Patents

Literature

173 results about "Green liquor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Green liquor is the dissolved smelt of sodium carbonate, sodium sulfide and other compounds from the recovery boiler in the kraft process. The liquor's eponymous green colour arises from the presence of colloidal iron sulfide.

Method for control of mercury

InactiveUS20050169824A1Inherent safety advantageEfficient removalUsing liquid separation agentEmission preventionCoalWet scrubber

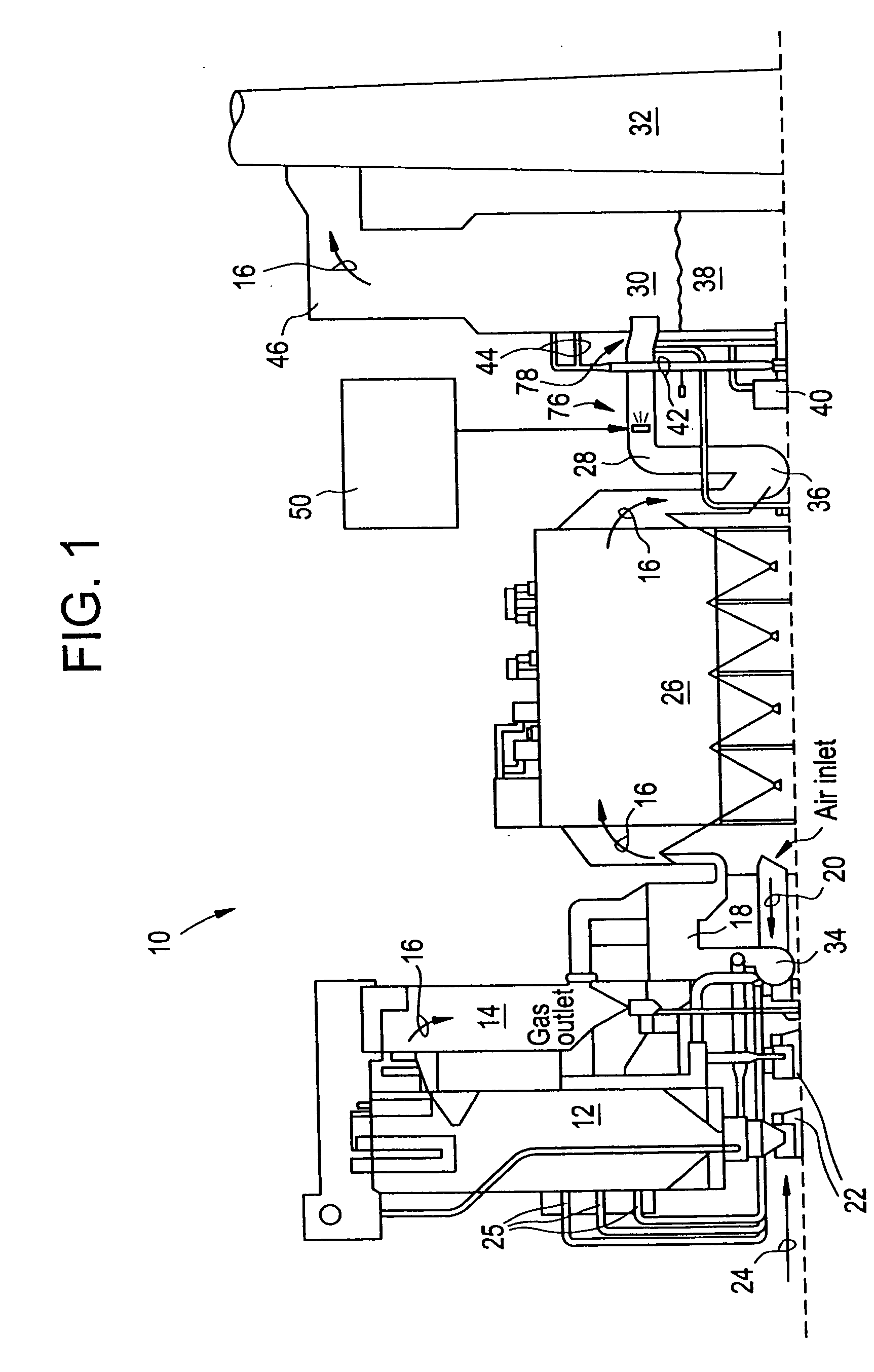

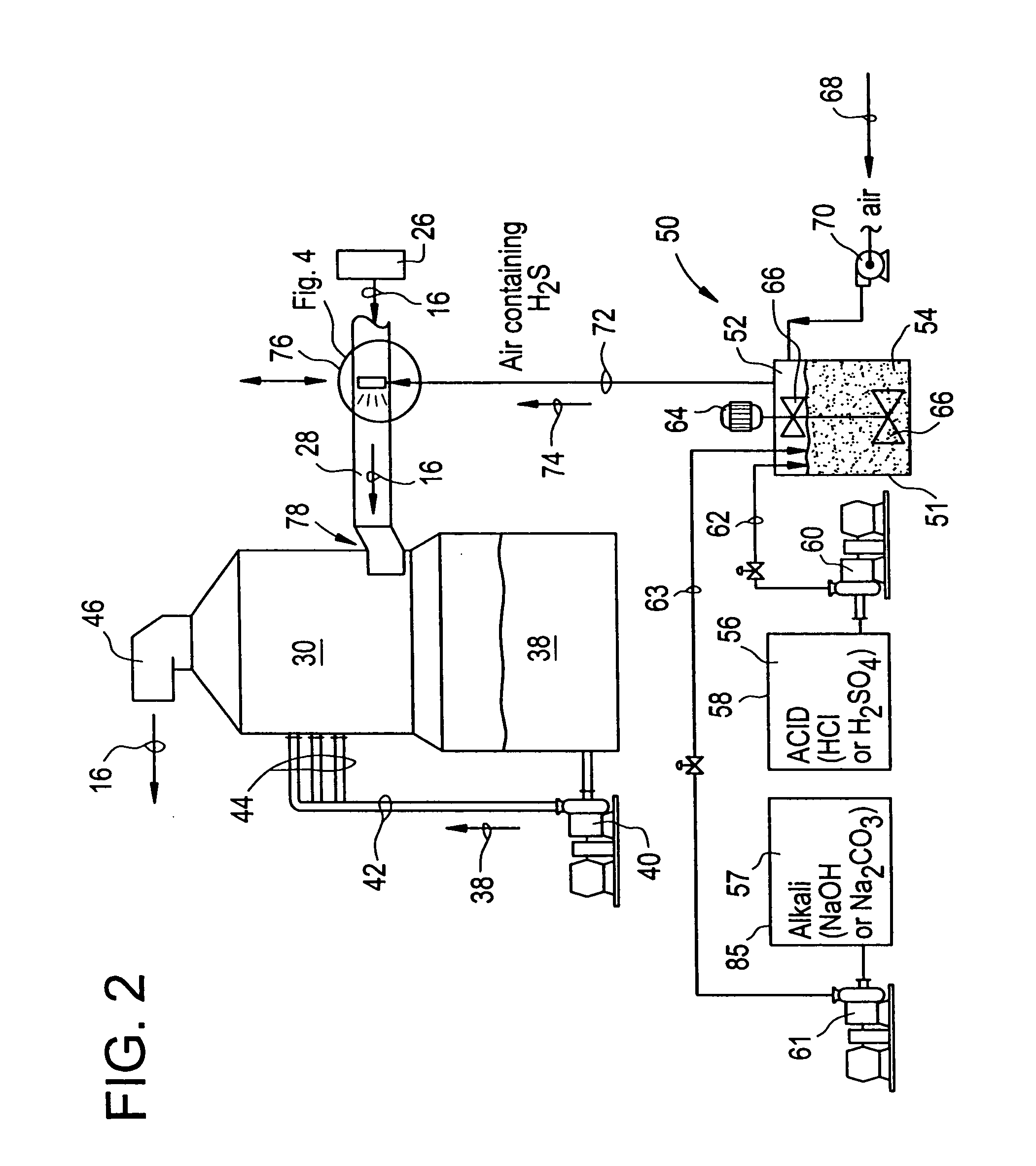

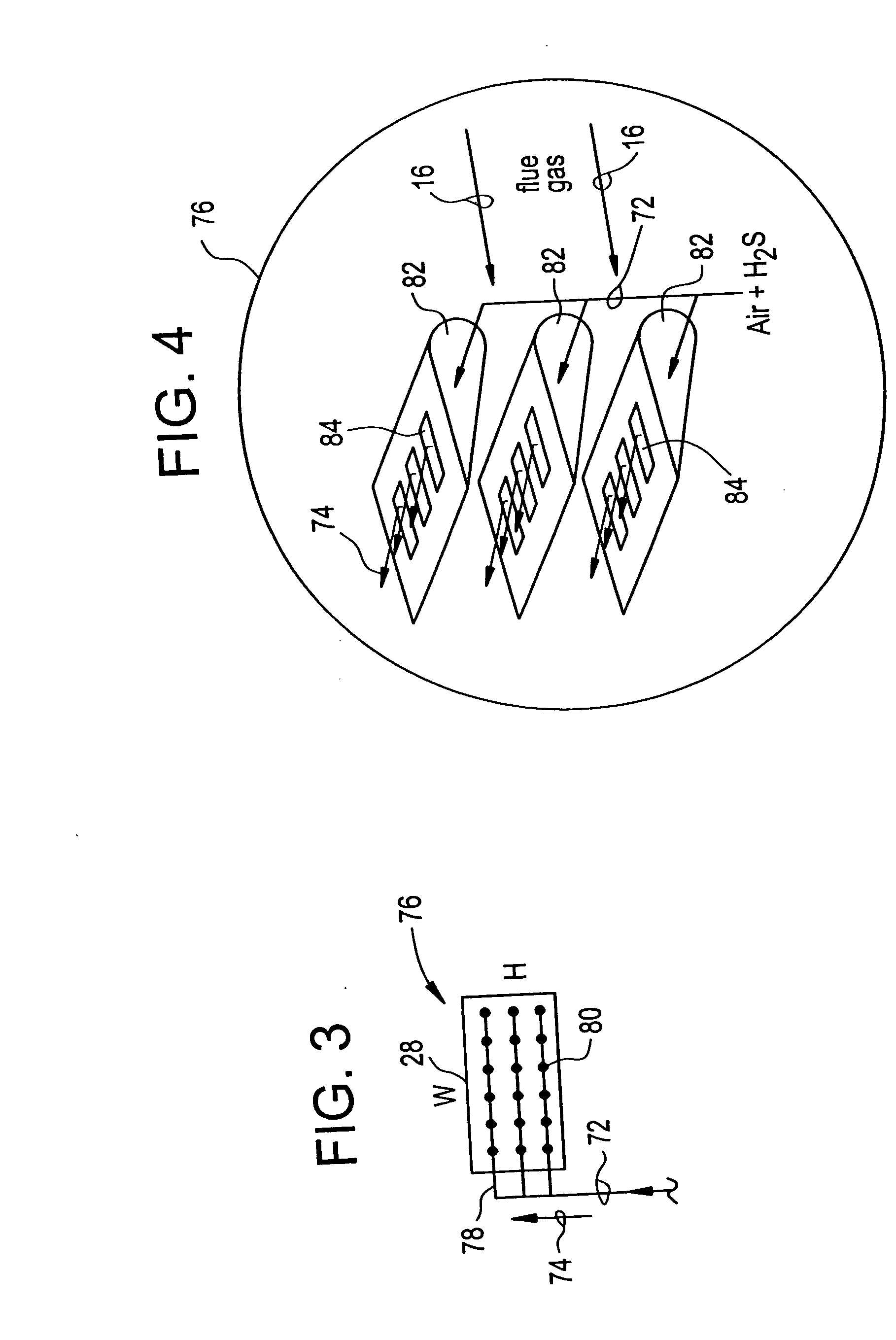

A method and apparatus for reducing mercury in industrial gases such as the flue gas produced by the combustion of fossil fuels such as coal adds hydrogen sulfide to the flue gas in or just before a scrubber of the industrial process which contains the wet scrubber. The method and apparatus of the present invention is applicable to installations employing either wet or dry scrubber flue gas desulfurization systems. The present invention uses kraft green liquor as a source for hydrogen sulfide and / or the injection of mineral acids into the green liquor to release vaporous hydrogen sulfide in order to form mercury sulfide solids.

Owner:DOWNS WILLIAM +1

Method for recovering superfine calcium carbonate by clean causticization of green liquor

ActiveCN1641100ALow viscosityIncrease the sedimentation rateRegeneration of alkali lyeAlkalinityCalcium hydroxide

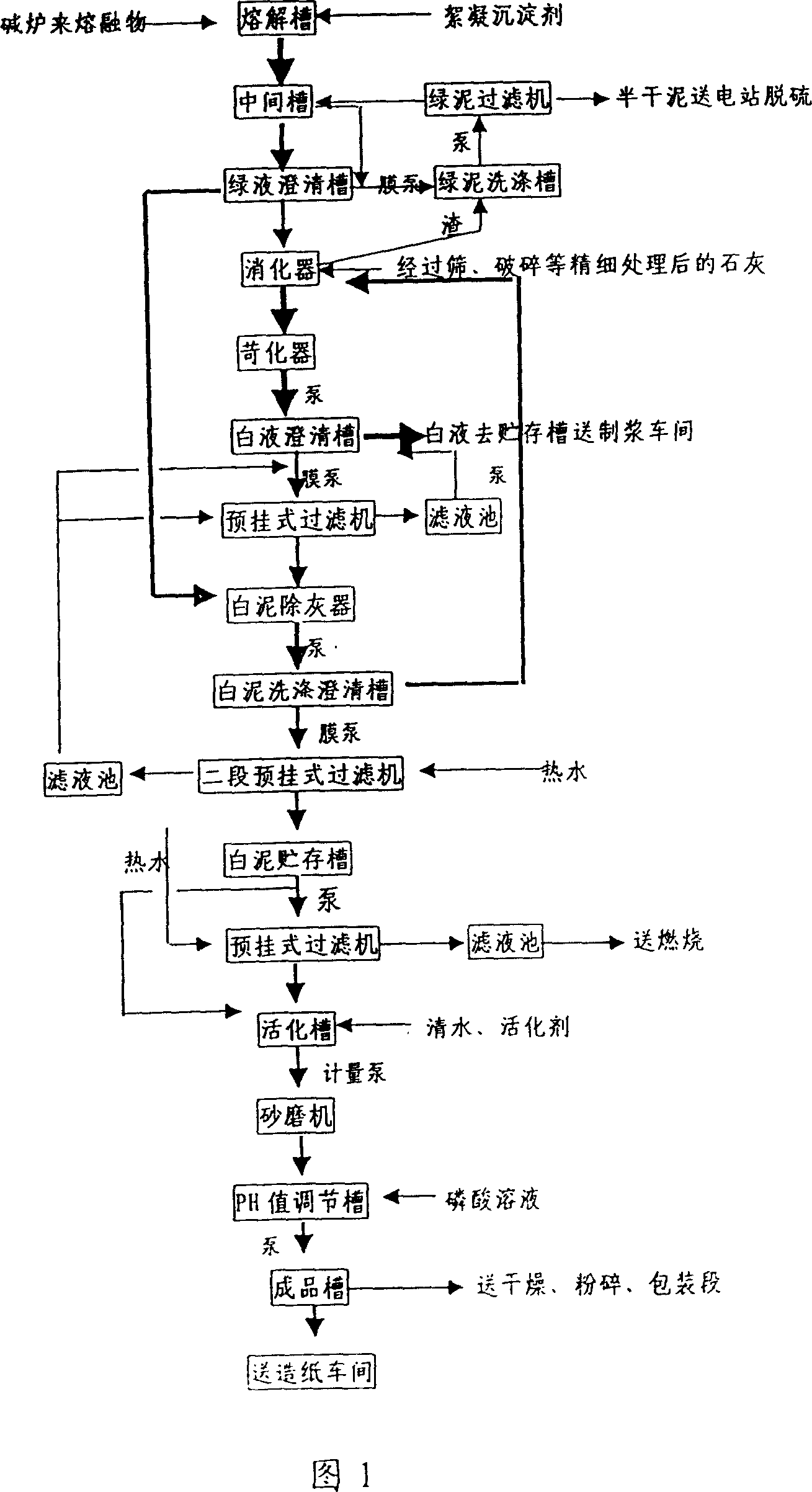

The invention relates to the method to recover super thin calcium carbonate, mainly including the following step: a, join the high macromolecule flocculating agent in green liquid, mix blend even then do away with to descend the sediments, stay the upper level clearness liquid to provide as refined green liquid; b, make the calcium oxide join in the water into the calcium hydroxide syrup, separate the syrup with impurity using the griddle net; c, mix the refined green liquid and the calcium hydroxide syrup, carry on the reaction, add crystal regulator; D: After the syrup responded, carry on the solid- liquid separate, rinse the sieve cake by hot water, take back the sieved liquid; E: prepare sieve cake and waters into suspended liquid syrup, put into the carbon dioxide, get the very thin calcium carbonate syrup.

