Patents

Literature

1289 results about "Anaerobic reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellular Respiration is divided into two series of biochemical reactions: anaerobic and aerobic reactions. Anaerobic reactions occur in the cytoplasm of the cell and aerobic reactions occur in the mitochondria of the cells.

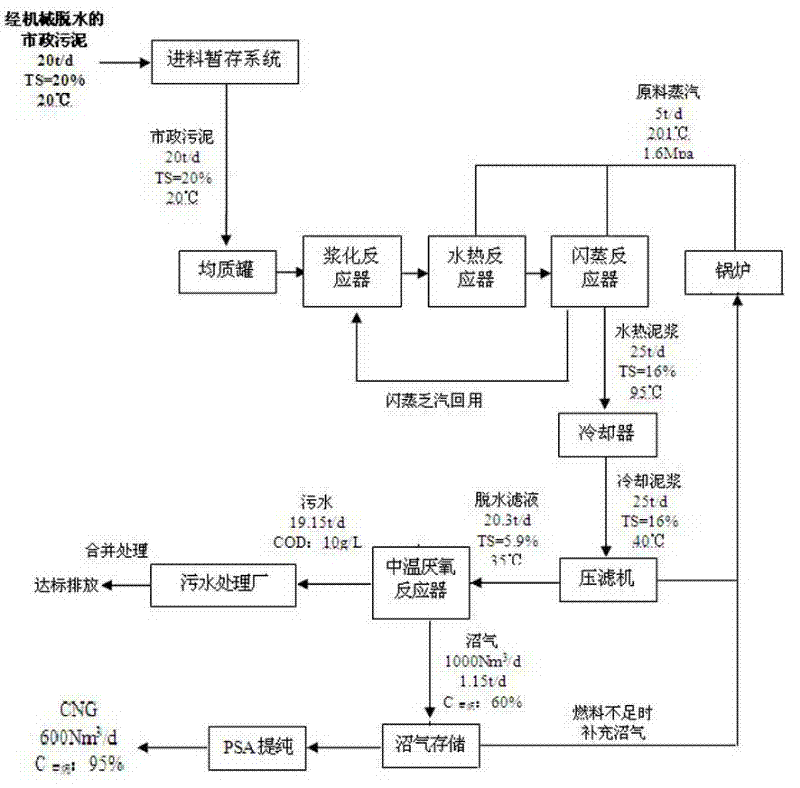

Sludge treatment process based on hydrothermal modification technology

InactiveCN102381820AAdvanced technologyHighlight energy savingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAnaerobic reactorHigh pressure

The invention relates to a sludge treatment process based on a hydrothermal modification technology. The sludge treatment process is carried out by comprising the following steps of: (1) temporarily storing the sludge which is subjected to mechanical dehydration and has the water content of 70-85% to a pretreatment unit and deodorizing the sludge; (2) introducing to a homogeneous device, fully mixing and homogenizing, introducing the homogenized sludge to a slurrying device, introducing the slurried sludge to a hydrothermal reactor for hydrothermal reaction, and introducing the hydrothermal sludge to a flash evaporator for decompression and flash evaporation; (3) cooling to 35-45 DEG C by using a cooler, then introducing to a high-pressure diaphragm pressure filter for pressure filtering and dehydration to obtain a dehydrated mud cake with the solid content of 35-45% and dehydrated filtrate; (4) introducing the dehydrated filtrate to an intermediate temperature anaerobic reactor, wherein the residence time is for 5.5-7.5d, the inlet water temperature is controlled below 40 DEG C, and the anaerobic reaction temperature is 30-40 DEG C; and (5) preparing a biomass fuel rod by using the dehydrated mud cake, and introducing the biomass fuel rod to a boiler to provide steam for the hydrothermal reactor and the flash evaporator. The sludge treatment process has the advantages of goodtreatment effect, obvious volume reduction effect, high harmless degree, recycling of methane, good economic benefit and the like.

Owner:FUZHOU DEV ZONE SANSHUI ENVIRONMENTAL PROTECTION TECH

Treatment method of high-concentration wastewater

InactiveCN103663860AReduce wasteReduce dosageMultistage water/sewage treatmentHigh concentrationChemical oxygen demand

The invention relates to a treatment method of high-concentration wastewater. The treatment method comprises the following steps: (1) pretreatment; (2) flocculent sedimentation treatment; (3) biochemical treatment; (4) membrane biological reaction treatment; (5) adsorption treatment; (6) oxidation treatment; (7) filtration treatment; (8) membrane treatment; (9) disinfection treatment; and (10) evaporative crystallization treatment. The method disclosed by the invention has the advantages that the wastewater with the COD (Chemical Oxygen Demand) concentration up to 96000mg / L can be treated and the COD removing rate is up to 99.98% to ensure that the treated wastewater meets the standards of drinking water and an unexpected technical effect is brought; compared with a dozen or dozens of hours in the prior art, the aerobic reaction time and the anaerobic reaction time are greatly shortened and the treatment efficiency is obviously increased; and the concentrated solution finally generated in the method only accounts for below 2% of water inflow, which is greatly reduced compared with the prior art, so that the waste of water is obviously reduced and the treatment cost is saved.

Owner:曹寅亮

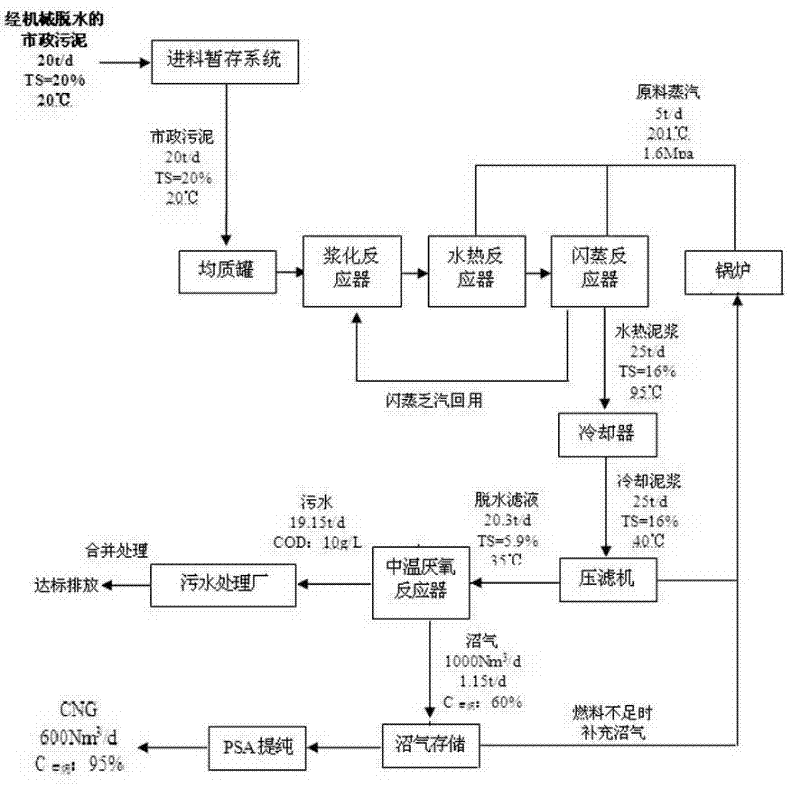

Novel technology for treating domestic sewage in rural area

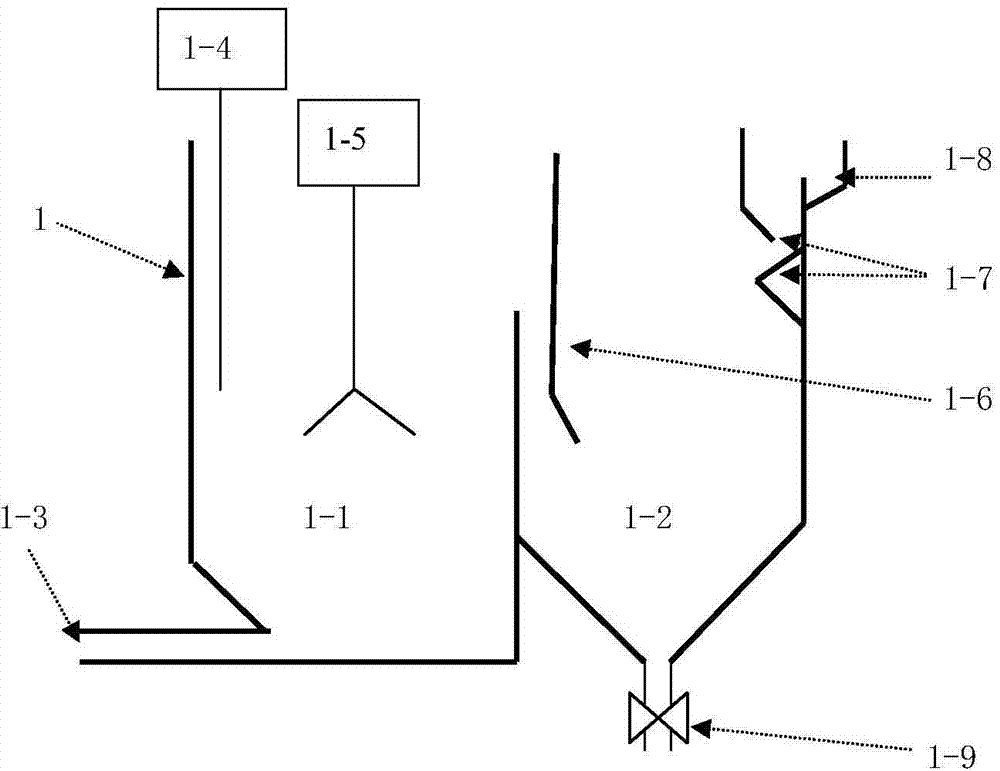

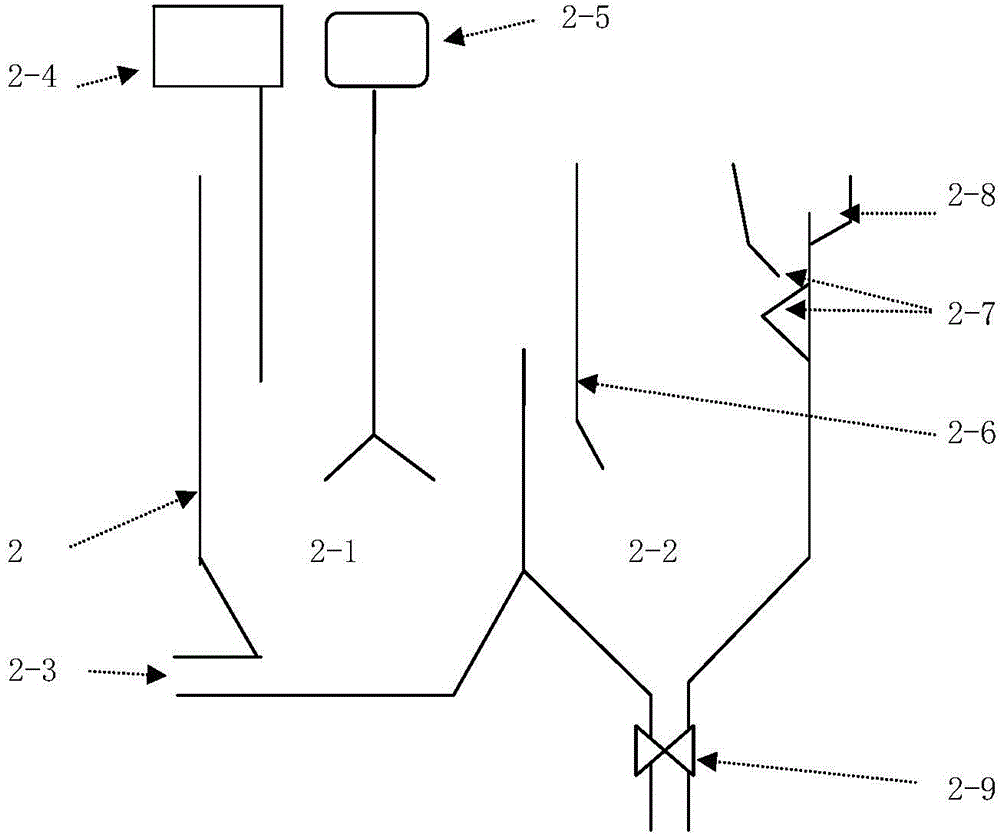

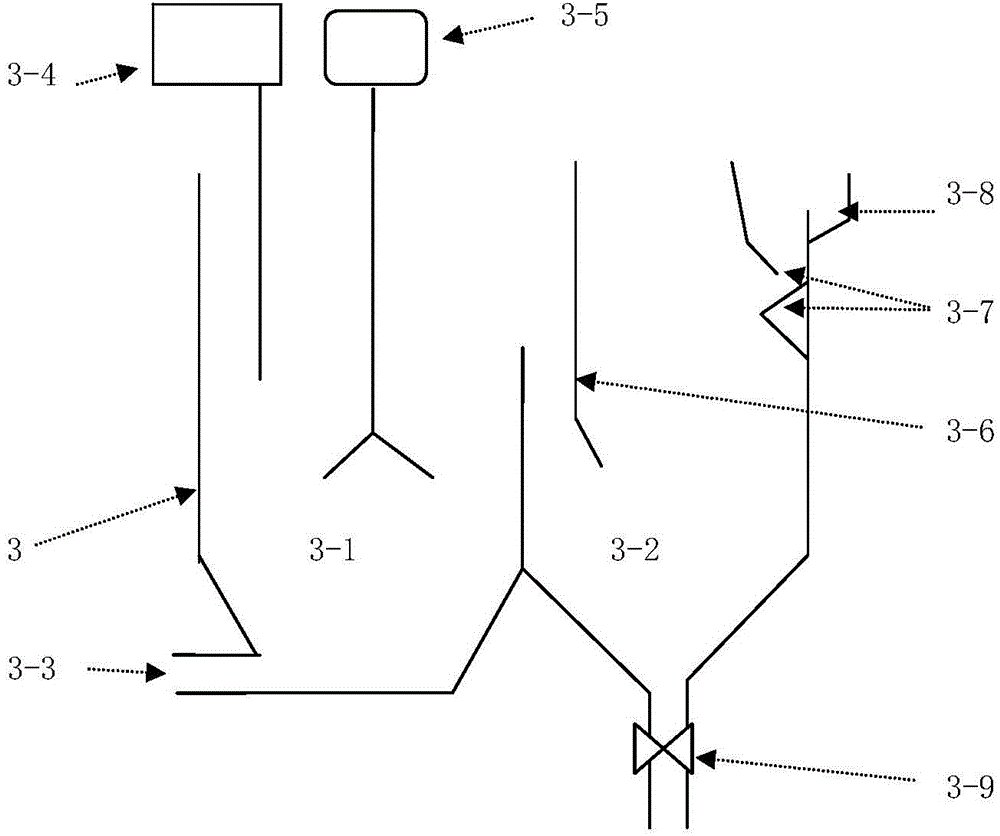

ActiveCN102219332AIncrease economic benefitsLess investmentWaste based fuelTreatment with anaerobic digestion processesRural areaNitrogen

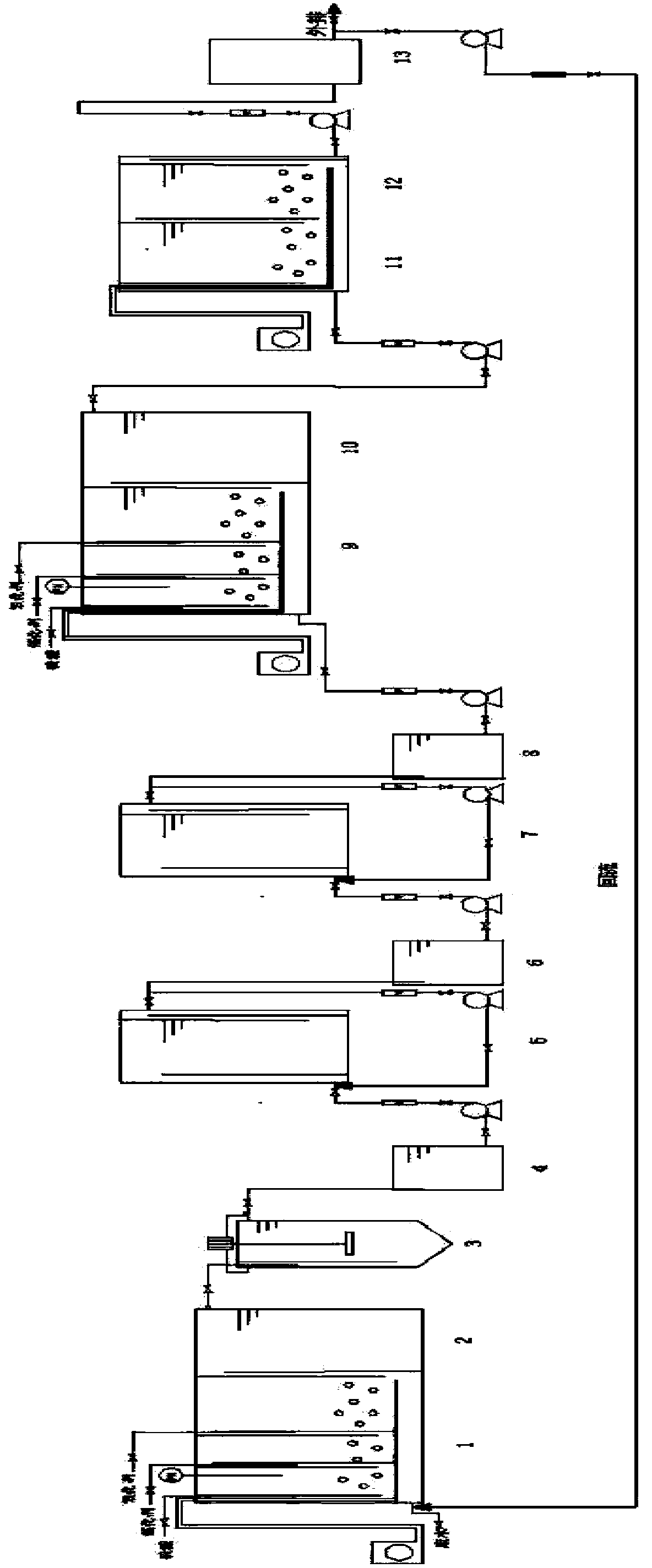

The invention discloses a system and method for treating domestic sewage in a rural area, which belongs to the technical field of environment-friendly sewage treatment. The domestic sewage enters an aerated grit chamber also serving as an adjusting tank for carrying out appropriate grit setting and adjusting, so that a part of inorganic pollutants is removed; the sewage is conveyed to a concentration type two-stage anaerobic reaction tank through a lifting water pump, suspended matters in the sewage are filtered and intercepted when the sewage passes through a concentration filter layer; contaminated gases, such as CH4, H2S and the like generated in the concentration type two-stage anaerobic reaction tank are discharged through a gas port; a part of concentration liquid is discharged out of the system through a concentration bottom sediment drainage pipe by opening a valve regularly; supernatant fluid from a water outlet of the concentration type two-stage anaerobic reaction tank enters a ladder plunge type wetland, a non-medium wetland, an economic income type wetland, a bacteria filter and a fishpond in turn; and nitrogen and phosphorus eutrophic pollutants in water are filtered, intercepted, adsorbed, decomposed, absorbed and precipitated by rootstocks of aquatic plants and the like. Therefore, according to the novel technology disclosed by the invention, the purpose of water purification can be achieved through regular harvest.

Owner:上海欧保环境科技有限公司

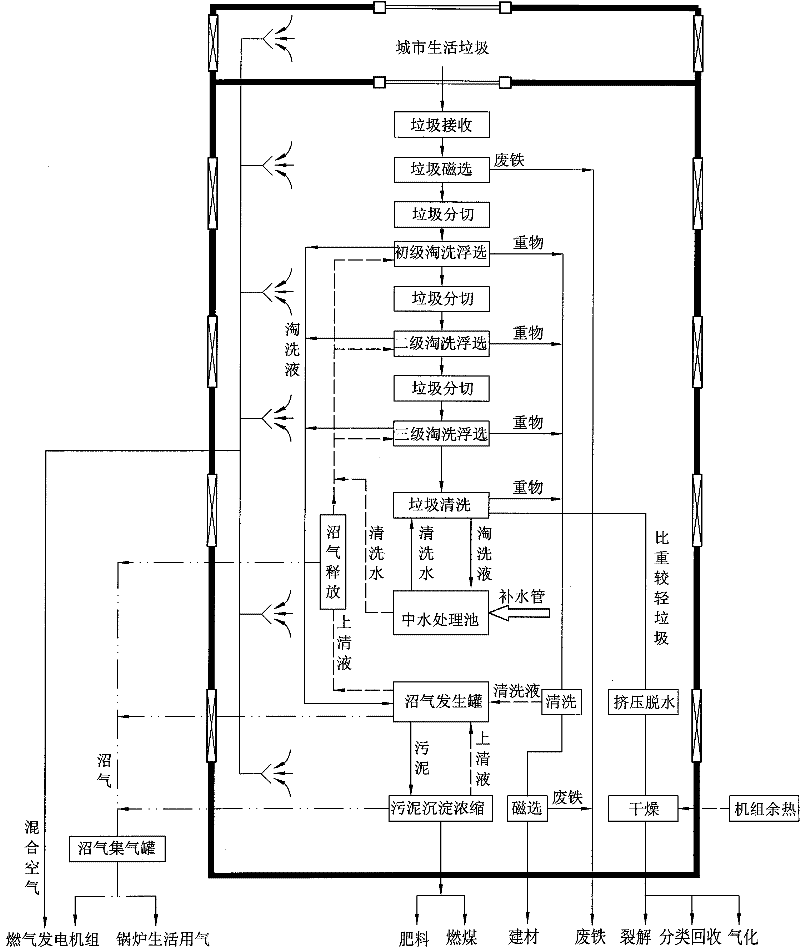

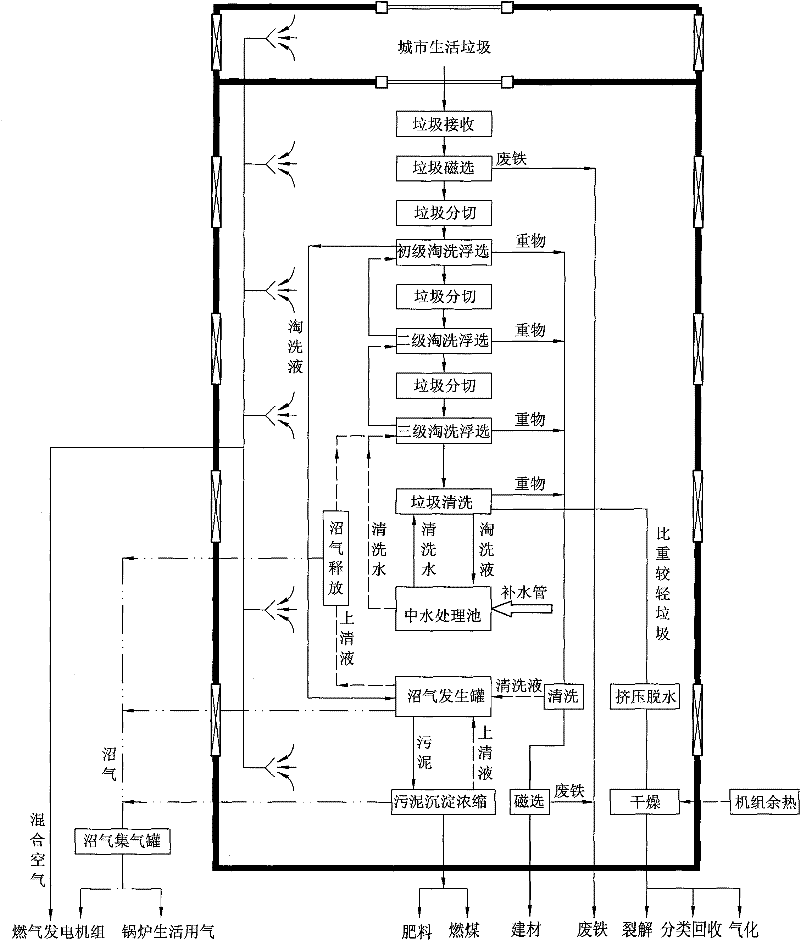

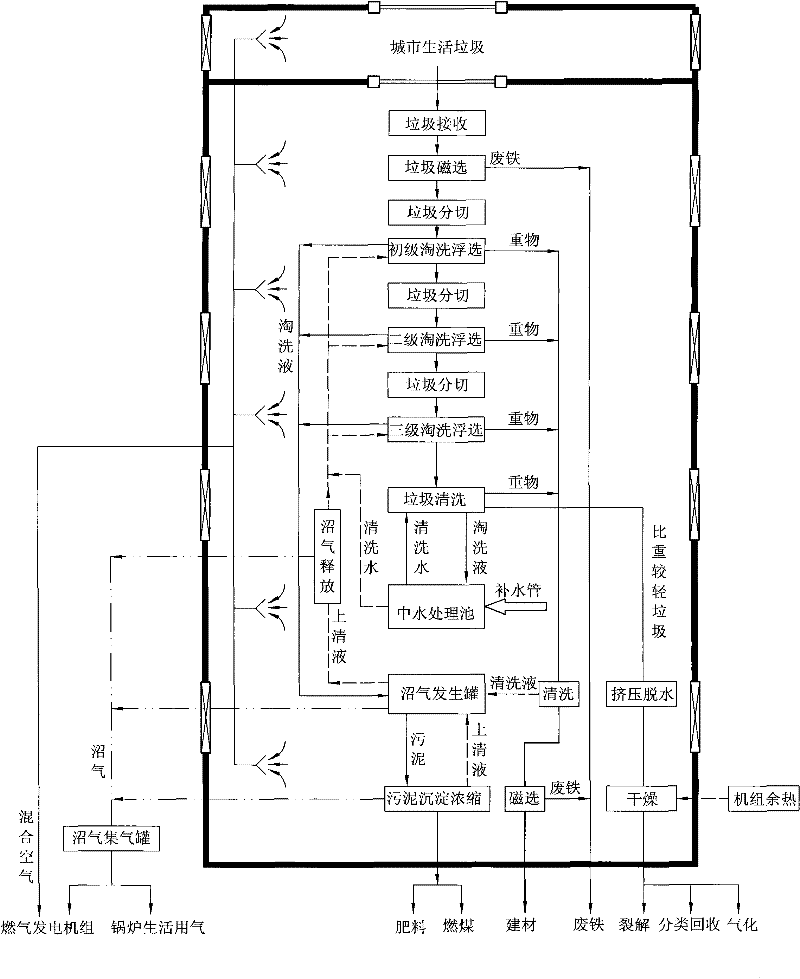

Method for resource recovery and classification utilization of urban domestic waste

