Water treatment system in two-stage moving bed biomembrane reactor

A moving bed biofilm and treatment system technology is applied in the field of reclaimed water treatment systems in two-stage moving bed biofilm reactors, and can solve the problems of restricting the application of reclaimed water treatment equipment, affecting the quality of reclaimed water treatment, poor resistance to impact load, etc. , to achieve the effect of small footprint, high degree of automation, strong impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

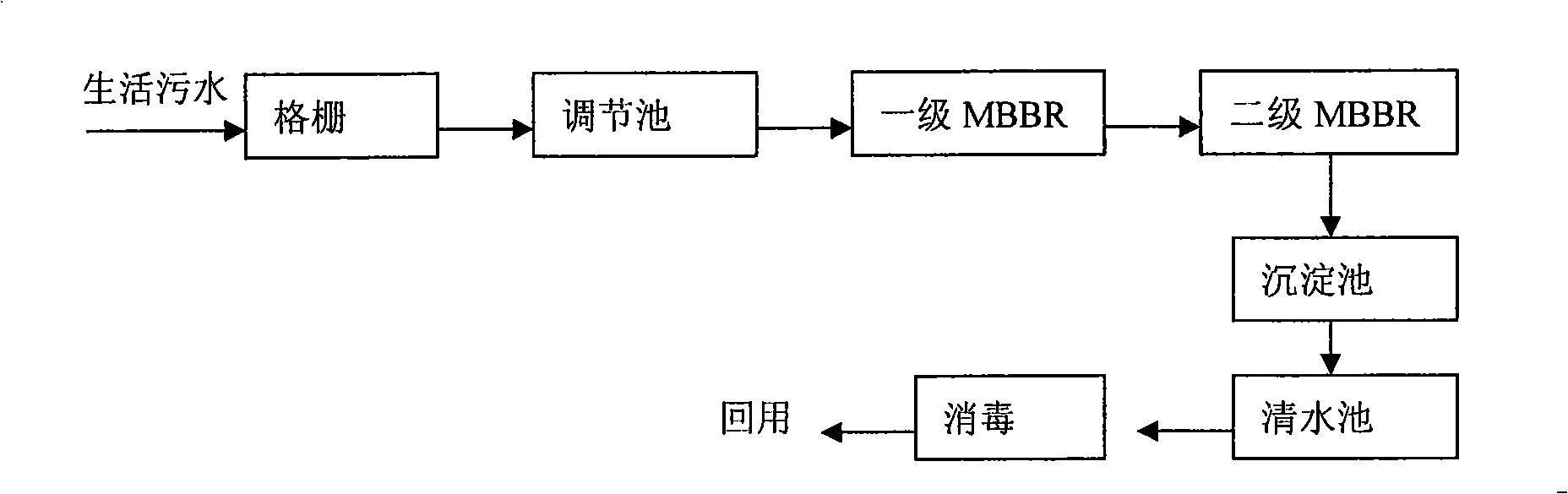

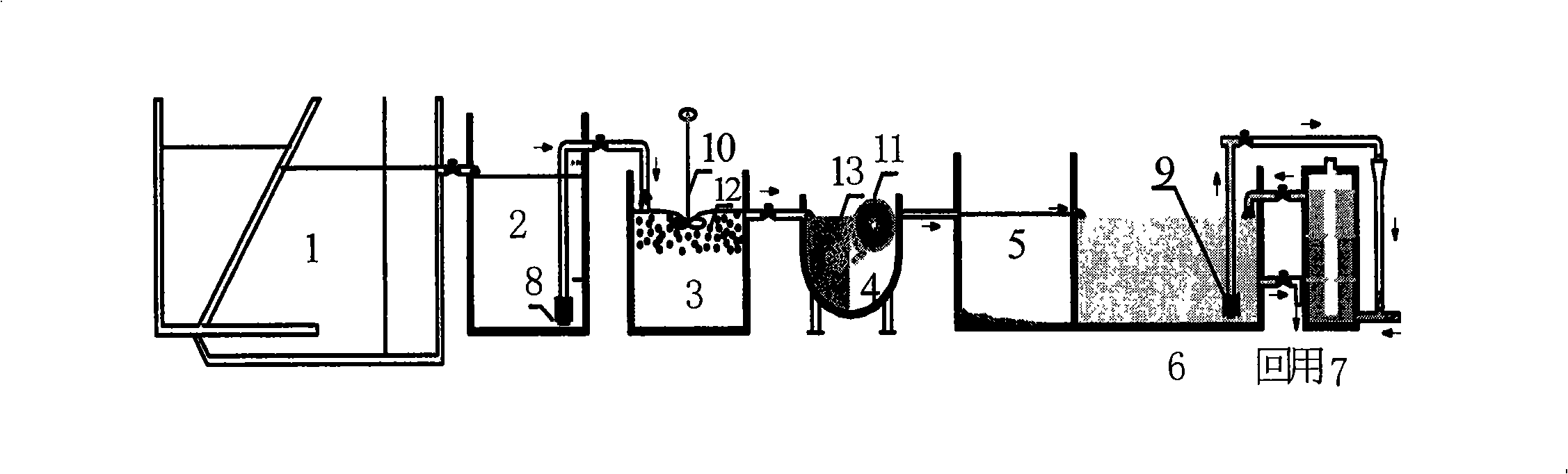

[0020] Such as figure 1 , 2 As shown, the domestic sewage enters the regulating tank 2 through the grid 1, and then enters the primary MBBR reactor 3 and the secondary MBBR reactor 4 in sequence through the pump 8, and then the effluent overflows in the sedimentation tank 5 and enters the clean water tank 6, and then passes through The circulating ultraviolet disinfection device 7 is reused. Depending on the quality and quantity of treated water, the secondary MBBR reactor 4 can be connected in multiple parallel ways.

