Pretreatment method of copper-containing organic waste water

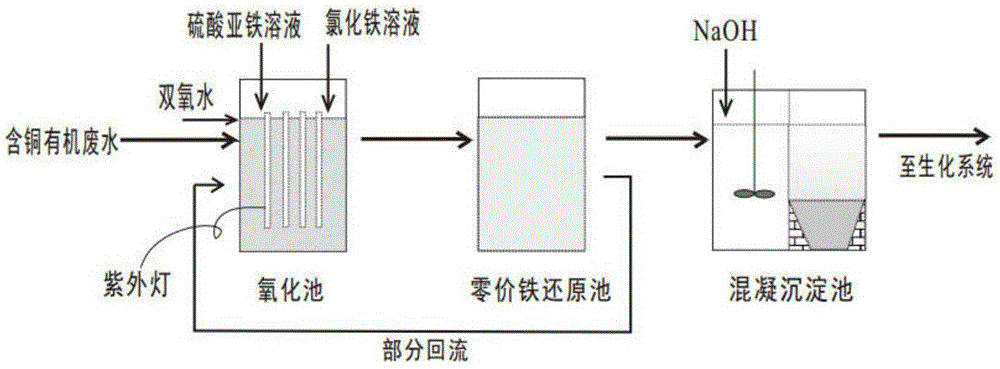

A kind of organic wastewater pretreatment technology, applied in the field of Fenton-like coagulation sedimentation coupled in one system, Fenton, iron reduction of heavy metal ions, can solve the problems of limited application range and cumbersome actual operation, and reduce the treatment effect Gradually reduce, broaden the pH range, and reduce the effect of sludge volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Acidic copper-containing wastewater (COD=2540mg / L, total copper about 2100mg / L, pH value 2.5) is pumped into the oxidation tank, hydrogen peroxide is added and ultraviolet light is turned on to make H 2 o 2 The concentration is 3000mg / L, then add ferrous sulfate solution, ferric chloride solution, after mixing, Fe 2+ The concentration is 700mg / L, Fe 3+ The concentration is 1000mg / L, the reaction is started for 60 minutes, and the pollutants are degraded under the action of Fenton and Fenton-like;

[0035] (2) The effluent from step (1) was transferred to the zero-valent iron reduction tank, and reacted for 30 minutes. The copper ions in the solution were replaced by copper, covering the surface of zero-valent iron, and the zero-valent iron was converted into ferrous iron. The supernatant was used as Part of the effluent flows back to the oxidation tank;

[0036] (3) The effluent from step (2) enters the coagulation sedimentation tank, adjusts the pH value to 7-8 ...

Embodiment 2

[0038] (1) Alkaline complex copper wastewater (COD=4600mg / L, total copper is about 560mg / L, pH value is 9) is pumped into the oxidation tank, hydrogen peroxide is added and the ultraviolet light device is turned on to make the H 2 o 2 Concentration is 5000mg / L, then add ferrous sulfate solution, ferric chloride solution, make Fe after adding 2+ The concentration is 300mg / L, Fe 3+ When the concentration is 300mg / L, the reaction is started, and a large amount of copper ions are replaced, and pollutants are degraded under the action of Fenton and Fenton-like. Part of the complexed copper ions are destroyed and released by the Fenton reaction, and the reaction time is 120 minutes;

[0039] (2) Transfer the effluent from step (1) to the pre-acid-washed zero-valent iron reduction tank, react for 60 minutes, and use the supernatant as effluent, and partly return to the oxidation tank;

[0040] (3) The effluent from step (2) enters the coagulation sedimentation tank, adjusts the pH...

Embodiment 3

[0042] (1) Acidic copper-containing wastewater (COD=800mg / L, total copper is about 180mg / L, pH value is 4) is pumped into the oxidation tank, and hydrogen peroxide is added to make the H 2 o 2 The concentration is 1500mg / L, turn on the ultraviolet light and add ferrous sulfate solution and ferric chloride solution, after mixing, Fe 2+ The concentration is 100mg / L, Fe 3+ The concentration is 100mg / L, and the reaction is 90min;

[0043] (2) The effluent from step (1) is transferred to the zero-valent iron reduction tank, reacted for 30 minutes, and the supernatant is used as effluent, and part of it is returned to the oxidation tank;

[0044] (3) The effluent from step (2) enters the coagulation sedimentation tank, adjusts the pH value to 7-8 with sodium hydroxide, flocculates and settles for 45 minutes, and the Fe in the effluent 2+ Concentration below 15mg / L, Cu 2+ When the concentration is lower than 0.8mg / L, COD drops to 450mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com