Patents

Literature

1528 results about "Kraft paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kraft paper or kraft is paper or paperboard (cardboard) produced from chemical pulp produced in the kraft process. Sack kraft paper, or just sack paper, is a porous kraft paper with high elasticity and high tear resistance, designed for packaging products with high demands for strength and durability.

Low odor faced insulation assembly

Owner:JOHNS MANVILLE INT INC

Composite structural material and method of making same

A composite structural material suitable, for example, as a replacement for wooden boards, is disclosed. It comprises a dimensionally stable core material ensheathed in a dimensionally stable, laminar covering that is adherent to the core material. The laminar covering is comprised of at least one layer of parallel cords bonded to at least one layer of a rigidified web material selected from the group consisting of paper and cloth. Suitable core materials include polyurethane foam, optionally filled with granulated rubber and / or expandable polymer beads. The parallel cords preferably are supplied in the form of a strip of polyester cloth, as the warp cords thereof. The web material preferably is kraft paper that is rigidified with an epoxy resin.

Owner:CODA CAPITAL MANAGEMENT GROUP

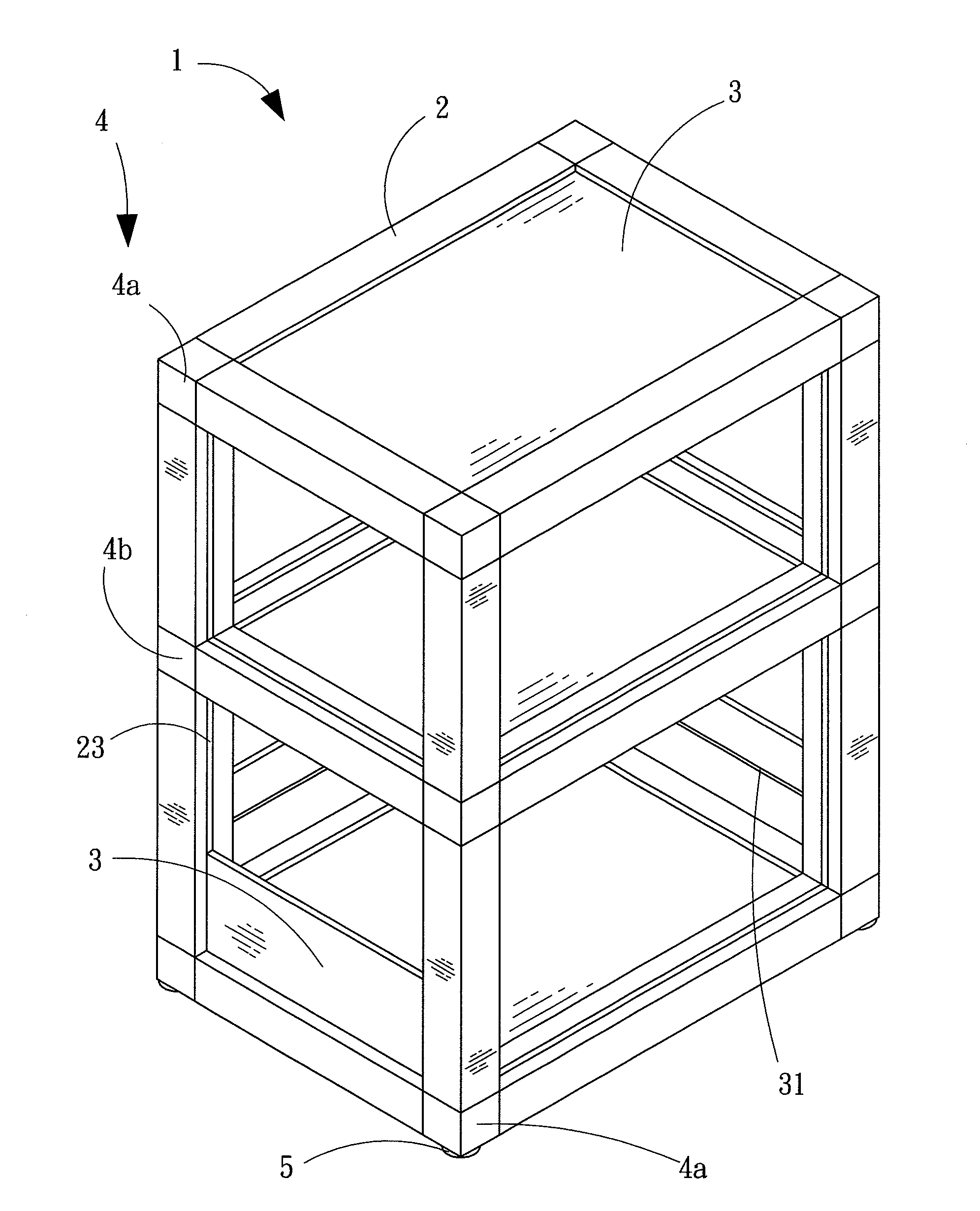

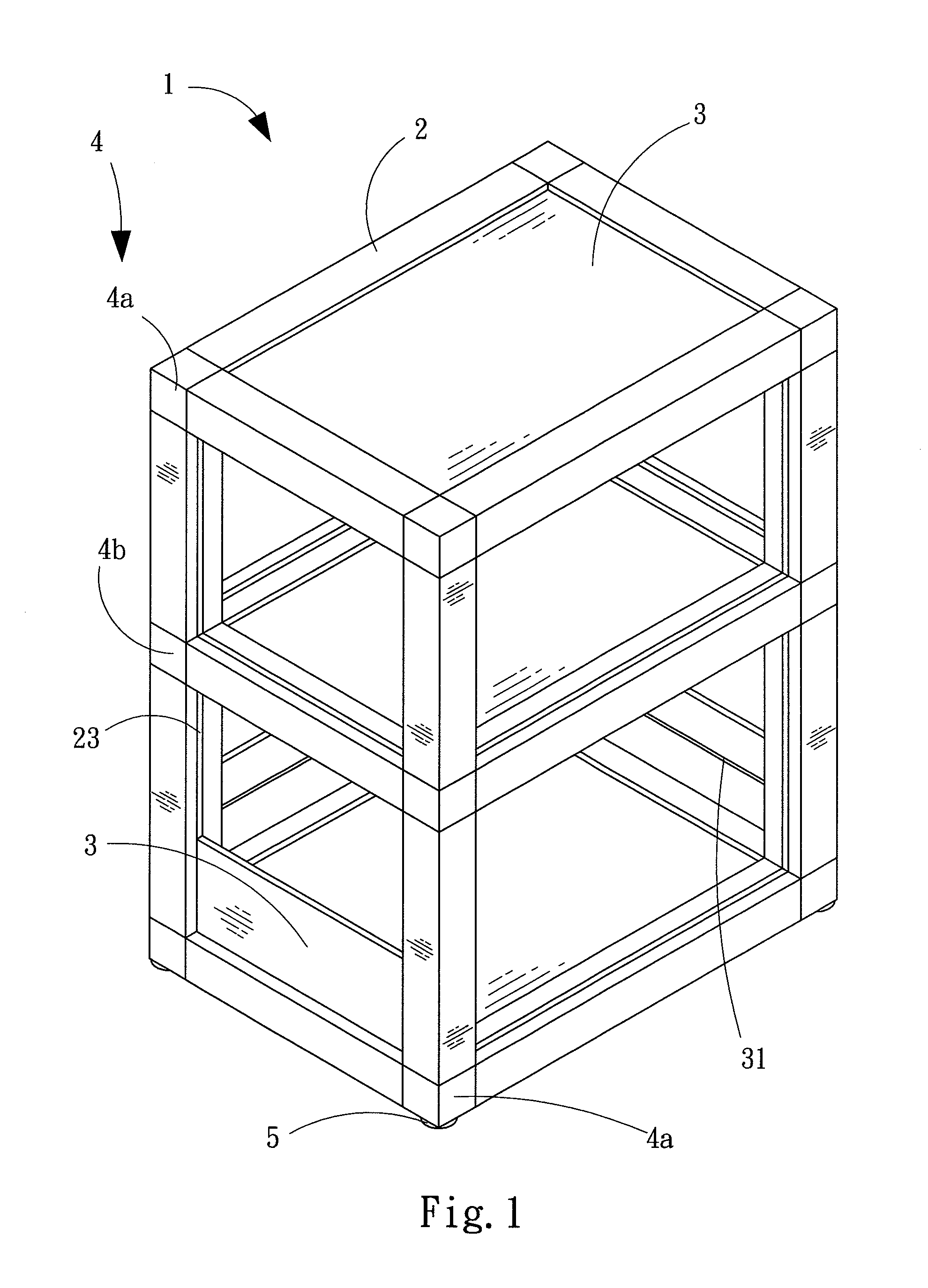

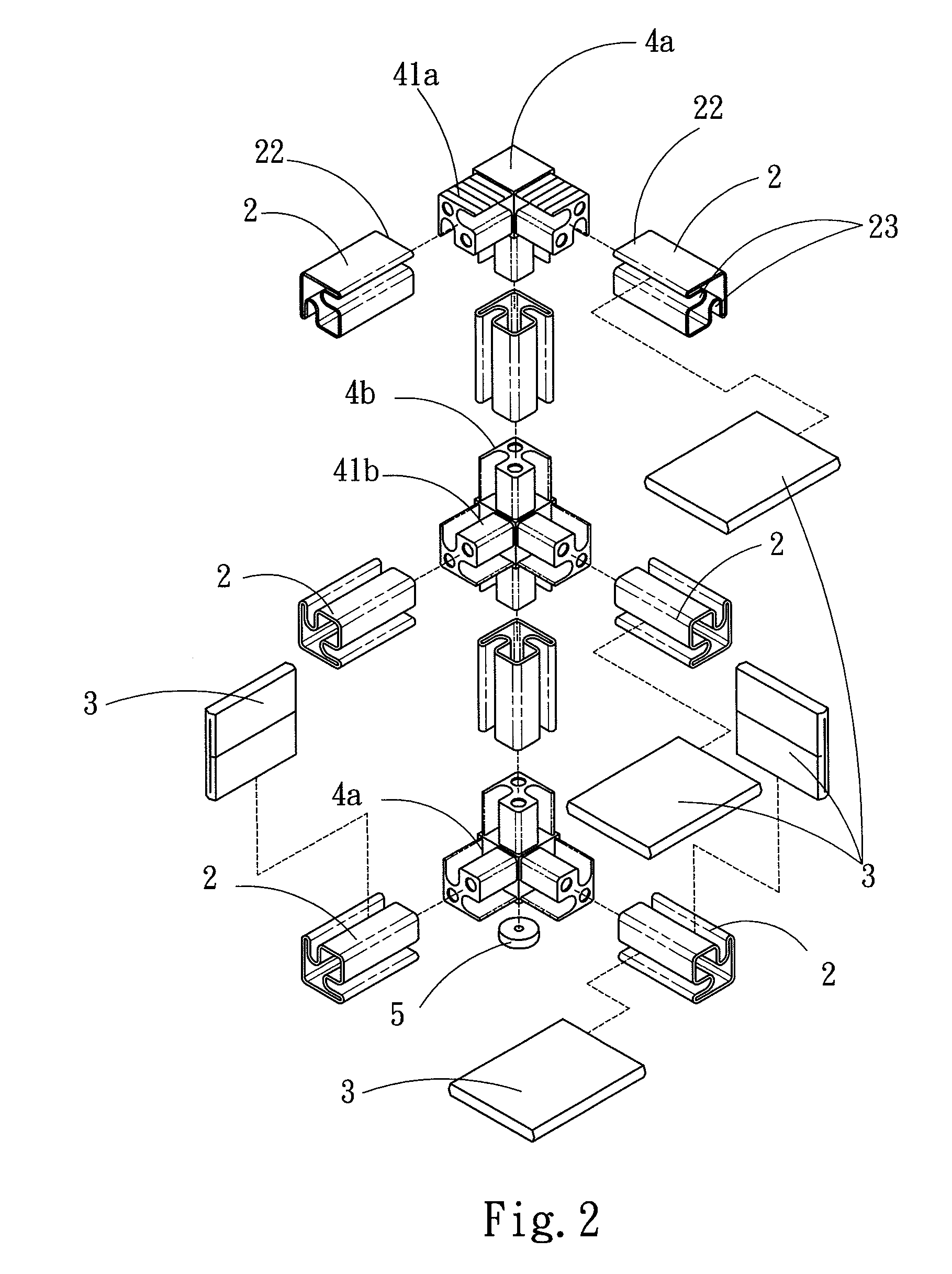

Environmental protection shelving combination

InactiveUS20110017691A1Easy constructionEasy to processFurniture partsFolding cabinetsEnvironmental resistanceMetal framework

The environmental protection shelving combination of the present invention includes sleeves and panels made of corner protection paper for support and plastic connector sets used for coupling the sleeves. Therefore, in accordance with different requirements, the assembly thereof can be altered as desired. Furthermore, since the corner protection paper is formed by pressing Kraft paper and the sand tube paper into a supporting structure, it can provide bearing and pressure capability, so that can replace the conventional wood, plastic or metal framework. Accordingly, not only the costs of material, conveying and assembly can be reduced, the pollution to the environment also can be minimized.

Owner:WU CHUAN CHING

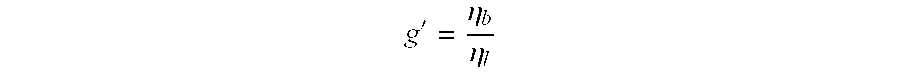

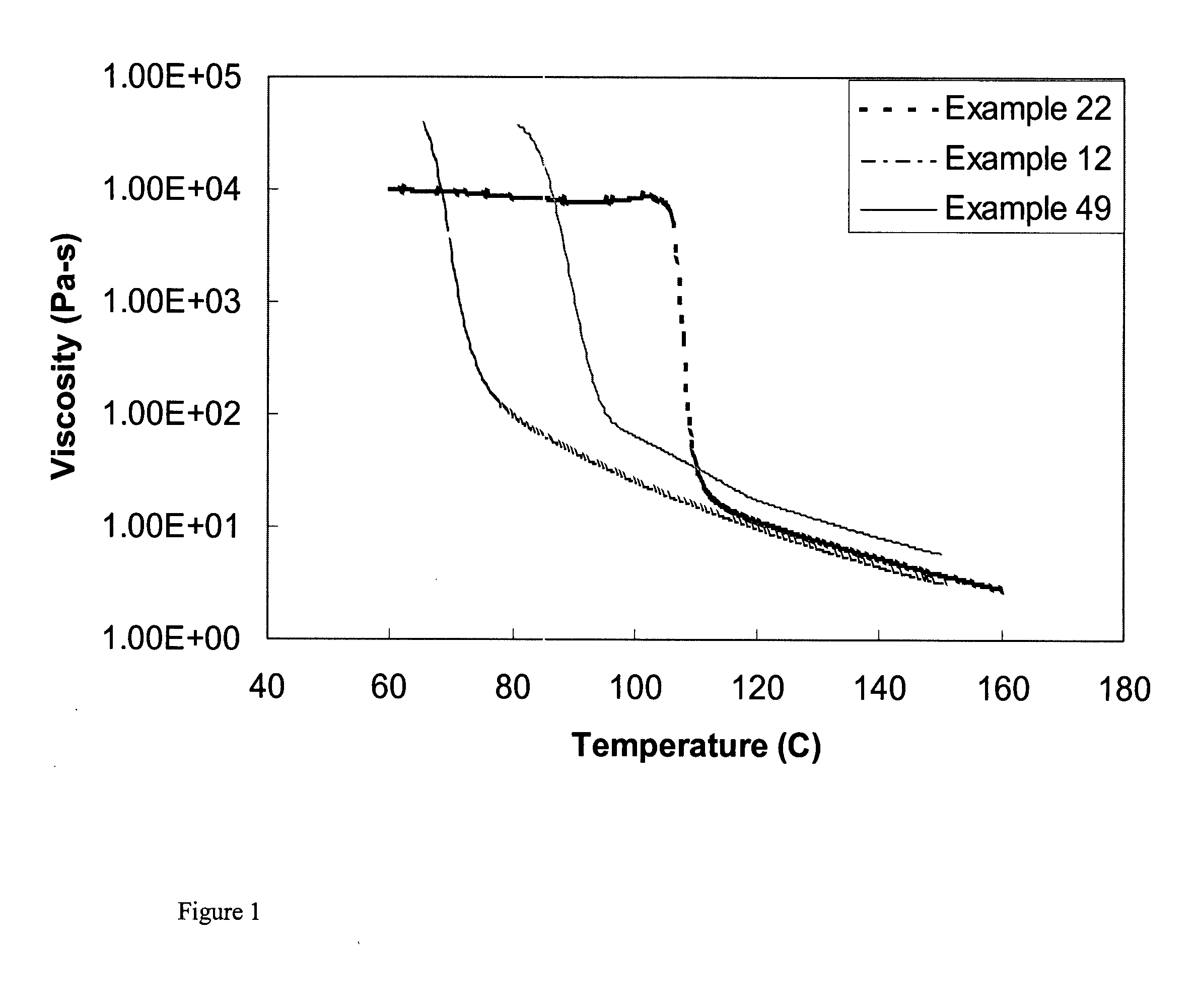

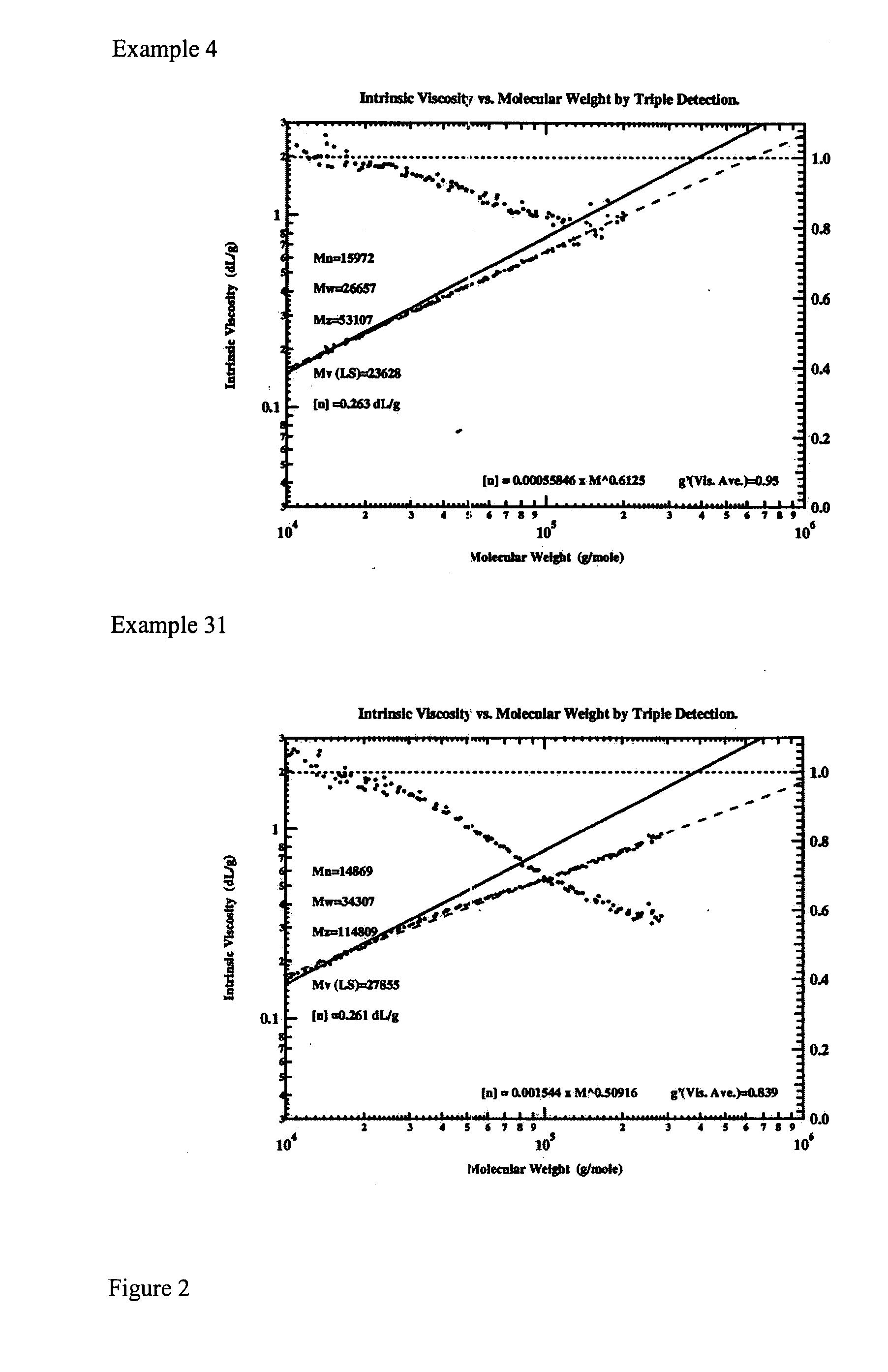

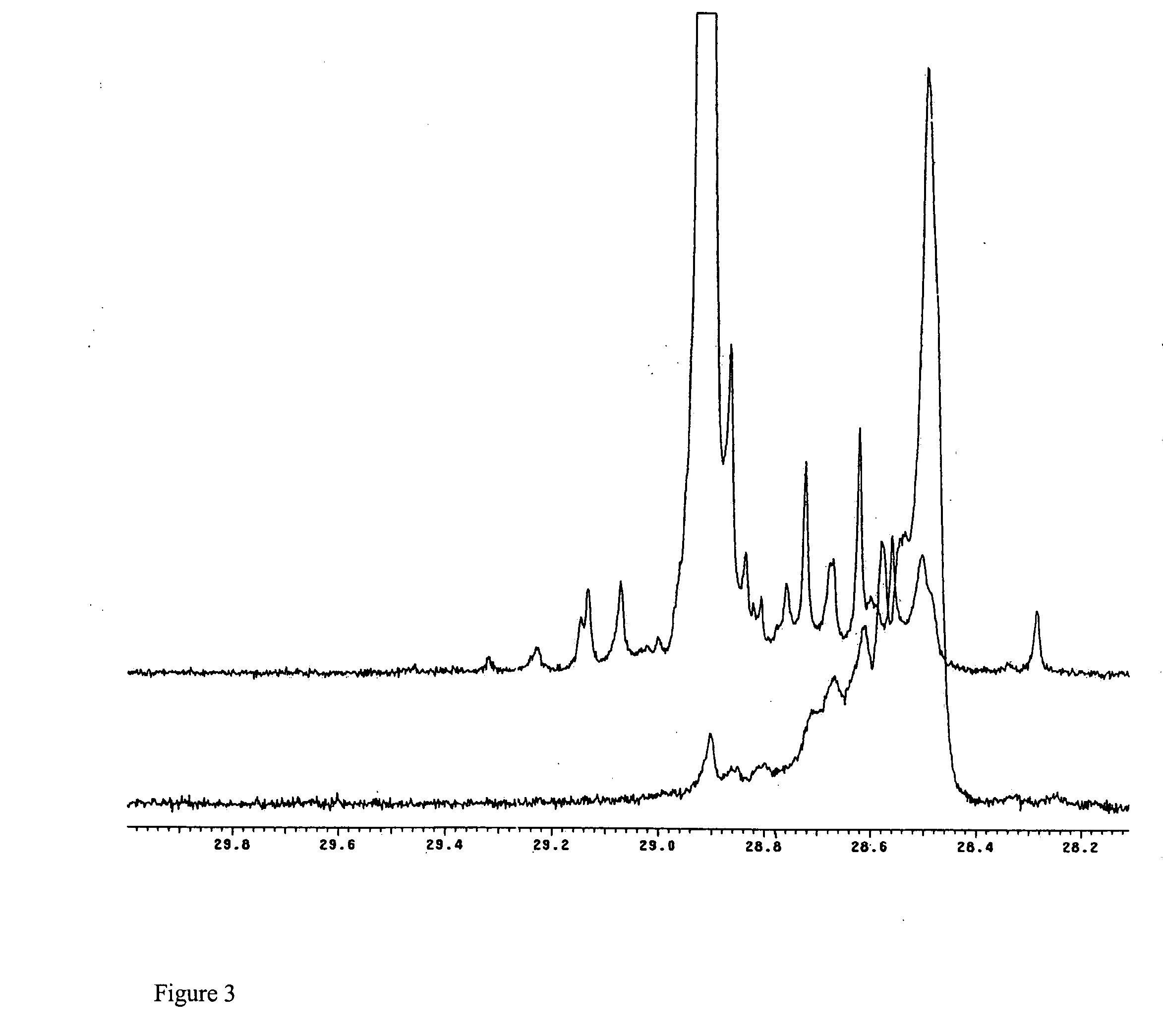

Functionalized olefin polymers

This invention relates to a composition comprising a functionalized C3 to C40 olefin polymer comprising at least 50 mol % of one or more C3 to C40 olefins, and where the olefin polymer, prior to functionalization, has:a) a Dot T-Peel of 1 Newton or more on Kraft paper;b) an Mw of 10,000 to 100,000; andc) a branching index (g′) of 0.98 or less measured at the Mz of the polymer when the polymer has an Mw of 10,000 to 60,000, or a branching index (g′) of 0.95 or less measured at the Mz of the polymer when the polymer has an Mw of 10,000 to 100,000; and where the C3 to C40 olefin polymer comprises at least 0.001 weight % of an functional group, preferably maleic anhydride. This invention further relates to blends of such functionalized polymers with other polymers including non-functionalized C3 to C40 olefin polymers as described above.