Owner:SHANGHAI DONGSHENG NEW MATERIALS +1

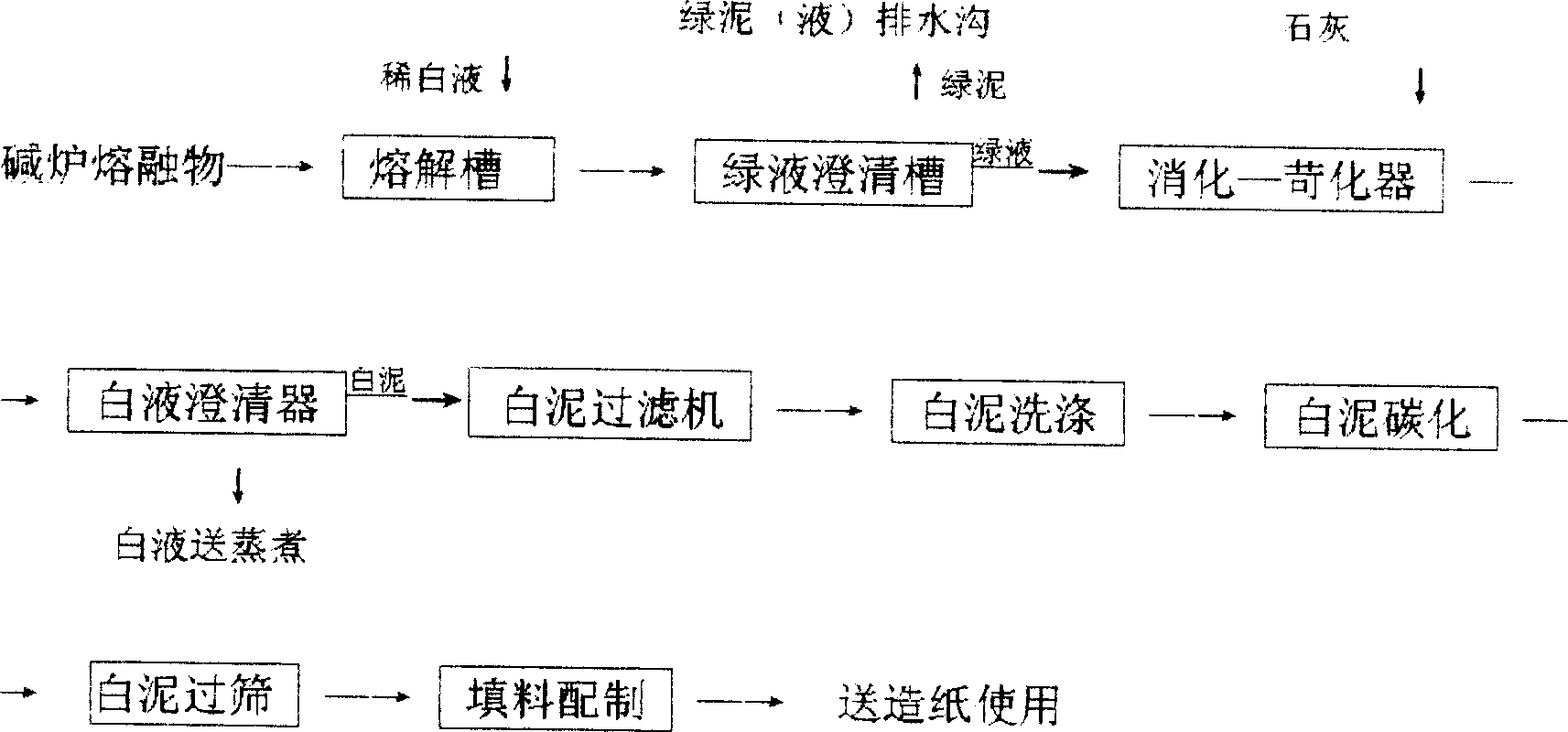

Process of comprehensively utilizing caustic sludge from papermaking industry

ActiveCN101020182AAvoid secondary pollutionEconomic and technical indicators are rising steadilySolid waste disposalSludgePulp and paper industry

The present invention is process of comprehensively utilizing caustic sludge from papermaking industry. The improved process has increased green liquid purifying treatment procedure, lime material pre-treating procedure, green mud treating procedure, white mud deashing and dealkalizing procedure, and fine white mud treating procedure. The process has no secondary pollution and low running cost, and can produce green mud for desulfurizing in coal burning boiler, superfine white mud calcium carbonate powder product and active calcium carbonate product.

Owner:王梅林

Process for preparing calcium carbonate

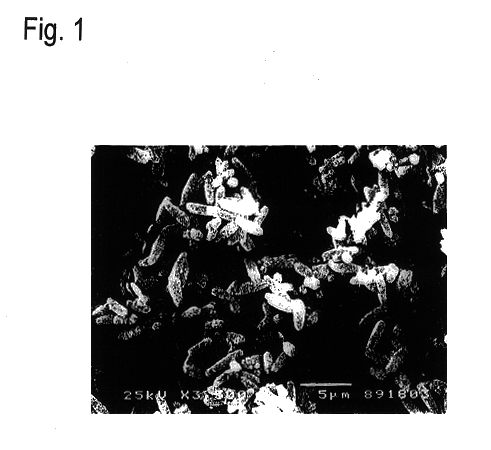

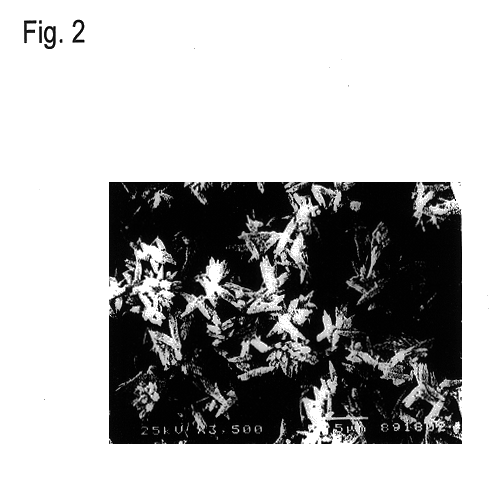

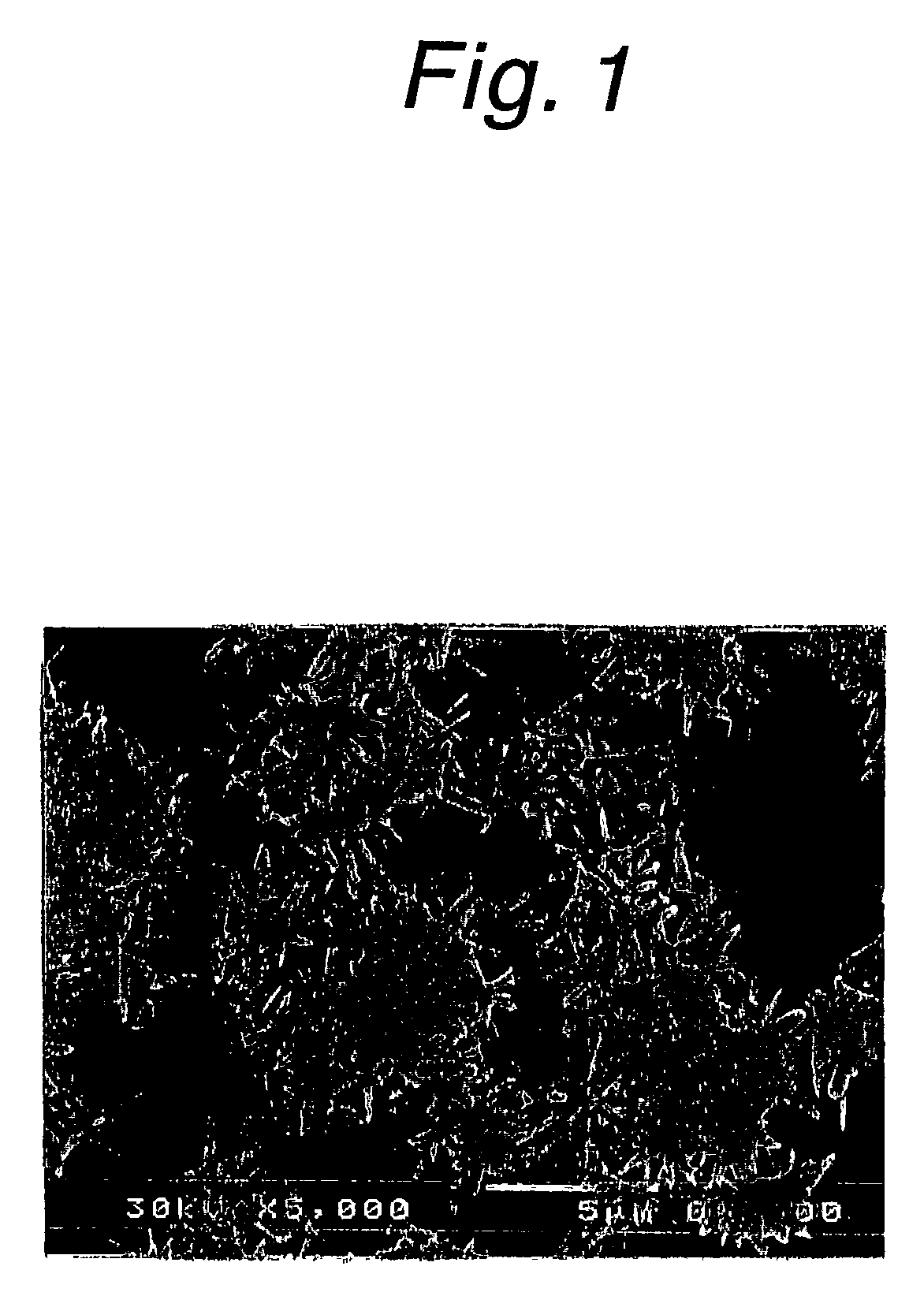

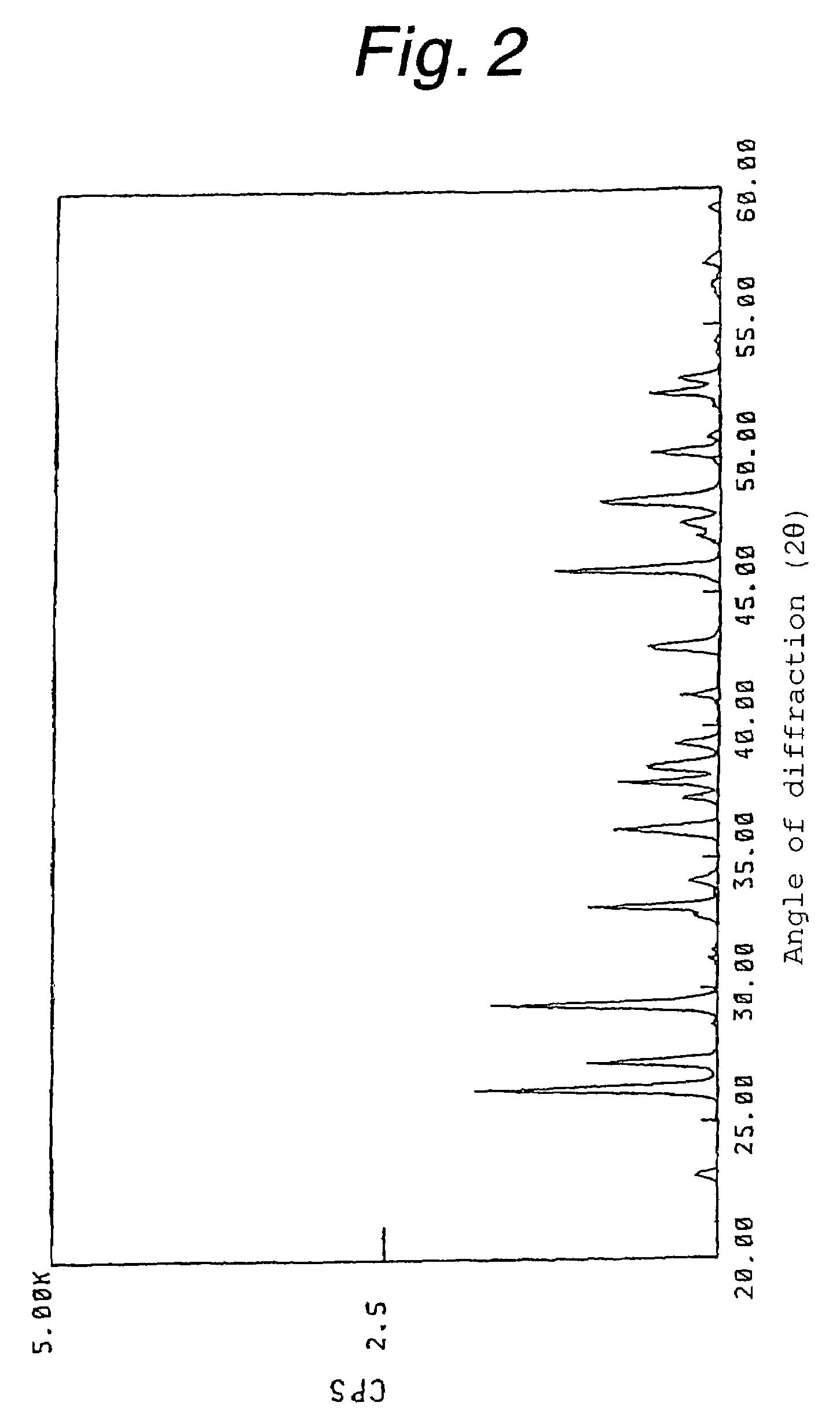

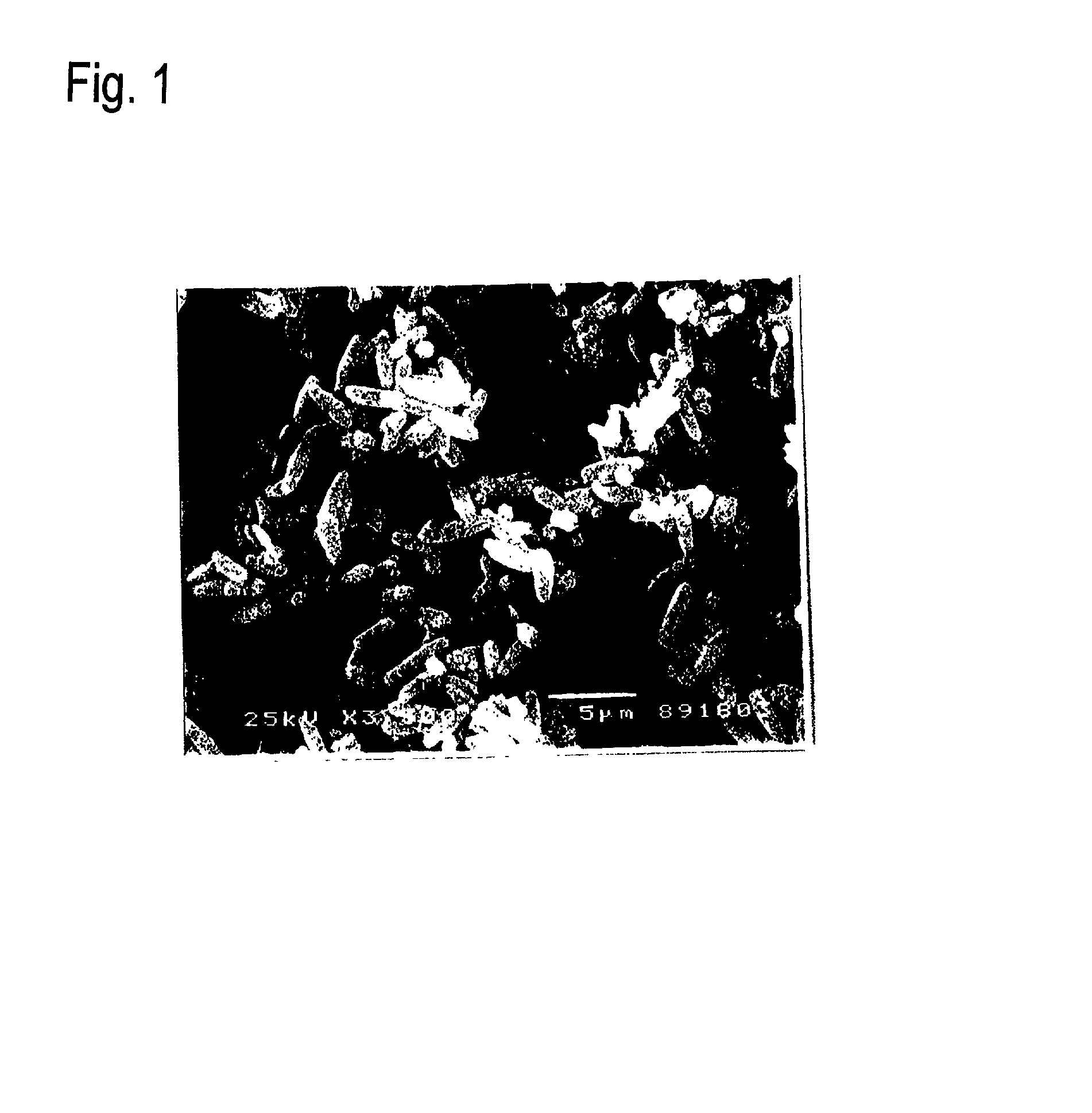

InactiveUS6190633B1Excellent abrasion resistanceLess sharp edgeCalcium/strontium/barium carbonatesPulp liquor regenerationReaction temperatureGreen liquor

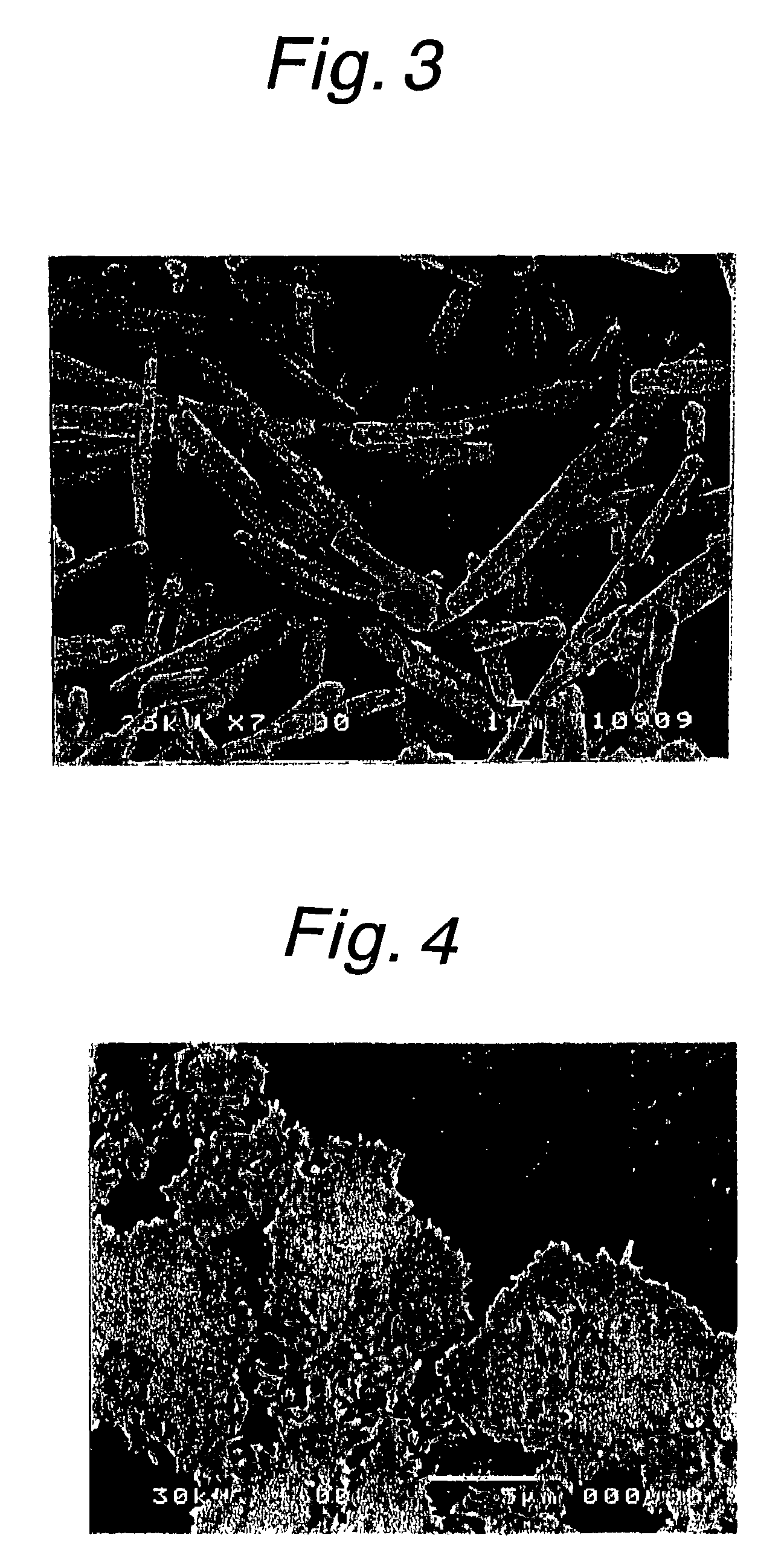

Inexpensive spindle- or needle-like calcium carbonate giving useful properties for bulk, brightness, opacity, wire abrasion resistance and yield as a paper filler is provided by taking advantage of the causticization step. In a first step, a quick lime having a calcium carbonate content of 10% by weight or less is slaked with a liquor having a pH of 5.5 to 13.5 at a concentration of 20 to 60% to prepare a milk of lime. In a second step, causticization reaction takes place at a green liquor loading rate of 0.02 to 0.5 cc (green liquor) / min / g (quick lime) at a reaction temperature of 20 to 105° C. to afford spindle- or needle-like calcium carbonate.

