Patents

Literature

583results about How to "Strong resistance to shock loads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

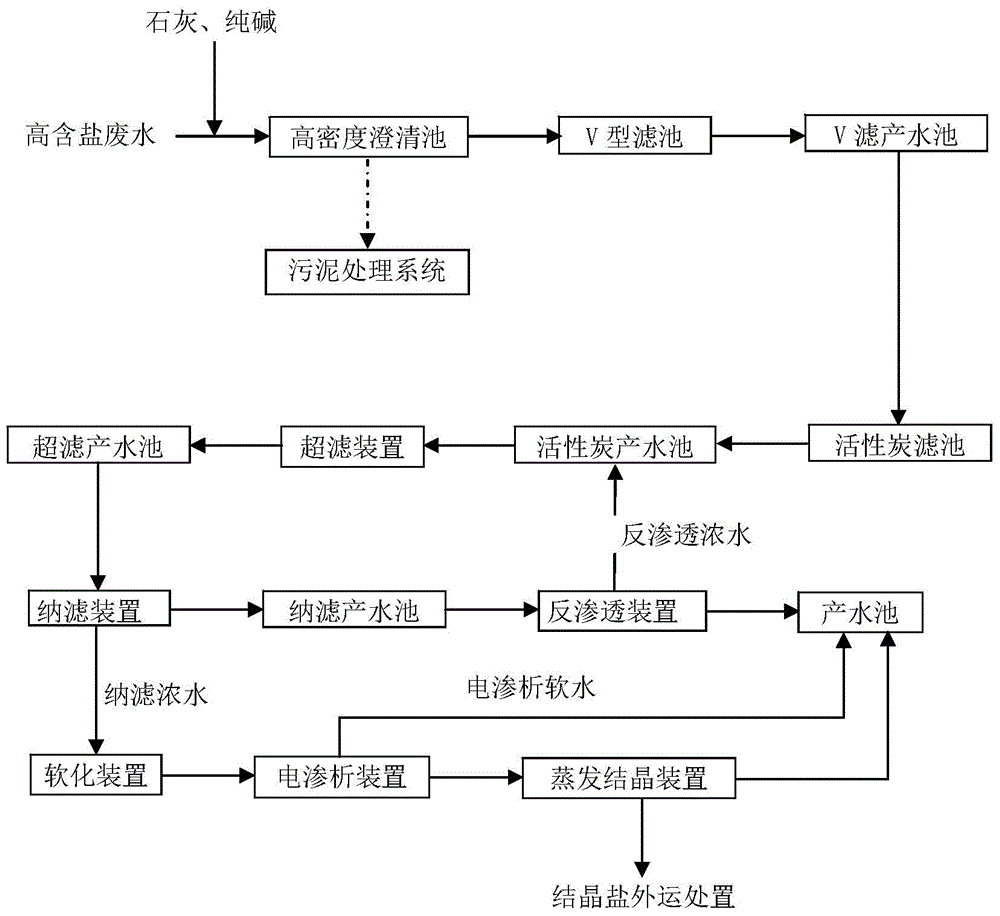

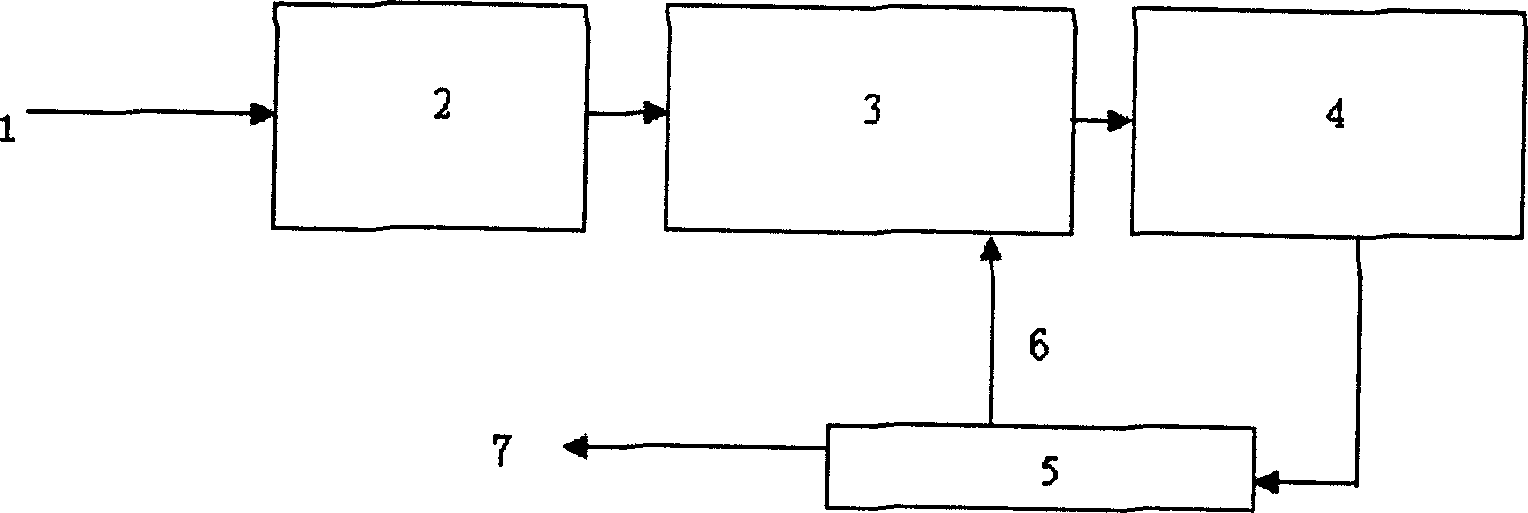

Zero-emission integrated process for treatment and reuse of high-salinity wastewater

ActiveCN104445788AHigh filtration precisionEasy to handleGeneral water supply conservationMultistage water/sewage treatmentSoftened waterEvaporation

The invention discloses a zero-emission integrated process for treatment and reuse of high-salinity wastewater. The invention relates to a softening desalination treatment technology of water and particularly relates to a reuse treatment system for reverse osmosis concentrated water containing low-concentration organic matters which can achieve the requirement of 'zero emission'. The integrated process comprises the following steps: (1) firstly softening and pre-treating the high-salinity wastewater; (2) acquiring pre-treated water by virtue of activated carbon adsorption and an ultrafiltration device; (3) acquiring nanofiltration softened water and nanofiltration concentrated water by virtue of a nanofiltration device; (4) acquiring reverse osmosis softened water and reverse osmosis concentrated water by virtue of a reverse osmosis device; (5) acquiring electrodialysis softened water and electrodialysis concentrated water by virtue of an electrodialysis device; and (6) carrying out evaporation crystallization treatment on the electrodialysis concentrated water by virtue of an evaporation-crystallization device, regularly outwards transporting salts generated by the evaporation crystallization, feeding generated salt into a water-producing tank to enter a reuse system and finally completing the treatment and reuse of high-salinity wastewater. The integrated process is mainly used for the integrated treatment of the high-salinity wastewater.

Owner:XINJIANG DELAND

Attapulgite clay porous ceramsite, and preparation method and purpose thereof

ActiveCN102225870AWide variety of sourcesLow priceCatalyst carriersTreatment with aerobic and anaerobic processesWater resistancePorosity

The invention discloses an attapulgite clay porous porous ceramsite, a preparation method of the ceramsite, and a purpose of the ceramsite. The ceramsite is prepared from raw materials of attapulgite clay and biomass, and a binder of industrial soluble glass. The ceramsite is prepared through calcining and oxidizing. The attapulgite clay porous ceramsite prepared by the present invention has advantages of high porosity, large specific surface area, high strength, strong water resistance, high water absorption, high catalytic activity, and the like. The porous ceramsite prepared by the presentinvention can be applied as a carrier for a catalyst, and a filling material for an aerated biological filter.

Owner:HEFEI UNIV OF TECH

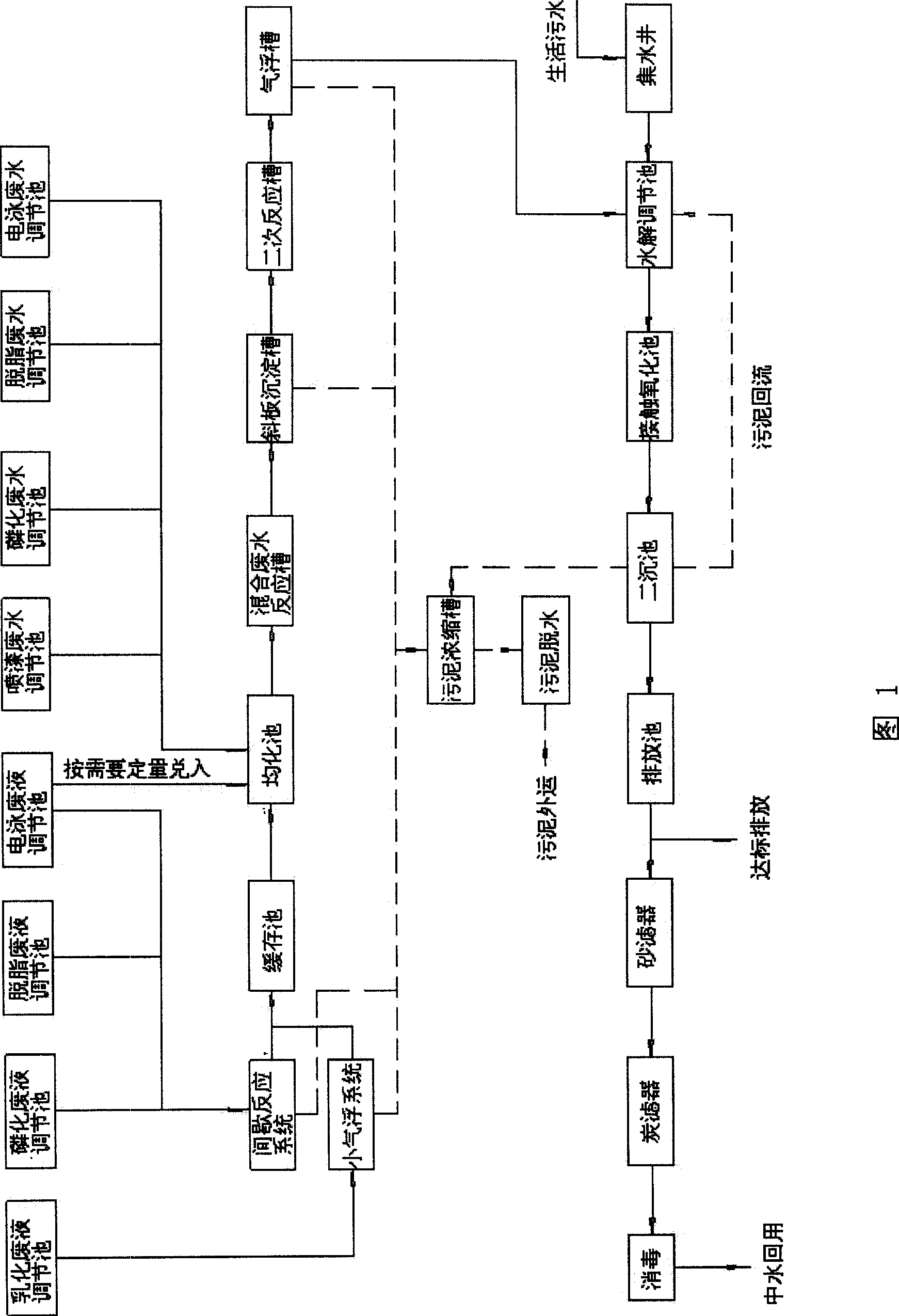

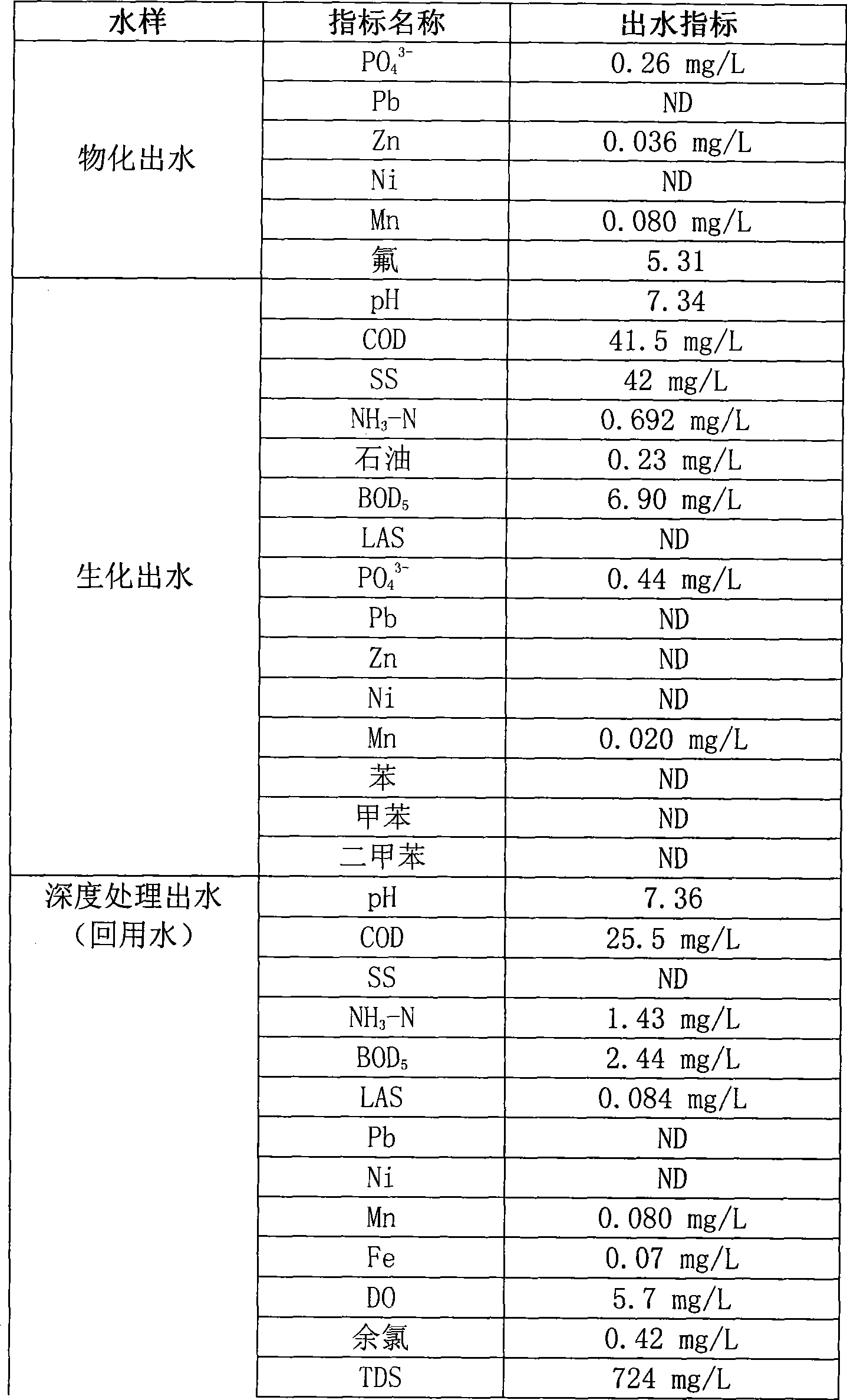

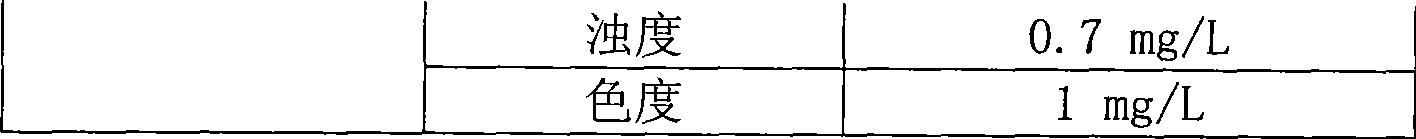

Automobile manufacturer wastewater treatment method

ActiveCN101456647AEasy to handleHigh activityTreatment using aerobic processesDispersed particle separationOperational costsIndustrial waste water

The invention relates to a method for treating wastewater and discloses a method for treating wastewater in an automobile manufacturing plant. A method of pretreatment, two-stage physicochemical treatment, biochemical treatment and advanced treatment is adopted to treat wastewater. The method for treating wastewater in the automobile manufacturing plant has little investment, small occupied area and low operating cost and has good integrated treatment effect on industrial wastewater and domestic sewage discharged from the automobile manufacturing plant.

Owner:SHANGHAI YIKE GREEN ENG

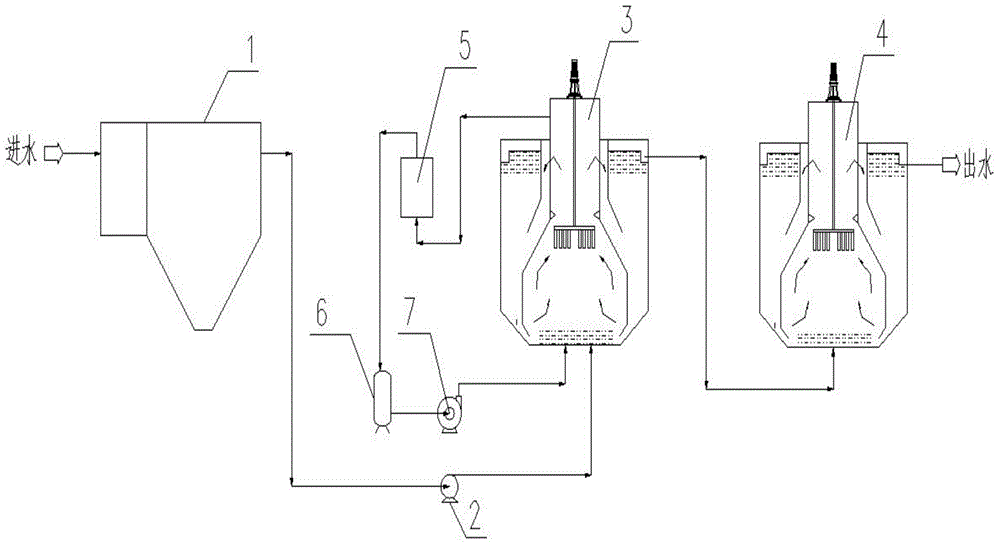

Apparatus and method for entire journey autotrophy denitrification of digested sludge dewatered liquid biomembrane

ActiveCN101293707AImprove nitrogen removal efficiencyReduce inhibitionTreatment with aerobic and anaerobic processesMonosodium glutamateToxic material

The invention relates to a biofilm full-rang autotrophic nitrogen removal device of digested sludge dehydrolysis liquid and a method thereof; wherein, the device is provided with a digested sludge dehydrolysis liquid pool, a pre-hypoxia denitrification pool, a short-range biofilm nitrification pool, a sedimentation pool, an intermediate pool and a biofilm anaerobic ammonia oxidation pool; the method consists of the following steps: 1. the pre-hypoxia denitrification pool and the short-range biofilm nitrification pool are started to operate; 2. the biofilm anaerobic ammonia oxidation pool is started; 3. the biofilm full-rang autotrophic nitrogen removal system of the digested sludge dehydrolysis liquid is operated in series. The device is suitable for biological nitrogen removal of wastewater containing high ammonia nitrogen, such as the digested sludge dehydrolysis liquid, late landfill percolate, coking wastewater, monosodium glutamate wastewater, etc. The device realizes efficient biological nitrogen removal of wastewater with high NH4<+>-N and low ratio of C / N, greatly decreases the construction and operation cost of nitrogen removal of wastewater, reduces alkalinity demand of the nitrification, runs stably, operates easily and has stronger shock resistance loading capability; meanwhile, the device is strongly adaptable to temperature fluctuation and toxic substances, which is easy to recover after being restrained.

Owner:BEIJING DRAINAGE GRP CO LTD +1

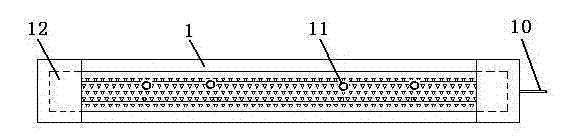

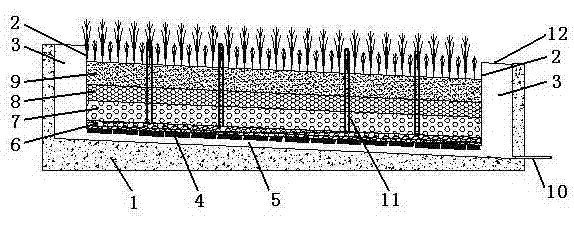

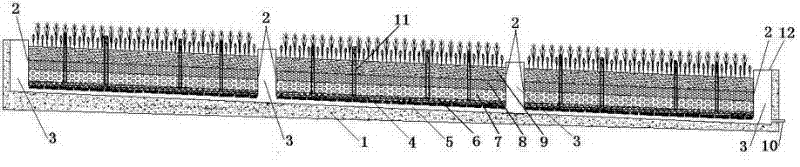

System for carrying out collection, purification and utilization on rainwater on road surfaces

InactiveCN102251459AEfficient use ofEasy to handleGeneral water supply conservationPaving gutters/kerbsGratingEngineering

The invention provides a system for carrying out collection, purification and utilization on rainwater on road surfaces, and the system comprises a groove and one or more packing units arranged in the groove, wherein the two sides of each packing unit are respectively provided with a baffle, a ventilation well is formed between two baffles arranged at the head end and tail end of two adjacent packing units, and a ventilation well is formed among the baffles at the two ends of the groove and the inner side wall of the groove; the bottom surface of each packing unit is provided with a concrete grating, a water collecting sump is formed between the concrete grating and the internal bottom surface of the groove, and the water collecting sump is mutually communicated with all the ventilation wells; and the packing unit on the concrete grating is composed of a cobble layer, a gravel layer, a matrix layer and a planting soil layer which are sequentially arranged from bottom to top, and plants are planted in the planting soil layer. Rainwater which is purified by the system disclosed by the invention can satisfy the needs of agricultural water and general landscape water.

