Patents

Literature

202 results about "Particulate metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

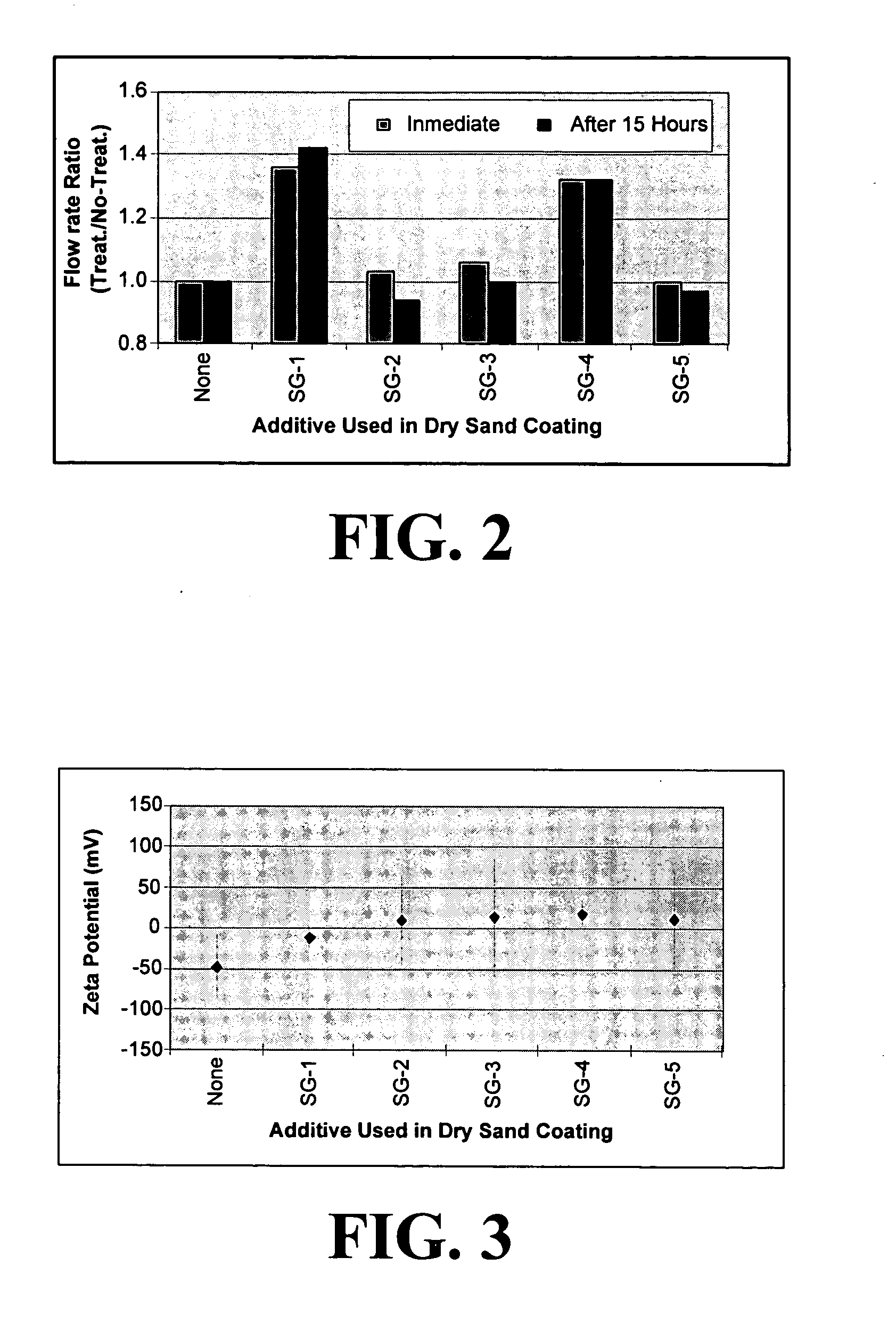

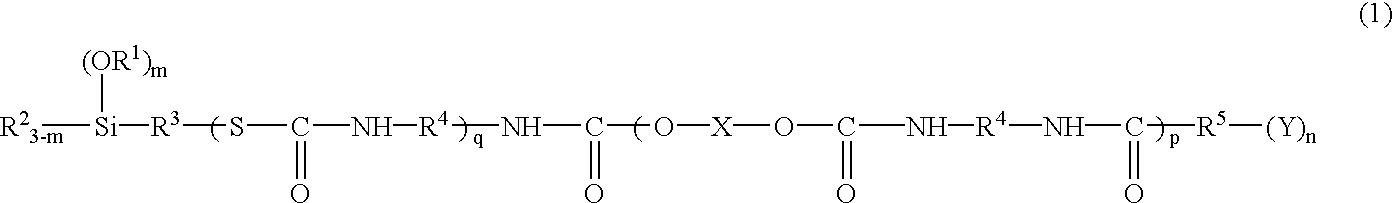

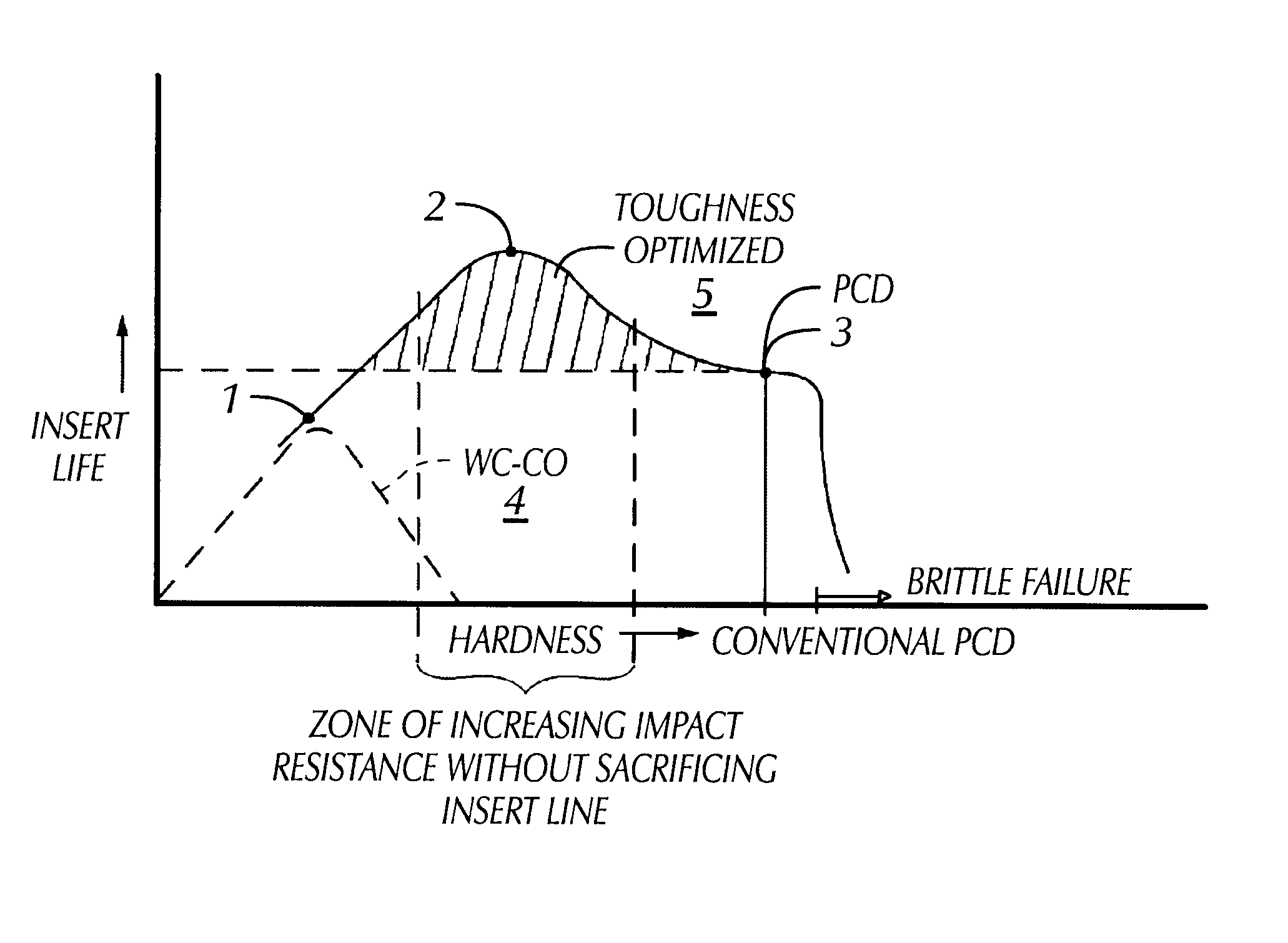

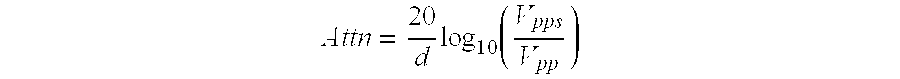

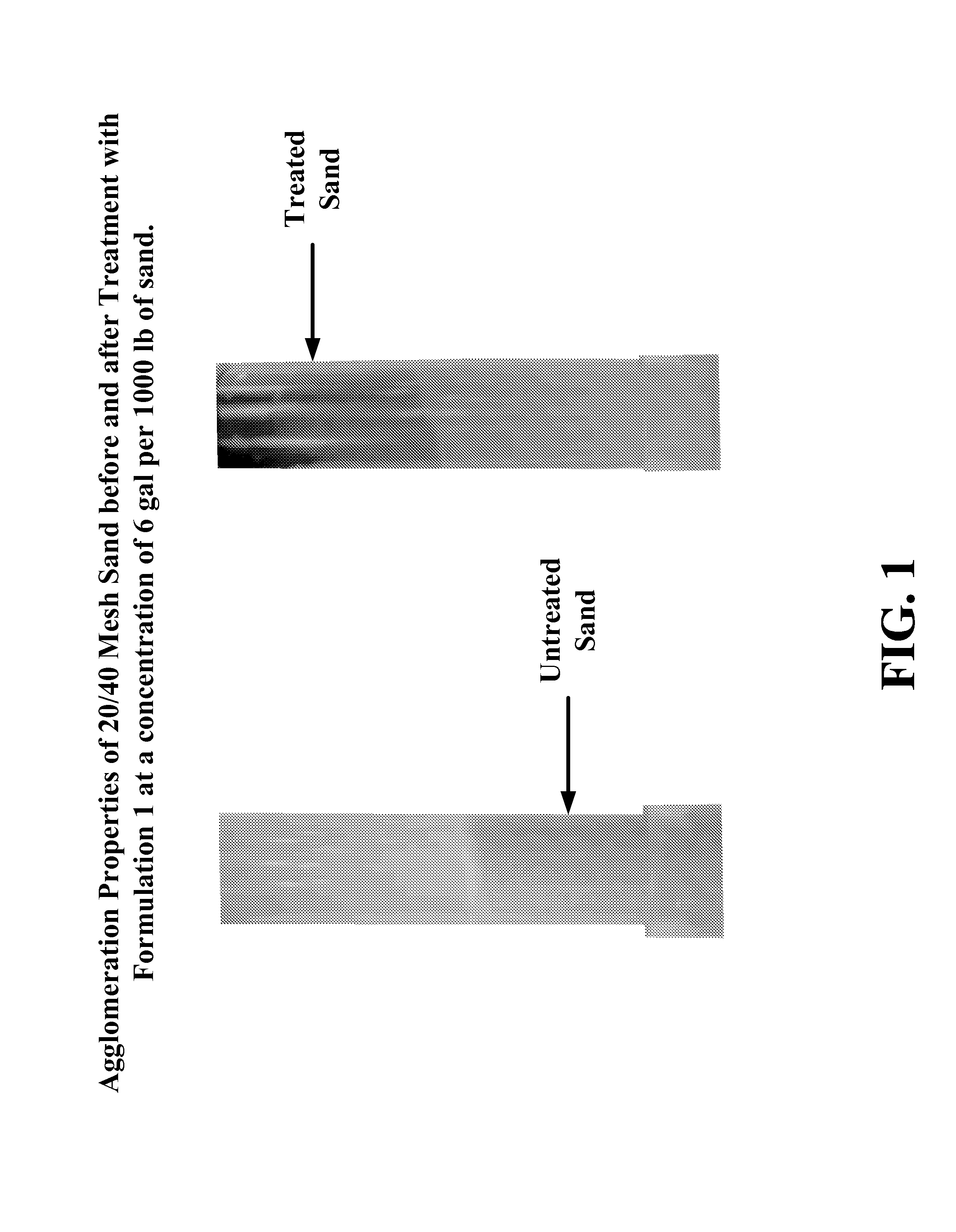

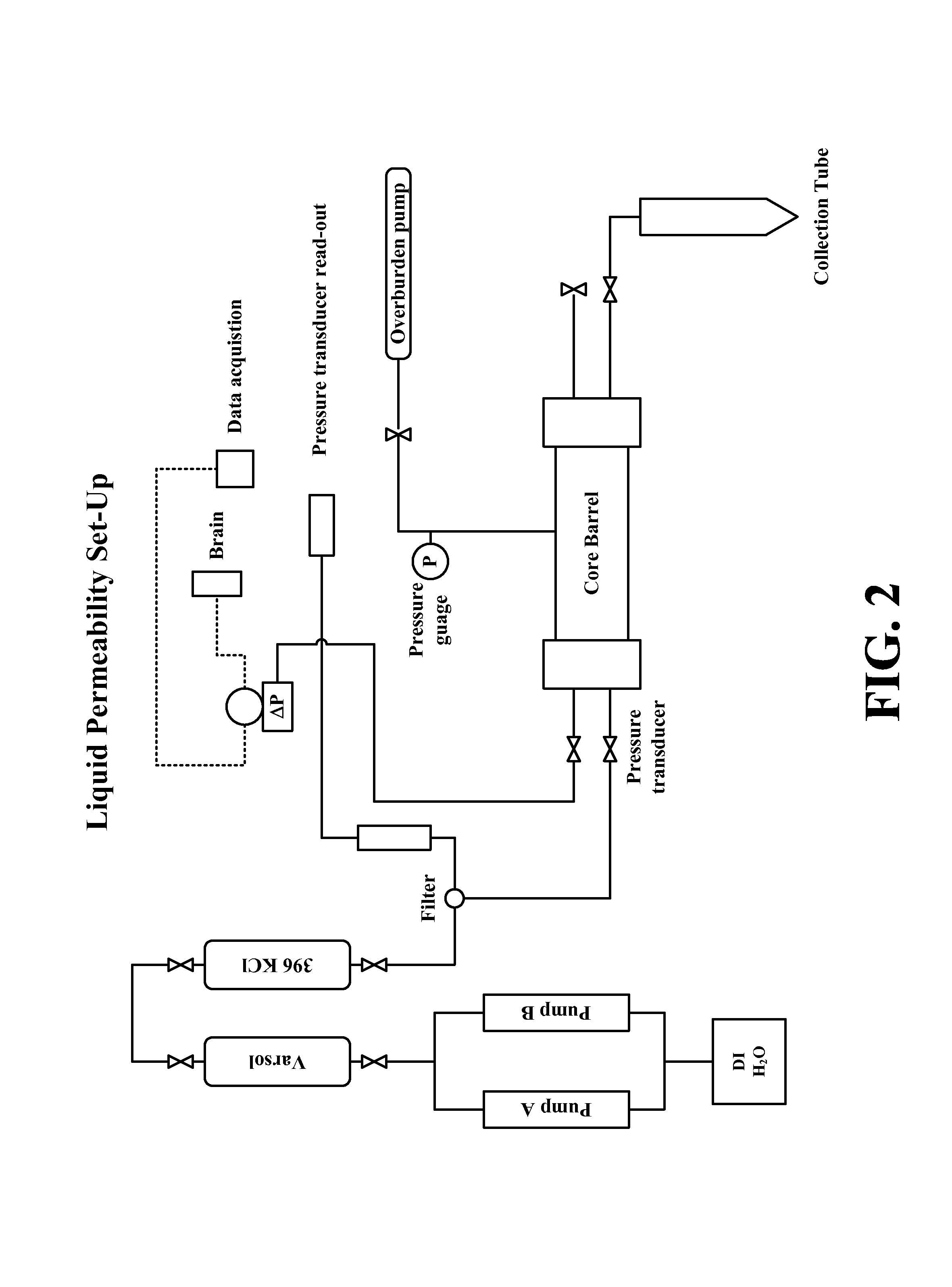

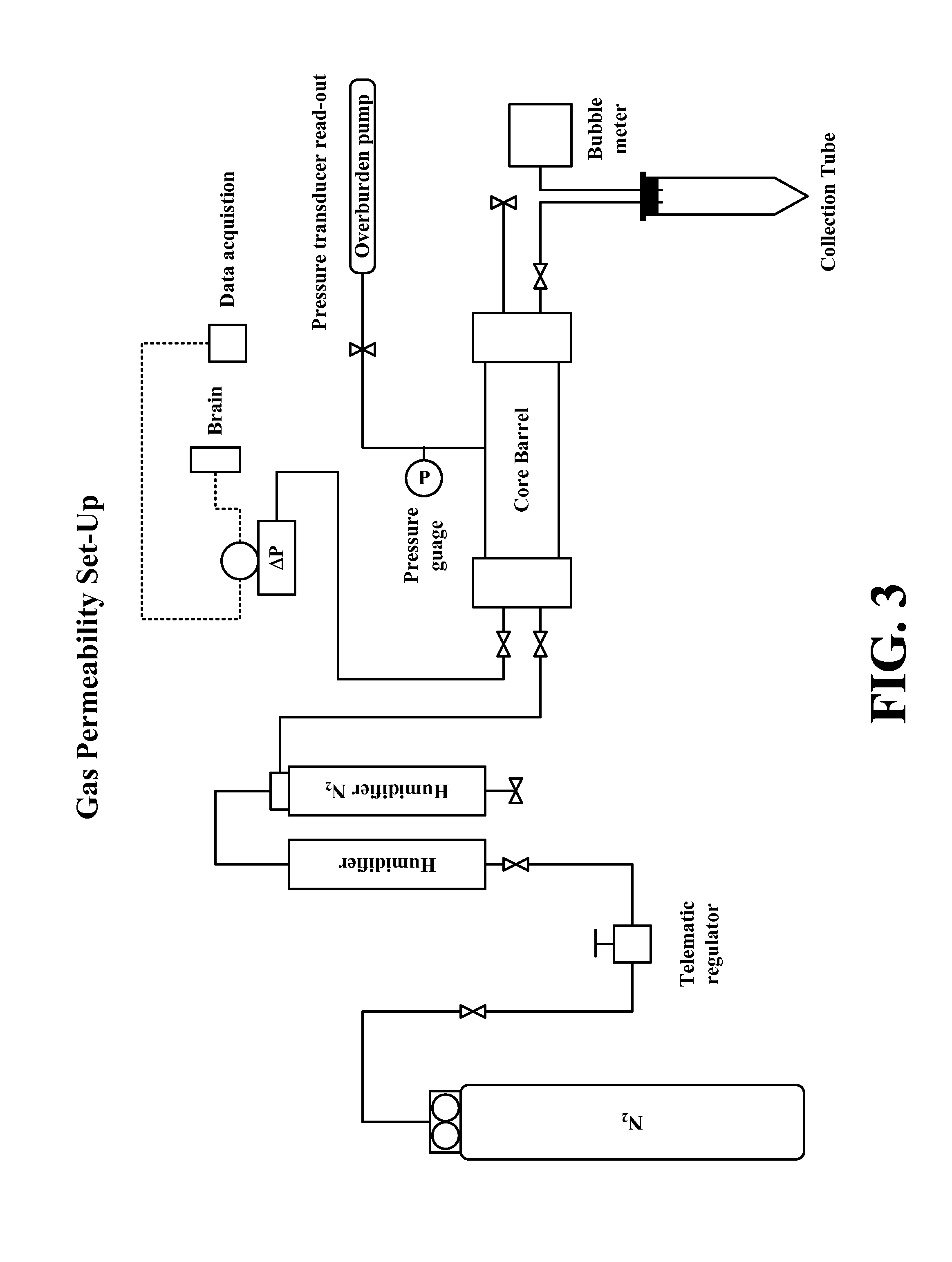

Aggregating reagents, modified particulate metal-oxides, and methods for making and using same

ActiveUS7392847B2Improved self-aggregating propertyIncrease propensityBiocideLiquid/gas jet drillingParticulate metalMaterials science

