Patents

Literature

808results about How to "Less sludge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

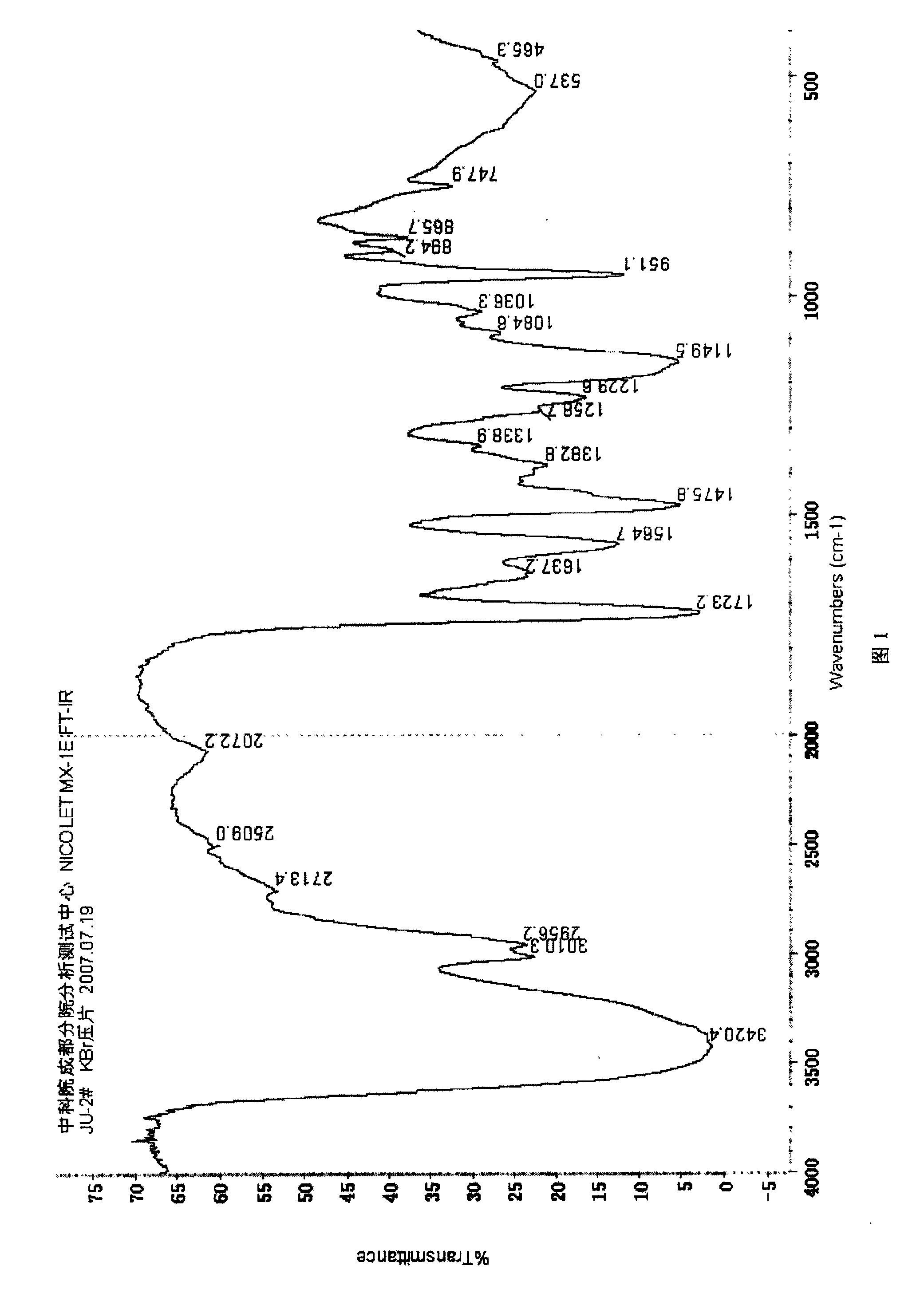

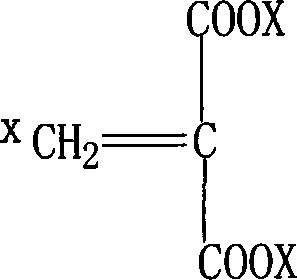

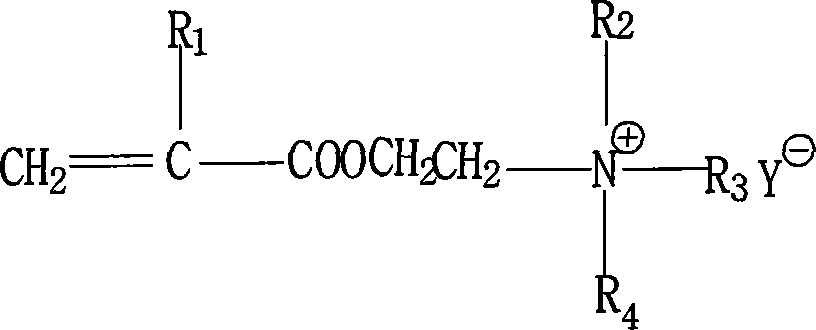

Organic high polymer coagulant and preparation method thereof

InactiveCN101249996AReduce dosageLess sludgeWater/sewage treatment by flocculation/precipitationWater soluble polymersWater soluble

The invention relates to an organic polymer flocculating agent and a process for preparation thereof, in particular to a water-soluble polymer flocculating agent and a process for preparation thereof. The molecular weight of the water-soluble polymer flocculating agent is 1*10 4-1*10 6, and the flocculating agent is formed through mixing and copolymerization of three monomers of itaconate, quaternized alkyl acrylic dialkyl aminoethyl ester and tertiary amine alkyl acrylic dialkyl aminoethyl ester, a certain amount of polymerization promoter is added, previously redox initiator is employed, and latterly water-soluble azo type initiator is added, thereby guaranteeing sufficiently high molecular weight of the flocculating agent, increasing conversion rate and reducing monomer content. The monomers selected by the product are nontoxic, and the process for preparation is simple and is suitable for promotion and application, under the condition of unchanging the anion degree, the cationic degree can be freely regulated, and the application range is enabled to be wider. The flocculating agent combines the advantages of the three monomers; thereby the performance of the flocculating agent is more excellent with more varieties of processed wastewater, less input amount and more obvious social and economical benefits.

Owner:SICHUAN NORMAL UNIVERSITY

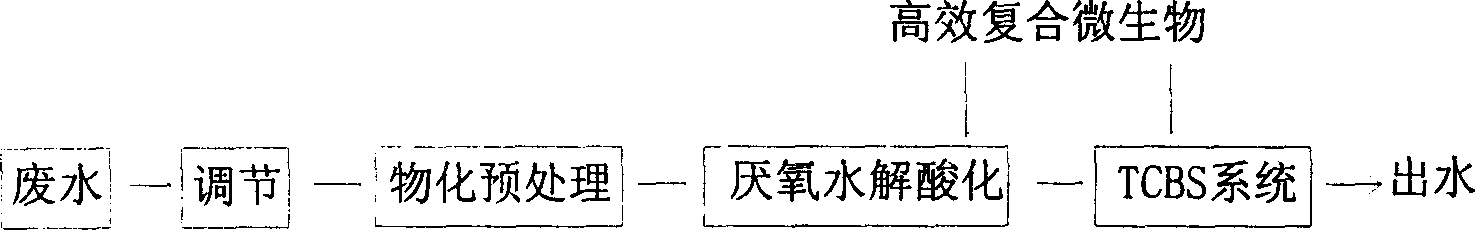

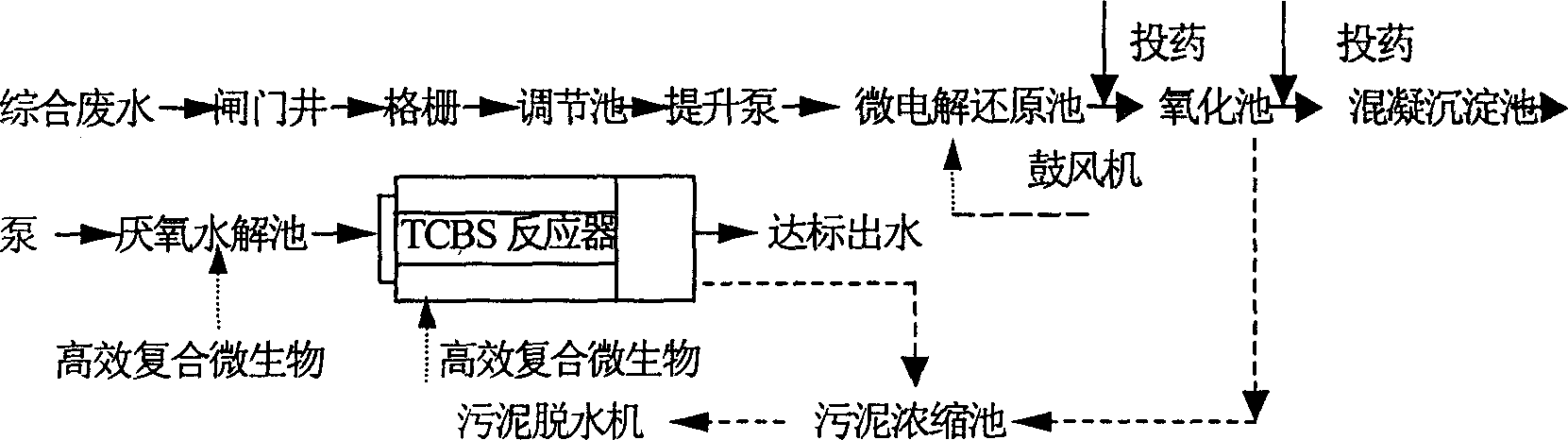

Organic waste water treatment process

InactiveCN1631818AAvoid toxicityHigh removal rateMultistage water/sewage treatmentHigh densityElectrolysis