Owner:XIAN UNIV OF TECH

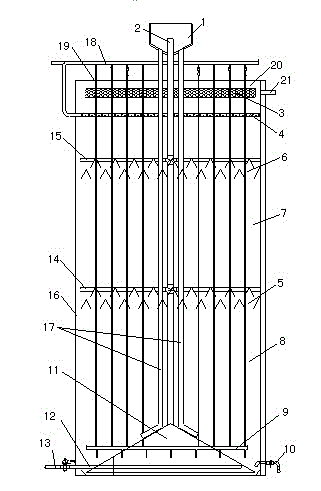

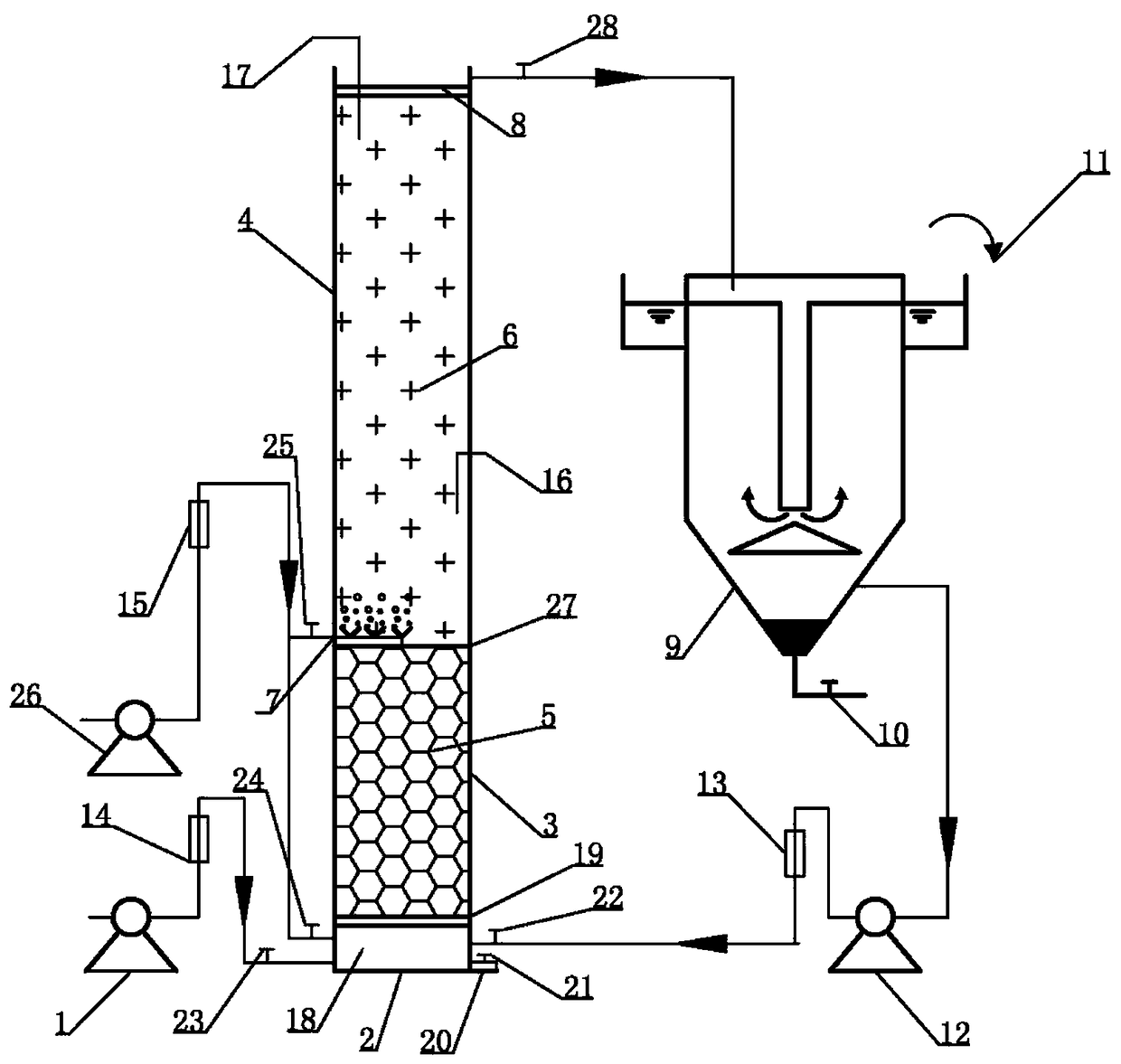

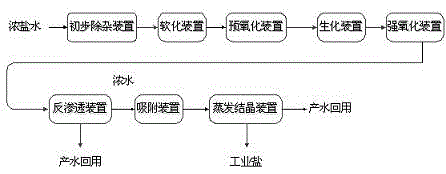

Three-stage circulation aerobic reactor

ActiveCN103332784AStart fastGrow fastSustainable biological treatmentBiological water/sewage treatmentLoad resistanceThree stage

The invention discloses a three-stage circulation aerobic reactor, which comprises a pond body, wherein the inside of the pond body is partitioned into a conical sewage expansion area, an aerobic reaction area, an anaerobic reaction area and a sediment filtering layer from bottom to top in sequence; the upper part of the aerobic reaction area is provided with a primary gas-solid-liquid separation area; the upper part of the anaerobic reaction area is provided with a secondary gas-solid-liquid separation area; three-phase separators are respectively arranged in the primary gas-solid-liquid separation area and the secondary gas-solid-liquid separation area; a water outlet weir is arranged above the sediment filtering layer; a water outlet pipe is arranged on the water outlet weir; the top of the pond body is provided with a double-stage circular reflowing system; the double-stage circular reflowing system comprises an air-lift pipe, a gas-liquid separating tank and a lower layer reflowing pipe; an upper layer reflowing pipe is arranged between the secondary gas-liquid separation area and the sediment filtering layer; and the upper layer reflowing pipe is connected with an aeration air inlet pipe arranged above the pond body. The reactor is provided with a three-stage circular reflowing system, and has the characteristics of rapid start of flocculent sludge, high impact load resistance, low requirement on the PH value of inflow water, high particle sludge increasing speed, low energy consumption, high treating efficiency and stable water yielding quality.

Owner:山东许中华环保科技有限公司

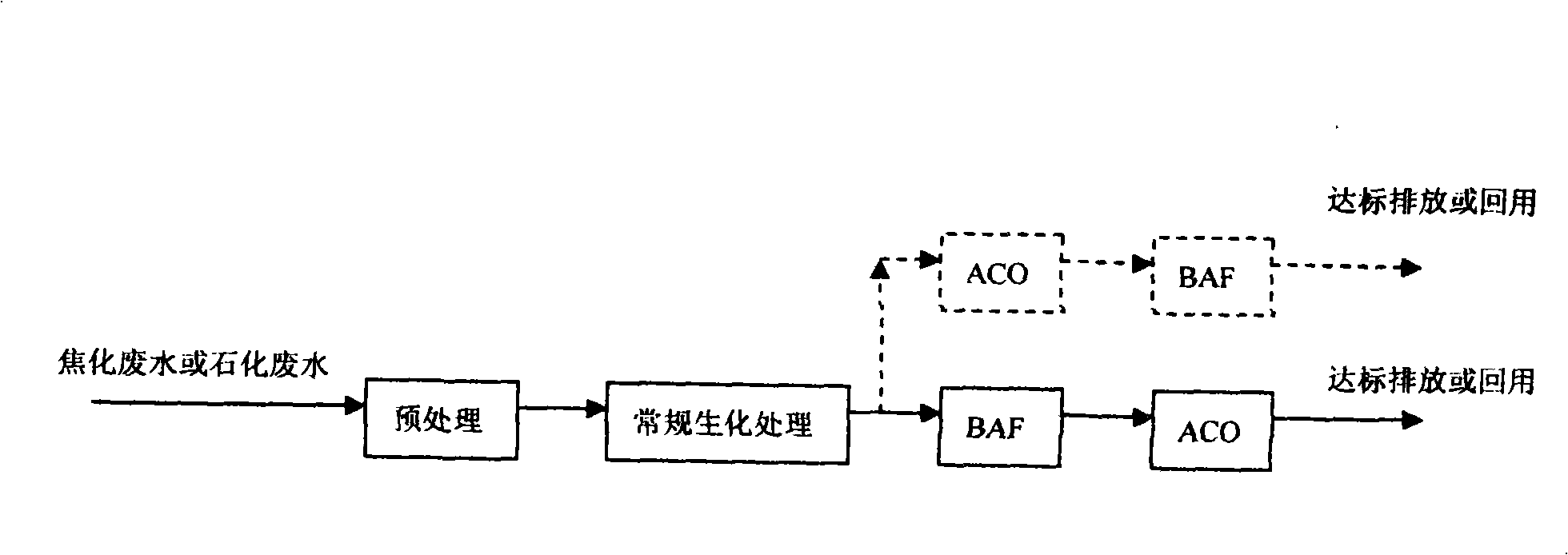

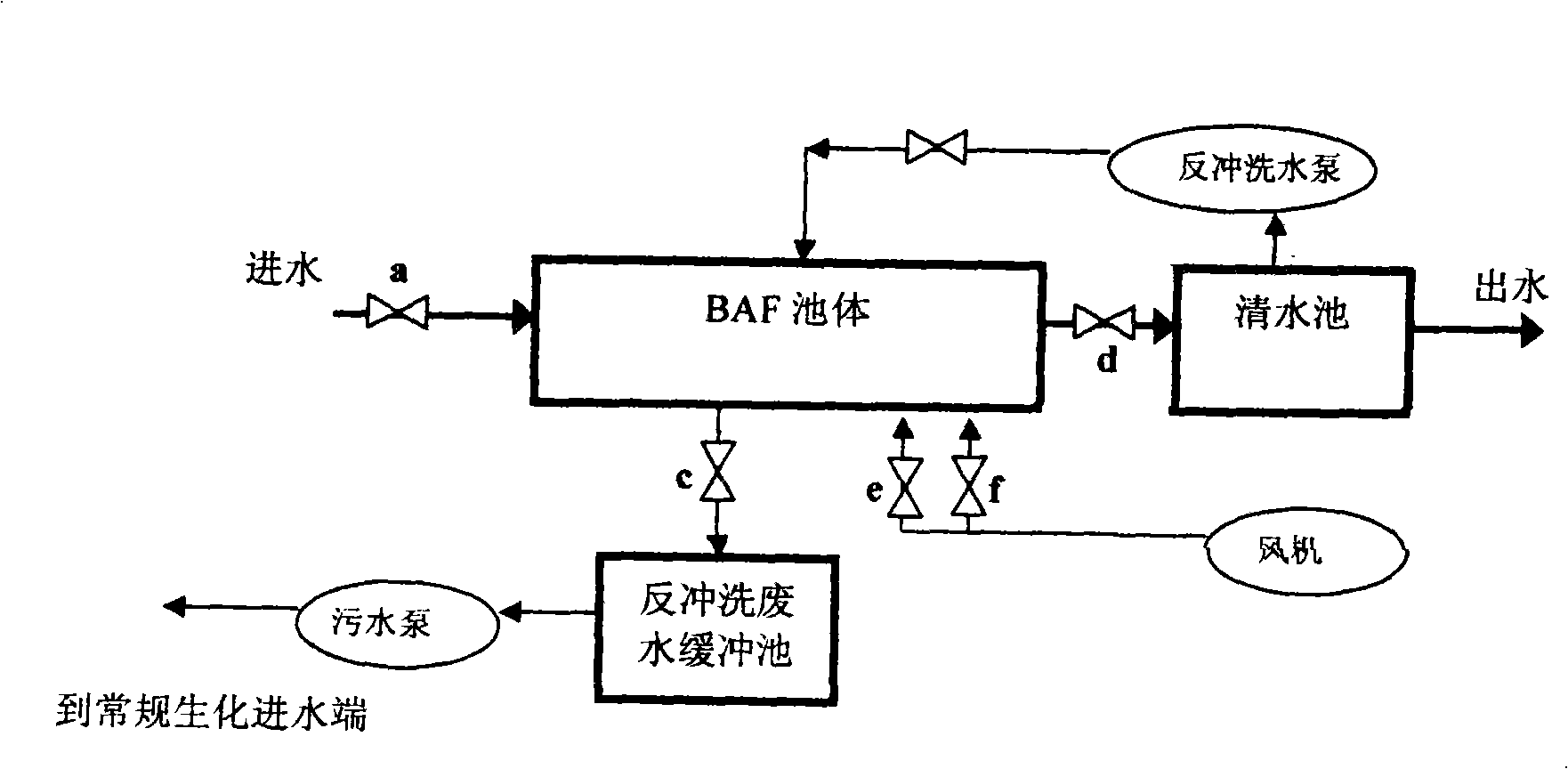

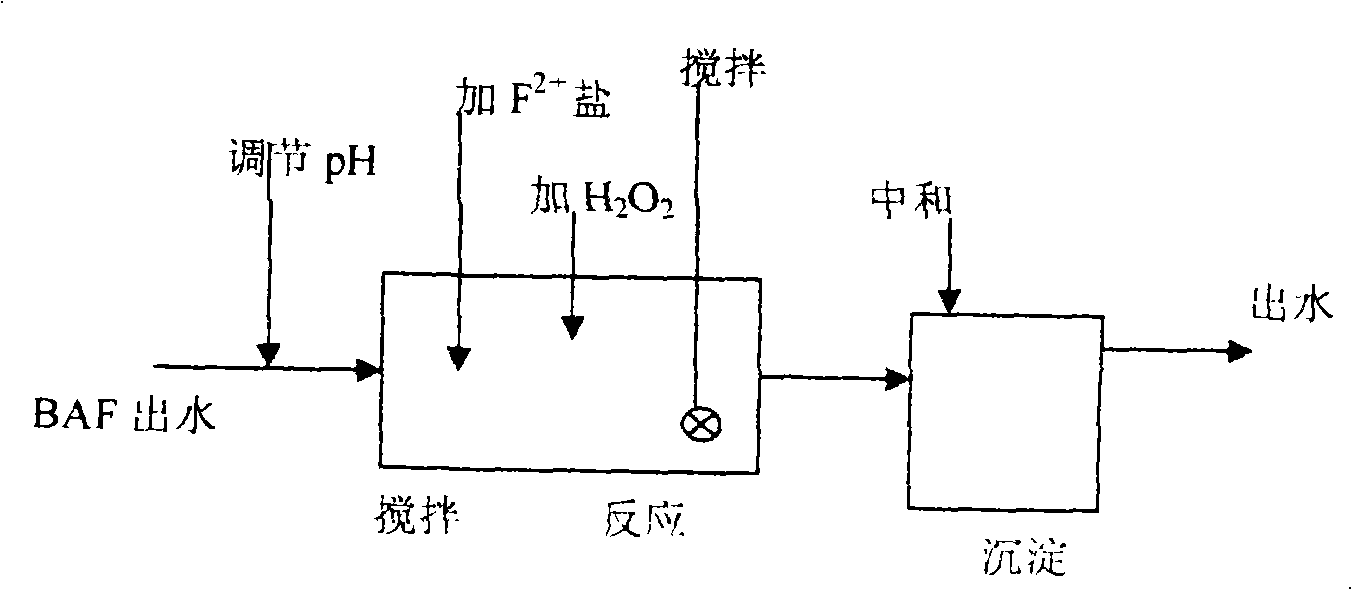

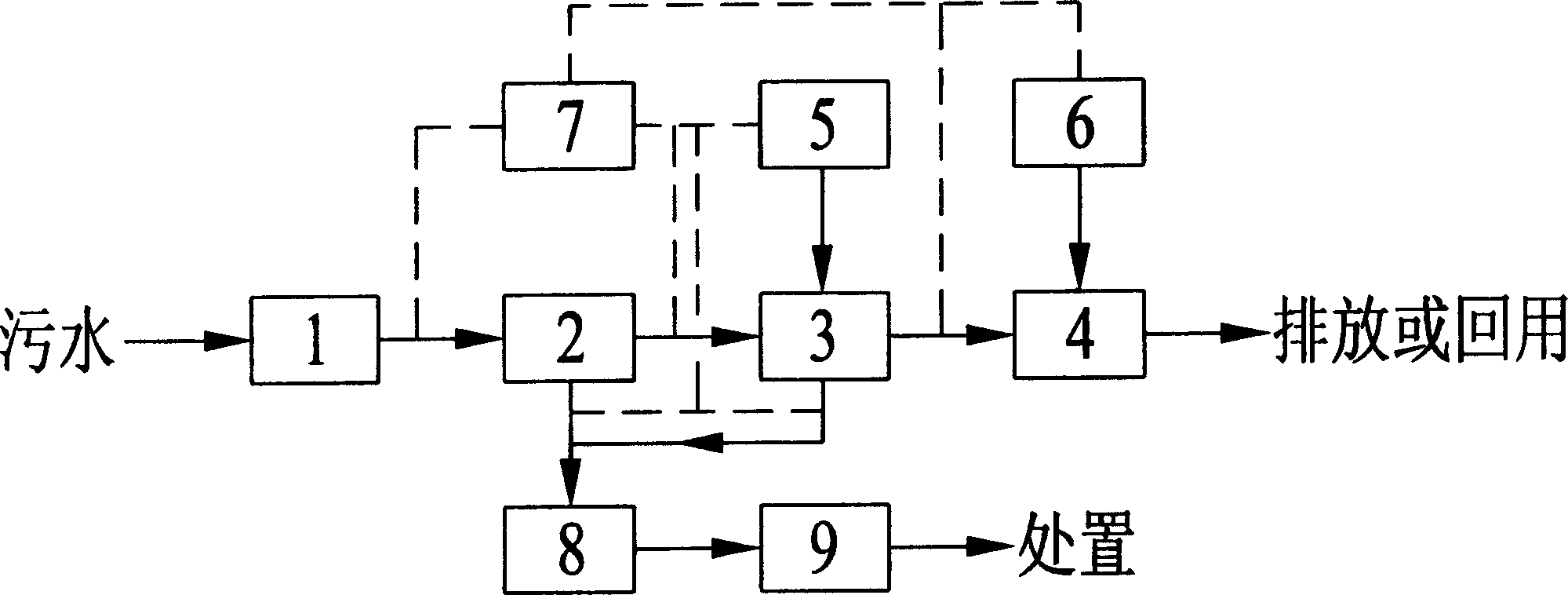

Coked and petrochemical wastewater treatment process having deep biochemical treatment and physicochemical treatment

InactiveCN101302070AStrong resistance to shock loadsSimple operation and maintenanceFatty/oily/floating substances removal devicesTreatment with aerobic and anaerobic processesAutomatic controlChemistry

The invention discloses a process method for treating coking wastewater and petrochemical wastewater with advanced biochemical and physic-chemical treatment. The method comprises a step of pretreatment, a step of conventional biological treatment, a step of advanced biochemical treatment and a step of materialized treatment, wherein, the step of pretreatment comprises adjustment, oil removal and floatation; the step of conventional biological treatment consists of an anaerobic-anoxybiotic-aerobic activated sludge process, an anoxybiotic-aerobic bio-film activated sludge process or an anoxybiotic-aerobic bio-film process which are performed in sequence; the step of advanced biochemical treatment adopts a filtering stage and a back purging stage which are performed alternately and repeatedly in a biological aerated filter, and the switching of the two stages are executed by an automatic control system; the step of materialized treatment adjusts pH of water treated in the biological aerated filter to be subacidity, adds Fe<2+> salt and H2O2 into the water and stirs to react in an advanced chemical oxidation pond, and then performs an operation mode of neutralization and precipitation. Therefore, final effluent organic substances can be reduced to a lower level, which can completely fulfill the first-grade national effluent standard, and can achieve recycle-water quality through increasing the dosage for the advanced chemical oxidation pond. The wastewater treatment process has simple operation and maintenance, and both BAF and ACO adopt automatic control.

