Patents

Literature

957 results about "Textile dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dyeing in textiles is a process in which color is transferred to a finished textile or textile material (like fibers and yarns) to add permanent and long-lasting color.

Textile dyeing wastewater advanced treatment recycling technology

InactiveCN102145965AReduce chromaImproved BioprocessingMultistage water/sewage treatmentWater/sewage treatment by neutralisationTextile fiberChemical treatment

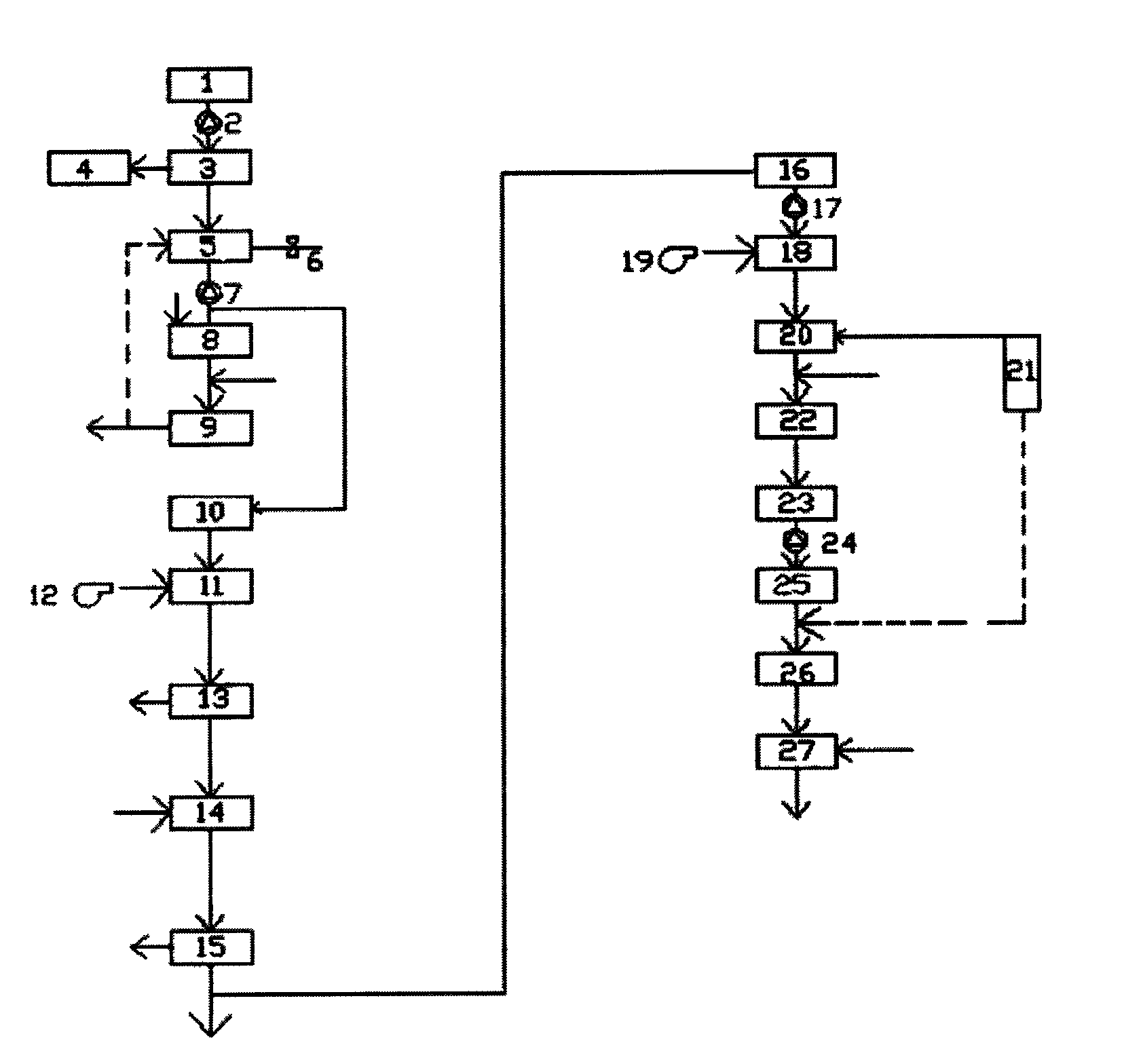

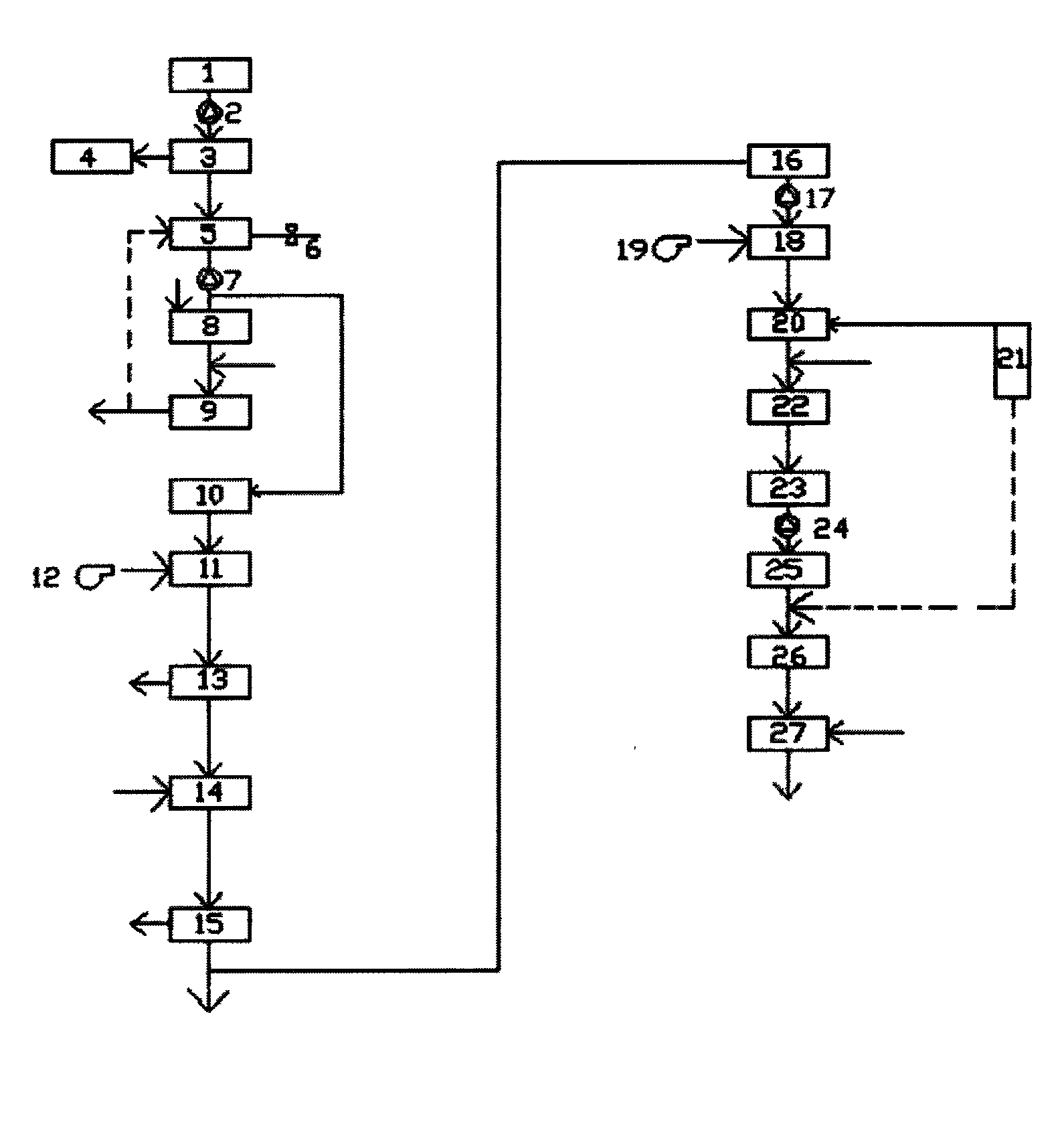

The invention discloses a textile dyeing wastewater advanced treatment recycling technology. The technology comprises the following steps: filtering to remove textile fibers; cooling; neutralizing, degrading organic matters and decomposing, replacing or degrading (cracking) the chormophoric groups of the organic matters to reduce the chroma of the wastewater; performing biochemical treatment with the biomembrane; precipitating to ensure that the precipitated sludge enters a sludge treatment system and the supernatant enters a flocculation pool; performing chemical treatment, namely adding a medicament in the flocculation pool to remove the suspended matter (SS), CODcr (chemical oxygen demand), BOD (biochemical oxygen demand) and chroma of the water; performing secondary precipitation to ensure that the free SS is precipitated and the wastewater is decolored further; separating to remove and degrade the chloride ions of the reuse water; performing secondary biochemical treatment to further reduce the concentrations of the SS, CODcr and BOD in wastewater; performing ozone oxidation treatment, decoloring, degrading organic matters; performing chemical treatment to remove insoluble dye materials and SS and reduce the COD and chroma; and performing secondary filtration, and forming an ozone / activated carbon system to ensure that the hydroxyl radicals of activated carbon are used and the organic reaction in wastewater is adopted to decolor and degrade organic matters. The invention overcomes the defects of the existing physical method, chemical method and chemical method treatment technologies; and the technology has been used in many enterprises, and the good treatment effects are obtained.

Owner:李斌 +2

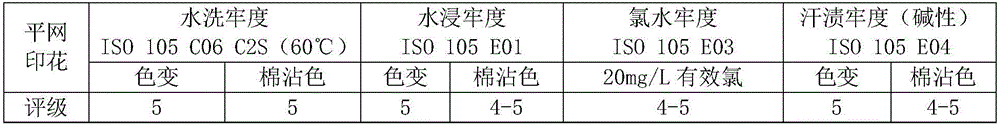

Dyeing and coating integrated dye dyeing and printing paste-shaped compound and application thereof

ActiveCN105970671AGuaranteed high sublimationGuaranteed wet rubbing fastnessDyeing processDisperse dyeHigh concentration

The invention relates to a textile dyeing and printing technique and specifically relates to a dyeing and coating integrated dye dyeing and printing paste-shaped compound for a hydrophobic textile material and an application thereof. The dye dyeing and printing paste-shaped compound is composed of 1-25% of dyeing and printing concentrated paste, 0.5-10% of thickening agents, 0.05-3% of pH modifiers and 62-98.45% of water. The paste-shaped compound provided by the invention is used for dyeing and printing the hydrophobic textile material and has the advantages of dye dyeing and printing and pigment dyeing and printing; the high sublimation, washing and dry and humid rubbing fastness are ensured while the color is bright and the hand feeling is soft; the generation of high concentration waste water in the traditional disperse dyeing and printing processes is avoided; and therefore, the dyeing and coating integrated dye dyeing and printing paste-shaped compound is a clean and environment-friendly dye dyeing and printing product.

Owner:SHENYANG RES INST OF CHEM IND

One-bathing integrated finishing method for real silk fabric by natural extract

InactiveCN101338518AAchieve antibacterialReduce processing stepsDyeing processAnimal fibresEngineeringTextile dyeing

The invention discloses a method for real silk fabric functional finishing, especially relates to a method for one-bath multifunctional finishing of real silk fabric by utilizing natural extract, which pertains to textile dyeing and finishing technical field. The invention includes the following steps: placing real silk fabric in solution with 5-20%(o.w.f) natural extract, liquor ratio of 1:10 to 1:100 and PH value of 2-8, treating for 10-100min; then treating for 10-100min in solution with 3-15%(o.w.f.) metal salt, liquor ratio of 1:10 to 1:100 and PH value of 4-8; after washing, dehydrating and furnace drying, completing one-bath finishing with dyeing, antimicrobial and anti-ultraviolet function to real silk fabric. The invention reduces manufacturing procedure of real silk fabric, has effect of energy-saving and emission-reduction, improves cleaning production of textile processing, is harmless to human body and surroundings, and conforms to ecological textile processing requests.

Owner:SUZHOU UNIV +1

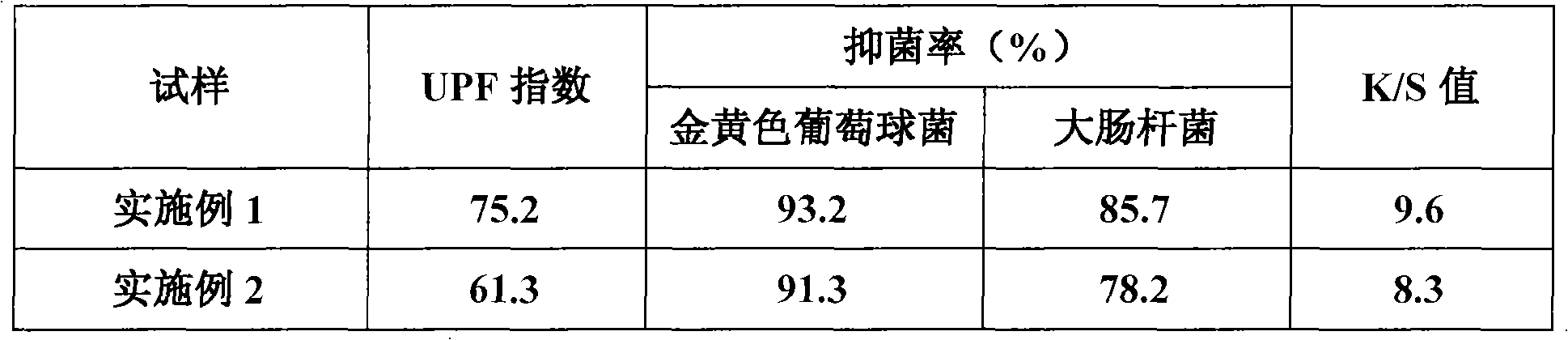

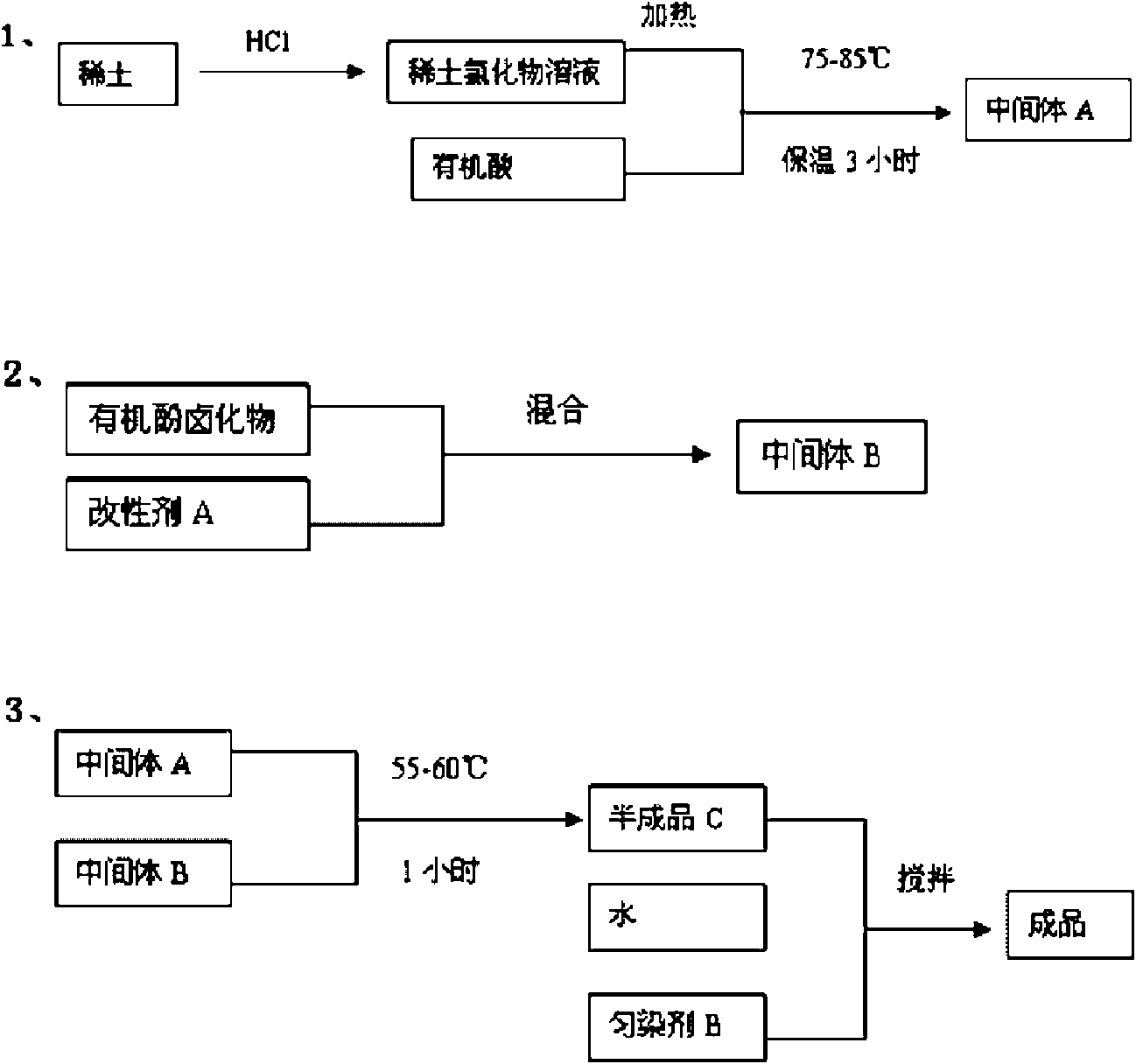

Accelerant for textile dyeing, preparation method and applications thereof

InactiveCN101560736AChange colorPromote environmental protectionDyeing processRare-earth elementFiber

The invention discloses an accelerant for textile dyeing, which is prepared by the following raw materials by weight portions: 2-5 portions of rare earths (calculated by rare earth element), 10-20 portions of organic phenol halide, 1-10 portions of organic acid, 1-5 portions of modifier A and 1-5 portions of leveling agent B; the preparation method of the accelerant comprises the following steps of (1) preparing the rare earths into a chloride solution, heating the chloride solution and adding the organic acid into the chloride solution, keeping the temperature and obtaining an intermediate A; (2) mixing the organic phenol halide and the modifier A to obtain an intermediate B; and (3) adding the intermediate B into the intermediate A, keeping the temperature and adding the leveling agent B and water; mixing the solution and obtaining the accelerant; the accelerant can be used for cotton fiber active dyes, can greatly reduce the use of sodium sulfate in the dyeing process of the active dye, is beneficial for environmental protection and reduces the production cost of the dyeing enterprises.