Owner:NIPPON PAPER IND CO LTD

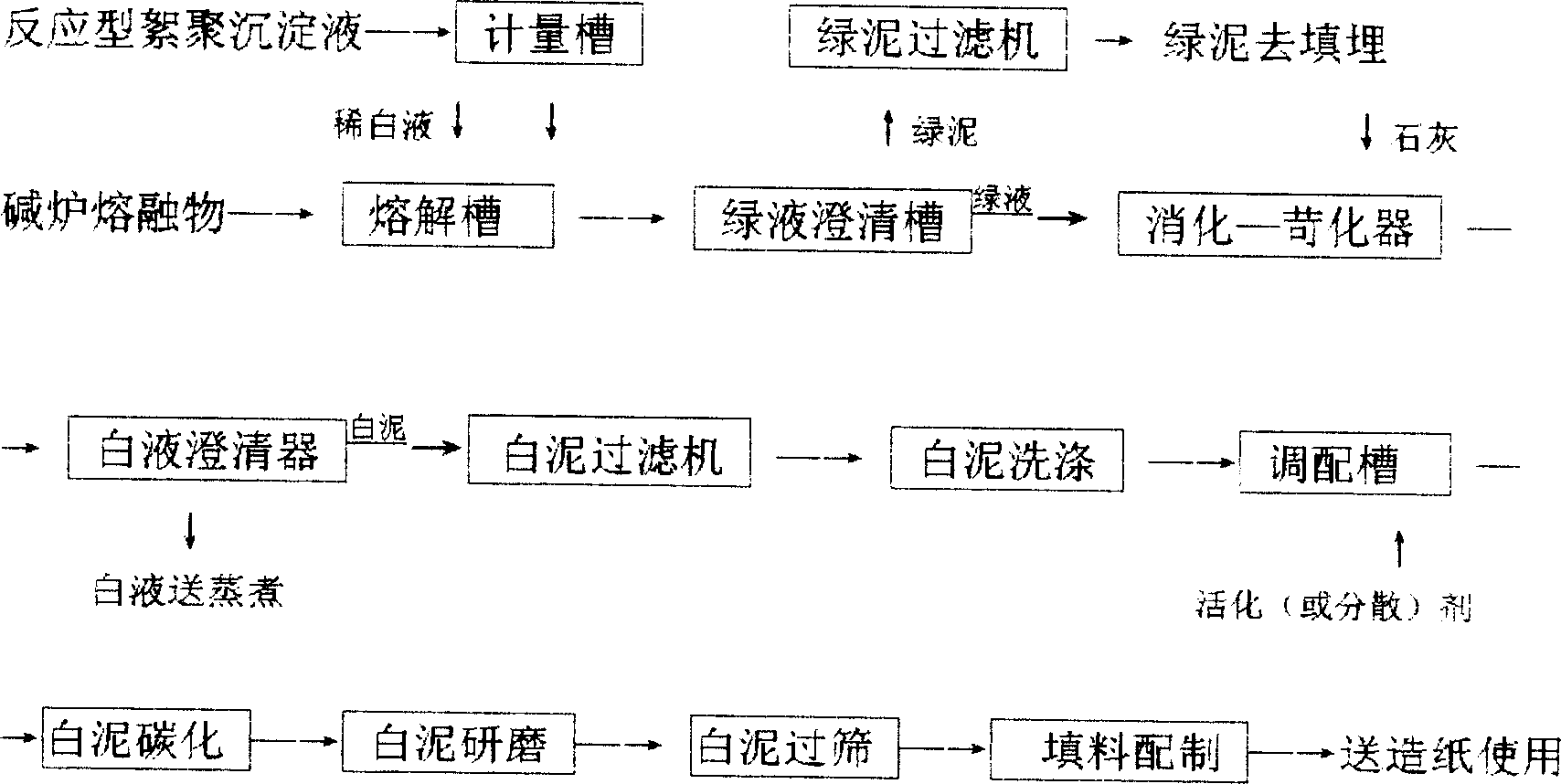

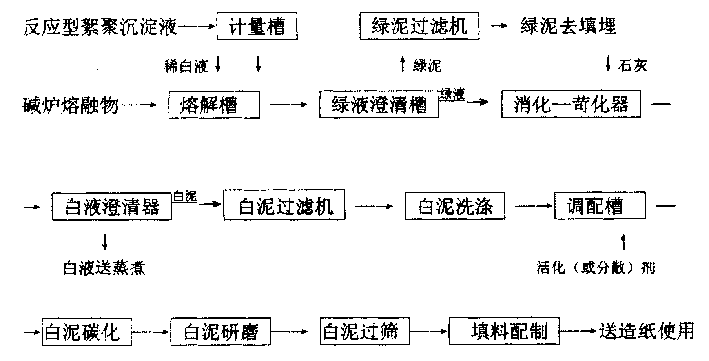

Technological process of recovering white clay to produce stuffing calcium carbonate

InactiveCN1441117AHigh whitenessImprove purity and whitenessCarbonate/bicarbonate preparationRegeneration of alkali lyeWhite liquorCompound (substance)

The technological process of recovering white clay, as one side product of recovering pulping chemical in paper making, to produce stuffing calcium carbonate includes purifying green liquid in dissolving tank by adding reaction type flocculating precipitation assistant; clarifying green liquid, causticizing; clarifying white liquid; and refining white clay through carbonizing and grinding in grinder. The present invention produces white clay with high whiteness white vacuum treating green clay to reduce loss of sodium salt and raise alkali recovering rate. During purifying green liquid, only lime milk as assistant is added.

Owner:王梅林

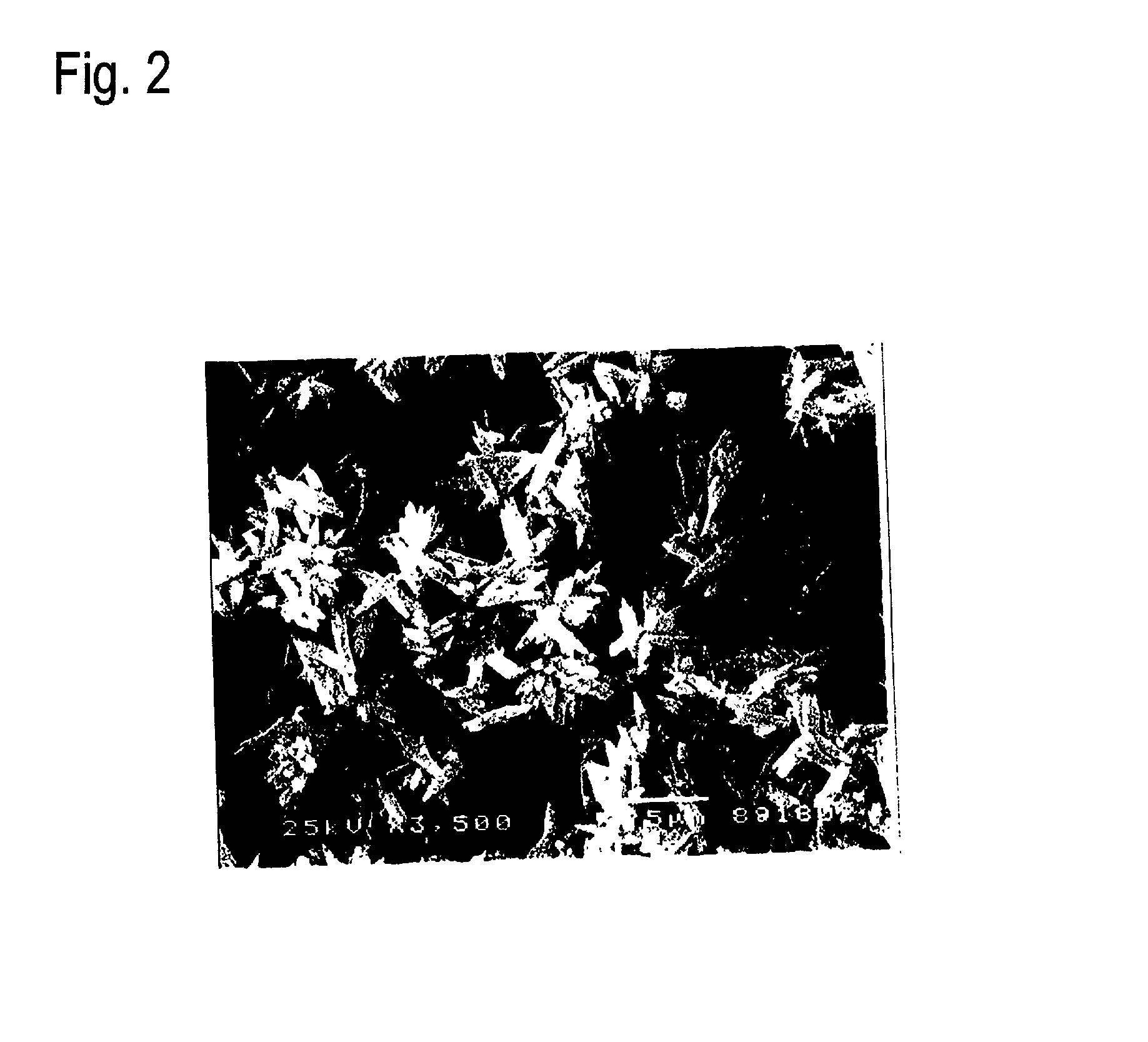

Process for preparing calcium carbonate

InactiveUS6627170B2Decreasing the amount of the filler passing through wire partsHigh aspect ratioCalcium/strontium/barium carbonatesCoatings with pigmentsWhite liquorPhysical chemistry

Inexpensive spindle- or rice-like calcium carbonate giving useful properties for brightness, opacity and wire abrasion resistance as a paper filler is provided by taking advantage of the causticization step. When a white liquor is used for slaking a quick lime, the quick lime used in the slaking reaction of a first step has a calcium carbonate content of 10% by weight or less and is slaked with the white liquor at a concentration of 20 to 60% to prepare a milk of lime. When a green liquor is used for slaking a quick lime, the quick lime used in the slaking reaction of a first step has a calcium carbonate content of 0.1 to 10% by weight and is slaked with the green liquor at a concentration of 20 to 60% to prepare a milk of lime. In a second step, causticization reaction takes place at a green liquor loading rate of 0.02 to 0.5 cc (green liquor) / min / g (quick lime) at a reaction temperature of 20 to 105° C. to afford spindle- or rice-like calcium carbonate.

Owner:NIPPON PAPER IND CO LTD

Method for producing calcium carbonate

InactiveUS20030049194A1Promote precipitationReduce the ratioCalcium/strontium/barium carbonatesCoatings with pigmentsPersulfateSulfate