Owner:北京嘉瑞环保股份有限公司

Device and method for treatment of low-temperature and low-carbon ammonia nitrogen wastewater on basis of solid-phase denitrification and heterotrophic nitrification-aerobic denitrification

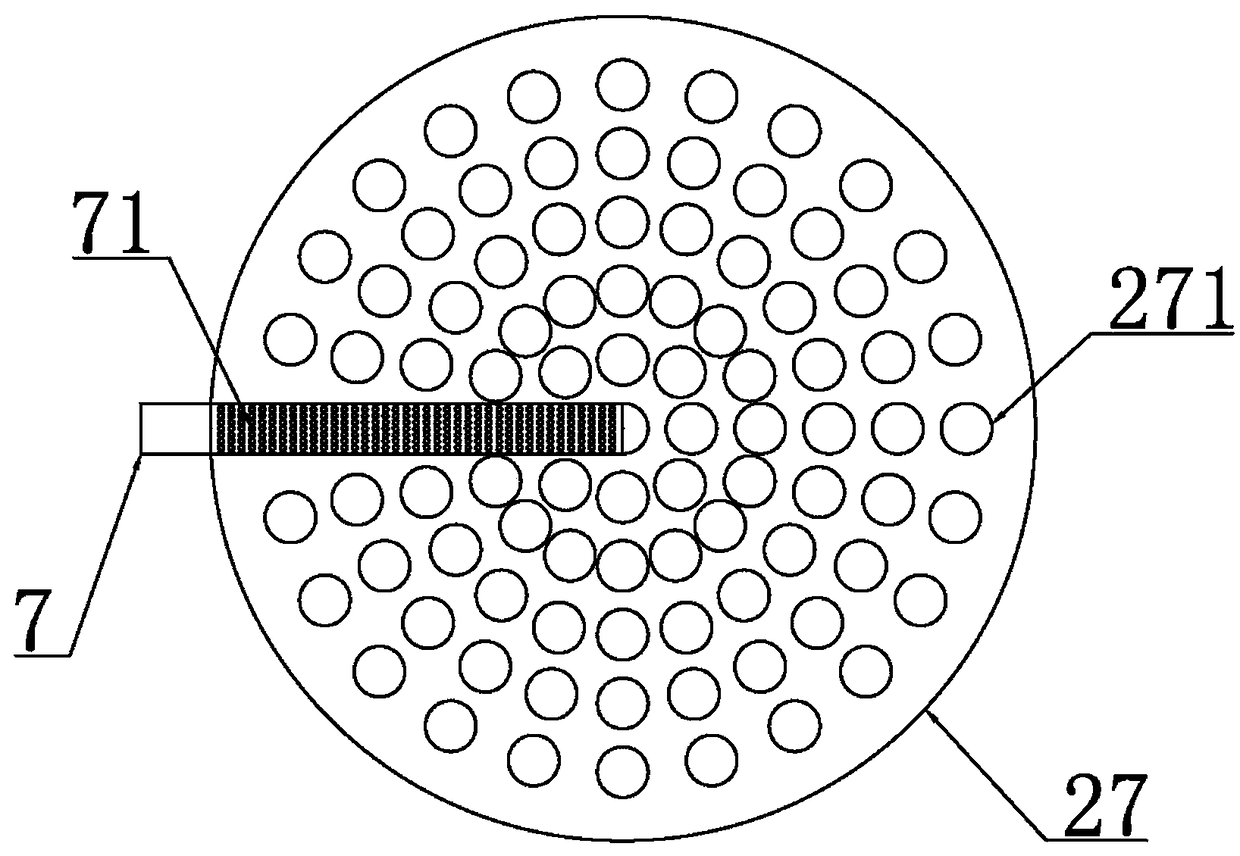

ActiveCN108585195AEfficient removalHigh HN-AD performanceWater treatment compoundsWater contaminantsSolid carbonWater storage tank

The invention provides a device and a method for treatment of low-temperature and low-carbon ammonia nitrogen wastewater on the basis of solid-phase denitrification and heterotrophic nitrification-aerobic denitrification. The device comprises a reactor and a reflux system, wherein the upper part and lower part of the reactor are respectively provided with a fluidized bed aerobic zone and a filterpool anoxic zone which are filled with a solid carbon source filling material and separated by a porous water distribution plate; an aeration tube is arranged on the water distribution plate and connected with an aeration device through a gas flowmeter; the lower end of the reactor is provided with a water inlet; the upper end of the reactor is provided with a water outlet; an effluent of the reactor enters a secondary sedimentation tank, and an effluent of the secondary sedimentation tank enters an intermediate water storage tank through an overflowing opening; the upstream end of the refluxsystem communicates with an effluent of the intermediate water storage tank; the downstream end of the reflux system communicates with the reflux opening of the lower end of the reactor through a liquid flowmeter; and the interior of the fluidized bed aerobic zone is provided with a dissolved oxygen monitor and a nitrate concentration monitor. The device and the method provided by the invention can still realize highly-efficient removal of ammonia nitrogen and total nitrogen under the conditions of low temperature and low carbon.

Owner:CHONGQING UNIV OF TECH

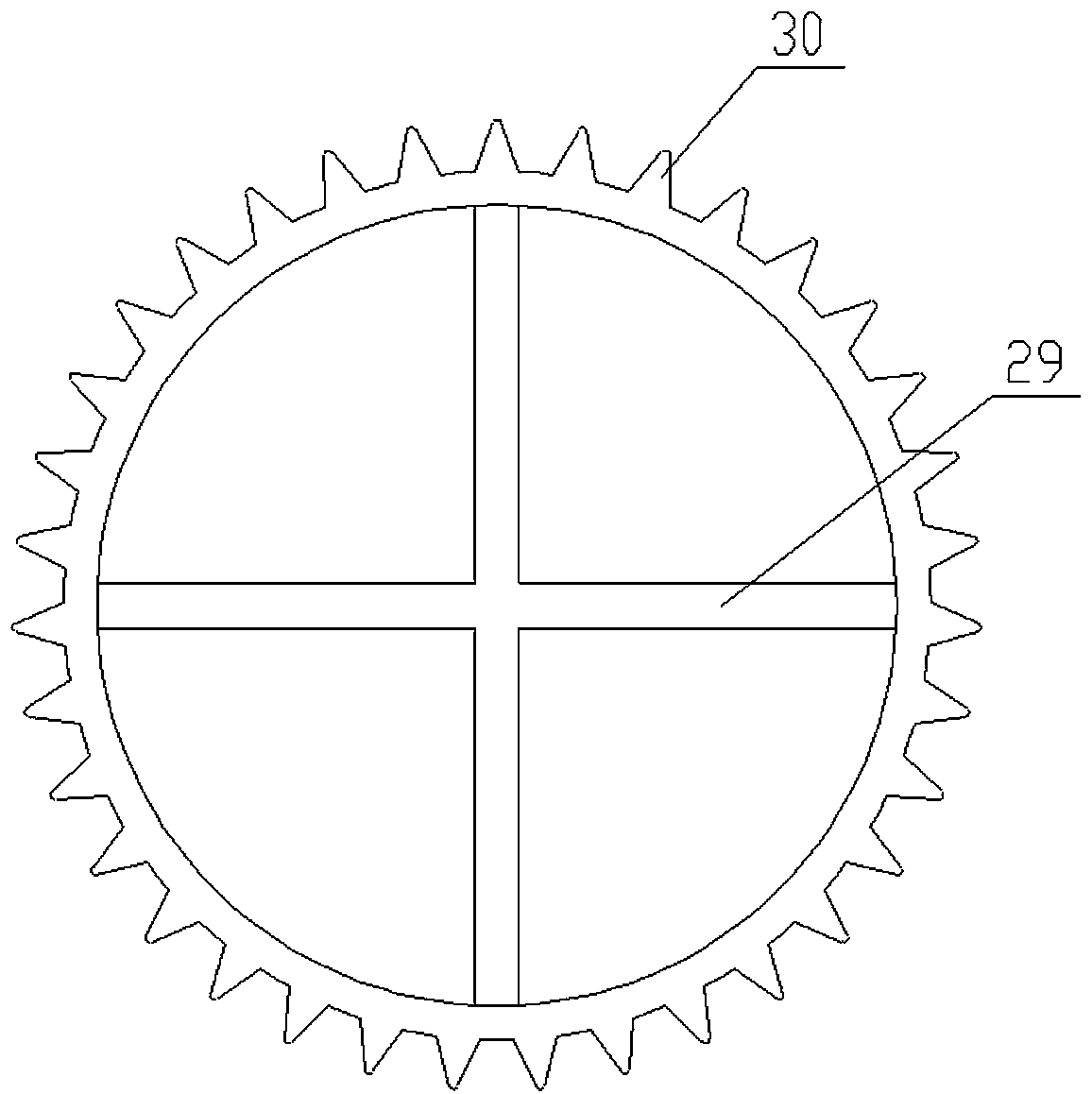

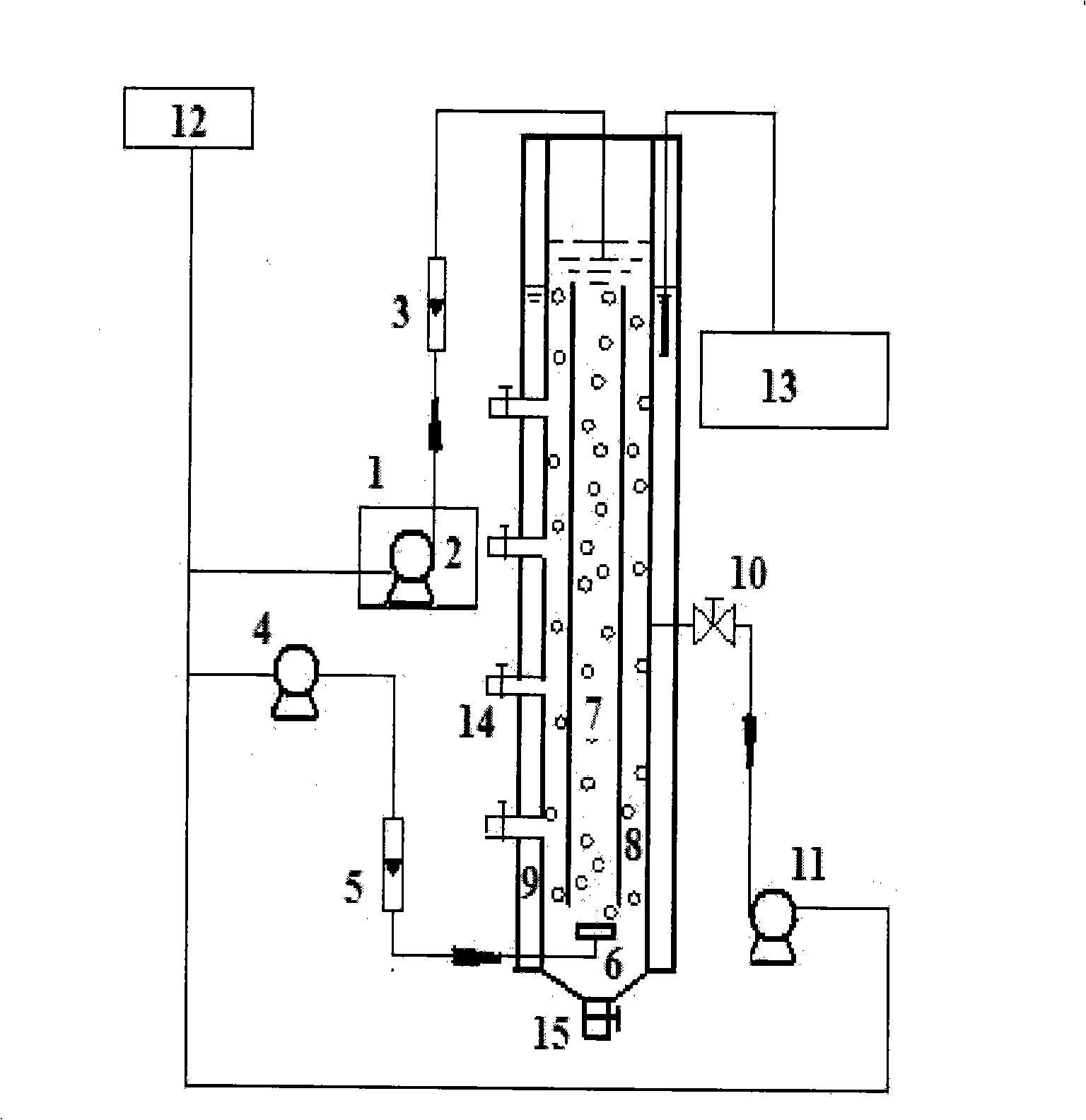

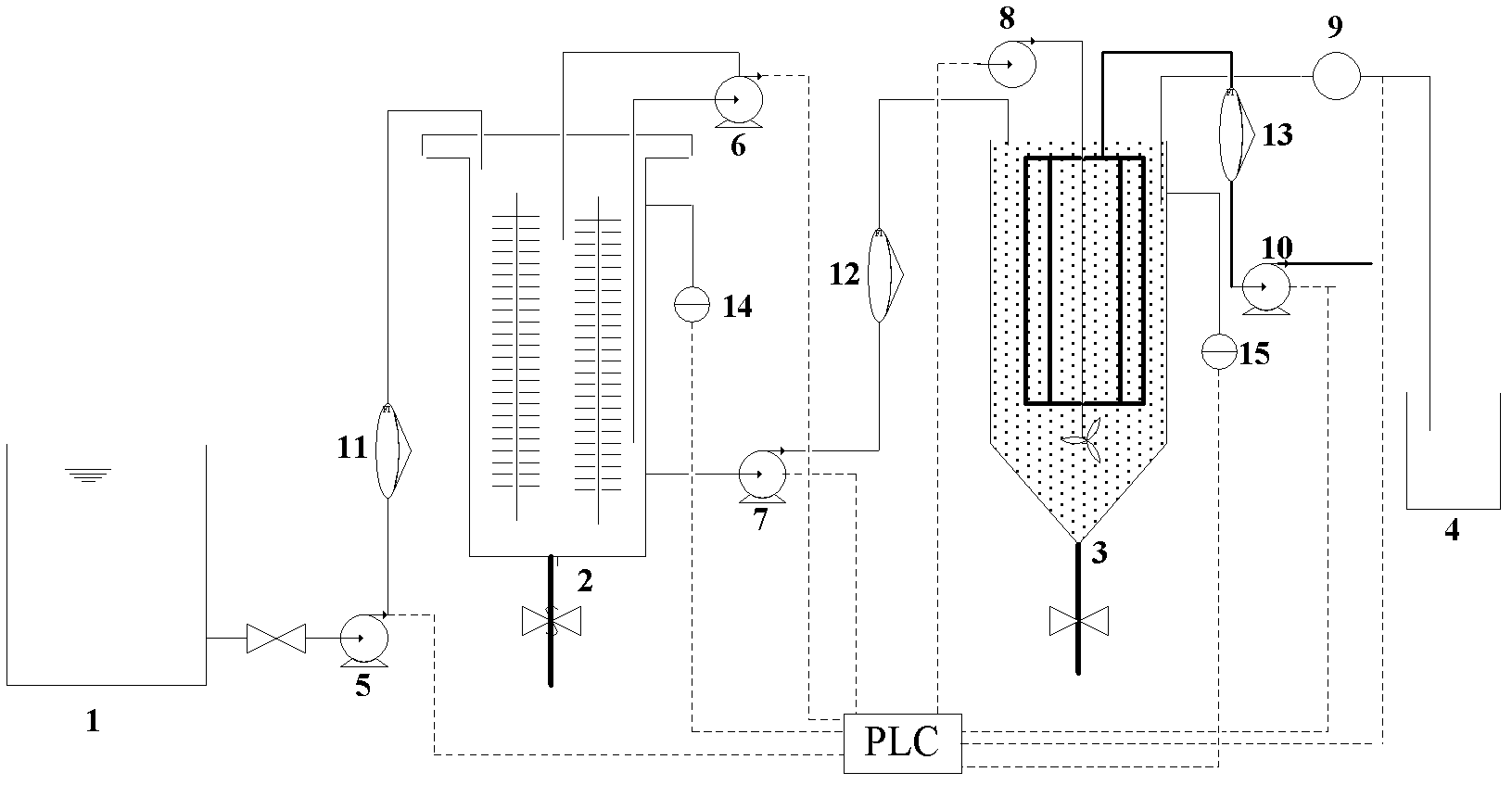

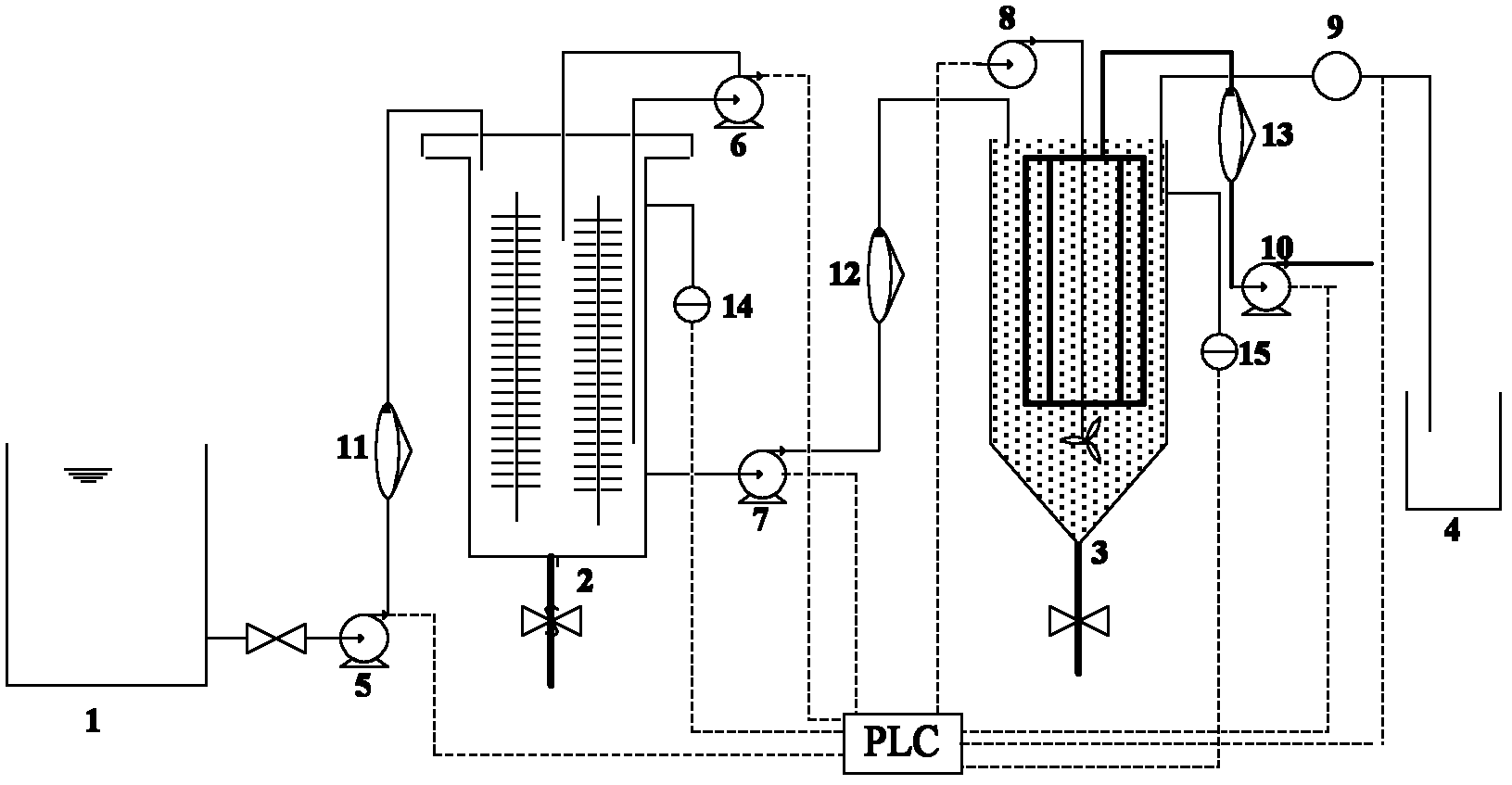

Gas-lifting internal circulation intermission aerobic granule sludge reactor and water treatment process thereof

InactiveCN101333037AEnhanced mass transferImprove the mixing effectSustainable biological treatmentBiological water/sewage treatmentWater bathsMicroecosystem

The invention discloses an airlift type internal circulation intermittent aerobic granular sludge reactor, which comprises an organic glass column, a temperature controller, a water inlet tank, an aeration pump, a water feed pump, a draining pump, a flow meter, a programmable logical controller, etc. The main body of the reactor is the organic glass column and can be divided into an inner sleeve and an outer sleeve, and the inner one is an upspout, while the outer one is a downcast pipe; the ratio of height to diameter is 15. The exterior of the downcast pipe is provided with a water bath heating casing for controlling reaction temperature. Mixed liquor in the reactor flows between the upspout and the downcast pipe in internal circulation to endow granular sludge with a self-balanced micro-ecosystem, the property of the micro-ecosystem is suitable for an up-flow type wastewater treatment system. The reactor adopts the sequence batch operation mode and can realize automatic control by the programmable logical controller. The reactor of the invention has the advantages of flexible operation, compact structure, little sludge remained, good treatment effect, and the like, and can bear high volume load and impact load; furthermore, the reactor has small occupying space and can reduce pork barrel due to relatively large H / D.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

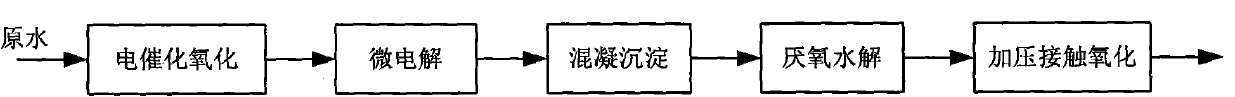

Technique of biological treatment for wastewater of carbonization

InactiveCN1686863APoor biodegradabilityWater quality fluctuates greatlyTreatment with aerobic and anaerobic processesSustainable biological treatmentChemistryAnaerobic treatment

The present invention relates to a coker waste water biological treatment, and is characterized by that it is a process adopting biological membrane method and utilizing anaerobic treatment, anoxybiotic treatment and two aerobic treatment stages to treat coker waste water, said process equipment is formed from four reactors including anaerobic hydrolysis acidification reactor, up-flowing anoxybiotic reactor, first aerobic biological reactor and second aerobic biological reactor. Said invention also provides the concrete steps of said waste water treatment process and its process condition.

