Dye waste water treatment system

A treatment system and technology for dye wastewater, applied in textile industry wastewater treatment, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of pH, alkalinity, poor biodegradability of anaerobic treatment, and unreachable effluent First-level standards and other issues, to achieve the effect of reducing or water pollution, realizing waste water resource utilization, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

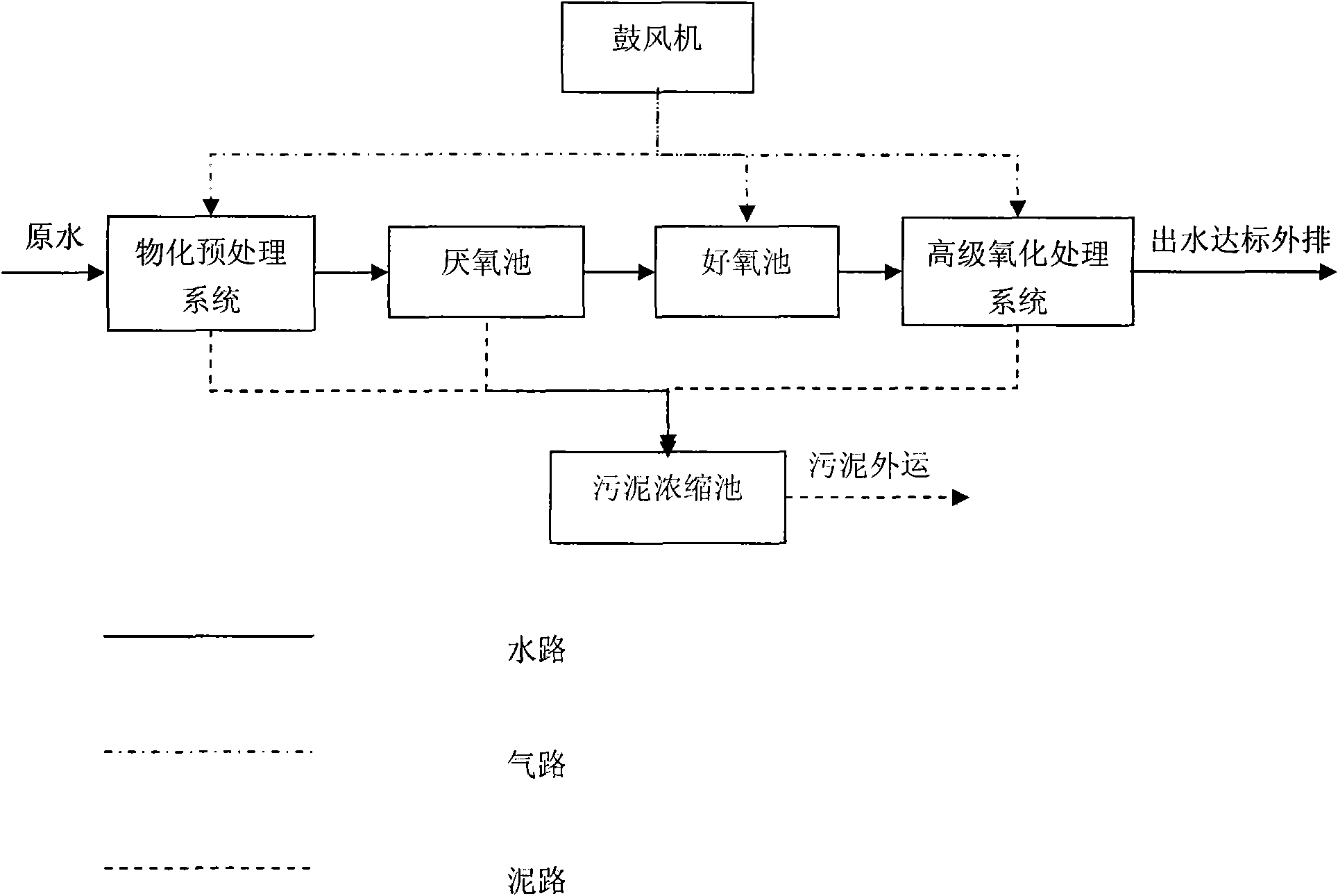

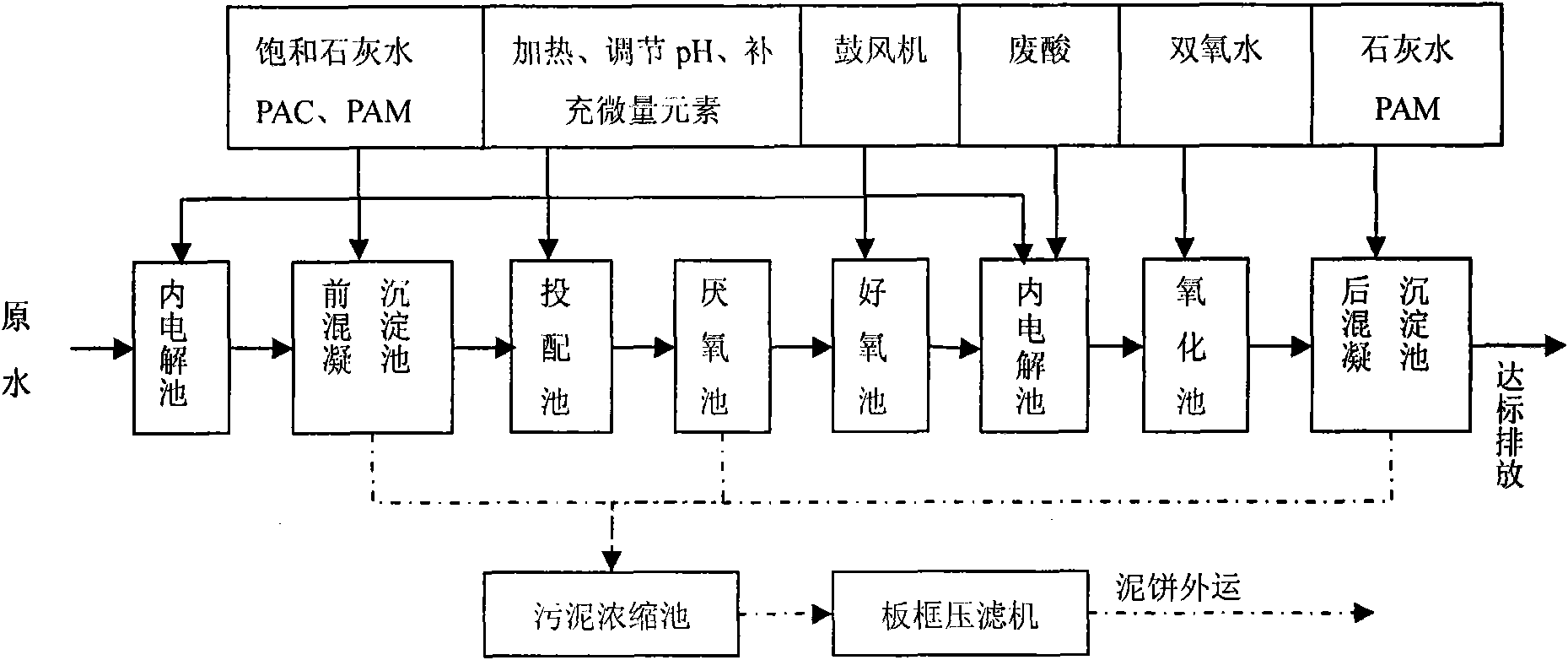

[0031] The present invention will be further described below in conjunction with the accompanying drawings. figure 1 It is a schematic diagram of the dye wastewater treatment system of the present invention, figure 2 for figure 1 detailed schematic diagram.

