Finishing technology for aromatic anti-bacteria cotton textile

A cotton fabric and process technology, which is applied in the field of finishing process of aromatic and antibacterial cotton fabrics, can solve the problems of pH sensitivity of chitosan antibacterial activity, and achieve the effects of wide antibacterial spectrum, strong environmental adaptability and environmental optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

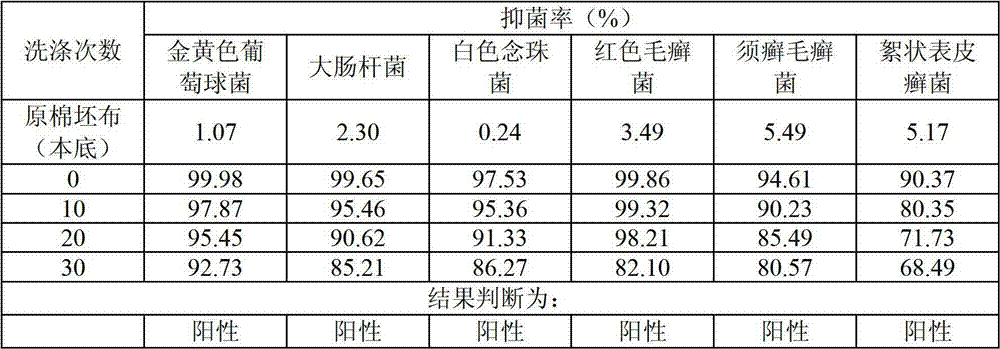

Embodiment 1

[0041] (1) Extraction of plant active substances:

[0042] Take 100g of leaves of lemongrass, flowers of clove, root of comfrey and leaves of Artemisia argyi of fresh plants, grind them, distill them with steam respectively, collect 100mL of distillate, filter the medicinal solution in the distiller, and obtain the four kinds of plants. Active substance extract.

[0043] (2) Preparation of natural antibacterial agent:

[0044] Mix the extracts of active substances of citronella, clove, comfrey and mugwort leaves described in step (1) according to (volume ratio) 10:30:30:30 to obtain a natural antibacterial agent.

[0045] (3) Chitosan cross-linking finishing process of cotton fabric:

[0046] The first step is to prepare the finishing liquid, wherein:

[0047] Natural antibacterial agent 200mL / L;

[0048] Chitosan 3g / L;

[0049] Citric acid 40g / L;

[0050] Sodium hypophosphite 10g / L;

[0051] The solvent is water.

[0052] In the second step, the finishing liquid is he...

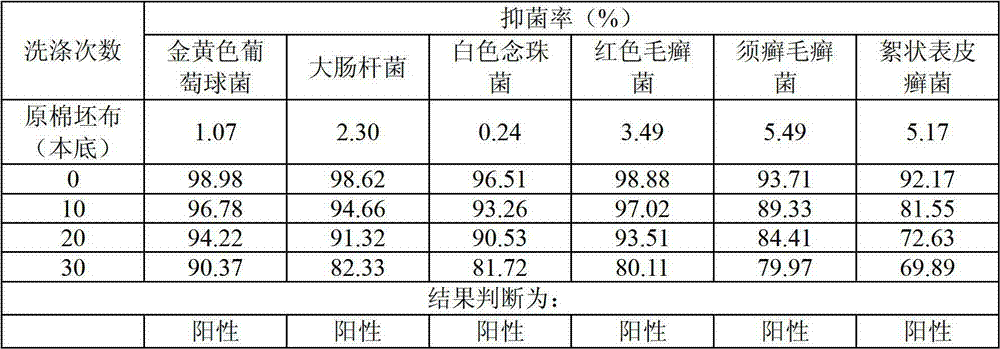

Embodiment 2

[0061] (1) Extraction of plant active substances:

[0062] Take 100g of leaves of lemongrass, flowers of clove, root of comfrey and leaves of mugwort leaves of fresh plants, grind them, distill them with water steam respectively, collect 80mL of distillate, filter the liquid medicine in the distiller, and obtain the four kinds of plants. Active substance extract.

[0063] (2) Preparation of natural antibacterial agent:

[0064] Mix the extracts of active substances of citronella, clove, comfrey and mugwort leaf as described in (1) according to (volume ratio) 10:50:30:10 to obtain a natural antibacterial agent.

[0065] (3) Chitosan cross-linking finishing process of cotton fabric:

[0066] The first step is to prepare the finishing liquid, wherein:

[0067] Natural antibacterial agent 100mL / L;

[0068] Chitosan 3g / L;

[0069] Citric acid 20g / L;

[0070] Sodium hypophosphite 10g / L;

[0071] The solvent is water.

[0072] The second step is to heat the finishing solution...

Embodiment 3

[0081] (1) Extraction of plant active substances:

[0082] Take 100g of leaves of lemongrass, flowers of clove, root of comfrey and leaves of Artemisia argyi of fresh plants, grind them, distill them with steam respectively, collect 100mL of distillate, filter the medicinal solution in the distiller, and obtain the four kinds of plants. Active substance extract.

[0083] (2) Preparation of natural antibacterial agent:

[0084] Mix the extracts of active substances of citronella, clove, comfrey and mugwort leaves as described in (1) according to (volume ratio) 30:30:30:10 to obtain a natural antibacterial agent.

[0085] (3) Chitosan cross-linking finishing process of cotton fabric:

[0086] The first step is to prepare the finishing liquid, wherein:

[0087] Natural antibacterial agent 300mL / L;

[0088] Chitosan 20g / L;

[0089] Citric acid 60g / L;

[0090] Sodium hypophosphite 4g / L;

[0091] The solvent is water.

[0092] In the second step, the finishing liquid is heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com