Patents

Literature

19520results about How to "High catalytic activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

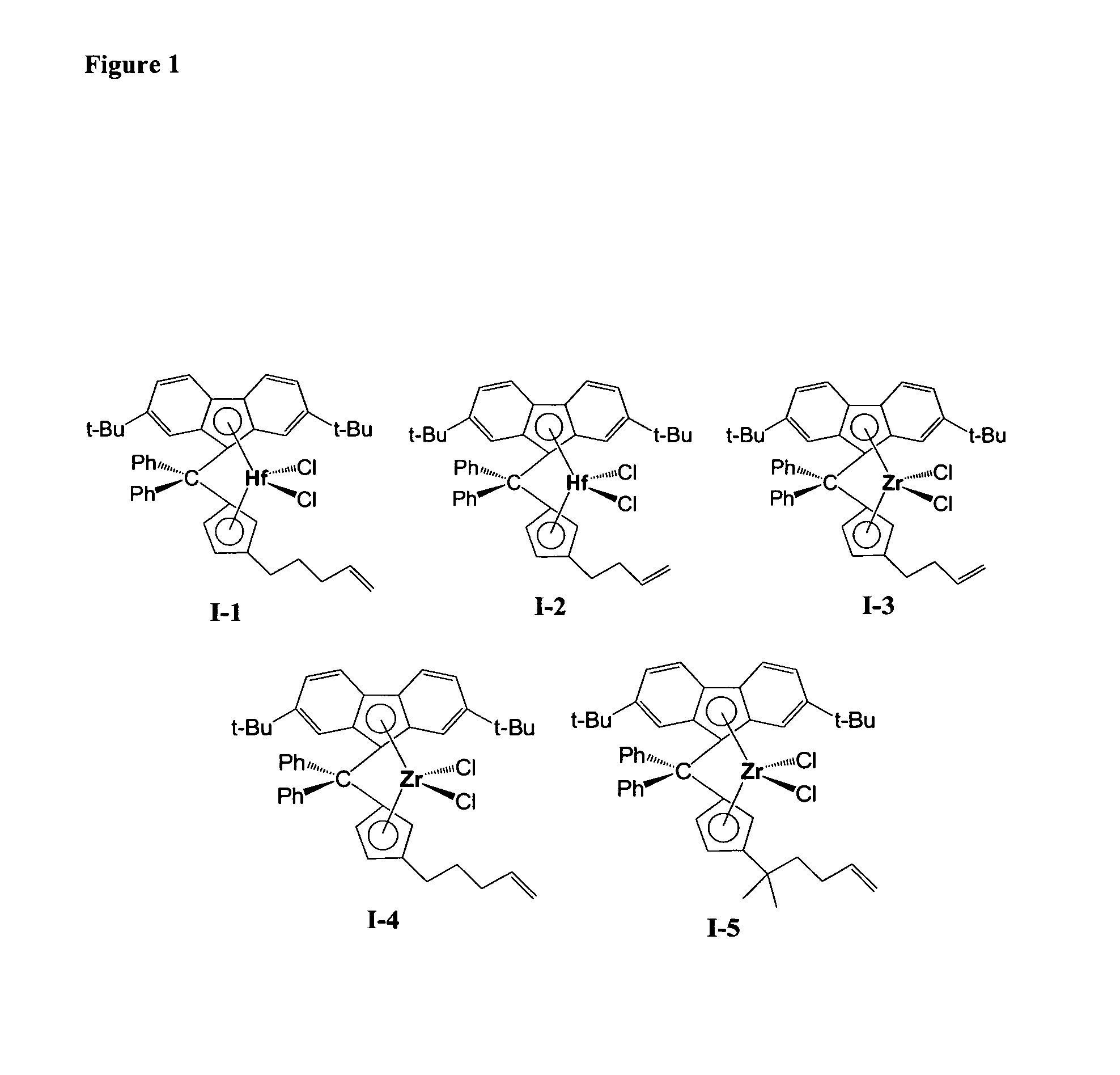

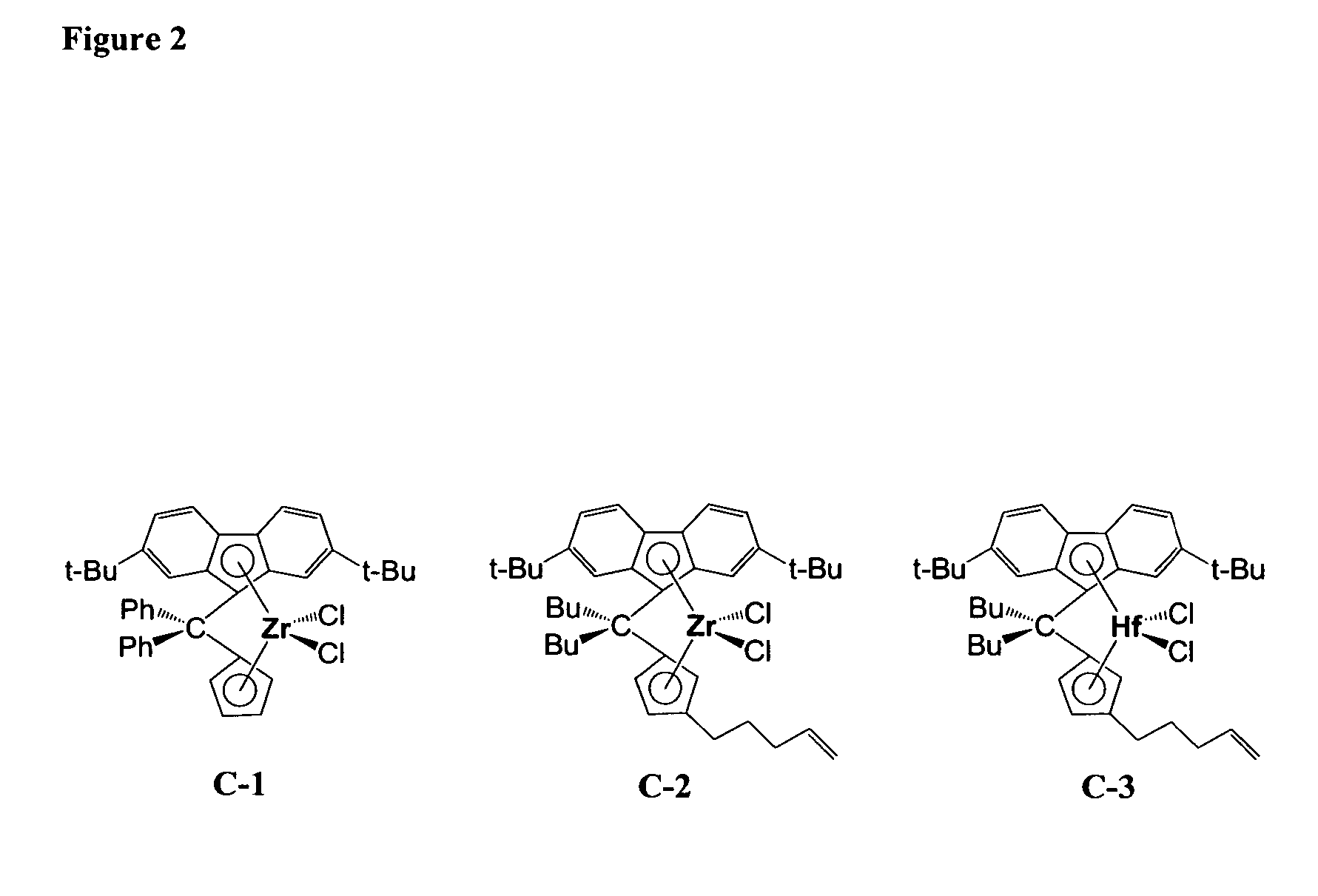

Dual metallocene catalysts for polymerization of bimodal polymers

ActiveUS7619047B2Good balance of stiffnessHigh impact strengthGroup 8/9/10/18 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsEthylene PolymersEthylene

