Patents

Literature

153 results about "Clean appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

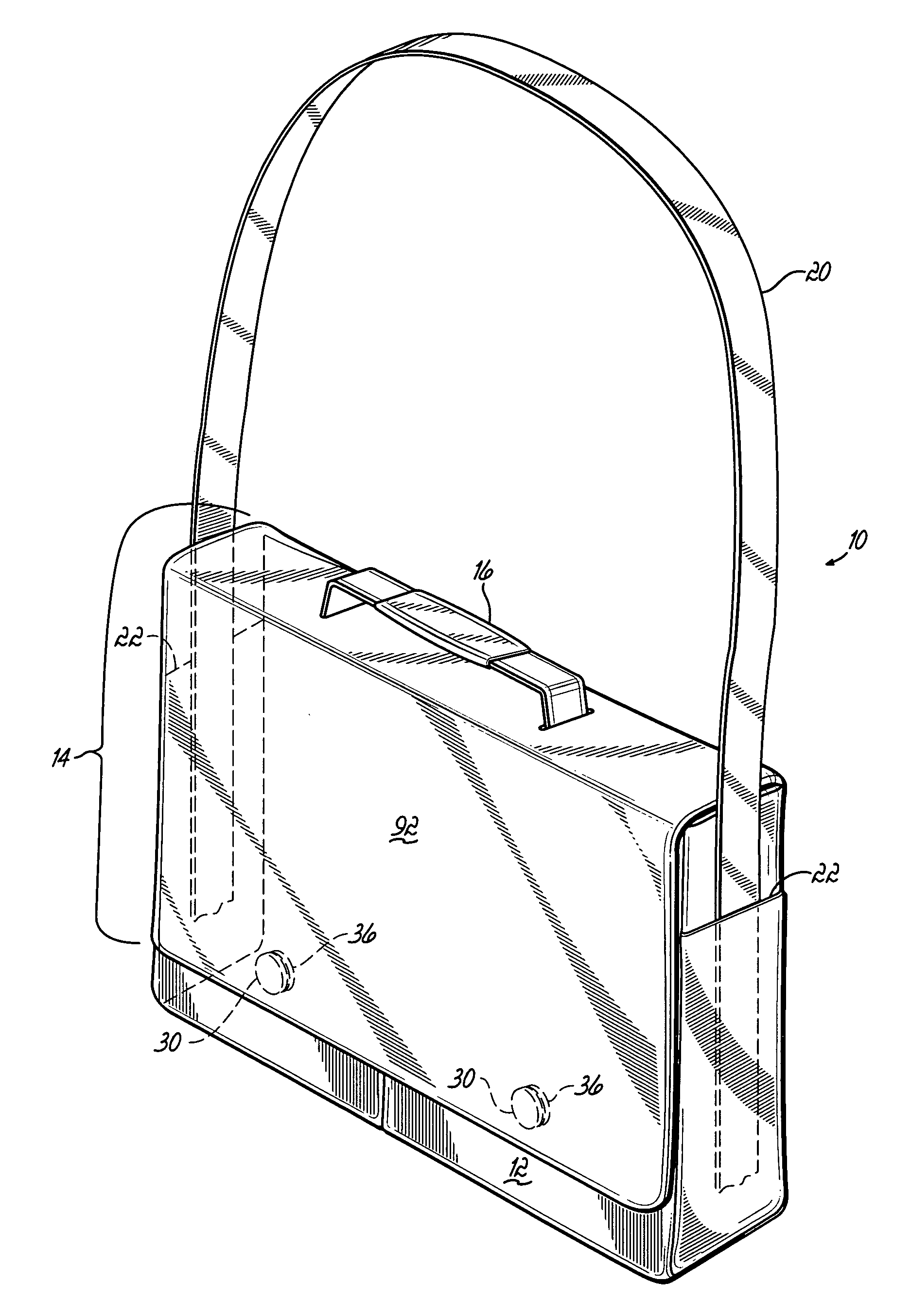

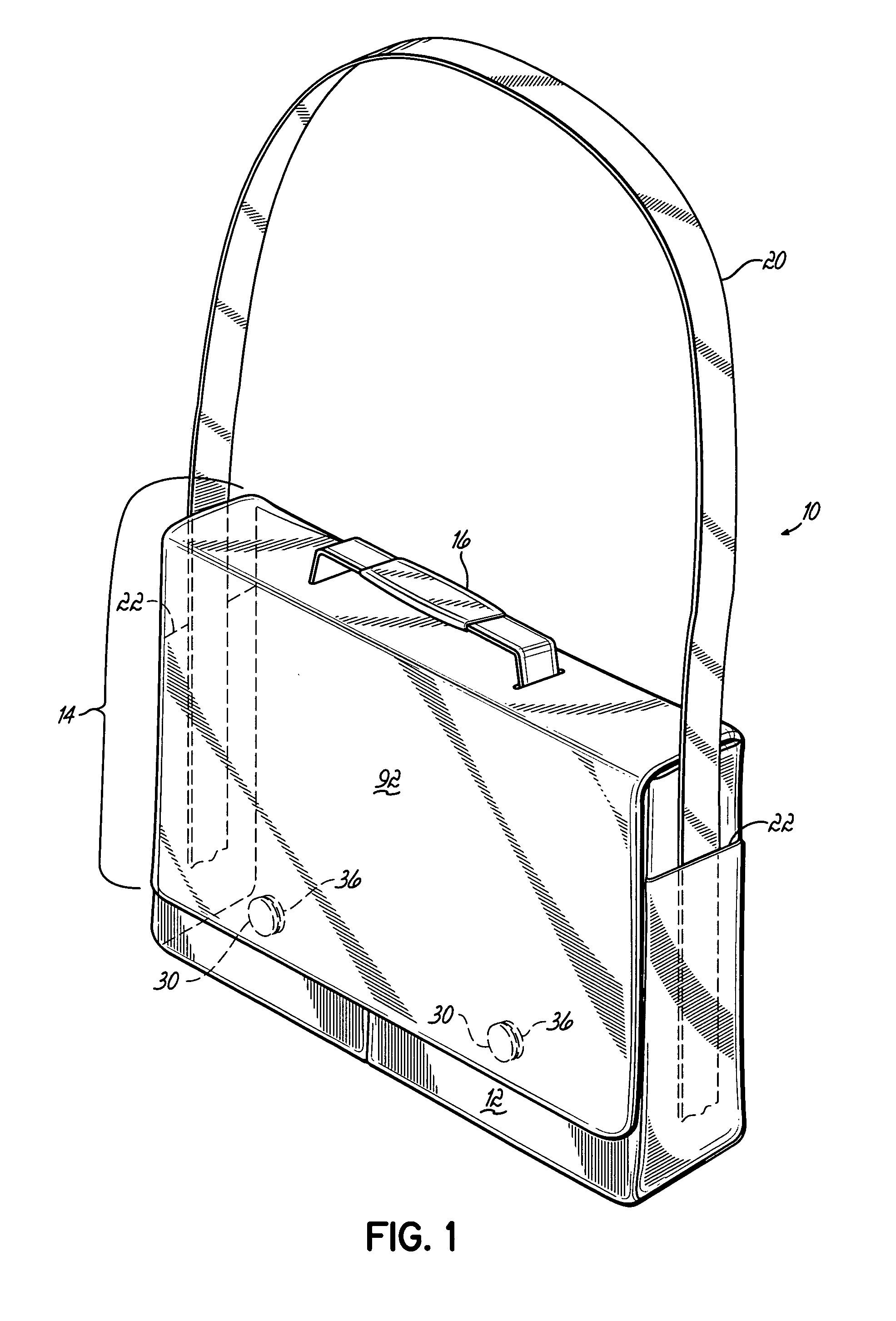

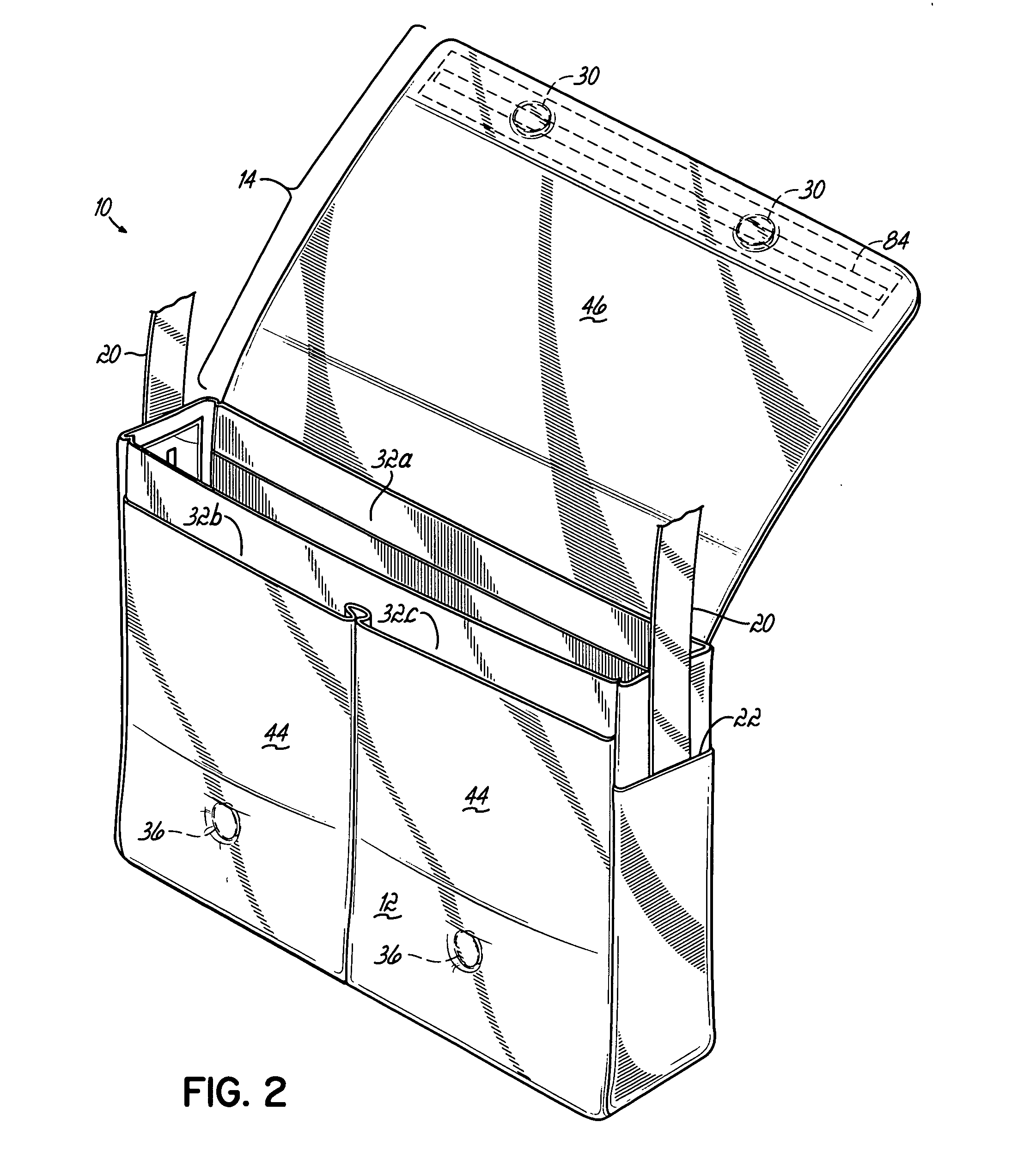

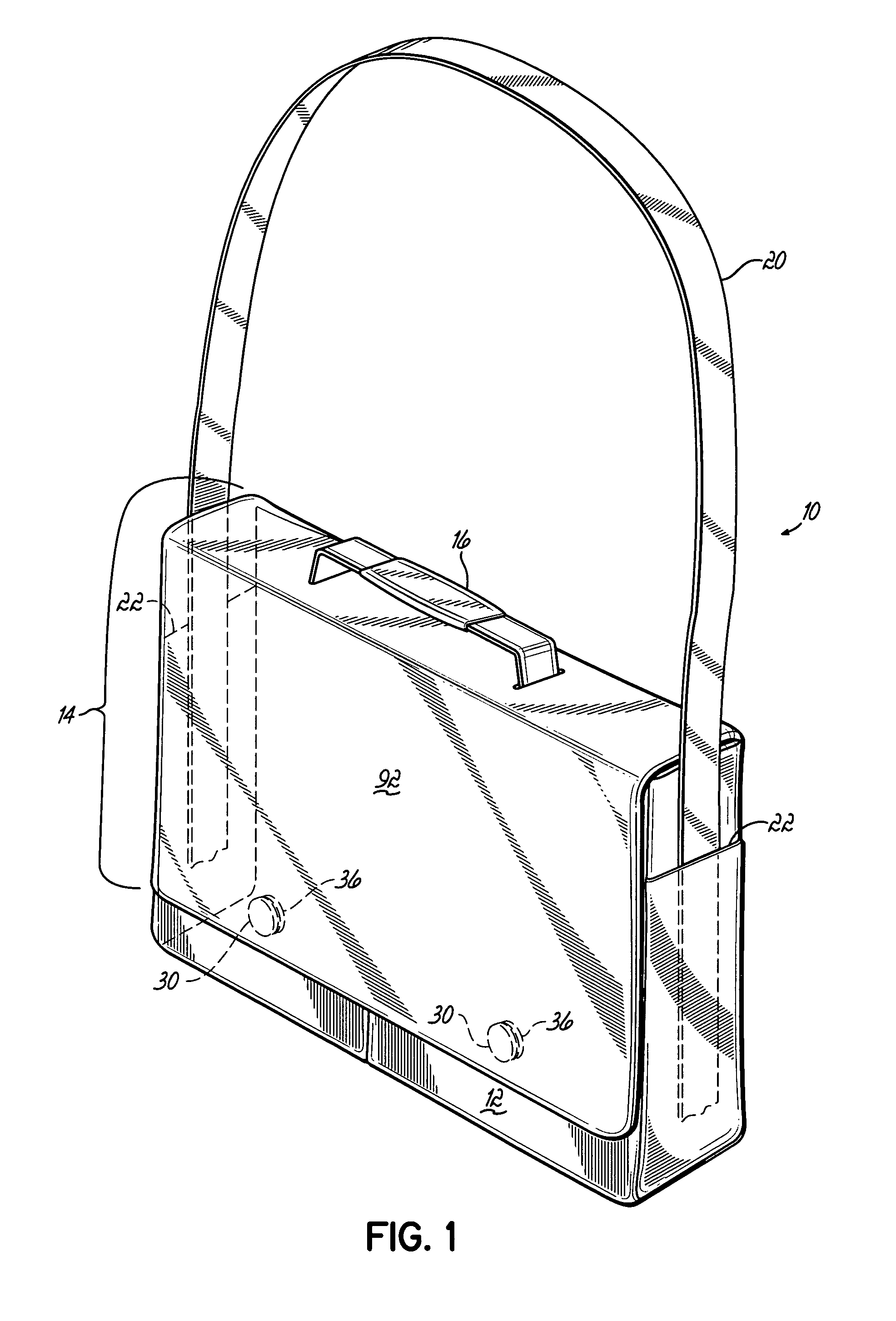

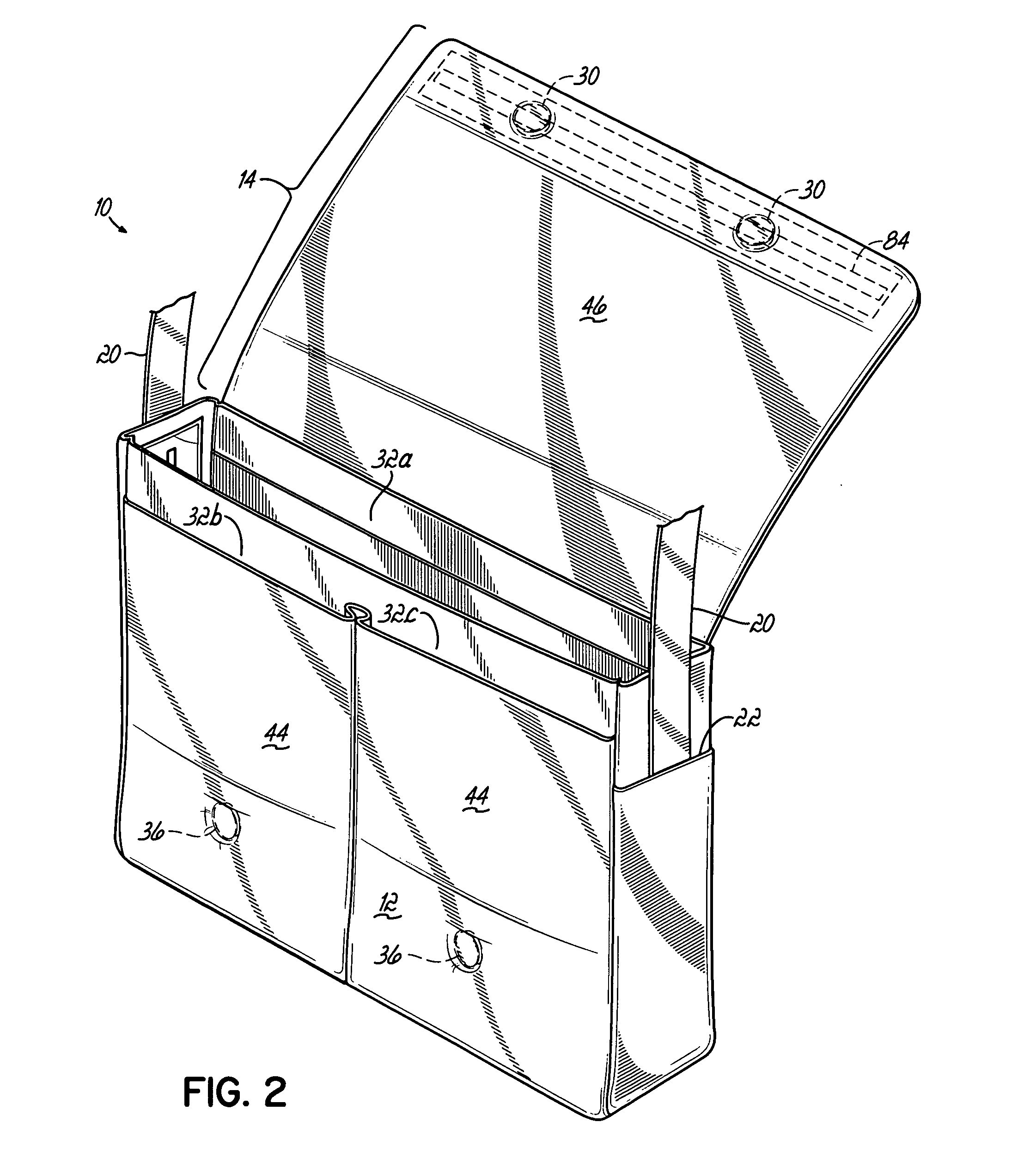

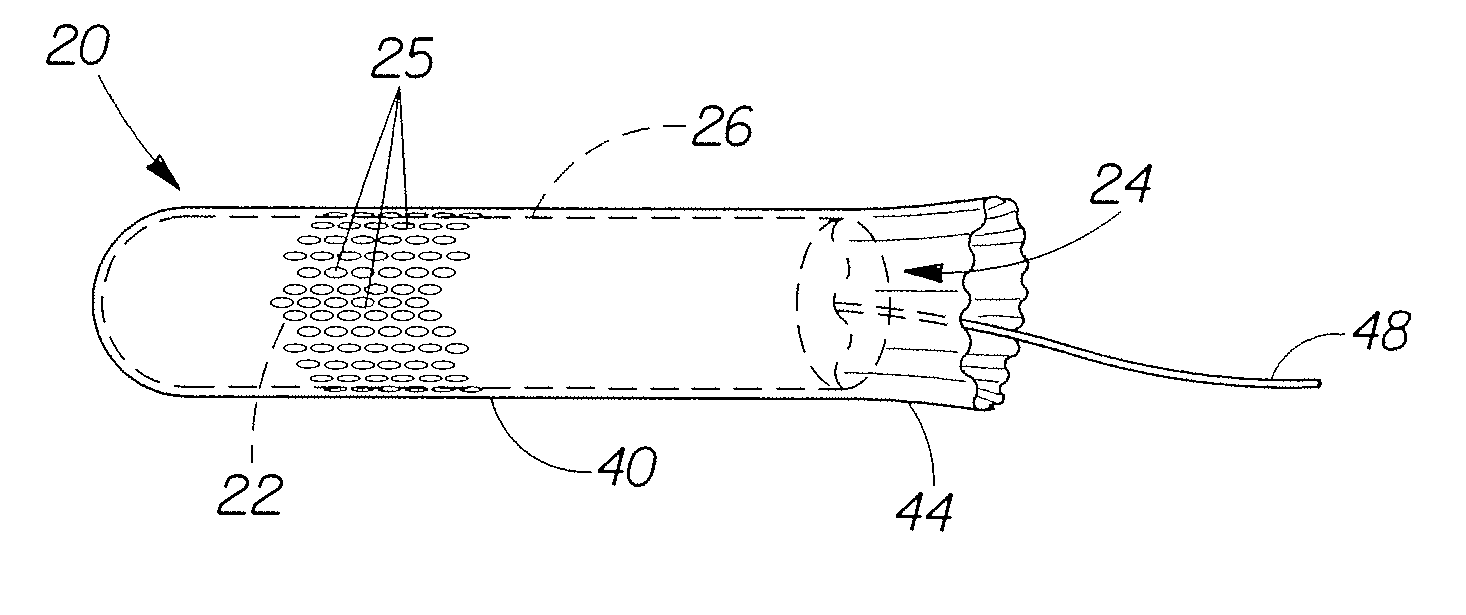

Article storage bag

ActiveUS20070199966A1Dissipating magnetic flux densityAccurate configurationTravelling sacksTravelling carriersClean appearanceElectrical and Electronics engineering

An article storage bag is described, having a concealed magnetic closure system and concealed strap adjustment system. The bag presents a clean appearance, without any apparent components for adjusting the carrying strap length.

