Patents

Literature

288 results about "E-textiles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electronic textiles, also known as smart garments, smart clothing, smart textiles, or smart fabrics, are fabrics that enable digital components such as a battery and a light (including small computers), and electronics to be embedded in them. Smart textiles are fabrics that have been developed with new technologies that provide added value to the wearer. Pailes-Friedman of the Pratt Institute states that "what makes smart fabrics revolutionary is that they have the ability to do many things that traditional fabrics cannot, including communicate, transform, conduct energy and even grow".

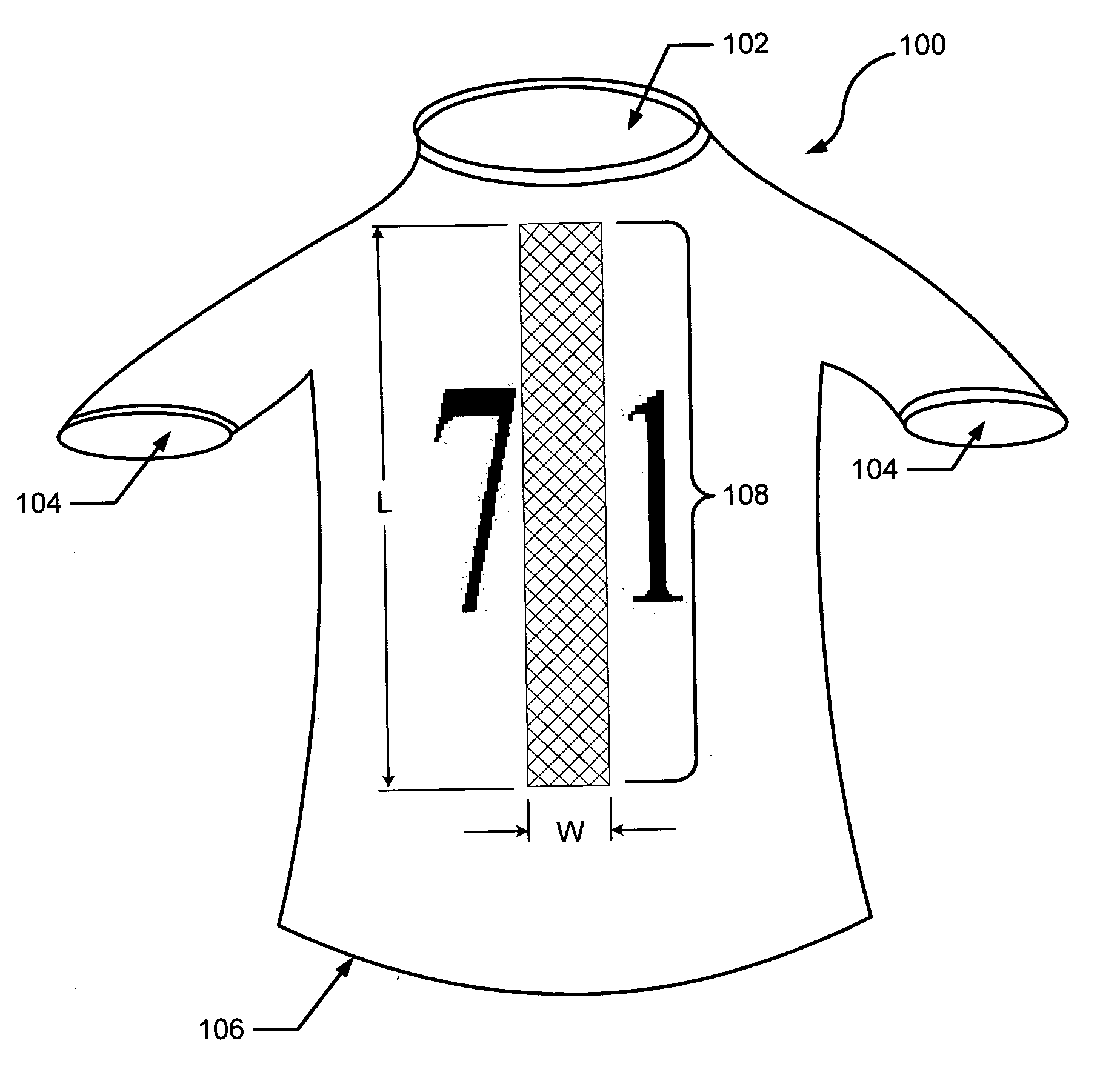

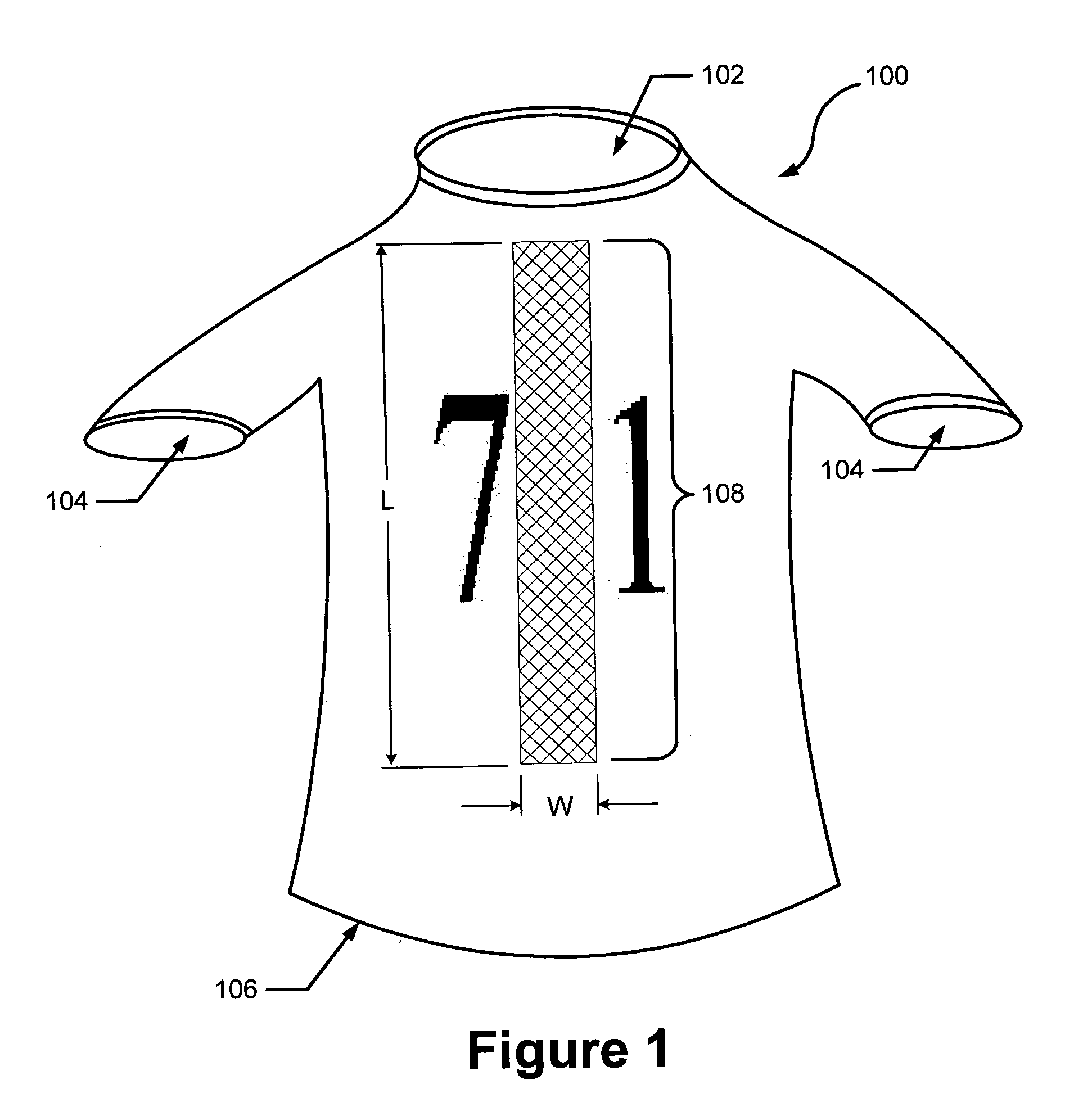

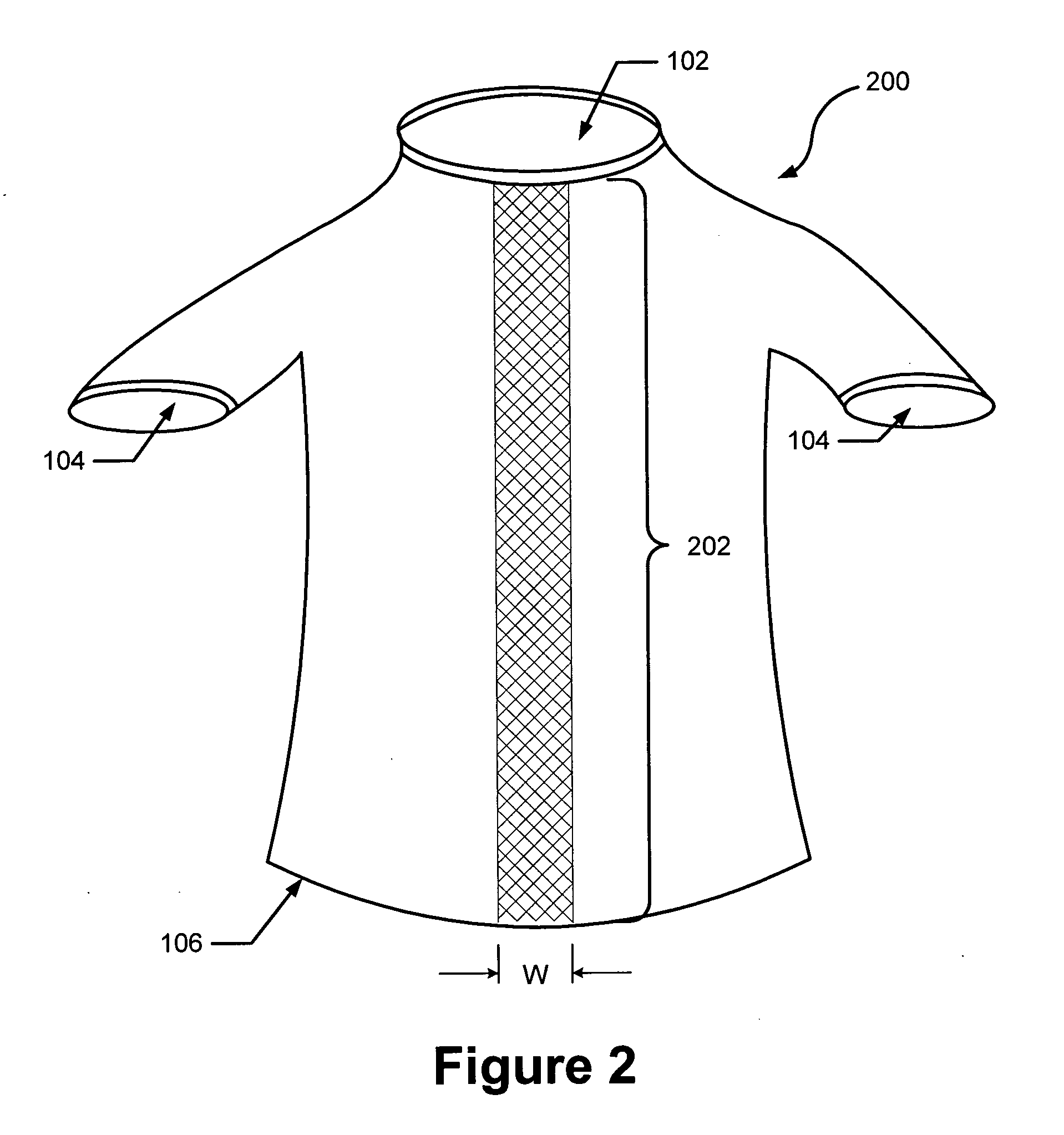

Article of apparel incorporating a zoned modifiable textile structure

ActiveUS20050204449A1Improve understandingGarment special featuresWeft knittingEngineeringE-textiles

An article of apparel is disclosed that includes zones with a textile having a structure that changes or is otherwise modified by a physical stimulus, such as the presence of water or a temperature change, to modify a property of the textile. The zones may be along a center back area and side areas of the apparel, and the textile may increase in air permeability when exposed to water. The zones may also be in an upper area of the torso and in a lower back area, and the textile may increase in texture when exposed to water. In some embodiments, slits are formed in the textile.

Owner:NIKE INC

Papermaking belts and industrial textiles with enhanced surface properties

InactiveUS7105465B2Improve adhesionFibre treatmentSynthetic resin layered productsThermoplasticPolymer substrate

An industrial textile including a polymeric substrate and a resin system grafted onto the polymeric substrate by way of a primer. The resin system includes a water-borne thermoplastic, a polyhydroxyether resin and / or an analogue of a polyhydroxyether resin, and at least one co-resin.

Owner:VOITH FABRICS HEIDENHEIM GMBH & CO KG

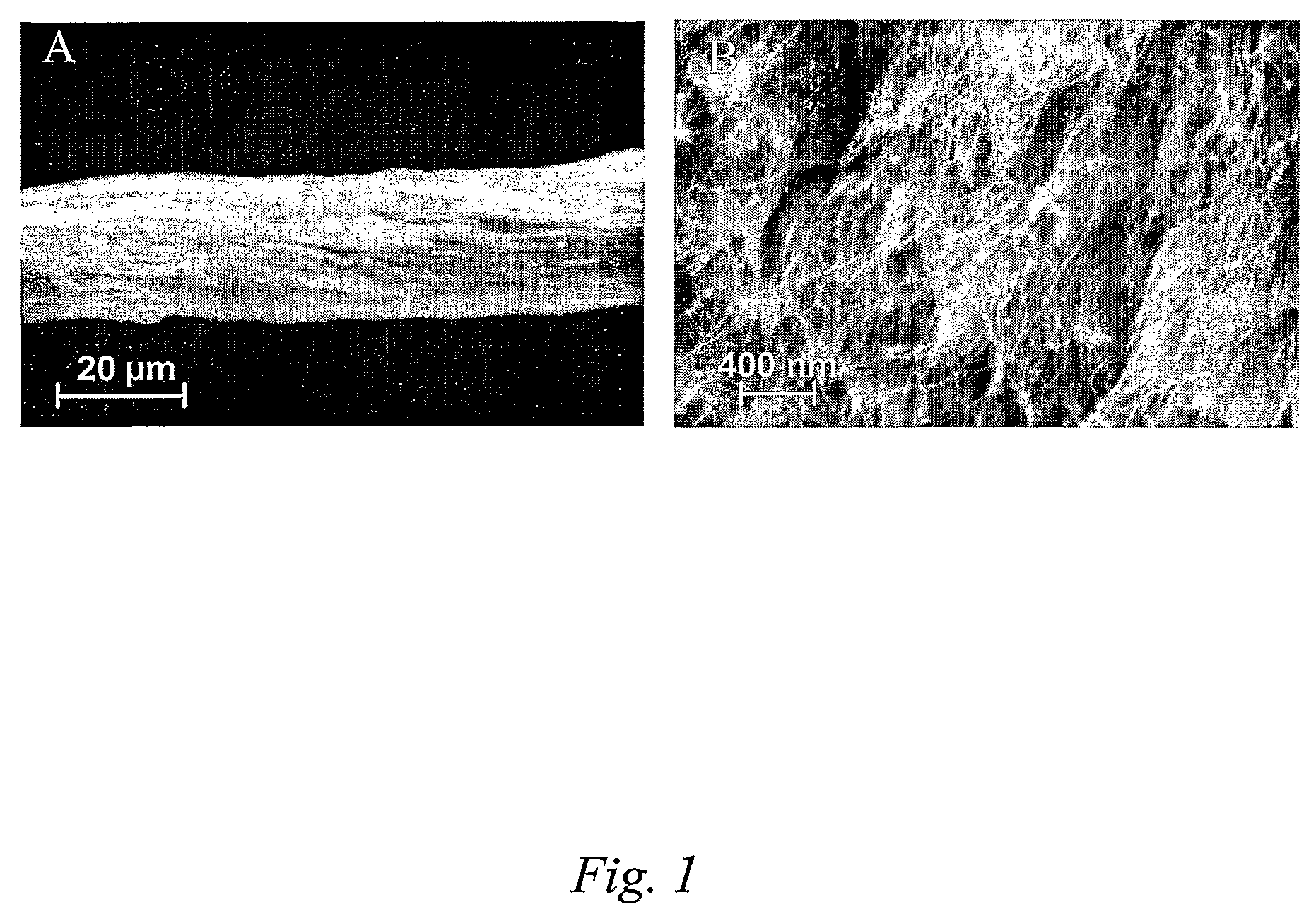

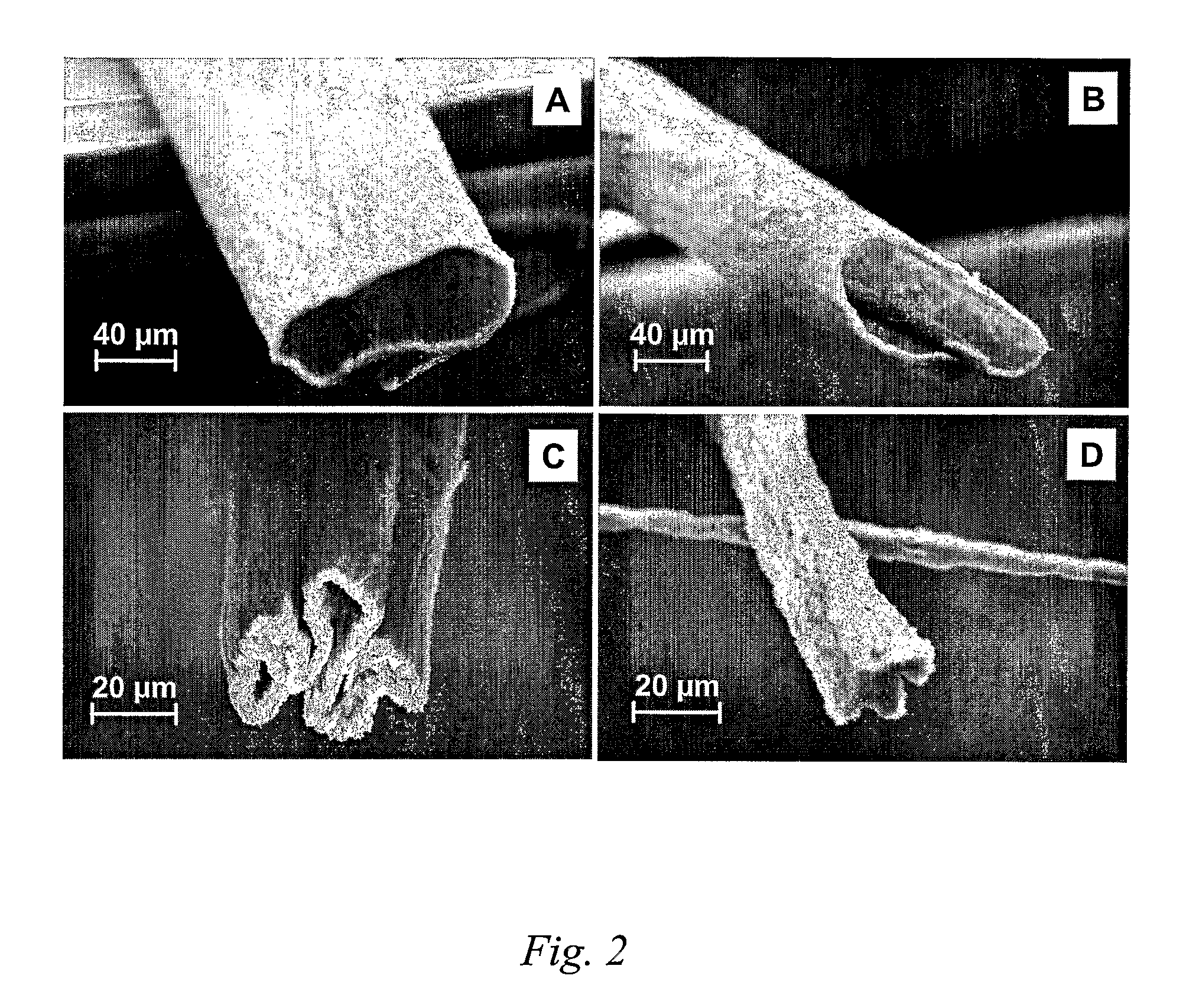

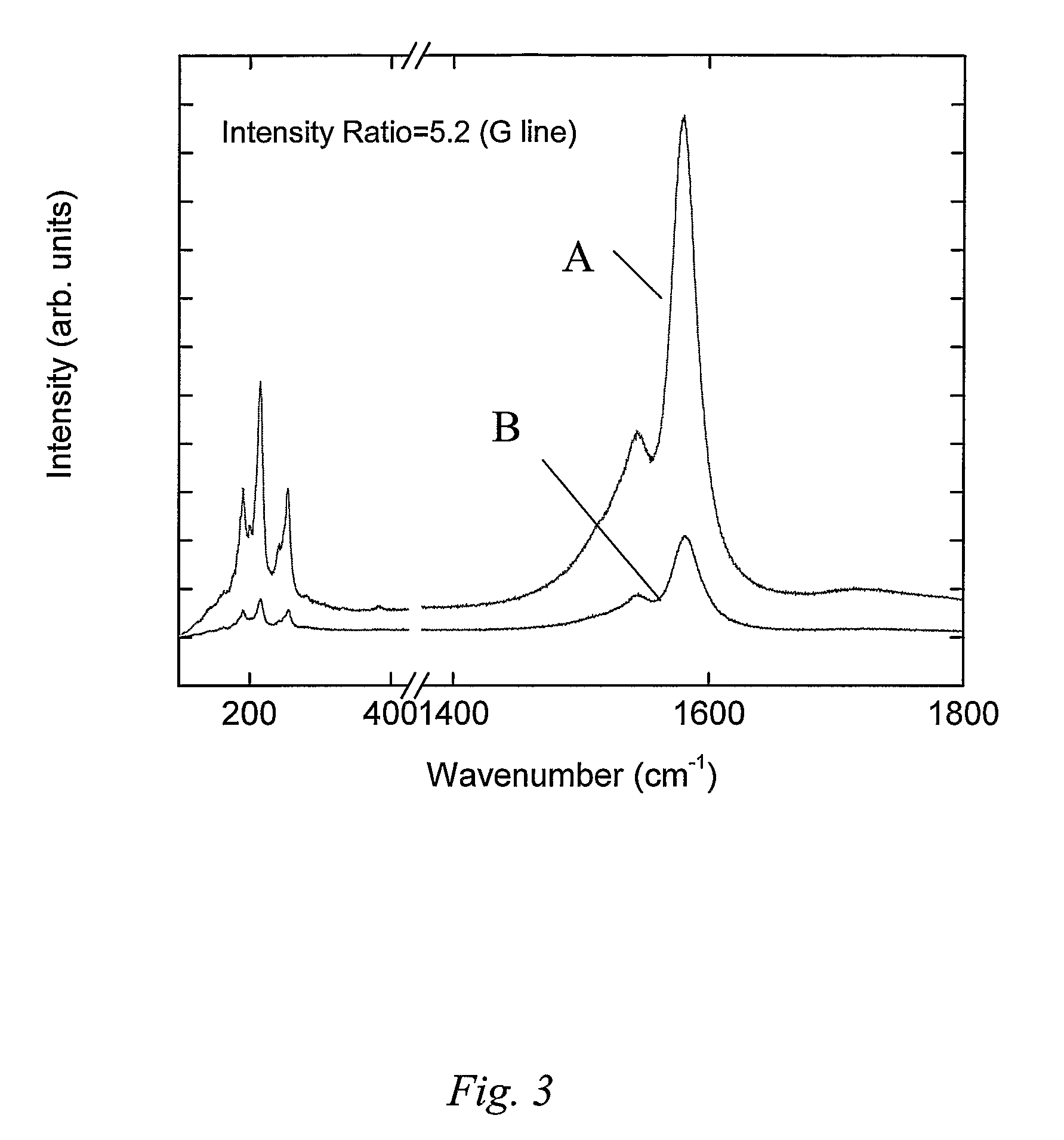

Polymer-free carbon nanotube assemblies (fibers, ropes, ribbons, films)

InactiveUS7938996B2Improve mechanical propertiesHigh mechanical strengthPigmenting treatmentRotating receptacle mixersFiberFlocculation

Process, apparatus, compositions and application modes are provided that relate to nanofiber spinning without the use of superacids in the spinning solution. The methods employ either acids or bases for a flocculation solution. The advances disclosed therein enable the use of nanofibers, including carbon nanotubes, for a variety of applications including, but not limited to, electromechanical actuators, supercapacitors, electronic textiles, and in devices for electrical energy harvesting.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