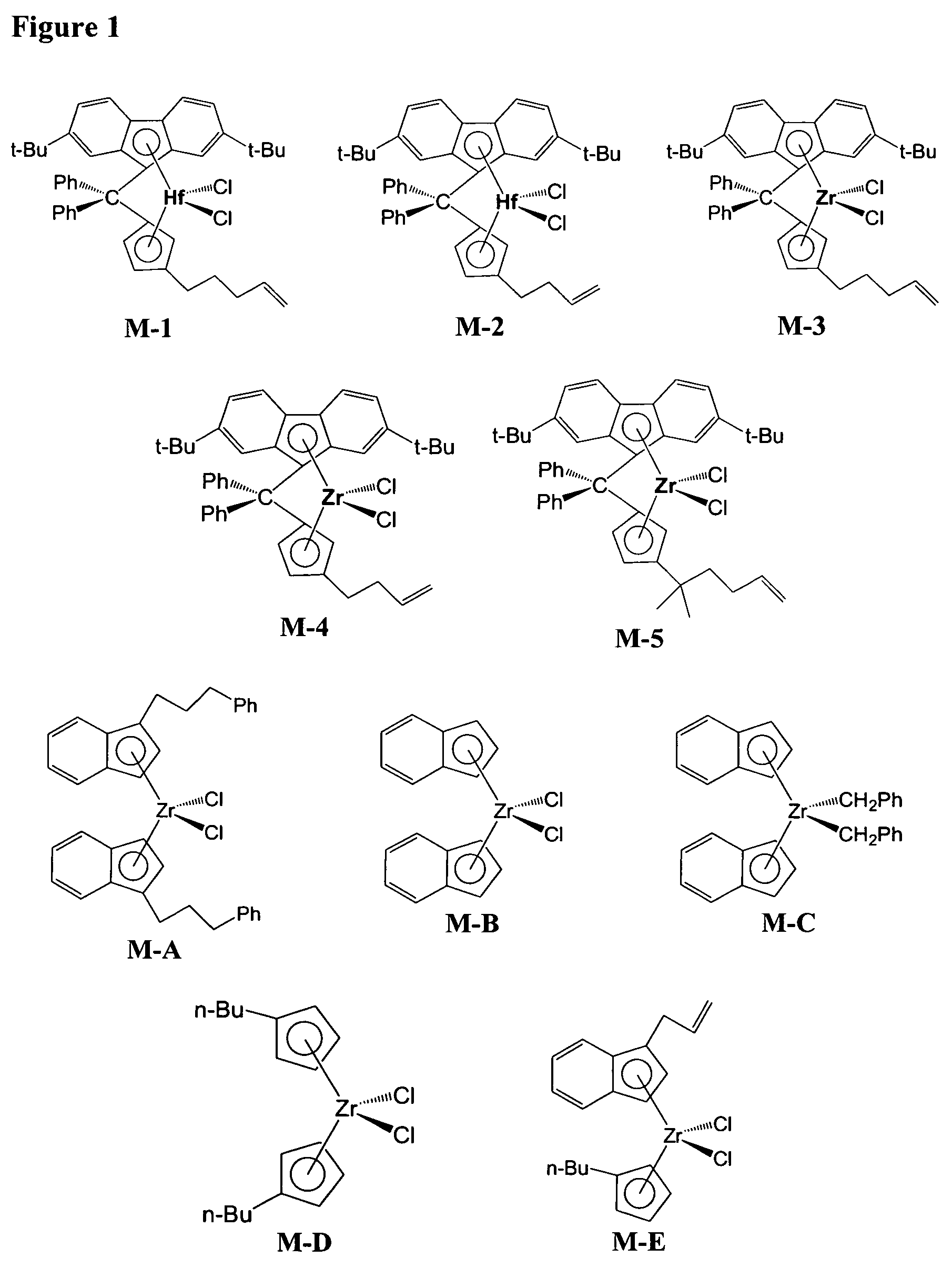

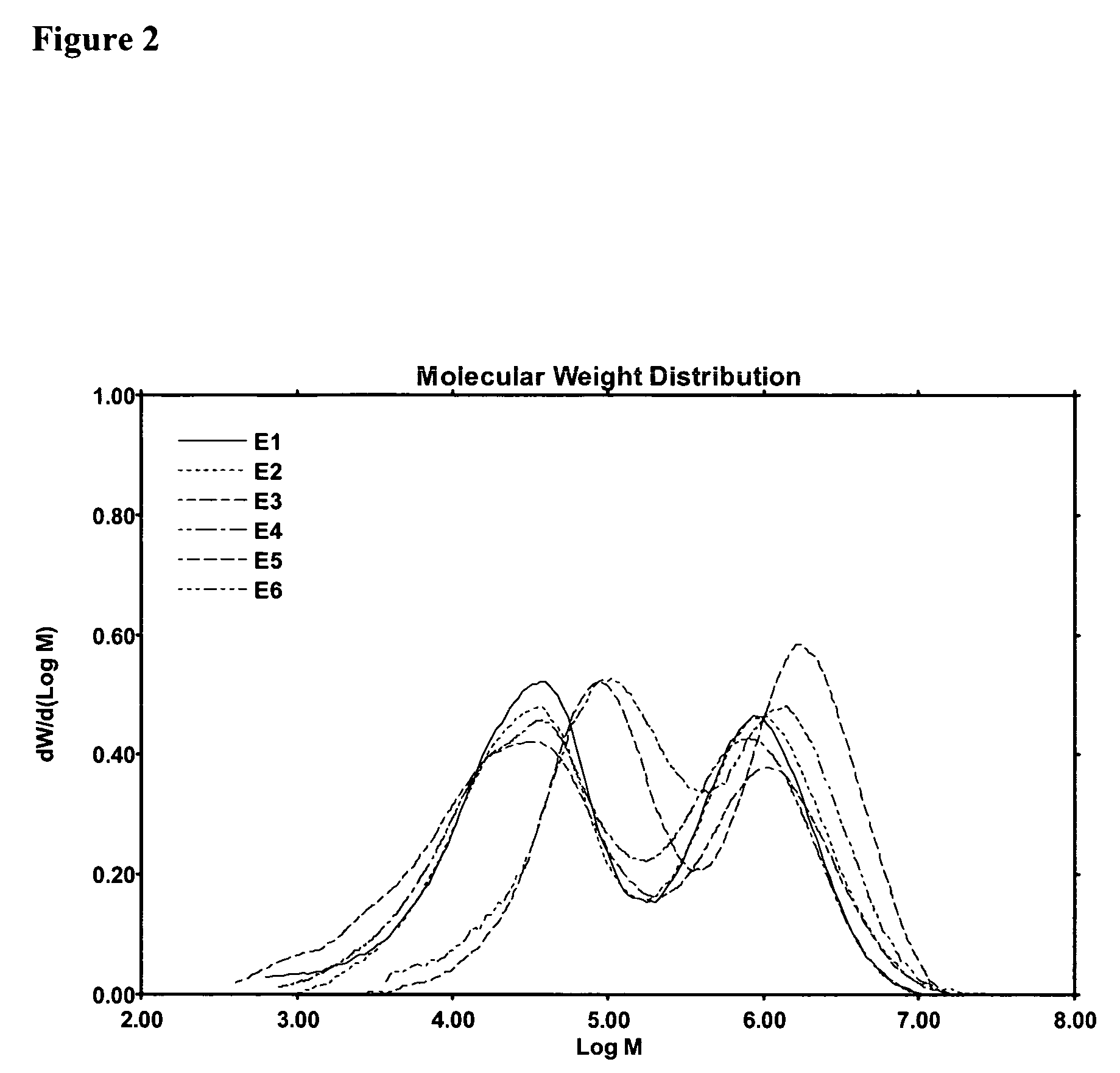

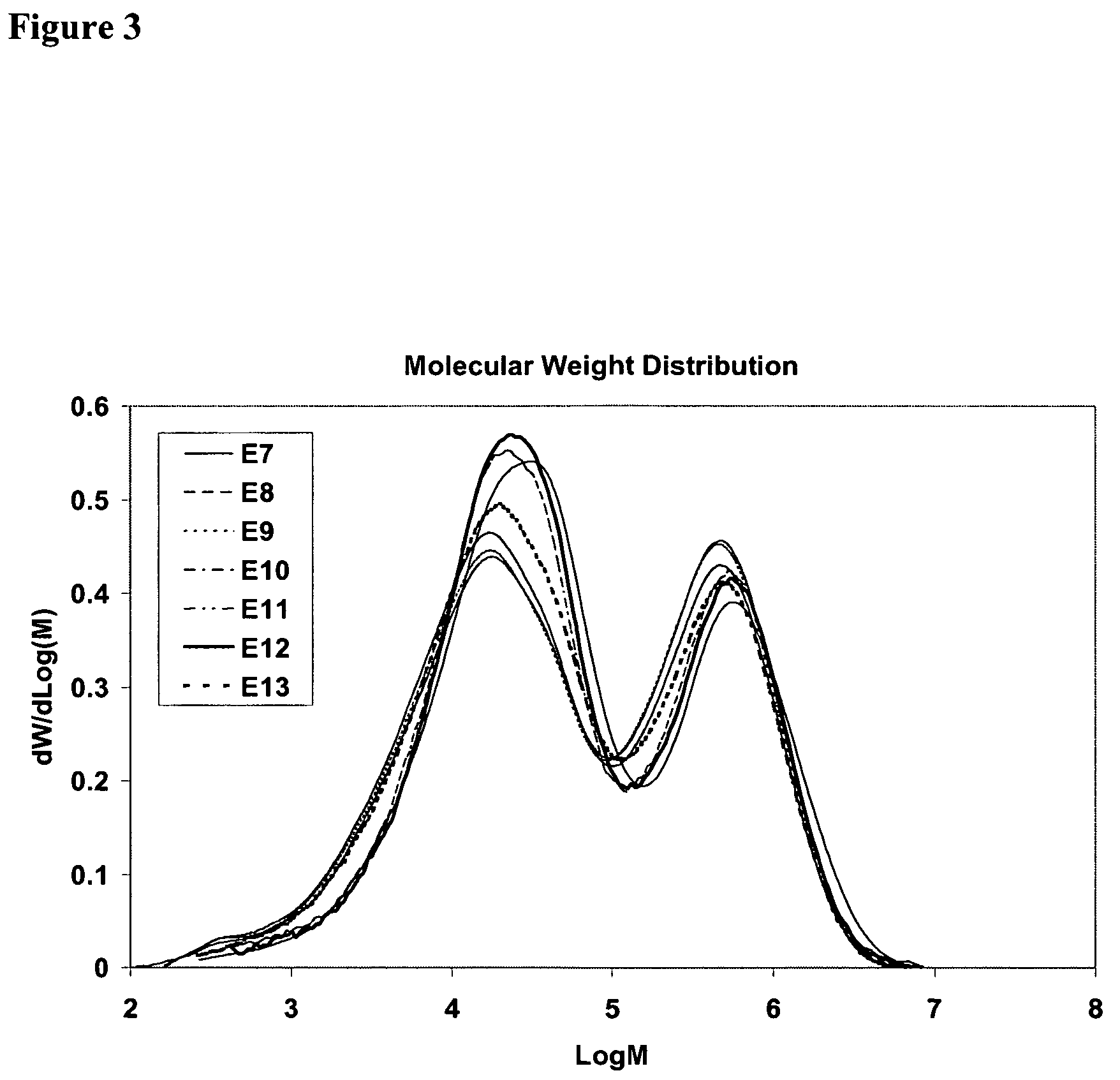

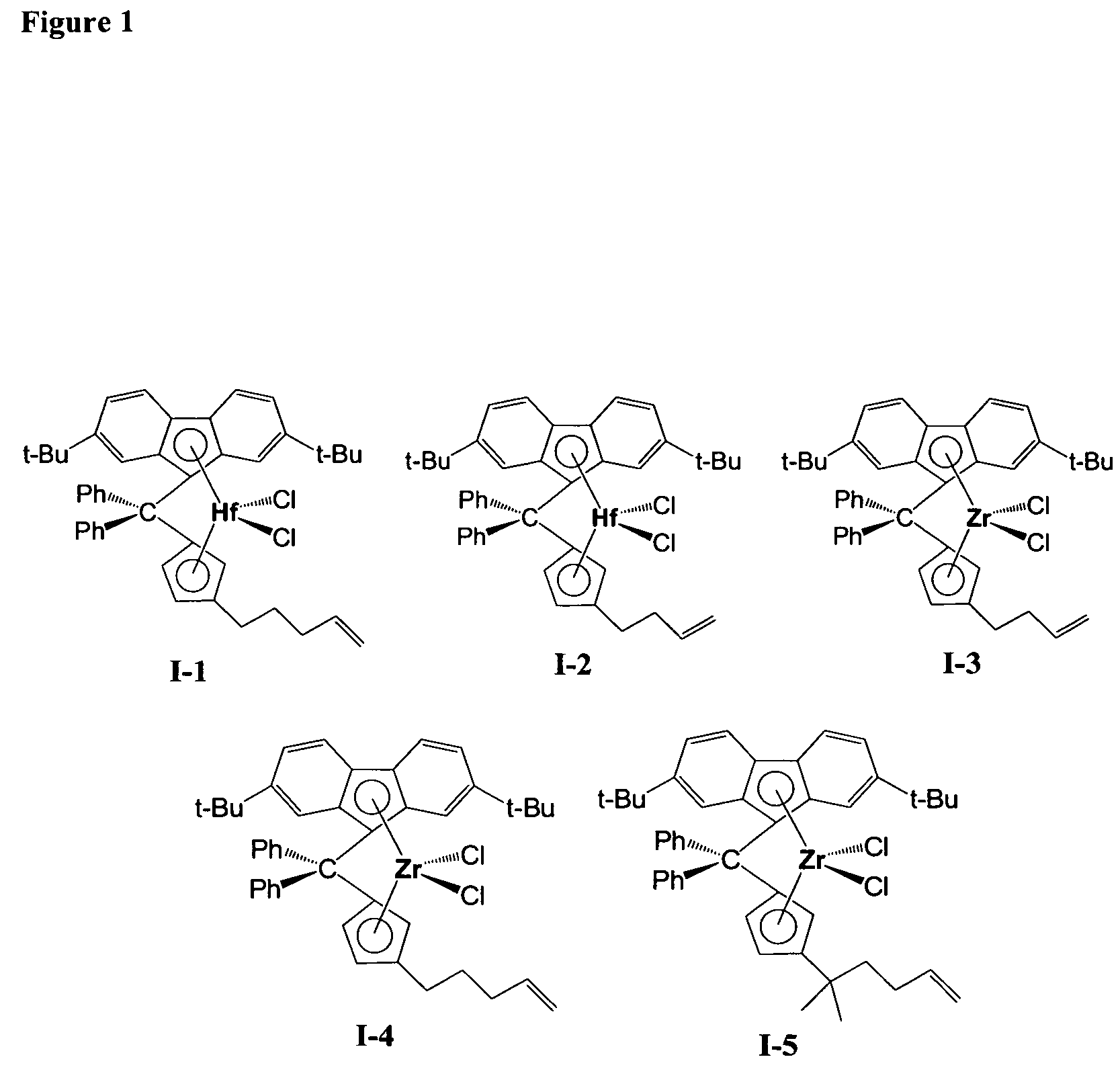

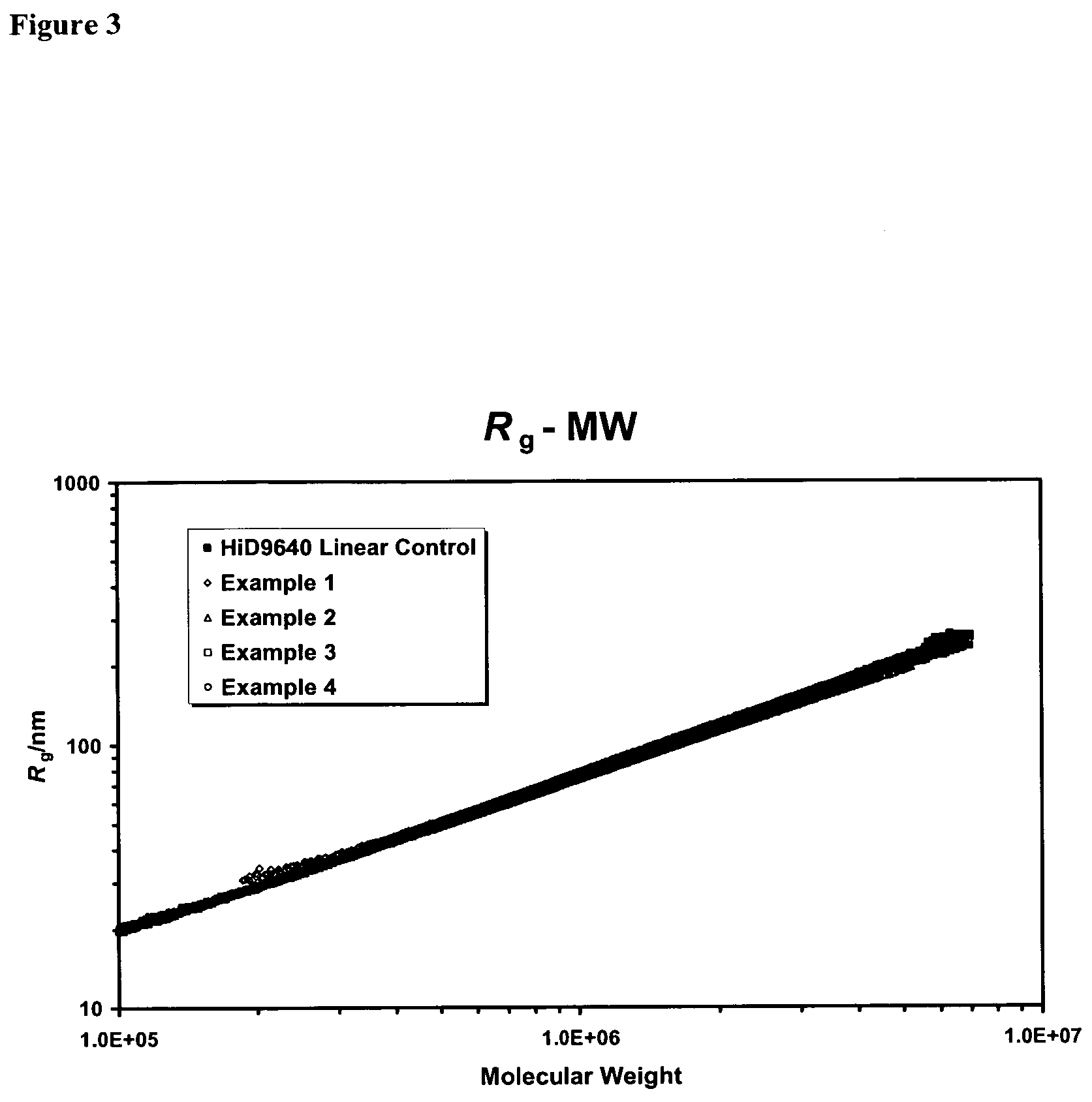

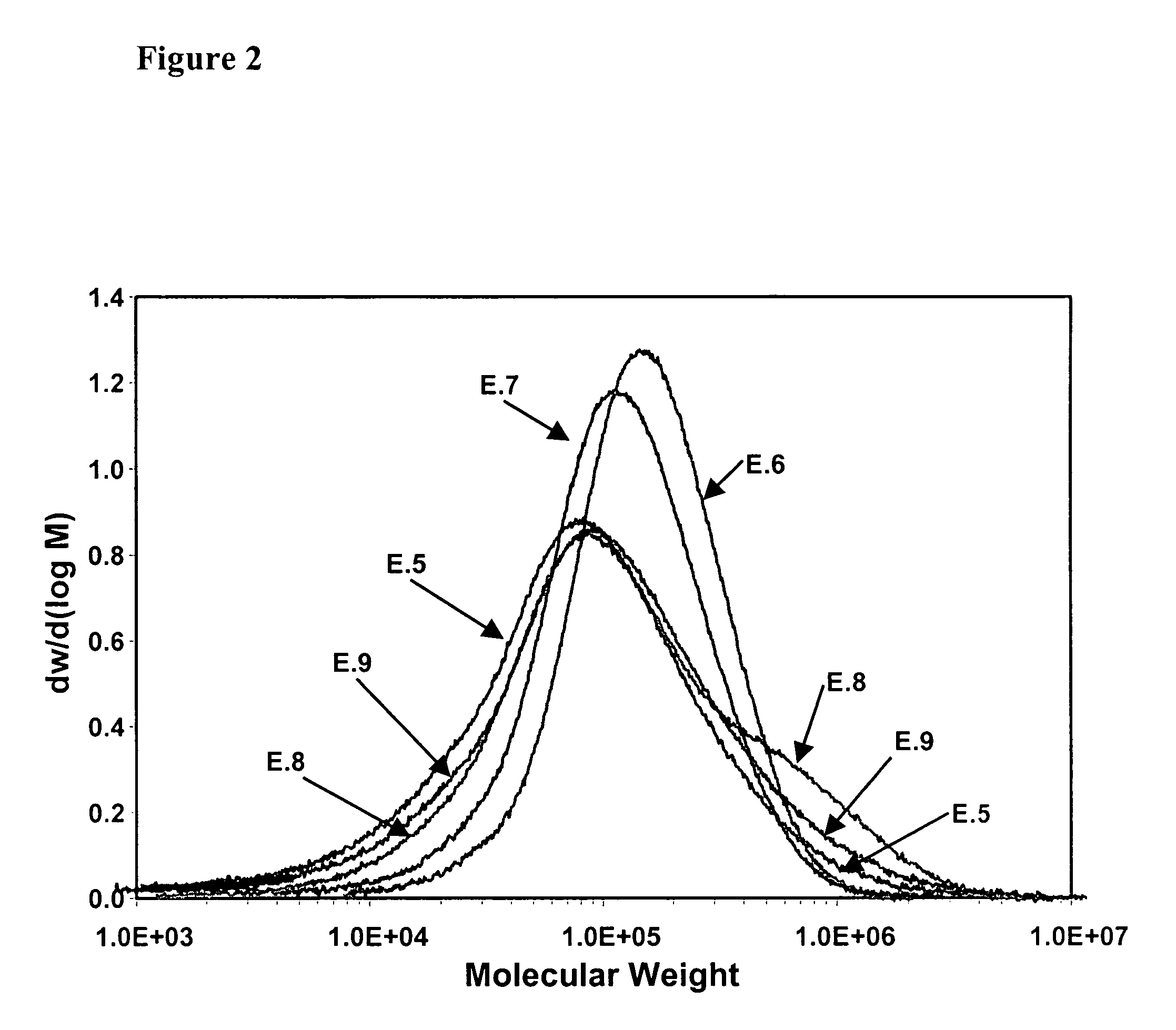

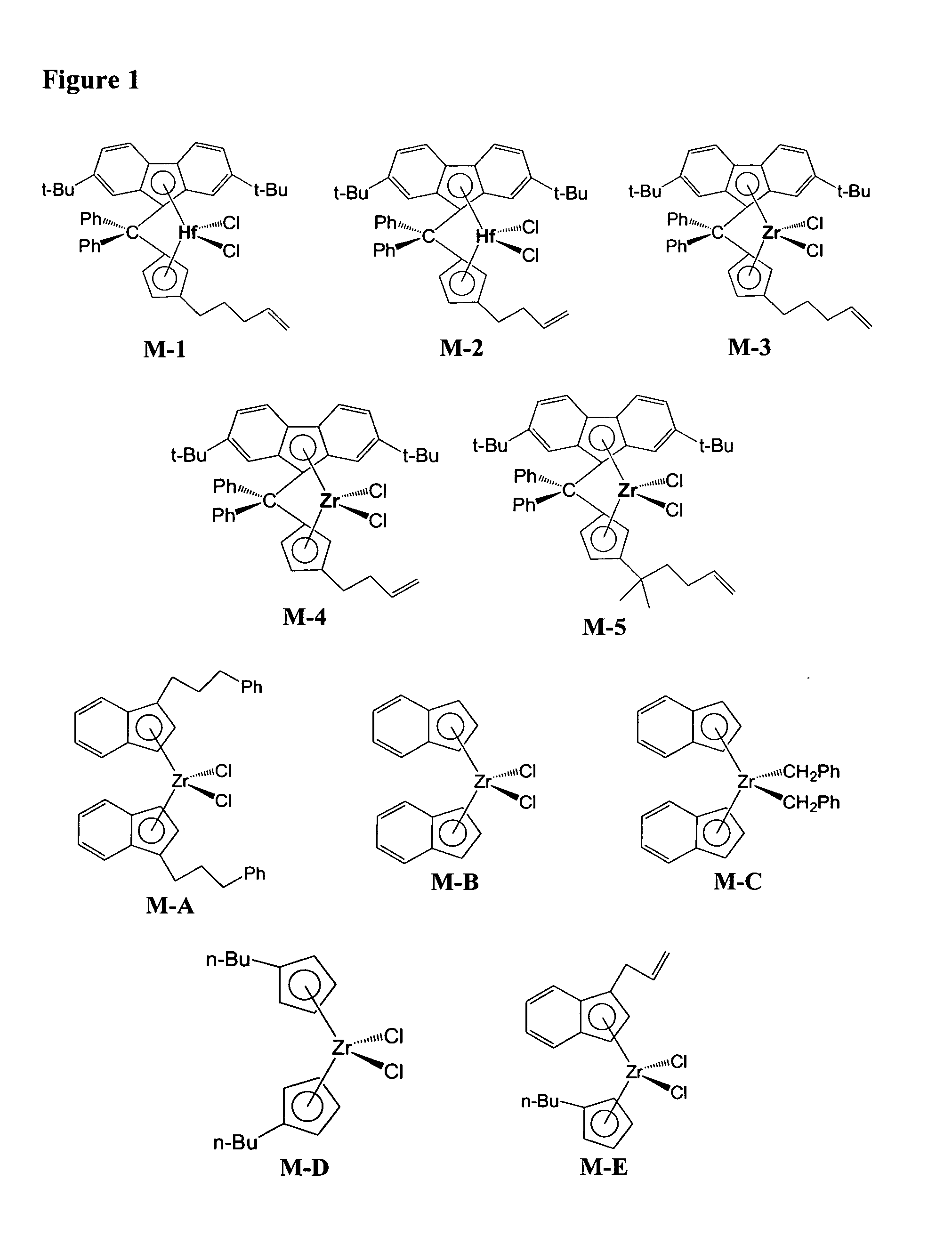

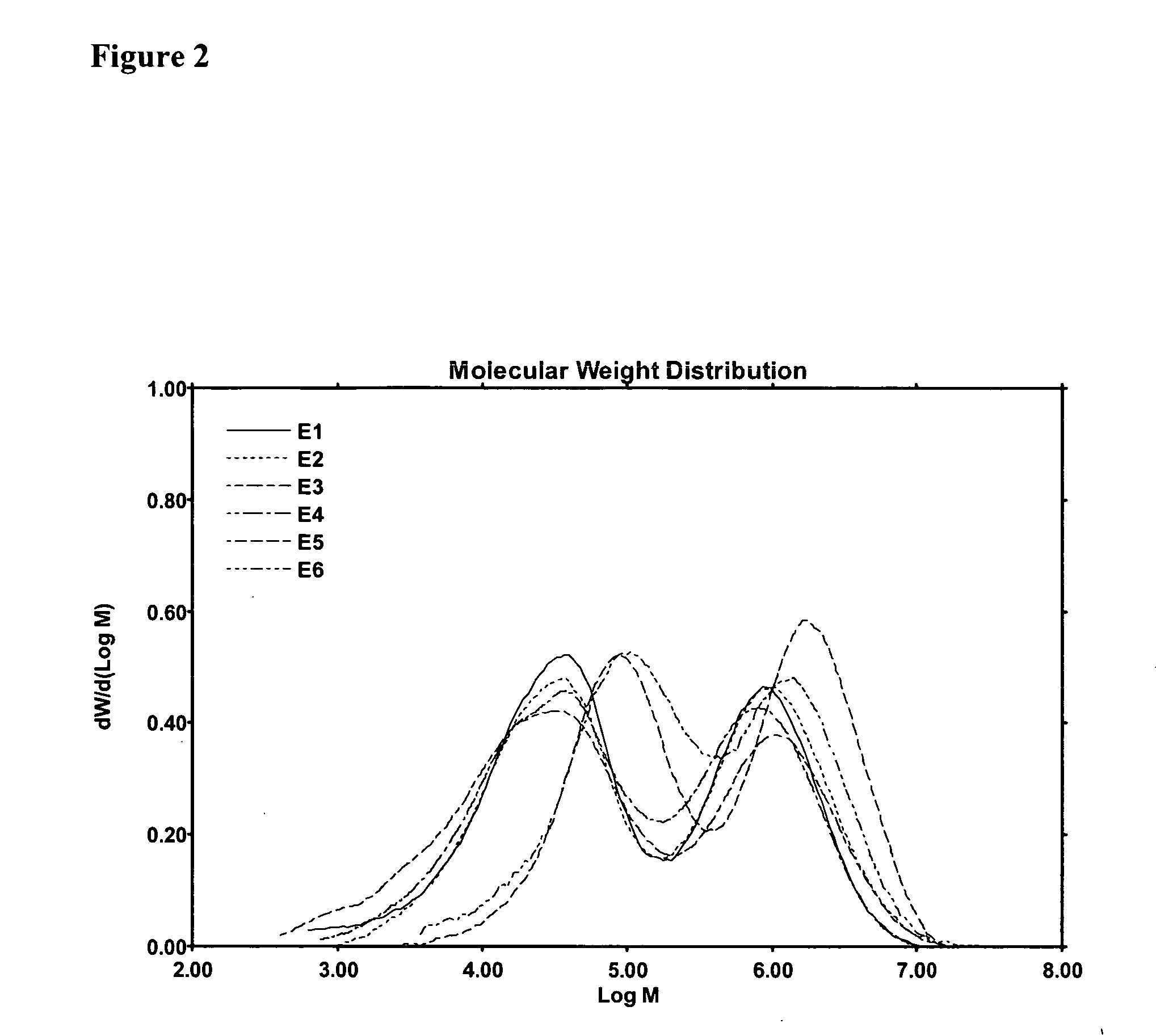

This invention relates to catalyst compositions, methods, and polymers encompassing at least one first Group 4 metallocene compound comprising bridging η5-cyclopentadienyl-type ligands, in combination with at least one second Group 4 metallocene with non-bridging η5-cyclopentadienyl-type ligands, typically in combination with at least one cocatalyst, and at least one activator. The compositions and methods disclosed herein provide ethylene polymers with a bimodal molecular weight distribution.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