Owner:EXXONMOBIL CHEM PAT INC

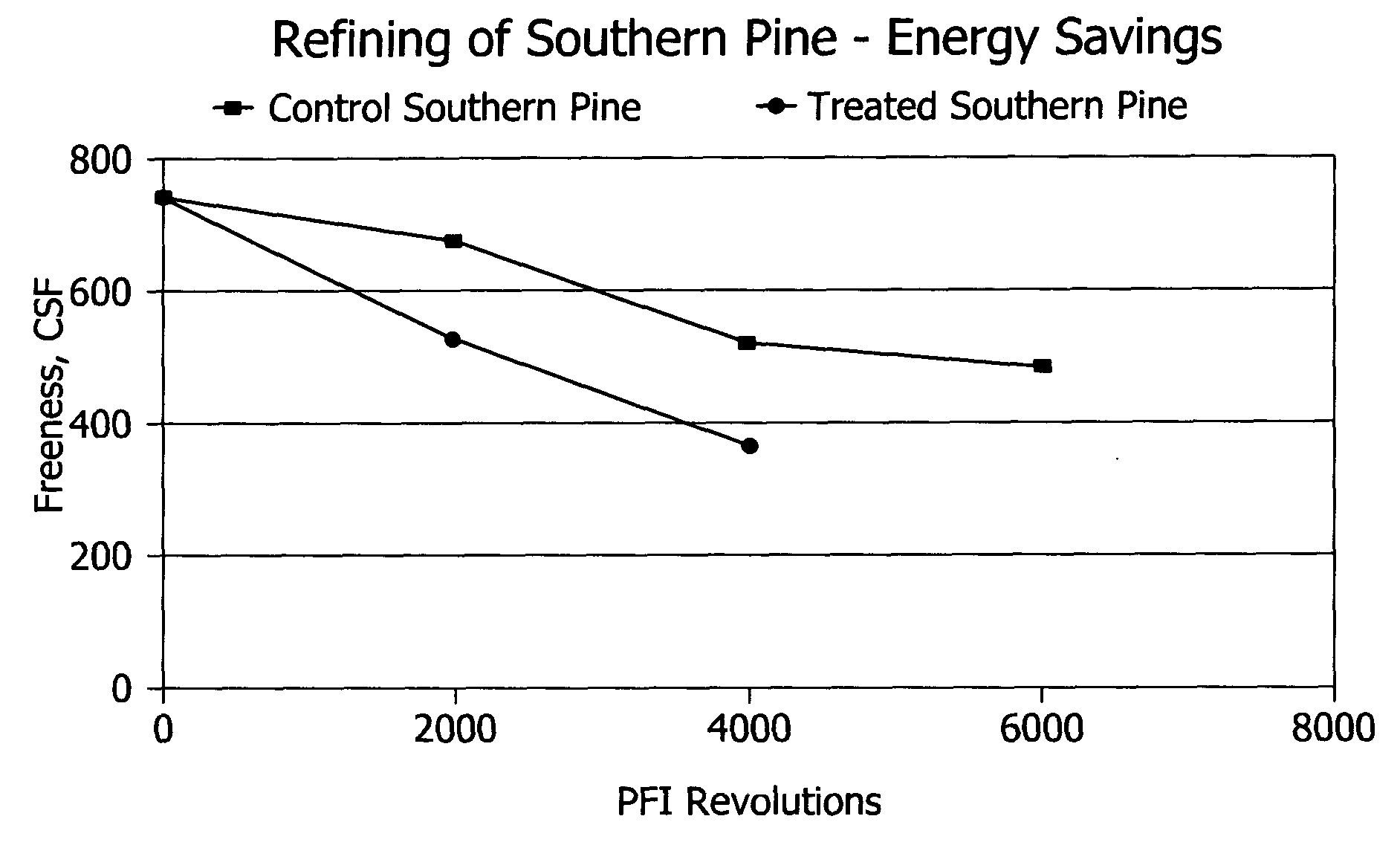

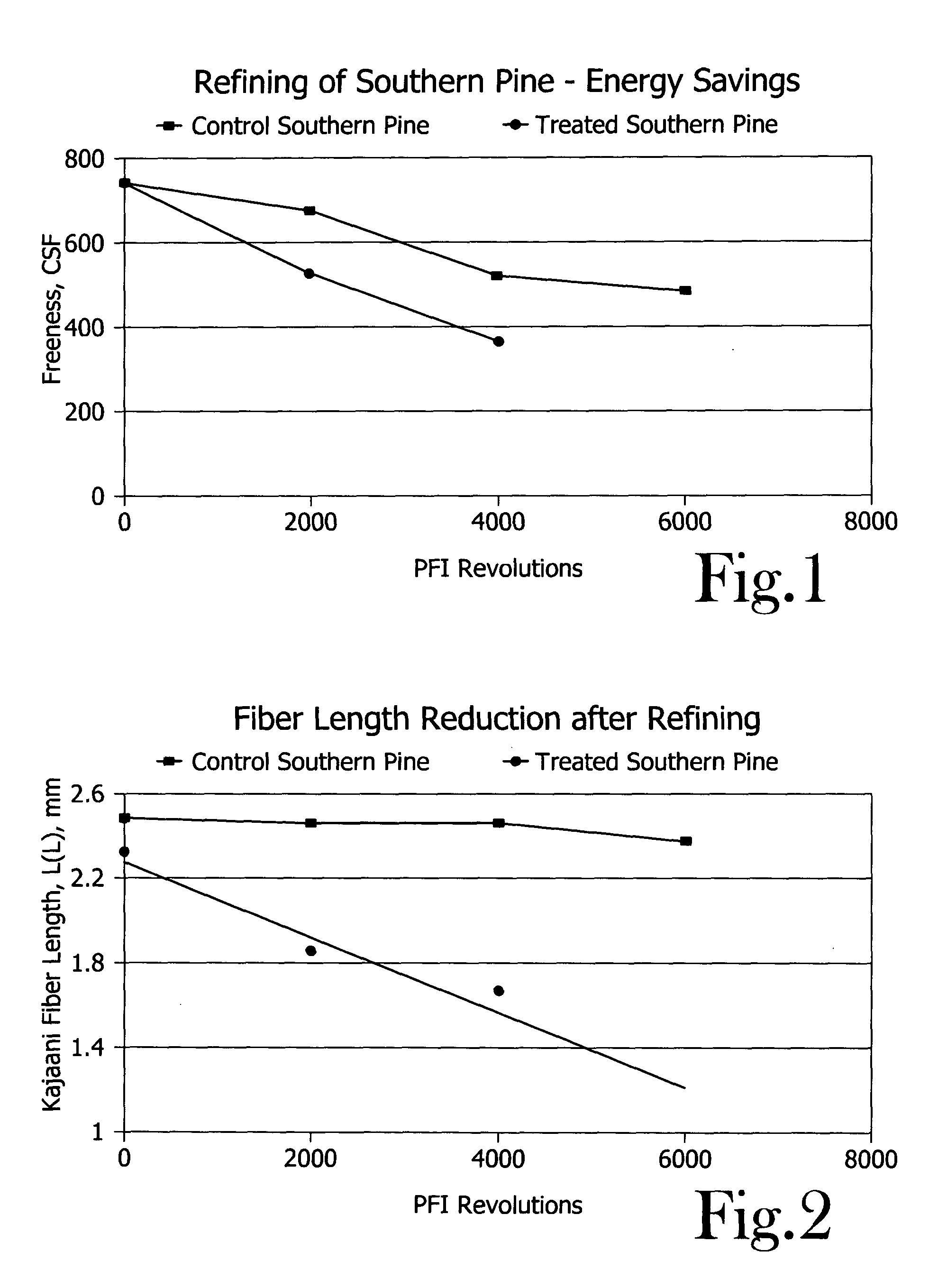

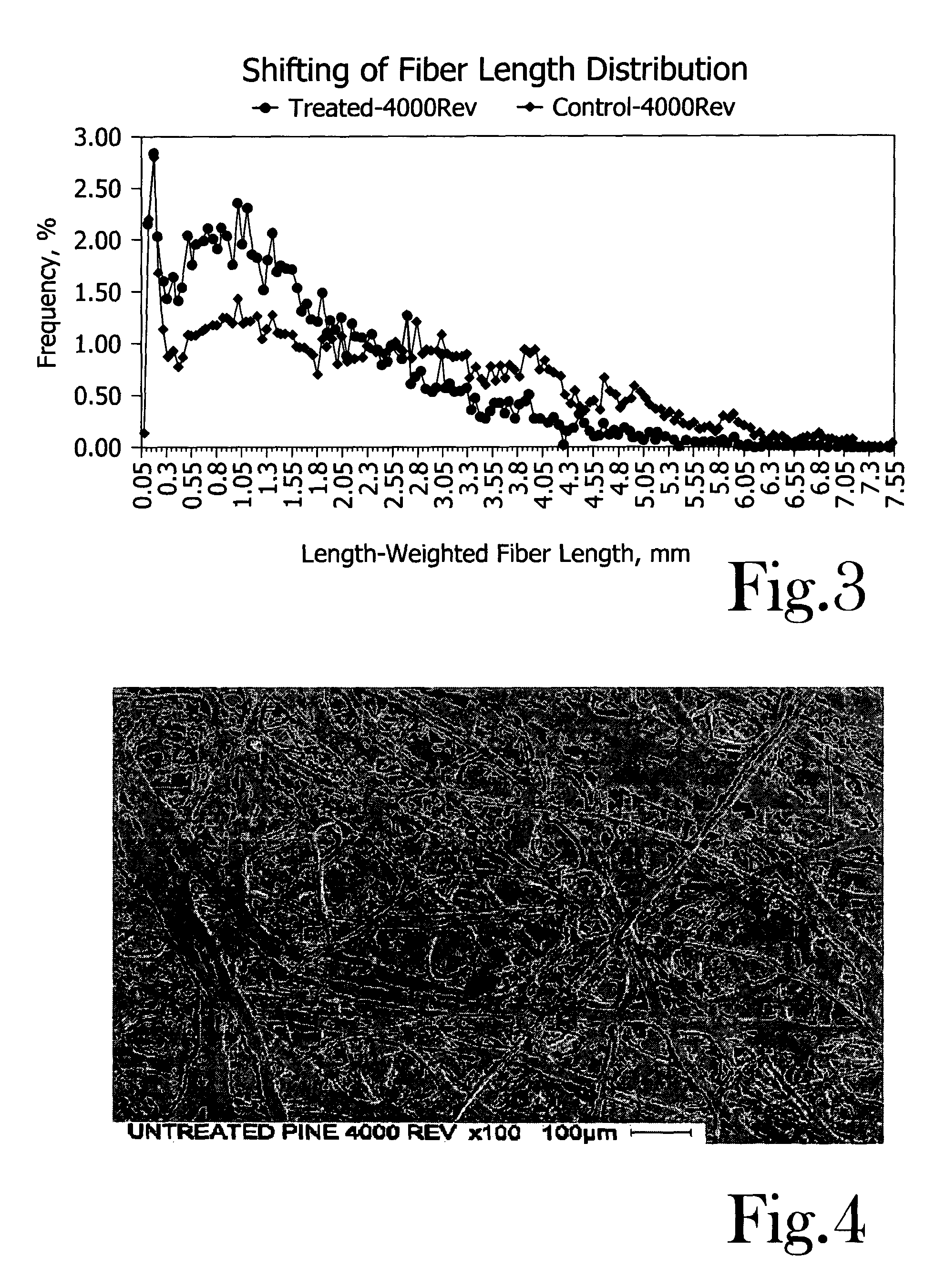

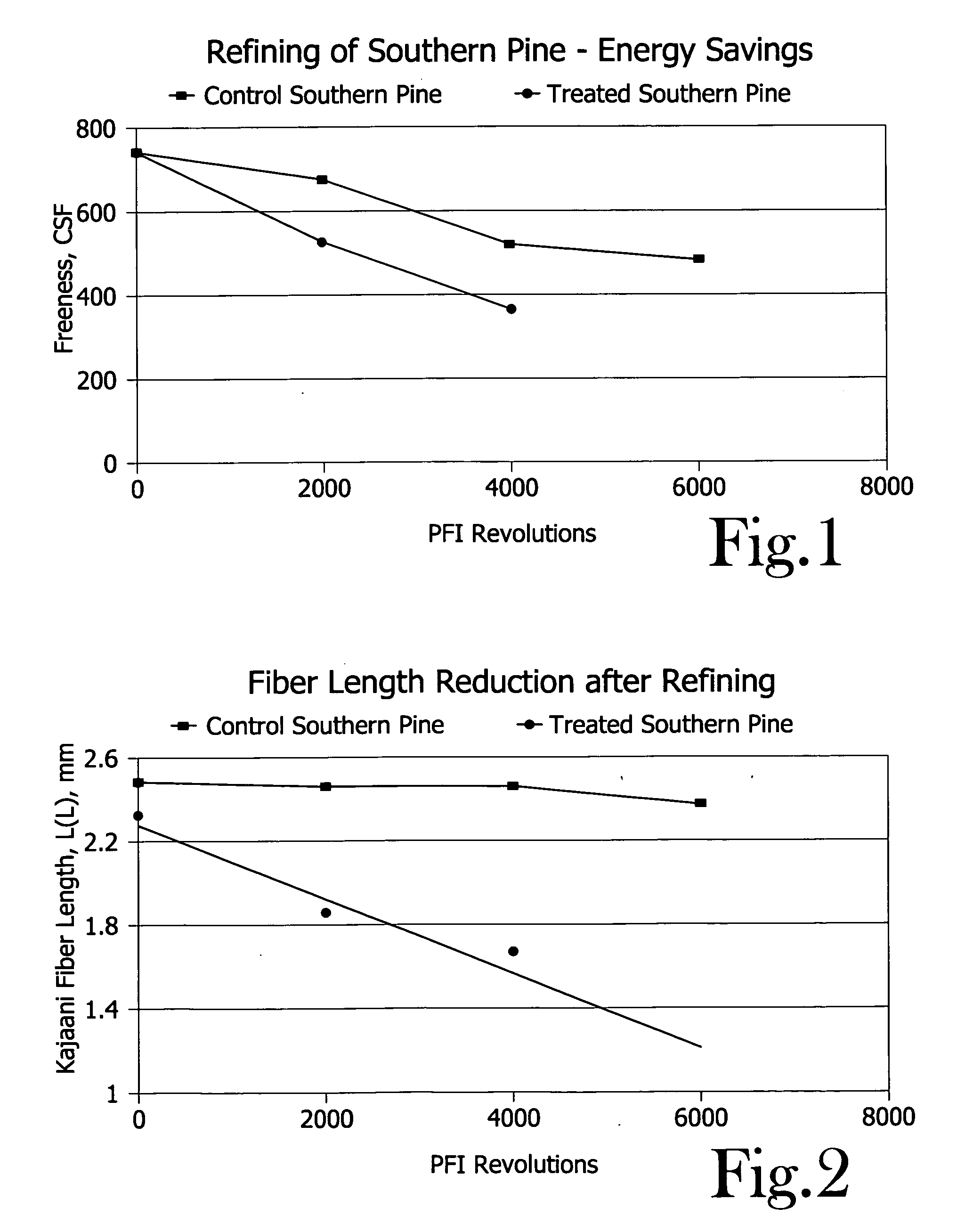

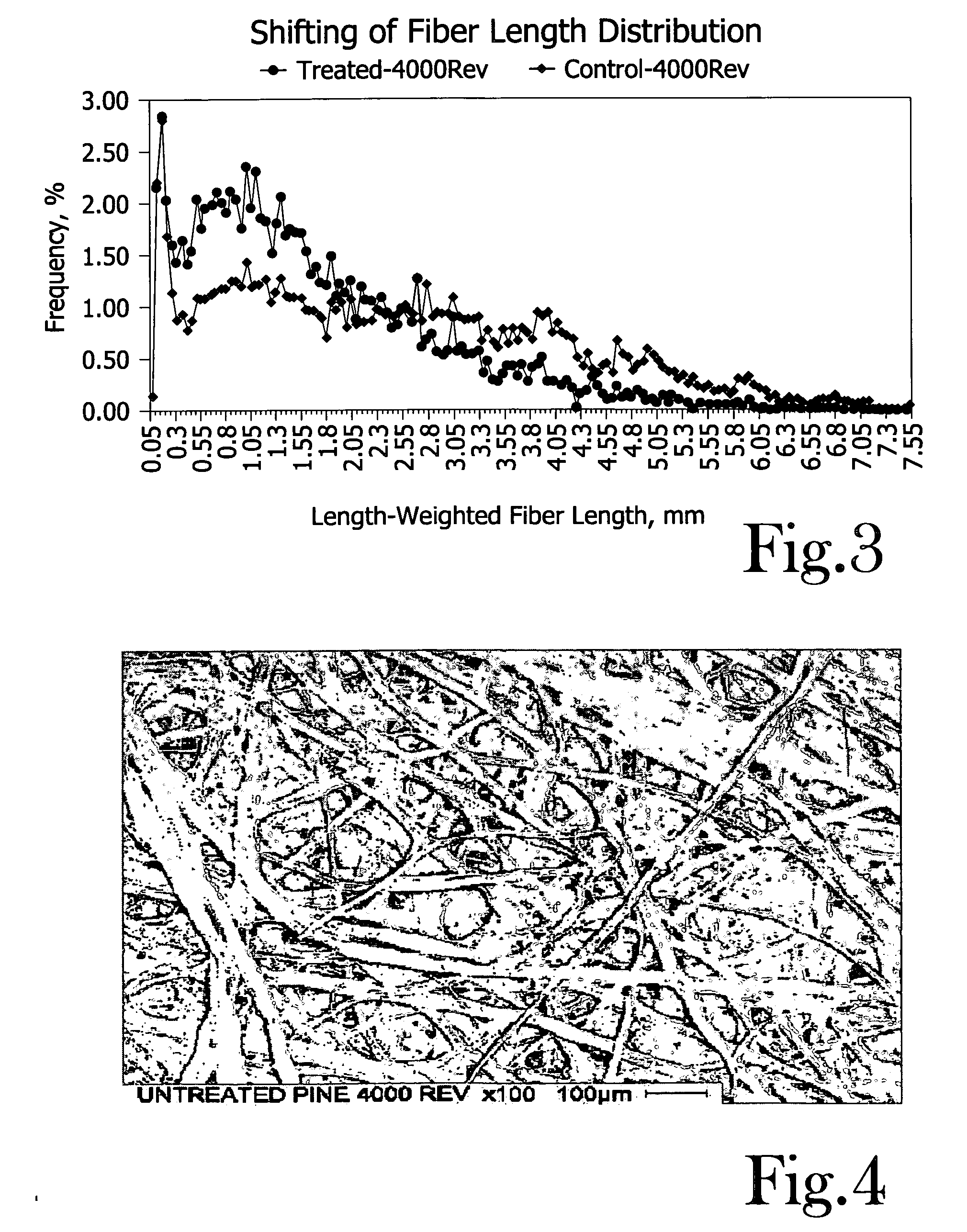

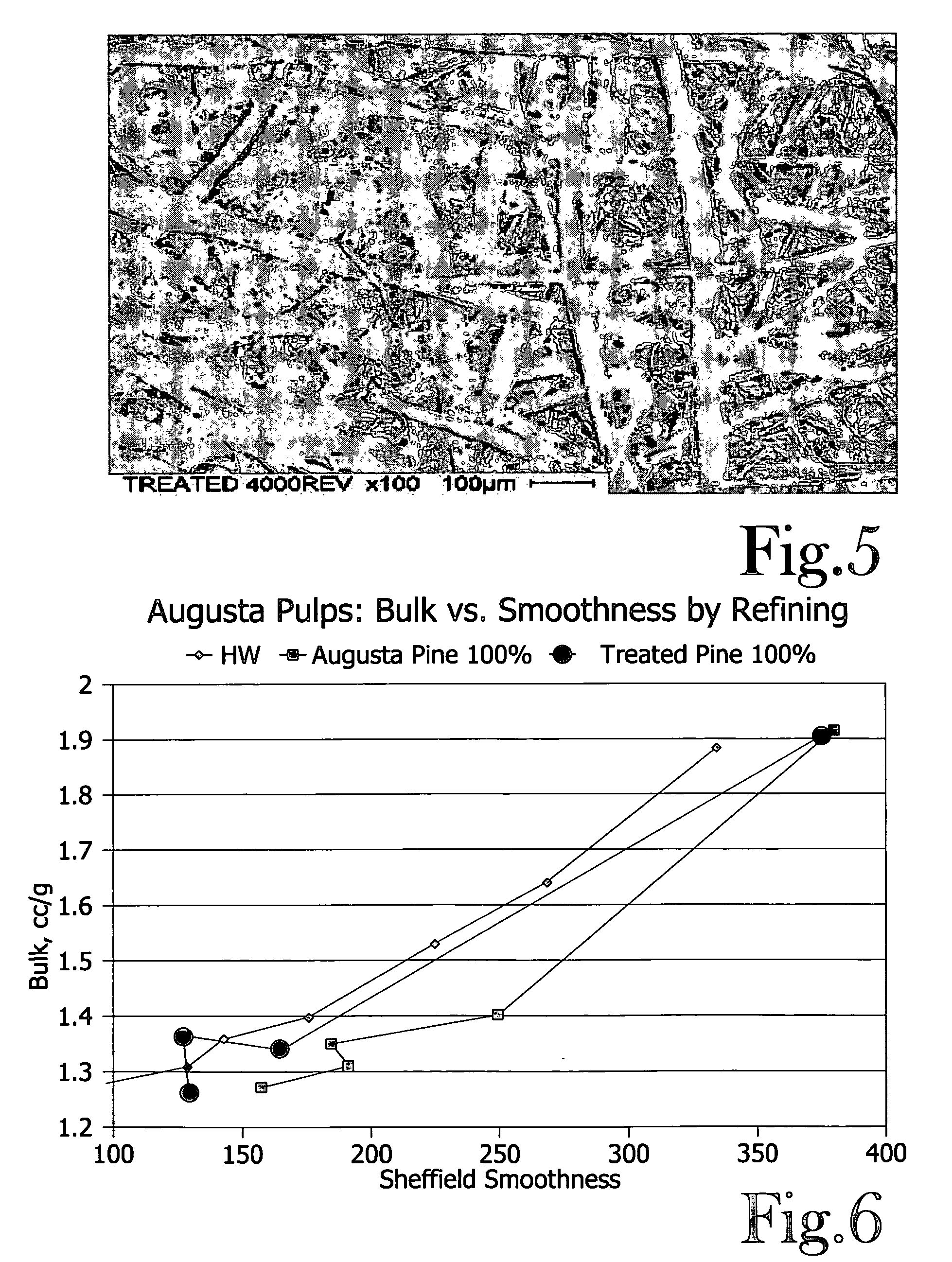

Chemical activation and refining of southern pine kraft fibers

InactiveUS20050061455A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

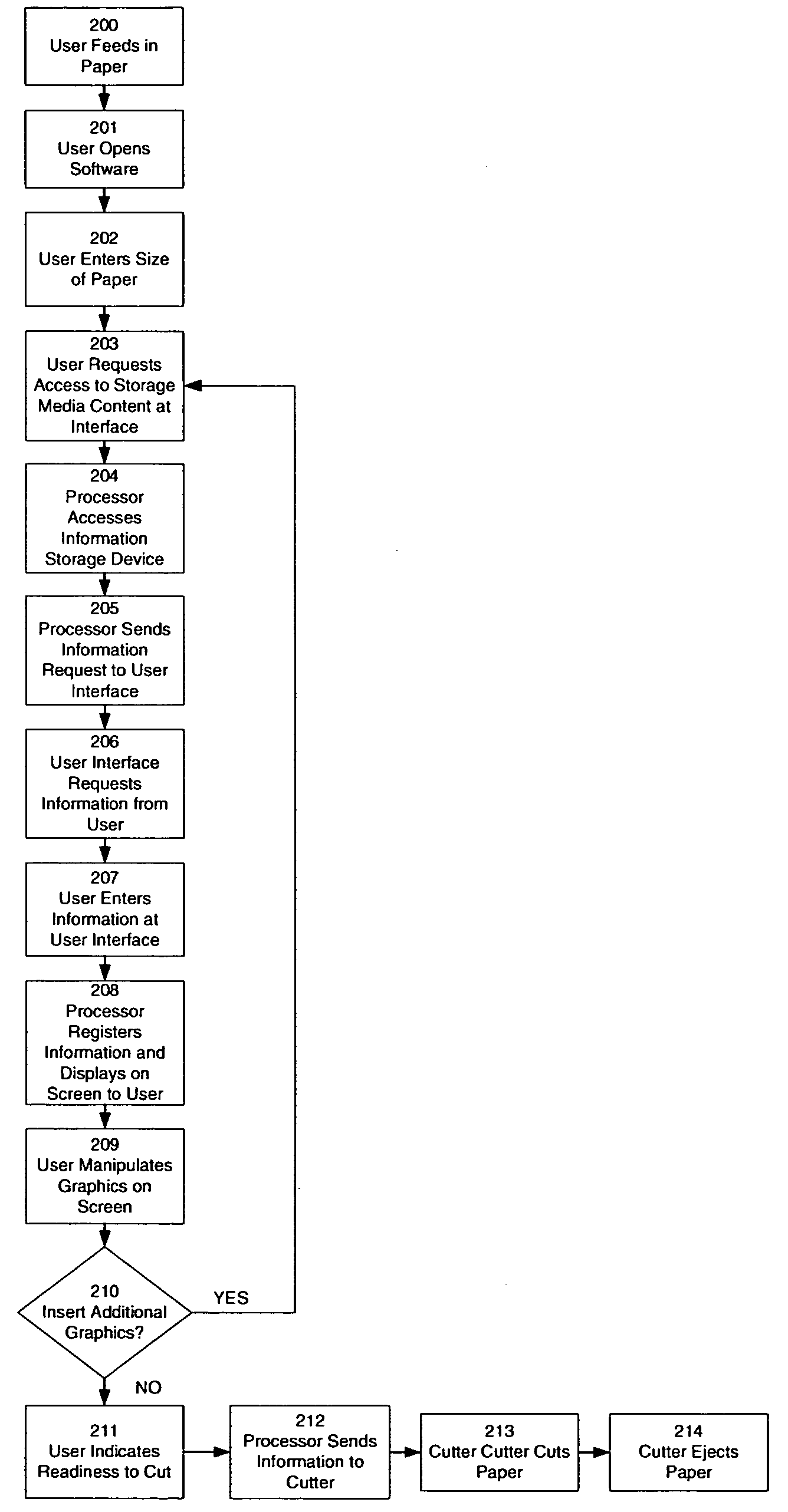

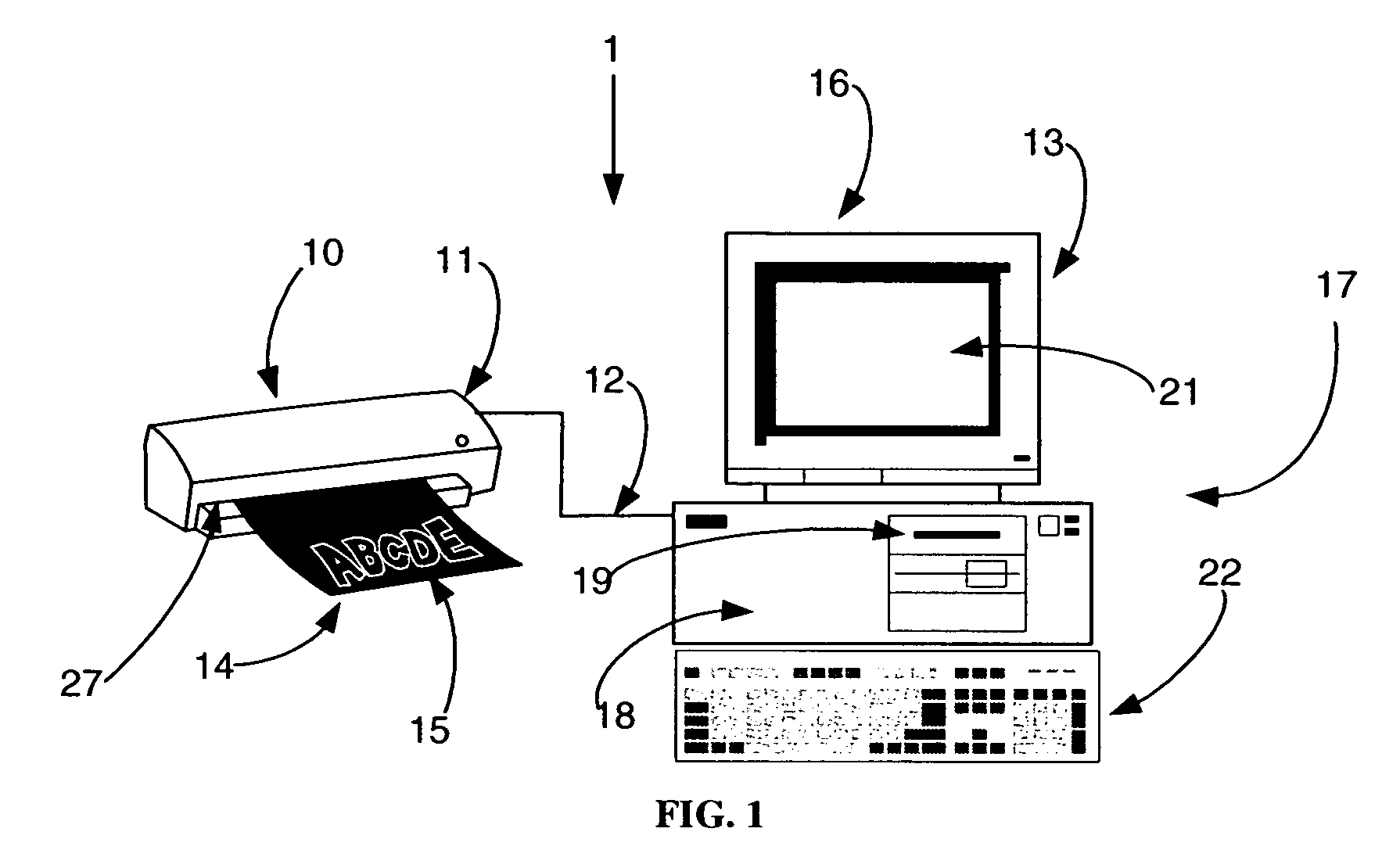

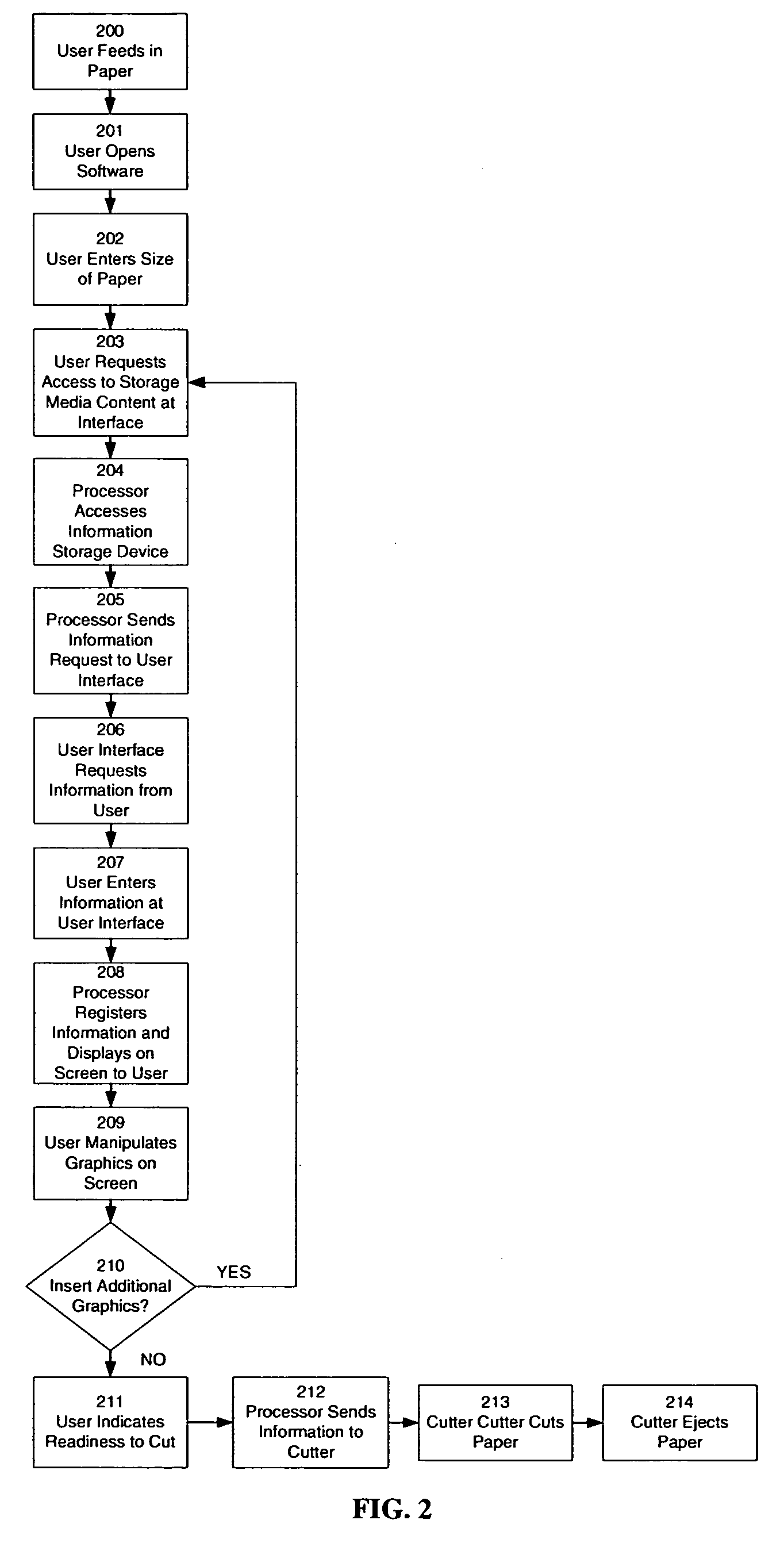

Sheet material cutting system and methods regarding same

A system and / or method for cutting designs of text and / or shapes out of sheet material, such as paper, vellum, and other materials used in, for example, the scrapbooking and card making industries.

