Preparation of Cellulose Nanofiber Airgel Microspheres by Ultrasonic Atomization

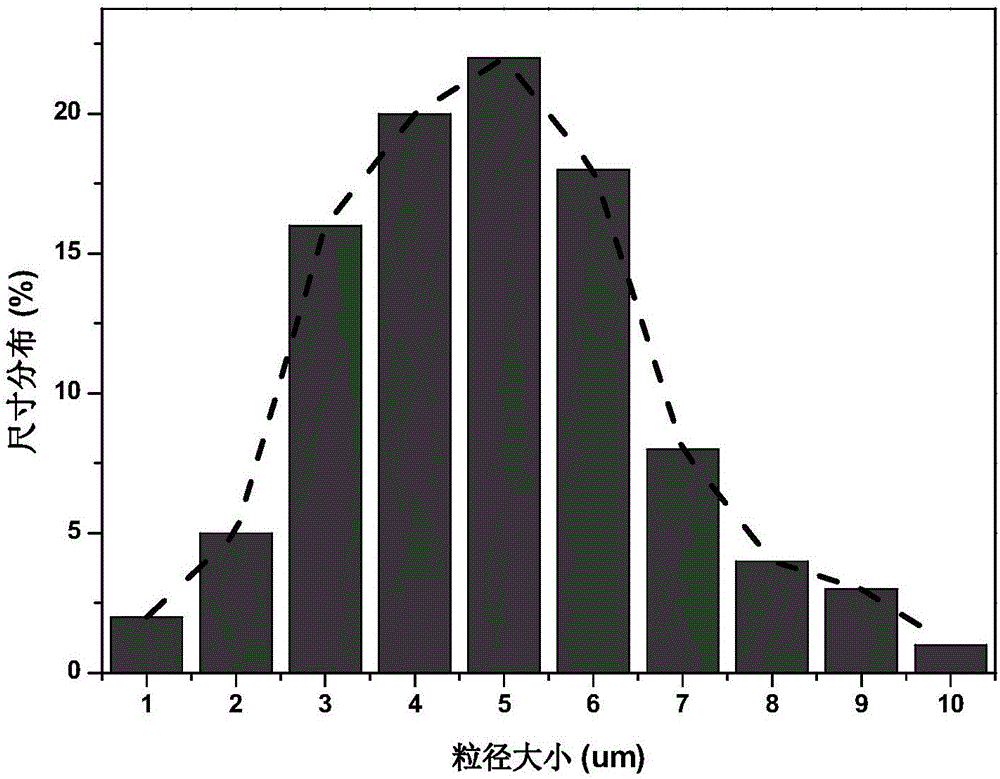

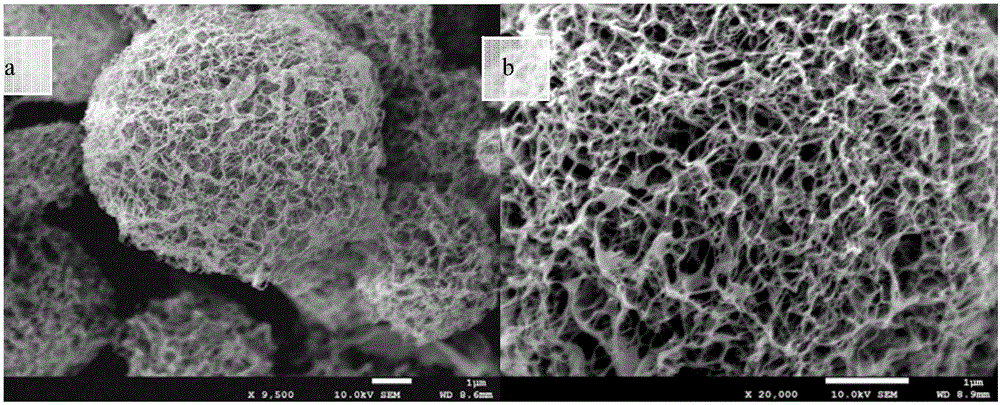

A nanofiber and ultrasonic technology, which is applied in the field of preparing cellulose nanofiber airgel microspheres by ultrasonic atomization, can solve the problems of uneven particle size distribution, limit the application of microspheres, and affect the application of microspheres, and achieve uniform distribution , Good void structure uniformity, high water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of TEMPO Oxidized Nanocellulose Suspension (TOCN): After the bleached coniferous wood pulp board was thawed, under the pulp concentration of 1.5wt%, by adding TEMPO (0.016g / g absolute dry pulp), sodium hypochlorite (20mmol / g absolute Dry pulp), sodium bromide (0.16g / g dry pulp), reacted for 2h under the condition of pH10.5, the carboxyl content was measured at 1.82mmol / g dry pulp. The oxidized slurry was ultrasonically dissociated (Ultrasonics FS-300; 8 min) to prepare a cellulose nanofiber suspension, and the concentration of the suspension was controlled at 0.8 wt%.

