Patents

Literature

60results about How to "Reduce weld length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

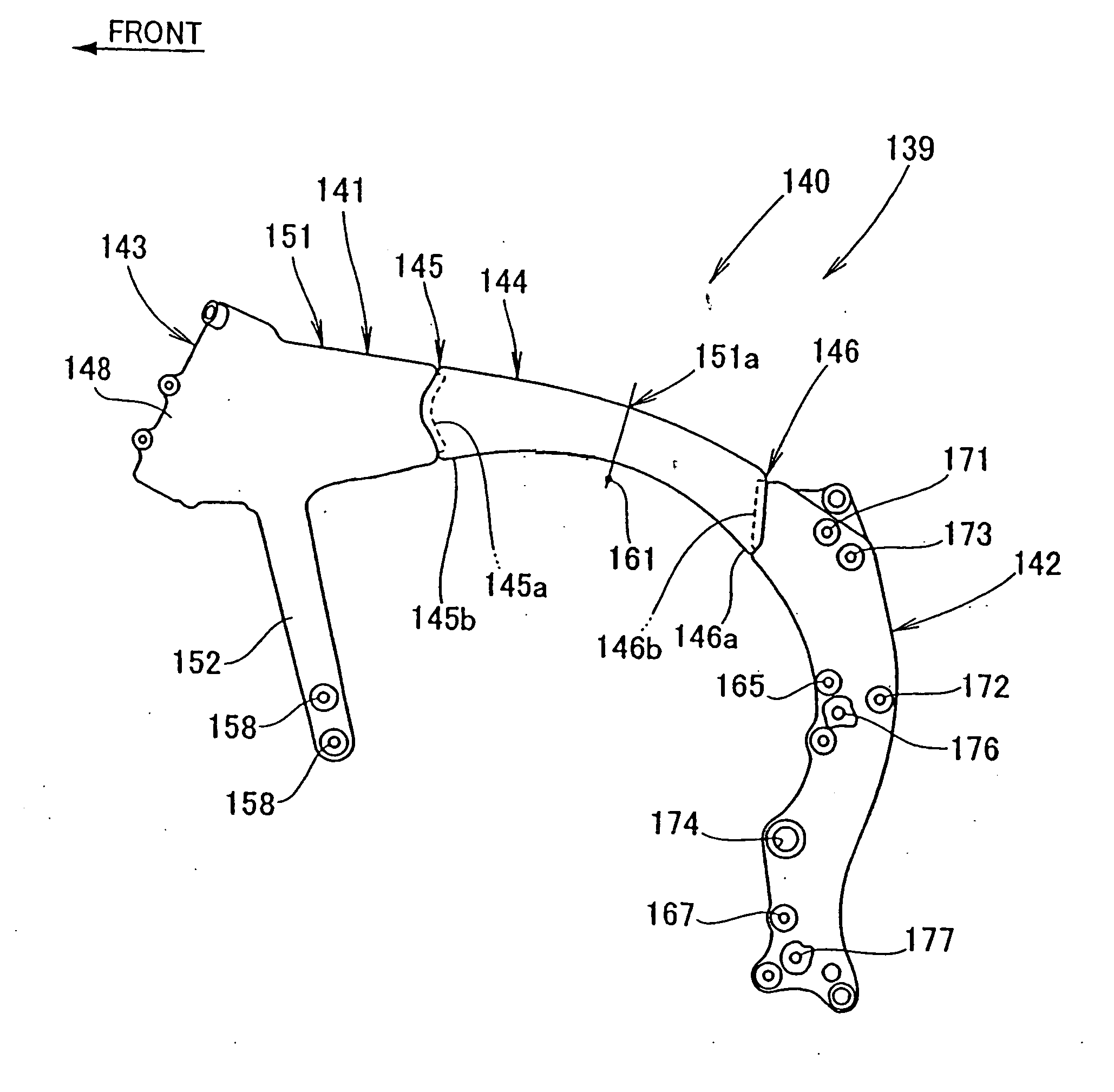

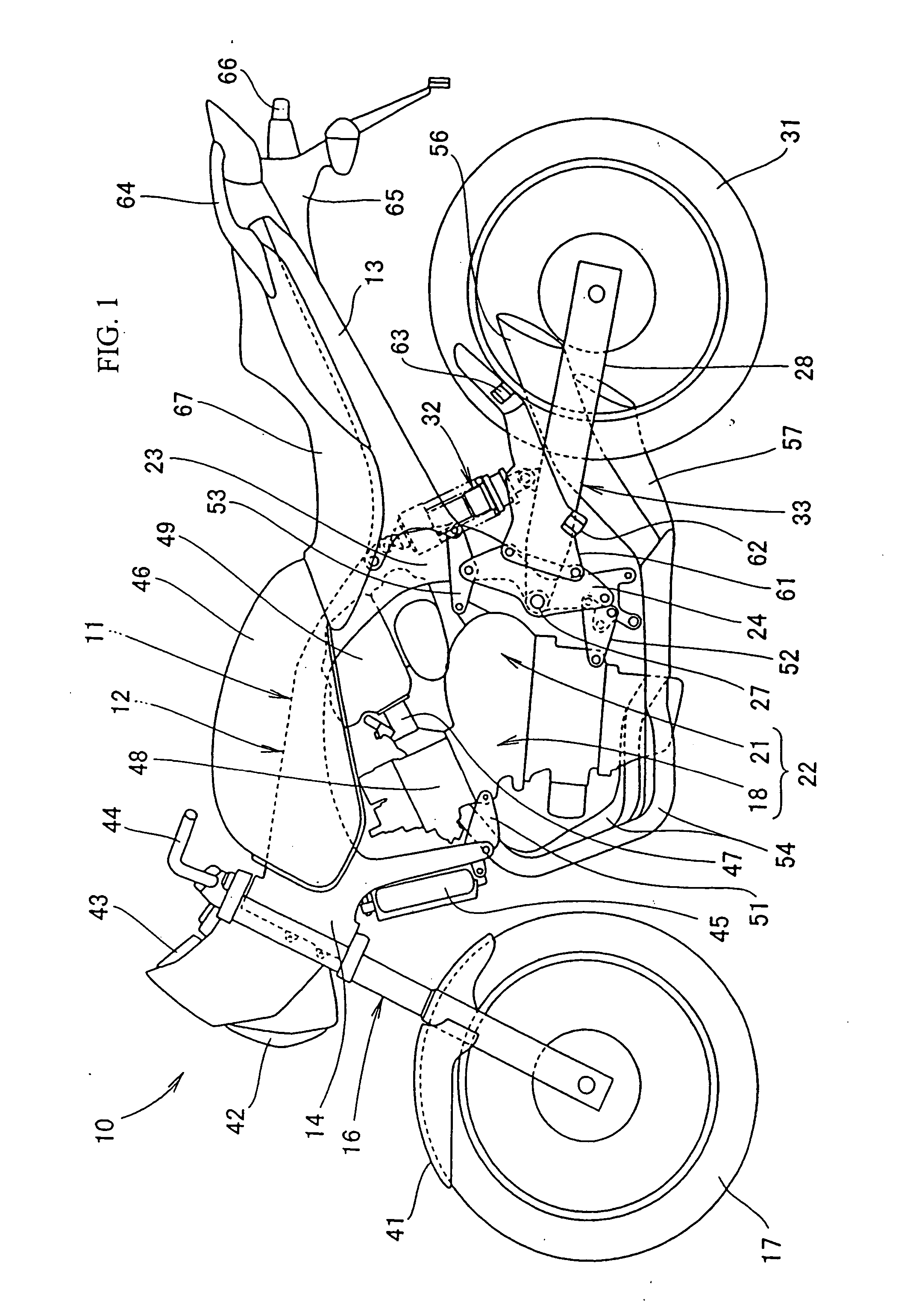

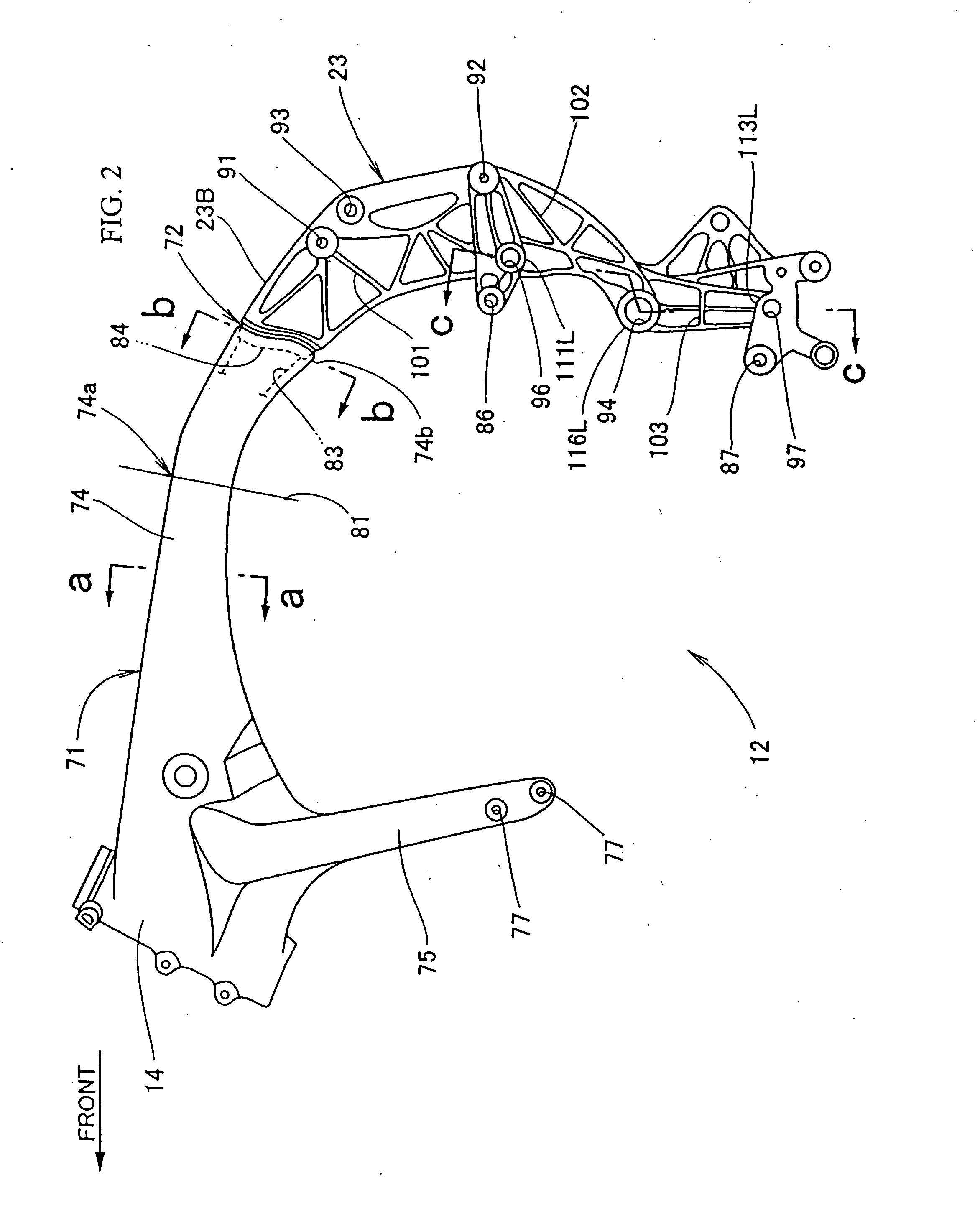

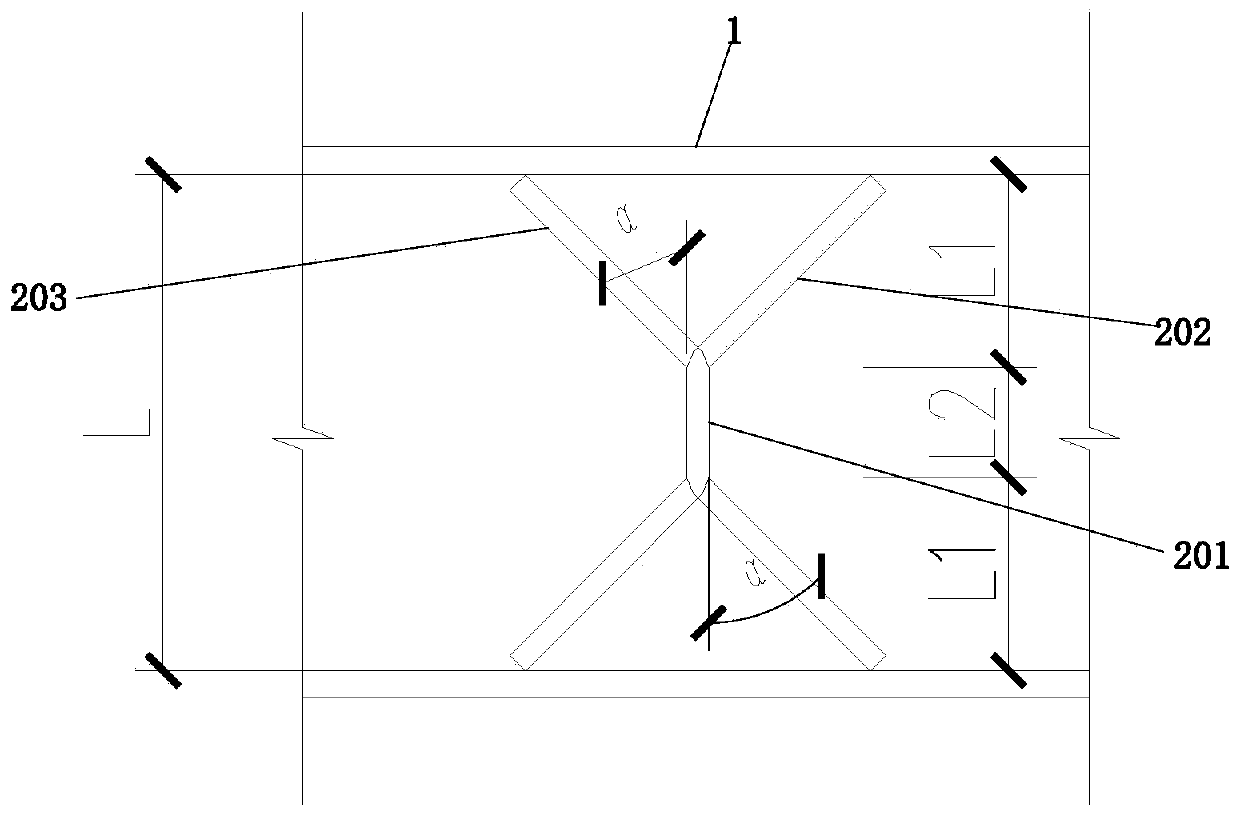

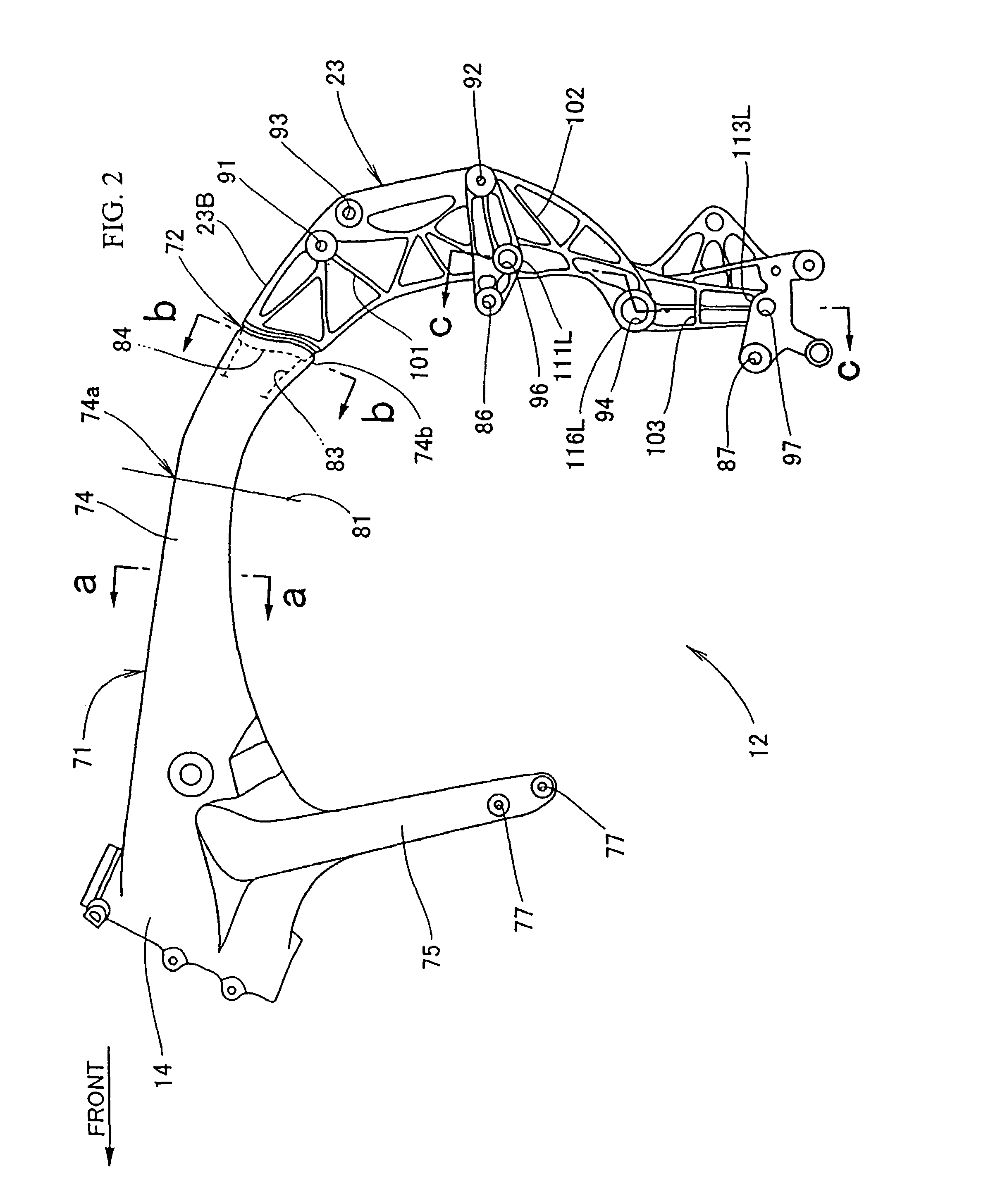

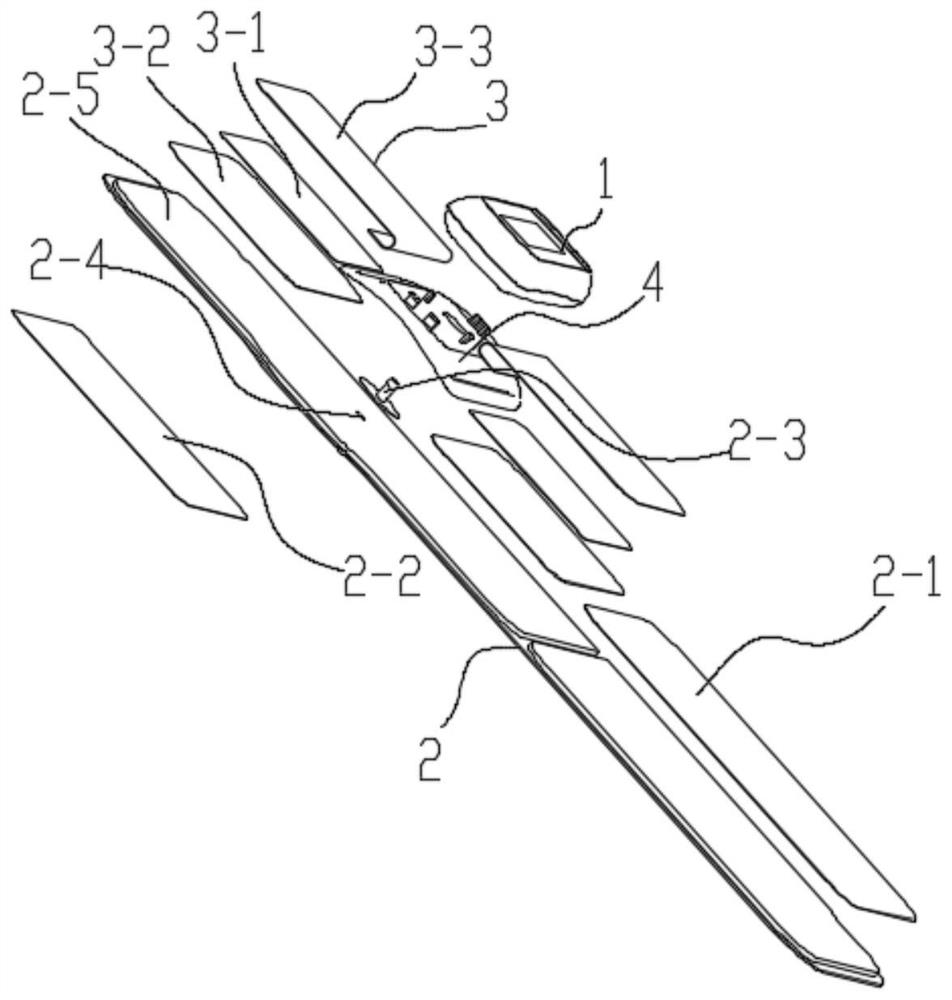

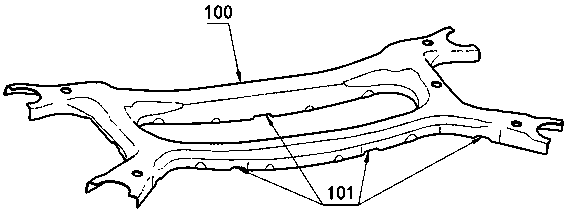

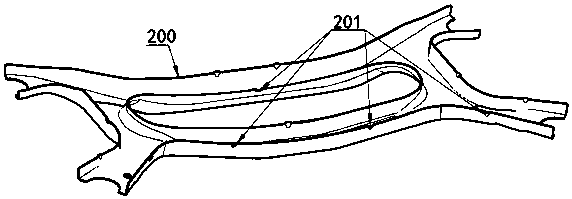

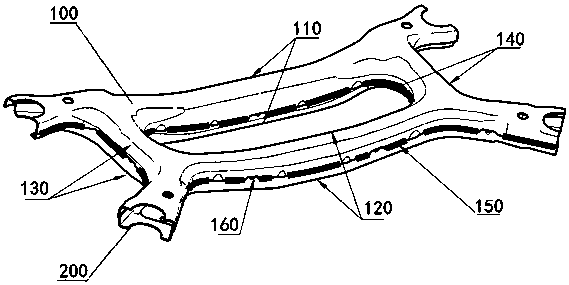

Frame assembly for a motorcycle

ActiveUS20060197304A1Improve manufacturing productivityReduce weld lengthPassenger cyclesChildren cyclesVehicle frameCoupling

A motorcycle body frame includes a main frame including a head pipe for supporting a front suspension at the front end thereof, a single leading frame portion extending rearwardly from the head pipe, and a rear frame portion for supporting a rear wheel suspension. The rear frame portion extends substantially downwardly from a rear part of the leading frame portion. The main frame, cast from an aluminum alloy, includes two component parts arranged front-to-rear. For example, a front frame portion is provided, and a rear frame portion is fixed to the rear side of the front frame portion. The leading frame portion has a small section portion, where the main frame is smallest in sectional area, disposed substantially centrally in the longitudinal direction thereof. The two component parts of the frame are joined at a coupling portion of the main frame situated in back of the small section portion.