Owner:KORCHMAR MICHAEL D

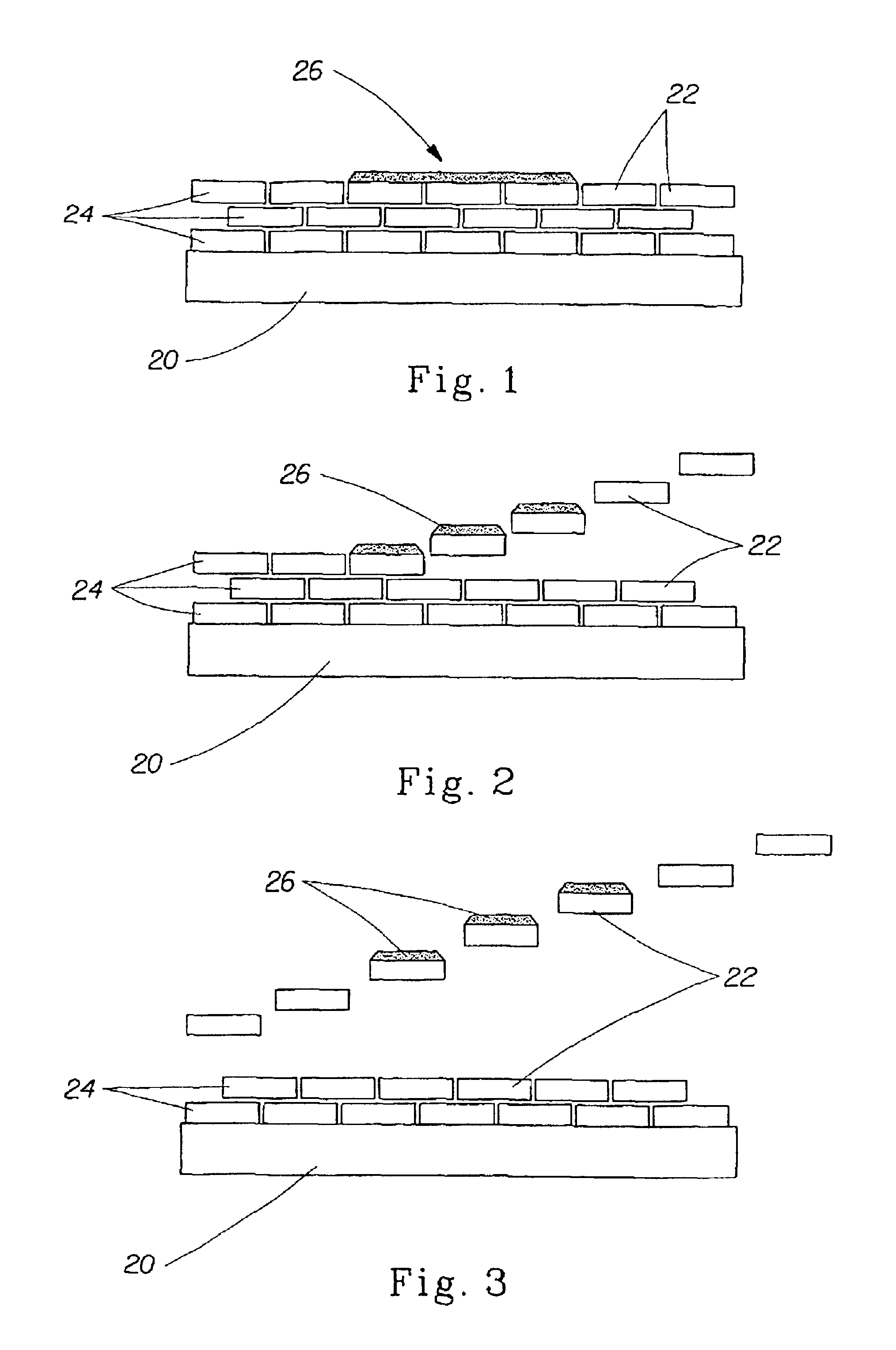

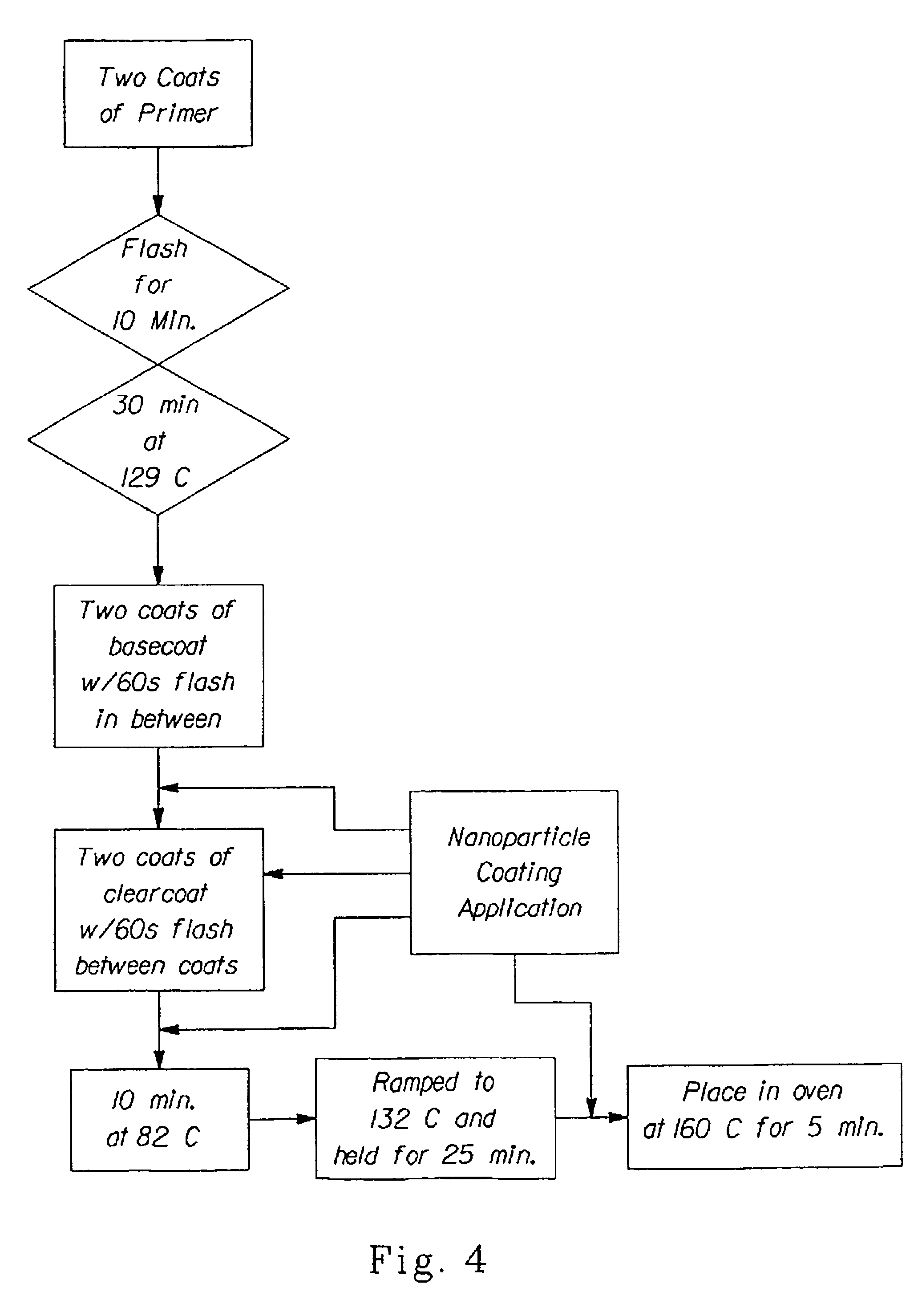

Long lasting coatings for modifying hard surfaces and processes for applying the same

InactiveUS6955834B2Improve smoothnessImprovement in wetting and sheetingInorganic/elemental detergent compounding agentsOrganic anion exchangersMetallurgyDefect repair

Materials for coating, coating compositions, methods and articles of manufacture comprising a nanoparticle system or employing the same to impart surface modifying benefits for all types of inanimate hard surfaces are disclosed. In some embodiments, dispersement of nanoparticles in a suitable carrier medium allows for the creation of coating compositions, methods and articles of manufacture that create multi-use benefits to modified hard surfaces. These surface modifications can produce long lasting or semi-permanent multi-use benefits that include at least one of the following improved surface properties: wetting and sheeting, quick drying, uniform drying, soil removal, self-cleaning, anti-spotting, anti-soil deposition, cleaner appearance, enhanced gloss, enhanced color, minor surface defect repair, smoothness, anti-hazing, modification of surface friction, release of actives and transparency, relative to hard surfaces unmodified with such nanoparticle systems. Actively curing the coating composition on the hard surfaces, including, but not limited to by radiative heating the air surrounding the hard surface with the coating thereon can be used to increase the durability of the hard surface coating.

Owner:THE PROCTER & GAMBLE COMPANY

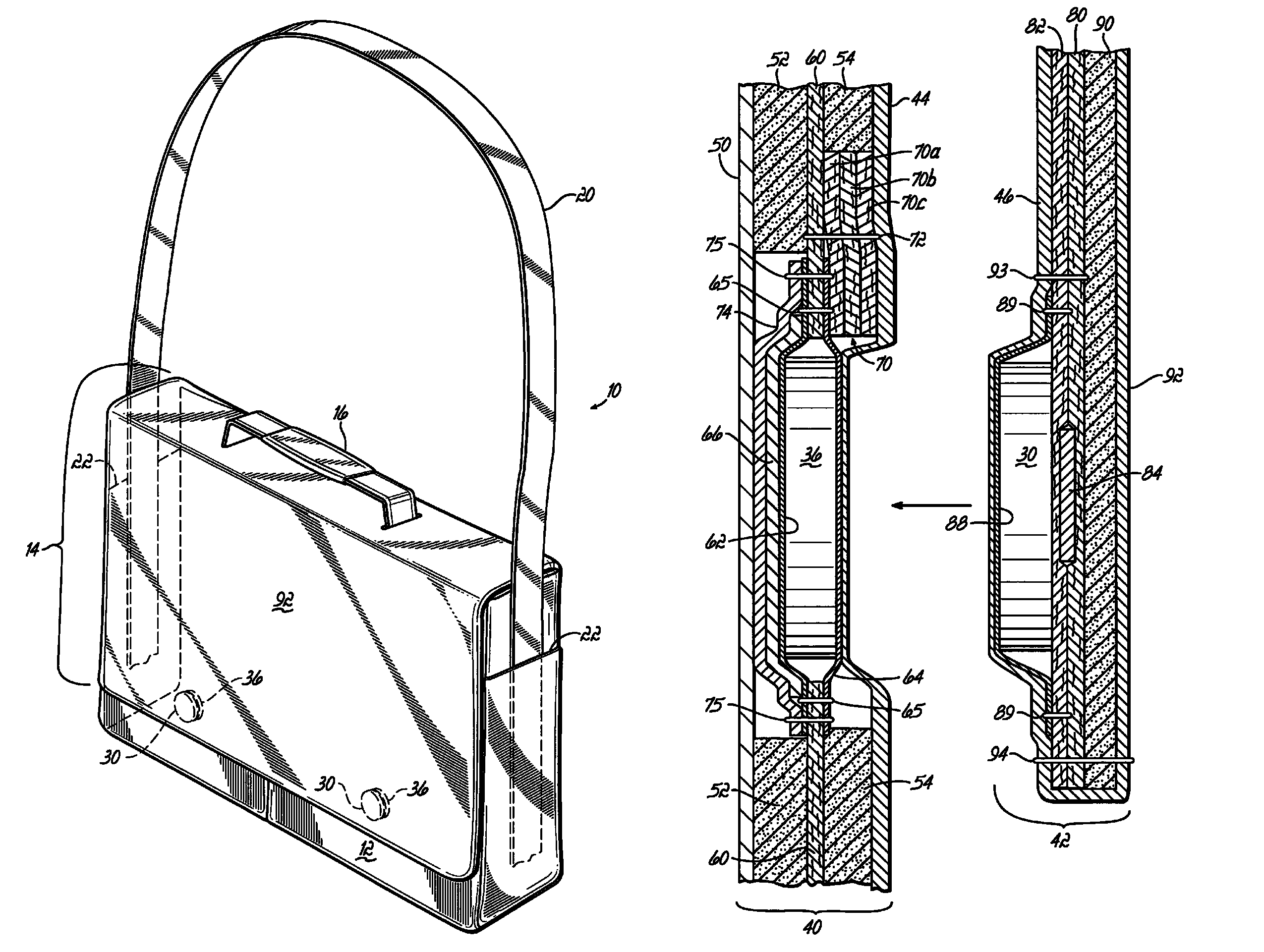

Article storage bag

ActiveUS7806309B2Magnetic flux densityTravelling sacksTravelling carriersClean appearanceElectrical and Electronics engineering

An article storage bag is described, having a concealed magnetic closure system and concealed strap adjustment system. The bag presents a clean appearance, without any apparent components for adjusting the carrying strap length.

Owner:KORCHMAR MICHAEL D

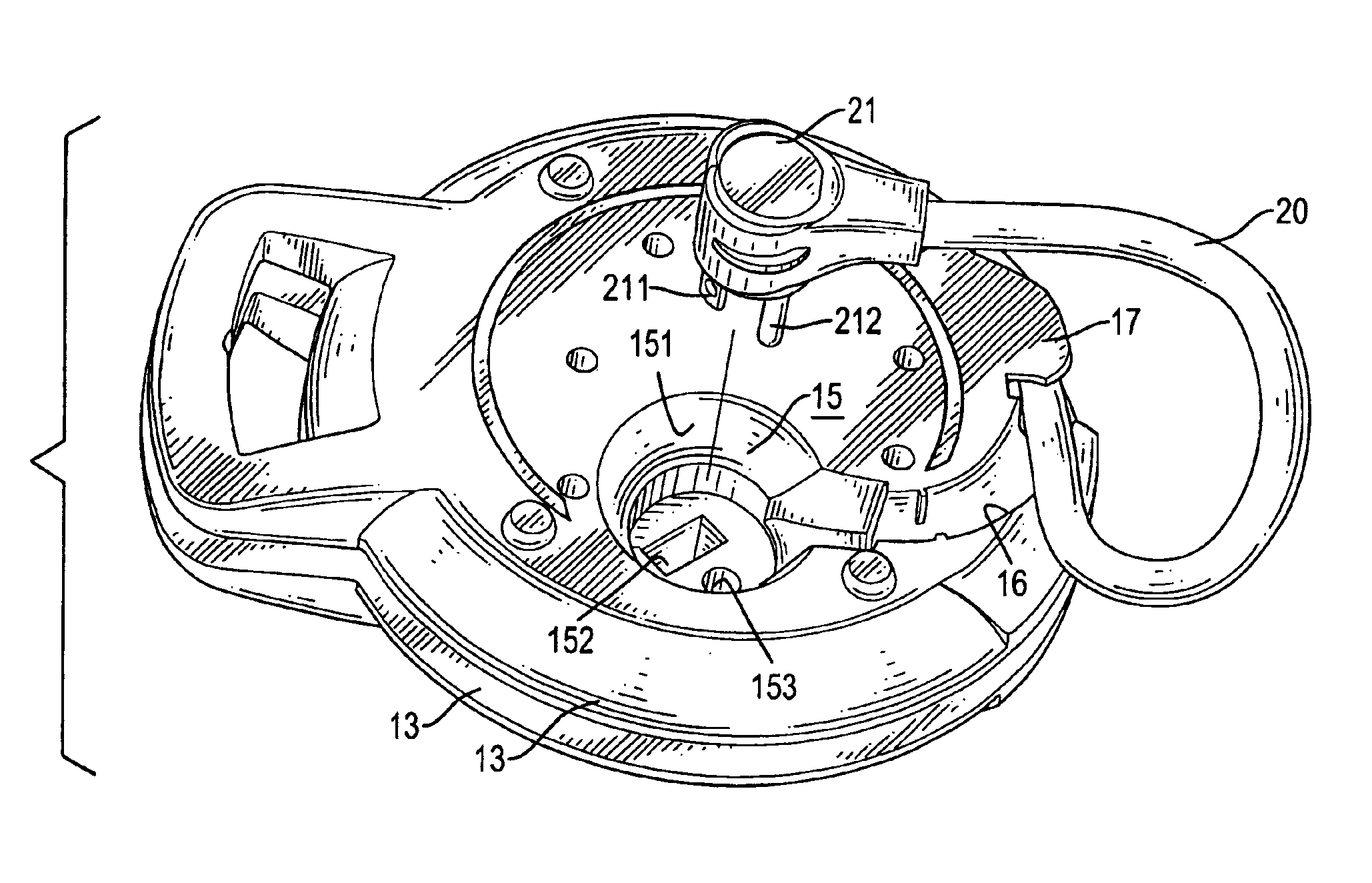

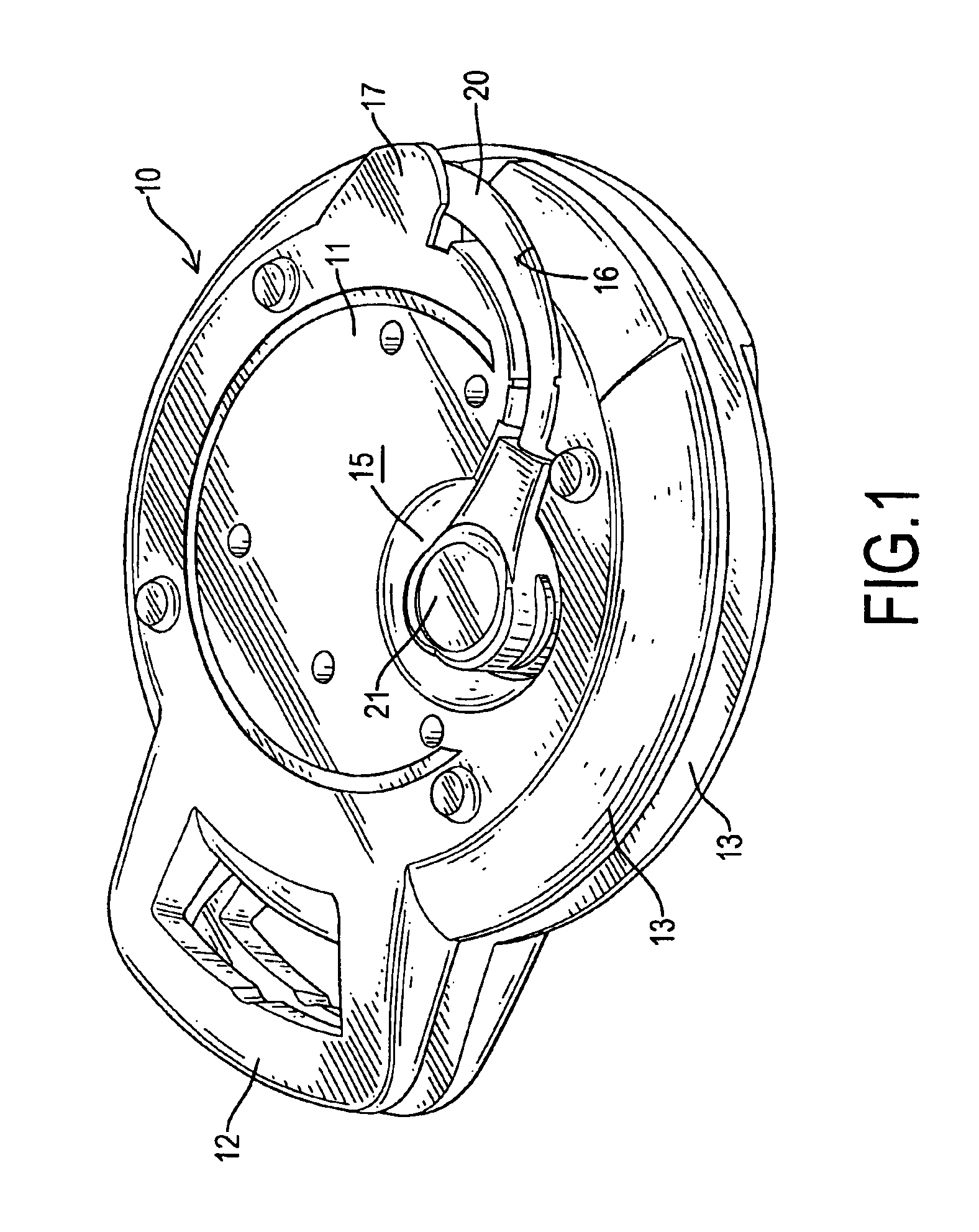

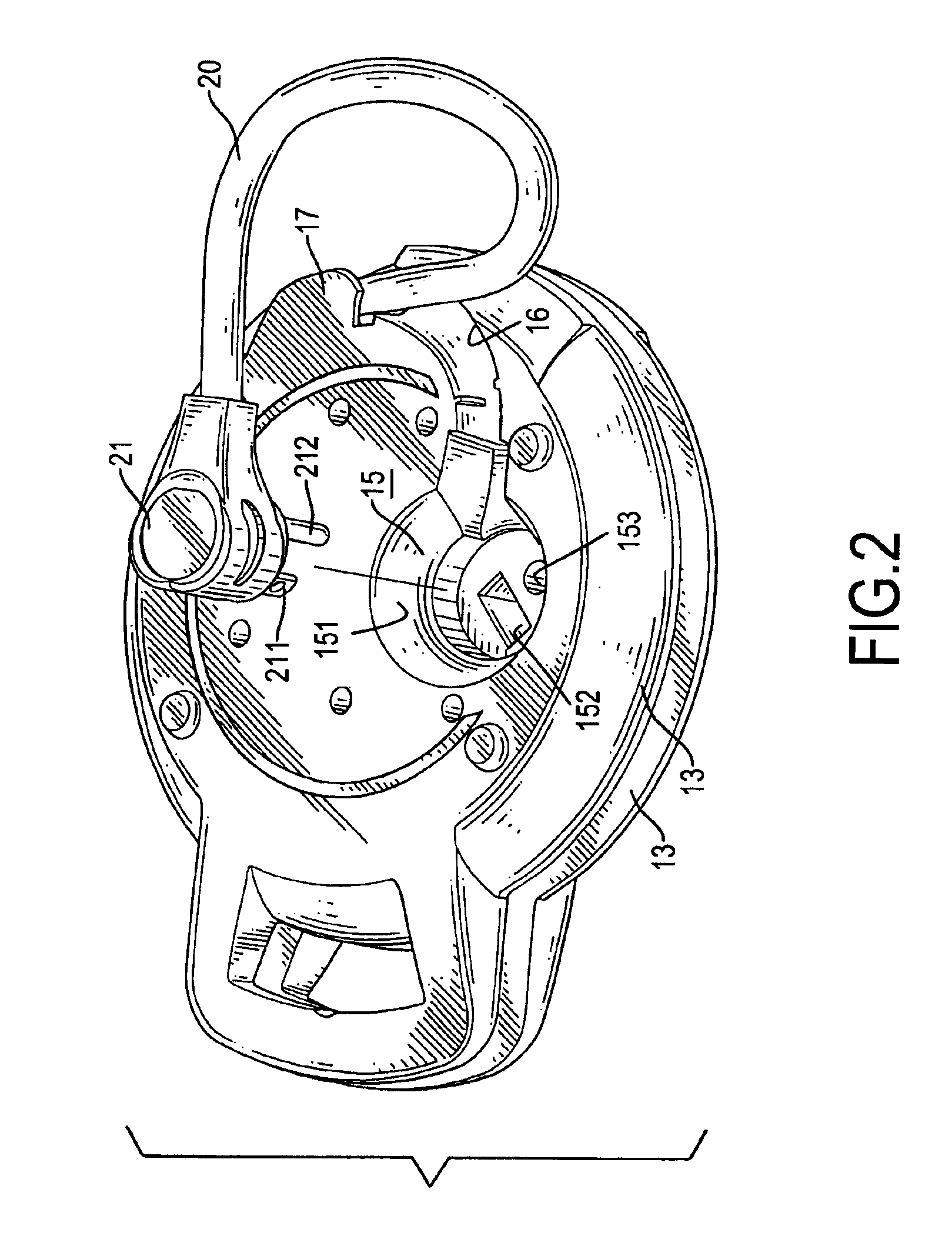

Retractable extension cord housing having a low-profile plug holder

ActiveUS6848937B1Arrangements using take-up reel/drumFlexible lead accommodationEngineeringClean appearance