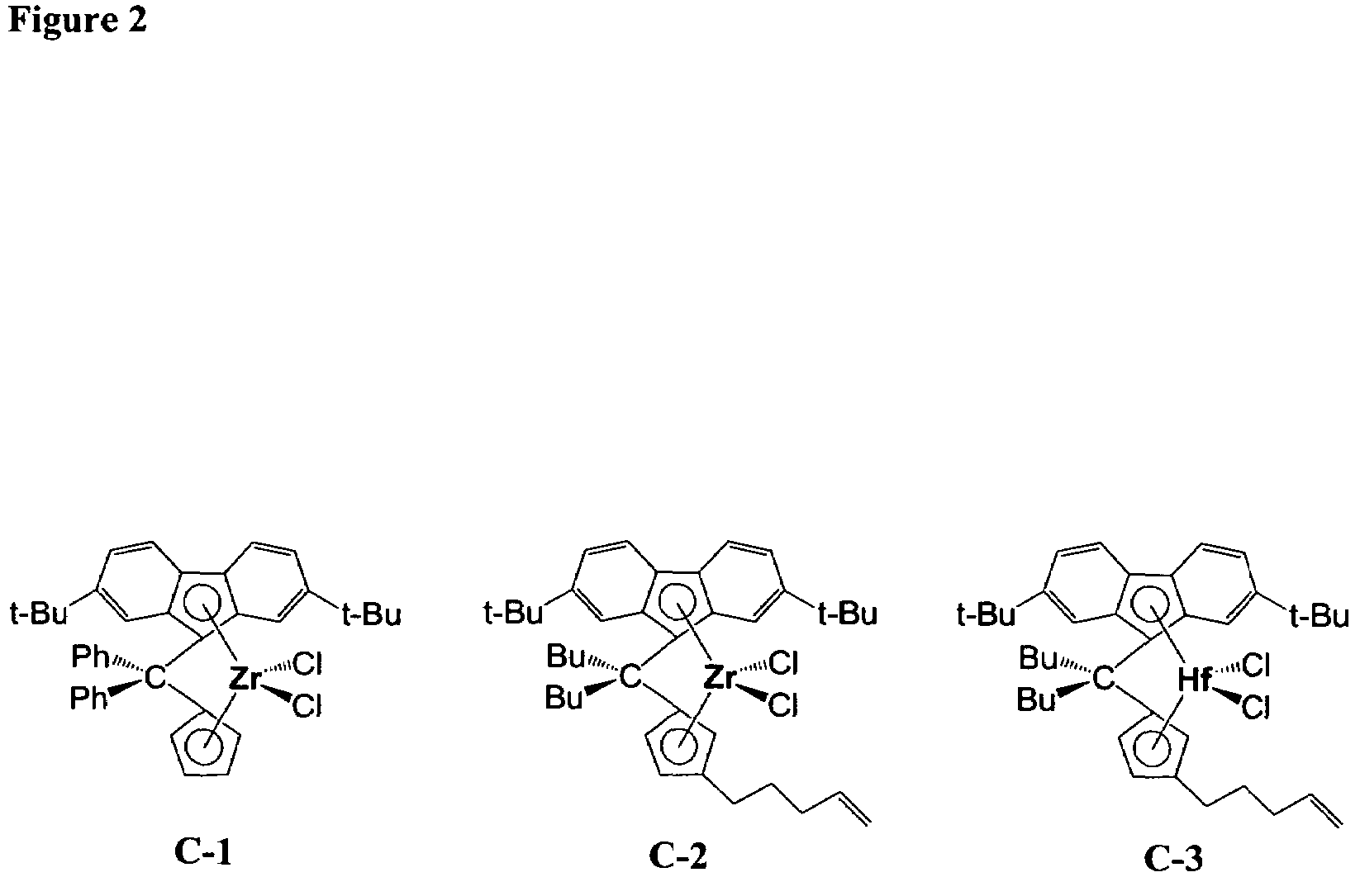

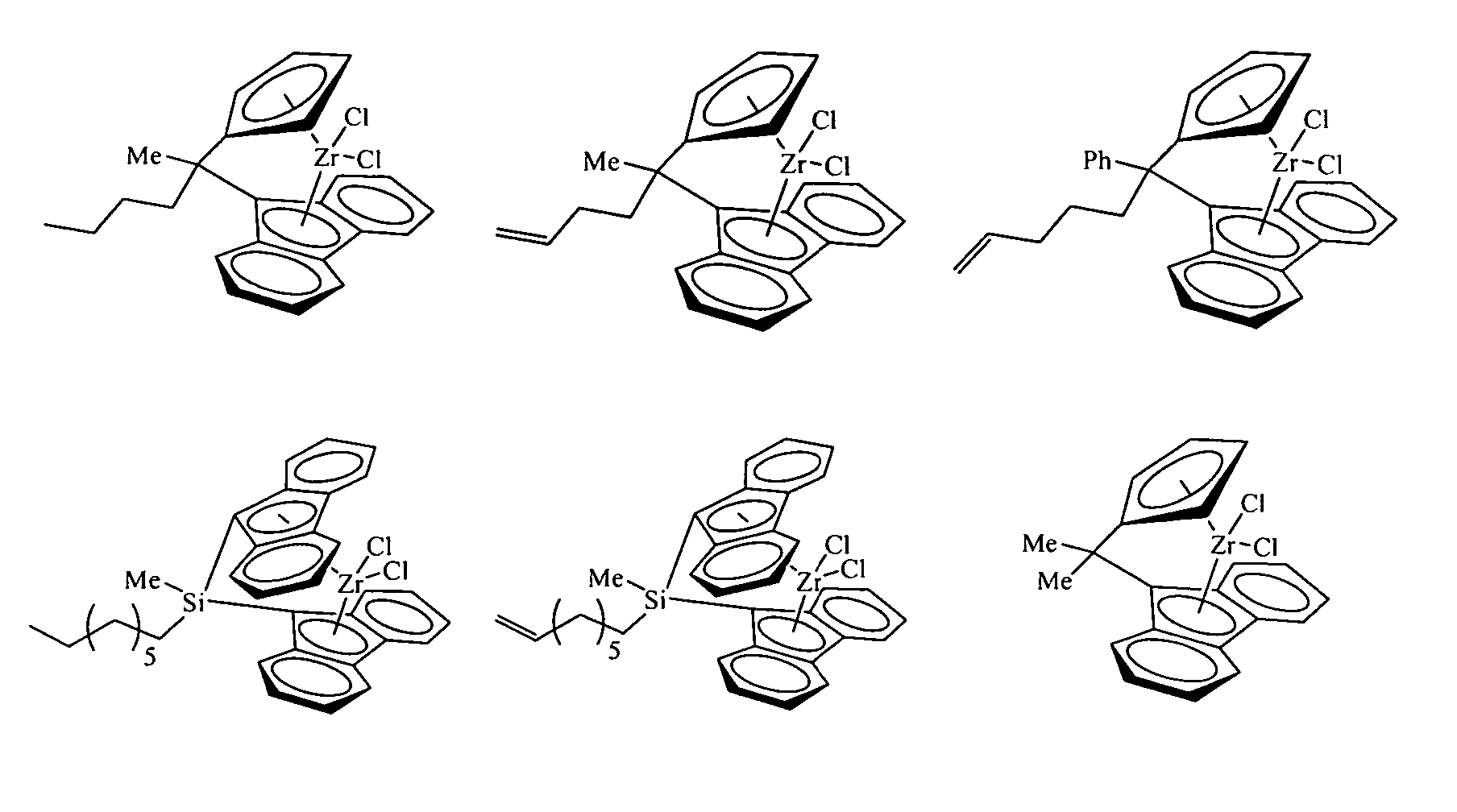

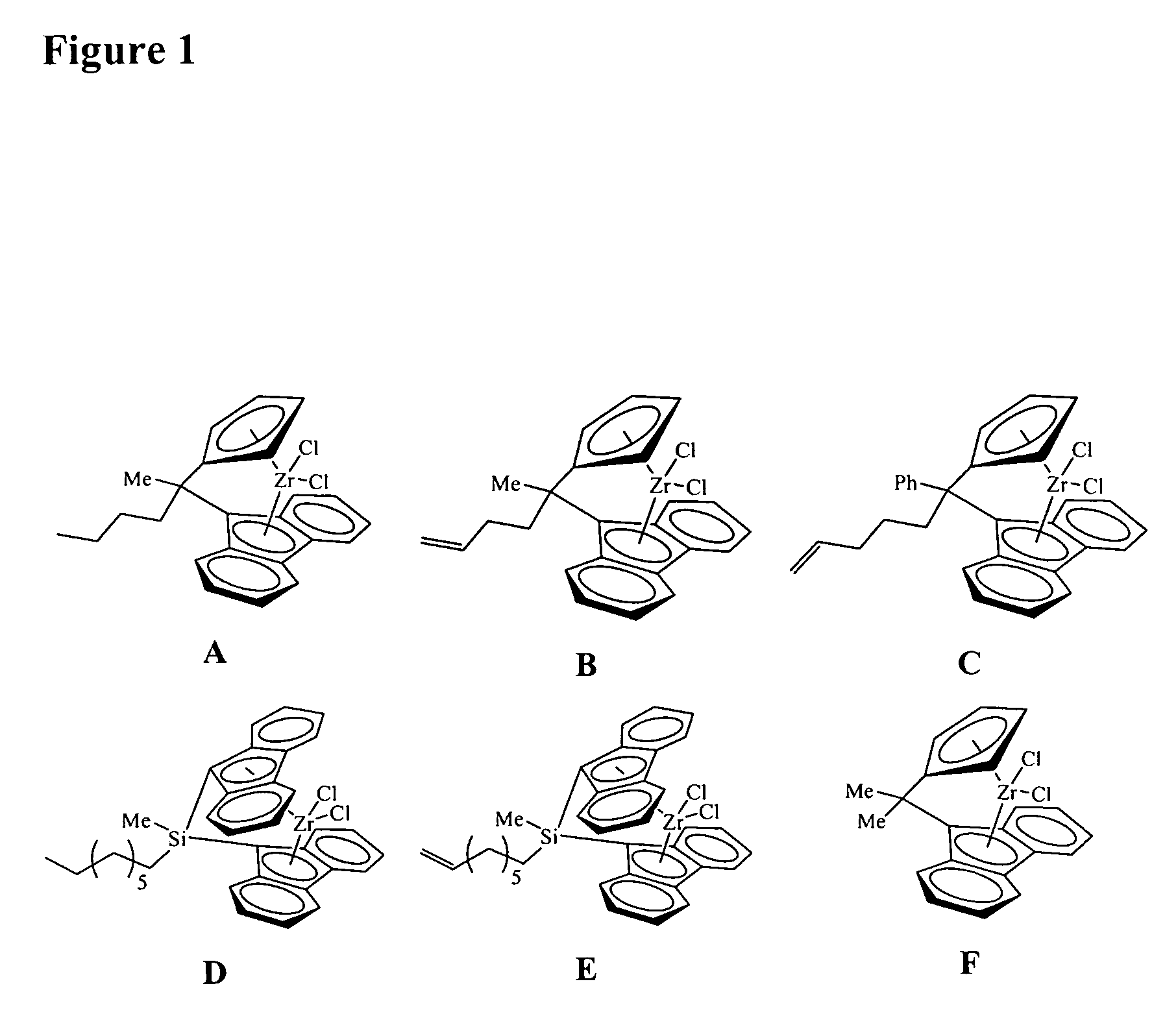

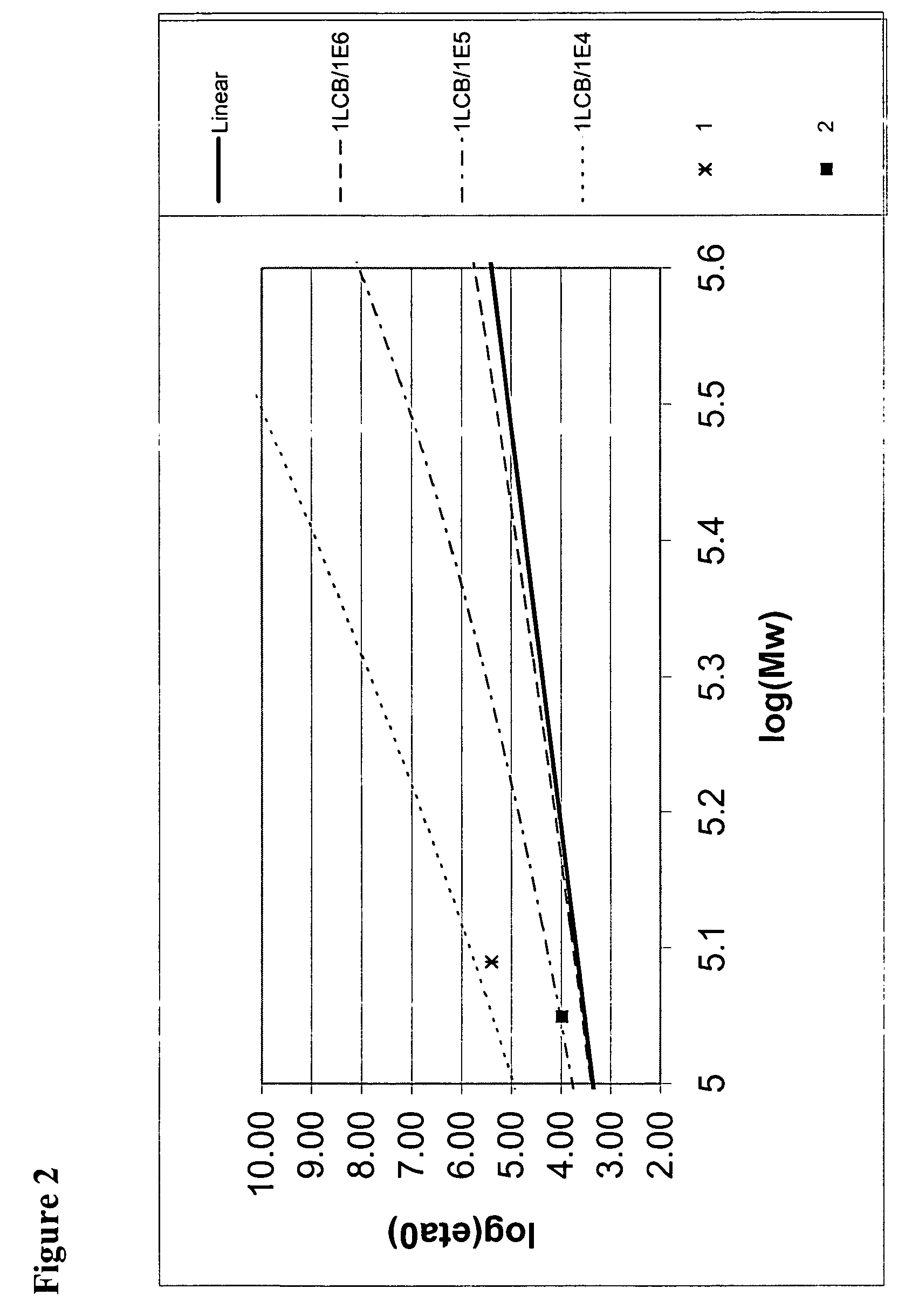

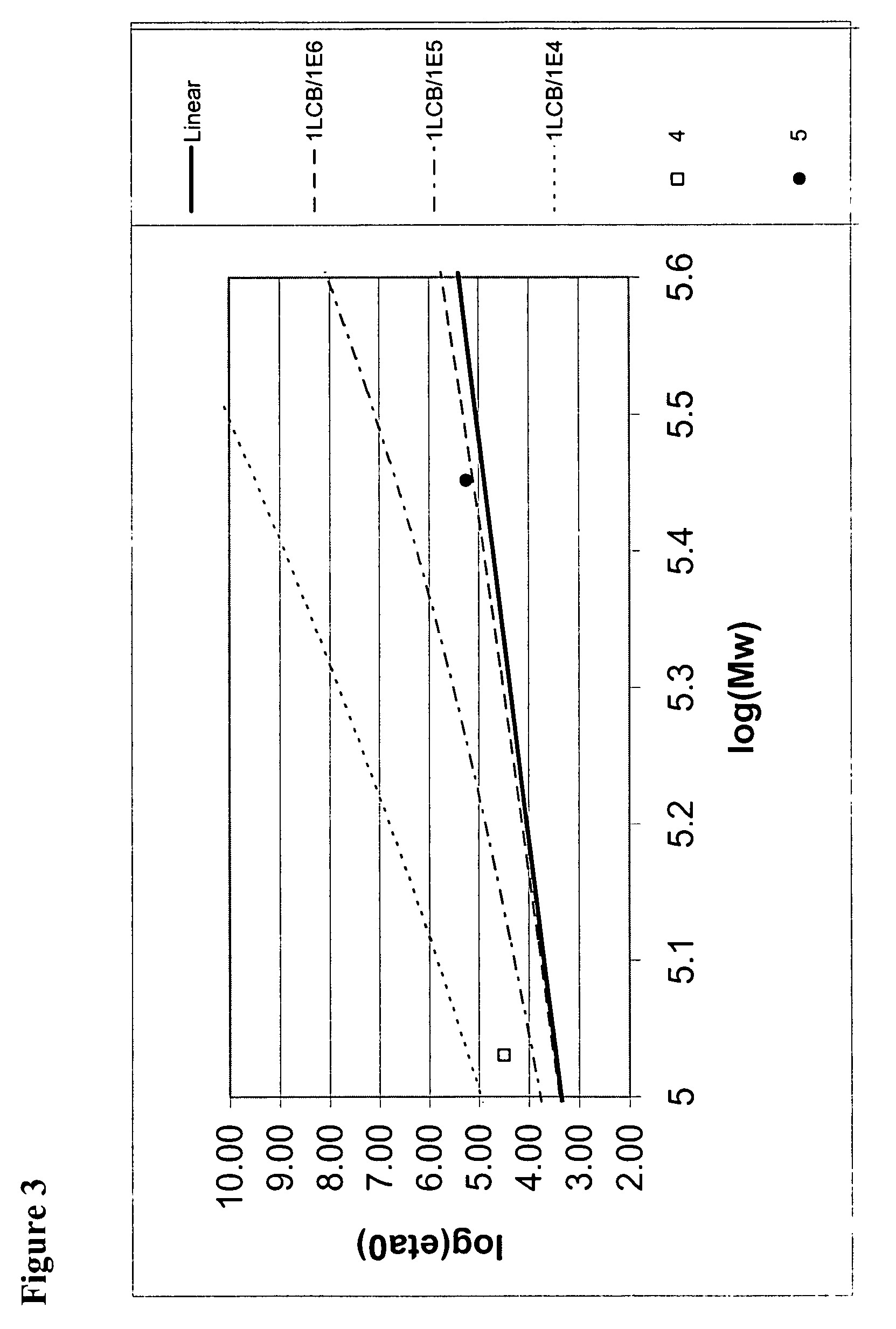

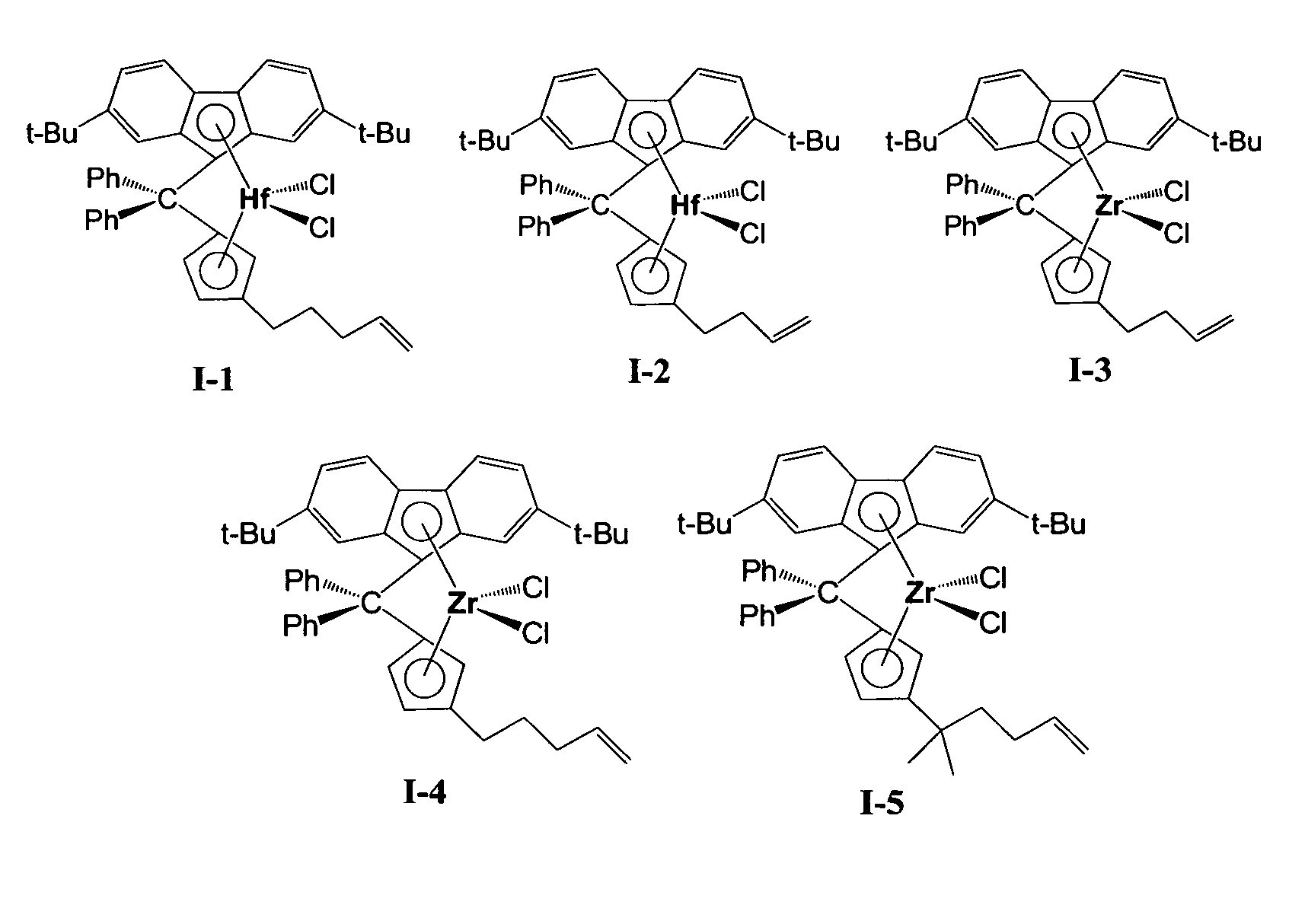

Polymerization catalysts for producing high molecular weight polymers with low levels of long chain branching

ActiveUS7517939B2High catalytic activityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsHigh molecular massEthylene Polymers

This invention relates to catalyst compositions, methods, and polymers encompassing at least one Group 4 metallocene compound comprising bridging η5-cyclopentadienyl-type ligands, typically in combination with at least one cocatalyst, and at least one activator. The compositions and methods disclosed herein provide ethylene polymers with low levels of long chain branching.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

