Patents

Literature

41results about How to "Reduce waste water treatment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for biological treatment of mine acidic wastewater

InactiveCN101219844AReduce waste water treatment costsGood processing effectWaste water treatment from quariesTreatment with aerobic and anaerobic processesSlow sand filterChemistry

The invention relates to a process for biologically treating wastewater with sulfate and hydrochloric acid and recycling elemental sulfur, belonging to the technical fields of environmental protection and wastewater treatment, which is characterized in that in the process, the sludge acidic fermentation products from a wastewater treatment plant is used as carbon source sulfate reducing bacteria for treating acidic sulfate wastewater and recycling the elemental sulfur; the sulfate reducing bacteria SRB in an anaerobic biological reactor reduces sulfate SO4<2-> creature as hydrogen sulfide H2S of colorless sulfur bacteria CSB in an aerobic biofilm reactor reduces H2S or S<2->creature as the elemental sulfur and then the obtained substance is filtered and sand-scrapped by a slow sand filter; the elemental sulfur S in sand filtering material is completely dissolved by an extraction equipment; the extractant CS2, the sand filtering material and the biofilm are separated by a solid-liquid separator; the extracted solution is distilled by a distillation equipment; the distilled solution is parched by a drying device and then the elemental sulfur is recycled.In the invention the mine wastewater with the sulfate and the hydrochloric acid is treated; the elemental sulfur is recycled and the sludge from the wastewater treatment plant achieves resource utilization and harmlessness.

Owner:TAIYUAN UNIV OF TECH

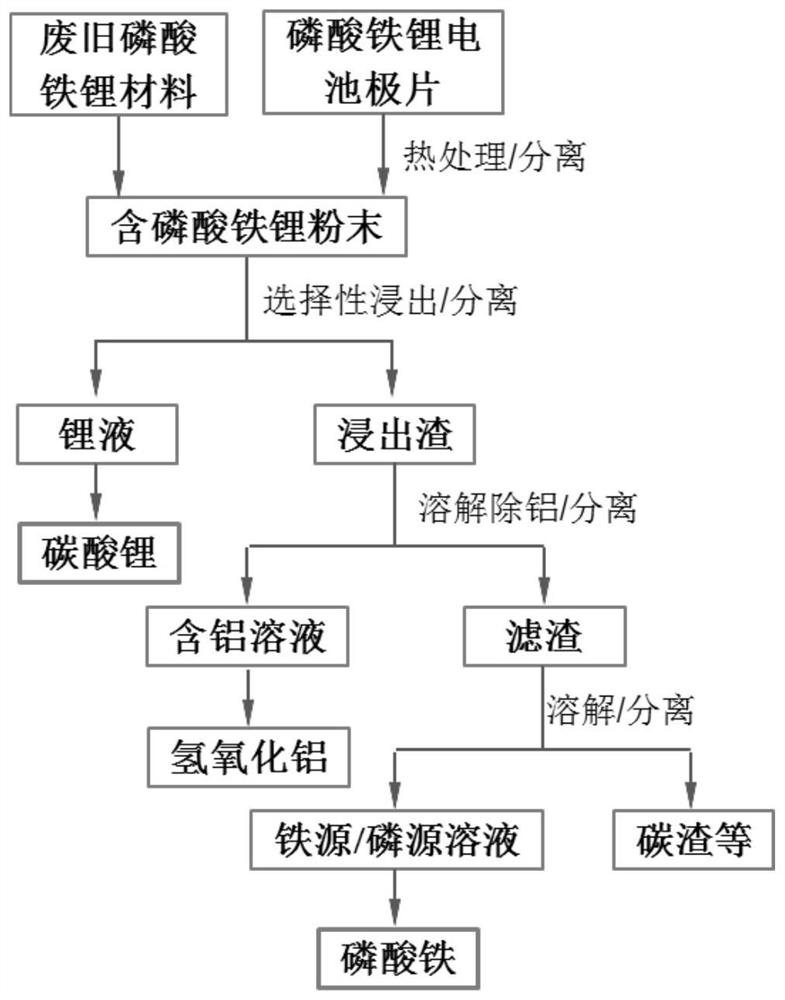

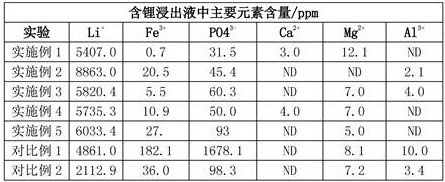

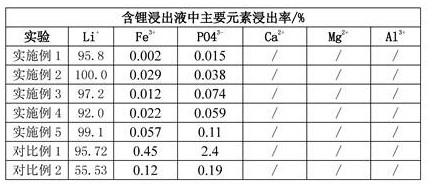

Recovery method of waste lithium iron phosphate positive electrode material

ActiveCN112441572AImprove leaching rateRealize full recyclingAluminium oxide/hydroxide preparationWaste accumulators reclaimingPregnant leach solutionO-Phosphoric Acid

The invention provides a recovery method of a waste lithium iron phosphate positive electrode material. The method comprises the following steps: S1, adding waste lithium iron phosphate powder to a leaching agent A, slowly adding a leaching agent B, adjusting the pH value to be more than or equal to 2, and carrying out solid-liquid separation to obtain a lithium-containing leaching agent and a leaching residue; S2, adding a precipitator into the lithium-containing leachate to obtain lithium carbonate; S3, adding a first alkaline solution into the leaching residues, and filtering to obtain an aluminum-containing solution and filter residues; S4, adjusting the pH value of the aluminum-containing solution to obtain an aluminum hydroxide precipitate; S5, adding the filter residue into a firstacidic solution, performing filtering, adding a second alkaline solution into the obtained filtrate, adjusting the pH value to 2.0-2.7 to obtain basic iron phosphate, and adding phosphoric acid to obtain iron phosphate. The leaching agent A comprises a mixed solution of at least one of a weak base solution or a weak acid solution and a first oxidizing agent; and the leaching agent B comprises a mixed solution of a second acidic solution and a second oxidant. By the adoption of the method, the leaching rate of lithium is high, impurities are few, the purification and wastewater treatment cost during lithium carbonate preparation is reduced, and meanwhile iron phosphate can be efficiently recycled.

