Corbel support for cast-in-place concrete construction on the top of bridge pier

A technology for concrete and bridge piers, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of difficult to achieve on-site and high quality requirements, achieve high work reliability, overcome the length of welds, and reduce the length and height of welds. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

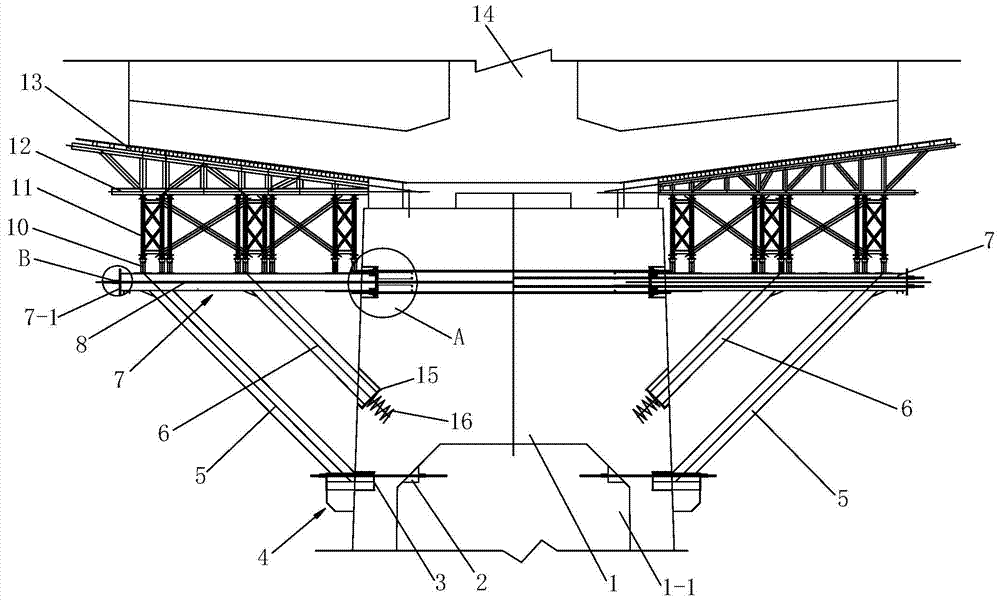

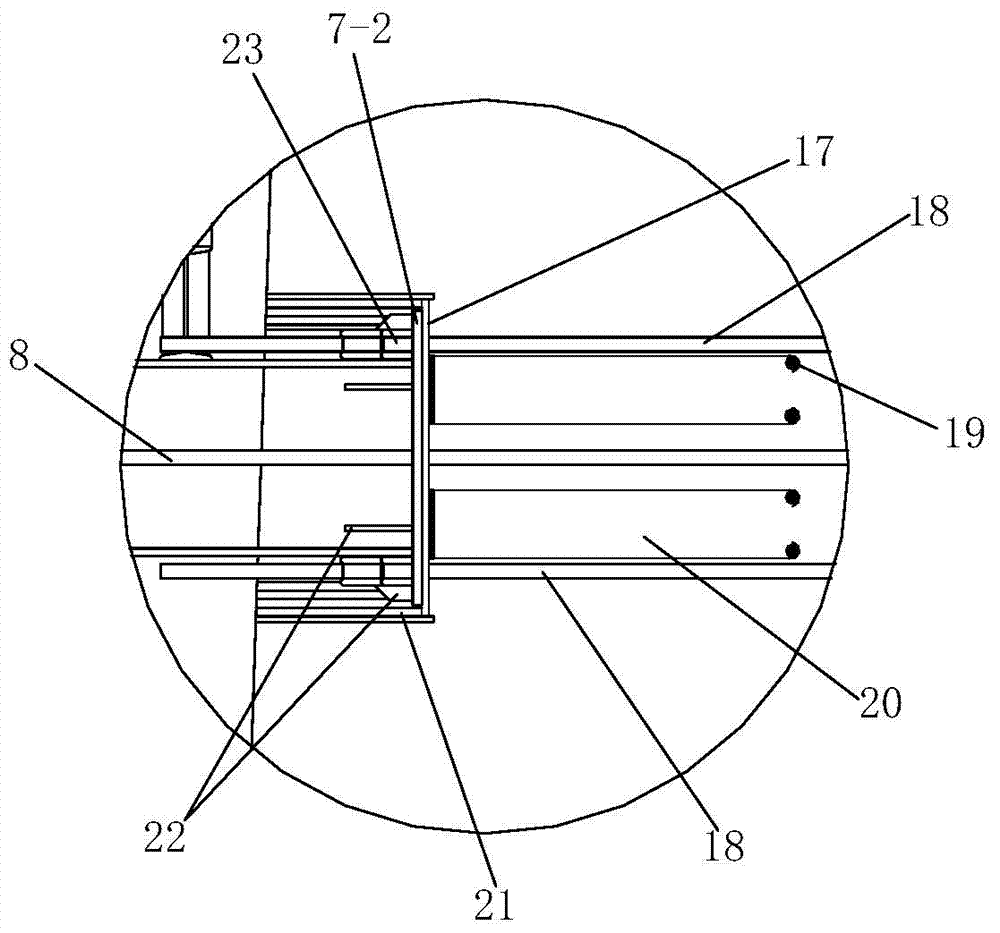

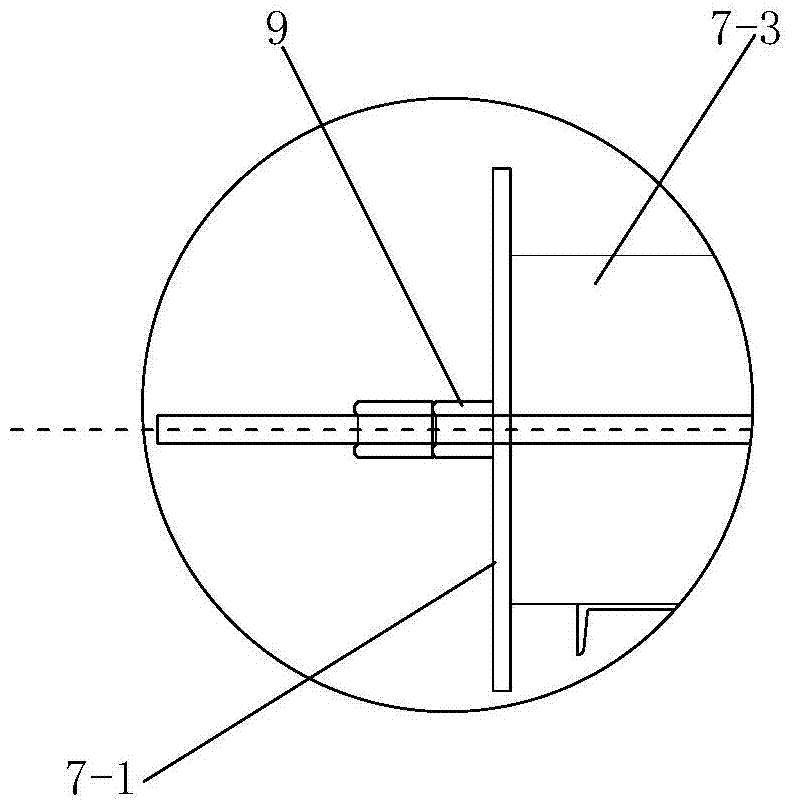

[0041] Such as figure 1 , figure 2 and Figure 4The shown corbel bracket for cast-in-place concrete construction on the top of a bridge pier includes a plurality of horizontal rods 7 arranged on the side of the large mileage and the side of the small mileage of the pier 1, and the lower parts of the multiple horizontal rods 7 correspond to each other one by one. A plurality of first diagonal struts 6 are provided, and a plurality of second diagonal struts 5 are uniformly arranged below the plurality of first diagonal struts 6 , and the upper ends of the plurality of first diagonal struts 6 The upper ends of the plurality of second diagonal braces 5 are all connected to the horizontal rods 7 directly above them, and the pier 1 is provided with a plurality of first boxes corresponding to the first diagonal braces 6 one-to-one. 15. A plurality of second box bodies 3 corresponding to the second diagonal struts 5 and a plurality of third box bodies 17 corresponding to the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com