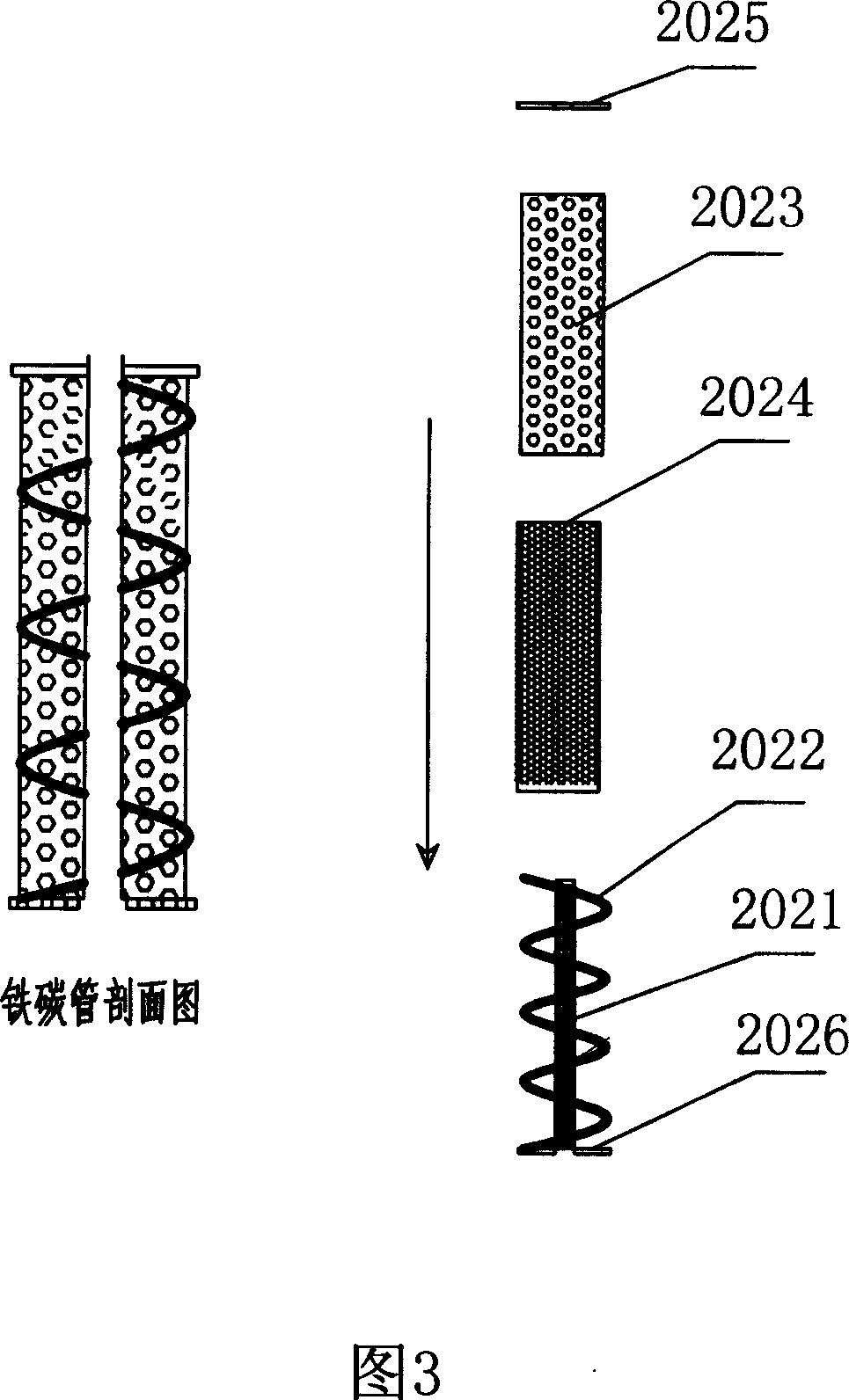

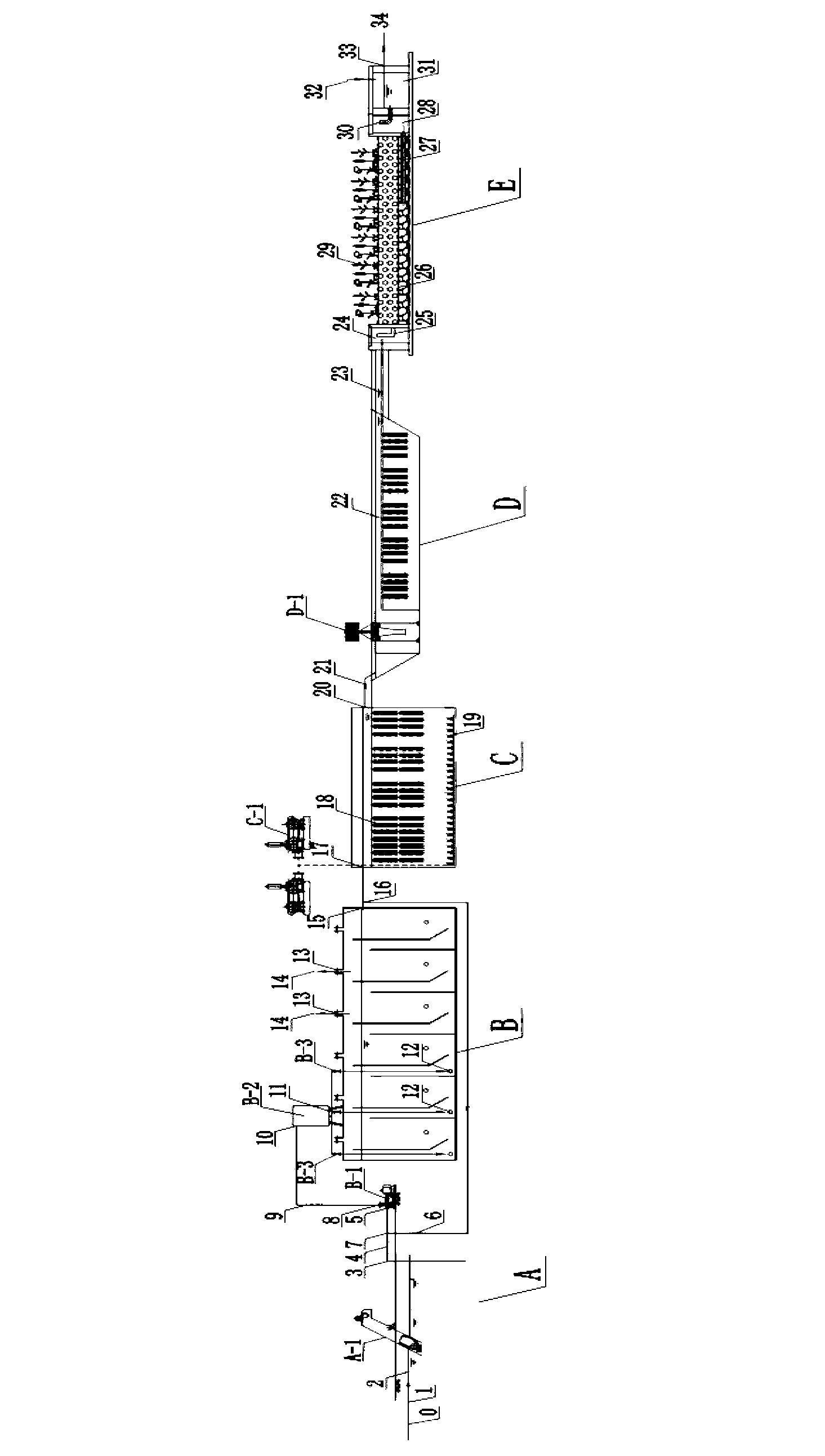

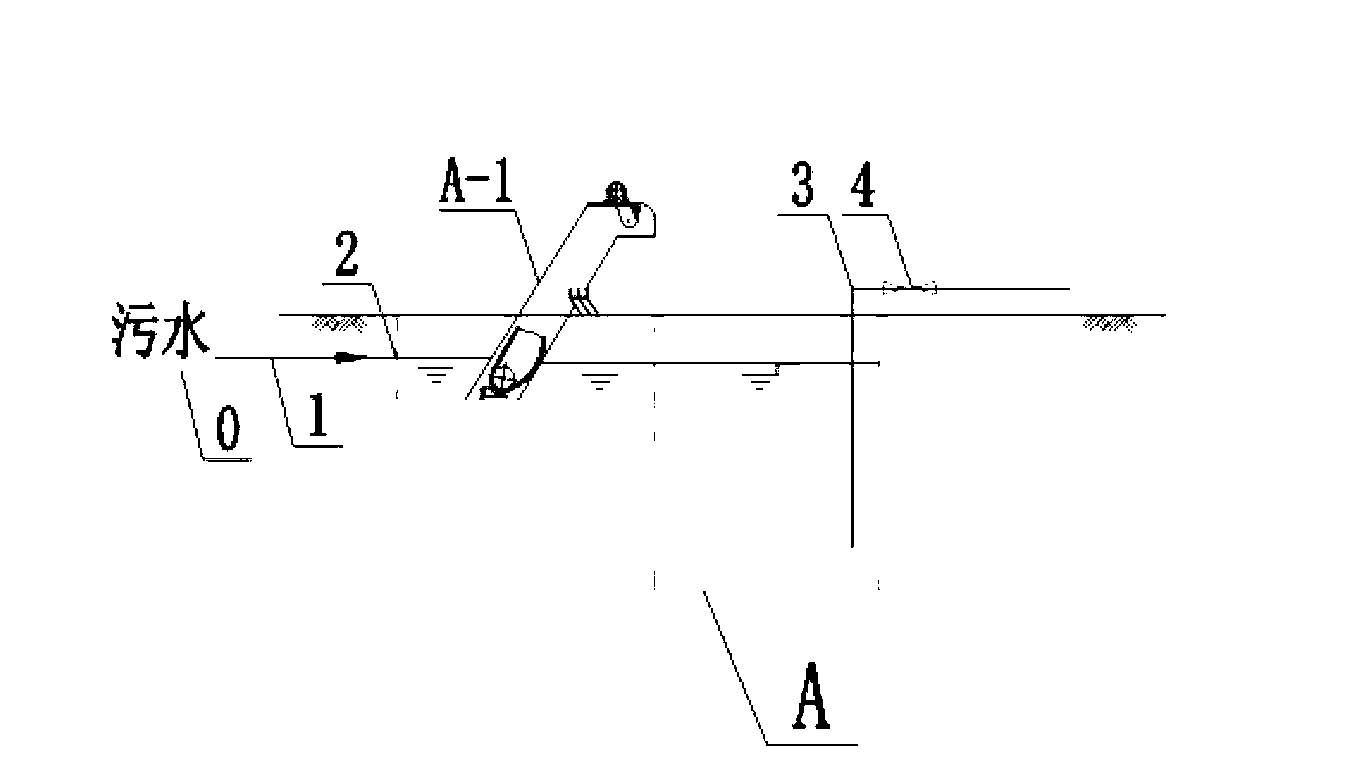

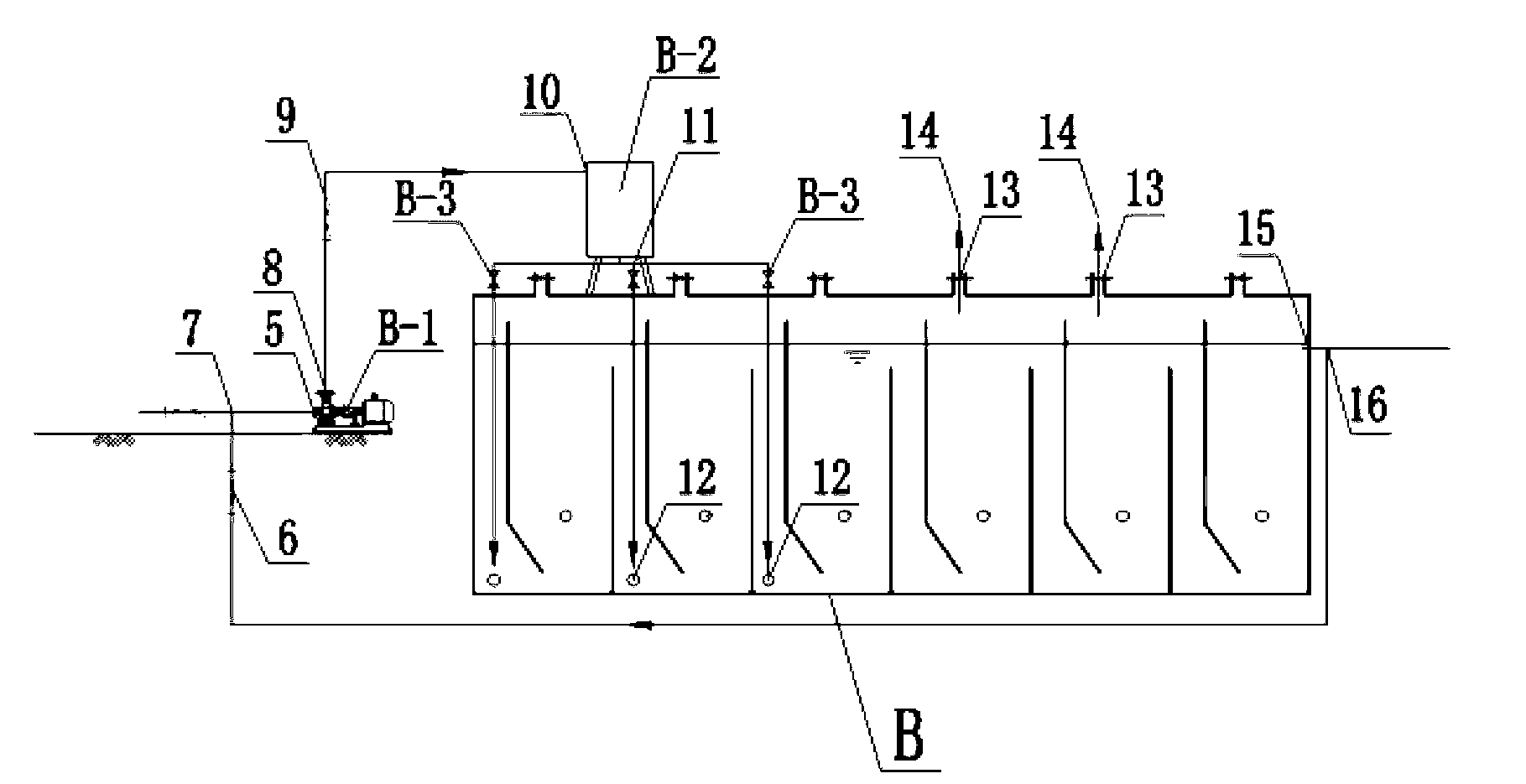

Disclosed is a technique for processing organic waste water, including the following steps: (a) preprocession: pour the waste water into the micro electrolytic reducing pool where the iron-carbon micro electrolytic reaction occurs under the agtatering effect, add hydrogen peroxide into it to have. Fento oxidation, then the water enters into coagulation pool into which add NaOH and PAM; (b) anaerobe hydrolysis oxidation procession: power the organic waste water preprocessed into high effective anaerobe hydrolysis oxidation pool in which add into the TCBS reactor in which add into high effective compound microbe, making the water mix with the flowing-back mud with high density after denitrification. The invention can increase the biochemical of organic waste water, strengthen its resistance to poison and impact as well as the biological denitrification funcation, and making the waste water reach the national environment protection requirement by reducing the polluting load by steps.

Owner:何义亮 +1

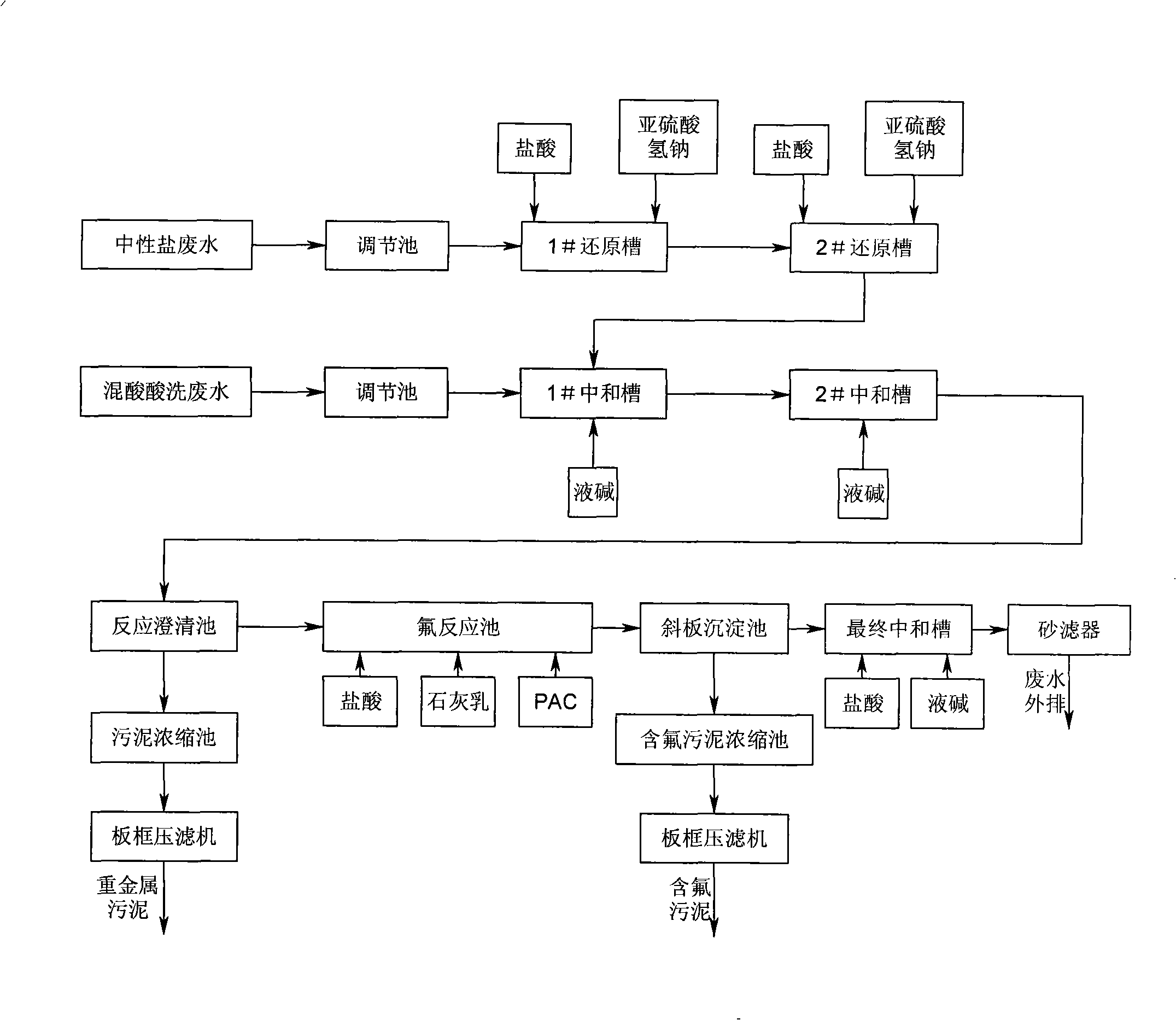

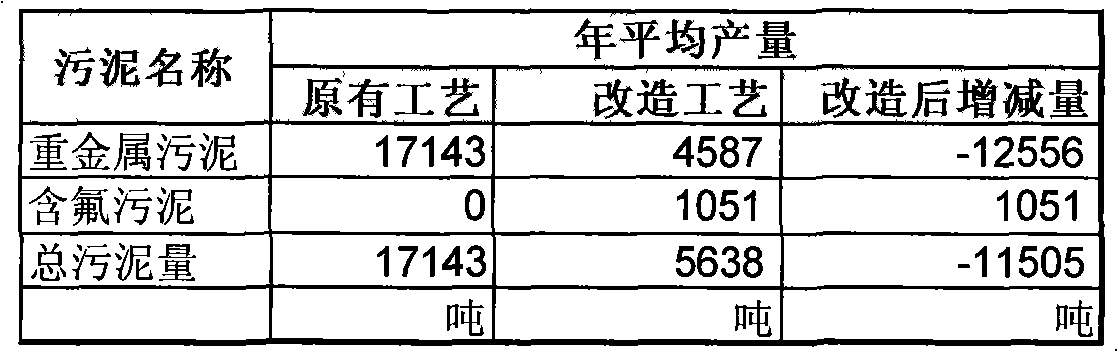

Processing method for stainless steel acid cleaning waste water and liquid

InactiveCN101269889AMeet emission compliance requirementsMeet compliance requirementsSludge treatment by de-watering/drying/thickeningIron oxides/hydroxidesLiquid wasteSludge

The invention relates to a processing method of stainless steel pickling waste liquid, which is characterized in that the processing method includes the steps that: neutral salt wastewater flows into a neutral reduction cell, and mixed acid pickling waste waters flow into a neutralizing tank; reducing agent is added into the neutral reduction cell, and then the reduced wastewater liquid is put into the neutralizing tank and is mixed with the adjusted mixed acid pickling waste waters, and liquid alkali is added into the neutralizing tank; the separated clear waste liquid removes fluorin ions in a settlement tank; neutralizing liquid is added into a final neutralizing tank to cause the pH value of treatment liquid to adjust to be neutralized wastewater liquid which passes through a sand filter to be discharged. The processing method has the advantages that metal ions and fluorin ions are performed the subsection treatment, and neutralizing agent is changed into the liquid alkali from lime cream, the requirement of reaching the standard of the waste liquid emission is not only achieved, but also the mud quantity produced by a mass of lime cream is greatly reduced, heavy metal mud of a retention pond only contains heavy metal compound, the salts of calcium fluoride and calcium sulphate, etc. are separated from the inclined plate settlement tank during the fluoridation stage, thereby the treatment cost is effectively lowered.

Owner:NINGBO BAOXIN STAINLESS STEEL

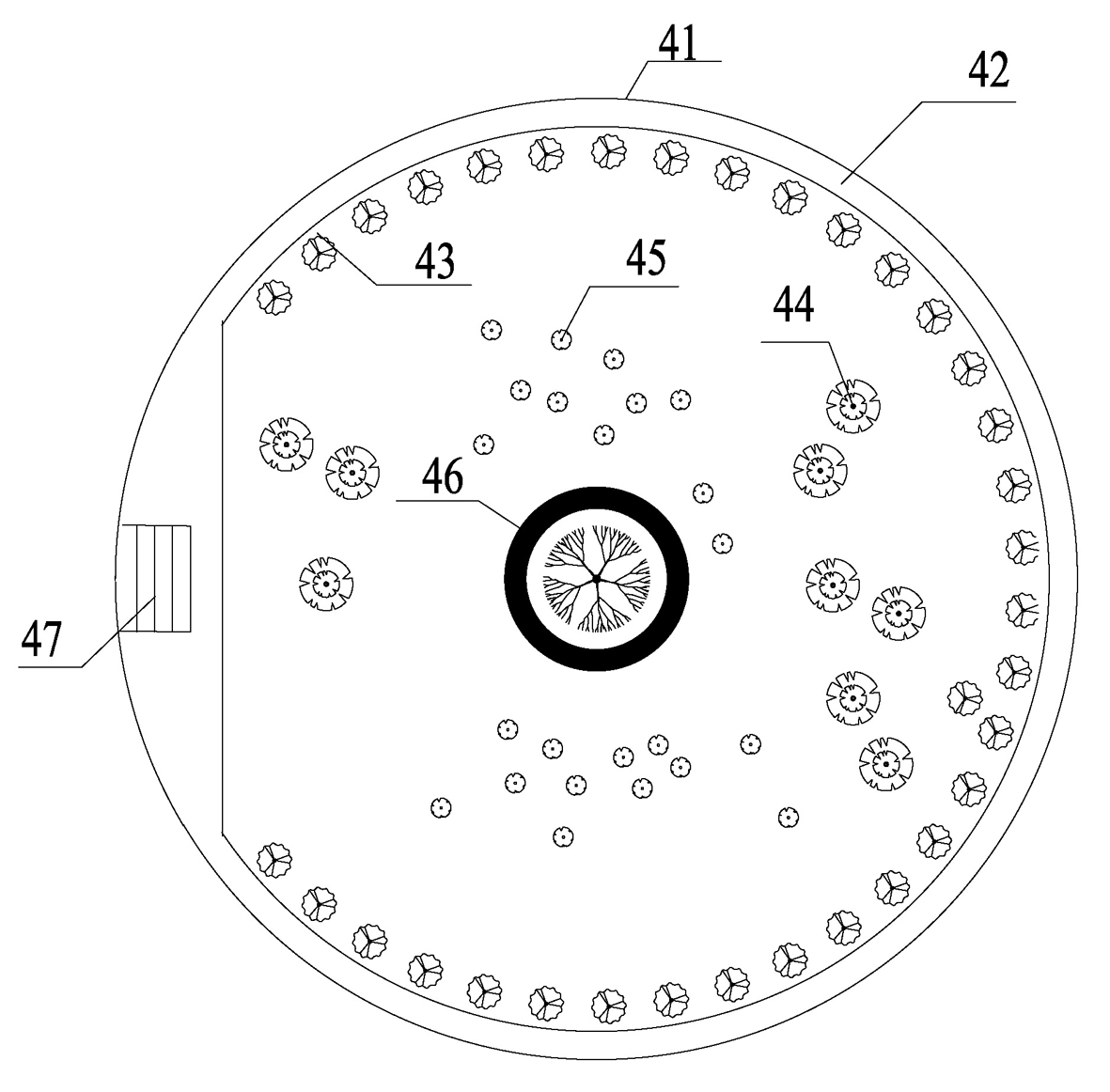

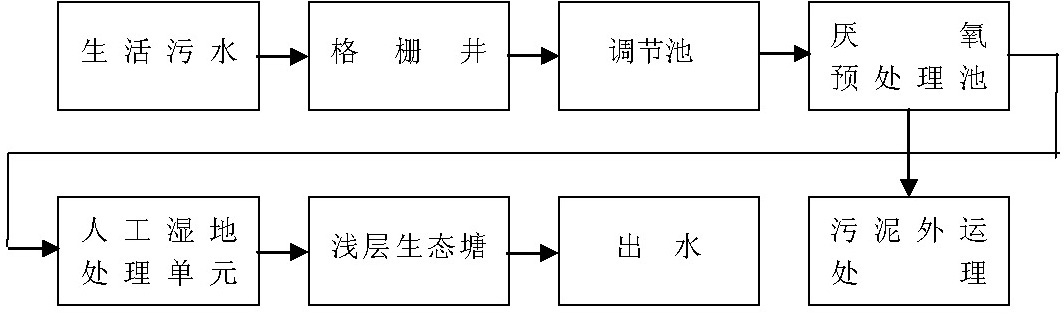

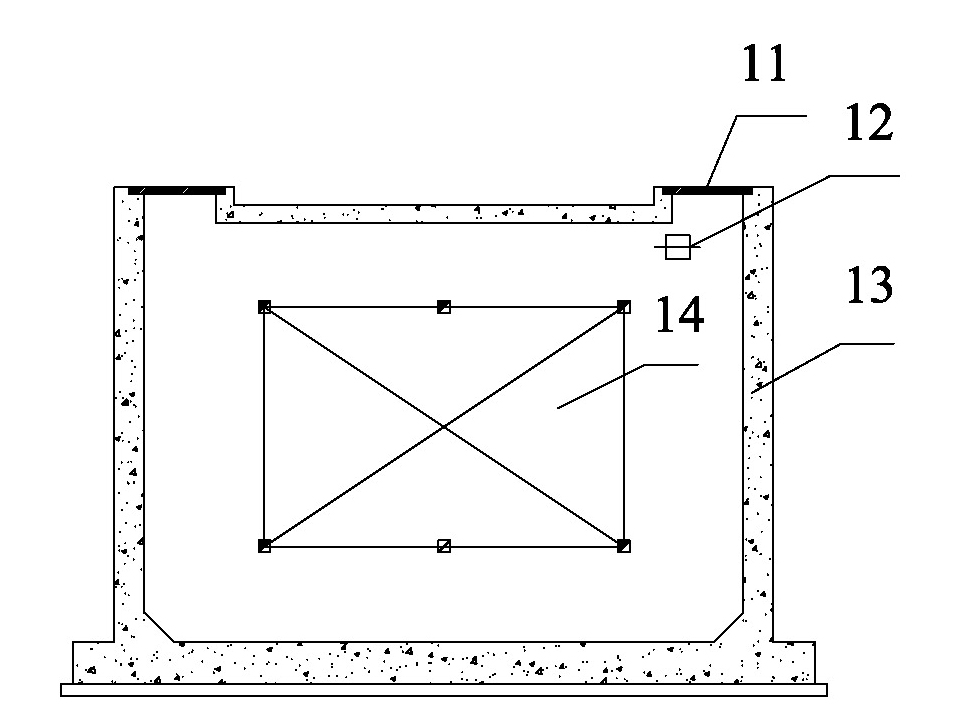

Ecological greenbelt treatment process and system for treating rural domestic sewage

ActiveCN101948214AEasy to handleLess investmentTreatment using aerobic processesWaste based fuelConstructed wetlandReclaimed water

The invention relates to an ecological greenbelt treatment process for treating rural domestic sewage, which mainly comprises the steps of: (1) anaerobic pretreatment: performing anaerobic hydrolysis pretreatment to domestic sewage; (2) artificial wetland treatment: performing artificial wetland treatment to pretreated domestic sewage; and (3) shallow ecological pond aerobic biotreatment: further performing shallow ecological pond aerobic biotreatment to outlet water treated by the artificial wetland, degrading and converting organic matters and nutrients entering the pond, and recycling purified sewage as a regenerated water resource. The invention adopts an ecological greenbelt treatment system comprising the anaerobic pretreatment, the artificial wetland and the shallow ecological pond to treat the rural domestic sewage, and has the characteristics of good treatment effect, recycling on site, low investment, low system operating cost, simple maintenance, obvious ecological benefit and the like.

Owner:浙江博世华环保科技有限公司

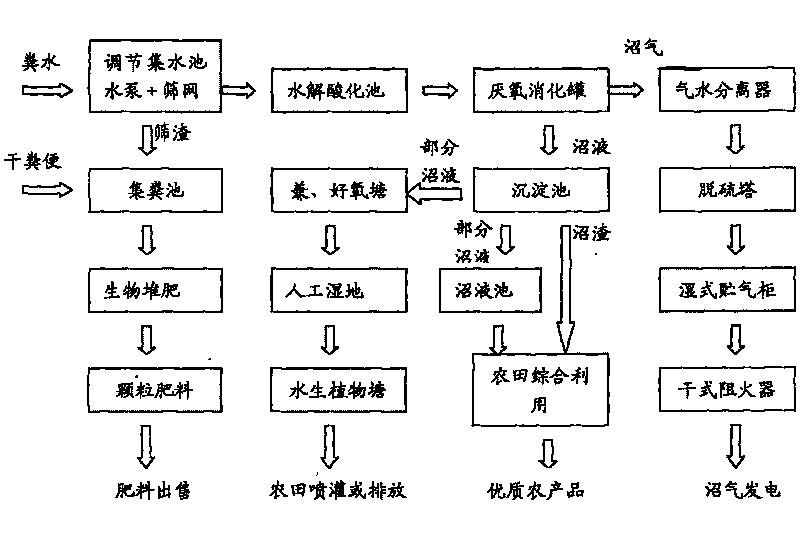

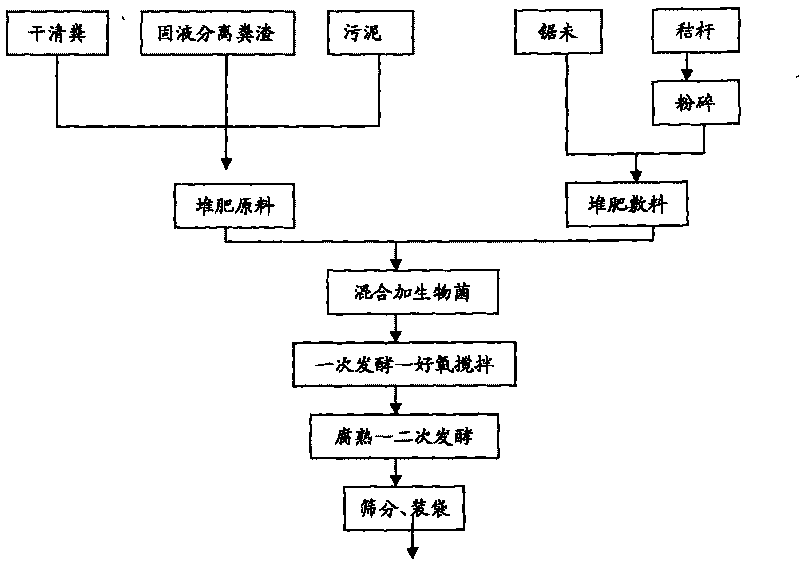

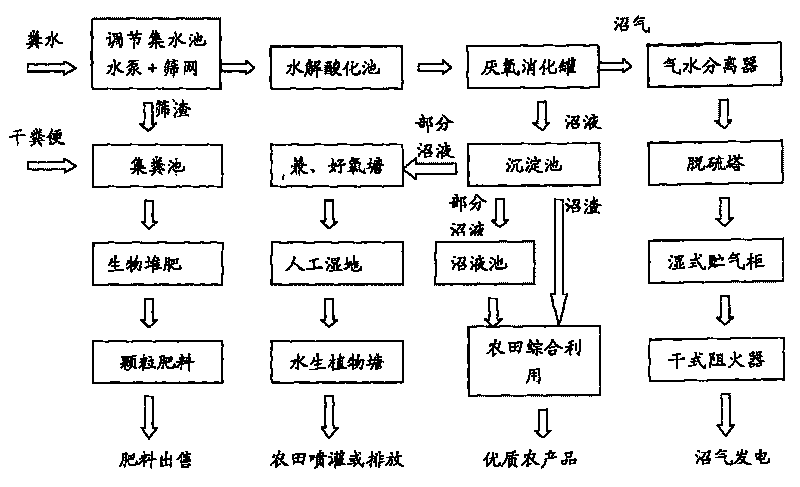

Method for comprehensively treating livestock waste and utilizing resource

InactiveCN101709004ALess sludgeLow running costBio-organic fraction processingClimate change adaptationAgricultureSewage treatment

The invention provides a method for comprehensively treating livestock waste and utilizing resource, which is beneficial for reducing local water quality pollution, improving soil environment, improving ecological environment and promoting the sustainable development of agricultural production. The method is realized by a sewage treating and resource utilizing process and a solid waste treating process. The method for comprehensively treating the livestock waste and utilizing the resource, for a large-scale culturing farm, has the advantages of small sludge quantity, low operating cost and the like by adopting biogas fermentation and ecological combinative technology to treat sewage, has the advantages of economy, high efficiency and resource utilization by adopting composting technology to treat dejection garbage, solves partial production and living energies and living energy by adopting produced marsh gas to generate electricity so as to produce direct economic benefit, develops nuisanceless agricultural product bases and realizes agricultural efficiency by taking produced biogas residues and biogas liquid as nuisanceless organic fertilizers.

