Patents

Literature

1250results about How to "Good processing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

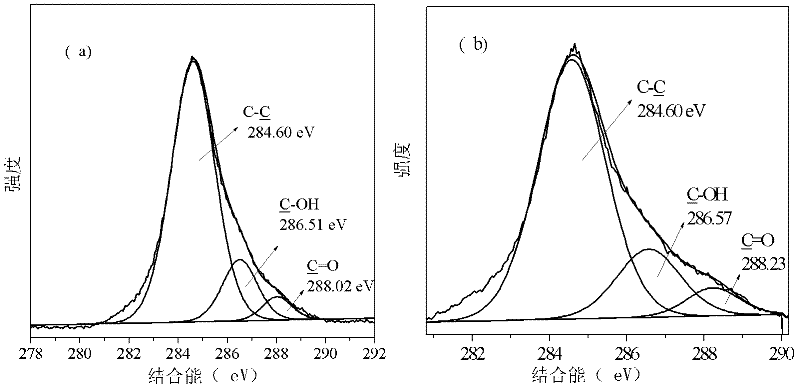

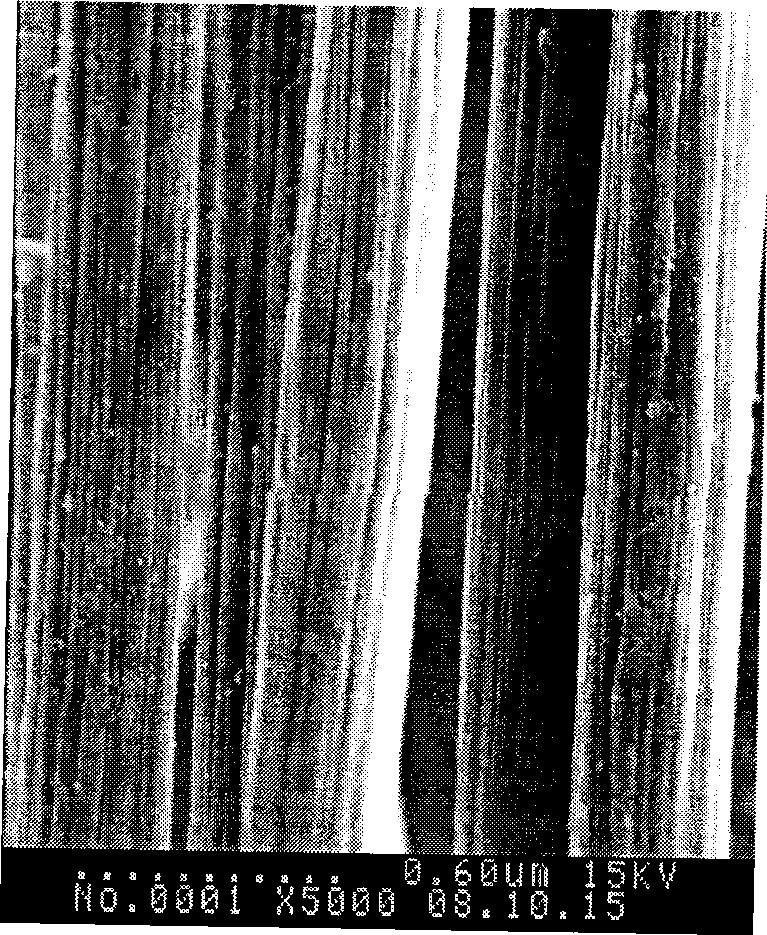

Processing method for silane coupling agent modified carbon fiber surface

ActiveCN103643503AIncreased monofilament tensile strengthGood processing effectCarbon fibresUltrasonic/sonic fibre treatmentChemistryLithium aluminium hydride

A processing method for silane coupling agent modified carbon fiber surface comprises the following steps: removing the sizing agent coated on the sizing carbon fiber surface by using acetone, drying, then carrying out oxidation etching on the fiber surface by using concentrated nitric acid, water-washing until the pH reaches 6 to 8, drying, then dispersing the fiber into tetrahydrofuran, adding lithium aluminium hydride to reduce the oxygen containing groups on the fiber surface and convert all the oxygen containing groups into hydroxyl groups, then adding hydrochloric acid, stirring for 1 to 2 hours, filtering so as to obtain carbon fibers, soaking and washing the carbon fibers with tetrahydrofuran, drying, then dispersing the carbon fiber into a silane coupling agent hydrolysate, stirring or subjecting the carbon fiber to an ultrasonic treatment, filtering so as to obtain the carbon fiber, and drying the carbon fiber. The method improves the surface activity of the carbon fiber, does not harm the fiber body, and is capable of being applied to mass production.

Owner:山西泰宝科技有限公司

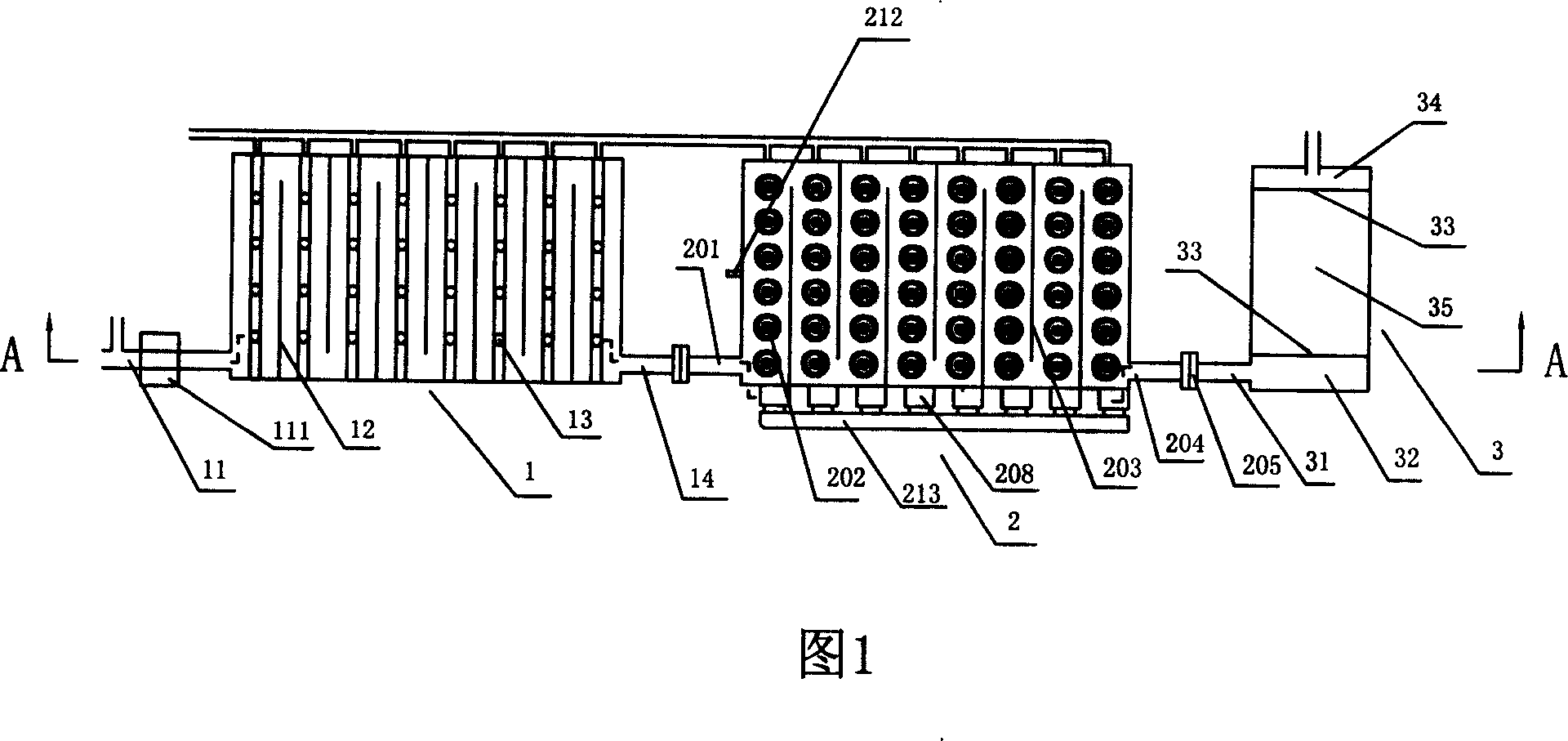

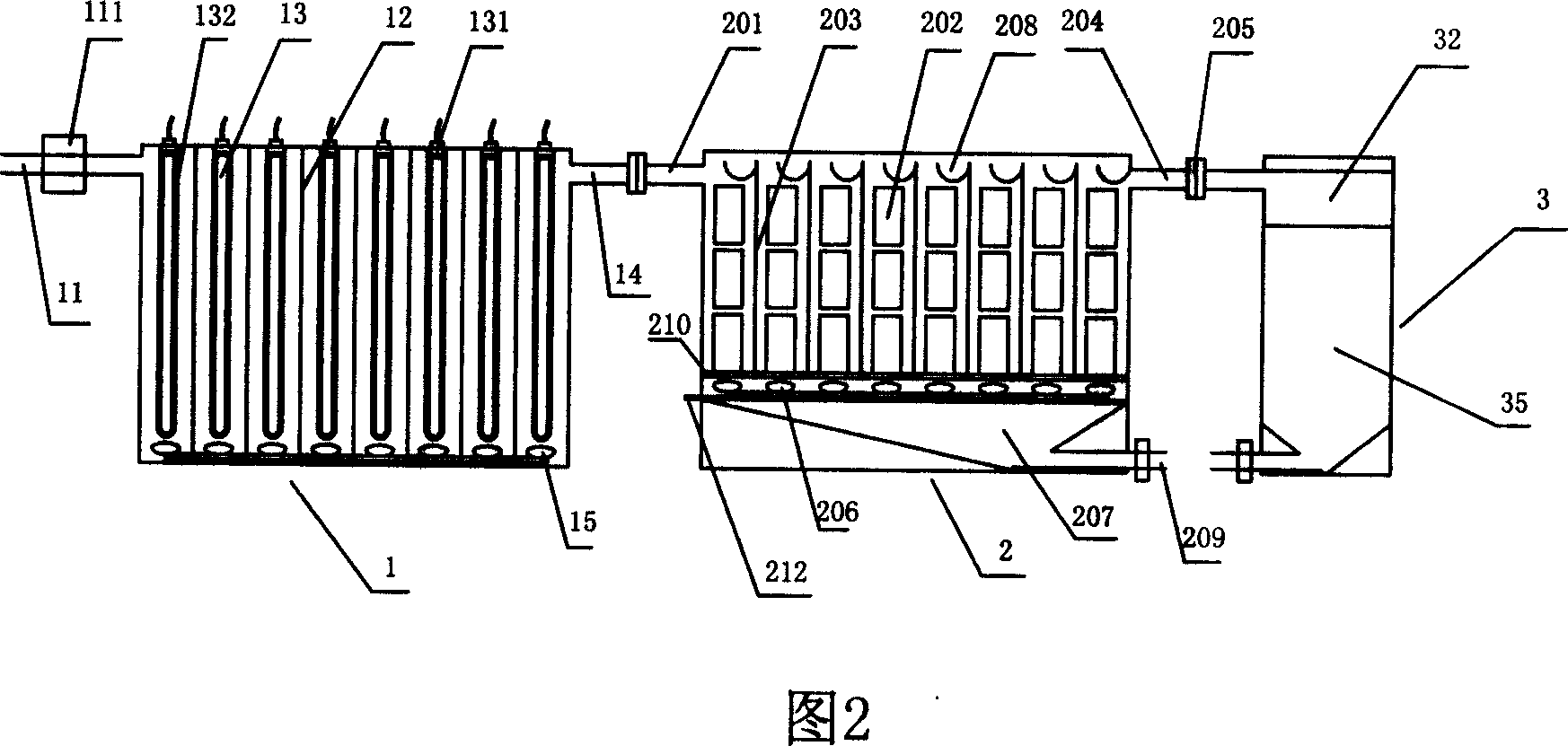

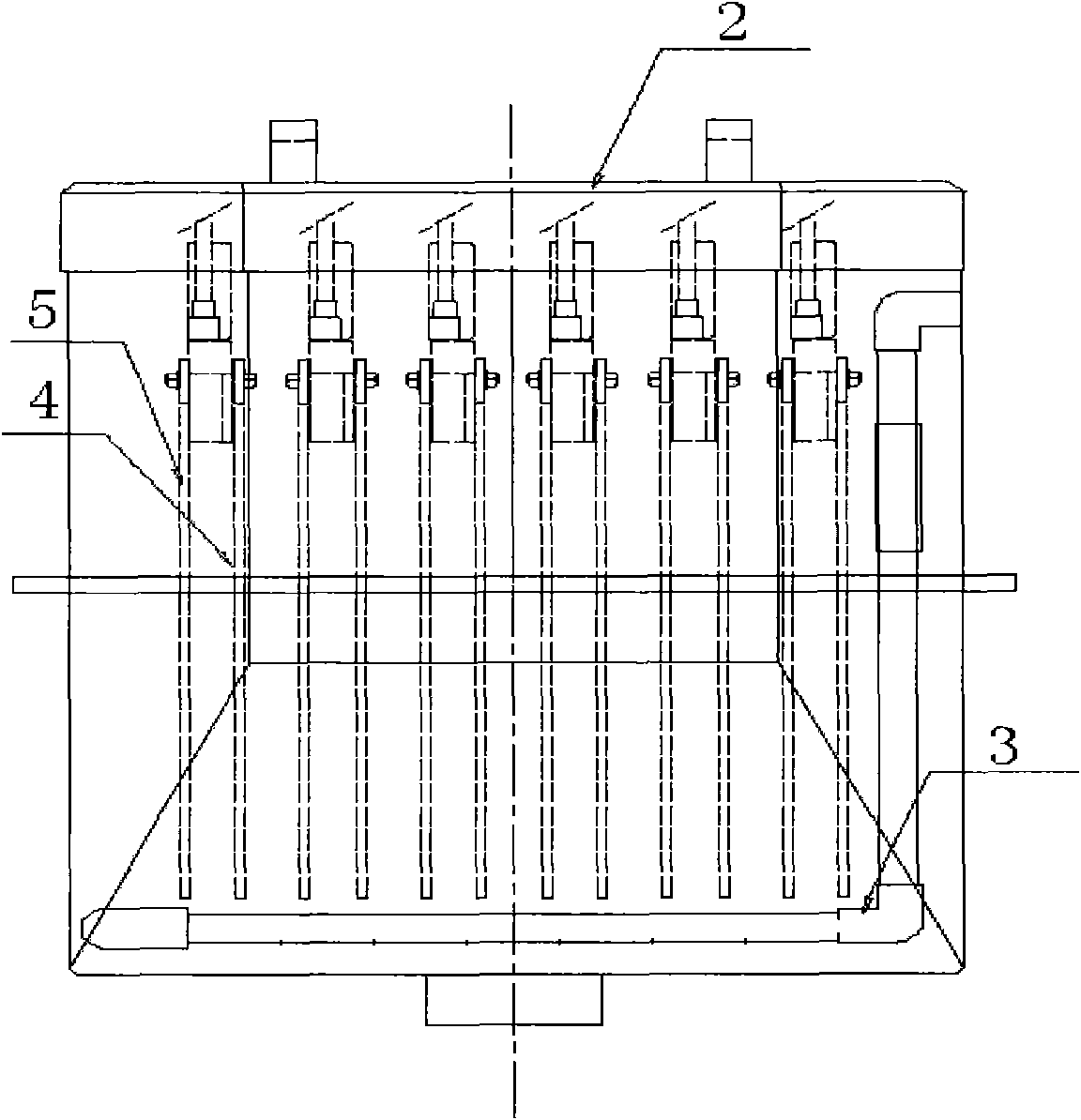

Photoelectromagnetism integrated waste water advanced oxidization method and device thereof

ActiveCN101033105AWide applicabilityGood processing effectWater/sewage treatment by irradiationWater contaminantsUltraviolet lightsWeak current

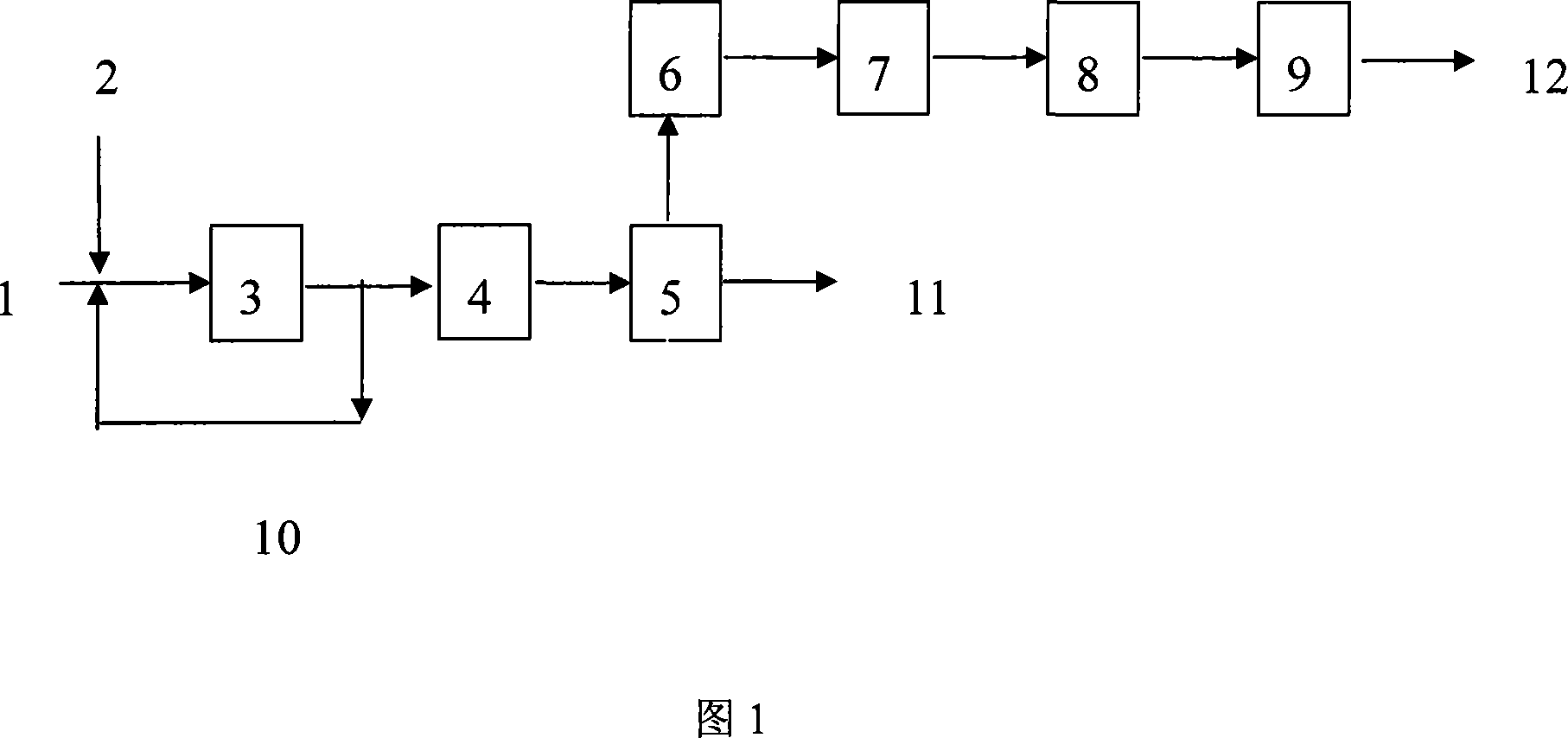

This invention relates to a photoelectromagnetic integrated advanced oxidation method and its device for waste water, which first of all acidizes the waste water, then strongly magnetizes it to generate energy of physical change and chemical change then enters into a photo-catalyzing box to be oxidated mostly to CO2 and water under the actioin of photo-catalyst, ultraviolet light, ozone and oxydol, in which, molecular chains of some hard-degradated substances are broken, then the waste water is micro-electrolysed to adsorb and recover the hard degraded substances under the action of extra low voltage, weak current and air, ozone and oxydol to get rid of COD, color degree, deodorizatin and disinfectant finall to filter it by diatomite and filter out suspending substances to reach the standard or recover it.