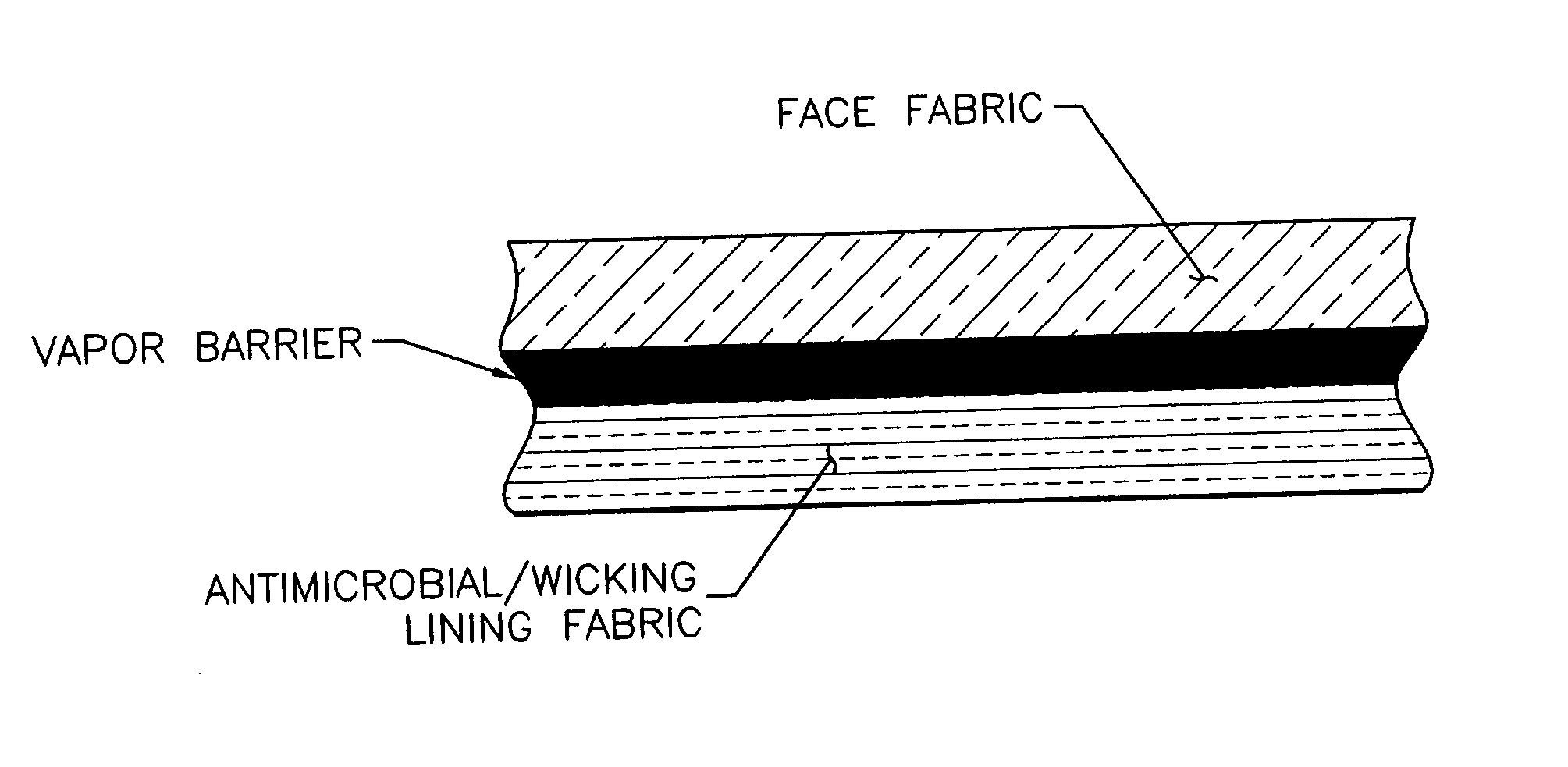

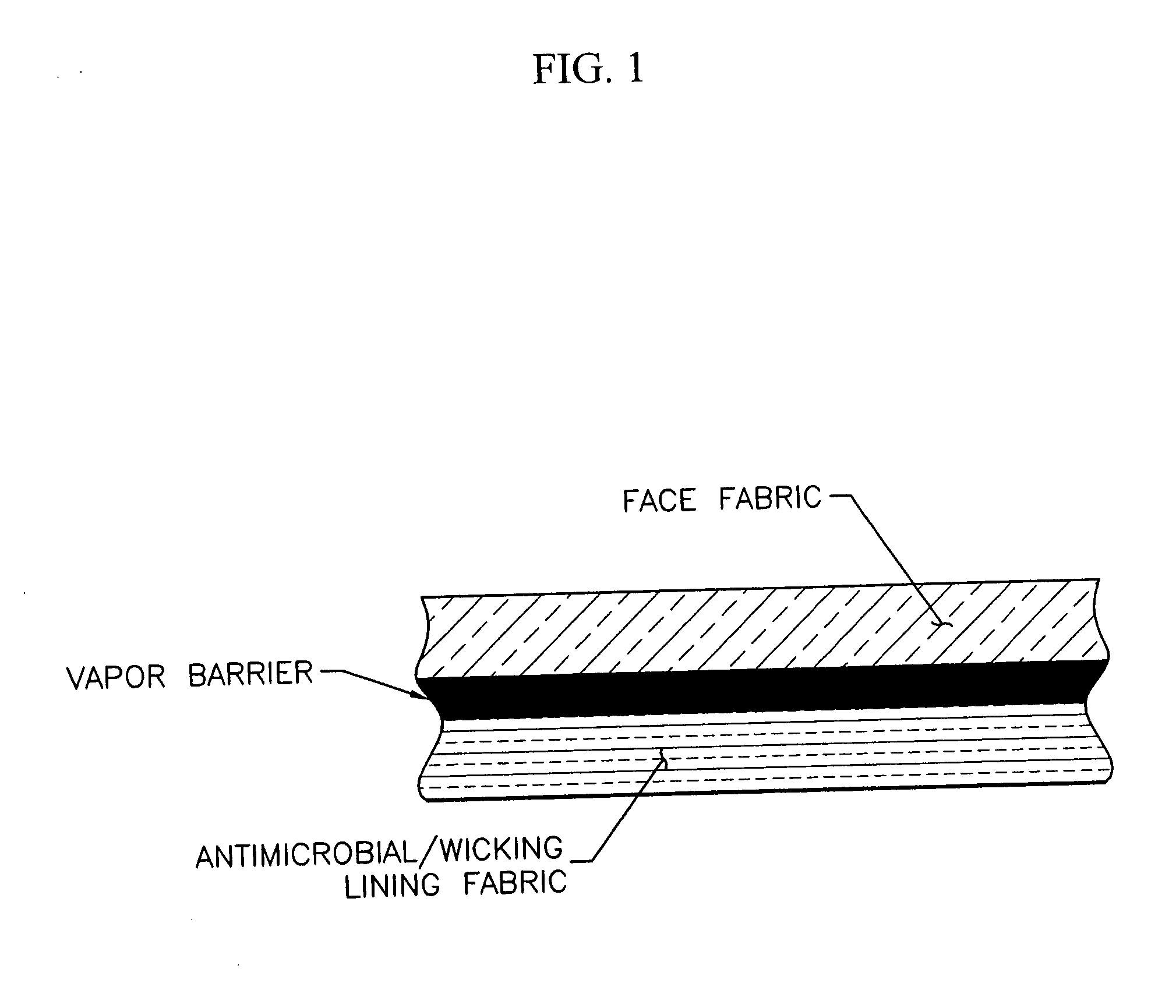

Multifunctional composite vapor barrier textile

InactiveUS20070166503A1Relieve overheatingAdd to comfort and aesthetic propertyGarment special featuresSynthetic resin layered productsVapor barrierAdhesive

The present invention is directed to a multifunctional waterproof / vapor barrier fabric for use in industrial, medical, outdoor apparel (hunting, fishing, skiing, mountaineering, etc.) and military applications. The invention combines functional elements that are especially suited for the above applications. The fabric comprises a lining with wicking and antimicrobial properties, a vapor barrier film or coating with low Moisture Vapor Transmission Rate (M.V.T.R.), and a woven or knit face fabric enhanced with a hydrophobic face coating. The fabric performs admirably in various uses due in part to the use of hydrophobic adhesive, film and coatings, which renders the fabric subject to negligible moisture gain. The durability and water proof properties of the fabric are enhanced due to the impermeable low M.V.T.R design. The fabric of the present invention incorporates a unique combination of properties that addresses issues commonly associated with vapor barrier fabrics. The invention provides a waterproof / barrier fabric that is desirable to wear in direct contact with the skin to prevent evaporative heat loss in cool or cold conditions. The fabric is also effective when worn over one or more layers of other clothing. The fabric is particularly effective because it is capable of use as a base layer and waterproof shell, which helps to minimize the number of layers of clothing needed in cold weather.

Owner:HANNIGAN RYAN B

Electronic textile

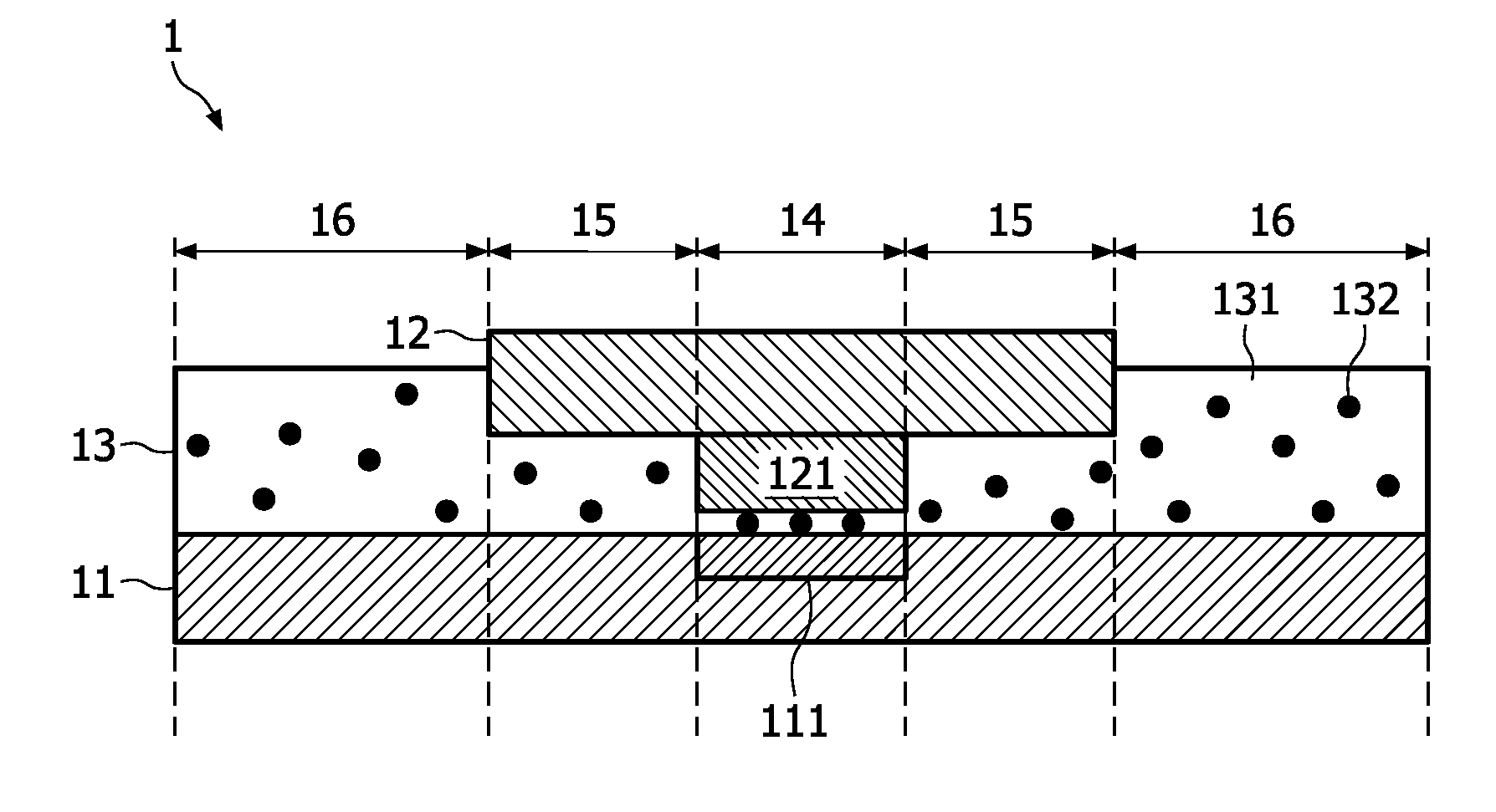

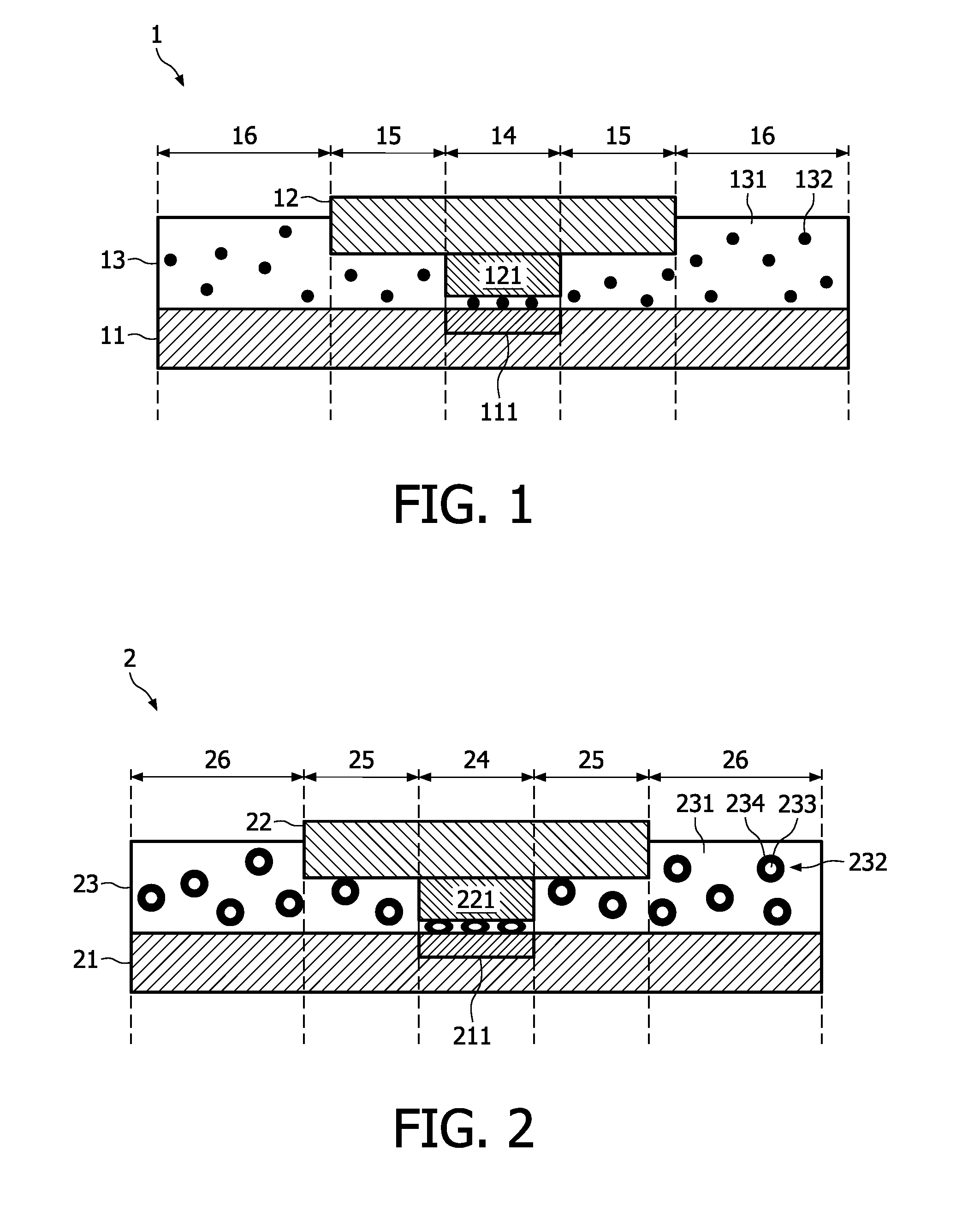

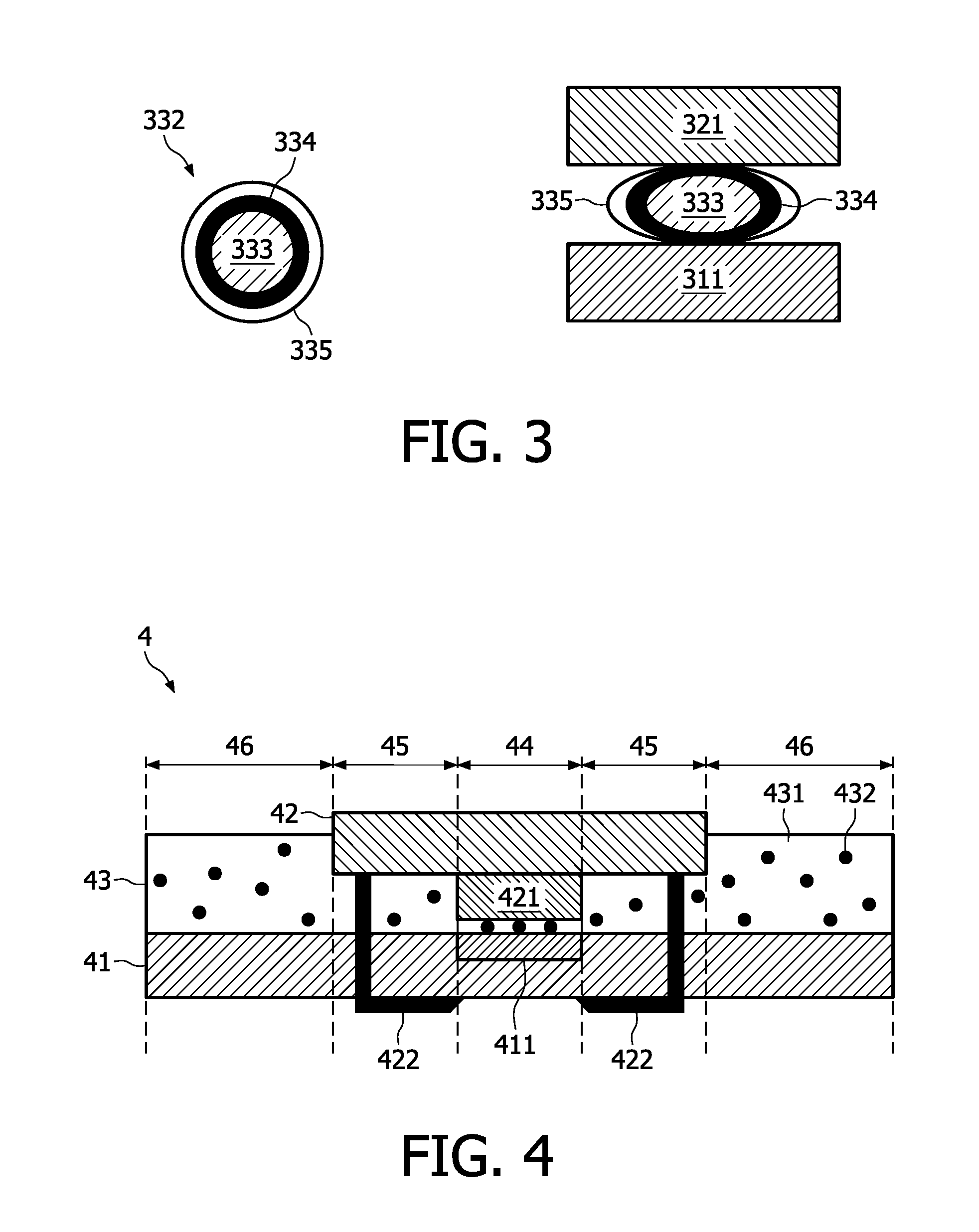

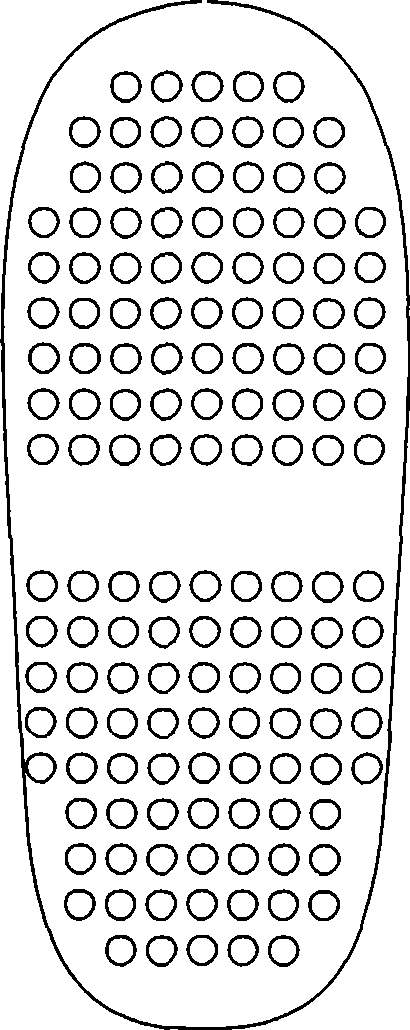

InactiveUS8569189B2Improve reliabilityLine/current collector detailsSynthetic resin layered productsPower flowCoupling

The invention relates to an electronic textile comprising a textile substrate having a substrate electrode, and an electronic component having a component electrode. The component electrode is in electrically conductive contact with the substrate electrode via a coupling layer having a directionally dependent conductance so as to preferentially allow an electrical current to flow between the substrate electrode and the component electrode. As the coupling layer does not have to be patterned to prevent the occurrence of parasitic electrical currents, the electrically conductive contact between the substrate electrode and the component electrode has an improved reliability.

Owner:SIGNIFY HLDG BV +1

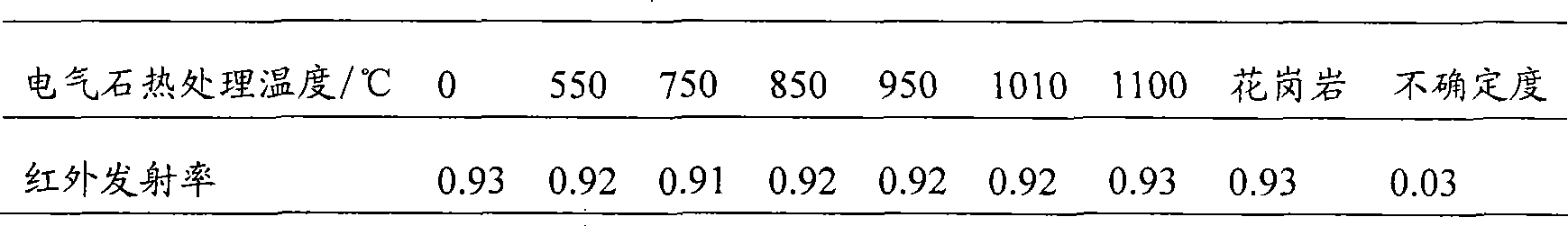

Textile finishing agent with thermal protecting, antibacterial and moisture-keeping functions, and health socks using the same

InactiveCN101476240AStay hydratedAvoid crackingFibre treatmentPanty-hoseTextile technologyHuman body

The invention provides a weaving finishing agent with the functions of emitting far infrared ray, generating air negative ion, resisting bacterium and retaining moisture, which has positive roles to human body health, belonging to the functional textile technology field. The invention further provides the socks applying the weaving finishing agent, which achieves the functions of warming, killing and resisting bacterium, retaining skin moisture, preventing skin seasoning check, promoting blood circulation, promoting metabolism and alleviating fatigue and ache.