Owner:HONDA MOTOR CO LTD

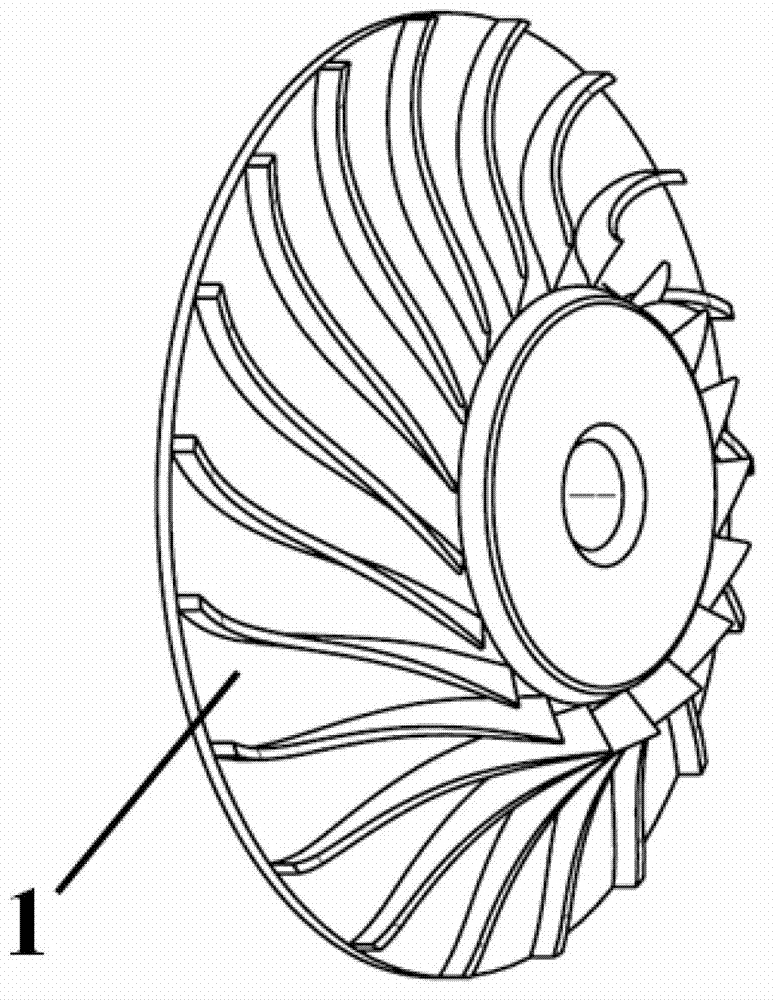

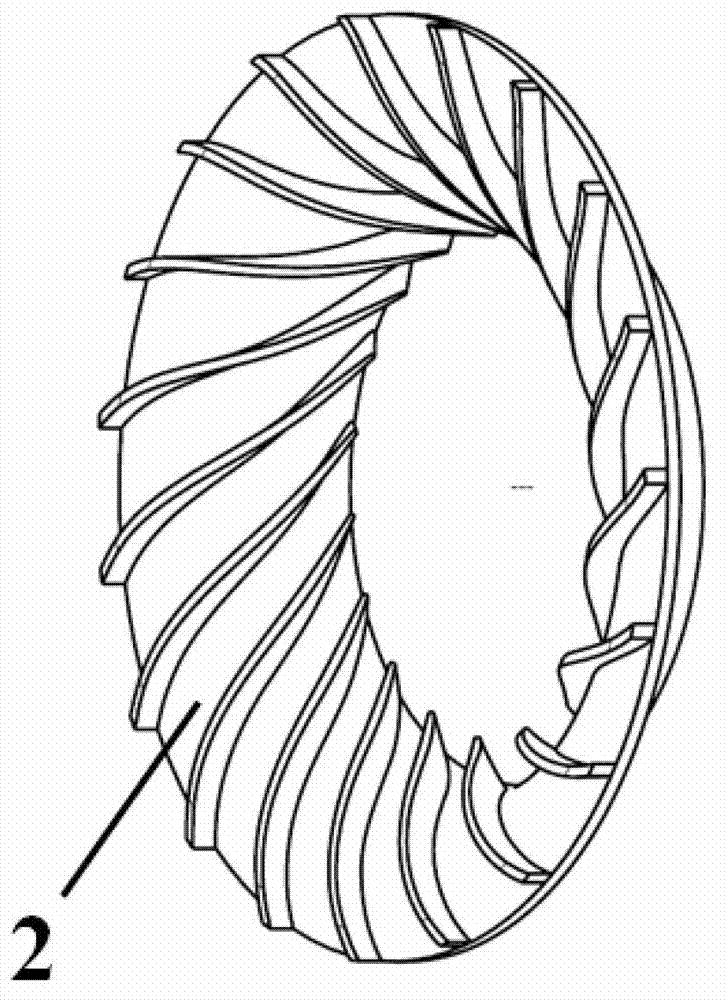

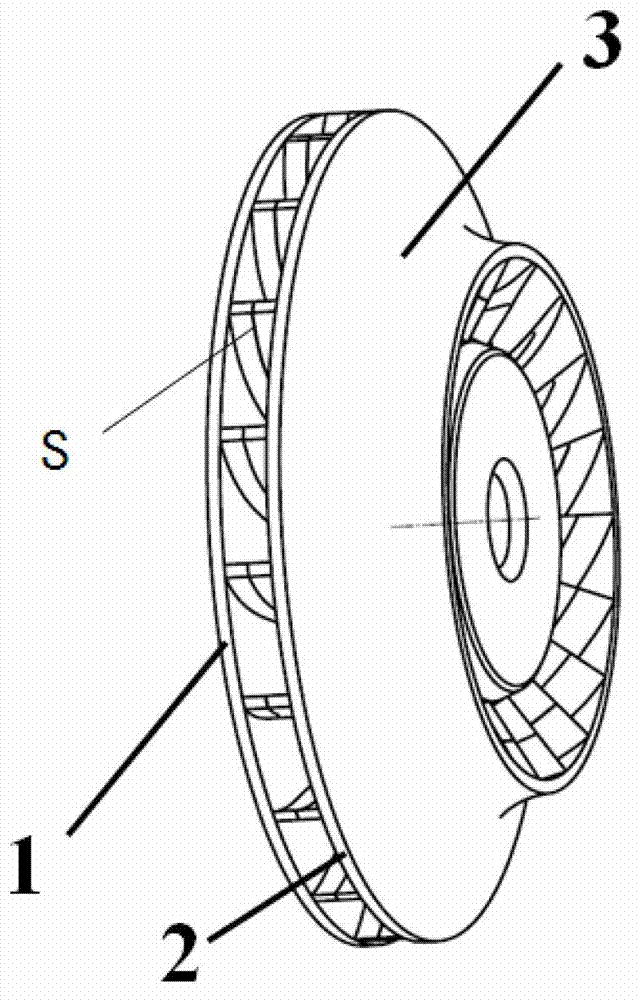

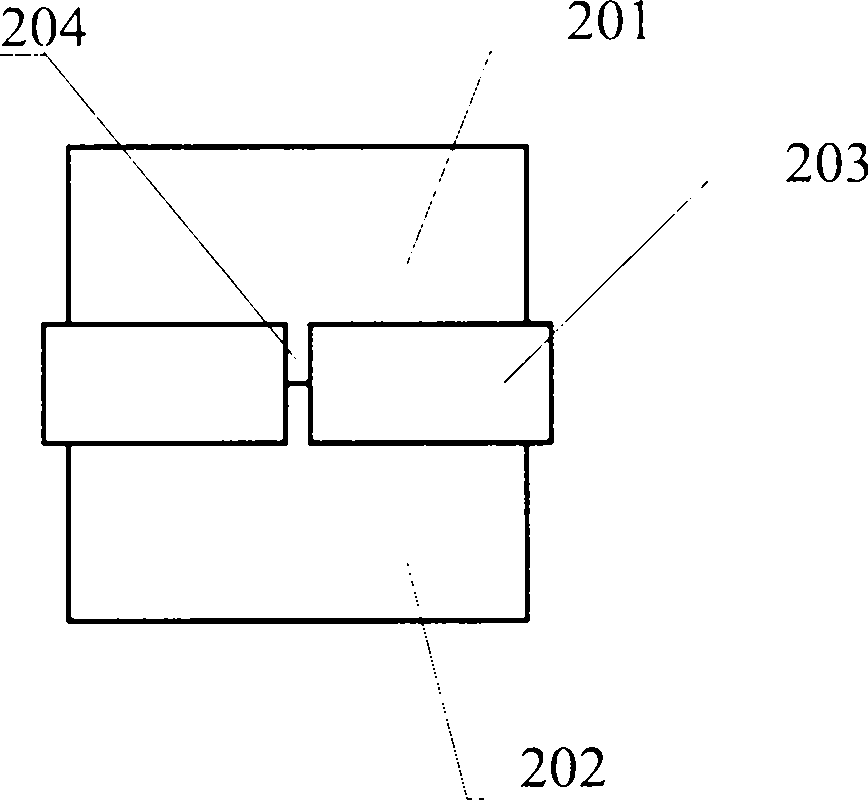

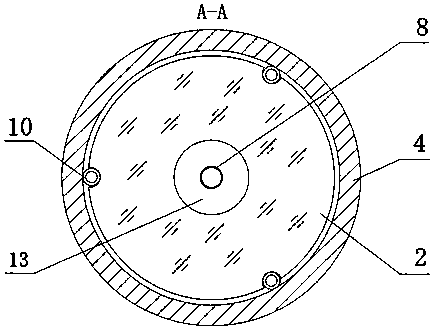

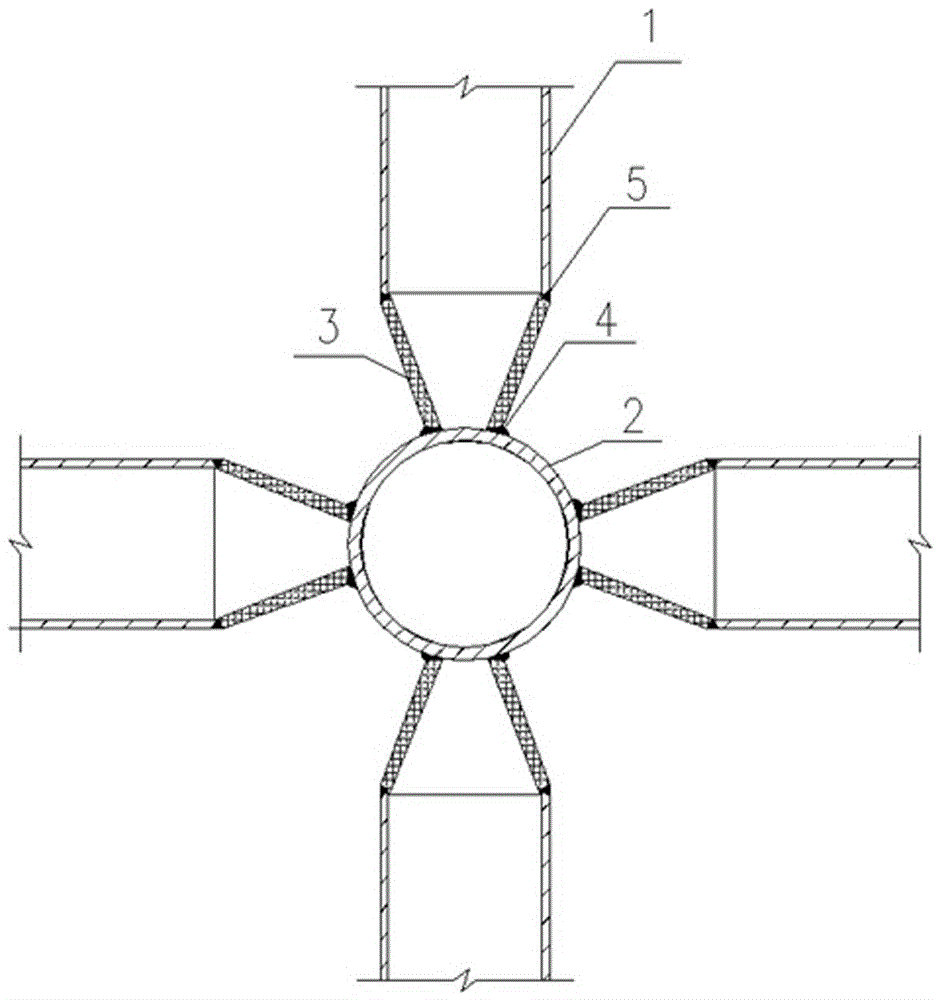

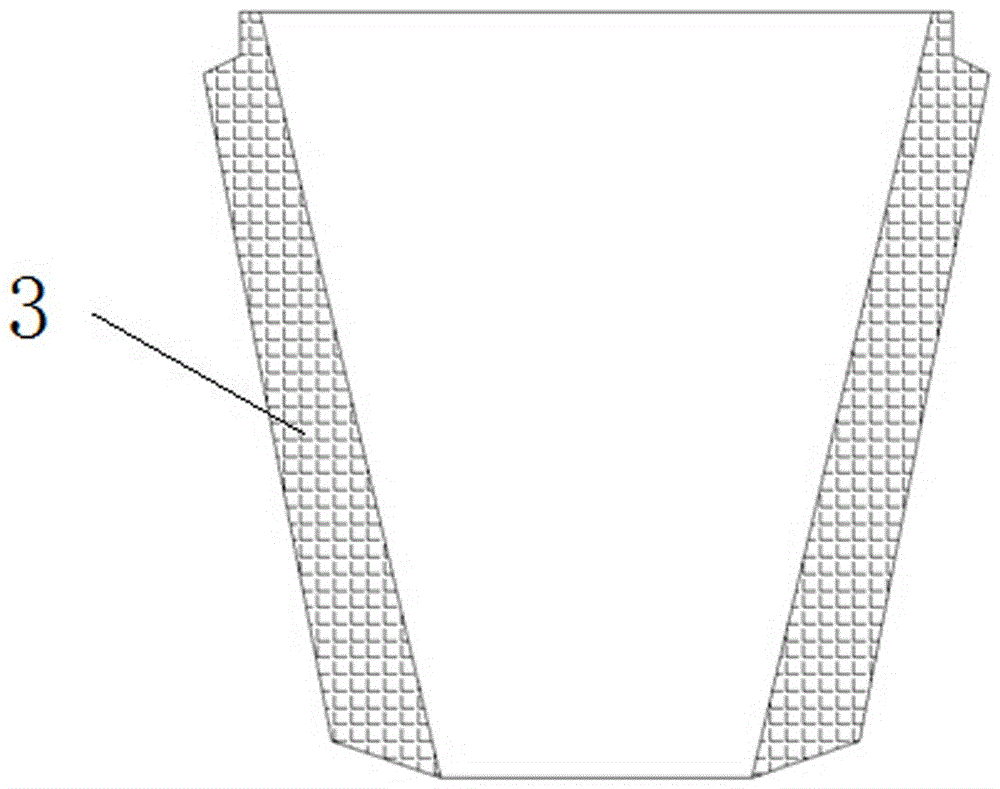

Large-scale centrifugal compressor impeller and machining forming method thereof

InactiveCN102817869AImprove aerodynamic performanceHigh precisionPump componentsPumpsWelding deformationCentrifugal compressor

The invention provides a large-scale centrifugal compressor impeller and a machining forming method of the large-scale centrifugal compressor impeller. The large-scale centrifugal compressor impeller comprises an impeller disc side part and an impeller cover side part, wherein the impeller disc side part consists of an impeller disc and an impeller disc side semi-leaf high blade formed by wholly milling, and the impeller cover side part consists of an impeller cover and an impeller cover side semi-leaf high blade formed by wholly milling. The invention has the advantages that the milled blade is higher in precision compared with that of the conventional stamped blade; the welding mode and the welding position can be optimized, the length of a weld joint can be reduced, and the welding deformation quantity and the weld beading polishing treatment can be preferably reduced by adopting a novel welding technology; and the fillet angle of an interface among the blade, the impeller disc and the impeller cover is smoother, so that the aerodynamic performance of the large-scale centrifugal compressor can be preferably improved.

Owner:XECA TURBO TECH (BEIJING) CO LTD

Manufacturing method of engine inlet

Provided is a manufacturing method of an engine inlet. The process method comprises the steps of uncapping subsection casting, casting pre-welding machining, vacuum electron jet assembling and welding, sizing destressing vacuum annealing, overall machining, hydrostatic testing and overall precise machining; an engine thin-wall titanium alloy component with the profile of a surface being less than or equal to 0.1mm, the surface roughness being less than or equal to Ra3.2, the dimensional precision being less than or equal to 0.2mm, and the form and location tolerance meeting design requirements is machined and manufactured. The manufacturing method overcomes defects in the prior art, meets all design requirements, resolves the problems of deformation, poor surface quality and poor dimensional precision which cannot be overcome by other machining methods, and is advanced and reasonable in technological process, smooth in technological production line, and especially suitable for developing and producing various engine thin-wall titanium alloy components.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

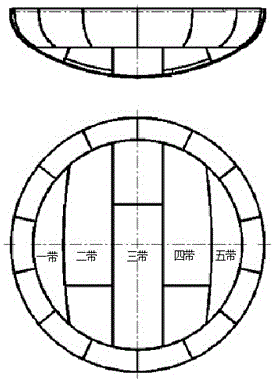

Segmental molding making method of end socket

ActiveCN106670749AIncrease profitThe number of sub-bands and sub-lobes is reducedFluid heatersSteam boilersCompression moldingLacquer

The invention discloses a segmental molding making method of an end socket. The method comprises the following steps: step 1, making a segmental plate mould; step 2, making single material plate and vertical material plates and checking; step 3, gluing kraft paper to the surfaces of material pieces for protection, polishing the working surface of the segmental plate mould and wiping clean; step 4, carrying out compression molding; step 5, after cutting, trimming; step 6, beveling, trimming after welding, scribing and cutting; step 7, assembling, clamping, brushing a paint, and assembling a top circle; step 8, leveling, determining height, and drawing an end opening cutting line; step 9, cutting the end surface of the top circle, cutting segment small openings according to the actual size of the end surface of the top circle, and then assembling segments; step 10, after finishing all assembly in the step 9, leveling the end surface, determining the height, and drawing an end opening cutting line; step 11, cutting an end opening, and examining the whole; and step 12, packaging and loading onto a vehicle. The number of the split segments is reduced, the utilizing rate of materials is increased, the length of weld joints is reduced, the manufacturing cycle is short, and actual use requirements are met.

Owner:ANHUI XINLIANXIN HEAVY HEAD

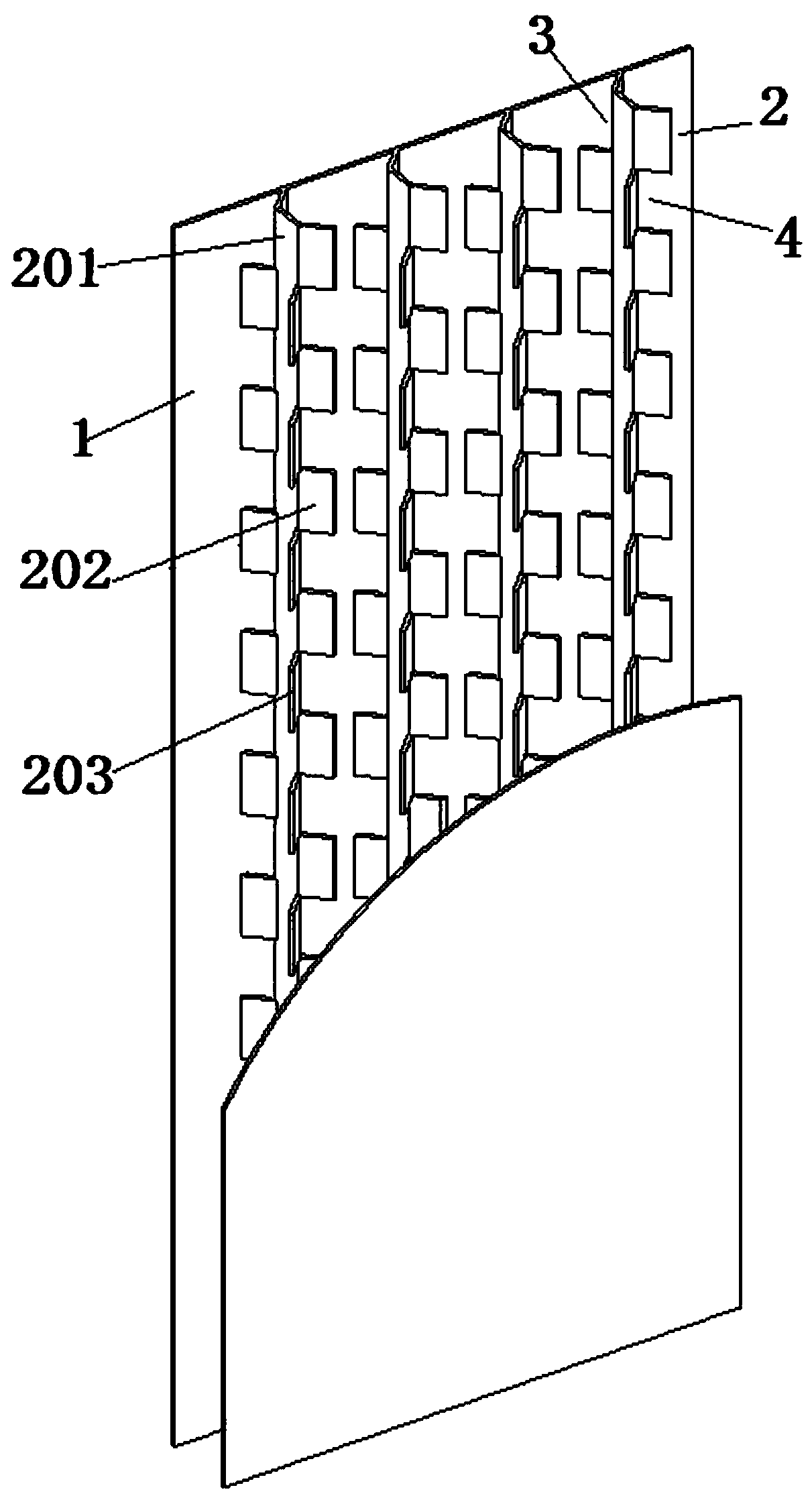

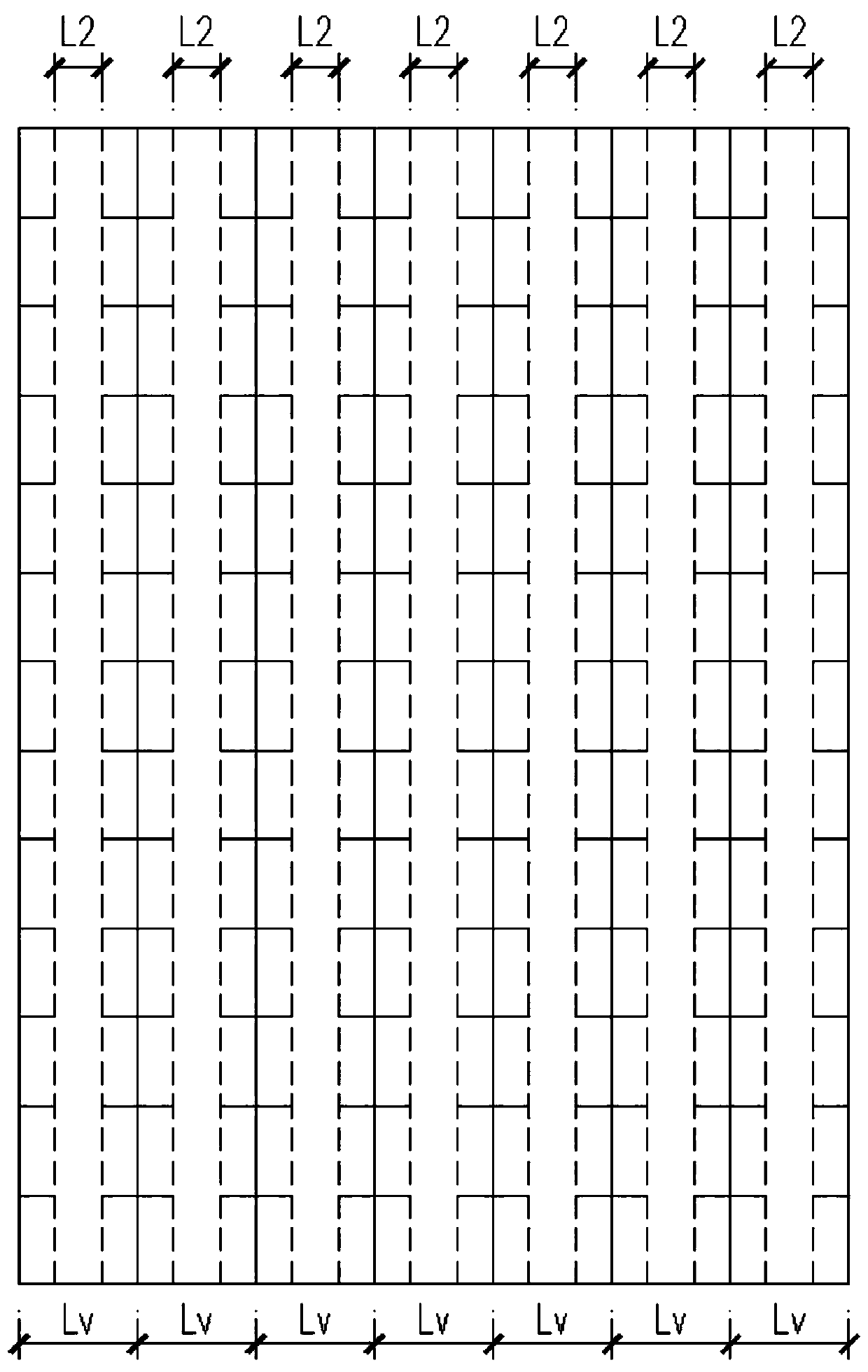

Steel plate combined shear wall capable of achieving connection through crossed bending type partition board and preparing method

PendingCN110469043AImprove stabilityEasy to moveConstruction materialWallsEngineeringSteel plate shear wall

The invention discloses a steel plate combined shear wall capable of achieving connection through a crossed bending type partition board and a preparing method. The wall comprises two parallel external package steel plates, the crossed bending type partition board is arranged between the two external package steel plates, and a first opening and a second opening which are alternatively distributedup and down are formed between the crossed bending type partition board and the external package steel plates. According to the steel plate combined shear wall, the quality of the steel plate combined shear wall can be effectively improved, and the whole stress property of the steel plate shear wall is improved.

Owner:THE ARCHITECTURAL DESIGN & RES INST OF ZHEJIANG UNIV

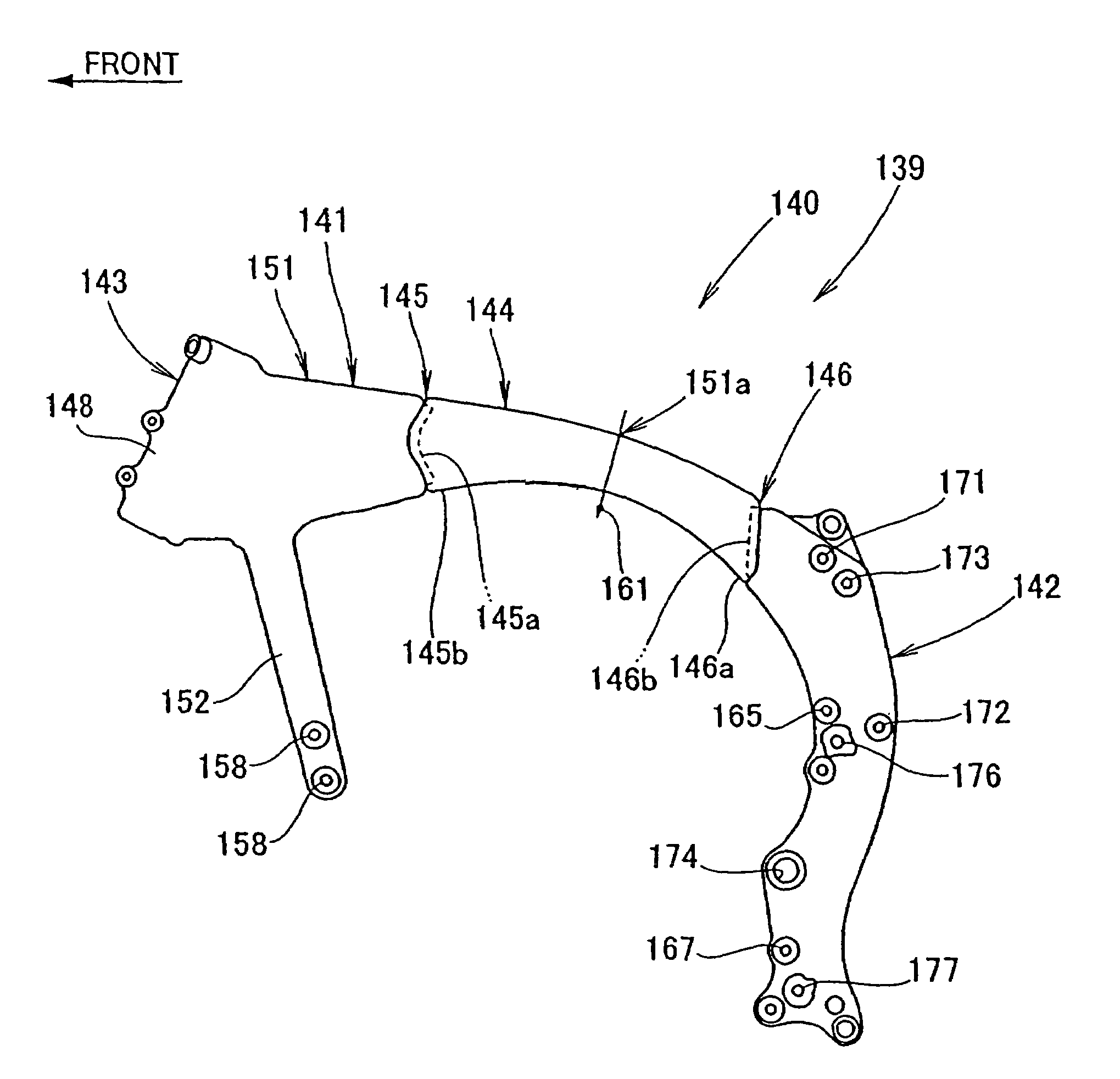

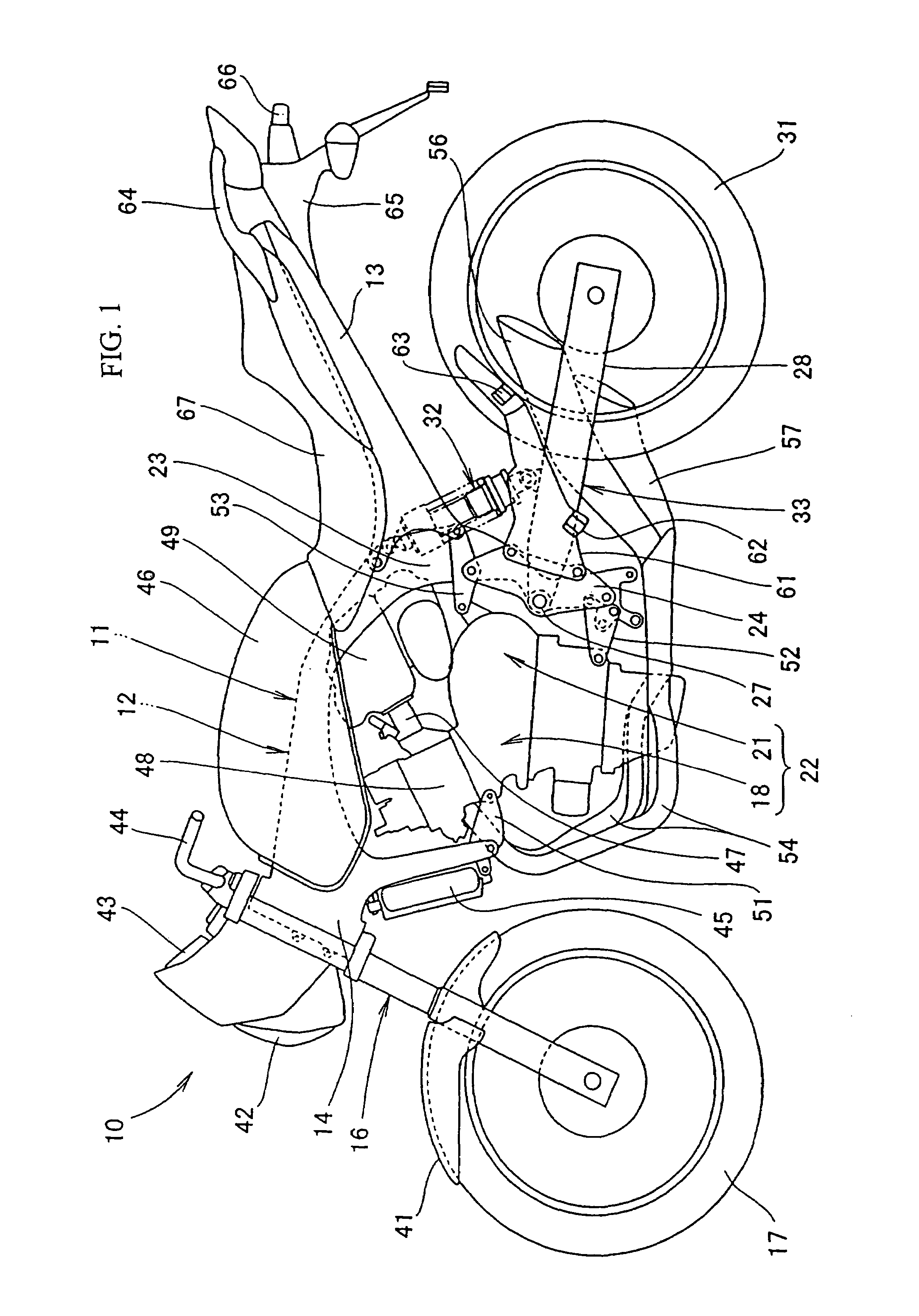

Frame assembly for a motorcycle

ActiveUS7681680B2Reduce the cross-sectional areaReduce errorsPassenger cyclesChildren cyclesVehicle frameCoupling

A motorcycle body frame includes a main frame including a head pipe for supporting a front suspension at the front end thereof, a single leading frame portion extending rearwardly from the head pipe, and a rear frame portion for supporting a rear wheel suspension. The rear frame portion extends substantially downwardly from a rear part of the leading frame portion. The main frame, cast from an aluminum alloy, includes two component parts arranged front-to-rear. For example, a front frame portion is provided, and a rear frame portion is fixed to the rear side of the front frame portion. The leading frame portion has a small section portion, where the main frame is smallest in sectional area, disposed substantially centrally in the longitudinal direction thereof. The two component parts of the frame are joined at a coupling portion of the main frame situated in back of the small section portion.