Owner:深圳市华旭半导体科技有限公司 +1

Preparation method and application of a kind of citric acid modified rape straw adsorbent

ActiveCN102266756AGood processing effectImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionIndustrial waste waterSorbent

The invention belongs to the technical field of industrial waste water treatment and pollution treatment, in particular to a preparation method of a citric acid modified rape straw adsorbent and an application thereof. The method comprises the following steps of: firstly washing natural rape straws, drying, crashing, sieving for standby; and then modifying the surface of the rape straws with citric acid so as to prepare the novel adsorbent citric acid modified rape straws. The prepared adsorbent is used for treating industrial waste water, and removing cationic dye and heavy metal ions form the waste water. The result of a static absorption test shows the adsorbent has excellent adsorption effect for the cationic dye and heavy metal ions. By the invention, the agriculture waste resource is recycled; and cheap and efficient novel adsorbent is obtained to be used for treating the industrial waste water. The preparation process of the adsorbent is simple, and the prepared adsorbent has low cost and excellent adsorption effect.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for effectively reducing metal content in polyetheretherketone

ActiveCN101486784ASimple purification processNo need for heat and pressureCentrifugationDistilled water

The invention relates to a method for effectively reducing the metal content in a polyetheretherketone at normal temperature and pressure. The method mainly comprises purification, centrifugation, washing, and drying. The invention uses hydrochloric acid as purification agent and adds the polyetheretherketone particles into hydrochloric acid solution with certain concentration; after the purification treatment is finished and the centrifugation hydrochloric acid removal is carried out, and then the distilled water is washed to neutral and dried; and polyetheretherketone particles of high quality can be obtained. The method not only can effectively reduce the metal content in the polyetheretherketone and does not change the physical and chemical properties of the polyetheretherketone, but also has the advantages of simple process, easily-fetched raw material, no need of temperature and pressure increase, and low cost.

Owner:JILIN ZHONGYAN HIGH PERFORMANCE PLASTIC

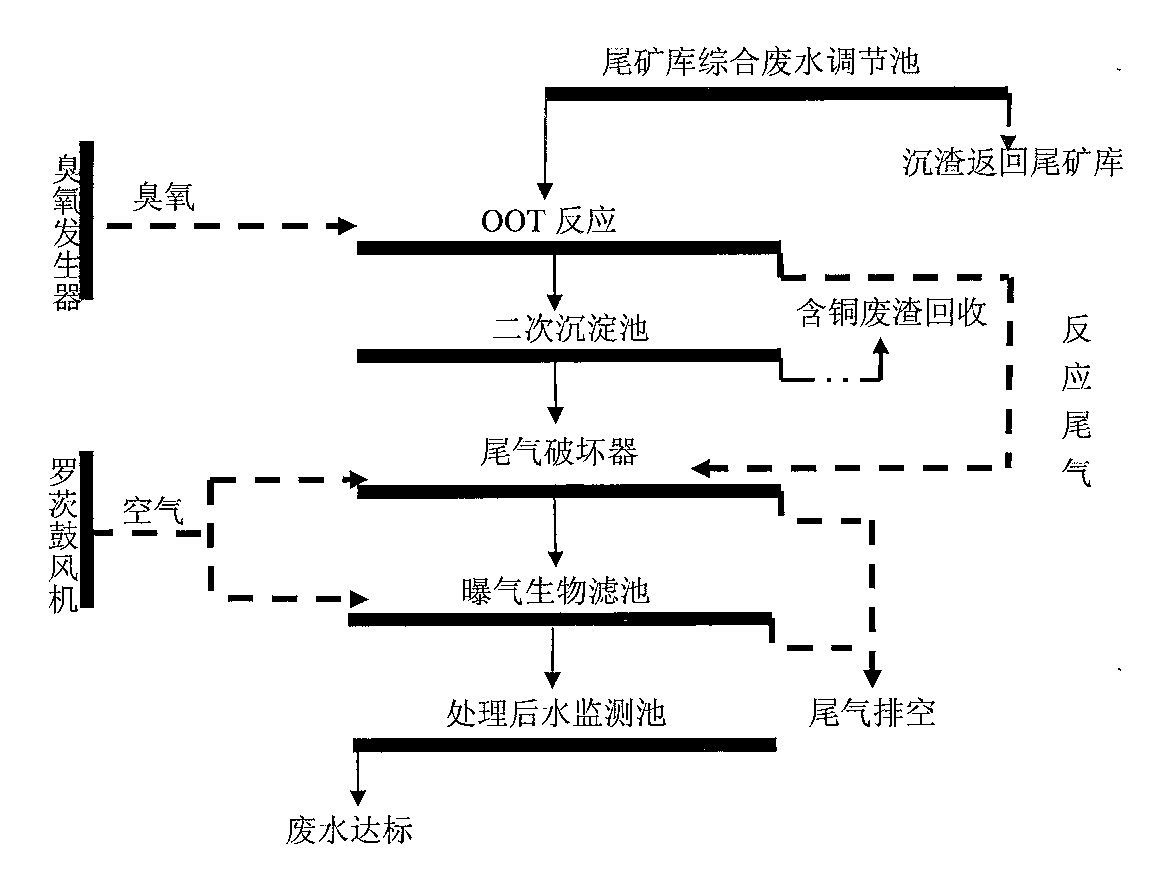

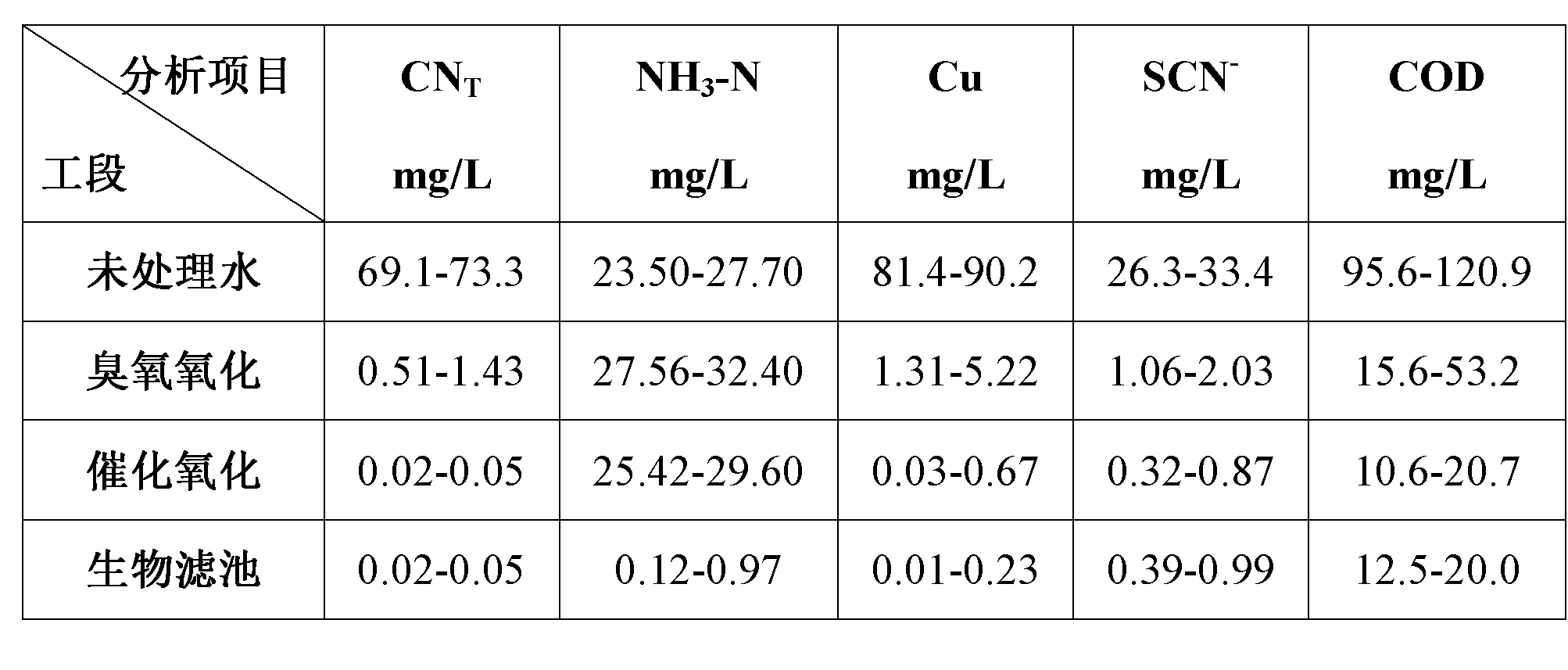

Deep treatment method for cyanide-containing waste water of tailings pond in gold industry

InactiveCN103253834AGood processing effectReduce processing costsMultistage water/sewage treatmentChemistryHeavy metals

The invention discloses a deep treatment method for cyanide-containing waste water of a tailings pond in the gold industry. The process adopts an ozone oxidation method, a catalytic oxidation method and a biological treatment method to collectively deeply treat the cyanide-containing waste water of the tailings pond in the gold industry. Through the combination of the three methods, a good treatment effect on the cyanide, thiocyanate, arsenic and heavy metals is good, the content of the cyanide after being treated is less than or equal to 0.05mg / L, the content of ammonia and nitrogen after being treated is less than 1mg / L, and other pollutants after being treated can meet the requirement of the ground surface water grade-B water quality standard. The method is used for treating the cyanide-containing waste water of the tailings pond in the gold industry, the treatment effect on the cyanide, the COD, As and heavy metals is good, the heavy metals such as the gold and silver as well as other metal resource can be recovered, and the secondary pollution caused by the ammonia and nitrogen can be avoided. By adopting the deep treatment method for the cyanide-containing waste water of the tailings pond, a good environment, a good economic benefit and a good social benefit can be achieved.

Owner:CHANGCHUN GOLD RES INST

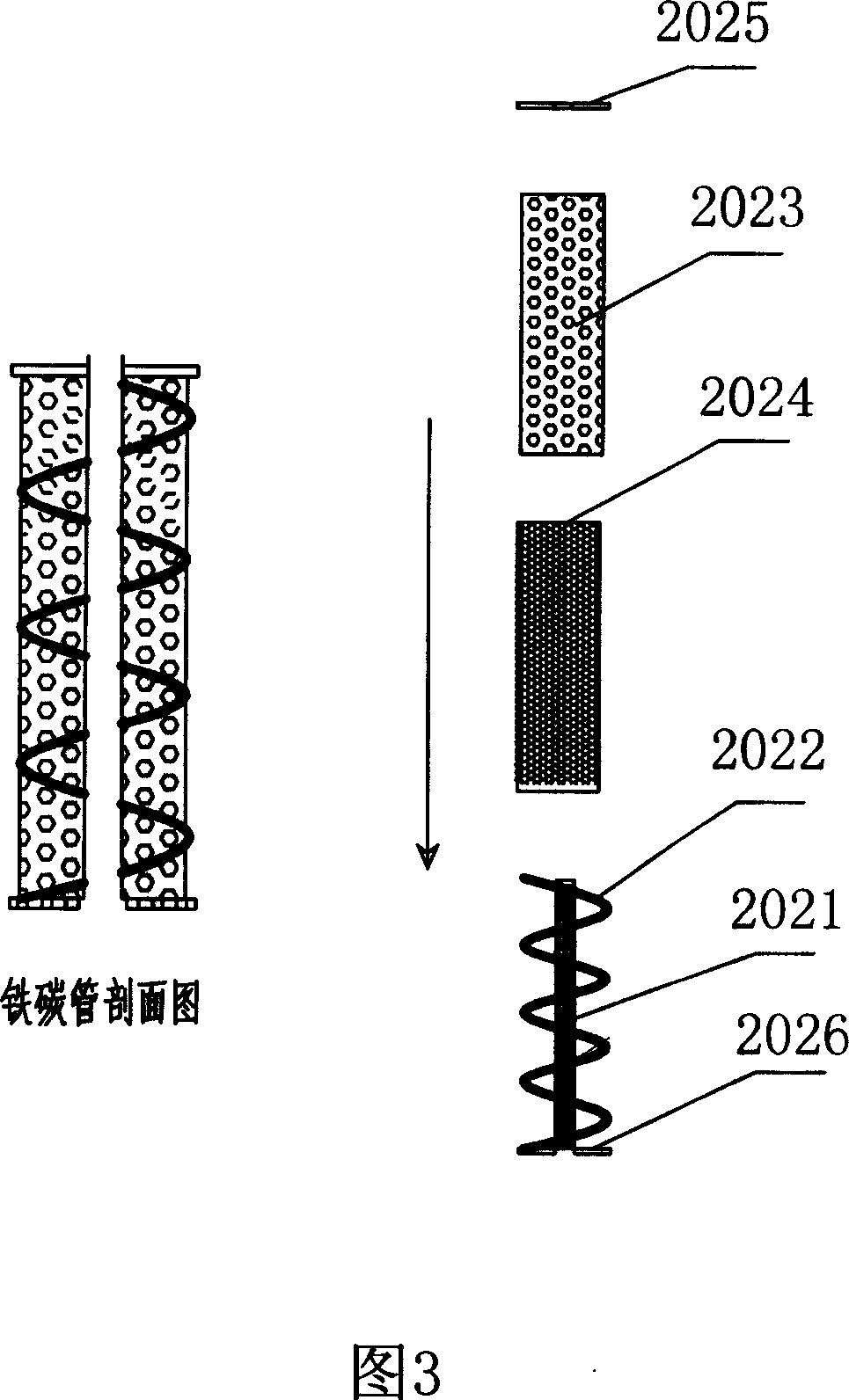

Regular iron-carbon micro-electrolysis filler and preparation method thereof

InactiveCN101817574AGood processing effectPrevent compactionWater contaminantsWater/sewage treatmentElectrolysisSewage treatment

The invention discloses a regular iron-carbon micro-electrolysis filler and a preparation method thereof, belonging to the technical field of sewage treatment. The filler comprises the following components by weight percent: 50 to 80 percent of scrap iron with the diameter is 0.1 to 1 mm , 5-17 percent of powdery active carbon with the diameter of less than 0.1 mm and 15-35 percent of clay with diameter of less than 0.15 mm. The preparation method of the iron-carbon micro-electrolysis filler comprises the following steps of: a, uniformly mixing the filler according to the weight percentages; b, adding water to make the mixture into granular filler with the diameter of 3 to 10 mm; c, putting the filler into an oven and drying at 30 to 50 DEG C; d, moving the filler into a muffle furnace and baking for 2 to 4 hours at 250 to 600 DEG C in an oxygen-isolated condition; and e, cooling after the filler is baked to obtain the regular iron-carbon micro-electrolysis filler. The invention prevents hardening and passivation of the iron-carbon micro-electrolysis filler, is easy to fill and has advantages of good sewage treatment effect, low cost and easy preparation.