Owner:BYD CO LTD +1

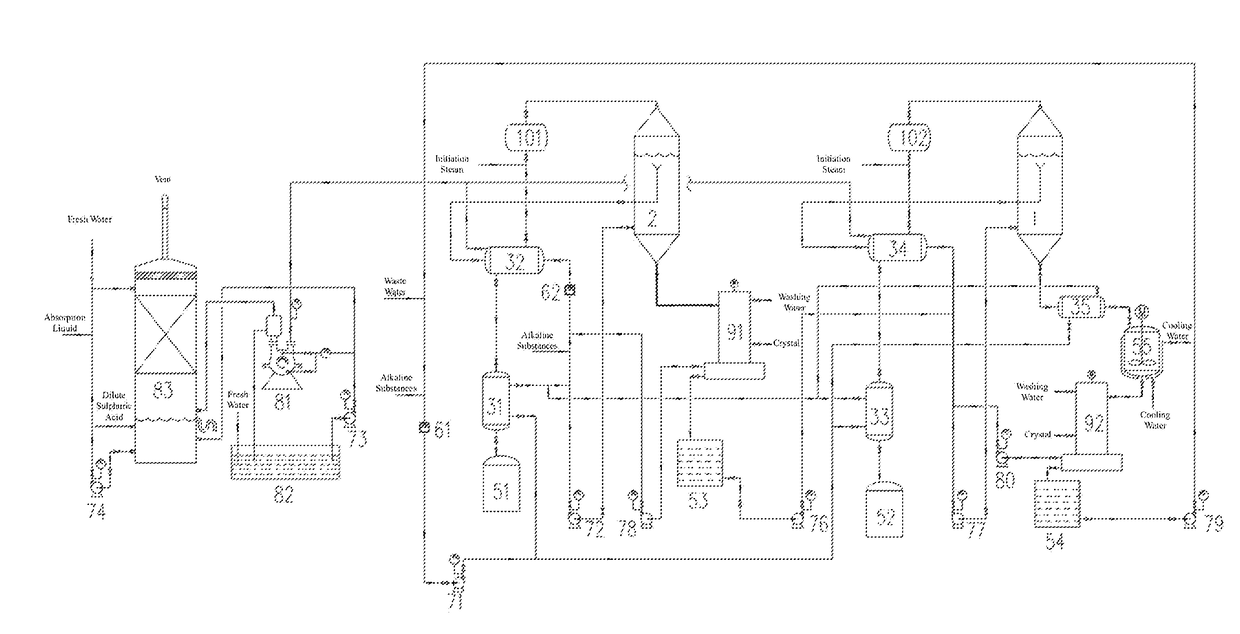

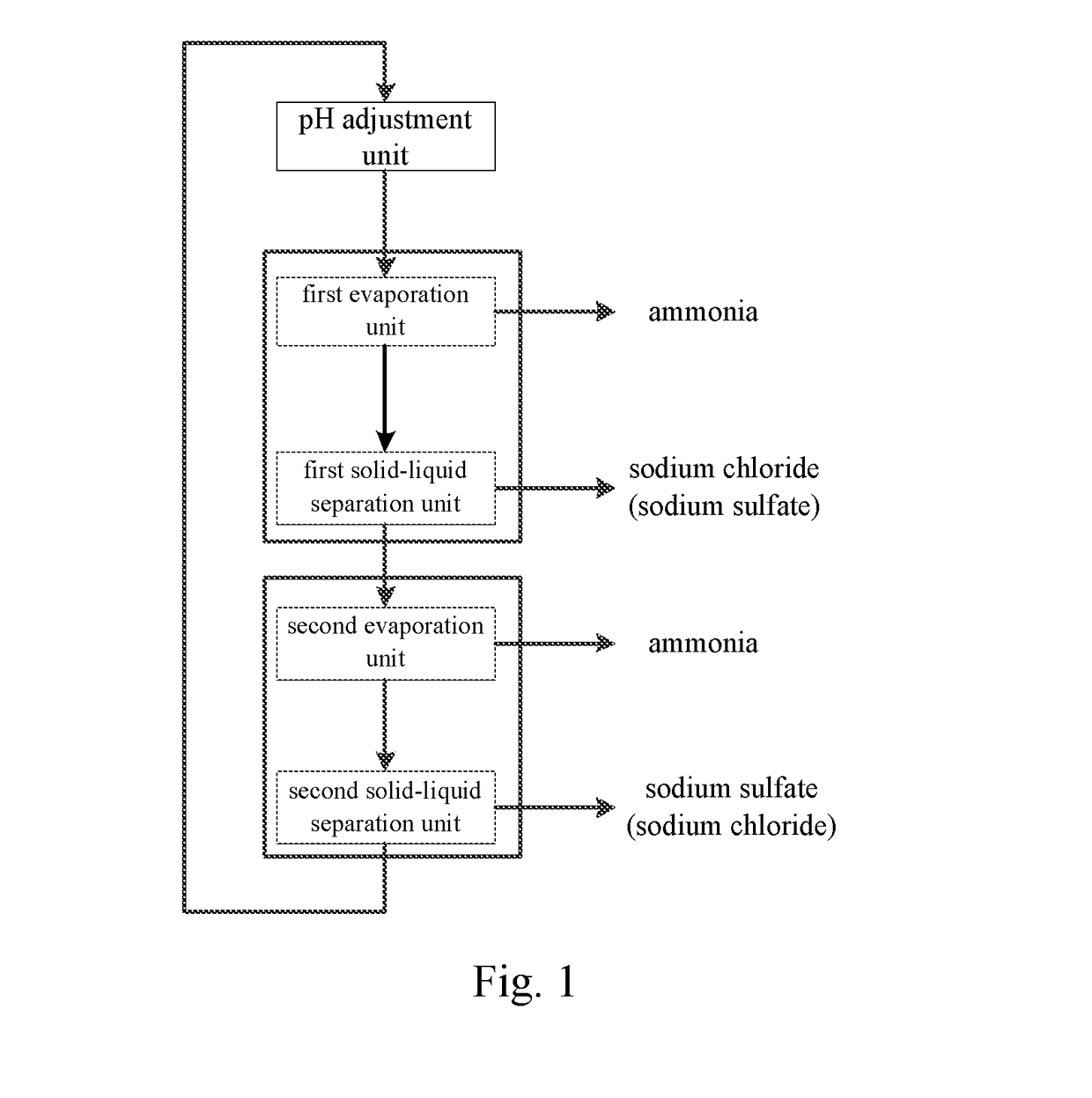

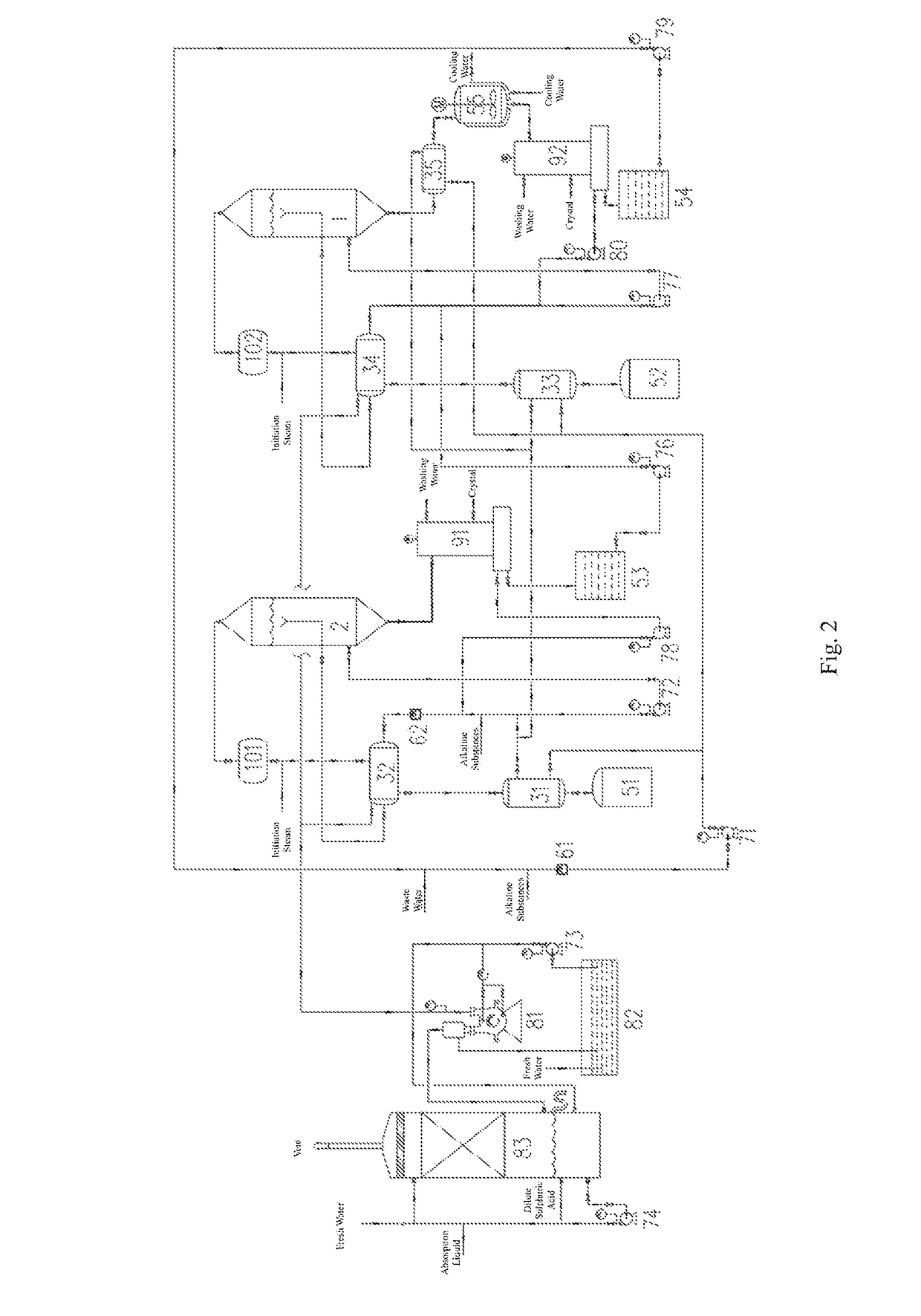

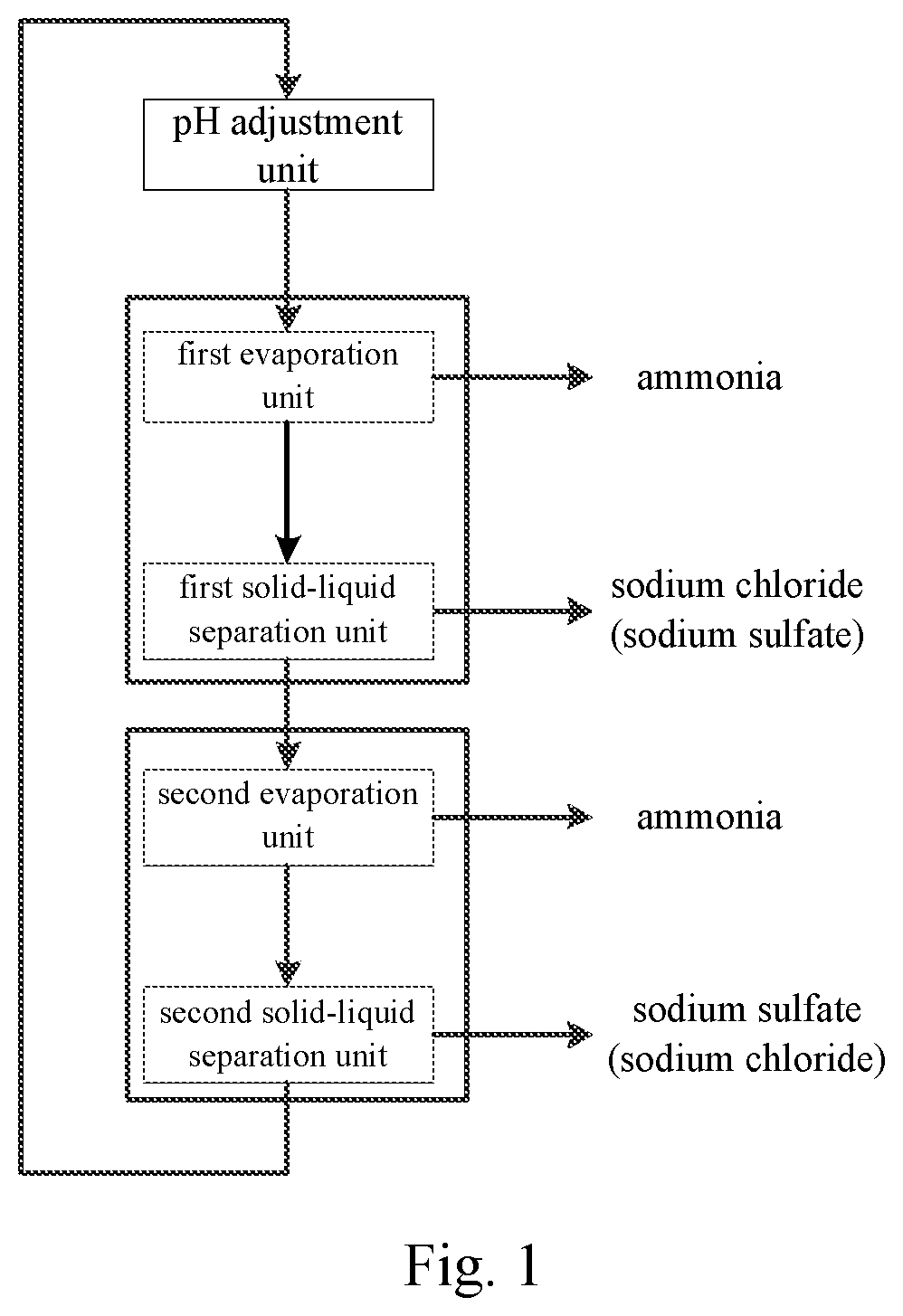

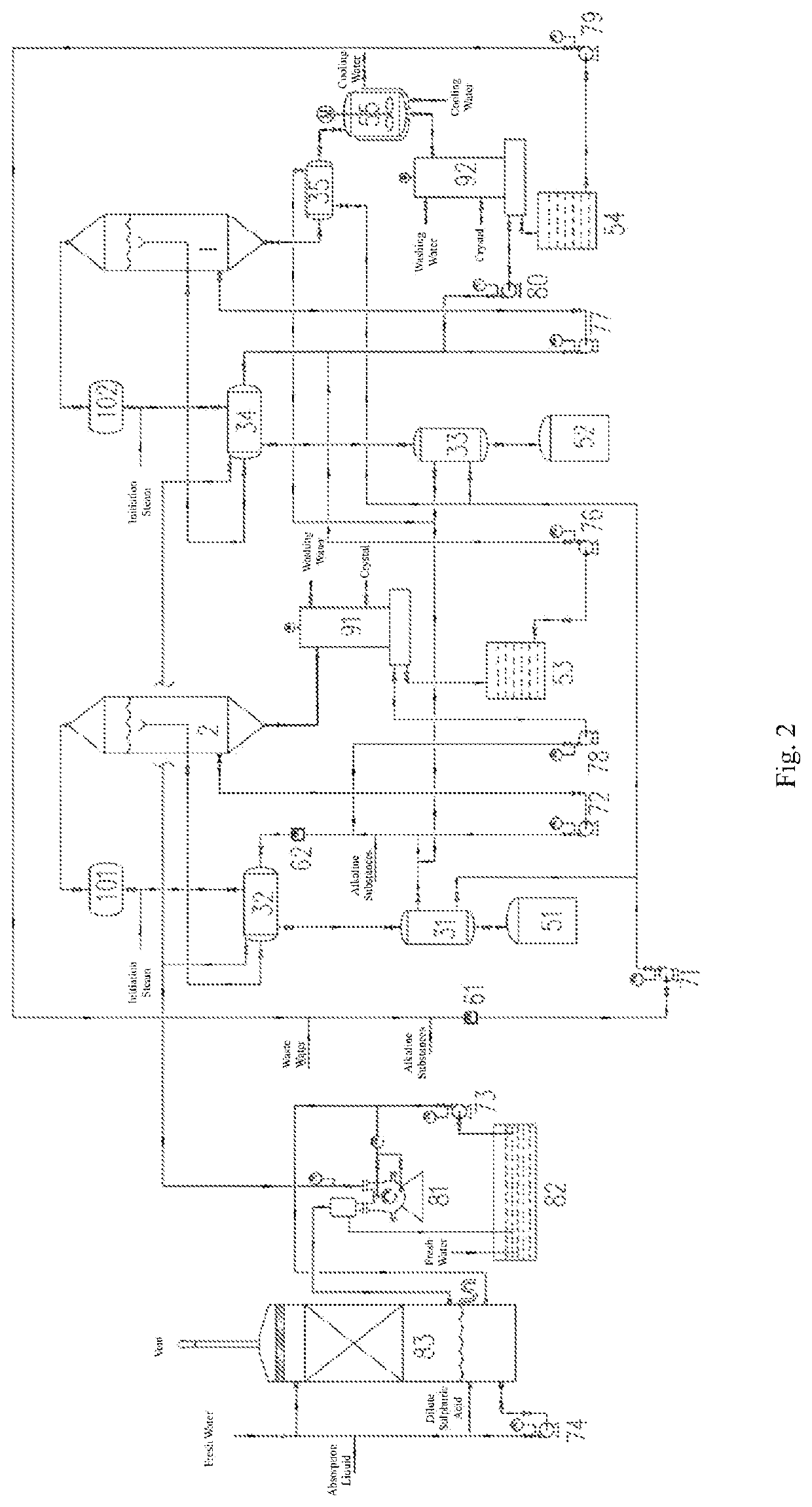

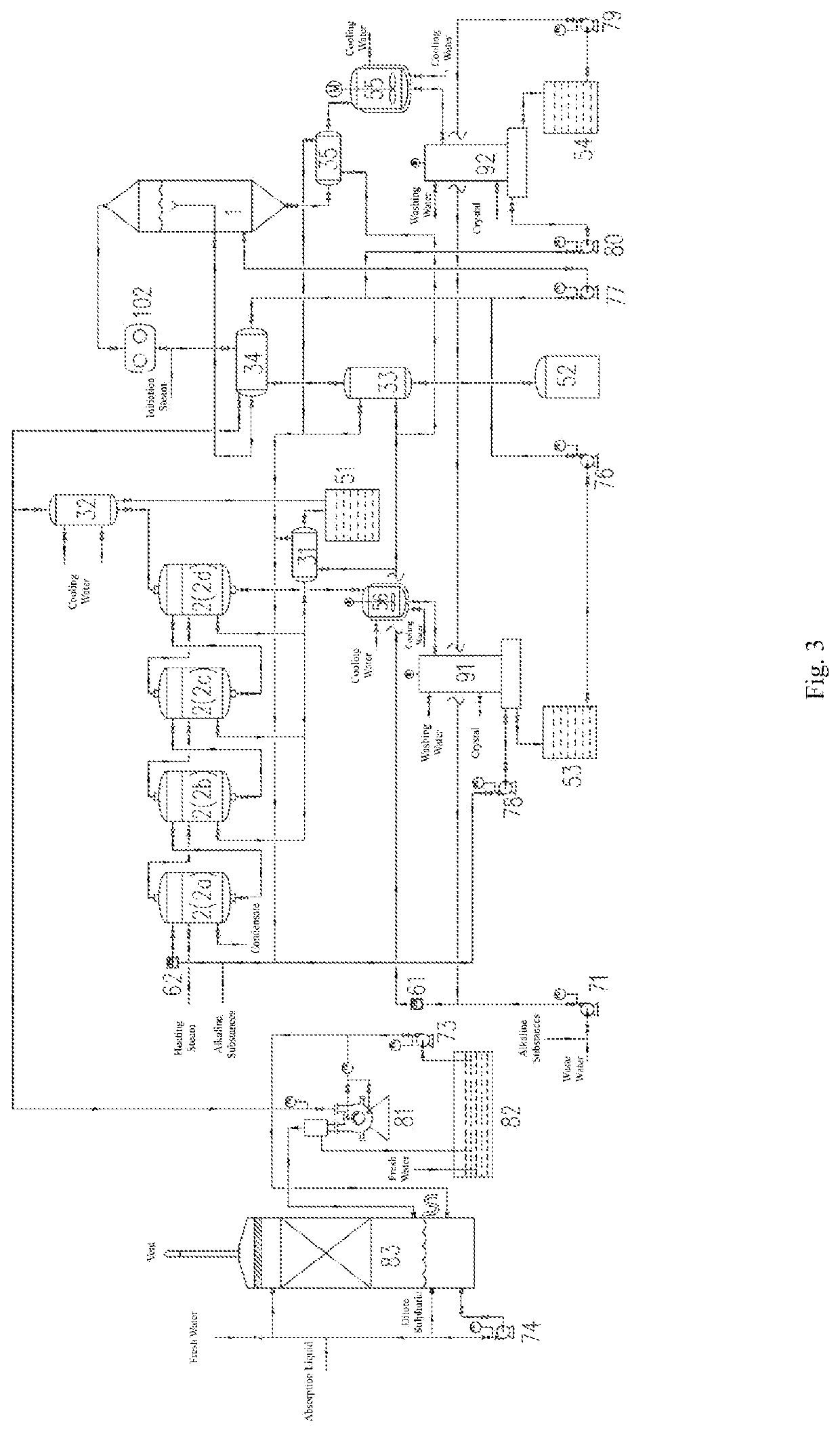

Apparatus and Method for Treating Waste Water Containing Ammonium Salts

ActiveUS20180305221A1Waste of resourceOvercomes drawbackWater treatment parameter controlEvaporation with vapour compressionEvaporationWastewater

The present invention relates to the waste water treatment field, and discloses apparatus and method for treating waste water containing ammonium salts, which contains NH4+, SO42−, Cl−, and Na+. In the method of the present invention, the pH value of the waste water to be treated is adjusted to a specific range in advance; sodium sulfate crystal and relatively concentrated ammonia are obtained by first evaporation, and then sodium chloride crystal and relatively dilute ammonia is obtained by second evaporation; alternatively, sodium chloride crystal and relatively concentrated ammonia is obtained by third evaporation, and then sodium sulfate crystal and relatively dilute ammonia are obtained by fourth evaporation. The method of the present invention can recover ammonia, sodium sulfate, and sodium chloride from the waste water respectively, so that the resources in the waste water can be reused as far as possible.

Owner:CHINA PETROCHEMICAL CORP +1

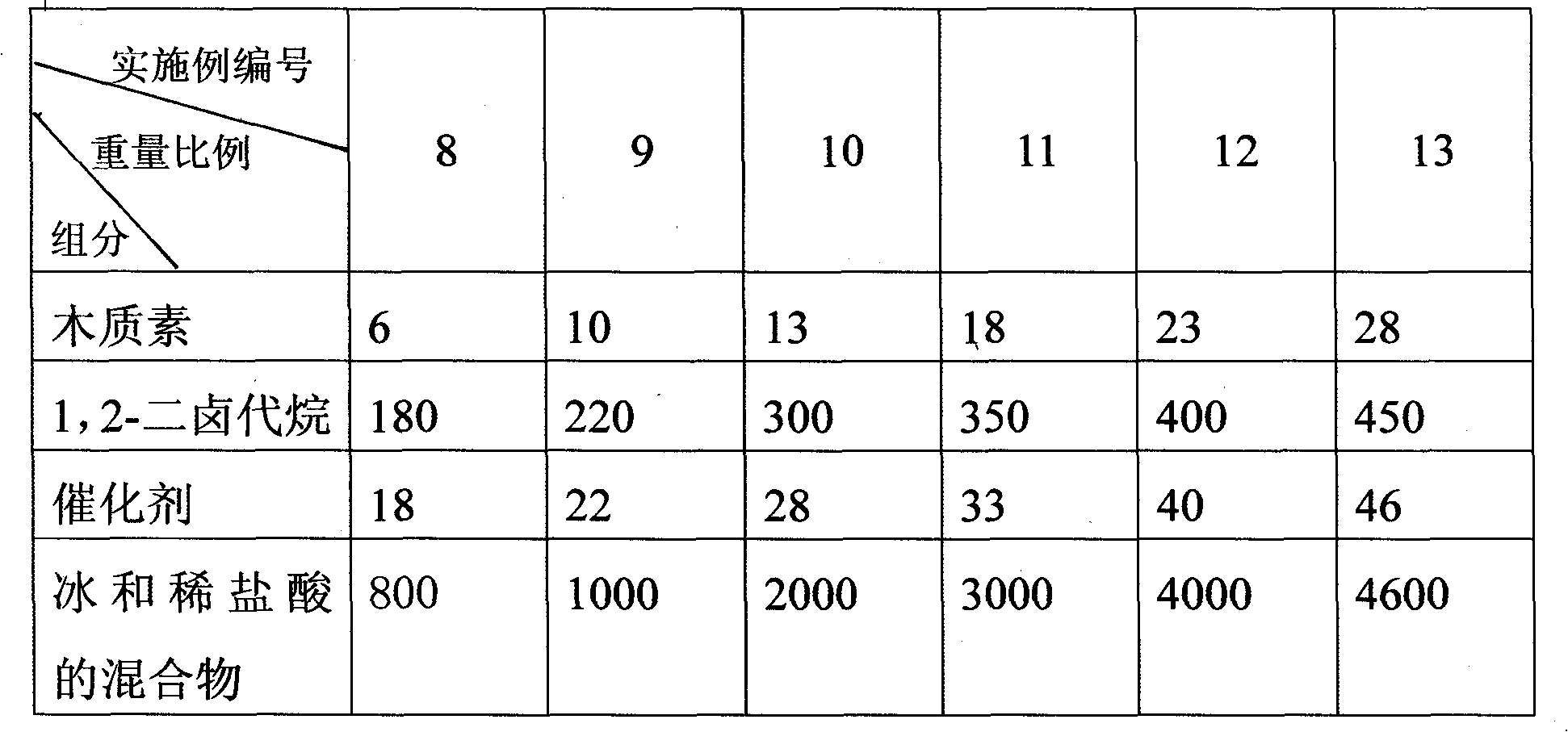

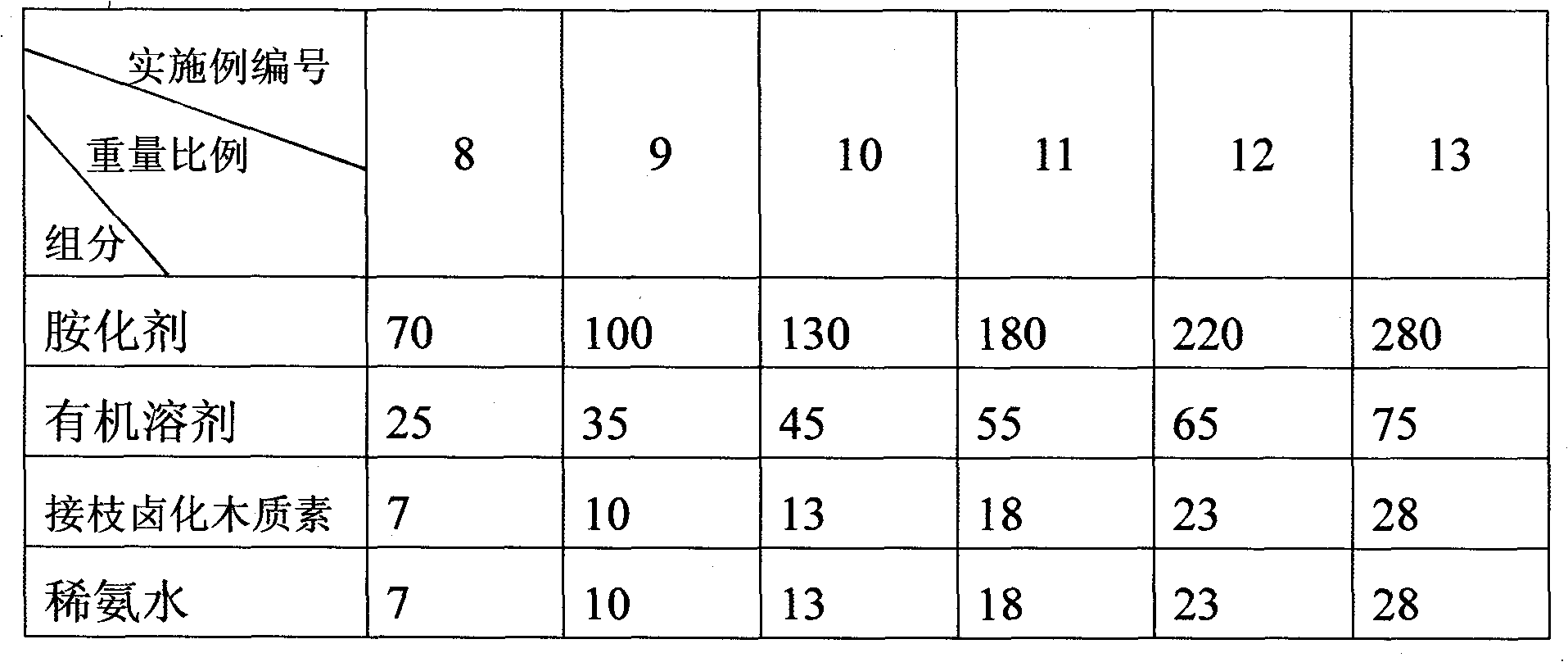

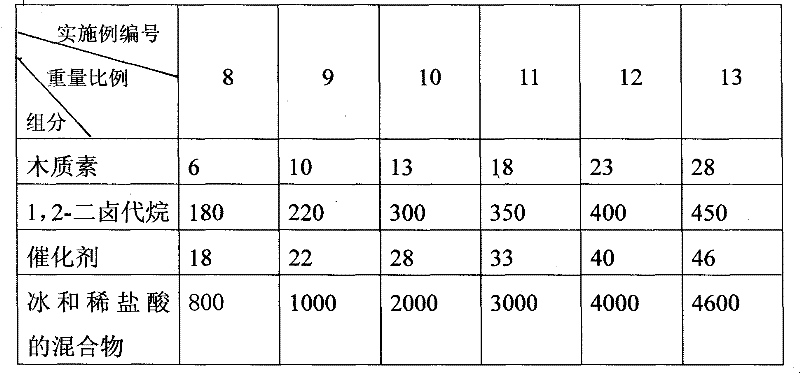

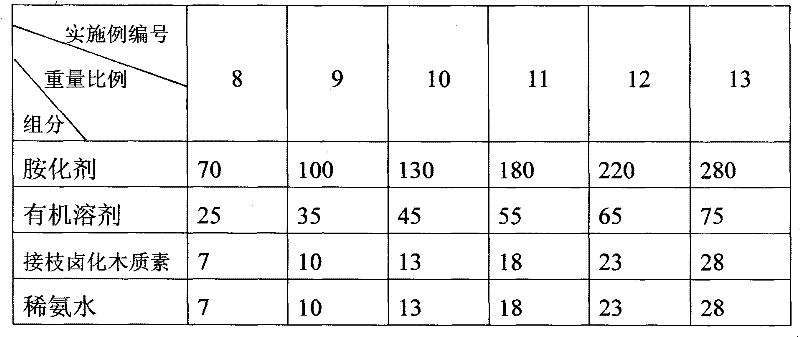

Preparation method of modified lignin absorbent for absorbing TNT (Trinitrotoluene)

InactiveCN101829546AAbundant resourcesSave resourcesOther chemical processesWater contaminantsAbsorption capacityOrganic solvent

The invention discloses a preparation method of a modified lignin absorbent for absorbing TNT (Trinitrotoluene), which is characterized by comprising the steps of: adding 5-30 parts by weight of lignin into 150-500 parts by weight of 1,2-alkyl dihalide, adding 15-50 parts of catalysts, stirring for 3-10 hours at 50-90 DEG C, washing reacted materials by using a mixture of ice and diluted hydrochloric acid, filtering and washing by using water, and drying to prepare grafted halogenated lignin; and then adding 50-300 parts of aminating agents into 20-80 parts of organic solvents, adding 5-30 parts of the grafted halogenated lignin, stirring for 4-10 hours at 60-90 EG C, filtering, washing by using diluted ammonia water and water, and drying to obtain the modified lignin absorbent. The absorbent has higher selective absorption capacity on the TNT and other organic compounds containing nitryl and can be used for absorption and separation of the TNT and other organic compounds containing the nitryl in the explosive industrial wastewater so as to protect the environment.

Owner:SOUTHWEAT UNIV OF SCI & TECH

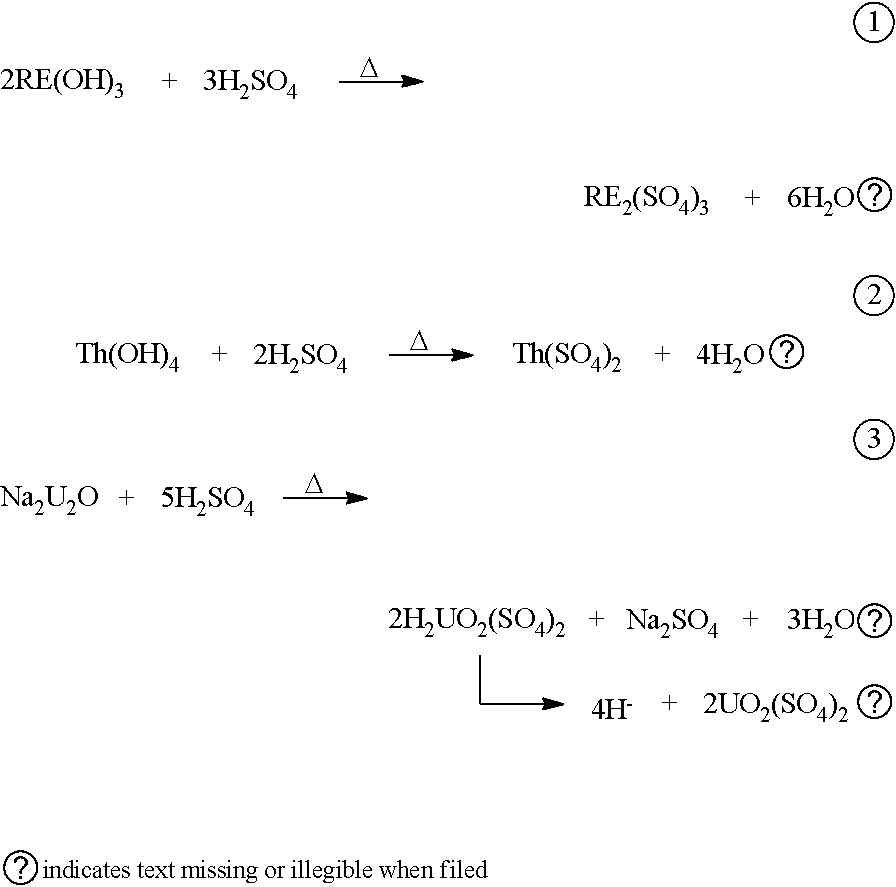

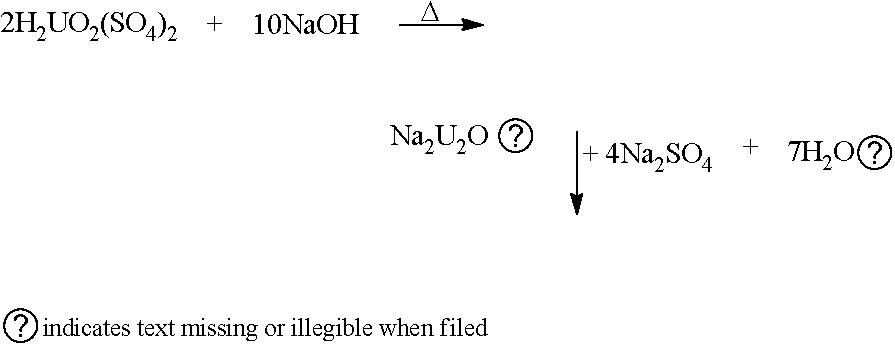

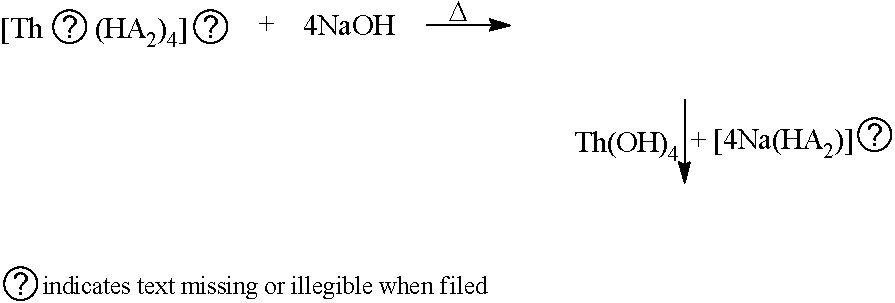

Monazite ballast separation and recovery method

ActiveUS20150307958A1The fermentation process is simpleEasy to separateRare earth metal compoundsProcess efficiency improvementRecovery methodSlag

The invention relates to a separation and recovery method for radioactive waste slag and specifically relates to a separation and recovery method for monazite slag. The separation and recovery method comprises the following steps: acid leaching, pressure filtration, water washing, extraction of valuable components and treatment of filtration slag. The separation and recovery method provided by the invention performs low-acid and low-temperature leaching on monazite slag, so that a liquid phase and a solid phase are easy to separate; after an ore dressing process is adopted for performing ore dressing and alkali decomposition on secondary slag, closed-loop circulation and recovery of uranium, thorium and rare earth is realized; and simultaneously, extraction raffinate waste acid is recycled, so that the emission of waste water is reduced, the consumption of sulfuric acid and fresh water and the treatment cost of the waste water are reduced, the production cost is reduced, the recovery rate of the valuable elements, namely the uranium, the thorium and the rare earth is more than 97%, and the whole process has no emission of the radioactive waste water and waste slag.

Owner:YIYANG HONGYUAN RARE EARTH

Alkaline high-calcium wastewater decalcification treatment method

InactiveCN102001774AReduce salt contentReduce waste water treatment costsMultistage water/sewage treatmentWater/sewage treatment by neutralisationSodium carbonateChemistry

The invention discloses an alkaline high-calcium wastewater decalcification treatment method, which comprises the following steps of: 1, introducing alkaline high-calcium wastewater into a first neutralizing tank, and performing preneutralization treatment through aeration by using a proper amount of carbon dioxide exhaust; 2, introducing turbid wastewater subjected to the preneutralization treatment into a first sedimentation tank for sediment separation; 3, introducing supernatant wastewater in the first sedimentation tank into a reaction tank, and adding a proper amount of sodium carbonate; 4, introducing the turbid wastewater subjected to the sodium carbonate treatment into a second sedimentation tank for sediment separation; 5, introducing the supernatant wastewater in the second sedimentation tank into a second neutralizing tank, and neutralizing through aeration by using a proper amount of carbon dioxide exhaust; and 6, introducing the supernatant wastewater in the second sedimentation tank into a filtering tank for filtering. The alkaline high-calcium wastewater decalcification treatment method is suitable for treating the alkaline high-calcium wastewater with the pH value of more than or equal to 11.0 and the calcium concentration of more than or equal to 500mg / L, the treatment cost is lower than that of a traditional method, and the water quality is improved.