Owner:HSIAO FENG SHEN

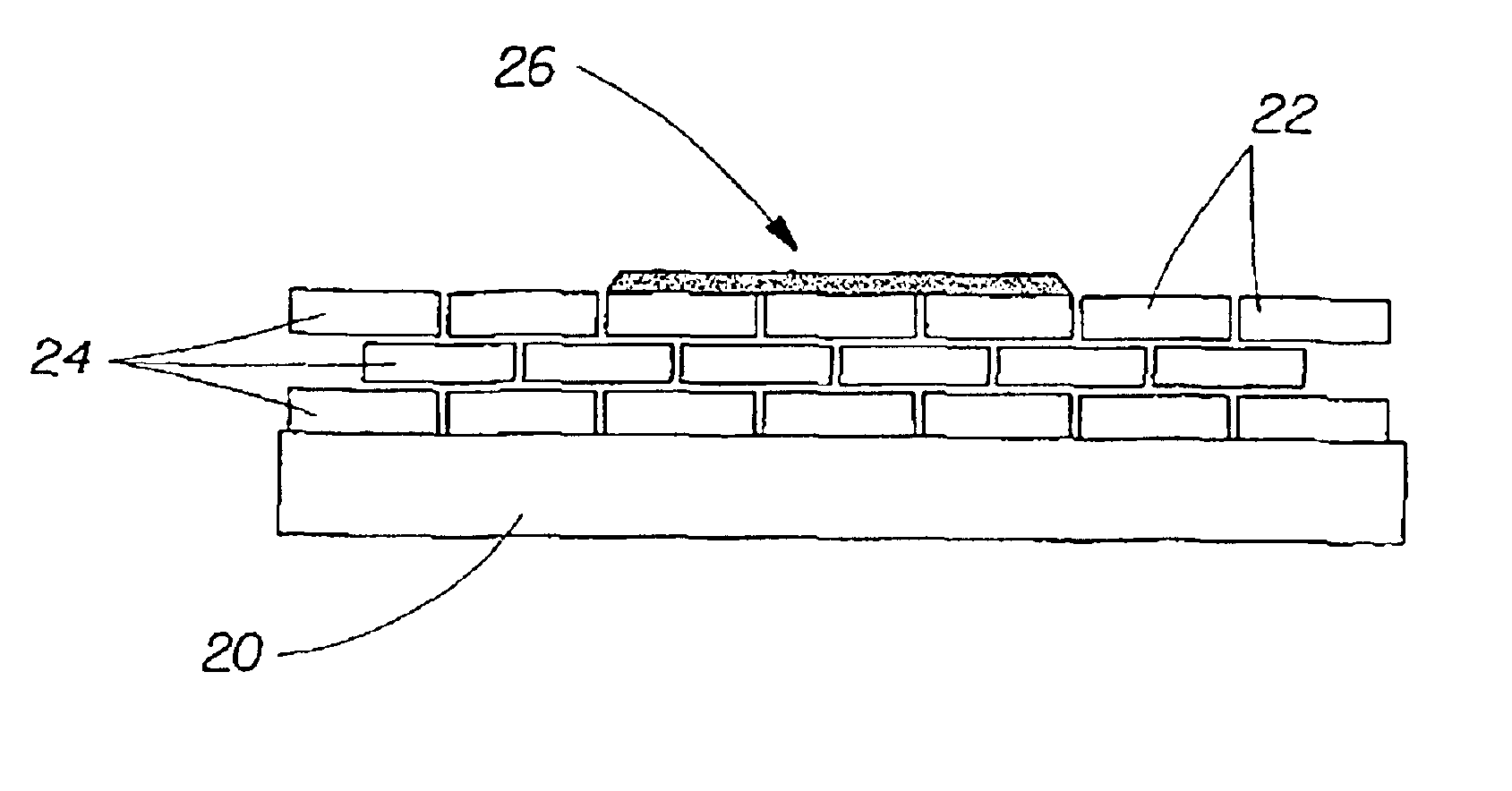

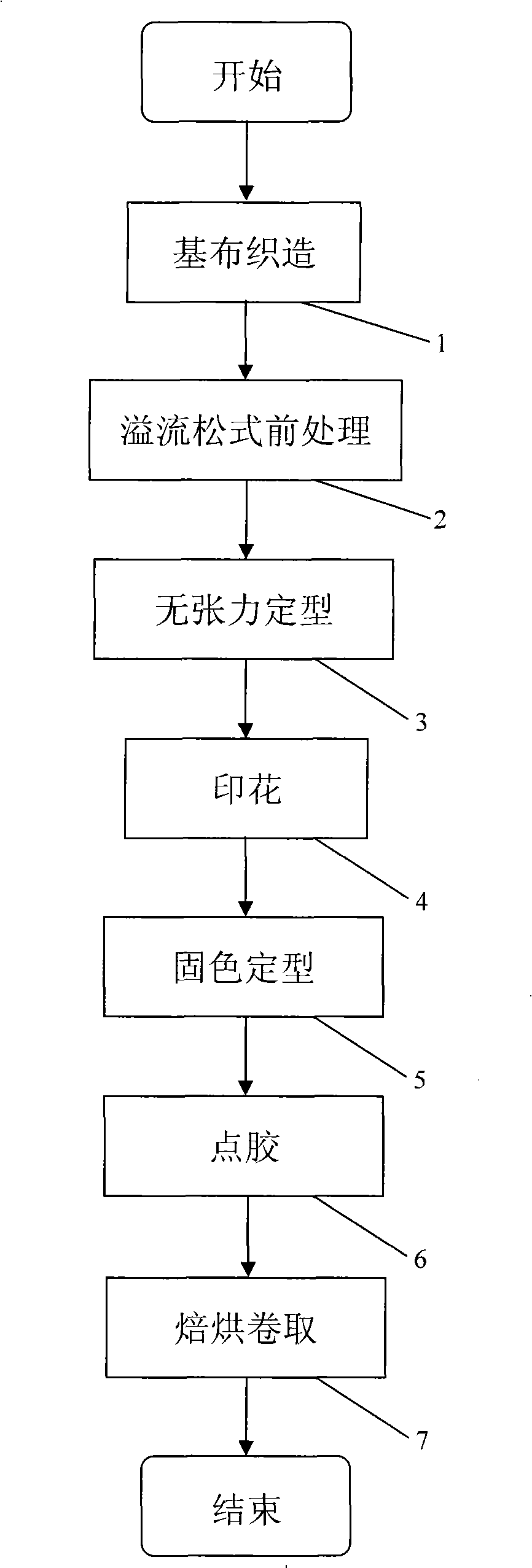

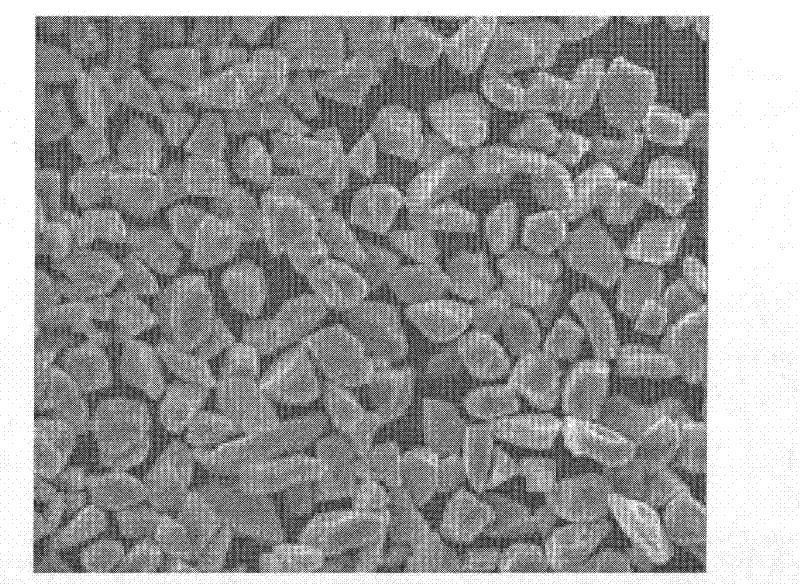

Technique for preparing multifunctional liner of printing sarcenet

The invention discloses a production technology of multifunctional liner of printing lining, which sequentially includes the steps of basic fabric weaving, loosening overflow pretreatment, tension-free shaping, printing, color fixing and shaping, gluing, baking, rolling, etc. By adopting the loosening pre-shrinking shaping technology, the invention can cause fiber pores to be tighter, thus generating loose and clean appearance. Dual point coating is conducted by adopting thermosetting-typed hot melt glue of polyurethane and polyamide; the hot melt glue of polyurethane after heating loses cross linking generated by hydrogen bonds in polyurethane molecules and changes into melt viscous fluid, and after cooling, the hot melt glue of polyurethane recovers to the original property; both the polyurethane and the polyamide at the upper layer have good elasticity and strength and comparatively good affinity and can integrate with each other and endure various washing methods. The production technology is applicable to various fiber fabrics without glue seeping and can realize the integration of products with fabrics by ironing. The interlining produced by the technology is light and soft and has good drape property and is applicable to being as the fabrics of upscale wear of women.

Owner:严华荣

A kind of production method of silicon wafer cutting blade material

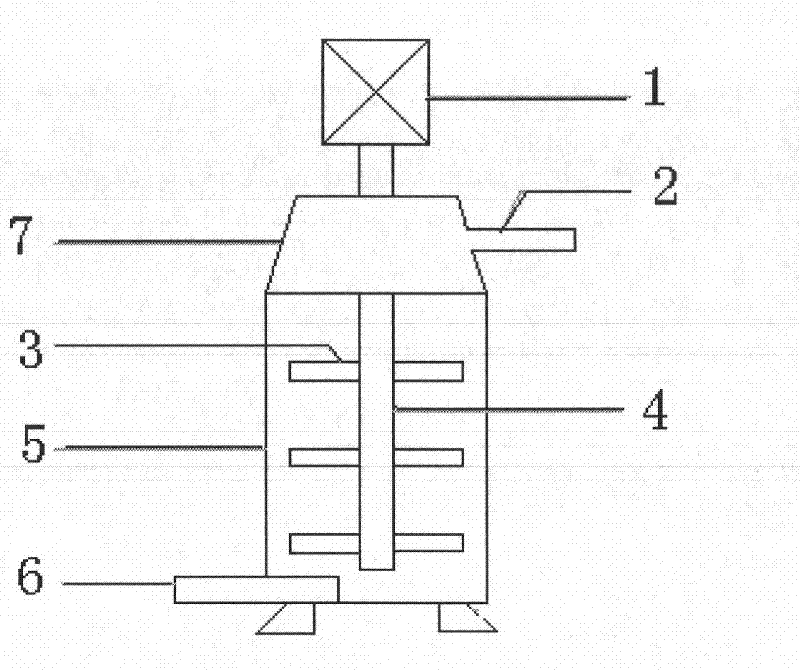

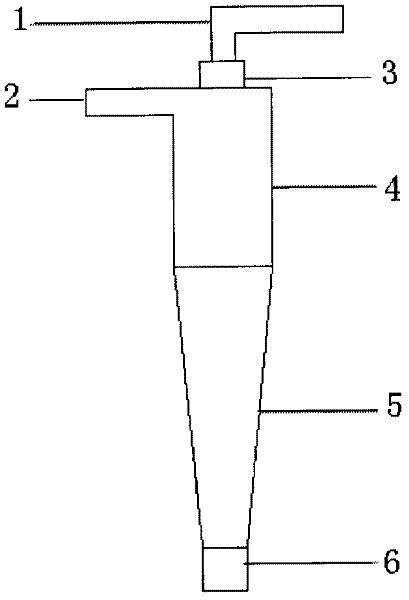

The invention relates to a production method of a silicon wafer cutting blade material. The production method of the silicon wafer cutting blade material uses high-purity green silicon carbide as the raw material and comprises the following steps: performing jaw crushing, screening, performing automatic circulation type wet ball milling and hydraulic cyclone classification, performing automatic overflow carbon removal, performing magnetic separation to automatically remove iron, performing alkali washing, cleaning, performing overflow classification under automatic control of a programmable logic controller (PLC), centrifuging to dewater, drying, mixing, performing fine screening and the like. The silicon carbide blade material prepared by the method has equiareal shape, sharp edges and high cutting capability; the blade material particles have large specific surface area and clean appearance and high suitability to cutting fluid such as polyethylene glycol; the product ground by automatic circulation type wet ball milling and cyclone classification has more equiareal shapes, good grain shape and high yield, and overgrinding can be avoided; and automatic magnetic separation is adopted to perform acid-free iron removal, thus the method has high efficiency, environmental friendliness and high degree of automation and is suitable for large-scale production. The product ground by the method has high particle size concentration degree and good grain shape, and better cutting effect can be realized.

Owner:JIANGSU TAYAL PHOTOVOLTAIC AUXILIARY MATERIAL

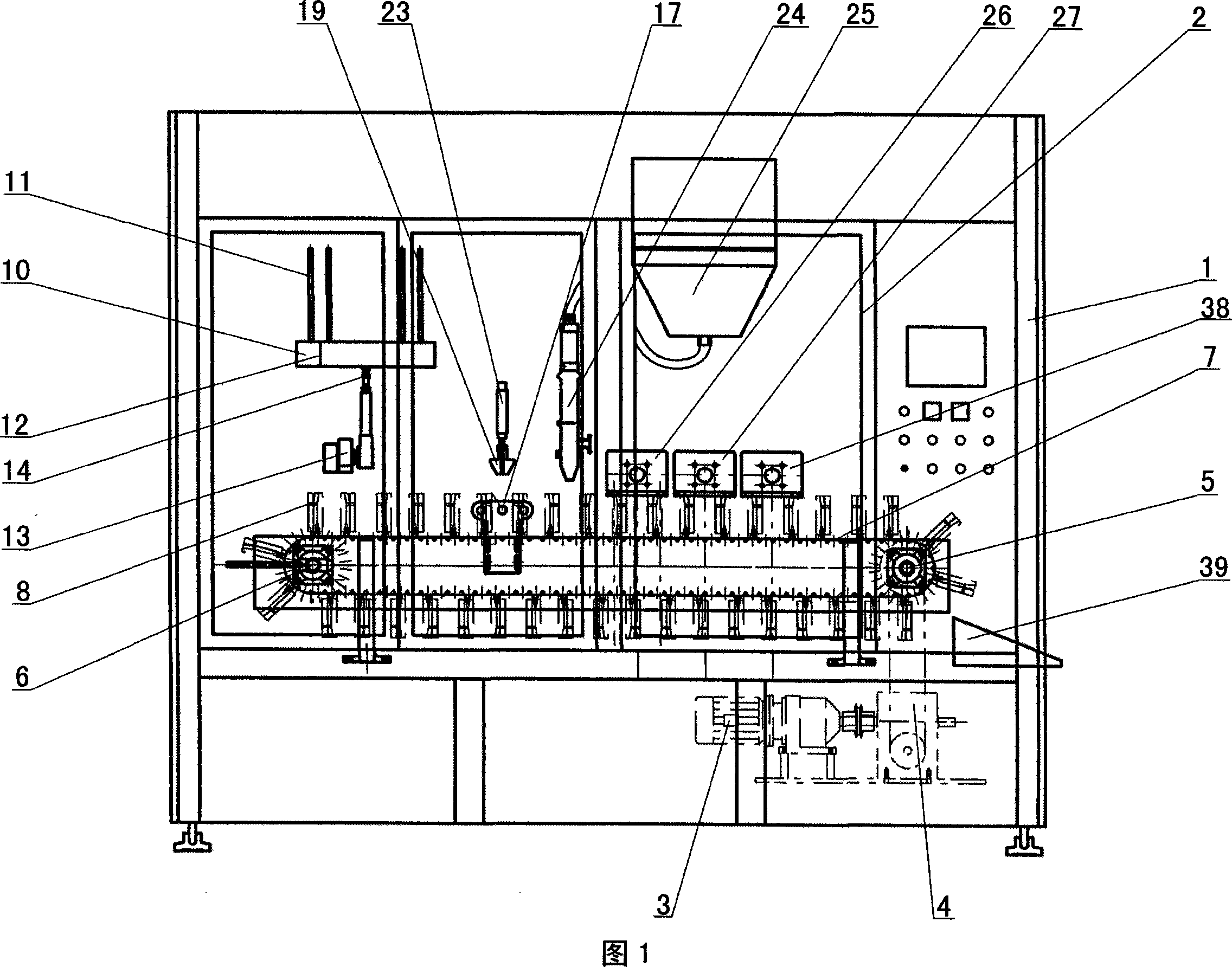

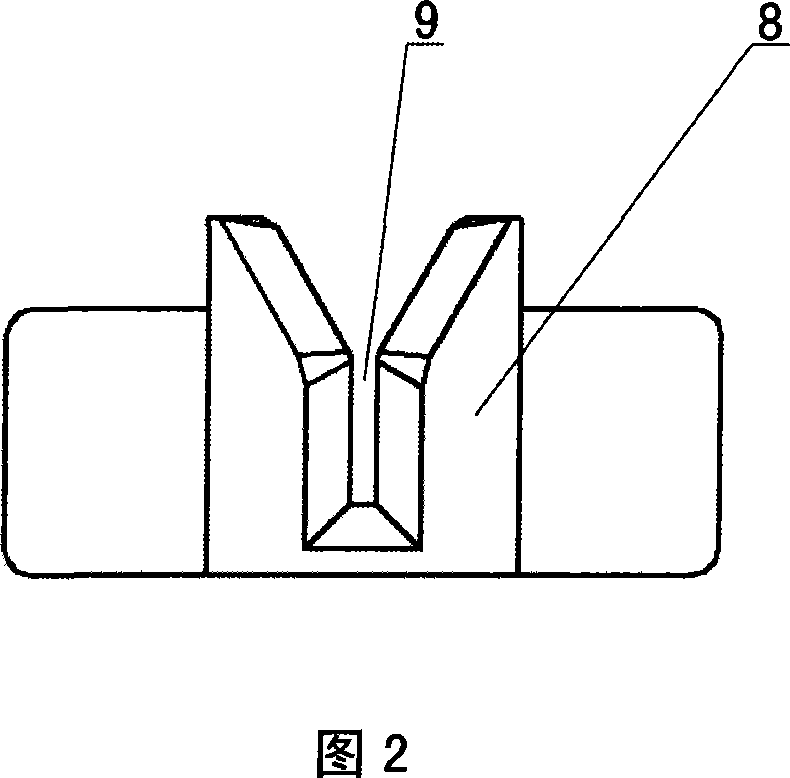

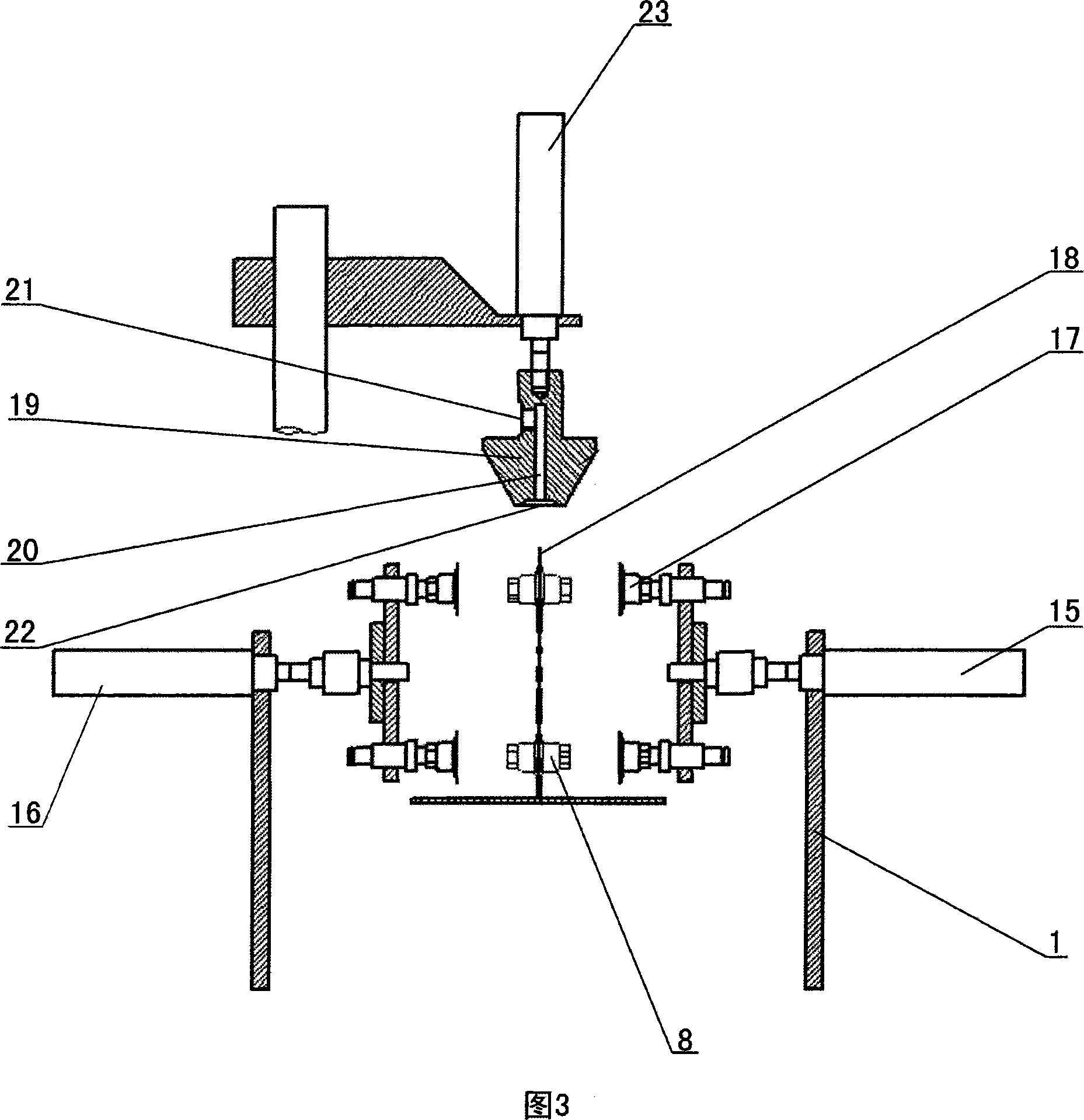

Automatic bag-feeding filling sealer

ActiveCN101074054ARealize automated productionReduce labor intensityWrapper twisting/gatheringControl systemClean appearance

The invention is concerned with a kind of automatic filling capper for bag, relates to machine rack, feeding equipment, filling equipment, heating and close equipment and cool and shaping equipment. The sending equipment is on the machine rack, the filling equipment, heating and close equipment and cool and shaping equipment on the rack and at the top of sending equipment in turn. The capper relates to bag-feeding equipment and bag-expanding equipment both on the rack. The bag-feeding equipment is on the top of import end of feeding equipment, while the bag-expanding equipment is between the bag-feeding equipment and filling equipment. For the capper has bag-feeding equipment and bag-expanding equipment, the whole work circulation is controlled by PLC control system to reduce work force greatly and enhance the production efficiency. The bag-expanding effect is good with high precision filling amount. It has easy structure with clean appearance and fit for the demand of foodstuff sanitation.

