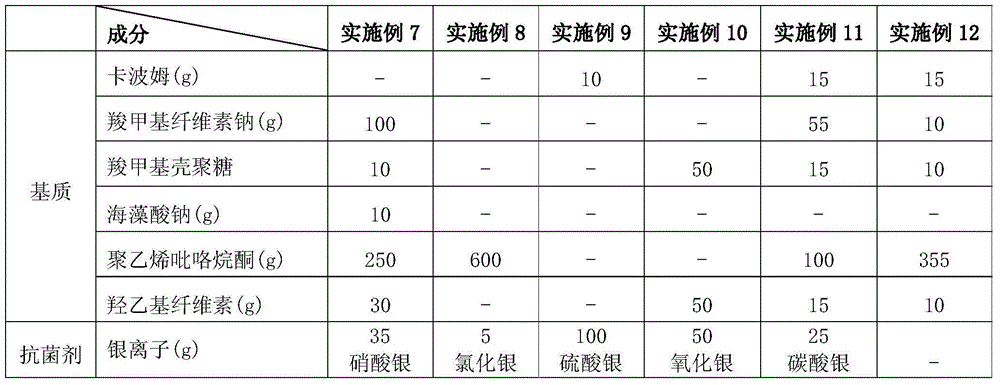

Patents

Literature

38results about How to "Cool to the touch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

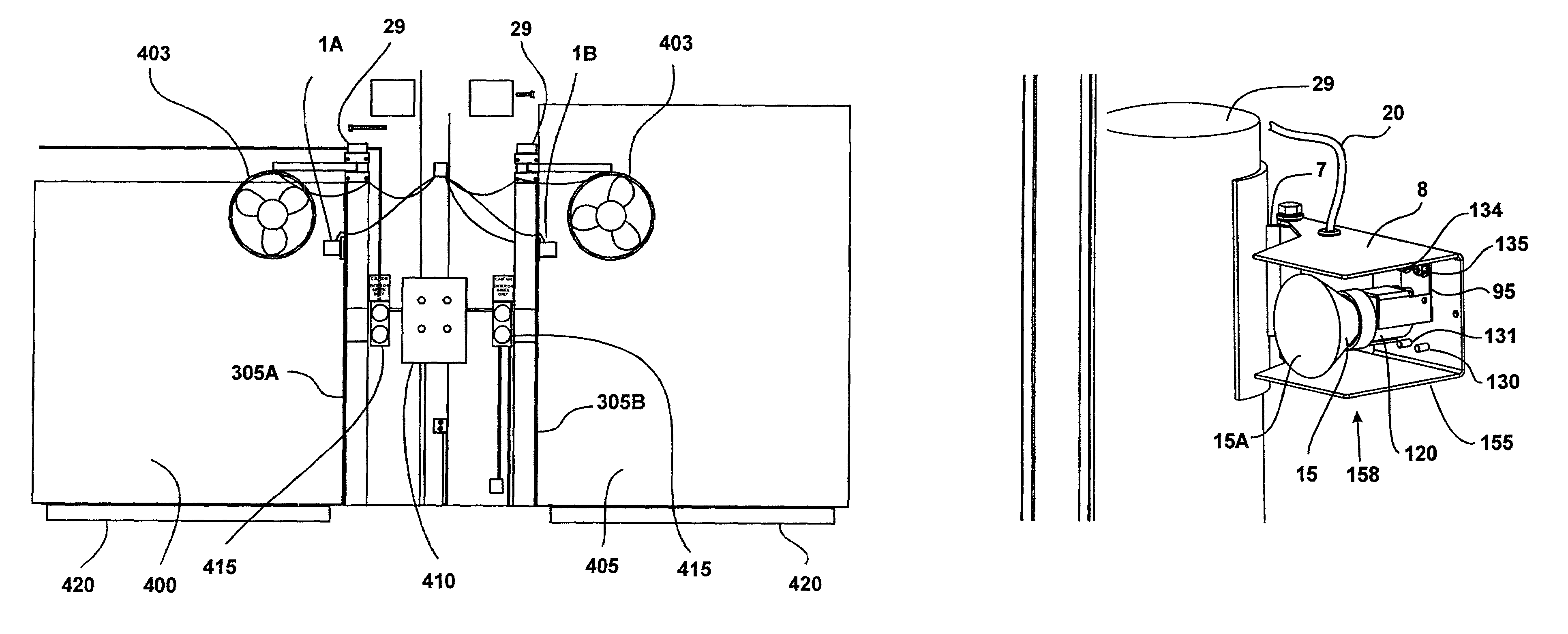

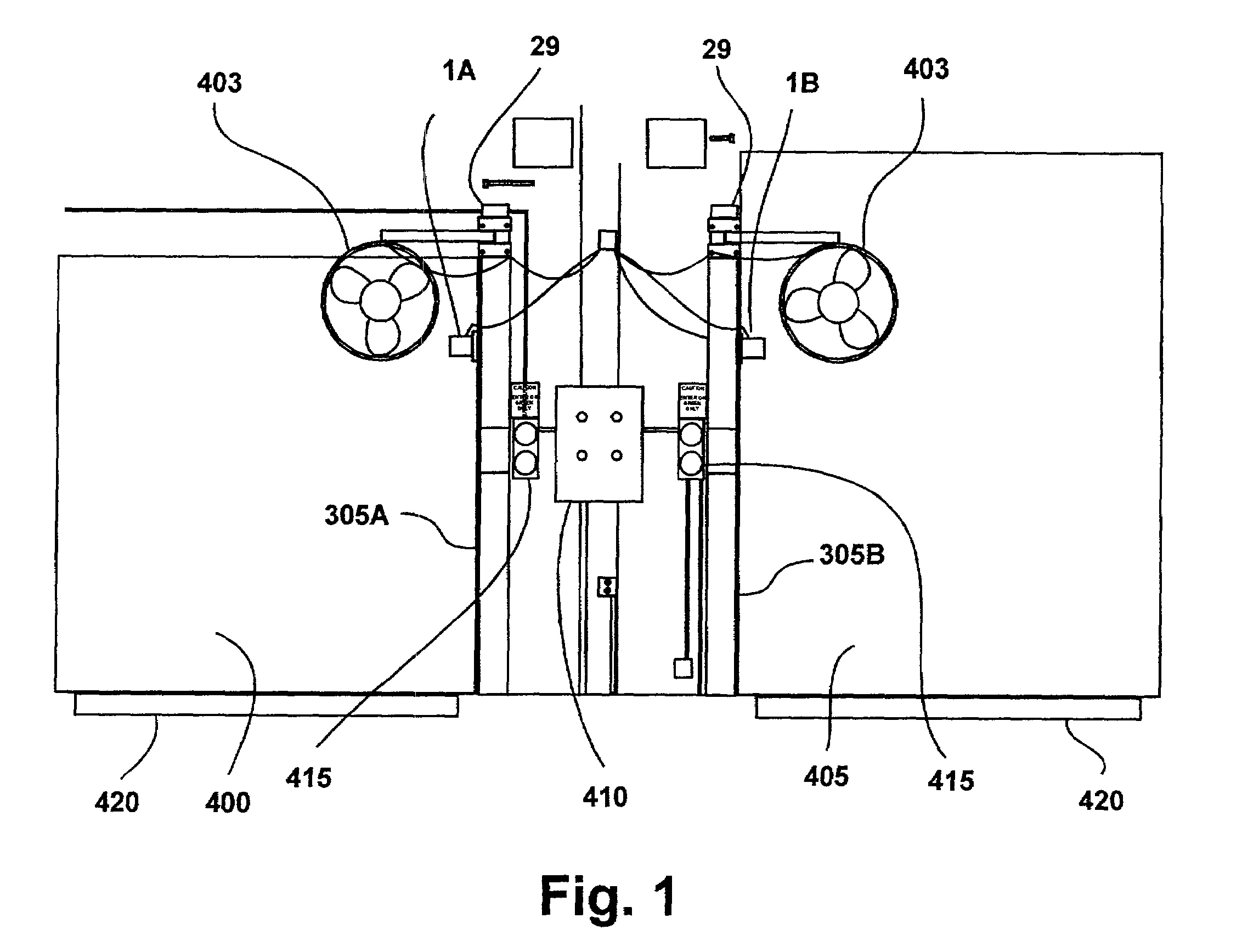

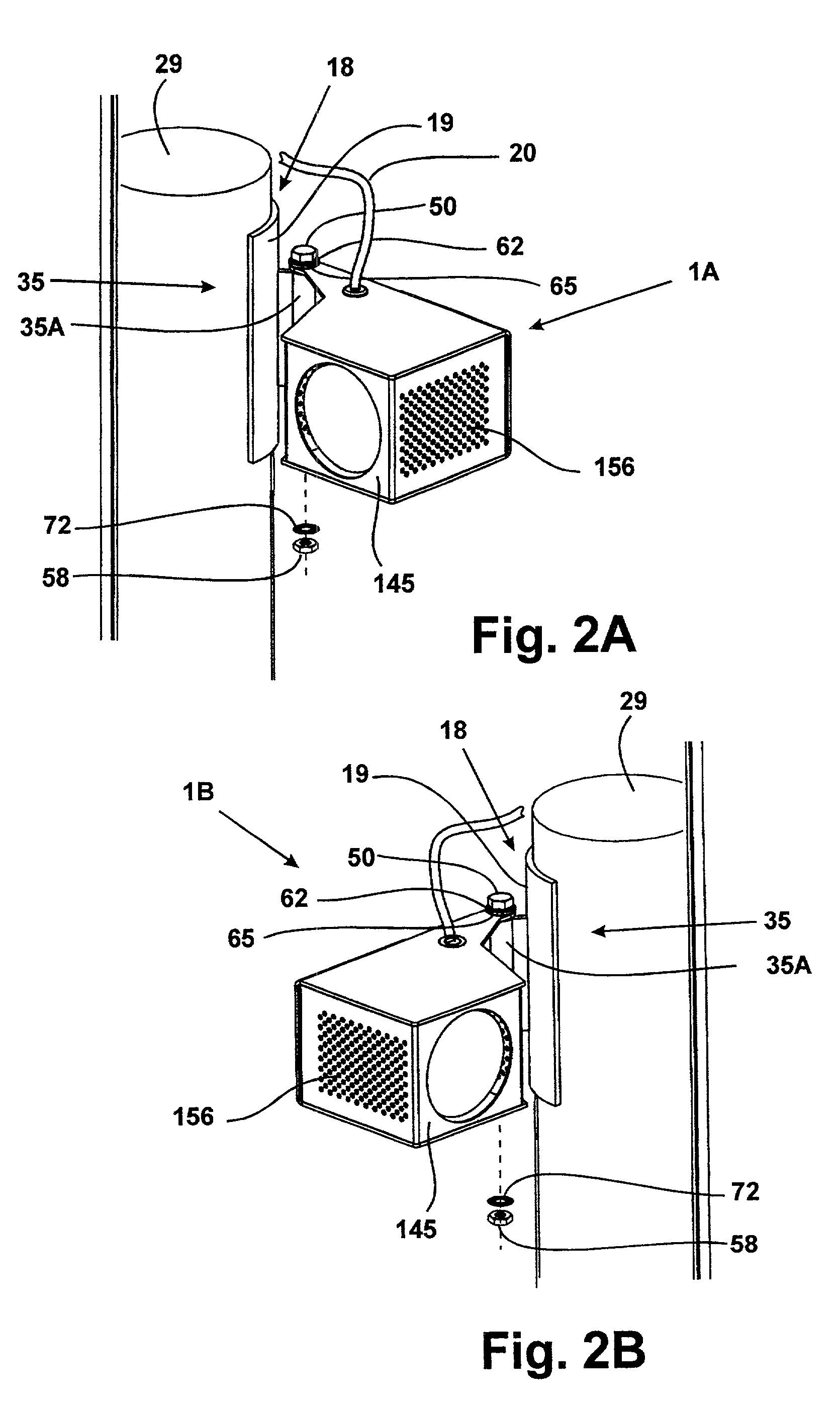

Loading dock light system

InactiveUS7101064B2Cool to the touchReduce confusionLighting support devicesLight fasteningsTruck-trailerEngineering

Owner:ANCEL THOMAS A

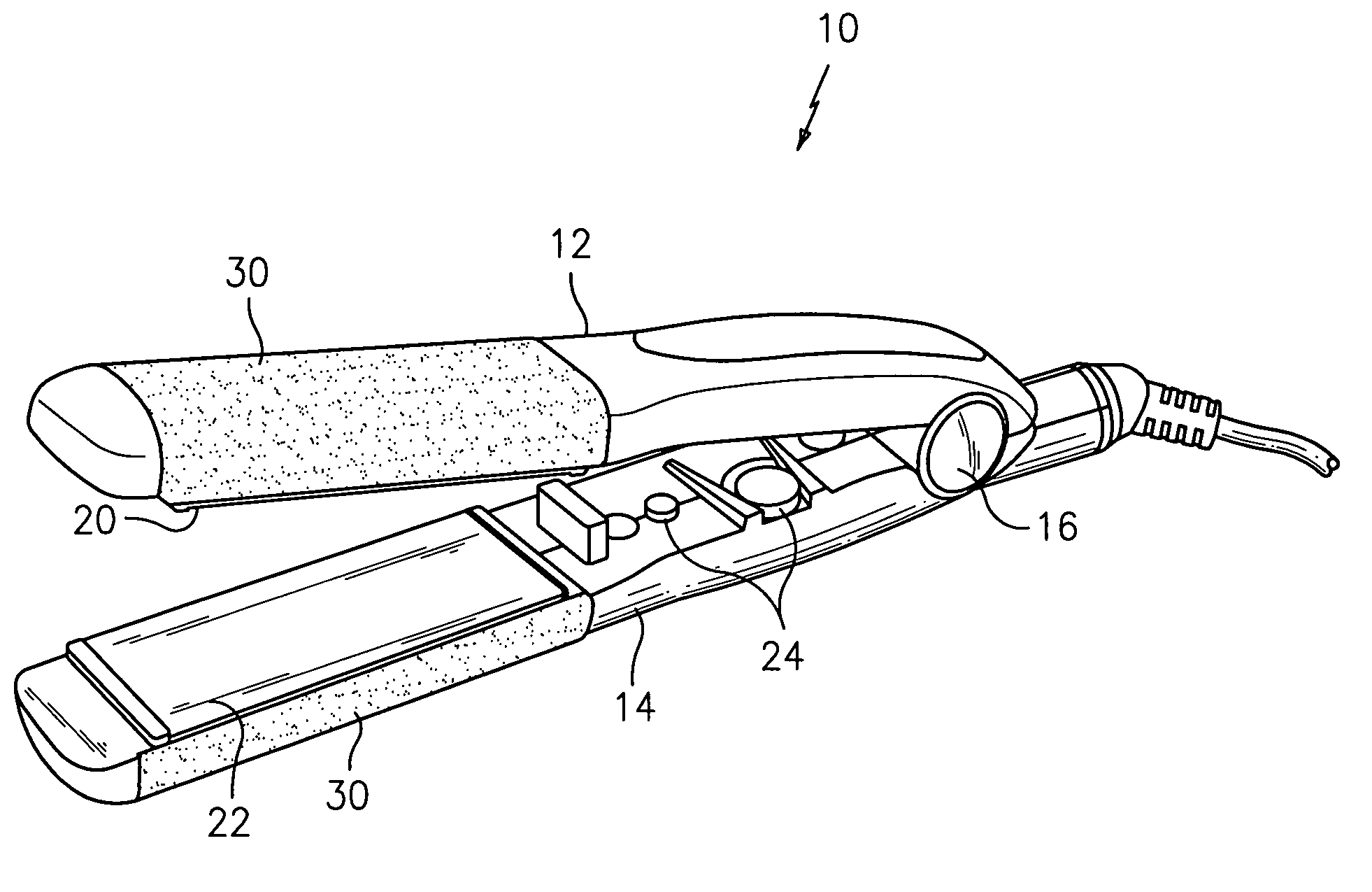

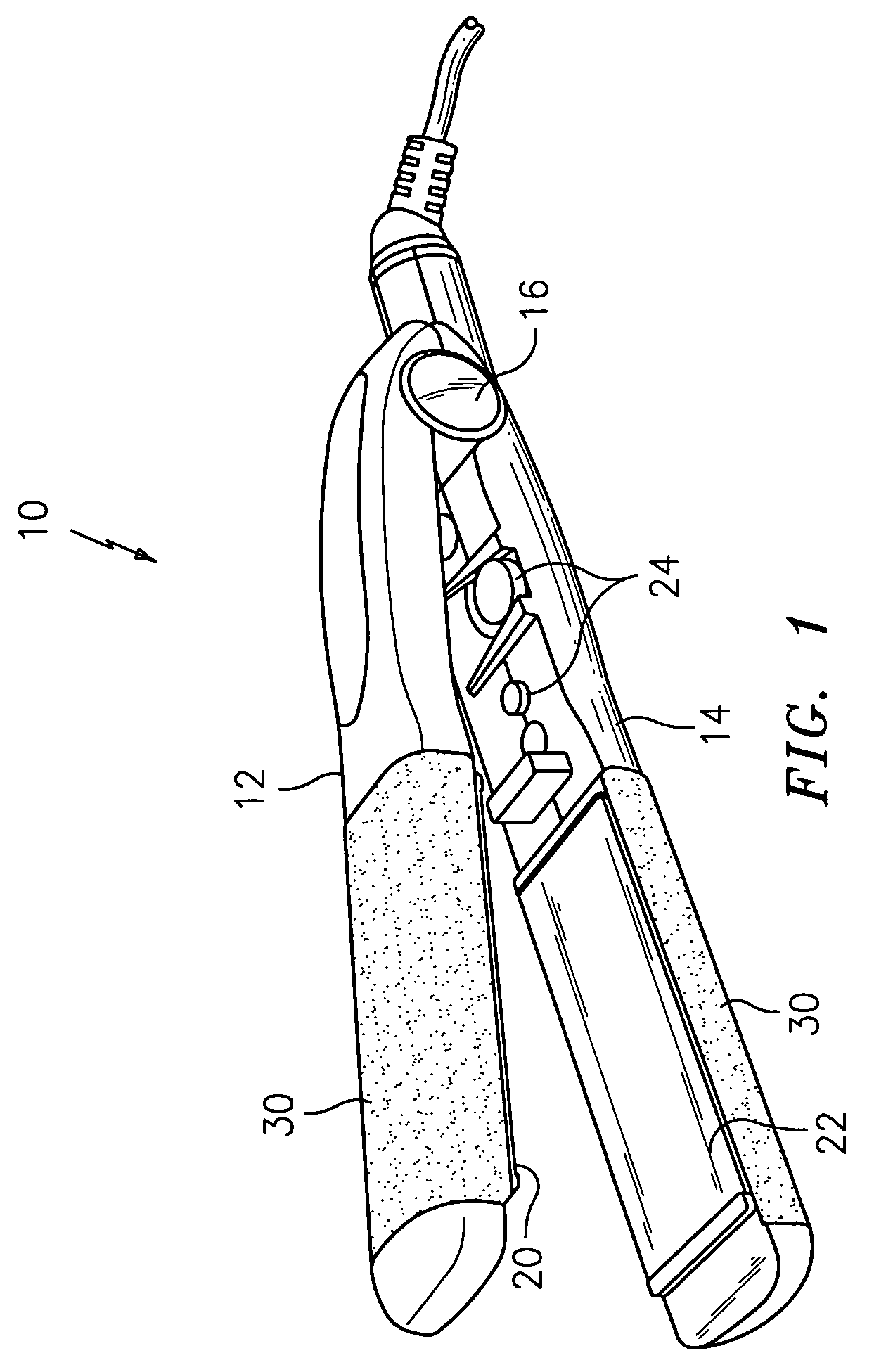

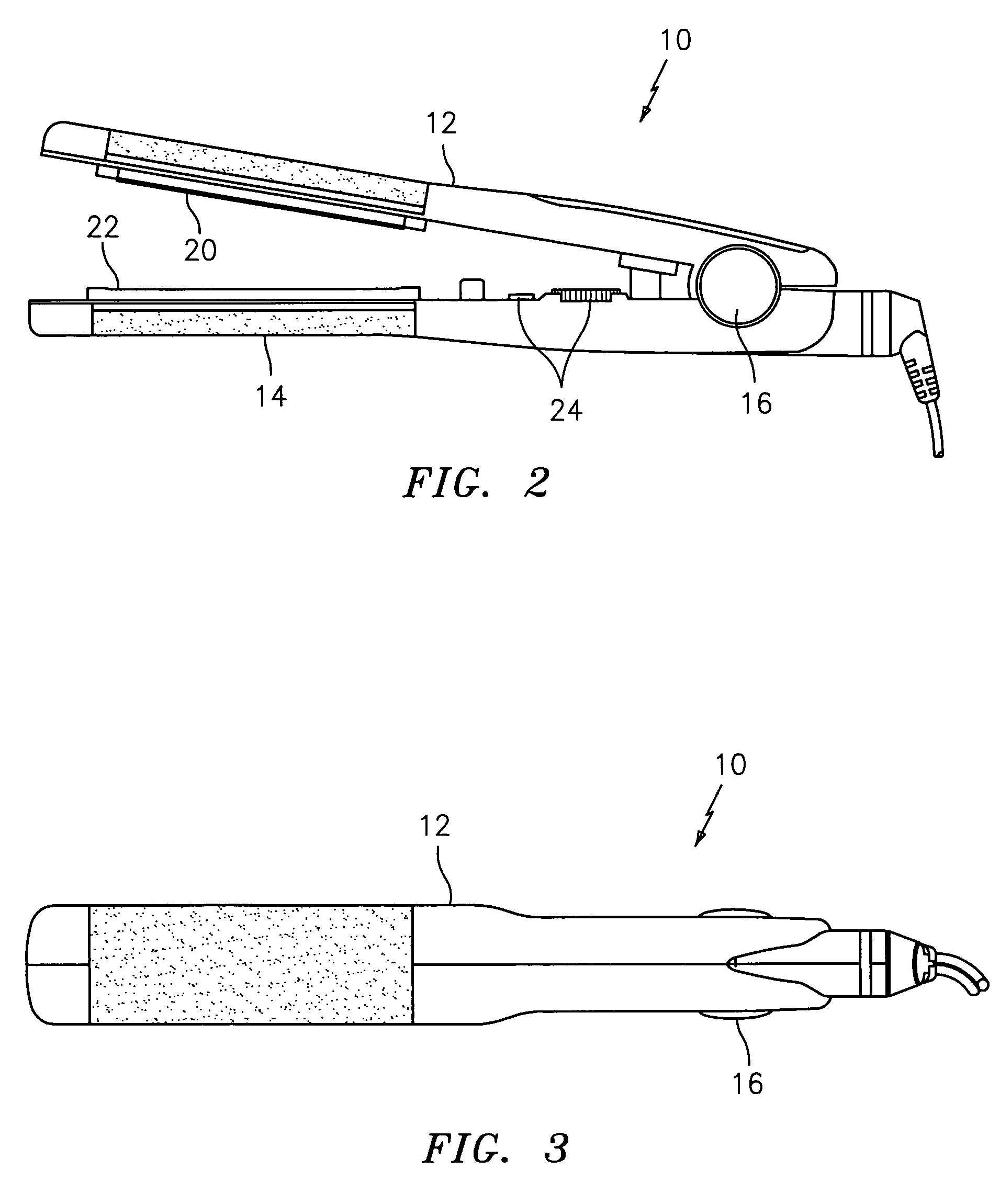

Hair straightening appliance with flocked arms

InactiveUS20060037625A1Easy to straightenImprove gripCurling-ironsCurling-tongsHair straighteningEngineering

