Ceramic nanofiber and its preparation method and equipment

A nanofiber and ceramic technology, applied in the field of material science and engineering, can solve the problems of high cost, low output, and difficult preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] In this example, titanium oxide nanofibers and their three-dimensional sponge structures were prepared.

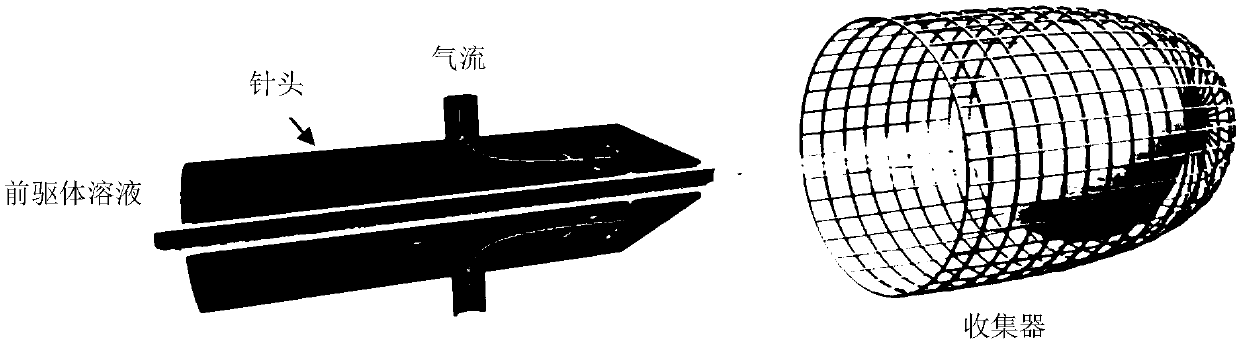

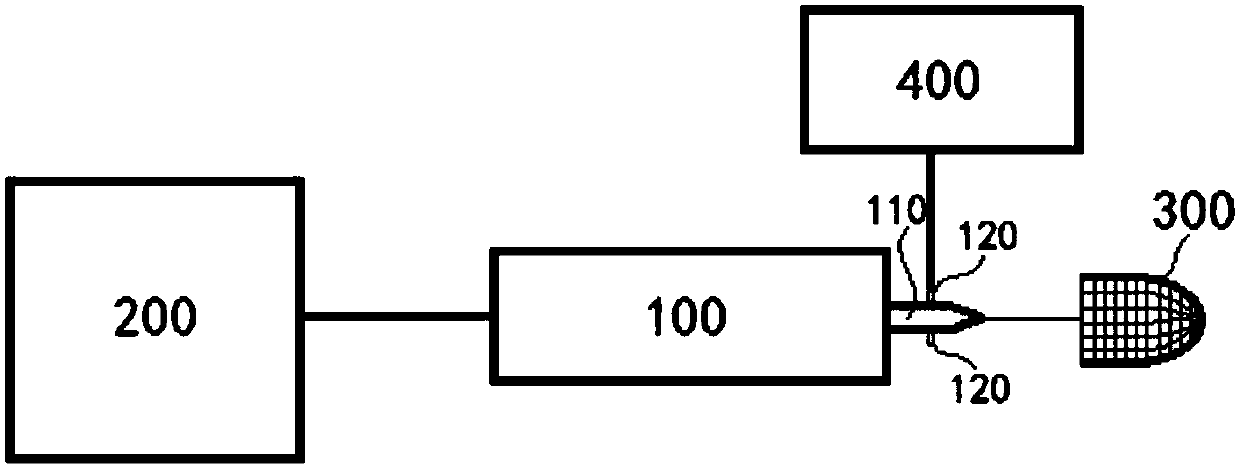

[0087] The specific preparation method is as follows: first prepare the precursor solution, first mix the mixed solvent of acetic acid and ethanol with a mass ratio of 1:3, add tetrabutyl titanate and PVP with a mass ratio of 1:2, and mix The mass fraction of PVP in the obtained precursor solution was 7%; and the prepared precursor solution was passed through a sealed vial and stirred for 6 hours until the PVP was completely dissolved. Then, draw a certain amount of precursor solution into the syringe, and inject the precursor solution from the inner shaft of the coaxial needle at a speed of 3mL / h through the injection pump, while the airflow passes through the outer shaft of the needle at a speed of 21m / s , the precursor solution is stretched into fibers in the air, and the solvent is also rapidly volatilized, and finally nano-scale fibers are formed, which are col...

Embodiment 2

[0090] In this example, zirconia nanofibers and their three-dimensional sponge structures were prepared according to the same preparation method as in Example 1. The difference is that zirconium oxychloride (ZrOCl 2 ·8H 2 The mass ratio of O) and PVP is 2:1, the mass ratio of water and ethanol in the mixed solvent is 1:1, the mass fraction of PVP in the precursor solution is 8%, and the precursor solution is stirred at room temperature until the solute is completely dissolved ; The airflow passes through the outer axis of the needle at a speed of 18m / s, and the distance between the liquid outlet and the porous cage collector is 15cm; the sintering temperature is 800°C, and the holding time is 200min, and finally a zirconia nanometer with a diameter of 200nm to 300nm is obtained. Three-dimensional structure composed of fibers.

Embodiment 3

[0092] In this example, barium titanate nanofibers and their three-dimensional sponge structures were prepared according to the same preparation method as in Example 1. The difference is that barium acetate (Ba(Ac) 2 ) and tetrabutyl titanate at a mass ratio of 1:1, the solvent is ethanol, and the precursor solution is stirred at room temperature until the solute is completely dissolved; the precursor solution is injected from the inner shaft of the coaxial needle at a speed of 2.5mL / h , the airflow passes through the outer axis of the needle at a speed of 16m / s, and the distance between the liquid outlet and the porous cage collector is 16cm; the sintering temperature is 750°C, and the holding time is 60min, and finally a barium titanate nanometer with a diameter of about 300nm is obtained. Three-dimensional structure composed of fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com