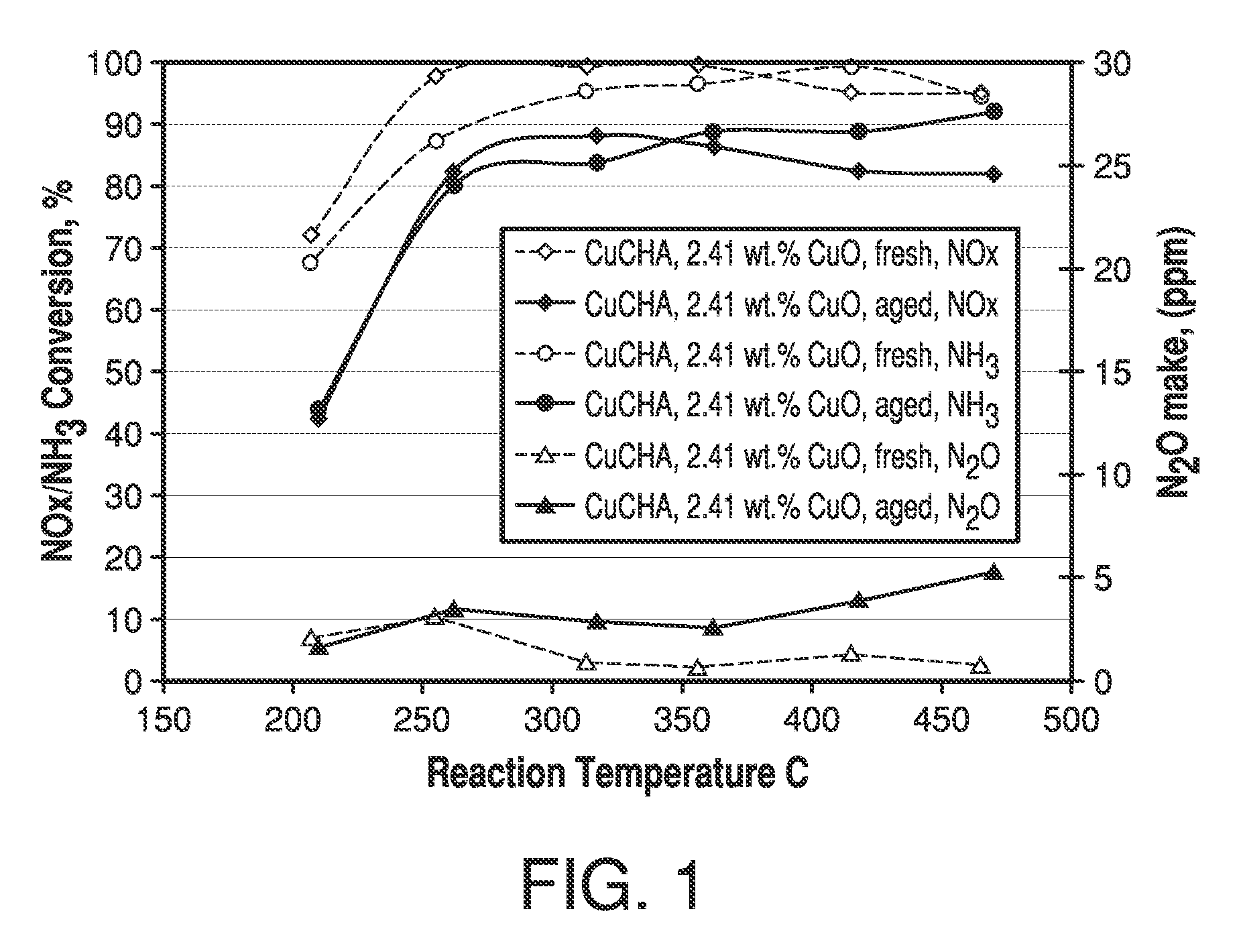

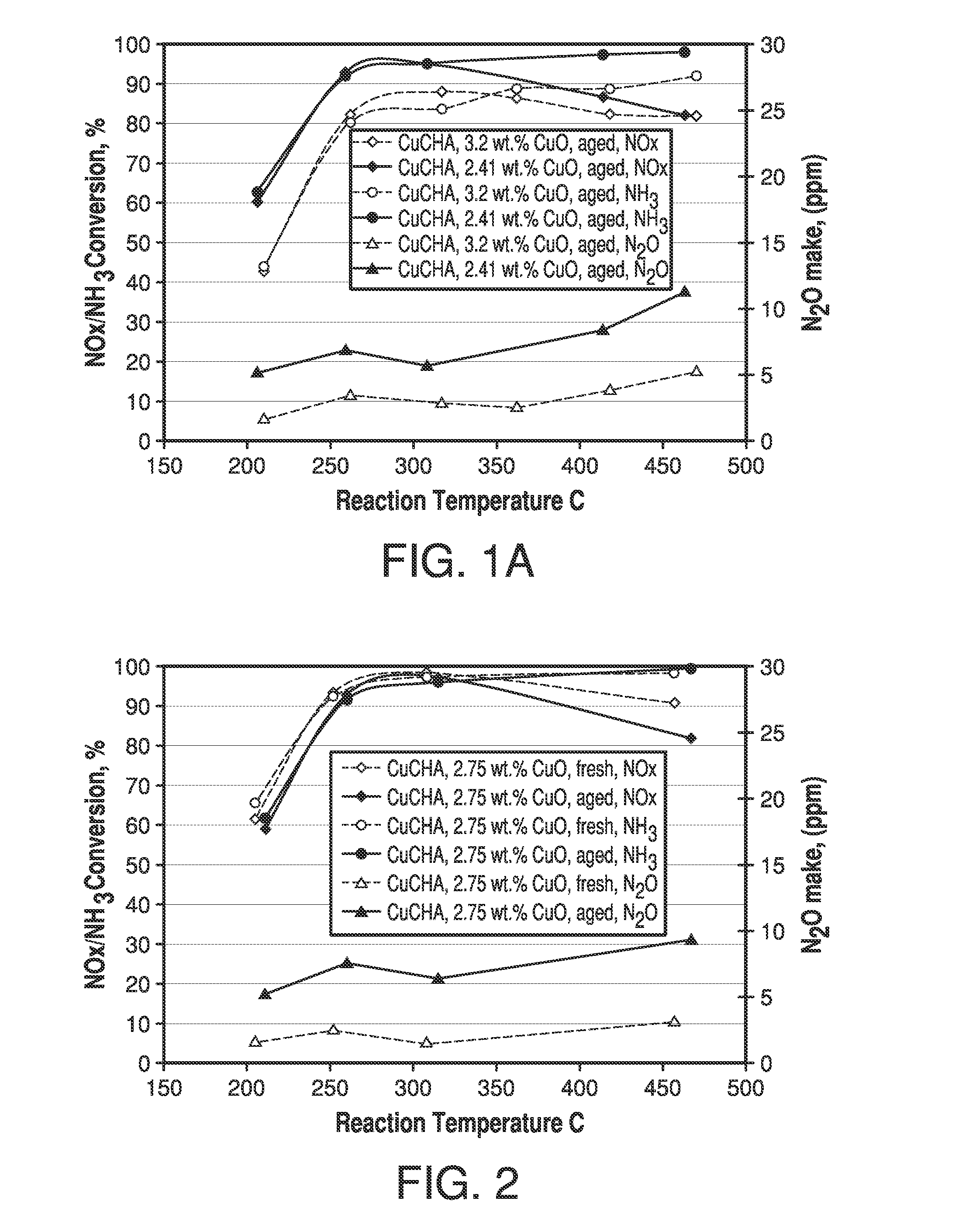

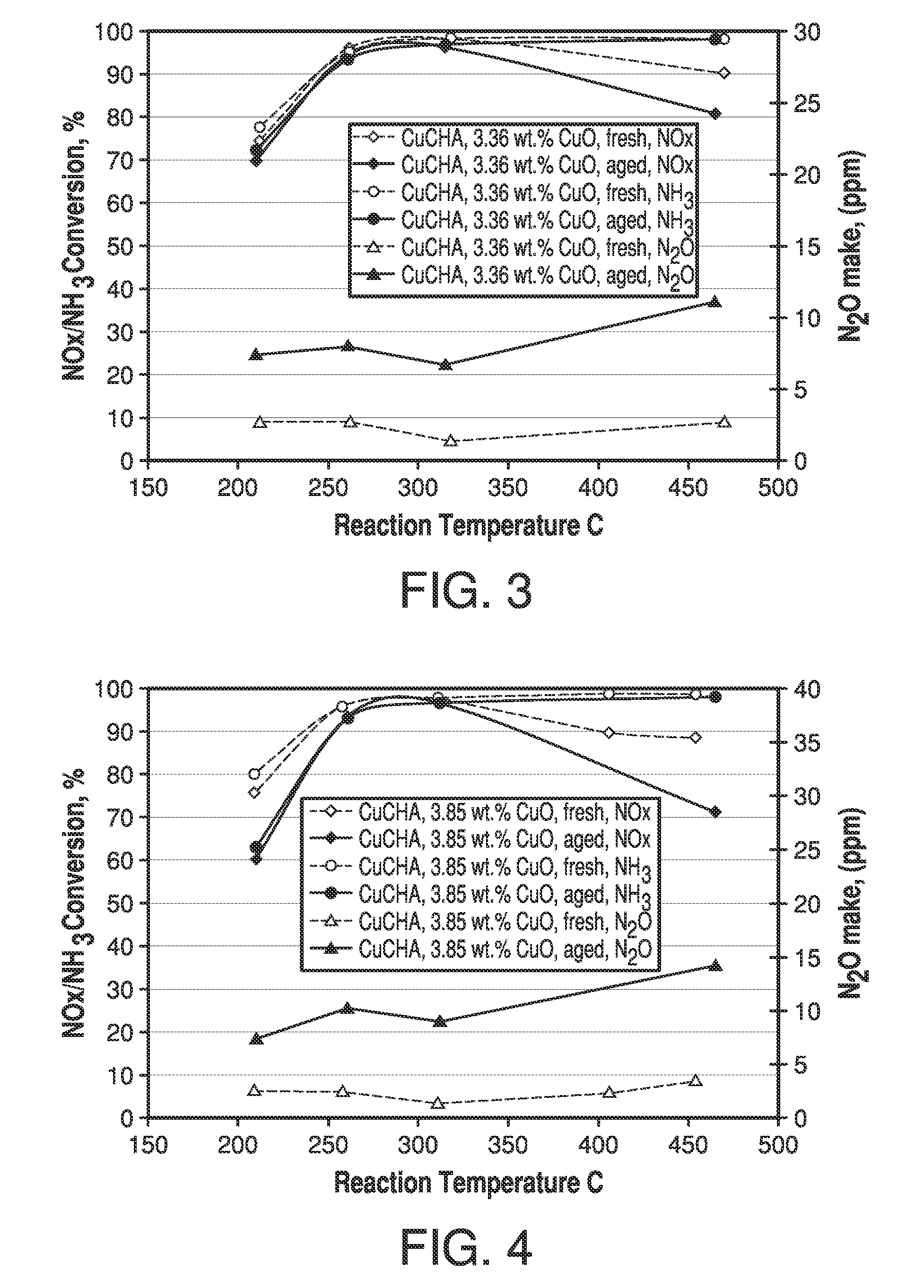

Copper CHA zeolite catalysts

ActiveUS7601662B2Good hydrothermal stabilityHigh catalytic activityCombination devicesAluminium compoundsReaction temperatureCrystal structure

Zeolite catalysts and systems and methods for preparing and using zeolite catalysts having the CHA crystal structure are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stable at high reaction temperatures. The zeolite catalysts include a zeolite carrier having a silica to alumina ratio from about 15:1 to about 256:1 and a copper to alumina ratio from about 0.25:1 to about 1:1.