Owner:CONAIR CORP

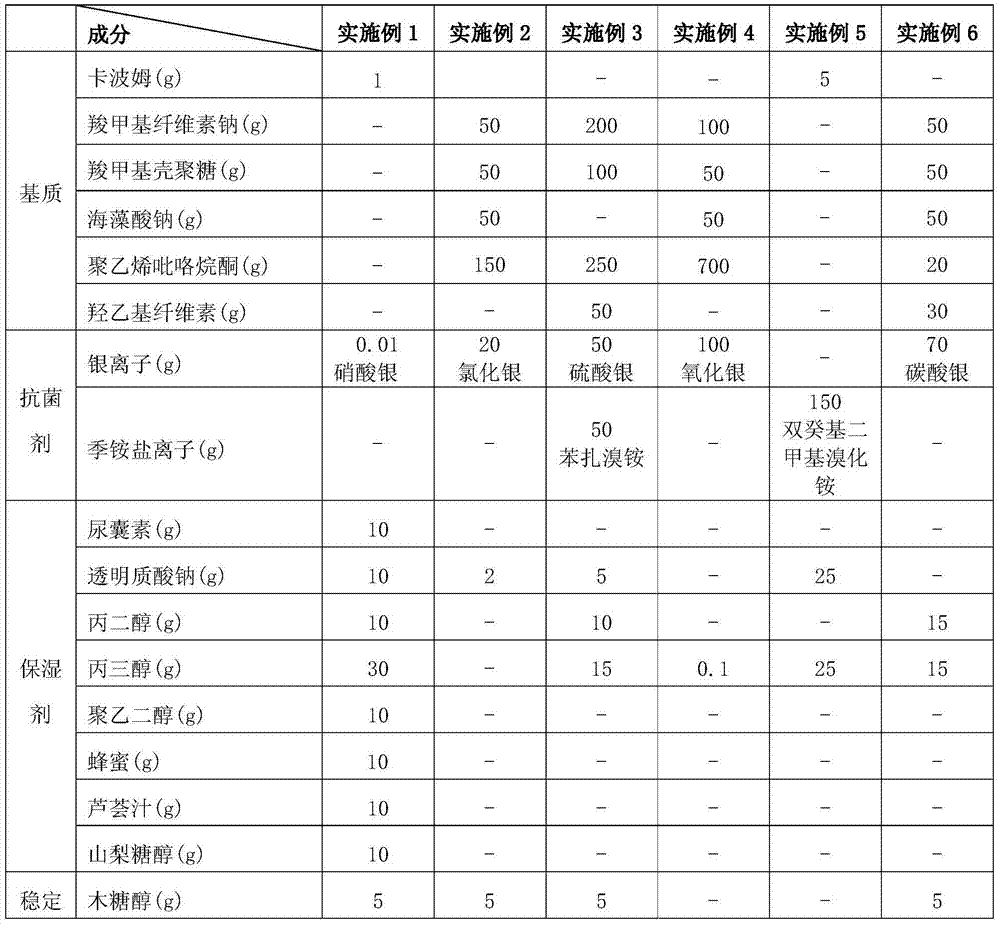

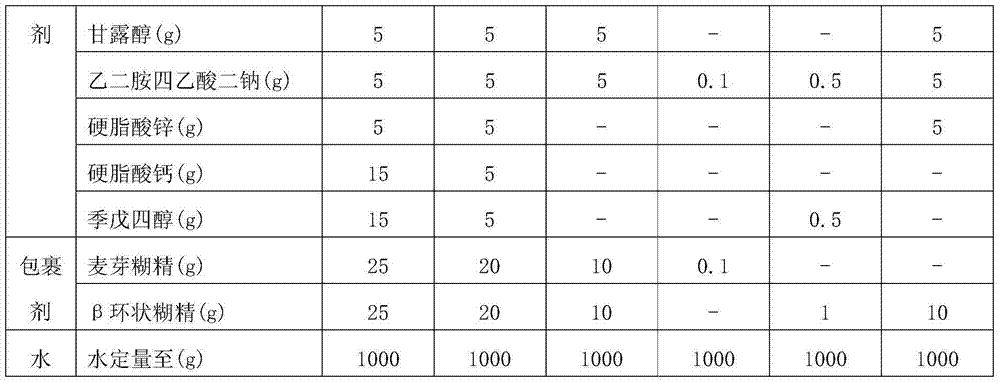

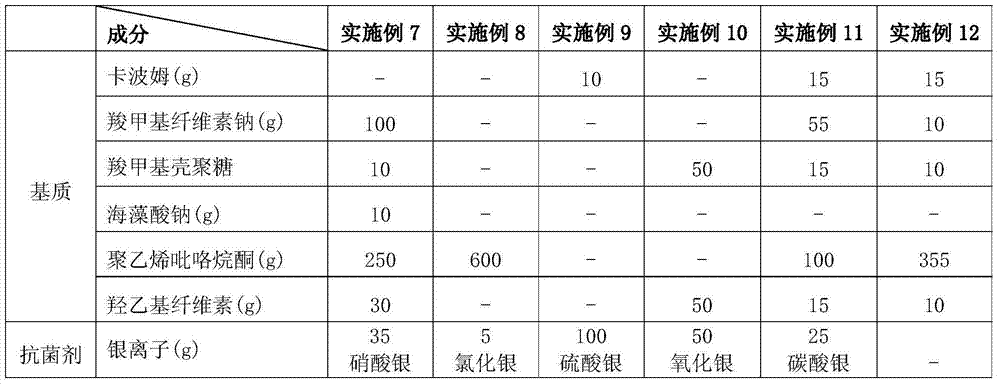

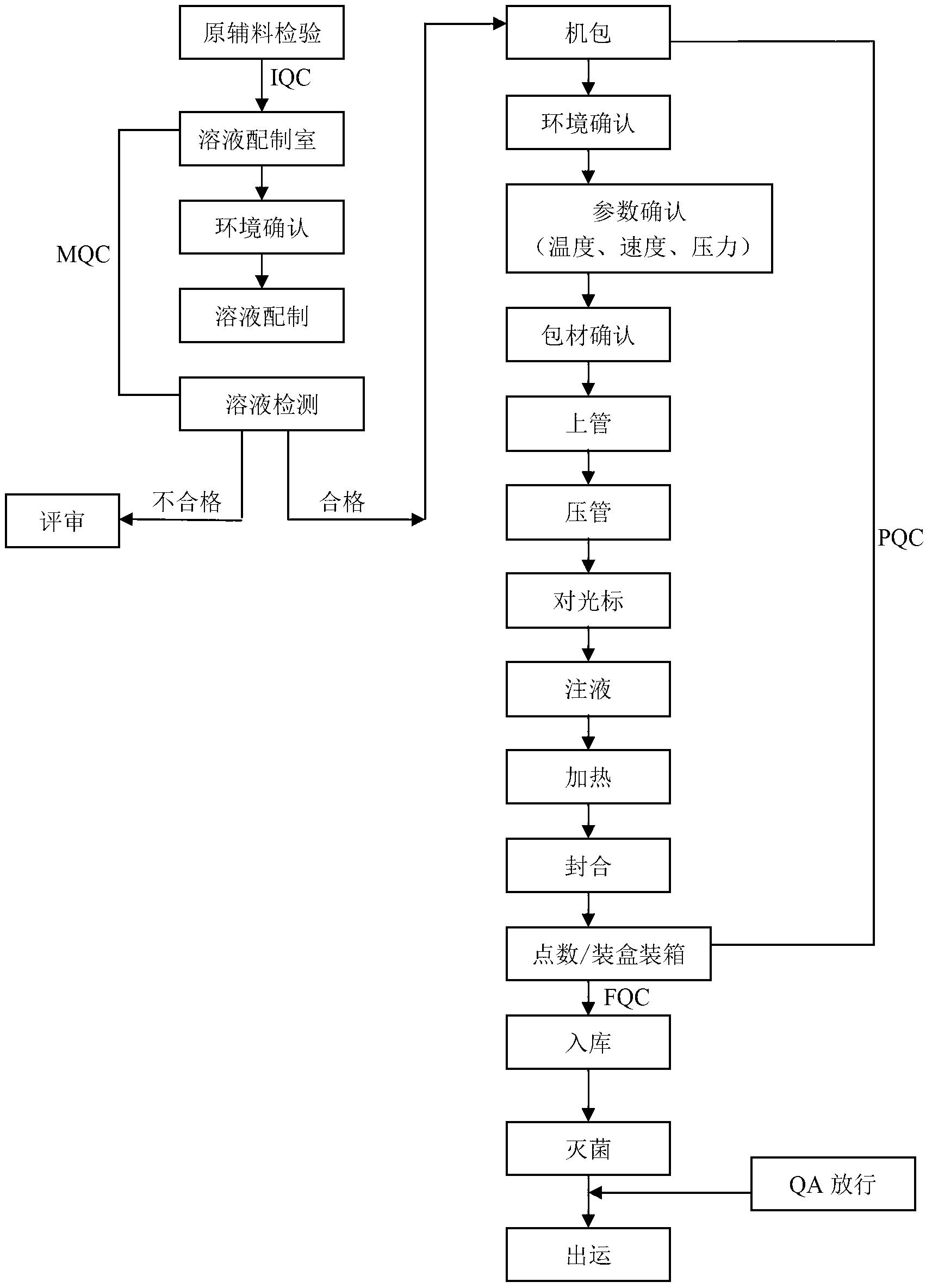

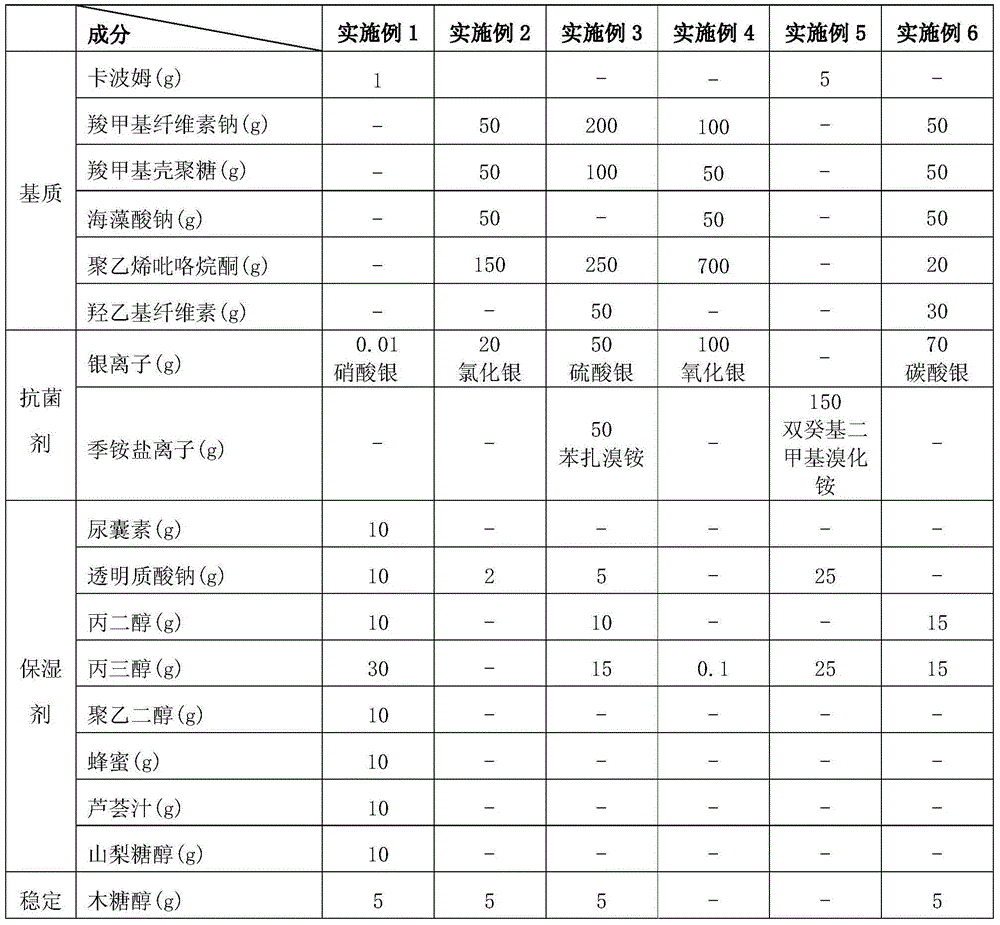

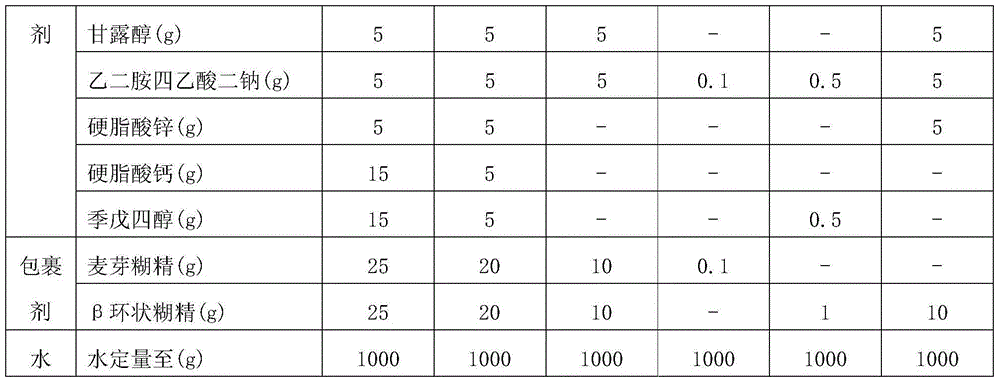

Hydrogel wound dressing for treating laser cauma and burns and scalds as well as preparation method thereof

ActiveCN103495199APromote wound healingImprove antibacterial propertiesAbsorbent padsBandagesBurned skinLaser burn

The invention relates to hydrogel wound dressing for treating laser cauma and burns and scalds. The active components of the hydrogel wound dressing include an antibacterial agent, a humectant and a stabilizer, wherein the antibacterial agent inhibits adhesion and growth of the wound of laser cauma and surrounding bacteria and can kill various pathogenic bacteria at the cauma part, so as to effectively promote union of the laser cauma. The antibacterial agent adopted by the invention does not generate drug resistance, the humectant can maintain moisture of the wound, promote union of the wound surface, prevent formation of scars and alleviate wound pain. With the adoption of the stabilizer, the hydrogel maintains long-time antibacterial effectiveness. Experiments verify that the hydrogel dressing provided by the invention has the effects of effectively relieving wound pain, controlling local infection, maintaining moisture of wound skins, protecting skins, accelerating and promoting union of wound surface and wound and preventing formation of scars, and can be used for healing laser-burned skin wound surfaces (such as laser mole removal and the like) and wound surfaces of burns and scalds.