Owner:汕头市高雄海包装机械有限公司

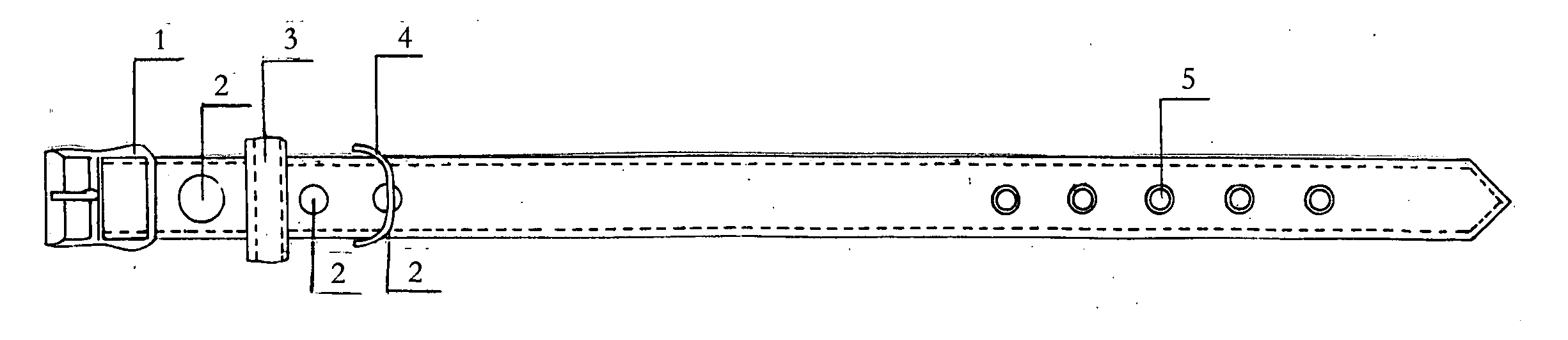

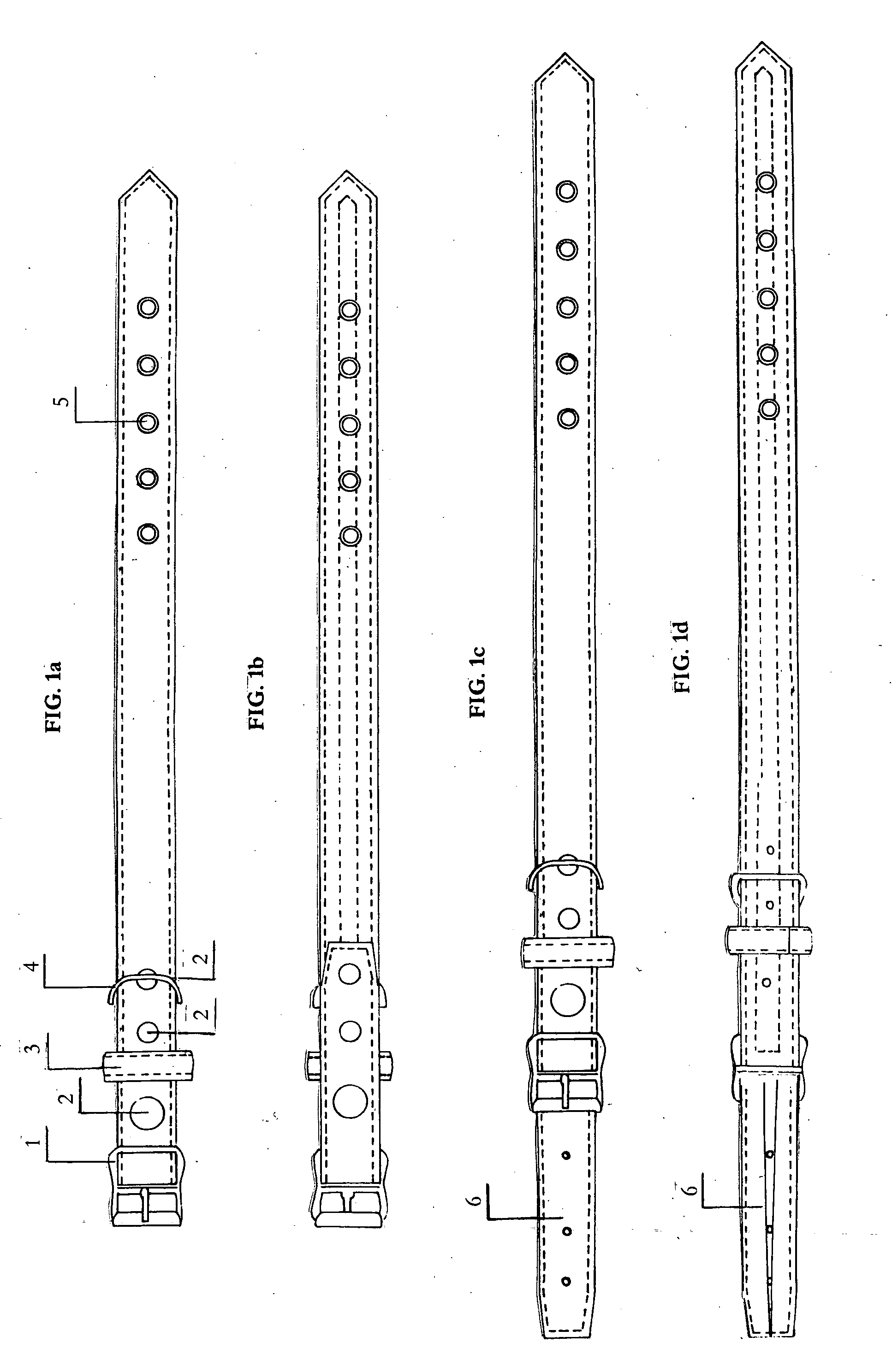

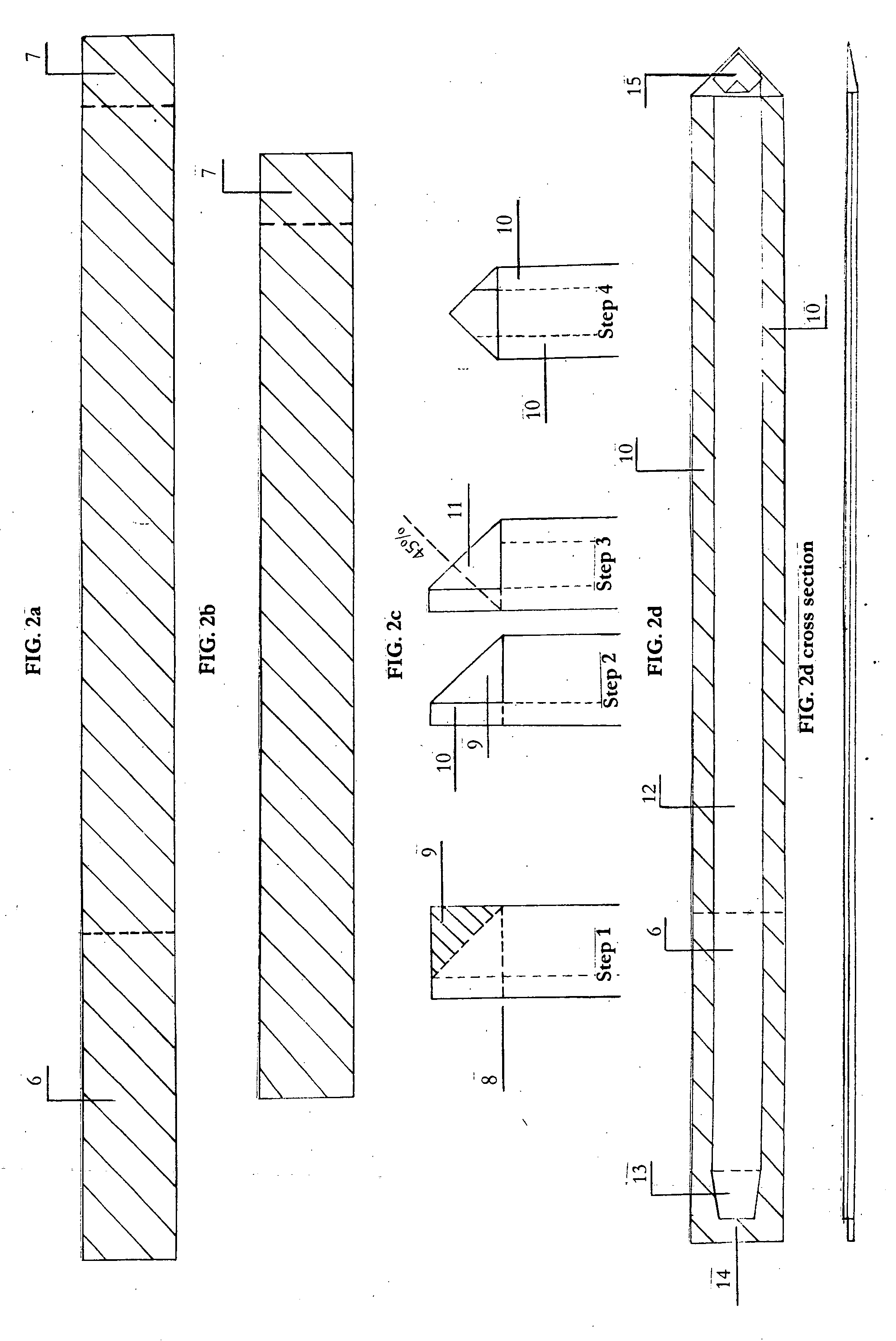

Fabric-covered pet collar

InactiveUS20050284419A1Satisfactory in their functional aspectLack fashionable creativityTaming and training devicesEngineeringCompanion animal

Owner:BAZAR THERESA MARIE

Method for processing low-salt dried poultry snack product

ActiveCN101606722ASimple manufacturing processSave the pickling processFood preparationSnack foodPotassium

The invention relates to a method for processing a low-salt dried poultry snack product. The method is characterized by adopting a new technical method which comprises steps of 'cutting and separating poultry, wringing, proportioning, low temperature cutting and mixing, shaping, infrared high temperature baking, intermediate temperature hot air drying, cooling, slitting, packing and outputting finished products', adopting food-grade compounded salt comprising potassium, sodium and calcium to replace traditional sodium salt so as to reduce the content of sodium salt in product and enhance the microelement composition of meat product while preserving original quality of meat product, and introducting the advanced methods such as low-temperature cutting and mixing, infrared high temperature baking and the like to simplify traditional process. The method is applicalbe to the preparation of dried poultry such as chicken, duck, goose and the like, and the low-salt dried poultry snack with easy-chewing property, strong meat flavor, even cutting section, clean appearance and salt content of not greater than 3.5 percent can be obtained while simplifying traditional dried meat preparing process and shorting process period. The method is positively significant for promoting technical development of traditional poultry food industry and meeting the requirement to health-keeping snack foods.

Owner:HEFEI UNIV OF TECH

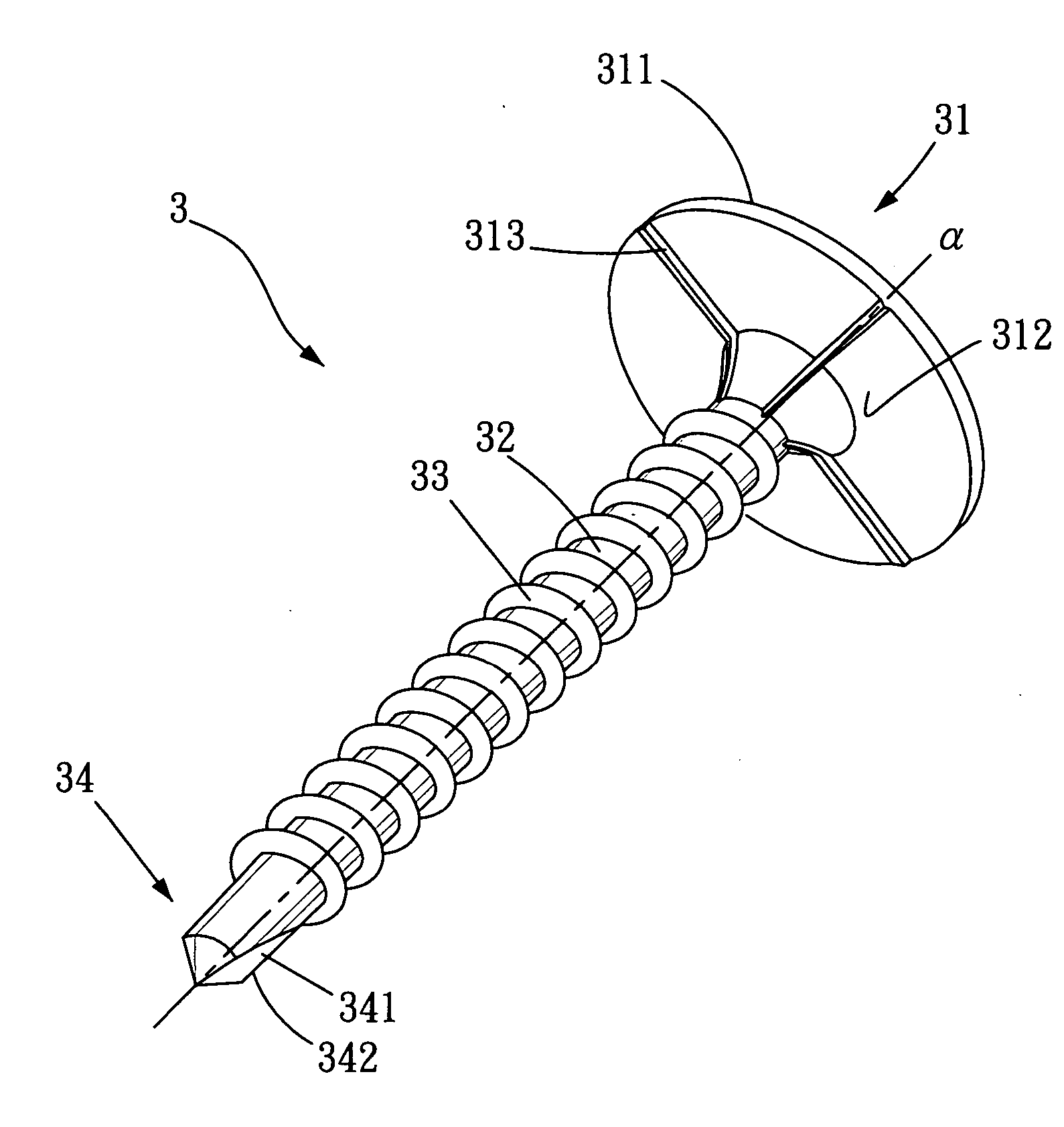

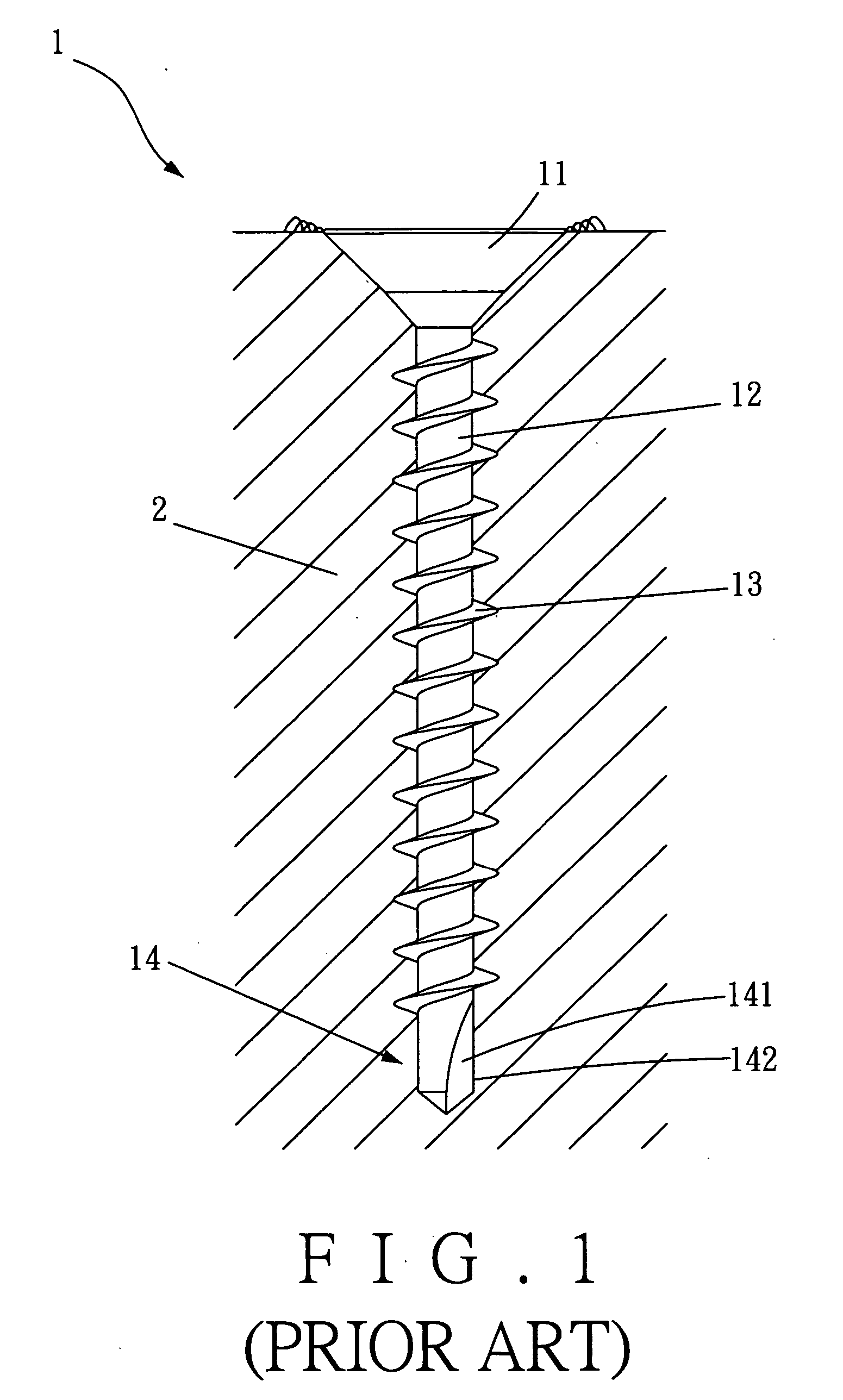

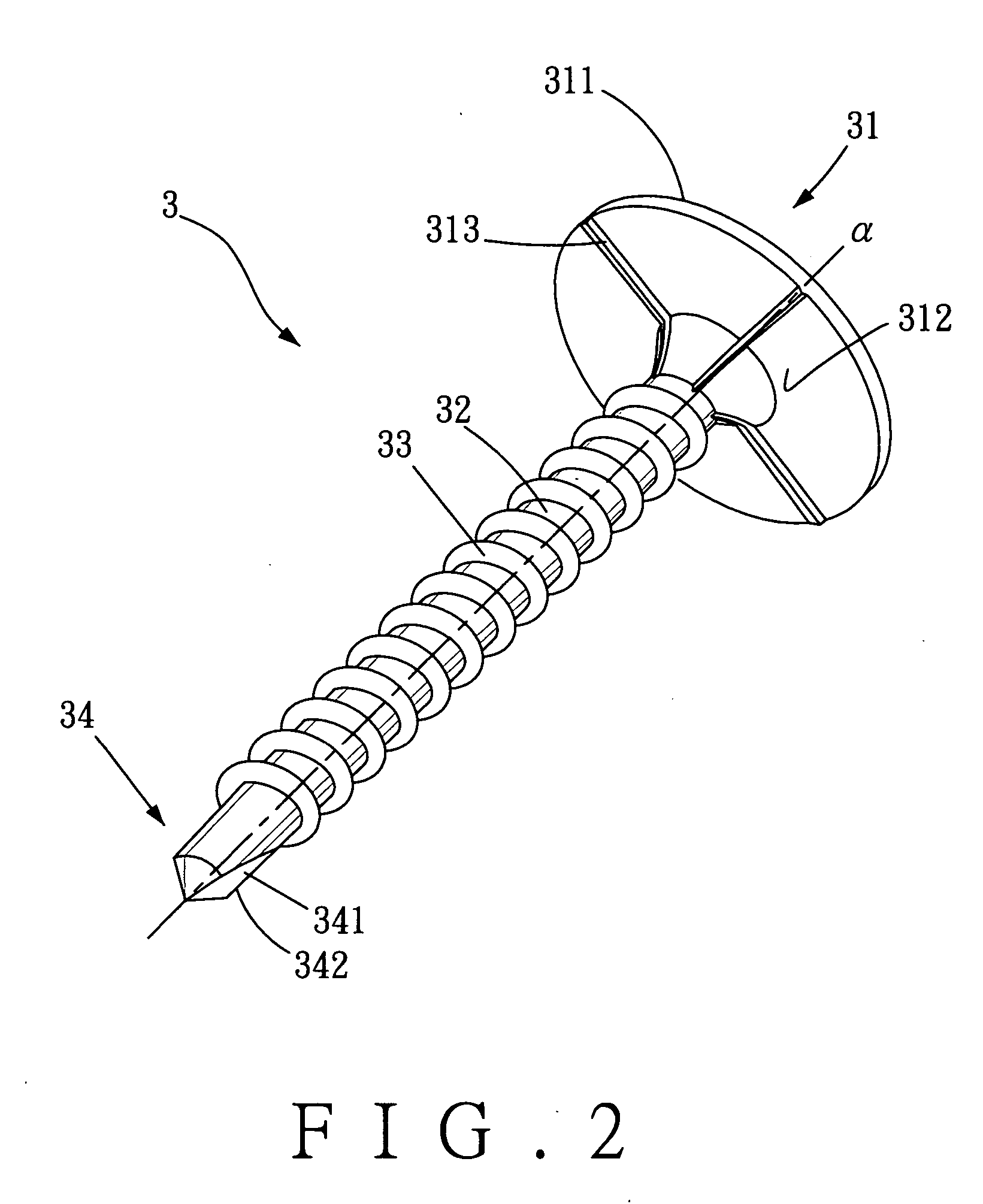

Screw

InactiveUS20070224020A1Increase frictional resistanceKeep the appearance cleanNutsBoltsEngineeringClean appearance

A screw includes an enlarged head and a threaded shank longitudinally extending from said head; said head has a bottom surface with a plurality of ribs protruded therefrom so as to provide with high frictional resistance and waterproof effect when screwing in. Further, the ratio of the outer diameter of head to the outer diameter of shank is 1:3.5˜5.5. Accordingly the head has greater areas to cover the ejected debris of object so as to maintain clean appearance.

Owner:HSIEH JUI TSE +1

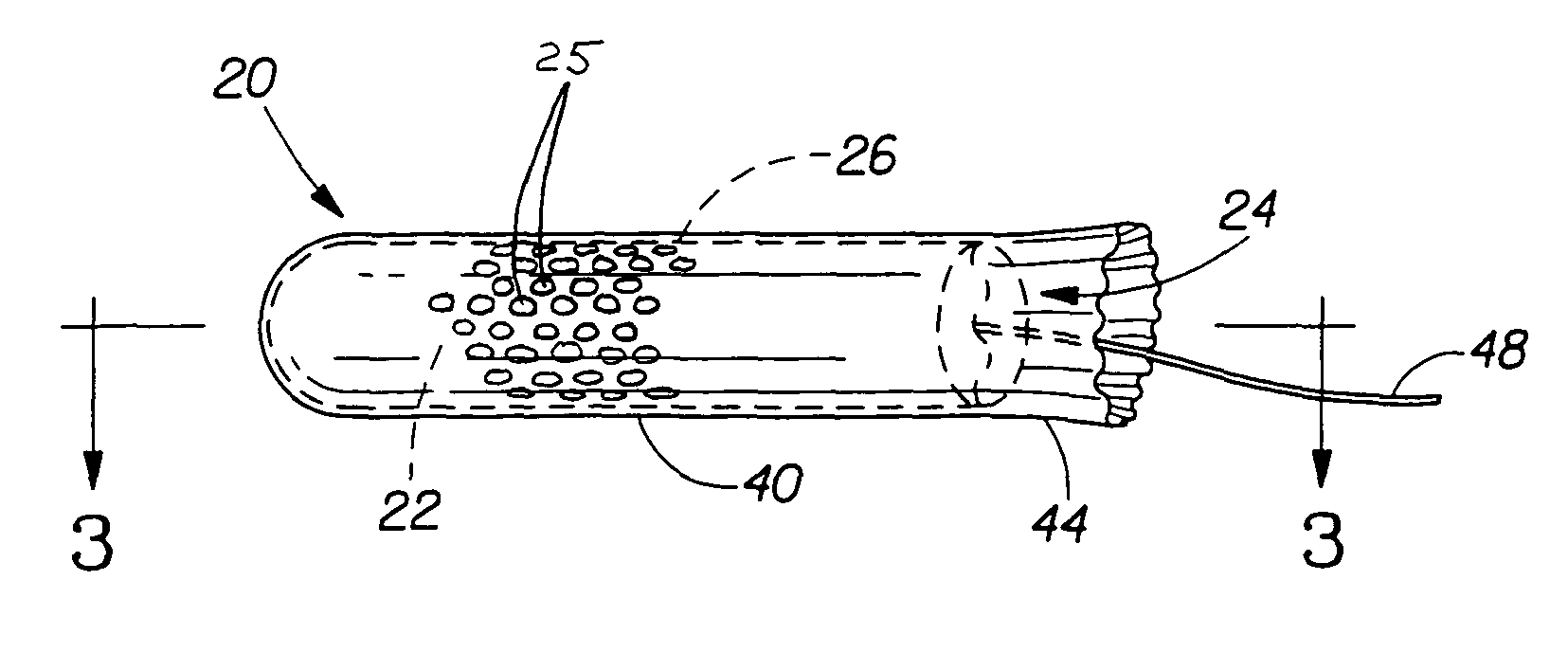

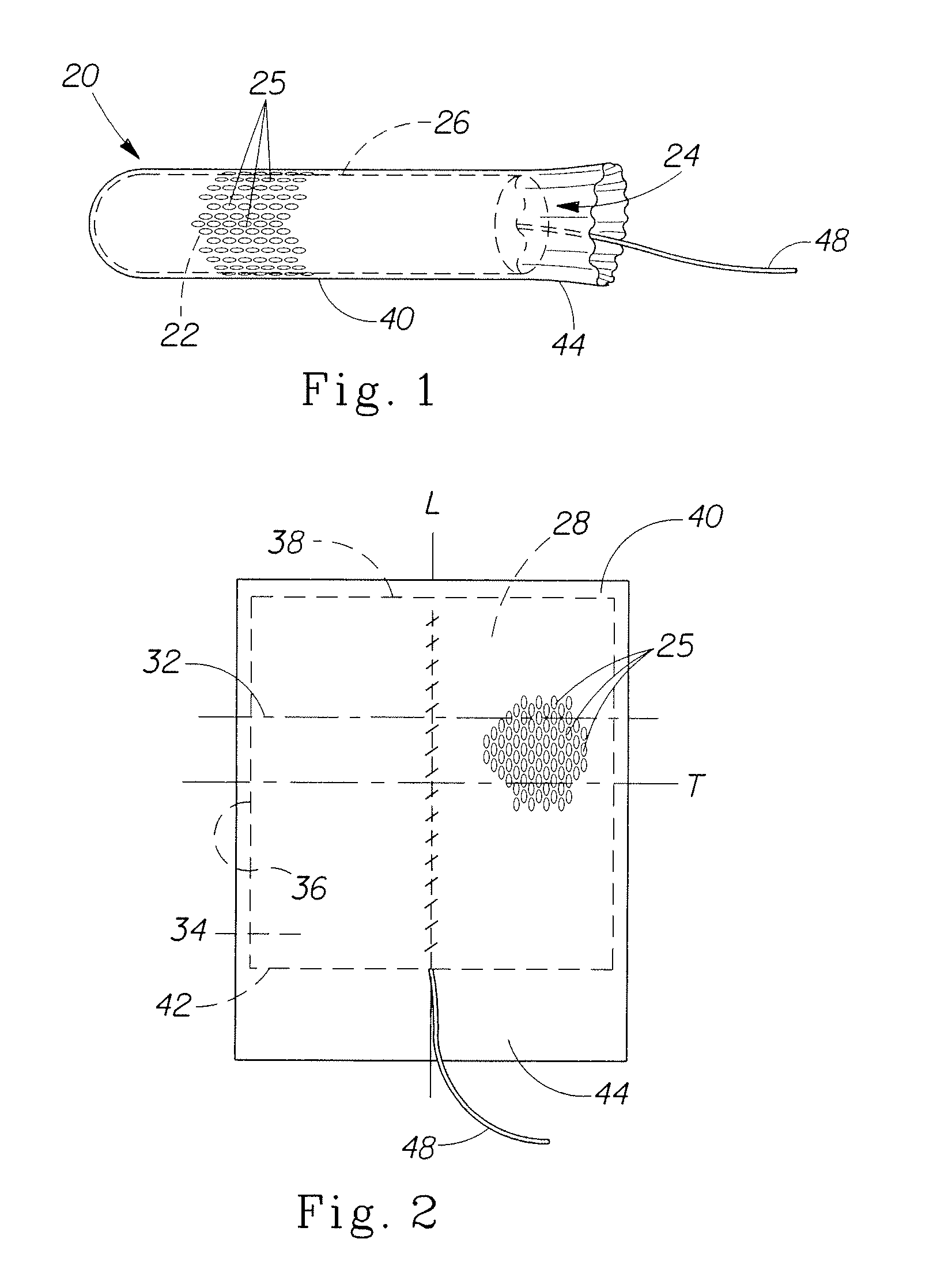

Tampon with clean appearance post use

InactiveUS7977532B2Good acquisitionCleaner post-use appearanceSurgeryBaby linensAbsorbent materialTampon

A catamenial tampon comprises a compressed absorbent member having an inner region and an exterior surface, the compressed absorbent member comprising an absorbent material. An overwrap substantially covers the exterior surface of the compressed absorbent member. The overwrap comprises an apertured fluid pervious material that is hydrophobic or rendered hydrophobic relative to the compressed absorbent member. The fluid pervious overwrap therefore tends to remain free of fluid as the fluid is preferentially partitioned into the absorbent member.