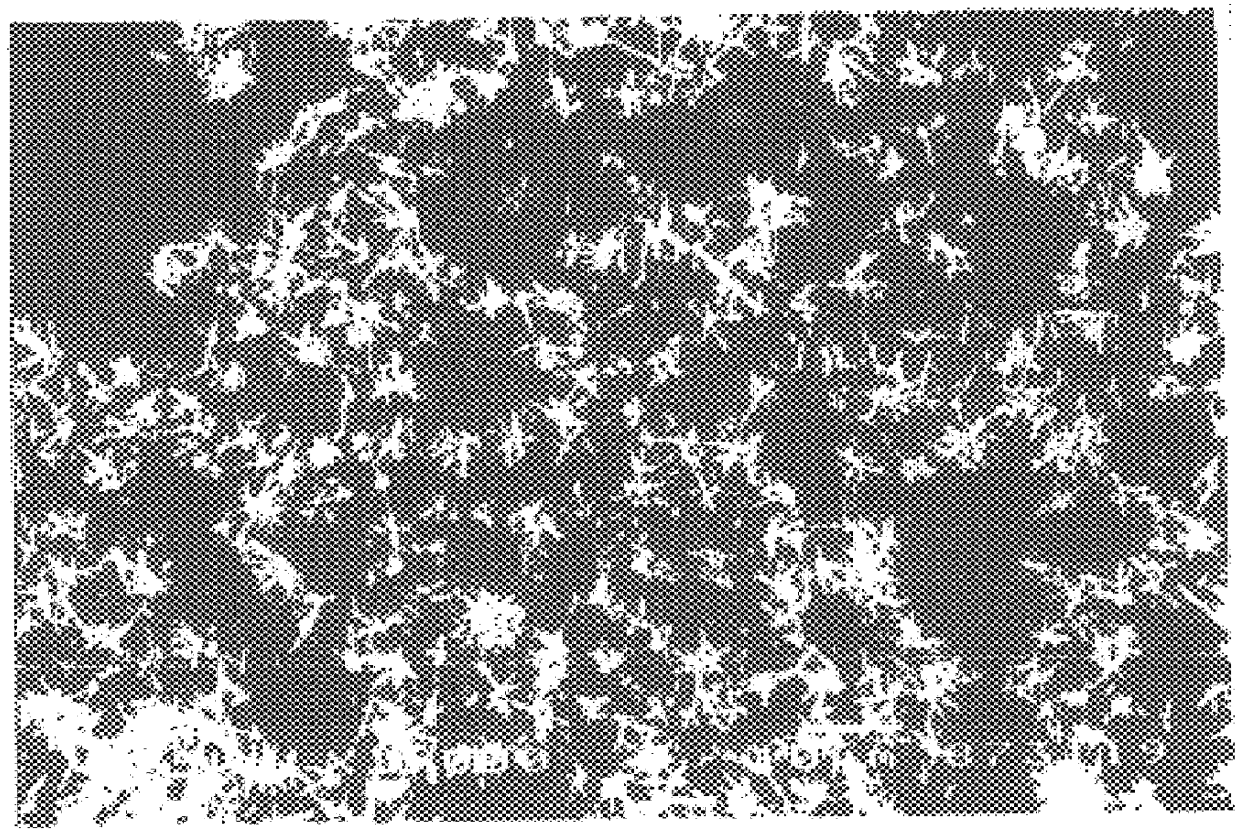

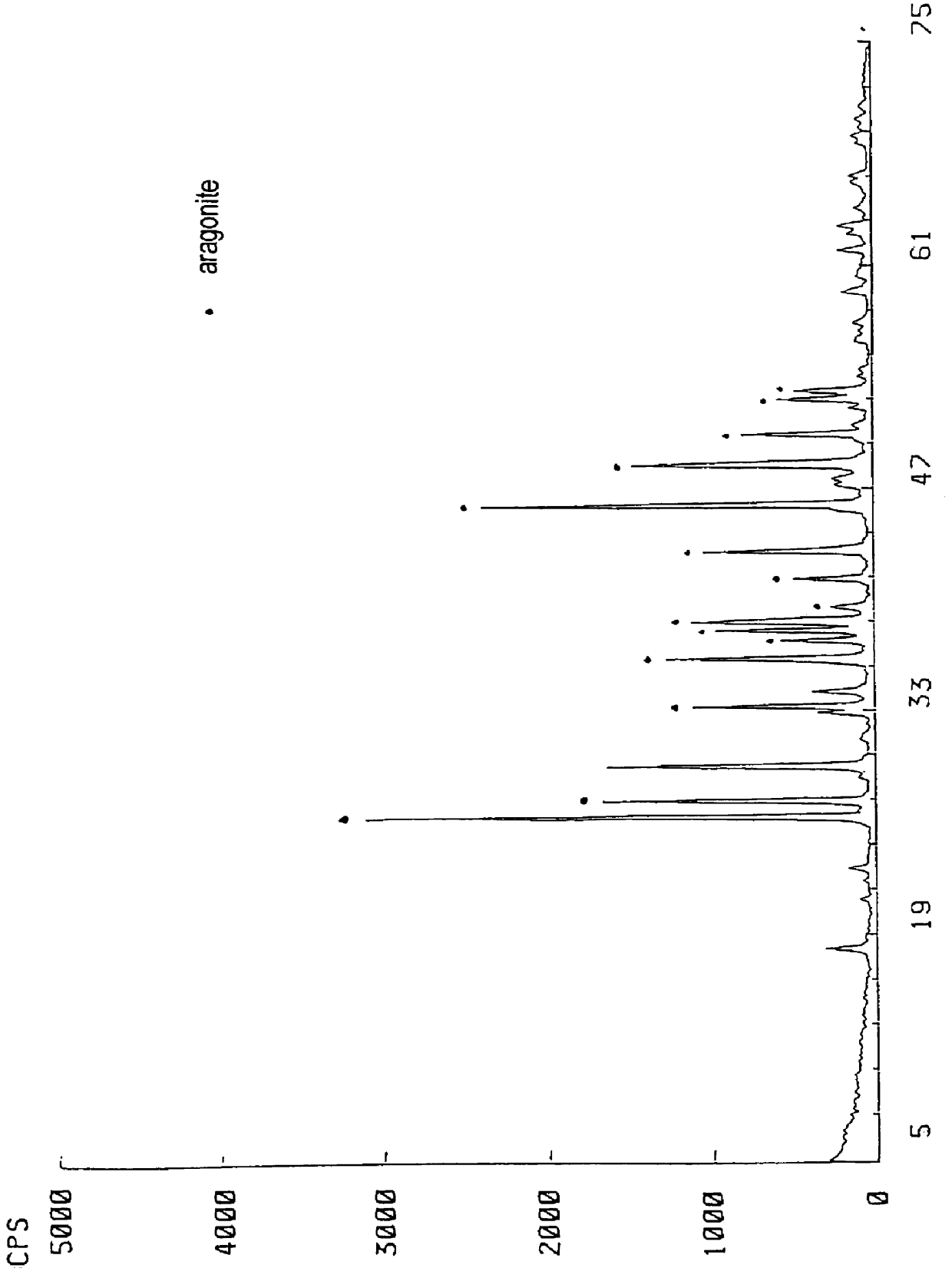

Calcium carbonate in the form of aragonite crystals suitable for use as a filler for papermaking to give useful properties for bulk, whiteness, opacity, wire abrasion and yield is obtained by taking advantage of the causticization step. Herein disclosed is a process for producing calcium carbonate in the form of aragonite crystals which is useful as a filler for papermaking via the causticization step of the sulfate or soda pulping process, comprising adding an aqueous alkaline solution having a hydroxide ion level of 3 mol / l or less and containing 0.25 mol or less of carbonate ion per 1 mol of quick lime to quick lime and / or slaked lime at a quick lime concentration of 1-60% by weight with stirring to prepare milk of lime, and then adding green liquor to said milk of liquor at a loading rate of 0.002-0.12 g (sodium carbonate) / min / g (quick lime) to perform a causticization reaction at a temperature of 30-105° C.

Owner:NIPPON PAPER IND CO LTD

Preparation method for desilication modified-attapulgite adsorbent

InactiveCN104907041AImprove adsorption capacityRelieve pressureOther chemical processesSolid sorbent liquid separationSorbentWastewater

The invention discloses a p reparation method for a desilication modified-attapulgite adsorbent. According to the invention, cheap attapulgite is used as a raw material and treated by hydrochloric acid with certain concentration and solid-liquid ratio, and then high temperature treatment is carried out so as to prepare modified attapulgite with good soluble-silicon adsorption performance. The modified attapulgite prepared in the invention has good adsorption and removal capabilities to soluble silicon in green liquor of papermaking waste water, is cheap, can perfectly reduce and mitigate difficulty in alkali recovery in the paper-making industry and produces good economic effects.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing calcium carbonate

InactiveUS7097819B2Proportion of aragonite crystals tends to be loweredPromote precipitationCalcium/strontium/barium carbonatesCoatings with pigmentsPersulfateSulfate

Calcium carbonate in the form of aragonite crystals suitable for use as a filler for papermaking to give useful properties for bulk, whiteness, opacity, wire abrasion and yield is obtained by taking advantage of the causticization step. Herein disclosed is a process for producing calcium carbonate in the form of aragonite crystals which is useful as a filler for papermaking via the causticization step of the sulfate or soda pulping process, comprising adding an aqueous alkaline solution having a hydroxide ion level of 3 mol / l or less and containing 0.25 mol or less of carbonate ion per 1 mol of quick lime to quick lime and / or slaked lime at a quick lime concentration of 1–60% by weight with stirring to prepare milk of lime, and then adding green liquor to said milk of liquor at a loading rate of 0.002–0.12 g (sodium carbonate) / min / g (quick lime) to perform a causticization reaction at a temperature of 30–105° C.

Owner:NIPPON PAPER IND CO LTD

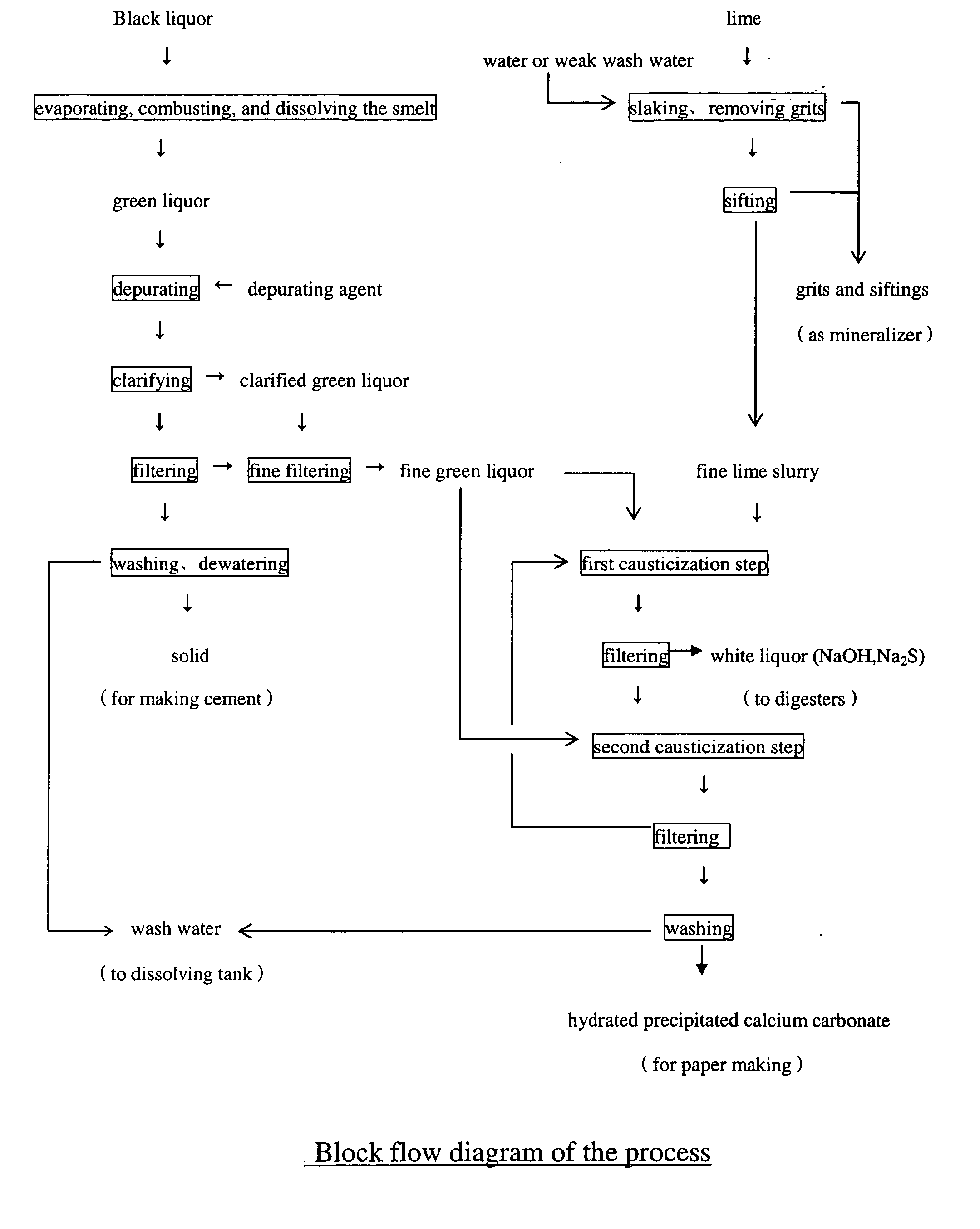

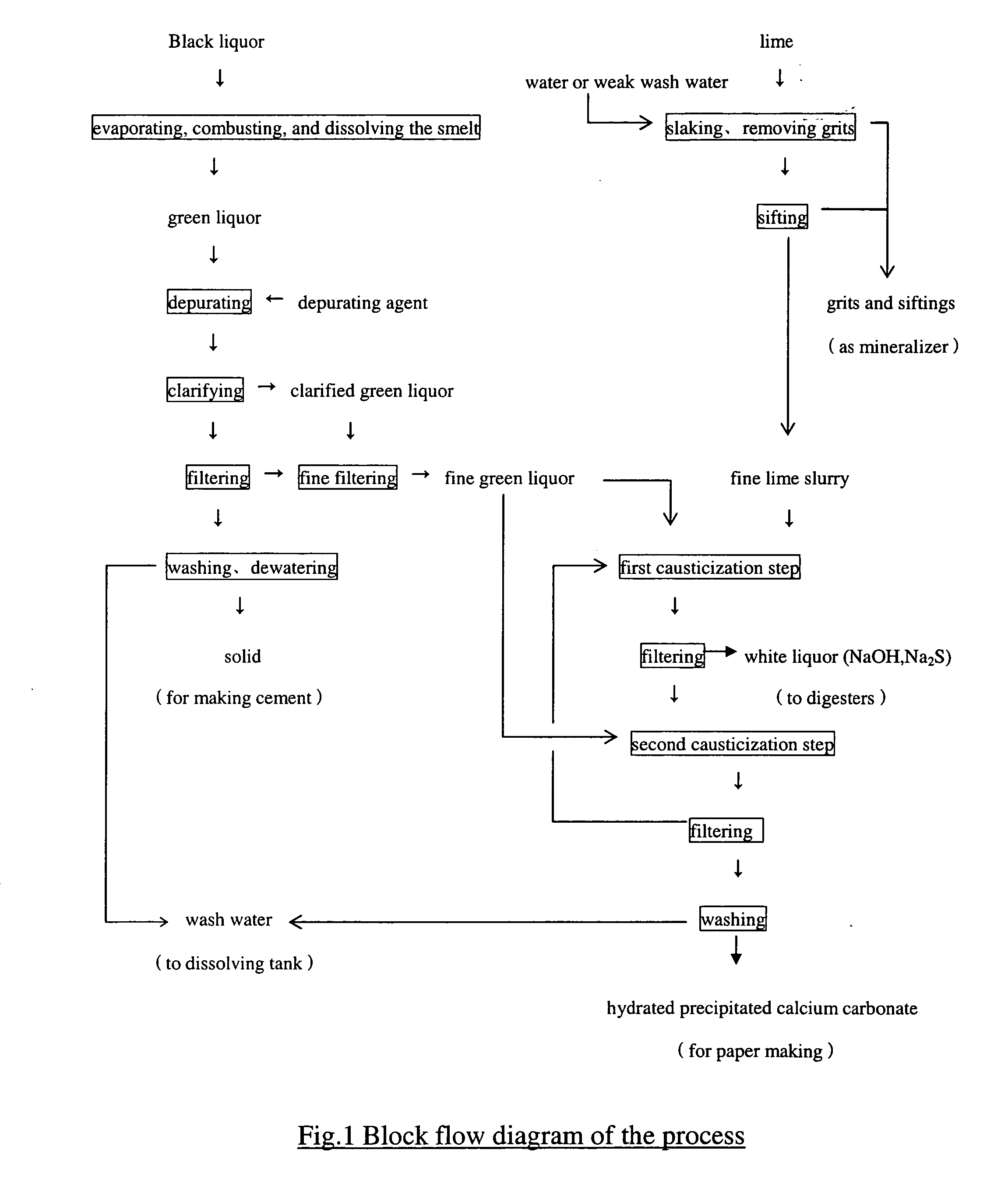

Process of recovering alkali from black liquor of papermaking

InactiveUS20050199358A1Equipment investmentReduce energy consumptionCalcium/strontium/barium carbonatesPulp liquors combustionBlack liquorPrecipitated calcium carbonate

This invention provides an improved process for recovering chemicals from black liquor in alkaline pulping, which is achieved by introducing depuration treatments of green liquor and lime before causticization reaction and a two-step-causticization procedure in the causticization procedure of the conventional chemical recovery process. The process of this invention not only avoids the generation of the waste residue (lime mud) from the beginning and saves the recovery and treatment of lime mud, but also can directly produce a series of precipitated calcium carbonate products with various particle sizes by regulating process conditions while the alkali is recovered, said CaCO3 products including a CaCO3 suitable for making coated paper, wherein >=50% of the CaCO3 has a particle size below 2 mum; a CaCO3 suitable for making neutral sized paper, wherein >=90% of the CaCO3 have a particle size below 2 mum; a superfine CaCO3 having an average particle size <1 mum. The present invention can be used for treatment of pollution of black liquor in the alkaline pulping.

Owner:AI TIANZHAO +3

Method for manufacturing high-quality jasmine tea

ActiveCN103704385ALixiang is rich and freshThe taste is mellow and sweetPre-extraction tea treatmentFragrance extractionBud

The invention discloses a method for manufacturing high-quality jasmine tea. The method comprises the steps of (1) tea base manufacturing, (2) scenting and (3) flower frying. Compared with an existing flower frying method, the method has the advantages that a product is manufactured by scenting a high-quality tea base which is obtained by performing cooling, withering, green-removing, arranging, reshaping, rod flattening, drying and fragrance extraction on Mengshan locally-optimized tea variety 131 early-spring tail buds for three times, and frying Qianwei jasmine fresh flowers which are picked between July 20th and September 20th at one time; the manufactured product is flat, level, uniform and straight; pekoe and Zang gold tea are rich and fresh in jasmine fragrance; the high-quality jasmine tea is durable in fragrance and freshness, and mellow and sweet in taste, has a bright yellow-green liquor color, and has a tender leaf bottom.