Owner:SHENZHEN BAOLI VOGUE TECH

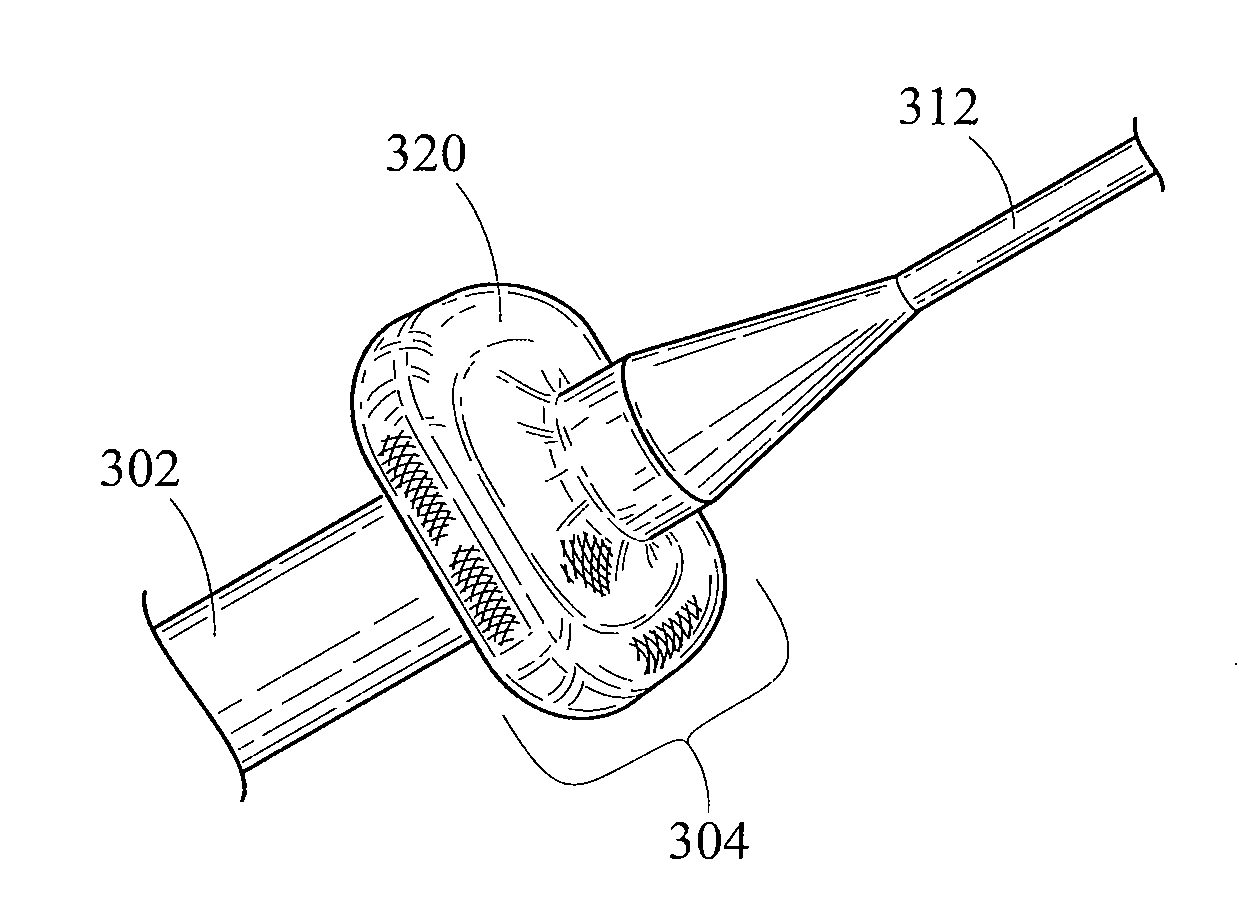

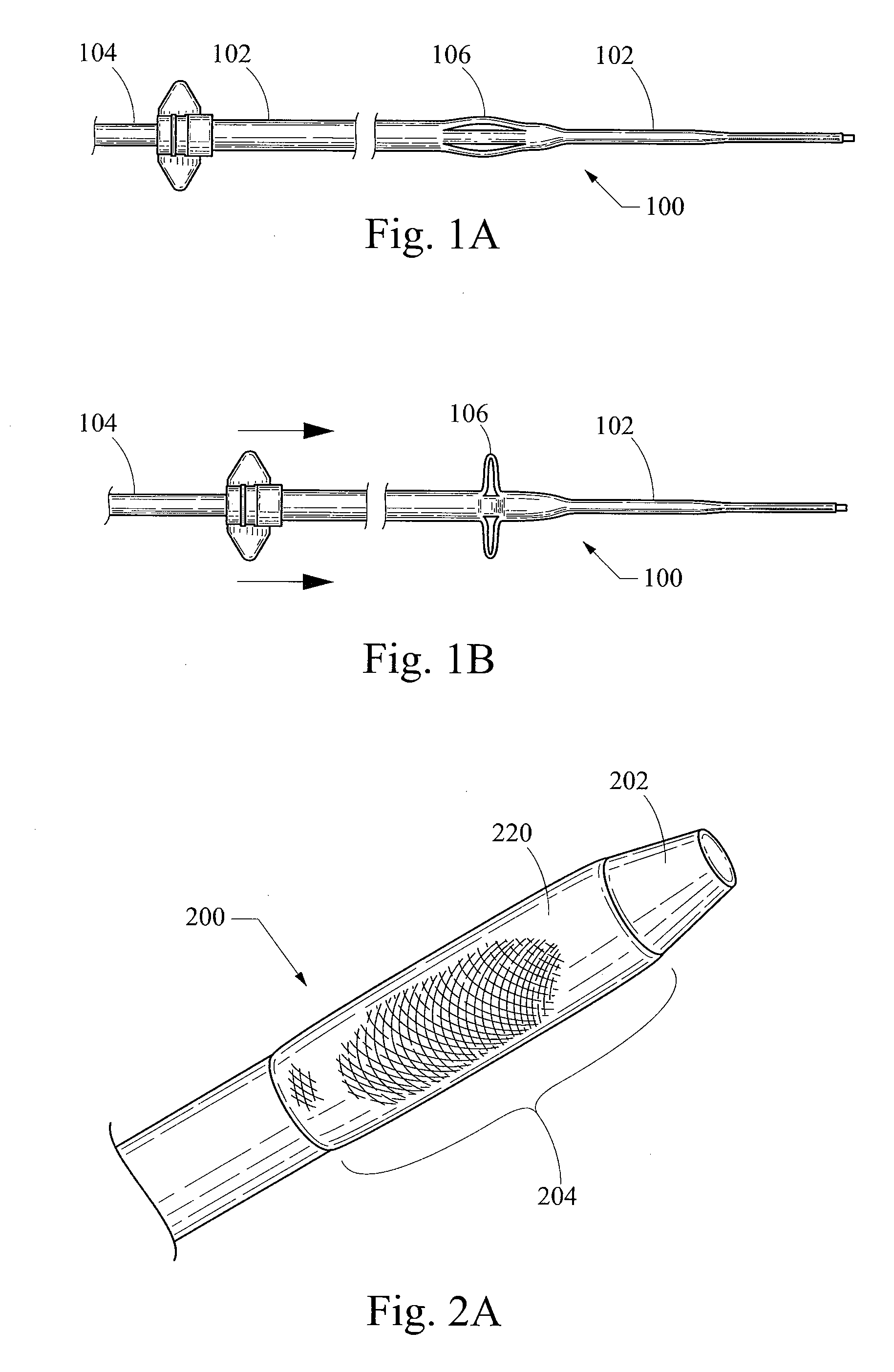

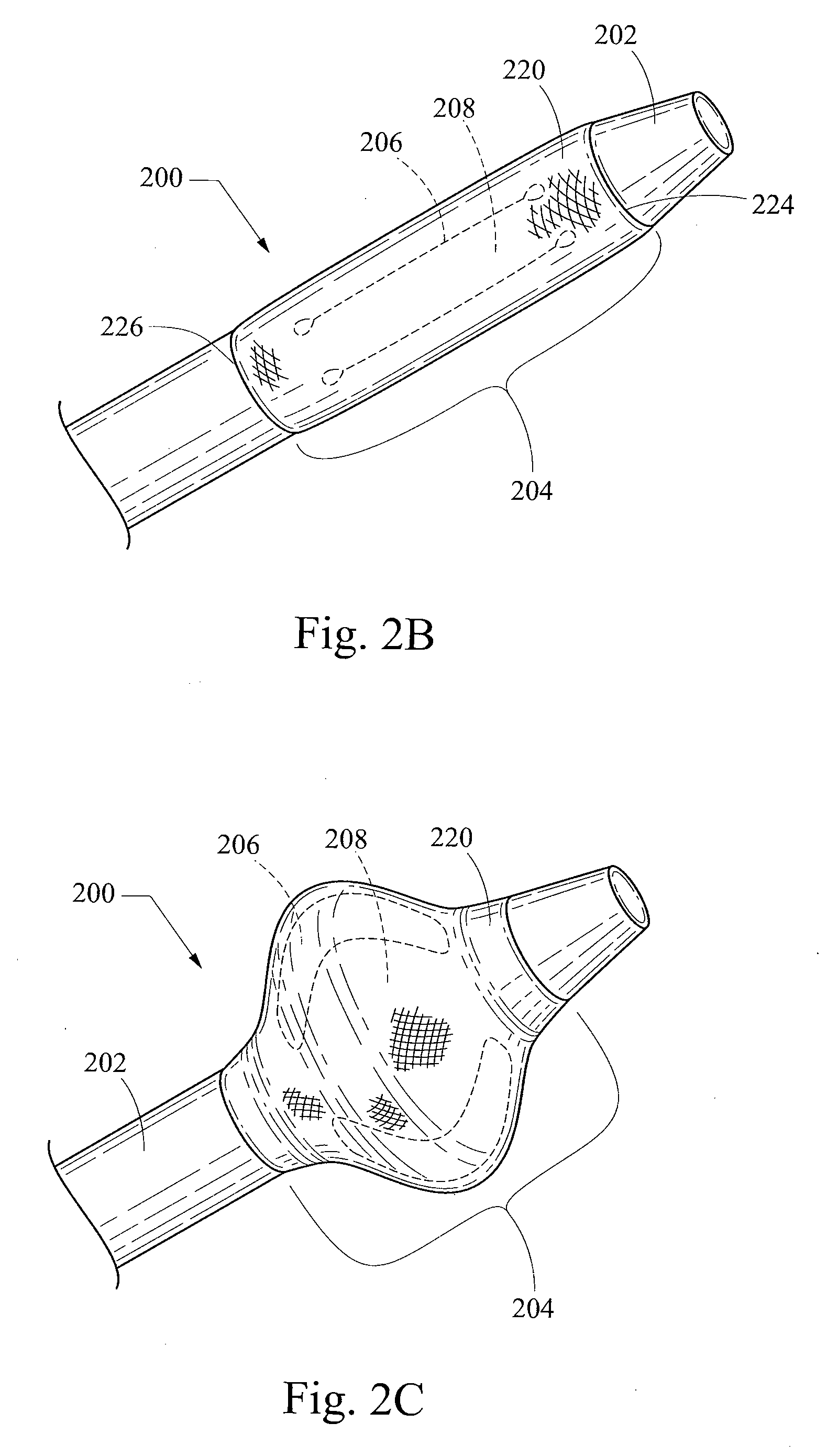

Malecot with textile cover

A malecot device includes a textile material covering its deployable malecot wing portion. The textile material is woven in a manner allowing it to be compactly disposed around an undeployed malecot and then expanded to cover malecot wings when those wings are deployed to an expanded outer device diameter.

Owner:COOK INC

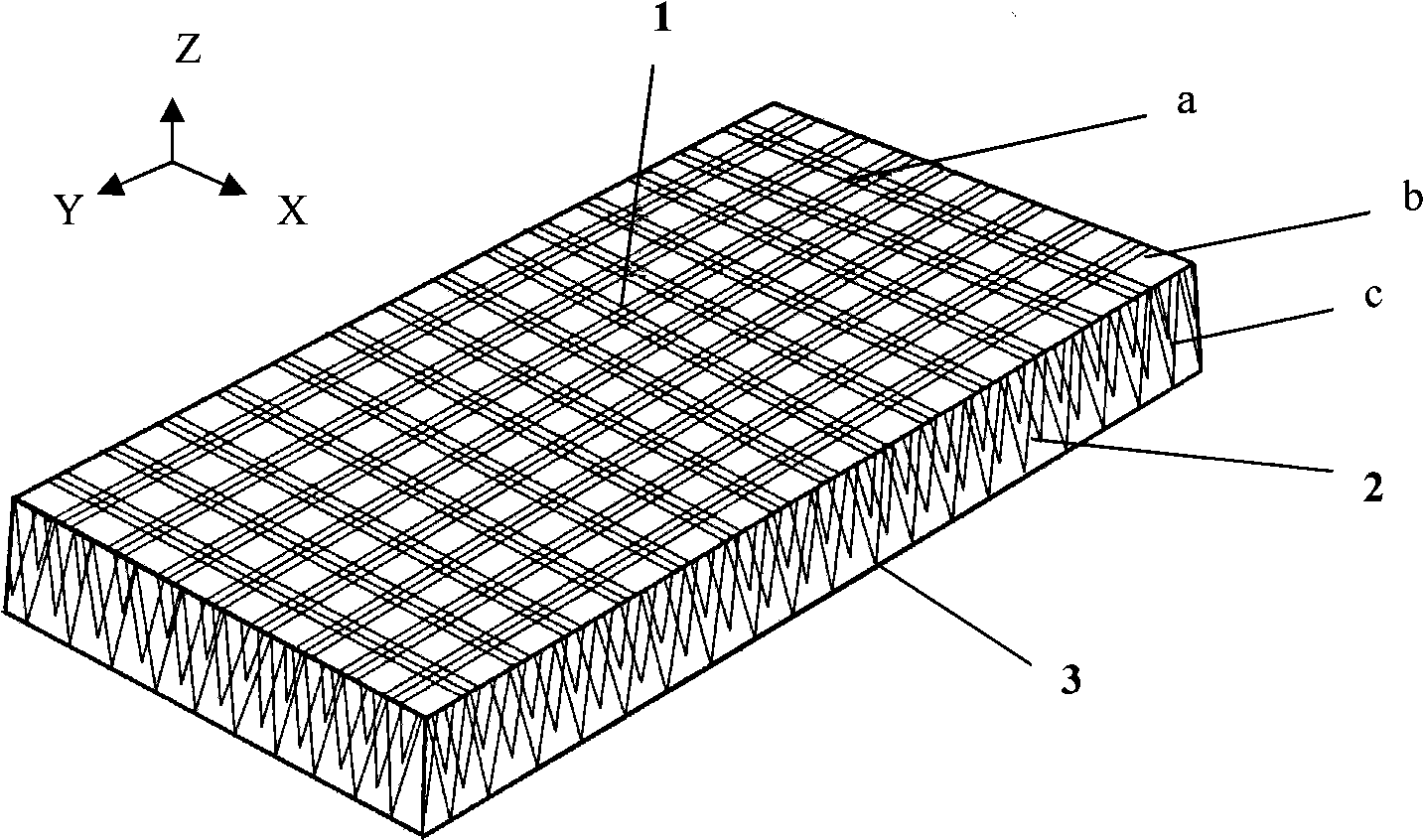

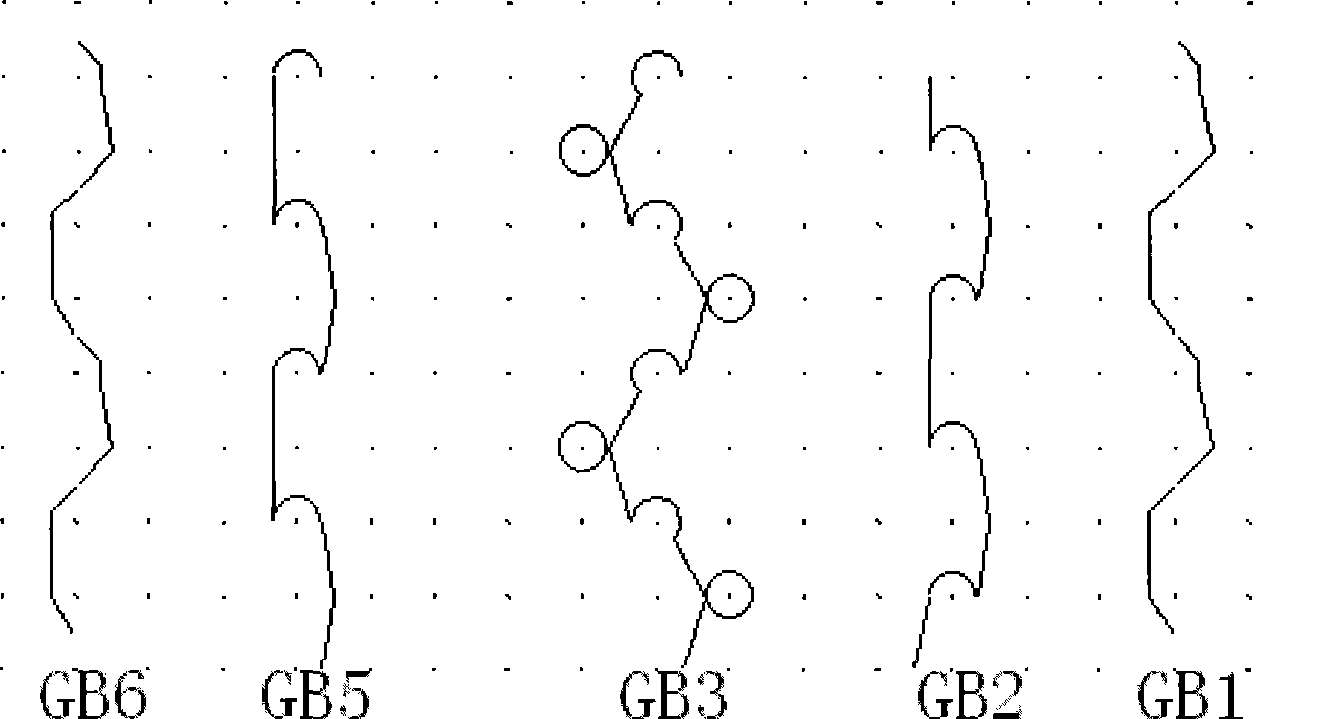

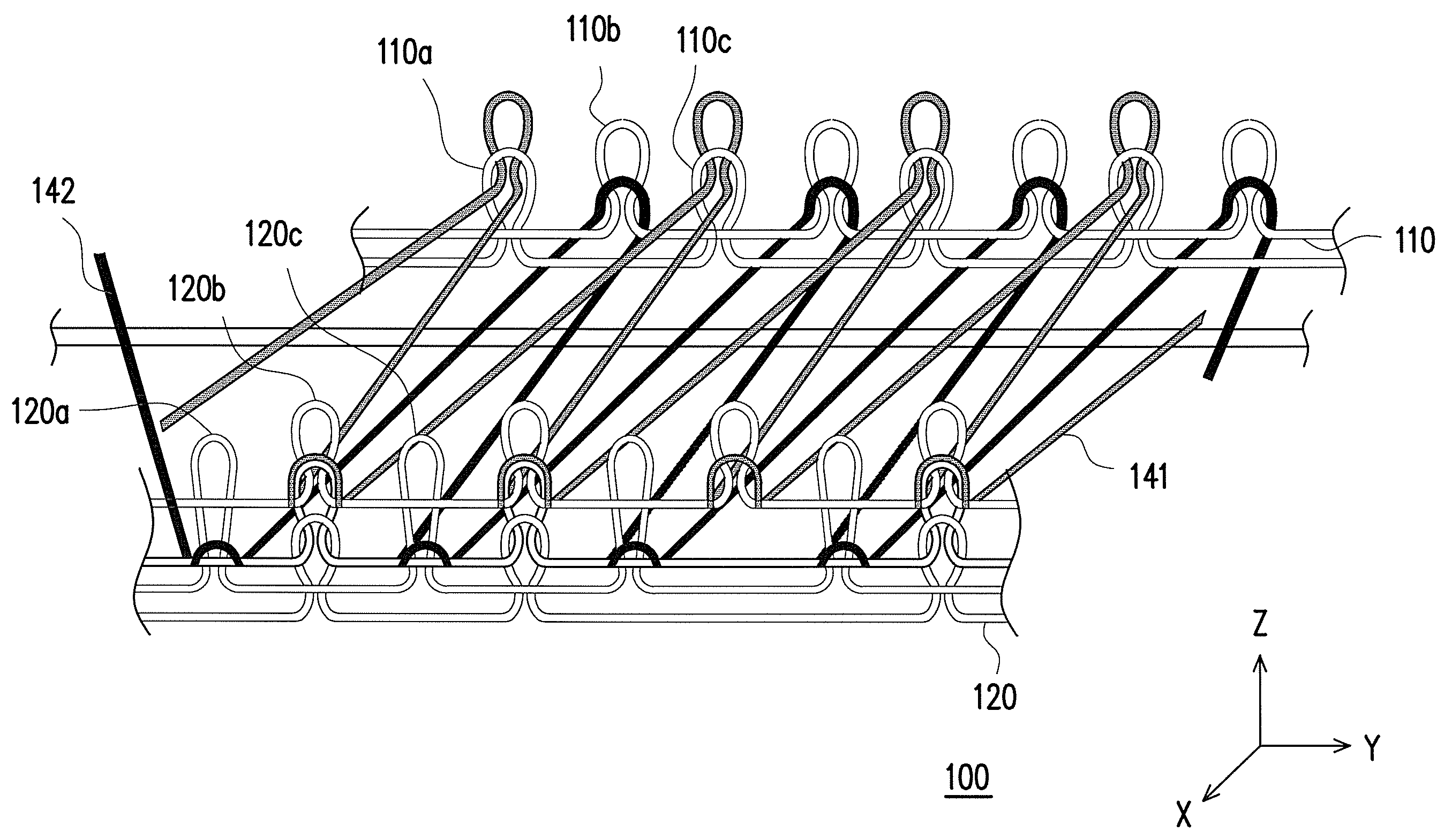

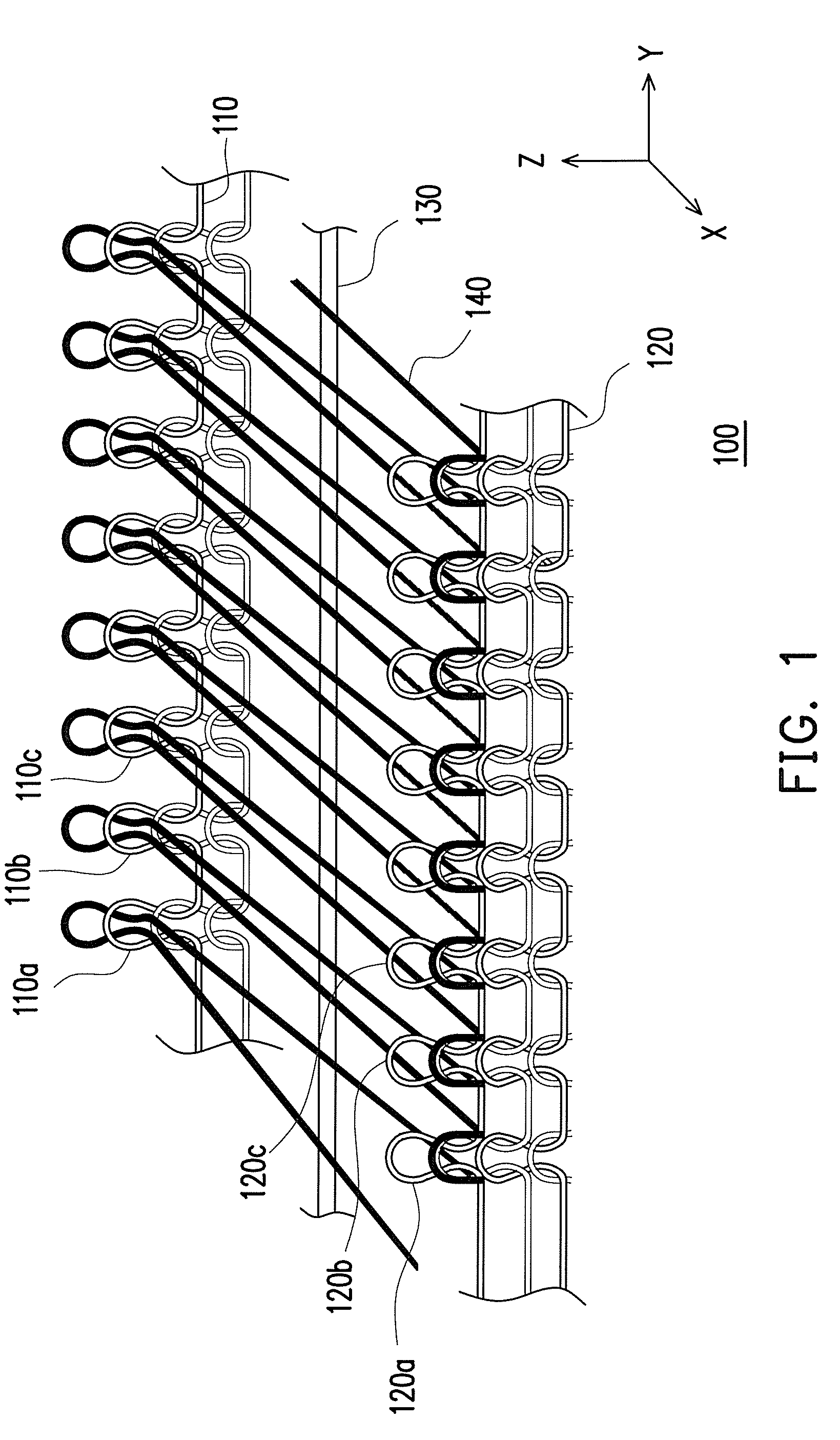

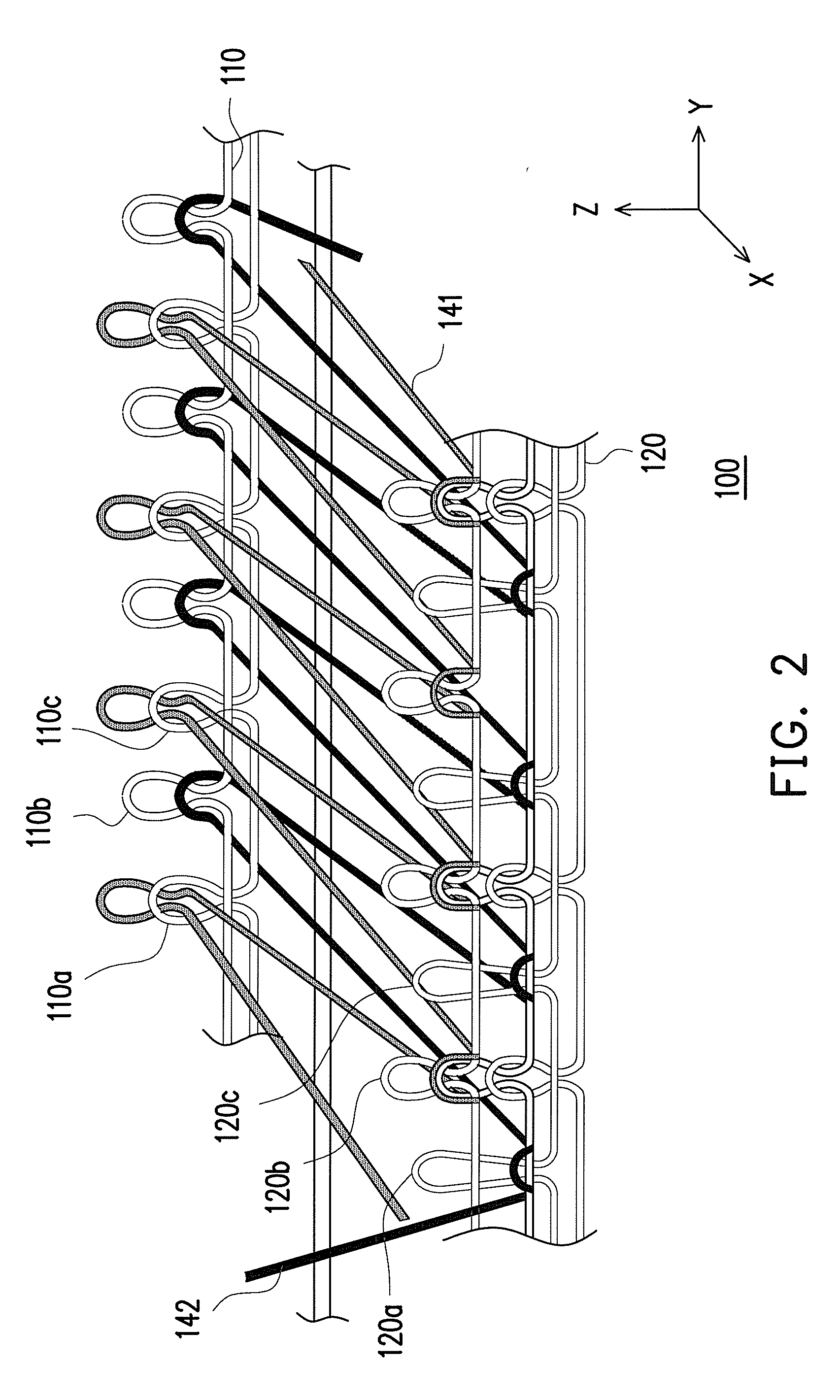

Production method for three-dimensional reinforced warp knitted spaced fabric

The invention relates to a manufacture method for three-dimensional reinforced warp knitted spaced fabric, and the warp knitted spaced fabric is produced on a modified double tricot raschel machine with full weft insertion devices. A main body of adopted raw materials is tows of high-performance fiber such as fiber glass, carbon fiber, aramid fiber, ultra high modulus polyethylene and the like. The manufacture method comprises the following steps: introducing high-performance fiber inserted weft yarns on the whole width of the machine in the X-axis direction through two weft insertion devices arranged on the front and the back of the machine; introducing high-performance fiber inserted warp yarns in the Y direction through guide bars; binding and fixing the inserted warp yarns and the inserted weft yarns through chain stitch or tricot stitch of common or high strength synthetic fiber filament yarns; adopting the high-performance fiber on upper and lower surface layer connecting yarns, ensuring the distance of 5 to 6 cm between the two surface layers, and providing reinforcing fiber in the Z-axis direction; and designing raw materials, densities, arrangement modes and interlayer thickness of the inserted warp and weft yarns of the surface layers and interlayer connecting yarns according to the requirements to form three-dimensional mesh structures with different mesh sizes and specifications. The manufacture method is characterized in that the high-performance fiber is extended and arranged in three-dimensional directions so as to overcome the defects and disadvantages of the prior spaced fabric taken as a reinforced material, and the manufacture method provides an ideal three-dimensional reinforced fabric for production of composite boards with good tensile, bending, shearing and compression properties and shock resistance.

Owner:JIANGNAN UNIV

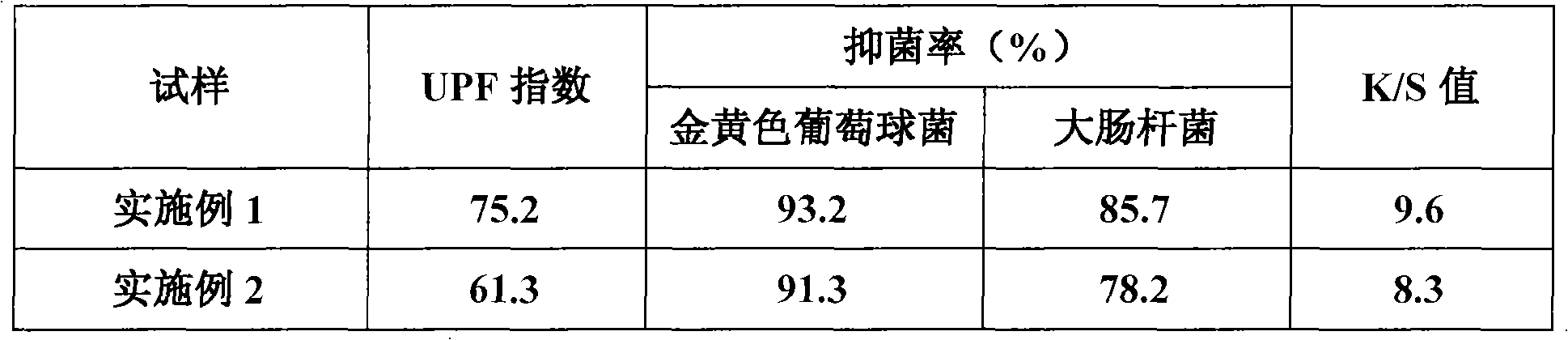

One-bathing integrated finishing method for real silk fabric by natural extract

InactiveCN101338518AAchieve antibacterialReduce processing stepsDyeing processAnimal fibresEngineeringTextile dyeing

The invention discloses a method for real silk fabric functional finishing, especially relates to a method for one-bath multifunctional finishing of real silk fabric by utilizing natural extract, which pertains to textile dyeing and finishing technical field. The invention includes the following steps: placing real silk fabric in solution with 5-20%(o.w.f) natural extract, liquor ratio of 1:10 to 1:100 and PH value of 2-8, treating for 10-100min; then treating for 10-100min in solution with 3-15%(o.w.f.) metal salt, liquor ratio of 1:10 to 1:100 and PH value of 4-8; after washing, dehydrating and furnace drying, completing one-bath finishing with dyeing, antimicrobial and anti-ultraviolet function to real silk fabric. The invention reduces manufacturing procedure of real silk fabric, has effect of energy-saving and emission-reduction, improves cleaning production of textile processing, is harmless to human body and surroundings, and conforms to ecological textile processing requests.