Owner:THE PROCTER & GAMBLE COMPANY

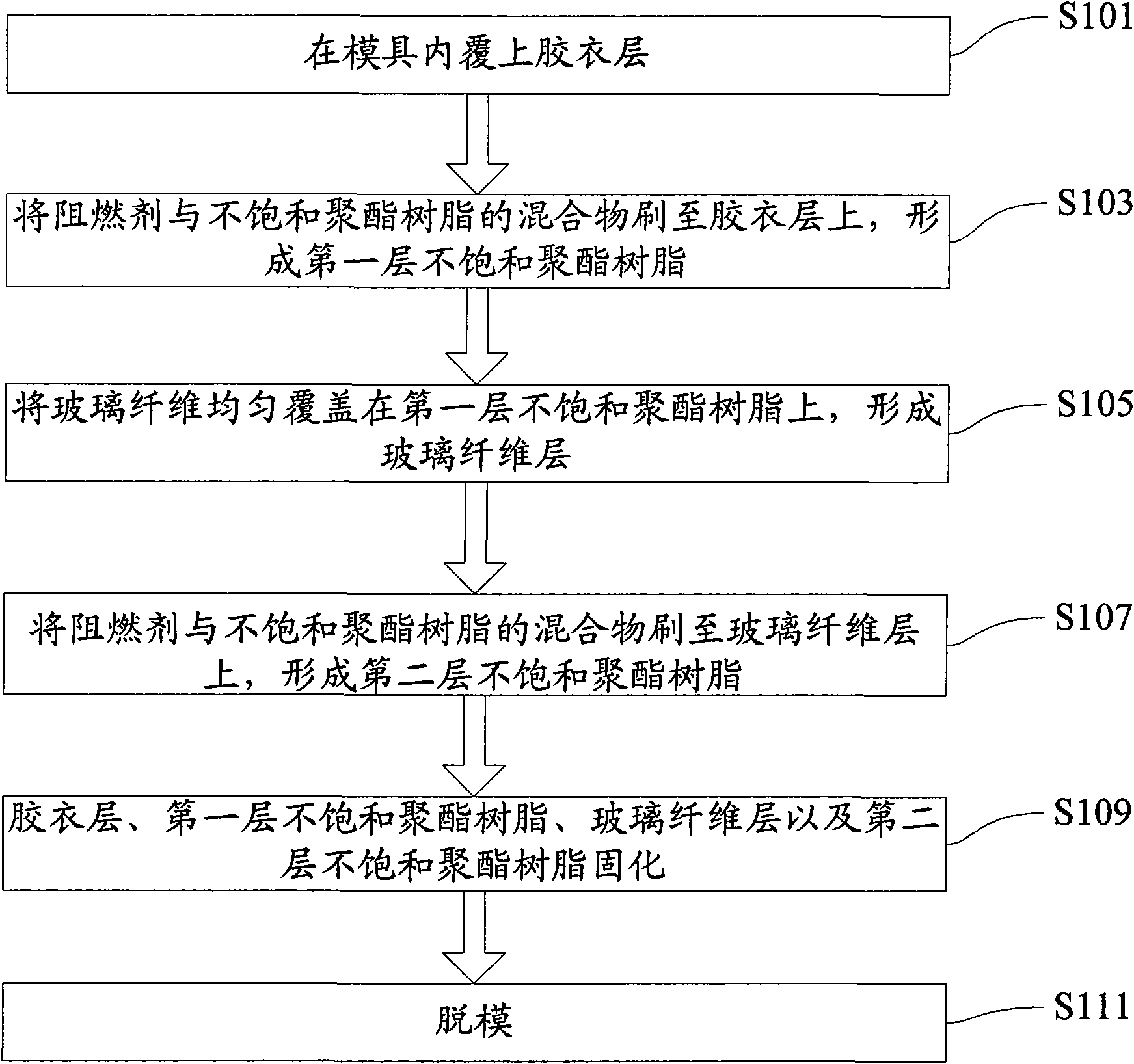

Shell of anticorrosion distribution box and preparation method thereof

The invention provides a shell of an anticorrosion distribution box and a preparation method thereof. The method for preparing the shell of the anticorrosion distribution box comprises the steps: a) covering a gel coat layer in a mold; b) brushing a mixture of a fire-retardant agent and an unsaturated polyester resin onto the gel coat layer to form a first layer of the unsaturated polyester resin; c) evenly covering glass fiber on the first layer of the unsaturated polyester resin to form a glass fiber layer; d) brushing the mixture of the flame retardant and the unsaturated polyester resin onto the glass fiber layer to form a second layer of the unsaturated polyester resin; e) solidifying the gel coat layer, the first layer of the unsaturated polyester resin, the glass fiber layer and the second layer of the unsaturated polyester resin; and f) demolding. Components according to the mass ratio are as follows: 28 to 32 percent of the glass fiber, 63 to 67.5 percent of the unsaturated polyester resin, and 4.5 to 5 percent of the fire-retardant agent. The shell of the anticorrosion distribution box has the advantages of paint-free property, bright and clean appearance, light weight, corrosion resistance, ultraviolet resistance, fire retardance and long service life.

Owner:JIANGSU HENGKAI ELECTRIC

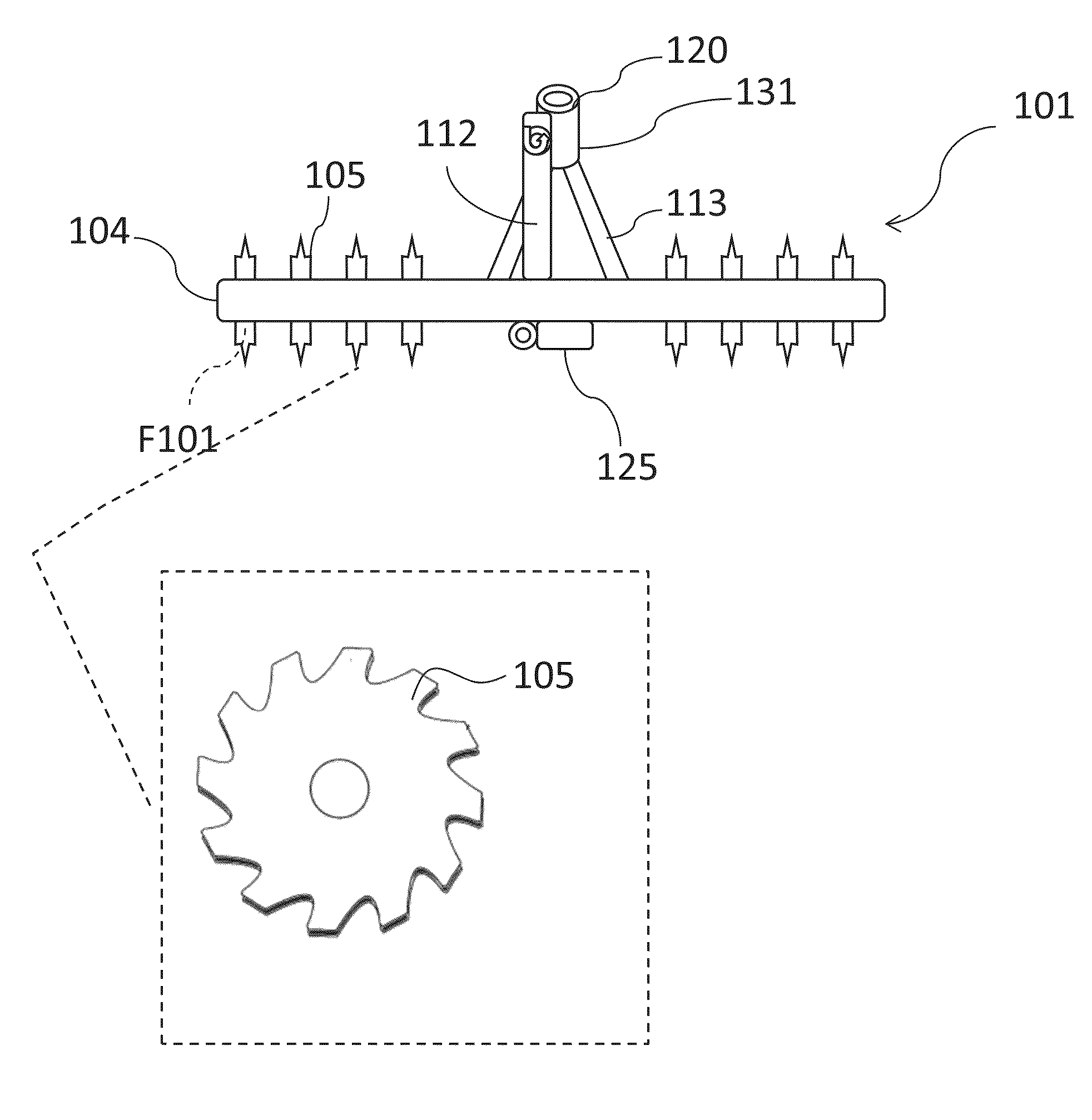

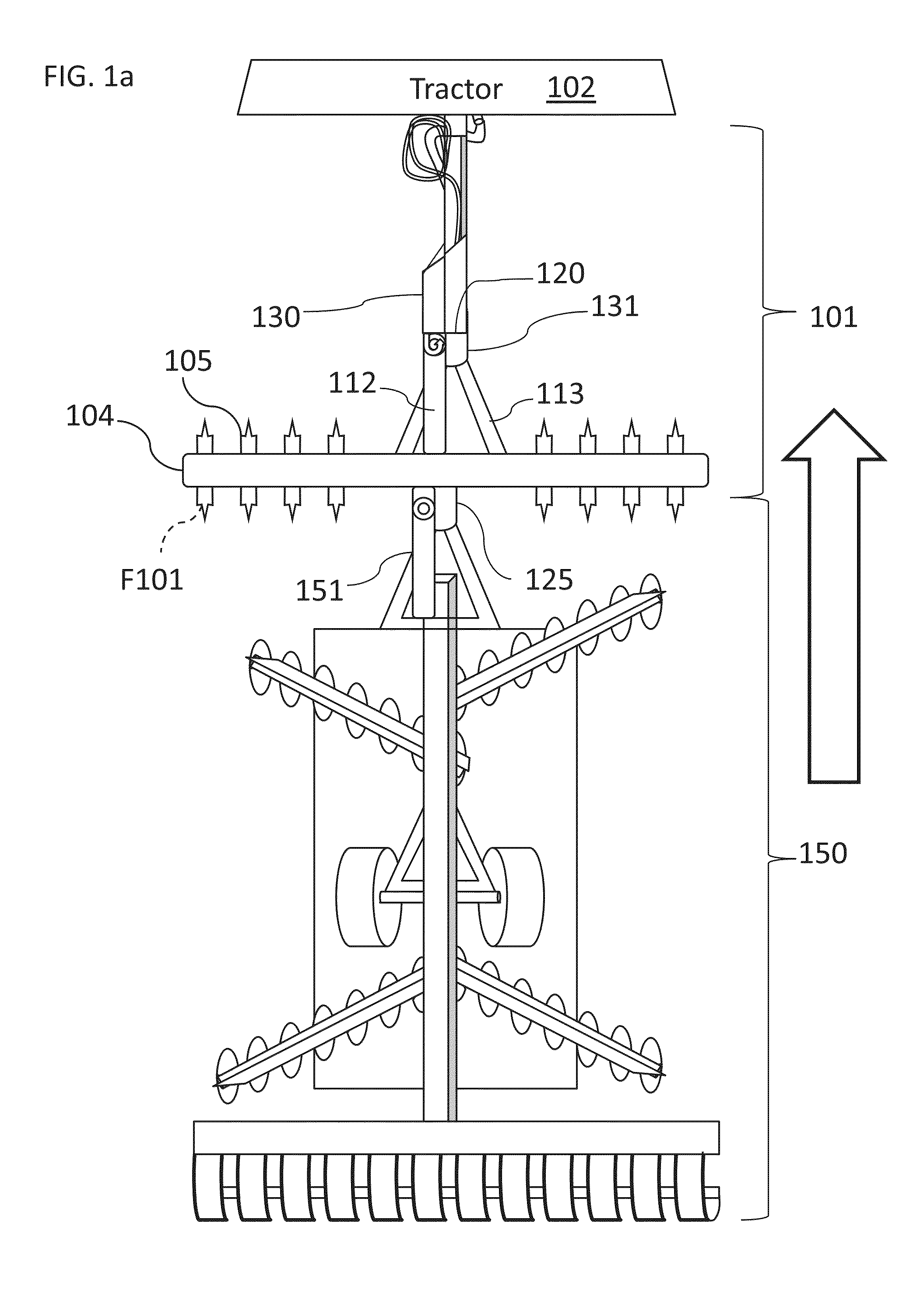

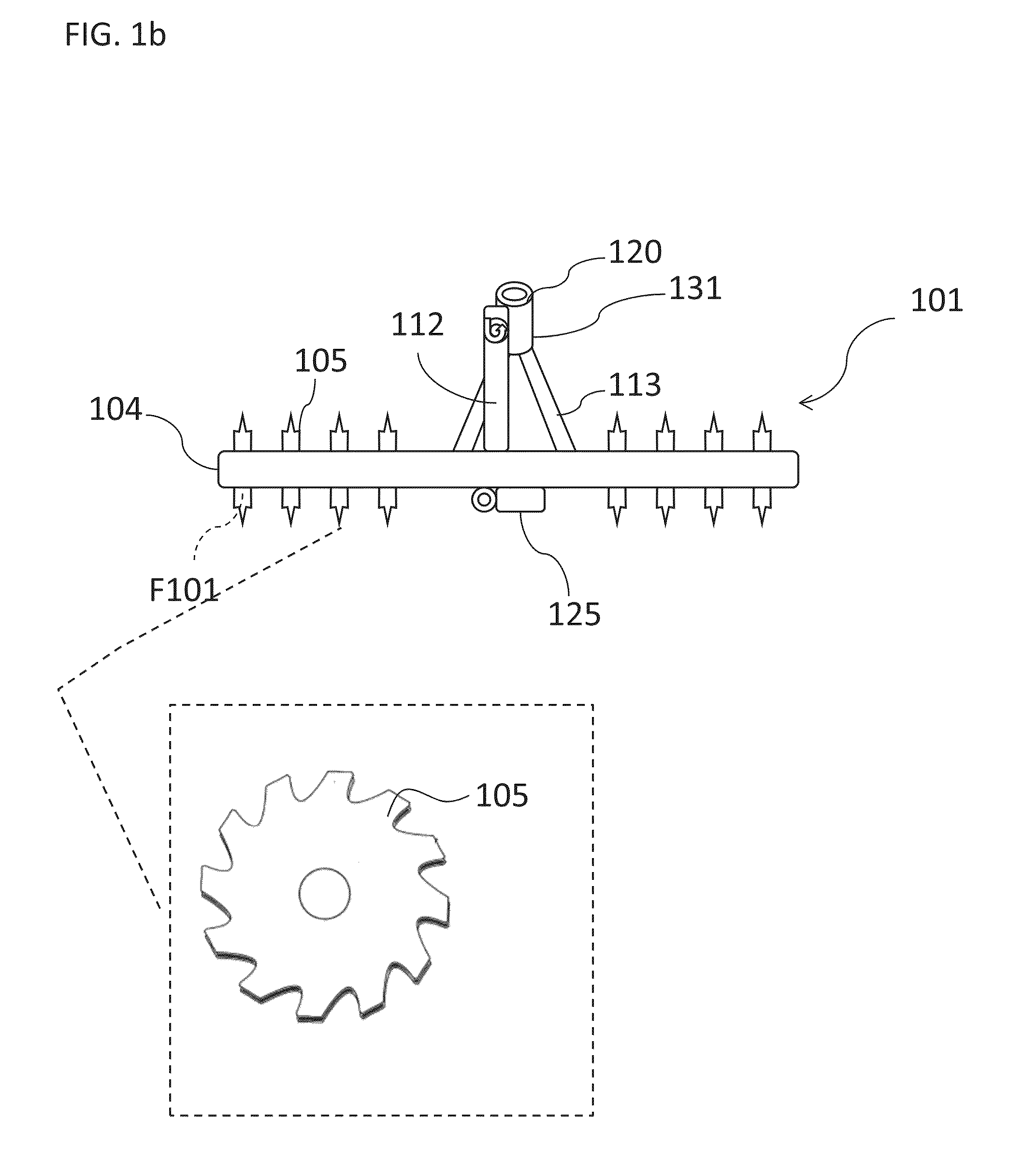

Tillage system

InactiveUS20140123885A1Prevent soil erosionSmoothen the soil surfaceSpadesLiquid fertiliser distributionSpring forceAgricultural engineering

An add-on tillage system is adapted to be mounted on an agricultural device to enhance tilling ability. The add-on tillage system includes a tilling unit with a common tool bar having attached thereto a first set of a plurality of tilling tines or coulters adapted to produce deep grooves in a tilled field. Means are provided for adjusting spacing between the tines or coulters, tilling tines or coulters up and down as a group being loaded by spring force, compressed air pistons or hydraulically actuated rams. A first mount is adapted to receive a tongue with hydraulic operations for mounting to a tractor. A second mount is adapted to receive a tongue with hydraulic mount to an agricultural device adapted to be pulled by the tractor. The add-on tillage system tills surface soil for a clean appearance, providing improved rain / irrigation water absorption, eliminating water run-off and erosion.

Owner:NANCE JOHN D

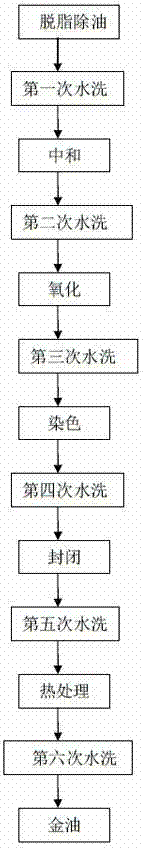

Aluminum alloy hub surface anodic oxidation treatment process

The invention discloses an aluminum alloy hub surface anodic oxidation treatment process which comprises the following steps: removing grease and oil on the surface of an aluminum alloy hub, washing with water for the first time, neutralizing, washing with water for the second time, oxidizing, washing with water for the third time, dyeing, washing with water for the fourth time, sealing, washing with water for the fifth time, performing thermal treatment, washing with water for the sixth time, and spraying golden oil. The process aims at performing anodic oxidation on the aluminum alloy hub, a cold water hole sealing method is adopted, and an anionic surfactant 2-butanol is added into a hole sealing liquid, so that the sealing effect is good. By spraying the golden hole on the surface of the hub, the hub has a surface which is glossy, smooth and clean in appearance, and thus the attractiveness is improved, and the service life of the hub is prolonged.

Owner:GUANGDONG DCENTI AUTO PARTS STOCK LTD

Method for reinforcing alpha hemihydrate gypsum hydrated hardenite by employing organic complex additive agent

InactiveCN101314534A2h wet flexural strength increasedIncrease dry-dry flexural strengthAcid waterSuperplasticizer

The invention discloses a method which adopts an organic compound additive to reinforce an alpha-semi-hydrated gypsum hydration hardened body. Calculated by the total mass of alpha-semi-hydrated gypsum and an additive, the additive is prepared according to the following percentage by mass: 0.01 to 3.0 percent of high efficient naphthalene water reducing agent (FDN), 0.01 to 3.0 percent of high efficient melamine water reducing agent (SM), 0.01 to 3.0 percent of high efficient polycarboxylic acid water reducing agent (PC) and 0 to 1.3 percent of antifoaming agent. The additive and an alpha-semi-hydrated gypsum raw material or a powder grinding material undergo even dry mix and then are fully mixed with an amount of water inside mixing equipment; and mixed gypsum undergoes condensation and hardening according to product requirements. The 2h wet rupture strength of modified gypsum is increased by 20 to 60 percent, while 2h wet compressive strength is increased by 30 to 100 percent; meanwhile, the absolute dry rupture strength of the modified gypsum is increased by 35 to 70 percent, while the absolute dry compressive strength is increased by 30 to 100 percent; moreover, the method has appropriate condensation time, fine and clean appearance and excellent leveling property and water resistance.

Owner:ZHEJIANG UNIV

Floor finish with lightening agent

InactiveUS20050154109A1Increased lightness valueBrightness value increasedSpecial surfacesCoatingsEngineeringLightness

A jobsite-renewable floor finish comprising a film former and an appropriate amount of a lightness-inducing agent provides a translucent hardened finish layer having an increased lightness value (as evaluated in relation to an appropriate color space) and a cleaner appearance than a finish made without such pigment.