Owner:NINGBO XINKE TEXTILE AUXILIARY

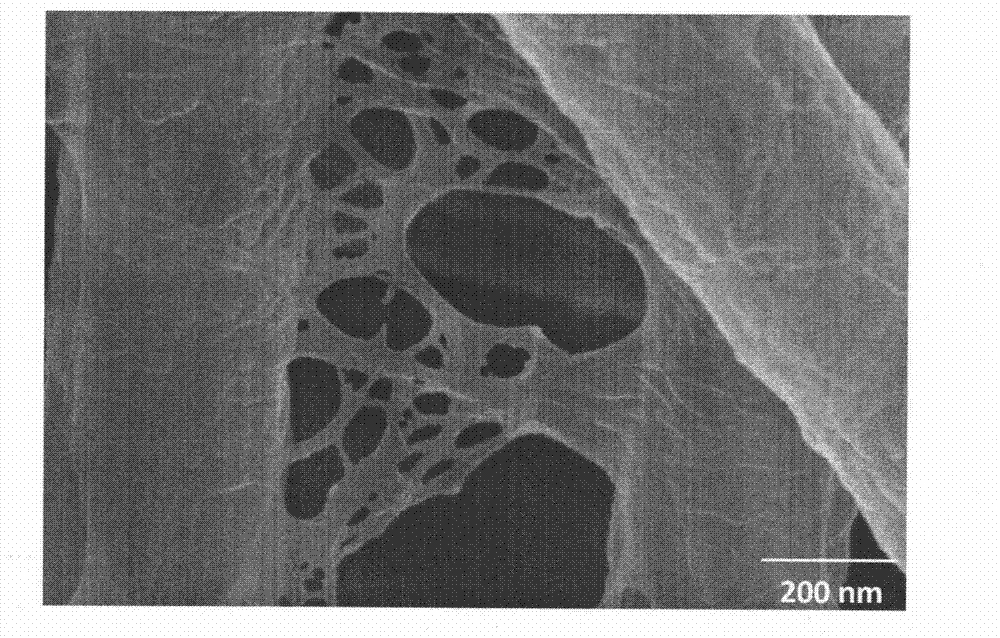

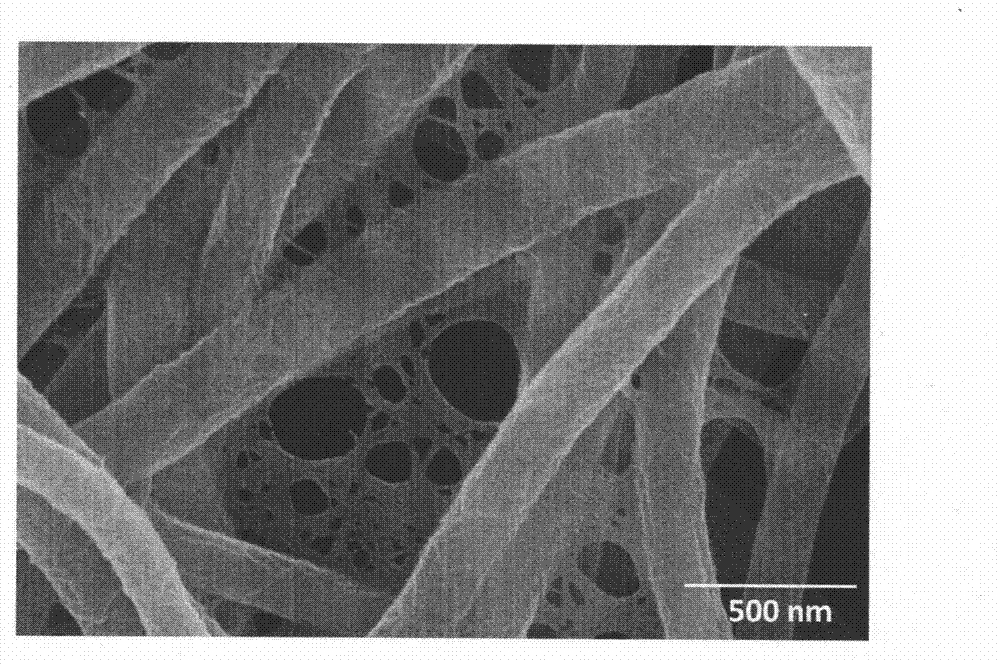

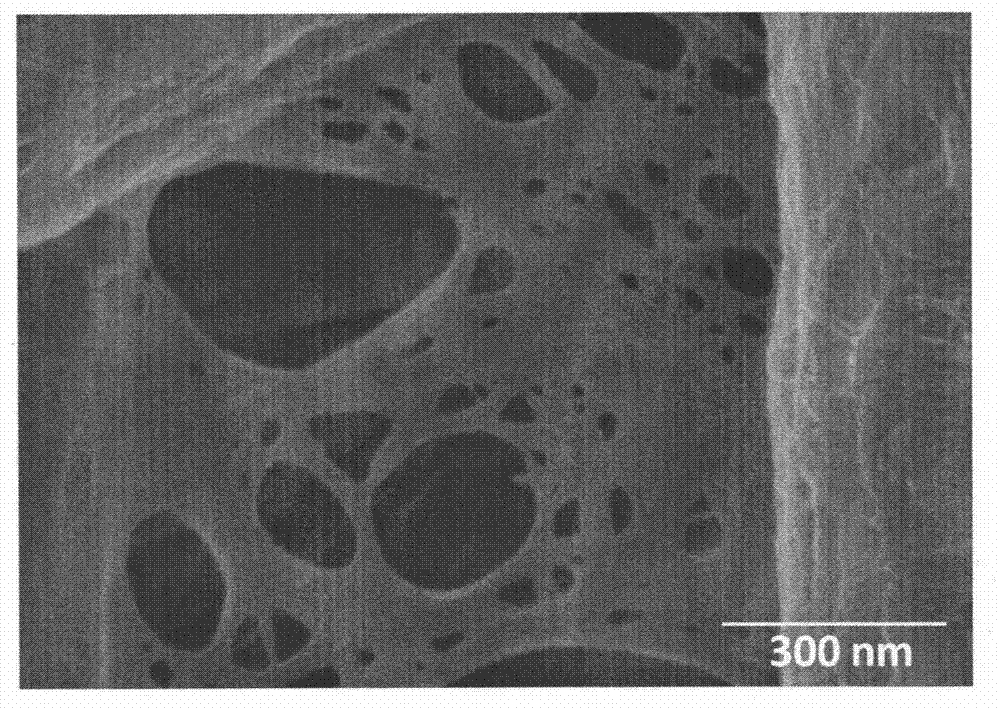

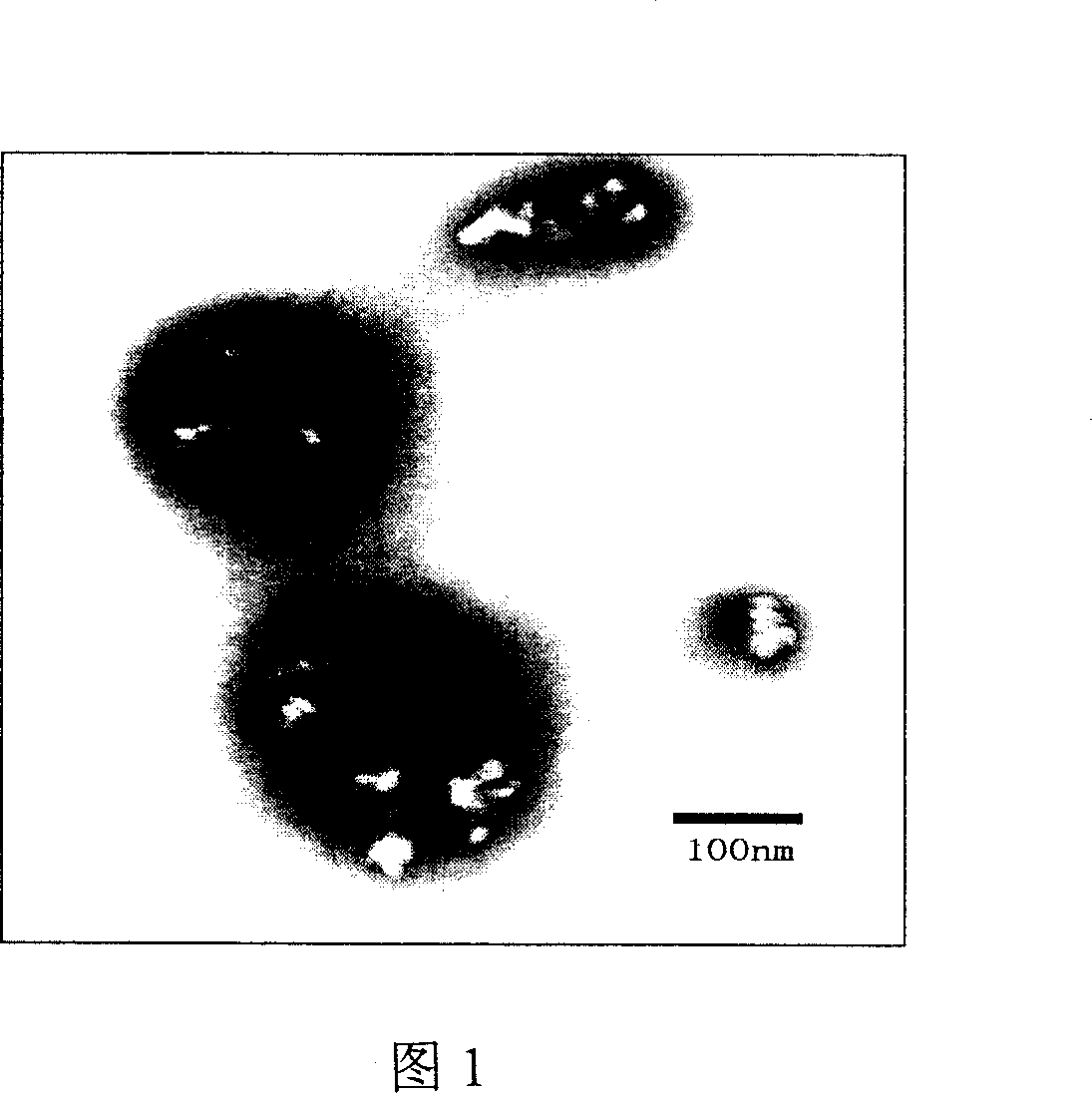

Method for preparing cellulose nanocrystal/electrostatic spinning nanofiber filter film

InactiveCN102806021AImprove adsorption capacityPurify waterSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiberPolymer science

The invention provides a method for preparing a cellulose nanocrystal / electrostatic spinning nanofiber filter film. The method is characterized in that the prepared cellulose nanocrystals of which the diameter is 3 to 10nm are coated on the surface of an electrostatic spinning nanofiber film to form a network structure so as to filter out impurities in raw water, intercept suspended solids, colloid, bacteria and the like in the water and effectively adsorb residual chlorine and heavy metal in the water; and therefore, the aim of purifying water quality can be fulfilled. Moreover, due to the adoption of a multi-layer compounded mode, the mechanical strength of the nano fiber film can be improved by the cellulose nanocrystals, so that the filter film has the advantages of simple structure, high mechanical strength, good filtering effect, low cost and the like, and has wide application prospect in the fields of drinking water purification, textile dyeing wastewater treatment, polyvinyl acetate (PVA) slurry recycling and the like.