Owner:HONDA MOTOR CO LTD

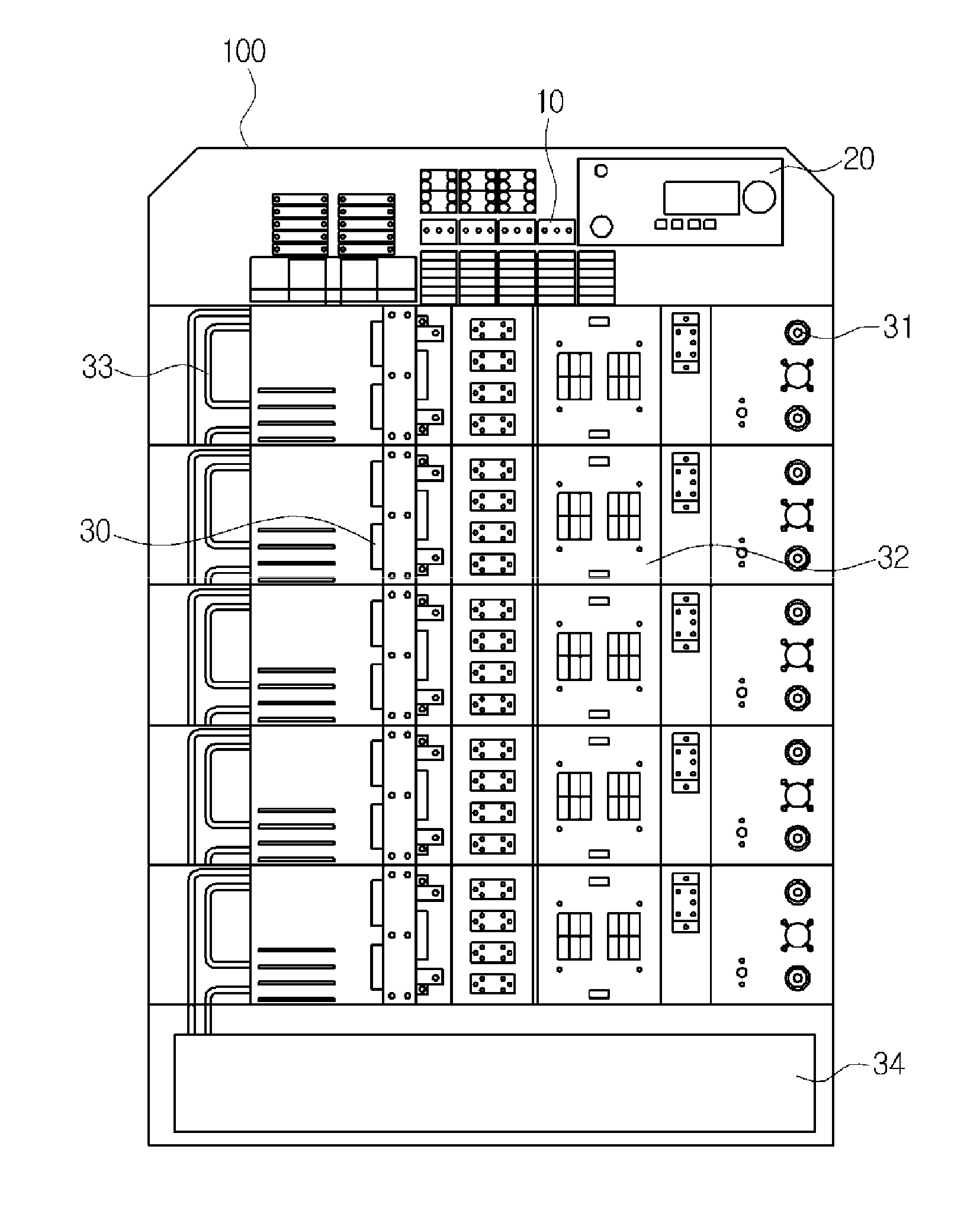

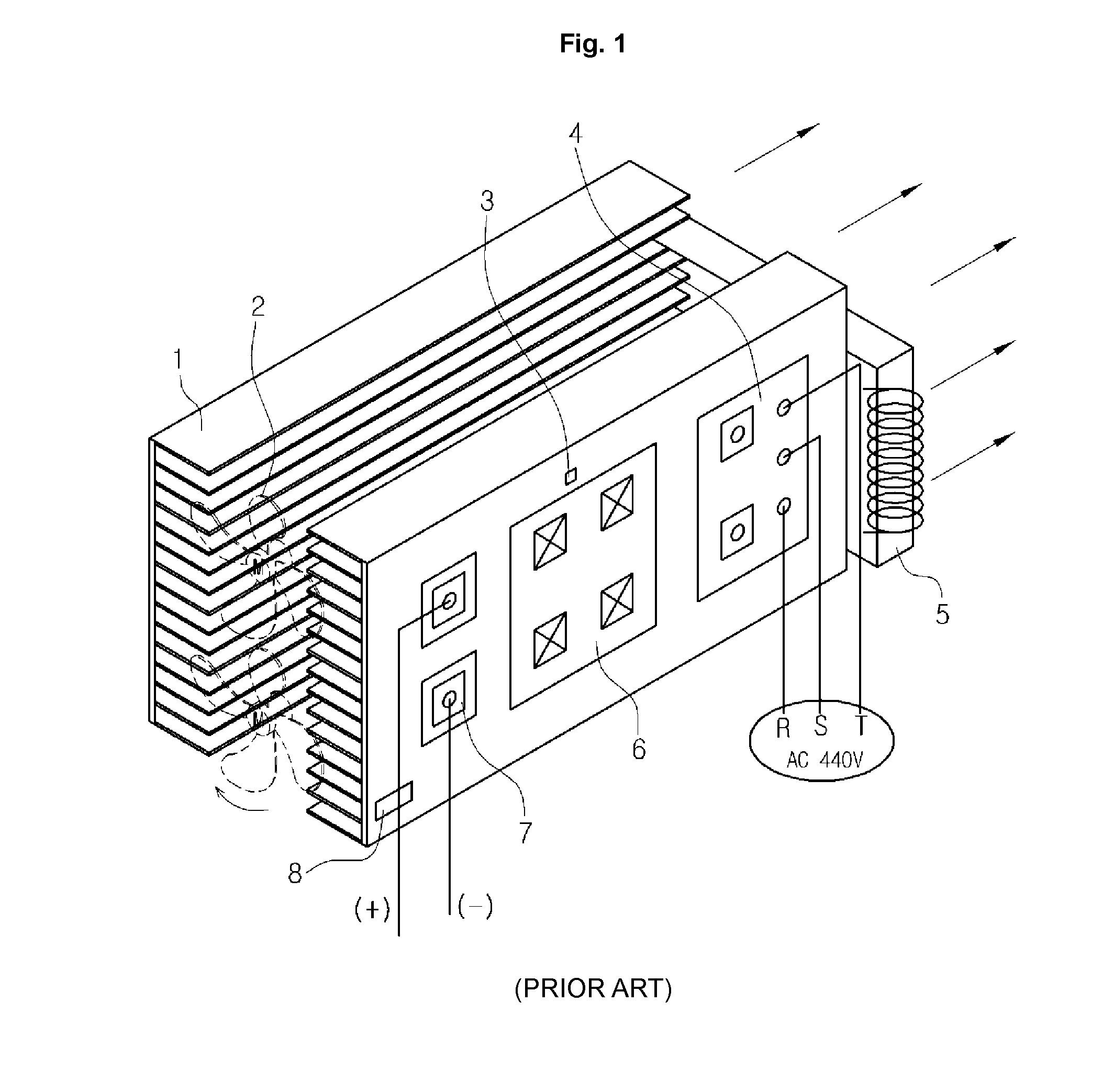

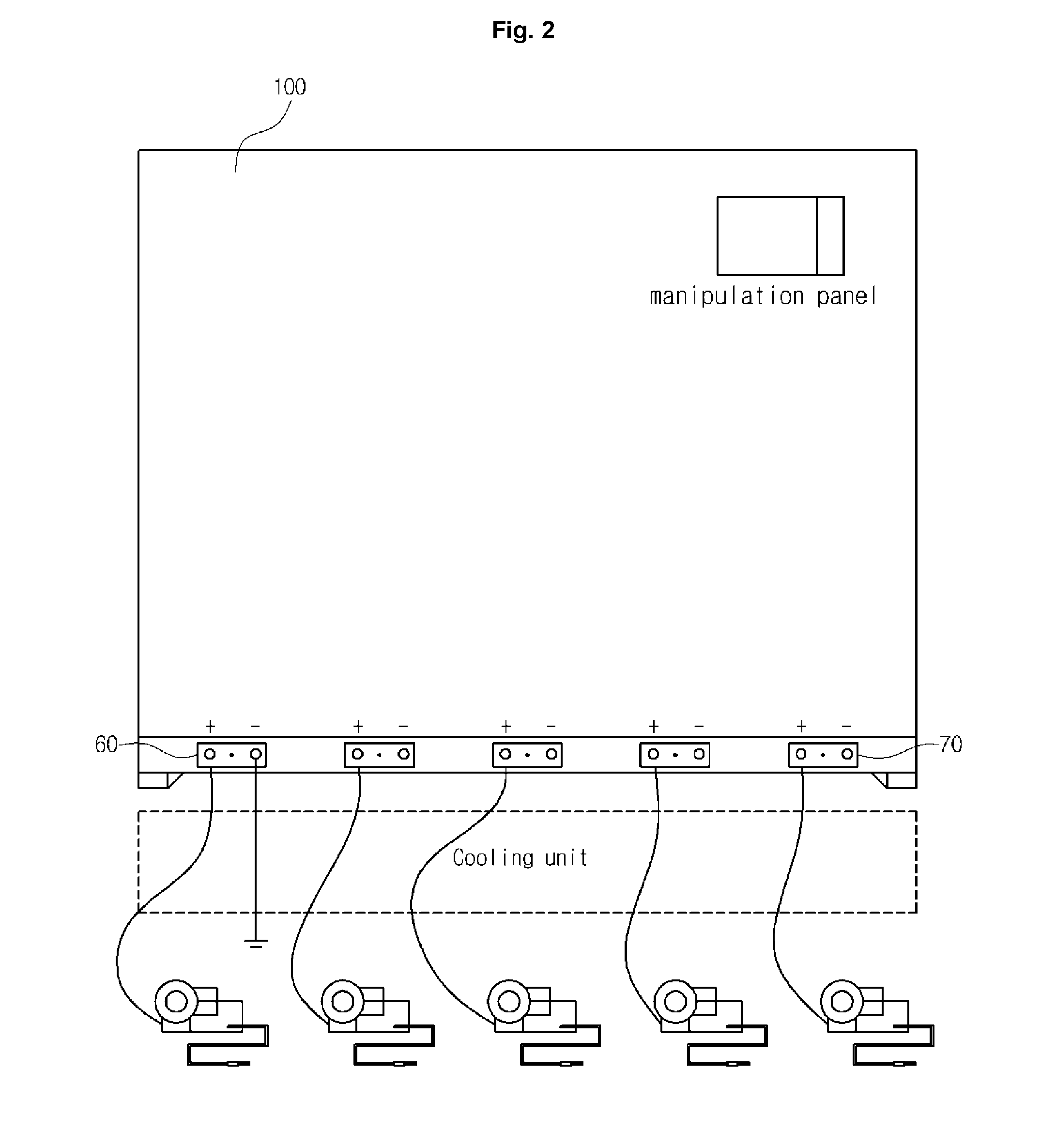

Modular welding machine

InactiveUS20160136749A1Save welding power energyImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHeat generation

A modular welding machine effectively recovers heat generated from each individual welding machine by applying a lightened and simplified water-cooled cooling structure. A plurality of the modularized welding machines is provided to perform multiple welding processes in multi-positions. Each component parts of the modularized welding machine is modularized into groups to be configured on a single panel and installed within a single case. The modular welding machine can perform multiple welding processes in multi-positions and includes a plurality of individual welding machine modules. A water-cooled cooling plate is installed in each module. The cooling plate has a flow path in which the cooling water circulates for cooling the heat-radiating parts. A micro-miniature and micro-light water-cooled modular welding machine can be manufactured with increased welding power efficiency by circulating stable cooling water to each water-cooled individual welding machine module to prevent heat generation and by eliminating the air-cooled heat-radiating part.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

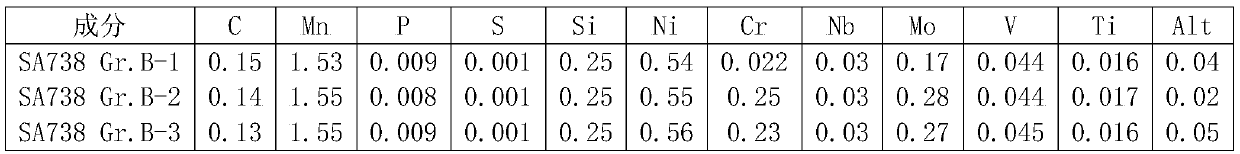

SA738GrB steel plate for nuclear power plant containment and manufacturing method thereof

InactiveCN110791712AReduce weld lengthIncrease profitFurnace typesContainmentSteel platesNuclear power plant

The invention discloses a SA738GrB steel plate for nuclear power plant containment, and relates to the technical field of iron and steel smelting. The thickness specification of the steel plate is 101mm, the width specification is 4650mm, and the chemical composition and mass percentage are as follows: C <= 0. 2%, Si = 0.13%-0.6%, Mn = 0.9%-1.6%, Ni <= 0. 6%, Cr <= 0. 3%, Nb <= 0. 05%, Mo <= 0. 35%, V <= 0. 08%, Ti <= 0. 03%, and the balance is Fe and inevitable impurities. The thickness of the finished product is 101 mm and the width is 4650 mm at the same time. The steel plate has the advantages of good strength, toughness, weldability and the like, and meets the use requirements of nuclear power plant containment.

Owner:NANJING IRON & STEEL CO LTD +1

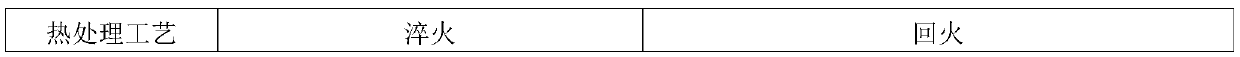

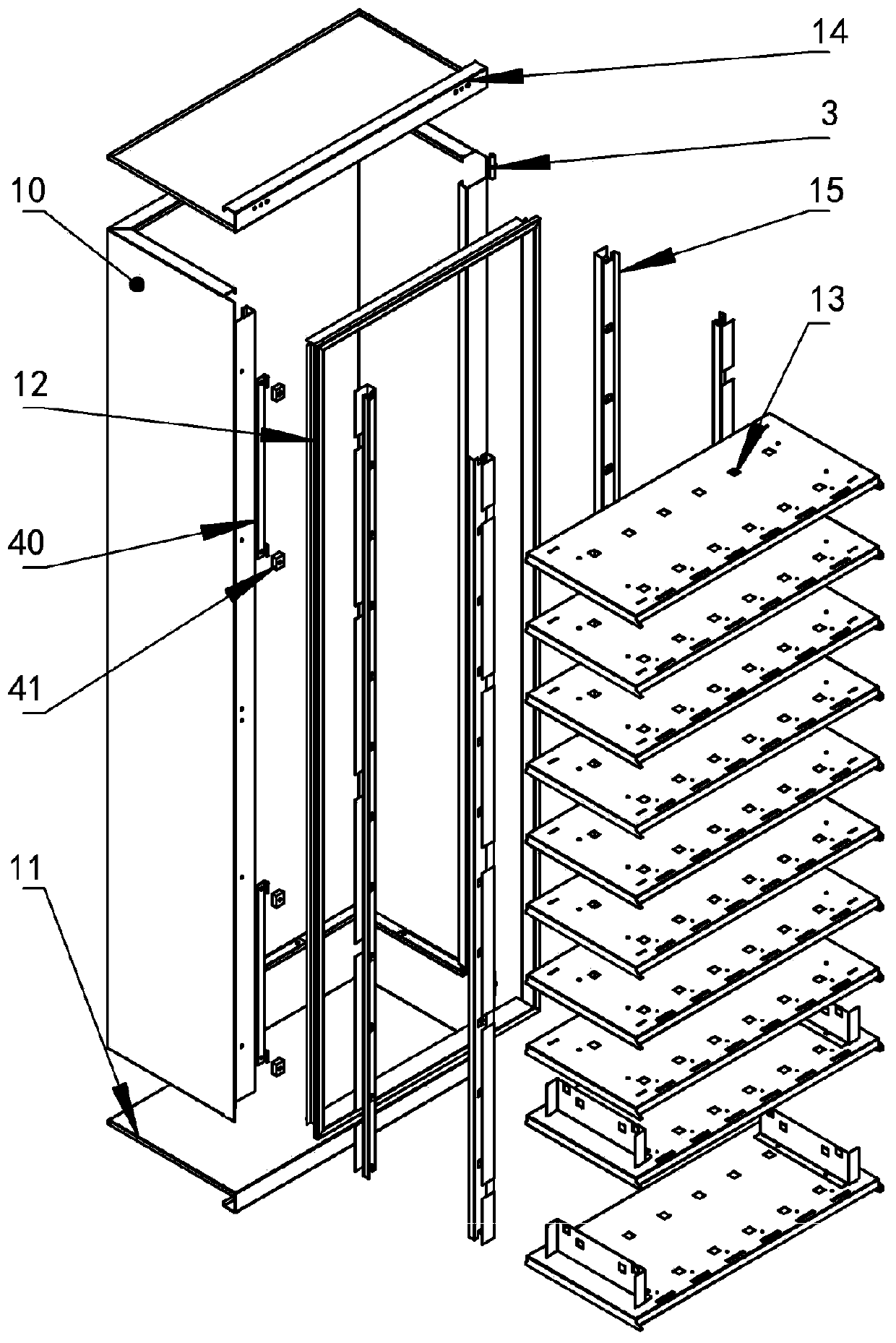

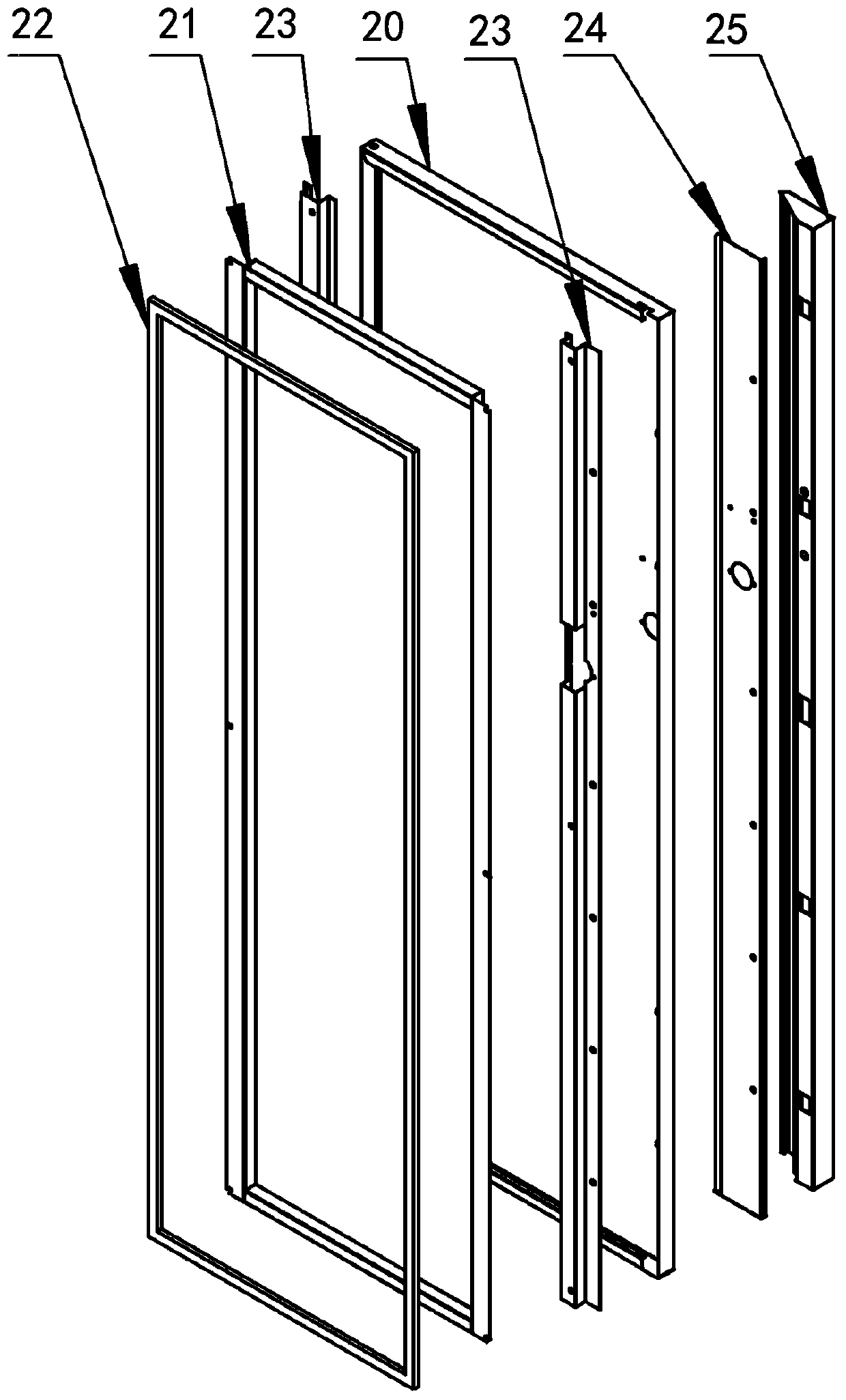

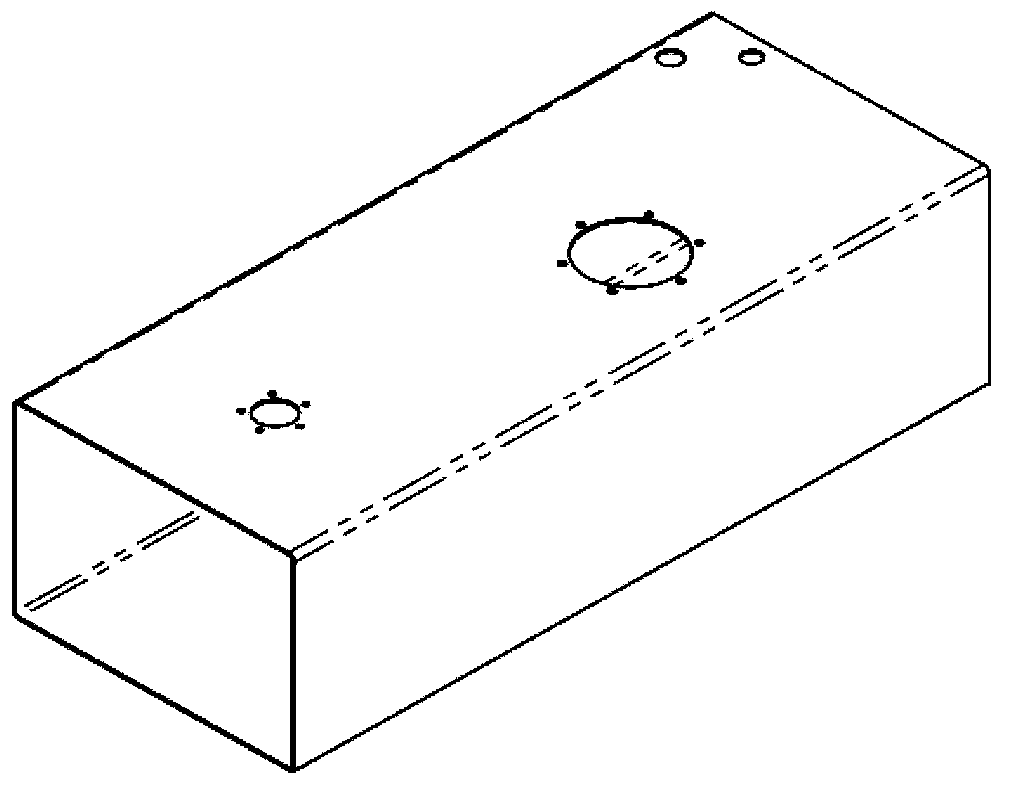

Shielding cabinet

PendingCN111543798AImprove rust resistanceAffect shieldingRadiation protectionScreening casingsManufactured materialStructural engineering

The invention discloses a shielding cabinet which comprises a cabinet body and a shielding door, the shielding door is rotatably connected with the cabinet body through a door shaft, three vertical faces of the cabinet body are cabinet body metal plates formed by bending a complete steel plate, the top of each cabinet body metal plate is fixedly connected with a top plate metal plate, and the bottom of each cabinet body metal plate is fixedly connected with a bottom plate metal plate. Welding a stainless steel shielding edge metal plate on an opening edge formed by the cabinet body metal plate, the top plate metal plate and the bottom plate metal plate; the shielding door comprises a shielding door outer door plate and a stainless steel inner door plate which are sequentially installed from outside to inside, and the stainless steel inner door plate is matched with the stainless steel shielding edge metal plate in shape. Shielding can be achieved through combination of the stainless steel inner door plate and the stainless steel shielding edge metal plate between the cabinet body and the shielding door, a stainless steel plate does not need to be adopted for manufacturing the cabinet body, and a large amount of raw material cost is saved; the shielding door is divided into the shielding door outer door plate and the stainless steel inner door plate, the shielding door outer door plate is independently processed and sprayed with anti-rust paint, and the welding difficulty and sealing requirements of the shielding door outer door plate are reduced.

Owner:GUANGZHOU GUUB TECH

Steel pipe concrete column and beam main bar connecting node and construction method thereof

PendingCN107938837ALow shape change impactGuarantee the quality of finished productsBuilding constructionsPorosityThick plate

The invention relates to a steel pipe concrete column and beam main bar connecting node, which comprises a steel pipe column, thick plate steel corbels and straight threaded sleeves, wherein one end of each thick plate steel corbel is welded with the steel pipe column; the other end of each thick plate steel corbel is welded with the end surface of the corresponding straight threaded sleeve; and two concrete ventilated holes are also formed in each thick plate steel corbel. The connecting node provided by the invention effectively solves the difficult problems that beam bars, column bars, corbels, stiffening plates and the like in the node position are staggered and converged, and the construction space for node steel bar binding welding, concrete casting and the like is narrow, so that the steel bar anchoring quality and the concrete pouring compactness are difficult to control. Through the design of the thick plate steel corbels, the straight threaded sleeves are welded on the thickplate steel corbels; beam longitudinal bars are connected by using the straight threaded sleeves; and the phenomena of zero aperture ratio, zero node steel bar welding in a construction site and zeronode steel bar crossed penetration on the steel pipe column can be realized.