Owner:JILIN UNIV

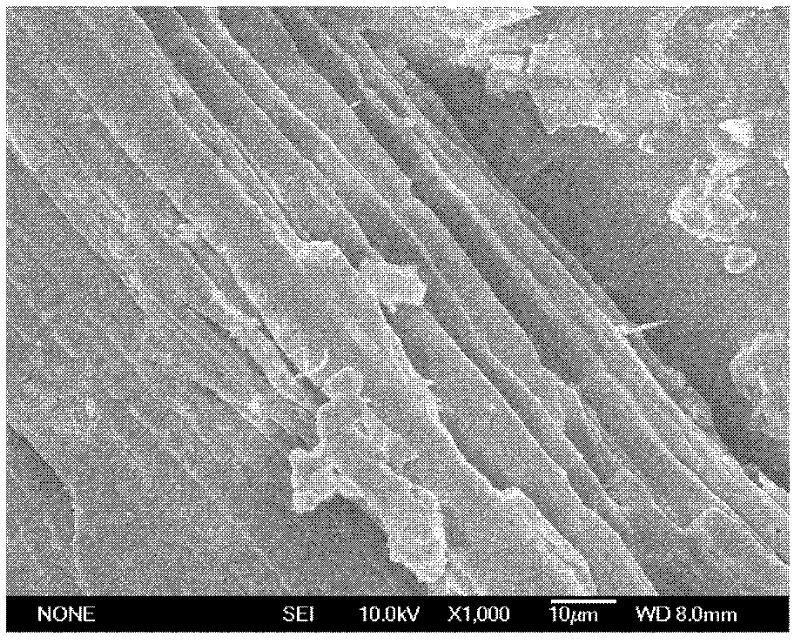

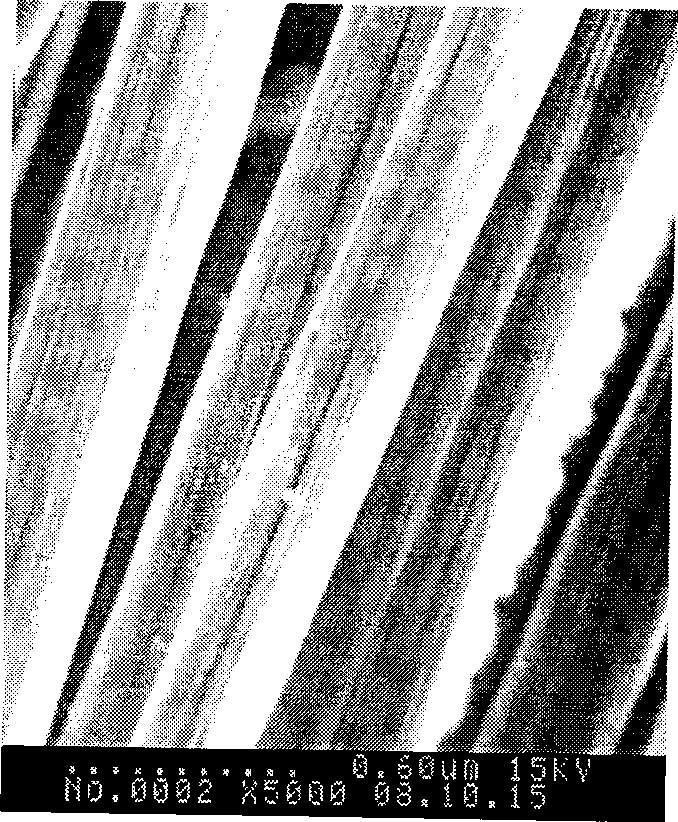

Method for carbon fiber surface modification of plasma coated with nano colloidal sols by plasma treatment

InactiveCN101413209AImprove performanceImprove surface propertiesPhysical treatmentCarbon fibresFiberCarbon fibers

The invention relates to a method for modifying the surface of carbon fiber coated with nano sol through plasma treatment, which comprises the following steps: firstly, nano particles are prepared into an organic solvent, a sol solution of water or a sol solution prepared by hybridization reaction of a precursor solution of organic-inorganic nano particles by the ultrasonic vibrating technology; secondly, the sol solution is coated on the surface of the carbon fiber, treated by means of spray coating and padding, and dried; and thirdly, the dried carbon fiber is placed on a special transport unit for plasma processing equipment and a plasma is sprayed on the surface of the carbon fiber to make the carbon fiber move in the plasma atmosphere, so as to generate surface modification, wherein the treating power is between 10 and , watts, and the treatment time is between 0.5 and 300 seconds. The method can effectively improve the performance of the fiber, improves the molded manufacturability and the overall properties of composite materials of the fiber, has simple technology, quick processing speed, good treatment effect and low cost, is convenient to operate and difficult to cause environmental pollution, can reduce energy consumption, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

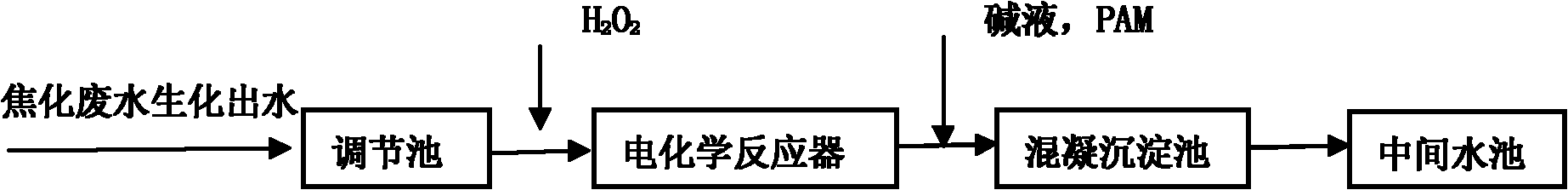

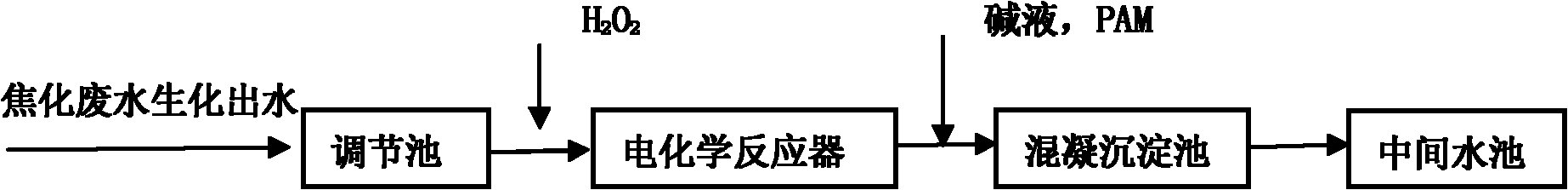

Method for treating coking waste water by electro-Fenton-coagulation combination process

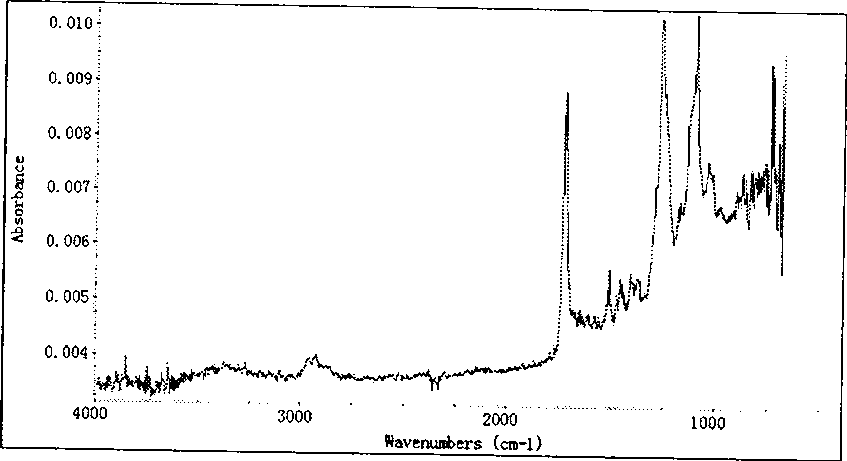

ActiveCN102139979AGood processing effectLess investmentMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationElectrochemical responseWater quality

The invention relates to a method for treating coking waste water by an electro-Fenton-coagulation combination process, which comprises the following steps of: 1) introducing biochemical effluent of the coking waste water into a regulation pond, regulating water quality and water volume, and regulating the pH value to be between 2 and 4; 2) introducing the effluent in the regulation pond into an electrochemical reactor, adding H2O2, and regulating current density to be between 50 and 300 A / m<2>; 3) introducing the effluent in the electrochemical reactor into a coagulation sedimentation pond, regulating the pH value to be between 7 and 8 by using alkaline liquor, adding a flocculating agent, performing a flocculating reaction, and performing mud water separation in the sedimentation pond; and 4) filtering the effluent in the sedimentation pond by a sand leach unit, and discharging. By the method, the biochemical effluent of the coking waste can be deeply treated, chemical oxygen demand(COD), ammonia nitrogen and chromaticity of the effluent can meet the requirements of national first-level discharge standards and the water inflow requirement of the advanced treatment of membrane separation.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Technique for biological treatment of mine acidic wastewater

InactiveCN101219844AReduce waste water treatment costsGood processing effectWaste water treatment from quariesTreatment with aerobic and anaerobic processesSlow sand filterChemistry

The invention relates to a process for biologically treating wastewater with sulfate and hydrochloric acid and recycling elemental sulfur, belonging to the technical fields of environmental protection and wastewater treatment, which is characterized in that in the process, the sludge acidic fermentation products from a wastewater treatment plant is used as carbon source sulfate reducing bacteria for treating acidic sulfate wastewater and recycling the elemental sulfur; the sulfate reducing bacteria SRB in an anaerobic biological reactor reduces sulfate SO4<2-> creature as hydrogen sulfide H2S of colorless sulfur bacteria CSB in an aerobic biofilm reactor reduces H2S or S<2->creature as the elemental sulfur and then the obtained substance is filtered and sand-scrapped by a slow sand filter; the elemental sulfur S in sand filtering material is completely dissolved by an extraction equipment; the extractant CS2, the sand filtering material and the biofilm are separated by a solid-liquid separator; the extracted solution is distilled by a distillation equipment; the distilled solution is parched by a drying device and then the elemental sulfur is recycled.In the invention the mine wastewater with the sulfate and the hydrochloric acid is treated; the elemental sulfur is recycled and the sludge from the wastewater treatment plant achieves resource utilization and harmlessness.

Owner:TAIYUAN UNIV OF TECH

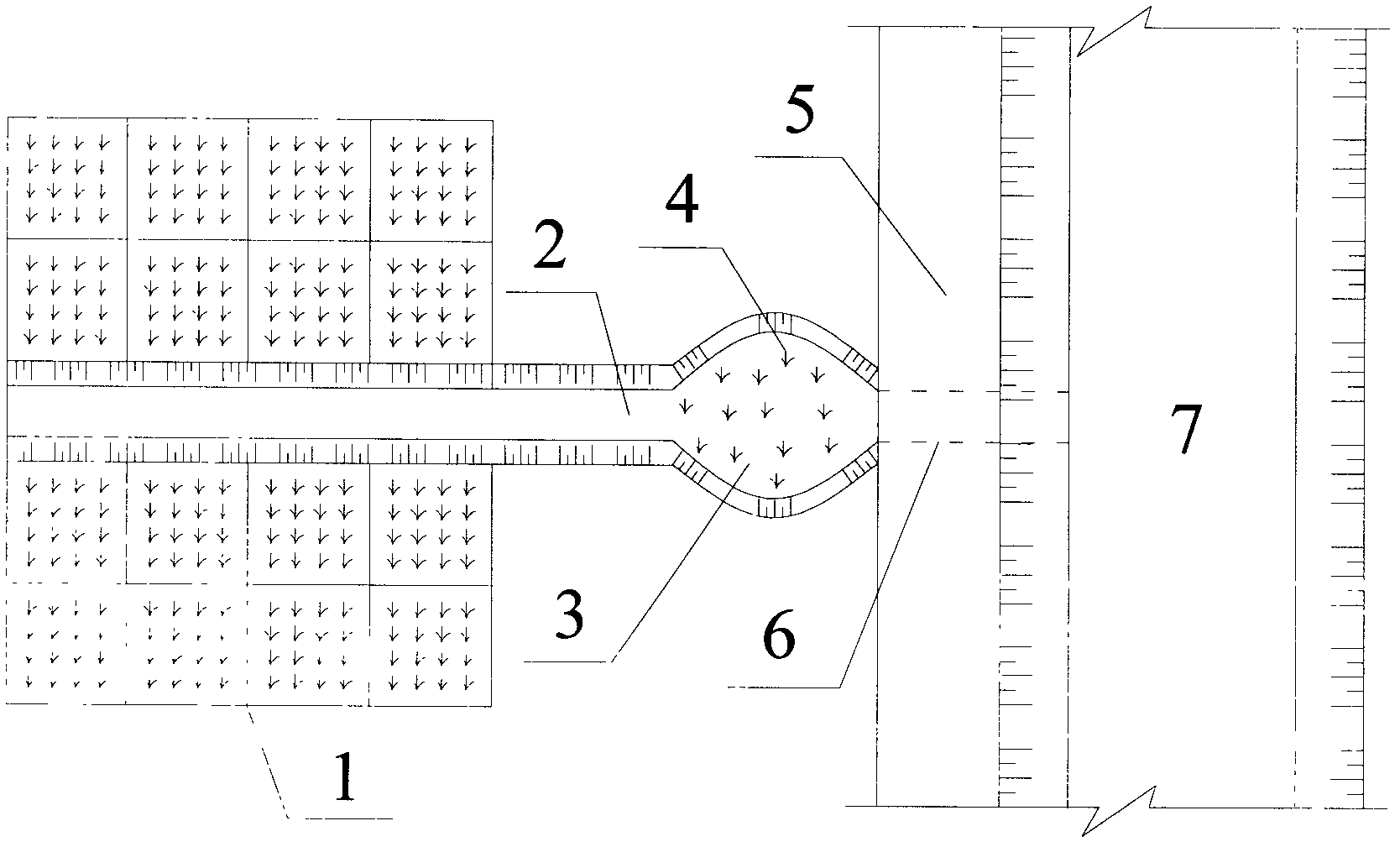

Method for constructing agricultural drainage and ecological purification system

InactiveCN102145957AGood processing effectEasy to install on siteConstructionsSoil drainageEutrophicationRetention time

The invention relates to a method for constructing an agricultural drainage and ecological purification system. The method comprises the following steps that: an elliptic ecological buffer area is formed at the tail end of an agricultural drainage channel and before an agricultural drainage culvert pipe; aquatic plants which can easily absorb N and P nutrient elements are planted in the ecological buffer area; an agricultural drainage ecological purification barrel is arranged in the agricultural drainage culvert pipe; a biological purification ring is arranged on the ecological purification barrel; water drained out of a farmland flows through the ecological buffer area by the agricultural drainage channel; certain suspended pollutants are settled and intercepted by staying for a certainperiod of time in the ecological buffer area to achieve a preliminary water purification effect and the effect of controlling the flow rate and the retention time; and larger suspended sundries are further intercepted by a wire mesh at the front end of the agricultural drainage ecological purification barrel before the water drained out of the farmland flows into the agricultural drainage ecological purification barrel to ensure that the inside of the purification barrel cannot be blocked. The method has the advantages that: the N and P nutrient elements in the water drained out of the farmland is effectively reduced by an ecological method in combination with the construction of the agricultural drainage culvert pipe, so that a receiving water body is prevented from being eutrophicated.

Owner:HOHAI UNIV

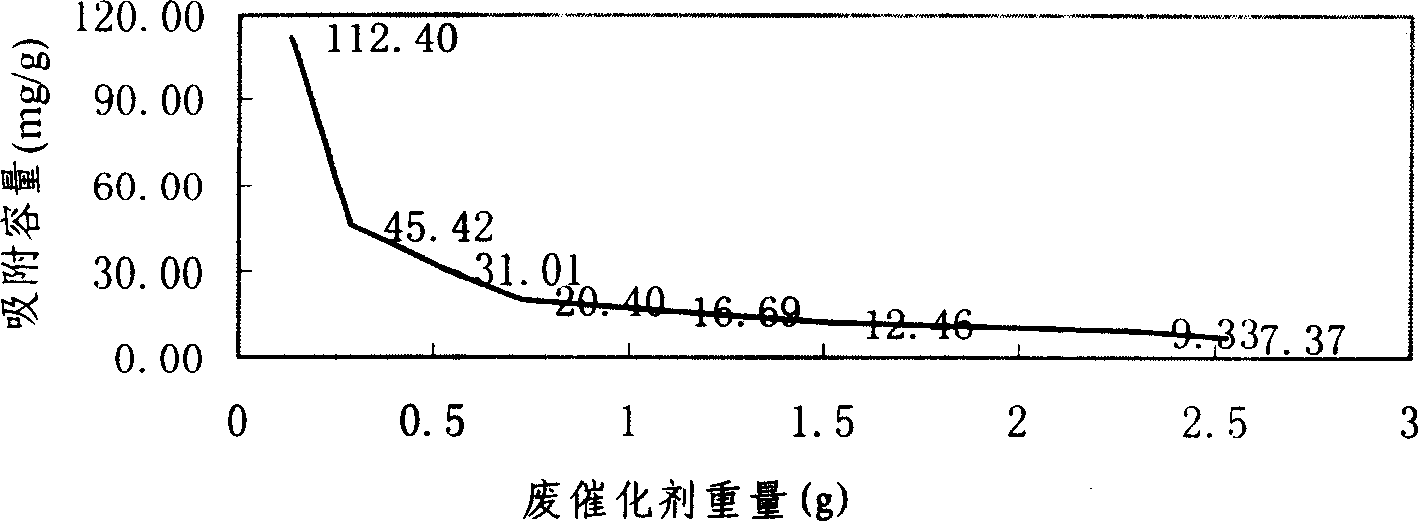

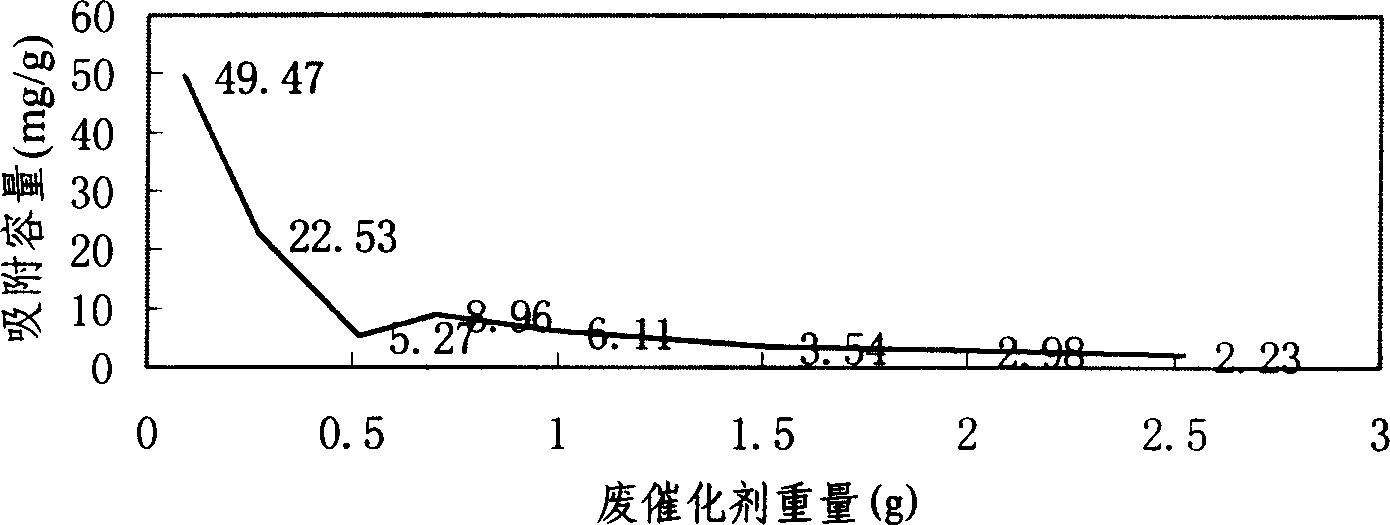

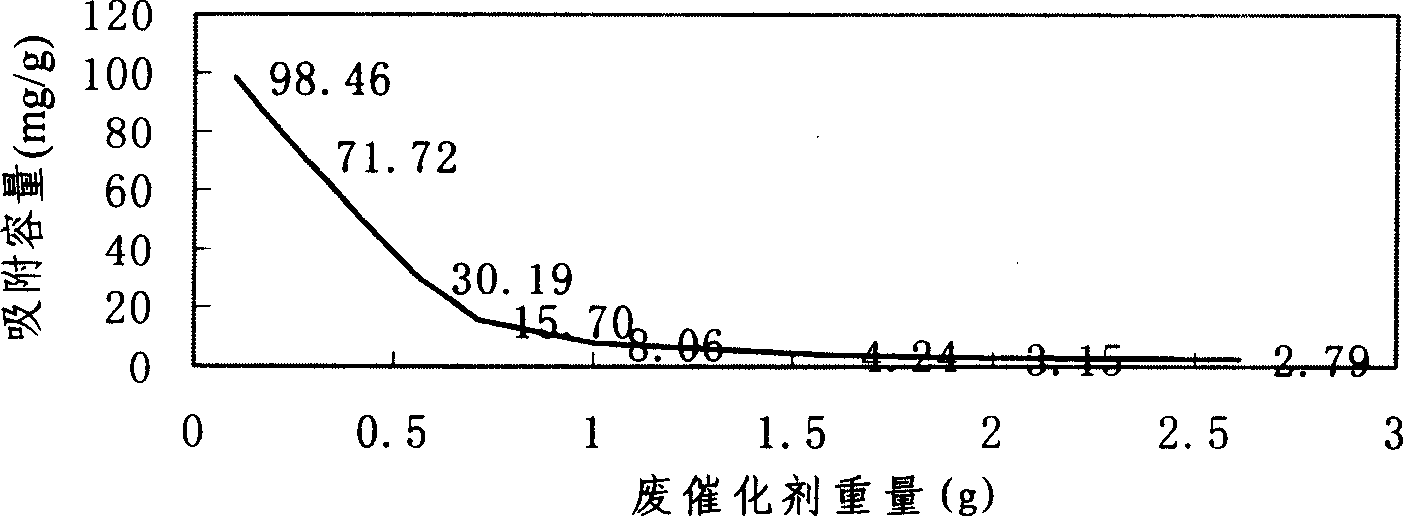

Method for treating sewage utilizing oil refining waste catalyst

ActiveCN1814556AEase of useGood processing effectWater/sewage treatment by sorptionMolecular sieveSorbent

