Patents

Literature

1514 results about "Bed sheets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

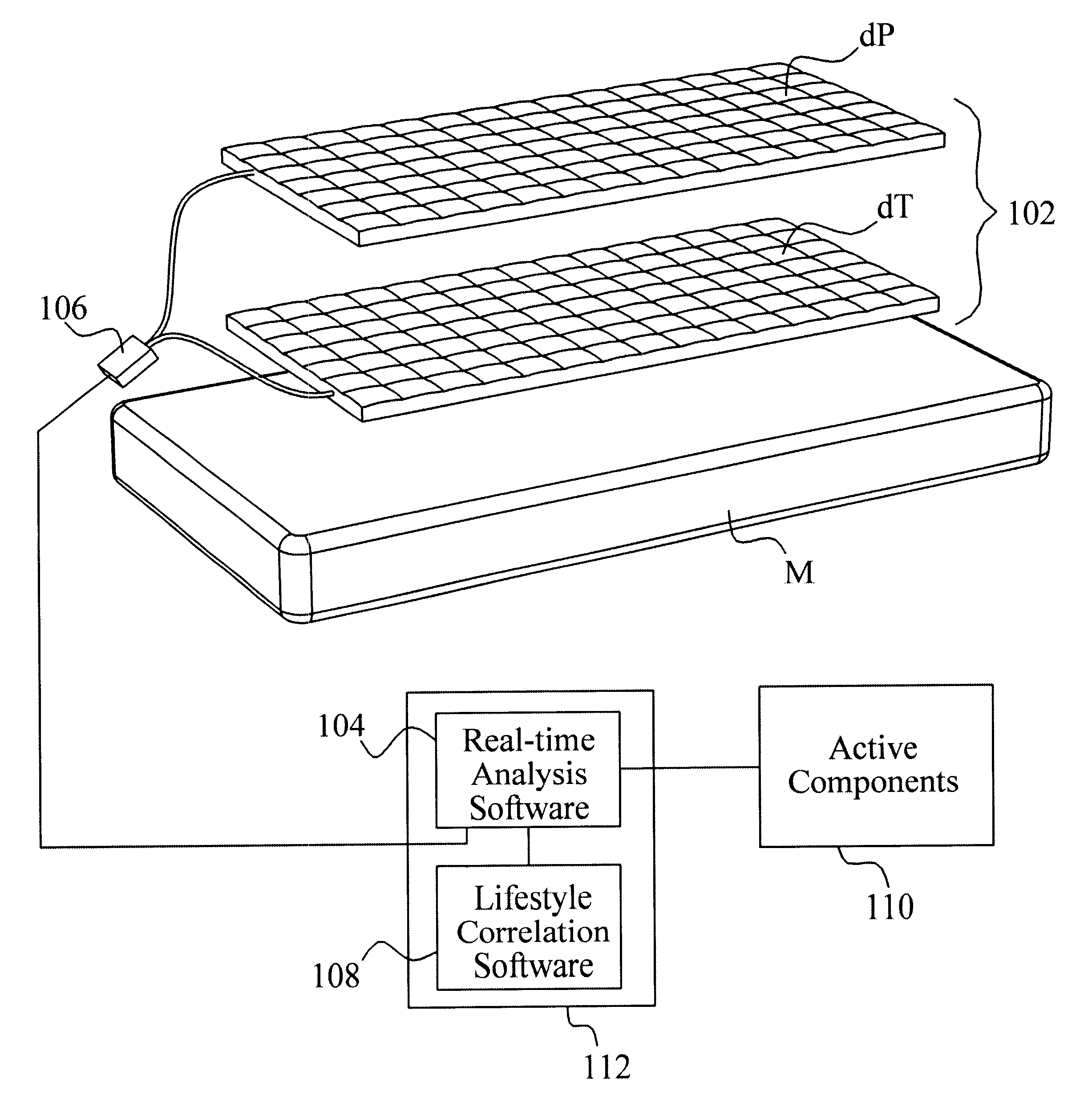

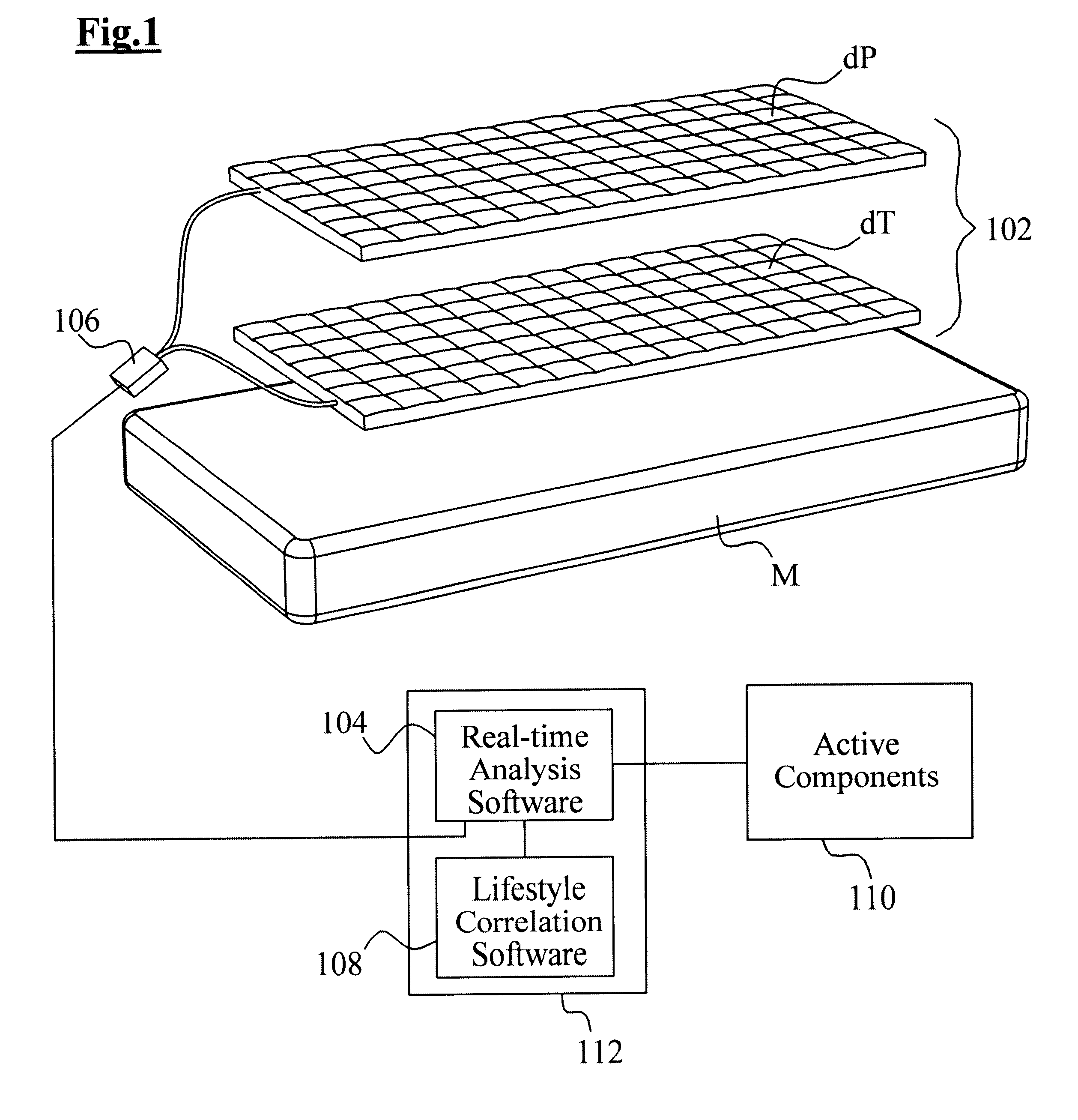

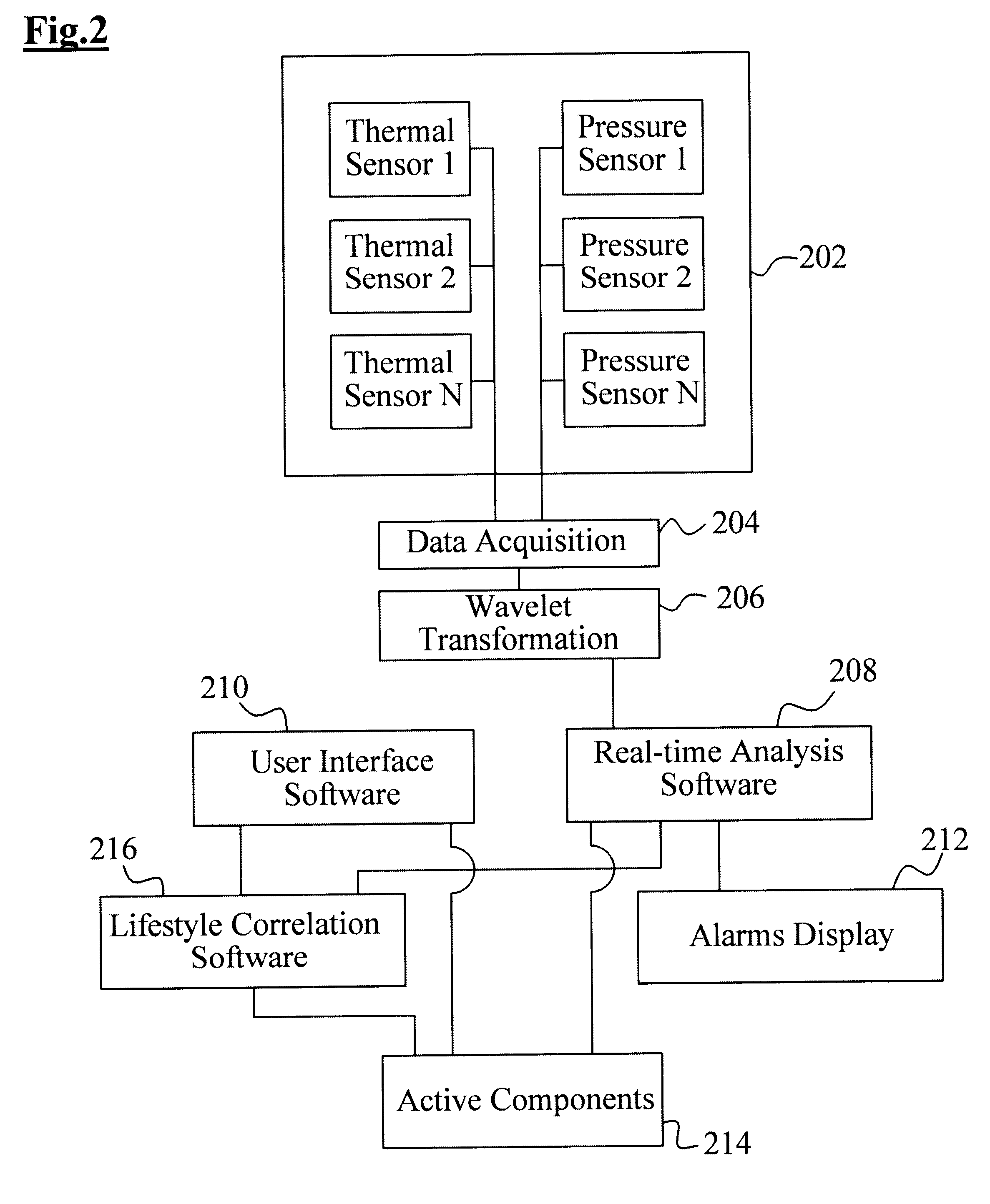

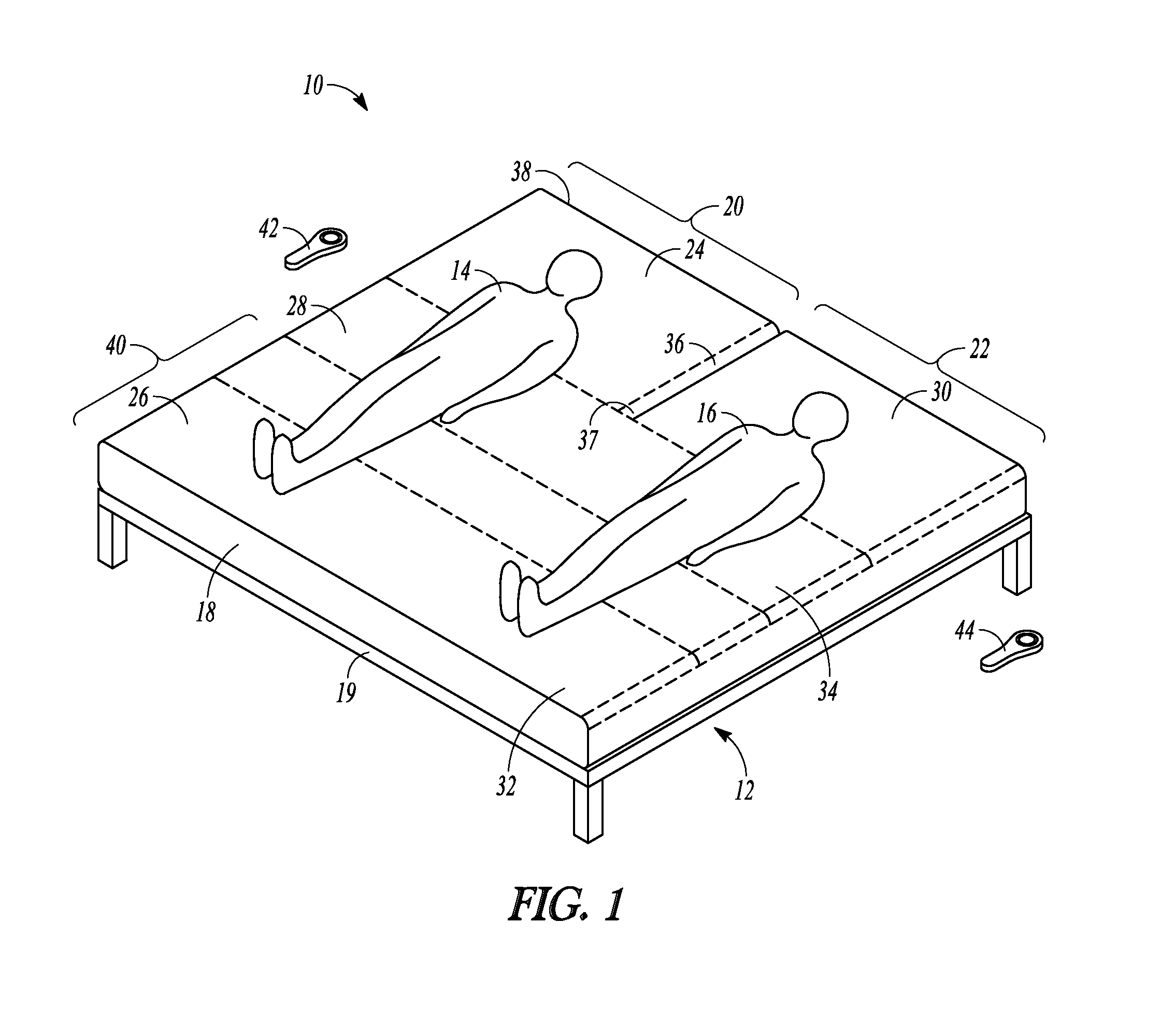

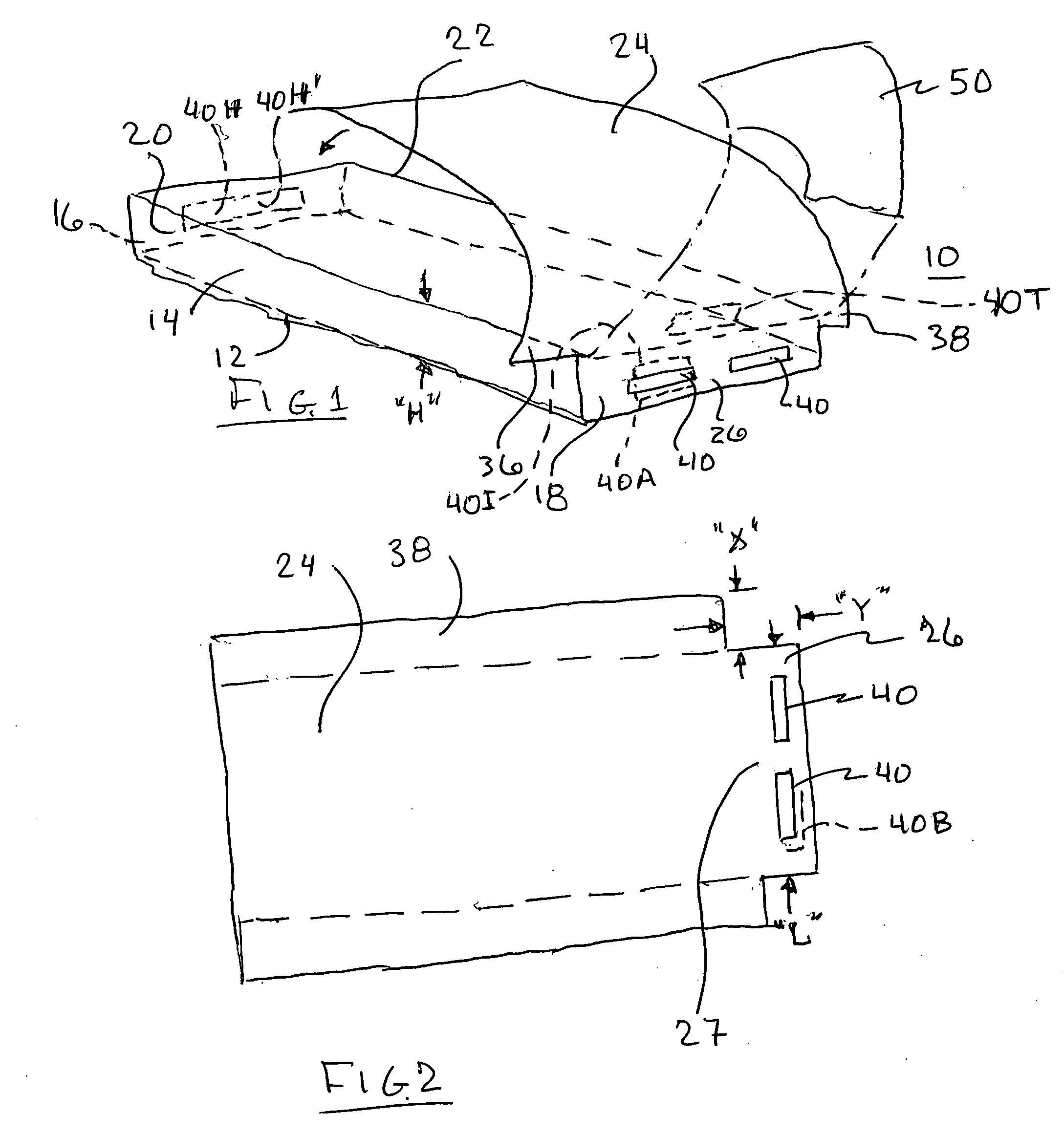

SleepSmart

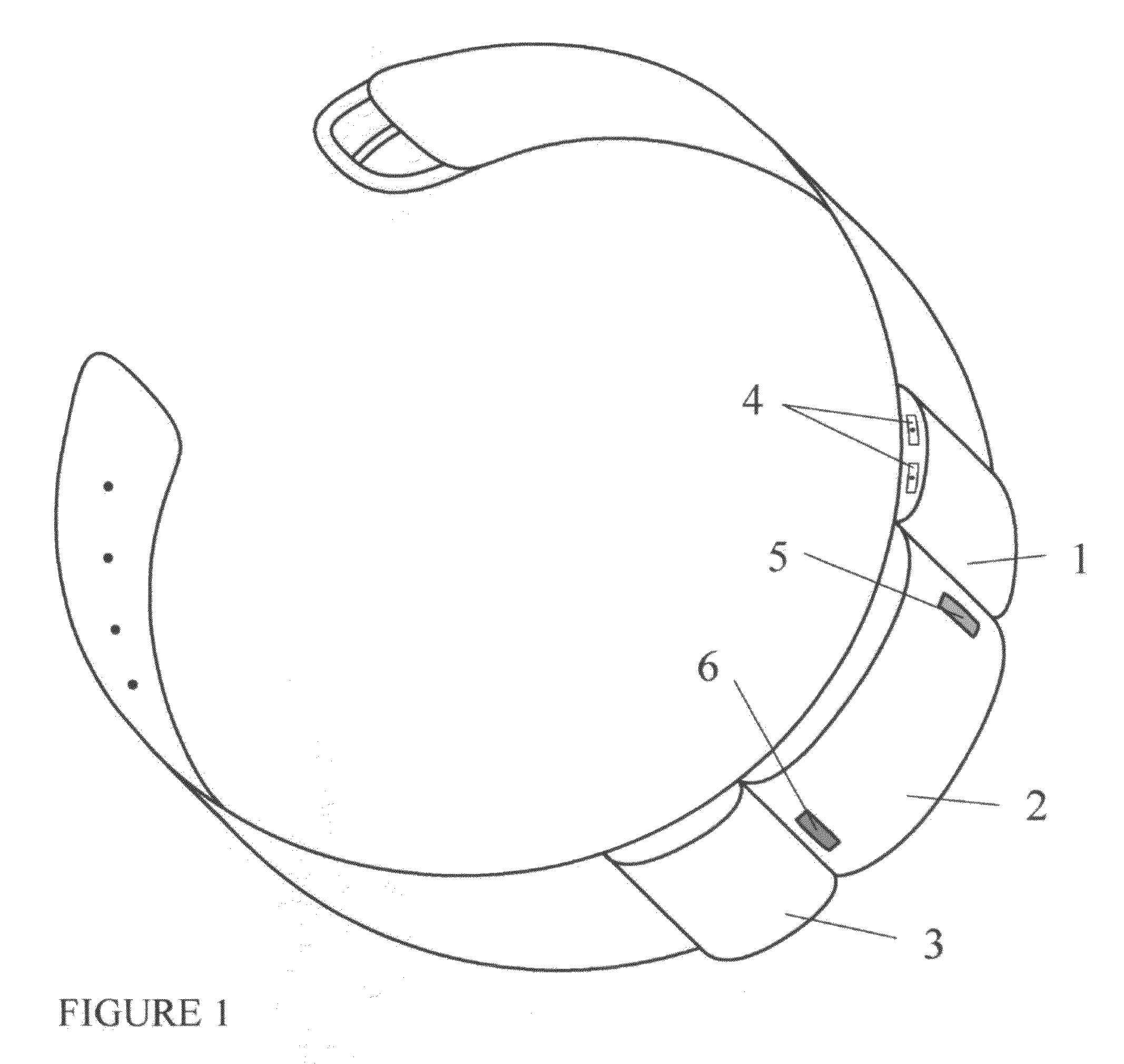

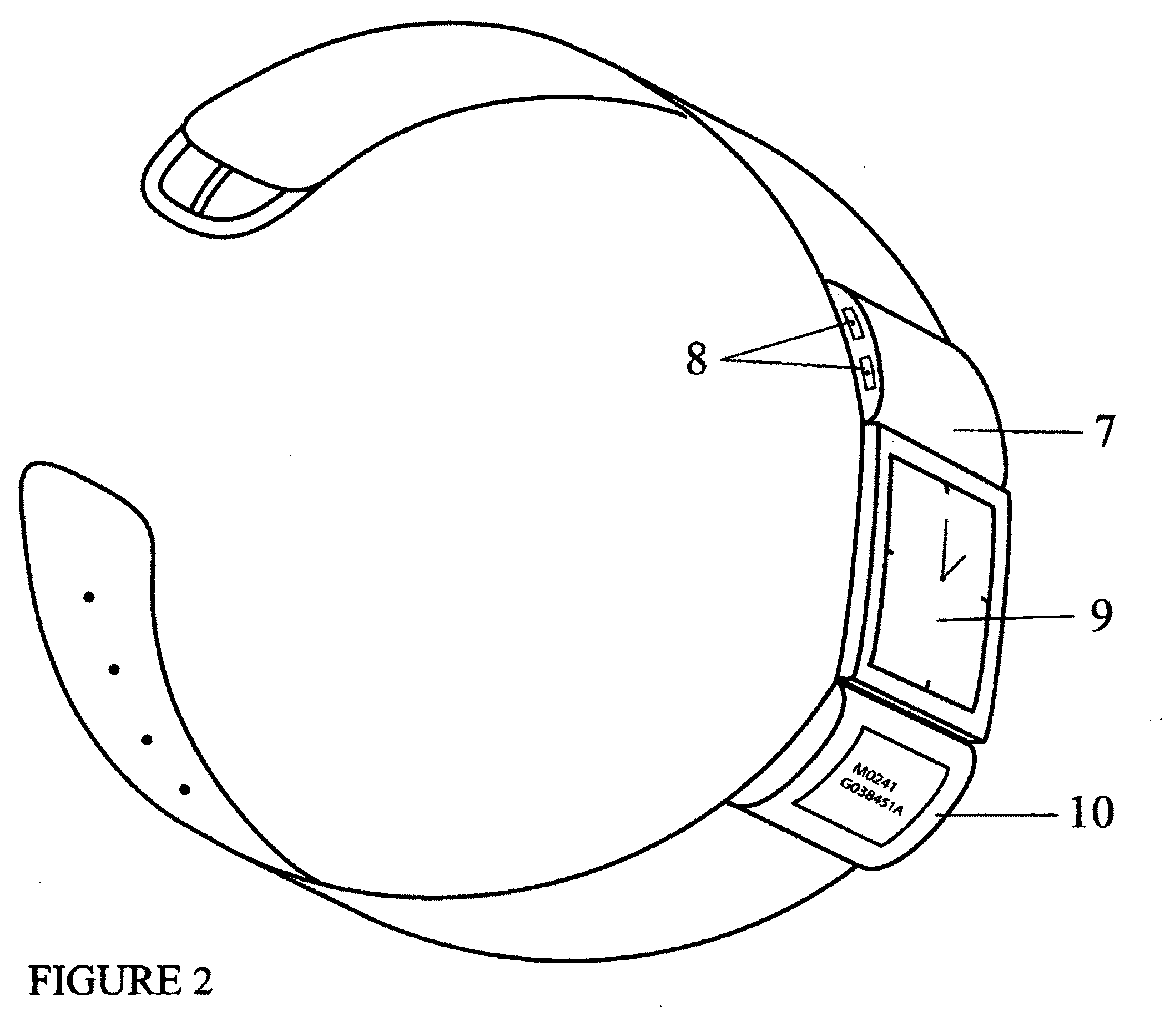

A method and apparatus for measuring sleep quality that utilizes sensors incorporated in a sheet which is laid on top of a conventional mattress on which the subject sleeps. The sensors can collect information such as the subject's position, temperature, sound / vibration / movement, and optionally other physical properties. The apparatus for monitoring an individual's sleep quality is comprised of one or more layers of arrays of integrated sensors, which can be incorporated in layer pads, which is then placed on a conventional mattress; one or more controllers coupled with the arrays of integrated sensors in each layer pad for the purpose of acquiring data from the sensors; a real-time analysis software for analyzing data acquired by the controller from the array of integrated sensors; an interface software for collecting user lifestyle data; a lifestyle correlation software for correlating the lifestyle data with the data acquired by said array of sensors; one or more active components to improve sleep quality based on the data acquired through the sensors and the lifestyle data. The array of sensors provide one or more of the following data: position, temperature, sound, vibration, and movement data. Each layer pad can be individually removed or added as necessary depending on the data being collected.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

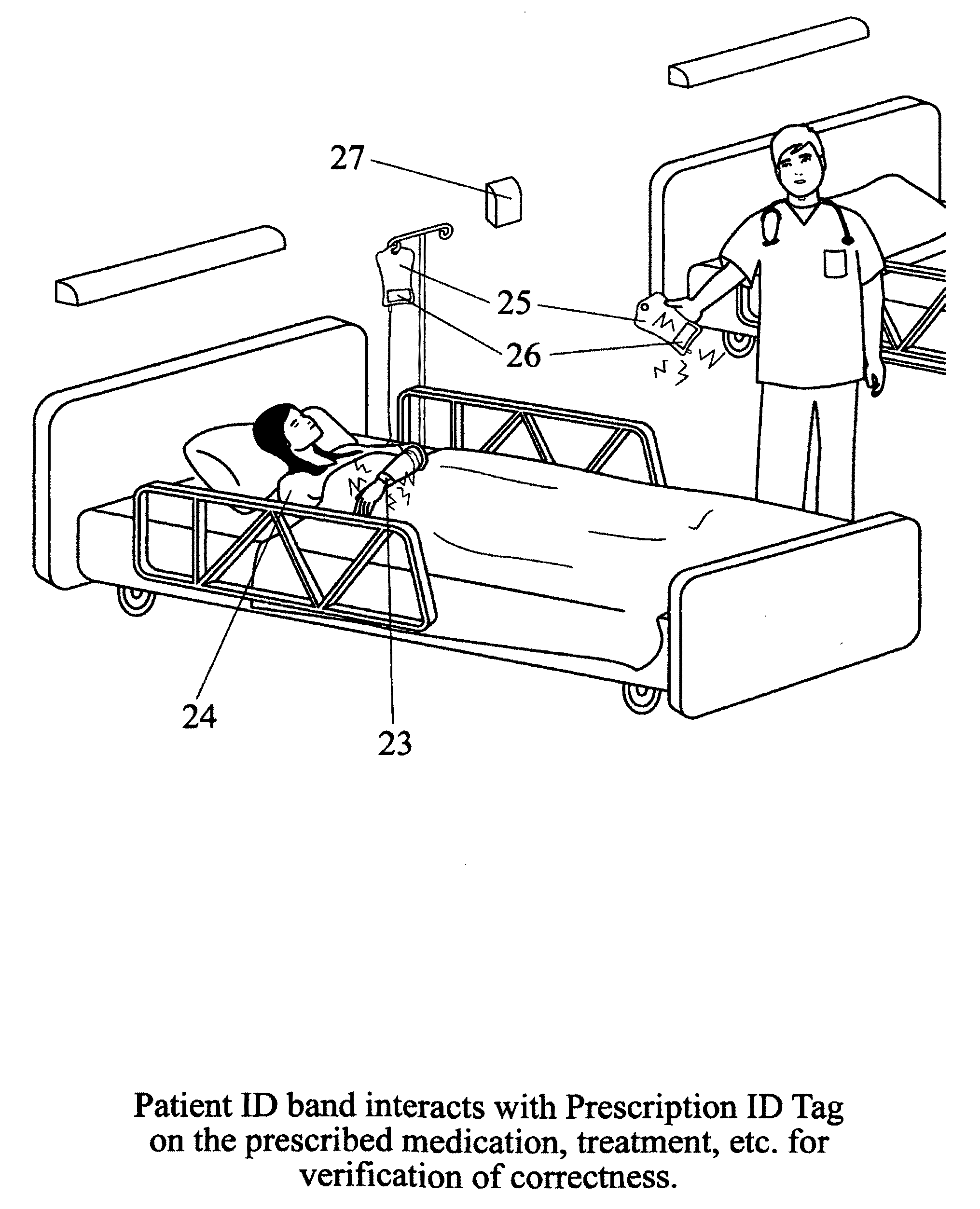

Monitoring system and method for patient care

A patient care monitoring system and method employ active RFID devices integrated with digital processing, memory and timing circuitry for patient identification, care giver identification and for identification of each prescribed treatment, procedure, medication and general and / or special care action. At the point-of-care, each care action identity device will match directly with the targeted patient identity device or issue an error warning to prevent mistakes. The patient identity device will also interact with an associated sensor network to proactively prompt care givers to provide general care actions, such as altering a patient's laying position, changing bed pan / clothing / bed sheet, etc. for invalid patients. Also the patient identity tag will furnish periodic records of every care action, mistakes, remedies, care givers' identities and time and date for a central processor of a healthcare facility to monitor the quality of patient care. Such record can also be potentially accessed via the Internet by the responsible regulatory agencies, accreditation associations, insurance firms and even patients' families to ensure patient care is meeting the standards as well as medical billing accuracy.

