Rare earth high-strength foam aluminum prepared through melt foaming method and preparation process of rare earth high-strength foam aluminum

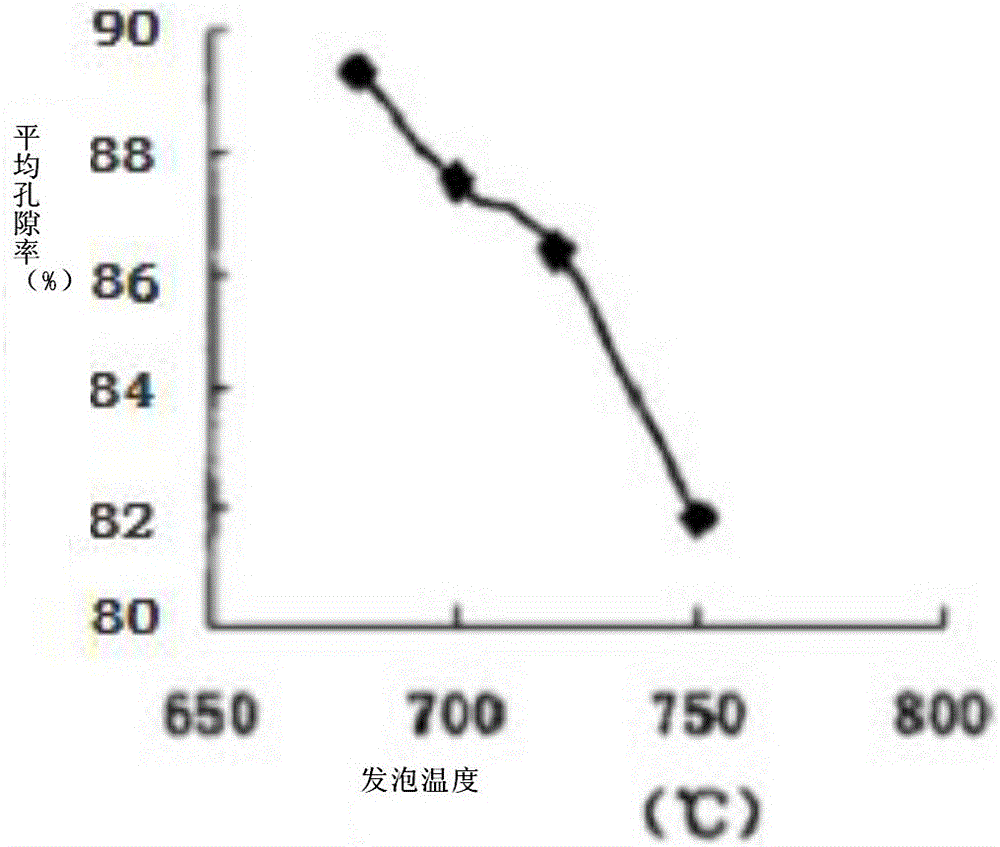

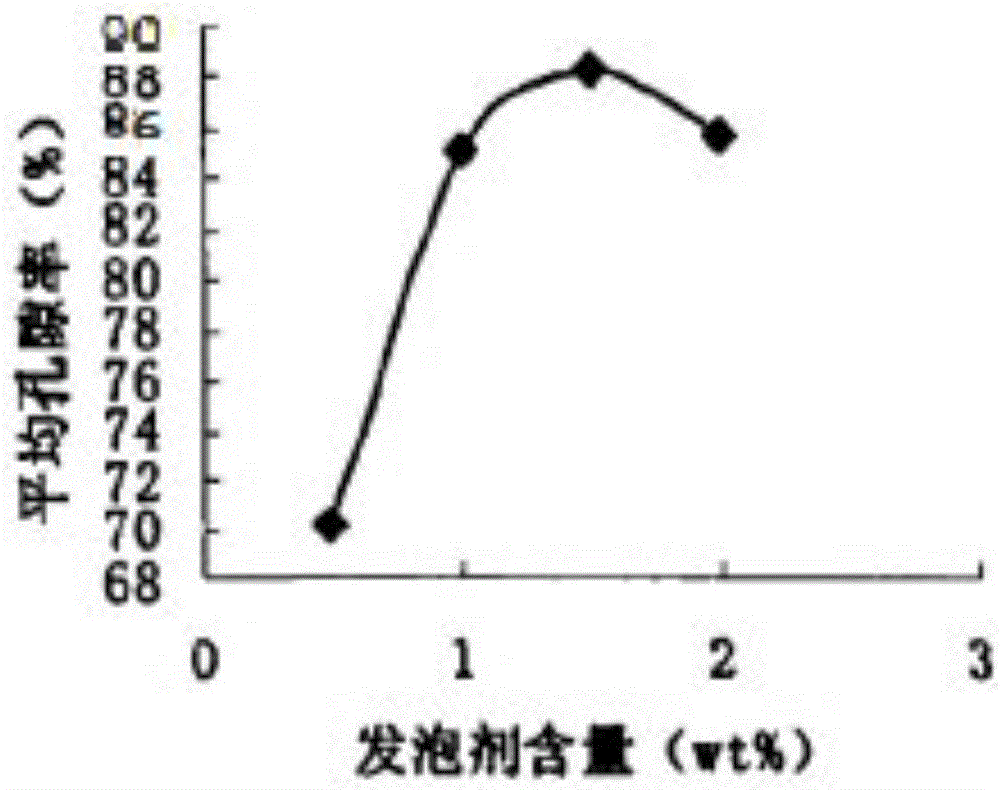

A melt foaming method and technology of preparation process, applied in the field of foamed aluminum materials, can solve the problems of uneven porous structure of foamed metal, difficult process control, high density, etc., and achieve moderate size of pores, uniform density distribution, and low alloy. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Rare earth high-strength aluminum foam is mainly prepared from the following weight components:

[0035] 10kg of aluminum powder or aluminum ingot is added to the aluminum melting furnace, and the ratio is 85-99.3wt% of aluminum; 0.1-2wt% of rare earth additive; 0.3-5wt% of tackifier; and 0.5-6wt% of foaming agent.

[0036] Prepare as follows:

[0037] (1) heating and melting aluminum powder or aluminum ingot into aluminum liquid;

[0038] (2) adding rare earth additives for smelting to obtain a rare earth aluminum alloy melt;

[0039] (3) Add a tackifier to the rare earth aluminum alloy melt, and fully stir to increase the melt concentration;

[0040] (4) adding a foaming agent to the melt obtained in step (3), continuing to fully stir for heat preservation and foaming, to obtain a rare earth aluminum alloy foam;

[0041](5) Cooling and cutting to produce a rare-earth foamed aluminum bare board or further processing to make a rare-earth foamed aluminum sound-absorbi...