Owner:DONGHUA UNIV

Textile dyeing method

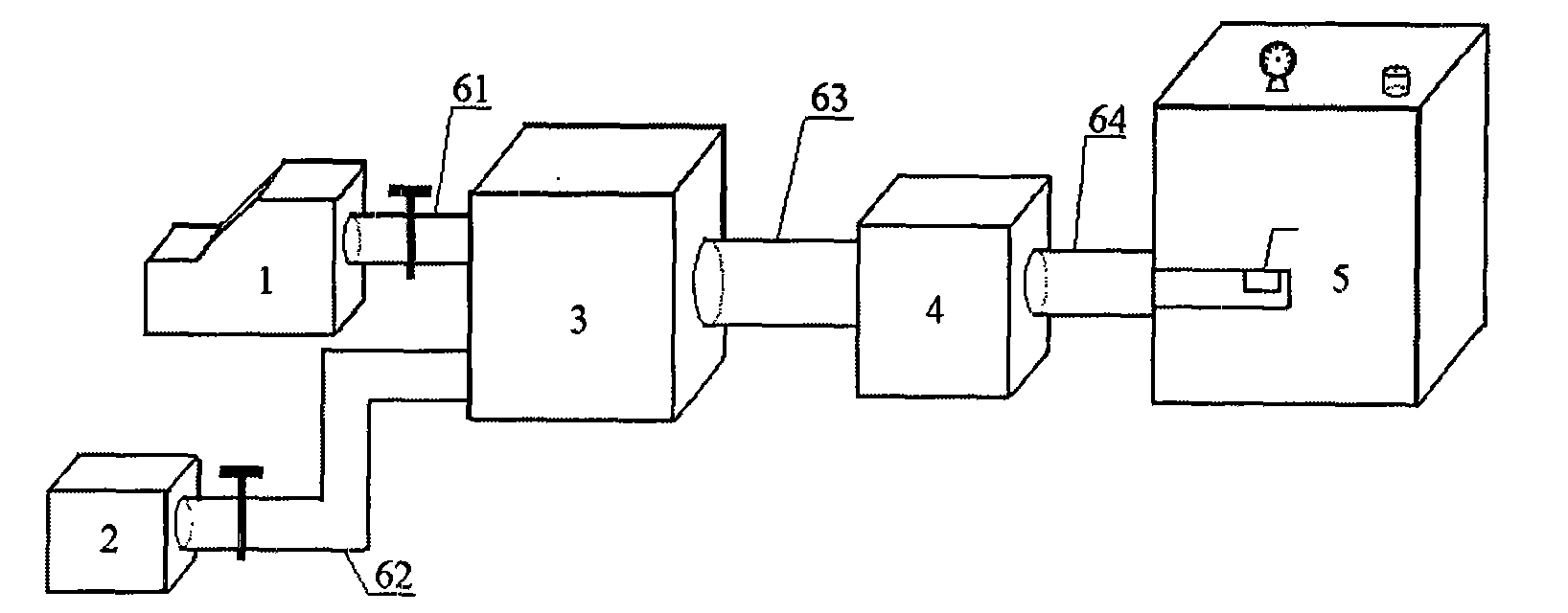

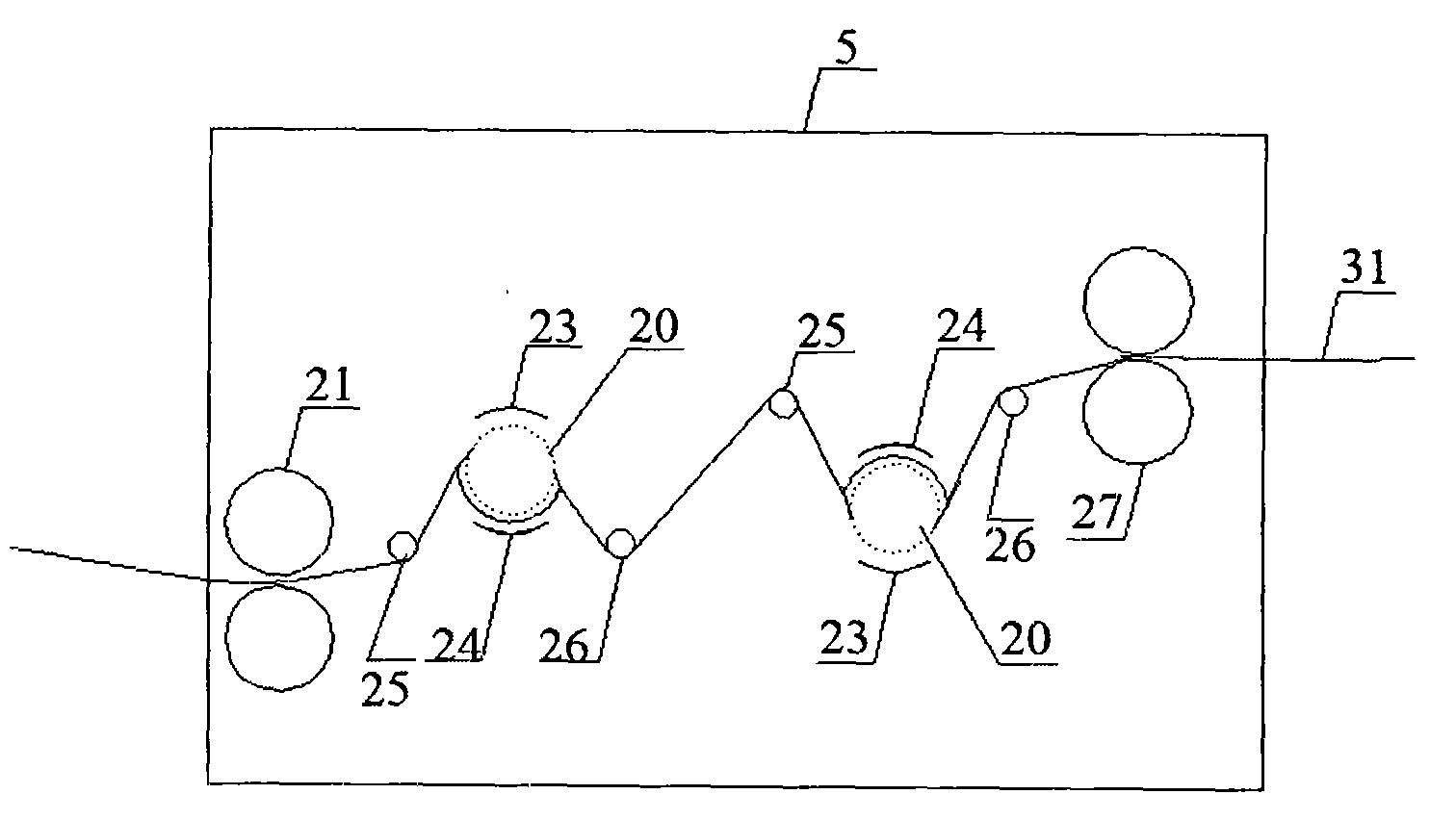

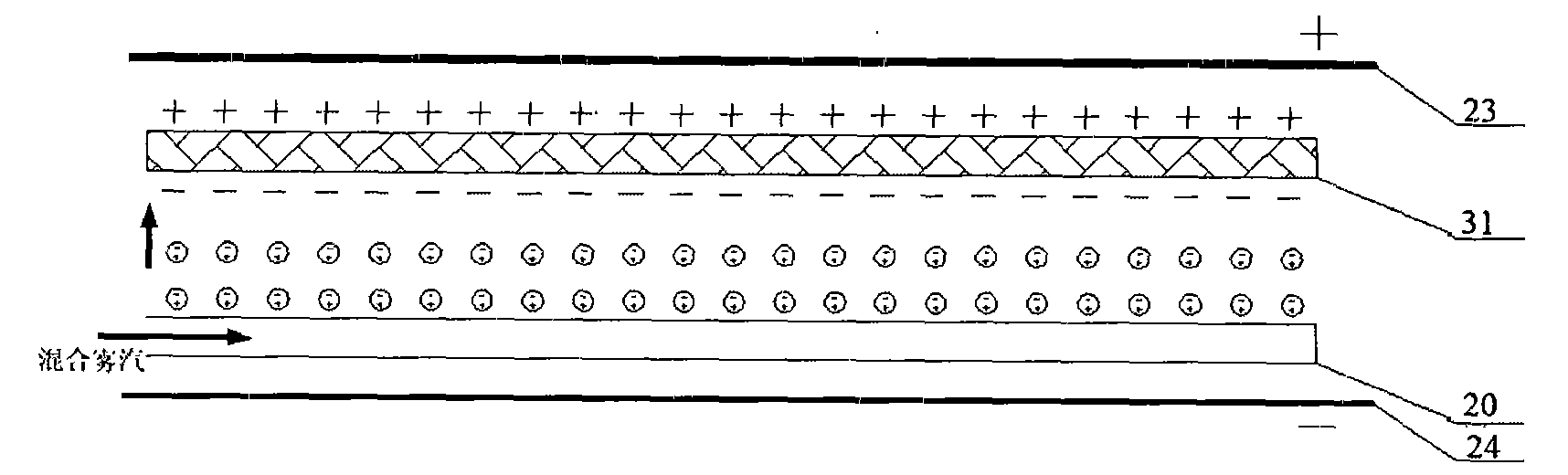

InactiveCN102002834AIncrease profitSmall particle sizeTextile treatment containersTextile treatment with treating outlet contectFiberTextile printer

The invention relates to a method for dyeing textile materials and products thereof, and belongs to the field of textile printing and dyeing processing. In the method, prepared dye solution is subjected to ultrasonic atomization to form dye solution microbeads, and the dye solution microbeads directionally infiltrate the textile under the action of certain pressure and an electric field so as to complete the dyeing process. Due to the adoption of the technical scheme, dye solution atomized microbeads prepared from the dye solution through a high-frequency ultrasonic atomizer have smaller grain size, a small dispersion range on the textile and more fine and smooth dyeing effect; the dye solution atomized microbeads enter fibers more easily under the action of the air pressure and the electric field, and have better dyeing effect; and the atomized microbeads carry less solution, the utilization rate of the dye is high, water can be saved and the environmental pollution is lightened. The dyeing method has a wide application range, low energy consumption and light pollution, and is suitable for small-batch and multi-variety printing technology development direction.

Owner:WUHAN TEXTILE UNIV

Method for dyeing textile by dye liquor prepared by mutually dissolving organic solvent and water

The invention relates to a method for dyeing textile by dye liquor prepared by mutually dissolving organic solvent and water and belongs to the technical field of textile printing and dyeing processing. The dye liquor applies organic solvent soluble in water and lower than water in boiling point, and dye is soluble in water and insoluble in organic solvent, so that effective liquor ratio is lowered, distribution coefficient of dye on fiber is changed, and dye uptake is of dye is increased. Adding the organic solvent allows boiling point of the dye liquor to reduce, energy is saved, water consumption in dyeing process is greatly reduced, the organic solvent can be recycled and reused, and discharge of waste liquor is reduced. The dyeing process includes performing twice-soaking and twice-rolling accelerant solution to textile, and solid accelerant is prevented from being precipitated out at a great amount by being added in dyeing process. The method is low in water consumption, utilization rate of dye is increased, energy consumption is low, the organic solvent can be recycled and reused, and cleaning and dyeing are achieved simultaneously.

Owner:WUHAN TEXTILE UNIV

Method for preparing cationic water-based pigment colour paste

InactiveCN1935910ASmall particle sizeImprove dispersion stabilityDyeing processPigment treatment with macromolecular organic compoundsDispersion stabilityWater based

The invention relates to cationoid aquosity dye color paste preparing method. It includes the following steps: using polymer with active group to modify dye surface, then cationic grafting. It can be used to prepare various cationoid aquosity dye color pastes. And the produced cationoid aquosity dye color paste has the advantages of good dispersion stability, quality stability, wide application prospect in ink jet printing, advertising, textile dyeing, and stain for wood fields etc.

Owner:SUNVIM GROUP

Non-aqueous media dye-fixation method suitable for reactive dye

The invention discloses a non-aqueous media dye-fixation method suitable for reactive dye and belongs to the field of textile dyeing and finishing technologies. The dyeing method comprises the following steps: (1) applying a reactive dye solution onto textile; (2) carrying out dye fixation on the textile in anon-aqueous media after the application of the reactive dye solution; and (3) soaping, washing and drying the textile after dye fixation so as to obtain a dyeing finished product. As there is no need to add inorganic salt or other dyeing additives by the method, water for dyeing and dyeingwastewater are greatly reduced, and dye fixation rate is raised. After dye fixation, the non-aqueous media is easy to purify and recycle, thus truly realizing ecological dyeing of reactive dyes. Thedefect that traditional reactive dye dyeing wastewater is much and hard to process and dye fixation rate is low is changed.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

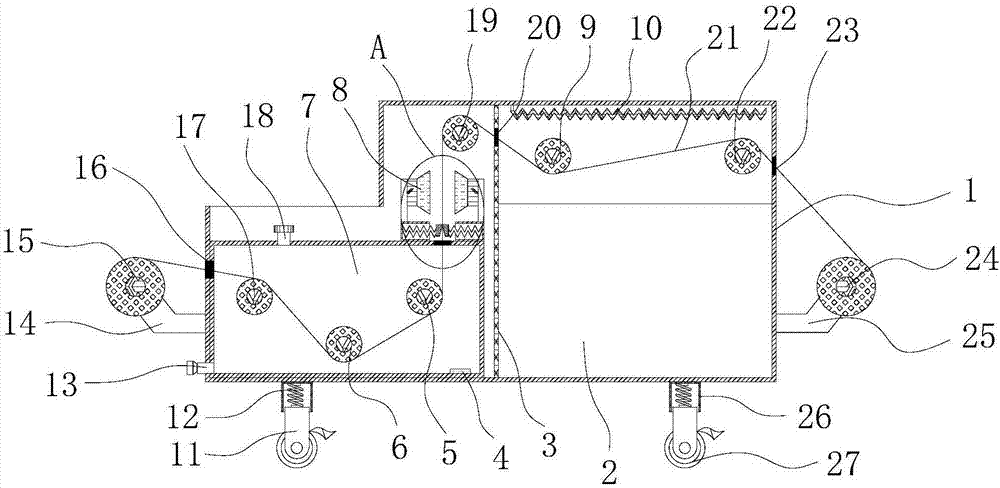

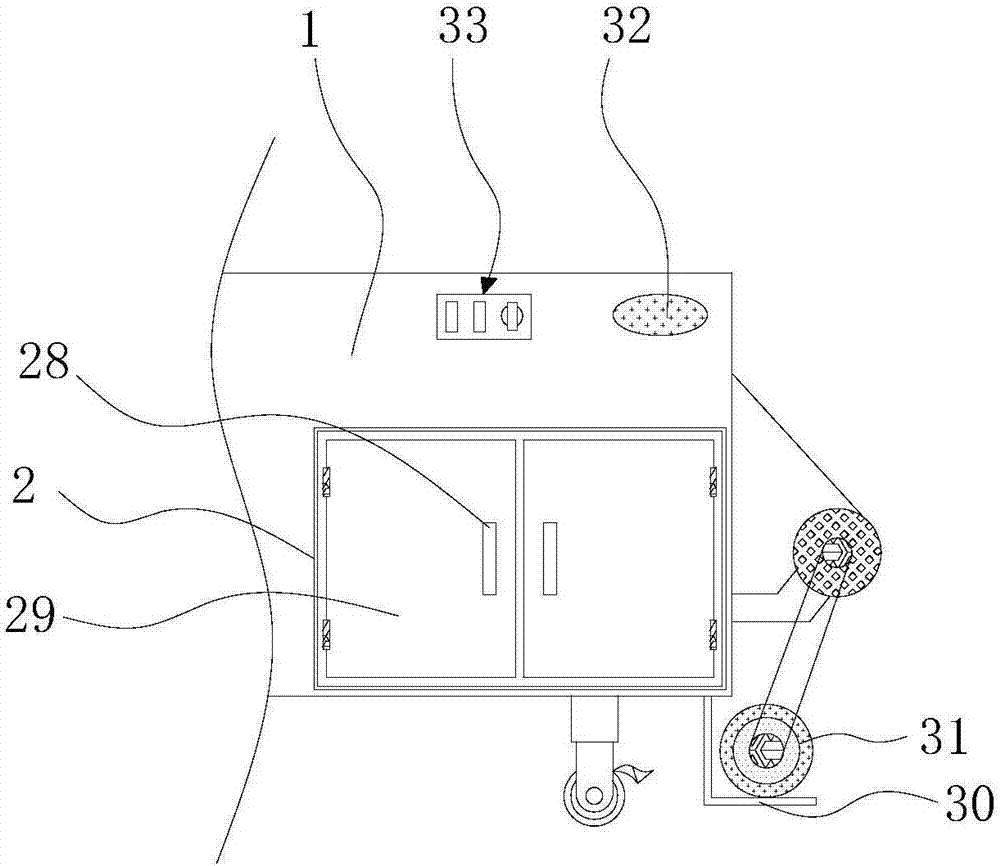

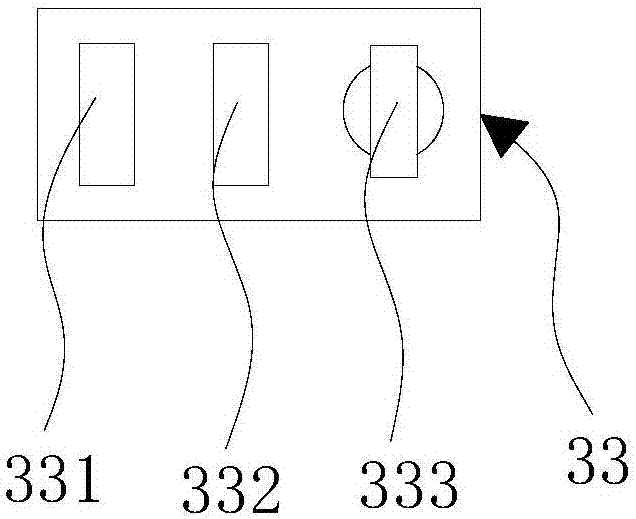

Textile dyeing device

InactiveCN106968069AExtended drying timeGuarantee normal dyeing workTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringDrying time

The invention discloses a textile dyeing device, comprising a box body, a dye box is fixedly installed at the left end of the bottom of the inner cavity of the box, and a first drive roller is movably installed at the upper left end of the inner cavity of the dye box. The lower end of the cavity is movably installed with a second transmission roller, the upper right end of the inner cavity of the dye box is movably installed with a third transmission roller, the right end of the upper surface of the dye box is provided with a second through hole, and the right end of the bottom of the inner cavity of the dye box is provided with a second through hole. A pressure sensor is fixedly installed. In the invention, the scraper is movably connected to the inner cavity of the second sleeve through the second spring, which can scrape off the dye adhering to the surface of the dyed fabric after dyeing. The fabric is air-dried, which solves the problem that a large amount of dye will adhere to the surface of the fabric during the dyeing process of the existing fabric dyeing machine, which not only prolongs the drying time of the fabric after dyeing, but also causes the waste of dye.

