Patents

Literature

665 results about "Sodium bromide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium bromide is an inorganic compound with the formula NaBr. It is a high-melting white, crystalline solid that resembles sodium chloride. It is a widely used source of the bromide ion and has many applications.

Conversion of carbohydrates to hydroxymethylfurfural (HMF) and derivatives

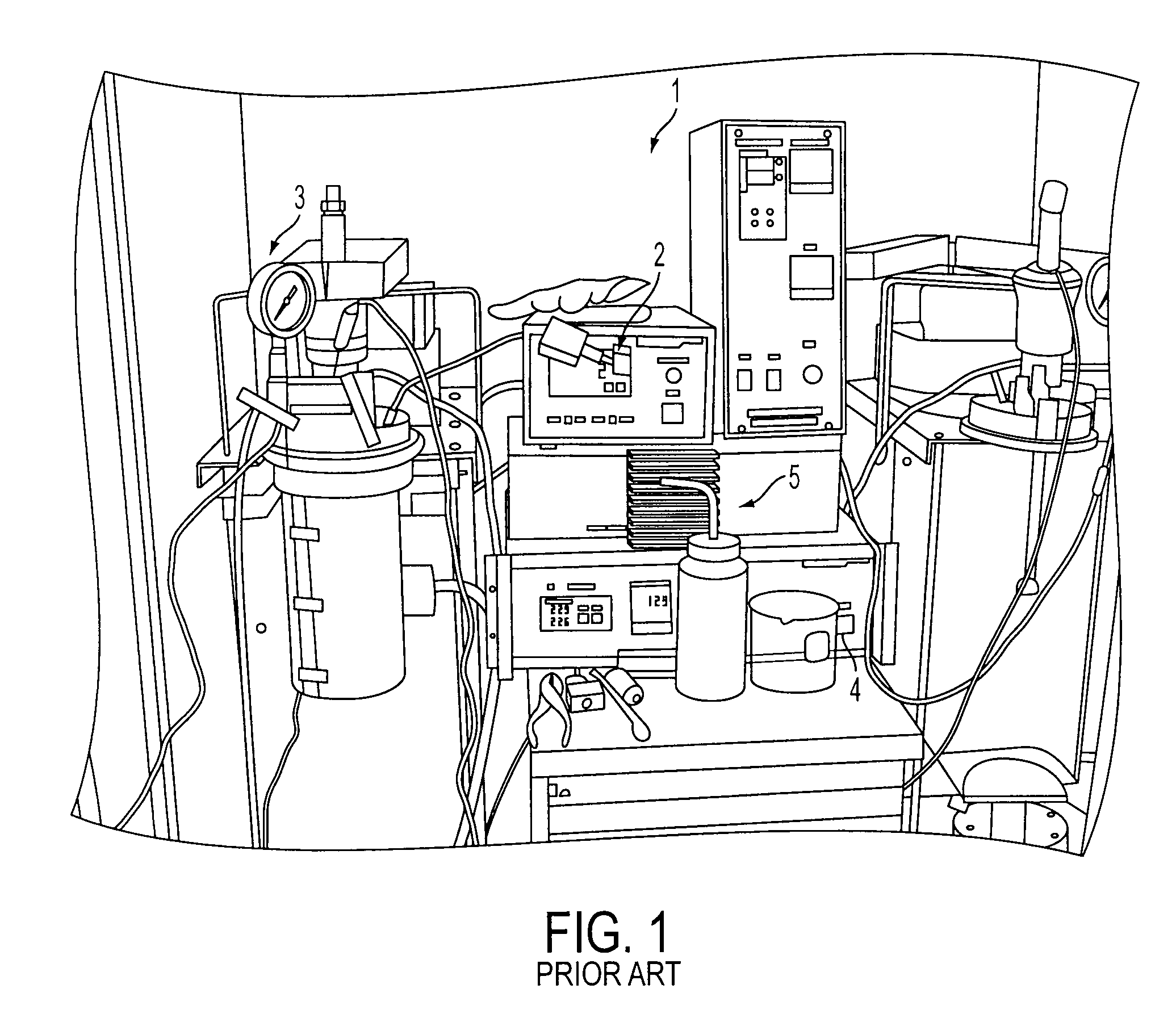

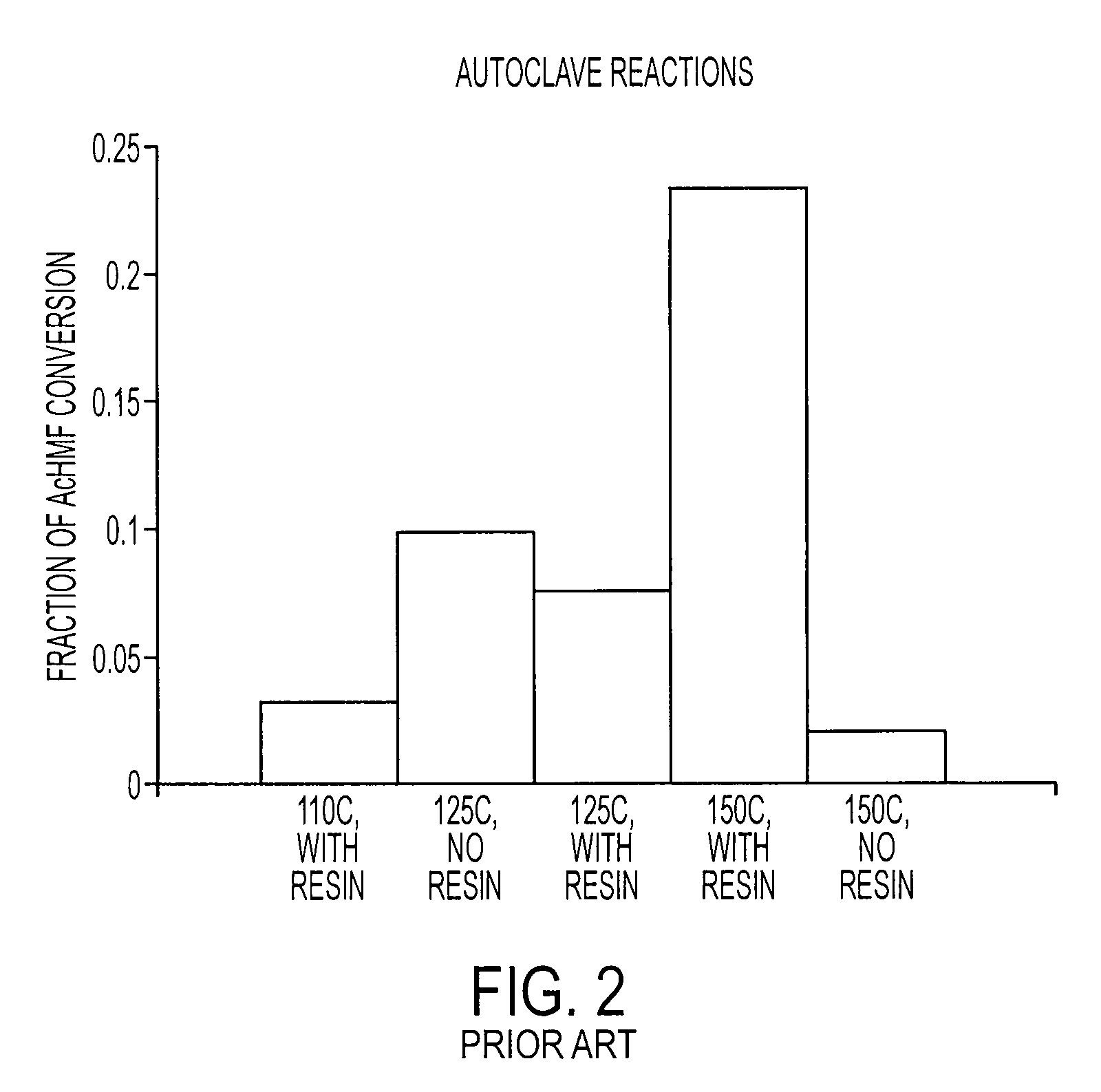

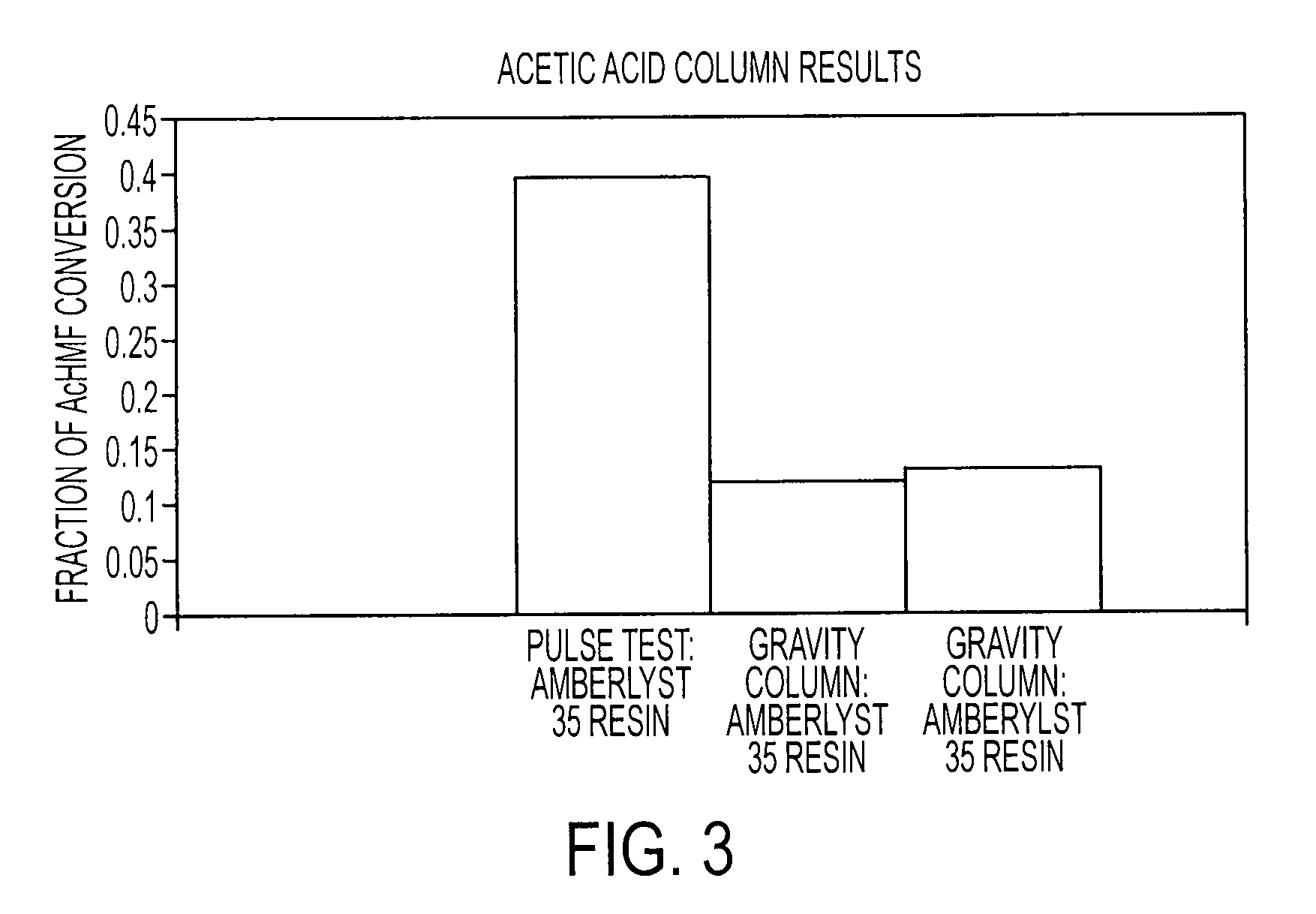

InactiveUS20090156841A1Increase conversion rateStable formOrganic compound preparationCarboxylic compound preparationMANGANESE ACETATEFuran

A method of producing substantially pure HMF, HMF esters and other derivatives from a carbohydrate source by contacting the carbohydrate source with a solid phase catalyst. A carbohydrate starting material is heated in a solvent in a column and continuously flowed through a solid phase catalyst in the presence of an organic acid, or heated with the organic acid and a solid catalyst in solution to form a HMF ester. Heating without organic acid forms HMF. The resulting product is purified by filtration to remove the unreacted starting materials and catalyst. The HMF ester or a mixture of HMF and HMF ester may then be oxidized to 2,5-furandicarboxylic acid (FDCA) by combining the HMF ester with an organic acid, cobalt acetate, manganese acetate and sodium bromide under pressure. Alternatively, the HMF ester may be reduced to form a furan or tetrahydrofuran diol.

