Patents

Literature

1347 results about "FERRIC IRON" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

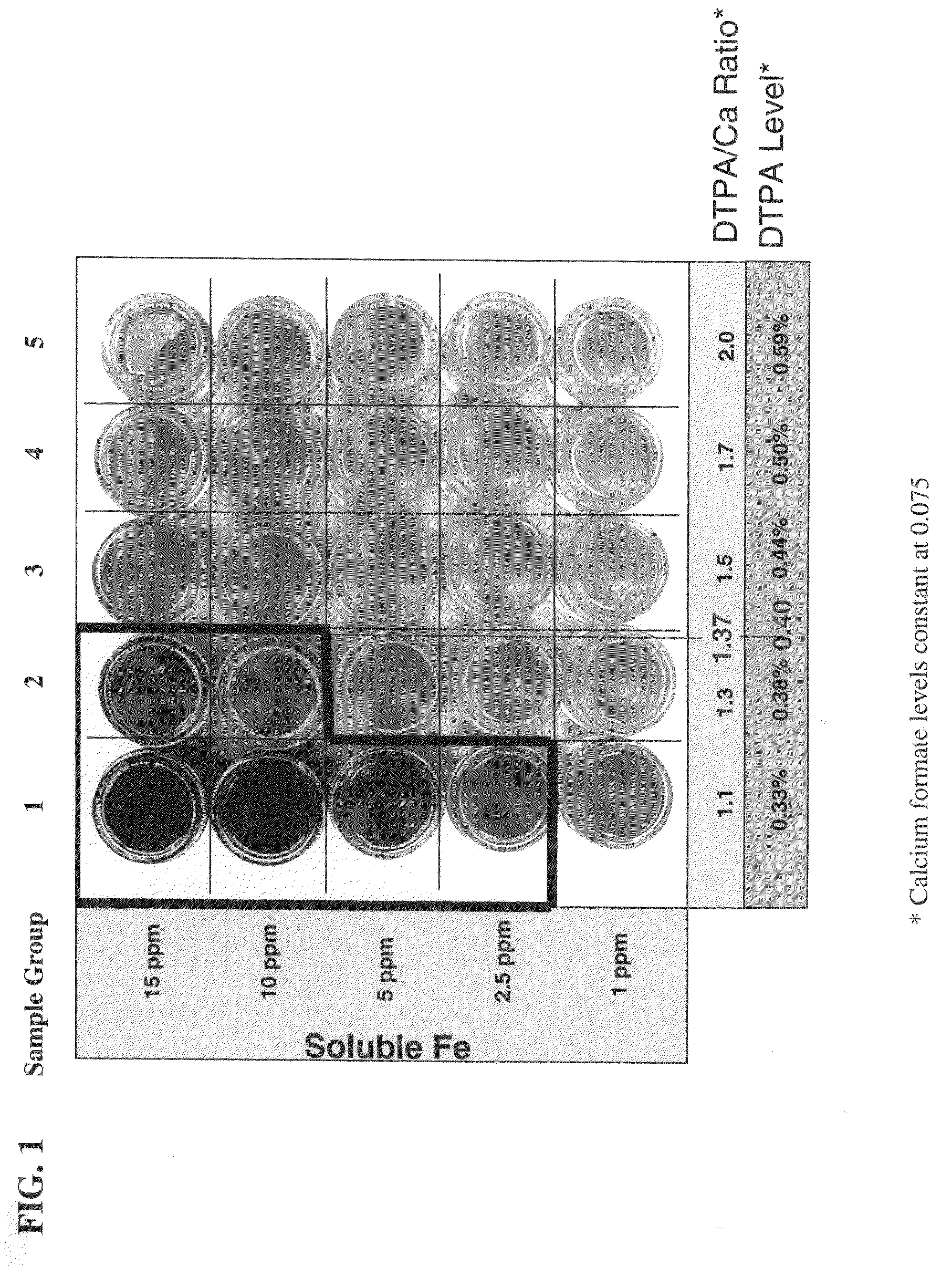

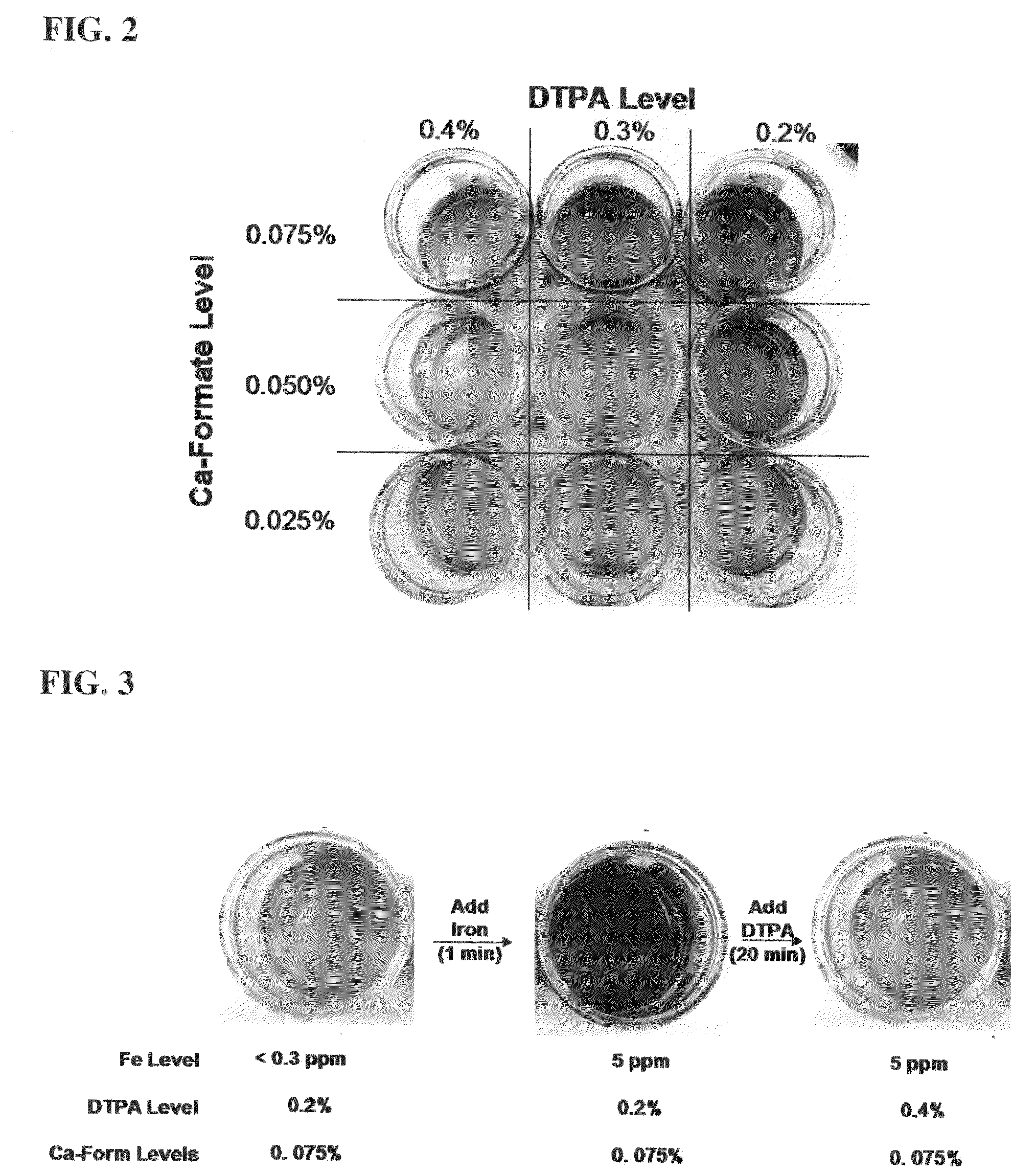

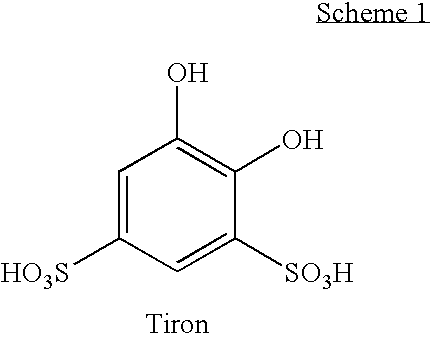

Detergents having acceptable color

InactiveUS20090176684A1Reduce intensityOrganic detergent compounding agentsSurface-active detergent compositionsBenzeneTitanium

Detergent compositions containing catechols, such as tiron (1,2-dihydroxybenzene-3,5-disulfonic acid), which do not have or do not develop the reddish color associated with the catechol / ferric iron chelate are disclosed. Methods for reducing the intensity of red color in a tiron containing detergent composition are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

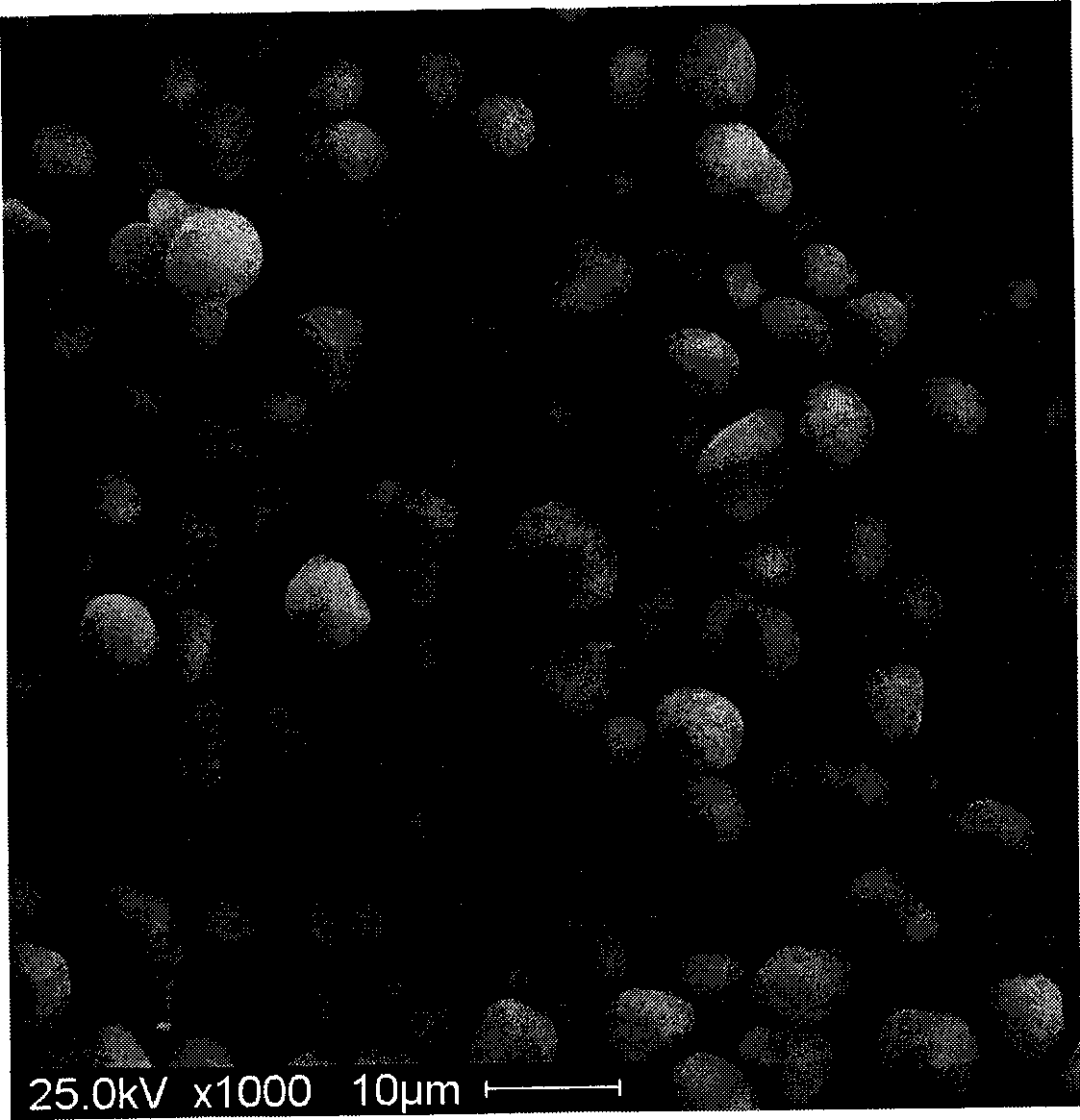

Method for preparing high-density spherical ferric lithium phosphate as anode material of lithium-ion battery

InactiveCN1635648AHigh bulk densityIncrease volume capacityElectrode manufacturing processesLithium compoundsPhosphateLithium-ion battery

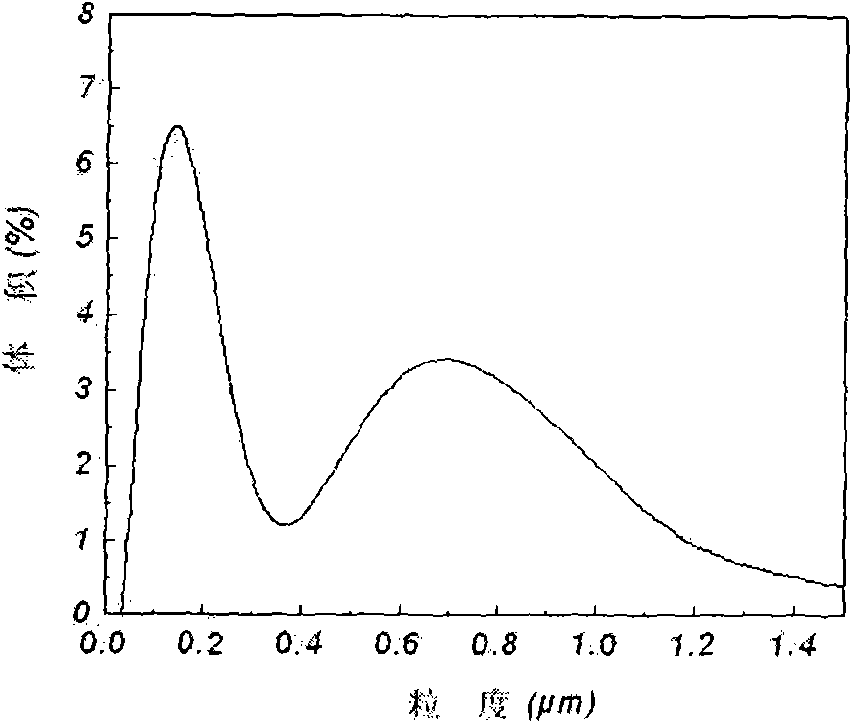

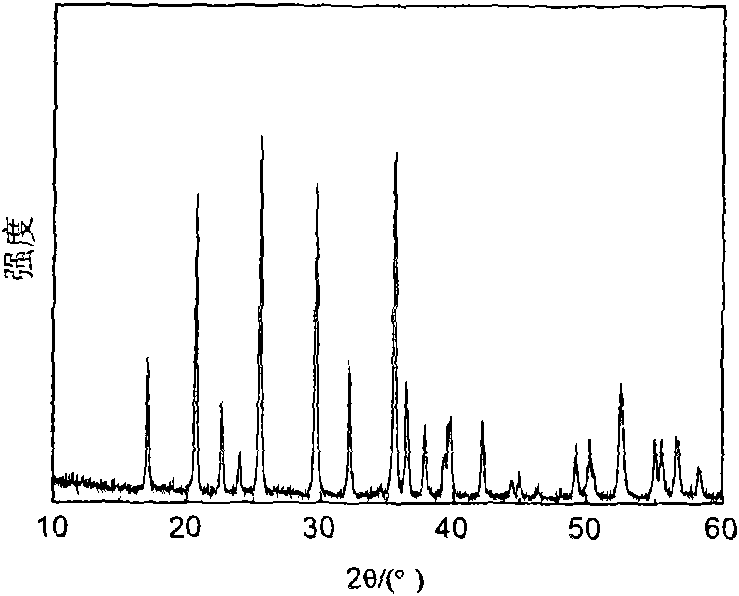

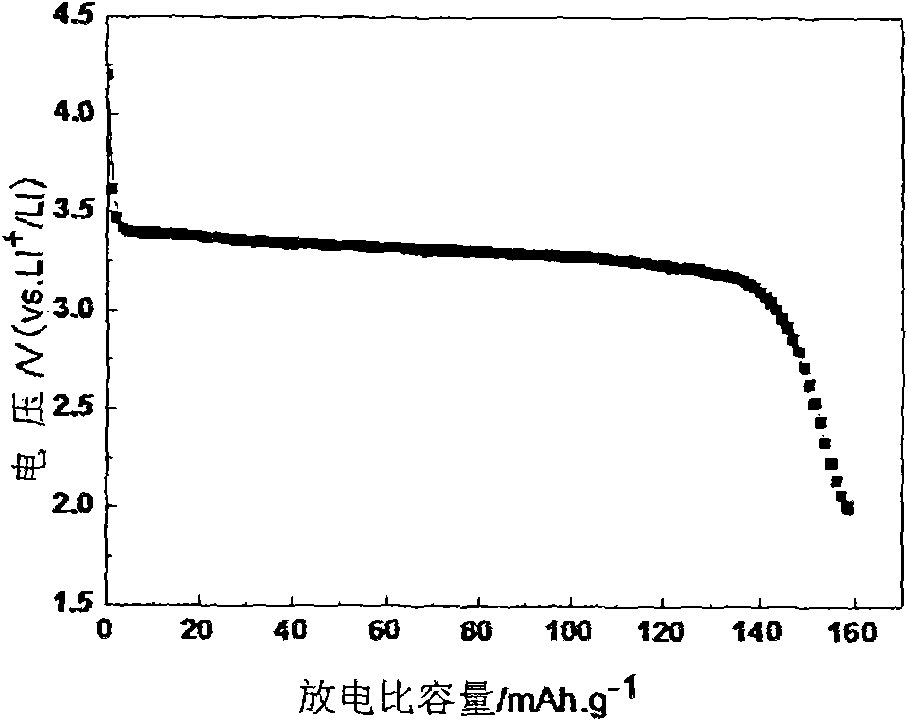

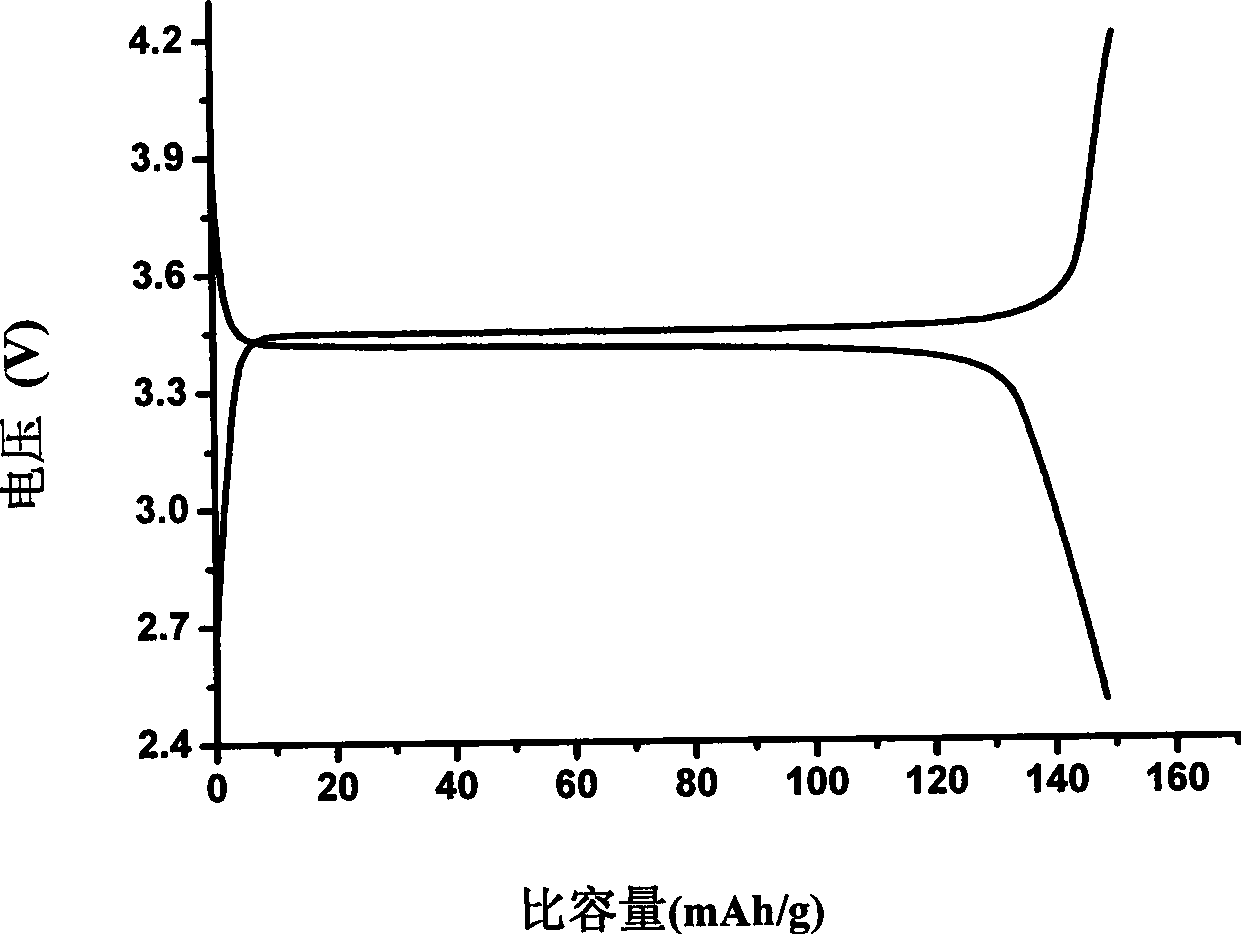

This invention discloses the method for preparing high-density spherical lithium ferric phosphate used as the positive material of lithium ion cell, which contains synthesizing the ferric iron salt aqueous solution, phosphorus source aqueous solution and alkali aqueous solution to form spherical or spheroid ferric phosphate precursor, uniformly mixed with lithium source, carbon source and doped metal compound after being washed and dried, high temperature heat treating at 600-900 degree centigrade for 8-48 hr under inertia or reducing atmosphere protection to obtain lithium ferric phosphate with mean grain size of 7-12 micrometer,2.0-2.2g / cm3 of tap density, high buck density of 140-155mAh / g first discharge ratio capacity at normal temperature, and high volume ratio capacity.