Owner:SAIKE SAISI BIOTECH CO LTD

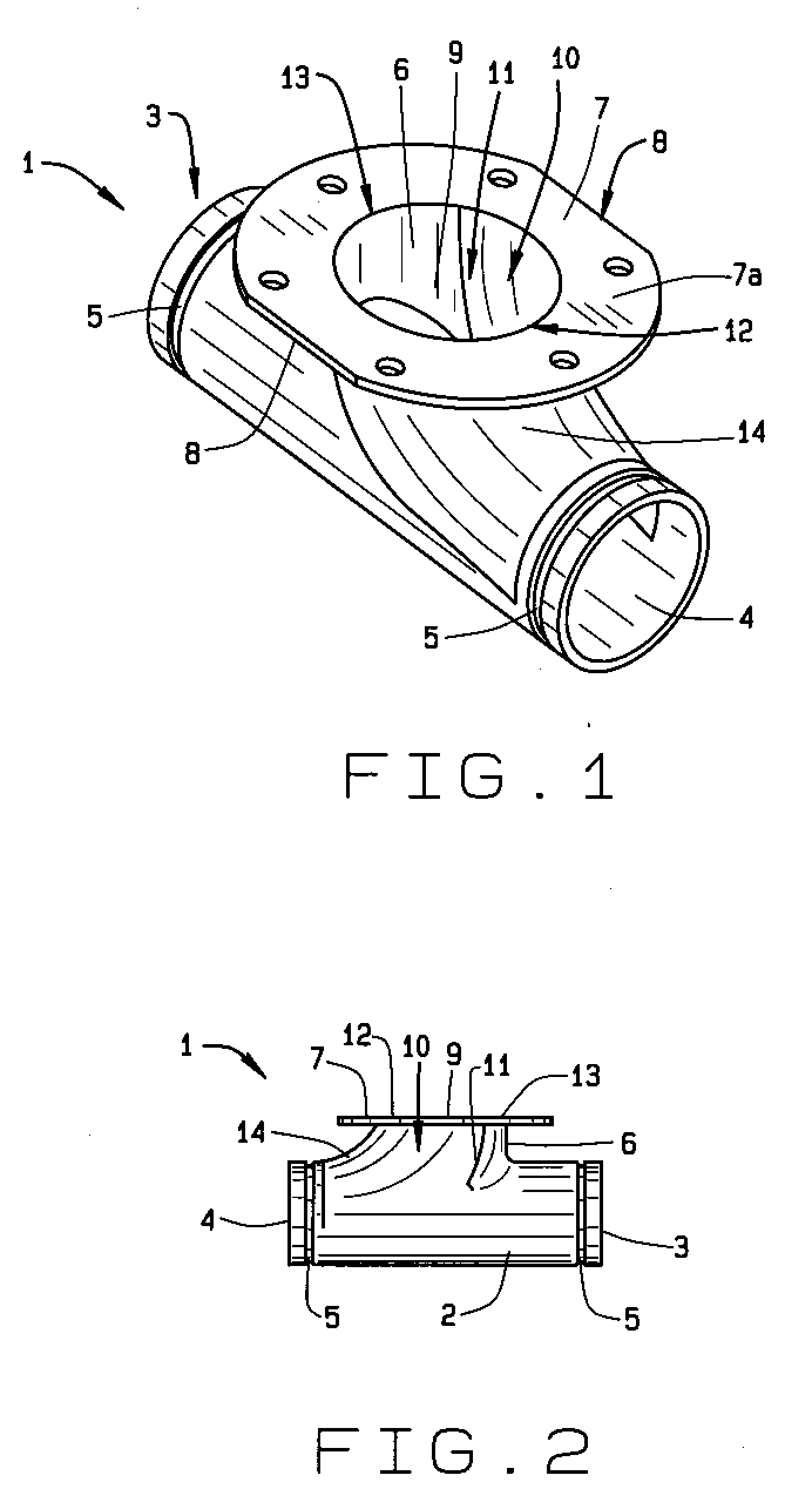

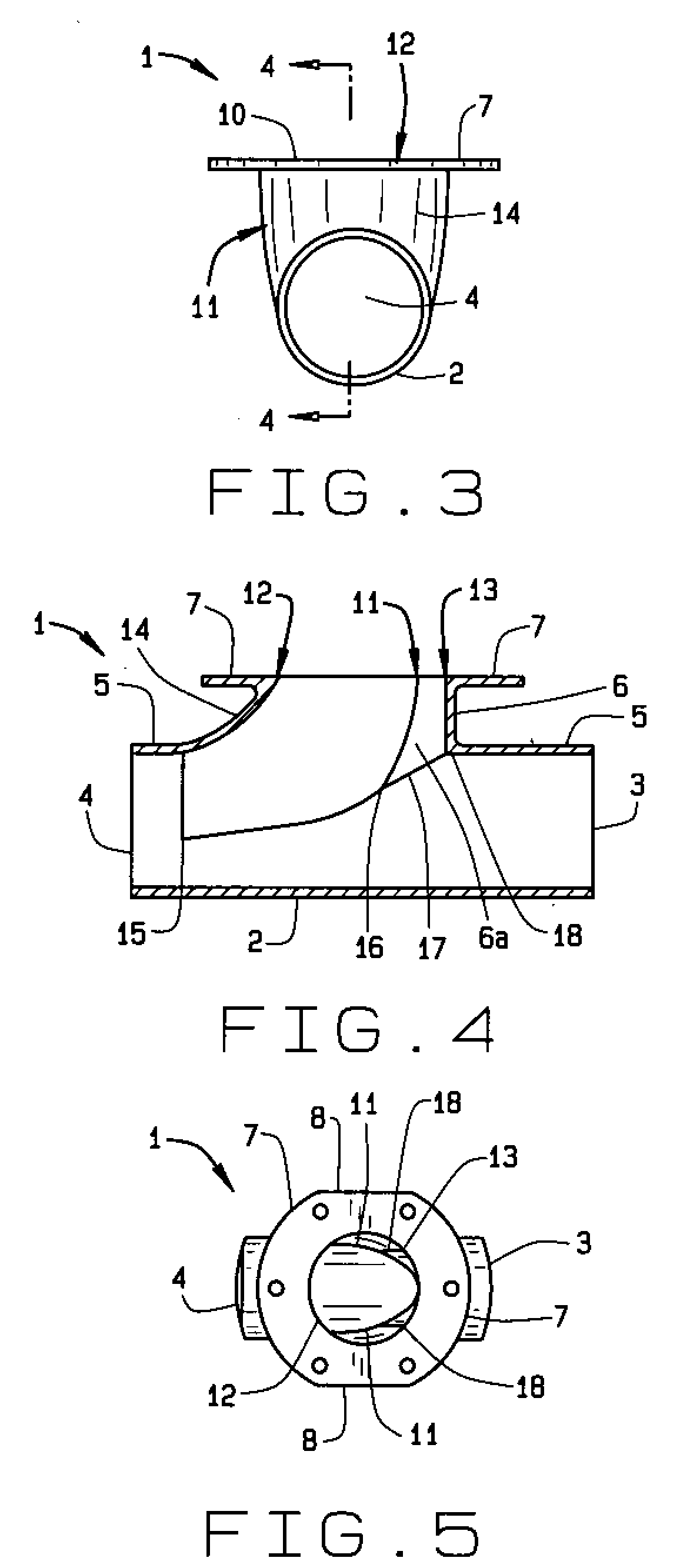

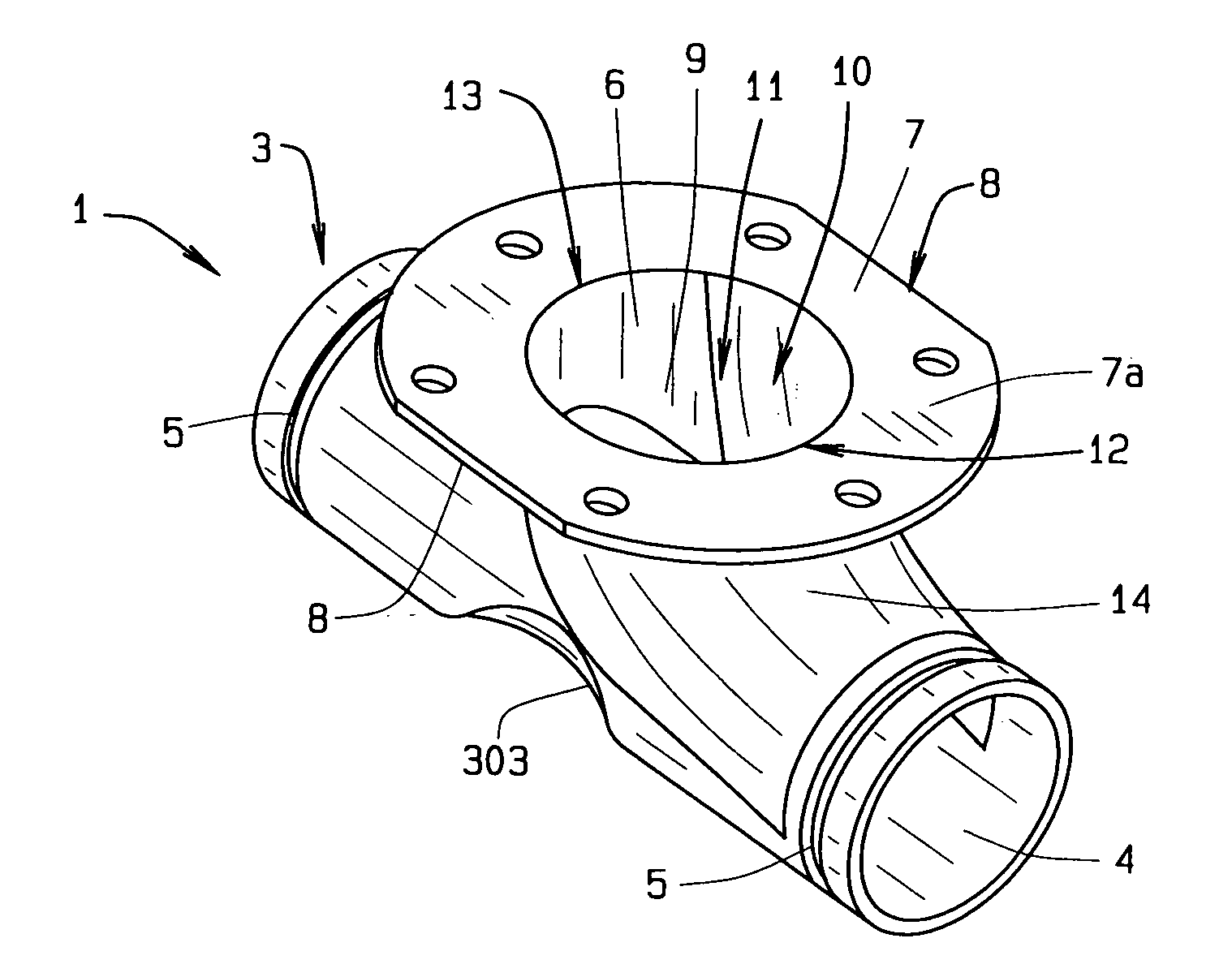

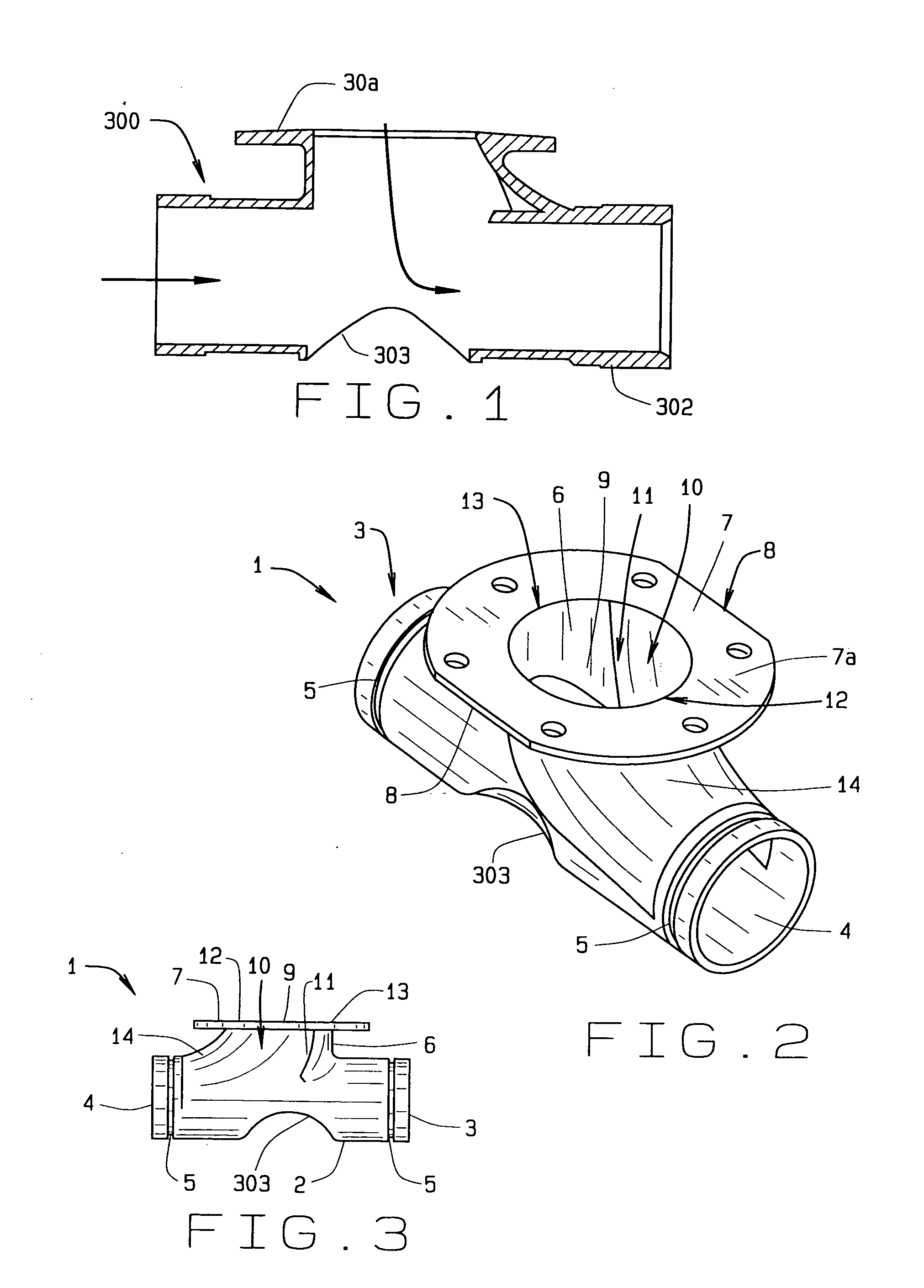

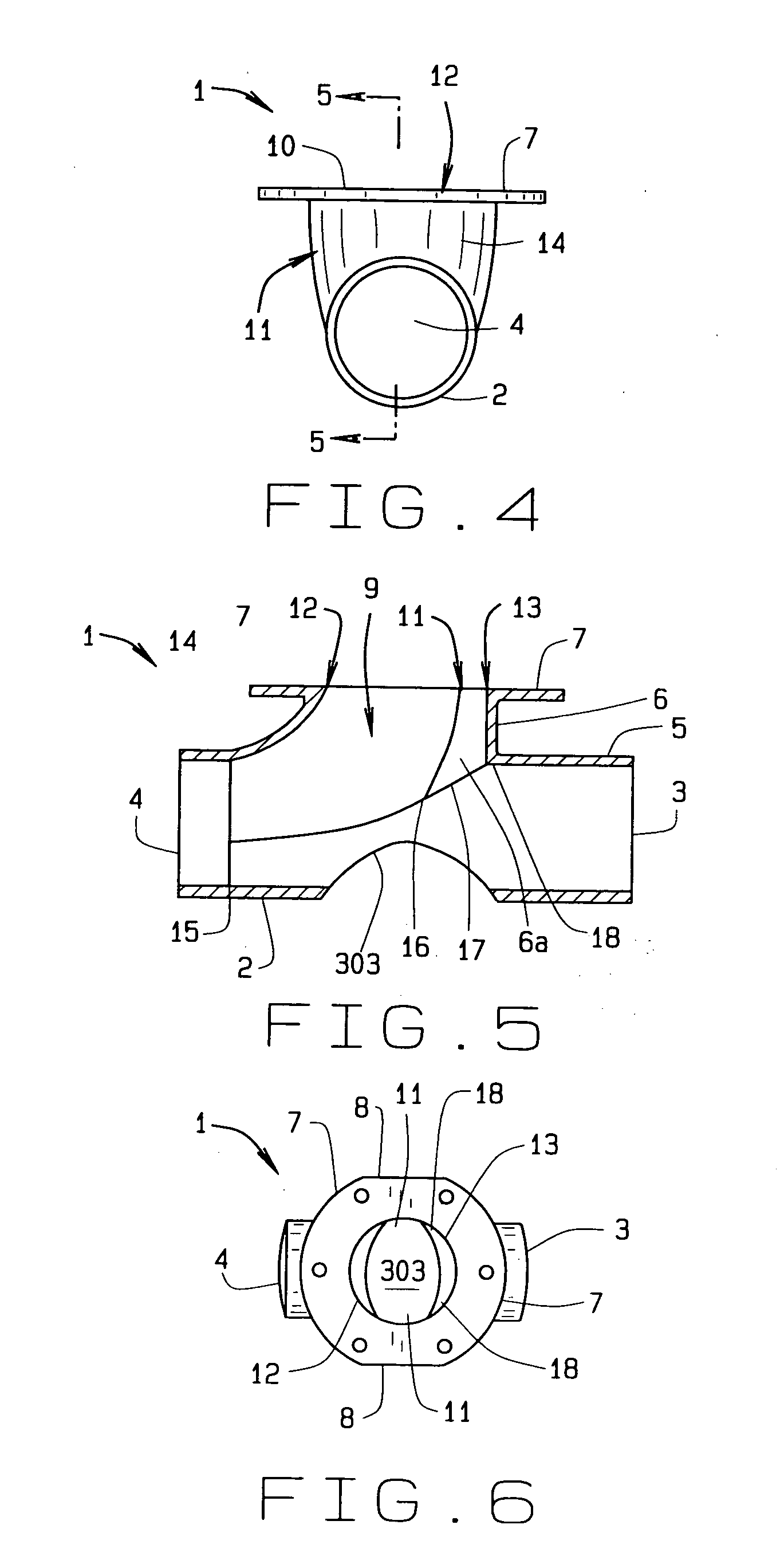

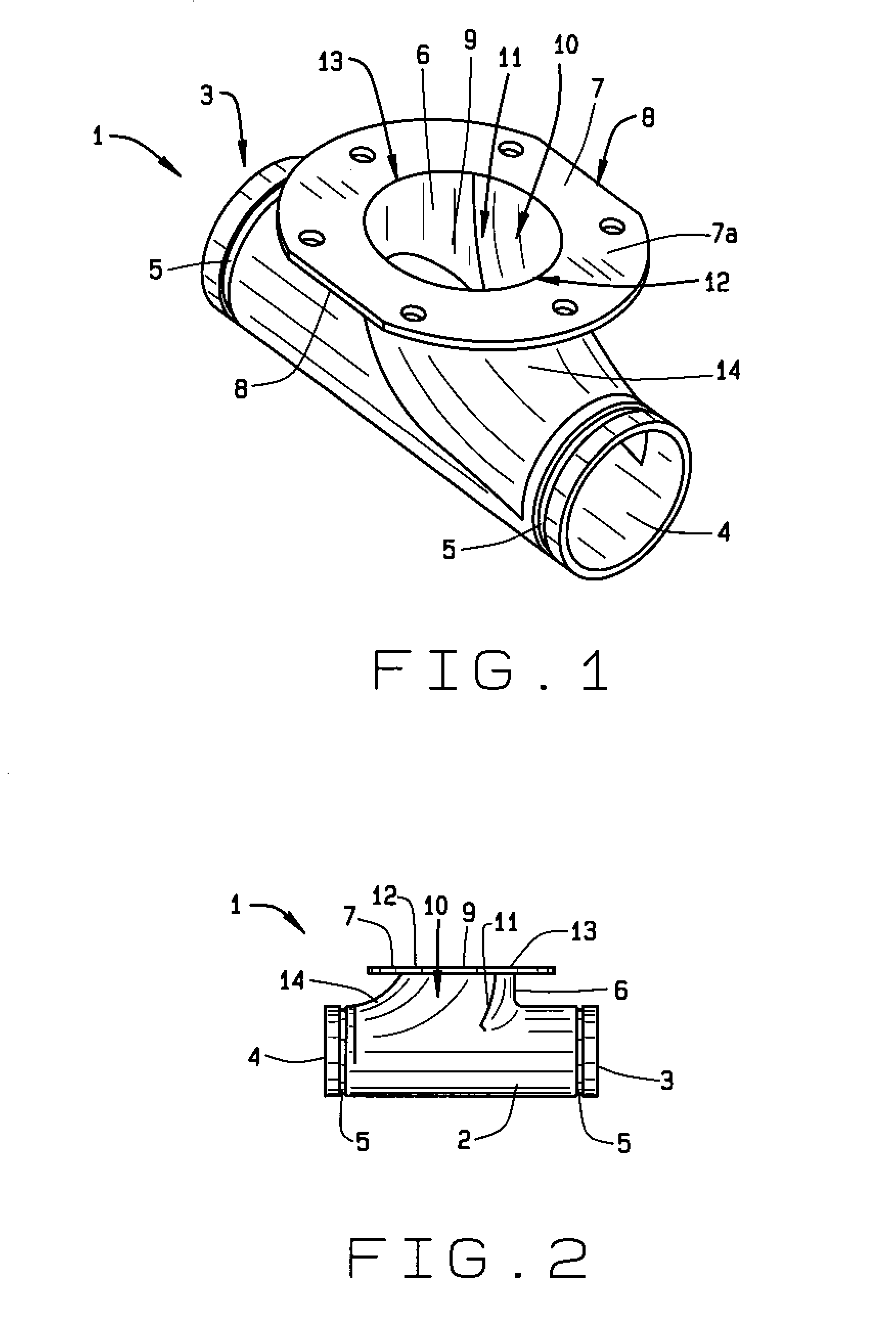

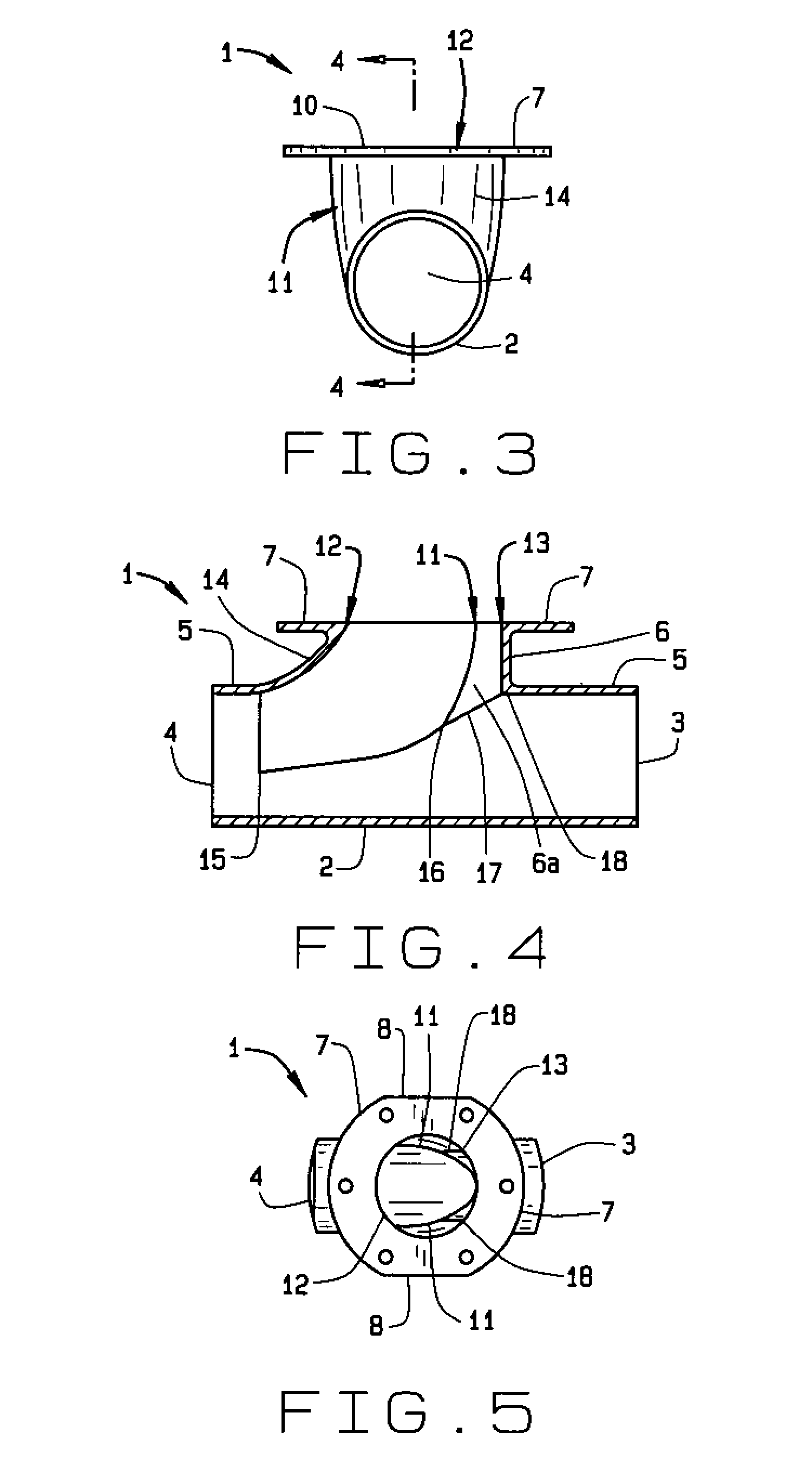

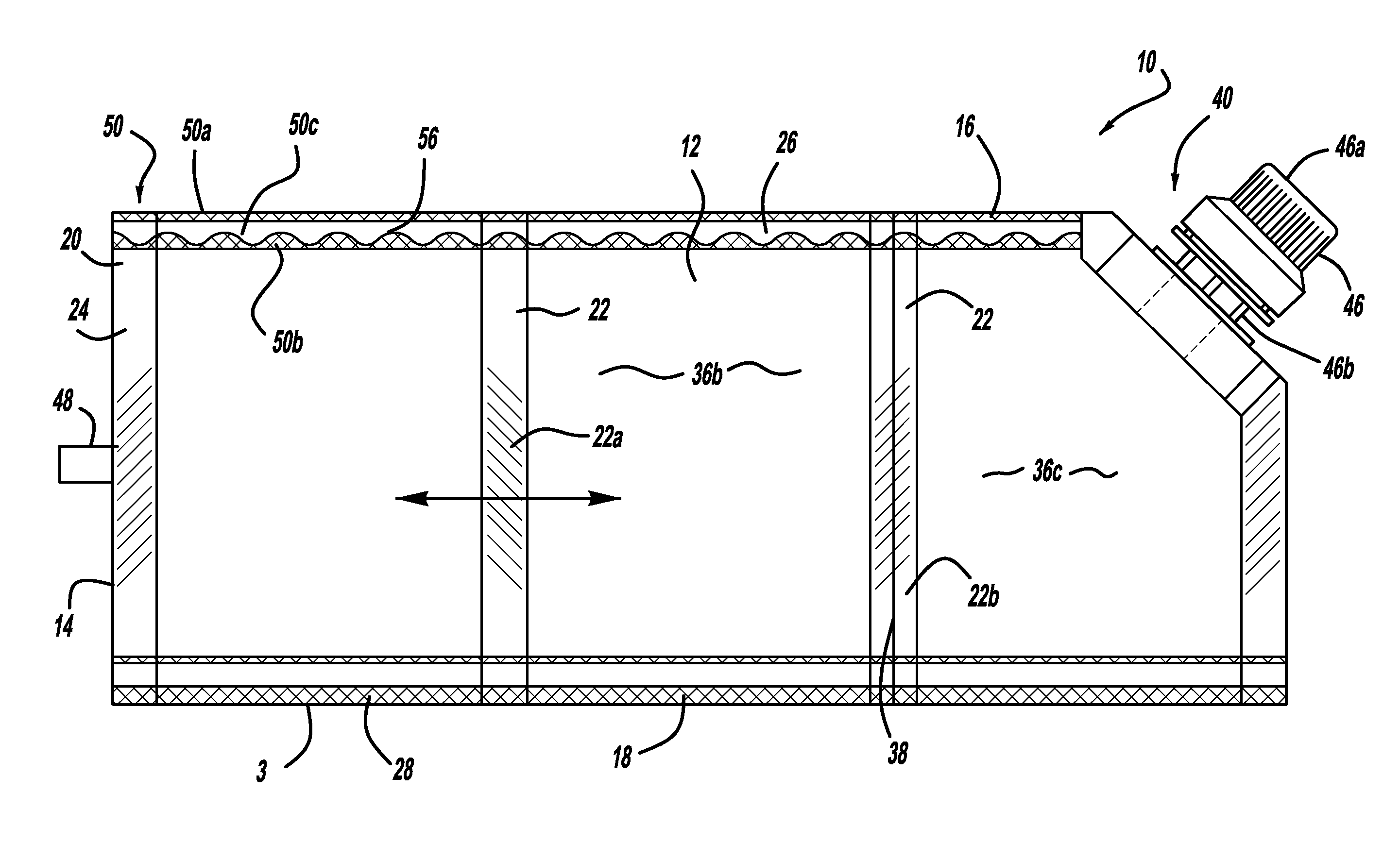

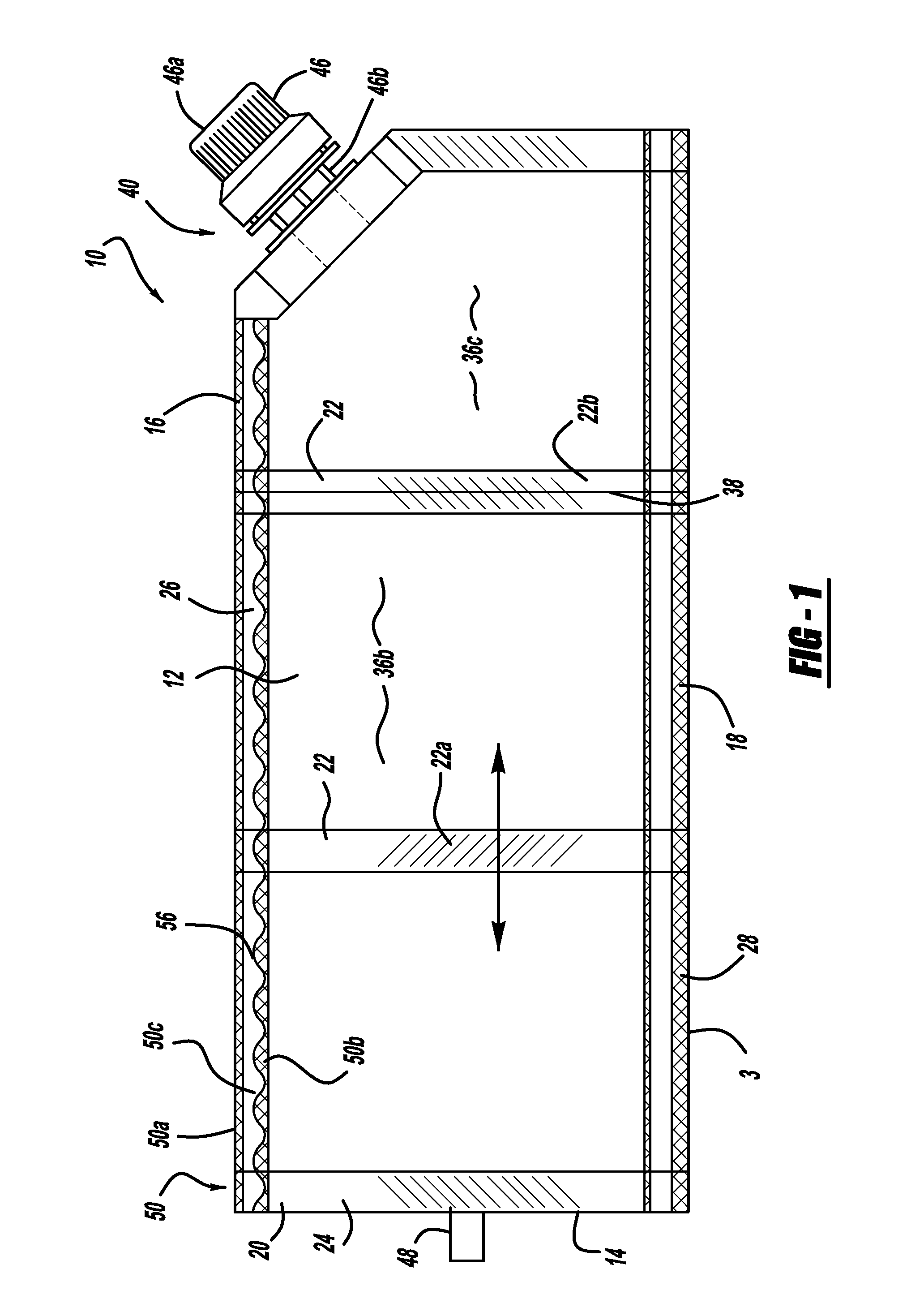

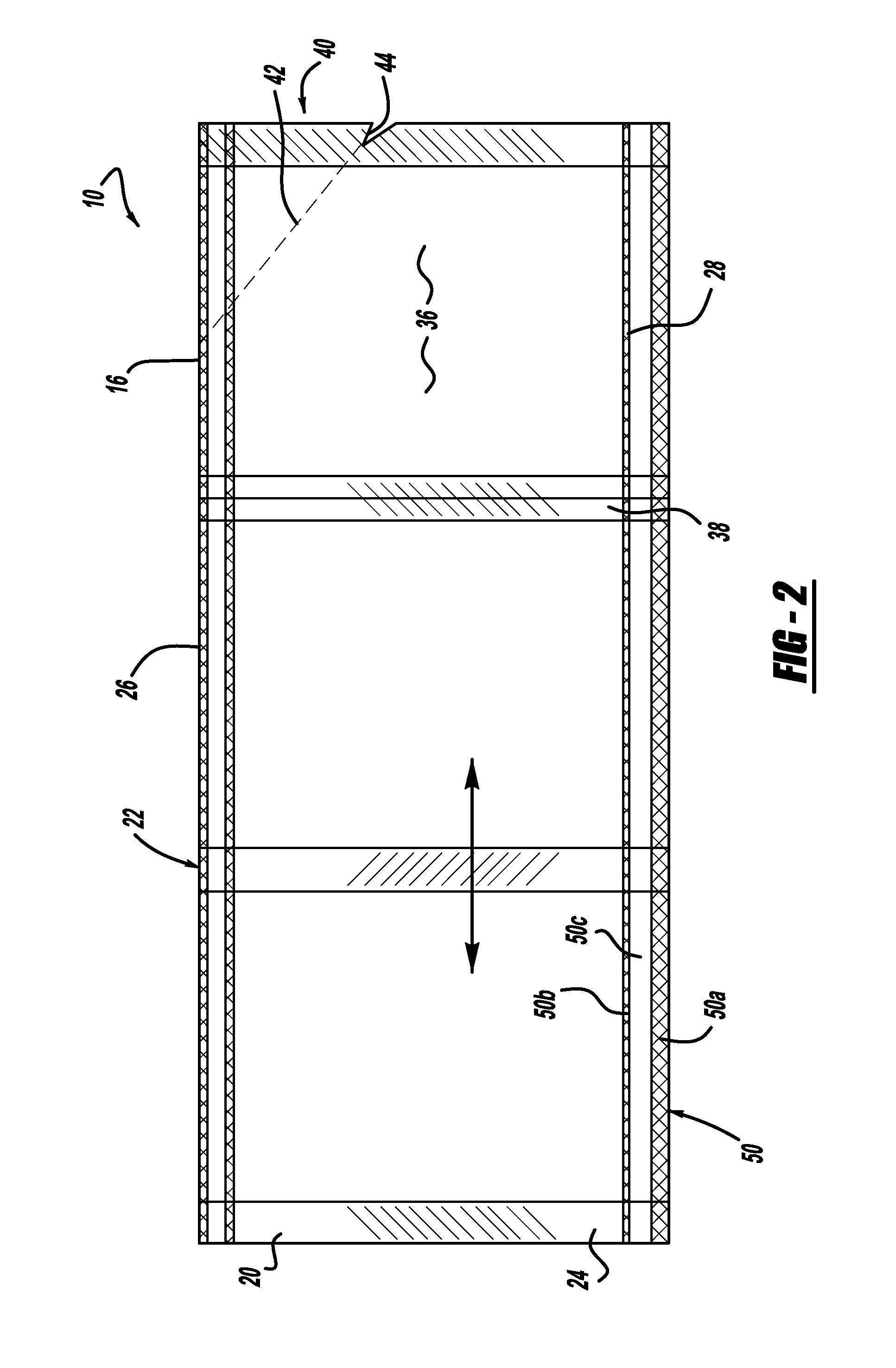

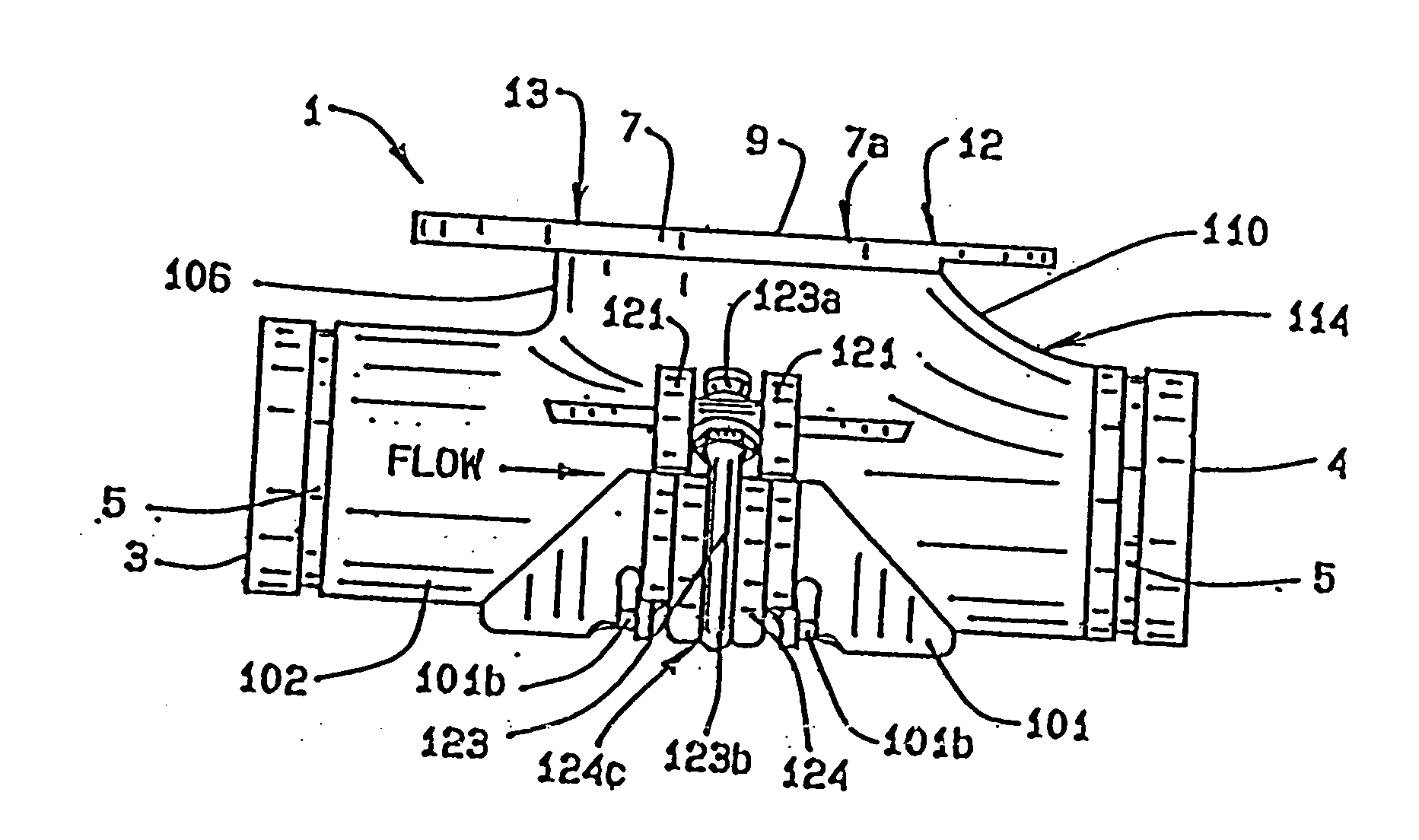

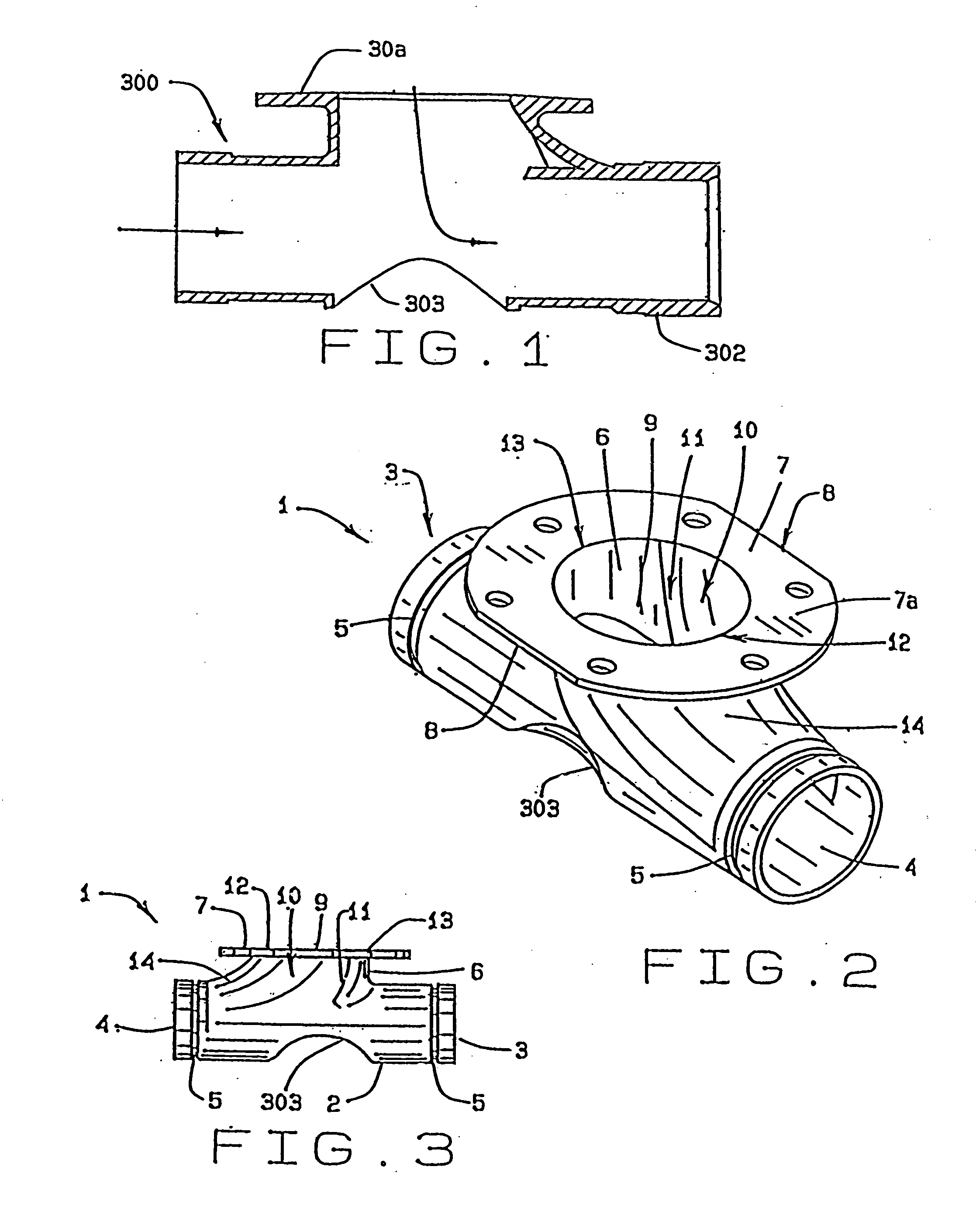

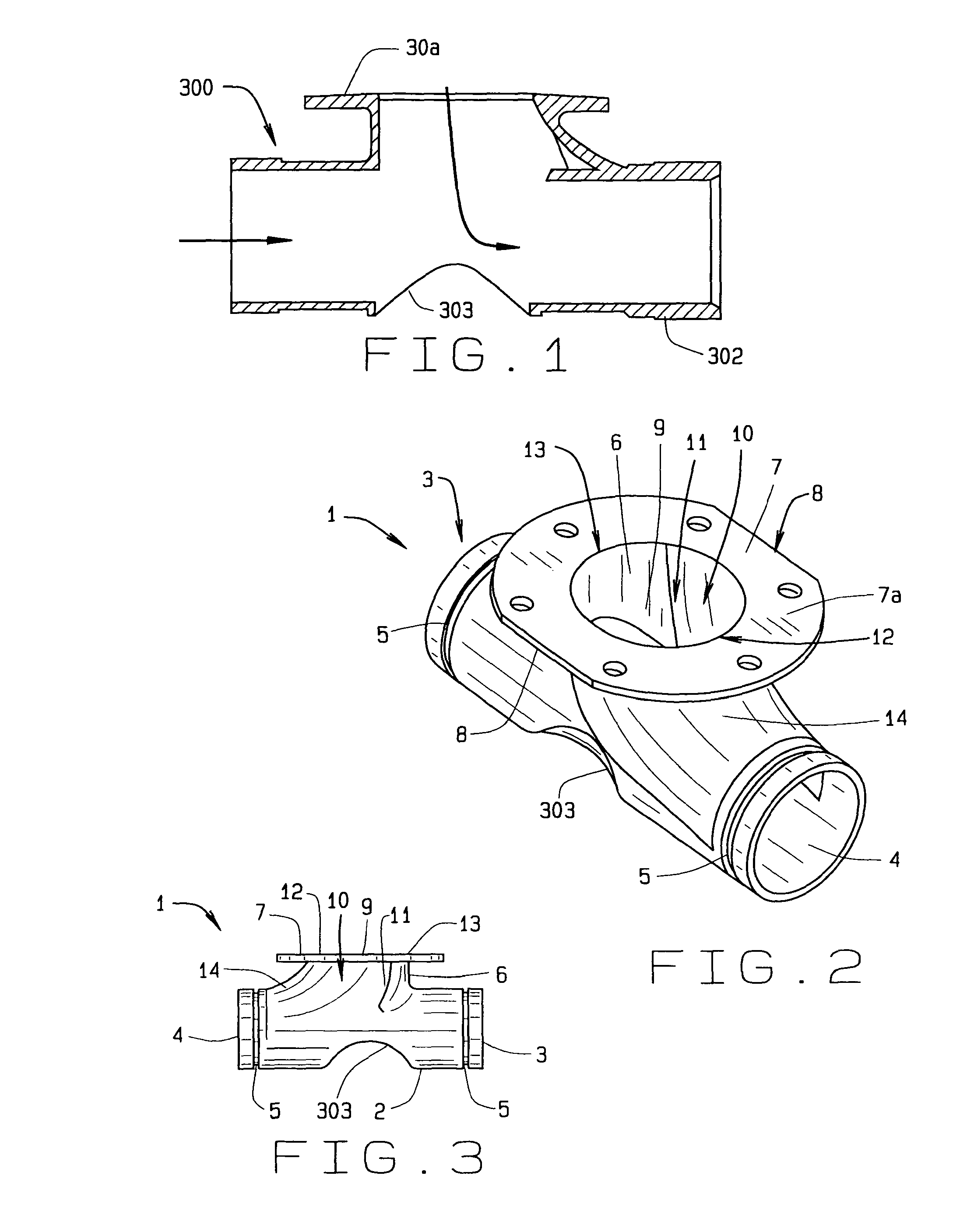

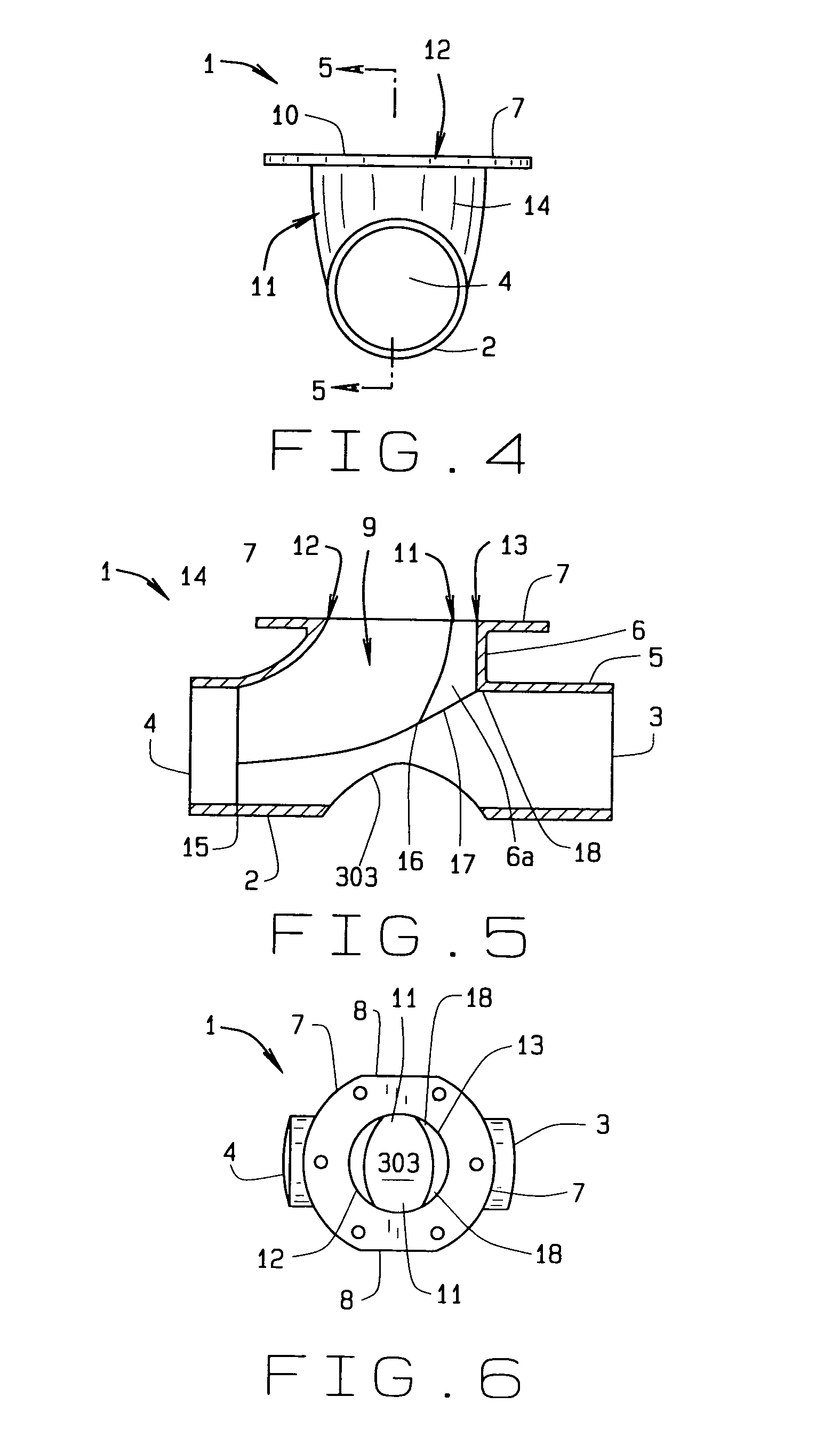

Fluted hopper tee

ActiveUS20090212555A1Reduce frictionIncrease frictionPipeline expansion-compensationLarge containersCurve shapeFlute

A directional hopper tee has a fluted interior vertical pipe that merges into a horizontal pipe. The vertical pipe has an opening that connects to a hopper to receive bulk material, or product, and a horizontal pipe centered upon the end of the vertical pipe. The horizontal pipe has an inlet that also receives bulk material and pressurized air from ahead of the hopper and an opposite outlet that discharges the bulk material from the hopper tee. The vertical pipe has a flange that abuts the hopper and an opening in the flange that matches the opening of a valve on the hopper itself. At the opening, the vertical pipe begins to turn towards the outlet of the lower pipe with an internal flute. The flute begins immediately at the flange resulting in a vertical pipe with a curved shape towards the outlet and a square shape towards the inlet. The present invention raises the ground clearance of the horizontal pipe by at least an inch resulting in a hopper tee