Owner:HUANG CHING CHING +4

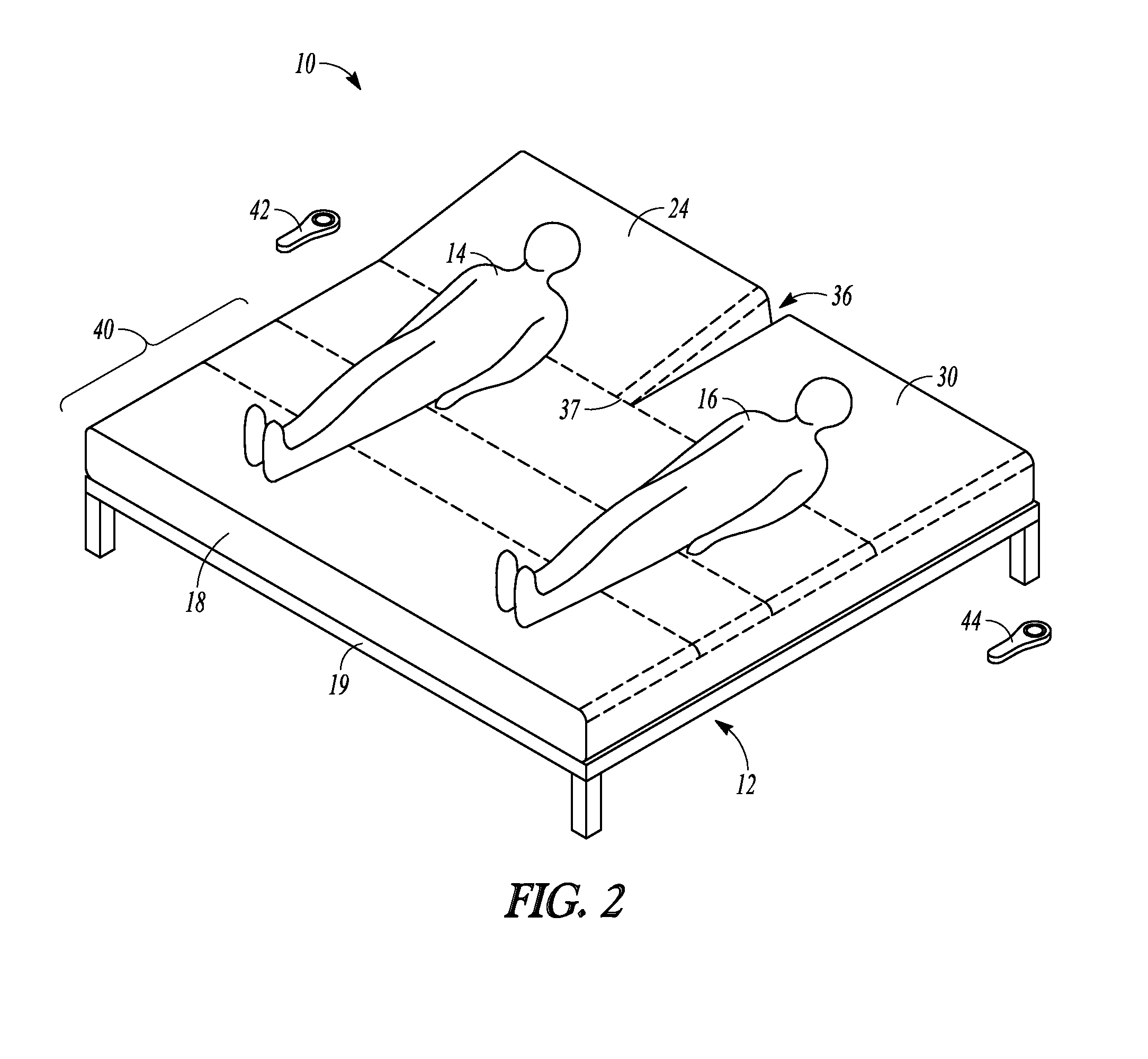

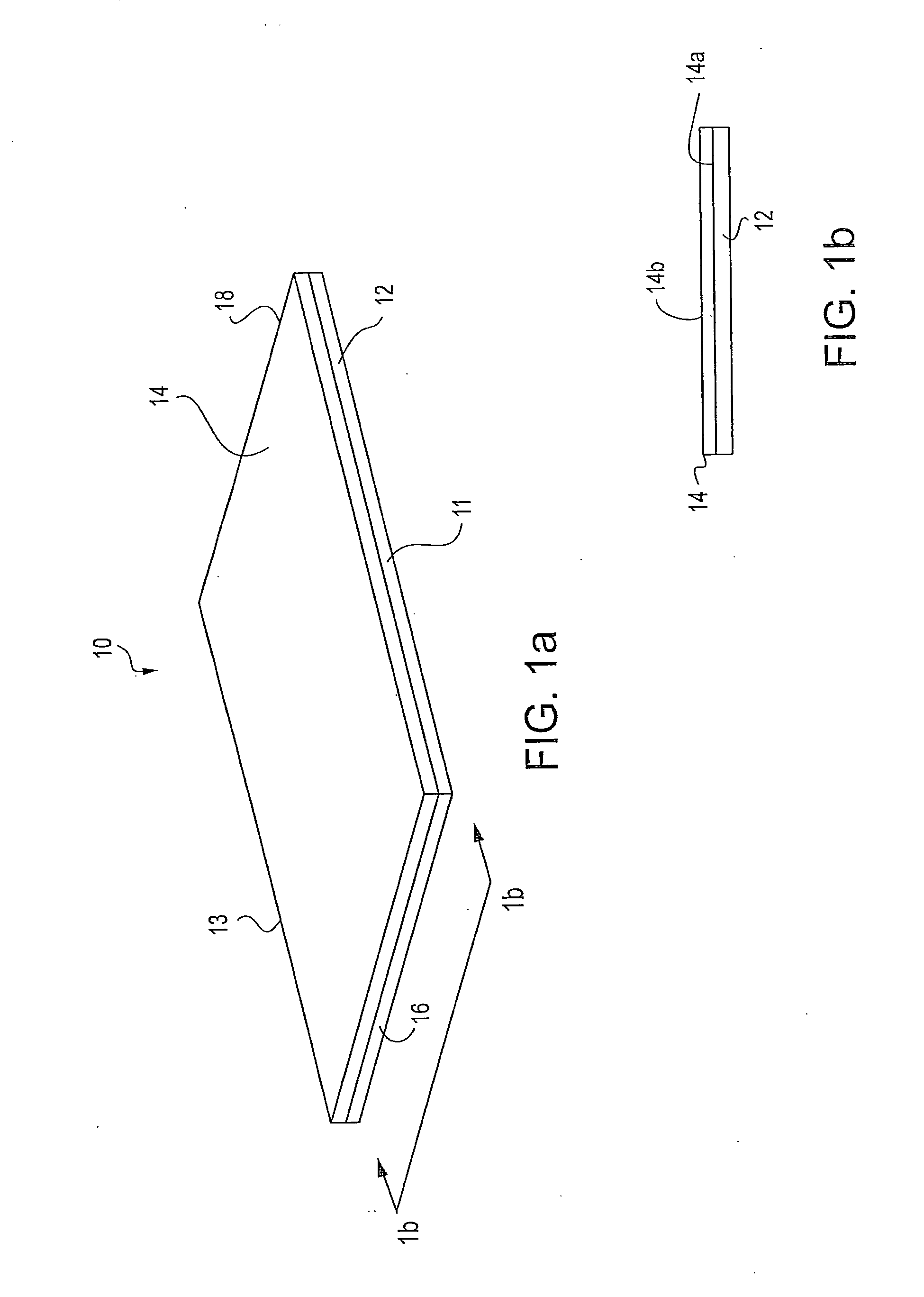

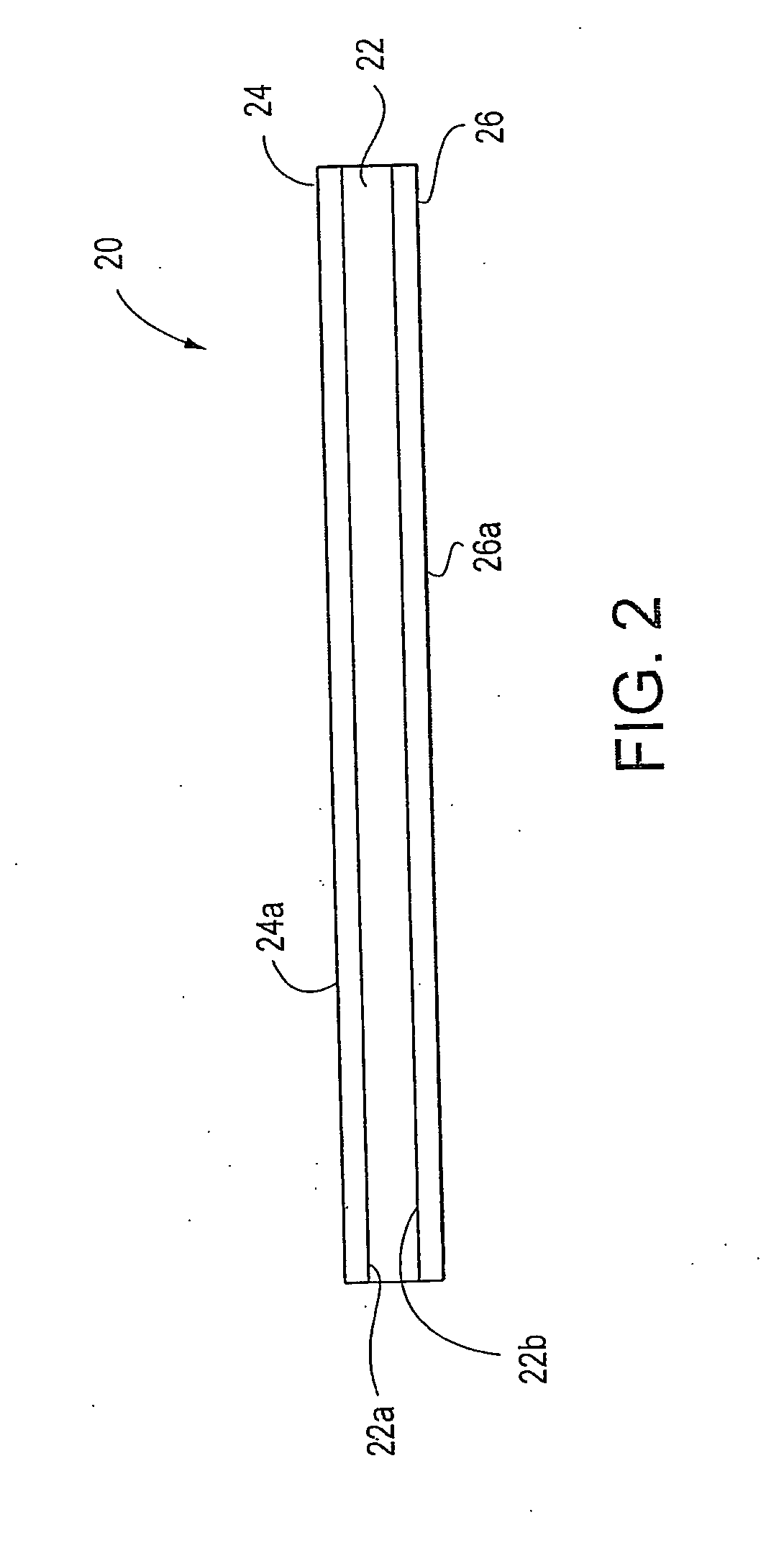

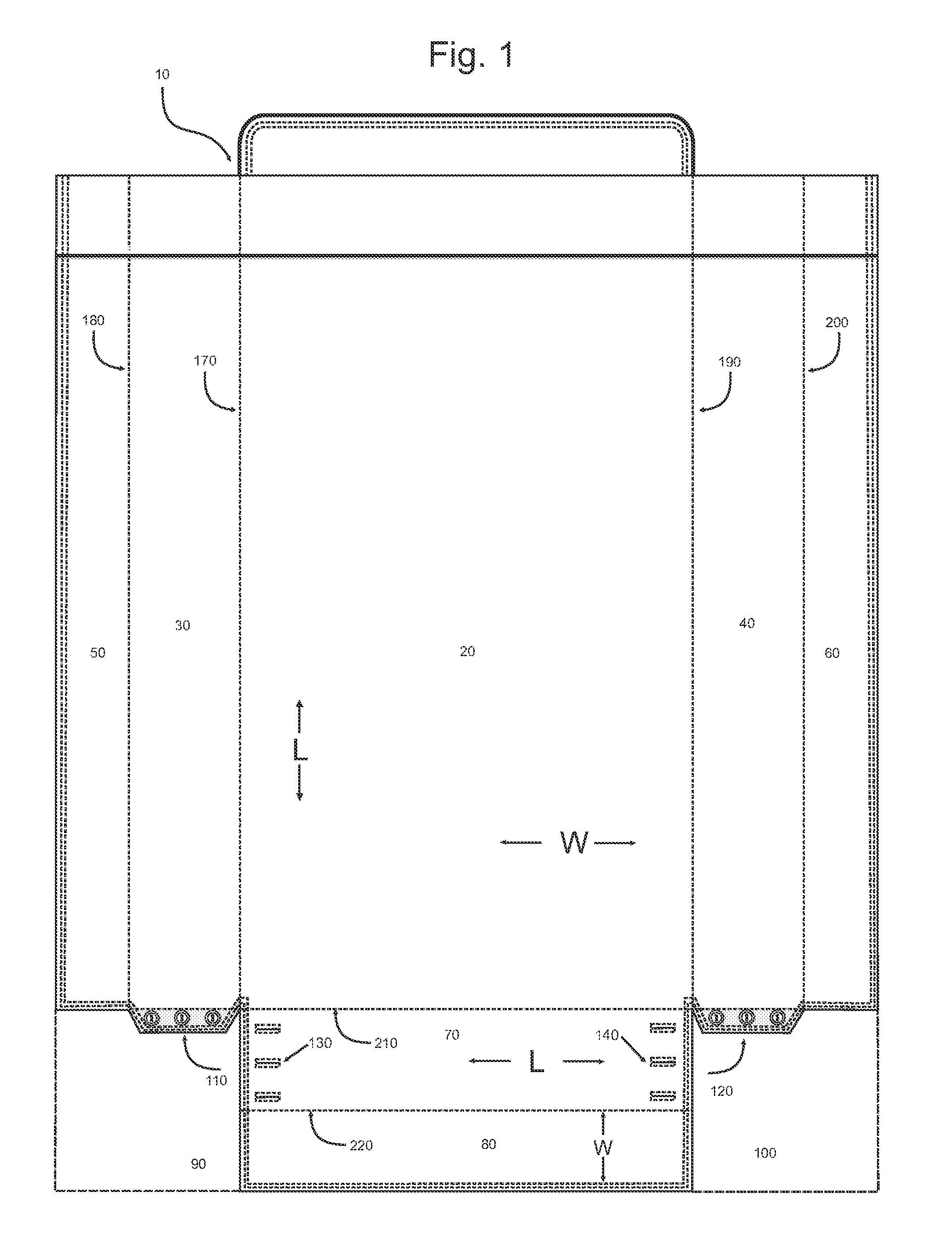

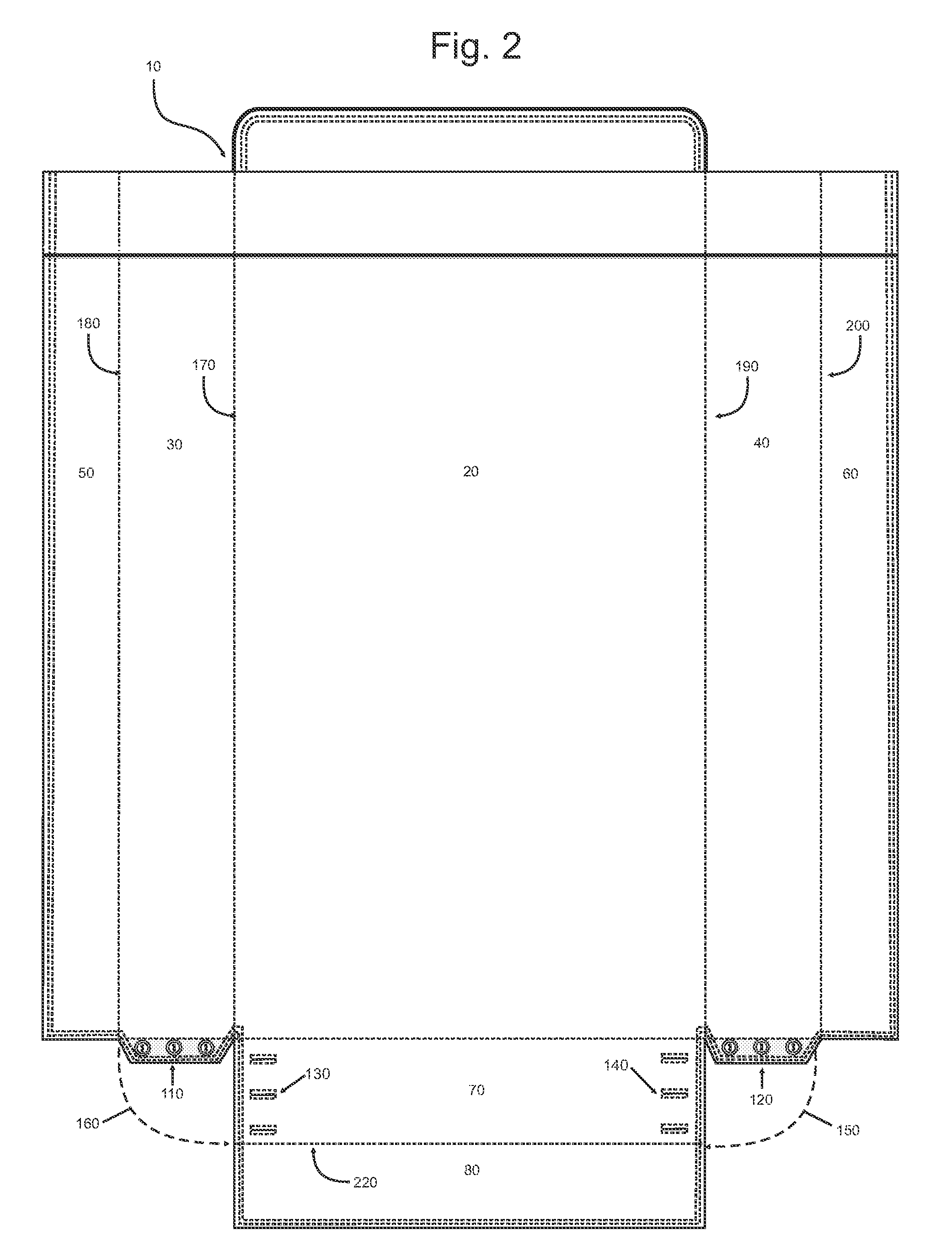

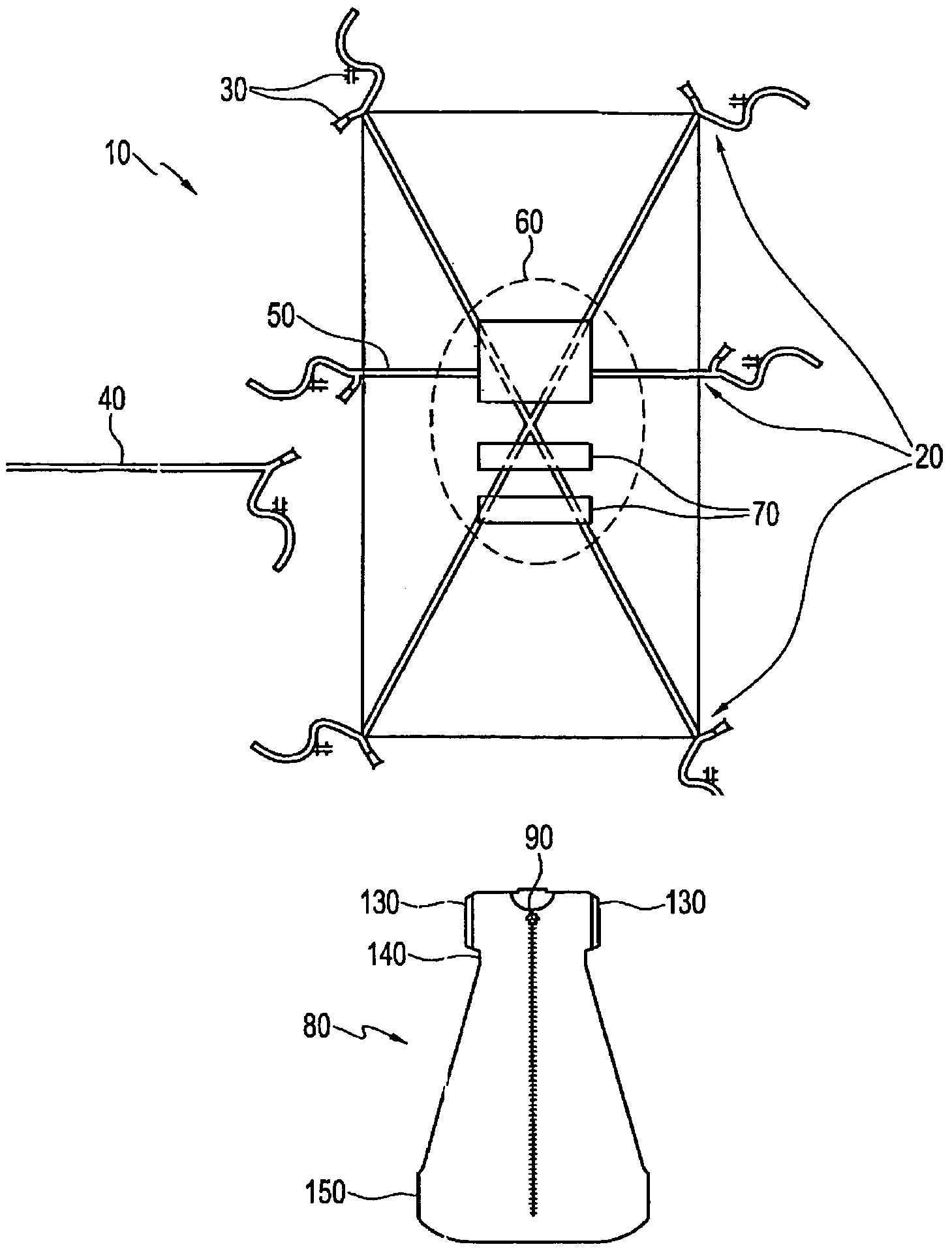

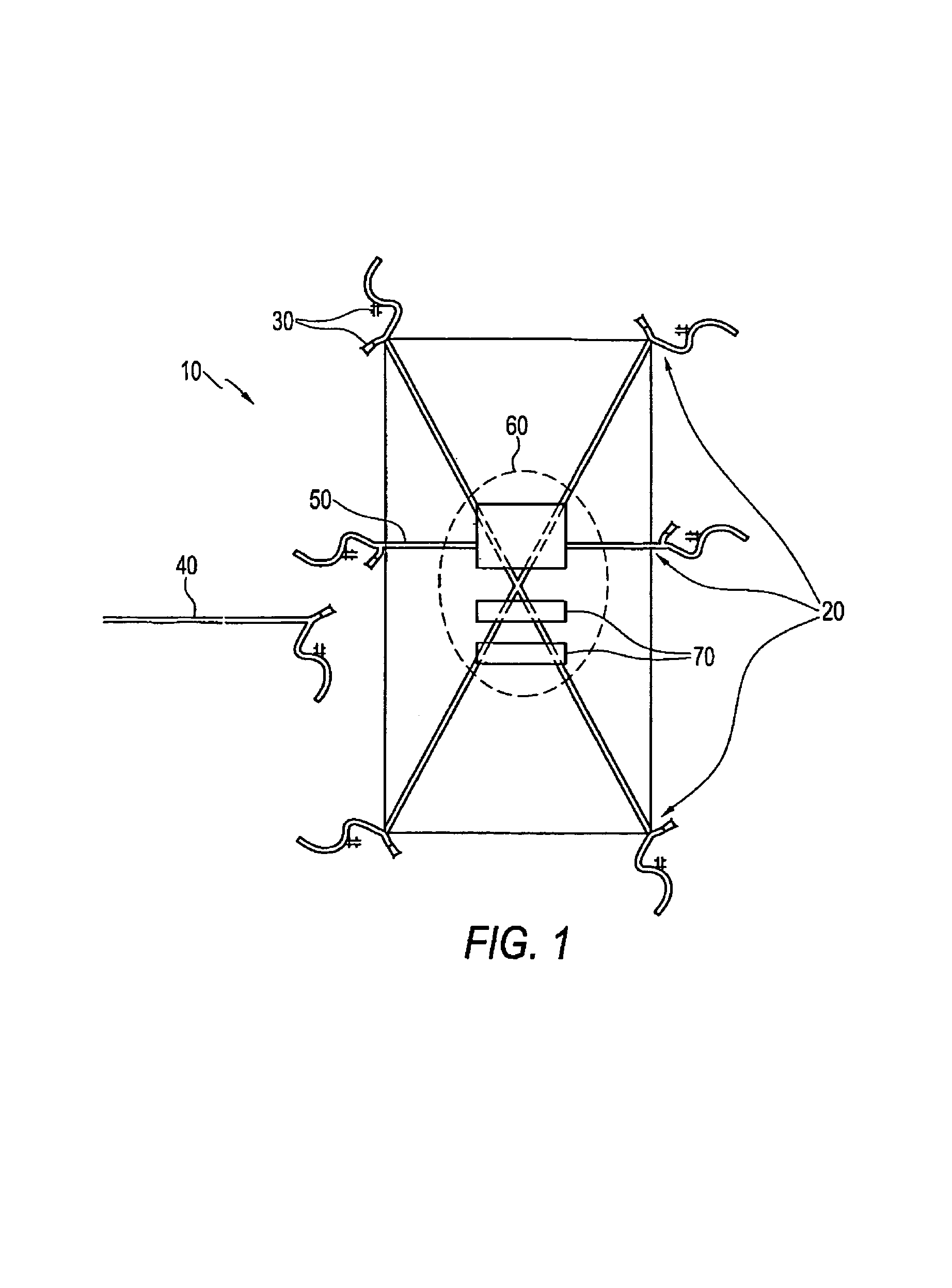

Sheet for a split-top adjustable bed

A sheet for covering at least a portion of a mattress that includes a movable first section and a movable second section adjacent to and proximate to the movable first section comprises a first sheet section for covering at least a portion of the movable first section, a second sheet section laterally adjacent to the first sheet section configured to cover at least a portion of the movable second section, wherein the first and second sheet sections are joined together at a sheet junction, a first member projecting laterally from the first sheet section toward the second sheet section and extending up to the sheet junction, and a second member projecting laterally from the second sheet section toward the first sheet section and extending up to the sheet junction, wherein a portion of the first member overlays a portion of the second member proximate the sheet junction.

Owner:SLEEP NUMBER CORP

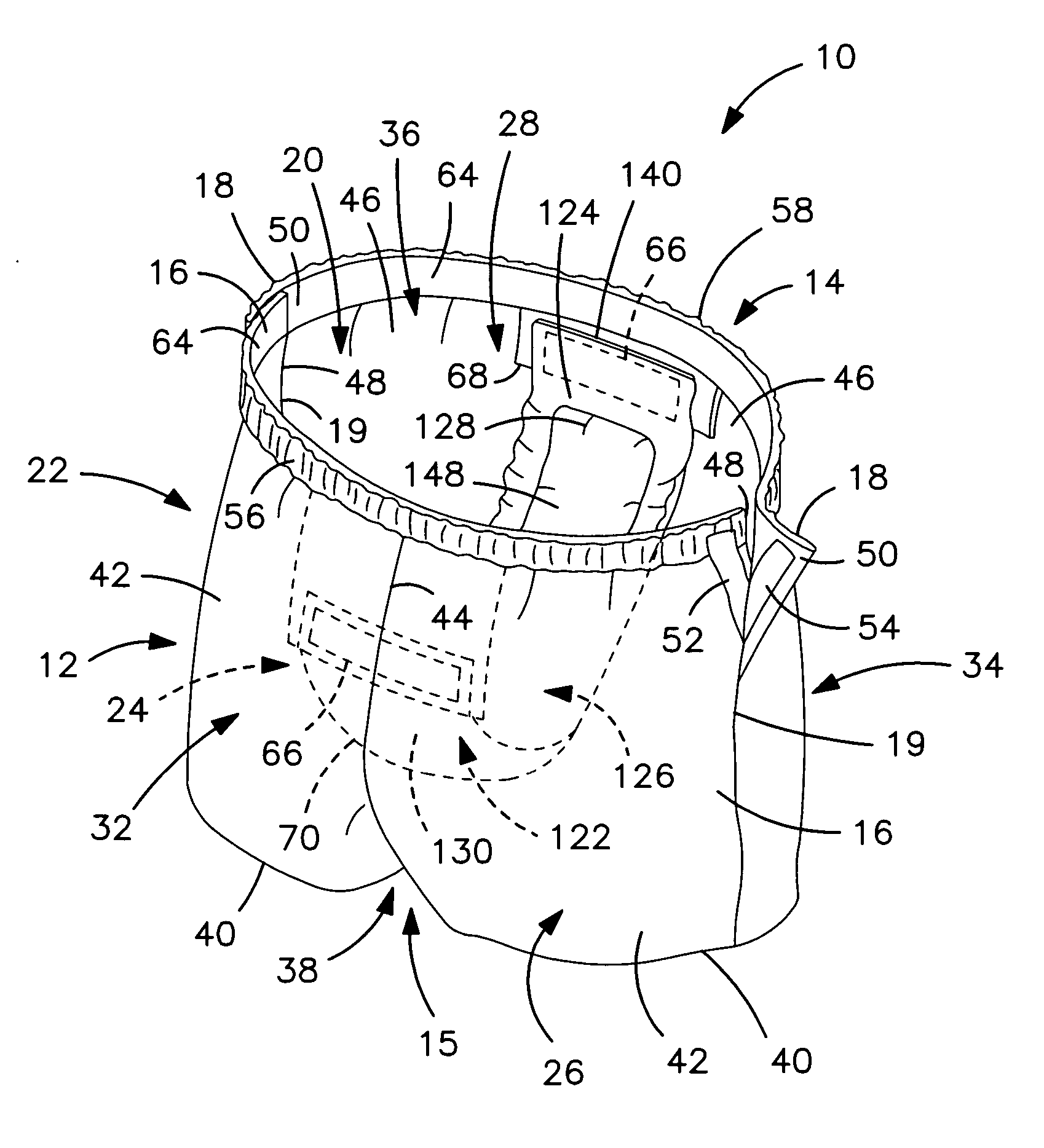

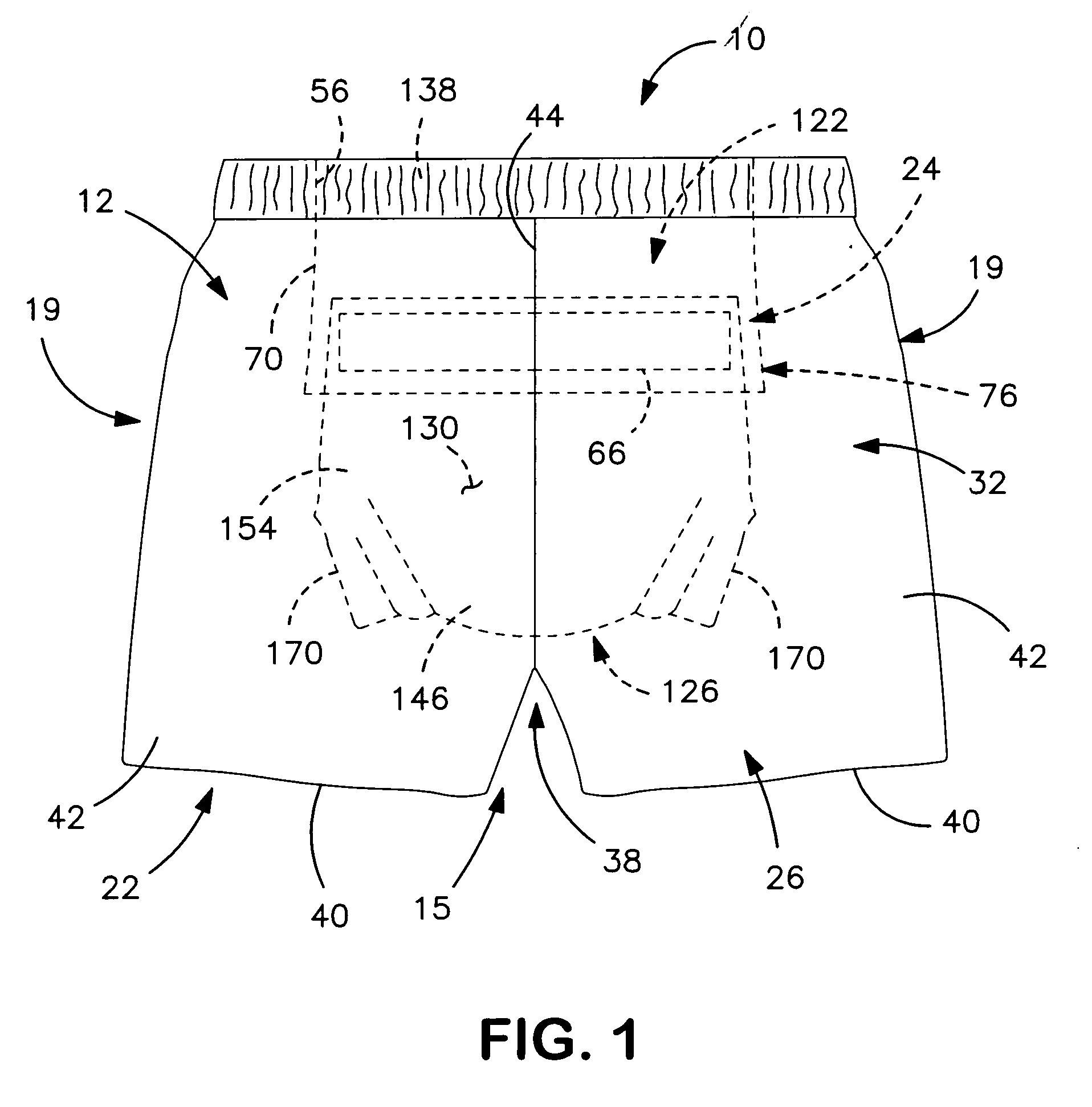

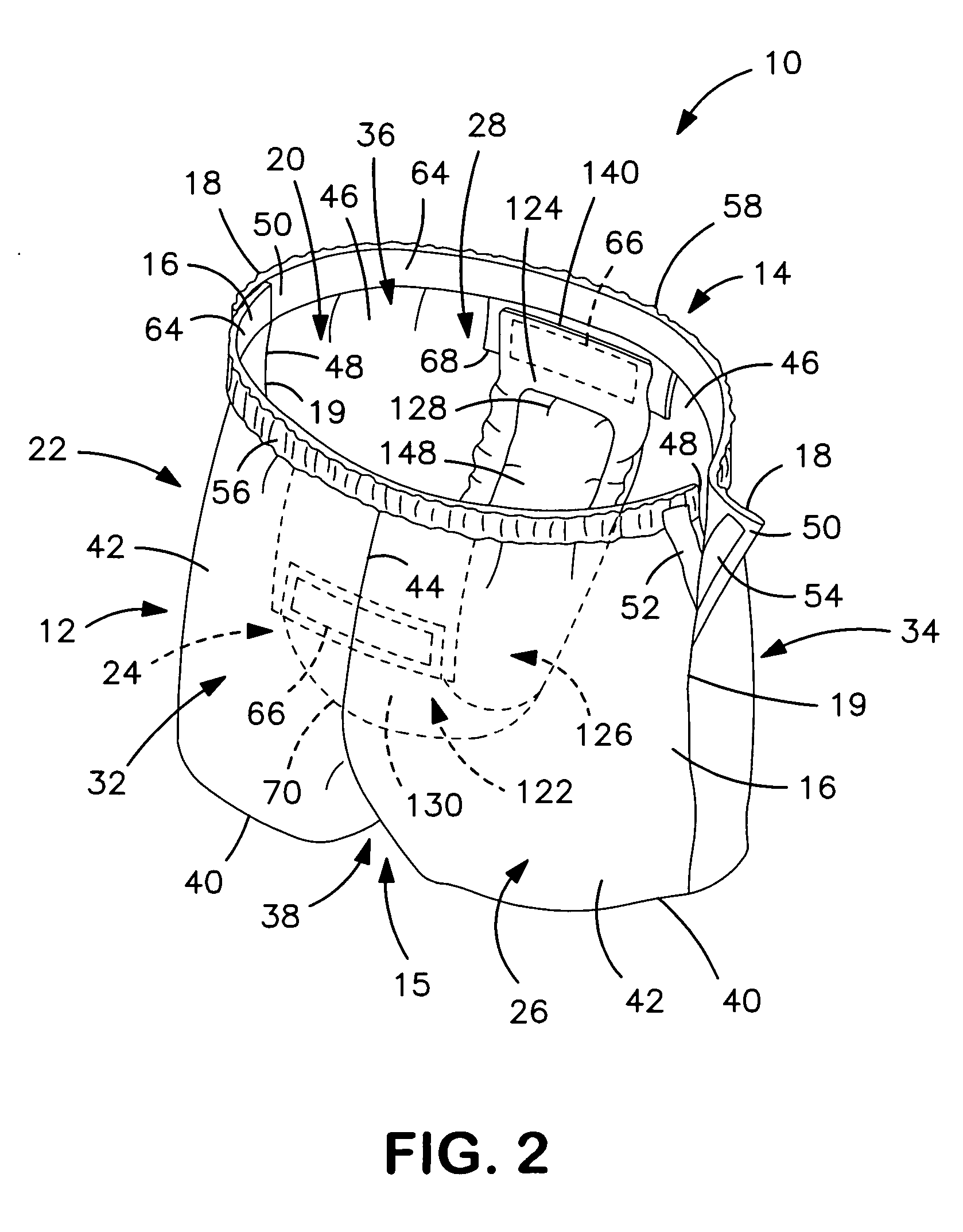

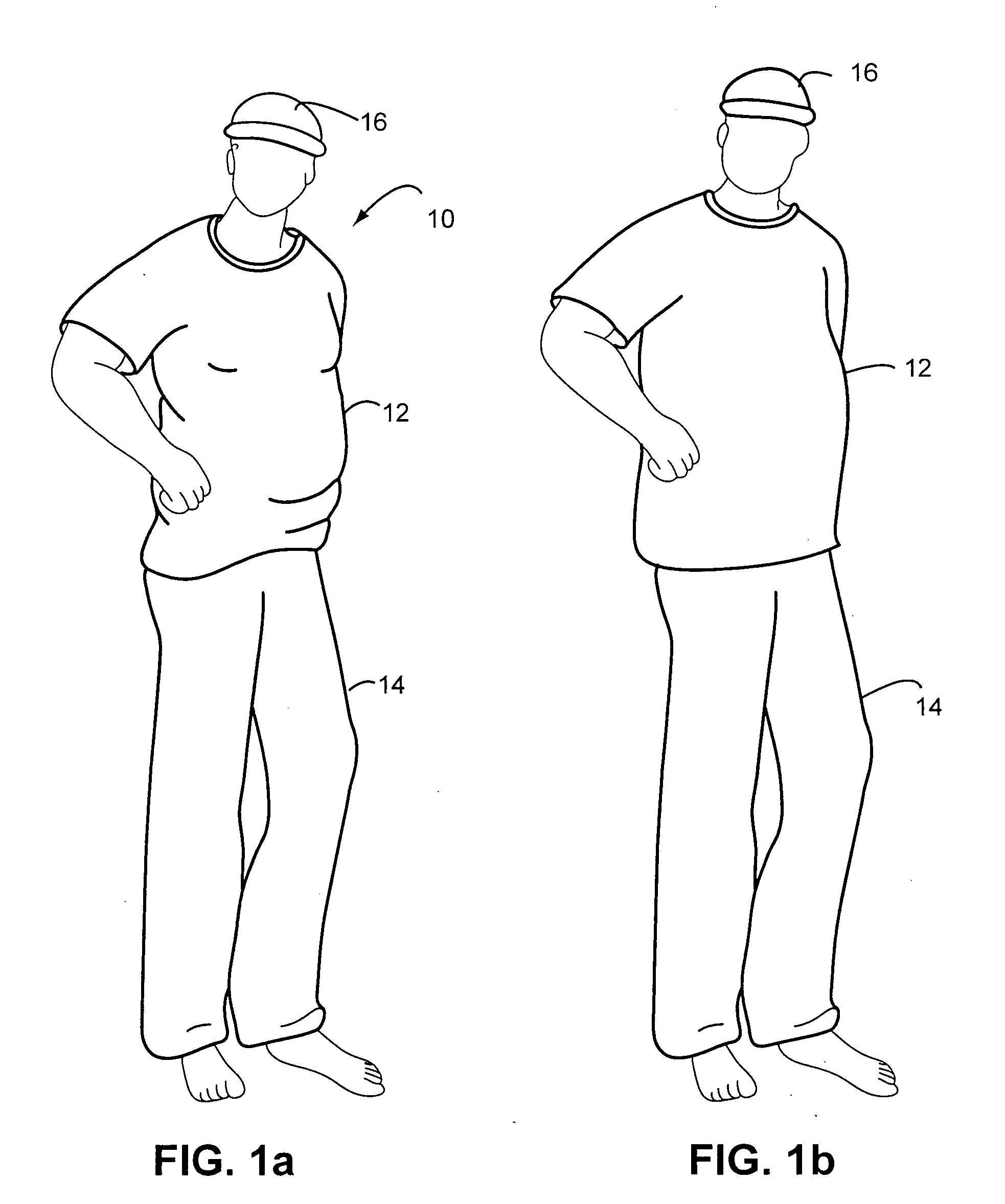

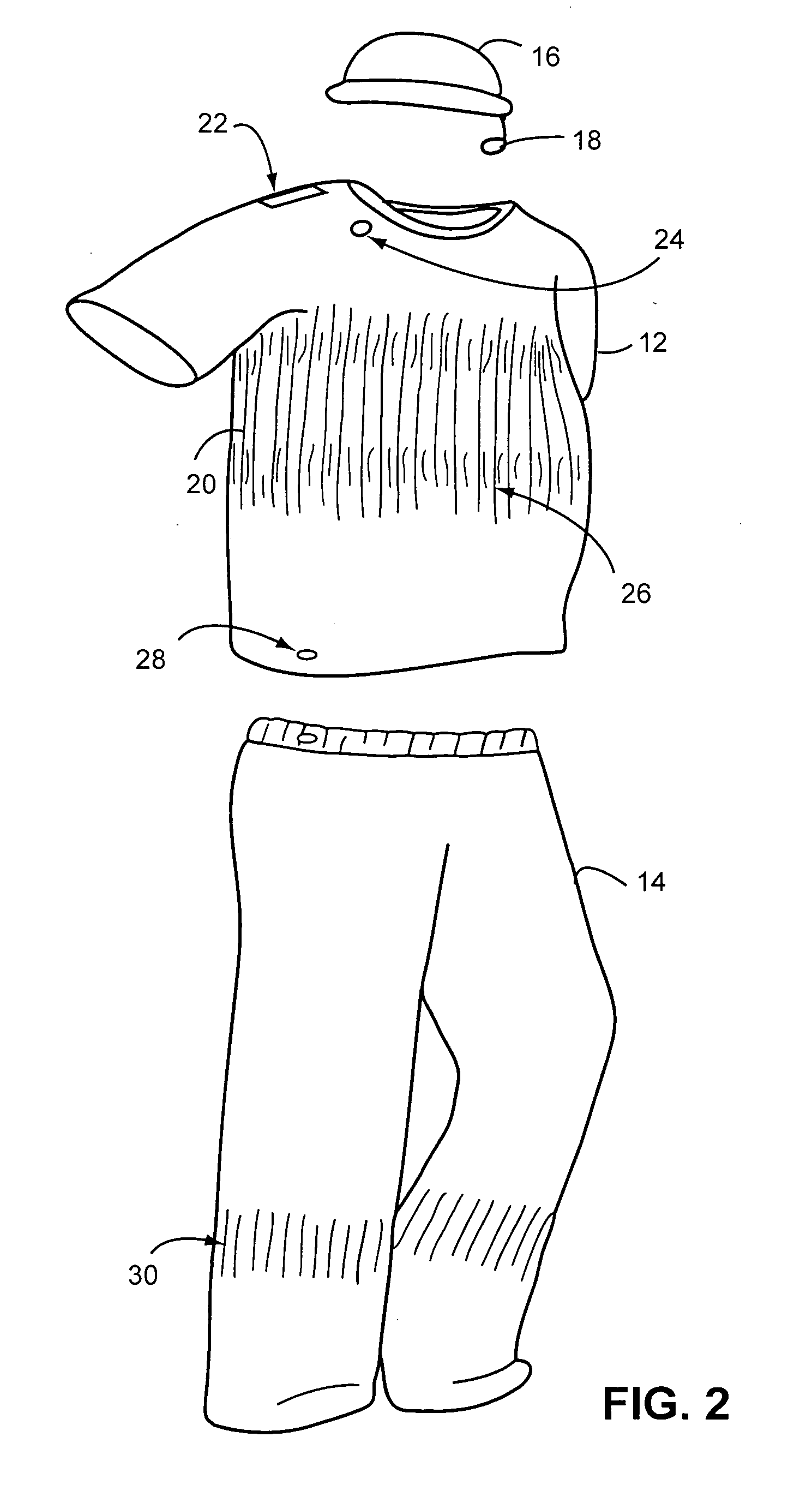

Garment having an outer shell that freely moves in relation to an absorbent assembly therein

InactiveUS20060247599A1Prevent twisting and bunchingPrevents twisting and bunchingAbsorbent padsBaby linensStandard bedControl material

An absorbent garment having a garment-like outer shell and an absorbent assembly positioned therein as disclosed. In particular embodiments, the outer cover of the absorbent assembly has a relatively low coefficient of friction with the interior side of the garment shell. In one embodiment, the garment shell may be constructed such that the coefficient of friction between the garment shell and the outer cover of the absorbent assembly is less than, such as at least 15 percent less than the coefficient of friction between the exterior side of the garment shell and an adjacent material. The adjacent material may include, for instance, a standard bed sheet material. By carefully controlling the frictional properties of the materials as described above, problems associated with bunching and twisting of the garment are minimized.