Owner:广西建工第五建筑工程集团有限公司

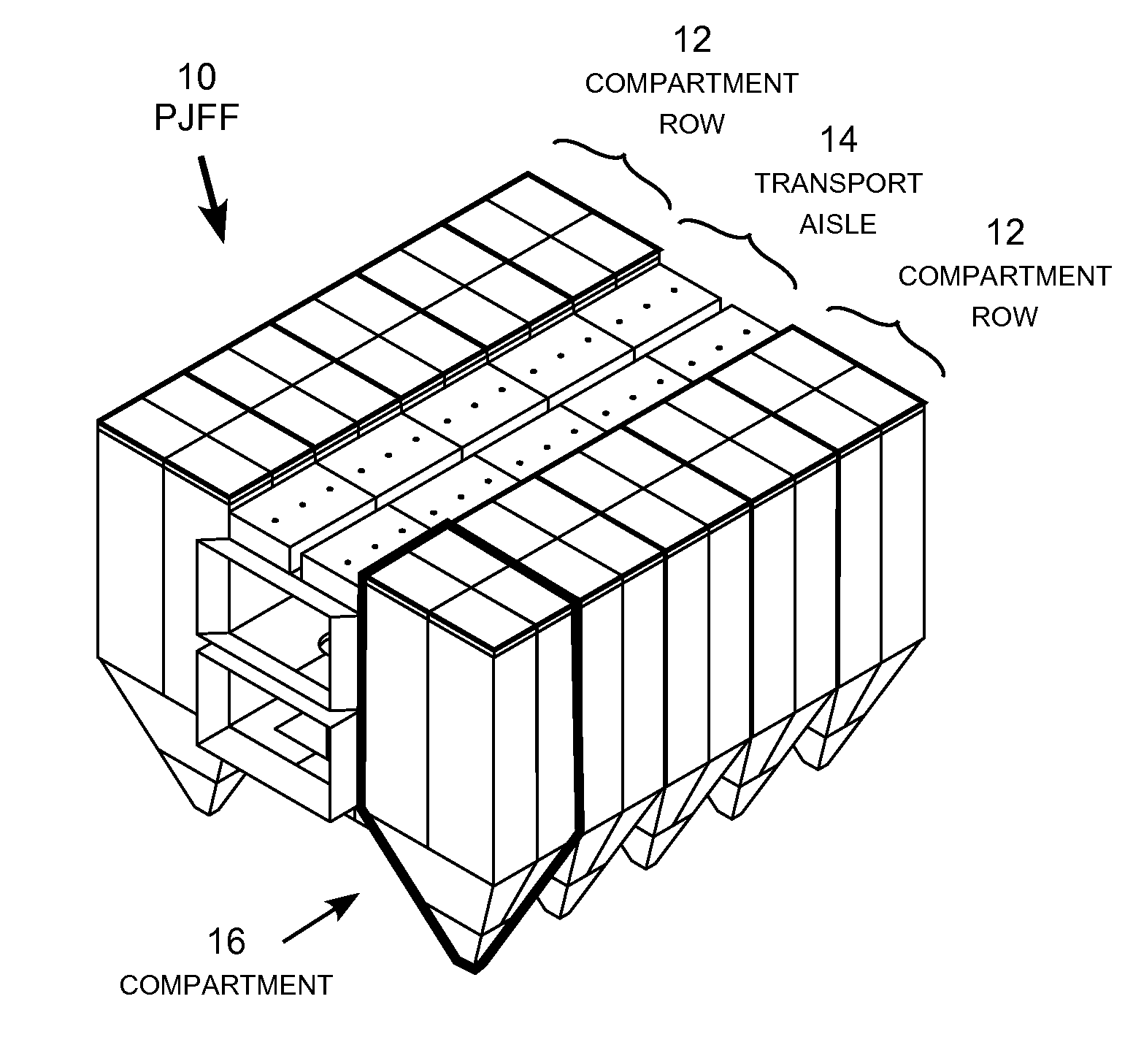

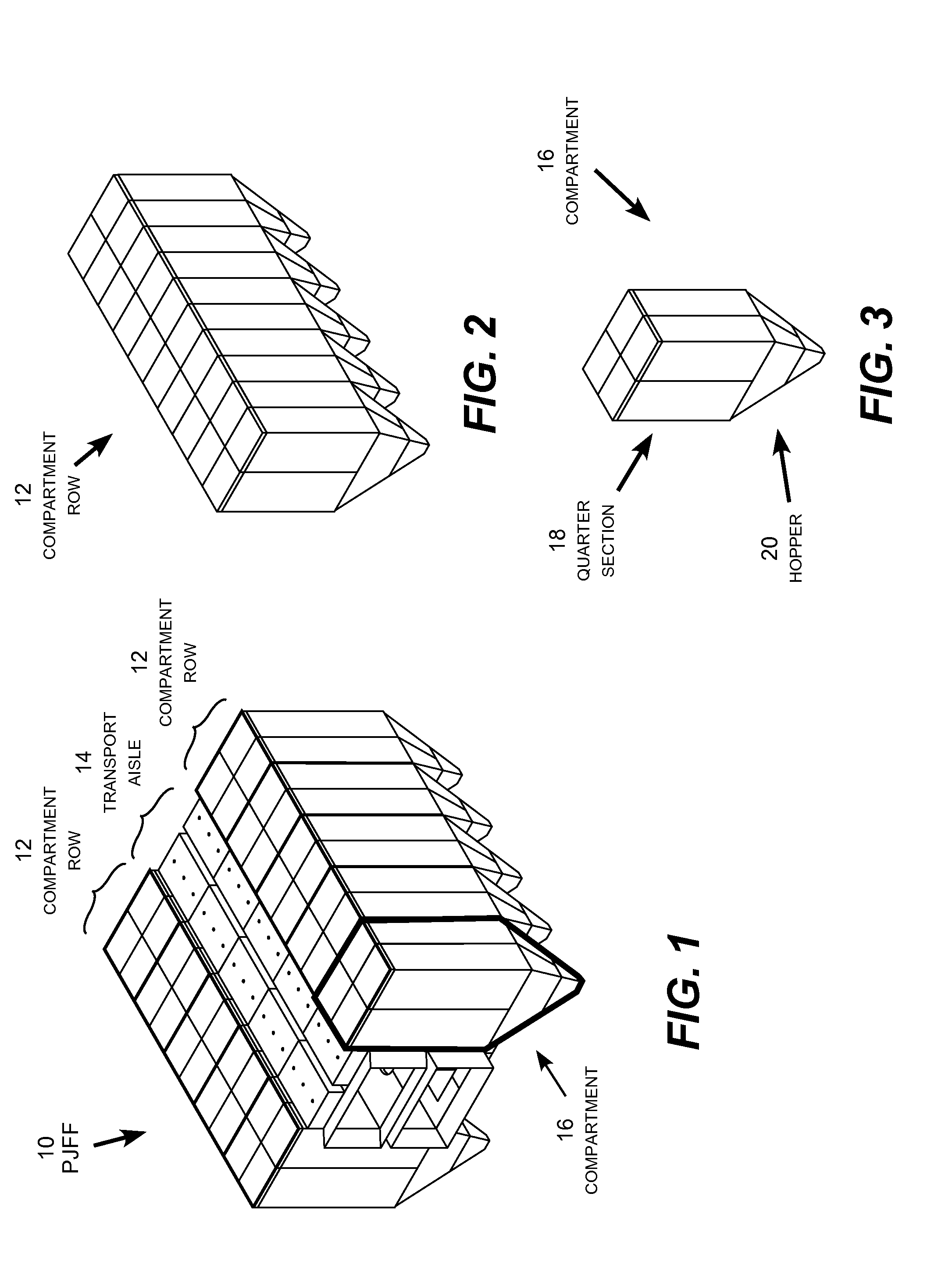

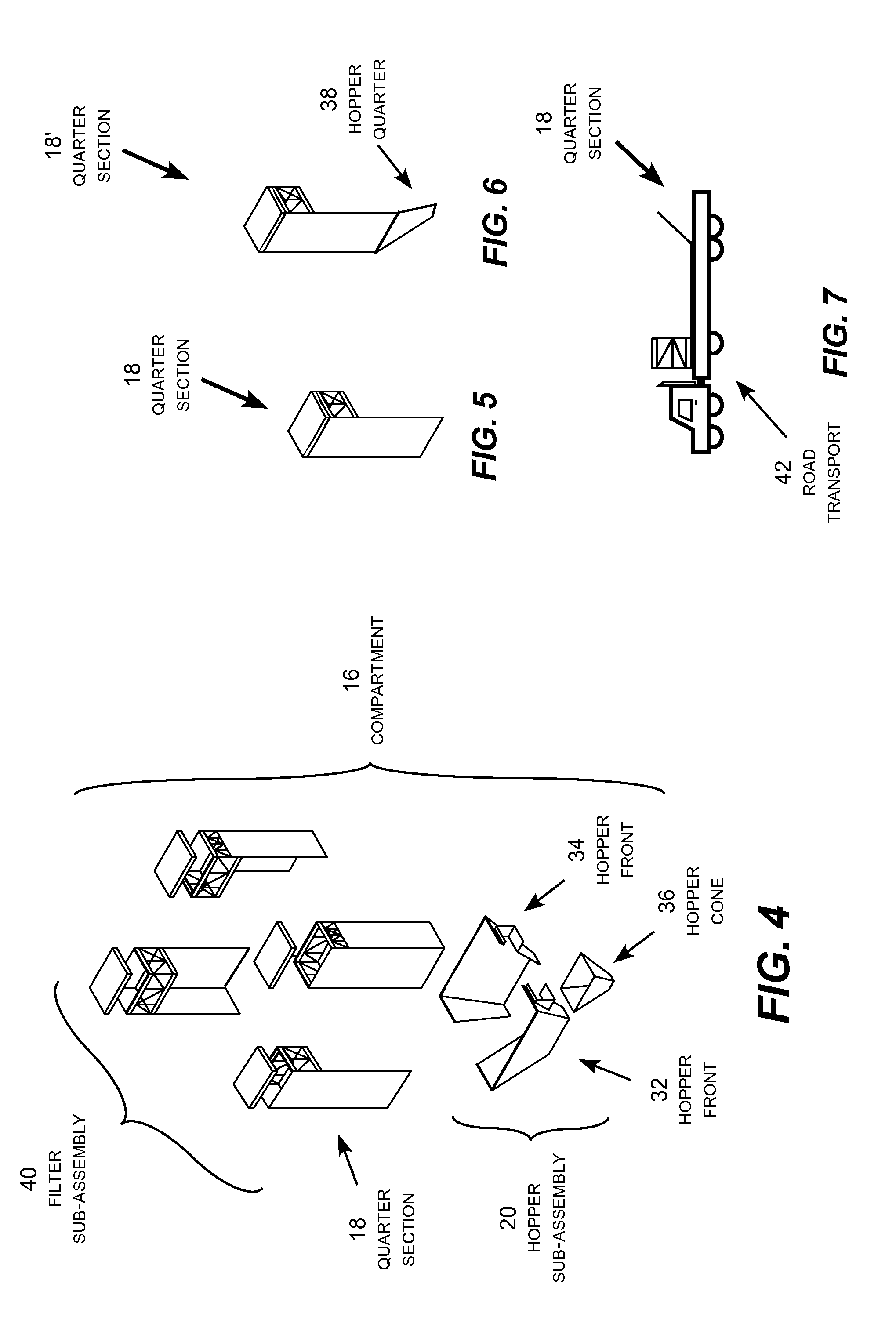

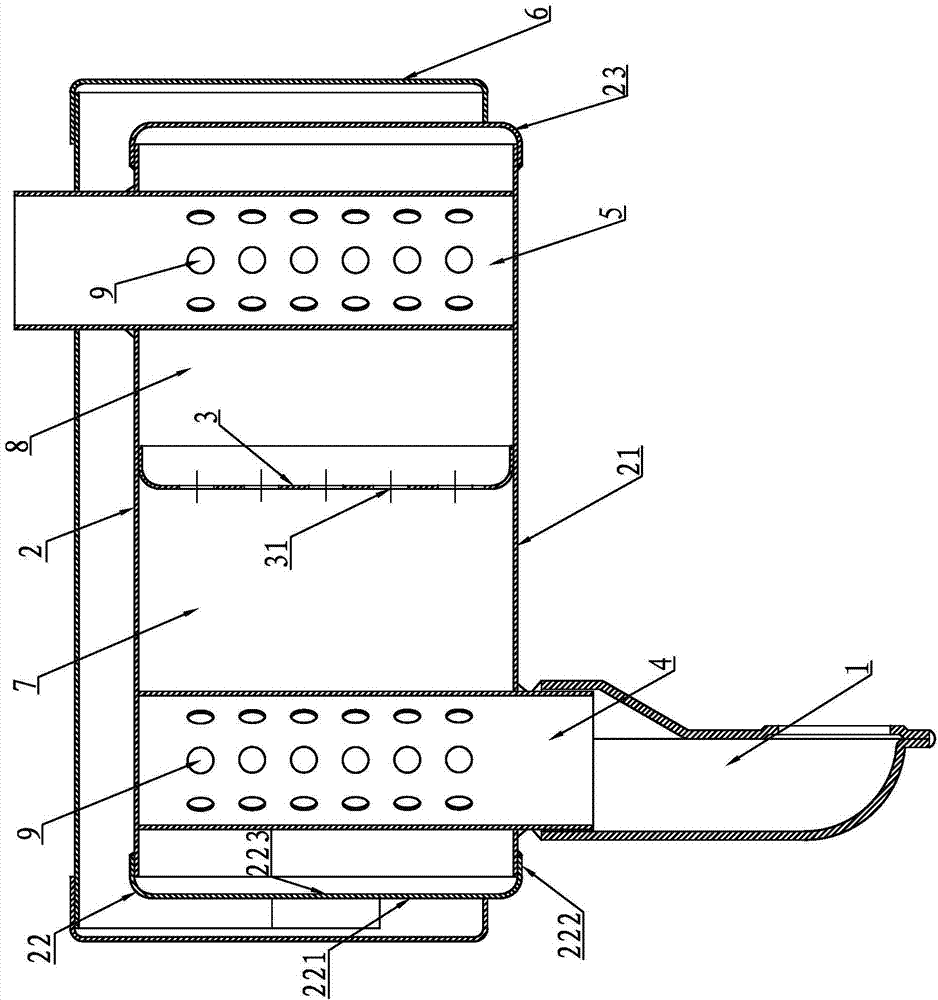

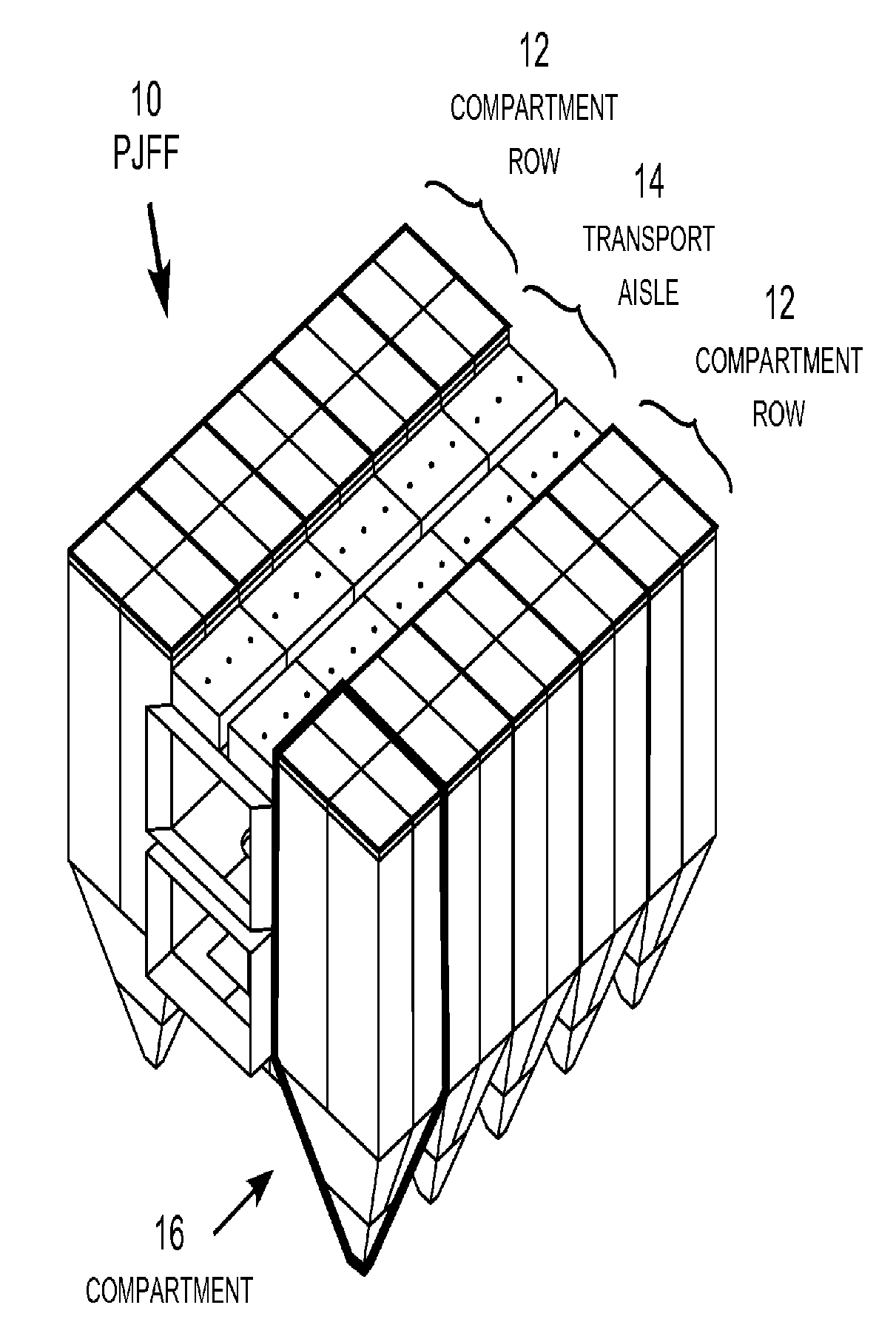

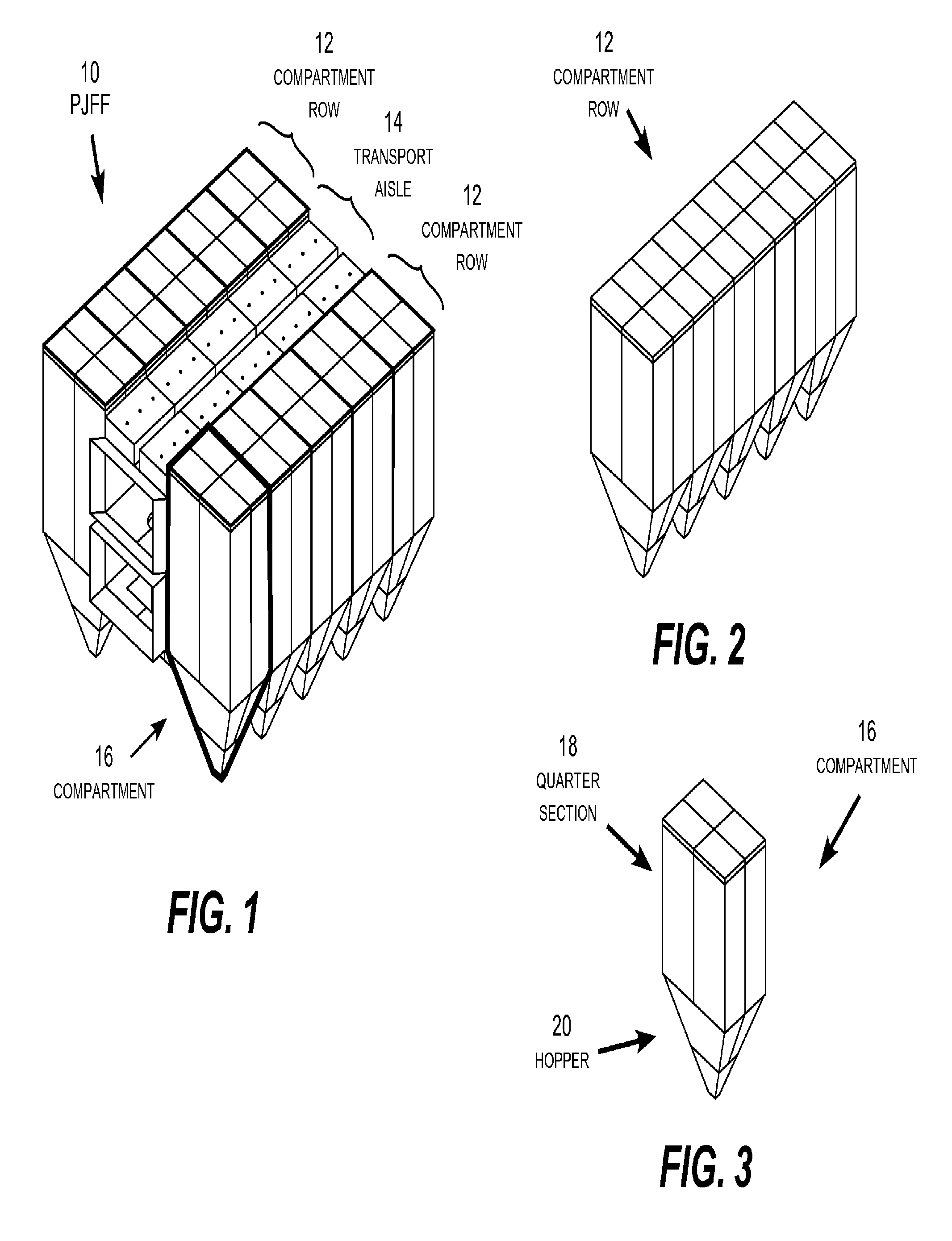

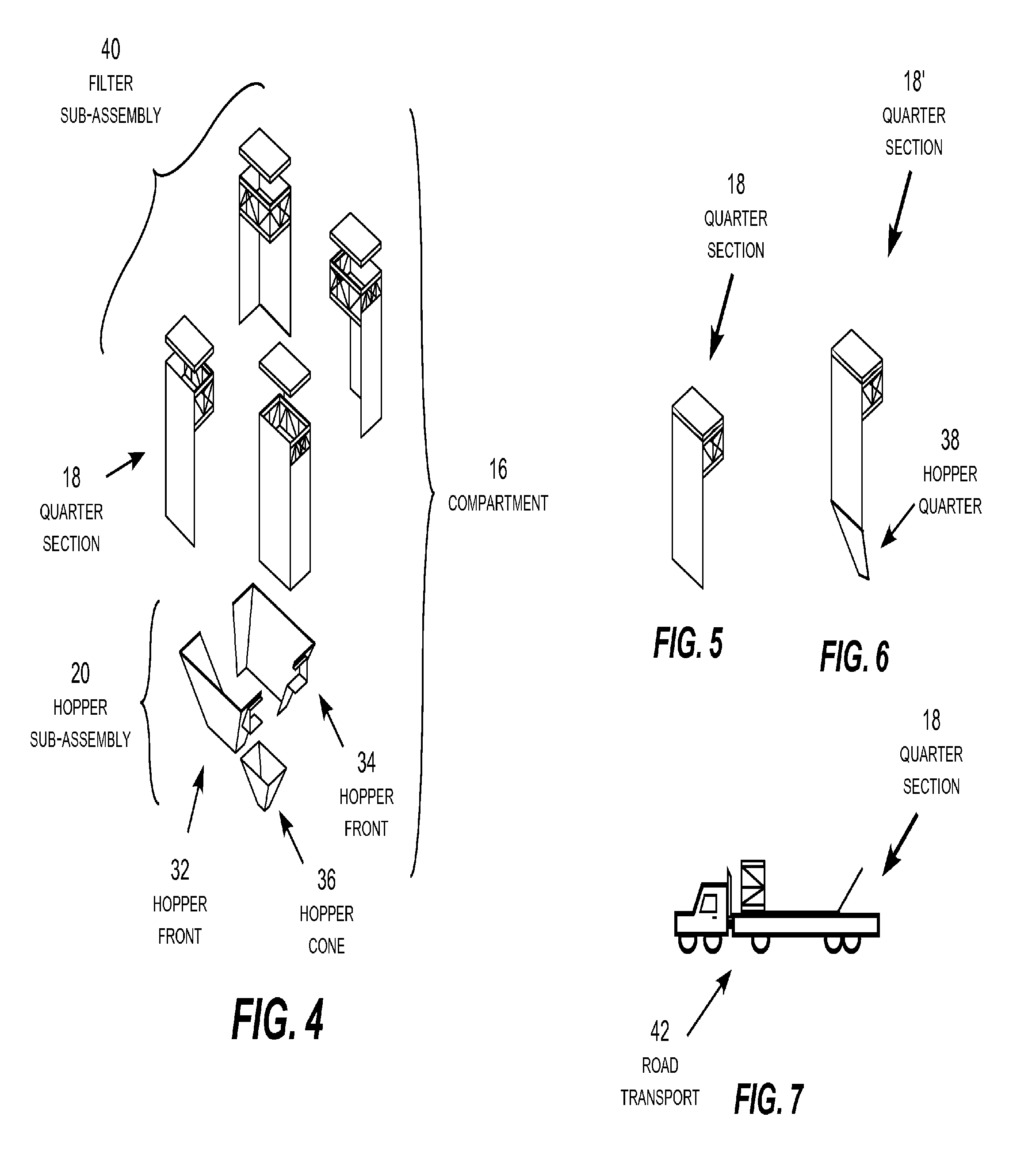

Modular Pulse Jet Fabric Filter

ActiveUS20140202122A1Efficient manufacturingQuality improvementDispersed particle filtrationLighting and heating apparatusPower stationModularity

A modular design for large pulse jet fabric filters (PJFF) is divided into similar compartments, which are each “shop-fabricated” in quarter sections prior to delivery to the power plant site. The quarter sections of the compartments are modular and sized so that they can be fabricated at a shop located away from the power plant site and transported by truck over public roads to the power plant site. Once delivered to the site, the quarter sections are bolted together and seal welded to form a PJFF compartment, without requiring additional internal fabrication or welding. The assembled compartment is then lifted onto the support structure as an assembled unit and bolted and / or welded in place. The additional components of the PJFF may also be shop-fabricated offsite to further the benefits of the modular design.