Owner:TAIYUAN UNIV OF TECH

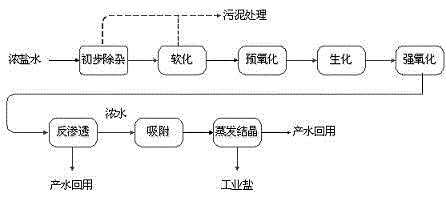

Method and device for realizing zero emission of strong brine

ActiveCN105541017ATake advantage ofEase of useGeneral water supply conservationWater treatment compoundsLoad resistanceEvaporation

The invention provides a method and a device for realizing zero emission of strong brine, overcoming the defects that the existing strong brine treatment technology is high in crystallized impurity salt treatment cost and severe in harm. The impurity removal, softening, pre-oxidation, biochemical and strong oxidation techniques are used for purifying the strong brine, the strong brine after being treated is pre-concentrated by adopting a reverse osmosis way, the reverse osmosis concentrated water is further purified by adopting an adsorption method, and finally the evaporation and quality-divided crystallization technology is used for separating the water to obtain industrial salt. By adopting the method and device, the zero emission of the strong brine is realized, the emission of dangerous waste is reduced, and the recycling is realized. Meanwhile, the general process is mature, the design is reasonable, the impact load resistance is relatively high, the chemical source is convenient, and the cost is low.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

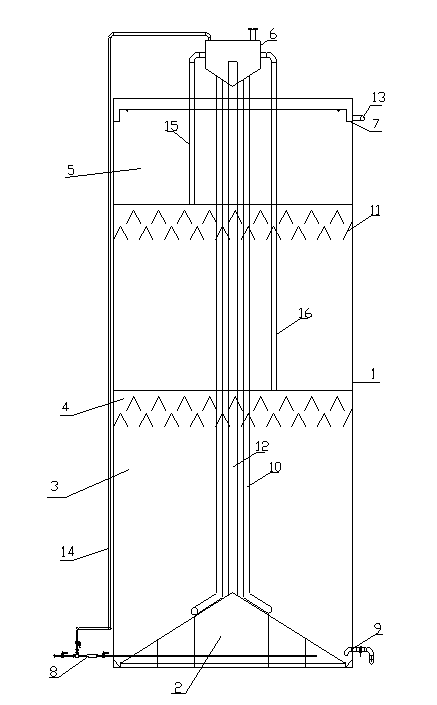

Double-circulation anaerobic reactor

ActiveCN103011402AGrow fastPool heightWaste based fuelTreatment with anaerobic digestion processesLoad resistanceWater quality

The invention provides a double-circulation anaerobic reactor. The double-circulation anaerobic reactor comprises a cell body, wherein the cell body is sequentially divided into a cone-shaped sludge bulking region, a main reaction region, a secondary reaction region and a sediment region from bottom to top, a first-stage gas-solid-liquid separation region is arranged at the upper part of the main reaction region, a second gas-solid-liquid separation region is arranged at the upper part of the secondary reaction region, an effluent weir is arranged above the sediment region, a first-stage sewage gas pipe is connected between an air-water separation tank and the first-stage gas-solid-liquid separation region, a second-stage sewage gas pipe is connected between the air-water separation tank and the second-stage gas-solid-liquid separation region, a sewage gas circulating pipe is connected between the air-water separation tank and a water distribution pipe, the water distribution pipe is arranged at the bottom of the cell body, and a sludge discharging pipe is further arranged at the bottom of the cell body. The double-circulation anaerobic reactor has the advantages that the cell body has low height, the double-circulation anaerobic reactor can be started quickly by flocculent sludge with high shock load resistance, the requirement on a PH value of inflow water is low, granule sludge increases quickly, the processing energy consumption is low, the processing efficiency is high, the effluent quality is stable, and the double-circulation anaerobic reactor is simple to operate and convenience to run.

Owner:山东许中华环保科技有限公司

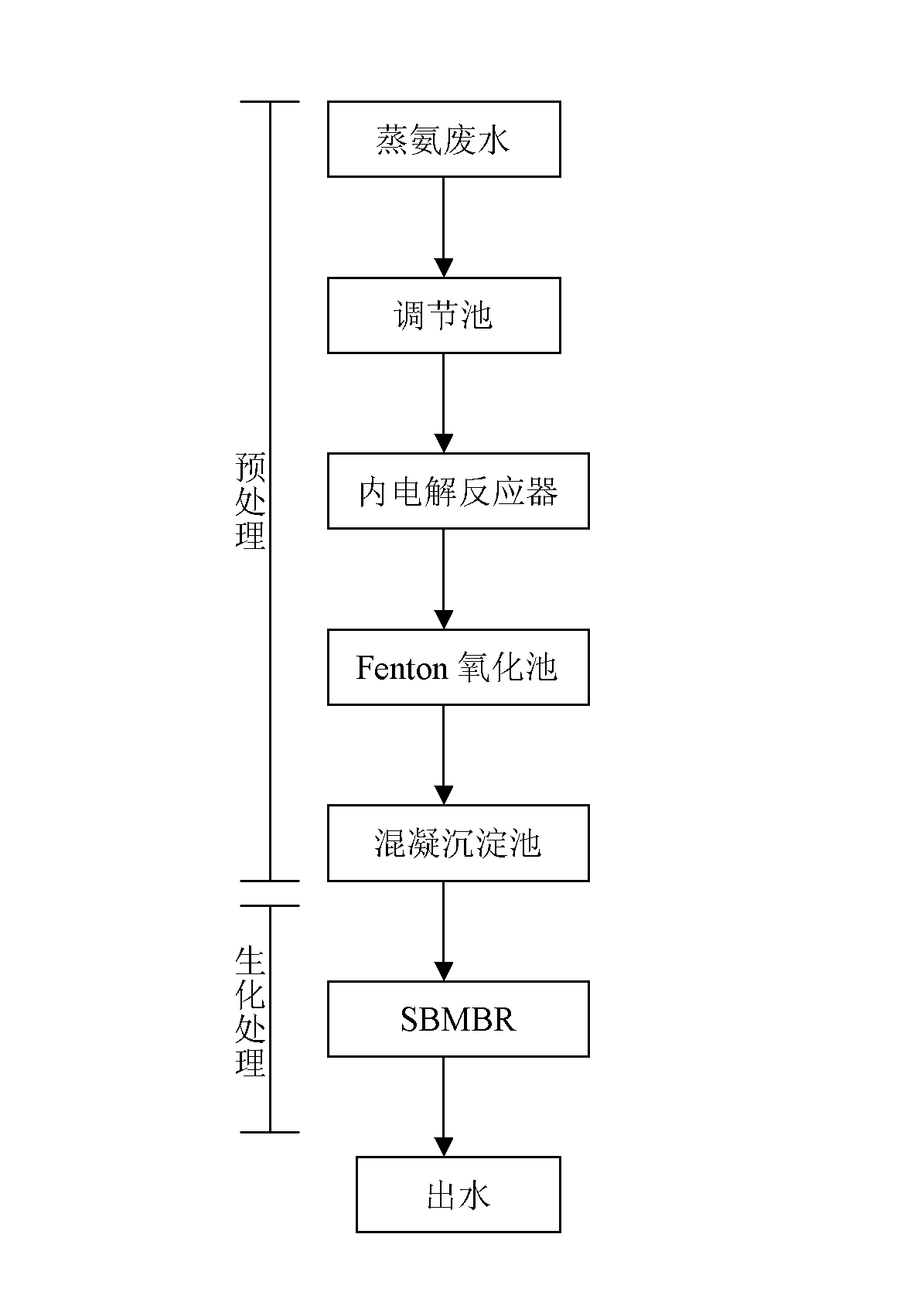

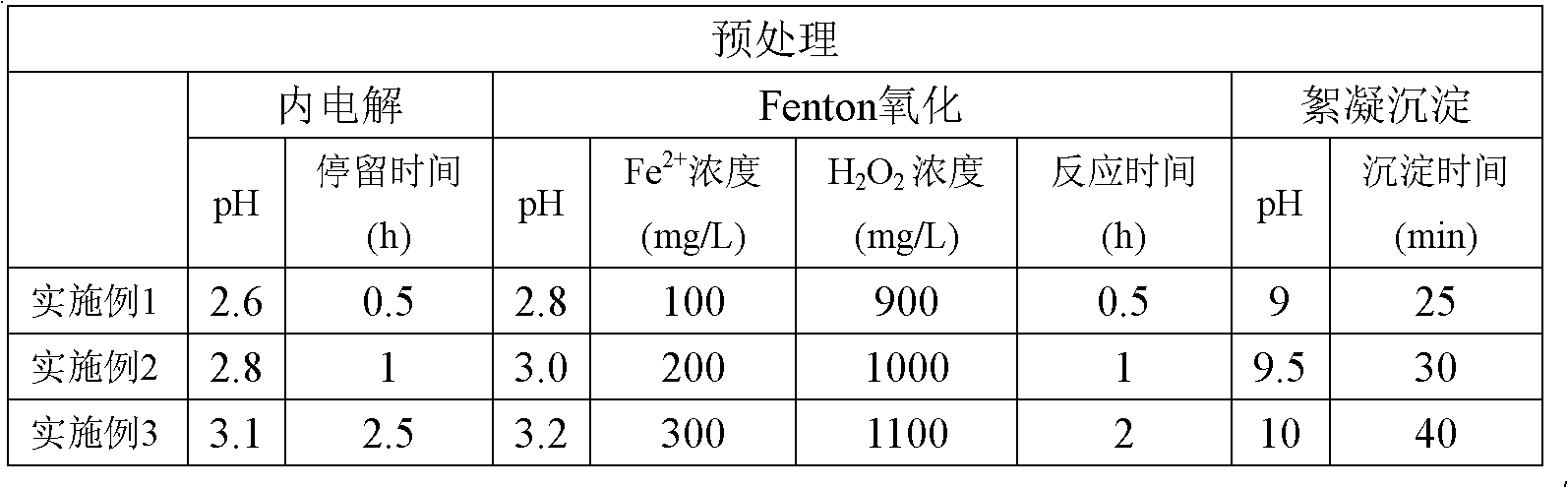

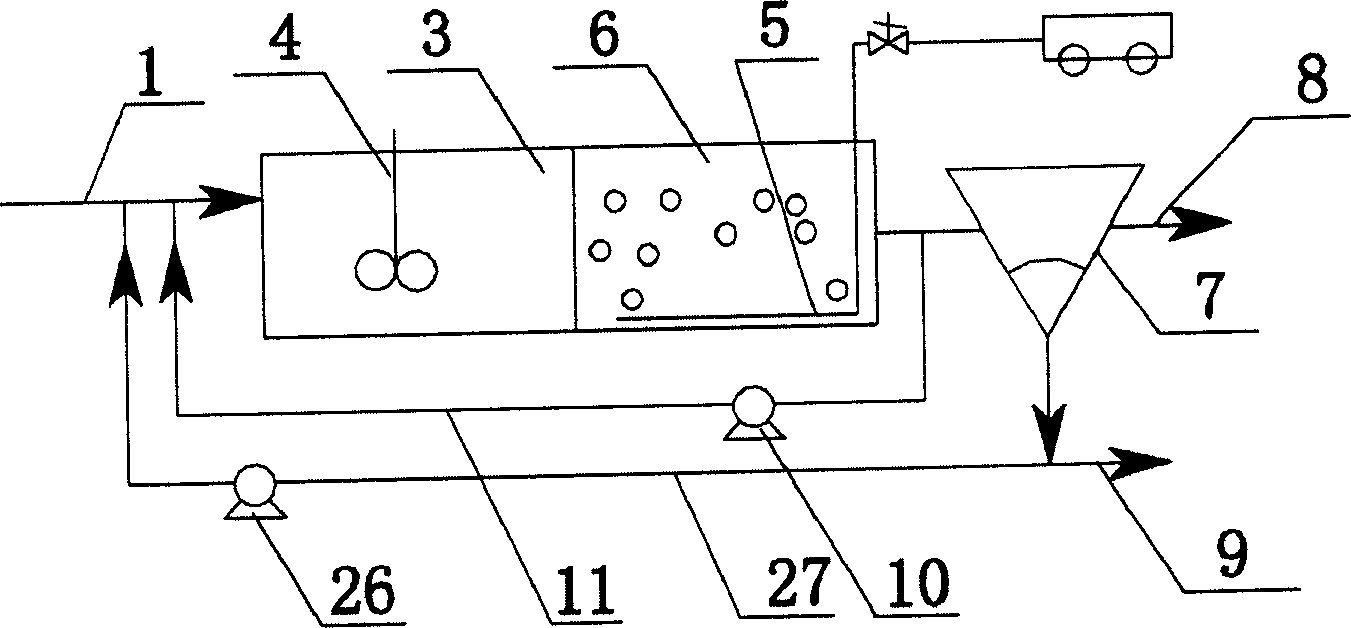

Processing method of coking steaming ammonia wastewater

ActiveCN103130379AEasy to useEasy to recycleMultistage water/sewage treatmentElectrolysisPersistent organic pollutant

The invention discloses a processing method of coking steaming ammonia wastewater. The processing method of the coking steaming ammonia wastewater comprises pretreatment of coking steaming ammonia wastewater and biochemical treatment of the coking ammonia wastewater. The pretreatment of the coking steaming ammonia wastewater uses an adjusting pool, an internal electrolysis reactor, a Fenton oxidation pond and a coagulative precipitation tank. A sequencing batch membrane bioreactor technology is adopted by the biochemical treatment, and working procedures of inflow, unused-leaving, reacting and discharging are sequentially performed according to a time period. The processing method of the coking steaming ammonia wastewater can effectively remove persistent organic pollutants and ammonia nitrogen, strengthen effluent quality, and reduce operational and investing costs of equipment.

Owner:ANGANG STEEL CO LTD

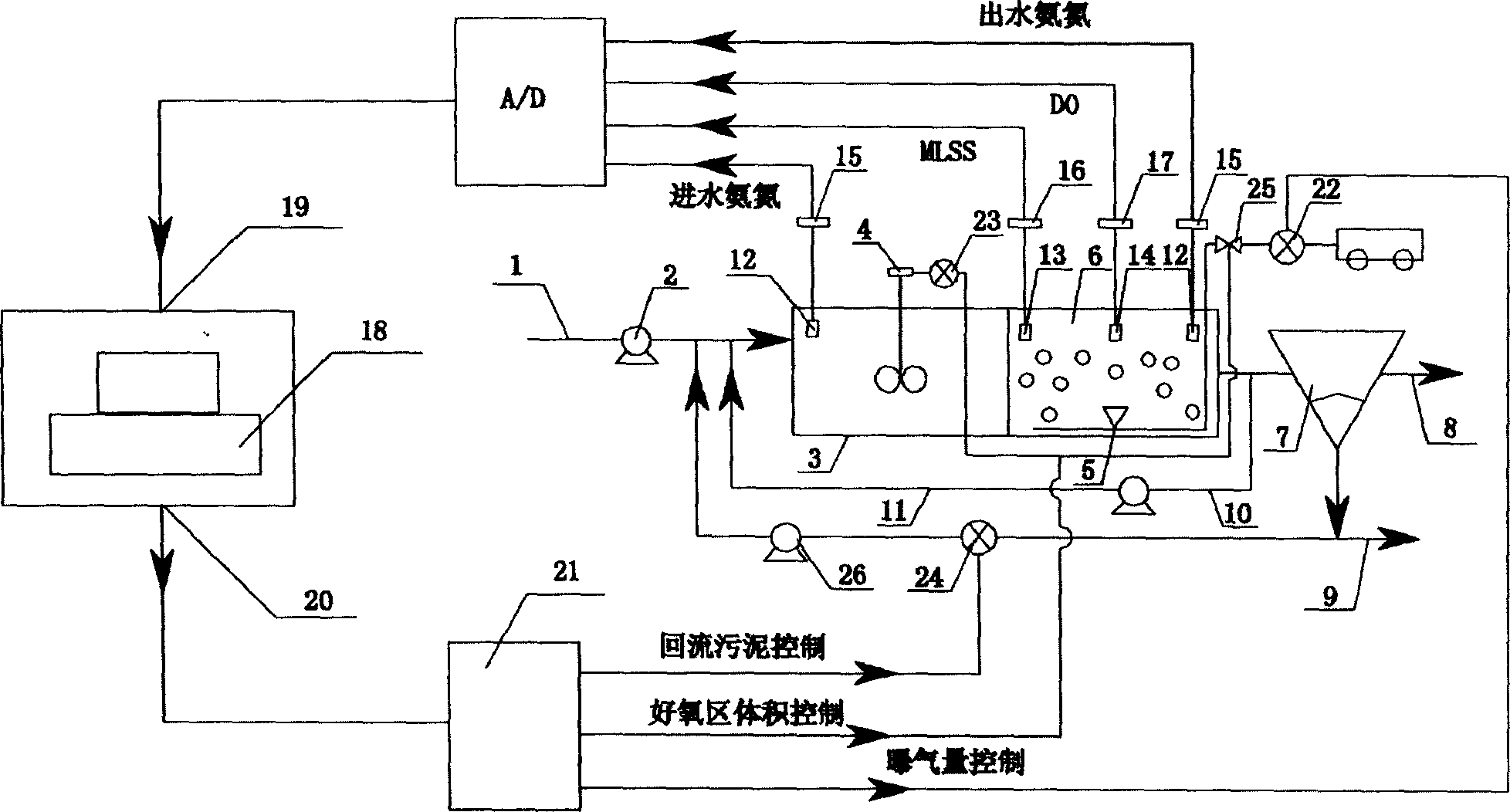

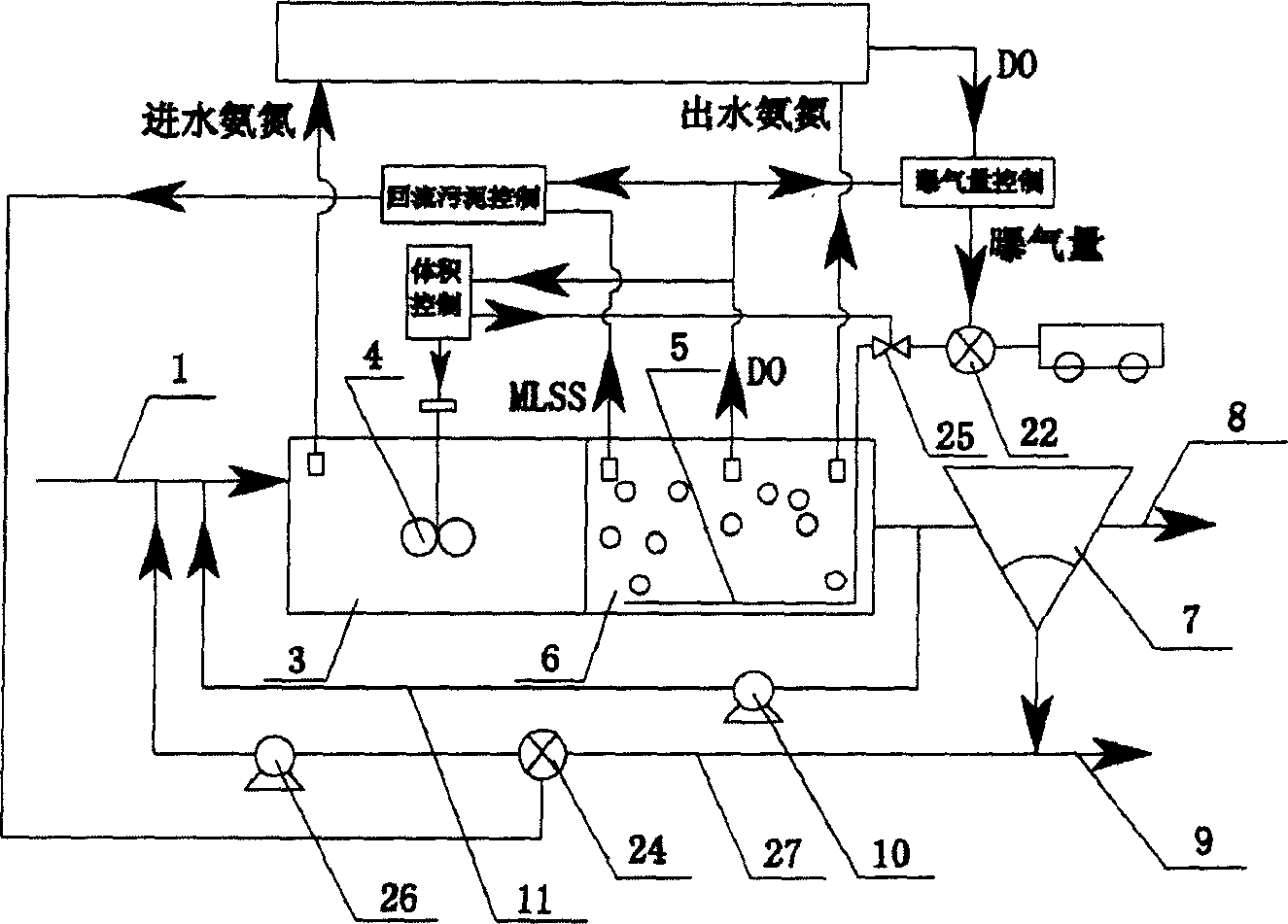

Adjusting method for A/O biological denitrification reactor and nitrification process, its on-line fuzzy controller and control thereof

InactiveCN1778714ASave dosing costOrganic load reductionControlling ratio of multiple fluid flowsChemical variable controlSludgeMarine engineering

Owner:姚宏

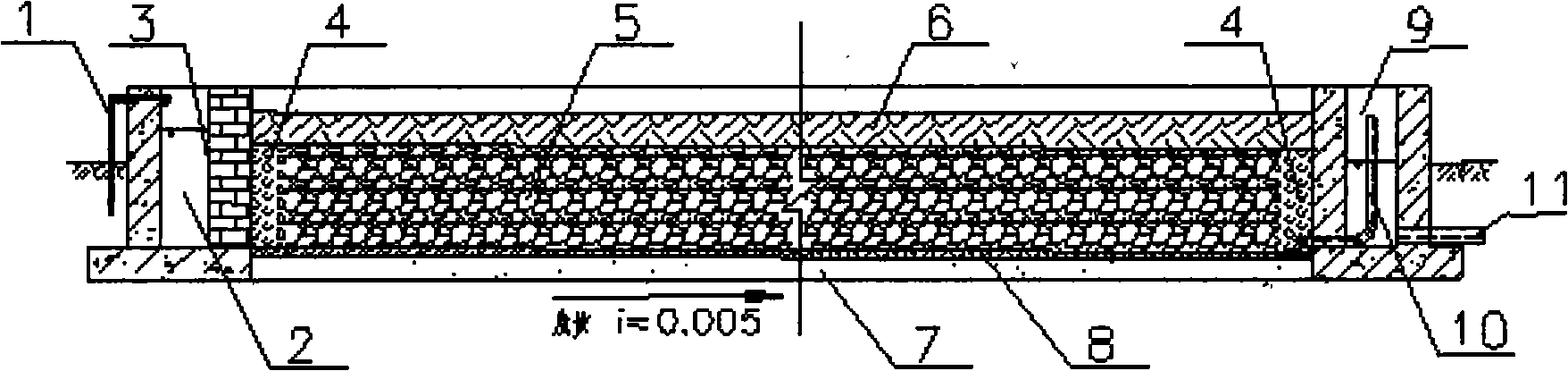

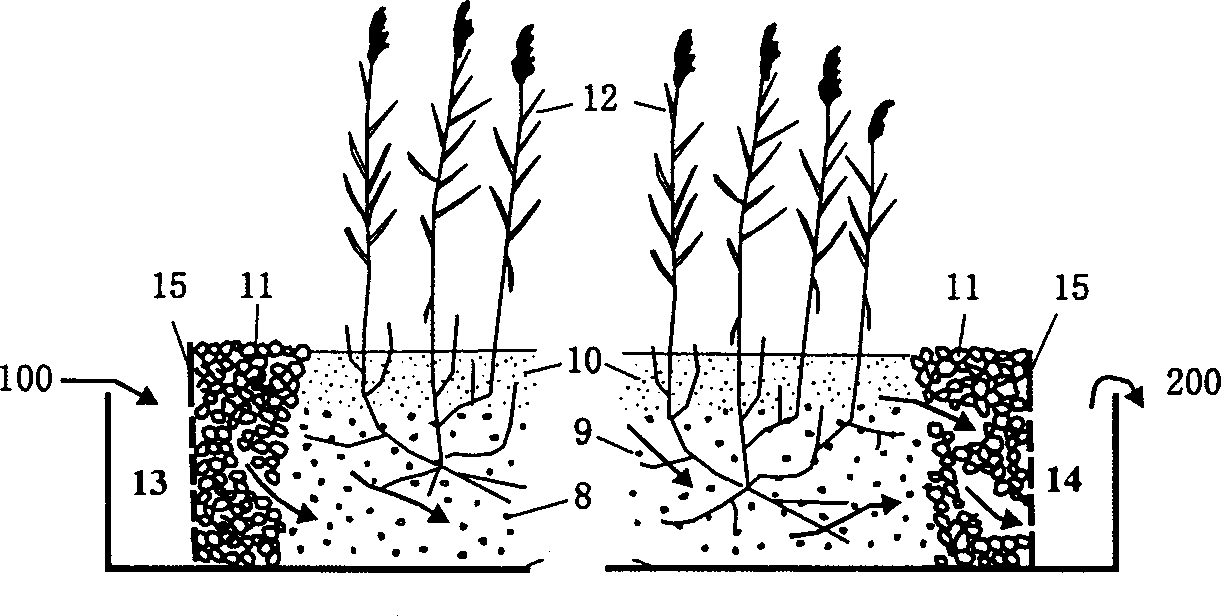

Artificial wet land and uses thereof

ActiveCN101293708ALow construction costReduce processing costsWaste water treatment from metallurgical processSustainable biological treatmentConstructed wetlandWater use