Owner:XIANGTAN UNIV

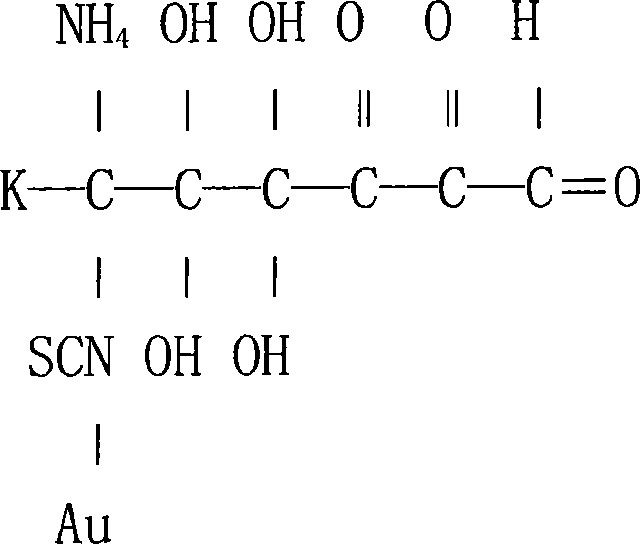

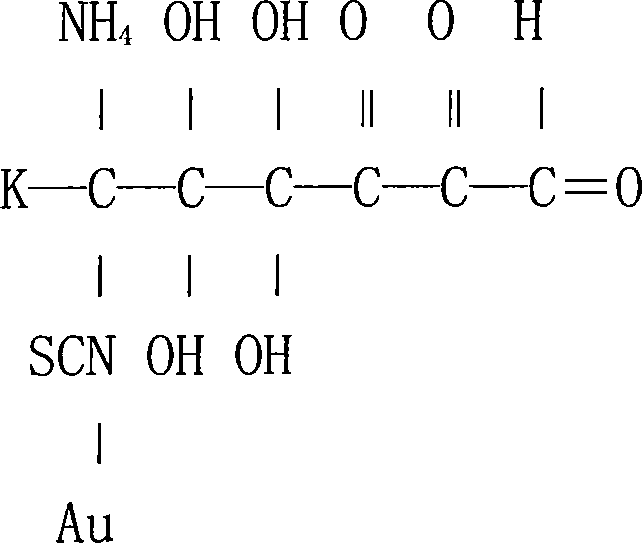

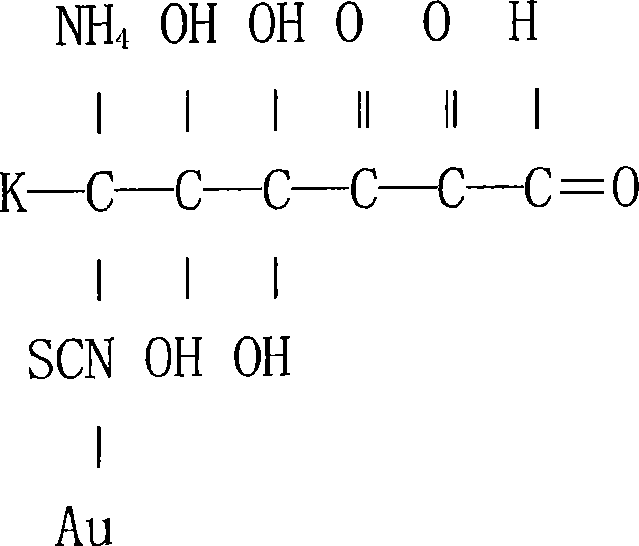

Lemon acid gold salt for gold plating and manufacture method thereof

The invention discloses citric acid gold salt used for plating gold and a method for preparing the citric acid gold salt, the molecular formula of the citric acid gold salt is K3Au2C9H5O7N2, and the method comprises the following steps: dissolving gold trichloride in water with certain temperature, then concentrating and diluting the gold trichloride time after time under the temperature, and preparing and obtaining organometallic salt through reacting with potassium citrate, EDTA and thiocyanate amine in certain temperature and time in a catalyst case. The citric acid gold salt has the advantages that the toxicity is low, the discharge liquid after the gold plating only contains trace quantity free CN-, the cost of treating waste water of electroplating enterprises is reduced, and the pollution to environment of discharging of cyanide is originally reduced.

Owner:HENGSHENG TECH R&D CO LTD

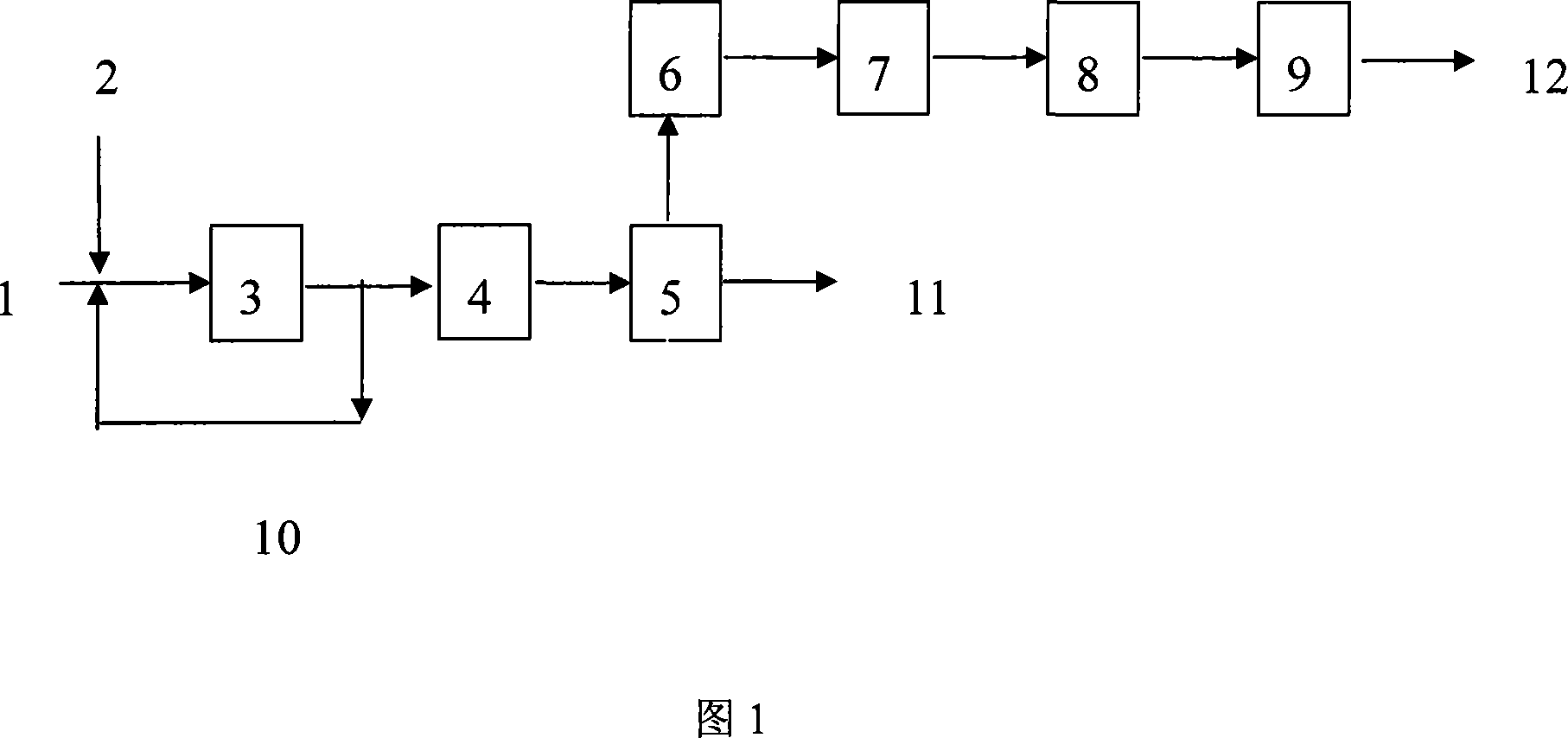

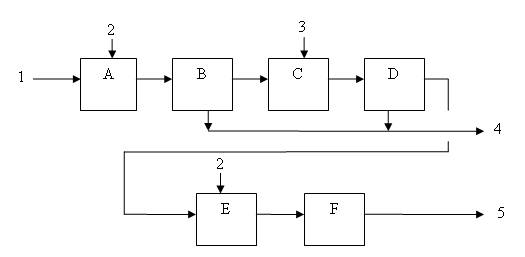

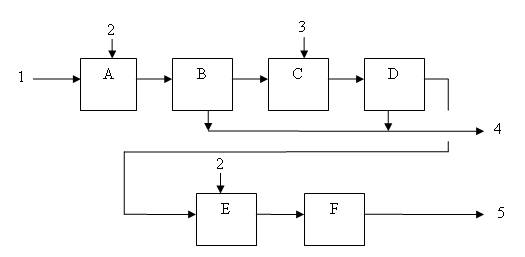

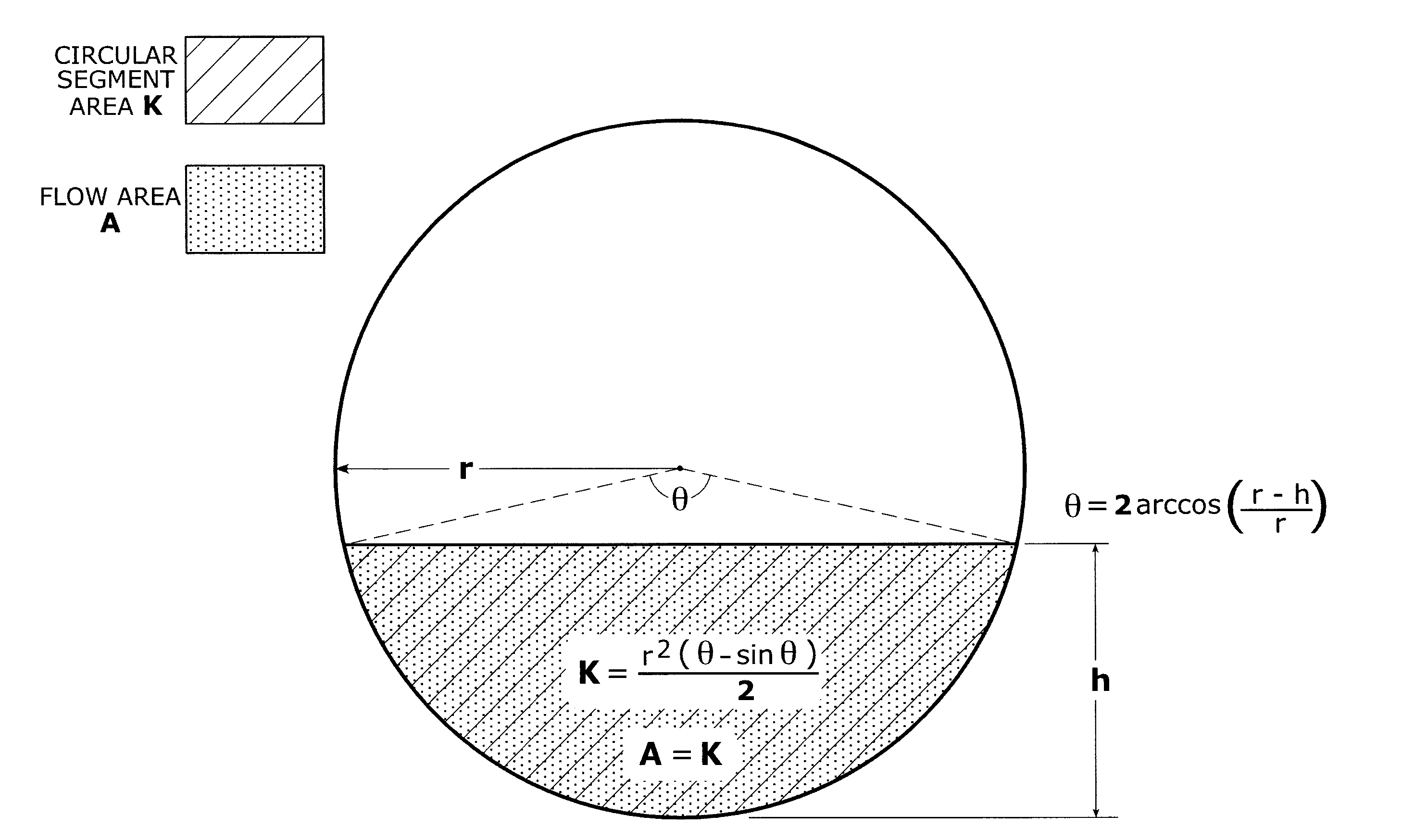

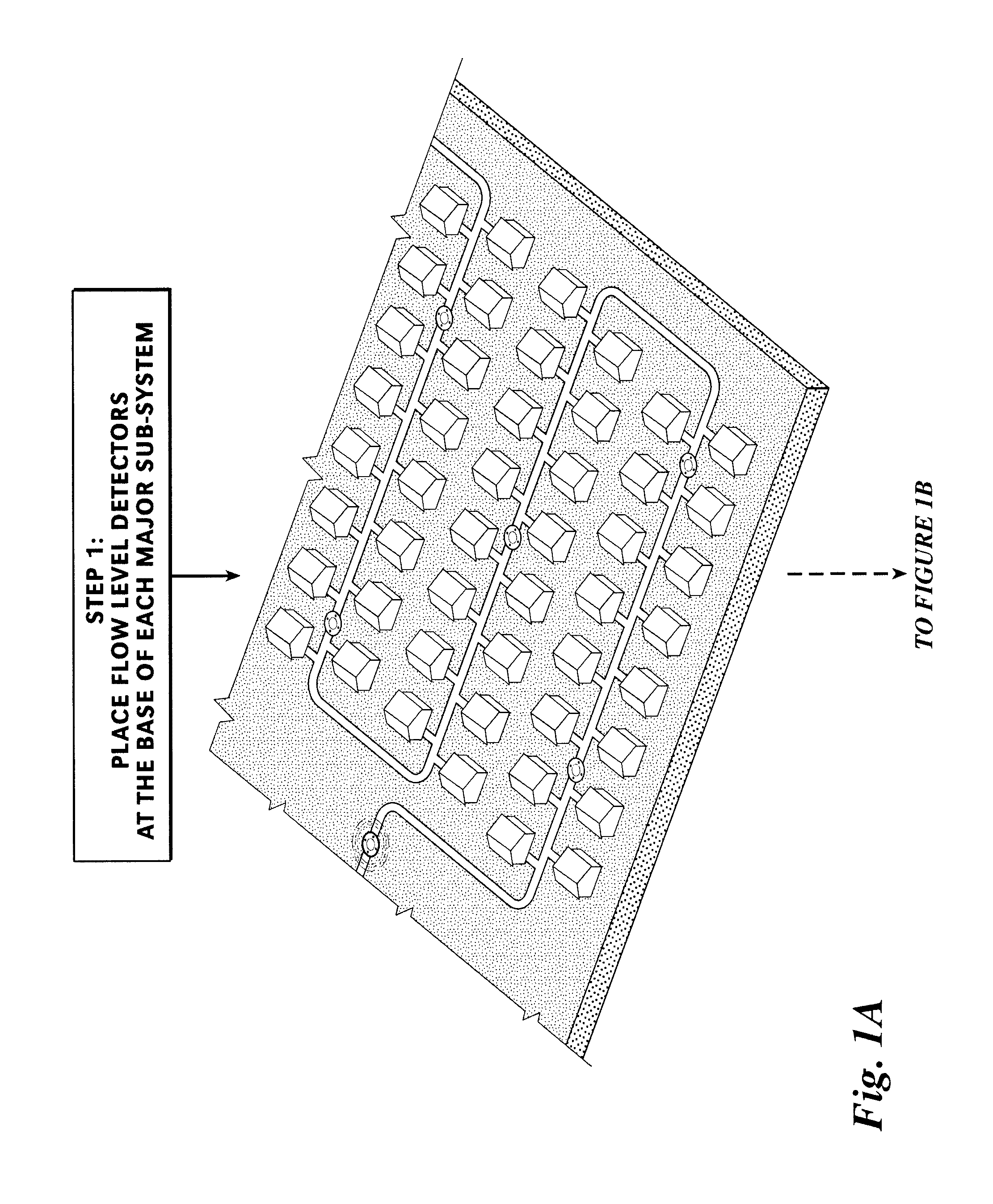

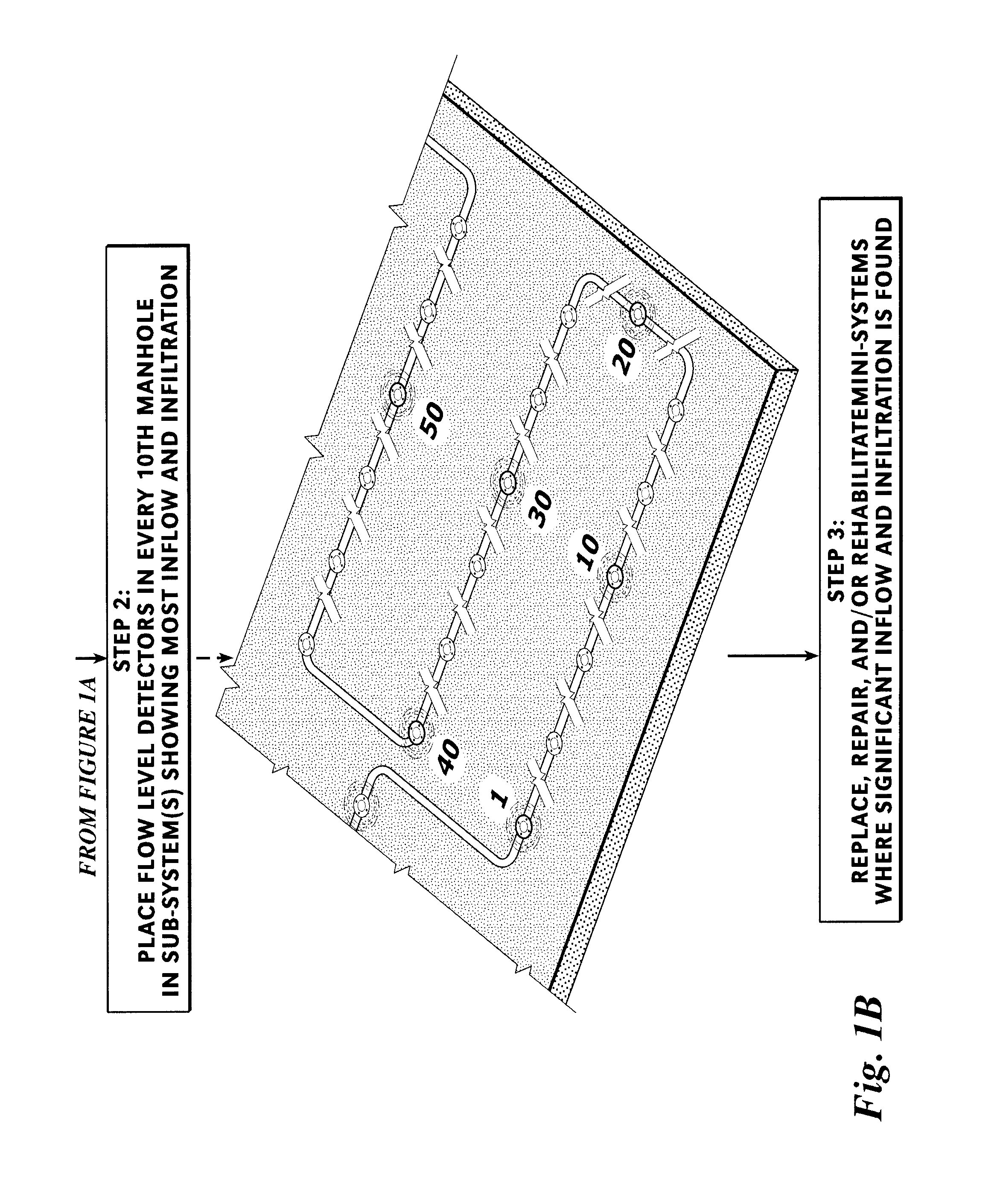

Method of wastewater flow measurement, system analysis, and improvement

ActiveUS8447533B1Reduce waste water treatment costsReduce rainFlow propertiesVolume/mass flow measurementLevel measurementFlow ratio

A method of reducing rainwater and / or groundwater inflow and infiltration into a wastewater treatment collection grid. The method preferably involves the steps of (a) dividing the grid into a plurality of major subsystems, (b) determining flow depth levels in each major subsystem under dry and wet conditions, (c) using these wet weather and dry weather flow depth measurements to determine a volume flow ratio for wet versus dry conditions, (d) using these flow ratios to identify the particular major subsystem(s) in which the greatest amount of inflow or infiltration is occurring, and then (e) further dividing the highest ranking major subsystem(s) into smaller subsystems in which the same dry and wet weather level measurement and ranking analysis is preferably conducted to further isolate problem locations for surveillance, maintenance, and / or repair.

