Patents

Literature

766 results about "Degradation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Degradation reactions reduce the number of atoms in a molecule through a specific type of chemical transformation.

Lower alkyl ester recycling in polyol fatty acid polyester synthesis

InactiveUS6465642B1Quality improvementReduce side effectsEsterified saccharide compoundsSugar derivativesPolyesterPolyol

Process for synthesizing polyol fatty acid polyesters which includes the steps of reacting an excess of lower alkyl ester with polyol to esterify hydroxyl groups thereof and form polyol fatty acid polyester, separating at least a portion of the unreacted lower alkyl ester from the polyol fatty acid polyester, and recycling the separated unreacted lower alkyl ester for further reaction with polyol or partially esterified polyol. The recycled lower alkyl ester is substantially free of lower alkyl ester degradation reaction products, such as carbonyls and free fatty acids.

Owner:THE PROCTER & GAMBLE COMPANY

Starch ester and preparation method and use thereof

InactiveCN101139401ALow viscosityReduce the degree of polymerizationFood scienceFlavorEsterification reaction

The present invention provides a starch ester and the preparation method as well as the application of the starch ester. The starch ester takes natural starch as raw material and is obtained through esterification. The present invention is characterized in that: a degradation reaction takes place before and after the esterification. The preparation method of the starch ester lies in that the natural starch is degraded to reduce the viscosity of the starch. And then the starch experiences esterification to generate starch ester, which is low-viscosity starch ester. Or the natural starch material experiences the esterification first to generate starch ester, which then takes the degradation reaction to reduce the viscosity of the starch ester so as to generate low-viscosity ester. The present invention is suitable to the oily substances such as oil plants, flavors, spices and so on which are of stable emulsification and good effect in water. The present invention also provides the application of the starch ester as emulsification stabilizer in the thin system such as in the drinks and so on.

Owner:重庆泰威生物工程有限责任公司

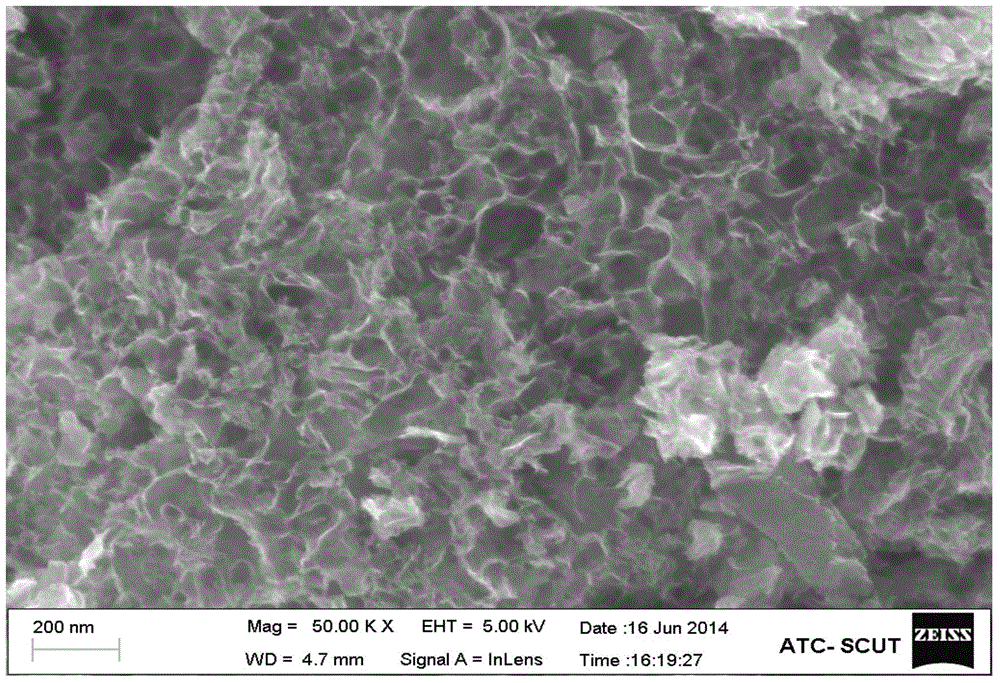

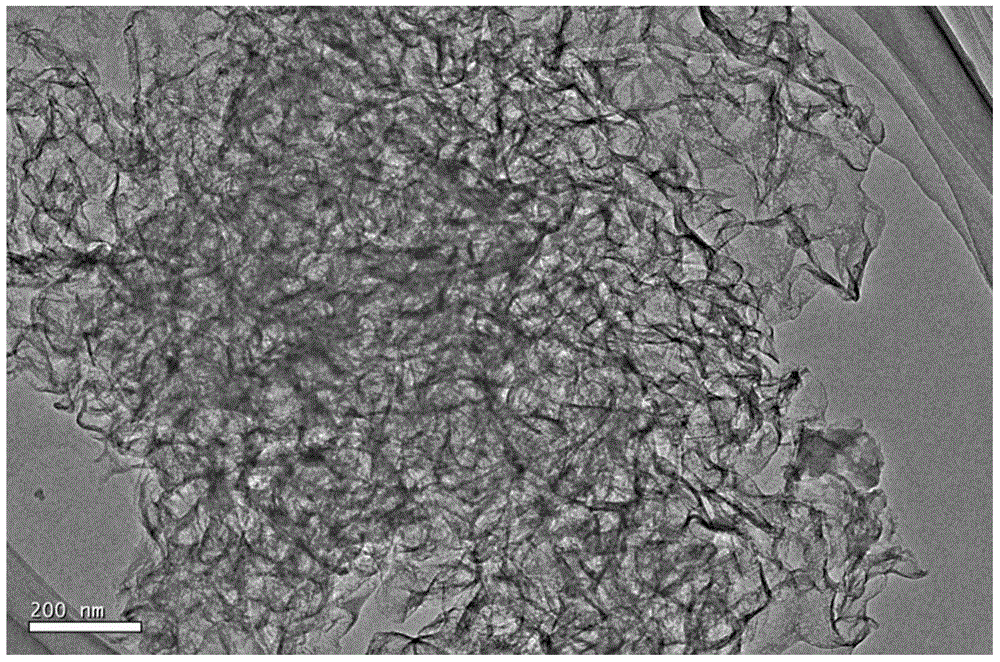

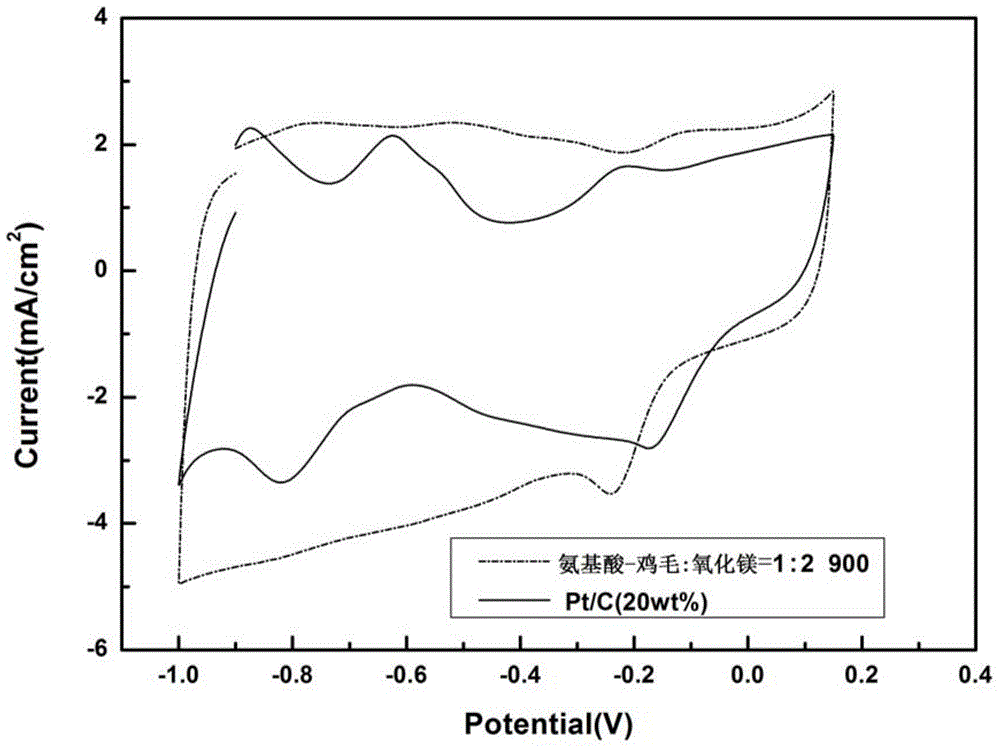

Nitrogen-sulfur co-doped carbon material with electro-catalytic oxygen reduction activity and preparation method of carbon material

InactiveCN104399508AAvoid synthetic stepsGood removal effectPhysical/chemical process catalystsCell electrodesOxygenOxygen reduction

The invention provides a nitrogen-sulfur co-doped carbon material with an electro-catalytic oxygen reduction activity and a preparation method of the carbon material, and belongs to the technical field of new material application. The technologic process comprises the following steps: performing ultrasonic cleaning on hairs with acetone, then shearing and crushing the hairs, pouring the hairs into a liner of a reaction kettle, adding analytically pure ammonia water, carrying out a hydrothermal degradation reaction, drying the solution obtained from hydrothermal degradation to obtain solid amino acid, mixing the solid amino acid with a template agent uniformly, thermally decomposing the mixture under an inert atmosphere, removing the template agent with diluted hydrochloric acid from the obtained sample, washing and drying, so as to prepare the nitrogen-sulfur co-doped carbon material. As the carbon material is prepared by taking hairs as the raw materials, the raw materials are simple and accessible, and low in cost; the selected template agent is low in cost and easy to remove; the preparation method is simple in technology; the prepared material is high in nitrogen and sulfur content, and has larger specific surface area, and is rich in pore structures; the nitrogen-sulfur co-doped carbon material prepared by the method shows up excellent properties in fuel cell cathode oxygen reduction and catalysis.

Owner:SOUTH CHINA UNIV OF TECH

Starch-base fully biodegradable resin with steady hydrophobic property and preparation method thereof

The invention discloses a starch-base fully biodegradable resin with steady hydrophobic property and a preparation method thereof, belonging to the technical field of biodegradable materials. The resin comprises the following raw materials in parts by weight: 20-50 parts of modified starch, 50-80 parts of fully biodegradable polyester, 0.1-5 parts of a lubricant, and 0.1-0.5 parts of an antioxidant. The starch-base fully biodegradable resin with steady hydrophobic property is rational in design, so that the dispersity of the starch is improved greatly through pre-treatment of the starch; the moisture content is relatively low, so that degradation reaction of the resin in the processing process is also reduced. Through rational micronization function, the performance of the starch-base fully biodegradable resin is improved obviously.

Owner:YIFAN XINFU PHARMA CO LTD +1

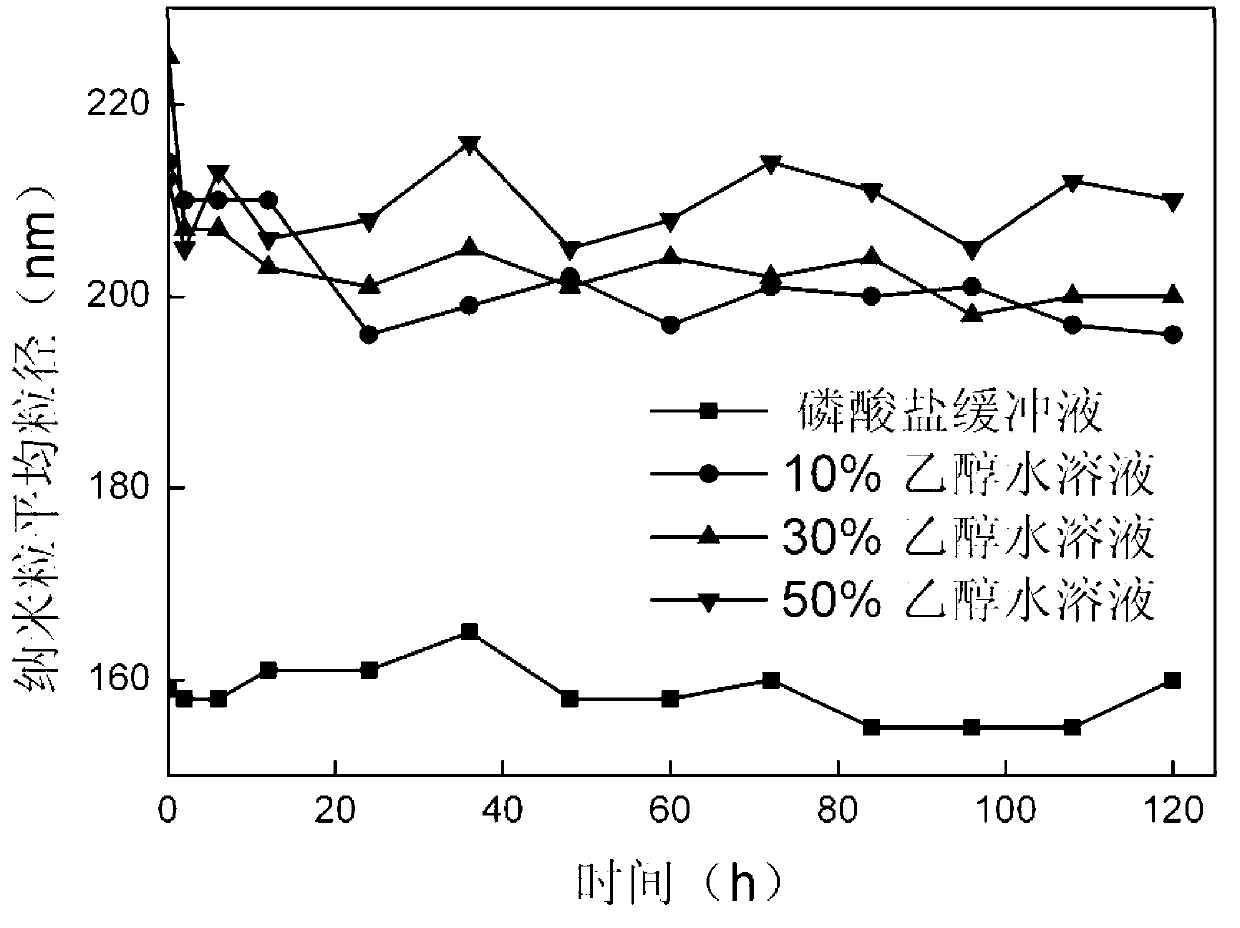

Method for preparing stable albumin nanoparticle

InactiveCN102988996AProcess stabilityPowder deliveryLyophilised deliveryRedox responsiveDisulfide bond

The invention relates to a method for preparing a stable albumin nanoparticle, and belongs to the technical field of preparation of biomedical materials. The method comprises the following steps: pretreating albumin by using glutathione and cysteine without biotoxicity; opening an intramolecular disulfide bond; precipitating the albumin by using anti-solvents such as alcohol and the like; and carrying out exchange reaction on a sulfydryl-disulfide bond to obtain the albumin nanoparticle containing the intramolecular disulfide bond. The prepared albumin nanoparticle can be used for the delivery of pharmacological active substances and / or diagnostic agents in an organism. The albumin nanoparticle provided by the invention has the advantages that the albumin nanoparticle has good stability under a dilution condition and gives an oxidation reduction response in a reduced environment. Based on the characteristics, the albumin nanoparticle can stably exist in a blood circulation system of the organism, and can carry out a degradation reaction in a cell under the action of reduced glutathione so as to release a wrapped medicine.