Owner:BASF CORP

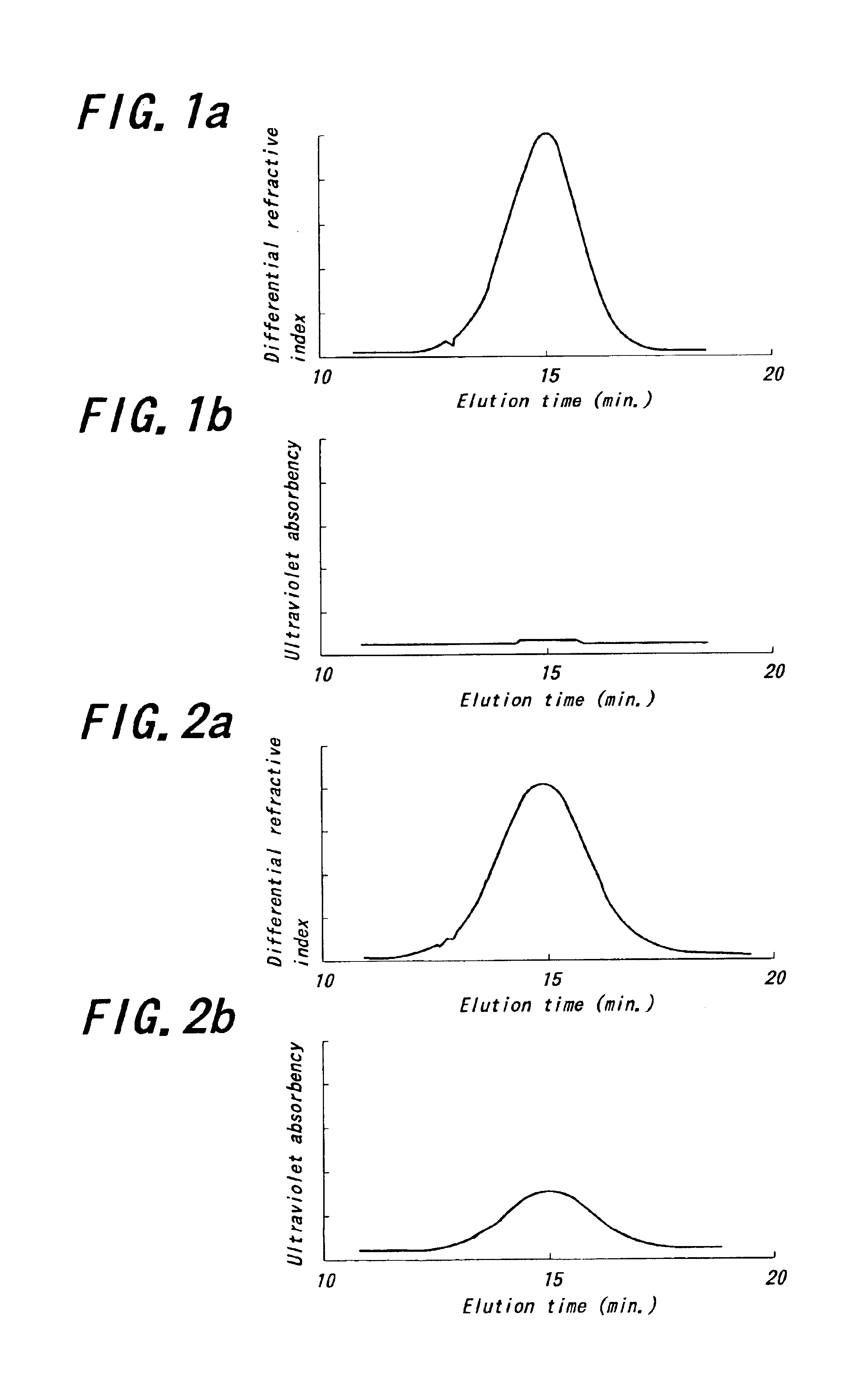

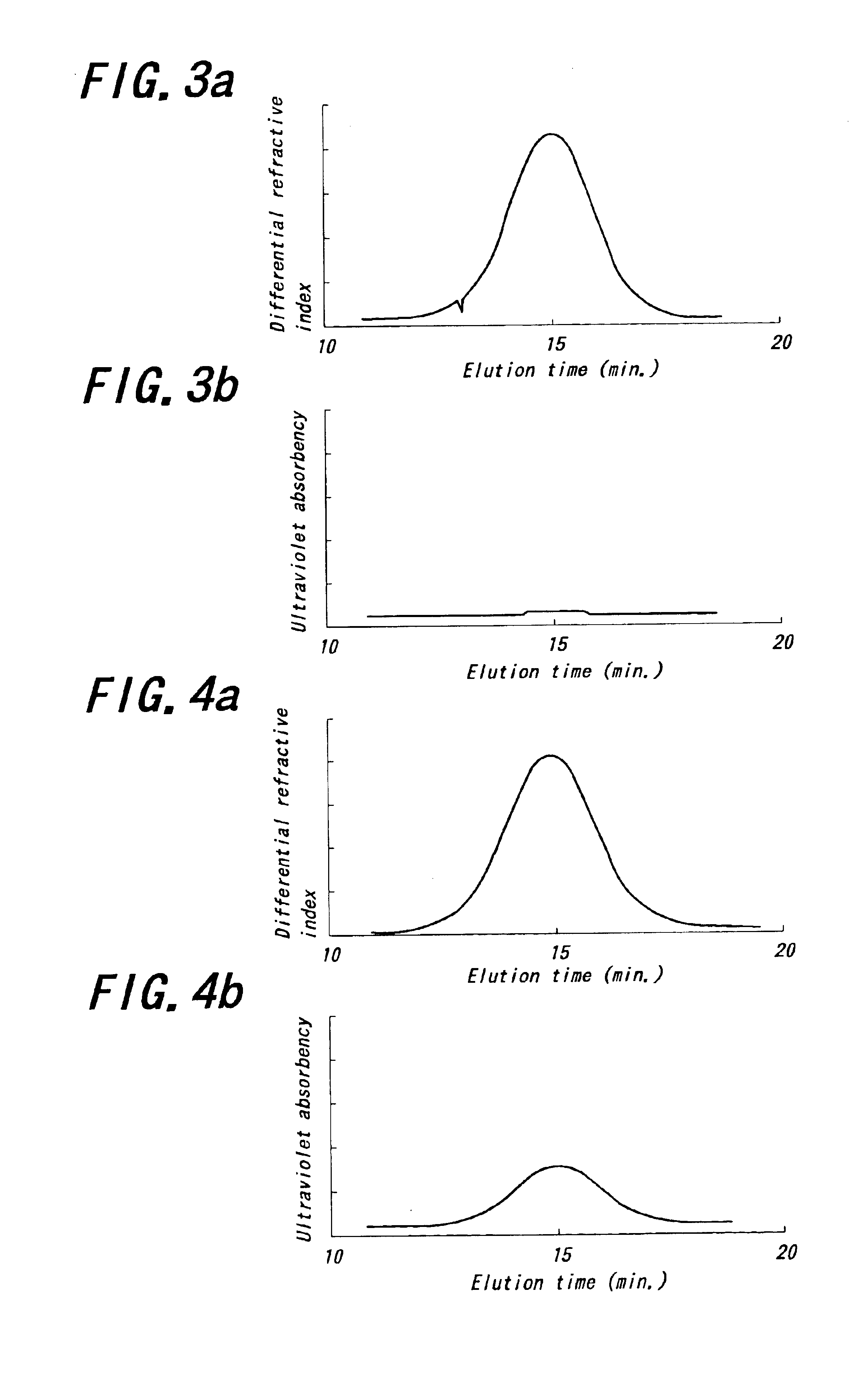

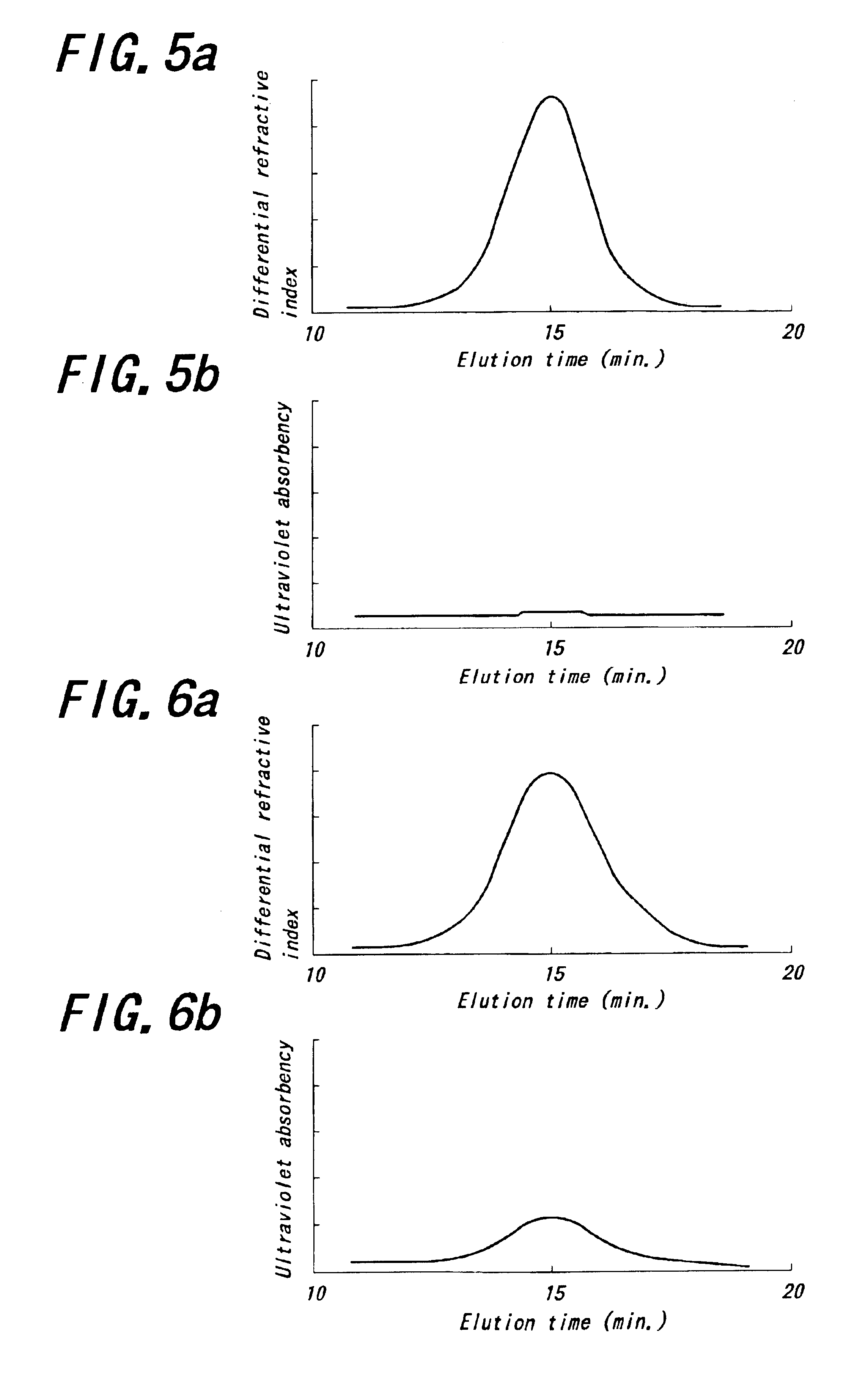

Modified conjugated diene polymer and method of producing the same and rubber composition

A novel modified conjugated diene polymer is obtained by polymerizing a conjugated diene compound with a specified catalyst consisting of components (a)-(c) and then reacting with at least one specified compound selected from the group consisting of components (d)-(l), and has a content of cis-1,4-bond of not less than 85% and a ratio of weight average molecular weight to number average molecular weight of not more than 4. And also, a rubber composition comprises the modified conjugated diene polymer a rubber ingredient.