that clears at least 7 inches above the ground. The hopper tee of the invention also unloads at least 15% more product per minute at temperatures closer to product temperature. Alternate embodiments of the present invention provide a reinforced flange, a drop tee, and a low profile drop tee. The present invention aids in the unloading of bulk materials from various haulers.

Owner:BULK TANK

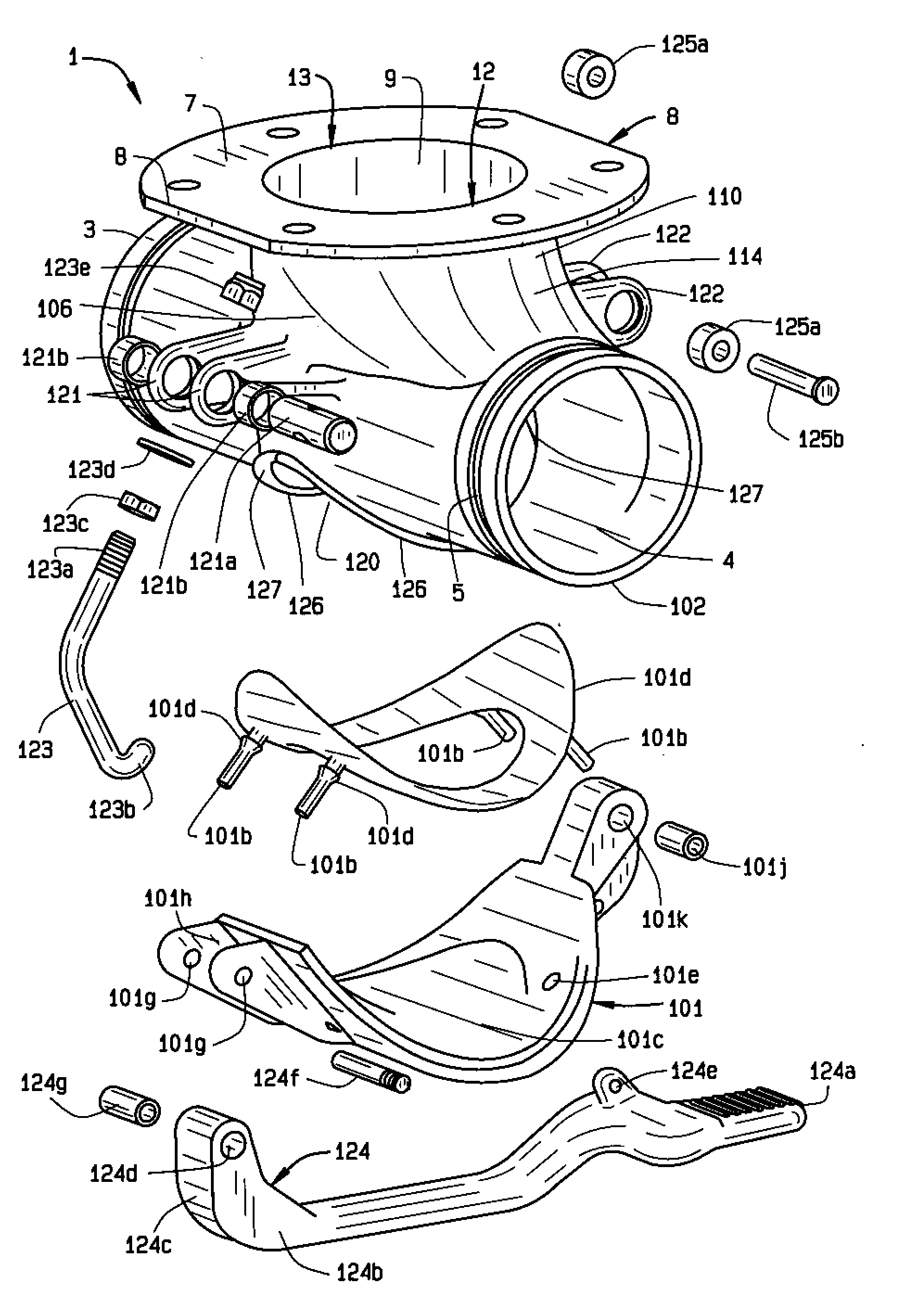

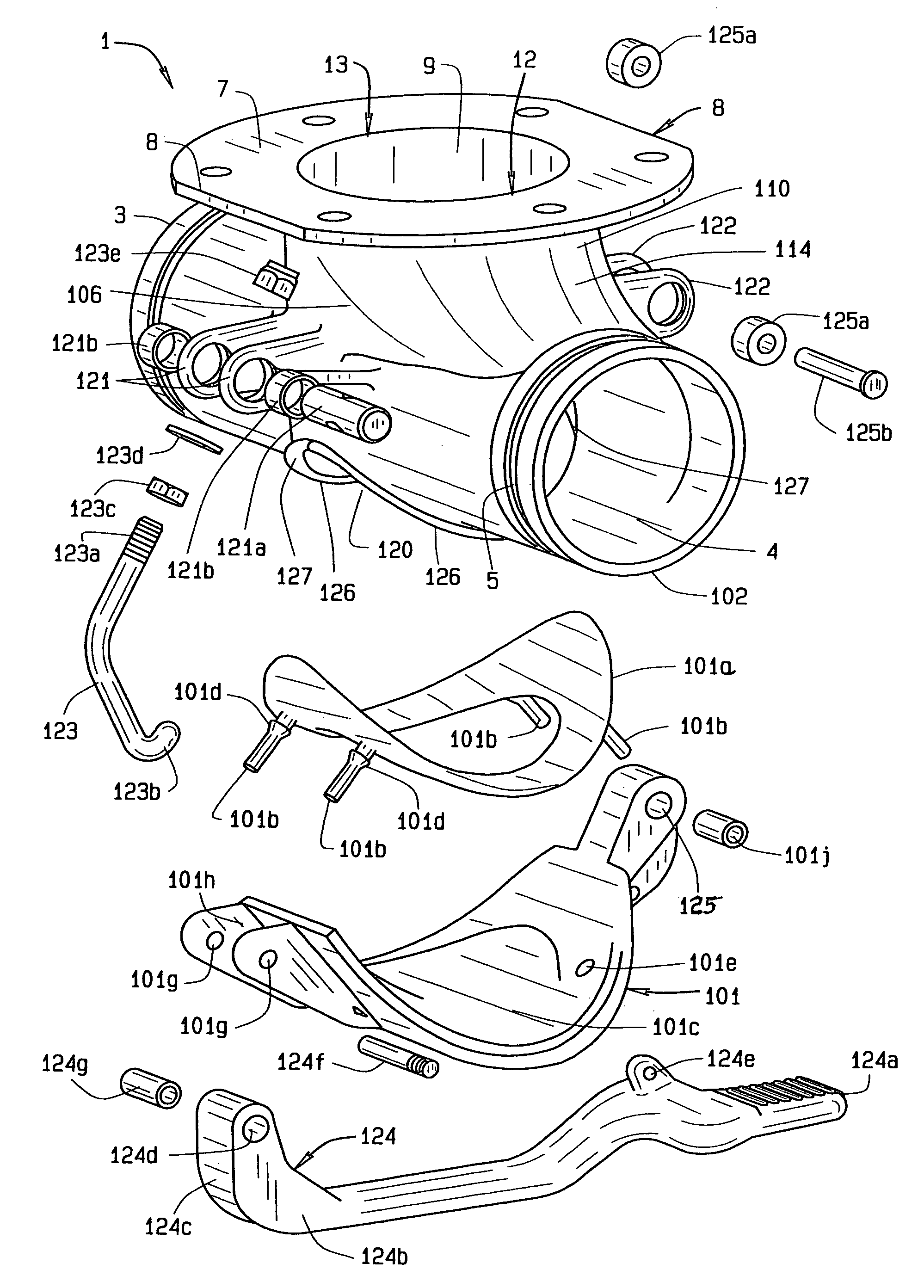

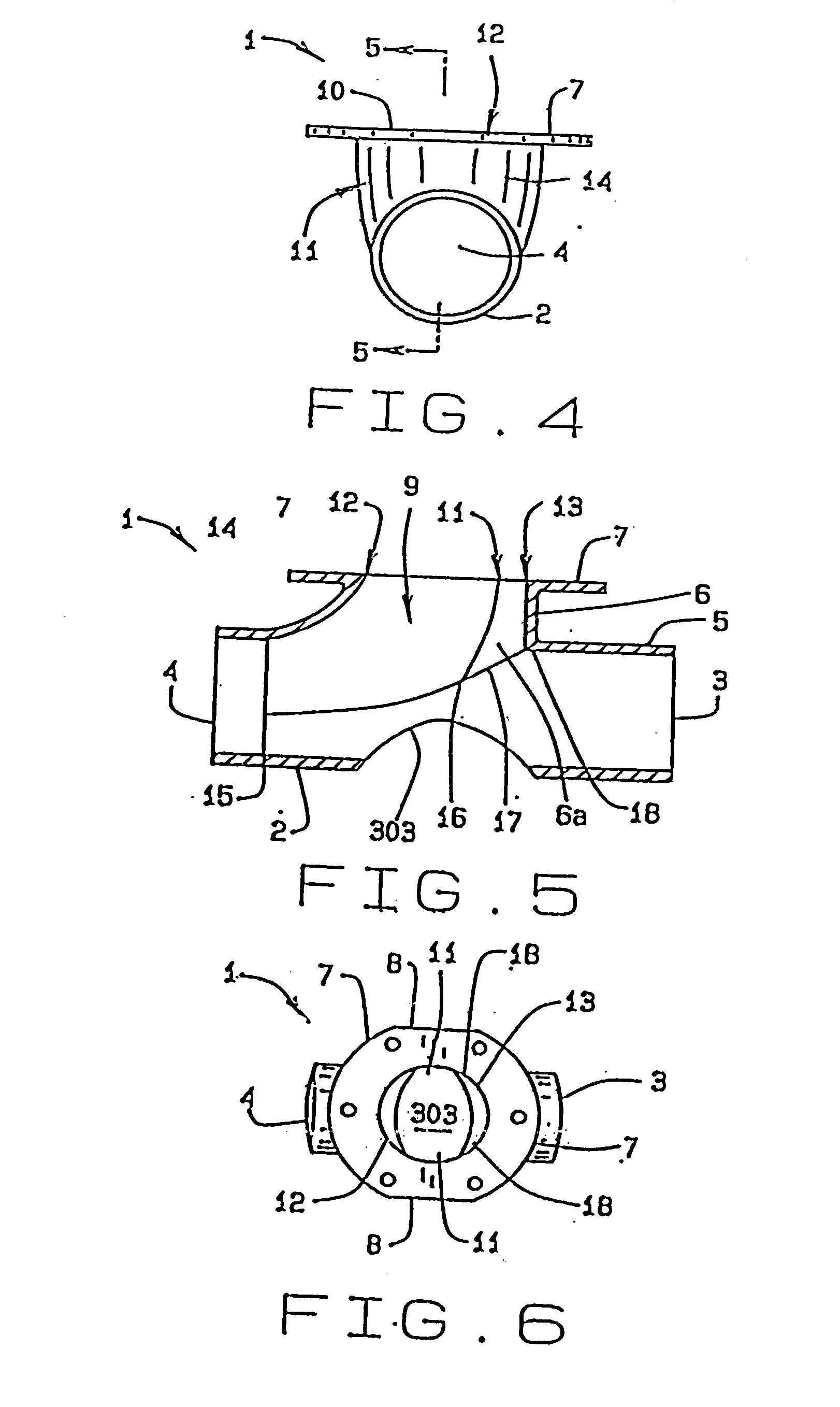

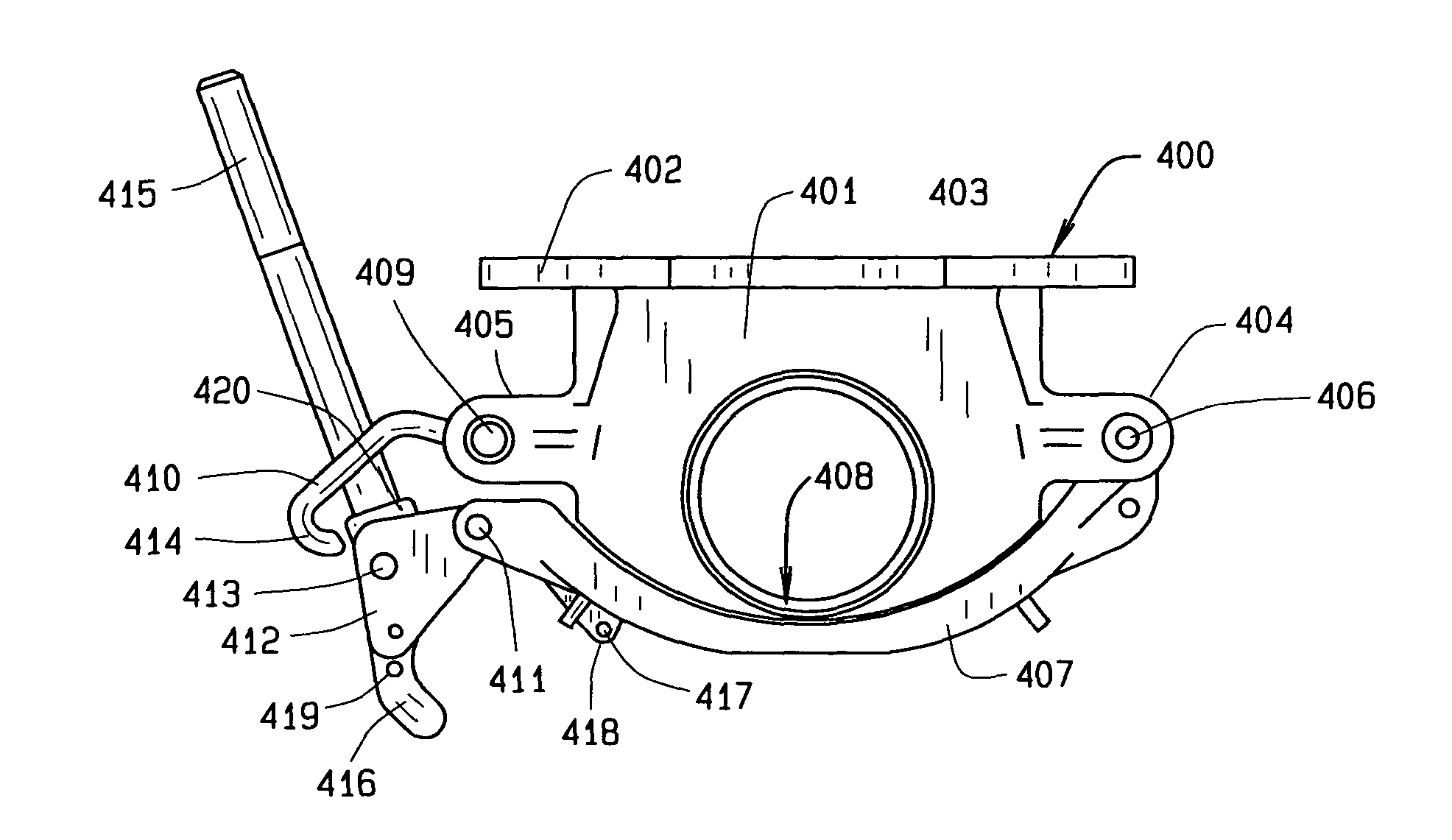

Hopper tee with comformable arcuate closure member

InactiveUS20130168956A1Reduce frictionIncrease frictionPipeline expansion-compensationLarge containersEngineeringCam

A directional hopper tee has a fluted interior vertical pipe that merges into a horizontal pipe. The horizontal pipe has an inlet that may receive bulk material, and subject to pressurized air that conveys the bulk material through the hopper tee. Bulk material may be discharged from a hopper through the vertical pipe, for conveyance for discharge from the horizontal pipe of the tee. A closure gate or door is provided through the bottom of the tee, generally in alignment with the vertical pipe, to allow for discharge or dropping of the granular material directly downwardly through and from the tee. The arcuate door is hinged on one side, and is locked by a cam lock on the opposite side, when located into closure against the bottom of the tee, but can be forced opened, through its cam mechanism, to provide for opening of the arcuate door and allow a direct downward discharge of the granular bulk material, from any hopper, and through the drop opening of the tee, as required.