Owner:TSINGHUA UNIV

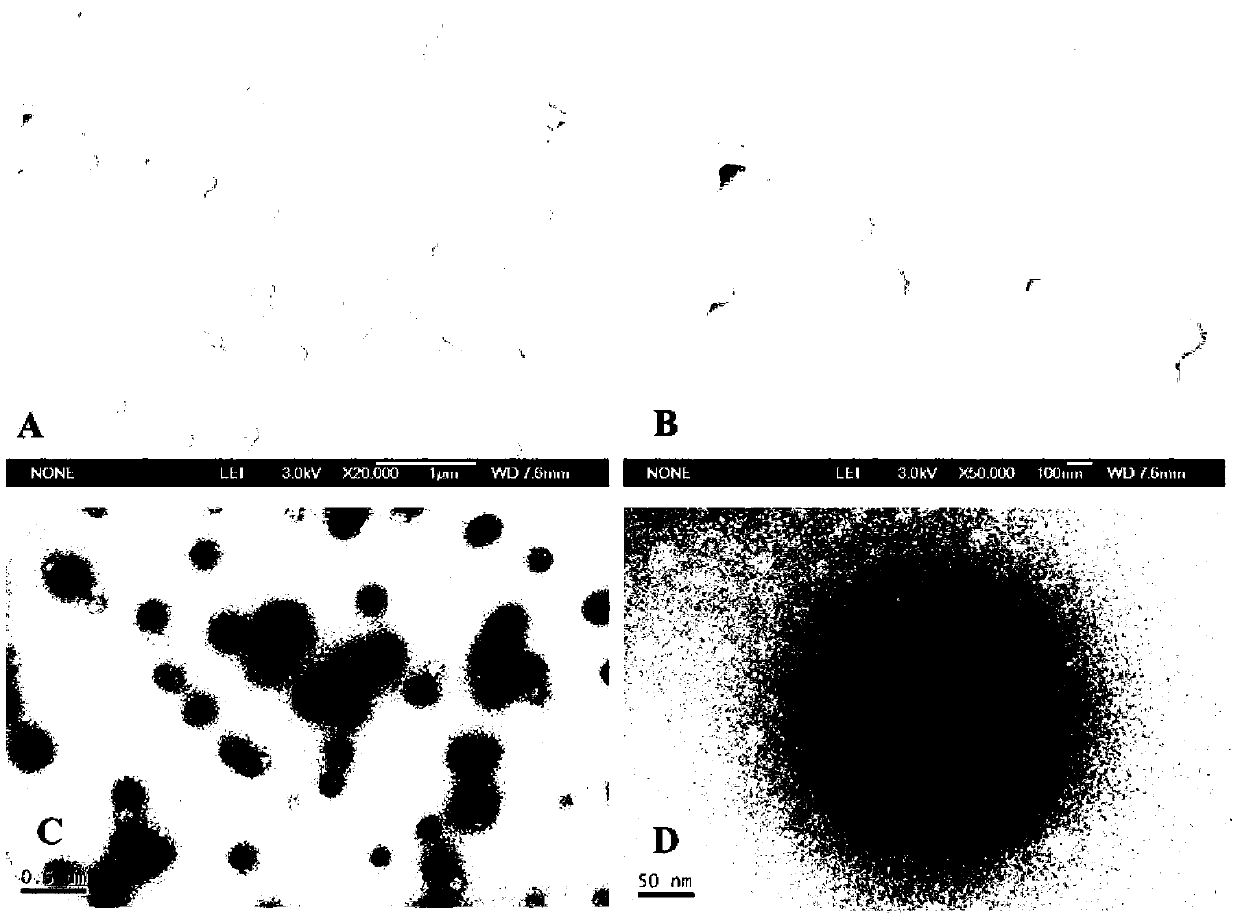

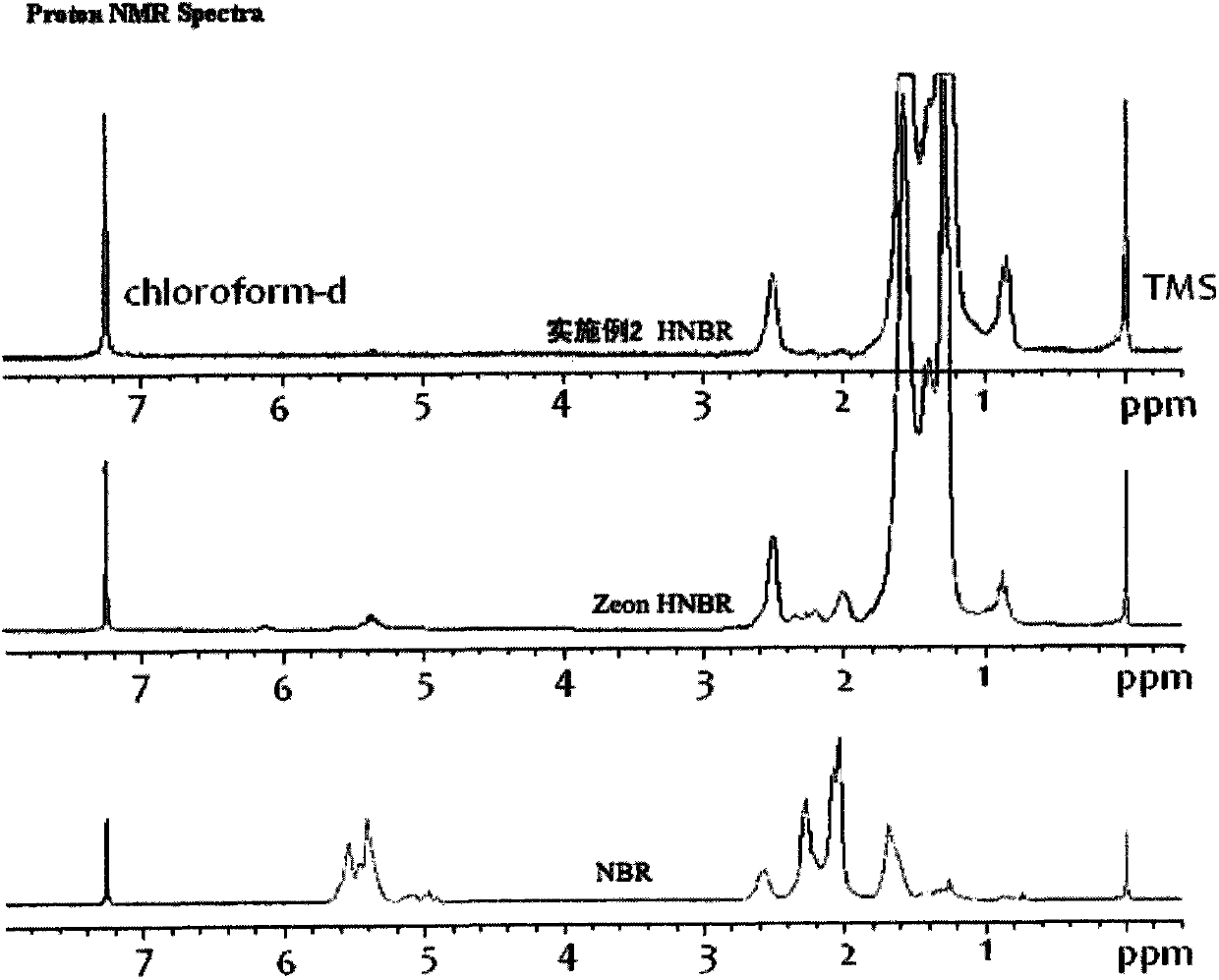

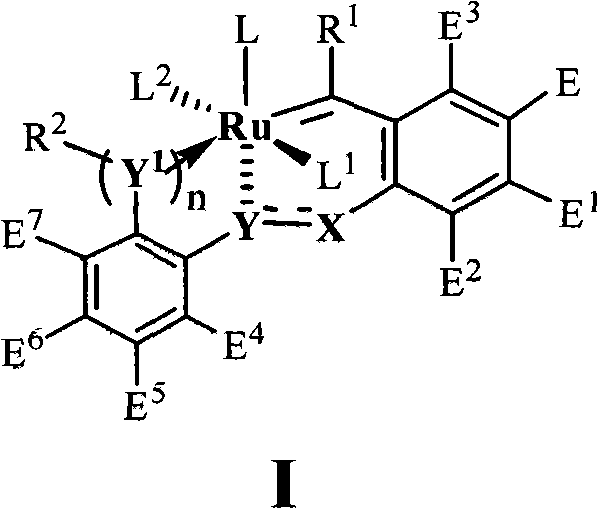

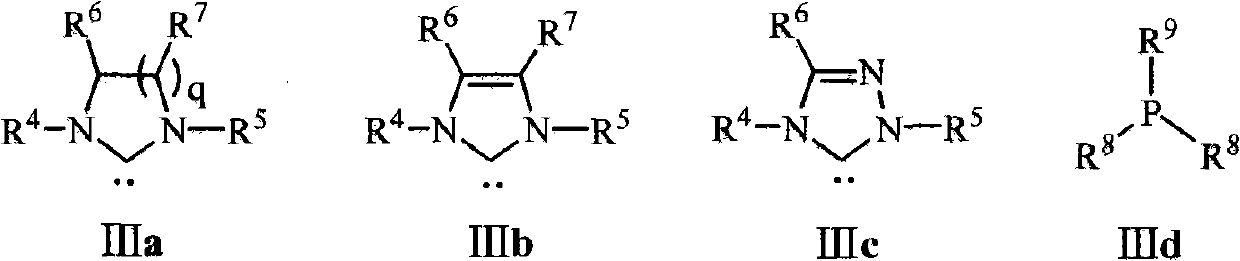

Preparation method of hydrogenated nitrile rubber and degradation and hydrogenation method of butadiene type rubber

The invention discloses a preparation method of hydrogenated butadiene special rubber, which comprises the following steps: subjecting butadiene rubber to a degradation reaction and a hydrogenation reaction under an action of a Zhan Catalyst as showed in the general formula I to obtain hydrogenated butadiene special rubber. The invention also provides a degradation reaction of the butadiene rubber, which is also under the action of a Zhan Catalyst as showed in the general formula I. The preparation method provided by the invention overcomes the shortcomings that the existing various types of catalysts can not be applicable to the preparation of low Mooney viscosity and high Mooney viscosity hydrogenated butadiene special rubber at the same time, so as to provide a preparation method of high-performance hydrogenated butadiene special rubber with a wide controllable Mooney viscosity range of 5-130. The catalyst used in the invention is the catalyst for both rubber degradation and hydrogenation reduction, so as to avoid a process requiring addition of the catalysts with different catalytic activities in two times respectively in the prior art. The method is simple, and easy to operate.

Owner:ZANNAN SCITECH

Conjugate linoleic acid or conjugate linoleate microcapsule

InactiveCN1357407AEasy to storeEasy to transportAnimal feeding stuffAccessory food factorsFood additiveFood Component

Conjugate linoleic acid or cnojugate linoleate microcapsule consists of wall material, capsule core, assistant, surfactant and plasticizer. Capsule core is added into wall material water solution and emulsified while adding assistant, surfactant and plasticizer; and the microcapsule product is obtained through spray drying. Great amount of experiment shower that the product has high antioxidant performance and high store stability, can mask bad smell, avoid mutual effect of different incompatible food components and decrease degradation reactions and reach controlled release. The present invention may be used in health food, food additive and feed additive and has health functions of anticancer, resisting arteriosclerosis, regulating metabolism, strengthening body's immunity, regulating blood sugar, etc.

Owner:XINJIANG TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

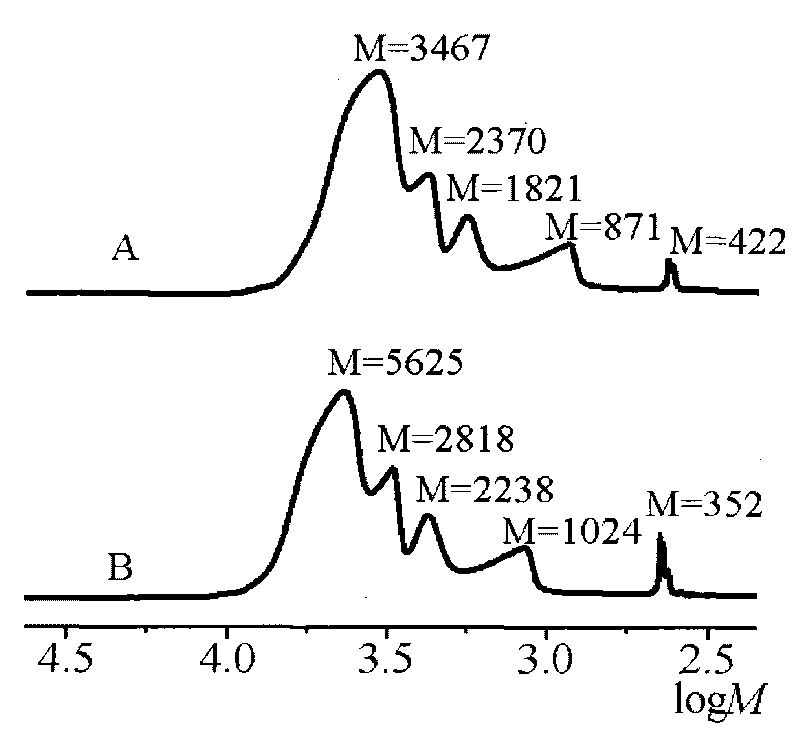

Method for degrading enteromorpha polysaccharide

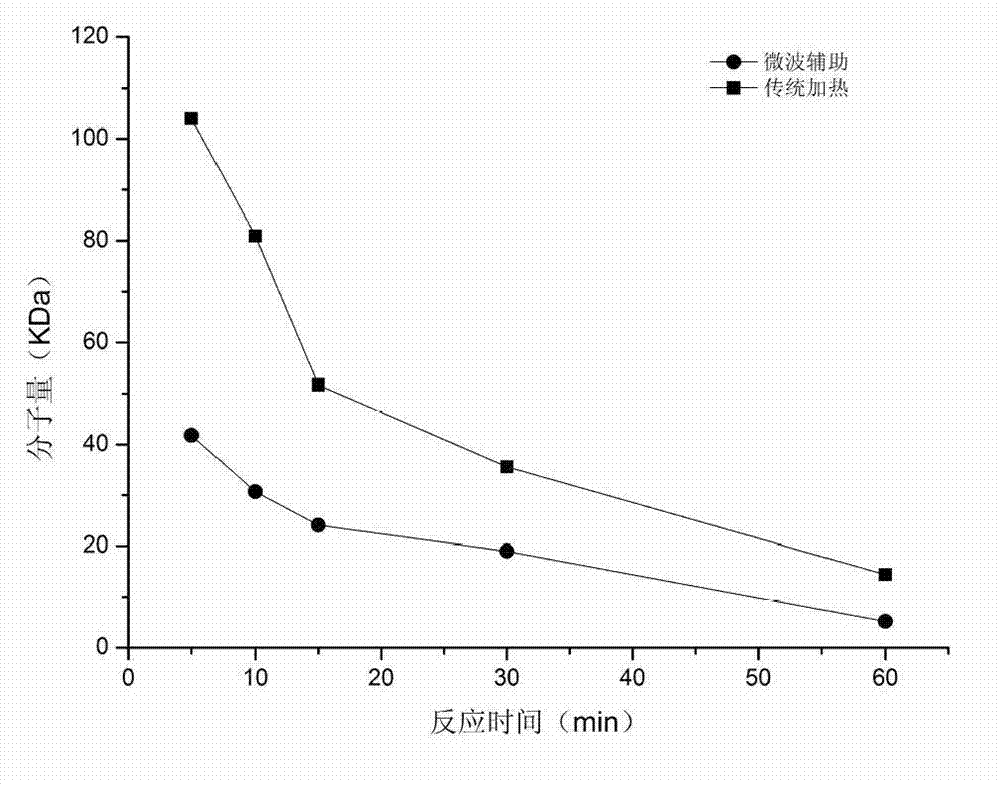

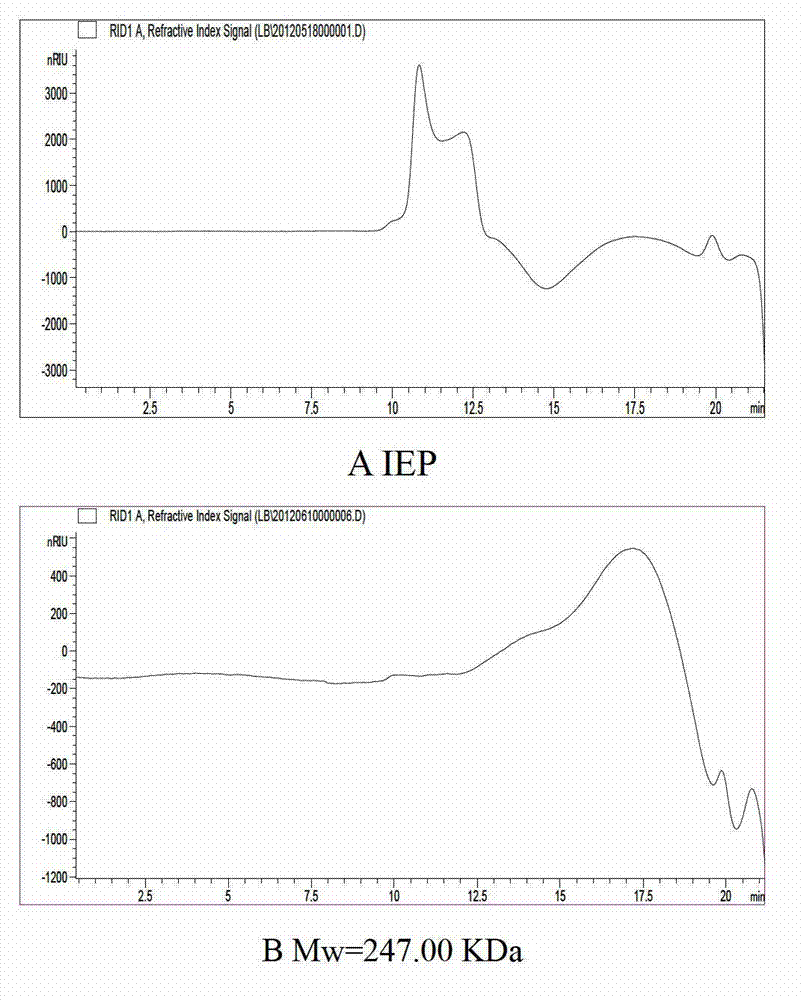

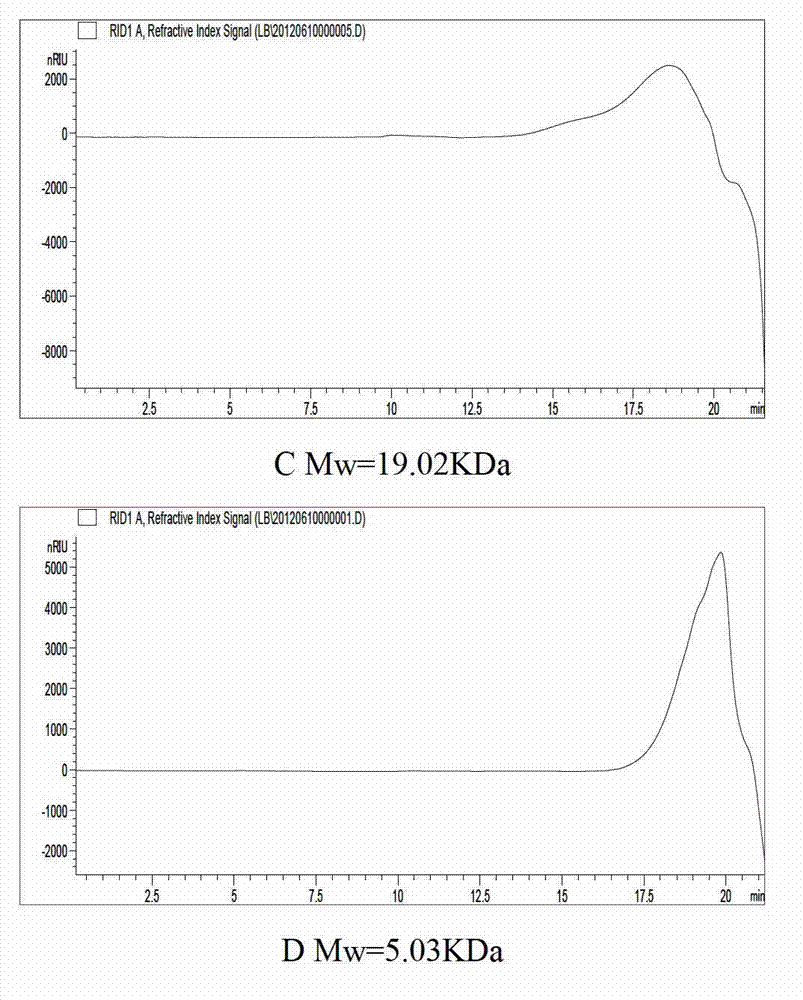

ActiveCN102898536AIncrease reaction rateRapid responseSugar derivativesOligosaccharidesChemistryDegradation reaction

The invention belongs to a marine chemical engineering technology, in particular to a method for degrading enteromorpha polysaccharide, which concretely comprises the steps of: adding hydrochloric acid and hydrogen peroxide into enteromorpha polysaccharide solution, and carrying out degradation reaction under the assistance of microwave to obtain the enteromorpha polysaccharide or oligosaccharide with the low molecular weight of 3-400K Da. Compared with the traditional heating reaction, the method can be used for preparing the enteromorpha polysaccharide with the low molecular weight and greatly shortens the action time; and the obtained enteromorpha polysaccharide or oligosaccharide has no obvious difference in the aspect of basic chemical structure compared with the initially prepared enteromorpha polysaccharide raw material.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Method for low-temperature oxidative degradation of organic gas