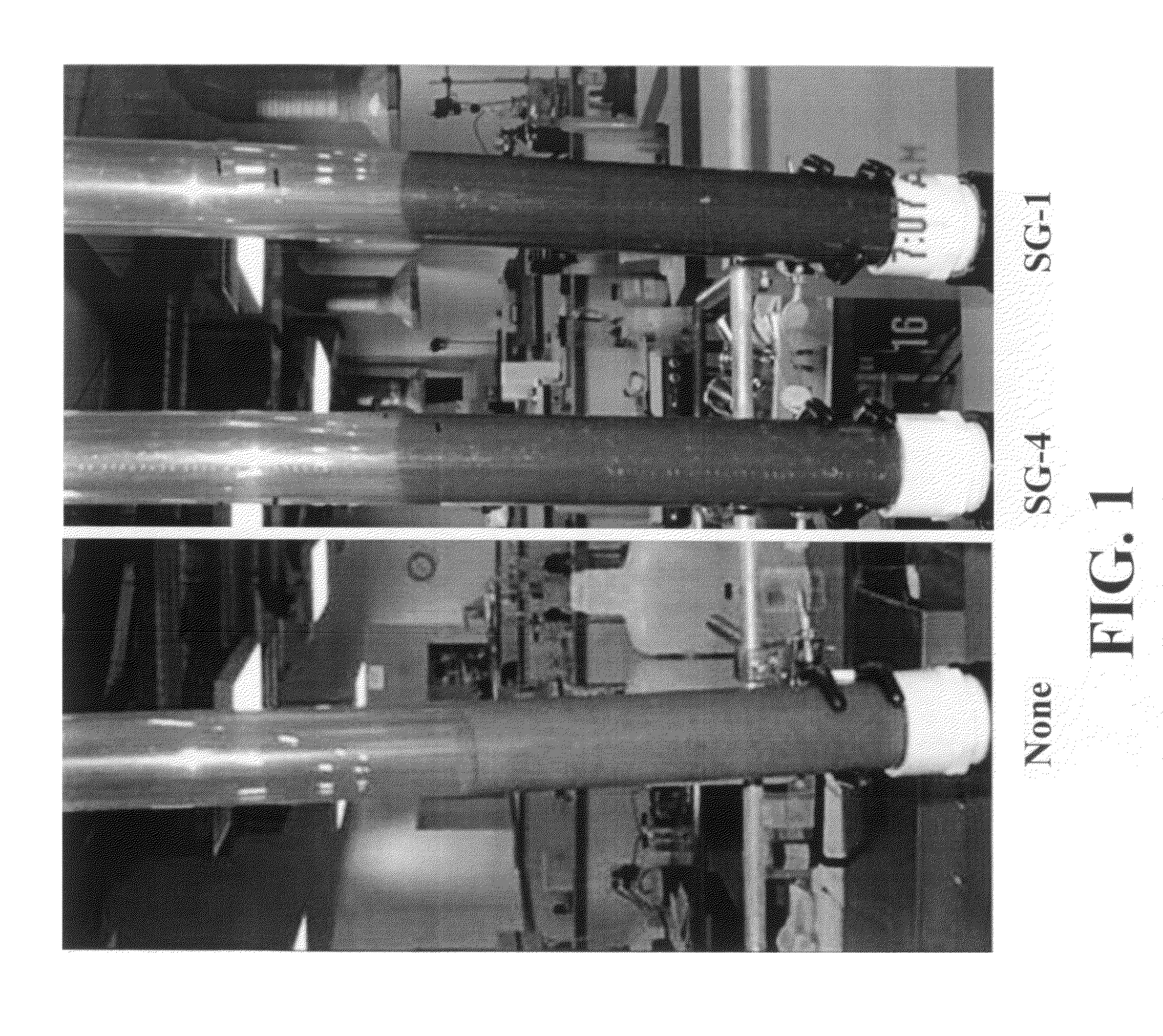

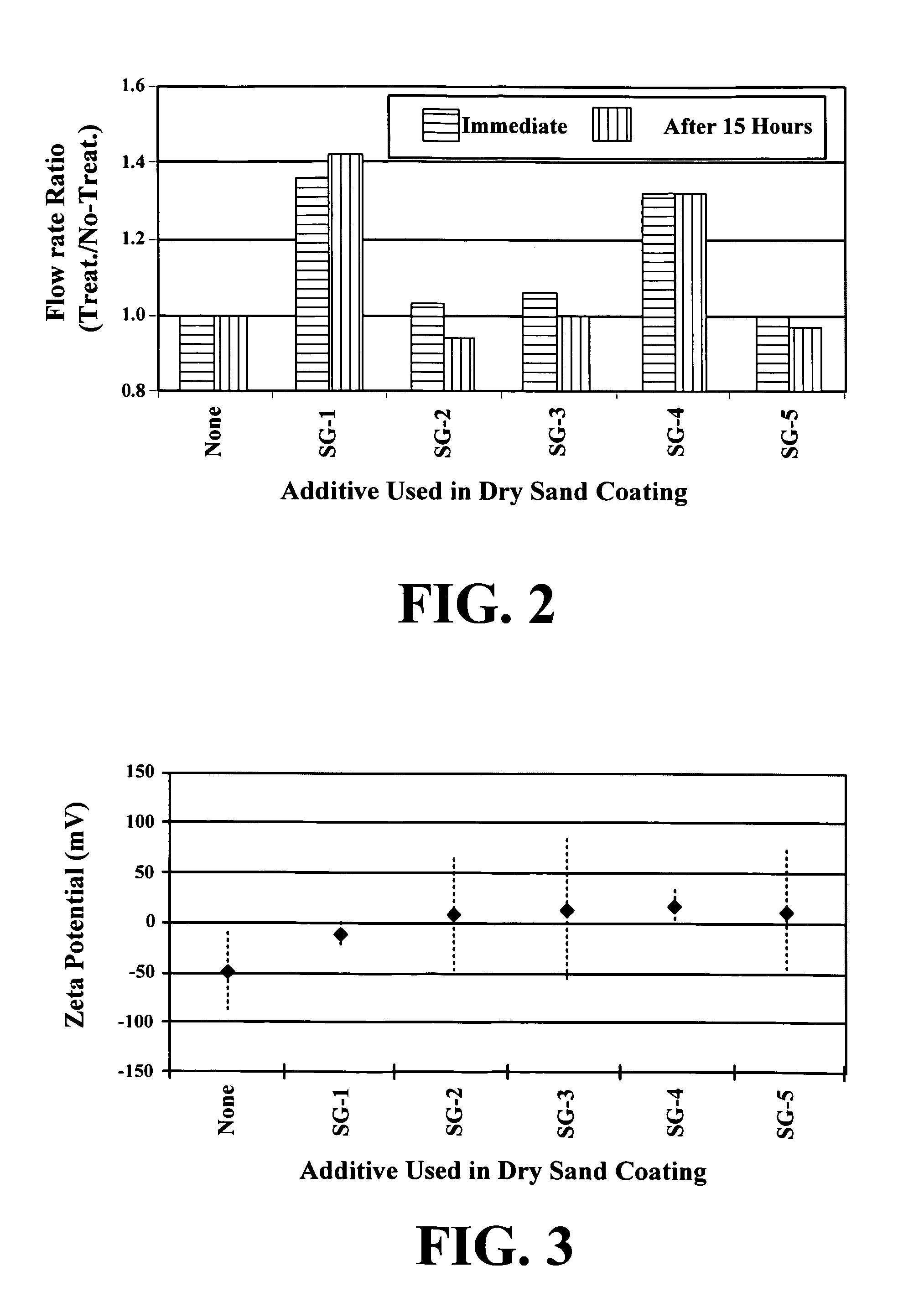

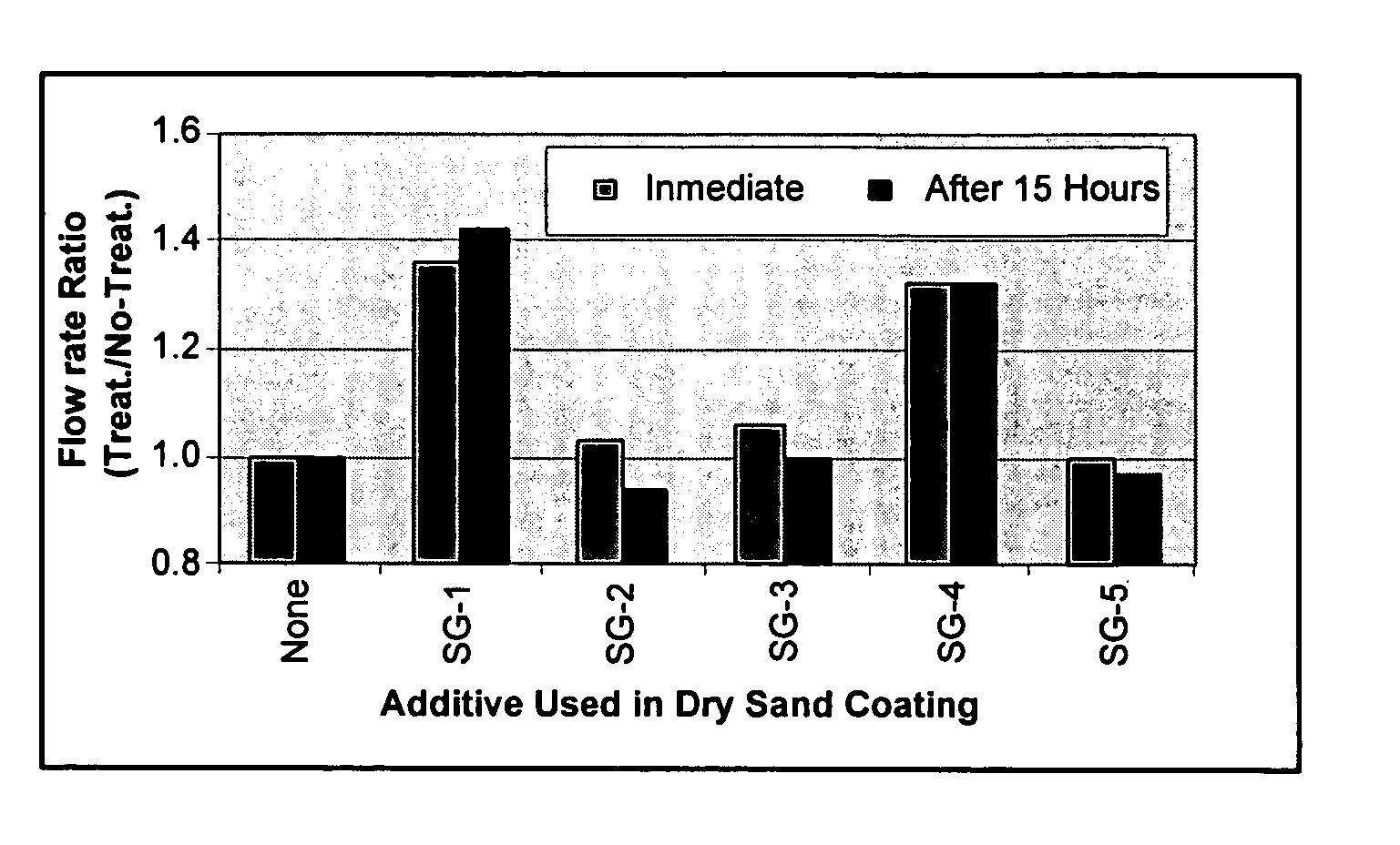

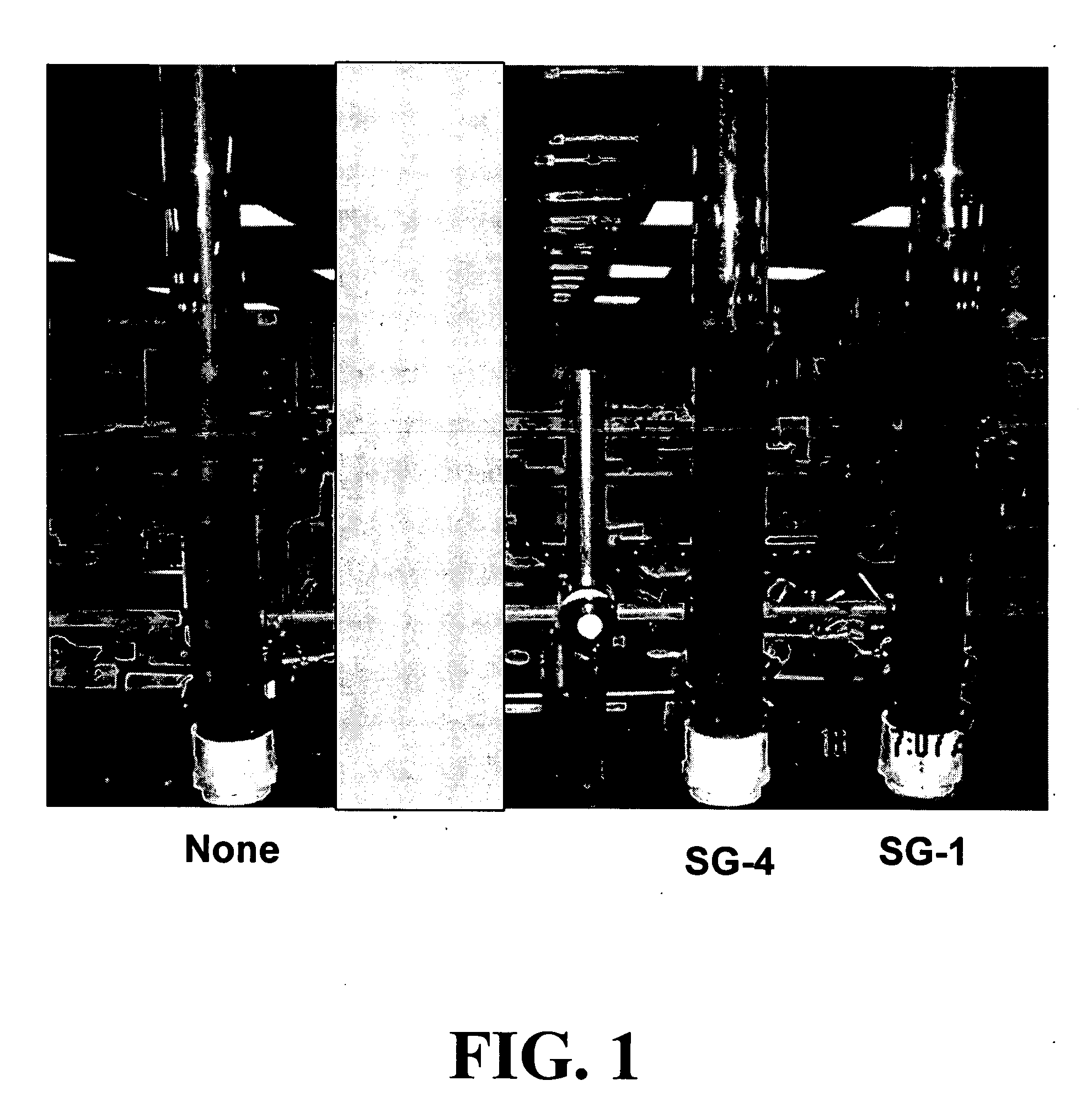

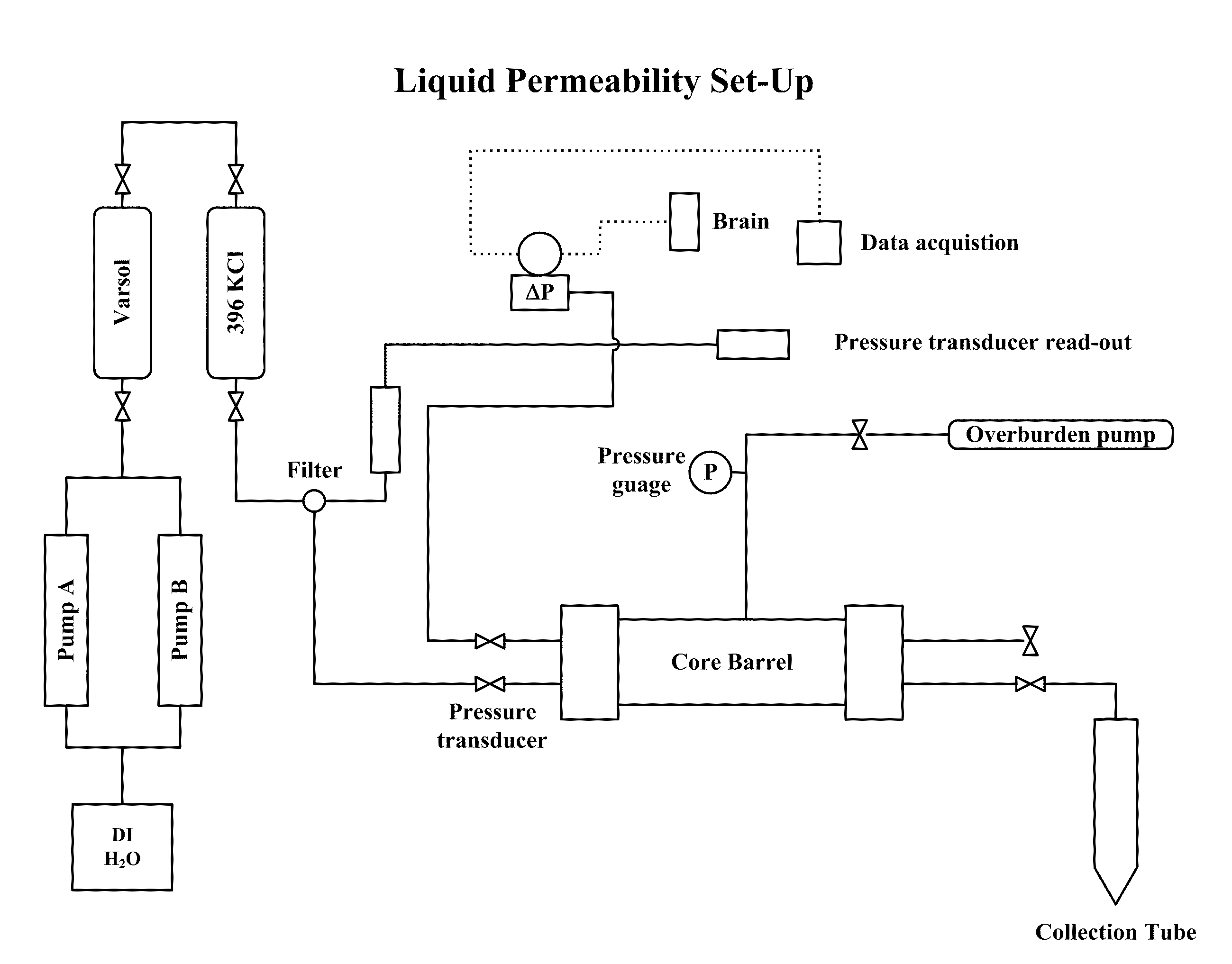

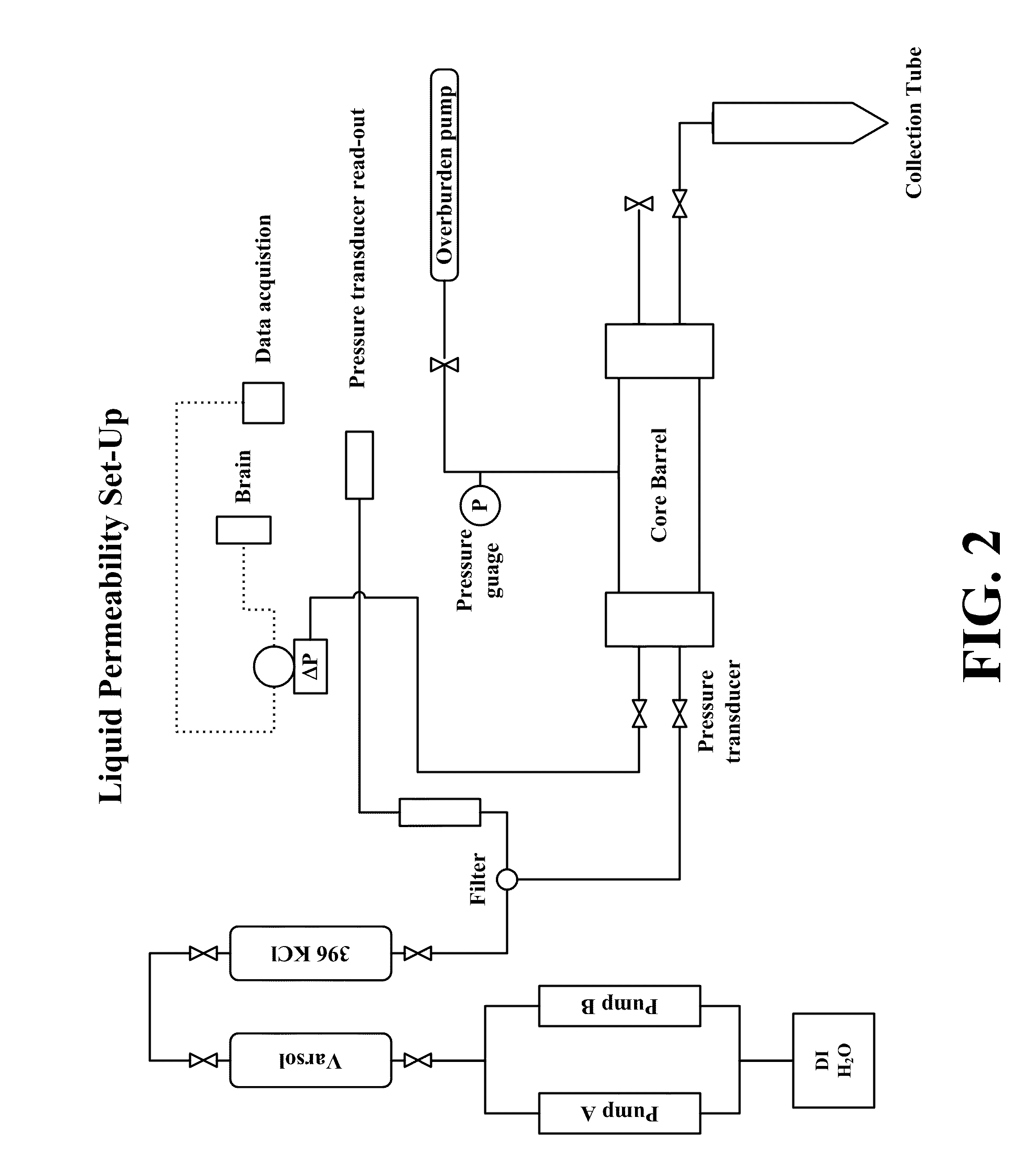

A method for treating solid materials is disclosed, where the treating compositions coats surfaces or portions of surfaces of the solid materials changing an aggregation or agglomeration propensity of the materials. Treated solid materials are also disclosed. The methods and treated materials are ideally suited for oil field applications.

