Photoelectromagnetism integrated waste water advanced oxidization method and device thereof

An oxidation device and advanced oxidation technology, applied in chemical instruments and methods, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as methods or technical parameters that have not been researched and disclosed, and achieve excellent treatment effect and occupy an area Small area, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

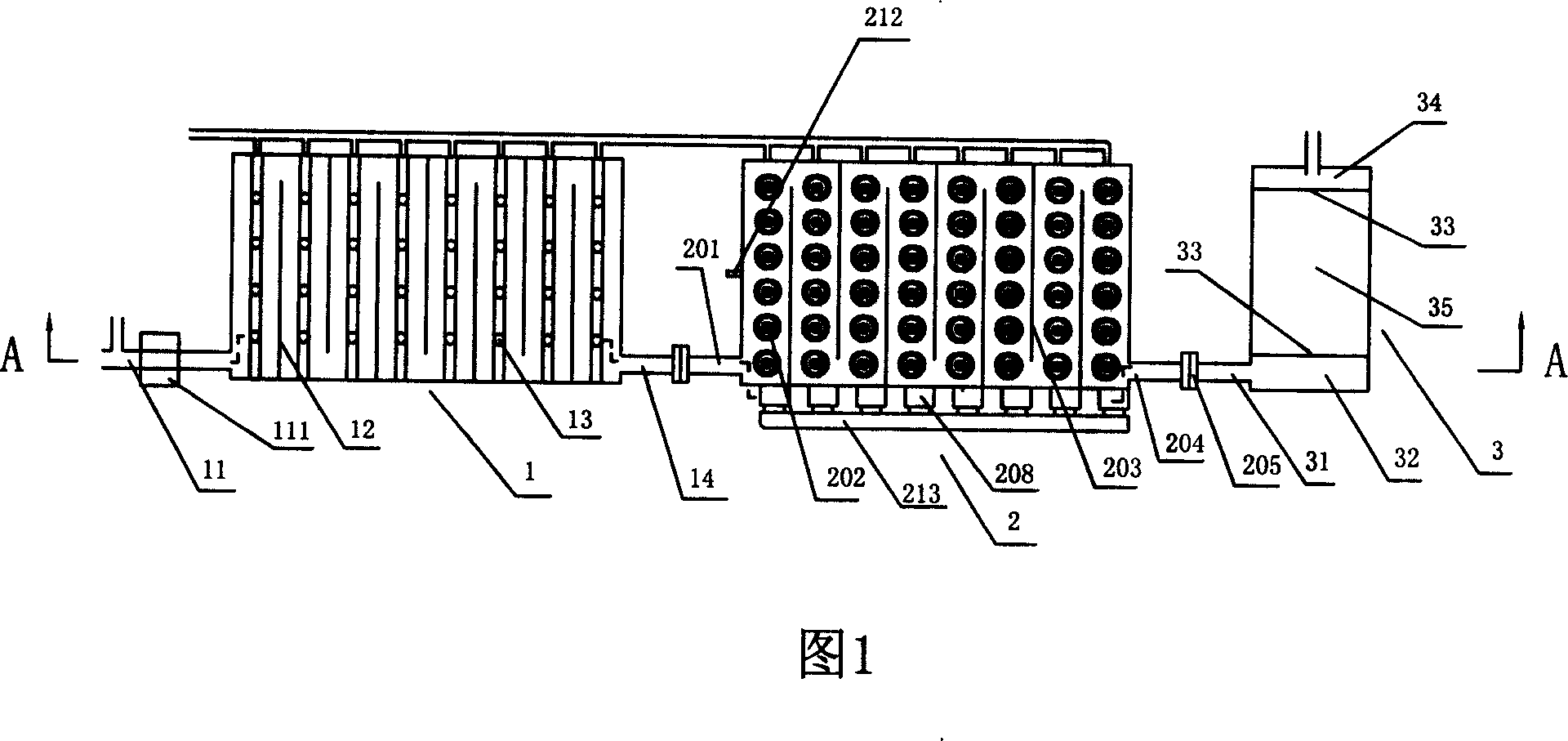

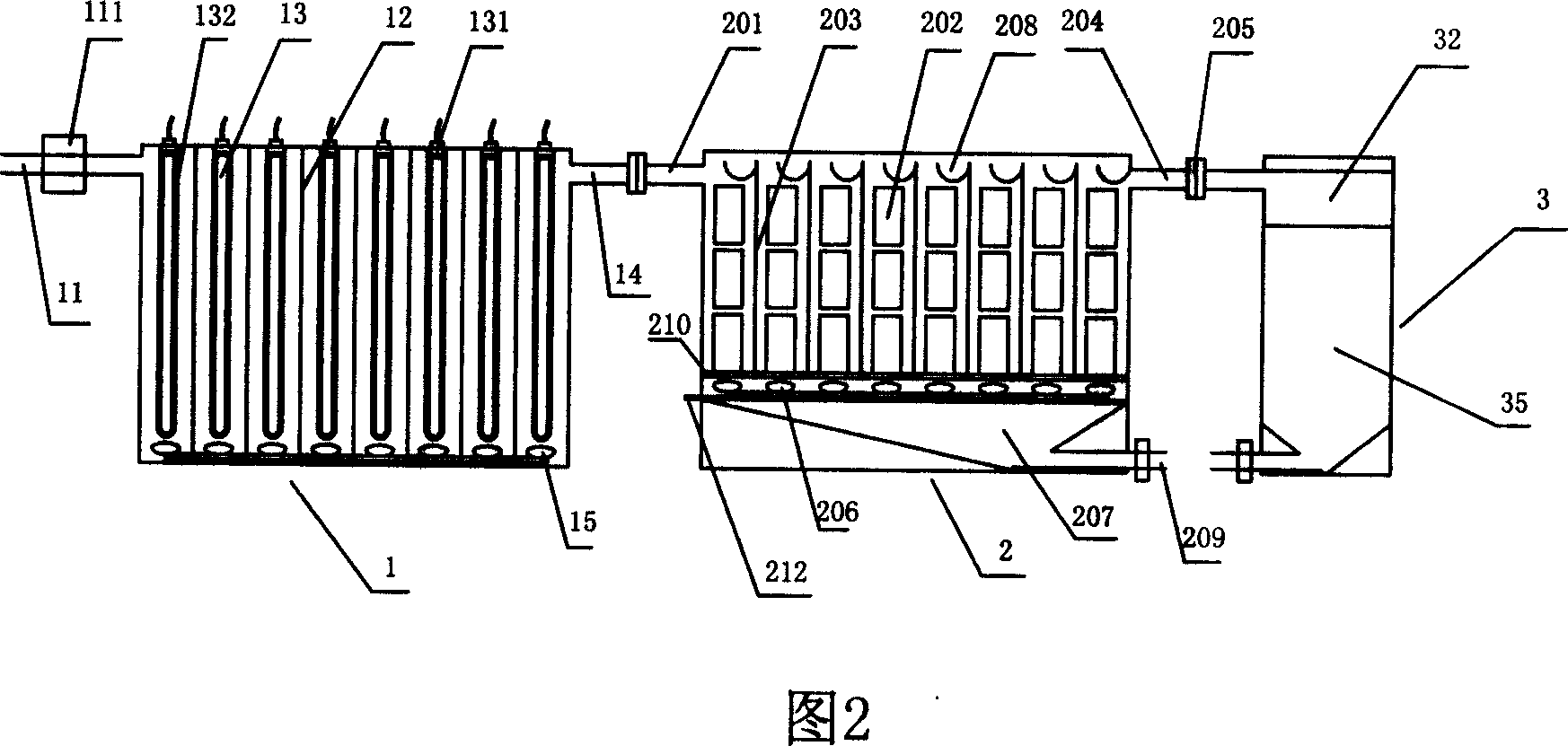

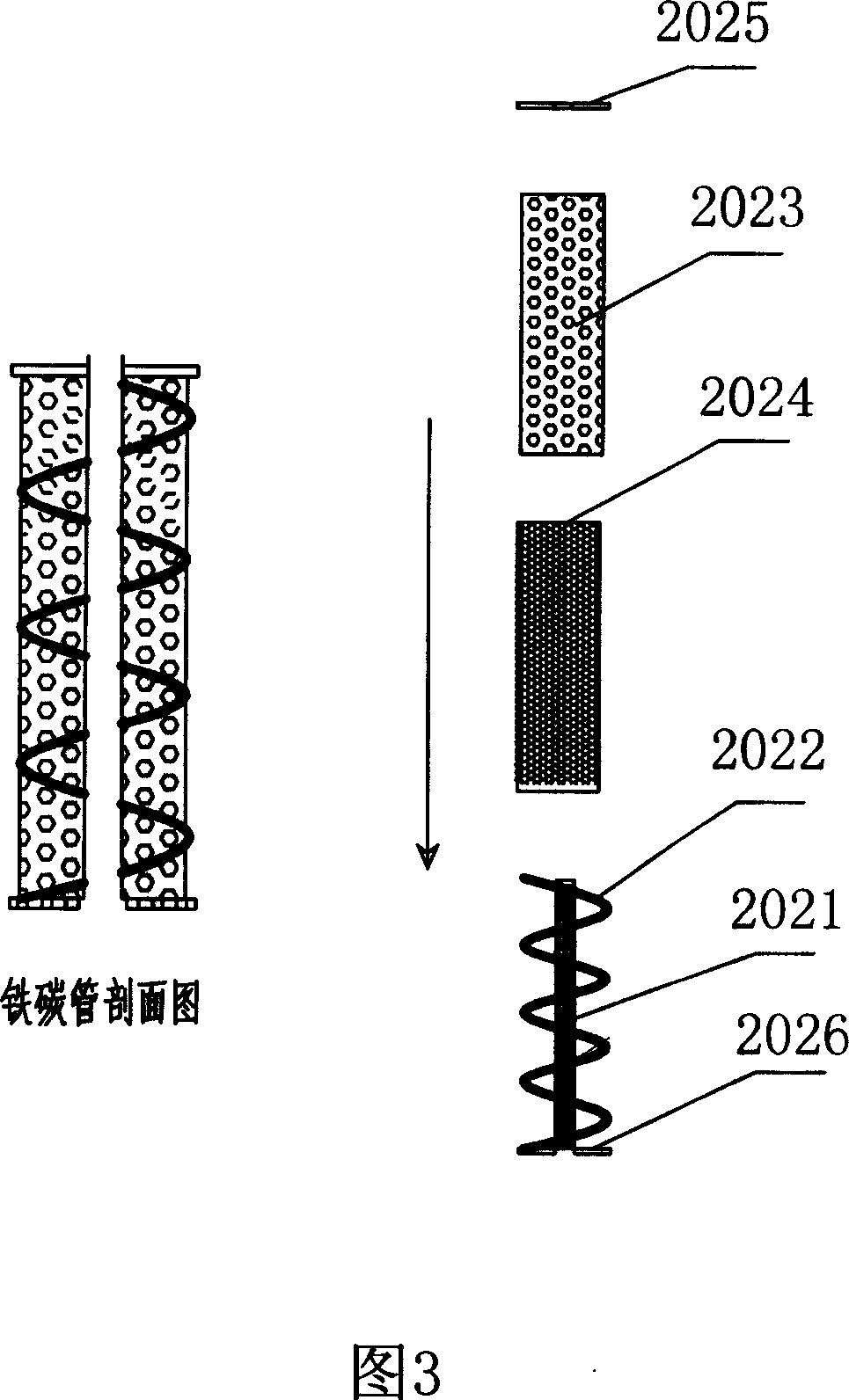

[0093] Figure 1 and Figure 2 show the application examples of the modular opto-electromagnetic integrated wastewater oxidation device with a processing capacity greater than 2 tons per hour. As shown in the figure, it includes a photocatalytic box 1, a micro-electrolysis reactor 2 and a filter 3, and the three are connected in sequence. The outer end of the photocatalytic box 1 is connected with a photocatalytic box inlet pipe 11 and a photocatalytic box outlet pipe 14. The water inlet pipe 11 of the photocatalytic box is connected to the organic wastewater pool (omitted in the figure), and the organic wastewater that has been