Owner:SUZHOU UNIV +1

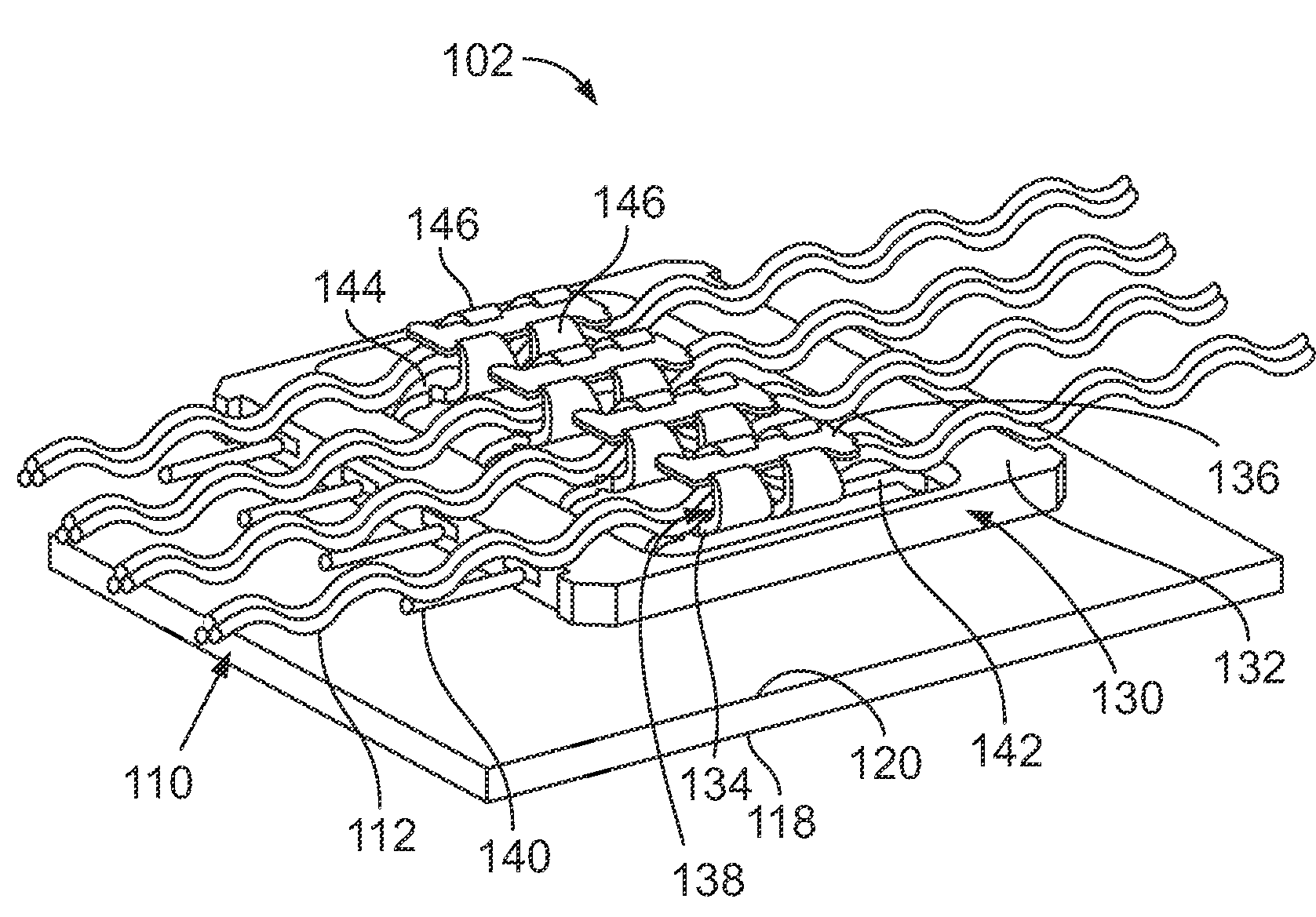

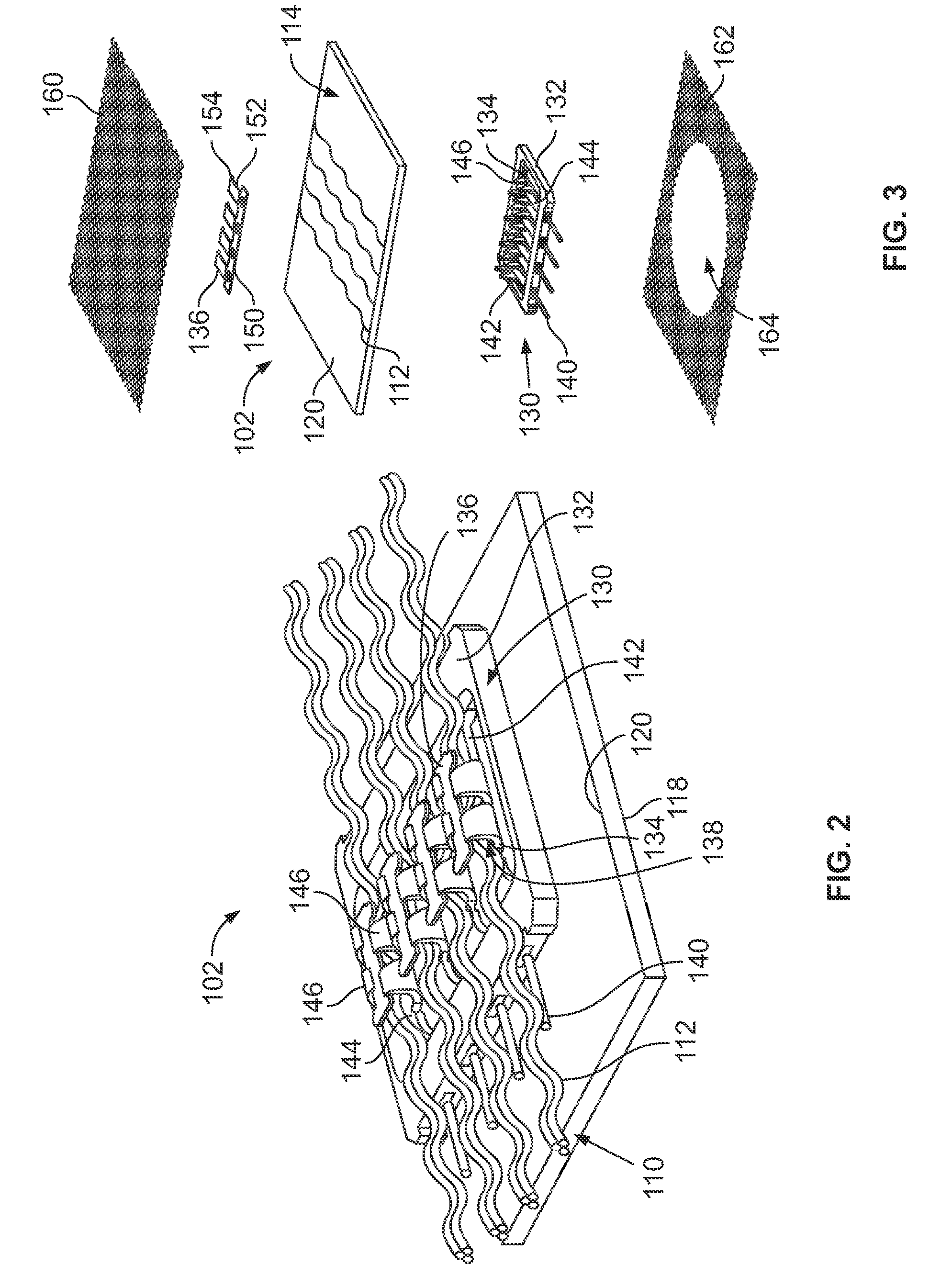

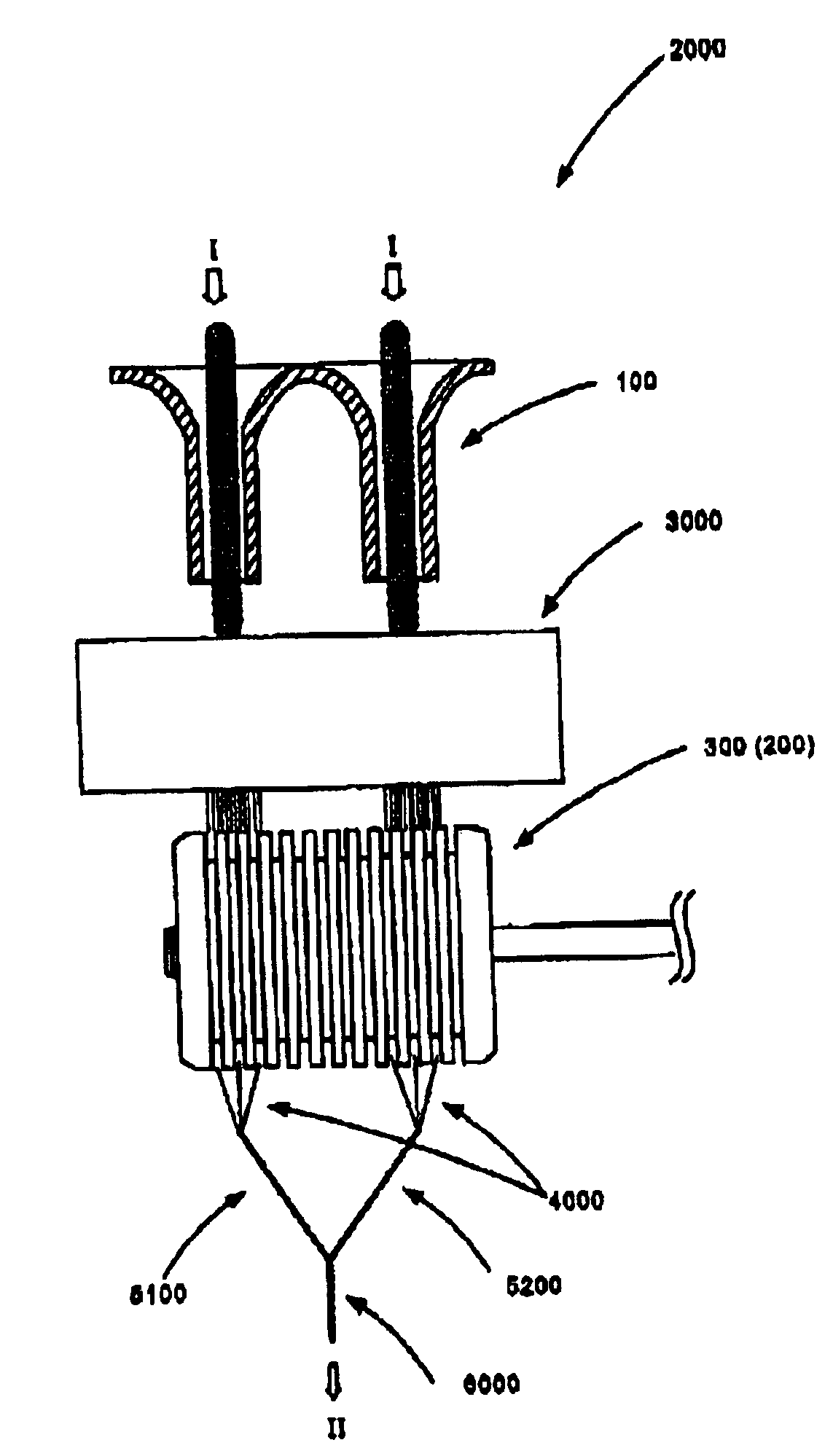

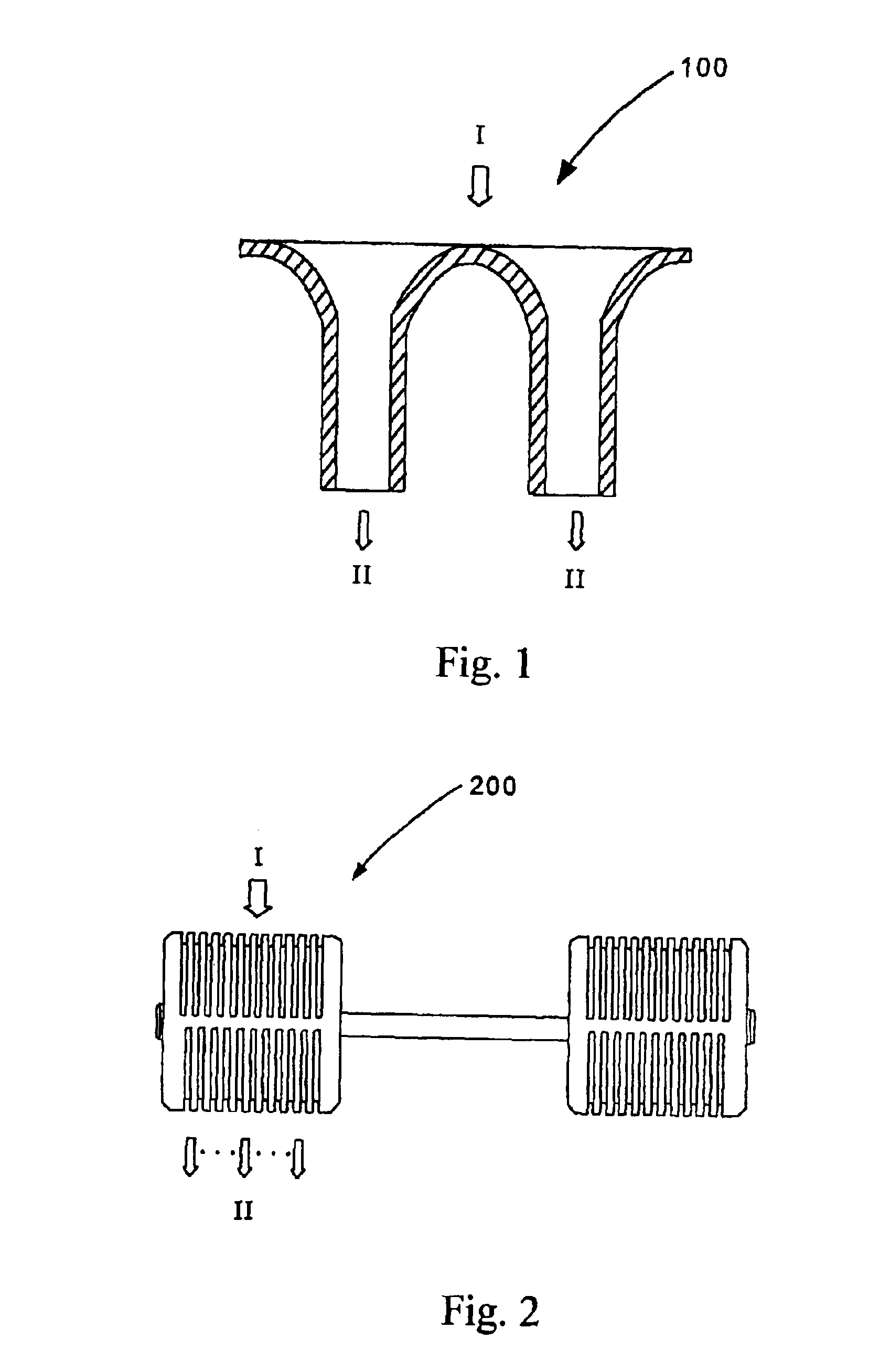

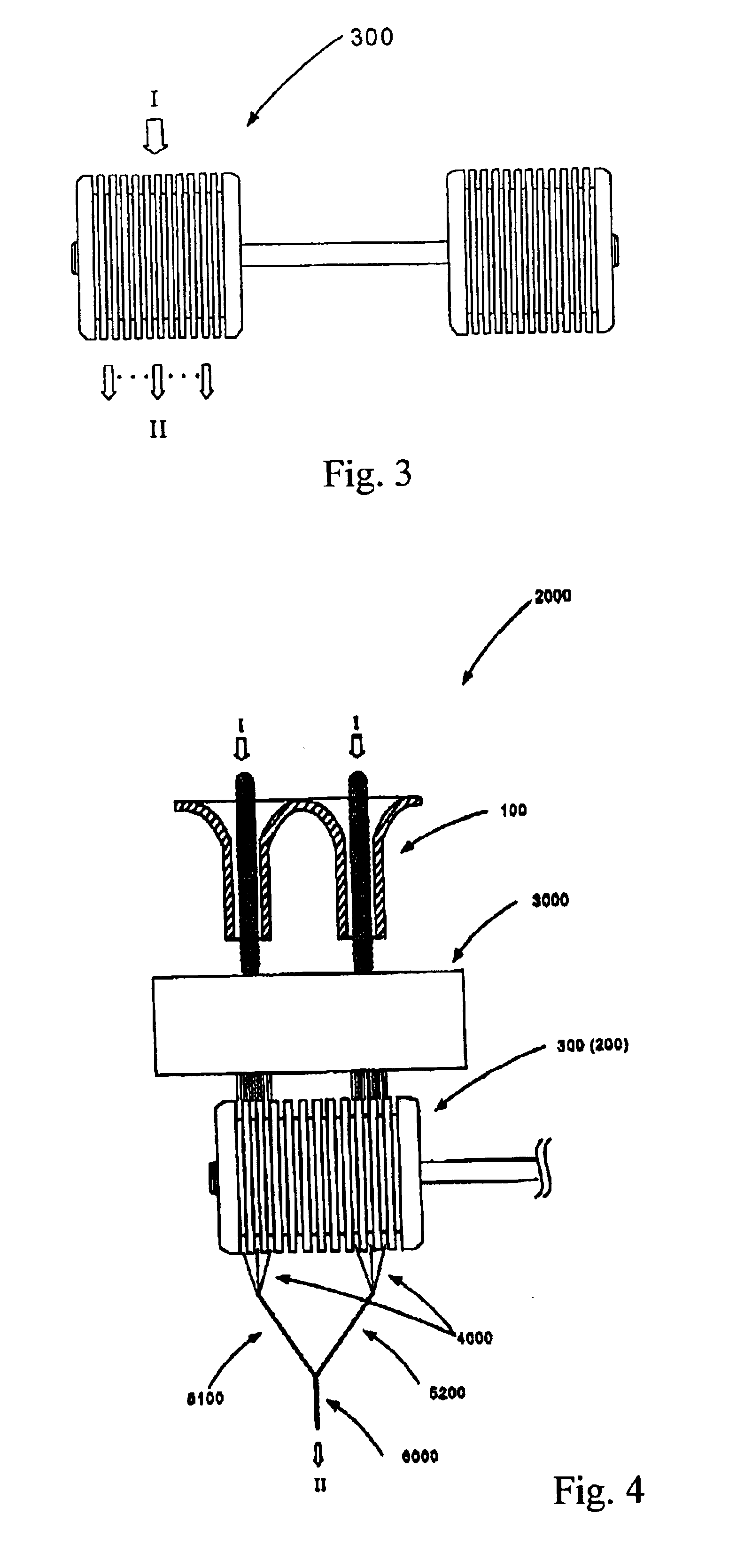

Interconnect and termination methodology for e-textiles

ActiveUS20120071039A1Firmly connectedElectrically conductive connectionsElectric discharge tubesElectrical conductorEngineering

A connector for an e-textile having a conductive layer that includes conductors includes a terminal and a base separately provided from the terminal. The terminal has a mating end and a mounting end. The mounting end is terminated to the e-textile's conductors. The mating end is configured to be mated with a mating contact of a mating component. The terminal has a body and a plurality of tines extending from the body. The base is arranged opposite the body of the terminal such that the e-textile's conductors are positioned between the base and the body of the terminal. The terminal is crimped to electrically connect the terminal and the base to the e-textile's conductor. The tines are folded against the base to electrically connect the terminal to the base. The body of the terminal and the base engage the e-textile's conductors.

Owner:TE CONNECTIVITY CORP

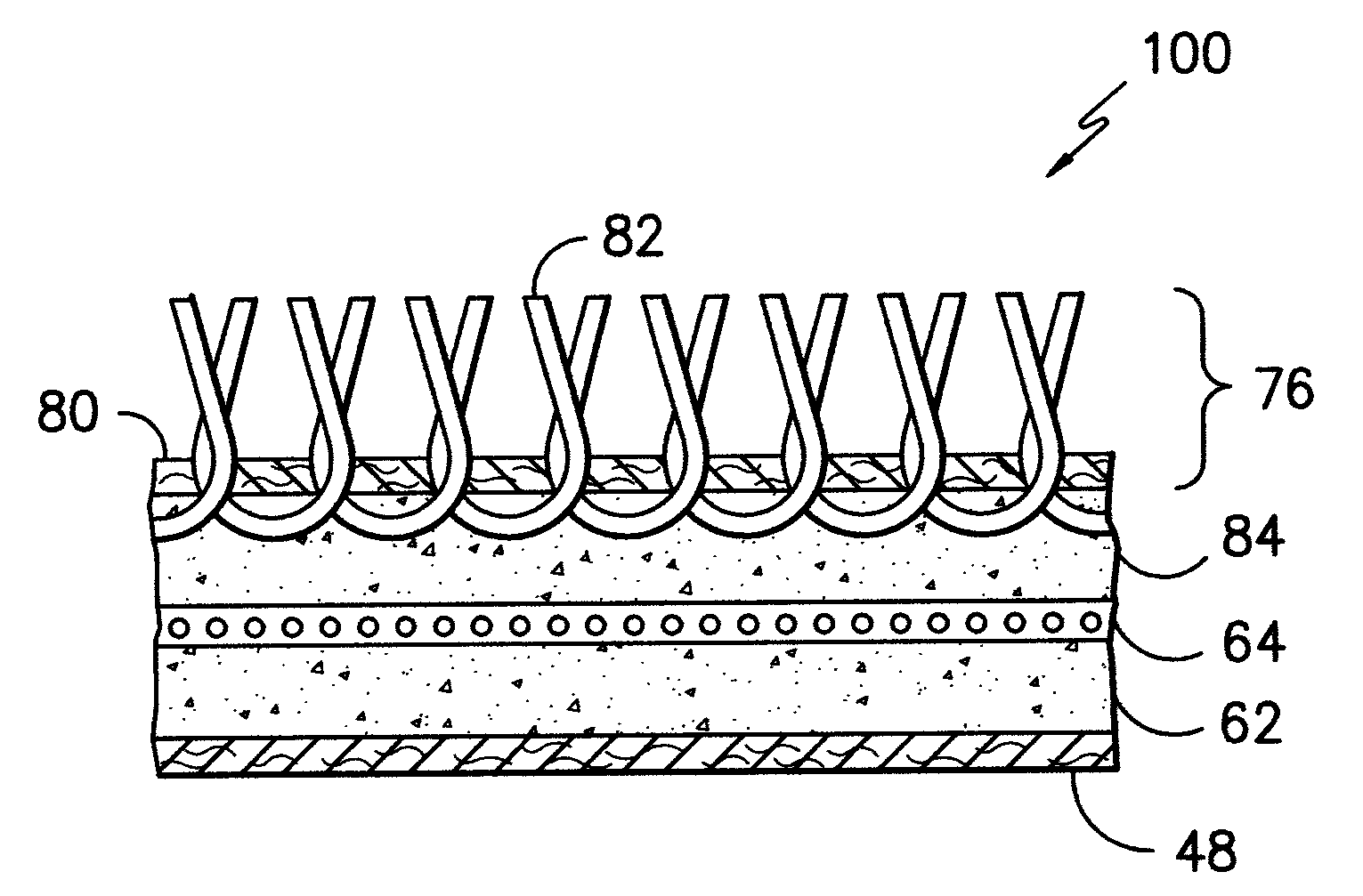

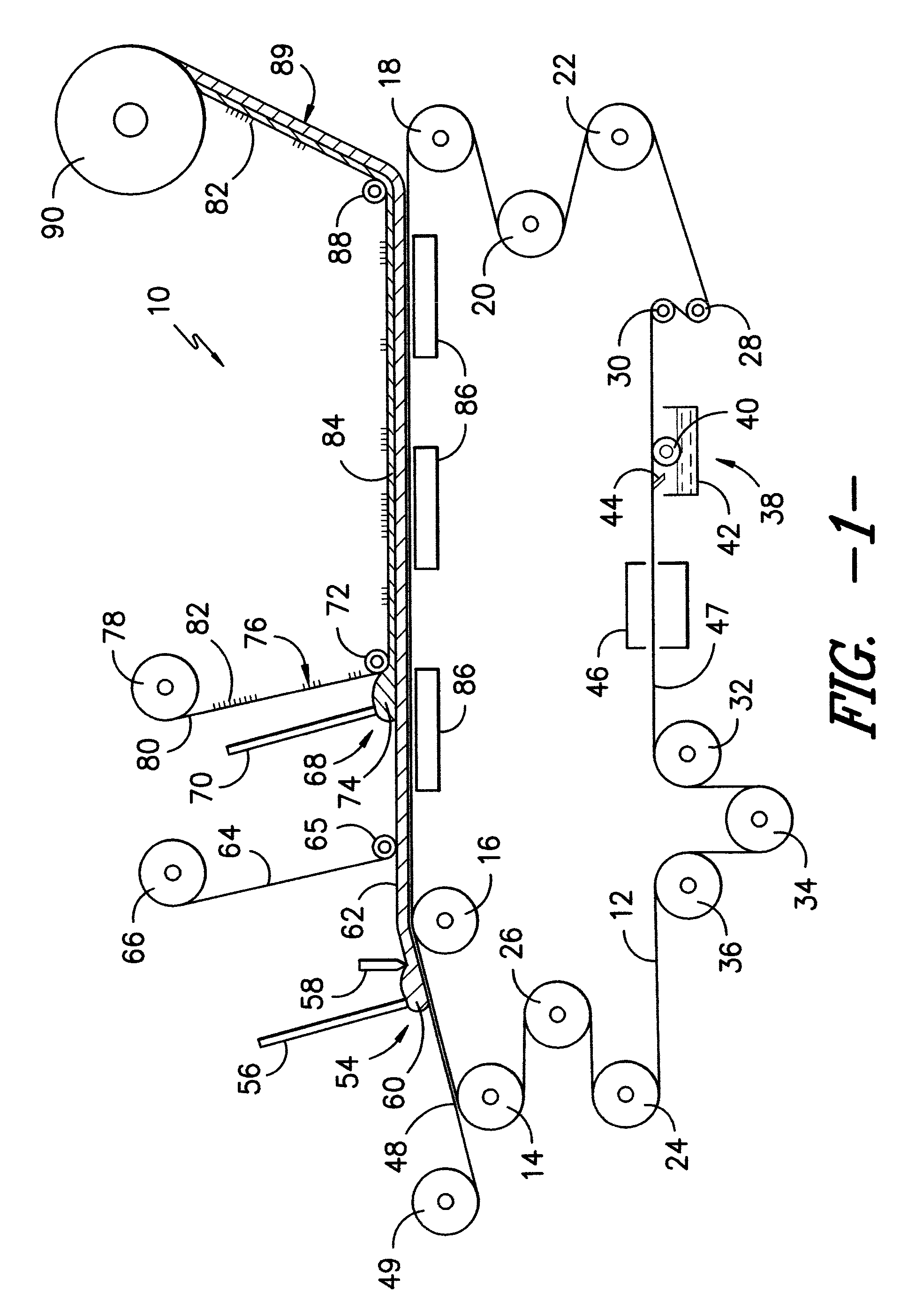

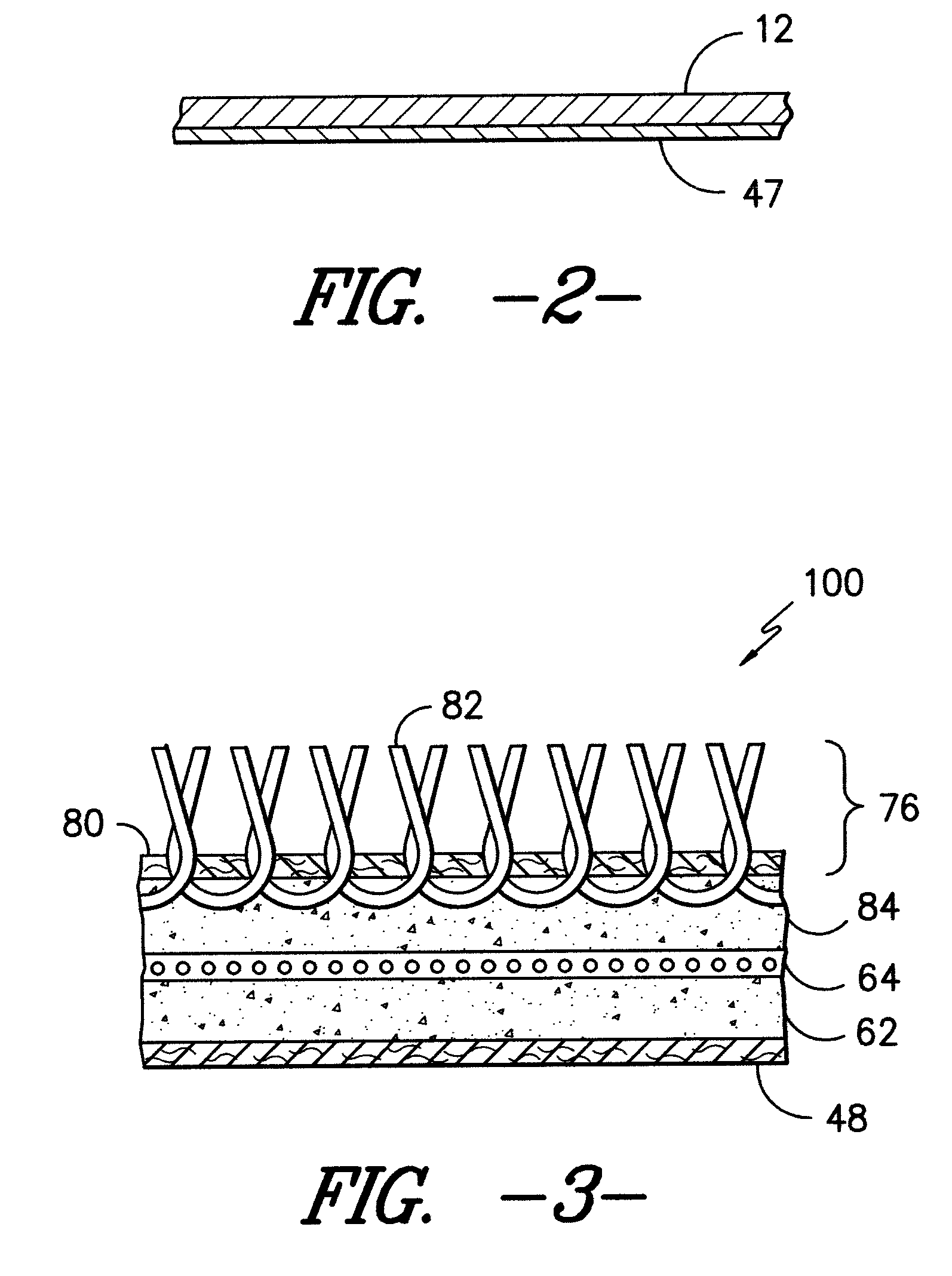

Flooring products and methods

InactiveUS20090029097A1Simple methodLow shape requirementPretreated surfacesWood working apparatusFloor coveringWater content

At least certain embodiments of the present invention relate to flooring products, methods of producing flooring products, and polyurethane compositions for use in flooring products, for example, for forming a layer of polyurethane on a textile, fabric or material, such as a flooring fabric. The compositions comprise the reaction product of castor oil having a water content of less than or equal to about 0.2% by weight; a monol, and an isocyanate, wherein the reactants have a soft segment functionality of about 2.0 to about 2.64. Methods of using the compositions and flooring products including the compositions are also disclosed. At least selected embodiments may provide compositions for use in floor coverings having a show surface such as a textile or fabric face material in contacting overlying relation to a polyurethane backing with or without additional structures, layers, backings, and / or the like, as well as apparatus, processes, and / or methods for making such floor coverings, uses for such floor coverings, and / or the like. In at least one particular embodiment, a floor covering such as a carpet, carpet tile, area rug, floor mat, roll goods, or the like incorporates a textile or fabric face disposed in contacting overlying relation to at least one polyurethane layer.