ActiveCN102247969AHigh thermal efficiencyEasy to wash and separateSolid waste disposalFurniture waste recoveryEngineeringFuel oil

The invention discloses a method for resource recovery and classification utilization of urban domestic wastes, which at least comprises the following steps of: a magnetic separation step, a waste cutting step, a elutriation flotation step, a waste extrusion dehydration step, an anaerobic treatment step and a sludge deposition concentration step; scrap iron is separated by the magnetic separationstep for the recovery and utilization of the scrap iron; anaerobic organic matter is crushed by the waste cutting step; pasty organic matter and block non-anaerobic wastes are thoroughly separated bythe elutriation flotation step so as to allow the pasty anaerobic organic matter to enter a biogas generation pool or tank for an anaerobic reaction and to allow the clean non-anaerobic wastes to be extruded, dehydrated and dried for individual treatment, and the waste decrement is above 90%; after elutriation, the left 10% non-anaerobic wastes are prepared into fuel oil by a cracking reaction; or are recycled through screening with no screening difficulty being caused by dust and organic matter containing in the wastes; or are delivered into a gasifier for fuel gas production, which preventsthe energy consumption of water-containing organic matter during waste incineration treatment, and greatly increases the thermal efficiency of waste treatment.

Owner:刘振亮

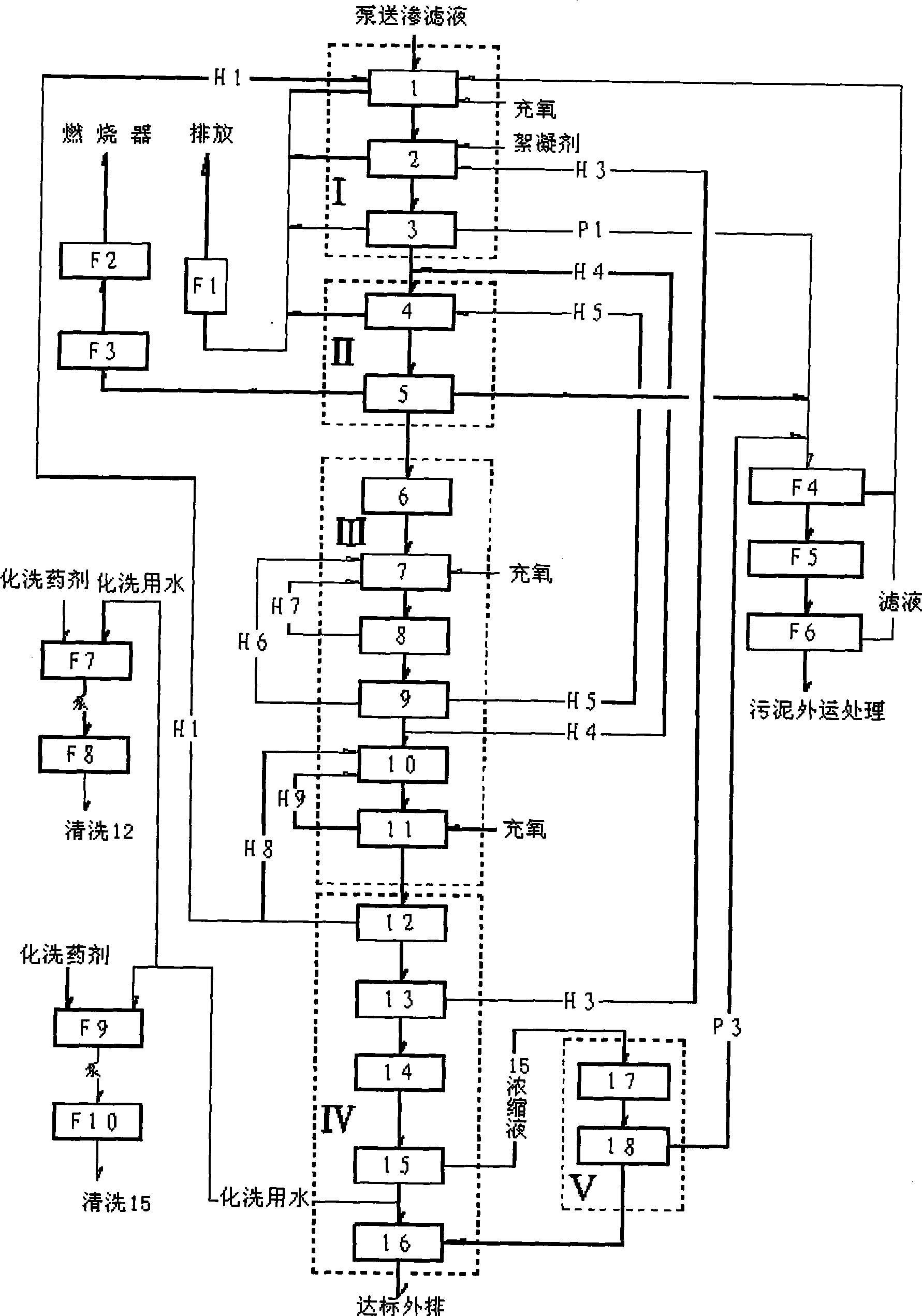

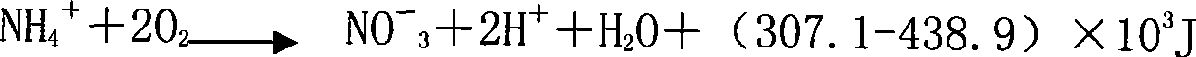

Treatment process for garbage leachate

ActiveCN101428938AImprove biodegradabilityPrevent rancidityTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationHydrolysis

The invention discloses a method for treating landfill leachate, which orderly comprises flocculation precipitation pretreatment, hydrolysis pre-acidification treatment, anaerobic treatment, aerobic treatment comprising shortcut nitrification-denitrification and secondary nitrification-denitrification, membrane separation treatment and oxidation flocculation treatment. The method has the advantages of having higher removal rate of ammonia nitrogen and lower energy consumption, realizing the up-to-standard discharge of leachate concentrated solution, ensuring sound operation of the whole system, greatly lowering the oxidation-reduction potential in the anaerobic reaction, and improving the anaerobic treatment effect, thereby making the landfill leachate fully meet the first-level discharge standard of the Integrated Wastewater Discharge Standard.

Owner:浙江永峰环保科技股份有限公司 +1

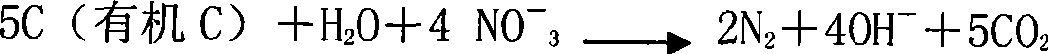

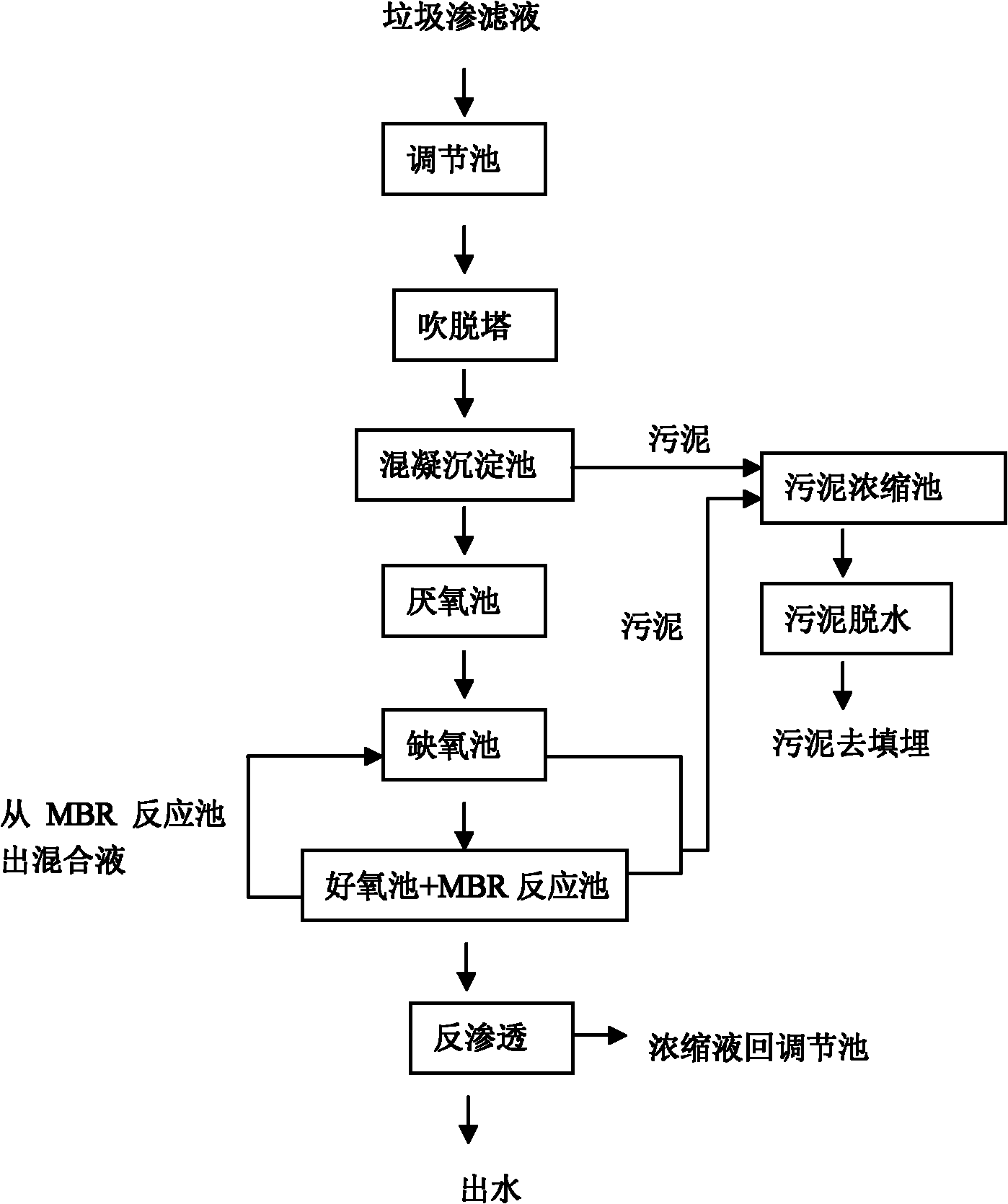

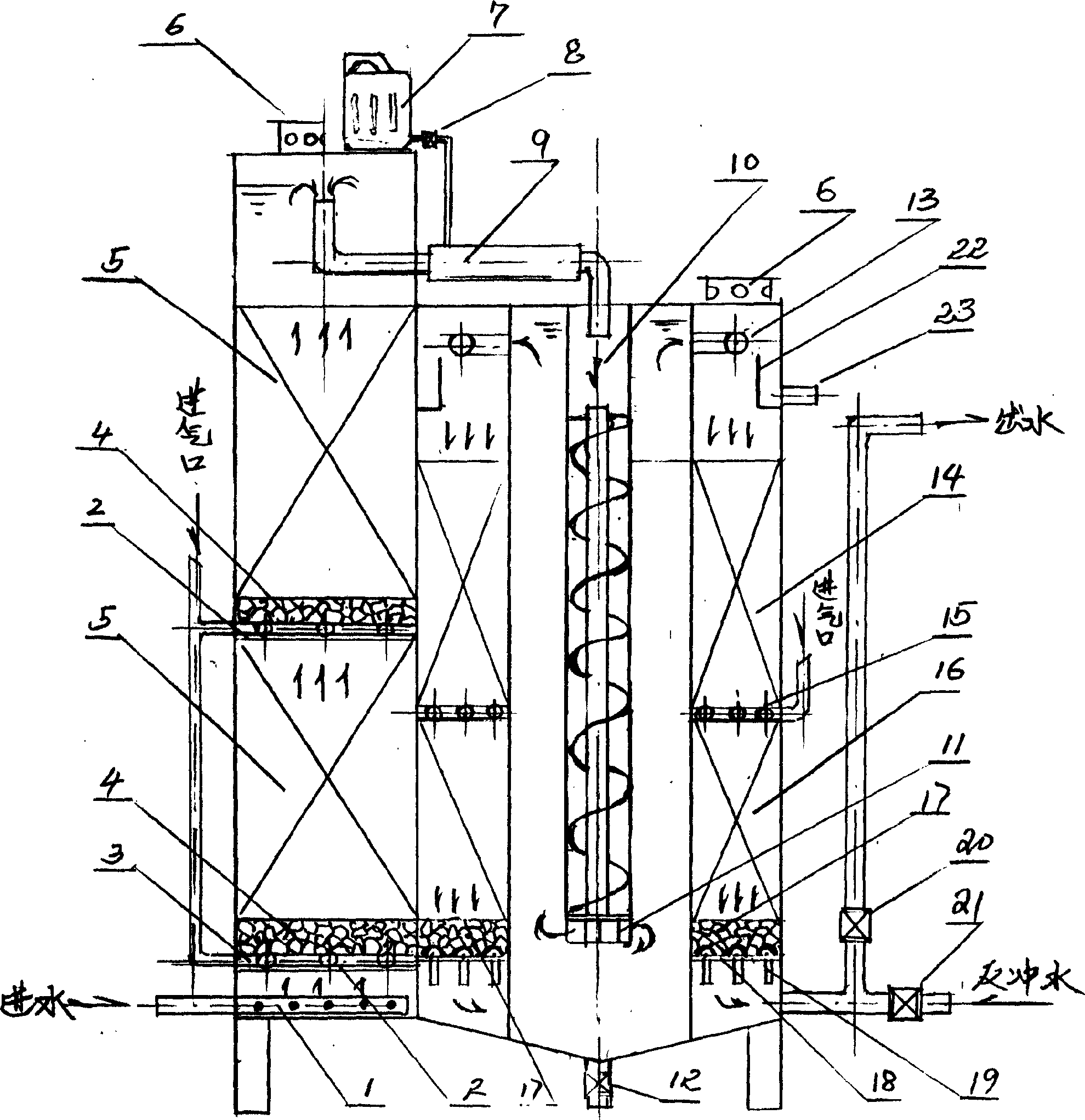

Landfill percolate treatment novel process

InactiveCN101870543AEfficient removalReduce concentrationMultistage water/sewage treatmentWater qualityReverse osmosis

The invention relates to a landfill percolate treatment novel process method, which comprises the following steps: (1) collecting and gathering the landfill percolate into a regulating tank; (2) lifting the outlet water of the regulating tank to enter an ammonia stripping reaction vessel; (3) carrying out coagulating sedimentation treatment on the landfill percolate after ammonia stripping; (4) making the outlet water of the coagulating sedimentation enter an anaerobic reaction vessel for carrying out anaerobic treatment; (5) sequentially making the outlet water of the anaerobic reaction vessel enter an anoxic tank, an aerobic tank and an MBR reaction tank, wherein mixed liquid carries out back flowing from the MBR reaction tank to the anoxic tank, a membrane assembly used in the MBR reaction vessel is a flat plate MBR film assembly, and the MBR has the form of the submerging form; and (6) making the outlet water of the MBR reaction tank enter a reverse osmosis system, directly discharging the treated outlet water, and making reverse osmosis concentrated solution flow back to the regulating tank. The invention aims at the water quality features of the landfill percolate, reasonably combines the physicochemical treatment and biological treatment unit, and has the advantages of short and compact process flow, high treatment efficiency, low energy consumption, long service life of the membrane assembly and the like.

Owner:广西森淼环保科技有限公司 +1

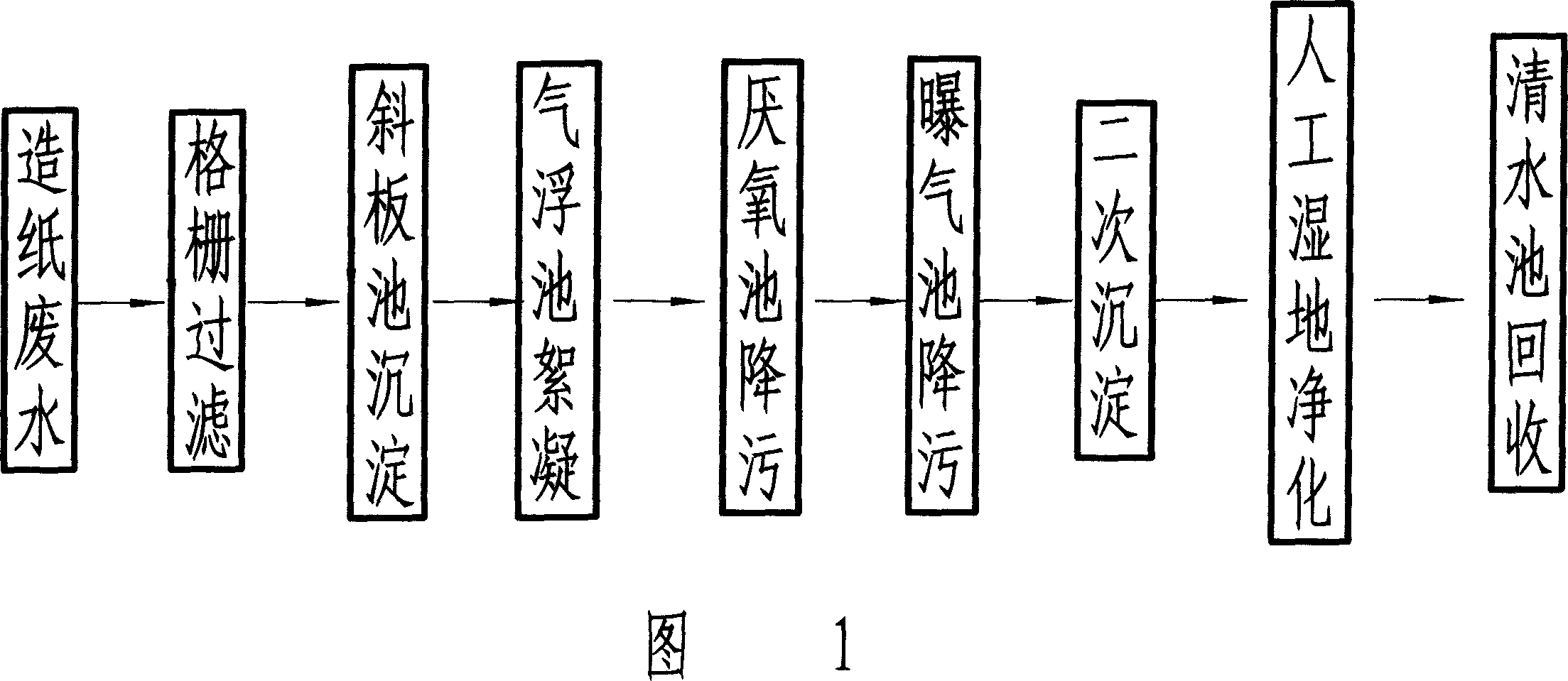

Method for processing paper-making waste water of regenerative paper

InactiveCN101077817AMeet the requirements of emission standardsSS reductionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentConstructed wetlandFiber

The process of treating effluent from making paper with waste paper belongs to the field of industrial effluent treating technology, and aims at lowering the harmful matter content in the effluent from making paper with waste paper to reach the exhaust standard. The process includes the first passing the effluent through grating to filter out fiber and suspended matter, the subsequent settling in a sloping plate settling tank to eliminate granular impurity, flocculating in an air floating tank with flocculant and fishing out the resultant suspended matter, anaerobic reaction in an anaerobic settling tank, treating with introduced air and active sludge in an aeration tank and eliminating suspended matter and colloidal matter, clarifying in a settling tank, and treating in artificial wetland to eliminate nitrogen and phosphate and obtain clear water. The process can reduce SS, BOD5 and CODcr of the effluent obviously and make the effluent reach draining standard.