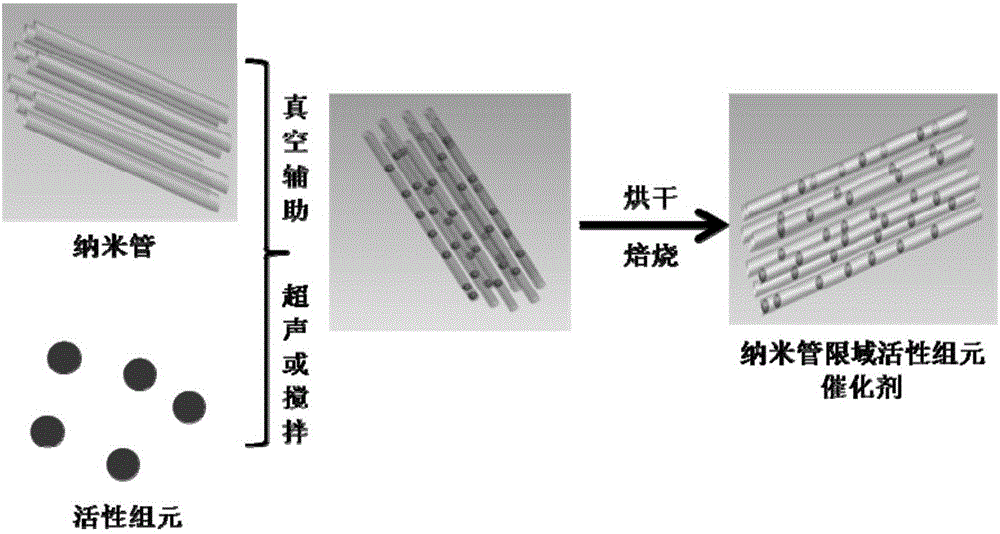

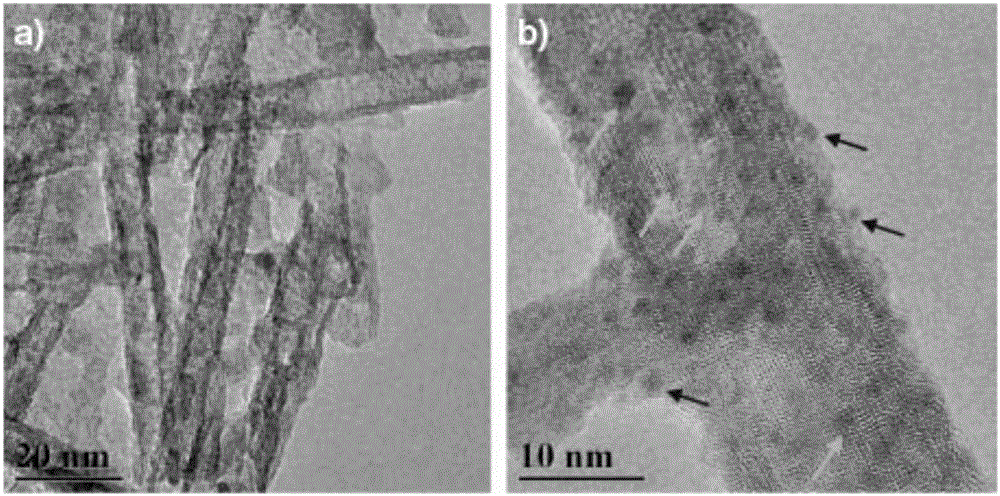

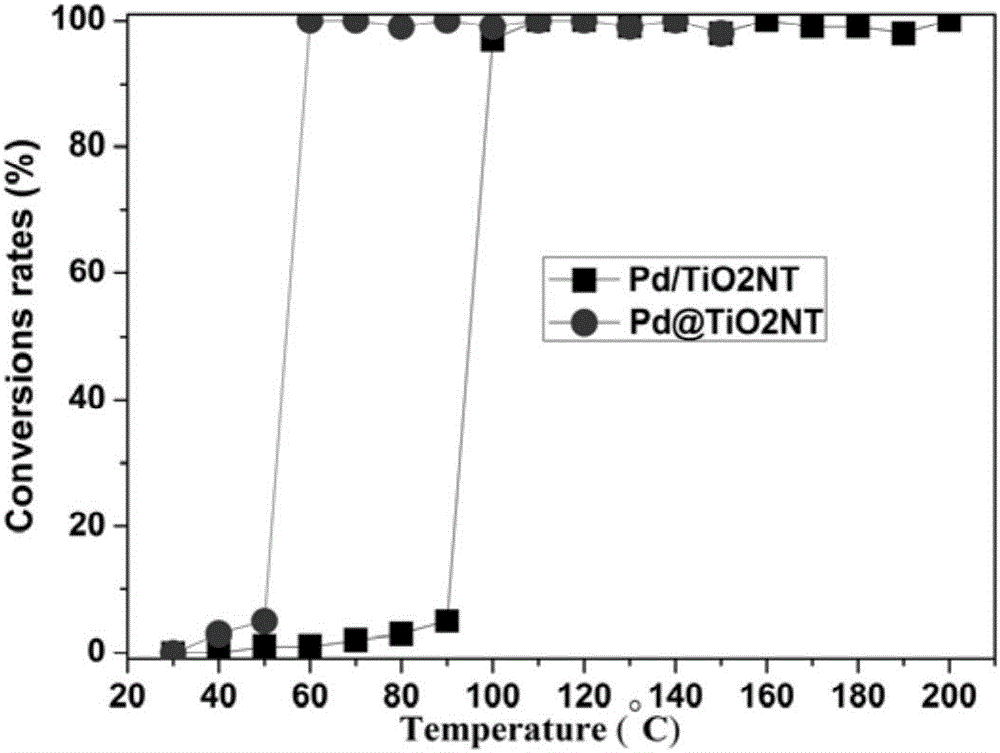

InactiveCN106076113AImprove stabilityAvoid reunionGas treatmentHeterogenous catalyst chemical elementsReaction temperatureCatalytic oxidation

The invention discloses a method for low-temperature oxidative degradation of organic gas. The method comprises the steps that a nanotube limited-range active component catalyst is used as a catalyst, a reaction is carried out under the conditions that the temperature is 45-220 DEG C and the airspeed is 100-100000h<-1> for 0.5-1500h for a catalytic oxidation degradation reaction of organic gas, and the organic gas is oxidized into degradation reaction and water. According to the method, by means of the nanotube open-framework structure and micronanospace, the active component of the catalyst for treating organic gas is planted into the nanotube open-framework structure to prepare the nanotube limited-range active component catalyst with high activity and stability, the limited-range catalyst is used for oxidative degradation of organic gas and can rapidly oxidize the organic gas at a low temperature into carbon dioxide and water, the organic gas removal rate reaches up to 95% or more, the catalyst is high in activity and long in service life, and the problems that reaction temperature is high, catalyst activity and stability are low and the catalyst active component service life is short in the prior art are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

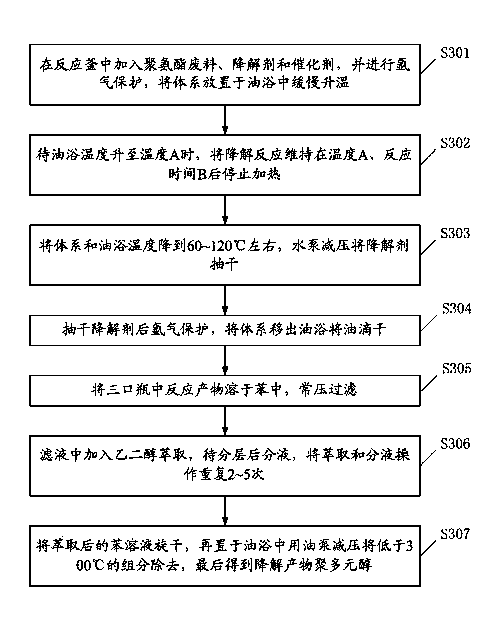

Recovery process of polyurethane waste

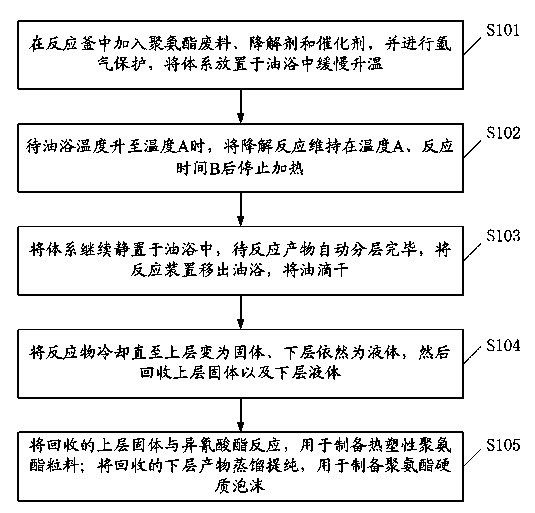

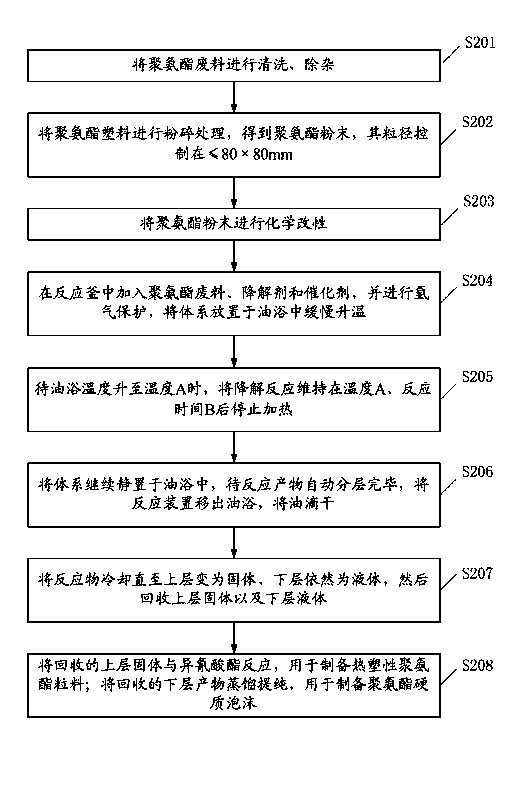

ActiveCN103374145AReduce degradationImprove recycling efficiencyPlastic recyclingPentaerythritolPolyol

The invention discloses a recovery process of polyurethane waste. The recovery process comprises the following steps: (1) adding polyurethane waste, a degradation agent and a catalyst in a reaction kettle, and performing argon shield, placing the system in an oil bath to slowly warm, wherein the degradation agent is selected from a mixture of more than any two of alkyl polyols, the dosage of the degradation agent is 1-3 times of that of the polyurethane waste, the alkyl polyols comprise glycol, propanediol, diethylene glycol, dipropylene glycol, ethanolamine, diglycol and pentaerythritol; (2) stopping heating after keeping the degradation reaction at temperature A and reaction time B when the oil bath temperature is raised to the temperature A; and (3) performing recovery processing on a target reaction product by using the recovery process. By adopting the recovery process disclosed by the invention, the recovery efficiency can be obviously improved, byproducts produced during degradation of the polyurethane waste are reduced, and the recovery cost is lowered.

Owner:佛山市高明区业晟聚氨酯有限公司

Preparation of Ni<2+> doped geopolymer catalyst and its application in organic matter degradation

InactiveCN102430419ASimple processRealize large-scale preparationWater/sewage treatment by irradiationWater contaminantsSlagIon exchange

The invention discloses preparation of a Ni<2+> doped geopolymer catalyst and application of the catalyst in organic matter degradation. The preparation method utilizes industrial solid waste fly ash or mineral slag or steel slag as the raw material, which, excited by a chemical exciting agent sodium silicate, can generate a fly ash or mineral slag or steel slag based geopolymer respectively. Then through NH4<+> and Ni<2+> ion exchange reactions in order, a Ni<2+> doped geopolymer catalyst can be generated. The catalyst can be used for degradation reaction of methylene blue in industrial wastewater and has a degradation rate up to 77.29%. The preparation and organic matter degradation processes have the advantages of simplicity and practicability, no need for heating, energy saving and environmental protection, thus being able to realize large scale preparation and application.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method for sulphuric acid glucosamine

ActiveCN101343294ASimple structurePromote safe productionSkeletal disorderAminosugarsPotassiumPrecipitation

The invention discloses a preparation method of glucosamine sulfate, relating to a compound containing aminosugar. The preparation method of glucosamine sulfate has the advantages that a great deal of sulfate precipitation by-product is avoided being generated and a great deal of organic solvent is avoided being used, the operation is in complete aqueous phase, the production processes are safe, the sulfuric acid removed by the membrane method can be recovered and used, the production cost is reduced, exhaust and waste residue are not produced, the prepared product does not contain sodium, potassium or chlorine, the purity of the product reaches over 95 percent, and the glucosamine sulfate can be used to treat osteoarthritis without usage taboo. The preparation method is characterized in that chitin is adopted as the raw material, and a degradation agent of concentrated sulfuric acid is used to cause the chitin to generate degradation reaction; diluted sulfuric acid is used as a deacetylation agent to cause the degraded chitin to generate deacetylation reaction; the chitin which is not reacted after the deacetylation reaction is filtered, and the unreacted sulfuric acid is removed by the membrane method; and the solution, in which the unreacted sulfuric acid is removed, is decolorized, concentrated and dried, and glucosamine sulfate is obtained.