Owner:EASTECH FLOW CONTROLS

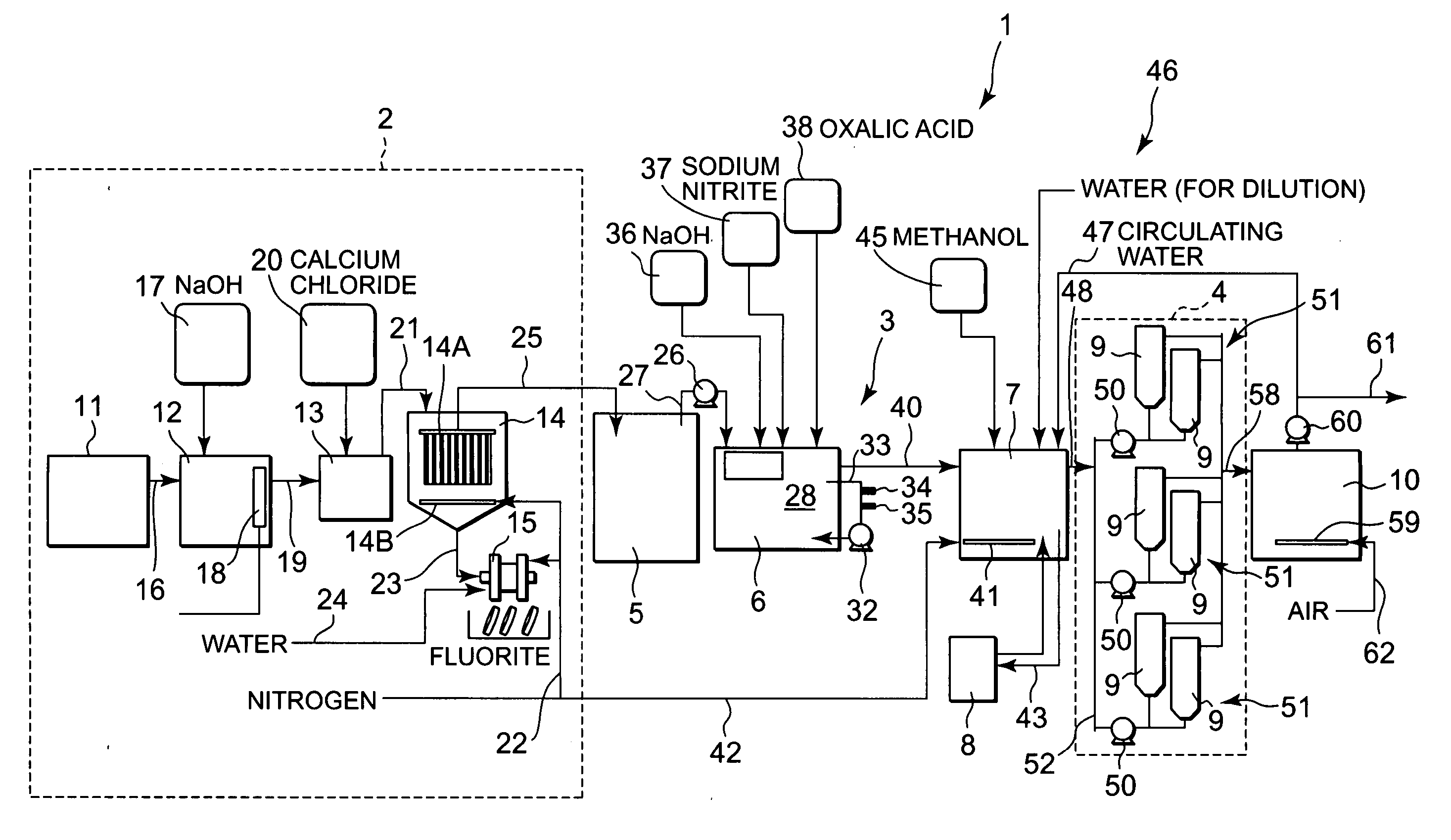

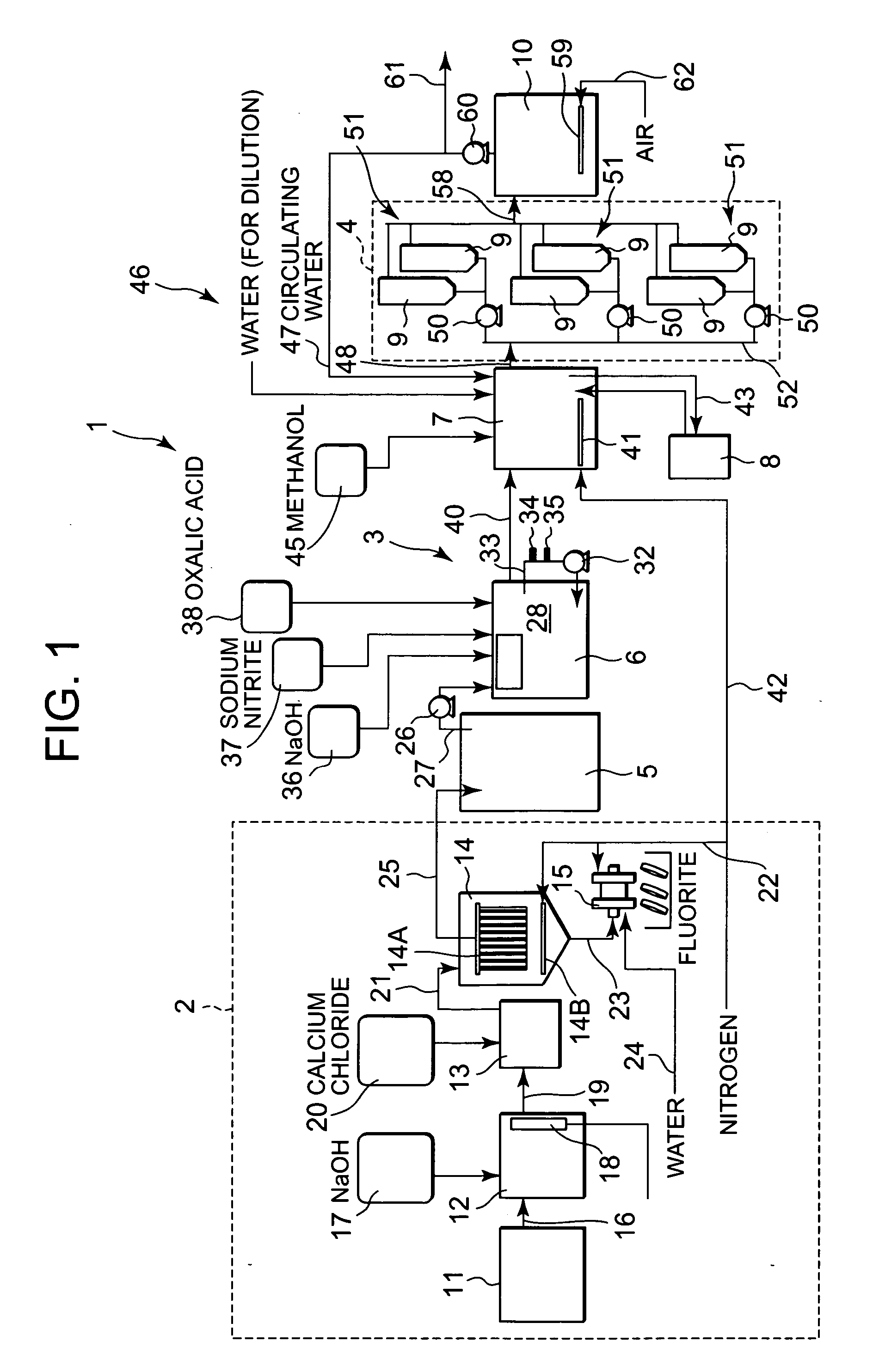

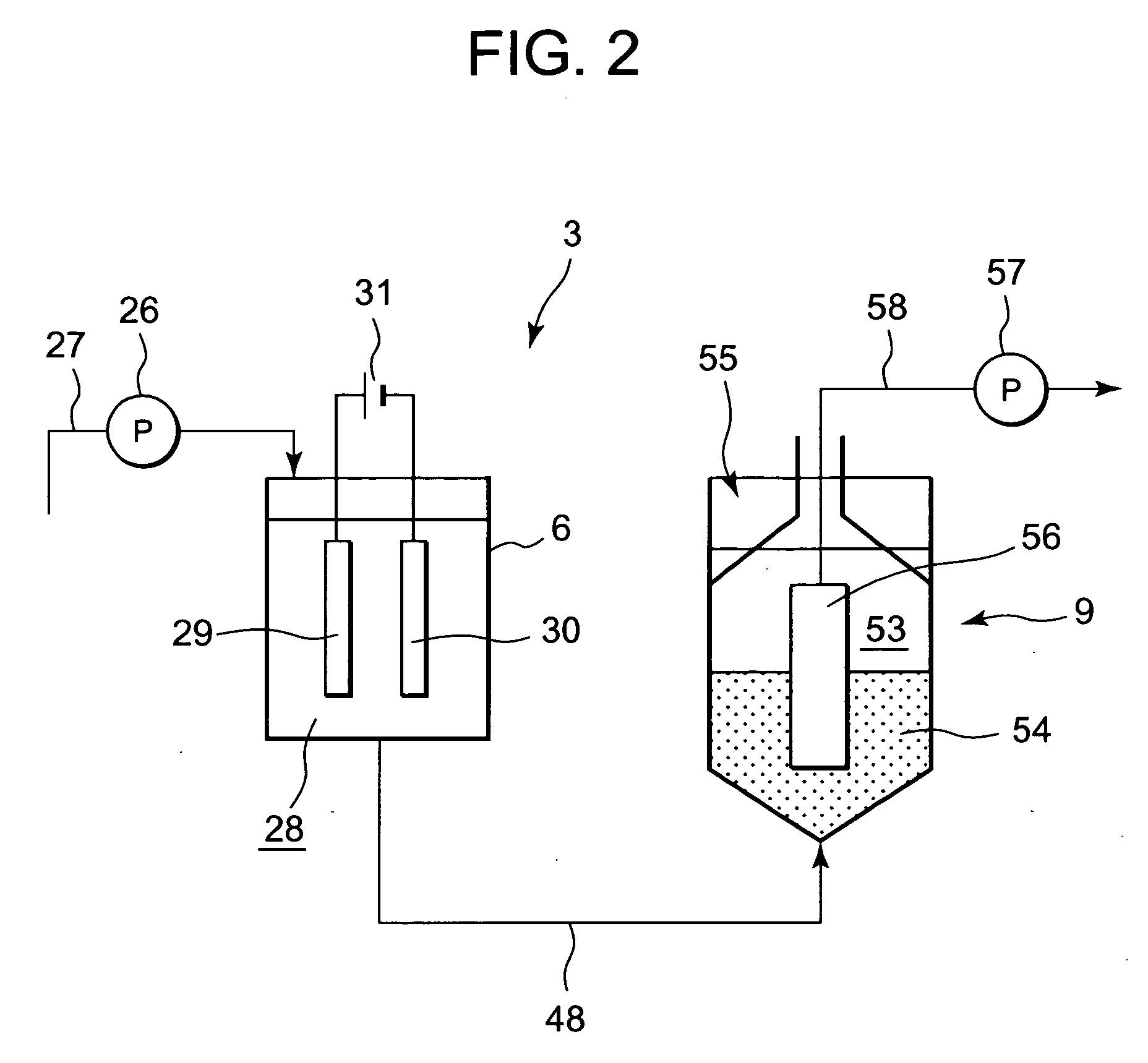

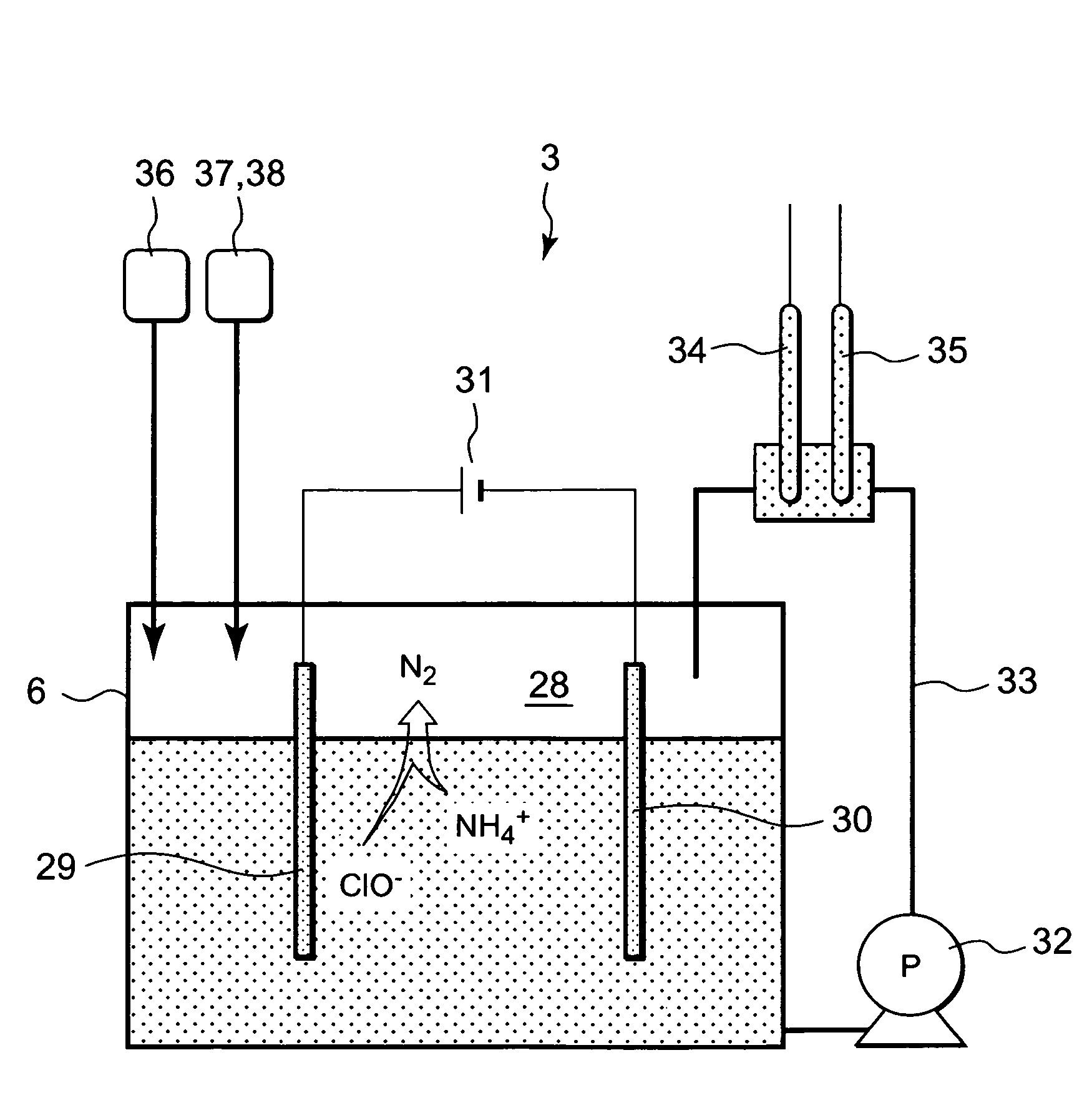

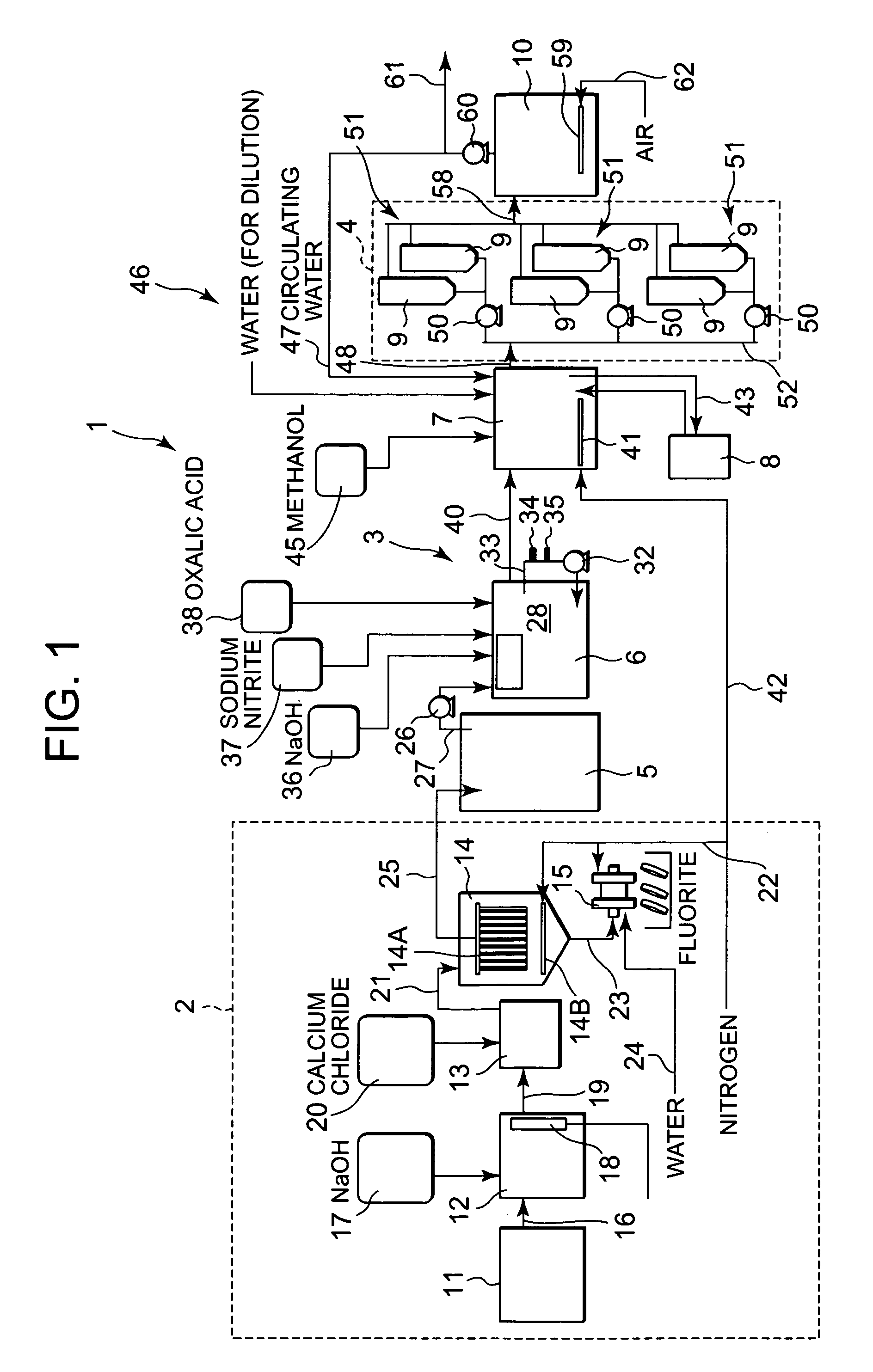

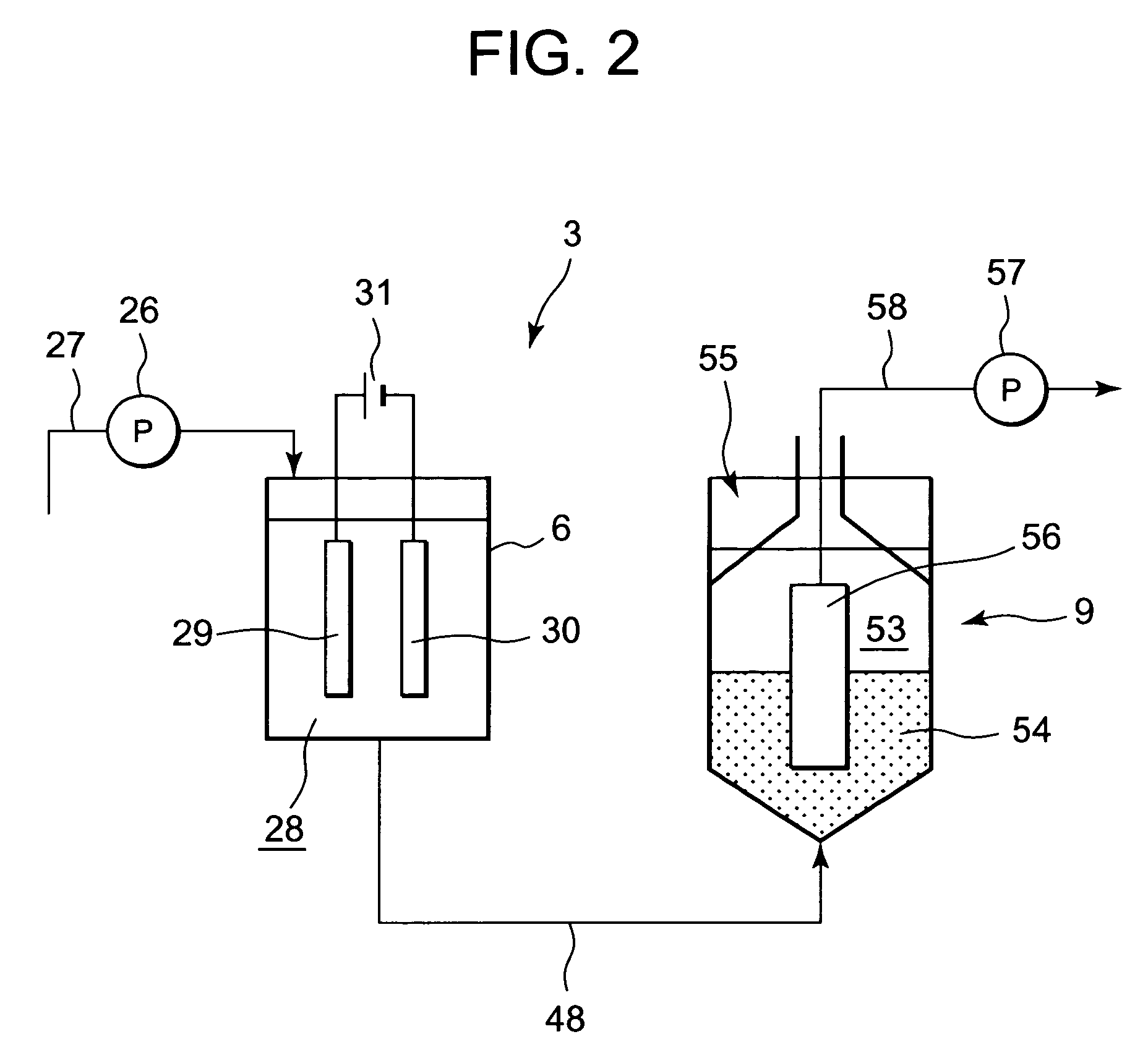

Water treatment device

InactiveUS20070034567A1Improve processing efficiencyEnvironmental load increaseWater treatment parameter controlOther chemical processesNitrogenTreatments water

An object is to provide a water treatment device which can treat for-treatment water containing fluorine components into a state adaptable to the environment and which can treat nitrogen compounds without influencing a concentration of the for-treatment water containing the nitrogen compounds. The water treatment device includes: a fluorine content removing unit to separate a substance to be removed from the for-treatment water in which the substance to be removed including a fluorine content is mixed; an electrochemical treatment unit including at least a pair of electrodes submerged at least partially in the for-treatment water, from which the substance to be removed has been separated, to perform a treatment by an electrochemical technique; and a biological treatment unit which biologically treats the water treated by the electrochemical technique.

Owner:SANYO ELECTRIC CO LTD

Acidic ammonium salt vanadium precipitation waste water recycling method

ActiveCN104986909AReduce productionReduce waste water treatment costsWaste water treatment from metallurgical processMultistage water/sewage treatmentChemistryPrecipitation

The invention relates to an acidic ammonium salt vanadium precipitation waste water recycling method, belongs to the field of metallurgy and aims to provide the acidic ammonium salt vanadium precipitation waste water recycling method. The acidic ammonium salt vanadium precipitation waste water recycling method comprises the following steps: a, partial ammonium salt vanadium precipitation waste water is subjected to vanadium-extraction tailing sand filtration, so that filtrate A is obtained; the rest ammonium salt vanadium precipitation waste water is subjected to heating evaporation concentration treatment, and after produced steam is cooled, condensate water is obtained; b, the filtrate A is mixed with condensate water, so that a mixed solution is obtained, and is returned to a vanadium extraction process. Compared with the conventional waste water treatment process, the method provided by the invention reduces waste water yield, reduces waste water treatment cost, recycles fine particles APV in the waste water and improves the system efficiency.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Water treatment device

InactiveUS7300592B2Reduce waste water treatment costsImprove adaptabilityWater treatment parameter controlOther chemical processesNitrogenTreatments water

An object is to provide a water treatment device which can treat for-treatment water containing fluorine components into a state adaptable to the environment and which can treat nitrogen compounds without influencing a concentration of the for-treatment water containing the nitrogen compounds. The water treatment device includes: a fluorine content removing unit to separate a substance to be removed from the for-treatment water in which the substance to be removed including a fluorine content is mixed; an electrochemical treatment unit including at least a pair of electrodes submerged at least partially in the for-treatment water, from which the substance to be removed has been separated, to perform a treatment by an electrochemical technique; and a biological treatment unit which biologically treats the water treated by the electrochemical technique.