Owner:ARCHER DANIELS MIDLAND CO

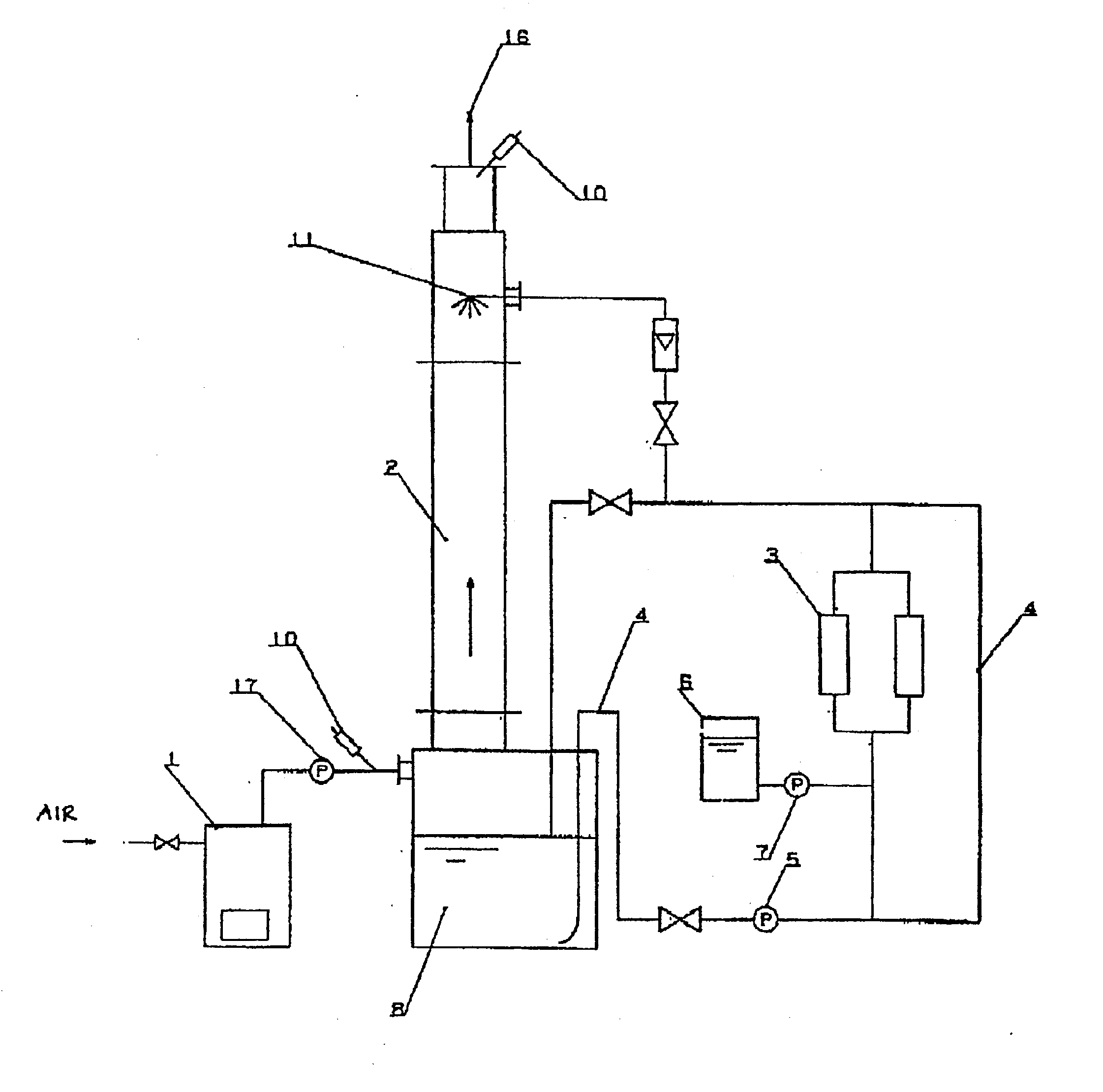

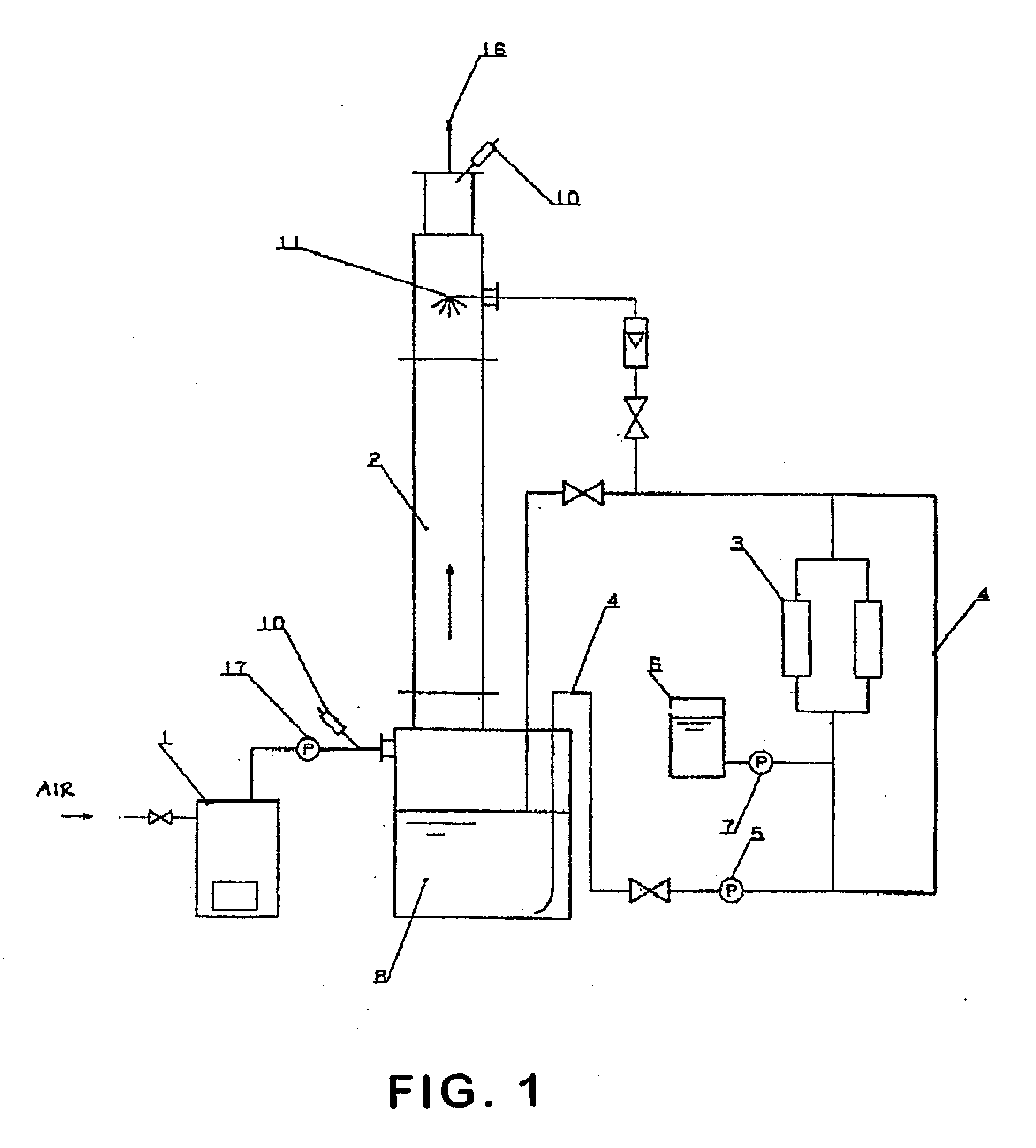

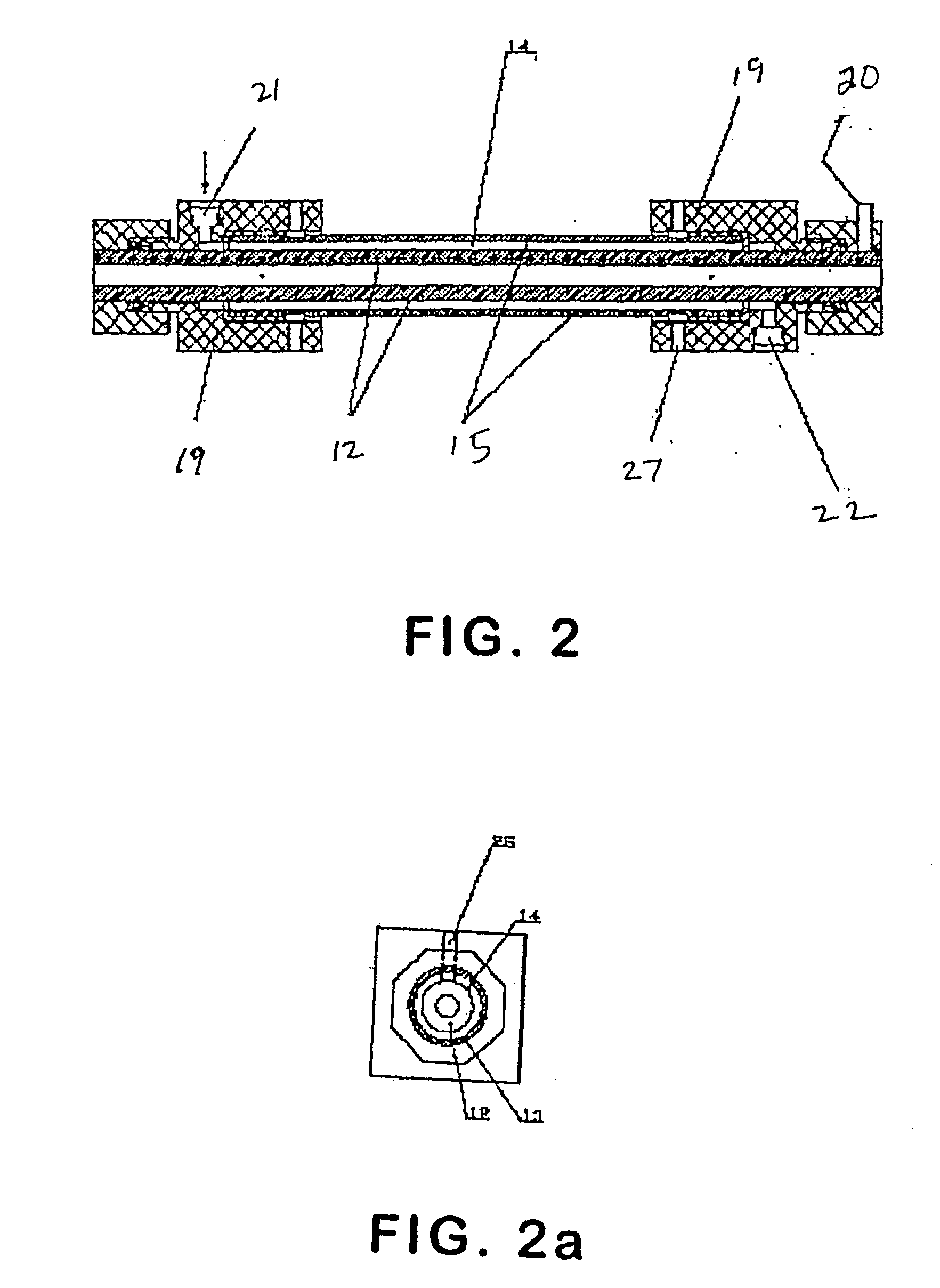

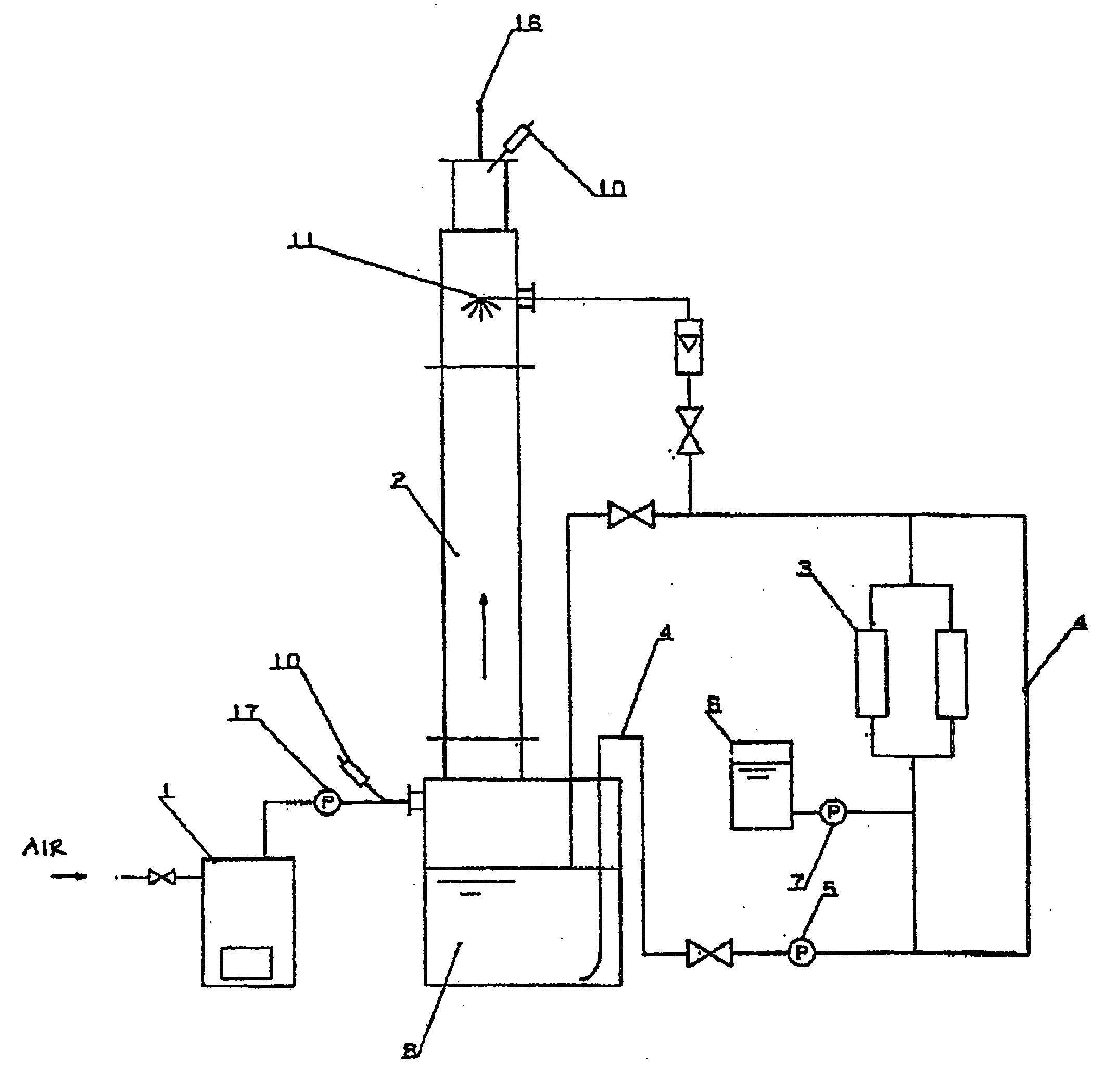

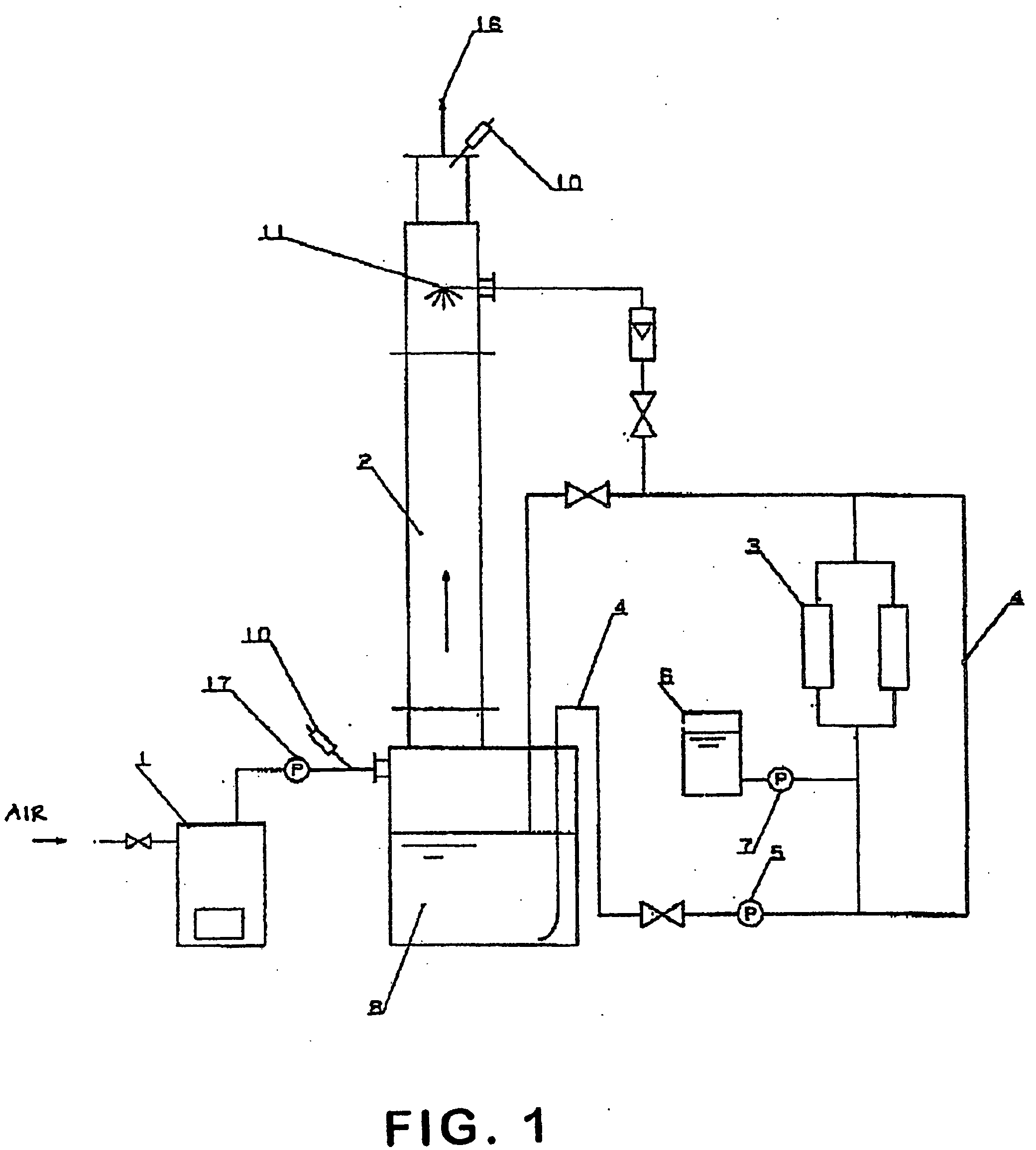

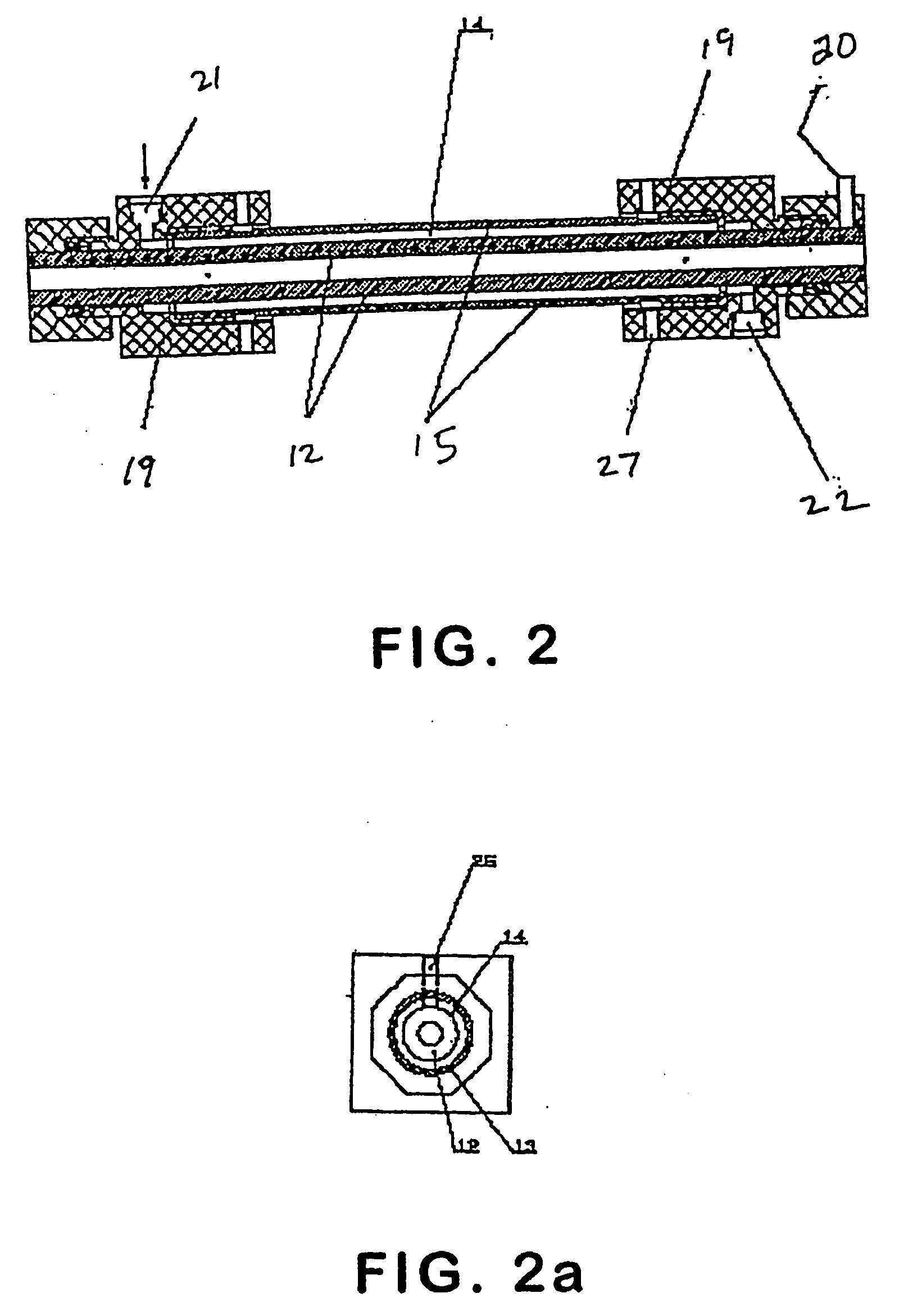

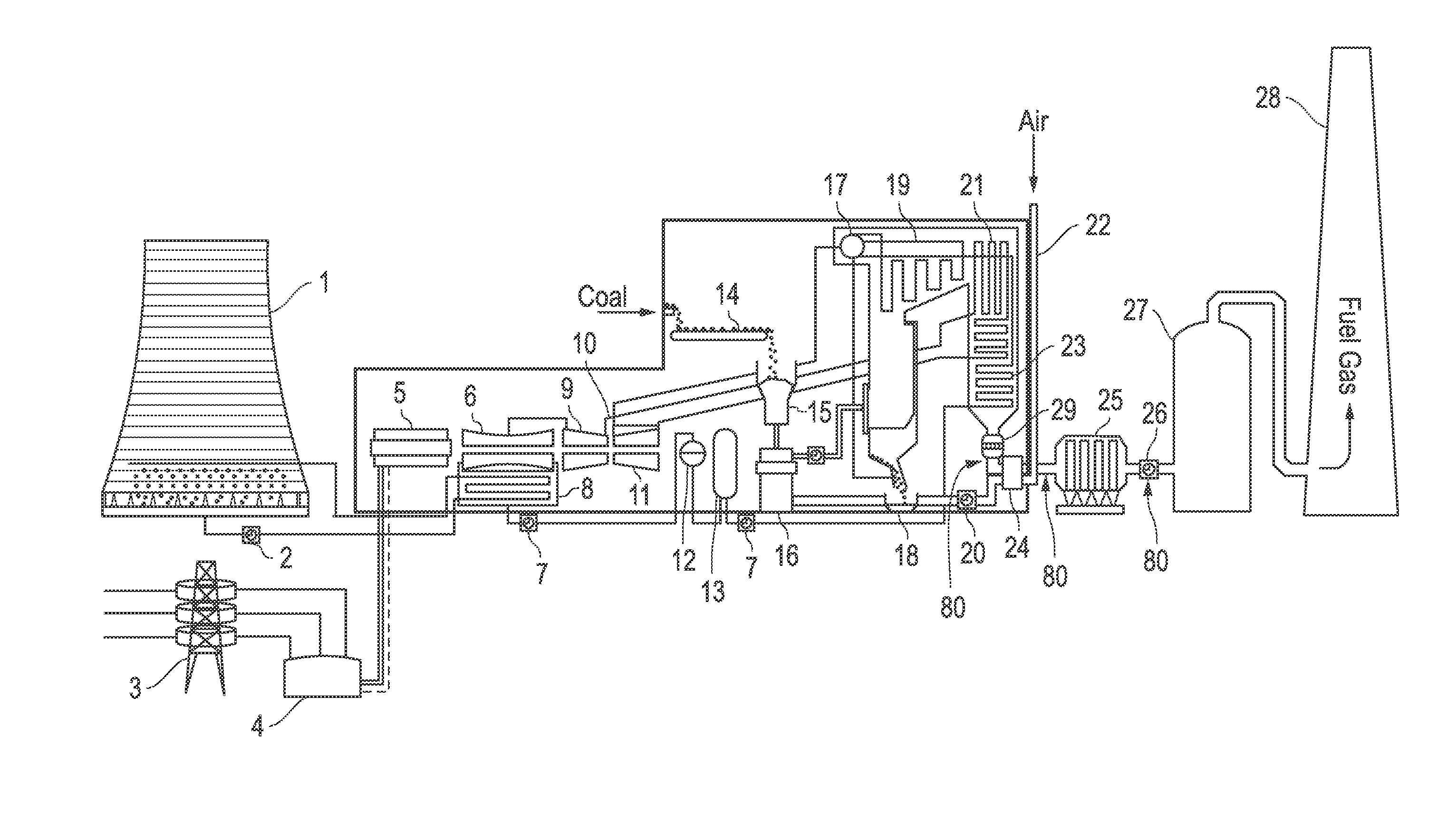

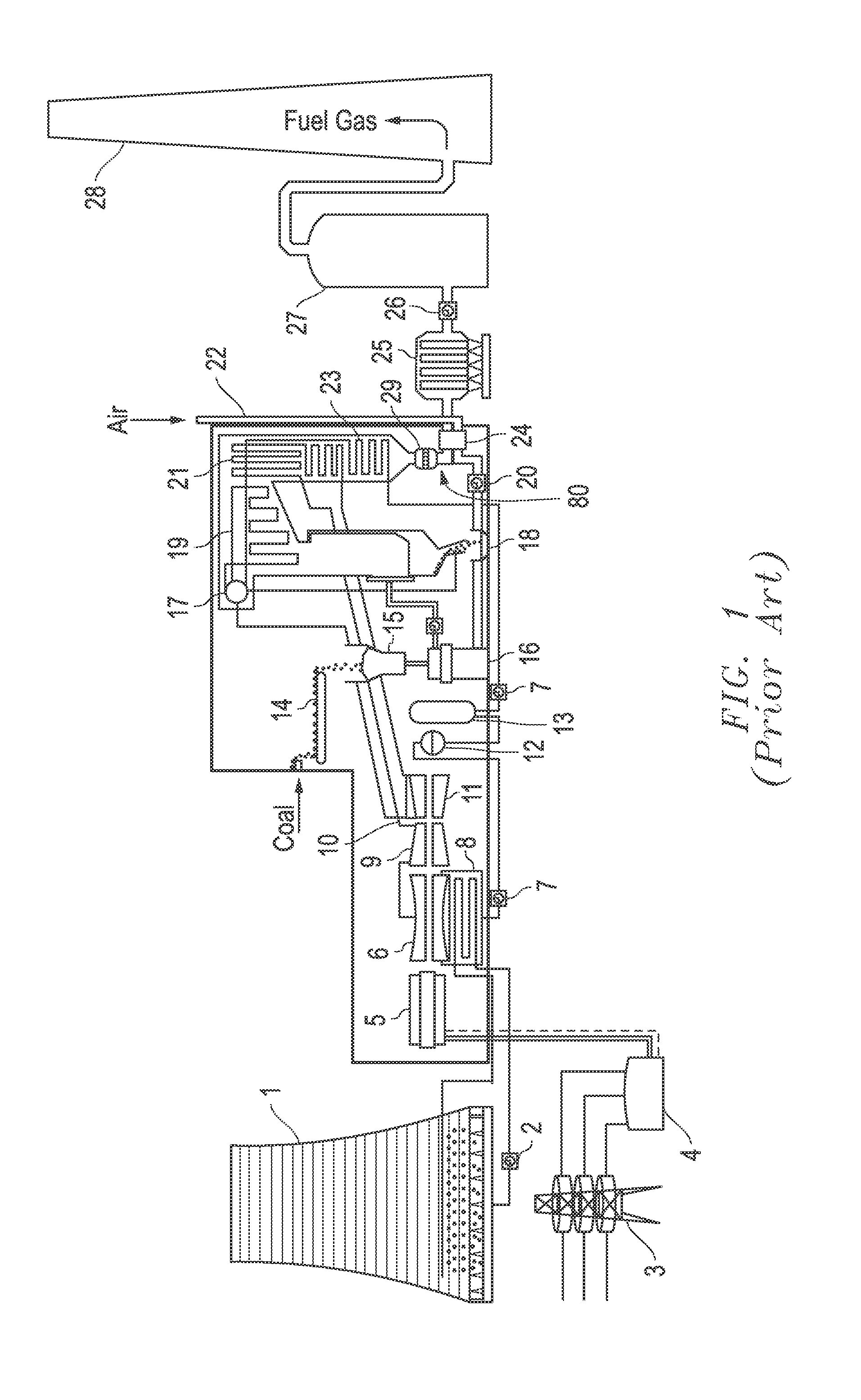

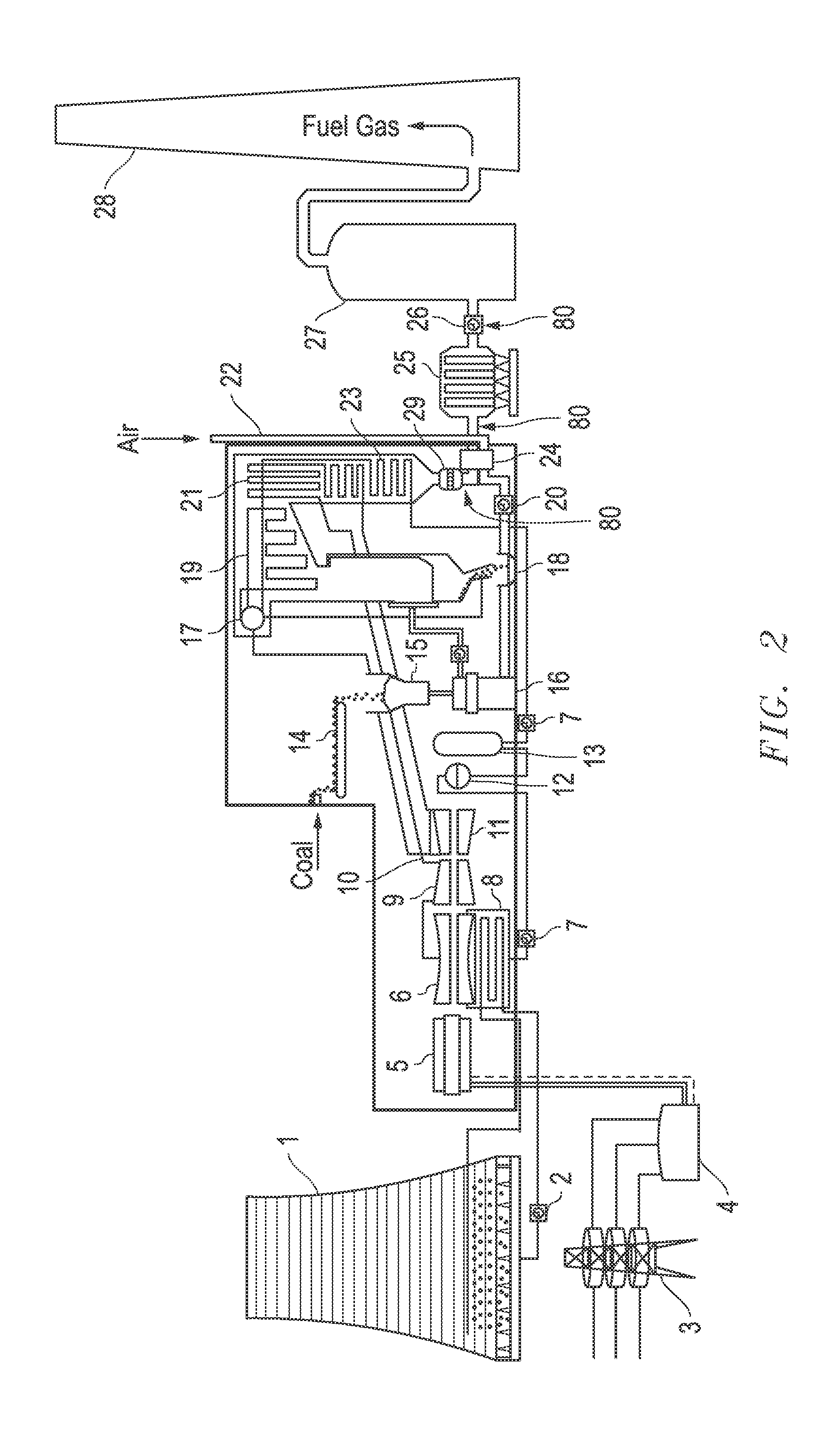

Method and device for deodorization and purification of exhaust gas or flue gas

InactiveUS20030164309A1Easy can be electrolyzedHigh densityCyanogen compoundsLighting and heating apparatusHazardous substancePotassium hydroxide

A method and device for removing, deodorizing and purifying odor, smoke and harmful substances from exhaust gas or flue gas employs a water solution containing hypohalogen acid such as hypochlorous acid soda, an alkaline electrolyte such as potassium hydroxide or sodium hydroxide and a saline electrolyte such as sodium chloride, potassium chloride, sodium bromide or potassium bromide which is electrolyzed to produce an electrolytic water solution which is fed to a deodorizing tower and brought into contact with exhaust gas or flue gas to remove odor, smoke and harmful substances in the exhaust gas or flue gas.

Owner:OMEGA CO LTD

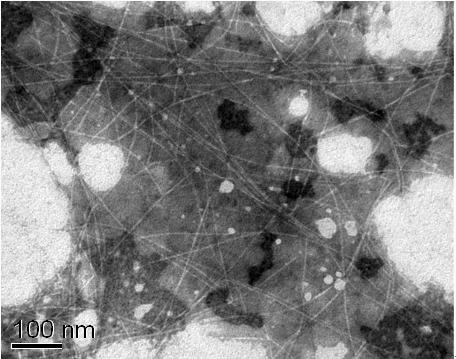