Owner:HARBIN INST OF TECH

Process for treating used water difficult to degradate by catalytic internal electrolysis of iron

InactiveCN1382649AWiden the potential differenceImprove the effect of electrolysisWater/sewage treatmentMultistage water/sewage treatmentElectrolysisSewage

A process for removing heavy metals and the organic substance difficult to degradate from sewage includes proportioning Fe and Cu, adding cationic surfactant modified zeolite, stirring, loading the mixture in filter pool, regulating pH value to 4.5-11, reaction, and regulating pH value to 8-9 to generate Fe(OH)3 as flocculant, which can coagulate the suspended solid and colloid and absorb and soluble pollutants for depositing them. Its advanrtages are high power, effect and high speed.

Owner:上海城市污染控制工程研究中心有限公司

Photoelectromagnetism integrated waste water advanced oxidization method and device thereof

ActiveCN101033105AWide applicabilityGood processing effectWater/sewage treatment by irradiationWater contaminantsUltraviolet lightsWeak current

This invention relates to a photoelectromagnetic integrated advanced oxidation method and its device for waste water, which first of all acidizes the waste water, then strongly magnetizes it to generate energy of physical change and chemical change then enters into a photo-catalyzing box to be oxidated mostly to CO2 and water under the actioin of photo-catalyst, ultraviolet light, ozone and oxydol, in which, molecular chains of some hard-degradated substances are broken, then the waste water is micro-electrolysed to adsorb and recover the hard degraded substances under the action of extra low voltage, weak current and air, ozone and oxydol to get rid of COD, color degree, deodorizatin and disinfectant finall to filter it by diatomite and filter out suspending substances to reach the standard or recover it.

Owner:深圳市华旭半导体科技有限公司 +1

Low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method

ActiveCN102701521AEasy to handleReduce load ratioEnergy based wastewater treatmentMultistage water/sewage treatmentConstructed wetlandRural area

The invention discloses a low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method. The method comprises the steps that: 1, the to-be-treated wastewater is collected by a sewage pipe network and then is filtered by lattices, and is lifted by a pump to enter a pulse water distribution pot of a novel efficient turn-back anaerobic biochemical pool (ABR); 2, the swage subjected to the treatment in step 1 flows into a circulation-flow biological oxidization pool; 3 the effluent water from the step 2 flows into an artificial reinforced biological contact oxidization pool reconstructed by a water body from natural tunnels and reservoirs; and 4, the effluent water from the step 2 or the step 3 flows into constructed wetlands. After the sewage is treated by the above steps, the most pollutants in the water are effectively removed and the treated effluent water reaches the standard first-grade A in GB 18918-2002 ''Discharge standard of pollutants for municipal sewage treatment plant''. The energy-saving sewage treatment purification process with low cost, low energy consumption, low carbon emission and low operating cost is particularly suitable for the sewage treatment in small towns or rural areas.

Owner:武汉昌宝环保工程有限公司

Method for promoting sludge to be reduced by ozone

InactiveCN101708937ASmall particle sizeLow mineralization rateSludge treatment by oxidationWaste based fuelBrickBiological filter

The invention relates to a method for promoting sludge to be reduced by ozone, in particular to a technology used for pretreating the sludge and accelerating anaerobic sludge digestion speed by utilizing ozone oxidation technique, which is widely applied to the sludge treatment technique of a sewage plant. The method comprises: the residual sludge of the sewage plant is concentrated and then treated by a sludge pretreatment reactor; due to the strong oxidizing property of ozone, the cell wall and the cell membrane of microorganism inside the sludge are broken, and a great deal of organic matter is released out of cells; after being treated by the ozone, the sludge enters into an anaerobic digestion reactor, and anaerobic digestion can be carried out in a closed anaerobic state; gas generated by digestion is treated by a gas purifying device, and methane can be obtained; after anaerobic digestion, the sludge is treated by flocculation and dehydration, and dewatering sludge can be obtained; then, final treatment can be carried out, for example, the sludge can be used for manufacturing agricultural fertilizer, bricks, porcelain granules or auxiliary fuel of fire coal; and anaerobic supernate is treated by biological filtering bed technique, so that the organic matter, ammonia and nitrogen in the solution can be removed.

Owner:NANJING UNIV OF TECH

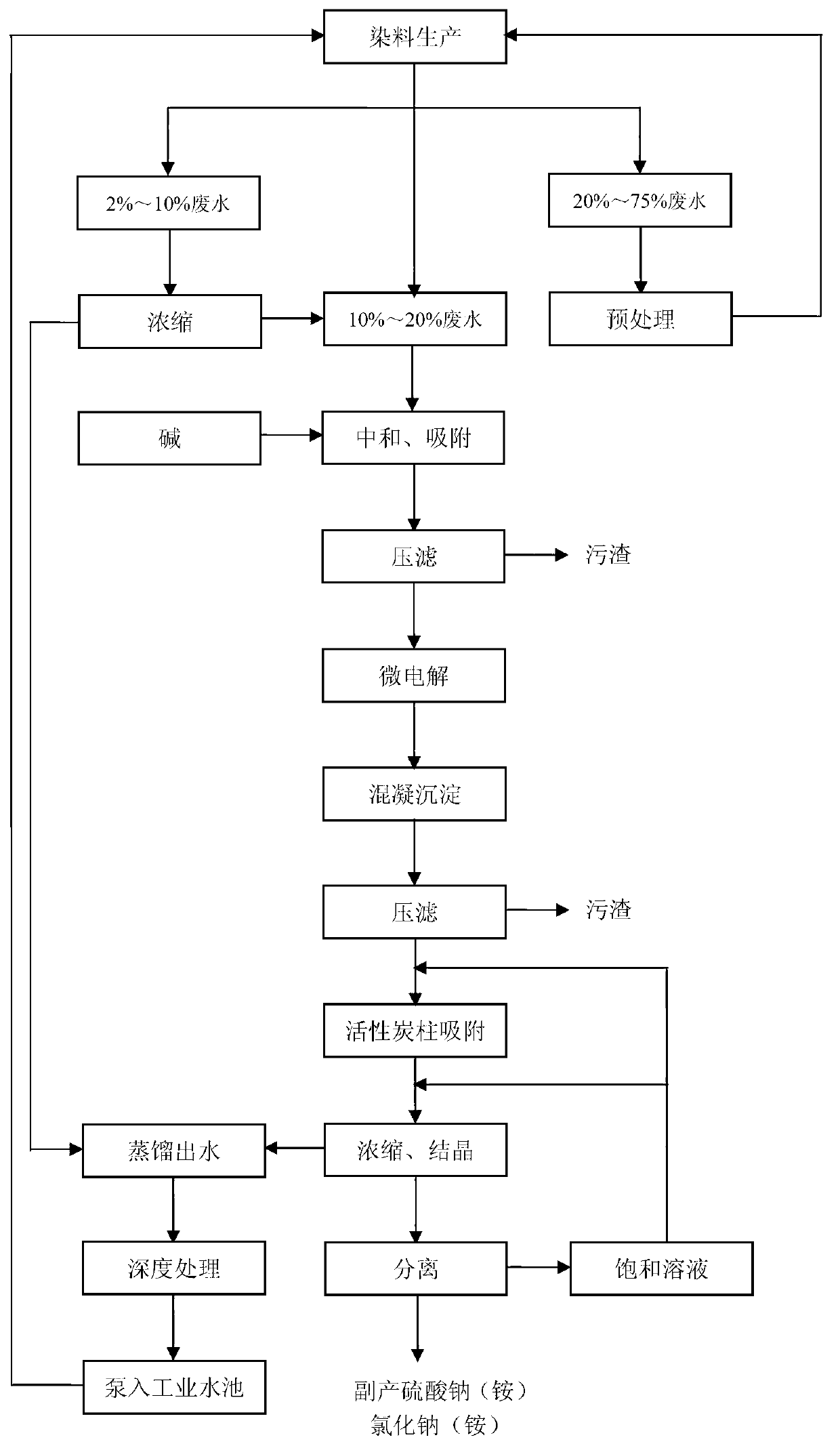

Dye acidic waste water treatment method and device

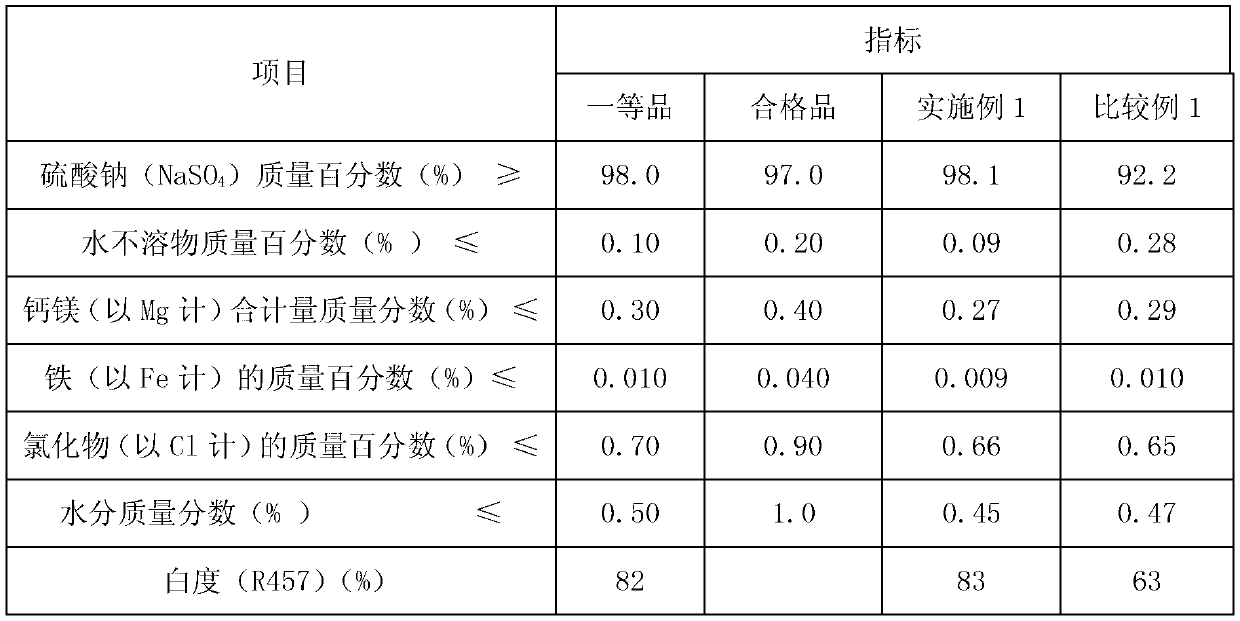

ActiveCN103130370AWide pH rangeLow costAmmonium sulfatesMultistage water/sewage treatmentAutomatic controlWater discharge

The invention relates to a dye acidic waste water treatment method and device. The method comprises steps as follows: separately collected dye waste acid is subjected to distilling concentration, neutralization, adsorption, micro-electrolysis, coagulative precipitation, activated carbon column adsorption, concentrating crystallization and separation through an automatic control system to prepare sodium (ammonium) sulfate or sodium (ammonium) chloride; and the distilled water is subjected to advanced treatment to reach the industrial reuse water standard, enters an industrial water storage tank, and is circulated to the dye production procedure. The method and device are especially suitable for industries generating abundant waste sulfuric acid and waste hydrochloric acid, such as production of dyes, titanium white and the like. The abundant waste sulfuric acid and waste hydrochloric acid generated in the production process can be utilized to prepare sodium (ammonium) sulfate or sodium (ammonium) chloride, thereby recycling acidic waste water, and changing wastes into valuable substances; and meanwhile, the distilled water can be circulated into industrial production after advanced treatment, thereby reducing the waste water discharge.

Owner:ZHEJIANG DIBANG CHEM

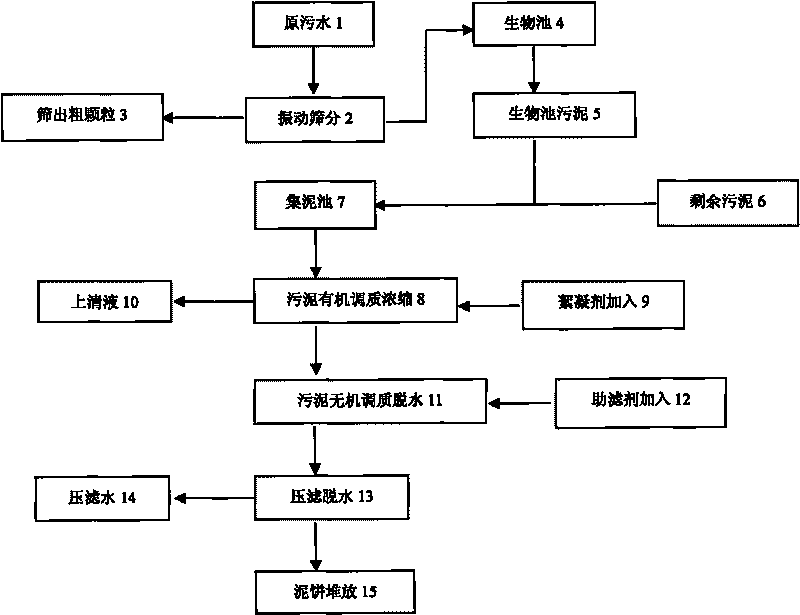

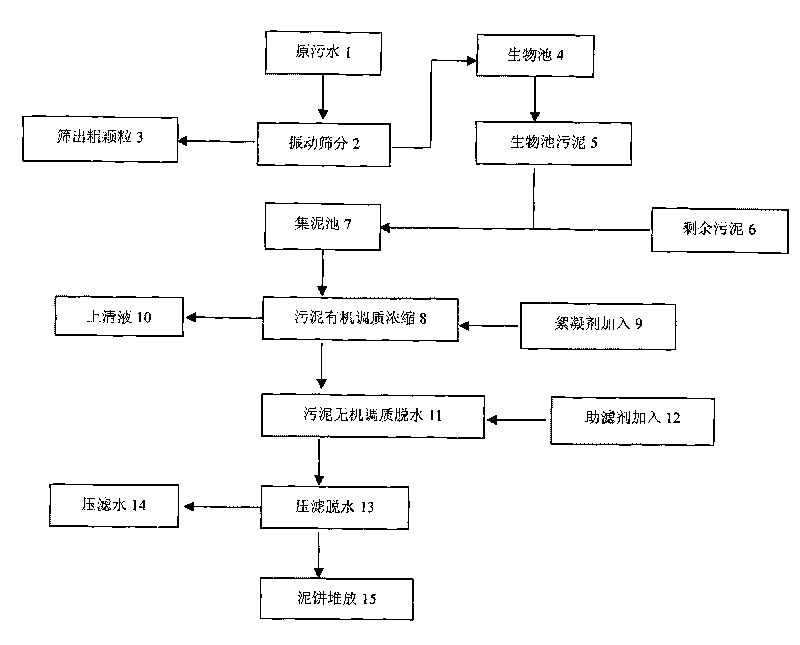

Method for screening and dewatering urban sludge efficiently

ActiveCN101696077ARealize automatic controlRealize managementSludge treatment by de-watering/drying/thickeningRemote controlWastewater

Owner:SAFECLEEN TECH

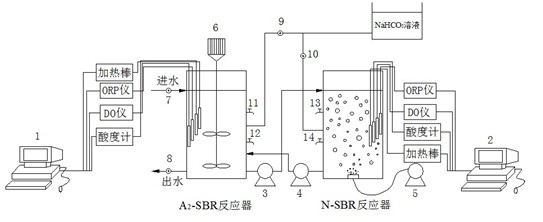

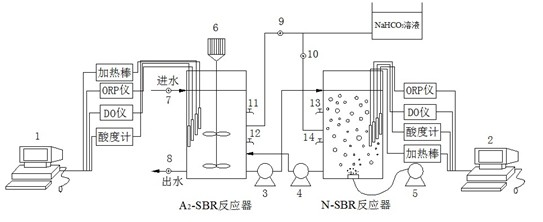

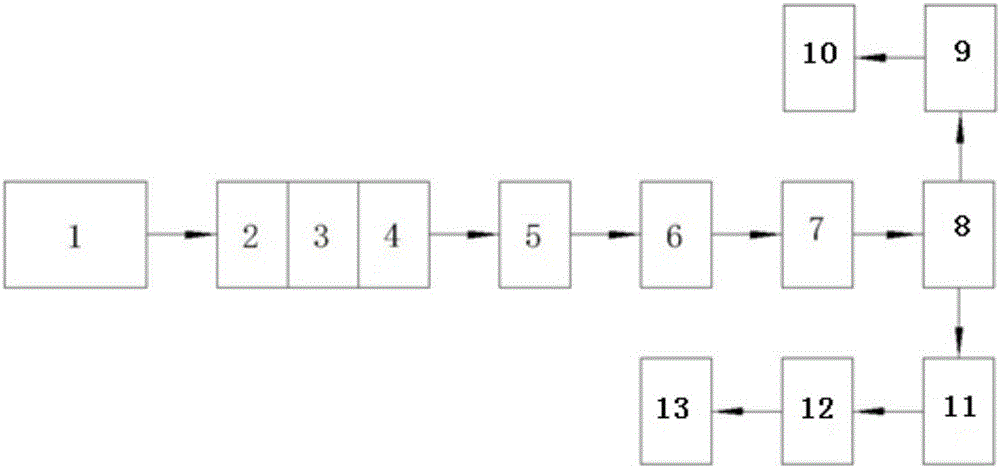

A2N-SBR (Anaerobic-anoxic/nitrification-sequencing batch reactor) process with shortcut nitrification-denitrification denitrifying and dephosphorizing function

InactiveCN102381818AReduce aerationLess sludgeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentChemistryBacterial growth

The invention relates to an A2N-SBR (anaerobic-anoxic / nitrification-sequencing batch reactor) process with a shortcut nitrification-denitrification denitrifying and dephosphorizing function. Compared with an A2N-SBR process with a complete nitrification-denitrification denitrifying and dephosphorizing function, the A2N-SBR process provided by the invention saves aeration amount and organic carbonsource amount, greatly reduces residual sludge amount and saves operation cost. The A2N-SBR process provided by the invention comprises a main reaction tank and auxiliary equipment, wherein the main reaction tank comprises an A2-SBR and an N-SBR; and the auxiliary equipment comprises stirring equipment, aeration equipment, a dissolved oxygen detection device, a reflux pump, pH adjusting equipment, a pH detection device, heating equipment and a temperature detection device. The A2N-SBR process provided by the invention has the advantages that: two independent SBRs are adopted; nitrite bacteriaand denitrifying phosphate-accumulating bacteria grow separately in the two reactors through controlling proper conditions, so that denitrification is carried out when NH4<+>-N oxidation goes to NO2<-> stage, thus operation energy consumption is greatly saved, bacteria are not mutually influenced in the operation process, and the bacterial activity is higher in the whole bacterial growth process;and the process is simple, the arrangement is compact and the automation degree is high.