The invention provides a constructed wetland and the application thereof; wherein, the constructed wetland takes gravels and manganese sands as combined packing and can be used for treating wastewater in industries, such as iron and steel industry, etc., the wetland can reduce the nutrient content of organics, nitrogen, phosphorus, etc. in water, and meanwhile can remove metal ions, such as Fe, Mn, Cd, Pb, etc., more particularly, can reduce higher content of ions of Fe and Mn in iron and steel industry wastewater so that the index achieves the water quality standard of reclaimed water used as cooling water and the water intake quality requirement of reverse osmosis desalination process in Code for Engineering Design of Wastewater Reclamation and Reuse. The wetland has less engineering investment, simple management, low operation and maintenance cost, stable processing effect, so as to have better environmental, economic and social benefits. The wetland has better wastewater processing effect, stronger treatment capacity and stronger shock resistance loading capability, so the wetland can greatly solve the problem of excessively high concentration of Fe and Mn ions in wastewater reuse of the iron and steel industry, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Acidic high sulfate organic wastewater treatment process and apparatus

ActiveCN105439374AWill not cause churnStrong resistance to shock loadsMultistage water/sewage treatmentGas phaseAnaerobic reactor

The present invention discloses an acidic high sulfate organic wastewater treatment process and apparatus. The present invention belongs to the technical field of wastewater treatment. The specific process comprises the steps of: (1) neutralization and precipitation treatment: using lime milk to adjust PH of wastewater, and forming CaSO4 precipitation separated from the water; (2) first-stage anaerobic treatment, entering the first-stage anaerobic treatment after neutralization and precipitation treatment, introducing nitrogen into the bottom of an anaerobic reactor with stirring and blowing off, parsing H2S from an aqueous phase into a gas phase above a liquid level, introducing the H2S in the gas phase to a dry desulfurizer for desulfurization, and re-introducing the sulfur removed nitrogen into the first-stage anaerobic reactor for recycling through a blower; and (3) second-stage anaerobic treatment, introducing the sulfur removed wastewater into a second-stage anaerobic reactor to complete an anaerobic methane production reaction, and taking second-stage anaerobic effluent into an aerobic reaction tank for further processing. According to treatment process disclosed by the present invention, inhibition and toxic effects generated by the SO42- and S2- to the anaerobic biological treatment can be effectively reduced, and sewage treatment effects can be improved.

Owner:武汉森泰环保股份有限公司

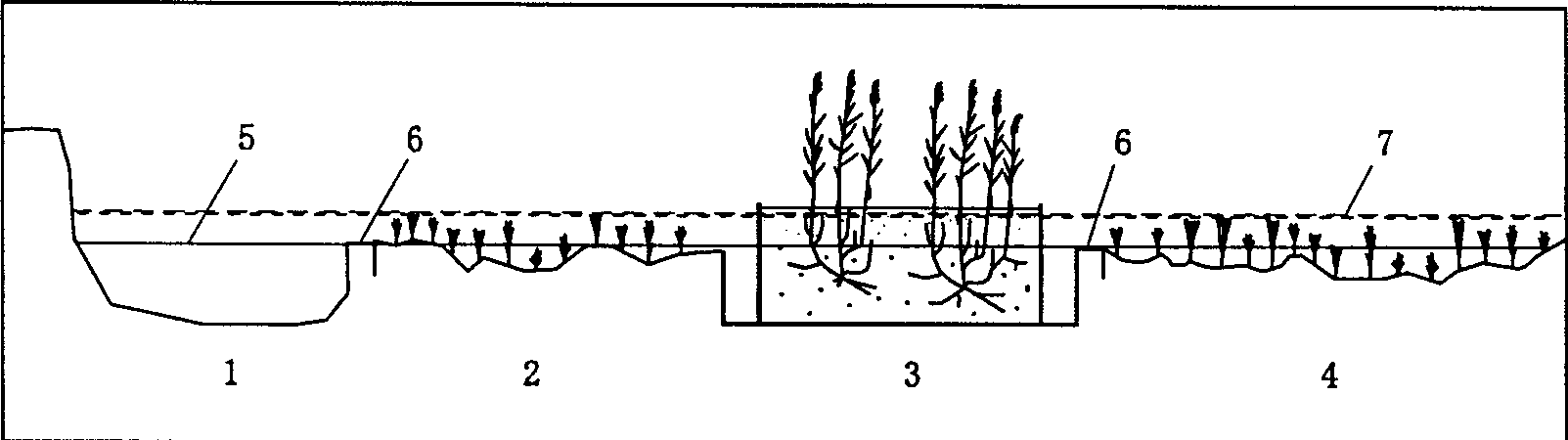

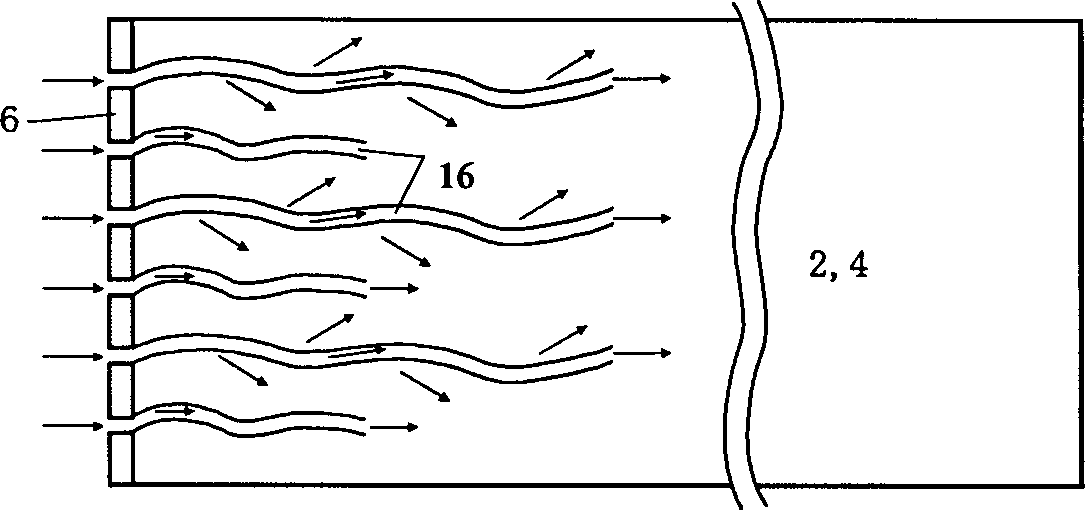

Compound wetland ecology method and system for controlling pollution of nitrogen and phosphor

InactiveCN1446759AEvenly distributedEfficient removalMultistage water/sewage treatmentConstructed wetlandPhosphor

An ecological method using artifical marshland system for controlling N-P pollution includes such steps as sequentially flowing the rain or sewage in sand deposition pool, in stage-one free-surface artificial marshland (staying for more than 1.5 hr), in zeolite undercurrent marshland containing zeolite and cinder (staying for more than 1 hr), and in stage-two free-surface artificial marshland (staying for more than 8 hr). Its advantage is high effect.

Owner:TSINGHUA UNIV +1

Synchronous denitrogen dephosphorus technology of city sewagte

InactiveCN1830844AAchieve coexistenceIncrease the number ofTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeNitrogen

A technology for synchronously removing N and P from the city sewage features that the composite suspended living things system with active sludge and biomembrane is created in a batch of composite bioreactors, which in running by the sequence of anaerobic, aerobic and anoxic steps. Its advantages are short reaction flow, less consumption of carbon source, high effect and low cost.

Owner:HUNAN UNIV

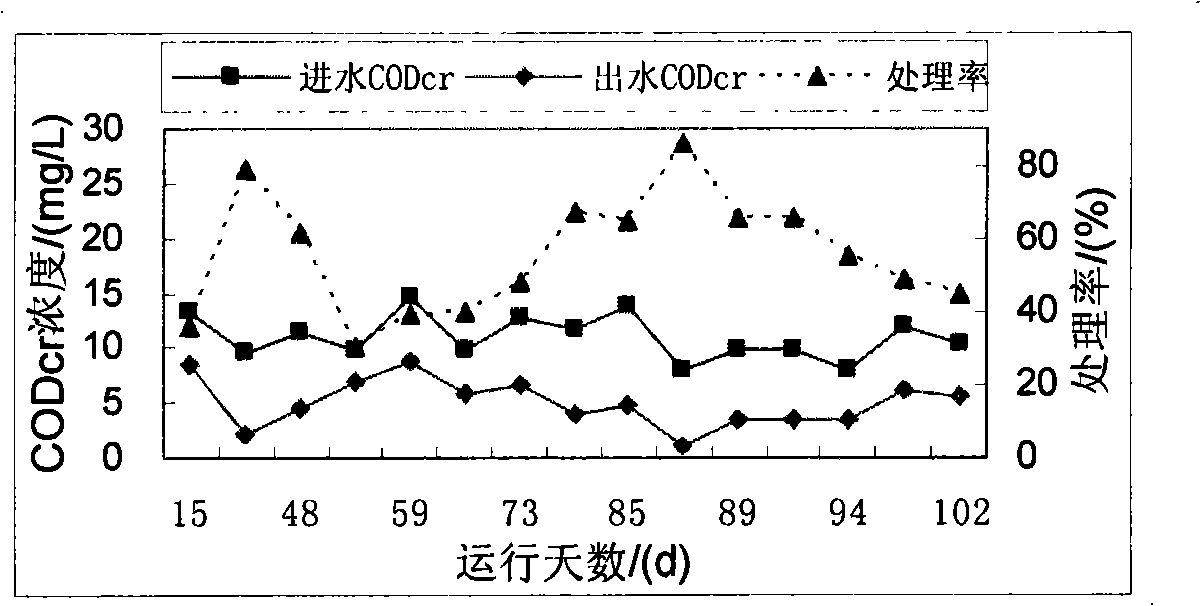

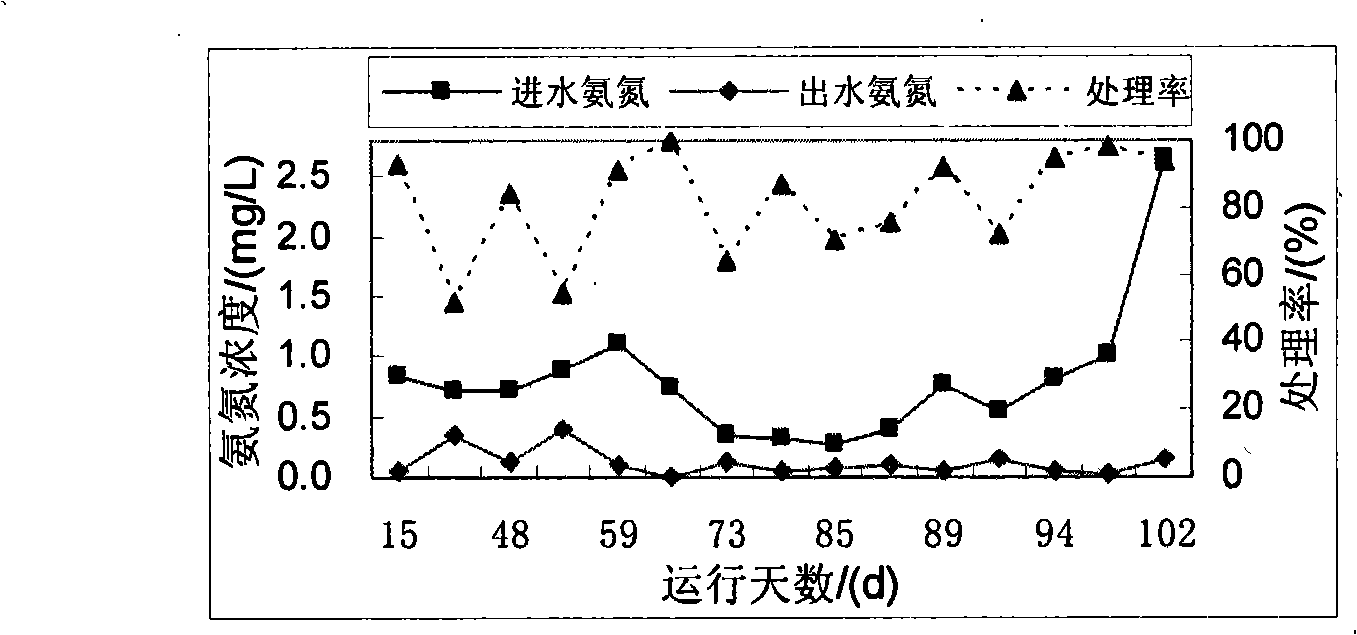

Method for treating organic nitrogen in sewage

ActiveCN102531300AInorganic nitrogen concentration decreasedReduce eutrophicationWater contaminantsWater/sewage treatment bu osmosis/dialysisFiberFiltration

The invention discloses a method for treating organic nitrogen in sewage. The method comprises the following steps of: treating sewage by using a sequencing batch biofilm reactor, decomposing macromolecular organic nitrogen into micromolecular organic nitrogen under the coexistence of anaerobic, anoxic and aerobic conditions, removing the micromolecular organic nitrogen by using the degradation of microbes, and simultaneously removing ammonia nitrogen and nitrate nitrogen through short-cut nitrification and denitrification and anaerobic ammonium oxidation; and treating by using a coagulation-microfiltration method, precipitating to remove bacteria, suspended solids (SS) and other nitrogen-containing substances by adding a coagulant, and removing refractory macromolecular organic nitrogen such as humic acid, fulvic acid and the like through filtration of a hollow fiber microfiltration membrane to reduce the total amount of the organic nitrogen in the sewage. The invention also discloses a device for implementing the treatment method.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

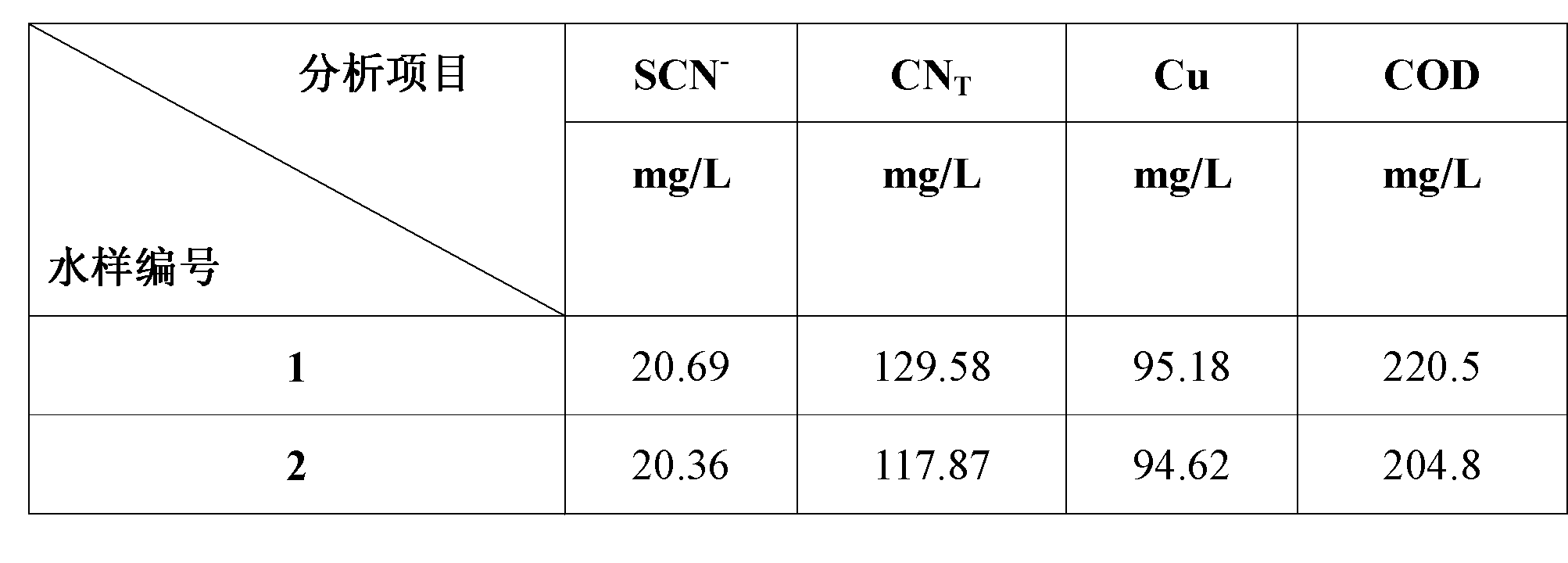

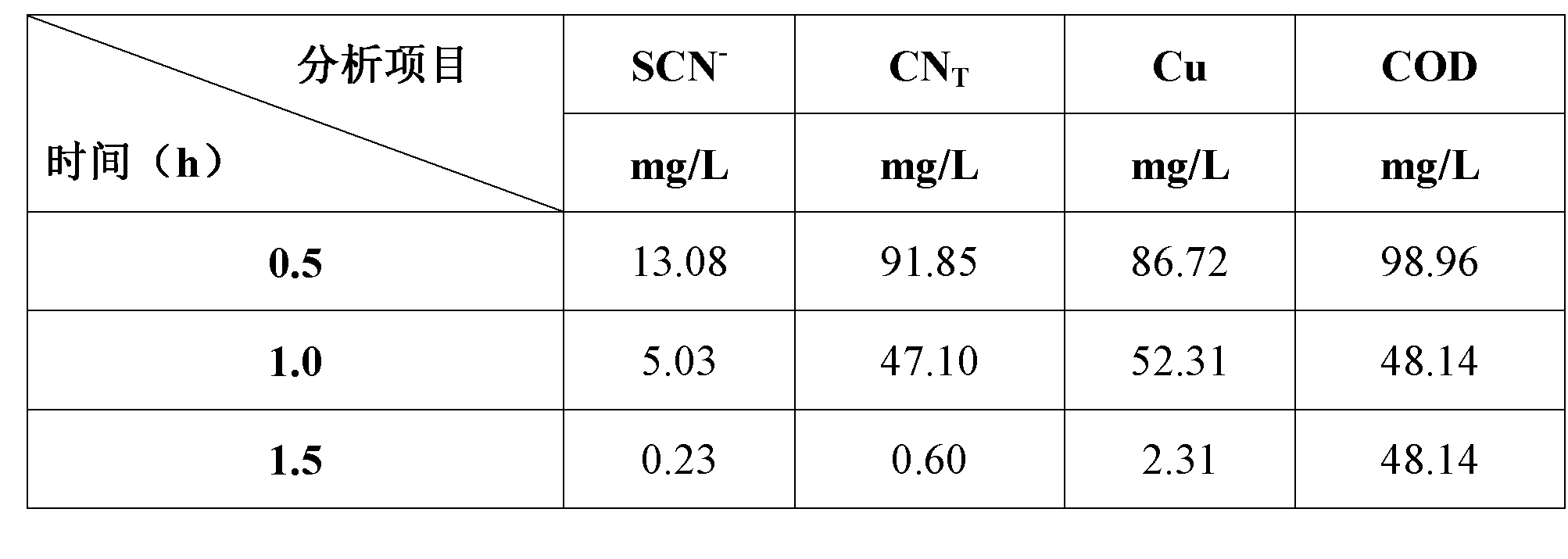

Method for processing waste water containing cyanide, thiocyanogen and heavy metal

ActiveCN103253796AEasy to handleReduced processing costs aloneWater contaminantsMultistage water/sewage treatmentSocial benefitsChemical oxygen demand

The invention discloses a method for processing waste water containing cyanide, thiocyanogen and heavy metal. The method is characterized by reasonably combining an INCO method and an ozone method, so that the defects of the two methods can be avoided, and the advantages of the two methods can be maintained. The cyanide-containing waste water in a tailings pond of the gold industry can be treated in four steps of reaction medicine preparation, INCO treatment, ozone oxidation treatment and solid-liquid separation, the treatment effect on the cyanide, COD (chemical oxygen demand), As and heavy metals is good, the treatment cost is low, the impact resistance and load capacity are strong, and the secondary pollution can be avoided. Therefore, by adopting the method to treat the cyanide-containing waste water in the tailings pond, a good environmental benefit and a social benefit can be realized.