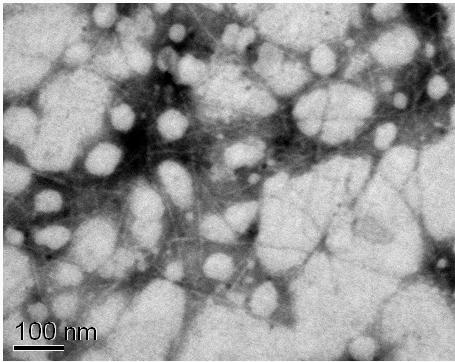

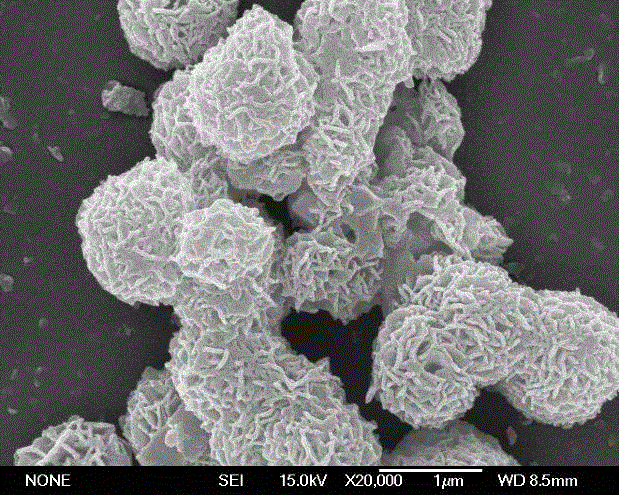

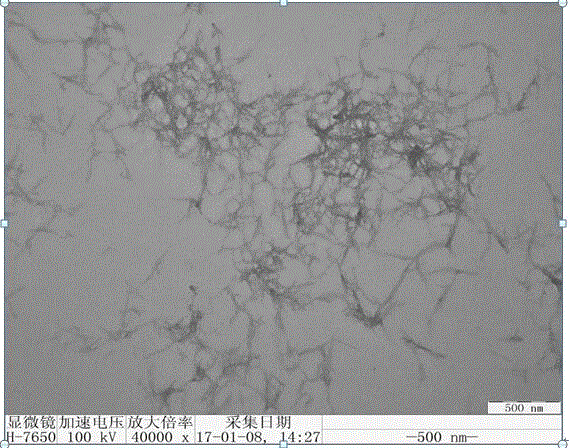

Preparation method of homogenized fine nano-cellulose fiber

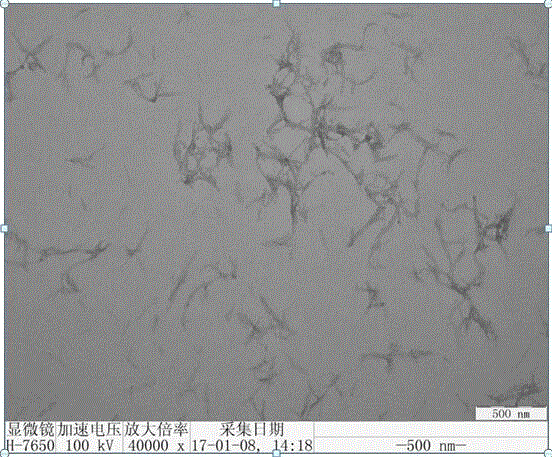

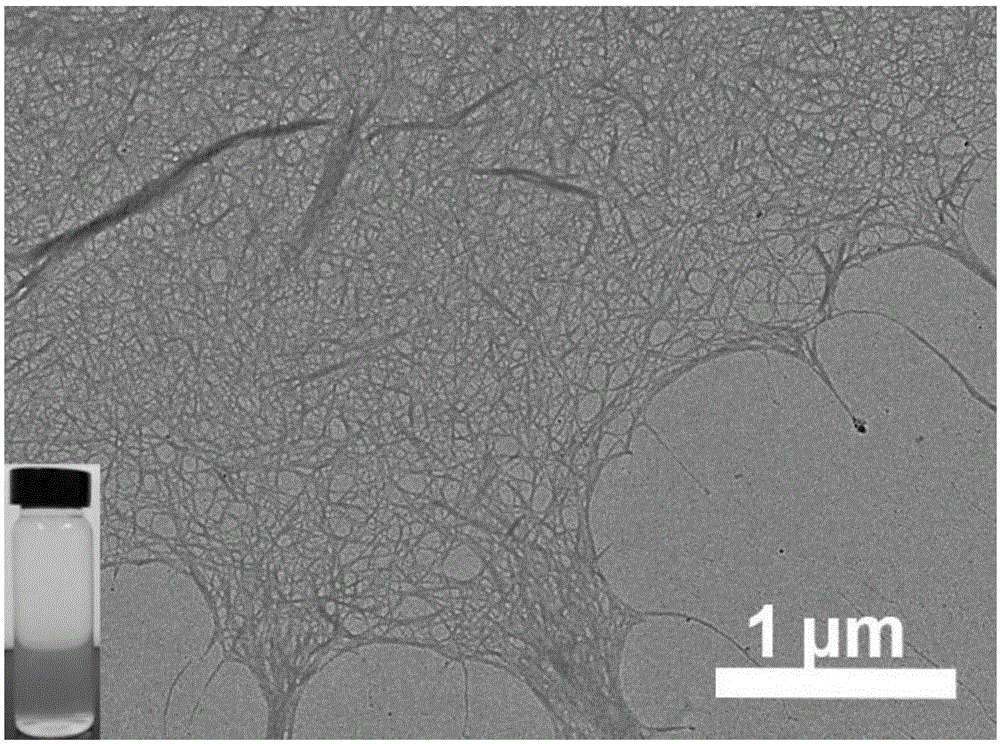

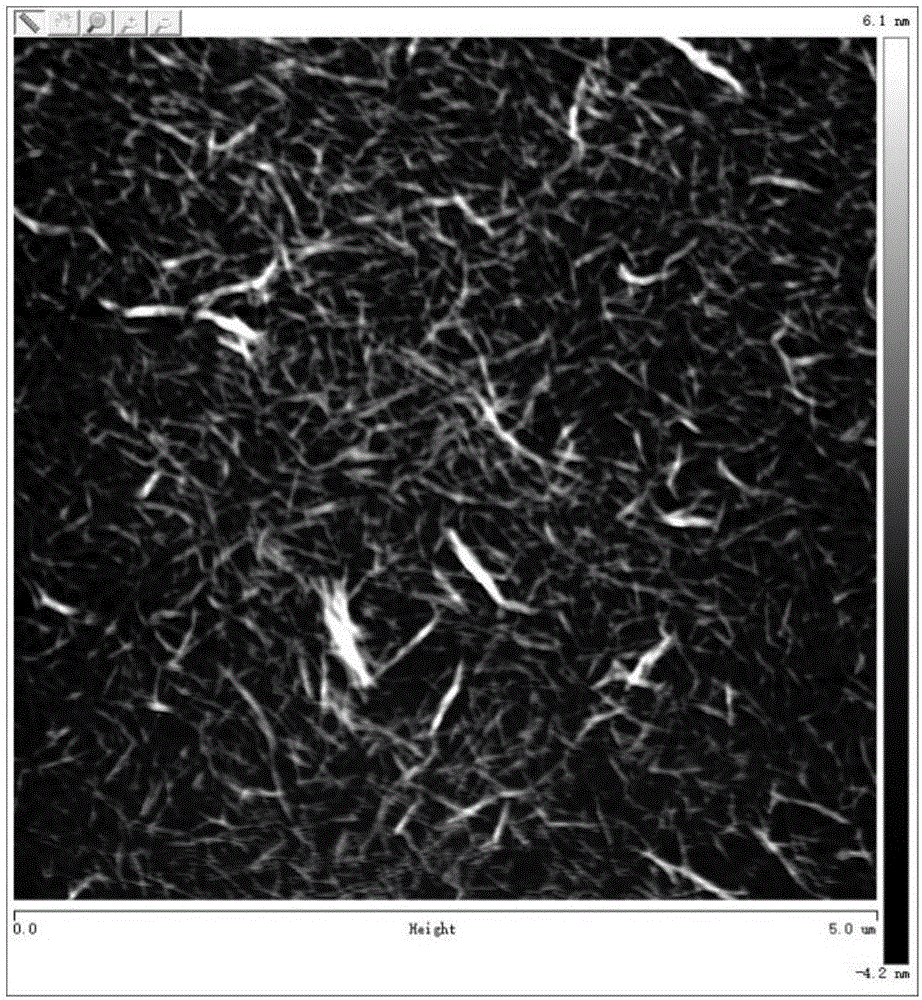

InactiveCN101851295ALow degree of mutual aggregationEvenly dispersedArtificial filaments from cellulose solutionsStrong acidsCatalytic oxidation

The invention relates to a preparation method of a homogenized fine nano-cellulose fiber. The preparation method can solve the problems of uniform diameter distributor of biomass nano-cellulose prepared by the existing strong acid hydrolysis method and the high-strength mechanical shearing method, easy gathering among the nano-fiber and a narrow range of applications of the TEMPO catalytic oxidation method. The preparation method comprises the following steps: 1) extracting biomass fiber with benzyl alcohol solution; 2) carrying out treatment by using acidified sodium chlorite; 3) carrying out gradient treatment with alkaline liquor; 4) using TEMPO, sodium bromide and sodium hypochlorite for catalytic oxidation treatment; 5) using sodium chlorite for treatment; and 6) carrying out nano-scale processing by using the long-term stirring method, the ultrasonic method or the high-pressure homogenization method, drying, and then obtaining the homogenized fine nano-cellulose fiber. The fiber has the uniform diameter distribution, the diameter is 3-5nm, the length-diameter ratio is not less than 500, the fiber is mutually interwoven into a mesh snarling structure, and the method is applicable to preparing the nano-cellulose fiber by using wood pulp, paper-making pulp, wood, bamboo and crop straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method and device for deodorization and purification of exhaust gas or flue gas

InactiveUS20060124444A1Reduce needRemove films of protein oil and fatsLighting and heating apparatusExhaust apparatusElectrolysisHazardous substance

A method and device for removing, deodorizing and purifying odor, smoke and harmful substances from exhaust gas or flue gas employs a water solution containing hypohalogenous acid compounds such as sodium hypochlorite, an alkaline electrolyte such as potassium hydroxide or sodium hydroxide and a saline electrolyte such as sodium chloride, potassium chloride, sodium bromide or potassium bromide which is electrolyzed to produce an electrolytic water solution which is fed to a deodorizing tower and brought into contact with exhaust gas or flue gas to remove odor, smoke and harmful substances in the exhaust gas or flue gas.