Owner:SHENYANG JIANZHU UNIVERSITY

Desulfurization waste water zero discharge processing system and processing method

InactiveCN106365371AQuality assuranceSave on medicine costsWater treatment parameter controlWater contaminantsSludgeClarifier

The invention discloses a desulfurization waste water zero discharge processing system and a processing method. The desulfurization waste water zero discharge processing system comprises a regulation sedimentation basin, triple connecting tanks, a defecator and a nanofilter which are connected in sequence, wherein the concentrated water outlet end of the nanofilter is connected with a mistorizer which sprays the concentrated water into a chimney flue; the triple connecting tanks include a neutralization tank, a reaction tank and a flocculation tank which are connected in sequence, wherein the neutralization tank is communicated with the water outlet of the regulation sedimentation basin, and is used for adjusting the pH value of desulfurization waste water, so that bicarbonate ions in the desulfurization waste water are removed; the reaction tank provides a reaction chamber for removing calcium ions in the desulfurization waste water; the flocculation tank is connected with the defecator. The desulfurization waste water zero discharge processing system and the processing method have the advantages of saving the cost of the agent for removing magnesium ions in the desulfurization waste water, reducing the quantity of sludge, lowering the operating cost, using no lime milk and improving the site working conditions. The sodium chloride salt in the waste water is purified and then crystallized, thus the recycle of the sodium chloride salt in the desulfurization waste water is achieved, the solid waste disposal cost is reduced, and certain economic benefits are produced.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

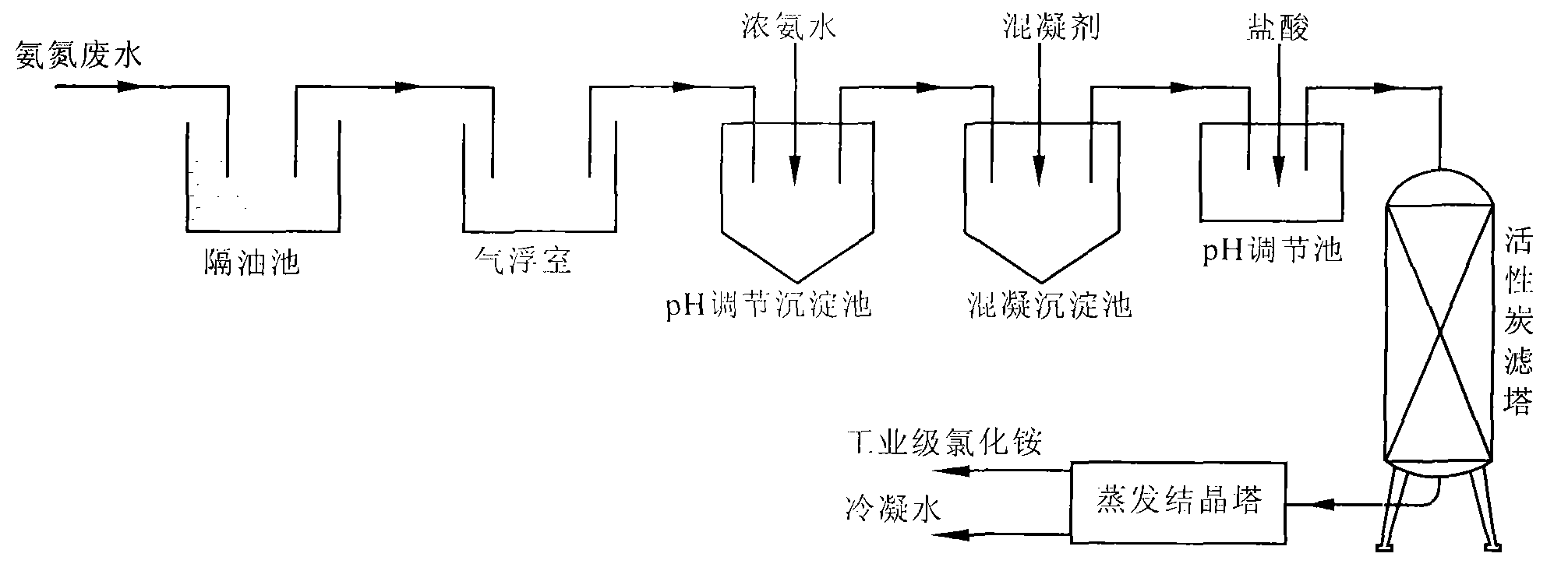

Compound coagulant used for treating rare-earth highly concentrated ammonian wastewater to recover industry ammonium chloride and treatment method

InactiveCN101555053ASimple processing methodLow costFatty/oily/floating substances removal devicesMultistage water/sewage treatmentRare earthPolyacrylamide

The invention provides a compound coagulant used for treating rare-earth highly concentrated ammonian wastewater to recover industry ammonium chloride and a treatment method, belonging to the technical field of chemical environment protection and resource recovery. The compound coagulant is a mixed liquor of ammonium oxalate, ammonium sulphate, heavy metal precipitator DTCR and polyacrylamide (PAM). The treatment method for treating wastewater by using the compound coagulant comprises the following steps: firstly, oil substances in the wastewater are removed through a separation tank and an air floating chamber; secondly, the wastewater enters a pH adjusting precipitation tank to adjust the pH value to be 7.5-8.5; thirdly, the wastewater enters a coagulative precipitation tank, the compound coagulant is added, the wastewater after being coagulated and precipitated enters the pH adjusting precipitation tank to adjust the pH value to be 2.5-4, the wastewater after being adjusted the pH value enters an active carbon filter tower to be absorbed and filtered and then is evaporated and concentrated under the condition of negative pressure. The compound coagulant has simple treatment method, low cost and good effect. The treatment method has short process and simple and easy treatment, not only solves the problem of the pollution of the highly concentrated ammonian wastewater, but also achieves the purpose of recovering valuable materials.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Treatment method of arsenic wastewater

ActiveCN103112974AShort process routeShort construction periodMultistage water/sewage treatmentFlocculationResource recovery

The invention discloses a treatment method of arsenic wastewater. The treatment method comprises the following steps: optionally adding acid liquor into the arsenic wastewater to adjust the pH value to 0-5; introducing the arsenic wastewater into a reaction unit, continuously removing arsenic by adding sulfide in multistage manner; carrying out solid-liquid separation on the effluent after reaction, recycling the separated arsenic slag; adding alkali into the separated effluent to perform electrochemical advanced treatment, wherein the electrochemical advanced treatment includes an electrolytic coagulation step, an electrolytic flotation step and an electrolytic oxidation reduction step, in the electrolytic coagulation, cations are generated by the electrolyzation of a soluble anodic iron plate for flocculation; carrying out aerated oxidation on the effluent after flocculation to generate floc and micelle sediment including ferric ions, and then carrying out solid-liquid separation, wherein the liquid supernatant after separation can be recycled or reach the standard and drain outwards. The treatment method of arsenic wastewater has the advantages of simple technology, low investment, low cost and high resource recovery and recycling rate, and being green and environment-friendly, and being capable of treating continuously and the like.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Method for treating sludge digestive liquid by coupling anaerobic ammonia oxidation and anaerobic methane oxidation

ActiveCN103833186AInhibitory activityReduce consumptionMultistage water/sewage treatmentAnaerobic oxidation of methaneWater quality

The invention provides a method for treating sludge digestive liquid by coupling anaerobic ammonia oxidation and anaerobic methane oxidation, and belongs to the technical field of wastewater treatment. The method comprises the steps that anaerobic digested sludge is inoculated into an anaerobic methanogenic reactor, partial nitrification sludge is inoculated into a partial nitrification reactor, and anaerobic ammonia oxidation and denitrification-type methane anaerobic oxidation bacterium symbiotic bacterium group sludge is inoculated into an anaerobic ammonia oxidation coupled anaerobic methane oxidation reactor; firstly the sludge digestive liquid enters the anaerobic methanogenic reactor, after water quality of yielding water is adjusted by a middle water tank, the yielding water enters the partial nitrification reactor, and the nitrosation process is realized by controlling aeration time; finally the water quality of yielding water is adjusted by the middle water tank, the yielding water enters the anaerobic ammonia oxidation coupled anaerobic methane oxidation reactor, meanwhile, methane generated by the anaerobic methanogenic reactor is used for aeration, and the autotrophic nitrogen removal process is completed with the help of anaerobic ammonia oxidation bacteria and anaerobic methane oxidation bacteria. The method can be used for solving the problems of insufficient organic carbon source, relatively low C / N ratio, release of greenhouse gases and the like existing in a sludge digestive liquid nitrogen removal treatment process.

Owner:BEIJING UNIV OF TECH

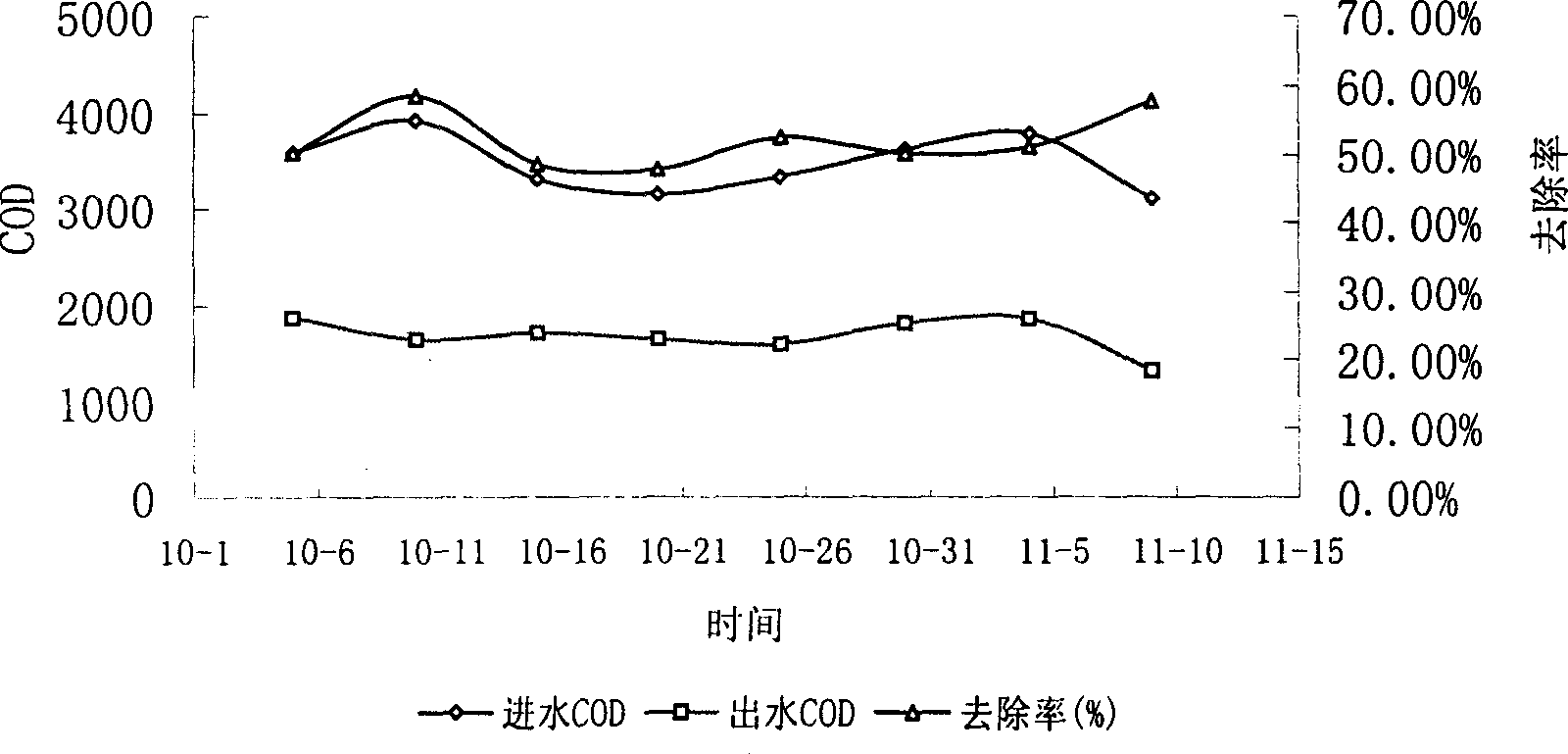

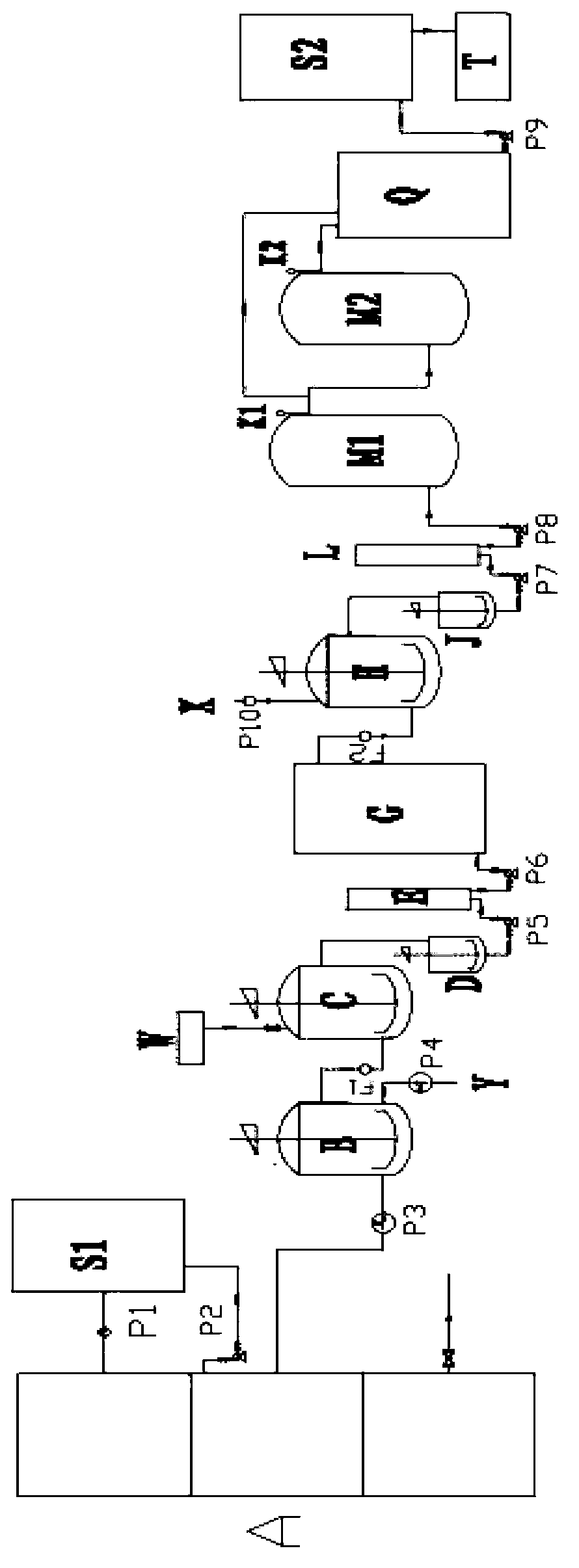

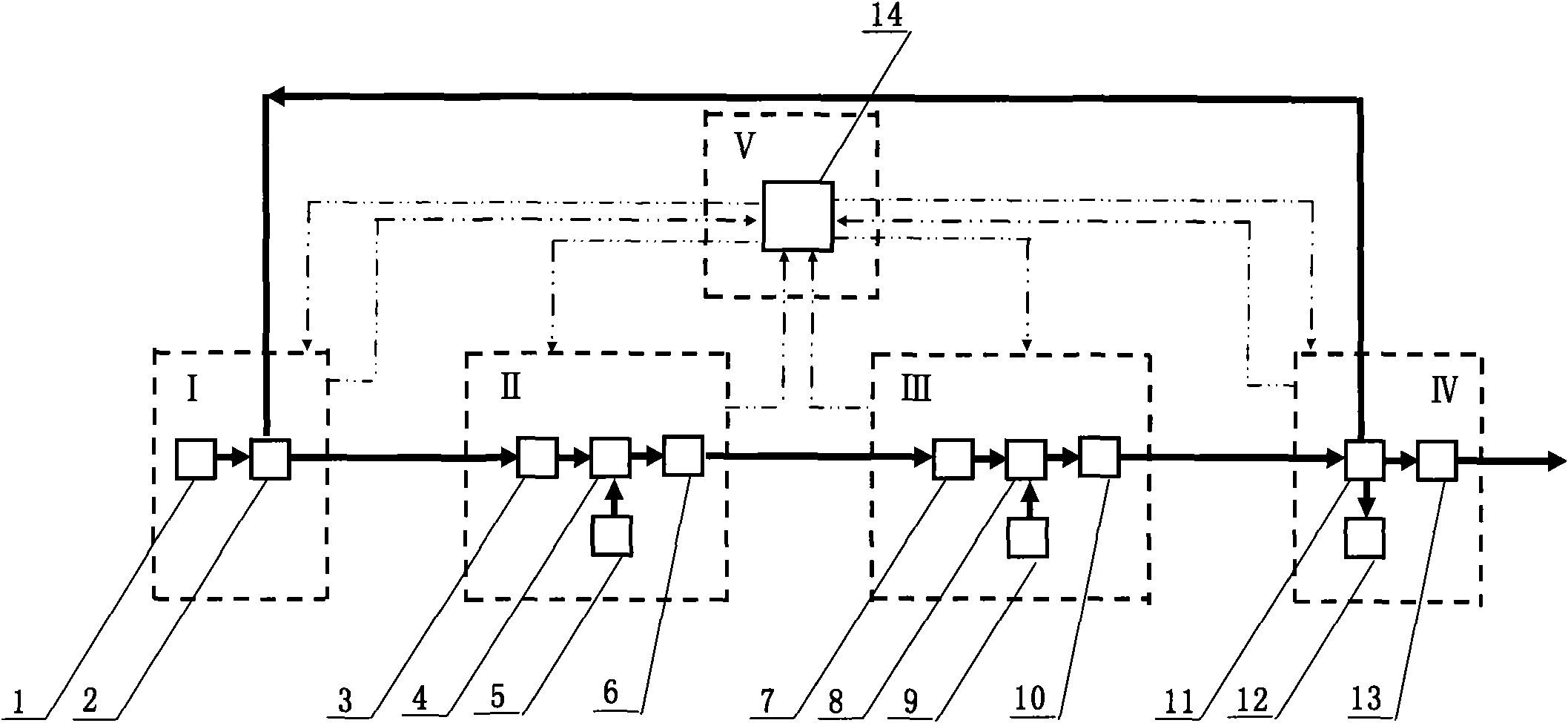

Biochemical treatment method of acrylic ester industrial wastewater

InactiveCN101830602AImprove living conditionsSafe and stable operationWaste based fuelTreatment with aerobic and anaerobic processesChemical oxygen demandSludge

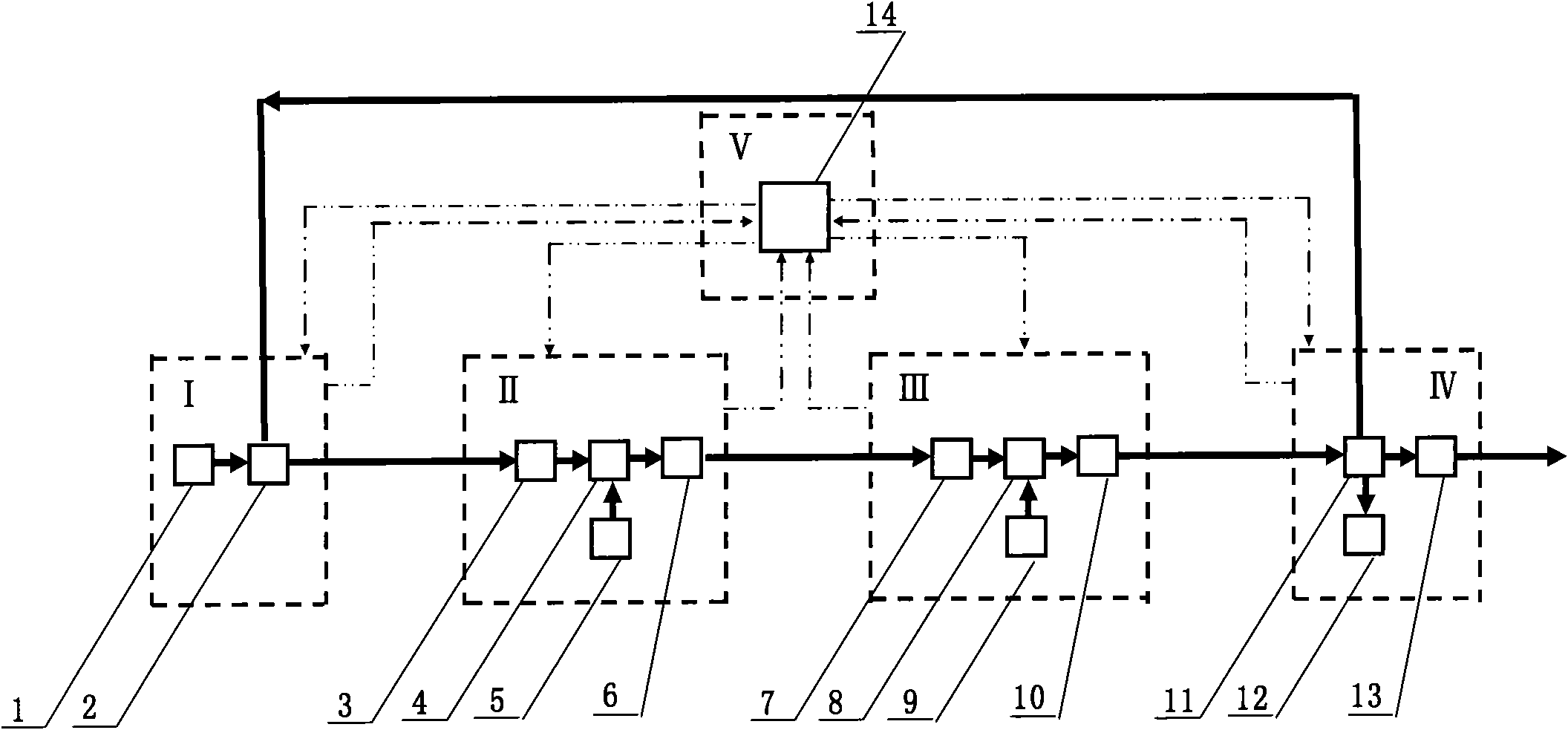

The invention provides a biochemical treatment process method of acrylic ester wastewater. The acrylic ester wastewater with high COD (Chemical Oxygen Demand) and high slat content produced by production equipment is pretreated by using a wastewater pretreatment system (I) and enters a primary biochemical treatment system (II) for step anaerobic and aerobic biochemical treatment; the wastewater subjected to the step treatment enters a secondary biochemical treatment system (III) for secondary anaerobic and aerobic biochemical treatment and then enters a purification treatment system (IV) for removing sludge and organic pollutants; and finally a small part of wastewater reaching the standard is fed back to the wastewater pretreatment system (I) for recycling and mostly is discharged. By adopting a specially-screened and domesticated high-efficiency microbial strain to treat the acrylic ester wastewater, the biochemical treatment system can thoroughly degrade the acrylic ester wastewater and has no secondary pollution; in the step of flocculation precipitation, clean water treated by the purification treatment system reflows to the pretreatment system for secondary utilization; and compared with a method for treating the wastewater by incineration, the invention can save large amount of fuels and steam and has remarkable economic benefits.