Owner:厦门蓝湾科技有限公司

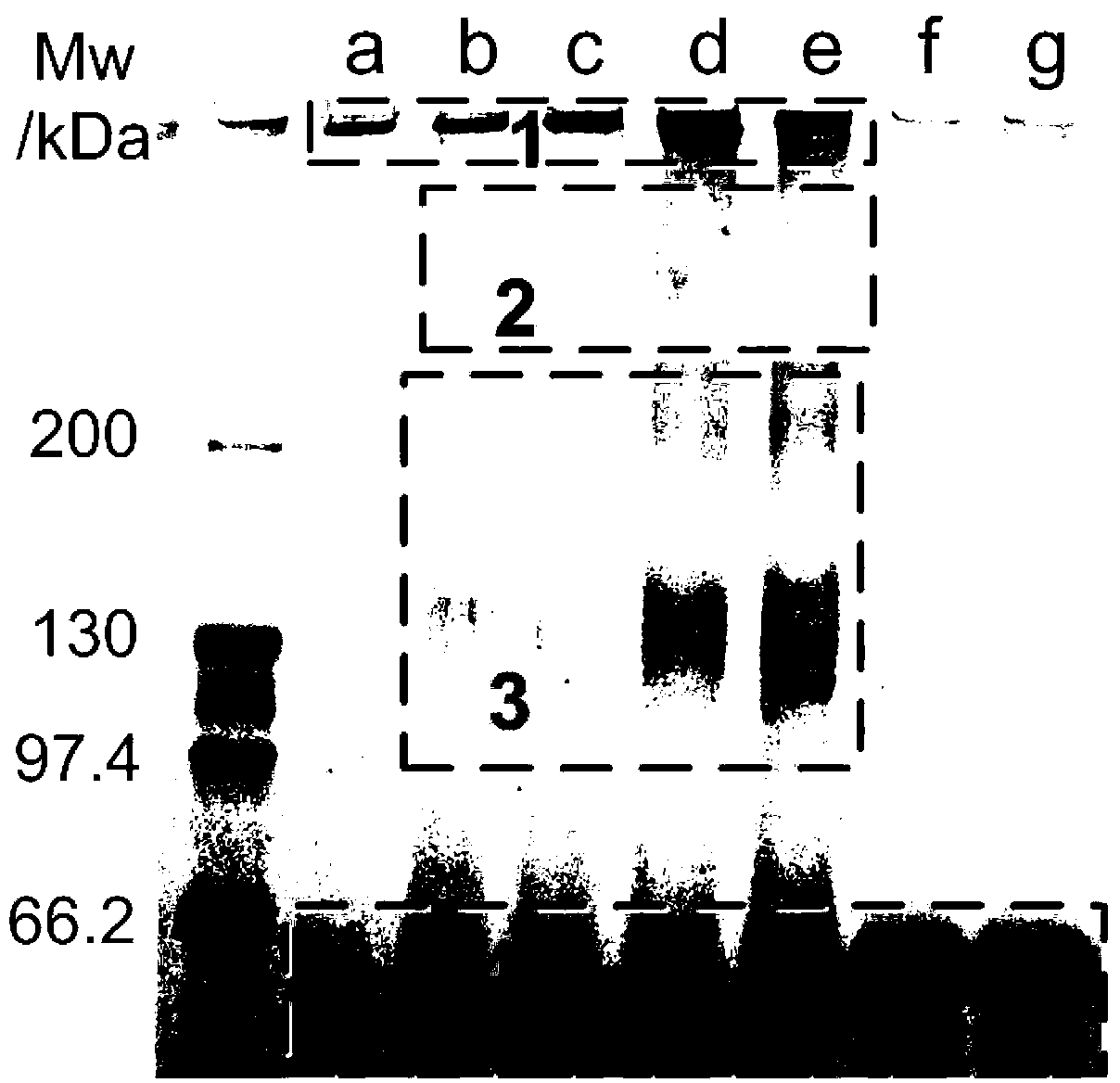

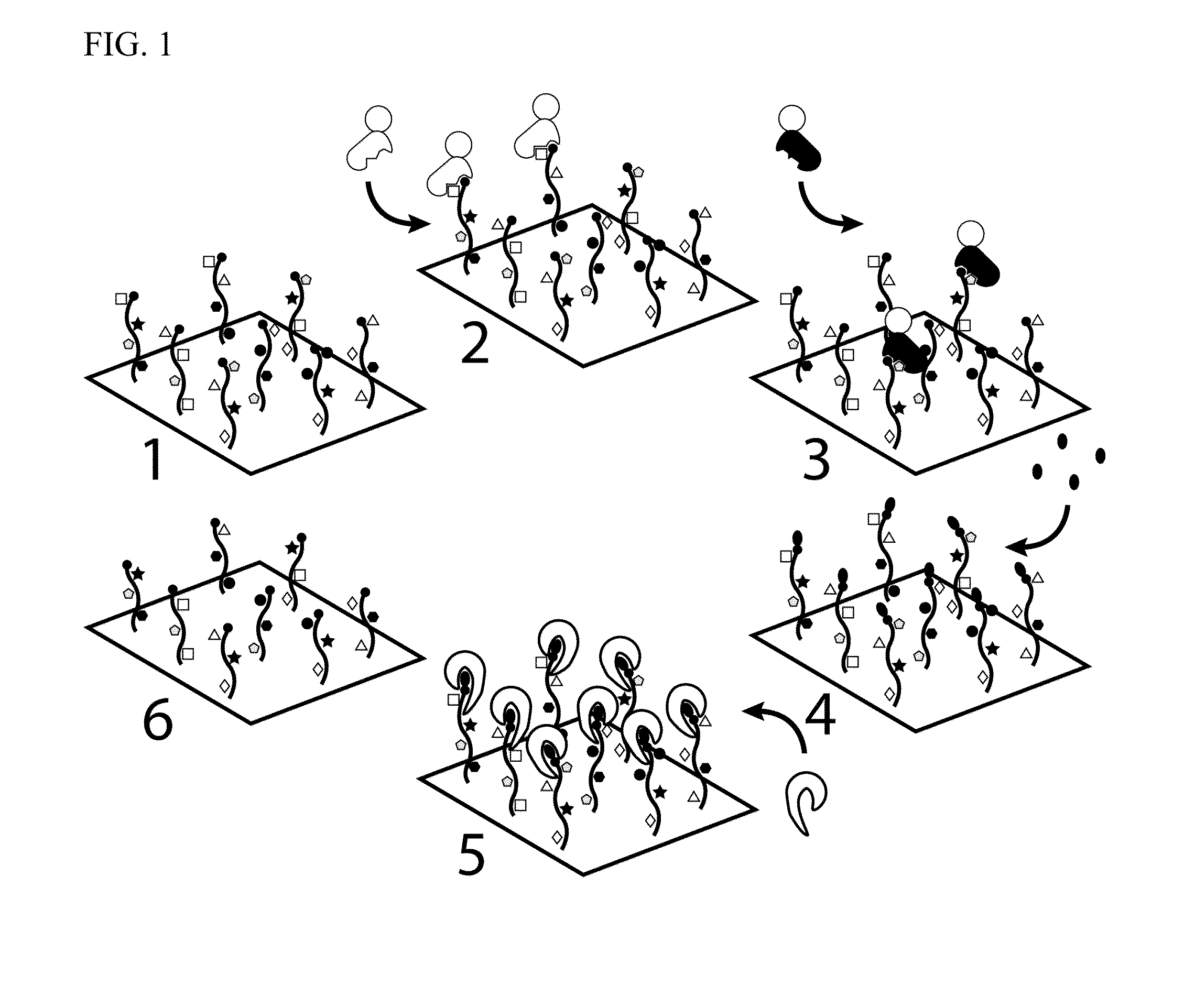

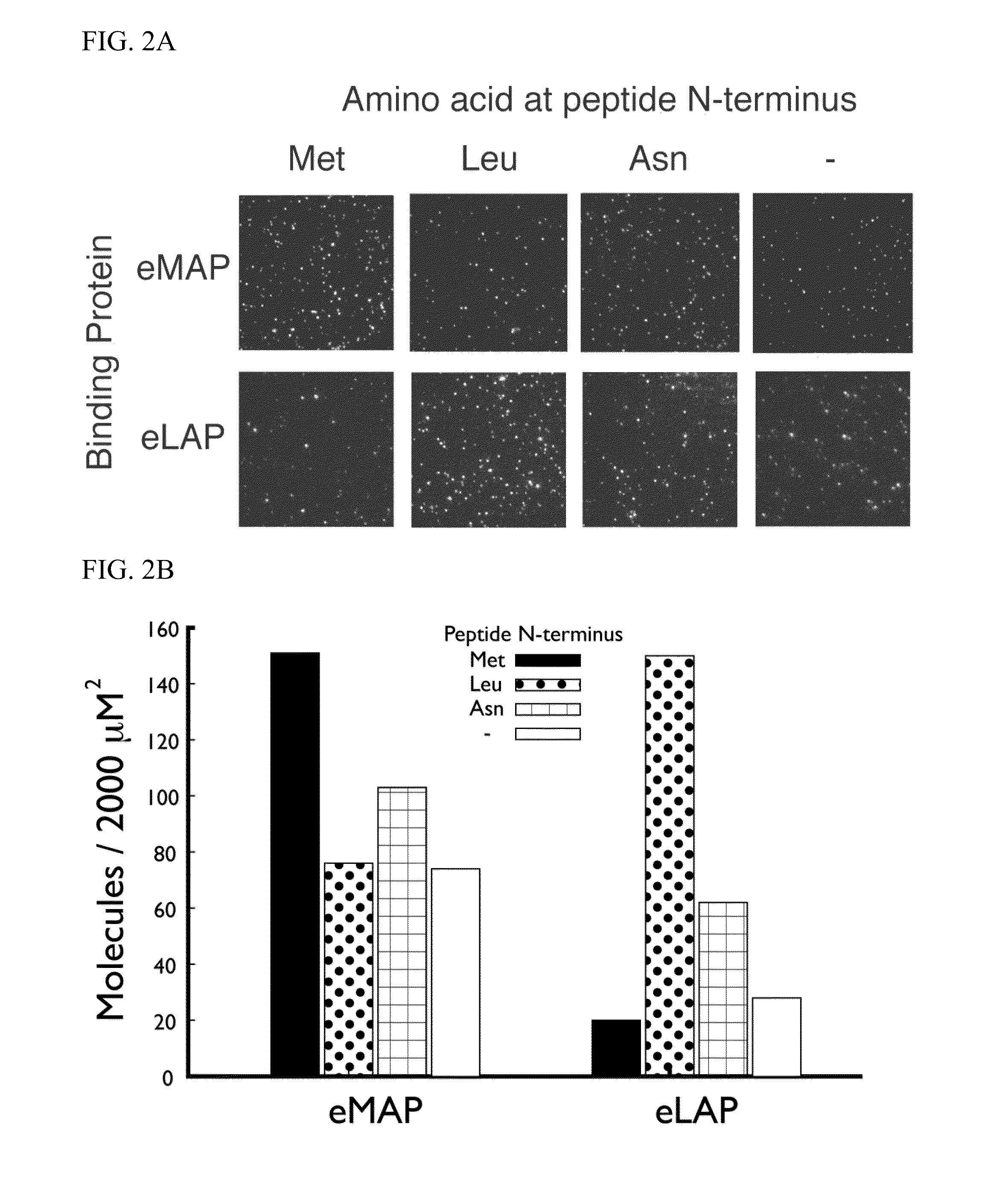

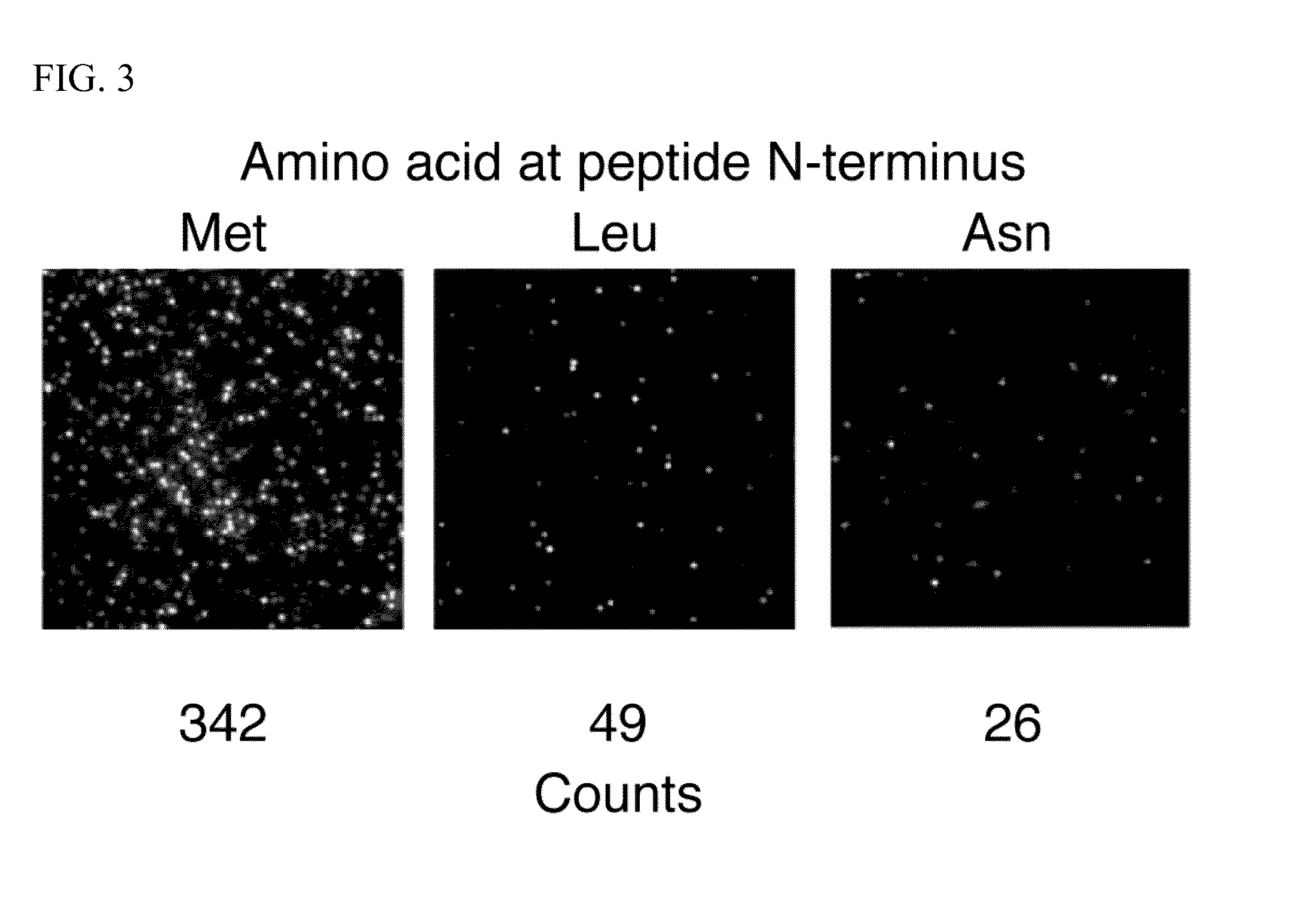

Molecules and methods for iterative polypeptide analysis and processing

Reagents and methods for the digital analysis of proteins or peptides are provided. Specifically provided herein are proteins for identifying the N-terminal amino acid or N-terminal phosphorylated amino acid of a polypeptide. Also, an enzyme for use in the cleavage step of the Edman degradation reaction and a method for using this enzyme are described.

Owner:WASHINGTON UNIV IN SAINT LOUIS

Method for degrading waste polyurethane foam to recycle polyether polyol

InactiveCN107955206AAchieve recyclingMeet recycling requirementsPlastic recyclingEnvironmental resistanceAlcohol

The invention belongs to the technical field of recycling and reutilization of waste polyurethane foam products, and in particular relates to a method for degrading waste polyurethane foam to recyclepolyether polyol. The method provided by the invention comprises the following steps: mixing and compounding low molecular alcohol and degradation auxiliary agents to form an alcoholysis solution; adding the waste polyurethane foam into the alcoholysis solution and carrying out degradation reaction; carrying out vacuum degassing treatment on degraded crude polyether to obtain recyclable crude polyether polyol. According to the method provided by the invention, the low molecular alcohol is used as an alcoholysis agent and various degradation auxiliary agents are added, so that the recycling ofthe waste polyurethane foam with different physical and mechanical properties is realized under a relatively moderate condition through reaction mechanisms of chemical alcoholysis and alkaline hydrolysis, and recycled polyether polyols with various viscosity and different hydroxyl values are obtained; the method has the advantages of low cost, simple technology, high recycling efficiency, greenness and environment protection and the like; different polyurethane foam recycling requirements are met, and the method can be stably applied to subsequent polyurethane foaming.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

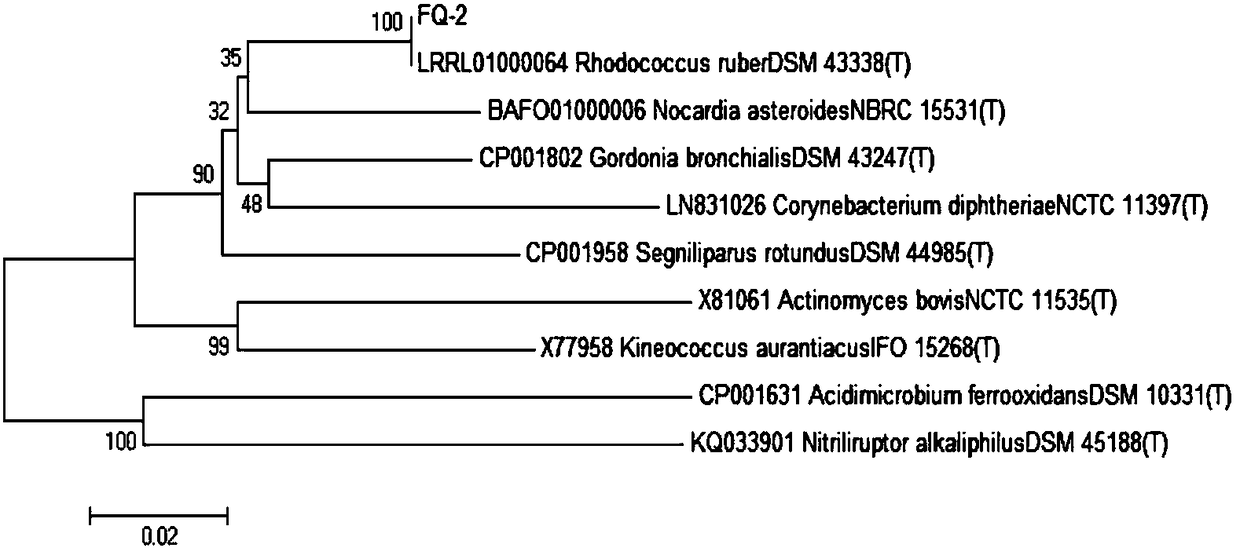

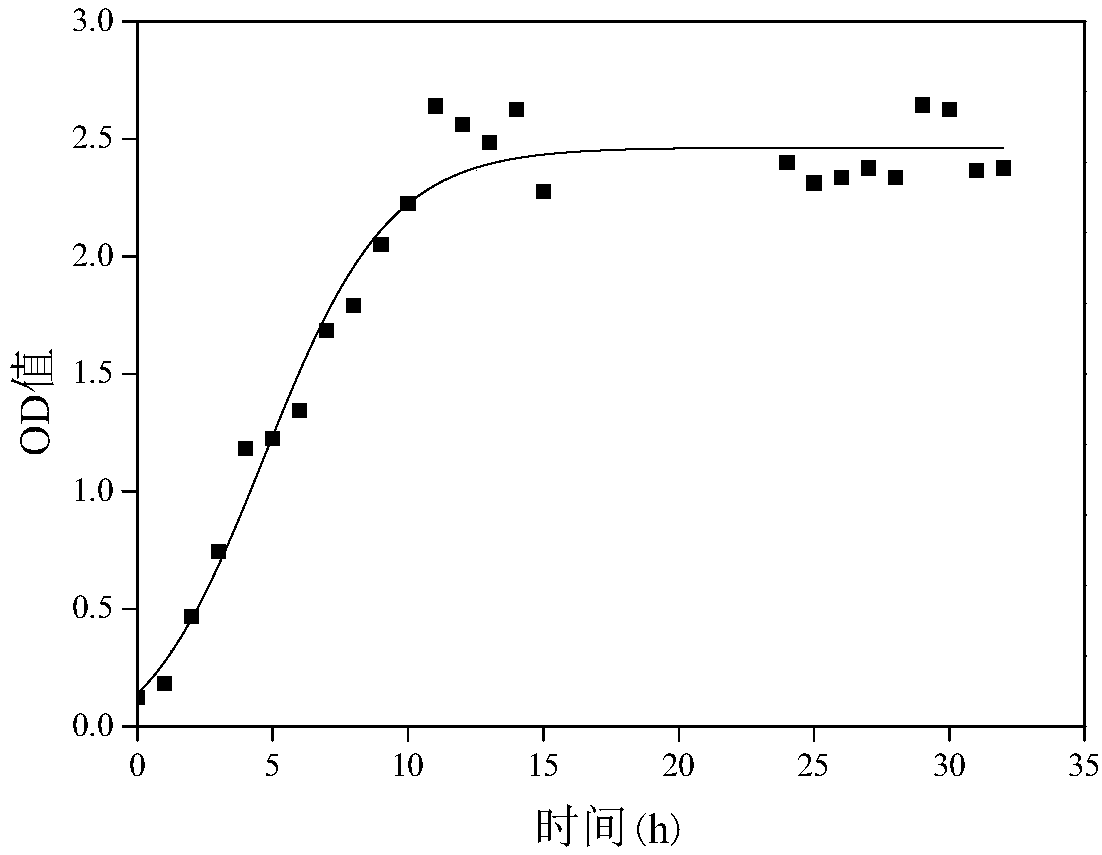

Rhodococcus ruber and application thereof in degradation of organic pollutants

The invention discloses rhodococcus ruber FQ-2 and an application thereof in degradation of acetone and other common industrial organic pollutants. The application method comprises the steps: an inorganic salt culture medium containing acetone and other common industrial pollutants is inoculated with the rhodococcus ruber FQ-2, a degradation reaction is carried out under the conditions of the temperature of 30 DEG C and the rotating speed of 160 r / min, and thus the organic pollutants are degraded; the common organic pollutants comprise acetone, n-hexane, carbon disulfide, chlorobenzene, butylacetate, ethyl acetate or alpha-pinene. The rhodococcus ruber FQ-2 is taken from activated sludge of an aeration tank of a pharmaceutical factory in Zhejiang province, has good degradation effect on VOCs organic pollutants, especially acetone, and can completely convert acetone into harmless substances such as CO2, H2O, cell biomass and the like; at the same time, the bacterial strain also can degrade common industrial pollutants such as carbon disulfide and chlorobenzene in different extent, so the bacterial strain has broad application prospects in biological purification of industrial wastegas and wastewater.

Owner:ZHEJIANG UNIV OF TECH

Activated arylamine-based polybenzoxazines

InactiveUS6160079AFacilitate ring openingLow polymerization temperatureSilicon organic compoundsGlass transitionElectron

Arylamines with electron donating groups such as alkyl and alkoxy groups in the meta position on the aromatic ring change the polymerization temperature of the benzoxazine prepared therefrom and offer an opportunity for an additional crosslinking site (the para position on the aromatic amine can couple to a Mannich base generated by the opening of the oxazine ring of the benzoxazine or a methylene bridge generated by a degradation reaction). Naphthenic amines with an alkyl or alkoxy substituent on the 5th through the 8th carbon atom on the naphthalene ring can function similarly. The polymers for benzoxazines prepared from at least 10% substituted aromatic or naphthenic amines are useful due to low polymerization temperatures and higher Tg (glass transition temperature).

Owner:EDISON POLYMER INNOVATION EPIC

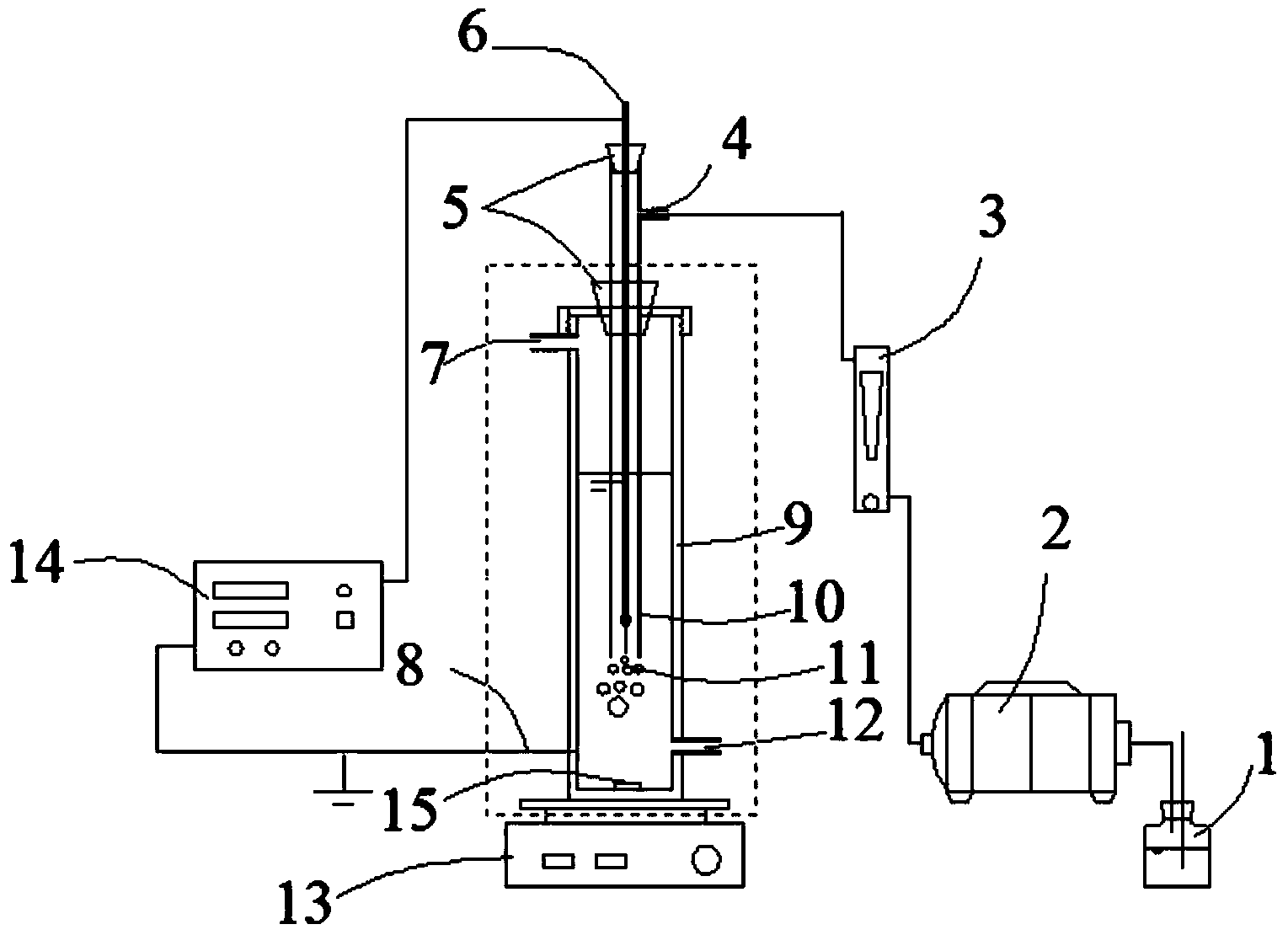

Device and method for degrading antibiotic wastewater by utilizing low temperature plasma in coordination with bismuth molybdate catalyst

