Frame assembly for a motorcycle

a frame assembly and motorcycle technology, applied in the direction of folding cycles, cycles, transportation and packaging, etc., can solve the problems of excessive stress and lowering manufacturing productivity, and achieve the effects of short time, enhanced manufacturing productivity, and reduced welding length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

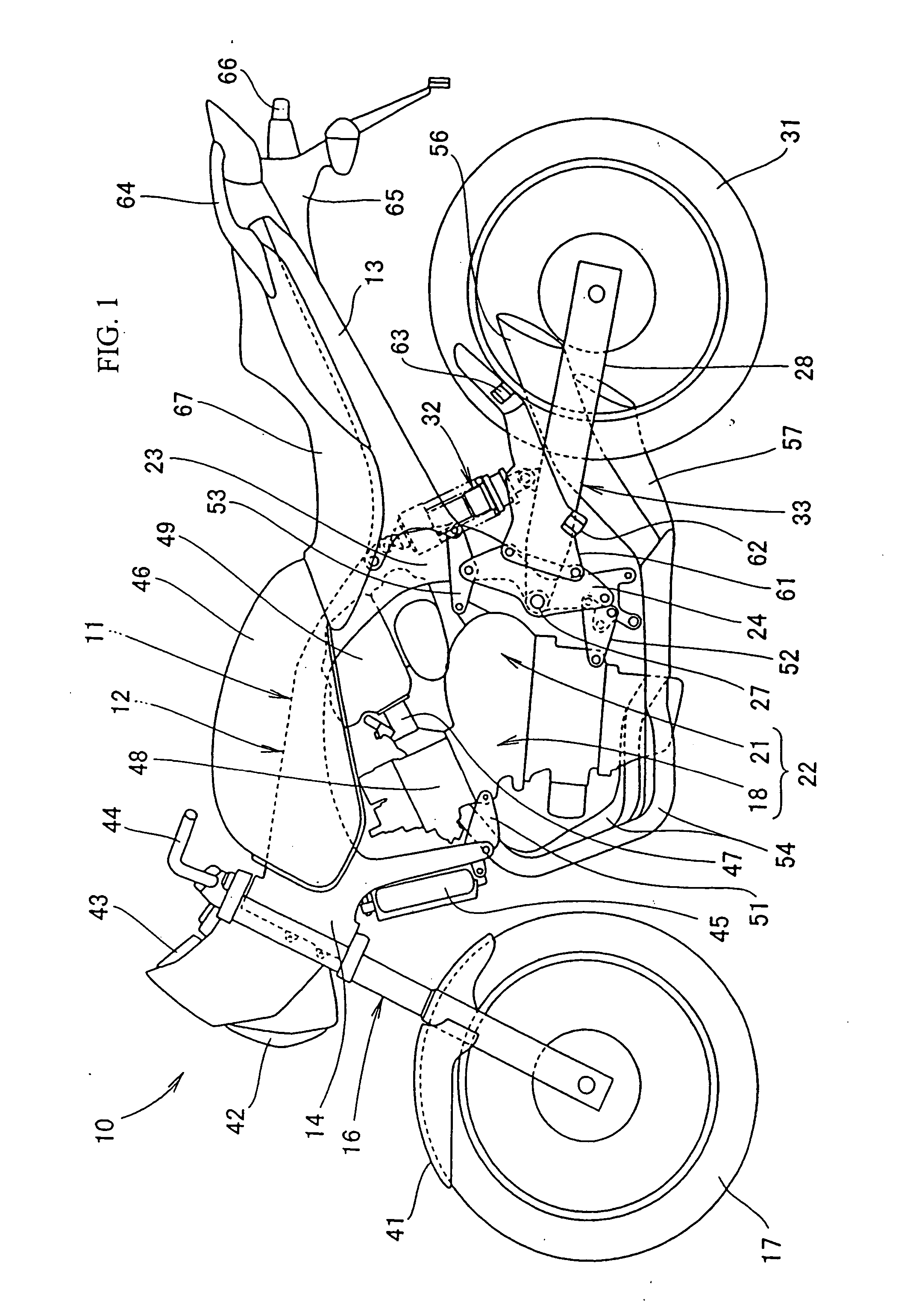

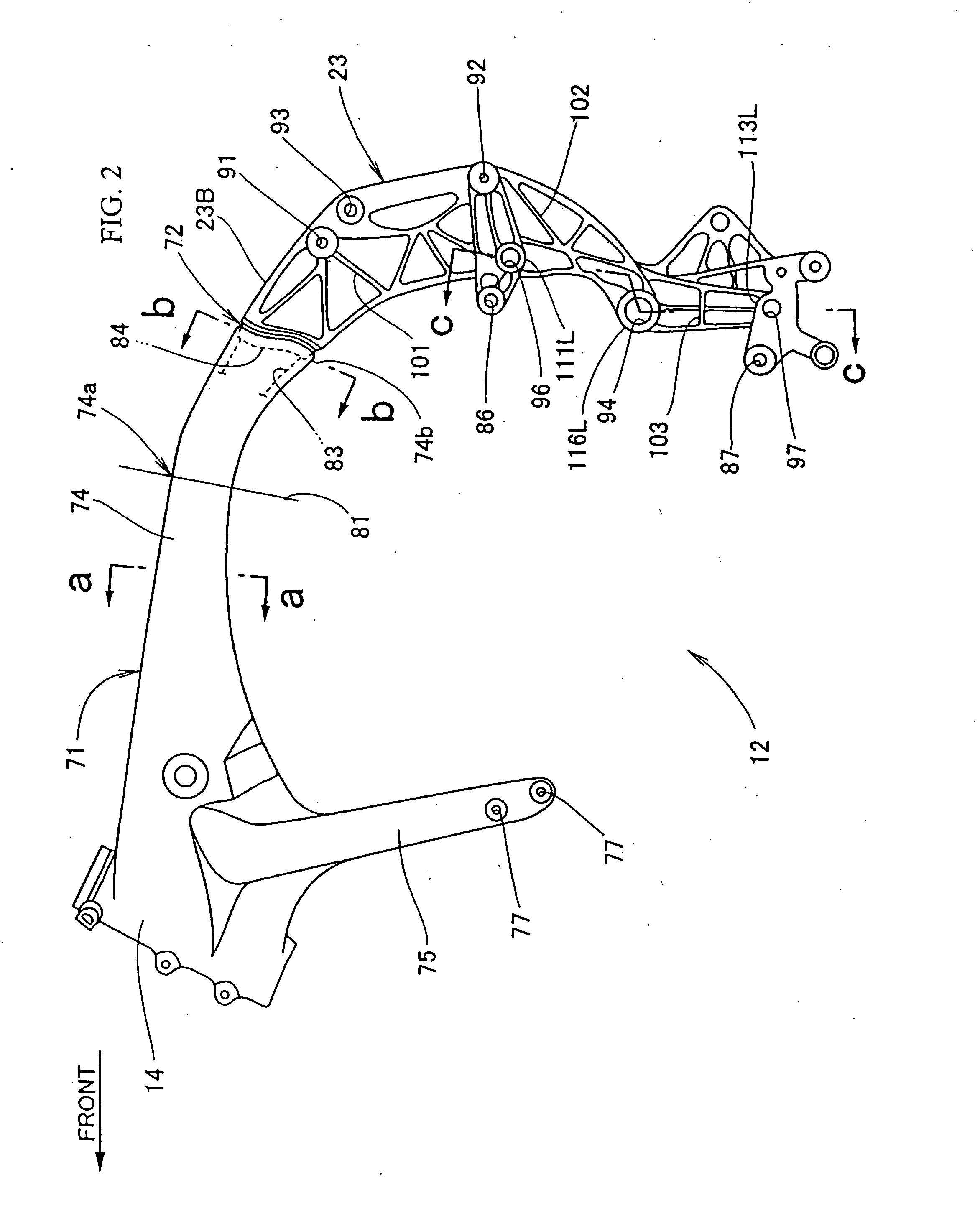

[0050]FIG. 2 is an isolated side plan view (the arrow labeled “FRONT” in the figure indicates the direction corresponding to the front side of the vehicle) of a main frame according to the first embodiment of the present invention. The main frame 12 of FIG. 2 is cast from an aluminum alloy, and includes two primary component parts arranged serially in the front-to-rear direction of the vehicle. Specifically, the main frame 12 includes a front component part and a rear component part, namely, a front frame portion 71 on the front side, and the rear frame portion 23 connected to the rear end of the front frame portion 71 by welding. In the Figures, symbol 72 denotes a welded coupling portion between the front frame portion 71 and the rear frame portion 23.

[0051] The front frame portion 71 is a member that is formed so as to be hollow by placing a core within the mold for the front frame portion 71 at the time of casting. The front frame portion 71 integrally includes the head pipe 14...