Owner:TSINGHUA UNIV

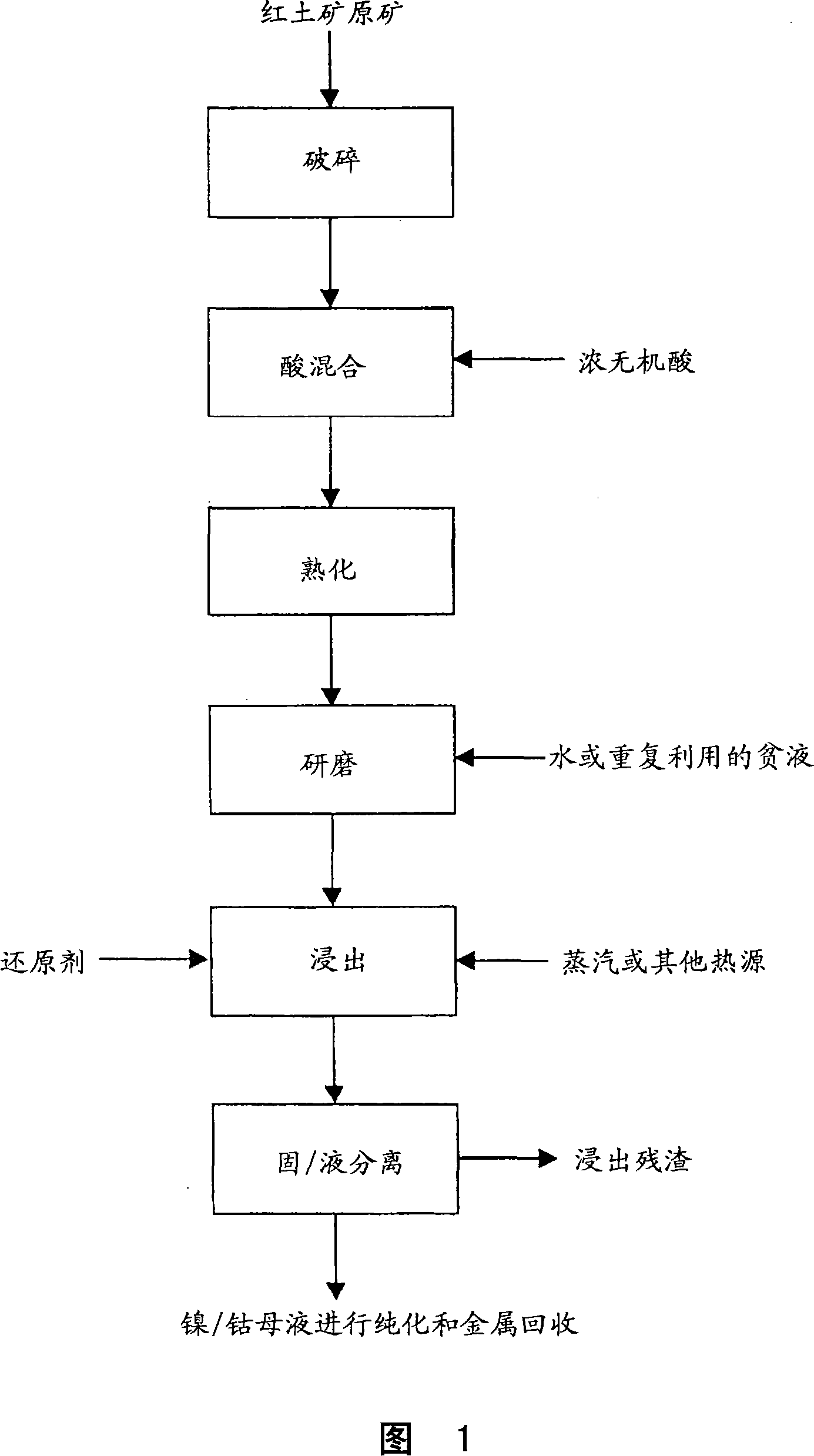

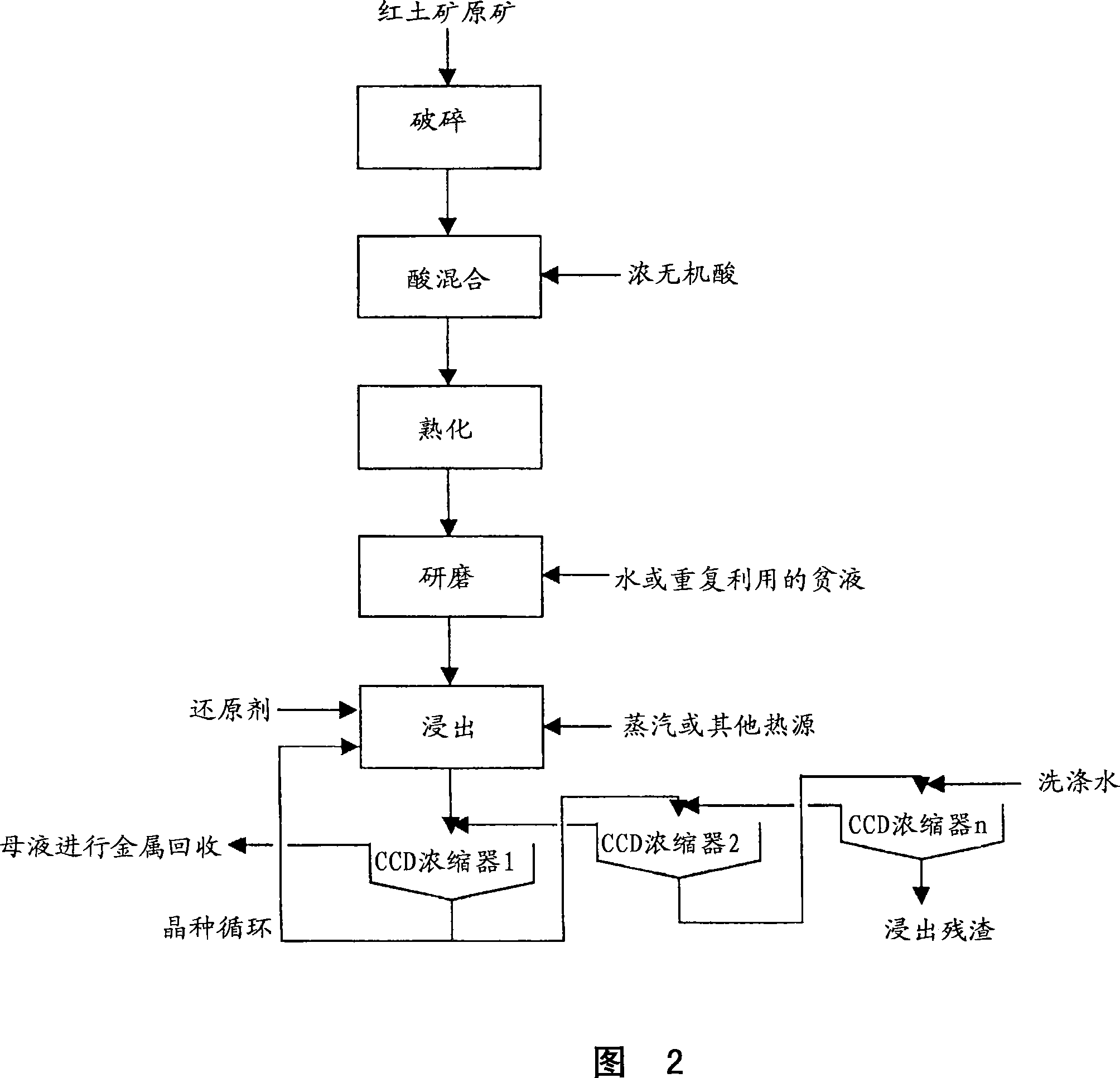

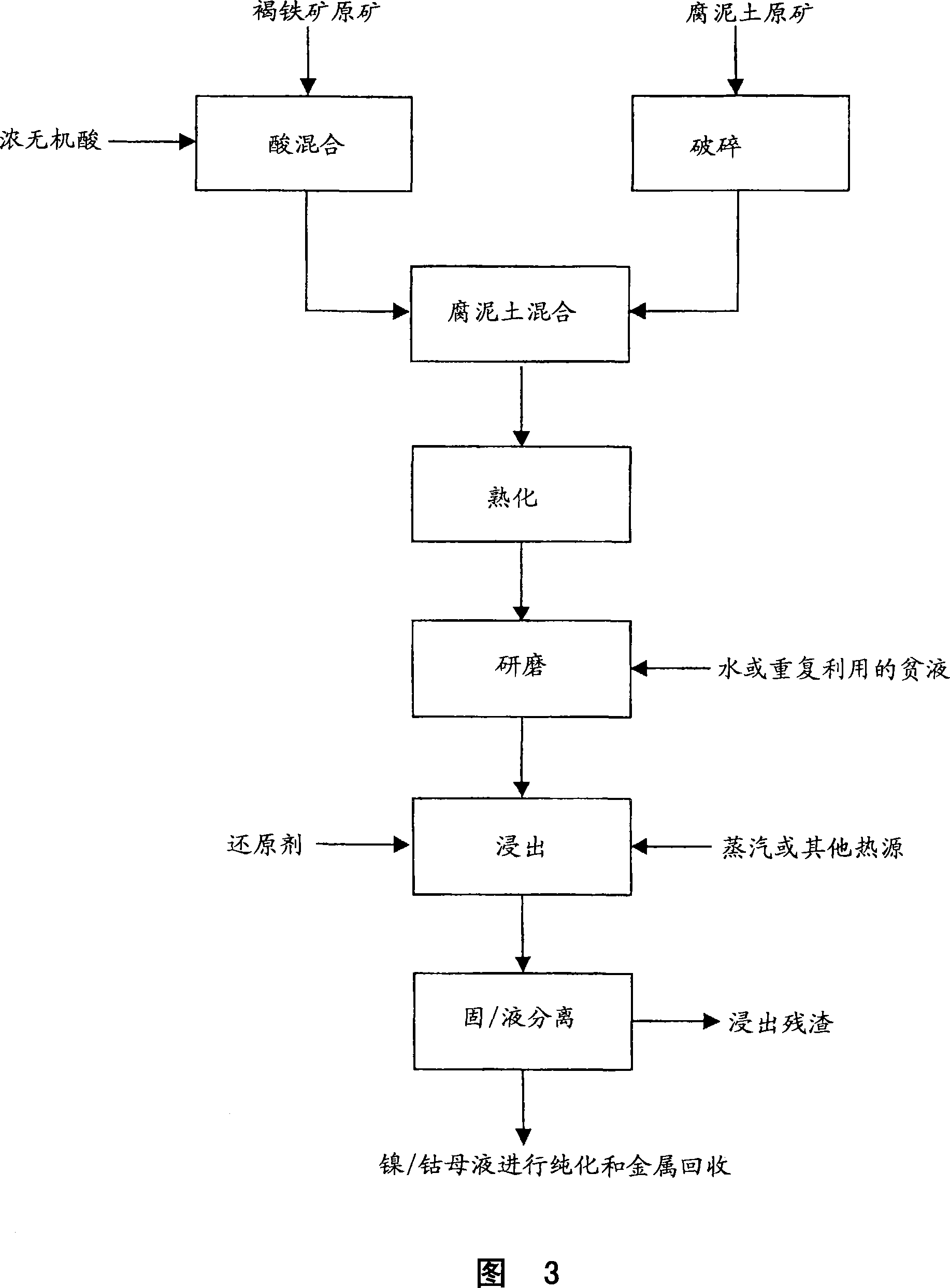

Method for nickel and cobalt recovery from laterite ores by reaction with concentrated acid and water leaching

InactiveCN101006190AHigh extraction rateLow extraction rateProcess efficiency improvementPotassiumSlurry

A process for leaching laterite ores containing limonite and saprolite in a two stage process. The first stage consisting of mixing and reacting the ore with concentrated mineral acid, and the second stage consisting of preparing a slurry of the acid / ore mixture in water and leaching the mixture to dissolve nickel and cobalt. Iron is efficiently separated from nickel and cobalt in the solid leach residue primarily as an oxide or hydroxide of ferric iron other than jarosite.

Owner:SKYE RESOURCES

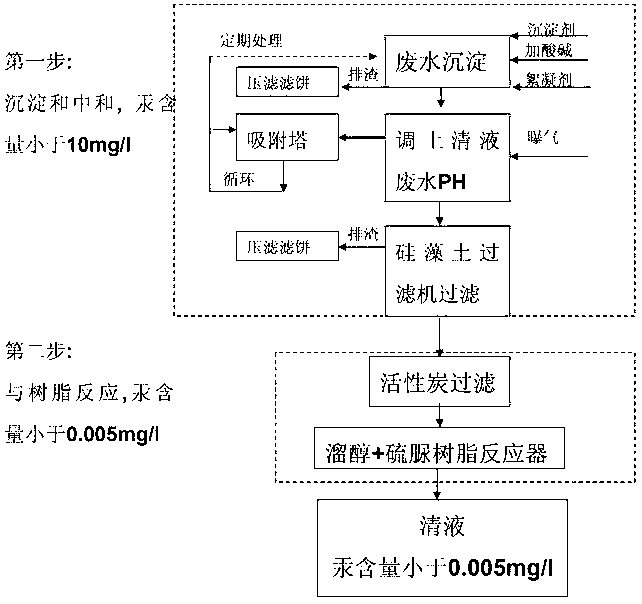

Method for treating mercury-containing wastewater during PVC (Polyvinyle Chloride) production through two-step process

InactiveCN102936070AEnsuring a circular economyImprove processing efficiencyMultistage water/sewage treatmentNature of treatment waterSlagGas phase

The invention discloses a method for treating mercury-containing wastewater during PVC (Polyvinyle Chloride) production through a two-step process. The method comprises the following steps of: firstly, completing primary removal of mercury, copper, ferrous and ferric iron, cadmium, zinc, manganese, lead and suspending impurities of above 10mg / l by using a precipitator and a flocculating agent, regulating PH to 6-8 and then adding the flocculating agent and stirring for 30 minutes, standing for above 1 hour, discharging slag and aerating, absorbing mercury carried away by a gas phase through a sulfide adsorber, purifying water by using a plate type kieselguhr filter, removing residual suspended matters; and 2, carrying out complete reaction on the mercury in the wastewater by using an active carbon and a mercaptan and thiourea resin combining method again for being removed, and finally reaching the standard that the content of the mercury is less than 0.005mg / l. The treated wastewater can be recycled to salt melting or an acetylene generator, so that zero emission of the treated wastewater is achieved; and the mercury-containing waste acid water of hydrochloric acid desorption in the industry of chlor-alkali can be treated, the consumption of acid is reduced, and the great popularization significance is achieved in the industry of chlor-alkali.

Owner:赵建军

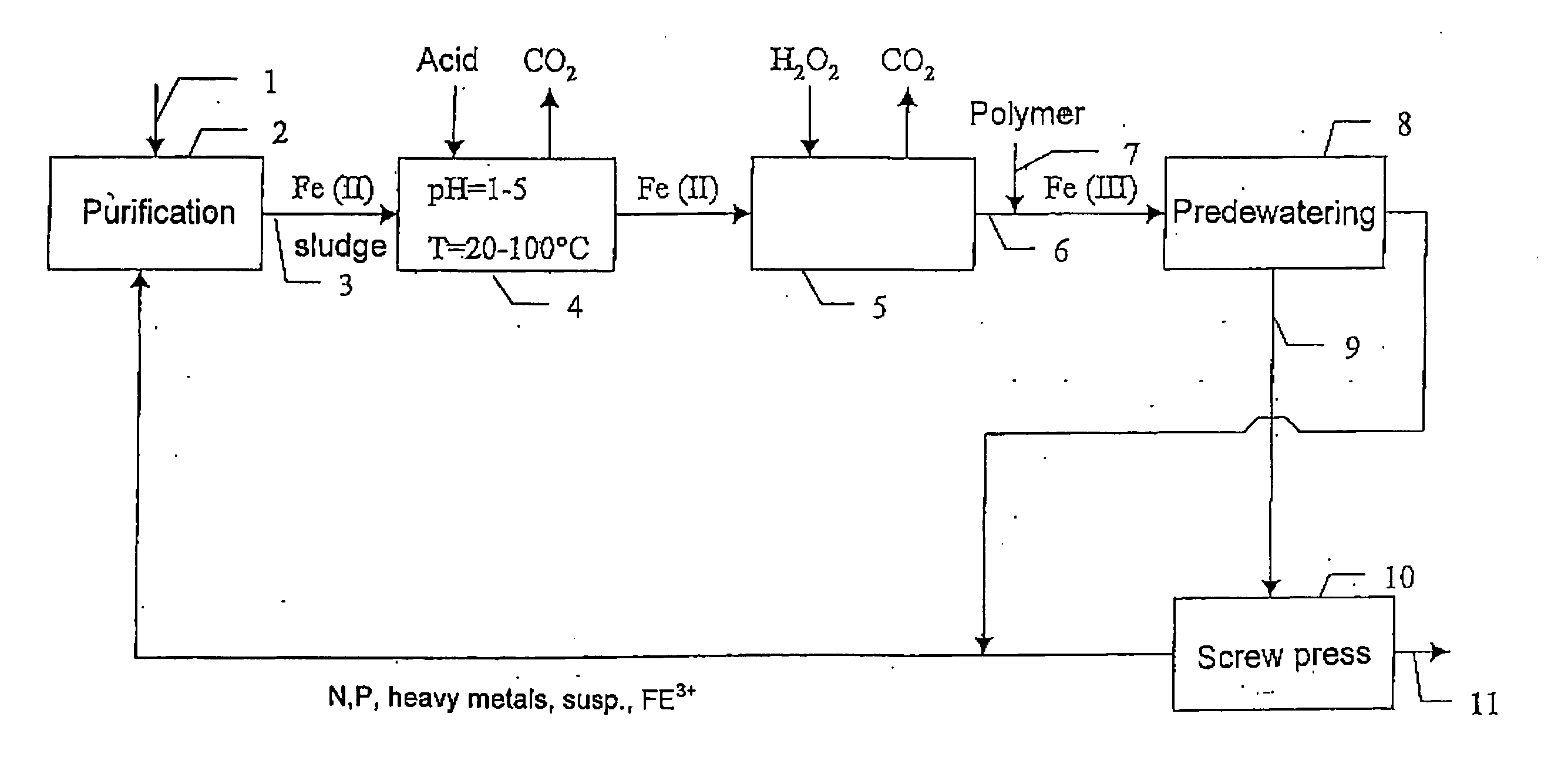

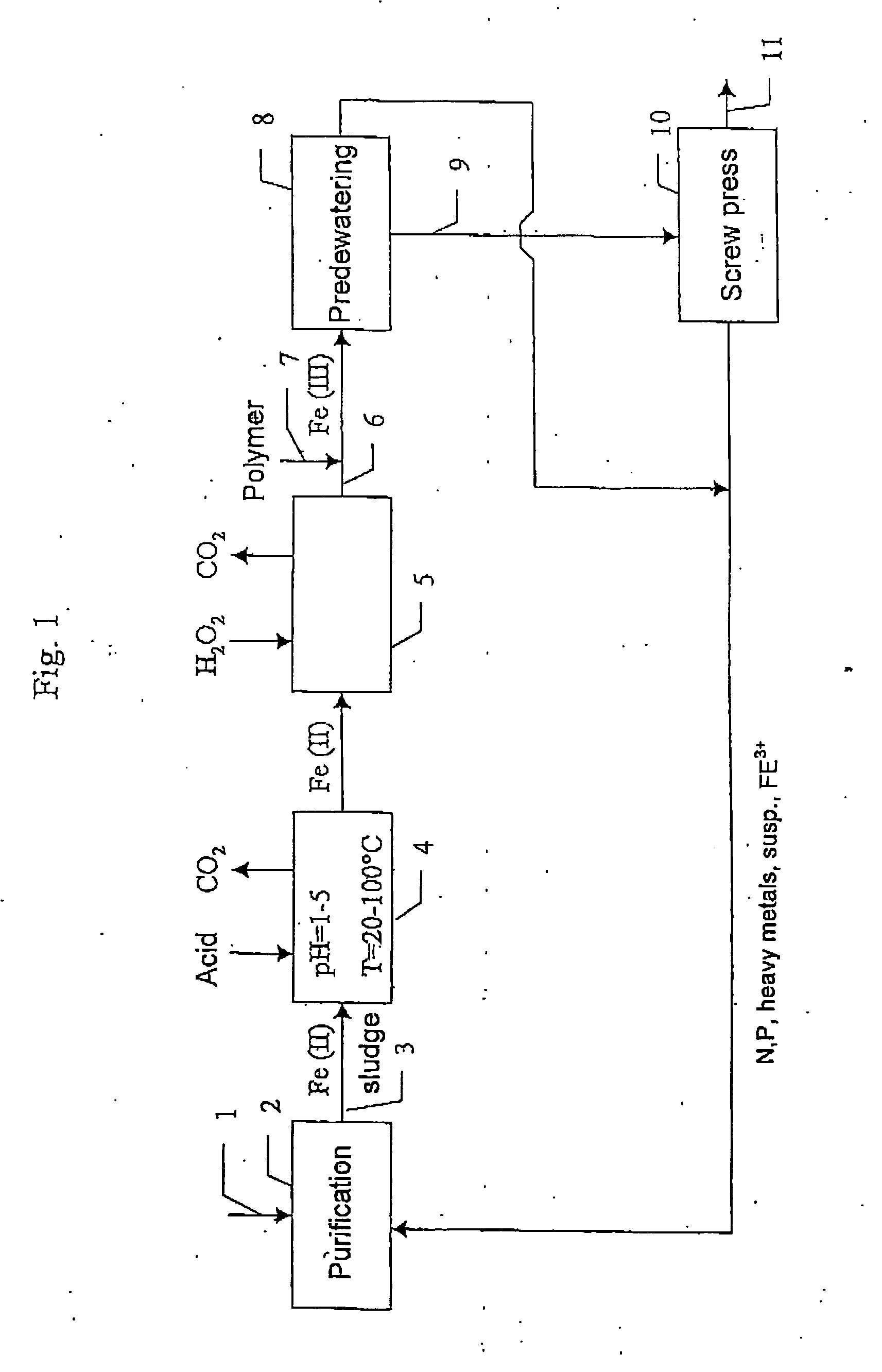

Method of treating digested sludge

InactiveUS20050000908A1Improve filtering effectKeep drySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeWastewater

A method of treating, in wastewater purification, sludge containing organic matter, divalent iron and phosphorus, in which the sludge that is treated is made to contain dissolved iron and phosphorus at a molar ratio Fe:P of above 1:1, the sludge is treated at 0-100° C. with an acid at a pH of 1-5 for dissolution of divalent iron and phosphorus from the sludge, the sludge is supplied with an oxidiser selected from hydrogen peroxide and percompounds, wherein divalent iron is oxidised by Fenton's reaction to trivalent iron, and (i) trivalent iron is precipitated as trivalent iron phosphate (ii) free radicals with a deodorisation and sanitation effect are formed by Fenton's reaction, the sludge is then dewatered at a pH of at most 7, and the aqueous solution obtained in dewatering is recirculated to the wastewater purification.