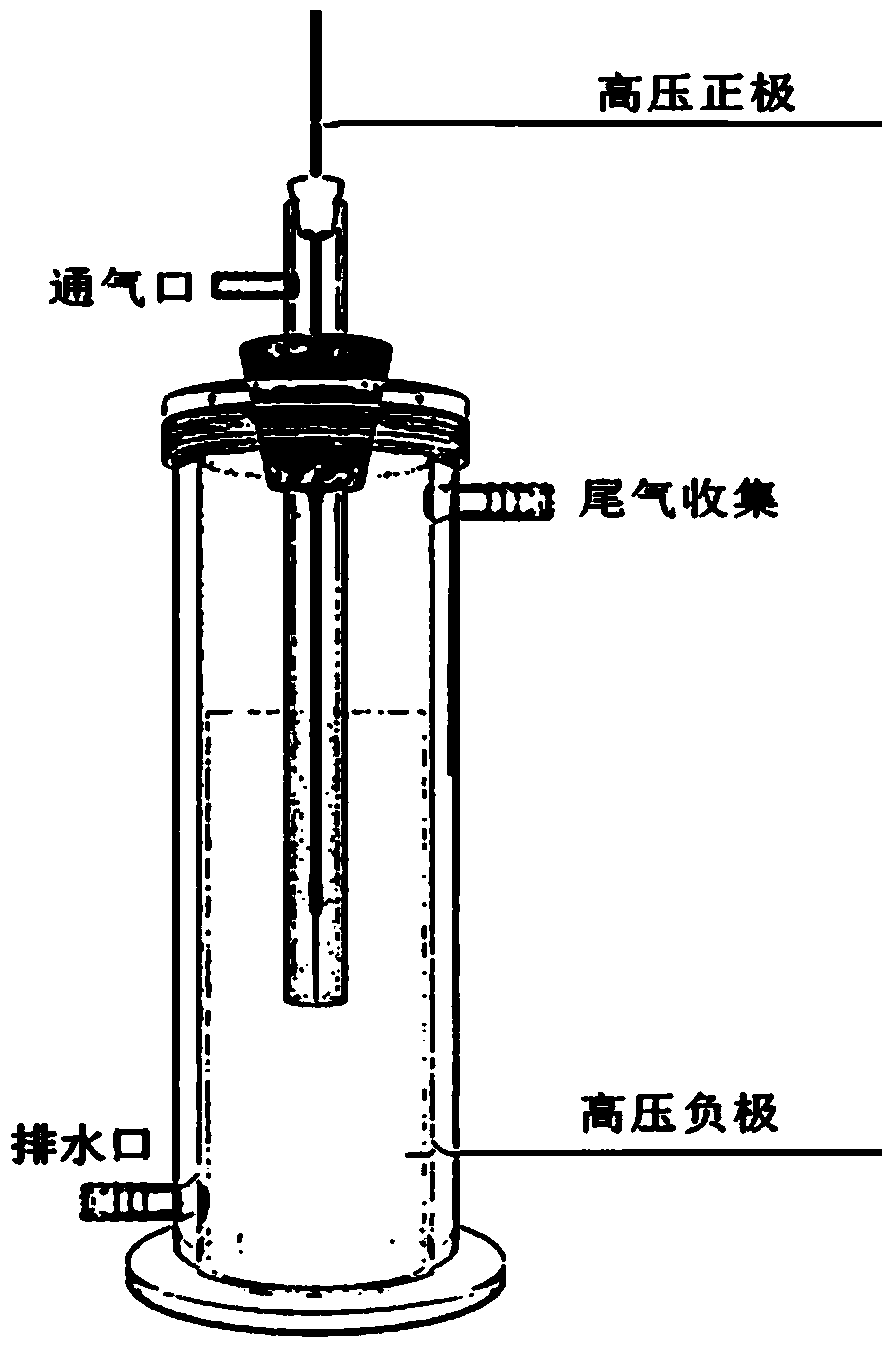

InactiveCN103848484AImprove degradation rateHigh removal rateWater/sewage treatment using germicide/oligodynamic-processMetal/metal-oxides/metal-hydroxide catalystsCatalyst degradationBreather

The invention discloses a device and a method for treating antibiotic wastewater by utilizing low temperature plasma in coordination with a bismuth molybdate catalyst. The device for treating the antibiotic wastewater by utilizing the low temperature plasma in coordination with the bismuth molybdate catalyst comprises a barrel-shaped reactor, a breather pipe, a high voltage electrode, an alternating current high voltage power supply, an air pump and a stirrer, wherein the breather pipe is arranged inside the barrel-shaped reactor and is coaxial with the barrel-shaped reactor, the high voltage electrode is suspended inside the breather pipe, the lower port of the breather pipe is arranged at the lower bottom part inside the barrel-shaped reactor, the upper part of the breather pipe is arranged outside the barrel-shaped reactor, an air inlet is formed in the side wall of the upper part of the breather pipe, the air inlet is communicated with the outlet of the air pump by virtue of a pipeline; the alternating current high voltage power supply is respectively connected to the high voltage electrode and grounded, and the stirrer is arranged at the lower part of the barrel-shaped reactor. The device for treating the antibiotic wastewater by utilizing the low temperature plasma in coordination with the bismuth molybdate catalyst has the characteristics of simple design, low equipment investment and no secondary pollution and can be applied to the filed of treatment on antibiotic wastewater and organic wastewater difficult to be biochemically degraded, wherein a degradation reaction temperature can be increased by fully utilizing heat produced in a discharge process.

Owner:NANJING UNIV

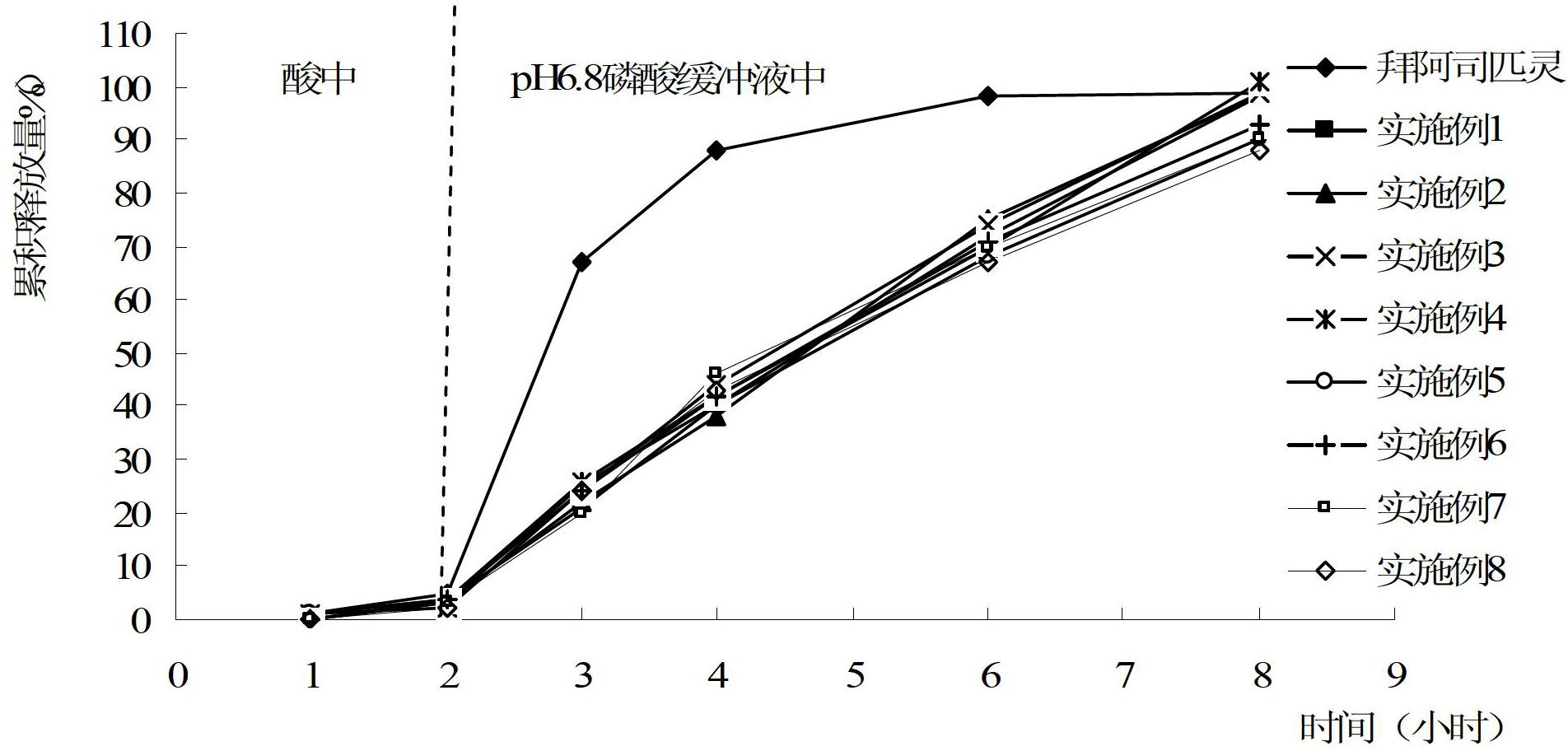

Preparation method of aspirin enteric-coated sustained-release preparation

ActiveCN102641254AAvoid degradation reactionsReduce the number of dosesOrganic active ingredientsAntipyreticSustained Release TabletRelease time

The invention relates to a preparation method of an enteric-coated sustained-release preparation, in particular to a preparation method of an aspirin enteric-coated sustained-release preparation. According to the preparation method, a prepared aspirin sustained-release tablet is used as a core tablet, and an enteric coating is packaged on the outer layer of the core tablet. In order to prevent aspirin in the core tablet from interacting with an enteric-coated material, an isolating layer can be packaged between the core tablet and the enteric coating. After the aspirin is prepared into the enteric-coated sustained-release preparation provided by the invention, the aspirin is not released or a little aspirin is released in a stomach, the release time in intestines is greatly extended, the phenomena of violent disintegration and dissolution do not occur in the intestines, the aspirin is released more slowly, the bioavailability is greatly increased, the degradation reaction of the aspirin in water is avoided, the frequency of administration is lower, and the compliance of a patient is improved.

Owner:SHANDONG XINHUA PHARMA CO LTD

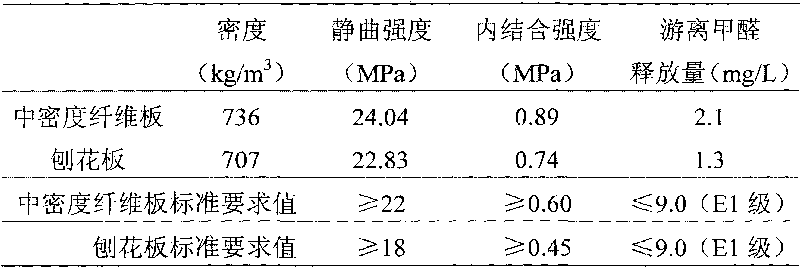

Wood adhesive prepared by degrading soybean protein by utilizing strong basicity and preparation method thereof

InactiveCN101724376AHigh viscosityImprove adsorption capacityProtein adhesivesGlue/gelatin preparationMedium densityAdhesive

The invention discloses a wood adhesive prepared by degrading soybean protein by utilizing strong basicity and a preparation method thereof, and relates to a soybean protein-based wood adhesive and a preparation method thereof. The invention solves the problems of low content of the soybean protein, high moisture content and large viscosity existing in conventional soybean adhesives or soybean protein adhesives. The product is prepared by performing a degradation reaction of defatted soybean protein powder or soybean protein isolate, strong base and water, then using strong phosphoric acid to adjust the pH value of the obtained solution, and then adding dialdehyde into the obtained solution to mix the solution evenly. The method comprises the steps of: 1, weighing; 2, preparing strong base solution, heating the strong base solution, adding the defatted soybean protein powder or the soybean protein isolate into the strong base solution under stirring, and then cooling the strong base solution to a room temperature after heating reflux; and 3, using the strong phosphoric acid to adjust the pH value, adding the dialdehyde into the solution, and stirring the solution evenly. The adhesive has the advantages of high content of the soybean protein, low moisture content and low viscosity, and can be used for preparing plywood, flakeboards and medium-density fiberboards.

Owner:NORTHEAST FORESTRY UNIVERSITY

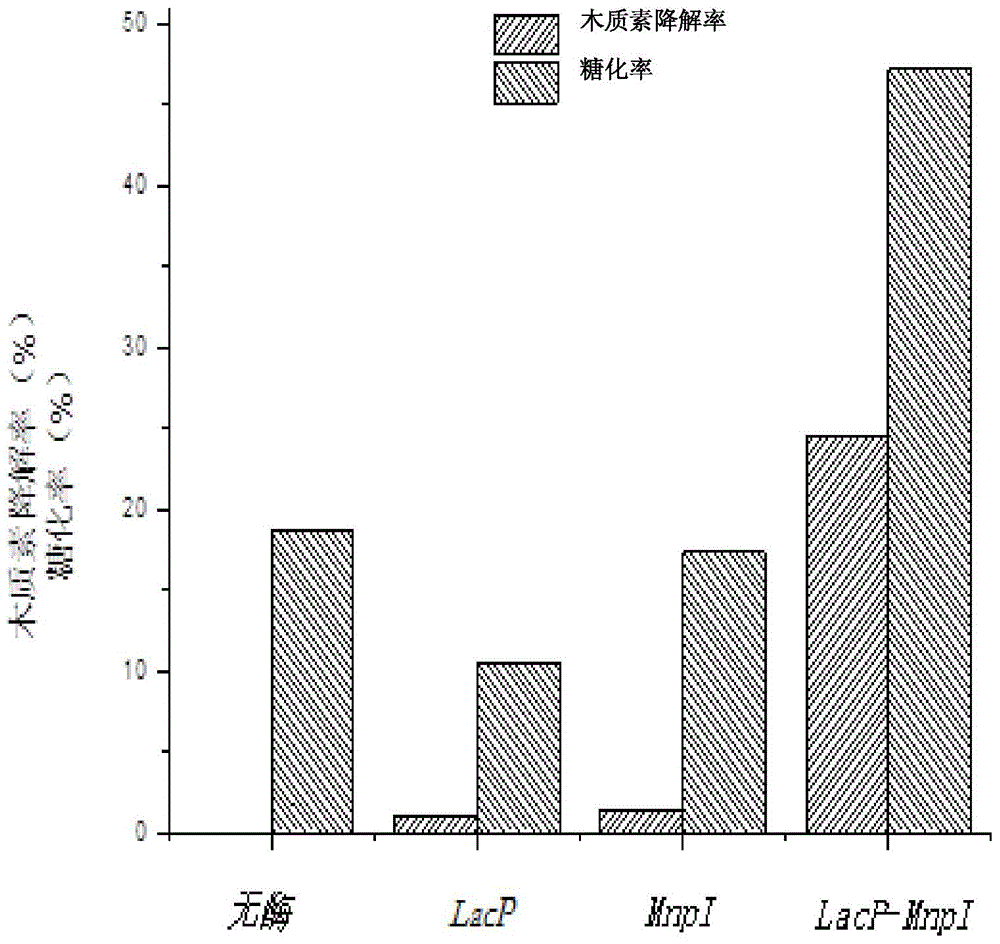

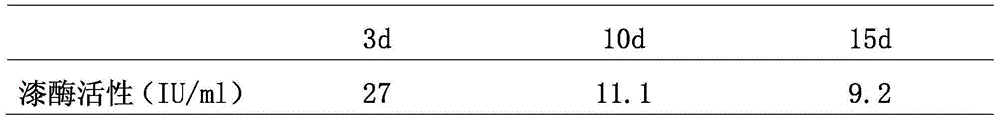

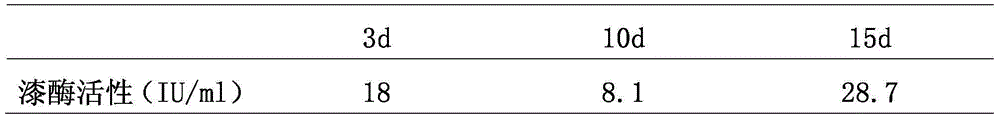

Lignin degradation solution and preparation method thereof as well as method for degrading lignin by using lignin degradation solution

InactiveCN104894079AEfficient degradationImprove degradation conversion efficiencyOxidoreductasesFermentationCelluloseSodium acetate

The invention discloses a lignin degradation solution and a preparation method thereof as well as a method for degrading lignin by using the lignin degradation solution, and belongs to biochemical and bio-refinery methods to solve the problem that the efficient biodegradation of lignin is difficult to realize by adopting single ligninase of laccase at present. The lignin degradation solution is prepared by the following steps: dissolving laccase and manganese peroxidase into an acetic acid-sodium acetate buffer solution of which the pH value is 4-6 in an enzyme load ratio of (10:1)-(1:5) to ensure that the enzyme loads of the laccase and manganese peroxidase are respectively 1U / ml-50U / ml and 1U / ml-50U / ml; and then adding 1-10mM of MnSO4 and 0.1-1mM of H2O2, wherein the laccase and manganese peroxidase are obtained by fermenting white rot fungi to obtain extracellular crude enzyme liquid and then performing separation and purification respectively. According to the lignin degradation solution and the methods disclosed by the invention, the synergistic oxidative degradation of macromolecular lignin with rich structural diversity is realized, and compared with a degradation reaction system with single ligninase, the degradation rate of the macromolecules of the lignin can each 30-50%, the degradation conversion efficiency is significantly improved, and the degradation solution and the methods can be applied to the fields of bio-refinery of lignocelluloses, biological pulping or environmental treatment and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for recovering carbon fibers from carbon fiber composite material

The invention discloses a method for recovering carbon fibers from a carbon fiber composite material. The method comprises the following steps: 1. putting the carbon fiber composite material in a microwave oven, carrying out radiation heating treatment on the carbon fiber composite material in a protective atmosphere to initiate degradation reaction on the carbon fiber composite in the microwave oven, wherein the protective atmosphere is an inert gas or an inert gas-oxygen gas mixture, and the oxygen content in the gas mixture is less than or equal to 20v%; and 2. after finishing the degradation reaction, obtaining the solid product which is the recovered carbon fibers. The method can obtain the regenerated carbon fiber material with uniform performance, and effectively enhances the recovery rate of the carbon fibers.