Owner:THE LUBRIZOL CORP

Aggregating reagents, modified particulate metal-oxides, and methods for making and using same

ActiveUS20070131425A1Improved self-aggregating propertyIncrease propensityBiocideLiquid/gas jet drillingParticulate metalMaterials science

A method for treating solid materials is disclosed, where the treating compositions coats surfaces or portions of surfaces of the solid materials changing an aggregation or agglomeration propensity of the materials. Treated solid materials are also disclosed. The methods and treated materials are ideally suited for oil field applications.

Owner:THE LUBRIZOL CORP

Radiation-curable metal particles and curable resin compositions comprising these particles

InactiveUS6521677B2High refractive indexHigh hardnessMaterial nanotechnologyConductive materialPolymer scienceMeth-

Provided is a liquid curable resin composition which can produce transparent cured products with a high refractive index, high hardness, and superior abrasion resistance, and which can be suitably used as a coating material. The liquid curable resin composition comprises: (A) a poly-functional (meth)acrylic compound having at least three (meth) acryloyl groups in the molecule; (B) a reaction product obtained by the reaction of a compound having a polymerizable unsaturated group and alkoxysilyl group in the molecule and particles metal oxide, the metals being preferably selected from the group consisting of zirconium, antimony, zinc, tin, cerium, and titanium; and (C) a radiation polymerization initiator.

Owner:JSR CORPORATIOON

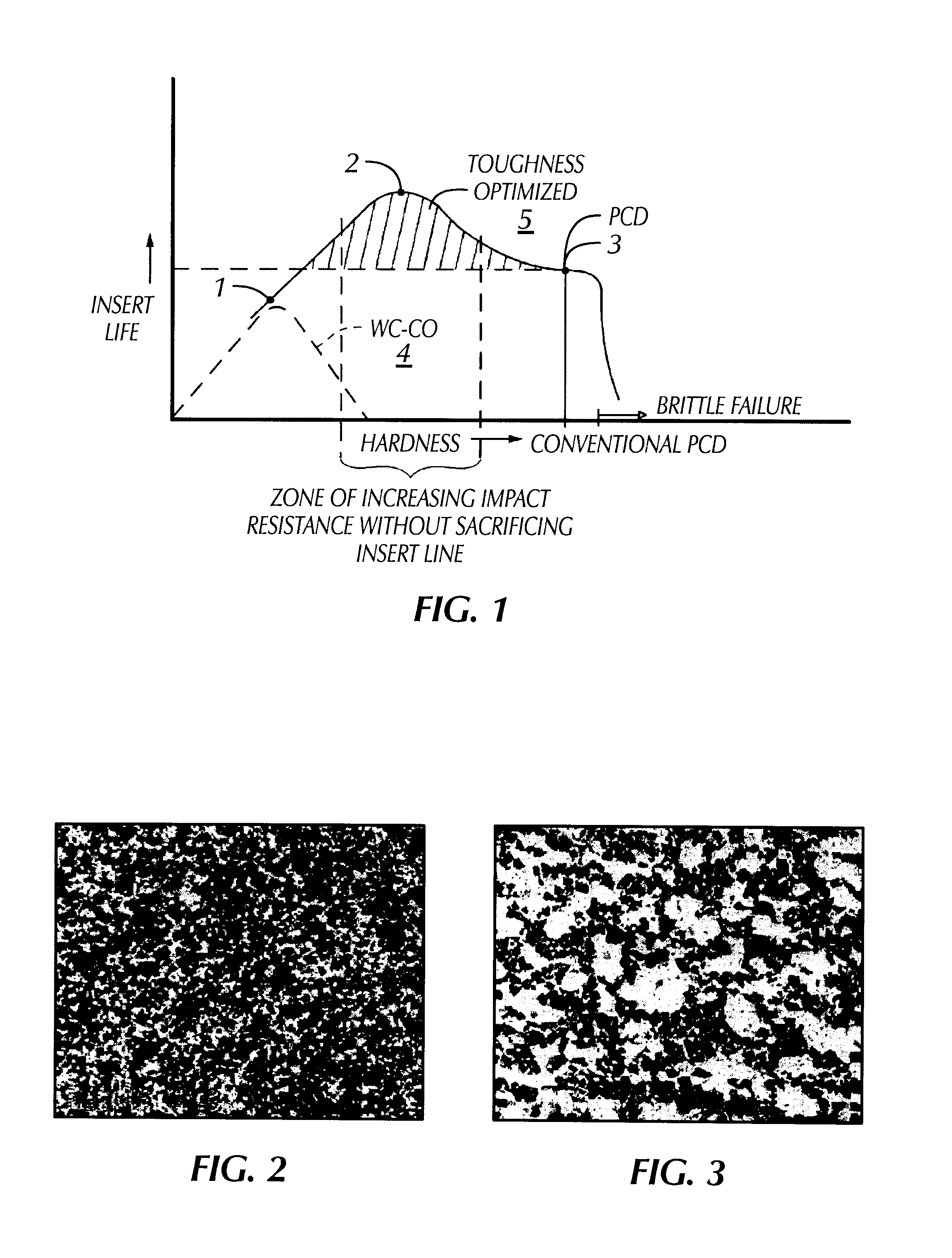

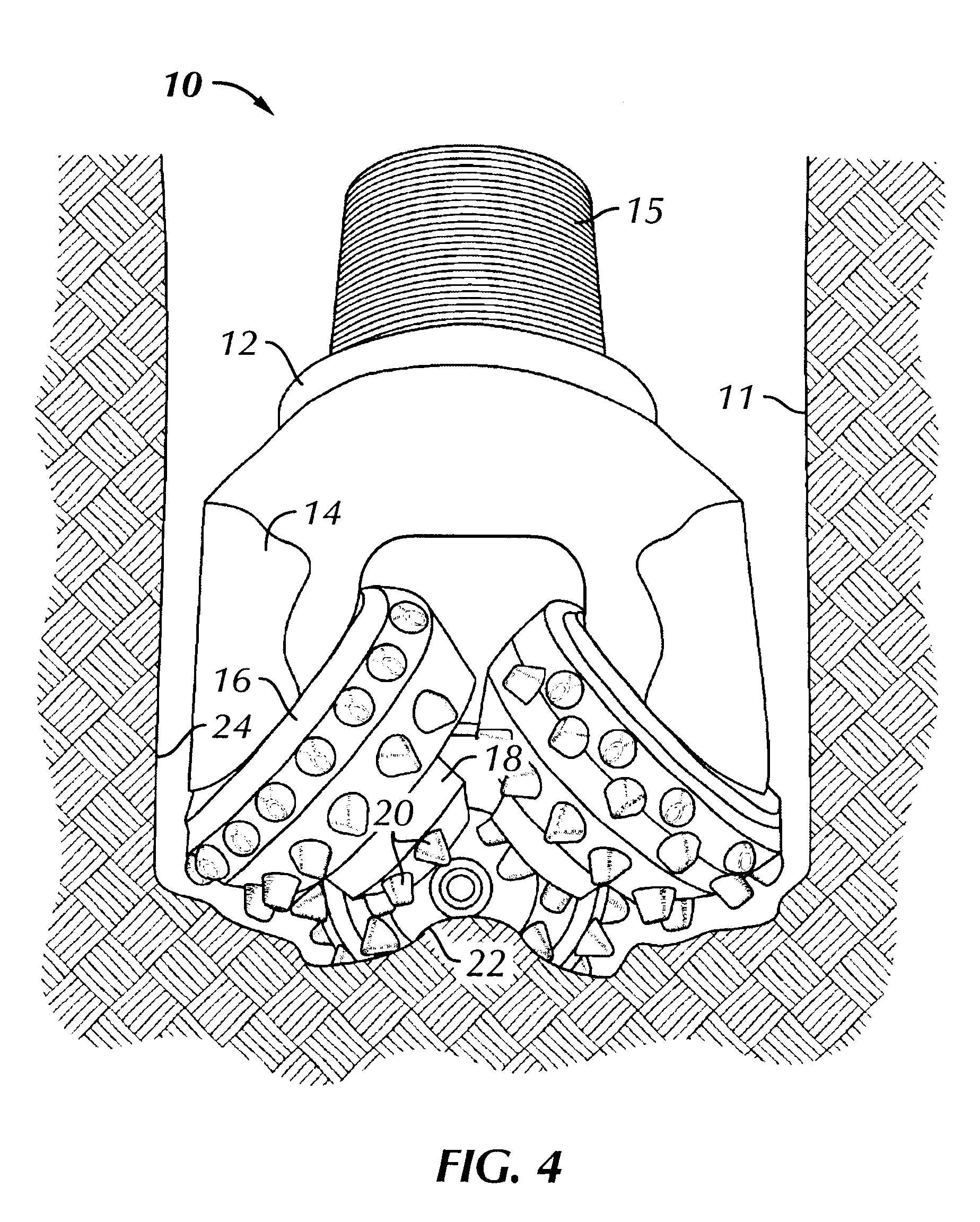

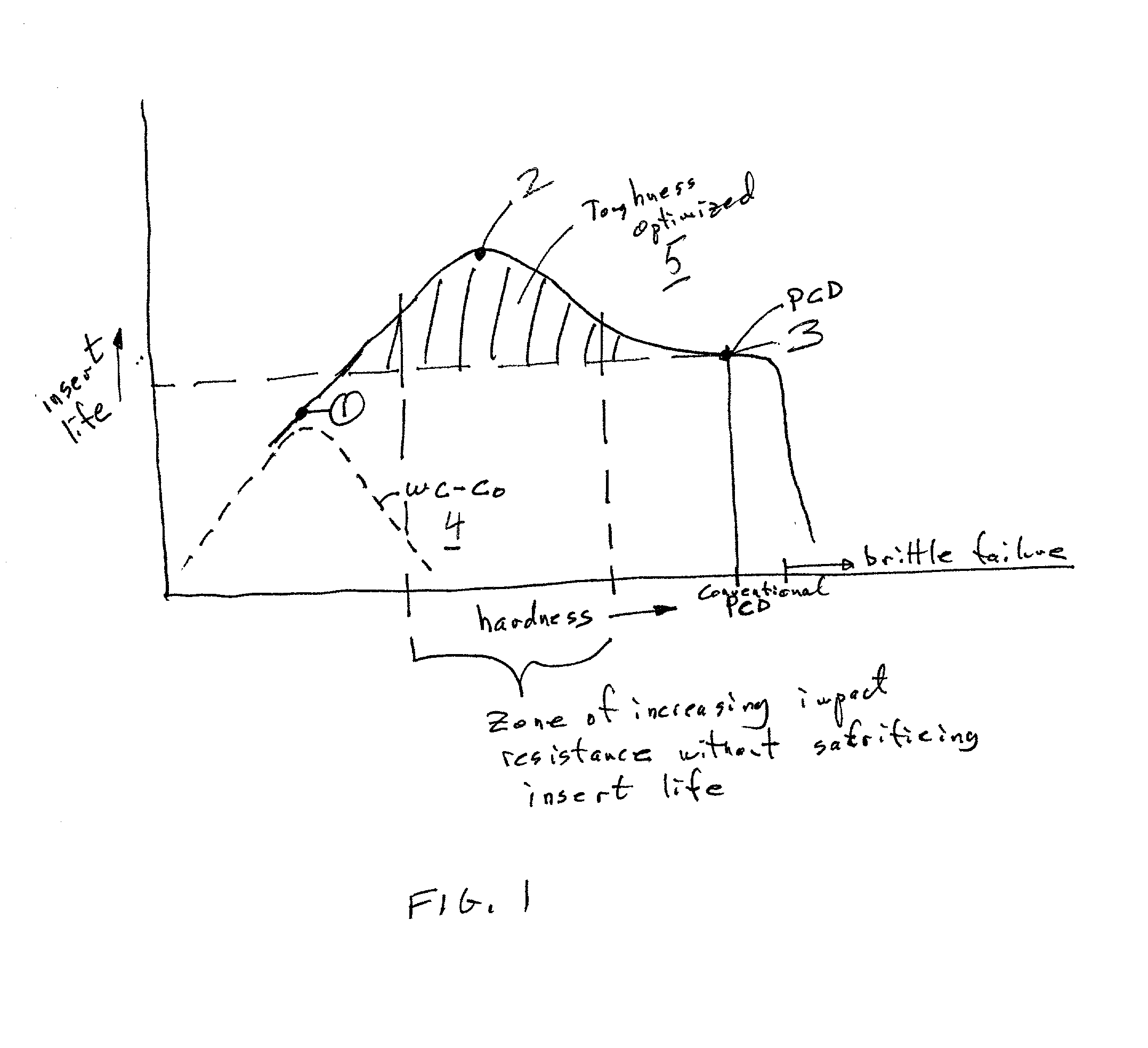

Toughness optimized insert for rock and hammer bits

Owner:SMITH INT INC

Negative Electrode Material For Lithium Secondary Battery, Method For Producing Same, Negative Electrode For Lithium Secondary Battery Using Same And Lithium Secondary Battery

InactiveUS20080032192A1High electrode-mechanical strengthImprove immersion effectNegative electrodesNon-aqueous electrolyte accumulator electrodesHigh current densityMetal particle

A negative-electrode material for a lithium secondary battery is provided that can be produced through a simple procedure and can yield a lithium secondary battery having a high electrode-mechanical strength, being excellent in immersibility, involving a small initial irreversible capacity, being excellent in charge-discharge characteristic under high current densities, and having a high cycle retention ratio, i.e. having an excellent balance of various battery characteristics. The material includes particles (A), which are selected from the group consisting of carbon-material particles, metal particles, and metal-oxide particles, and two or more different polymeric materials each attached to different sites of the particles.

Owner:MITSUBISHI CHEM CORP

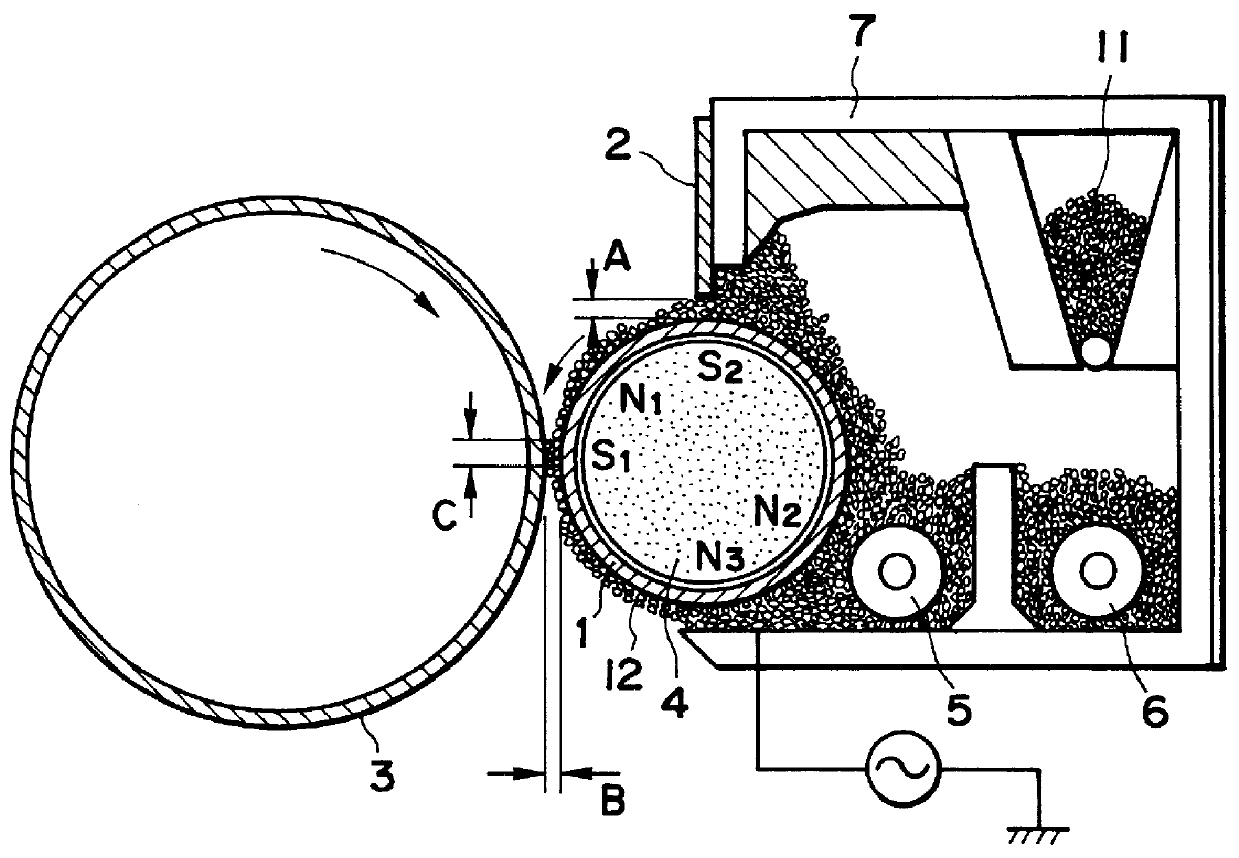

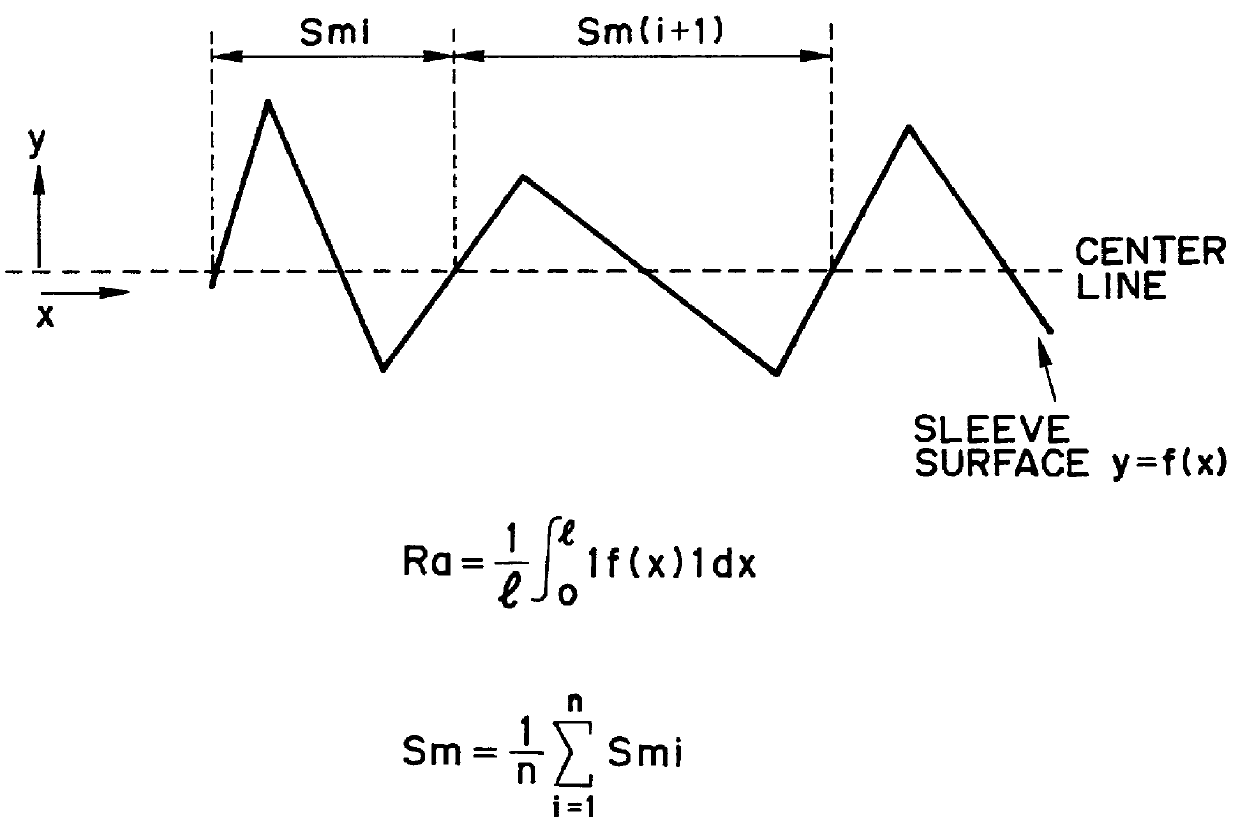

Magnetic coated carrier two-component type developer and developing method

InactiveUS6165663AImprove liquidityIncreased durabilityDevelopersElectrographic processes using charge patternCoated surfaceParticulate metal