Owner:ESSELTE LLC

Multiple catalyst system for olefin polymerization and polymers produced therefrom

This invention relates to a polymer comprising one or more C3 to C40 olefins, optionally one or more diolefins, and less than 15 mole % of ethylene, where the polymer has: a) a Dot T-Peel of 1 Newton or more; and b) a branching index (g′) of 0.95 or less measured at the Mz of the polymer; c) an Mw of 100,000 or less. This invention also relates a polymer comprising one or more C3 to C40 olefins where the polymer has: a) a Dot T-Peel of 1 Newton or more on Kraft paper; b) a branching index (g′) of 0.95 or less measured at the Mz of the polymer; c) a Mw of 10,000 to 100,000; and d) a heat of fusion of 1 to 70 J / g. This invention also relates a polymer comprising one or more C3 to C40 olefins where the polymer has: a) a Dot T-Peel of 1 Newton or more on Kraft paper; b) a branching index (g′) of 0.98 or less measured at the Mz of the polymer; c) a Mw of 10,000 to 60,000; d) a heat of fusion of 1 to 50 J / g. This invention also relates to a homopolypropylene or a copolymer of propylene and up to 5 mole % ethylene having: a) an isotactic run length of 1 to 30 (isotactic run length “IRL” is defined to be the percent of mmmm pentad divided by 0.5× percent of mmmr pentad) as determined by Carbon 13 NMR, preferably 3 to 25, more preferably 4 to 20, b) a percent of r dyad of greater than 20%, preferably from 20 to 70% as determined by Carbon 13 NMR, and c) a heat of fusion of 70 J / g or less, preferably 60 J / g or less, more preferably between 1 and 55 J / g, more preferably between 4 and 50 J / g. This invention further relates to a process to produce an olefin polymer comprising: 1) selecting a first catalyst component capable of producing a polymer having an Mw of 100,000 or less and a crystallinity of 5% or less at selected polymerization conditions; 2) selecting a second catalyst component capable of producing polymer having an Mw of 100,000 or less and a crystallinity of 20% or more at the selected polymerization conditions; 3) contacting the catalyst components in the presence of one or more activators with one or more C3 to C40 olefins, at the selected polymerization conditions in a reaction zone; 4) obtaining the polymer. This invention further relates to a continuous process to produce a branched olefin polymer comprising: 1) selecting a first catalyst component capable of producing a polymer having an Mw of 100,000 or less and a crystallinity of 5% or less under selected polymerization conditions; 2) selecting a second catalyst component capable of producing polymer having an Mw of 100,000 or less and a crystallinity of 20% or more at the selected polymerization conditions; 3) contacting the catalyst components in the presence of one or more activators with one or more C3 to C40 olefins, and, optionally one or more diolefins; 4) at a temperature of greater than 100° C.; 5) at a residence time of 120 minutes or less; 6) wherein the ratio of the first catalyst to the second catalyst is from 1:1 to 50:1; 7) wherein the activity of the catalyst components is at least 100 kilograms of polymer per gram of the catalyst components; and wherein at least 20% of the olefins are converted to polymer.

Owner:EXXONMOBIL CHEM PAT INC

High Strength Multi-Layer Bags

InactiveUS20080292223A1Avoid tearingAvoid puncturePaper/cardboard wound articlesSynthetic resin layered productsAdhesiveEngineering

A plastic reinforced, gusseted pinch bag. The bag is preferably formed from a sheet of clay coated kraft paper. High quality graphics may be printed on the clay coating. A plastic matrix is laminated to the exterior of the sheet which is then formed into a gusseted tube and separated into sections. Each section is then closed at one end to form bags. The plastic matrix on the exterior of the bags will protect them from tears and punctures and help prevent spreading of any tears that may form. Additionally, the matrix and the adhesive used to laminate the matrix to the sheet will form a plastic coating on the exterior of the bags which will make the bags more resistant to moisture. The preferred adhesive and matrix will be transparent or very nearly so, allowing the graphics on the bags to be viewed without obstruction.

Owner:BANCROFT BAG

Detumescent and analgesic ointment for curing rheumatism and contusion and preparation method thereof

InactiveCN102000302AHeavy metal active ingredientsHydroxy compound active ingredientsInjury causeRheumatism

The invention discloses detumescent and analgesic ointment for curing rheumatism and contusion and a preparation method thereof. The ointment is a pure herbal pharmaceutics, which is composed of monarch drugs, ministerial drugs, adjuvant drugs and conductant drugs. The preparation method comprises the following steps: placing 5kg of tung oil in a pan; grinding all traditional Chinese bug bulk pharmaceutical chemicals (BPC) into refined powder, wrapping the adjuvant drugs and the conductant drugs with gauzes, and placing into a frying pan for boiling; boiling with charcoal fire for 90min, putting the powder in to the frying pan after generating smokes, and boiling the mixture to obtain semi-creamy mixture; placing the ministerial drugs into the pan for even stirring to obtain semi-creamy mixture; taking the pan away from the fire and putting the monarch drugs into ointment for even stirring; placing 2.5kg of rosin into the ointment and evenly stirring to obtain the ointment, and pasting the ointment on kraft papers with 11 centimeters; and pressing the ointment on the kraft papers by a 6-centimeter iron module to obtain the ointment with diameter of 6 centimeters, and placing the obtained ointment on fixed patches. The detumescent and analgesic ointment for curing rheumatism and contusion can be used for stimulating the circulation of the blood and causing the muscles and joints to relax, relieving bruises and pains, and curing traumatic injuries and rheumatoid arthritis.