Owner:SOUTHERN FIELD MAINTENANCE & FAB L L C

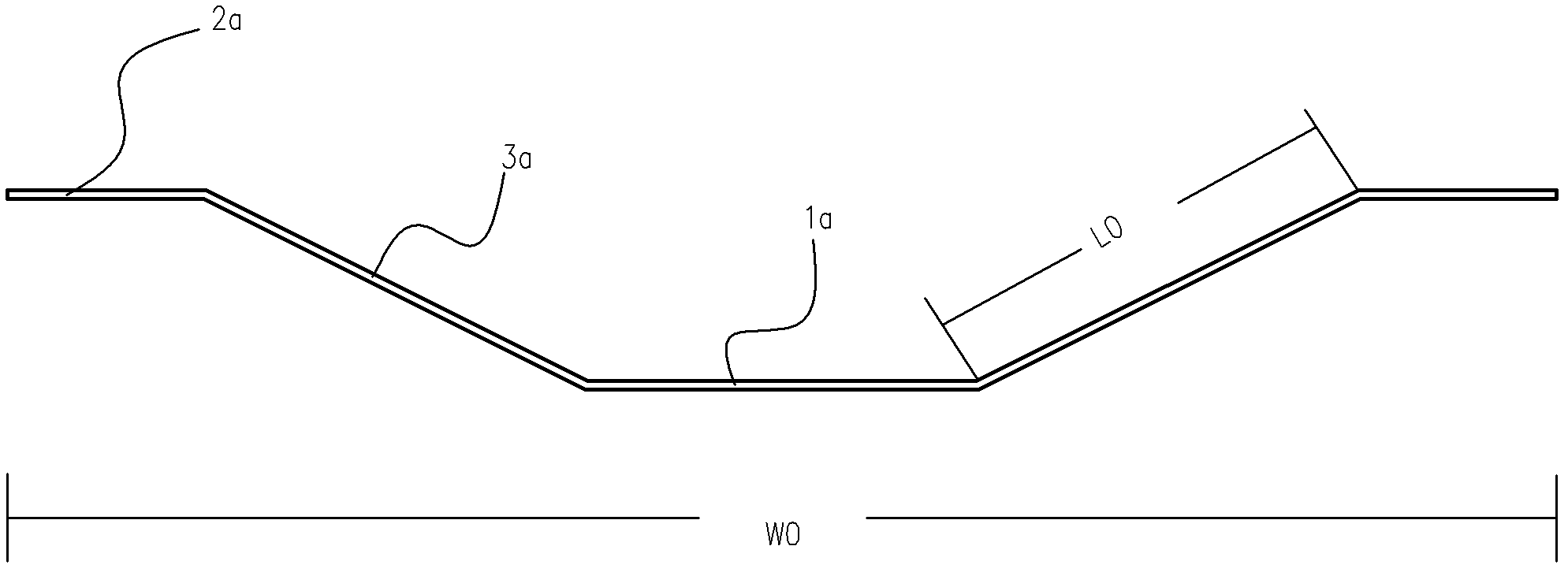

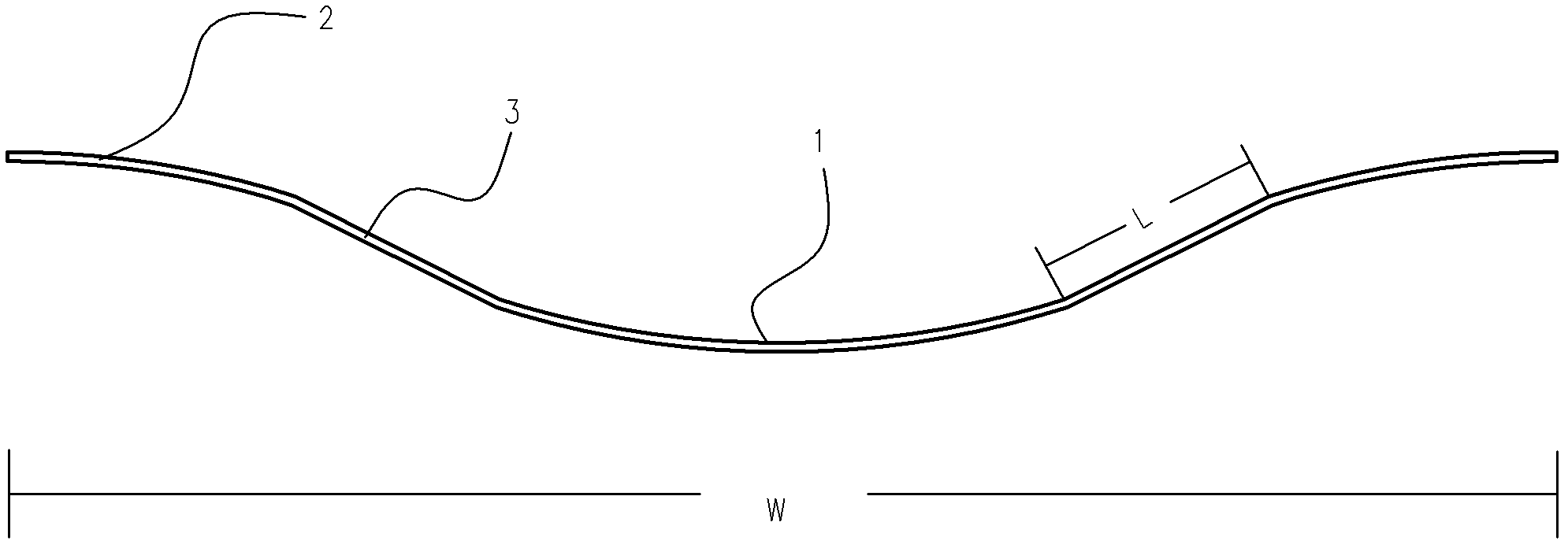

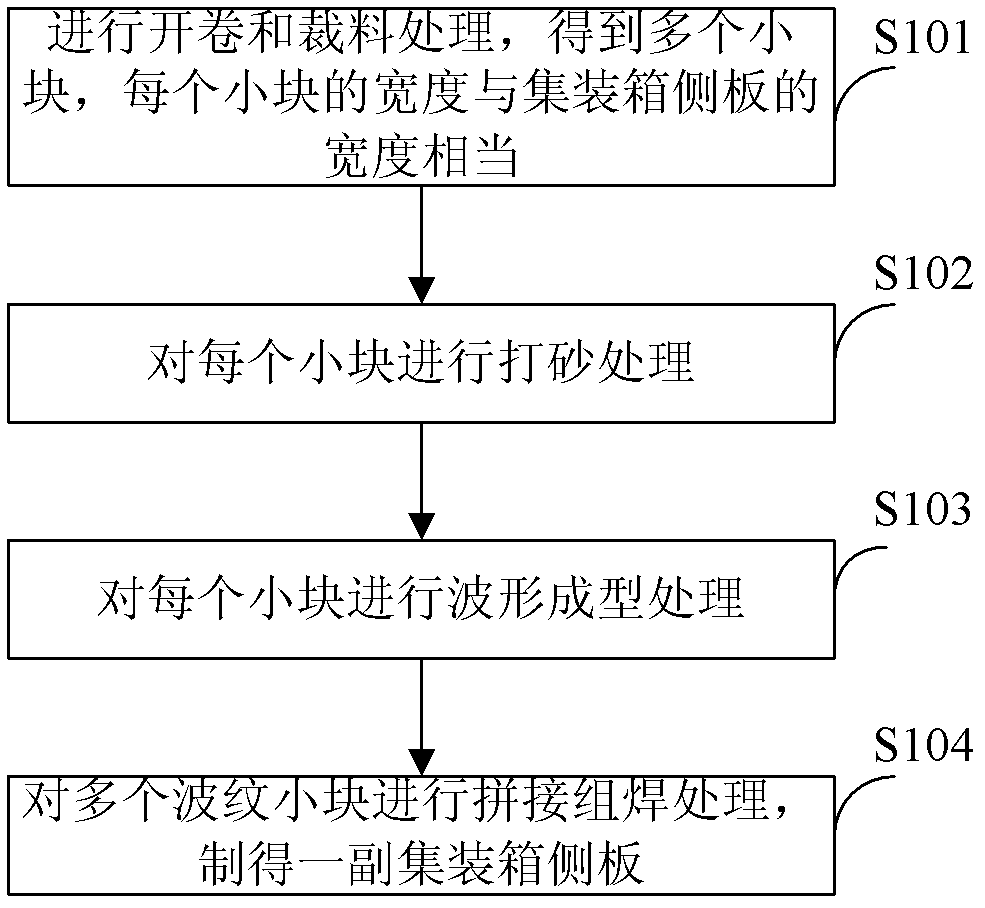

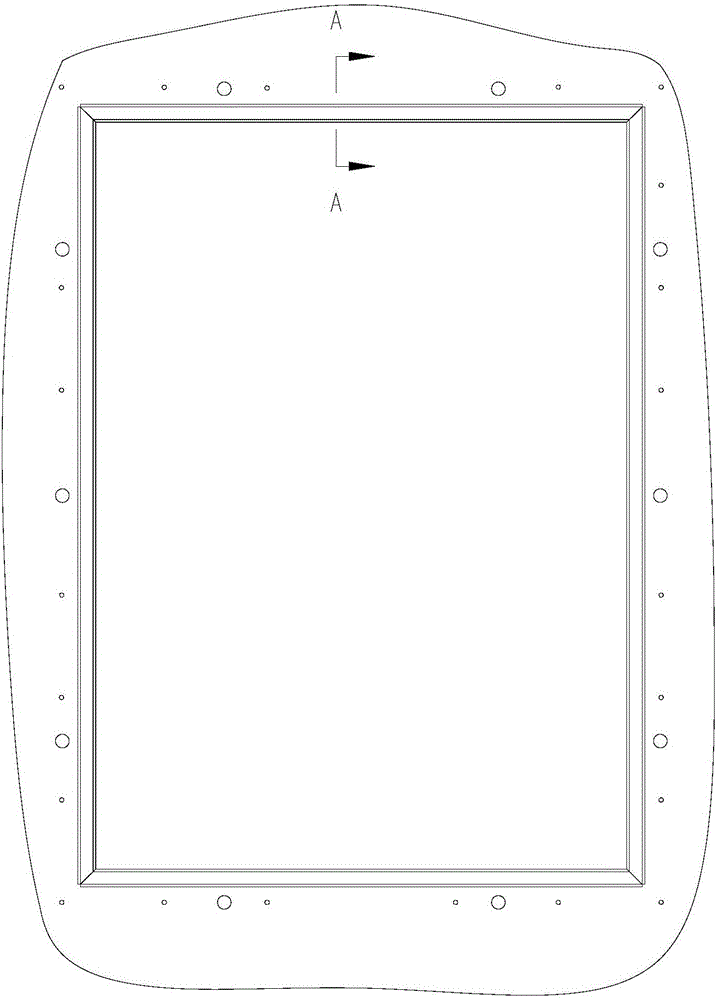

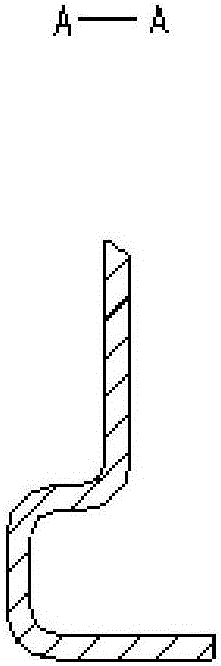

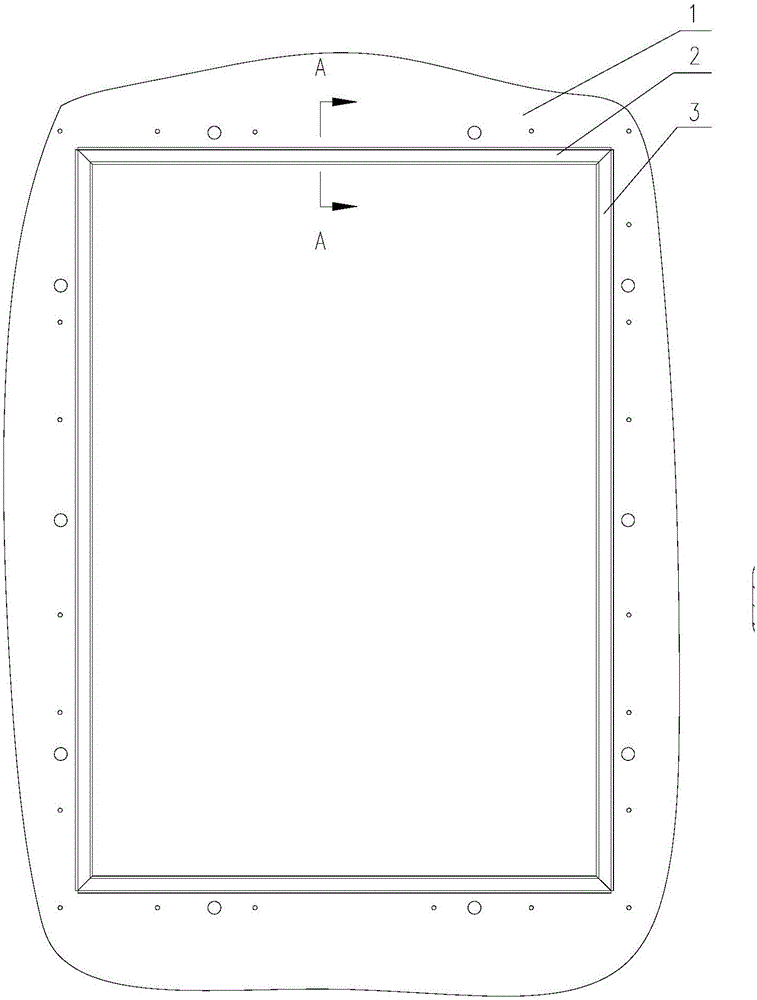

Arched side plate of container, manufacturing method for arched side plate and container with arched side plate

The invention discloses an arched side plate of a container, a manufacturing method for an arched side plate and a container with the arched side plate. The cross section of the arched side plate has a wave-shaped form which has a wave crest and a wave trough. One method for manufacturing the arched side plate comprises the following steps of: performing wave form treatment on a plurality of small blocks, and splicing and performing assembly welding; and another method for manufacturing the arched side plate comprises the following steps of: splicing two long blocks and performing assembly welding, and performing wave form treatment. By the arched side plate and the manufacturing method for the arched side plate, materials are saved, the process cost is reduced, and the overall cost of the container is reduced.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

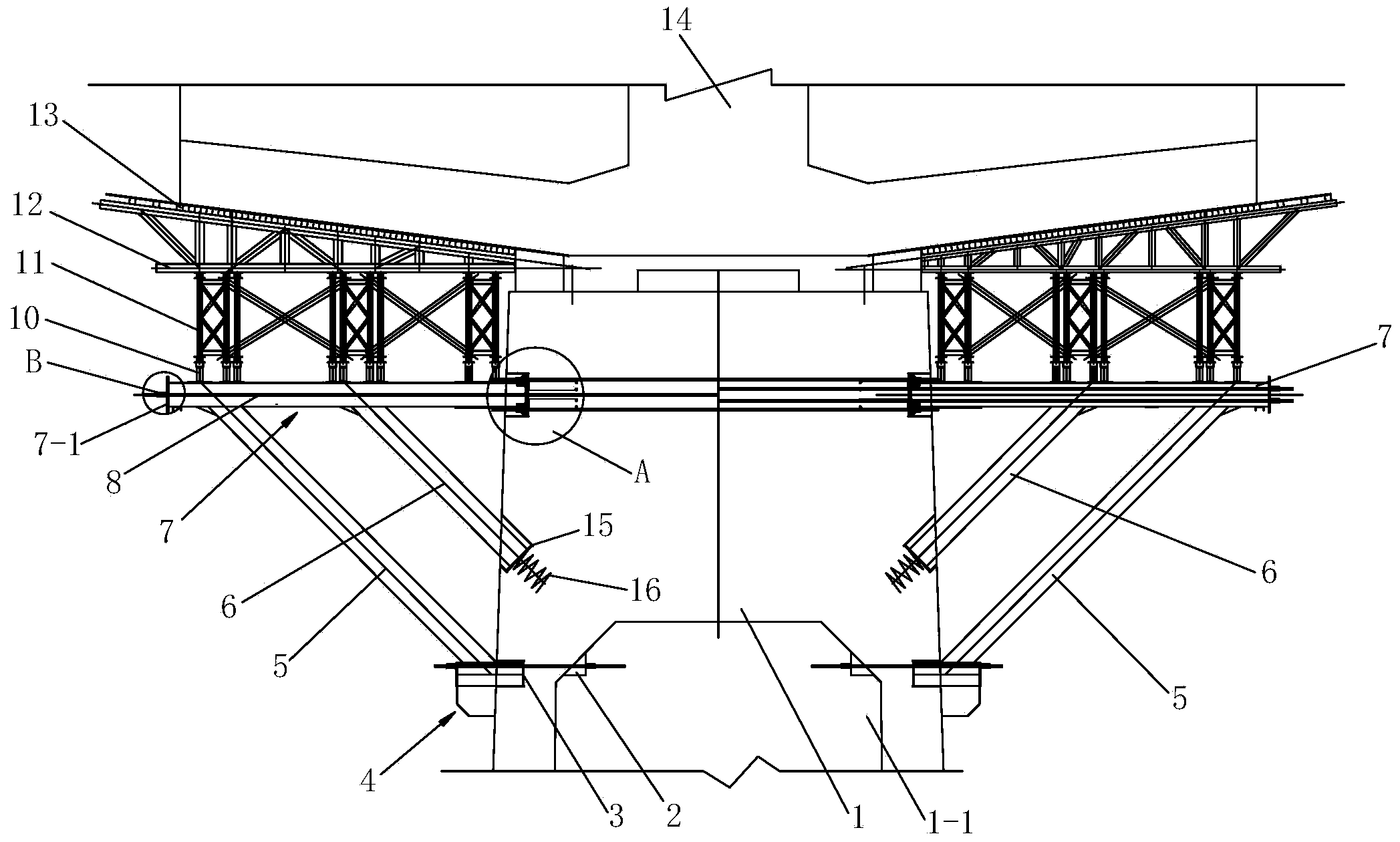

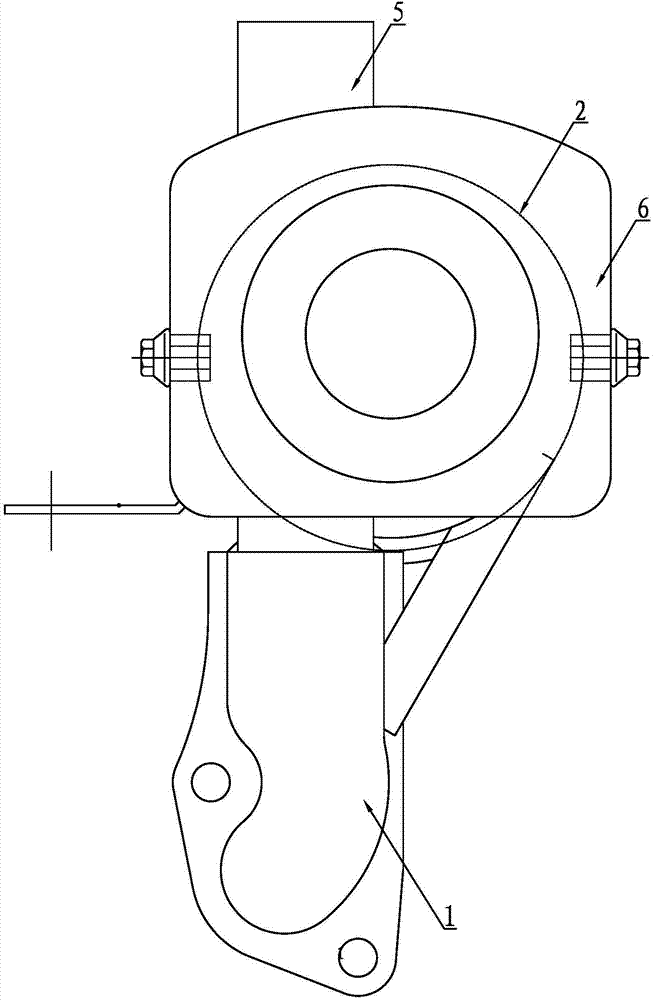

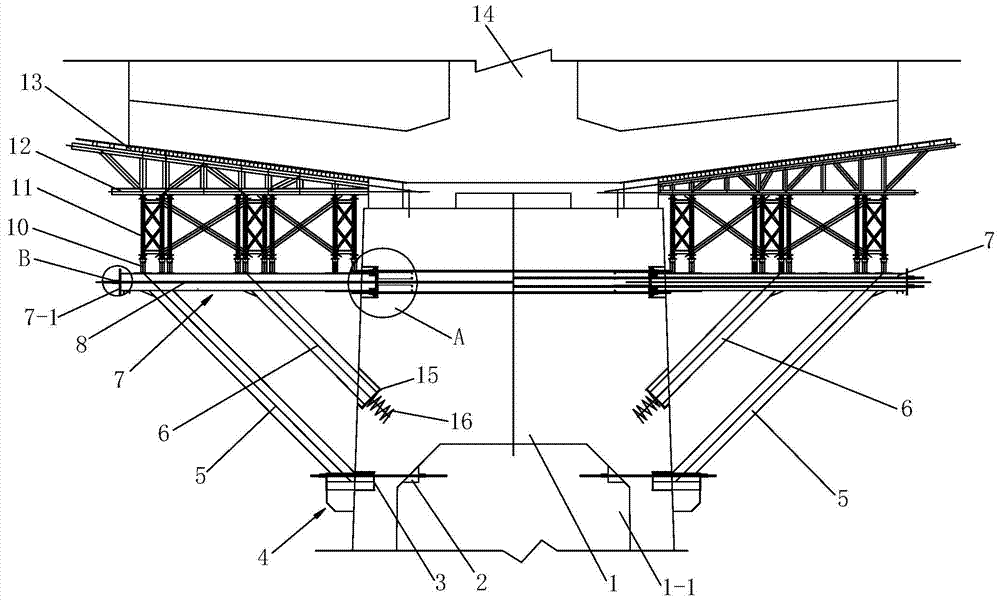

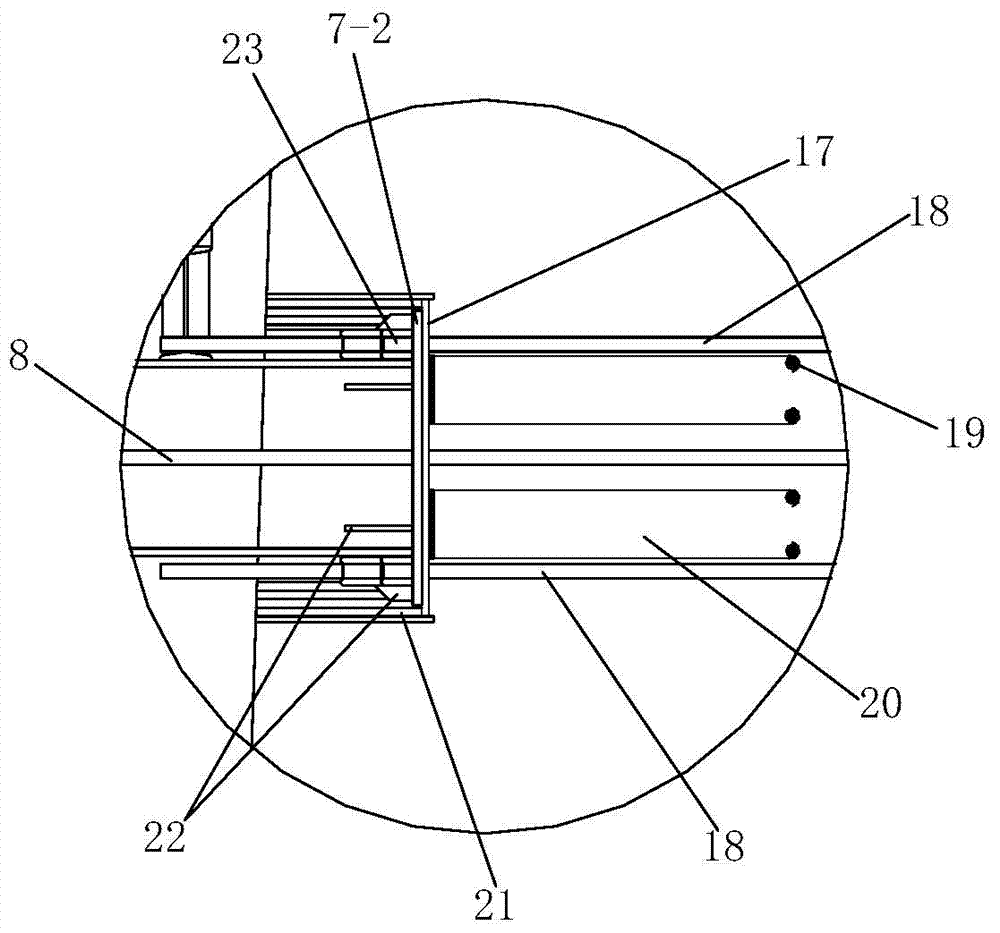

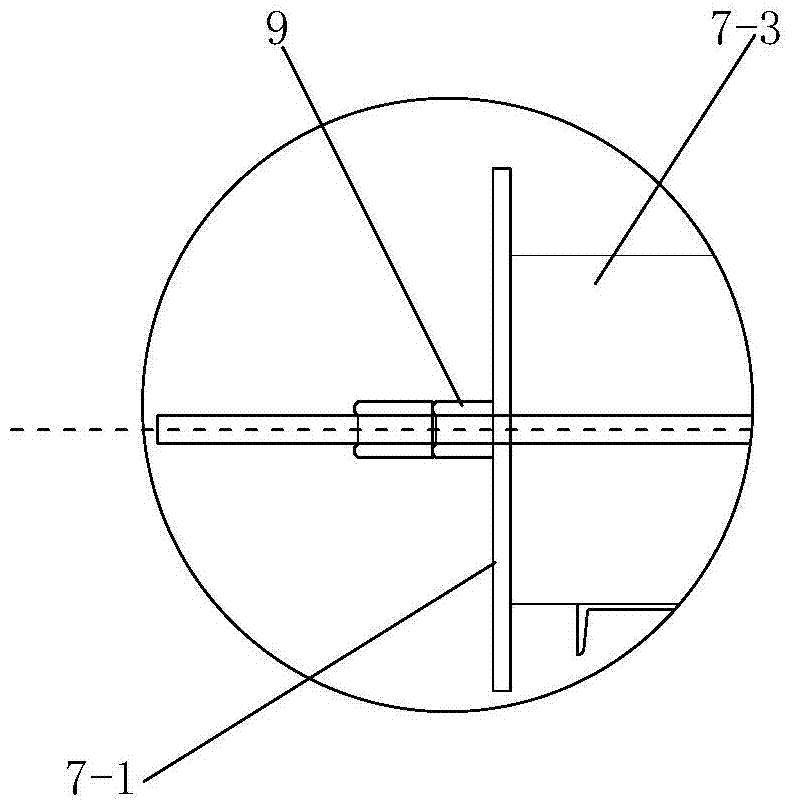

Corbel bracket for cast-in-place concrete construction at top of bridge pier

ActiveCN103452049ASimple structureNovel and reasonable designBridge structural detailsBridge erection/assemblyCorbelBuilding construction

The invention discloses a corbel bracket for cast-in-place concrete construction at the top of a bridge pier. The corbel bracket comprises a plurality of horizontal rod pieces arranged on the large-mileage side and the small-mileage side of the bridge pier. A plurality of first diagonal bars are correspondingly arranged below the horizontal rod pieces; a plurality of second diagonal bars are correspondingly arranged below the first diagonal bars; both the upper ends of the first diagonal bars and the upper ends of the second first diagonal bars are connected with the horizontal rod pieces above the first diagonal bars and the second diagonal bars; a plurality of first box bodies corresponding to the first diagonal bars, a plurality of second box bodies corresponding to the second diagonal bars and a plurality of third box bodies corresponding to the horizontal rod pieces are arranged on the bridge pier; the lower ends of the first diagonal bars are connected with the first box bodies; the lower ends of the second diagonal bars are connected with the second box bodies; one ends of the horizontal rod pieces are connected with the third box bodies; the horizontal rod pieces are connected with a plurality of prestressed pull rods in a fastening manner. The corbel bracket overcomes the defects of high requirements on the length and quality of weld joints between the horizontal rod pieces and the third boxes and difficulty in meeting the requirements on the length and quality of the weld joints on site.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