Owner:SANYO ELECTRIC CO LTD

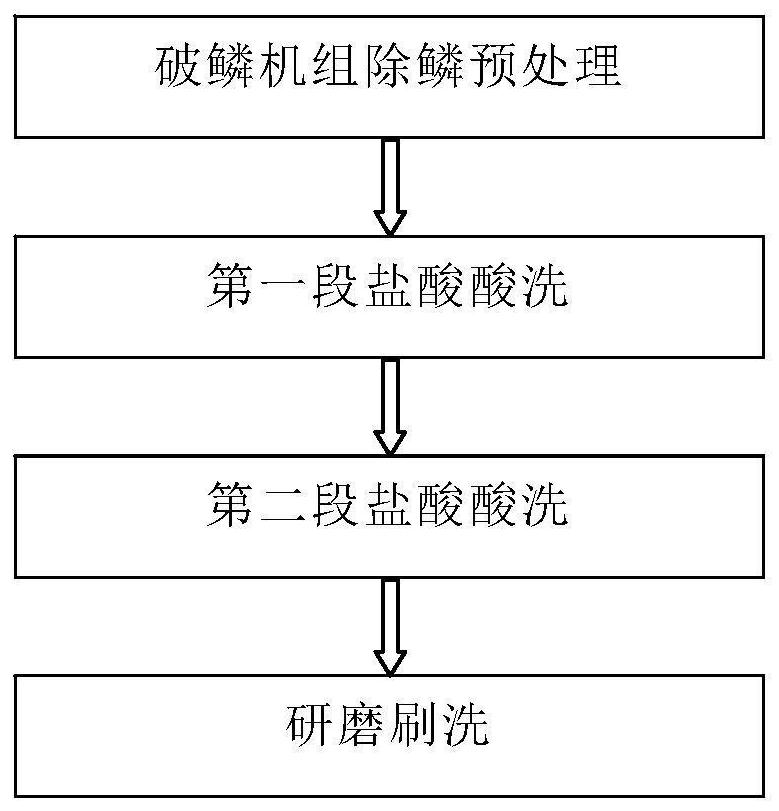

Stainless steel hot rolling strip steel acid pickling process

InactiveCN111604786AImprove surface qualityImprove pickling effectGrinding drivesGrinding machinesCarbide siliconStrip steel

The invention relates to a stainless steel hot rolling strip steel acid pickling process. The process comprises the steps of scale breaking unit scale removal pretreatment, wherein the total extensionrate of strip steel is controlled to be larger than or equal to 3.0%; first-segment hydrochloric acid acid pickling, wherein the strip steel is immersed in first-segment hydrochloric acid acid pickling liquid to be subjected to first-segment hydrochloric acid acid pickling, the hydrochloric acid concentration of the first-segment hydrochloric acid acid pickling liquid is controlled to 50 to 300 g / L, the iron ion concentration is controlled to 5 to 100 g / L, the temperature is controlled to 60 to 80 DEG C, and the acid pickling time is controlled to 25 s to 50 s; second-segment hydrochloric acid acid pickling, wherein the strip steel is immersed in second-segment hydrochloric acid acid pickling liquid to be subjected to second-segment hydrochloric acid acid pickling, the hydrochloric acid concentration of the second-segment hydrochloric acid acid pickling liquid is controlled to 50 to 250 g / L, the iron ion concentration is controlled to 5 to 100 g / L, the temperature is controlled to 50to 75 DEG C, and the acid pickling time is controlled to 25 s to 50 s; grinding scrubbing, wherein the strip steel is subjected to grinding scrubbing, the diameter of roller brush bristles is controlled to 0.7 to 1 mm, the bristles contain silicon carbide abrasives with meshes being 170 to 200 meshes, the rotating speed of a roller brush motor is controlled to 600 to 1000 rpm, and the current of the roller brush motor is controlled to 100 to 200 A.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

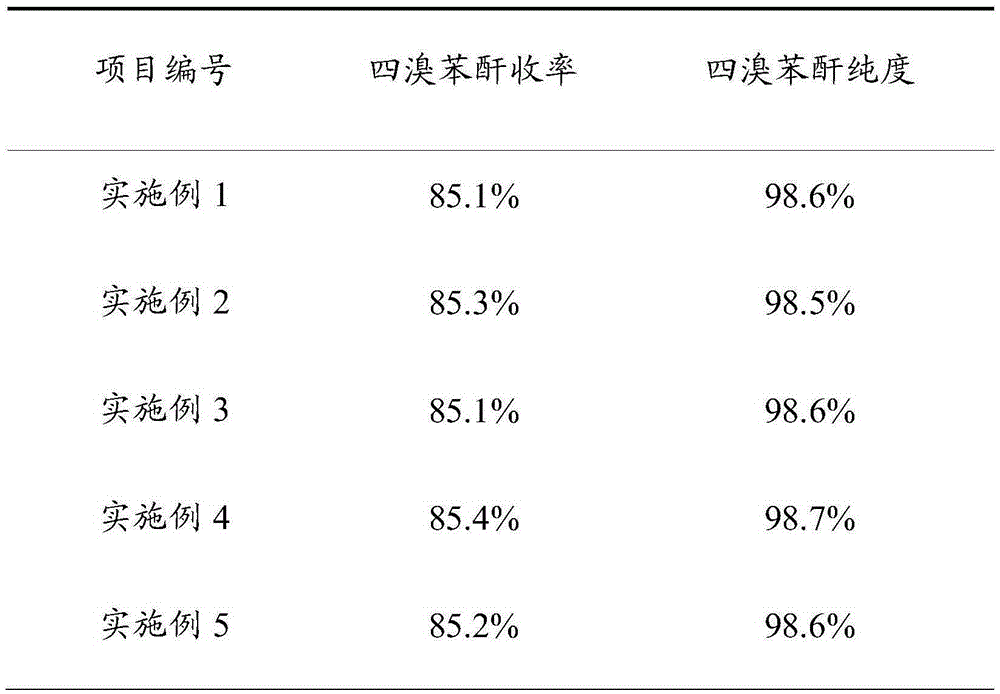

Preparation method of 4-bromo phthalic anhydride

ActiveCN105399712AReduce energy costsReduce waste water treatment costsOrganic chemistryDistillationSodium hydroxide

The invention belongs to the field of chemical engineering, and relates to a preparation method of 4-bromo phthalic anhydride. The preparation method includes the following steps that sodium hydroxide is dissolved in water, phthalic anhydride and a phase transfer catalyst are added and evenly mixed, a reaction is performed in the mode that programmed temperature control is performed in three stages and reactants are added in three times, 20% fuming sulphuric acid is added for acidification, a sodium bisulfite aqueous solution is added after cooling for removing excessive bromine, an organic solvent is added for extraction, the organic solvent is removed through distillation, then temperature is increased to obtain a crude 4-bromo phthalic anhydride product, rectification dehydration is performed under the vacuum condition, fraction is collected, and the finished 4-bromo phthalic anhydride product is obtained. Compared with a multi-step reaction in the prior art, the process steps are simplified, the product yield is high, the production energy consumption is reduced, the three-waste emission is greatly reduced, the energy consumption and wastewater treatment cost for extraction of 4-bromophthalic acid crystals are reduced, production cost is reduced, and environmental protection pressure is relieved.

Owner:WEIFANG YUCHENG CHEM

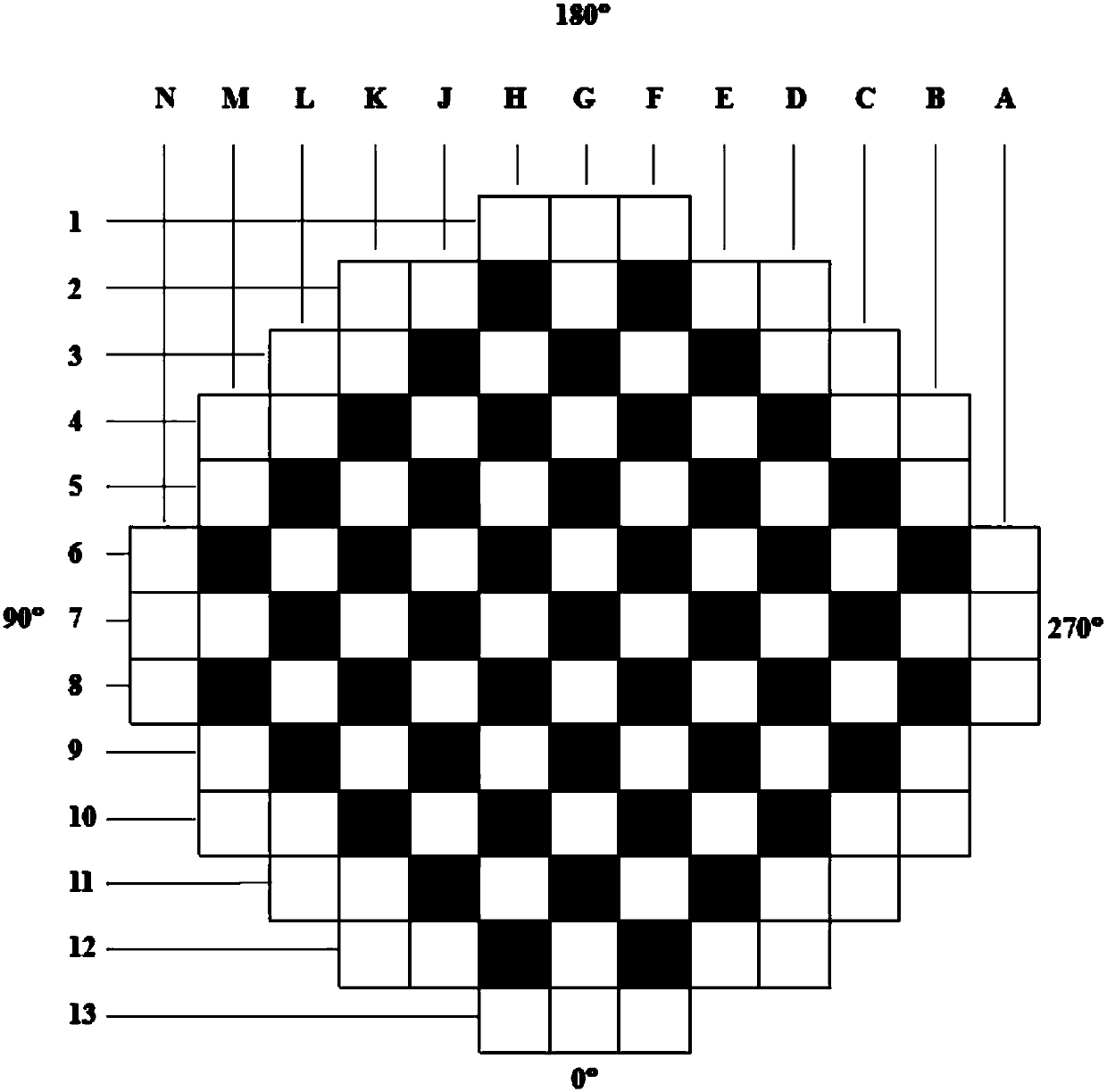

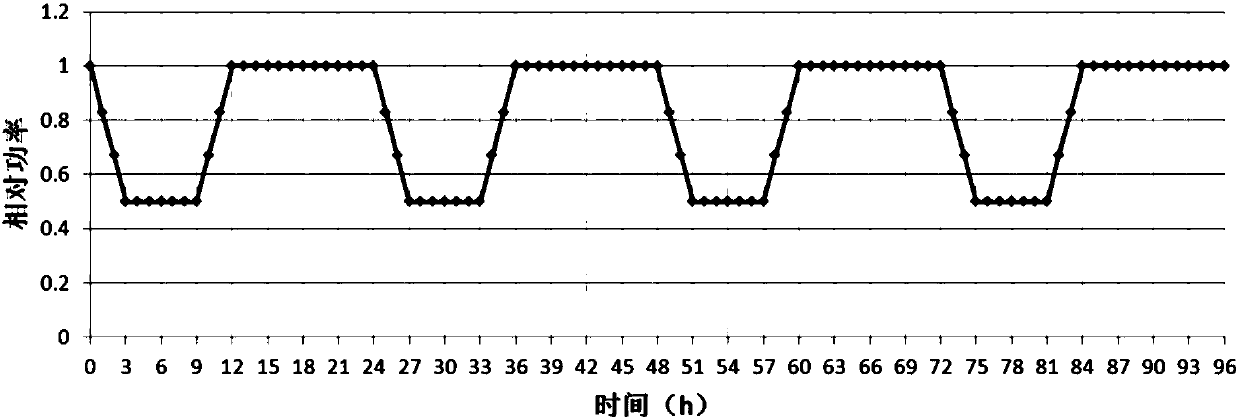

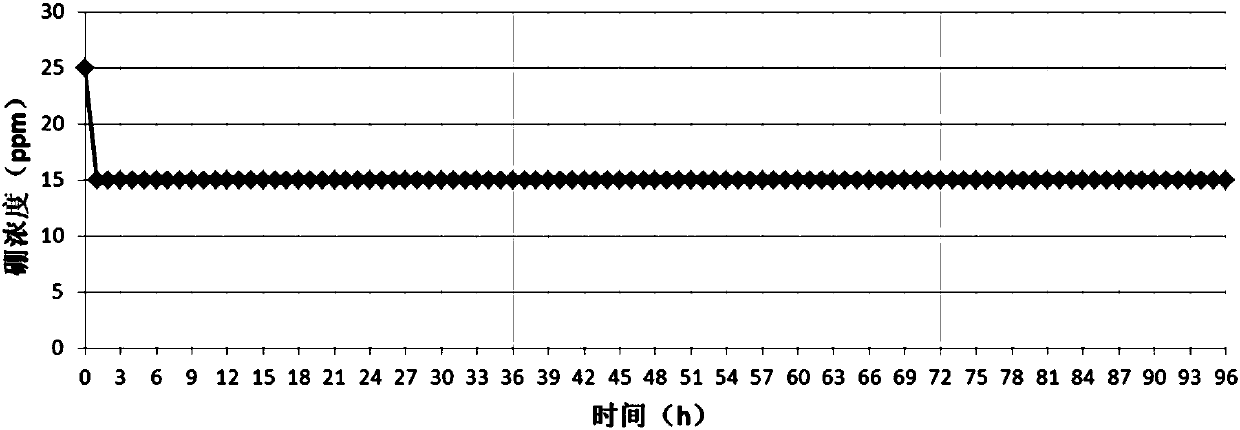

Method for realizing nuclear reactor load tracking

ActiveCN107945889AReduce waste water treatment costsOscillation amplitude is smallNuclear energy generationNuclear reaction controlPower controlNuclear reactor

The invention discloses a method for realizing nuclear reactor load tracking. The method uses two groups of relatively-independent control rods for reactive and axial power shift power control of a nuclear reactor; the two groups of relatively-independent control rods are a T rod group and a K rod group respectively, wherein the K rod group consists of a plurality of beams of black rods; the T rodgroup comprises a plurality of beams of grey rods and black rods; during the base load operation of the nuclear reactor, only the K rod group is inserted into a reactor core, and the insertion depthof K rod group is greater than or equal to the bite amount plus 24 steps; during the load tracking operation of the nuclear reactor, both the T rod group and the K rod group are inserted in the reactor core. The method disclosed by the invention has the benefits that only one group of control rods is required to be inserted into the reactor core during the base load operation, and the defects thatthe fuel consumption is non-uniform, the control rod fluence is increased, the control rod absorption body fuel consumption is more, the control rod drive mechanism load is increased, and the like due to the insertion of the more control rods into the reactor core during the base load operation are overcome.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

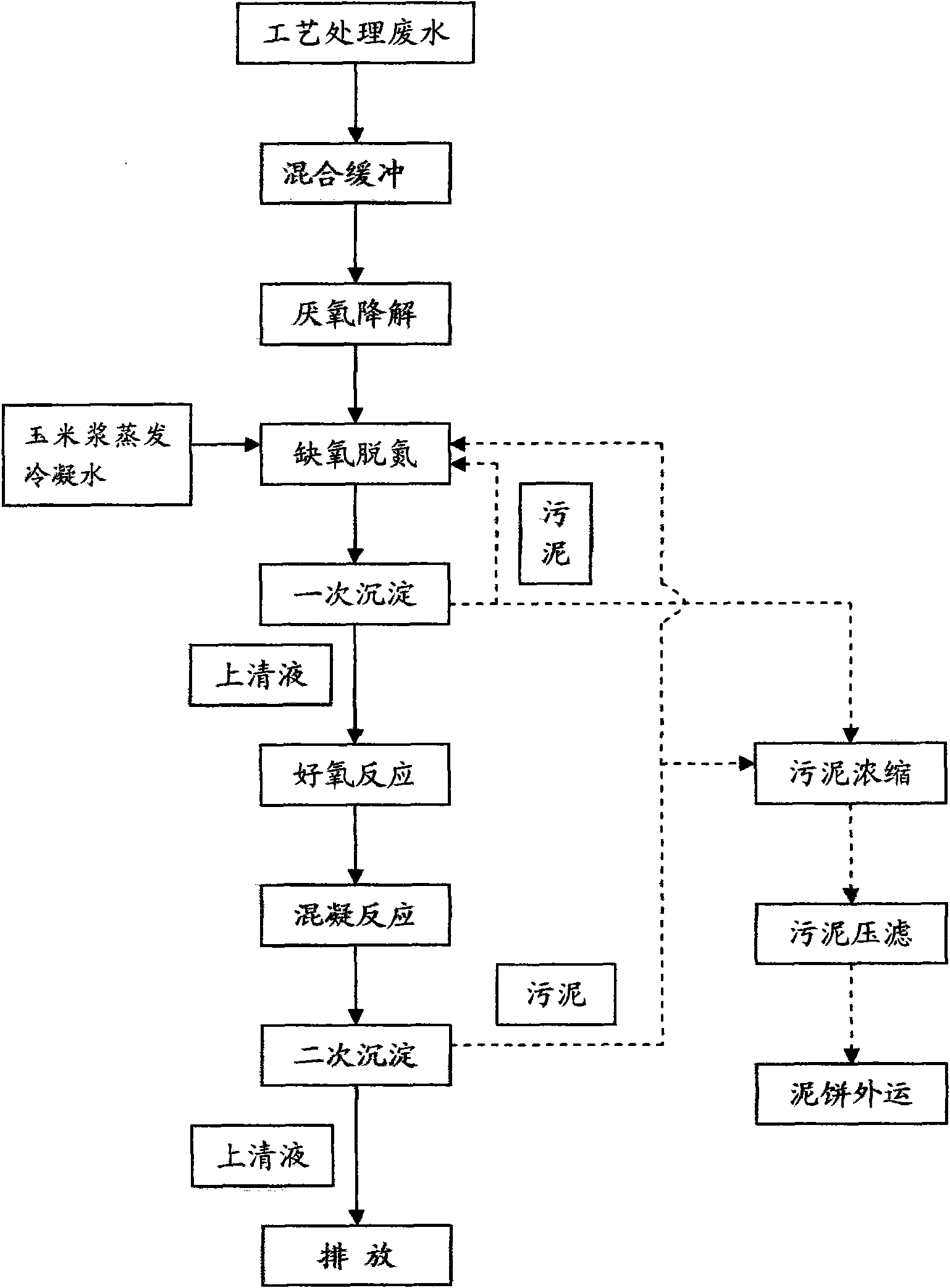

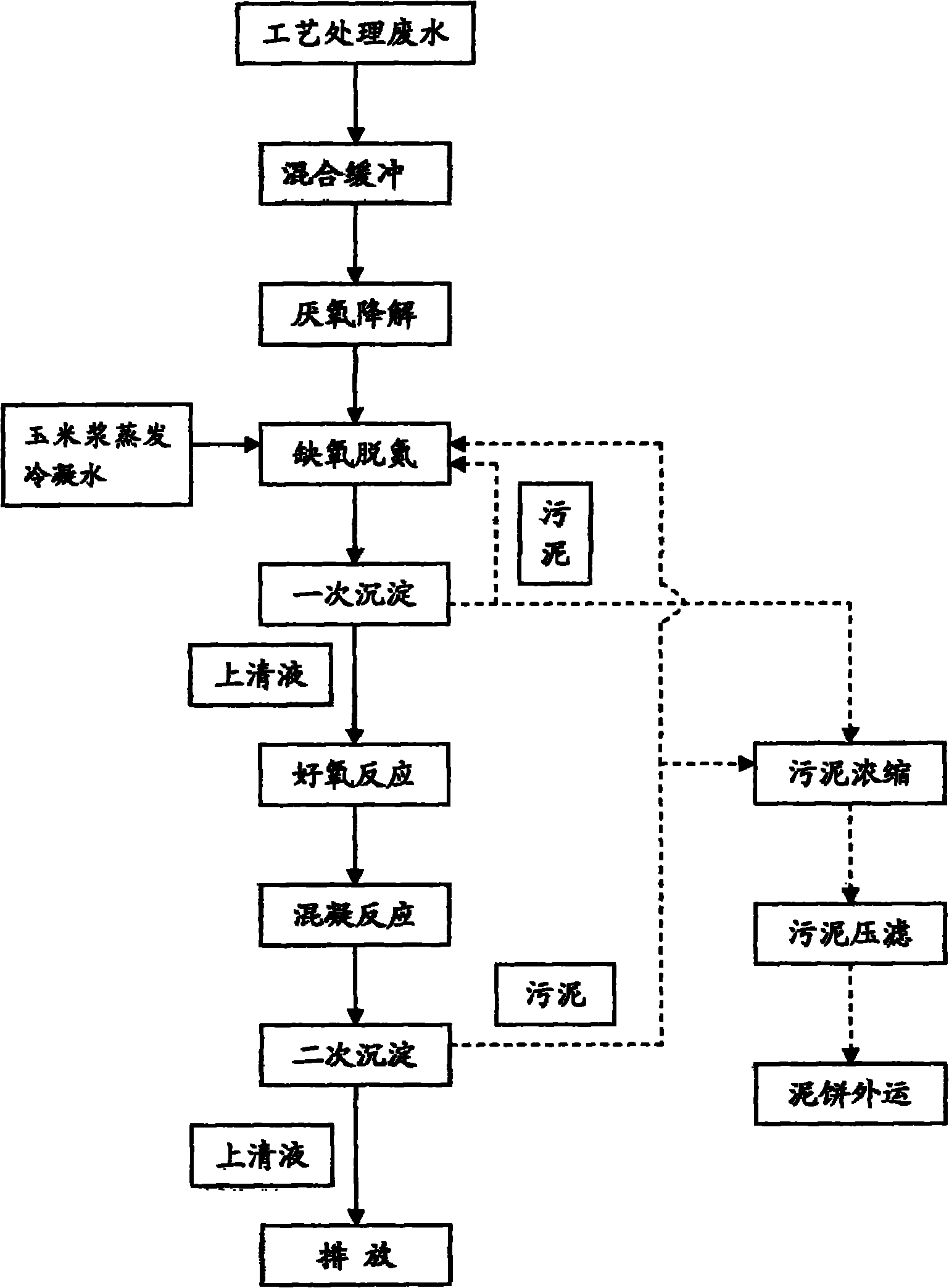

Waste water treatment method in starch and glucose production

ActiveCN101891338AGuarantee the effect of sewage treatmentReduce waste water treatment costsMultistage water/sewage treatmentWaste water treatment from food industryGlucose productionChemistry

The invention discloses a waste water treatment method in starch and glucose production, wherein the waste water comprises corn steep liquor evaporative condensate water and processing waste water. The method comprises the following steps: a. firstly performing an anaerobic degradation reaction on the processing waste water after mixing and buffering; b. mixing the processing waste water treated by anaerobic degradation with the corn steep liquor evaporative condensate water, and performing an anaerobic denitrification reaction; c. performing an aerobic reaction on the waste water treated by the anaerobic denitrification reaction, and carrying out ammonia nitrogen removal and further degradation; and d. adding flocculants to the waste water treated by the aerobic reaction to perform a coagulation reaction, and removing suspended matters from the waste water before discharging. By comprehensively utilizing industrial waste water produced in the starch and glucose production in the waste water treatment to achieve the purpose of treating waste with waste, the method ensures the waste water treatment effect and simultaneously reduces the waste water treatment cost.

Owner:WEIFANG SHENGTAI PHARM CO LTD

Method for extracting sap and pulping from paper mulberry branches and comprehensively utilizing paper mulberry branches

InactiveCN104088181AImprove conversion rateIncrease productivityPulp beating/refining methodsCellulose material pulpingResource utilizationEvaporation

The invention relates to a method for extracting sap and pulping from paper mulberry branches and comprehensively utilizing paper mulberry branches. The method is characterized by including A, cutting raw branches into segments to obtain rough roughage by a stock cutter; B, screening and washing the roughage into fine materials; C, feeding the fine materials into an extraction tank to heat, pressurize and boil, separating the materials from liquid, wherein the separated materials are boiling materials and the separated liquid is boiling liquid; D, feeding the boiling liquid into an evaporation tank to purify and prepare sap of the paper mulberry; E, debarking the boiling materials to a debarking machine, and separating barks from stems; F, pulping by the separated bast and the stems. With adoption of multi-industry comprehensive utilization and conversion of waste resources, waste is made profitably, smog due to air pollution caused by burning the waste outdoors is avoided, production cost is reduced, and utilization rate of the paper mulberry is increased. Meanwhile, a novel way to convert and utilize the paper mulberry at high value is provided, and the method has high economic, social and environmental benefits.