Owner:BULK TANK

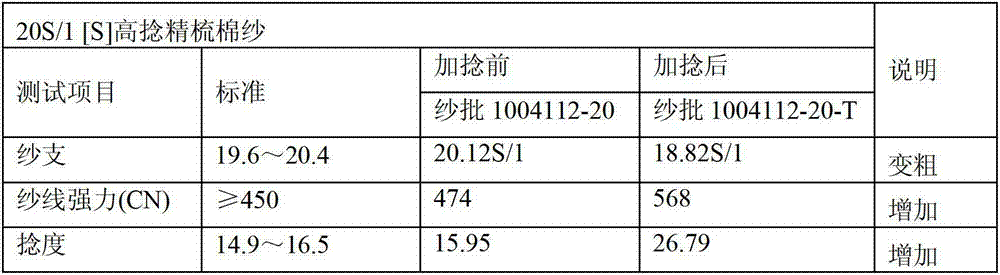

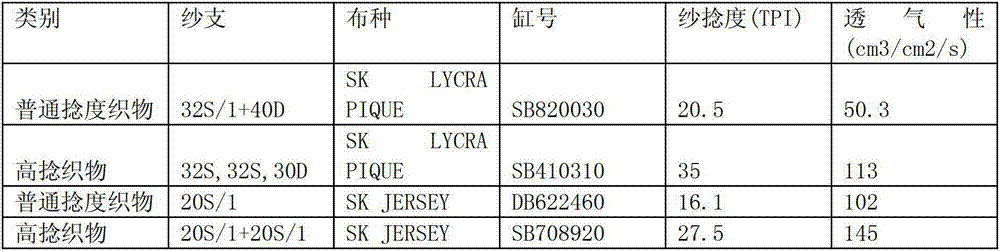

Cool-to-touch breathable dry washable smooth all-cotton fabric and manufacture method thereof

ActiveCN102808335AImprove breathabilityHigh contact coldYarnLiquid/gas/vapor yarns/filaments treatmentYarnEngineering

The invention belongs to the field of textile fabrics and relates to a cool-to-touch breathable dry washable smooth all-cotton fabric and a manufacture method thereof. The fabric is characterized in that the twist factor of fabric yarns is higher than 4.5, and the fabric is obtained by means of mercerized finish, biological enzyme finish, resin finish and softener finish. The obtained fabric has the advantages of coolness in touch, gorgeous gloss, clean appearance, smoothness in hand feeling, good hygroscopicity and excellent washability.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

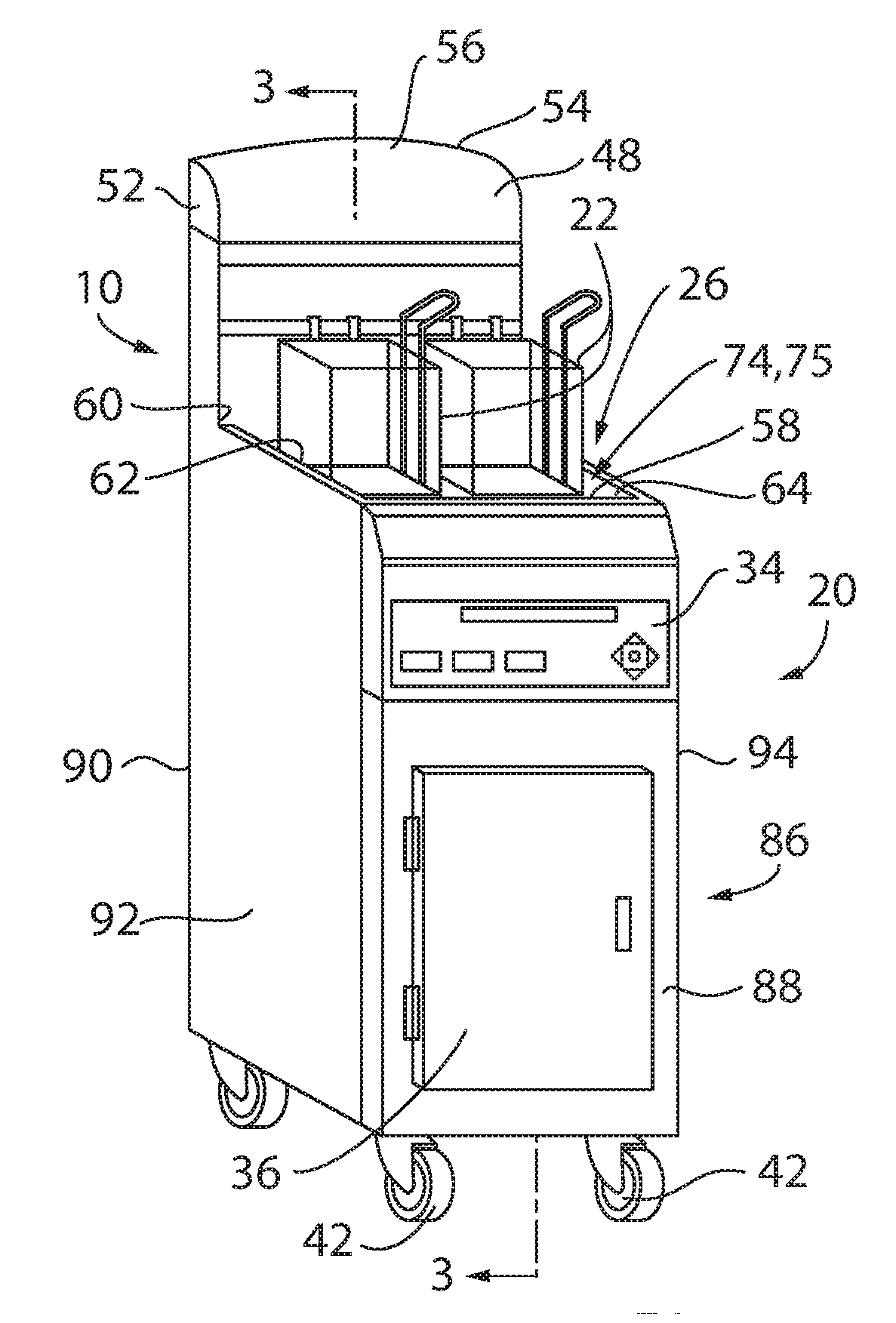

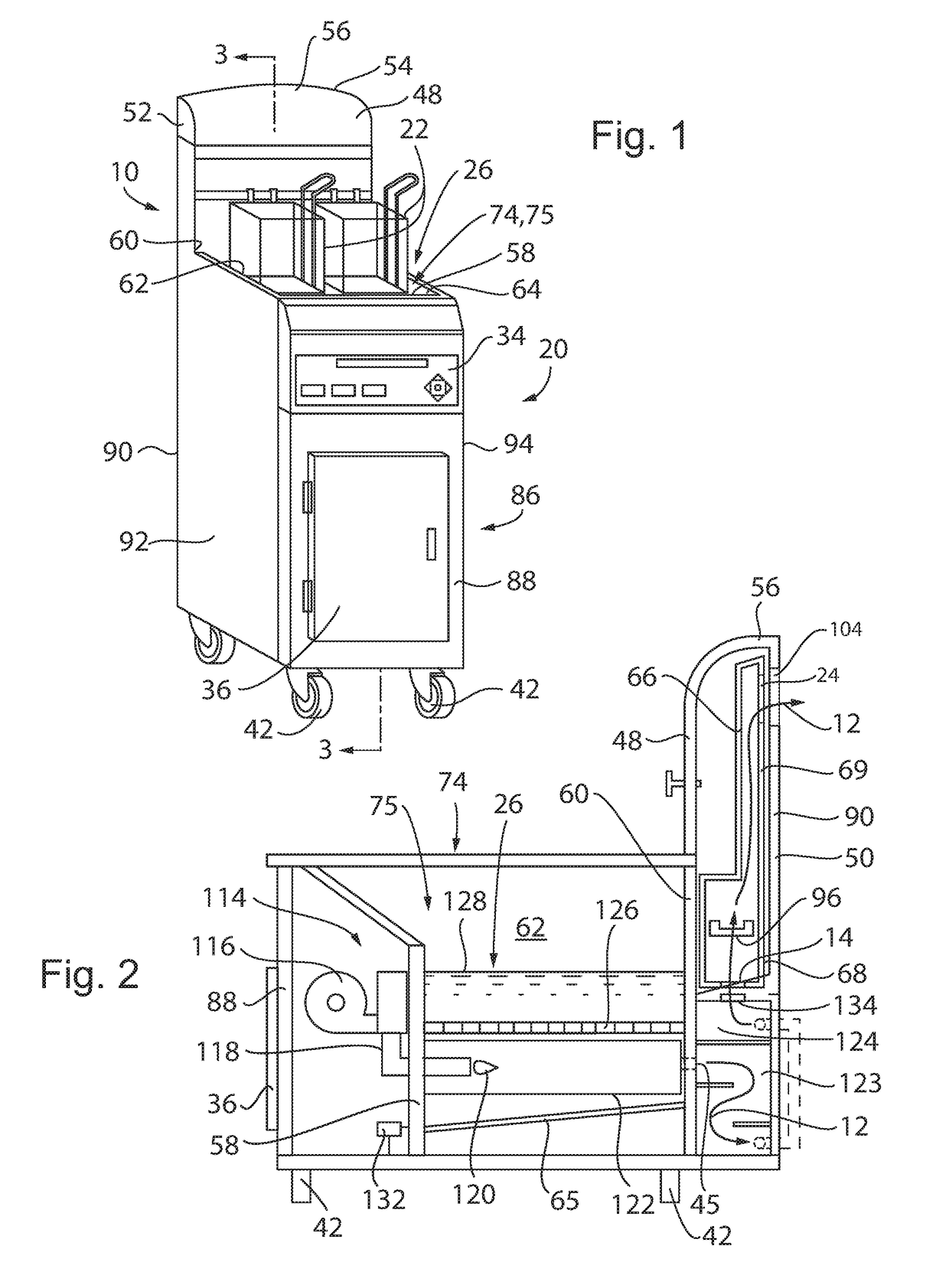

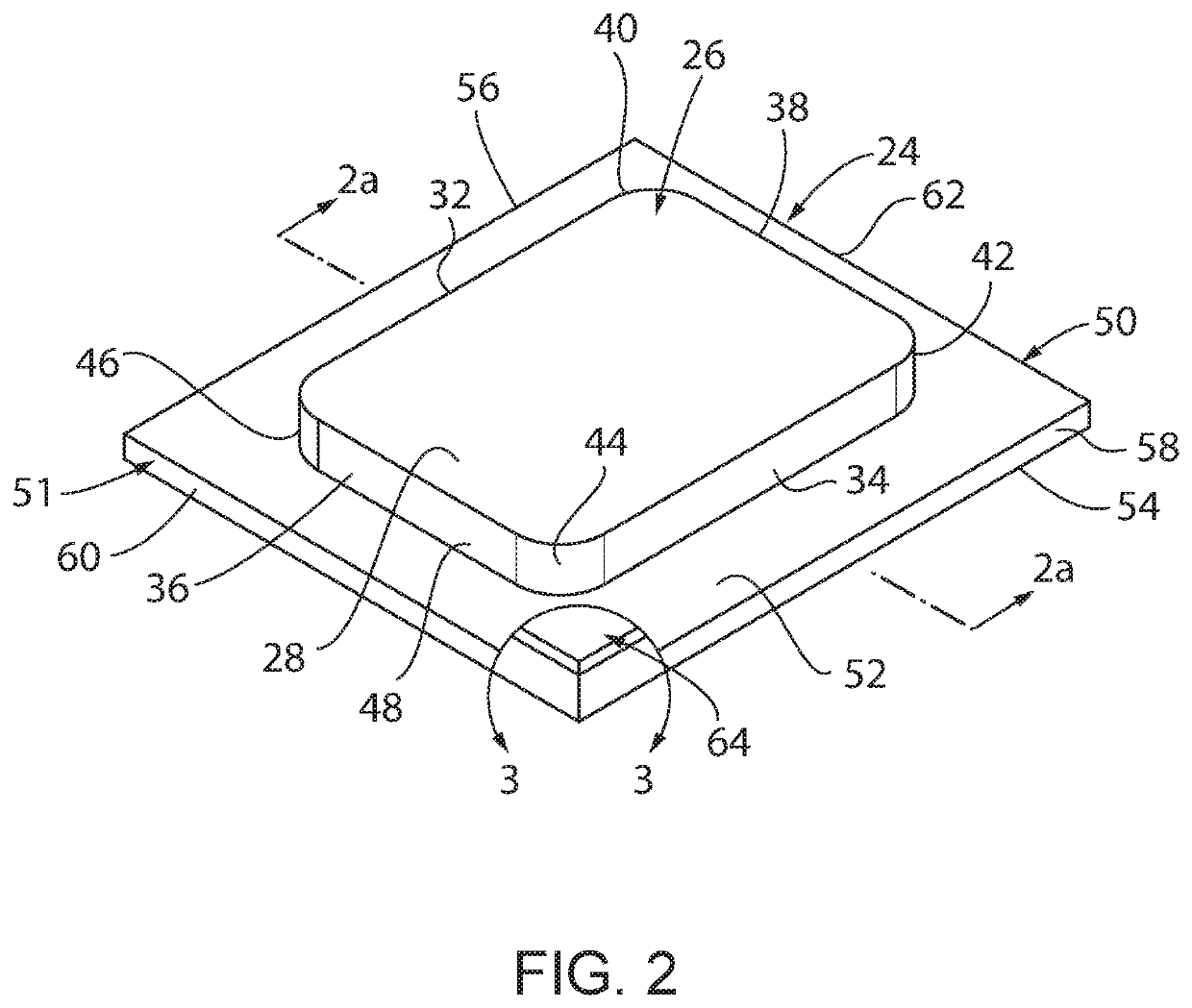

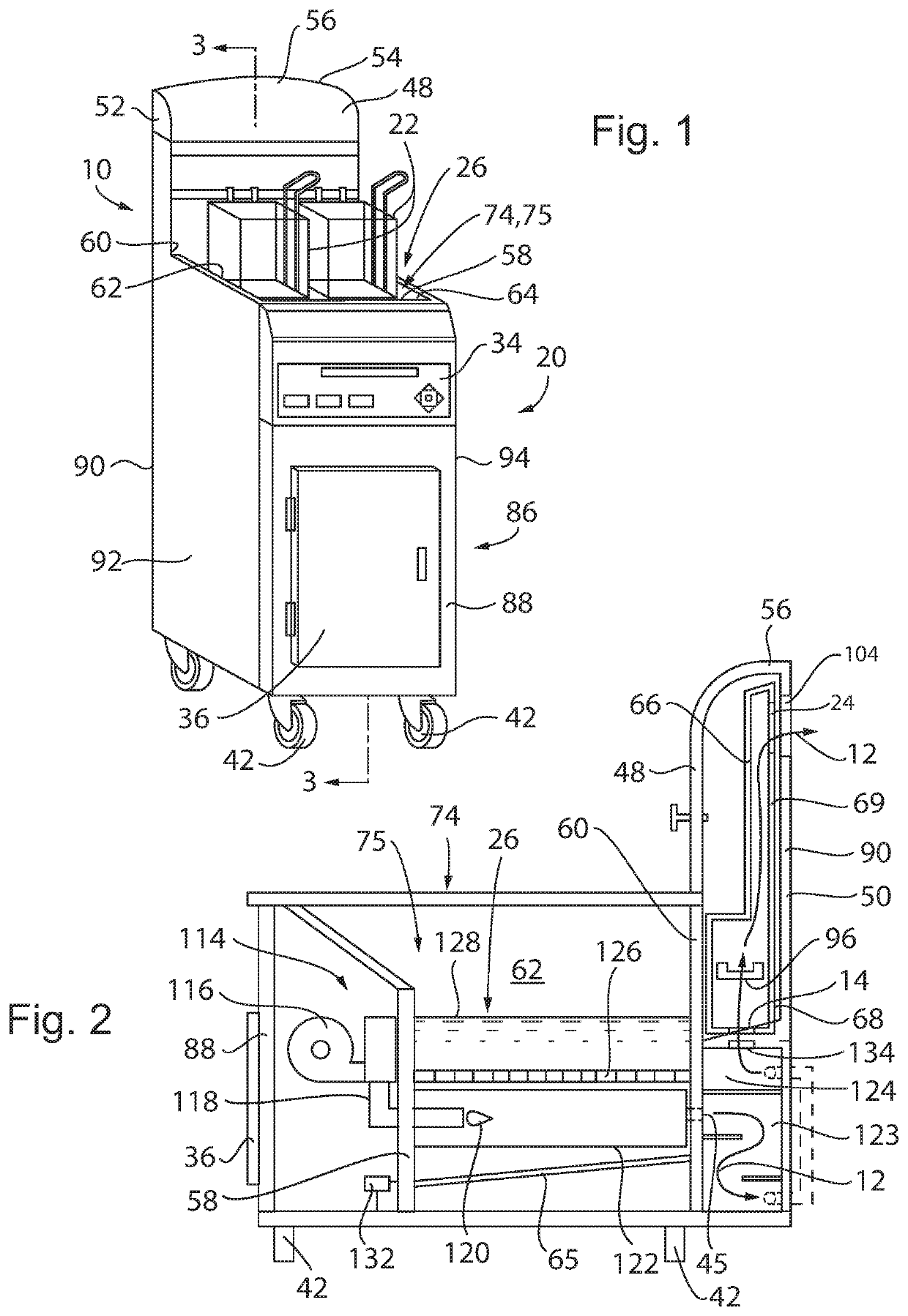

Flue Assembly and Splash Back Panel for a Cooking Appliance

ActiveUS20180289217A1Prevent “ baking-on ”Easy to cleanDomestic stoves or rangesLighting and heating apparatusForeign objectMechanical engineering

The present invention provides a deep fat fryer separating the flue from the splash back panel and with a flue opening directed not upwardly, but rearwardly from the flue. By arranging the flue opening on the rear wall, the opening is protected from grease fallback (e.g., dripping from an overhead exhaust hood) or other foreign objects falling into the opening. The splash back panel further provides a seamless curved design that is easy to clean and also insulated from the heat of the flue. A baffle installed within the flue allows the combustion products to mix, cool, and slow upon exiting the baffle opening and entering the atmosphere reducing the exit temperature and also reducing the heating of the splash back panel.

Owner:ALTO SHAAM

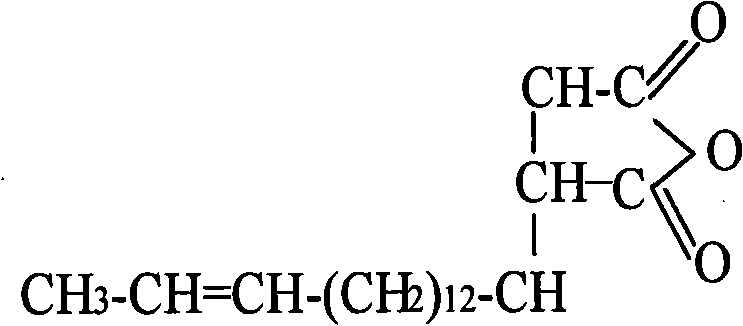

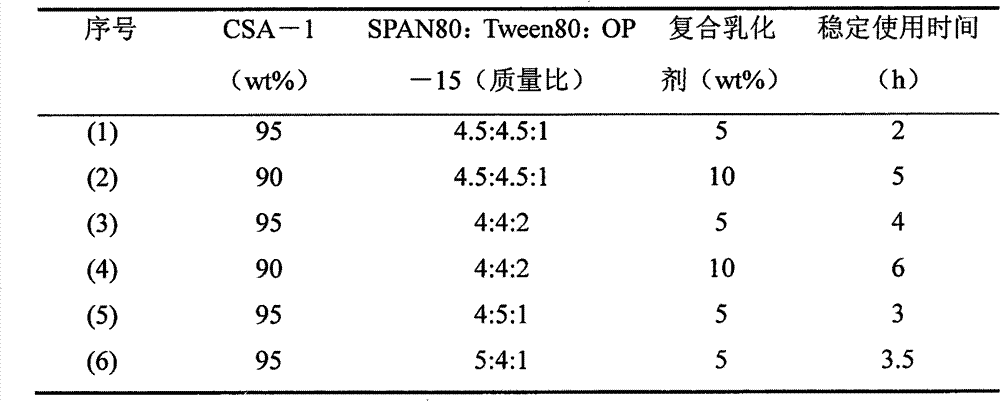

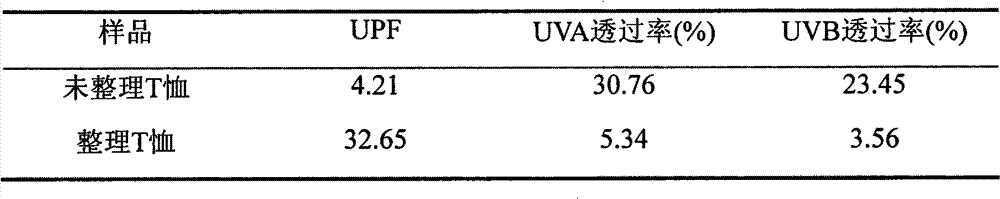

Preparation method of novel anti-UV textile fabric

InactiveCN104726833AEasy to prepareEasy to operateFibre treatmentVacuum evaporation coatingThermal energyUltraviolet

The invention discloses a preparation method of a novel anti-UV textile fabric and belongs to the field of textile processing. By a magnetron sputtering technology, nano-silver, nano-zinc oxide and nanometer titania particles are respectively sputtered onto a fabric base material to form an uniform nanocomposite film so as to finally obtain the anti-UV fabric. The novel anti-UV textile fabric has advantages of simple preparation method, simple operation, low cost, no pollution, high chemical stability and thermal stability, no odor, nontoxicity, no irritating performance, using safety, especially high capability of absorbing ultraviolet rays and shielding effect on ultraviolet rays in UV-A zone and UV-B zone. Absorptivity or reflectivity of ultraviolet rays reaches more than 90%. In addition, the fabric not only has a reflection effect on ultraviolet radiation but also has special selection and absorption properties. By the fabric, ultraviolet energy can be converted to thermal energy or other harmless low-energy forms. Thus, the fabric provided by the invention has properties of heat stroke prevention, heat insulation and cool handtouch.

Owner:JIANGNAN UNIV +1

Fluted hopper tee

ActiveUS8091925B2Reduce frictionIncrease frictionPipeline expansion-compensationLarge containersFluteCurve shape

Owner:BULK TANK

Liquid wound-dressing with functions of promoting heal of wound and bacterial-resisting

InactiveCN100471528CAnti-inflammatory and pain-relievingPromotes anti-inflammatory pain reliefBandagesWound healingWound dressing

The present invention provides a liquid wound dressing with the functions of promoting wound healing and resisting bacteria. Said liquid wound dressing contains 0.5-5.0 wt% of hyaluronic acid and its derivative and 0.0005-0.04 wt% of gel of nano silver. It also can contain water-soluble high-molecule and humectant. Said invention also provides its concrete application method.