Owner:JSR CORPORATIOON +1

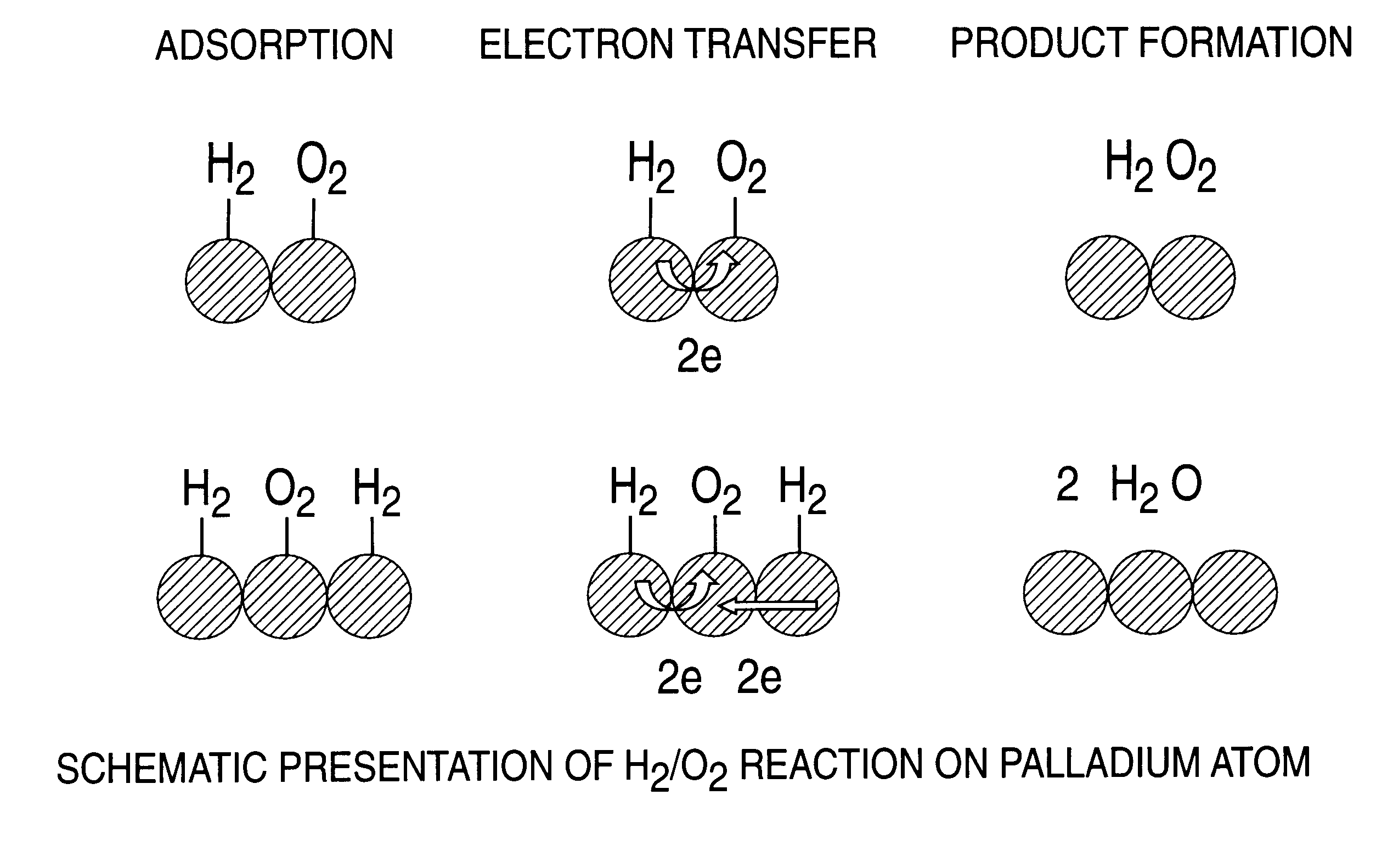

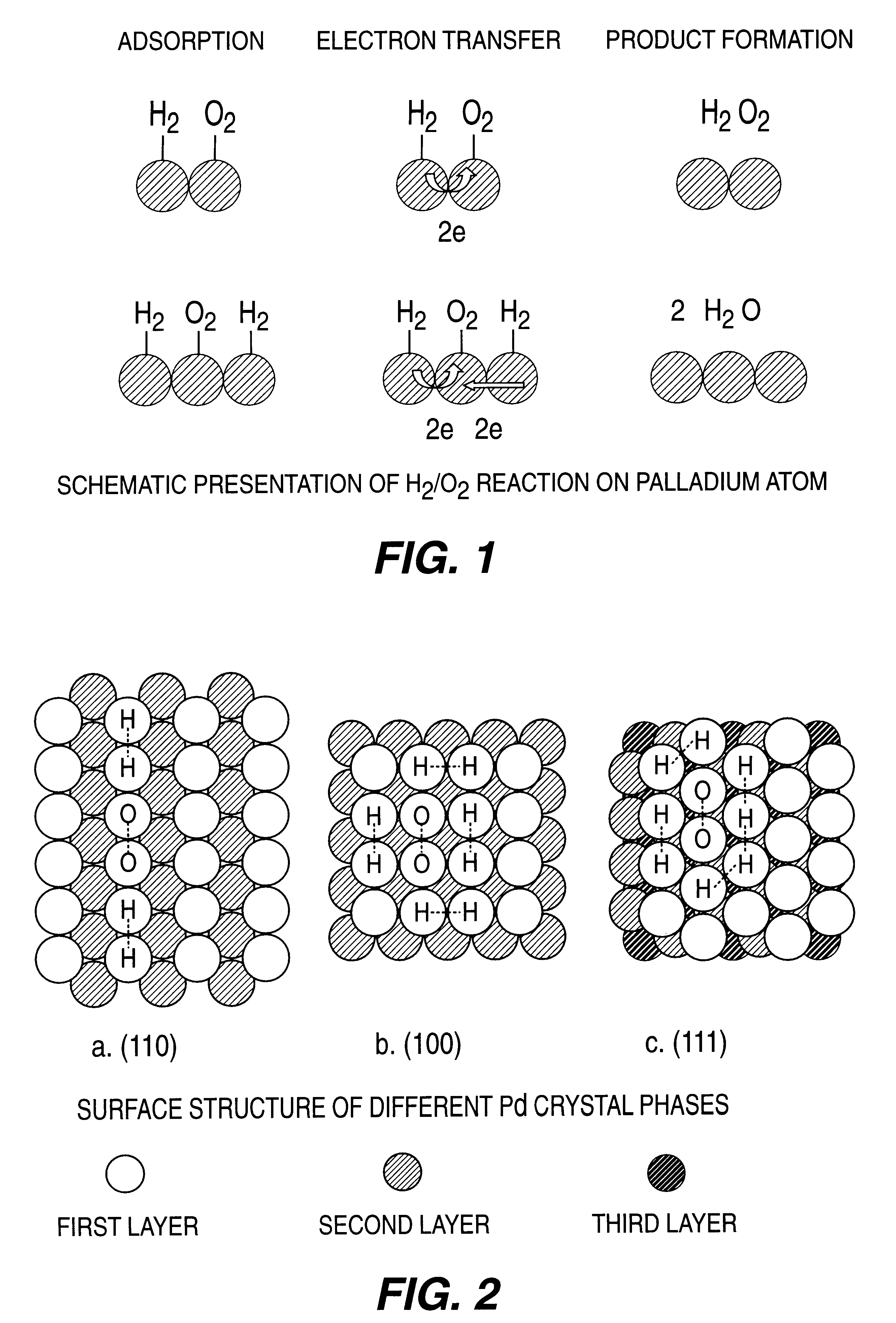

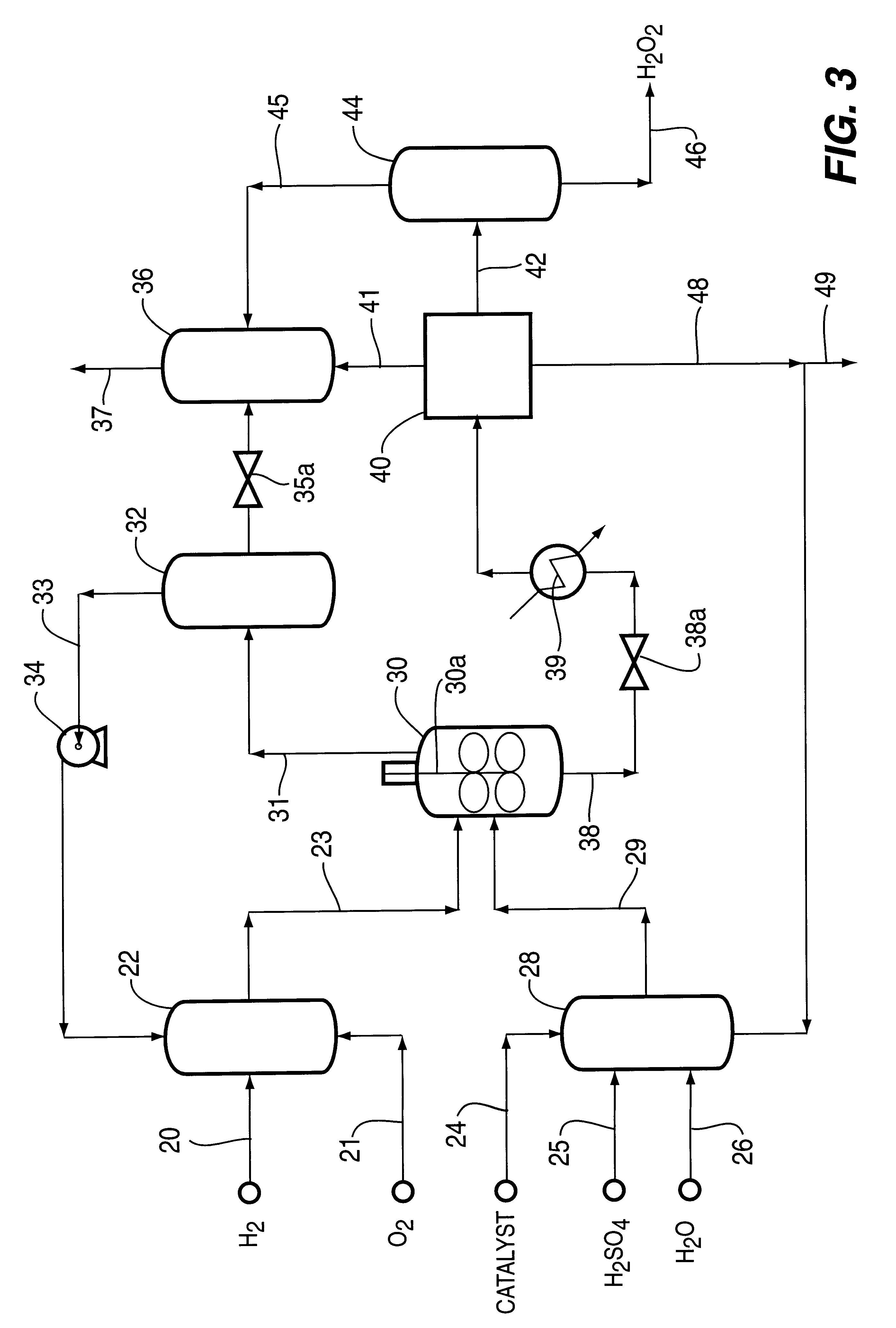

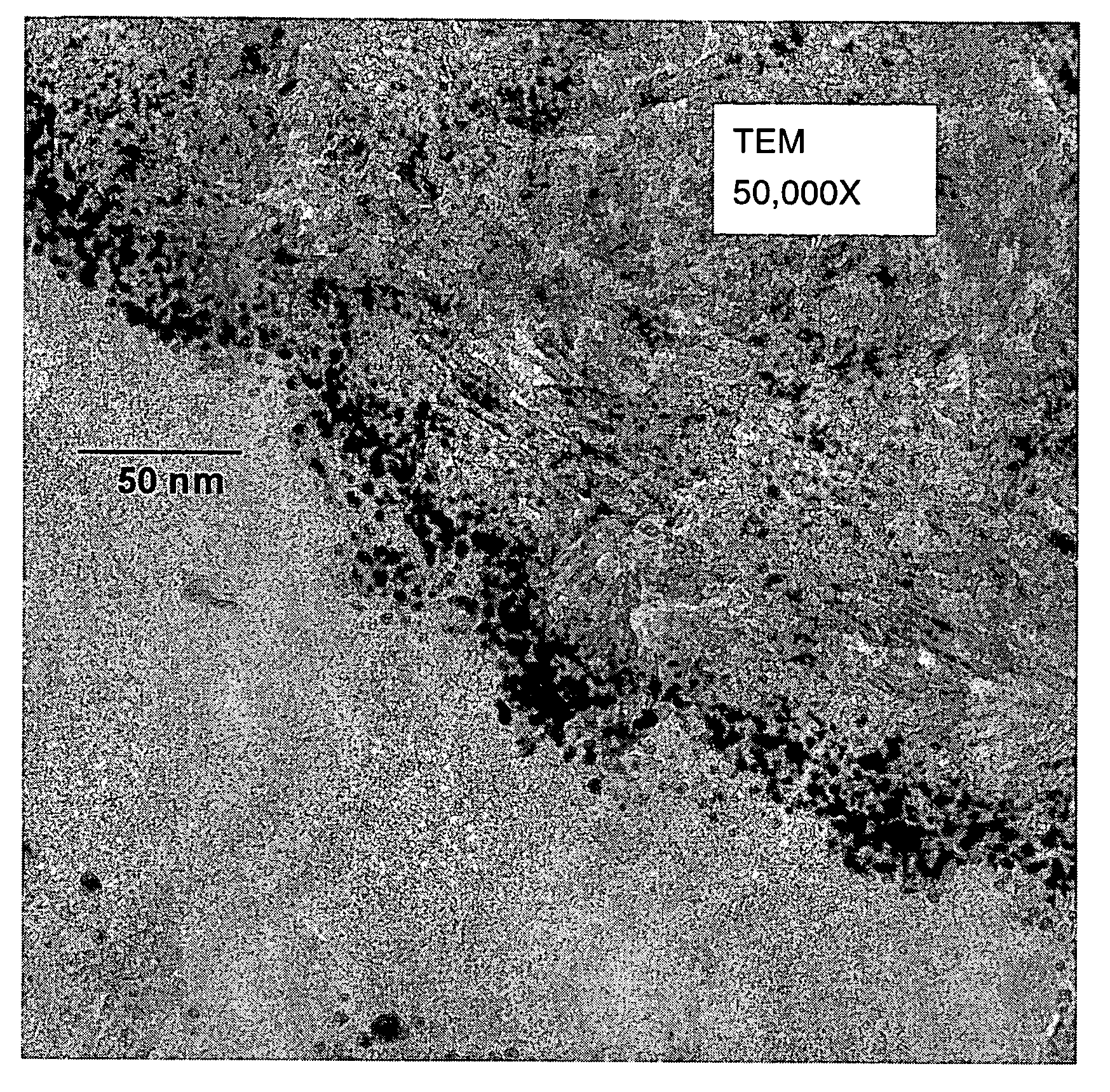

Catalyst and process for direct catalytic production of hydrogen peroxide, (H2O2)

InactiveUS6168775B1High catalytic activityHigh activityHydrogen peroxideCatalyst activation/preparationParticulatesHydrogen

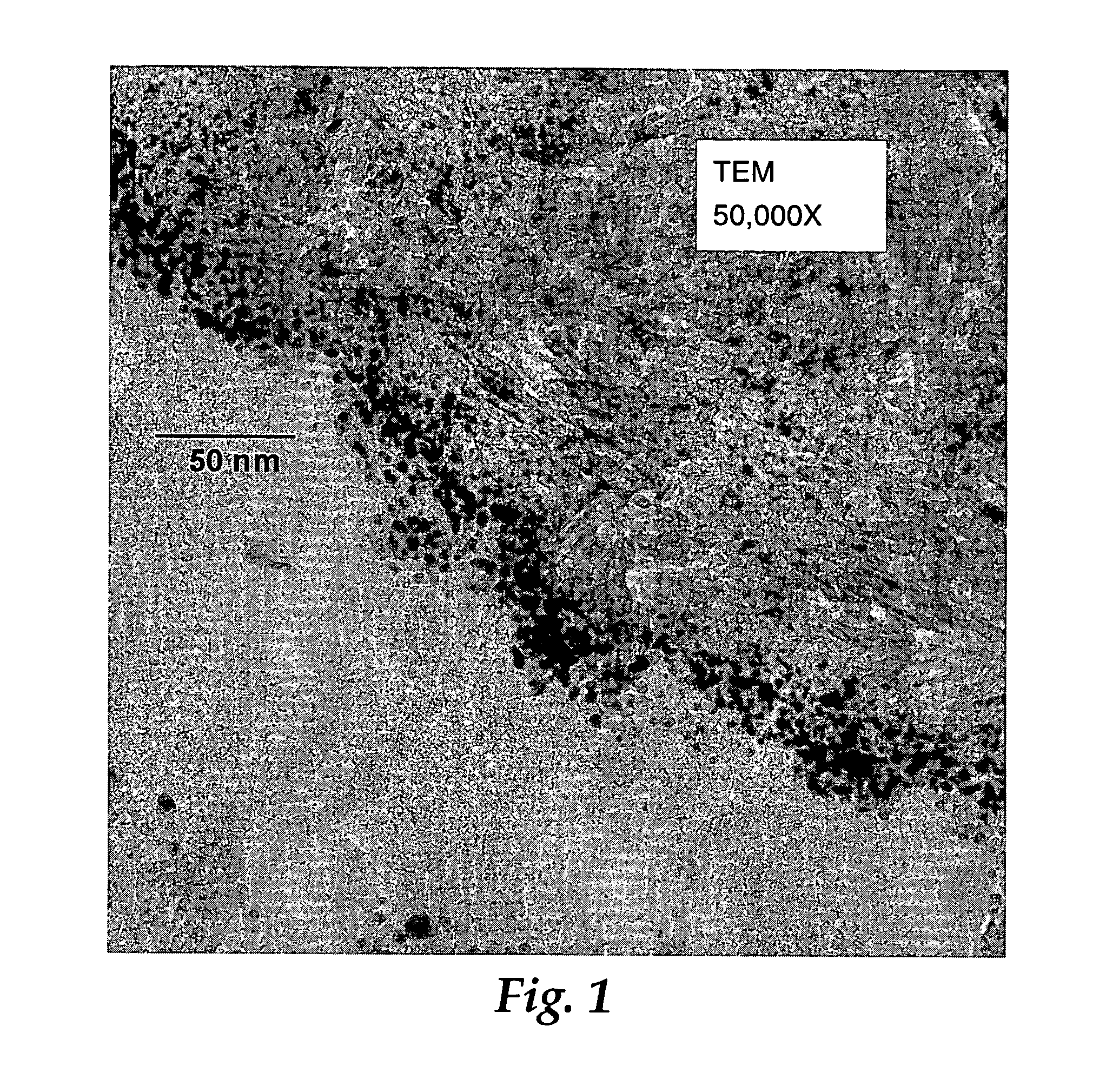

A particulate supported noble metal phase-controlled catalyst material having 5-1000 mum surface area of 50-500 m2 / gm is provided for use in direct catalytic production of hydrogen peroxide (H2O2) product from hydrogen and oxygen-containing feedstreams. The catalyst is made by depositing phase controlled crystals of a noble metal such as palladium on a suitable particulate support material such as carbon black, by utilizing a precursor solution of the metal and a suitable control ionic polymer having molecular weight of 300-8000 such as sodium polyacrylate in a selected metal to polymer molar ratio of 1:0.1 to 1:10, which procedure provides desired phase control of the noble metal atoms to form widely dispersed minute noble metal crystals on the support material. The invention includes methods for making the catalyst, and also a process for utilizing the catalyst to directly produce high yields of hydrogen peroxide (H2O2) product from hydrogen and oxygen-containing gaseous feedstreams.

Owner:BORAL IP HLDG

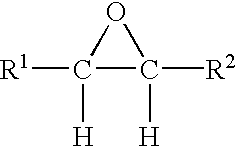

Alkylene oxide catalysts having enhanced activity and/or stability

InactiveUS6511938B1High catalytic activityEnhanced Efficiency StabilityOrganic chemistry methodsCatalyst activation/preparationChemistryOxide

Catalysts for the production of alkylene oxide by the epoxidation of alkene with oxygen comprise a silver-containing support, and a sufficient amount of cobalt component to enhance at least one of activity and / or efficiency and / or stability as compared to a similar catalyst which does not contain cobalt component.