Owner:湖州梦源环保科技有限公司

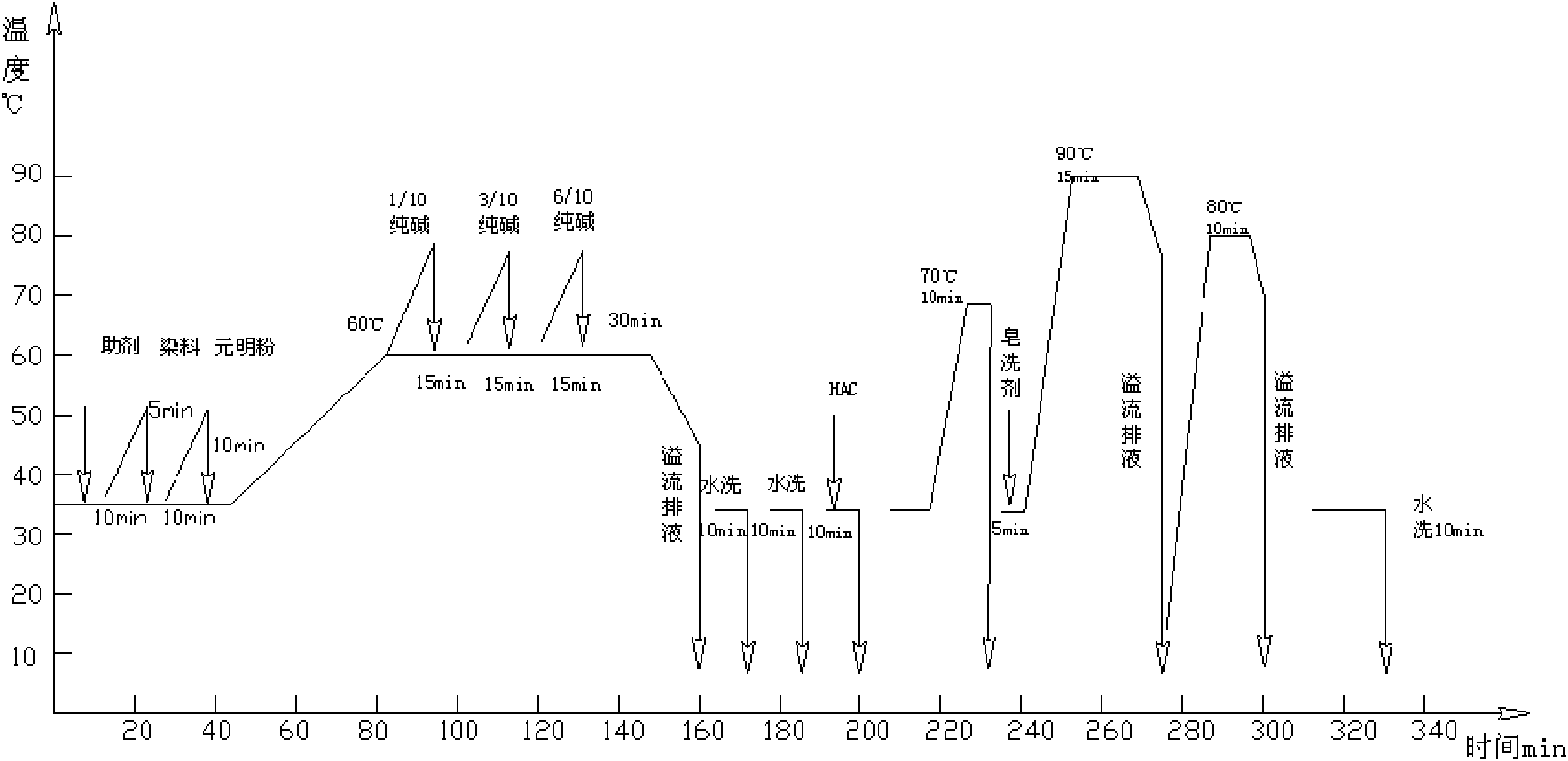

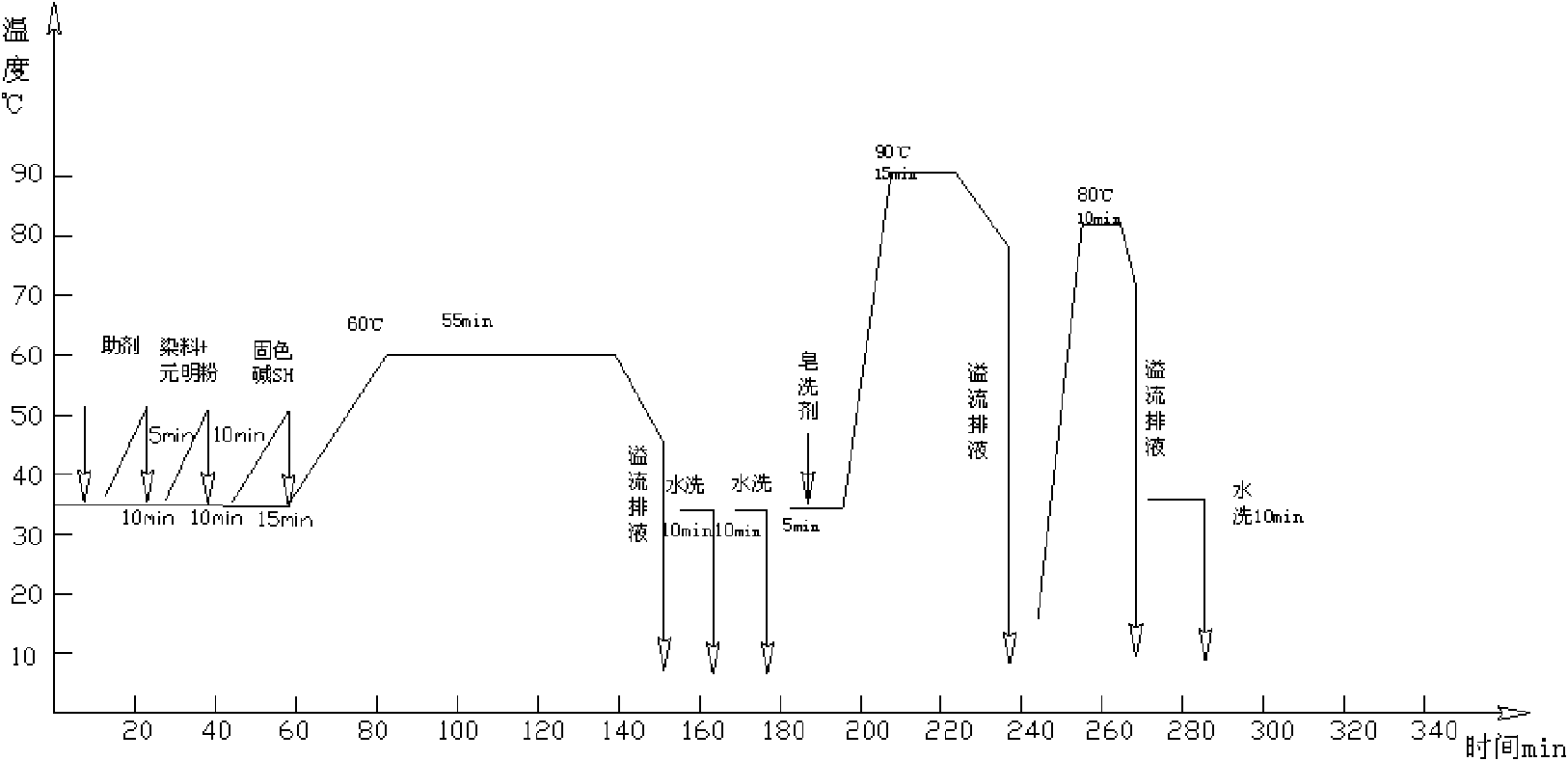

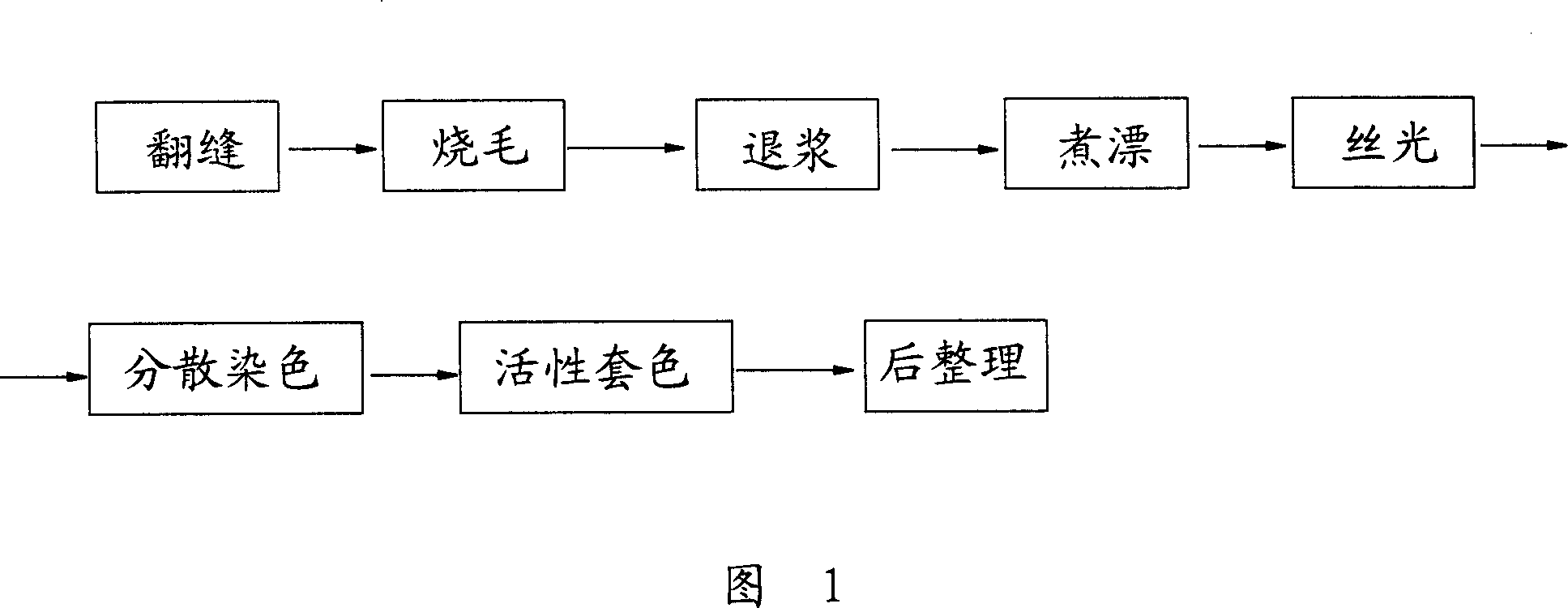

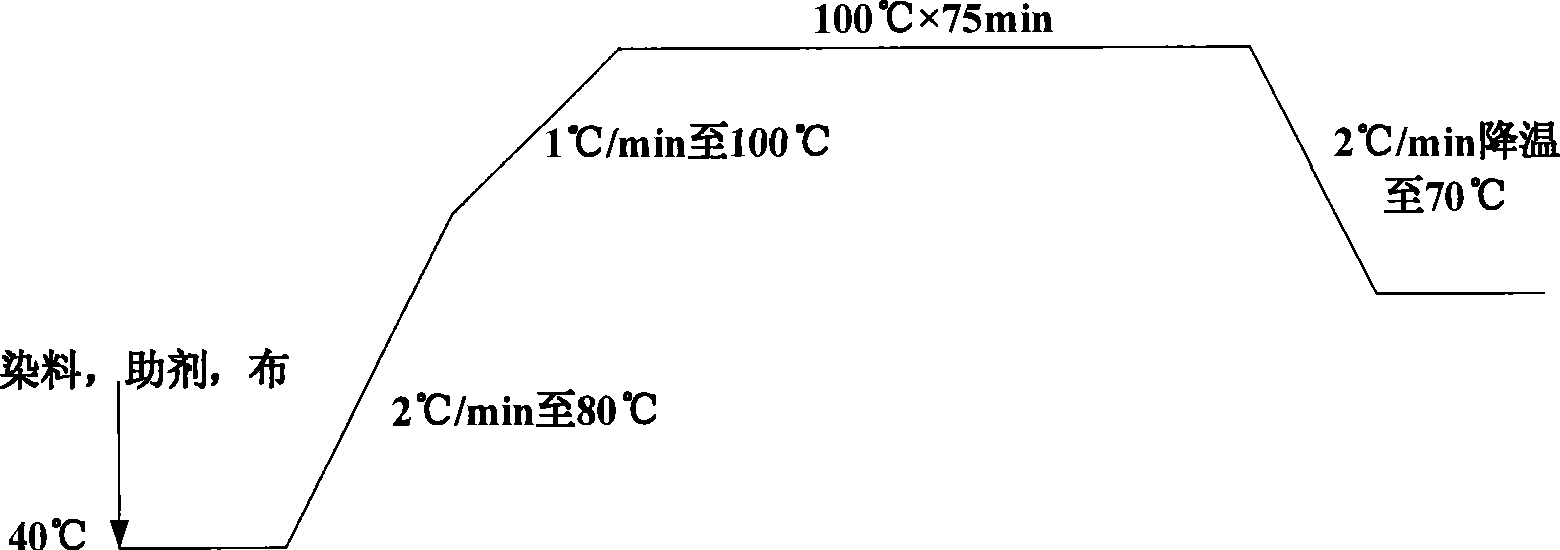

Dyeing technique for polylactic acid fabric/cotton blended shuttle weaving

InactiveCN101082154AHigh color fastnessBright colorMercerisingDyeing processDisperse dyeTextile dyeing

The process of dyeing woven polylactic acid fiber / cotton blended fabric belongs to the field of textile dyeing technology. The process of dyeing woven polylactic acid fiber / cotton blended fabric has China produced disperse dye and assistant adopted and improved steps of desizing, boiling and rinsing, mercerizing and dyeing. The dyed product has bright colors, proper shade and high color fastness. The present invention is suitable for industrial production.

Owner:SHANDONG UNIV OF TECH

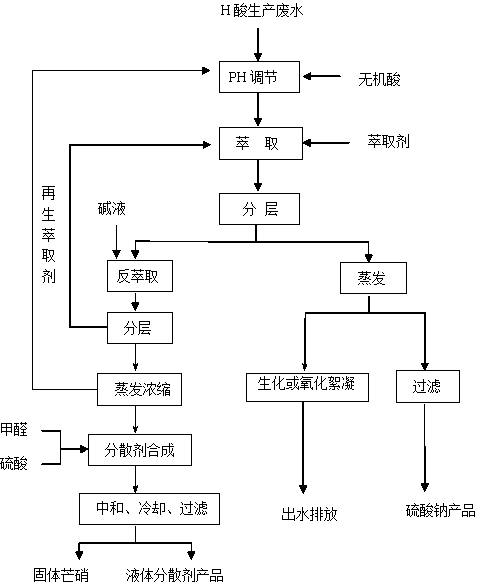

Comprehensive treatment method of H acid production wastewater

ActiveCN104326614AImprove extraction efficiencyHigh partition coefficientTransportation and packagingMixingLeather industryResource utilization

The invention discloses a comprehensive treatment method of H acid production wastewater. The method comprises the following steps: regulating the pH value of the H acid production wastewater, afterwards complexing and extracting a naphthalene sulfonic acid type substance in the wastewater, back-extracting an extract phase by using alkaline liquor, recycling an extracting agent after the extracting agent is regenerated, evaporating and concentrating back-extraction liquid to synthesize a liquid dispersant product; transferring a raffinate phase into an evaporation system, evaporating and separating to obtain a sodium sulfate byproduct, and discharging the desalted evaporation and condensation water after the water reaches the standards by means of biochemical or oxidization flocculation treatment. According to the method disclosed by the invention, the naphthalene sulfonic acid type substance in the wastewater is recycled by utilizing a complexation-extraction method, and the sodium sulfate salt product is recycled by utilizing an evaporation method. The liquid dispersant product (degree of polymerization is 1-3) synthesized by utilizing the recycled naphthalene sulfonate solution is used as a dispersing agent in textile dyeing and leather industries. The method disclosed by the invention is reasonable in process design and can be used for effectively realizing comprehensive treatment and resource utilization of the H acid production wastewater.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