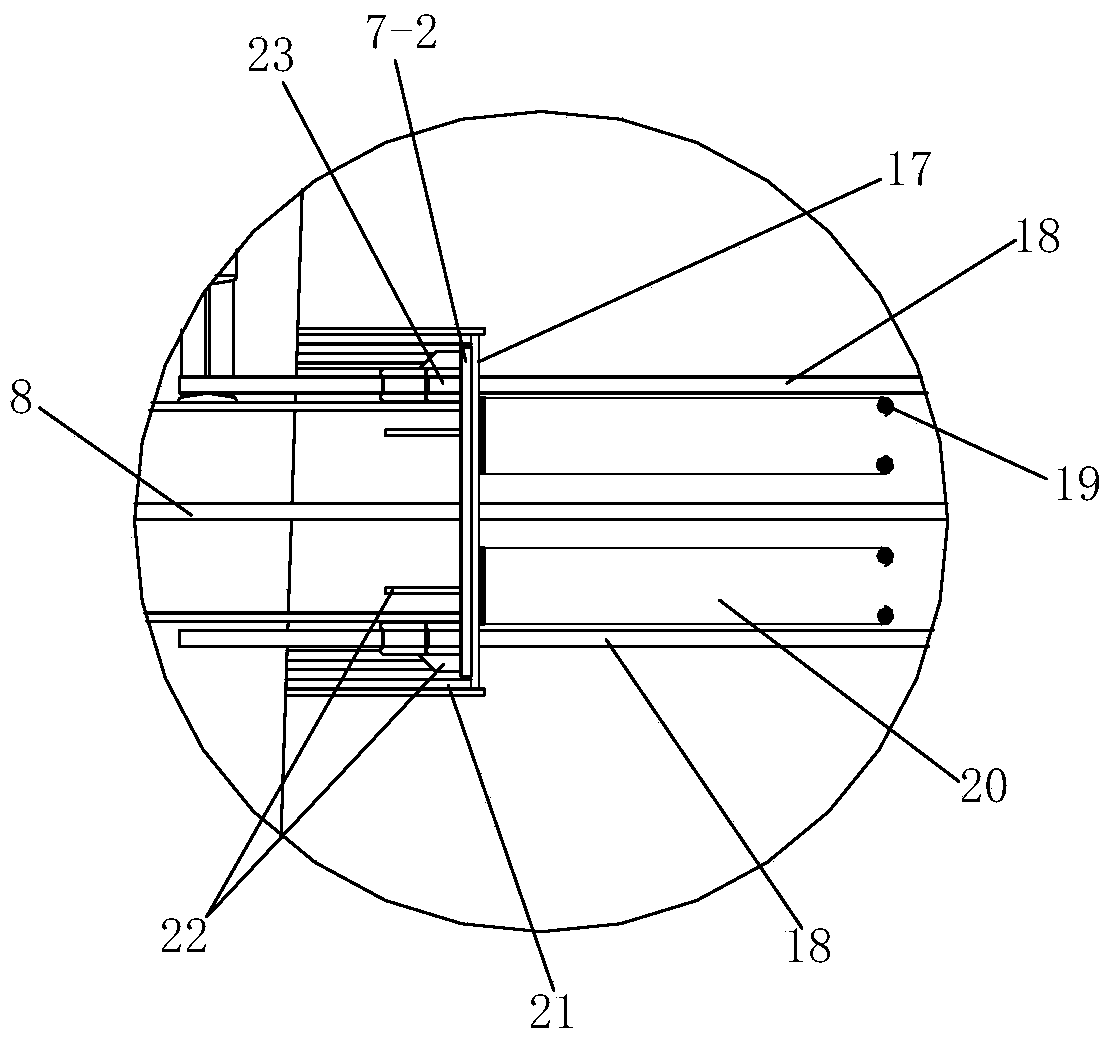

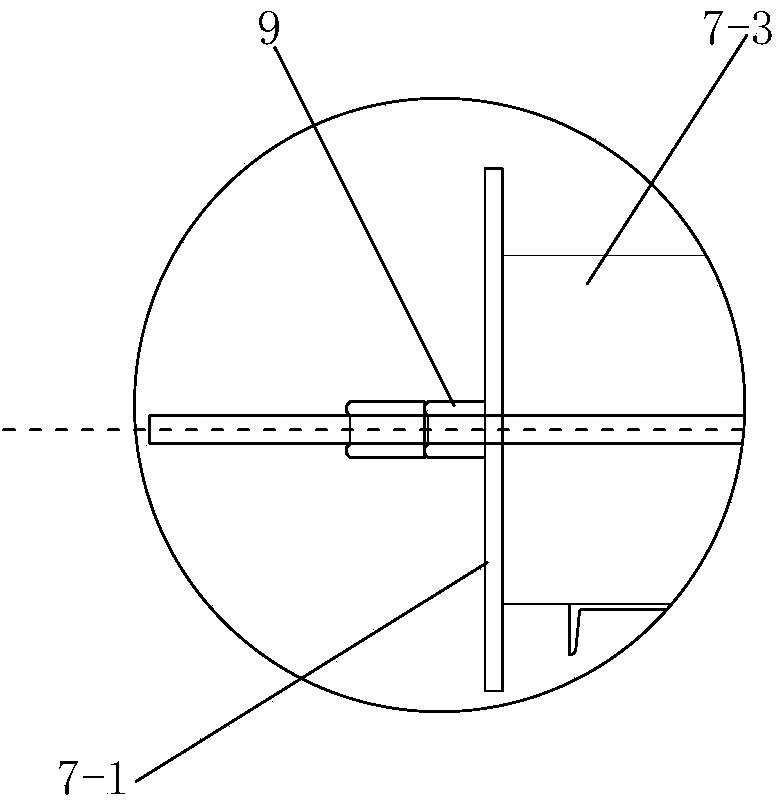

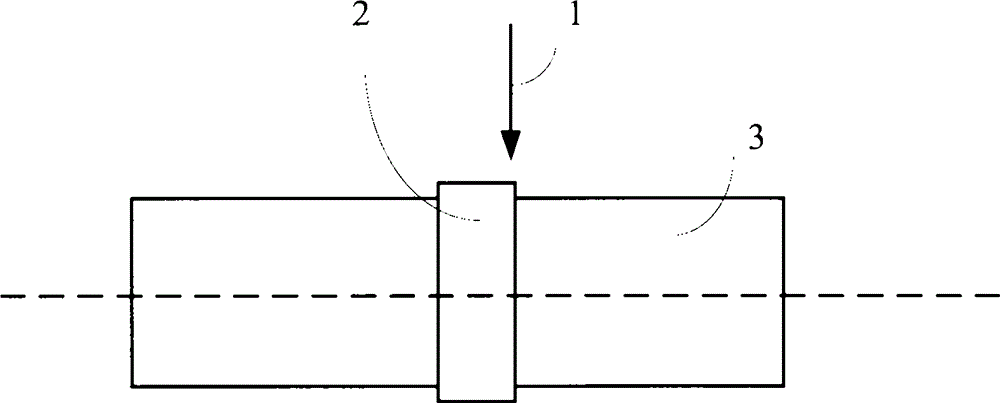

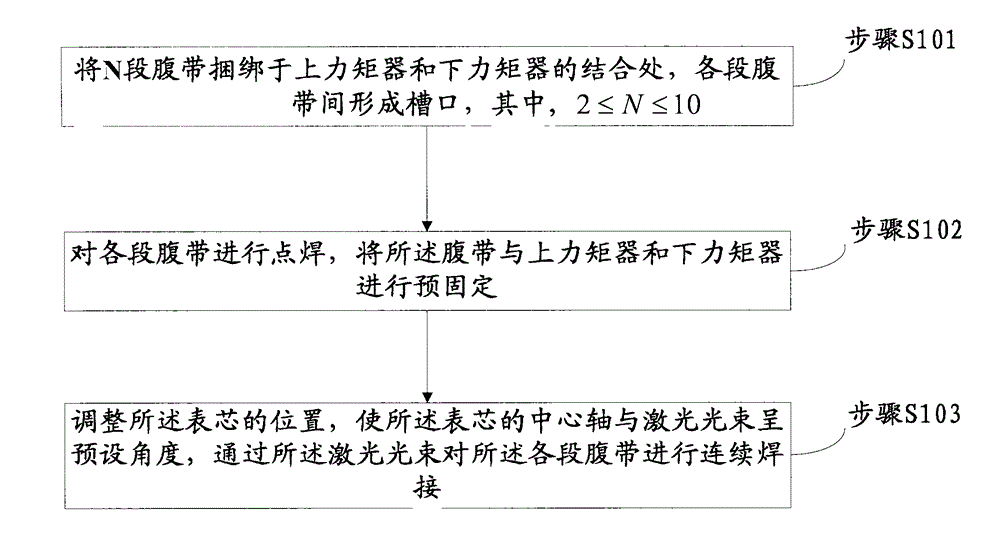

Welding method and welding structure of accelerometer movement

ActiveCN104400236AFully meltedIsolation of welding stressAcceleration measurementLaser beam welding apparatusAccelerometerLight beam

The invention provides a welding method and welding structure of an accelerometer movement. The welding method comprises the steps that N belly bands are bundled at the combination position of an upper torquer and a lower torquer, and groove openings are formed between the belly bands, wherein N is larger than or equal to 2 and smaller than or equal to 10; spot welding is carried out on the belly bands, and the belly bands, the upper torquer and the lower torquer are fixed in advance; the position of the movement is adjusted to enable the central axis of the movement and a laser beam to form a preset angle, and the belly bands are continuously welded through the laser beam; and the groove openings of the N belly bands can effectively isolate welding stress to achieve low-stress welding, and in the continuous welding process, due to the fact that a certain preset angle is formed between the central axis of the movement and the laser beam, the edges of the belly belts are fully melted through energy of the laser beam, and the welding quality is improved.

Owner:航天科工惯性技术有限公司

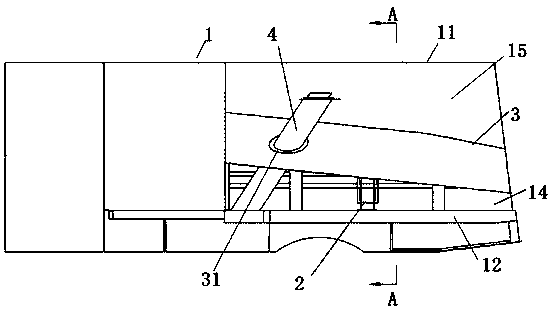

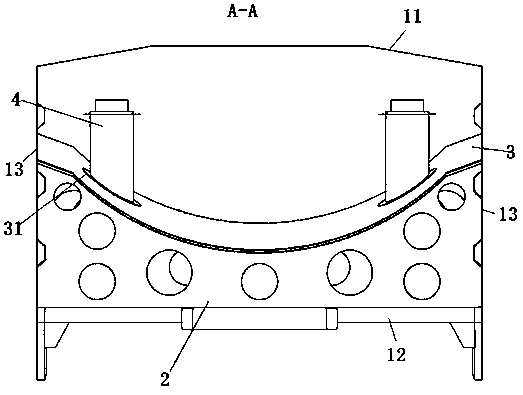

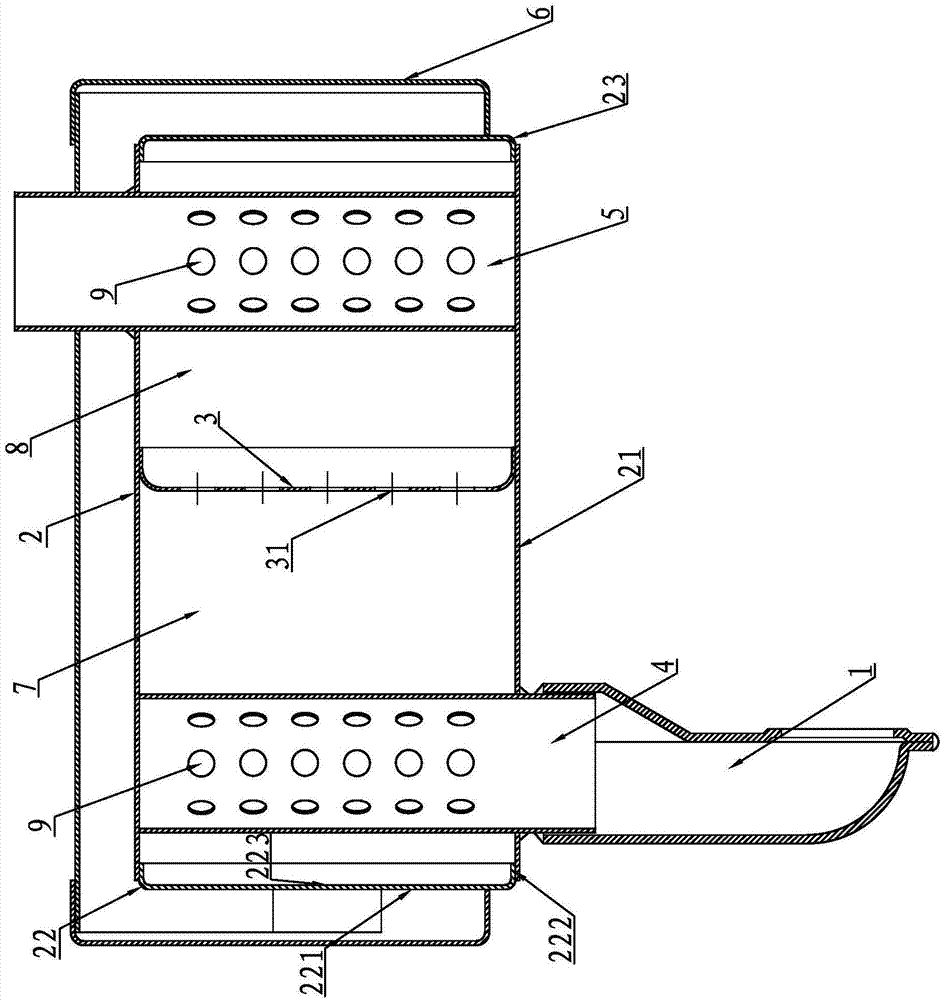

Sanitation truck and case structure thereof

The invention relates to a sanitation truck and a case structure thereof. The case structure of the sanitation truck includes a case body; the front and back directions of the case body are defined asthe front and back directions of the sanitation truck when the case body is installed on the sanitation truck; the case body is provided with a separating plate which can divide the case body into anupper side sewage chamber and a lower side clear water chamber; the separating plate has an arc-shaped part whose middle is projected downward; and the heights on the two sides of the arc-shaped partin the left and right directions are higher than that in the middle. As the separating plate having the arc-shaped part can bear larger water pressure and can also bear larger liquid surge impact during the starting and stopping of the vehicle, the design of a swash plate and a reinforcement structure at the internal can be saved, the total weight and weld length of the case structure can be decreased, and therefore, production costs can be reduced, and the service life of the case body can be prolonged.

Owner:ZHENGZHOU YUTONG HEAVY IND

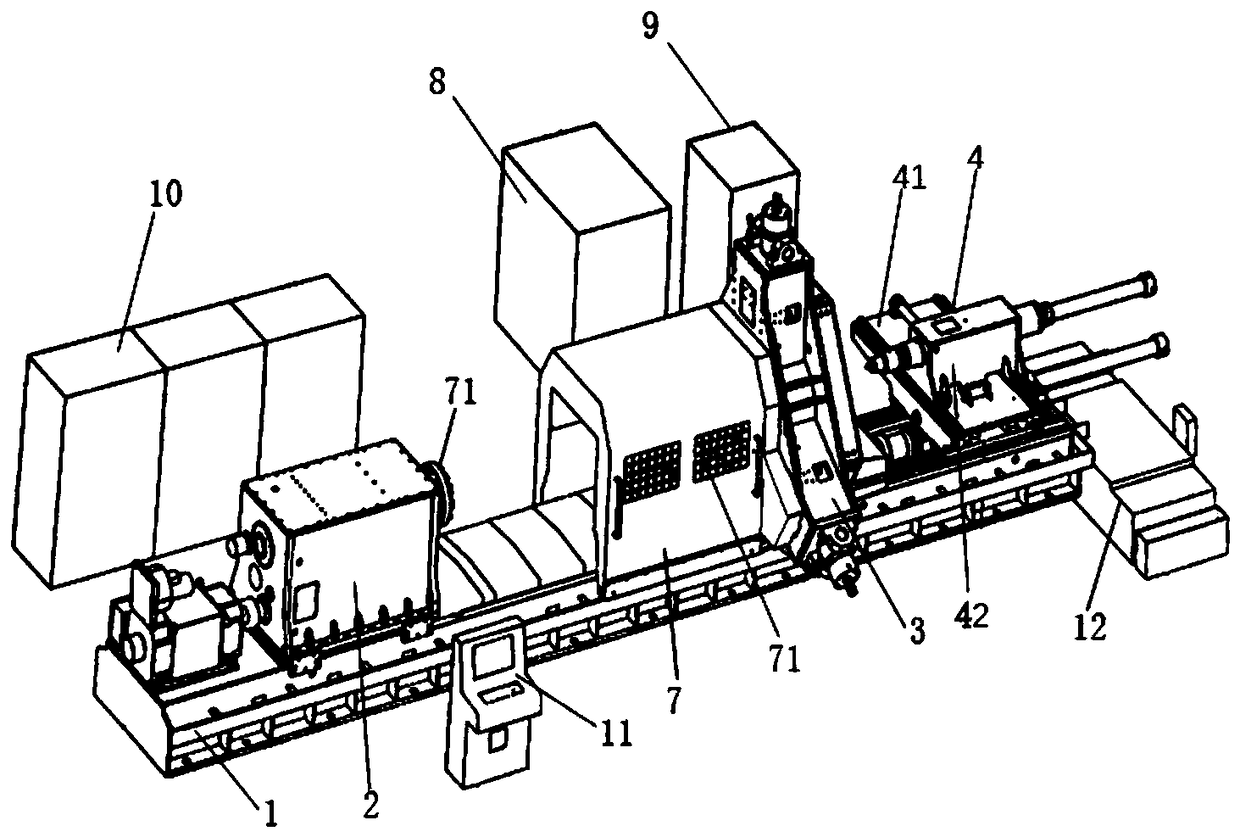

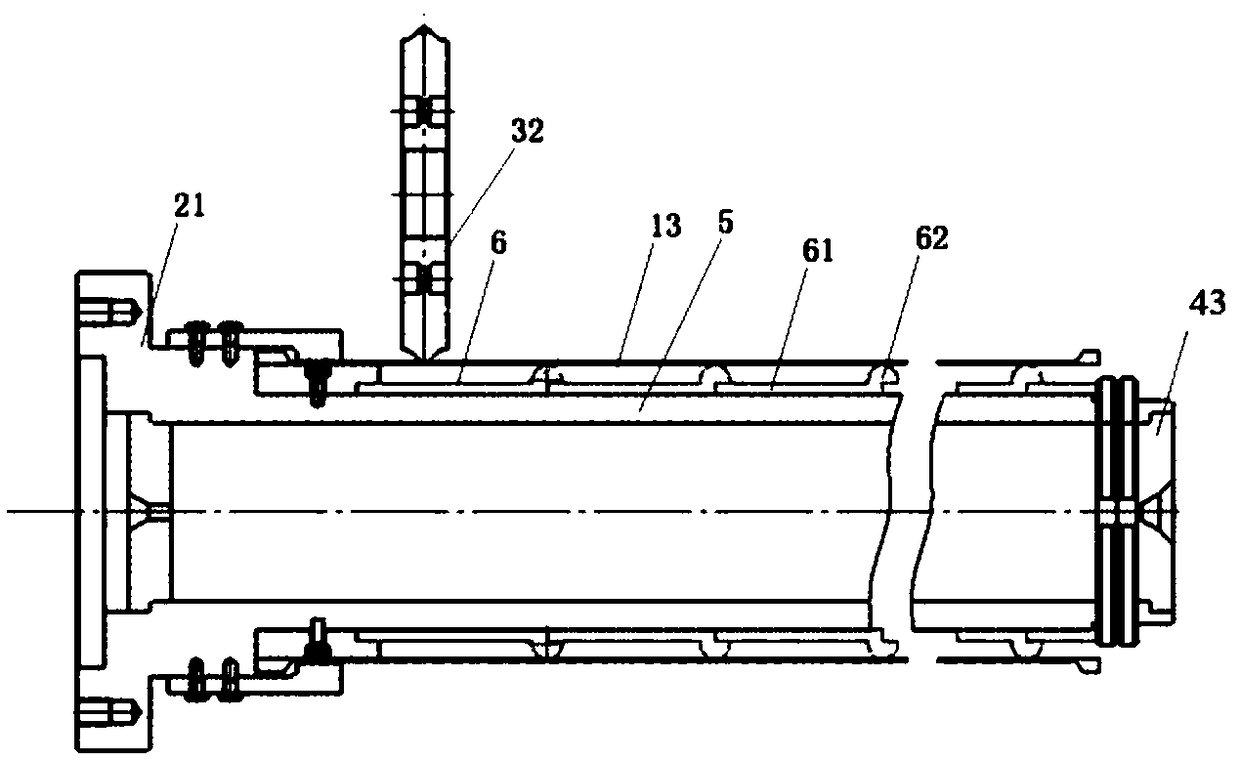

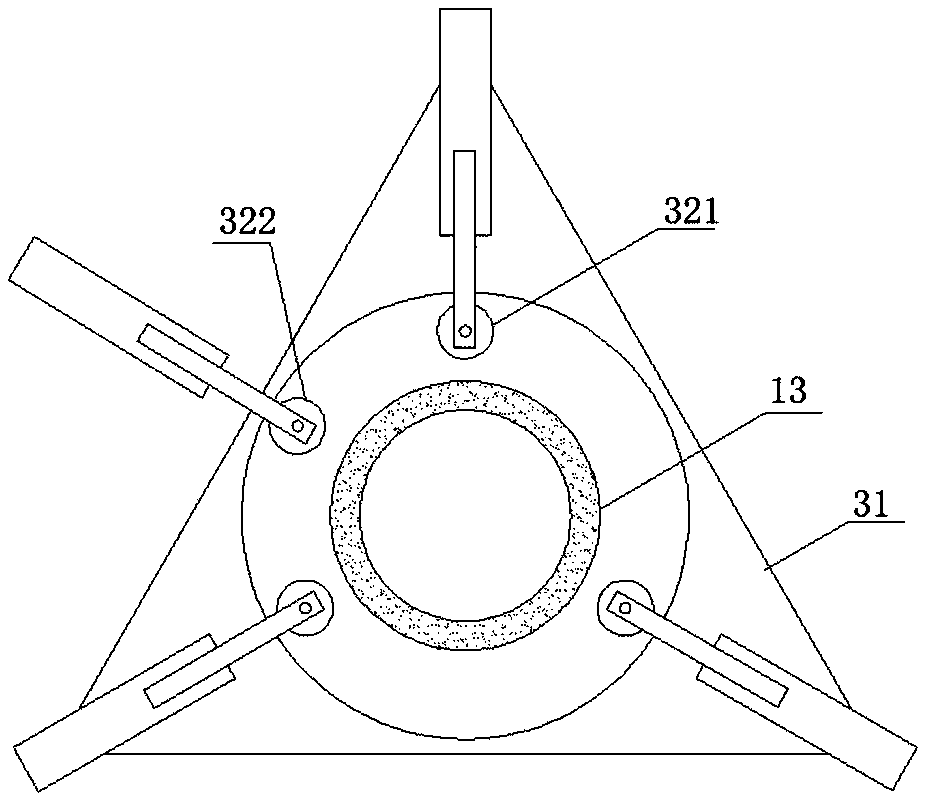

Necking-down spinning numerical-control forming equipment for corrugated pipe type thin-walled parts

The invention provides necking-down spinning numerical-control forming equipment for corrugated pipe type thin-walled parts. The necking-down spinning numerical-control forming equipment comprises a machine tool, a spindle device, a spinning roller device and a tail jack device; the spindle device, the spinning roller device and the tail jack are disposed on the machine tool in sequence; and a core die and a corrugation die which is disposed outside the core die in a sleeving mode are disposed between the spindle device and the tail jack device. The spinning roller device comprises a spinningroller frame and a spinning roller; the spinning roller device is in sliding connection with the machine tool; a machining area is disposed on the spinning roller frame; one end of the core die is connected with a spindle in the spindle device; the corrugation die penetrates through the machining area on the spinning roller frame to be connected with the tail jack device; and the spinning roller is disposed in a spinning roller frame and can perform radial servo feeding relative to the core die. The tail jack device comprises a tail seat frame body and a tail jack; the tail seat frame body isin sliding connection with the machine tool; the tail jack is mounted on the tail seat frame body and can perform axial feeding and radial transverse movement; and annular male dies are uniformly distributed on the outer wall of the corrugation die. By means of the necking-down spinning numerical-control forming equipment for the corrugated pipe type thin-walled parts, the potential quality hazards of transverse and longitudinal welding seams and welding defects which are prone to occurring in a welding seam intersection region by a traditional tailor welding process of corrugated pipes are eliminated.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

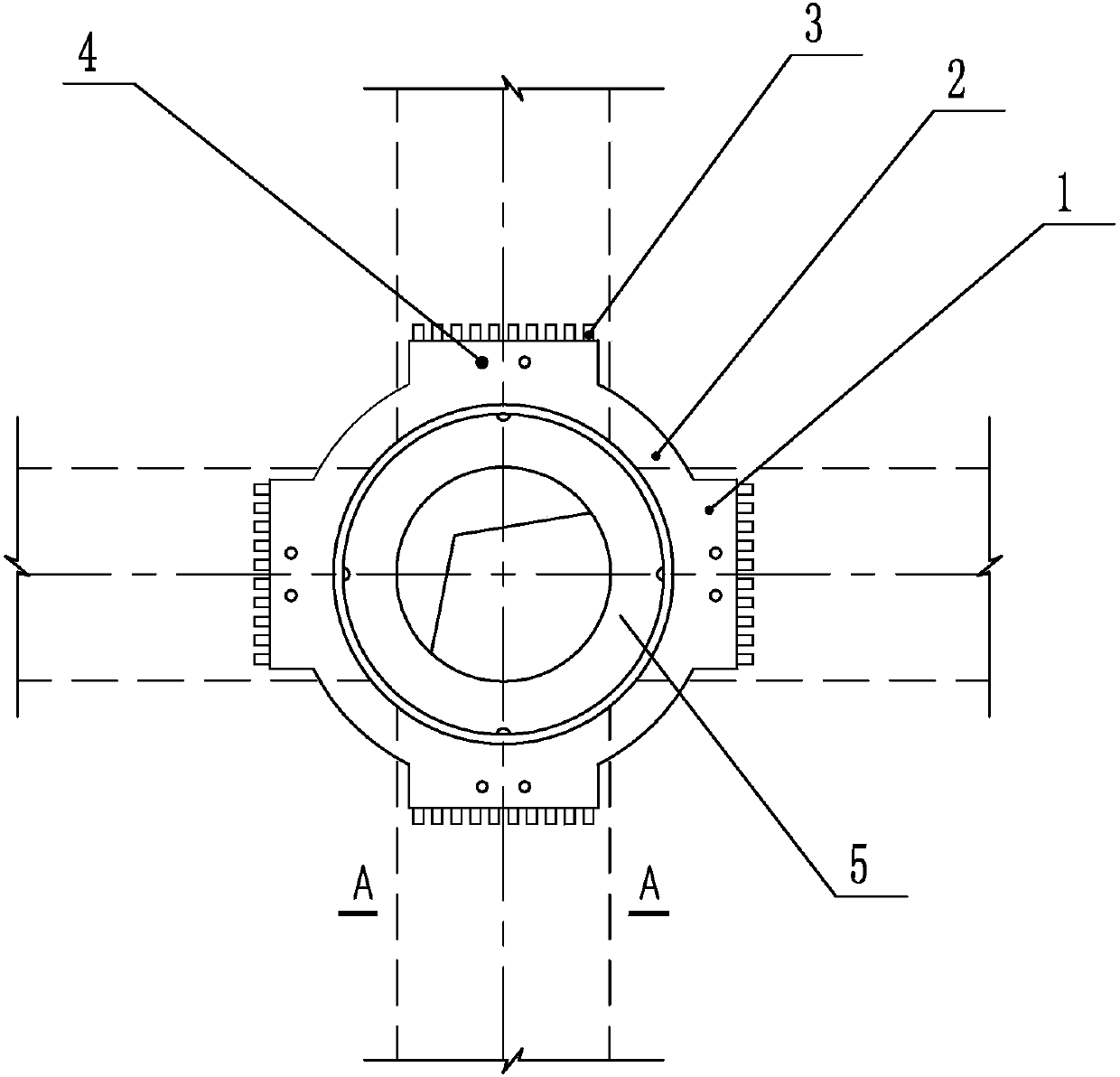

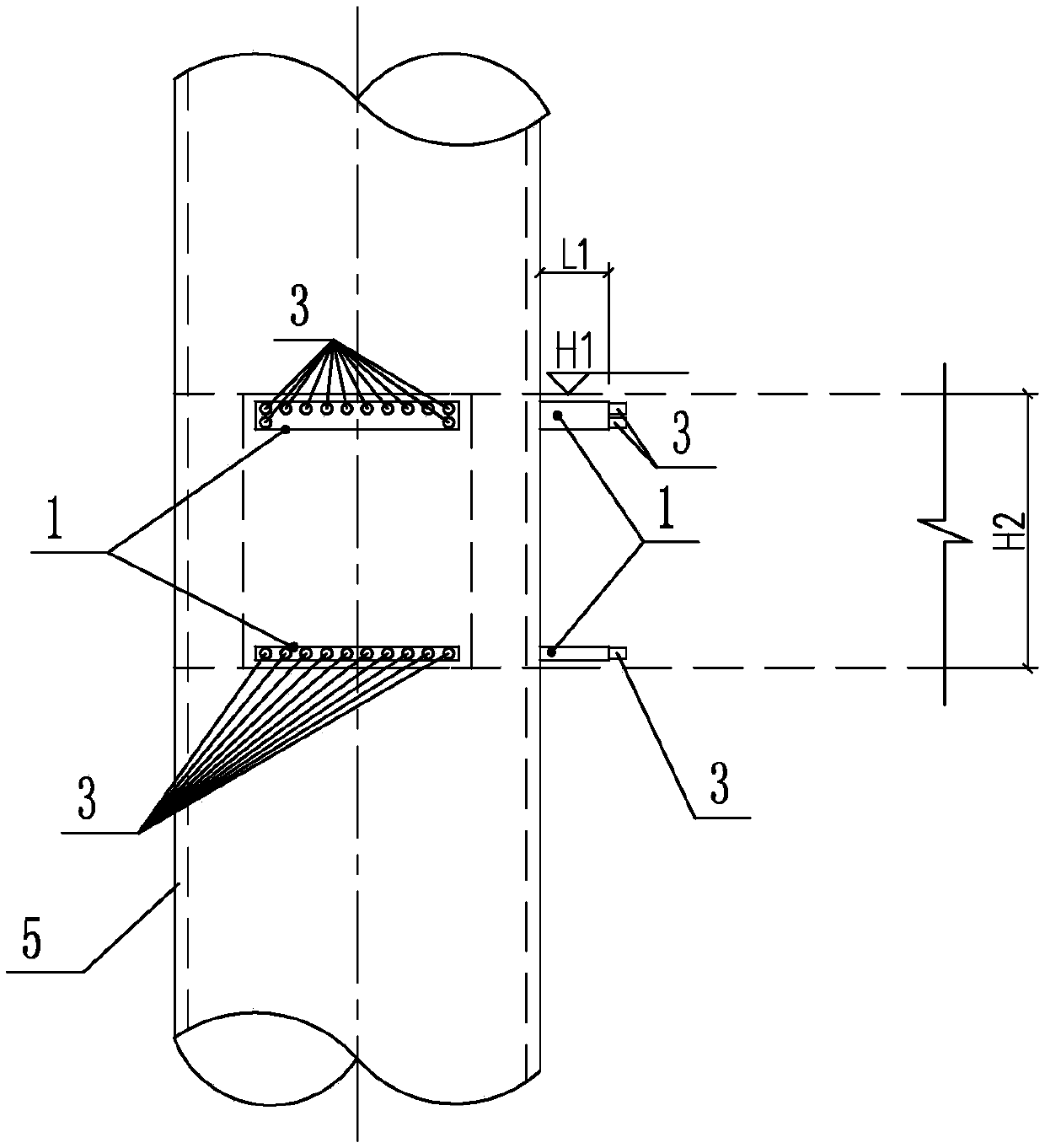

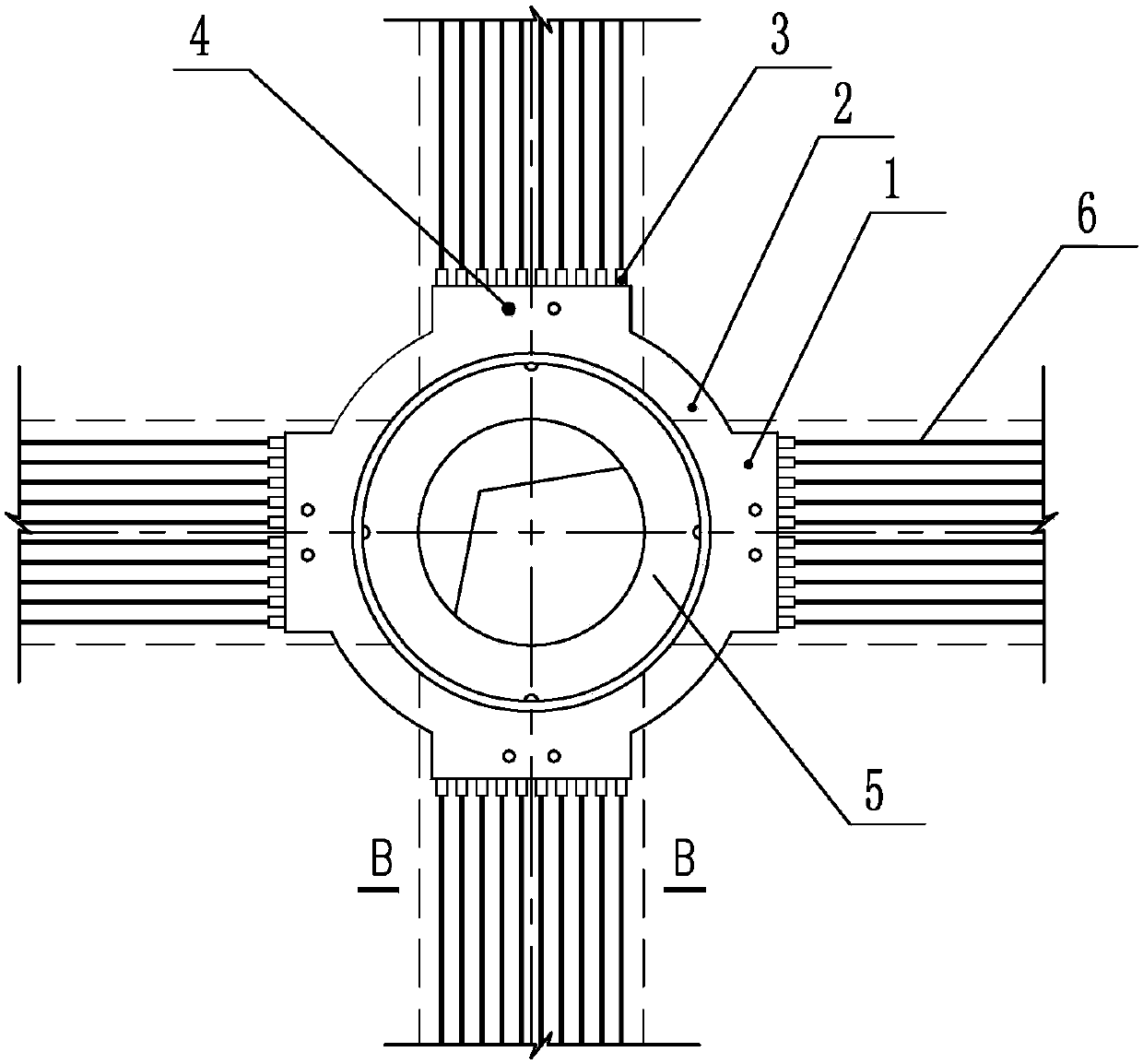

Magnet yoke for electric induction furnace

ActiveCN104320870AIncrease the waterwayReduce leak pointsInduction heatingCooling/ventilation/heating modificationsWater leakageWater flow

The utility model discloses a magnet yoke for an electric induction furnace, and the magnet yoke comprises a stacked silicon steel plate group, a back plate, two side plates, and a plurality of fixed plates. The side plates are hollow plates, and are symmetrically fixed at two sides of the back plate. The stacked silicon steel plate group is disposed between the side plates. The fixed plates are provided with fixed installation holes, and two ends of each fixed plate are respectively in fixed connection with the two side plates. The magnet yoke is advantageous in that a function of cooling and a function of supporting are integrated into one body; the back surface of the magnet yoke is additionally provided with an upper water path and a lower water path, thereby reducing the water leakage points; the magnet yoke achieves the maximization of a water area and a water-flowing cross sectional area and low pressure difference between a water inlet and a water outlet, enhances the cooling effect, and enables the heat dissipation to be more balanced.