Owner:NAKAMURA SHINICHI +2

Oxidation nanocellulose adsorbing material and preparation method thereof

ActiveCN105498733AMicroscale reductionImprove accessibilityOther chemical processesSorbentCatalytic effect

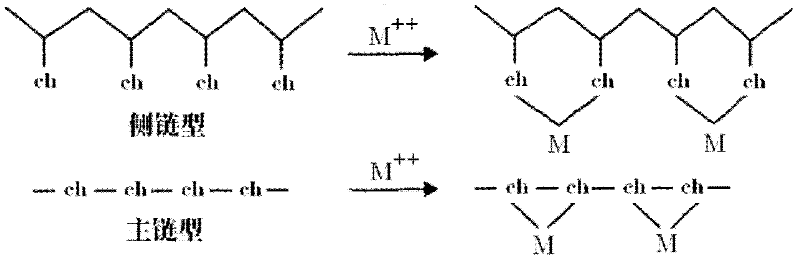

The invention provides a preparation method of an oxidation nanocellulose adsorbing material. The preparation method comprises the following steps of conducting pretreatment and then cleaning cellulose; and under the catalytic action of 2, 2, 6, 6-tetramethyl piperidine-nitrogen-oxide and sodium bromide, conducting an oxidation reaction on obtain cellulose under the action of an oxidizing agent, so that oxidation nanocellulose is obtained, wherein sodium hypochlorite serves as the oxidizing agent; mixing the nanocellulose with an organic solution containing amino high molecules, then conducting centrifugation, then mixing the mixture with a cross-linking agent, and conducting a reaction, so that the oxidation nanocellulose adsorbing material is obtained. By means of the preparation method, the specific surface area of the cellulose is increased, the contactable performance of heavy metal pollutants and adsorbent is improved, the surface of the material can have a large number of adsorption functional groups, and heavy metal ions can be aggregated to the surface of the adsorbent from a sewage system through the complexation effect and the electrostatic effect. The invention further provides the oxidation nanocellulose adsorbing material.

Owner:UNIV OF SCI & TECH OF CHINA

Method and test strip of detecting oxidizing adulterant in urine

A single reagent system and a method to detect and measure oxidizing adulterants in bodily fluid being screened for drugs of abuse are disclosed. The system comprising a strip containing 0.05 to 0.2 micromole / 25 sq. mm. of a benzidine derivative and is used to detect sodium hypochlorite (bleach), chlorine, hydrogen peroxide, sodium bromide, sodium iodide, sodium nitrite, and pyridinium chlorochromate adulterants in urine, sweat, saliva, blood or other bodily fluids during screening for drugs of abuse.

Owner:BRANAN MEDICAL

Preparation method of nano-cellulose

The invention discloses a preparation method of nano-cellulose, comprising the following steps of: firstly, swelling the raw material cellulose by aqueous alkali, soaking for a while, centrifugally separating out cellulose, and washing by deionized water till the filter liquor is neutral; dispersing the separated cellulose in water, adding sodium bromide, 2, 2, 6, 6-tetramethyl piperidine-1-oxide and sodium hypochlorite solution, carrying out an oxidation reaction under sonic oscillation, centrifugally separating after reaction, and carrying out freeze drying treatment on suspension liquid to obtain the nano-cellulose powder. Compared with the prior art, the preparation method is incompact in cellulose structure, can enlarge the unit cell distance, and can improve the reaction accessibility after the raw material cellulose is pretreated, so that the oxidation reaction efficiency can be improved, and the product yield can be obviously improved; the oxidation reaction conditions are mild, and are easy to control, and the product quality can not be influenced due to the fact that only a small quantity of sodium chloride and minute quantity of oxidizing agent are mixed in a reaction system after the reaction; and the sonic oscillation is adopted in the process of reaction, so that the oxidation reaction speed can be accelerated, and the reaction time can be obviously shortened.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

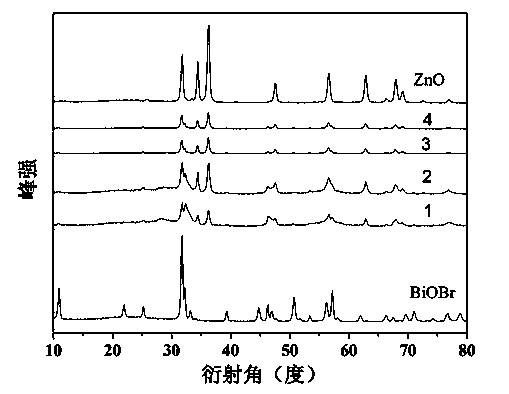

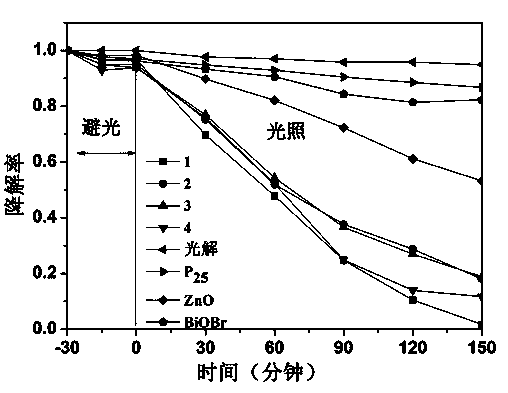

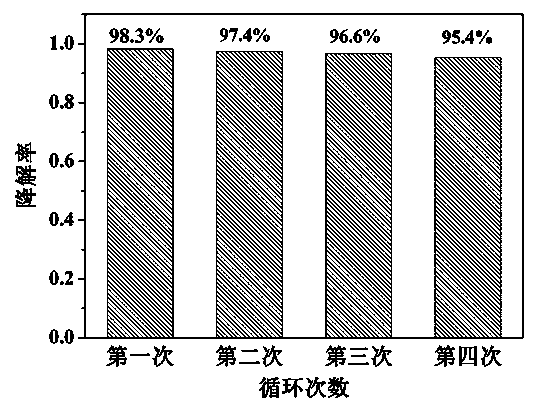

Preparation method of BiOBr/ZnO nano photocatalyst powder

InactiveCN103464184AHigh reuse ratePromote degradationPhysical/chemical process catalystsBismuth compoundPhysical chemistry

The invention discloses a preparation method of BiOBr / ZnO nano photocatalyst powder, belonging to the field of nano photocatalyst preparation. The method is characterized by comprising the steps of adding two bromine compounds CTAB (cetyl trimethyl ammonium bromide) and potassium bromide or sodium bromide at a proper proportion and a zinc-containing compound into an ethanol solvent, adding a bismuth-containing compound, and uniformly mixing; transferring the solution into a Teflon high-pressure reaction kettle, and performing a solvothermal reaction at certain temperature to generate precipitates; washing the precipitates with water and ethanol, and drying at 80 DEG C to obtain novel efficient BiOBr / ZnO nano photocatalyst powder. The method disclosed by the invention is quick, simple, convenient and high in operability, and the prepared BiOBr / ZnO heterojunction nano photocatalyst powder has perfect photocatalytic degradation efficiency on organic pollutants as well as good reusability.

Owner:TAIYUAN UNIV OF TECH

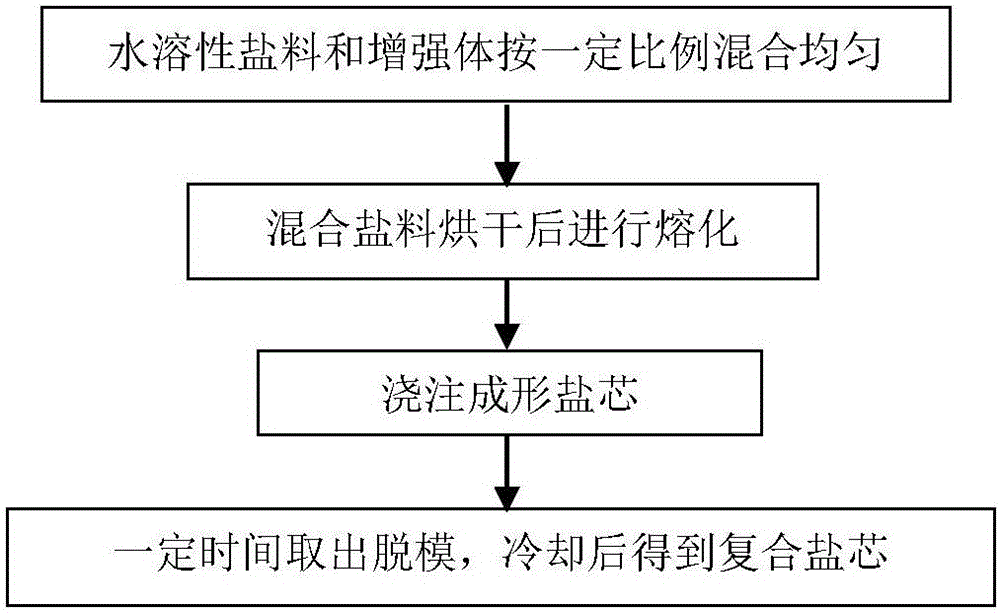

High-strength composite salt core material for low-melting-point alloy casting, salt core and preparation method

ActiveCN106670376AImprove flexural strengthReduce energy consumptionFoundry mouldsFoundry coresAlloySodium nitrate

The invention belongs to the technical field of casting, and particularly relates to a high-strength composite salt core material for low-melting-point alloy casting. The high-strength composite salt core material comprises, by mass, 70%-100% of water-soluble inorganic salt and 0%-30% of a reinforcement, wherein the water-soluble inorganic salt comprises one of low-melting-point salts including potassium nitrate and sodium nitrate, and at least one of high-melting-point salts including potassium chloride, sodium chloride, potassium bromide and sodium bromide, and positive ions of the low-melting-point slats are the same as positive ions of the high-melting-point salts. The invention further discloses a preparation method of a high-strength composite salt core, and an obtained salt core product. The prepared composite salt core has extremely high bending strength, excellent hygroscopicity and small volume shrinkage, and the comprehensive performance is excellent. In addition, the preparation technique of the high-strength composite salt core is simple, raw materials are cheap, and industrial production is easy.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and system for removal of mercury from a flue gas

Processes and methods exist for decreasing emissions of mercury upon combustion of fossil fuels such as coal. Halide salts can be effective when used at locations where they are thermally decomposed to form reactive halogen species, or in combination with an adsorbent material such as activated carbon. Halide salts, such as calcium bromide and sodium bromide, are not typically used at locations downstream of the economizer, where the temperature is typically below around 500° C., because these salts are non-thermolabile and do not decompose to produce reactive halogen species. However, in flue gas streams that certain flue gas constituents, such as sulfur trioxide or sulfuric acid, reactive halogen species can be produced via chemical reaction. These species react with elemental mercury through various means to form an oxidized form of mercury that is more easily captured in downstream pollution control devices such as particulate control devices or SO2 scrubbers.

Owner:URS

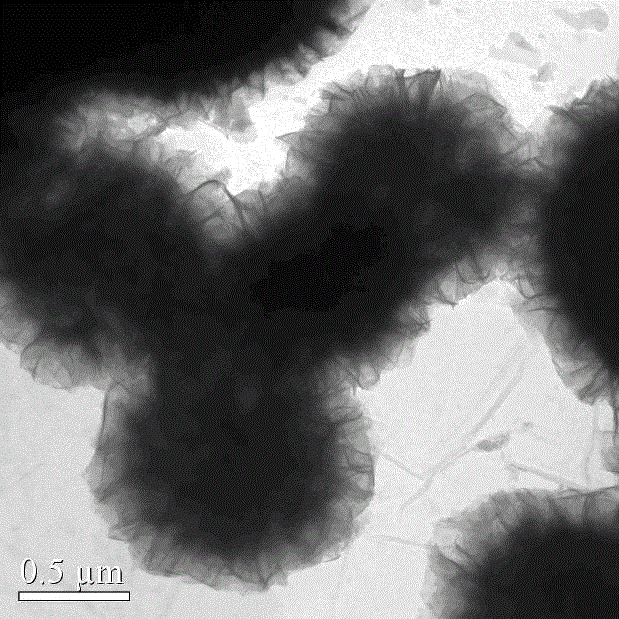

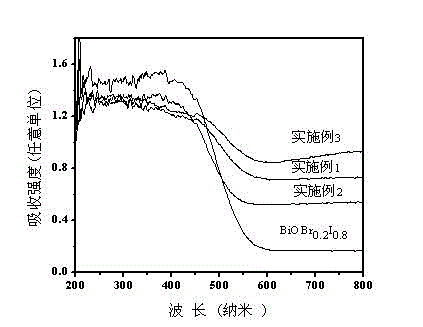

BiOBr0.2I0.8/graphene composite visible-light-induced photocatalyst and preparation method thereof

InactiveCN103182315ASimple preparation processThe preparation process is economical and environmentally friendlyPhysical/chemical process catalystsMicrosphereGraphene flake

The invention relates to a BiOBr0.2I0.8 / graphene composite visible-light-induced photocatalyst and a preparation method thereof and belongs to the field of photocatalysis technology. BiOBr0.2I0.8 is microspheres composed of a large quantity of nanoflakes; the microspheres are 1.0 mum in diameter and are uniformly distributed on graphene flakes; and the mass percent of graphene is 5.0-15.0%. Firstly, graphite oxide is ultrasonically dispersed in absolute ethyl alcohol to obtain a suspension of graphene oxide; secondly, while stirring, adding the suspension of graphene oxide to a certain amount of ethylene glycol solution of sodium bromide, potassium iodide and bismuth nitrate; thirdly, the suspension of graphene oxide is transferred into a high pressure reactor with a polytetrafluoroethylene liner to be subjected to crystallization reaction for 12-16 h at 160-180 degrees; and finally, the obtained solid product is filtered, washed and dried to obtain the BiOBr0.2I0.8 / graphene composite visible-light-induced photocatalyst.

Owner:SHANGHAI UNIV

Eco-friendly method of preparation of high purity tetrabromobisphenol-A

InactiveUS6365786B1High yieldMost efficientOrganic chemistryOrganic compound preparationTetrabromobisphenol AOrganic layer

A highly pure and colorless tetrabromobisphenol-A (TBBPA) possessing melting point in the range of 178-182° C. is prepared in yields of 50-70% in first batch and 90-100% when the spent organic layer is recycled. In this method, the corrosive liquid bromine is displaced by sodium bromide / hydrobromic acid as brominating agent. Further, sodium bromate is used as an oxidizing as well as brominating agent to utilize the hydrobromic acid that is produced during the bromination of bisphenol-A (BPA). The reaction is conducted at 10-15° C. in a mixture of methylene chloride-water or carbon tetrachloride-water in the presence of hydrochloric acid and sodium lauryl sulfate. The crystalline product settled at the bottom of the reaction vessel is filtered, washed, dried and weighed. The spent organic layer is recycled in subsequent batches to maximize the overall yield of product recovered directly as solid and to minimize generation of organic effluent.