Owner:SHENYANG PARAFFIN CHEM

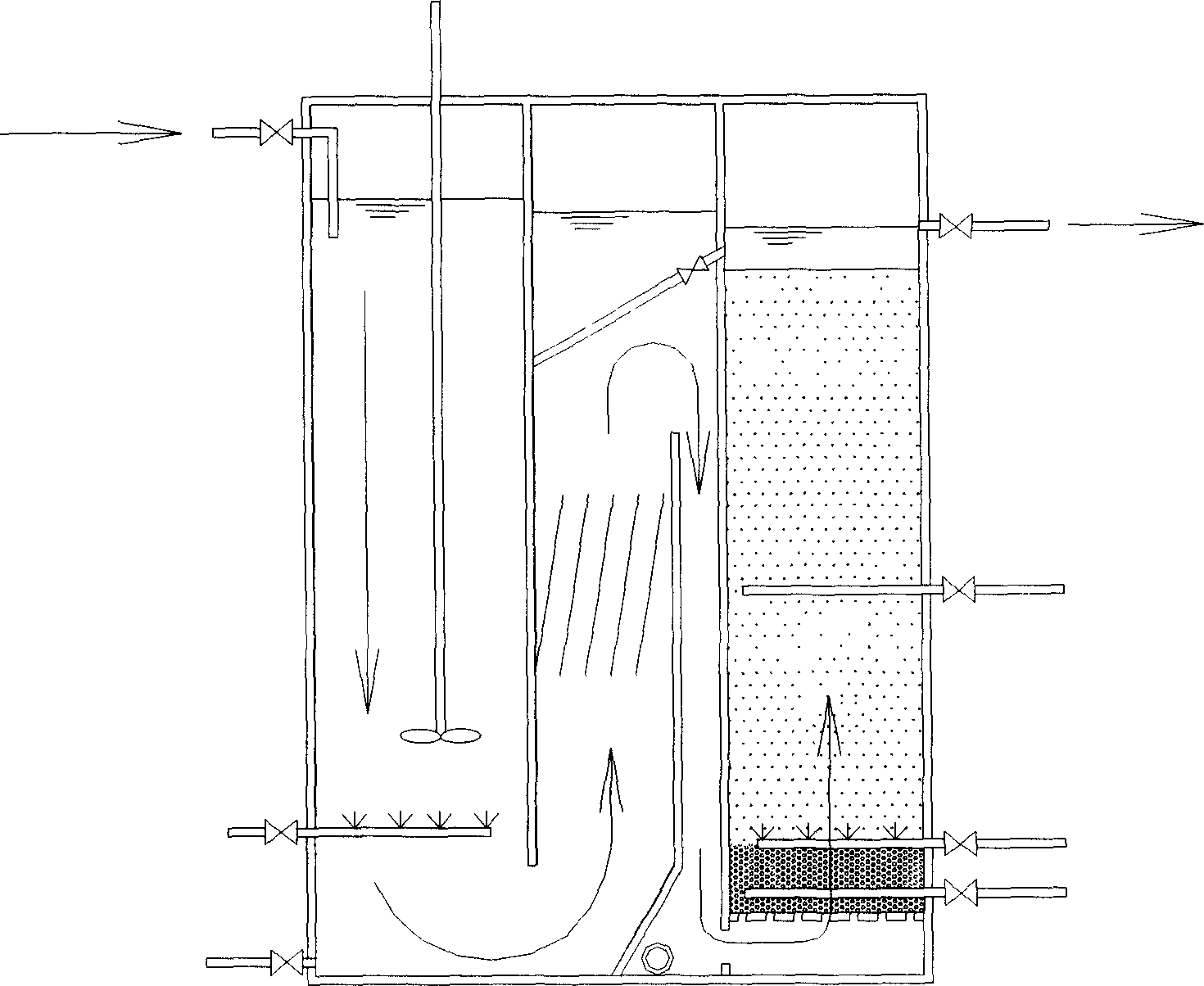

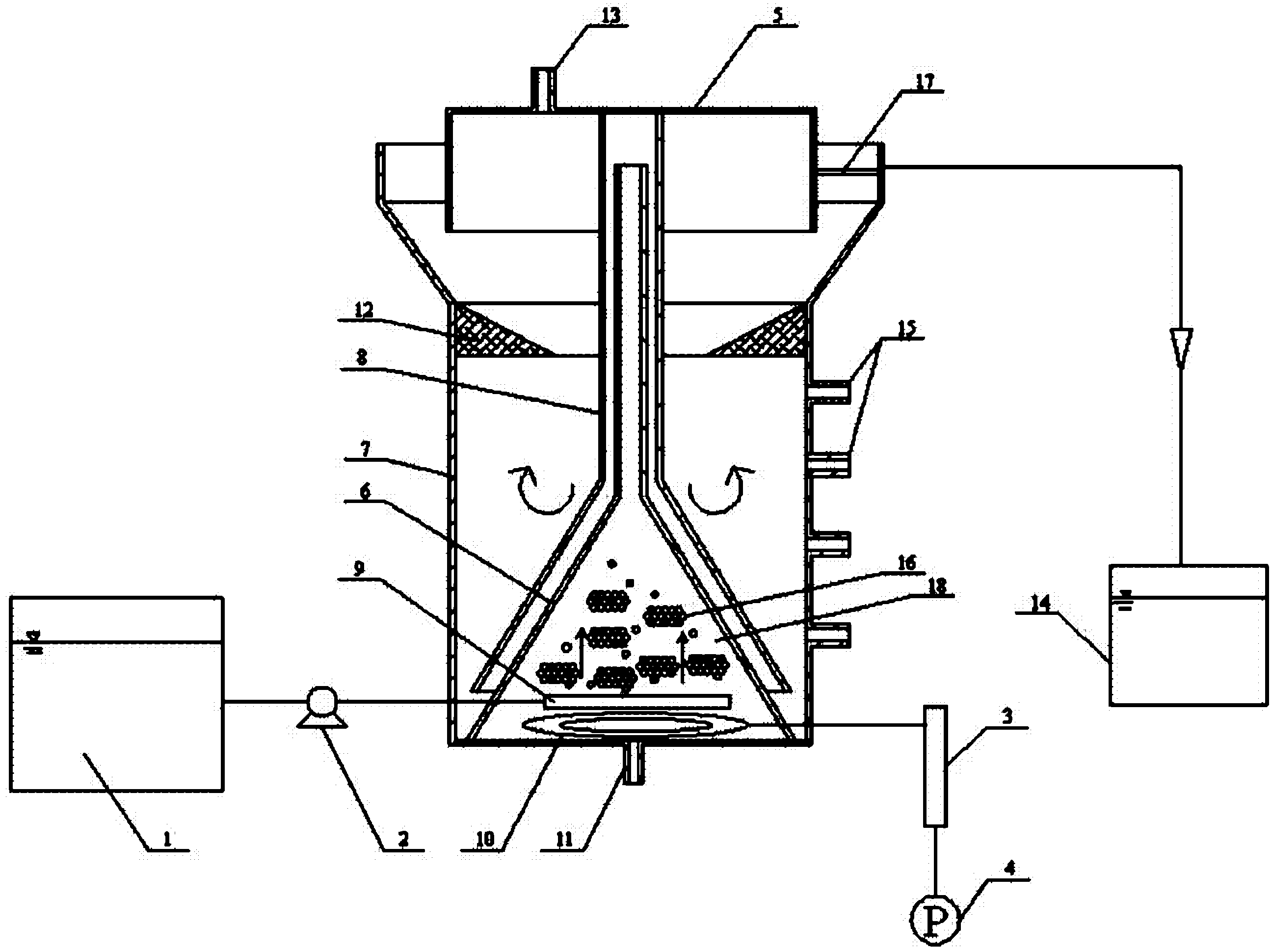

Aeration biological filter chamber facility

ActiveCN102107947AReduce the impactGood effectTreatment with aerobic and anaerobic processesSludgeBiological filter

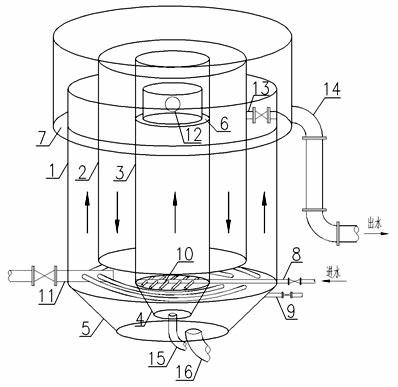

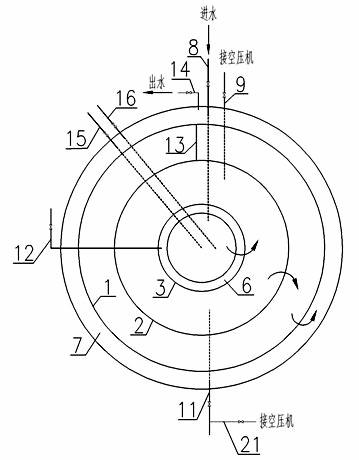

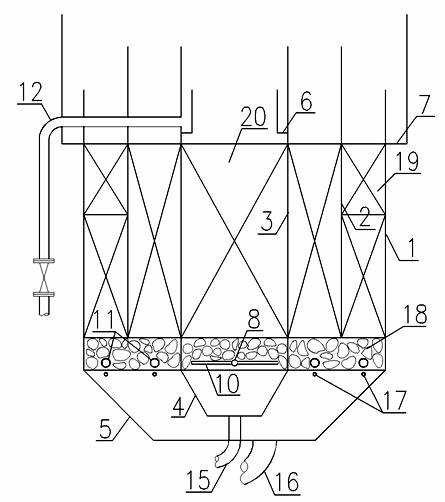

The invention relates to an aeration biological filter chamber facility which is an integrated sewage treatment facility in a multistage series combination technique. The aeration biological filter chamber facility comprises a chamber body, a filler layer, a supporting layer, a sludge hopper, a water inlet / outlet system, a back-purge system, various control valves and metering devices. From inside to outside, the whole facility is sequentially divided into an anaerobic zone filter chamber, a first aerobic zone filter chamber and a second aerobic zone filter chamber in the form of concentric circles. When the facility operates, sewage enters from the bottom of the inner layer anaerobic zone, sequentially flows through the filter chambers in an upflow-downflow-upflow mode, and finally converges in a water collection tank on the chamber top to be discharged. While the sewage enters, air is introduced into a microporous aeration hose on the lower part of the aerobic chamber so as to provide required oxygen for decomposing organic substances. In the back-purge stage, back-purge gas and water of the aerobic zone filter chamber share one set of perforated pipes, and a gas-water-gas three-step purge mode is adopted; and at the anaerobic zone filter chamber, a water inlet perforated pipe is utilized to carry out back-purge, and only water is used for the back-purge in the whole process. After the upflow water purge finishes, the downflow water starts purging to remove aged biomembranes, thereby ensuring the stable operation of the filter chamber.