A magnetic coated carrier suitable for constituting a two-component type developer for use in electrophotography is composed of magnetic coated carrier particles comprising magnetic coated carrier particles comprising magnetic carrier core particles each comprising a binder resin and metal oxide particles, and a coating layer surface-coating each carrier core particle. The metal oxide particles have been subjected to a surface lipophilicity-imparting treatment. The magnetic carrier core particles have a resistivity of at least 1x1010 ohm.cm, and the magnetic coated carrier has a resistivity of at least 1x1012 ohm.cm. The magnetic coated carrier has a particle size distribution such that (i) it has a number-average particle size Dn of 5-100 mu m, (ii) it satisfies a relationship of Dn / sigma > / =3.5, wherein sigma denotes a standard deviation of number-basis particle size distribution of the carrier, and (iii) it contains at most 25% by number of particles having particle sizes of at most Dnx+E,fra 2 / 3+EE .

Owner:CANON KK

Particulate compositions of particulate metal and polymer binder

A particulate composition wherein each particle thereof includes a first metal (e.g., tungsten), an optional second metal (e.g., tin), and a polymer binder (e.g., thermoplastic polyvinyl alcohol) is described. The first metal has a particle size of less than or equal to 10 μm, and the second metal has a particle size of less than or equal to 20 μm. The polymer binder is typically present in each particle of the particulate composition in an amount of from 0.5 to 2.5 percent by weight, based on the total weight of the particulate composition. The particulate composition has an average particle size of 25 to 300 μm, and is free flowing. The particles of the particulate composition are preferably substantially spherical. Also described is a method of preparing the particulate composition by means of spray drying. The particulate compositions may be used to prepare molded articles, such as frangible projectiles (e.g., frangible bullets).

Owner:H C STARCK INC

Aggregating compositions, modified particulate metal-oxides, modified formation surfaces, and methods for making and using same

ActiveUS20100292108A1Improved self-aggregating propertyIncrease propensityConstructionsFluid removalParticulate metalMaterials science

Owner:THE LUBRIZOL CORP

Particulate zinc oxide with manganese, iron and copper dopant ions

A particulate metal oxide includes a cationic portion that includes a zinc portion, a first iron dopant portion and a second dopant portion consisting of manganese and copper, where the zinc portion is about 99% by weight or more of the cationic portion, and the weight percent of the second dopant portion is greater than twice the weight percent of the first iron dopant portion.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

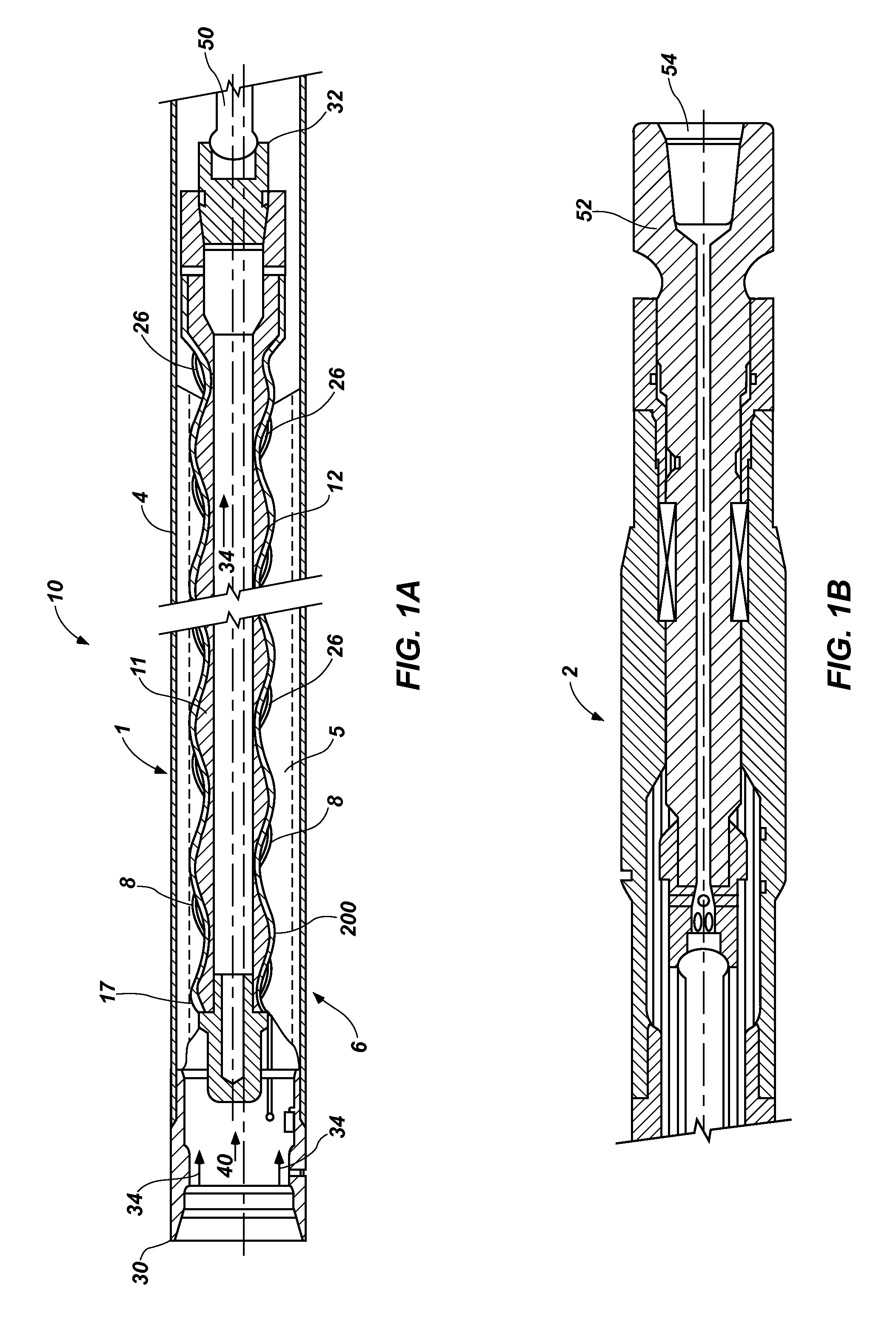

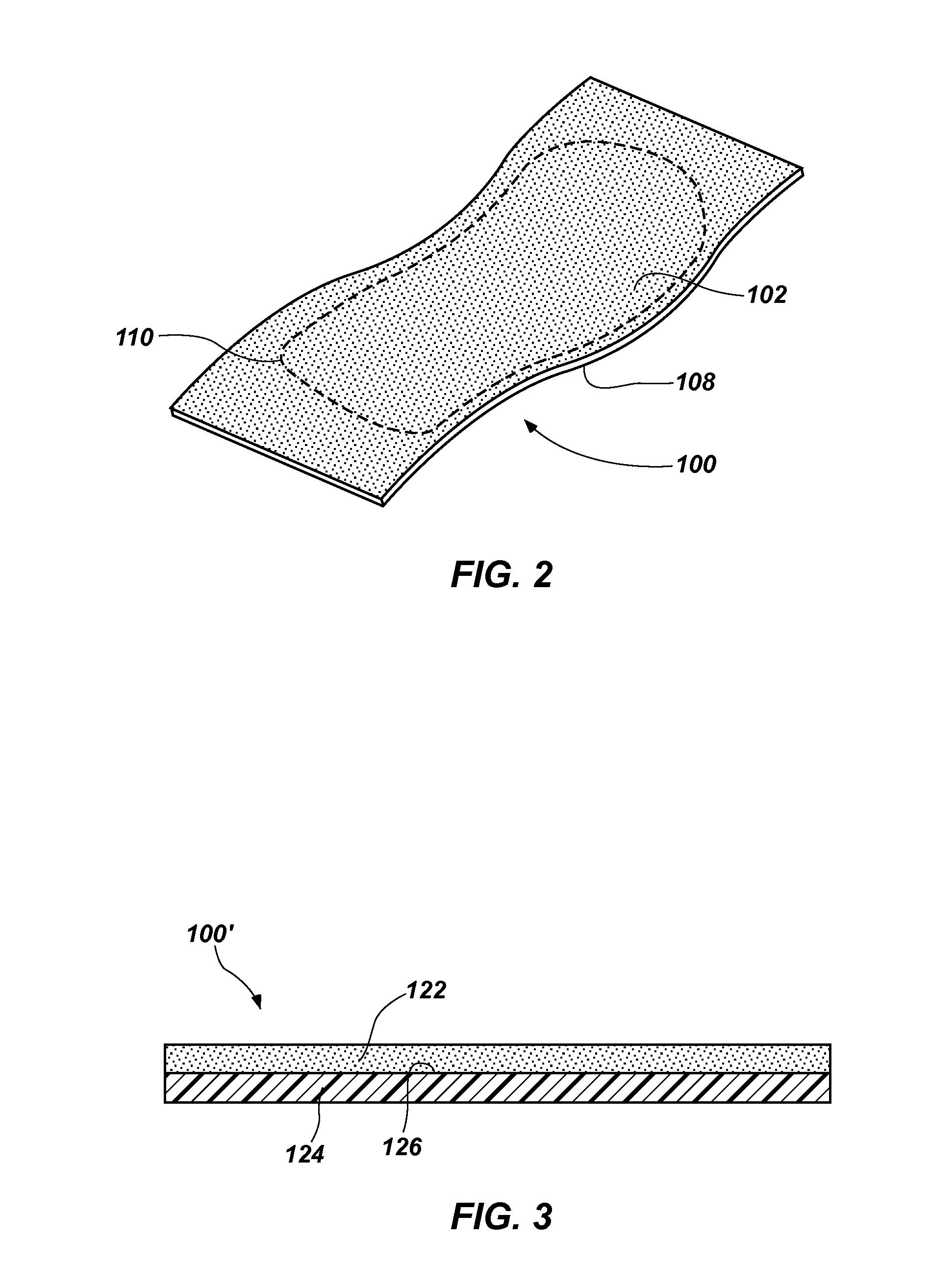

Components and motors for downhole tools and methods of applying hardfacing to surfaces thereof

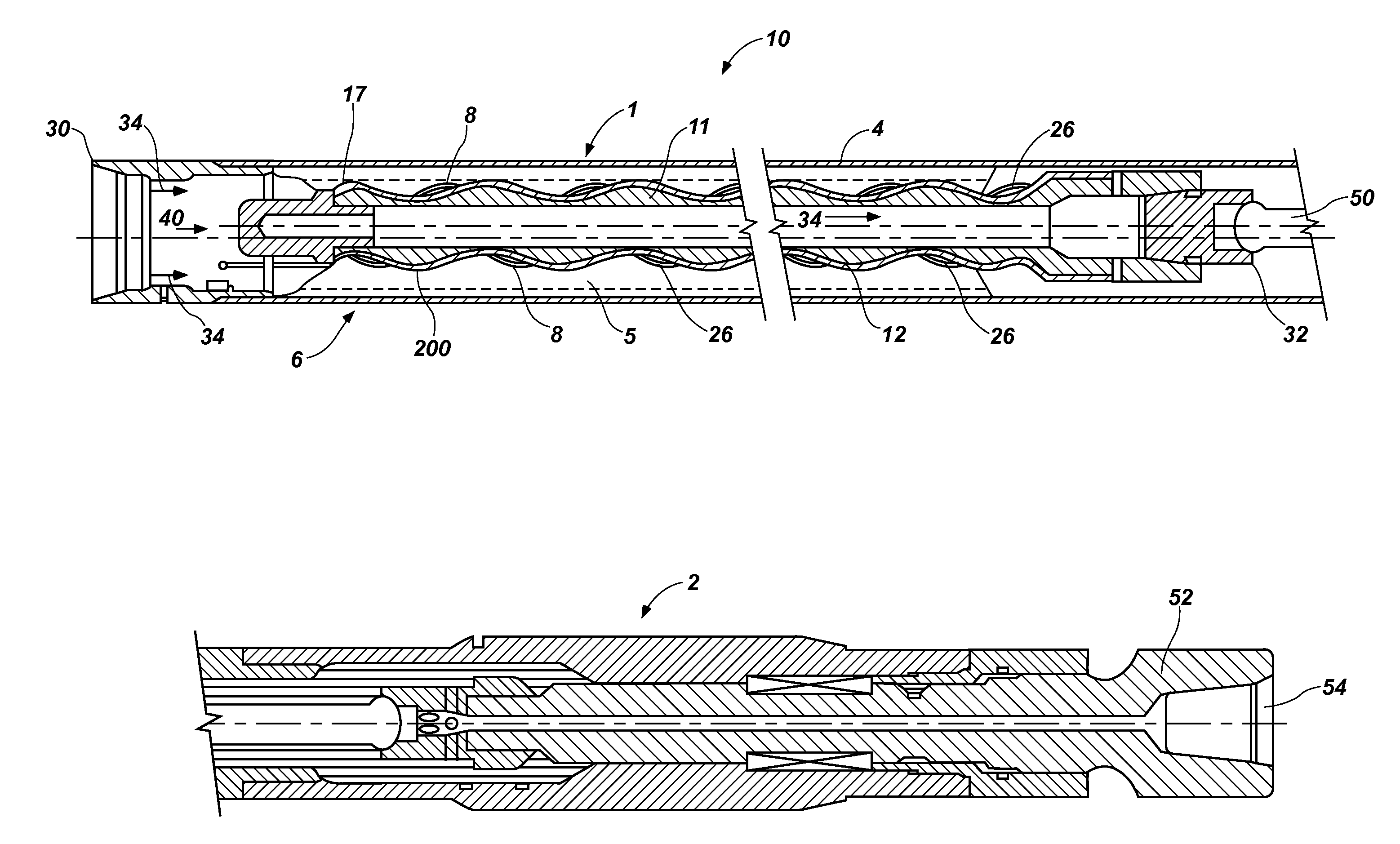

A component for a downhole tool includes a rotor and a hardfacing precursor. The hardfacing precursor includes a polymeric material, hard particles, and a metal. A hydraulic drilling motor includes a stator, a rotor, and a sintered hardfacing material on an outer surface of the rotor or an inner surface of the stator. Methods of applying hardfacing to surfaces include forming a paste of hard particles, metal matrix particles, a polymeric material, and a solvent. The solvent is removed from the paste to form a sheet, which is applied to a surface and heated. A component for a downhole tool includes a first hardfacing material, a second hardfacing material over the first hardfacing material and defining a plurality of pores, and a metal disposed within at least some of the pores. The metal has a melting point lower than a melting point of the second hardfacing material.

Owner:BAKER HUGHES INC

Particulate zinc oxide with manganese ion dopant

A particulate metal oxide is provided that includes a cationic portion containing a zinc portion, a first manganese dopant portion and a second dopant portion selected from the group consisting of iron and aluminum, wherein the zinc portion is about 99% by weight or more of the cationic portion and the manganese dopant portion and second dopant portion are present in a weight ratio of from about 5:1 to 1:5.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

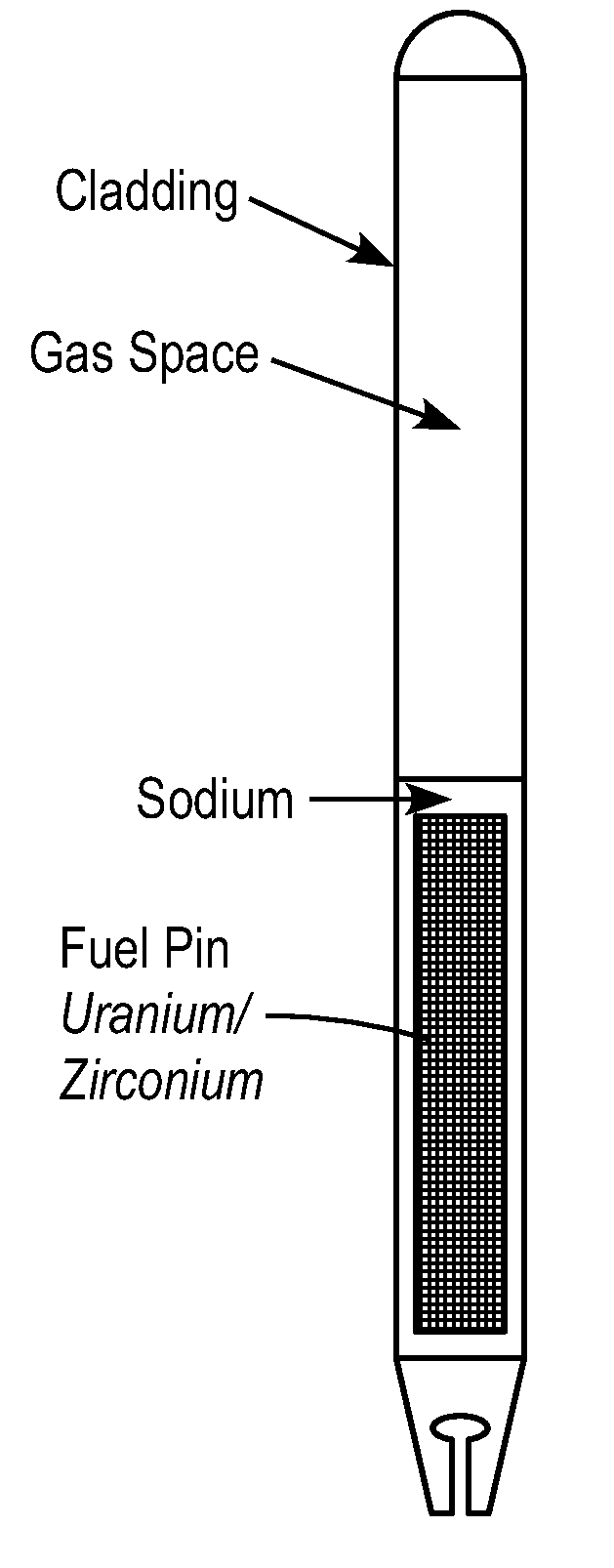

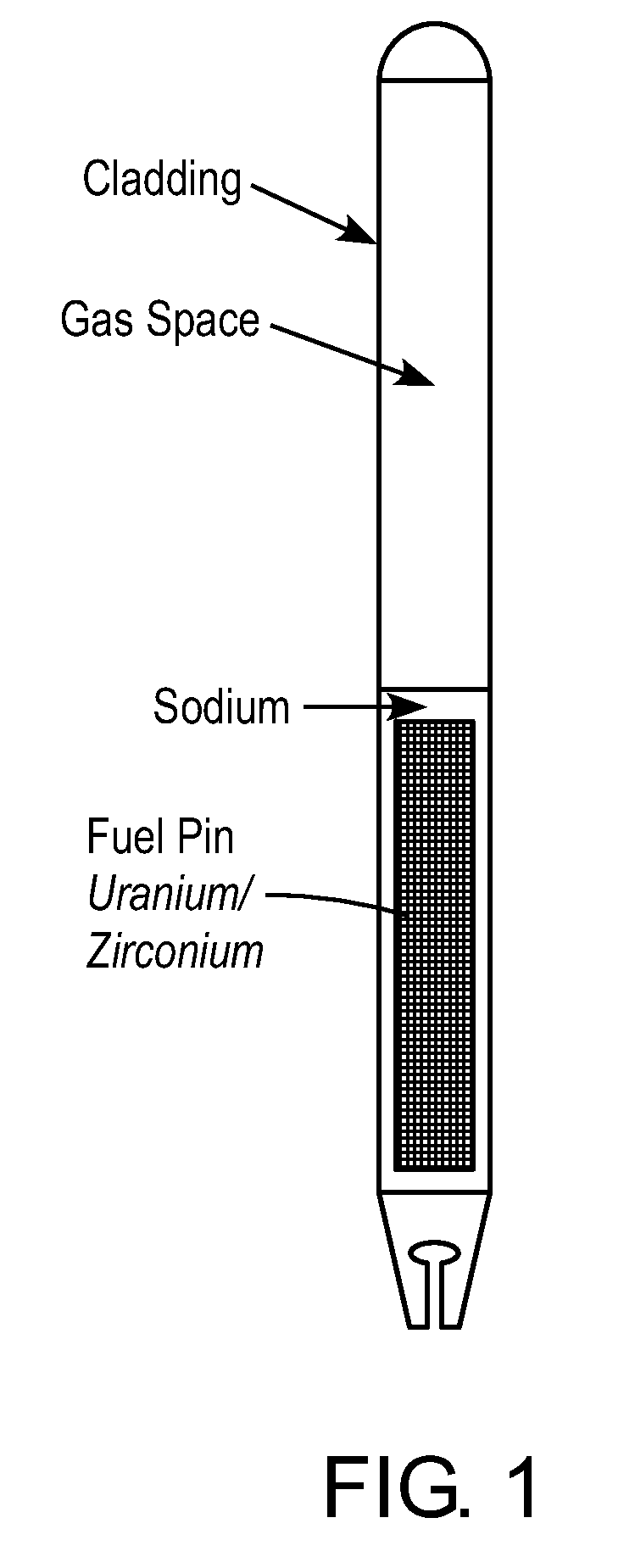

Particulate metal fuels used in power generation, recycling systems, and small modular reactors