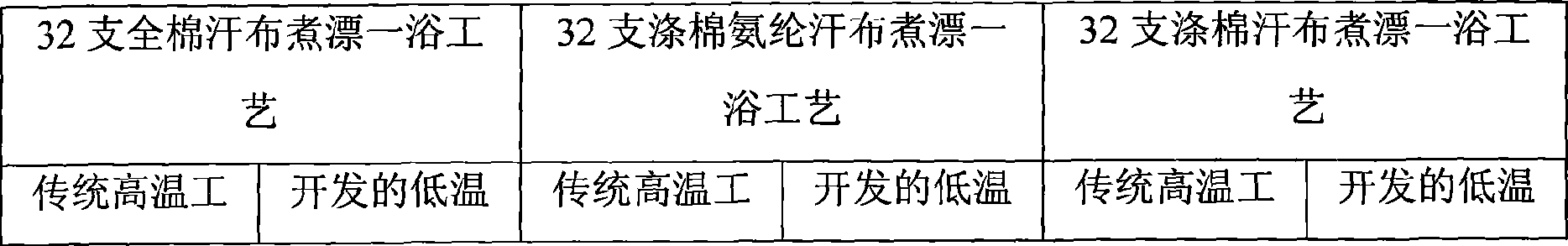

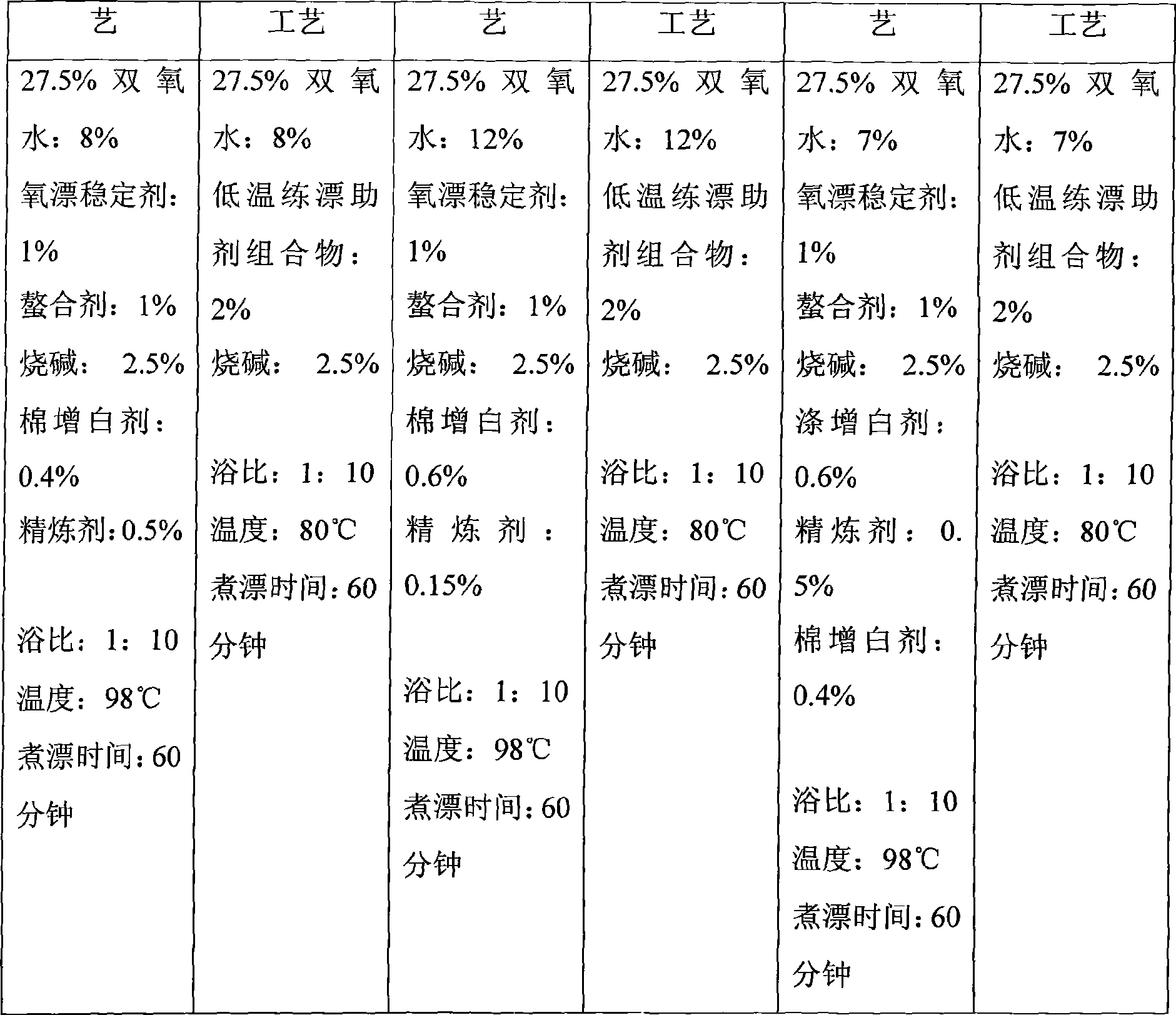

Method for environment-friendly low-temperature scouring and bleaching in spinning dyeing and finishing

ActiveCN101487183ASuitable for processingLittle loss of strengthBleaching apparatusVegetal fibresOxygenTextile dyeing

The invention relates to a method of environment-protective low-temperature scouring and bleaching used for textile dyeing and finishing, comprising the following steps: a dyeing and finishing solution which consists of low-temperature scouring and bleaching promoter composition, 25-30% of hydrogen peroxide and caustic soda, with the mass percentage of 2:8-12:2.5-3 is prepared; subsequently, the dyeing and finishing solution is used for processing cotton knitted fabric with the bath proportion of 1:8-15, the temperature of 75-80 DEG C and the time of 40-60s. The method carries out scouring and bleaching one bath processing at the temperature of 75-80 DEG C, with the scouring and bleaching effect achieving the whiteness and capillary effect standard of the traditional high-temperature alkali-oxygen one bath process at the temperature of 98-100 DEG C or even 130 DEG C; furthermore, the cost is low, the processing time is saved, and the possibility of wrinkle of cotton and cotton blended fabric (such as blended polyurethane and cotton) is reduced.

Owner:NINGBO GUANG YUAN FABRIC

High efficiency soap cleaning agent compsn. for textile dyeing soap cleaning and prepn. process

InactiveCN1834216AComply with environmental standardsImprove color vibrancyNon-ionic surface-active compoundsDetergent compounding agentsSulfonateCoconut diethanolamide

This invention provides a method for manufacturing a high-efficiency environment-friendly soaping agent composition for cleaning printed fabrics. The soaping agent composition is manufactured by mixing and adequately stirring C12 fatty alcohol polyoxyethylene ether, coconut diethanolamide, sodium secondary alkane sulfonate (SAS), dyeing-proof salt (S), sodium tripolyphosphate and water. The soaping agent composition has good soaping and anti-contaminating effects on printed fabrics, and can improve the strength of printed fabrics.

Owner:东莞市德能化工有限公司

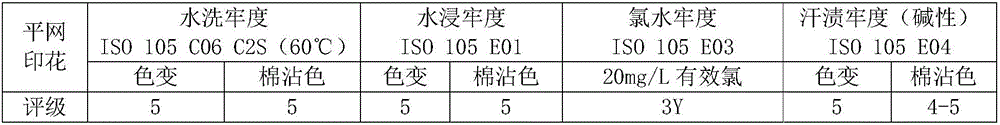

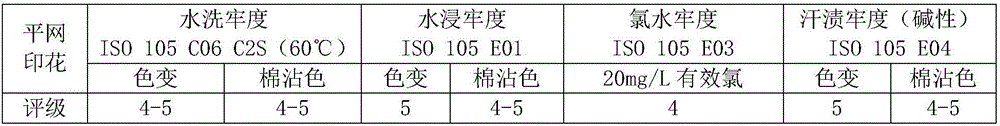

Washing-free continuous dyeing method of terylene fabric with disperse dyes

The invention relates to a washing-free continuous dyeing method for polyester fabrics with disperse dyes. The invention mixes disperse dyes, surfactants and water and grinds them uniformly to obtain disperse dye slurry; then dilutes with water, and adds emulsified paste and Thickening agent to obtain liquid disperse dyes; add water to obtain disperse dye dyeing baths, padding polyester fabrics for dyeing, then drying, and then baking to fix the color, and finally drop the cloth to cool, and the dyeing is completed. The dyeing process of the invention is simple, the chemicals used are ecological and environment-friendly, the production efficiency is high, no dyeing waste water is discharged, energy is saved, and the invention has important practical significance for energy saving and emission reduction. The dye uptake rate of the dyed product obtained by the present invention is higher than 95%, the chemical content on the fabric is not more than 3%, the dyed fabric does not need to be washed, and the dry and wet rubbing fastness and staining fastness can reach 4-5 grades. The color fastness to fading is grade 5, meeting the quality requirements for textile dyeing.

Owner:DONGHUA UNIV

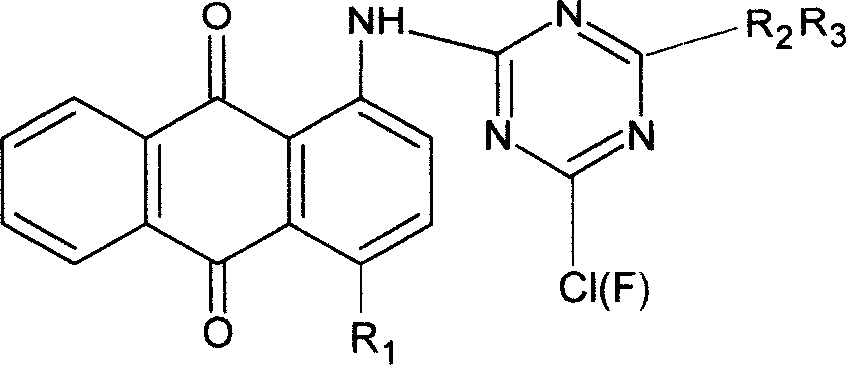

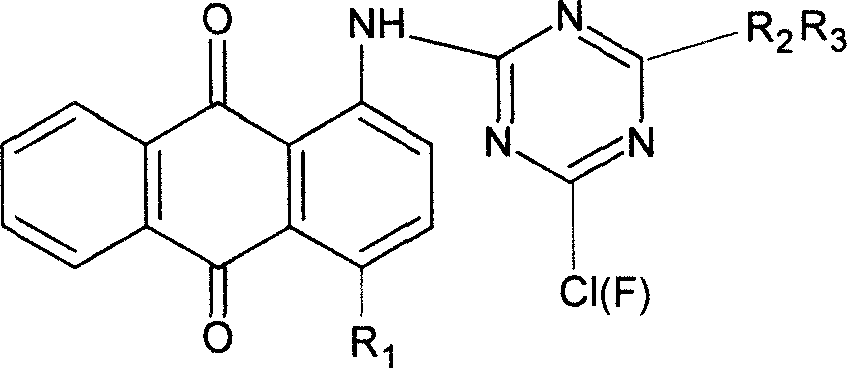

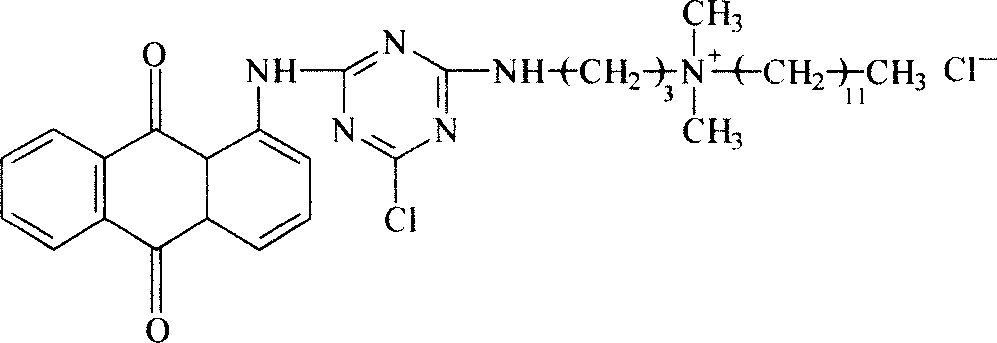

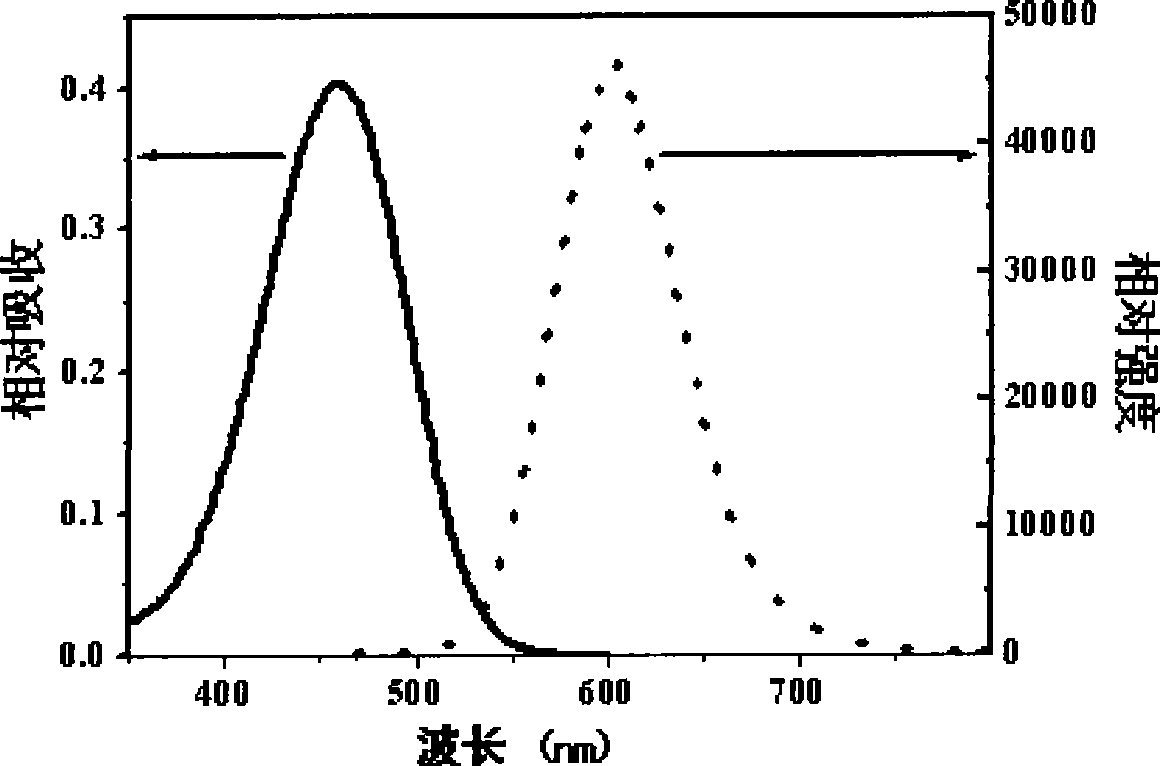

Antiseptic active cationic dye and its preparing method

InactiveCN1986647AExcellent chromogenIncreased durabilityReactive dyesDyeing processChemical structureQuaternary ammonium cation

The present invention relates to one kind of antiseptic active cationic dye and its preparation process. The dye has matrix in anthraquinone structure, active group of sym-triazine monochloride or sym-triazine monofluoride, water soluble group of long carbon chain quaternary ammonium salt structure and the chemical structure as shown. The dye may be used in dyeing and antiseptic finishing of various kinds of fiber and has high antiseptic effect, high color fastness and lasting antiseptic performance. It is prepared through the following steps: dissolving anthraquinone A and sym-triazine trichloride or sym-triazine trifluoride in nitrobenzene solvent, heating, cooling and filtering to obtain intermediate B; dissolving the intermediate B in DMF solvent, adding tertiary amine, heating to react, evaporating DMF and vacuum drying to obtain intermediate D; dissolving the intermediate D in DMF solvent, adding alkyl halide, heating to react, washing with ethyl ether, re-crystallizing and drying.

Owner:DONGHUA UNIV

Dyeing method for common goldenrod herb natural dye

The invention relates to a dyeing method for a common goldenrod herb natural dye. The dyeing method comprises the following steps: preparing a 2 to 20 g / I common goldenrod herb dye, and setting a dyeing temperature of 40 to 100 DEG C, a bath ratio of 1:50 to 200 and dyeing time of 10 to 90 minutes; taking a 2 to 20 g / I mordant solution, and setting a mordanting temperature of 40 to 100 DEG C and mordanting time of 10 to 90 minutes; and adding a mordant before or after natural fiber yarn or natural fiber textile is added into common goldenrod herb dye liquor or simultaneously when the natural fiber yarn or the natural fiber textile is added into the common goldenrod herb dye liquor for one-bath dyeing. The method uses the prior textile dyeing device for direct dyeing without adding devices or increasing cost. The textile dyed by the method is soft, primitive and simple and natural color, and has good dye fastness, no fading, no discoloring, good reproducibility, and chromatic aberration around a half level. The method is suitable for the industrialized production, and has no toxicity, no harm and no pollution.