Owner:KIMBERLY-CLARK WORLDWIDE INC

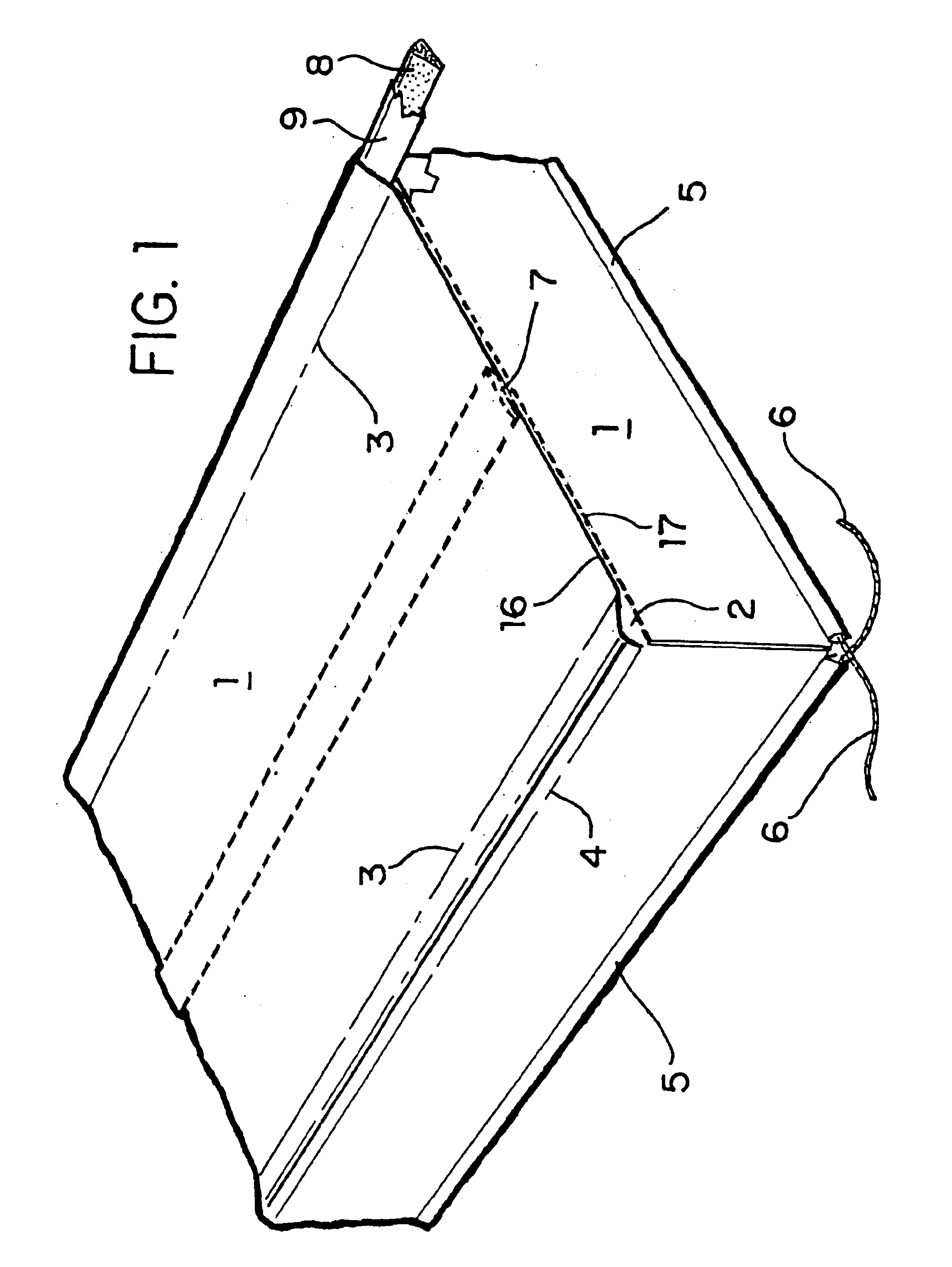

Quick change bed sheet set

A set of sheets includes an upper sheet with a top panel and a lower sheet with a bottom panel. In conjunction, the upper and lower sheets are sized, structured and configured to enclose a mattress. A waterproof panel is positioned between the upper sheet and the top of the mattress to protect the mattress from damaging exposure to moisture and liquids, including bodily fluids. In several embodiments, the upper sheet and waterproof panel are removable for washing and changing thereof while the lower sheet remains fitted to the mattress, thereby avoiding the need to lift or move the mattress when changing the sheets. The waterproof panel may be independently removable to selectively control air permeability of the sheets, and particularly the upper sheet. In a further embodiment, a minor waterproof panel is removably attachable in covering relation to a portion of the top surface of the upper sheet to protect the upper sheet and mattress from becoming soiled, and thereby extending the period of time between laundering and changing of the set of sheets.

Owner:WORRY FREE INVENTIONS

Sleep disorder diagnostic system and method

Systems and / or methods for diagnosing sleep disorders in a patient are provided. In certain example embodiments, articles of bed clothing and / or bed sheets comprising sensors operable to obtain patient condition data related to sleep-disordered breathing (SDB) are provided to patients. The patient condition data is stored to a data recorder operably connected to the sensors. The sensors and the data recorder may communicate wirelessly. The bed clothing (e.g. wearable articles of clothing, bed sheets or mats, pillows, etc.) may have batteries and / or battery fibers disposed therein to power the sensors. In certain example embodiments, a bed sheet may be physically connected to a power supply and / or the data recorder. In certain example embodiments, a bed sheet and articles of bed clothing both may be provided to the patient.

Owner:RESMED LTD

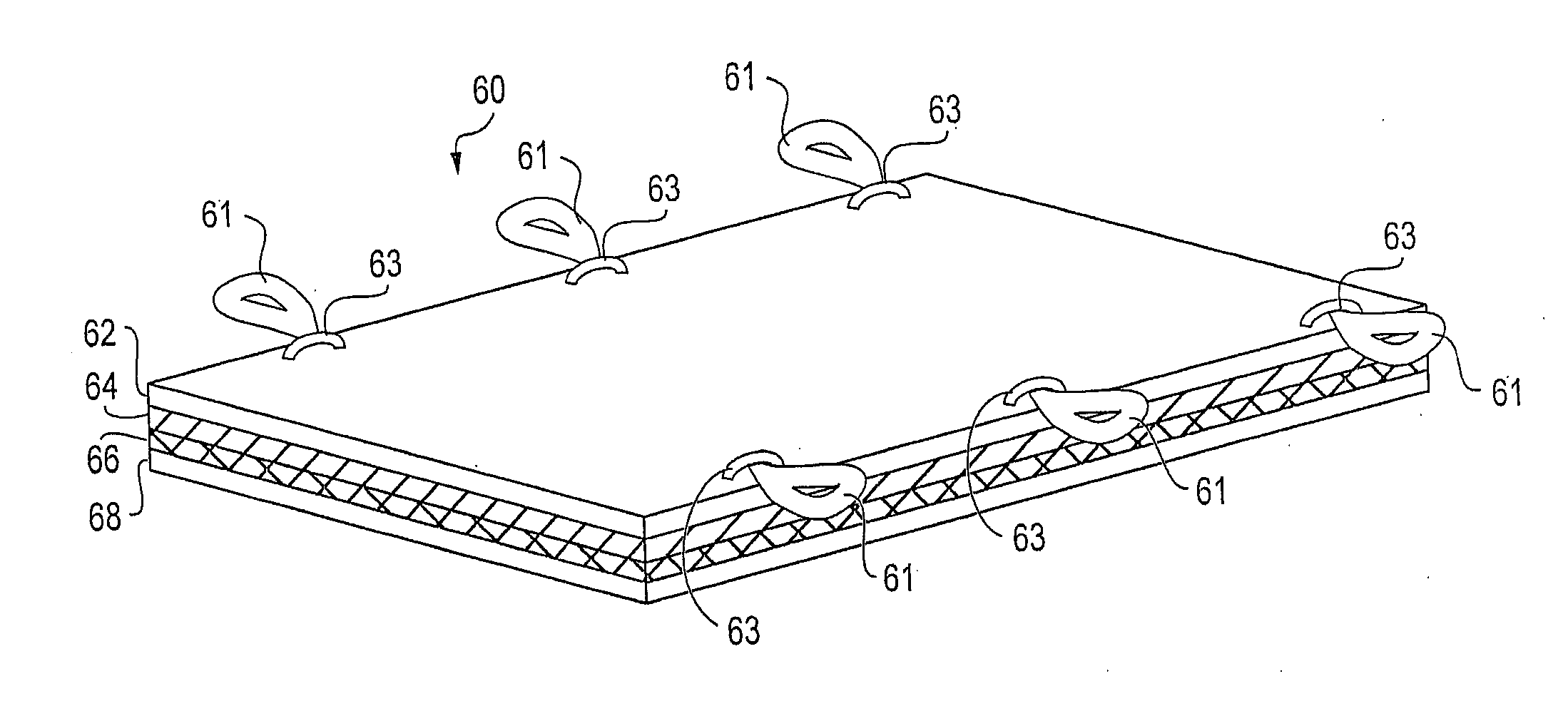

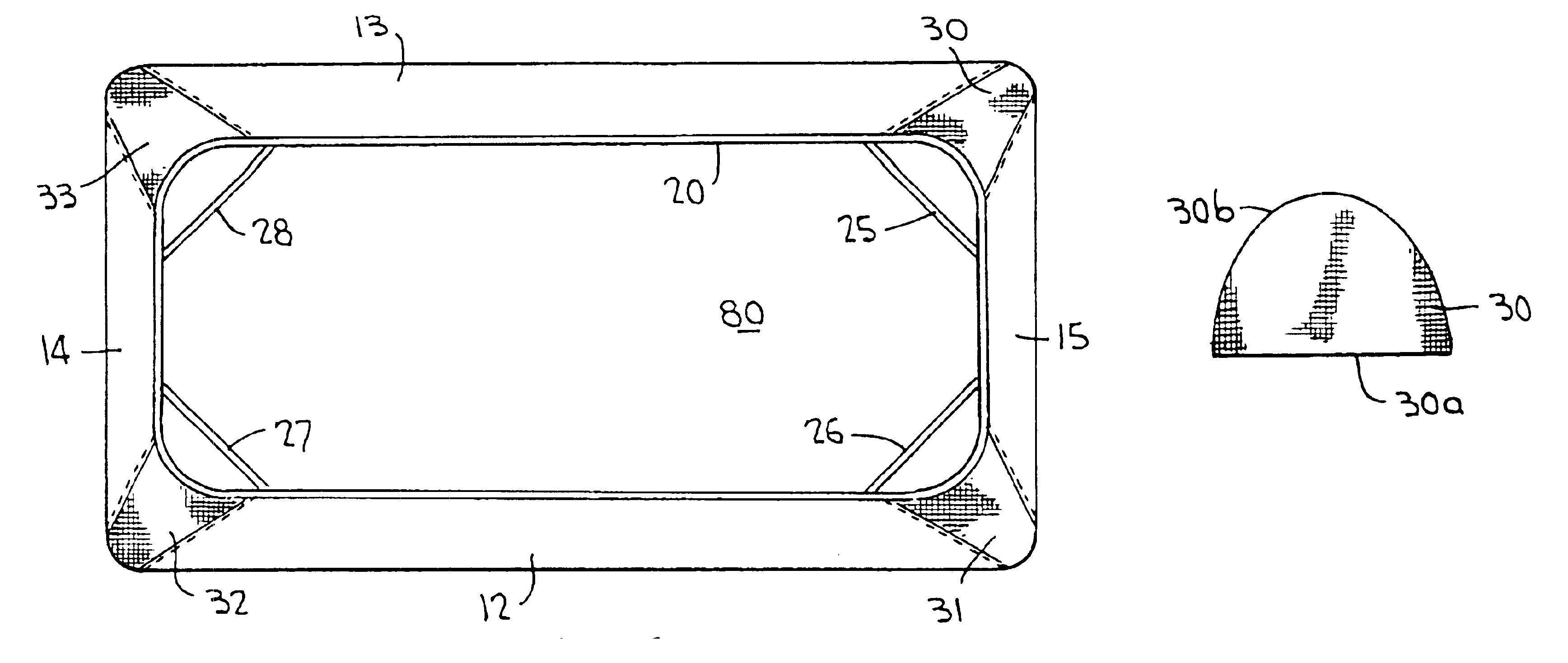

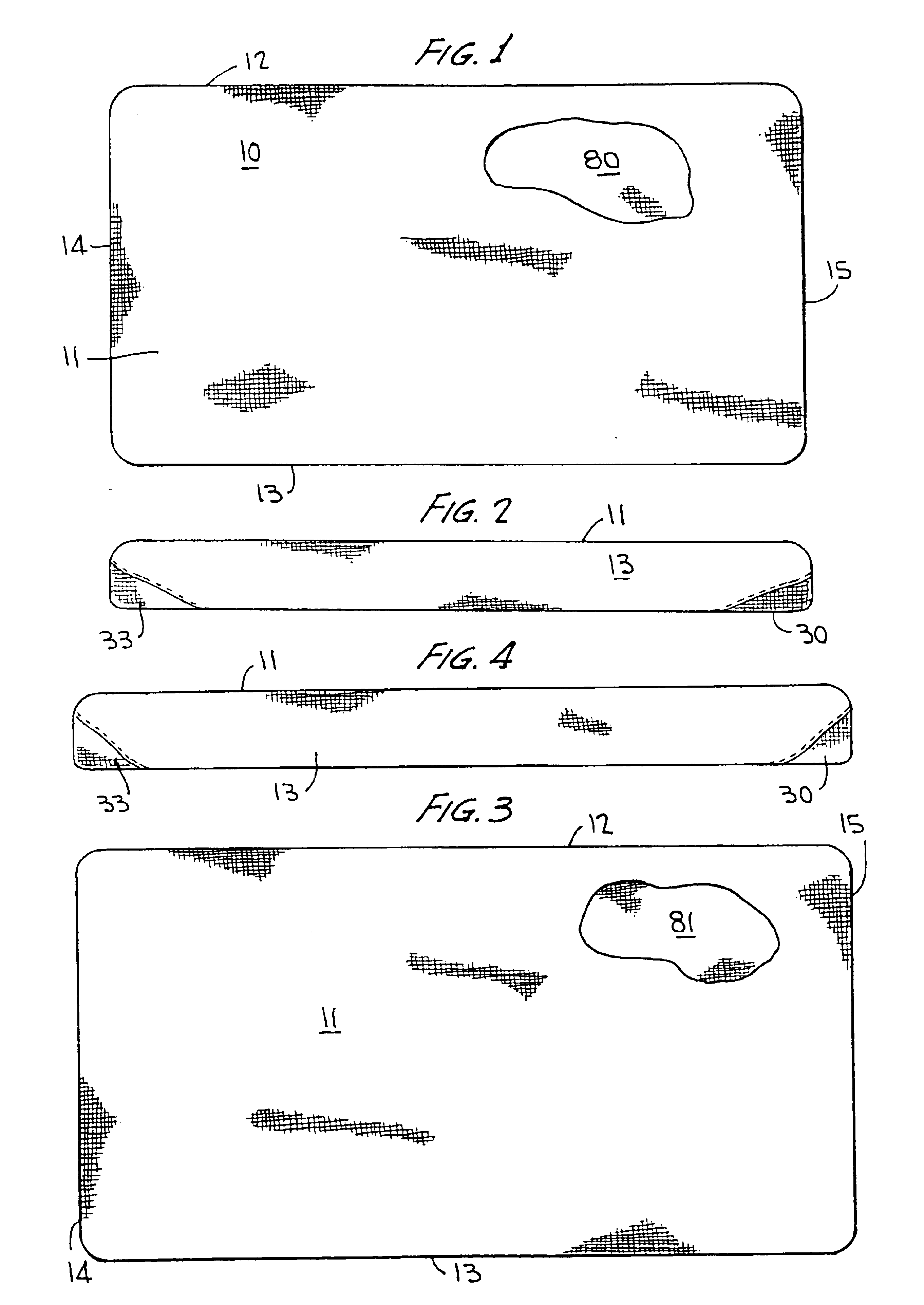

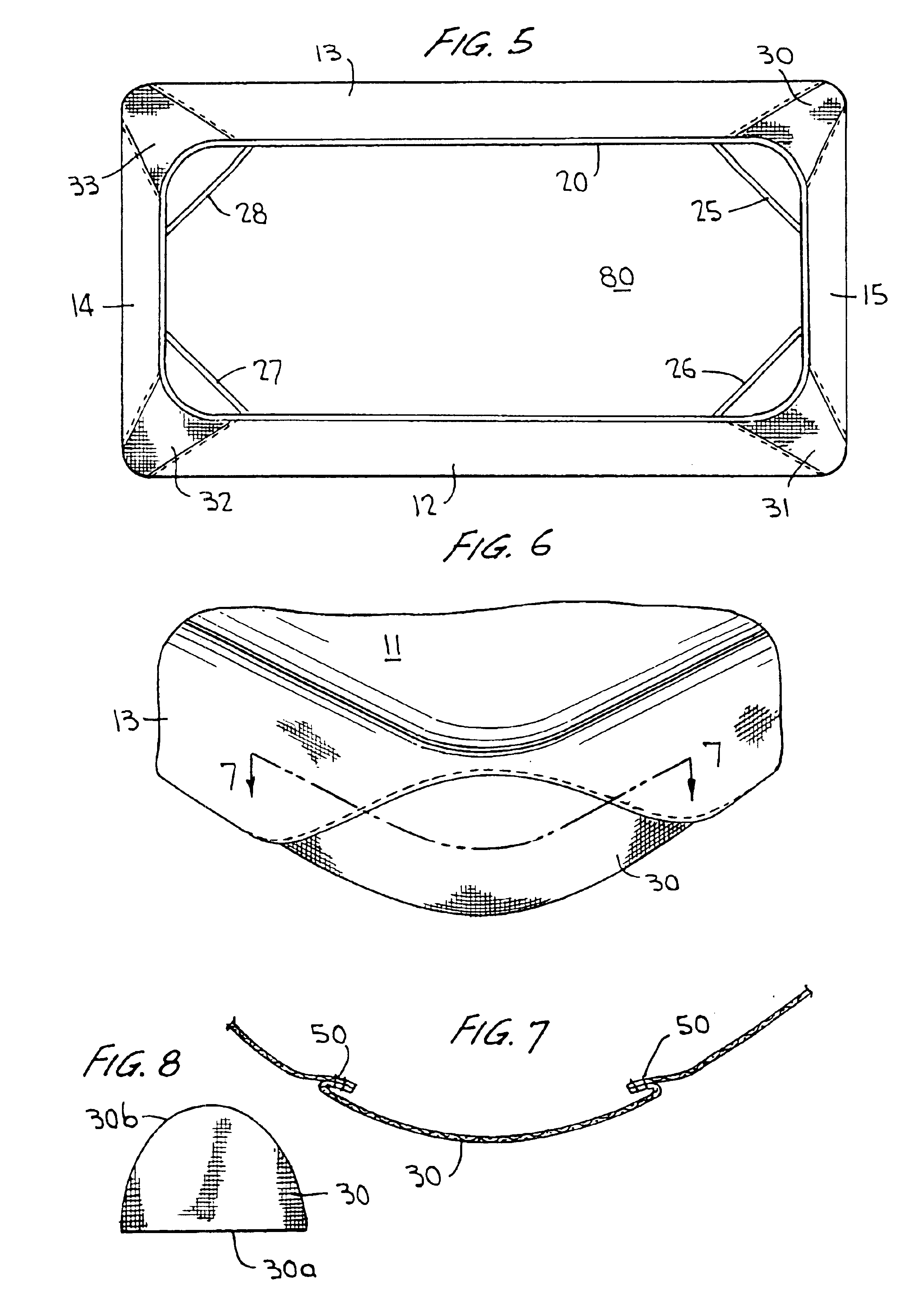

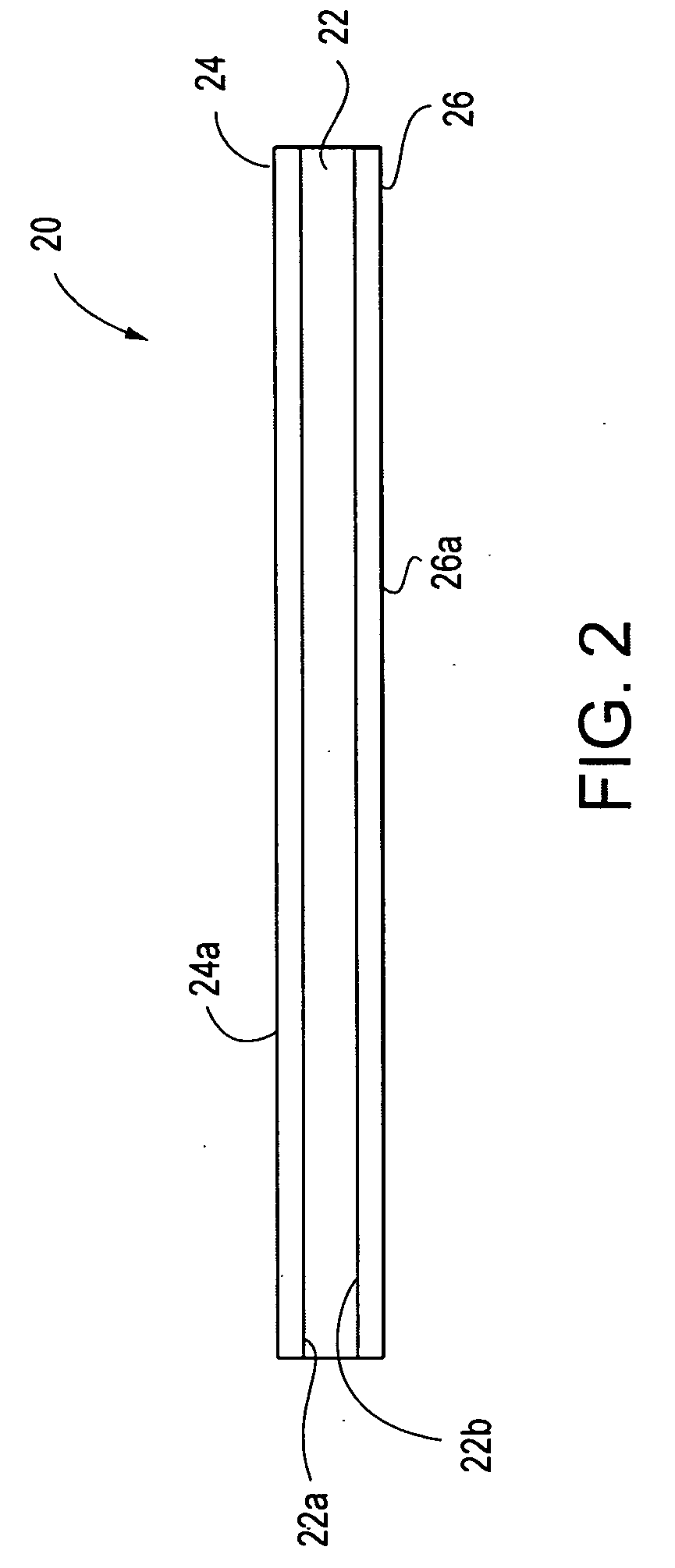

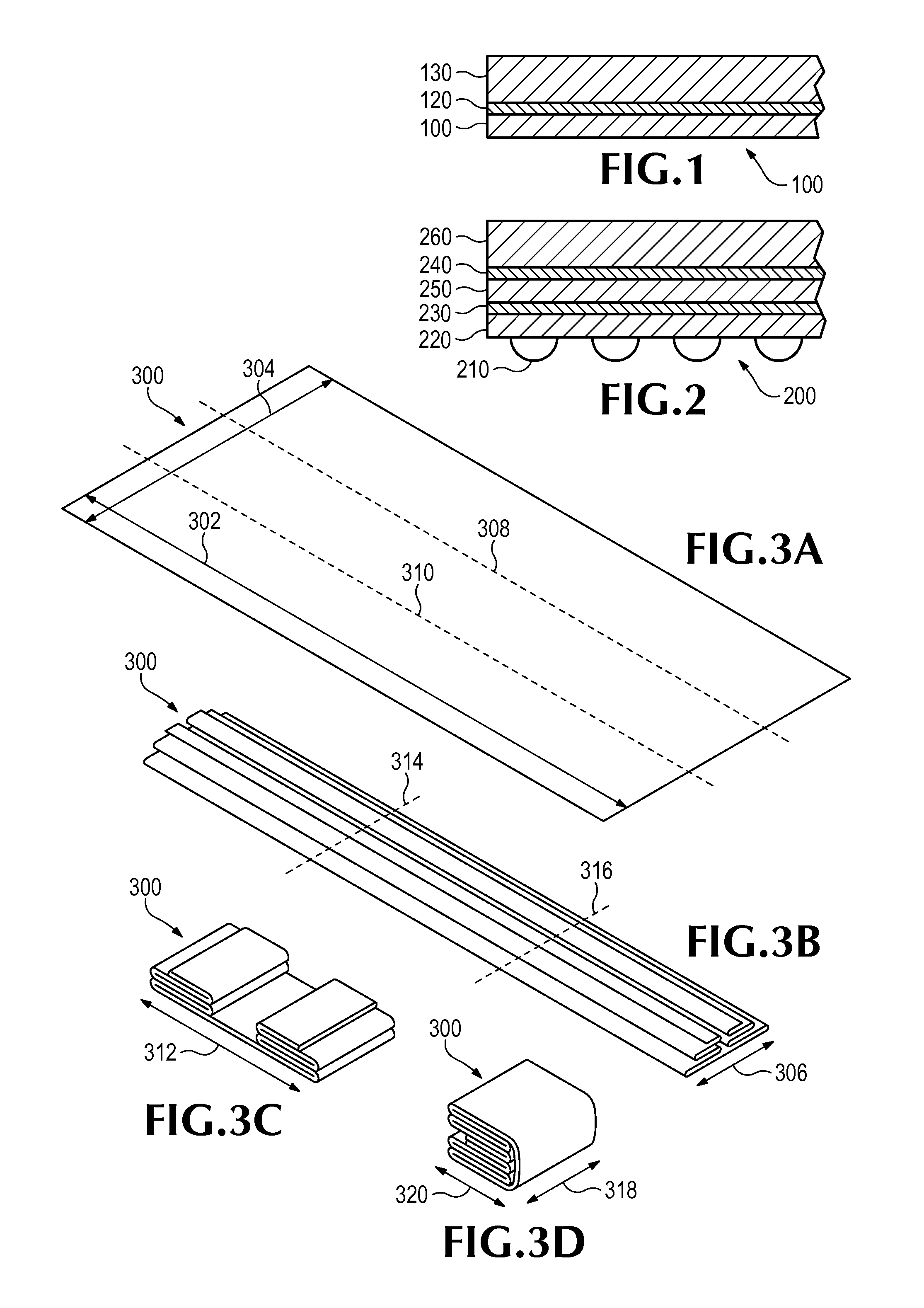

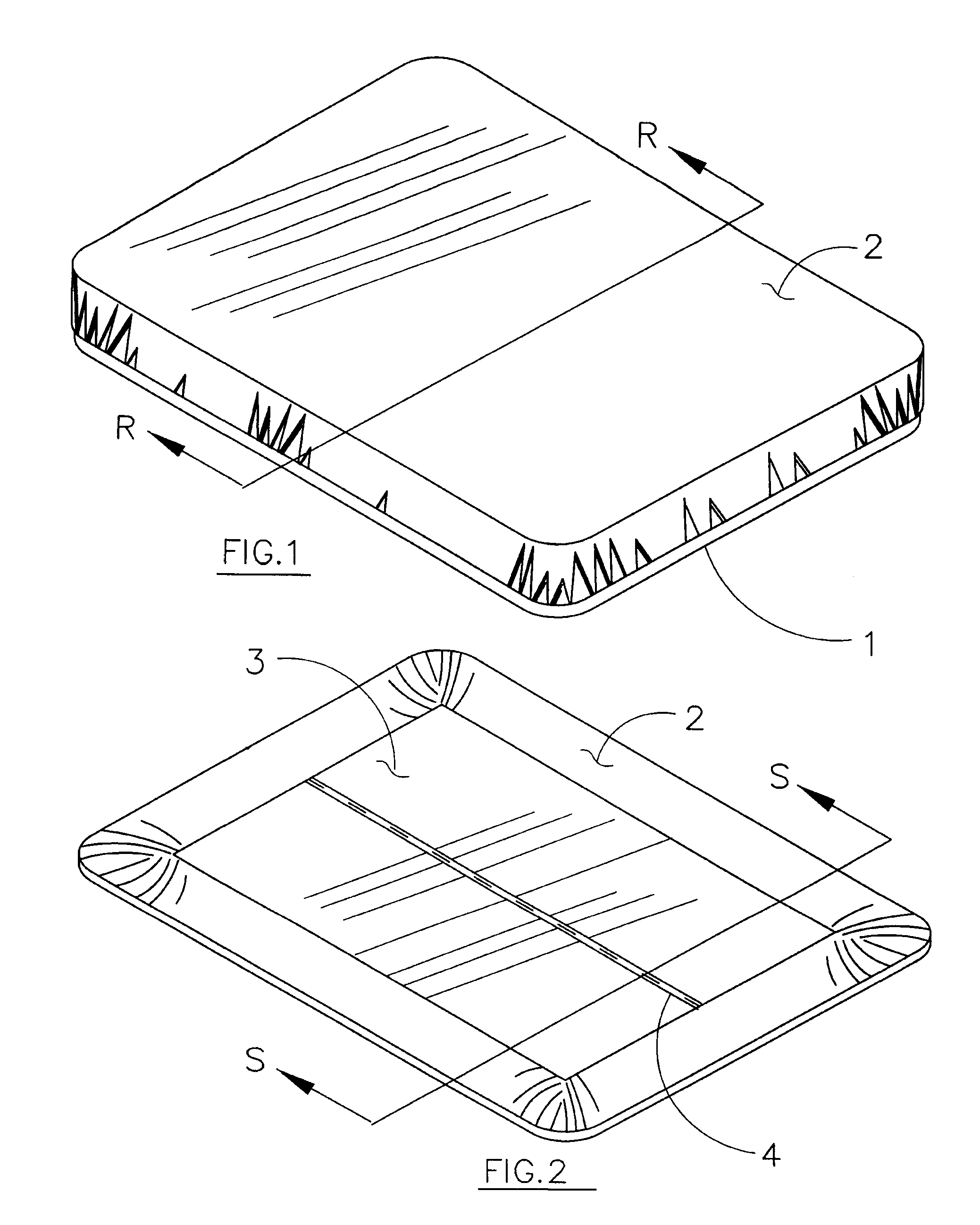

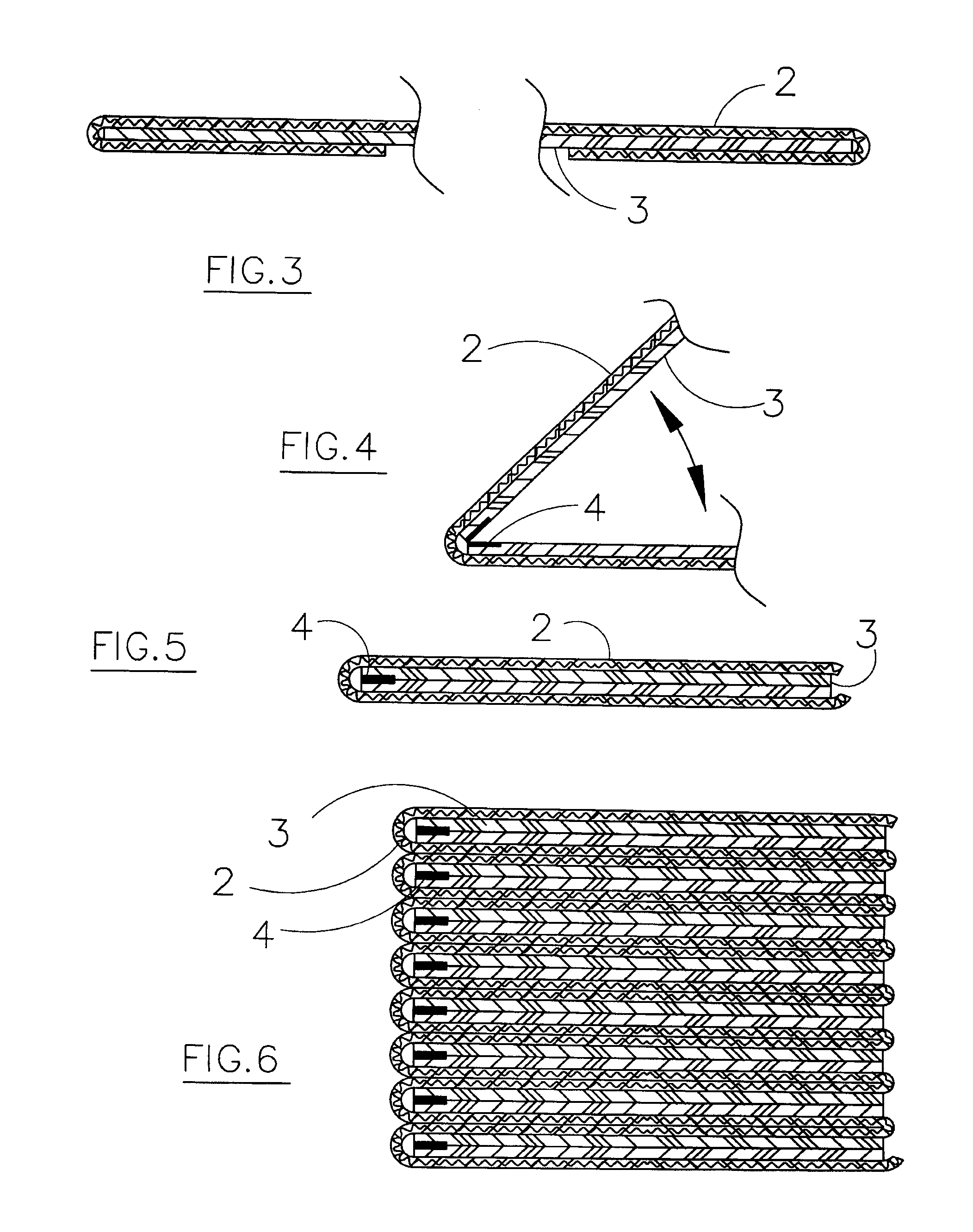

Bed pad with polyethylene layer

InactiveUS20070056096A1Improve carrying capacityStuffed mattressesStretcherFiberBiomedical engineering

A bed pad is described comprising a padding layer and at least one sheet layer adjacent to the padding layer. The sheet layer is formed from a web of very fine polyethylene fibers. The padding layer provides support for the patient. The sheet layer comprises a fabric material that is comfortable for the patient to use. The bed pad provides a means for either adjusting a patient within a bed or for transferring a patient from one bed to another bed or medical table. The bed pad may also be used as part of a stretcher or separately as a bedroll. The bed pad may optionally contain gripping components and drapes.