ActiveUS20100303193A1Fix fuel costEliminate needNuclear fuel reprocessingFuel elementsNuclear reactor coreNuclear reactor

A metal particulate fuel system is described. The metal fuel system may include particulate metal fuel for use in nuclear reactors. The particulate metal fuel may include a plurality of particles of at least one enriched alloy where the particles are compacted into a fuel column. The metal particulate fuel system may also include a cladding and / or a gas-filled plenum.

Owner:ADVANCED REACTOR CONCEPTS

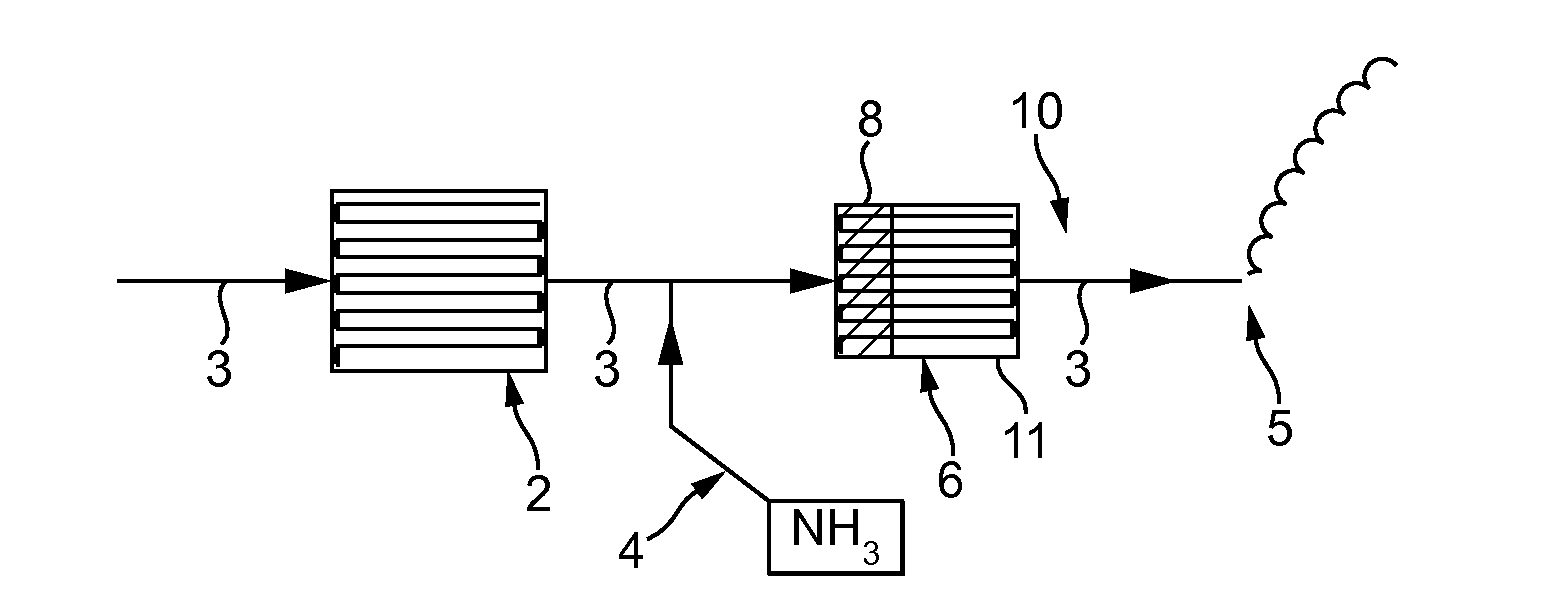

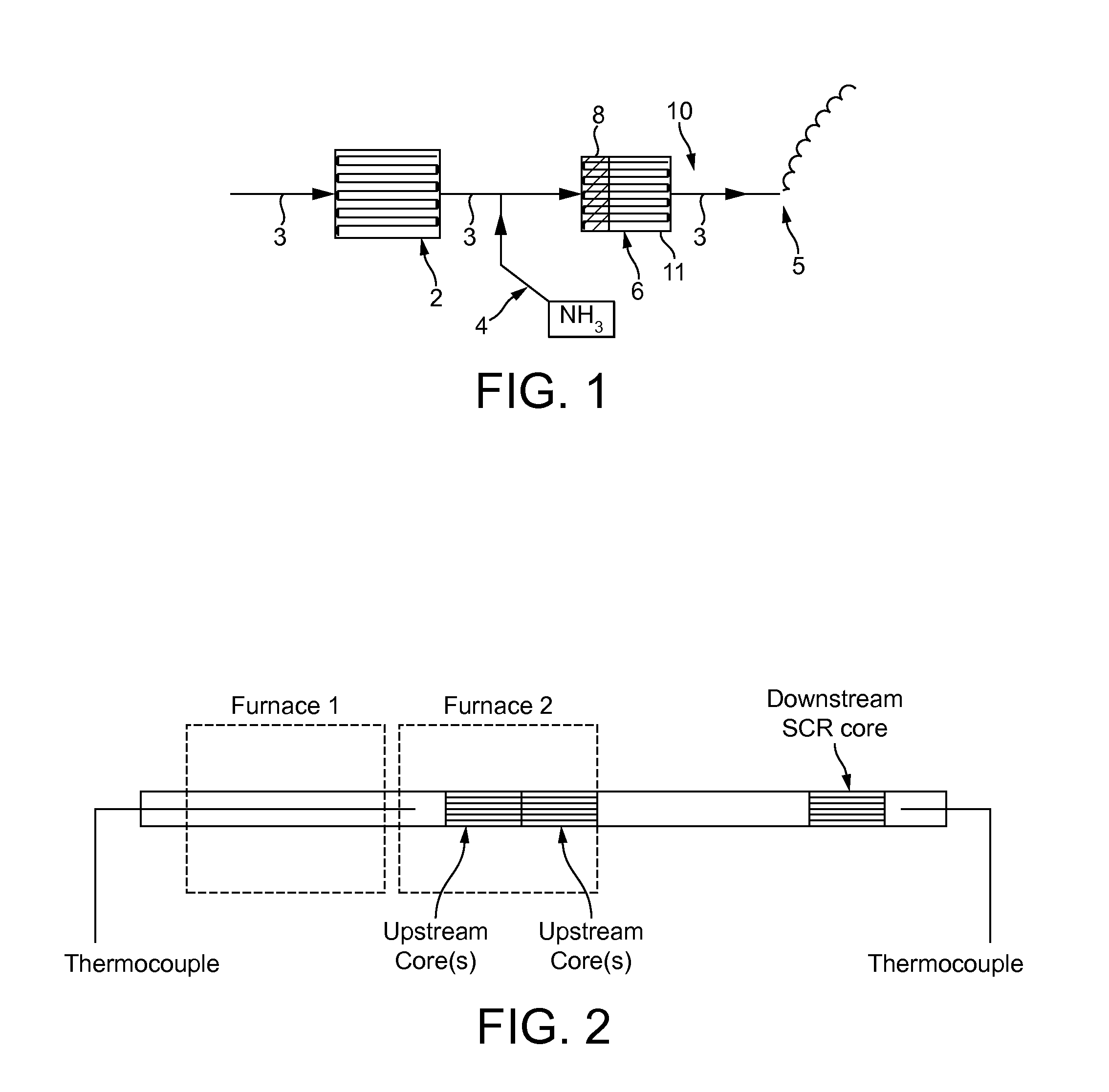

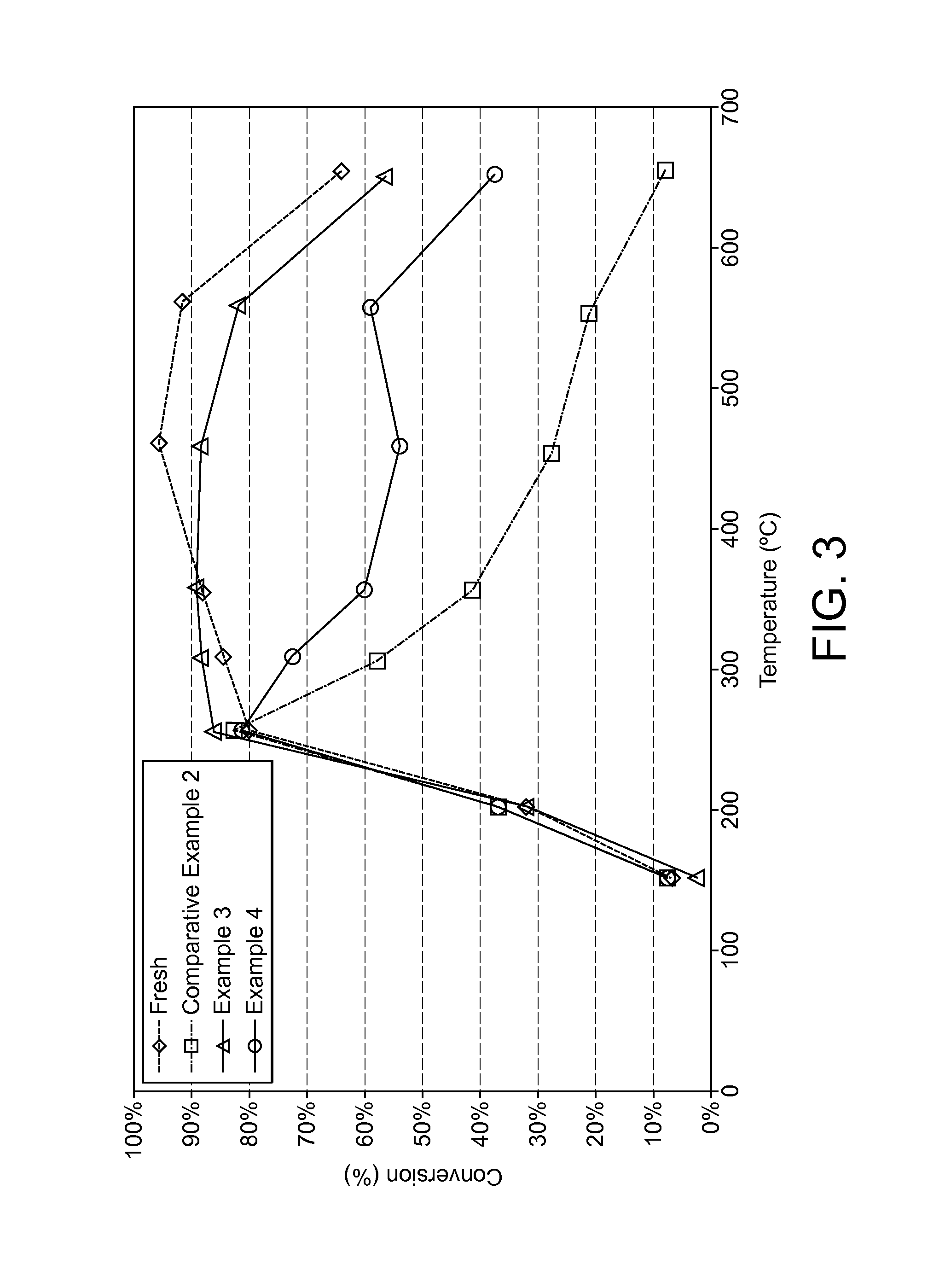

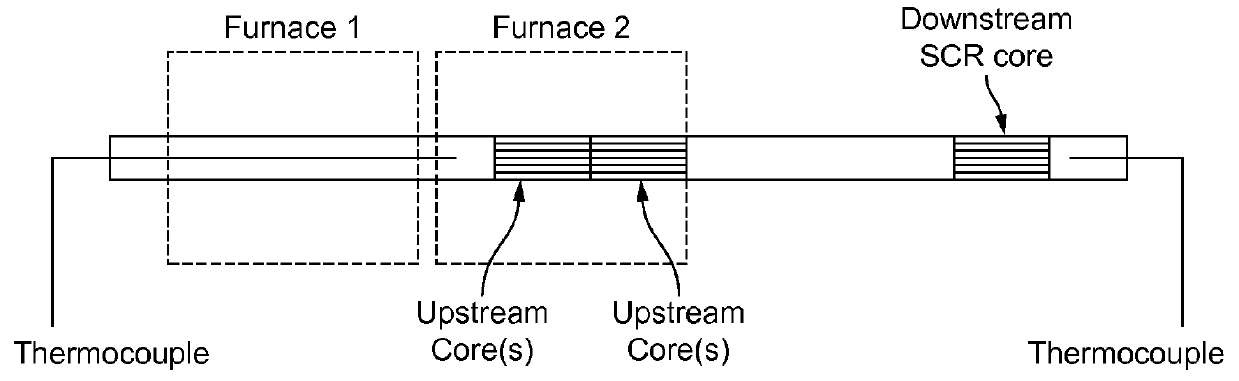

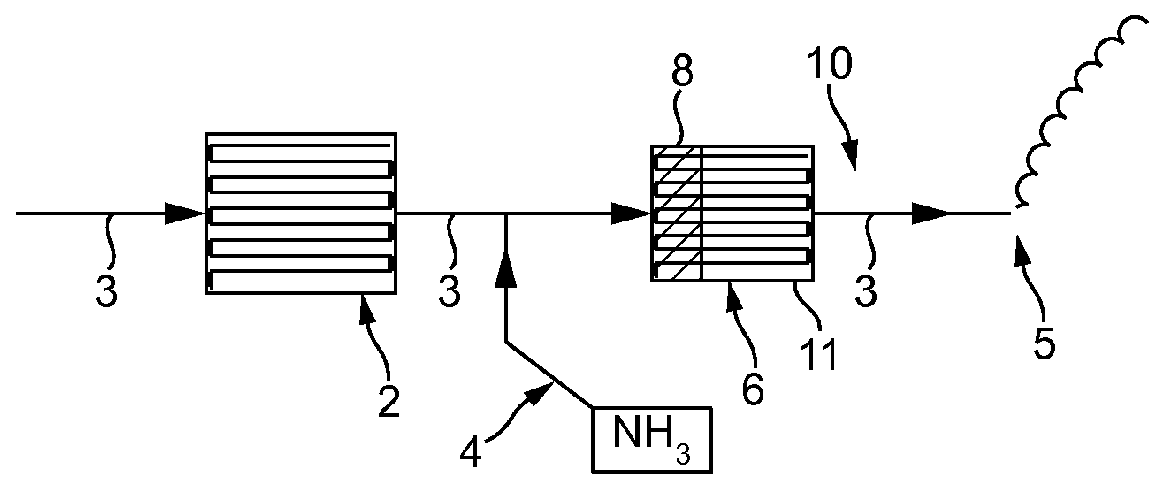

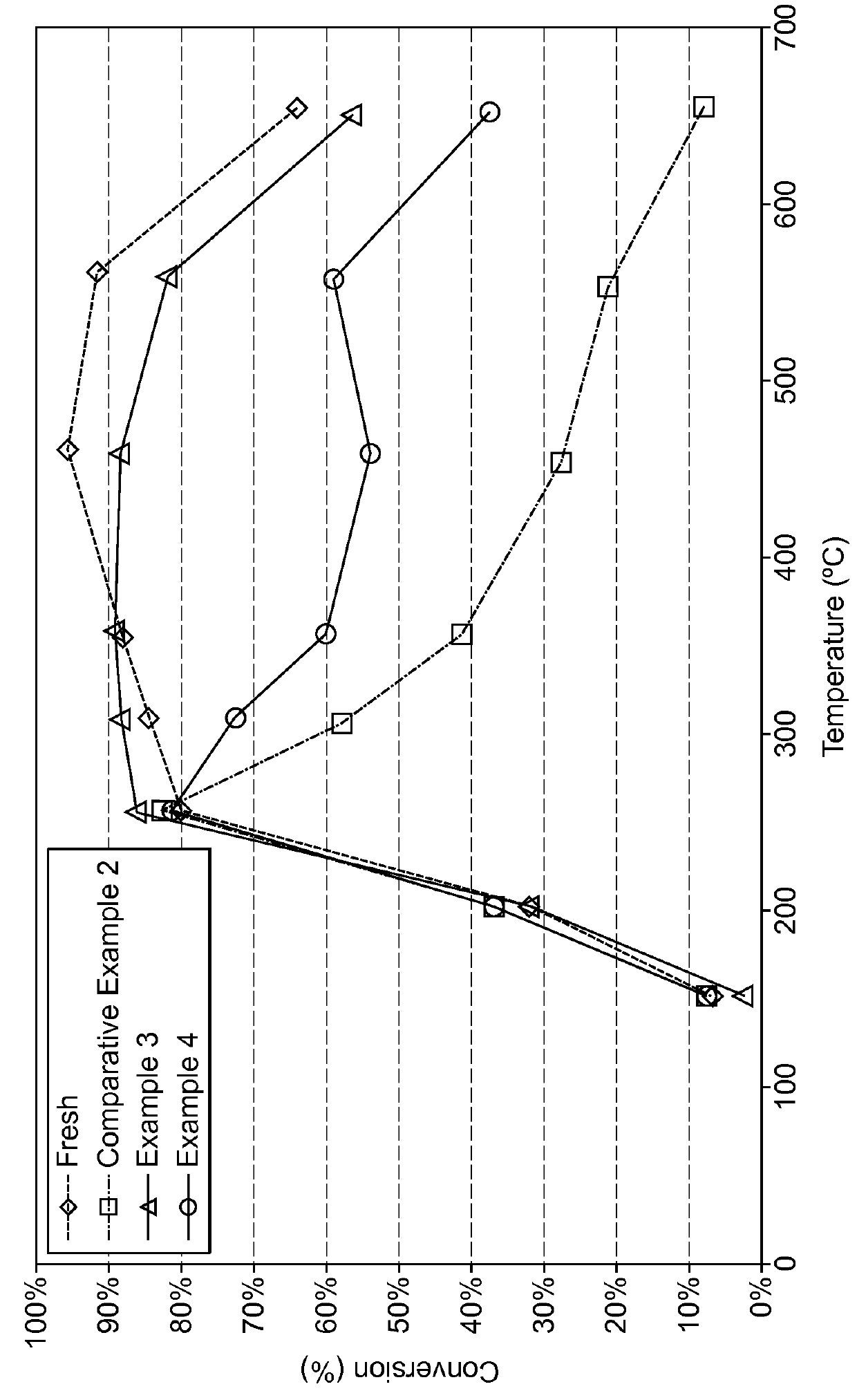

Substrate monolith comprising scr catalyst

ActiveUS20130149207A1Reduce and prevent poisoningAvoids and reduces problemCombination devicesInternal combustion piston enginesPtru catalystExhaust fumes

A substrate monolith 6 having a length L and comprising a first zone 11 of substantially uniform length defined at one end by a first end of the substrate monolith, which first zone comprising a selective catalytic reduction (SCR) catalyst for reducing oxides of nitrogen with a nitrogenous reductant in exhaust gas emitted from an internal combustion engine and a second zone 8 of substantially uniform length less than L defined at one end by a second end of the substrate monolith, which second zone comprising (a) at least one particulate metal oxide or a mixture of any two or more thereof for trapping gas phase platinum group metal (PGM), which at least one particulate metal oxide does not act as a support for any other catalytic component; or (b) a component capable of trapping and / or alloying with gas phase PGM.