The invention relates to a method to process sewage by using catalyst that includes the following process: adsorbent of oil refining spent catalyst fully contacting the sewage to take organic adsorbing in the sewage; the oil refining spent catalyst contains molecular sieve, clay, and adhesive agent, ratio surface is 100-300m2g, hole volume is 0.01-0.4ml / g; using the gross weight of catalyst as benchmark, the content of Al2O3 is 45-70%, the content of SiO2 is 25-50%, the content of P2 O5 is 0.2-4%, the content of Fe2O3 is 0-0.5%, and the total content of Na2O, MgO, K2O, CaO, TiO 2, and Re2O3 is 3-8%. The invention has widely application range and has mild using condition. It could have good effect to process the sewage that the pH value is 2-10, and water temperature is 0-60 degree centigrade.

Owner:CHINA PETROLEUM & CHEM CORP +1

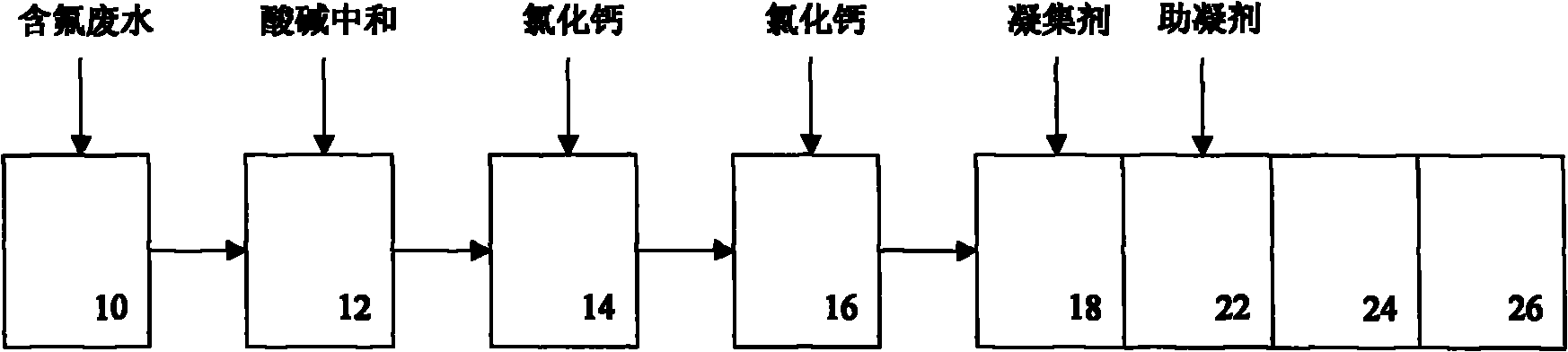

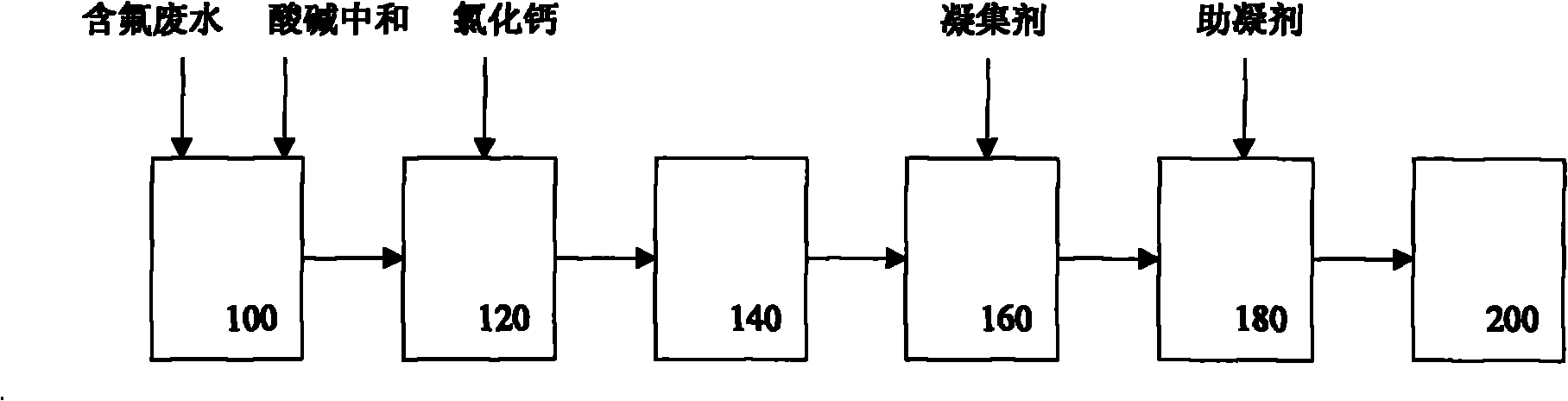

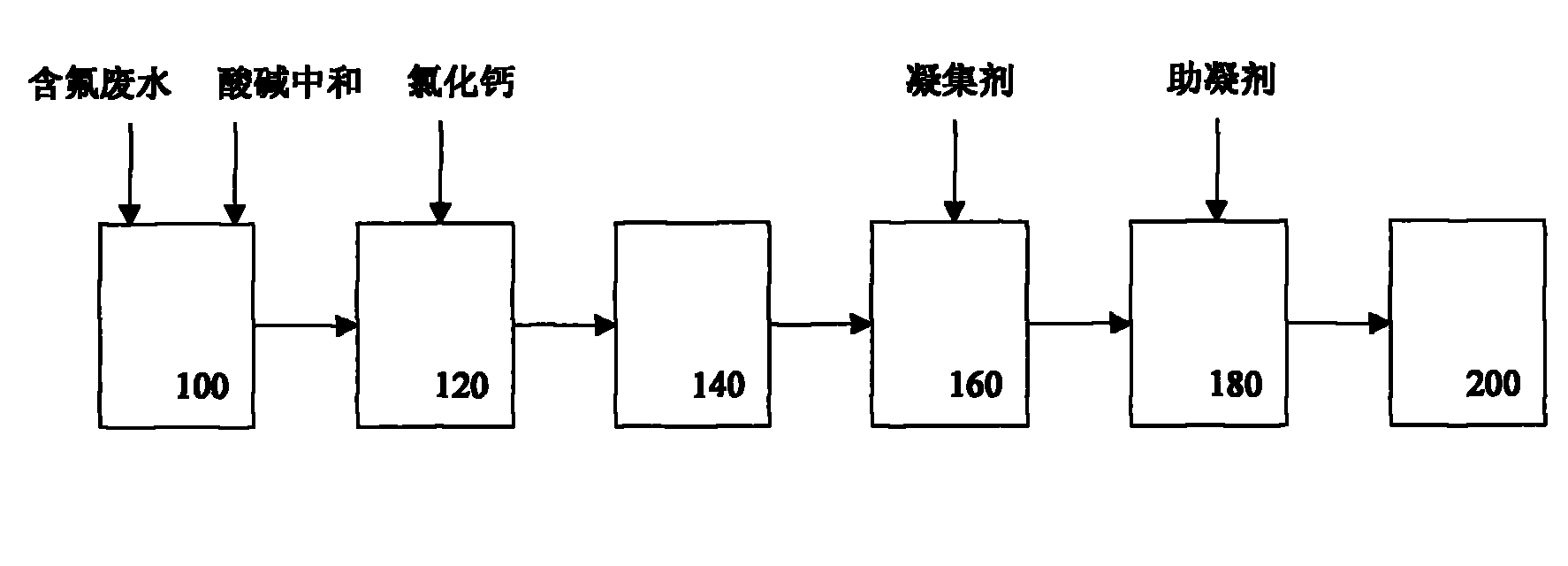

Fluorine-containing wastewater treatment method

InactiveCN102050531AReduce consumptionGood processing effectWater contaminantsMultistage water/sewage treatmentFlocculationWastewater

The invention provides a fluorine-containing wastewater treatment method, which comprises the following steps of: detecting pH value of the fluorine-containing wastewater; adjusting the adding amount of alkali or acid solution according to the pH value detection result to control the pH value of the fluorine-containing wastewater; detecting fluorine ion concentration of the fluorine-containing wastewater, and determining the adding amount of a calcium salt according to the result; delivering the fluorine-containing wastewater to a first reaction tank and a second reaction tank in turn, stirring the wastewater and performing full mixing reaction; delivering the treated wastewater to a third reaction tank, stirring the wastewater, adding coagulant into the wastewater to generate flocculation reaction to realize solid-liquid separation, and separating calcium fluoride from the wastewater; delivering the treated wastewater to a fourth reaction tank, stirring the wastewater, and adding coagulant aid to improve the settling effect; and finally, delivering the treated wastewater into a settling tank, discharging clear solution, and filter-pressing silt into mud cakes. The fluorine-containing wastewater treatment method provided by the invention has ideal treatment effect, meanwhile saves the consumption of chemicals, and reduces the treatment cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP

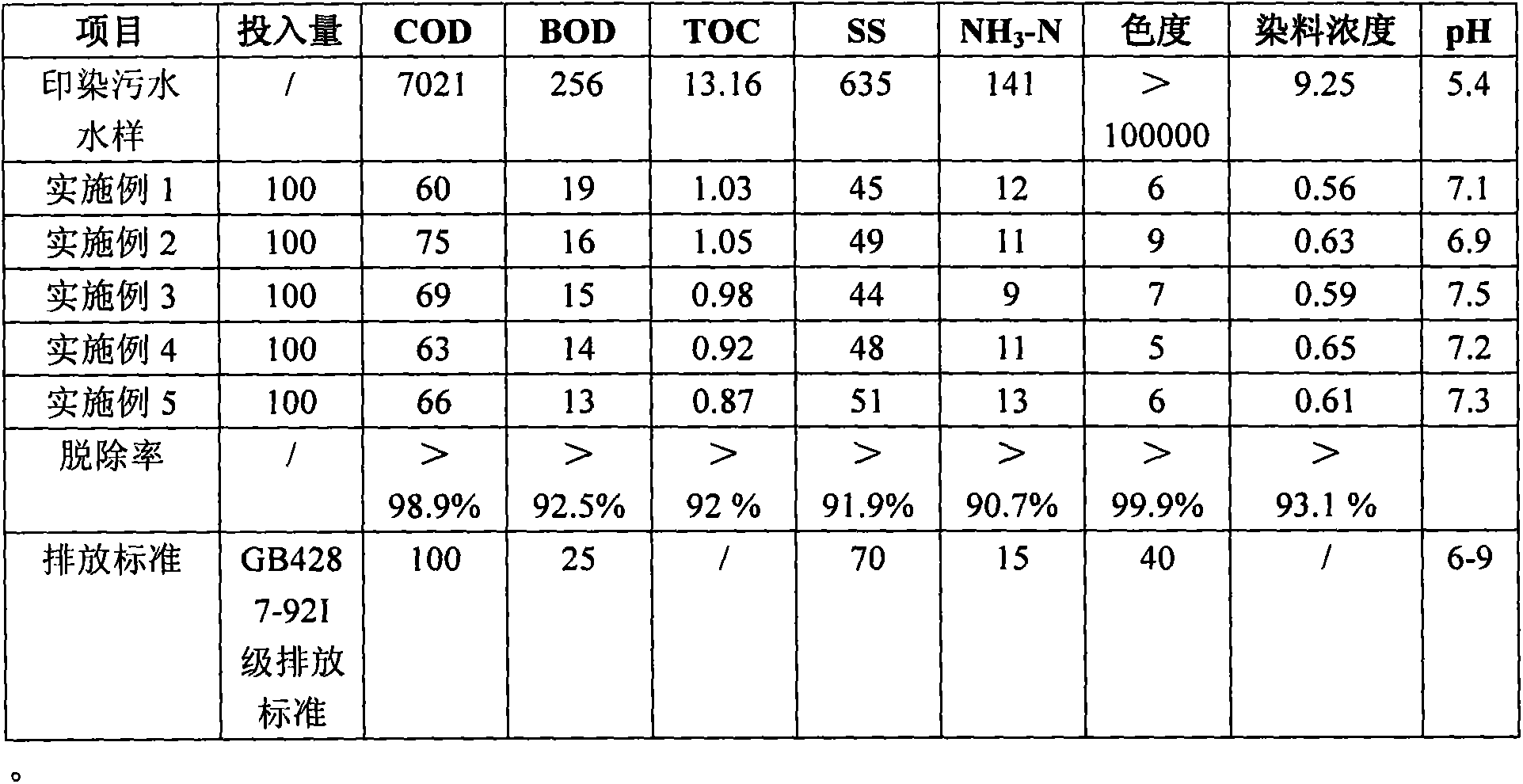

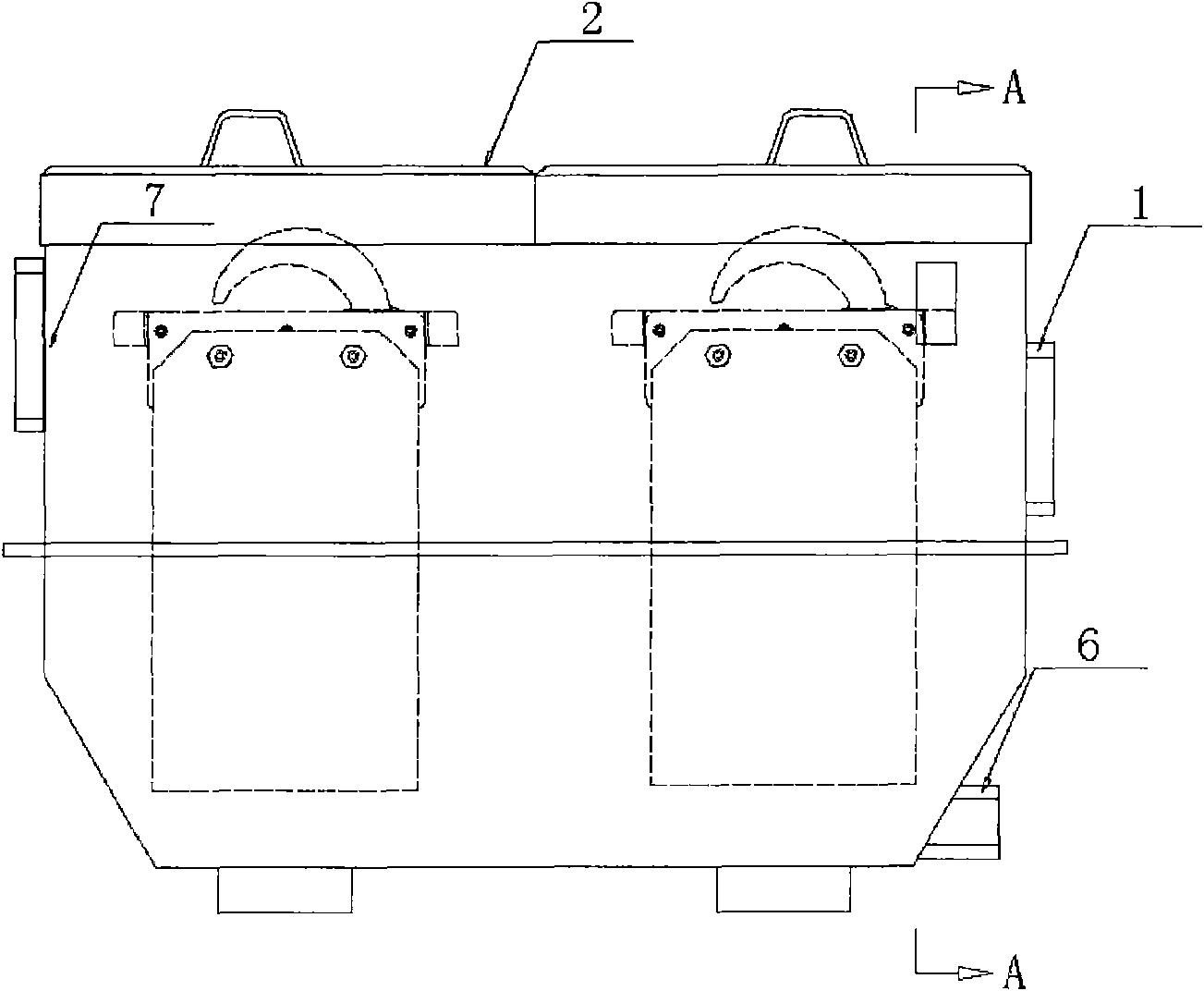

Dyeing wastewater treatment agent and preparation method thereof

InactiveCN103708593ASustainable processingHigh chromaWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionDyeing wastewaterPollution

The invention relates to the technical field of wastewater treatment, and particularly relates to a dyeing wastewater treatment agent and a preparation method thereof. The dyeing wastewater treatment agent comprises the following raw materials in parts by weight: 2-10 parts of ferrous sulfate, 20-30 parts of magnesium sulfate, 0.5-2 parts of polyacrylamide, 10-20 parts of iron nitrate, 1-5 parts of nickel nitrate, 40-60 parts of polyaluminum chloride, 10-20 parts of modified kieselguhr, 8-22 parts of meerschaum powder, 10-20 parts of crosslinked rectorite, 5-10 parts of chitosan-graphene composite material and 1-3 parts of graphene nano layer / MnO2 compound. The dyeing wastewater treatment agent provided by the invention has the advantages of convenient production method, low investment, quick effect taking and no secondary pollution.