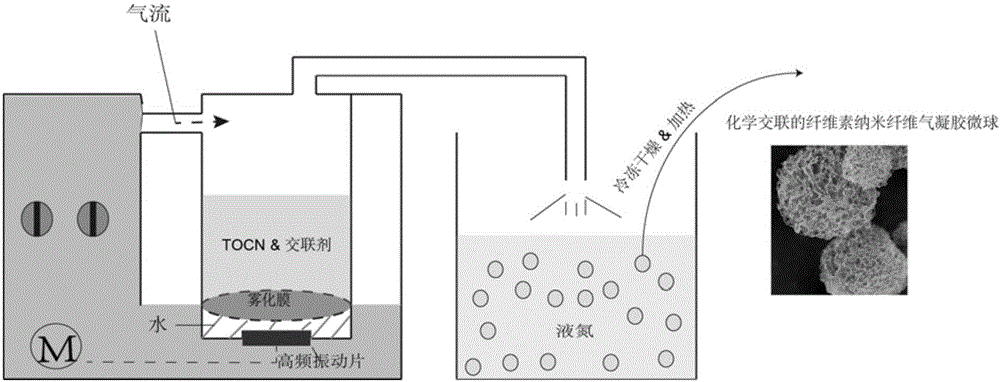

[0032] Preparation of chemically crosslinked cellulose nanofiber airgel microspheres: Pour about 150ml of cellulose nanofiber suspension with crosslinking agent (polyamide epichlorohydrin resin, 5% g / g dry pulp) into medical In the atomization cup of the ultrasonic nebulizer (Yuwell, 420AI, power 1.7MHz±10%). The atomized TEMPO oxidized cellulose nanofiber droplets are blown into a container...

Embodiment 2

[0034] Preparation of TEMPO oxidized nanocellulose suspension (TOCN): After the bleached coniferous wood pulp board was decomposed, under the pulp concentration of 0.8wt%, by adding TEMPO (0.01g / g absolute dry pulp), sodium hypochlorite (15mmol / g absolute dry pulp), sodium bromide (0.10g / g dry pulp), and reacted for 3h under the condition of pH9. The oxidized slurry was ultrasonically dissociated (Ultrasonics FS-300; 5 min) to prepare a cellulose nanofiber suspension, and the concentration of the suspension was controlled at 0.3 wt%.

[0035] Preparation of chemically cross-linked cellulose nanofiber airgel microspheres: add about 150ml of cellulose nanofiber suspension with cross-linking agent (polyamide epichlorohydrin resin, 1% g / g dry pulp) into medical In the atomization cup of the ultrasonic nebulizer (Yuwell, 420AI, power 1.7MHz±10%). The atomized TEMPO oxidized cellulose nanofiber droplets are blown into a container filled with liquid nitrogen through an airflow. The...

Embodiment 3

[0037] Preparation of TEMPO oxidized nano-cellulose suspension (TOCN): after the bleached coniferous wood pulp board is thawed out, under the pulp concentration of 2wt%, by adding TEMPO (0.02g / g dry pulp), sodium hypochlorite (25mmol / g dry pulp) pulp), sodium bromide (0.20g / g dry pulp), and reacted for 4h under the condition of pH11. The oxidized slurry was ultrasonically dissociated (Ultrasonics FS-300; 10 min) to prepare a cellulose nanofiber suspension, and the concentration of the suspension was controlled at 1.2 wt%.

[0038]Preparation of chemically crosslinked cellulose nanofiber airgel microspheres: add about 150ml of cellulose nanofiber suspension with crosslinking agent (polyamide epichlorohydrin resin, 7% g / g dry pulp) into medical In the atomization cup of the ultrasonic nebulizer (Yuwell, 420AI, power 1.7MHz±10%). The atomized TEMPO oxidized cellulose nanofiber droplets are blown into a container filled with liquid nitrogen through an airflow. Then the quick-fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com