Owner:吴兴保

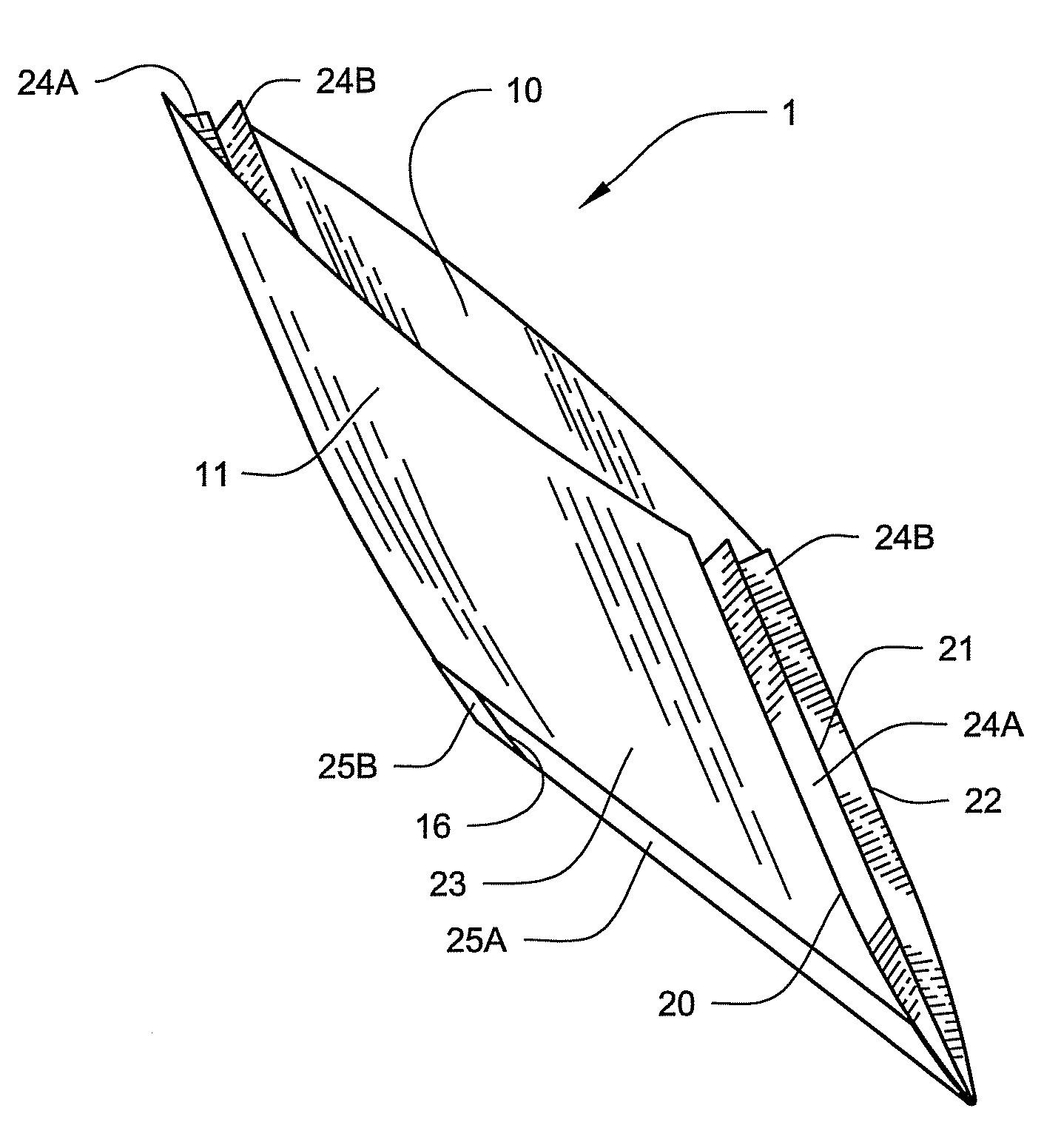

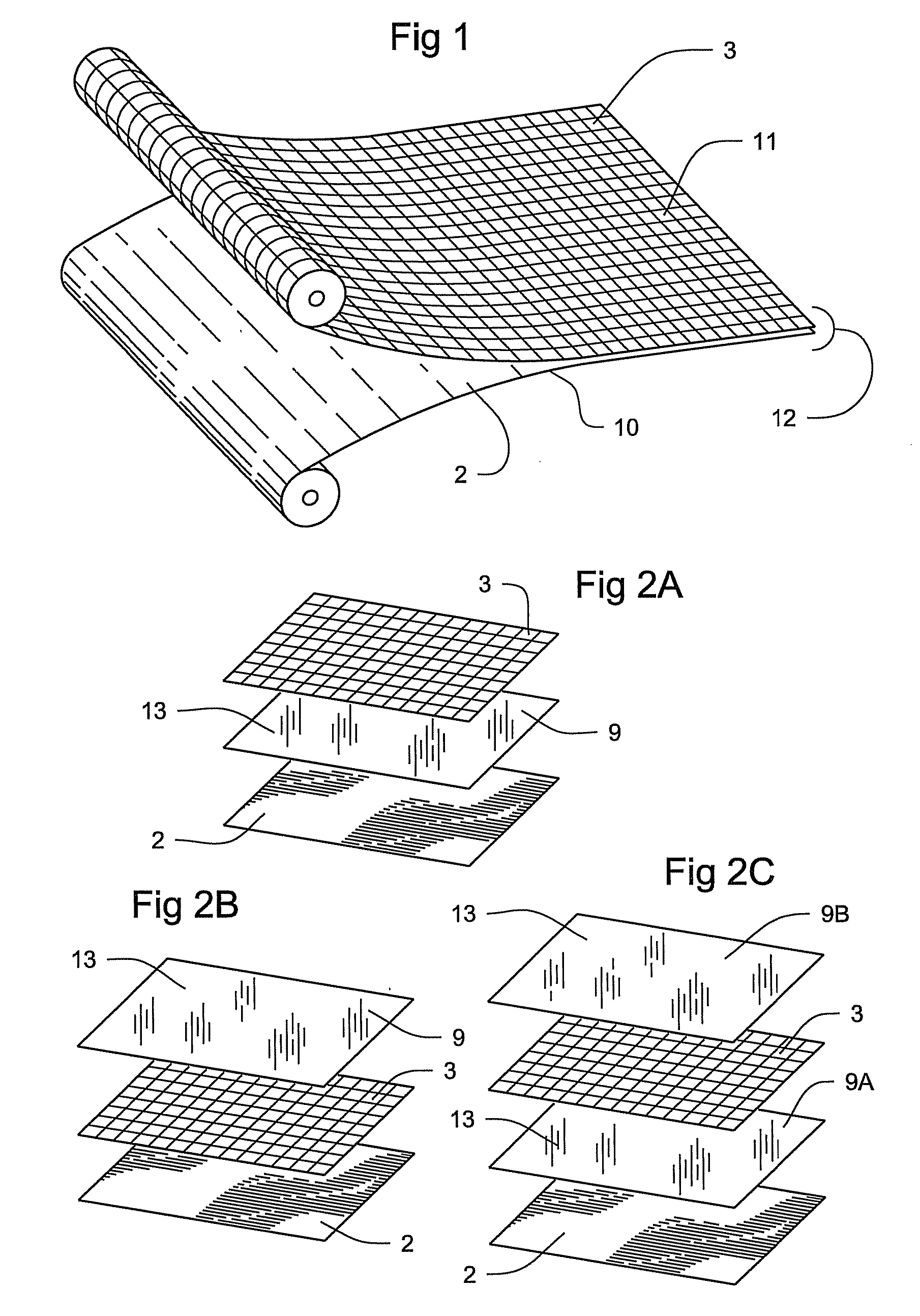

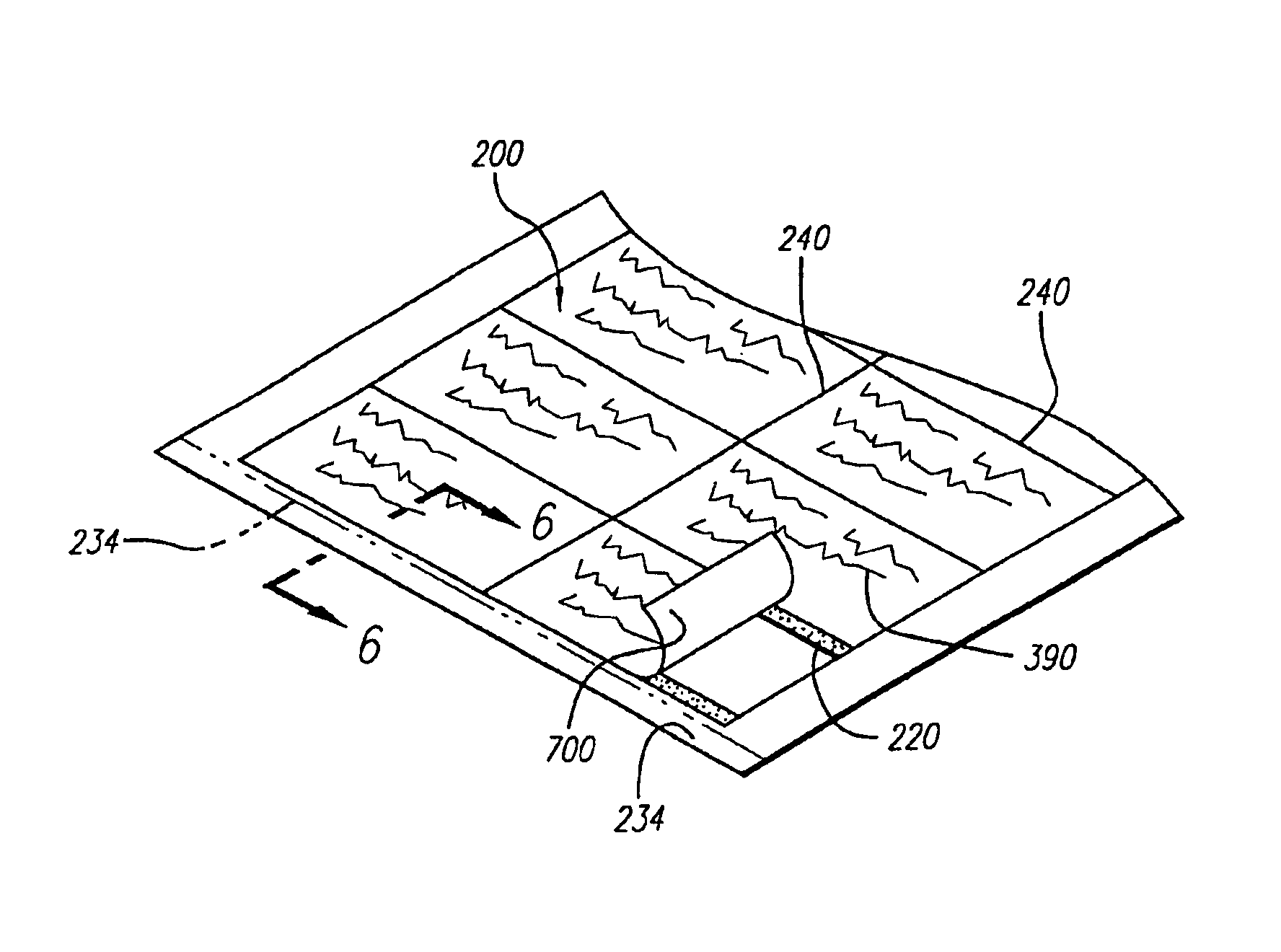

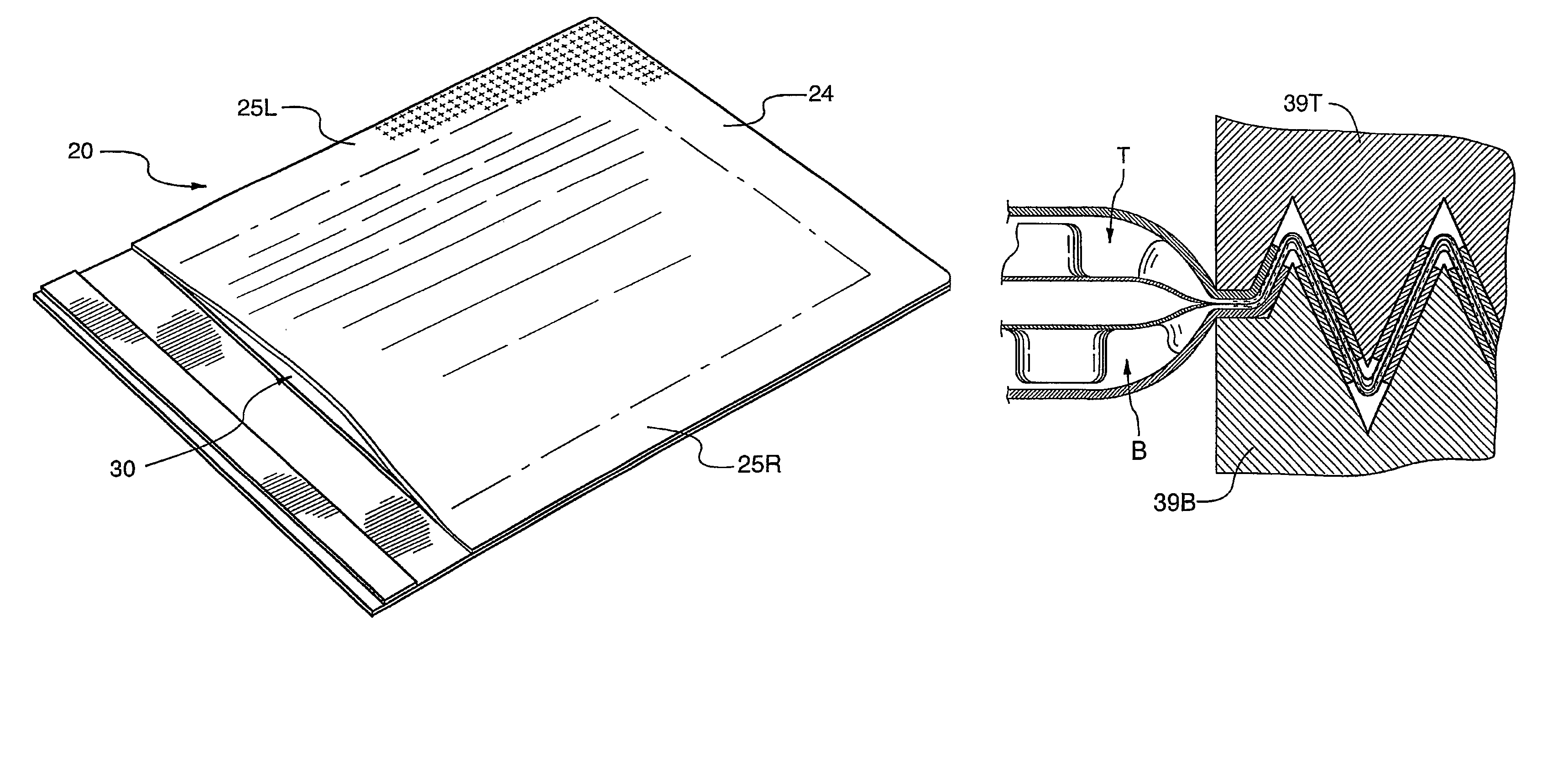

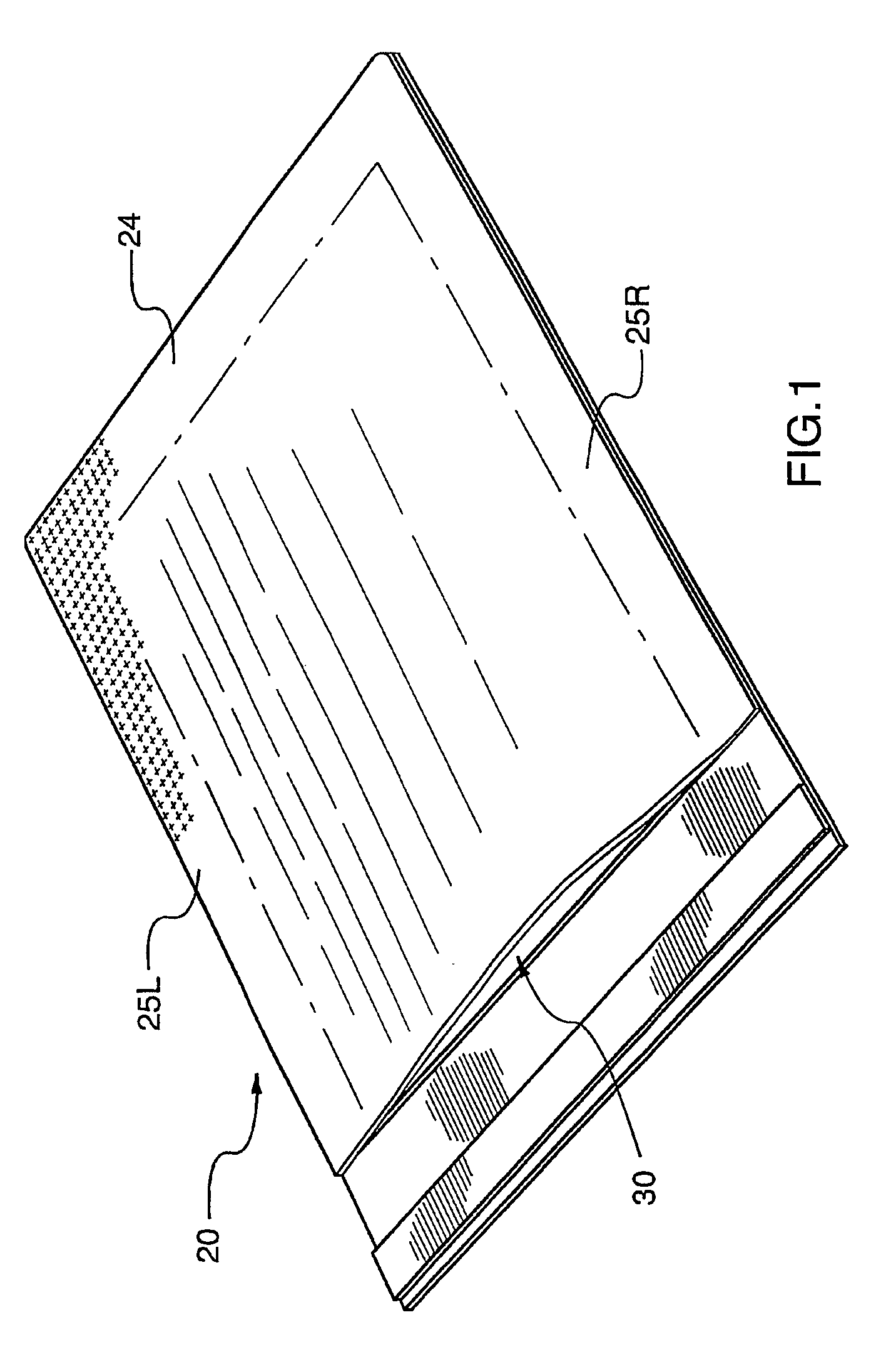

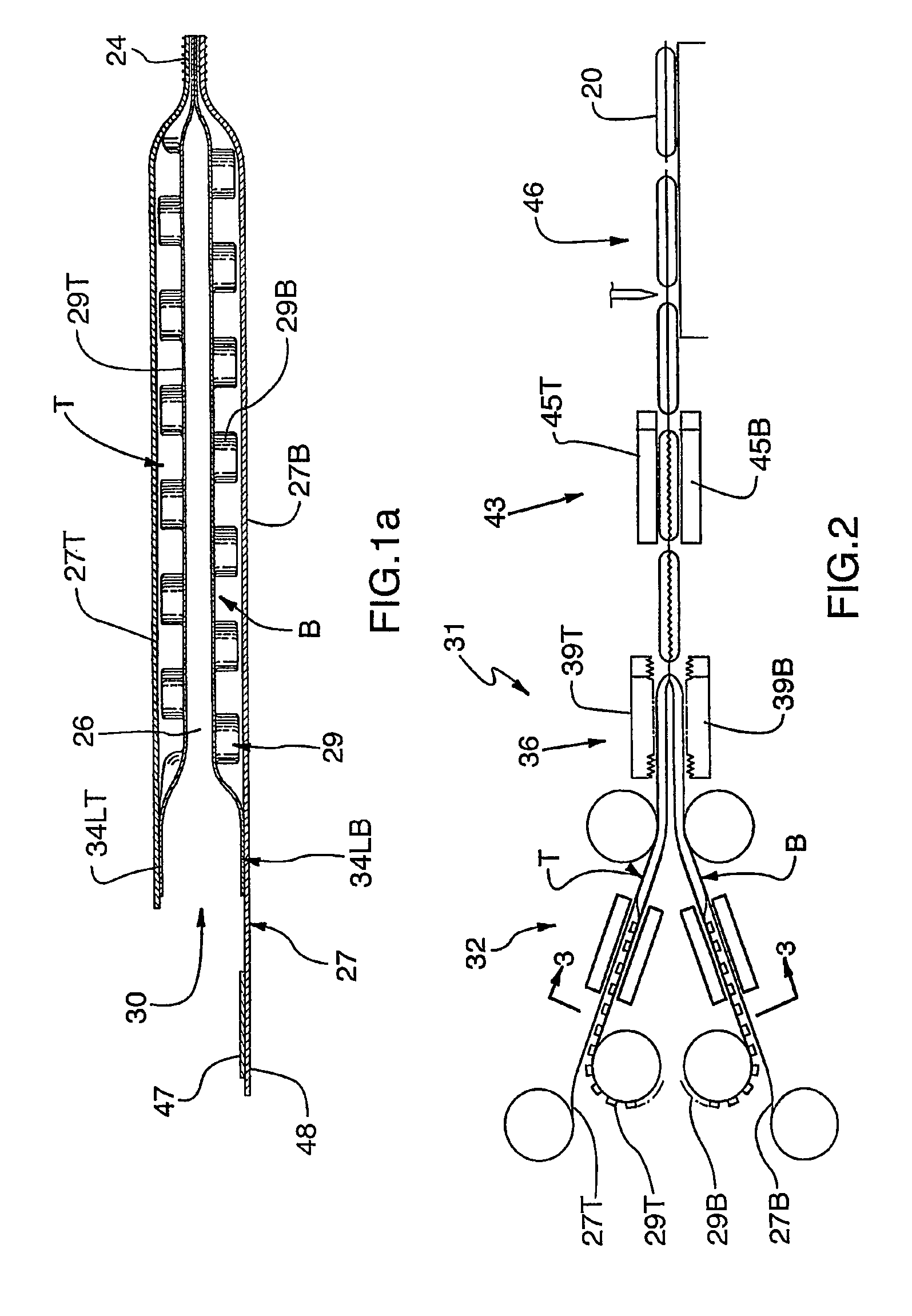

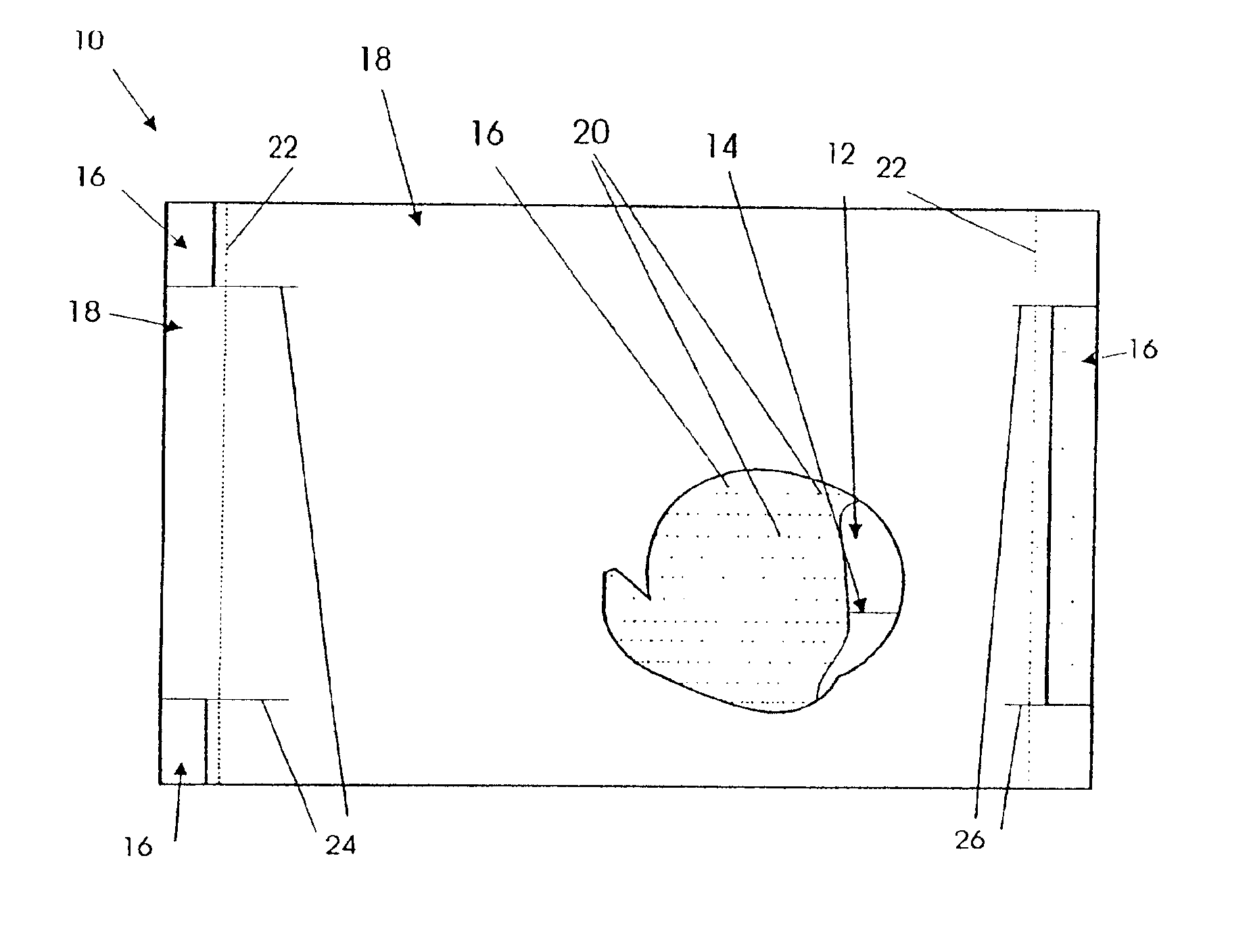

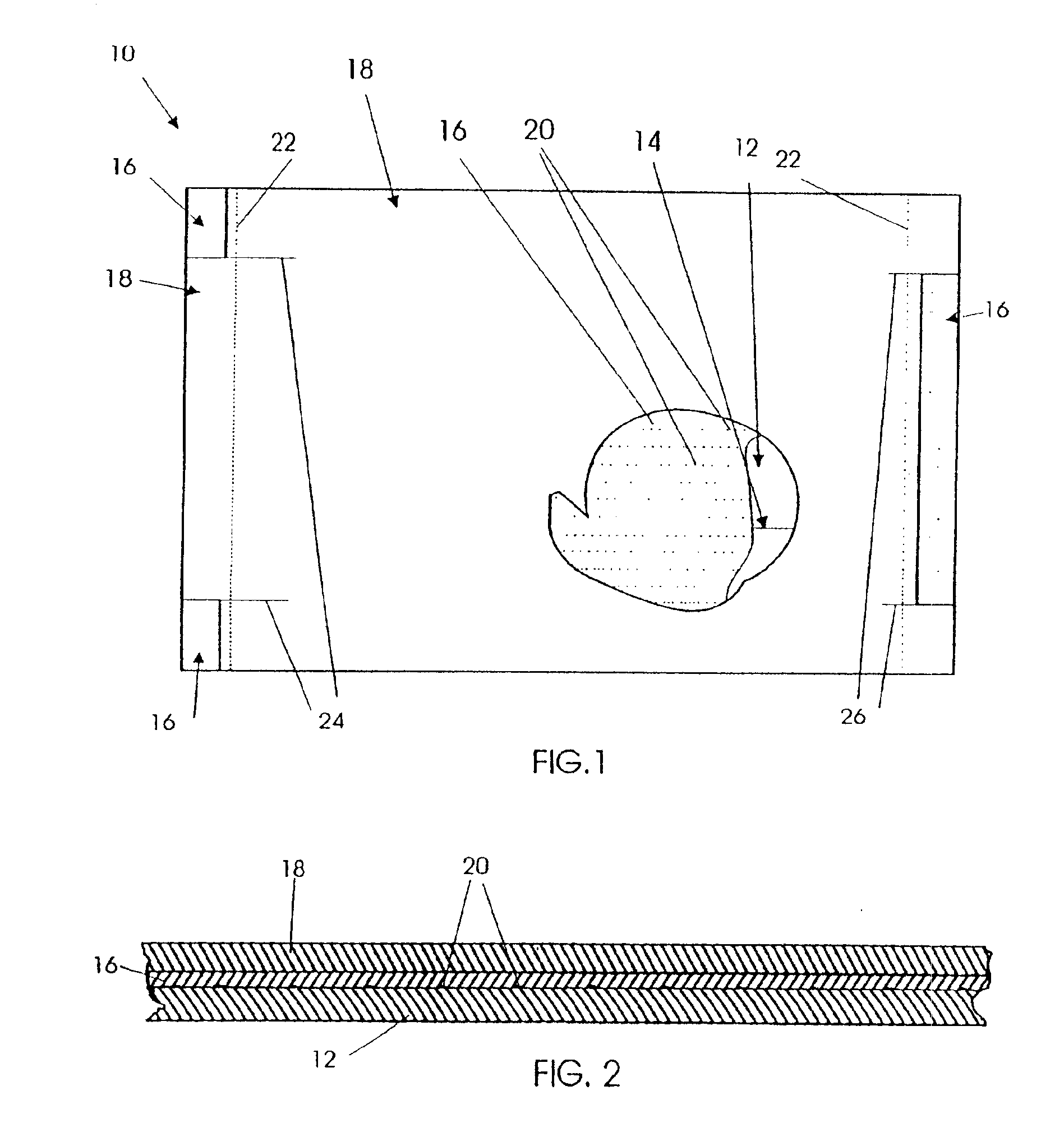

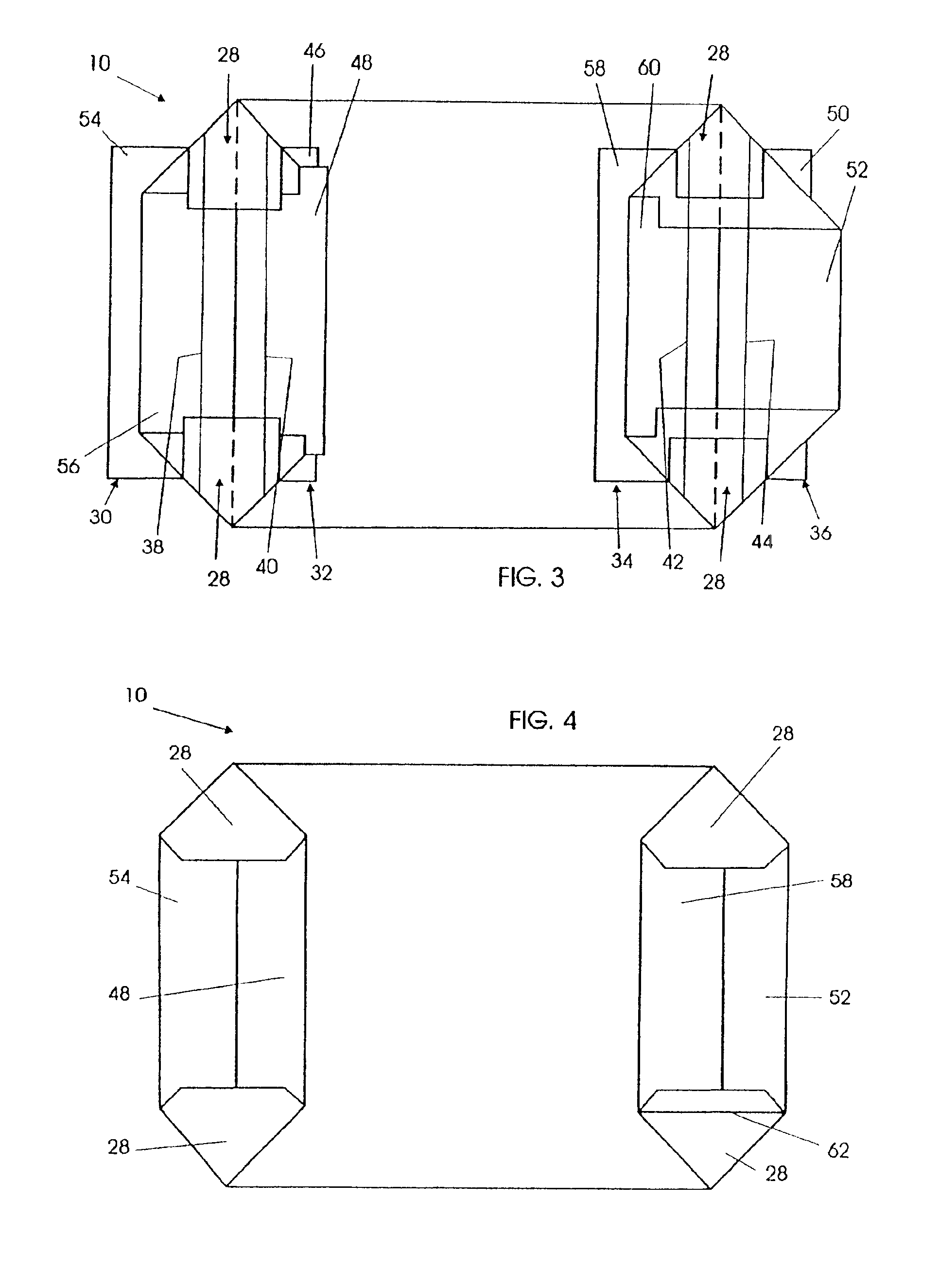

Composite structural material and method of making same

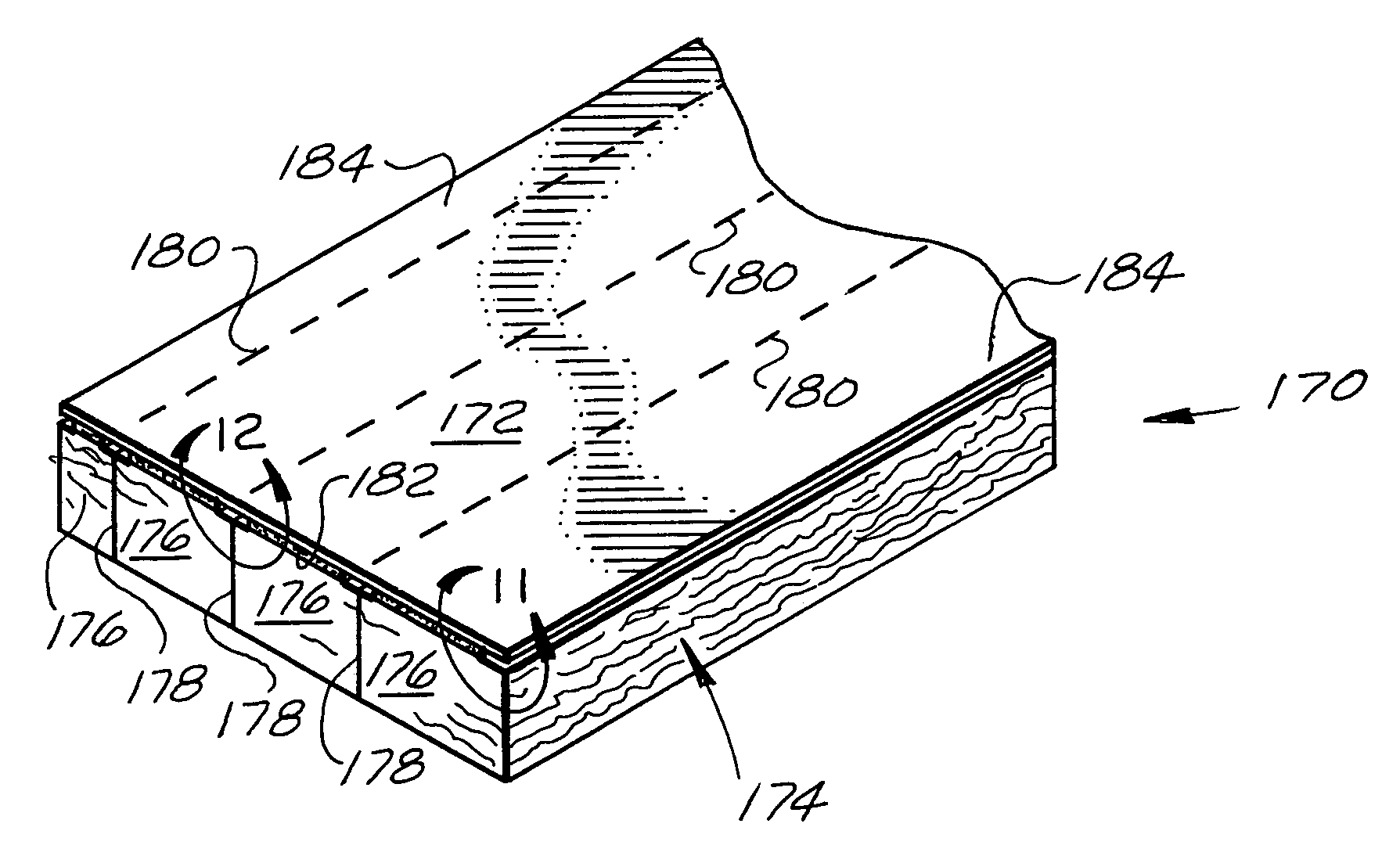

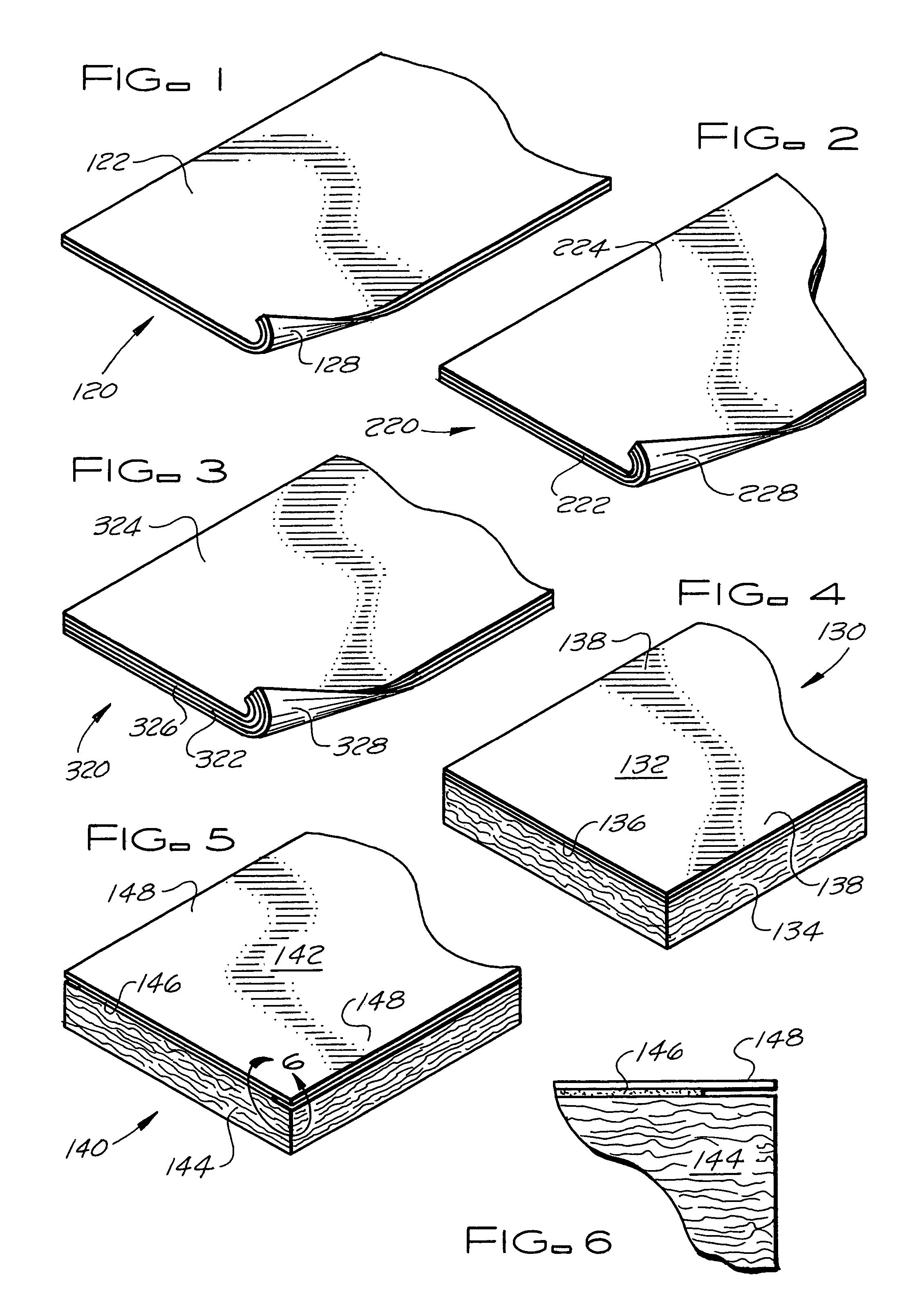

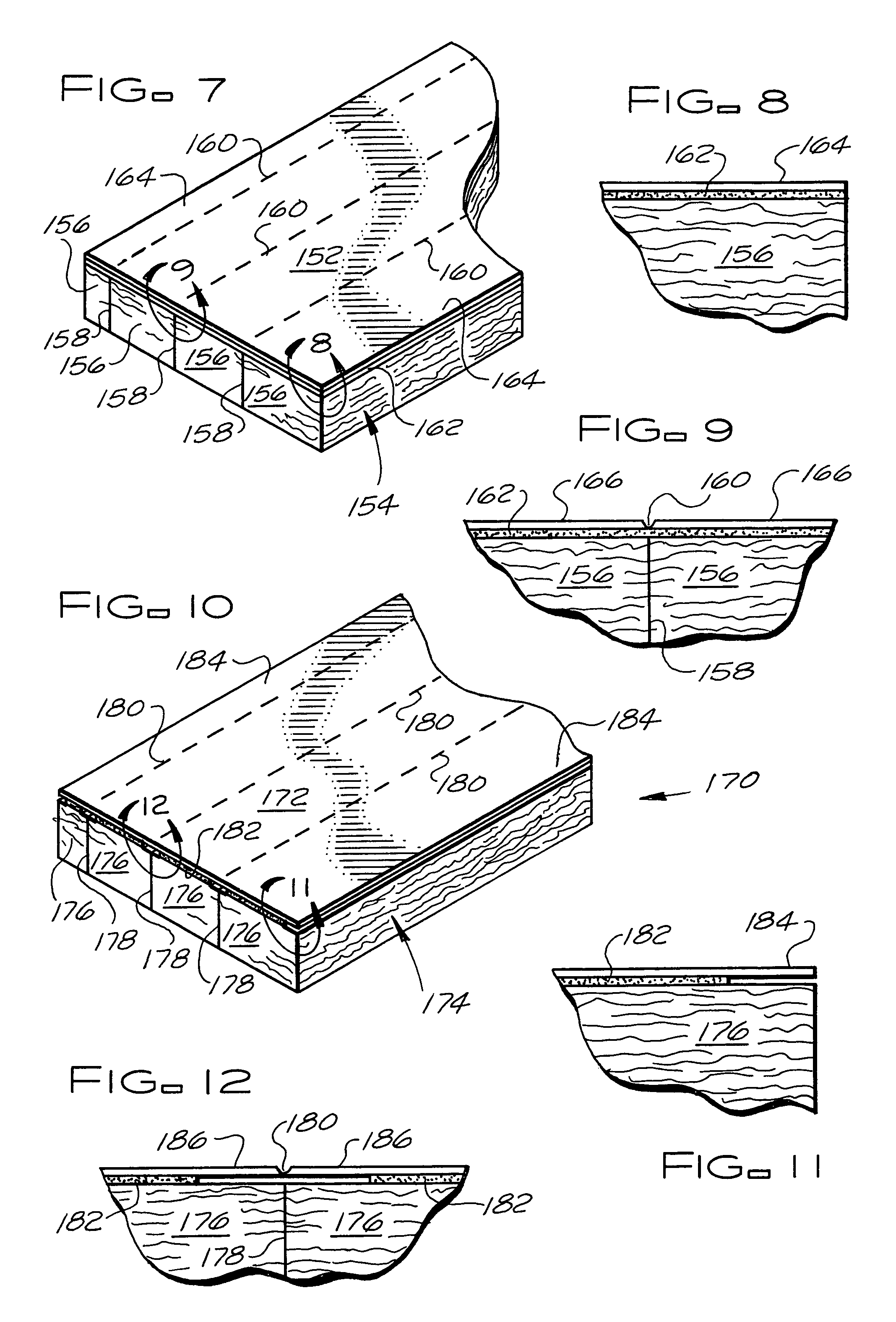

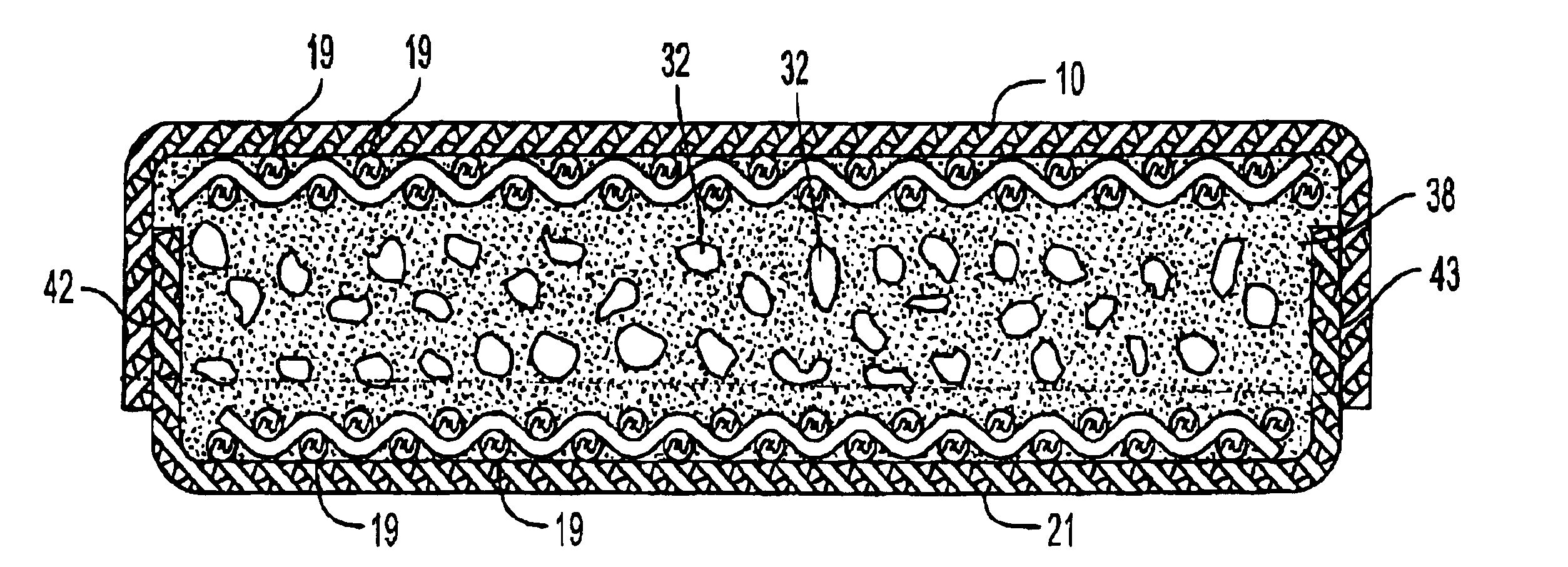

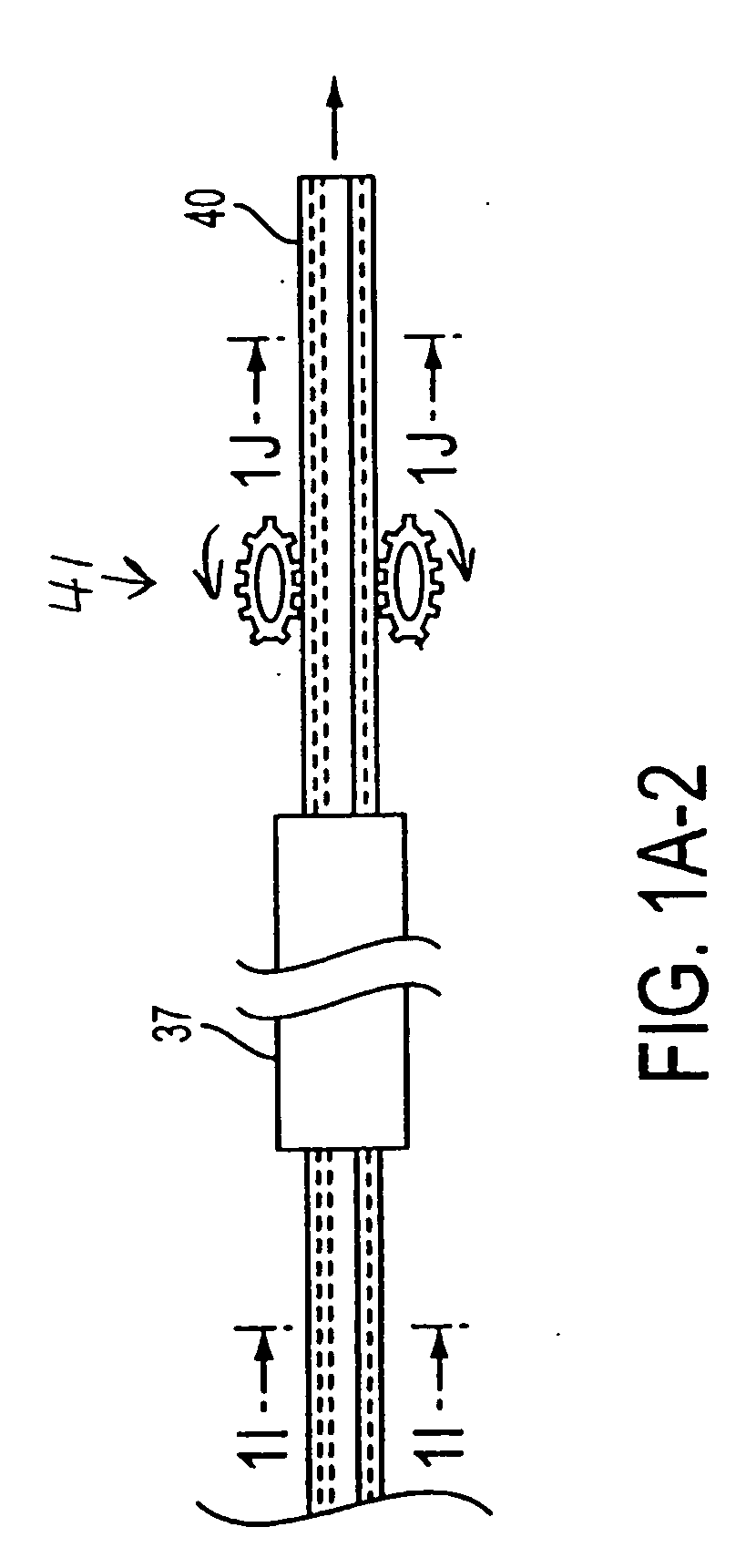

InactiveUS20070113759A1Conserve costIncrease the proportionSynthetic resin layered productsPaper/cardboard layered productsPolyesterEpoxy

A composite structural material suitable, for example, as a replacement for wooden boards, is disclosed. It comprises a dimensionally stable core material ensheathed in a dimensionally stable, laminar covering that is adherent to the core material. The laminar covering is comprised of at least one layer of parallel cords (19) bonded to at least one layer of a rigidified web material (10) selected from the group consisting of paper and cloth. Suitable core materials include polyurethane foam (38), optionally filled with particles (32) of granulated rubber, expanded perlite, expandable polymer beads, and / or glass microspheres. The parallel cords (19) preferably are supplied in the form of a strip of polyester cloth, as the warp cords thereof. The web material (10) preferably is kraft paper that is rigidified with an epoxy resin.

Owner:CODA CAPITAL MANAGEMENT GROUP

Method of preventing or reducing aluminosilicate scale in kraft pulp mills

InactiveUS20050274926A1Reduce and eliminate aluminosilicate scalingReduce and even prevent formationAluminium compoundsDigestersEnd-groupPulp mill

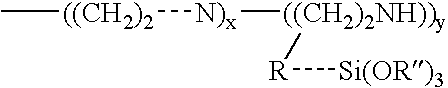

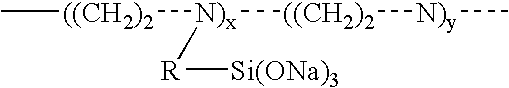

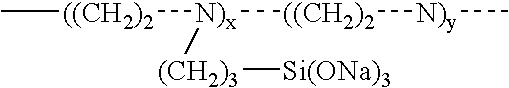

Materials and a method are provided whereby polymers with least 0.5 mole % of the pendant group or end group containing —Si(OR″)3 (where R″ is H, an alkyl group, Na, K, or NH4) are used to control aluminosilicate scaling in an industrial process having an alkaline process stream such as a pulping mill process stream. When materials of the present invention are added to the alkaline process stream, they reduce and even completely prevent formation of aluminosilicate scale on equipment surfaces such as evaporator walls and heating surfaces. The present materials are effective at treatment concentrations that make them economically practical.

Owner:CYTEC TECH CORP

Chemical activation and refining of southern pine kraft fibers

InactiveUS20070119556A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

Acoustic ceiling tiles made with paper processing waste

ActiveUS20090173464A1Promote absorptionReduce the amount of solutionFibreboardNatural cellulose pulp/paperCellulose fiberSlurry

A composition and process suitable for making acoustic tiles are disclosed. Certain embodiments of the composition comprise: perlite; inorganic material selected from the group consisting of calcium sulfate, calcium carbonate, clay and mixtures thereof; a binder selected from the group consisting of starch, a combination of starch and cellulosic fibers, latex, kraft paper gel and mixtures thereof; optionally mineral wool; optionally gypsum; and cellulosic fiber, wherein at least a portion of the cellulosic fiber and at least a portion of the inorganic material are pulp and paper processing waste comprising cellulosic fiber, clay and calcium carbonate. Certain embodiments of the process comprise: forming an aqueous slurry; continuously flowing slurry onto a moving foraminous wire to form a cake; dewatering the cake to form a base mat; and drying the base mat.