Owner:DOW TECH INVESTMENTS

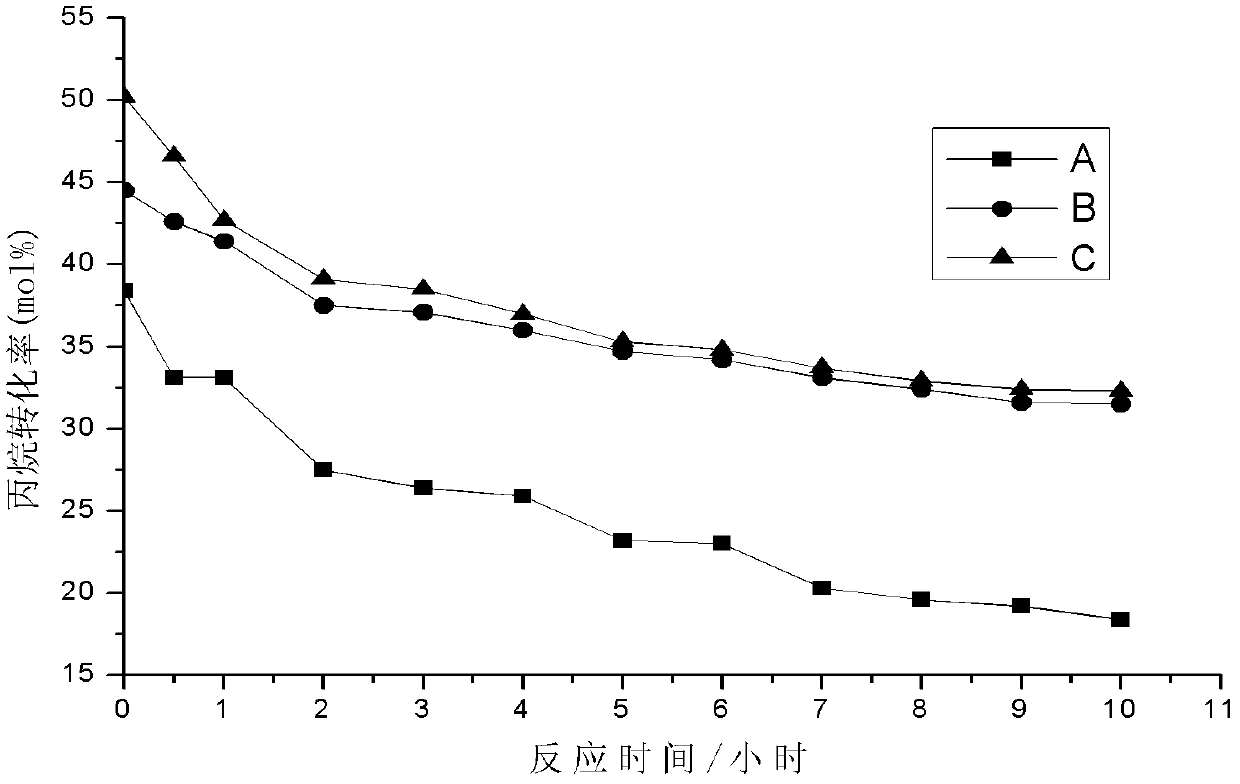

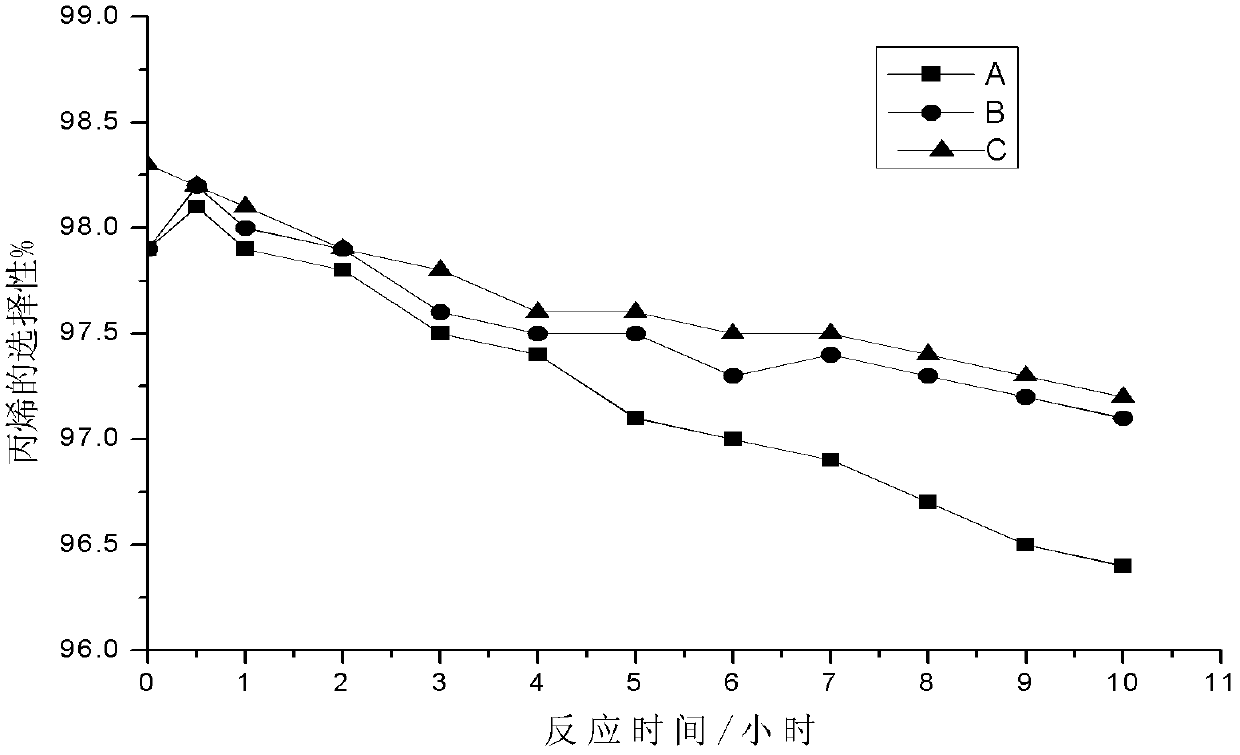

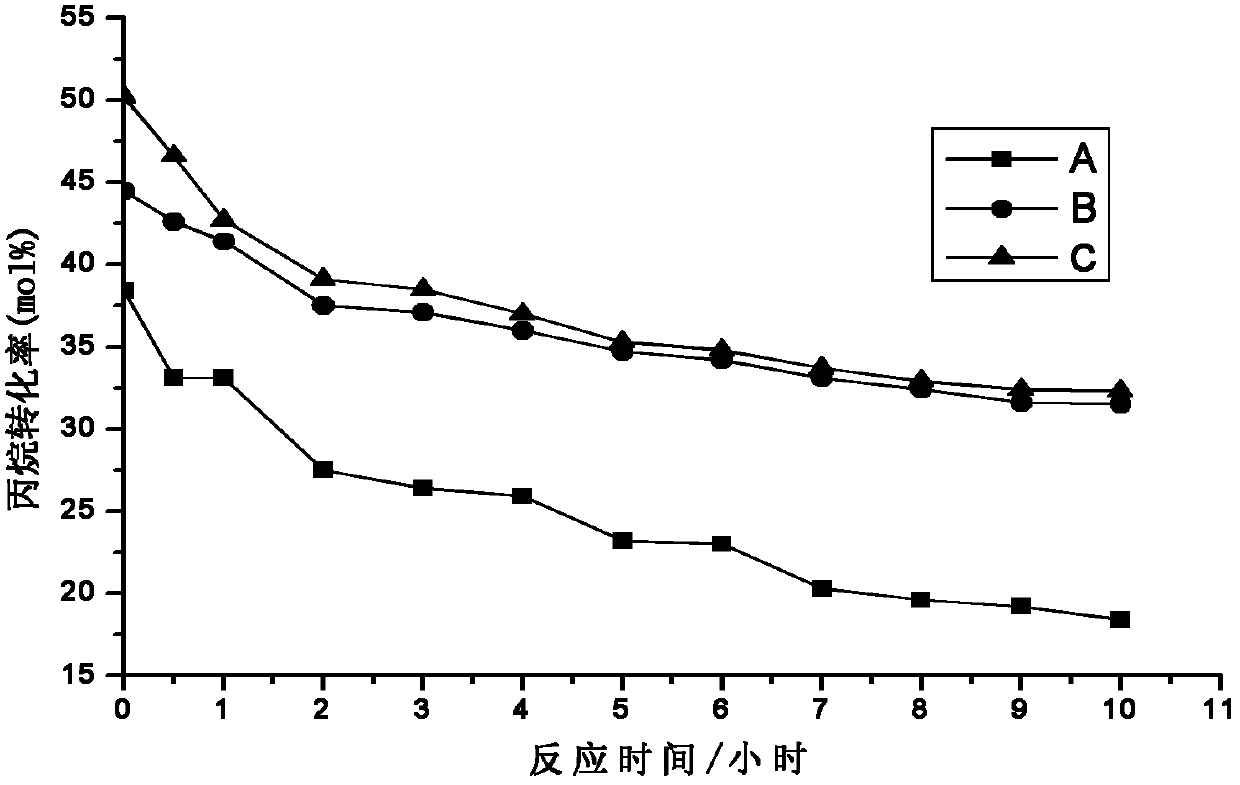

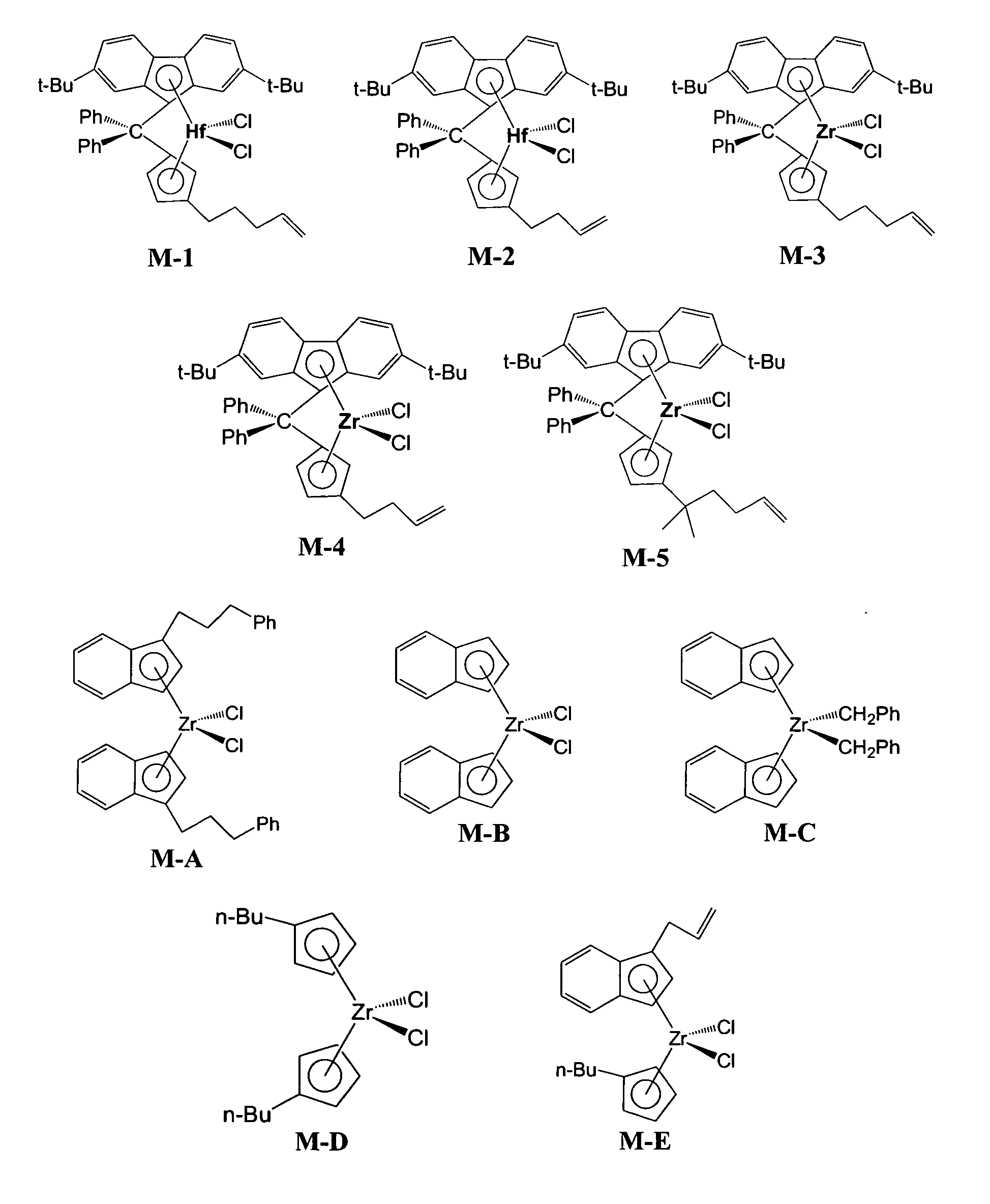

Catalyst for preparing propylene by propane dehydrogenation and its prepn.

InactiveCN101015802AHigh selectivityImprove reaction stabilityCatalyst carriersHydrocarbonsAdhesiveDehydrogenation

The invention relates to a catalyst for dehydrogenating propane to prepare propone, which uses thermal-resistant oxide as carrier, uses palladium-group metal as main catalyst, uses IV A group metal and rare-earth metal as agents, uses halogen as modifier, and uses inorganic oxide with high temperature resistance as adhesive. The inventive catalyst under high temperature and low pressure has higher propane transfer rate, propone selectivity and reaction stability. And the preparation comprises that at 60-100Deg. C, immerging thermal-resistant oxide with rare-earth metal water solution for 2-10h, at 60-180Deg. C baking for 2-10h, at 400-600Deg. C baking for 3-10h, immerging said carrier and the water solution which contains palladium metal and IVA metal at 60-100Deg. C for 2-10h, and baking for 2-10h at 60-180Deg. C, adding adhesive, protruding agent and acid gel solvent, protruding and shaping, baking for 2-10h at 60-180Deg. C, activating for 3-10h at 400-600Deg. C, and reducing for 2-10h in hydrogen flow at 400-600Deg. C.

Owner:SOUTHEAST UNIV

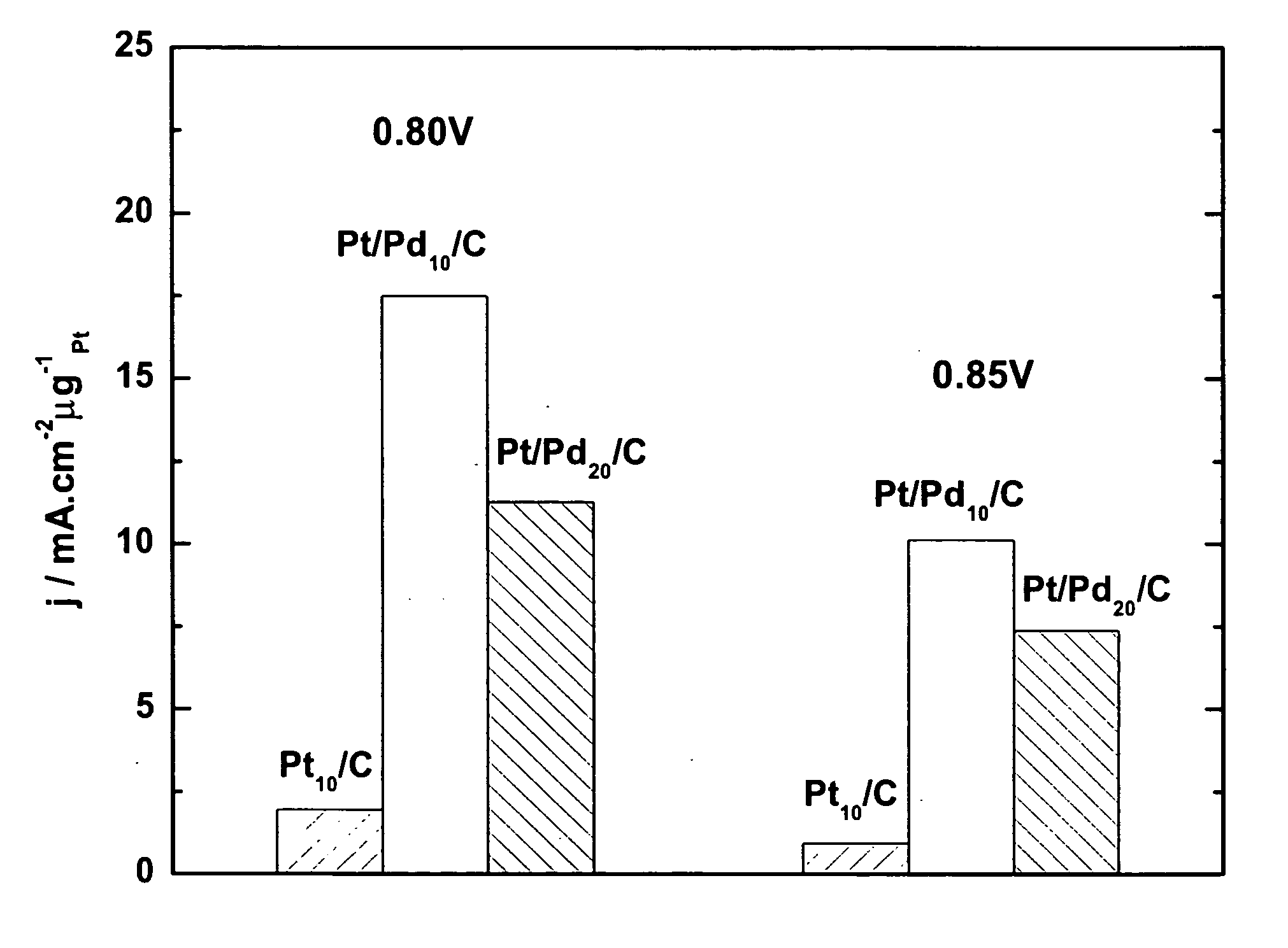

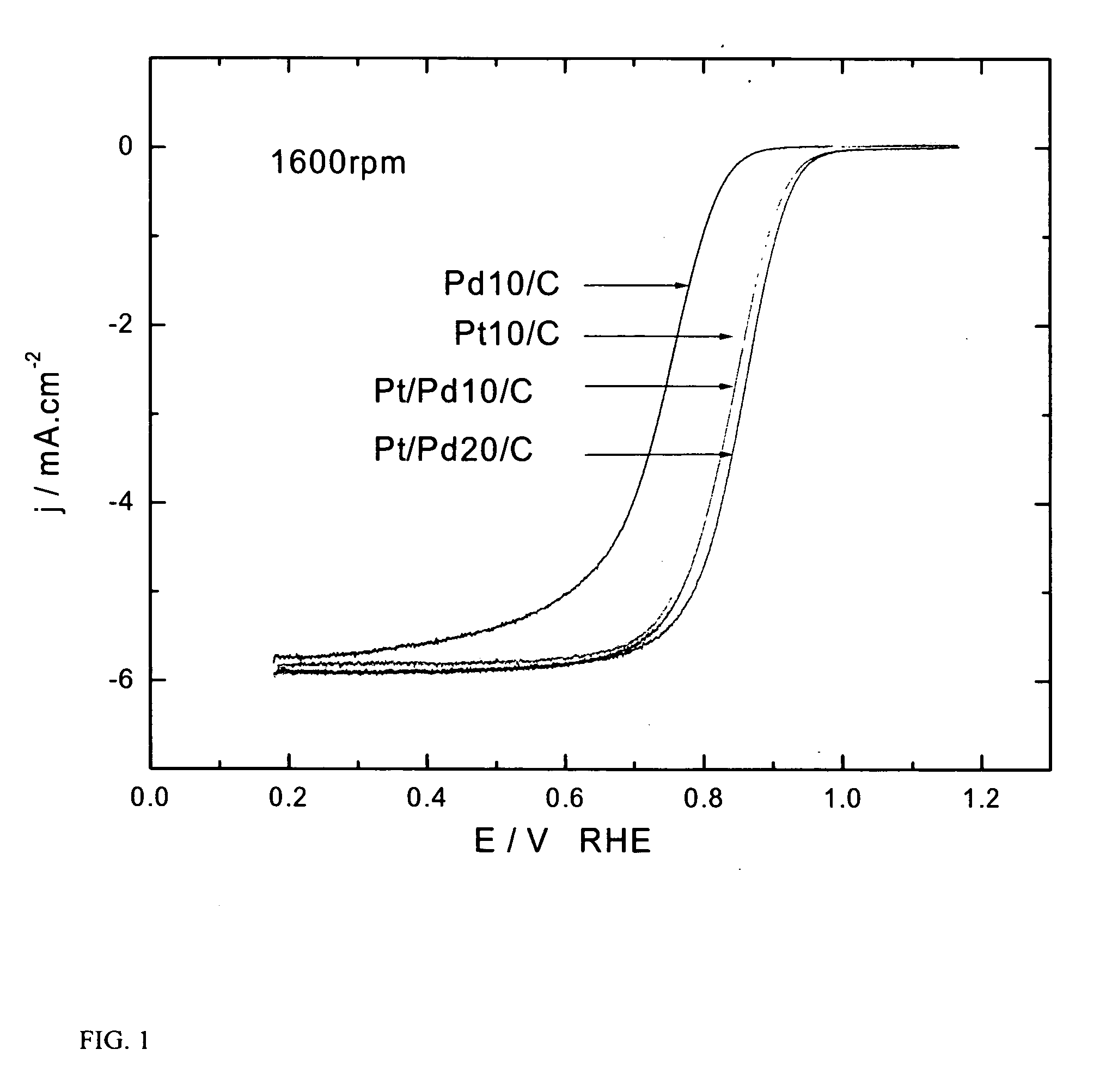

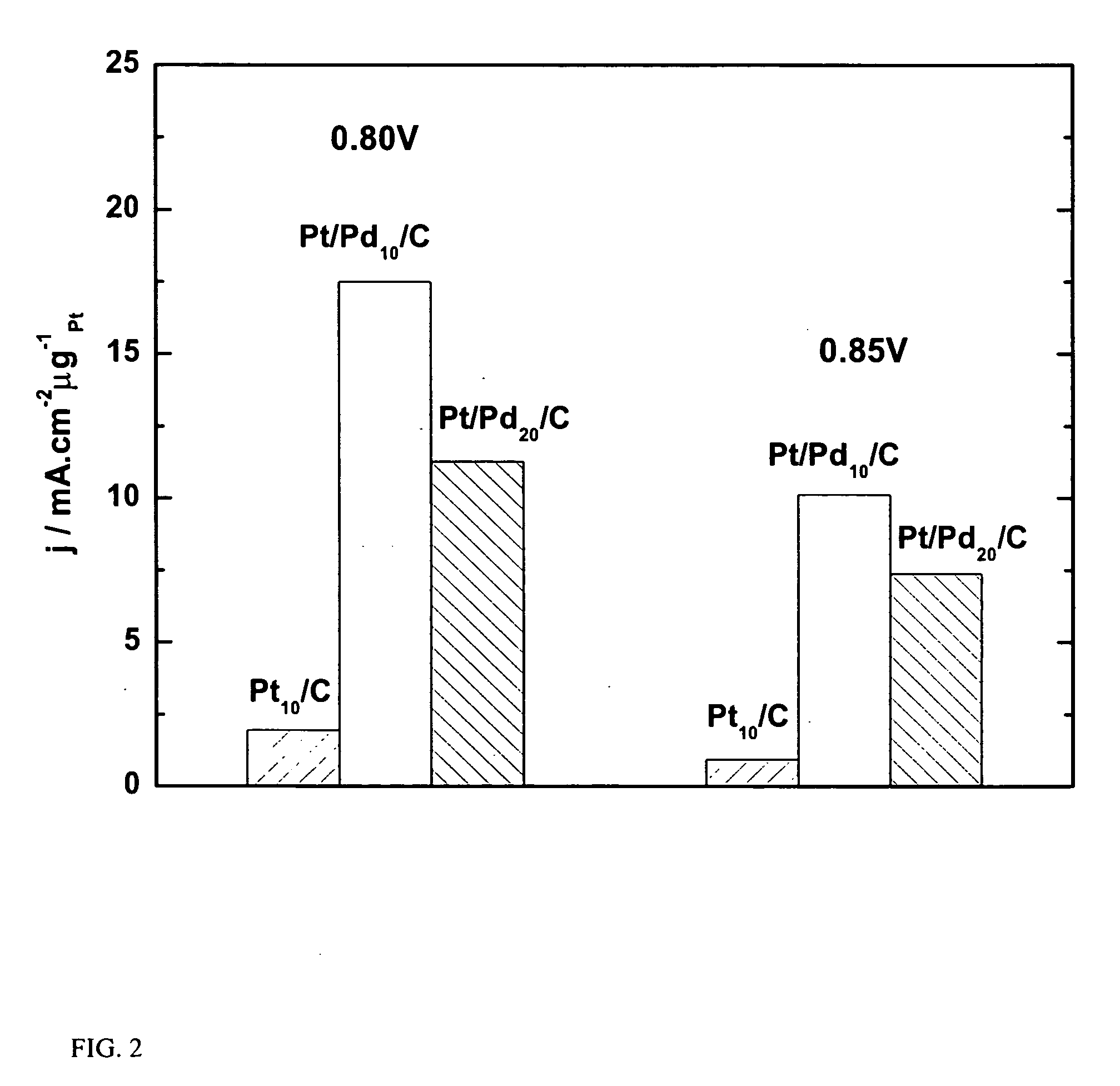

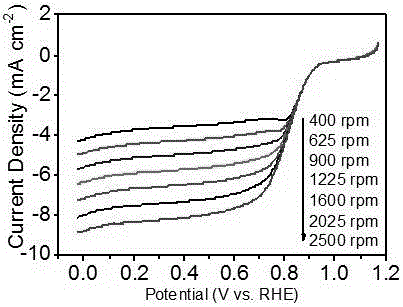

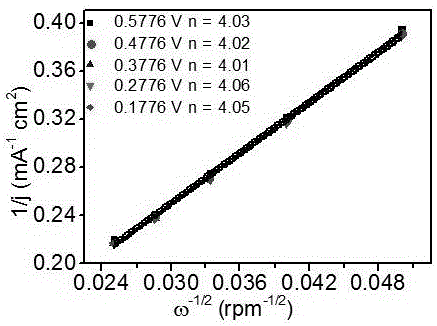

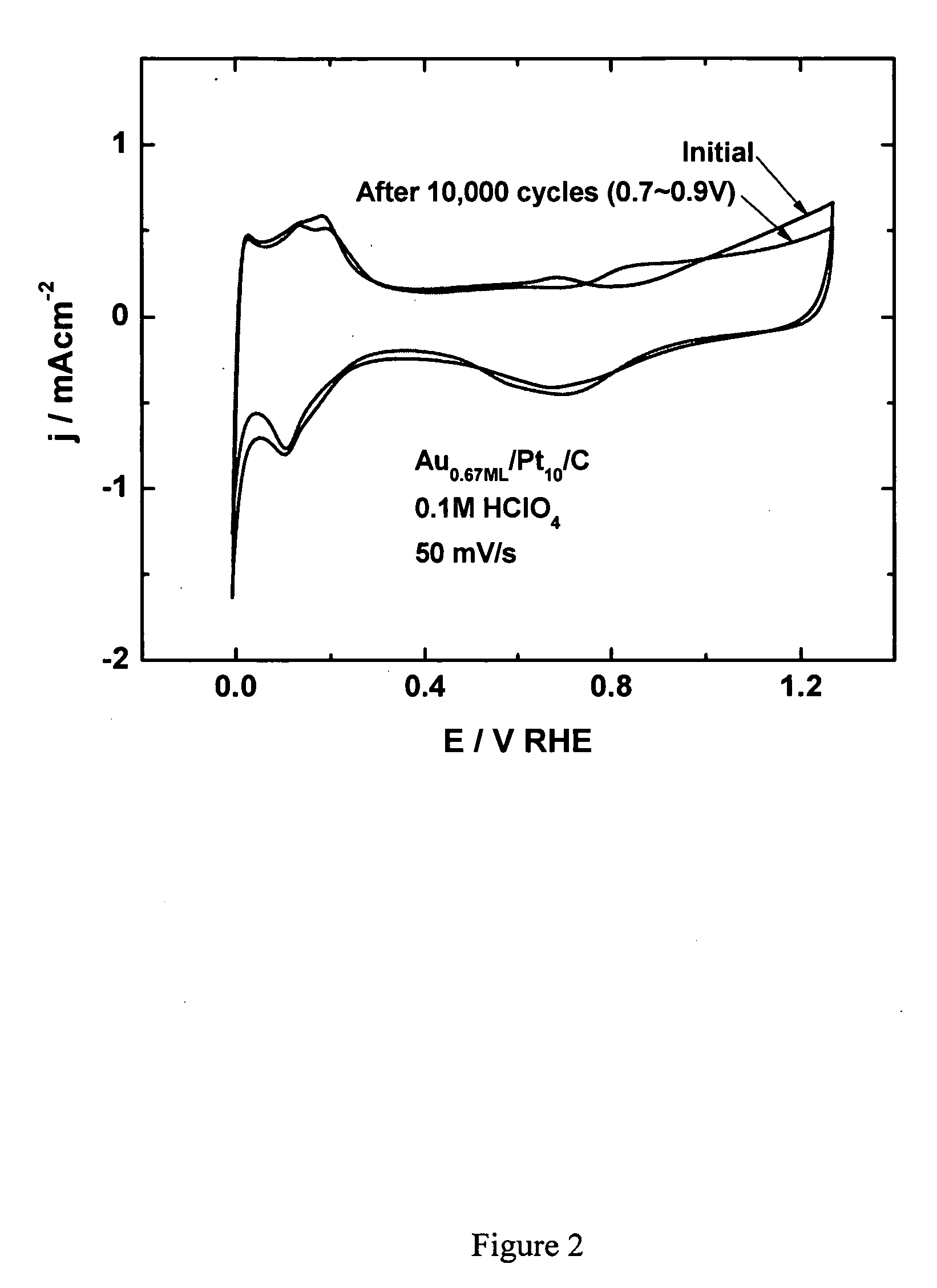

Electrocatalysts having platinum monolayers on palladium, palladium alloy, and gold alloy nanoparticle cores, and uses thereof