Owner:四川省大川茶业有限公司

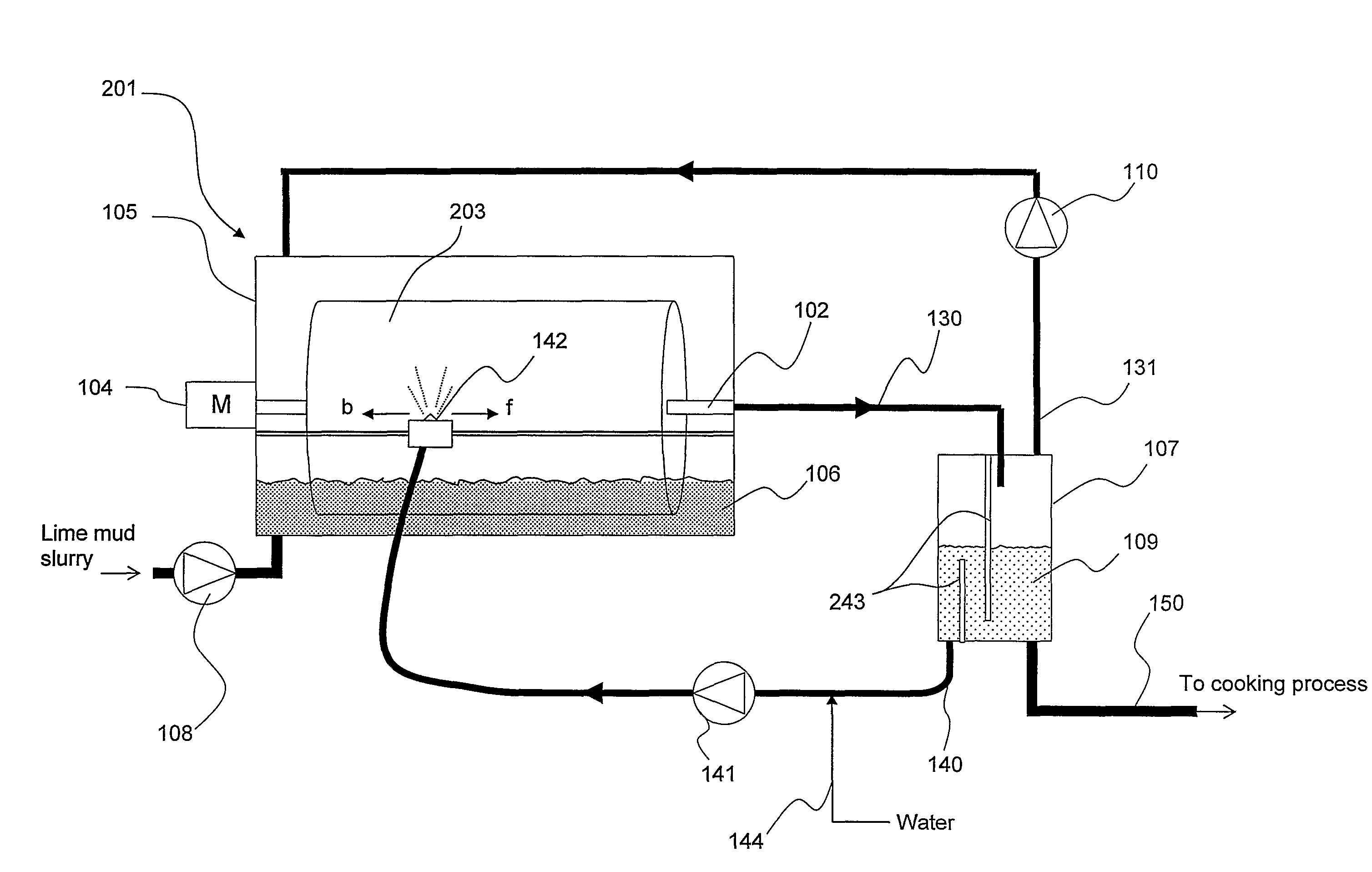

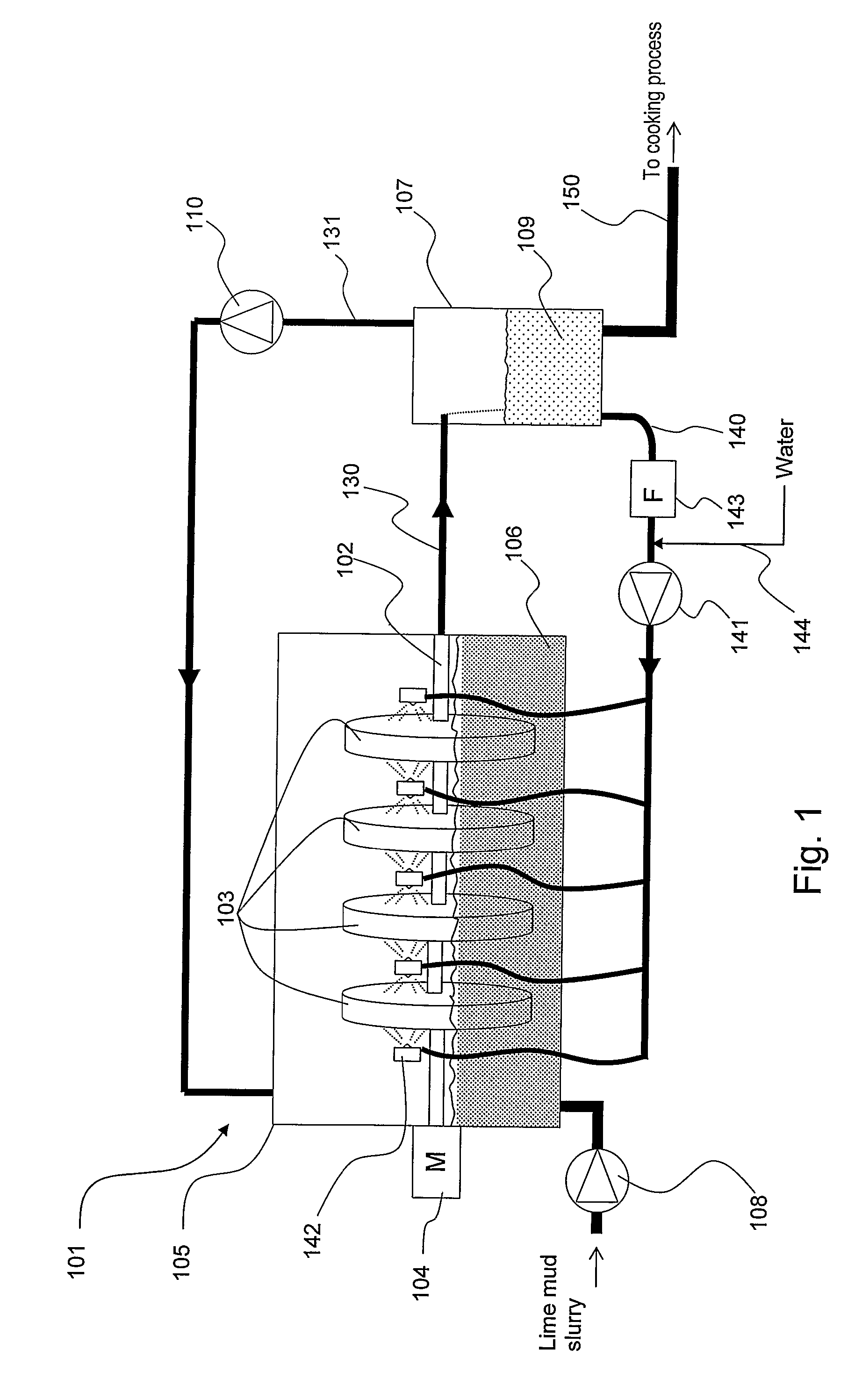

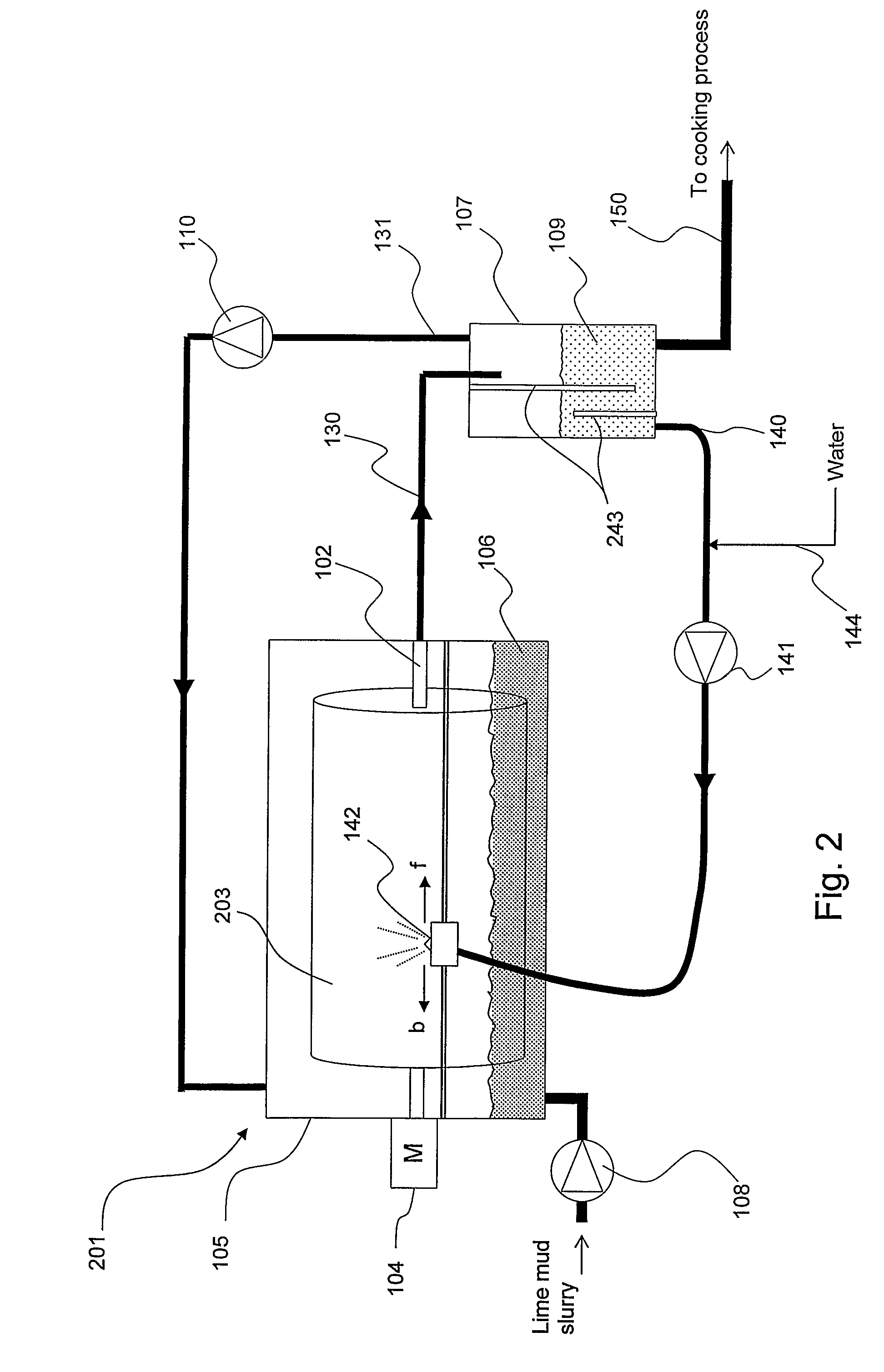

Method and device for cleaning of filter

The method and arrangement is for cleaning at least one of filter sheets and filter cakes in a pressurized white liquor filter with spray nozzles and driving fluid. The white liquor filter is used in a causticizing process in which green liquor is causticized before the white liquor filter by the addition of lime and in which it forms during the process a lime mud slurry. The white liquor filter 101 is used to separate white liquor from the lime mud. The driving fluid for the spray nozzle is constituted principally by the filtrate that is obtained from the filter.

Owner:METABO PAPER SWEDEN

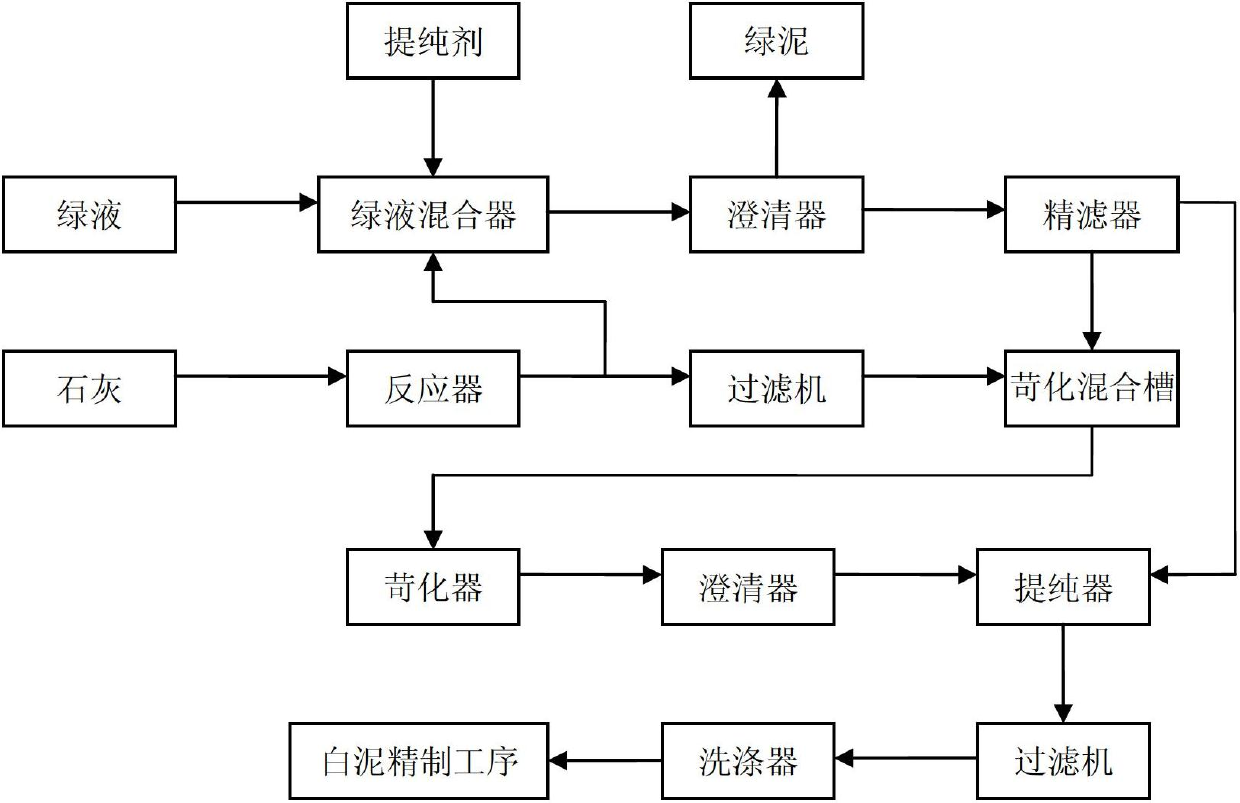

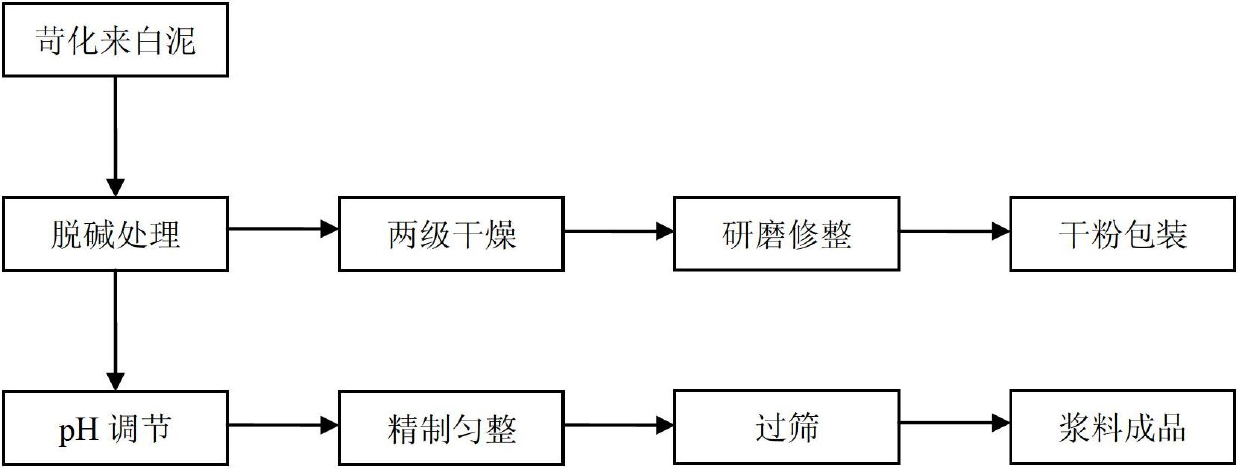

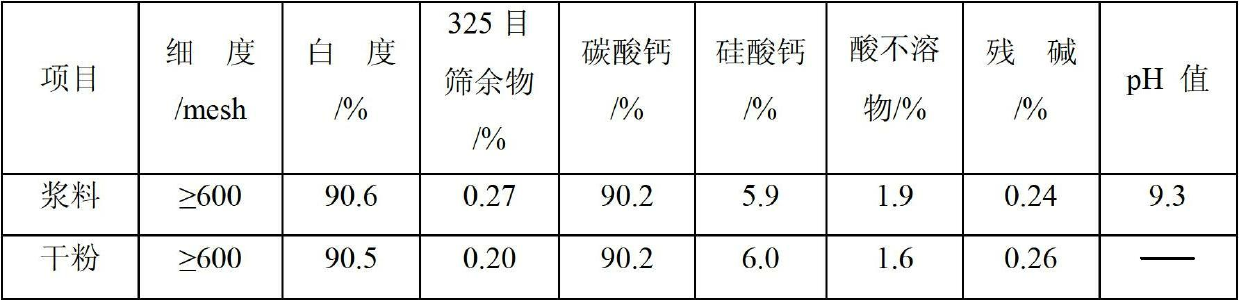

Process for preparing light-weight calcium carbonate by recycling white mud by alkali

InactiveCN102653411ALower quality requirementsThe crystal form of calcium carbonate is more regularCalcium/strontium/barium carbonatesPapermakingSlurry

The invention relates to a process for preparing light-weight calcium carbonate by recycling white mud by alkali. The process comprises the following steps of: purifying lime by a wet method, thus obtaining lime slurry; putting part of the lime slurry into a green liquor mixer for purifying green liquor, performing solid and liquid separation on the other part of the lime slurry, thus obtaining purified slaked lime; stepping into a causticization working procedure; performing causticization reaction to obtain white mud with relatively high purity; refining the high-purity white mud; and dealkalizing, adjusting the pH and uniformly mixing. The conventional causticization workshop is technically improved; according to wet-method purification, green liquor impurity removal and green liquor purification on causticized white mud, the quality and the recycling rate of alkali can be improved, and a foundation is laid for the next step of refining the white mud, so that the white mud in the causticization workshop can be refined; and therefore, the requirement on papermaking and filling is met, and the quality of a product is improved.