Owner:COUNCIL OF SCI & IND RES

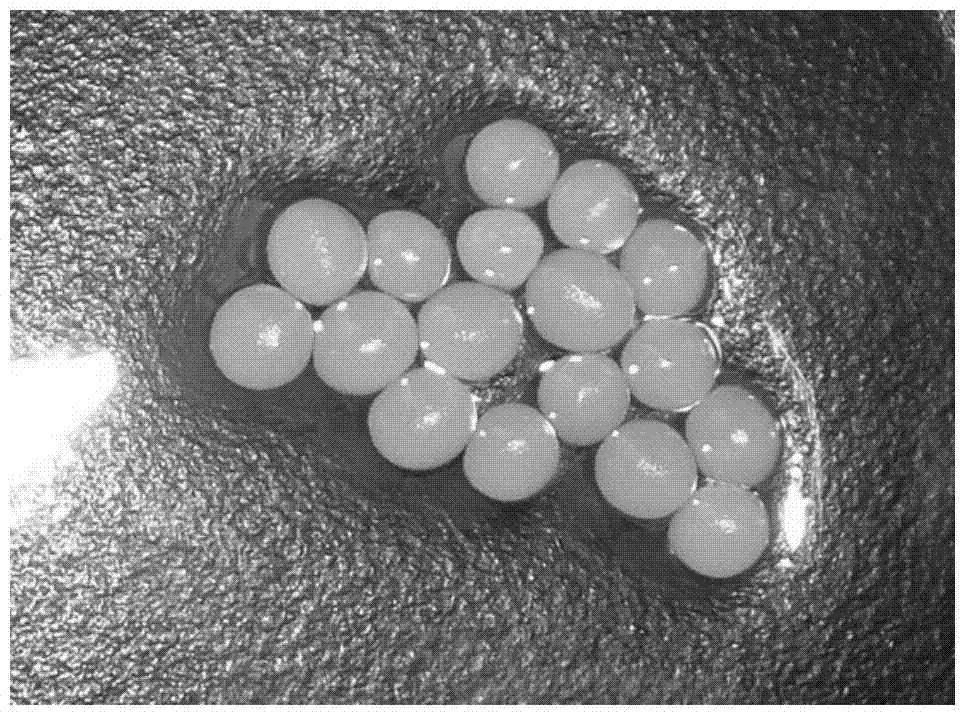

Method for preparing regenerated cellulose spherical aerogel modified through carboxylation

InactiveCN103570967AImprove permeabilityAvoid gatheringOther chemical processesChemical recyclingFreeze-dryingSolvent

The invention relates to a method for preparing regenerated cellulose spherical aerogel modified through carboxylation, which aims at the problem of poor adsorptive property of the cellulose aerogel prepared by the existing methods. The method comprises steps of firstly, mixing sodium hydroxide, urea and deionized water, then adding into a cellulose raw material, preparing a cellulose solution, adding the cellulose solution into a regeneration solution for solidifying, washing and obtaining spherical hydrogel; and secondly, dissolving TEMPO (tetramethyl-piperidin-1-oxyl) and sodium bromide into deionized water, adding the spherical hydrogel, then adding a sodium hypochlorite solution, regulating pH value of a system through a sodium hydroxide solution, steeping, exchanging the collected solid phase objects sequentially through absolute ethyl alcohol and a tertiary butanol solvent, then cooling, finally, freeze drying so as to finish preparing the cellulose spherical aerogel. The largest capacity of the obtained spherical aerogel in adsorbing metal ions Cu<2+> reaches 0.55m mol / g, and the adsorptive property is good.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Mineral dressing additive for gold mine and preparation method thereof

The invention discloses a mineral dressing additive for a gold mine, which is prepared by taking inorganic substances as raw materials, and reacting at high temperature of 600-950 DEG C for 1-3 hours and pulverizing. The mineral dressing additive for a gold mine comprises the following components in parts by weight: 20-50 parts of urea, 5-10 parts of sodium hexametaphosphate, 5-10 parts of sodium sulfide, 0-10 parts of sodium bromide, 0-30 parts of sodium ferrocyanide, 20-50 parts of soda and 5-10 parts of sodium hydroxide. The product is free of virulent compounds, can not injure human and animals during production and use, can not cause significant pollution, and is environment-friendly. Proven by industrial trial, the product has the advantages of better mineral dressing effect, high recovery rate, simple production method, short process flow, easy technological operation, abundant and cheap raw materials for production, low production cost and better economic benefit and social benefit.

Owner:GUANGXI SENHE HIGH TECH CO LTD

Antifoaming agent

InactiveCN103127748AFast defoamingEnhanced inhibitory effectFoam dispersion/preventionPotassium iodinePhenol

The invention discloses an antifoaming agent which comprises, by weight, the following raw materials: 1 part to 3 parts of potassium iodide, 2 parts to 5 parts of boric acid, 1 part to 4 parts of sodium bromide, 2 parts to 4 parts of calcium stearate, 4 parts to 8 parts of nonyl phenol polyoxyethylene ether, 2 parts to 6 parts of tetrabutyl phosphorus bromide, 1 part to 5 parts of benzyl triphenyl phosphorus bromide, 3 parts to 6 parts of isoamylene alcohol, 4 parts to 7 parts of tert-amyl chloride, 1 part to 2 parts of trifluoroacetylacetone and 3 parts to 9 parts of simethicone. The antifoaming agent is rapid in antifoaming and good in inhibition performance, and does not affect basic property of a foaming system. Meanwhile, the antifoaming agent is good in diffusivity and permeability, stable in chemical property, free from corrosion, toxicity and adverse side effect and high in safety.

Owner:NANTONG HAISHUN CHEM

Brominated styrene/butadiene copolymer fire retardant and bromination method thereof

InactiveCN104327214AEffect on mechanical propertiesImprove flame retardant performancePtru catalystButadiene Dioxide

The invention provides a brominated styrene / butadiene copolymer fire retardant and a bromination method thereof. The copolymer of the fire retardant is formed by polymerizing a brominated styrene monomer and a butadiene monomer. In the brominated styrene / butadiene copolymer, the brominated aryl of styrene comprises 2-bromostyrene, 4-bromostyrene and 2,4-dibromostyrene. A preparation method comprises the following steps: (1) selecting the following raw materials: a styrene / butadiene copolymer (shortened as SBS), sodium bromide of which the content is 98%-99%, chlorine gas of which the content is higher than 99% and isobutyl alcohol of which the content is higher than 99%; (2) adding the SBS in an enamel reactor and dissolving the SBS in a heating manner by using isobutyl alcohol; (3) adding a sodium bromide solution, introducing an oxidant, stirring during a reaction process, and absorbing unreacted oxidant by using lime milk at the tail part of the reactor; (4) afterwards cooling to room temperature, adding a catalyst and continuing to stir and heat; (5) filtering after cooling to room temperature to obtain a target product brominated styrene / butadiene polymer.

Owner:青岛方泰克新材料有限公司 +2

Paper for painting and calligraphy and manufacturing process of paper for painting and calligraphy

ActiveCN106283837AWith flame retardant effectImprove waterproof performanceOrganic non-cellulose fibresWater-repelling agents additionHigh volume manufacturingPolyvinyl alcohol

The invention provides paper for painting and calligraphy. The paper for painting and calligraphy is prepared from, by weight, 10-30 parts of bamboo pulp, 50-80 parts of herba junci setchuensis pulp, 5-20 parts of wood pulp, 5-15 parts of water-soluble polyvinyl alcohol fibers, 5-20 parts of silk, 0.01-1 part of starch adhesive and 0.001-0.5 part of a waterproof agent. The starch adhesion is prepared from starch, carbamido resin, sodium bromide, ammonium chloride and water. The invention further discloses a manufacturing process of the paper for painting and calligraphy. By addition of the starch adhesive according to a specific formulation, the paper for painting and calligraphy has flame-retardant and fireproof effects; due to addition of the silk, light weight, thinness and softness of the paper are achieved; by spraying of the waterproof agent, water resistance of the paper is improved. The manufacturing process is suitable for large-batch production, and operation efficiency is improved.

Owner:ZHEJIANG VOCATIONAL COLLEGE OF COMMERCE

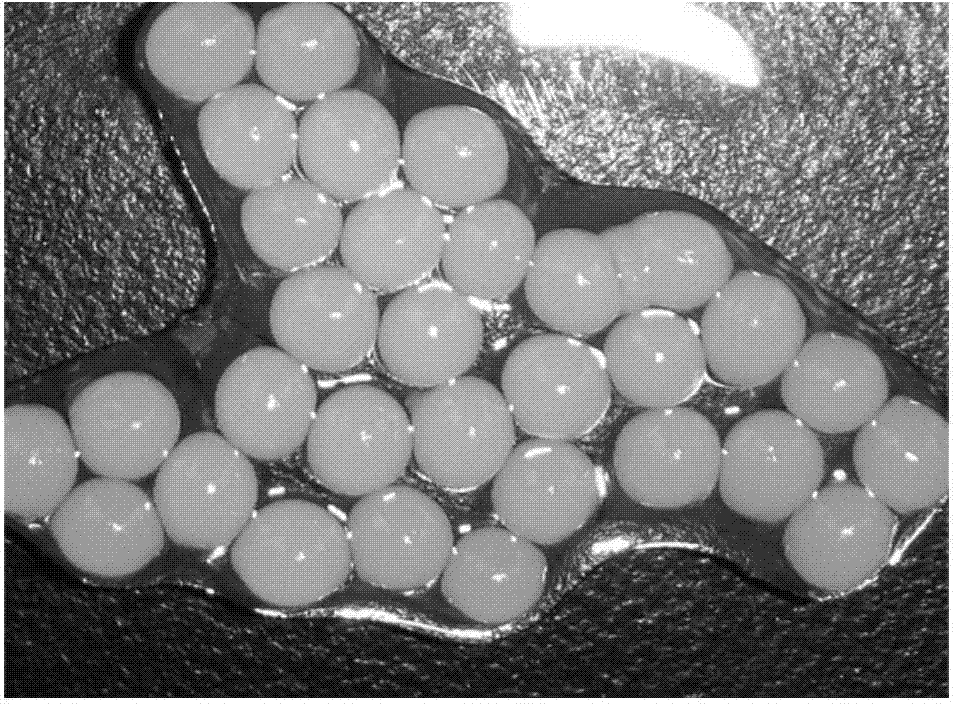

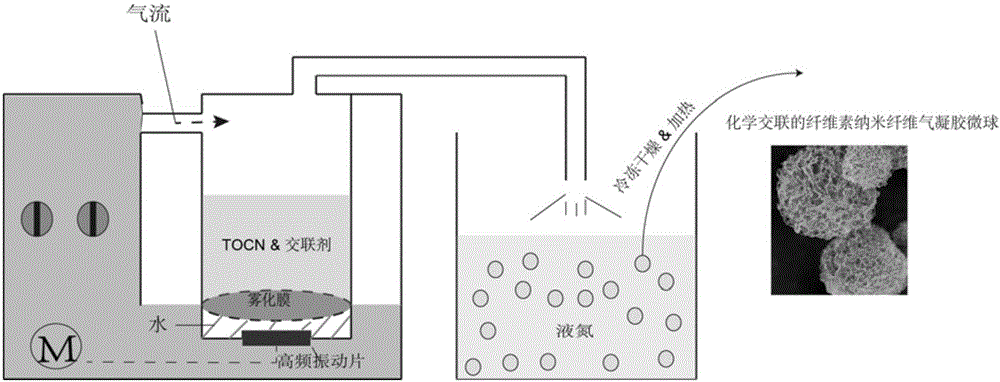

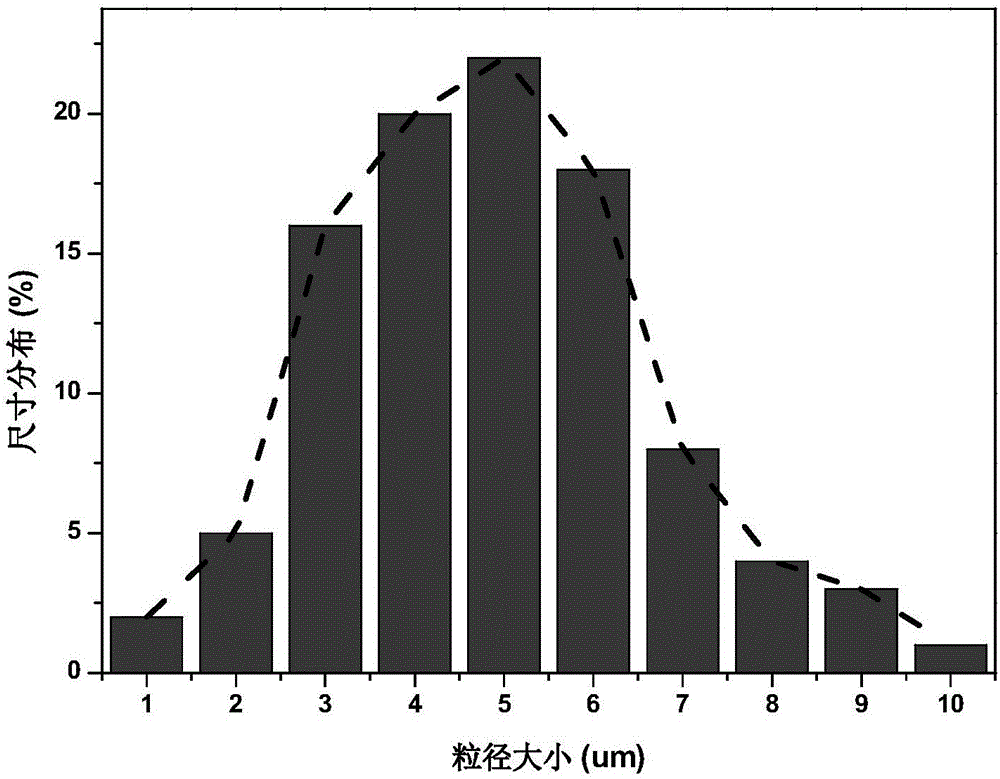

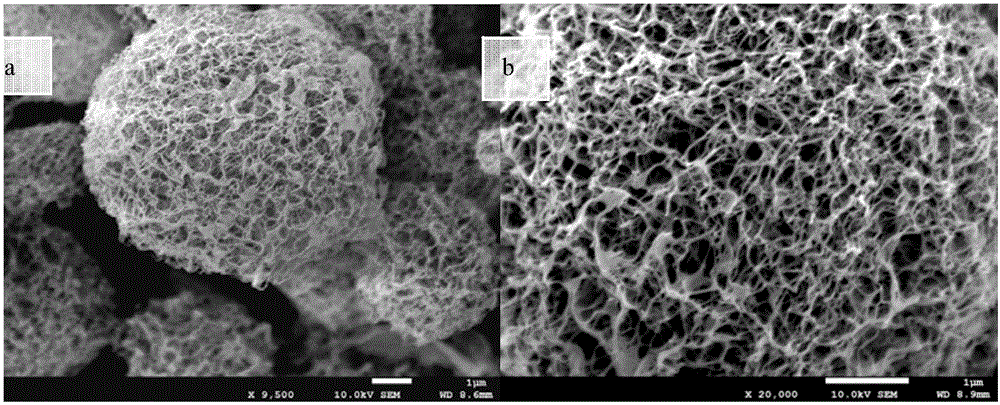

Technique for preparing cellulose nano fiber aerogel microspheres by ultrasonic atomization

The invention discloses a technique for preparing cellulose nano fiber aerogel microspheres by ultrasonic atomization. The technique comprises the following steps: defibering bleached coniferous wood sheet pulp, adding tetramethyl piperidine oxide, sodium hypochlorite and sodium bromide, and carrying out oxidation reaction for 2-4 hours under the pH value of 9.5-11; carrying out ultrasonic dissociation on the oxidated pulp to prepare a cellulose nano fiber suspension; and adding a crosslinking agent into the cellulose nano fiber suspension, pouring into an atomization cup of an ultrasonic atomizer, blowing the atomized oxidated nano cellulose fog drops containing the crosslinking agent and tetramethyl piperidine oxide into a liquid-nitrogen-filled container, carrying out freeze-drying on fast-frozen ice microspheres, and finally, carrying out crosslinking reaction on the dried aerogel microspheres at 110-130 DEG C for 2-4 hours, thereby obtaining the cellulose nano fiber aerogel microspheres.