Owner:JOHNSON MATTHEY PLC

Particulate metal oxide

InactiveUS20050069706A1Easily redispersibleEvenly dispersedMaterial nanotechnologyCosmetic preparationsUv protectionPhosphate

A particulate metal oxide having a coating layer comprising phosphate wherein the mean length of the primary particles is in the range from 50 to 90 nm, and the mean width of the primary particles is in the range from 5 to 20 nm. The metal oxide is particularly suitable for forming aqueous dispersions. The metal oxide and aqueous dispersions thereof can be used in a sunscreen product that exhibits both effective UV protection and improved transparency.

Owner:CRODA INT PLC

Microencapsulated particulate metal material, method for producing the same, and aqueous dispersion and ink jet ink using the same

ActiveUS20060240259A1Satisfied with the effectLow isotropyPigmenting treatmentLiquid surface applicatorsPolymeric surfaceMetallic materials

Owner:SEIKO EPSON CORP

Silicone rubber compositions comprising bismuth oxide and articles made therefrom

InactiveUS20090243436A1Maintain good propertiesIncrease resistancePiezoelectric/electrostriction/magnetostriction machinesRecord information storagePhotopigmentParticulate metal

The present invention provides novel filled silicone compositions comprising a nano-particulate metal oxide filler selected from nano-particulate monoclinic alpha-phase bismuth oxide, nano-particulate erbium oxide, and mixtures thereof. The new composite compositions exhibit a combination of outstanding performance characteristics in both the cured and uncured states. Thus, the uncured formulations are typically free flowing liquids which are self-leveling, which de-gas readily under vacuum, are readily colorable through the addition of pigments, and which cure at temperatures of about 60° C. The cured compositions possess outstanding acoustic characteristics which make them ideally suited for use in applications such as acoustic lenses for medical imaging and therapy. For example, the acoustic impedance of compositions provided by the present invention is closely matched to the acoustic impedance of human tissue. This may result in an enhancement of ultrasound transmission efficiency between the lens of an ultrasound probe comprising such a composition and the patient.

Owner:GENERAL ELECTRIC CO

Aggregating compositions, modified particulate metal-oxides, modified formation surfaces, and methods for making and using same

ActiveUS8466094B2Improved self-aggregating propertyIncrease propensityConstructionsFluid removalParticulate metalMaterials science

A method for treating solid materials is disclosed, where the treating compositions coats surfaces or portions of surfaces of the solid materials changing an aggregation or agglomeration propensity of the materials. Treating composition and treated solid materials are also disclosed. The methods and treated materials are ideally suited for oil field applications.

Owner:THE LUBRIZOL CORP

Mould material mixture having improved flowability

InactiveCN101842175AImprove liquidityImprove stabilityFoundry mouldsFoundry coresMetalworkingParticulate metal

The invention relates to a mould material mixture for producing casting moulds for metal processing, a process for producing casting moulds, casting moulds which can be obtained by the process and their use. The production of the casting moulds is carried out using a refractory base moulding material and a binder based on water glass. A proportion of a particulate metal oxide selected from the group consisting of silicon dioxide, aluminium oxide, titanium oxide and zinc oxide is added to the binder, with particular preference being given to using synthetic amorphous silicon dioxide. The mould material mixture contains a surface-active material as further significant constituent. The addition of the surface-active material enables the flowability of the mould material mixture to be improved, which makes it possible to produce casting moulds having a very complicated geometry.

Owner:ASHLAND SUEDCHEM KERNFEST

Particulate metal alloy coating for providing corrosion protection

InactiveUS7078076B2Improve coating adhesionGood storage stabilityPigmenting treatmentAlkali metal silicate coatingsWater basedZinc metal

Coatings containing particulate metal alloy are disclosed. The coatings provide corrosion protection to a substrate, such as a metal substrate. The coatings contain zinc-metal-containing alloy in flake form, most particularly an alloy flake of zinc and aluminum. The coating can be from compositions that are water-based or solvent-based. The compositions for providing the coating may also contain a substituent such as a water-reducible organofunctional silane, or a hexavalent-chromium-providing substance, or a titanate polymer, or a silica substance constituent. The coating may desirably be topcoated.

Owner:NOF METAL COATINGS NORTH AMERICA INC

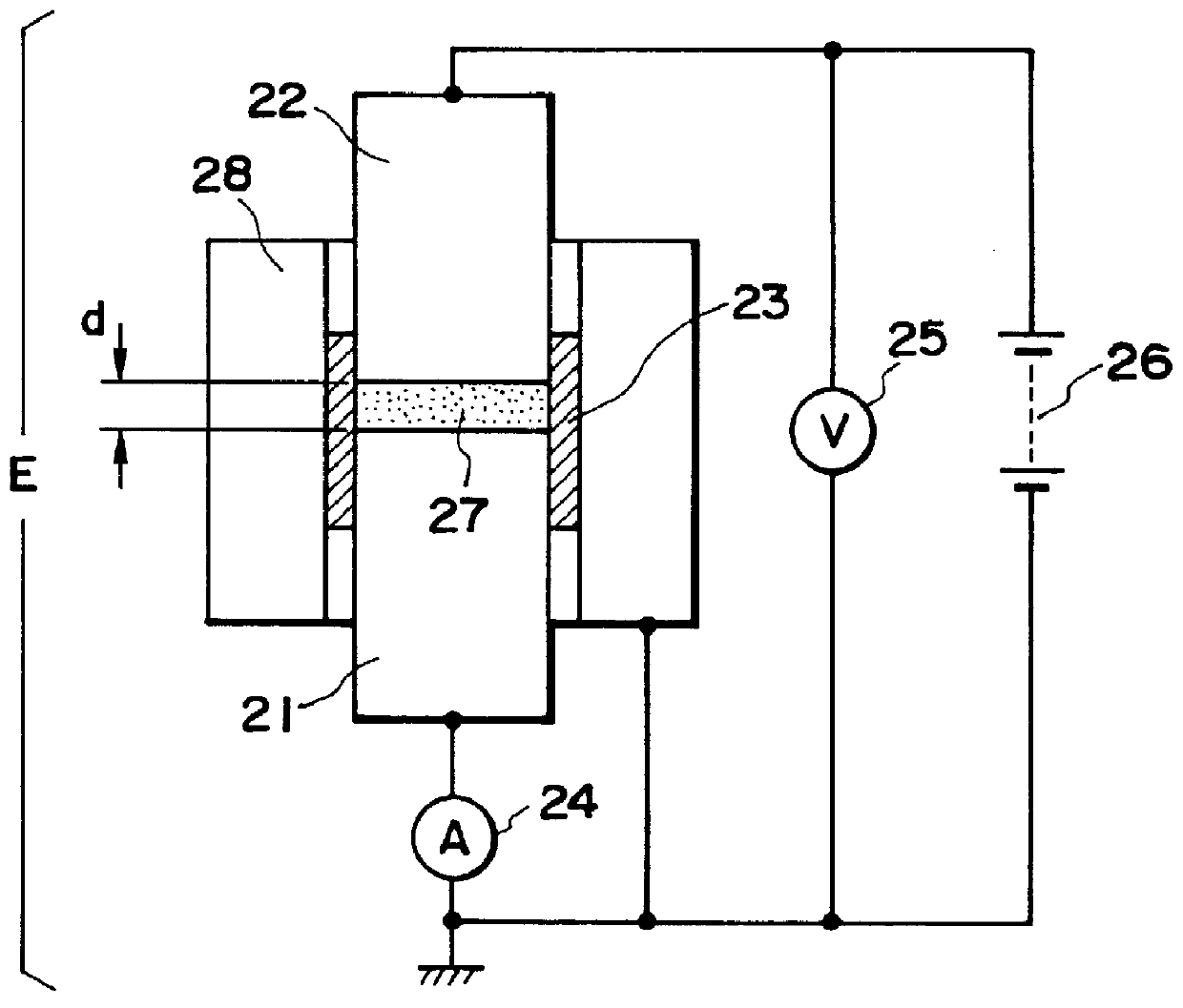

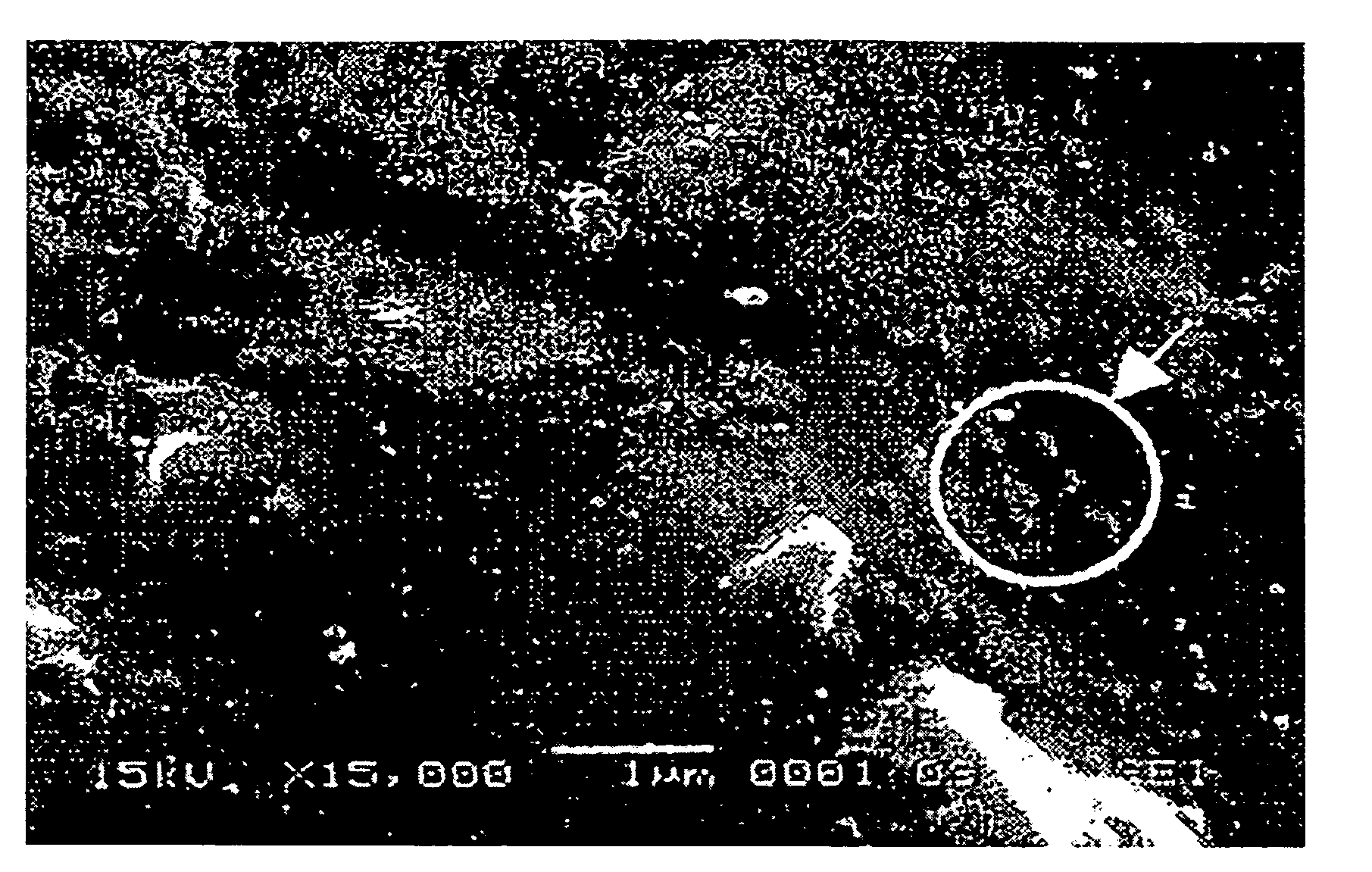

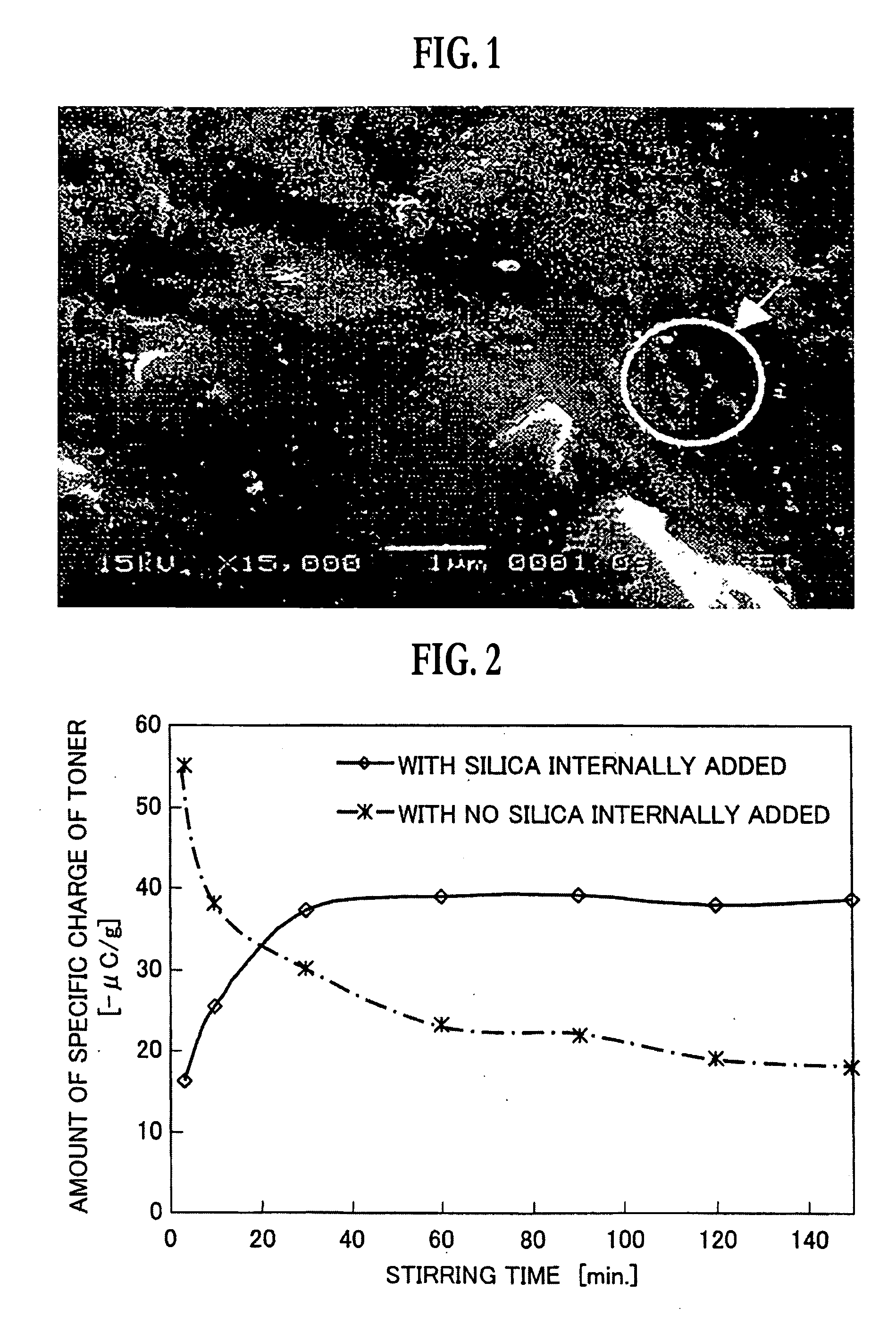

Developer

InactiveUS20090047594A1Improve charging characteristicsMinimize changesDevelopersEngineeringParticulate metal

A developer according to the present invention is arranged such that the composition of particulate metal oxide added as an external additive to a toner surface and the composition of particulate metal oxide added to a resin layer covering a carrier surface are identical to each other, so that the amount of frictional charge that is generated between the toner and the external additive is made larger than the amount of frictional charge that is generated between the external additive and the carrier surface. With this, the external additive is prevented from migrating from the toner surface onto the carrier surface. This makes it possible to prevent the external additive from migrating from the toner surface onto the carrier surface, and thereby to remedy (i) defects in charge and fluidity and (ii) secondary failures, i.e., defects in development that are caused by deterioration in performance of the developer due to the defects in charge and fluidity.