Owner:CHANGCHUN GOLD RES INST

Device for treating oil field waste water

ActiveCN101215060AReduce power consumptionLow running costWaste water treatment from quariesMultistage water/sewage treatmentAutomatic controlFiltration

A device used for treating oil field waste water is characterized of including a water inlet area, a reacting area and a water outlet area. The water inlet area comprises a waste water tank, a water inlet pump and a flowmeter; the water inlet pump is arranged at the outlet of the waste water tank and the flowmeter is arranged on the water inlet pipeline, the reacting area and a water outlet area are located inside the reacting groove, the reacting area is divided into a electrical floating region and a modified magnetic particle adsorption filtration region, wherein the electrical floating region comprises an electric plate the bottom of which is fixed on the device wall by insulation material, a guide flow inclined plate at a dip angle of 45 DEG-60 DEG with the level surface, a perforated pipe which is located on the bottom side of the guide flow inclined plate, a baffle plate located at the bottom and a oil collecting pipe. The modified magnetic particle adsorption filtration region includes a porous plate, a separating plate and modified magnetic particles, wherein the modified magnetic particles are placed in an iron frame. The water outlet area is located on the opposite side of the water inlet area. The disposal unit of the invention is small and compact, the electric devices are less, the power consumption is low and direct current is employed, thereby having low cost working, convenient operation, automatic control and better operability for utilization of actual project.

Owner:溧阳常大技术转移中心有限公司

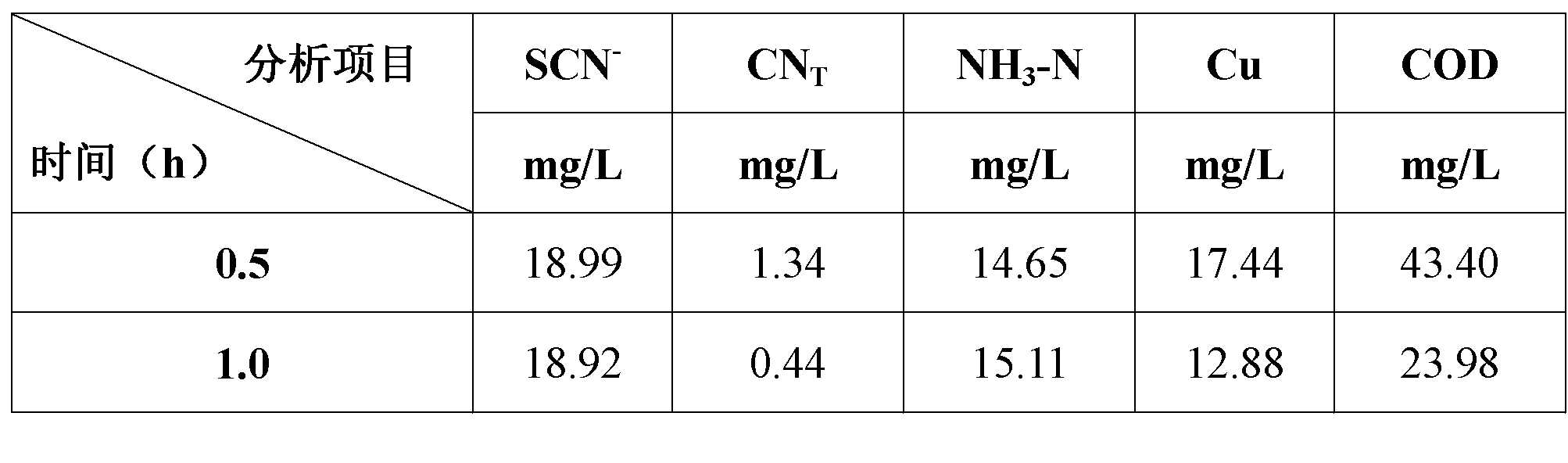

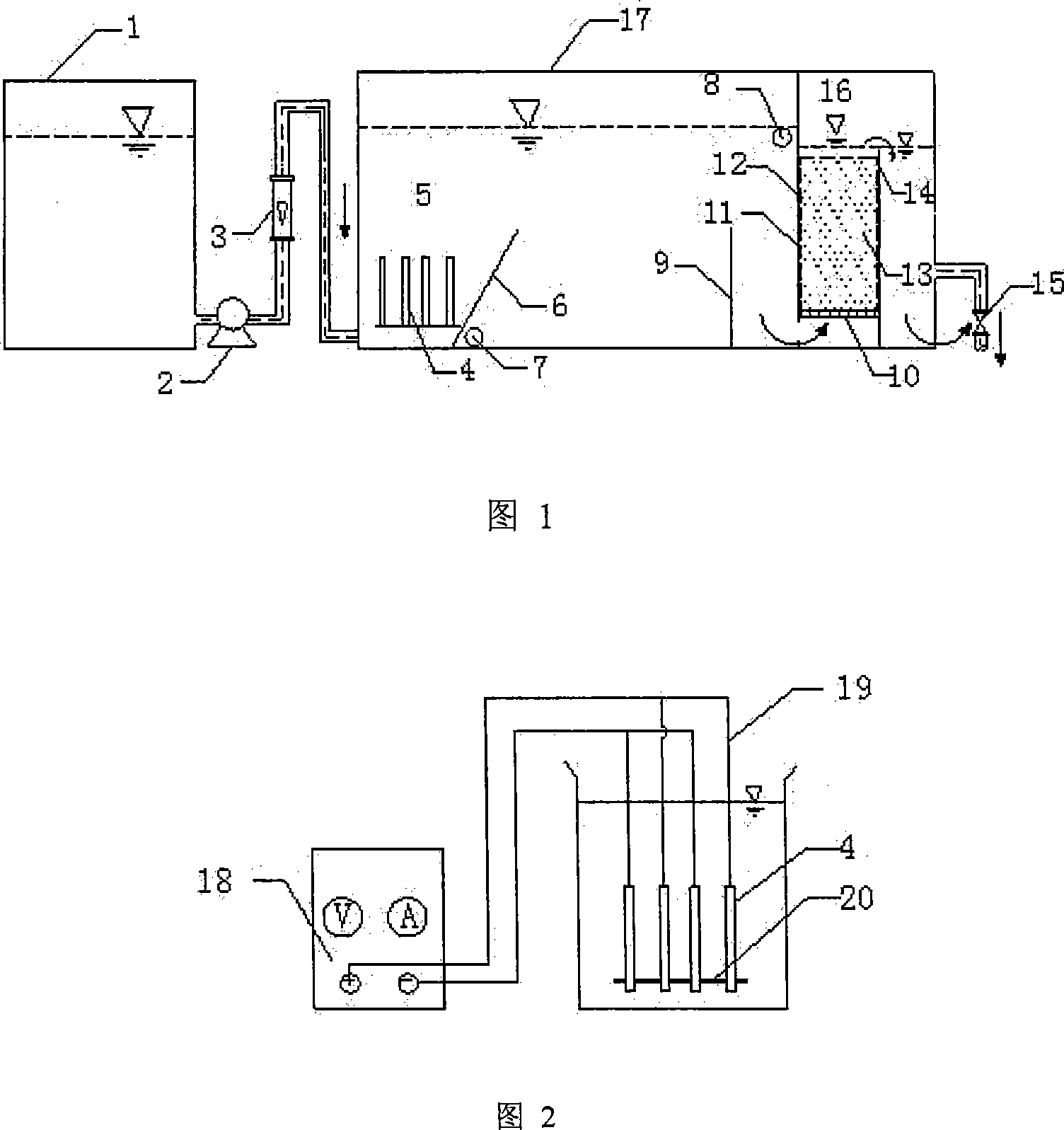

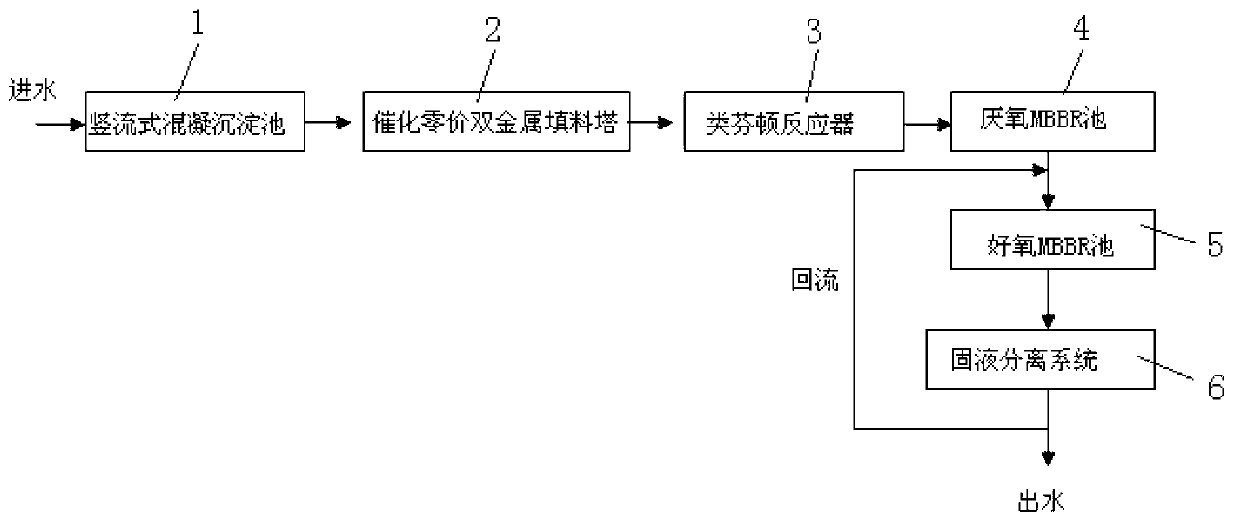

Pharmaceutical chemical wastewater treatment device and treatment method thereof

ActiveCN103011533AReduce consumptionEasy to handleMultistage water/sewage treatmentChemical industryReaction rate

The invention relates to a pharmaceutical chemical wastewater treatment device and a treatment method thereof. The treatment device comprises a vertical flow type coagulative precipitation tank, a catalysis zero valence bimetallic packing tower, a Fenton-like reactor, an anaerobic MBBR (Moving Bed Biofilm Reactor) pool, an aerobiotic MBBR pool and a solid-liquid seperation system which are sequentially connected. The treatment method is a catalysis zero valence bimetallic- Fenton-like-MBBR coupling treatment method. The treatment device has the advantages of being capable of simultaneously treating multiple organic pollutants, occupying a small area and being simple in structure and easy for finalization and industrialization. The catalysis zero valence bimetallic packing tower enables the performance of reducing and treating degradation-resistant organic matters to be stronger, does not harden after running for long-term and is suitable for a wide pH value range and low in operating cost, and the consumption of metallic iron is little. The Fenton-like reactor is faster in oxidation reaction rate and suitable for the wide pH value range. The pharmaceutical chemical wastewater treated by the wastewater treatment method provided by the invention can reach the new emission standard of wastewater in a pharmaceutical chemical industry.

Owner:TAIZHOU UNIV

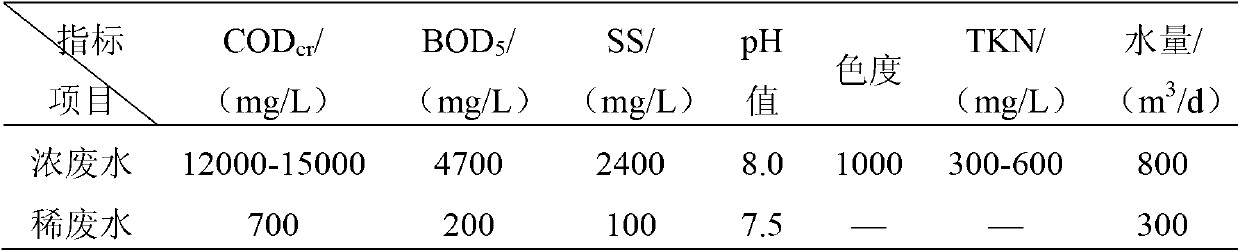

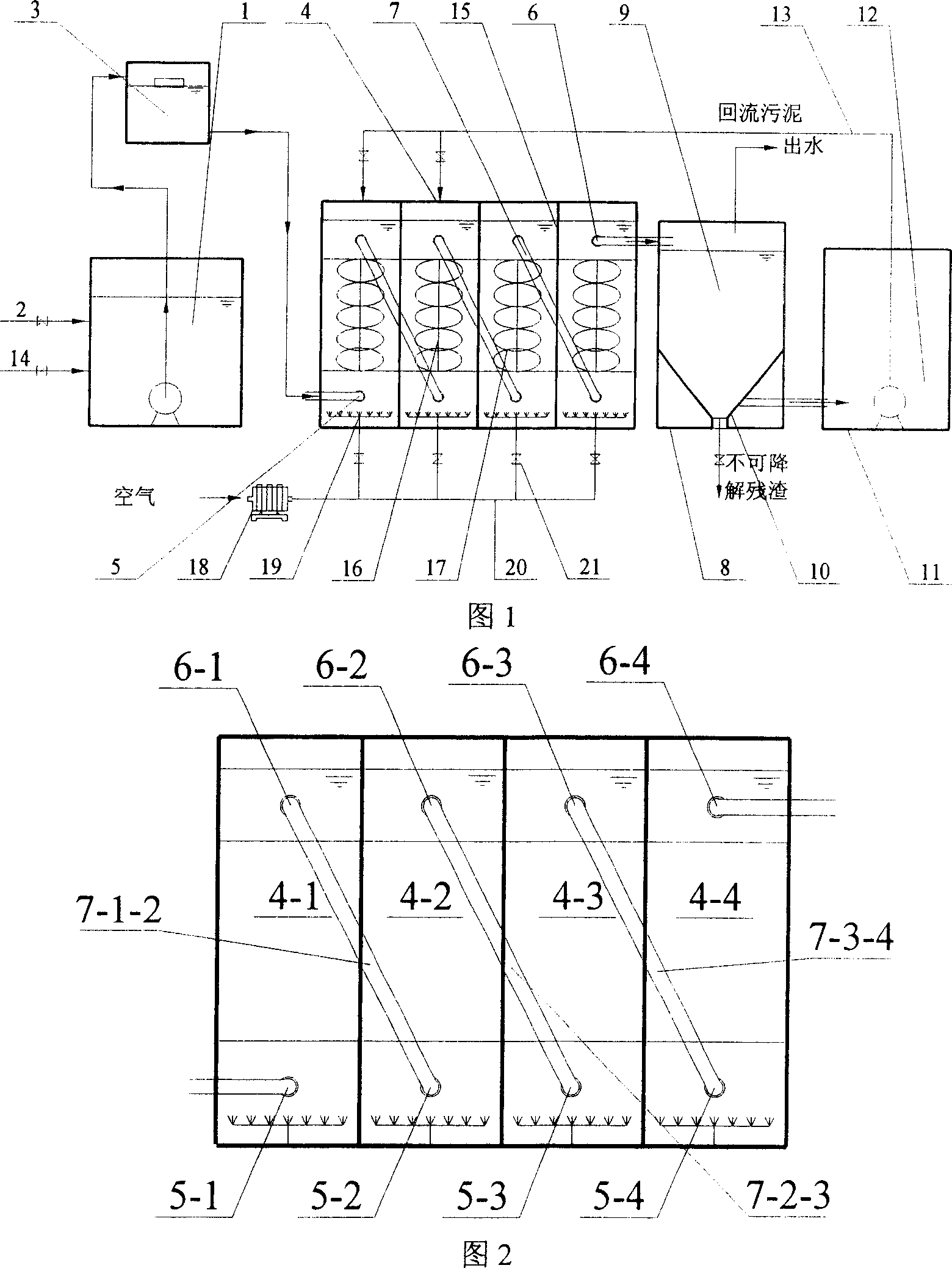

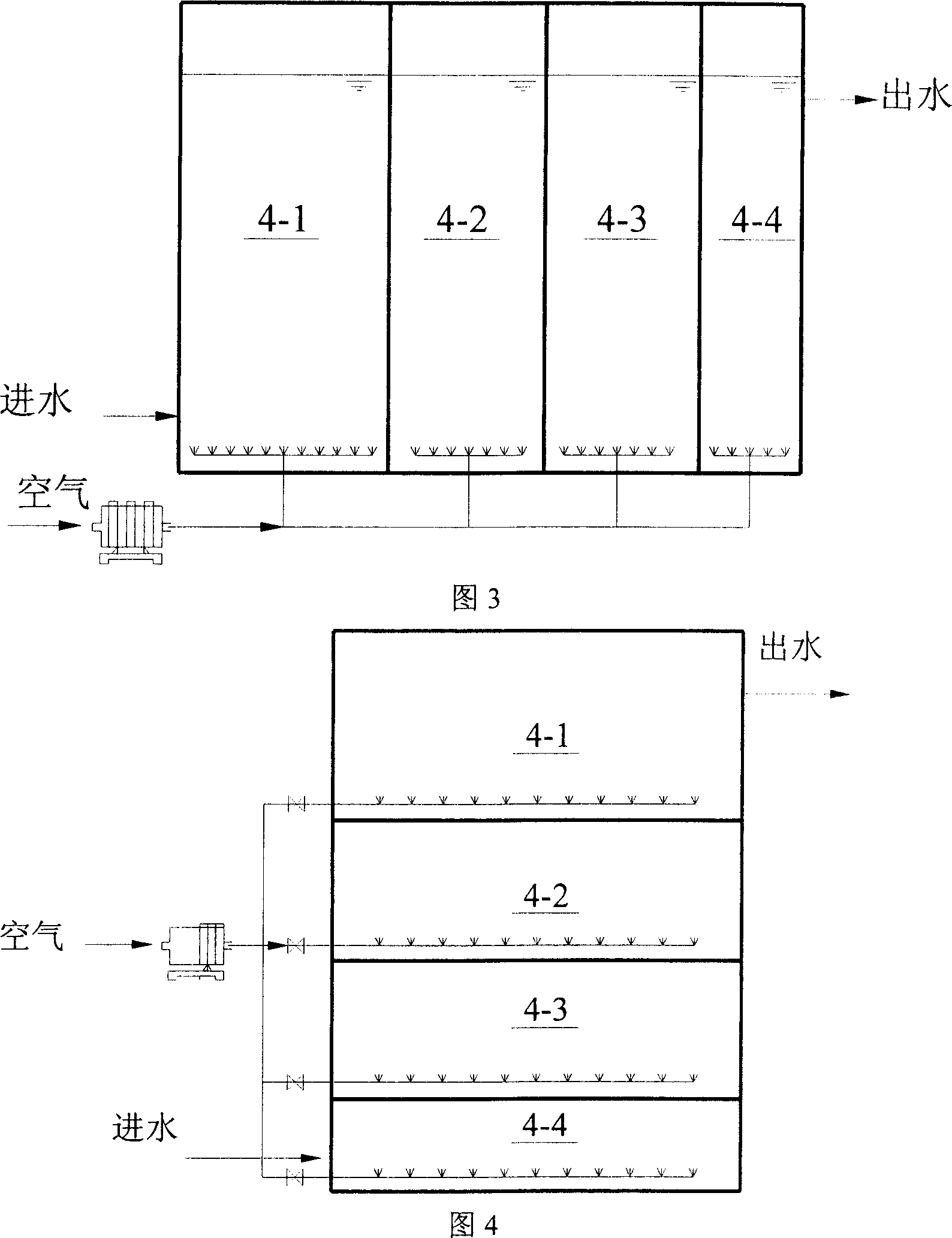

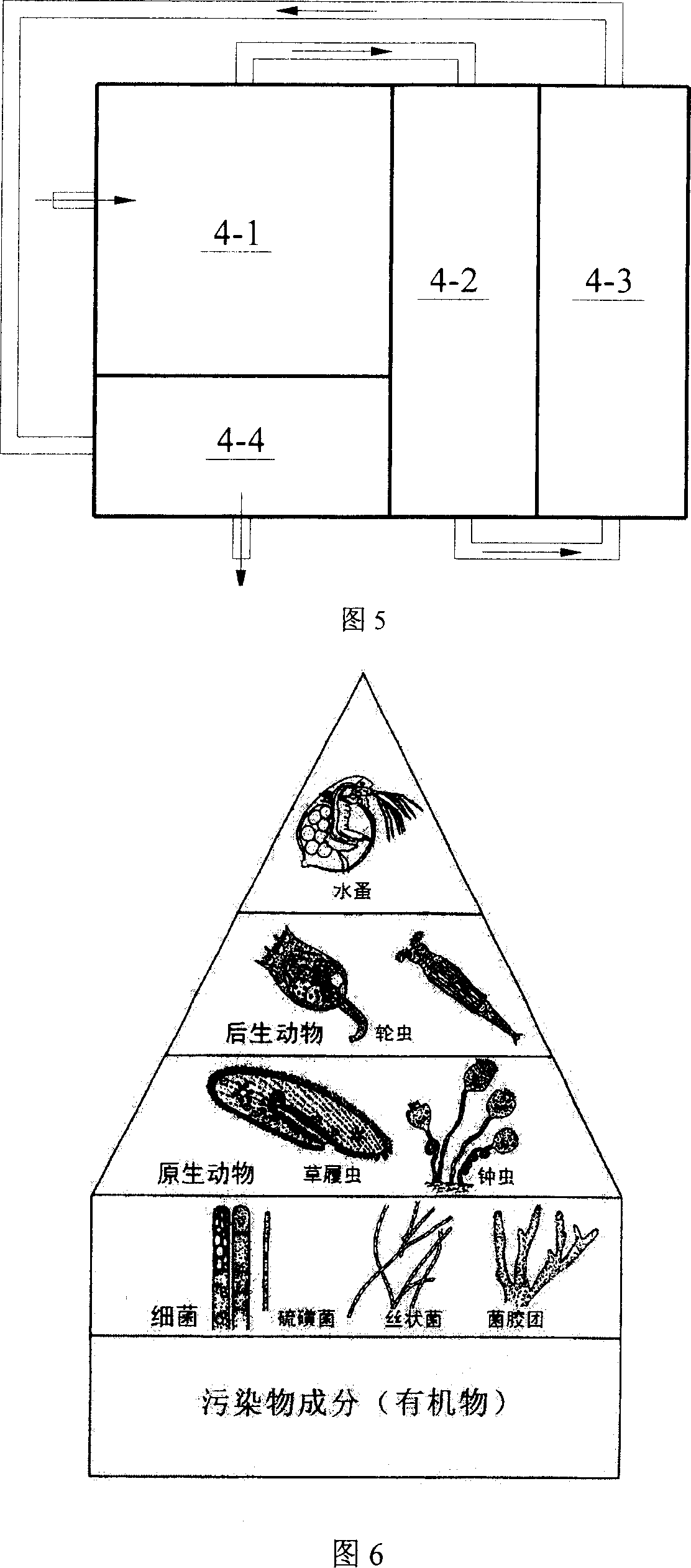

Treatment device with bio-sludge degrading and denitrogenation, and its operating method

InactiveCN1935708AReduction of excess sludgeStrong resistance to shock loadsSludge treatment by oxidationSustainable biological treatmentSubstrate concentrationEcosystem

The invention relates to a biological mud degrading and denitrogenating treating device and the operating method thereof, belonging to environmental protection field, especially relating to a device of strengthening predation of food chain of microbical ecosystem to degrade biological mud and denitrogenating in high performance and the operating method thereof, where the treating device comprises multistage contact oxidation tank, solid-liquid separation settling tank, and anaerobic hydrolyzing tank. And the peculiar propreties of spiral biological carriers in the multistage contact oxidation tank and the flexbilly controllable per-tank substrate concentration and oxygen supply conditions offer various microbes appropriate growth environments, thus composing an ecosystem with a food chain of bacilli, protozoans, metazoans, and senior micro animals. By the food chain, at the middle and rear stages of the multistage oxidation tank, higher microbes can largely prey on the residual mud with bacilli and other lower microbes as the main, thus largely reducing the residual mud.

