Scouring and bleaching agent combination and application thereof

A composition and technology of scouring and bleaching agent, applied in the field of scouring and bleaching agent composition and its application, can solve the problems affecting the effect of scouring and bleaching, and achieve the effect of high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] The preparation technology of bleaching agent composition of the present invention is:

[0086] 1. The preparation operation is carried out at room temperature in a solid mixing tank.

[0087] 2. Add the adsorption detergent, water-soluble alkali, scouring and bleaching synergist and chelating dispersant into the solid mixing kettle, and start stirring to mix evenly.

[0088] 3. While stirring, slowly add the surfactant to the above mixture, stir well and mix evenly.

[0089] 4. The output is the finished product.

[0090] The specific technological process that the scouring and bleaching agent composition of the present invention is applied on the continuous process of scouring and bleaching of cotton and blended fabrics is:

[0091] Gray cloth turning --- singeing --- padding and desizing liquid --- stacking --- washing --- padding --- padding and bleaching liquid (including scouring and bleaching agent) --- steaming --- -washing---drying---mercerizing---washing---...

Embodiment 1

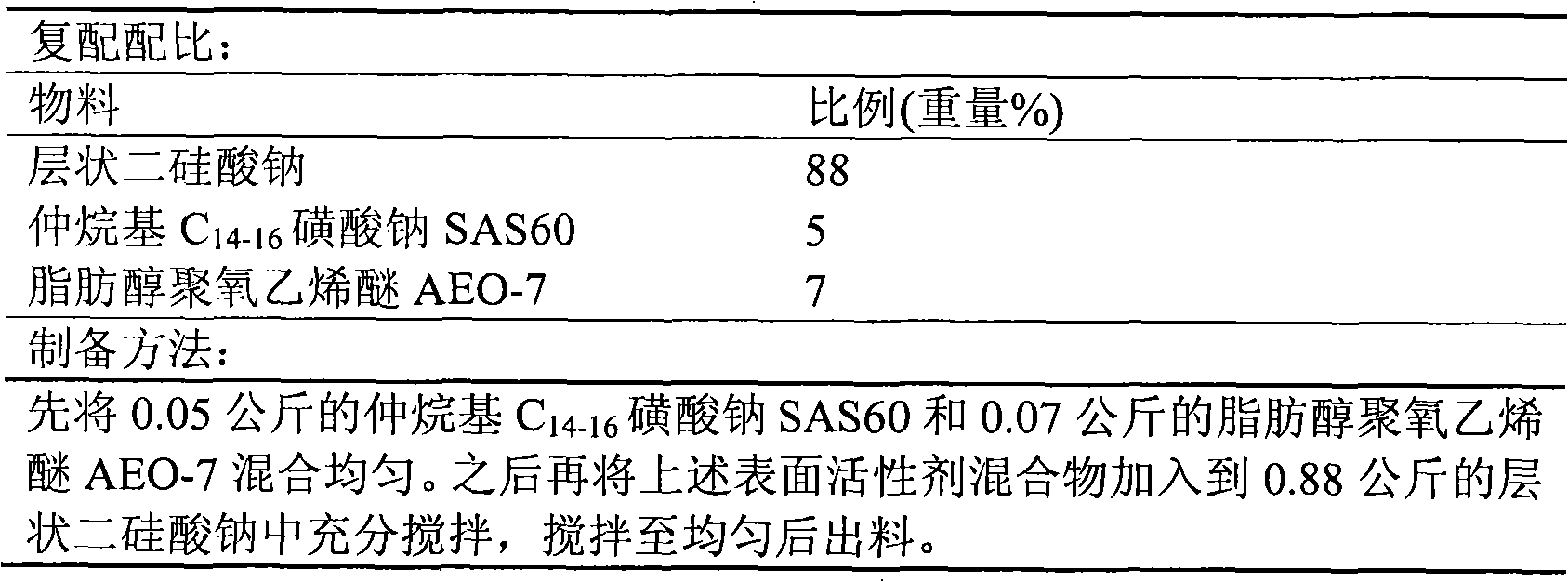

[0111] Table 1

[0112]

Embodiment 2

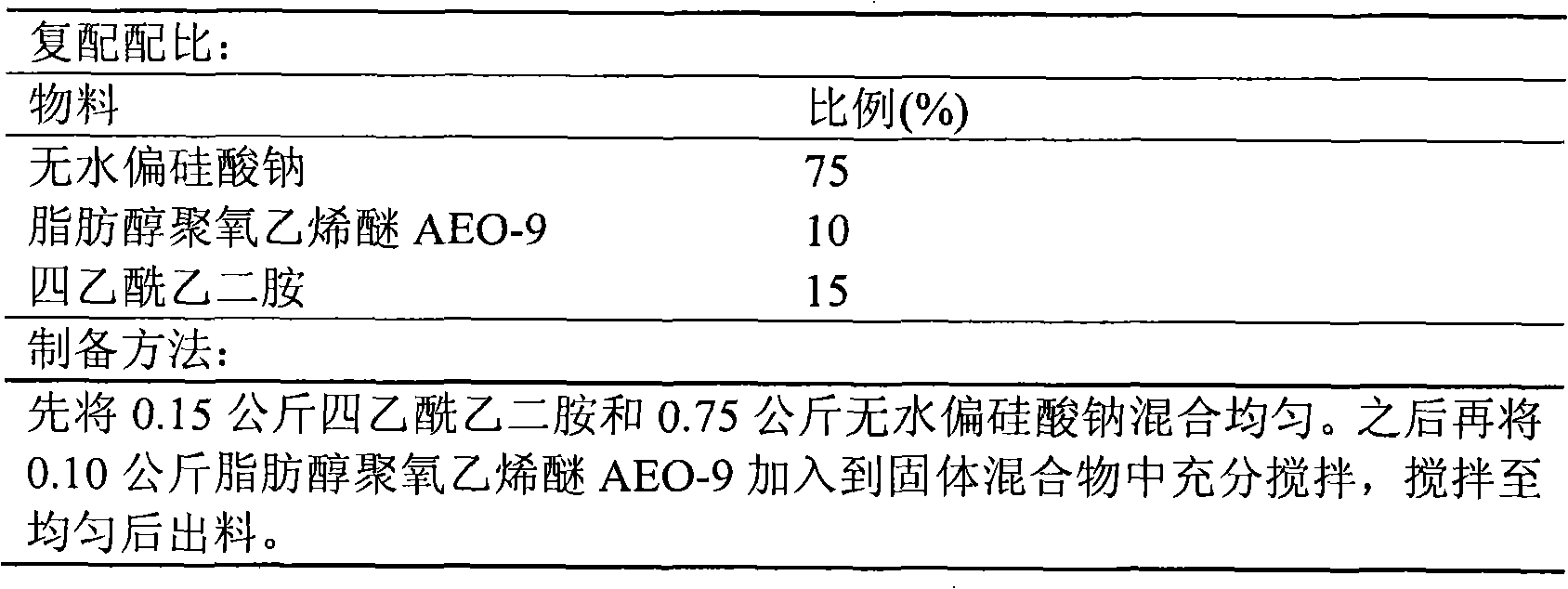

[0114] Table 2

[0115]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com