Owner:云南恒昌造纸有限责任公司

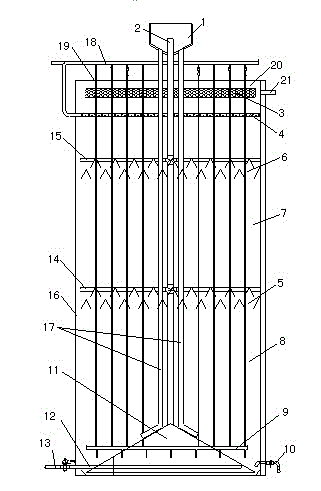

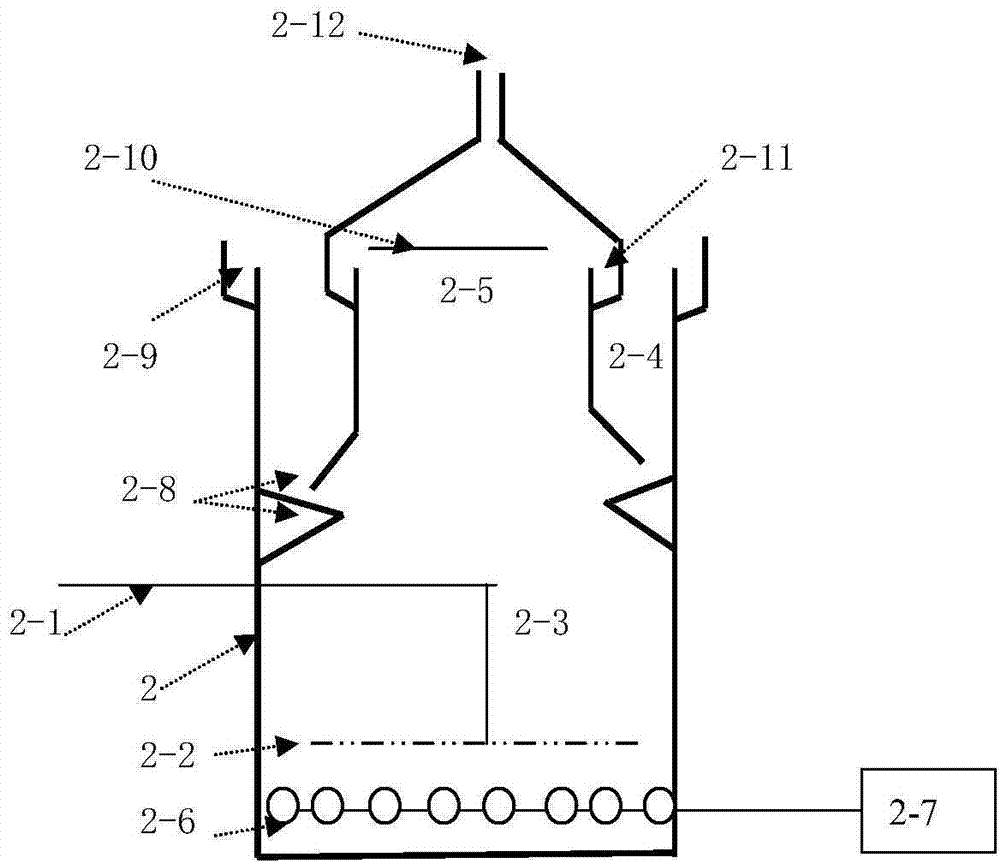

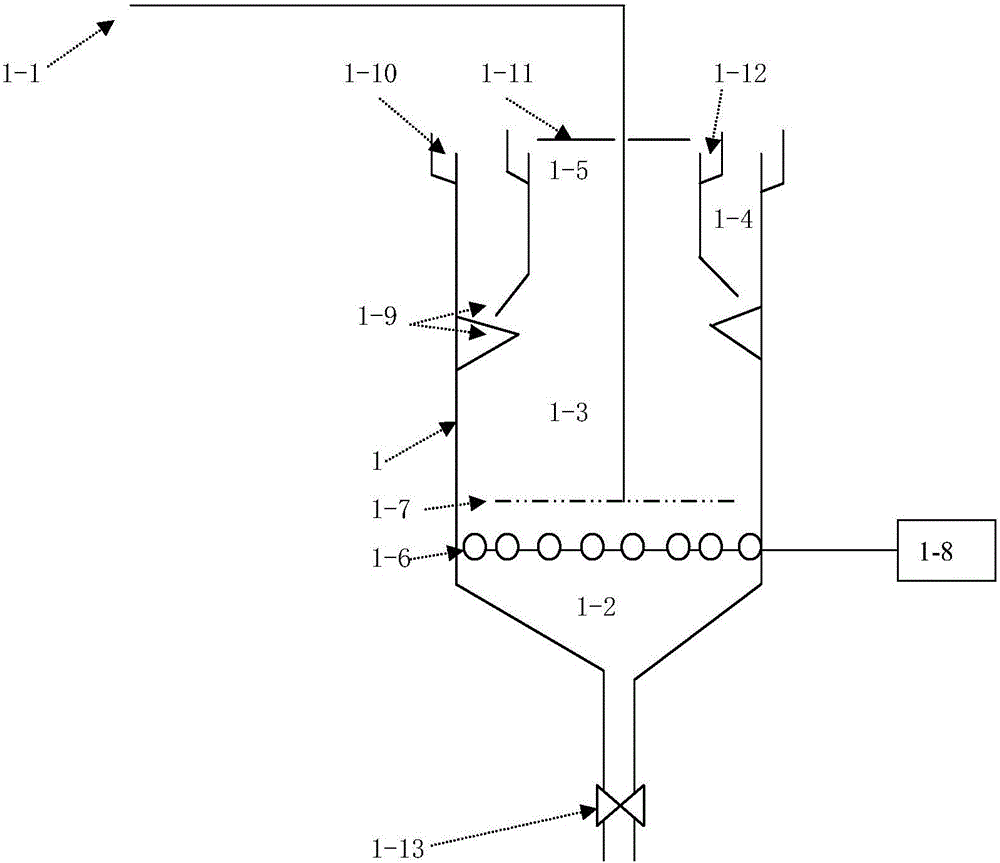

Three-stage circulation aerobic reactor

ActiveCN103332784AStart fastGrow fastSustainable biological treatmentBiological water/sewage treatmentLoad resistanceThree stage

The invention discloses a three-stage circulation aerobic reactor, which comprises a pond body, wherein the inside of the pond body is partitioned into a conical sewage expansion area, an aerobic reaction area, an anaerobic reaction area and a sediment filtering layer from bottom to top in sequence; the upper part of the aerobic reaction area is provided with a primary gas-solid-liquid separation area; the upper part of the anaerobic reaction area is provided with a secondary gas-solid-liquid separation area; three-phase separators are respectively arranged in the primary gas-solid-liquid separation area and the secondary gas-solid-liquid separation area; a water outlet weir is arranged above the sediment filtering layer; a water outlet pipe is arranged on the water outlet weir; the top of the pond body is provided with a double-stage circular reflowing system; the double-stage circular reflowing system comprises an air-lift pipe, a gas-liquid separating tank and a lower layer reflowing pipe; an upper layer reflowing pipe is arranged between the secondary gas-liquid separation area and the sediment filtering layer; and the upper layer reflowing pipe is connected with an aeration air inlet pipe arranged above the pond body. The reactor is provided with a three-stage circular reflowing system, and has the characteristics of rapid start of flocculent sludge, high impact load resistance, low requirement on the PH value of inflow water, high particle sludge increasing speed, low energy consumption, high treating efficiency and stable water yielding quality.

Owner:山东许中华环保科技有限公司

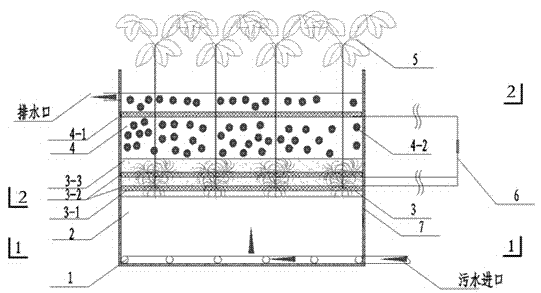

Algal fungi synergistic ecological type microbial fuel cell and method for generating electricity by utilizing water purification

ActiveCN104505529AHigh energy efficiencyOxygen electrode has high reactivityCell electrodesBiological treatment apparatusHigh concentrationInternal resistance

The invention discloses an algal fungi synergistic ecological type microbial fuel cell and a method for generating electricity by utilizing water purification. The fuel cell consists of a fuel cell body, a water inlet distribution system, an anaerobic reaction area, a wetland ecological anode area and an algal fungi symbiotic cathode area. A cation exchange resin is added into a matrix, straw biological carbon is adopted in the wetland matrix, the conductivity is improved, and the internal resistance is reduced; an algal ecological cathode is constructed, and energy conservation and low carbon are realized; and moreover, a deep anaerobic zone is increased on the lower layer of the anode area and adapts to sewage feeding of high-concentration COD, the height of the cell body is increased, and the electrical activity of the cell is improved. The ecological wetland and the microbial fuel cell are combined, a wetland ecological anode and an algal fungi symbiotic oxygen-releasing ecological cathode are constructed, the ecological type microbial fuel cell is formed, and sewage treatment and energy recycling are realized.

Owner:HARBIN INST OF TECH

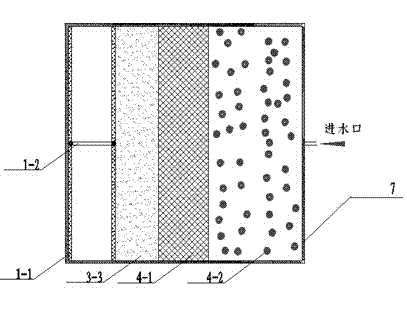

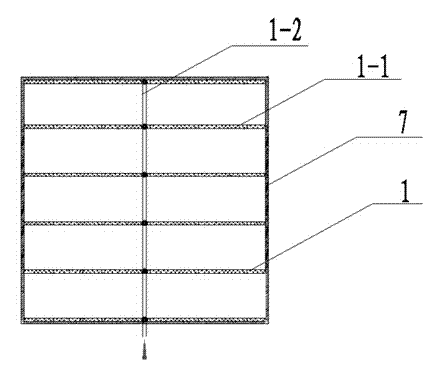

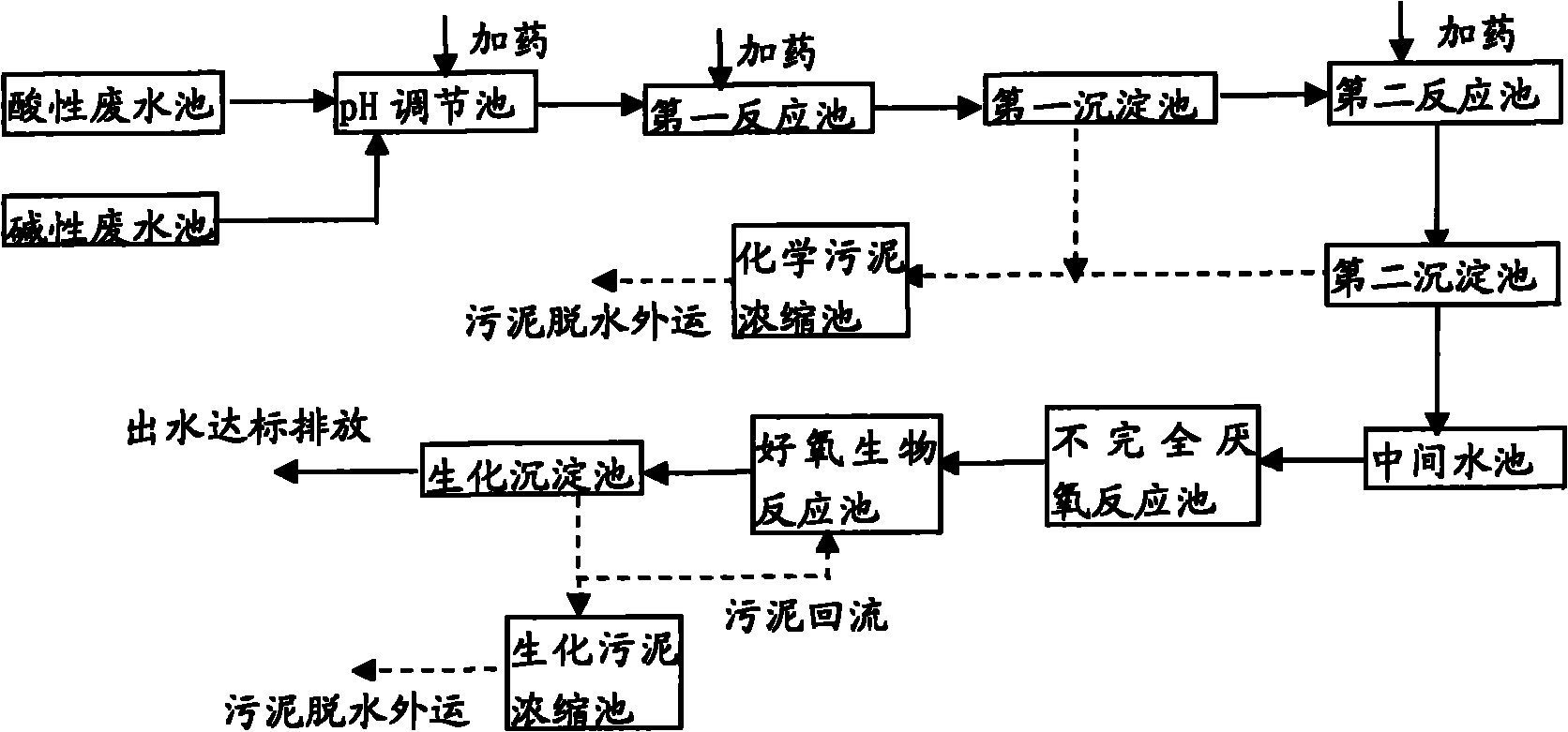

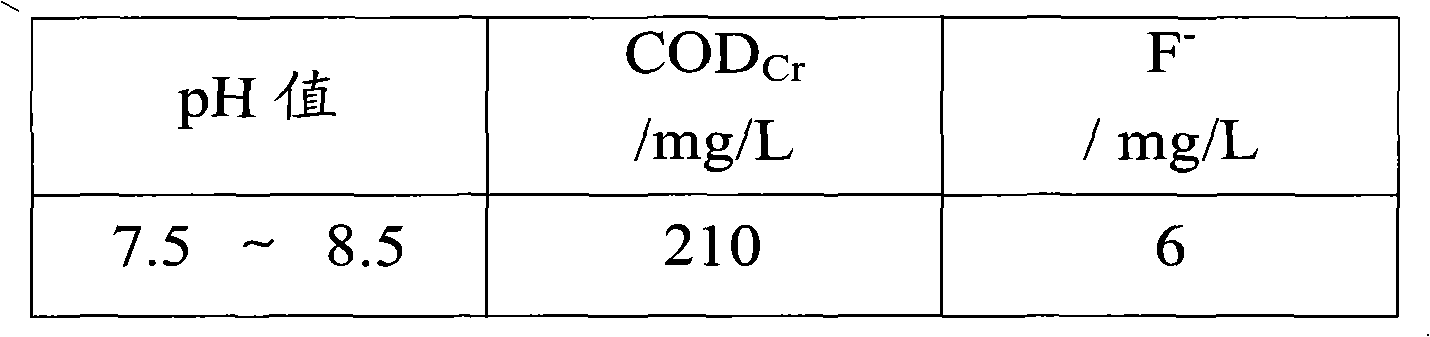

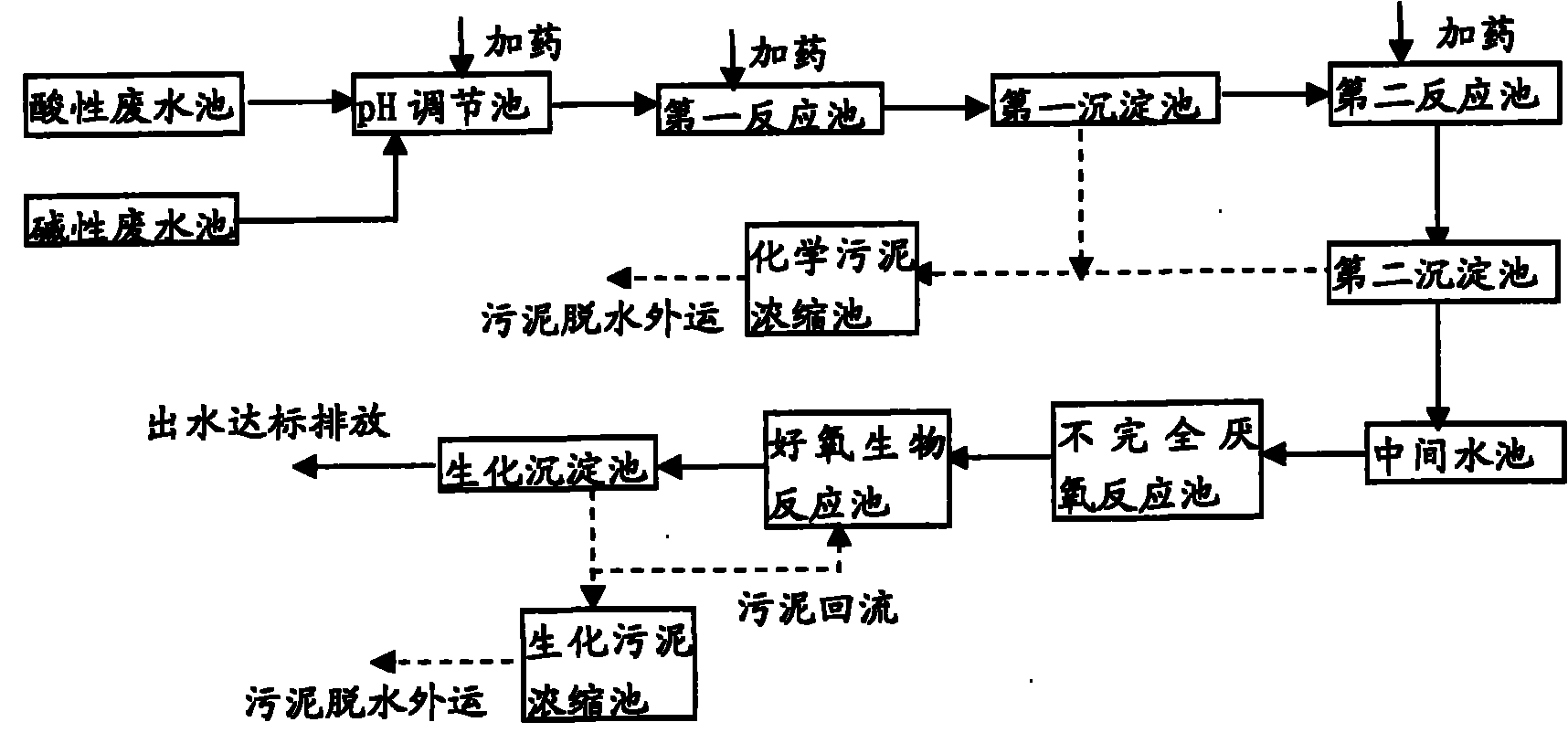

Method and system for treating industrial wastewater of photovoltaic solar cell plates

ActiveCN101973662AEfficient removalReduce concentrationGeneral water supply conservationEnergy based wastewater treatmentChemical oxygen demandStrong acids

The invention discloses a process for treating industrial wastewater of photovoltaic solar cell plates. The process comprises the following steps of: collecting wastewater, namely collecting acid wastewater and alkaline wastewater respectively; regulating pH, namely adding strong acid or strong base into the acid wastewater, alkaline wastewater or acid-alkaline mixed wastewater mixed by the acid wastewater and the alkaline wastewater, and regulating the pH value to be between 8.0 and 8.5 to form conditioning fluid; defluorinating the conditioning fluid and / or removing chemical oxygen demand (COD) from the conditioning fluid, wherein the defluorinating step means throwing calcium salt into the conditioning fluid so as to remove fluorion from the wastewater, and the COD removing step means performing incomplete anaerobic reaction on the conditioning fluid; performing aerobic biological treatment; and sequentially completing the steps to discharge the wastewater meeting the discharge standard. The invention provides a treatment process aiming at the water quality characteristics of the industrial wastewater of the photovoltaic solar cell plates and main design operational parameters.By a treatment system, the fluorion can be effectively removed, the fluorion concentration of effluent can be reduced to be below 10mg / L, and the wastewater CODCr is below 300mg / L and meets the discharge standard. Meanwhile, the invention also provides a system for treating the industrial wastewater of the photovoltaic solar cell plates.

