Method for refining white clay calcium carbonate from green solution produced in alkali recovery from grass pulp

A technology of calcium carbonate and green liquor, applied in the field of papermaking industry, can solve problems such as secondary pollution, and achieve the effects of cost saving, uniform crystal form, and reduction of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

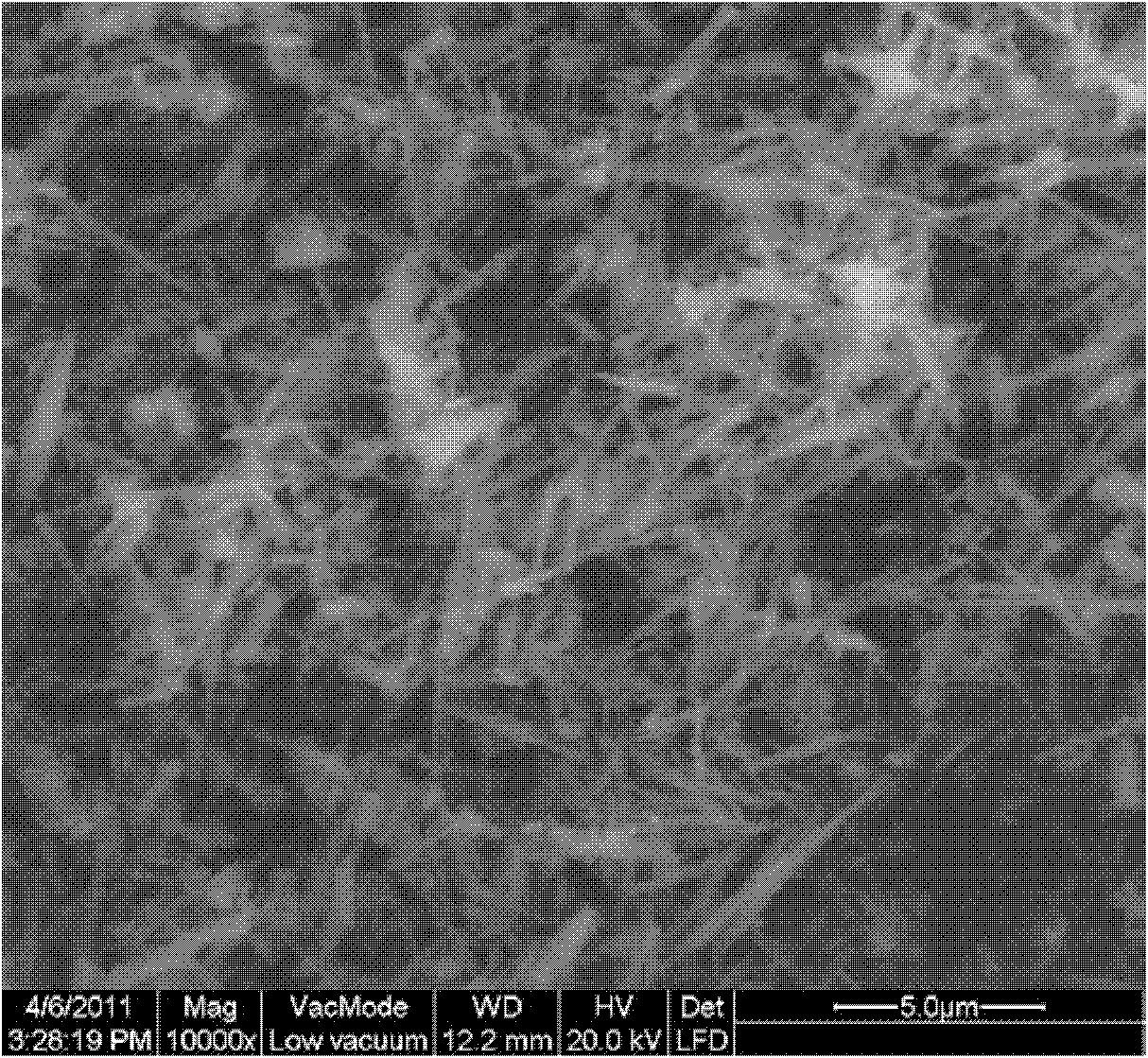

Image

Examples

Embodiment 1

[0010] Embodiment 1, quicklime is added in water and quicklime is digested and made mass concentration completely and is 10% lime solution; Add 0.02ml straw pulp green liquor by every gram of quicklime, straw pulp green liquor is added in lime solution and causticizing reaction occurs, reaction The temperature is 10°C, and the stirring speed is 5000rpm to make white mud calcium carbonate.

Embodiment 2

[0011] Embodiment 2, quicklime is added in water and quicklime is digested and made mass concentration completely and is 30% lime solution; Add the straw pulp green liquor of 0.08ml by every gram of quicklime, straw pulp green liquor is added in the lime solution and causticizing reaction occurs, reaction The temperature is 50°C, and the stirring speed is 100rpm to make white mud calcium carbonate.

Embodiment 3

[0012] Embodiment 3, quicklime is added in water and quicklime is digested and made mass concentration completely and is 20% lime solution; Add the straw pulp green liquor of 0.3ml by every gram of quicklime, straw pulp green liquor is added in the lime solution and causticizing reaction occurs, reaction The temperature is 80°C, and the stirring speed is 2000rpm to make white mud calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com