Owner:KEMIRA KEMI AB

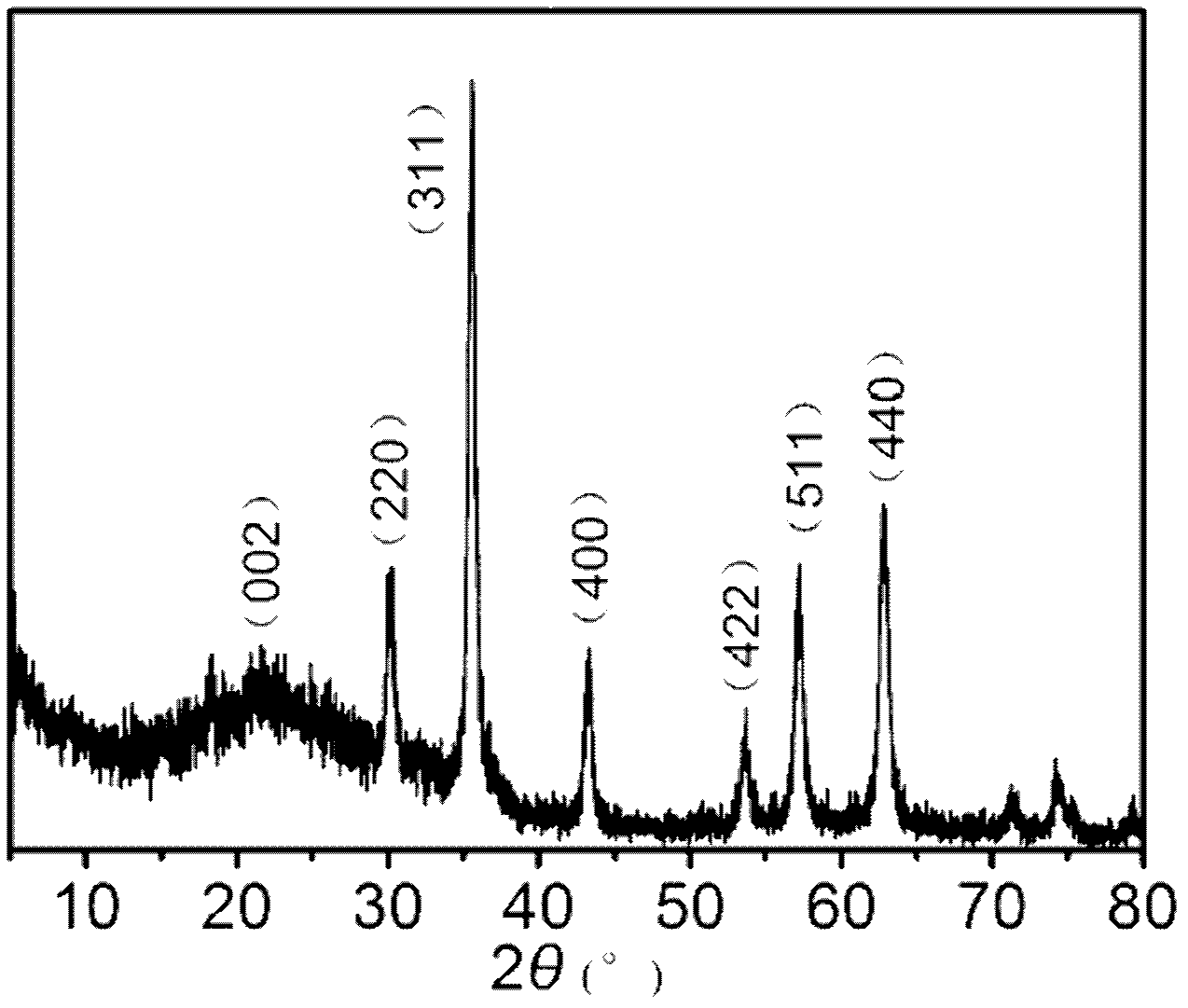

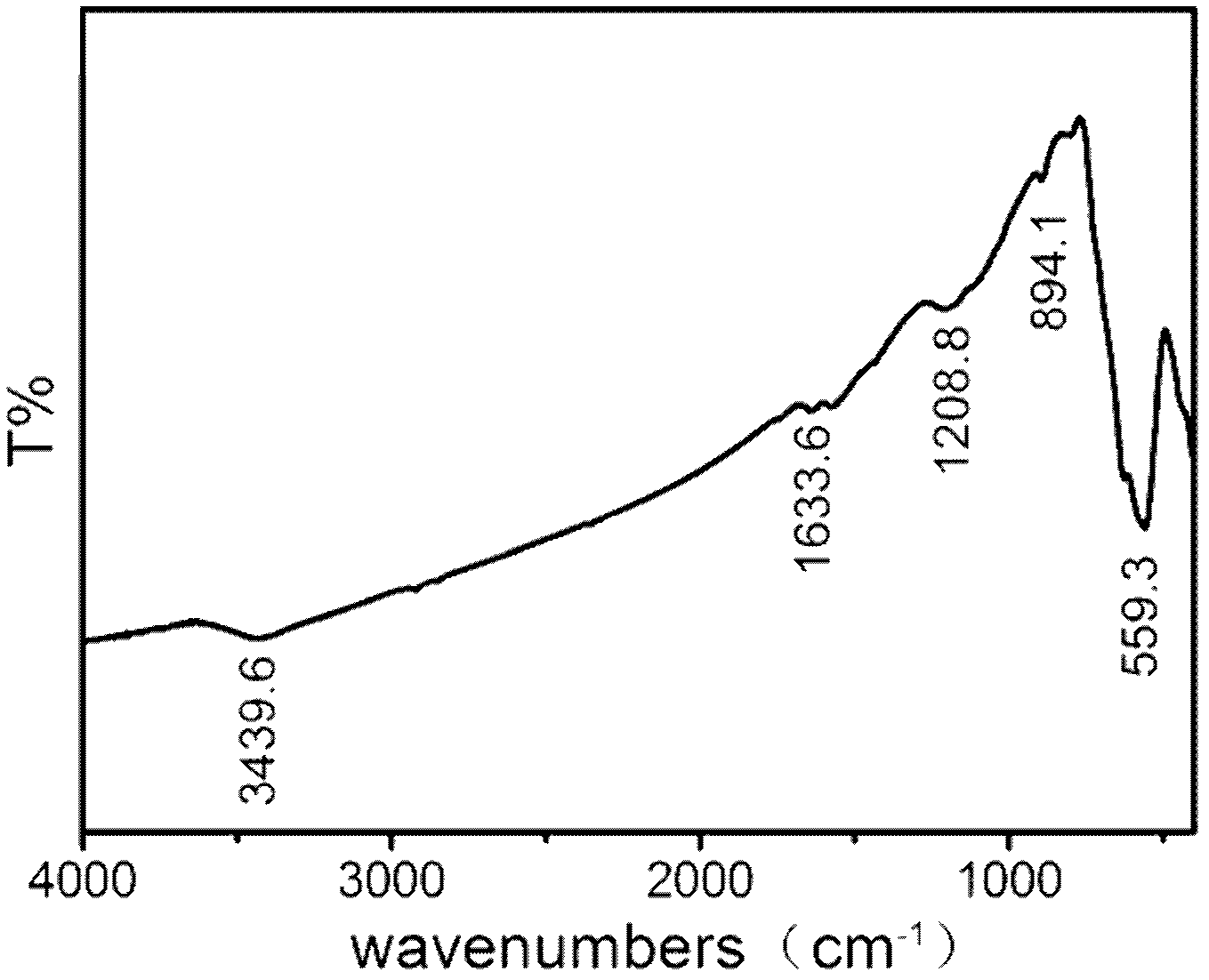

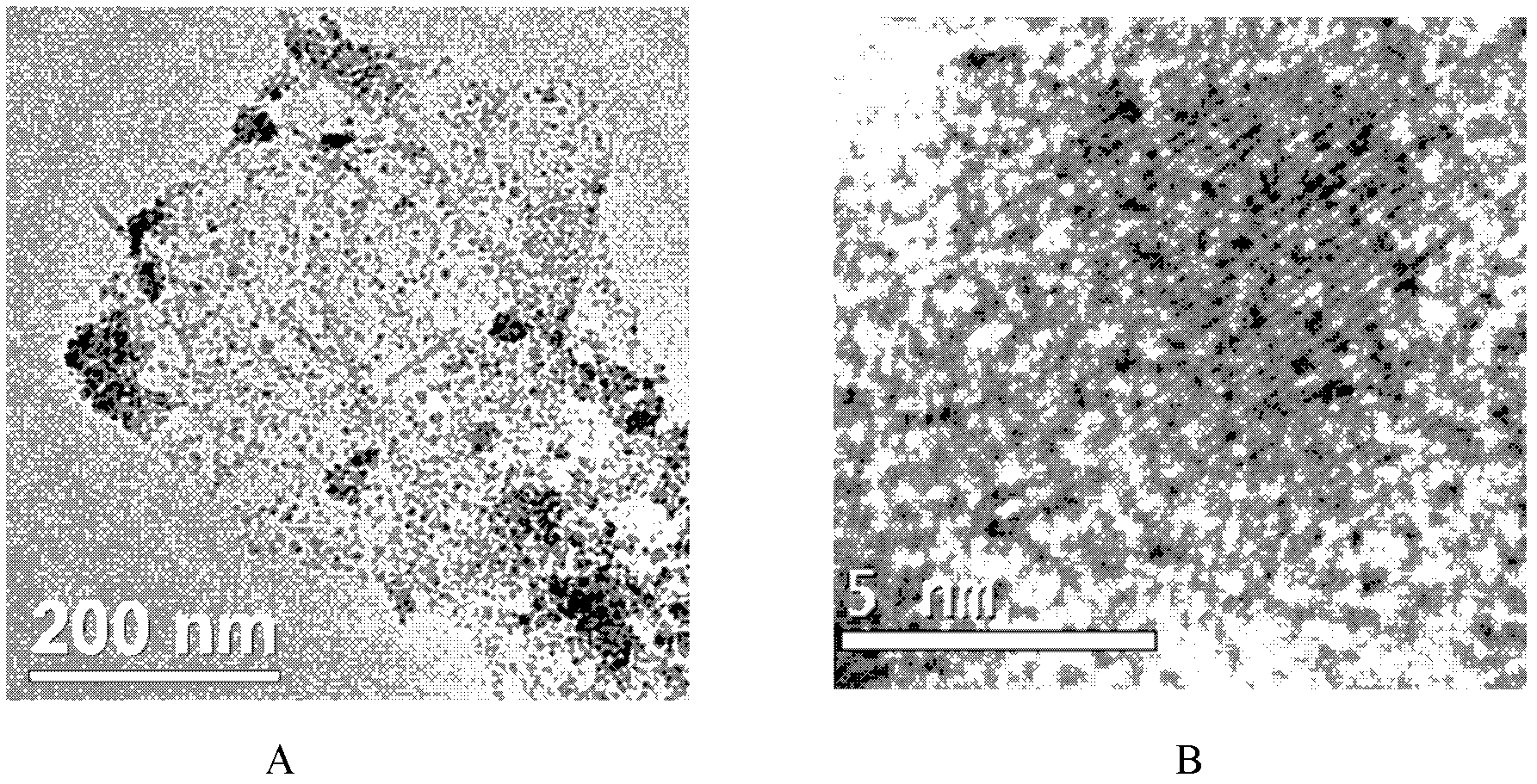

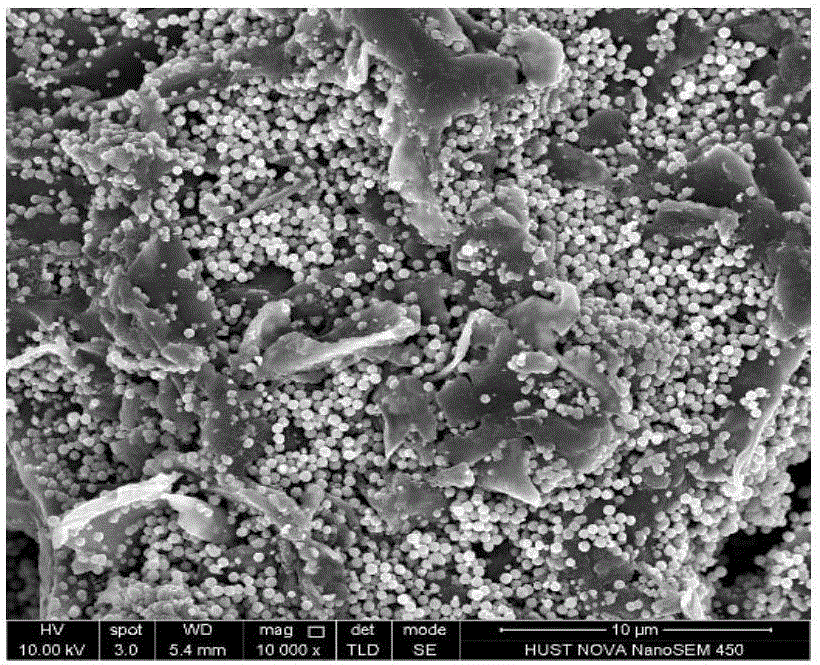

Method for preparing magnetic nanometer ferroferric oxide-graphene composite catalyst

ActiveCN102553593AReduce usageNo pollution in the processWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsMagnetic separationGraphite oxide

The invention relates to a method for preparing a magnetic nanometer ferroferric oxide-graphene composite catalyst, which includes steps of: 1) dispersing graphite oxide in ethanol and water system; 2) respectively mixing soluble trivalent ferric salt and divalent ferric salt in ethanol; 3) mixing and stirring systems obtained in step 1) and step 2); 4) heating reaction system of 3) at temperature of 50 DEG C to 90 DEG C, and adjusting pH to be 9-11 for reaction by adding ammonia water; and 5) performing magnetic separation on products of step 4), washing through deionized water, and obtaining magnetic nanometer ferroferric oxide-graphene composite catalyst. The method provides a simple and practical coprecipitation method for preparing the nanometer ferroferric oxide-graphene composite catalyst which is uniform in particular sizes, even in dispersing and good in magnetism. The nanometer ferroferric oxide-graphene composite catalyst prepared by the method has excellent catalytic activity and is easy in preparing process and environment-friendly.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

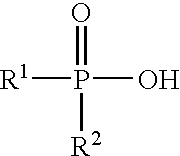

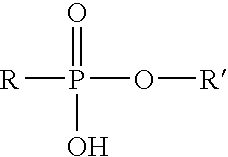

Methods and compositions for treating subterranean formations with gelled hydrocarbon fluids

Improved methods and compositions for treating subterranean formations penetrated by well bores are provided. A method for breaking a gelled hydrocarbon fluid comprised of a hydrocarbon liquid, a ferric iron or aluminum polyvalent metal salt of a phosphonic acid ester or dialkylphosphinic acid is provided.

Owner:HALLIBURTON ENERGY SERVICES INC

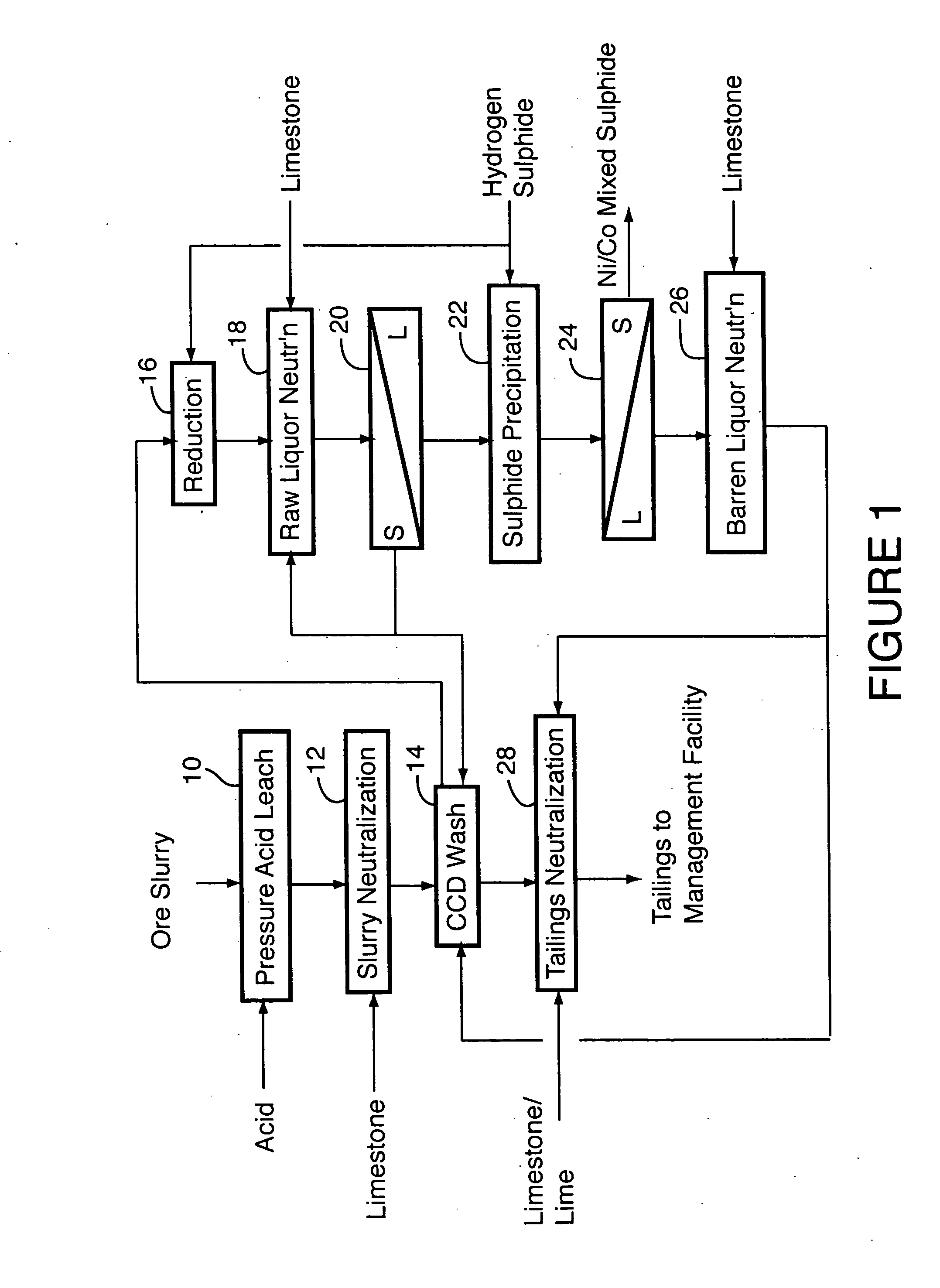

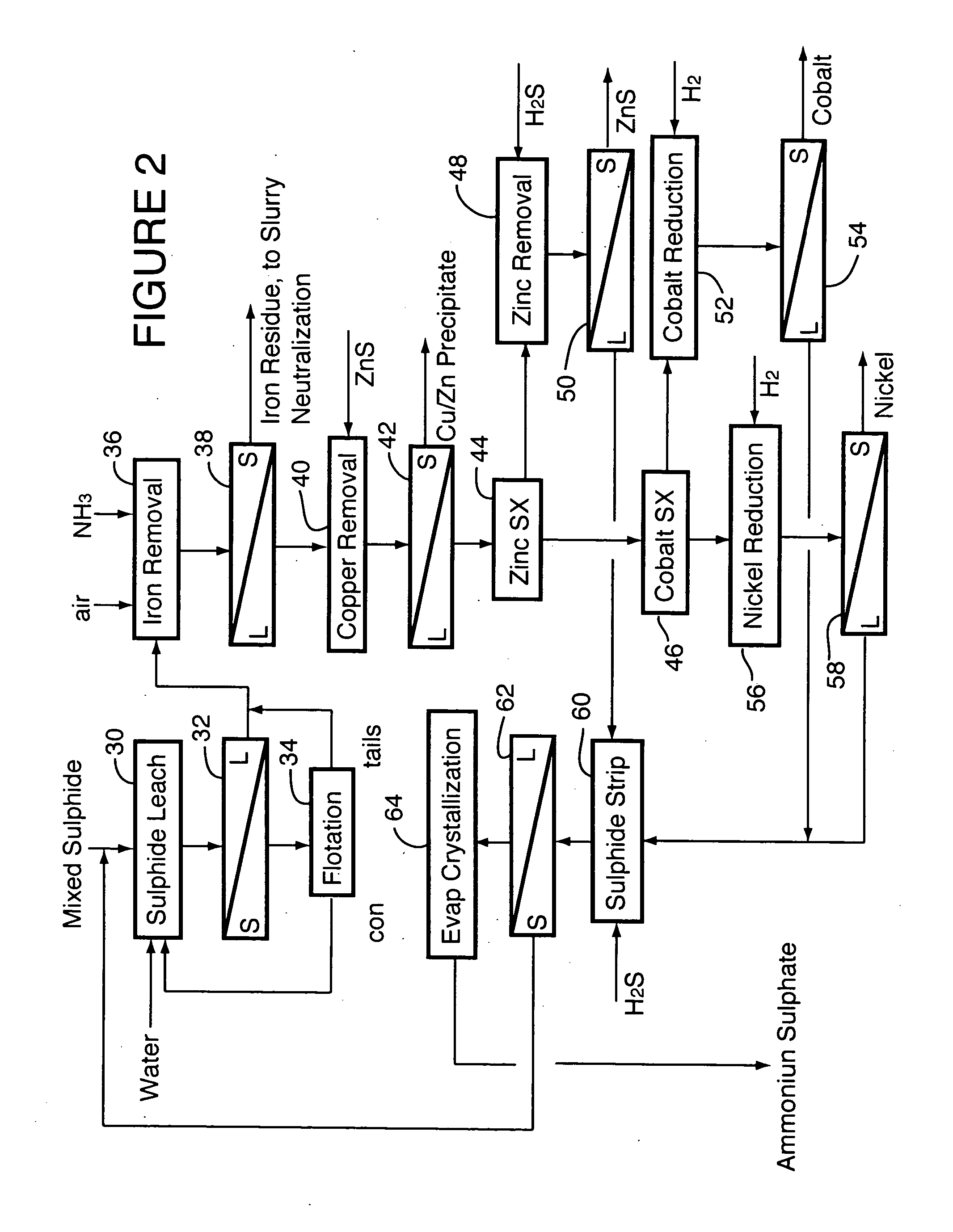

Process for recovery of nickel and cobalt from laterite ore

ActiveUS20060228279A1Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INTERNATIONAL