Owner:山东华特达因健康股份有限公司

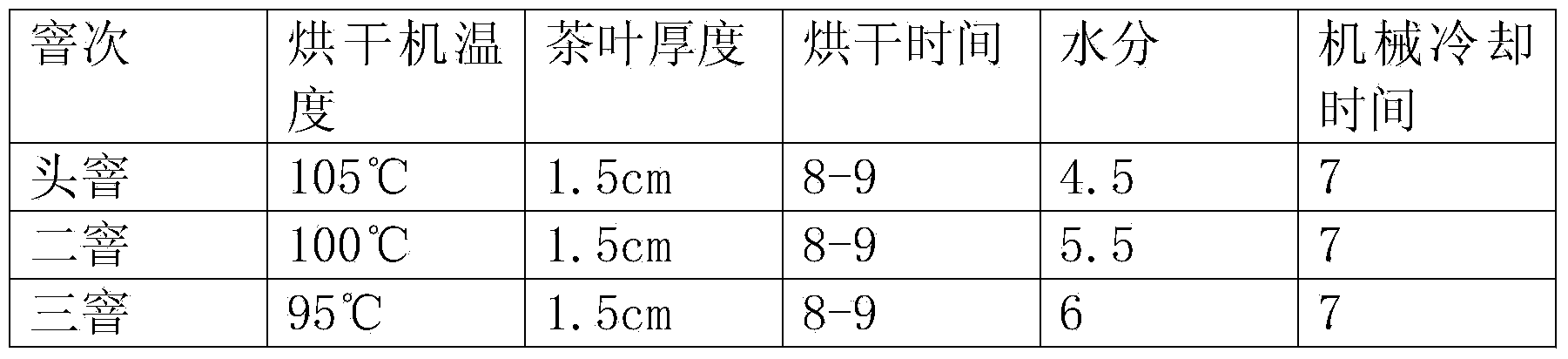

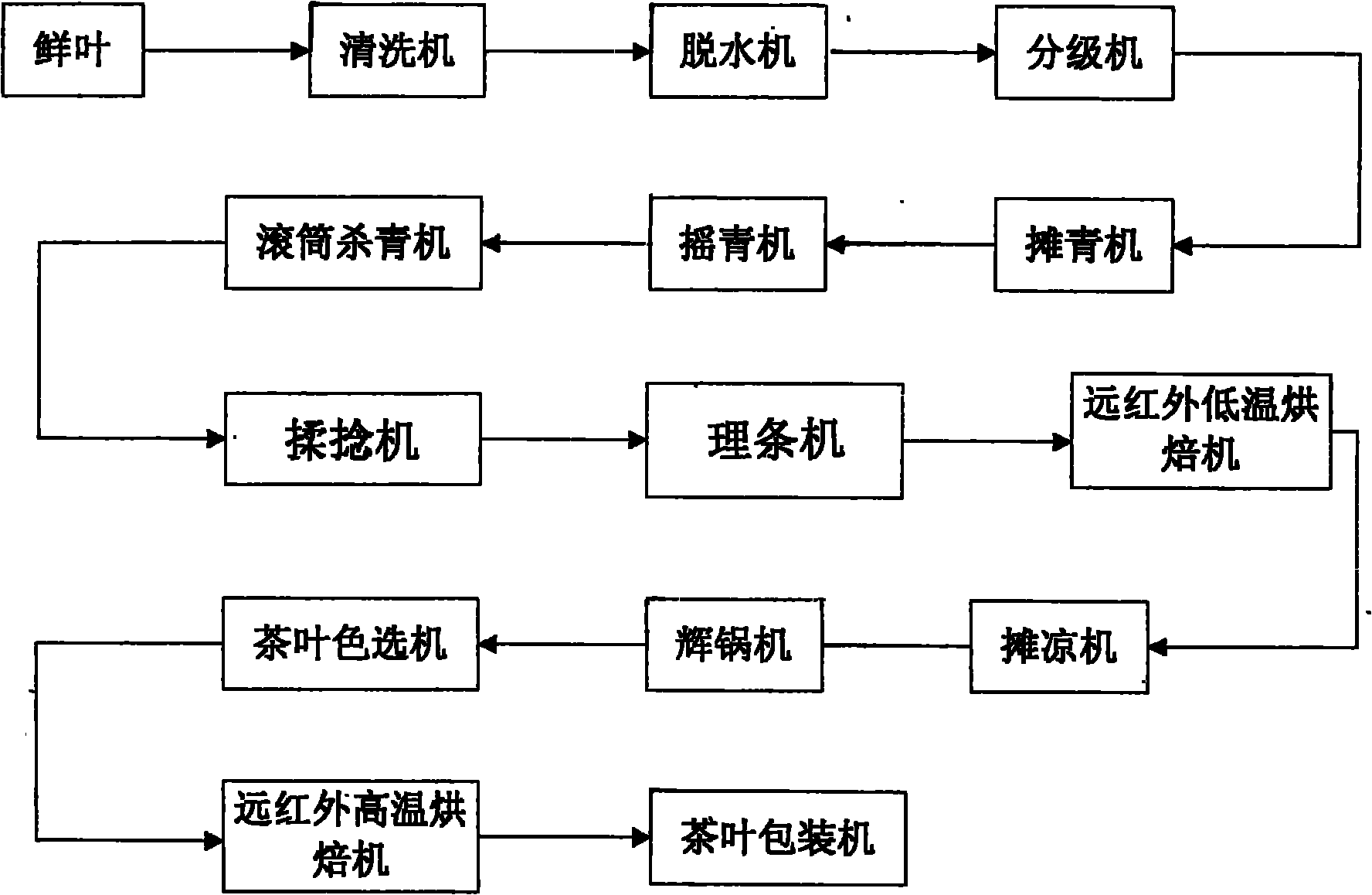

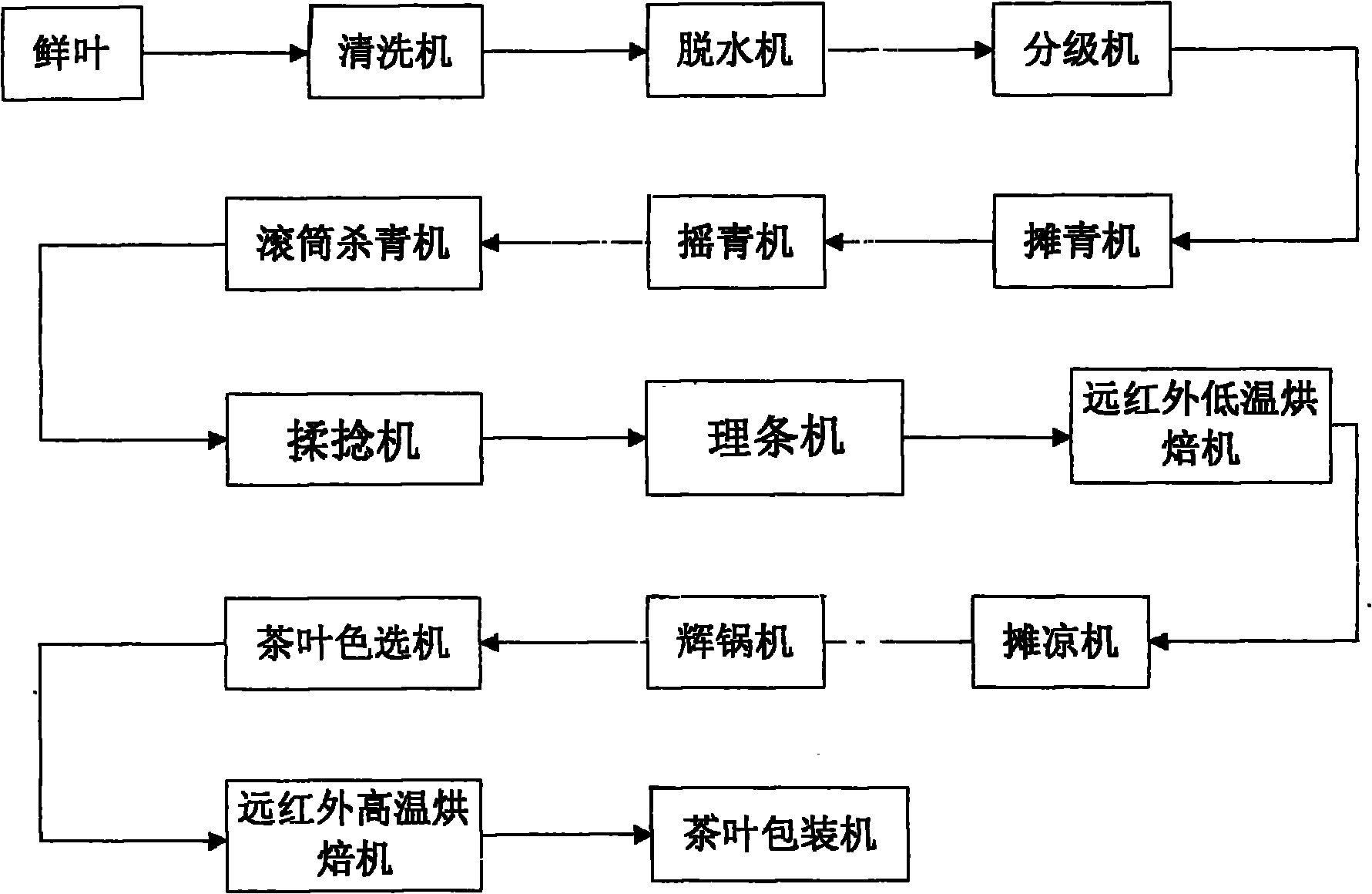

Mechanical tea making process of Liuan Guapian

InactiveCN101953404AFlat and beautiful shapeIn line with the trend of industrialization developmentPre-extraction tea treatmentEmeraldEngineering

The invention discloses a mechanical tea making process of Liuan Guapian, which fully adopts the mechanical tea making process on the basis of simulating the traditional manual tea making process. The processed Liuan Guapian tea not only has the special characters such as emerald green color, frost during humidification, clear and green liquor color, lasting aroma, long aftertaste, and the like of the traditional manually processed Liuan Guapian tea, but also has the advantages of flat and elegant shape, natural curling, melon-seed shape and uniform quality; moreover, the mechanical tea making process is suitable for the standard, automated, continuous, clean and scale production, and beneficial to increasing the additional value of the product and strengthening the market competitive force, and accords with the industrial development trend of the Liuan Guapian.

Owner:ANHUI AGRICULTURAL UNIVERSITY +1

Process for preparing white mud calcium carbonate from green liquor recovered from wood pulp sulfate-method pulping alkali

InactiveCN102659161AHigh whitenessSimple processCalcium/strontium/barium carbonatesRegeneration of alkali lyeBlack liquorSulfide

The invention relates to the field of recovering black liquor in alkaline method pulping in the technical field of pulping and papermaking, in particular to a process for preparing white mud calcium carbonate from green liquor recovered from wood pulp sulfate-method pulping alkali. The process comprises the following steps of: (1) purifying the green liquor; (2) purifying calcined lime; (3) pre-causticizing the green liquor; and (4) causticizing the green liquor. According to the process, most of divalent ferrum ions in the green liquor are masked by adding an aid, trivalent ferrum ions in the calcined lime are masked by purifying the calcined lime, reaction of the trivalent ferrum ions in the calcined lime and the divalent ferrum ions in the green liquor is inhibited, and the generation quantity of hydroxides or sulfides of divalent ferrum in the causticizing process is reduced, so that the high-whiteness white mud calcium carbonate is obtained. The green liquor recovered from the wood pulp sulfate-method pulping alkali is treated by the process, a process flow is simple, and used chemicals are clean and environment-friendly.

Owner:QILU UNIV OF TECH

Process for preparing calcium carbonate

InactiveUS20030059362A1Excellent abrasion resistanceLess sharp edgeCalcium/strontium/barium carbonatesCoatings with pigmentsWhite liquorReaction temperature

Inexpensive spindle- or rice-like calcium carbonate giving useful properties for brightness, opacity and wire abrasion resistance as a paper filler is provided by taking advantage of the causticization step. When a white liquor is used for slaking a quick lime, the quick lime used in the slaking reaction of a first step has a calcium carbonate content of 10% by weight or less and is slaked with the white liquor at a concentration of 20 to 60% to prepare a milk of lime. When a green liquor is used for slaking a quick lime, the quick lime used in the slaking reaction of a first step has a calcium carbonate content of 0.1 to 10% by weight and is slaked with the green liquor at a concentration of 20 to 60% to prepare a milk of lime. In a second step, causticization reaction takes place at a green liquor loading rate of 0.02 to 0.5 cc (green liquor) / min / g (quick lime) at a reaction temperature of 20 to 105° C. to afford spindle- or rice-like calcium carbonate.

Owner:NIPPON PAPER IND CO LTD

Flue gas treatment using kraft mill waste products

The present invention relates in general to a process for removing mercury from a mercury-containing flue gas using dregs from a Kraft pulp mill green liquor clarifier. The dregs are washed with water to produce a particulate carbon slurry which is activated with hydrobromic acid and injected into a mercury-containing flue gas to oxidize and adsorb the mercury at temperatures less than about 900° F. A slurry of sodium hydroxide and calcium carbonate, optionally also obtained from Kraft mill waste, is injected into the hot flue gas to absorb and remove CO2, SO2, and SO3.

Owner:S&S LIME

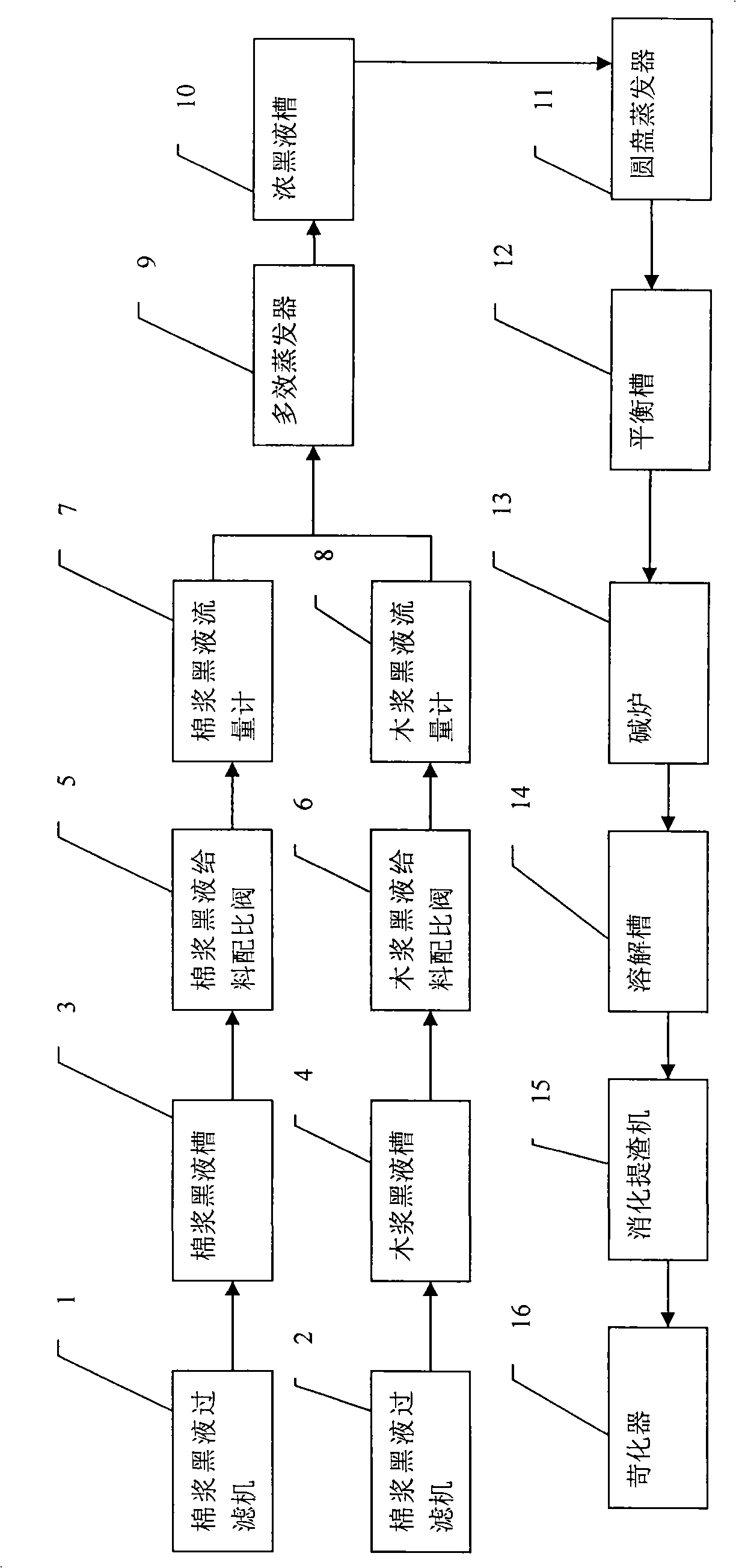

Process for treating chemical fiber cotton pulp black liquor

ActiveCN101585617AReduce pollutionReduce manufacturing costMultistage water/sewage treatmentWater/sewage treatment by heatingFiberChemical reaction

The invention discloses a process for treating chemical fiber cotton pulp black liquor, which comprises the following steps: filtering the chemical fiber cotton pulp black liquor and wood pulp black liquor by a black liquor filter, mixing the two black liquors according to a proportion, then evaporating the mixture through a two-stage evaporator, spraying the thick black liquor after evaporating into an alkali reclaiming furnace, drying the thick black liquor sprayed into the furnace by using heat in the furnace, drying, fully burning and oxidizing the thick black liquor during falling, and introducing the burned molten substances into a dissolving tank to form green liquor; and conveying the green liquor in the dissolving tank to a slaking slag extractor, simultaneously adding enough amount of calcium oxide into the slaking slag extractor so as to carry out chemical reaction on the that the green liquor and the calcium oxide, and conveying emulsion generated in the reaction to a causticizer to generate NaOH. The process overcomes the defects of low combustion value and high treatment cost existing in the process of treating the chemical fiber cotton pulp black liquor only by using an alkali reclaiming system, lowers the production cost and reduces environment pollution; and the obtained alkali liquor can be recycled.

Owner:山东光华纸业集团有限公司

Green tea processing method

InactiveCN103053719AImprove qualityBright green colorPre-extraction tea treatmentAdditive ingredientGreen liquor

The invention relates to the technical field of agriculture product processing, in particular to a green tea processing method. The green tea processing method comprises the following steps: a, leaf selection; b, spreading and airing; c, de-enzyme; d, rolling; and e, drying. The green tea processing method also comprises a withering processing step executed between the step a and the step b; in the withering processing step, fresh leaves are dewatered to be softened. Compared with a conventional green tea processing method, the green tea processing method has the advantage that before fresh leaves are spread and aired, the withering dewatering process is added, so that obtained dry tea has vivid green color and tea water obtained by brewing with boiled water has green liquor color, fresh aroma and pure taste. Moreover, by controlling various process parameters in the conventional process and particularly and strictly controlling the temperature adopted in each step in the conventional green tea processing method, most of organic ingredients in tea can be preserved so as to further ensure high quality of the obtained green tea.