Owner:USG INTERIORS INC

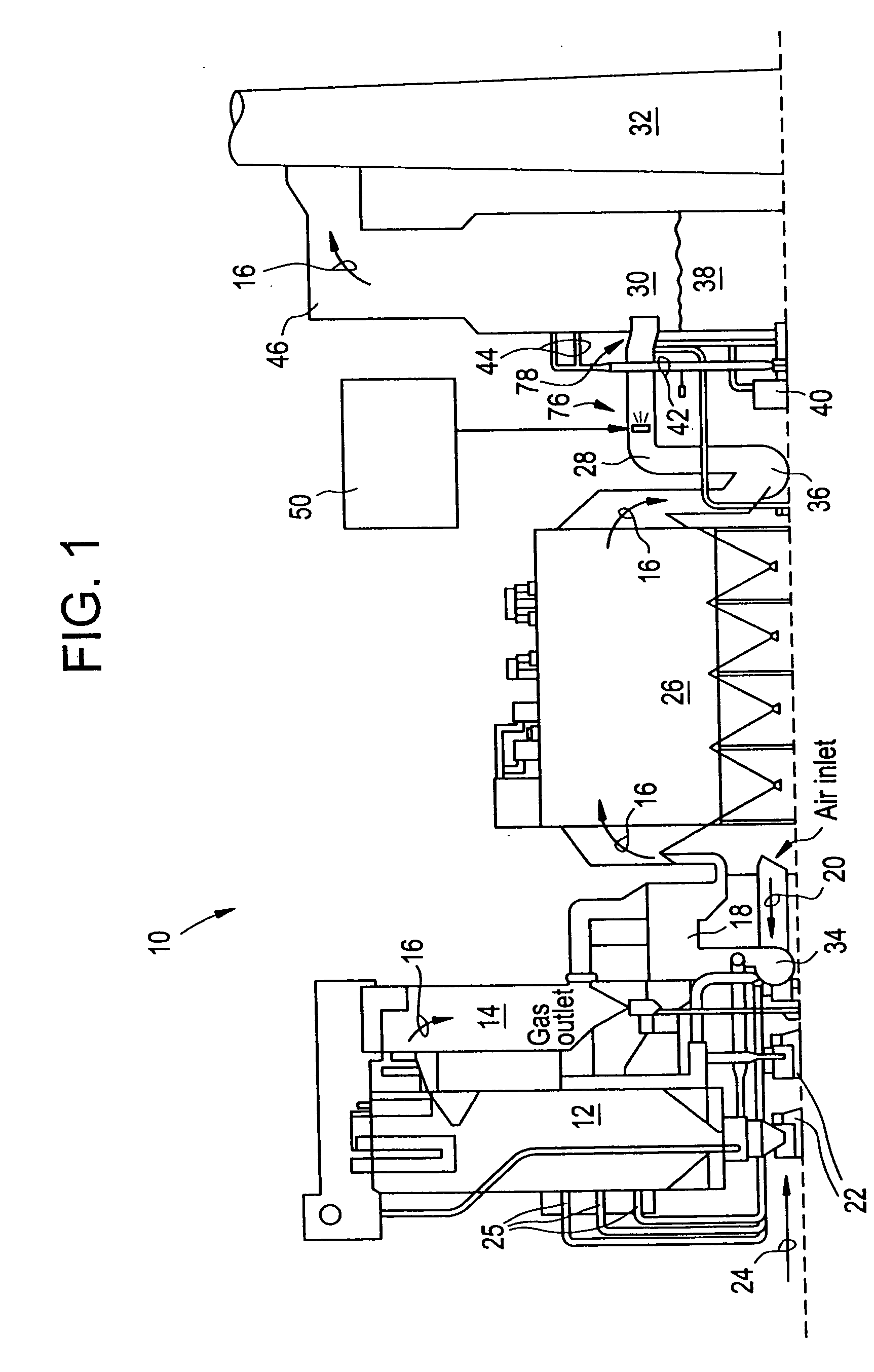

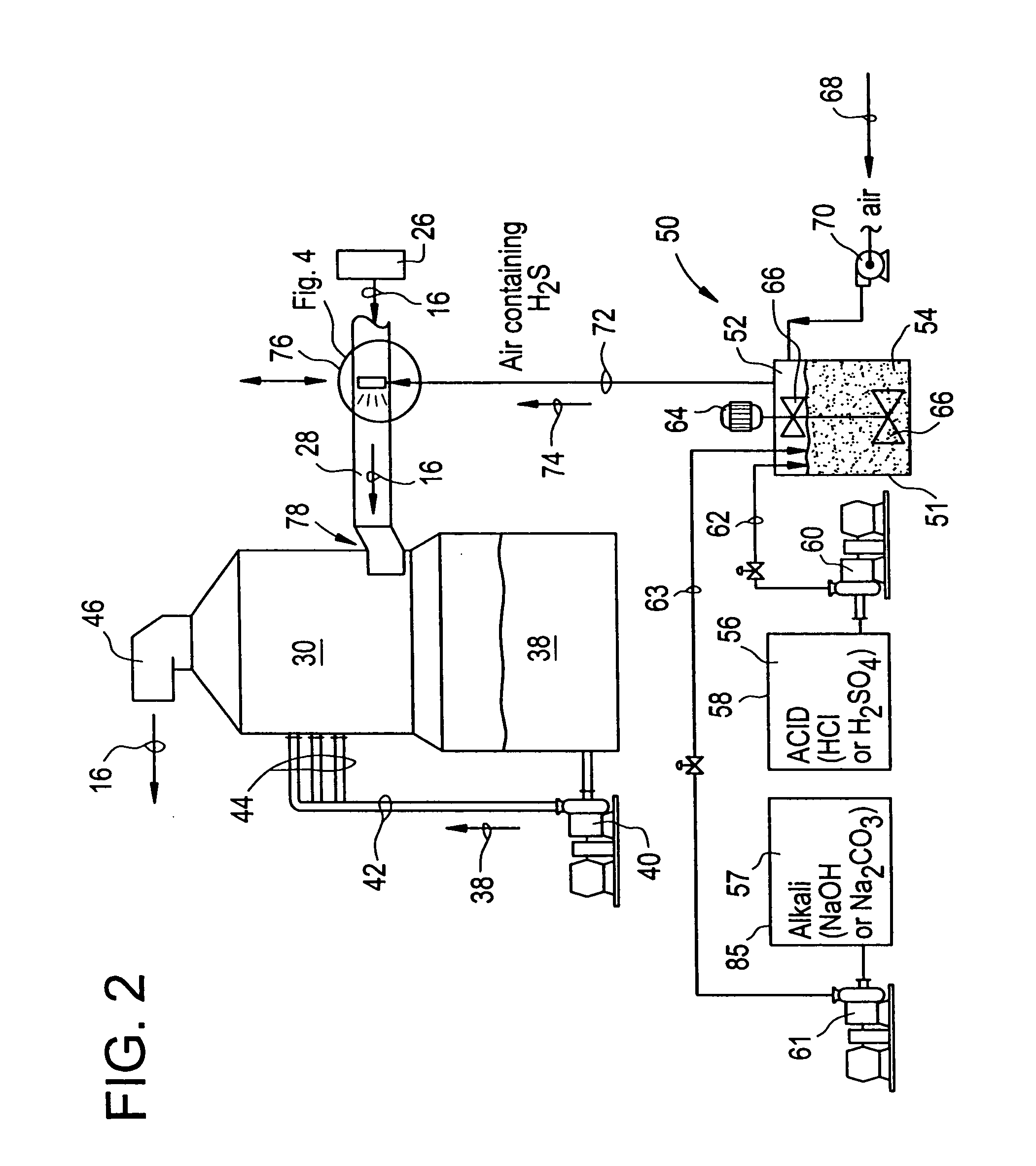

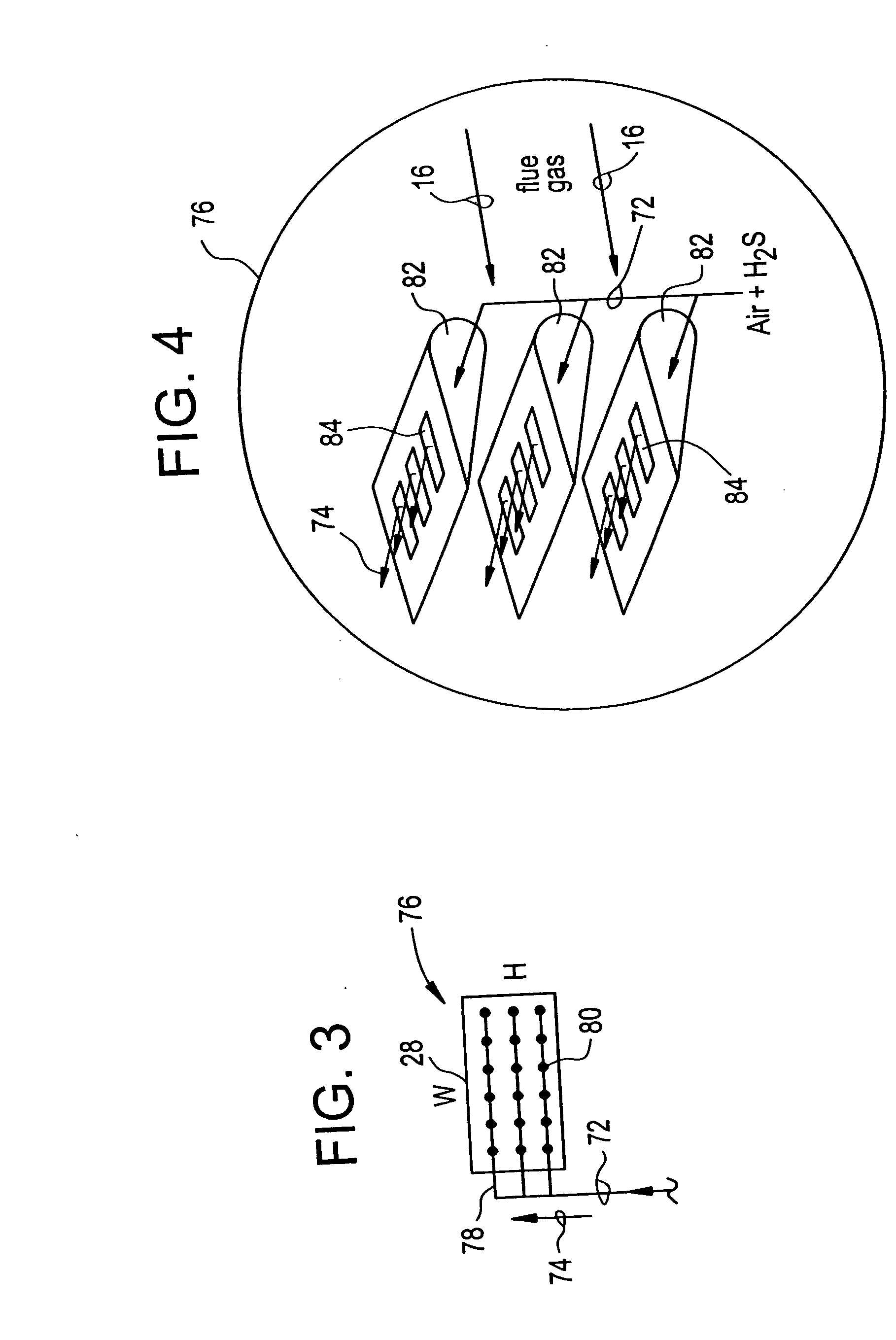

Method for control of mercury

InactiveUS20050169824A1Inherent safety advantageEfficient removalUsing liquid separation agentEmission preventionCoalWet scrubber

A method and apparatus for reducing mercury in industrial gases such as the flue gas produced by the combustion of fossil fuels such as coal adds hydrogen sulfide to the flue gas in or just before a scrubber of the industrial process which contains the wet scrubber. The method and apparatus of the present invention is applicable to installations employing either wet or dry scrubber flue gas desulfurization systems. The present invention uses kraft green liquor as a source for hydrogen sulfide and / or the injection of mineral acids into the green liquor to release vaporous hydrogen sulfide in order to form mercury sulfide solids.

Owner:DOWNS WILLIAM +1

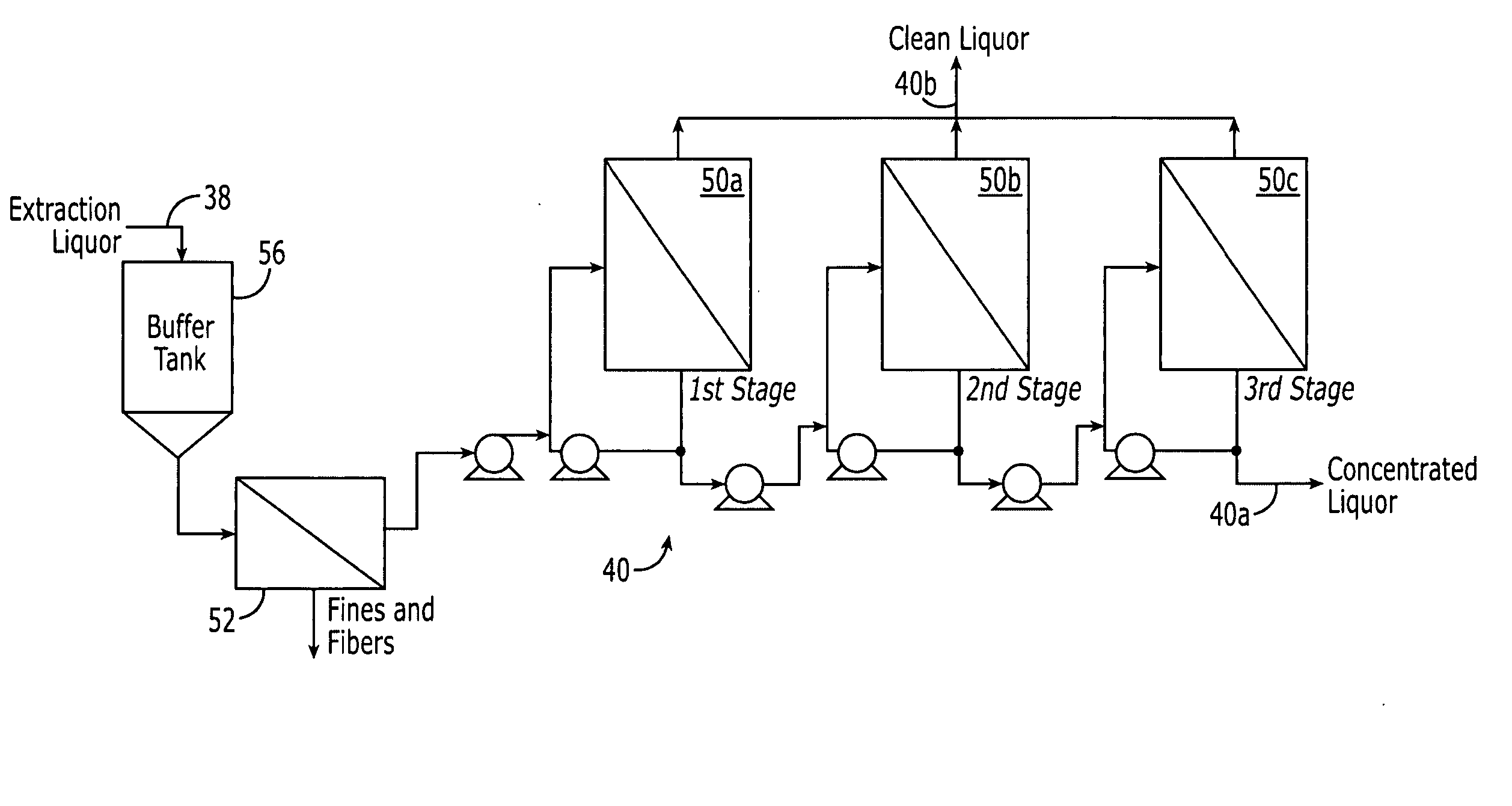

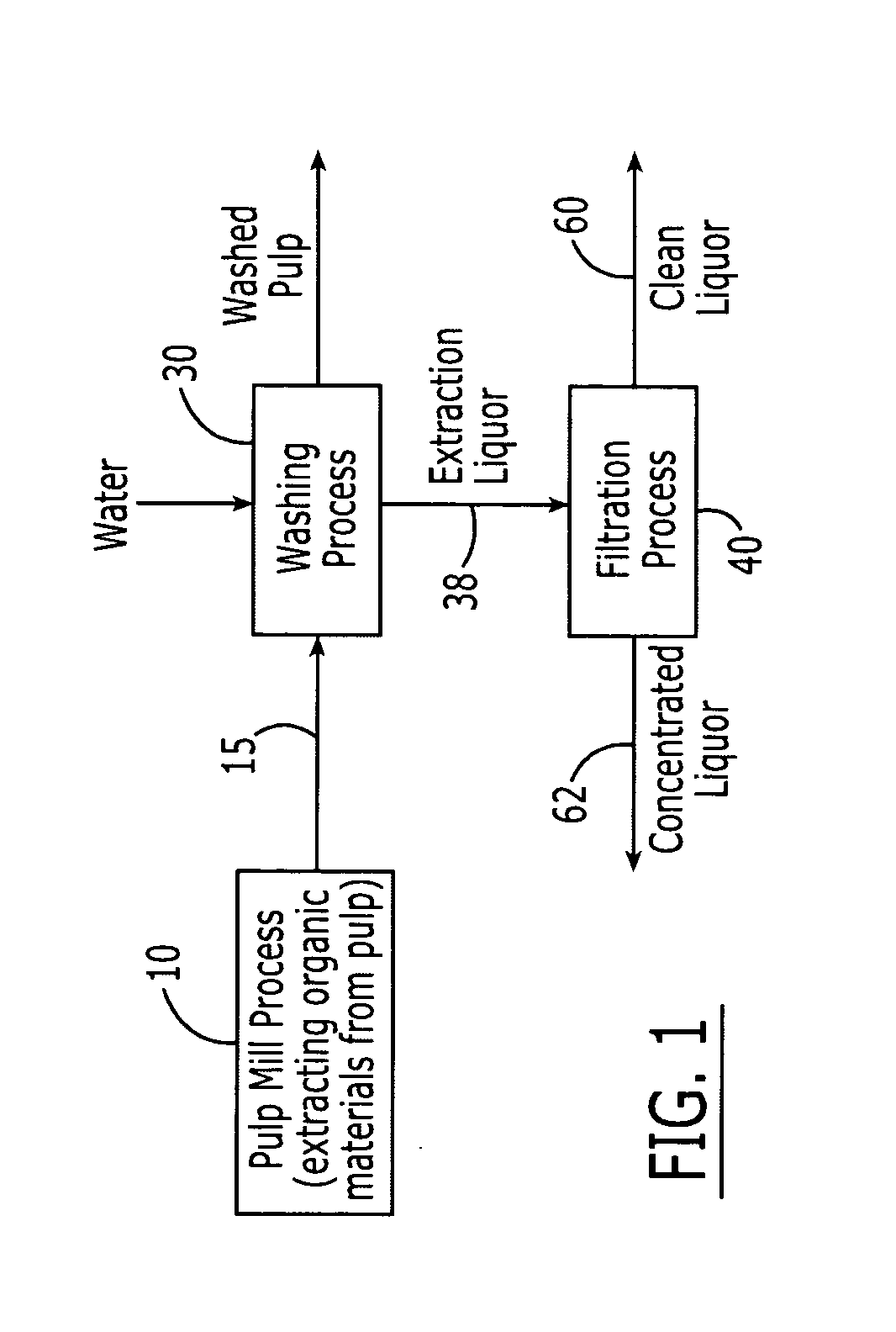

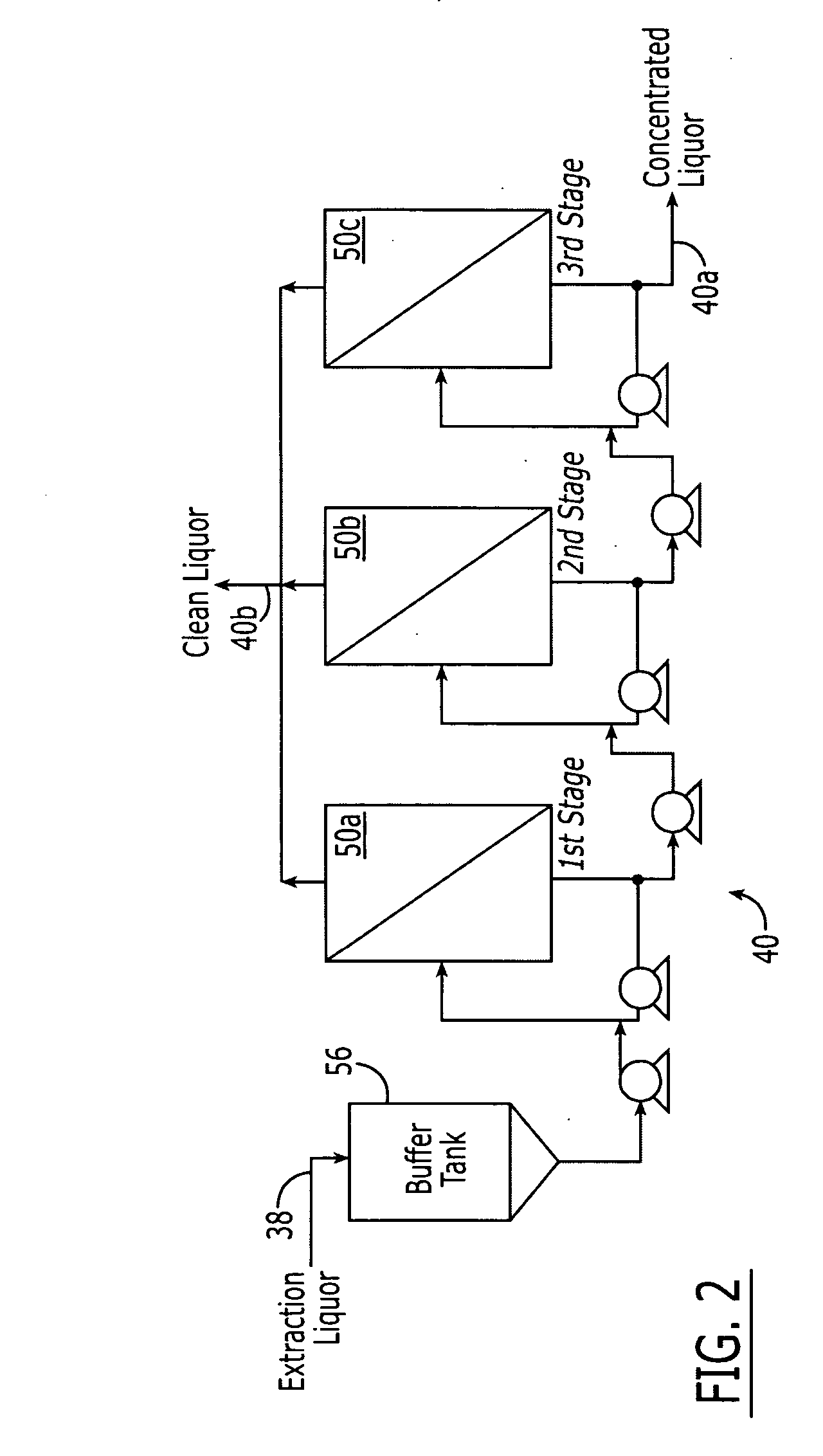

Method of concentrating pulp mill extracts

InactiveUS20060016751A1Reduce loadReduce processMembranesPulp liquors combustionWaste streamPulp mill

A process for separating organic components from a pulp mill waste stream comprising the steps of washing a cellulose pulp to obtain an aqueous extraction liquor containing organic components, and separating at least a portion of said organic components from the extraction liquor by passing the extraction liquor through at least one nanofiltration membrane. The process may be used in conjunction with a variety of pulp mill processes, including kraft cooking processes, hot caustic extraction processes, sulfite cooking processes, and bleaching processes.