Owner:张明勋

One-pot method for preparing 1,3,5-three (five-bromine benzyl) isocyanurate

InactiveCN102924392AReduce energy costsReduce waste water treatment costsOrganic chemistryBenzoyl bromideFiltration

The invention discloses a one-pot method for preparing 1,3,5-three (five-bromine benzyl) isocyanurate. The method comprises the following steps of (1) adding cyanuric acid and alkali or salt of potassium or sodium into organic solvent, and enabling the mixture to react with stirring under the temperature of 0-100 DEG C until no bubbles is generated, wherein the mole ratio of cyanuric acid to alkali or salt of potassium or sodium is 1: (0.5-5); (2) adding five-bromine benzyl bromide into the reaction solution, and enabling the mixture to perform thermal reaction under the temperature of 100-150 DEG C until the reaction solution becomes white and white crystals are generated, wherein the mole ratio of the five-bromine benzyl bromide to the cyanuric acid is (3-10):1; and (3) cooling the reaction material to perform crystallization, and performing suction filtration, washing, suction filtration and purification on the precipitated crystals to obtain the 1,3,5-three (five-bromine benzyl) isocyanurate. By means of the one-pot method, process steps are simplified, product yield is high, production cost is reduced, environmental protection stress is relieved, and the product is high in purity, low in impurity content and high in yield.

Owner:SHANDONG RUNKE CHEM

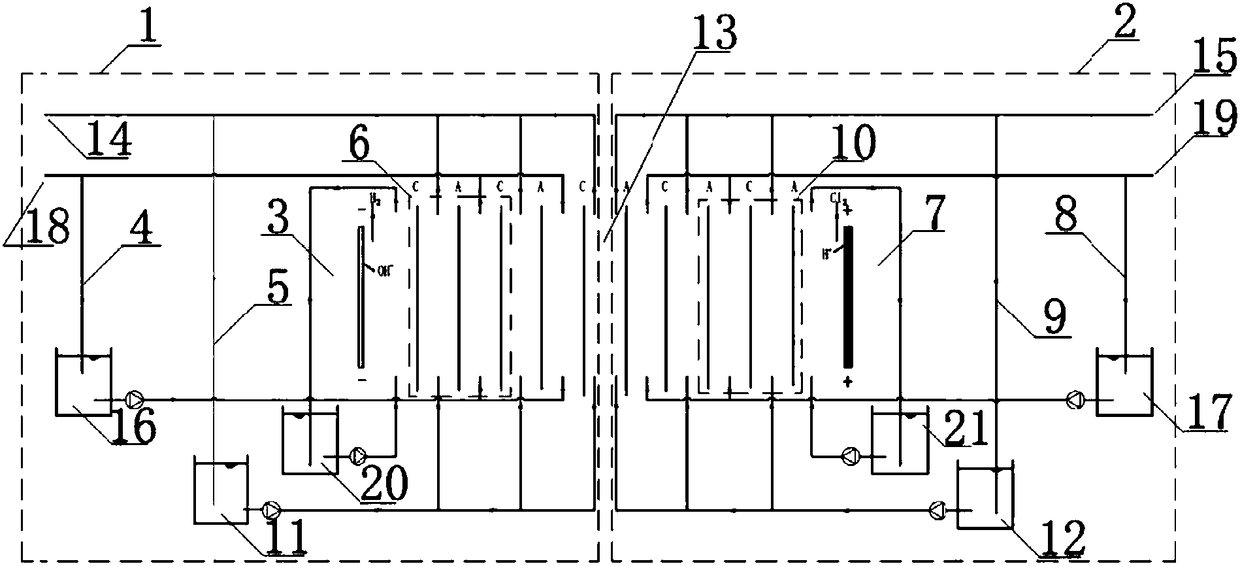

Efficient waste water salt separation, concentration and desalting integral device

PendingCN108298644AReduce potion consumptionReduce waste water treatment costsWater/sewage treatment by electrochemical methodsDispersed particle separationIon-exchange membranesSalt water

The embodiment of the invention provides an efficient waste water salt separation, concentration and desalting integral device, which comprises a first membrane pile region and a second membrane pileregion, wherein a cathode chamber, a concentration liquid circulation pipeline a, a freshwater circulation pipeline a and a plurality of membrane pairs a are arranged in the first membrane pile region; an anode chamber, a concentration liquid circulation pipeline b, a fresh water circulation pipeline b and a plurality of membrane pairs b are arranged in the second membrane pile region; a freshwater box a is arranged on the freshwater circulation pipeline a; a freshwater box b is arranged on the freshwater circulation pipeline b; a middle freshwater chamber is arranged between the first membrane pile region and the second membrane pile region; the membrane pairs a comprise cation exchange membranes and selective anion exchange membranes; the membrane pairs b comprise anion exchange membranes and selective cation exchange membranes. The device has the advantages that easy-to-scale concentrated brine is separated into difficult-to-scale calcium chloride concentrated solution and sodium sulfate concentrated solution; the concentrated brine softening through sodium carbonate addition is not needed; the chemical cost is reduced; during the salt classification, the waste water is subjected to desalinization; the concentrated brine desalinization is realized.

Owner:博天工业技术(北京)有限公司 +1

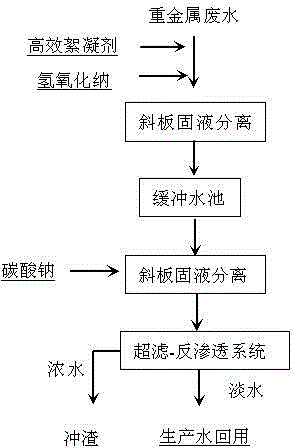

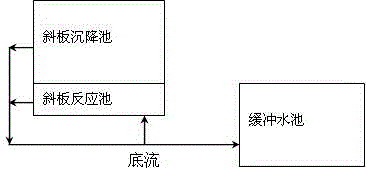

Technology for recycling low-calcium and low-chlorine purified water

InactiveCN104402147AHigh water reuse rateReduce waste water treatment costsWaste water treatment from quariesWater softeningUltrafiltrationIon

The invention discloses a technology for recycling low-calcium and low-chlorine purified water after heavy-metal-containing wastewater is treated. A high-efficiency flocculating agent is added into the heavy-metal-containing wastewater; by acid-base adjustment, the pH is adjusted to be base, and solid-liquid separation is finally executed through an inclined plate settling basin so as to remove most heavy metal ions; supernate enters a buffering water basin for calcium reduction treatment and then enters an ultrafiltration-reverse osmosis system for advanced purification; produced fresh water serving as production water returns to a production system, and concentrated water serves as water for flushing residues. Part of bottom flow subjected to calcium reduction is used as crystal seeds for backflowing, and most of the bottom flow enters the buffering water basin for repeated use. The recycling rate of the recycled water is high; the phenomenon of calcium scaling is avoided; the wastewater treatment cost is low, and zero emission of the wastewater is realized.

Owner:ZHUZHOU SMELTER GRP

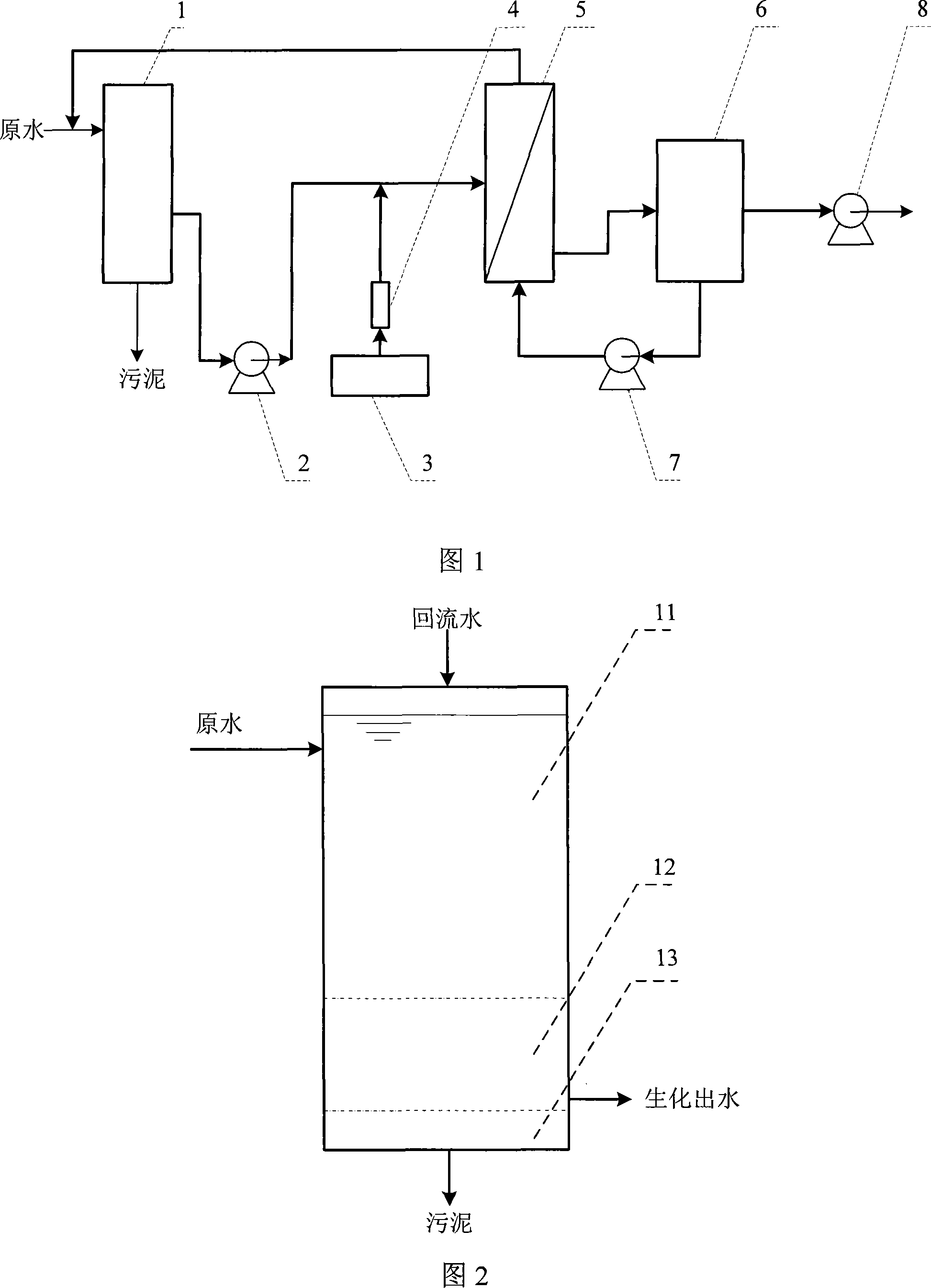

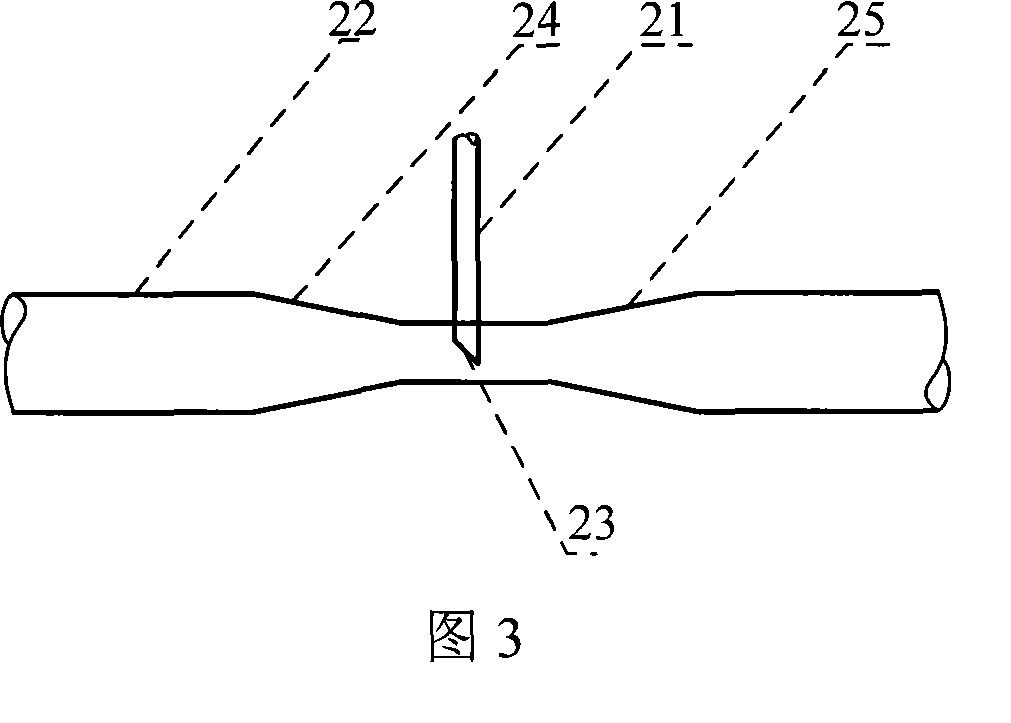

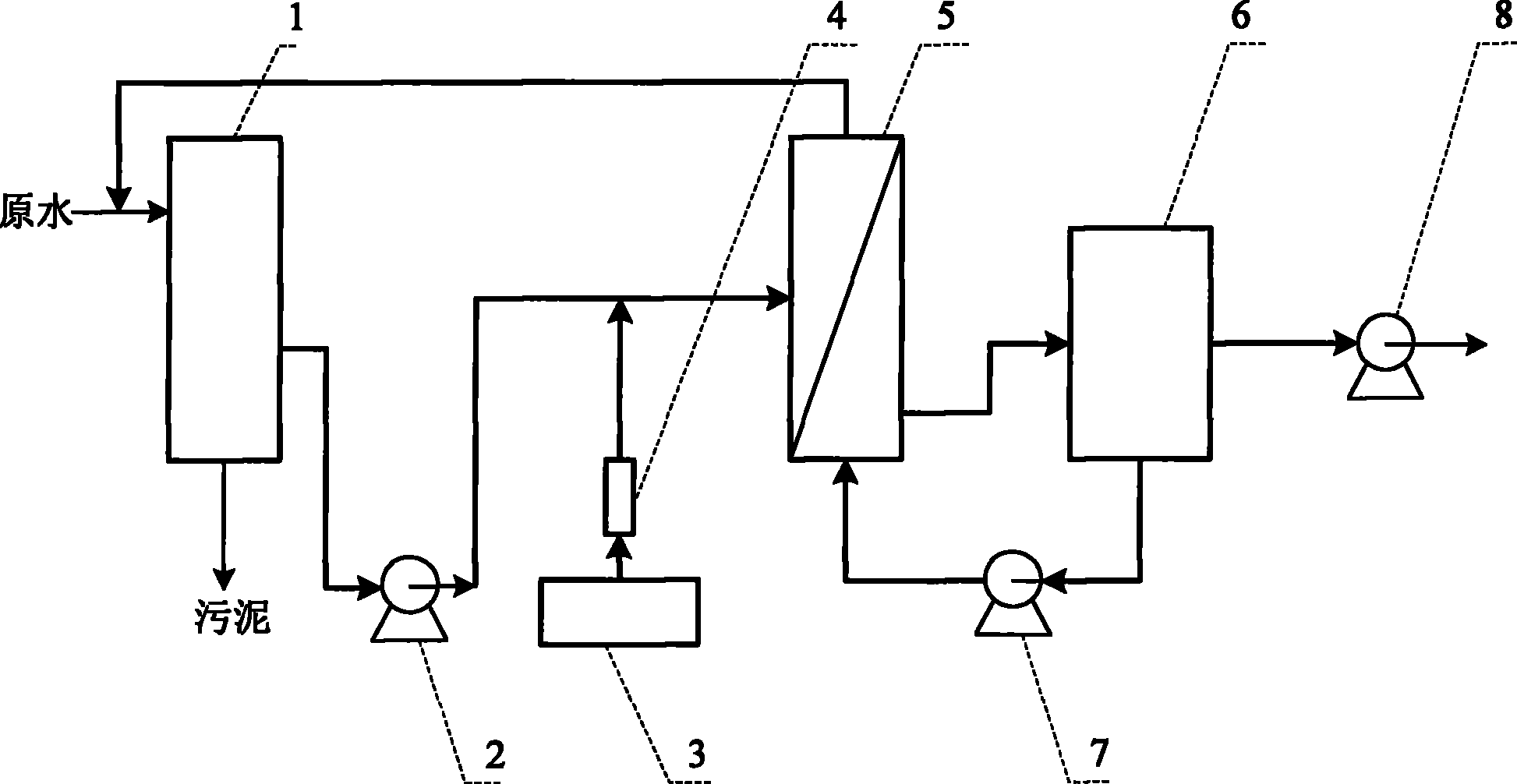

Membrane bioreactor and use thereof in wastewater treatment

ActiveCN101434444BEasy loadingIncrease concentrationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentMembrane surfaceMembrane bioreactor

The invention discloses a membrane bioreactor and an application method thereof in wastewater treatment. The membrane bioreactor comprises a biochemical reaction unit which adopts a particle biofilm medium, a pulse type air supply unit and a membrane filtering unit, wherein, a pulse airflow transforms wastewater entering the membrane filtering unit into pulse aerated flow, the particle biofilm medium in the wastewater is fluidized and rubbed and scraped with a membrane component, and fouling sedimentary on the membrane surface is removed. The membrane bioreactor and the application method have the advantages that the biochemical treatment of the particle biofilm medium has good effect, and the effect of rubbing and cleaning the membrane component is good; combined with the disturbing strengthening cleaning effect of the pulse aerated flow, synergistic effect is played, thus improving the membrane pollution preventing effect of an MBR unit, reducing the running cost of the unit, and being applicable to various wastewater treatment occasions.

Owner:CHINA PETROLEUM & CHEM CORP +1

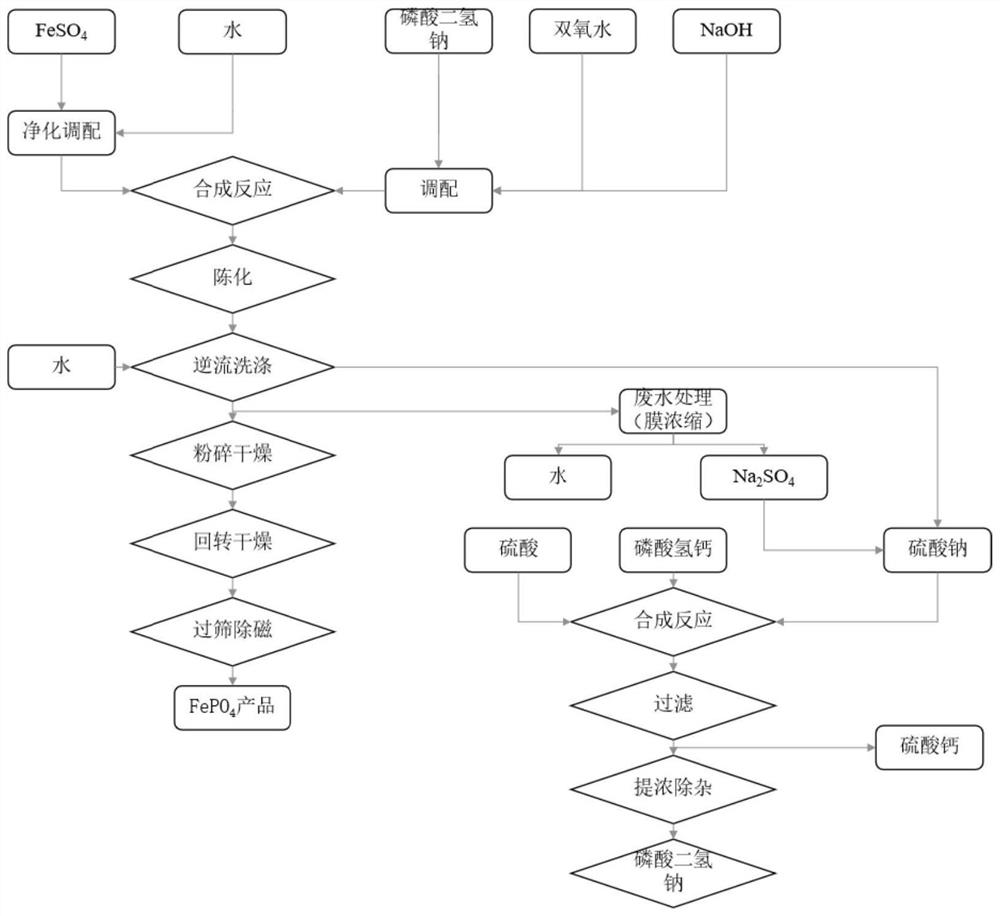

Method for preparing iron phosphate by recycling mother liquor

ActiveCN113336212ARaw materials are cheap and easy to getReduce waste water treatment costsPhosphorus compoundsIron phosphateLithium electrode

The invention belongs to the technical field of lithium ion battery positive electrode materials, and particularly discloses a method for preparing iron phosphate by recycling mother liquor. The method comprises the steps of mixing calcium hydrophosphate, sulfuric acid and sodium sulfate mother liquor, stirring for reaction, and filtering to obtain a sodium dihydrogen phosphate solution; adding sodium hydroxide into the sodium dihydrogen phosphate solution, and stirring to obtain filtrate B; mixing the filtrate B with hydrogen peroxide to obtain a solution C; adding the solution C and a ferrous sulfate solution into a reaction kettle, stirring for reaction, and heating for aging after reaction; filtering the slurry obtained in the previous step to obtain mother liquor D and a filter cake E; washing the filter cake E to obtain a filter cake F and filtrate G; performing membrane concentration on the filtrate G to obtain pure water and high-concentration wastewater H, recycling the pure water as washing water, and recycling the high-concentration wastewater H and the mother liquor D as sodium sulfate mother liquor; and enabling the filter cake F to be subjected to crushing drying, rotary drying, sieving and iron removal, and obtaining anhydrous iron phosphate. The raw materials of the method are cheap and easy to obtain, the mother liquor can be recycled, and the production cost is reduced.