Owner:梁平县平川茶厂

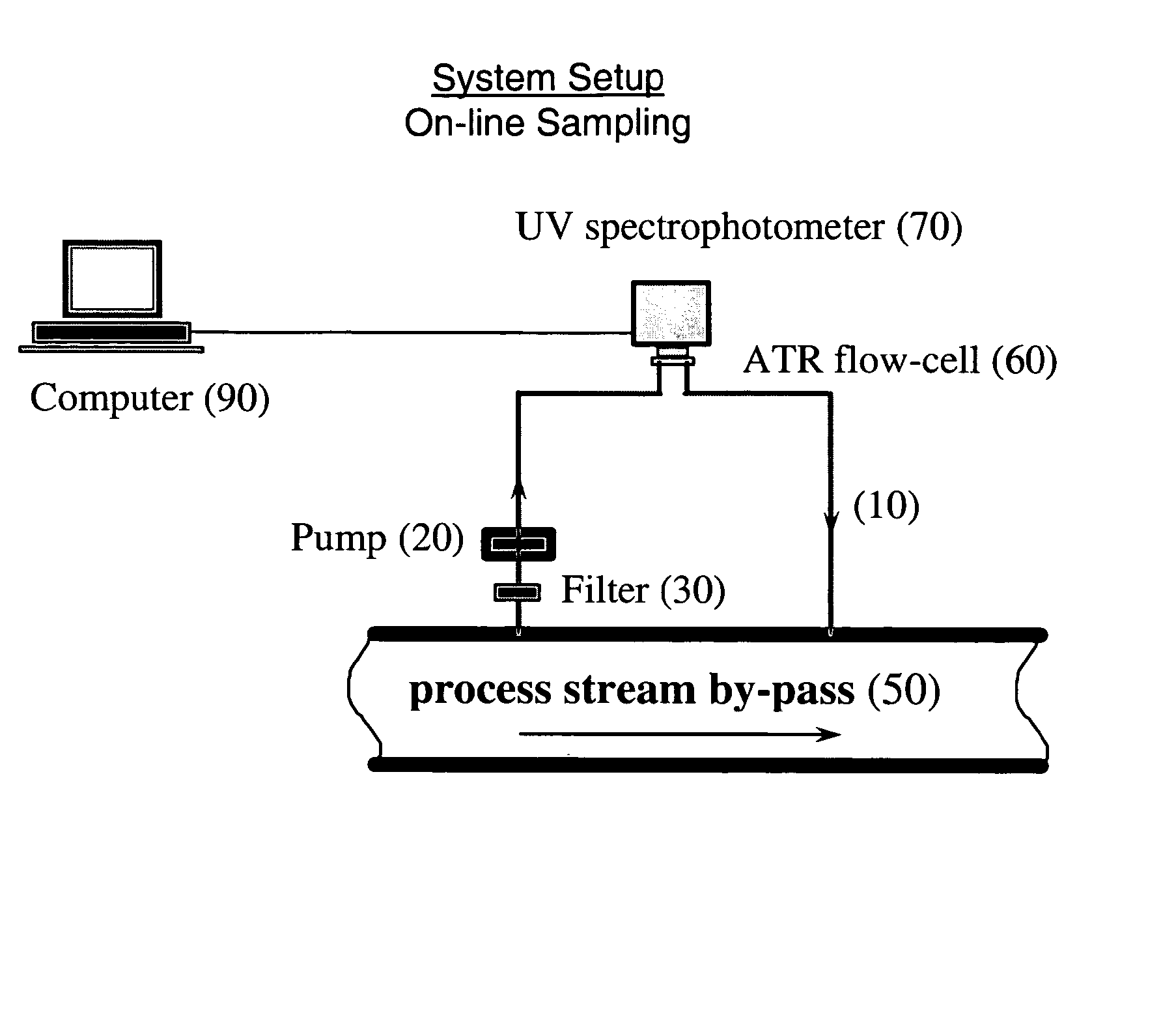

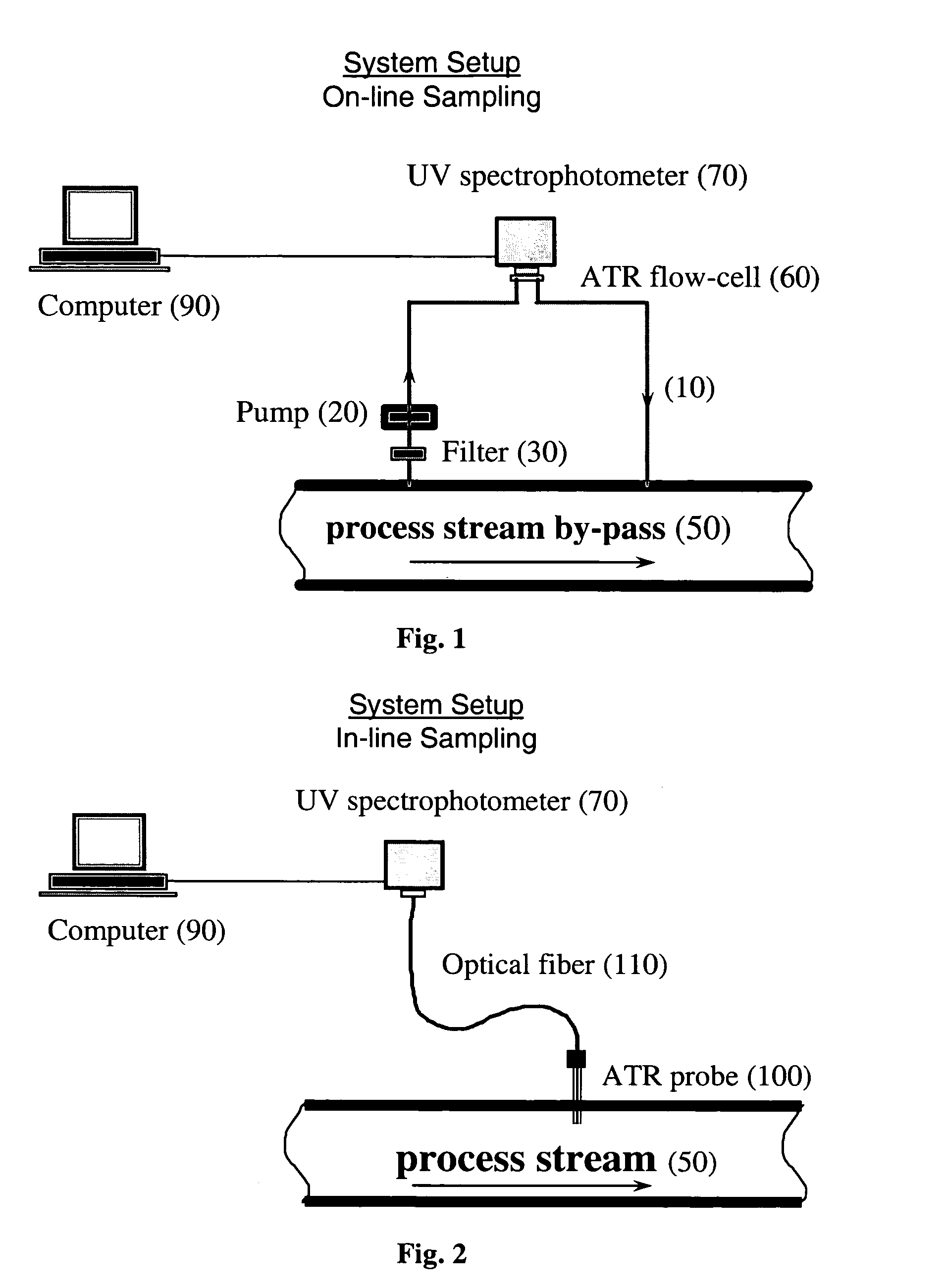

Simultaneous and rapid determination of multiple component concentrations in a multi-component chemical process stream

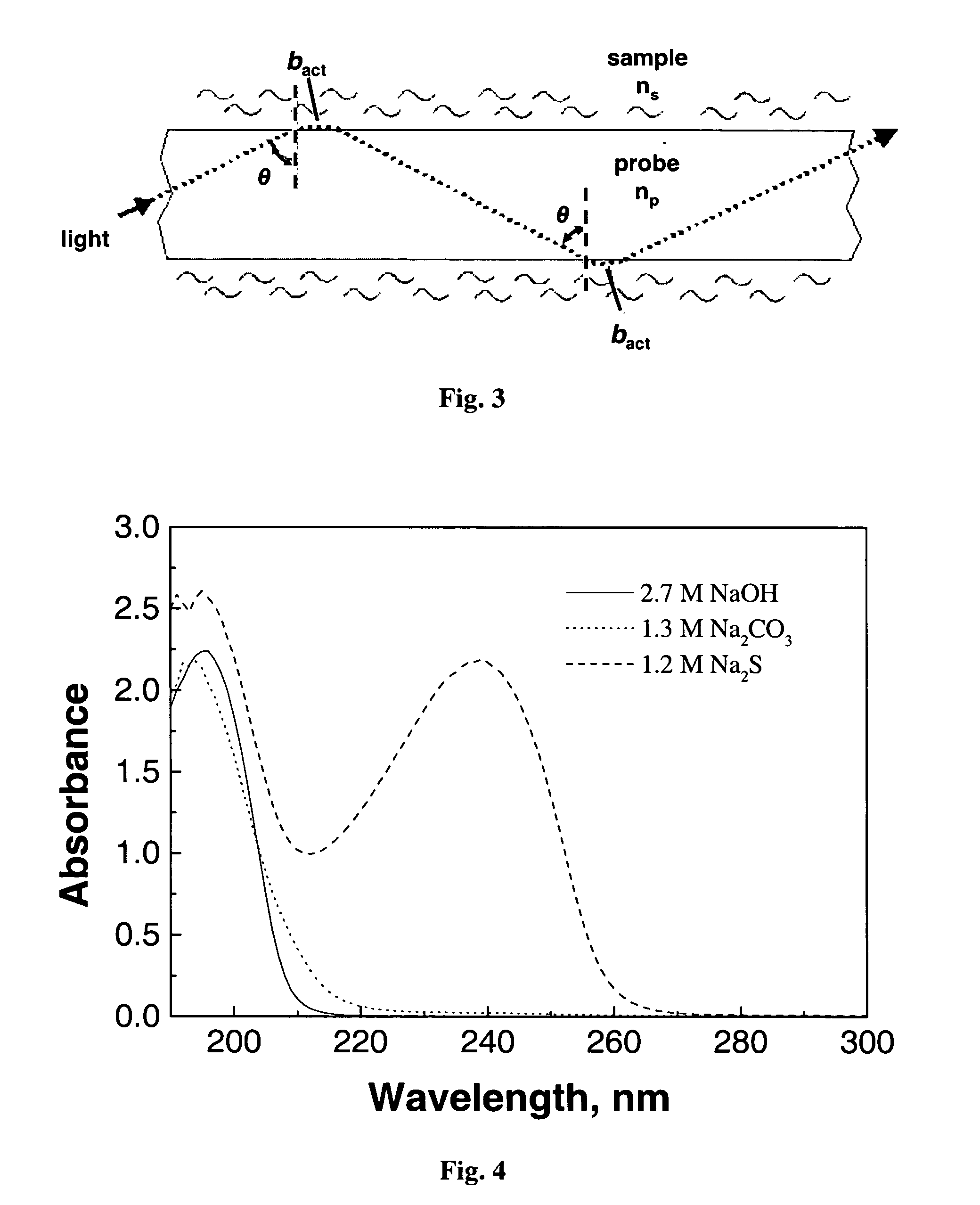

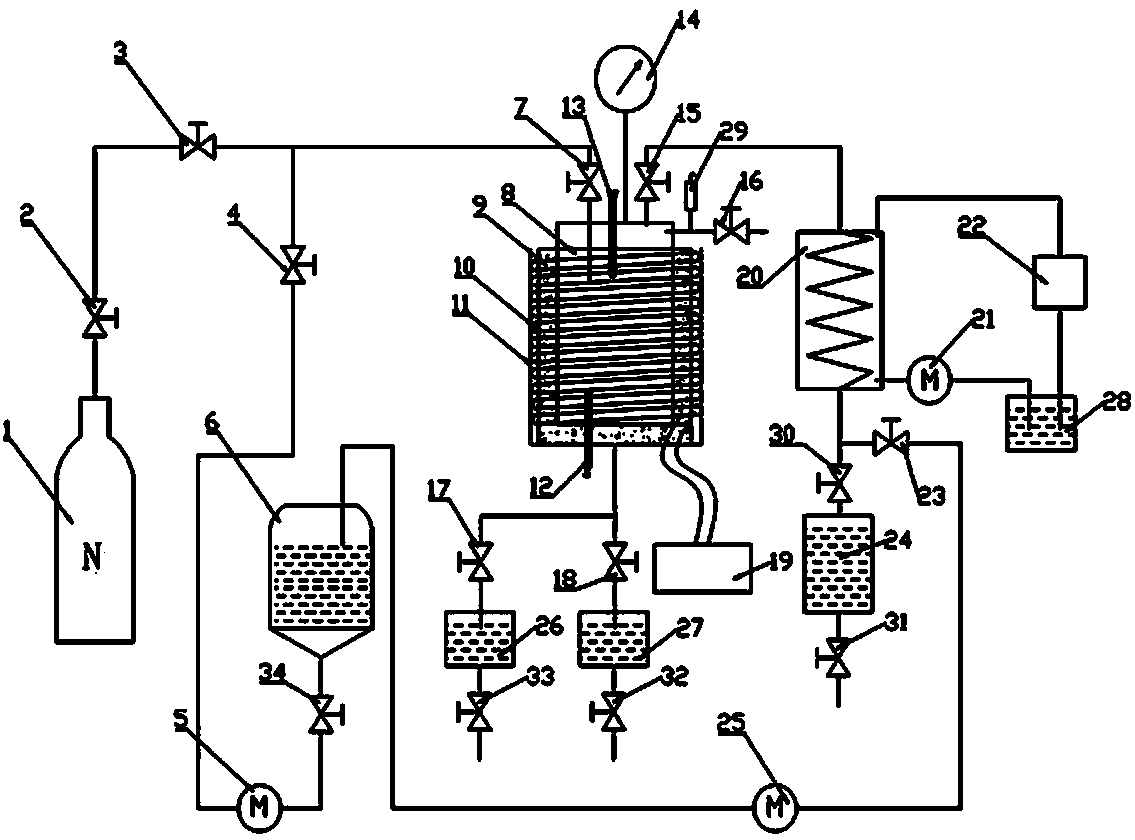

InactiveUS20050139337A1Scattering properties measurementsPulping with acid salts/anhydridesFlow cellSodium hydroxide

The present invention is a rapid method of determining the concentration of the major components in a chemical stream. The present invention is also a simple, low cost, device of determining the in-situ concentration of the major components in a chemical stream. In particular, the present invention provides a useful method for simultaneously determining the concentrations of sodium hydroxide, sodium sulfide and sodium carbonate in aqueous kraft pulping liquors through use of an attenuated total reflectance (ATR) tunnel flow cell or optical probe capable of producing a ultraviolet absorbency spectrum over a wavelength of 190 to 300 nm. In addition, the present invention eliminates the need for manual sampling and dilution previously required to generate analyzable samples. The inventive method can be used in Kraft pulping operations to control white liquor causticizing efficiency, sulfate reduction efficiency in green liquor, oxidation efficiency for oxidized white liquor and the active and effective alkali charge to kraft pulping operations.

Owner:GEORGIA TECH RES CORP

Liquid-state re-distilling device for pure-grain solid-state fermented liquor by electromagnetic induction heating

InactiveCN104371901AImprove qualityEasy to separateAlcoholic beverage preparationBiotechnologyDistillation

The invention relates to a liquid-state re-distilling device for pure-grain solid-state fermented liquor by electromagnetic induction heating. The device comprises a distillation kettle body, a heating system, a liquor fraction cooling system and a liquor and nitrogen supply system, wherein the systems are connected by virtue of a pipeline, a control valve and a material pump and form a circuit; a pressure gauge, a safety valve, an emptying valve and a thermo detector II are installed on the upper part of the distillation kettle body; the upper part of the distillation kettle body is connected with an inlet valve of the distillation kettle and is connected with a condenser by virtue of a pipeline and a valve; the distillation kettle body is externally coated by a heat preserving layer which is externally provided with an electromagnetic induction coil and an electromagnetic induction controller; and a thermo detector I is installed on the lower part of the distillation kettle body, and a lower outlet end of the distillation kettle body is connected with a parallel connecting valve and then is respectively connected with a residual liquor collector and the emptying valve. According to the device provided by the invention, the temperature of liquor in the distillation kettle body is raised to a certain temperature to separate liquor components higher than or lower than the certain temperature and various adverse components in green liquor can be quickly removed by virtue of liquid circular distillation and collection for many times, so that the quality of the liquor is improved.

Owner:SHAOYANG UNIV

A kind of preparation method of green tea

The invention provides a method for preparing green tea. After a series of processing techniques such as air-drying, high-temperature curing, heat-drying, rolling, medium-temperature roasted tea, and low-temperature tea-making, the fresh tea leaves are processed into a unique tea fragrance, Green tea with clear soup color, strong tea flavor, mellow and refreshing; in addition, no additives are used in the processing process, so that the quality of the finished tea is stable, and the taste of pure natural aftertaste is maintained, which can effectively reduce the damage to chlorophyll in the process of tea processing. The chlorophyll content of the green tea leaves reaches 85%, and the tea soup color is green and transparent. The fried green tea produced by the present invention has beautiful appearance, tight knots, elegant shape, clear green and bright soup color, strong and lasting aroma, fresh and refreshing taste, long aftertaste The sweet taste persists for a long time, the quality is good, especially the taste is excellent, and it is favored by consumers.

Owner:云南省双柏县白竹山茶业有限责任公司

Desulfurizer prepared by causticized white mud and method thereof for flue gas desulphurization

The invention discloses a desulfurizer prepared by causticized white mud and a method of the desulfurizer for flue gas desulphurization. The desulfurizer is prepared by the following steps: when alkali furnace smelt is dissolved into a green liquid, adding 2-3 % of the smelt amount of lime and 0.5-1 % of the smelt amount of flocculating agent in the green liquid, mixing lime with the green liquid after clarification according to theoretical amount ratio of calcium hydrate in the lime to sodium carbonate in the green liquid being 1.05-1.1, then carrying out causticization at a temperature of 90-102 DEG C to obtain a causticized solution, clarifying the causticized solution to obtain a white liquid and white mud, washing the white mud with 50-70 DEG C water, and then filtering and dehydrating the white mud to let the dryness of the white mud be more than 60 %. A saturated or oversaturated absorption liquid comprsing the desulfurizer and water is used for flue gas desulphurization, and a scale and corrosion inhibitor having a concentration of 5-30 mg / L is added in the saturated or oversaturated absorption liquid. According to the invention, the purity of the desulfurizer prepared by causticized white mud is raised, the problems of easy scale formation, blocking, corrosion and the like in the process of desulphurization are solved, and the desulfurizer can be applied for desulphurization inside the furnace.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for refining white clay calcium carbonate from green solution produced in alkali recovery from grass pulp

InactiveCN102303885AHigh whitenessUniform crystal formCalcium/strontium/barium carbonatesGreen liquorProcess conditions

The invention discloses a method for refining white clay calcium carbonate from green solution produced in alkali recovery from grass pulp, which comprises: adding quick lime into water to completely digest quick lime to obtain solution of lime; and adding grass pulp green solution into the solution of lime to carry out a causticizing reaction or adding the solution of lime into the grass pulp green solution to obtain white clay calcium carbonate. In the invention, based on study of mechanism of alkali recovery, the current alkali recovery process conditions are improved and a digestive reaction and the causticizing reaction are carried out separately under controlled reaction conditions; therefore, the form of white clay calcium carbonate produced by the causticizing reaction is needle-like, the white clay calcium carbonate byproduct of alkali recovery is high in whiteness and uniform in crystal form and can be used in paper filling with high quality in place or part or all commercial calcium carbonate, and the cost of pulp making enterprises and pollution to the environment are reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method and application of polyaluminum sulfate modified bentonite

ActiveCN103521170AHigh removal rateEasy to GrindOther chemical processesWater/sewage treatment by sorptionAluminium sulfateSodium Bentonite

The invention relates to a preparation method of polyaluminum sulfate modified bentonite, and an application of the polyaluminum sulfate modified bentonite. The preparation method comprises the following steps: dissolving aluminum sulfate in water, adjusting the pH value of the obtained aluminum sulfate solution to 4.0-8.0, allowing the solution to stand, pouring out the obtained supernatant, adding bentonite to the obtained lower turbid liquid according to a mass ratio of bentonite to aluminum sulfate of 1:(1-5), stirring, allowing the obtained stirred solution to stand, pouring the obtained new supernatant, and drying the obtained new lower turbid liquid to obtain the polyaluminum sulfate modified bentonite. The preparation method has the advantages of fast reaction speed, simple operation and good modification effect. The prepared polyaluminum sulfate modified bentonite has the advantages of porous loosening, large specific surface area, easy grinding and good silicon removal effect, can be used as a green liquor silicon removal agent or for preparing green liquor silicon removal agents, and can realize silicon removal agent consumption reduction and silicon removal rate increase. Additionally, the invention provides a method for removing silicon in a green liquor by using the polyaluminum sulfate modified bentonite. The polyaluminum sulfate modified bentonite use method has the advantages of simple and convenient operation, fast reaction speed, low consumption of the polyaluminum sulfate modified bentonite, high silicon removal rate, very small change of the pH value of the green liquor, reduction of the energy consumption and cost of an enterprise, and economic benefit increase.