Owner:LIANSHENG PAPER IND LONGHAI

Method for preparing nano-crystalline cellulose by multi-site oxidation method, and application thereof

ActiveCN106758492AEliminates mechanical defibrillation stepReduce energy costsCellulose pulp after-treatment modificationFiberMulti site

The invention relates to a method for preparing nano-crystalline cellulose by a multi-site oxidation method. The method comprises the following steps: adding cellulose raw materials into reaction liquid, continuously stirring and reacting for 4.5-18.0 hours under a specific pH (Potential of Hydrogen) value; terminating reaction by absolute ethyl alcohol; carrying out centrifugation, precipitant sedimentation, cleaning solution washing and filter membrane suction filtration on a reaction product to obtain the nano-crystalline cellulose, wherein the reaction liquid is the mixture of TEMPO (2,2,6,6-Tetramethylpiperidinooxy), periodate, sodium bromide and sodium hypochlorite, oxidizing substances are TEMPO, periodate and sodium hypochlorite; the periodate selectively oxidizes C2 and C3 site hydroxyl, TEMPO selectively oxidizes a C6 site hydroxyl, and therefore, the method is called a multi-site oxidation method. The multi-site oxidization process of the method is finished in one step, processing time is short, and a technology is simple; oxidization and fiber separation processes are simultaneously carried out, a mechanical fiber separation step is not required, energy consumption is low, and a separation and purification method is simple and is suitable for industrial scale production. The prepared nano-crystalline cellulose has a wide application prospect in fields including nanocomposite materials, functional clothes, 3D printing and photoelectricity and the like.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for preparing AgBr/PANI/TiO2 nano composite material with visible light catalytic activity

InactiveCN101411995AEasy to makeVisible light catalytic effect is remarkableOrganic-compounds/hydrides/coordination-complexes catalystsIn situ polymerizationMicroparticle

The invention discloses a method for preparing an AgBr / PANI / TiO2 nanometer composite particle with catalytic activity of visible light and belongs to the technical field of new photocatalyst material. The photocatalyst prepared by the method has good effect of the photocatalytic degradation of organic pollutant under the visible light. The method comprises the following process: nanometer TiO2 is subjected to ultrasonic dispersion in deionized water; according to certain proportion, an aqueous silver nitrate solution and an aqueous sodium bromide solution are slowly dripped to a TiO2 suspending solution; after the solutions react for certain time, the prepared AgBr / PANI / TiO2 nanometer composite particle is separated; the composite particle, an aniline monomer and an oxidant solution are sequentially added into a hydrochloric acid solution while stirring at constant temperature; the surface of the composite particle is subjected to in-situ polymerization; and the reaction product is fully washed through hydrochloric acid, absolute ethyl alcohol and deionized water sequentially, is dried to constant weight and is ground to obtain the AgBr / PANI / TiO2 nanometer composite material. The method has the advantages that the preparation process is simple; and the AgBr / PANI / TiO2 nanometer composite particle has remarkable effect in the photocatalytic degradation of the organic pollutant under the visible light.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Nanometer bacteria cellulose aldehyde grouping modified method

InactiveCN101182561AHigh reactivityImprove adhesionMicroorganism based processesFermentationFiberCelsius Degree

The invention relates to a method for modifying nano-bacillus fibrin aldehyde group. The method takes the nano-bacillus fibrin as the basic raw material and the nano-bacillus fibrin is provided with a fine three-dimensional network structure; the diameter of micro-fiber is 3 to 10nm; the nano-bacillus fibrin is suspended in deionized water and oxidant is added into the deionized water; the oxidant is 2,2,6,6- Tetramethylpiperidinooxy, sodium bromide and sodium hypochlorite; the reaction is implemented for 20 to 40 min under an alkaline environment with a temperature of 20 to 30 Celsius degrees and the pH value of the alkaline solution is 10 to 12. The invention can prepare nano-bacillus fibrin which contains aldehyde group under very moderate conditions and can greatly enlarge the application field of the nano-bacillus fibrin.

Owner:TIANJIN UNIV

Modified lime sulphur and application thereof in gold leaching technology

ActiveCN103243222AReduce dosageImprove stabilityProcess efficiency improvementLead nitrateCalcium peroxide

The invention discloses a modified lime sulphur and an application thereof in a gold leaching technology. The modified lime sulphur comprises a stabilizer sodium-hexametaphosphate, oxidants-calcium peroxide and potassium cyanate, and additives-lead nitrate and soluble bromides (such as sodium bromide, potassium bromide, calcium bromide and the like). The modified lime sulphur is used as a gold leaching agent so as to effectively recover gold from gold-containing ores, gold concentrate powder and gold-containing wastes. The modified lime sulphur has the characteristics that the modified lime sulphur is easy to synthesize; the preparation cost is low; the preparation process is environment-friendly and toxic-free; and when the prepared modified lime sulphur is used for gold leaching, the gold leaching technology is simple, and the gold leaching velocity is high; and moreover, the modified lime sulphur is suitable for more ores than cyaniding gold leaching.

Owner:CENT SOUTH UNIV

Electrochemical synthesis method for tetra-n-butylammonium tribromide

InactiveCN101054680ANothing producedConvenient sourceElectrolysis componentsElectrolytic organic productionElectrolysisSynthesis methods

The present invention relates to an electrochemistry synthetic method of tetributyl tribromide of ammonium and belongs to the field of chemical formulation preparing technology. Sadi synthetic method in accordance with the present invention is as follow: dissolving tetrabutyl ammonium bromide in a aqueous solution of bromium salts such as ammonium bromide, potassium bromide or sodium bromide, magnetic-stirring it until reaching a entire solubilization, and then restirring it after adding organic solvent such as methylene dichloride or acetonitrile therein; putting the solution into an electrolytic tank of non-diaphragm type, selecting platinum meshwork as cathode and anode, inputting a constant electrical current for electroanalysis; electrolyzing for 3 hours under normal temperature and magnetic stirring to obtain tetributyl tribromide of ammonium in oil phase finally; washing the oil phase with distilled water, evaporating the organic solvent off and exposing it to air for a period of time, after the product solidifies, washing it with water, performing a recrystallization with methanol to obtain high-purity tetributyl tribromide of ammonium solid.

Owner:SHANGHAI UNIV

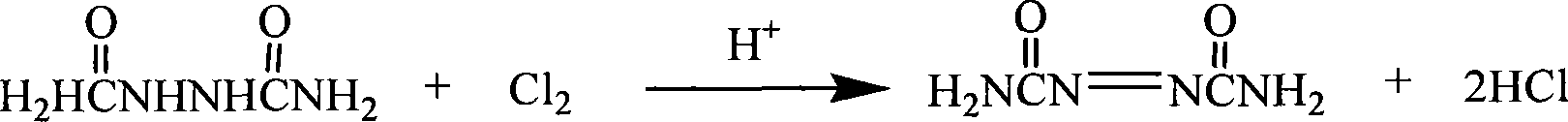

Method for recovery utilization of mother solution hydrochloric acid for ADC foaming agent production

ActiveCN101219974AAvoid degradationHigh yieldChlorine/hydrogen-chloride purificationOrganic chemistryBiureaHydrazine compound

The invention relates to a recycling and reusing method for producing an ADC foaming agent mother liquor hydrochloride, which includes the following steps: A) a hydrazine hydrate and a urea liquor carry out a concentration reaction by pumping a hydrogen chloride gas in or adding a sulfate; the hydrogen chloride gas is pumped in to control and maintain the pH value as 4 to 6 to generate a biurea and an ammonium salt; and a biurea solid and a corresponding ammonium salt mother liquor can be acquired after separation; B) the biurea is made into a suspension liquid of 10 to 40 percent and a sodium bromide which accounts for 0.2 to 1.0 percent of the amount of the biurea is added as a catalyzer to oxidize and generate the ADC foaming agent by pumping in an chlorine-oxygen, and then the ADC foaming agent and hydrochloride mother liquor can be gotten after separation; C) the separated hydrochloride mother liquor is added with an anhydrous magnesium chloride or a dihydrate magnesium chloride accounting for 20 to 40 percent of the amount of hydrochloride mother liquor feed rate, and then heated to distill a hydrogen chloride gas under the state of stirring; D) the distilled hydrogen chloride gas is returned to the biurea concentration technique to be used as the raw materials for neutralization . The beneficial effects of the invention are that the invention can save 60 percent of the amount of the acid used in the concentration process, make full use of the resources, reduce the production cost, decrease the discharging of the pollutions and has significant economic benefits.

Owner:HANGZHOU HI TECH FINE CHEM

Method for preparing carbon nanofiber aerogel from wood

ActiveCN106517144ASimple manufacturing methodGood repeatabilityNanotechnologyNano-carbonSupercritical dryingFiltration

The invention provides a method for preparing carbon nanofiber aerogel from wood. The method comprises the following steps: a) pre-treating the wood to obtain wood pulp; b) mixing the wood pulp with tetramethylpiperidine oxide, sodium bromide and sodium hypochlorite for an oxidation reaction to obtain a cellulose suspension; c) performing suction filtration on the cellulose suspension, dispersing the cellulose suspension in water to obtain a homogeneous viscous nanometer cellulose solution; d) acidizing the nanometer cellulose solution in an acidic environment to obtain nanometer cellulose hydrogel; e) performing solvent exchanging on the nanometer cellulose hydrogel in acetone containing p-toluenesulfonic acid, performing drying with a CO2 supercritical drying method to obtain nanocellulose aerogel; f)performing high temperature pyrolysis on the nanocellulose aerogel in a tubular furnace inert gas atmosphere to obtain the carbon nanofiber aerogel. According to the method, the carbon nanofiber aerogel is prepared from the wood as a raw material and has characteristics of uniform diameter, low density and large specific surface area as well as properties of heat insulation, fire resistance and the like.

Owner:UNIV OF SCI & TECH OF CHINA

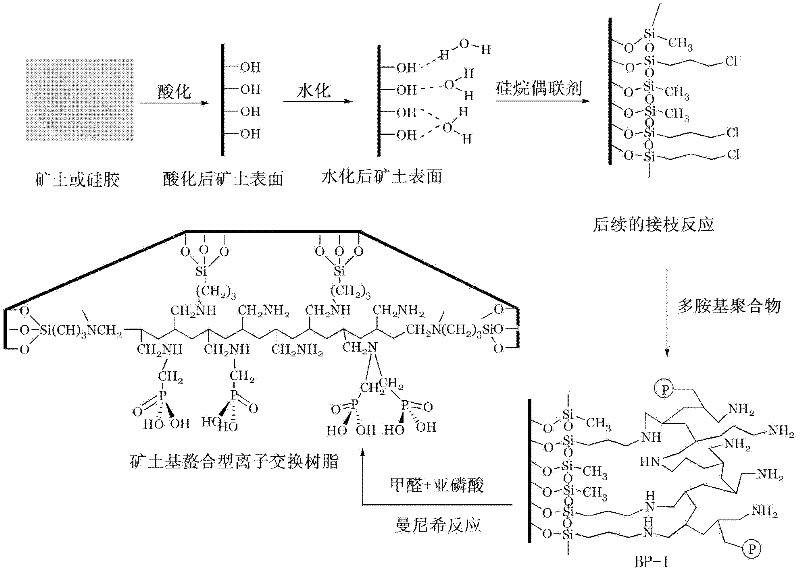

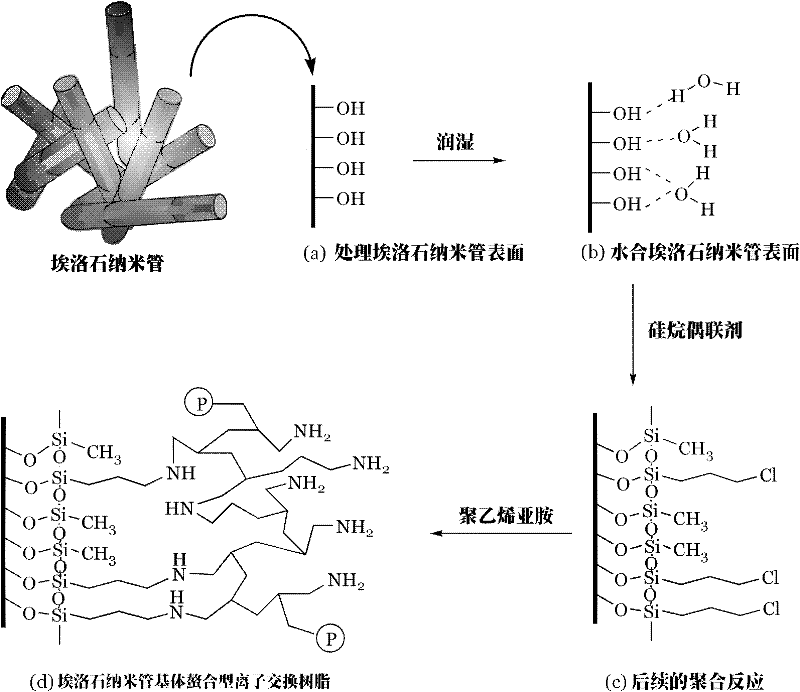

Preparation method for chelating ion exchange resin using inorganic substance as matrix

ActiveCN102391399AImprove performanceIncrease the ion exchange capacityComplex ion-exchangersPhosphorous acidHydration reaction

The invention belongs to the technical field of macromolecular ion exchange resin, and relates to a preparation method for chelating ion exchange resin. The preparation method comprises the following steps of: acidizing a matrix by using acid under the heating condition; washing the matrix by using deionized water until the matrix is neutral; allowing damp air in a sodium bromide or potassium bromide saturated solution reaction kettle to enter the matrix which is treated in the previous steps, so that a water molecule single layer is generated on the surface of the matrix; performing silanization reaction on the hydrated matrix, alkane and a silane coupling agent to obtain a silanized matrix; performing grafting reaction on the silanized matrix and multi-amino polymer to obtain a functional resin material; and performing Mannick reaction on the functional resin material, formaldehyde and phosphorous acid so as to obtain the final chelating ion exchange resin using an inorganic substance as the matrix. The method has the advantages that the operation process is short and the method is convenient to operate. A reagent is not required to be added into an ion exchange column when noble metal ions are adsorbed, so pollution and wastes are avoided.