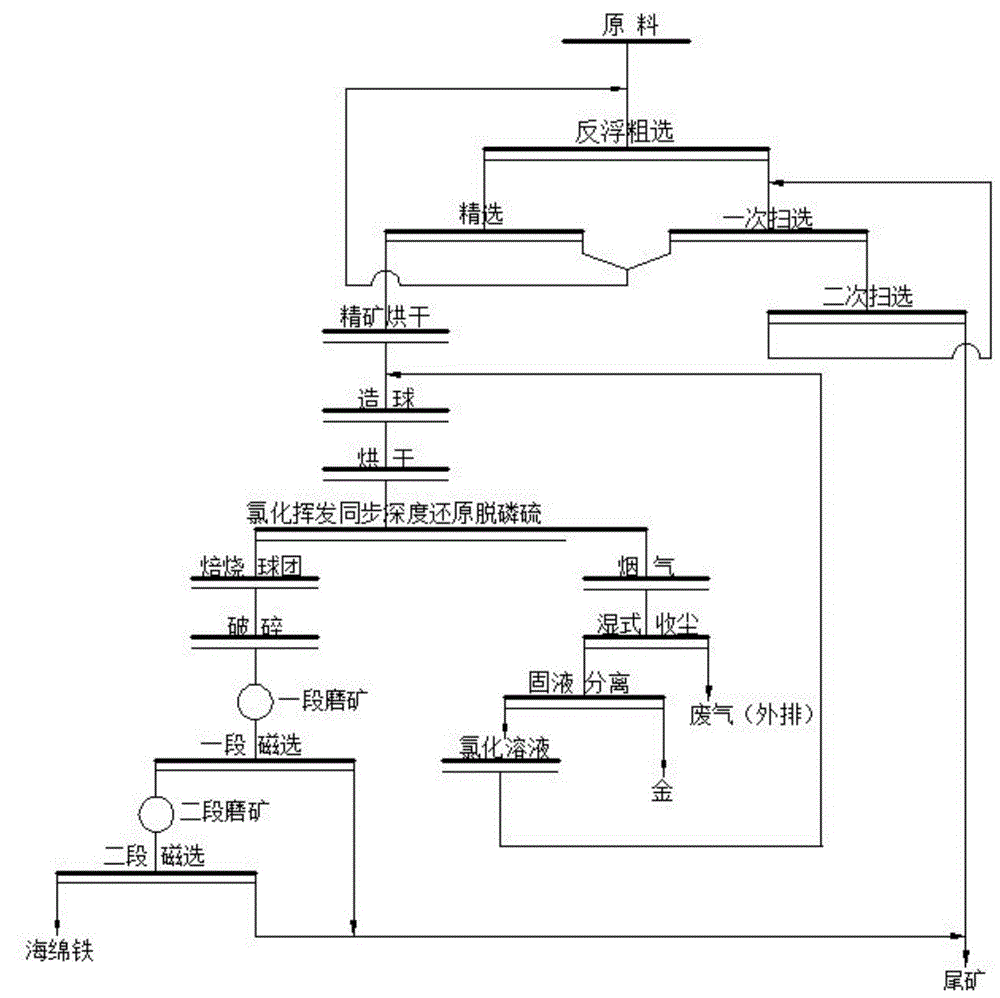

Method of performing chloridizing roasting to synchronously reduce and recover gold and iron from gold concentrate cyanide tailings

The invention provides a method of performing chloridizing roasting to synchronously reduce and recover gold and iron from gold concentrate cyanide tailings, and belongs to the technical field of comprehensive utilization of resources. The method comprises the following steps: performing reverse flotation desilicication preconcentration on the gold concentrate cyanide tailings which comprise 0.5-0.95% of phosphorus, 0.9-1.4% of sulfur, 20-25% of iron, and 3.0-4.5 g / t of gold, drying the obtained concentrate, then mixing the concentrate with a chlorinating agent, a reducing agent, a dephosphorization agent and a desulfurizing agent, pelletizing, performing high temperature chlorination to volatilize gold and synchronously performing deep reduction to remove sulfur and phosphorus, collecting the exhaust gas to recover gold, and then performing crushing, ore grinding, magnetic separation on the roasted pellets to recover iron. With application of the method, a gold product and a sponge iron product can be obtained, wherein the gold recovery rate of the gold product is 92-96%; in the sponge iron product, the iron grade is 90-92.5%, the sulfur content is less than 0.06%, the phosphorus content is less than 0.07%, and the iron recovery rate is 88-93%. Through the reverse flotation preconcentration, the method can reduce the energy consumption of the follow-up treatment process and realize recycling of the low-grade gold and iron in the gold concentrate cyanide tailings.

Owner:JIANGXI YIYUAN REGENERATION RESOURCE CO LTD

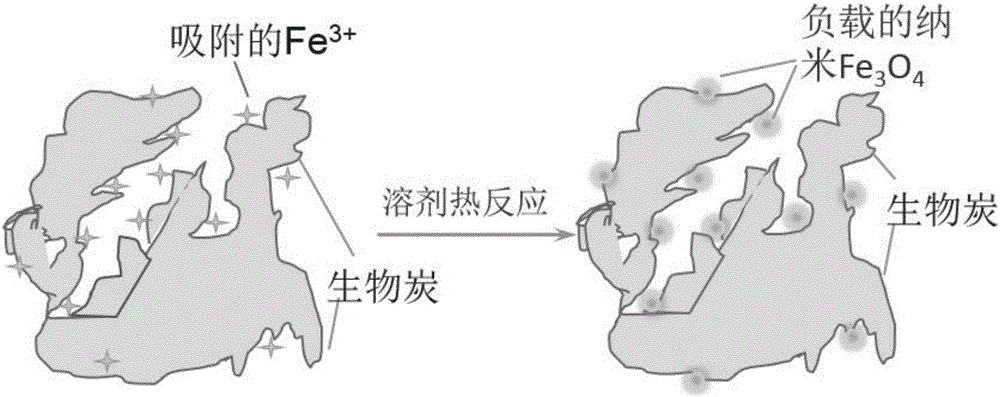

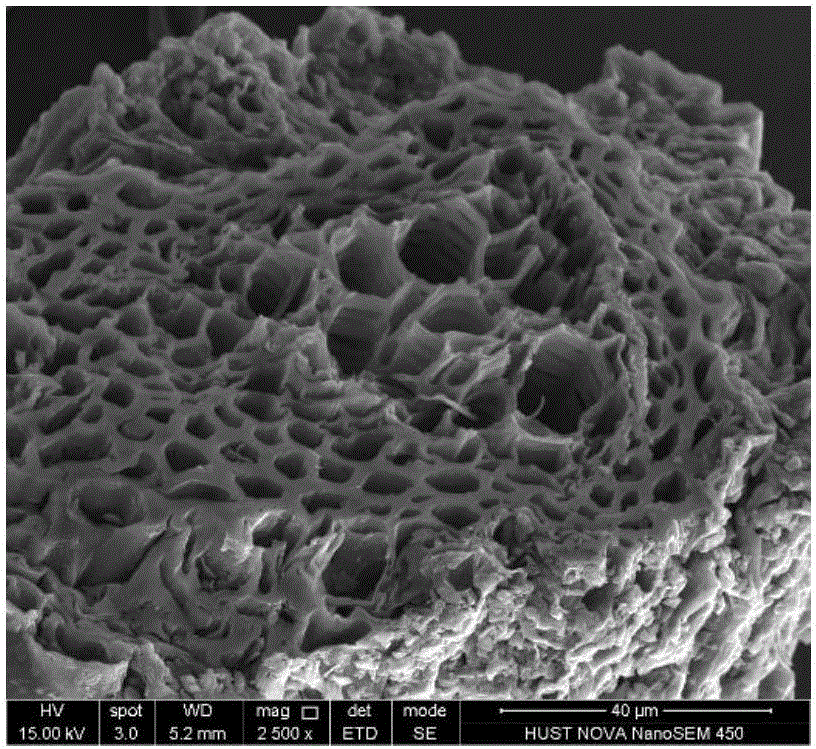

Magnetic biochar adsorbing material and preparation method thereof

InactiveCN106362690AGood lookingSimple structureOther chemical processesWater contaminantsSodium acetateSodium acetrizoate

The invention discloses a magnetic biochar adsorbing material and a preparation method thereof. The preparation method comprises the following steps: (1) preparation of biochar: by using powder obtained by treating plant biomass as a raw material, roasting under oxygen-free conditions to obtain porous biochar; (2) preparation of ferric iron precursor liquid: by using ethanediol as a dispersing agent, adding a solid-state ferric iron salt, continuing adding sodium acetate and a surfactant into the ethanediol, and stirring to form a disperse system which is the ferric iron precursor liquid; and (3) solvothermal reaction: uniformly mixing the biochar and ferric iron precursor solution to obtain a mixture, putting the mixture into a teflon hydrothermal reaction kettle, and carrying out solvothermal reaction to obtain the magnetic biochar adsorbing material. The pretreatment technique of the key biomass raw material and the specific conditions of solvothermal reaction in the preparation method are improved, thereby effectively solving the problem of poor connection stability between the magnetic biochar material magnetic particles and biomass.

Owner:HUAZHONG UNIV OF SCI & TECH

Particulate zinc oxide with manganese, iron and copper dopant ions

A particulate metal oxide includes a cationic portion that includes a zinc portion, a first iron dopant portion and a second dopant portion consisting of manganese and copper, where the zinc portion is about 99% by weight or more of the cationic portion, and the weight percent of the second dopant portion is greater than twice the weight percent of the first iron dopant portion.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Method for directly restoring and recovering copper iron from smelting copper slag

ActiveCN102952952AMeet the requirements of energy saving and emission reductionEfficient recyclingProcess efficiency improvementGas emission reductionMolten stateOxygen

The invention belongs to the field of metallurgy, and particularly relates to a method for directly restoring and recovering copper iron from smelting copper slag. The method comprises the following steps of: transferring high-temperature molten state copper slag to a high-temperature reducing furnace by a tundish, jetting oxygen to previously desulfurize, adding slagging constituent to keep temperature, jetting natural gas to carry out smelting reduction, slowly cooling to 1096 DEG C at the speed of 1.5-2 DEG C / min, and keeping the temperature for 1h to obtain 7.3at% Cu-Fe copper alloy melt and gamma pig iron, or slowly cooling to 850 DEG C at the speed of 1.5-2 DEG C / min, and keeping the temperature for 1h to obtain 2.7at% Cu-Fe copper alloy melt and gamma pig iron. According to the method provided by the invention, the total recovery use of valuable components, i.e. copper, iron and the like, can be realized, and the alloy melt obtained by the reduction smelting is slowly cooled and separated to obtain copper-rich alloy and low-sulfur gamma pig iron, so that separation of copper and iron is realized and the additional values of products can be improved.

Owner:NORTHEASTERN UNIV

High-performance lithium iron phosphate cathode material and preparation method of lithium iron phosphate cathode material

The invention relates to a cathode material lithium iron phosphate for a lithium ion cell and a preparation method of lithium iron phosphate. The preparation method comprises the following steps: synthesizing a lithium iron phosphate cathode material through a hydrothermal method by taking a ferric iron salt as an iron source and a nanocrystalline metal oxide as a doped source, subsequently mixing lithium iron phosphate with organic acid or sugars, and sintering at high temperature to obtain the high-performance lithium iron phosphate cathode material coated by carbon. According to the preparation method disclosed by the invention, the ferric iron salt with low price is used as the raw material, so that the cost is saved; and the nanoscale metal oxide is used as the doping element, so that a crystal nucleus is provided for hydrothermal crystallization and the implementation of the reaction is accelerated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