Owner:SHAANXI UNIV OF SCI & TECH

Method for removing silicon in green liquid through cooperation of calcium oxide and aluminum salt

InactiveCN102337696AReduce silicon contentPlay a role in removing siliconRegeneration of alkali lyeLime productionFiberFiltration

The invention relates to a method for reducing the silicon content in a green liquid of a non-wood fiber material pulping causticization section through the cooperation of calcium oxide and aluminum salt. In the method, calcium oxide and aluminum sulfate, aluminum oxide, aluminum hydroxide or sodium metaaluminate are sequentially added into the green liquid of the causticization section, the temperature is 90-100 DEG C in the reaction process, a stirrer is used for continuous stirring in the reaction process, the reaction time is 25-30 minutes, and insoluble precipitate is removed by filtration after the reaction is completed. The method is provided for the green liquid produced during non-wood fiber material pulping, and comprises the following steps: adding calcium oxide and aluminum salt into the green liquid of the pulping causticization section to react with silicate in the green liquid so as to generate insoluble precipitate, then filtering to remove the generated insoluble precipitate from the green liquid. The method can achieve a silicon removal rate higher than 87%, and ensures that white slime can be used for calcining and recycling lime after causticization.

Owner:SHAANXI UNIV OF SCI & TECH

Momordica charantic leaf insect-resisting extract, and its preparation and use

InactiveCN1709065AStrong insect resistanceBroad spectrum insect resistanceBiocideArthropodicidesSolventChemistry

The present invention relates to a bitter melon leaf insect-resisting extract, its preparation method and application. It is characterized by that it utilizes bitter melon leaf as raw material, and uses deionized water, ethyl ether or acetone as extraction solvent, and adopts the processes of grinding, standing still, oscillation, filtering and constant volume extraction so as to obtain the green liquor containing protein. The ratio of bitter melon leaf and solvent is 1g / 1ml. Said product can obtain good insect-resisting and insect-killing effect.

Owner:TIANJIN NORMAL UNIVERSITY

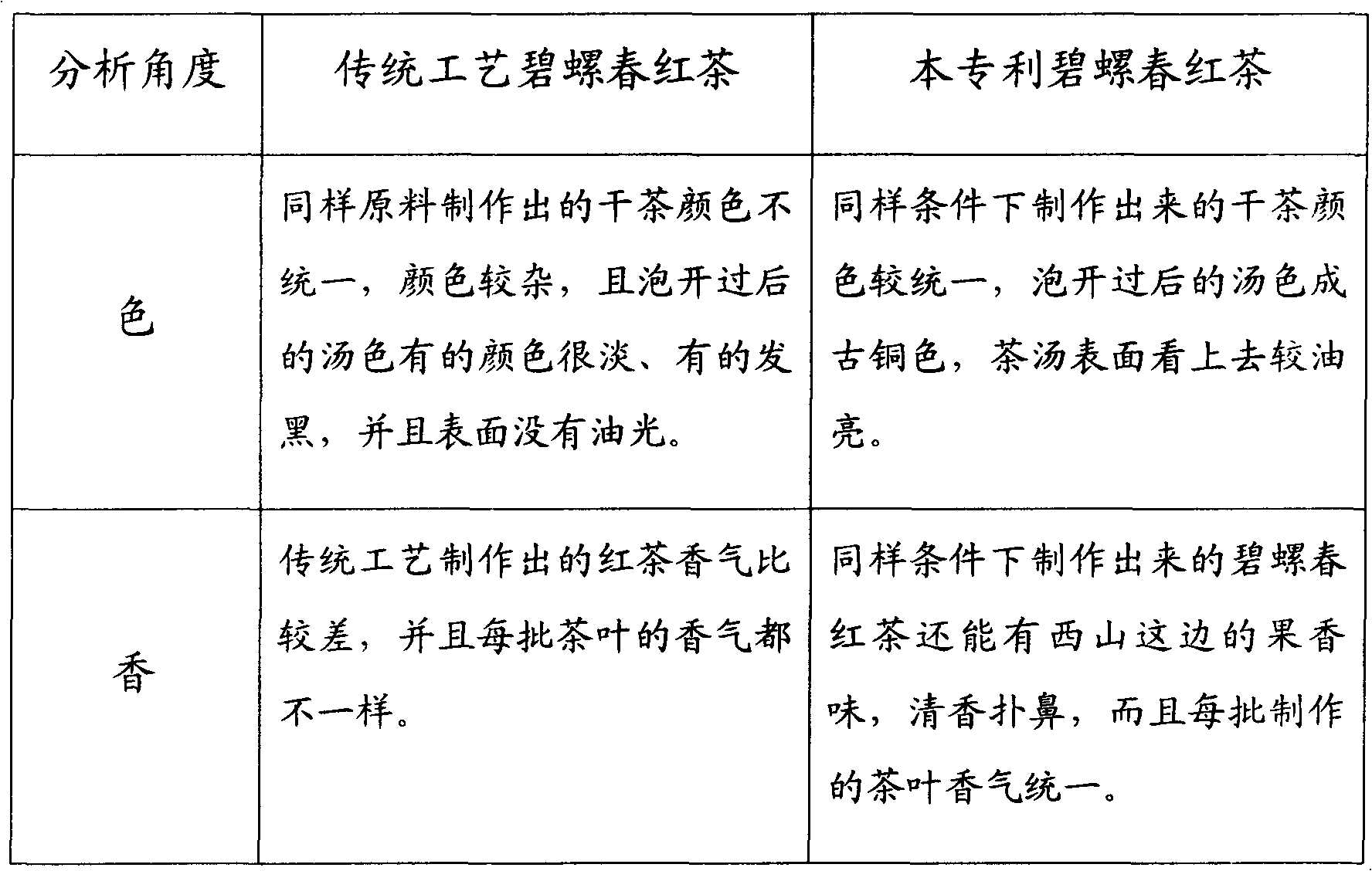

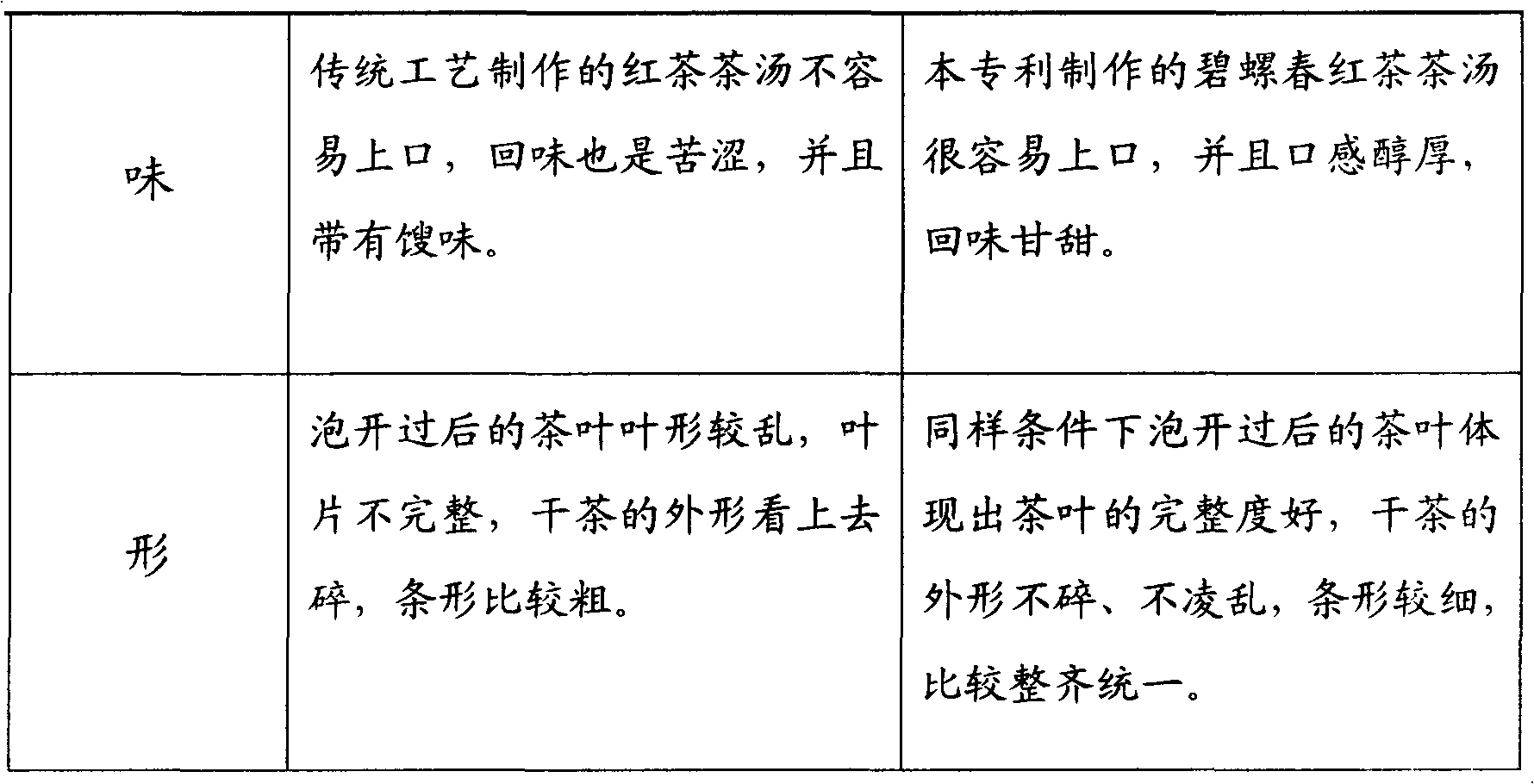

Production process for Biluochun black tea

The invention relates to a production process for Biluochun black tea. The production process comprises the steps of withering, rolling, fermenting, twisting into clumps and forming, drying, packaging and the like, wherein the traditional Biluochun black tea has a red and opaque colour or has a green liquor colour after being made with boiling water, the tea leaves have messy shapes and no aroma, and the black tea made every time have different tastes, some are sweet and bitter, and some have a faint scent of green tea; the differences between the Biluochun black tea disclosed by the invention and the traditional Biluochun black tea are as follows: the defect of original roughness in a production technology for the traditional Biluochun black tea is overcome, a technological improvement is performed on each process step by adopting a modern scientific production method, thus effectively guaranteeing the mellow taste and stable quality of the black tea produced by the production process disclosed by the invention; and the Biluochun black tea disclosed by the invention has a red and transparent liquor colour in a glass cup, a fresh and strong aroma, and a mellow and sweet taste after being made with boiling water.

Owner:苏州市吴中区金庭镇天王坞茶果专业合作社

Process for removing silicon in green liquor of papermaking alkali recovery section by seeding

The invention provides a process for removing silicon in green liquor of a papermaking alkali recovery section by seeding. The technical scheme of the process is as follows: adding silica crystal micro-particles to the green liqor of the papermaking alkali recovery section, or regulating the pH value of the green liquor to 9-14 by utilizing acid or a carbon dioxidegas, and adding the silica crystal micro-particles to the green liquor; or adding acid to the green liquor in which the silica crystal micro-particles are added, wherein the reaction temperature is 20-100 DEG C, the reaction time is 5-120 minutes, and the pH value of the green liquor at an end point is controlled 7.5-11.5; and after finishing the reaction, and then removing separated silicic acid. In the process, the silica crystal micro-particles are added to the green liquor of the papermaking alkali recovery section, and then the acid or the carbon dioxide gas is added to the green liquor so as to gradually reduce the pH value of the green liquor, thus the silicon separated out from the green liquor grows on silica crystals to produce the particles with larger partical size; and the particles are deposited in and separated out from the green liquor as well as are removed by centrifugal separation or mechanical filter or sedimentation and other modes, thus the rate of silicon removal reaches over 90%.

Owner:SHAANXI UNIV OF SCI & TECH

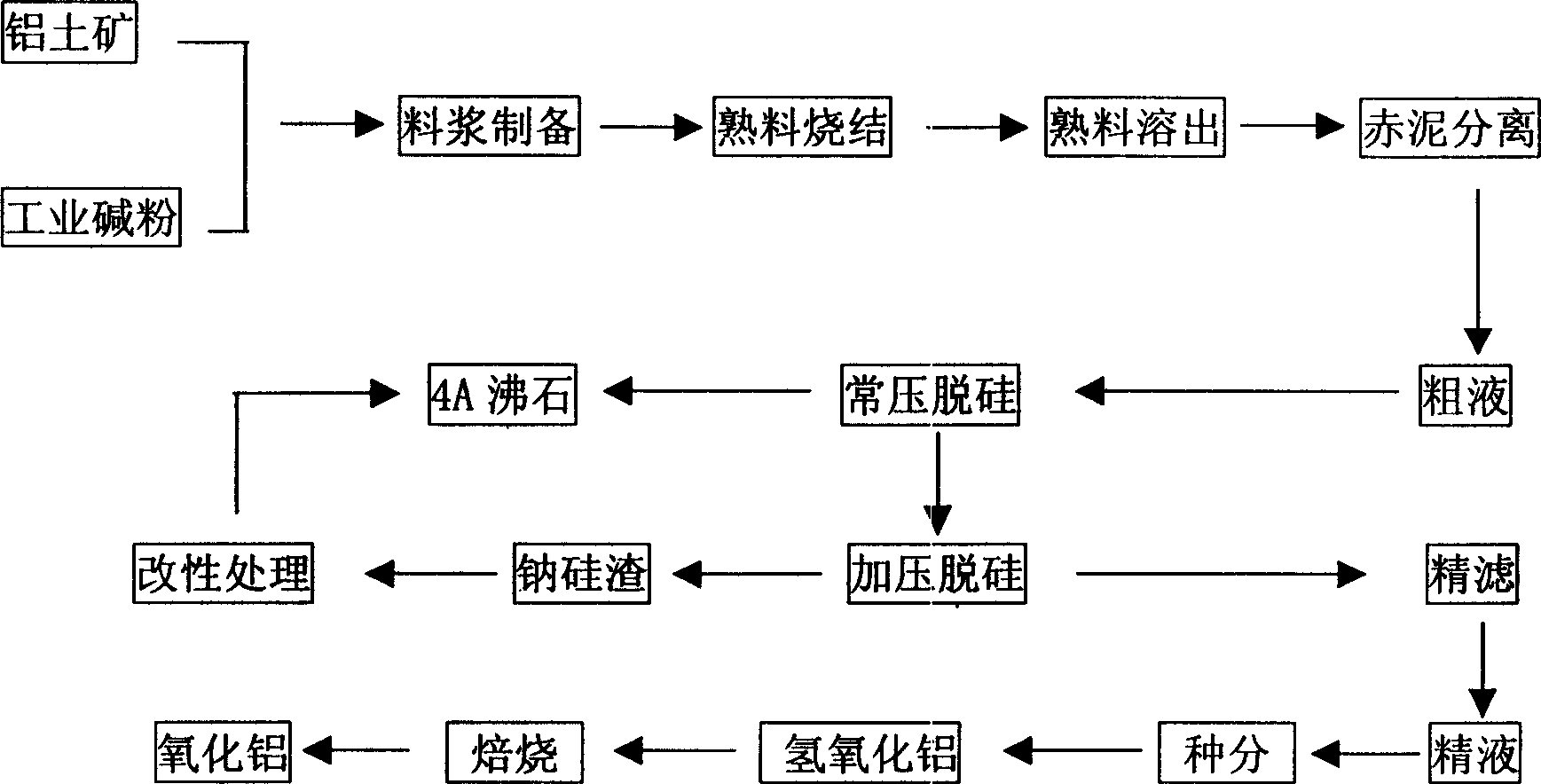

Process for preparing alumina by two-component sintering method

ActiveCN1579942AAvoid generatingRaise the gradeAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationRed mudAluminium hydroxide

The invention discloses a double-component sintering process to produce Alumina. Its technics include: batching, slime preparation, chamotte agglomeration, chamotte stripping, green liquor desilication and filtering to obtain aluminium hydroxide, after roasting to get Alumina. Its characters lie in that the Alumina is produced by bauxite and industrial ground caustic, two component batching. Compared with old high alumina silica ratio sintering process, grog reduced ratio reduces from 3.3-3.6 to 2.4-2.7, grog alumina grade improves from 38-40 percent to 45-50 percent, energy consumption reduces from 1,400-1,500kgbm to 1,100-1,300kgbm. Grog red mud yield reduces from 38 percent to 14 percent. The invention realizes target of little waste residue, high productivity, low cost and energy consumption and adapts to industrialized application.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com