Cool-to-touch breathable dry washable smooth all-cotton fabric and manufacture method thereof

A manufacturing method and tactile technology, applied in the field of textile fabrics, can solve the problems of pure cotton fabrics such as stuffiness, dull luster, and poor washability, and achieve the effect of smooth hand feeling, gorgeous luster, and clean appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

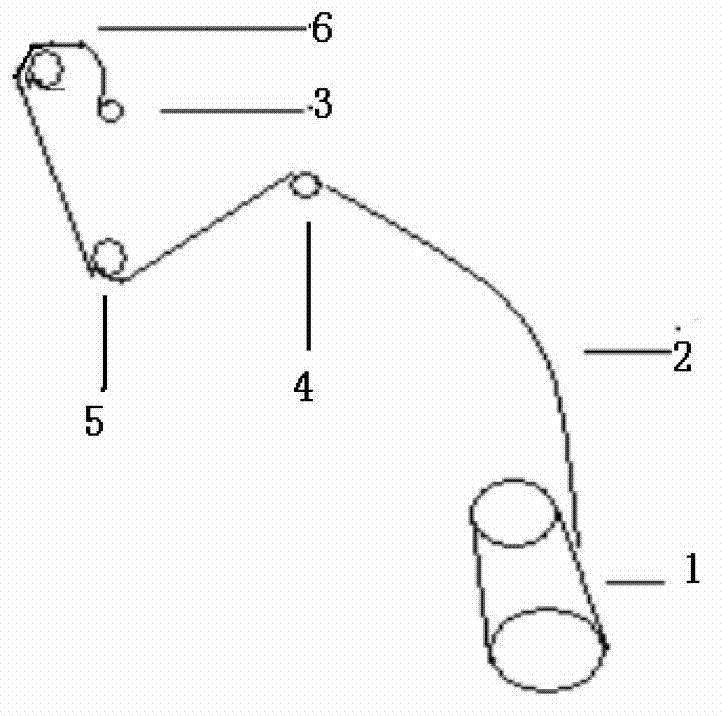

Method used

Image

Examples

Embodiment

[0117] The fabric is prepared according to the following conventional process: twisted yarn→cooked yarn→weaving→cloth inspection→fabric preparation→open width→open width mercerizing→enzyme washing before dyeing→dyeing→dehydration→handling→SANT drying→medium inspection→setting→ Pre-shrink → post-check. in:

[0118] 1. Yarn treatment

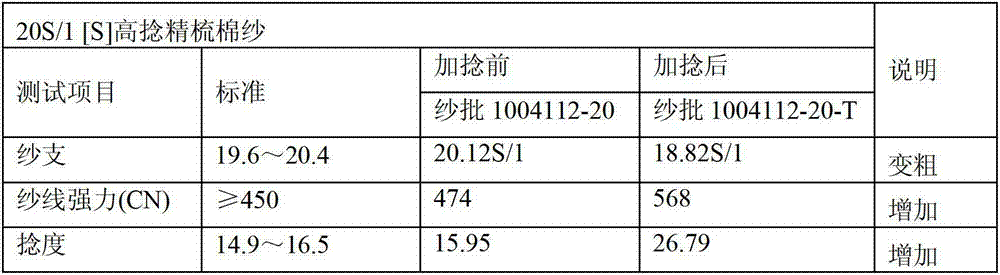

[0119] Twist the cotton yarn to the twist coefficient of the yarn in the following table 10, and then use 5kg of scouring solution for 1 kilogram (kg) of cotton yarn, that is, the bath ratio is 1:5, and boil the yarn at 100°C for 60 minutes .

[0120] The scouring liquid is an aqueous solution, containing ZJ-C302 (Guangzhou Zhuangjie Chemical ZJ-C302 refining degreasing agent) with a concentration of 2 grams per liter (g / l) and soda ash with a concentration of 4g / l.

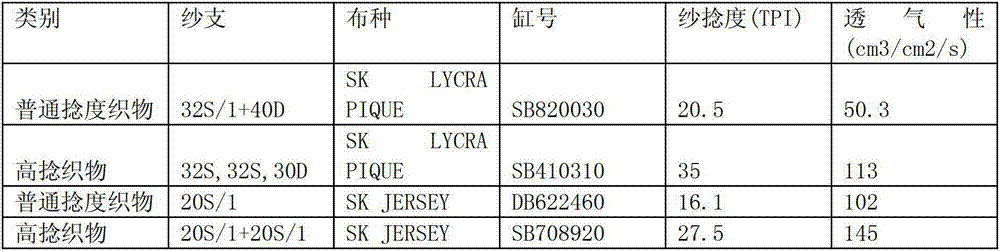

[0121] 2. Weaving of cloth

[0122] The yarns treated in the above 1 were woven according to the organizational structure in the following table 10 to obtain a gray cloth.

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com