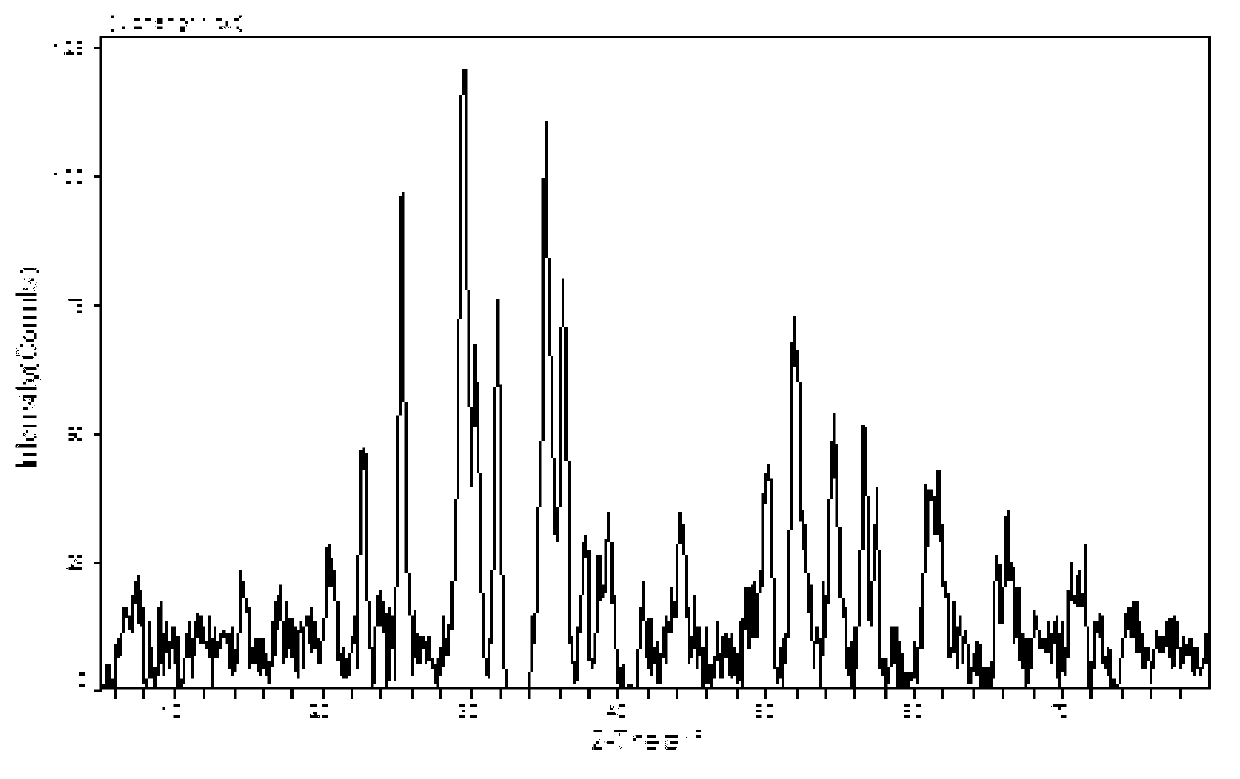

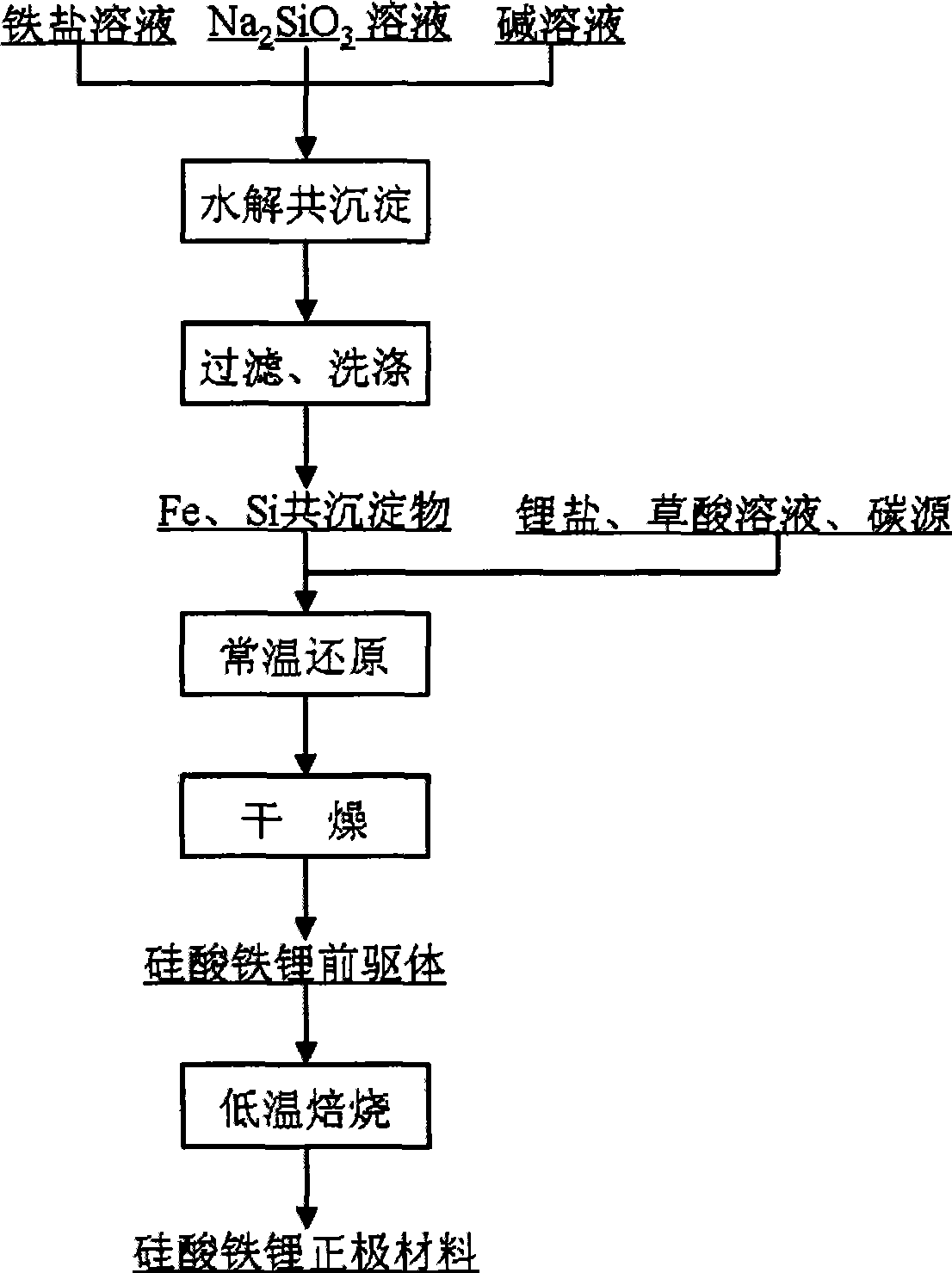

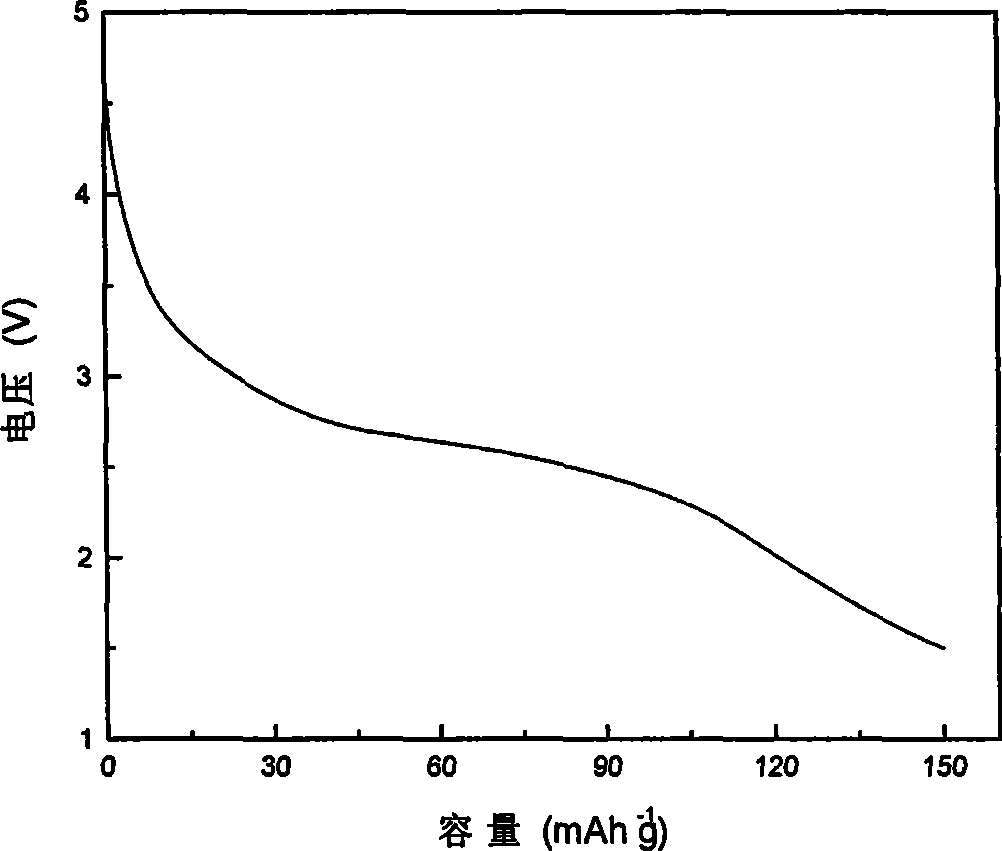

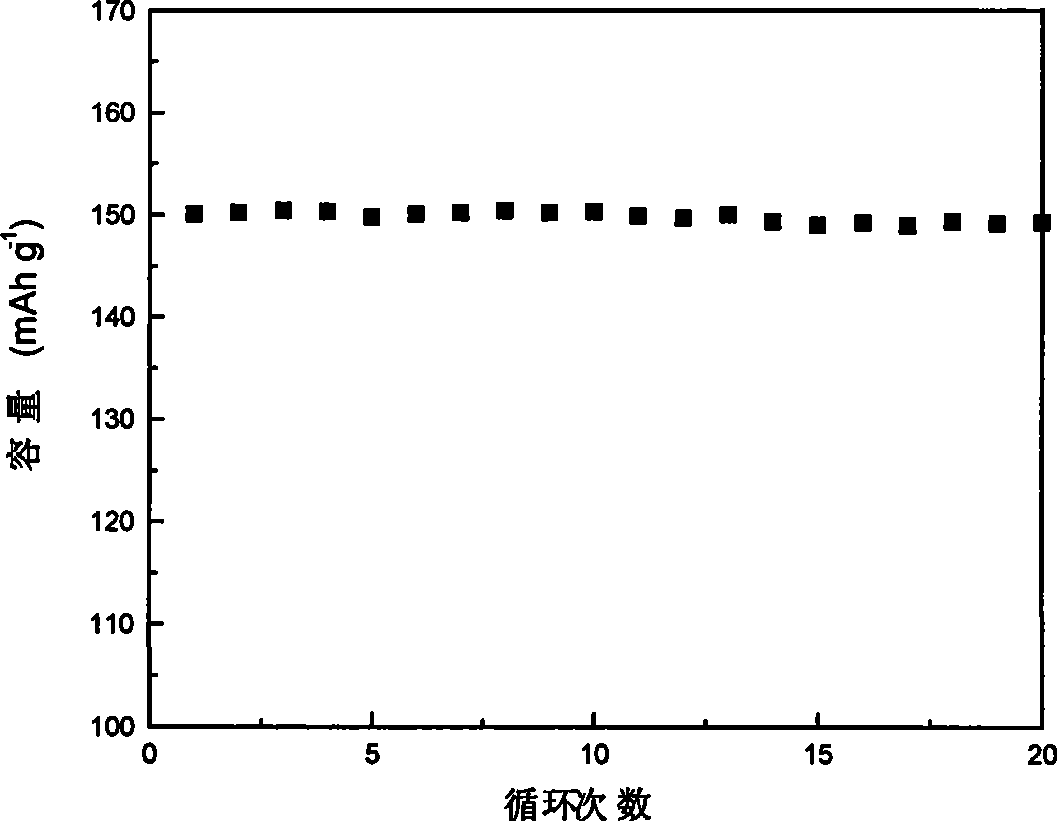

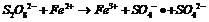

Production method of lithium ferric metasilicate anode material

InactiveCN101499527AWide variety of sourcesConvenient sourceElectrode manufacturing processesMetasilicateFERRIC IRON

The invention relates to a preparation method of lithium iron silicate cathode material. In the method, ferric saline, Na2SiO3 and lye are added into a reactor in a flowing way; the pH value of the reaction system is controlled, so that the hysrolysis reaction between the ferric iron and the SiO3 can occur; the common deposit of iron and silicon is prepared by filtering and washing; the common deposit of iron and silicon, the lithium source compound, the oxalic acid solution and the carbon source compound are mixedto become pulp state; the Fe is reduced to be Fe through ball milling; the precursor material of lithium iron silicate can be prepared by drying; the precursor material is calcinated under the conditions with the protective atmosphere and at the low temperature to form the agglomerated acidic lithium-iron anode material which is composed of nanoparticles. The method has the strong process adaptability; the industrial production can be easily realized; and the product has higher density and excellent electrochemical properties.

Owner:CENT SOUTH UNIV

Method for treating organic waste water by using electrochemistry under assistance of persulfate

InactiveCN102249378AReduce dosageLess side effectsWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationElectrochemical responseSulfate radicals

The invention relates to a method for treating organic waste water by using electrochemistry under the assistance of persulfate. The method comprises the following steps of: putting sulfate, a divalent or tervalent ferric salt and organic waste water into an electrochemical reactor consisting of a DSA (Dimensional Stable Anode) and an anti-corrosive cathode; adjusting the pH value of a reaction liquid to 3-9; stirring; and switching on a power supply for reacting. The method is characterized in that: special requirement on the ferric salt is not made, the ferric salt can be divalent or tervalent, generated free sulfate radicals can be used for effectively treating organic pollutants in water; meanwhile, in the electrochemical reactor, reutilization of divalent ferric ions can be realized under the reducing action of the cathode, so that the adding amount of the ferric salt is reduced, side reactions between an excessive amount of ferric salt and free sulfate radicals are reduced, ineffective consumption of free sulfate radicals is avoided, and the generation of iron sludge is reduced simultaneously.

Owner:WUHAN UNIV

Shale gas reservoir pre-fracture composite acid solution, preparation method and application thereof

InactiveCN105086989APrevent collapseCore dissolution rate maintenanceDrilling compositionAcetic acidHydrofluoric acid

The invention belongs to the field of petroleum engineering and relates to a shale gas reservoir pre-fracture composite acid solution and its preparation method and application. The composite acid solution comprises the following components: Component a) at least one component of hydrochloric acid, hydrofluoric acid, fluorboric acid, phosphoric acid, formic acid and acetic acid; and Component b) a corrosion inhibitor, a discharge aiding agent, a ferric iron stabilizer and a clay stabilizer. The composite acid solution containing different acids is selected for different reservoirs. Rock core corrosion ratio is 25-30%. A certain rock core corrosion ratio is maintained, and borehole wall collapse caused by too high corrosion ratio is also prevented. The corrosion inhibitor, the discharge aiding agent, the ferric iron stabilizer and the clay stabilizer which are used as additives have good compatibility with acid. The composite acid solution provided by the invention has advantages of fast dissolving speed, uniform mixing, high corrosion inhibition efficiency, high surface activity, good clay stabilizing effect and wide range. Applicable temperature of the composite acid solution is 20-180 DEG C. by the use of the composite acid solution, normal construction of large-scale fracturing of long horizontal-section shale gas wells can be guaranteed under the condition of existing equipment capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

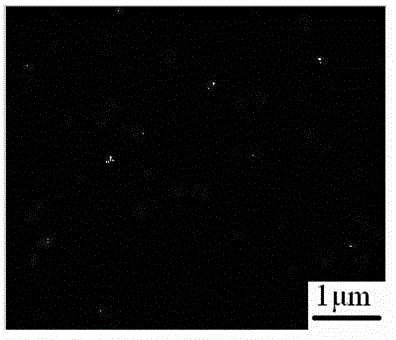

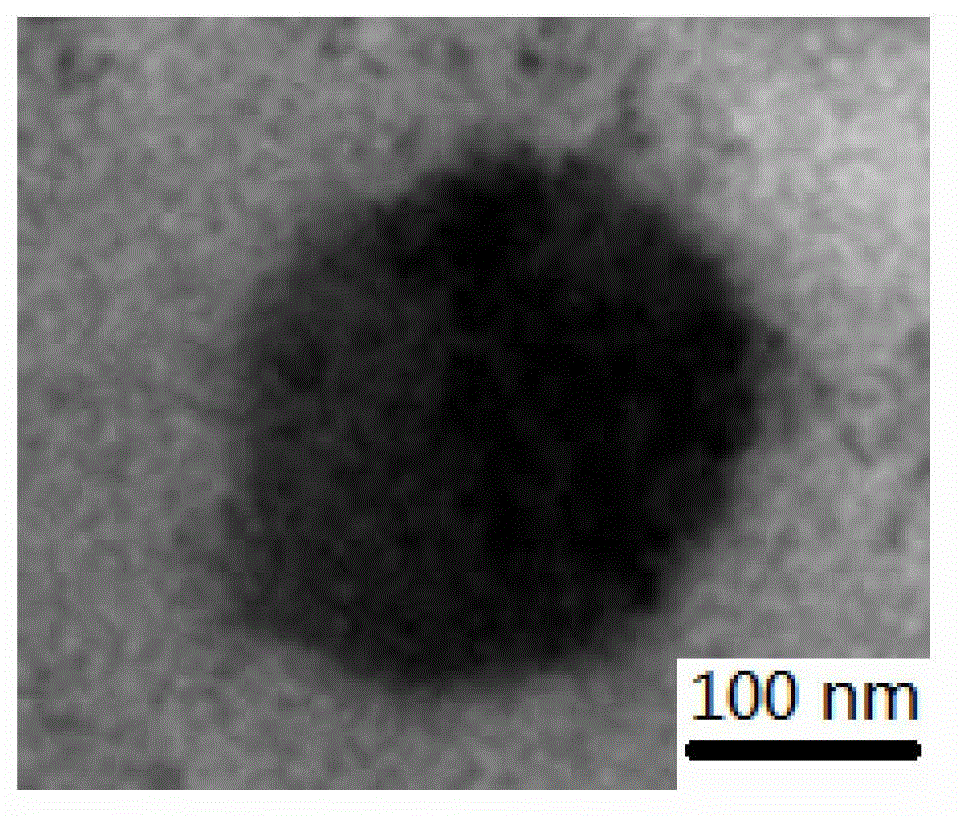

Method for preparing drug carrier based on magnetic carbon quantum dot/chitosan composite microsphere

InactiveCN102973948ALow costSimple methodInorganic active ingredientsInorganic non-active ingredientsSodium methoxideIron salts

The invention relates to a method for preparing a drug carrier based on a magnetic carbon quantum dot / chitosan composite microsphere. The method specifically comprises the following steps of: (1) carrying out a coprecipitation reaction on bivalent and trivalent iron salts in an alkaline aqueous solution so as to prepare nano magnetic ferroferric oxide; (2) carrying out microwave radiation reaction on a glucose and polyethylene glycol mixed solution to prepare carbon quantum dots, and forming magnetic carbon quantum dot composite particles through electrostatic adsorption; (3) reacting the chitosan which is dissolved in a mixed solution of sodium methoxide / absolute methanol with nitric oxide in a high-pressure kettle, and forming a chitosan-nitric oxide addition product; and (4) dropwise adding the magnetic carbon quantum dots into the addition product, and forming the magnetic carbon quantum dot / chitosan composite microsphere through electrostatic adsorption. Compared with the prior art, the method is simple, rapid, low in cost, and the prepared product can be developed into the drug carrier which integrates magnetic targeting, fluorescence imaging or tracing, nitric oxide in-situ release and fluorescence detection.

Owner:SHANGHAI JIAO TONG UNIV

Lithium iron phosphate cathode material and preparation method thereof

InactiveCN101559935AEasy to buyReduce manufacturing costCell electrodesPhosphorus compoundsPhosphoric acidLarge particle

The invention discloses a lithium iron phosphate cathode material and a preparation method thereof. The cathode material comprises 30-450nm of small particle size lithium iron phosphate accounting for 25-50% of the total volume, 450-3000nm of large particle size lithium iron phosphate accounting for 50-75% of the total volume and conductive carbon. In the preparation, lithium phosphate and iron phosphate are firstly prepared; then, the lithium phosphate and the iron phosphate are mixed according to the mol ratio of 2 / 3-2:1 and then added with phosphorus source compound, ferric iron source compound and lithium source compound; afterwards, absolute ethyl alcohol is added into the mixture for ball milling, and the lithium iron phosphate cathode material is obtained after the processing. The invention adopts a coprecipitation method to prepare the spherical iron phosphate and lithium phosphate which have controllable particle sizes, and then uses a solid state sintered technology to synthesize the lithium iron phosphate, so that the tap density reaches 1.6g / cm; the source of the raw materials is wide, and the requirements for the equipment and the cost are low, so that large-scale production can be realized.

Owner:SOUTH CHINA UNIV OF TECH

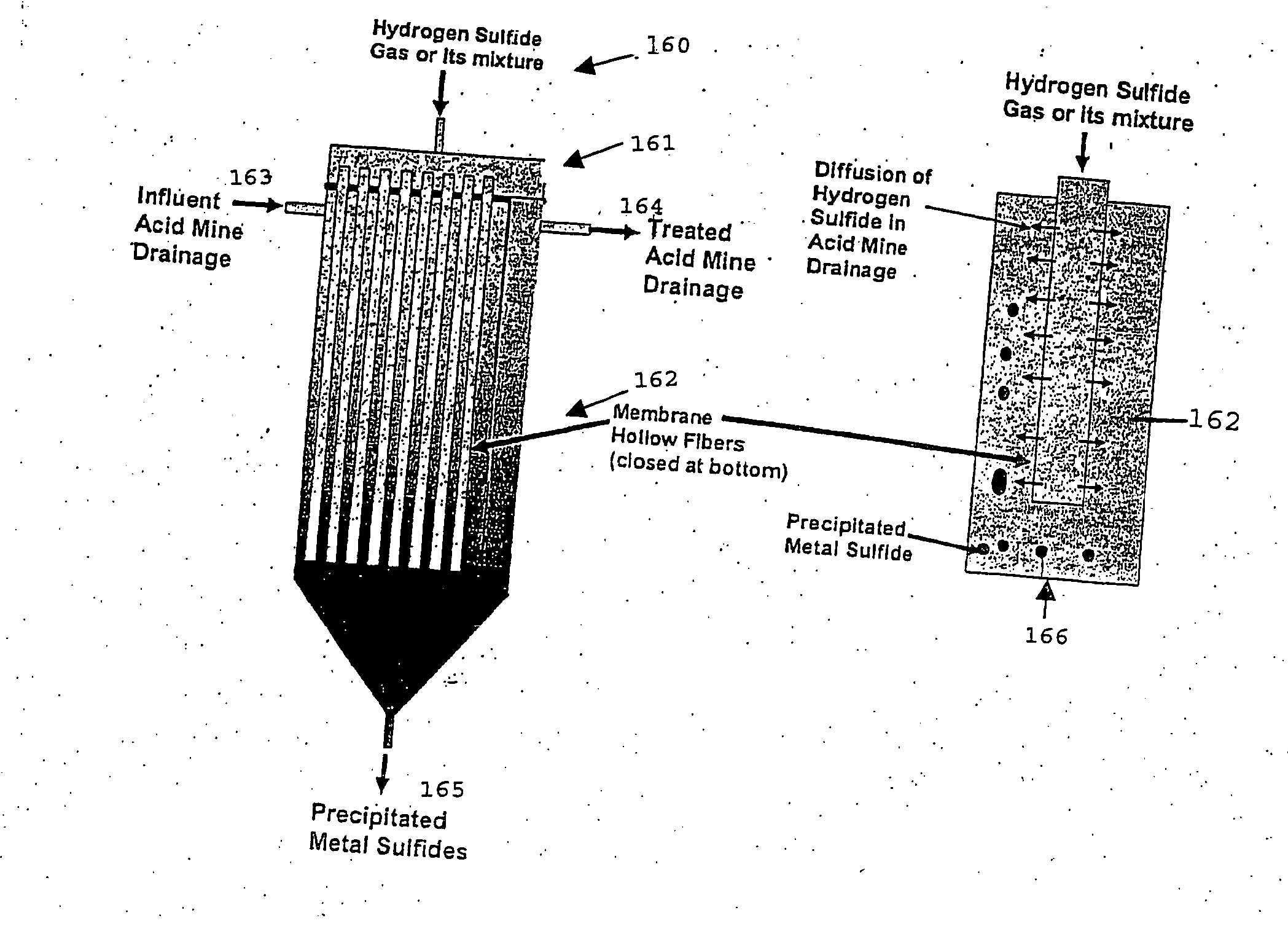

Process for the purification of acidic metal-bearing waste waters to permissable discharge levels with recovery of marketable metal products

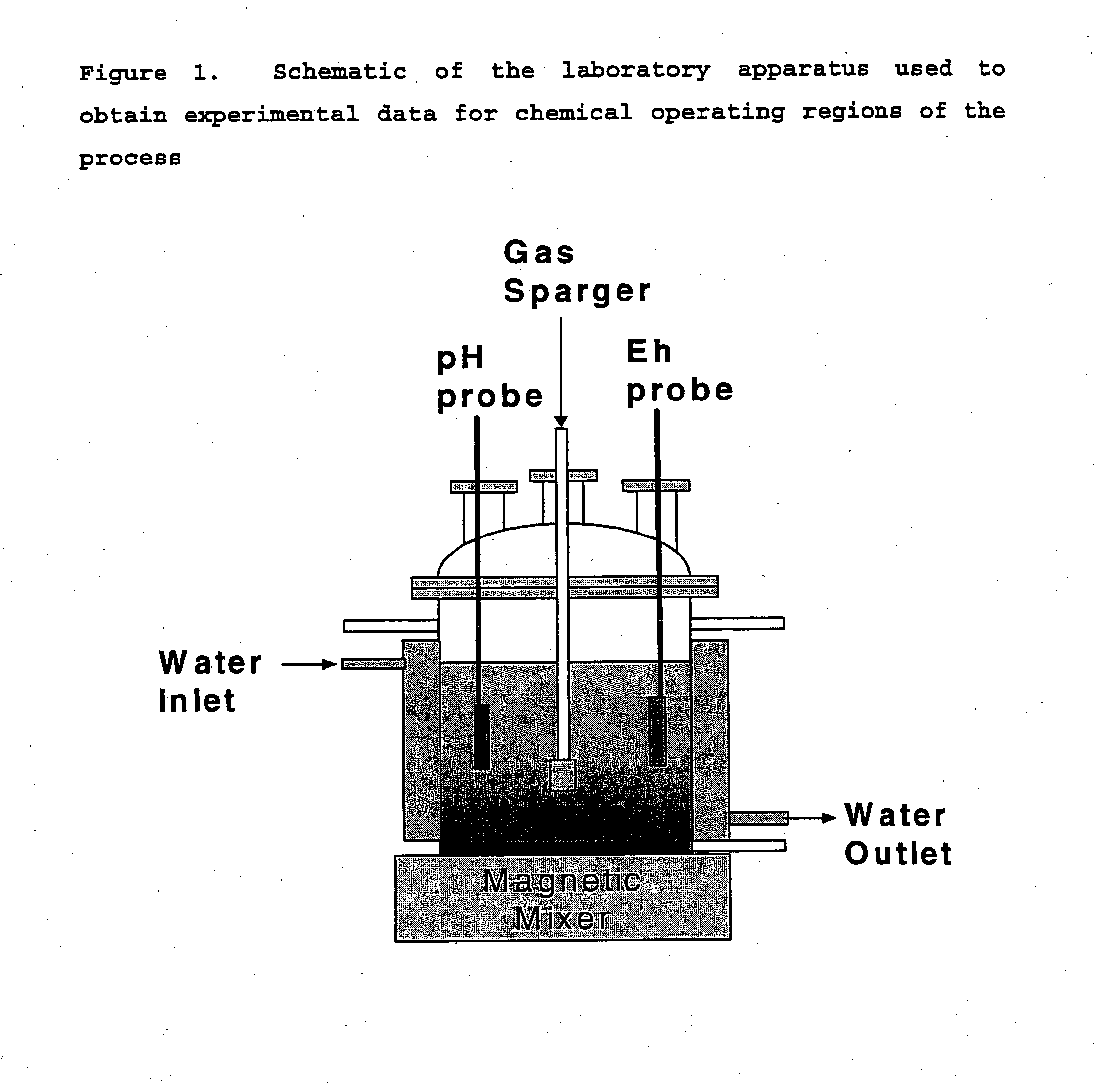

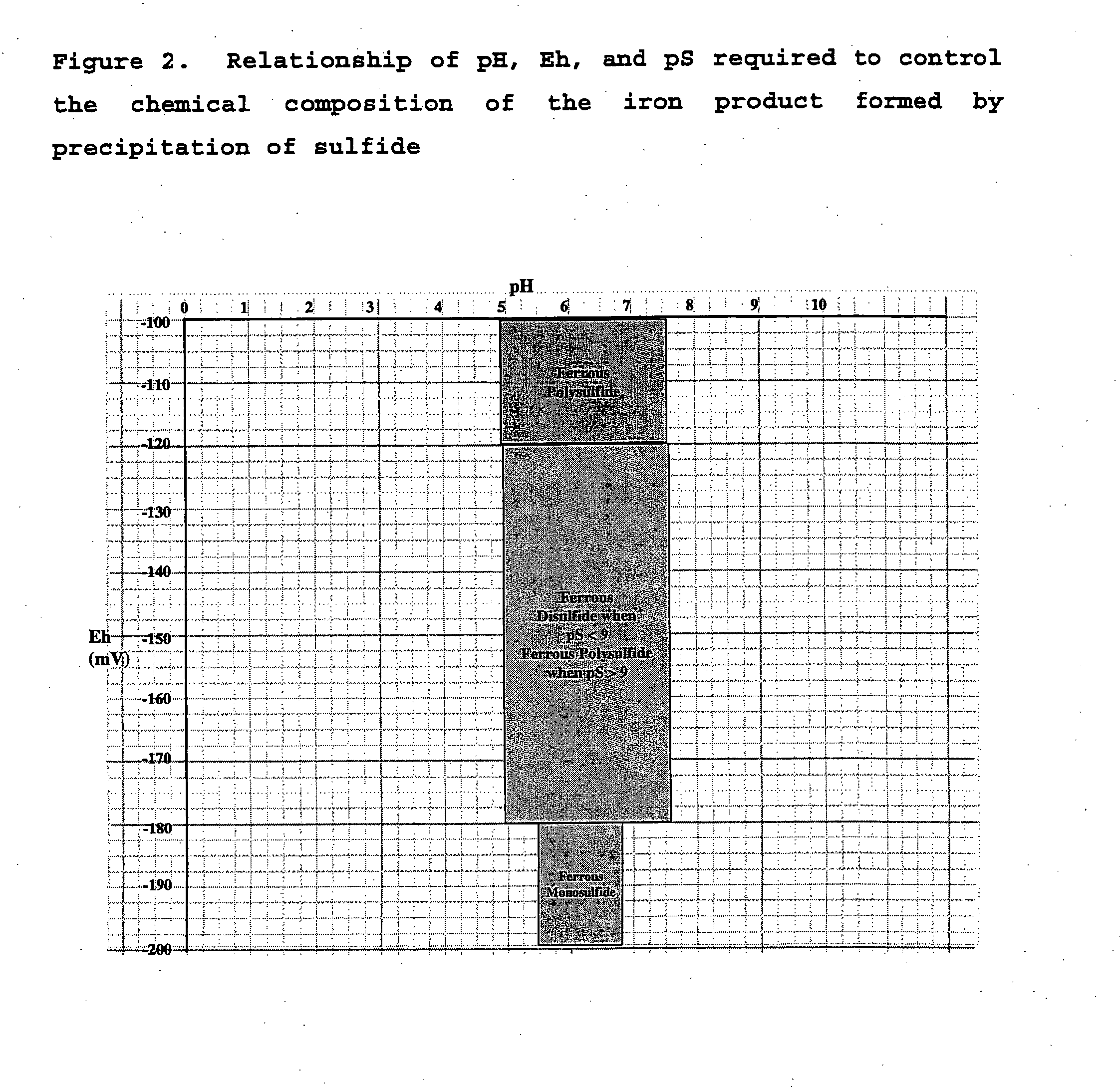

InactiveUS20070090057A1Reduce sulfate concentrationQuality improvementWaste water treatment from quariesWater contaminantsBioconversionPrecipitation