acidified and pretreated can be introduced to carry out photocatalytic treatment. The water inlet pipe 11 of the photocatalytic box is covered with a magnetizer 111. The magnetic field strength of the magnetizer is 12000-20000 Gauss and can be made of ferrite or NdFeB. The water outlet pipe 14 of the photocatalytic box is connected to the micro-electrolys...

Embodiment 2

[0108] As another embodiment of the present invention, the micro-electrolysis reactor 2 in the embodiment one can also adopt the structure of following water inlet at the bottom:

[0109] In the present embodiment, photocatalytic box 1 and filter 3 structures are basically the same as embodiment one, and micro-electrolysis reactor 2 is provided with dividing plate 211 that it is divided into upper and lower cavity, as shown in Figure 4 and Figure 5, The separator 211 is connected to the negative pole of the external power supply, and the upper and lower cavities are communicated through the round holes on the separator. The upper cavity is provided with an iron-carbon tube 202 with built-in electrode material at the round hole of the separator, and the structure of the iron-carbon tube can be the same as that of the first embodiment. The lower chamber is provided with a reactor water inlet pipe 201 and a microporous aeration head 206, and has a positive metal plate 212 connect...

Embodiment 3

[0114] Figures 7 and 8 show an application example of an integrated device with a processing capacity of less than 2 tons per hour. As shown in the figure, it is composed of an upper box photocatalytic box 1 and a lower box micro-electrolysis reactor 2. The photocatalytic box 1 is provided with partitions 12, and multiple groups of ultraviolet lamps 13 are installed between the partitions 12. The bottom layer between the ultraviolet lamps 13 can choose whether to install a microporous aeration head (the device that is too small can not be installed) ), the ultraviolet lamp 13 is covered with a quartz sleeve 132. The outer end of the photocatalytic box 1 is connected with the photocatalytic box inlet pipe 11 and the photocatalytic box outlet pipe 14. The photocatalytic box inlet pipe 11 is covered with a magnetizer 111, and the photocatalytic box outlet pipe 14 passes through the reactor inlet pipe 201 and the micro-electrolysis reactor. 2 connected. The micro-electrolysis re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com