Owner:DONGHUA UNIV

Silicon based non-aqueous medium dyeing method suitable for cheese

ActiveCN107794788AGood dyeing effectMedia is easy to recycleDyeing processPulp and paper industryDyeing wastewater

The invention discloses a silicon based non-aqueous medium dyeing method suitable for cheese, and belongs to the technical field of textile dyeing and finishing. The dyeing method comprises the following steps: (1) preparing a dye solution; (2) dyeing cheese: soaking cheese in a silicon based non-aqueous medium, and adding the dye solution to carry out dyeing in a cheese dyeing facility; and (3) after dyeing, carrying out dehydration, soap washing, water washing, and drying to obtain a finished product. The method has the advantages that only a little amount of water and alkali is needed, other dyeing aids are not needed; the water for dyeing and dyeing wastewater are largely reduced, and dye uptake and fixation rate of cheese dyeing are improved effectively. After dyeing, the silicon based non-aqueous medium can be separated from water and is capable of being used repeatedly. The ecological dyeing of cheese is realized. The shortages of conventional water bath cheese dyeing such as much wastewater, difficulty in wastewater treatment, low dye uptake and fixation rate, and the like, are overcome.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

Acrylon fluorescent dyeing method

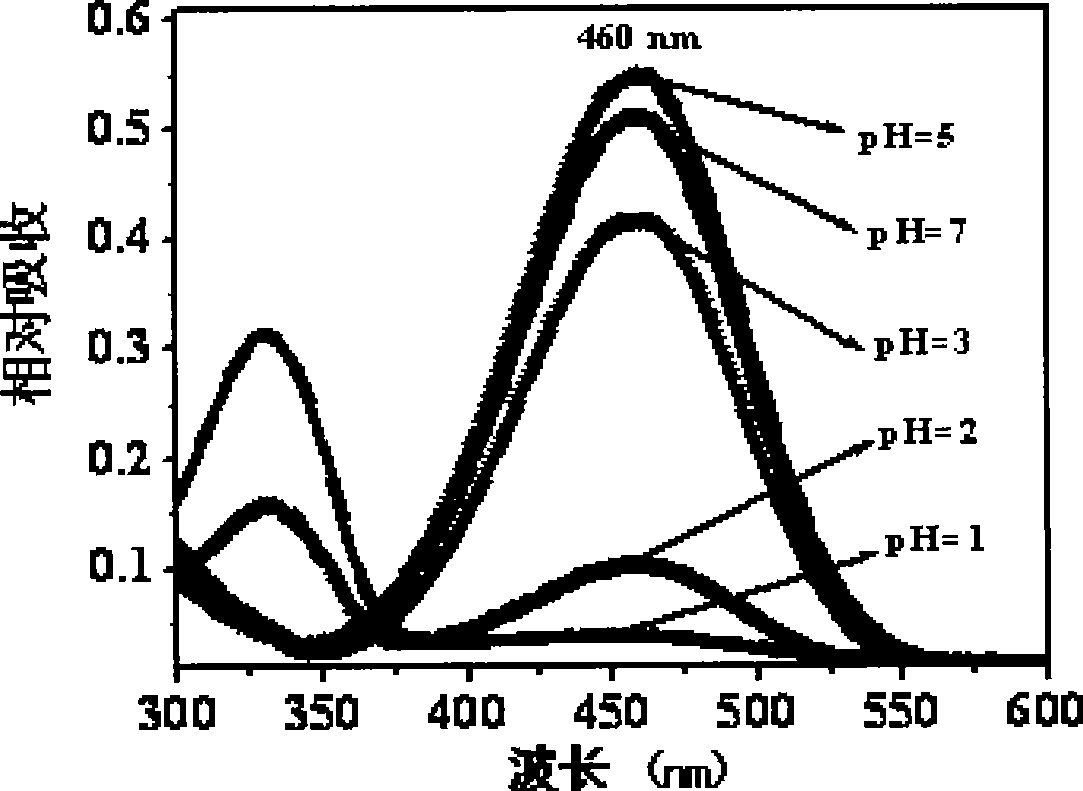

InactiveCN101424055ASynthetic reaction is simpleHigh yieldStyryl dyesDyeing processSodium acetateVisibility

The invention relates to a method for fluorescent staining of orlon, which belongs to the field of dye synthesis and textile dyeing. Stilbazole salt is taken as a cation fluorescent dye, 0.2 and 2.5 percent owf fluorescent dye, 0.5g / L Peregal 0, a 1.0 percent owf leveling agent and 4g / L glauber salt are mixed to prepare a dye solution, acetic acid and a sodium acetate buffer solution are used to adjust the pH value of the dye solution to 5, and the dyeing processing with the dyeing bath ratio of 100 to 1 is performed to obtain a fluorescent orlon fabric. The stilbazole salt provided by the method has simple synthesis reaction, has relative flexibility in molecular design and assembly, and also has good linear optical performance and non-linear optical performance; and under specific dye bath concentration, the dyed orlon fabric satisfies the coordinate range of orange color stipulated in European EN471 standard High-visibility Warning Clothing for Professional Use-Test Methods (2003).

Owner:SUZHOU LONGJIE SPECIAL FIBER

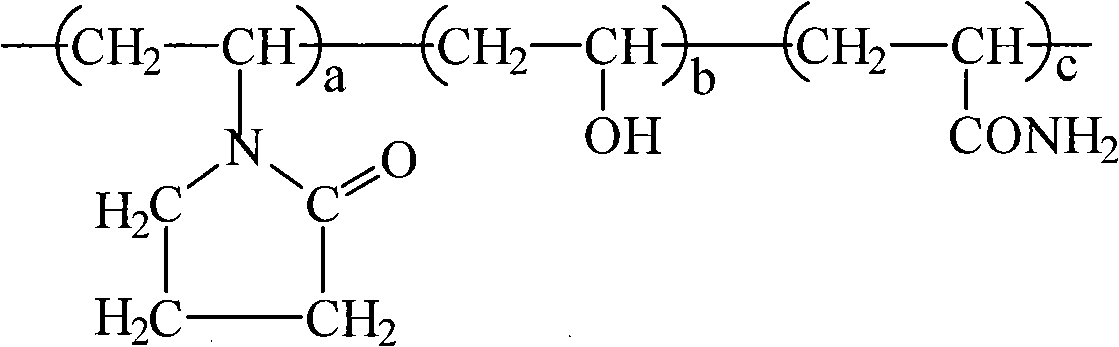

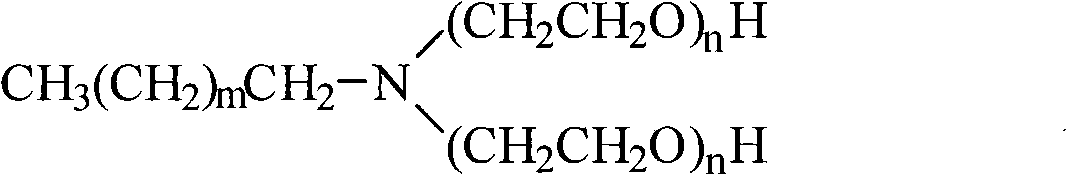

Contamination-proof detergent washing agent for textile dyeing printing process

InactiveCN101314922AProcess stabilityImprove stabilityDry-cleaning apparatus for textilesDyeing processCleansing AgentsFatty alcohol

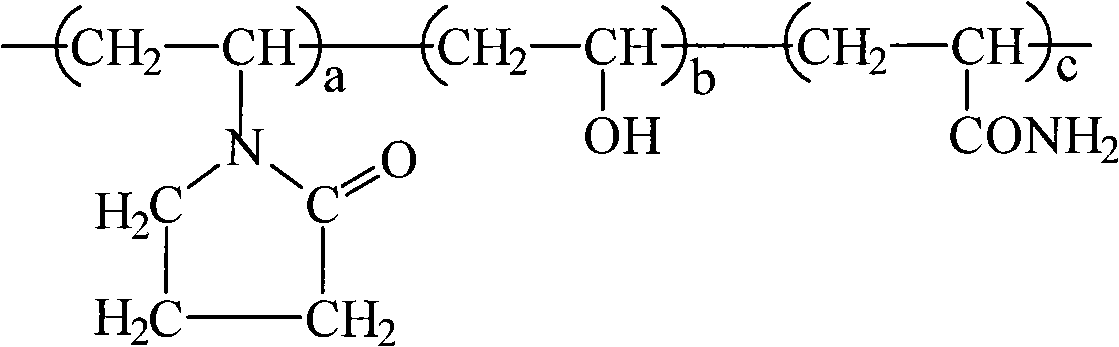

The invention relates to an assistant agent used for dyeing and printing a textile, particularly a cleaning agent used for preventing a contaminant during the soaping process after the textile is dyed and printed, and belongs to the textile dyeing technology field. The assistant agent comprises the following components by mass percentage: 2% to 15% of N-vinyl pyrrolidone / acrylamide / vinyl alcohol terpolymer, 2% to 15% of maleic acid / acrylic copolymer, 0 to 10% of sodium polyacrylate, 2% to 15% of aliphatic amine polyethenoxy ether, 2% to 15% of fatty alcohol polyoxyethylene ether, and water in balancing amount. The assistant agent has the advantages that: the components meet the standard of ecological textiles and the environmental protection requirements, the assistant agent has a certain cationic nature, thus having good affinity for the anionic dye used for conventional dyeing and printing, is conducive to washing and removing the dye which is attached to the textile, and meanwhile, has protective colloidal properties, thus allowing the removed dye to be stably existing in a washing solution, so as to prevent second contamination.

Owner:SUZHOU UNIV

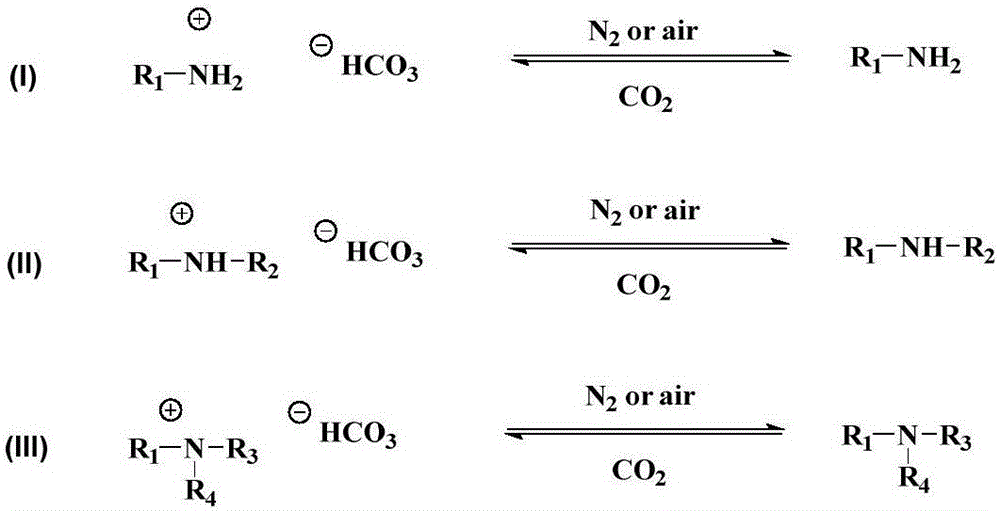

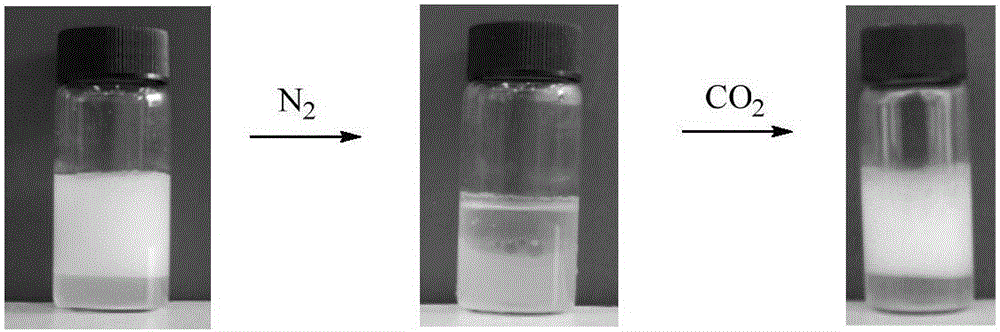

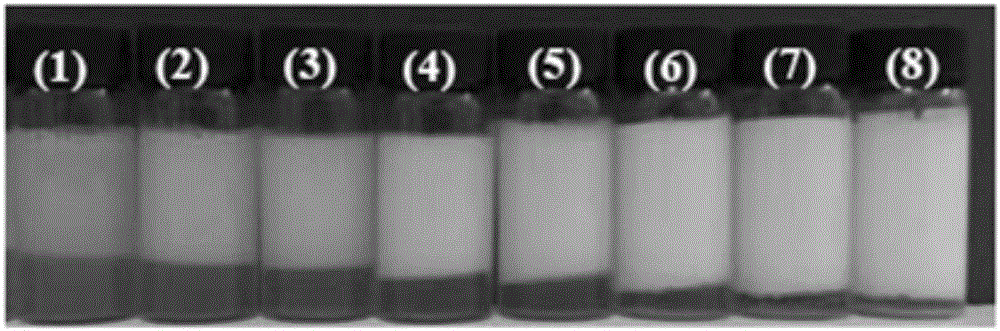

Room-temperature CO2 switch type compound emulsifier

InactiveCN106582431AImprove efficiencyTransportation and packagingMixingSilica particleEmulsion polymerization

The invention relates to a room-temperature CO2 switch type compound emulsifier and belongs to the field of colloid and interface chemistry. The emulsifier is prepared from unmodified commercial nano silica particles and a CO2 / N2 switch type surfactant, the primary particle size of nano silica particles is 20-200 nm, the use concentration is 0.1%-10% (based on the aqueous phase), an emulsifier stabilized emulsion belongs to Pickering emulsion, inactivation of the emulsification and demulsification of the emulsion are caused after introducing N2 or air into the emulsion at the room temperature (subzero 5-35 DEG C), CO2 is introduced into the emulsion at the room temperature (subzero 5-35 DEG C), the activity of the emulsion can be recovered, and a Pickering emulsion can be obtained again. The emulsifier and the emulsion have important application value in chemistry and chemical engineering related fields of oil delivery and processing, emulsion polymerization, wastewater treatment, emulsion explosives and the like as well as multiple fields of food, textile dyeing and finishing, leather and the like.