Owner:CHONGQING UNIV

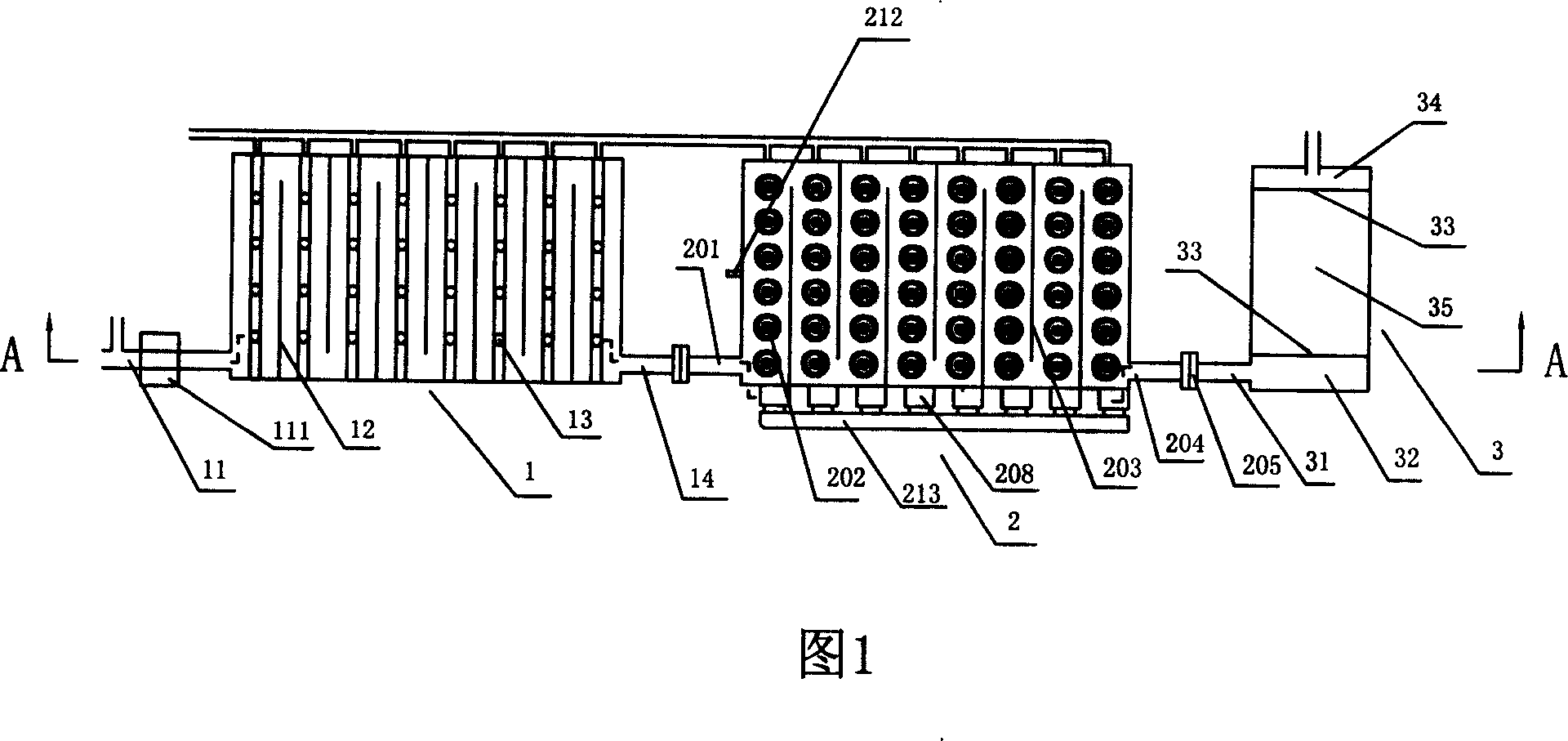

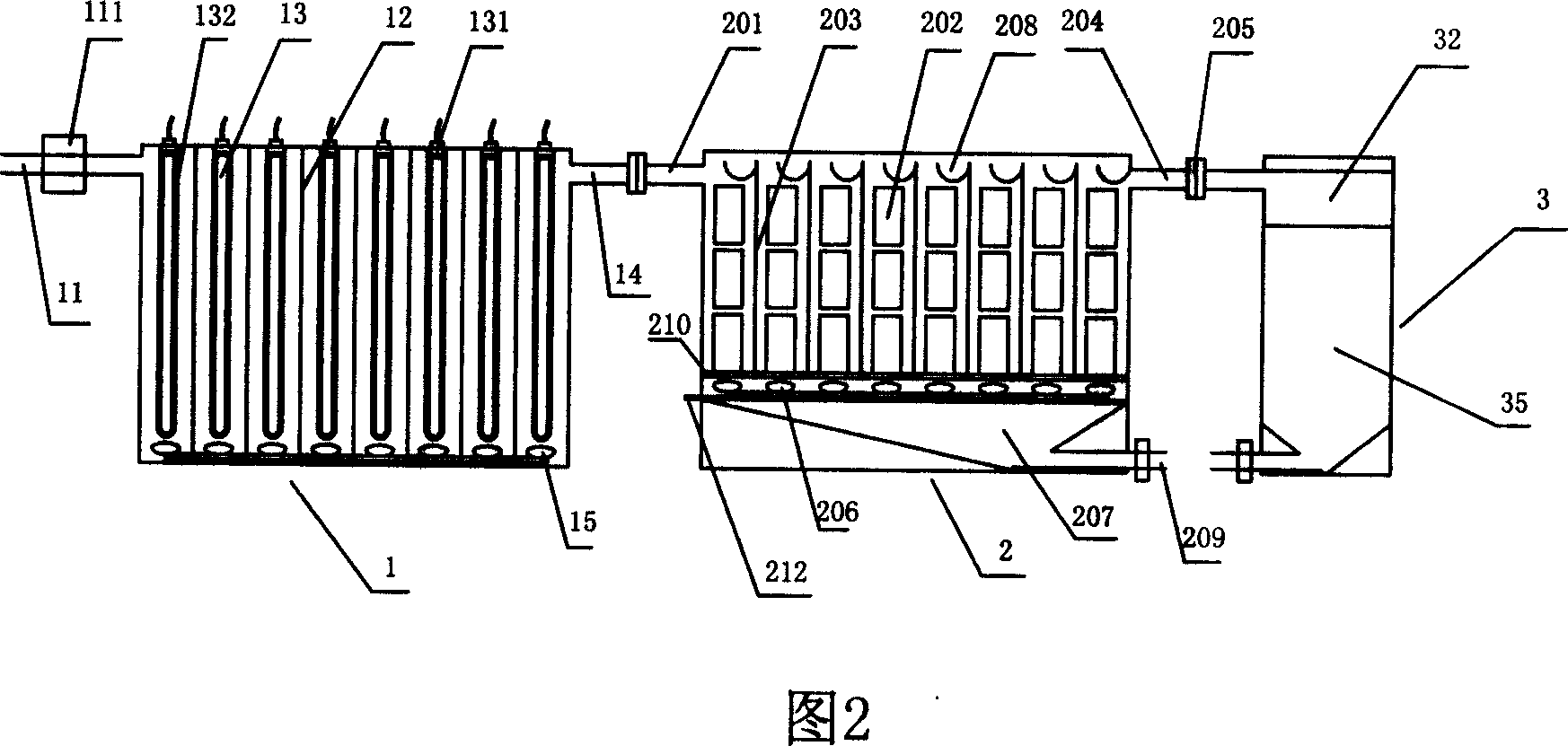

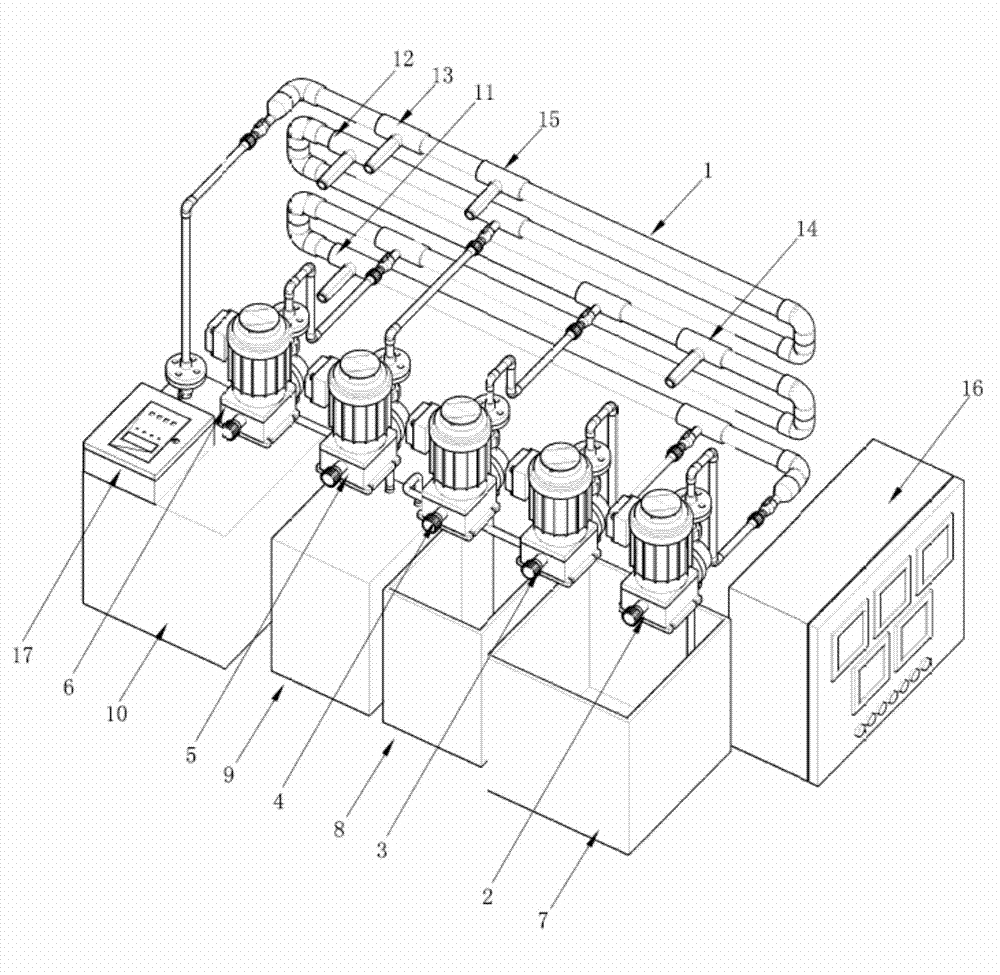

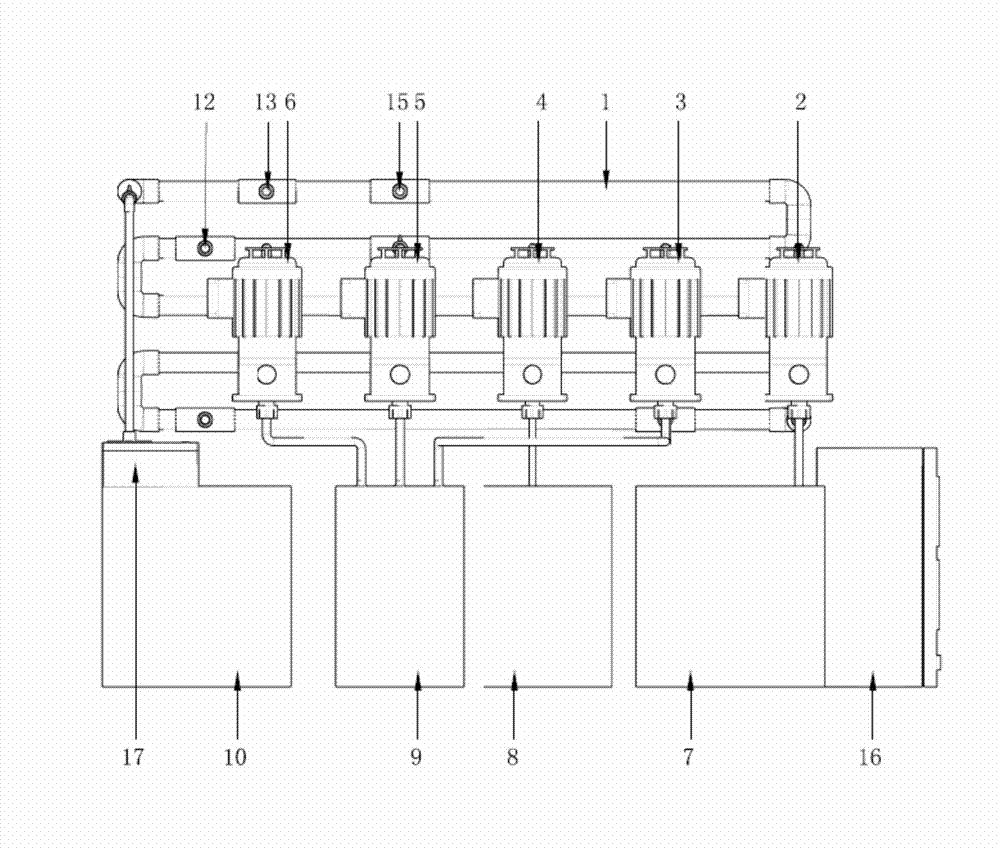

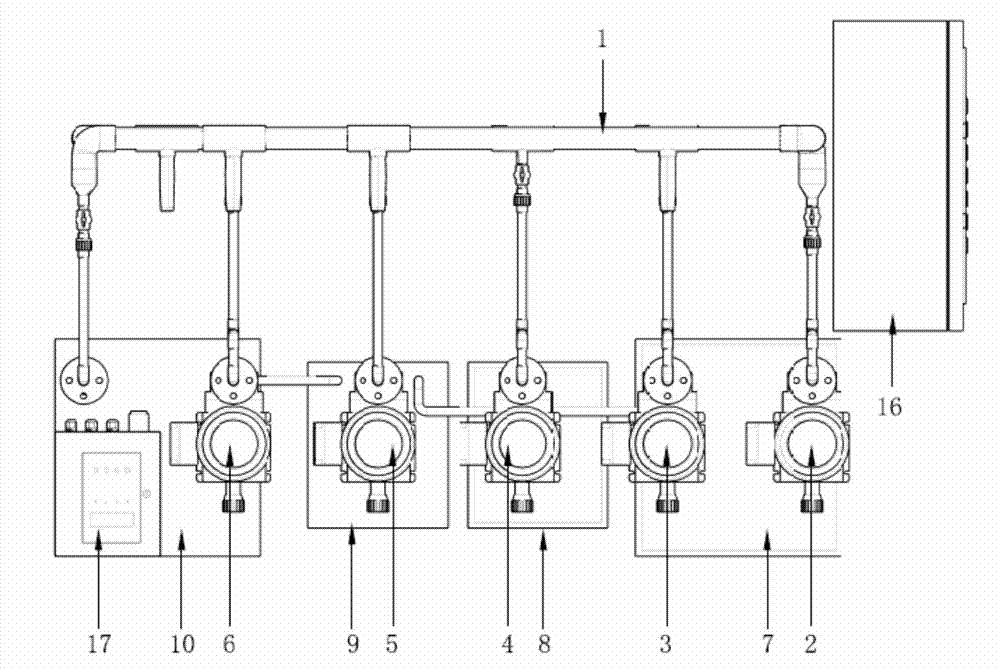

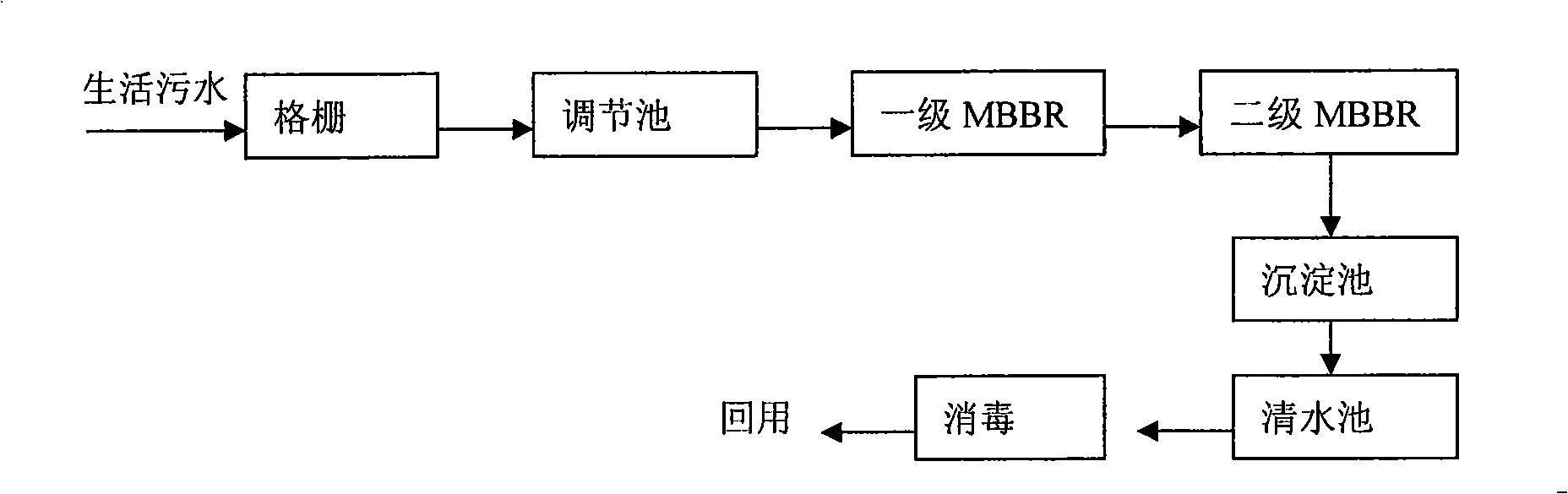

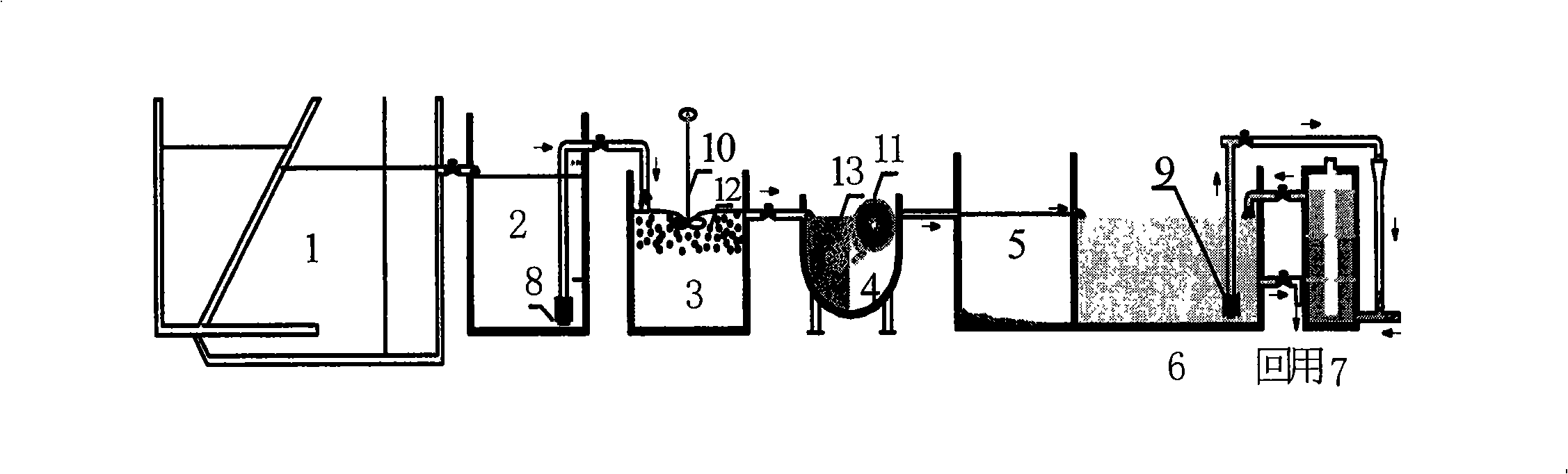

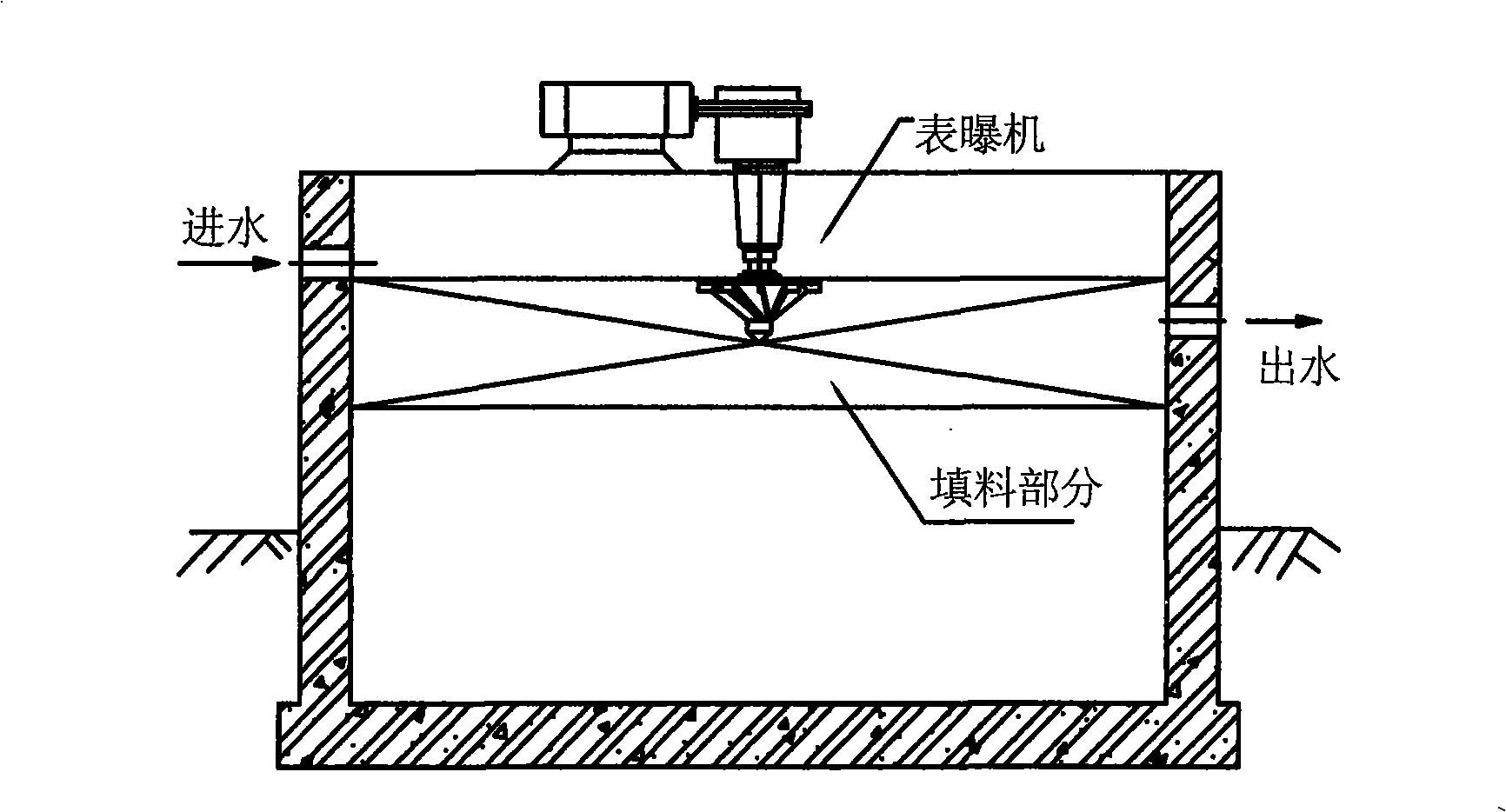

Water treatment system in two-stage moving bed biomembrane reactor

InactiveCN101402487AEasy to handleStrong resistance to shock loadsSustainable biological treatmentBiological water/sewage treatmentAutomatic controlSludge

The invention belongs to the field of water treatment, and relates to a two-stage moving bed biomembrane reactor medium water treatment system. The two-stage moving bed biomembrane reactor medium water treatment system is characterized in that the whole process adopts a programmable PLC automatic control system; the main treatment structure is two-stage cascade connected moving bed biomembrane reactors; and the concrete process flow is as follows: domestic sewage or sewage with similar water quality enters a regulating pond through grates and then enters a first-stage MBBR reactor and a second-stage MBBR reactor in turn by pump lifting; and then the water is outputted into a depositing pond, enters a clear water pond and is reused for flushing toilet or as landscape water after cyclic ultraviolet sterilization. The two-stage moving bed biomembrane reactor medium water treatment system has the advantages that: 1 the system has good medium water treatment effects, stronger resistance to shock load and stable outputted water quality; 2 the system has simple and convenient operating management, a small floor area, convenient maintenance and little excessive sludge; and the system adopts the PLC automatic control system with high automatic degree; 3 the system adopts a mechanical aeration mode, thereby bringing about low energy consumption and good oxygenation performance without an independent blower; 4 the system adopts a cyclic ultraviolet sterilization mode without any medicament added during the whole process, thereby avoiding the secondary pollution; and 5 the system has a wide application range.

Owner:UNIV OF SCI & TECH BEIJING

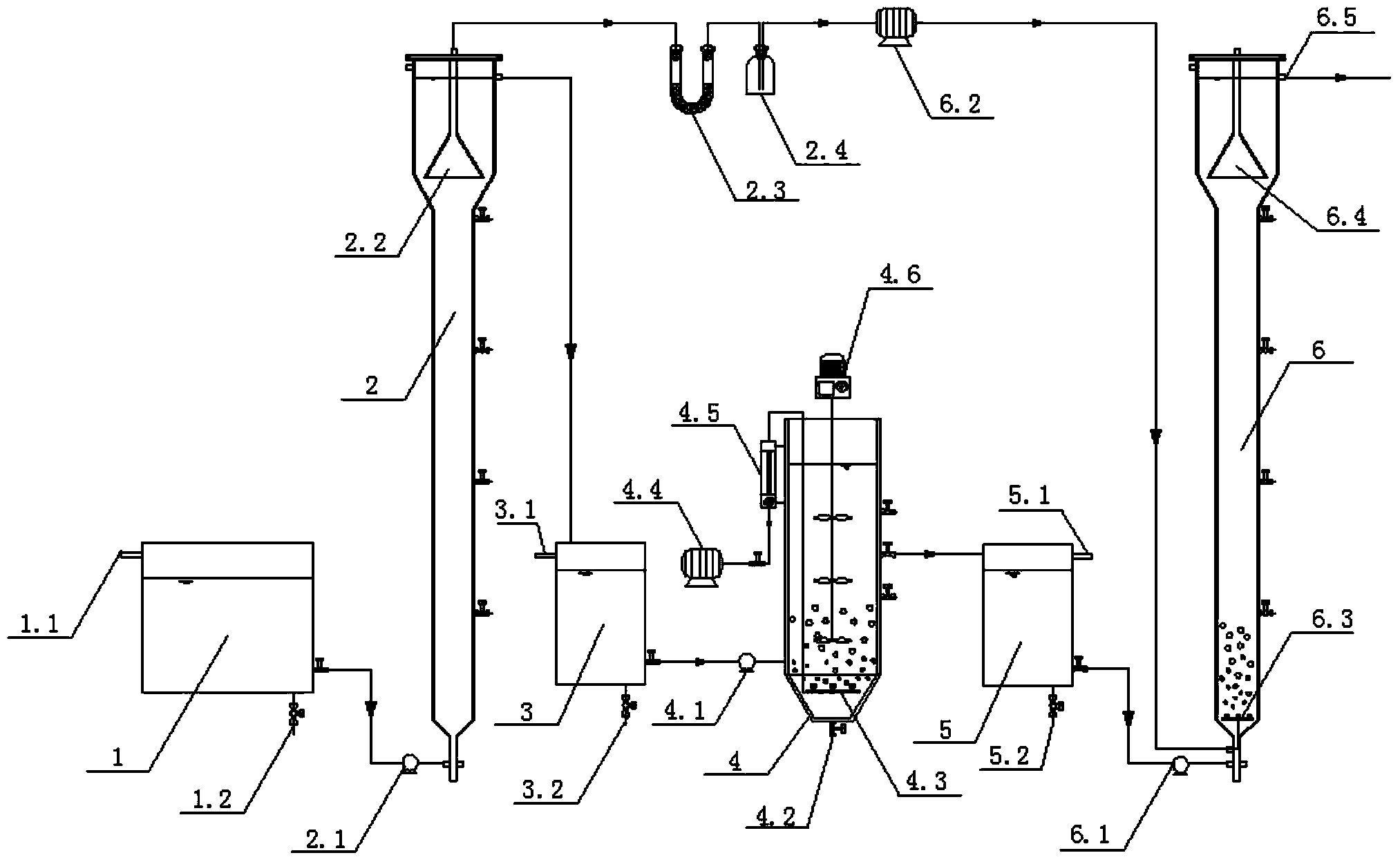

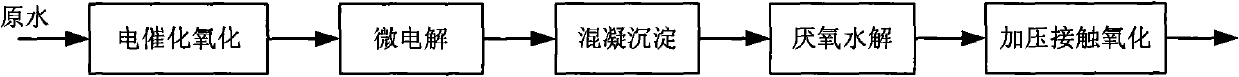

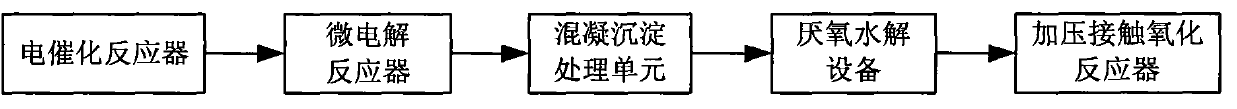

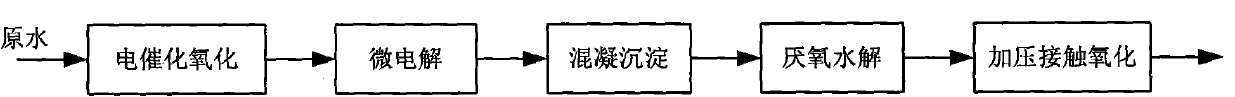

Process and equipment for treating high-concentration pyridine waste water

InactiveCN102139992AStrong resistance to shock loadsEfficient decompositionMultistage water/sewage treatmentWater/sewage treatment by oxidationChemical treatmentHigh concentration

The invention relates to a process for treating high-concentration pyridine waste water, which comprises the following steps of: regulating raw water of waste water to be acidic, and treating the raw water in electro-catalytic oxidation equipment; leading effluent to a micro-electrolysis device for treatment under the condition of maintaining the acidity and oxygen enrichment of the waste water; regulating the effluent to be meta-alkalescent, and adding chemicals to perform coagulating sedimentation; and controlling the salinity of the waste water to be below 2 percent, and performing biochemical treatment in an anaerobic hydrolyzing device and a pressurizing biological contact oxidation device, so that the effluent reaches the conventional first-level standards for sewage discharge. Due to the adoption of a physico-chemical treatment process serving electro-catalytic oxidation as a core, pyridine pollutants can be decomposed effectively, the toxicity of the waste water can be reduced, and the biodegradability of the waste water can be improved; for biochemical treatment is realized by a combination process of anaerobic hydrolysis and pressurizing biological contact oxidation, the organic loads, treatment efficiency and salt-tolerant capacity of the biochemical treatment are improved; and the process has the characteristics of high impact load resistant capacity, good treatment effect and low operating cost, and the treated high-concentration pyridine waste water can reach the standard stably before discharge.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +1