Owner:SHANGHAI XINYAN IND EQUIP

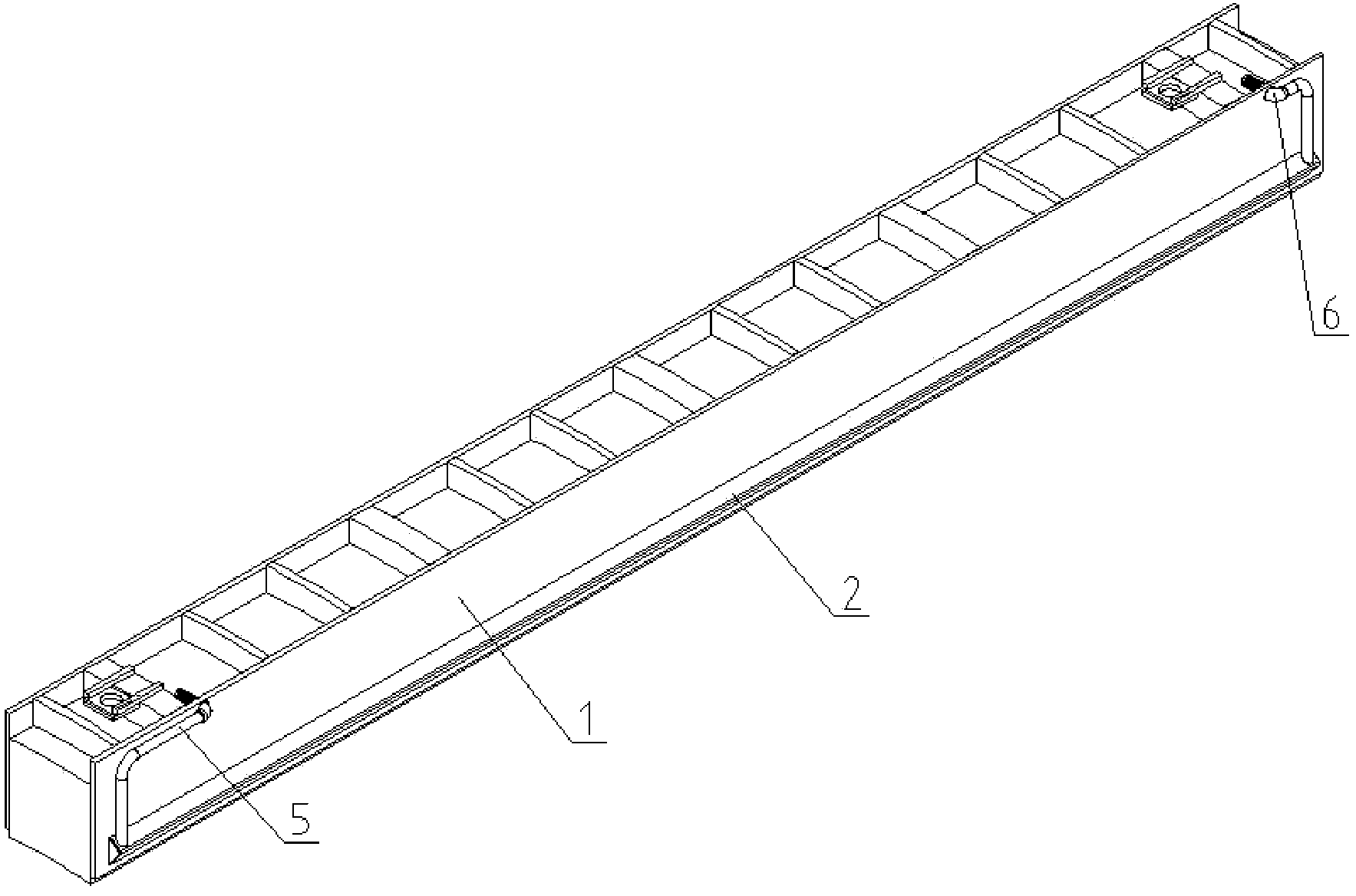

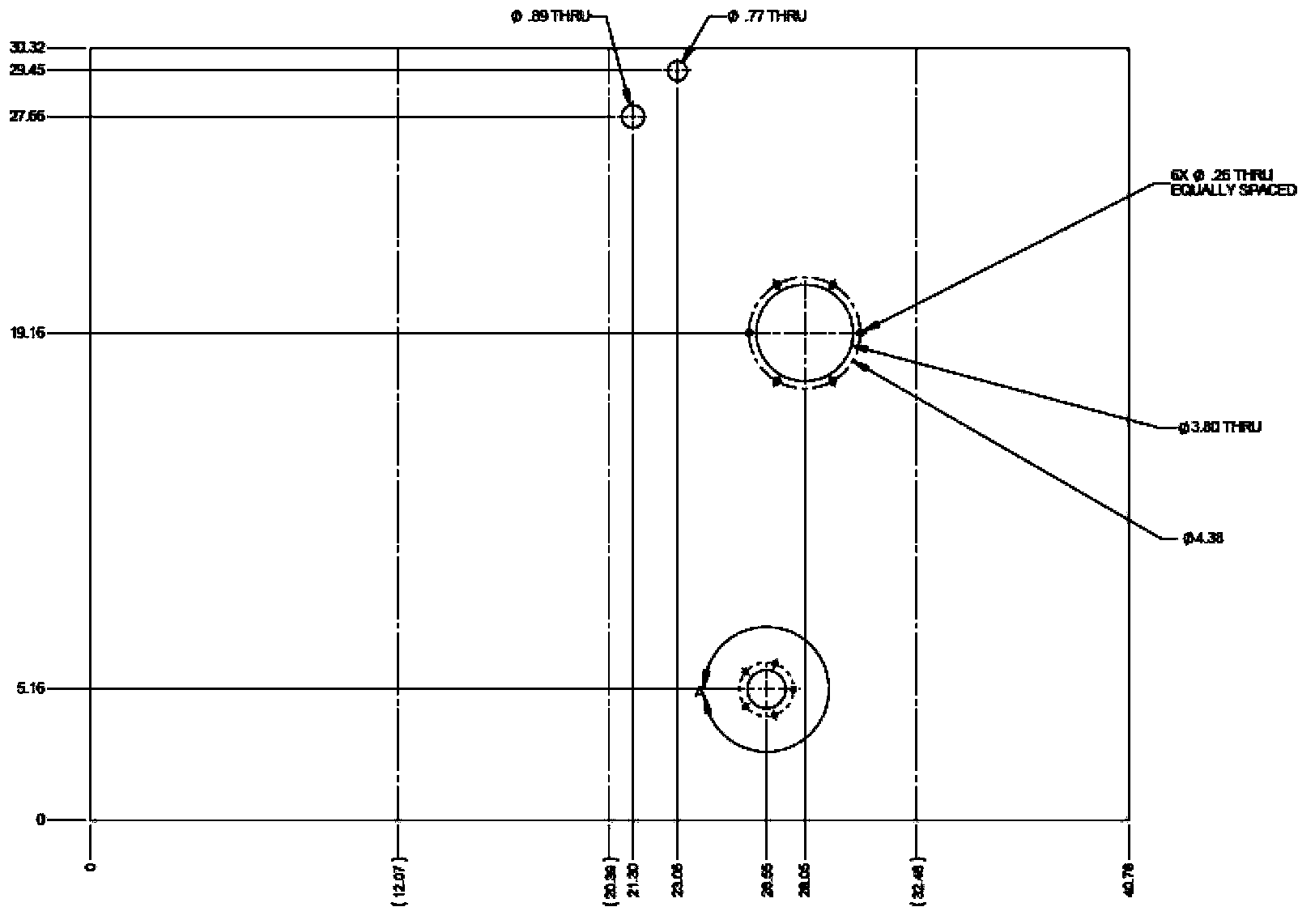

Concentric-square-shaped groove frame machining method and series connection insert joint bending die

ActiveCN106734443ASolve the production narrow mouth problemReduce the length of split weldingShaping toolsUltimate tensile strengthWelding defect

The invention provides a concentric-square-shaped groove frame machining method and a series connection insert joint bending die, and belongs to the technical field of mechanical stamping. Welding defects are reduced, leveling labor hours caused by heat deformation are shortened, and the labor intensity is reduced; and the problem about production narrow openings of Z-shaped bending is solved. The die is composed of three parts including a male die assembly, a female die assembly and a positioning device; insert series connection combining and jointing male and female die inserts are adopted in the male die assembly and the female die assembly correspondingly; the male die assembly comprises seven male die inserts of the same structure and with different lengths; and the concentric-square-shaped groove frame machining method comprises three times of bending. An insert joint tool bending process technology is used for reducing the split welding length, and a common angle supplementing process method is used for manufacturing. Bending of multiple products is completed through the insert joint bending die, the die manufacturing cost is reduced, die replacement can be rapidly carried out, and the product batch consistency is improved.

Owner:BEIJING NORTH VEHICLE GROUP CORP

Diesel engine silencer of tension-free silencing chamber structure

InactiveCN103790677AReduce manufacturing costReduce consumptionSilencing apparatusMachines/enginesManufacturing technologyAtmospheric air

The invention relates to a diesel engine silencer of a tension-free silencing chamber structure. The diesel engine silencer comprises a gas intake pipe, a tension-free silencing shell, a silencing partition plate, a primary noise reducing pipe, a terminal noise reducing pipe and a scalding-proof shield. The tension-free silencing shell comprises a sectional material pipe body, a left end cover and a right end cover. The left end cover and the right end cover are fixed at the two ends of the sectional material pipe in a sealed mode respectively. The silencing partition plate is arranged in the tension-free silencing shell. A silencing hole is formed in the silencing partition plate. The tension-free silencing shell is divided by the silencing partition plate into a primary noise reducing cavity and a silencing cavity of a terminal noise reducing cavity. The primary noise reducing cavity is communicated with the primary noise reducing pipe. The terminal noise reducing cavity is communicated with the terminal noise reducing pipe. The outlet of the terminal noise reducing pipe is communicated with the air. The gas intake pipe is communicated with the primary noise reducing cavity through the primary noise reducing pipe. The scalding-proof shield is fixed to the outer end of the tension-free silencing shell. The diesel engine silencer of the tension-free silencing chamber structure is simple in structure, good in manufacturing technology, low in production cost, good in anti-vibration anti-fracture performance and reliable in use and the noise reducing performance of the diesel engine silencer is equal to that of an existing product.

Owner:常州金坛佳越机械有限公司

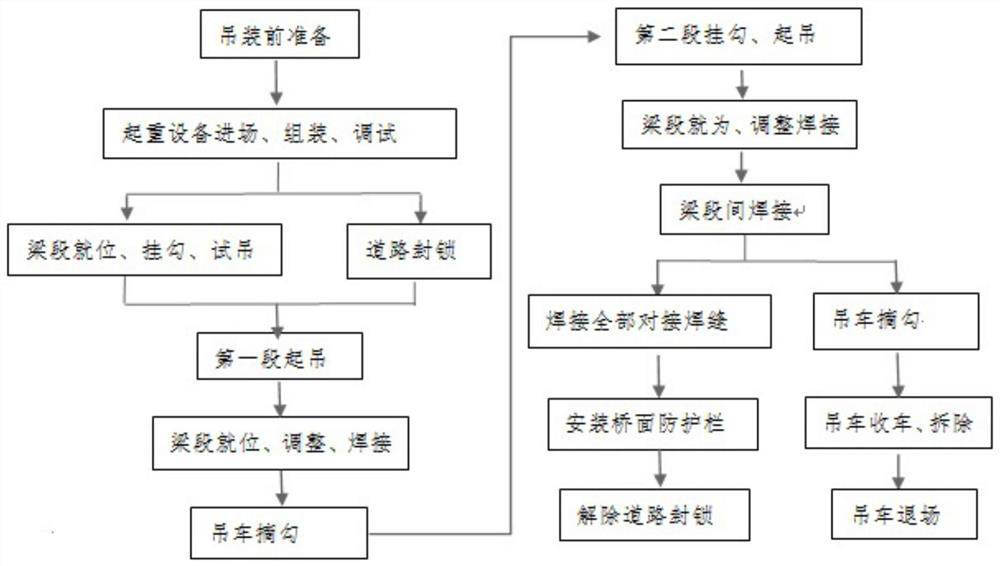

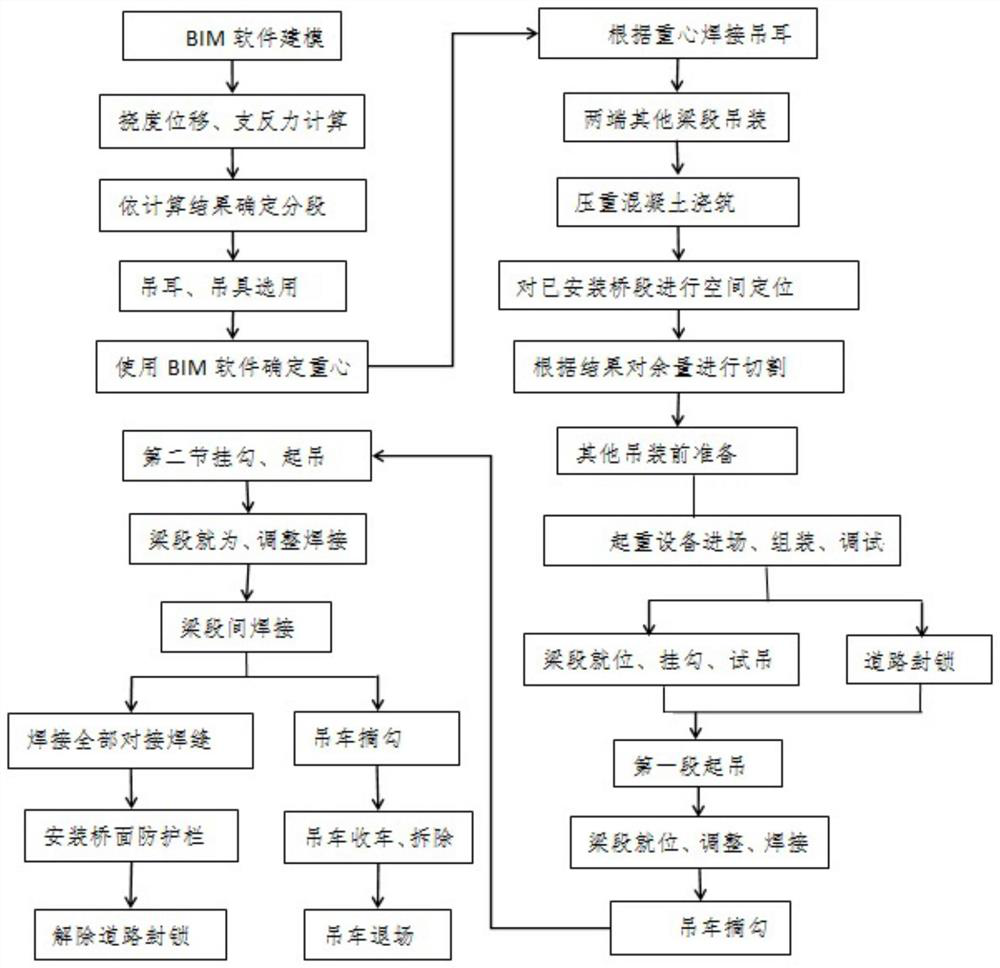

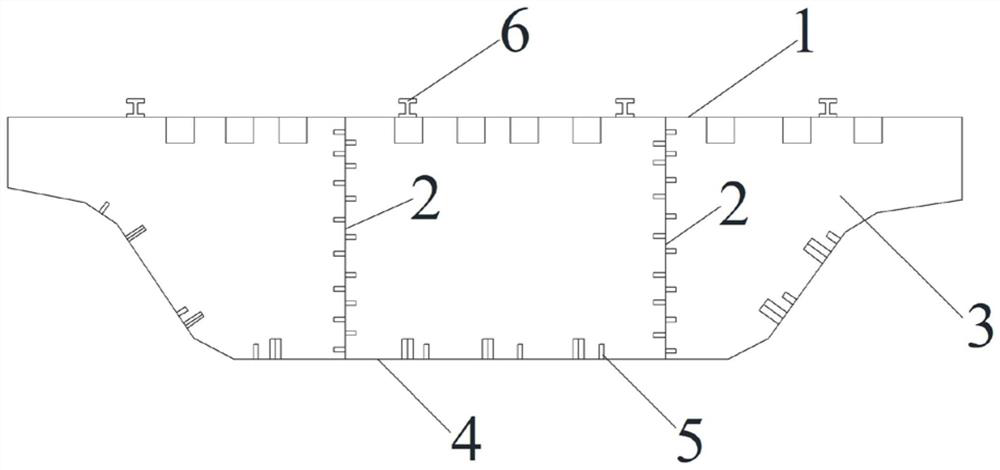

Unsupported large-span hyperbolic cross-city viaduct steel box girder sectional construction method

The invention provides an unsupported large-span hyperbolic cross-city viaduct steel box girder sectional construction method. The method comprises the steps that S1, other girder sections except a first arc girder section and a second arc girder section in a cross-bridge section are installed in advance; S2, the first arc girder section is hoisted firstly, and the two ends of the first arc girdersection are connected with two fractures of the cross-bridge section correspondingly; S3, the second arc girder section is hoisted, the two ends of the second arc girder section are connected with the two fractures of the cross-bridge section correspondingly, and the arc joint of the second arc girder section and the arc joint of the first arc girder section are connected; and S4, hoisting is completed, and a crane evacuates from the site. According to the method, a support-free hoisting is adopted, a temporary buttress does not need to be erected on an existing bridge during construction, the influence on traffic on the bridge during buttress erection is avoided, the number of cross-bridge sections is smaller than that of cross-bridge sections adopting a conventional hoisting method, thehoisting progress is accelerated, meanwhile, the number of welded junctions and the length of weld joints are reduced, the construction time of the cross-bridge sections is shortened, and the influence on the ground traffic for a long time is also avoided.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY NO 9 GRP

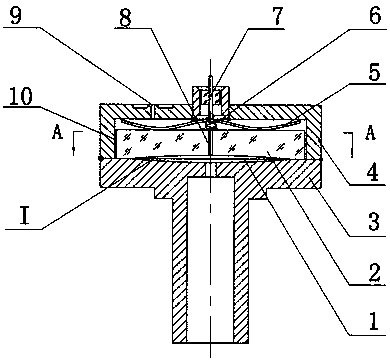

Assembled type fixed electrode capacitive pressure sensor

PendingCN107843379AThe contact between the film moving electrode and the fixed electrode insulatorClose contactFluid pressure measurement using capacitance variationCapacitive pressure sensorSingle crystal

An assembled type fixed electrode capacitive pressure sensor can help solve problems of large quantities of fittings, easy attachment of gas in the ceramic insulating body, affected vacuum degree, large non-linearity, mismatch of a movable electrode shape change and a fixed electrode surface shape, and the like in a conventional capacitive pressure sensor. A fixed-electrode insulator made of a sapphire single-crystal is fixedly supported at a center position of a cavity of a clamping and pressing ring with a cover via an elastic positioning device, a thin film movable electrode made of constant elastic metal is pressed between an annular plane on a bottom part of the fixed-electrode insulator and an annular plane with an pressure guiding opening in a supported manner, and both faces of thethin film movable electrode are coated with precious metal layers; the film movable electrode of which the both faces are coated with precious metal layers is in close contact with the fixed-electrode insulator under pressure applied via a triple wave gold plated pressure spring. The sensor disclosed in the invention is simple in structure, reasonable in design, easy in manufacture, high in production efficiency and reliable in use; zeroing is not needed for a long time, an air inflow and an air outflow are reduced, leak rates are greatly lowered, a vacuum degree can be kept for a long time,and measurement stability and measurement precision can be improved markedly.

Owner:SHENYANG SENSOR TECH INST

Steel pipe necking and welded hollow sphere connection joint

InactiveCN106320536AOvercome outstanding problems of earthquake damageSmall diameterBuilding constructionsButt weldingMetallurgy

The invention relates to connection joints of space grid structures, in particular to a steel pipe necking and welded hollow sphere connection joint. The problems that according to an existing connection joint, the dimension of a welded hollow sphere is too large, and the earthquake damage risk of bolt sphere joints is severe are solved. The steel pipe necking and welded hollow sphere connection joint comprises a steel pipe, a welded hollow sphere and a steel taper pipe. A butt welding seam connected with one end of the steel taper pipe and the steel pipe is arranged between one end of the steel taper pipe and the steel pipe. A butt welding seam I connected with the other end of the steel taper pipe and the welded hollow sphere is arranged between the other end of the steel taper pipe and the welded hollow sphere. The wall thickness of the side, along the welded hollow sphere, of the steel taper pipe is increased gradually. According to the connection joint, the performance of a welded hollow sphere joint grid structure is greatly improved, and the steel amount of the joint is reduced; in addition, the bearing capacity of a hollow sphere joint with the same thickness is greatly improved, and the technological difficulty of field installation is lowered; and meanwhile, the steel sphere manufacturing efficiency is improved.

Owner:TAIYUAN UNIV OF TECH

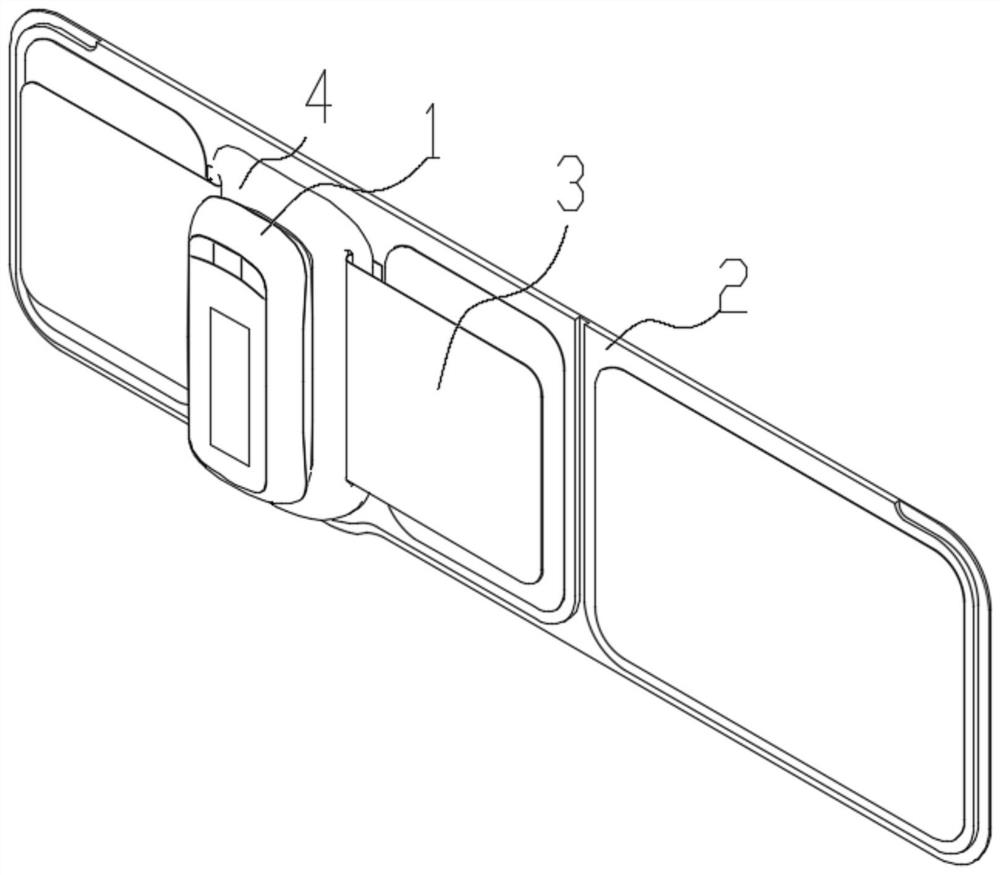

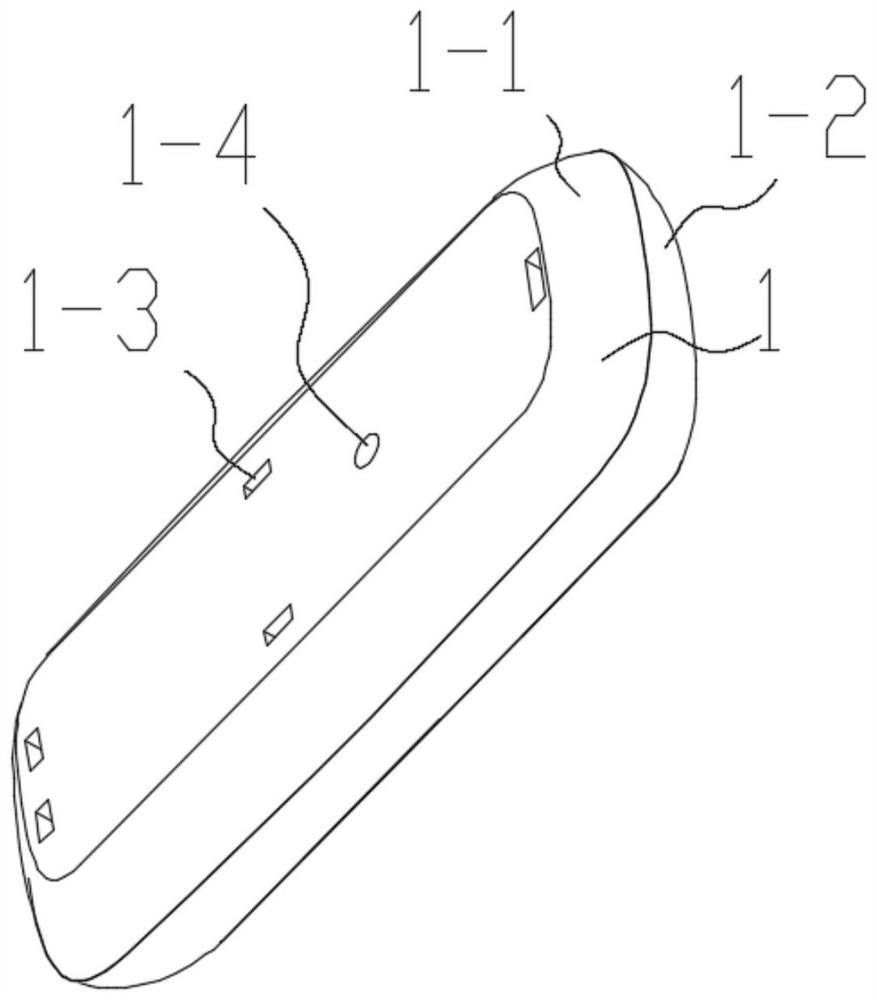

Cuff type sphygmomanometer

PendingCN111772612AFirmly connectedEasy to cleanEvaluation of blood vesselsAngiographySphygmomanometerCuff

The invention discloses a cuff type sphygmomanometer. The sphygmomanometer comprises a sphygmomanometer body and a cuff, and the sphygmomanometer body and the cuff are detachably connected through a strap type detachable connecting component. The sphygmomanometer and the cuff are detachably connected through the strap type detachable connecting component, which means that: the sphygmomanometer andthe cuff are directly and detachably connected through the strap type detachable connecting component, or the sphygmomanometer and the cuff are indirectly and detachably connected through the strap type detachable connecting component. The sphygmomanometer and the cuff are indirectly and detachably connected through the strap type detachable connecting component, which means that a clamping plateis arranged between the strap type detachable connecting component and the sphygmomanometer. According to the cuff type sphygmomanometer, the cuff and the sphygmomanometer can be easily separated with small force, disassembly is convenient, the strap type detachable connecting component is not prone to damage, the cuff replacement cost is greatly reduced, the cuff cleaning time is short, the cuffis easy to clean, and the cuff is not prone to damage.