Owner:ILLINOIS TOOL WORKS INC

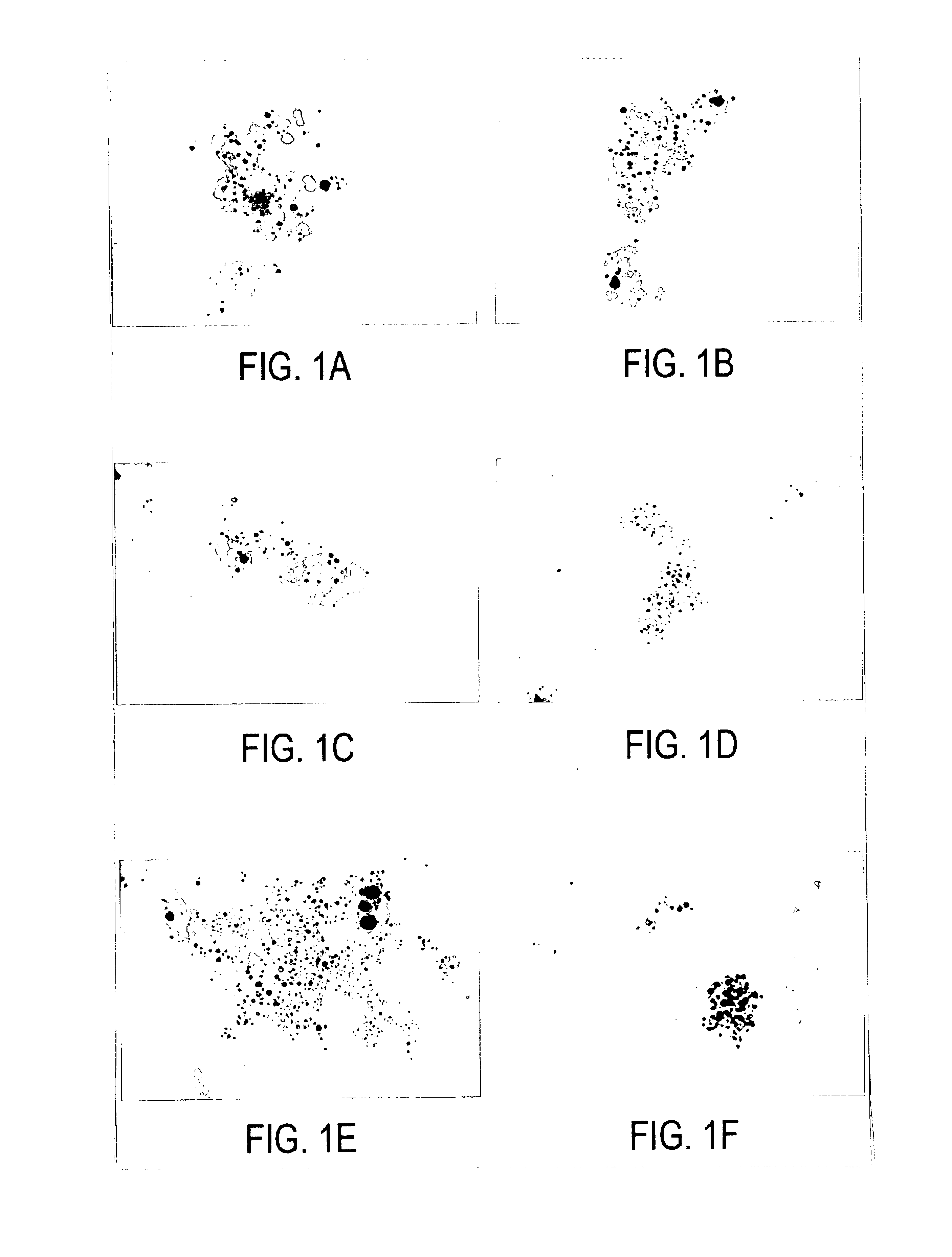

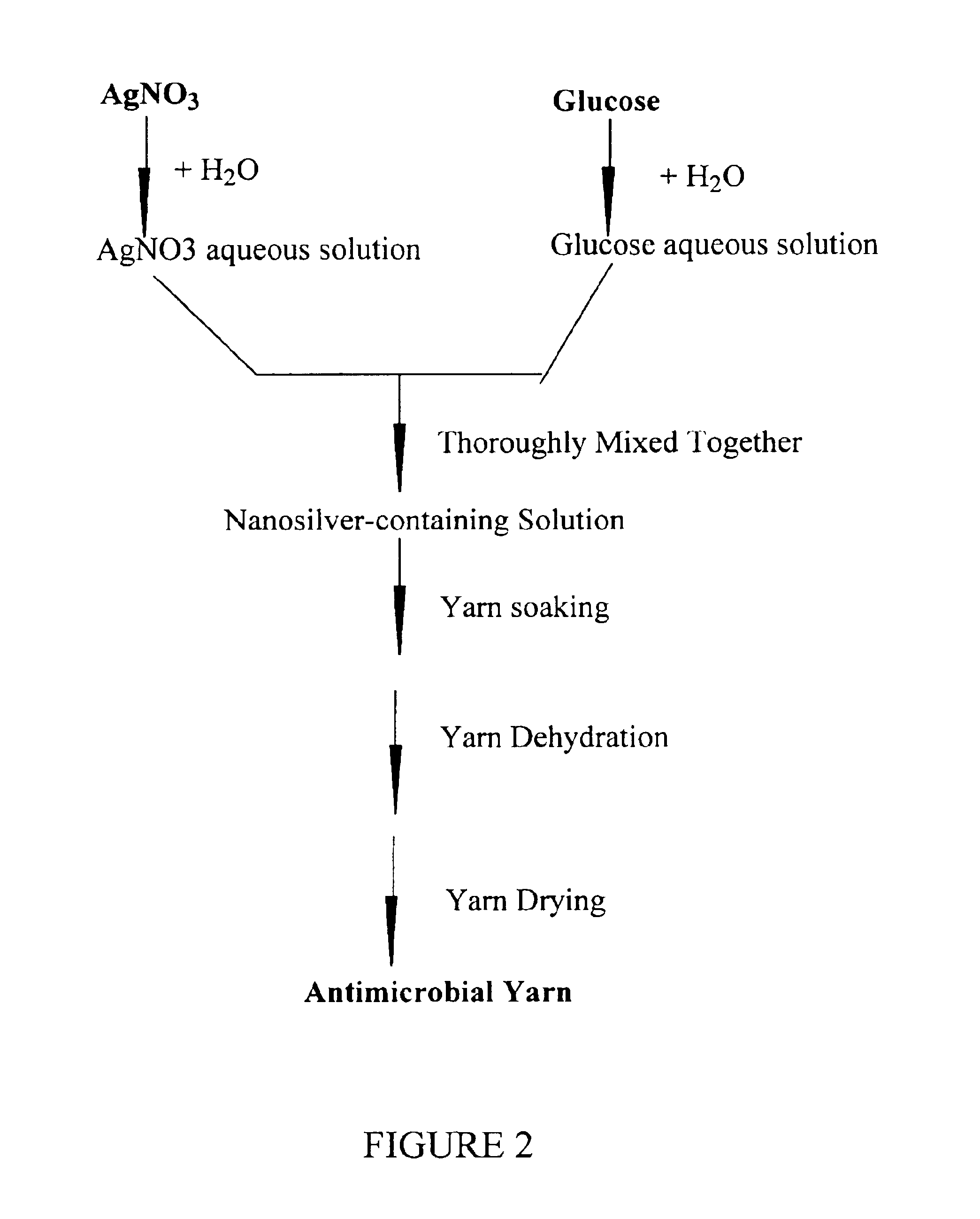

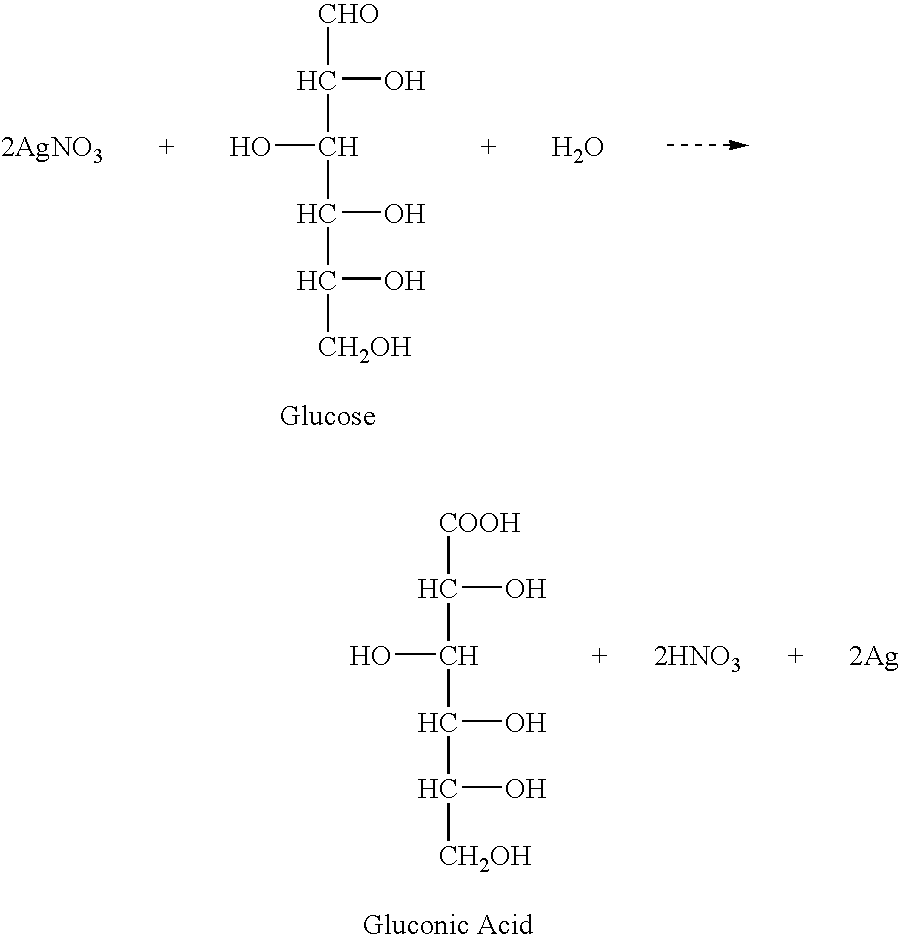

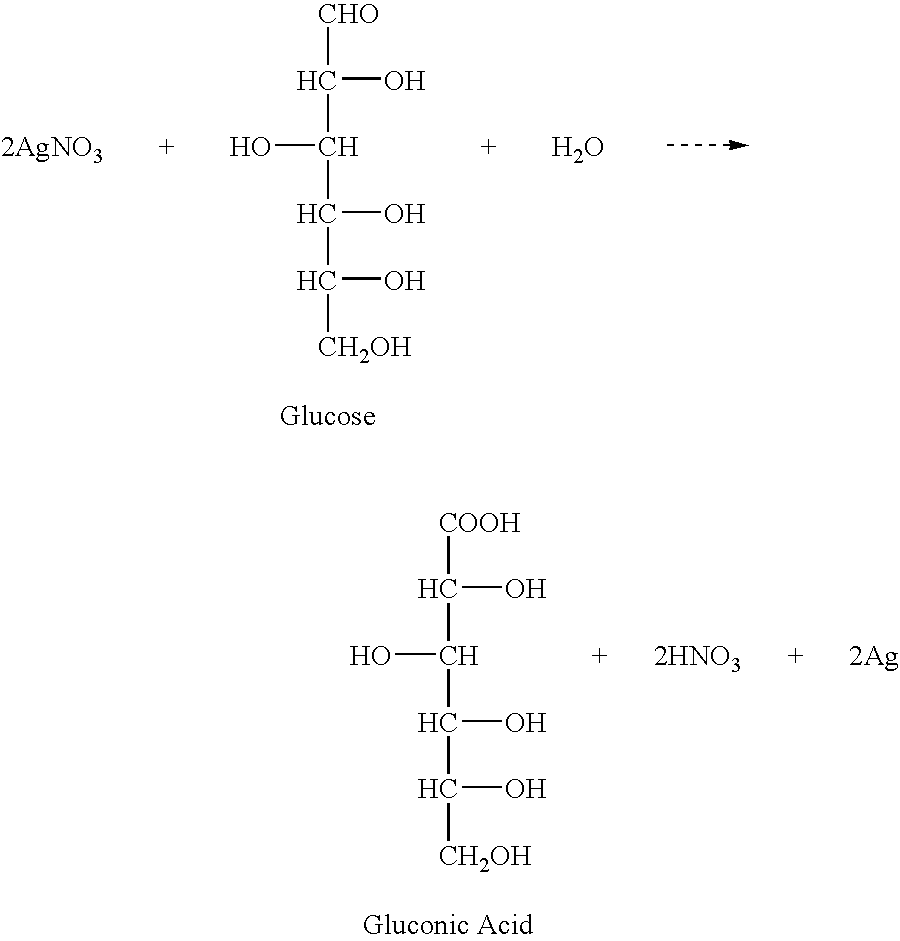

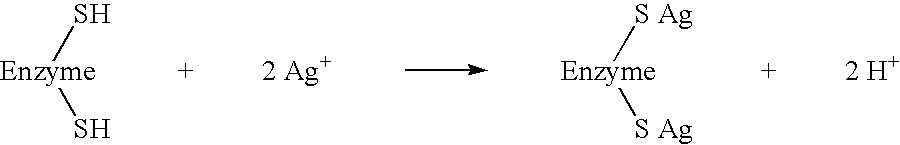

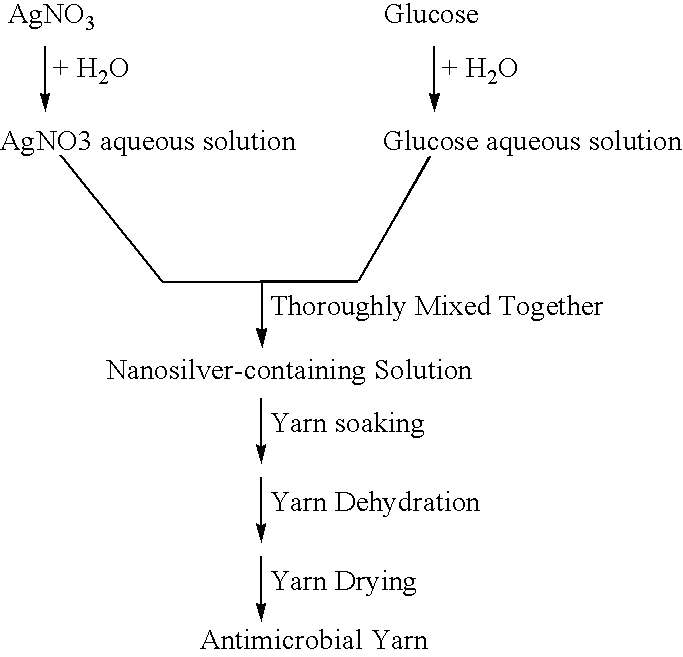

Antimicrobial yarn having nanosilver particles and methods for manufacturing the same

InactiveUS6979491B2The process is simple and fastEasy to carryYarnConductive materialsYarnEngineering

The present invention provides a yarn with antimicrobial effects. The antimicrobial antifungal effect of the yarn is derived from nanosilver particles (diameter between 1 and 100 nm) which are adhered to the yarn. The yarn contains fibers which are made of cotton, linen, silk, wool, leather, blending fabric, synthetic fiber, or any combination thereof. The yarn can be used to make cloth to be used particularly for treating patients with burns or wound. The cloth made from the antimicrobial yarn can be further used to make clothes such as underwears, socks, shoe cushions, shoe linings, bed sheets, pillow cases, towels, women hygiene products, laboratory coats, and medical robes. The present invention also provides a method for making the antimicrobial yarn.

Owner:CC TECH INVESTMENT

Fitted sheets with elastic side segments

A fitted cornerless bedclothing item such as a sheet, mattress pad, anti-allergy cover, blanket or coverlet includes a top portion, side portions and end portions, and elastic segments stitched to edges of respective side and end portions. One or more elastic bindings are provided at lower edges of the side and end portions to cause the tops of the elastic segments to be positioned below the respective upper corners of the mattress on which the bedclothing item is mounted, such that no ears or pockets are formed when the bedclothing item is mounted on mattresses of at least two different sizes and / or thicknesses. The elastic segments are made of knitted or woven elastic filaments, such as SPANDEX® fabric, and can be shaped to have a straight lower edge and a curved upper edge, the curved upper edge advantageously approximating an end of an ellipse.

Owner:HOMTEX

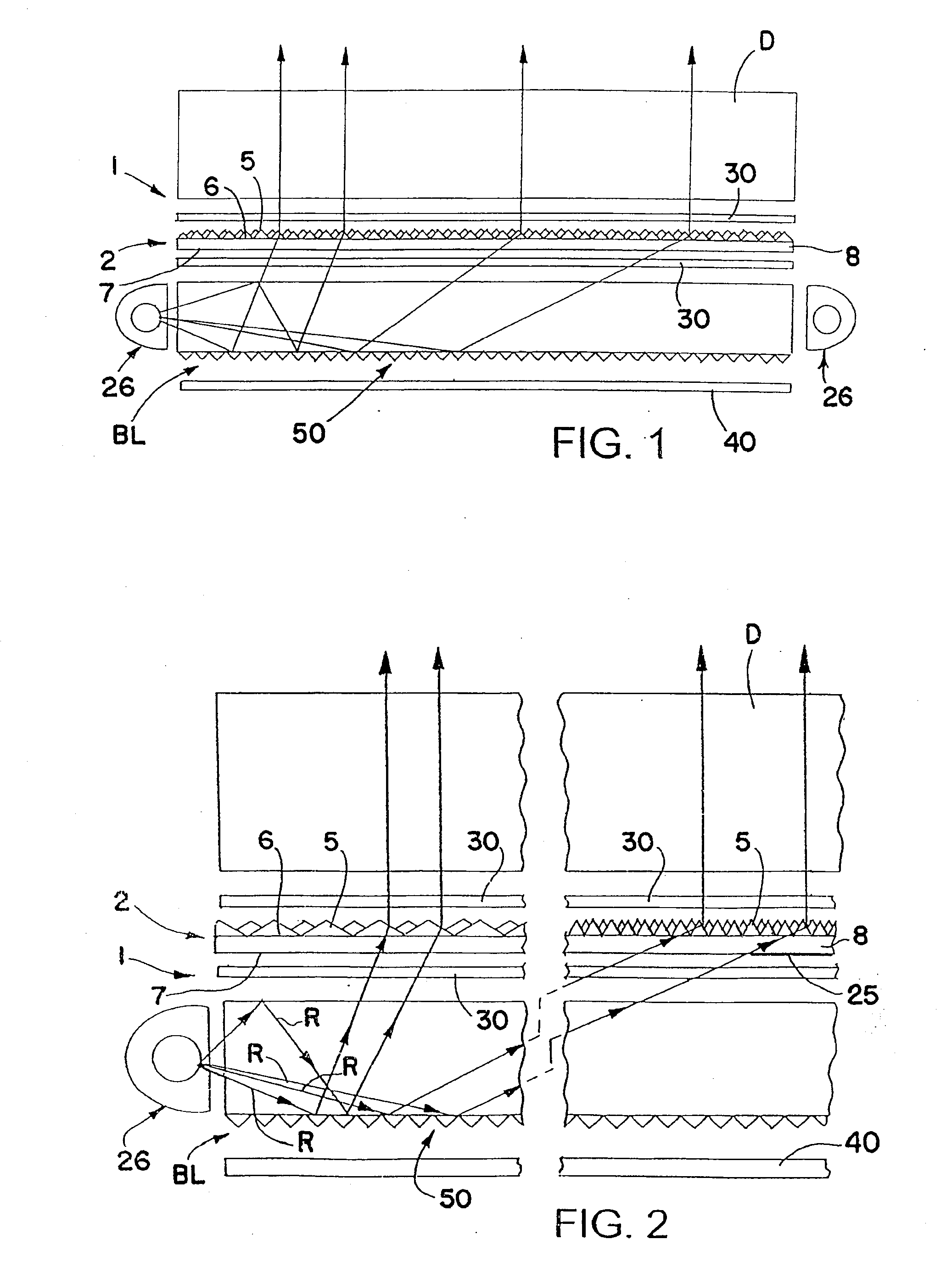

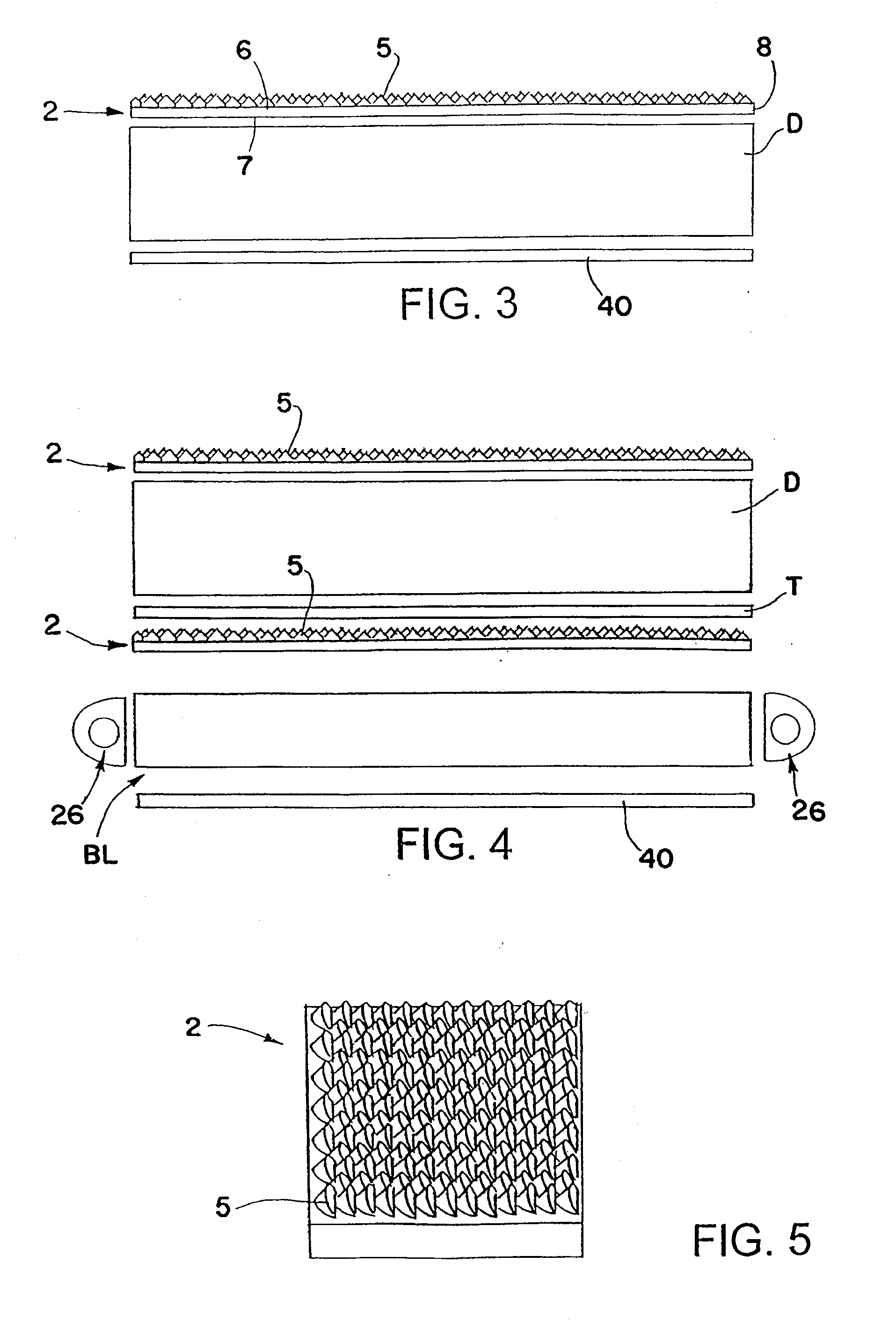

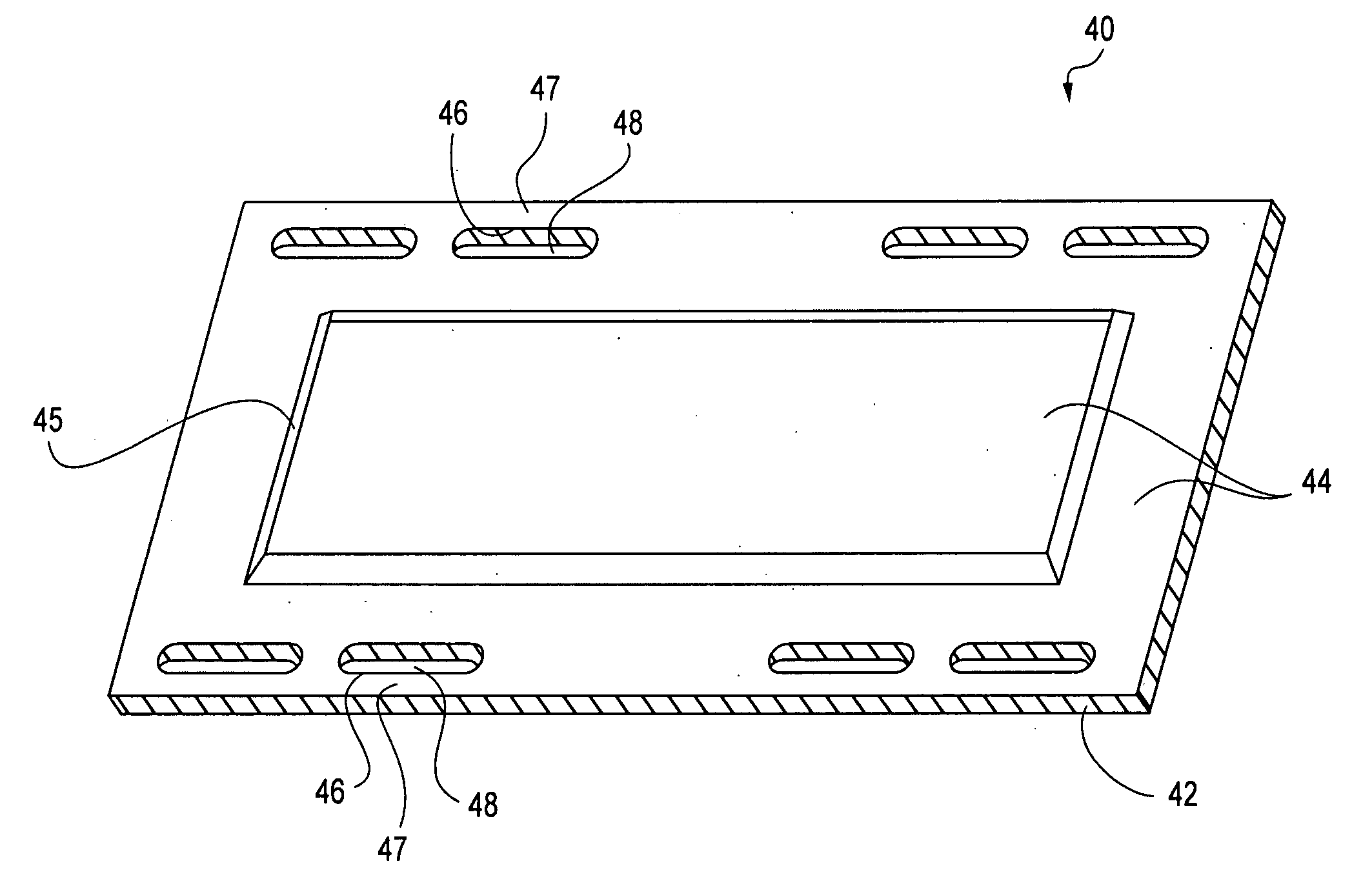

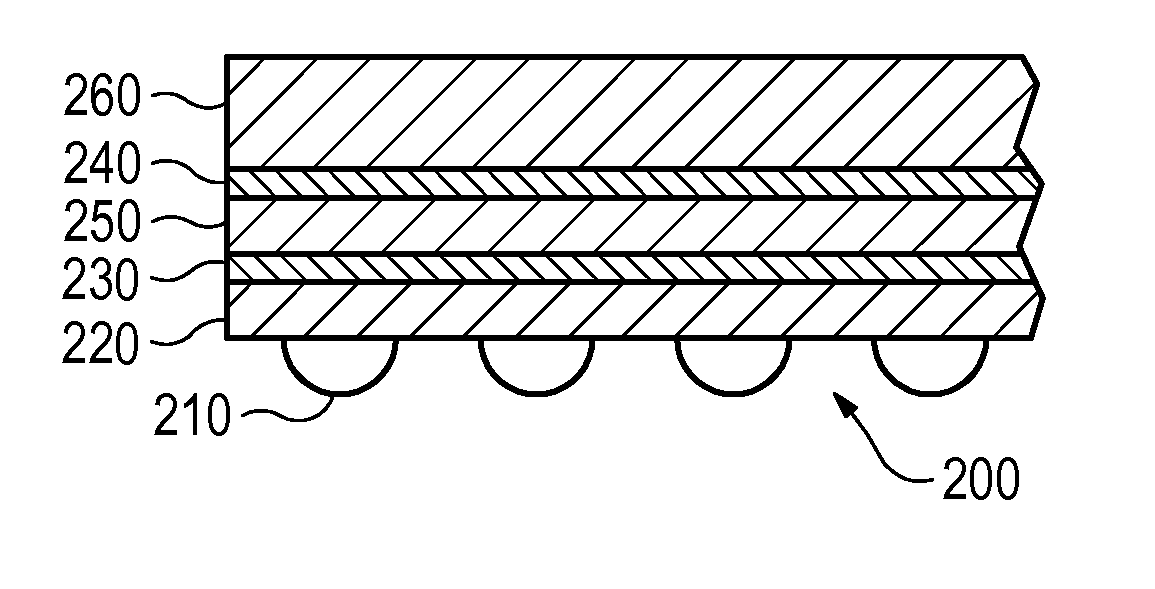

Optically transmissive substrates and light emitting assemblies and methods of making same, and methods of displaying images using the optically transmissive substrates and light emitting assemblies

InactiveUS20100026703A1Improve image qualityBoosting of luminancePoint-like light sourceElectrical apparatusLiquid-crystal displayLight valve

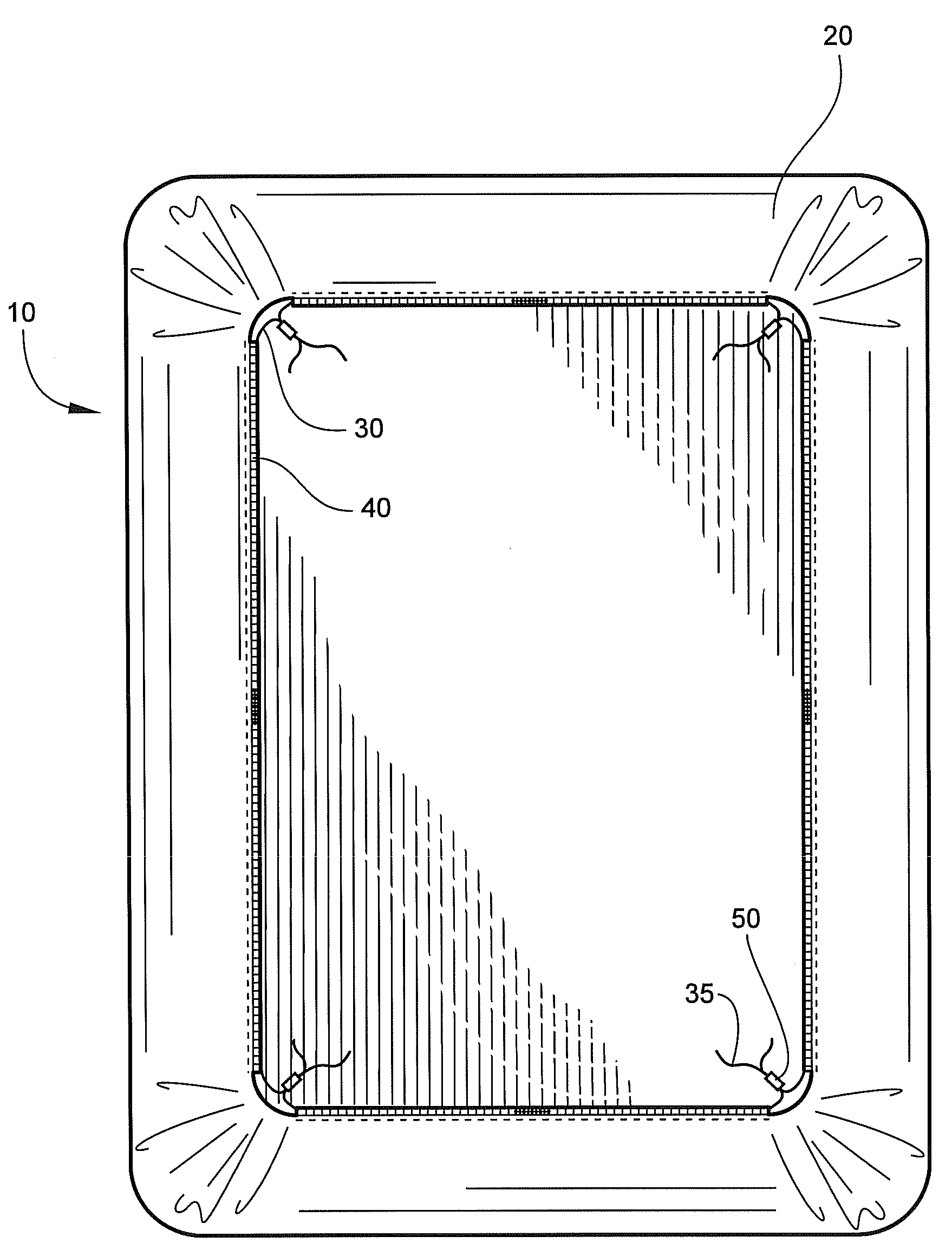

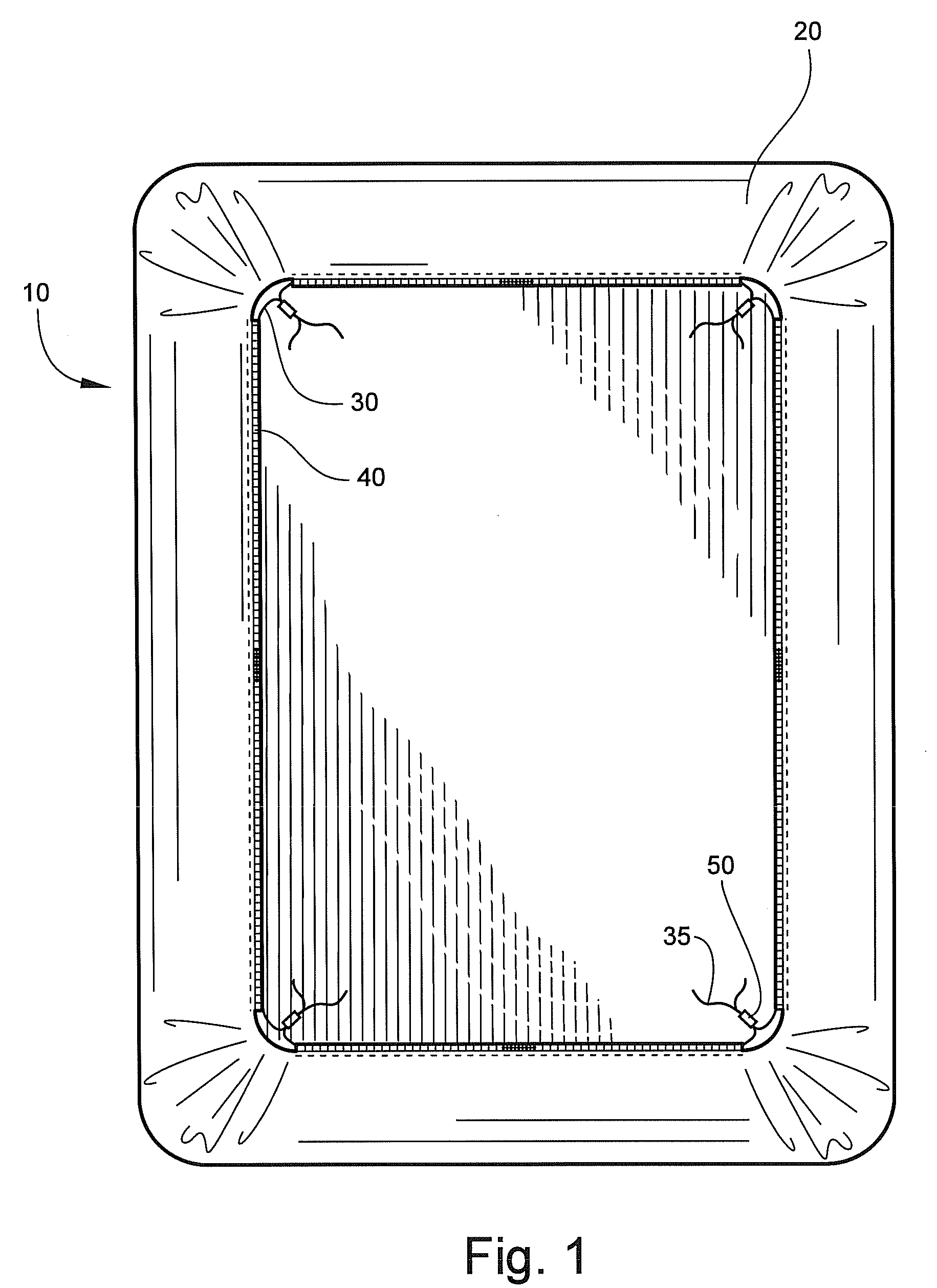

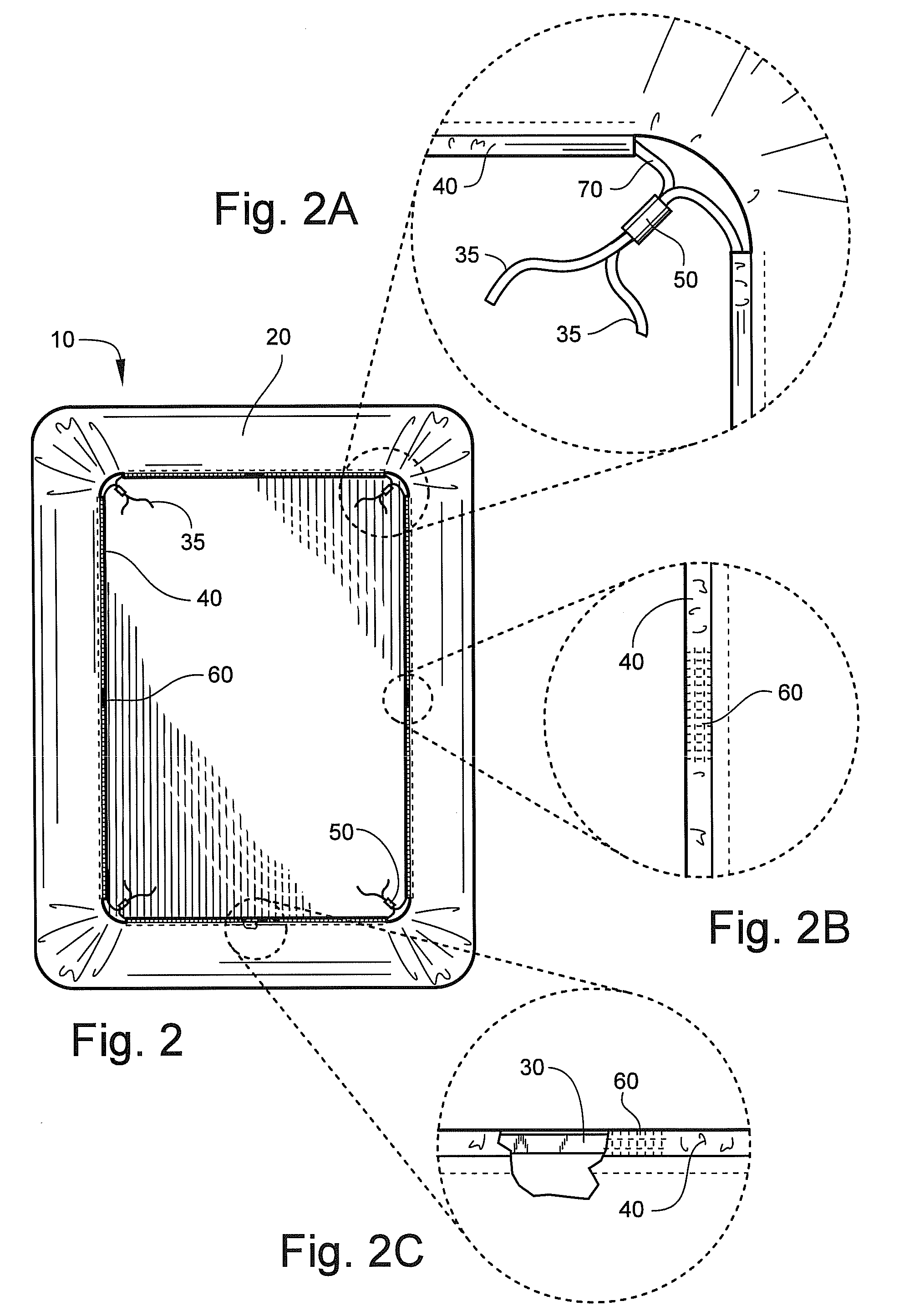

Images are displayed in response to a video signal using a light emitting assembly having one or more optically transmissive substrates, films or sheets, each having at least one pattern of optical elements on or in the substrates, films or sheets. A plurality of light sources are configured to illuminate one or more output areas of one or more of the substrates, films or sheets. The light emitting assembly is configured to emit light through the pattern of optical elements and produce a predetermined luminance profile of the light emitting assembly. At least one of the light sources is dimmed or boosted in response to an input video signal while operating a liquid crystal display as a light valve to illuminate the liquid crystal display by the light emitting assembly. At least some adjacent substrates, films or sheets may have portions that overlap, and at least one pattern of optical elements on or in at least one side of the substrates, films or sheets may be configured so that discontinuities between the adjacent substrates, films or sheets are minimized. A predetermined light output from the light emitting assembly may be produced by varying the electrical input to at least some of the light sources.

Owner:RAMBUS DELAWARE

Safety sheet

ActiveUS7904977B1Maximize utilizationRestricts lateral movementStuffed mattressesBlanketSoft materialsElectrical and Electronics engineering

The safety sheet of the present invention may include a bed sheet with sleeves along one or more sides. The sleeves may be continuous or slotted and may accommodate inserts constructed of a material soft enough to avoid injury yet sturdy enough to provide an effective barrier to lateral motion of a bed's occupant. The safety sheet may include solid or hollow inserts. Portability of the safety sheet may be maximized by the use of inflatable / deflatable inserts. Inserts may vary in size and shape, and the sleeves may vary in size to accommodate a range of insert sizes. Alternatively, the sleeves may be stuffed with soft materials such as socks or other clothing when inserts are unavailable. The safety sheet may be reversed with inserts in place for aesthetic and comfort purposes or without inserts to hide the sleeves when inserts are no longer needed.

Owner:SINGH NEERAJ

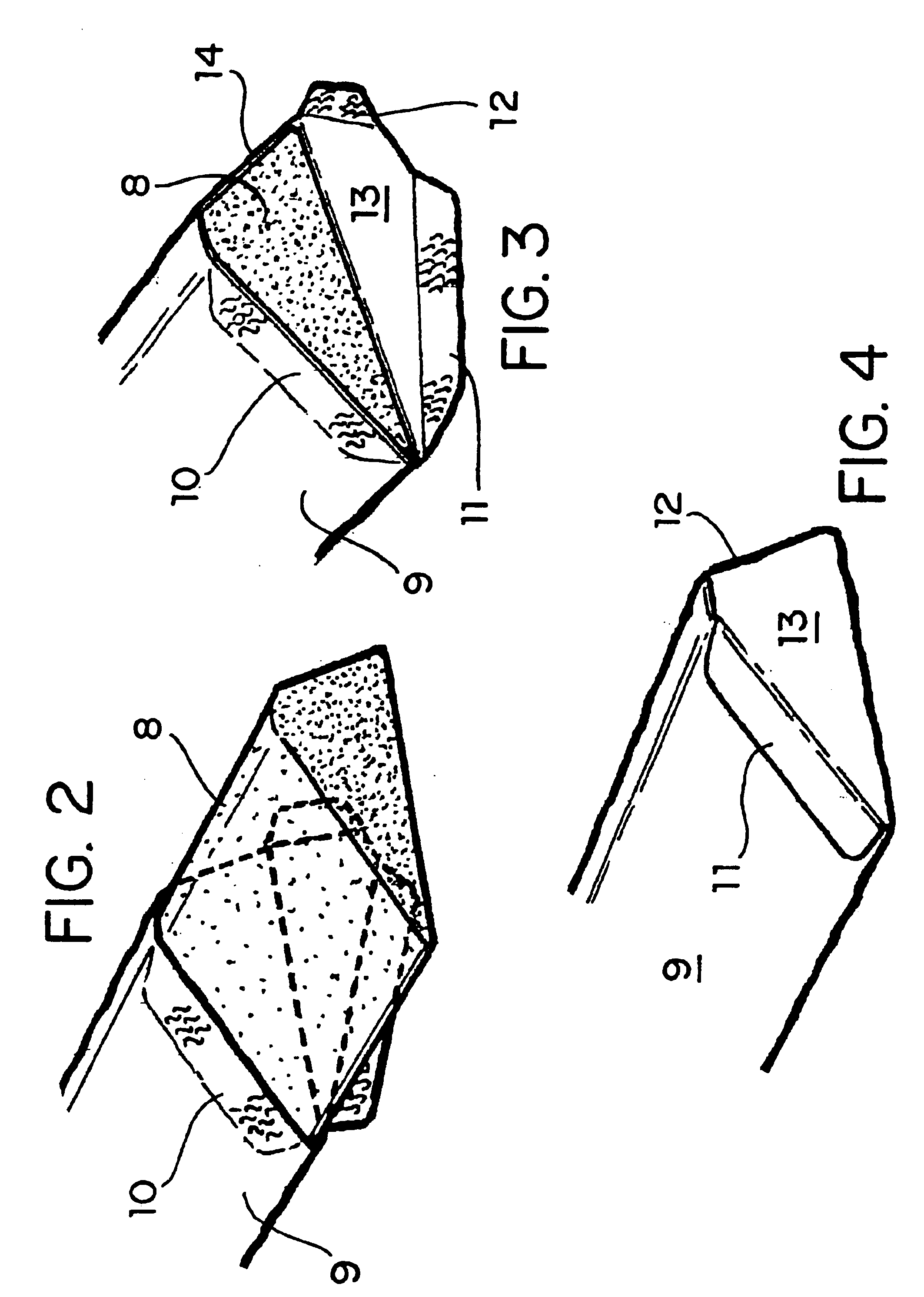

Allergy barrier for bedding

An allergy barrier for bedding comprised of a sheet adapted to fit a wide variety of mattress depths by enclosing a top, all sides, and a portion of the bottom of a mattress. A pull string inserted within an outer hem of the sheet where the pull string is adapted to secure the sheet to the mattress. The pull string terminates outside of the outer hem. The sheet is made of a material having a mean average pore size of less than ten (10) microns.