Owner:RIDDLE DENNIS L +5

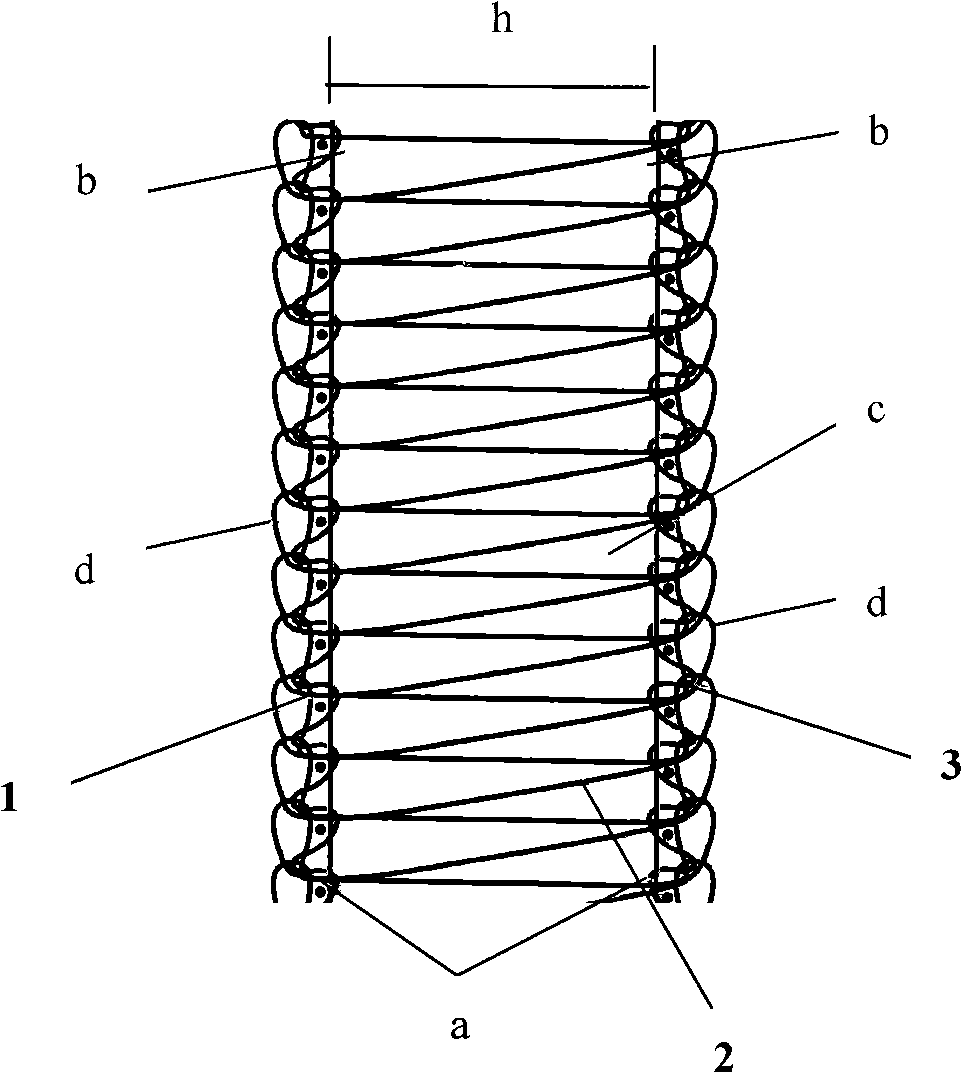

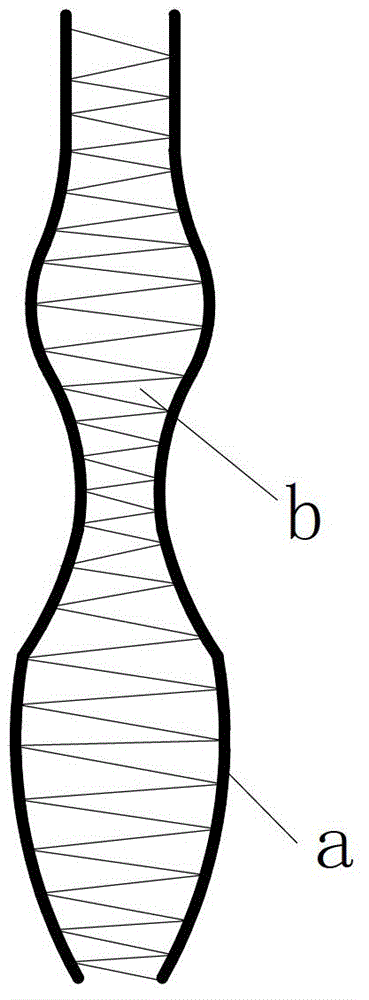

Special-shaped three-dimensional knitted fabric and manufacturing method thereof

The invention relates to a special-shaped three-dimensional knitted fabric and a manufacturing method thereof, which relate to the knitted fabric. The special-shaped three-dimensional knitted fabric with at least one of an upper surface and a lower surface being a concave-convex special-shaped curved face, and favorable air permeability, support performance and shearing resistance, and the manufacturing method thereof are provided. The special-shaped three-dimensional knitted fabric comprises an upper fabric layer, a middle fabric layer and a lower fabric layer, wherein the upper fabric layer or / and the lower fabric layer is / are provide with a concave-convex curved face(s) in a knitted longitudinal direction(s); and the middle fabric layer is formed by connecting yarns with flexural rigidity. According to a fabric structure and a texture requirement, required materials of the upper fabric layer, the required lower fabric layer and the middle fabric layer are selected; according to structural features of the fabric, the yarns are sewed on a guide bar; according to special-shaped structural features of the fabric, warp run-in of the fabric is set, and a distance between two needle beds can be adjusted in real time when the fabric is knitted in different horizontal lines according to variation in thicknesses of the different horizontal lines of the fabric; and a drawing device draws the knitted textile from the needle beds when knitting is carried out simultaneously.

Owner:福建福联精编有限公司

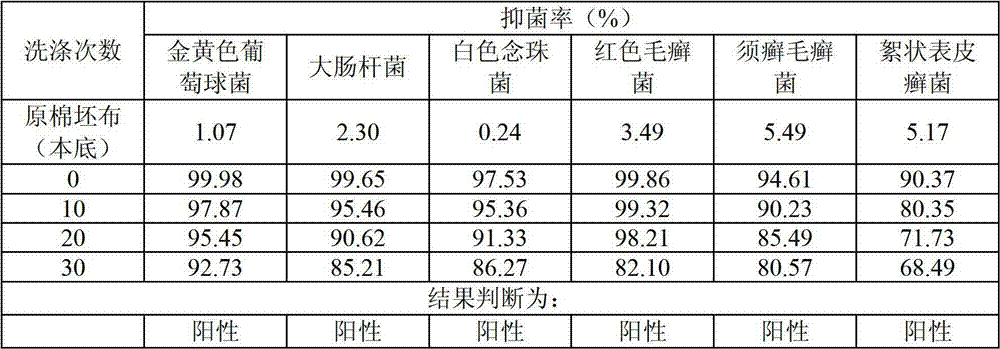

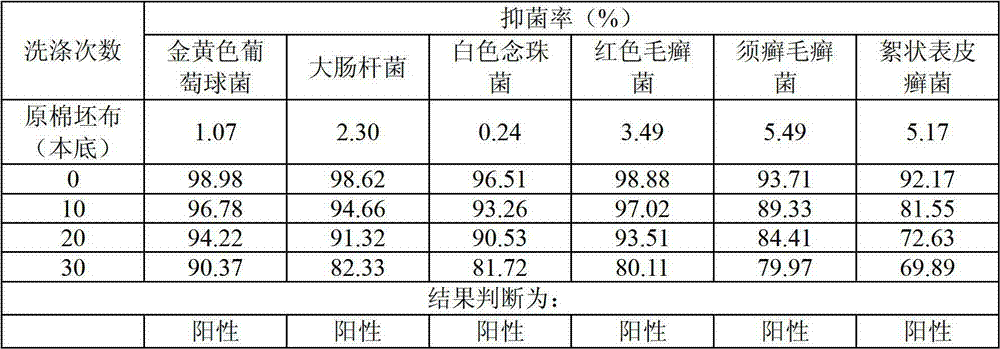

Finishing technology for aromatic anti-bacteria cotton textile

The invention discloses finishing technology for aromatic anti-bacteria cotton textile, which comprises the steps of extraction of active matters of plants, preparation of natural germicide and chitosan cross-linking and finishing technology of the cotton textile; finished knitted or machine-made cotton textile has long-time aroma and has health-care effect such as broad-spectrum bacteriostasis, sterilization, desinsectization and the like; in addition, the cotton textile disclosed by the invention has very good washability; and the cotton textile can be prepared as a plurality of knitted or machine-made health-care fabrics such as bras, underwear, pants, pajamas, pillowcases, bed sheets and the like.

Owner:JIANGSU SANFONDO TEXTILE BIOLOGICAL SCI & TECH

Contact and capacitive touch sensing controllers with electronic textiles and kits therefor

InactiveUS20080050550A1Increase the areaMany contactsLiquid surface applicatorsLayered productsYarnTouch Senses

A tufted controller using electronic textiles offers a unique way of controlling on / off and similar functions of electric and electronic devices. The uniquely soft and tactile tufted controllers offer relatively larger areas of more versatile contact over the prior art (i.e., flat, hard capacitive contact sensors). The tufted controllers may be constructed with yarn, string, thread, cordage or the like—even novelty yarns, like boucle- or eyelash type. Kits for building such controllers—especially for lamps and patches are popular craft projects.

Owner:ORTH MARGARET A

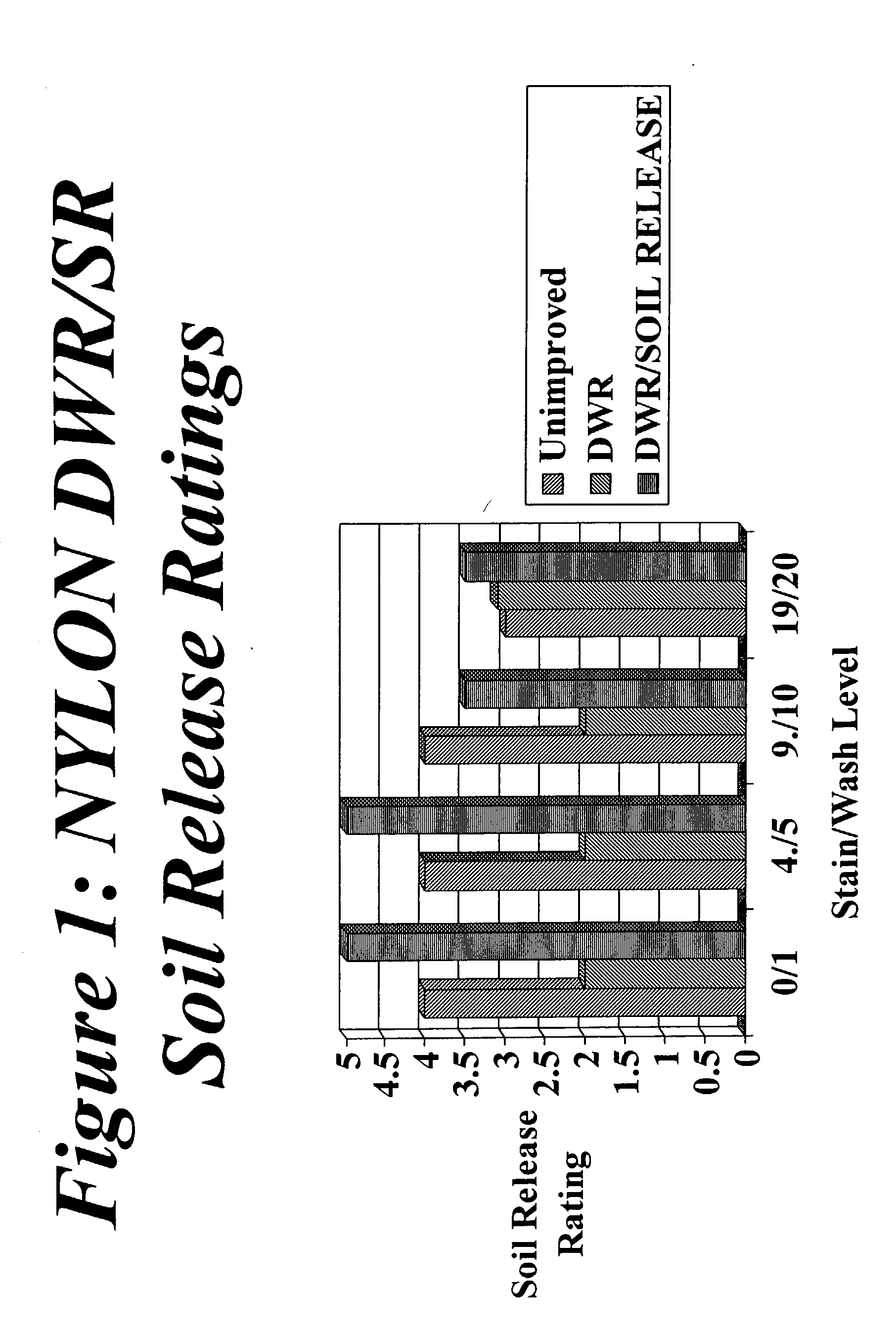

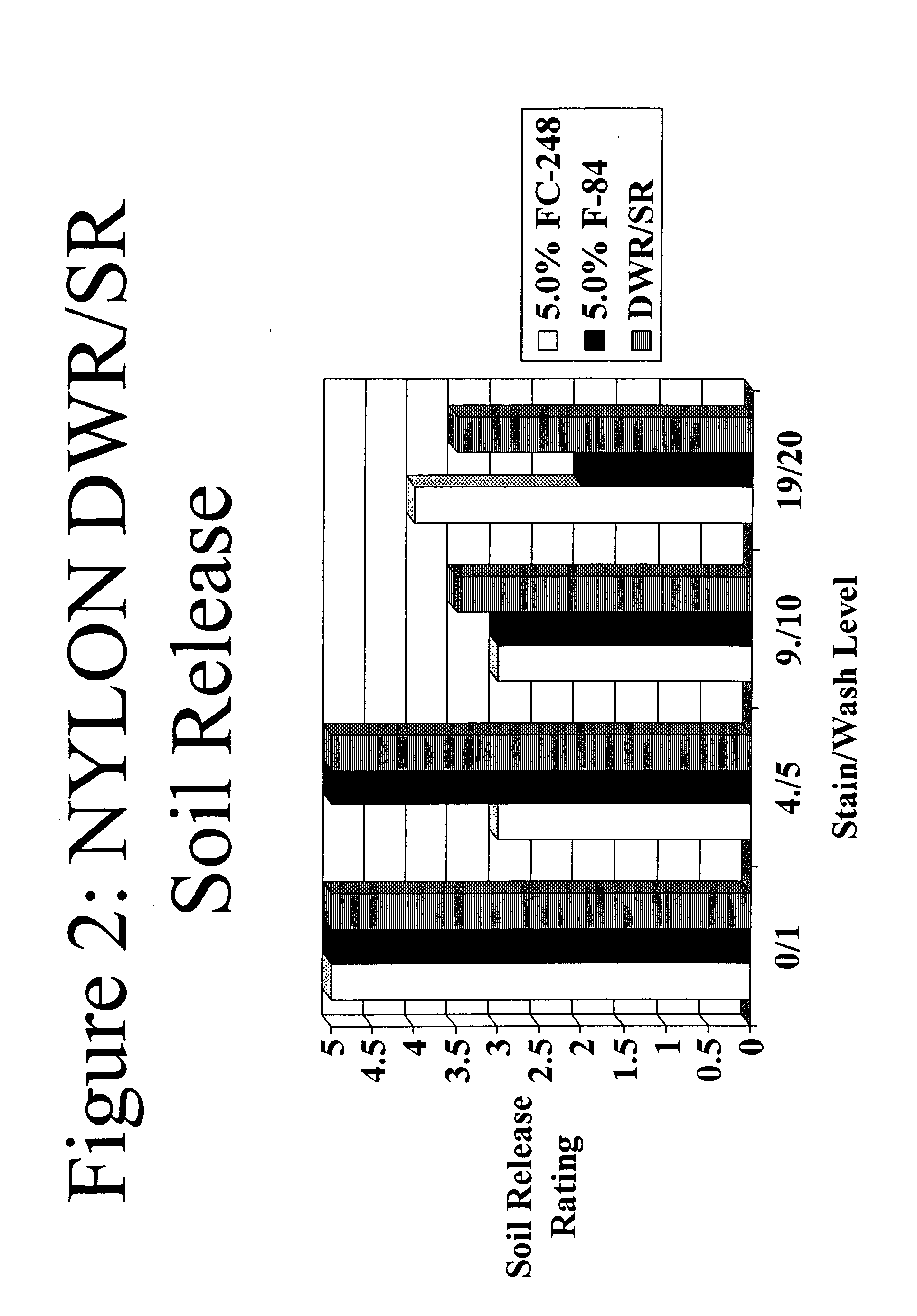

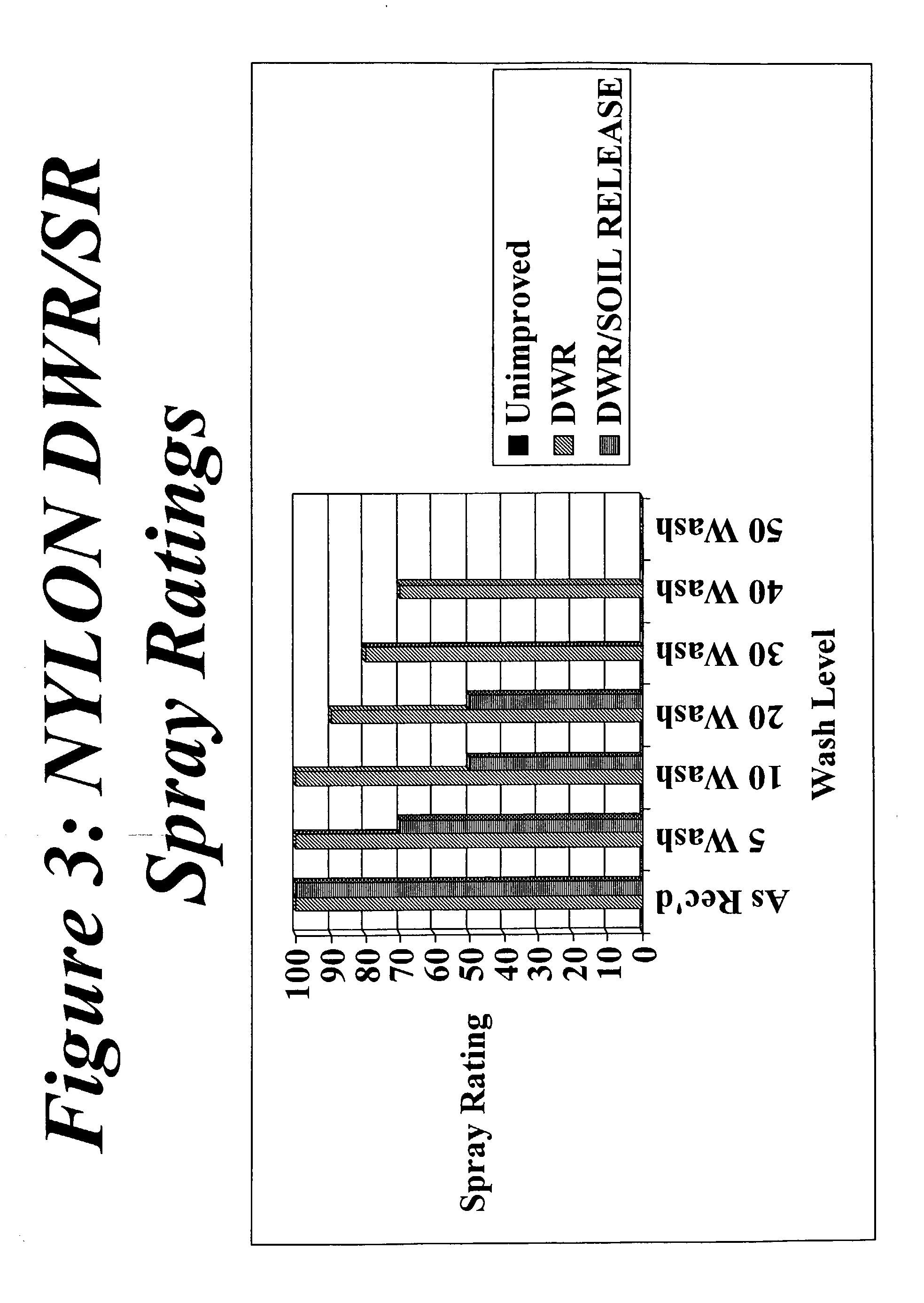

Textile substrates having improved durable water repellency and soil release and method for producing same

InactiveUS20030116744A1Improved durable water and oil repellencyFacilitated releasePhysical treatmentOther chemical processesPolyesterAramides

A process for imparting durable water and oil repellency and durable soil release characteristics comprises the application of an aqueous mixture having a water repellent component such as a fluorocarbon polymer and a separate hydrophilic soil release polymer to a textile substrate, followed by a drying step. Optionally, a curing or thermosetting step may also be employed, if desired. This process is carried out in a preferred embodiment in a generally mild pH, which allows the process to be performed on a wide variety of textile substrates that may not be capable of withstanding more extreme pH values. Polyamides, aramids, polyesters, and poly / cotton substrates, when treated according to the present process, have all yielded improved performance with respect to durable water and oil repellency and durable soil release characteristics. A novel mixture or bath and novel treated substrates are also disclosed.

Owner:MILLIKEN & CO

Polymeric fiber composition and method

InactiveUS7074499B2Shortening and lengthening the wavelength of the incident lightRecord information storageLight beam reproducingFiber compositionActive particles

The present invention generally relates to specific combinations of active particles, forming a powder, that may be combined with carrier materials such as resins to produce fibers for textiles, films, coatings, and / or protective or insulating materials. The specific mixture of particles and materials may be carefully engineered to impart unique and valuable properties to end products including integration with optical energies, heat, and other electromagnetic energies. Resultant compositions may interact with light in the visible spectrum and optical and electromagnetic energy beyond the visible spectrum.