second embodiment

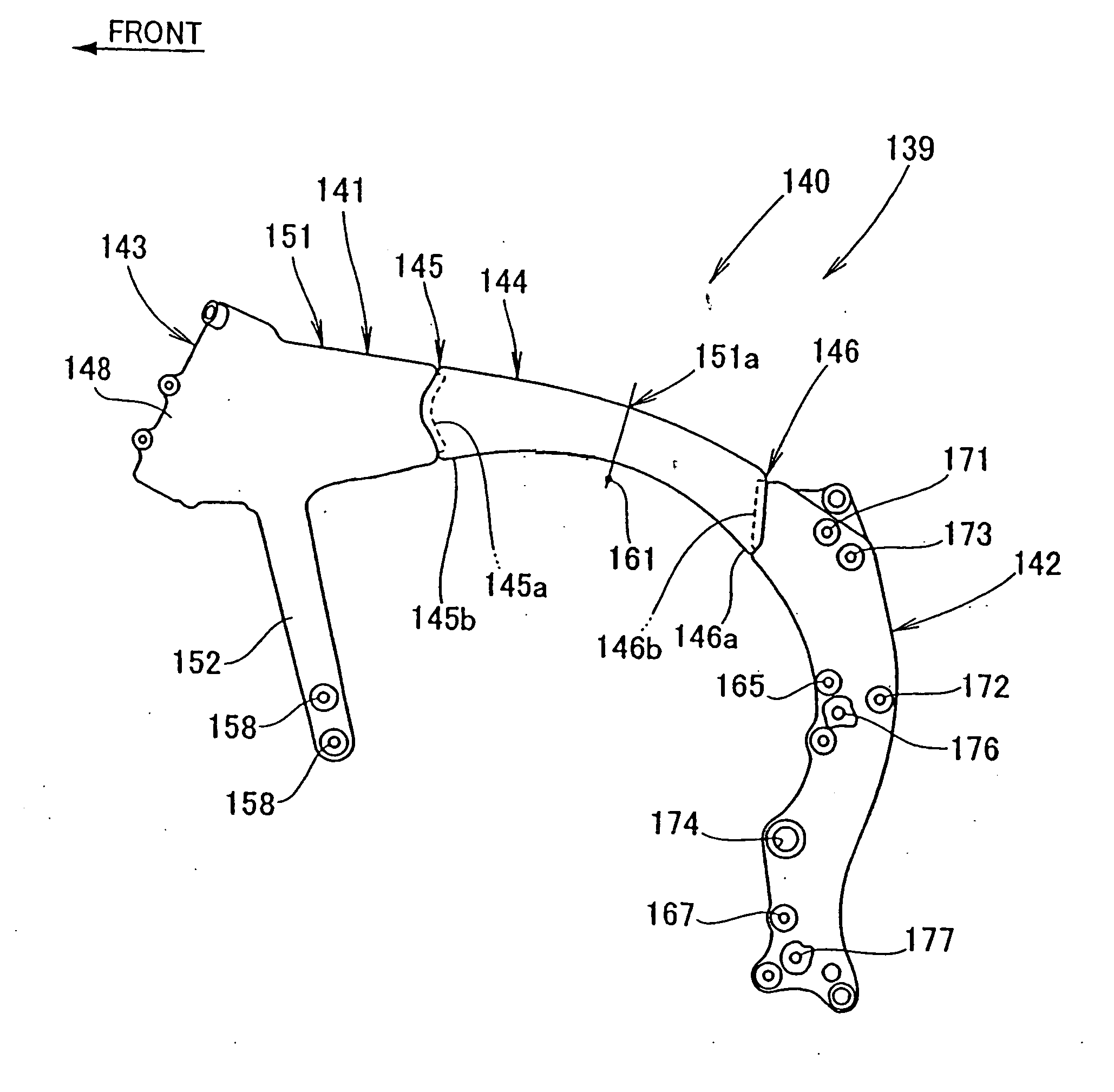

[0080]FIG. 7 is a side view of a main frame 140 according to a second embodiment of the present invention. The main frame 140 of a frame assembly 139 is a member cast from an aluminum alloy and composed of a front frame portion 141, for placement on the front side of the vehicle, and a rear frame portion 142 welded to the rear end of the front frame portion 141.

[0081] The front frame portion 141 is a member formed to be hollow by placing a core within the mold at the time of casting, and is composed of two component parts, i.e., a front half portion 143 and a rear half portion 144 welded to the rear end of the front half portion 143. Incidentally, in FIG. 7, symbol 145 denotes a first coupling portion between the front half portion 143 and the rear half portion 144, and symbol 146 denotes a second coupling portion between the rear half portion 144 and the rear frame portion 142. Thus, the main frame 140 is trisected in the front-rear direction.

[0082] In addition, the front half po...

third embodiment

[0090] FIGS. 8(a) and 8(b) are side views of a main frame 180 according to a third embodiment of the present invention. In FIGS. 8(a) and 8(b), the same components as those in the second embodiment shown in FIG. 7, where unchanged from the second embodiment, are denoted by the same symbols as used above, and detailed description thereof is omitted.

[0091] In FIG. 8(a), a main frame 180, constituting a frame assembly 179, is cast from an aluminum alloy. The main frame 180 is composed of a front frame portion 181 on the front side of the vehicle, and a rear frame portion 142 welded to the rear end of the front frame portion 181. Incidentally, denotes a welded coupling portion 183 is provided between the front frame portion 181 and the rear frame portion 142. The coupling portion 183 includes a front-side coupling portion 183a. The front-side coupling portion 183a is a recessed portion provided at the rear end of the front frame portion 181. The coupling portion 183 also includes a rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com