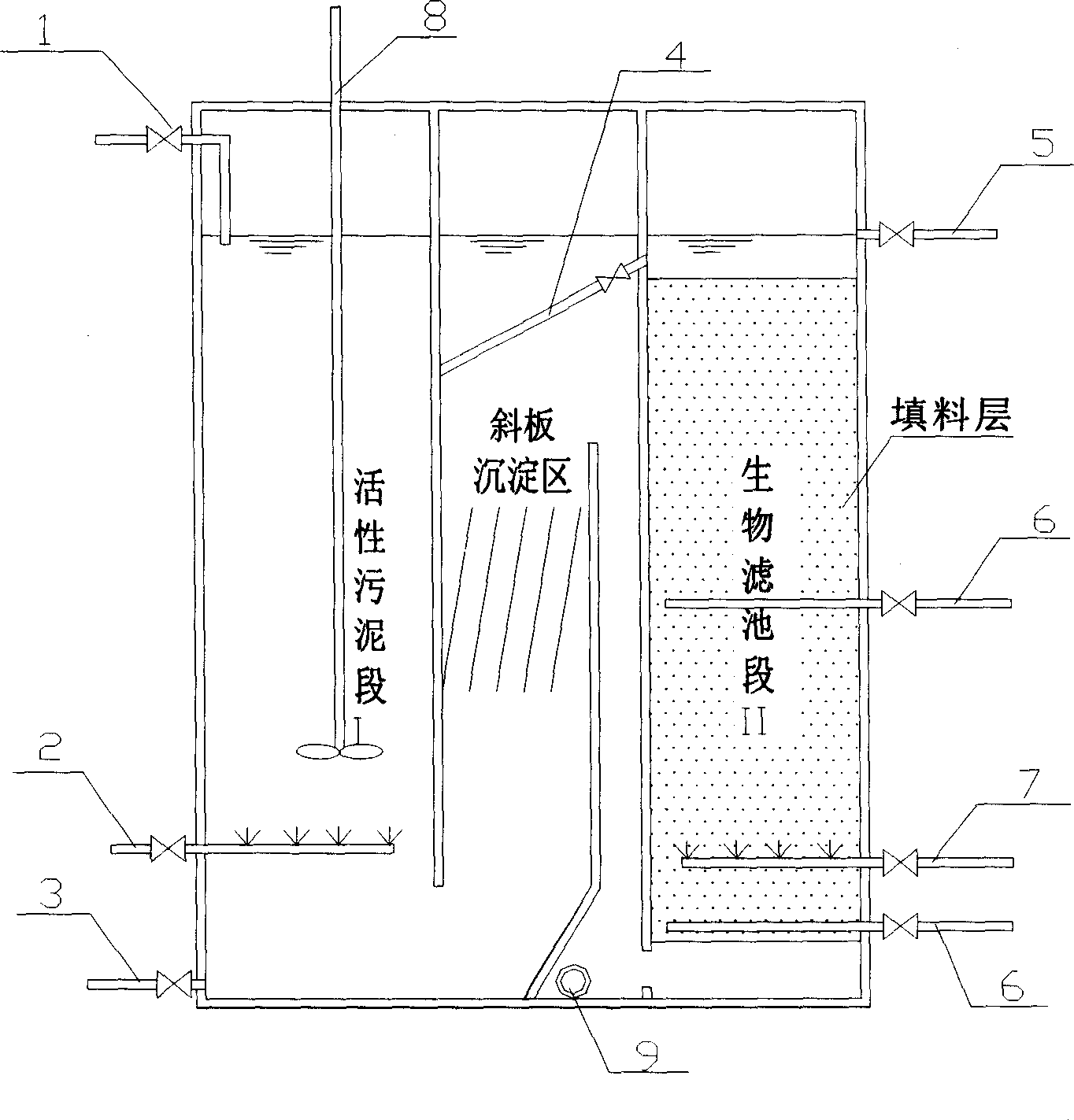

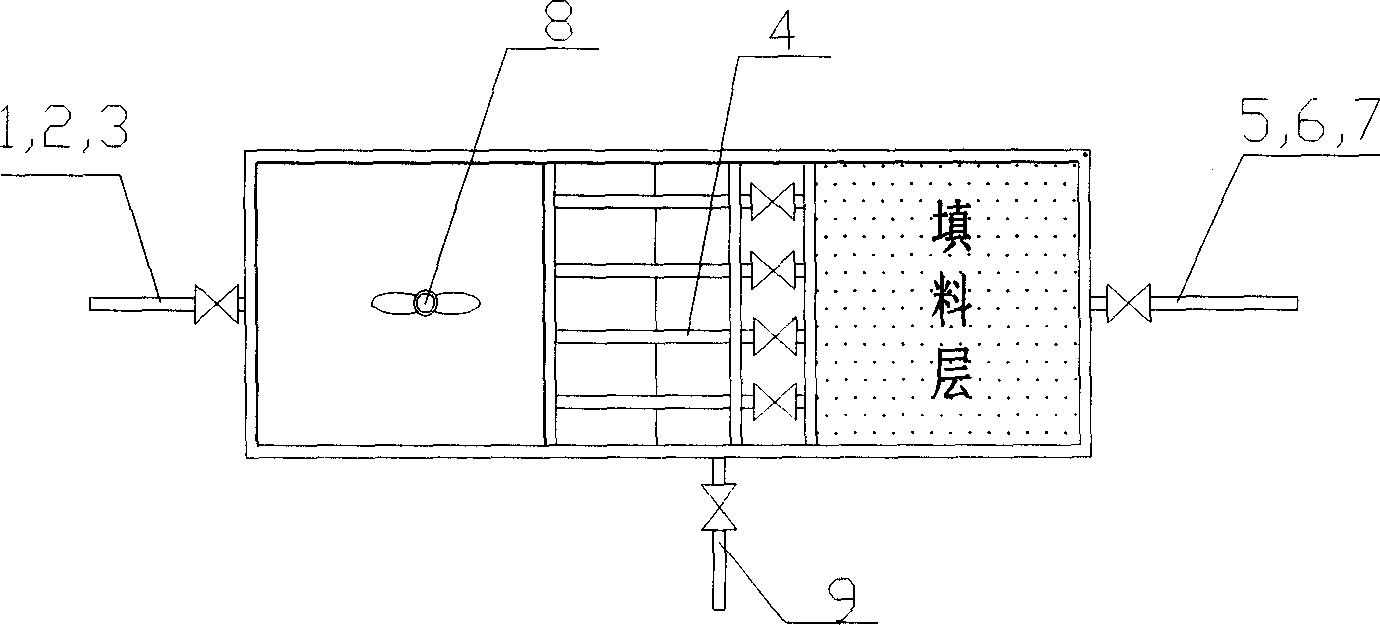

Sewage treatment method using active sludge-biological filtering pond revere flow and integral device

InactiveCN1657443AEasy to handleGuaranteed uptimeSustainable biological treatmentBiological water/sewage treatmentActivated sludgeReflux

Owner:CHONGQING UNIV

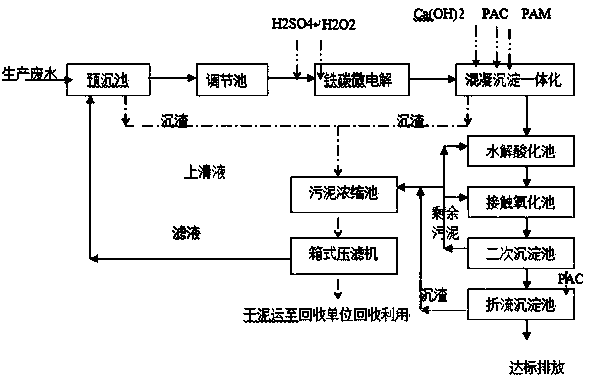

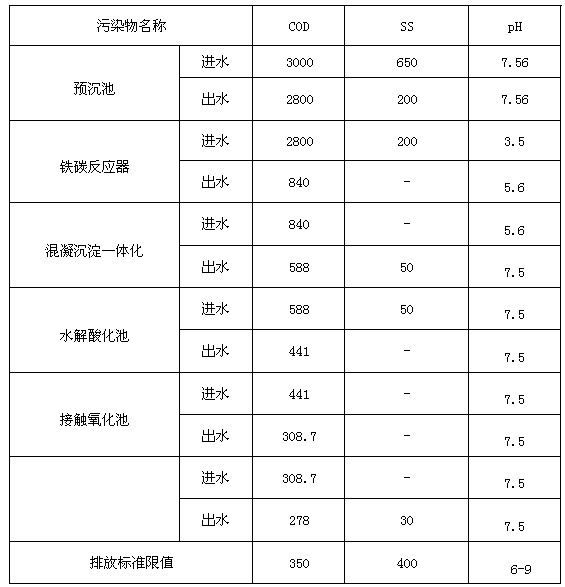

Process for treating wastewater generated in solar silicon wafer production process

InactiveCN103466885ARapid responseEase of conditionsGeneral water supply conservationEnergy based wastewater treatmentAluminium chlorideChemical oxygen demand

The invention discloses a process for treating wastewater generated in a solar silicon wafer production process and relates to wastewater treatment in the field of the electronic semiconductor industry. The process comprises the following steps of: pretreating wastewater in a preliminary sedimentation tank; carrying out Fenton and iron-carbon micro-electrolysis combined oxidization reaction on the wastewater in an iron-carbon micro-electrolysis reactor; after the reaction, feeding the wastewater into a coagulation-sedimentation integrated pool, feeding PAC (Poly Aluminium Chloride) and PAM (Poly Acryl Amide) to arouse the coagu-flocculation reaction of the wastewater, and after the reaction, performing sludge-water separation on the wastewater; causing the supernate to flow to a hydrolysis acidification pool, and then causing the wastewater to flow to a contact oxidation tank; causing the mixed liquid to flow to a secondary sedimentation tank for sludge-water separation, while causing the supernate to flow to a deflection sedimentation pool, and feeding PAC for purifying water so that the supernate is up to the stand and can be discharged after sedimentation; finally, performing concentration treatment on sludge. After non-degradable organic wastewater is treated by the process provided by the invention, the BOD5 (Biological Oxygen Demand) / CODcr (Chemical Oxygen Demand) ratio of the wastewater is obviously increased.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

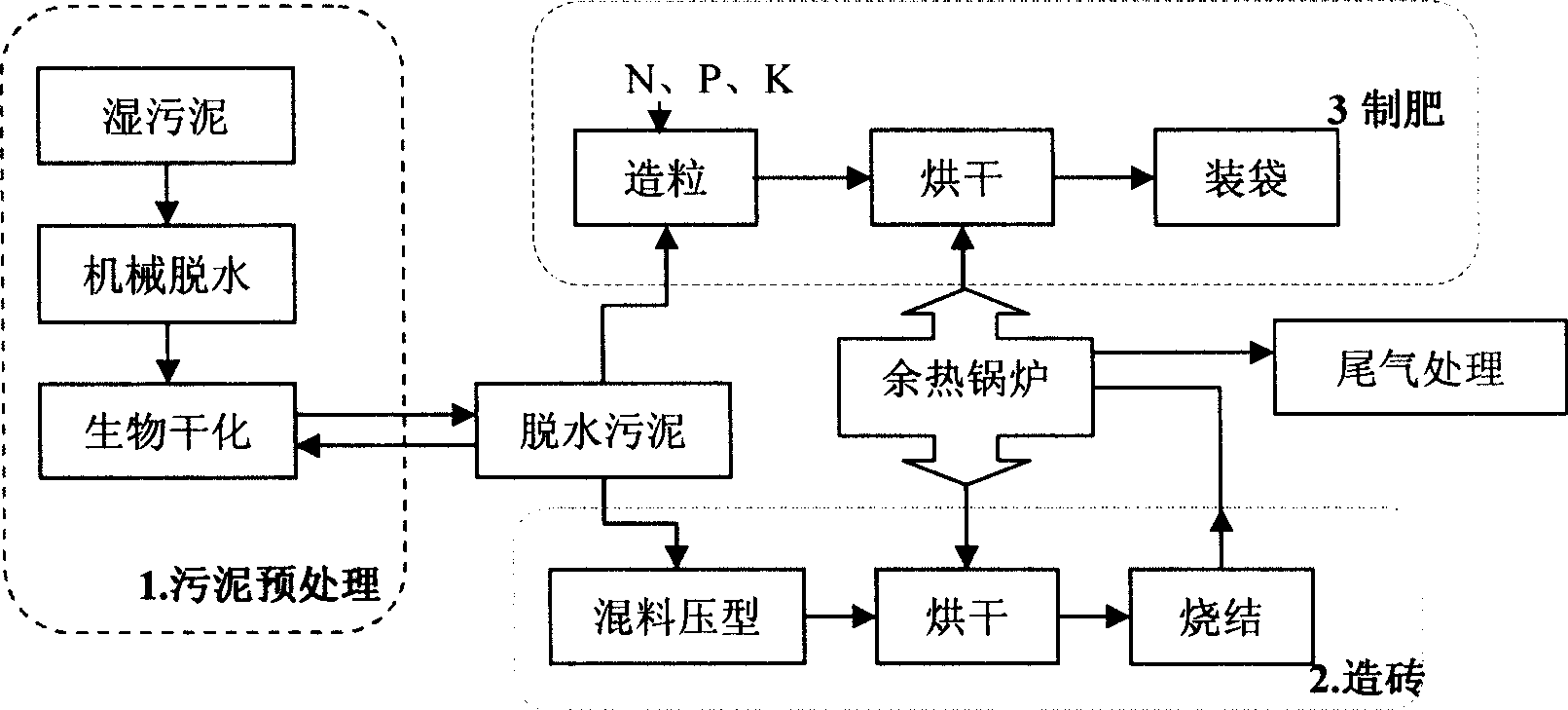

Mechanical deep dehydration, biological desiccation and reclamation combined treatment process for sewage sludge

InactiveCN101428955ASignificant reductionSave storage areaSludge treatment by de-watering/drying/thickeningClimate change adaptationBrickResource utilization

The invention relates to a treatment technology for combination of mechanical deep dehydration of sludge, biological drying and resource utilization, which consists of three parts of mechanical deep dehydration of the sludge, biological drying and resource utilization. The treatment technology comprises the following steps: firstly, dirty and wet sludge is subjected to dehydration by the mechanical method through a diaphragm high-pressure plate and frame filter press, and the water content is reduced to less than 65 percent; secondly, the sludge which is subjected to mechanical dehydration is dried by using biological energy, and the water content of the sludge is reduced to between 30 and 35 percent again; and finally, dried sludge after dehydration is used for producing fertilizer and building materials, wherein the production of the fertilizer adopts the compound fertilizer producing technique, that is, the dried sludge is subjected to nutrition adaptation, granulation, drying and bagging; and the production of the building materials adopts the sintering technique, that is, the dried sludge is subjected to mixture, green brick briquetting, drying and sintering. High-temperature flue gas generated during brick baking is utilized by a waste heat boiler, and tail gas is treated and exhausted after reaching the standards. The three working procedures of the technology are organically combined and conditional mutually, and the technology realizes reduction, innoxiousness and stability of the sludge, and simultaneously creates economic benefit.

Owner:宋乾武 +1

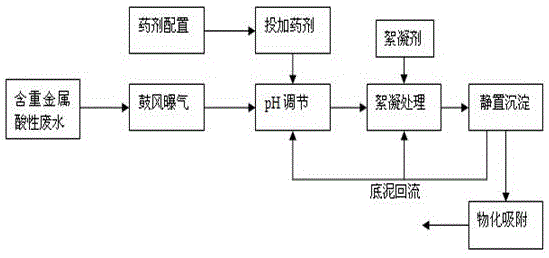

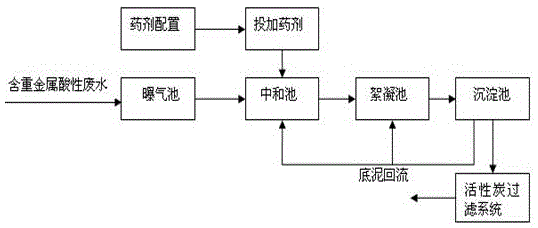

Improved treatment method of acidic waste water containing heavy metals

The invention discloses an improved treatment method of acidic waste water containing heavy metals; the treatment method comprises the following processes and steps: (1) blast aeration: carrying out blast aeration oxidation treatment on mine acidic waste water containing the heavy metals in an aeration tank with the aeration time of 30-50 min, wherein an aeration system adopts a ceramic-prepared microporous aeration head; (2) pH adjustment: carrying out pH adjustment and neutralizing treatment with a lime emulsion, and adjusting and controlling the pH value to be 8.0-8.5; (3) flocculation treatment with the flocculant dosage of 8-12 mg / L and the hydraulic retention time of 25 min-40 min; (4) standing precipitation: allowing most of bottom mud subjected to standing precipitation in a precipitation tank to synchronously return to a water pool and a flocculation tank, and scraping the rest part to a mud bucket by a mud scraper and discharging, wherein the backflow ratio of backflow slurry of the bottom mud is (8-10):1; and (5) physical and chemical adsorption treatment. The method can greatly reduce the consumption amount of a neutralizing agent and a flocculant, the amount of eventually produced sludge is substantially reduced, the content of the heavy metal elements in the sludge is increased significantly, the concentration treatment of the sludge is facilitated, the production process is simple, and the production cost is low.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