Owner:ECOLAB USA INC

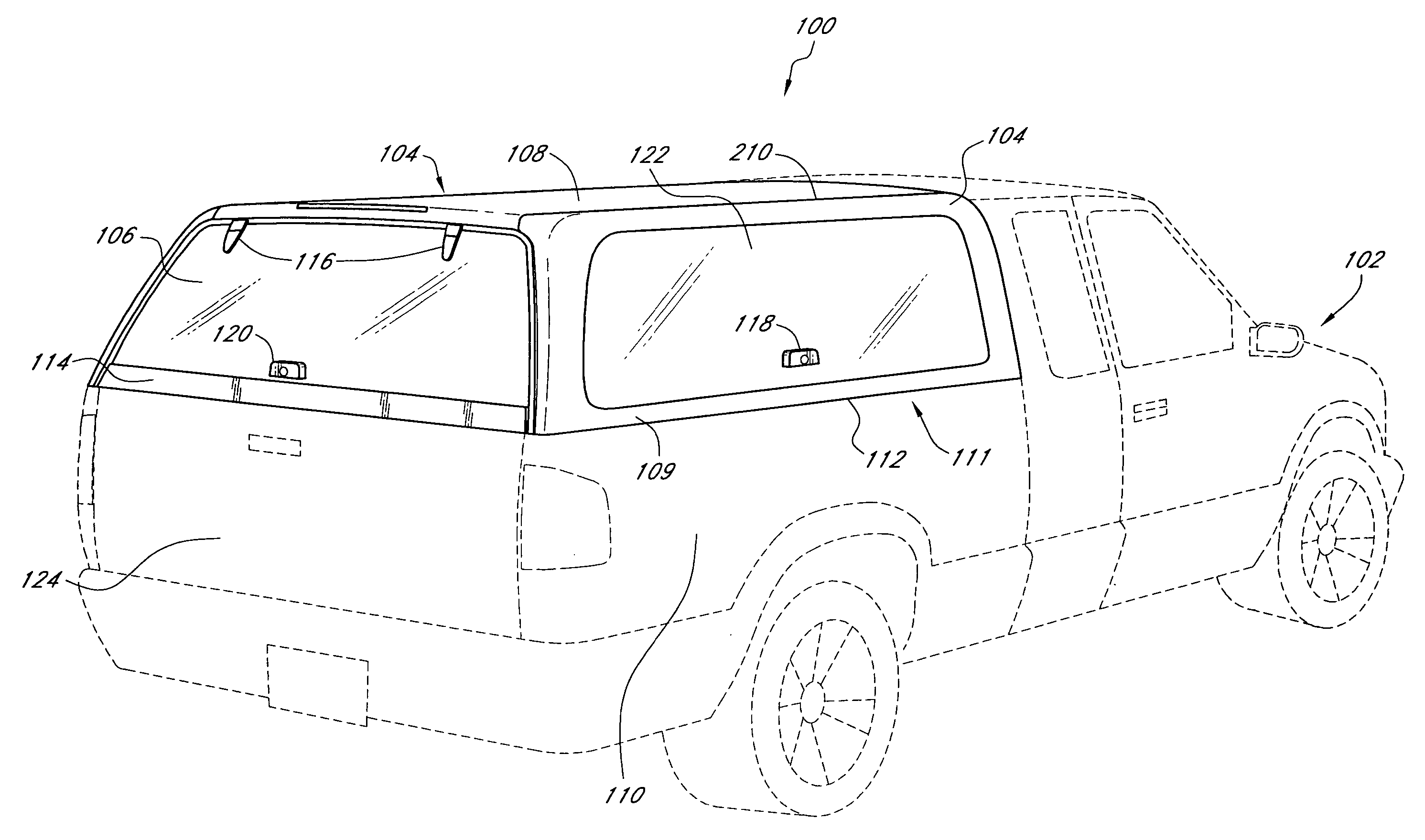

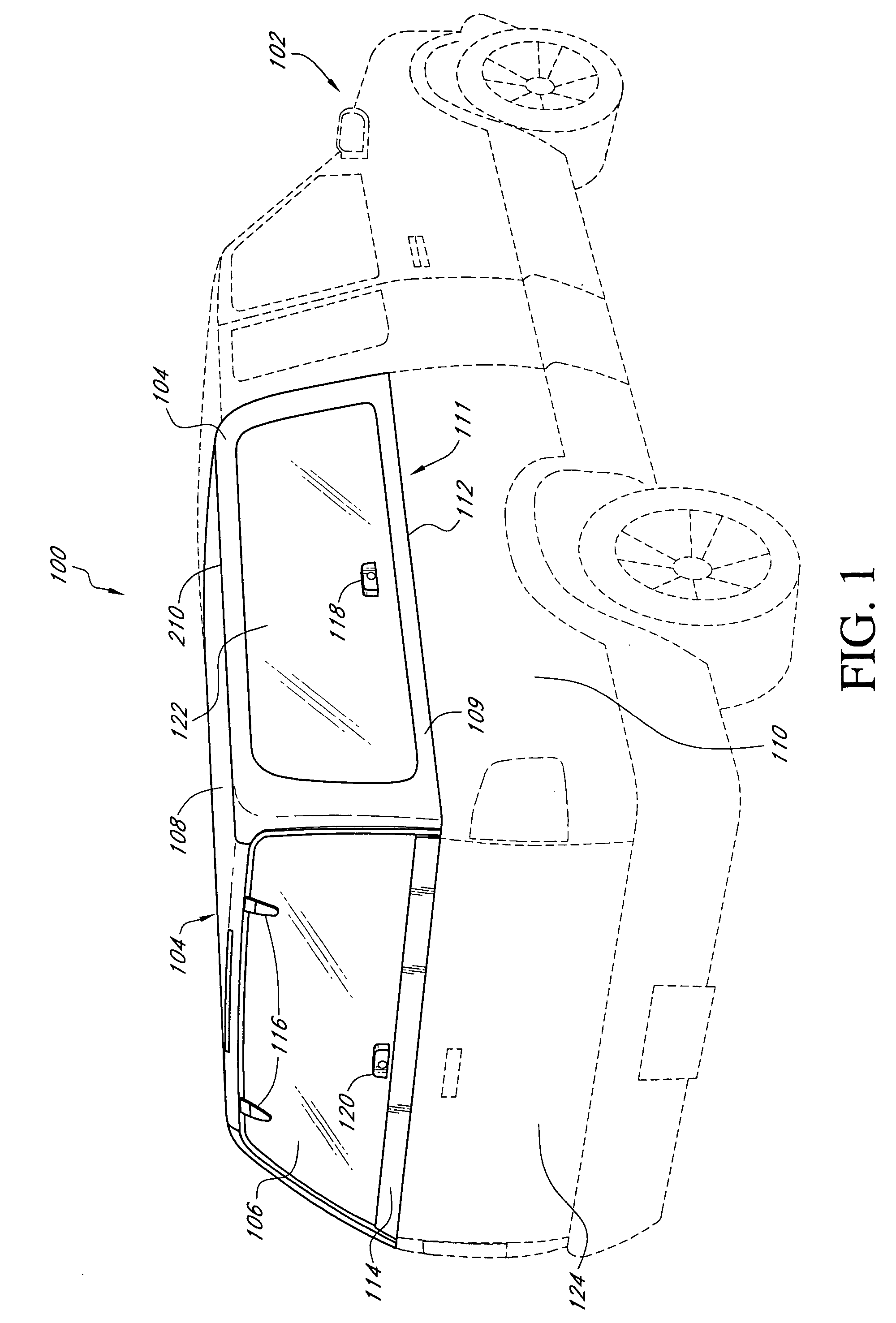

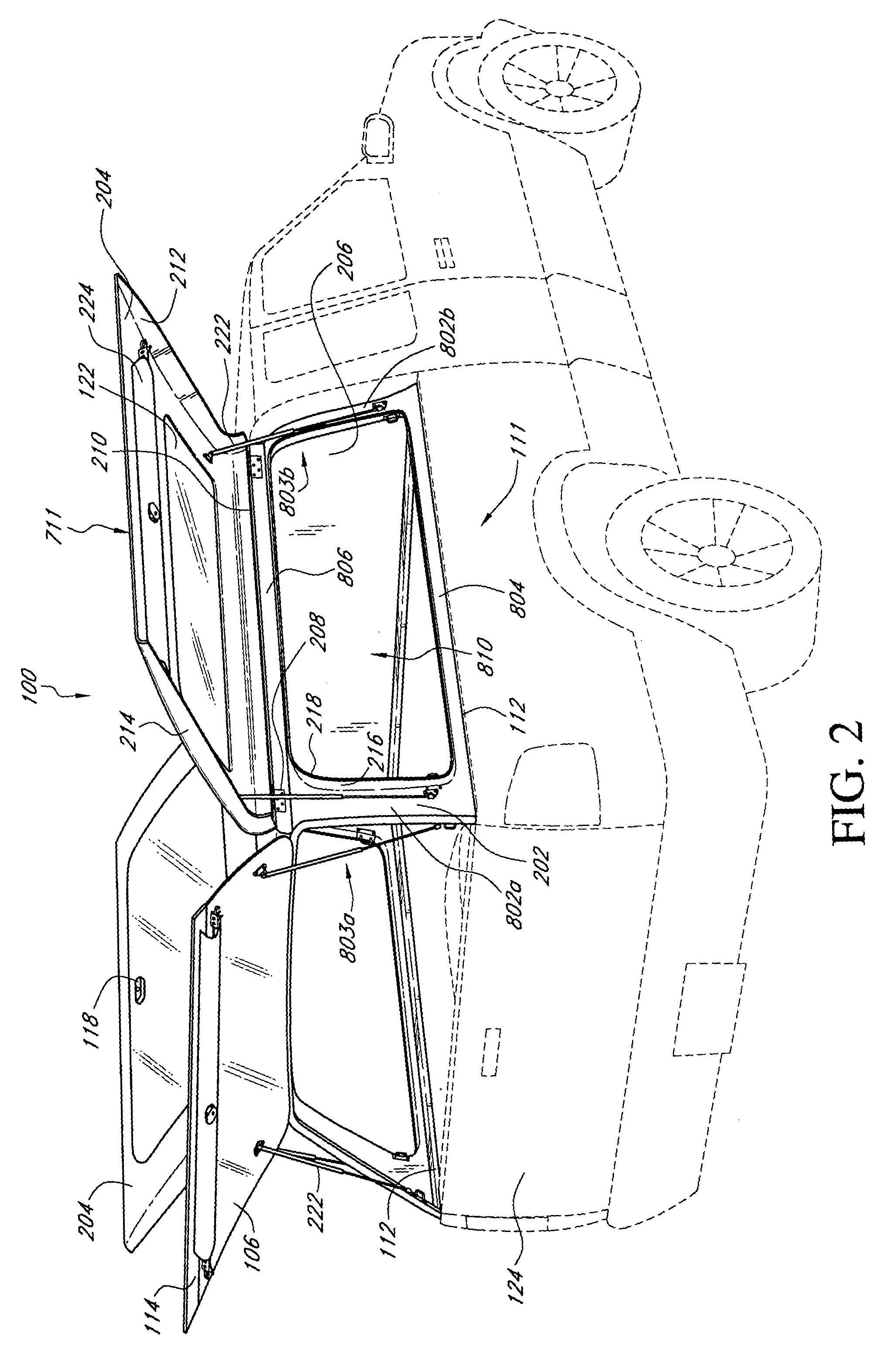

Truck shell

A molded truck shell having side walls hinged along the top of the shell, allowing the entire side wall to pivot upwardly and outwardly, providing increased access to cargo stored in a truck bed. Additional lateral seams between the side wall and shell are located on the front and rear of the shell rather than on the side of the shell thereby further increasing the opening into the truck bed and creating a visually clean appearance. Water penetrating through the side wall hinge line is directed away from the interior of the truck bed by a moisture flange that conducts the water to the exterior of the truck.

Owner:BLOCK DAVID C

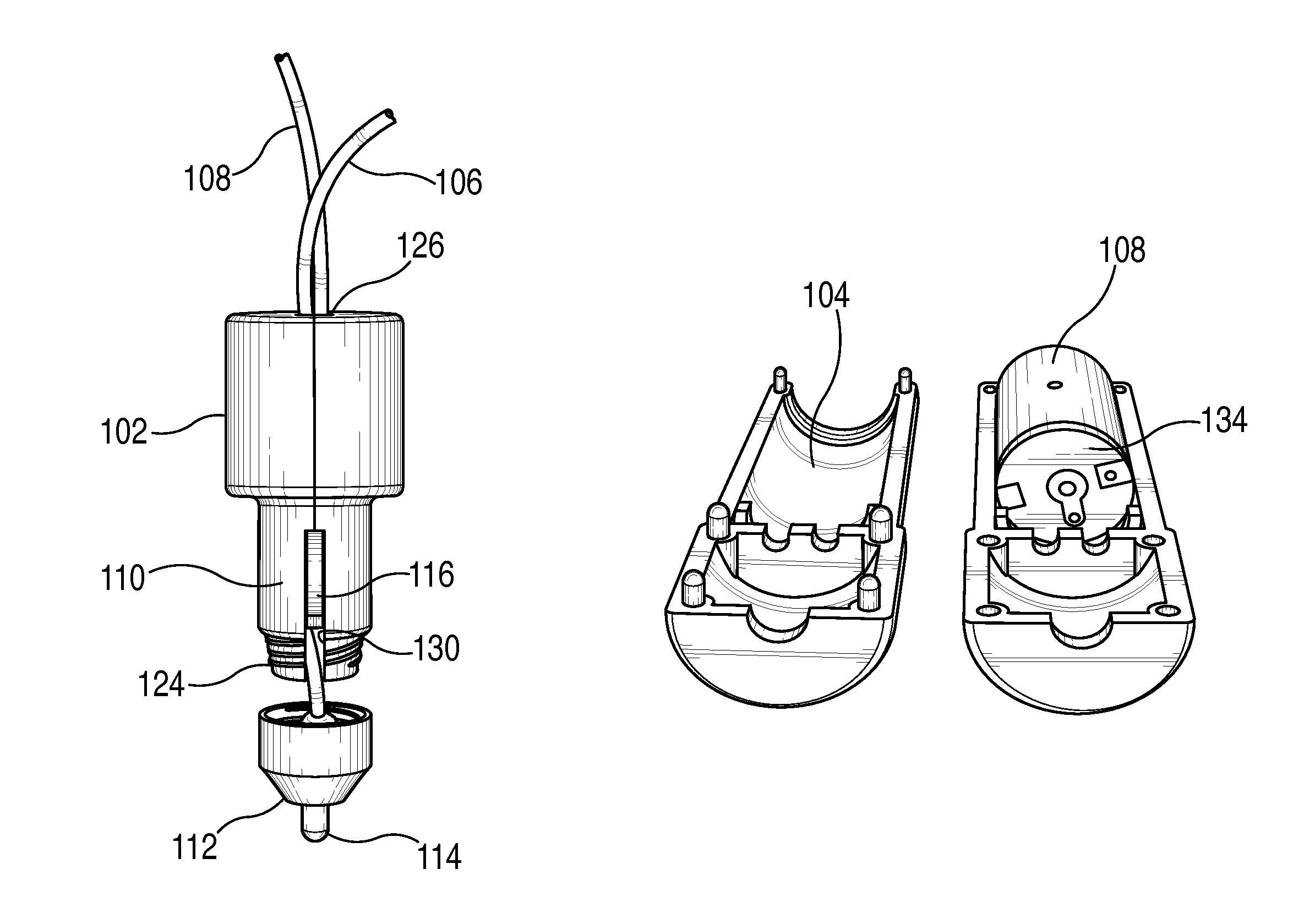

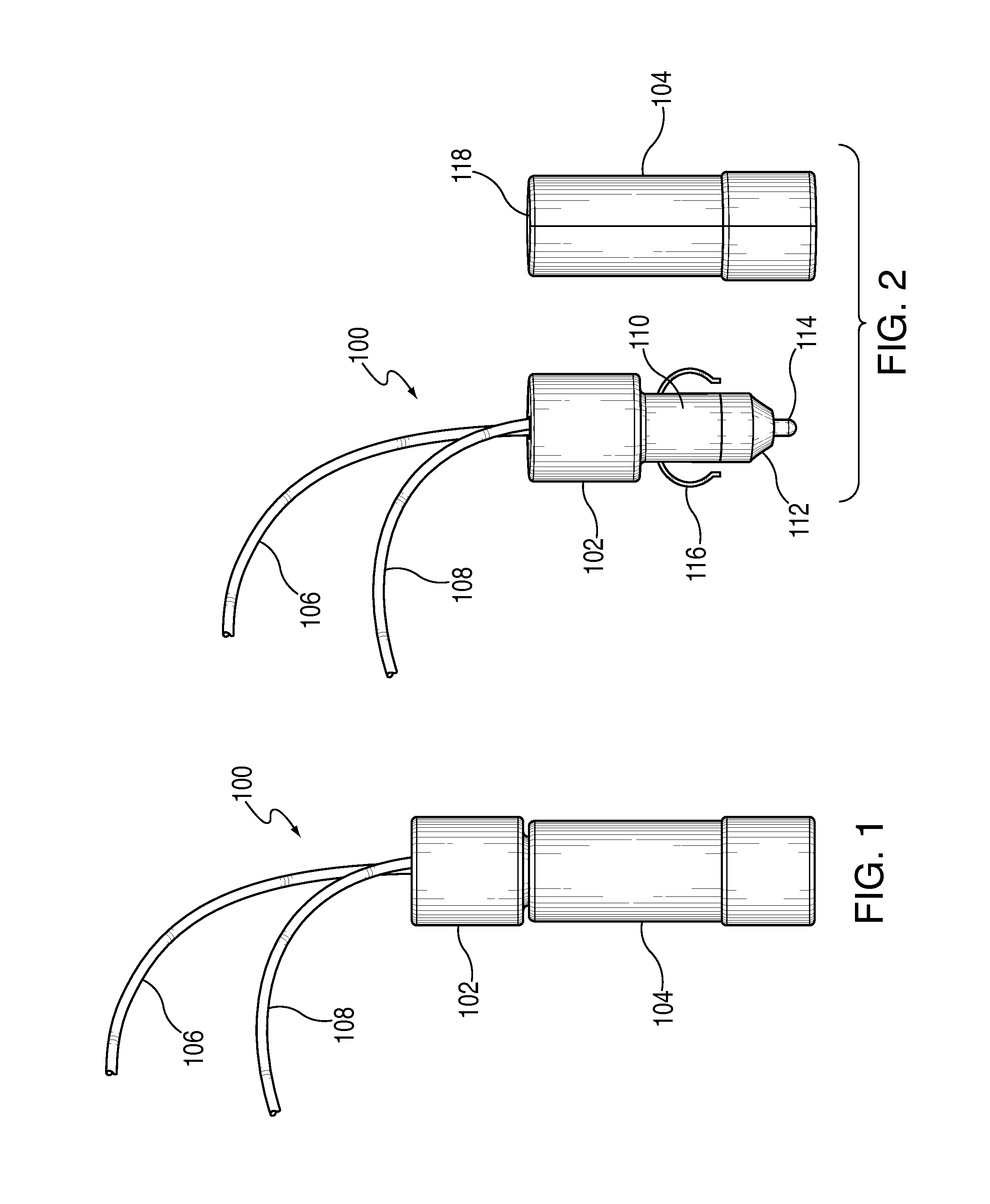

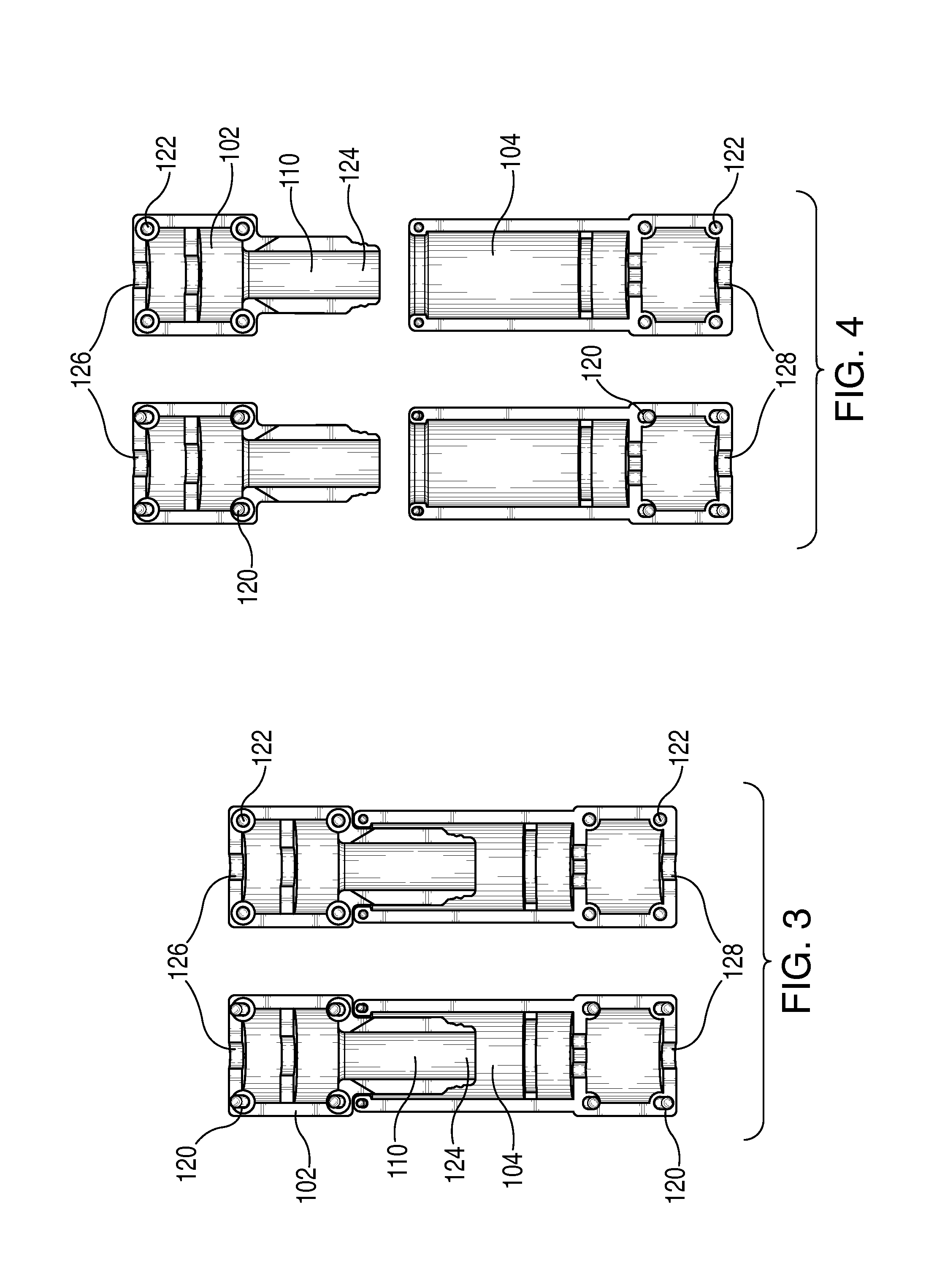

Radially uniform spring-biased intra-pole plug connector and transformer outside the trunk configuration for electric artificial tree

ActiveUS8753152B1More lightweightLess bulkyTwo pole connectionsElectric discharge tubesTransformerTree trunk

A radially uniform spring-biased intra-pole plug connector and transformer outside the trunk configuration for an electric artificial tree is described. The radially uniform plug comprises a springed-tip and a prong, and allows the tree trunk segments to be connected at any point along their 360 degree circumference. The plug connector resembles the structure of a car cigarette lighter. A mold is used to sandwich the plug within the trunk. A plug portion of the plug connector is housed in one trunk segment, and a receptacle portion is housed in a different trunk segment, such that when the trunk segments are assembled, the plug is connected, illuminating the tree. The plug allows the electrical wiring to be hidden and housed within the trunk, providing safety, convenience to the user and giving the tree a cleaner appearance. The transformer outside the trunk configuration makes the trunk safer, more lightweight and less bulky.

Owner:EVERGREEN TREE

Nylon 66 compound capable of use for weaving glass-fiber-free shuttle

InactiveCN101760021AImprove impact resistanceHigh strengthPolyamideUltra-high-molecular-weight polyethylene

The invention relates to the field of polyamide compound, in particular to a nylon 66 compound capable of use for weaving glass-fiber-free shuttles. The nylon 66 compound is prepared with raw materials according to the following mass ratios: 40-67% of nylon 66 slices, 15-30% of nylon 66 slices, 1-5% of ultra-high molecular weight polyethylene, 15-30% of compatilizer, 0.1-0.5% of antioxygen and 1-10% of lubricant. The preparation method of the nylon 66 compound comprises the following steps: 1. weighting the raw materials; 2. putting all the raw materials in a high mixing machine for mixing; and 3. putting the raw material mixture into a double-screw extruder for extrusion and pelleting. In the invention, nylon 66 resin is used as the base material, the ultra-high molecular weight polyethylene is used, and no glass fiber is used. The invention has the advantages of high fluidity, strong impact resistibility, high strength, wearability, stable dimension, smooth and clean appearance, no glass fiber exposure and antistatic performance.

Owner:PINGDINGSHAN HUABANG ENG PLASTIC

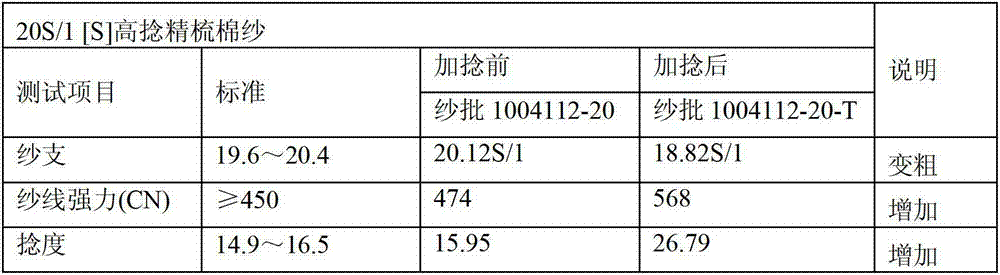

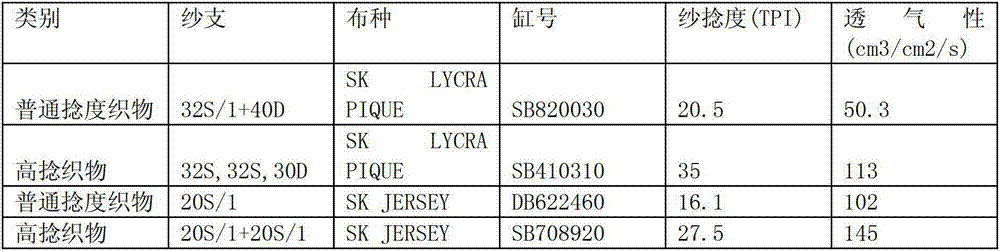

Cool-to-touch breathable dry washable smooth all-cotton fabric and manufacture method thereof

ActiveCN102808335AImprove breathabilityHigh contact coldYarnLiquid/gas/vapor yarns/filaments treatmentYarnEngineering

The invention belongs to the field of textile fabrics and relates to a cool-to-touch breathable dry washable smooth all-cotton fabric and a manufacture method thereof. The fabric is characterized in that the twist factor of fabric yarns is higher than 4.5, and the fabric is obtained by means of mercerized finish, biological enzyme finish, resin finish and softener finish. The obtained fabric has the advantages of coolness in touch, gorgeous gloss, clean appearance, smoothness in hand feeling, good hygroscopicity and excellent washability.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Low-temperature processing method for finished rice

InactiveCN109126938ABright and clean appearanceGuaranteed qualityGrain treatmentsBroken riceEngineering

The invention discloses a low-temperature processing method for finished rice. The low-temperature processing method comprises the steps of a cleaning procedure, husking and husked rice separation, low-temperature rice milling, polishing, rice cooling, grading, color sorting, secondary polishing, secondary grading, packaging, etc. The temperature is controlled to be under 10 DEG C, a sand roller device, a second sand roller device and a third iron roller device are adopted for multi-stage light milling for brown rice in sequence, and the rice is precisely polished after being cooled. Moreover,multiple nodes in a system are improved, therefore the broken rice rate is greatly reduced, the rice yield is improved, the bright and clean appearance of rice is ensured, the nutrient substances arepreserved furthest, and the quality of unprocessed grain is maintained.