Owner:JIANGSU 139 MEDICAL DEVICES

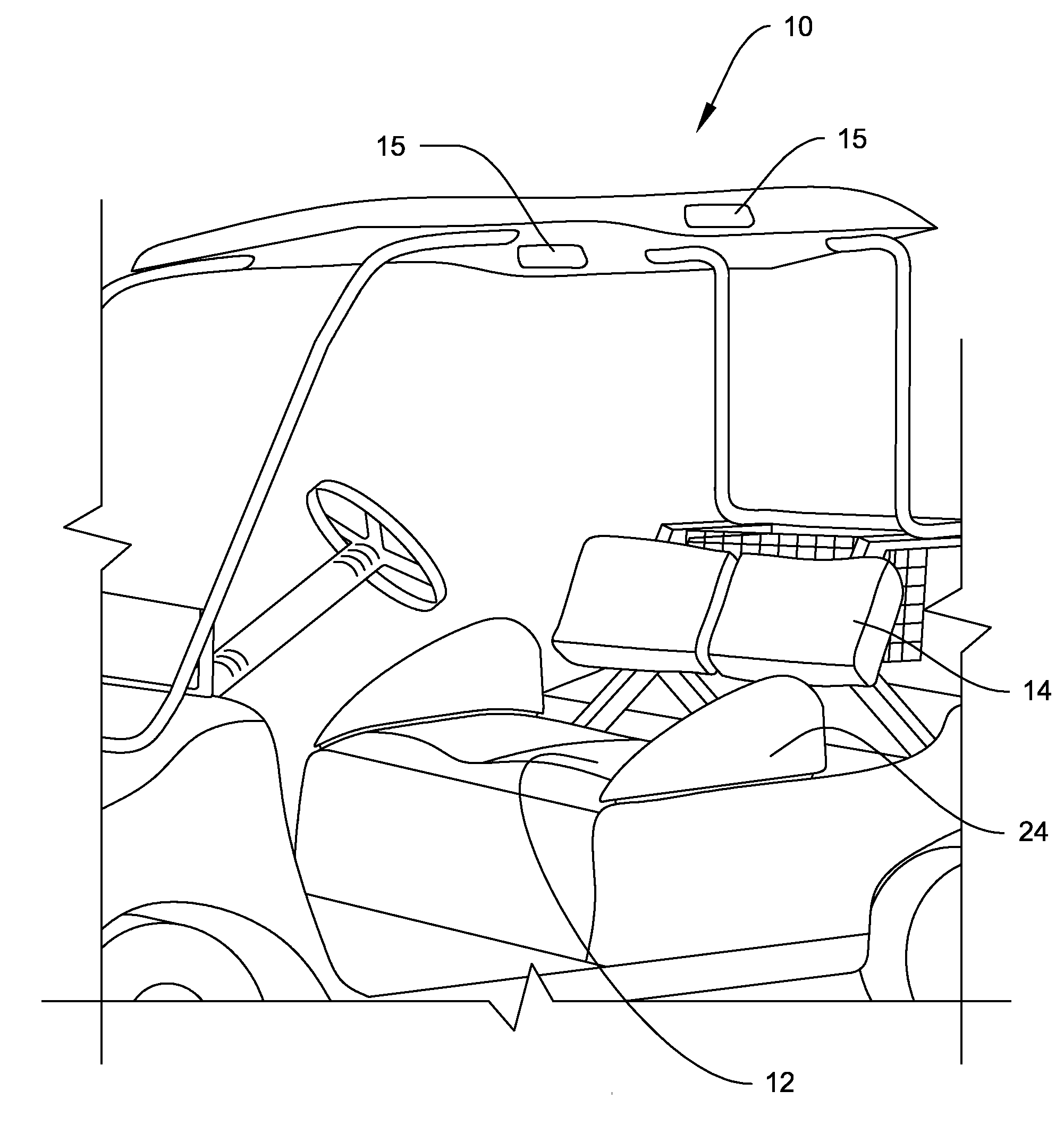

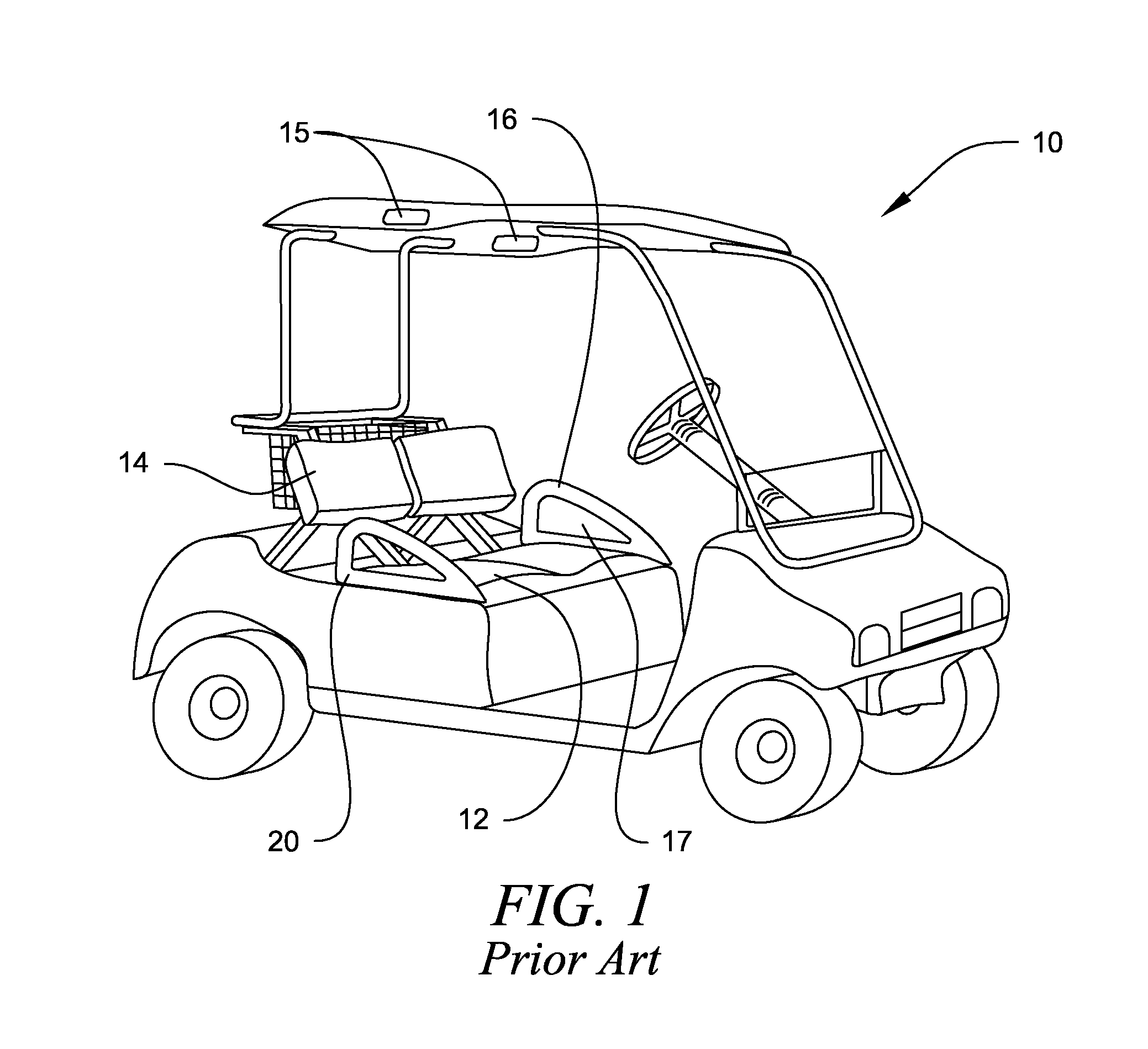

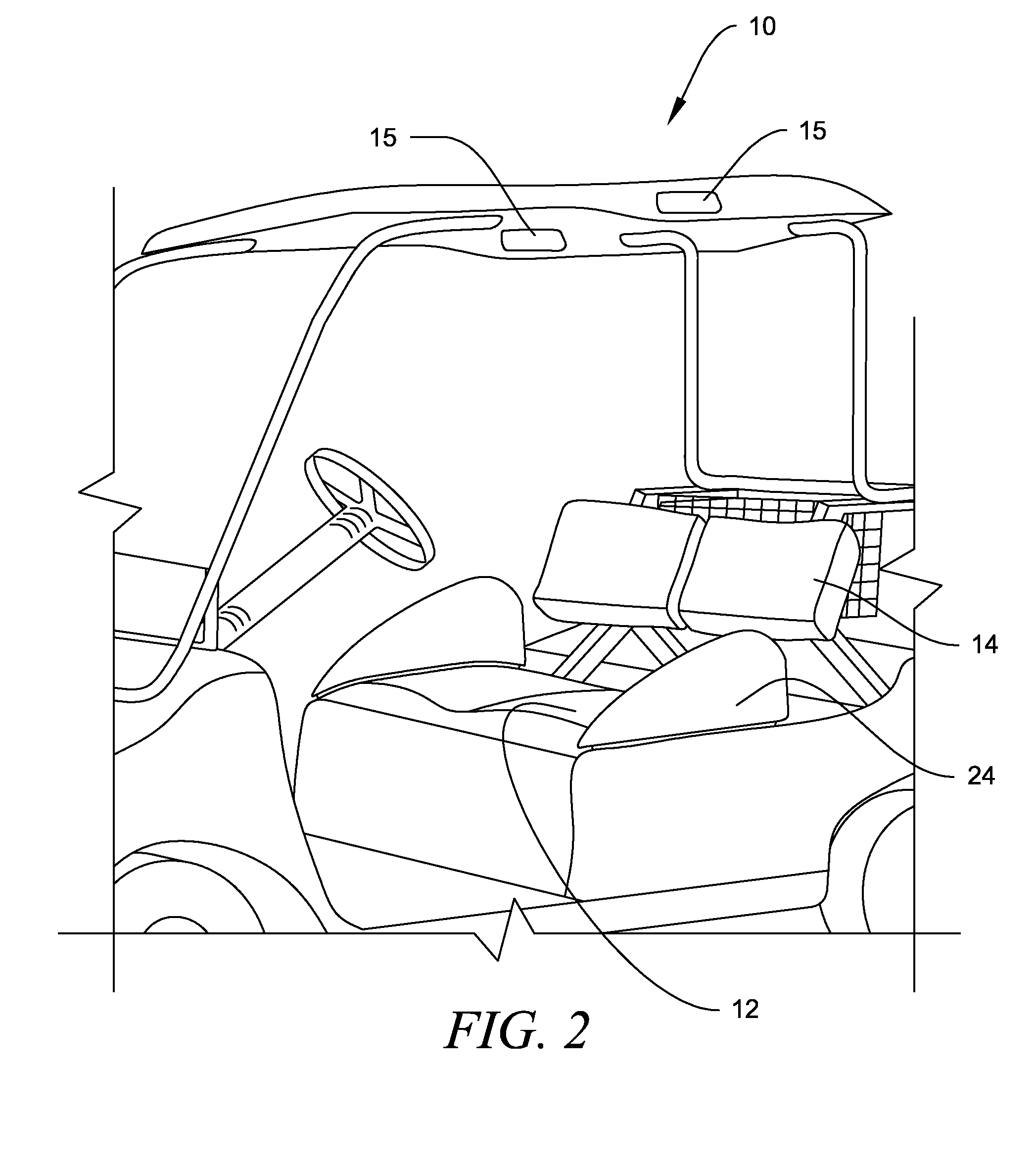

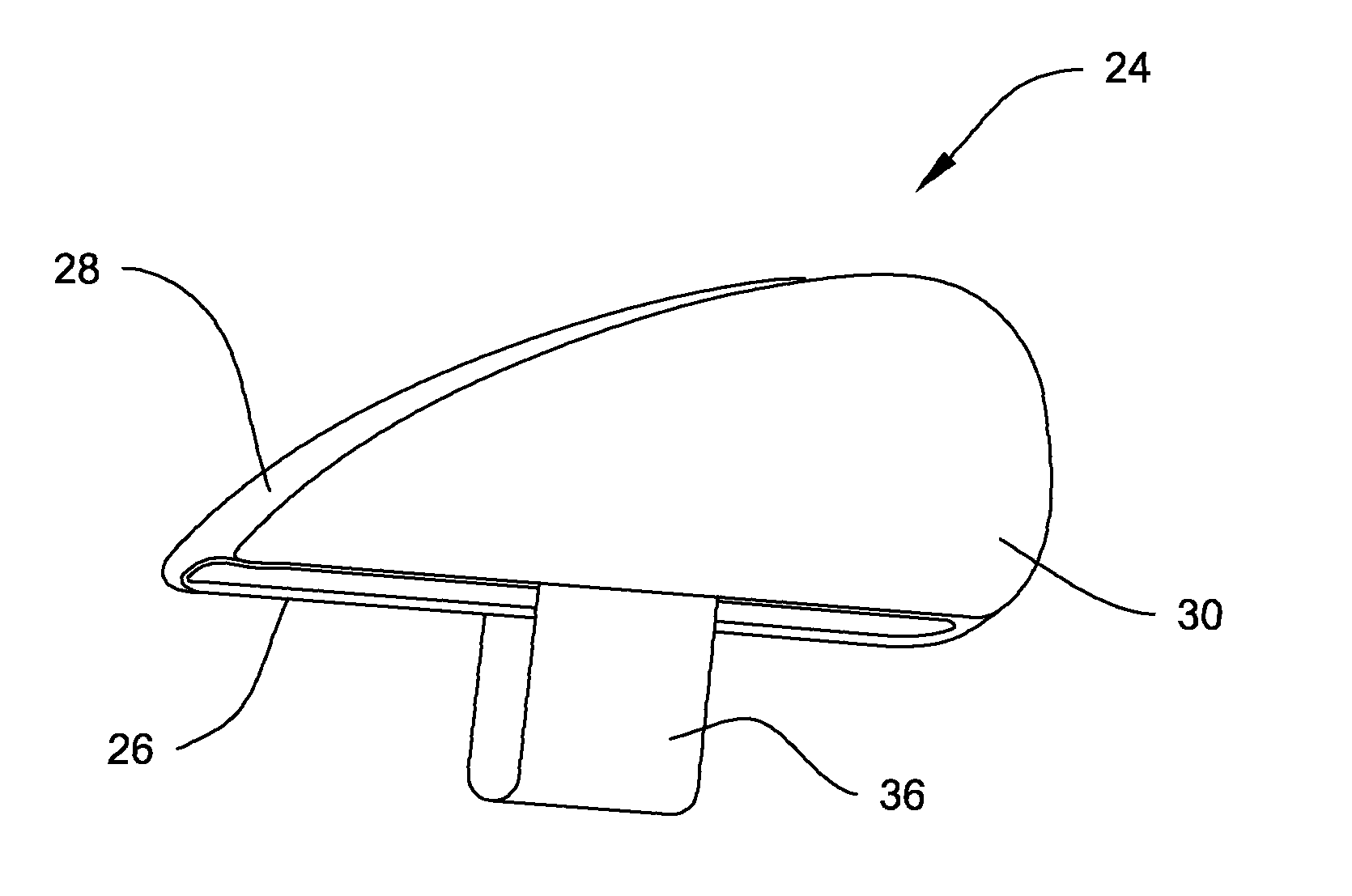

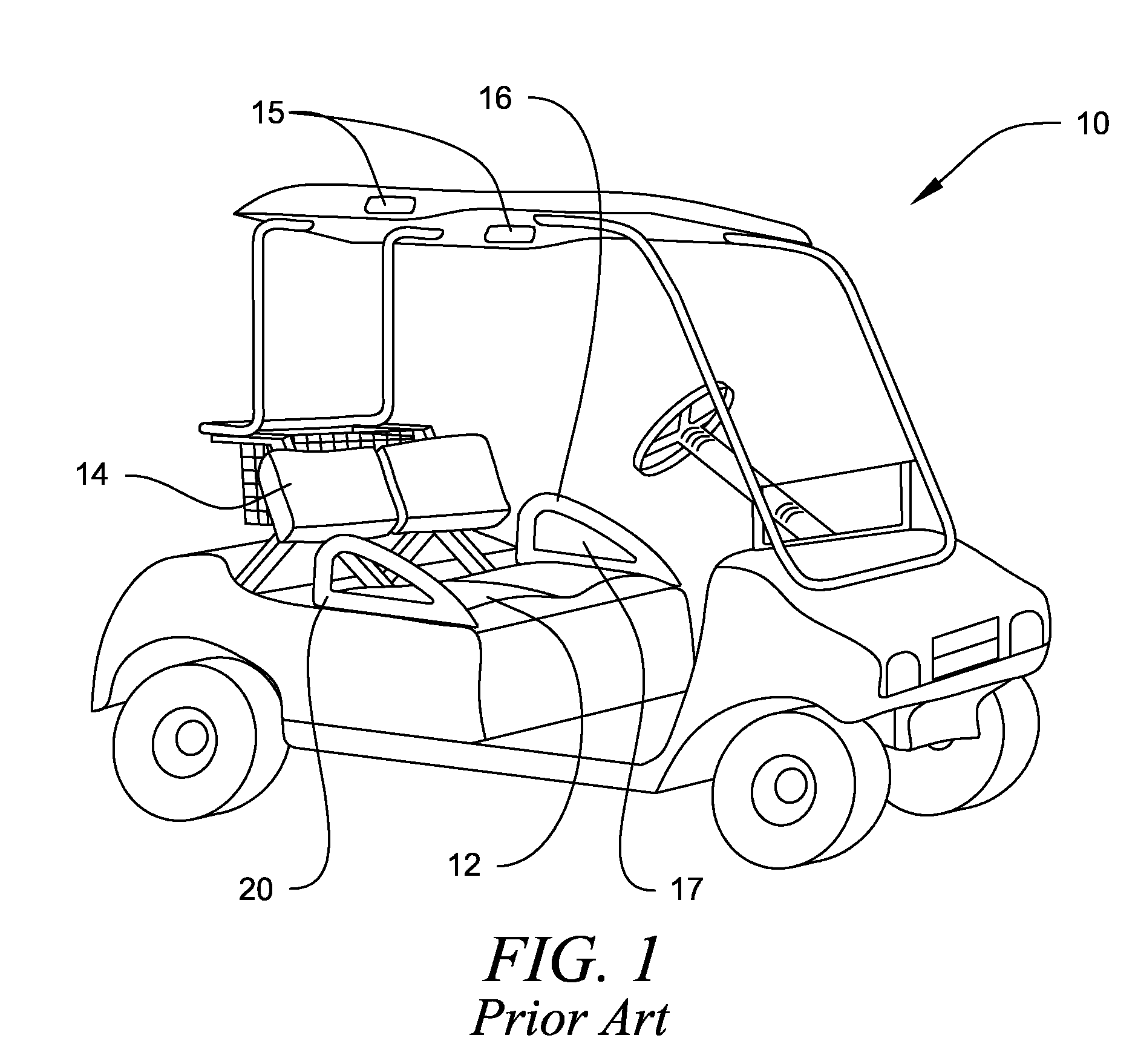

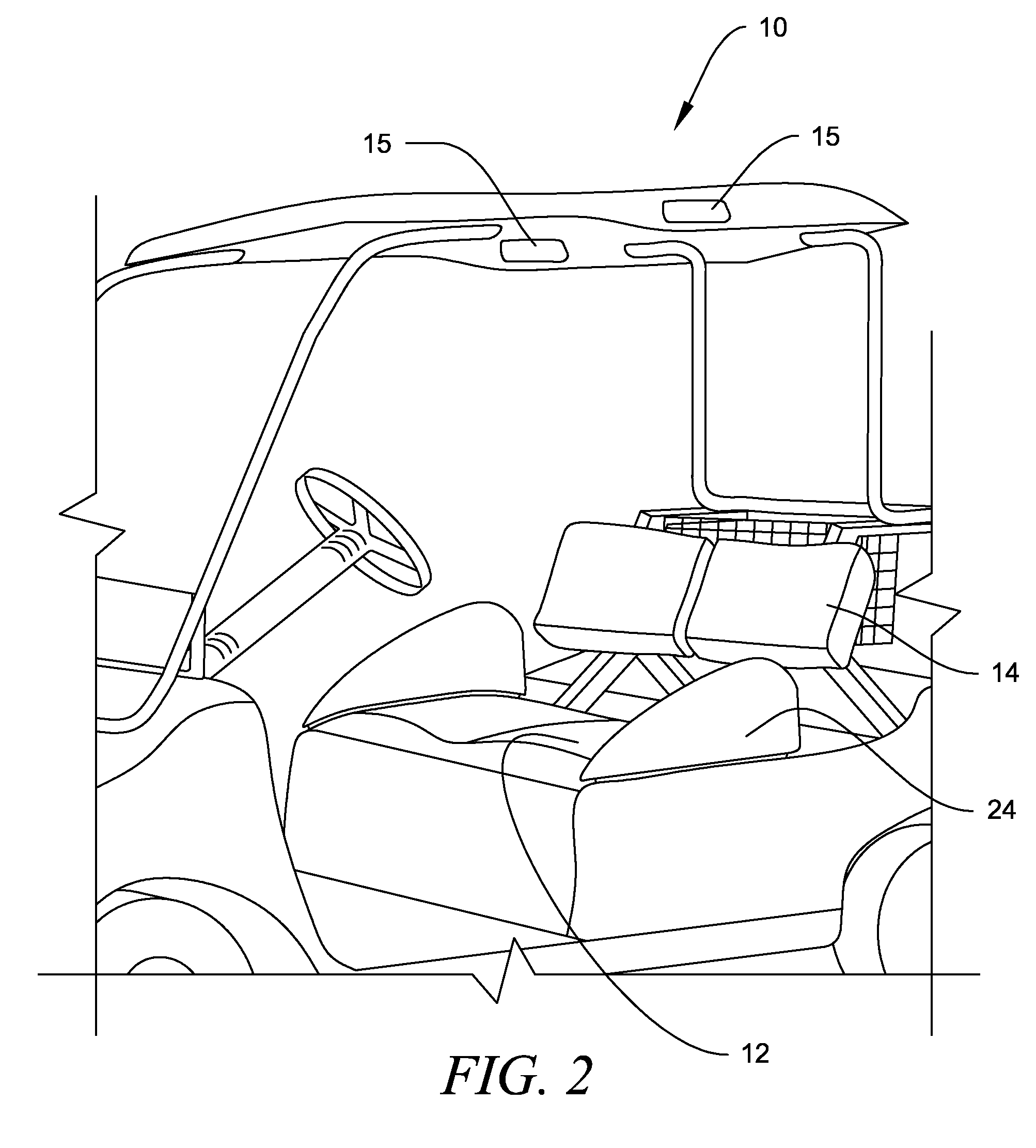

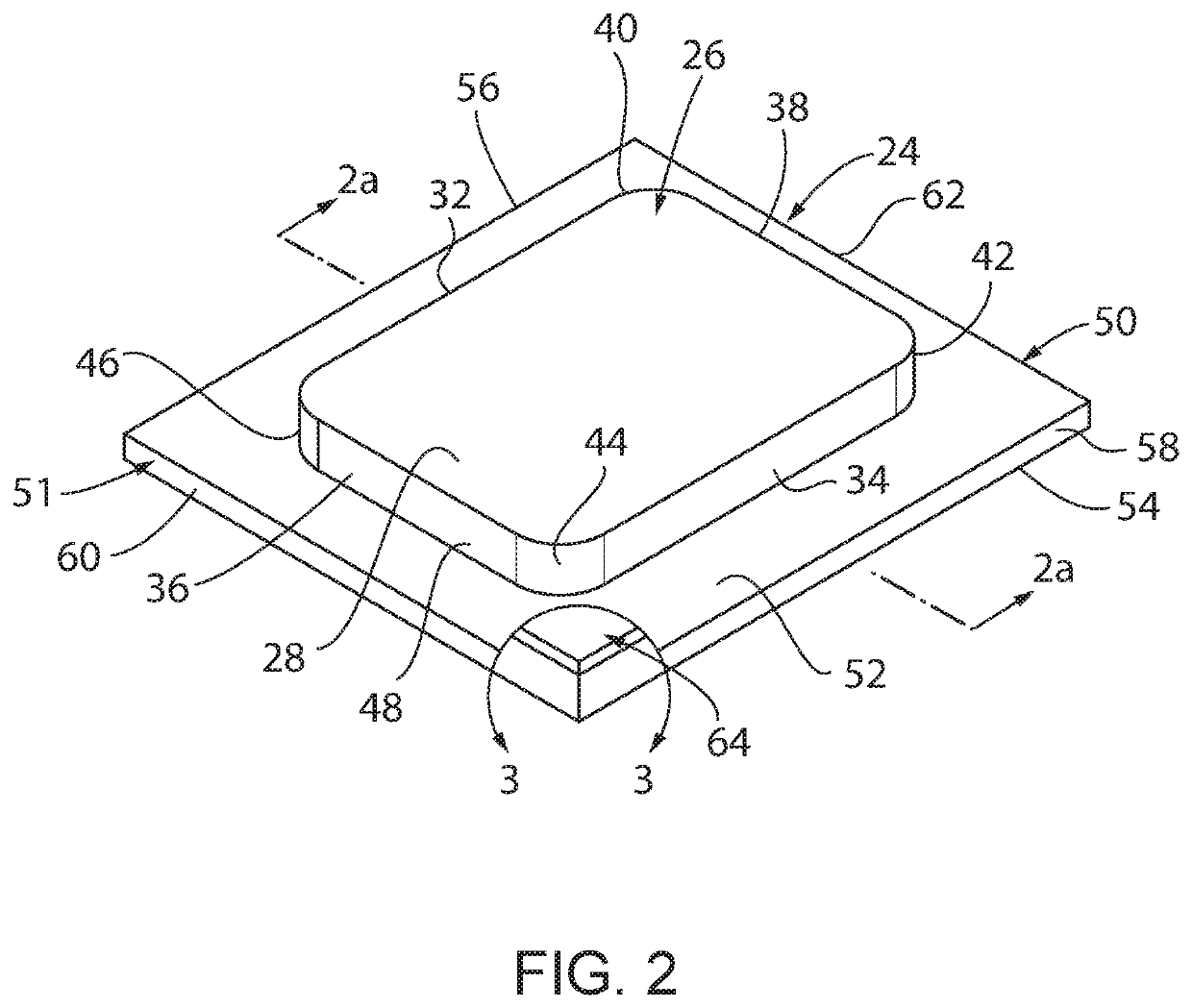

Protective Padded Sleeve for Hip Restraints on Golf Carts

ActiveUS20140367949A1Improve comfortAccurate fitPedestrian/occupant safety arrangementArm restsEngineeringCause injury

The present invention relates generally to protective padding for golf carts, and more specifically, the invention relates to a protective padded sleeve that comprises a sleeve, a fastener and padding, which is placed over and around the hard plastic hip restraint of a golf cart to prevent a rider from being injured. When a rider sits on the bench-style seat of a golf cart, the rider's hip and leg are in contact with this hip restraint. The invention operates by both absorbing the shock with padding placed between a rider and the hard plastic hip restraint of a golf cart, as well as, completely enclosing the hip restraint to prevent obstacles from protruding through the large opening in the hip restraint and causing injury to the rider. This invention further incorporates an auxiliary power source for wireless devices, a wireless speaker and accessory holders.

Owner:INNOVATIVE ACCESSORIES

Multi-compartment flexible pouch with an insulated compartment

ActiveUS8960438B2Cost-effective manufacturingLow heat sealDomestic cooling apparatusLighting and heating apparatusBiomedical engineering

Owner:POUCH PAC INNOVATIONS

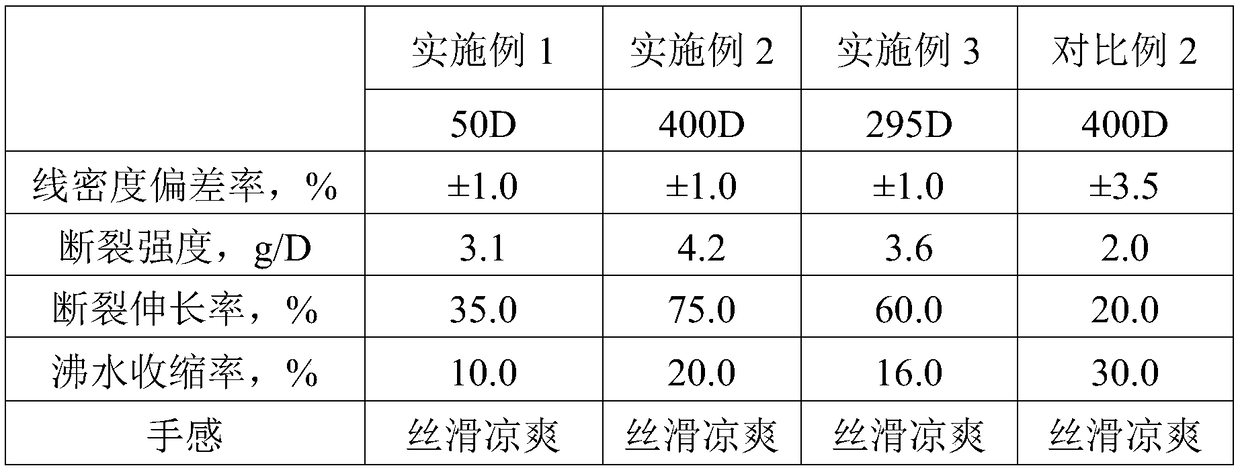

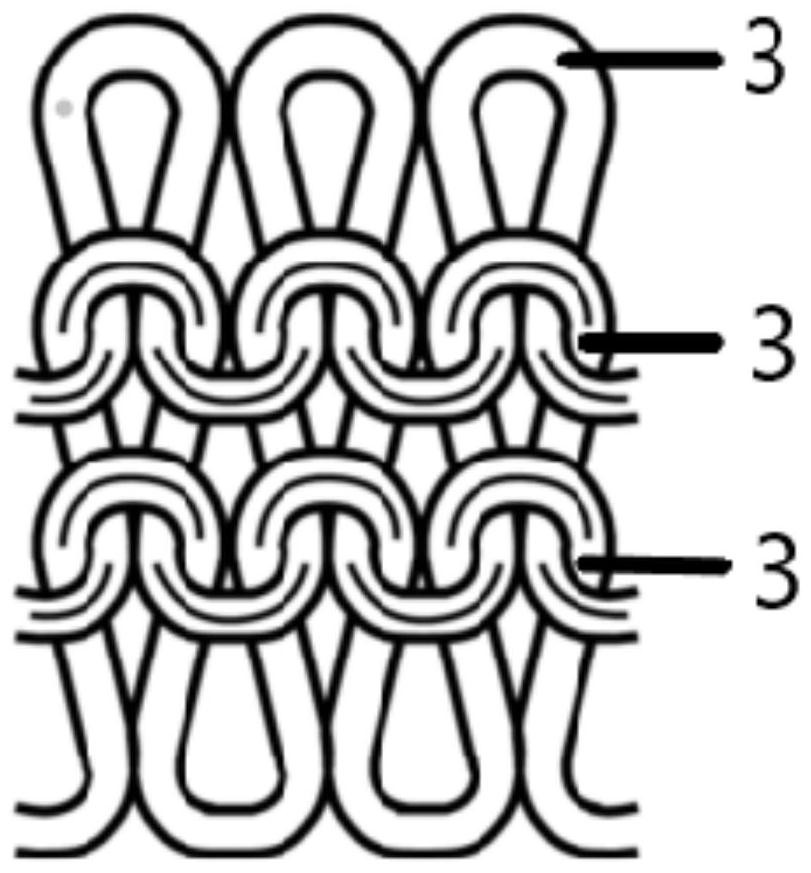

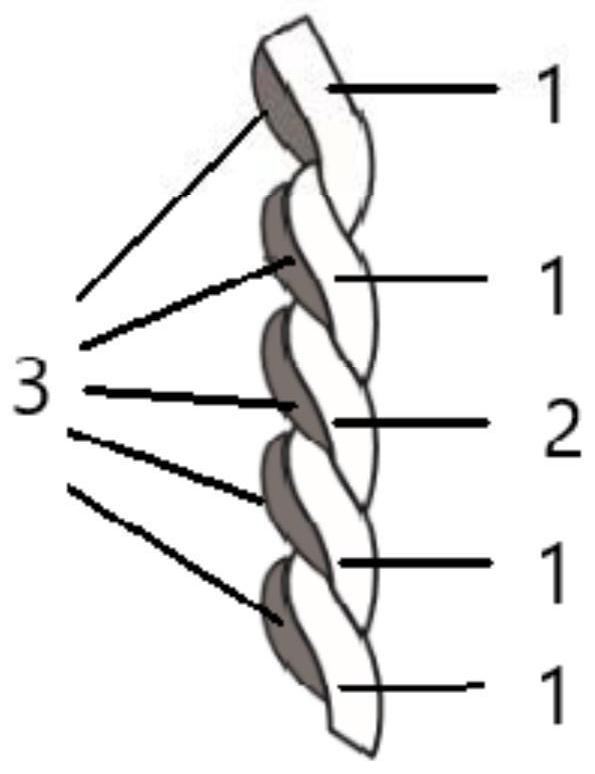

Sliding cool fiber and preparation and application thereof

InactiveCN108691029AHigh strengthImprove toughnessFilament/thread formingConjugated synthetic polymer artificial filamentsPolyamideToughness

The invention discloses sliding cool fiber and preparation and application thereof. The sliding cool fiber is skin-core structure complex fiber which uses chinlon as a core material and uses polyethylene as a skin material; the sliding cool fiber is prepared from the following raw materials by mass percentage: 30%-70% of the chinlon and 30%-70% of the polyethylene. The fiber filament is high in strength, good in toughness and stability, smooth and cool in hand feeling, can be used as a warp and a weft in spinning, and can be used for both of a shuttle loom and a shuttleless loom, the fiber filament can also be used for knitting fabric containing the sliding cool fibers, and the knitted fabric is good in wearability; a preparation method of the sliding cool fiber is improved on the basis ofan existing composite spinning technology of complex fibers, and the main improvement is that two melt distribution pipes are provided in a spinning manifold: a PA melt distribution pipe and a PE melt distribution pipe, wherein the length of the PE melt distribution pipe is 30%-40% shorter than the length of the PA melt distribution pipe, so that PE and PA, the two types of materials in large specific difference are guaranteed to be successfully compounded, the compact compounding of pure polyethylene and pure polyamide is realized, the operation is convenient, and the method is suitable forindustrial production.