Owner:RAYONIER PRODUCTS AND FINANCIAL SERVICES COMPANY

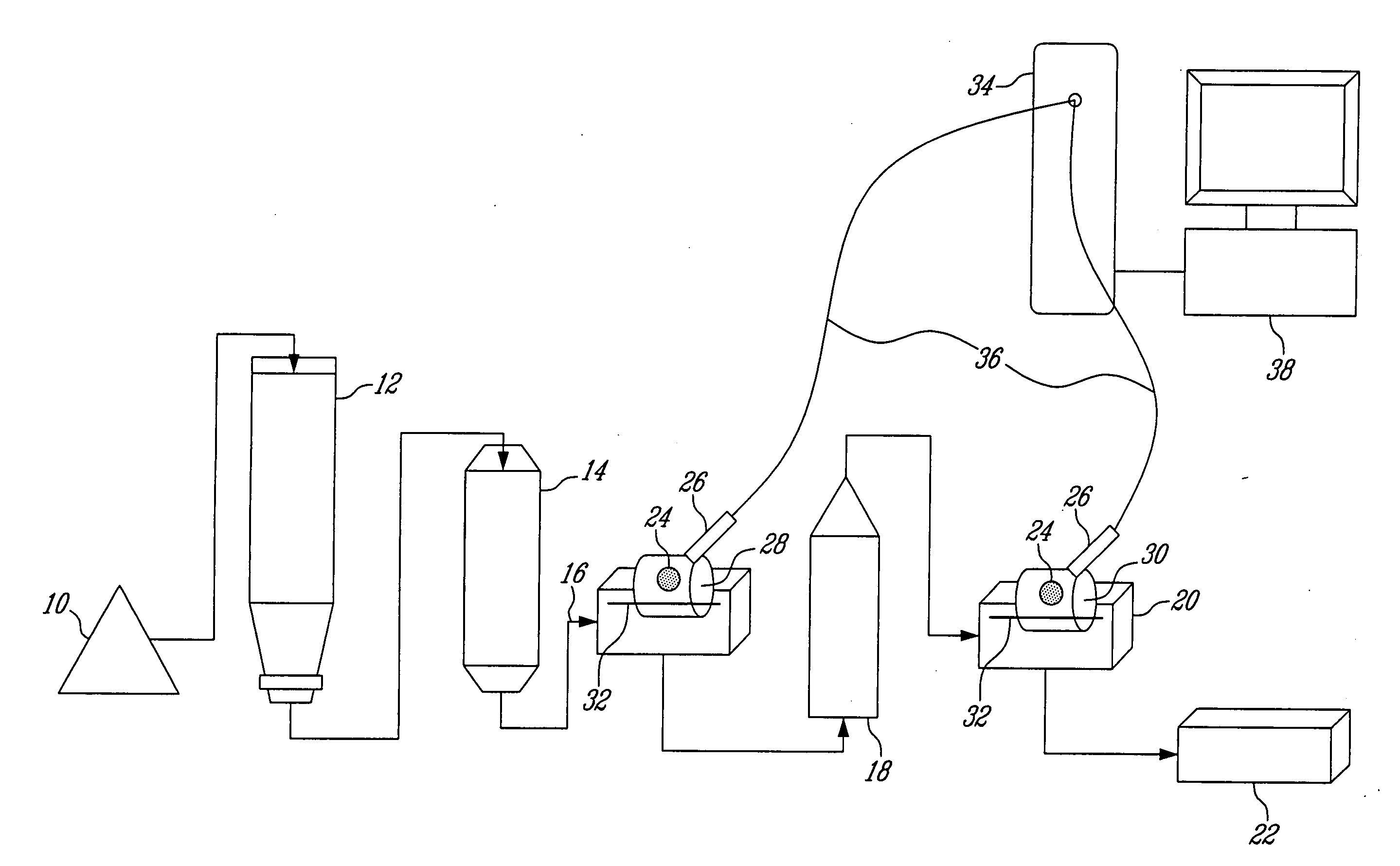

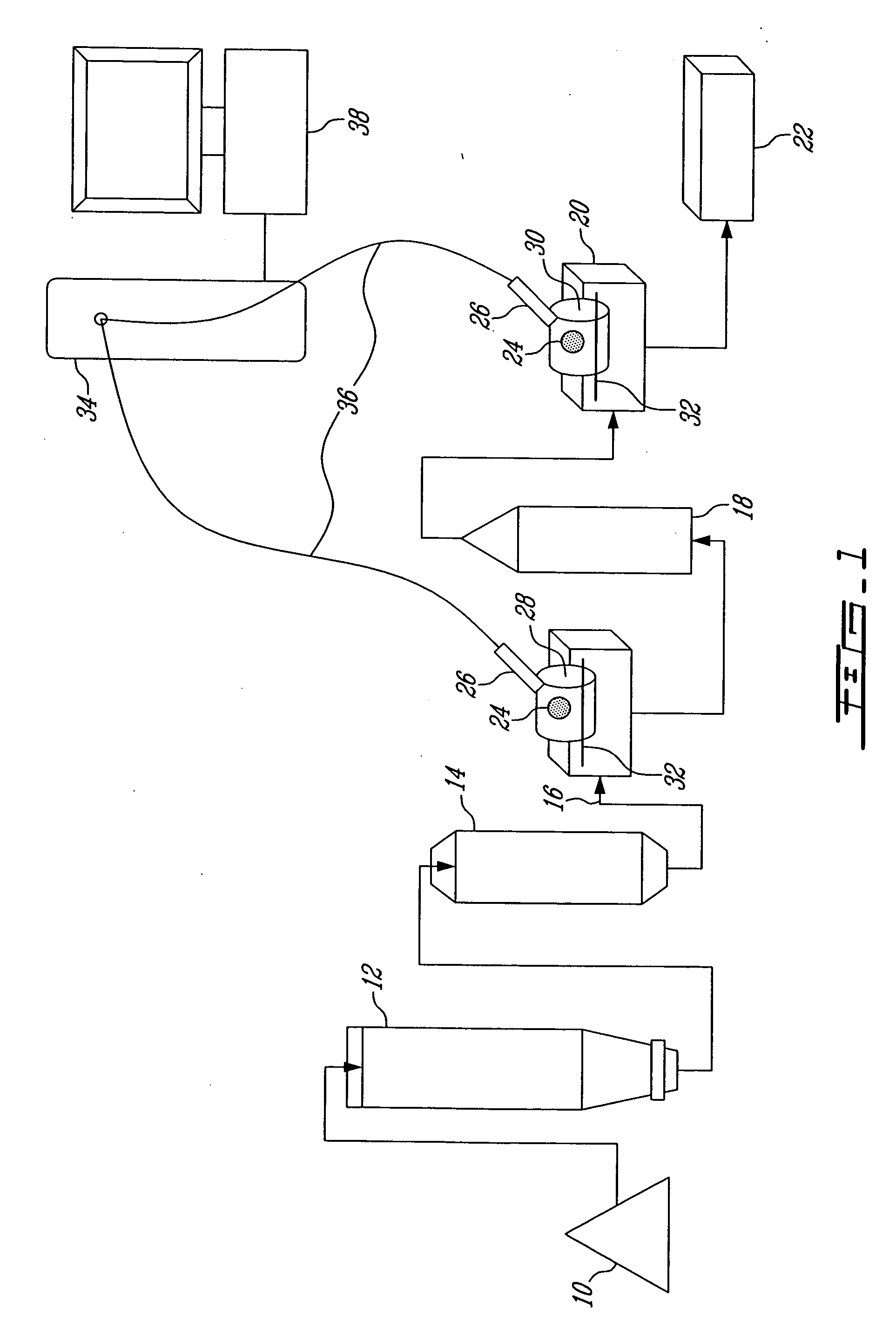

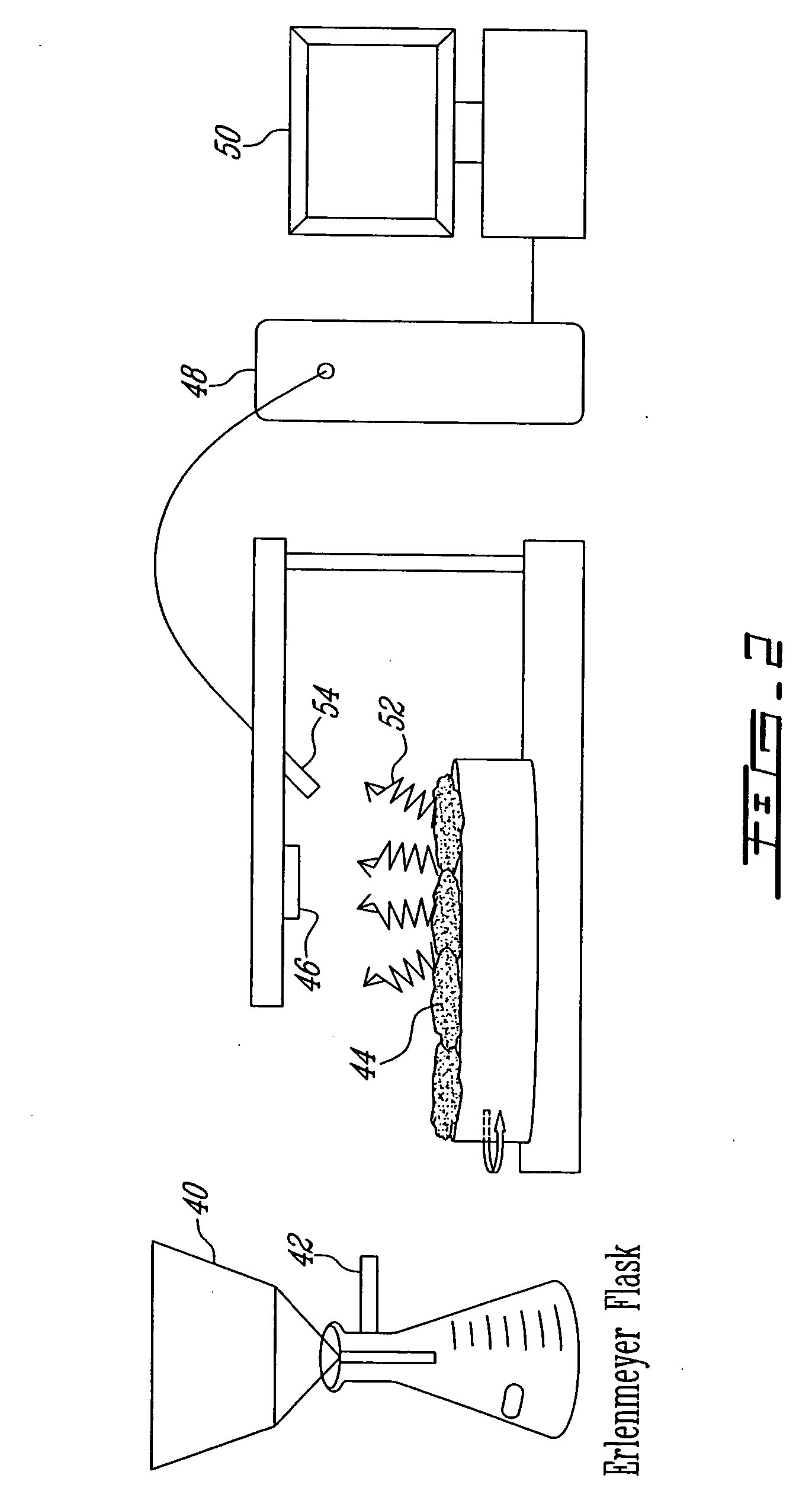

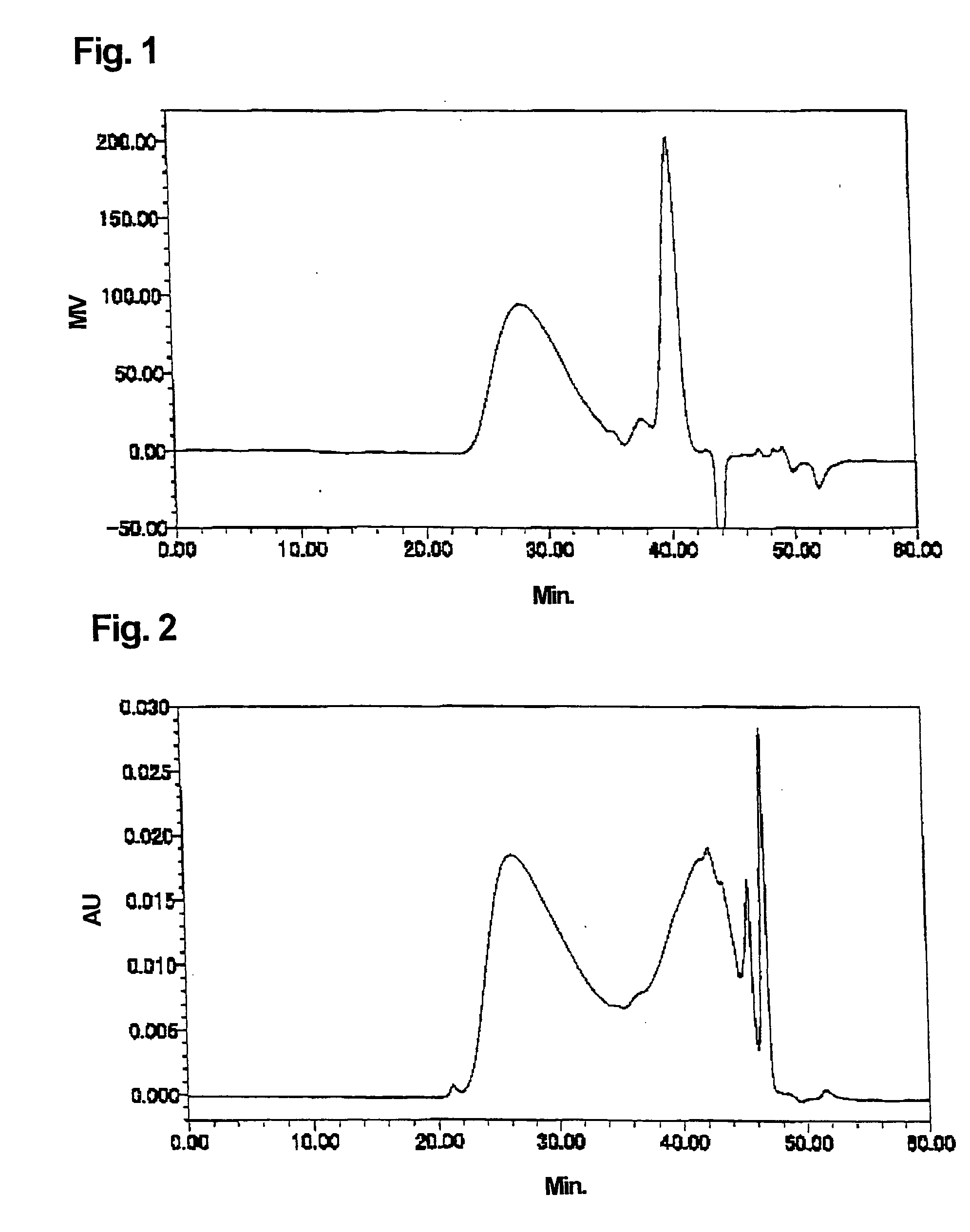

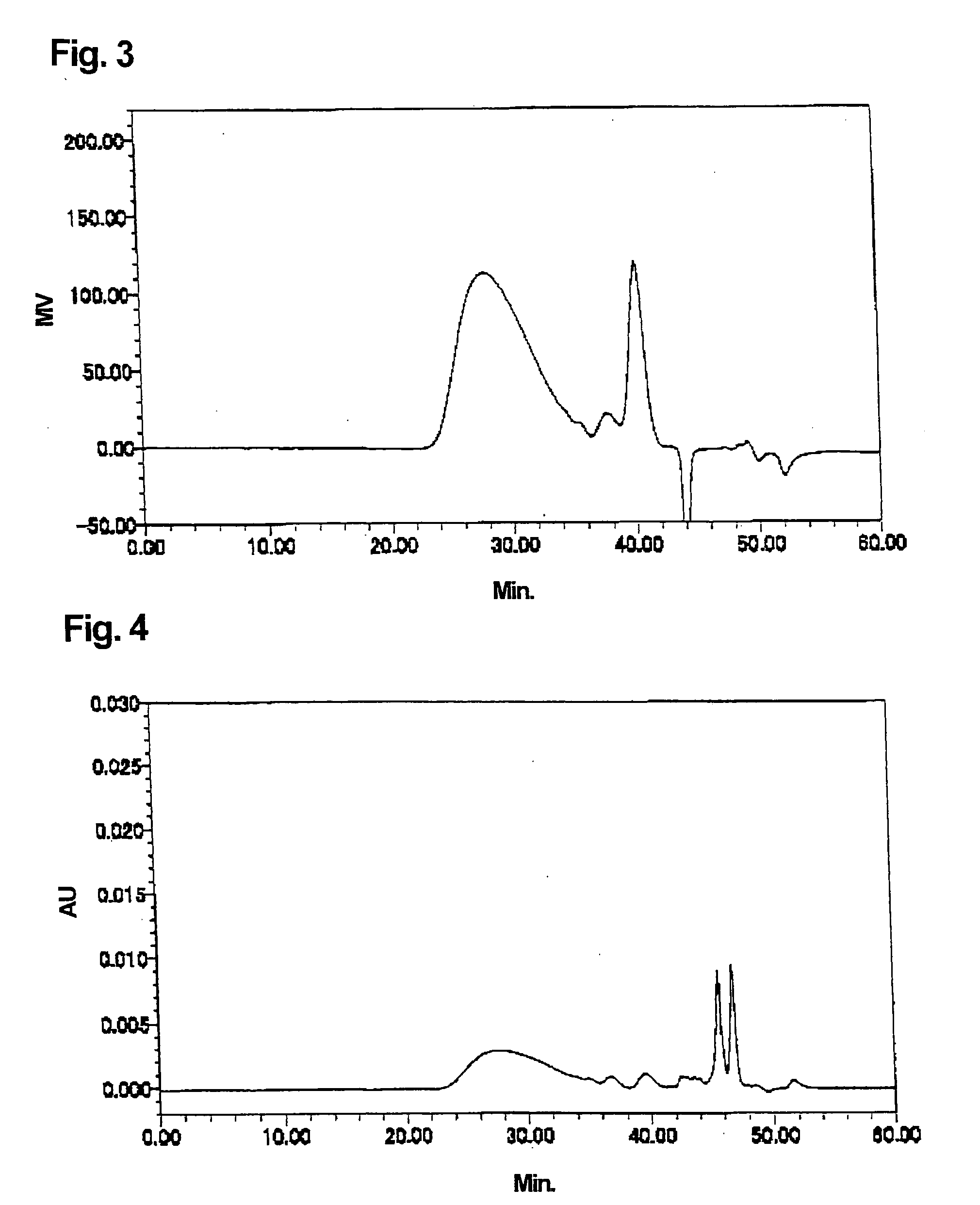

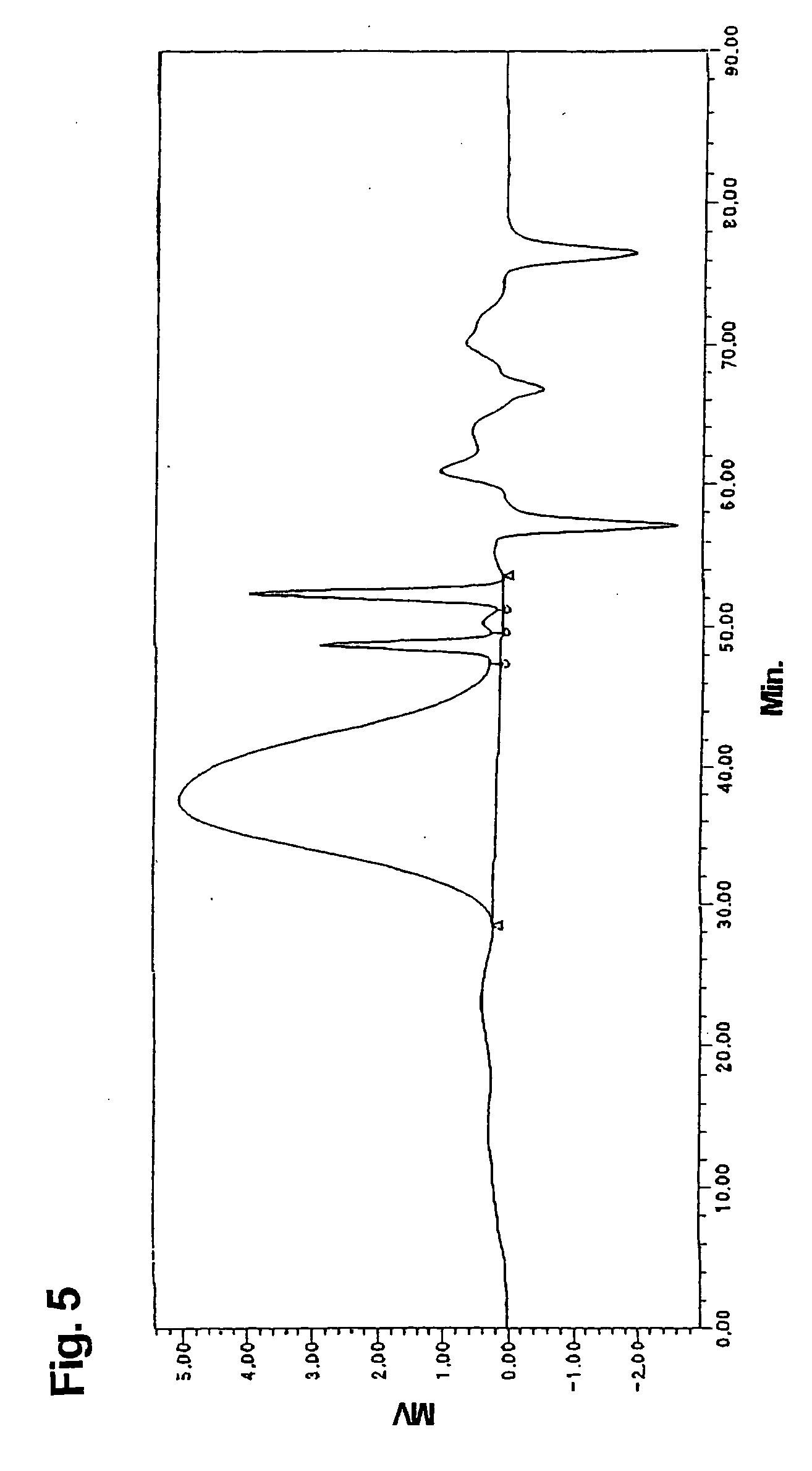

Method for determining chemical pulp Kappa number with visible-near infrared spectrometry

ActiveUS20060196622A1Overcomes shortcomingCellulosic pulp after-treatmentRadiation pyrometryContinuous measurementPresent method

A method for the determination of cellulosic-fibre properties, such as, but not limited to, residual lignin content of chemical pulp, with the aid of a spectroscopic technique obtained over a range covering the visible and the near-infrared regions of the electromagnetic spectrum, comprising the steps of obtaining a sample from the process line, minimally removing some excess water, exposing the fibres in the sample to a large beam light source, optionally moving the sample at a constant speed, and acquiring the spectral data over a pre-determined length of time, and correlating the spectrum to a previously determined calibration so as to determine the Kappa number. Alternatively, as an arrangement for process control, along with other varying configurations, the instant invention includes the mounting of the excitation light source and fibre-optic probe along the various locations of the kraft cooking and bleaching process, such as 1) at the drum brownstock washers and 2) throughout the bleach plant deckers, located just before the doctored blade, the probe being connected to a fast scanning spectrometer, via fibre optic cables, with a computer sequencing spectral acquisition and correlating the spectrum against a predetermined calibration, and logging the results. The process configuration, with the use of the instant invention, overcomes all limitations of prior art, including sampling hardware and sample preparation, and provides true online Kappa number determinations of the order of seconds, as compared to current state of the art Kappa analyzers which require 10 to 15 minutes per analysis. The present method is capable of measuring residual lignin content of chemical pulps with varying consistency, accounts for species effects to provide species insensitivity and can provide analysis in less than 10 seconds. The method can provide true online continuous measurement of Kappa number for feedforward and feedback control of the bleaching, paper machine and kraft cooking processes.

Owner:FPINNOVATIONS INC

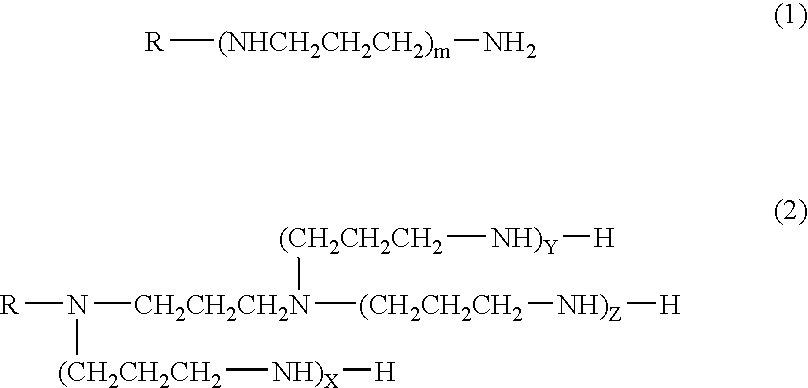

Dispersant Using Kraft Lignin and Novel Lignin Derivative

InactiveUS20070260046A1Good dispersionLow viscosityTransportation and packagingMixingWater solubleKraft paper

The dispersant of the present invention comprises at least one component unit derived from kraft lignin and / or its salt and at least one component unit derived from at least one water-soluble monomer. The novel lignin derivative of the present invention comprises at least one component unit derived from kraft lignin and / or its salt, at least one polyoxyalkylene chain, and at least one anionic functional group.