Owner:SUZHOU DEBAO KAIDI NEW MATERIAL

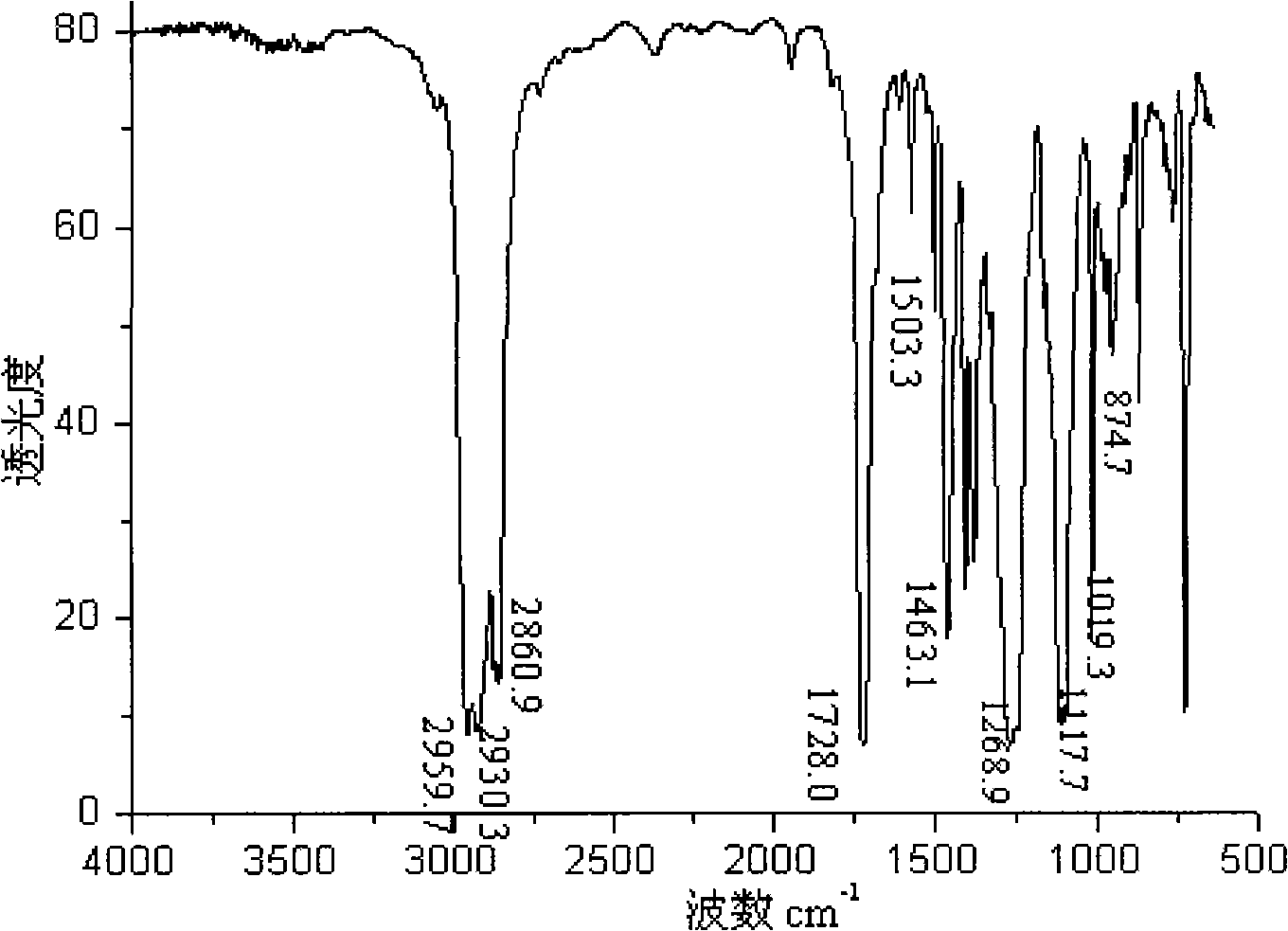

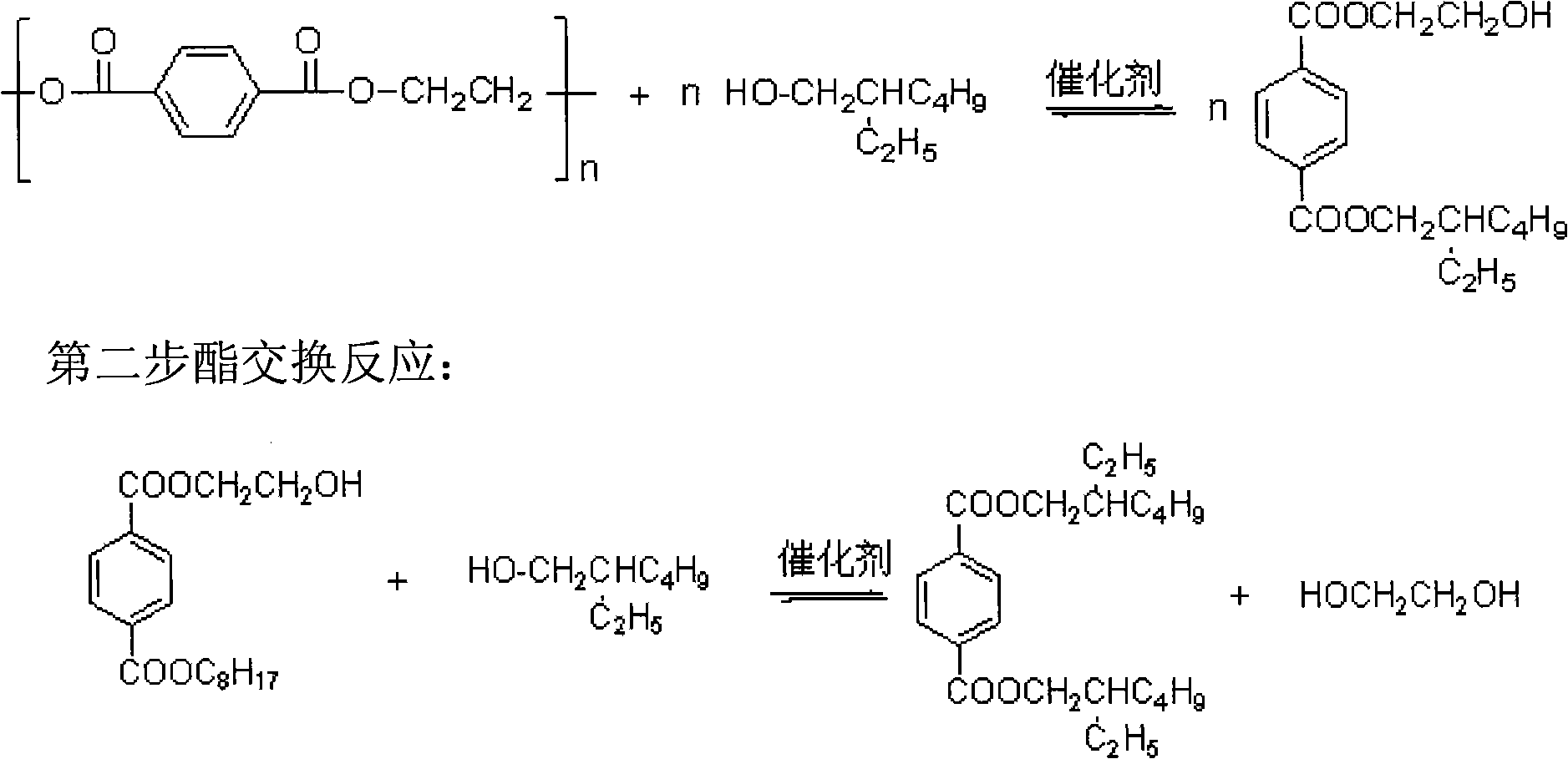

Method for synthesizing PVC plasticiser by reclaiming waste polyester

InactiveCN101302158AShort reaction timeShort processPreparation by ester-hydroxy reactionOrganic compound preparationPolyesterFiber

The invention discloses a method for synthesizing PVC plasticizer DOTP by waste polyester resource utilization, which belongs to the plasticizer technical field. The method comprises the following steps that: 1. under the existence of catalyst, waste polyester scraps are heated with 2-ethyl hexanol to carry out the degradation reaction; 2. glycol produced by the reaction and the 2-ethyl hexanol are coboiled and condensed, and then the glycol is removed through water scrubbing and is reclaimed; 3. reactant coarse ester is orderly subject to aqueous alkali and water for washing, an aqueous layer and an organic layer are separated; the organic layer is added with adsorbent, then the unreacted 2-ethyl hexanol is steamed out, and the plasticizer product dioctyl terephthalate (DOTP) is obtained after the filtration. The raw material of the invention, namely waste polyester can be polyester fiber, waste terylene cloth, leftover materials, waste polyester bottles, and polyester films and so on; the removal method of the catalyst adopts a water scrubbing filtration mode, the catalyst is simultaneously removed during neutralization, water scrubbing and filtration processes, and no additional process operation needs to be added for the removal of the catalyst, so the method has short process flow and low production cost.

Owner:JIANGNAN UNIV

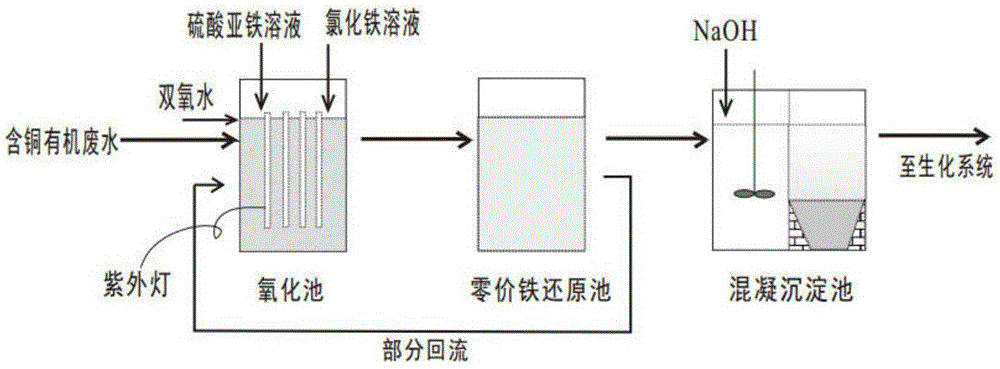

Pretreatment method of copper-containing organic waste water

ActiveCN105347552AImprove operational flexibilityImprove biodegradabilityWater treatment compoundsWater contaminantsPretreatment methodFenton reagent

The invention discloses a pretreatment method of copper-containing organic waste water. The copper-containing organic waste water contains copper ions, the copper-containing organic waste water is added with hydrogen peroxide and ferrous iron and ferric iron solutions, the mixed solution forms Fenton and Fenton-type reagents under the UV irradiation and the Fenton and Fenton-type reagents can realize catalytic degradation of organic pollutants and release of complex copper ions. The oxidized waste water goes through a zero-valent iron reduction system, the copper ions are displaced by the zero-valent iron and the ferric ions are reduced to form ferrous ions. A part of product water containing the ferrous ions is returned into an oxidation tank for Fenton / Fenton-type oxidation reaction and undergoes an oxidation degradation reaction. The product water is subjected to pH adjustment, pollutants are further removed by flocculation deposition and the deposited product water directly enters into a biochemical system. The zero-valent iron reduction system has a simple and easy replacement method. The pretreatment method fully utilizes copper ions in the system, effectively degrades organic pollutants and effectively recovers copper ions.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

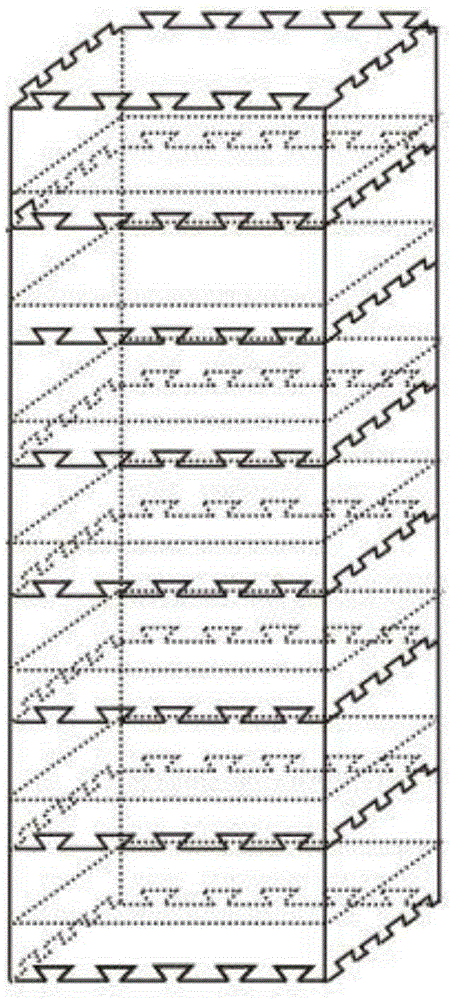

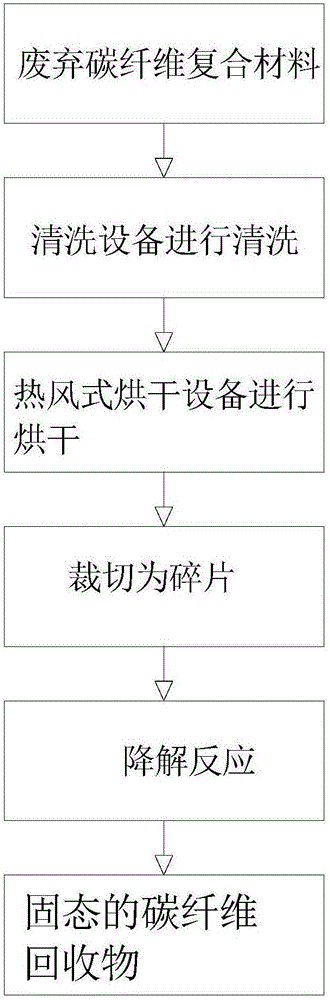

Carbon fiber composite material recovery method

InactiveCN105199139AHigh recovery rateImprove recycling efficiencyPlastic recyclingRecovery methodMicrowave oven

The invention relates to a carbon fiber composite material recovery method. The method comprises the following steps: putting a waste carbon fiber composite material in stirring cleaning equipment to be cleaned, spreading fragments on a tray, putting the tray in a microwave oven, carrying out radiation heating treatment on the carbon fiber composite material fragments in the tray, filling an inert gas in the microwave oven to protect the carbon fiber composite material when the carbon fiber composite material undergoes degradation reaction in the microwave oven and obtaining a solid recovered carbon fiber material after degradation of the carbon fiber composite material is completed. The method has the beneficial effects that the impurities on the surface of the carbon fiber composite material can be removed and the recovery rate of the carbon fibers in the carbon fiber composite material can be increased by cleaning the carbon fiber composite material; meanwhile, the degradation reaction efficiency of the carbon fiber composite material in the microwave oven is further improved by cutting the carbon fiber composite material into the fragments; and the recovery rate of the carbon fibers can be greatly increased, the recovery time can be shortened and waste of the carbon fiber material can be avoided by adopting the recovery method.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

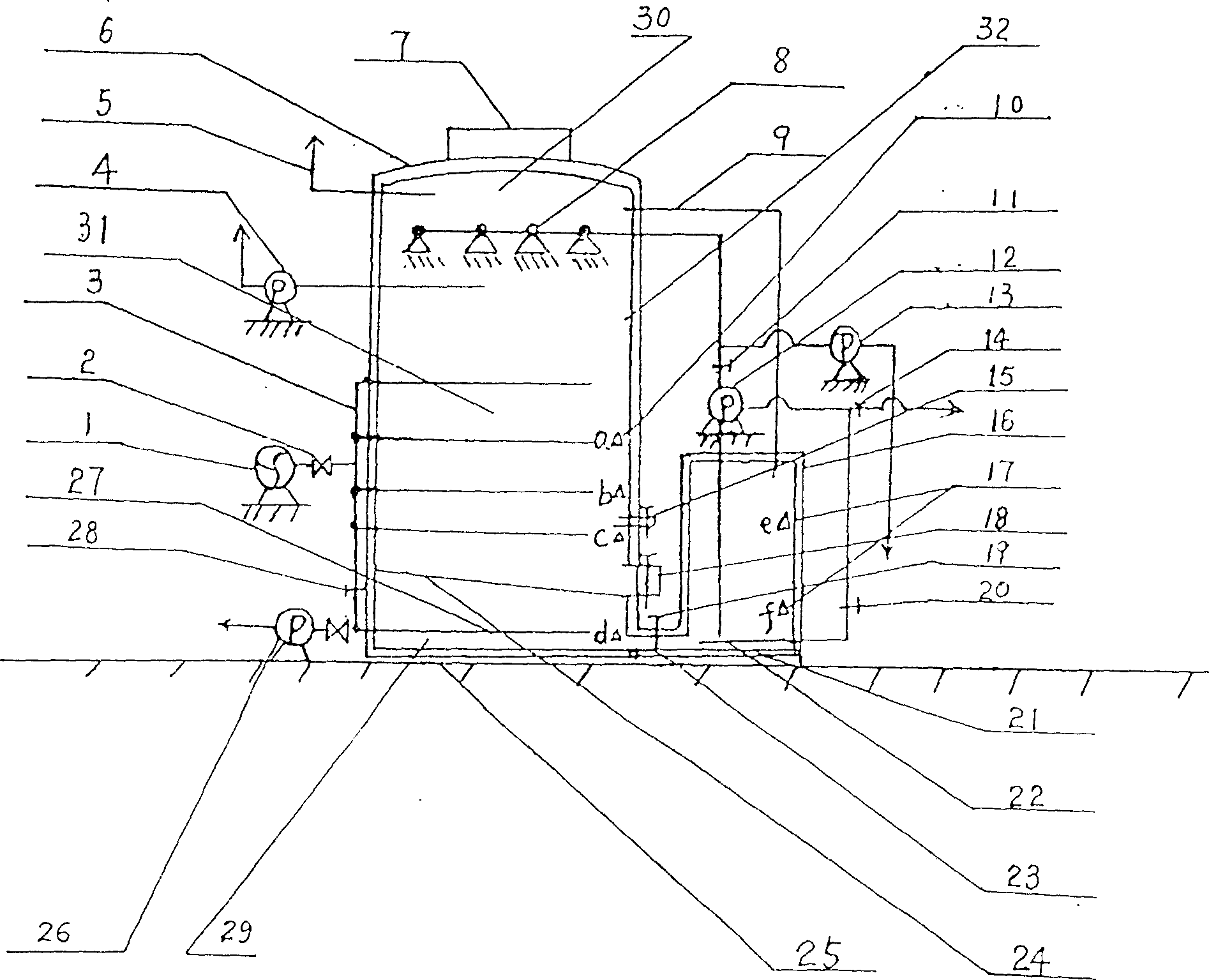

Feedback type organic waste matter biological fermentation device

InactiveCN1869192AImprove securityShort cycleBio-organic fraction processingGas production bioreactorsCushioningEngineering

The invention relates to the feedback biology ferment device of organic waste matter. It comprises the feed-in mouths on the top of the reacting room. The solid-liquid separating gridiron is mounted in the reactor, solid-liquid separating gridiron vertically separates the reactor into the reacting chamber and collecting liquid chamber. Gas section is on the top of reacting chamber and reacting section is on the bottom of it. The insolating gas cloth trachea is mounted on the reacting section on the solid-liquid separating gridiron, the bacterium liquid circumfluence jar is mounted on the gas room section, the bacterium liquid circumfluence cushioning storing jar is mounted outside of the reacting setting, the bacterium liquid circumfluence cushioning storing jar connects the collecting liquid room in the reactor, the bacterium liquid circumfluence cushioning jar connects the bacterium liquid circling adopting spray through the one route out mouth of the bacterium liquid circling pump. The invention is using two-phase dry ferment technique to reach a high rate of degradation reaction.