Owner:BEIJING GUOHUAN TSINGHUA ENVIRONMENT ENG DESIGN & RES INST CO LTD BEIJING CHINA

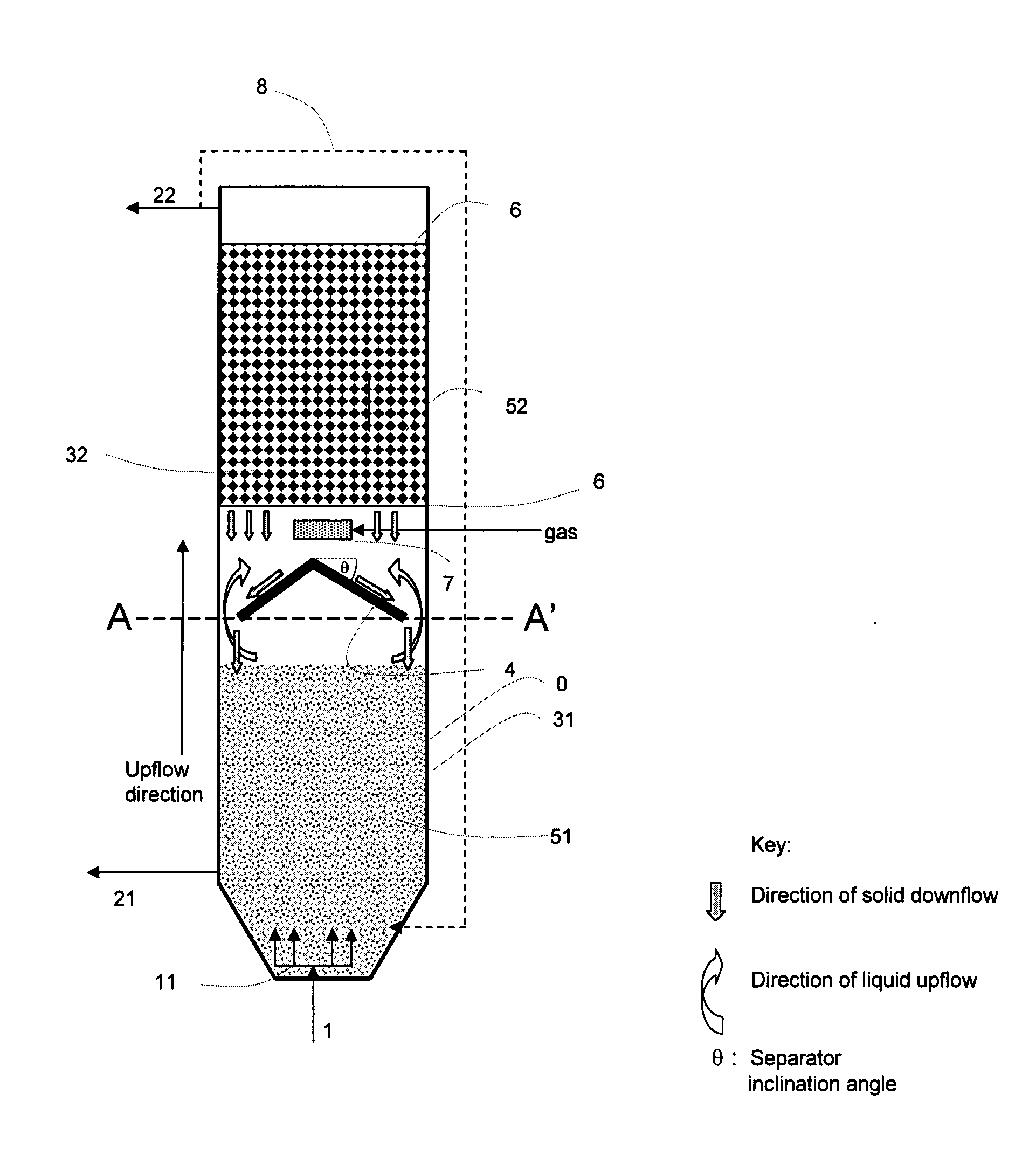

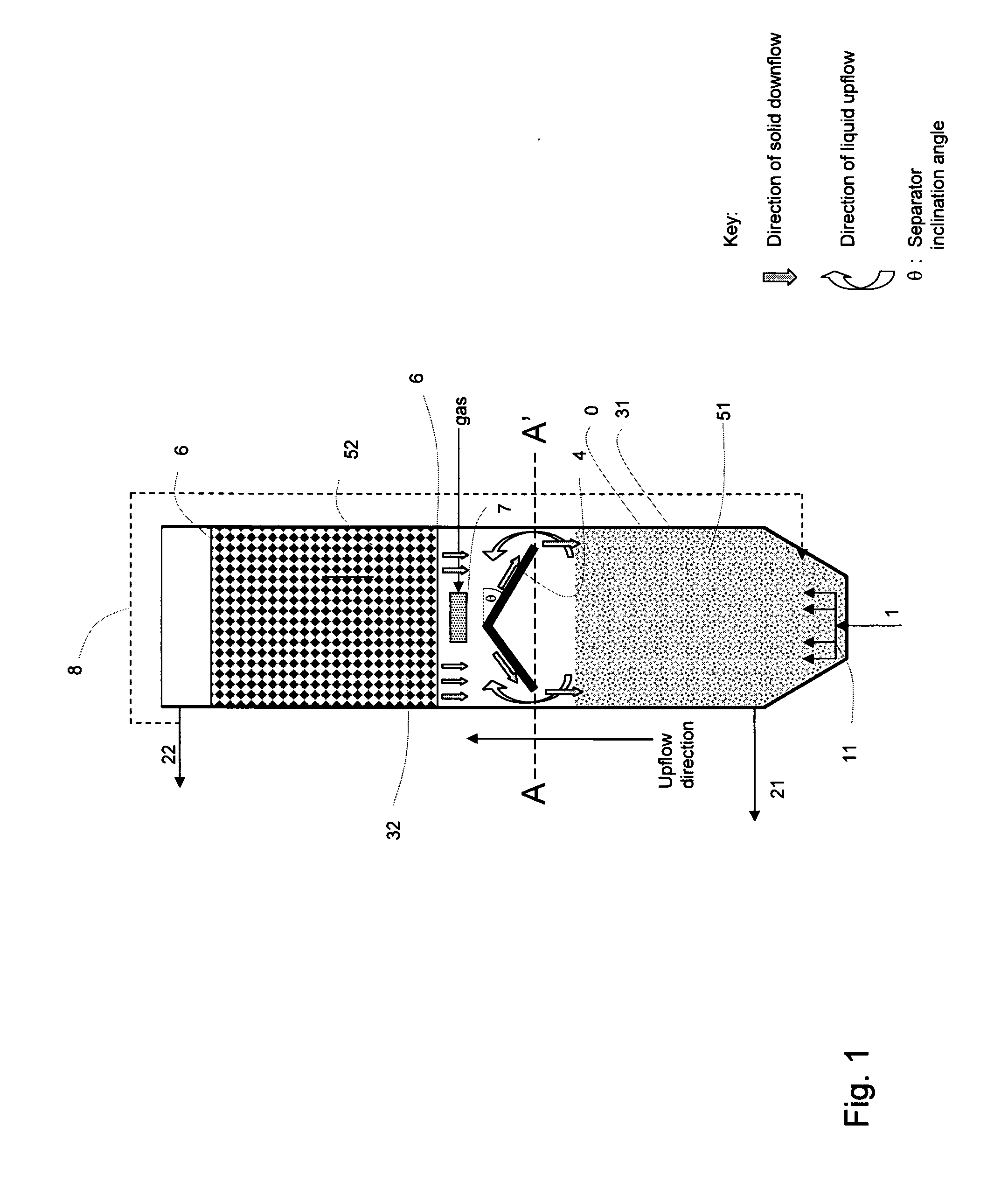

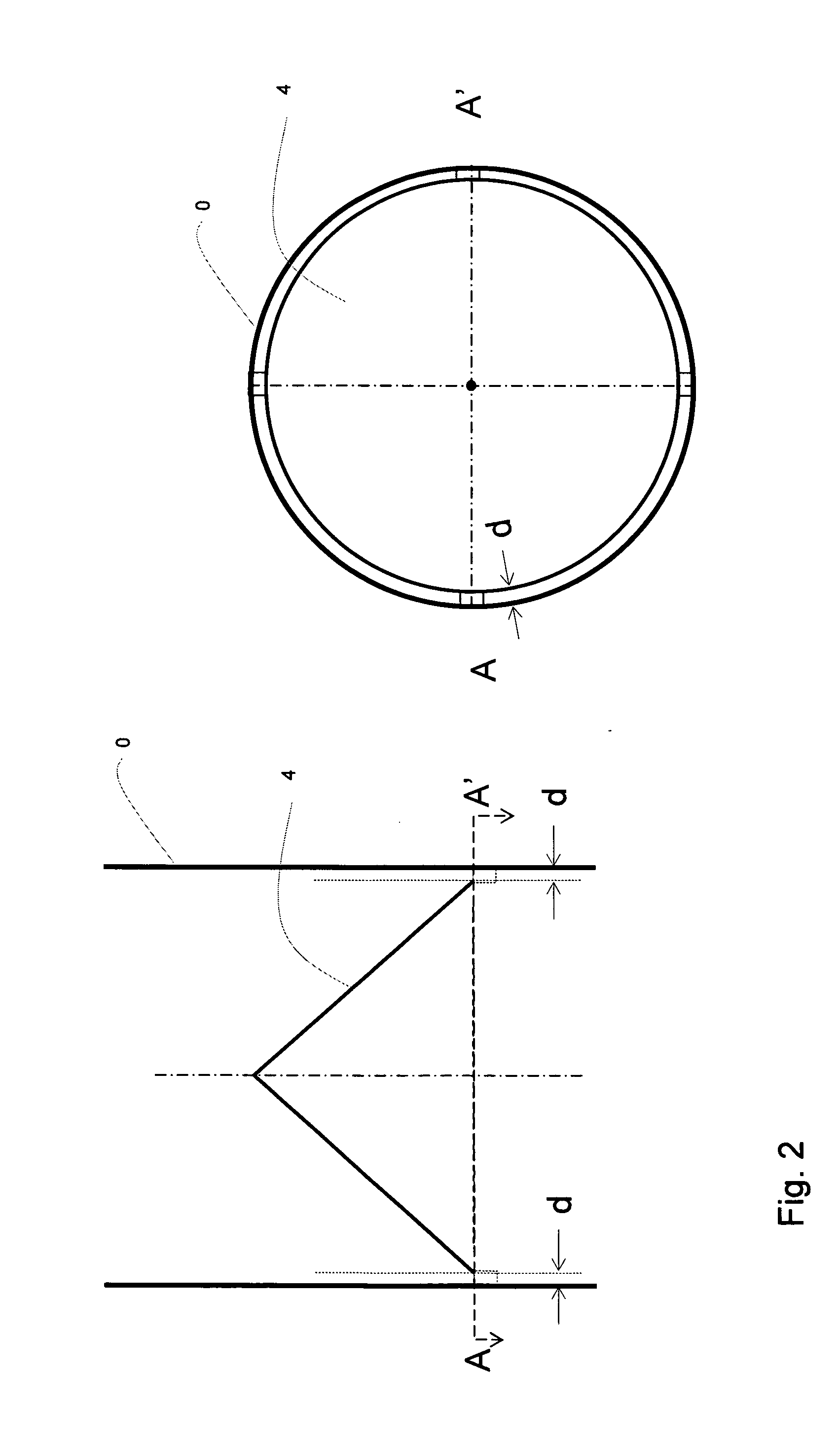

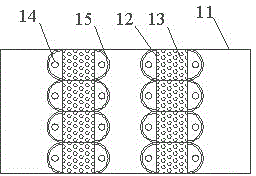

Method and device for the treatment of waste water

ActiveUS20120006744A1High solid contentReduce amountTreatment using aerobic processesTreatment with aerobic and anaerobic processesReaction zoneHydrodynamic separator

The invention relates to a reactor for treatment of waste water for being subject to both anoxic / anaerobic and aerobic treatment within one single reactor volume. The anoxic / anaerobic reaction zone is separated from the aerobic reaction zone by a separator which also works as a hydrodynamic separator between the two reaction zones. The reactor makes it possible that the effluent water has a lower proportion of suspended solids and also that it produces less sludge than reactors of comparison. The reactor is further more energy efficient than prior art reactors. Several reactors according to the invention may be arranged in parallel so as for the inlet waste water may be treated in a modular way, and thus allowing the maintenance of the units to be facilitated.

Owner:BIOWATER TECH AS

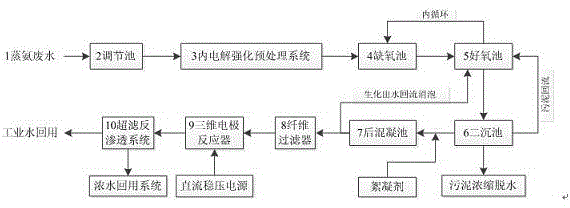

Advanced treatment and zero emission process for coking wastewater

ActiveCN104016547AReduce processingImprove BOD/COD valueMultistage water/sewage treatmentElectrolysisUltrafiltration

The invention relates to an advanced treatment and zero emission process for coking wastewater. The process comprises the following steps: performing ammonia stilling and dephenolizing on the coking wastewater, allowing the treated coking wastewater to enter a regulation pond, conveying the wastewater to an inner electrolysis intensified pretreatment system by using a pump, wherein the inner electrolysis intensified pretreatment system forms an anaerobic biofilter through iron carbon inner electrolysis fillers, and carrying out an iron carbon inner electrolysis reaction and a biological anaerobic reaction; and allowing the wastewater to sequentially enter an anoxic pool and an aerobic pool for carrying out an A / O biological reaction, then allowing the wastewater to enter a secondary sedimentation tank and a later coagulating basin, and further performing advanced treatment on the wastewater in a three-dimensional electrode reactor and an ultrafiltration reverse osmosis treatment system. The coked reverse osmosis concentrated water is treated in a concentrated water recycling system, and zero emission of the coking wastewater is achieved. The process has the aims that dilution water is not added in the conventional coking wastewater treatment process, the coking wastewater subjected to biochemical treatment is subjected to advanced treatment for recycling, and reduction, harmlessness and recycling of the coking wastewater are realized.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Integrated urban waste water treating apparatus and process

ActiveCN1579967AEasy to removeTo achieve the purpose of phosphorus removalMultistage water/sewage treatmentFlocculationElectrolysis

The invention discloses equipment of processing incorporate urban sewage and its technics. The equipment is made of armor plate. It includes internal electrolysis reaction area, machine-adding mixing system, helix flocculation depressed area and biolobical reaction area. Sewage can reach GB8978-1996 discharging standard through internal electrolysis reaction, flocculating settling (to remove phosphor), aerobic biological reaction, anaerobic reaction and filtration. Adopting incorporate treatment technics, the invention has a little floor space, low investment and a good effect. It adapts to urban subzones, blocks in villages and towns and micromidi companies such as urban diet, food processing and abattoir.

Owner:广西国宏智鸿环保科技集团股份有限公司

Pharmaceutical wastewater advanced treatment system

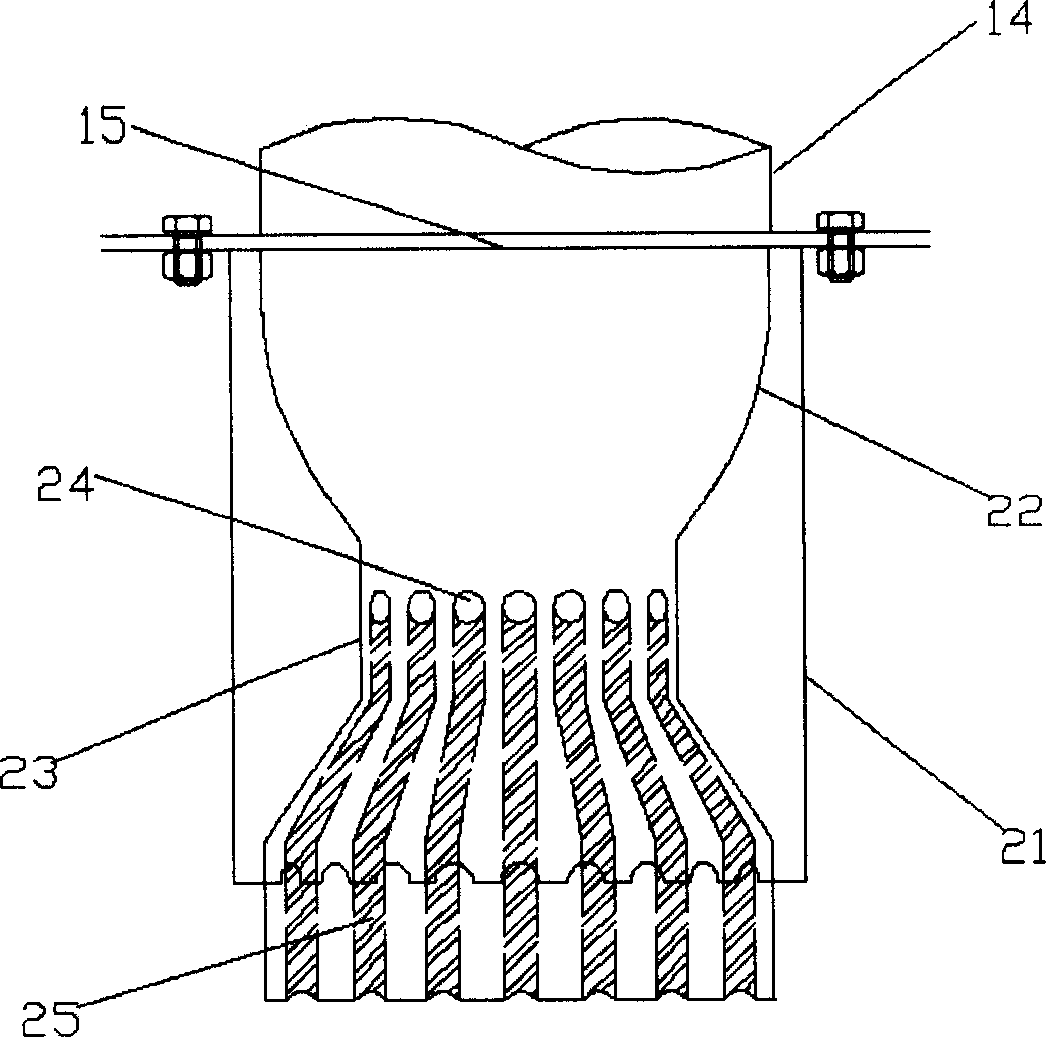

ActiveCN104773919AEasy to handleRealize resourcesMultistage water/sewage treatmentAir blowerPrecipitation

The invention relates to a pharmaceutical wastewater advanced treatment system. The pharmaceutical wastewater advanced treatment system comprises a wastewater regulating tank, a coagulative precipitation tank, an ozone oxidation floatation tank, a packed-type anoxic / anaerobic reaction tank, an aerobiotic contact oxidation tank, a secondary sedimentation tank, an electrolytic tank, a countercurrent type biological aerated filter and a clear water tank, wherein the coagulative precipitation tank comprises a stirring mixing zone and a precipitation zone, the ozone oxidation floatation tank comprises a mixing zone and a separation zone, the packed-type anoxic / anaerobic reaction tank is divided into a facultative anaerobic section, an anoxic section and an anaerobic section by baffle plates, the aerobiotic contact oxidation tank is provided with a water inlet pipe and a water distribution triangle pyramid, an aeration regulation control system is arranged at the lower part of the water distribution triangle pyramid and comprises an aeration tray, an air blower and a dissolved oxygen measurement regulation control device, the electrolytic tank is divided into a left compartment and a right compartment which are respectively a positive electrode compartment and a negative electrode compartment, the bottoms of the positive electrode compartment and the negative electrode compartment are communicated, the middle upper parts of the positive electrode compartment and the negative electrode compartment are separated by baffles, and the positive electrode compartment and the negative electrode compartment are respectively provided with a positive electrode plate and a negative electrode plate, and the countercurrent type biological aerated filter comprises a downstream zone, an upstream zone and a sludge zone.

Owner:如东文园投资开发有限公司

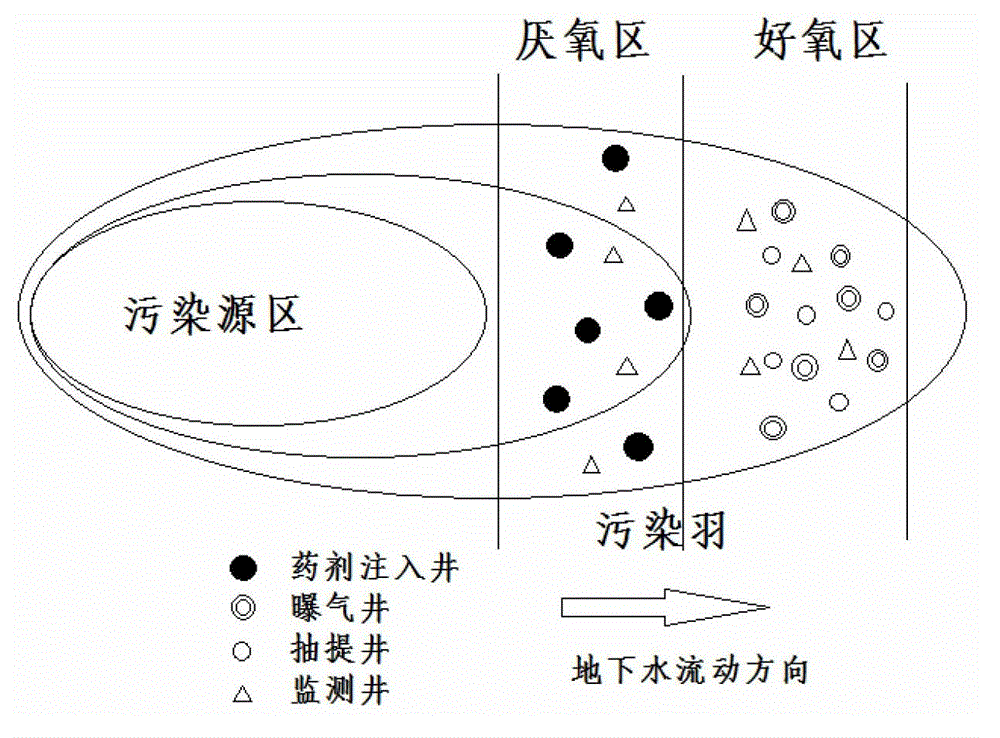

Method for in-situ bioremediation of pollution caused by chlorohydrocarbon of underwater

InactiveCN102976490AReliable in situ repairMaintain securityWater contaminantsTreatment with aerobic and anaerobic processesElectron donorIn situ bioremediation

The invention discloses a method for in-situ bioremediation of pollution caused by chlorohydrocarbon of underwater, which specifically comprises a coupling process of anaerobic reductive dechlorination and aerobiotic oxydative degradation. An anaerobic reaction area and an aerobiotic reaction area are established in the front and back of a chlorohydrocarbon pollution area along the flowing direction of underwater in a zone of saturation. Poly-chlorohydrocarbon (trichloro or tetrachloro) in the anaerobic reaction area is quickly reduced and dechlorinated to low chlorohydrocarbon (monochloro or bichloro), the low chlorohydrocarbon is transferred to the aerobiotic reaction area and oxidized and degraded to products such as carbon dioxide. The anaerobic reaction area is realized by providing electron donor materials, a deoxidant and a reducer through the injection of an injection well, while the aerobiotic area is realized by aeration toward underground water.