Owner:河南佰利新能源材料有限公司

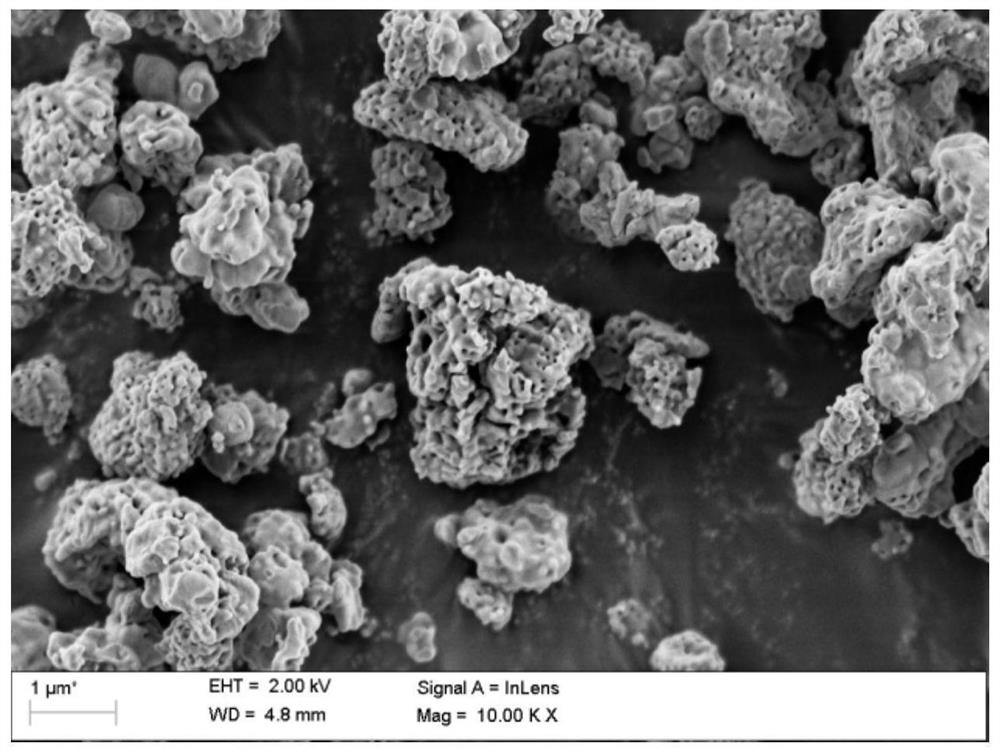

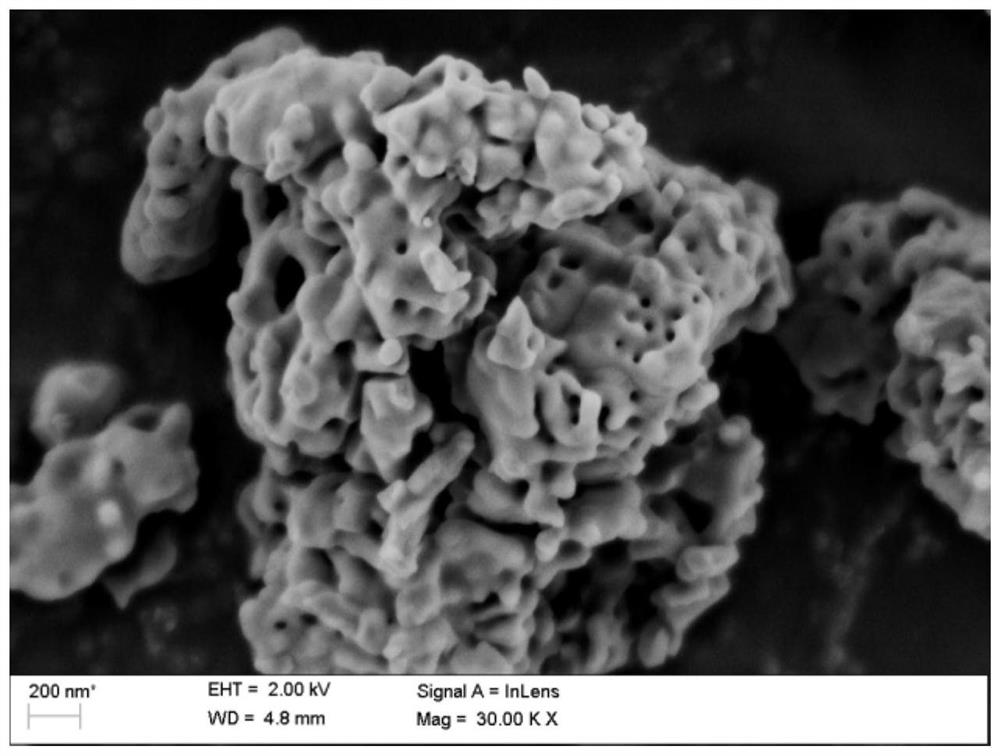

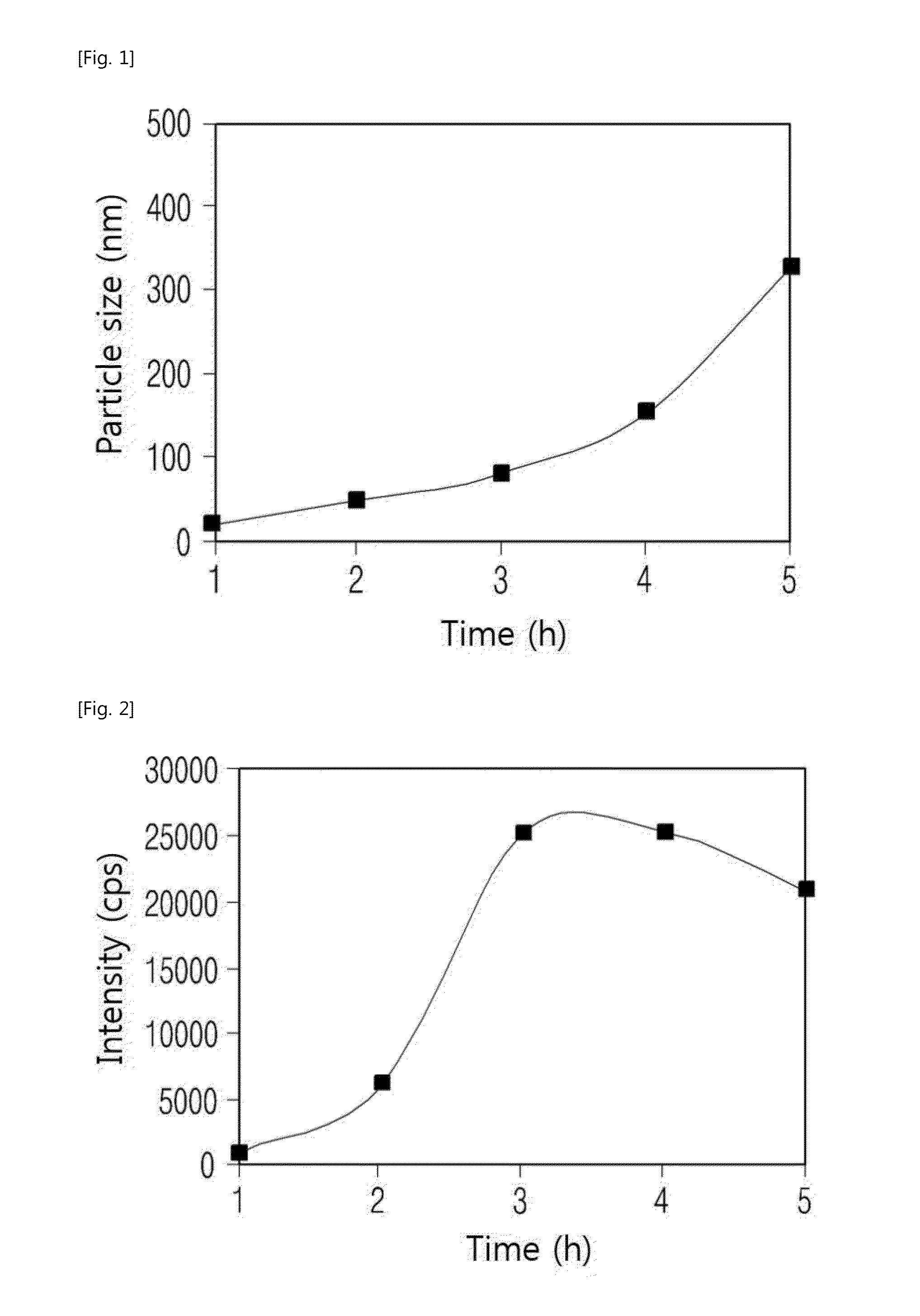

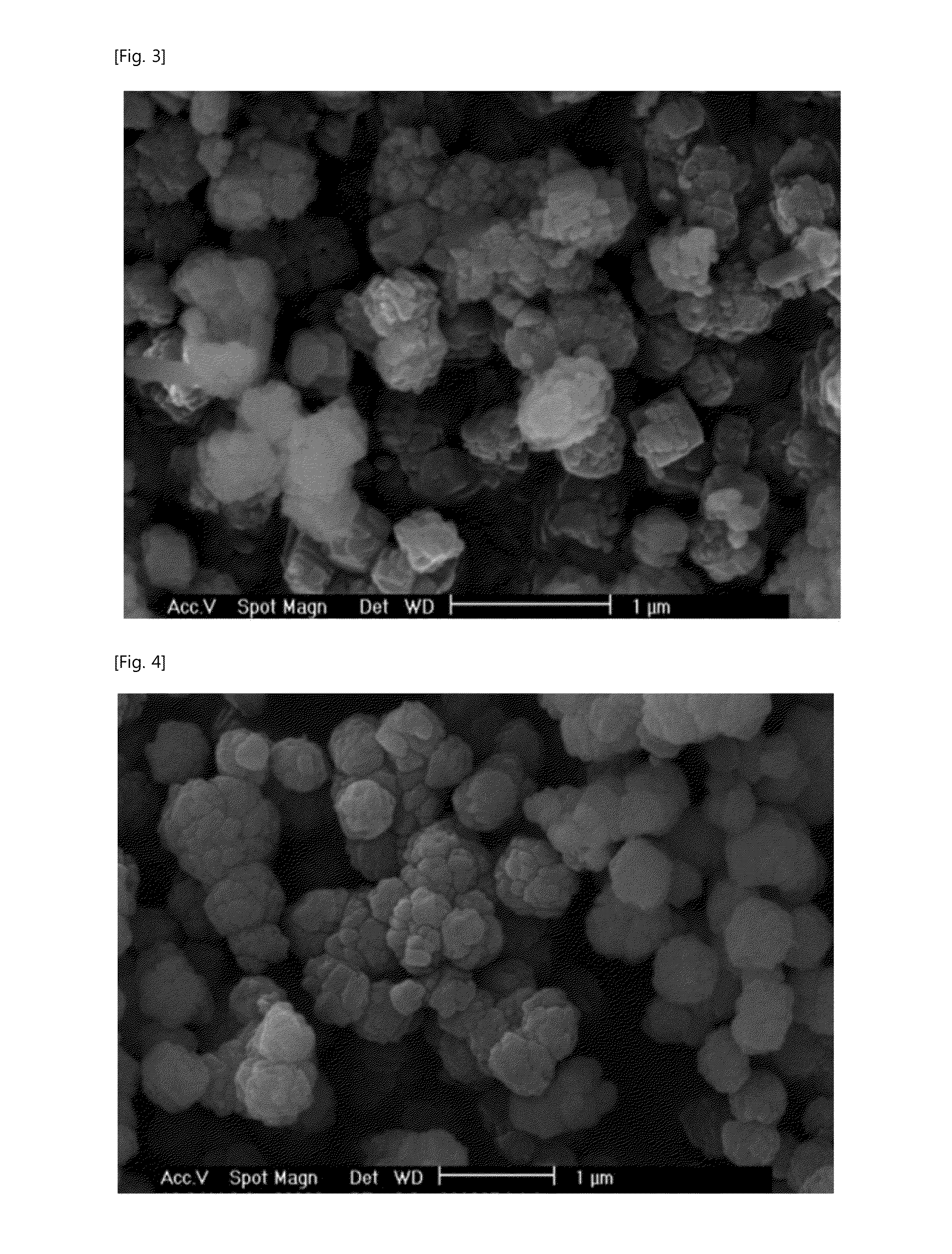

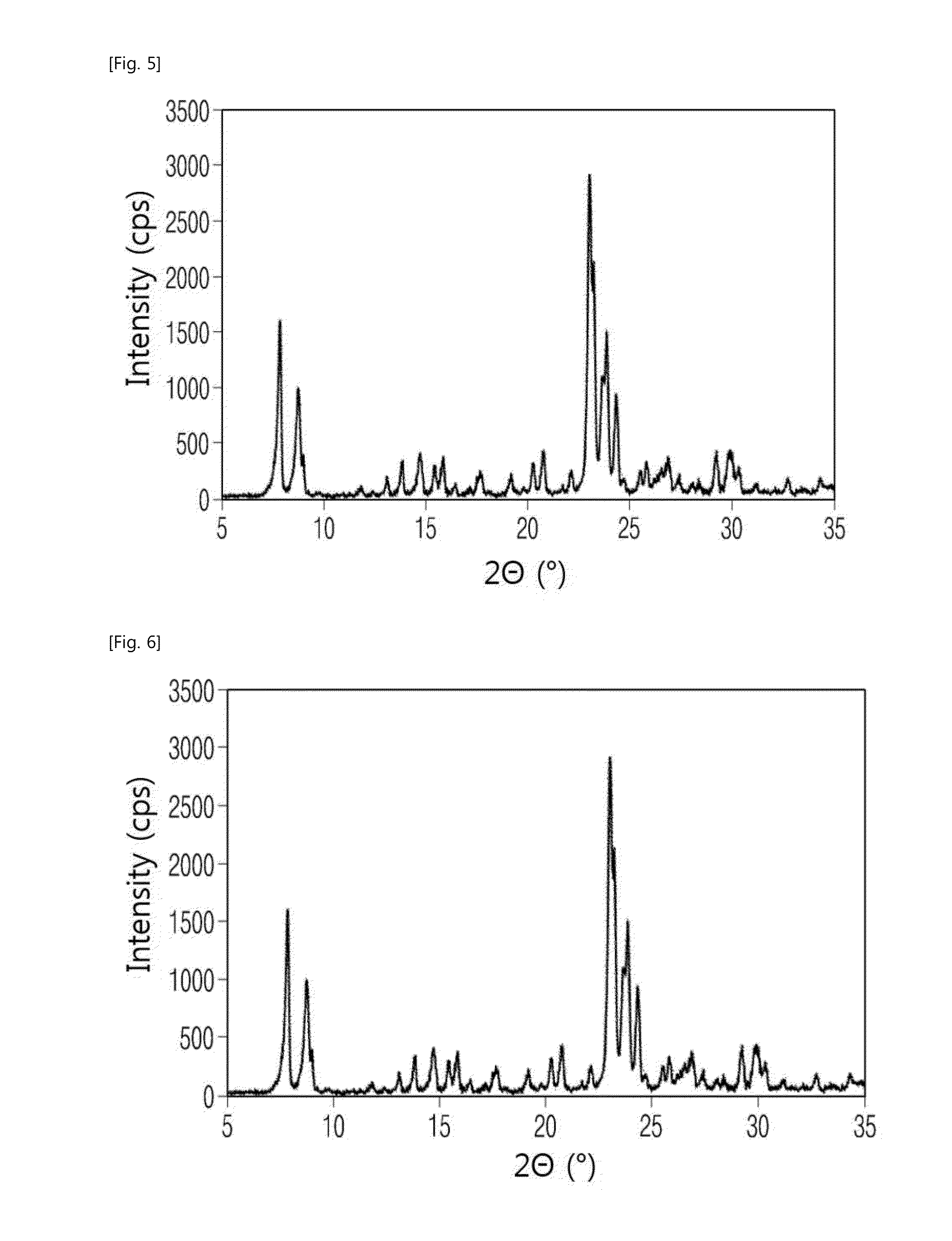

Method for producing high silica zeolite using recovered silica filtrate, and high silica zeolite produced according to said method

ActiveUS20150139898A1Reduce energy costsReduce cost chemical treatment cost costAluminium compoundsGranulation by liquid drop formationSilica gelSilicon dioxide

Provided are a method of manufacturing a high silica zeolite using a recovered silica filtrate, and a high silica zeolite manufactured according to the method. To this end, the present invention provides the method of manufacturing the high silica zeolite using the recovered silica filtrate, including manufacturing a solated agglomerated silica from the silica filtrate including a metal salt (step 1); filtering and washing the solated agglomerated silica of step 1 to manufacture a silica cake from which the metal salt is removed (step 2); peptizing the silica cake to manufacture a silica sol (step 3); and manufacturing the high silica zeolite using the silica sol manufactured in step 3 as a silica source (step 4). Further, the present invention provides a high silica zeolite manufactured from a recovered silica filtrate through the manufacturing method and having a Si / Al mole ratio of 5 or more. According to the present invention, it is possible to provide a process of manufacturing a high silica zeolite, in which economic feasibility, a manufacturing cost, and a manufacturing time of process steps are reduced, by reusing a recovered silica filtrate to manufacture the zeolite.

Owner:KOREA RES INST OF CHEM TECH

Copper strike plating bath

InactiveUS20060027462A1Decrease or fluctuationImprove macrothrowing powerAnti-corrosive paintsLiquid/solution decomposition chemical coatingOrganic acidCupric cyanide

Owner:SHINKO ELECTRIC IND CO LTD

Apparatus and method for treating waste water containing ammonium salts

ActiveUS10815132B2Overcomes drawbackDifficult to reuseTreatment involving filtrationVacuum distillation separationAmmoniaSodium sulfate

The present invention relates to the waste water treatment field, and discloses apparatus and method for treating waste water containing ammonium salts, which contains NH4+, SO42−, Cl−, and Na+. In the method of the present invention, the pH value of the waste water to be treated is adjusted to a specific range in advance; sodium sulfate crystal and relatively concentrated ammonia are obtained by first evaporation, and then sodium chloride crystal and relatively dilute ammonia is obtained by second evaporation; alternatively, sodium chloride crystal and relatively concentrated ammonia is obtained by third evaporation, and then sodium sulfate crystal and relatively dilute ammonia are obtained by fourth evaporation. The method of the present invention can recover ammonia, sodium sulfate, and sodium chloride from the waste water respectively, so that the resources in the waste water can be reused as far as possible.

Owner:CHINA PETROCHEMICAL CORP +1

Hazardous waste disposal fly ash and desulfurization wastewater co-treatment system and method

PendingCN111499078ALower Disposal CostsReduce waste water treatment costsTreatment involving filtrationWater/sewage treatment by ion-exchangeProcess engineeringEnvironmental geology

The invention discloses a hazardous waste disposal fly ash and desulfurization wastewater co-treatment system and method. The treatment system comprises a stirring tank, a diaphragm filter press, a filtrate tank, a coagulating sedimentation integrated device, a cation exchange resin device and an evaporative crystallization device which are sequentially arranged according to a treatment process, afilter pressing pump is arranged between the stirring tank and the diaphragm filter press, and a lifting pump is arranged between the filtrate tank and the coagulating sedimentation integrated device. By the adoption of the treatment system and method, fly ash and desulfurization wastewater are effectively treated, valuable metal and sodium chloride salt in hazardous waste treatment fly ash are recycled, the treatment system and method are an environment-friendly technology, and huge environmental and economic benefits can be created.

Owner:湖南申联环保科技有限公司

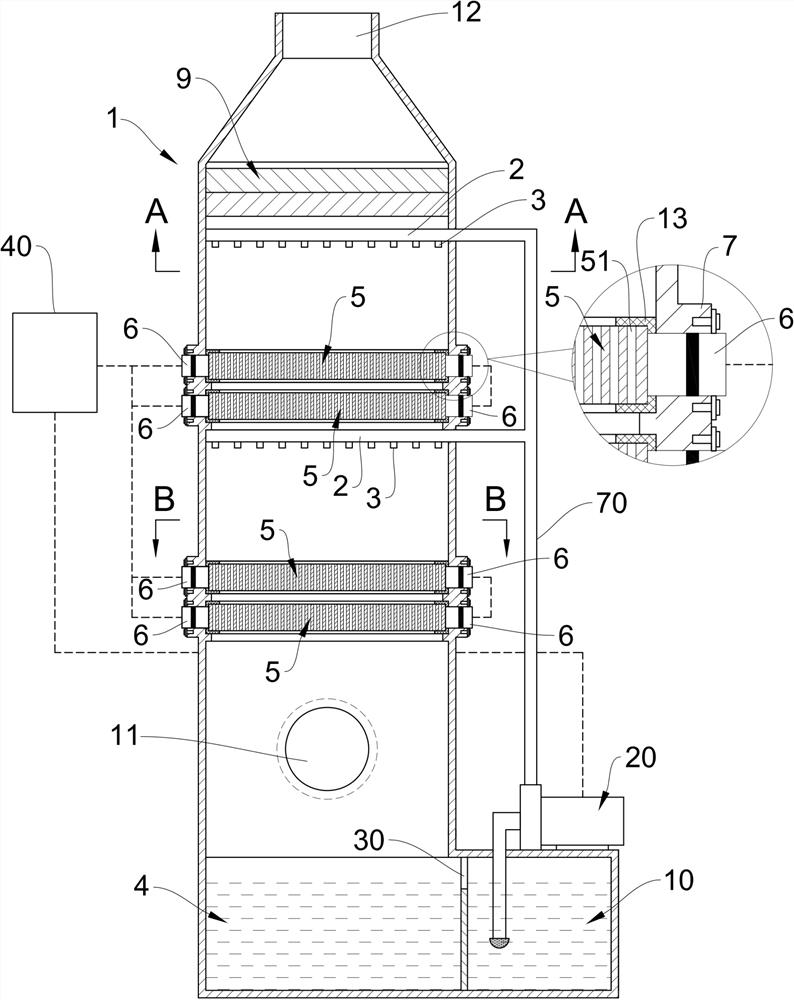

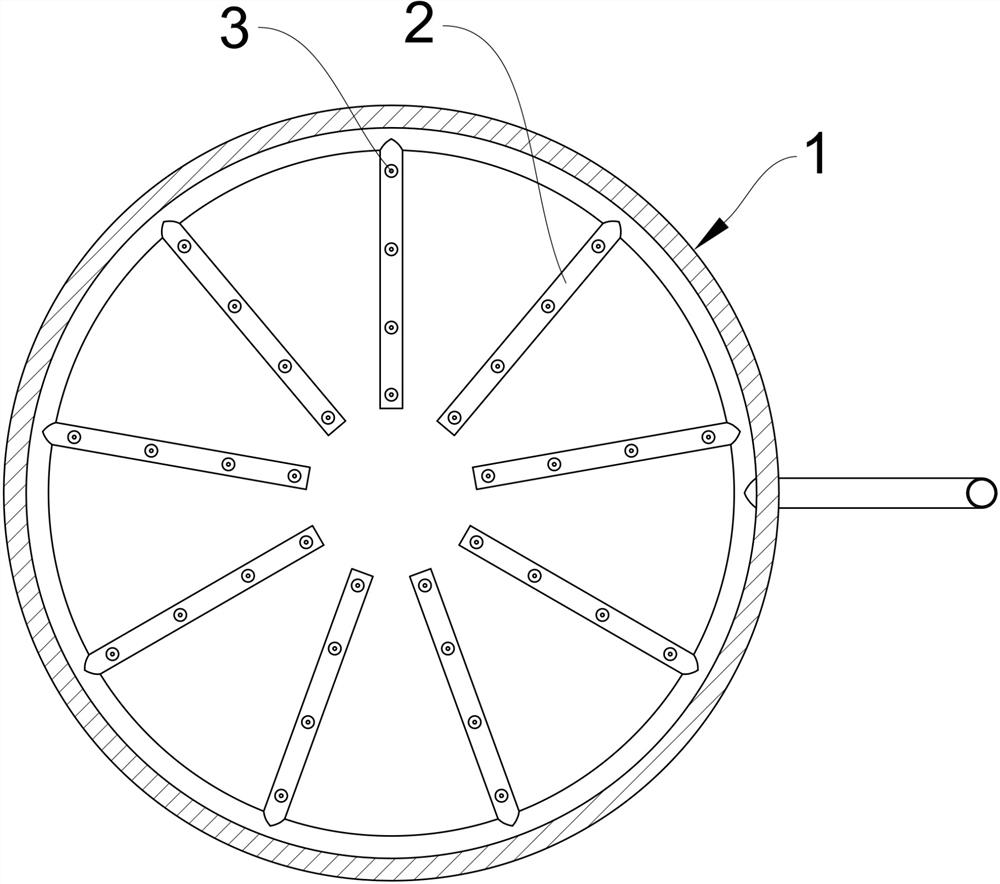

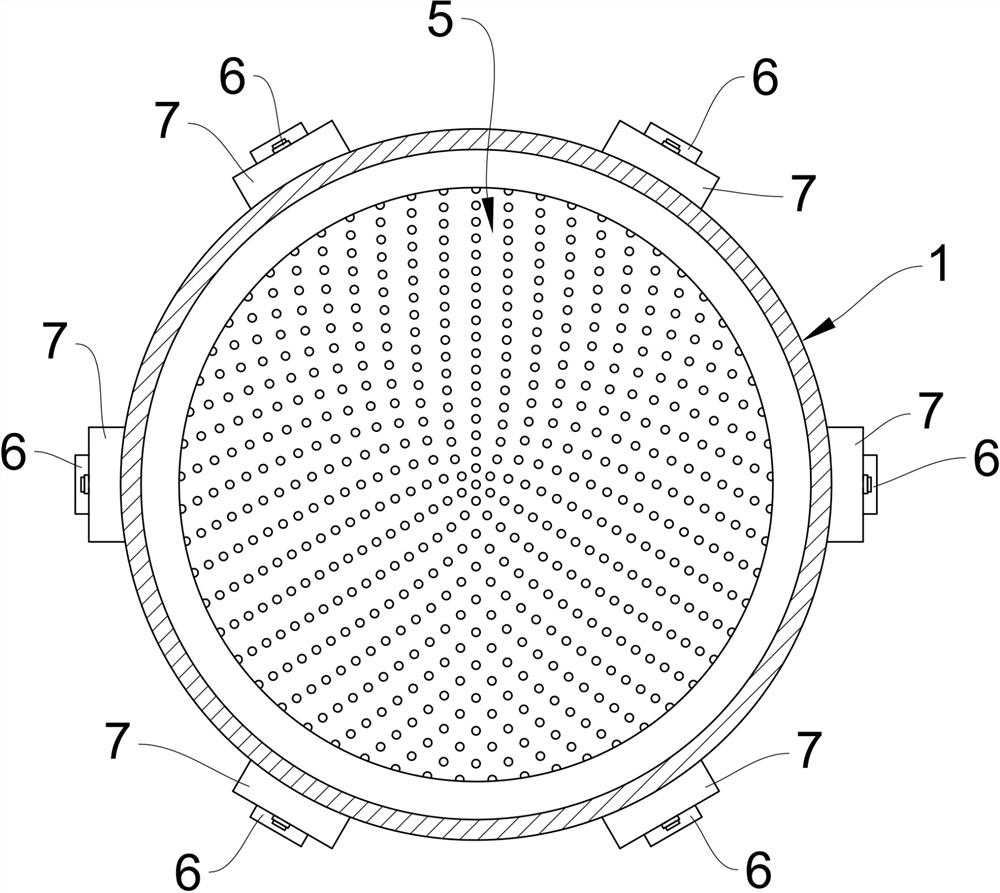

Ultrasonic vibration filter screen spray waste gas treatment tower

PendingCN111603874AStrong exhaust gas decomposition and treatment capabilitiesEffective handlingCombination devicesSpray nozzleEnvironmental geology

The invention relates to an ultrasonic vibration filter screen spray waste gas treatment tower. The tower comprises a tower body, a spray pipe, spray nozzles, a water receiving and slag storing pool,a metal filter screen and an ultrasonic transducer; the metal filter screen is transversely arranged in the inner cavity of the tower body; the ultrasonic transducer is connected with the metal filterscreen so as to drive the metal filter screen to perform ultrasonic high-frequency vibration to intercept and cut waste gas; the spray pipe is arranged in the tower body above the metal filter screen; the spray nozzles are arranged on the spray pipe and uniformly spray water mist towards the metal filter screen; and the water receiving and slag storing pool is arranged at the bottom of the towerbody. According to the tower of the invention, the metal filter screen with ultrasonic high-frequency vibration is utilized; ultrasonic high-frequency cutting is performed on the waste gas passing through the metal filter screen in the tower body, so that dust impurities entrained in the waste gas are intercepted or shredded and decomposed into finer particles; meanwhile, water mist is sprayed tothe metal filter screen to scour the metal filter screen, so that the dust impurities are condensed into particles and fall into the water receiving and slag storing pool to be recycled. The waste gasdecomposition treatment capacity of the tower is high; energy is saved; and the environment is protected.