Owner:魏晓路

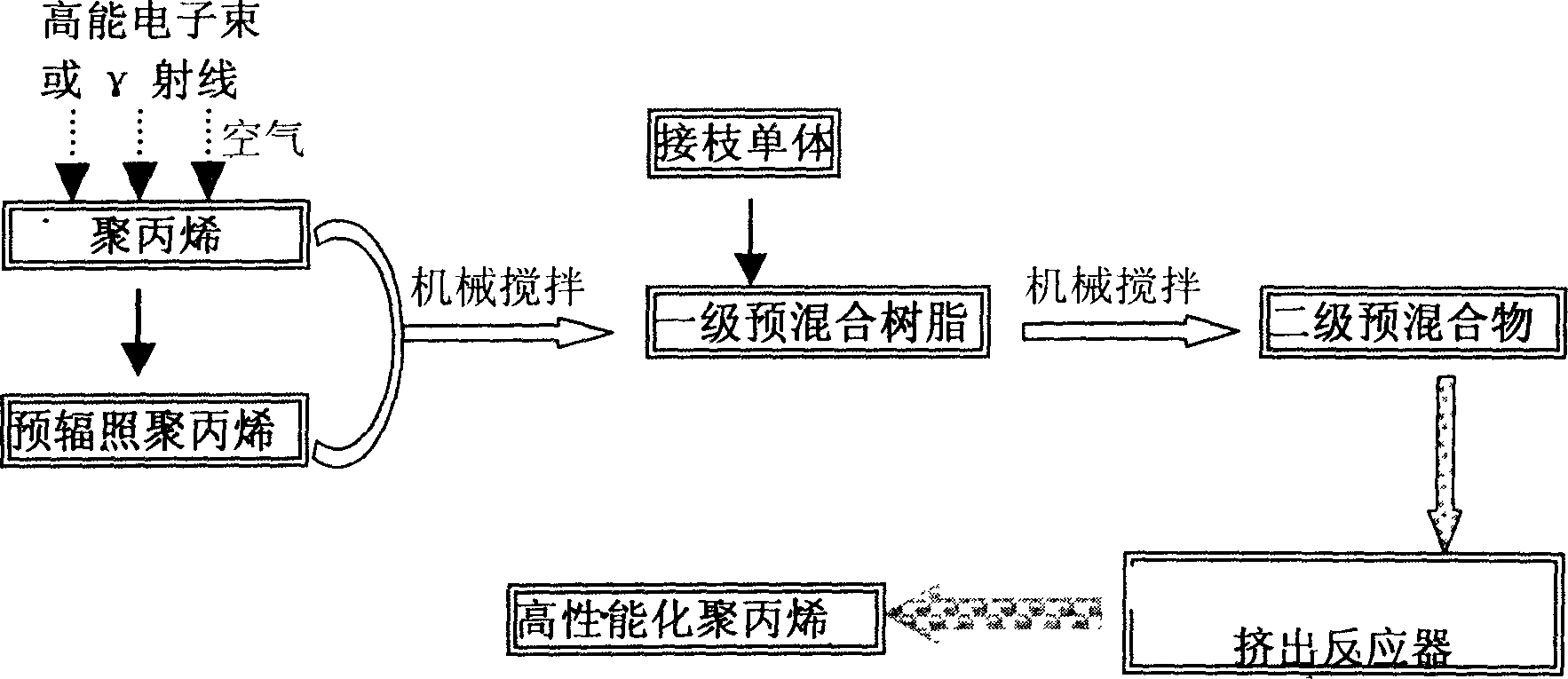

Process for preparing functional poly propylene material

The present invention provides functional polypropylene material preparing process, and adopts small amount of irradiated polypropylene as the initiator for the melt grafting of base polypropylene to prepare functional polypropylene. The present invention has the advantages of reduced degradation reaction, adjustable degradation degree, and lowered production cost. The prepared functional polypropylene has excellent metal adhering performance, and may be used the compatibilizer or main component for preparing polypropylene / polyester, polypropylene / polyamide and other alloy material.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

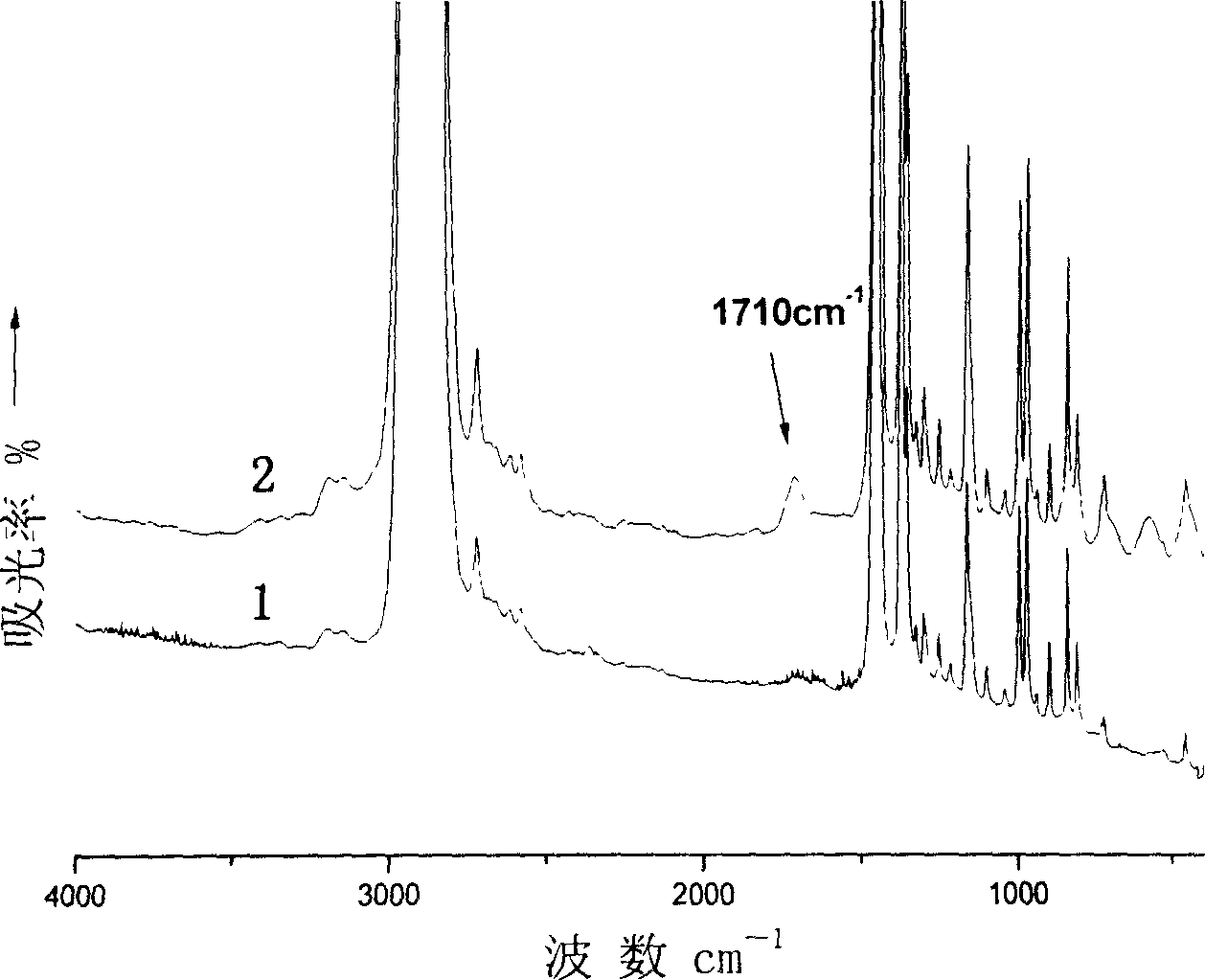

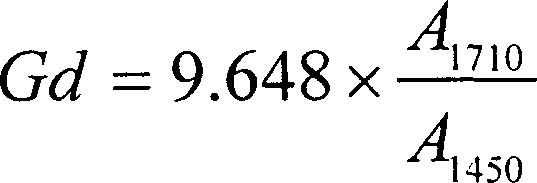

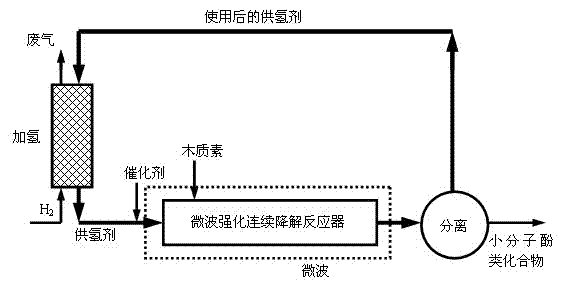

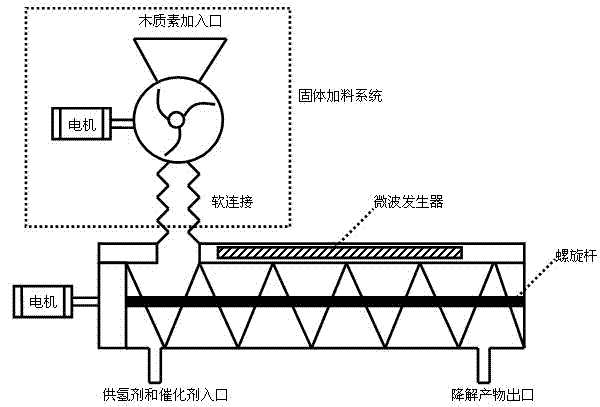

Technology for preparing micro-molecular phenolic compound through microwave reinforced continuous degradation of lignin in hydrogen donor

InactiveCN103073395ARealize continuous preparationIncrease reaction rateOrganic compound preparationCarbonyl compound preparationHydrogenMicrowave

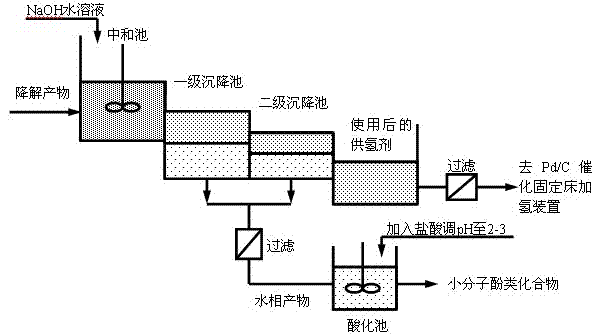

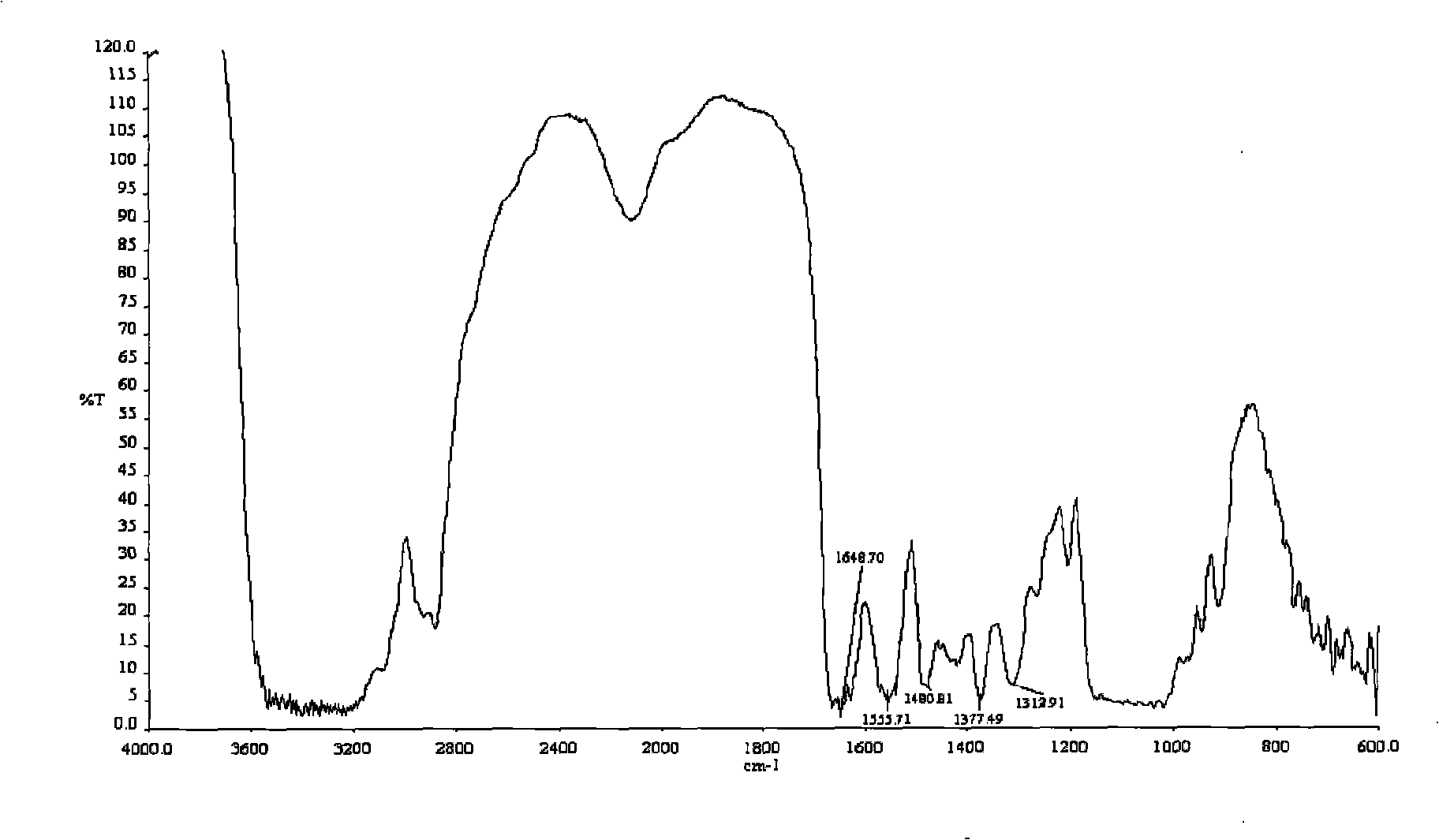

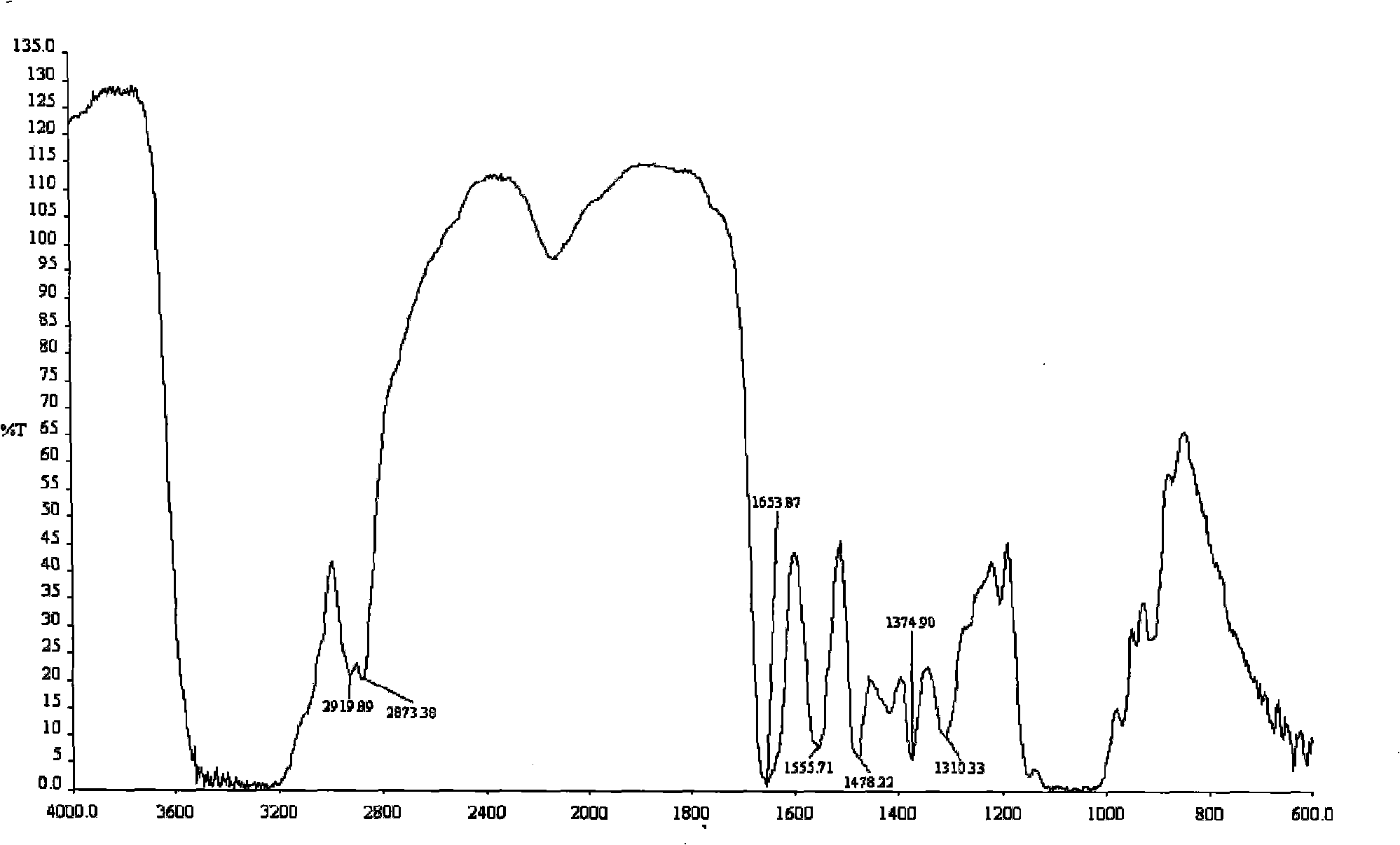

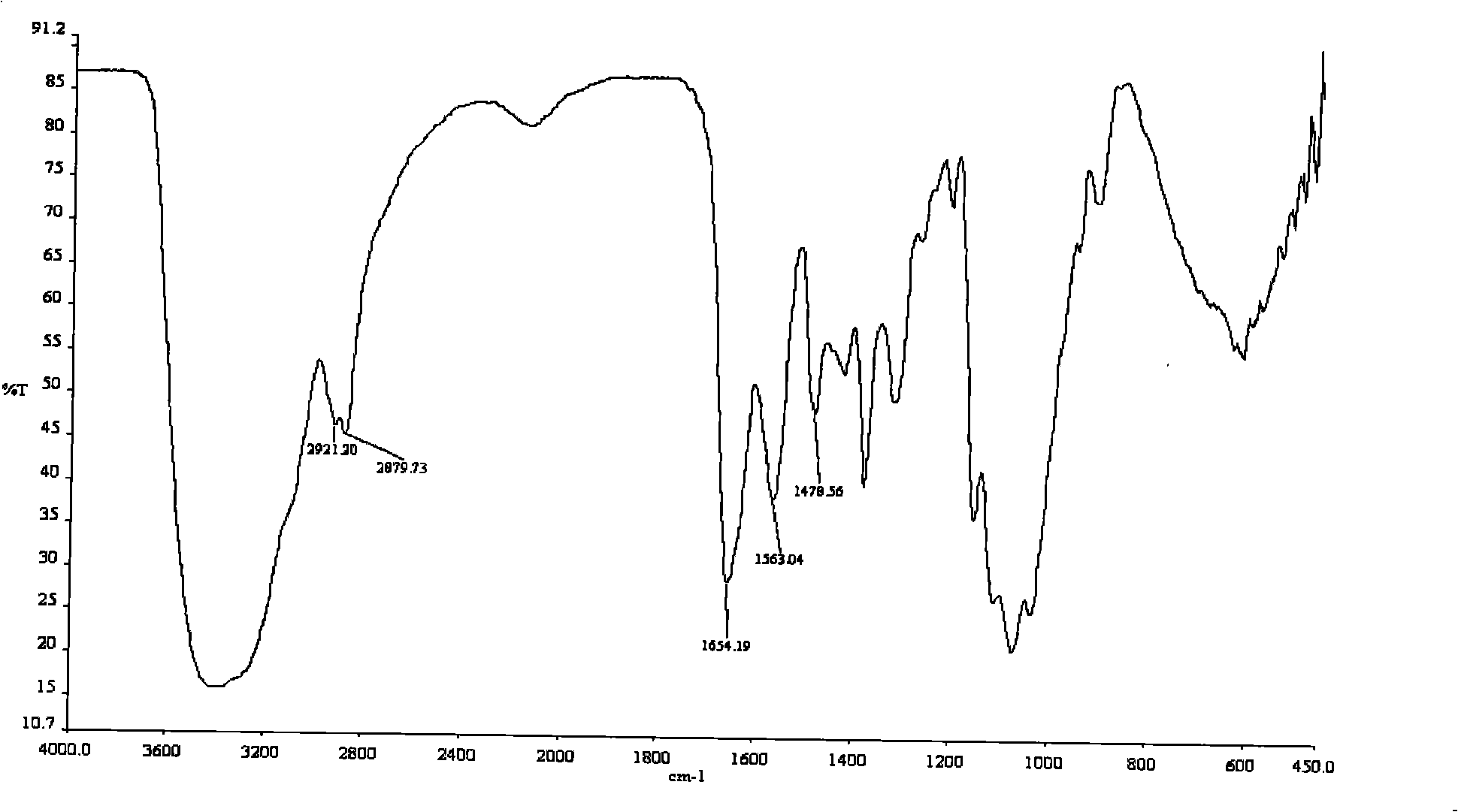

The invention discloses a technology for preparing a micro-molecular phenolic compound through the microwave reinforced continuous degradation of lignin in a hydrogen donor. The technology comprises the following steps: 1, continuously adding lignin to a microwave reinforced screw rod continuous degradation reacting device through a solid charging system, continuously adding the hydrogen donor and a catalyst to the continuous degradation reacting device through pumps, and carrying out a continuous degradation reaction of lignin at 150-200DEG C for 10-40min; 2, neutralizing degradation products in a neutralization pool in a degradation product separation device with an aqueous solution of NaOH, allowing the neutralized degradation products to enter a primary settling pool and a secondary settling pool, mixing lower-layer products of the primary settling pool and the secondary settling pool, filtering to obtain a water-phase product, using hydrochloric acid in an acidifying pool to adjust the pH to 2-3 in order to obtain the micro-molecular phenolic compound; and 3, filtering a used hydrogen donor which is the upper-layer product of the secondary settling pool, and regenerating in a Pd / C catalytic fixed bed hydrogenation device to obtain a regenerated hydrogen donor for cycle use. The technology which adopts continuous operation enables the treatment amount to be large and is suitable for the large-scale industrial application.