Owner:TIANJIN ECOLOGY CITY ENVIRONMENTAL PROTECTION

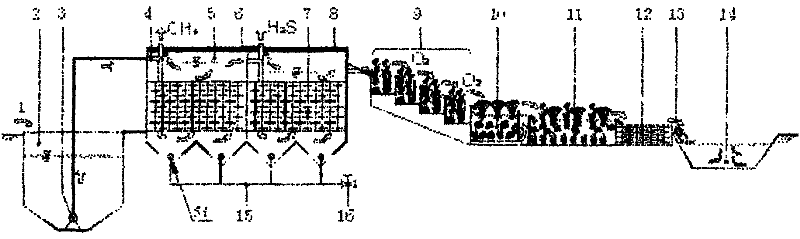

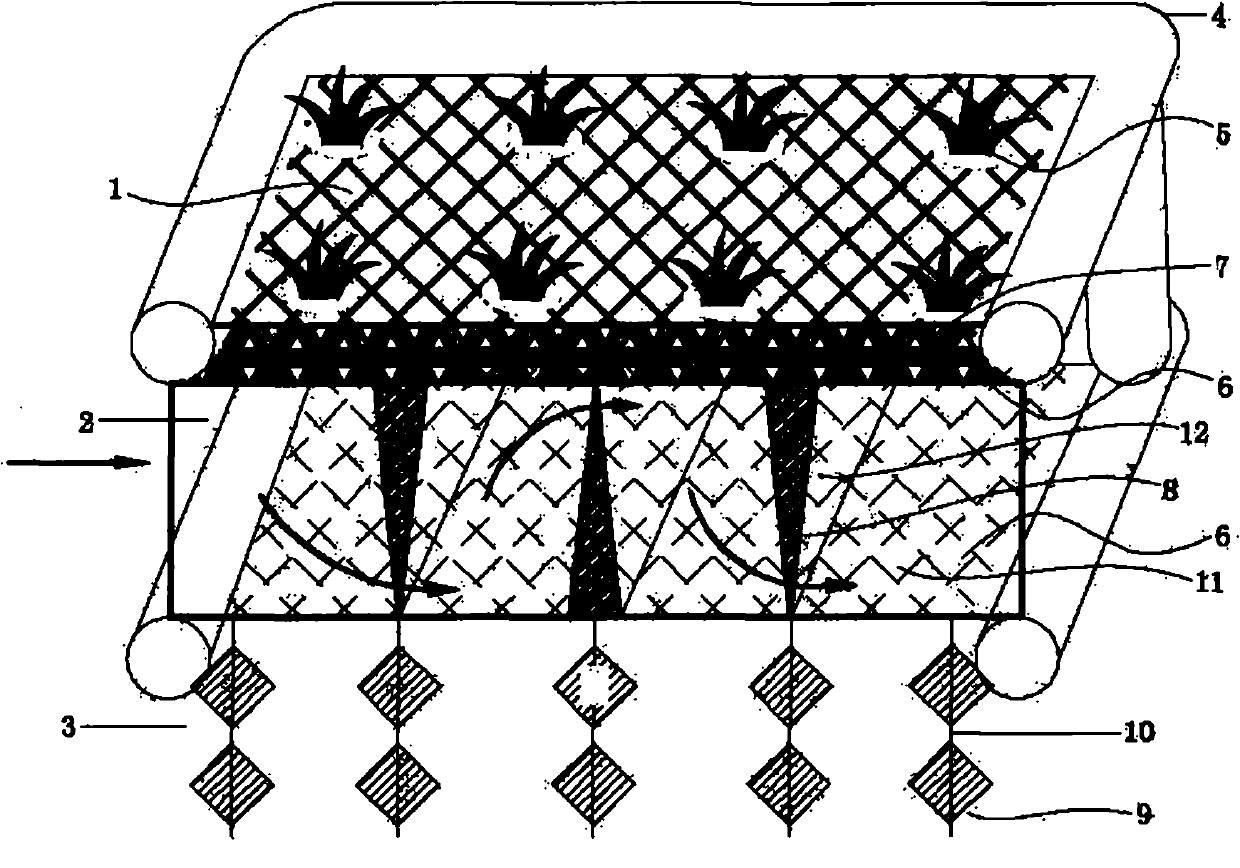

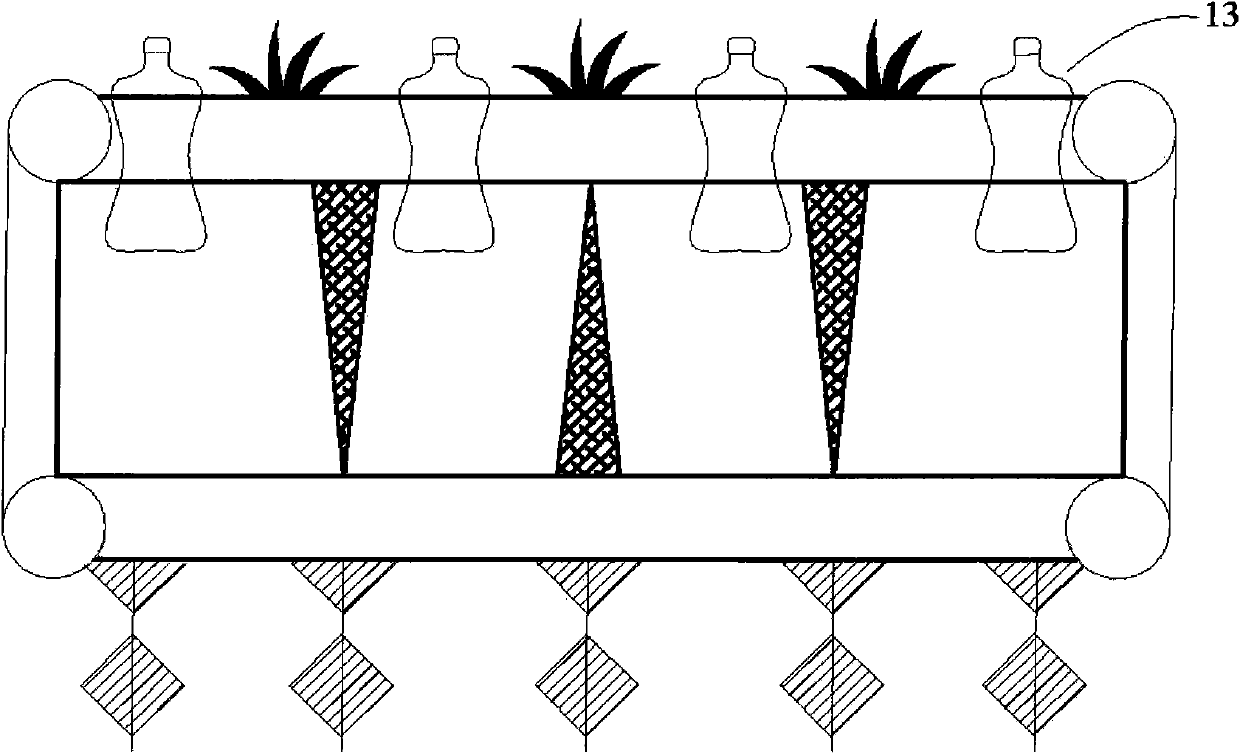

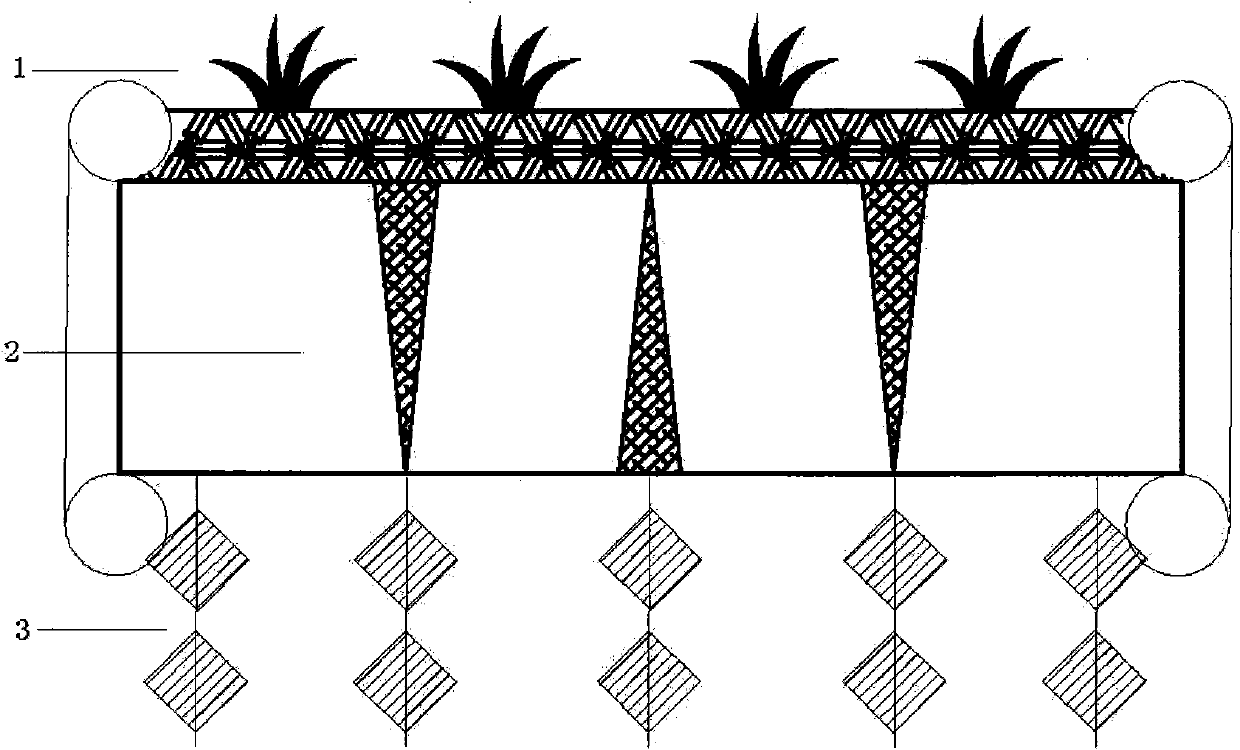

Automatic water oxygen-rich composite floating bed for strengthening biological carbon and phosphorous removal effect

InactiveCN101817591AOxygen enrichment achievedImprove self-cleaning functionTreatment with aerobic and anaerobic processesSupport matrixNitrogen

The invention relates to a method or a process for treating polluted water purification. An automatic water oxygen-rich composite floating bed for strengthening biological carbon and phosphorous removal effect is characterized by comprising a plant absorption and utilization unit (1), an automatic water oxygen-rich multistage aerobic-anaerobic reaction unit (2), a microbial film-forming reinforcement unit (3) and a framework (4); stainless steel wire gauzes (6) are fixed on the top, the bottom and the four sides of the framework (4); the plant absorption and utilization unit (1) consists of a support matrix (7) arranged on the top of the framework and a floating bed plant (5); and the floating bed converts the horizontal water flow passing through the automatic water oxygen-rich multistage aerobic-anaerobic reaction unit into N-shaped water flow so as to realize oxygen enrichment of water in an aerobic area on the middle layer of the floating bed and promote the self-cleaning function of the water of the middle layer.

Owner:HOHAI UNIV

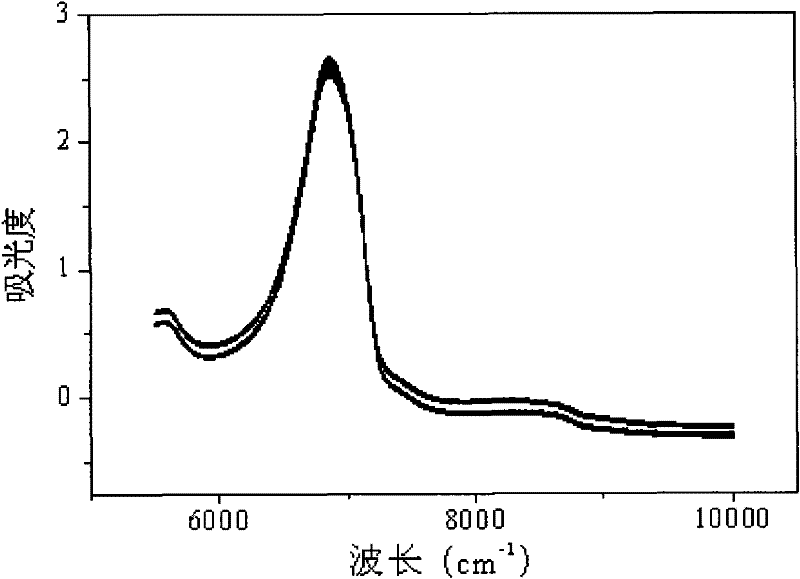

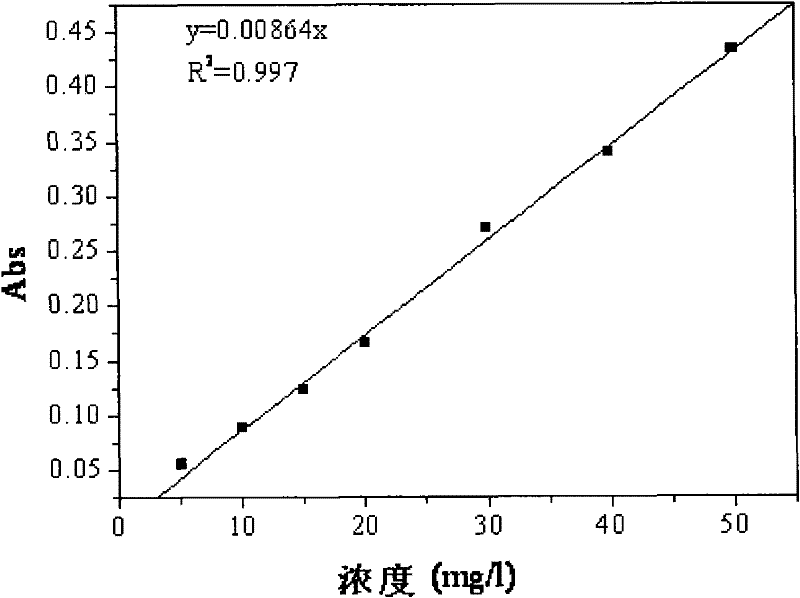

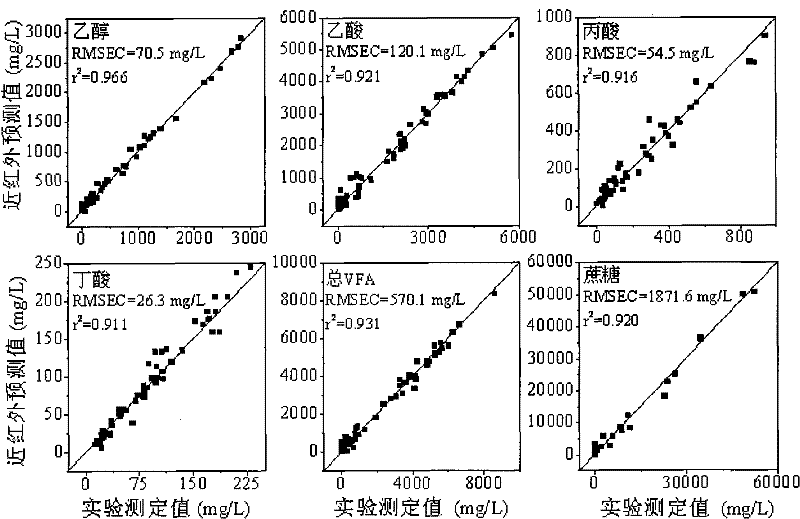

Method for measuring content of substance in process of anaerobic fermentation

InactiveCN102346136ARapid determinationSave analysis timePreparing sample for investigationBiochemistry apparatusInfraredMultivariate calibration

The invention discloses a method for measuring the content of substance in a process of anaerobic fermentation, comprising the steps of: 1) scanning fermentation liquor in the process of anaerobic fermentation by a near-infrared spectrometer, and obtaining a near-infrared spectrum signal; 2) measuring the content of the substance to be measured in the fermentation liquor of the step 1) by the existing technology; 3) building a near-infrared spectrum multivariate calibration model about the near-infrared spectrum signal and the content of the substance to be measured; 4) scanning the fermentation liquor in the process of the anaerobic fermentation by the near-infrared spectrometer again, and obtaining another near-infrared spectrum signal; and 5) obtaining the content of the substance in the process of the anaerobic fermentation according to the near-infrared spectrum multivariate calibration model and the near-infrared spectrum signal obtained in the step 4). After the method disclosed by the invention is adopted, the simple pretreatment is only needed to be carried out for a sample; and compared with the traditional method, a great deal of analysis time and expense can be saved, so that a good tool is provided for monitoring the fermentation process of anaerobic reaction.

Owner:UNIV OF SCI & TECH OF CHINA

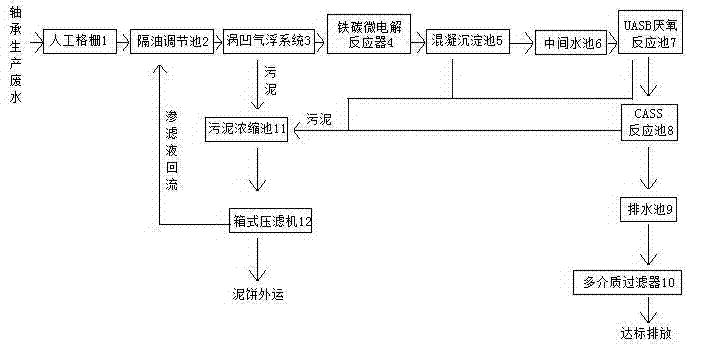

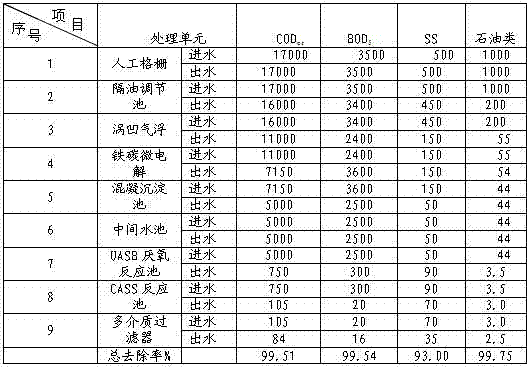

Treatment process for bearing production wastewater

InactiveCN103613247ASolve the bloat problemEasy to adjust working conditionsFatty/oily/floating substances removal devicesMultistage water/sewage treatmentEcological environmentElectrolysis

The invention discloses a treatment process for bearing production wastewater. The treatment process comprises the following steps: firstly, enabling bearing production wastewater to enter an oil-separation adjusting tank; separating floating oil in the wastewater and agitating uniformly; then lifting the wastewater into a cavitation air floatation system to remove suspension matters and petroleum in the wastewater; conveying the wastewater treated by the cavitation air floatation system into an iron-carbon micro-electrolysis reactor and carrying out a Fenton reagent and iron-carbon micro-electrolysis combined oxidation reaction to reduce chemical oxygen demand and improve the ratio value of biochemical oxygen demand / chemical oxygen demand of the wastewater; conveying the wastewater reacted in the iron-carbon micro-electrolysis reactor into a coagulation precipitation tank, adjusting the pH (Potential of Hydrogen) and carrying out a coagulation and flocculation reaction; enabling reacted liquid supernatant to flow into a middle water pond to sequentially enter a UASB (Up-flow Anaerobic Sludge Bed / Blanket) anaerobic reaction tank, a CASS (Cyclic Activated Sludge System) reaction tank and a water discharging tank and filtering by a multi-medium filter; discharging after the water reaches standards. The treatment process is simple in management and good in wastewater treatment effect; a sludge expansion problem which usually and easily occurs in a traditional active sludge method is overcome; the water can be discharged after the water quality reaches the standards and the treatment process is good for protecting the ecological environment.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

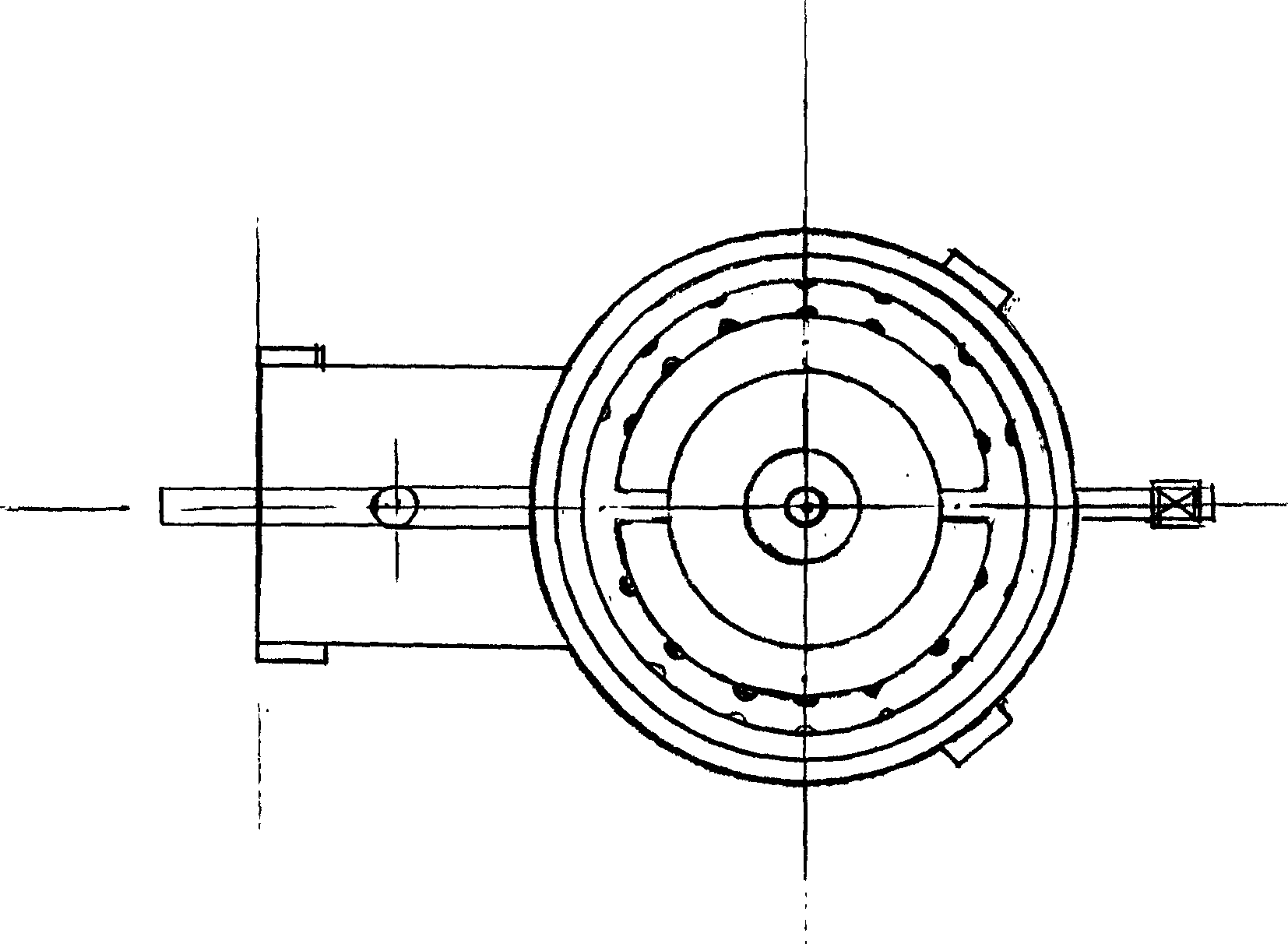

Integrated efficient autotrophic nitrogen removal reactor

ActiveCN104045156AClosely connectedSmall footprintTreatment with aerobic and anaerobic processesNitrogen removalThree-phase

The invention discloses an integrated efficient autotrophic nitrogen removal reactor. The reactor comprises an inner barrel and an outer barrel which are coaxially arranged, wherein a three-phase separator and a horn barrel which is tightly connected with an expanding part of the diameter at the upper part of the wall of the outer barrel are coaxially mounted at the upper part of the inner barrel in a sleeving manner; a space formed by the inner barrel and the outer barrel is divided into an anaerobic zone and a precipitating zone by utilizing the horn barrel; the inner barrel is taken as an aerobic zone; an annular overflow weir used for isolating the precipitating zone and the anaerobic zone is arranged on the top surface of the inner barrel; short-range nitrification sludge is inoculated in the aerobic reaction zone; a spiral micropore aeration pipe is arranged in the aerobic reaction zone; anaerobic ammonia oxidation sludge is inoculated in the anaerobic reaction zone; granule-state bamboo charcoal fillers are added into the anaerobic reaction zone to serve as a sludge carrier. According to the reactor, the individual culturing of different functional microorganisms in the single reactor is realized, so that the key operation requirements of partial nitrification and anaerobic ammonia oxidation processes can be satisfied; the efficient and stable running of the reactor is ensured. Thus, the reactor disclosed by the invention is suitable for treating wastewater with a high ammonia-nitrogen ratio and a low carbon-nitrogen ratio.