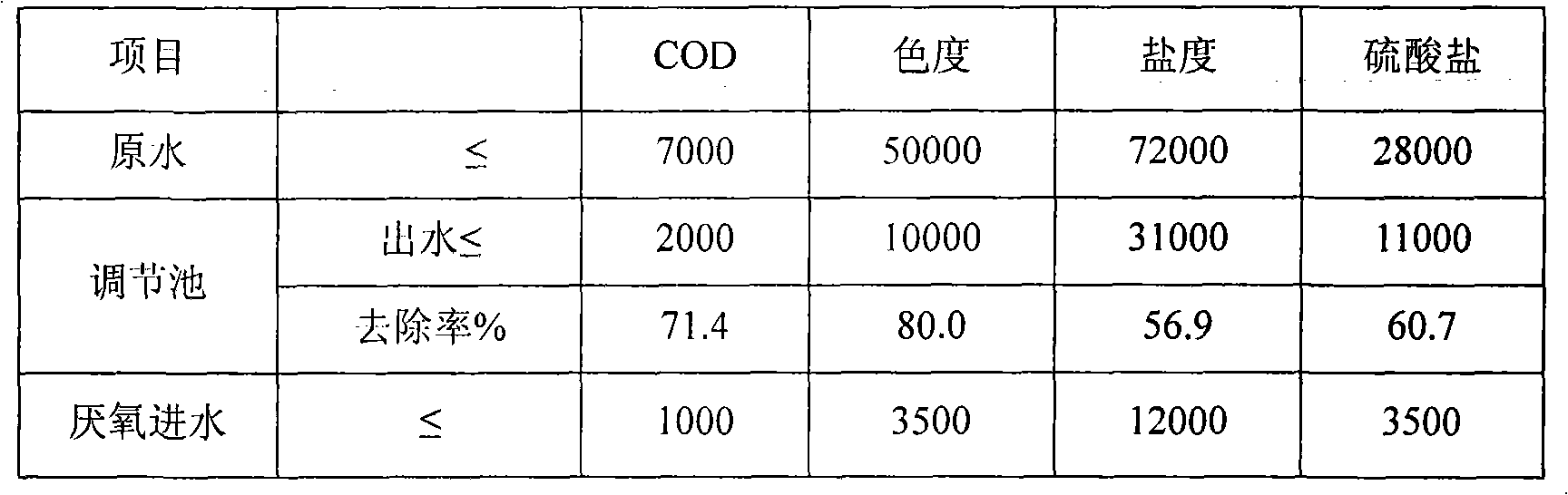

[0032] The invention provides a dye wastewater treatment system, such as figure 1 As shown, in the physical and chemical pretreatment system + anaerobic tank + aerobic tank + advanced oxidation treatment system connected in sequence, the combined process of "physical and chemical pretreatment + anaerobic + aerobic + advanced oxidation" (hereinafter referred to as PUBA combined process) to treat dye wastewater. Such as figure 2 As shown, the physical and chemical pretreatment system includes an internal electrolytic cell and a pre-coagulation sedimentation tank that are connected in sequence, and the advanced oxidation treatment system includes an internal electrolytic cell, an oxidation tank, and a post-coagulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com