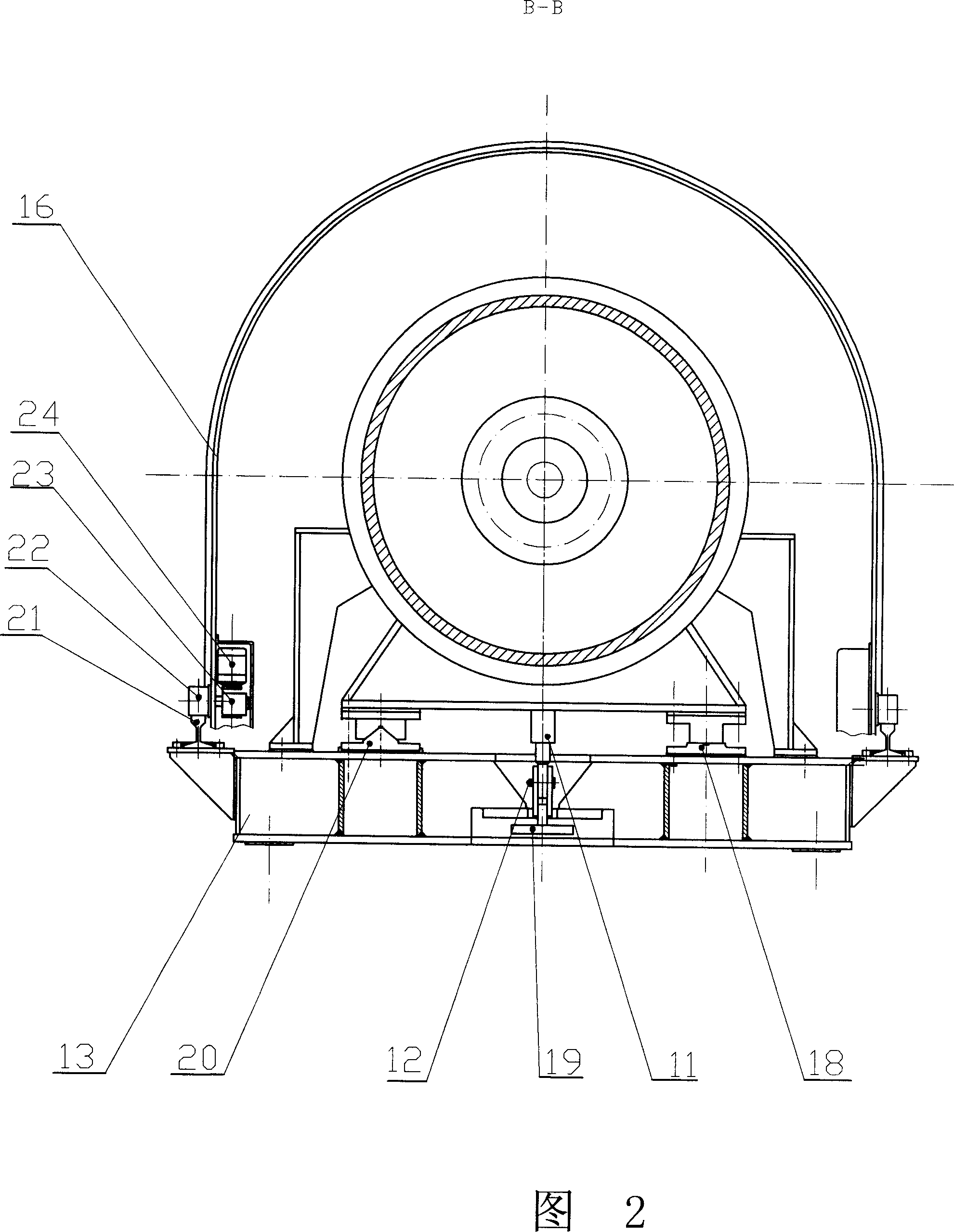

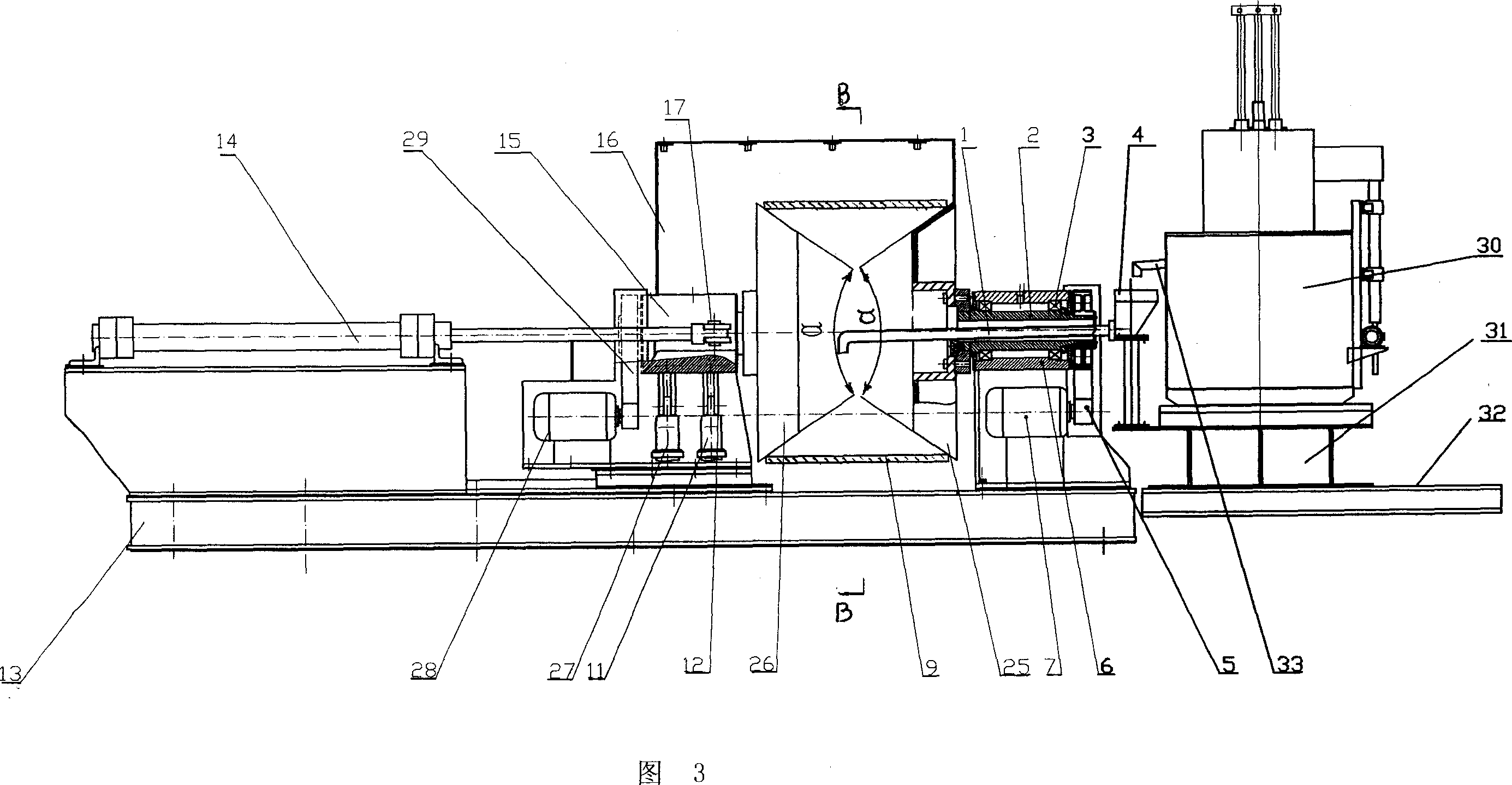

Centrifugal casting machine set

The present invention belongs to the field of metallurgical machine technology, and is especially one centrifugal casting machine set to cast metal melt centrifugally to inner wall of the work piece. The centrifugal casting machine set includes a metal melting furnace, a discharging and casting mechanism, a centrifugal casting machine, etc. It features the metal melting furnace on one pedestal with walking mechanism, the pedestal with material bin and casting conduct pipe, the centrifugal casting machine with two conic forcers, two motors on the frame to drive two forcers to rotate synchronously in the same direction, and two locking hydraulic cylinders below the movable frame. The present invention has the advantages of integrated metal melting furnace and centrifugal casting machine, small production space, high production efficiency, low heat loss and high product quality.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com