Owner:HANDAN COLLEGE

Integrated electrolysis nitrogen and phosphorus removal wastewater treatment method

InactiveCN101549896AGood conditionEfficient removalWater/sewage treatmentElectrode polaritySmall footprint

The invention relates to an integrated electrolysis nitrogen and phosphorus removal wastewater treatment method, which realizes to remove the nitrogenous and phosphorus nutrition salt and organic pollutants in wastewater in same electrolytic tank. The invention adopts graphite and iron plate as electrodes, alternates electrolysis phosphorus removal and electrolysis nitrogen removal process by alternating the electrode polarities to remove the nitrogenous and phosphorus nutrition salt and organic pollutants in wastewater. The invention performs optimization and integration according to the change characteristics of the parameters including electrolysis time, current density, pH value, pollutants removal rate in the electrolysis phosphorus removal and electrolysis nitrogen removal process, can remove the nitrogenous and phosphorus nutrition salt and organic pollutants in wastewater in high efficiency in short time without adding any medicament in the process, achieves the advantages of small occupation area, short treatment time and high pollutants removal efficiency.

Owner:SHANGHAI JIAO TONG UNIV

Purification for stink and organic waste gas

ActiveCN1745883AImprove purification rateStable growth environmentDispersed particle separationAir quality improvementSorbentSewage

A process for treating the offensive smell in petrochemical sewage treating plant and cleaning the low-concentration waste organic gas features use of immobilized microbial membrane as filler and 1-3 stages of microbial treatment. It includes such steps as wet dusting for pre-treating, microbial treating and post-treating by absorbent.

Owner:CHINA PETROLEUM & CHEM CORP +1

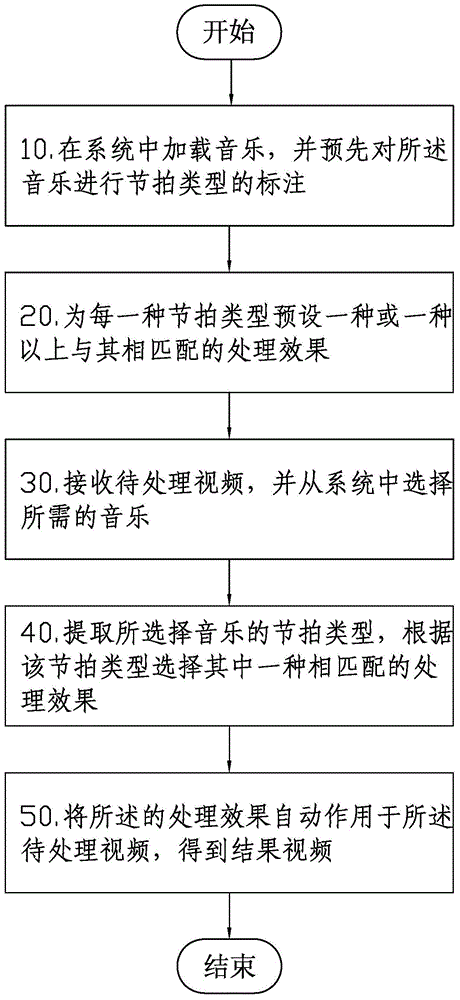

Method for automatically processing video according to music beats

InactiveCN104103300ASave time and costGood processing effectTelevision system detailsRecord information storageAutomatic processingSpeech recognition

The invention discloses a method for automatically processing a video according to music beats. Music in a system is subjected to beat type labeling, and one or more than one processing effect matched with each beat type is preset for the beat type; then, a video to be processed is received, the required music is selected from the system, and each beat type of the selected music is extracted; according to each beat type, one matched processing effect is selected; and finally, the processing effect automatically acts on the video to be processed to obtain a result video. A user can add the music to the video only by selecting favorite music, and the video is processed into an effect conforming to the music beats. Learning costs are not needed, few time costs are spent by the user, and the processing effect is good.

Owner:XIAMEN MEITUZHIJIA TECH

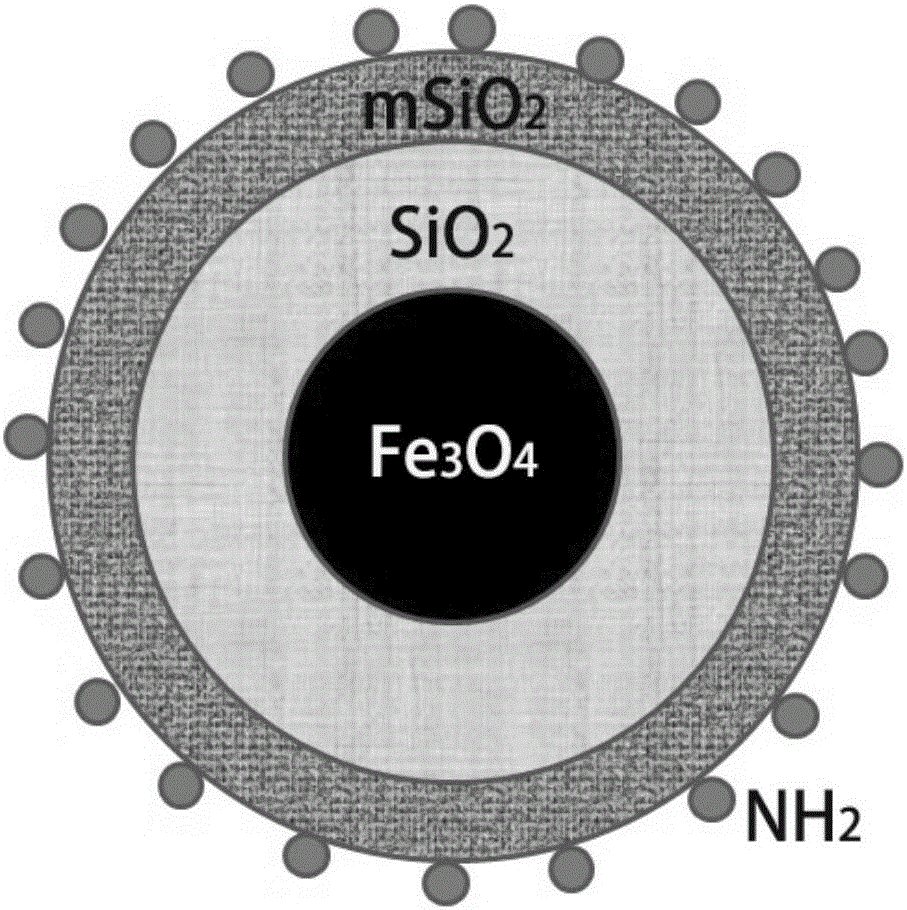

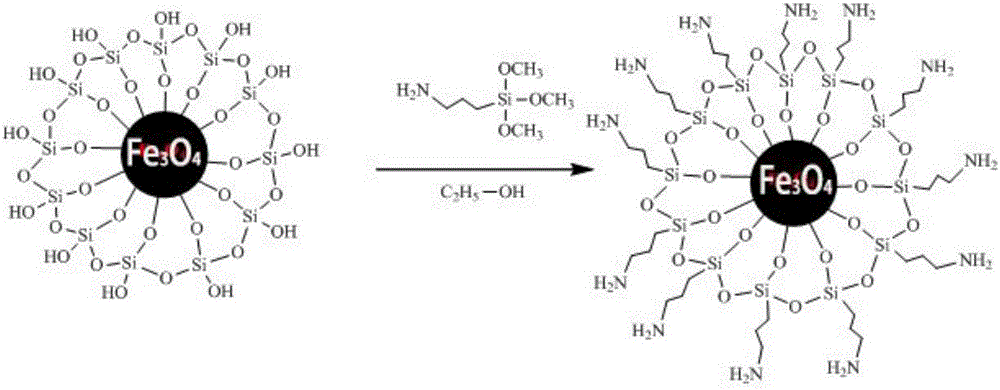

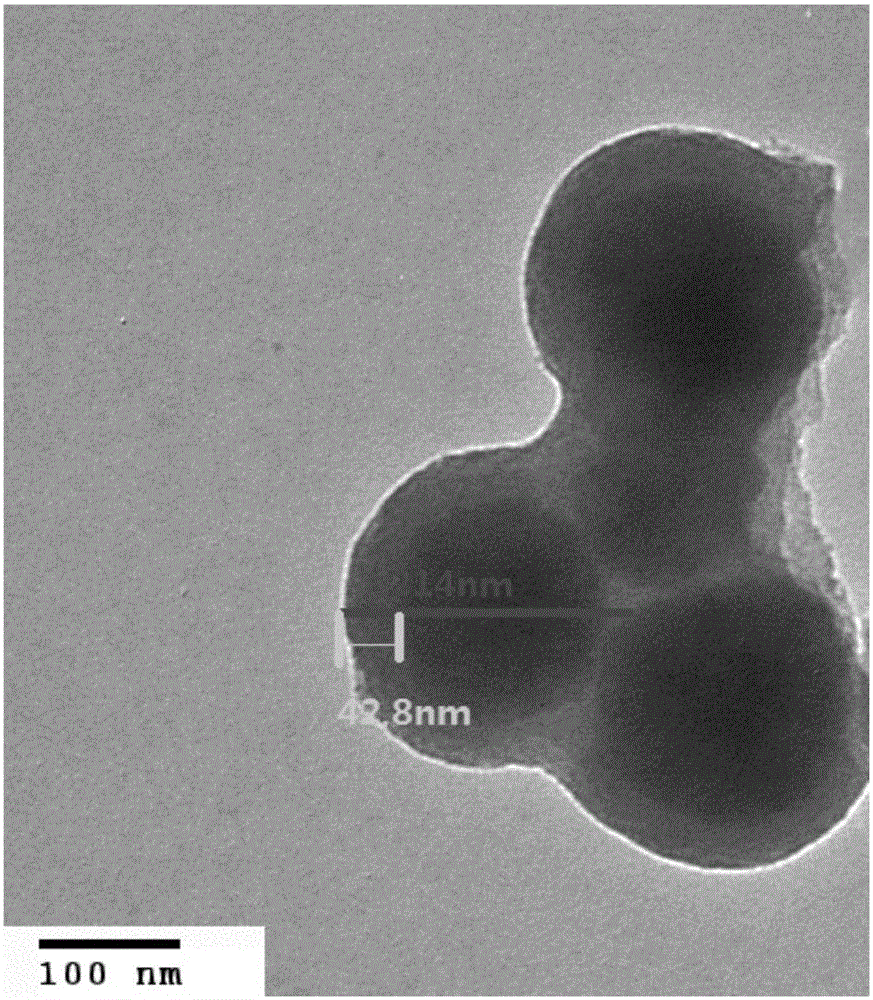

Preparation and application of amino modified Fe3O4@SiO2@mSiO2 composite particles with mesoporous structure

InactiveCN105964216AGood superparamagneticImproved saturation magnetizationOther chemical processesWater contaminantsSorbentSilanes

The invention relates to a preparation method of amino modified Fe3O4@SiO2@mSiO2 composite particles with a mesoporous structure. The preparation method comprises the steps: dispersing Fe3O4@SiO2 powder into a mixture solution of ethanol, deionized water, ammonia water and a template agent, so as to obtain a sol solution; then, dropwise adding TEOS into the sol solution, so as to prepare Fe3O4@SiO2@mSiO2 composite particles with the mesoporous structure; drying the Fe3O4@SiO2@mSiO2 composite particles, then, adding ethylene glycol into the dried Fe3O4@SiO2@mSiO2 composite particles, carrying out ultrasonic separation, then, adding a silane reagent, carrying out high-temperature refluxing while carrying out stirring so as to enable the silane reagent to be adsorbed into mesoporous pore passages of SiO2, carrying out a hydrolytic reaction, removing unreacted silane reagent or the silane reagent which is not adsorbed into the mesoporous pore passages, and finally, carrying out vacuum drying, thereby obtaining the amino modified Fe3O4@SiO2@mSiO2. According to the preparation method, SiO2 with a mesoporous structure serves as a shell layer, a nanoparticle Fe3O4 serves as a magnetic core, the stability in an acidic solution system is excellent, the difficult problem of the ordinary adsorbents that the separation is difficult after adsorption can be solved, the efficiency of adsorbing a target product is increased, and the reuse rate of an adsorbent is increased, so that the preparation method has good economic and environmental benefits.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

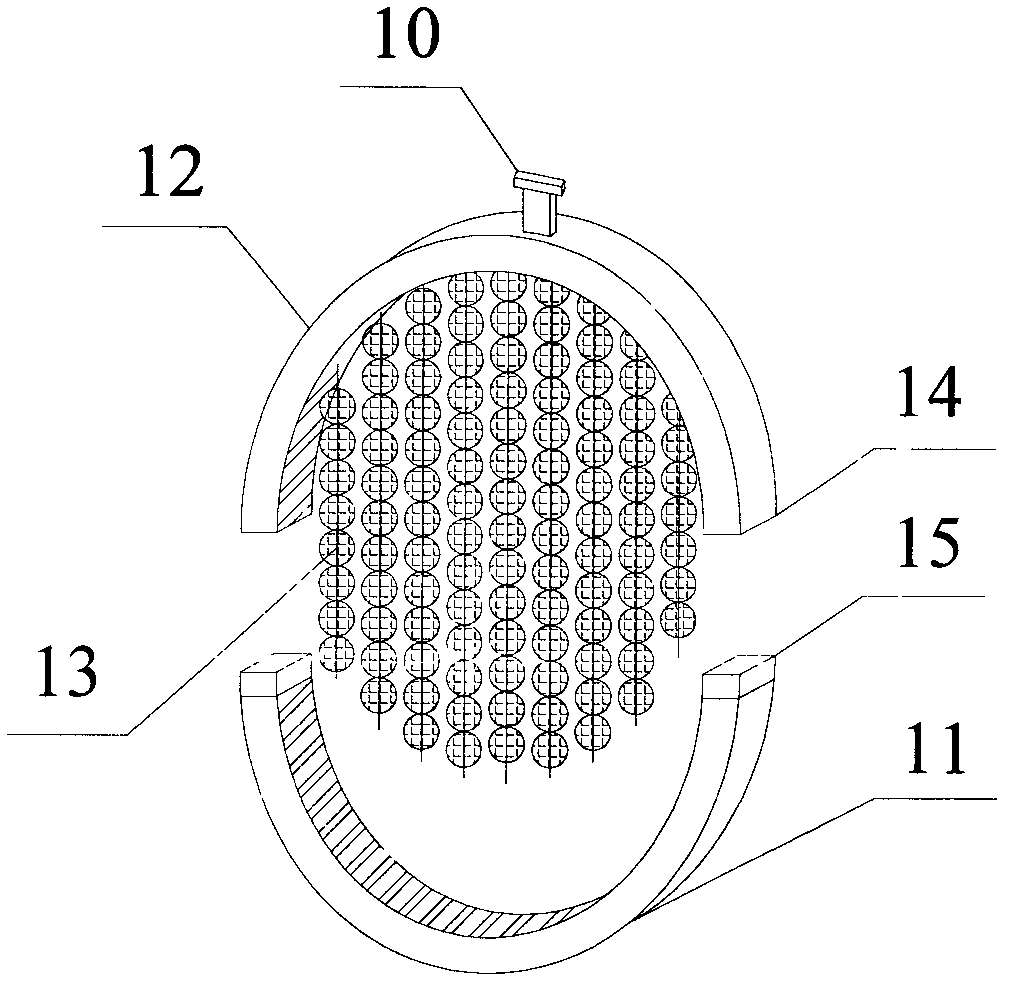

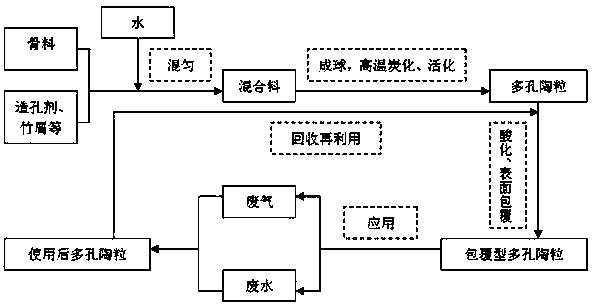

Bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as preparation method and application of bamboo-charcoal-shaped porous ceramsite

ActiveCN104291797AImprove physical strengthGood processing effectCeramicwareExpanded clay aggregateHoneycomb

The invention provides bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron as well as a preparation method and application of the bamboo-charcoal-shaped porous ceramsite. The preparation method of the bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron comprises the following steps: taking alpha-Al2O3 powder as ceramsite primary aggregate, clay and bentonite as auxiliary aggregates and surface-activated bamboo bits as bamboo charcoal preparation materials to combine with a pore forming agent to prepare pores without adding a sintering aid or a binder; adopting graded sintering at 400-600 DEG C to obtain bamboo-charcoal-shaped porous ceramsite by once molding; then, preparing the product bamboo-charcoal-shaped porous ceramsite coated by zero-valent iron by virtue of a reducing coating process of the coating material, wherein the product bamboo-charcoal-shaped porous ceramsite is a deep dark small ball with a grain size of 2-10 mm, internally a porous honeycomb spherical structure with a surface pore size of 15-25 mu m, has water absorption of 20-35% and a specific surface area of 40-60m<2> / g. The preparation method disclosed by the invention is environmentally friendly simple and energy-saving in preparation process, various in treated pollutants, and suitable for treating non-biodegradable wastewater such as flue gas wastewater, heavy metal wastewater, phenol-containing wastewater, emulsified oil wastewater, note printing and printing and dyeing wastewater, and raw material are easily available.