Owner:WHITE KNIGHT ENGINEERED PROD

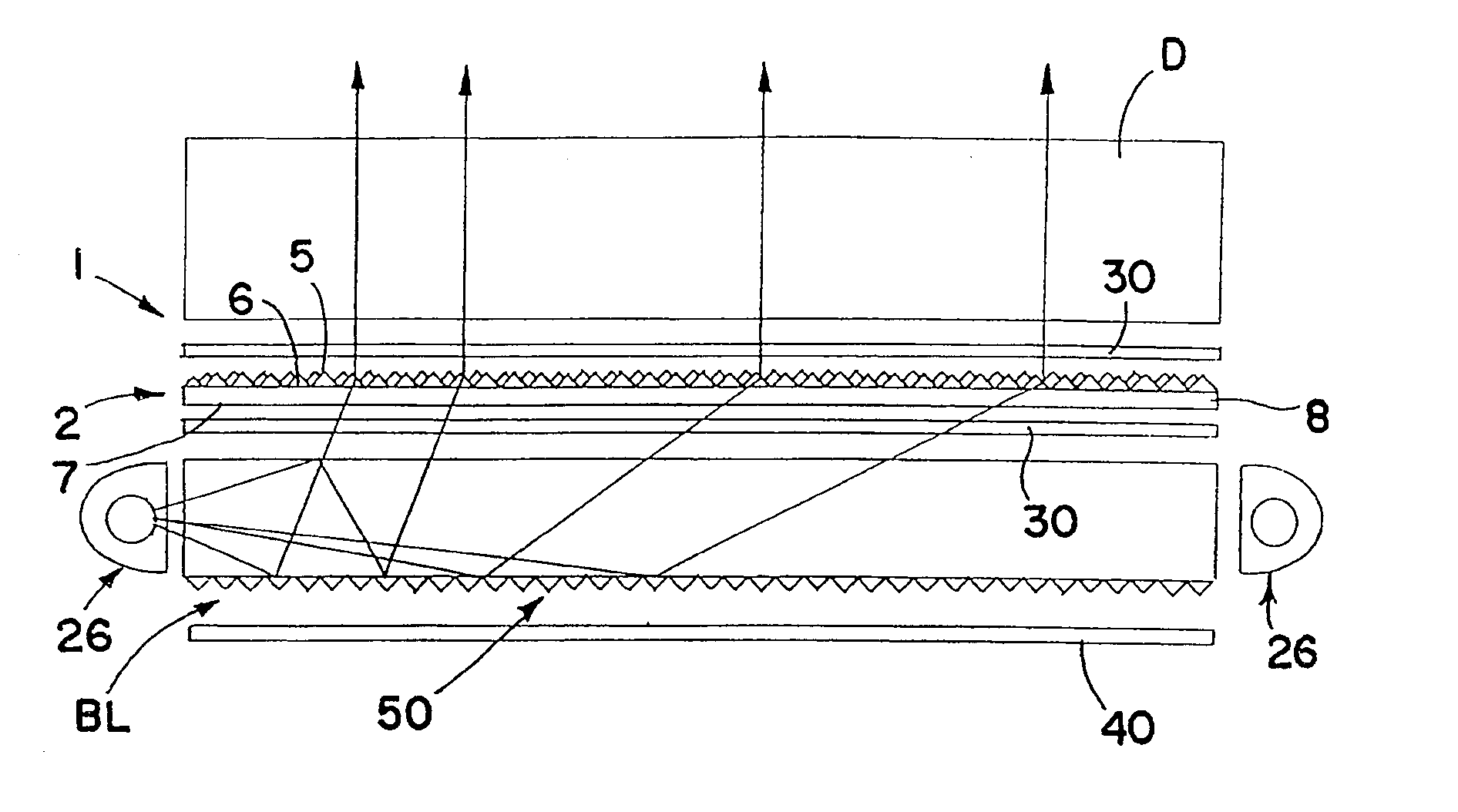

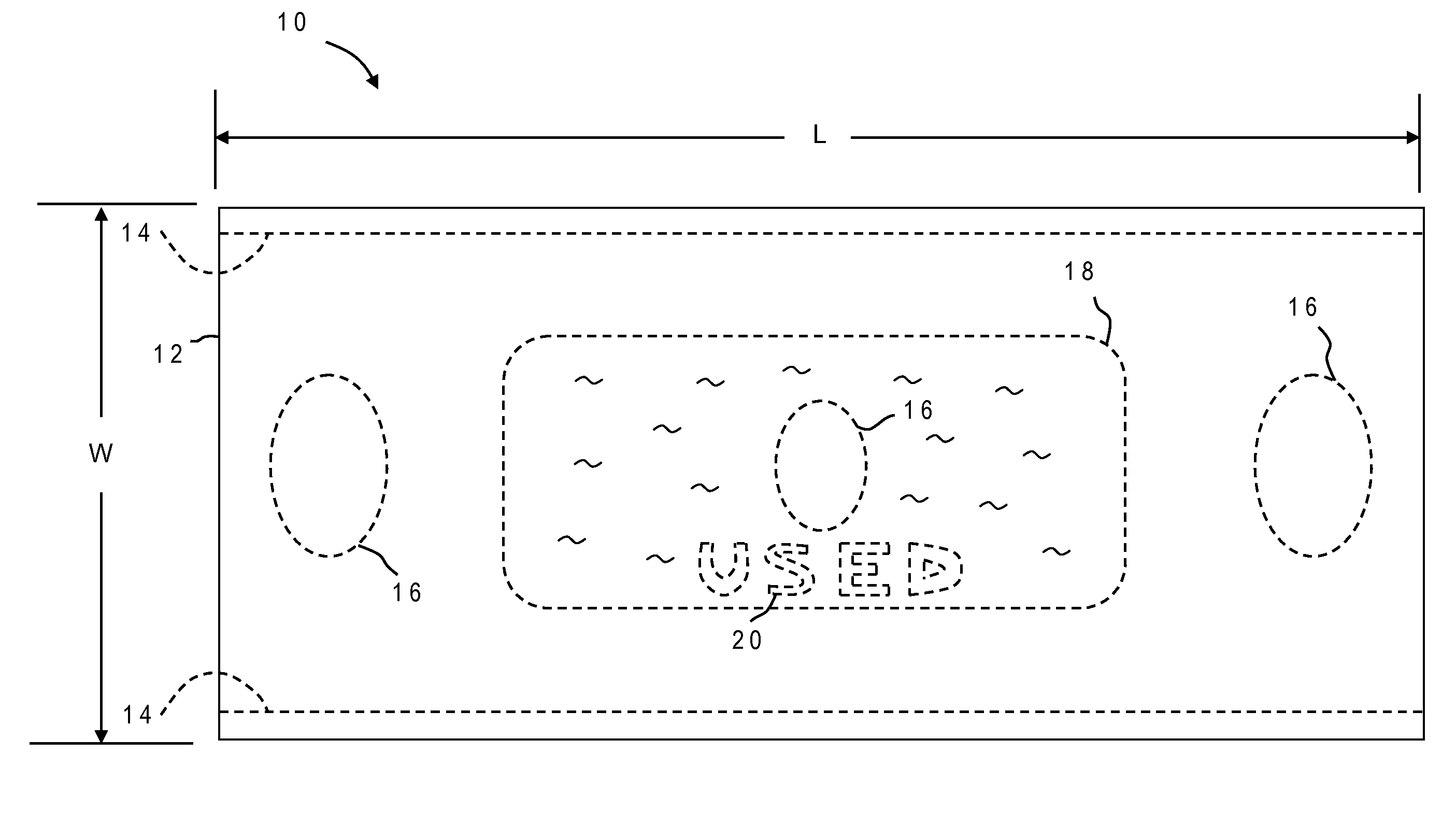

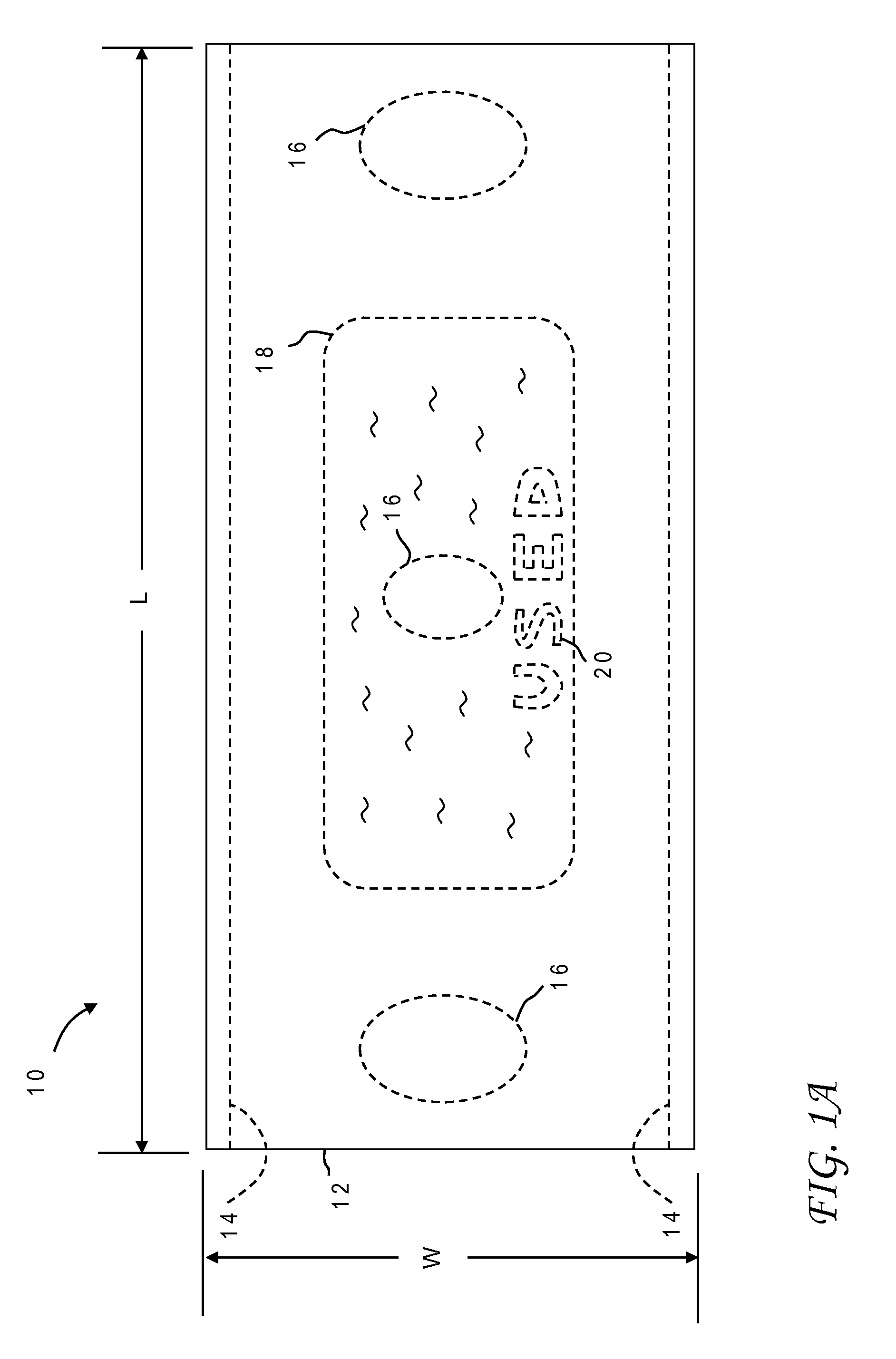

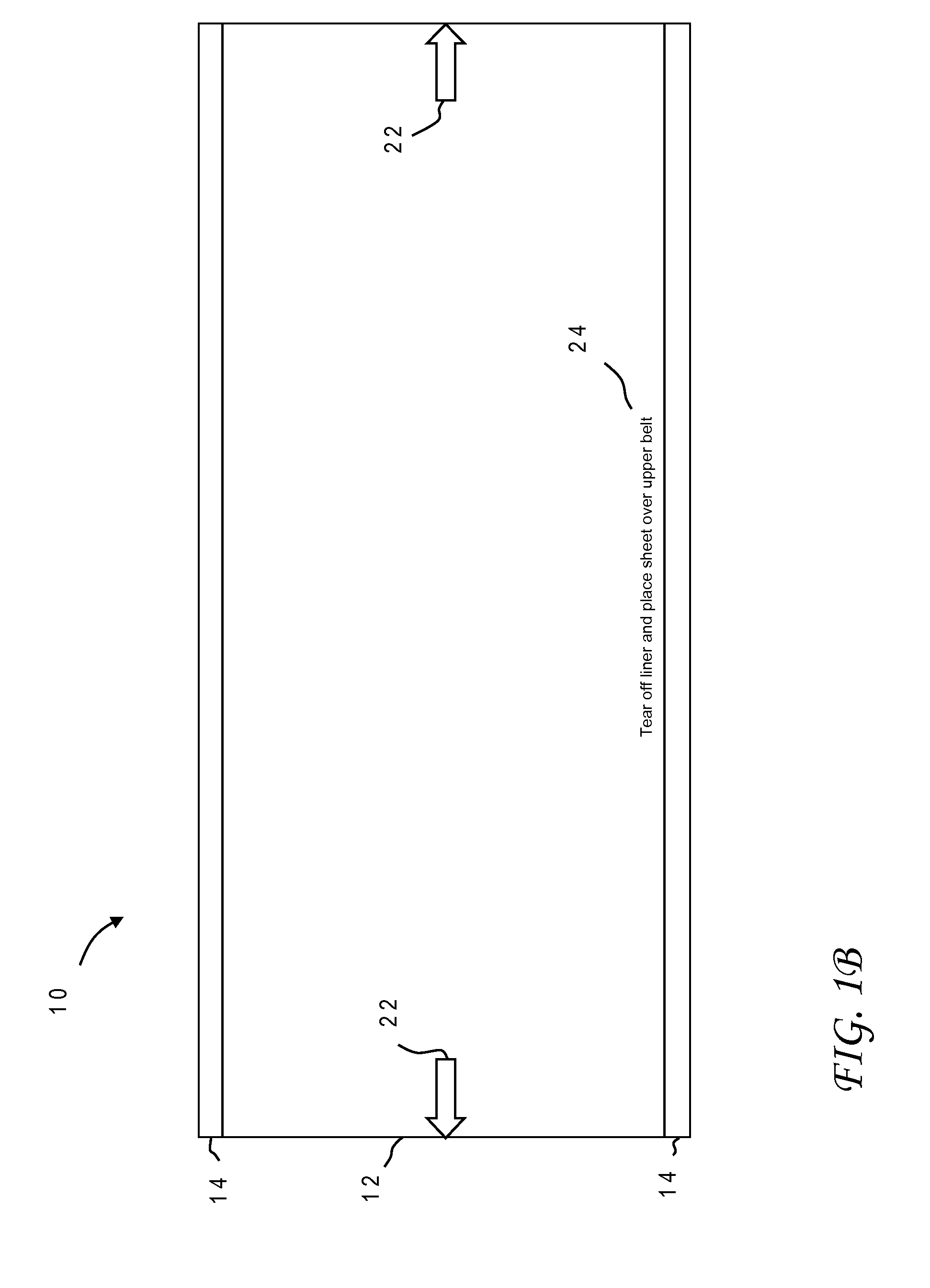

Disposable comfort sheet

A disposable comfort sheet has a waterproof layer and an absorbent layer, with adhesive strips applied to the waterproof layer along side edges. The sheet is adapted for use with a patient transfer device having upper and lower counter-rotating belts, and protects the upper belt against contamination. The patient transfer device may have registration marks for installation of the sheet, and indicator marks can be printed at predetermined locations on the waterproof layer for alignment with the registration marks. The sheet may include various means for indicating prior use by a patient, such as an ink pattern made of a heat-sensitive or moisture-sensitive ink. The sheet may further include a peel-away layer releasably bonded to the absorbent layer, with additional longitudinal adhesive strips applied to the side edges of the peel-away layer. The peel-away layer protects the lower belt against contamination from the sheet after a patient is delivered.

Owner:MEDIGLIDER

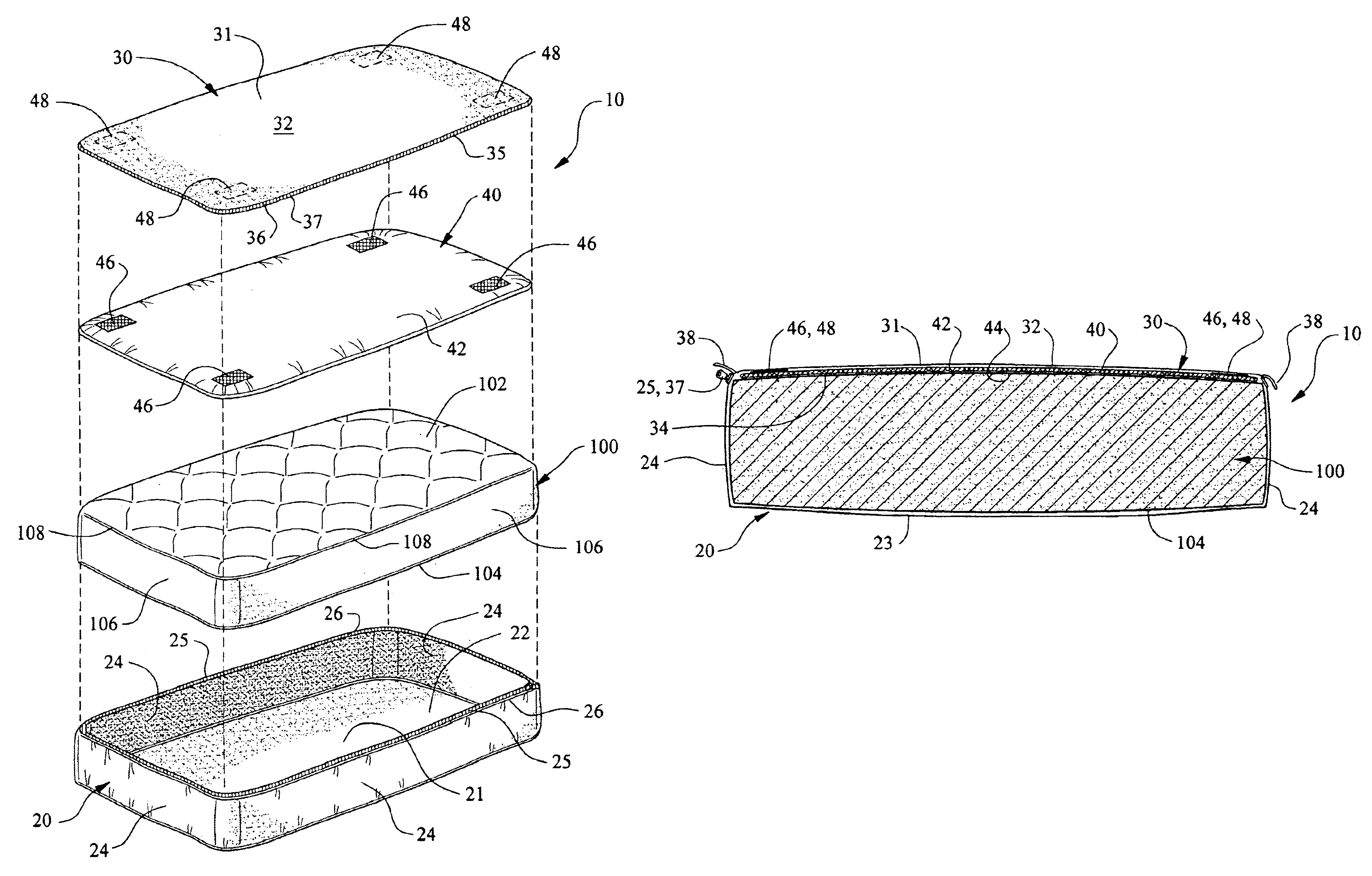

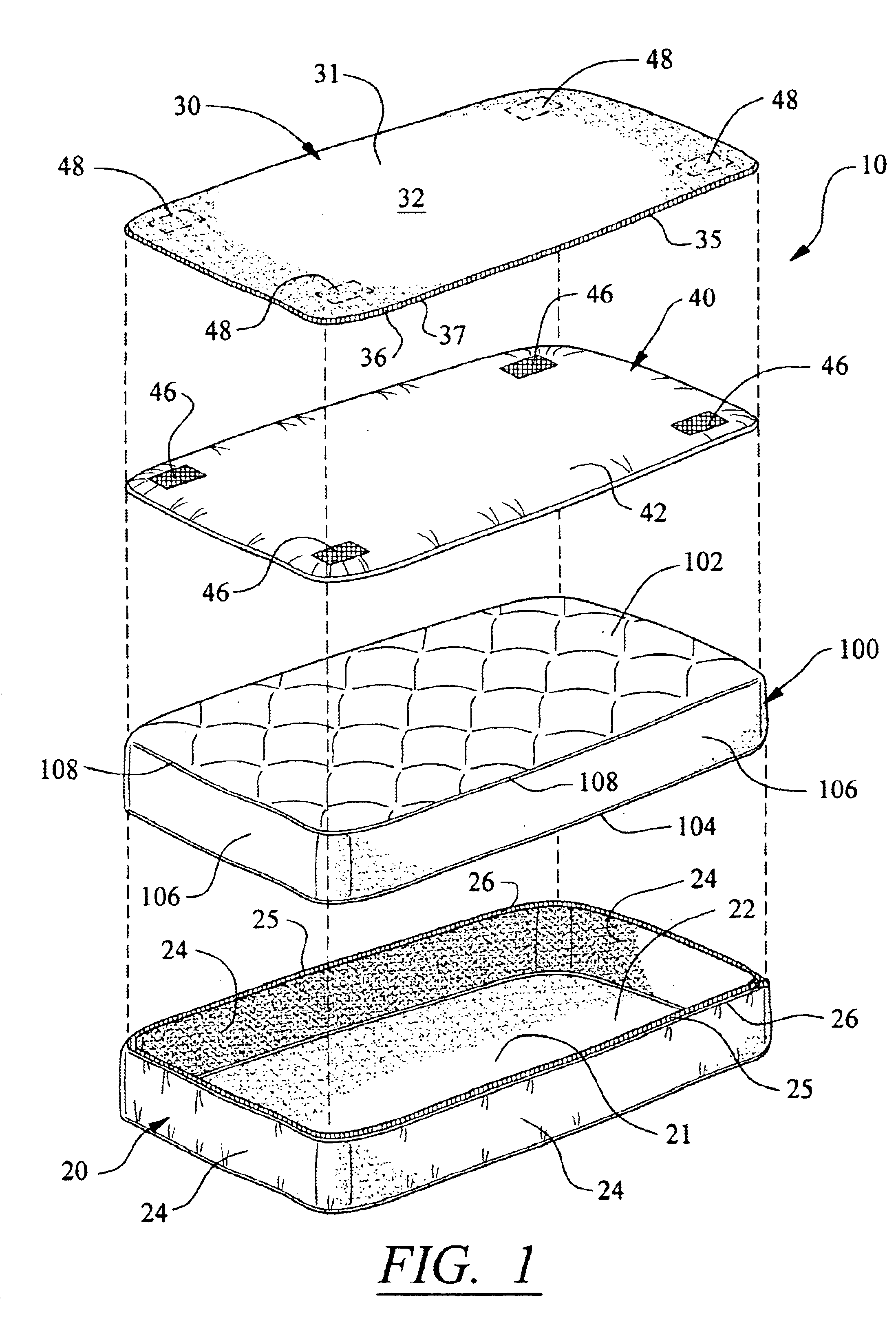

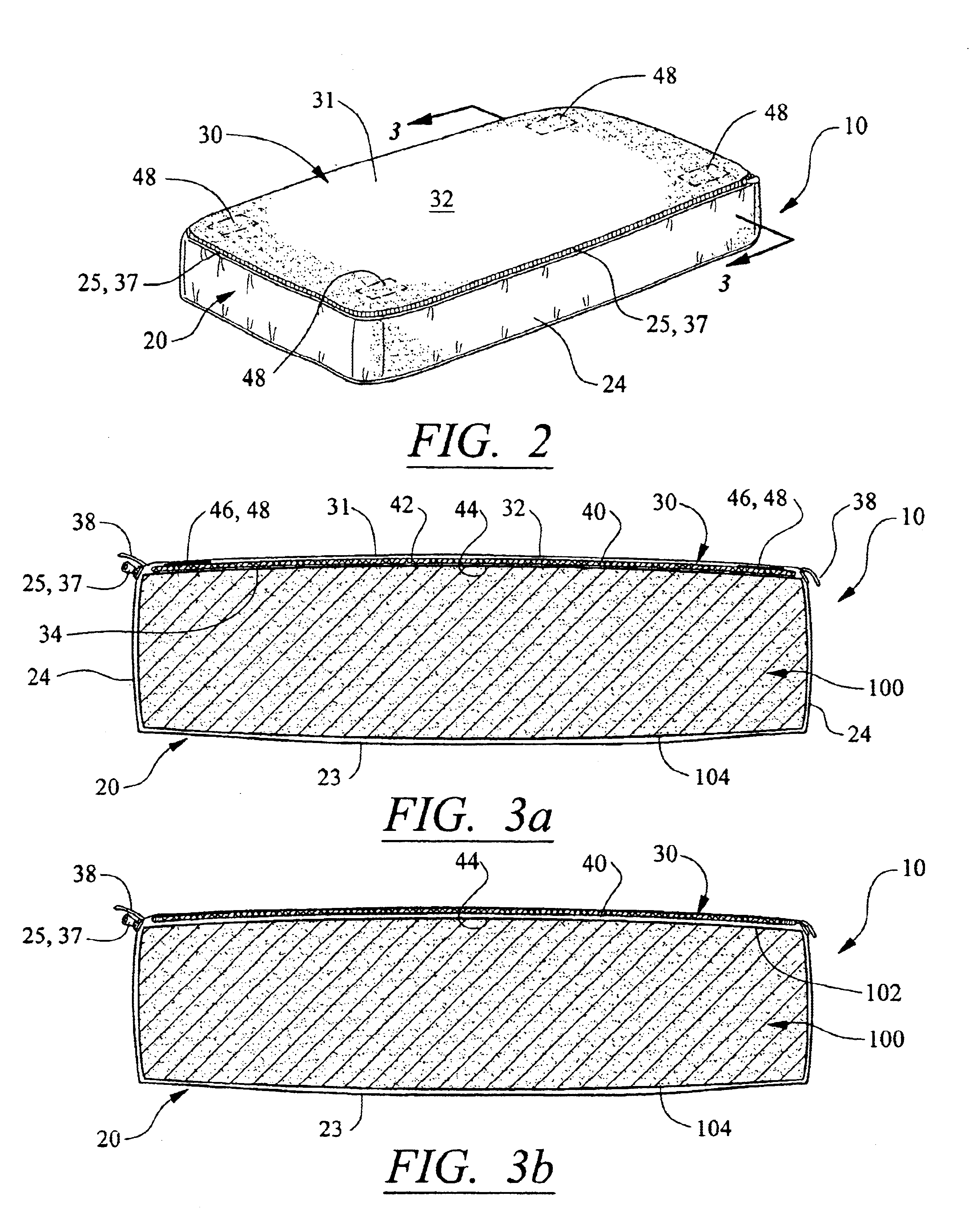

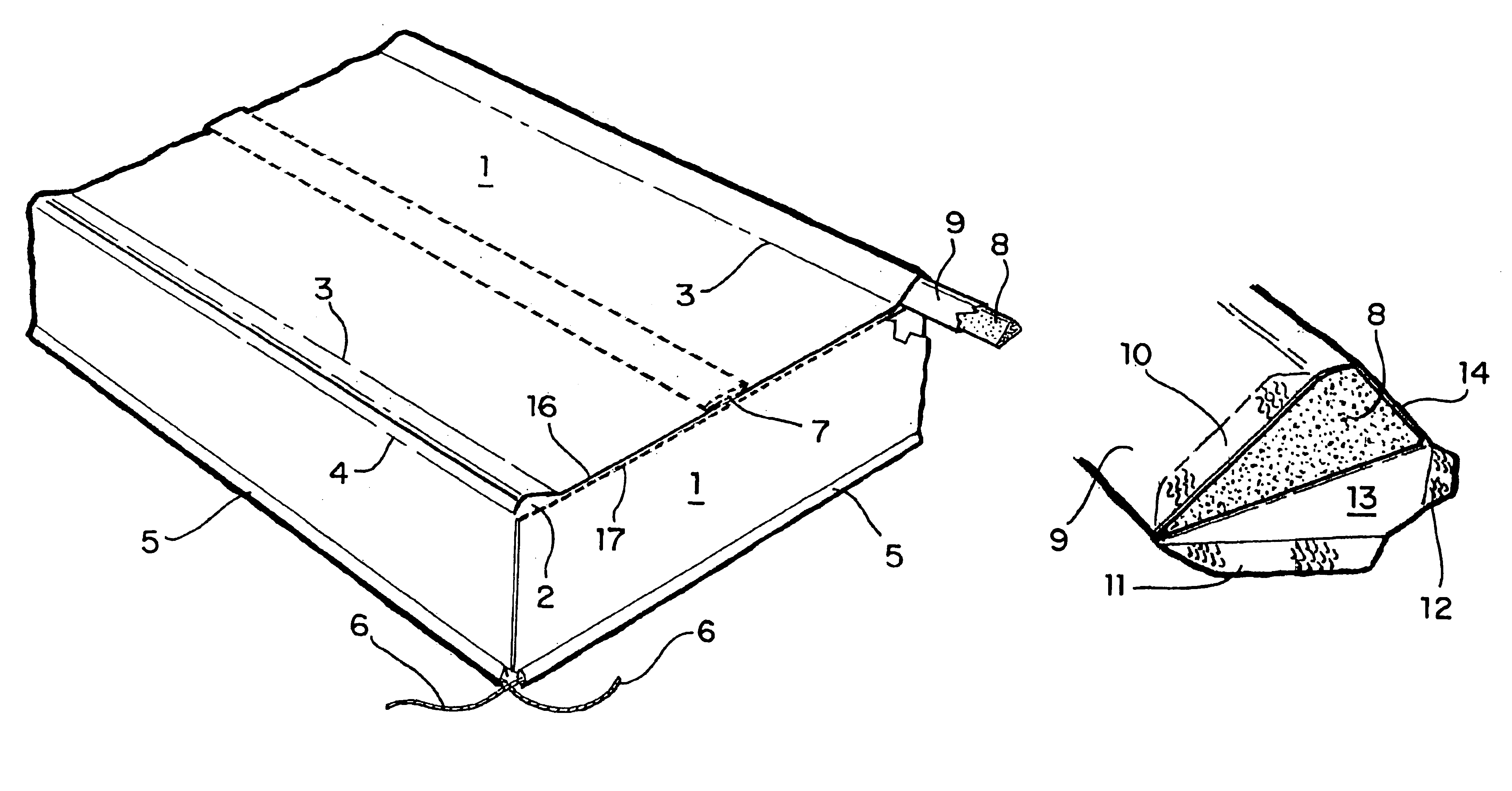

Bed wedge pad

A bed pad wedge system for inhibiting a person from falling out of bed. The system includes a fitted mattress pad fastened to a mattress. Each lateral edge of the fitted pad has pockets located therein that contain foam rubber wedges having the shape of an obtuse triangle. The pockets are installed on an underside of the fitted pad and are facing an outer edge of the mattress. The triangular foam rubber wedges are each encased in a slippery material to aid in installing the wedges in the pockets. A third wedge or triangle may be installed in the middle of a mattress between the outer wedges that are located at each edge of the mattress. The wedge system may be covered by standard sheets and bedding.