Owner:NINGXIA HAOWANG RICE IND GRP

Electroplating process and production line of solar cell sheet solder strip

ActiveCN102443831AReduce energy consumptionOvercome yieldSemiconductor devicesElectrolysisHigh energy

The invention discloses an electroplating process and electroplating production line of a solar cell sheet solder strip. The electroplating process comprises the following serial steps of: feeding, straightening and flattening, copper strip polishing and softening, electrolyzing for deoiling, copper ion regenerating, high-speed electroplating pretreatment, high-speed electrotinning, neutralizing, cleaning with pure water, tin layer repairing, ultrasonic cleaning, drying, solder strip destressing, fault detection, servo material collection and the like in turn. The electroplating production line is composed of a feeding part, electroplating and pretreatment and post-treatment parts, and a material collection part, which are sequentially connected. According to the invention, a high-performance weldable coating is obtained by adopting a high-grade electrochemical method, thus the defects of a tin hot-dipping process, such as high energy consumption, low yield and the like, are overcome, and efficient production is realized; multiple channels share an identical process, which is environmentally-friendly and energy-saving; the solder strip tin layer produced by adopting the electroplating process has adjustable thickness, very good uniformity and smooth and clean appearance without defects; and by adopting the electroplating process, the defects of tradition hot-dipping tin coating in the appearance and performance are avoided, and the high-quality solder strip can be produced.

Owner:SHANGHAI WELNEW MICRO ELECTRONICS

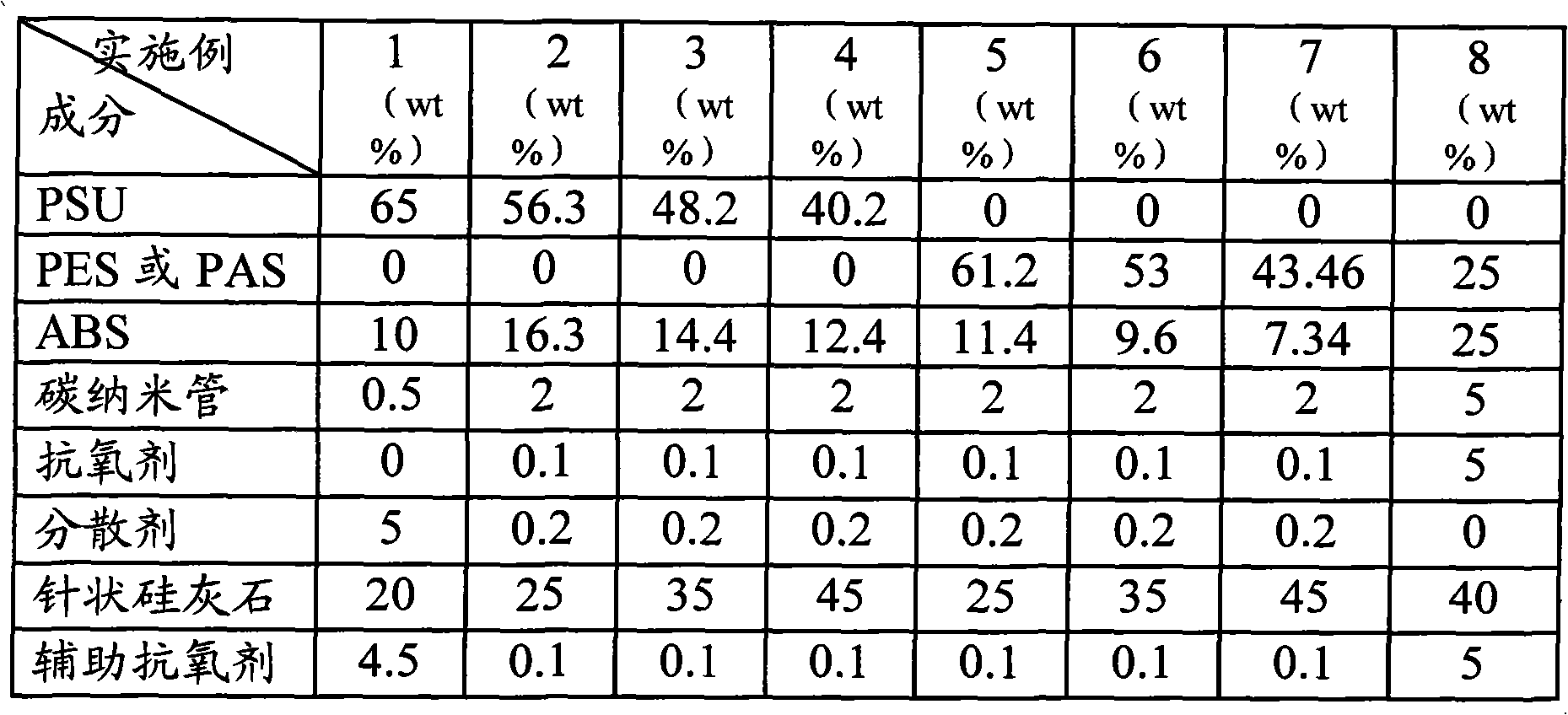

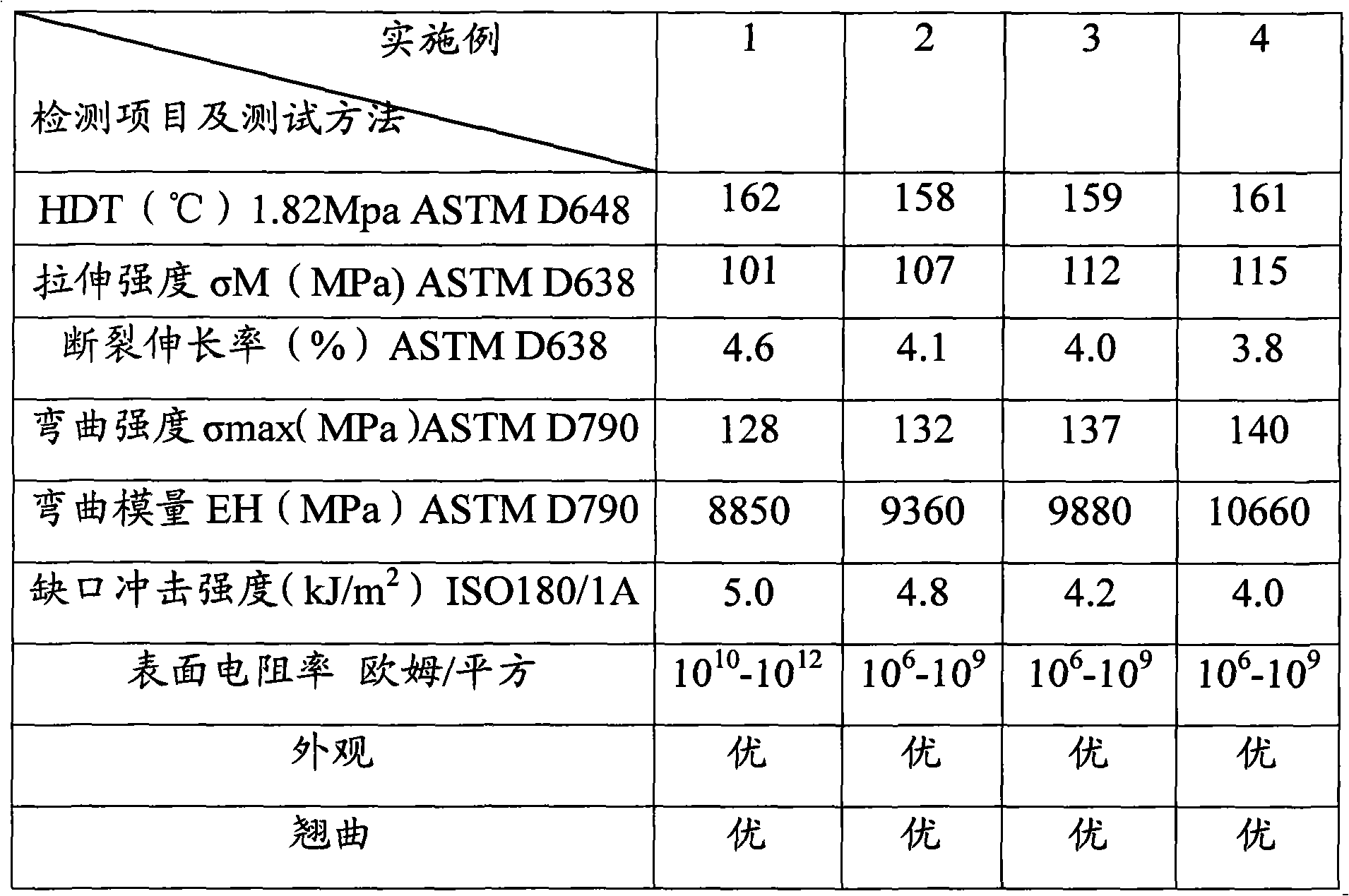

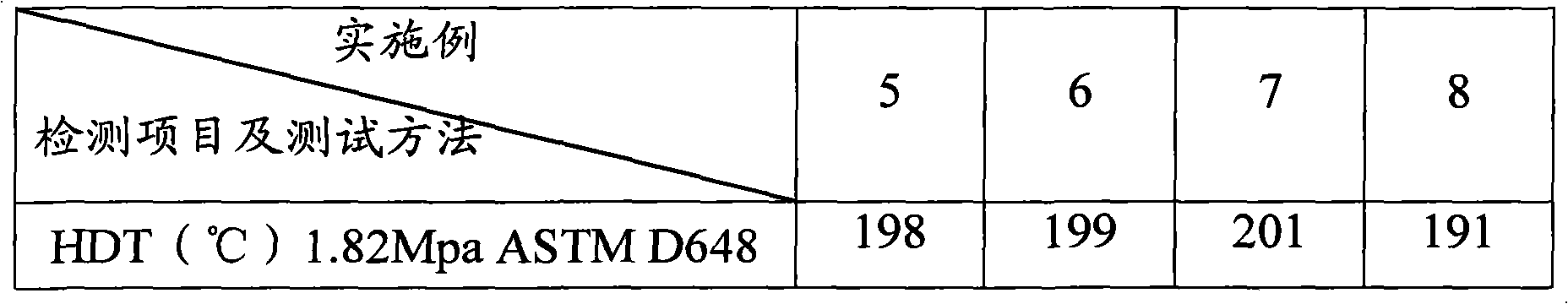

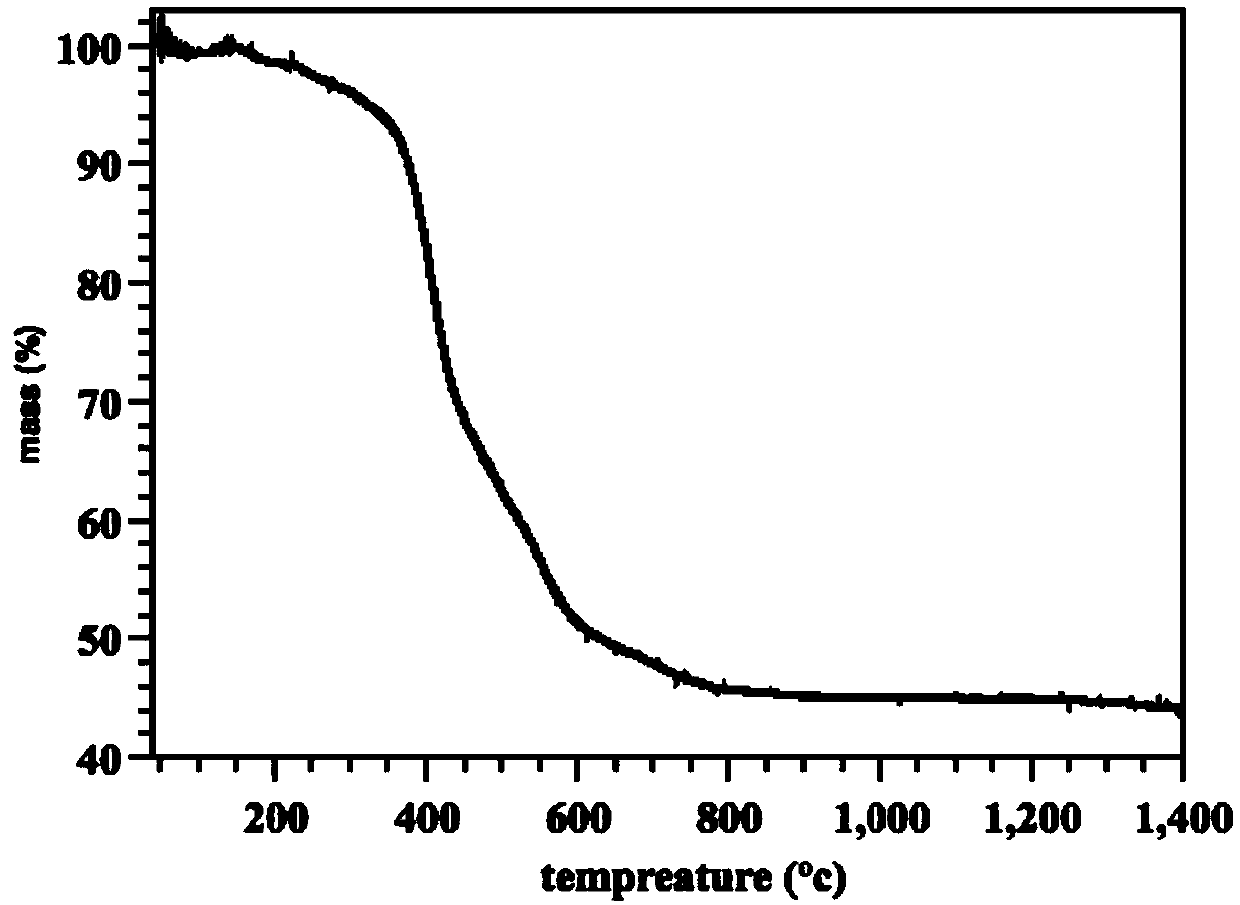

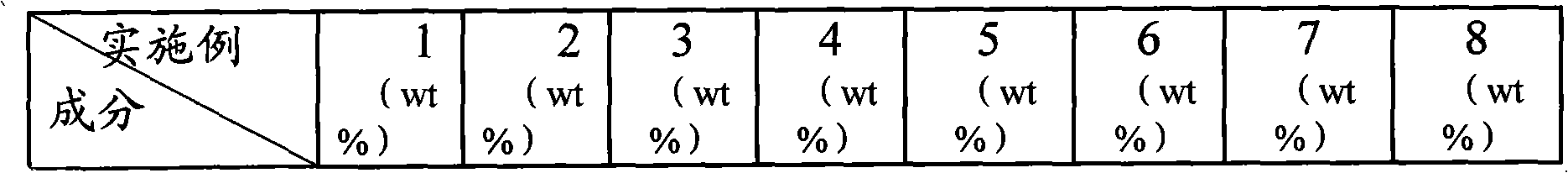

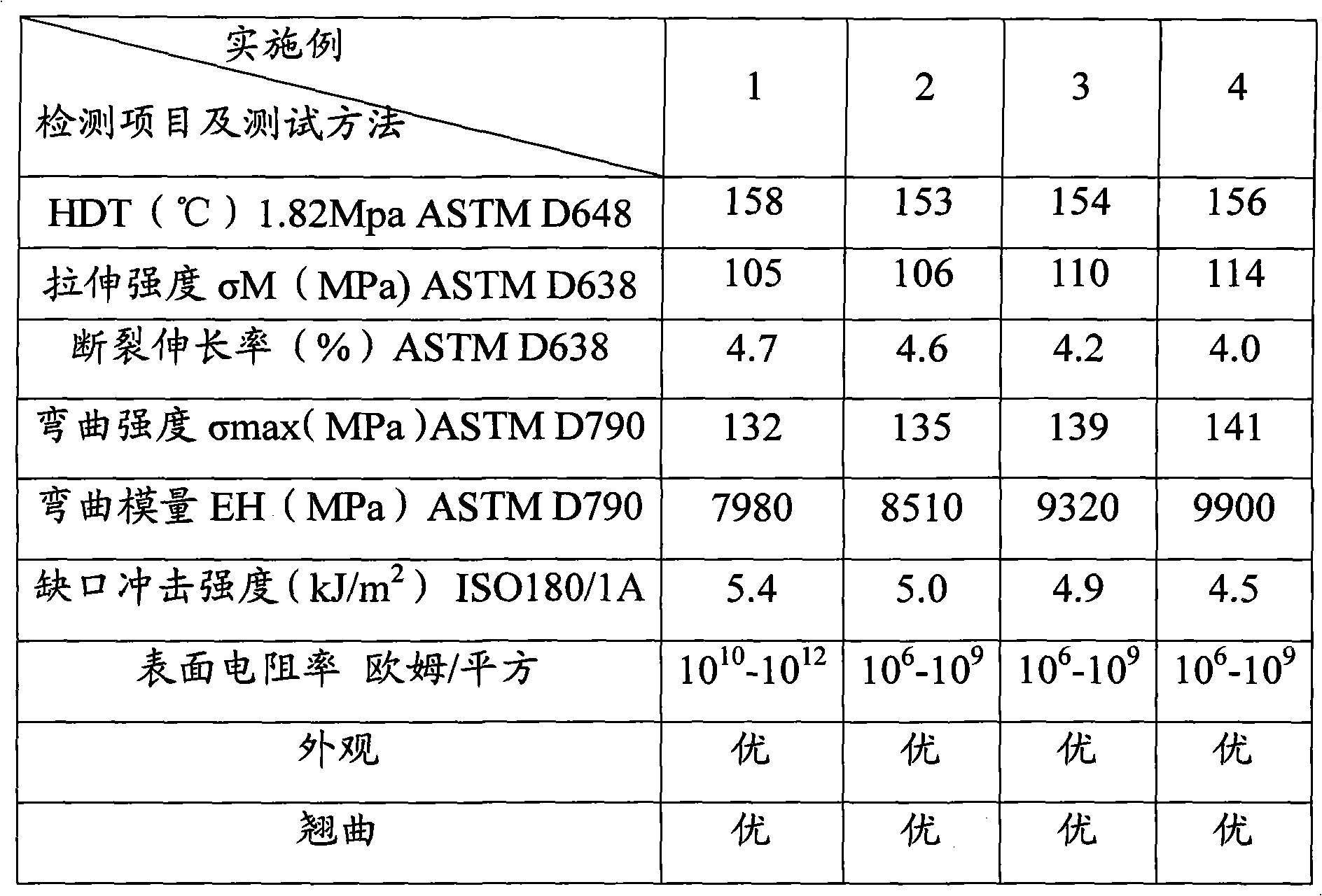

Conductive engineering plastics and preparation method thereof

The invention provides conductive engineering plastics and a preparation method thereof. The plastics contain the following ingredients by weight percent: 25-65% of polysulfone resin, 0.5-5% of carbon nano tubes, 15-45% of needle-like wollastonite, 10-30% of ABS plastics, 0-10% of antioxidant, 0-10% of secondary antioxidant and 0-10% of dispersant. The method comprises the following steps: (1) proportioning raw materials and adding the ingredients except the needle-like wollastonite and the carbon nano tubes to a main feeding mouth of a double-screw extruder after mixing the above ingredients; (2) adding the needle-like wollastonite and the carbon nano tubes to a side feeding mouth after mixing the two ingredients; (3) carrying out extruding, cooling, drying and granulating after kneading under the molten state of resins to generate composite plastics. The conductive engineering plastics can endow the products with good electrostatic dispersion capacities, mechanical properties and heat resistance, and have stable dimensions, small warping and clean appearance without dust falling.