Owner:HOLOGENIX

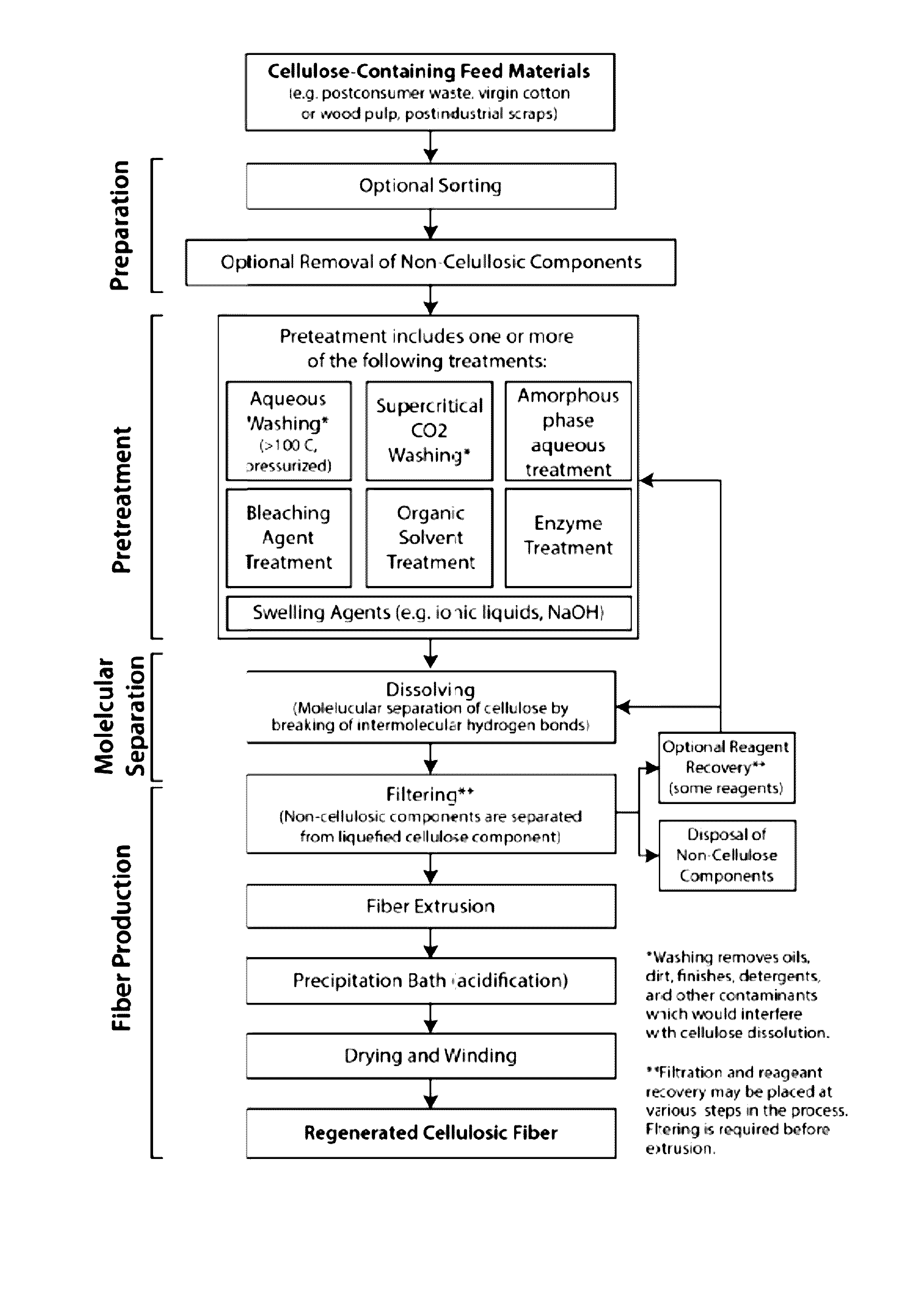

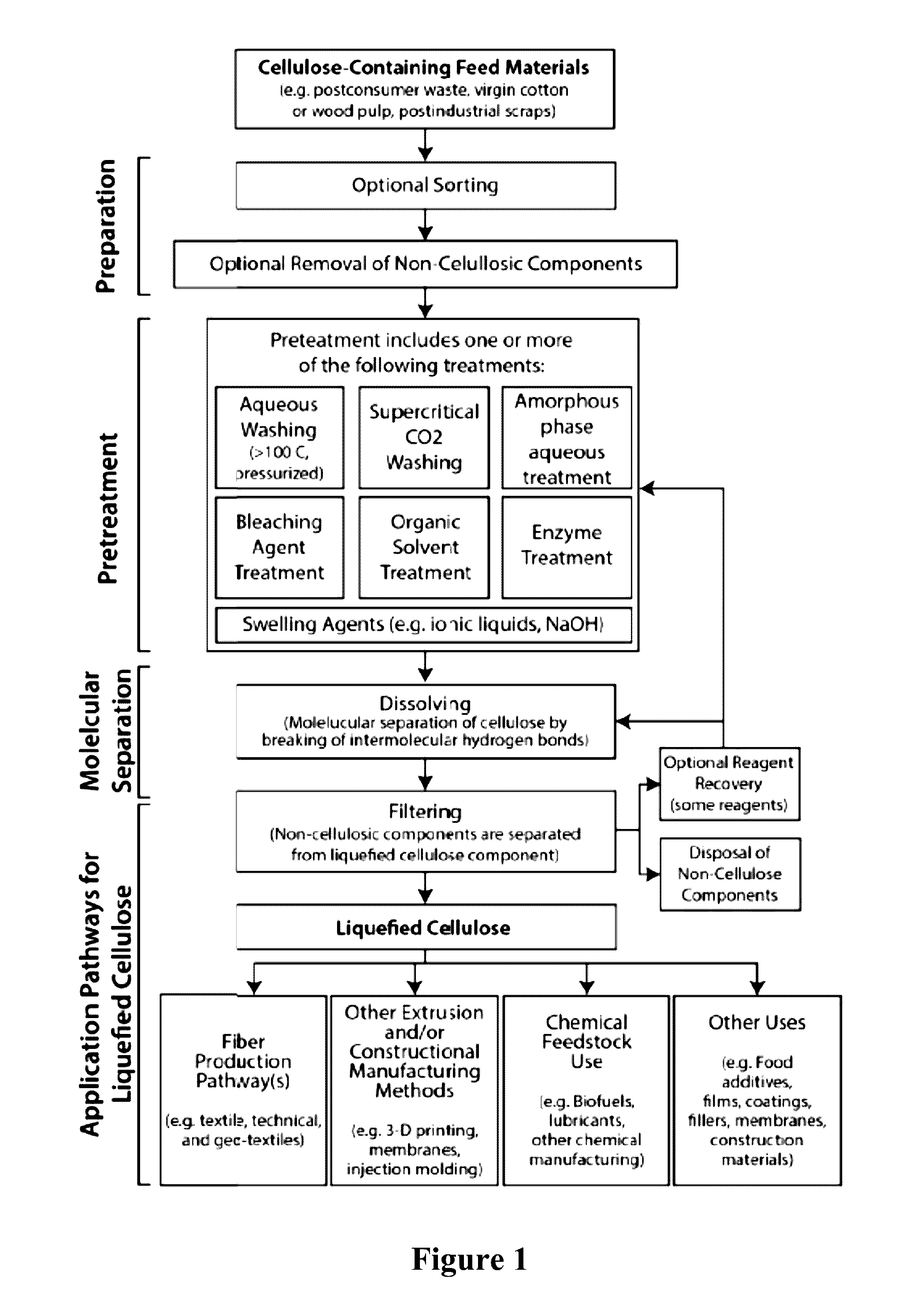

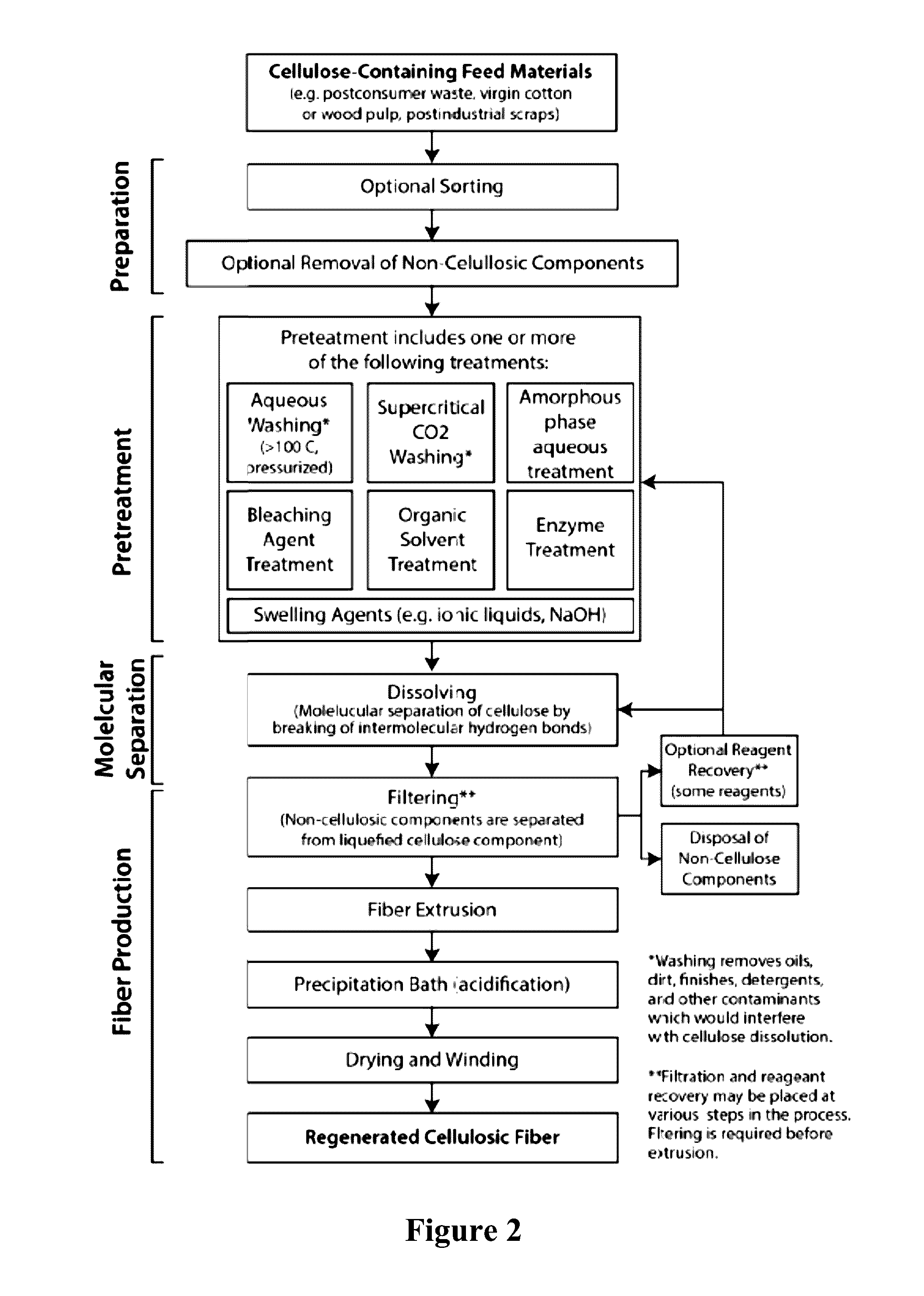

Methods and systems for processing cellulose-containing materials and isolating cellulose molecules; methods for regenerating cellulosic fibers

InactiveUS20160369456A1Reduce environmental impactPretreatment with water/steamPulp properties modificationPost-consumer wastePre treatment

Methods and systems of the present invention use cellulose-containing materials, which may include post-consumer waste garments, scrap fabric and / or various biomass materials as a raw feed material to produce isolated cellulose molecules having desirable properties that can be used in the textile and apparel industries, and in other industries. A multi-stage process is provided, in which cellulose-containing feed material is subjected to one or more pretreatment stages, followed by a pulping treatment, to isolate cellulose molecules. The isolated cellulose molecules may be used in a variety of downstream applications. In one application, isolated cellulose molecules are extruded to provide regenerated cellulose fibers having desirable (and selectable) properties that are usable in various industrial applications, including textile production.

Owner:EVRNU SPC

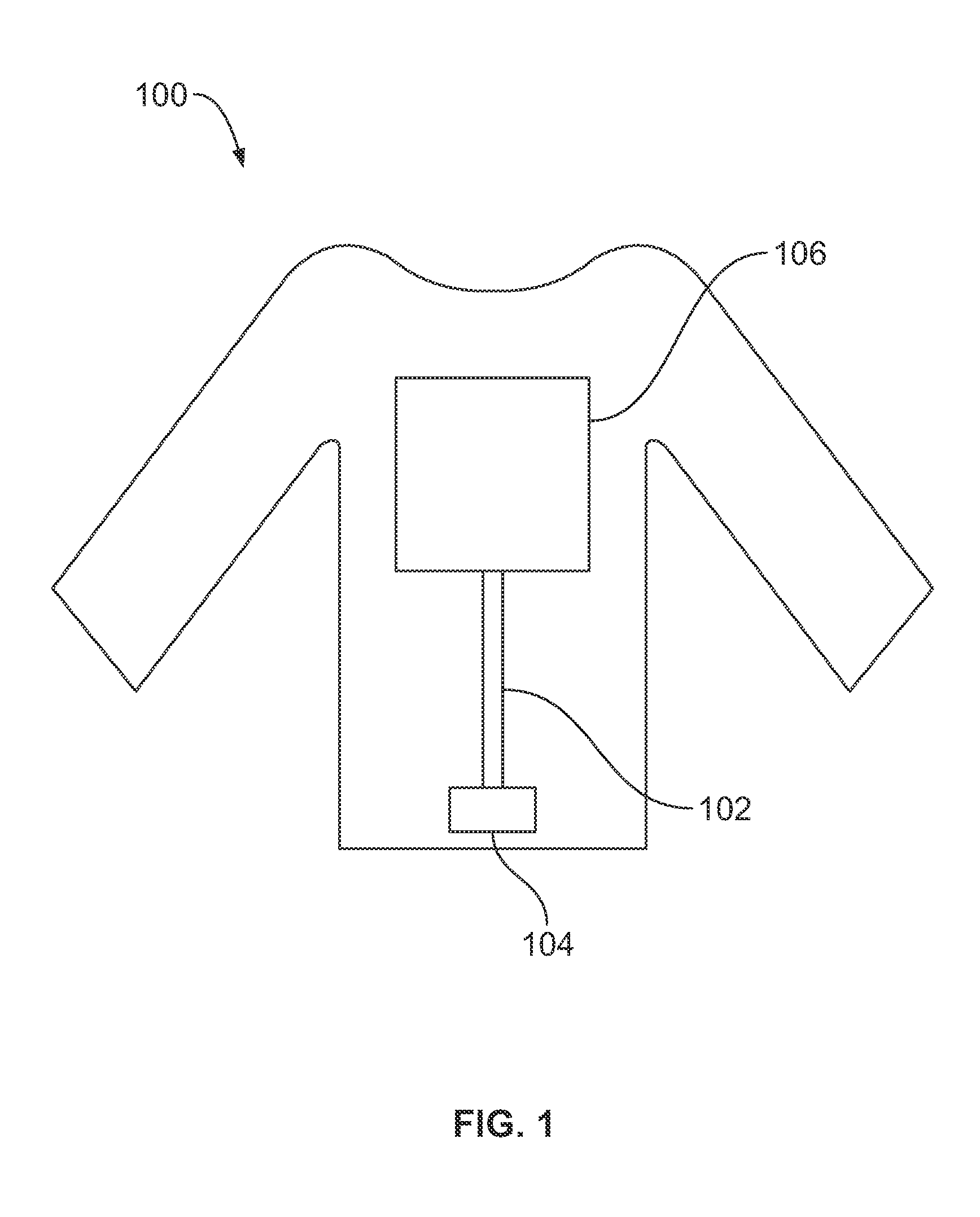

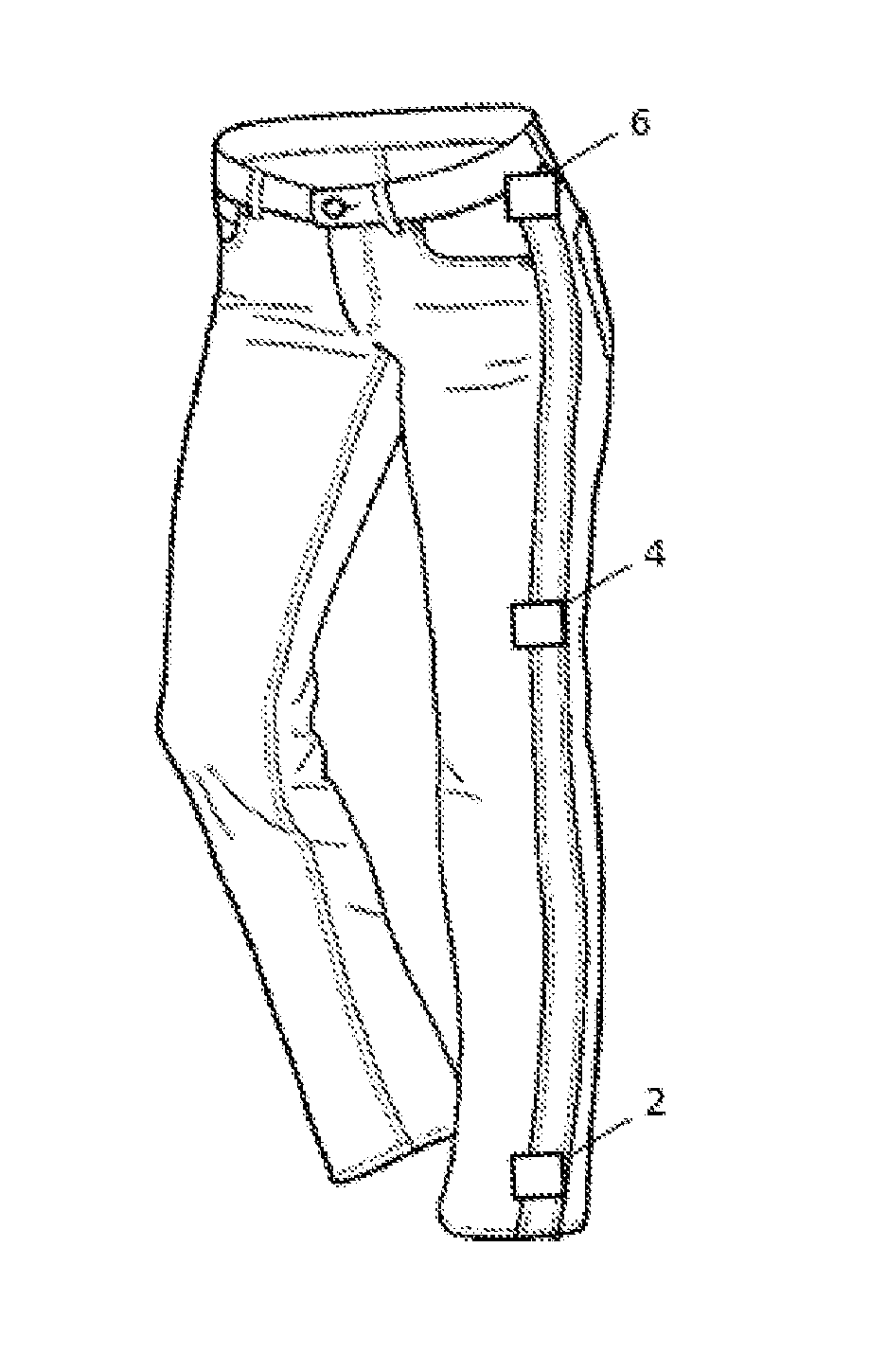

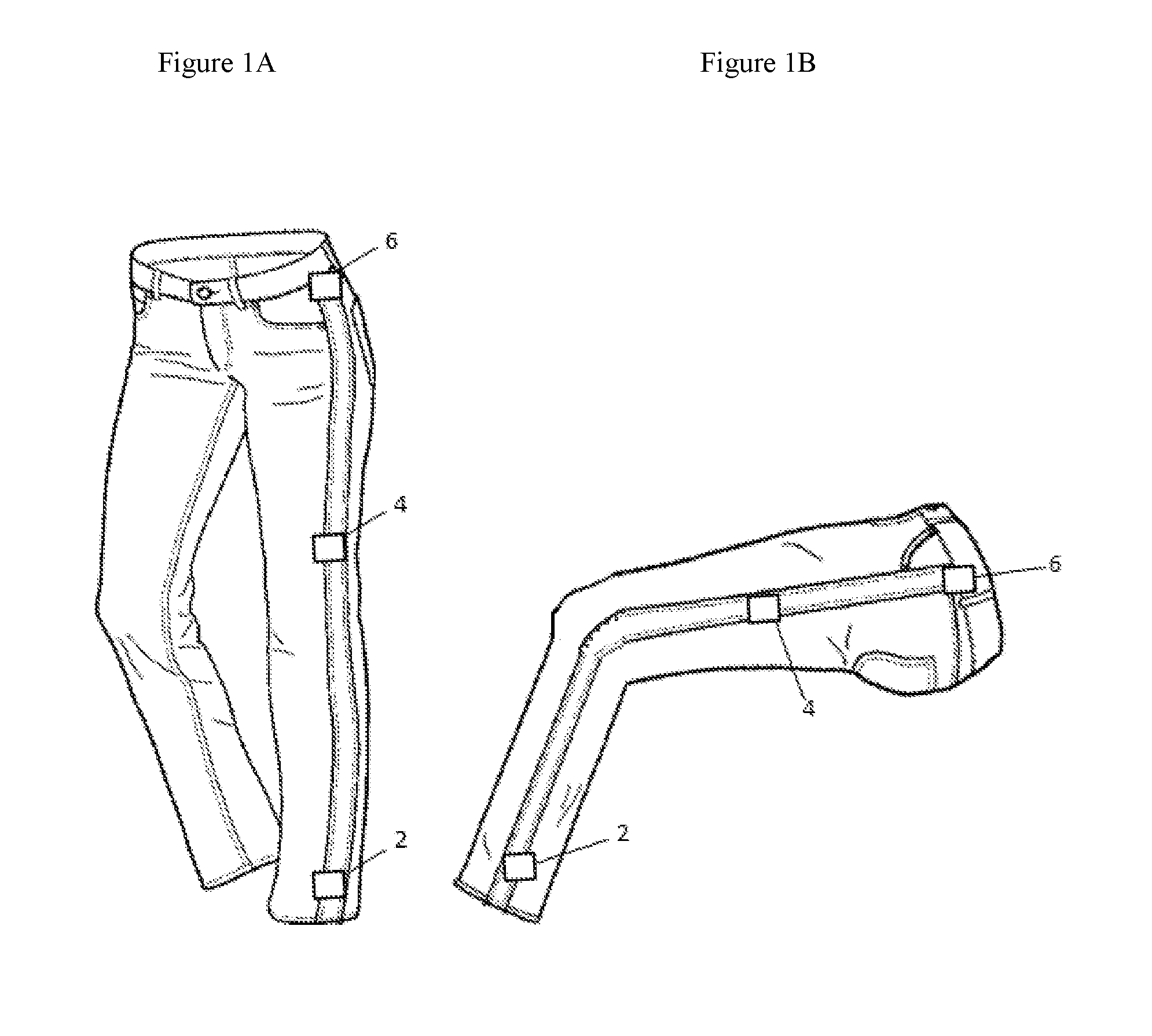

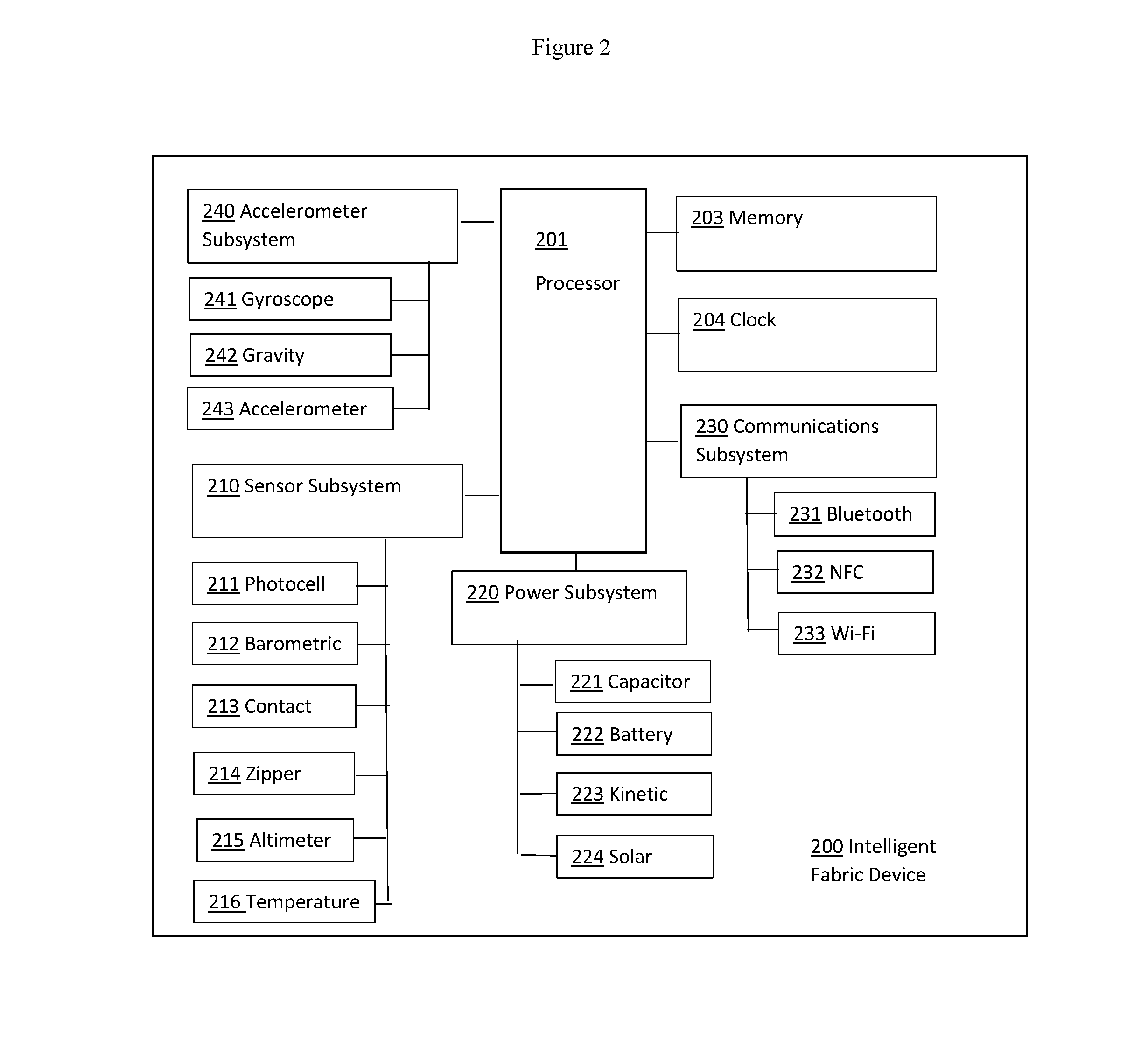

Monitoring Activity with Intelligent Fabrics

ActiveUS20160245665A1Function increaseGarmentsRegistering/indicating working of machinesGyroscopeAccelerometer

Textiles coupled with electrical components that are responsive to actions of the wearer and the surrounding environment. The textiles comprise a variety of sensors that interface with the cloud, networks, and devices. The textiles monitor physiological characteristics of the wearer. Objects in the environment may interact with the electrical components of the textiles. Micro-Electro-Mechanical Systems that include electrical components, such as, accelerometers, gyroscopes, Bluetooth chips, NFC chips, and RF tags integrate with the textiles to wirelessly communicate with networks.