Owner:ZHEJIANG UNIV

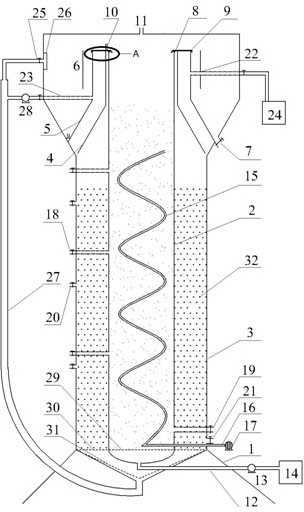

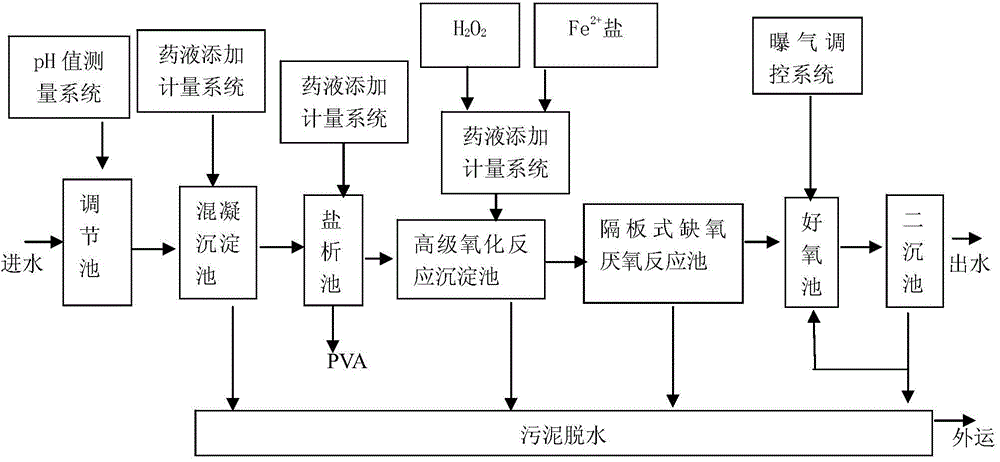

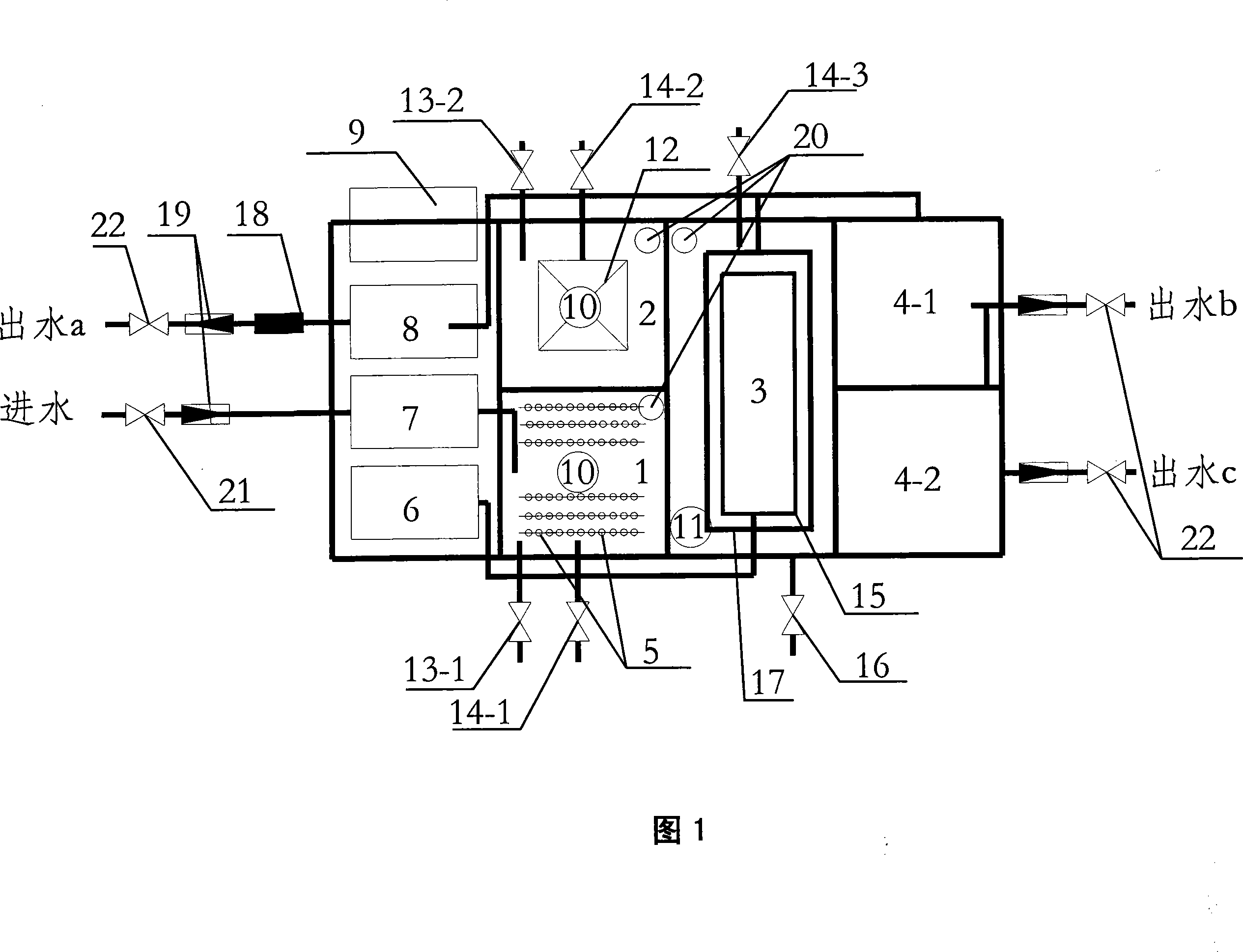

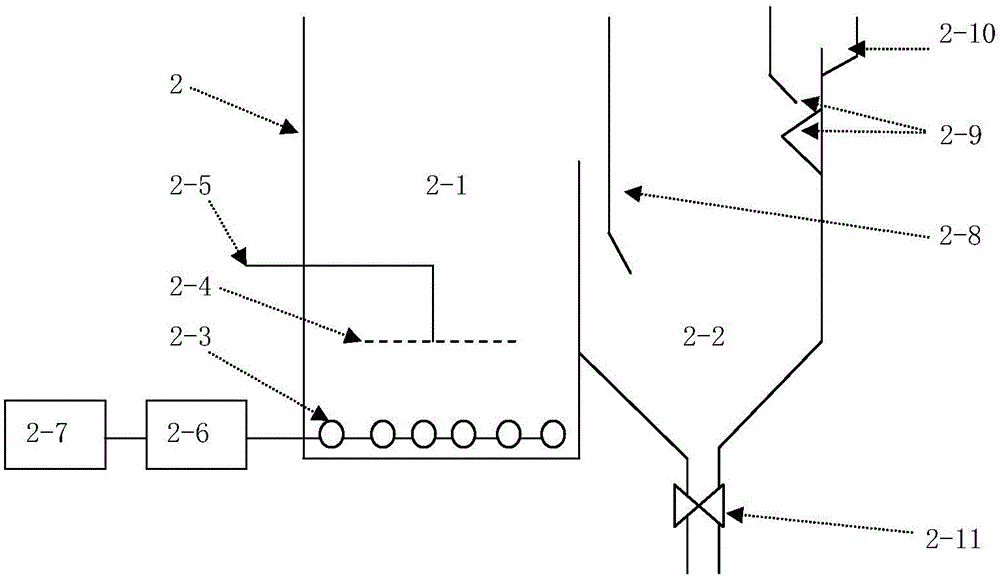

Method for processing high-density PVA-containing desizing wastewater and device thereof

ActiveCN103819050AEasy to handleSimple structureMultistage water/sewage treatmentHigh densityWater volume

The invention relates to a method for processing high-density PVA-containing desinzing wastewater and a device thereof. The device comprises a wastewater regulating tank, a coagulation sedimentation tank, a salting-out tank, an advanced oxidation reaction sedimentation tank, a diaphragm type hypoxic-anaerobic reaction tank, an aerobic tank, and a secondary sedimentation tank; the coagulation sedimentation tank, the salting-out tank, and the advanced oxidation reaction sedimentation tank all comprise a mixing and stirring area and a sedimentation area, the diaphragm type hypoxic-anaerobic reaction tank comprises a facultative segment, an anoxic segment, and an anaerobic segment which are formed by separating the diaphragm type hypoxic-anaerobic reaction tank with baffle plates; the water volume and pH value of waste water are adjusted in the wastewater regulating tank, then the wastewater enters the coagulation sedimentation tank and is mixed with a coagulation agent to carry out reactions, then wastewater enters the salting-out tank to carry out a salting-out reaction, the pollutant is oxidized and decomposed in the advanced oxidation reaction sedimentation tank, then wastewater enters the diaphragm type hypoxic-anaerobic reaction tank and the aerobic tank to carry out hypoxic, anaerobic and aerobic reactions, then the waste water is subjected to a sedimentation treatment, and finally the wastewater is discharged when the quality of the wastewater meets standards. The device has the advantages of simple structure, low manufacture cost, and very good processing effect.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

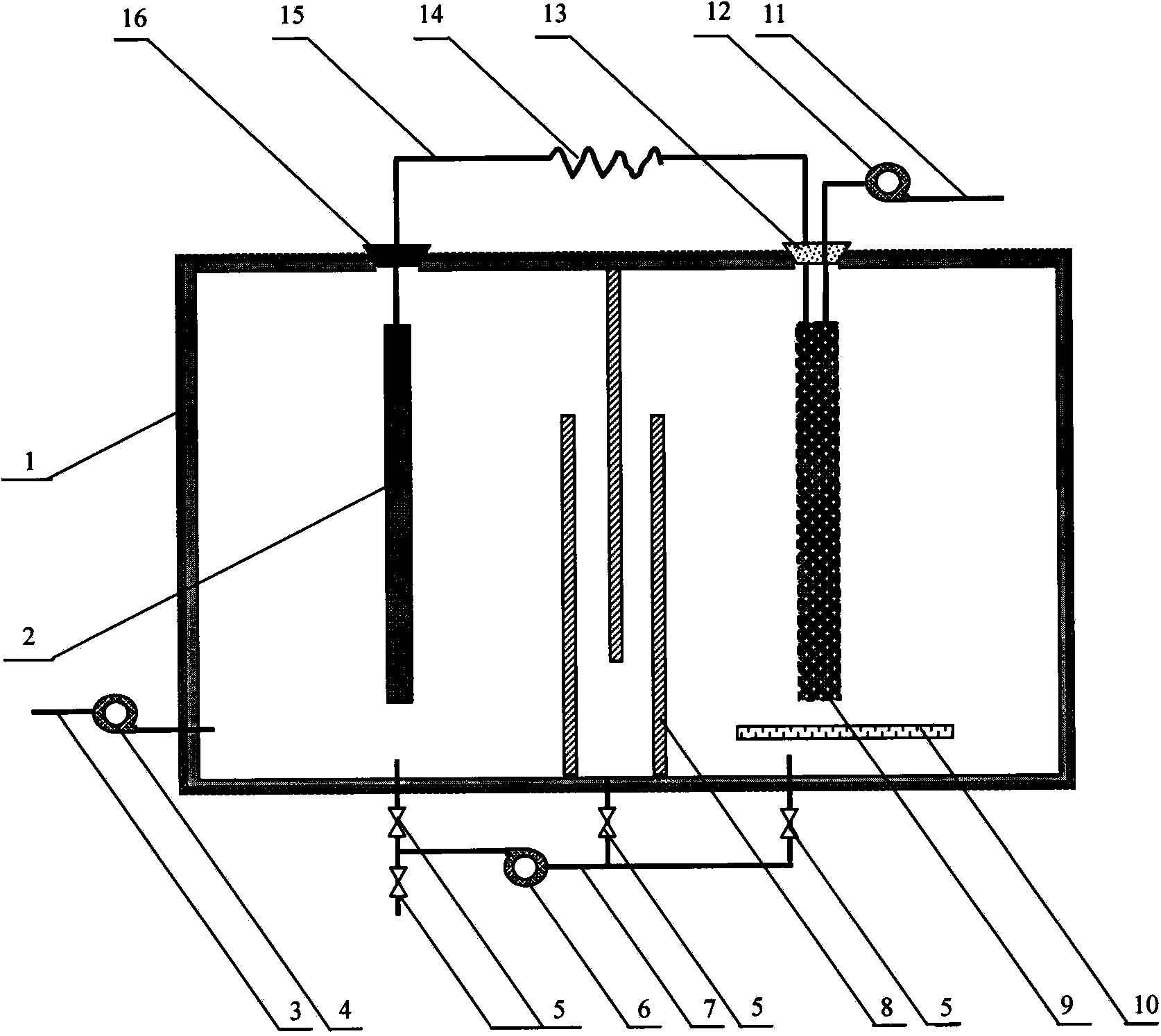

Organic wastewater treatment device coupled with low-energy-consumption membrane biological reactor of microbial fuel cell

InactiveCN103848539ALow running costReduce pollutionMultistage water/sewage treatmentWater qualityOxygen

The invention provides an organic wastewater treatment device coupled with a low-energy-consumption membrane biological reactor of a microbial fuel cell and belongs to the technical field of recycling organic wastewater resources. The invention aims to solve problems that the microbial fuel cell (MFC) is poor in outlet water quality, the membrane biological reactor (MBR) is high in energy consumption and membrane pollution is serious; according to the device disclosed by the invention, a cell body, an MFC anode and a guide plate form an anode chamber which is an anaerobic reaction region; the guide plate, the MBR membrane assembly (also an MFC cathode) and an aerator pipe form a cathode chamber which is an aerobic reaction region; the guide plate region is an anoxic reaction region; meanwhile, a baffle plate is adopted to replace a proton exchange membrane in the MFC, so that system denitrification effect is good, and construction cost is low; compared with the conventional MBR system, the organic wastewater treatment device has the advantages that energy consumption of treatment of one ton of wastewater is lowered by 30%-70%, and outlet water quality reaches grade A in pollution discharge standards (GB18918-002) of a municipal sewage treatment plant in China.

Owner:JIANGNAN UNIV

Packaging stage-type film bioreactor device for treating sewage or micro-polluted raw water

InactiveCN101186416ARealize quality water supplyFlexible and simple multi-functional areaTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater qualitySmall footprint

The invention relates to a staged membrane bioreactor device, for treating sewage or micro-polluted source water, with a water container, pertaining to the environmental protection technology field. The device consists of a half-reaction zone, an anaerobic reaction zone, an aeration reaction zone and a pure water zone. The half-reaction is communicated with the bottom of the aeration zone, the bottom of the half-reaction is provided with an empty valve, one side of the half-reaction zone has a water inlet pump, the inside of the half-reaction has an internal ring filled with stuff, and the top of the half-reaction is provided with a stirrer, and the effluent of the half-reaction automatically flows into the anaerobic reaction zone. The top of the anaerobic reaction zone is provided with a stirrer, the bottom thereof is provided with a sludge empty valve, and a sludge empty device is shaped like a horn mouth and positioned in the anaerobic reaction zone, and the top of the anaerobic reaction zone is provided with a drug feeding mouth. The bottom of the aeration reaction zone has an internal return pump, the lower part of the aeration reaction zone is provided with an aeration pipe with an air inlet positioned at one side of the aeration reaction zone, and a fan is connected to the aeration pipe through the air inlet; the top of the aeration reaction zone is provided with an overflow pipe, the bottom of the aeration reaction zone is provided with an empty valve, while the middle is provided with a membrane component. The pure water zone is divided into two units, and the inside of each unit is provided with an effluent valve. The invention has the advantages of good effluent quality, multi purposes, small land occupancy, flexible and convenient using method, and is applied to the treatment of domestic sewage and micro-polluted source water, and can widen and facilitate the application of membrane bioreactor water treatment and water resource reutilization technique.

Owner:TONGJI UNIV

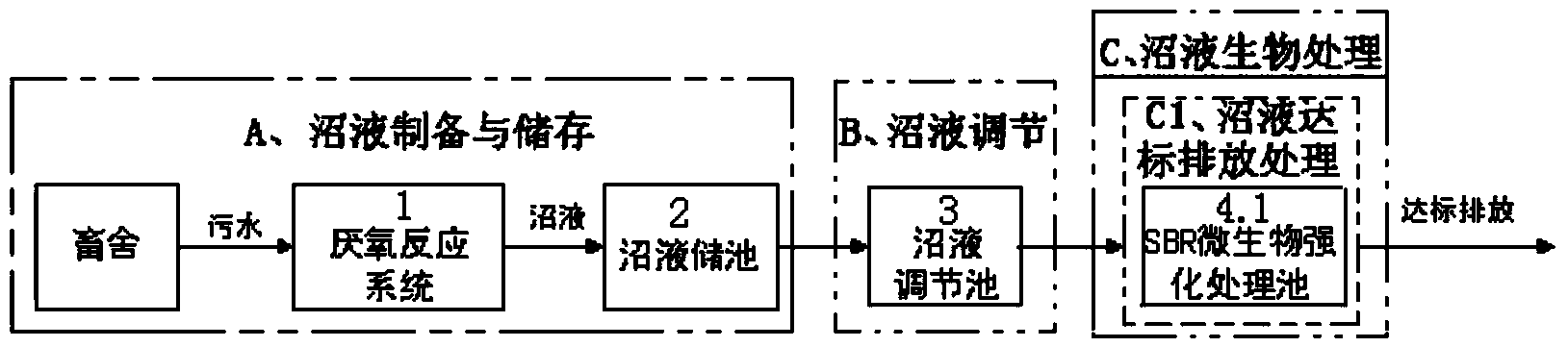

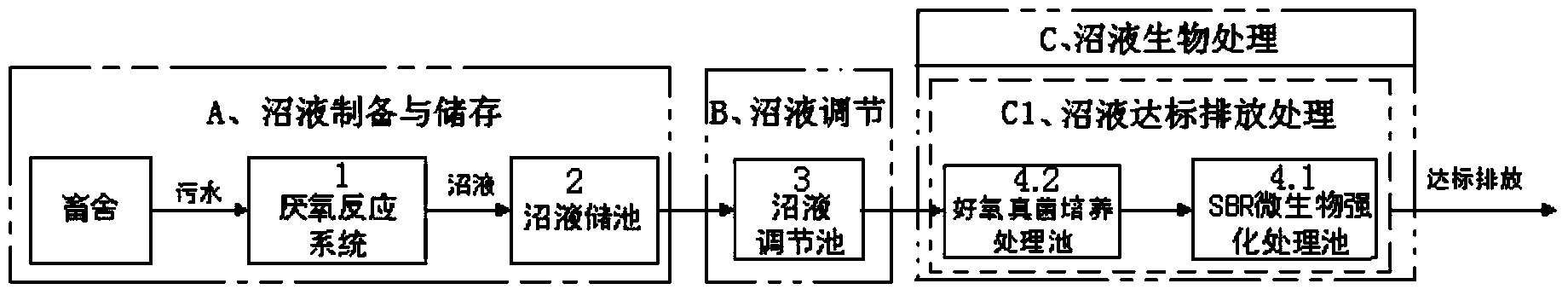

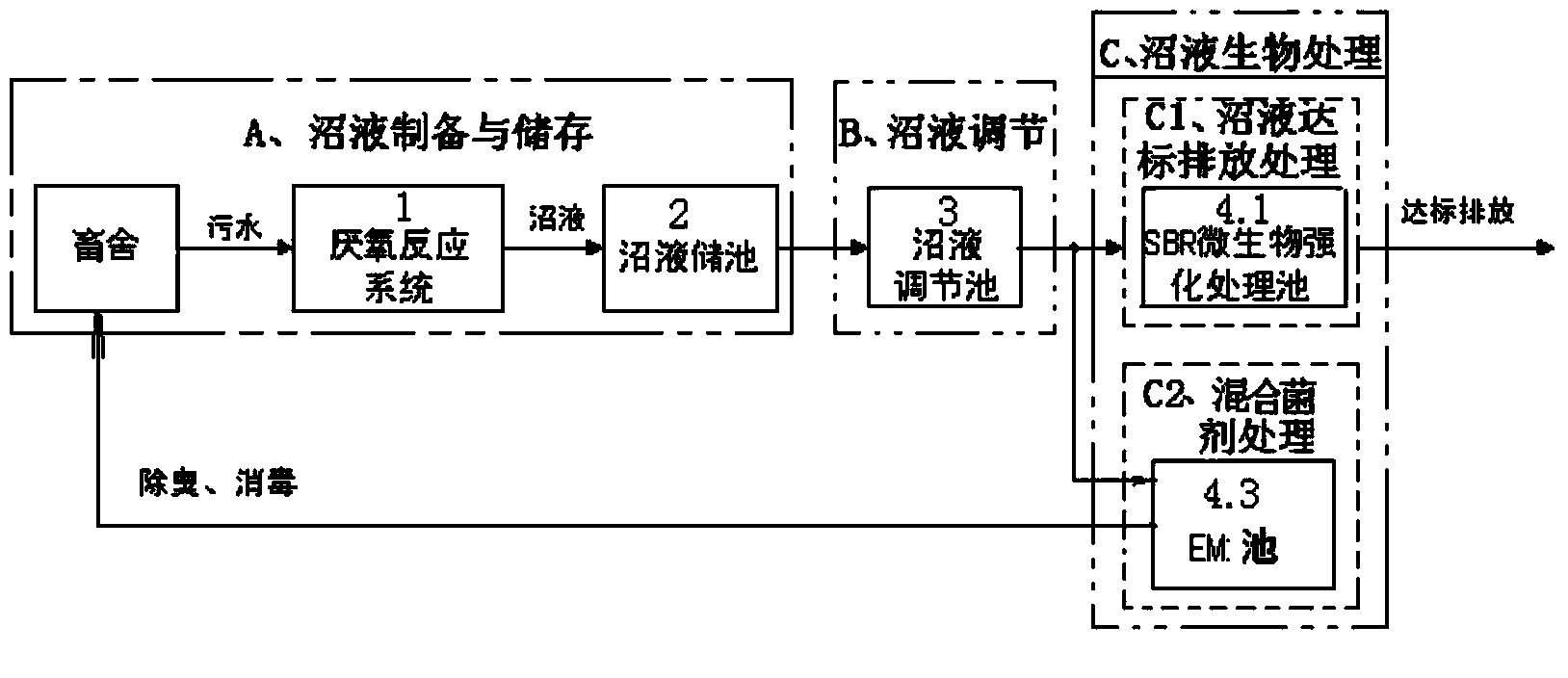

Treatment method and recycling method of livestock and poultry breeding wastewater and biogas slurry

InactiveCN103449672AMeet the yeast requirements for decolorization cultureWaste water treatment from animal husbandryMultistage water/sewage treatmentMicrobial agentLivestock

The invention relates to a treatment method and a recycling method of livestock and poultry breeding wastewater and biogas slurry. The treatment method comprises the steps of: A. preparation and storage of biogas slurry, i.e., treating livestock and poultry house wastewater by an anaerobic reaction system through a conventional approach and storing the treated wastewater in a biogas slurry tank; B. treatment of biogas slurry, i.e., conveying the biogas slurry from the biogas slurry tank into a biogas slurry adjusting tank to separate precipitation and / or remove suspended solids from the biogas slurry; and C. biological treatment of biogas slurry, i.e., discharging the biogas slurry which is treated in the biogas slurry adjusting tank and achieves standards, or treating the biogas slurry in another path by a mixed bacteria agent. The recycling method comprises the step of adding a reuse water disinfecting storage tank after the standardized discharge of biogas slurry, or at the back of a biogas slurry biological-treatment tank, connecting a branch for outputting to a by-product treatment tank. The treatment method and the recycling method have the advantages of combining a microbial agent with an aerobic treatment technology of wastewater, rapidly decomposing, decoloring and deodorizing pollutants, achieving the effects of standardized discharge, comprehensive utilization, energy conservation, discharge reduction and low cost, and being easy to popularize and apply.