Owner:UNIV OF SCI & TECH BEIJING

Nanometer composite powder zinc impregnation processing method

ActiveCN1730727AMeeting Corrosion Protection NeedsDoes not affect mechanical propertiesHeat inorganic powder coatingCooling downZinc

The invention provides a process for nanometer composite powder zinc impregnation processing method, which comprises metal member pretreatment, powder zinc impregnation processing and metal member post-treatment. The powder zinc impregnation processing comprises formulation of nano composite powder zinc impregnation agent, a zinc impregnation procedure and a cooling down separation process.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +4

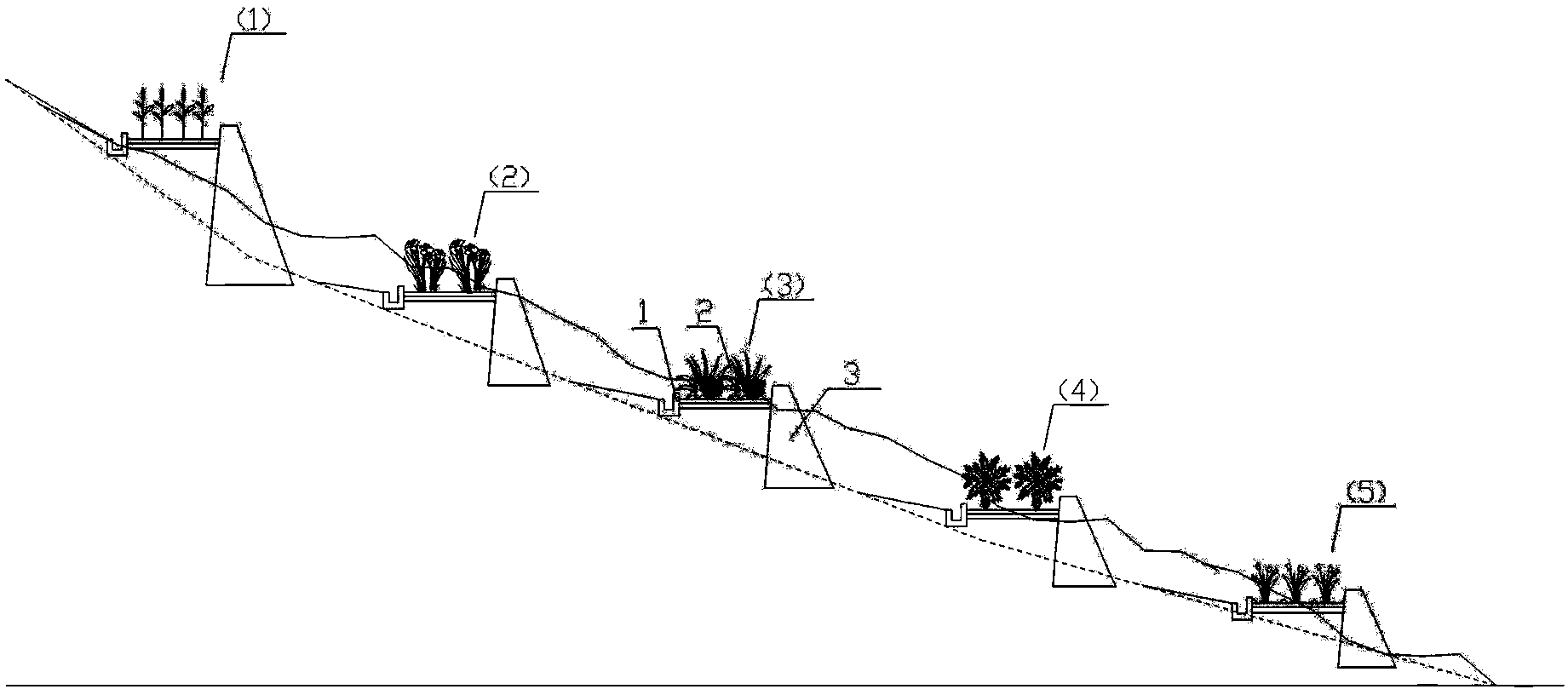

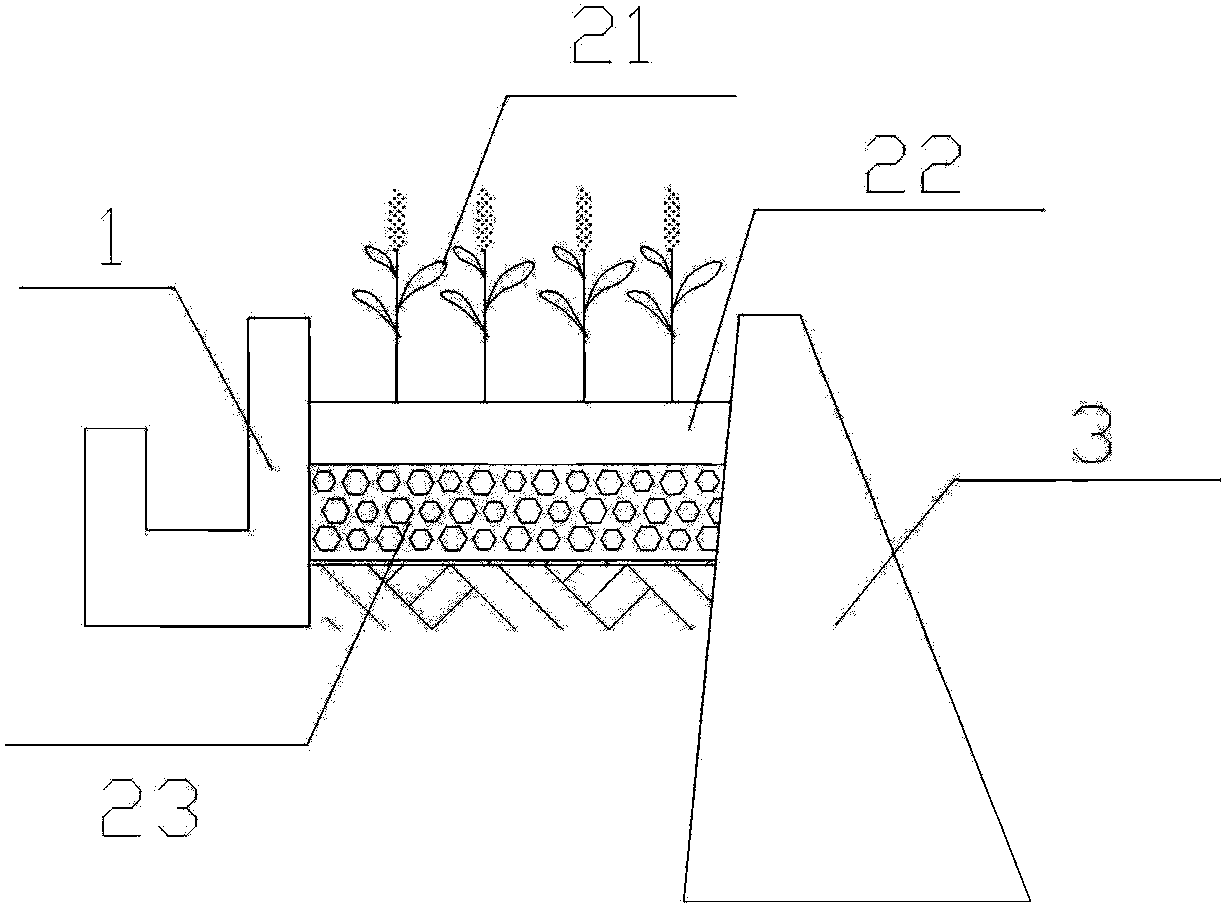

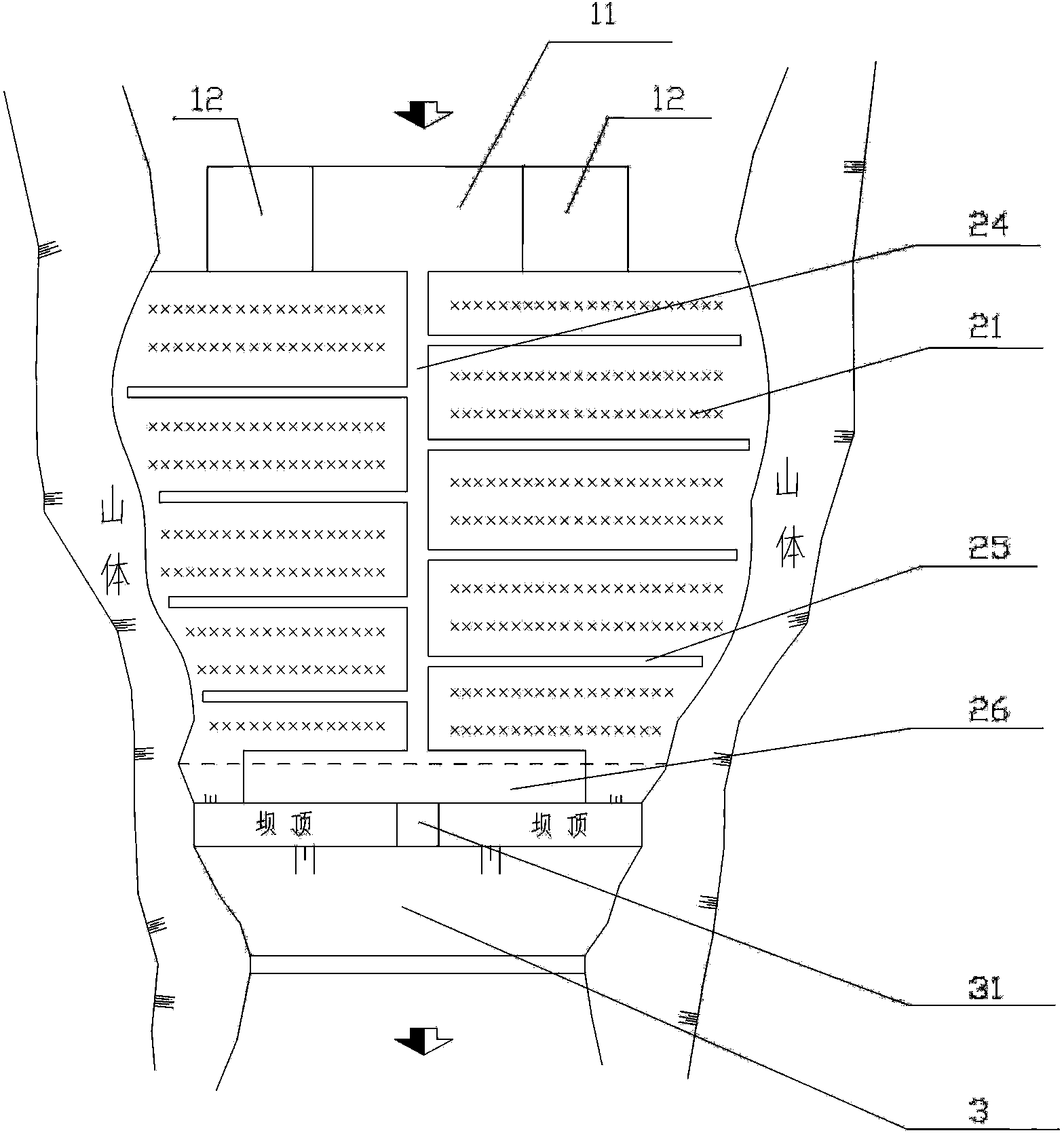

Ecological check dam prevention and control system for three gorges reservoir region hilly land ravine agricultural non-point source pollution

ActiveCN103588303ANo energy consumptionAvoid easy cloggingSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandEngineering

The invention relates to the fields of environmental engineering and ecological engineering. An ecological check dam prevention and control system for three gorges reservoir region hilly land ravine agricultural non-point source pollution is characterized in that multiple levels of ecological check dams are in trapezoidal distribution with natural fall from high to low along with the hilly land; each level of ecological check dam consists of a water storage regulating pond, a constructed wetland and a check dam main body, which are arranged sequentially according to the water flow direction; the water storage regulating pond is communicated with an overflow port in the previous level of the check dam main body. The system can effectively intercept and control the hilly land ravine agricultural non-point source pollution of the drainage basin, can reduce water and soil loss, can perform water-harvest irrigation, can reduce attenuation of channel nutrients before and after rainfall on sloping fields, and can realize ecological interception of agricultural non-point source pollutants.

Owner:WUHAN UNIV OF TECH

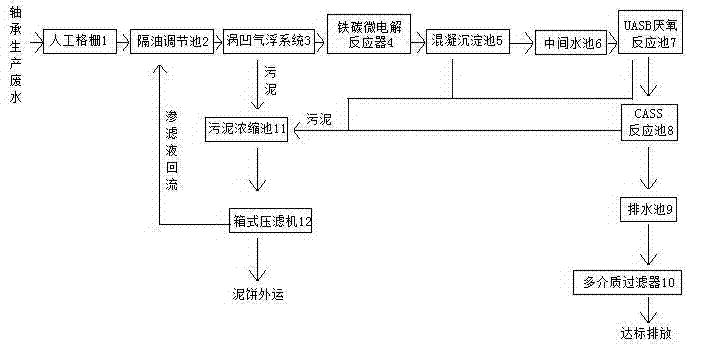

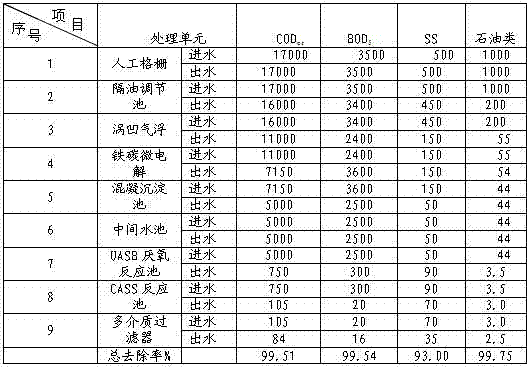

Treatment process for bearing production wastewater

InactiveCN103613247ASolve the bloat problemEasy to adjust working conditionsFatty/oily/floating substances removal devicesMultistage water/sewage treatmentEcological environmentElectrolysis

The invention discloses a treatment process for bearing production wastewater. The treatment process comprises the following steps: firstly, enabling bearing production wastewater to enter an oil-separation adjusting tank; separating floating oil in the wastewater and agitating uniformly; then lifting the wastewater into a cavitation air floatation system to remove suspension matters and petroleum in the wastewater; conveying the wastewater treated by the cavitation air floatation system into an iron-carbon micro-electrolysis reactor and carrying out a Fenton reagent and iron-carbon micro-electrolysis combined oxidation reaction to reduce chemical oxygen demand and improve the ratio value of biochemical oxygen demand / chemical oxygen demand of the wastewater; conveying the wastewater reacted in the iron-carbon micro-electrolysis reactor into a coagulation precipitation tank, adjusting the pH (Potential of Hydrogen) and carrying out a coagulation and flocculation reaction; enabling reacted liquid supernatant to flow into a middle water pond to sequentially enter a UASB (Up-flow Anaerobic Sludge Bed / Blanket) anaerobic reaction tank, a CASS (Cyclic Activated Sludge System) reaction tank and a water discharging tank and filtering by a multi-medium filter; discharging after the water reaches standards. The treatment process is simple in management and good in wastewater treatment effect; a sludge expansion problem which usually and easily occurs in a traditional active sludge method is overcome; the water can be discharged after the water quality reaches the standards and the treatment process is good for protecting the ecological environment.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

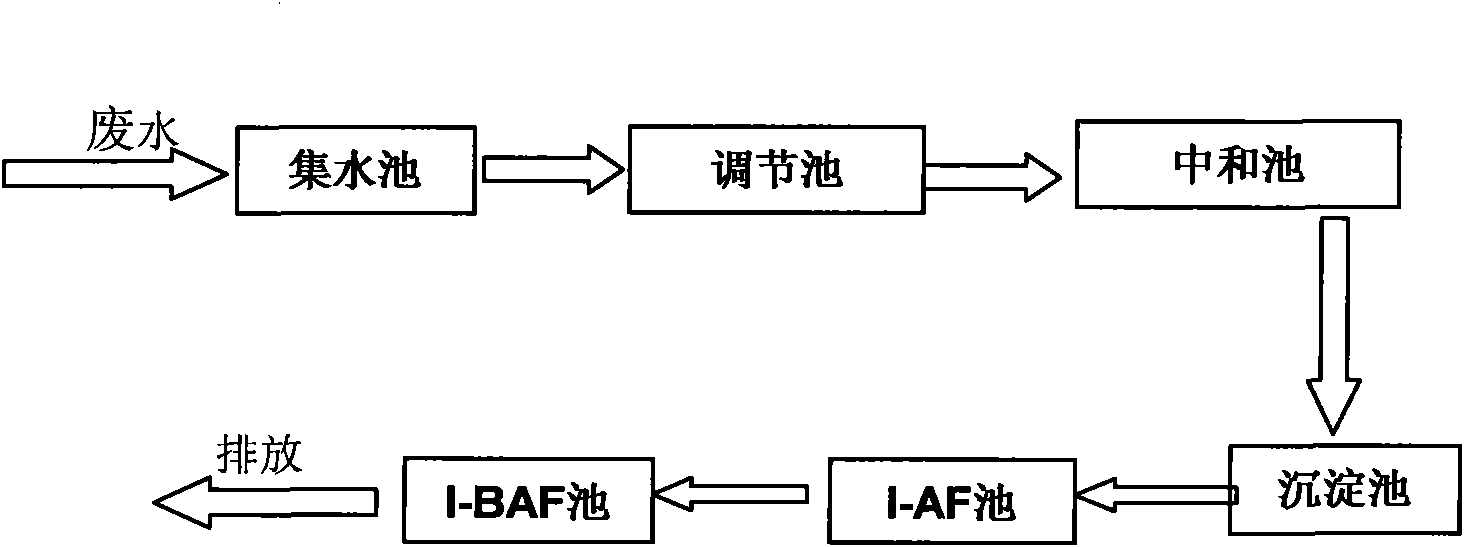

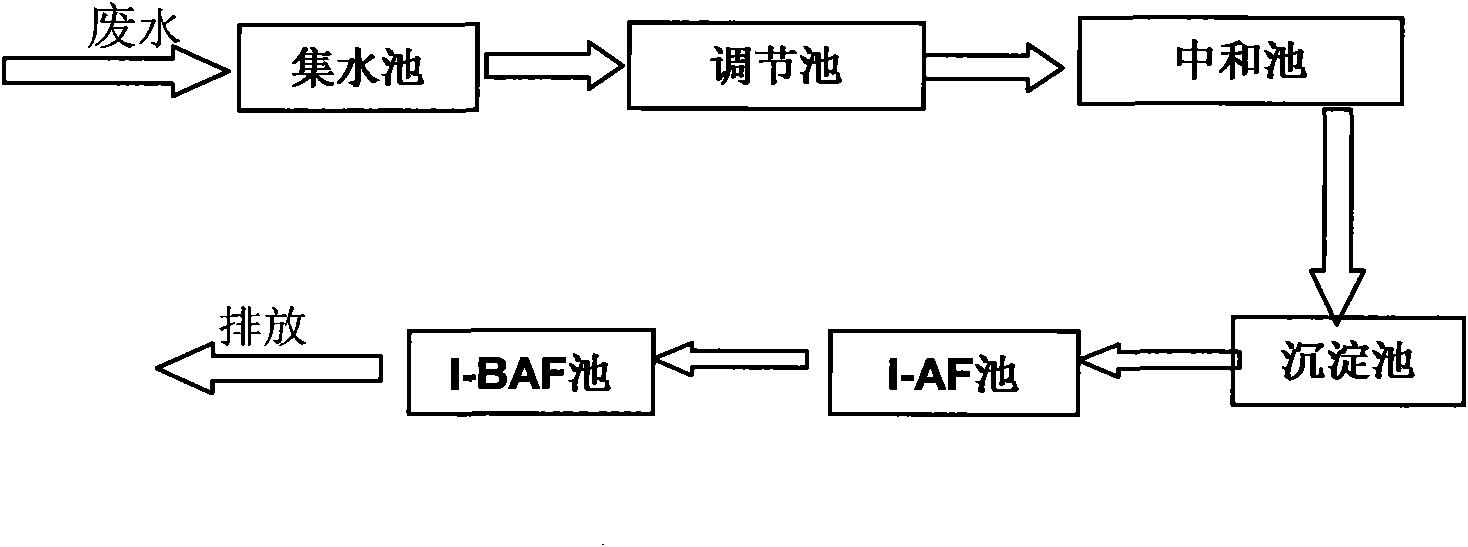

Method for treating 2,4,6-trinitrotoluene waste water and application thereof

ActiveCN101830606AAvoid inhibitionAvoid side effectsWater contaminantsMultistage water/sewage treatmentBiotechnologyHazardous substance

The invention provides a method for treating 2,4,6-trinitrotoluene (TNT for short) waste water. In the invention, waste water is mainly treated by immobilized microorganisms, an anaerobic biological filter (I-AF) and immobilized microorganisms and a biological aerated filter (I-BAF), wherein the waste water enters a collecting tank, is lifted by a pump to enter a regulating tank and enters a setting tank after being homogenized and neutralized by the regulating tank so as to remove suspended substances (SS) in the waste water; the effluent is discharged after reaching standards after enteringthree-stage I-AF and five-stage I-BAF for further treatment. The specific steps of the method are shown in the specification. The invention has the advantages that biological treatment adopts an immobilized microorganism technology, which improves the poison resistance of the microorganisms, realizes the high-efficiency removal on toxic and harmful substances of nitrobenzene and the like, reducesthe treatment cost and realizes the standard-reaching discharge of the waste water. The application of the invention is not only suitable for treating the TNT waste water but also is applied to treating nitrobenzene and aniline contained pollutants and organic waste water thereof.