Owner:GANZHOU RARE EARTH MINERAL IND

Surface-ornamental styrene-acrylic bromine-carbon latex fire-proof paint and preparation thereof

InactiveCN101255302AImprove the decorative effectGood chemical resistanceFireproof paintsWax coatingsAntimony trioxidePhenol

The invention provides a decorative type styrene-acrylic bromine carbon latex fire-retardant coatings and preparation method thereof. The induction of flameretardant element bromine and synthesis of intrinsic flamertardant polymer resin can increase ageing effect and flame retardant property of fire-retardant coatings, and conquer the defects of fireretardant system of addition type fire-retardant coatings such as effusion, movement and volatilization. The phenol is used as raw material to produce tribromo phenol in the present of sodium bromate and sodium bromide, furthermore the tribromo phenol reacts with acryloyl chloride to obtain acrylic 2,4,6-tribromo phenyl ester. The styrene-acrylic bromine carbon latex is produced through polymerizing the acrylic 2,4,6-tribromo phenyl ester with butyl acrylate, methyl methacrylate, styrene and acrylic acid by free radical. Finally the decorative type styrene-acrylic bromine carbon latex fire-retardant coatings can be produced by using styrene-acrylic bromine carbon latex as base material and mixing the ammonium polyphosphate, melamine, dipentaerythritol, molybdenum hemitrioxide, antimony oxide, zinc borate, boron-moisten soil and titanium white powder.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

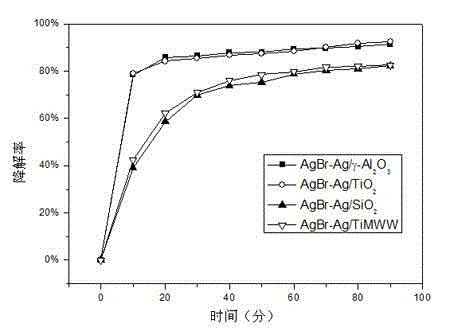

Visible-light-induced photocatalyst and preparation method thereof

InactiveCN103143389AHigh catalytic activitySimple and fast operationMolecular sieve catalystsMolecular sieveAmmonium bromide

The invention discloses a visible-light-induced photocatalyst and a preparation method of the visible-light-induced photocatalyst. According to the visible-light-induced photocatalyst, Al2O3 or TiO2 or SiO2 or titanium silicalite molecular sieves is used as a carrier, cetyl trimethyl ammonium bromide or tetraethyl ammonium bromide or tetra-normal-butyl ammonium bromide or sodium bromide is used as a bromide source, by a deposition and precipitation method, AgNO3 and the bromide source are subjected to reaction to prepare Ag-AgBr, and the Ag-AgBr is immobilized on the carrier to obtain a Ag-AgBr / carrier visible-light-induced photocatalyst. The photocatalytic activity of the Ag-AgBr / carrier visible-light-induced photocatalyst can be compared by the catalytic degradation of different azo dyes in simulated visible light, the result shows that in the visible light, the photocatalytic activity of the photocatalyst is greatly improved, and especially when 50 mg / L acid red B (ARB) dye waste water is degraded, the degradation efficiency reaches 79% in 10 min. The preparation and operation process is easy and convenient, and the raw material is easy to get.

Owner:EAST CHINA NORMAL UNIV

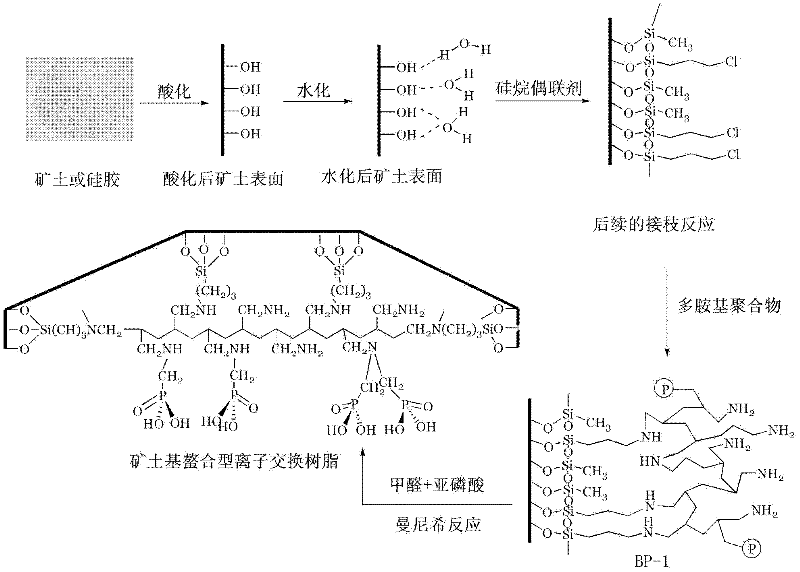

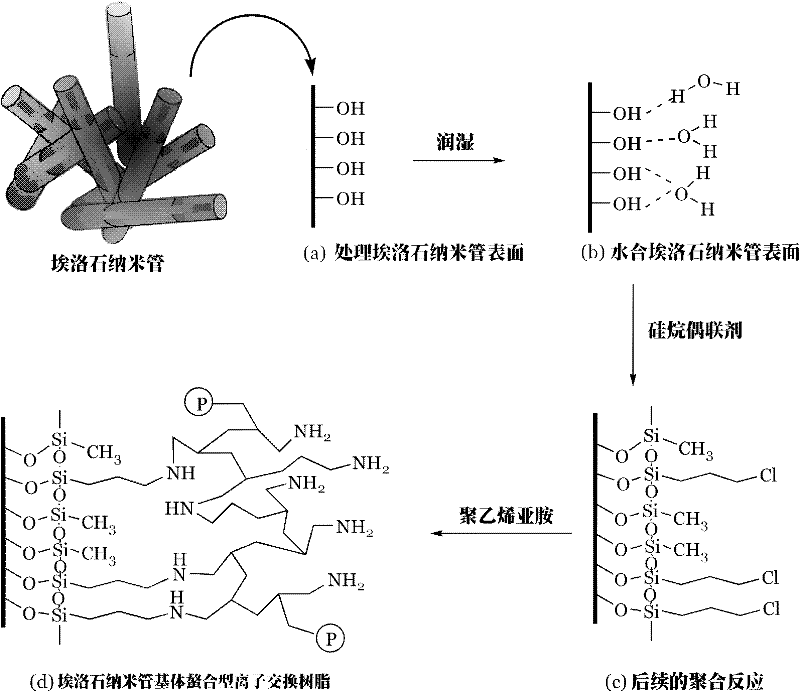

Preparation method of chelating type ion exchange resin with natural halloysite nanotube (HNT) as matrix

InactiveCN102250347AImprove performanceIncrease the ion exchange capacityComplex ion-exchangersAlkaneHalloysite

The invention relates to a preparation method of a chelating type ion exchange resin. The preparation method of a chelating type ion exchange resin with a natural halloysite nanotube as the matrix is characterized by comprising the steps of: taking a halloysite nanotube as the matrix and subjecting the halloysite nanotube to an acidification treatment under the condition of heating, and then washing the halloysite nanotube with deionized water until the acidified halloysite nanotube becomes neutral; introducing the humid air from a sodium bromide / potassium bromide saturated liquid reaction vessel into the water vapour saturated gas with the last step treated halloysite nanotube placed inside, thus obtaining a hydrated halloysite nanotube; subjecting the hydrated halloysite nanotube, alkane and a silane coupling agent to a silanization reaction so as to obtain a silanized halloysite nanotube, then conducting a grafting reaction to the silanized halloysite nanotube and an ethyleneimine polymer, thus obtaining the product. Characterized by brief operation process and convenient operation, the method of the invention has no need for any reagent to be added into an ion exchange column when absorbing precious metal ions, without any pollution and waste generated.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

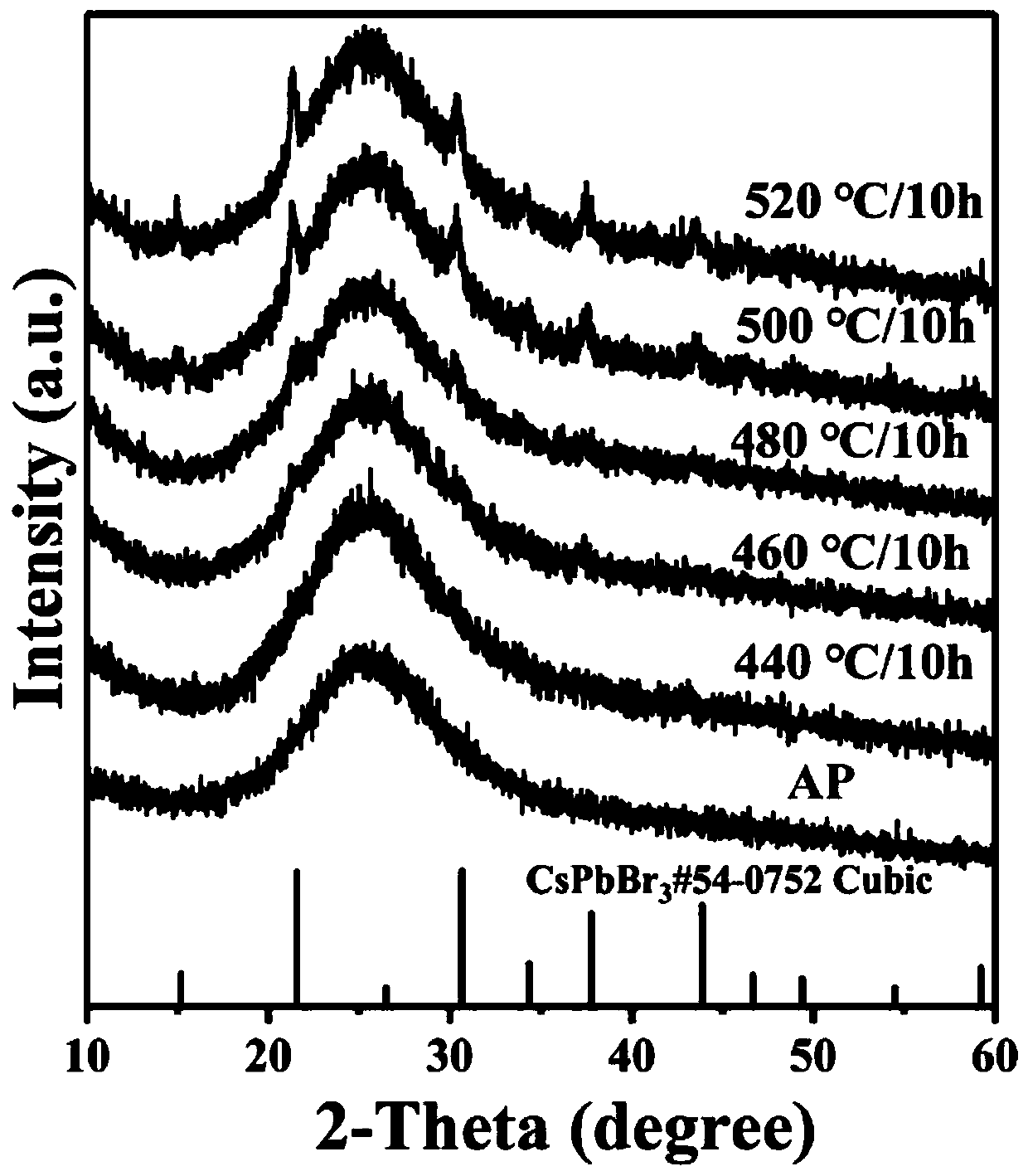

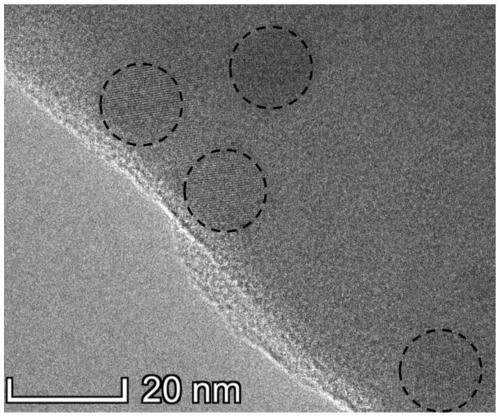

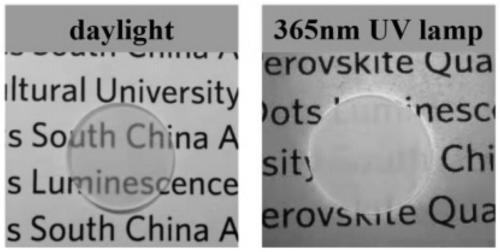

CsPbBr3 (cesium-lead-bromide) perovskite quantum dot fluorescent glass for display of wide color gamut and preparation method and application thereof

ActiveCN110294597AImprove internal quantum efficiencyImprove thermal stabilitySemiconductor devicesFluorescenceGermanium dioxide

The invention belongs to the technical field of display of fully-organic perovskite quantum dots, and discloses a CsPbBr3 (cesium-lead-bromide) perovskite quantum dot fluorescent glass for display ofwide color gamut and a preparation method and application thereof. The CsPbBr3 perovskite quantum dot fluorescent glass comprises the following components in percentage by mole: 0 to 45% of SiO2 (silicon dioxide), 0 to 45% of GeO2 (germanium dioxide), 30 to 40% of B2O3 (boron oxide), 2 to 8% of Al2O3 (aluminum oxide), 3 to 7% of MCO3 (metal carbonate), 1 to 5% of ZnO (zinc oxide), 5 to 15% of CsBr(cesium bromide) or Cs2CO3 (cesium carbonate), 2 to 10% of PbBr2 (lead bromide) or PbO (lead oxide), and 3 to 15% of NaBr (sodium bromide) or KBr (potassium-bromide), wherein M is Ca (calcium) or Sr(strontium); the sum of the components in percentage by mole is 100%. The CsPbBr3 perovskite quantum dot fluorescent glass has the advantages that the technology is simple, and the operation is easy;after in-situ crystallization, the quantum efficiency is higher, the light emitting stability is obviously improved, and the broad application prospect is realized.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com