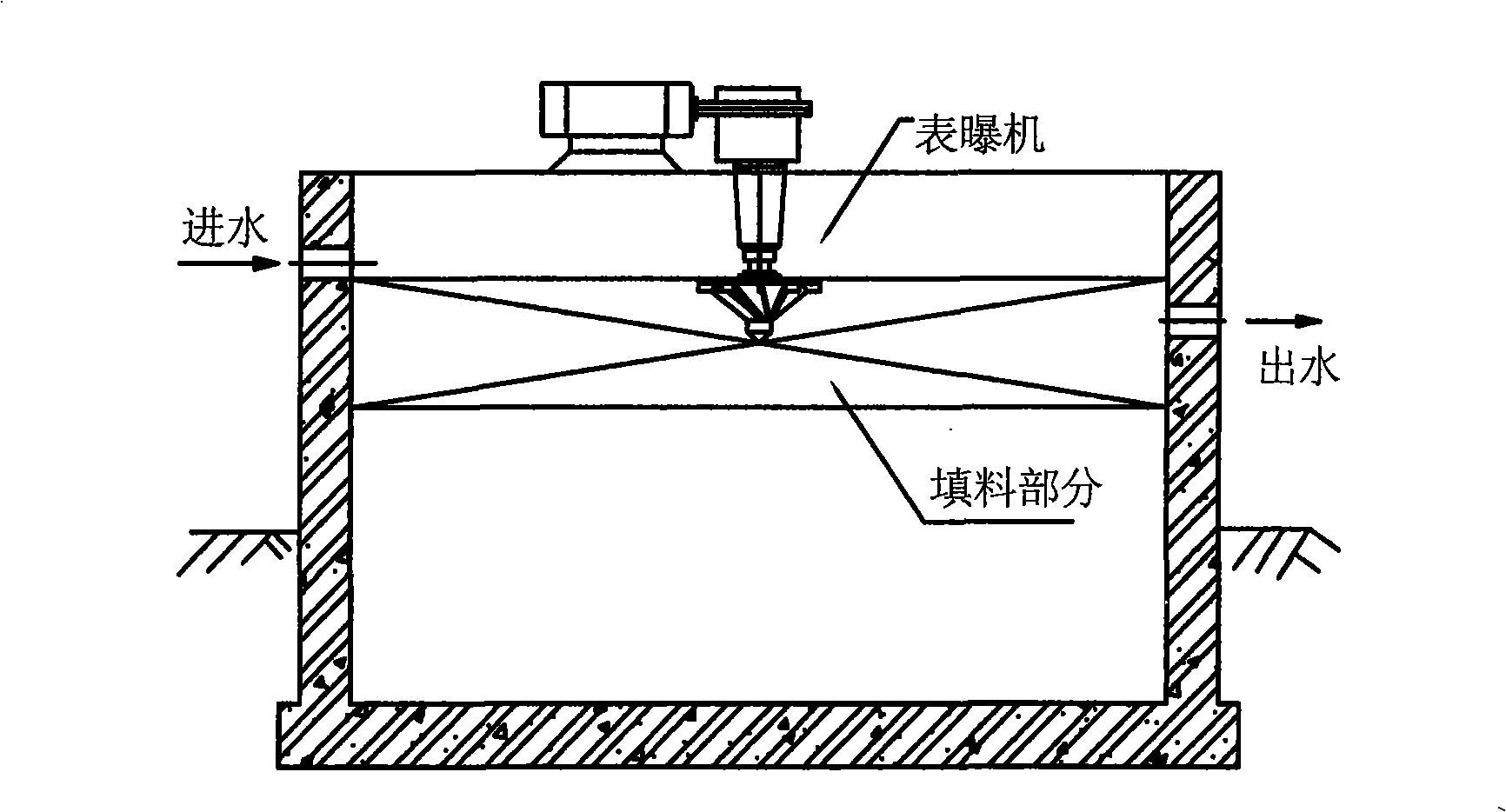

[0021] Such as Figure 4 , Figure 5 As shown, the upper part of the secondary MBBR reactor pool body is a cuboid, the lower part is a semi-cylindrical body, and the bottom is provided with a mud discharge port. The rotating cage aeration device 14 (rotating cage), 16 (motor), 17 (chain ), the tank is provided with suspended packing 15, with biofilm on the packing; the water outlet of the reactor is provided with a mesh screen 18 with a slightly smaller ape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com