Acidic metal-bearing wastewaters are treated to produce a finished water of sufficient purity to meet discharge standards while recovering metals removed in forms which are commercially valuable. The metals are selectively precipitated, either in a batch or in a continuous system, for removal of individual metal products in a specific sequence of steps from the wastewater. In each step, the pH is adjusted to the specific pH range and sulfide ion is introduced to precipitate the metals, excepting the removal of ferric iron and aluminum which is achieved using hydroxide precipitation. Bioconversion process using unique equipment converts sulfate in the wastewater to the hydrogen sulfide gas required for the precipitation process. This bioconversion process reduces the sulfate in the wastewater so that the water can be directly discharged or used for agricultural applications.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

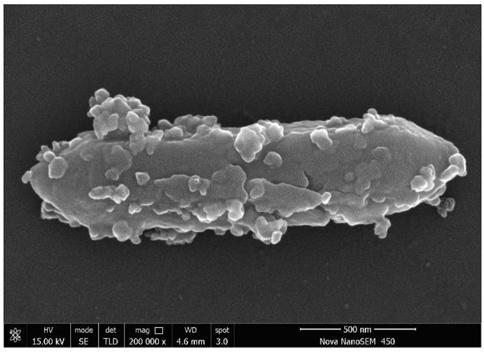

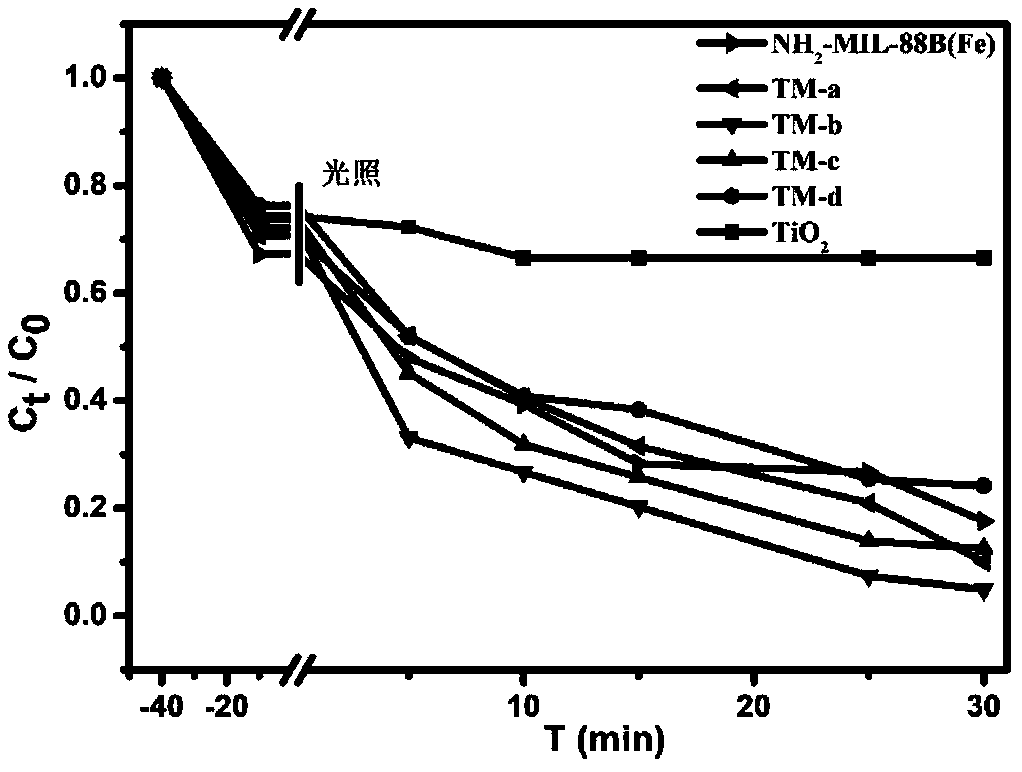

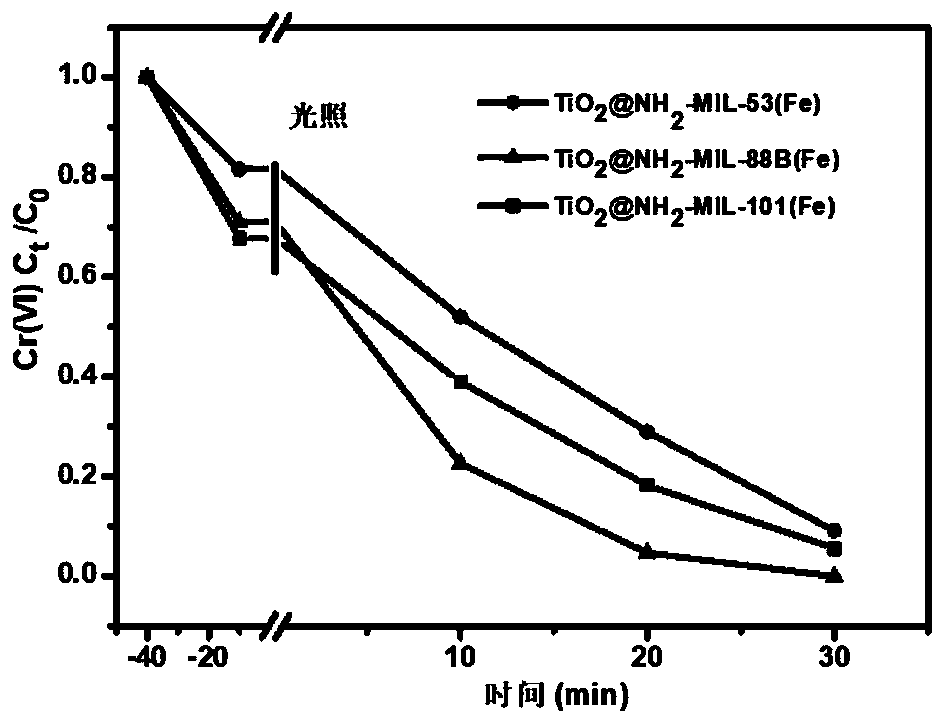

Preparation method and applications of nanometer titanium dioxide @ Fe-based MOF visible light composite catalyst

InactiveCN109289927AWide variety of sourcesLow priceWater/sewage treatment by irradiationWater treatment compoundsWastewaterPollution

The invention belongs to the field of environment pollution treatment, and more specifically relates to a preparation method and applications of a nanometer titanium dioxide @ Fe-based MOF visible light composite catalyst. The preparation method comprises following steps: a ferric iron salt, 2-amino terephthalic acid, and nanometer TiO2 are added into N, N-dimethyl formamide, ultrasonic uniform dispersion treatment is carried out so as to obtain a precursor solution; the precursor solution is subjected to hydro-thermal reaction so as to obtain the nanometer titanium dioxide @ Fe-based MOF visible light composite catalyst. Under sun light effect, the nanometer titanium dioxide @ Fe-based MOF visible light composite catalyst is capable of realizing high efficiency reduction of Cr(VI) under mild neutral conditions, efficiency is high, energy consumption is low, and the nanometer titanium dioxide @ Fe-based MOF visible light composite catalyst is widely suitable for processing of a plurality of chromium containing waste water.

Owner:NANJING UNIV

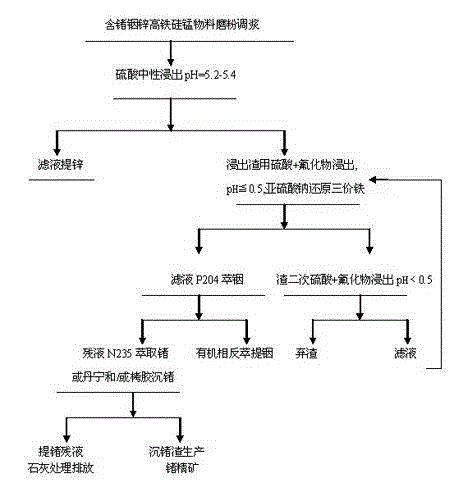

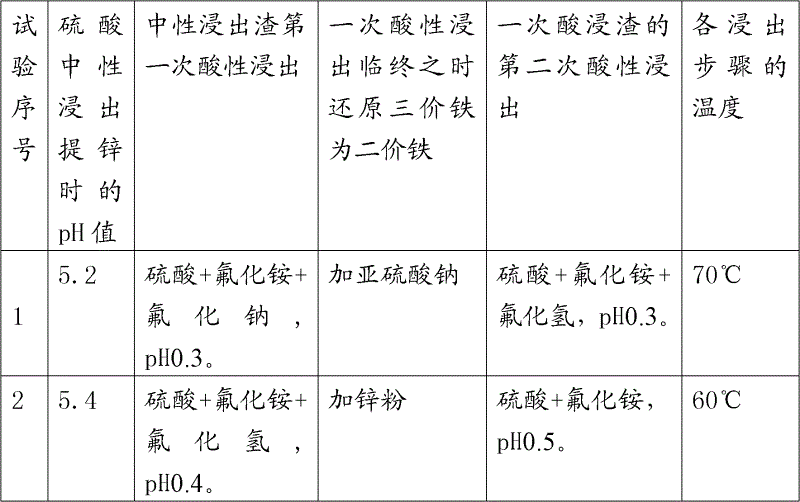

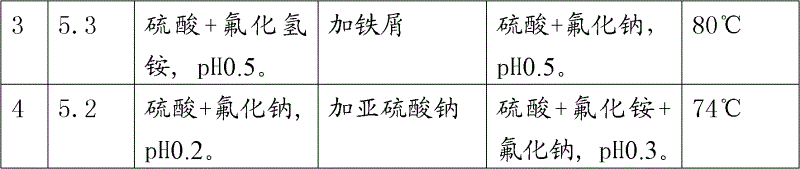

Method for extracting germanium, indium and zinc from high iron, silicon and manganese materials containing germanium, indium and zinc

A method for extracting germanium, indium and zinc from high iron, silicon and manganese materials containing germanium, indium and zinc belongs to the technology of hydrometallurgy. Sulfuric acid and fluoride are adopted for acid leaching for two times, leaching rate of germanium can reach 90% above, and secondary acid leaching slag contains germanium equal to and less than 0.005%. The total leaching rate of indium reaches 95% above, and tailings contain indium equal to and less than 0.003%. Germanium concentrate obtained by germanium extraction through an extraction method contains fluorine less than 1%. Low temperature leaching is performed at 70+-10 DEG C, the structure of iron vitriol slag is damaged as little as possible, and the concentration of ferric iron in leaching liquid is reduced. Ammonium iron hexafluoride produced in the leaching process shields the ferric iron, P204 indium extraction, N235 germanium or tannin extraction and tannin extract germanium deposit are improved, and the poisoning phenomenon in ferric iron of P204 and N235 is reduced. Comprehensive recovery utilization rate of germanium, indium and zinc in high iron, silicon and manganese materials is greatly improved.

Owner:YUNNAN WUXIN IND

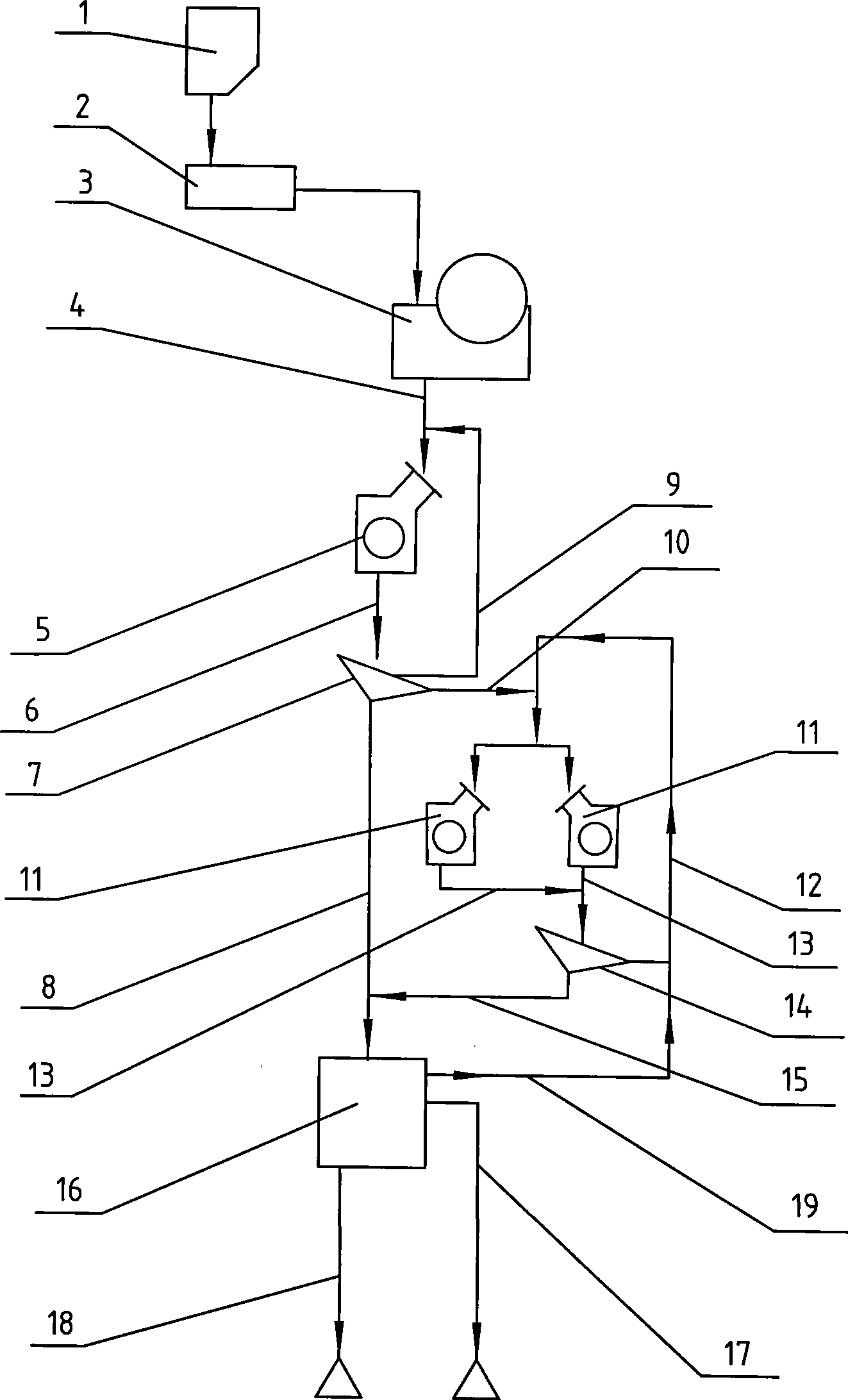

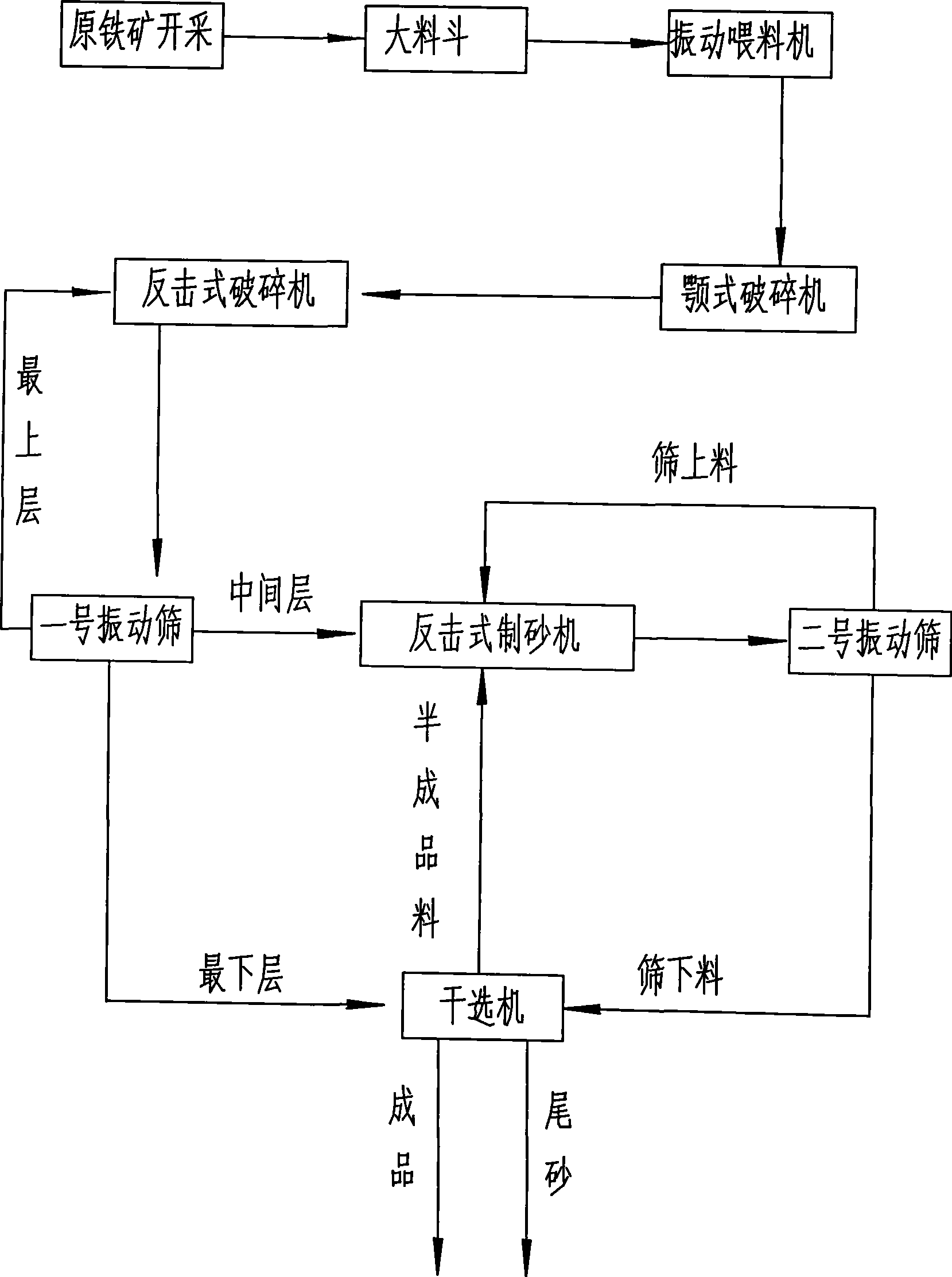

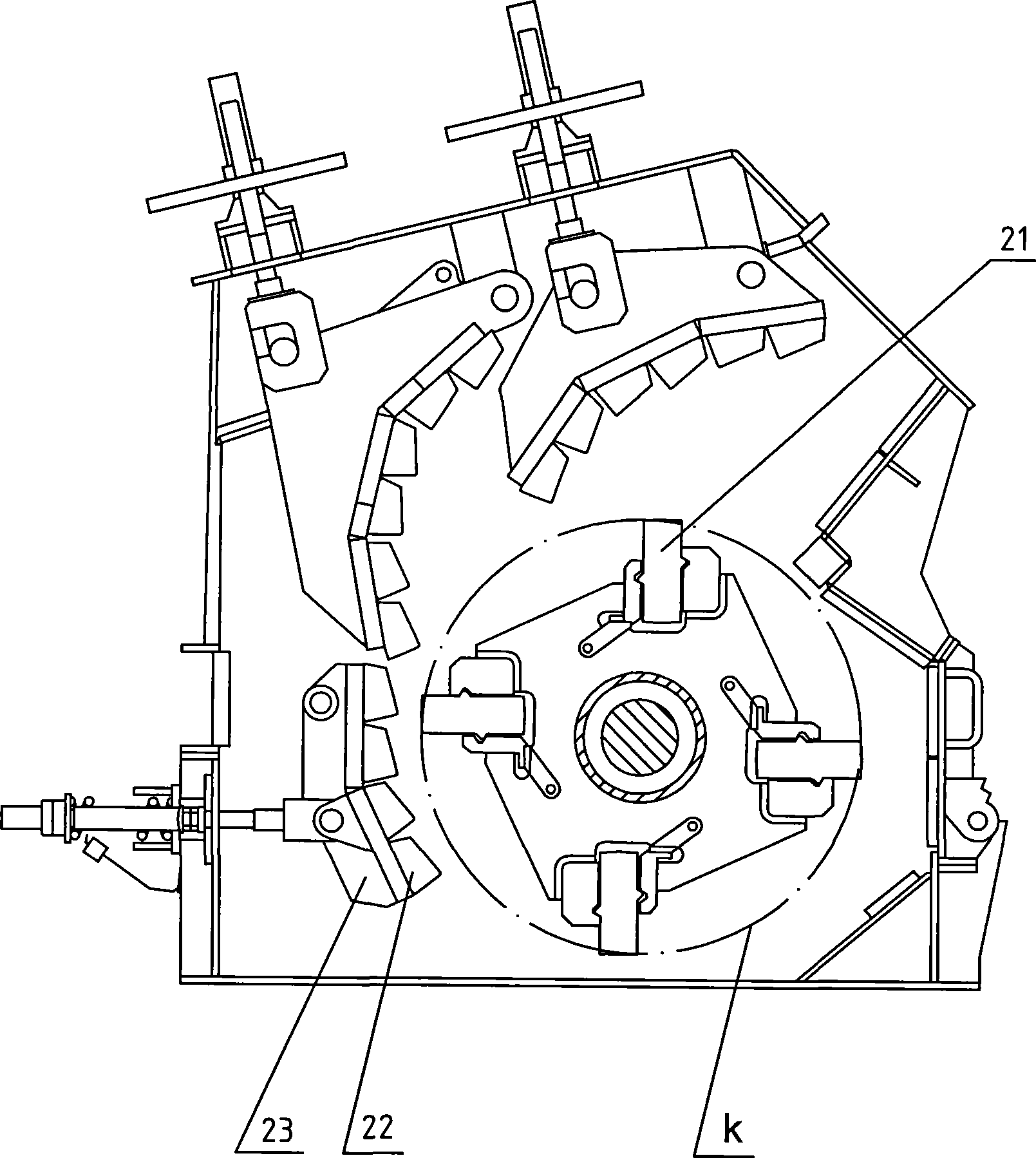

Dry dressing method for separating iron from iron ore

InactiveCN101385992AIncrease profitSimple processMagnetic separationGrain treatmentsIronstoneCrusher