Owner:SHARP KK

Particulate metal alloy coating for providing corrosion protection

Owner:NOF METAL COATINGS NORTH AMERICA INC

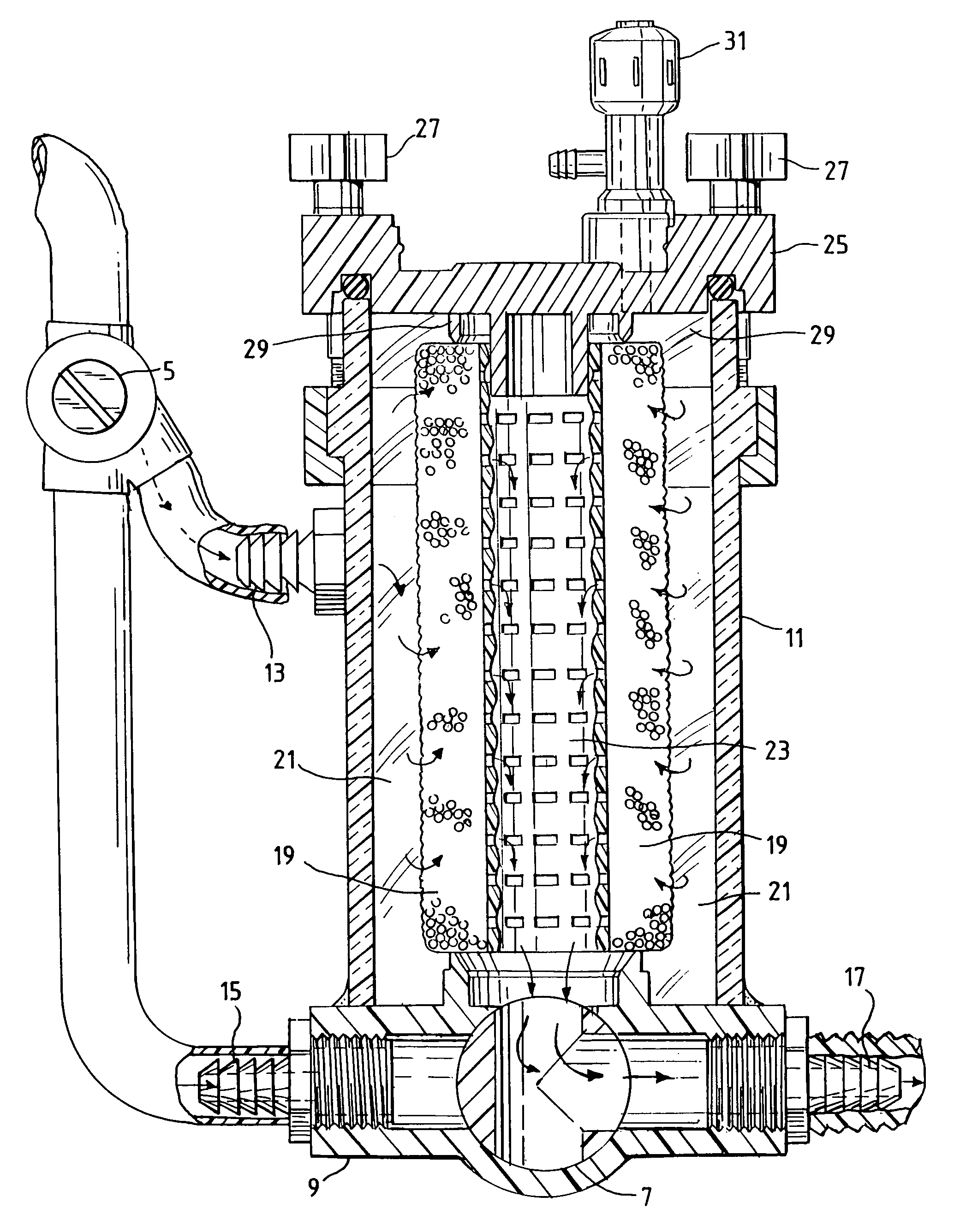

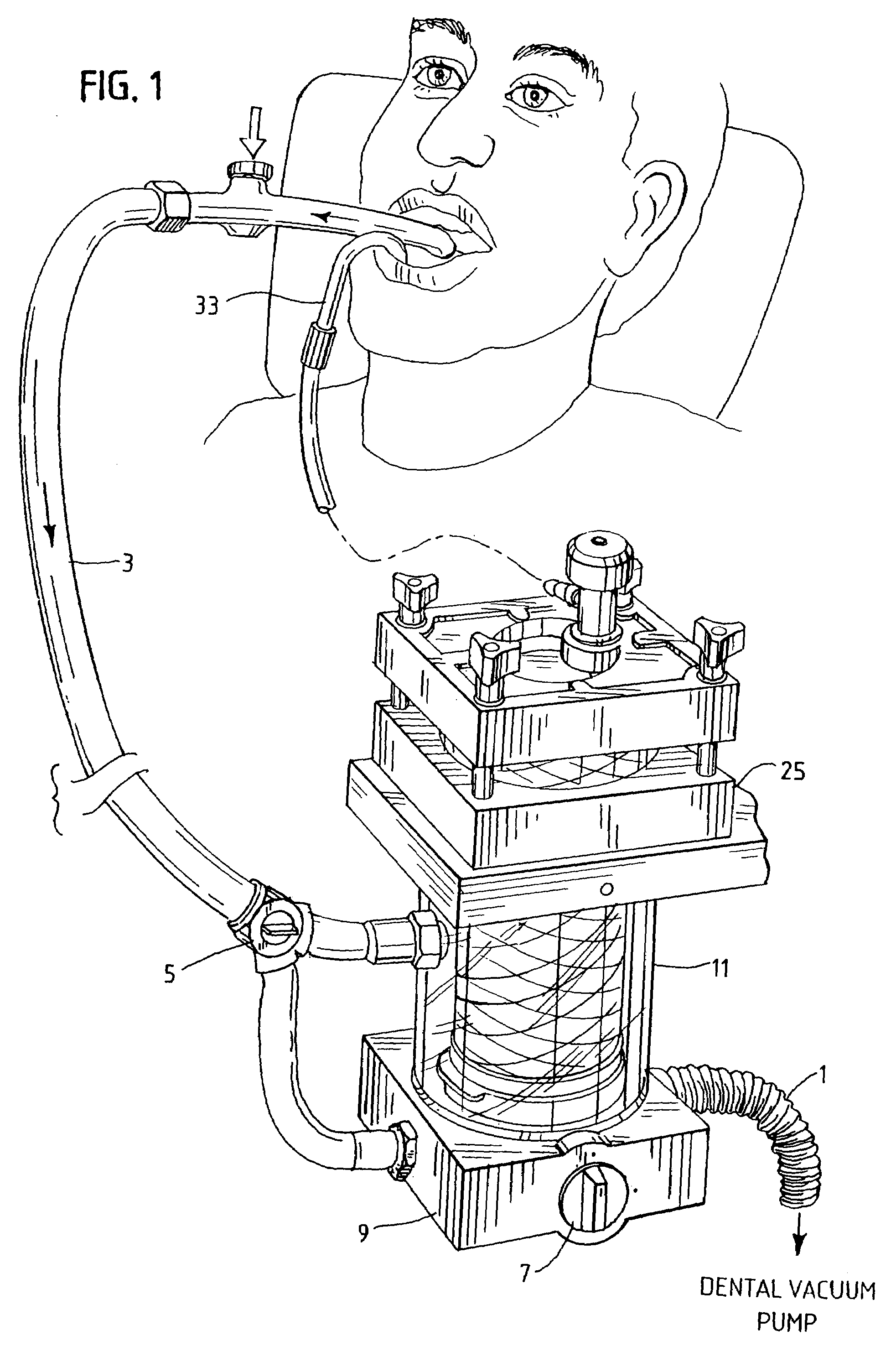

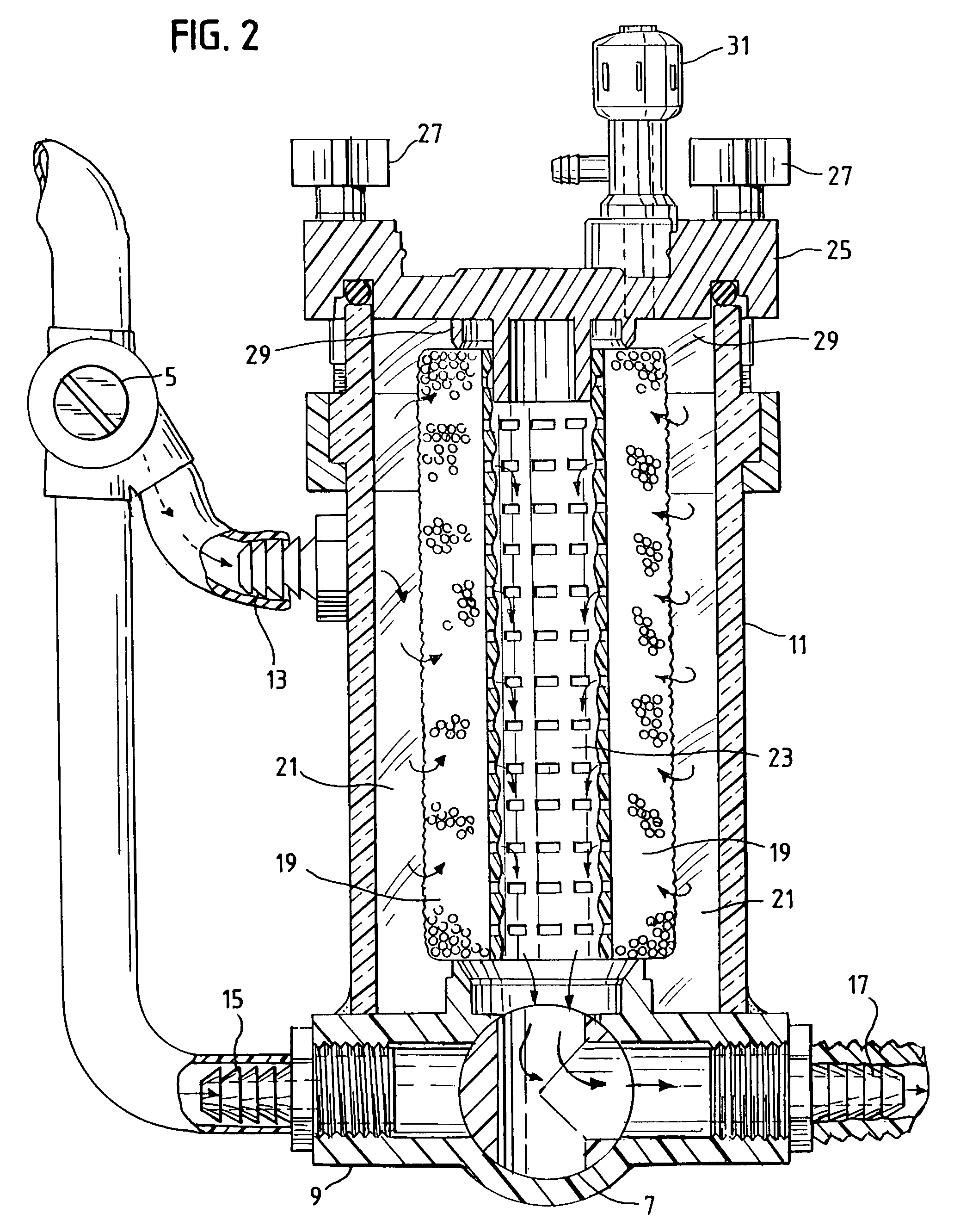

Method and apparatus for removing particulate metals from dental waste water

InactiveUS7182599B2Easy to replaceTransportation safetySettling tanks feed/dischargeIntravenous devicesWastewaterStopcock

Owner:NAVY UNITED STATES OF AMERICA AS REPRESENTED BY SEC OF THE

Toughness optimized insert for rock and hammer bits

An insert for a drill bit is disclosed which includes an exposed surface having a contact portion adapted to periodically contact earthen formation. The contact portion includes a polycrystalline diamond material having a hardness in the range of about 2000 HV to about 3000 HV. In some embodiments, the polycrystalline diamond material includes a composite having a first phase material including polycrystalline diamond and a second phase material selected from the group of oxide particulates metal carbides, and metallic particulates, nitrides, and mixtures of thereof.

Owner:SMITH INT INC

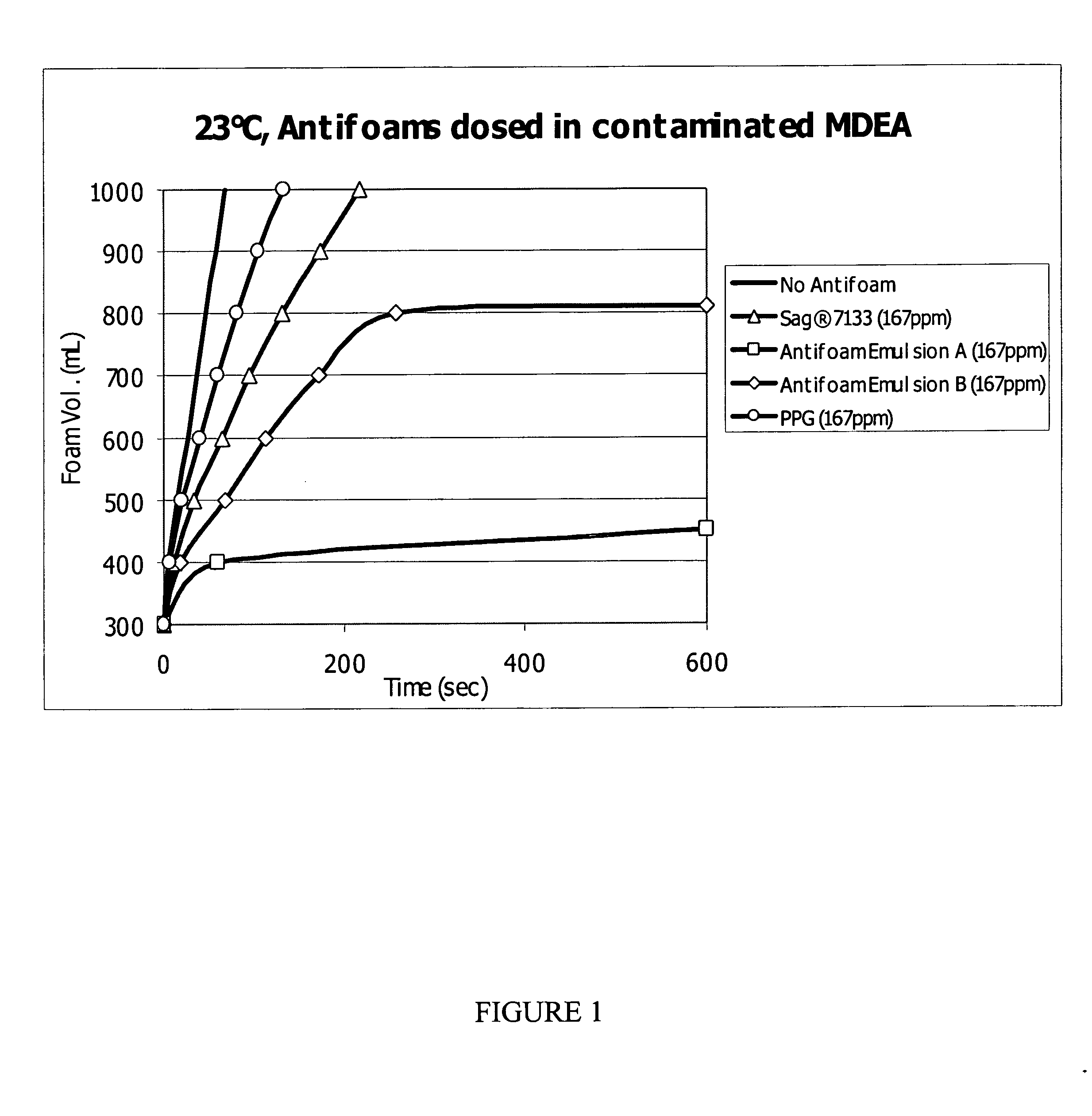

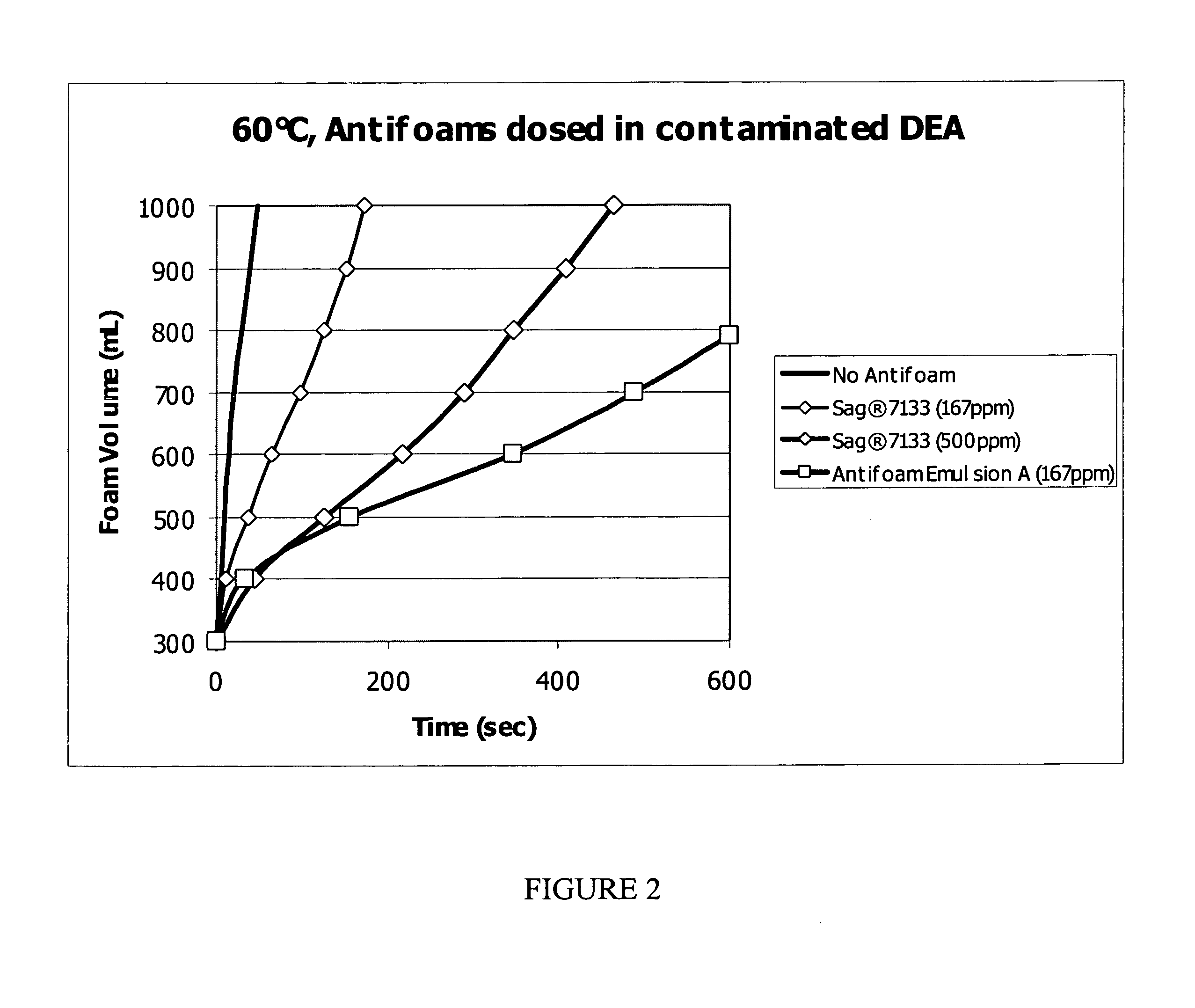

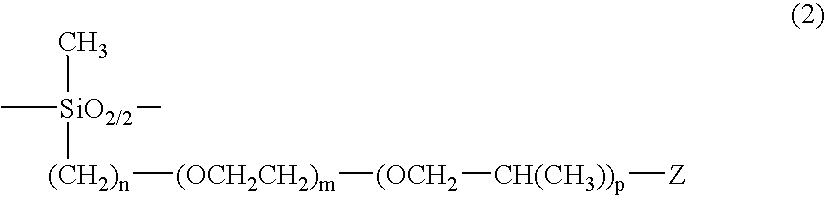

Low-foaming gas processing compositions and uses thereof

InactiveUS20070244205A1Improved foam suppressing abilityReadily dispersibleOther chemical processesUsing liquid separation agentWater dispersiblePolypropylene glycol

The invention relates to low-foaming gas processing compositions comprising (a) a silicone antifoam component comprising a base silicone fluid and a particulate metal oxide; (b) an emulsifying component in an amount suitable for the at least substantial emulsification of the silicone antifoam component in water; (c) a polypropylene glycol component at least partially soluble, emulsifiable, and / or dispersible in water; (d) a water-soluble or water-dispersible gas processing agent; and (e) water. The invention also relates to methods for processing a gas by treating the gas with these foam suppressing compositions.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