Owner:TWIN HARBOR LABS

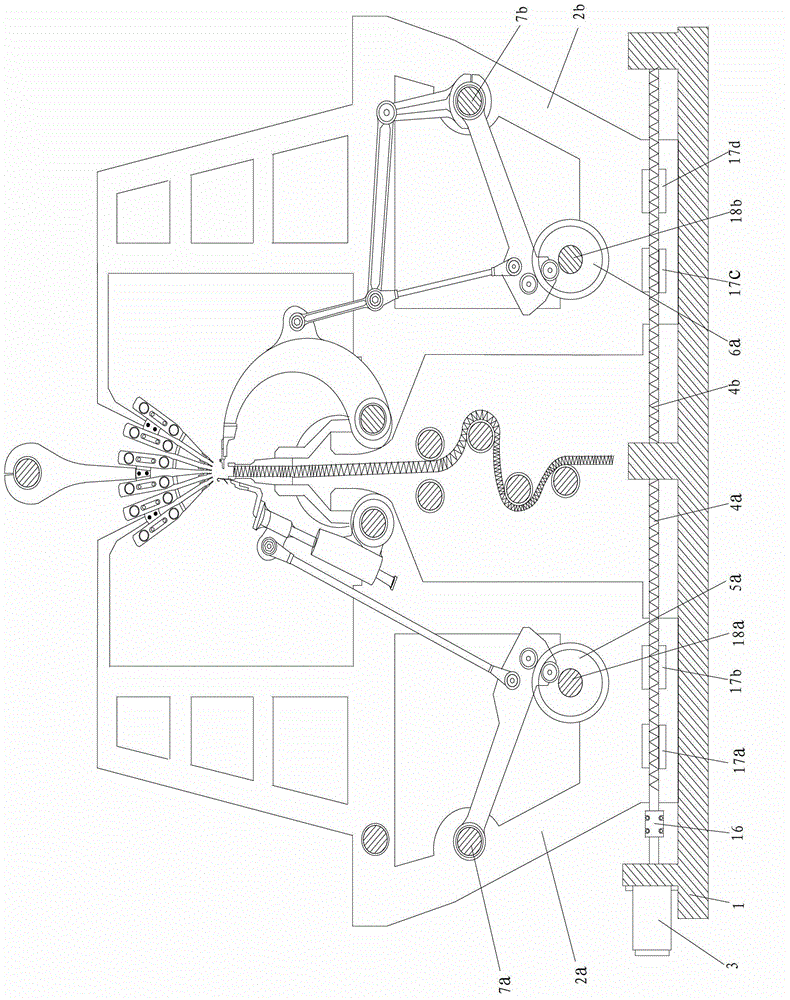

Manufacturing method and apparatus for torque-free singles ring spun yarns

InactiveUS6860095B2Simple methodImprove versatilityDomestic slide fastenersContinuous wound-up machinesEngineeringE-textiles

An internal torque balancing method of short fiber yarns related to the art of textile and the manufacturing apparatus thereof. The present invention proposes a completely new mechanical processing method of single torque-free yarns, and applies it into the process of ring spinning. Said method accomplishes a machine and a possibility of processing single torque-free yarns within one processing step by simple improvement on the existing ring spinning machine. Said technique is applicable to the production of all types of short fiber materials, and can overcome the maximum bundle yarn count of Ne limit of the torque-free yarns processed by the existing physical balancing technique. Meanwhile, said technique can process the yarns with low twist, which is unable to be processed normally by the conventional ring spinning machine. The torque-free singles ring spinning machine has good mechanical behavior, good handle, and evenness without residual torque.

Owner:THE HONG KONG POLYTECHNIC UNIV

Wool fiber modification treatment method

InactiveCN101424040AImprove shrinkageGood dimensional stabilityBiochemical fibre treatmentAnimal fibresYarnReduction treatment

The invention relates to a method for the modification treatment of wool fibre and belongs to the field of dyeing and finishing technology. The method adopts pre-oxidation treatment, oxidation treatment, reduction treatment, enzyme hydrolysis treatment, softening treatment and other modification procedures, can effectively improve the felting property of loose wool fibre, wool yarn, wool strips, wool flower type strips so as to prepare a worsted wool product, so as to achieve the effects of felting prevention and machine washablility, improve the dimension stability of the worsted wool product and simultaneously obtain soft and smooth hand feeling and excellent lustrousness. The standard washing shrinkage rate of the wool clothing product produced through the method is lower than 3 percent.

Owner:SUZHOU UNIV

Multe-component hemp blended spinning products and textile technology thereof

InactiveCN1483873AAnti-mold and antibacterialMoisture-absorbing and breathableWoven fabricsYarnFiberPolyester

The present invention relates to a multicomposition hemp blended spinning products and its technology. It is made from four fibres of hemp, yak cashmere, polyester fiber and modal as raw material, and its linear density is 9.7-200 tex, and its total compactness is 30%-99.5%. Its spinning technology includes the following steps: hemp and yak cashmere, dressing (A1860), pre-drawing (A272F) model and polyester fibre, dressing (FA201A), pre-drawing (FA304) mixed drawing first pass, mixed drawing second pass, roving (FA401), spinning (P7501), coning, warping, sizing, weaving and fabric finishing.

Owner:山西绿洲纺织有限责任公司

Integrally-woven three-layer heating textile

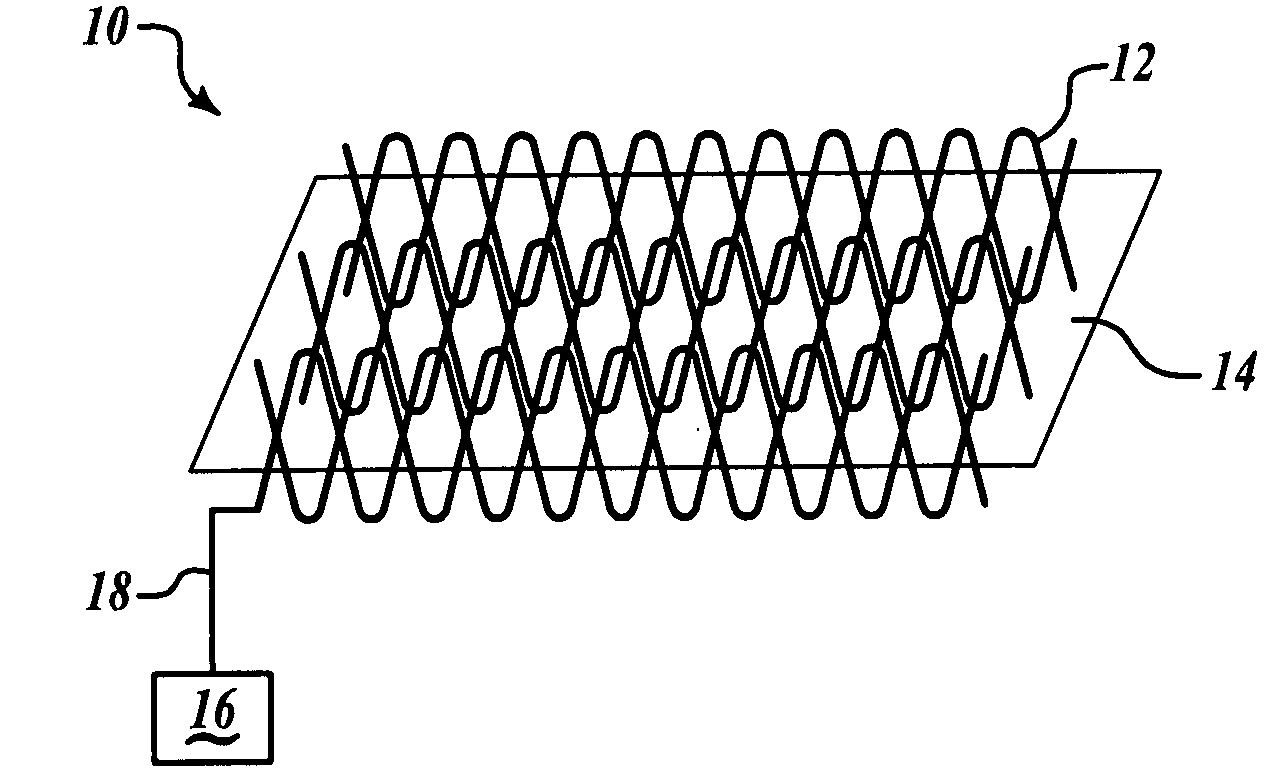

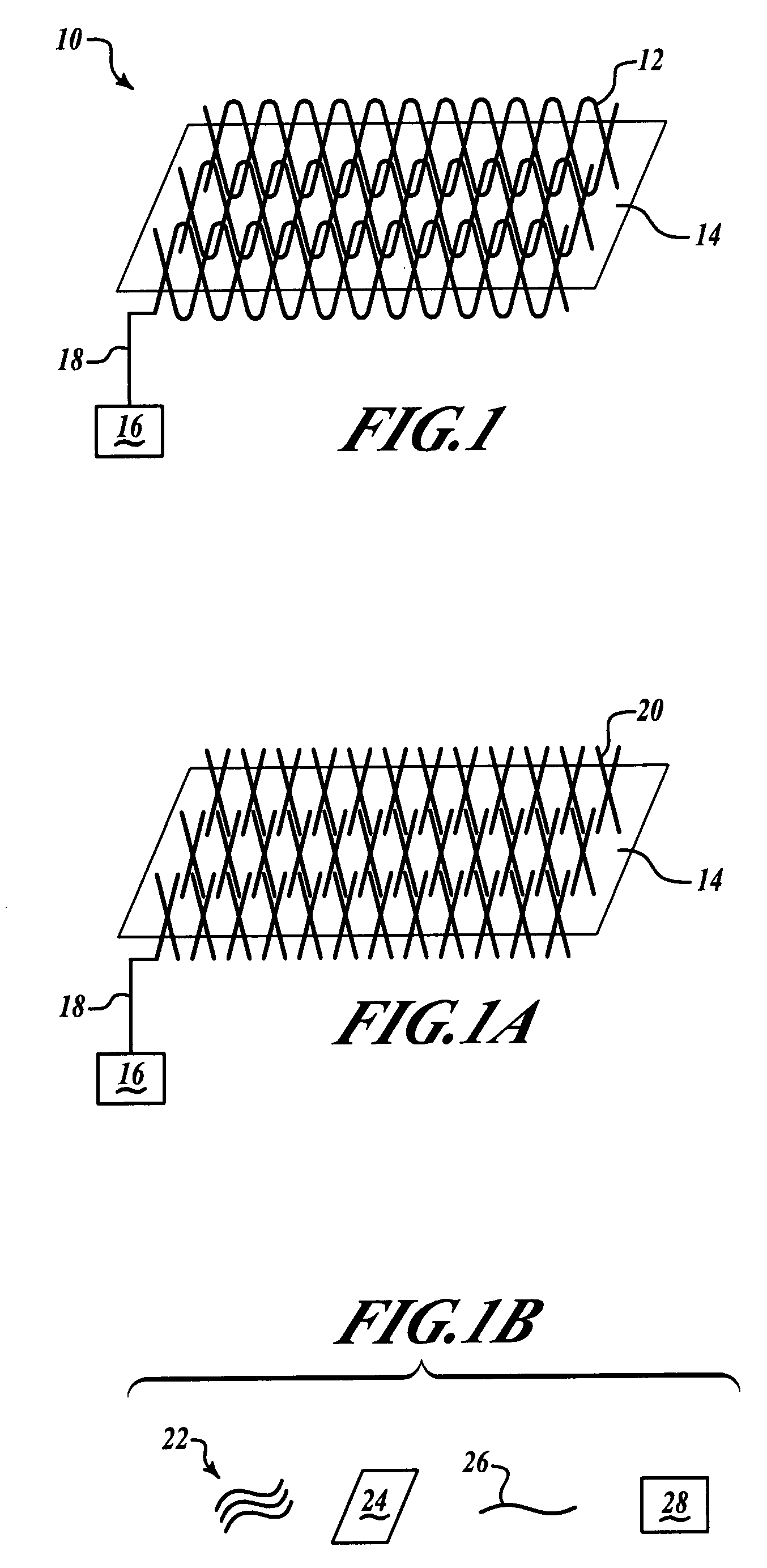

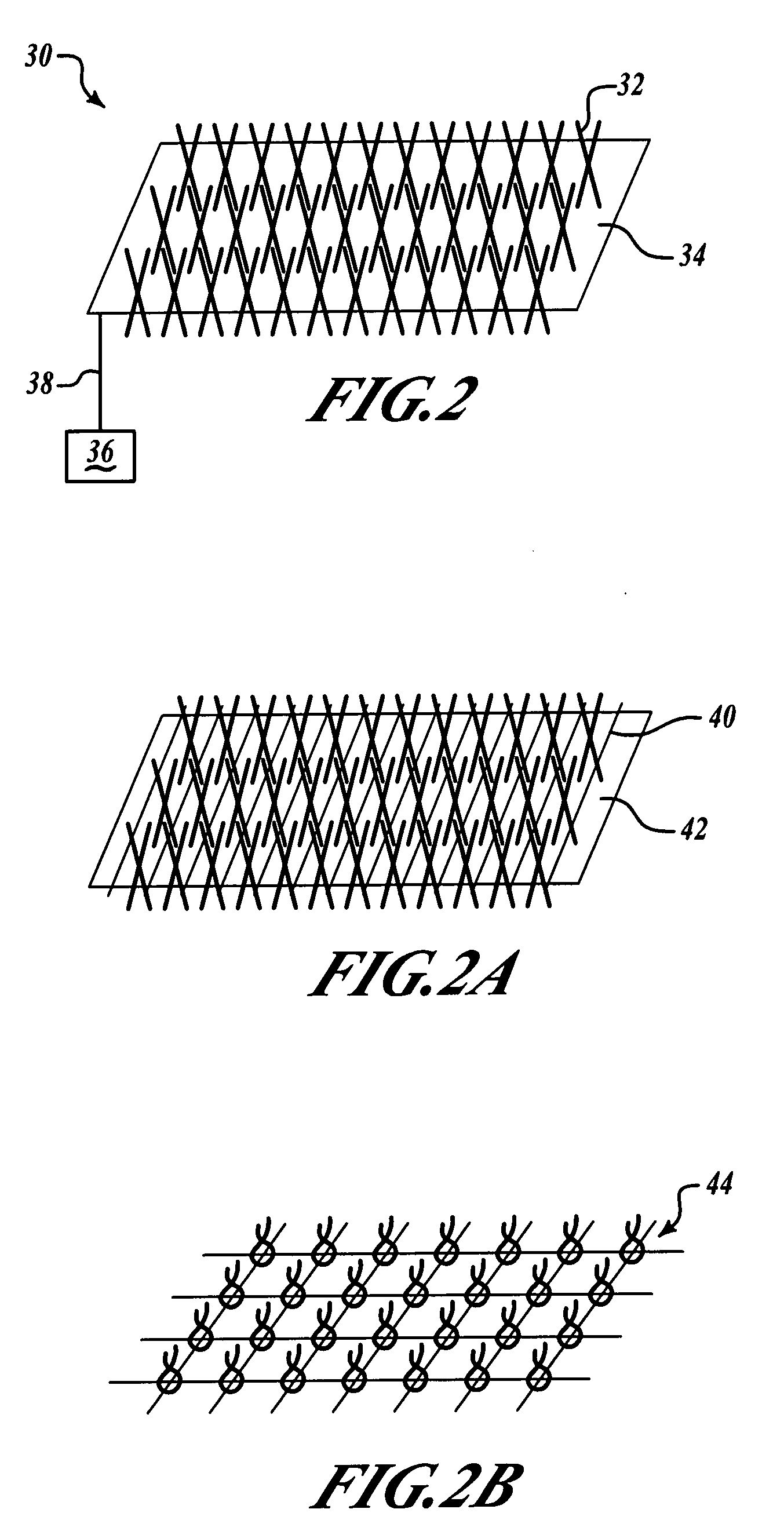

InactiveUS20100154918A1Shorten production timeSimple processWeft knittingMulti-ply fabricsEngineeringConductive yarn

An integrally-woven three-layer heating textile is provided. The integrally-woven three-layer heating textile includes a heat-isolated fabric layer, a thermal function fabric layer, a plurality of conductive yams and a plurality of connecting yarns. The conductive yarn is distributed between the heat-isolated fabric layer and the thermal function fabric layer. The connecting yam interlaces the heat-isolated fabric layer and the thermal function fabric layer so that the conductive yam is sandwiched between the heat-isolated fabric layer and the thermal function fabric layer.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

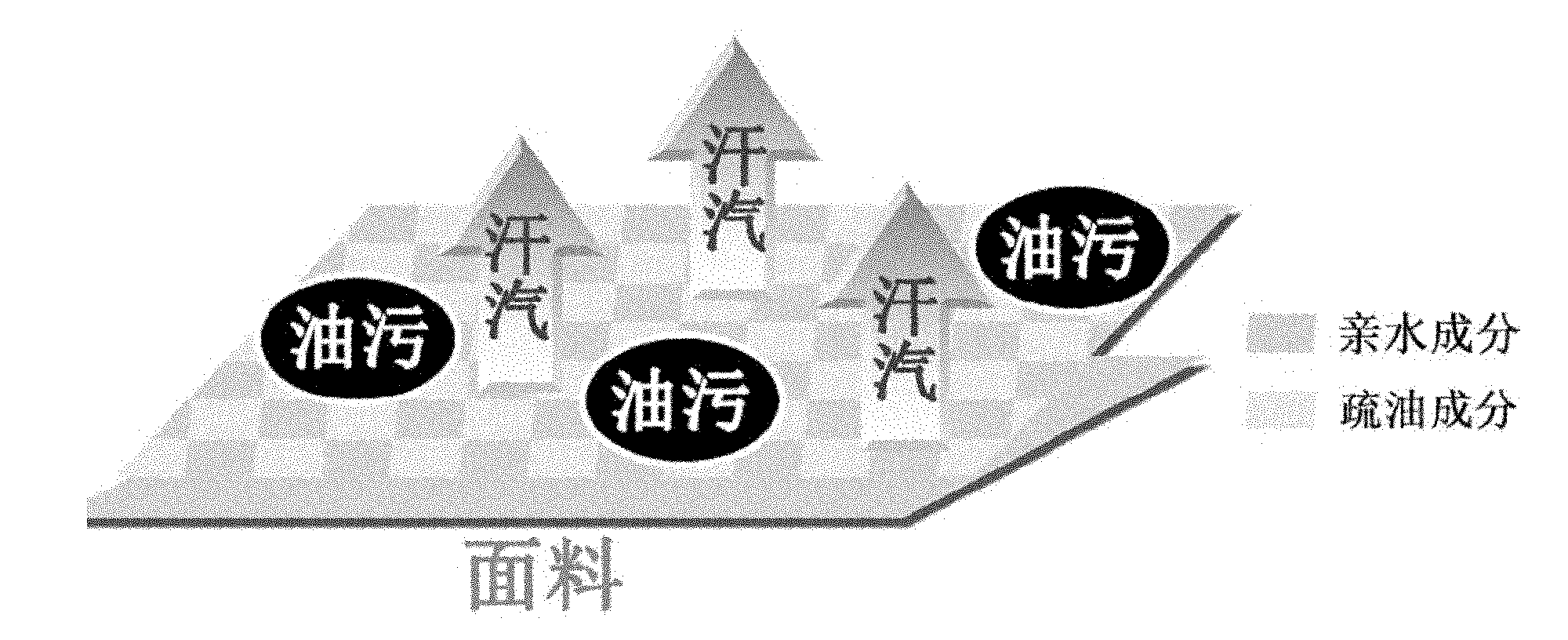

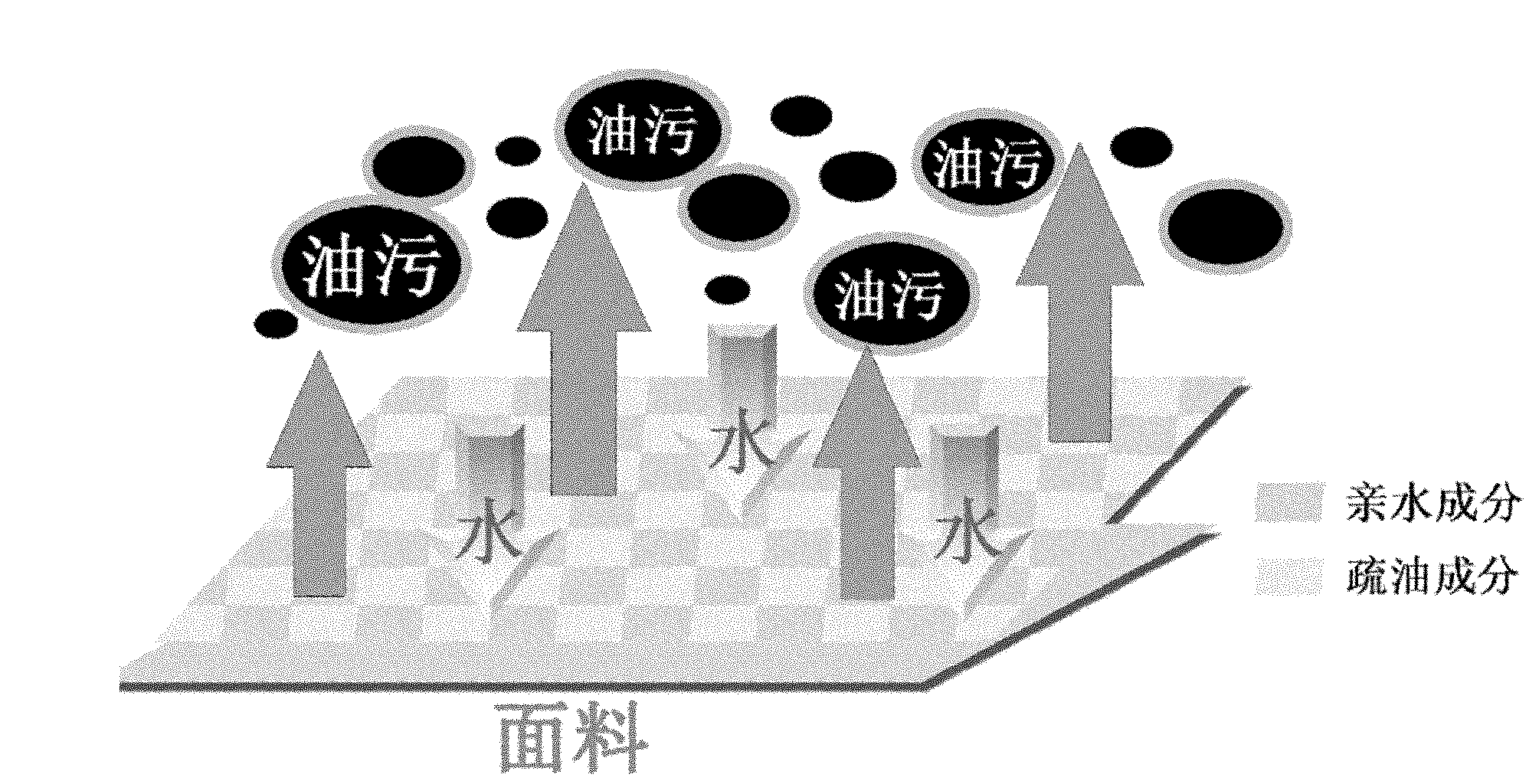

Finishing method of fiber product free of cleaning by detergent

InactiveCN102041685AImprove wettabilityReduce interfacial energyBiochemical fibre treatmentSingeingFiberPre treatment

The invention provides a finishing method of a fiber product free of cleaning by a detergent. The technical process comprises singeing, desizing, mercerizing, tentering and preshrinking. The finishing method is characterized in that enzyme piling is added between the singeing and the desizing; a high-efficiency desizing technique is adopted in desizing; liquid ammonia finish and pretreatment are added between the mercerizing and tentering; baking finish is added between the tentering and preshrinking so as to lead the whole technical process to be singeing, enzyme piling, desizing, mercerizing, liquid ammonia finish, pretreatment, tentering, baking and preshrinking. Textiles manufactured by adopting the technique is not cleaned by using the detergent for cleaning, has basically the same cleaning effect with that of cleaning during which the detergent is added, also can not generate secondary dirt in cleaning; and simultaneously, the textile manufactured by using the method has the functions of fouling resistance and easy decontamination, proper oil-proof function, excellent multiple functions of water absorption, air permeability, washing resistance and electrostatic resistance, meets the requirements of people and belongs to an ideal high-grade textile which is energy-saving, environment-friendly and low-carbon.

Owner:LUTAI TEXTILE

Method for dyeing silk broadcloth by using plant dye solution extracted from lily

InactiveCN102587153ASafe to takeIncrease added valueDry-cleaning apparatus for textilesNatural dyesFiltrationPollen

The invention discloses a method for dyeing silk broadcloth by using the pollen of lily as a natural dye and belongs to the technical field of textile dyeing and finishing. The method comprises the following steps of: soaking fresh or dried dark-red lily pistil, heating and performing suction-filtration to obtain a dye solution; adding silk broadcloth fabric which is refined, and dyeing the silk broadcloth fabric; and adding different mordants for mordanting and thus obtaining silk fabric with different colors. The method has the advantages of low cost, simple process, high performance, high additional value, non-allergic and non-carcinogenic to skin, and the like; raw materials are inexpensive, easy to get, and reproducible; and taking of dyeing products is safe. Particularly, by taking plant ash as a mordant, pollution is avoided. The method is environment-friendly and energy-saving, and clothes which are made of fabric dyed by using the method are natural, environment-friendly and nonirritating to the skin.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Fluorochemical-containing textile finishes that exhibit wash-durable soil release and moisture wicking properties

Wash-durable fluorochemical-containing textile and / or fiber treatments that simultaneously impart soil resistance (or soil-release) properties and moisture wicking characteristics to target fabric substrates are provided. Such treatments surprisingly impart these two simultaneous effects to target fabrics and / or fibers because fluorochemicals generally provide moisture repellency rather than moisture wicking capabilities. As prior soil release / moisture wicking treatments do not function properly, or, alternatively, compromise hand or other properties of certain target textiles after treatment application, a new, effective, soil release / moisture wicking formulation for such purposes was needed. The inventive treatment is extremely durable on such fabric substrates; after a substantial number of standard launderings and dryings, the treatment does not wear away in any appreciable amount and thus the substrate retains its soil release / moisture wicking properties. The method of adherence to the target yarn, fiber, and / or fabric may be performed any number of ways, most preferably through the utilization of a jet dyeing system or through a steam-transfer method. The particular methods of adherence, as well as the treated textile fabrics and individual fibers are also encompassed within this invention.