The invention relates to a dry separation method used for separating iron from iron ore, belonging to an ore dressing process. At present, no iron ore dry separation method with strong production capability, uniform selected grain size and high grade exist. The invention provides a dry separation method which separates iron from iron ore; firstly, original iron ore is crushed sequentially by a jaw crusher, an impact crusher and an impact sand making machine, screened and dry-separated by a dry separation machine; the method is characterized in that after the iron ore is crushed by the impact crusher and the grain size of the iron ore is less than 50mm; after the iron ore is crushed by the impact sand making machine, the grain size of the iron ore is less than 10mm; after the iron ore is screened and enters the dry separation machine, the grain size of the iron ore is less than 4mm; after the iron ore is dry-separated by the dry separation machine, the iron concentrates with the iron content more than 55% is gained. The method has simple process, the grade of the iron concentrate which is selected finally is high, and the iron content of the iron concentrate is more than 55%.

Owner:海盐机械厂

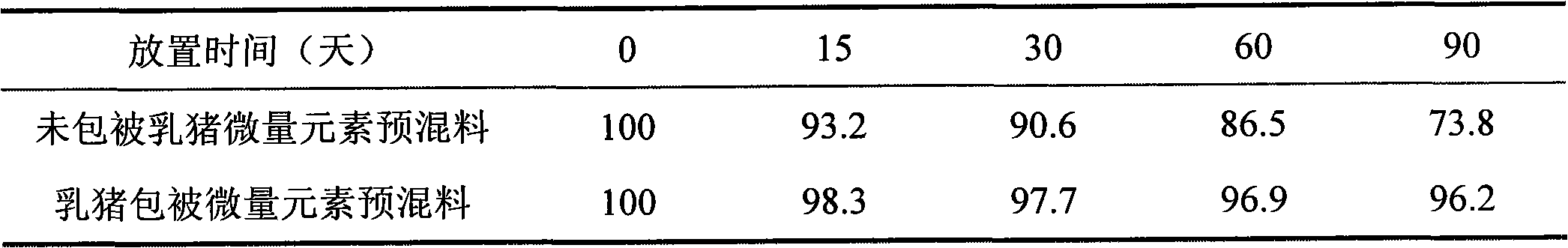

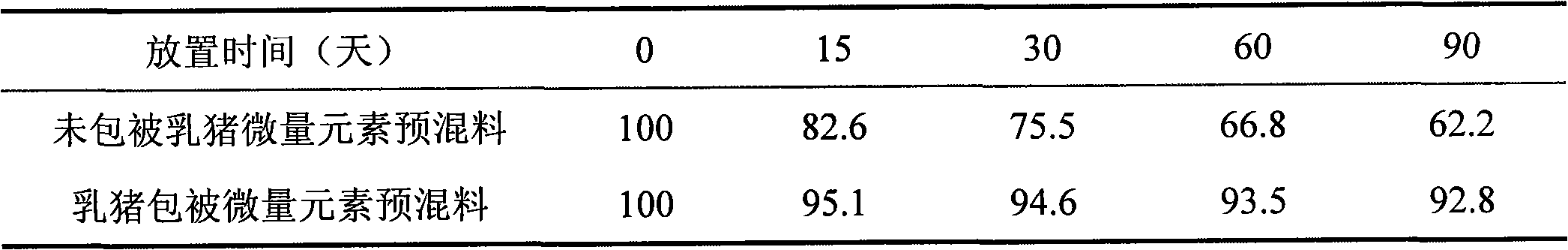

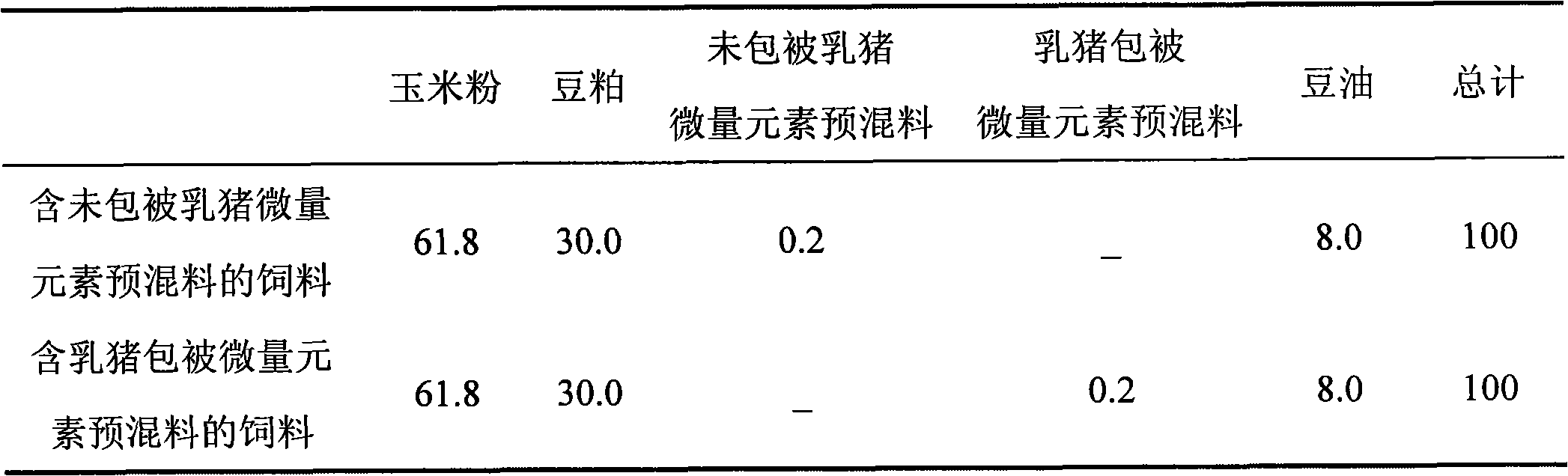

Premix coating trace elements and preparation method thereof

InactiveCN101912049AEvenly distributed ingredientsEnsure feeding effectAnimal feeding stuffAccessory food factorsDecompositionCatalytic oxidation

Owner:广州市正百饲料科技有限公司

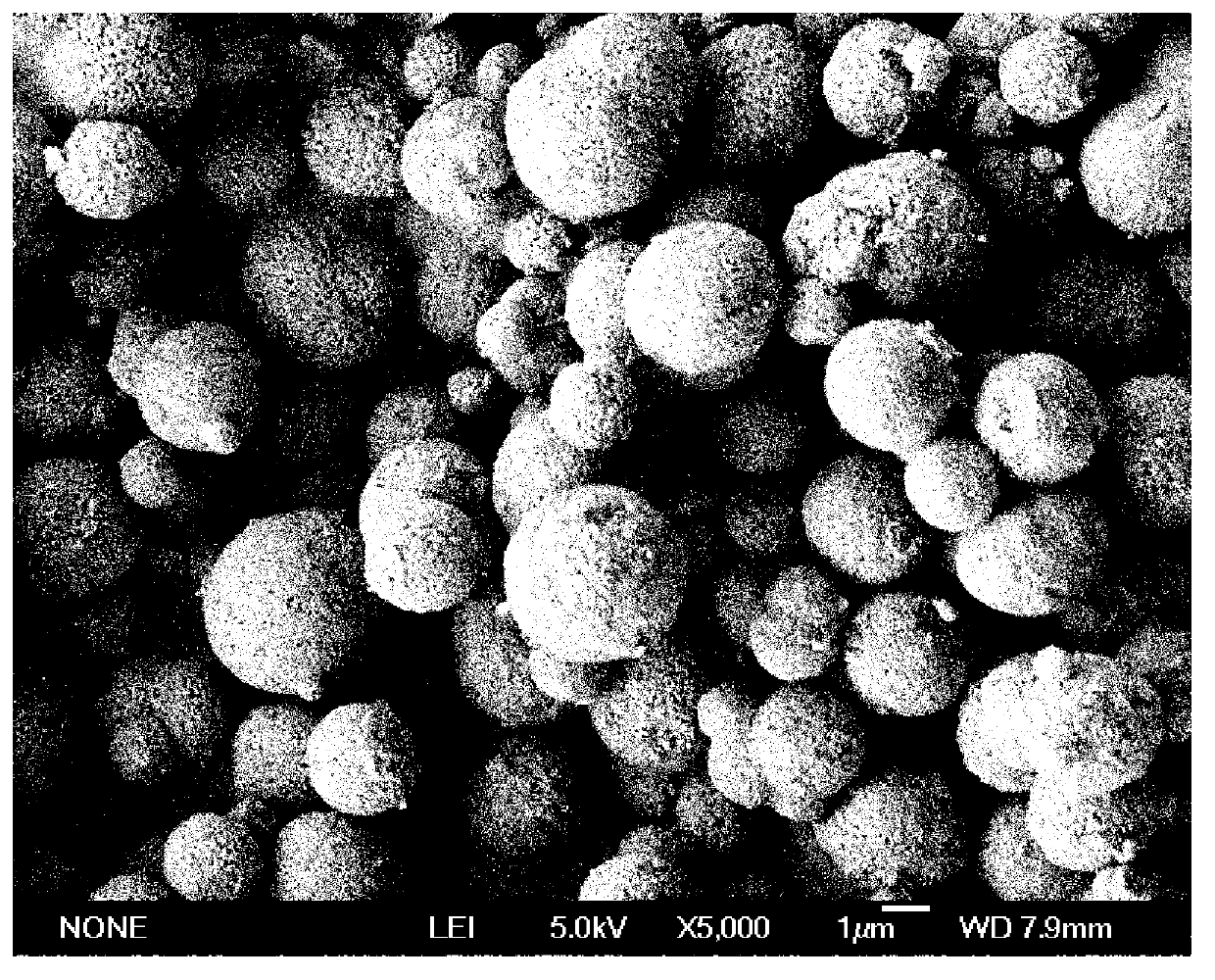

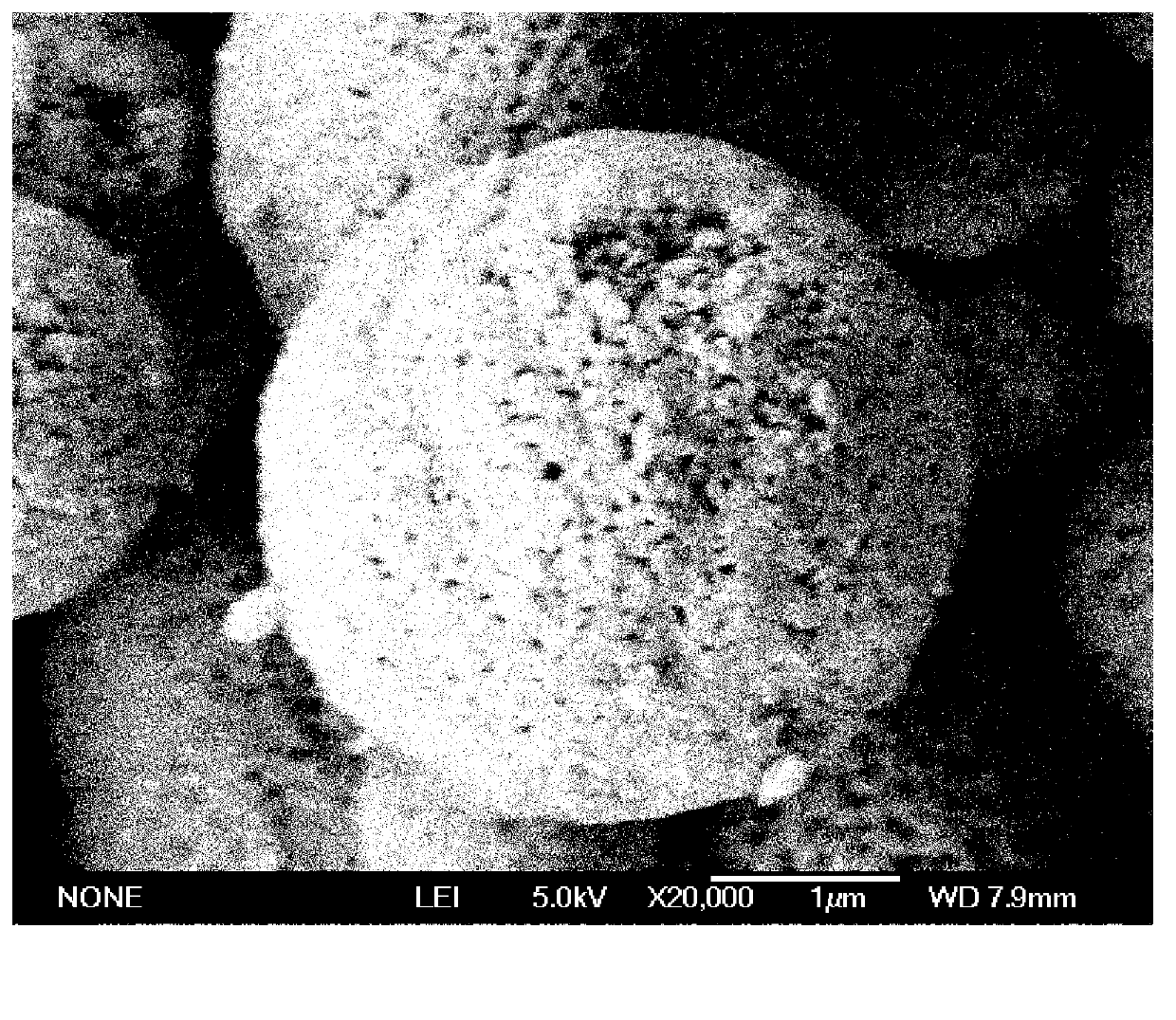

Method for preparing lithium ion battery anode material spherical LiFePO4

InactiveCN101746742AImprove conductivitySmall particle sizeCell electrodesPhosphorus compoundsChemical elementSolvent

The invention relates to a method for preparing lithium ion batter anode material spherical LiFePO4. The method is characterized in that: lithium source, iron source, phosphorous source, doped chemical element compound and carbon precursor are mixed, liquid phase stirring ball milling is carried out in solvent for 1-20h, then spray drying is carried out, thus obtaining spherical precursor with uniform particle size distribution, the precursor is placed into a high temperature furnace and heated to 500-1000DEG C at 1-6 DEG C / min under inert atmosphere, high temperature sintering is carried out for 5-24h, and temperature reduction is carried out, thus obtaining the spherical LiFePO4 powder. Available ferric iron is selected as iron source, thus reducing product cost; regular carbon bed structure is constructed in the interior of the main body of the material and on the surface of the main body of the material, thus improving conductivity of the material; liquid phase ball milling and spray drying are combined, and sintered precursor with small particle size and narrow particle size distribution is obtained, thus improving batch reproducibility of product.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Method for stabilizing and conditioning urban and industrial wastewater sludge

InactiveUS7497956B2Reduce moistureLower the volumeWater treatment parameter controlSludge treatment by de-watering/drying/thickeningIndustrial effluentSolid content

The invention concerns a method for stabilizing and conditioning wastewater sludge. The invention is characterized in that it consists in treating sludge in an acid environment (3.0≦pH≦5.0), with an inorganic acid and two oxidizing agents, that is a ferric iron salt and hydrogen peroxide. The ferric iron salt is used in such an amount as to obtain a concentration ranging between 5 and 40 kg of Fe per ton of dry sludge; the hydrogen peroxide is used in such an amount as to obtain a concentration ranging between 5 and 40 kg of H2O2 per ton of dry sludge; mixing the treated sludge for a time interval sufficient to stabilize the sludge and improve its dehydrability; then flocculating the stabilized sludge by adding an organic polymer; then dehydrating the flocculated sludge. Said method enables to significantly improve the dehydrability properties of the sludge while increasing the dry solid content during its mechanical dehydration.