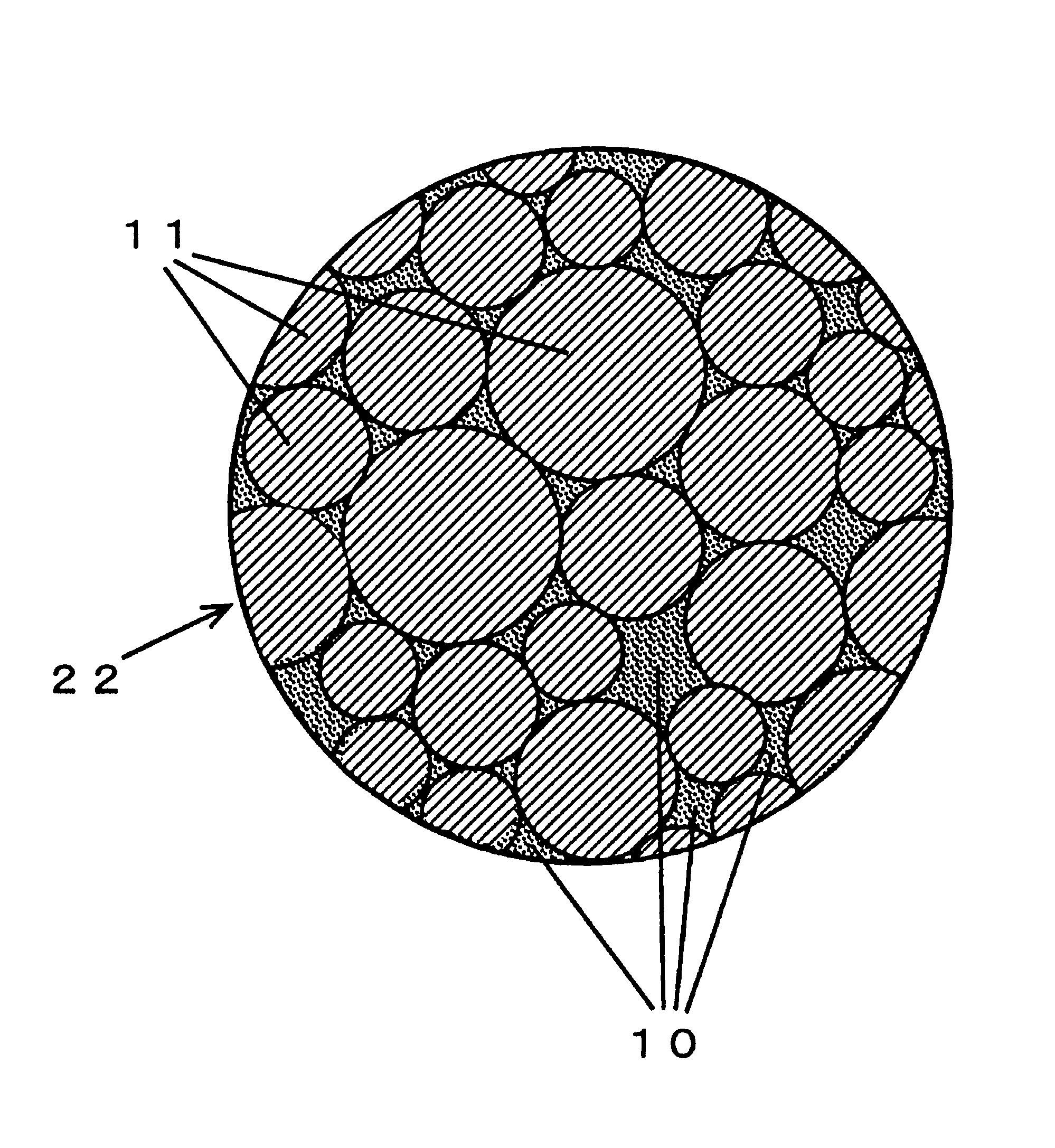

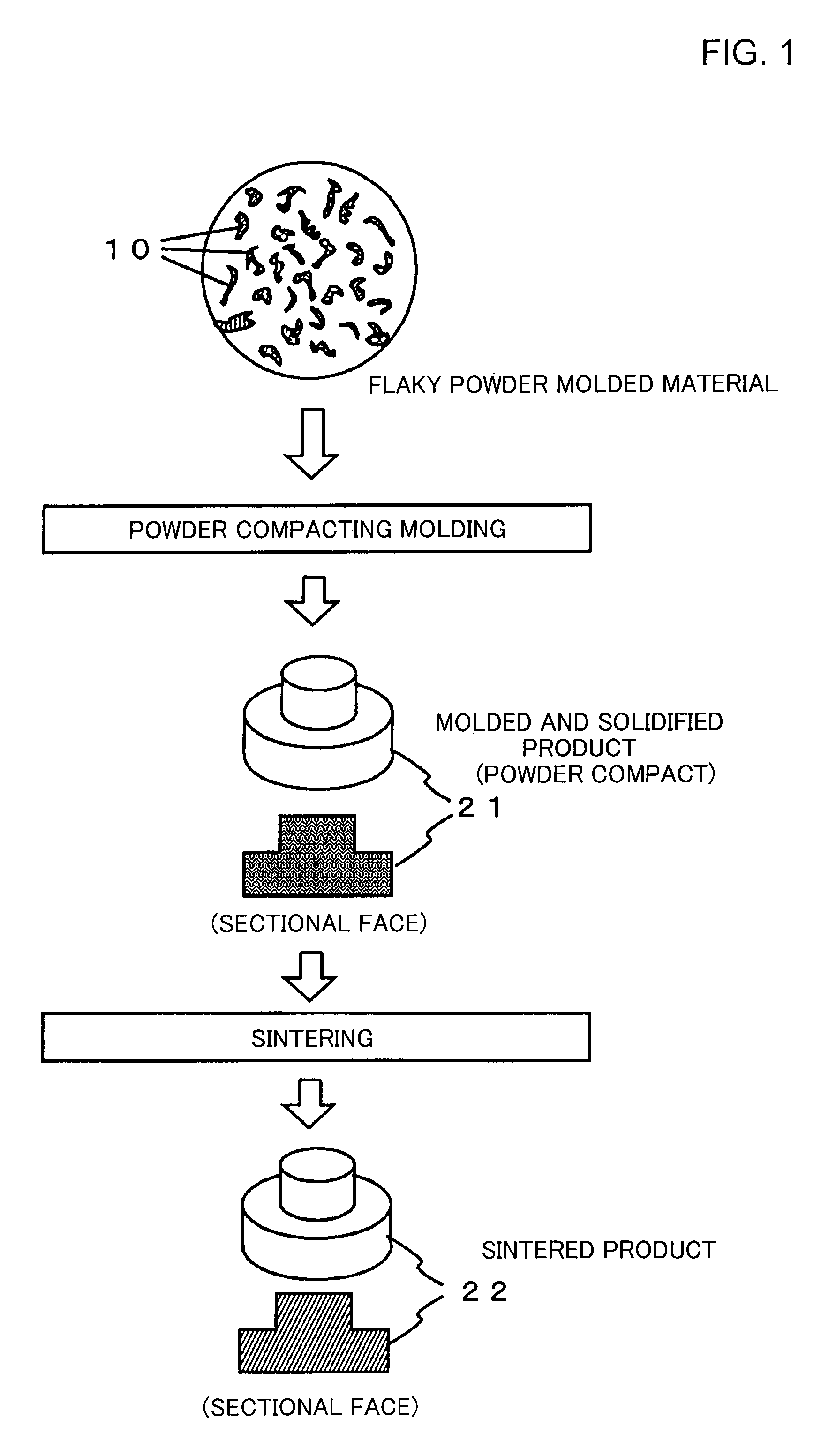

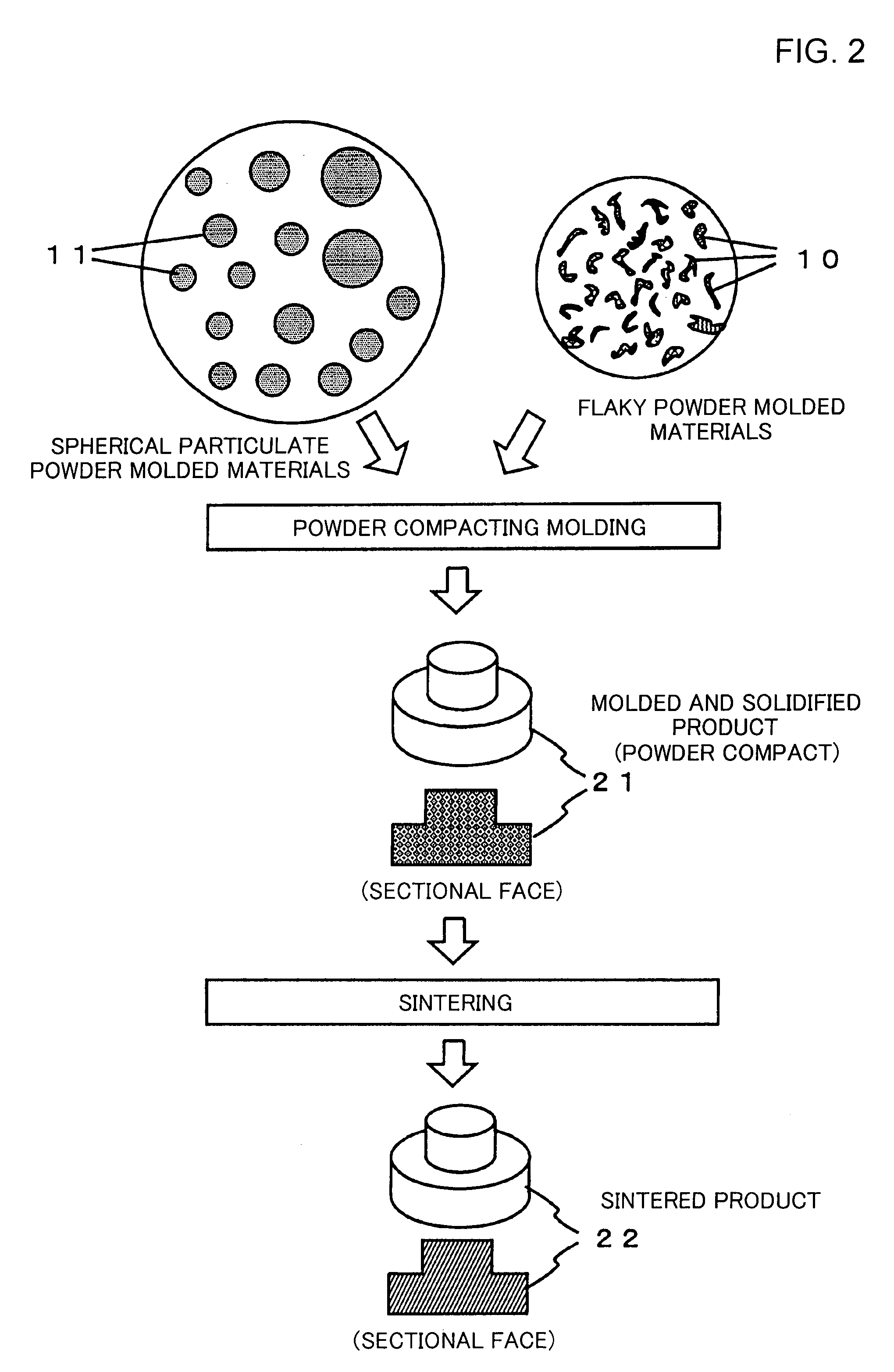

Manufacturing method of metal product and metal product

InactiveUS8439998B2Small air gapSecure strengthMetal-working apparatusMagnetic materialsShell moldingProduct gas

In sintering a metal powder after pressure molding into a given configuration, random amorphous flaky metal fine powders (10) are used as metal powder materials. In addition, spherical particulate metal powders 11 are used as main materials, and random amorphous flaky metal fine powders 10 having finer particle size than the metal powders 11 and produced by fracturing a metal fracture material by means of high-velocity gas swirling flow are used as sub-materials, and molding and sintering are performed in a state of dispersing the sub-materials (10) in the main materials (11). Thus, despite being a power metallurgical product, it is possible to obtain a metal product having a dense metallographic structure and excellent in properties such as mechanical strength.

Owner:SUNREX IND +2

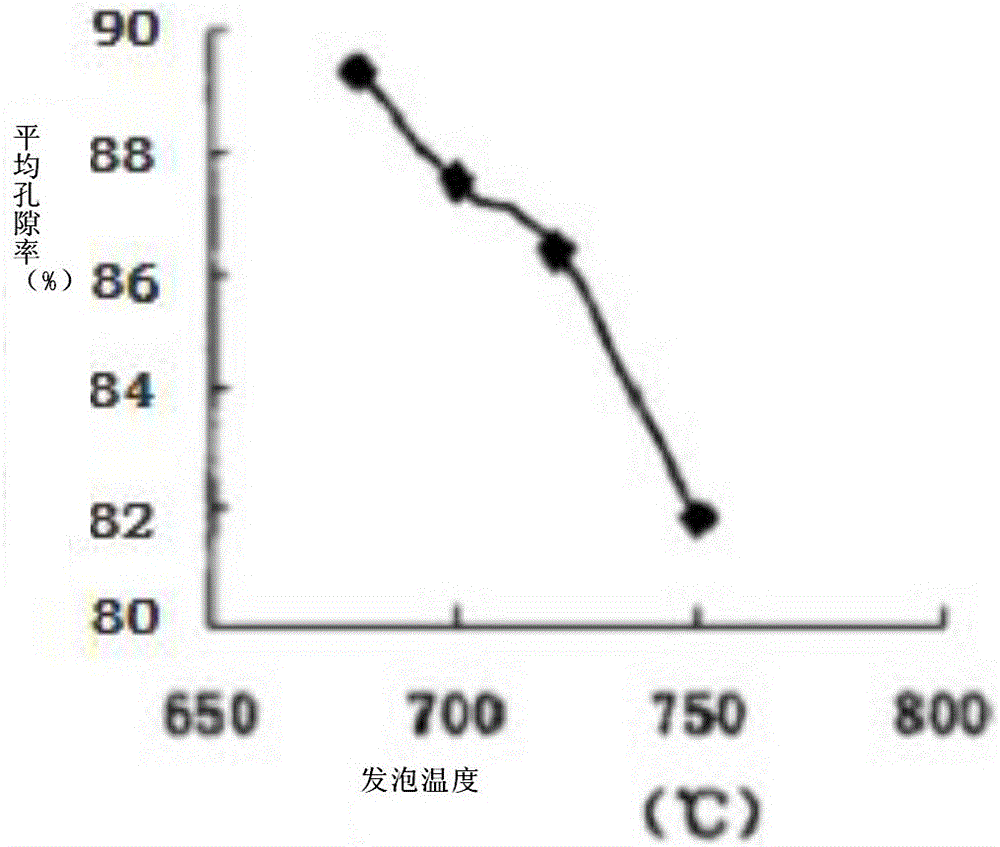

Rare earth high-strength foam aluminum prepared through melt foaming method and preparation process of rare earth high-strength foam aluminum

InactiveCN106435283ALow alloying temperatureEnergy-saving preparation methodZirconium hydrideCarbide silicon

The invention relates to a rare earth high-strength foam aluminum prepared through a melt foaming method. The rare earth high-strength foam aluminum is made of, by mass percentage, 85%-99.3% of aluminum powder or an aluminum ingot, 0.1%-2% of a rare earth additive, 0.3%-5% of a tackifier and 0.5%-6% of a blowing agent. The blowing agent is selected from one or more of particulate metal calcium, silicon carbide, alumina and ceramic particles. The blowing agent is selected from one or more of titanium hydride powder, lanthanum hydride powder and zirconium hydride powder. According to the rare earth high-strength foam aluminum, through holes and closed holes exist at the same time, and the pore size and density distribution are uniform; and the process has the beneficial effects of being low in production cost and facilitating large-scale production.

Owner:ZHONGAN SHUNXING BEIJING SAFETY TECH CO LTD

Substrate monolith comprising SCR catalyst

ActiveUS9333461B2Avoids and reduces problemReduce and prevent poisoningCombination devicesInternal combustion piston enginesGas phaseNitrogen

A substrate monolith 6 having a length L and comprising a first zone 11 of substantially uniform length defined at one end by a first end of the substrate monolith, which first zone comprising a selective catalytic reduction (SCR) catalyst for reducing oxides of nitrogen with a nitrogenous reductant in exhaust gas emitted from an internal combustion engine and a second zone 8 of substantially uniform length less than L defined at one end by a second end of the substrate monolith, which second zone comprising (a) at least one particulate metal oxide or a mixture of any two or more thereof for trapping gas phase platinum group metal (PGM), which at least one particulate metal oxide does not act as a support for any other catalytic component; or (b) a component capable of trapping and / or alloying with gas phase PGM.

Owner:JOHNSON MATTHEY PLC

Particulate metal oxide

InactiveUS20030223940A1Reduce whitenessGood dispersibilityCosmetic preparationsMaterial nanotechnologyUv protectionUltraviolet

A particulate metal oxide having a mean length of the primary particles in the range from 50 to 90 nm, the mean width of the primary particles in the range from 5 to 20 nm, and the median volume particle diameter of the secondary particles is less than 45 nm. The metal oxide can be used in a sunscreen product that exhibits both effective UV protection and improved transparency.

Owner:CRODA INT PLC

Particulate metal oxide

InactiveUS7220305B2Reduce whitenessGood dispersibilityCosmetic preparationsMaterial nanotechnologyUv protectionPhysical chemistry

A particulate metal oxide having the mean length of the primary particles in the range from 50 to 90 nm, the mean width of the primary particles in the range from 5 to 20 nm, and the median volume particle diameter of the secondary particles is less than 45 nm. The metal oxide can be used in a sunscreen product that exhibits both effective UV protection and improved transparency.

Owner:CRODA INT PLC

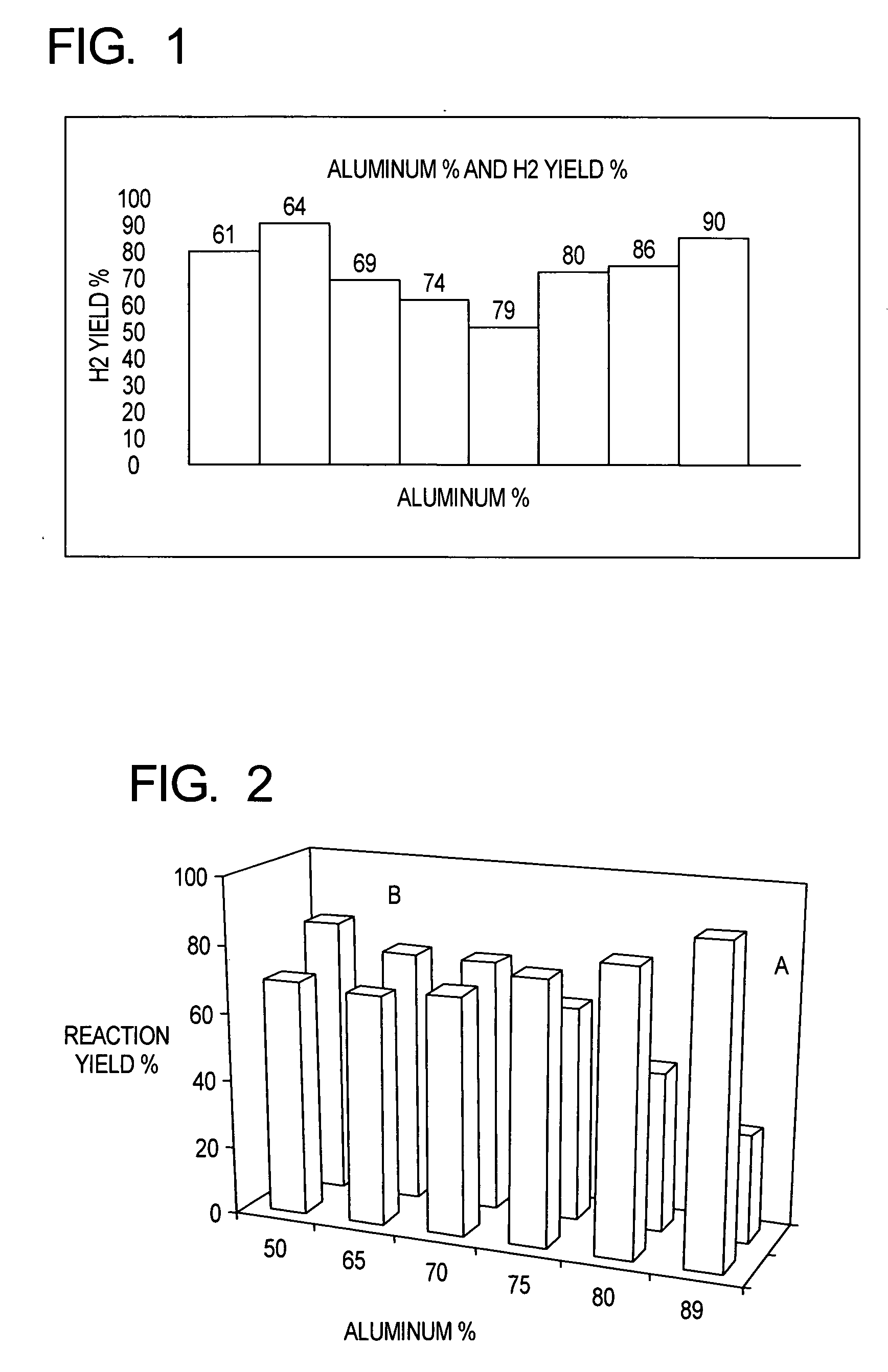

Production of hydrogen from aluminum and water

InactiveUS20080260632A1Effectively waterEasy to recycleOther chemical processesHydrogen productionMetallic aluminumHigh pressure

A method and compositions for producing hydrogen by water split reaction, at near neutral pH conditions and without requiring preheating of the reactant materials. Metallic aluminum in particulate form is blended particulate with a water-soluble inorganic salt that causes progressive pitting of the aluminum to prevent passivation and a particulate metal oxide initiator that raises the temperature of the reactant material upon exposure to water to a level which initiates reaction of water with the metallic aluminum to generate hydrogen. The metal oxide initiator may be an oxide of a Group II metal, such as calcium oxide. The catalyst may be a water soluble inorganic salt having an aggressive anion, such as the halides, sulfites, sulfates and nitrates of Group I and Group II metals, with sodium chloride being preferred. The particles of metallic aluminum are discrete from but blended with those of the salt and oxide. Blending may be performed in a drum or other mixer, and the metal component may be combined with the catalyst and initiator previously or in a reactor just prior to reaction. The reaction initiates upon adding water, and is capable of generating hydrogen at both low and elevated pressures. The reaction products can be recycled or disposed of safely through ordinary channels.

Owner:ANAND JASBIR KAUR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com