Embodiment 2

[0043] Rare earth high-strength aluminum foam is mainly prepared from the following weight components:

[0044] Add 10kg of aluminum powder or aluminum ingot to the aluminum melting furnace, with the ratio of 93wt% aluminum; 0.7wt% rare earth additive; 3wt% calcium metal; 2.5wt% titanium hydride powder.

[0045] Prepare as follows:

[0046] (1) After heating the aluminum melting furnace to a temperature of 300°C, add aluminum ingots or aluminum powder into the furnace;

[0047] (2) At a temperature of 450°C, add rare earth additives for melting, and then heat the temperature of the melting furnace to about 750°C to obtain a rare earth aluminum alloy melt;

[0048] (3) Add metal calcium to the rare earth aluminum alloy melt, and stir fully at a rotating speed of 500r / m to increase the melt concentration;

[0049] (4) Add titanium hydride powder to the melt obtained in step (3), continue to fully stir for heat preservation and foaming, the foaming temperature is 660 ° C, and t...

Embodiment 3

[0052] Rare earth high-strength aluminum foam is mainly prepared from the following weight components:

[0053] Add 10kg of aluminum powder or aluminum ingot to the aluminum melting furnace, with the ratio of 92.6wt% aluminum; 0.14wt% rare earth additive; 2.2wt% calcium metal; 2wt% titanium hydride powder.

[0054] The preparation method is as described in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com