Owner:WILSON WILLIAM H

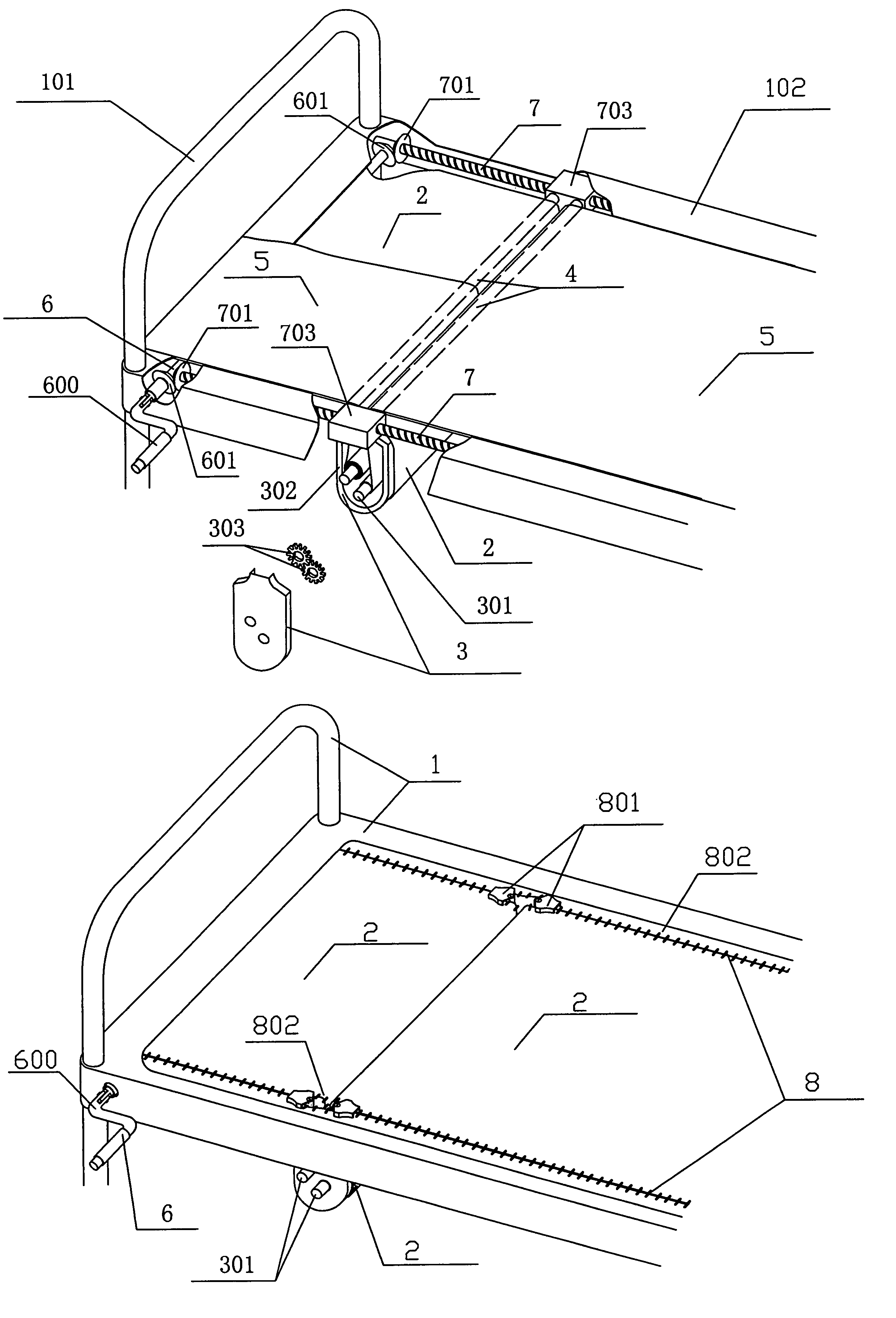

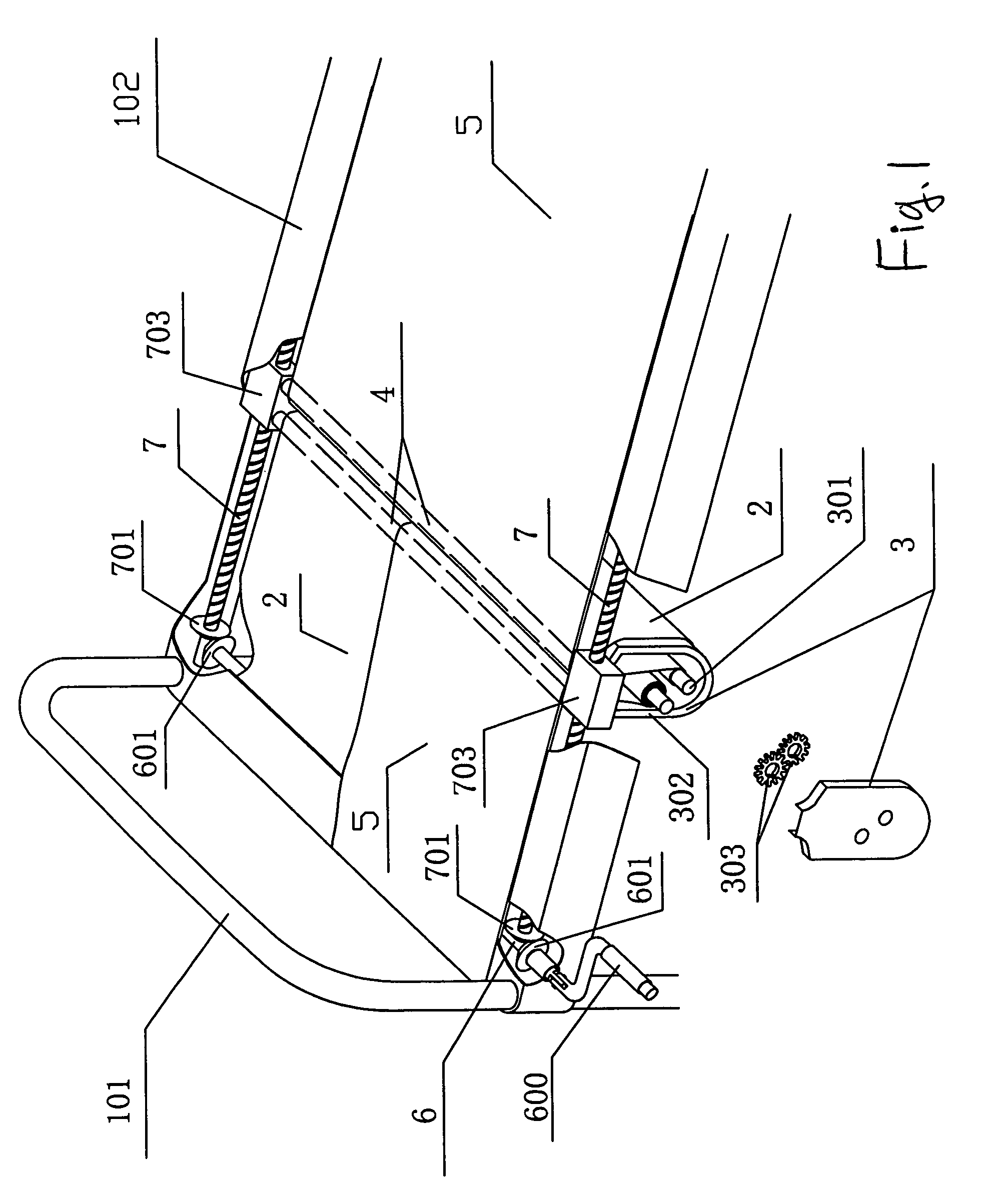

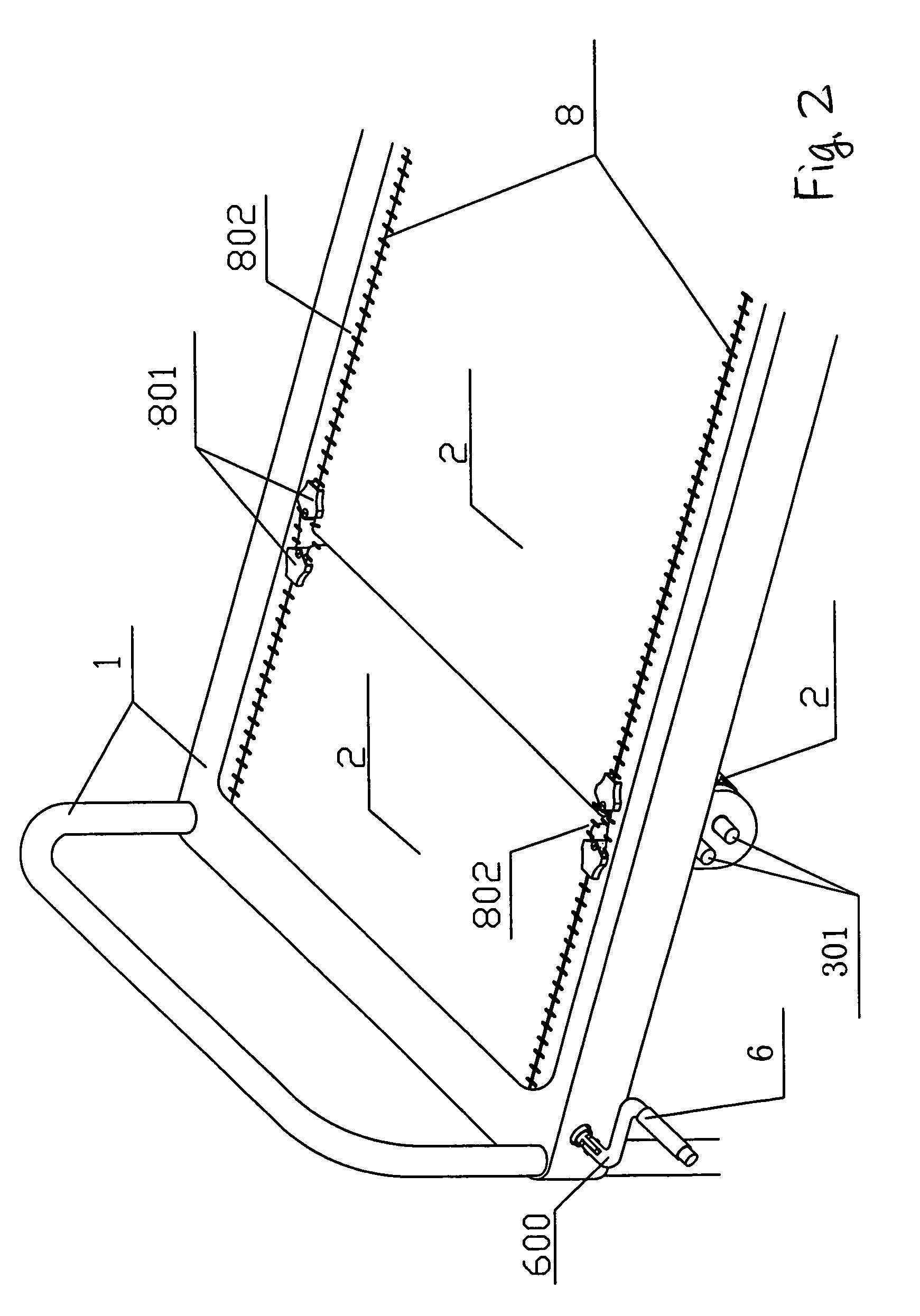

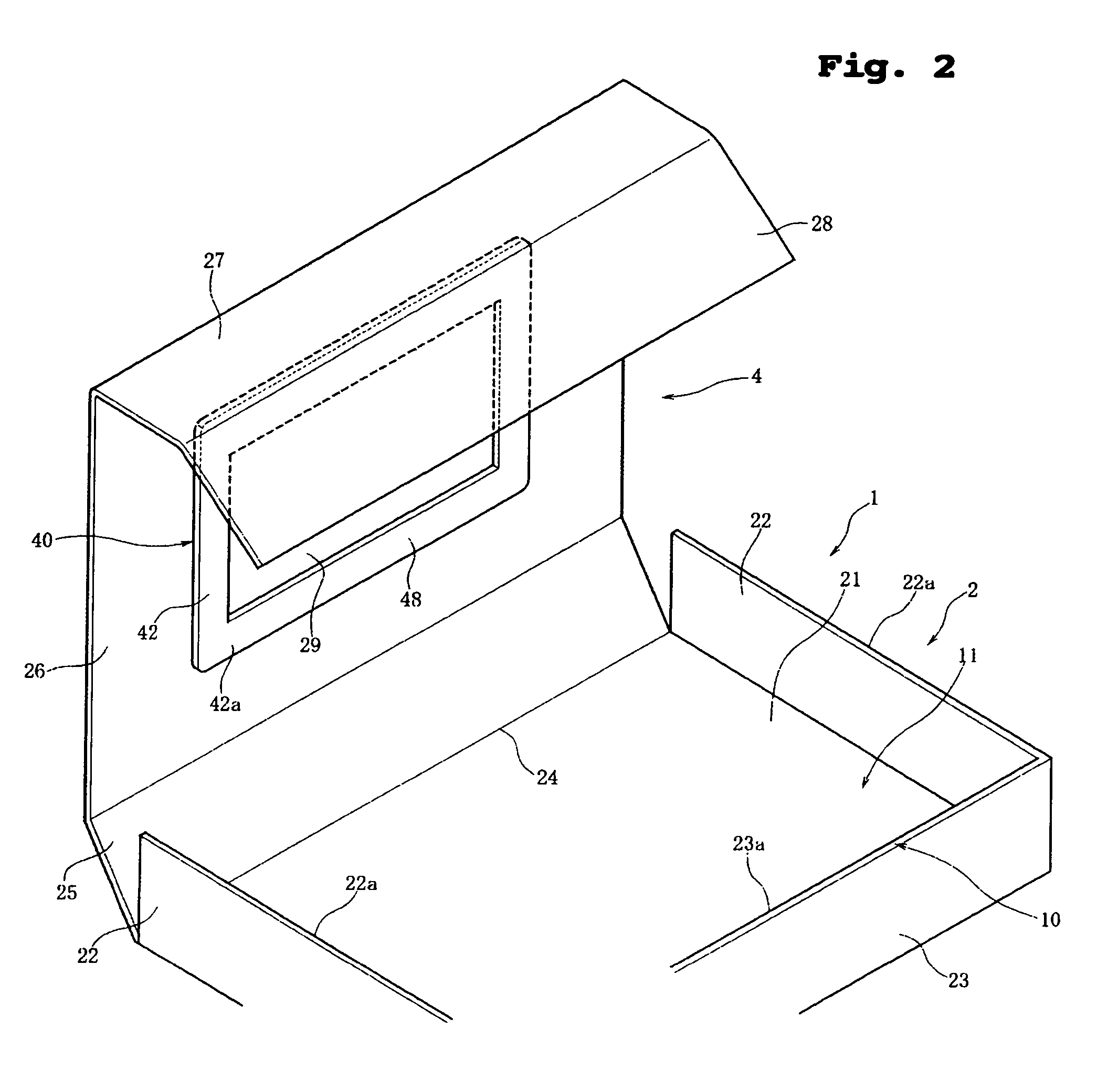

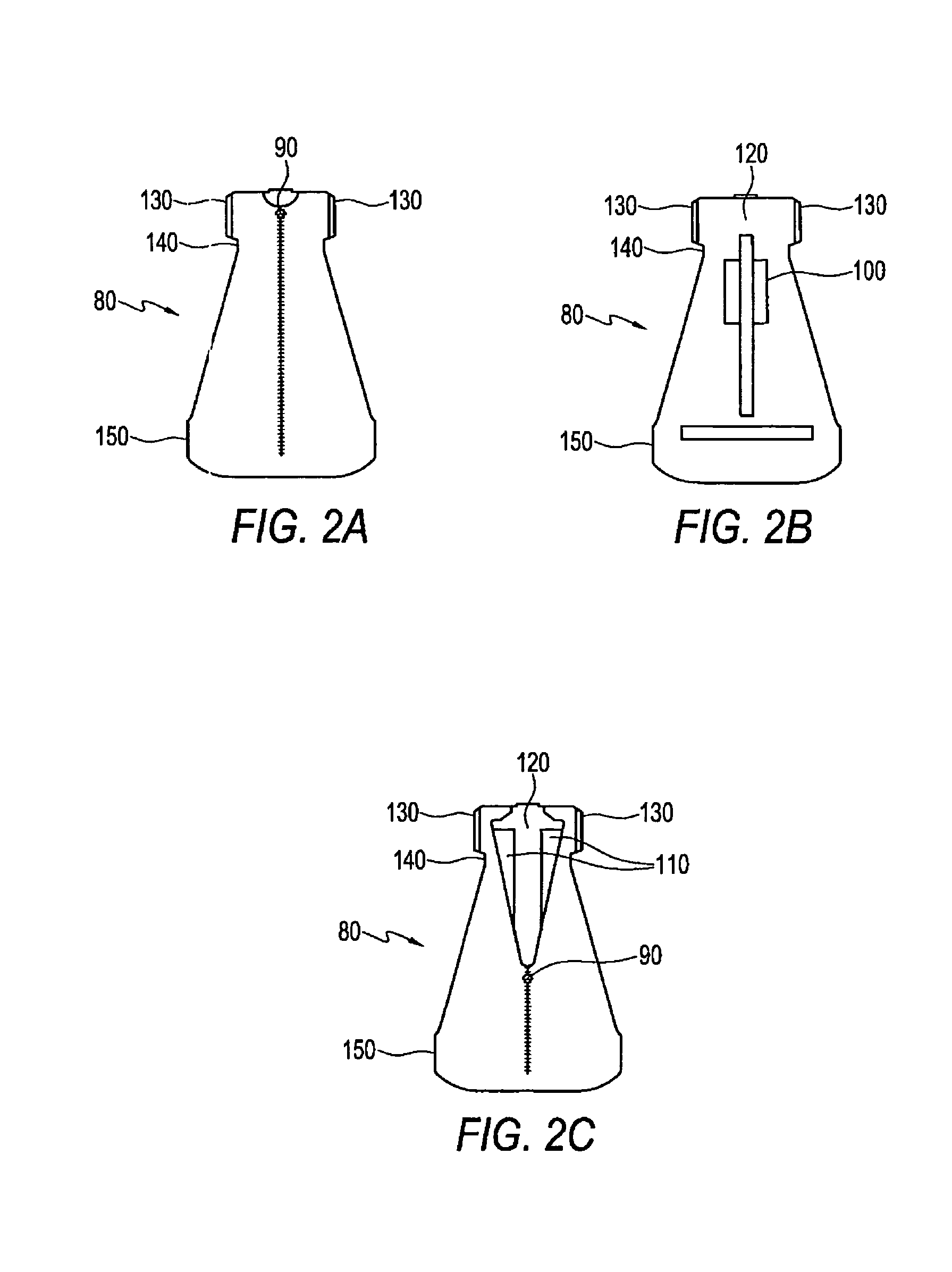

Hospital bed capable of changing bed sheet without moving the patient

InactiveUS7191479B1Easy to useWithout causing any harm or painBedsNursing bedsEngineeringHospital bed

A hospital bed that changes bed sheets without moving the patient. It is composed of a bedstead (including a headboard, a footboard and a bed frame), a deformable bed top, a spool rack and roller shafts on both sides; the ends of the deformable bed top are fixed on the headboard and footboard respectively, and the bed top is pressed into between the roller axles by the spool rack which forms a tightened and leveled bed top that is sunken in the spool rack. Two bed sheets cover the bed, extending respectively from headboard and footboard into the spool rack and rolling on a roller axle. The roller axles and roller shafts are parallel to the cross section of the bed, and are movable between the headboard and footboard with the spool rack. When the spool rack is moving, one bed sheet is spread, another one is rolled up automatically.

Owner:CHENG XIAO ZHOU

Bed pad

A bed pad is disclosed comprising a padding layer and at least one sheet layer adjacent to the padding layer. The padding layer provides support for the patient. The sheet layer comprises a fabric material that is comfortable for the patient to use. The bed pad provides a means for either adjusting a patient within a bed or for transferring a patient from one bed to another bed or medical table. The bed pad may also be used as part of a stretcher or separately as a bedroll. The bed pad may optionally contain gripping components and drapes.

Owner:ILLINOIS TOOL WORKS INC

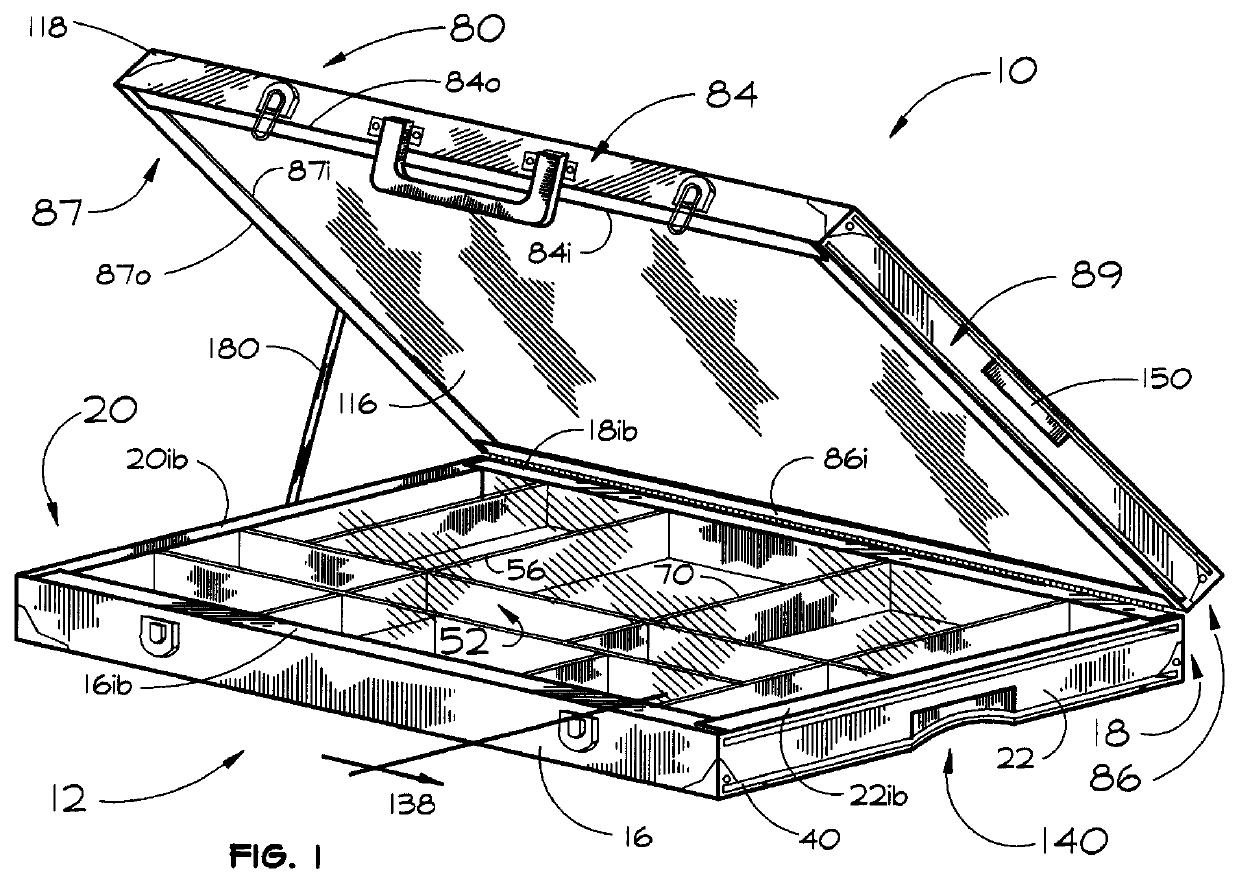

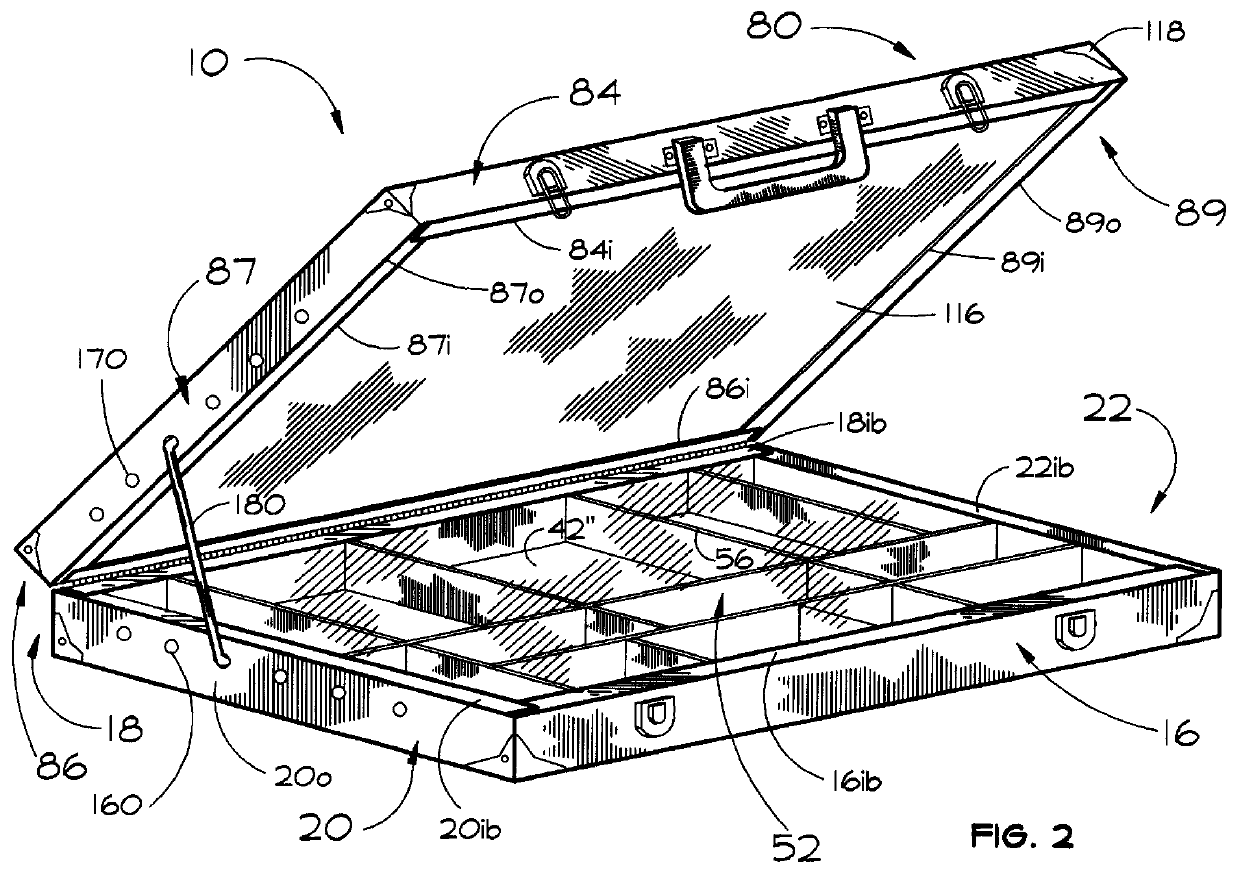

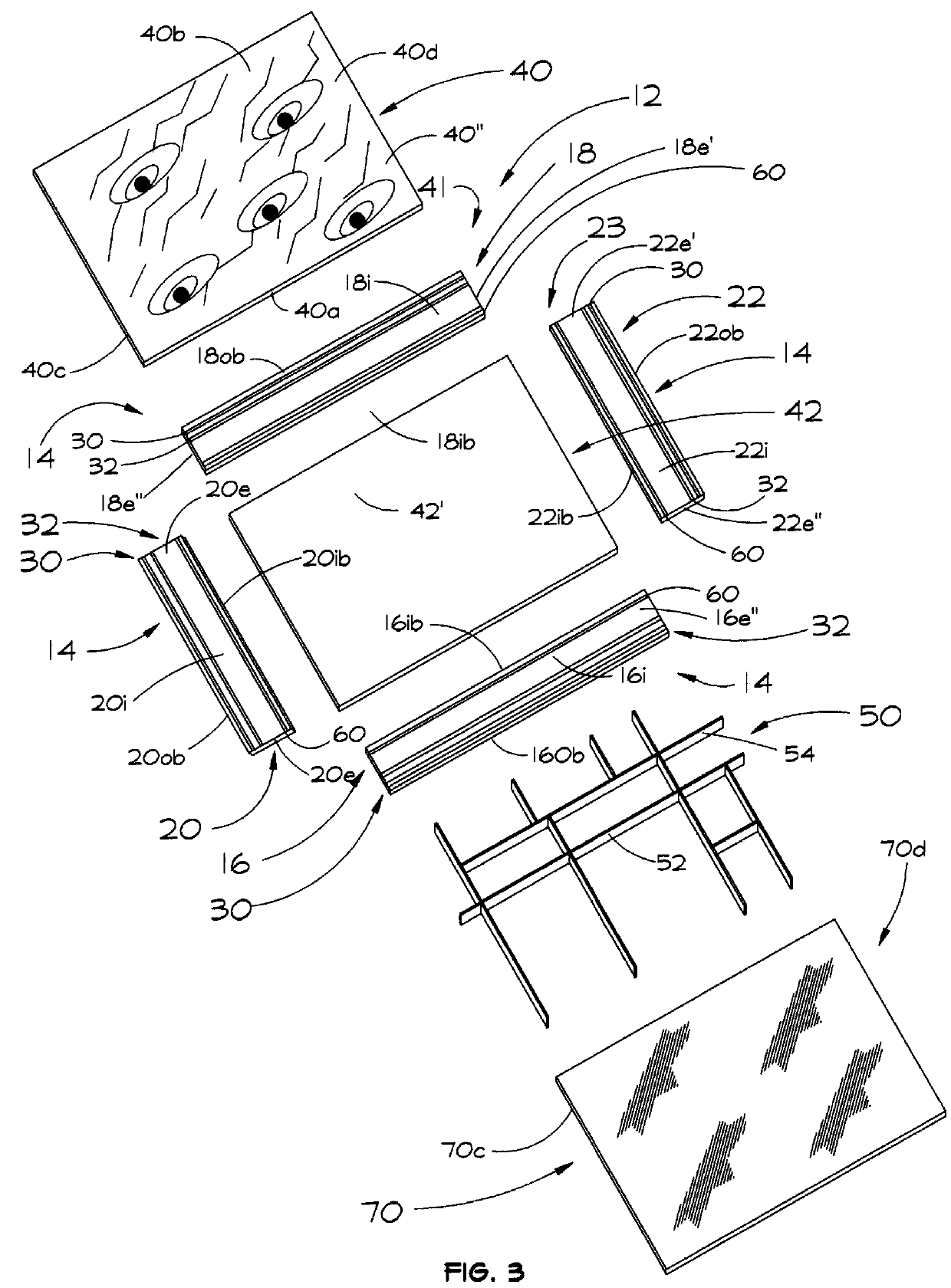

Portable therapy and game case assembly

InactiveUS6082545AEasy to operateImprove safety factorBoard gamesInternal framesEngineeringStorage area

A Self-contained, portable therapy and game case assembly having sliding and opening sections and compartments and portions of the therapy assembly which can be utilized together or separately is disclosed. The therapy assembly is provided for use with various symbolized or illustrated inlay and sliding sheets, for testing and prompting selected skills and associative thinking. The invention is provided as a coupled and portably transportable first and second subassemblies. The first subassembly is provided from outside or outboard to inside or inboard, when in assembled position, with a first sliding feature which recieves a sliding first transparent sliding member; a symbolized inlay sheet; a feature for securing a stationary member which receives an erasable board member; a dividing storage area secured adjacent and inboard or inside of the erasable board member; and a second sliding feature which receives a second transparent sliding member so that it can be positioned inside the divided storage area as a cover. The second subassembly is provided, outboard to inboard with a sliding feature which recieves one or more peg-board sheets; a first feature for stationary securement receiving a pivotable and symbolized multiple-door unit; second stationary feature receiving a transparent sheet; slot feature receiving a symbolized sheet; and a third stationary feature receiving an inboard wall panel.

Owner:FORD SHERRILL A +1

Medical protective table sheets

A disposable slip-resistant and preferably absorbent protective medical table sheet for protecting a medical table, such as an operating table or an examination table, from contamination due to contact with bodily fluids or other contaminants associated with a patient positioned upon the table sheet covering the medical table, and for resisting slippage between the patient and the table sheet and between the table sheet and the medical table and, if a lift sheet is used, between the table sheet and the lift sheet. The table sheet preferably includes an impermeable layer with a slip-resistant and absorbent layer of foam material on its upper side and a distribution of slip-resistant material on its lower side. The lower side of the impermeable layer may itself be comprised of slip-resistant material. The table sheet is preferably fan-and-book-foldable into a compact yet rapidly unfoldable table sheet.

