Visible-light-induced photocatalyst and preparation method thereof

A catalyst and visible light technology, which is applied in the field of photocatalysis and material chemistry, can solve the problems of no efficient and simple preparation method, and achieve the effects of short synthesis time, improved catalytic activity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

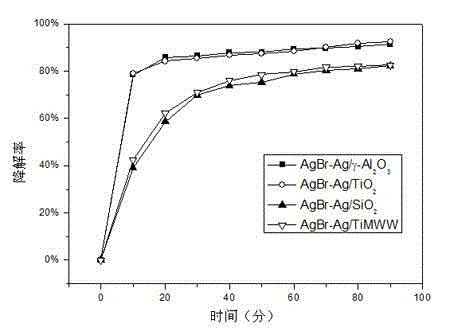

Embodiment 1

[0023] 2. 428 g of TiMWW (titanium silicon molecular sieve) powder was added to 97 mL of distilled water, and the suspension was sonicated for 10 minutes. Add 10.1839 g of cetyltrimethylammonium bromide (CTAB) into the suspension, and after stirring for 30 minutes, dissolve 0.510g of AgNO in 19.7mL 3 NH 3 ·H 2 O (25%NH 3 ) solution was added to the above mixture, and finally the resulting mixture was stirred at room temperature for 24 hours. The product was filtered, washed with water and dried. at 2°C·min -1 The Ag-AgBr / TiMWW composite photocatalyst was obtained after calcining in an air atmosphere at 500 °C for 3 hours.

Embodiment 2

[0025] 2. 428 g of TiMWW (titanium silicon molecular sieve) powder was added to 97 mL of distilled water, and the suspension was sonicated for 10 minutes. 20.1839 g of cetyltrimethylammonium bromide (CTAB) were added to the suspension. After stirring for 30 minutes, dissolve 0.510g AgNO in 19.7mL 3 NH 3 ·H 2 O (25%NH 3 ) solution was added to the above mixture, and finally the resulting mixture was stirred at room temperature for 24 hours. The product was filtered, washed with water and dried. at 2°C·min -1 After calcining in an air atmosphere at 500°C for 3 hours, the Ag-AgBr / TiMWW composite photocatalyst was obtained.

Embodiment 3

[0027] 2.428g TiO 2 The powder was added to 97 mL of distilled water, and the suspension was sonicated for 10 minutes. 20.1839 g of cetyltrimethylammonium bromide (CTAB) were added to the suspension. After stirring for 30 minutes, dissolve 0.510g AgNO in 19.7mL 3 NH 3 ·H 2 O (25%NH 3 ) solution was added to the above mixture, and finally the resulting mixture was stirred at room temperature for 24 hours. The product was filtered, washed with water and dried. at 2°C·min -1 After calcination at 500°C in an air atmosphere for 3 hours, the Ag-AgBr / TiO 2 composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com