Owner:ZHEJIANG UNIV

Process for preparing O-2'-hydroxypropyl trimethyl ammonium chloride chitosan

InactiveCN101343334AReduce the degree of main chain degradation reactionThe method is simple and reliableDisplacement reactionsChitin formation

The invention provides an O-2`-Hydroxypropyltrimethyl ammonium chloride chitosan preparation method, which comprises the following steps: firstly, Beta-Chitin is reacted with modifying agent to synthesize O-2`-Hydroxypropyltrimethyl ammonium chloride Chitin; secondly, acetyl of C2 digit on O-2`-HTACCt sugar ring is divested through reaction to obtain O-2`-HTACCts. Quaternary ammonium salt derivatives displacement reaction positioning in the invention occurs on hydroxyl of Beta-Chitin sugar ring, Chitin and chitosan quaternary ammonium salt derivatives of the hydroxyl positioning displacement are obtained, thus the method is simple and reliable. The degree of substitution (DS) of the intermediate product O-2`-HTACCt is more easily adjusted. The deacetylating reaction conditions are mild, the chitosan trunk chain degradation reaction degree is reduced, therefore O-2`-HTACCts with the high deacetylation degree (DD) and the high degree of substitution (DS) are obtained.

Owner:SHENZHEN UNIV

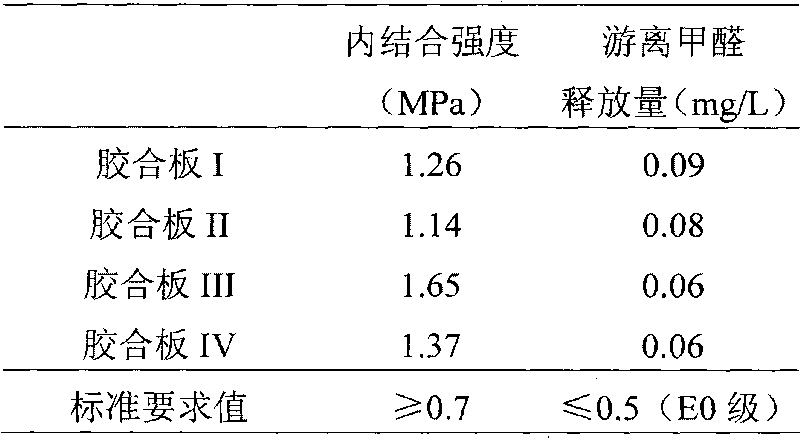

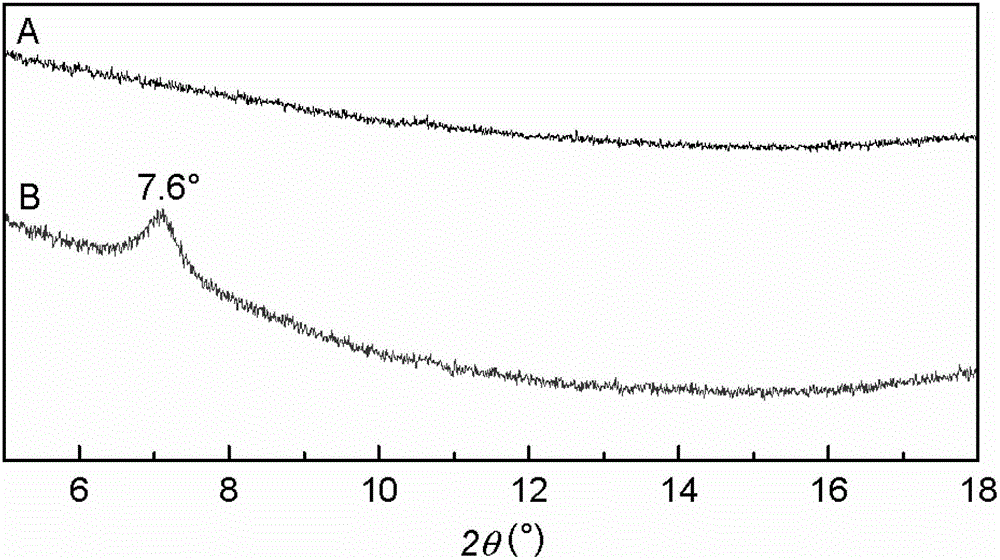

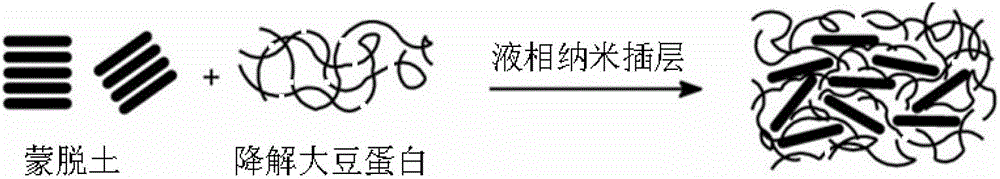

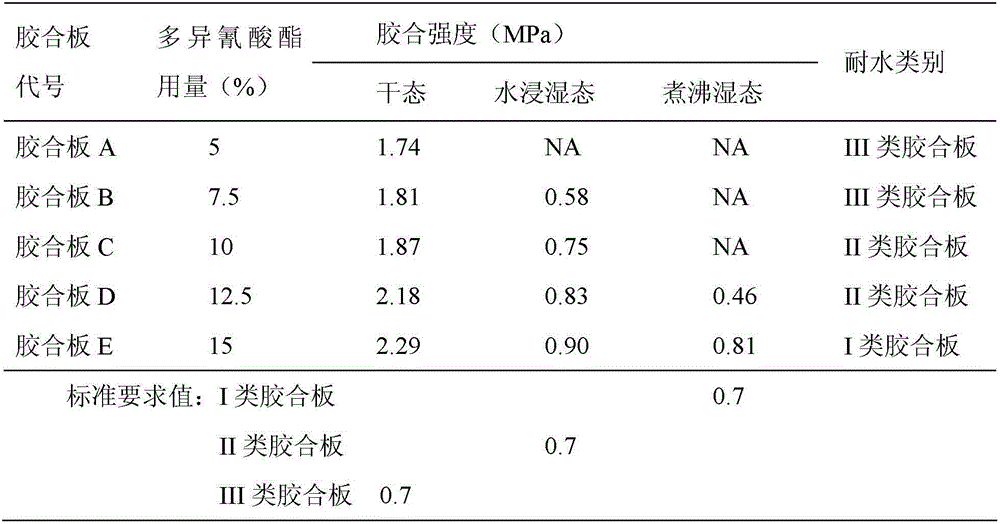

Water resistant soy protein adhesive for wood processing and preparation method thereof

InactiveCN102876284AHigh protein contentLow viscosityNon-macromolecular adhesive additivesProtein adhesivesHydrogenAdhesive

The invention discloses a water resistant soy protein adhesive for wood processing and a preparation method thereof, relates to an adhesive and solves the technical problem of poor water resistance in prior soy protein adhesives. Defatted soybean protein powers or soy isolate protein, strong base and water are subjected to degradation reaction according to parts by weight, potential of hydrogen (pH) value is adjusted by a concentrated acid, montmorillonite is added, and finally the polyaryl polymethylene isocyanate is added for uniformly mixing to obtain the water resistant soy protein adhesive for the wood processing. According to the obtained water resistant soy protein adhesive for the wood processing, the gelation time is 60 to 180 minutes, and the water resistance is good.

Owner:NORTHEAST FORESTRY UNIVERSITY

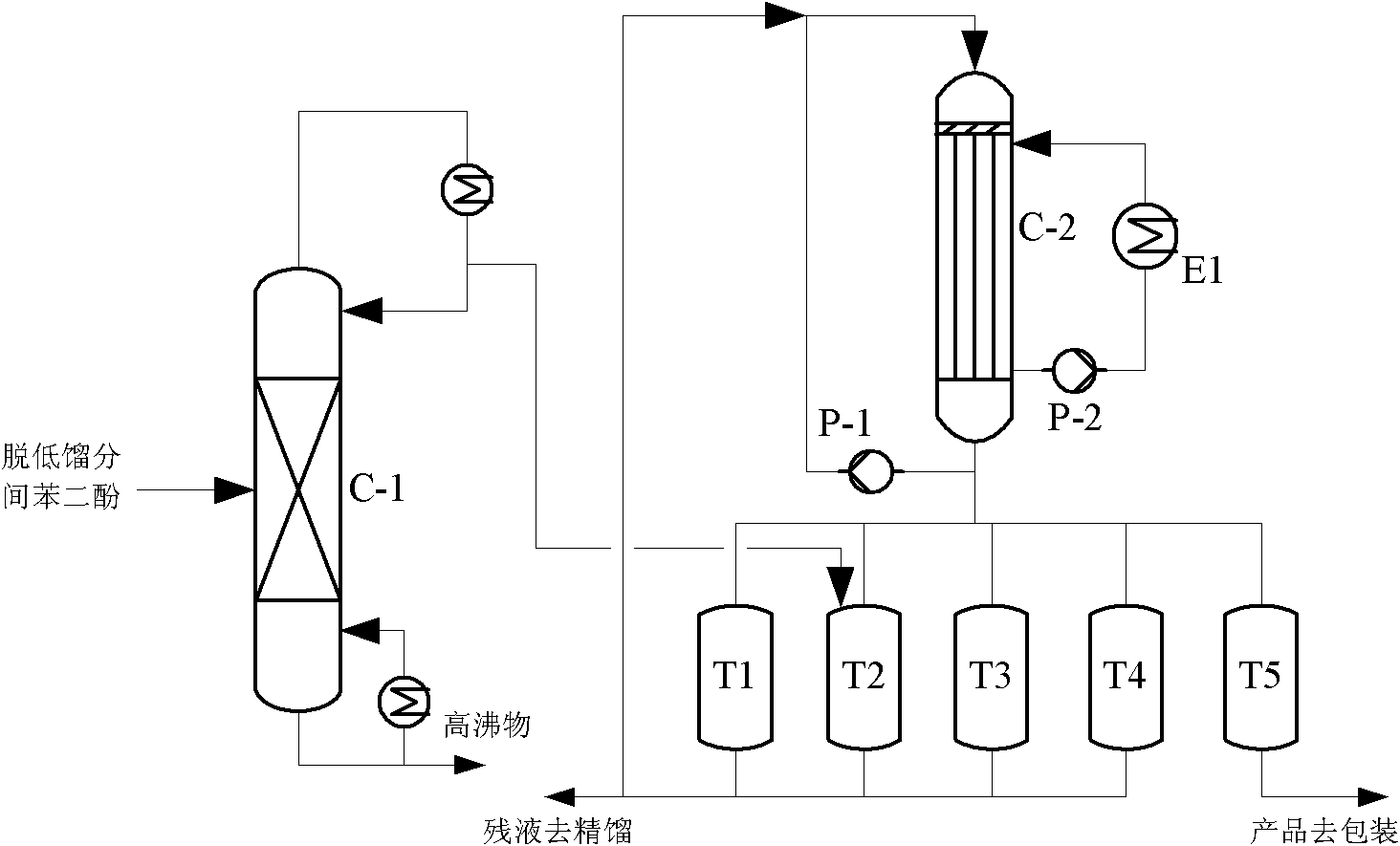

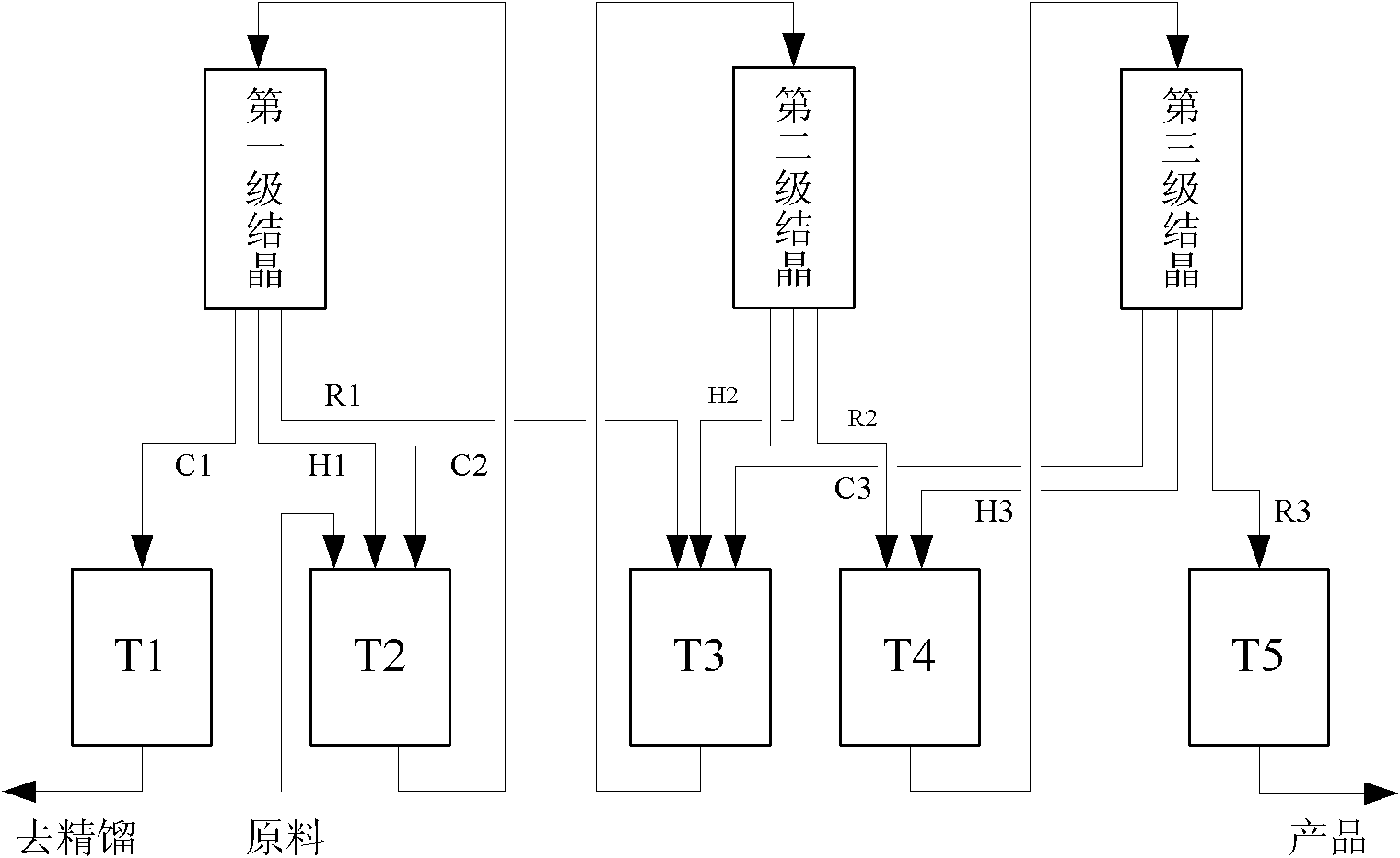

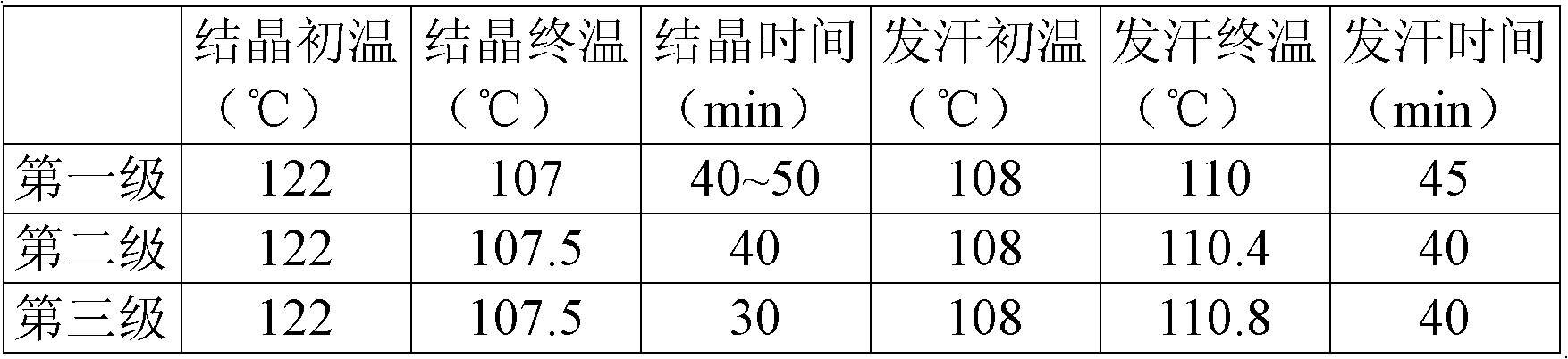

Method for preparing high-purity resorcinol through melt crystallization

ActiveCN102464573AHigh purityHigh yieldOrganic chemistryOrganic compound preparationWastewaterSolvent

The invention provides a method for preparing high-purity resorcinol through melt crystallization. The method mainly comprises steps of melt crystallization, partial melting (sweating) and melting. According to the invention, a graded melt crystallization method is adopted, and the process is carried out in a falling film dynamic crystallization device, such that non-pure resorcinol is purified. The adopted grade number should satisfy a final purity expectation obtained with a high yield. At least one grade is adopted, and commonly several grades are adopted. The grade number varies from 1 to 4, such that a complete resorcinol product crystallization refining circulation is formed. The method is advantaged in that: no solvent is required by melt crystallization, such that the product is prevented from being polluted by exterior solvents or other materials. Especially, latent pollution to resorcinol caused by back-mixing of solution crystallization impurities and degradation reactions caused by high rectification temperature can be prevented, and the influence of waste water caused by solution crystallization to the environment can be avoided. The product yield is high, the product purity is high, and the production efficiency is high.

Owner:ZHEJIANG HONGSHENG CHEM IND +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com