Owner:HANGZHOU CHANGXIANG CHEM FIBER

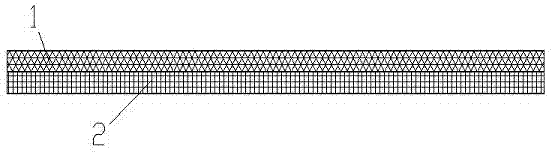

Double-sided pillow towel fabric

InactiveCN103879079AGood moisture absorption and air permeabilityCool to the touchPillowsLayered productsPolyesterBed sheets

The invention discloses a double-sided pillow towel fabric which comprises a front fresh and cool layer and a back soft layer, wherein the front fresh and cool layer is sewed to the back soft layer and is formed by blending linen fibers and polyester fibers; the back soft layer is formed by blending cotton fibers and aloe fibers; the linen fibers account for 65 weight percent in the front fresh and cool layer; the aloe fibers account for 57 weight percent in the back soft layer. According to the mode, the double-sided pillow towel fabric provided in the invention has the advantages that the front fresh and cool layer is mainly made of the linen fibers and is high in hygroscopicity and gas permeability and fresh and cool in touch, the back soft layer is mainly made of aloe fibers and soft in touch and good in moisture effect, the double-sided pillow towel fabric is suitable for manufacturing pillow towels or bed sheets and is wide in application range, and both sides can be used.

Owner:APPROACH SUZHOU GARMENT

Cationic dyeable polyester fabric dyeing and finishing process with composite functions of resisting ultraviolet light, having cool touch and repelling mosquitoes

The invention discloses a cationic dyeable polyester fabric dyeing and finishing process with composite functions of resisting ultraviolet light, having cool touch and repelling mosquitoes. The cationic dyeable polyester fabric dyeing and finishing process comprises the following steps: (1), soaking the cationic dyeable polyester fabric into a dyeing solution, adding acid to regulate the pH valueto 4.0-5.0, and performing dyeing treatment for 20-60 minutes at a temperature of 110-135 DEG C; (2), performing thermal washing, reduction washing and acid neutralizing on the fabric in sequence; and(3) dehydrating and drying the fabric, and padding after-finishing liquor, and finally roasting and shaping. The process selects a special ultraviolet-light absorber for cationic dyeable polyester fabric, simultaneously performs anti-ultraviolet functionalization and dyeing, only performs mosquito repelling and cooling functionalization for finishing link, can obtain relatively good ultraviolet light resistance through a special functional treatment way, and finally enables the cationic dyeable polyester fabric to have three functions of relatively good ultraviolet light resistance, cool touch and mosquito repelling.

Owner:CHANGZHOU NEW WIDE KNITTING & DYEING

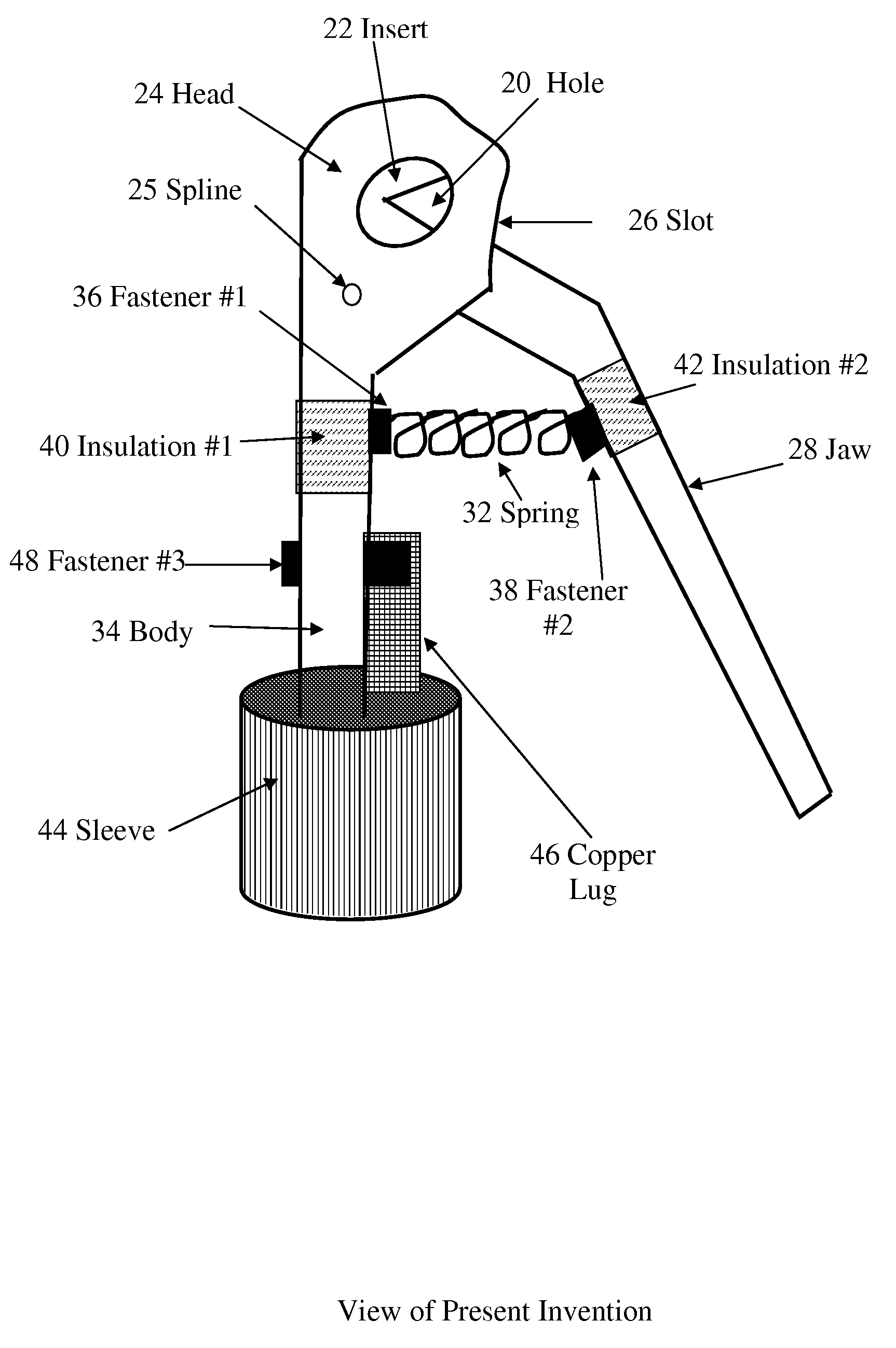

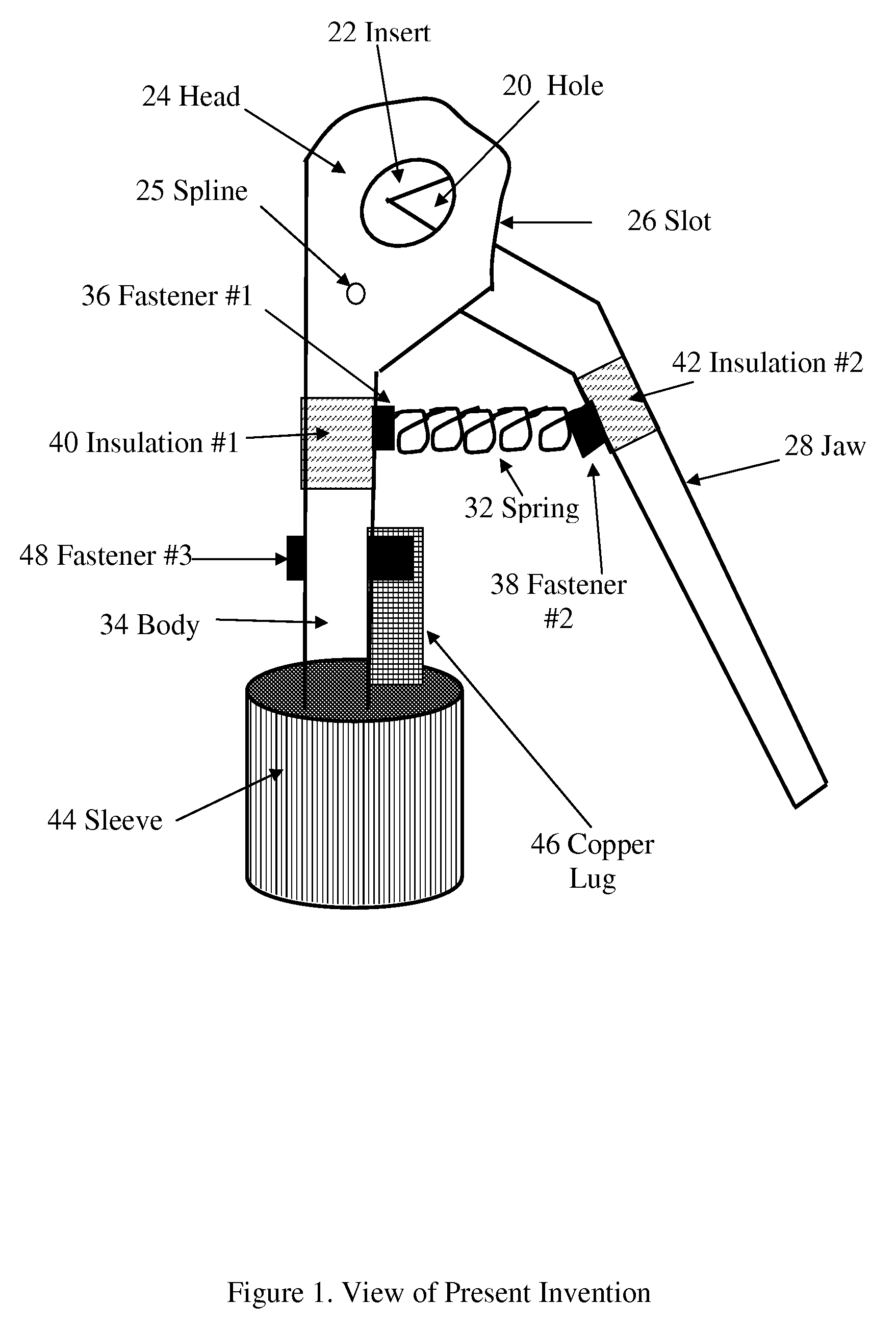

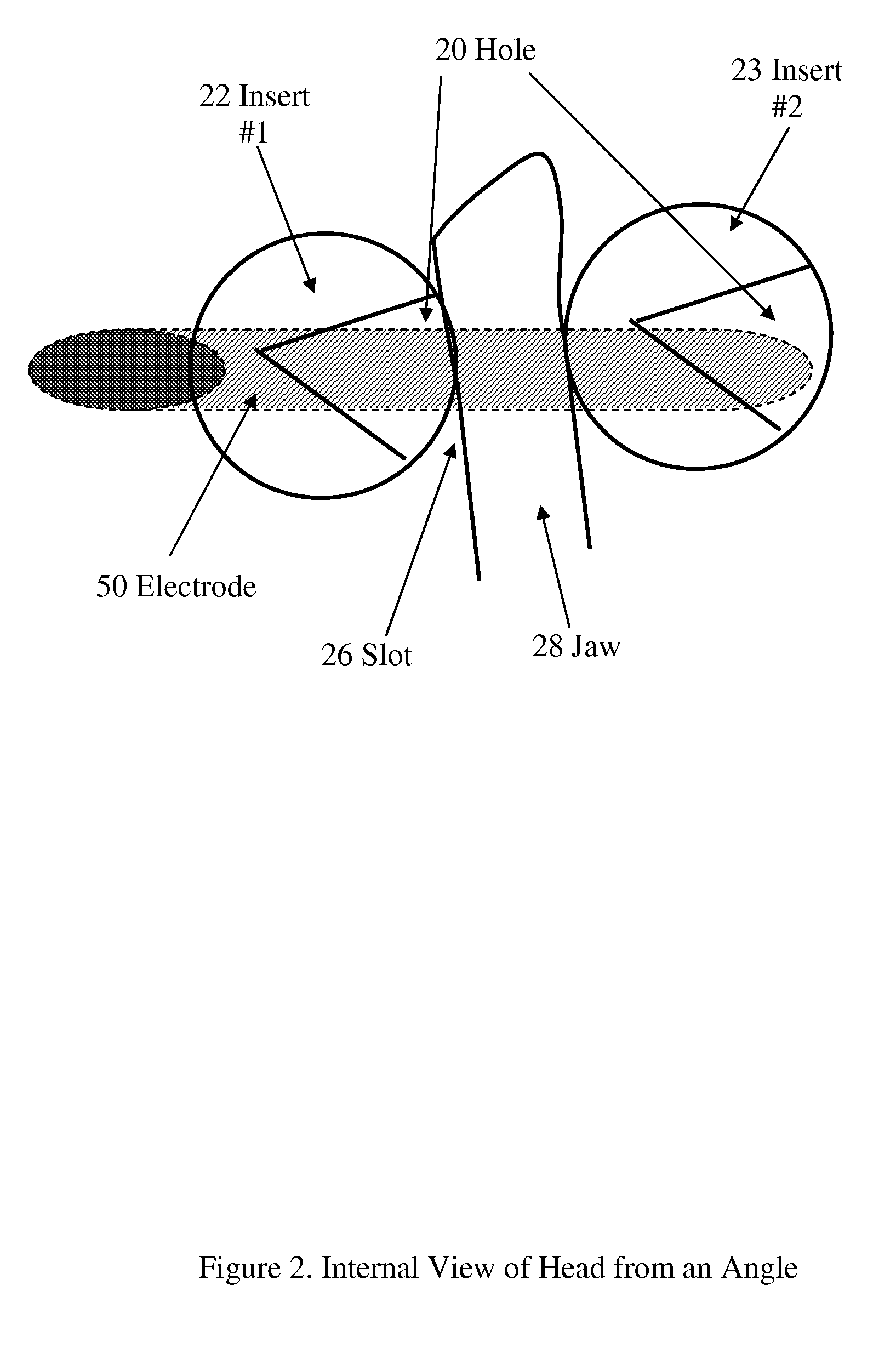

Closed-End Welding Electrode Holder

ActiveUS20100126977A1Avoid problemsClamp tightlyElectric discharge heatingNon-shielding electrode holdersEngineeringElectrode

Owner:LANGLEY CHARLES MARK

Hopper tee having drop opening with arcuate closure

InactiveUS20160200506A1Reduce frictionIncrease frictionValve arrangementsLarge containersEngineeringCam

A directional hopper tee has a fluted interior vertical pipe that merges into a horizontal pipe. The horizontal pipe has an inlet that may receive bulk material, and subject to pressurized air that conveys the bulk material through the hopper tee. Bulk material may be discharged from a hopper through the vertical pipe, for conveyance for discharge from the horizontal pipe of the tee. A closure gate or door is provided through the bottom of the tee, generally in alignment with the vertical pipe, to allow for discharge or dropping of the granular material directly downwardly through and from the tee. The arcuate door is hinged on one side, and is locked by a cam lock on the opposite side, when located into closure against the bottom of the tee, but can be forced opened, through its cam mechanism, to provide for opening of the arcuate door and allow a direct downward discharge of the granular bulk material, from any hopper, and through the drop opening of the tee, as required.

Owner:BULK TANK

After-finishing process for textile fabric with cooling function

InactiveCN104762778ACool to the touchGood antibacterial and antibacterial propertiesSolvent-treatmentSingeingWoven fabricYarn

The invention discloses an after-finishing process for textile fabric with a cooling function. The after-finishing process includes the technologies of scouring, singeing, flushing, soaking, dry rolling, dyeing, preshrunk shaping and drying. Warp and weft of the fabric comprise 65% to 73% of bamboo pulp fiber, 25% to 30% of polytrimethylene terephthalate fiber and 2% to 5% of medium-coarse high-elastic acrylic crease-resistant chopped fiber, wherein the density of the medium-coarse high-elastic acrylic crease-resistant chopped fiber ranges from 3.33 dtex to 5.56 dtex. The warp and the weft are twin-cord yarn, wherein the folded yarn twist is larger than or equal to 700 twists per meter. The twin-cord yarn is 27.8 tex carded yarn twin-cord yarn. The fabric is satin wave figured texture weave fabric, the warp density is 800 pieces to 900 pieces per 10 cm, and the weft density is 380 pieces to 420 pieces per 10 cm. The finished fabric has the cool touch sense, the excellent antibacterial property and the good crease-resistant performance, the fabric is soft in hand feeling compared with pure linen fabric, and meanwhile a certain body is achieved compared with chitin fabric so that the fabric can be quite suitable for being used as bedding fabric for spring and summer.

Owner:NANTONG YOUKAI TEXTILE TECH

Hopper tee with comformable arcuate closure member

InactiveUS9175796B2Reduce frictionIncrease frictionPipeline expansion-compensationLarge containersEngineeringCam

A directional hopper tee has a fluted interior vertical pipe that merges into a horizontal pipe. The horizontal pipe has an inlet that may receive bulk material, and subject to pressurized air that conveys the bulk material through the hopper tee. Bulk material may be discharged from a hopper through the vertical pipe, for conveyance for discharge from the horizontal pipe of the tee. A closure gate or door is provided through the bottom of the tee, generally in alignment with the vertical pipe, to allow for discharge or dropping of the granular material directly downwardly through and from the tee. The arcuate door is hinged on one side, and is locked by a cam lock on the opposite side, when located into closure against the bottom of the tee, but can be forced opened, through its cam mechanism, to provide for opening of the arcuate door and allow a direct downward discharge of the granular bulk material, from any hopper, and through the drop opening of the tee, as required.

Owner:BULK TANK

Modified plastic and processing method for manufacturing game console handle by using plastic

The invention discloses modified plastic and a processing method for manufacturing a game console handle by using the plastic. The modified plastic is prepared from 40 parts by weight of polypropylene, 25 parts by weight of polyvinyl chloride powder, 30 parts by weight of ceramic powder, 6 parts by weight of polyethylene octene co-elastomer, 4 parts by weight of plasticizer, 4 parts by weight of foaming agent, 4 parts by weight of corrosion inhibitor, 4 parts by weight of chelating agent and 6 parts by weight of peppermint oil. According to the modified plastic, the ceramic powder, the plasticizer, the corrosion inhibitor, the chelating agent, the peppermint oil and other components are added, compared with traditional plastic manufacturing, the modified plastic is smoother in touch feeling, sweat stains and peppermint oil are not prone to adhering, the touch feeling of the hand is cool, hand sweat can be reduced in cooperation with the strip-shaped grooves in the handle and the cooling factors in the strip-shaped grooves, and the problems that the existing game console handle is made of traditional plastic, hand sweat is generated when a user holds the game console handle to play games, the grip of the game console handle becomes sticky, the operation is influenced, and the game experience of game enthusiasts cannot be met are solved.

Owner:JIANGSU YOUFU AUTO PARTS TECH CO LTD

Summer fabric with sense of coldness

InactiveCN103898664ABreathable and lightGood moisture wicking effectWeft knittingWarp knittingFiberSunstrokes

The invention discloses a piece of summer fabric with a sense of coldness. The summer fabric comprises, by weight, 11%-15% of cotton fiber, 45%-49% of sense-of-coldness fiber, 22%-26% of linen fiber and 10%-14% of coir-carbon fiber. In this way, the summer fabric with the sense of coldness is breathable, light, thin, good in moisture absorption and sweat discharging performance, cool in touch feeling, fast in cooling, suitable for all kinds of summer clothes, good in wearing comfortableness and capable of preventing sunstroke and achieving cooling.

Owner:APPROACH SUZHOU GARMENT

Medical lubricant for sterilizing and balancing potential of hydrogen and preparation process of medical lubricant

The invention provides a medial lubricant for sterilizing and balancing potential of hydrogen. The lubricant comprises the following components based on the gross weight: 30 to 75wt% of glycerol, 5 to 15wt% of Carbomer, 10 to 20wt% of polyethylene glycol, and 10 to 20wt% of acid-base buffer agent, wherein the acid-base buffer agent is selected from acetic acid buffer pair, boric acid buffer pair, carbonic acid buffer pair, phosphoric acid buffer pair, citric acid buffer pair, acetate buffer pair, borate buffer pair, carbonate buffer pair, phosphate buffer pair and citrate buffer pair.

Owner:JIANGSU PROVINCE JIANERKANG MEDICAL DRESSING CO LTD

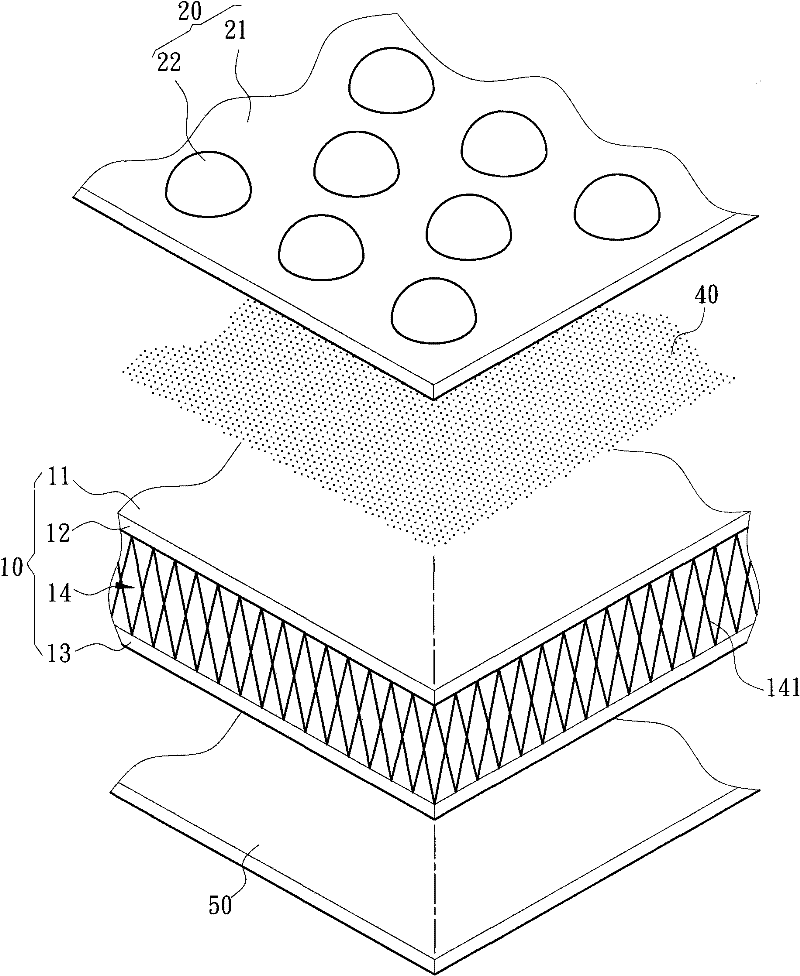

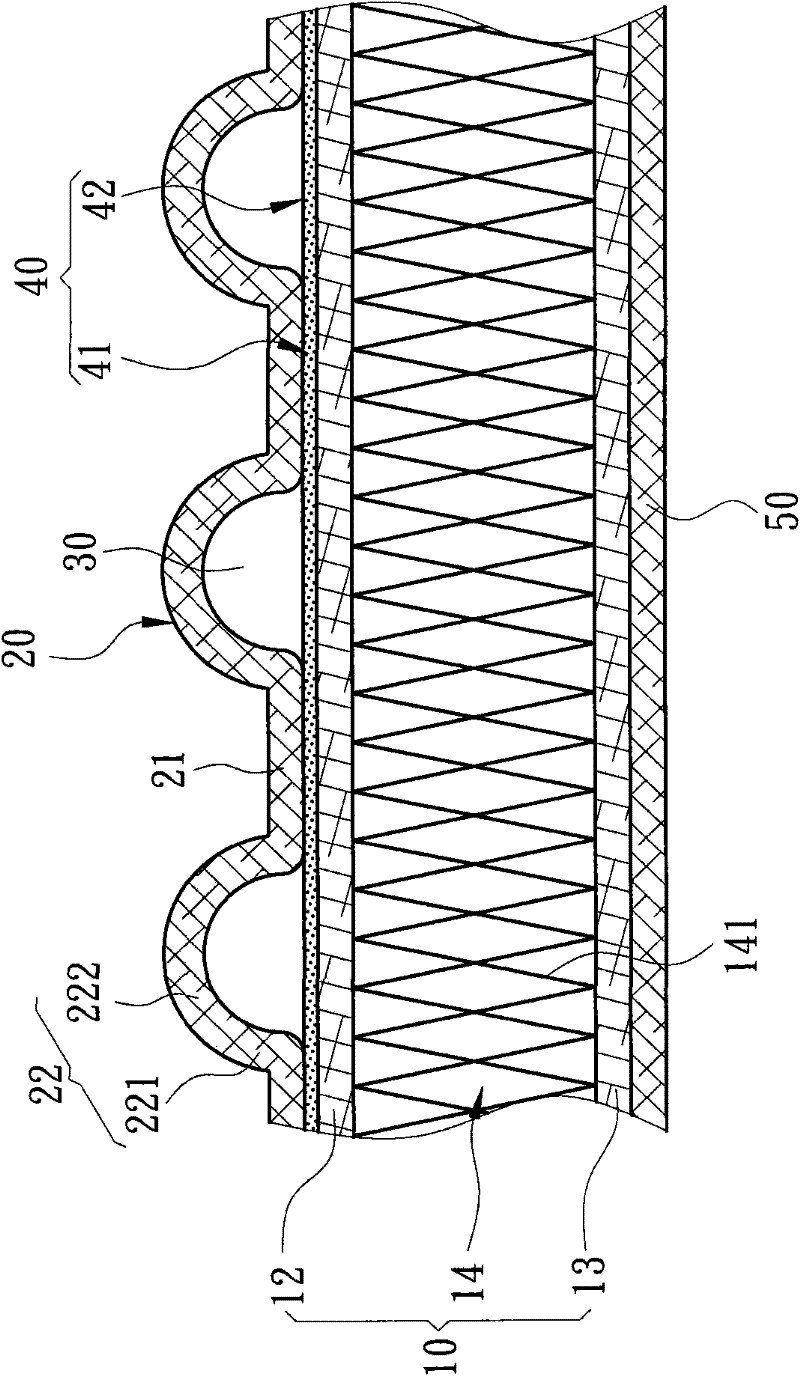

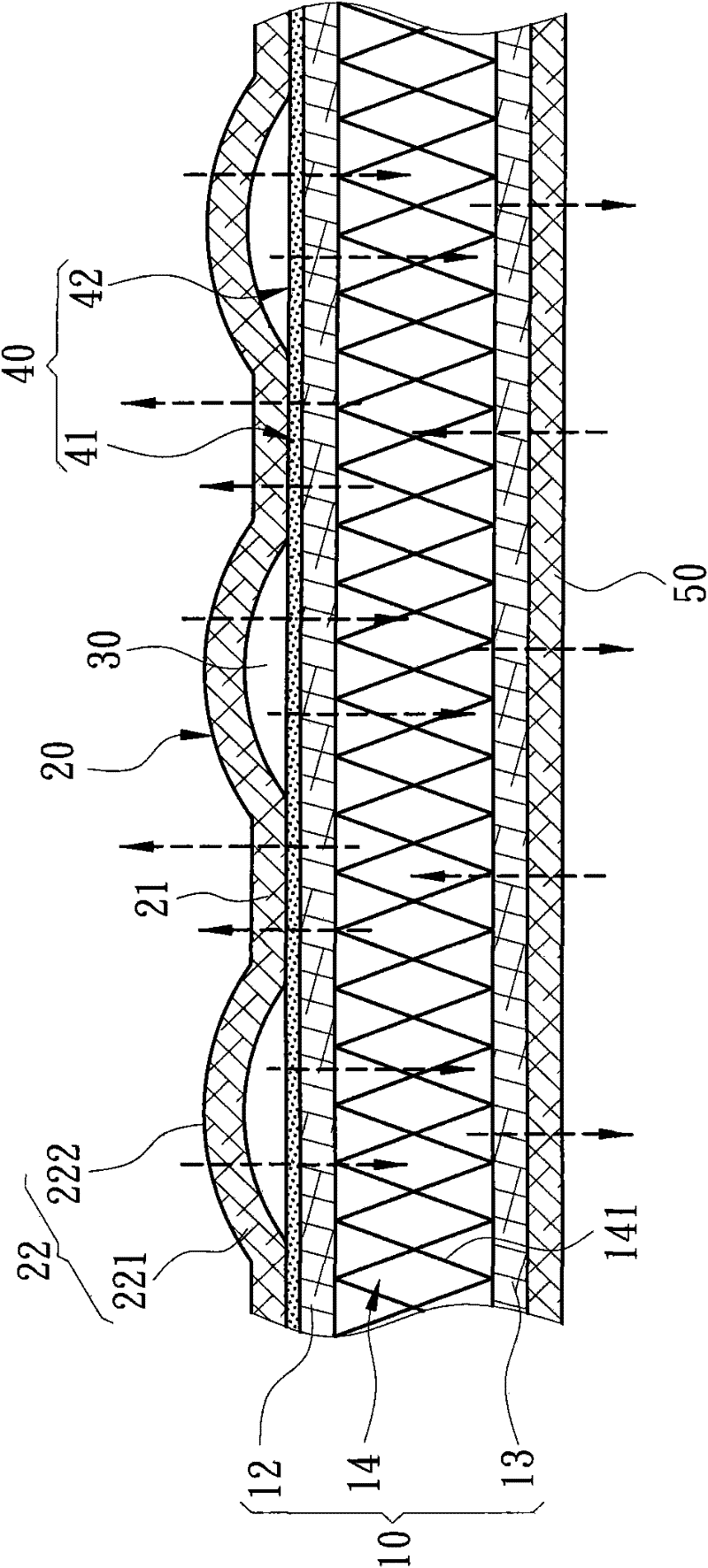

Highly breathable and protective functional fabric

InactiveCN102275347ACool to the touchReduce harmSynthetic resin layered productsEngineeringContact region

A functional cloth with high air permeability and protection, which includes an elastic cloth and an air-permeable cloth, the elastic cloth has a joint surface, the air-permeable cloth is arranged on the elastic cloth, and the air-permeable cloth includes a plurality of connecting A contact area to the joint surface and a plurality of raised areas adjacent to the contact area, the raised areas and the joint surface define a chamber containing gas. When the elastic fabric is changed between an unstretched state and a stretched state, the raised area will move toward the joint surface so that the chamber has a volume change, thereby increasing the pressure in the chamber , so that the gas is forced to penetrate the elastic cloth, thus, the functional cloth can have high air permeability.