Owner:NIPPON SHOKUBAI CO LTD

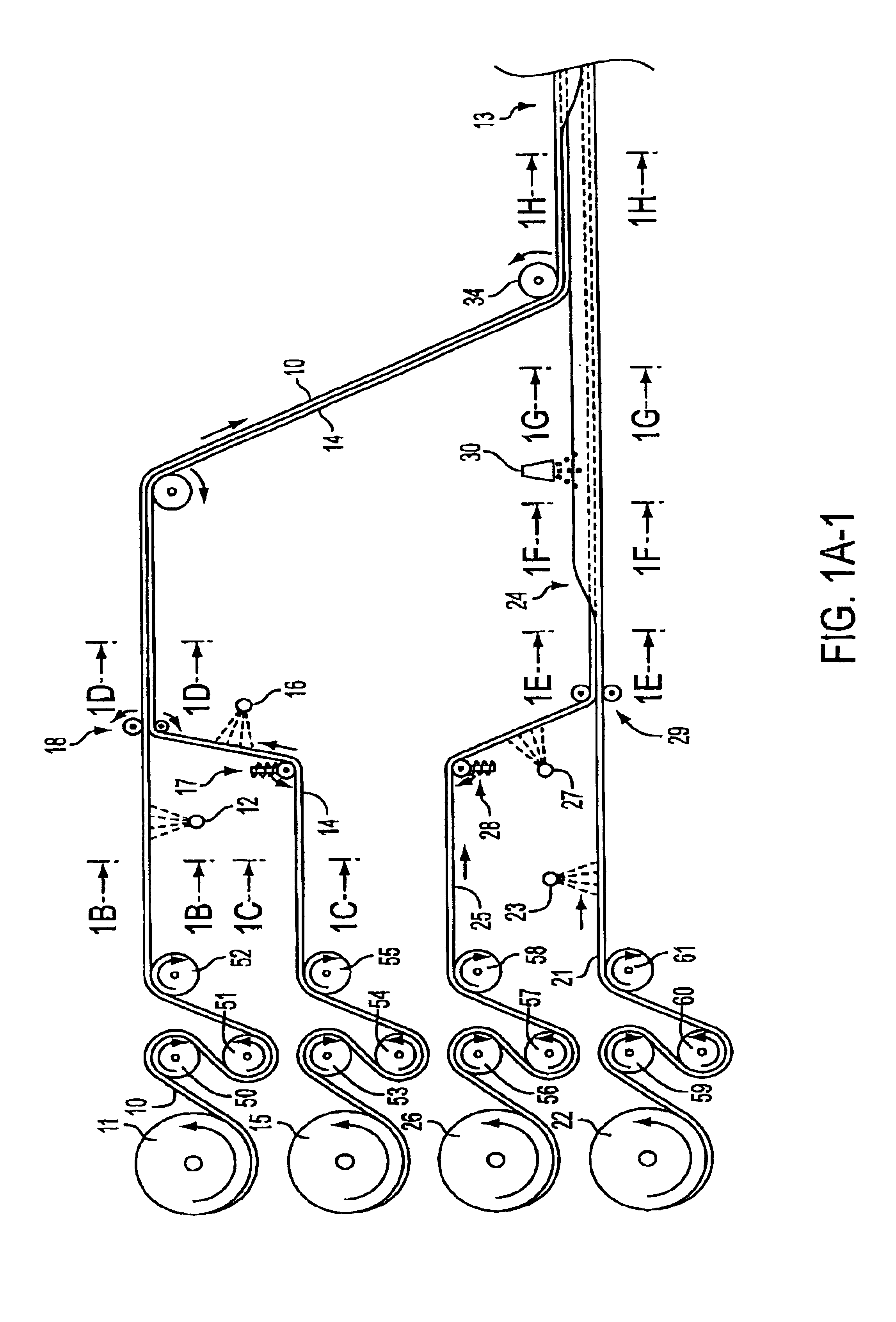

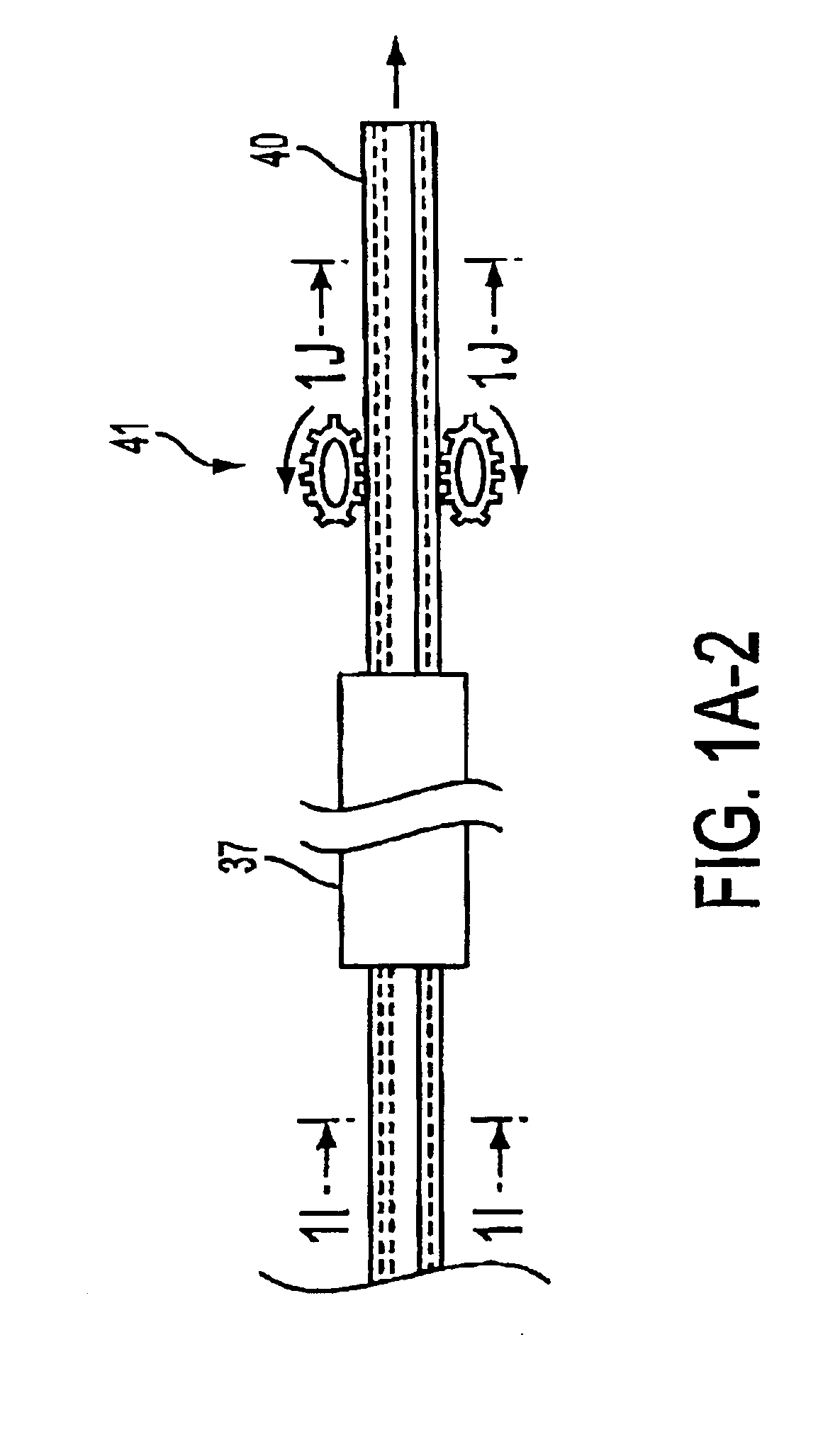

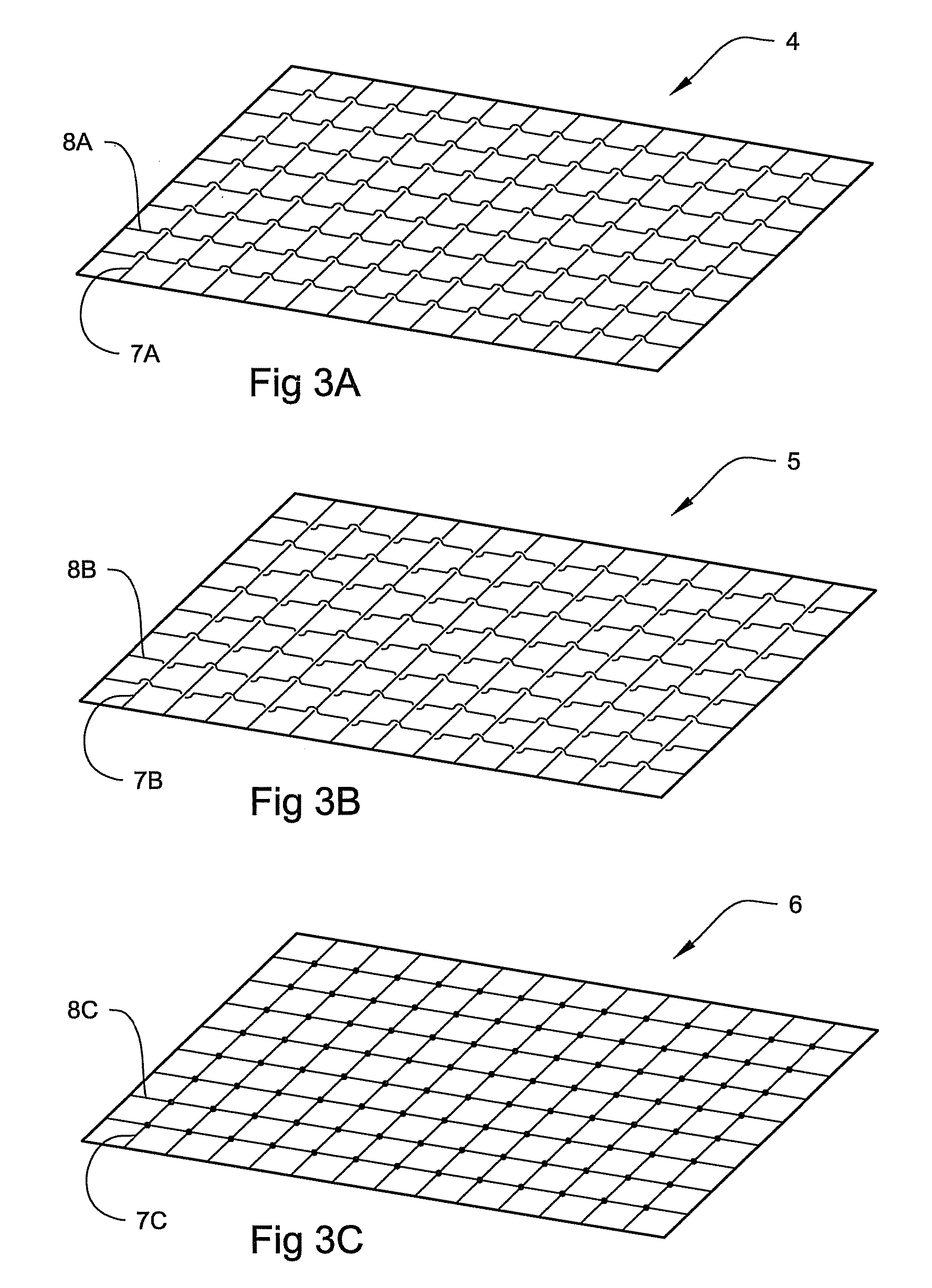

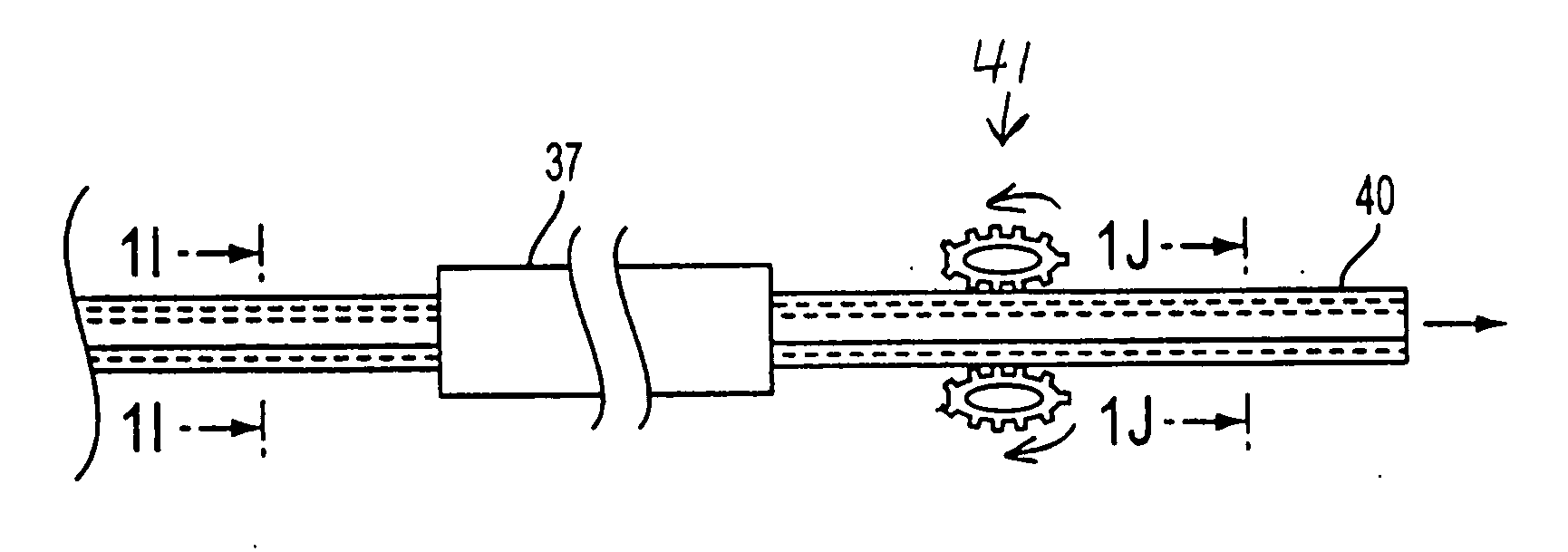

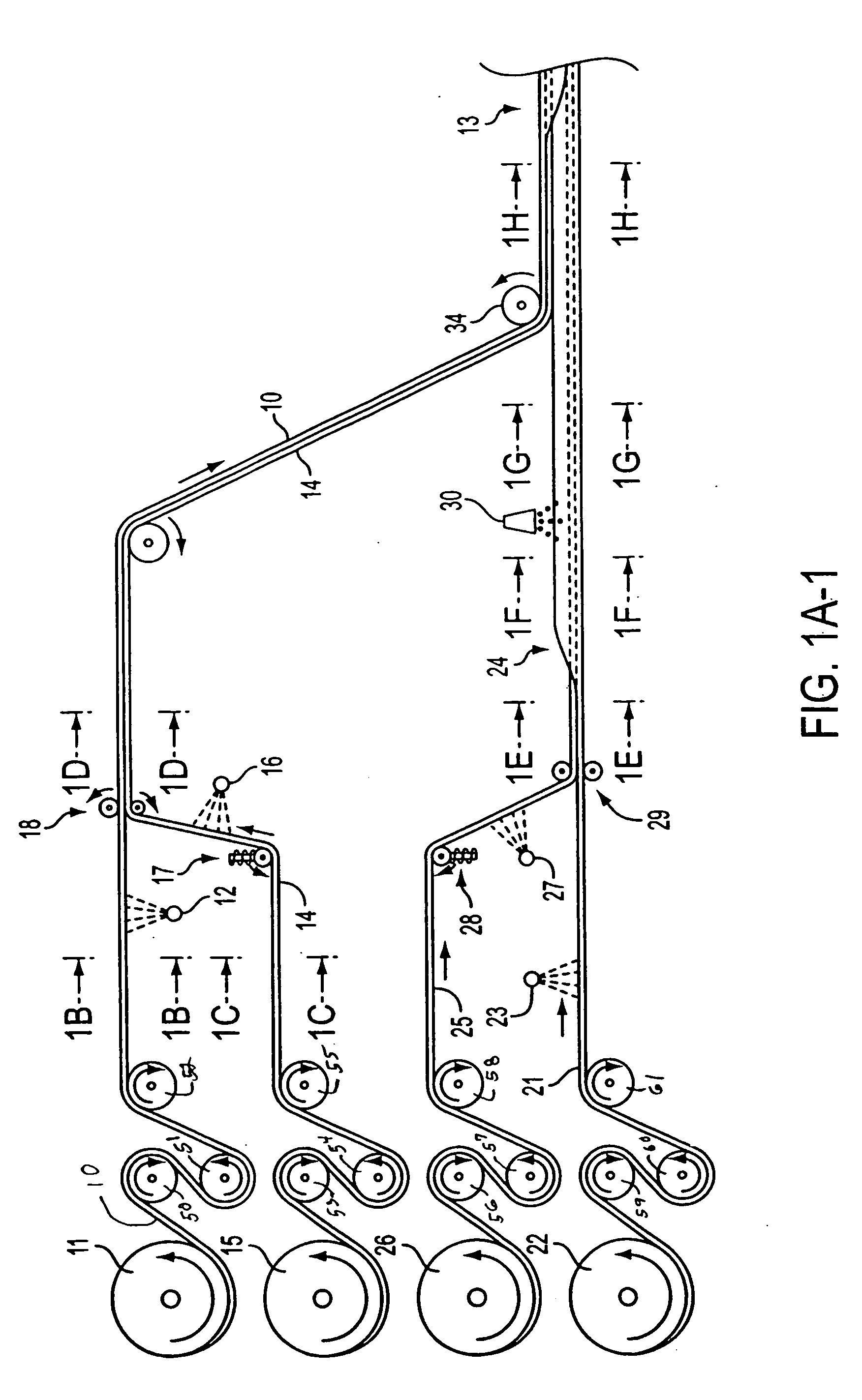

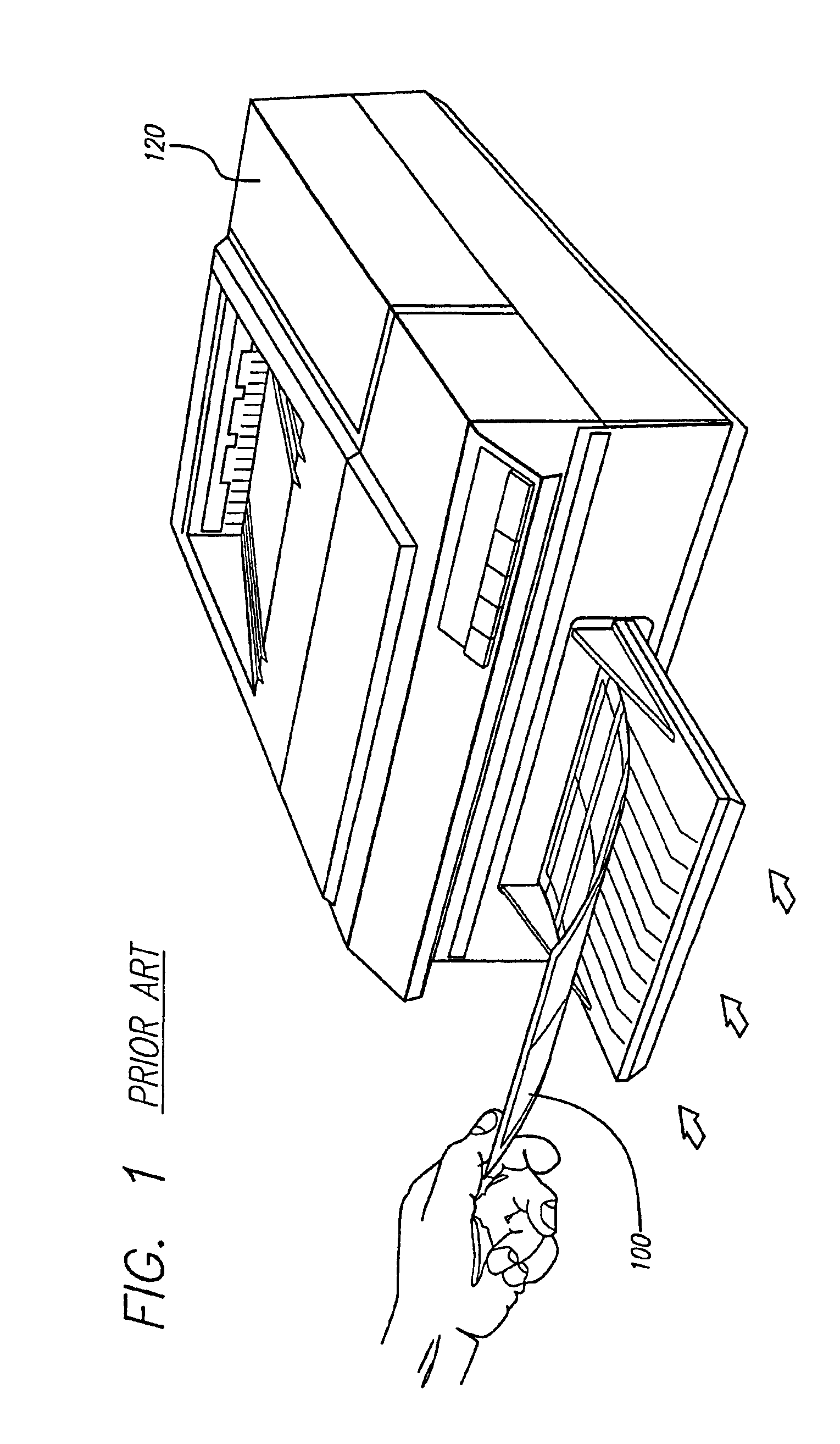

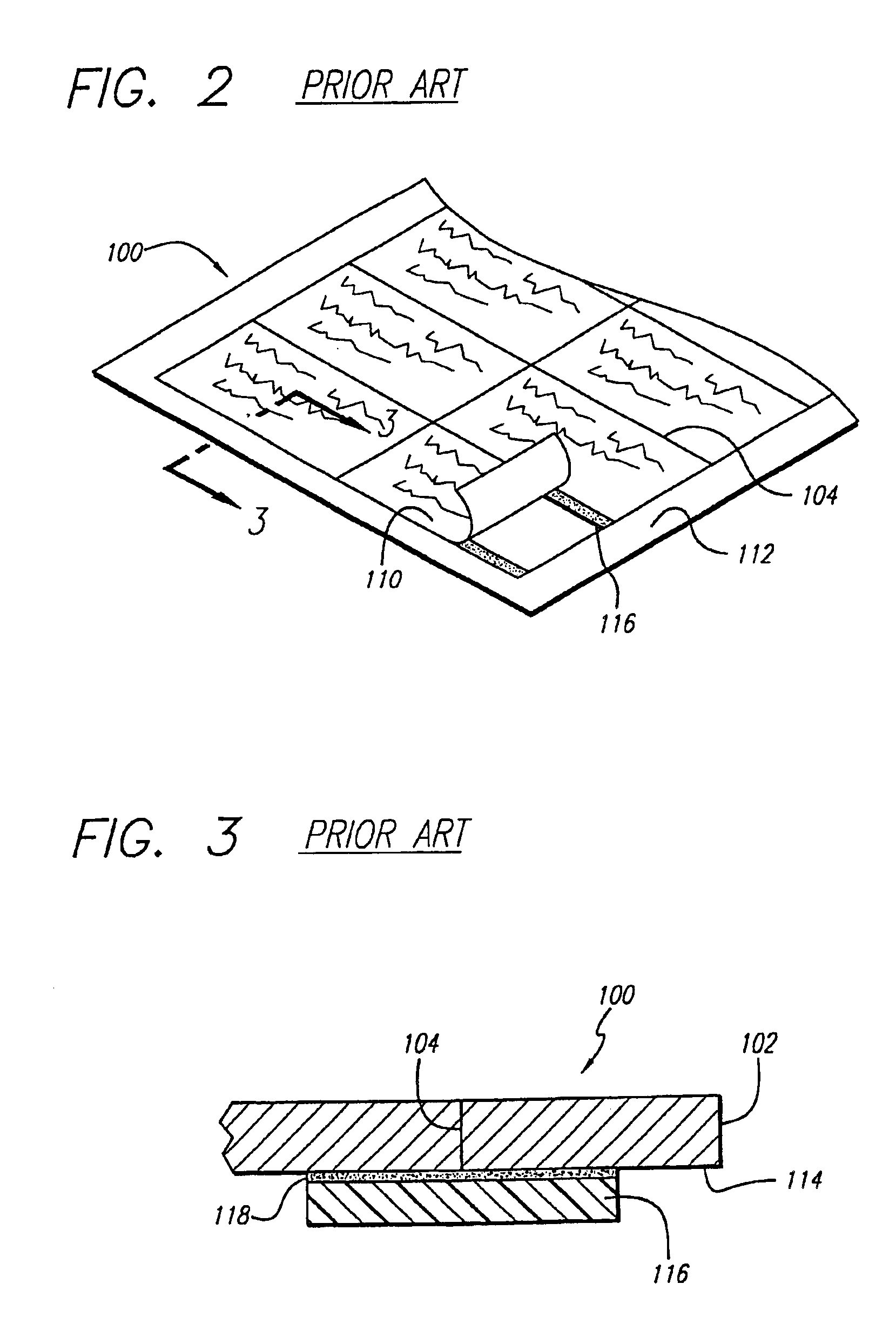

Method of forming sheets of printable media

InactiveUS6890397B1Reduce the amount requiredEffectively fed into printerOther printing matterLamination ancillary operationsLow-density polyethyleneEngineering

A low density polyethylene film layer is extrusion coated on densified bleached kraft paper liner to form a film-coated liner sheet. A facestock sheet is adhered with a layer of hot melt adhesive to the film layer to form a laminate sheet web, which is rolled on a roll. The facestock sheet, the film layer and the adhesive layer together define a laminate feedstock. The roll is transported to and loaded on a press with the liner side up. One (or both) edge(s) of the web is (are) crushed with a calendering die to form thin lead-in edge(s). The web is die cut on the bottom face, up through the laminate facestock, but not through the paper liner, to form the perimeters of a grid of blank business cards or other printable media, with a waste paper frame of the laminate facestock encircling the grid. The web is then die cut from the top through the paper liner and to but not through the laminate facestock, to form liner strips covering the back face of the laminate facestock. According to one preferred embodiment of the invention, alternate ones of the strips are then pulled off of the laminate facestock web. A final production step is to sheet the web to form the desired sheet width (or length) of the laminated sheet construction. The individual laminated business card sheets can be stacked into the infeed tray of an ink jet printer for example, and the sheets individually and automatically fed lead-in edge first into the printer and a printing operation performed on each of the printable media, to form a sheet of printed media. The remaining strips on the back of the laminate facestock cover the lateral cut lines in the laminate facestock and thereby hold the facestock together as it is fed into and passed through the printer. The user then individually peels the printed media off of the strips and out from the waste paper frame. Thereby printed business cards (or other printed media), each with its entire perimeter defined by clean die cuts, are formed. Instead of calendering both edges of the web and thus the sheet, one end can be calendered and a strip of the laminate facestock can be stripped off of the liner sheet from the other end. The remaining thin liner sheet strip at the other end forms a thin infeed edge for feeding into a horizontal feed, ink jet printer.

Owner:CCL LABEL INC

Procedure of attaching sheets and padded envelope

The envelope comprises layers of plain un-coated kraft paper and of bubble-wrap polyethylene. A stack of the layers is joined at the marginal edges of the envelope by squeezing the stack between a pair of points-dies, which are formed with points that puncture the kraft paper but do not puncture the polyethylene. The points push crowns of un-punctured polyethylene through the punctured boles in the paper. Then, the marginal edges are squeezed flat between flat-dies, the flat-dies being heated enough to cause fuse-bonding. The margins of the finished envelope are held together not only by fuse-bonding, but by the presence of the crowns, which, penetrating right through the holes in the paper, serve as mechanical rivets.

Owner:MARZANO DOMENICO

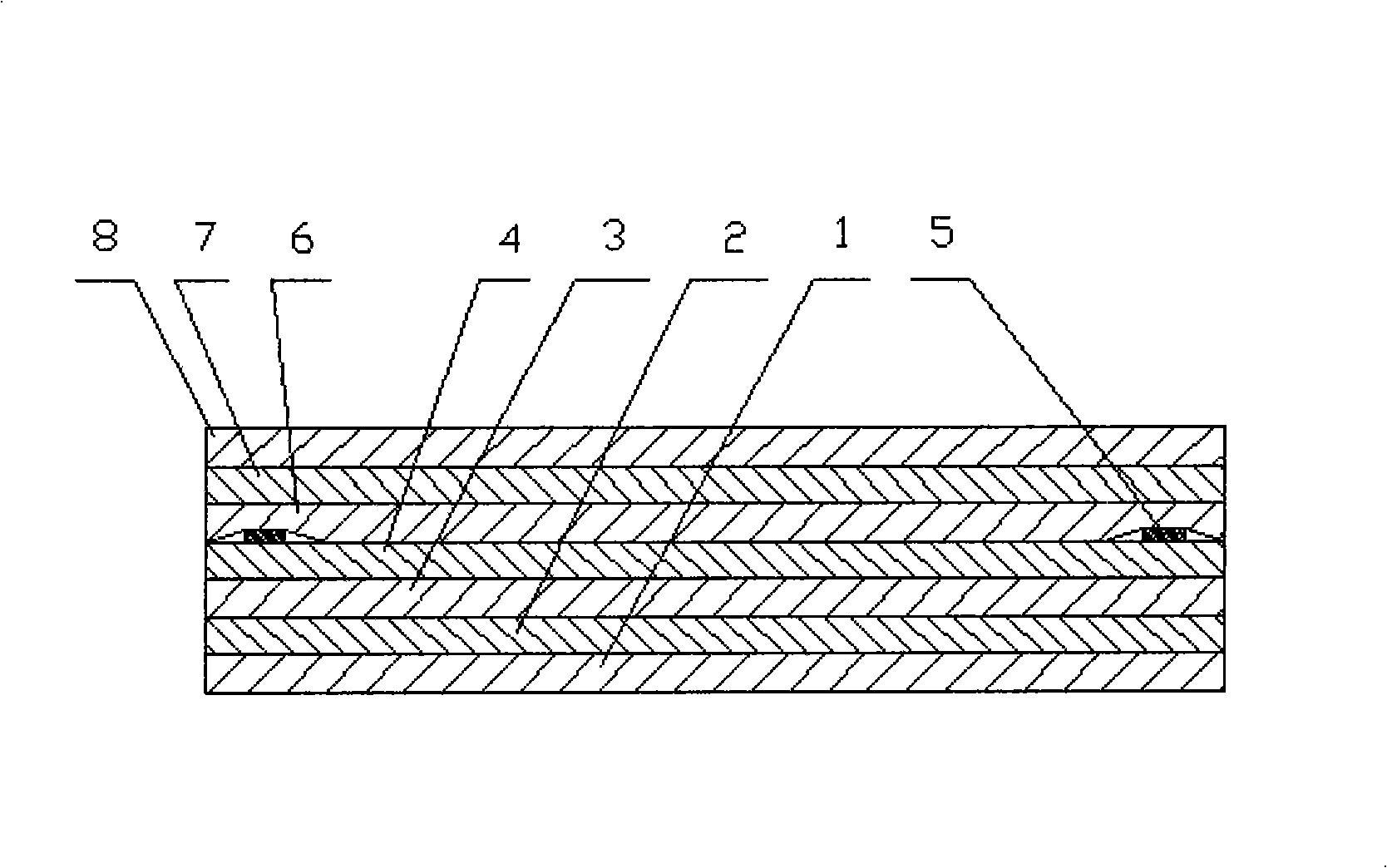

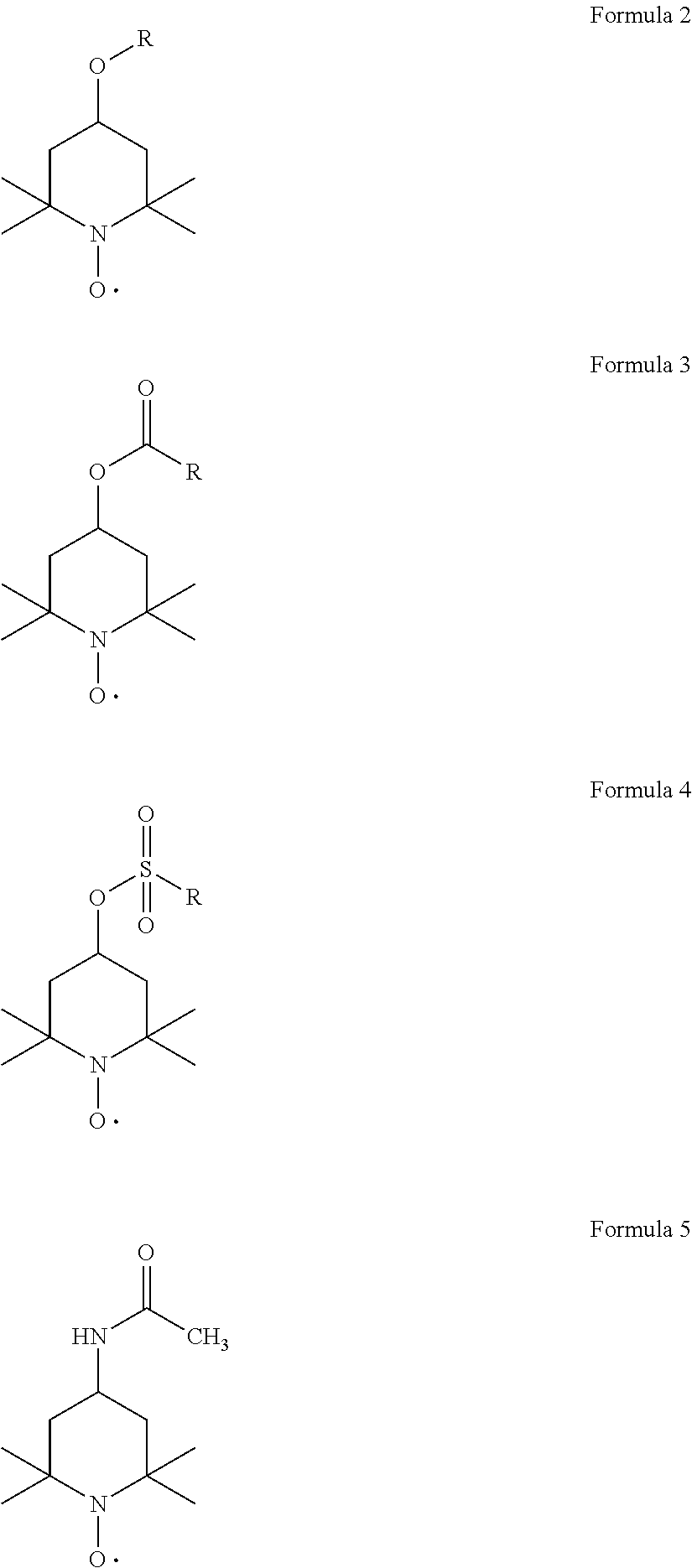

Carbon element crystal heating plate and preparation method thereof

InactiveCN101346016APrevent osmosisImprove stabilitySynthetic resin layered productsLaminationEpoxyPolyester

The invention discloses a carbon crystal calorific plate and the preparation method thereof, especially a carbon crystal calorific plate used for floor heating and preparation thereof. The calorific plate consists of a reflective metal coating, an epoxy resin proof fabric bottom, a kraft paper layer, a carbon crystal powder layer, a copper sheet electrode, an epoxy resin proof fabric layer, a decorative paper layer and a polyester film. The preparation method of the calorific plate comprises the preparation methods of the carbon crystal powder, the epoxy resin proof fabric and the carbon crystal calorific plate. The calorific plate in the invention has the advantages of strong far-infrared radiation, high electricity-heat radiation conversion efficiency, small surface temperature difference and strong acid / alkali / corrosion proof ability, and can be applied in the hidden project like floor heating safely.

Owner:朱思银 +2

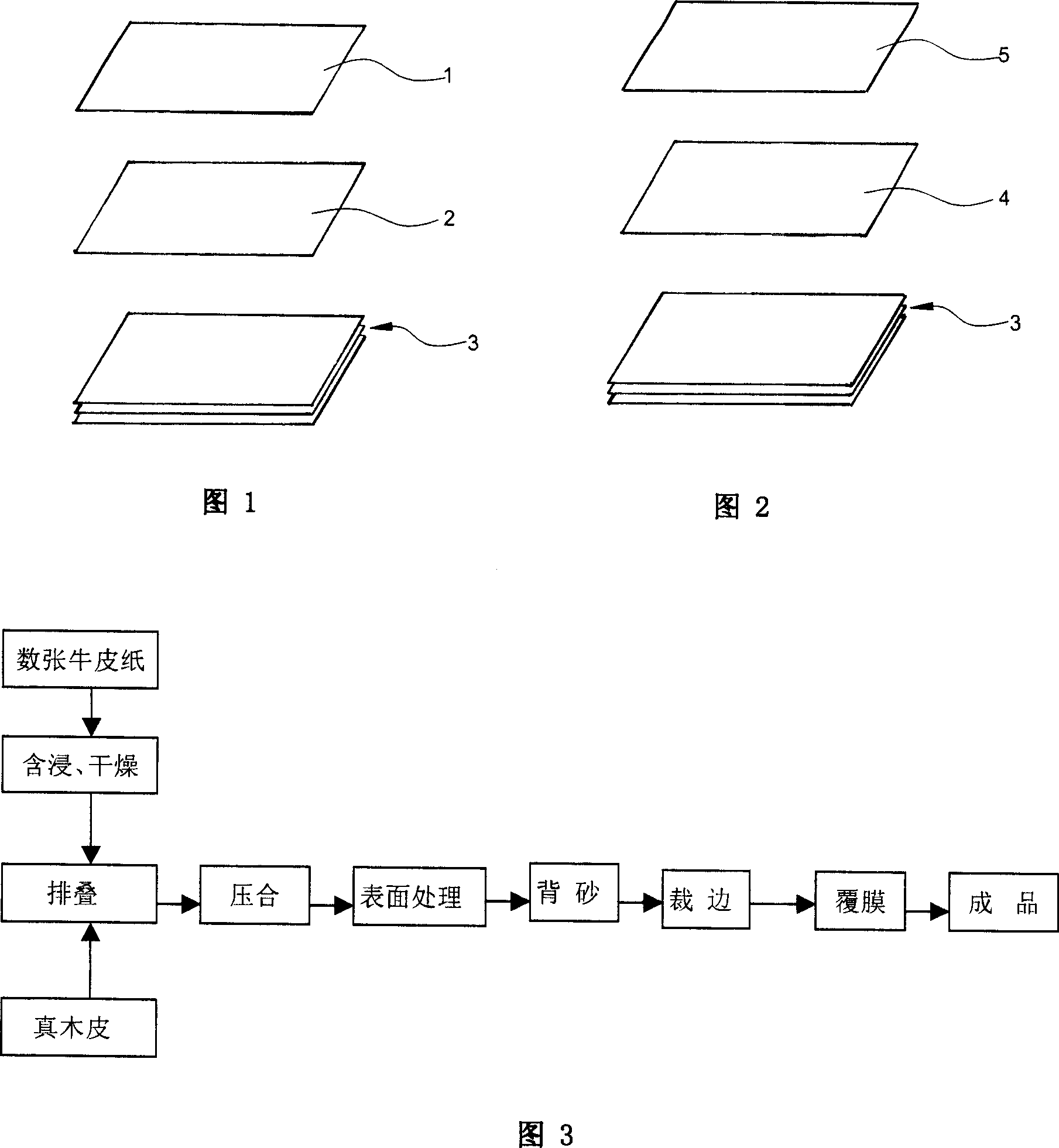

Method for manufacturing wood skin decorative high-pressure laminates sheets based on thermosetting resins

ActiveCN101104328AEasy GlossChange glossLamination ancillary operationsLaminationWear resistantPulp and paper industry

Disclosed is a making method of truewood hot setting resin soaked high-pressure laminated decorative fireproof board, comprising the following steps: immerses a plurality of kraft paper pieces in resin and then dry the kraft paper pieces so as to obtain soaked kraft paper pieces whose resin percentage in weight is more than or equal to 25 percent and less than or equal to 80 percent and whose fugitive constituent percentage in weight is more than or equal to 0.05 percent and less than or equal to 25 percent; pile up the dried kraft paper pieces and cover a truewood skin on the kraft paper pieces to form an initial blank; press the initial blank. In this way, a native truewood decorative fireproof board can be made. The invention is made with natural truewood skin and a plurality of kraft paper pieces immersed in resin under hot press treatment and is pressed into fireproof, heat-resistant, wear-resistant and scrape-resistant decorative materials with both the function of a wooden decorative board and the function of fire resistance of a fireproof board; with the advantages that the invention is of no need to paint, easy to maintain and is environment-friendly, the invention is suitable to be used in the fitment of an office, furniture and cooker.