Owner:合捷联创(北京)科技有限公司

Modular Pulse Jet Fabric Filter

InactiveUS20140373489A1Efficient manufacturingQuality improvementDispersed particle filtrationLighting and heating apparatusPower stationModular design

A modular design for large pulse jet fabric filters (PJFF) is divided into similar compartments, which are each “shop-fabricated” in quarter sections prior to delivery to the power plant site. The quarter sections of the compartments are modular and sized so that they can be fabricated at a shop located away from the power plant site and transported by truck over public roads to the power plant site. Once delivered to the site, the quarter sections are bolted together and seal welded to form a PJFF compartment, without requiring additional internal fabrication or welding. The assembled compartment is then lifted onto the support structure as an assembled unit and bolted and / or welded in place. The additional components of the PJFF may also be shop-fabricated offsite to further the benefits of the modular design.

Owner:CLYDE BERGEMANN POWER GRP AMERICAS

Corbel support for cast-in-place concrete construction on the top of bridge pier

ActiveCN103452049BSimple structureNovel and reasonable designBridge structural detailsBridge erection/assemblyCorbelBuilding construction

The invention discloses a corbel support for cast-in-place concrete construction on the top of a bridge pier, which includes a plurality of horizontal rods arranged on the side of the large mileage and the side of the small mileage of the bridge pier, and a plurality of first horizontal rods are correspondingly arranged under the multiple horizontal rods. A diagonal brace, a plurality of second diagonal braces are arranged one by one under the plurality of first diagonal braces, and the upper ends of the plurality of first diagonal braces and the upper ends of the plurality of second diagonal braces are connected with the horizontal bar above them. The pier is provided with a plurality of first boxes corresponding to the first diagonal braces, a plurality of second boxes corresponding to the second diagonal braces and a plurality of horizontal rods corresponding to each other. The third box body, the lower end of the first diagonal strut is connected with the first box body, the lower end of the second diagonal strut is connected with the second box body, one end of the horizontal bar is connected with the third box body, and the upper end of the horizontal bar is fastened and connected Multiple prestressed tie rods. The corbel bracket overcomes the defects of high requirements on the length and quality of the weld between the horizontal bar and the third box, and difficulty in achieving it on site.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

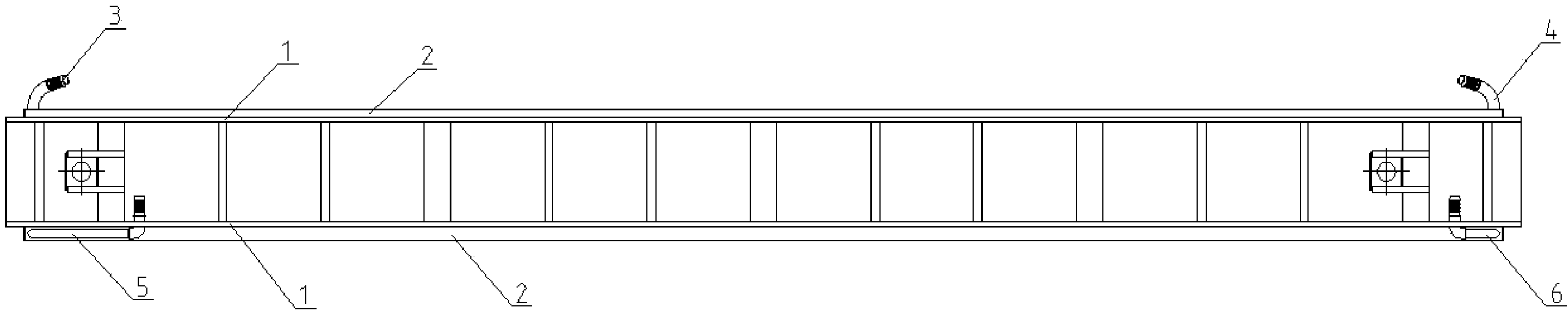

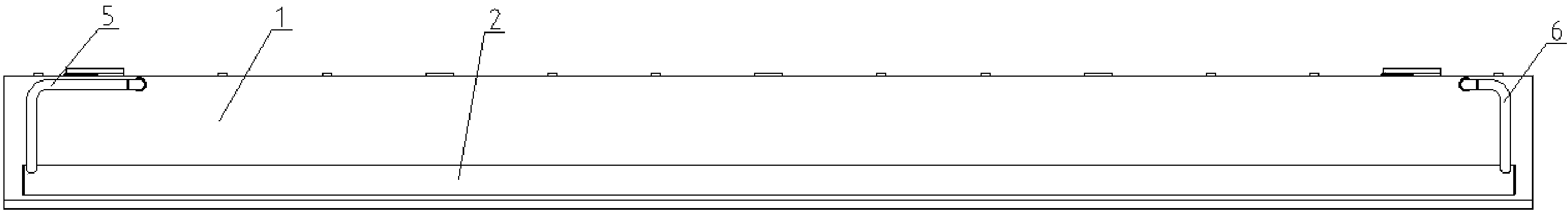

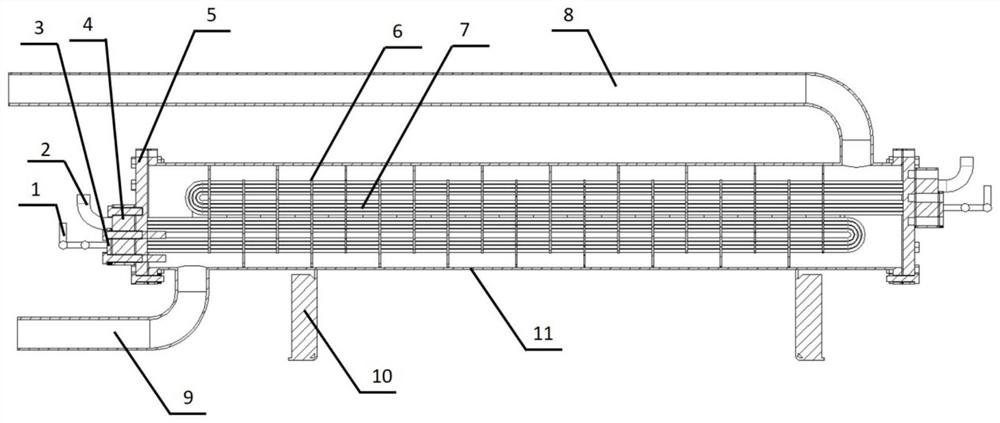

Shell-and-tube heat exchanger with refrigerant distribution device

ActiveCN113758056AAccurate control of working fluid flowReduce dosageEvaporators/condensersHeat exhanger sealing arrangementRefrigerant distributionEngineering

The invention discloses a shell-and-tube heat exchanger with a refrigerant distribution device. The shell-and-tube heat exchanger with the refrigerant distribution device comprises a refrigerant outlet pipe, a distribution structure, a tube plate and a barrel. A tube plate is arranged at one end of the barrel; a heat exchange tube and a plurality of segmental baffles are arranged in the barrel; the distribution structure is arranged at a refrigerant inlet at one end of the barrel and comprises a refrigerant distribution tube, a cover plate and an end cover; the refrigerant distribution tube is connected with the cover plate; the cover plate is connected with the end cover; and the end cover is connected with the tube plate. The refrigerant distribution pipe comprises a first-stage distribution pipe, a first-stage transverse pipe, a second-stage distribution pipe, a second-stage transverse pipe and a third-stage distribution pipe; the first-stage distribution pipe communicates with the first-stage transverse pipe; the first-stage transverse pipe communicates with the second-stage distribution pipe; the second-stage distribution pipe communicates with the second-stage transverse pipe; and the second-stage transverse pipe communicates with the third-stage distribution pipe. The shell-and-tube heat exchanger with the refrigerant distribution device has the advantages that the whole size of the shell-and-tube heat exchanger is close to that of an existing product, the matching degree with a system is high, and replacement is convenient. By arranging the inlet distribution structure and the segmental baffles, the amount of heat exchange tubes is reduced by more than 30%.

Owner:江苏世林博尔制冷设备有限公司

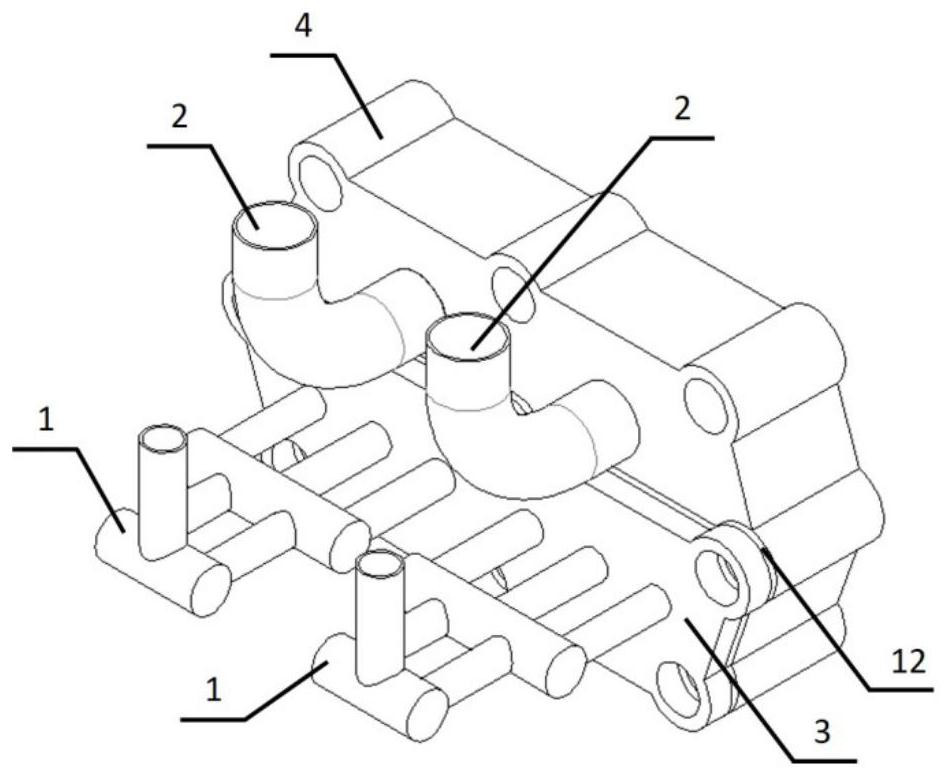

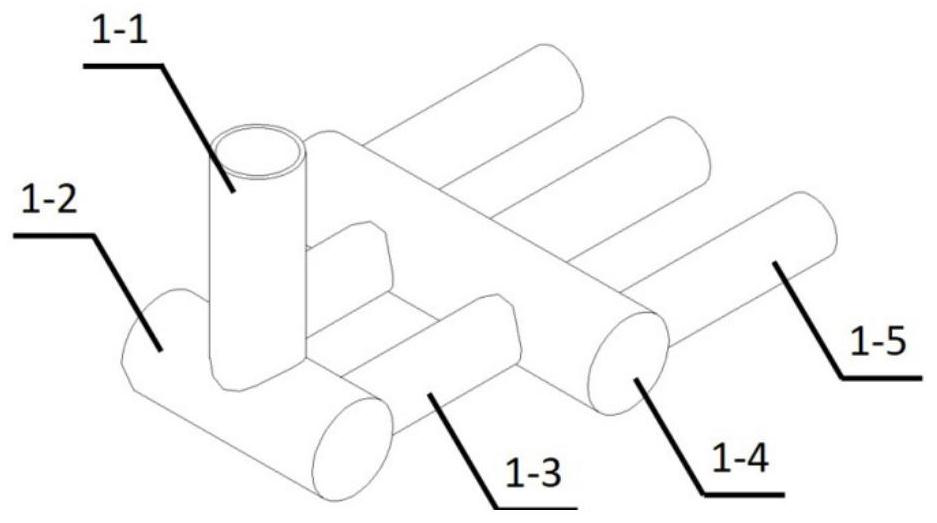

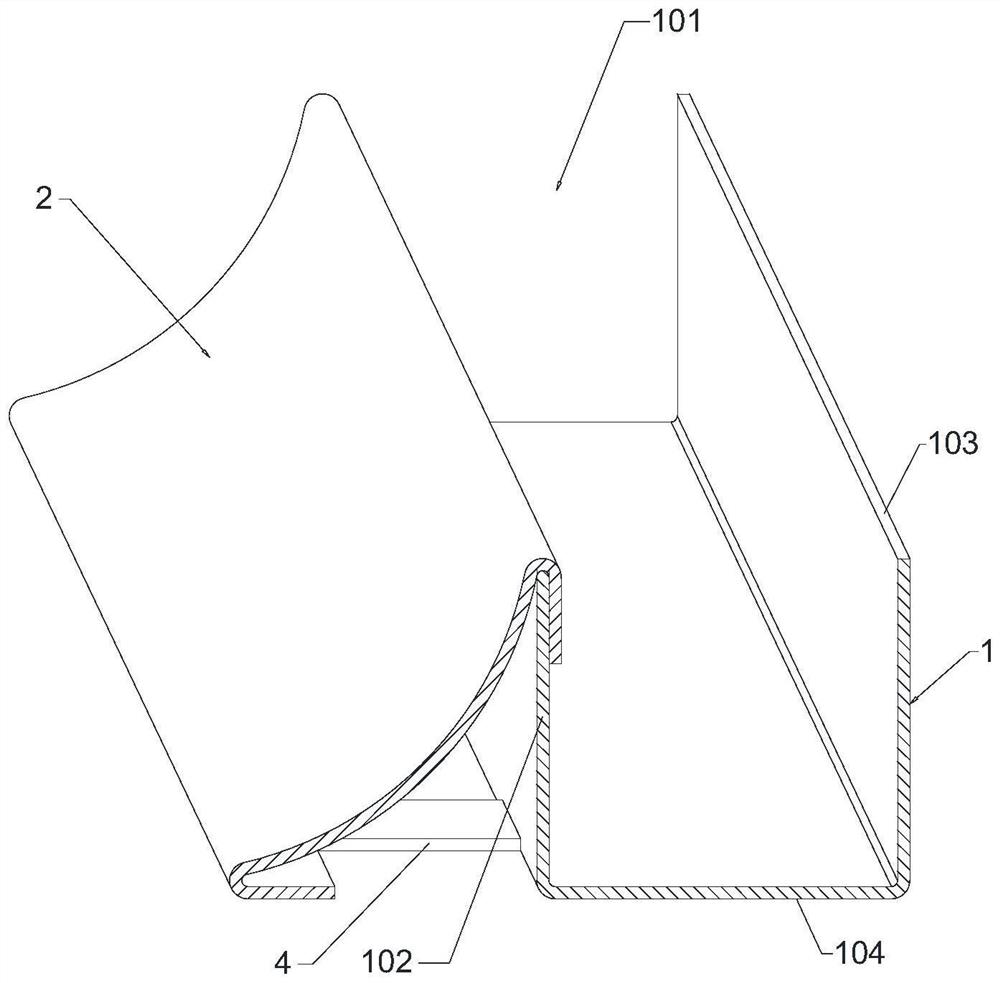

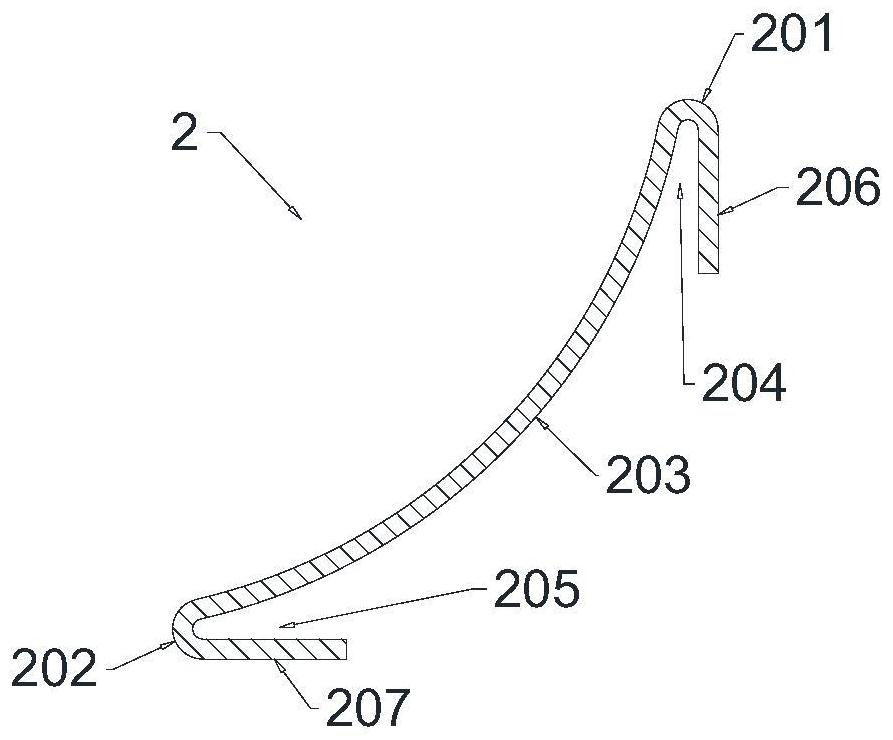

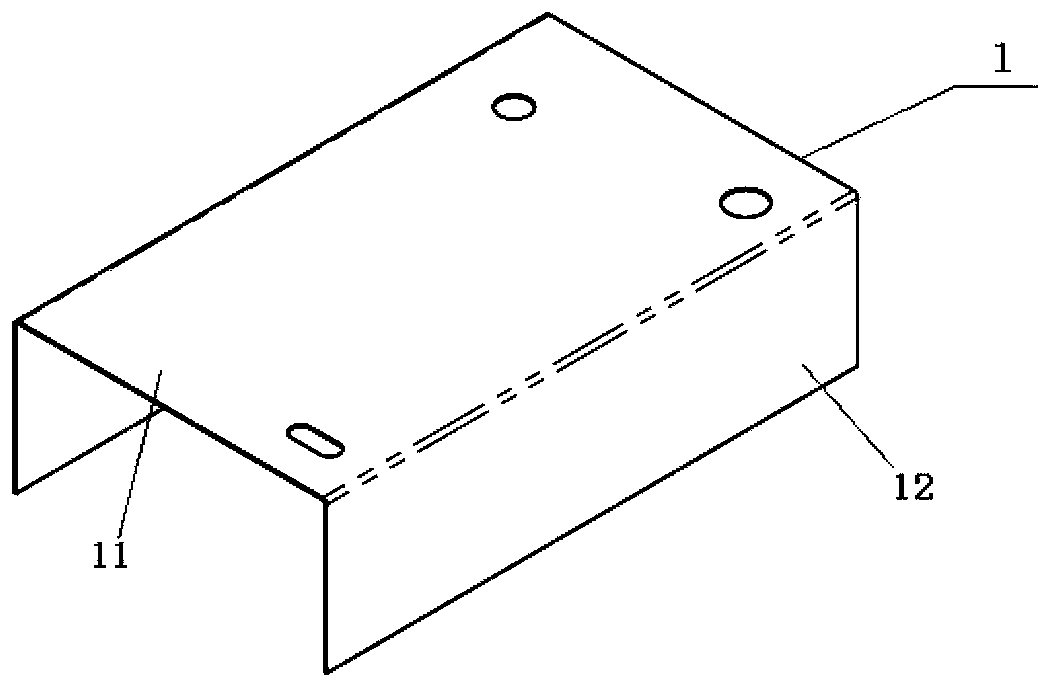

Back auxiliary frame assembly of automobile

InactiveCN109823398AReduce weld lengthReduce welding distortionUnderstructuresVehicle frameEngineering

The invention relates to a back auxiliary frame assembly of an automobile. The back auxiliary frame assembly comprises a back auxiliary frame body, and sleeves used for being connected with an automobile body are respectively arranged at the four corners of the back auxiliary frame body; the back auxiliary frame body is composed of an upper plate with the whole body in a shape like the Chinese character of 'jing' and the local section in an inverted U shape and a lower plate with the whole body in a shape like the Chinese character of 'jing' and the local section in an inverted U shape, wherein the upper plate and the lower plate are in fixed fastening connection through welding seams, and the back auxiliary frame assembly with the whole body in a shape like the Chinese character of 'jing'and the local section in a shape like the Chinese character of 'kou' is of a cavity body structure; the front portion of the cavity body structure is a front transverse beam, the back portion of thecavity body structure is a back transverse beam, the left portion of the cavity body structure is a left longitudinal beam, and the right portion of the cavity body structure is a right longitudinal beam; upper swing arm installing brackets in inverted U shapes are respectively arranged on the left and right end portions of the front transverse beam; transverse U-shaped pulling rod installing brackets are respectively arranged under the left and right end portions of the front transverse beam; lower swing arm installing brackets are separately arranged under the middle of the back transverse beam. The strength and rigidity of the whole back auxiliary frame assembly can be improved, welding deformation is small, the size accuracy is higher, and stress distribution is uniform.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

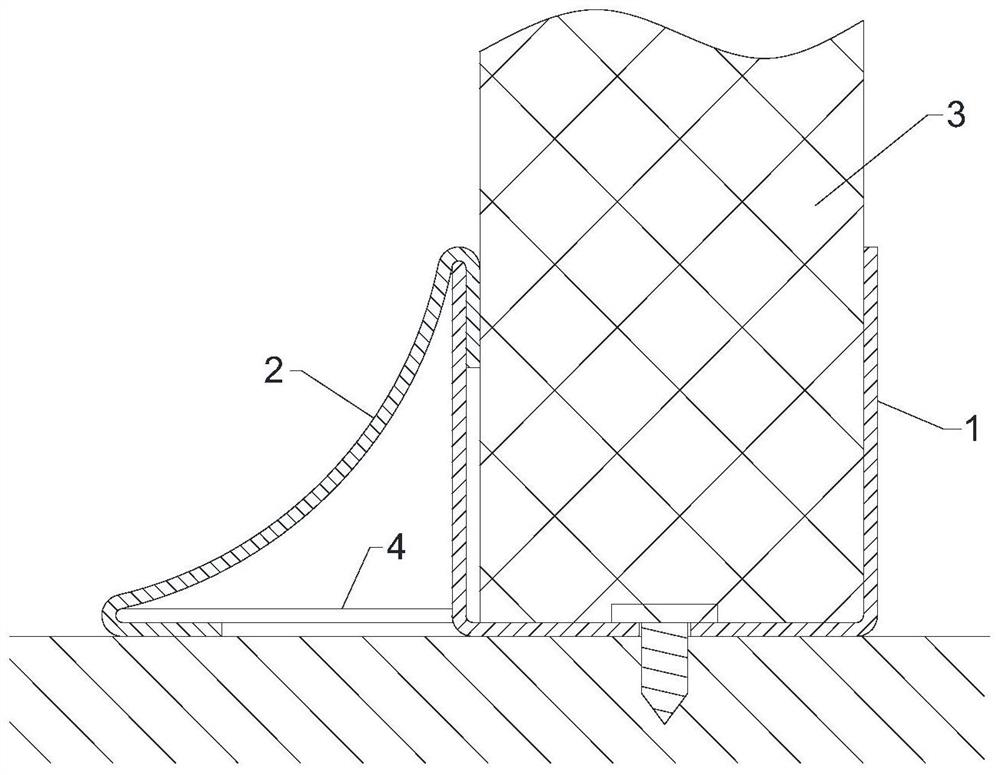

Partition wallboard base

The base comprises a U-shaped groove body with an upward opening and a first transition plate connected to one side of the groove body, and the first transition plate is tightly matched with the base in a clamping mode, so that the welding cost is greatly reduced, the height of the base can be effectively reduced, and the welding quality is improved. The stability of the whole structure is improved. In the aspect of installation, the installation process of the base is simple, the base is independently installed without field welding, the installation speed is effectively increased, and the installation cost is reduced.

Owner:江苏爱拼环保科技有限公司

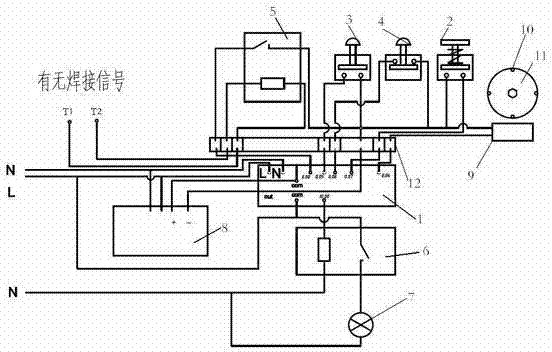

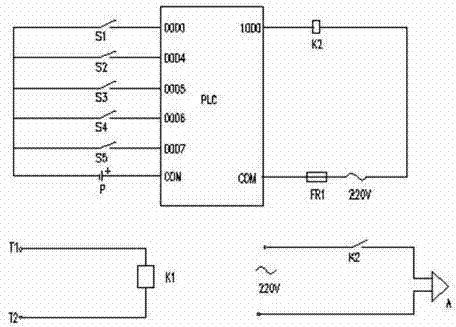

Warning device for preventing welding missing and welding lack during carbon dioxide welding

ActiveCN103600183BWelding length of less weldingReduce weld lengthWelding/cutting auxillary devicesUsing electrical meansElectricityProgrammable logic controller

Owner:JIANGLING MOTORS

Full-aluminum fuel tank and manufacturing method thereof

InactiveCN104343754AGuaranteed positionImprove reliabilityPump assembliesFuel supplyHigh volume manufacturingFuel tank

The invention relates to a full-aluminum fuel tank and a manufacturing method thereof. The full-aluminum fuel tank is rectangular and comprises an upper tank body and a lower tank body which are connected in a matched manner. The upper tank body comprises a cover plate and a lower folding edge. The cover plate is provided with mounting holes. The lower tank body comprises a bottom plate and an upper folding edge. The manufacturing method includes the steps of firstly, independently cutting plates needed by the upper tank body and the lower tank body according to fuel tank capacity; secondly, using a flanging die to perform flanging on the cut plates to allow the cover plate of the upper tank body to be vertical to the lower folding edge and the bottom plate of the lower tank body to be vertical to the upper folding edge; thirdly, using a die to punch the mounting holes in the cover plate; performing weld joint connection on the upper tank body and the lower tank body. Compared with the prior art, the full-aluminum fuel tank is reasonable in structural design, simple in structure, high in work efficiency, good in size consistency, suitable for large-batch production, high in machining precision and stable in machining quality.

Owner:SHANGHAI DELANG AUTO PARTS MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com