Owner:TRIMOUNTAIN MEDICAL RESOURCES

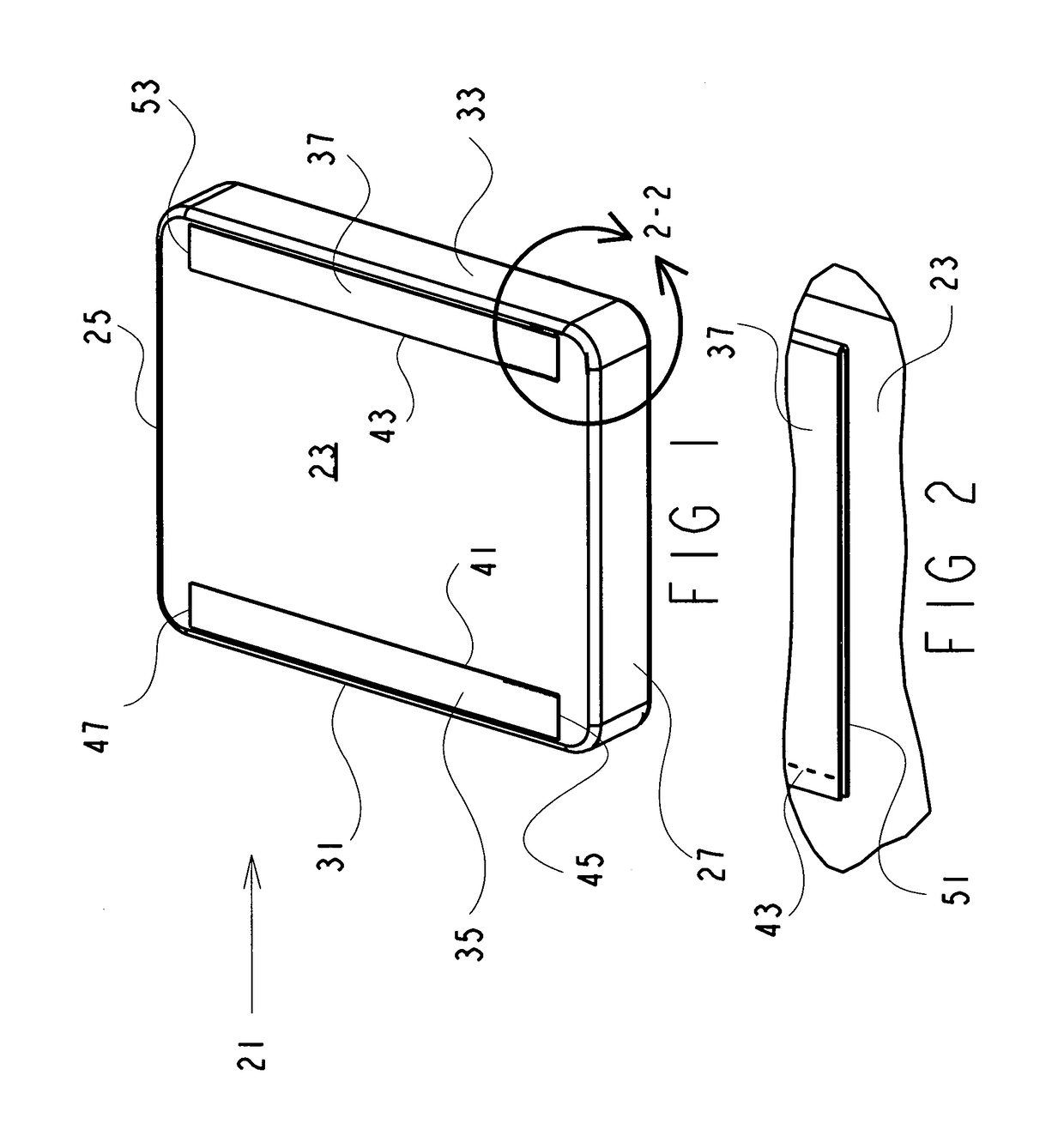

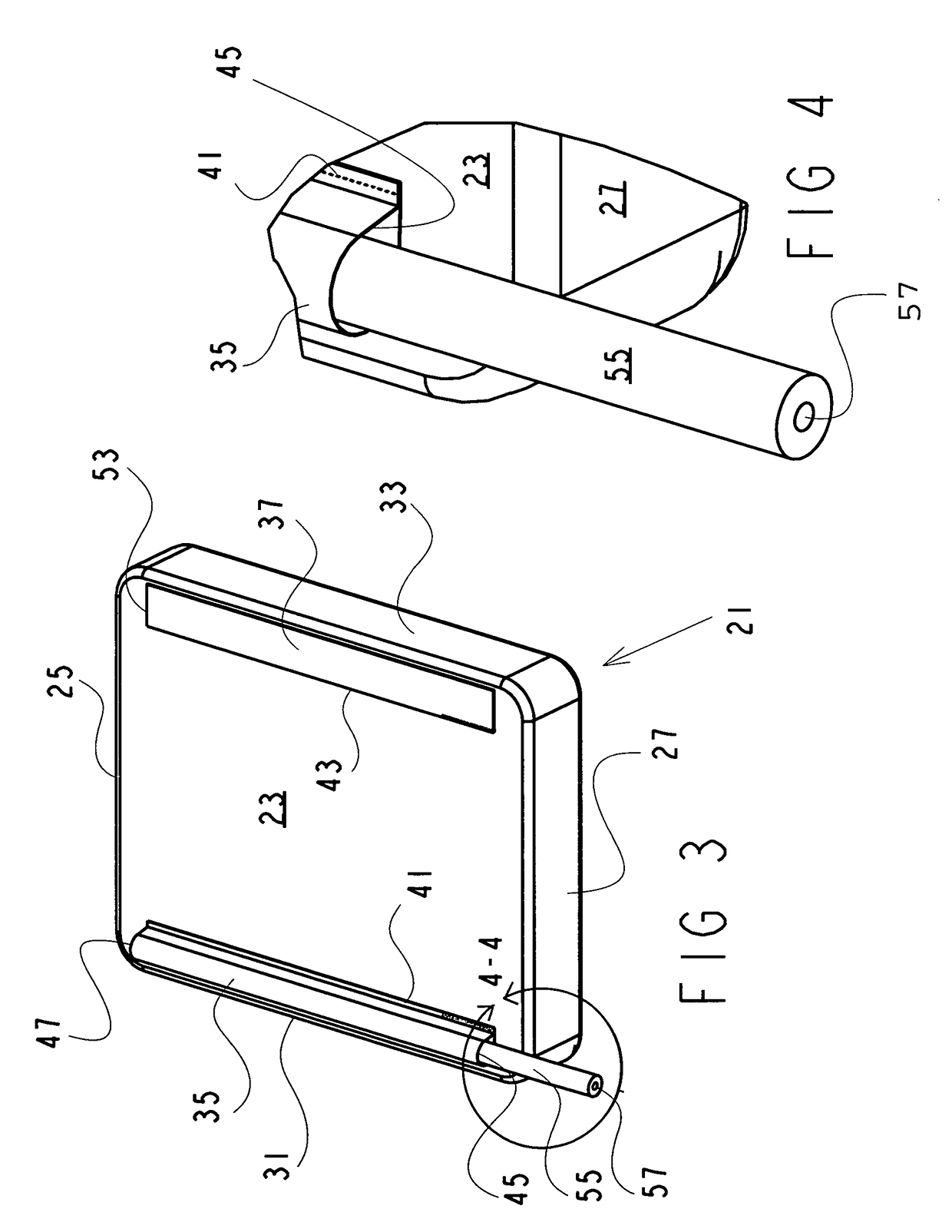

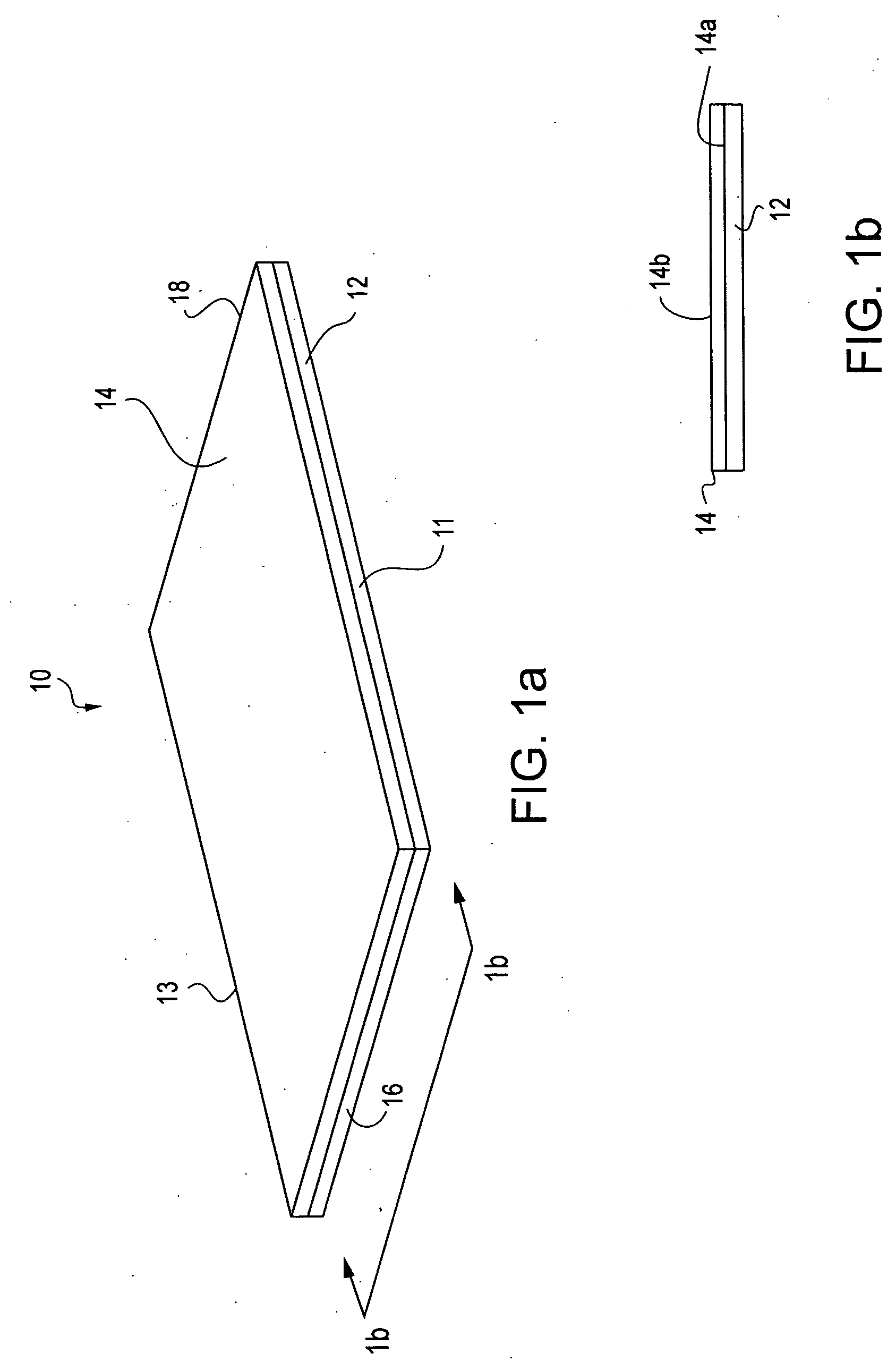

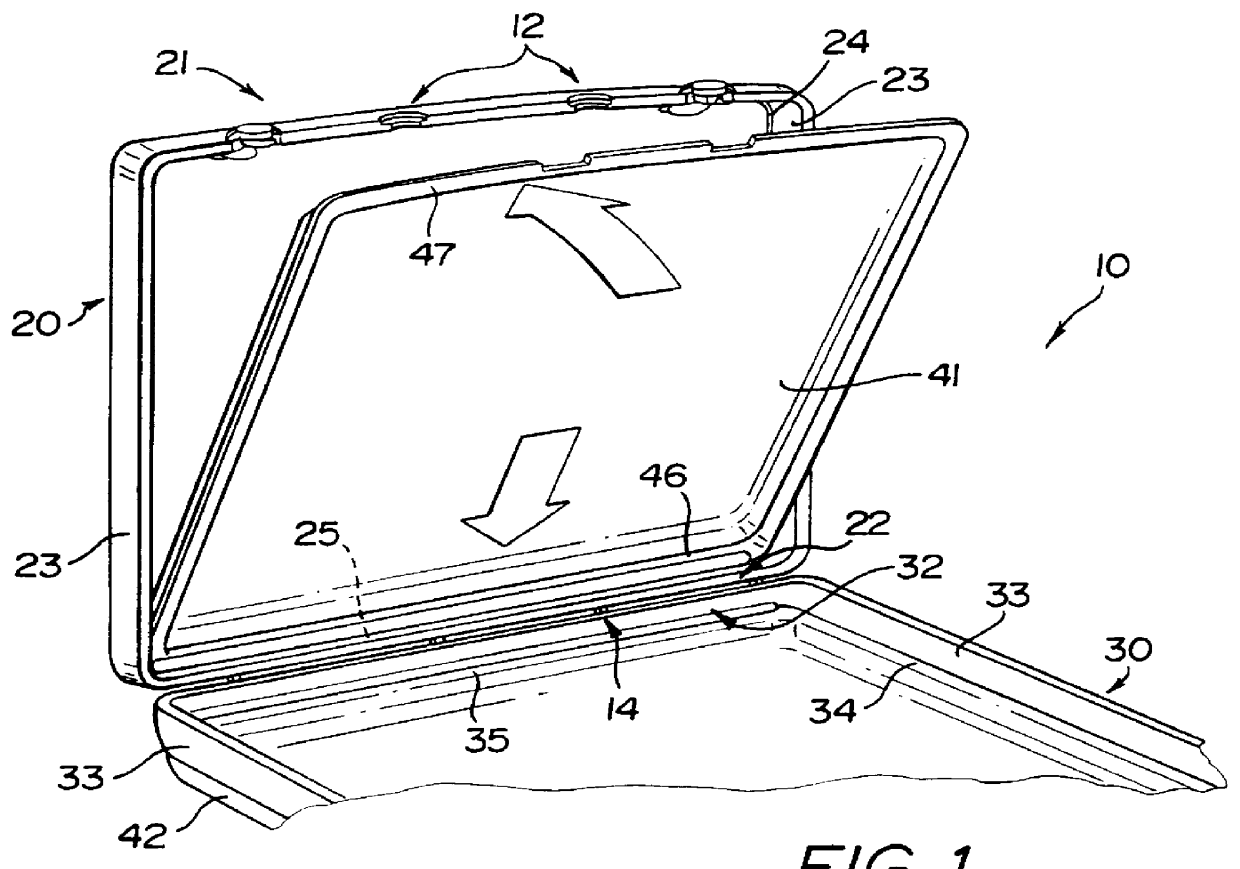

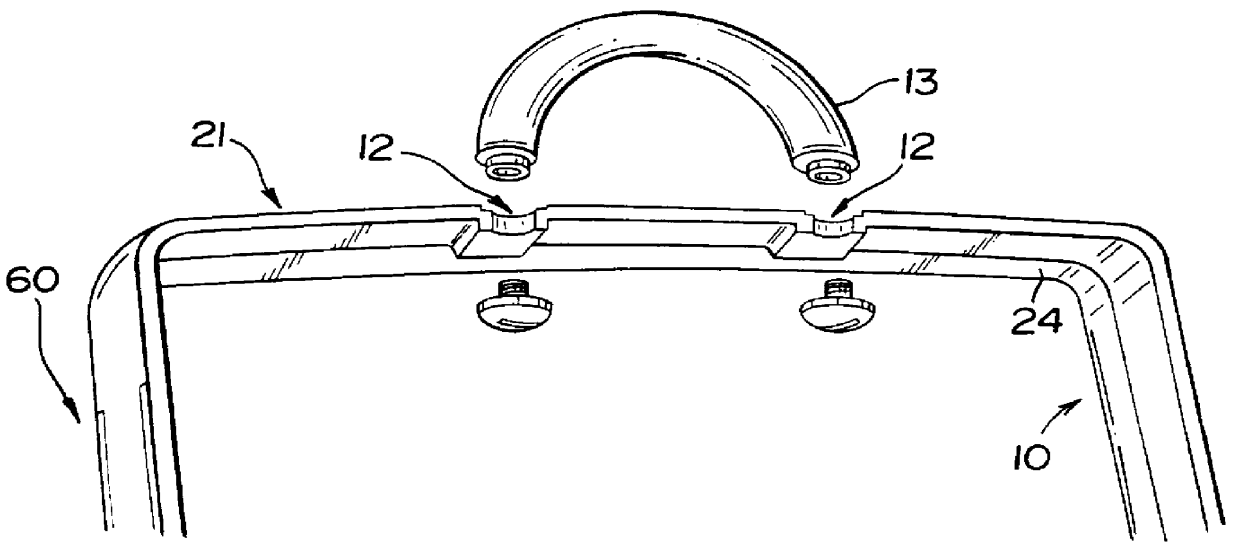

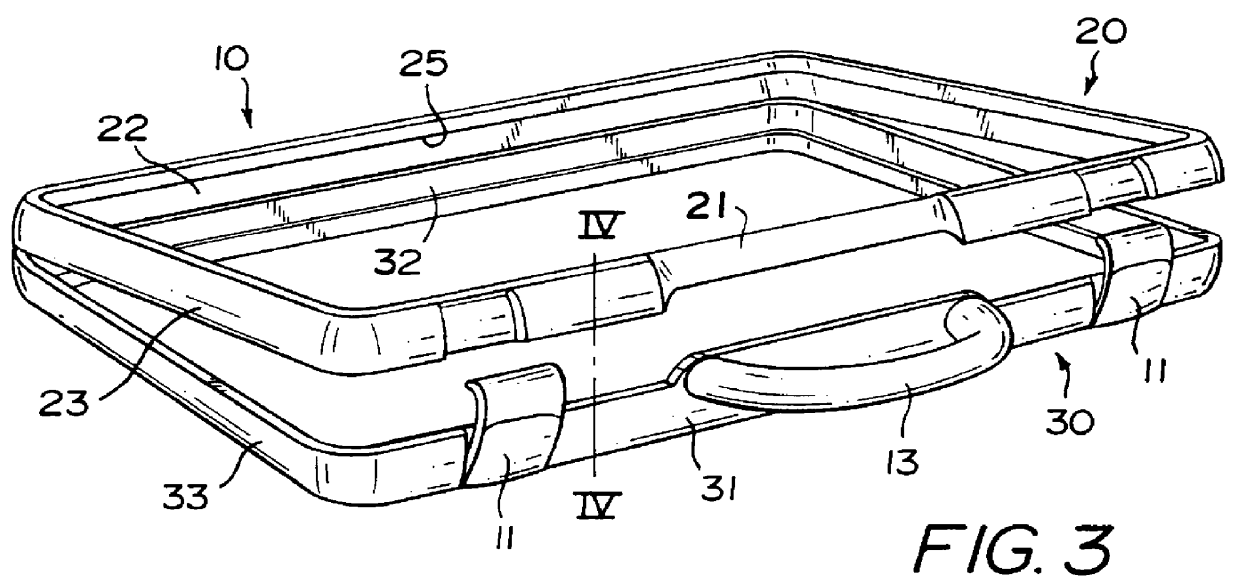

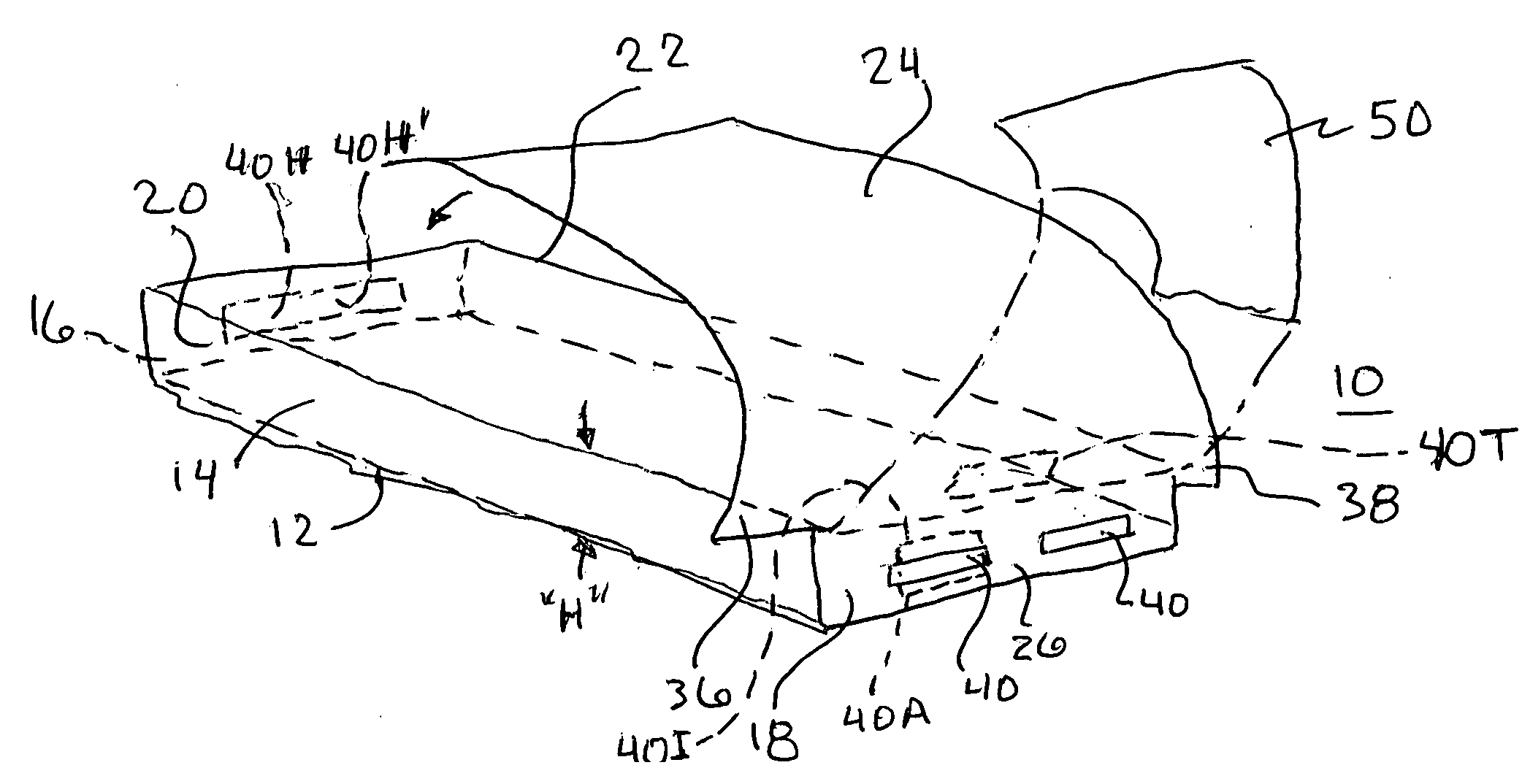

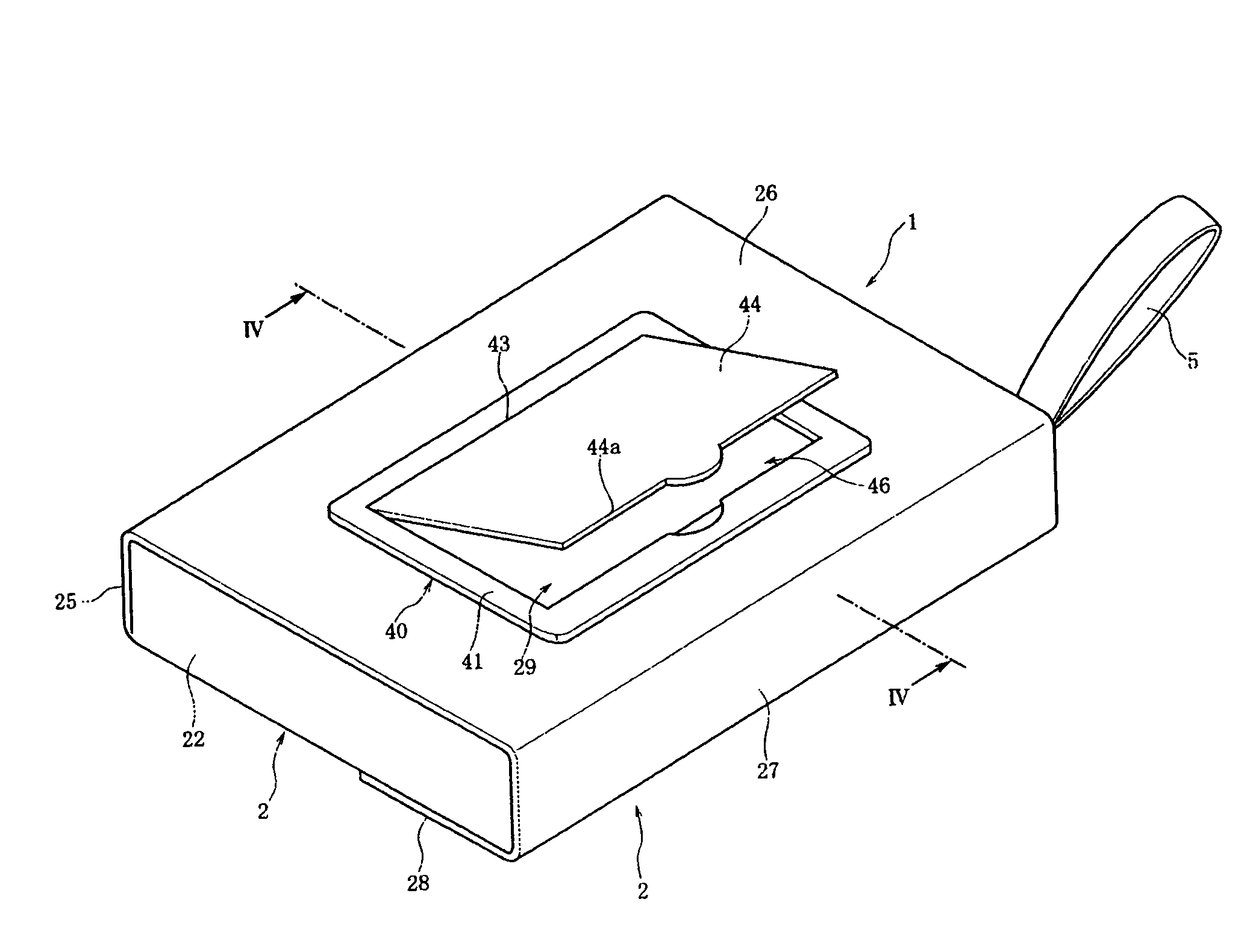

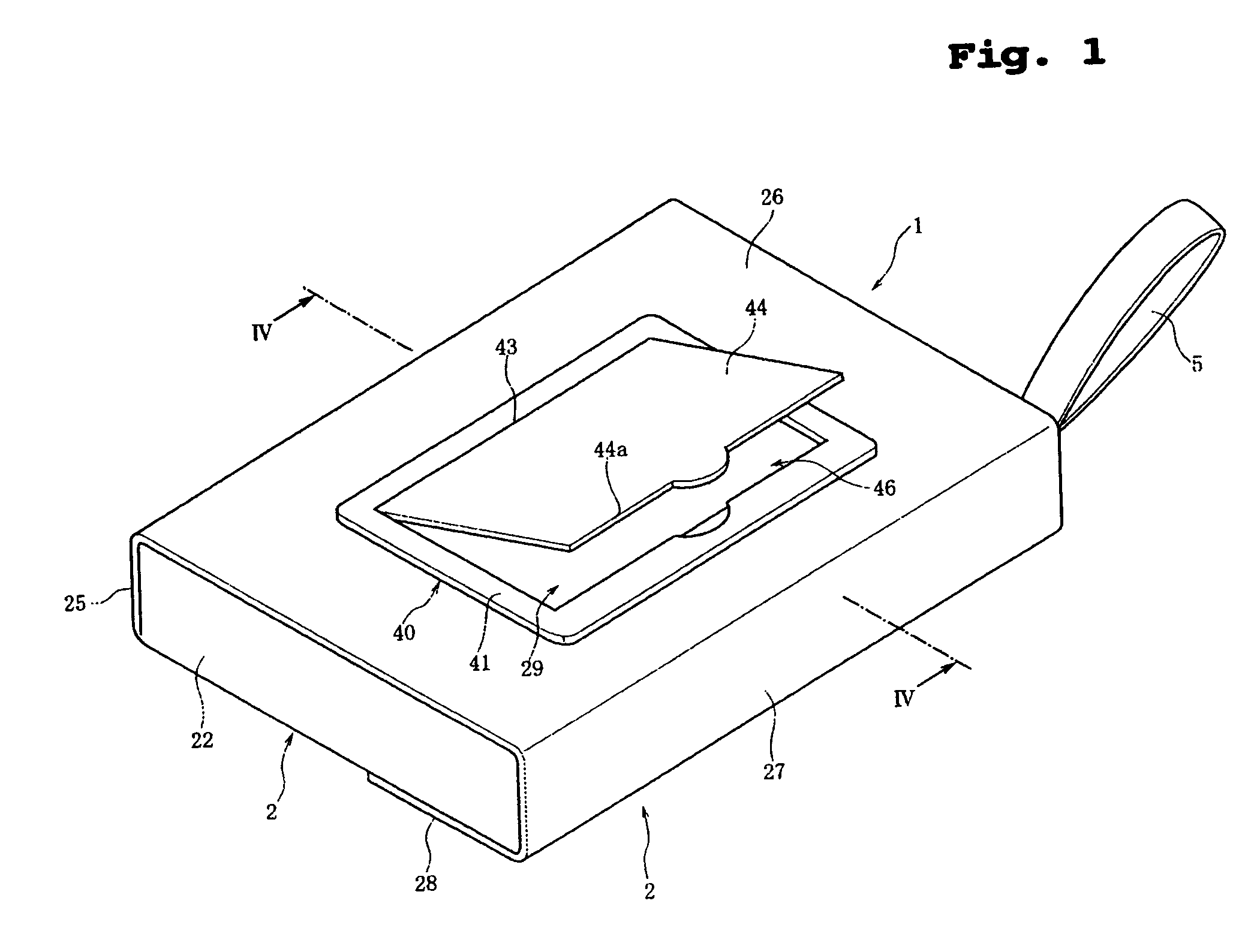

Suitcase with variable capacity

InactiveUS6050373AEasy to operateQuick exchangeTravelling sacksHandbagsEngineeringStructural engineering

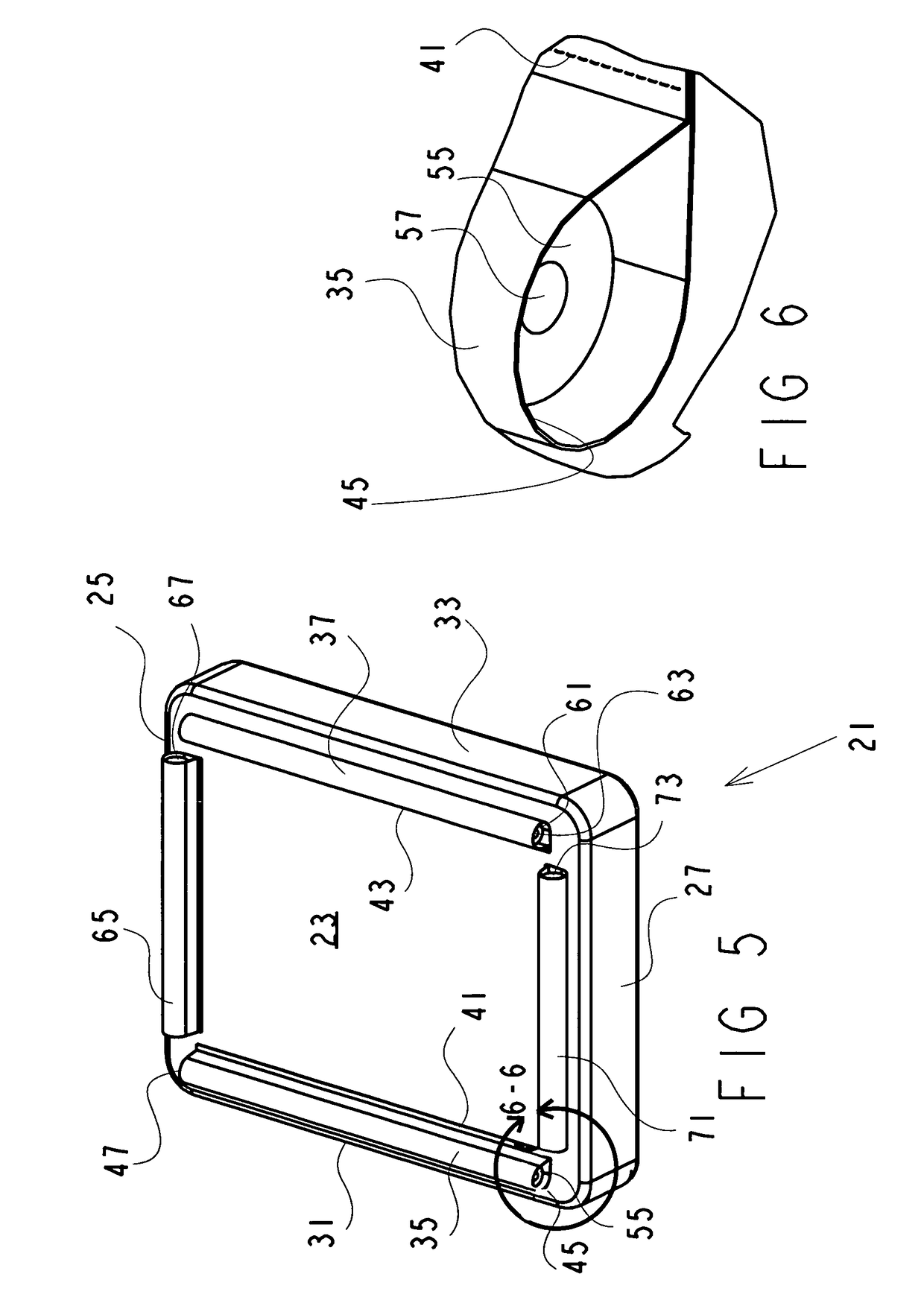

PCT No. PCT / EP95 / 02852 Sec. 371 Date Jan. 17, 1997 Sec. 102(e) Date Jan. 17, 1997 PCT Filed Jul. 19, 1995 PCT Pub. No. WO96 / 02160 PCT Pub. Date Feb. 1, 1996This invention relates to a case with a variable capacity, comprising a central part (10) which has two stable frame halves (20,30) hinged to one another which serve as supports for a single pair of various size sheet pairs (41,42;51,52) defining the interior of the case, the shells (41,42;51,52) being detachably connected to the frame halves (20,30) of the central part (10), so that shells of different depths may be used together with the same central part. The invention also relates to a set of cases, comprising a central part and two or several pairs of shells.

Owner:MP MICHAEL PFEIFFER DESIGN & MARKETING

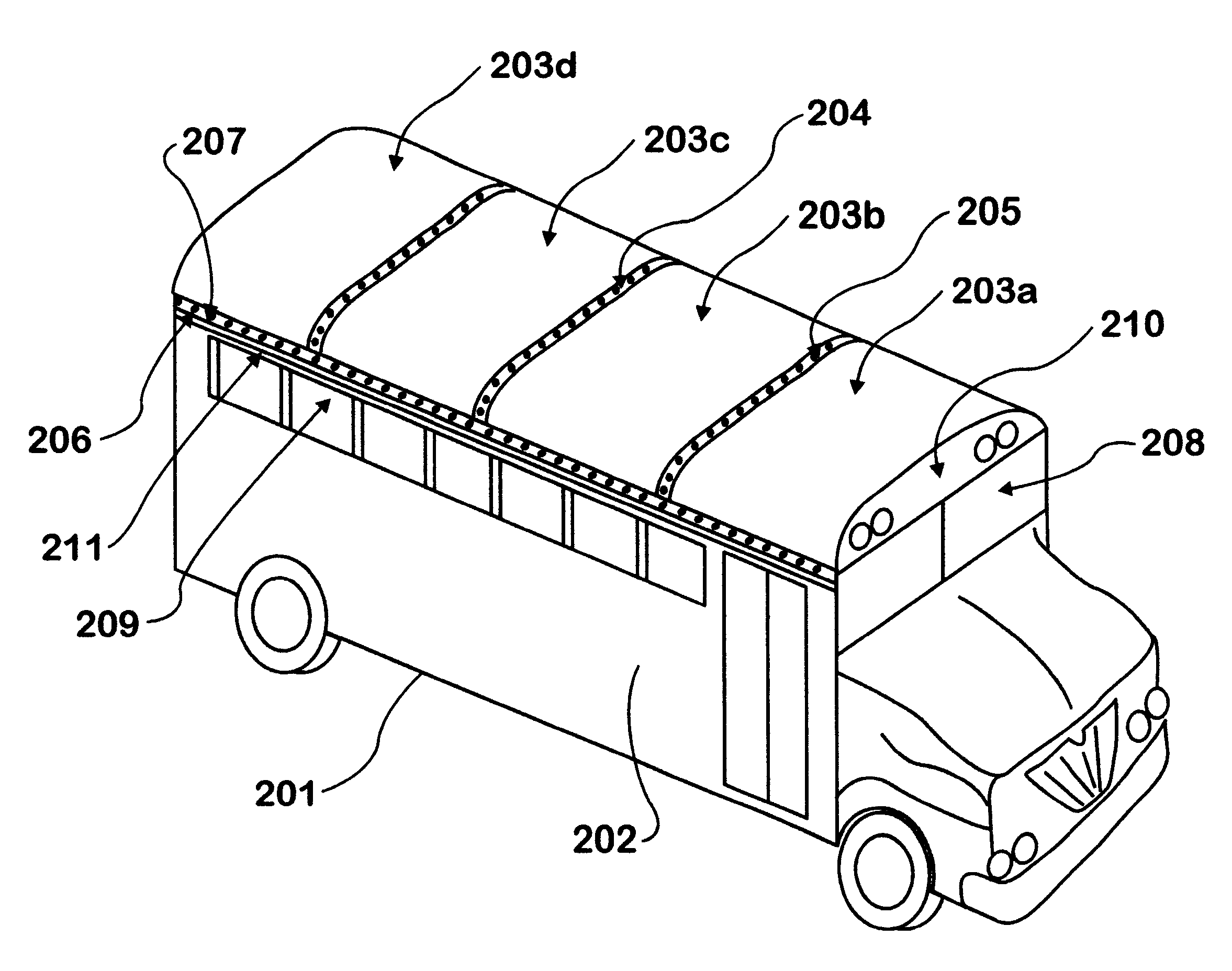

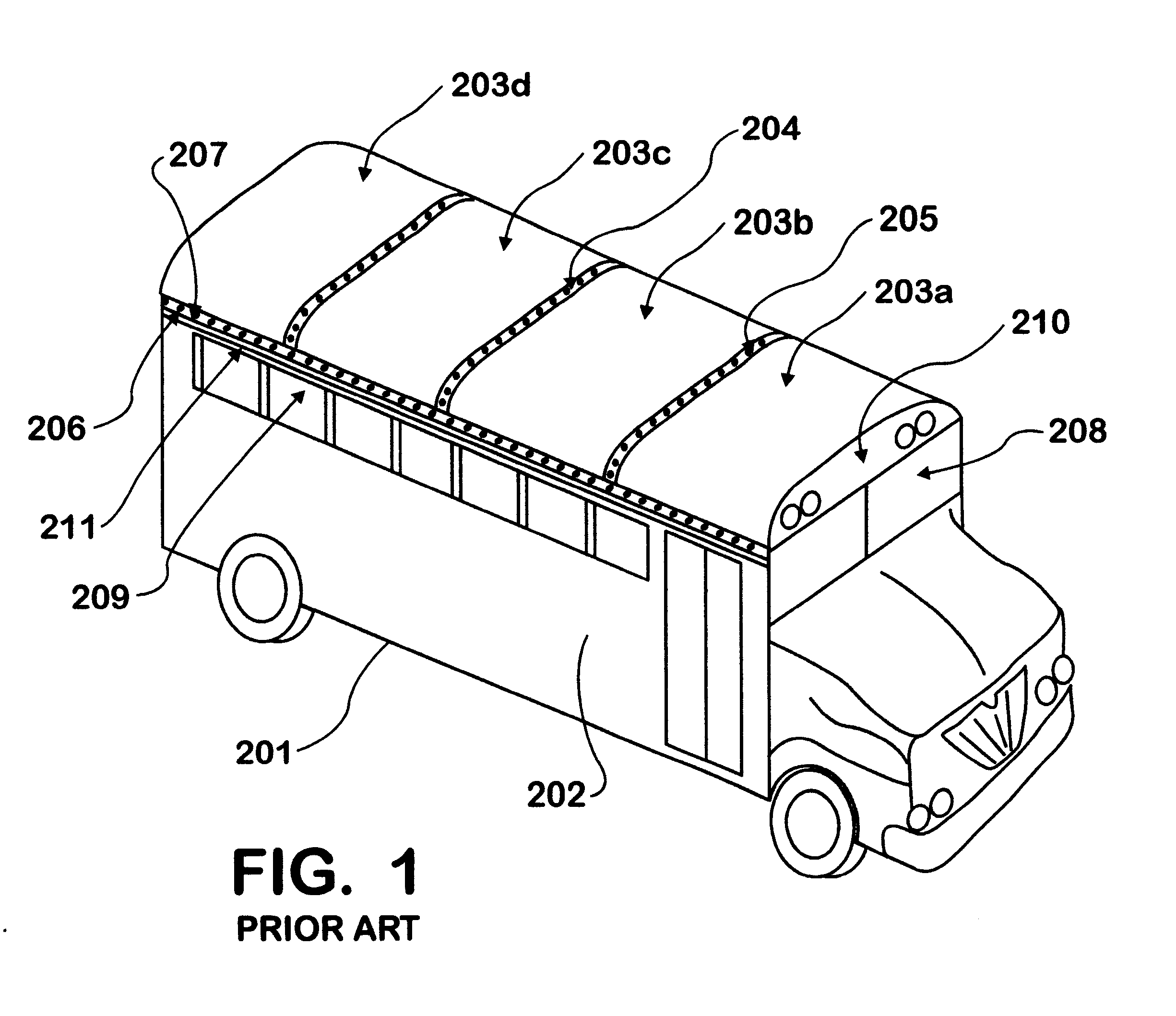

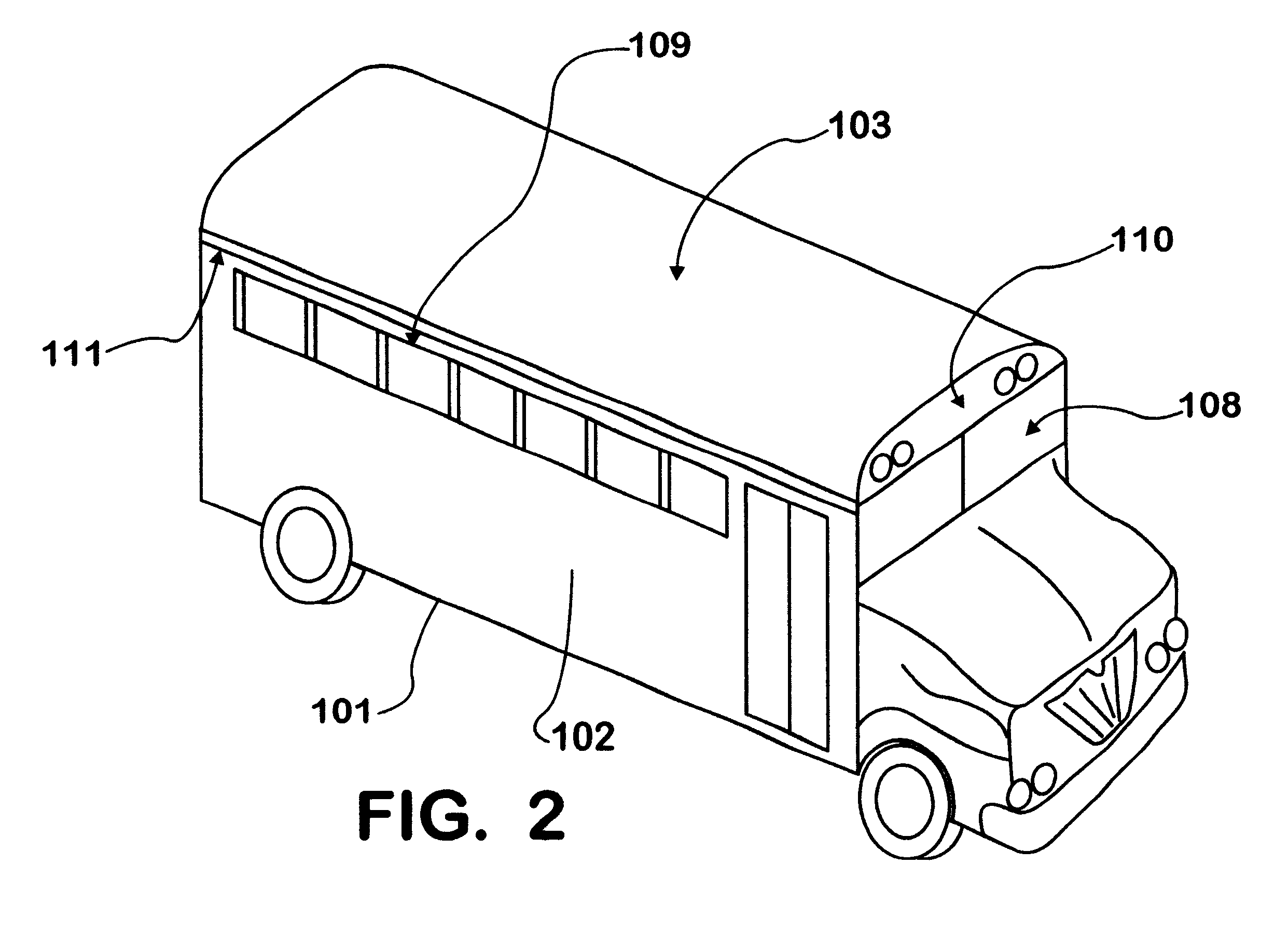

Unitized bus vehicle roof

A roof and mounting structure and a school or commercial bus vehicle provide improved leakage protection to the passenger compartment of the vehicle. The roof is an integral unitized roof structure that reduces or eliminates the opportunity for leakage by replacing rivets with adhesive or adhesive tape as the joining force between the roof skin and supporting structure and by decreasing the number of potential leakage points by decreasing the number of parts making up the roof from many overlapping panels to what is effectively a single sheet. This single unitized roof may actually be comprised of two strips of metal welded together or crimped together along a seam.

Owner:INT TRUCK INTPROP LLC

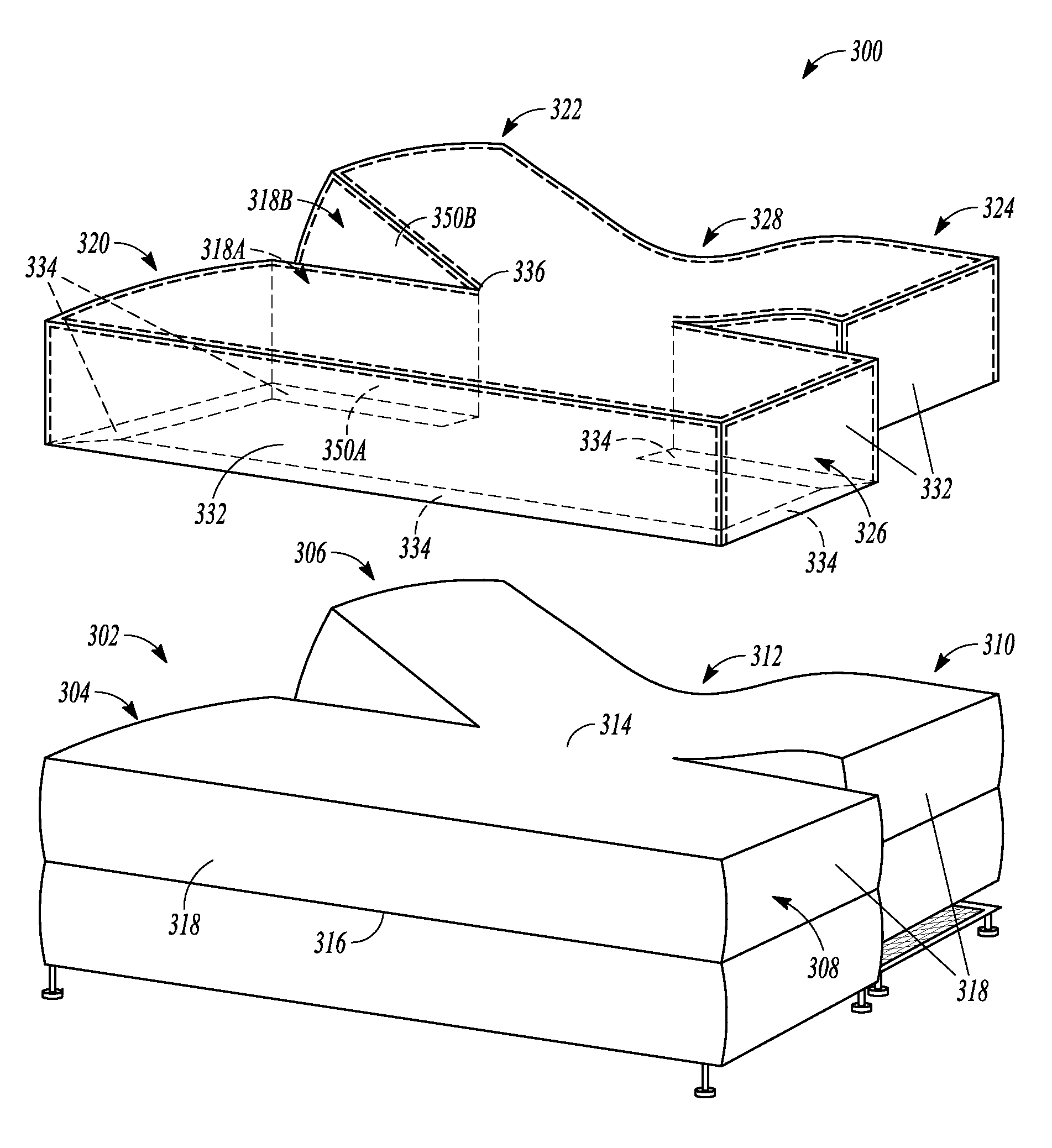

Conformable bedding arrangement

A bed sheet construction assembly utilized in the “making” of a bed mattress while eliminating unnecessary time and confusion therewith, comprising a lower mattress-fitted sheet having a first and a second side portion and a head and a foot portion thereon. The first and second side portions are longer than the head and foot portions. An upper or top sheet has a first and a second side portion and a head and a head and a foot portion thereon. The first and second side portions are longer than the head and foot portions. A notched-out corner is arranged on each side of the foot end of the top sheet. An attachment means is arranged between the lower fitted sheet and the upper or top sheet along their respective foot ends.

Owner:SACCHETTI WILLIAM B

Blended yarn weaved fabric based on novel flame retardant viscose, preparation method and application thereof

InactiveCN101538764AIdeal twistImprove flame retardant performanceWeft knittingFlame-proof filament manufactureYarnChemical treatment

The invention relates to a novel flame retardant fabric, a preparation method and an application thereof, particular to a blended yarn weaved fabric based on novel flame retardant viscose, a preparation method and an application thereof. The flame retardant viscose is prepared by blended spinning with nanometer SiO2 and cellulose solution; wherein the blended ratio of the flame retardant viscose and natural fiber is 20:80 to 80:20. The invention also provides the preparation method of the flame retardant blended yarn weaved fabric. As the nanometer SiO2 particles are adopted as inorganic flame retardant, the novel flame retardant blended yarn weaved fabric is good in fire resistance; limited oxygen index is more than 28%, meltdown or dripping can not appear when combusting, only a small quantity of flue gas which is safe and innoxious is produced, and the fabric is washing resistant and chemical treatment resistant. The invention has air and moisture permeability and soft feel. The blended yarn weaved fabric is mainly composed of the flame retardant viscose and cotton fiber, and can be applied to preparation of bedding such as bed sheet, quilt cover, pajamas, etc.

Owner:上海神九纺织科技有限公司

Container for housing wet sheet package

InactiveUS7416083B2Easy to carryGood effectFlat article dispensingOther accessoriesAdhesiveIndustrial engineering

A container for housing a package includes a case made of a flexible sheet. The package is adhered to a frame around a dispensing opening of the container through a pressure-sensitive adhesive layer. The frame has a lid. When the lid is opened, wet sheets can be taken out of the package. Since the frame is adhered to the package around the dispensing opening, a simple fastener can be used for keeping the case in an unopened state.