Owner:JIANGNAN UNIV

Dye waste water treatment system

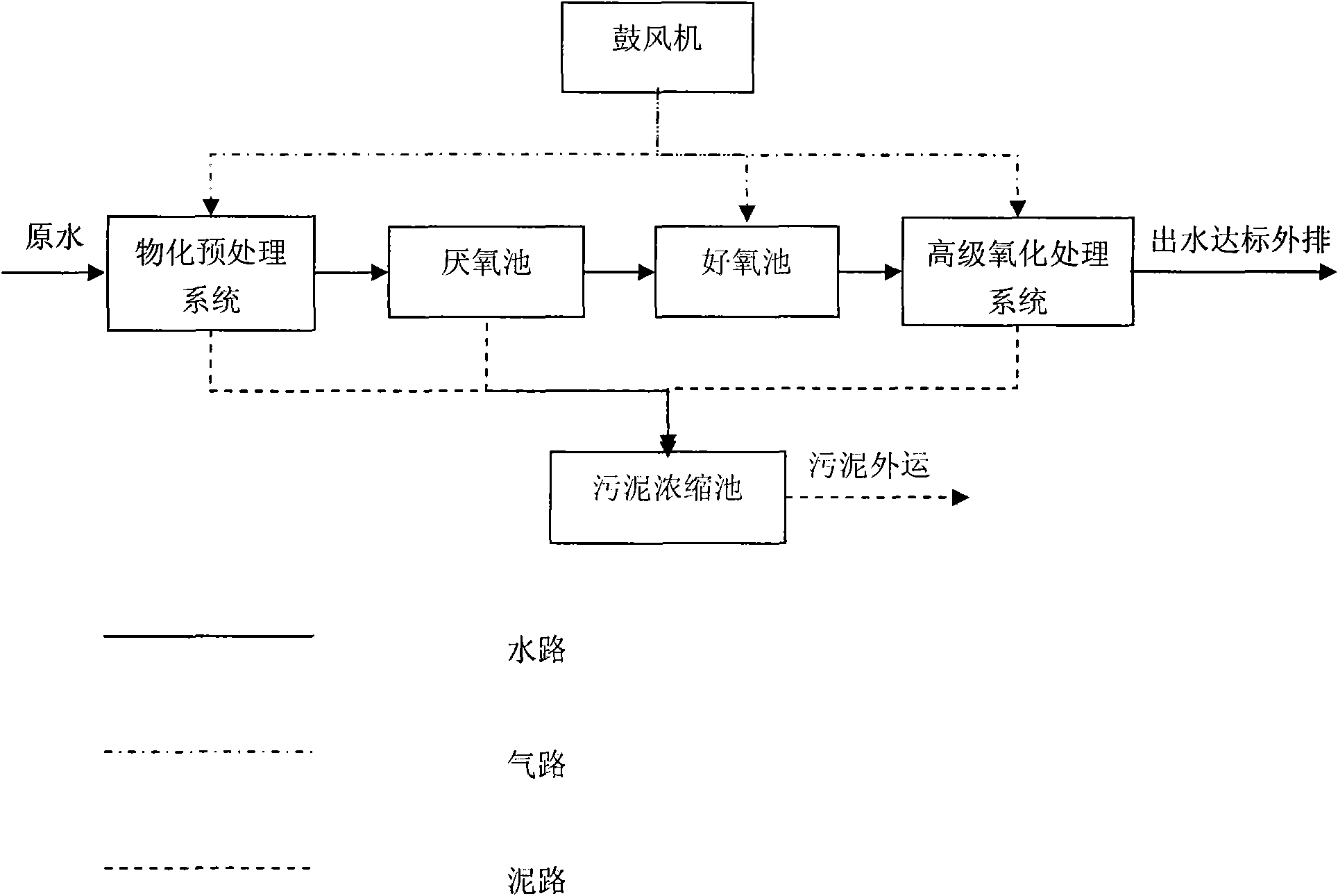

InactiveCN101659500ARealize resourcesAchieve the goal of energy saving and emission reductionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationMetabolite

The invention provides a dye waste water treatment system which sequentially comprises a physico-chemical pretreatment system, an anaerobic tank, an aerobic tank and an advanced oxidation treatment system; dye waste water to be treated firstly enters into the physico-chemical pretreatment system to remove part chromaticity, sulphate and COD in the dye waste water, so as to ensure the pH, the alkalinity and the proper sulfate concentration which are needed by high-efficiency and stable running of later stage of anaerobic technique; after that, the dye waste water enters into the anaerobic tankto have anaerobic reaction and then enters the aerobic tank to have aerobic reaction; finally, the dye waste water enters into the advanced oxidation treatment system to remove the residual chromaticity and organic matter hard to degraded in the aerobic effluent as well as intermediate metabolite generated in the process of biological treatment. When being used for treating the dye waste water, especially the waste water having high salinity, sulfate, chromaticity and COD as well as higher concentration organic matter hard to degraded, the combined system has good treating effect and ensures the finally yielding water to reach the first-grade standard in GB4287-92 pollutant emission standards for textile dyeing and finishing industry.

Owner:北京盖雅技术中心有限公司

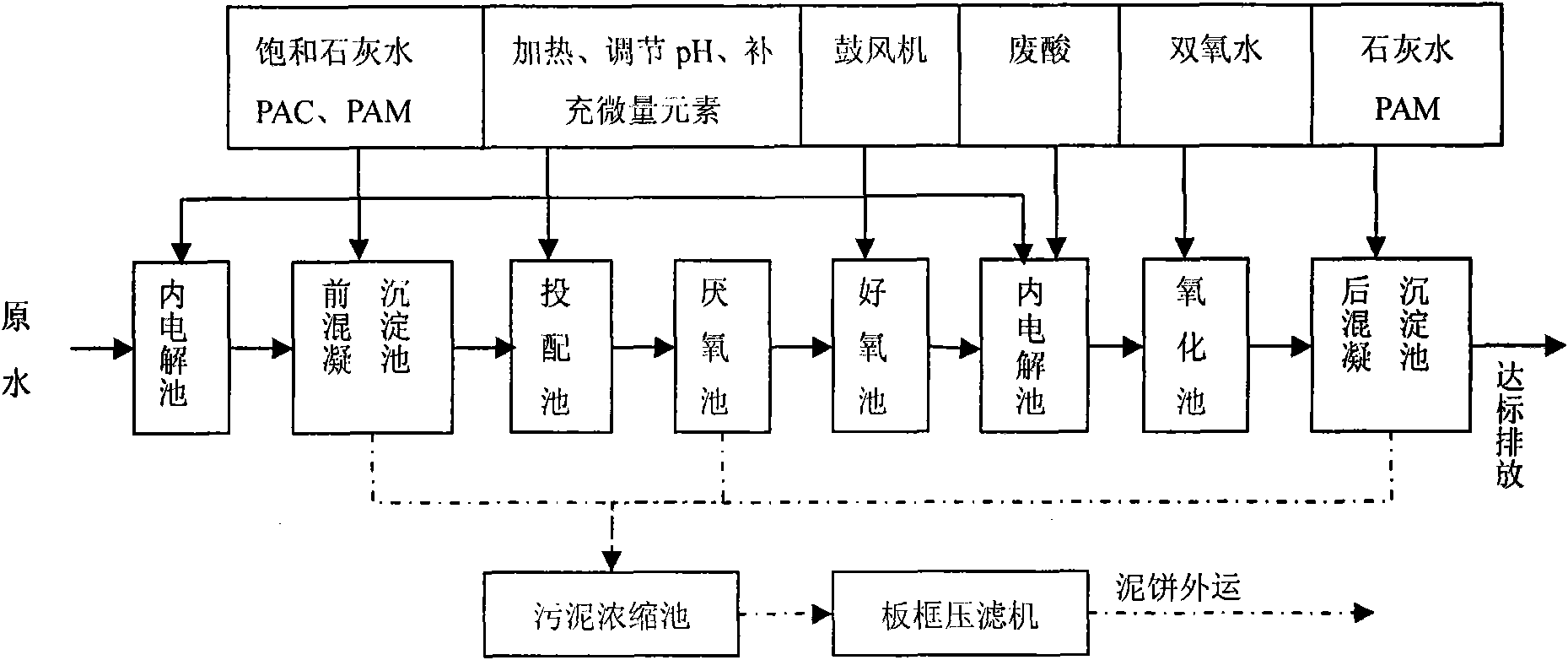

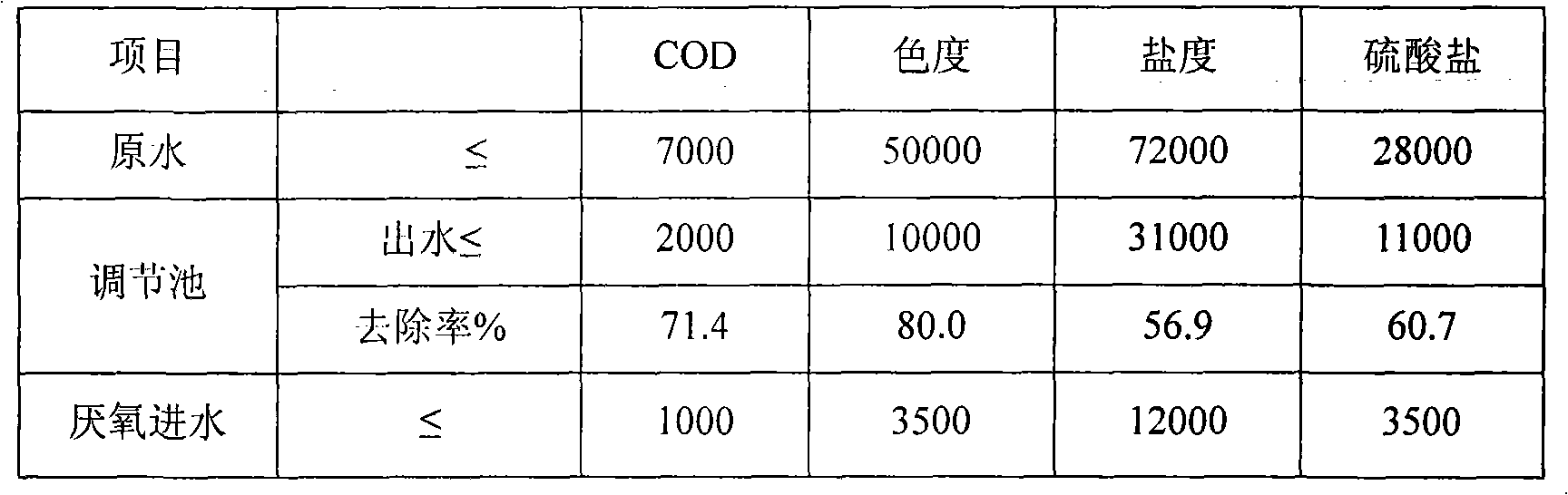

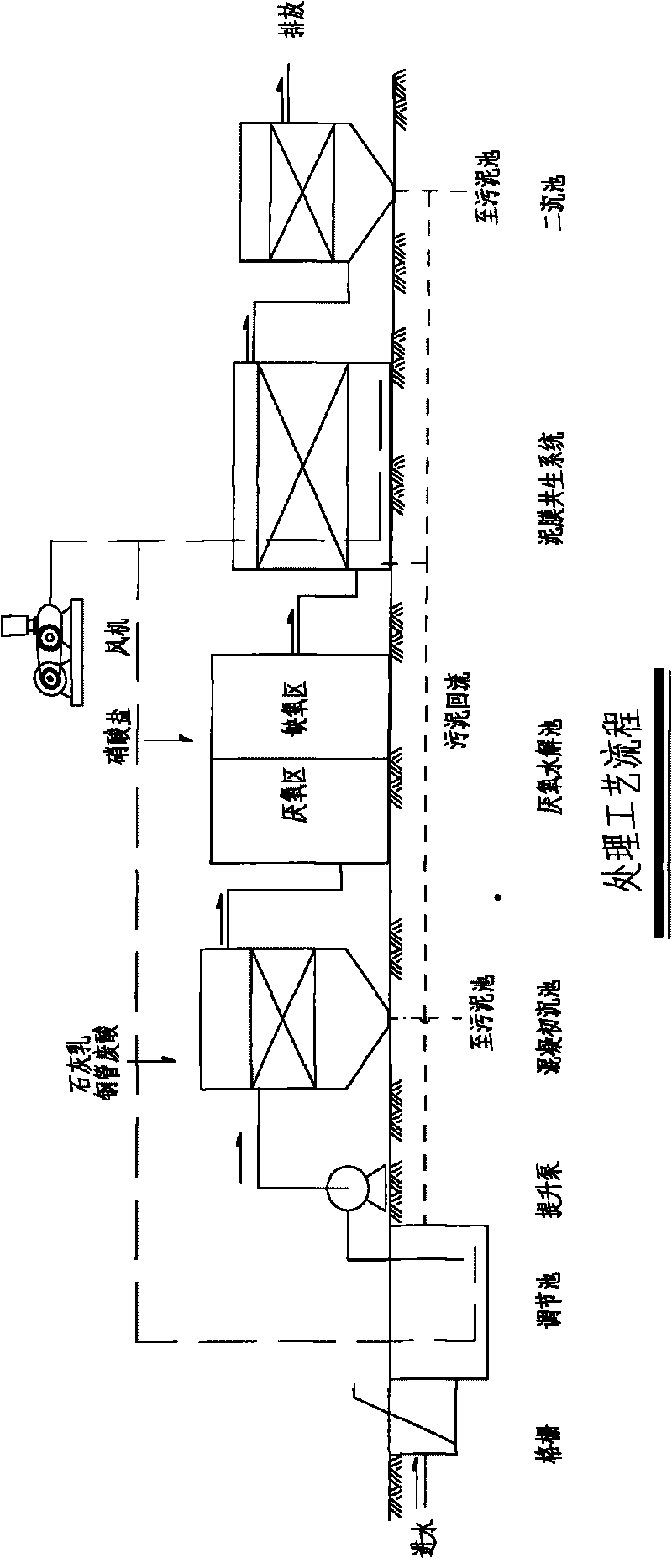

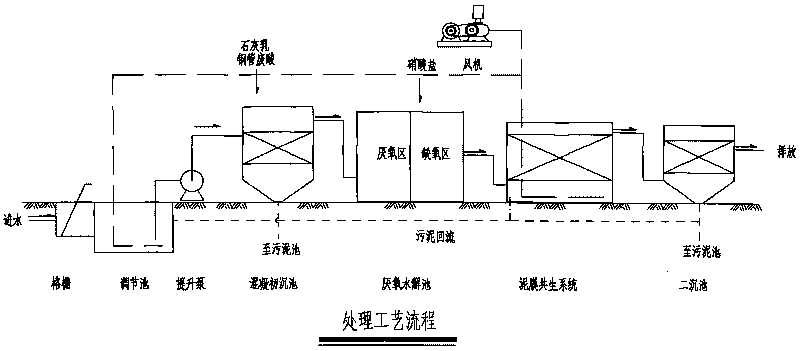

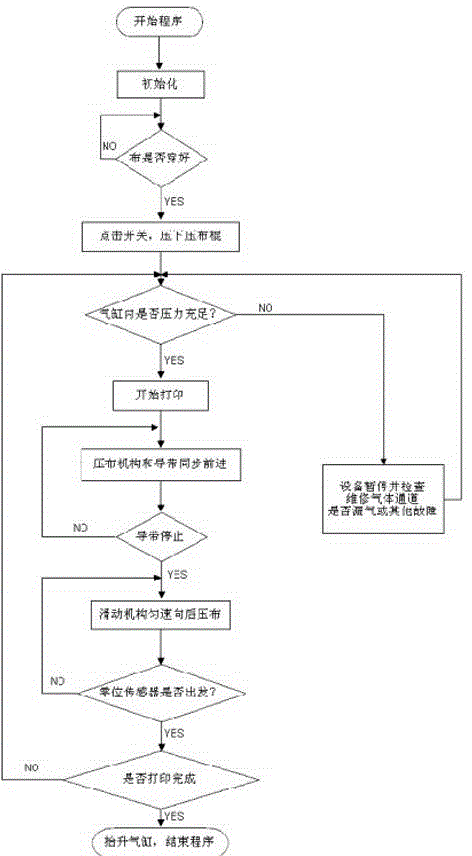

Wastewater treatment technology for textile dyeing and finishing industry

InactiveCN101700948ANo swellingReduce concentrationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeOrganic matter

The invention discloses a wastewater treatment technology for the textile dyeing and finishing industry. The technological process is as follows: leading wastewater to enter into a regulating tank for pre-aeration regulation treatment, then using a water pump for lifting to a coagulative precipitation tank for coagulative precipitation, then leading the wastewater to enter into an anaerobic / anoxic hydrolysis tank, transforming organic matters which are difficult to degrade to the organic matters which are easy to bio-degrade under the common action of anaerobic and anoxic microorganisms, further leading the wastewater to enter into a sludge-film symbiotic system which comprises both suspended activated sludge and biofilm sludge, and has the advantages of large biomass, abundant biological phases and high removal efficiency, and finally carrying out secondary settling, thereby leading the outlet water CODcr to be 30-60mg / L. Compared with other advanced treatment technologies, the technology has the advantages of strong operability, low operation cost, stable operation and the like.