Owner:湖北特微生物环保有限公司

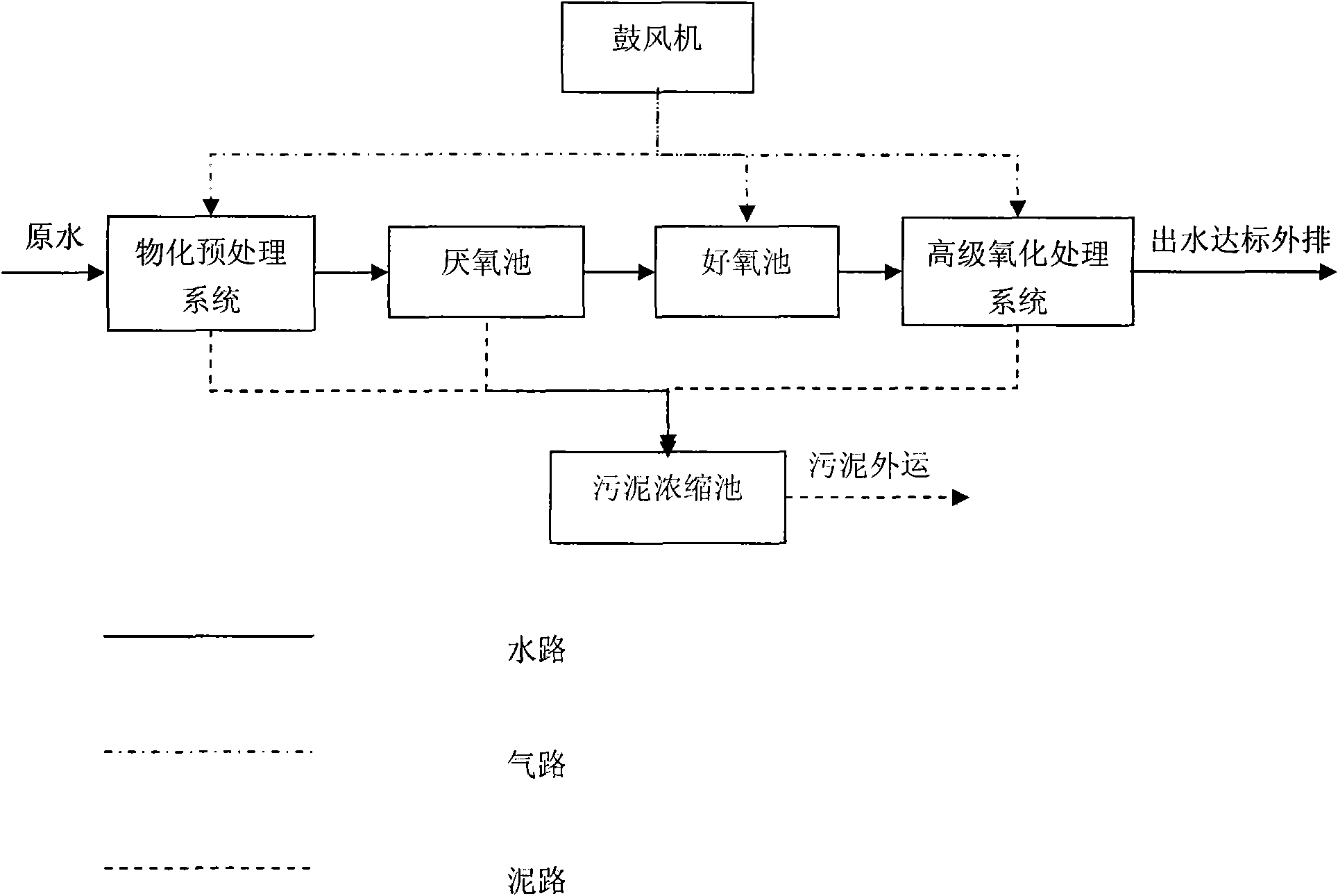

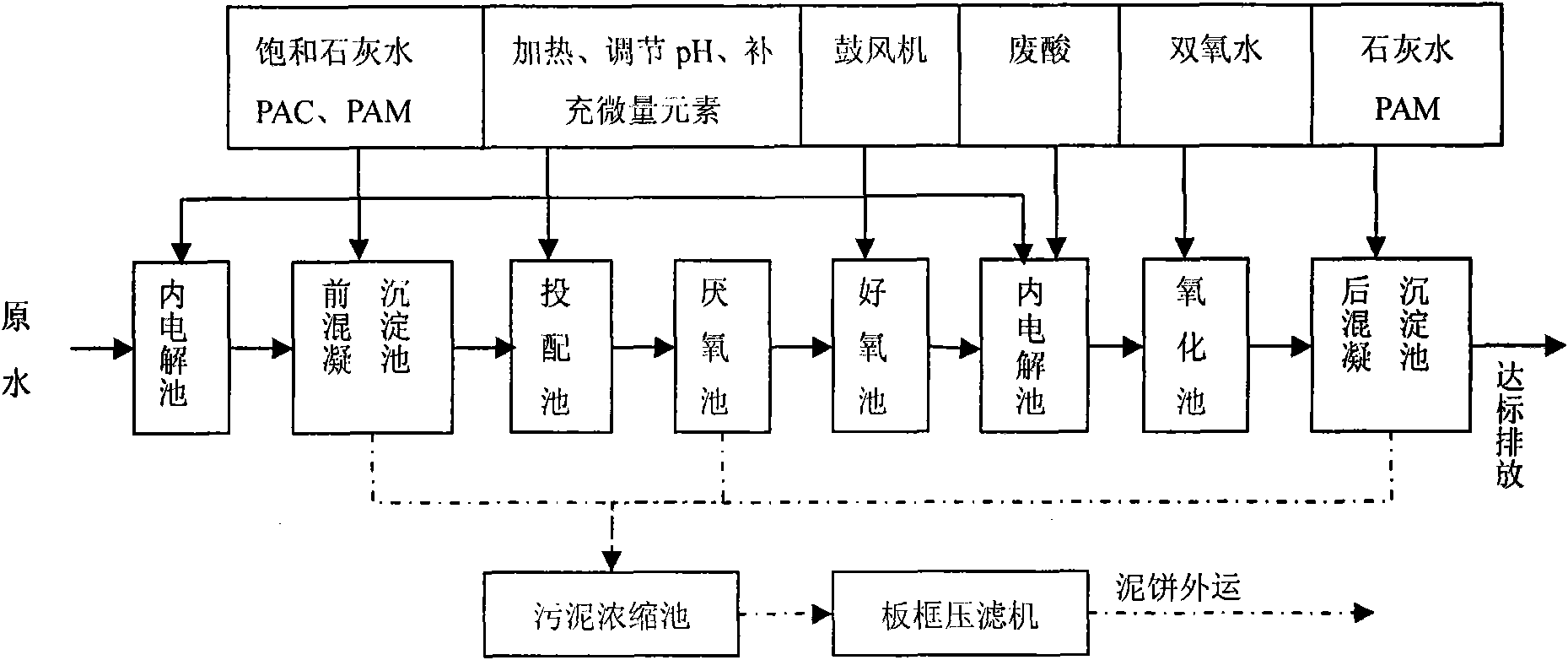

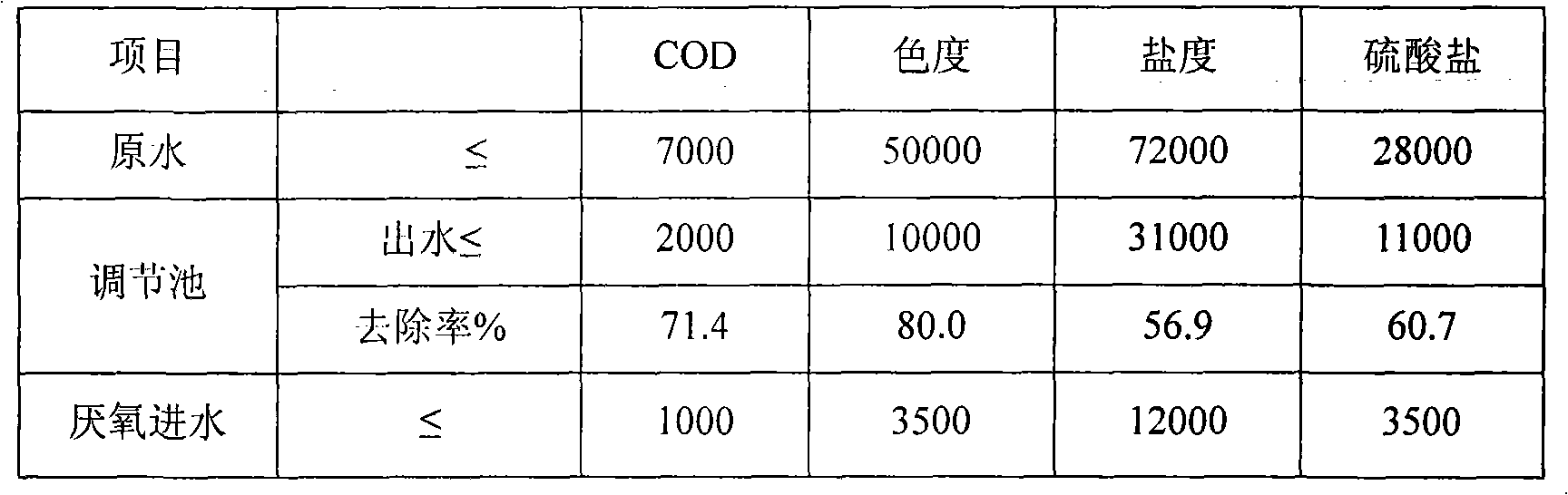

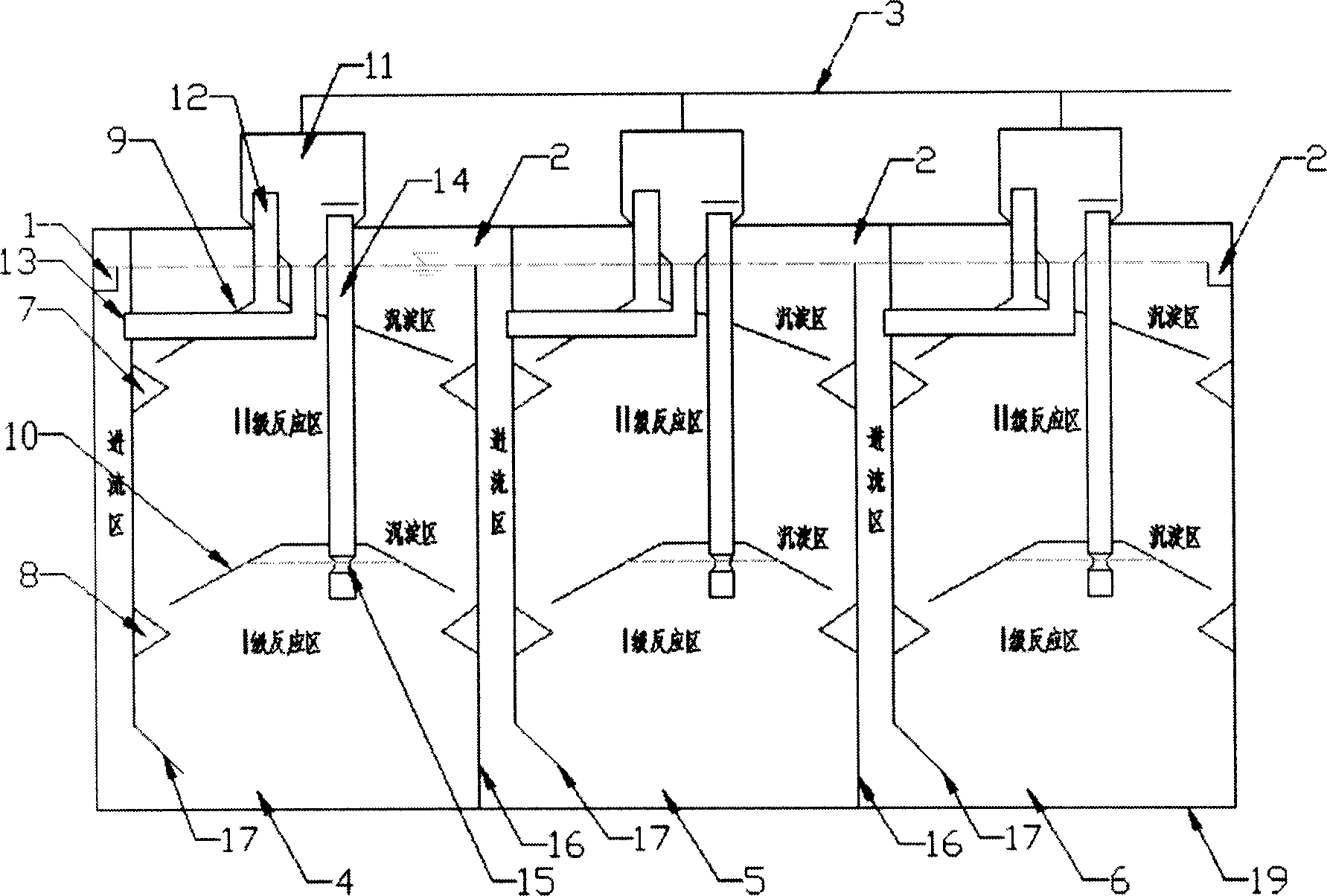

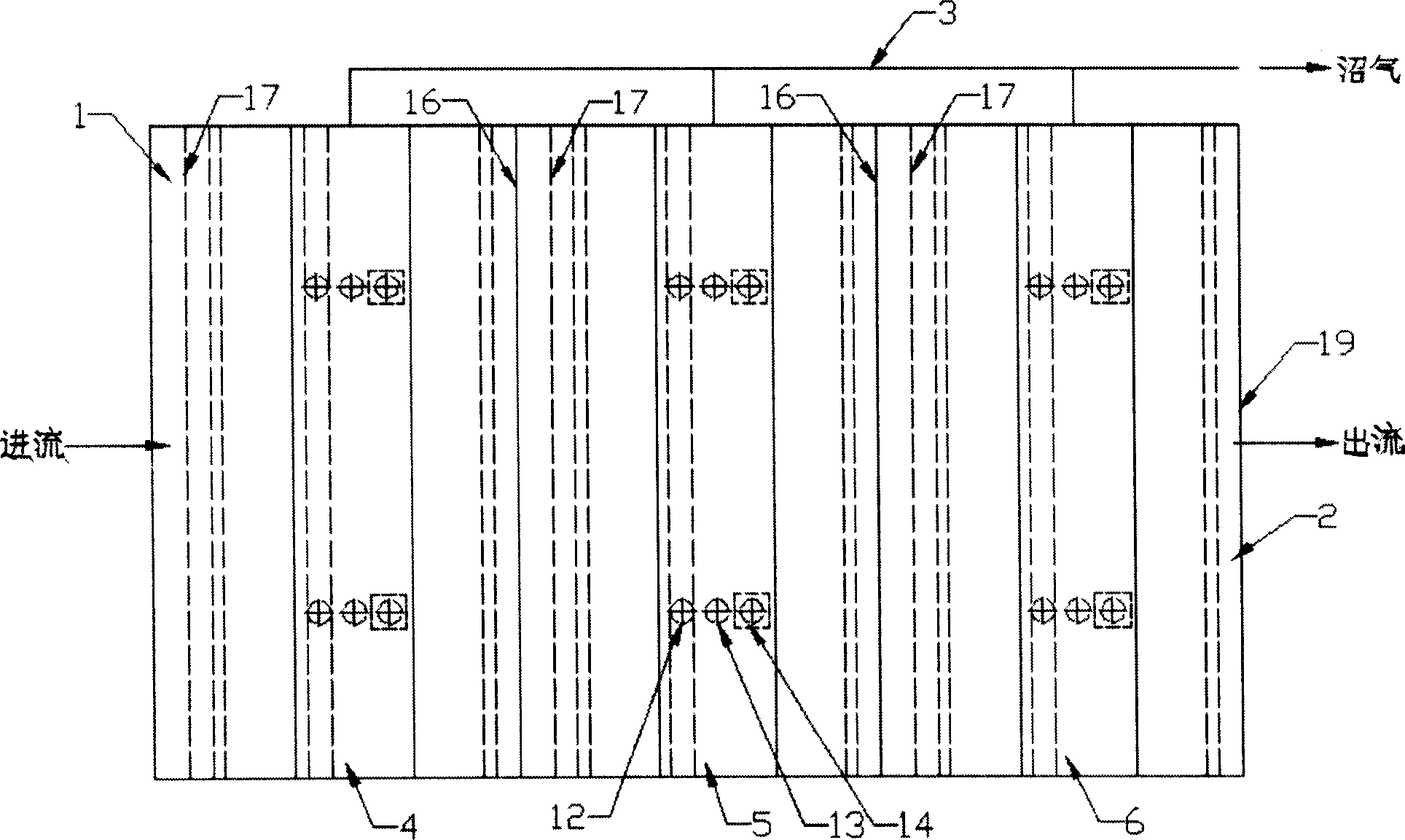

Dye waste water treatment system

InactiveCN101659500ARealize resourcesAchieve the goal of energy saving and emission reductionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationMetabolite

The invention provides a dye waste water treatment system which sequentially comprises a physico-chemical pretreatment system, an anaerobic tank, an aerobic tank and an advanced oxidation treatment system; dye waste water to be treated firstly enters into the physico-chemical pretreatment system to remove part chromaticity, sulphate and COD in the dye waste water, so as to ensure the pH, the alkalinity and the proper sulfate concentration which are needed by high-efficiency and stable running of later stage of anaerobic technique; after that, the dye waste water enters into the anaerobic tankto have anaerobic reaction and then enters the aerobic tank to have aerobic reaction; finally, the dye waste water enters into the advanced oxidation treatment system to remove the residual chromaticity and organic matter hard to degraded in the aerobic effluent as well as intermediate metabolite generated in the process of biological treatment. When being used for treating the dye waste water, especially the waste water having high salinity, sulfate, chromaticity and COD as well as higher concentration organic matter hard to degraded, the combined system has good treating effect and ensures the finally yielding water to reach the first-grade standard in GB4287-92 pollutant emission standards for textile dyeing and finishing industry.

Owner:北京盖雅技术中心有限公司

Preparation method of heterogeneous bacteria embedding particles

The invention provides a preparation method of heterogeneous bacteria embedding particles. The carrier particles can be used for embedding anaerobic bacteria in a load proportion of (1 to 2)-(1 to 3) (the weight of the bacteria to the weight of the embedding agent) and then embedding aerobic bacteria in a load proportion of (1 to 1.5)-(1 to 3) (the weight of the bacteria to the weight of the embedding agent). At 0-4 DEG C, the small particles are extruded into the solutions, such as CaCl2, acetic acid and glutaraldehyde, to be crosslinked, thus obtaining immobilized particles. Anaerobic environments are obtained inside the particles through microbial action to smoothly carry out microbial anaerobic reaction, and microbial aerobic reaction can be smoothly carried out as the particles have larger external hole and channel structures and are used for embedding aerobic microbes; therefore the composite particles can be used for carrying out anaerobic / aerobic reactions simultaneously and have better nitrogen and phosphorus removal effects. By utilizing the composite embedding particles, the wastewater treatment efficiency can be improved, the equipment volume can be reduced, the wastewater treatment process can be optimized and the microbial immobilization technology is expanded.

Owner:ZHEJIANG UNIV OF TECH

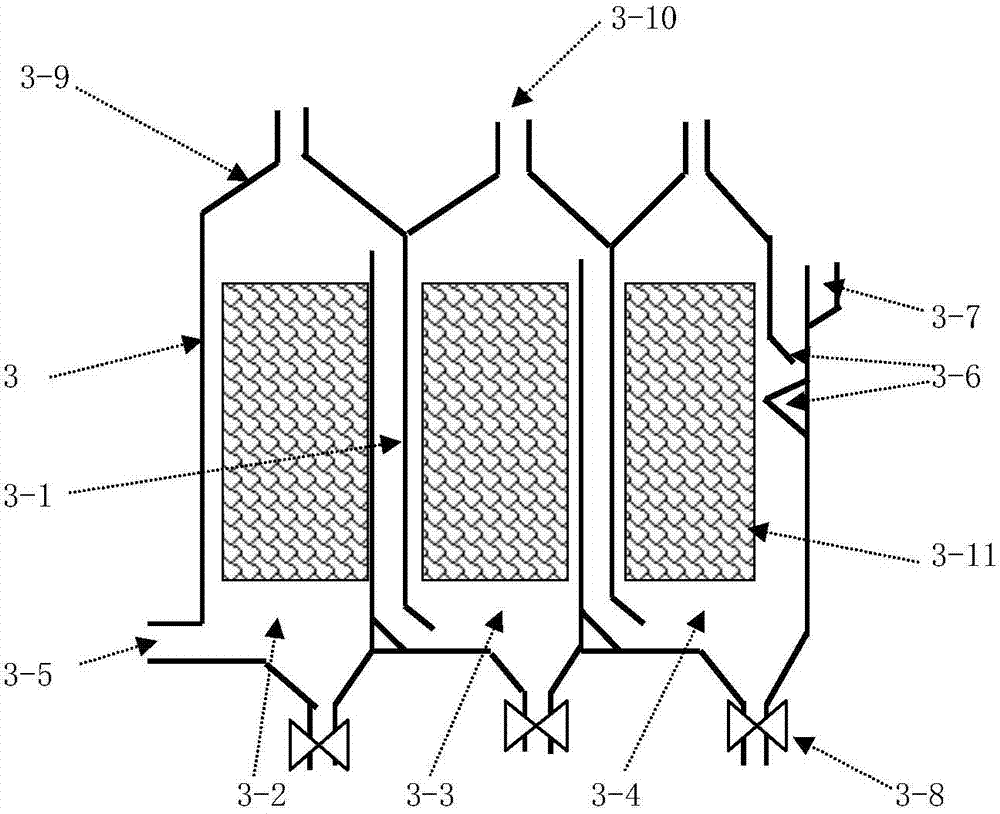

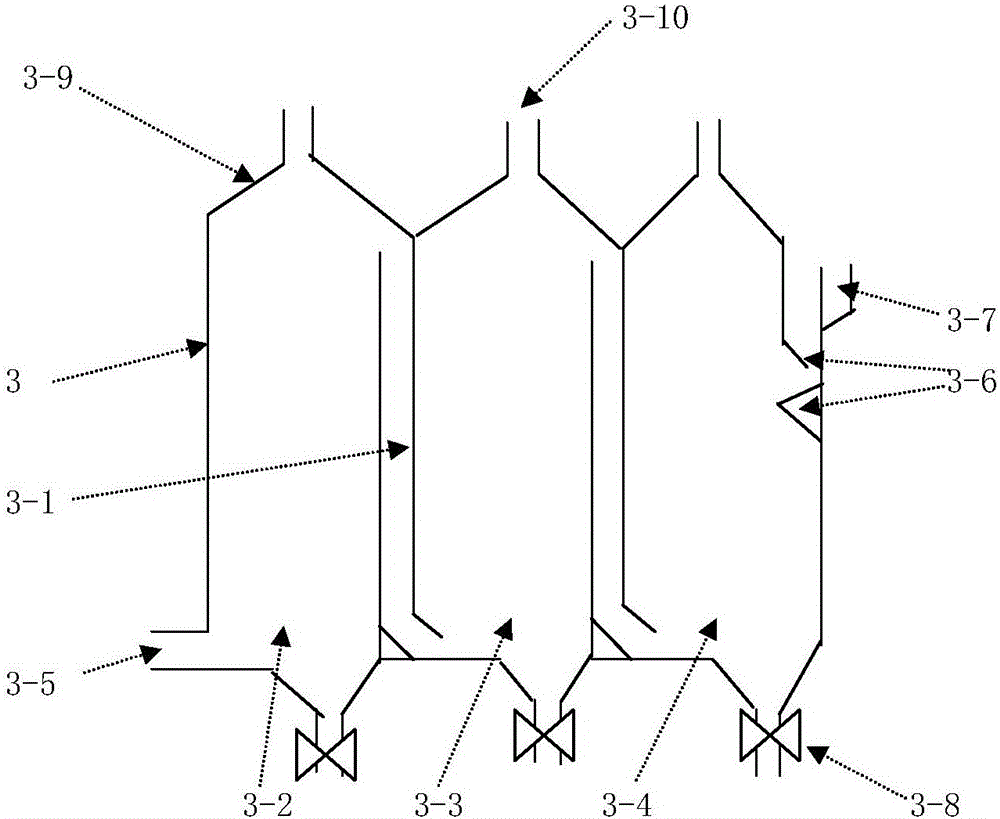

Multi-phase internal circulating anaerobic reactor

InactiveCN1803668AImproved separation propertiesHigh activityWater contaminantsWaste based fuelSeparated stateGas collecting tube

The disclosed multiphase inner cycle anaerobic reactor comprises: at least two gas-sealed inner cycle anaerobic reaction chambers separated by separator and connected in series and contained a two-stage reaction zone, an opposite gas-lift tube, a gas collecting tube, a backflow tube, gas-liquid separators parallel on one gas exhaust pipe or output respectively, and a three-phase separator; and arranging a water guide plate on the inlet of reaction chamber and a gas stripping device on bottom of the air-lift. This invention has well flow pattern, mixed liquid, well microbe separated state, and other advantages.