Owner:FUZHOU UNIV

Method for processing crisp-fried barking walnut kernel

The invention relates to the food processing field, specifically a processing method of a crispy peel free walnut kernel, which solves the problem that color, taste and nutritional components of walnut kernel are damaged in prior art of walnut kernel processing method, comprising the steps of (1) peeling off the walnut kernel; (2) drying: adjusting temperature of the microwave oven at 75 deg C to 85 deg C, baking 2min to 3min; (3) coating: coating the surface of the walnut kernel evenly by constant temperature liquid flavoring; (4) roasting: adjusting temperature of the microwave oven at 115 deg C to 125 deg C, baking 1.5min to 3.5min; it is appropriate when the walnut kernel observed is golden, then cooling the walnut kernel at constant temperature to prepare the crispy peel free walnut kernel. The walnut kernel is processed respectively before and after coating by microwave oven at low temperature, which enables the walnut kernel to be crispy in mouthfeel, bright in color and great preservation of the nutritional components. The peel off of the walnut kernel is dipped by low temperature, low concentration sodium hydroxide solution that is changed always, then neutralized by citric acid, finally washed to remove the peel of the walnut kernel.

Owner:王晶平

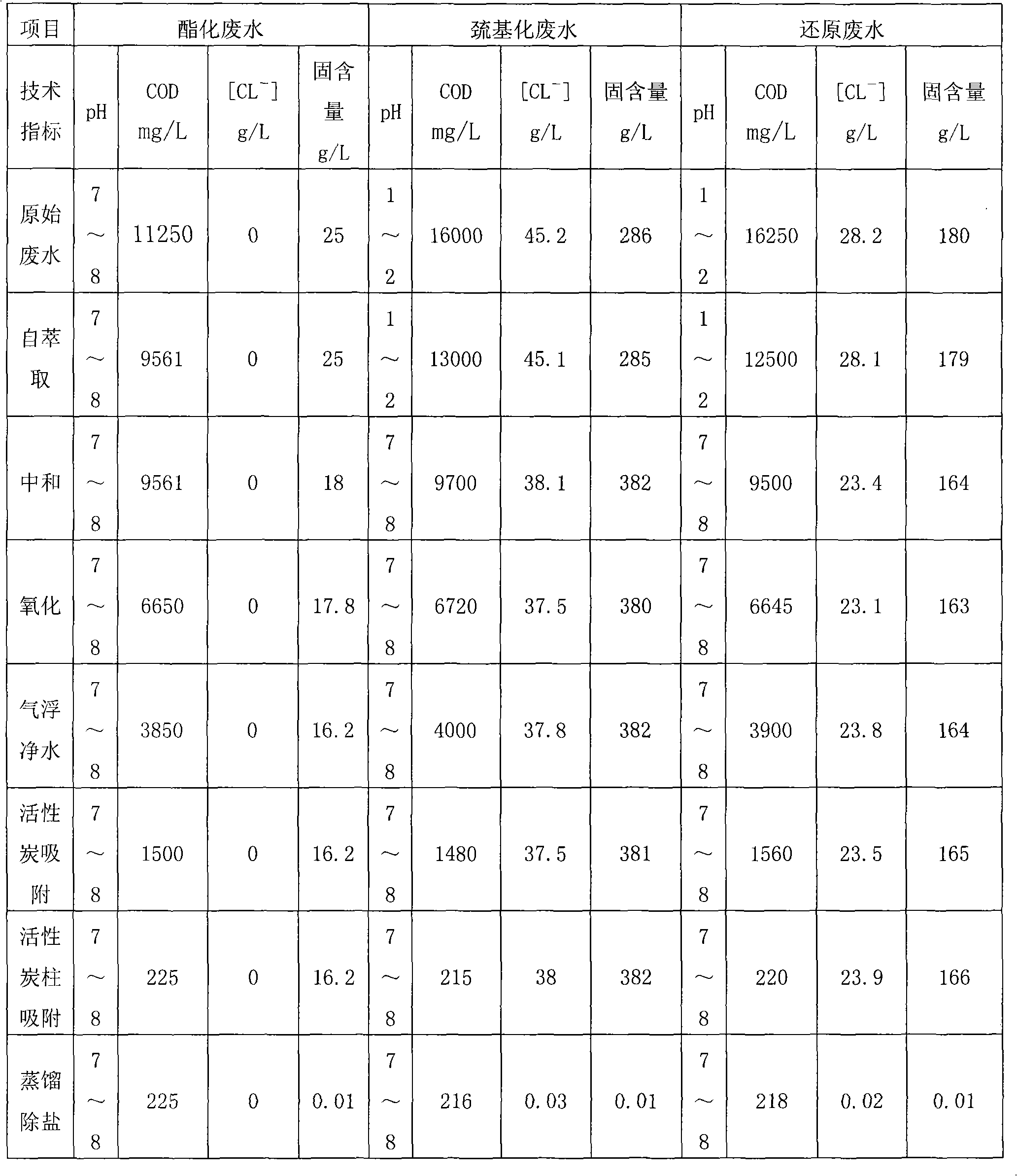

Method for treating waste water from acetic acid mercapto- isooctyl ester

ActiveCN101318750AGood processing effectSimple processMultistage water/sewage treatmentNature of treatment waterInorganic saltsAcetic acid

The invention relates to a method for treating wastewater in iso-octyl thioglycolate production. The method comprises the following specific steps that: when wastewater is treated, firstly, a part of organisms in the wastewater are reclaimed by adopting a self-extraction method; if the wastewater is acidic, the wastewater needs to be neutralized; secondly, a part of COD and solid suspended substances in the wastewater are respectively removed by a method of oxydol oxidation and air flotation purification; the wastewater is absorbed and discolored by active carbon to further remove COD in the wastewater; inorganic salt is removed by a distillation method; and finally the wastewater reaches the national emission standard. The method has obvious treatment effect, makes esterified wastewater, sulfhydrylated wastewater and deoxidized wastewater in iso-octyl thioglycolate production reach the national emission standard and has the effects of simple process and convenient popularization.

Owner:湖北犇星新材料股份有限公司

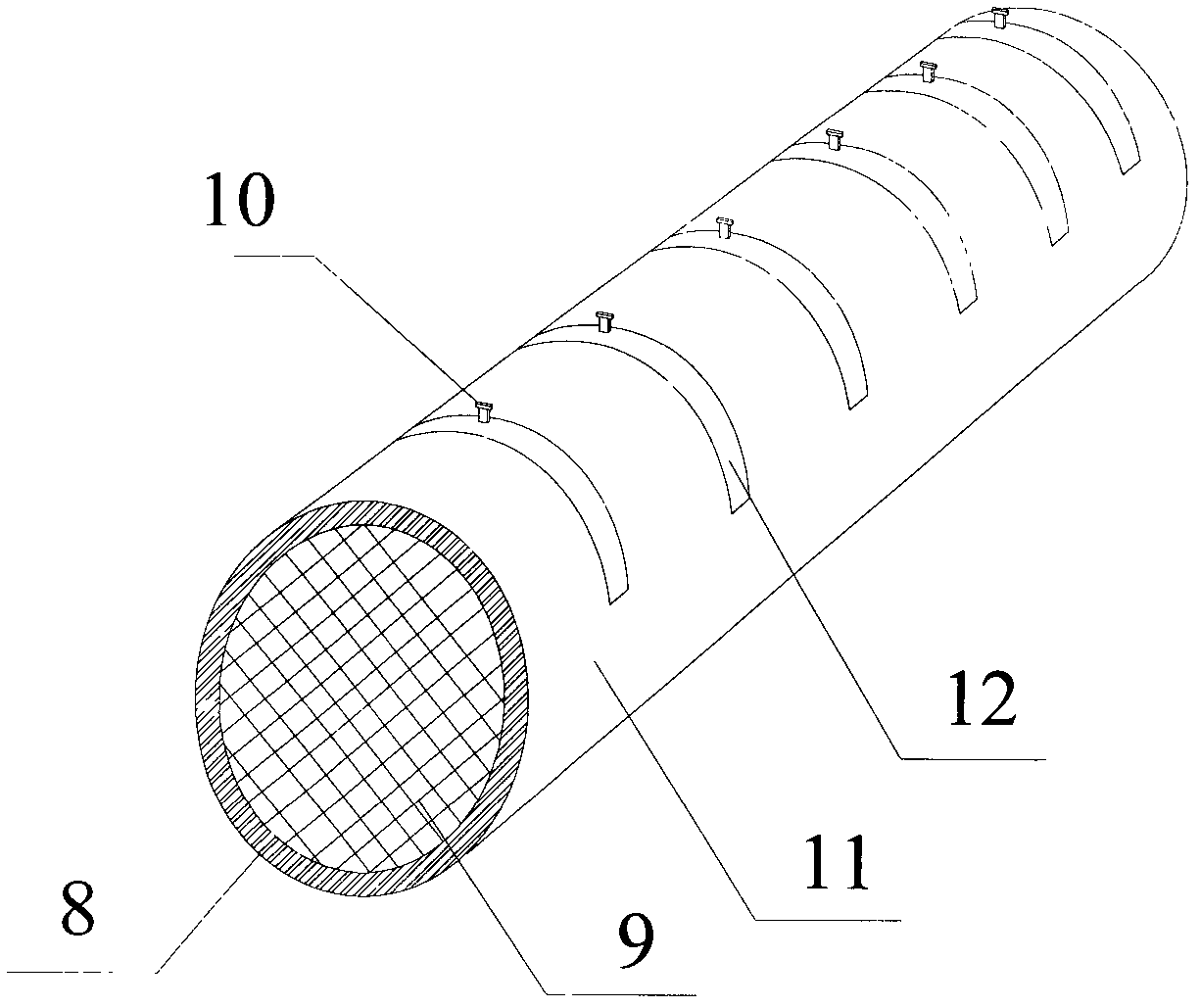

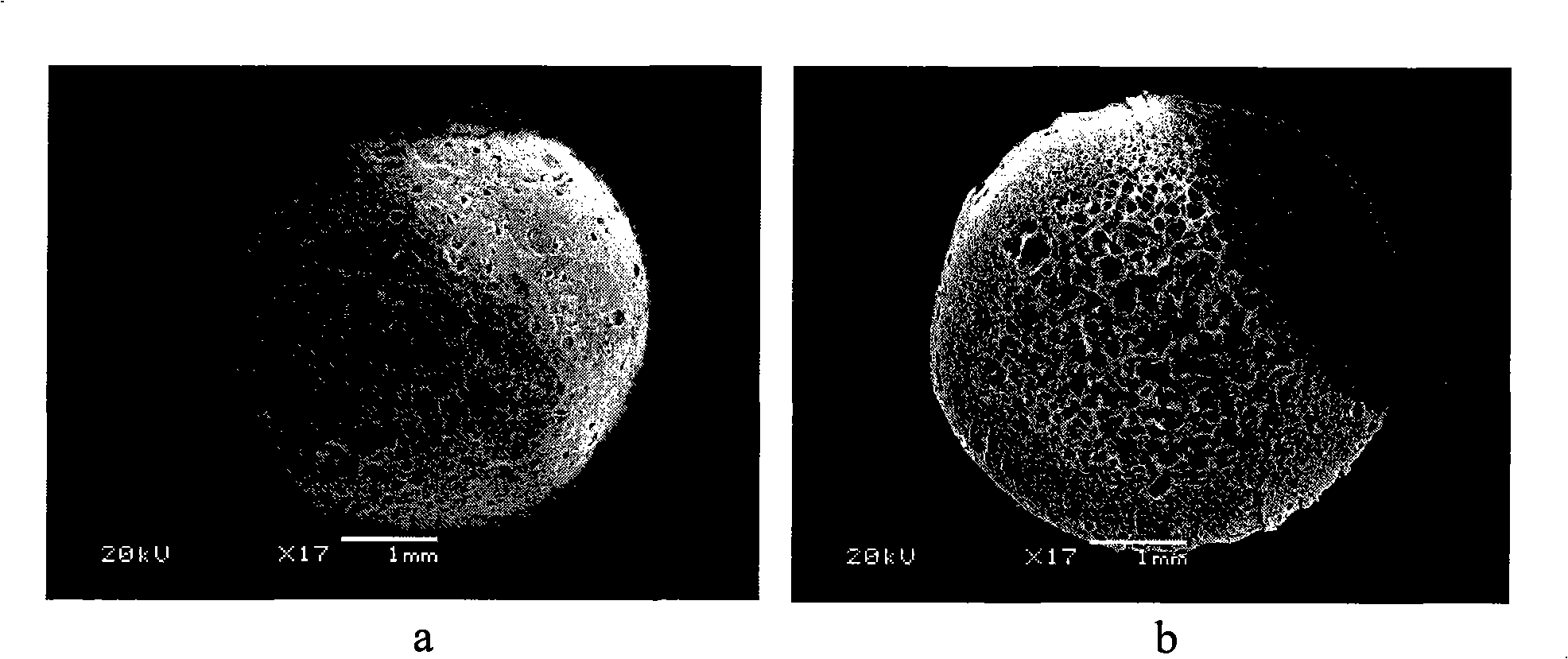

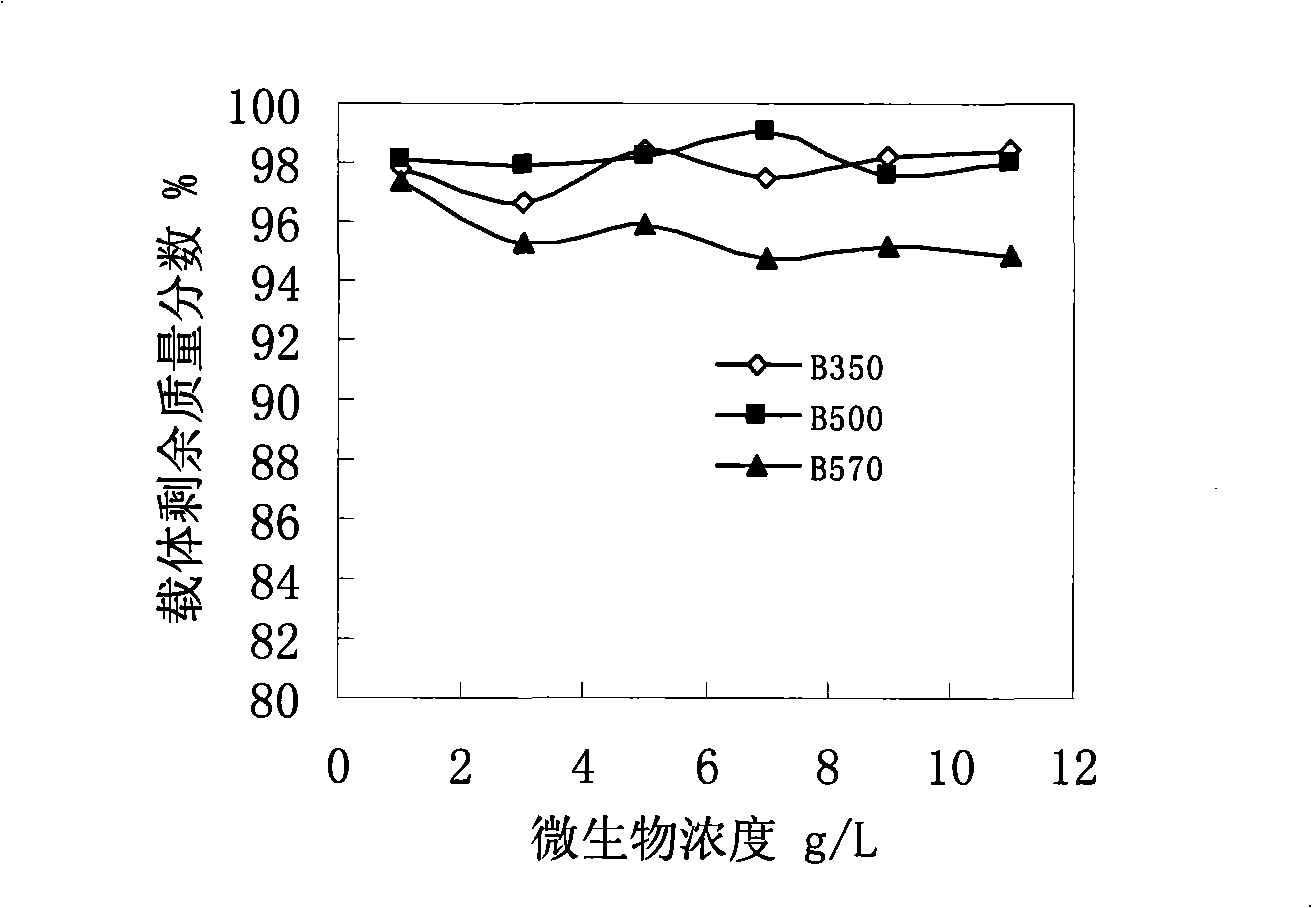

Macroreticular polyvinyl alcohol bead carrier and preparation thereof

InactiveCN101348782AIncrease the specific surface area of contactIncrease chance of contactOn/in organic carrierPeristaltic pumpDissolution

The invention provides a method for preparing a macroporous reticulated polyvinyl alcohol spherical vector. The method comprises the following steps: firstly, polyvinyl alcohol, calcium carbonate, sodium alginate and water are mixed in a certain mass proportion, and stirring is performed for full dissolution of the polyvinyl alcohol and uniform mixture, and then white PVA sol is obtained; secondly, the sol obtained is added into saturated boric acid solution containing 3 percent of calcium chloride by a peristaltic pump, and PVA gel beads are formed, cleaned by water and then placed into diluted hydrochloric acid solution for dipping until no air bubble is generated; thirdly, a spherical vector is thrown into glutaral pentanedial water solution and adjusted into acidity so as to generate crosslinking reaction to form a more stable crosslinking structure; and fourthly, the spherical vector is dipped into water and cleaned into neutrality, and then the white macroporous reticulated PVA spherical vector with elasticity is obtained. The macroporous reticulated polyvinyl alcohol vector prepared by the method has stable macroporous reticulated structure and good hydrophilicity, physical and chemical stability and anti-biological degradability, is suitable for immobilized enzymes and microorganisms so as to form a plurality of bed-shaped bioreactors, and is used in the modern bioengineering field such as sewage treatment and so on.