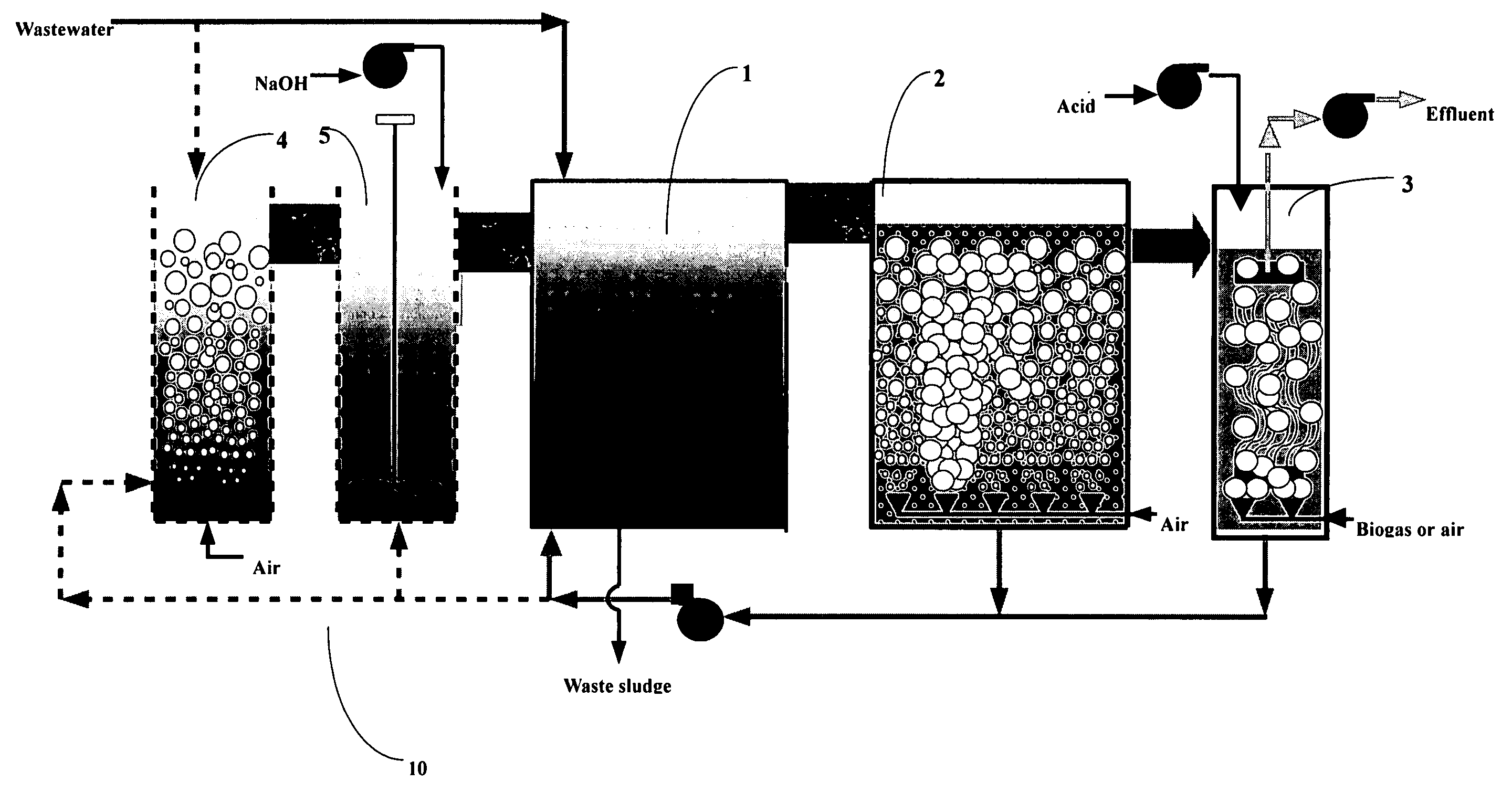

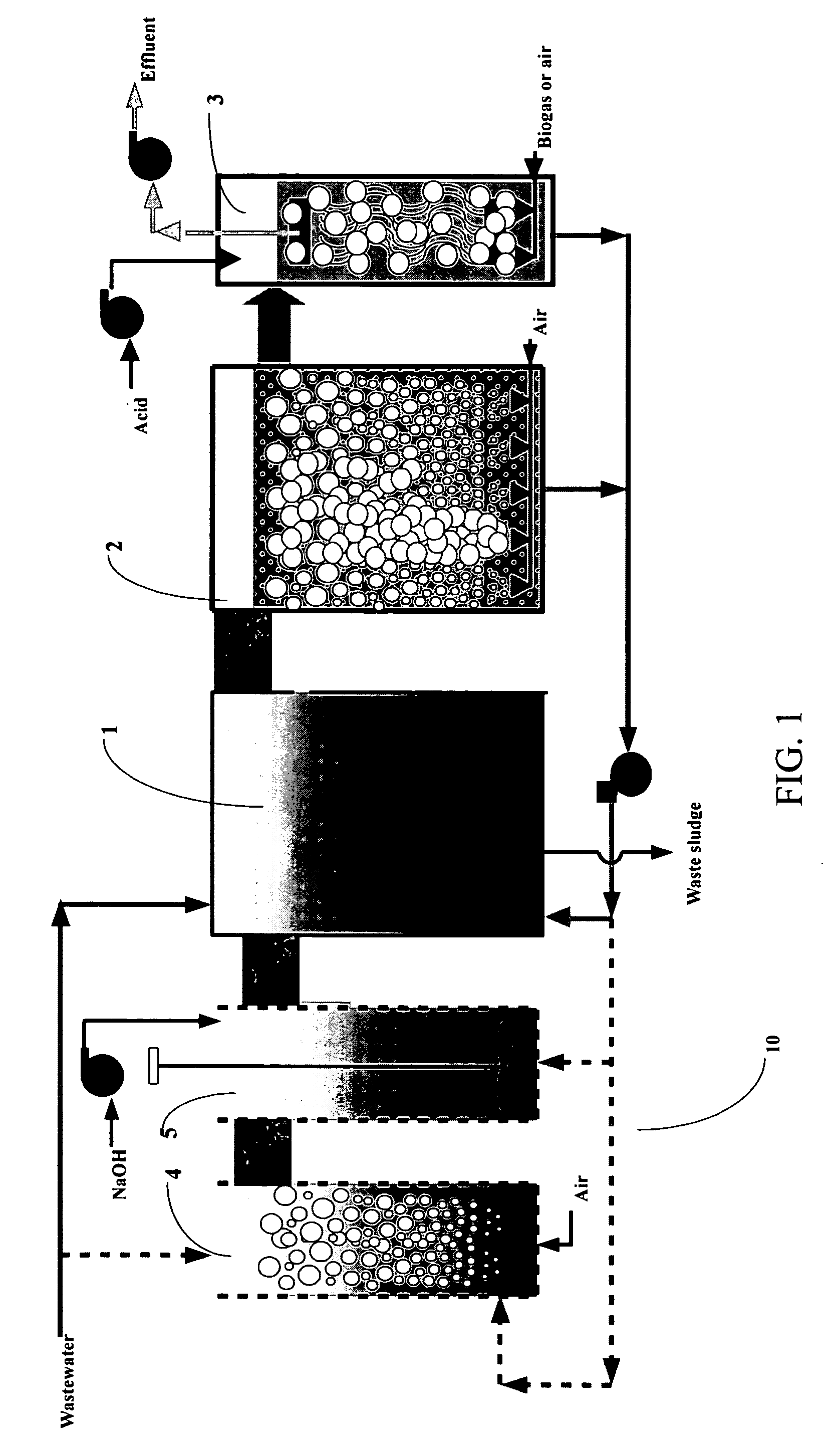

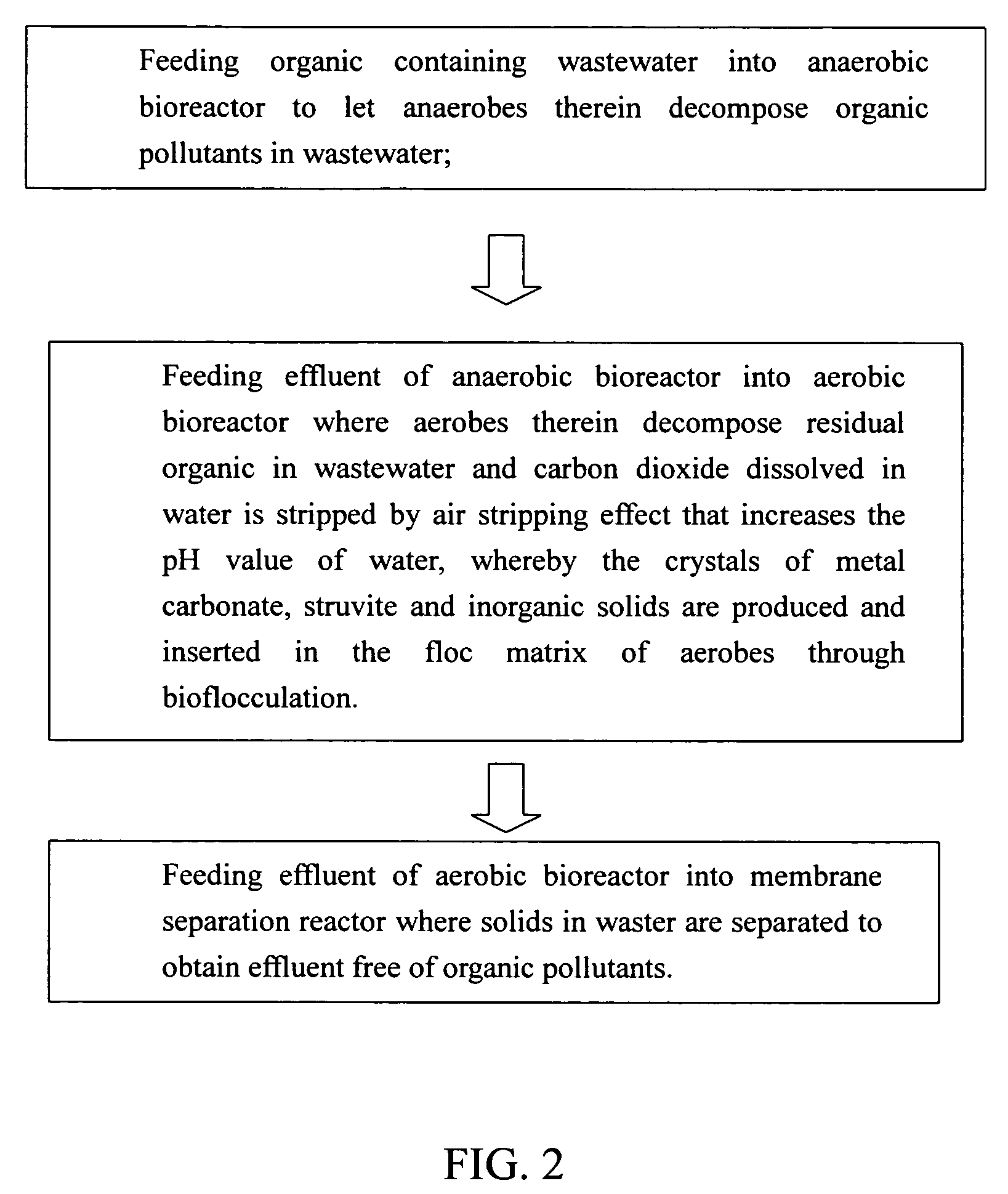

Method and system for treating wastewater containing organic compounds

ActiveUS7087170B2Reduce installation costsImprove efficiencyLiquid degasificationScale removal and water softeningWastewaterOxygen

A system for treating wastewater containing organic compounds is provided, comprising an anaerobic bioreactor, an aerobic bioreactor disposed rearwardly of the anaerobic bioreactor, and a membrane separation reactor disposed rearwardly of the aerobic bioreactor. The system is capable of removing organic pollutants in wastewater through biological treatment process and separating solid from the liquid ones by using a membrane. By employing the system for treating wastewater containing organic pollutants, organic pollutants can be effectively eliminated and the problem of scaling and fouling on the surface of the membrane prevented, thus achieving the objectives of lowering cost and improving efficiency.

Owner:IND TECH RES INST

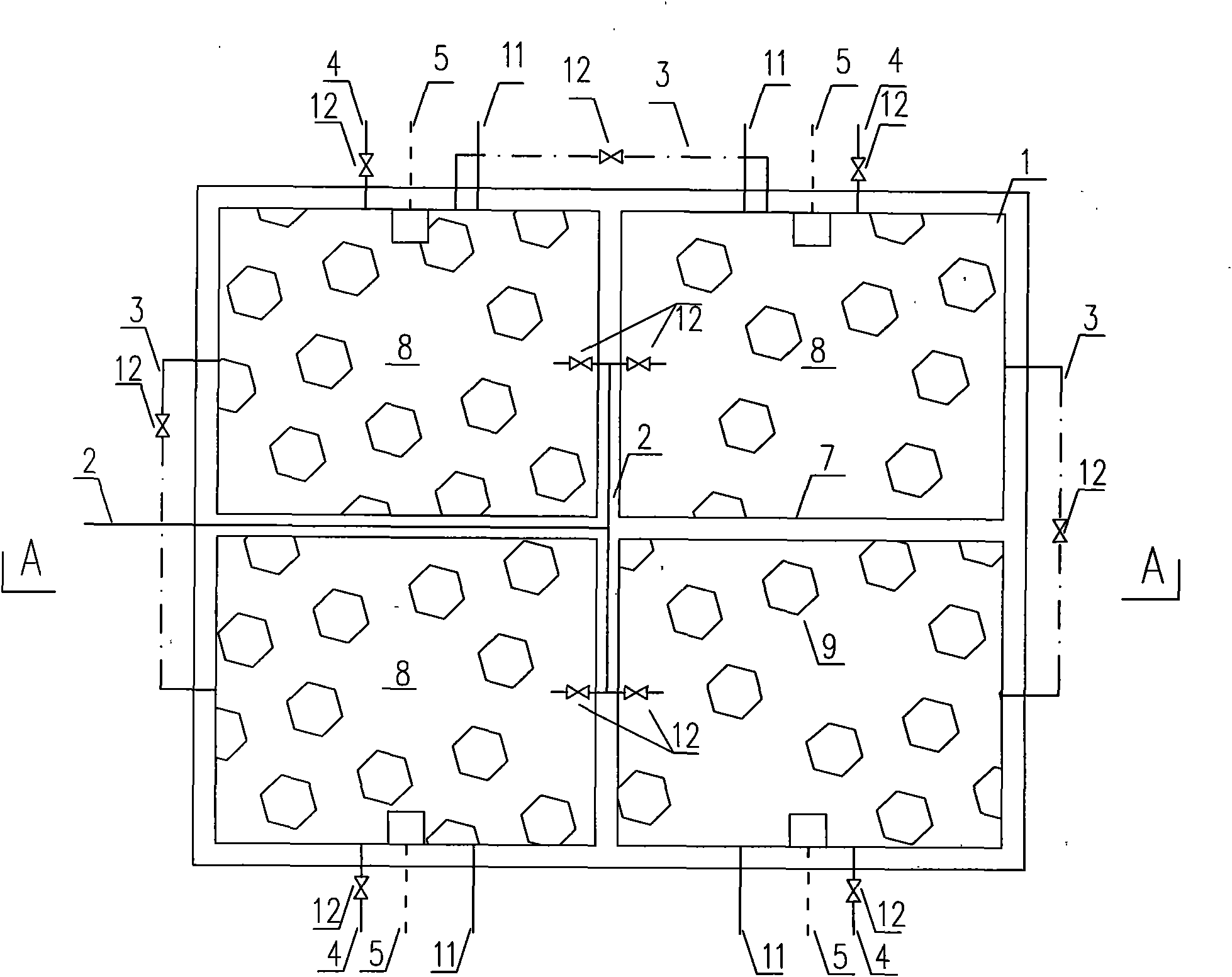

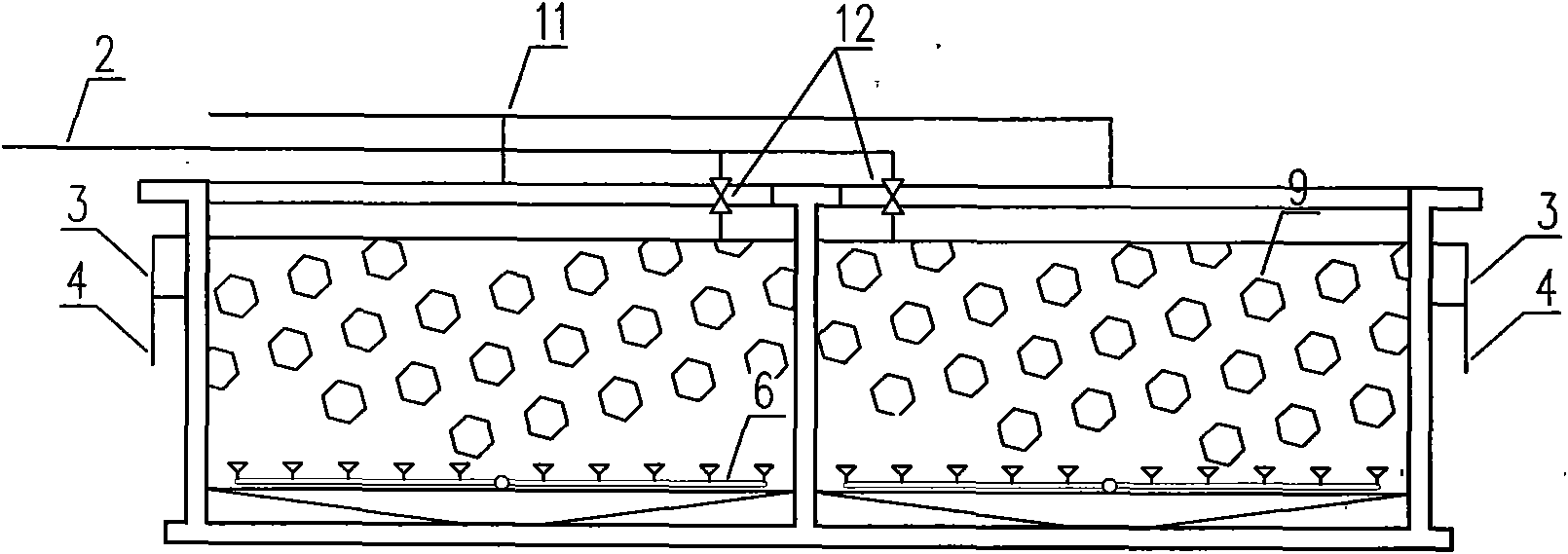

Sewage treatment reactor for alternately operating intermittent flow and continuous flow

InactiveCN101633531AReduce outputShort processTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAeration systemSludge

The invention discloses a sewage treatment reactor for alternately operating an intermittent flow and a continuous flow. The reactor comprises a tank body, an inlet / outlet water pipe, a connecting pipe, an eration system, and the like. Separation walls are vertically arranged in the biological treatment tank body and divide the biological treatment tank body into at least four grids which are respectively used as a biological reaction tank; each of the other tank is provided with an independent inlet / outlet water system and a connecting pipe which is arranged between two adjacent tanks; each tank is provided with suspension stuffing; and the bottom of each tank is provided with a microporous aeration device and a sludge discharge pipe. The invention has the advantages of flexible operation modes, high treatment efficiency, strong shockproof loading capacity, lower operation energy consumption, small remaining sludge amount, short process, small floor area, little investment, convenient management, and the like.

Owner:CHONGQING UNIV

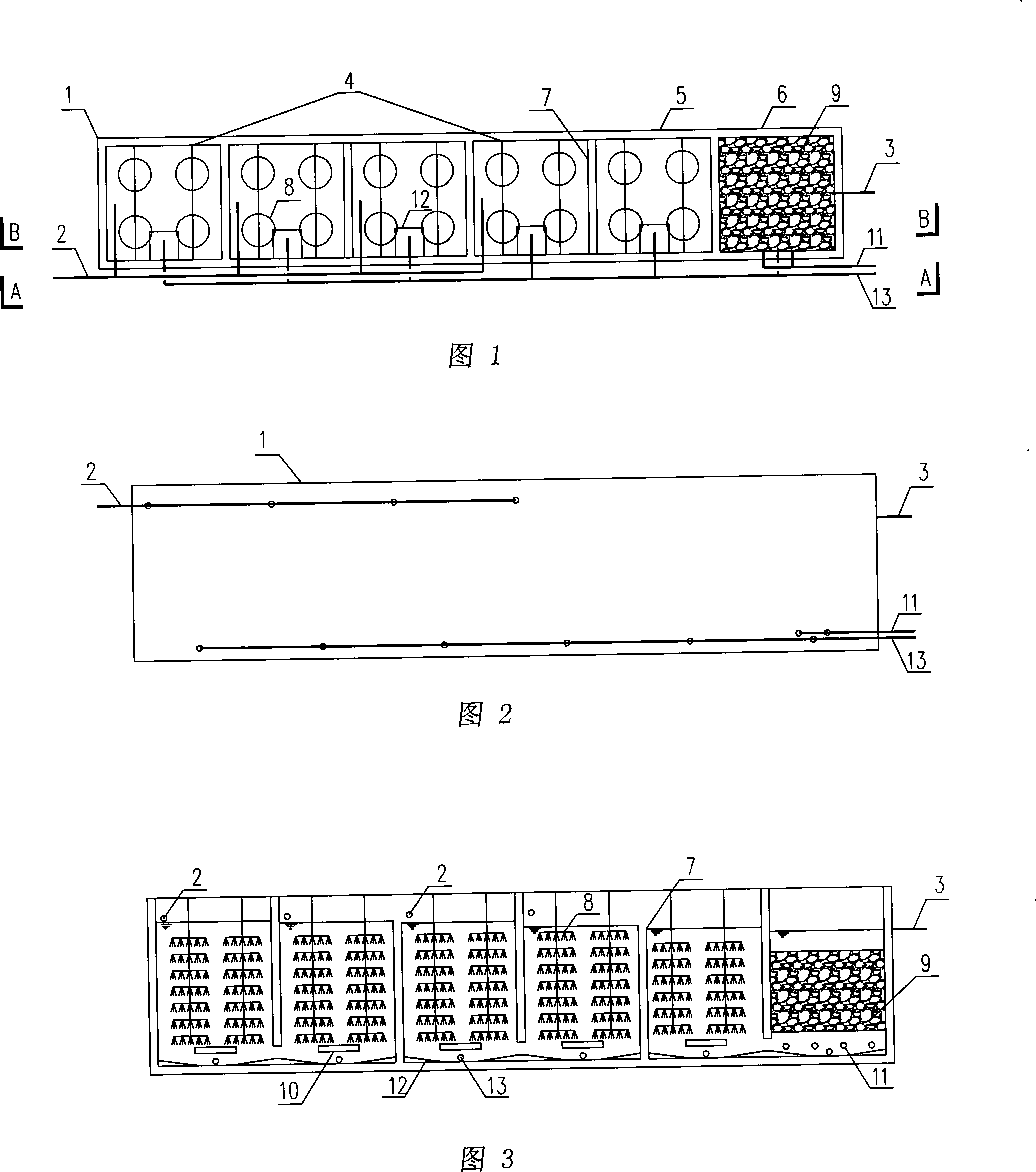

Sewage treating apparatus of point-division feed water multilevel biomembrane reactor

InactiveCN101172711AEasy to handleShort processTreatment with aerobic and anaerobic processesMultiple pointLower upper

The invention discloses a sewage treating device with a multiple water inlet point multi-grade bioflim reactor. N pieces of separating plates are vertically arranged inside a tank to divide the tank into N+1 reaction pools in series. The adjacent reaction pools are orderly communicated with the lower part to the upper part, wherein, the first N-1 grades are functioned with anaerobic and aerobic reaction alternately, every pool is provided with flexible assembled fillers; the N grad is the aerobic reaction area with flexible assembled filler, and the N+1 grad is the filtering and depositing area; a water inlet pipe is arranged at the top of the tank and is respectively communicated with the water inlet of the first N-1 grades, applying a water supply with multiple points; a water outlet pipe is led out of the upper part of the N+1 grade reaction pool; the bottom parts of the first N grade reaction pools are provided with an underwater aeration device, and the bottom part of the N+1 grade reaction pool is provided with a backwashing pipe. The bottom part of every pool is provided with a sludge discharge pipe. The treatment device has the advantages of great impact loading resistant ability, high treatment efficiency, low operation energy consumption, less left sludge, simple procedure, small land occupation, low investment and convenient operation.

Owner:CHONGQING UNIV

Polymerized titanium tetrachloride inorganic polymeric flocculant and preparation method of inorganic polymeric flocculant

ActiveCN102976462AGood flocculation effectSimple production processWater/sewage treatment by flocculation/precipitationChemical industrySludge

The invention relates to a preparation method of a polymerized titanium tetrachloride inorganic polymeric flocculant. The preparation method comprises the following steps: by using a titanium tetrachloride solution and sodium hydroxide as raw materials, adding sodium hydroxide into the titanium tetrachloride solution, wherein the alkalization degree is equal to 1.5-2, and the dropwise adding process of a sodium oxide solution is finished within 10-60 minutes; and then, further stirring for 1.5-5 hours until the solution becomes a colorless transparent liquid. The flocculant has the advantages of good product stability, strong colloidal substance adsorbing and bridging capabilities, good flocculation effect, wide application range, low sludge productivity and the like, can be widely applied to the fields of water supply, wastewater treatment, papermaking, textile dyeing and printing, daily chemical industry and the like and has a favorable water treatment effect. The method provided by the invention has the characteristics of simple and rapid process, economy, rapidness and the like.

Owner:SHANDONG UNIV

Room temperature nitrosation-anaerobic ammoxidation coupling symbiotic denitrification device for municipal sewage and sewage treatment method

InactiveCN102531172AReduce yieldReduce aerationTreatment with aerobic and anaerobic processesChemical oxygen demandNitration

The invention provides a room temperature nitrosation-anaerobic ammoxidation coupling symbiotic denitrification device for municipal sewage and a sewage treatment method and relates to a sewage treatment method, solving the technical problems that in the existing nitration-anaerobic ammoxidation process, occupied area is large and operation cost is high. The method comprises the following steps of: carrying out film formation with an intermittent film formation mode; introducing municipal sewage; completing the removal of COD (chemical oxygen demand) in the outer barrel and generating a small amount of NO2<-1>-N; and introducing mixed sludge subjected to nitrosation and anaerobic ammoxidation into the outer barrel so as to realize nitrosation-anaerobic ammoxidation coupling symbiotic denitrification. According to the invention, a continuous operation mode is adopted for the device; the device is small in occupied area, and the effective volume of a structure is reduced; and the device is simple and convenient in management, high in treatment efficiency, low in operation cost and the like, and specifically aims at domestic sewage having the characteristics of low substrate concentration and large water yield.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com