Owner:彭志军

Preparation method of modified lignin absorbent for absorbing TNT (Trinitrotoluene)

InactiveCN101829546BAbundant resourcesSave resourcesOther chemical processesWater contaminantsAbsorption capacityOrganic solvent

The invention discloses a preparation method of a modified lignin absorbent for absorbing TNT (Trinitrotoluene), which is characterized by comprising the steps of: adding 5-30 parts by weight of lignin into 150-500 parts by weight of 1,2-alkyl dihalide, adding 15-50 parts of catalysts, stirring for 3-10 hours at 50-90 DEG C, washing reacted materials by using a mixture of ice and diluted hydrochloric acid, filtering and washing by using water, and drying to prepare grafted halogenated lignin; and then adding 50-300 parts of aminating agents into 20-80 parts of organic solvents, adding 5-30 parts of the grafted halogenated lignin, stirring for 4-10 hours at 60-90 EG C, filtering, washing by using diluted ammonia water and water, and drying to obtain the modified lignin absorbent. The absorbent has higher selective absorption capacity on the TNT and other organic compounds containing nitryl and can be used for absorption and separation of the TNT and other organic compounds containing the nitryl in the explosive industrial wastewater so as to protect the environment.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Novel heavy metal adsorption agent and method for removing heavy metal in industrial waste water through adsorption

InactiveCN109896634AReduce waste water treatment costsImprove efficiencyWater contaminantsBiological water/sewage treatmentChemistryHeavy metals

The invention discloses a novel heavy metal adsorption agent and a method for removing heavy metal in industrial waste water through adsorption. The novel heavy metal adsorption agent is a dried bacterial ball obtained by drying a bacterial ball with the diameter being 20 to 50mm after the Aspergillus niger fermentation to a state with the moisture content being smaller than 10 percent. Waste materials are used for controlling waste materials; the Aspergillus niger bacterial ball is used for adsorbing, removing and recovering the heavy metal in the waste water; the waste water treatment cost is low; the efficiency is high; the resource recovery and utilization are sufficiently realized; important application prospects are realized.

Owner:中科协创环境科技江苏有限公司

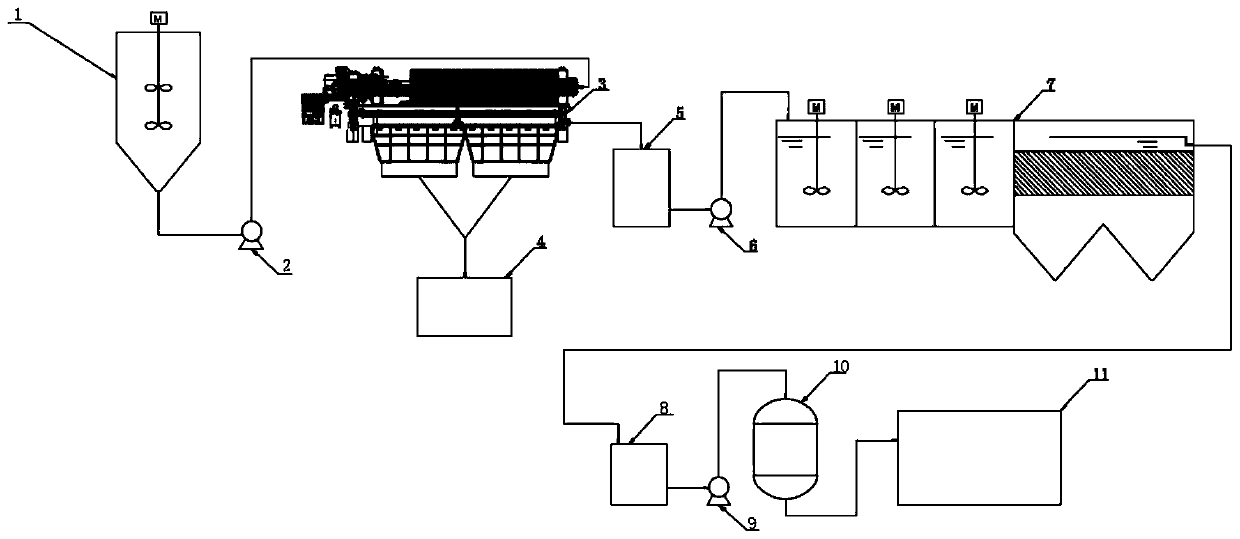

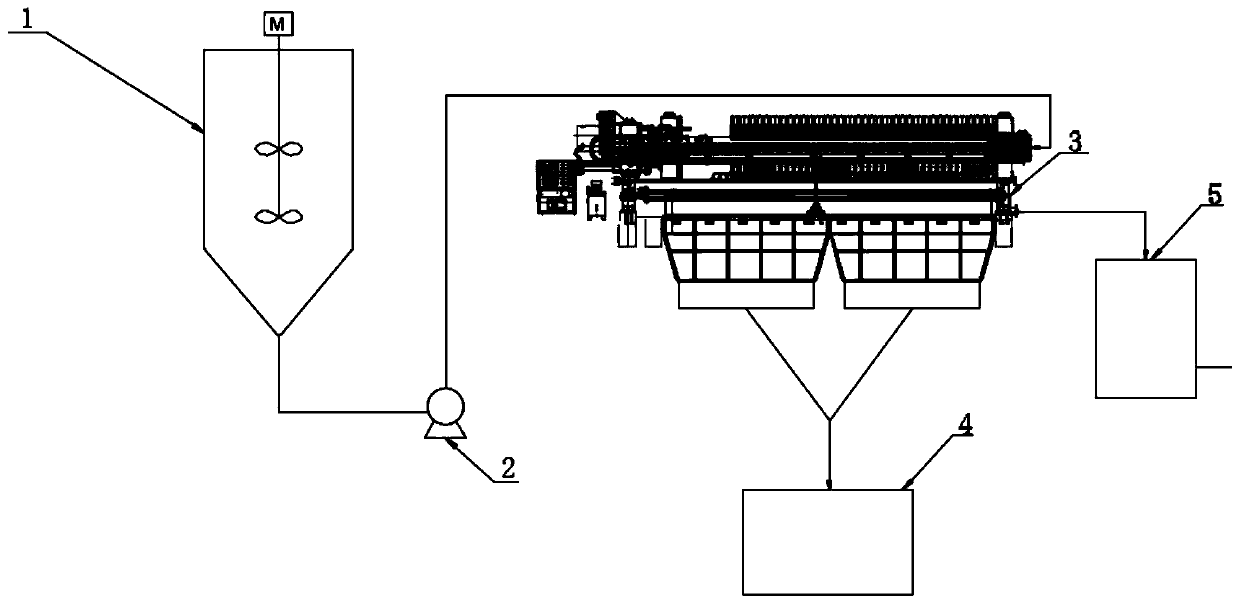

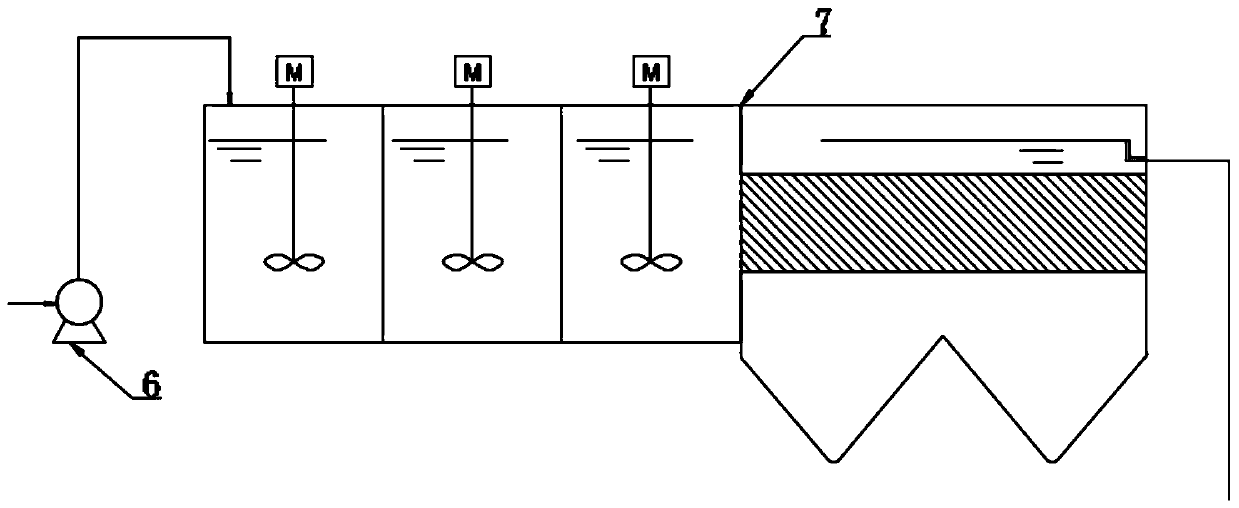

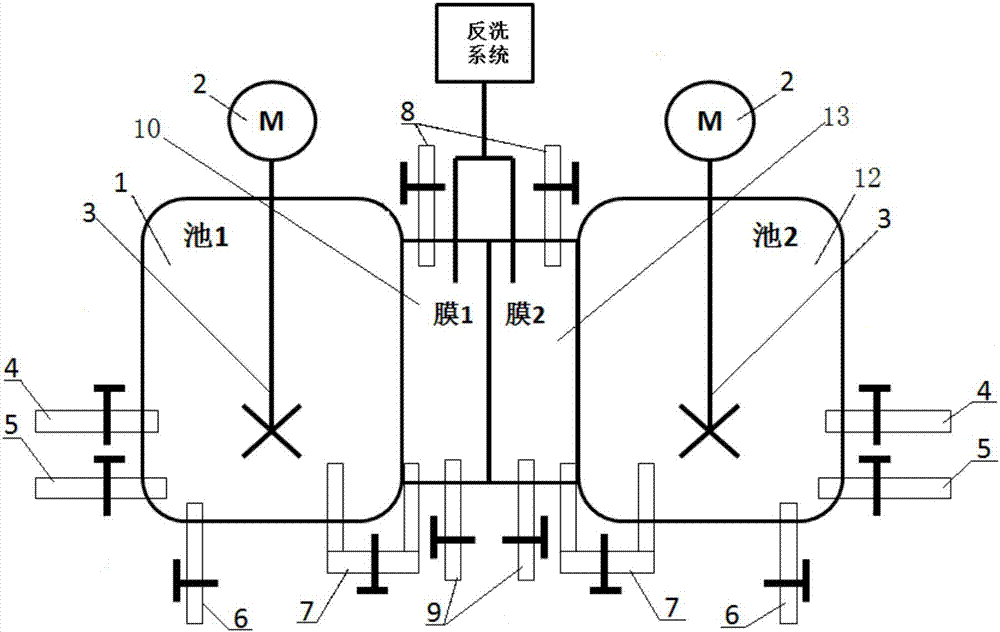

Automatic continuous water treatment apparatus suitable for powder absorbent

PendingCN107244712AReduce the difficulty of preparationReduce waste water treatment costsSpecific water treatment objectivesWater/sewage treatment bu osmosis/dialysisProcess engineeringEnvironmental geology

The invention discloses an automatic continuous water treatment apparatus suitable for powder absorbent. The automatic continuous water treatment apparatus comprises two reaction tanks, wherein each reaction tank is connected with a filter membrane, a powder absorbent is arranged in each reaction tank, the bottom of each reaction tank is provided with a waste water inlet pipe, a parsing liquid inlet pipe and a sludge discharging pipe, a backwash reflux pipeline is arranged between the bottom of the reaction tank and the bottom of the corresponding filter membrane, the top of the filter membrane is provide with the waste water outlet pipe, the bottom of the filter membrane is provided with the parsing liquid outlet pipe, the waste water inlet pipe, the parsing liquid inlet pipe, the parsing liquid outlet pipe, the sludge discharging pipe and the backwash reflux pipeline are respectively provided with a valve, and the filter membrane is connected with a backwash system. By adopting the automatic continuous water treatment apparatus, the continuous treatment for sewage can be realized, and the fluctuation of water quality and water quantity of a wider range can be treated; and the automatic continuous water treatment apparatus is suitable for the powder absorbent, directly applied to the water pollution governing engineering, does not need to form the absorbent, can alleviate the preparation difficulty of the absorbent, and can reduce the waste water treatment cost.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

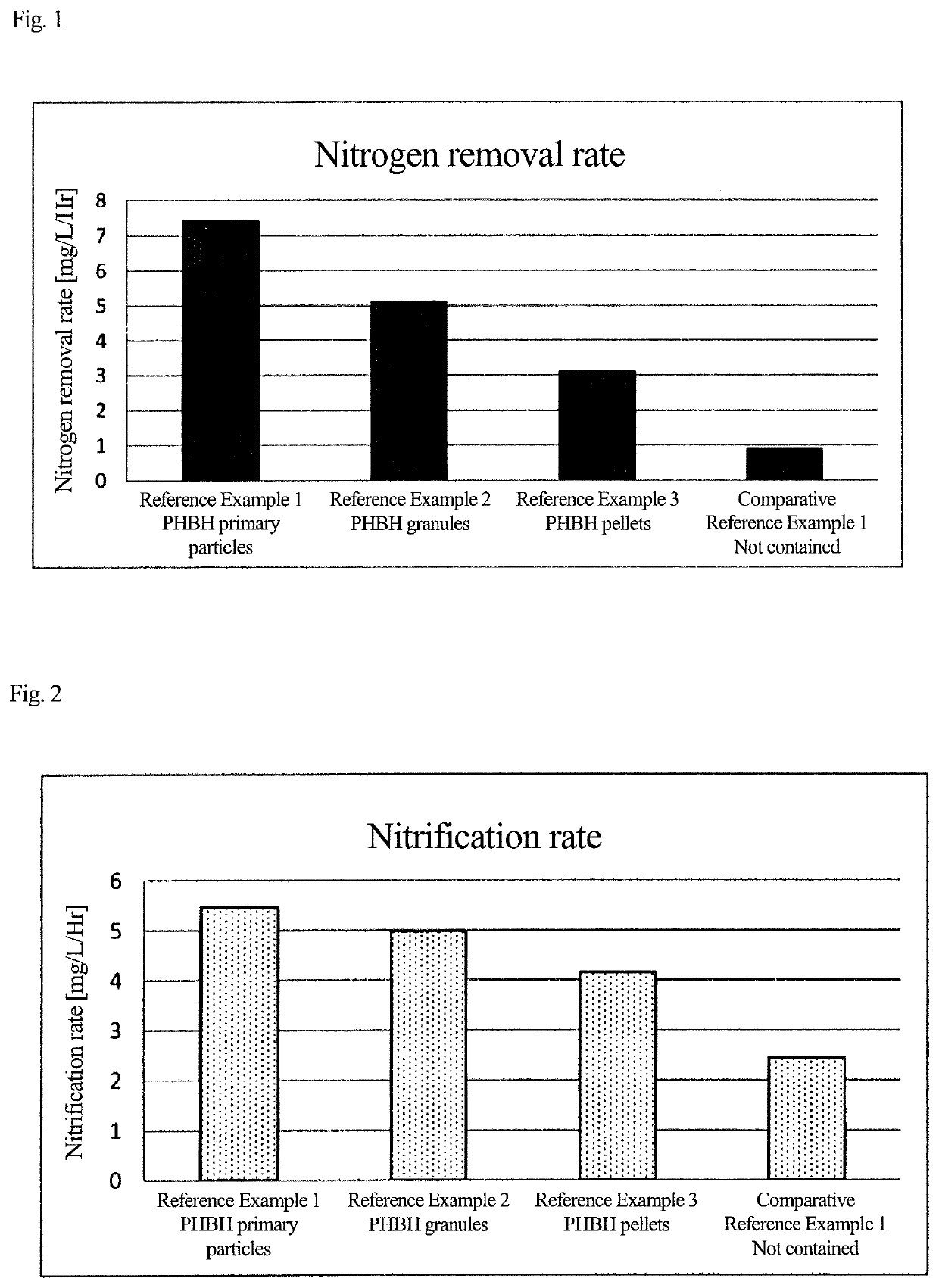

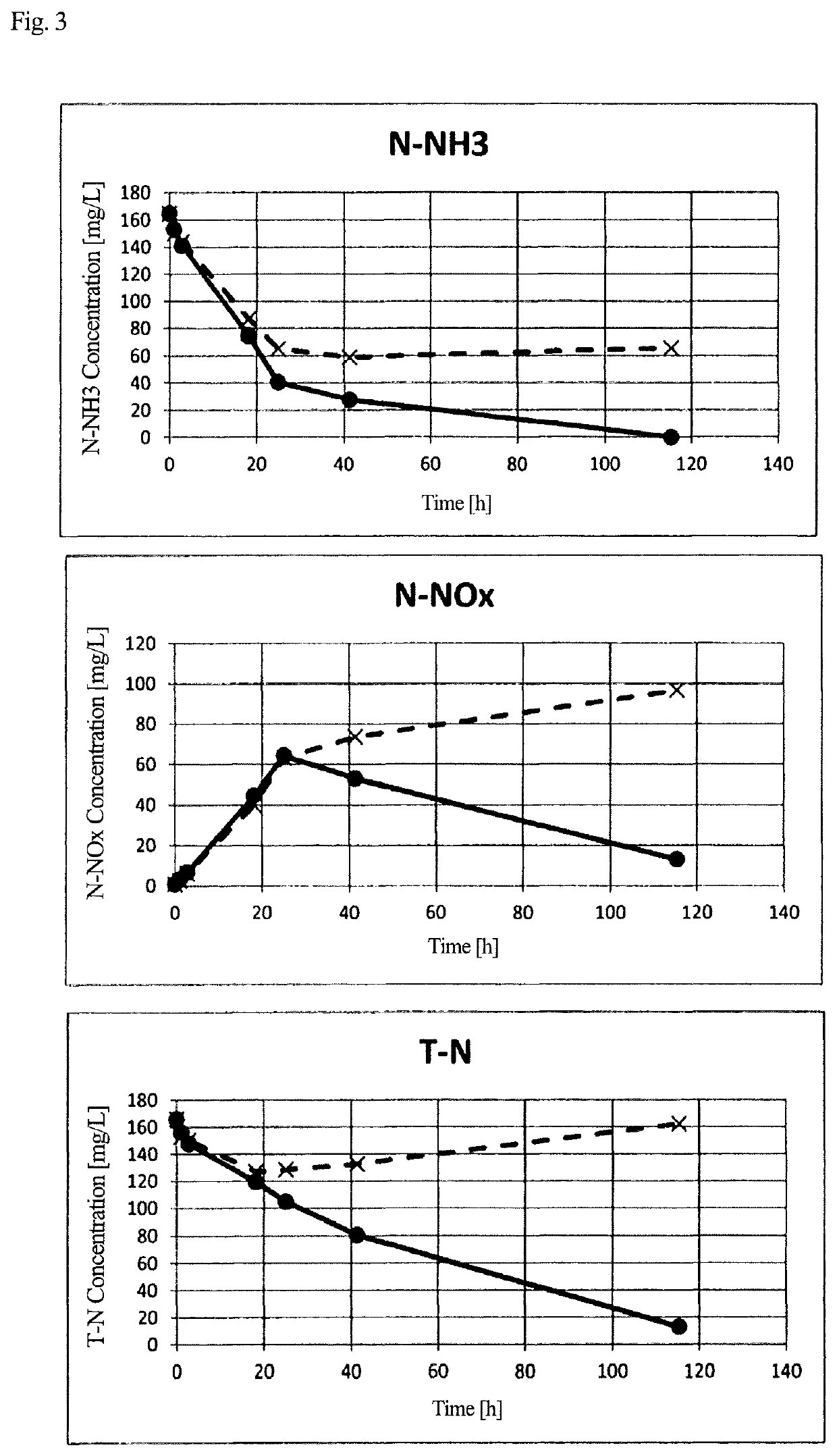

Method for producing polyhydroxyalkanoic acid

ActiveUS11440823B2Reduce in quantityReducing nitrificationWater treatment parameter controlTreatment using aerobic processesMicroorganismNitrogen removal

Owner:KANEKA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com