Owner:LANZHOU UNIVERSITY

Zero-sewage discharge novel process for development of natural gas fields

ActiveCN103304104AWide range of applicationsGood processing effectMultistage water/sewage treatmentNatural gas fieldPollutant

The invention discloses a zero-sewage discharge novel process for development of natural gas fields. The zero-sewage discharge novel process comprises the following steps of: classifying sewage in a gas field into normal production sewage, domestic sewage, overhauling sewage, accident waste liquid, rainwater, production wastewater and gas field water, and collecting separately; next, guiding the normal production sewage, domestic sewage, overhauling sewage, accident waste liquid and initial rainwater to a biochemical treatment unit, guiding the production wastewater to an electrodialysis treatment unit and guiding the gas field water to a gas field water pretreatment unit; guiding all of up-to-standard sewage which is treated by the biochemical treatment unit previously and not completely recycled, concentrate generated after the treatment of the electrodialysis treatment unit and the gas field water treated by the gas field water pretreatment unit to an evaporative crystallization unit for advanced treatment; and after the quality of the water is up to the standard, recycling the water as make-up water for circulating cooling water or water for other production in the gas field, and separating out pollutants from the sewage in the form of crystalline salts, backfilling or recycling the crystalline salts, and finally, realizing zero discharge of the sewage.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method and equipment for treating high-concentration refractory chemical wastewater

InactiveCN103992013AGood processing effectMultistage water/sewage treatmentHigh concentrationInorganic salts

The invention discloses a method and equipment for treating high-concentration refractory chemical wastewater. The method is formed by organically combining an efficient inorganic salt and organic salt separation technology, an improved organic matter degradation technology and an efficient organic matter filtration removal technology. The method is relatively low in treatment cost, relatively high in efficiency, relatively good in effect and capable of enhancing the biological reduction of refractory organisms and reducing environment pollution caused by chemical wastewater.

Owner:LIYANG SHENGTAI HEAVY MACHINERY

Dyeing wastewater treating agent and manufacturing method thereof

InactiveCN105152296AReduce COD valueGood processing effectWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationChemistryTreatment effect

The invention discloses a dyeing wastewater treating agent and a manufacturing method thereof. The dyeing wastewater treating agent is prepared from the following raw materials in parts by mass: 70-100 parts of diatomite, 40-70 parts of attapulgite, 90-120 parts of modified starch, 15-40 parts of acrylamide, 2-10 parts of ferrous sulfate, 20-30 parts of magnesium sulfate, 10-25 parts of meerschaum powder, 10-20 parts of crosslinked rectorite, 0.5-2 parts of polyacrylamide, 20-30 parts of cationic monomer, 0.17-0.21 part of initiator and 0.09-0.1 part of crosslinking agent. The treating agent can perform the flocculating settling purification and disinfection functions on the dyeing wastewater, has the characteristics of wide raw material sources, lower cost and favorable treatment effect, and is convenient for popularization and application.

Owner:杨洋

Low-temperature dyeing process of fiber fabric

ActiveCN103966867AGuaranteed functionAvoid damageFibre treatmentDyeing processFiberProcess engineering

The invention provides a low-temperature dyeing process of a fiber fabric. The low-temperature dyeing process comprises the processes of pretreatment, pre-sizing, dyeing, reduction clearing, fixing, softening treatment, drying, sizing, calendaring and rolling. In the dyeing process, the highest temperature does not exceed 100 DEG C, mild dyeing is carried out by using a gradual warming method and pH value regulation is carried out through a buffer solution, so that a proper acid environment required during the dyeing is satisfied and the dyeing effect is excellent; during the dyeing, a leveling agent is added to ensure that the dyeing is uniform; anhydrous sodium sulphate is added to postpone the dyeing process of the pigment and the temperature rises slowly at the same time, so that the uniform dyeing is ensured; a smoothing agent is added to prevent the scratching and local fibrillation; a penetrant and a diffusant are added to ensure that the penetration and the diffusion of the dyeing are relatively good; by means of the strict control in the aspects of temperature, acid, auxiliaries, time and the like, the low-temperature dyeing process of the fiber fabric has the advantages that the dyeing firmness is high, the dyeing is uniform, the dyeing stability is good and the effect is excellent at low temperature.

Owner:绍兴洁彩坊印染有限公司

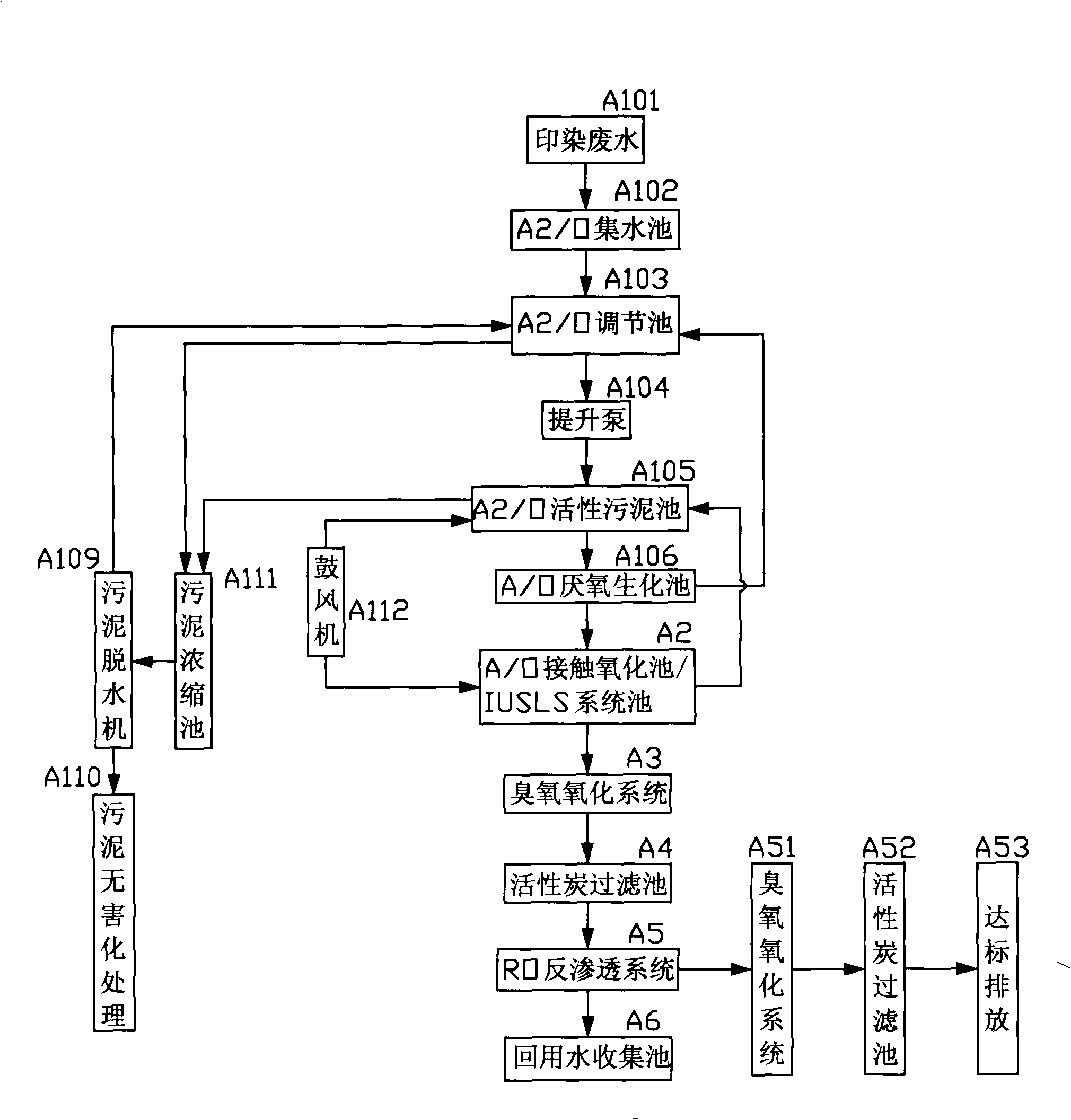

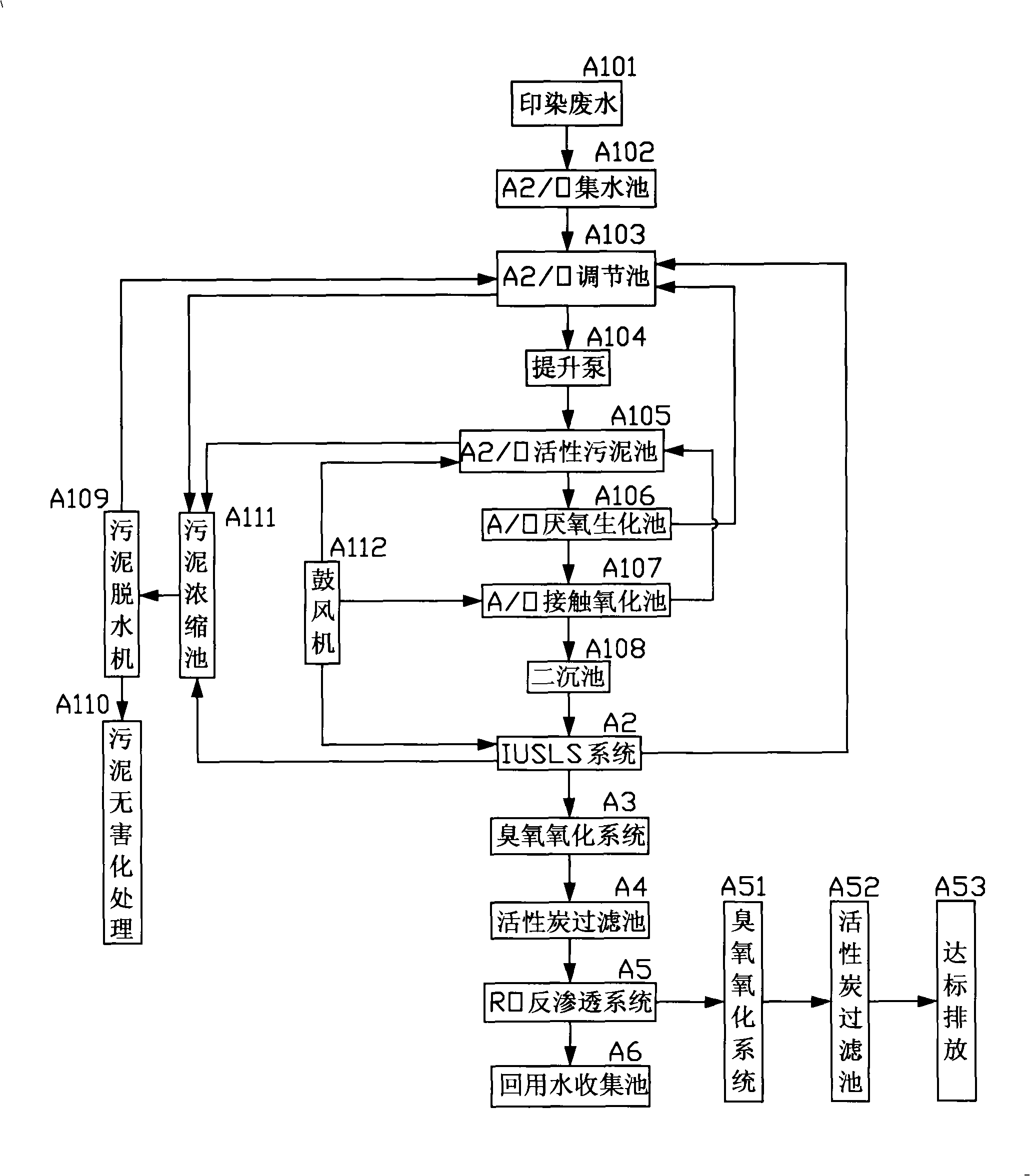

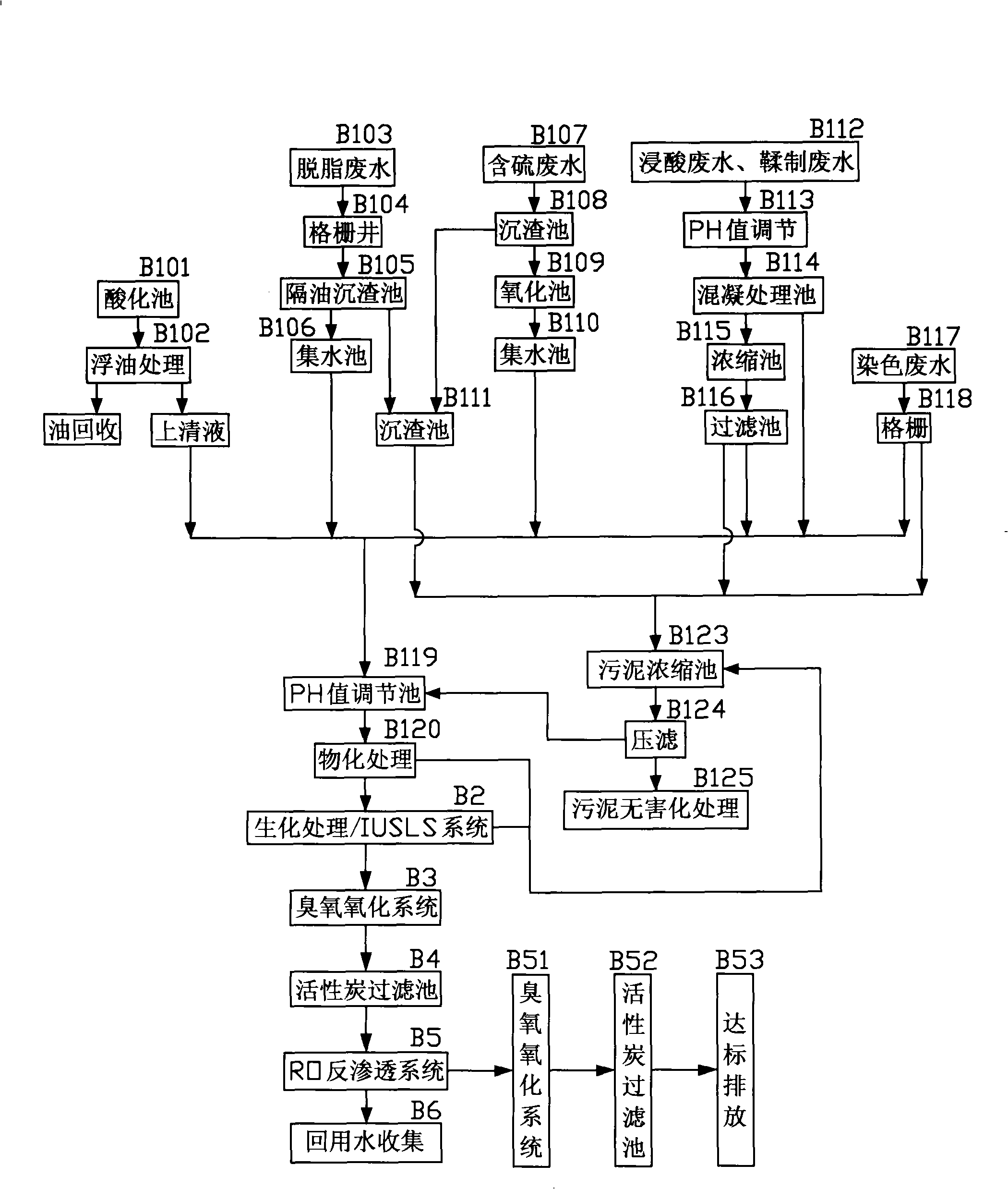

Waste water recycling comprehensive processing process

InactiveCN101311132AAvoid influenceGood processing effectWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentUltrafiltrationActivated carbon filtration

The invention relates to a sewage recycling comprehensive treatment technique, including that sewage is pretreated by a physicochemical technique and a biochemical technique; the pretreated sewage is separated by an immersed ultrafiltration solid-liquid separation system; ozone is used for eliminating part of organic matter and bacteria in the ultrafiltration membrane permeate liquid generated in the previous step; after being treated in the previous step, organic pollutant in the water is further removed by adopting activated carbon for filtering; after the treatment in the previous step, the water carries out reverse osmosis treatment to obtain permeate water of a reverse osmosis membrane, that is, reuse water. All sewage treatment techniques adopted by the invention are mutually matched, have reasonable sequence and play own roles independently, thus preventing the sewage treatment techniques from affecting with each other, allowing the equipment of each sewage treatment technique to achieve optimal treatment effect and leading to more complete sewage treatment.