Owner:庄启程 +1

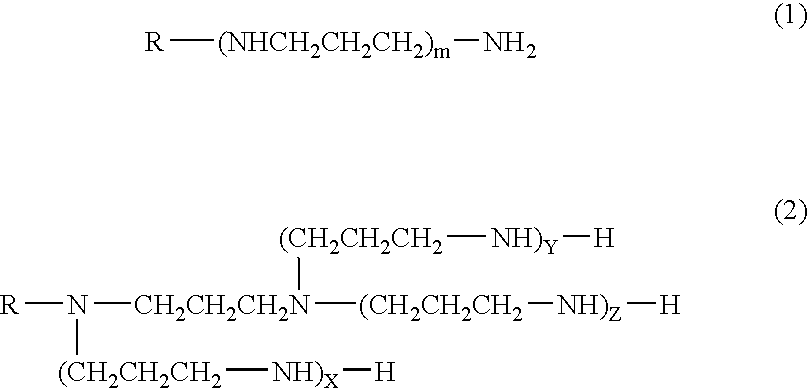

Asphalt emulsion composition

InactiveUS6840991B2Sufficiently secure the time required for mixing aggregatesIn situ pavingsAdhesivesSufficient timeEmulsion

Provided is, particularly, a cationic asphalt emulsion composition which is scarcely affected by temperature during paving and by the characteristics of the aggregates to be used, can secure a sufficient time required to mix aggregates and enables slurry fluidity suitable for paving. The asphalt emulsion composition contains asphalt and water, the composition comprising kraft lignin (A) having a molecular weight of 4000 to 60000 and a specific polyamine (B) in each specific ratio to the asphalt emulsion composition.

Owner:KAO CORP

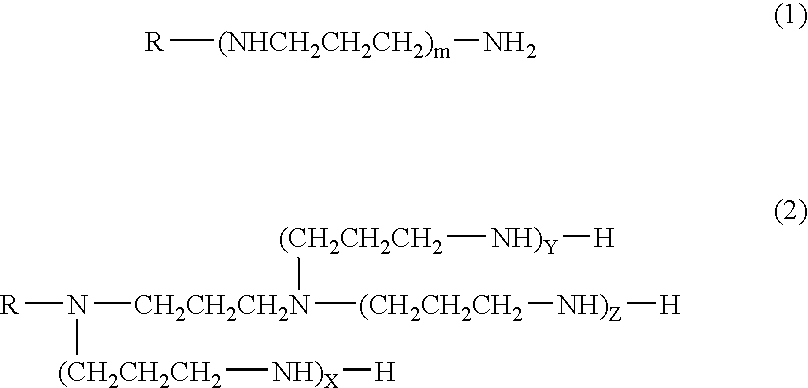

Method for producing cellulose nanofibers

ActiveUS20140238626A1Low viscosityImprove liquidityPretreatment with water/steamPulp properties modificationHigh concentrationWater use

Provided is a method which is capable of producing a cellulose nanofiber dispersion liquid that has a low viscosity and excellent fluidity even at a high concentration, while exhibiting excellent transparency. In a method for producing cellulose nanofibers, wherein a cellulosic starting material is oxidized in water using an oxidant in the presence of an N-oxyl compound and a compound that is selected from the group consisting of a bromide, an iodide and a mixture thereof and the thus obtained oxidized cellulose is defibrated and dispersed, pulp which is obtained by carrying out kraft cooking after a hydrolysis process is used as the cellulosic starting material.

Owner:NIPPON PAPER IND CO LTD

Method for removing metals from acid mine drainage

InactiveUS20040094484A1Increase settling velocityHigh densityWaste water treatment from quariesSolid waste disposalFerrous saltsSludge

A method for removing metal contaminants from acidic mine wastewater using lignin derivatives, such as lignosulfonates and kraft lignin, an alkali coagulant, such as a lime compound, and an alkaline composition for increasing the pH. The lignin derivatives are dispersed in the wastewater and the coagulant is added, increasing the pH to about 4.5-8.5 and causing the formation of a floc. The alkaline composition is then added to bring the pH to about 9 to 10, causing the further formation of a floc. Optionally, air oxidation is carried out, reducing the pH to about 8.1-8.6. Optionally, a ferric or ferrous salt may also be added. The flocs comprise metal-lignin colloids, metal hydroxides and metal salts. The flocs coagulate to form a sludge. Optionally, fly ash or diatomaceous earth may be added to increase the density and stability of the sludge. The sludge that is formed contains the metals and is separated from the treated water by filtration.

Owner:NORAM ENG & CONSTRS

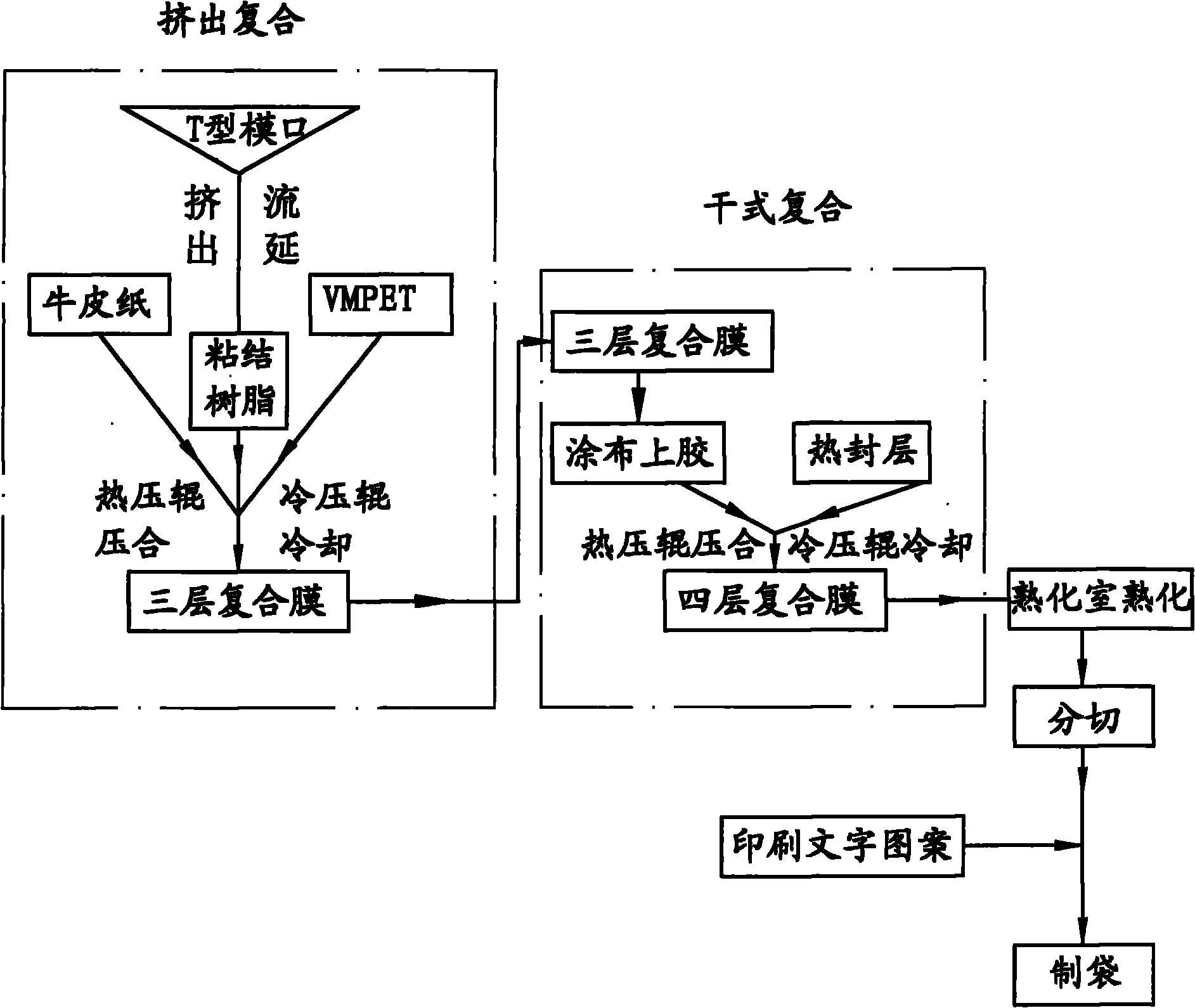

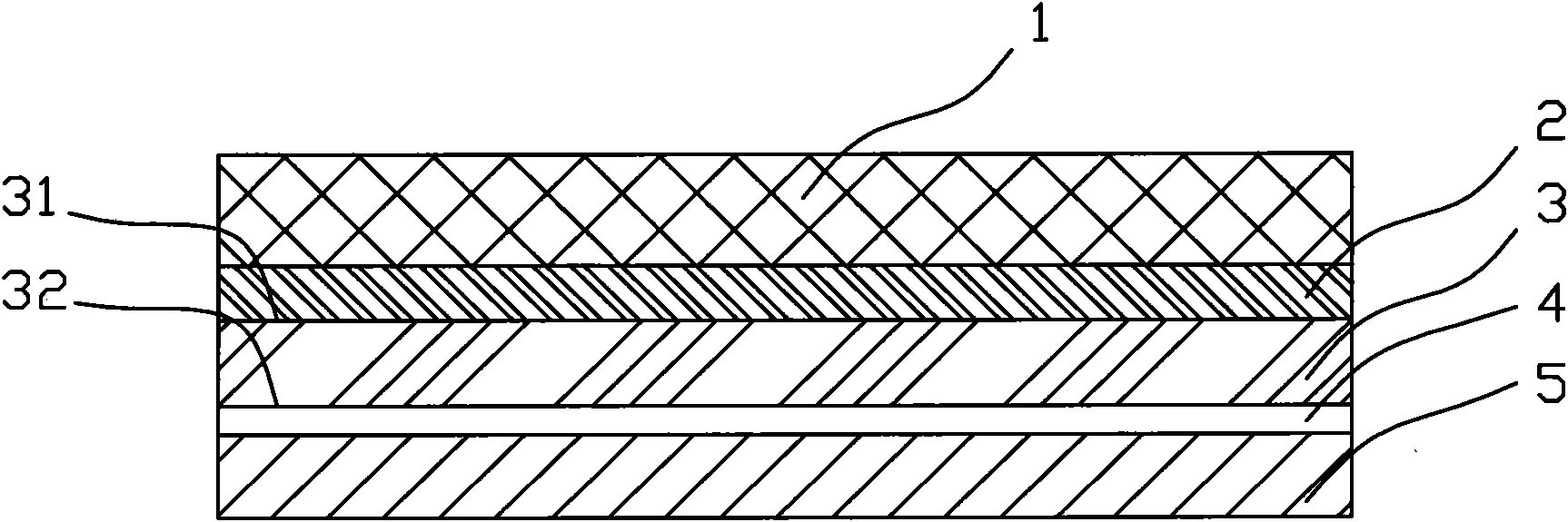

Paper-plastic composite film and production process thereof

ActiveCN101871187AImprove barrier propertiesGood crisp appearanceSpecial paperSynthetic resin layered productsComposite filmPolyethylene glycol

The invention discloses a paper-plastic composite film, which consists of kraft paper, a resin bonding layer, a vacuum aluminizing polyethylene glycol terephthalate film, an adhesive layer and a heat sealing layer which are connected in sequence from the top to the bottom. The invention also provides a production process of the paper-plastic composite film, which comprises the following steps of: 1) compounding films by extruding; 2) compounding films in a dry method; and 3) curing and slitting the composite film in a curing chamber. The production process of the paper-plastic composite film combines extrusion compounding with dry compounding, wherein the kraft paper and an aluminum coated layer of VMPET are subjected extrusion compounding to avoid the phenomenon of the transfer of the aluminum coated layer occurring in the conventional dry compounding and ensure the separating performance of the paper-plastic composite film; and higher compounding strength is provided by the dry compounding, so that the paper-plastic composite film has short production period, high compounding firmness and low solvent residue.

Owner:浙江粤海包装新材料有限公司

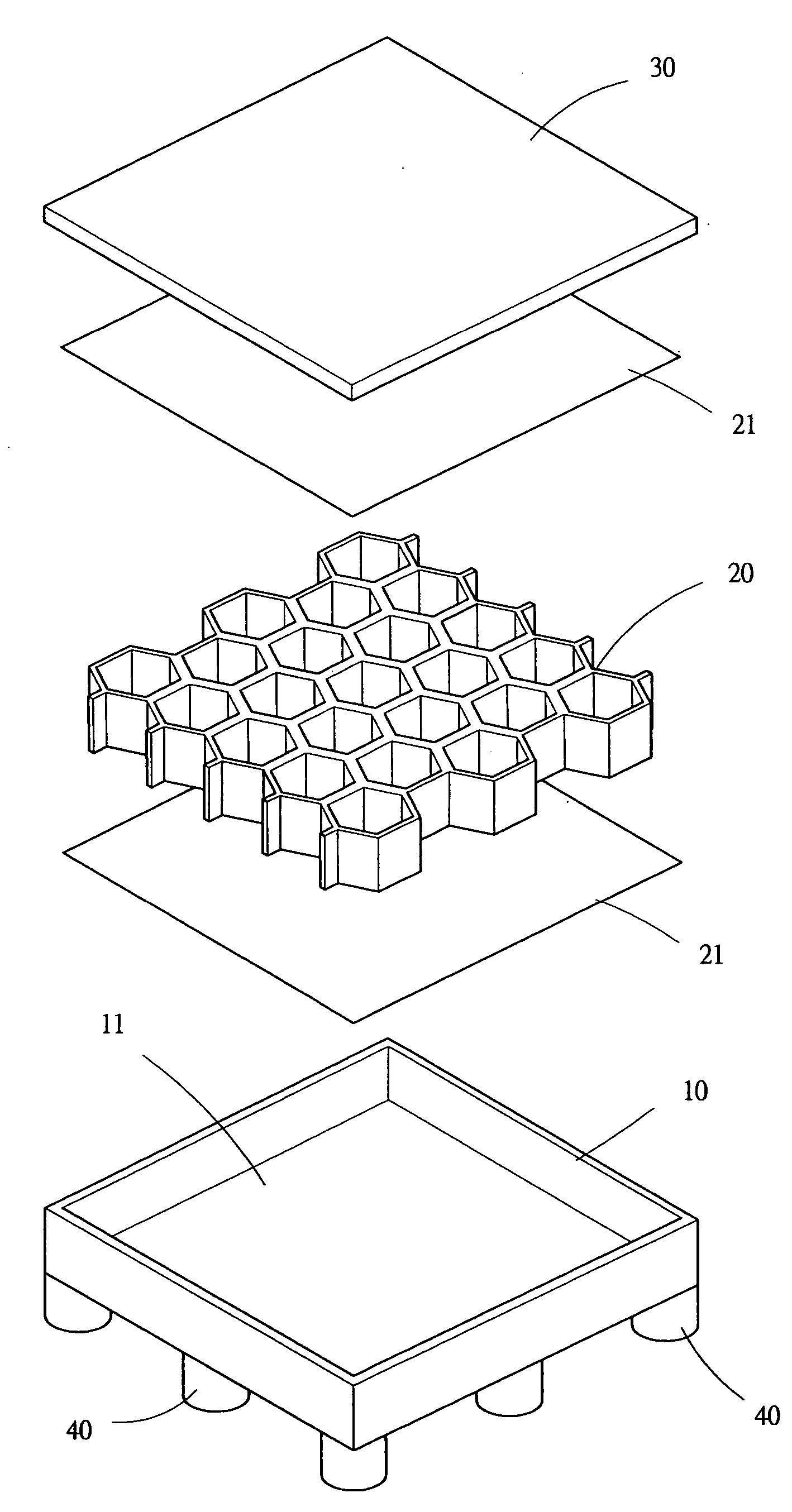

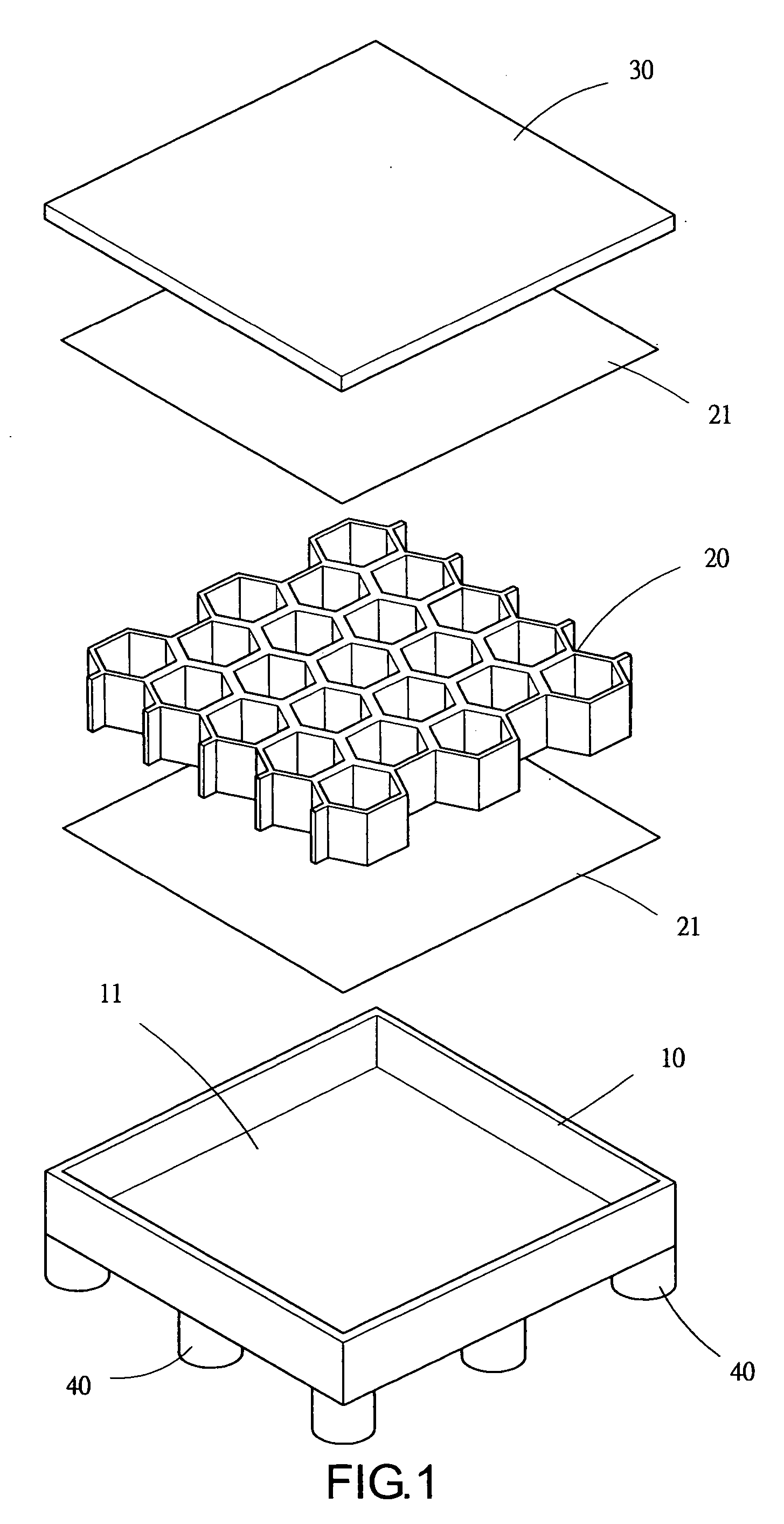

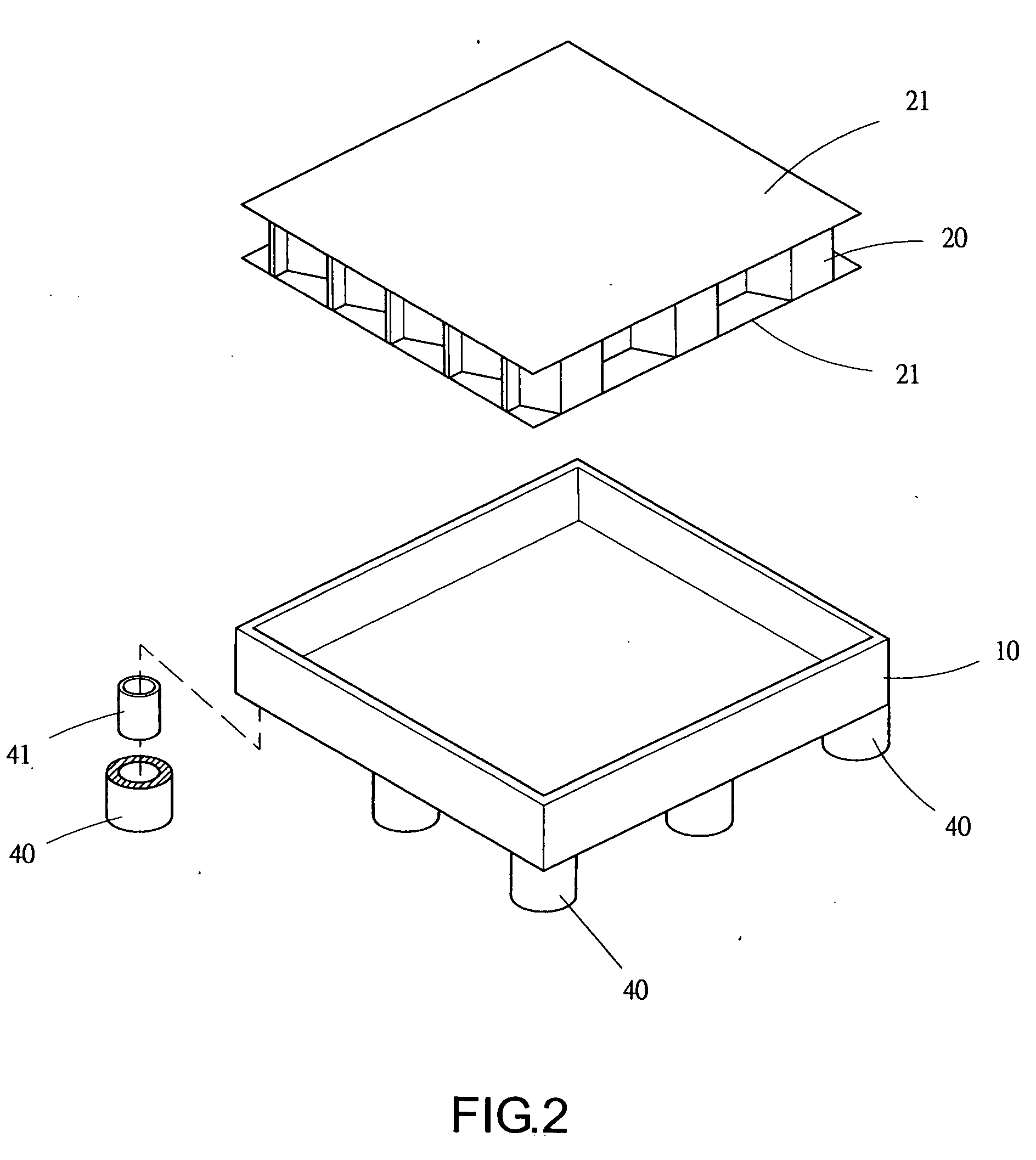

Pallet structure

InactiveUS20060130712A1Facilitate unloading operationHigh strengthRigid containersEngineeringHeavy duty

The present invention relates to a pallet including a base, a paper cellular structure, and a lid, wherein the base, being made of plastic, wood, plastic-wood, or plastic-stone, including a tray-like structure with paper-cylinder-inserted feet formed underneath, the paper cellular structure, having krafts adhere to the top and the bottom thereon to fix its shape and being fastened in the tray-like structure, and the lid being made of the same material as that in the base and being fixed on the base, thereby forming a light-weight, heavy-duty, and also environmental friendly pallet.

Owner:WANG SHIH CHIEH

Detergent compositions

InactiveUS20050176615A1Feel goodImprove stabilityInorganic/elemental detergent compounding agentsCosmetic preparationsPolyethylene glycolAcyl group

The present invention provides a paste or solid cleaning agent composition for cleaning human skin, hair and such that gives a mild and refreshing tactile sensation, and exhibits superior stability and a sufficient foaming performance. The first portion of the present invention characteristically comprises (a) 5-50 mass % of a specific acyl salt anionic surfactant, (b) one, two or more chosen from inorganic salts, organic acids, and organic salts, (c) polyethylene glycol, and (d) water wherein the total electrolyte molar concentration is 1.8 mol / kg or more. The second portion of the present invention characteristically is in a paste or solid form and has a system melting point of 40° C. or higher, comprising (a) an anionic surfactant having a Kraft point of 40° C. or lower, (b) one, two, or more chosen from inorganic salts and organic salts, (c) trihydric or higher polyol, and (d) water.

Owner:SHISEIDO CO LTD

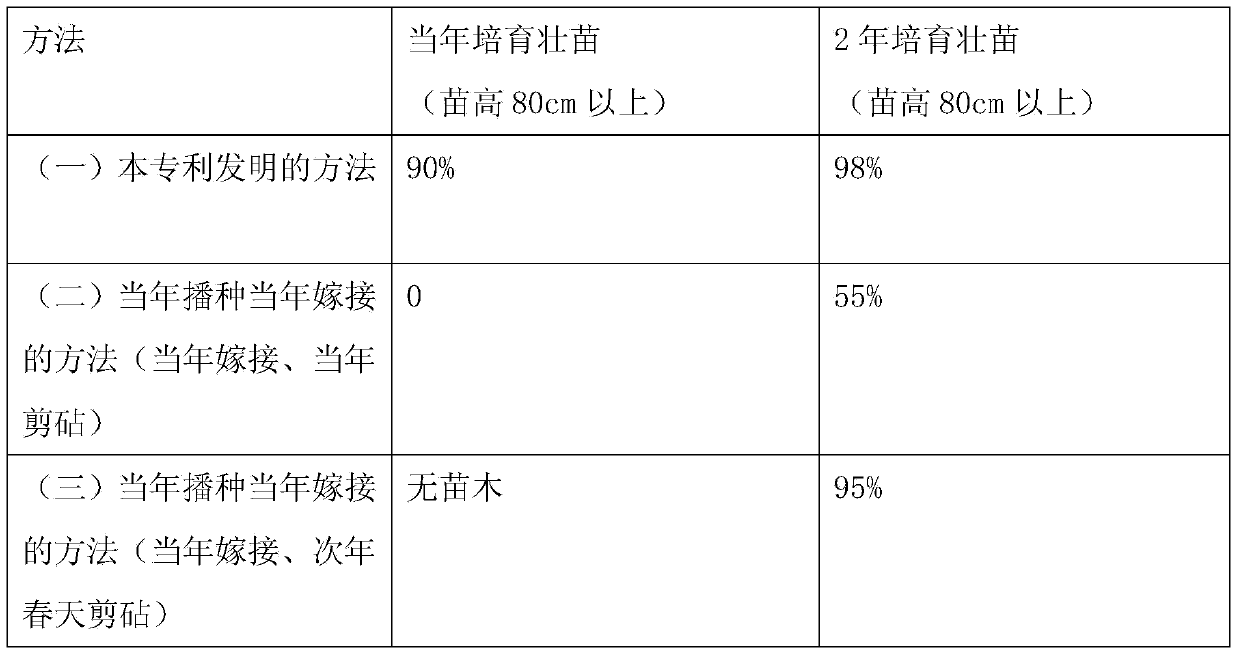

Method for propagating apocarya seedlings

ActiveCN103988697ALow costReduce incubation timeCultivating equipmentsHorticultureHigh densityPulp and paper industry

The invention discloses a method for propagating apocarya seedlings. The method comprises the steps of selecting an annual apocarya seedling branch, shearing the branch to be the length being 10 cm, and soaking the lower end of the sheared branch into an 800 mg / L NAA solution for 4 h; placing a matrix into a paper bag, inserting a cutting into the matrix, enabling the paper bag obtained by cuttage to tightly abut against a mesh disc with a hole, and placing the paper bag on a seedbed; in the cutting rooting process, keeping the soil humidity to be about 70%, and keeping the temperature of the lower end of the cutting to range from 25 DEG C to 30 DEG C; conducting grafting 40 days after cuttage, adopting the bark peg grafting method, transferring the kraft paper bag, obtained after grafting, with the cutting into a large pot, filling the periphery of the pot with the matrix, pulling out 4 / 5 of the kraft paper bag, observing the grafting survival rate 15 days after grafting, completely removing the paper bag, and then conducting high-density nutrient and water management. According to the method, the apocarya nursery stock can grow more than 80 cm in the current year, and the survival rate is more than 90%.

Owner:南京绿宙薄壳山核桃科技有限公司 +1

Composite quartz board and manufacturing process thereof

InactiveCN105415764AElasticFully bondedSynthetic resin layered productsLaminationFiberComposite plate

The invention relates to the technical field of a stone decoration material, and particularly relates to a composite quartz board and a manufacturing process thereof. The manufacturing process comprises the following steps: weighing a mortar raw material for molding a quartz layer, and stirring for standby application; laying a layer of kraft paper or PVC film on the bottom surface of a mold, uniformly pouring the stirred mortar raw material into the mold, laying a piece of fibrous web on the surface of the flattened mortar raw material, then laying a layer of kraft paper or PVC film on the fibrous web, and vacuumizing, vibrating and compacting to obtain an uncured quartz mortar layer; and removing the kraft paper or PVC film on the fibrous web, attaching a ceramic tile coated with modified glue onto the surface of the fibrous web, then compacting, curing at a high temperature, cooling, molding, and grinding for determining the size to obtain the composite quartz board. The quartz layer is unlikely to separate from the ceramic tile, the adhesive strength is high, the production process is simple, no air bubble is produced during the compositing process, and the prepared composite quartz board is high in strength and long in service life.

Owner:东莞友联建筑材料有限公司

Multiwall paper bag

A multiwall paper bag for bulk material, especially particulate or powdered material, has an inner ply of a high performance kraft paper, an intermediate layer or ply of a thin polyethylene secured to the outer surface of the inner ply, and an outer ply of high performance kraft paper that is secured to the intermediate ply. At least one end of the bag is closed during initial formation of the bag. The other end can be left open for filling and subsequent closing, or it can be initially closed and provided with a filling valve. At least the intermediate ply, and preferably the inner ply as well, is microperforated for venting of air during filling. The intermediate ply is secured to the inner ply either by a plurality of longitudinally extending transversely space apart lines of adhesive or the securing adhesive is spread completely over the mating surfaces of the two plies.

Owner:HOOD PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com