Owner:SHANGHAI INST OF TECH

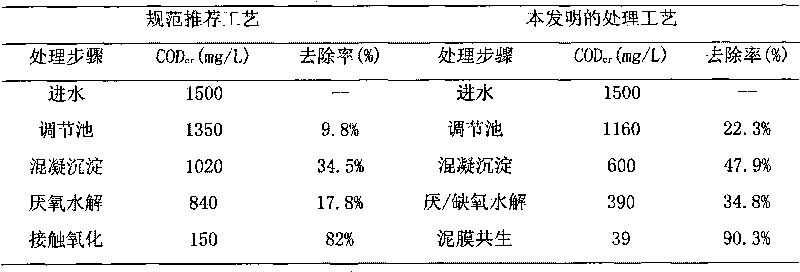

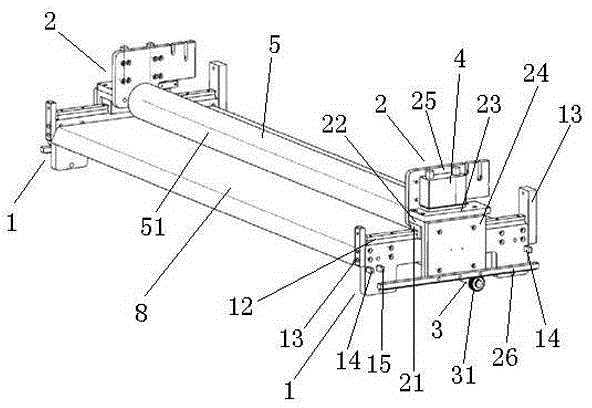

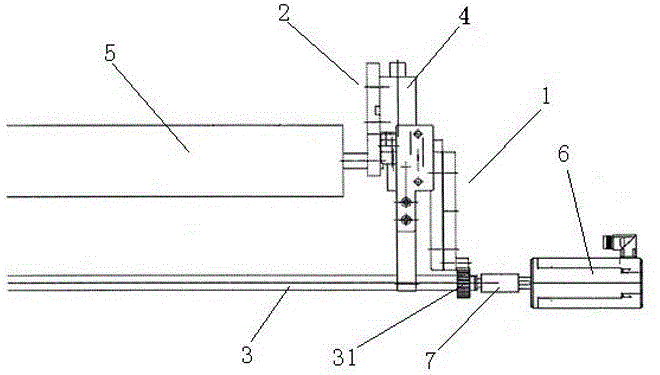

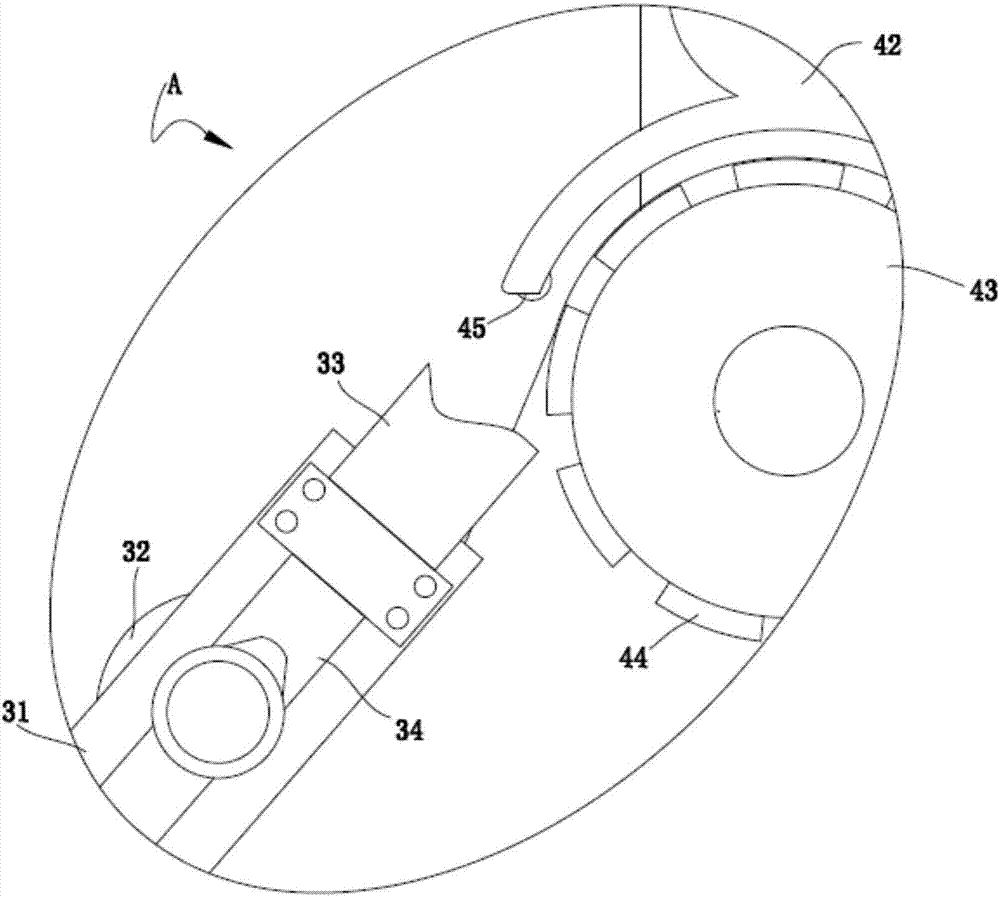

Fabric pressing mechanism and method

The invention belongs to the field of textile dyeing, and particularly relates to a fabric pressing mechanism and method. The mechanism comprises two symmetrically arranged supporting devices, two symmetrically arranged sliding devices, and a transmission shaft driving the two sliding devices, wherein the sliding devices are installed on the supporting devices in a sliding mode, cylinders are symmetrically installed on each sliding device, and a press roller is installed between the two sliding devices and can move vertically under the driving of the cylinders. The fabric pressing mechanism is realized mainly by means of the fabric pressing method that the press roller is suspended firstly; fabric is made to pass through the press roller, and cylinder buttons are pressed down manually to press down the press roller; a printing switch is pressed down, and the fabric is fed through the sliding devices at a speed same as the speed of a guiding belt; the guiding belt is stopped, printing is conducted through a spray head, and meanwhile, the press roller moves backwards at a constant speed to press the fabric. The fabric pressing mechanism and method are intelligent, efficient, and capable of preventing creases from appearing on the fabric to affect the fabric dyeing effect.

Owner:SHAOXING EACO DIGITAL CONTROL & INKJET TECHCO

Polymerized titanium tetrachloride inorganic polymeric flocculant and preparation method of inorganic polymeric flocculant

ActiveCN102976462AGood flocculation effectSimple production processWater/sewage treatment by flocculation/precipitationChemical industrySludge

The invention relates to a preparation method of a polymerized titanium tetrachloride inorganic polymeric flocculant. The preparation method comprises the following steps: by using a titanium tetrachloride solution and sodium hydroxide as raw materials, adding sodium hydroxide into the titanium tetrachloride solution, wherein the alkalization degree is equal to 1.5-2, and the dropwise adding process of a sodium oxide solution is finished within 10-60 minutes; and then, further stirring for 1.5-5 hours until the solution becomes a colorless transparent liquid. The flocculant has the advantages of good product stability, strong colloidal substance adsorbing and bridging capabilities, good flocculation effect, wide application range, low sludge productivity and the like, can be widely applied to the fields of water supply, wastewater treatment, papermaking, textile dyeing and printing, daily chemical industry and the like and has a favorable water treatment effect. The method provided by the invention has the characteristics of simple and rapid process, economy, rapidness and the like.

Owner:SHANDONG UNIV

Process for dyeing and finishing by using bamboo vinegar

InactiveCN102061619AGood antibacterial effectIncrease productivityBleaching apparatusDyeing processFiberGram

The invention relates to a process for dyeing and finishing by using bamboo vinegar, belonging to the technical field of textile dyeing and finishing. The process for dyeing and finishing by using bamboo vinegar comprises the following steps of: (1) boiling and blenching; (2) dyeing; and (3) after finishing. The after finishing specifically comprises the steps of: adding 18-22 grams of bamboo vinegar in each liter of water to make finishing liquor; carrying out after finishing on a bamboo fiber fabric by using the finishing liquor; and controlling the liquid entrainment rate of the bamboo fiber within 68-80%, the pre-drying temperature within 75-85DEG C and the curing temperature within 115-130DEG C during the after finishing. Compared with the prior art, the process of the invention is more suitable for dyeing and finishing the bamboo fiber; the bamboo fiber fabric dyed and finished by the process of the invention has favorable bacteriostasis rate and bacteriostasis value; and the physical properties such as air permeability, diffusivity, capillary effect and the like, which have larger influences on the bamboo fiber fabric, are improved obviously.

Owner:ANJI TANZHUZHUANG BAMBOO FIBER

Bofanic dye and its production process and use

The present invention is one kind of botanic dye and its production process and use. The botanic dye is prepared with plant material containing pigment, and through steaming, filtering the steamed liquid to obtain filtrate, adding lime water into the filtrate, stilling to make the liquid laminate into different layers of different colors, and taking the liquid of different layers as different dyes. The present invention utilizes plant material and has no pollution, simple technological process and low cost. The present invention obtains dyes of different shades with the same plant material to enrich color spectrum, and the botanic dye may be used widely in dyeing textile.

Owner:顾振新

Method for dyeing silk broadcloth by using plant dye solution extracted from lily

InactiveCN102587153ASafe to takeIncrease added valueDry-cleaning apparatus for textilesNatural dyesFiltrationPollen

The invention discloses a method for dyeing silk broadcloth by using the pollen of lily as a natural dye and belongs to the technical field of textile dyeing and finishing. The method comprises the following steps of: soaking fresh or dried dark-red lily pistil, heating and performing suction-filtration to obtain a dye solution; adding silk broadcloth fabric which is refined, and dyeing the silk broadcloth fabric; and adding different mordants for mordanting and thus obtaining silk fabric with different colors. The method has the advantages of low cost, simple process, high performance, high additional value, non-allergic and non-carcinogenic to skin, and the like; raw materials are inexpensive, easy to get, and reproducible; and taking of dyeing products is safe. Particularly, by taking plant ash as a mordant, pollution is avoided. The method is environment-friendly and energy-saving, and clothes which are made of fabric dyed by using the method are natural, environment-friendly and nonirritating to the skin.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

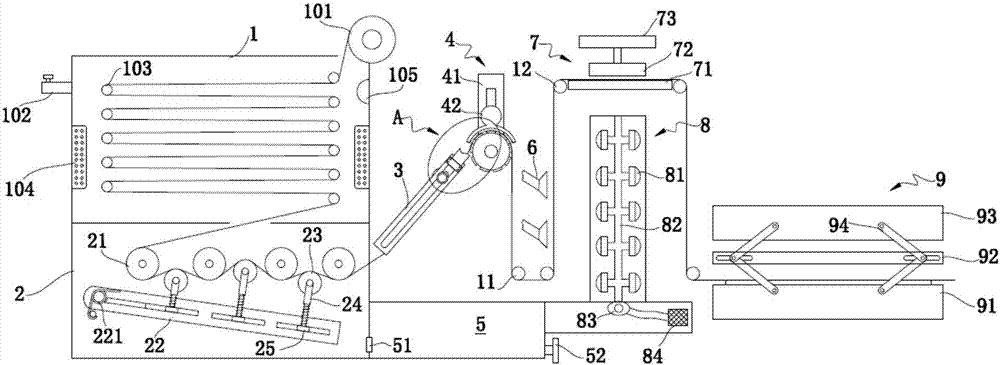

Printing and dyeing equipment

ActiveCN107974786AUniform dyeingAutomatically adjust the tensionLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersPulp and paper industryTextile dyeing

The invention provides printing and dyeing equipment. The printing and dyeing equipment comprises a dyeing box, a dewatering and drying mechanism and a printing machine which are arranged from left toright sequentially. The dewatering and drying mechanism comprises a dewatering mechanism, a water absorbing mechanism, an ironing mechanism and a drying machine which are arranged from left to rightsequentially. The dewatering mechanism comprises a guide rail frame. A water pressing roller is mounted in a groove of the guide rail frame movably through a wheel. An air cylinder is arranged on theright side of the guide rail frame. A piston rod of the air cylinder is connected with the water pressing roller. The water absorbing mechanism comprises a water pressing plate and a water absorbing roller. The printing and dyeing equipment has the advantages that centrifugal dewatering is not needed after textile dyeing through the dewatering and drying mechanism, so that flattening degree of textiles is guaranteed, and flattening on a scutcher is not needed; the dyeing equipment, the dewatering and drying equipment and the printing equipment are combined, so that equipment replacement time during working is reduced, dyeing and printing can be completed on one equipment, and working efficiency is improved.

Owner:TONGXIANG LONGXIANG PRINTING & DYEING CO LTD

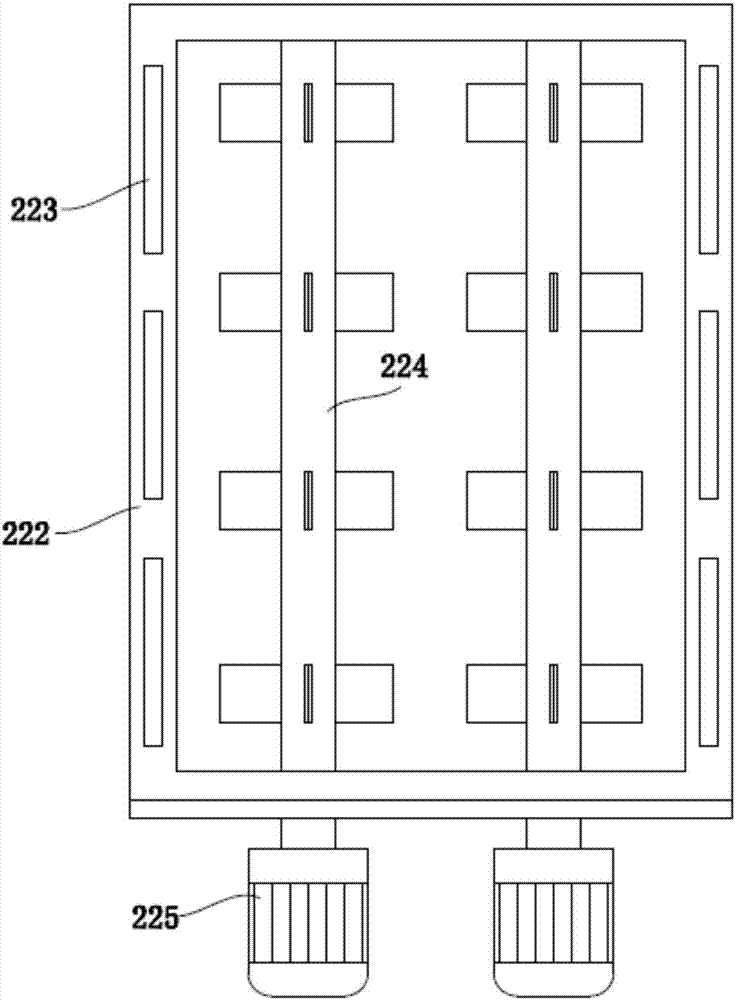

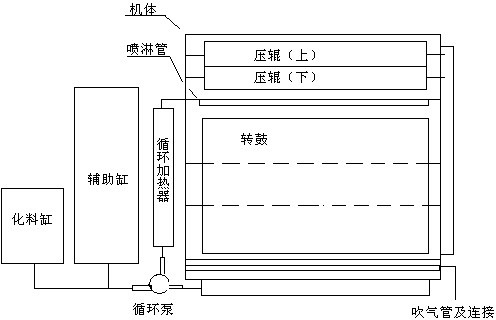

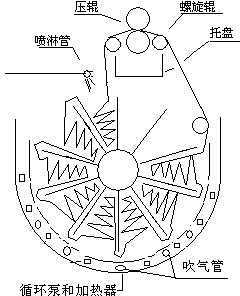

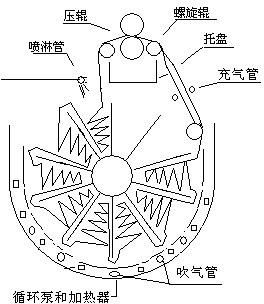

Textile dyeing machine

InactiveCN102587056AReduce dosageImprove washing efficiencyLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsTextile dyeingMechanical engineering

The invention discloses a textile dyeing machine which comprises a cylindrical dye vat, the cylindrical dye vat is internally provided with a rotary drum coaxial with the dye vat, blades are uniformly distributed on the rotary drum, and a group of press rolls arranged above one another is arranged above the cylindrical dye vat. The textile dyeing machine is also provided with a dye solution circulating pipe, one end of the dye solution circulating pipe is communicated with the bottom of the dye vat, the other end of the dye solution circulating pipe is communicated with a sprayer above the dye vat, and a heater and a circulating pump are arranged on the dye solution circulating pipe. The raffinate containing rate after each time of liquid discharge is reduced by the press rolls, so as to improve the washing efficiency, and greatly reduce the use amount of water, electricity and steam. A loose processing manner is adopted for the textile dyeing machine so as to adapt to all textiles and non-woven fabrics; and in operation, no mechanical friction exists between the fabric and the equipment, the fabric is free from rapid impact of the dye solution, and the fabric surface is lint-free.

Owner:SHANDONG COMPANION GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com