Owner:VISBE XIAMEN ENVIRONMENT TECH CO LTD

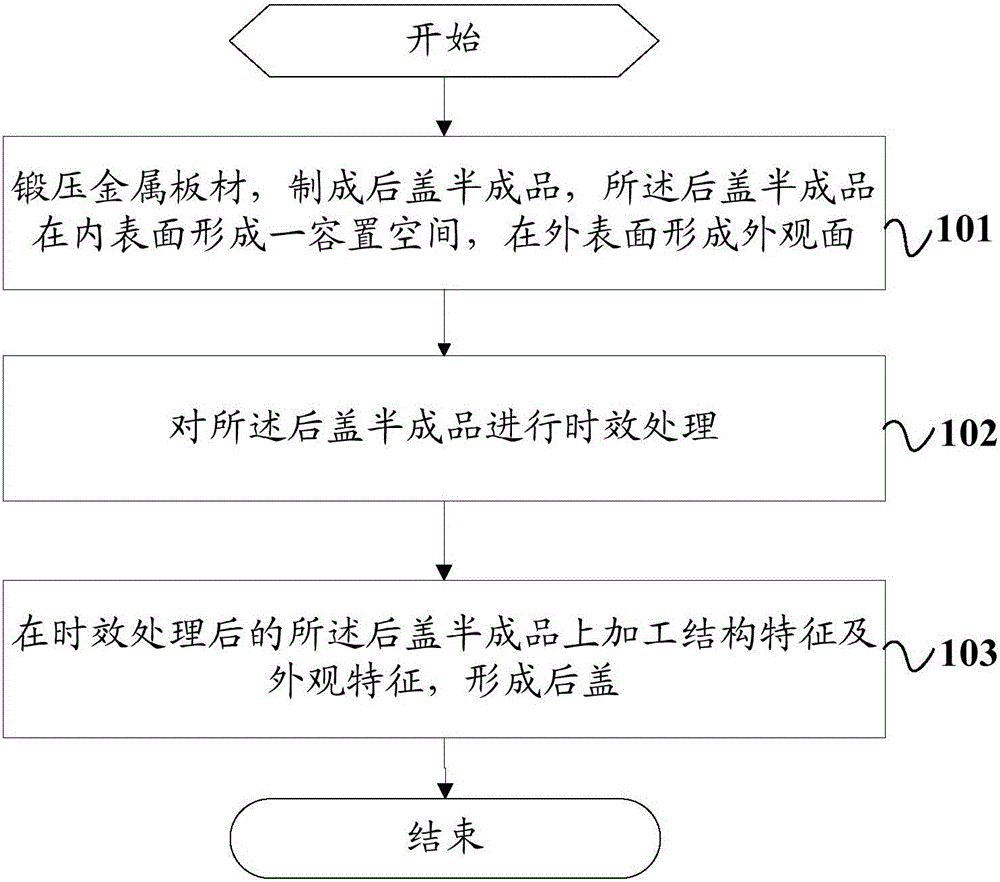

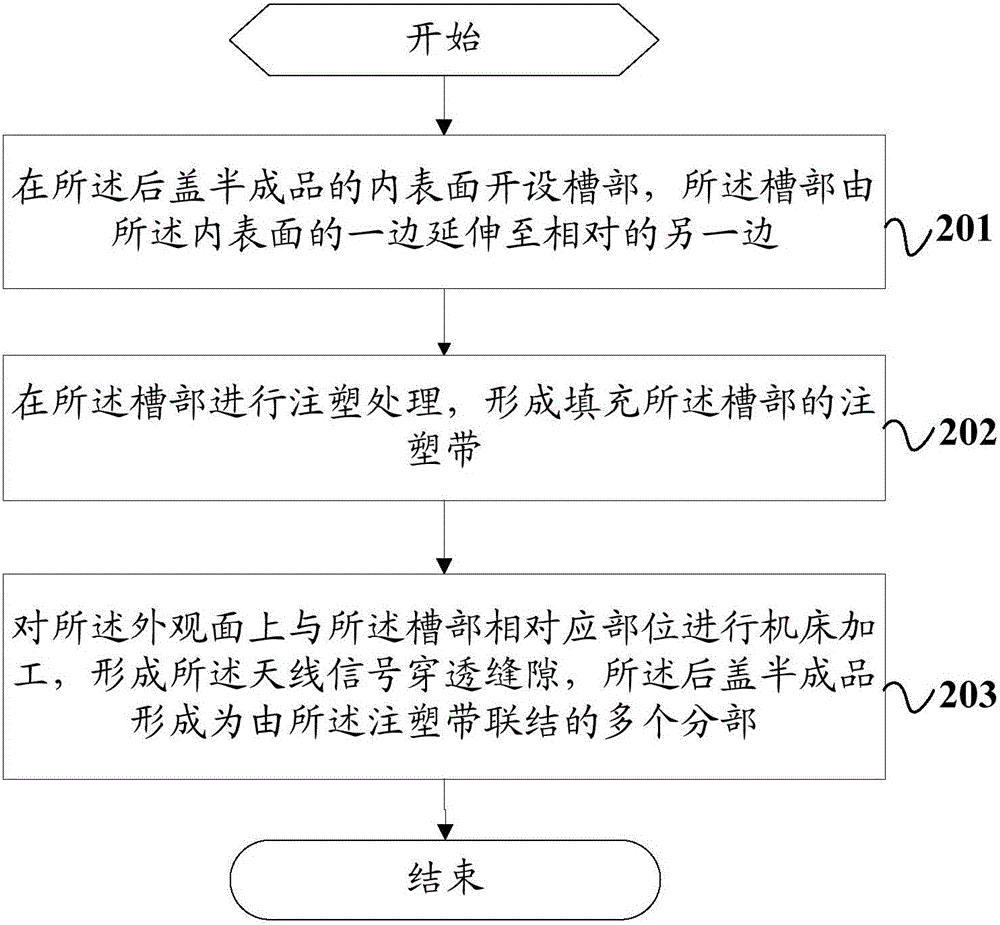

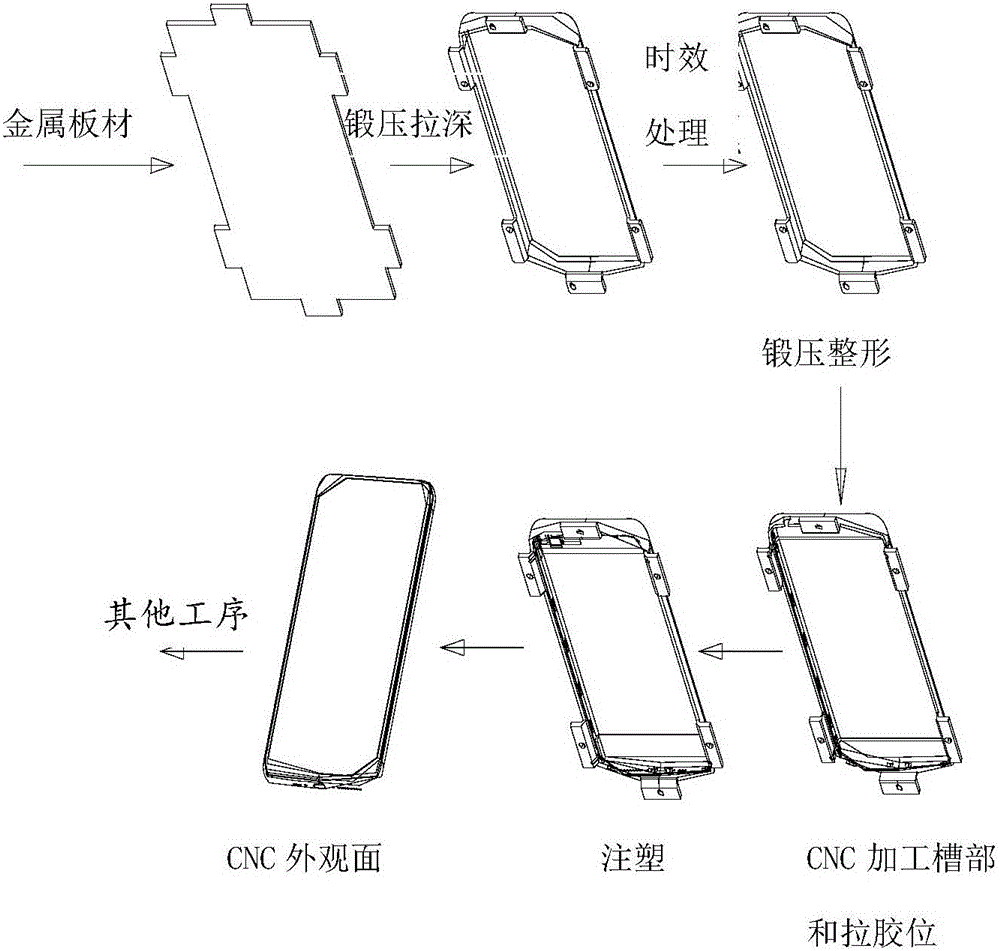

Processing method for back cover, back cover and electronic equipment

ActiveCN106028724AGood processing effectImprove production efficiency and product yieldMetal-working apparatusCasings/cabinets/drawers detailsWork in processEngineering

The invention provides a processing method for a back cover, the back cover and electronic equipment. The processing method comprises the steps of forging and pressing a metal sheet to prepare a semifinished product of the back cover, wherein an accommodating space is formed in the inner surface of the semifinished product of the back cover while an appearance plane is formed on the outer surface; the metal sheet is prepared by extrusion of an initial metal blank; performing aging treatment on the semifinished product of the back cover; and processing structural characteristics and appearance characteristics on the semifinished product of the back cover after the aging treatment is carried out so as to form the back cover. By adoption of the scheme, the raw materials can be reduced, the CNC (computer numerical control) processing time can be greatly shortened, and the cost can be lowered.

Owner:VIVO MOBILE COMM CO LTD

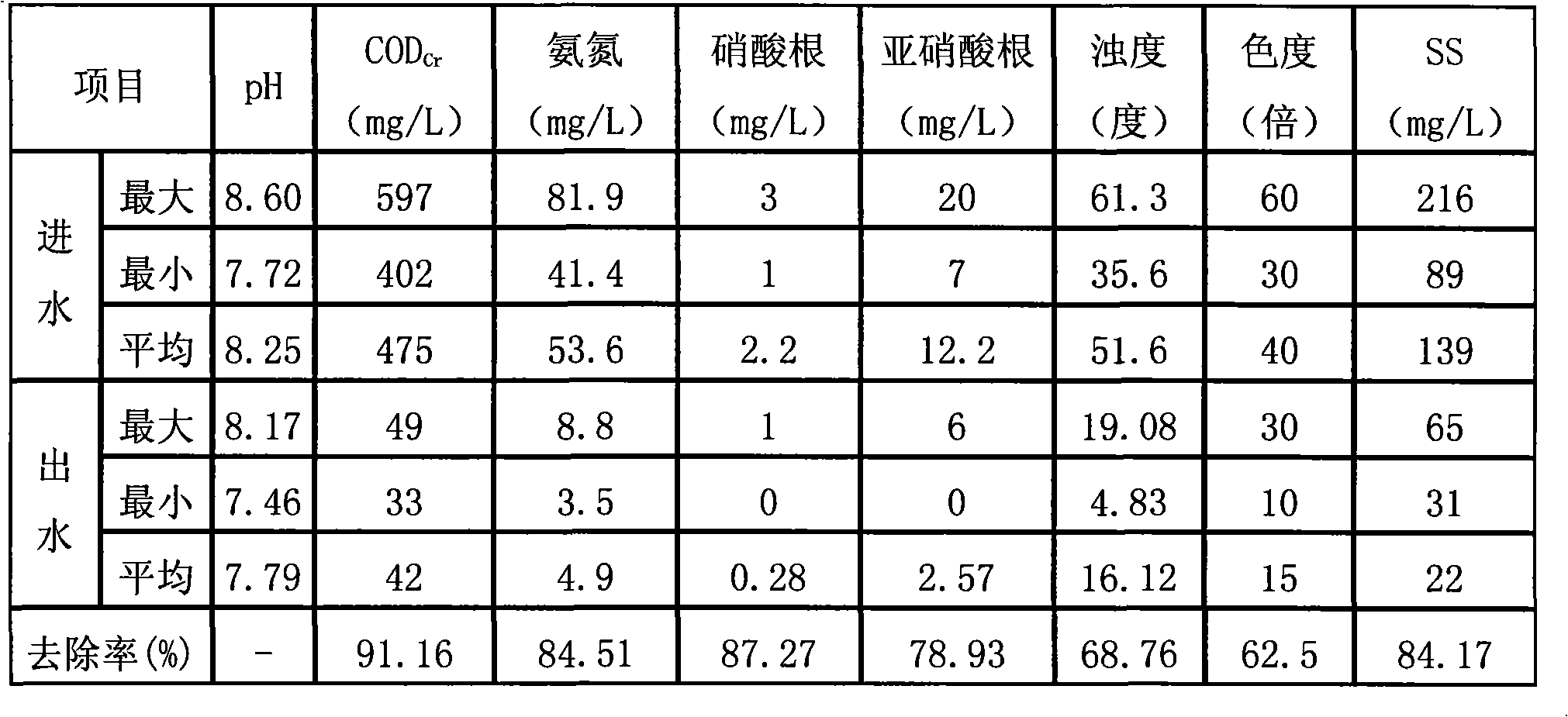

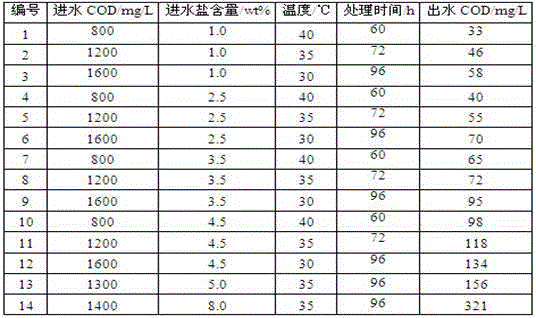

Paracoccus sp. and culture application thereof

ActiveCN106635858AStrong salt toleranceGood processing effectBacteriaMicroorganism based processesLaboratory cultureParacoccus sp.

The invention relates to paracoccus sp. and a culture application thereof. The strain is paracoccus sp. FSTB-2, collected at 'China General Microbiological Culture Collection Center' on June 1, 2015, and the preservation number is CGMCC No. 10938. The strain can be applied to efficiently removing COD (chemical oxygen demand) in salty wastewater with salt content of 1.0wt%-8.0wt%, and can grow at the high temperature of 40 DEG C. The invention further provides COD removing salt-tolerant bacteria which comprise the paracoccus sp. FSTB-2. The COD in the high-salt wastewater can be rapidly degraded by the paracoccus sp., the paracoccus sp. is high in salt resistance and good in treatment effect, combining strains are omitted, and the production cost of the salt-tolerant bacteria is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

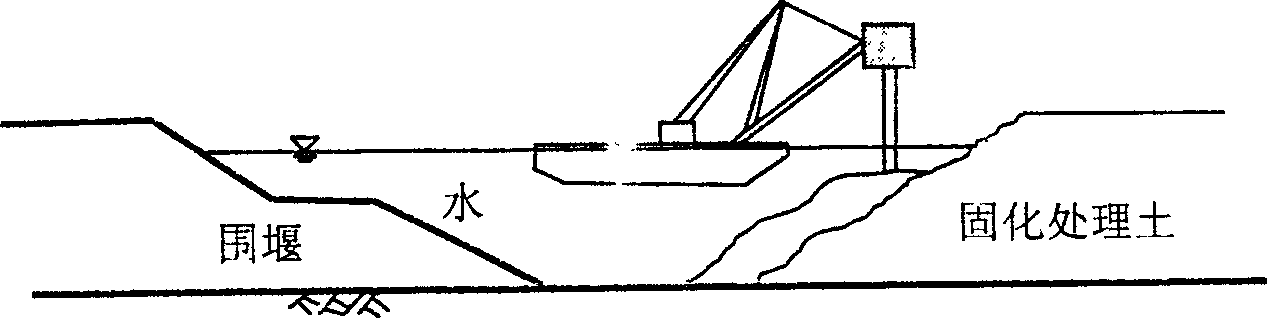

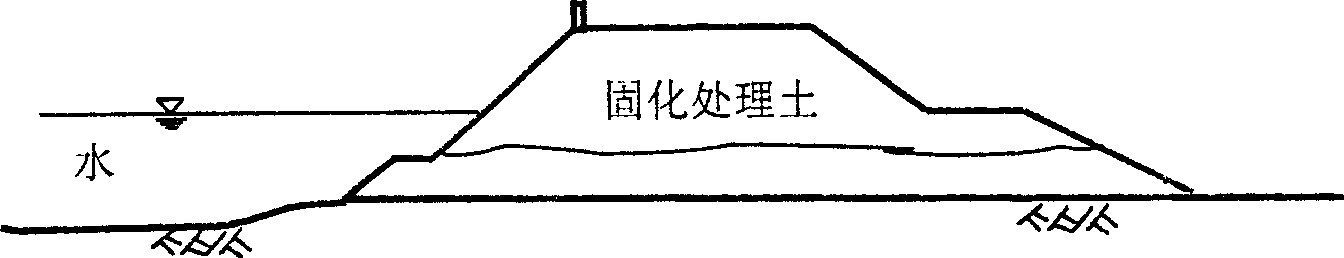

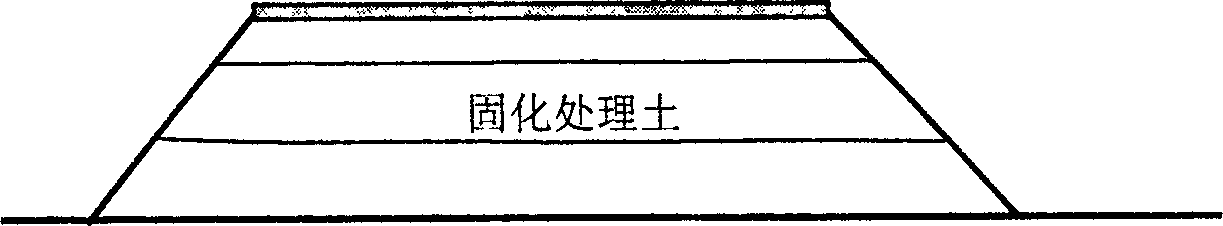

Composite silt solidified material

InactiveCN1448358AReduce pollutionGood processing effectSolid waste managementSolid waste disposalGypsumWater content

The present invention is one kind of composite sludge curing material for curing sludge produced in water engineering and civil engineering. It is cement-based curing material with certain amount offlyash as industrial waste and gypsum added. Through mixing with sludge, it is possible to improve the property of sludge, which has hydroxide water content and low strength, and reusing waste sludge with likely environmental pollution as engineering material. The utilization of industrial waste results in low cost.

Owner:HOHAI UNIV

Prepn and application in industrial effluent treatment of biomembrane carrier

InactiveCN101066802AFast fixationPromote growthTreatment with aerobic and anaerobic processesSustainable biological treatmentEpoxyElectrolytic agent

The present invention relates to one kind of functional biological carbon fiber and its preparation process and application as biomembrane carrier. The biomembrane carrier is prepared with polyacrylonitrile carbon fiber, and through electrochemical surface treatment in 5-20 % concentration ammonium bicarbonate electrolyte to increase the surface acid oxygen containing functional groups and raise wettability, and gluing with water soluble epoxy resin in the amount 0.5-2 %. The biomembrane carrier can fix nitrobacteria, sulfate reducing bacteria and anaerobic methanogen. It may be used in treating high concentration acrylon waste water, and can eliminate sulfate, COD and ammonia nitrogen effectively. In addition, the biomembrane carrier is easy to regenerate and has no secondary pollution.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com