Owner:UNI CHARM CORP

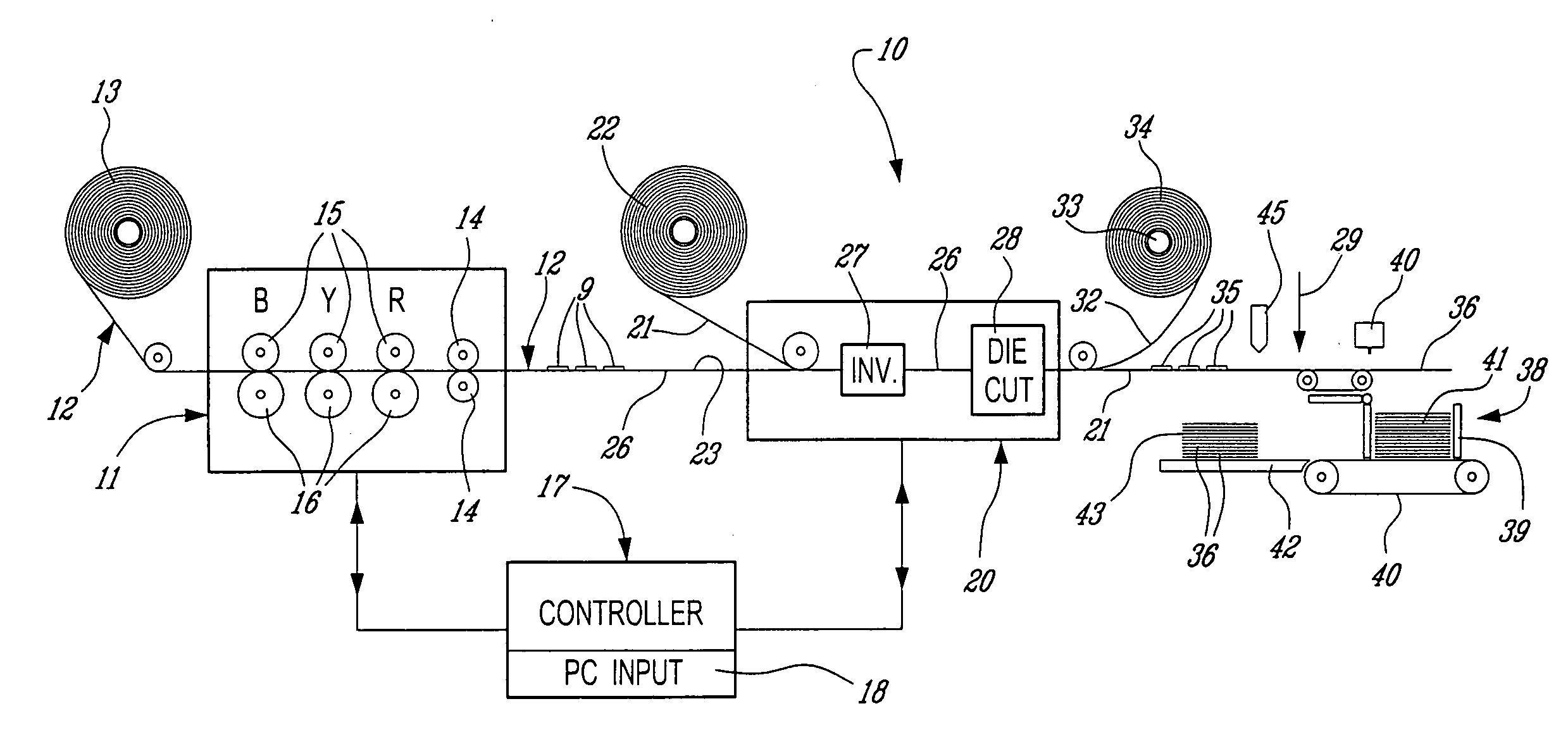

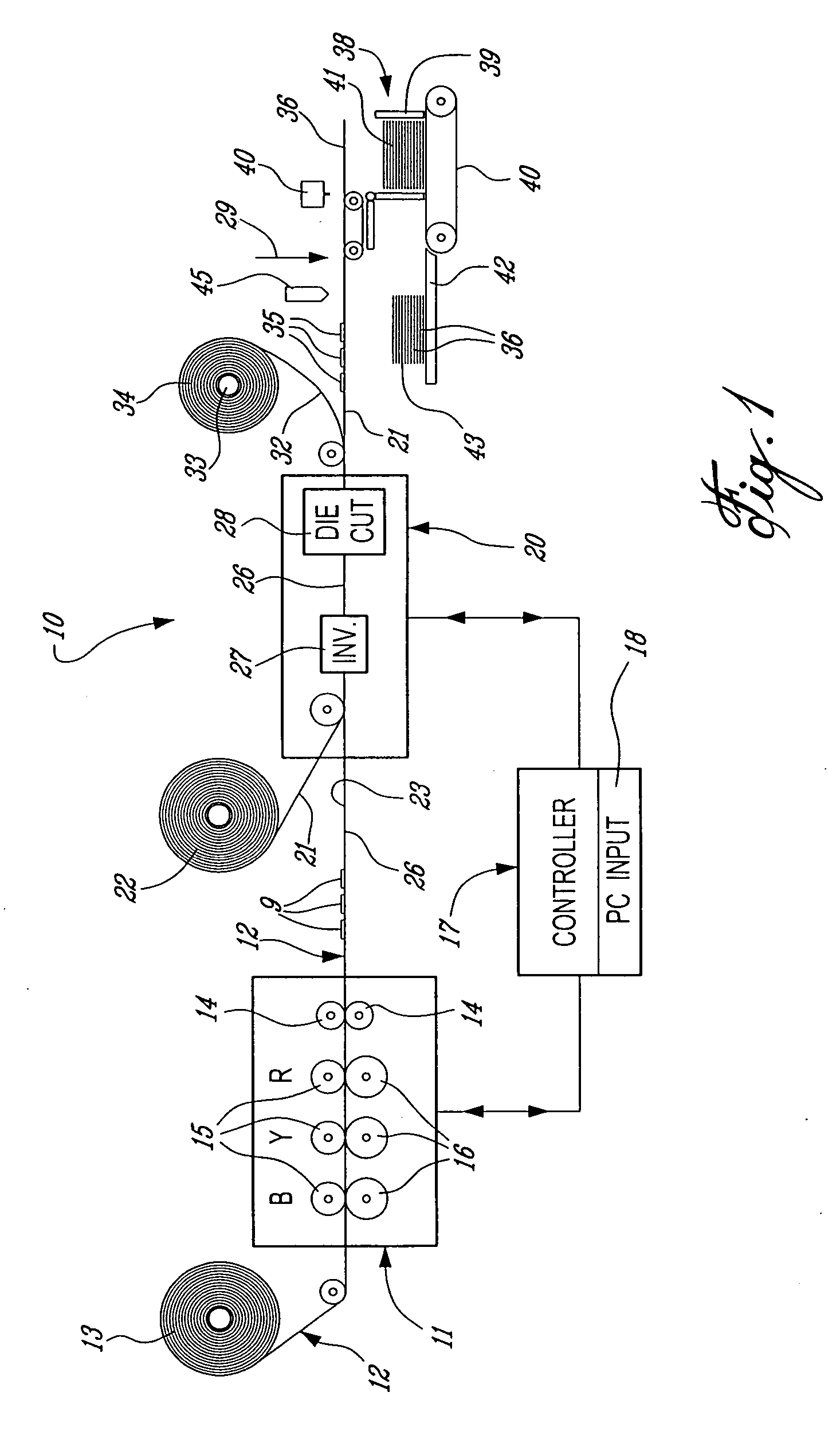

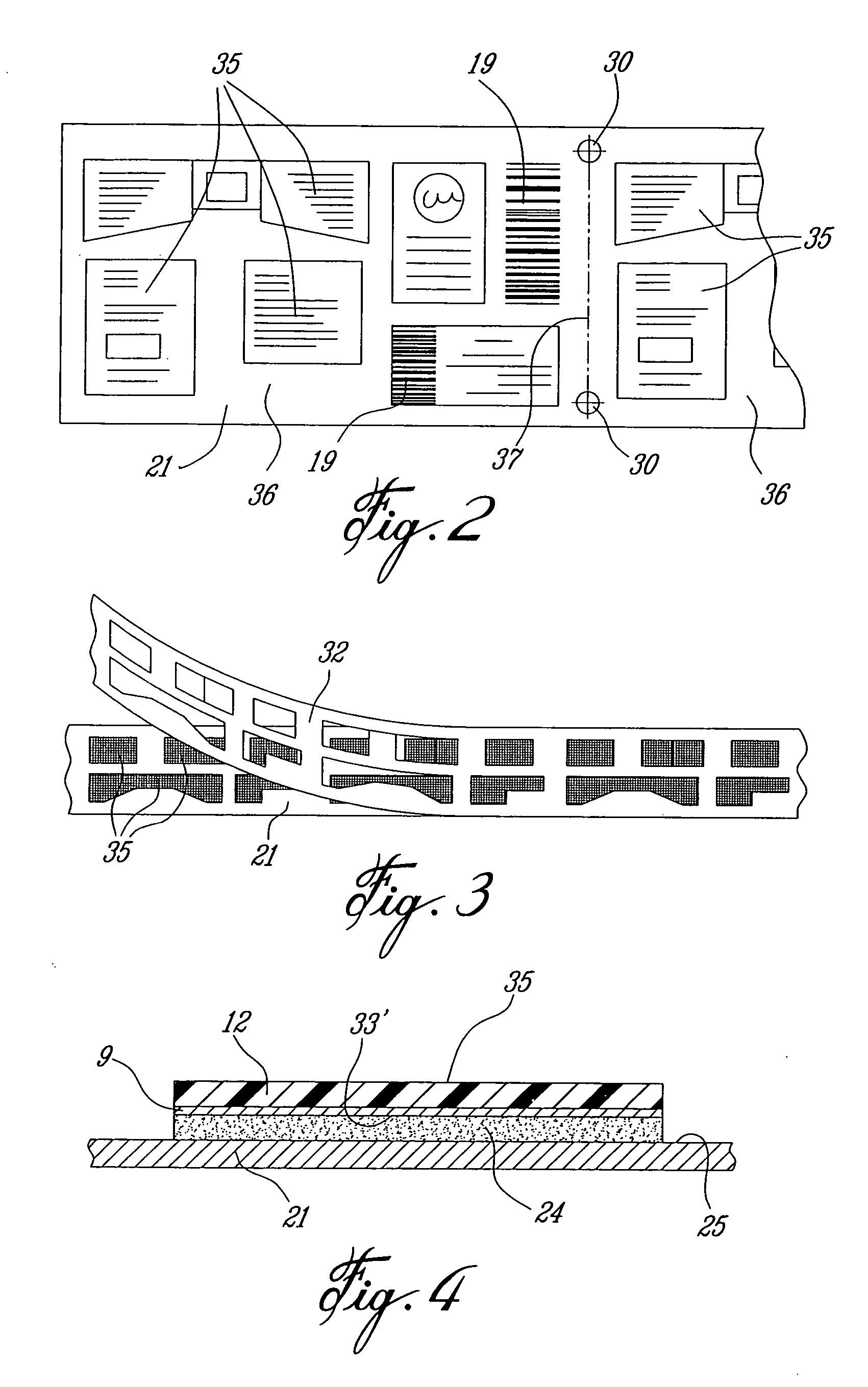

Method and system for manufacturing label kits comprised of carrier sheets having labels of specific shape removably retained thereon

InactiveUS20060233995A1Improve efficiencyStampsLamination ancillary operationsComputer printingControl data

A method and a system for the manufacture of label kits is described. Each kit comprises a one or more of carrier sheets having one or more labels of specific shape and containing specific information associated with a specific product or parts thereof on which they are to be affixed. The labels have an adhesive backing removably retained on a surface of the carrier sheet. The user person that applies the labels to the specific product, or parts thereof, does not have to go through a selection process in determining which of one or more labels should be applied to a single part of the specific product. The kit overcomes this selection process and provides error-proofing and improvements in the efficiency of current assembly processes where specific products vary along an assembly line requiring different labels applied from one assembly to the next, such as in the assembly of automotive vehicles. Parts or assemblies require differing language and content on labels depending on the country or region of shipment. Varying product models or option content requires different labels from part to part or assembly to assembly. The system uses a digital printer and a laminator die-cutting machine which is computer controlled with the data being automatically printed and labels automatically cut into a web whereby to form detachable labels, some having a UV protected clear or opaque synthetic or paper surface material face sheet. The carrier sheets are cut from the web and individually place or stacked into kits or piles to form label kits containing a predetermined number of such labels associated with a specific product or part with the carrier sheets potentially containing a tracking code identifying the specific kit to the product.

Owner:DURAMARK TECH INC

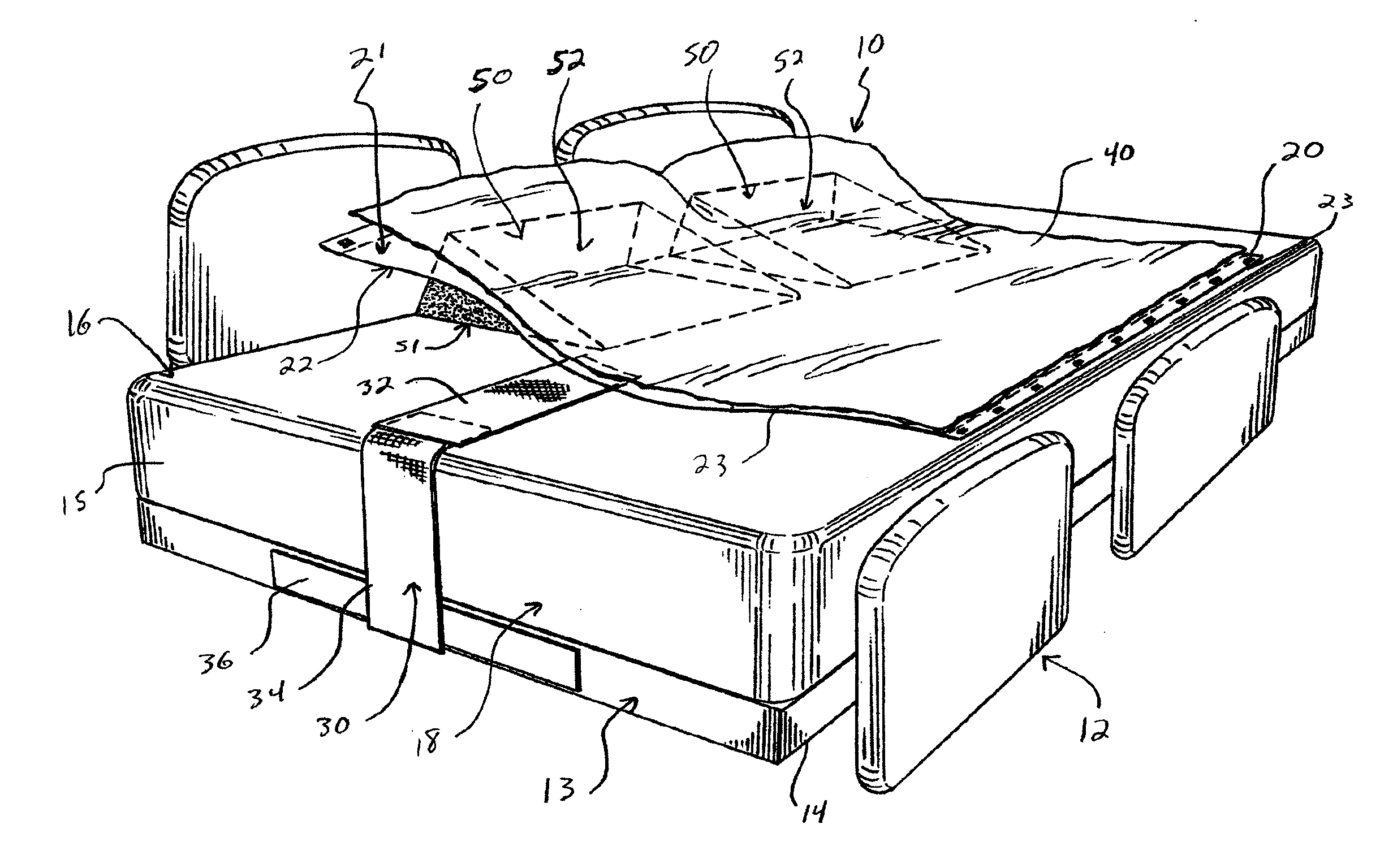

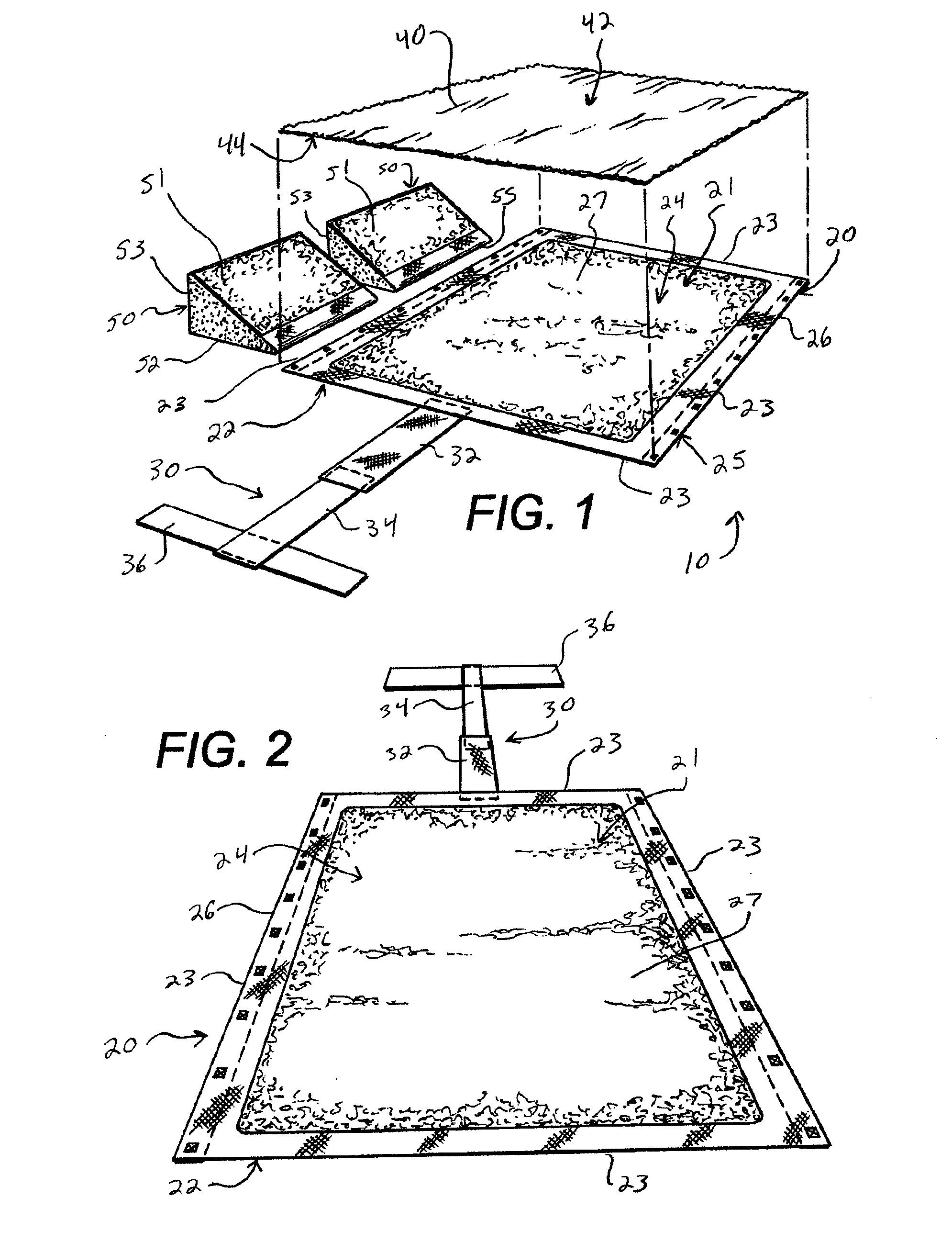

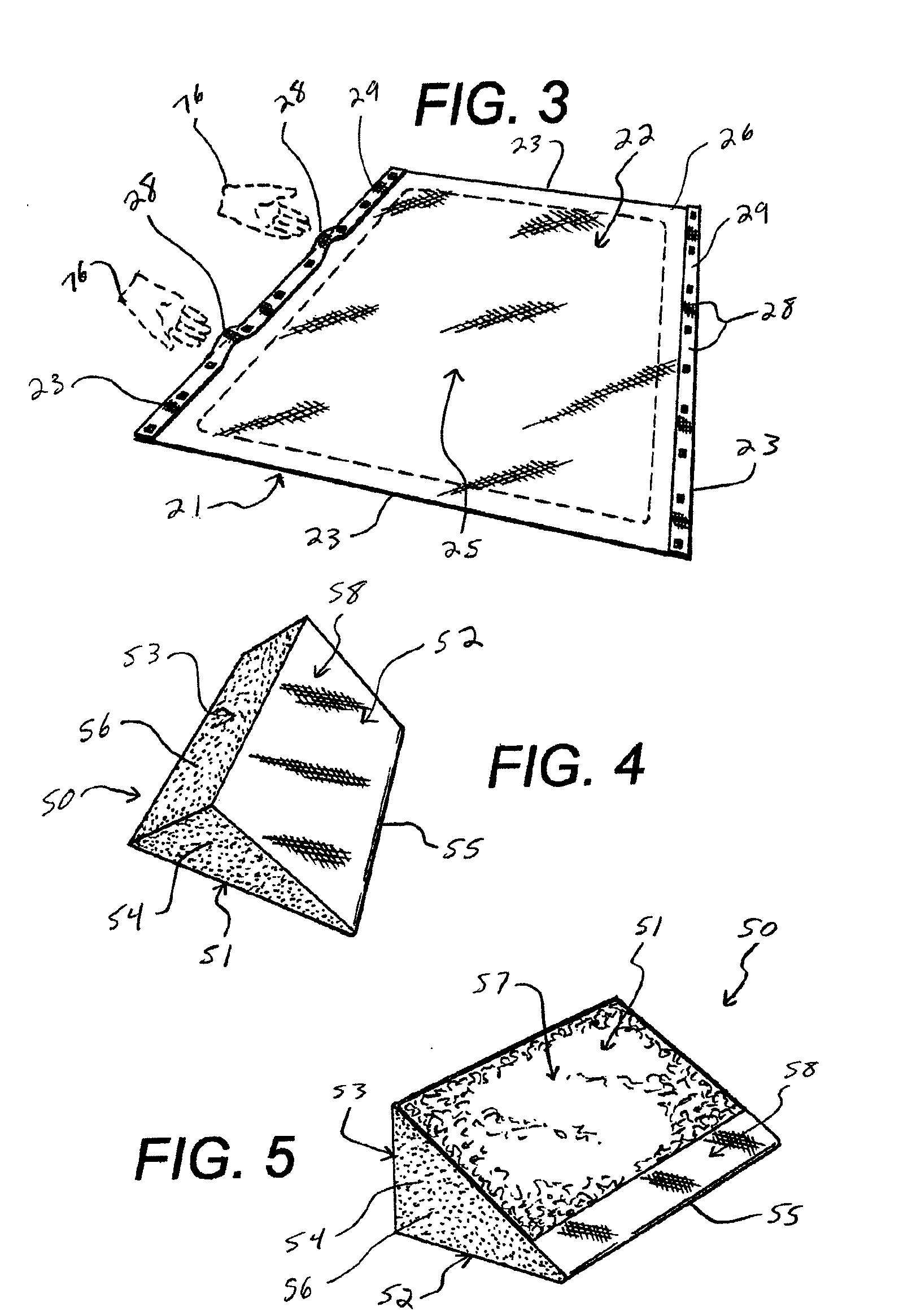

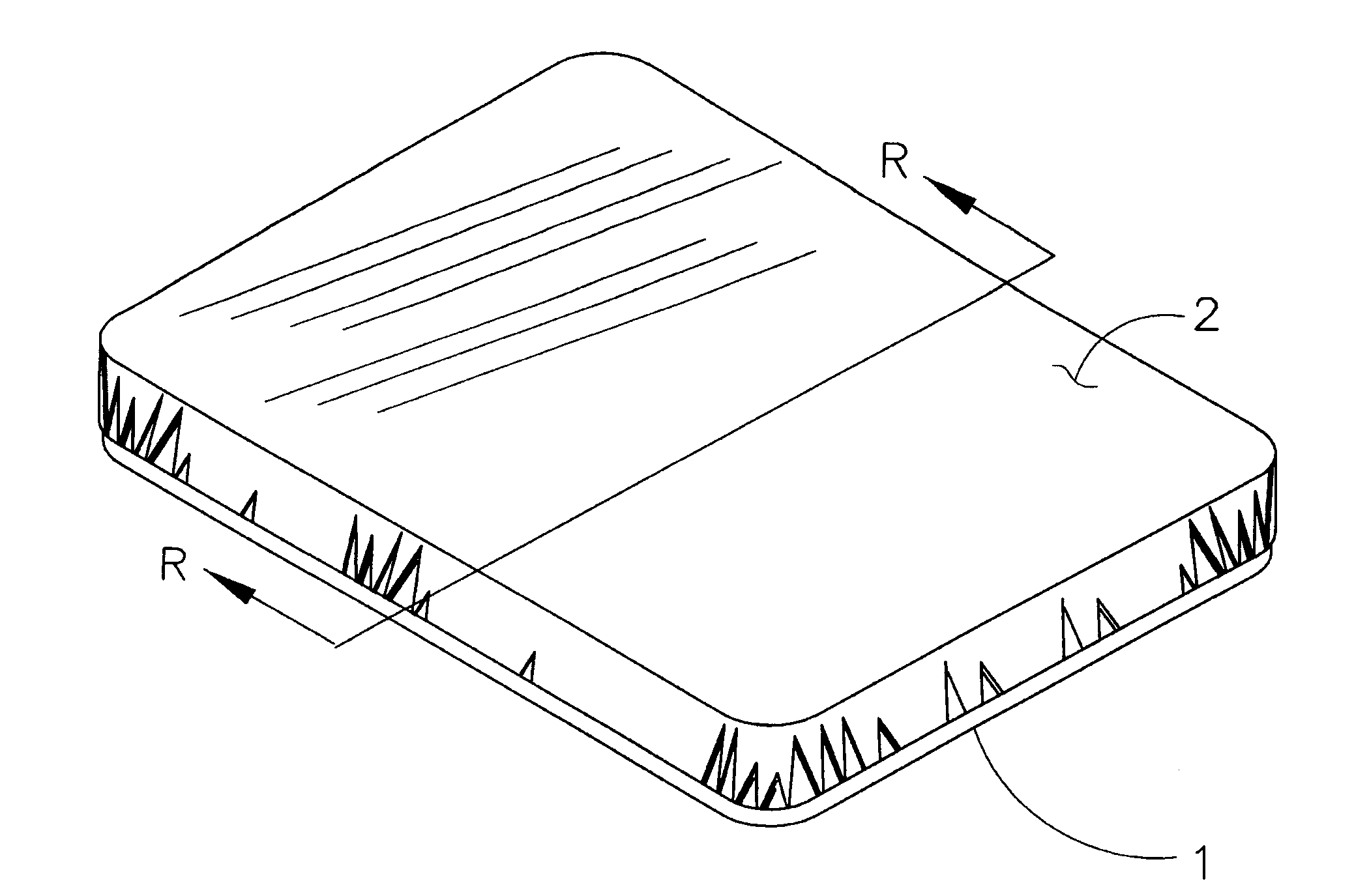

Apparatus and system for turning and positioning a patient

ActiveUS20120186012A1Reduce frictionIncrease the friction surfaceSofasWheelchairs/patient conveyanceClassical mechanicsEngineering

A device for use with a bed having a frame and a supporting surface includes a flexible sheet with a tether strap connected to the sheet and extending from the sheet. The flexible sheet has opposed top and bottom surfaces, with the top surface having a high friction material with a higher coefficient of friction as compared to the bottom surface, which includes a low friction material. The tether strap is configured for connection to the frame of the bed to secure the sheet in place. A system incorporating the flexible sheet may also include an absorbent pad configured to be placed on the top surface of the sheet, where the high-friction top surface resists sliding of the absorbent pad, as well as one or more wedges having a base wall that the wedge rests on and a ramp surface configured to confront the sheet when the wedge is placed under the sheet. The base wall and the ramp surface may also contain high friction and low friction materials, respectively.

Owner:SAGE PRODS

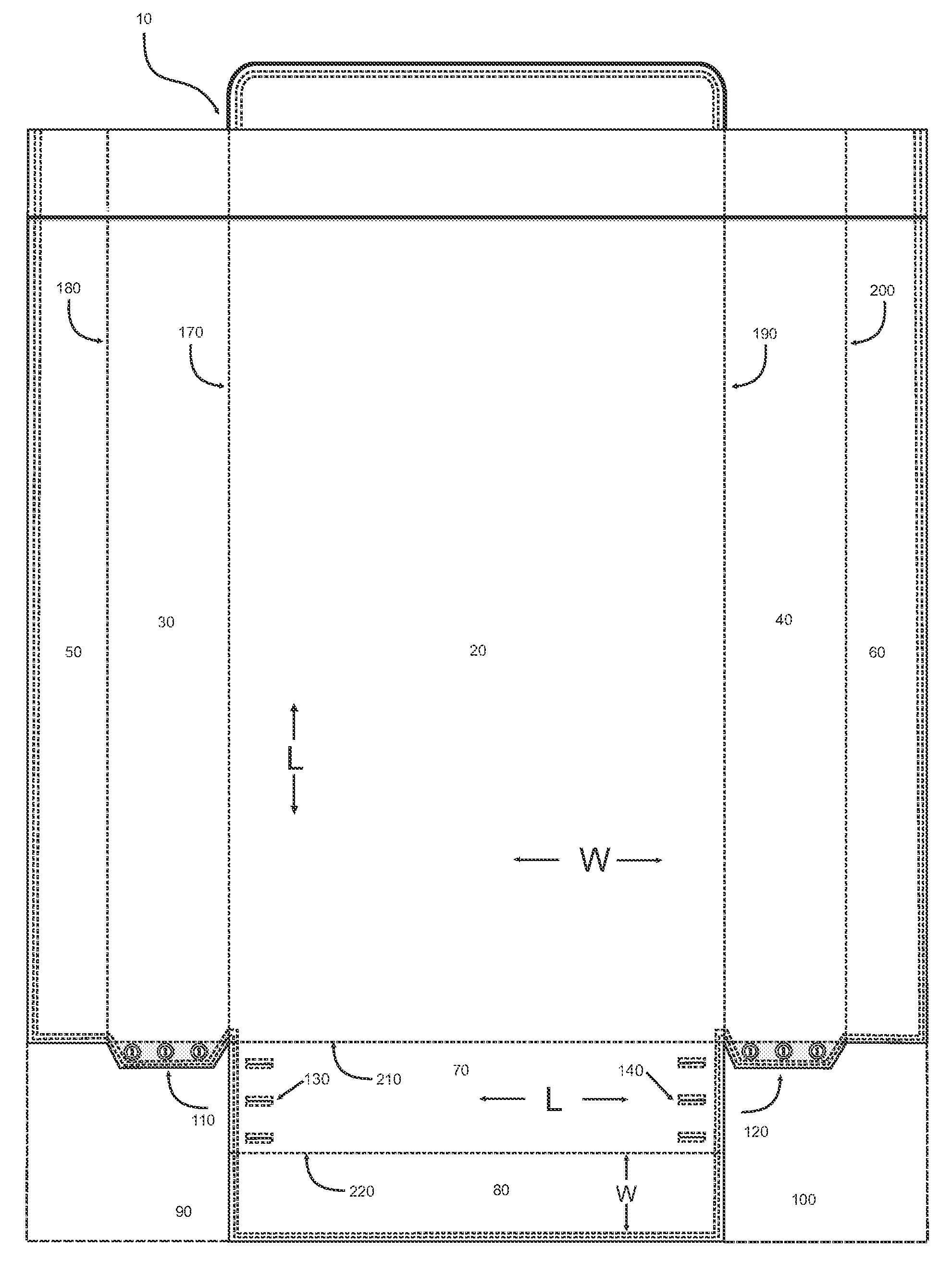

Cornerless sheets

ActiveUS20110023234A1Eliminates extra overageEliminates the extra overageBlanketBed linenEngineeringFastener

This invention relates to flat bedding top sheets having releasable corner fasteners adapted to releasably secure sheet to an underlying mattress by having male elements placed on one side panel brought into alignment and contact with female elements located on opposite corresponding side panels to form corners. Specifically, the bed sheet of the present invention is a fitted flat sheet having a cutout portions at both of its bottom corners that permit, with the aid of separable fasteners located at the cutout portions, to convert the sheet from a planar configuration to a configuration comprising two pockets adapted to retain the sheet on the mattress. The top sheets of the present invention do not require elastic strips around the corners of the sheets to secure the sheet to the mattress.

Owner:BOLISH ROBERT +1

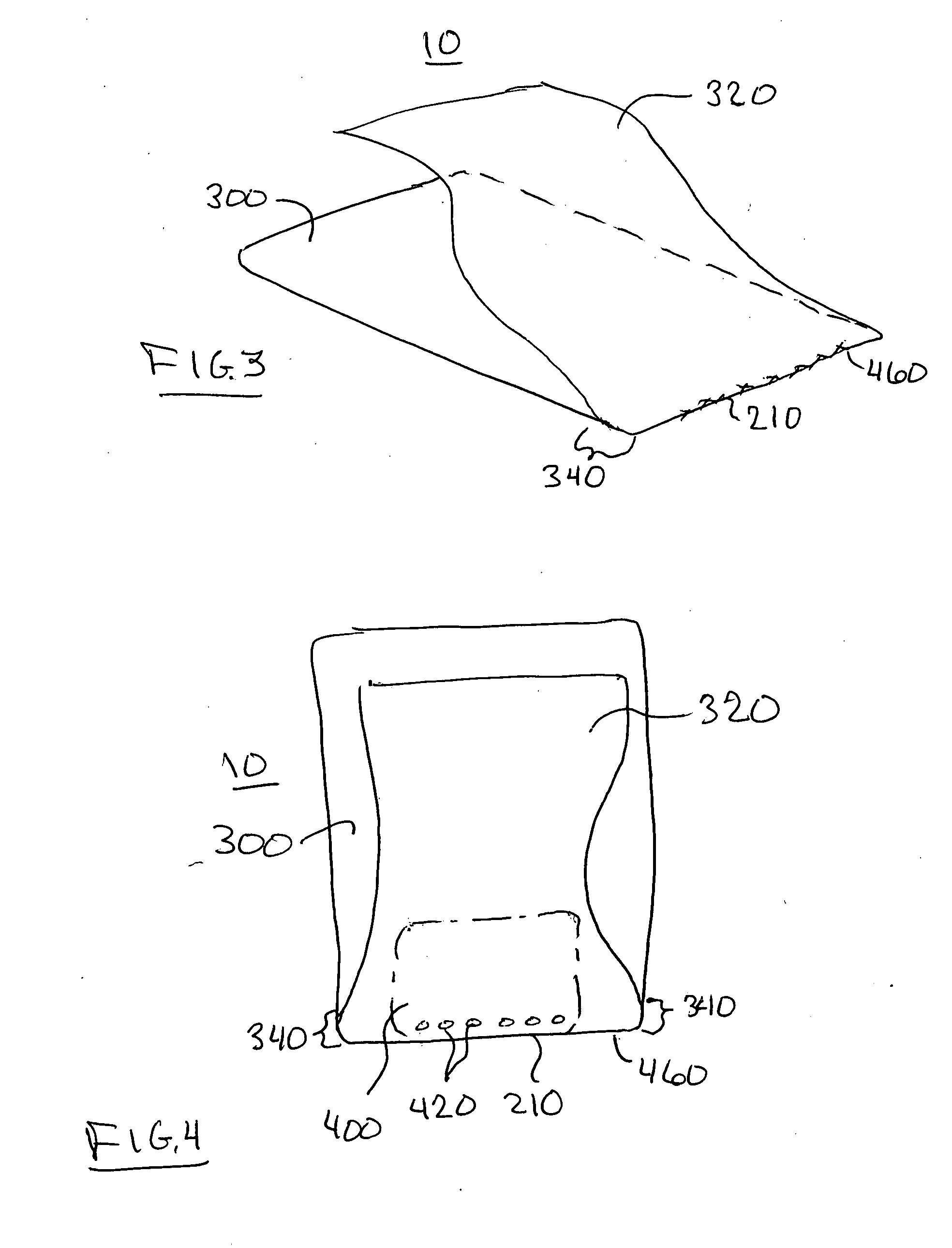

Infant sleeping system

A crib sheet with attachment points used to attach to the crib rails or bed frame. The crib sheet is used in combination with an infant sleep garment that attaches to the crib sheet by hook and loop mechanism. Attachment to the crib frame or bed frame, rather than the mattress, eliminates the risk that the infant's movements can cause the crib sheet to move or shift. Two points of attachment lie on either side of the shoulders or upper torso of the infant. The sleep garment has a arm restraint mechanism that acts to prevent movement of the infant's arms so that the infant cannot use its arms to escape the garment or to move itself about the crib or bed.

Owner:FRENCH DARCIE MARIE

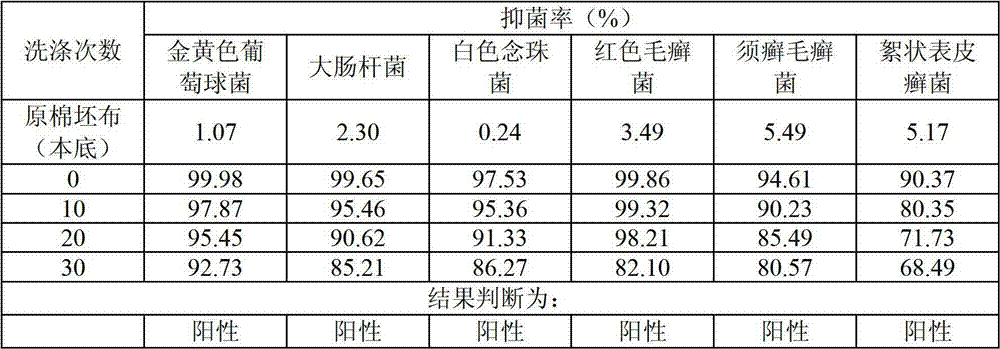

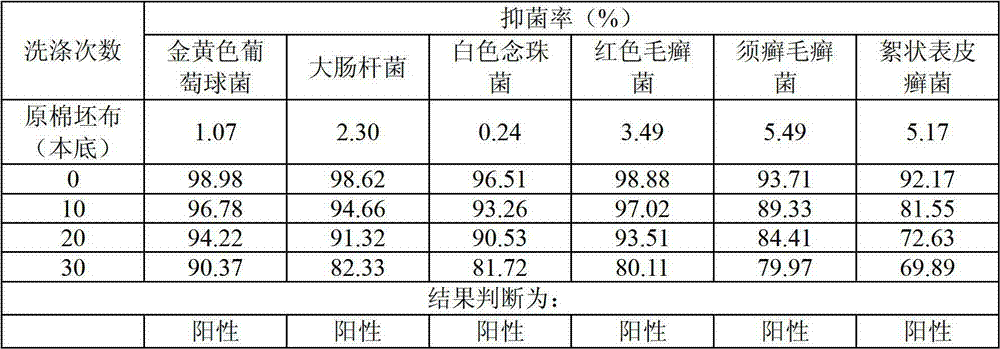

Finishing technology for aromatic anti-bacteria cotton textile

The invention discloses finishing technology for aromatic anti-bacteria cotton textile, which comprises the steps of extraction of active matters of plants, preparation of natural germicide and chitosan cross-linking and finishing technology of the cotton textile; finished knitted or machine-made cotton textile has long-time aroma and has health-care effect such as broad-spectrum bacteriostasis, sterilization, desinsectization and the like; in addition, the cotton textile disclosed by the invention has very good washability; and the cotton textile can be prepared as a plurality of knitted or machine-made health-care fabrics such as bras, underwear, pants, pajamas, pillowcases, bed sheets and the like.

Owner:JIANGSU SANFONDO TEXTILE BIOLOGICAL SCI & TECH

Apparatus for Folding, Stacking and Storing Bedsheets

InactiveUS20080264983A1Easy to useSimple and inexpensive to manufactureTextiles and paperFolding apparatusEngineeringBed sheets

This invention relates to a method and apparatus for folding cloth articles, such as bed sheets and the like, for stacking and storing by providing a rigid or semi rigid apparatus to be folded and incorporated with the folded sheets.

Owner:KASTAN JOSEPH

Antimicrobial yarn having nanosilver particles and methods for manufacturing the same

InactiveUS20030190851A1The process is simple and fastEasy to carryYarnConductive materialsYarnEngineering

The present invention provides a yarn with antimicrobial effects. The antimicrobial antifungal effect of the yarn is derived from nanosilver particles (diameter between 1 and 100 nm) which are adhered to the yarn. The yarn contains fibers which are made of cotton, linen, silk, wool, leather, blending fabric, synthetic fiber, or any combination thereof. The yarn can be used to make cloth to be used particularly for treating patients with burns or wound. The cloth made from the antimicrobial yarn can be further used to make clothes such as underwears, socks, shoe cushions, shoe linings, bed sheets, pillow cases, towels, women hygiene products, laboratory coats, and medical robes. The present invention also provides a method for making the antimicrobial yarn.

Owner:CC TECH INVESTMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com