Owner:CORP BIOLIX +1

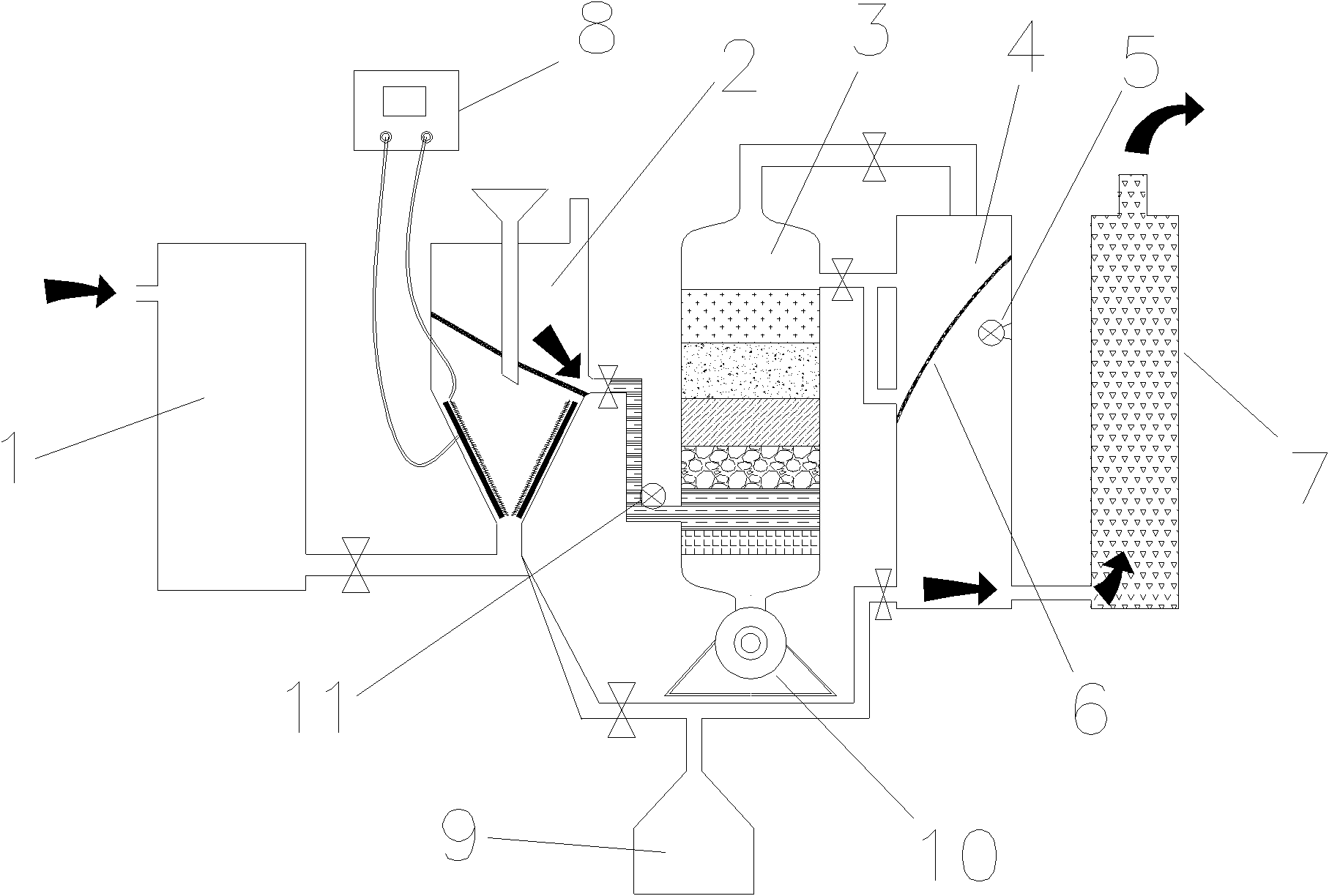

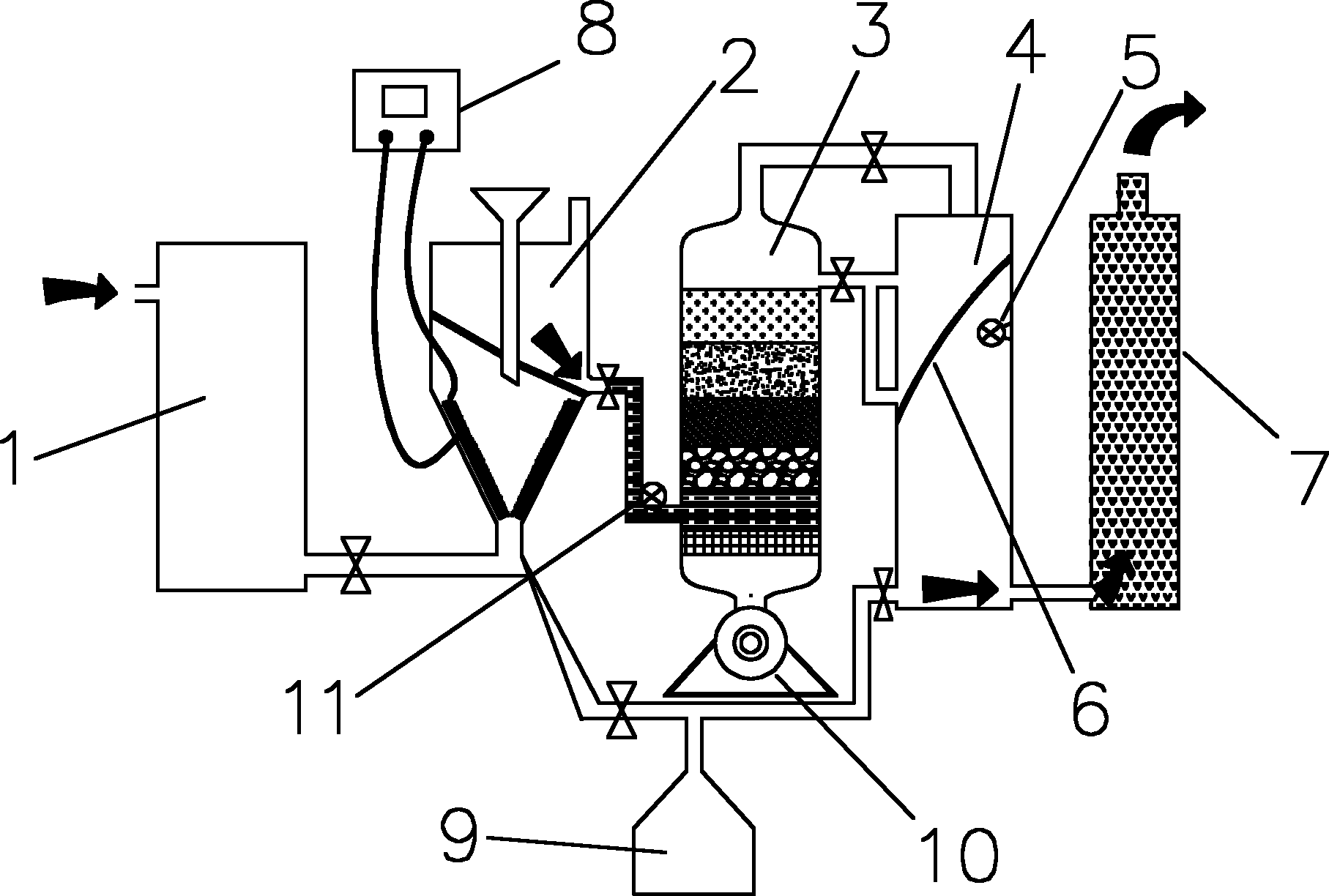

Device and method for processing restaurant wastewater

ActiveCN102145967AIncrease dissolved oxygenImprove the efficiency of degrading pollutantsMultistage water/sewage treatmentActivated sludgeElectrolysis

The invention discloses a device and a method for processing restaurant wastewater. A ferrallitic sheet is used as an anode and a graphite sheet is used as a cathode to carry out pulse direct current electrolysis on the restaurant wastewater so as to cause an electrocoagulation reaction; simultaneously ultrafine ozone bubbles are fed into an electrocoagulation reaction region to strengthen the electrocoagulation reaction, so that ferrous irons Fe2+ generated in the electrolysis process is rapidly converted into ferric irons Fe3+, the volume of flocculate becomes larger and the flocculate precipitates more efficiently to remove most of pollutants in the wastewater; sludge generated in the electrocoagulation process enters an activated sludge reactor and a sludge concentrating and extruding device; and clear water containing a little amount of organic matter enters an aeration-ozone-ultraviolet combined treatment degradation tank and a photocatalyst micro filtration membrane, and finally outflows through a fine porous sand filtering tank. The produced water can reach the primary standard in the industry. The processing method has high impact-load resistance. The outlet water quality is stable. In the engineering, consumables have long service life. Therefore, the processing cost of the restaurant wastewater can be greatly reduced.

Owner:TAIDEA TECH ZHONGSHAN

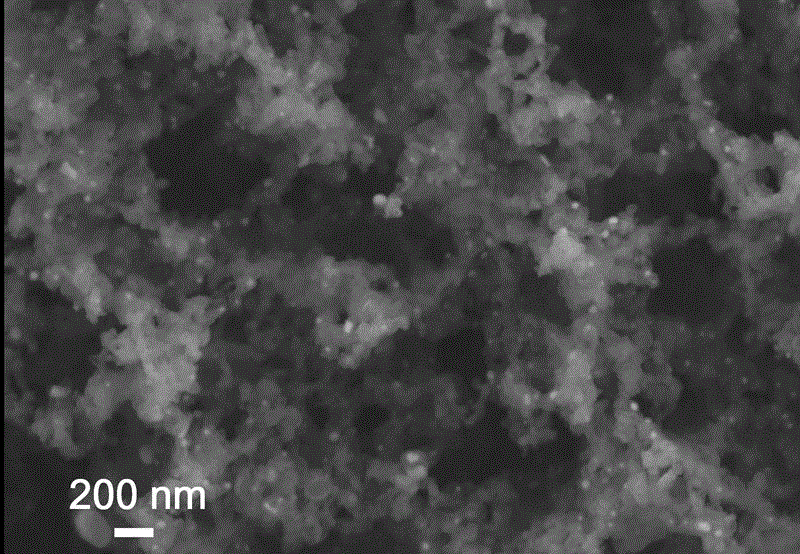

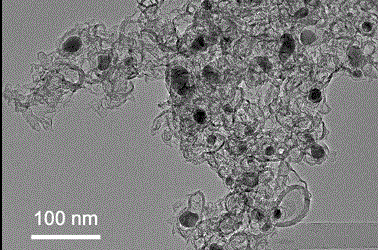

Iron-nitrogen-doped graphene porous material with dual-site catalytic oxygen reduction activity, and preparation method and application therefor

InactiveCN105609793ALarge specific surface areaMany active sitesCell electrodesPyrroleNitrogen doped

The invention belongs to the technical field of a nanomaterial, and specifically relates to an iron-nitrogen-doped graphene porous material with dual-site catalytic oxygen reduction activity, and a preparation method and an application therefor. The porous material is formed by embedding graphite-carbon-coated iron carbide into a nitrogen-doped porous graphene band network structure; the preparation method for the iron-nitrogen-doped graphene porous material comprises the steps of preparing a graphene oxide solution; adding a proper amount of conductive macromolecular pyrrole to the graphene oxide solution; obtaining uniform hydrogel through a hydrothermal process; performing oxidative polymerization on the hydrogel by ferric iron; then dispersing the hydrogel into a fresh ferric iron solution to complete adsorption; then performing drying and high-temperature carbonization thermal processing; and finally removing non-active and free iron phase from the reaction system by dilute acid so as to obtain the iron-nitrogen-doped graphene porous material. The porous material can be used as the negative electrode catalyst for a fuel cell, and shows quite high catalytic oxygen reduction activity, so that the porous material has quite important research meaning and bright application prospects.

Owner:FUDAN UNIV

Method for preparing high-density spherical lithium iron phosphate for lithium ion power battery

InactiveCN101519199APromote crystallizationSingle structureElectrode manufacturing processesPhosphorus compoundsElectrical batteryVolumetric Mass Density

The invention relates to a method for preparing high-density spherical lithium iron phosphate for lithium ion power batteries, which is characterized by comprising the preparing processes: acid, a ferric iron resource and phosphor resource are mixed into mixed water solution; alkali is prepared into water solution; the mixed water solution and the alkali water solution are respectively and continuously introduced into a reaction kettle to carry out coprecipitation reaction, and a spherical iron phosphate precursor is synthesized; the precursor is used as a raw material and is evenly mixed with a lithium resource, a carbon resource and a doping metal compound, and then, the mixture is heated in a stove to obtain a spherical lithium iron phosphate powder material under a protective atmosphere. The spherical lithium iron phosphate powder material prepared by the method has freely controllable average grain diameter being from 4 microns to 15 microns, narrow distribution of the grain diameter tap density as higher as 1.4 g / cm<3> to 2.2 g / cm<3>, and has the characteristics of high specific capacity, rate discharge and good safety performance. The method has simple technical processes and is suitable for industrial mass production.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

Method for recycling iron and zinc containing waste hydrochloric acid solution

ActiveCN105696010ATake advantage ofSolve the problem of no separation and recyclingProcess efficiency improvementZinc hydroxideChloride

The invention discloses a method for recycling an iron and zinc containing waste hydrochloric acid solution. The method specifically comprises the following steps that 1, acid consuming and reducing are carried out, acidity is made to meet the requirement, and ferric iron in waste acid is reduced into ferrous iron; 2, zinc and iron are extracted and separated, and a ferrous chloride solution is obtained; 3, an organic phase transfers zinc into a strip liquor through reverse extraction, and the organic phase is extracted for reuse; and 4, the strip liquor is subjected to subsection kalizing treatment, zinc hydroxide is obtained, and the strip liquor is reused. According to the method, iron and zinc are separated through different extracting capacities of N235 to the ferrous iron and zinc, and therefore pure ferrous chloride liquid and zinc hydroxide solids are obtained. Ferrous chloride can be oxidized into ferric trichloride, and ferrous chloride and ferric trichloride both can be used as a water treatment agent; and zinc hydroxide can be used as a raw material for preparing zinc oxide or zinc chloride.

Owner:3R ENVIRONMENTAL TECH CO LTD

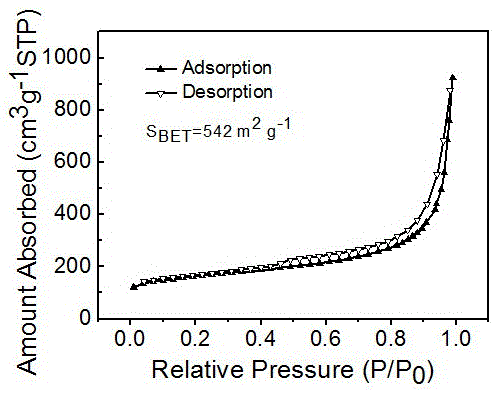

Ferrum oxidate nano magnetic material and method for preparing the same

InactiveCN101117241AAct as a reducing agentEasy to manufactureInorganic material magnetismFerroso-ferric oxidesSolventPolytetrafluoroethylene

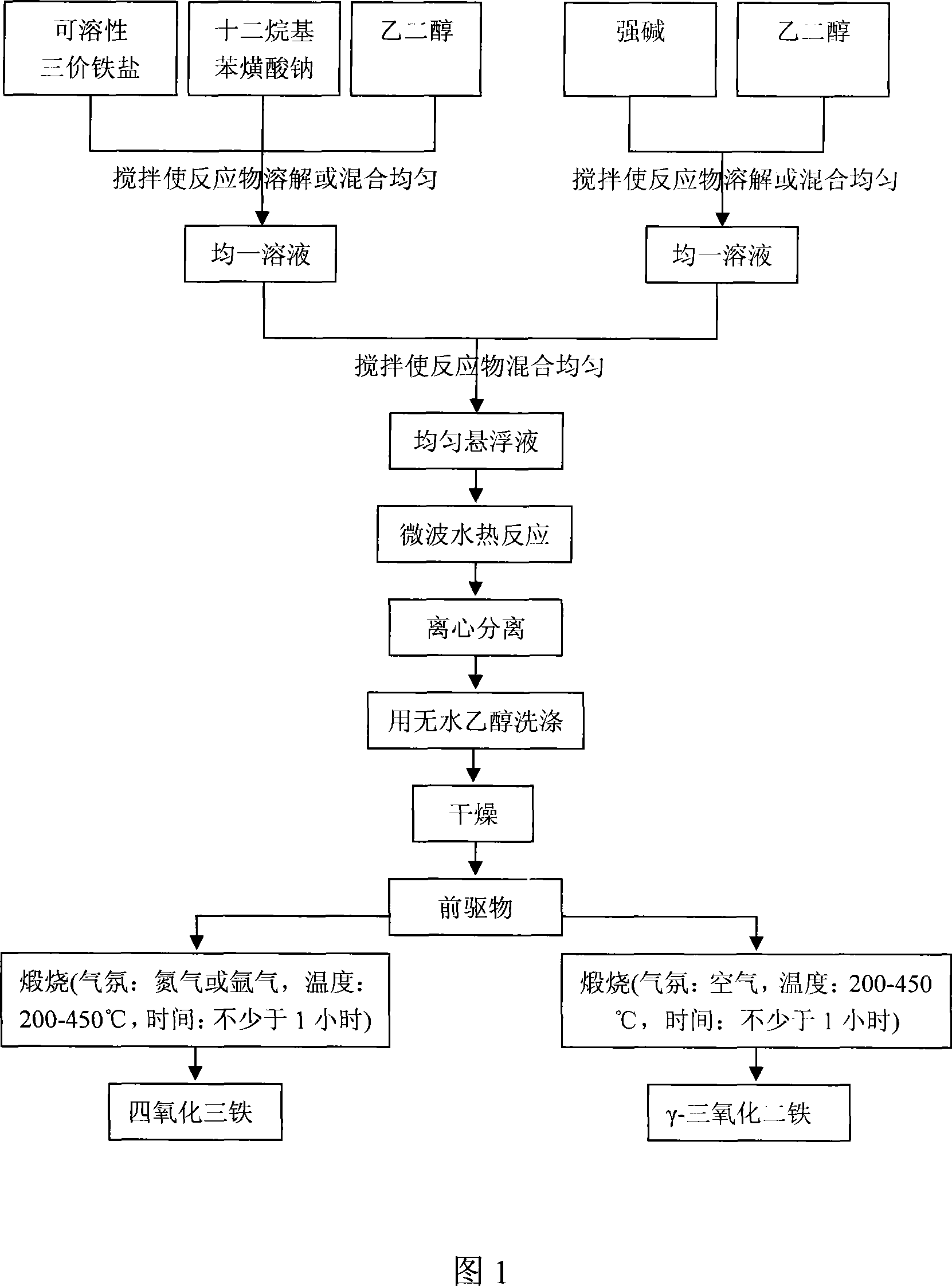

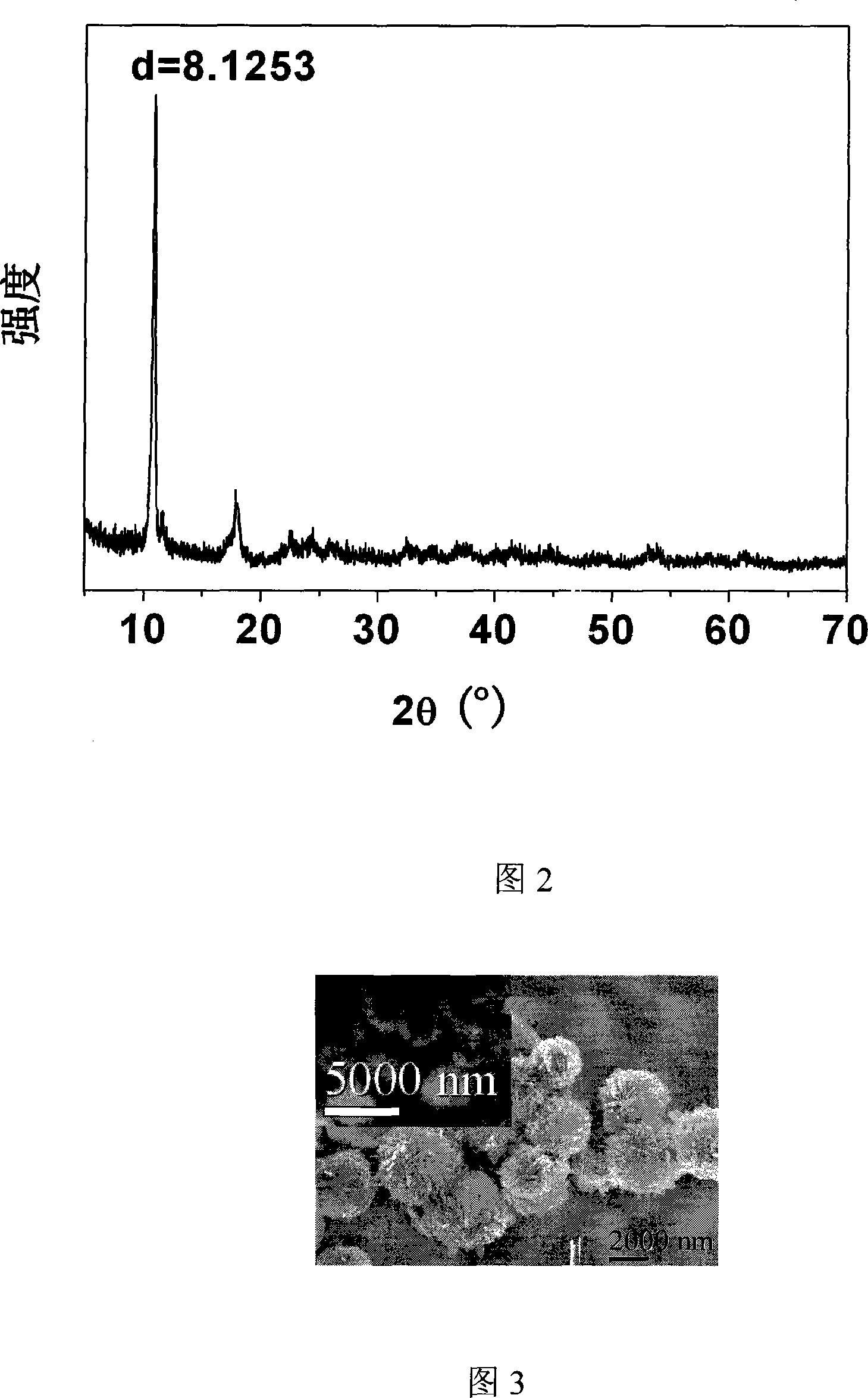

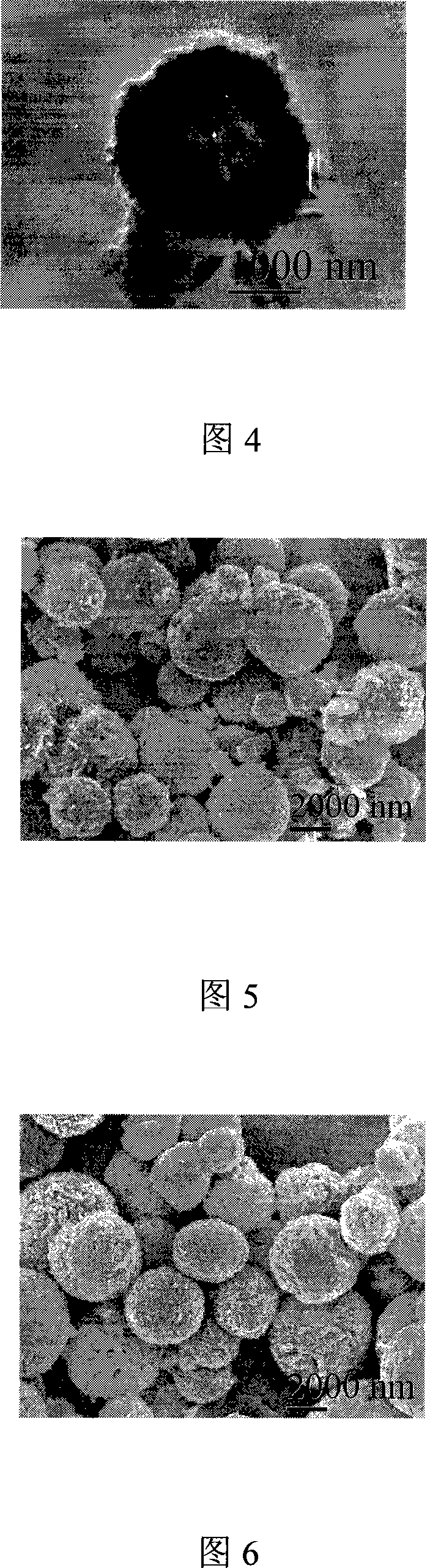

The invention relates to a nanomagnetic material of iron oxide and the fabrication method, and belongs to the nano-material fabrication field; the invention adopts glycol as a solvent and a reducing agent, and adopts sodium dodecyl benzene sulfonate as a surfactant, and adopts dissoluble trivalent iron sodium and alkali as a raw material, a mixing process under a room temperature is conducted to make a homogeneous suspension; the mixed liquid is turned into a polytetrafluoroethene lining to conduct a microwave water thermal reaction, after the reaction is over, the product from the reaction is separated, washed and dried to make a precursor nano-powder which is calcined to make a ferroferric oxide nano-powder or gamma ferric oxide nano-powder; the nano-powder body has a hollow ball structure assembled by a nano-piece, the hollow ball dimension is two to four micron while the inner hollow dimension of the hollow ball is one to three micron; the invention is characterized in low raw material cost, easy process, easy operation, controllable profile and so forth; the specific surface area is high, the magnetic performance is favorable.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com