Owner:PEKING UNIV +1

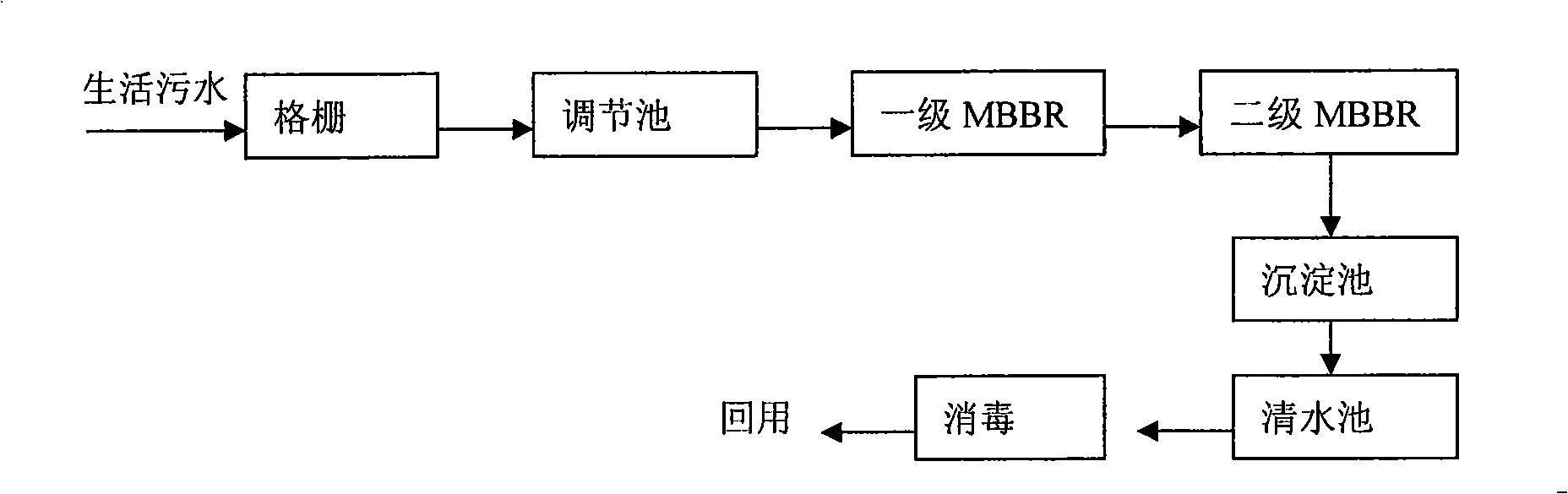

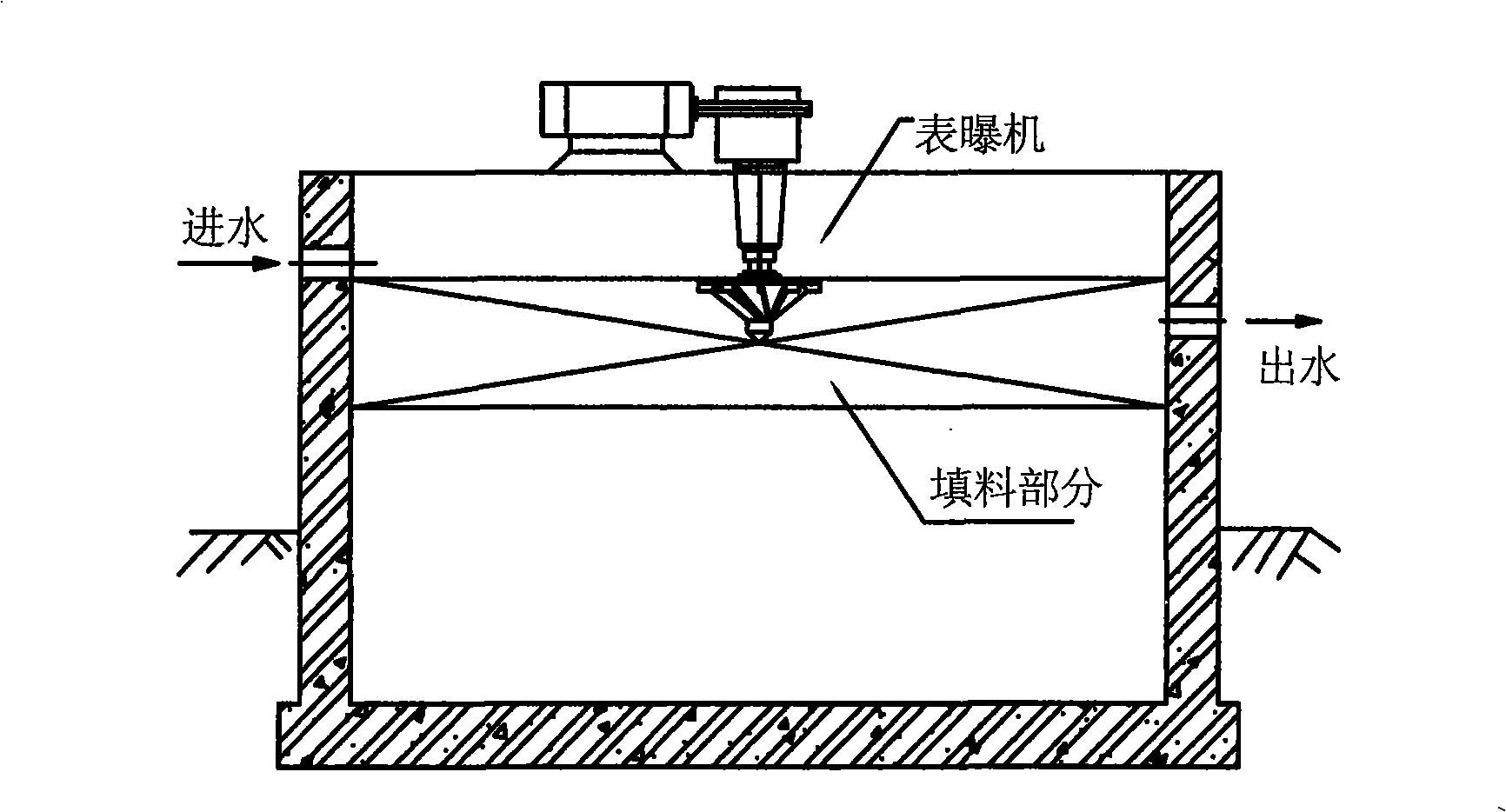

Water treatment system in two-stage moving bed biomembrane reactor

InactiveCN101402487AEasy to handleStrong resistance to shock loadsSustainable biological treatmentBiological water/sewage treatmentAutomatic controlSludge

The invention belongs to the field of water treatment, and relates to a two-stage moving bed biomembrane reactor medium water treatment system. The two-stage moving bed biomembrane reactor medium water treatment system is characterized in that the whole process adopts a programmable PLC automatic control system; the main treatment structure is two-stage cascade connected moving bed biomembrane reactors; and the concrete process flow is as follows: domestic sewage or sewage with similar water quality enters a regulating pond through grates and then enters a first-stage MBBR reactor and a second-stage MBBR reactor in turn by pump lifting; and then the water is outputted into a depositing pond, enters a clear water pond and is reused for flushing toilet or as landscape water after cyclic ultraviolet sterilization. The two-stage moving bed biomembrane reactor medium water treatment system has the advantages that: 1 the system has good medium water treatment effects, stronger resistance to shock load and stable outputted water quality; 2 the system has simple and convenient operating management, a small floor area, convenient maintenance and little excessive sludge; and the system adopts the PLC automatic control system with high automatic degree; 3 the system adopts a mechanical aeration mode, thereby bringing about low energy consumption and good oxygenation performance without an independent blower; 4 the system adopts a cyclic ultraviolet sterilization mode without any medicament added during the whole process, thereby avoiding the secondary pollution; and 5 the system has a wide application range.

Owner:UNIV OF SCI & TECH BEIJING

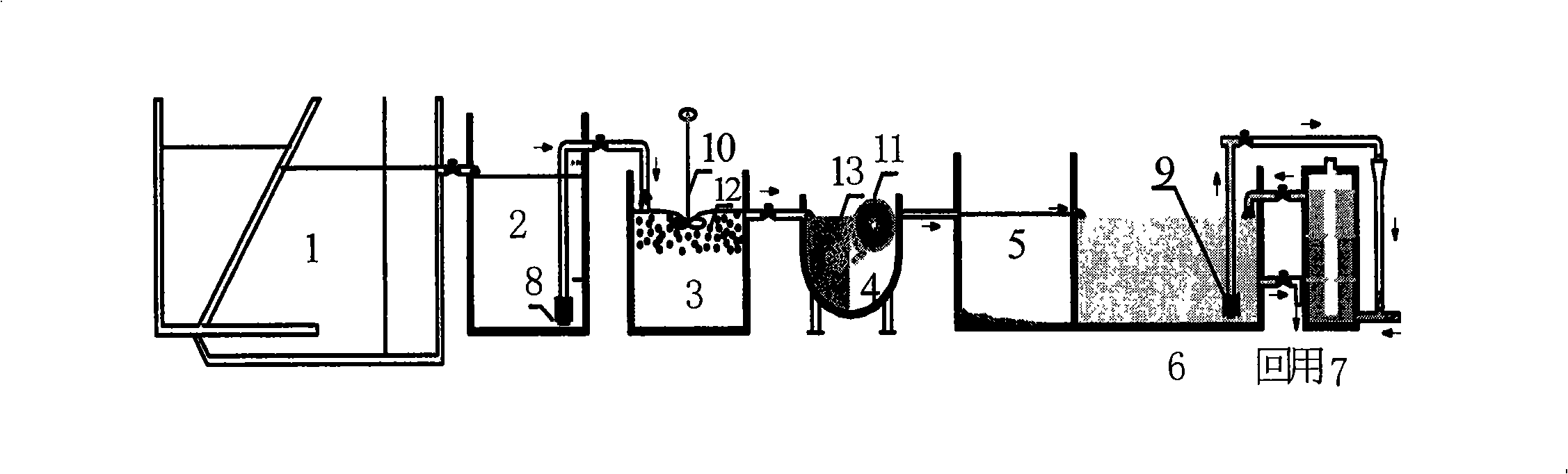

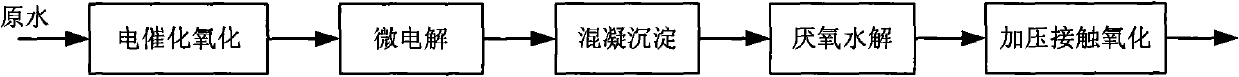

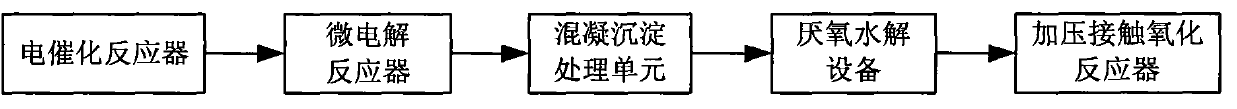

Process and equipment for treating high-concentration pyridine waste water

InactiveCN102139992AStrong resistance to shock loadsEfficient decompositionMultistage water/sewage treatmentWater/sewage treatment by oxidationChemical treatmentHigh concentration

The invention relates to a process for treating high-concentration pyridine waste water, which comprises the following steps of: regulating raw water of waste water to be acidic, and treating the raw water in electro-catalytic oxidation equipment; leading effluent to a micro-electrolysis device for treatment under the condition of maintaining the acidity and oxygen enrichment of the waste water; regulating the effluent to be meta-alkalescent, and adding chemicals to perform coagulating sedimentation; and controlling the salinity of the waste water to be below 2 percent, and performing biochemical treatment in an anaerobic hydrolyzing device and a pressurizing biological contact oxidation device, so that the effluent reaches the conventional first-level standards for sewage discharge. Due to the adoption of a physico-chemical treatment process serving electro-catalytic oxidation as a core, pyridine pollutants can be decomposed effectively, the toxicity of the waste water can be reduced, and the biodegradability of the waste water can be improved; for biochemical treatment is realized by a combination process of anaerobic hydrolysis and pressurizing biological contact oxidation, the organic loads, treatment efficiency and salt-tolerant capacity of the biochemical treatment are improved; and the process has the characteristics of high impact load resistant capacity, good treatment effect and low operating cost, and the treated high-concentration pyridine waste water can reach the standard stably before discharge.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +1

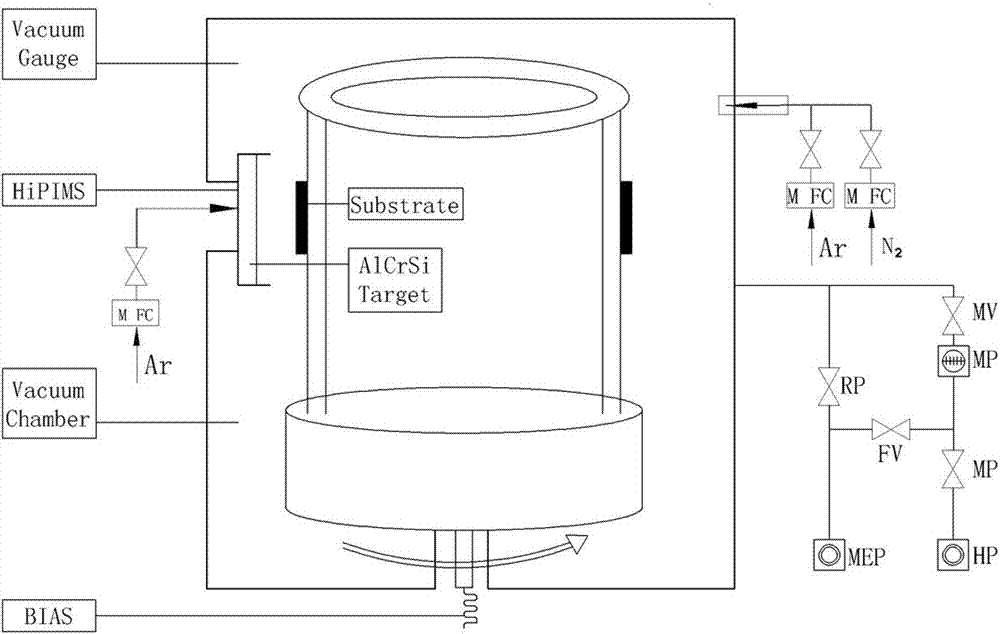

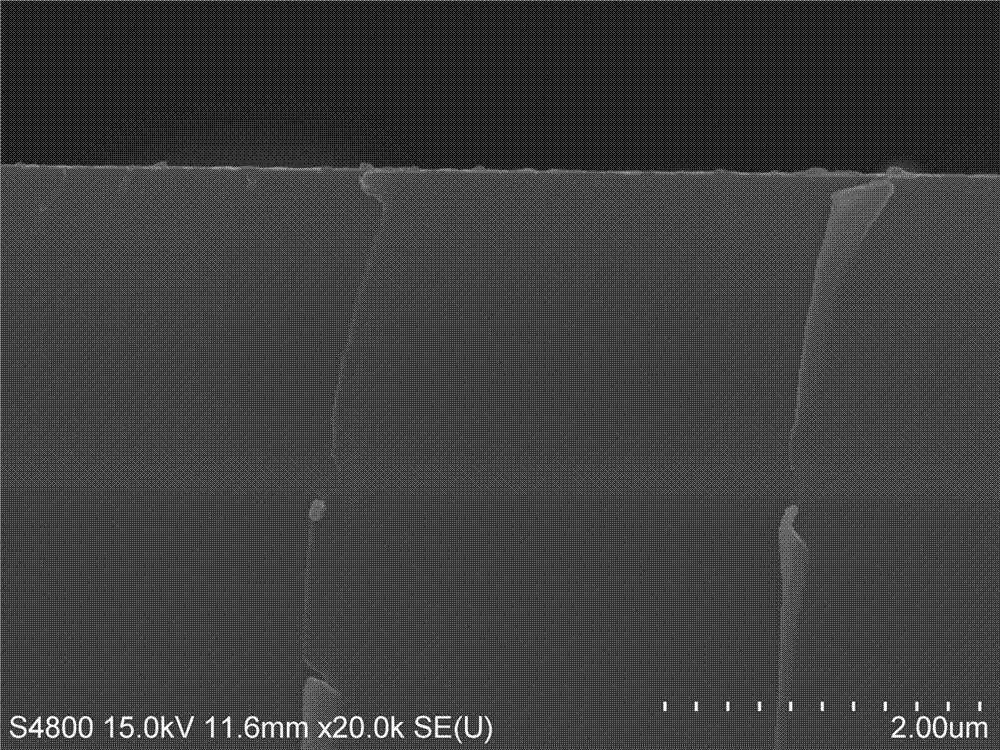

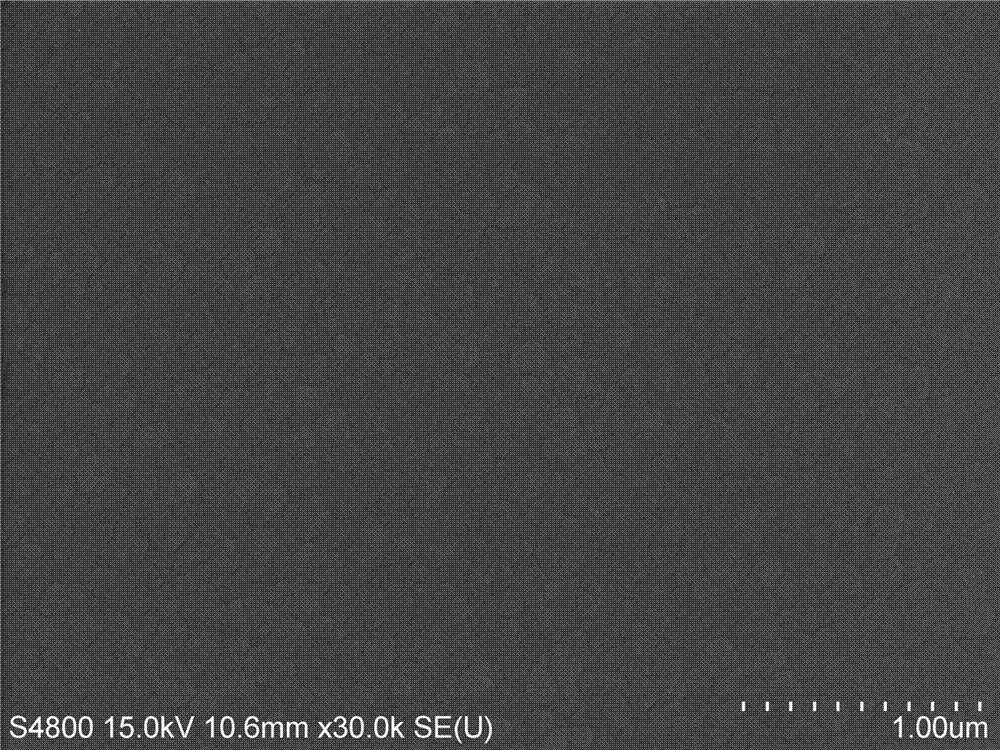

Preparing technology for high-aluminum-content ultra-dense Al-Cr-Si-N coating

ActiveCN106987816AImprove antioxidant capacityInhibited DiffusionVacuum evaporation coatingSputtering coatingAlloyMaterials science

The invention relates to a nano composite coating and a preparing technology thereof, in particular to a preparing technology for a high-aluminum-content ultra-dense Al-Cr-Si-N nano composite coating. An Al-Cr-Si-N nano composite coating is deposited on a metal or alloy base body through the high-power pulse magnetron sputtering technology. An Al-Cr-Si alloy target is selected as a target material, wherein the atomic ratio of Al to Cr to Si is 6:3:1, purity is 99.8 wt.%, and the size is 300 x 100 x 5 mm; before film coating, inflation of Ar is conducted firstly, striking is conducted at the bias voltage of -800 V, high-power pulse magnetron sputtering of the Al-Cr-Si target is conducted, and bombardment cleaning is conducted on the surface of the base body. Then, the bias voltage is reduced to -30 V, an Al-Cr-Si transition layer is deposited, then inflation of the reaction gas N2 is conducted finally, and deposition of the Al-Cr-Si-N coating is started. The related preparing technology for the high-aluminum-content ultra-dense Al-Cr-Si-N nano composite coating is simple, repeatability is good, and industrial production is easy. The prepared Al-Cr-Si-N coating is high in hardness, good in tenacity, low in internal stress and excellent in abrasion resisting performance; and the coating organization structure is extremely dense and is firmly combined with the base body, and the high-temperature oxidation resisting capability is high.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com