Treatment process for bearing production wastewater

A bearing production and treatment process technology, applied in water/sewage treatment, flotation water/sewage treatment, oxidized water/sewage treatment, etc., can solve environmental pollution and other problems, and achieve the ability to overcome sludge swelling and good shock load resistance , The effect of water clarification and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

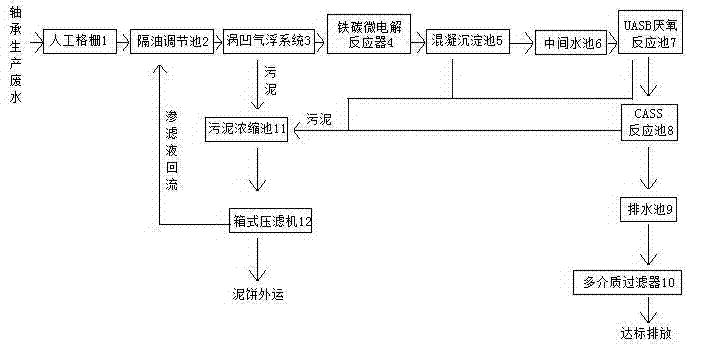

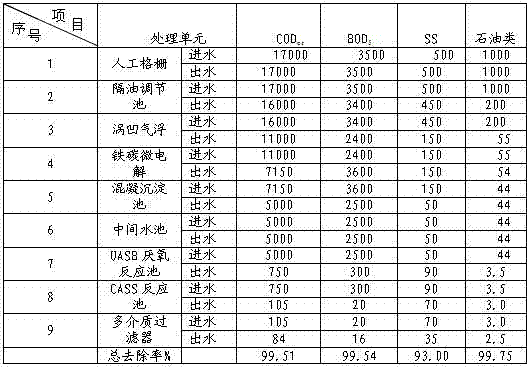

[0024] A treatment process for bearing production wastewater, comprising the following steps:

[0025] (1) The wastewater from bearing production first passes through the artificial grid 1 to remove larger floating objects and impurities in the sewage, and then enters the oil separation adjustment tank 2 to separate and stir the floating oil in the wastewater evenly (the oil separation adjustment tank includes There is a grease trap at the front end and a regulating pond at the rear. The grease trap separates the floating oil in the sewage, and an underwater agitator is installed in the regulating pond to make the water quality and quantity equal), and then it is lifted to the vortex by the suction pump In the concave air flotation system 3, polyaluminum chloride and polyacrylamide are used to remove suspended solids and petroleum in wastewater;

[0026] (2) The waste water treated by the vortex-concave air flotation system 3 enters the iron-carbon micro-electrolysis reactor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com