Owner:林知谚

Method for disposing high-salt high-polymer wastewater through Fenton oxidation and biology combined technology

ActiveCN103449685AImprove biodegradabilityReduce dosageMultistage water/sewage treatmentFiltrationOxygen

The invention provides a method for disposing high-salt high-polymer wastewater through the Fenton oxidation and biology combined technology. The disposed high-salt high-polymer wastewater is drilling wastewater. The method is characterized in that the technology comprises primary chemical oxidization, filtration, phosphorous removal, sedimentation, filtration, hydrolyzation, anaerobic processing, secondary chemical oxidization, primary aerobiotic processing and secondary aerobiotic processing. Firstly, due to the fact that the B / C ratio of the wastewater is low, primary chemical oxidization method processing is conducted on the wastewater the B / C ratio can be improved; after oxidized discharged water is filtrated, the water enters a phosphorous removal reaction pool and is deposited and filtrated again; the water with phosphorus removed enters a hydrolysis acidification pool and then enters a middle adjusting pool, and after a pH value is adjusted, the water enters an anaerobic reaction pool; secondary chemical oxidization method processing is conducted on anaerobic discharged water, the B / C ratio is improved, the water enters an aerobiotic biochemical system, and primary contact aerobiotic processing and secondary contact aerobiotic processing are conducted.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Wastewater advanced treatment system for corn processing

InactiveCN104986919ASimple structureLow costMultistage water/sewage treatmentWaste water treatment from food industryFiltrationControl system

The invention relates to a wastewater advanced treatment system for corn processing. The wastewater advanced treatment system comprises a wastewater adjustment tank, an enhanced air flotation tank, an ozonation sedimentation tank, a baffled anoxic / anaerobic reaction tank, a completely mixed aerobic tank, a secondary sedimentation tank and a multilayer aerobic activity filtration tower, wherein the enhanced air flotation tank comprises a mud and sand area, a mixing area and a separation area from bottom to top; the ozonation sedimentation tank comprises an aeration mixing area and a sedimentation area; the baffled anoxic / anaerobic reaction tank is divided by baffles into a facultative section, an anoxic section and an anaerobic section; a water inlet pipe, a water distribution cone and an aeration adjustment and control system are arranged in the completely mixed aerobic tank; wastewater enters the wastewater adjustment tank, and the adjusted wastewater enters into the enhanced air flotation tank for scum removing; the wastewater without scum enters the ozonation sedimentation tank for pollutant oxygenolysis; the wastewater subjected to pollutant oxygenolysis enters the baffled anoxic / anaerobic reaction tank and the completely mixed aerobic tank for anoxic, anaerobic and aerobic reactions; the wastewater subjected to the anoxic, anaerobic and aerobic reactions enters the multilayer aerobic activity filtration tower for filtration, and then the filtered wastewater can be recycled.

Owner:CHANGZHOU UNIV

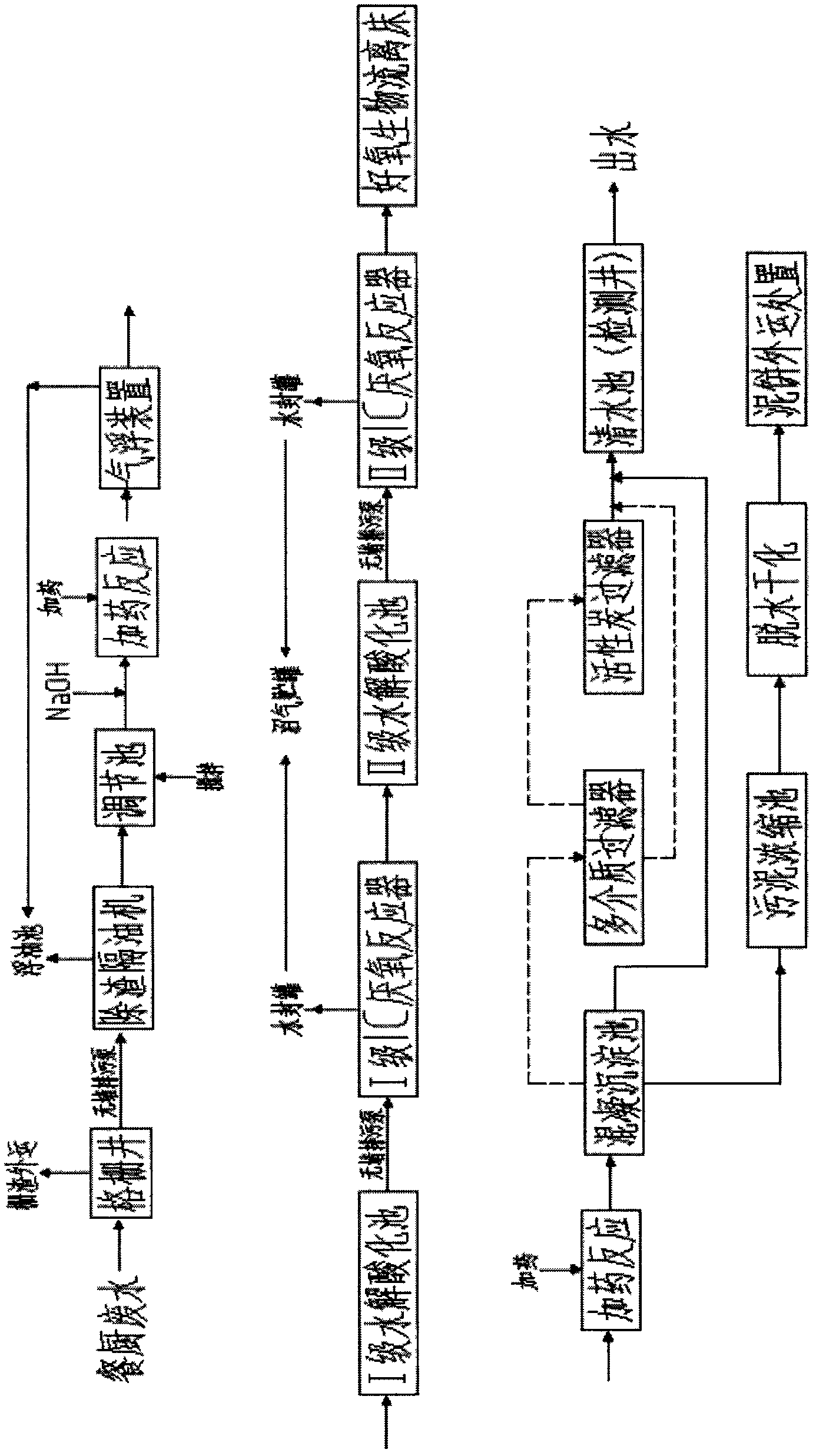

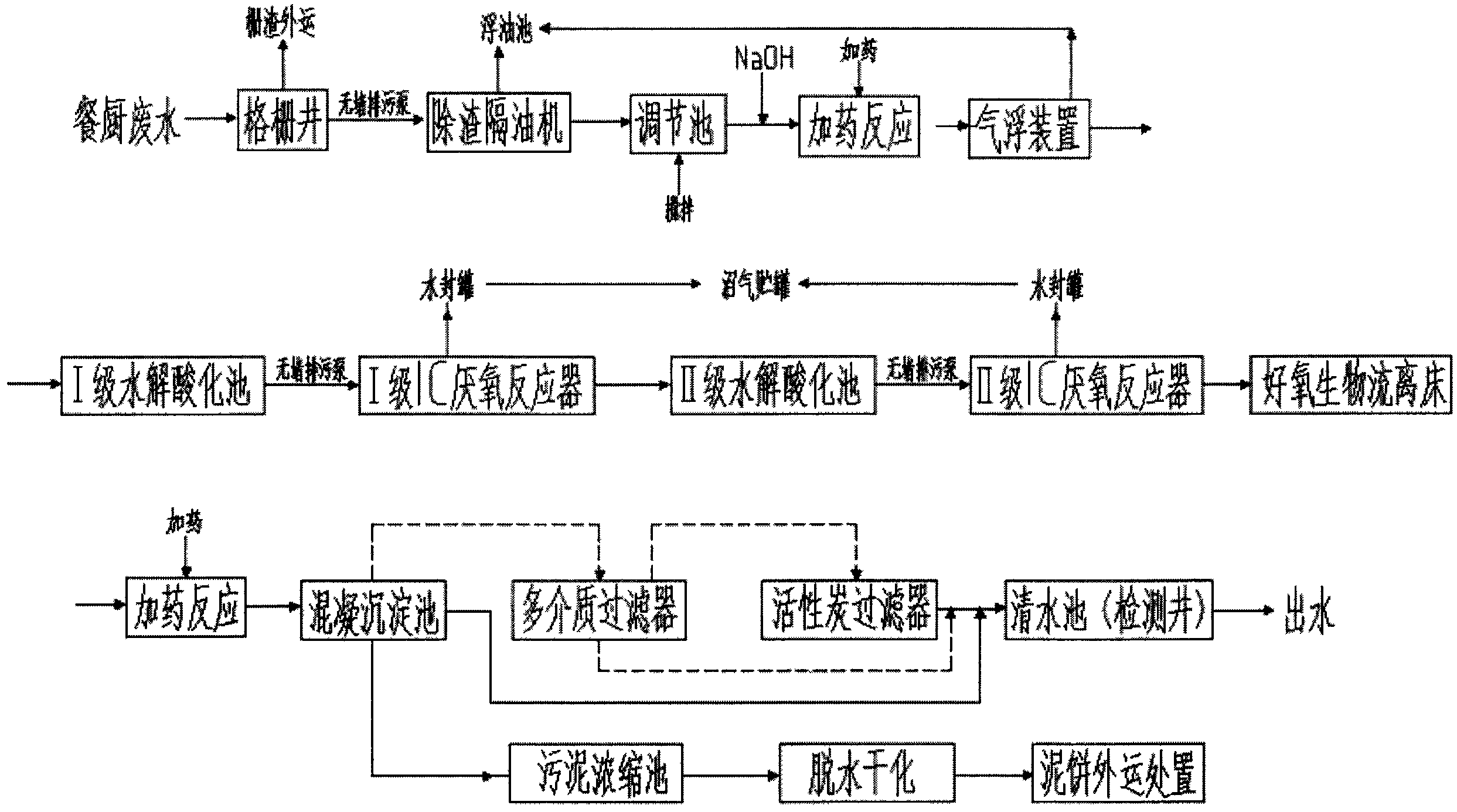

Treatment method of secondary wastewater of kitchen waste

ActiveCN102603117AReduce productionReduced processing system difficultyMultistage water/sewage treatmentFlocculationChemical oxygen demand

The invention discloses a treatment method of secondary wastewater of kitchen waste. The treatment method comprises the following steps of: (1) carrying out materialization pretreatment on kitchen wastewater to remove floater, animal or vegetable butter, oil and SS (suspended matter) in the wastewater; (2) carrying out the two-stage hydrolysis acidification-IC (internal circulation) anaerobic reaction treatment and biochemical treatment of an aerobiont separation bed on the wastewater; and (3) carrying out flocculation and precipitation on the biochemically-treated wastewater to discharge, and concentrating, dewatering and drying precipitate. The wastewater discharged by using the method reaches The people's Republic of China national standard of sewage comprehensive discharge standard (third-level discharge standard); through two-stage hydrolysis acidification-IC anaerobic reaction treatment, the gross removing rate of CODcr (chemical oxygen demand) can reach more than 92%, and carbon source does not needed to be supplied in the midway of the reaction, so that the normal running of equipment can be guaranteed.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

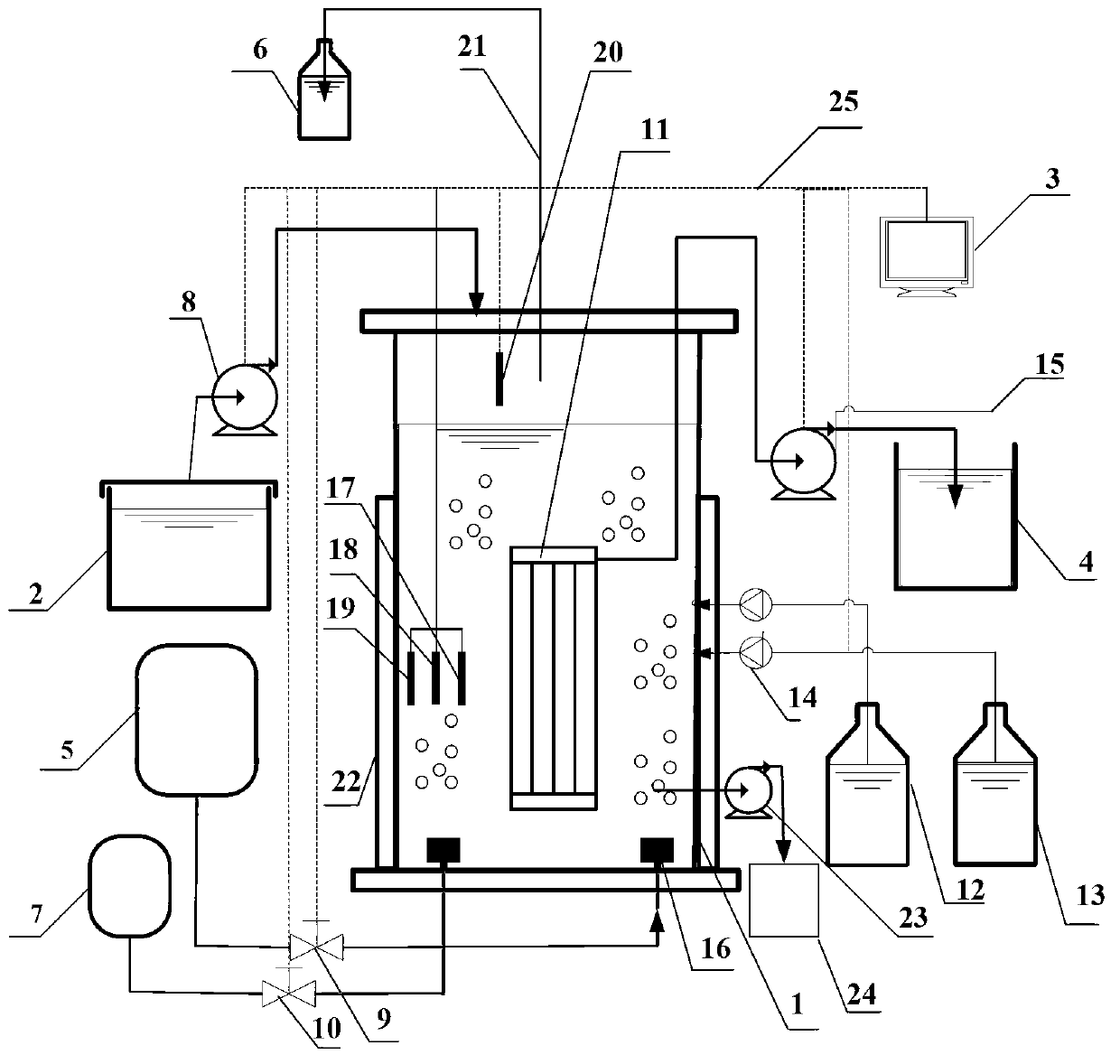

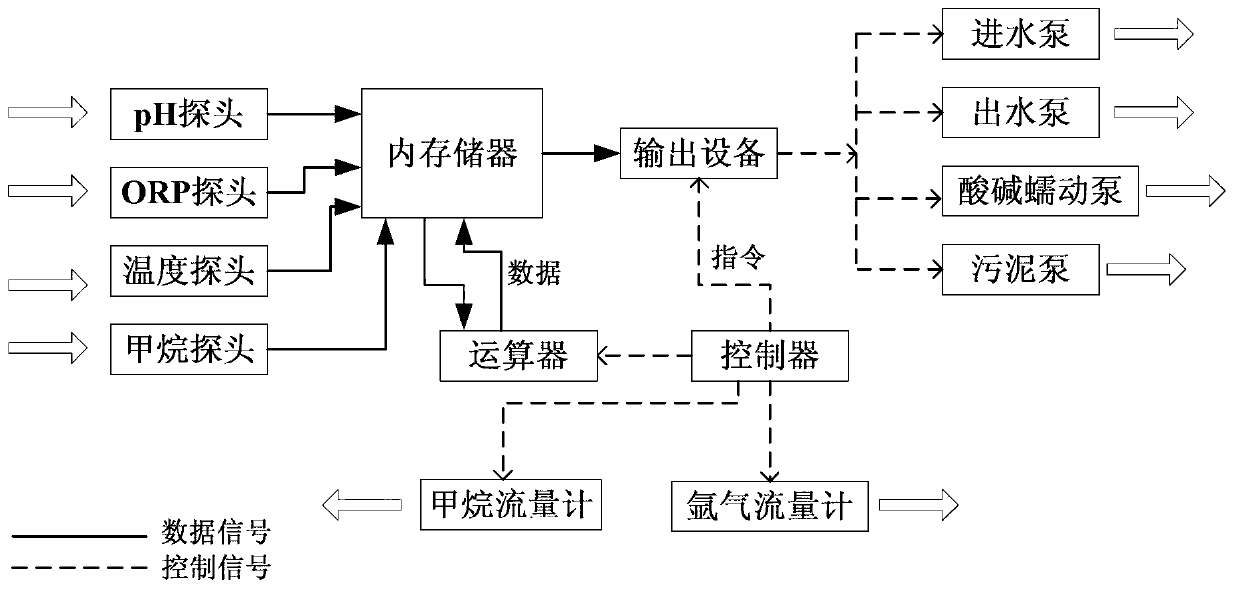

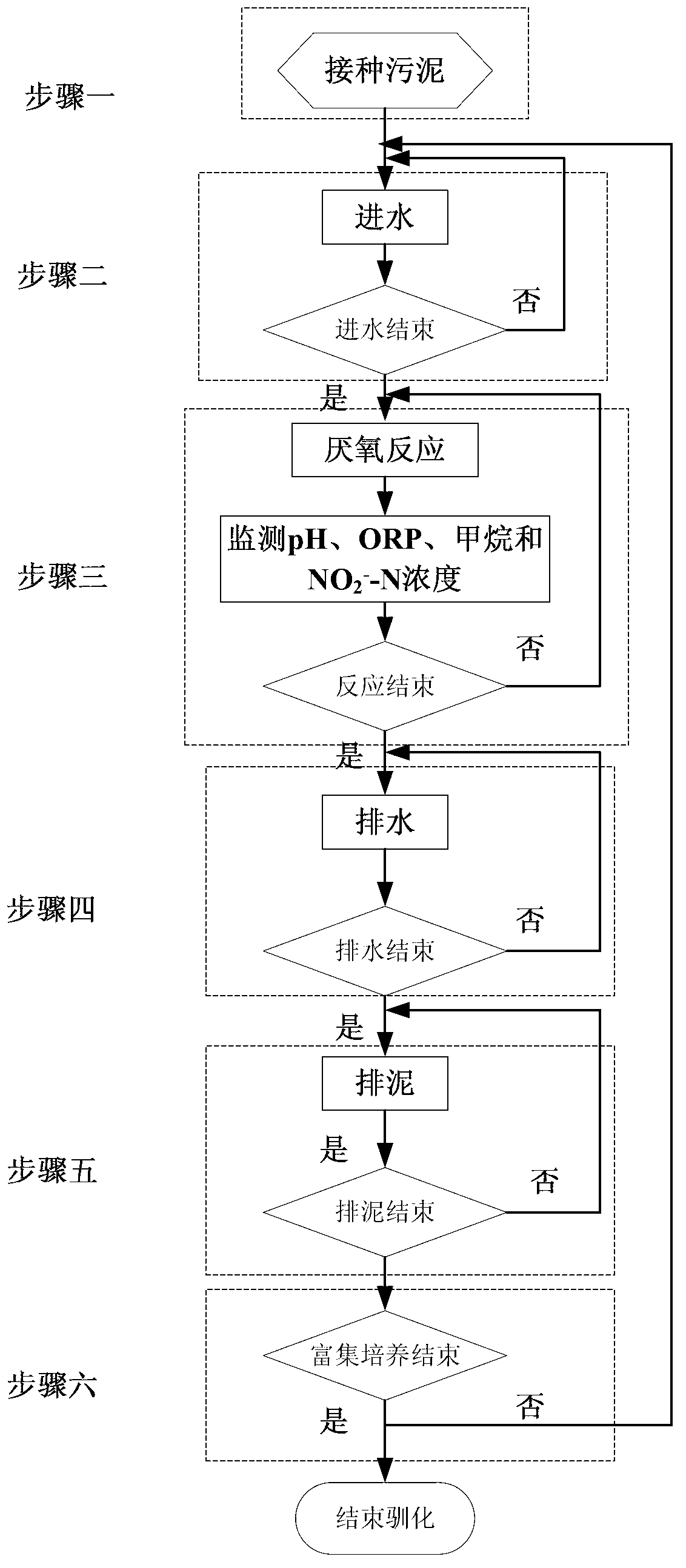

Device and method for enriching denitrification-dependent anaerobic methane oxidation bacteria based on intermittent membrane bioreactor

ActiveCN103275868AEmission reductionSave aeration energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlWater discharge

The invention relates to a device and method for enriching denitrification-dependent anaerobic methane oxidation bacteria based on an intermittent membrane bioreactor, and belongs to the technical field of sewage treatment. The device mainly comprises an SMBR (Submerged Membrane Bioreactor), a water inlet tank, an automatic control system, a water outlet tank, a methane gas storage tank, an argon gas storage tank and the like, wherein a membrane assembly is arranged in the SMBR; and the automatic control system can be used for controlling the steps including water intake, anaerobic reaction, water discharge and sludge discharge of the SMBR. According to the device and method disclosed by the invention, a high-purity enrichment culture can be obtained by optimizing operation parameters.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com