Segmental molding making method of end socket

A production method and head technology, which are applied to the components of steam boilers, steam boiler accessories, steam boilers, etc., can solve the problems of long welds, increased number of zoning and lobes, and reduced material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be described below in conjunction with specific embodiments.

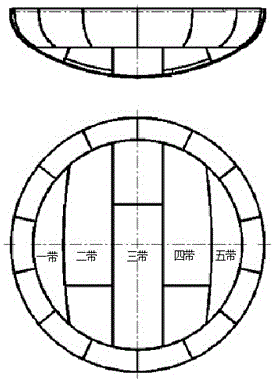

[0026] Such as figure 1 Shown is a method for manufacturing a split forming head according to the present invention. The manufacturing method is to use melon petals and a large diameter top circular plate to be divided into strips. The assembly method is to assemble the ports upward. First, the top circular plate is divided After the pressing and grouping are completed, the melon petals are pressed and the qualified melon petals are directly assembled on the top round plate, and finally the whole experience is received;

[0027] The steps of the manufacturing method of the split forming head are as follows:

[0028] Step 1: Make the melon plate mold according to the user's drawings and technical requirements;

[0029] Step 2: Cut the melon flap plate, the top round plate is not cut, and the drum hoisting tool is welded, and the single material plate and the three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com