Owner:SHENZHEN WOTE ADVANCED MATERIALS

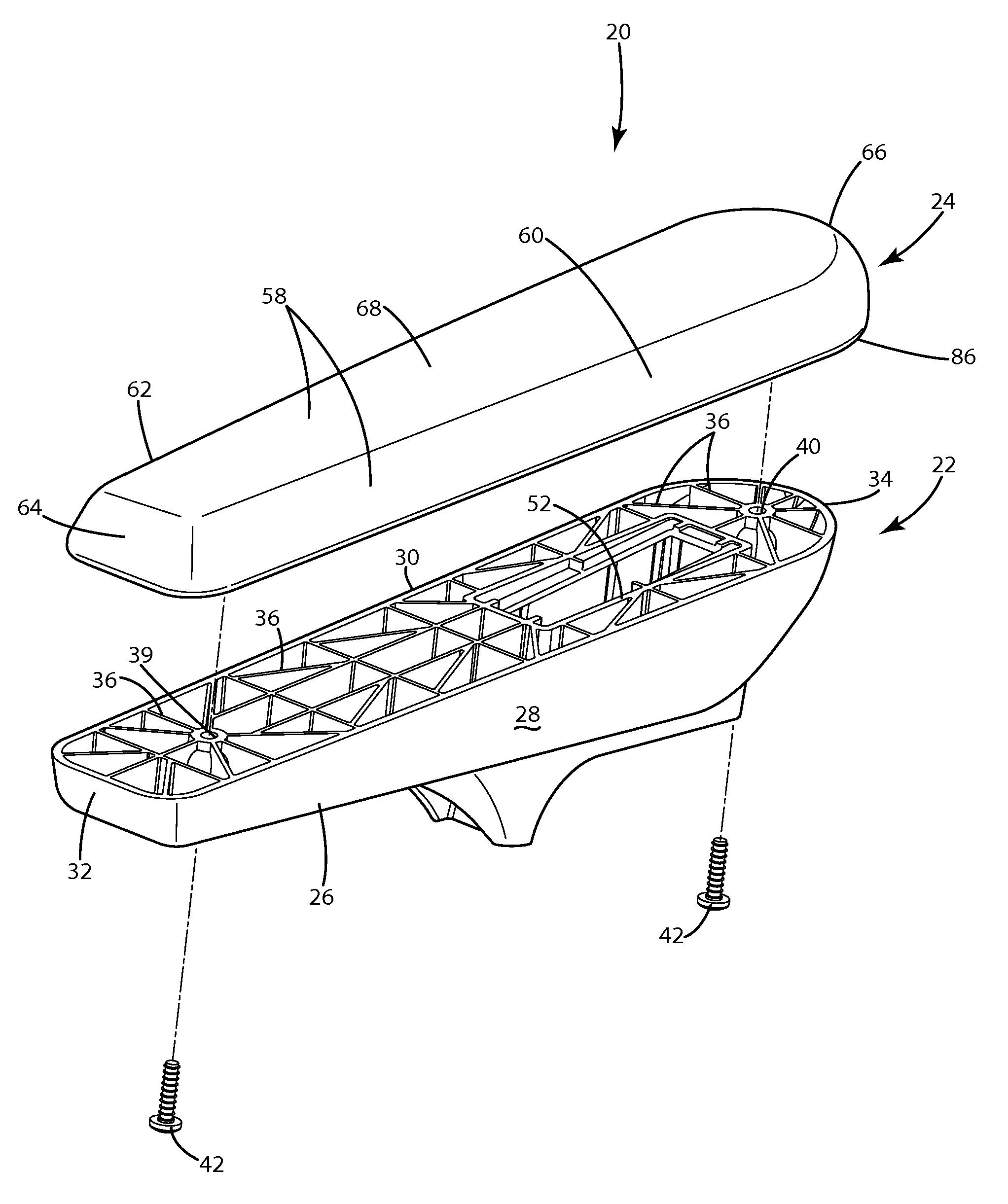

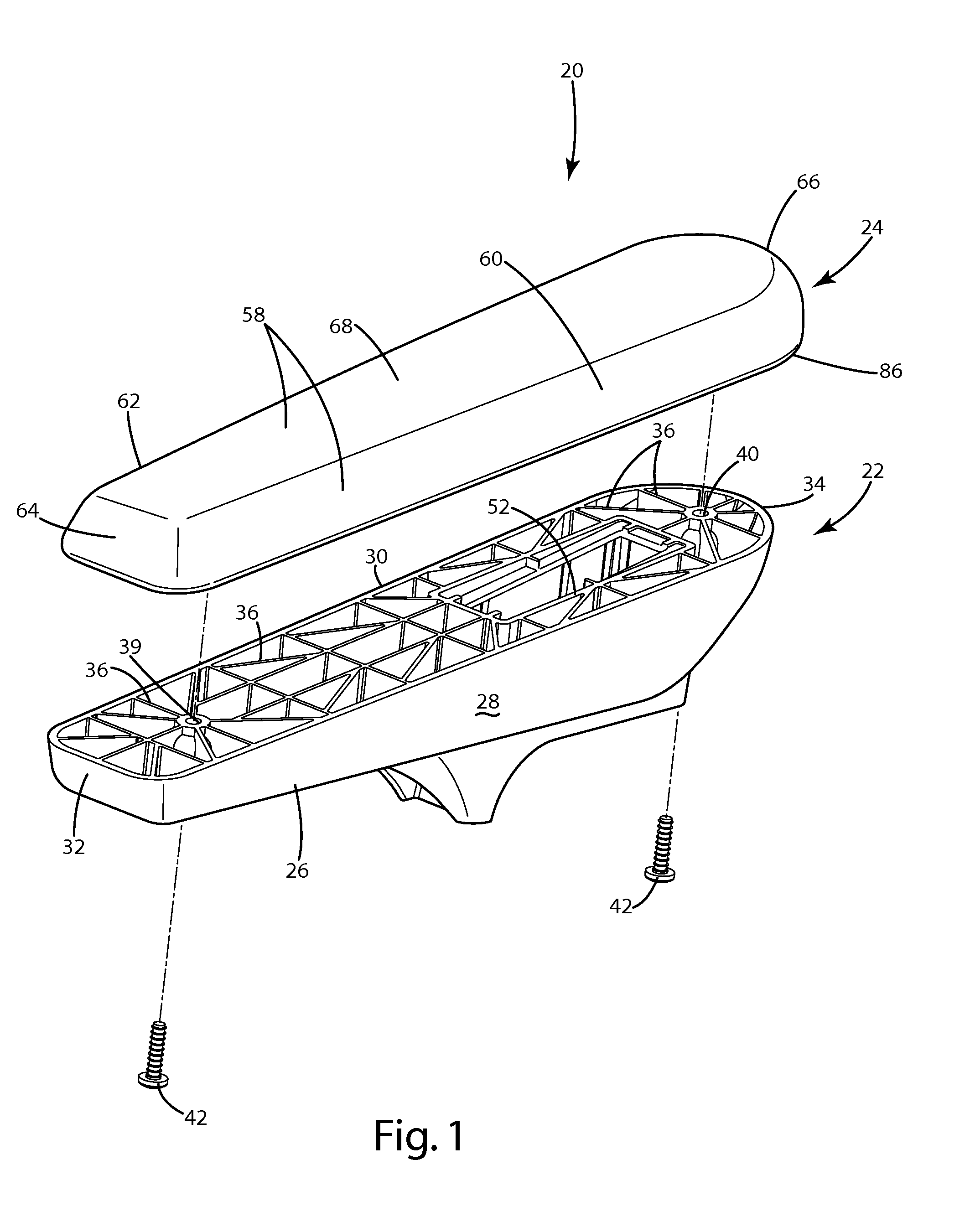

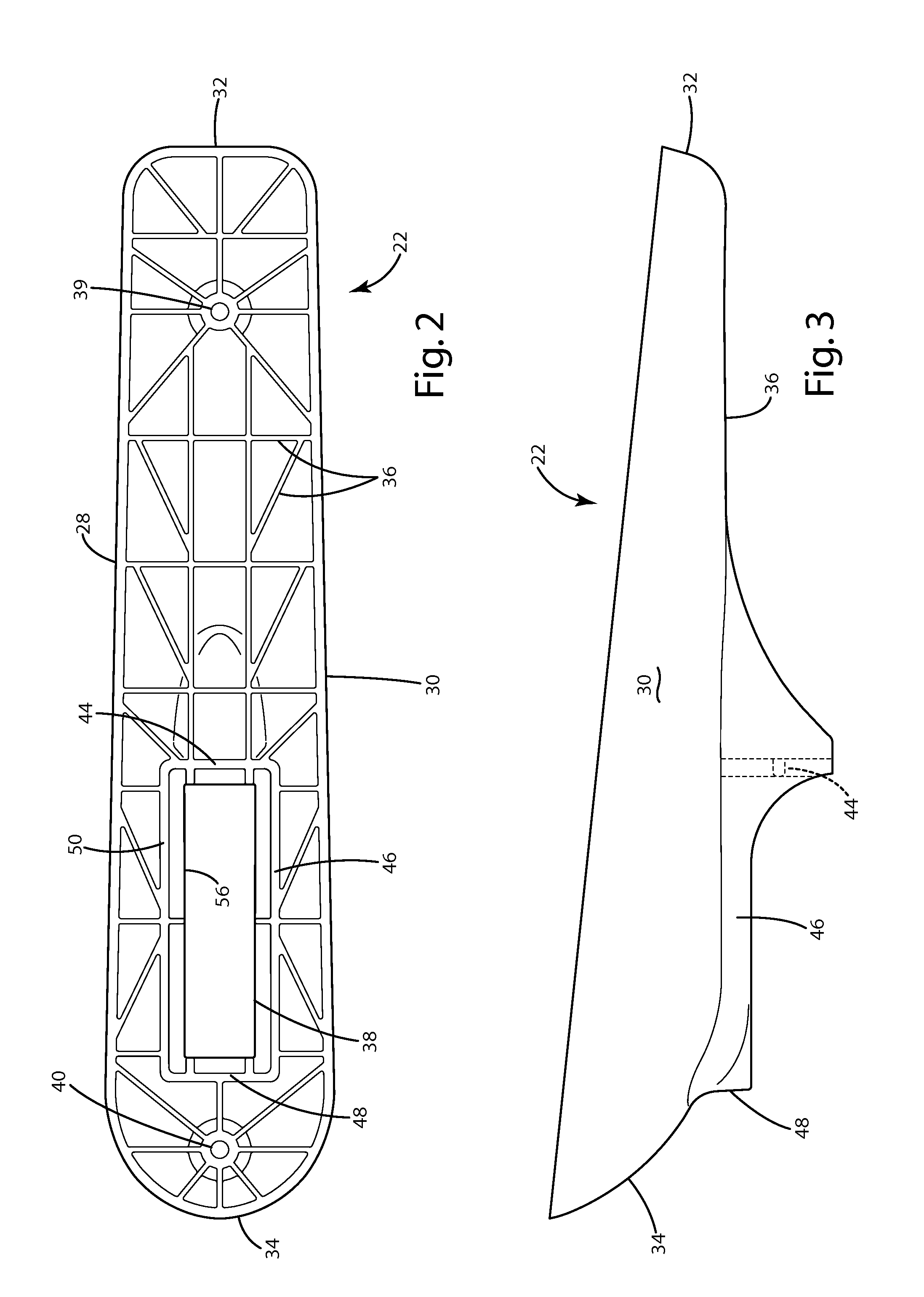

Armrest with interchangeable arm cap

InactiveUS20120146381A1Reduce exerciseImprove versatilityVehicle seatsStoolsEngineeringClean appearance

An armrest for arena, stadium, classroom and auditorium seating. The armrest includes a base and an interchangeable arm cap secured to the base. The base defines a rectangular recess sized to telescopically receive a support leg, the recess including vertical crush ribs to retain the support leg within the recess. The arm cap is releasably joined with the base opposite the recess and is interchangeable with multiple different arm caps while the support leg remains inserted in the recess. The arm cap can include any desired finish, and can extend over the interface between the base and the arm cap to provide a clean appearance.

Owner:AMERICAN SEATING

Compound praziquantel parasite repellent tablet for pets and preparation method thereof

InactiveCN103083344ASmooth appearanceDisintegrates quicklyOrganic active ingredientsPill deliverySlurryCompanion animal

The invention relates to a compound praziquantel parasite repellent tablet for pets. The tablet is characterized by comprising the following components by mass percent: 68-80 of praziquantel, 3-5 of ivermectin, 13-20 of starch, 1-10 of 10% starch slurry for soft material preparation, 3-6 of sodium carboxymethyl starch, and 0.5-1 of magnesium stearate. The preparation method consists of: weighing the praziquantel and the ivermectin, adding the starch, mixing them, conducting crushing and sieving to obtain a mixture; and adding the starch slurry to make a soft material, carrying out granulation with a sieve, performing drying at 50DEG C-70DEG C, subjecting the obtained dry granules to grain straightening through the sieve, adding the magnesium stearate and the sodium carboxymethyl starch, mixing them uniformly, and conducting tabletting, thus obtaining the product. With a smooth and clean appearance, the tablet provided in the invention can disintegrate rapidly, has all indicators optimized, and can achieve a good parasite repellent effect after oral administration. And the preparation method has a simple and feasible process and a low cost, thus being suitable for industrial production.

Owner:QINGDAO VLAND BIOTECH INC

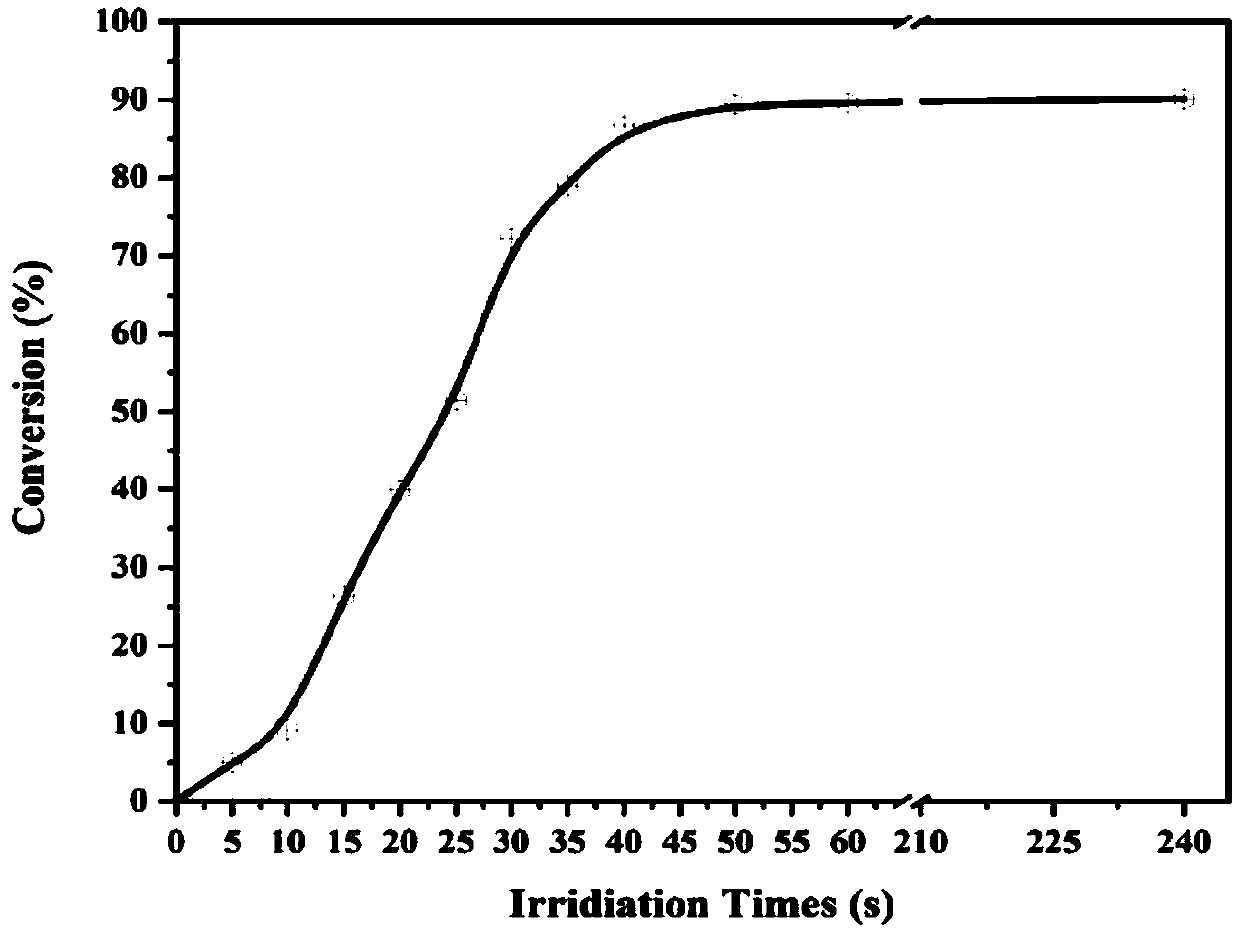

Method for preparing photosensitive ceramic precursor for manufacturing ceramic products by additive manufacturing technology

The invention discloses a method for preparing a photosensitive ceramic precursor for manufacturing ceramic products by an additive manufacturing technology; the method comprises the following steps:carrying out hydrolysis reaction of (chloromethyl)methyldichlorosilane with dichloromethylvinylsilane to obtain linear polysiloxane, then carrying out end-capping reaction of dimethylvinylchlorosilanewith linear polysiloxane, and carrying out reaction of the end-capped polysiloxane with 2-hydroxyethyl acrylate and triethylamine to obtain the photosensitive ceramic precursor. The UV-curable polysiloxane ceramic precursor is prepared, and the obtained photosensitive ceramic precursor can achieve 80% of double-bond conversion rate when being irradiated by ultraviolet light for 30 s and 90% of double-bond conversion rate when being irradiated by ultraviolet light for 40 s with the addition of a suitable initiator. The photosensitive ceramic precursor has quite high-efficiency photocuring performance. With the photosensitive ceramic precursor as the raw material, the stereolithography technology is used for additive manufacturing, and the cured product with regular appearance is obtained and has bright and clean appearance and high strength.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Conductive engineering plastics and preparation method thereof

The invention provides conductive engineering plastics and a preparation method thereof. The plastics contain the following ingredients by weight percent: 25-65% of polyphenyl ether, 0.5-5% of carbon nano tubes, 15-45% of needle-like wollastonite, 10-30% of HIPS, 0-10% of antioxidant, 0-10% of secondary antioxidant and 0-10% of dispersant. The method comprises the following steps: (1) proportioning raw materials and adding the ingredients except the needle-like wollastonite and the carbon nano tubes to a main feeding mouth of a double-screw extruder after mixing the above ingredients evenly; (2) adding the needle-like wollastonite and the carbon nano tubes to a side feeding mouth after mixing the two ingredients; (3) carrying out extruding, cooling, drying and granulating after full kneading under the molten state of polymer resins to generate composite plastics. The conductive engineering plastics can endow the products with good electrostatic dispersion capacities, mechanical properties and heat resistance, and have stable dimensions, small warping and clean appearance without dust falling.

Owner:惠州市沃特新材料有限公司

Tampon with clean appearance post use

InactiveUS20080177241A1Good acquisitionCleaner post-use appearanceSurgeryBaby linensAbsorbent materialTampon

A catamenial tampon comprises a compressed absorbent member having an inner region and an exterior surface, the compressed absorbent member comprising an absorbent material. An overwrap substantially covers the exterior surface of the compressed absorbent member. The overwrap comprises an apertured fluid pervious material that is hydrophobic or rendered hydrophobic relative to the compressed absorbent member. The fluid pervious overwrap therefore tends to remain free of fluid as the fluid is preferentially partitioned into the absorbent member.

Owner:THE PROCTER & GAMBLE COMPANY

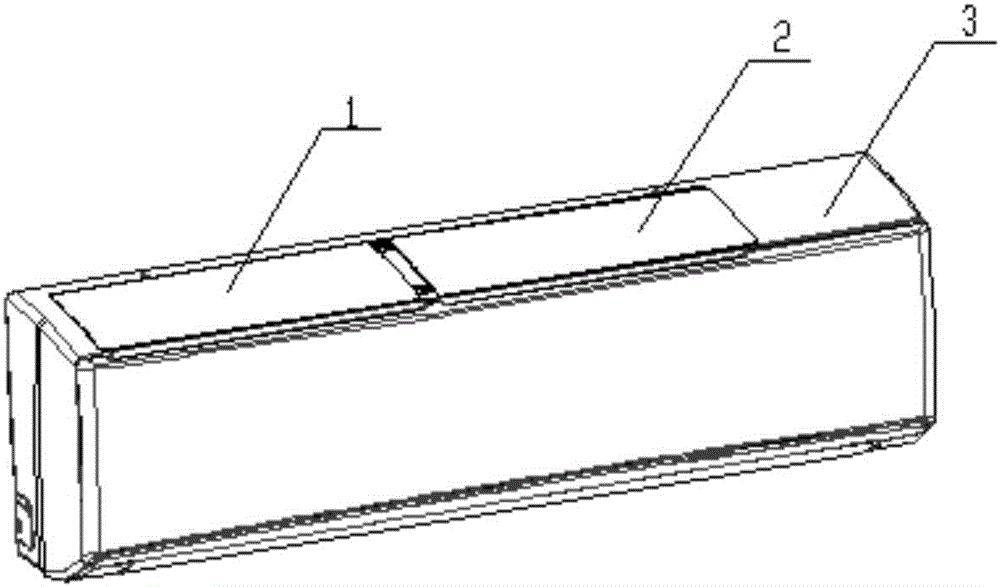

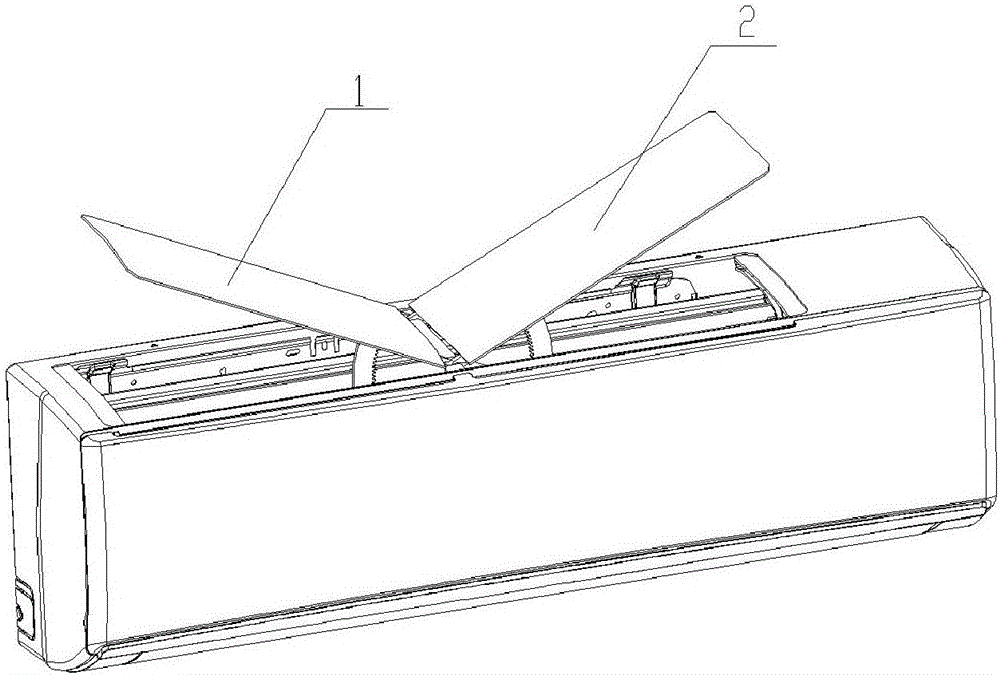

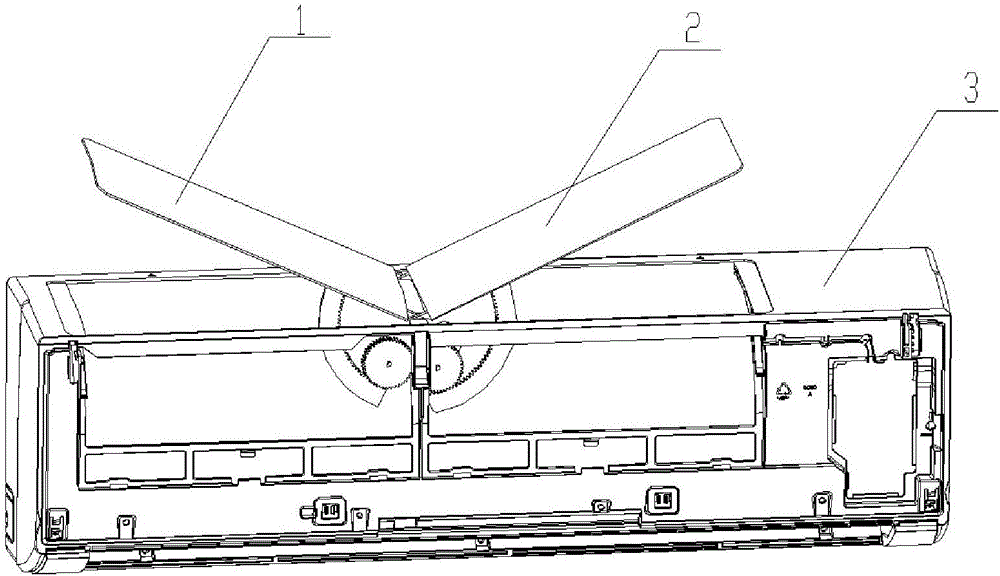

Air conditioner air inlet dustproof mechanism and air conditioner

InactiveCN106440304AIncrease the areaPrevent fallingHeating and ventilation casings/coversFriction gearingsClean appearanceOver the Air

The invention relates to the technical field of air conditioners and discloses an air conditioner air inlet dustproof mechanism. The air conditioner air inlet dustproof mechanism comprises baffles and a driving mechanism; one ends of the baffles are rotationally fixed to a shell of an air conditioner; the baffles rotationally move under the action of the driving mechanism so as to open or close an air inlet. According to the air conditioner air inlet dustproof mechanism provided by the invention, when the air conditioner does not work, the driving mechanism drives the baffles to rotationally move to close the air inlet, thus, dust cannot fall into the air inlet located over the air conditioner, the dust is completely prevented from falling into the interior of the air conditioner, and a clean appearance effect is achieved; and in addition, by means of the air conditioner of the structure, an air inlet grille structure at the air inlet can be omitted, the area of the air inlet is increased, air resistance is reduced, the air inlet amount is increased, and accordingly the heat exchange efficiency is improved. The invention further relates to the air conditioner comprising the air conditioner air inlet dustproof mechanism.

Owner:GREE ELECTRIC APPLIANCES INC

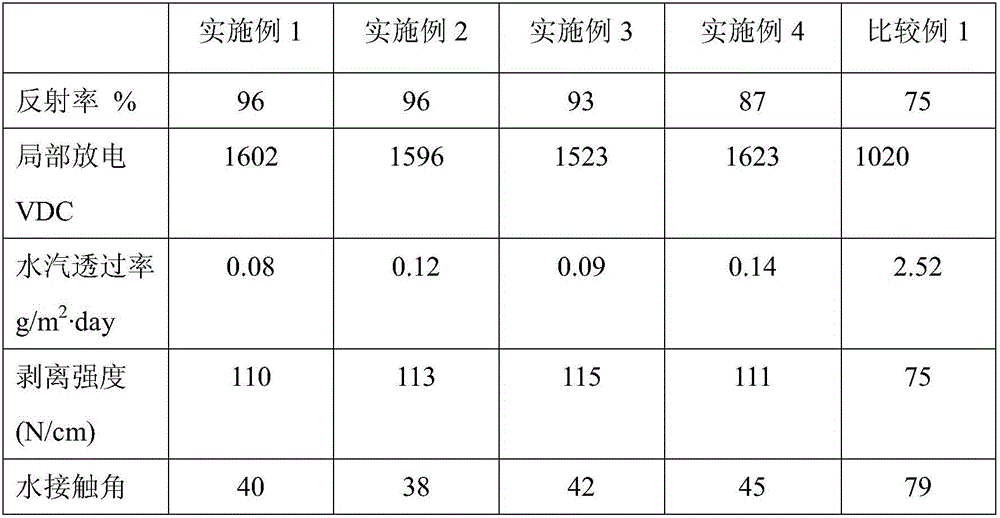

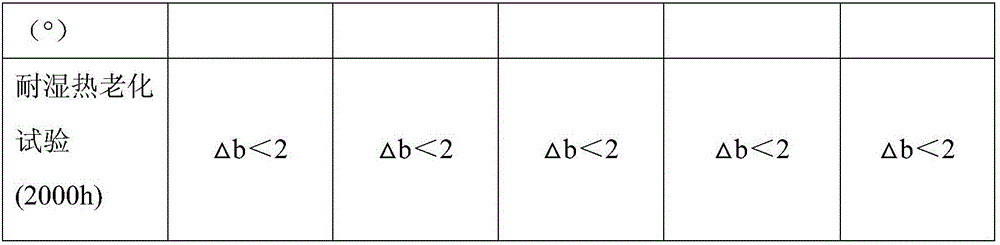

High-water blocking backplate material easy to clean for large system photovoltaic module

ActiveCN106206795AExcellent light reflectivityHigh bonding strengthSynthetic resin layered productsPhotovoltaic energy generationWeather resistanceTransmittance

The invention discloses a high-water blocking backplate material easy to clean for a large system photovoltaic module. The backplate material sequentially comprises an outer layer, a bonding layer, a base film layer and an inner layer, wherein the outer layer comprises fourth main body resin, a grafting auxiliary, an inorganic filler and a modified polymer brush grafted on a surface of the fourth main body resin. The local discharge voltage of the backplate material fabricated according to the invention is larger than 1,500V, the backplate material can be applied to the large system photovoltaic module, the power generation cost is reduced, and the power generation efficiency is improved; meanwhile, the backplate material is relatively low in moisture transmittance and can be used in a humid environment for a long time, and phenomena such as snail tracks and PID are improved; the outer surface of the backplate material also has a favorable function of being easy to clean, and the clean appearance can be maintained during the long-term application process of the photovoltaic module in the outdoors; and moreover, the backplate material fabricated according to the invention also has high reflectivity, excellent weather resistance and high cohesiveness with EVA adhesive films, is excellent in integral function and is suitable for the large system photovoltaic module.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com