Owner:MILLIKEN & CO

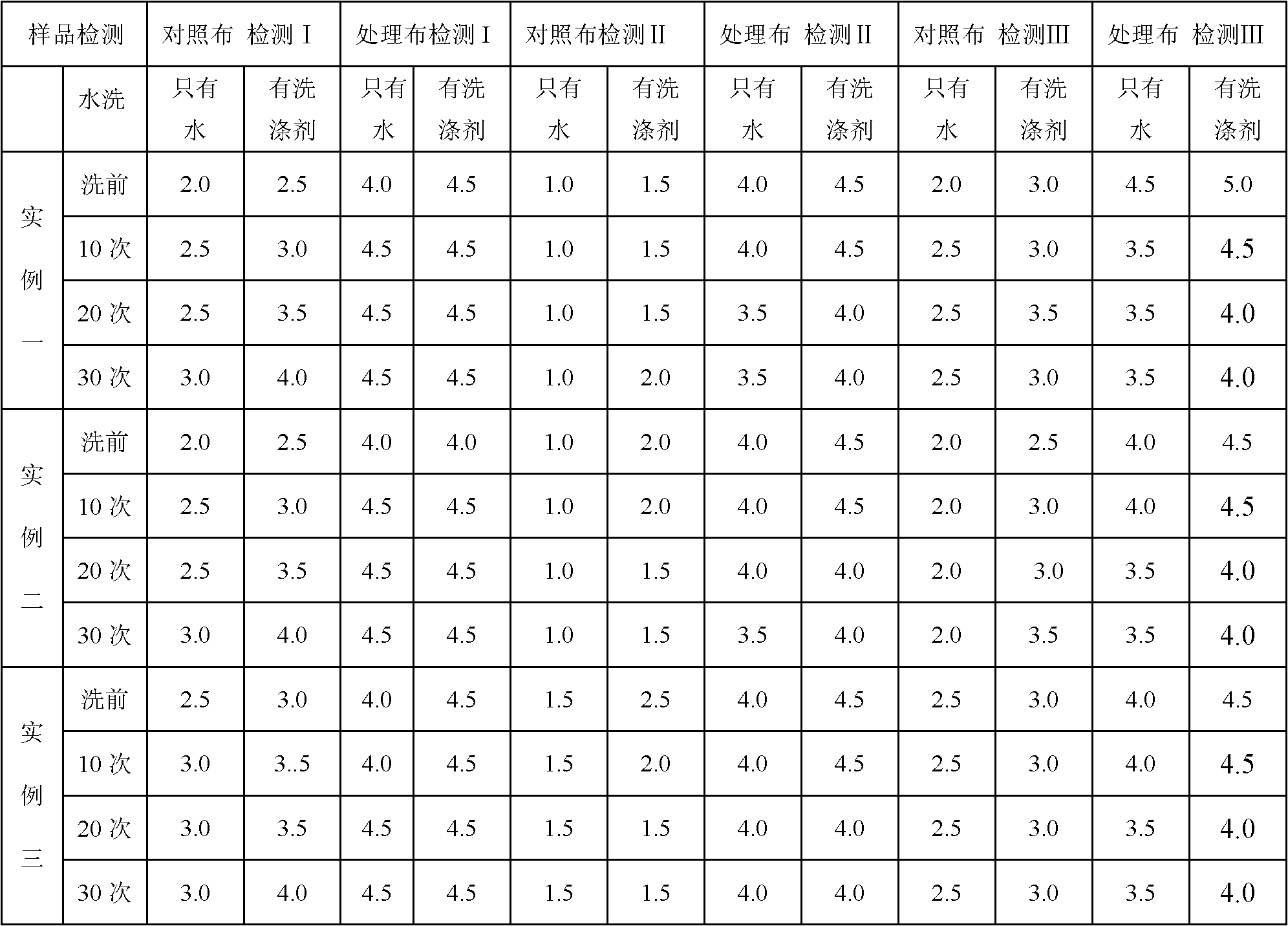

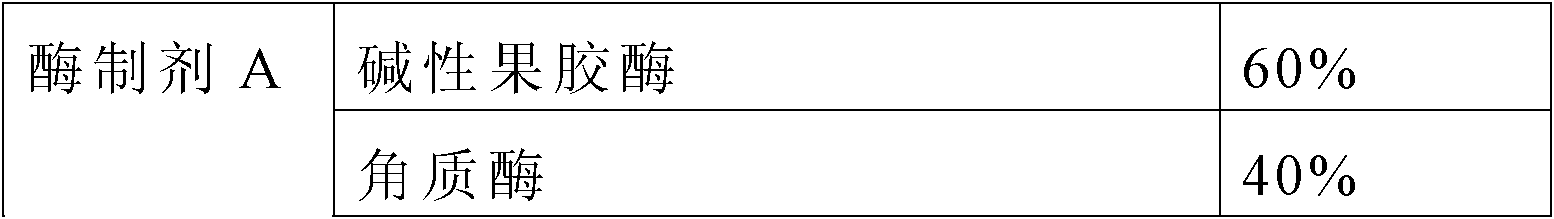

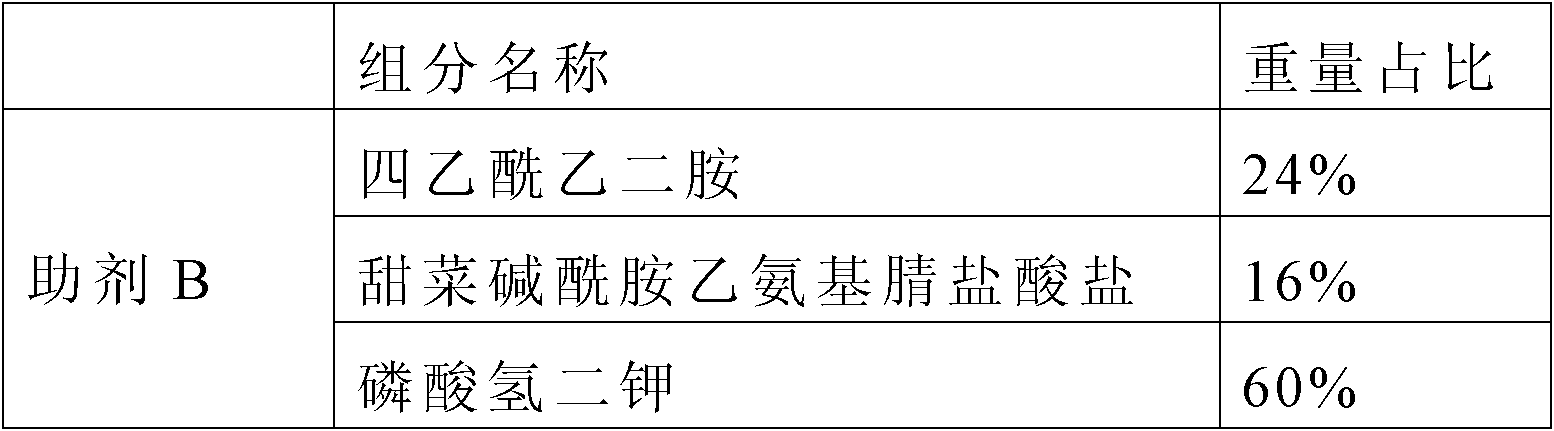

Low-temperature scouring and bleaching one-bath-process pretreatment process of cotton knitted fabrics

ActiveCN102587111AShort processHigh whitenessBiochemical fibre treatmentDry-cleaning apparatus for textilesDeoxygenationEnzyme

The invention discloses a low-temperature scouring and bleaching one-bath-process pretreatment process of cotton knitted fabrics, which includes the following steps: preparing scouring and bleaching solution according to the proportion of adding 0.2-0.8g of a scourzyme preparation A, 0.6-1.6g of an assistant B, 4-8g of hydrogen peroxide with the mass concentration of 30% and 1g of a penetrating agent in every liter of water; then, placing to-be-treated cotton knitted fabrics in the scouring and bleaching solution of 50-70 DEG C to be scoured and bleached for 30-60 minutes, emptying the scouring and bleaching solution and washing the cotton knitted fabrics with water, and then utilizing deoxygenation enzyme for deoxygenation to be prepared for dyeing. By combining scouring and bleaching and low-temperature bleaching ingeniously, one bath process can achieve a pretreatment process, scouring and high-temperature bleaching are not needed, and the low-temperature scouring and bleaching one-bath-process pretreatment process of cotton knitted fabrics saves water and energy, and shortens technological process. Products treated by the process meet quality requirements for fabrics and obtain good whiteness and wool effect, and comprehensive cost is lowered.

Owner:WUHAN SUNHY BIOLOGICAL

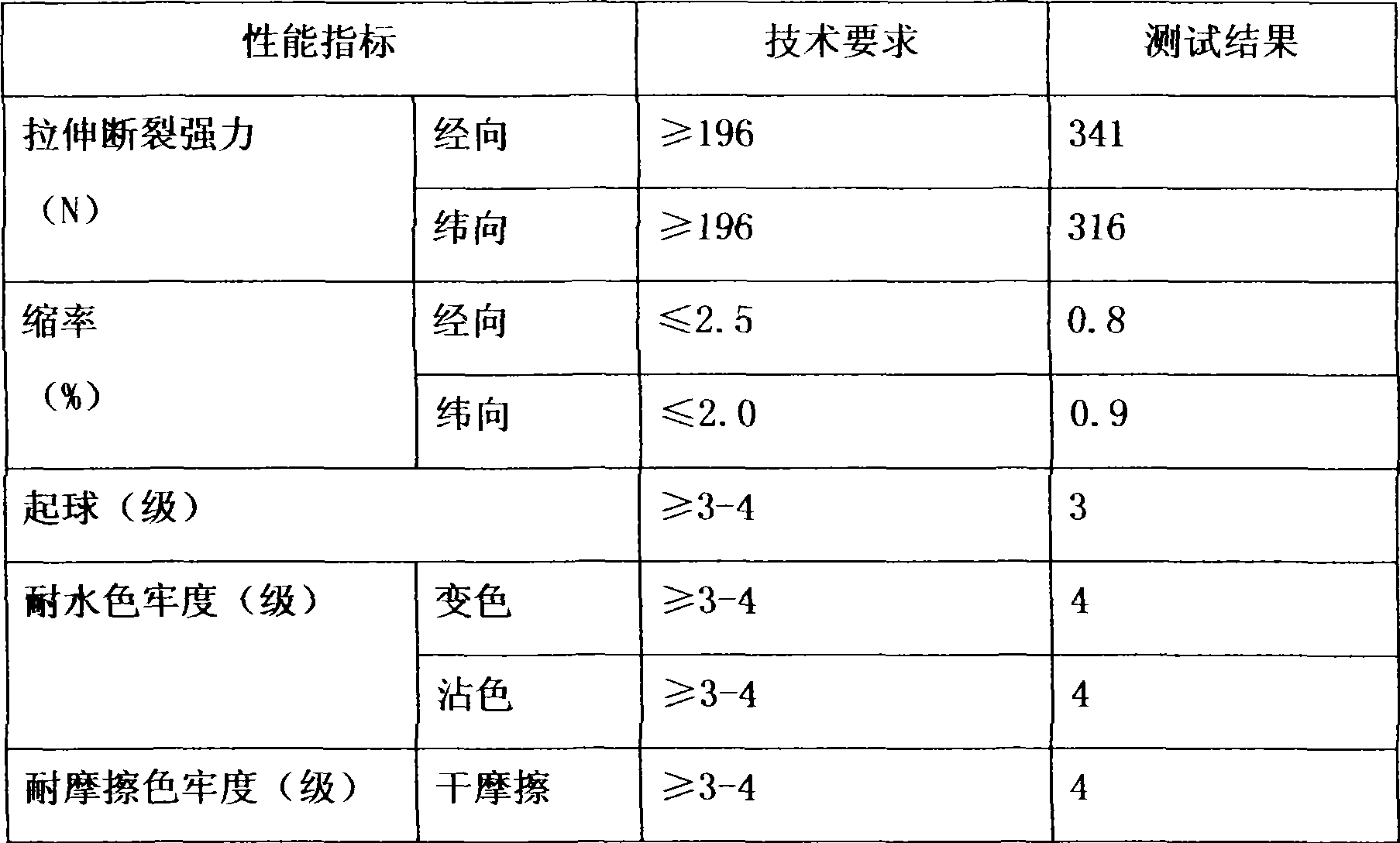

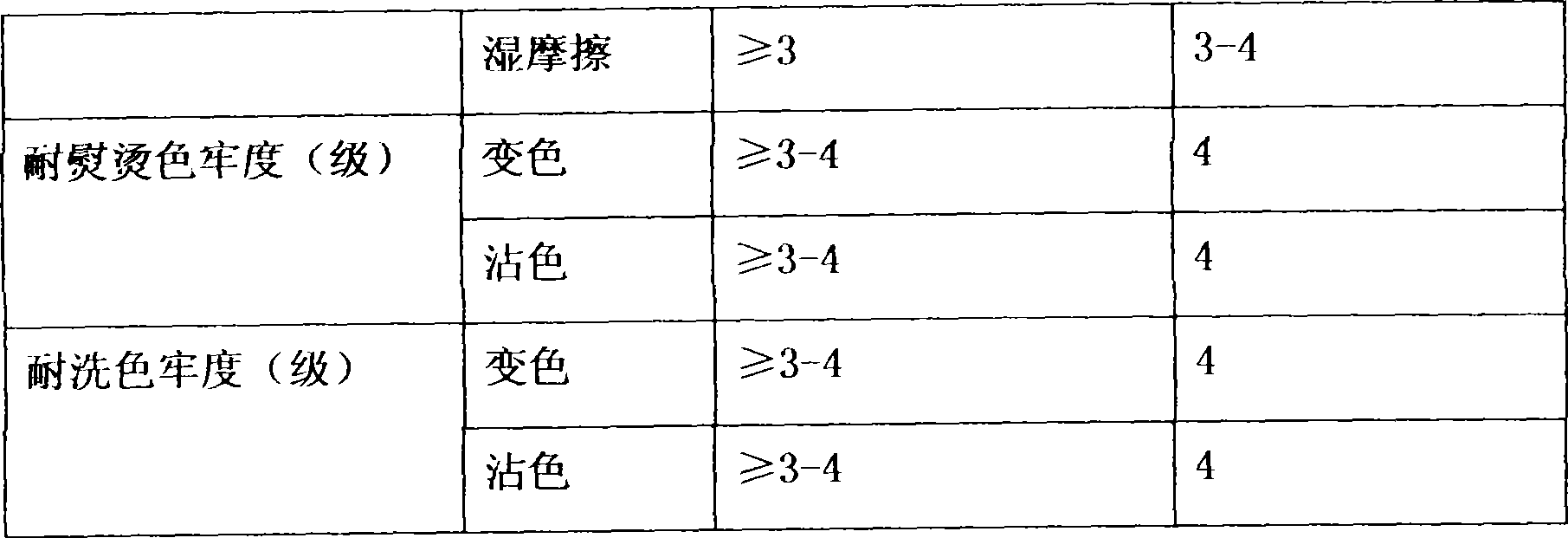

Method for producing sheep and rabbit hair combing elastic fabric

InactiveCN101418519AImprove spinnabilityIncreased scale angleBiochemical fibre treatmentWoven fabricsTextile technologyFiber

The invention discloses a method for producing a wool and rabbit hair combing elastic fabric and belongs to the field of textile technology. The method comprises raw material selection, a spinning process, a weaving process and fabric afterfinishing. The method is characterized in that before the spinning process, rabbit hair fiber is subjected to enzyme treatment, water washing and drying for spinning preparation; and the wool and the rabbit hair fibers are spun into wool and rabbit hair combed yarn through adopting the combination of combing spinning and semi-combing spinning; and the wool and rabbit hair combed yarn is interwoven to form the wool and rabbit hair combing elastic fabric. The method aims at the disadvantages that the rabbit hair fiber has poor spinnability and is easy to moult, creatively adopts oxidase to carry out pretreatment on the rabbit hair fiber in order to increase the angle of squama of the rabbit hair fiber, increase the friction coefficient of the surface of the rabbit hair fiber, have good spinnability and effectively improve the phenomena that a rabbit hair textile moults. The quality and added value of the product are greatly improved, and the product has good utility value and potential economic and social benefits.

Owner:SHAOXING UNIVERSITY

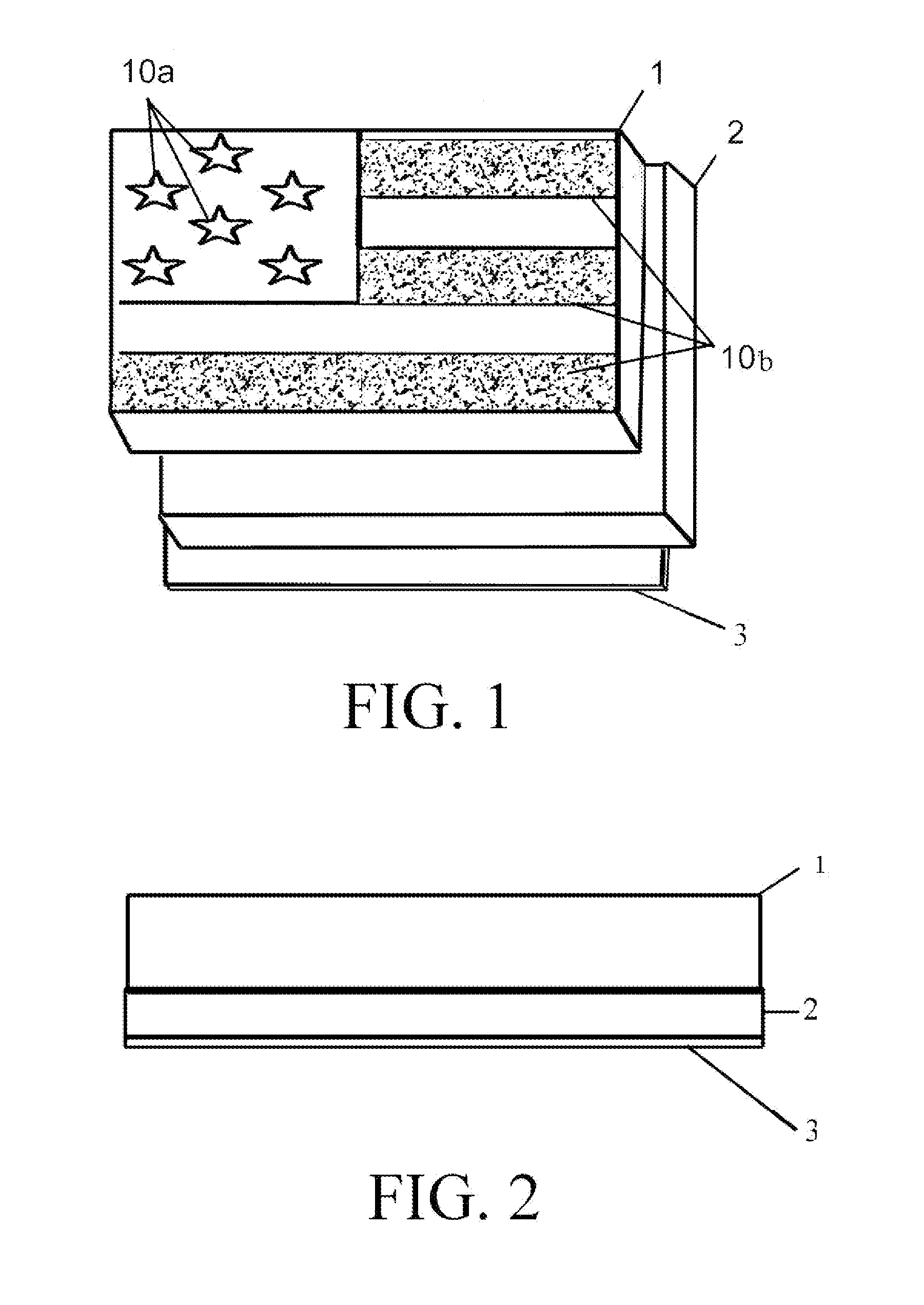

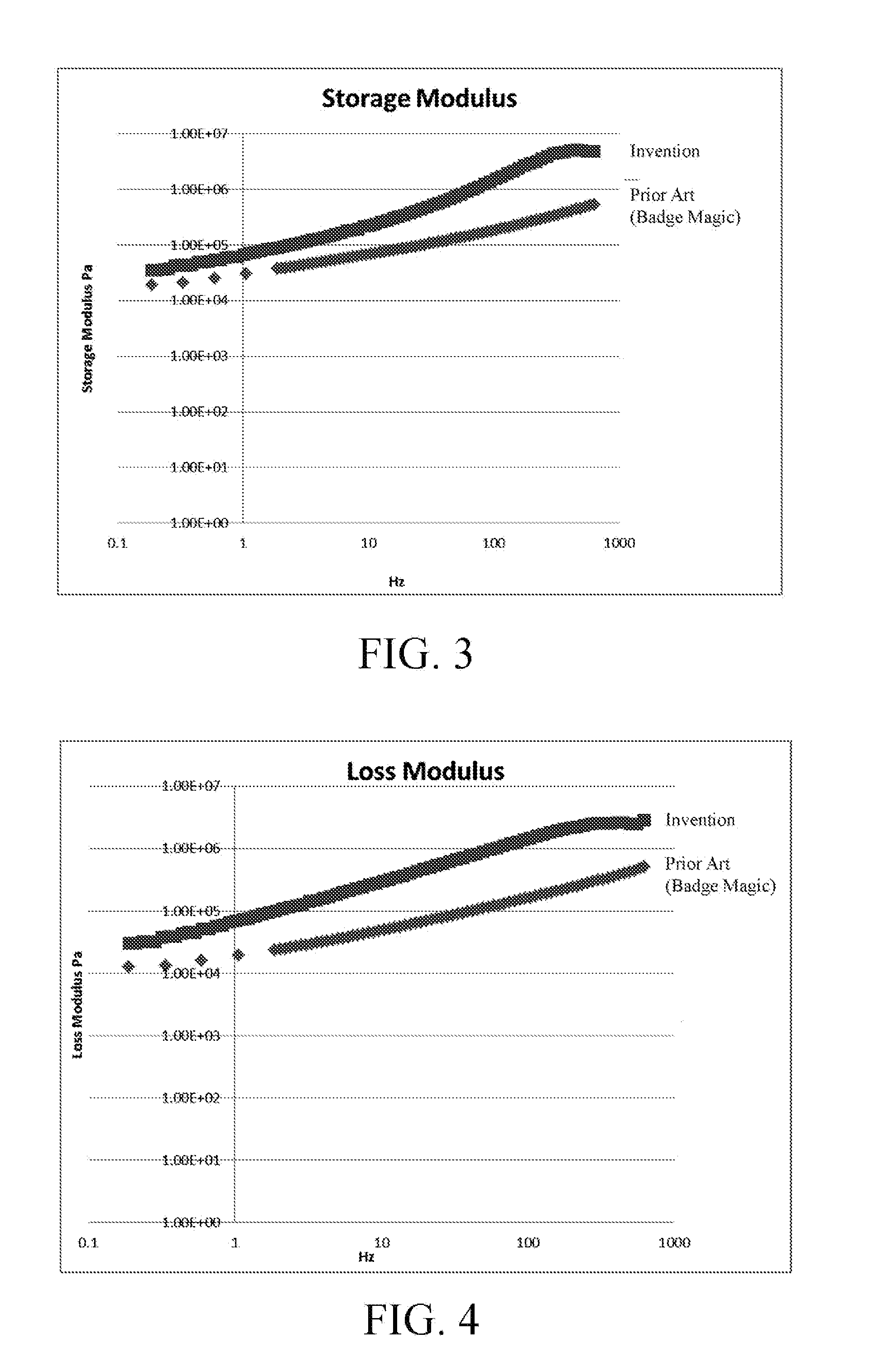

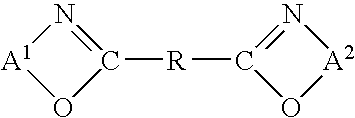

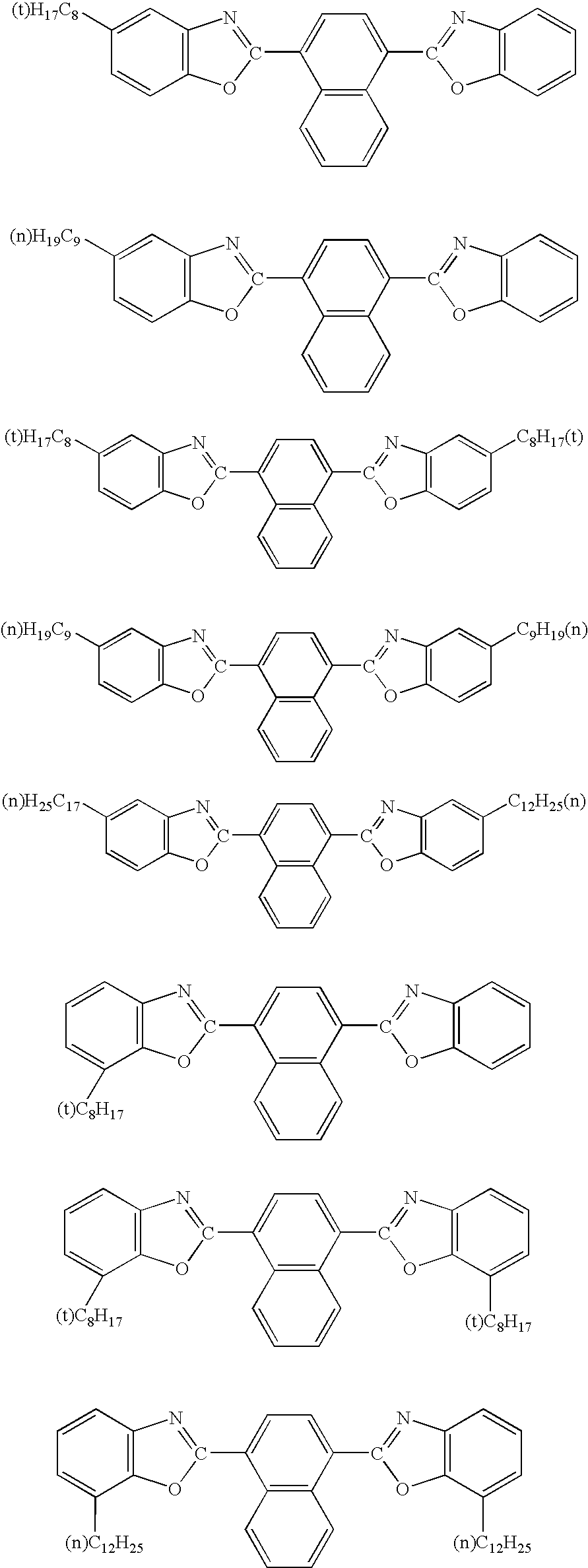

Pressure sensitive textile adhesive

ActiveUS20110168319A1DurableSecure bondingLamination ancillary operationsDecorative surface effectsCross-linkHigh energy

A method of wash-durably bonding integrated textile emblems such as patches, emblems, labels and cut textile parts to another textile article by laminating a pressure sensitive acrylic polymer adhesive to the back surface of the textile emblem. The acrylic polymer adhesive has a storage modulus that is greater than a loss modulus throughout a frequency range of from 0.1885 Hz to 628 Hz where bonding and debonding are expected to occur, and is devoid of any cross linking additives or reagents. The integrated textile emblem with laminated pressure sensitive acrylic polymer adhesive has improved adhesion to low-to-high energy surfaces, is not water soluble and is of adequate thickness to provide a wash-durable textile-to-textile bond capable of seaming or permanently attaching items such as textile panels, appliqué bearing text, numbers, logos and other indicia for the apparel, accessory and other industries.

Owner:LION BROS CO INC

Light reflecting polymeric articles containing benzoxazolyl-napthalene optical brighteners

ActiveUS7108913B1Good fluorescence propertiesOptimize allocationDollsSynthetic resin layered productsBenzoxazoleFiber

The present invention provides a highly reflective fluorescent polymer composition comprising a benzoxzolyl naphthalene optical brightener and a polymeric substrate support material formed into three dimensional articles or fibers. The enhanced light reflectivity of the instant compositions occurs over a wavelength range of from about 400 to 700 nanometers. The fiber embodiment comprises a body or support portion made of a flexible and durable thermoplastic material which is at least partially translucent and bis(benzoxazolyl)napthalenes optical brightener molecularly dispersed throughout the polymeric body potion of the fiber. The fibers are fluorescent to a UV source and can be effectively utilized for artificial hair for toy dolls as well as for various other textile applications.

Owner:MATTEL INC

Production method of inorganic nanometer light response type self-cleaning polyester fiber

InactiveCN102560724AConsiderable value-addedImprove efficacyFilament/thread formingMonocomponent polyesters artificial filamentPolyesterFiber

The invention provides a production method of inorganic nanometer light response type self-cleaning polyester fiber, comprising the following steps of: firstly specially producing visible light response type photochemical catalyst and easily-dispersed functional self-cleaning master batch, mixing the specially-produced functional master batch with polyester chip, and producing the inorganic nanometer light response type self-cleaning polyester fiber by a polyester fiber production technology. On the premise that the physical and chemical properties and the spinnability of the conventional fiber are not changed, the inorganic nanometer light response type self-cleaning polyester fiber has the characteristics such as bacteriostasis, air cleaning, self-cleaning function of easily desorbing greasy dirt, wide reaction condition, economical efficiency and the comprehensive treatment on pollutants. The various textiles made from the fiber, such as curtains, tablecloth, sofas, bedclothes and clothes, just like automatically running air cleaners, can be widely used in places such as bedrooms, hotel rooms, hospital wards, office, shopping malls, restaurants, indoor recreation grounds, etc.

Owner:SHANGHAI DEFULUN CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com