Owner:JADE LONG JOHN ENTERPRISE

Protective padded sleeve for hip restraints on golf carts

ActiveUS9573498B2Improve comfortAccurate fitPedestrian/occupant safety arrangementArm restsEngineeringGolf Ball

The present invention relates generally to protective padding for golf carts, and more specifically, the invention relates to a protective padded sleeve that comprises a sleeve, a fastener and padding, which is placed over and around the hard plastic hip restraint of a golf cart to prevent a rider from being injured. When a rider sits on the bench-style seat of a golf cart, the rider's hip and leg are in contact with this hip restraint. The invention operates by both absorbing the shock with padding placed between a rider and the hard plastic hip restraint of a golf cart, as well as, completely enclosing the hip restraint to prevent obstacles from protruding through the large opening in the hip restraint and causing injury to the rider. This invention further incorporates an auxiliary power source for wireless devices, a wireless speaker and accessory holders.

Owner:INNOVATIVE ACCESSORIES

A kind of hydrogel wound dressing for treating laser burn and burn and scald and preparation method thereof

ActiveCN103495199BPromote wound healingImprove antibacterial propertiesAbsorbent padsBandagesLaser burnBurned skin

Owner:SAIKE SAISI BIOTECH CO LTD

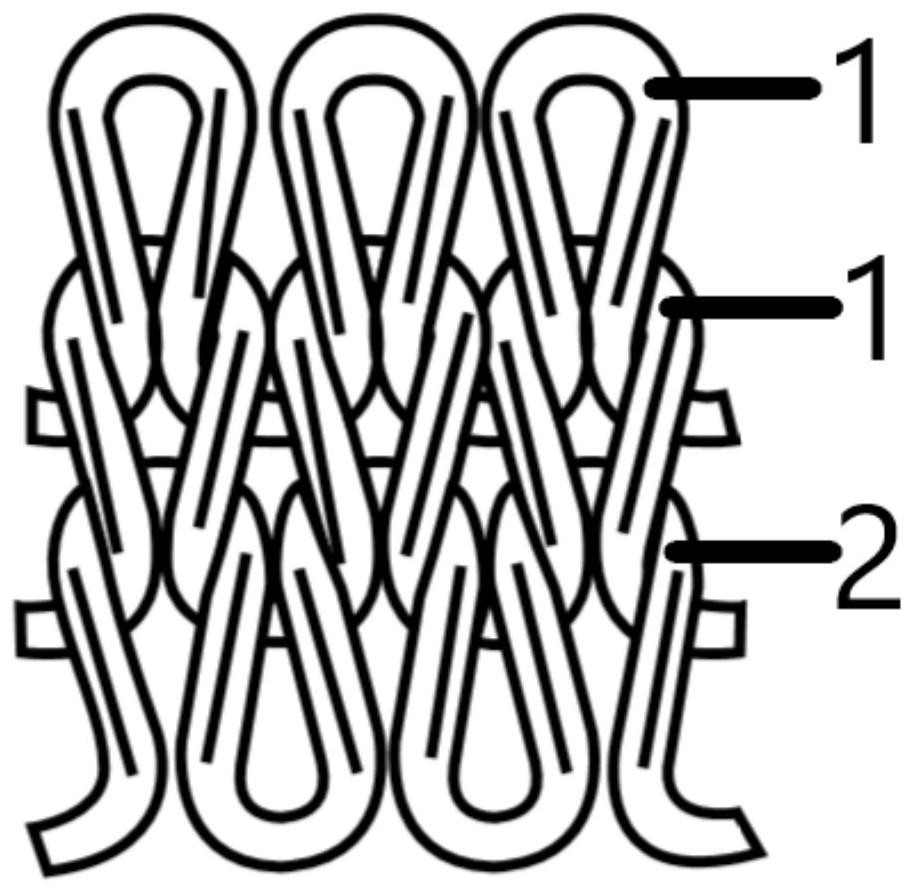

Copper ammonia silk-like elastic knitted fabric as well as preparation method and application thereof

The invention provides a copper ammonia silk-like elastic knitted fabric as well as a preparation method and application thereof. The fabric is formed by interweaving non-elastic yarns and elastic yarns, and each path of non-elastic yarns of the fabric covers each path of elastic yarns; and the non-elastic yarns comprise composite filaments containing copper ammonia fibers and cold sense filaments. The copper ammonia silk-like elastic knitted fabric disclosed by the invention has the advantages of draping feeling like real silk, smooth hand feeling, cool feeling in contact, sweat absorption, quick drying and ultraviolet resistance, and meanwhile, the problems that the copper ammonia fibers are poor in strength and difficult to weave and chemical fibers generate static electricity are solved.

Owner:QINGDAO IMEI FASHION INT TRADE CO LTD

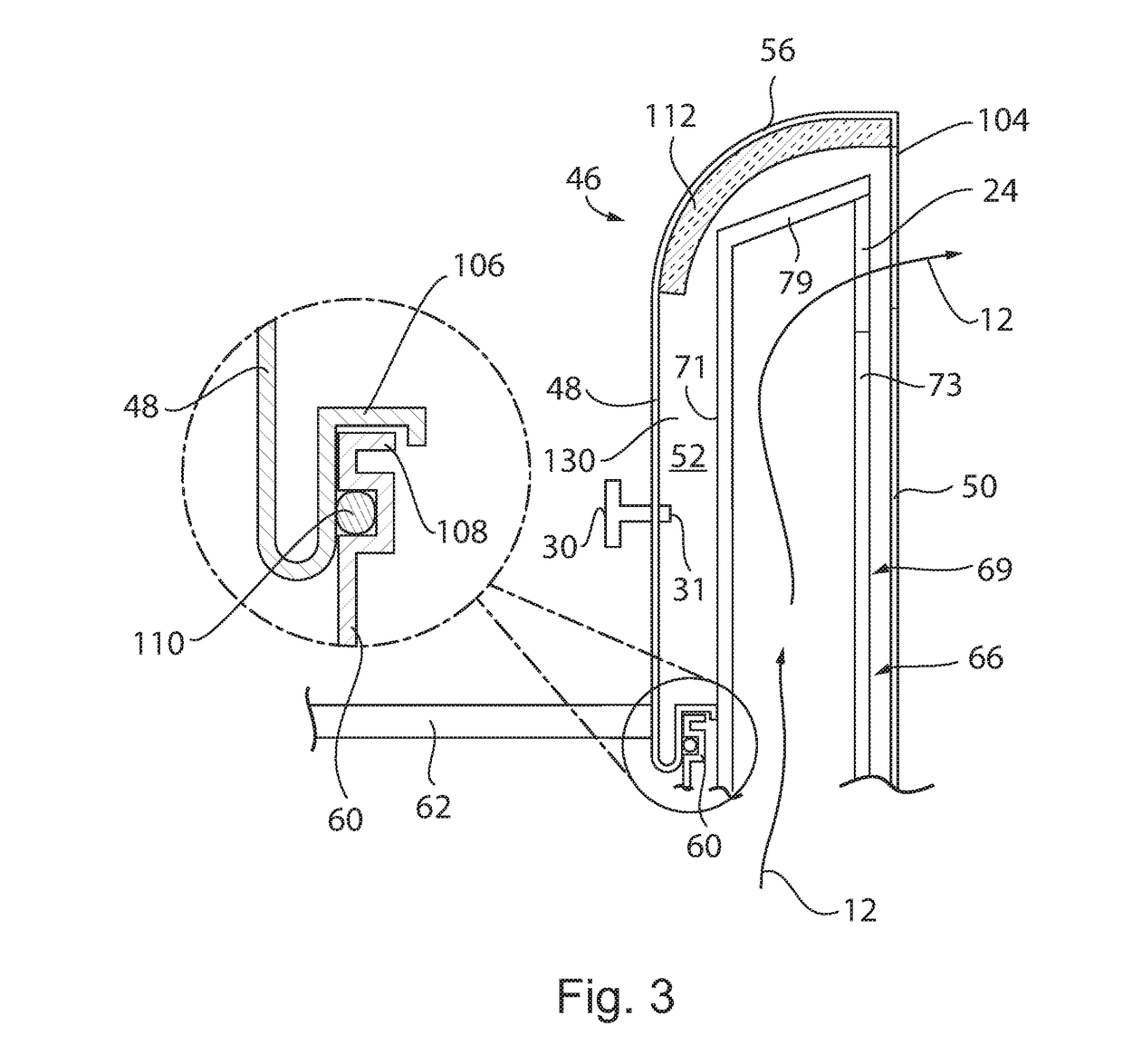

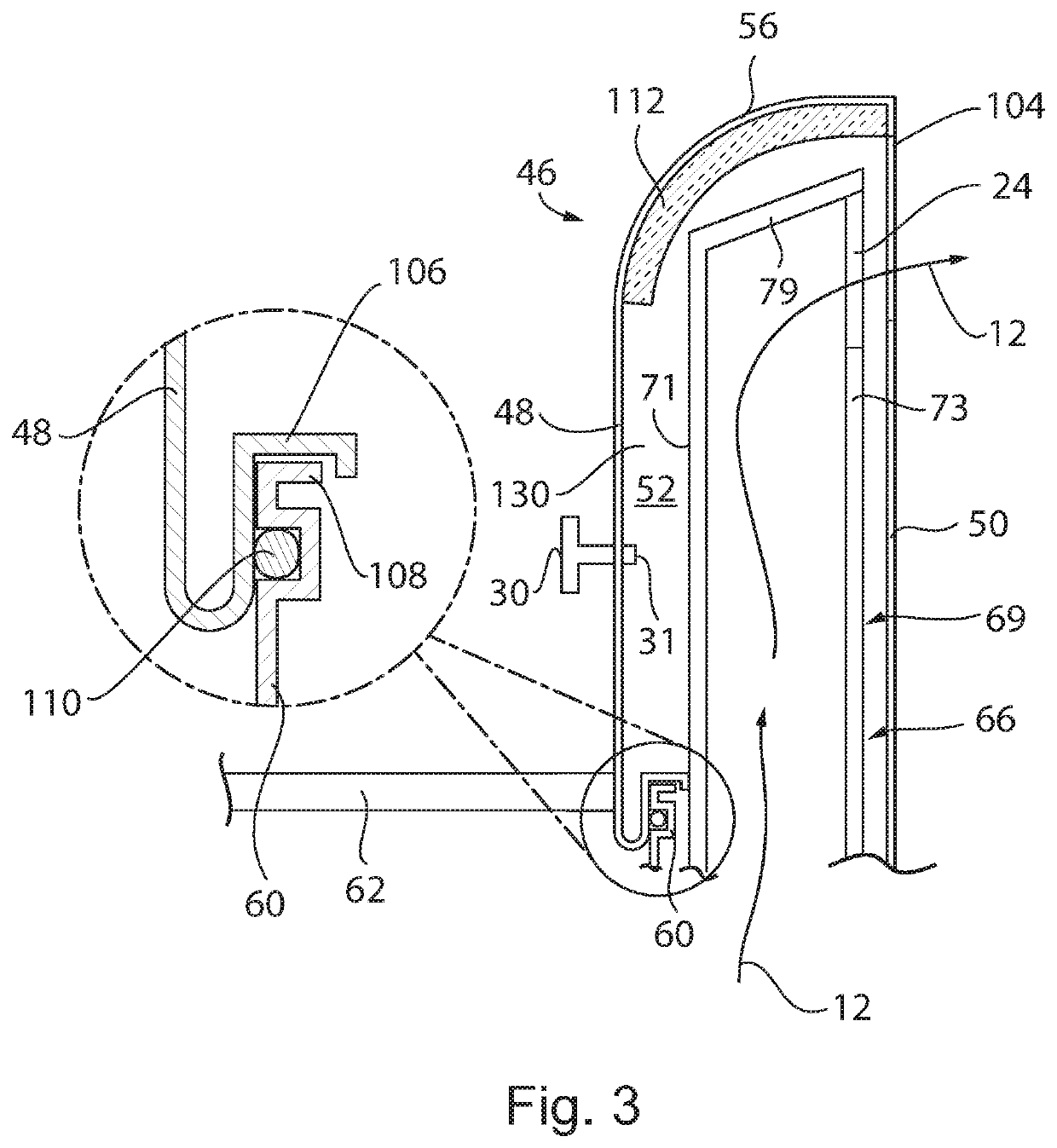

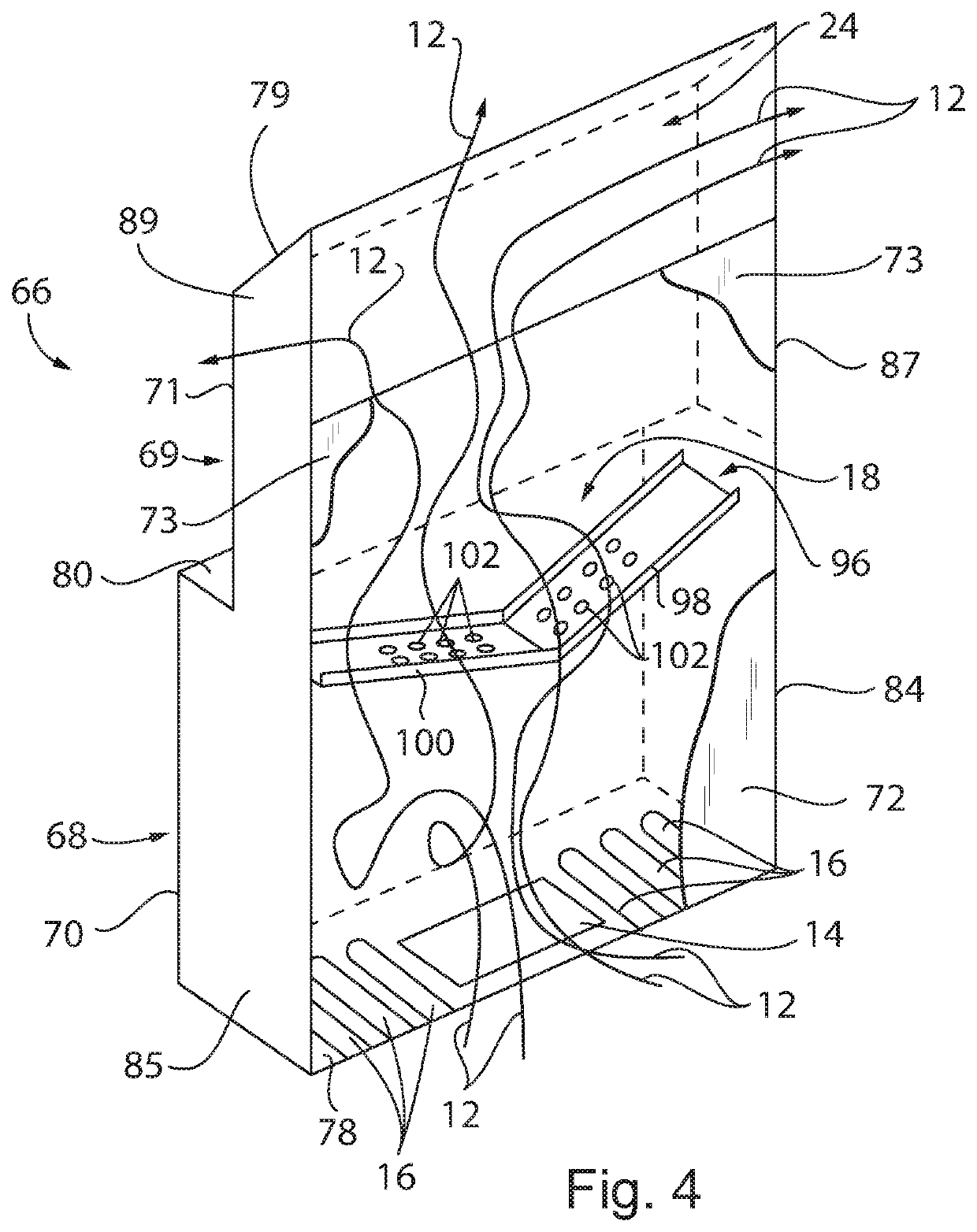

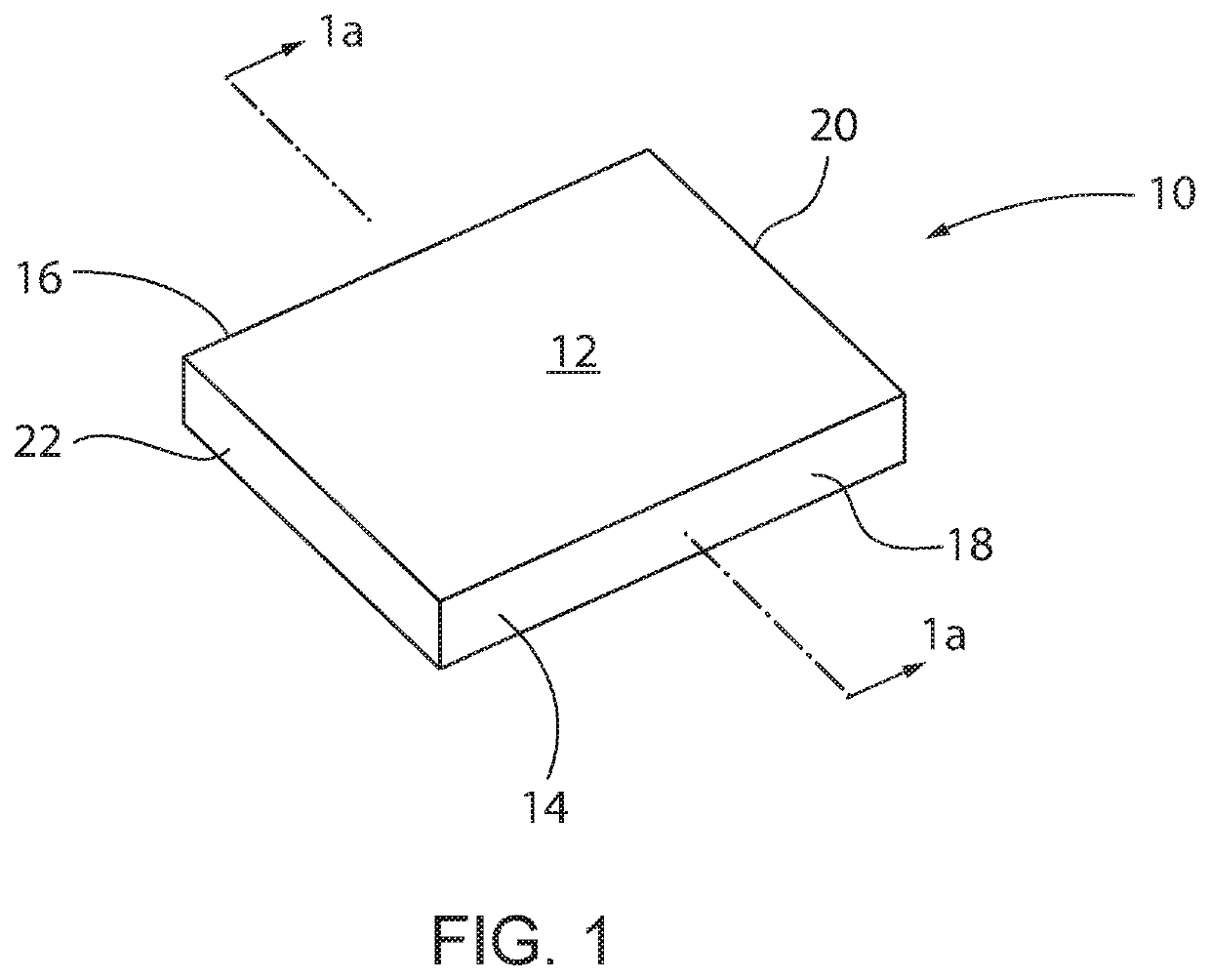

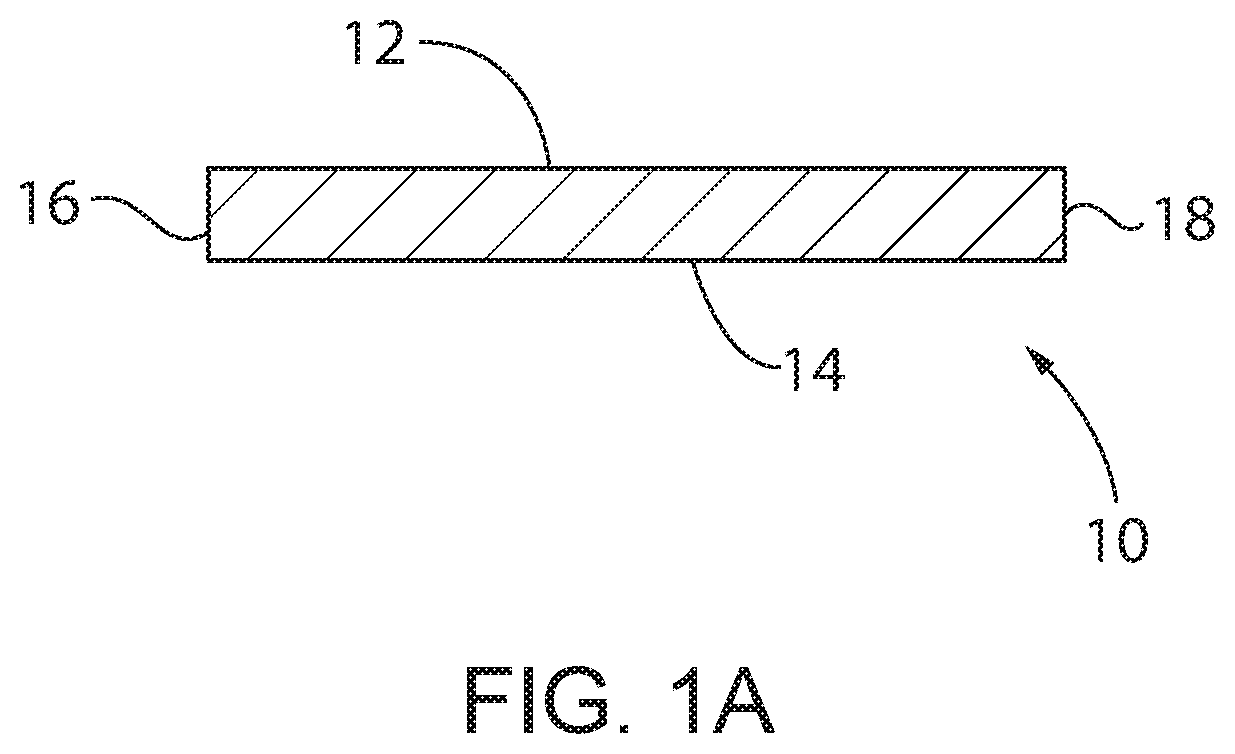

Covering and method of forming a covering for a hatch door

ActiveUS11492079B2Ease with which the marine carpet may be installedLow costHull decksDoors/windowsMarine engineeringFlange

Owner:BUSHEY RICHARD D +2

Flue assembly and splash back panel for a cooking appliance

ActiveUS10842320B2Easy to cleanLower outlet temperatureDomestic stoves or rangesLighting and heating apparatusForeign matterProcess engineering

The present invention provides a deep fat fryer separating the flue from the splash back panel and with a flue opening directed not upwardly, but rearwardly from the flue. By arranging the flue opening on the rear wall, the opening is protected from grease fallback (e.g., dripping from an overhead exhaust hood) or other foreign objects falling into the opening. The splash back panel further provides a seamless curved design that is easy to clean and also insulated from the heat of the flue. A baffle installed within the flue allows the combustion products to mix, cool, and slow upon exiting the baffle opening and entering the atmosphere reducing the exit temperature and also reducing the heating of the splash back panel.

Owner:ALTO SHAAM

Covering And Method Of Forming A Covering For A Hatch Door

A covering and a method of forming a covering for a hatch door or lid, e.g., the hatch door of a marine vehicle, such a boat or the like, is provided. The covering includes a central portion having a configuration corresponding to a configuration of the hatch door and a thickness. A flange projects from the central portion and has a thickness less than the thickness of the central portion. The flange movable between a first position wherein the flange lies in a first plane generally parallel to a first surface of the central portion and a second position wherein the flange is generally perpendicular to the first plane and defines a cavity in the covering for receiving the hatch door therein.

Owner:BUSHEY RICHARD D +2

Finishing method using anti-ultraviolet finishing agent

Owner:广东名鼠股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com