Waste water treatment method in starch and glucose production

A waste water treatment and glucose technology, which is applied in the field of waste water treatment in the production of starch and glucose, can solve the problems of unfavorable denitrification and denitrification, high discharge of COD per ton, unfavorable full nitrification of ammonia nitrogen, etc., so as to ensure the effect of sewage treatment and reduce waste water The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

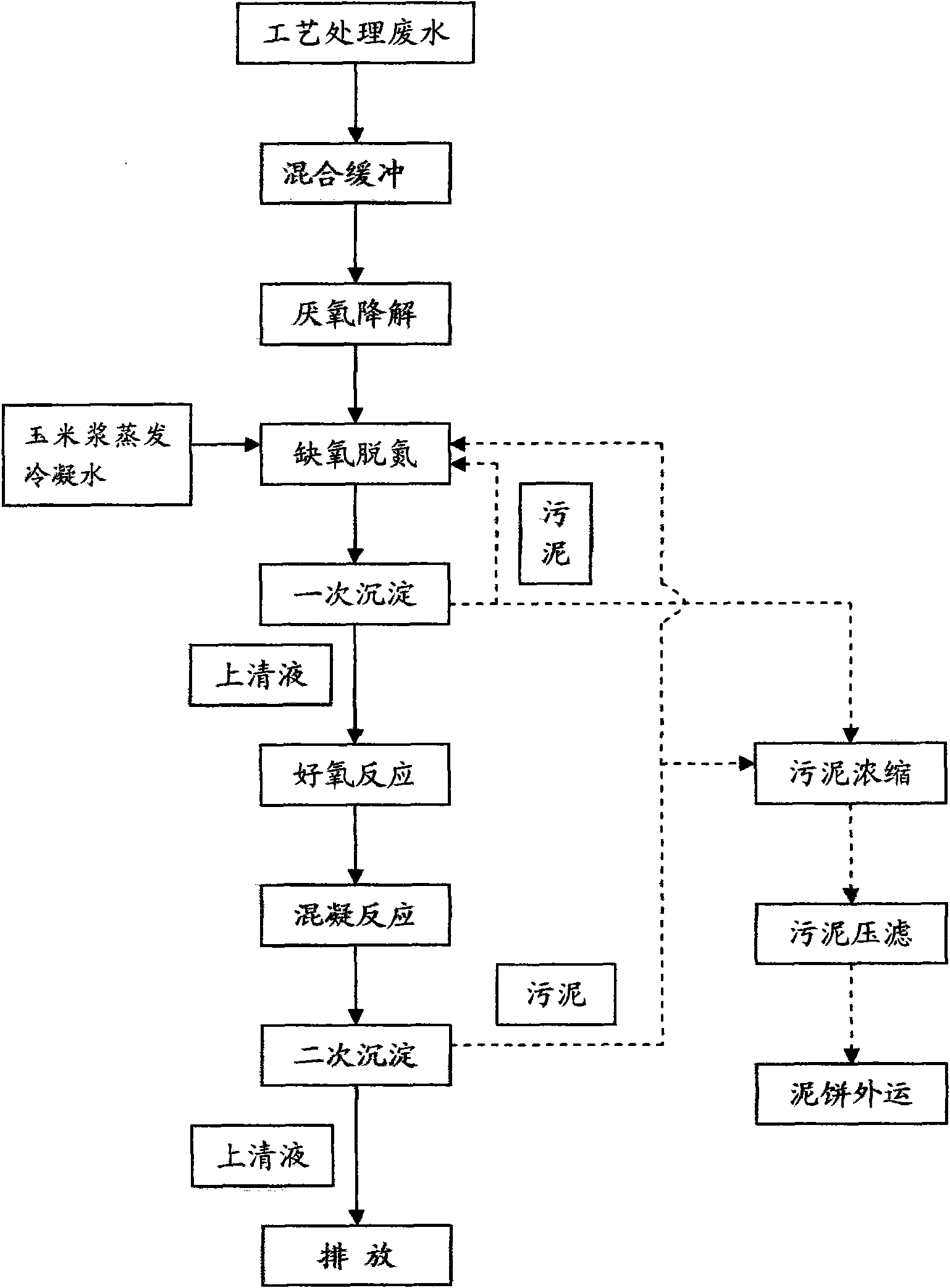

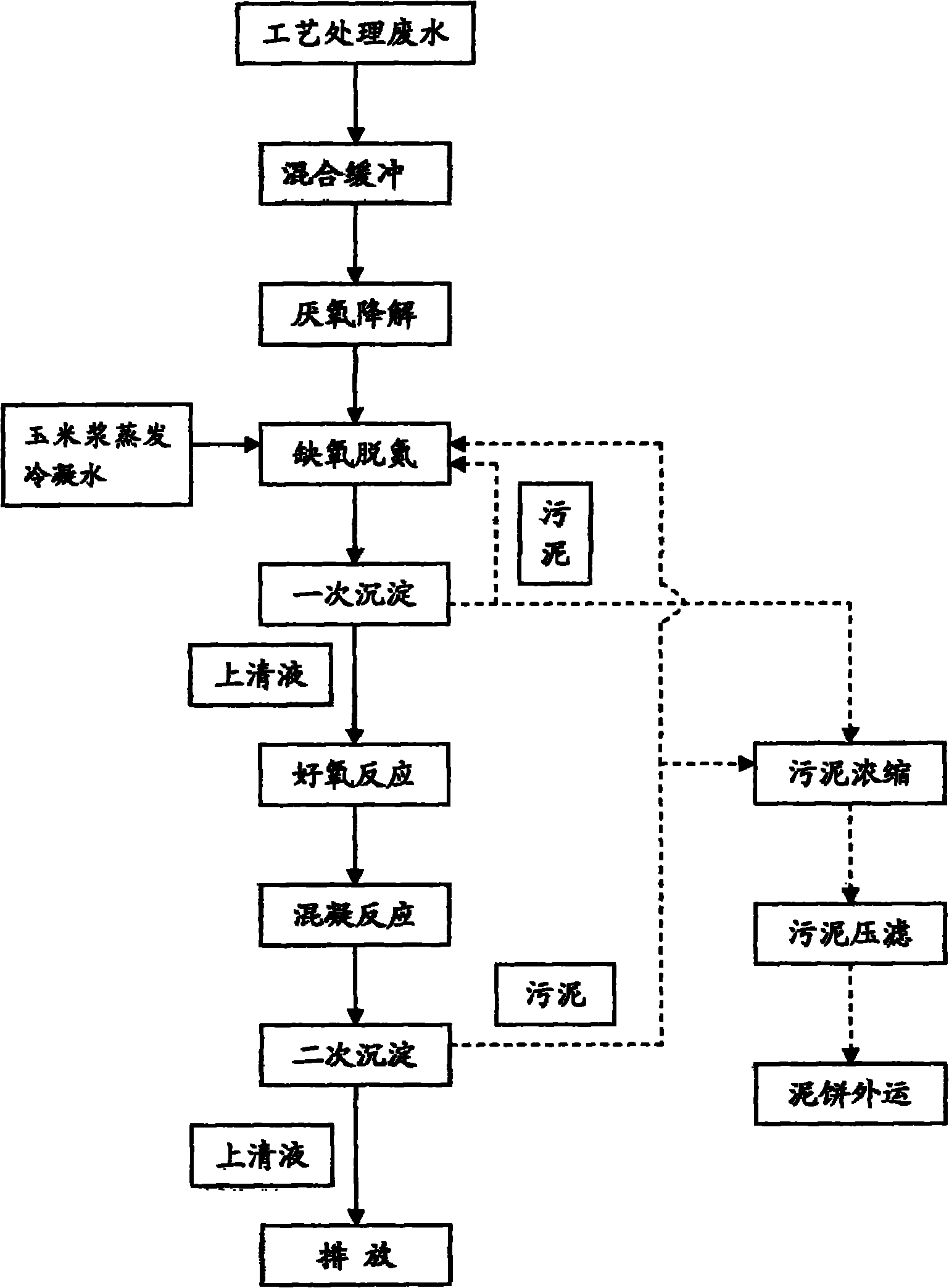

[0036] a. The process wastewater with COD of 8000mg / L mixed and buffered enters the anaerobic reactor for anaerobic degradation reaction.

[0037] b. The process treated wastewater after anaerobic degradation enters the A pool, and the influent COD=1000mg / L, BOD 5 =550mg / L, NH 3 -N=400mg / L, dissolved oxygen=0.4mg / L, pH value=7.6, water temperature is 30°C, introduce COD=5000mg / L, TKN=35mg / L corn steep liquor evaporated condensed water into pool A for mixing, adjust C / N=4.94, carry out anoxic denitrification reaction, and then separate into supernatant and sludge after a precipitation, part of the sludge is refluxed back to pool A, and the rest is concentrated for sludge, and press-filtered into a mud cake before transporting .

[0038] c. The supernatant after a precipitation separation enters the O tank for aerobic treatment. When the dissolved oxygen is 2.0mg / L; pH value = 6.6; temperature = 32°C, ammonia nitrogen removal and further degradation are carried out.

[0039]...

Embodiment 2

[0049]a. Process wastewater with a COD of 10,000mg / L is mixed and buffered and then enters the anaerobic reactor for anaerobic degradation reaction.

[0050] b. The process wastewater after anaerobic degradation enters the A pool, and the influent COD=1200mg / L, BOD 5 =660mg / L, NH 3 -N=550mg / L, dissolved oxygen=0.4mg / L, pH value=7.3, water temperature is 30°C, introduce COD=4500mg / L, TKN=40mg / L corn steep liquor evaporated condensed water into pool A for mixing, adjust C / N=4.15, carry out anoxic denitrification reaction, and then separate into supernatant and sludge after a precipitation, part of the sludge is returned to A pool, and the rest is concentrated for sludge, and press-filtered into a mud cake before transporting .

[0051] c. The supernatant after a precipitation separation enters the O tank for aerobic treatment. When the dissolved oxygen is 2.5 mg / L; pH value = 6.4; temperature = 32 °C, ammonia nitrogen removal and further degradation are carried out.

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com