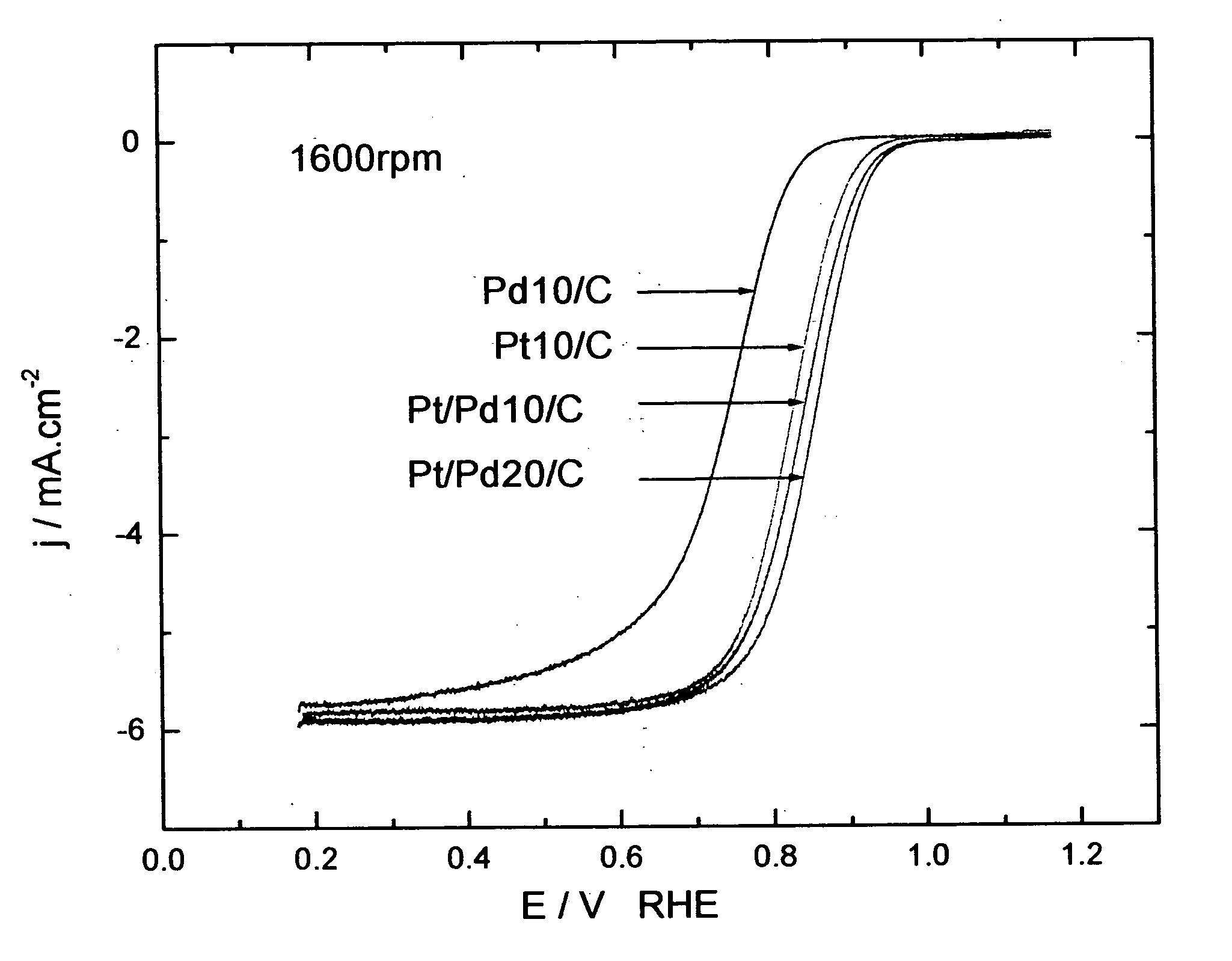

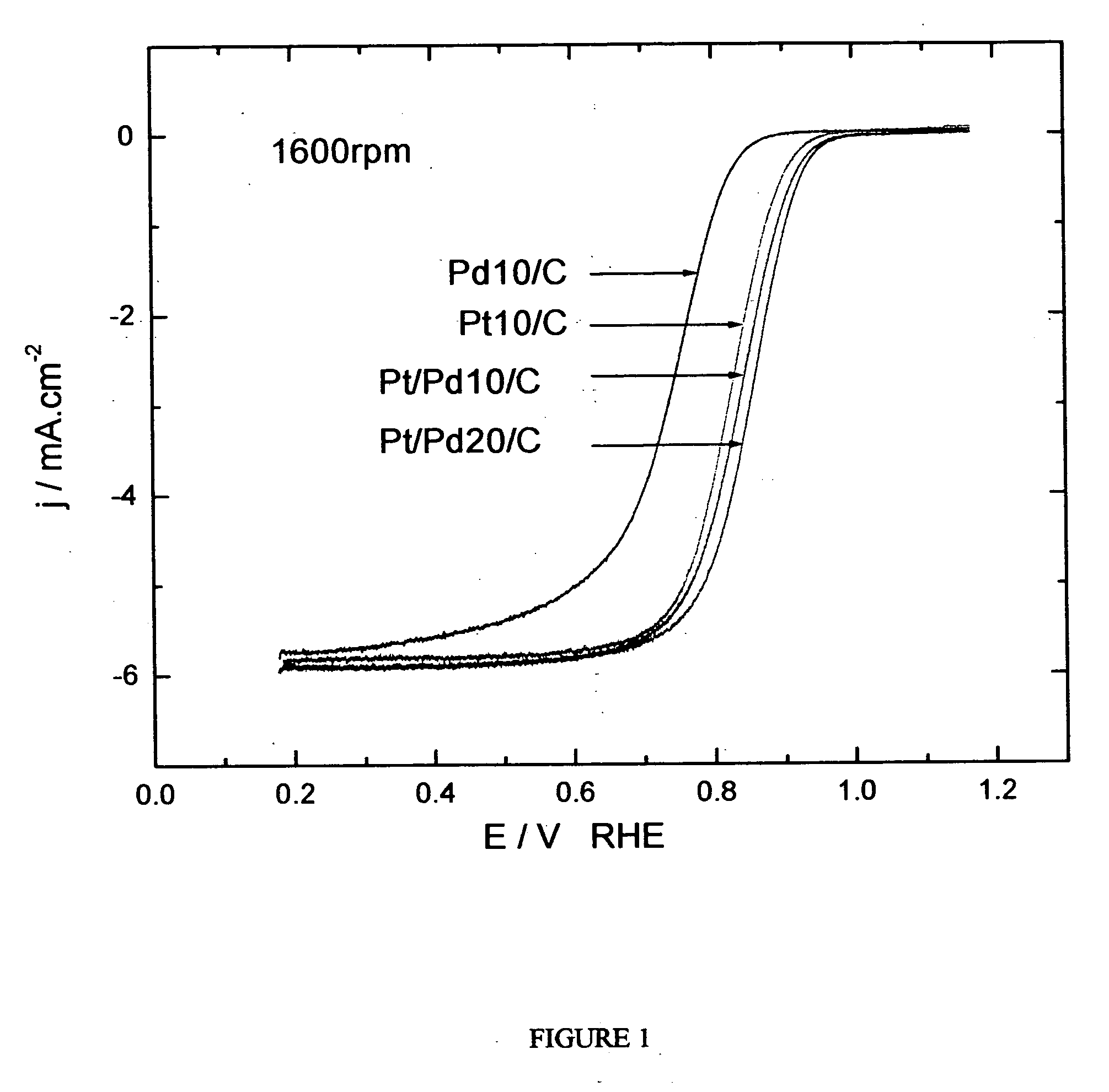

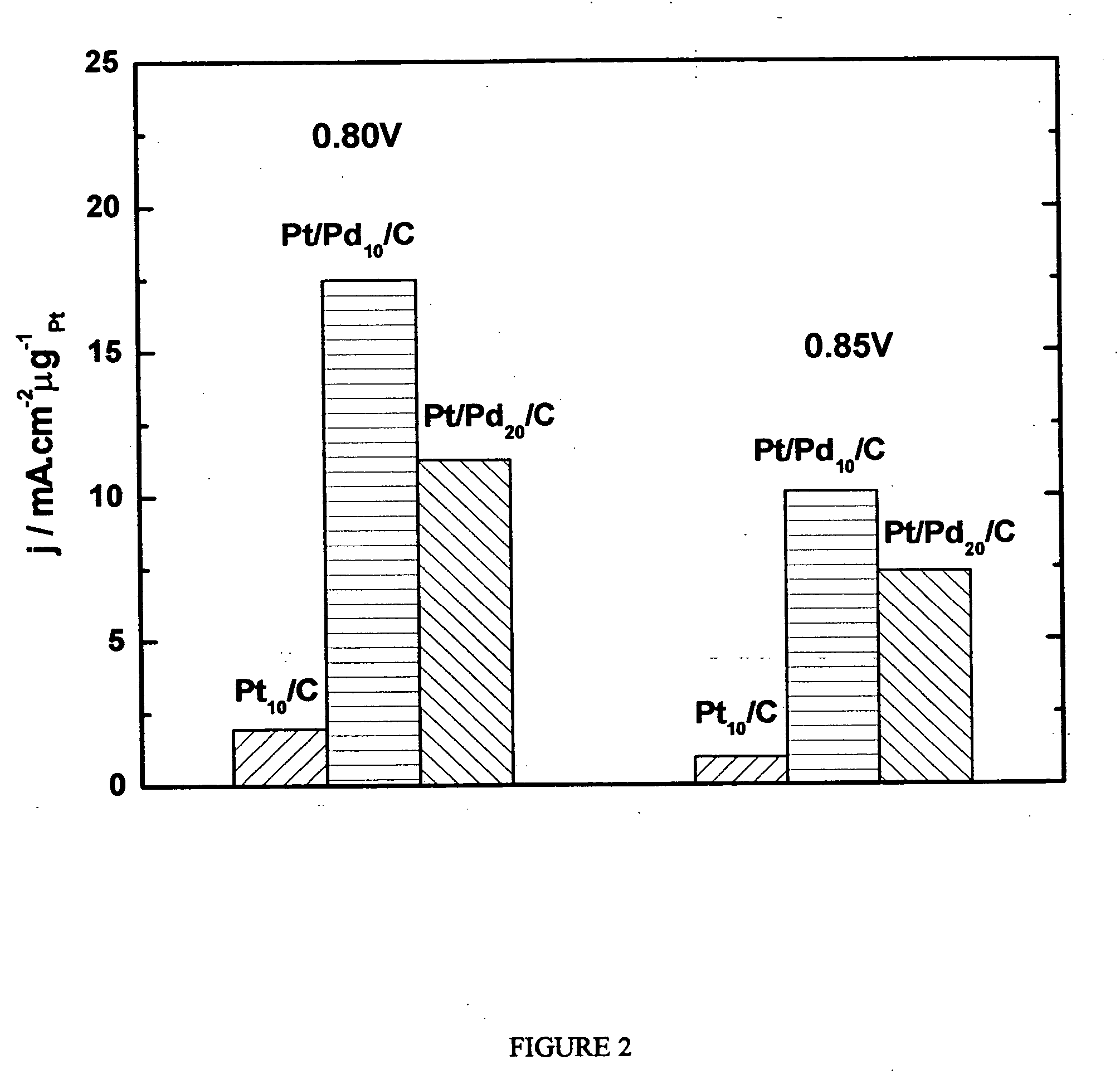

ActiveUS20070031722A1Improved oxygen-reducing catalytic activityLow platinum loadingMetal-working apparatusActive material electrodesRheniumGold alloys

The invention relates to platinum-coated particles useful as fuel cell electrocatalysts. The particles are composed of a noble metal or metal alloy core at least partially encapsulated by an atomically thin surface layer of platinum atoms. The invention particularly relates to such particles having a palladium, palladium alloy, gold alloy, or rhenium alloy core encapsulated by an atomic monolayer of platinum. In other embodiments, the invention relates to fuel cells containing these electrocatalysts and methods for generating electrical energy therefrom.

Owner:BROOKHAVEN SCI ASSOCS

Catalysts, activating agents, support media, and related methodologies useful for making catalyst systems especially when the catalyst is deposited onto the support media using physical vapor deposition

InactiveUS20050095189A1Improve performanceEasy to useMaterial nanotechnologyInternal combustion piston enginesGas phaseAdditive ingredient

Use of physical vapor deposition methodologies to deposit nanoscale gold on activating support media makes the use of catalytically active gold dramatically easier and opens the door to significant improvements associated with developing, making, and using gold-based, catalytic systems. The present invention, therefore, relates to novel features, ingredients, and formulations of gold-based, heterogeneous catalyst systems generally comprising nanoscale gold deposited onto a nanoporous support.

Owner:3M INNOVATIVE PROPERTIES CO

Platinum- and platinum alloy-coated palladium and palladium alloy particles and uses thereof

ActiveUS20060135359A1Improved oxygen-reducing catalytic activityLow platinum loadingSynthetic resin layered productsCellulosic plastic layered productsAlloyOxygen

The present invention relates to particle and nanoparticle composites useful as oxygen-reduction electrocatalysts. The particle composites are composed of a palladium or palladium-alloy particle or nanoparticle substrate coated with an atomic submonolayer, monolayer, bilayer, or trilayer of zerovalent platinum atoms. The invention also relates to a catalyst and a fuel cell containing the particle or nanoparticle composites of the invention. The invention additionally includes methods for oxygen reduction and production of electrical energy by using the particle and nanoparticle composites of the invention.

Owner:BROOKHAVEN SCI ASSOCS

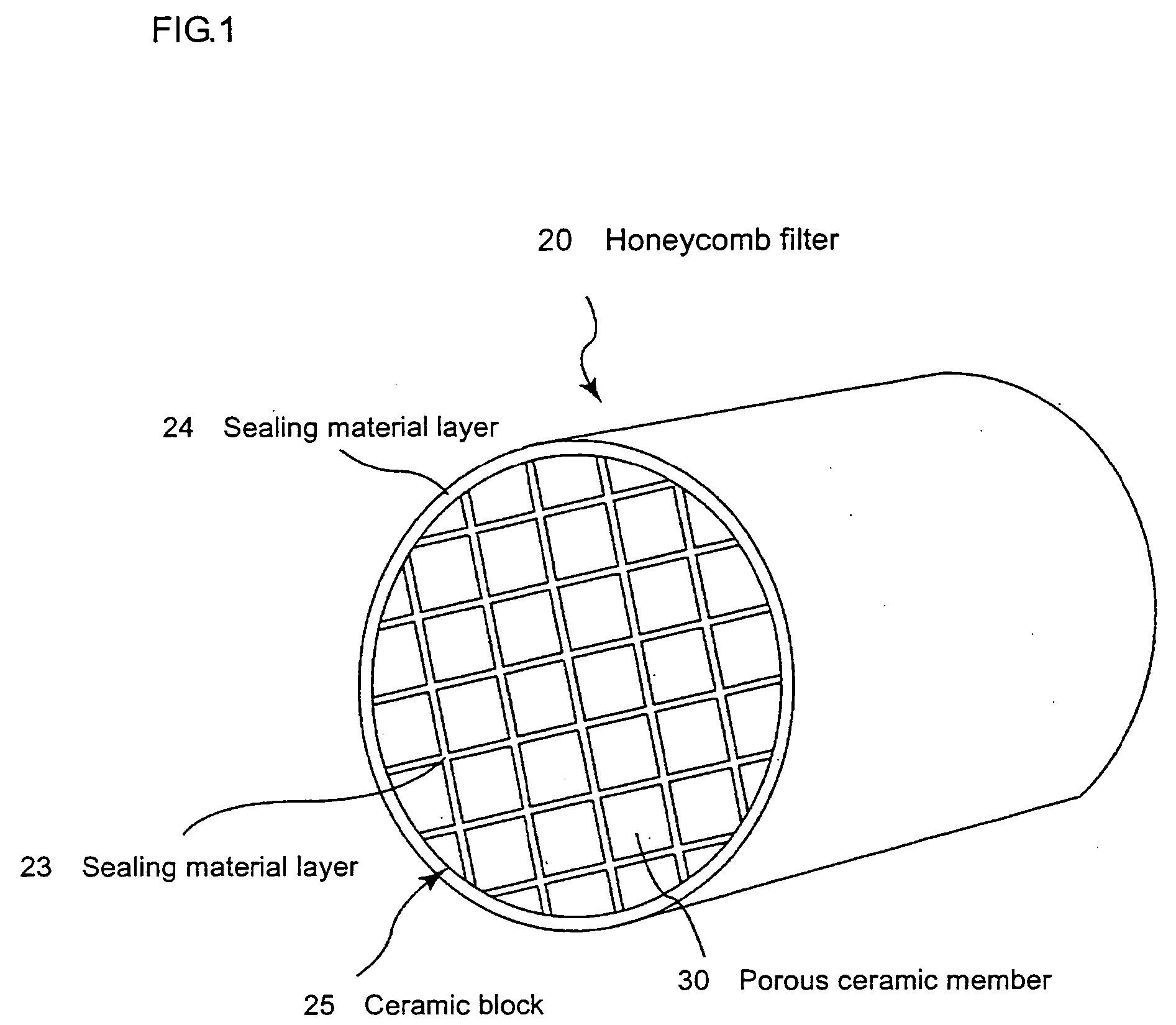

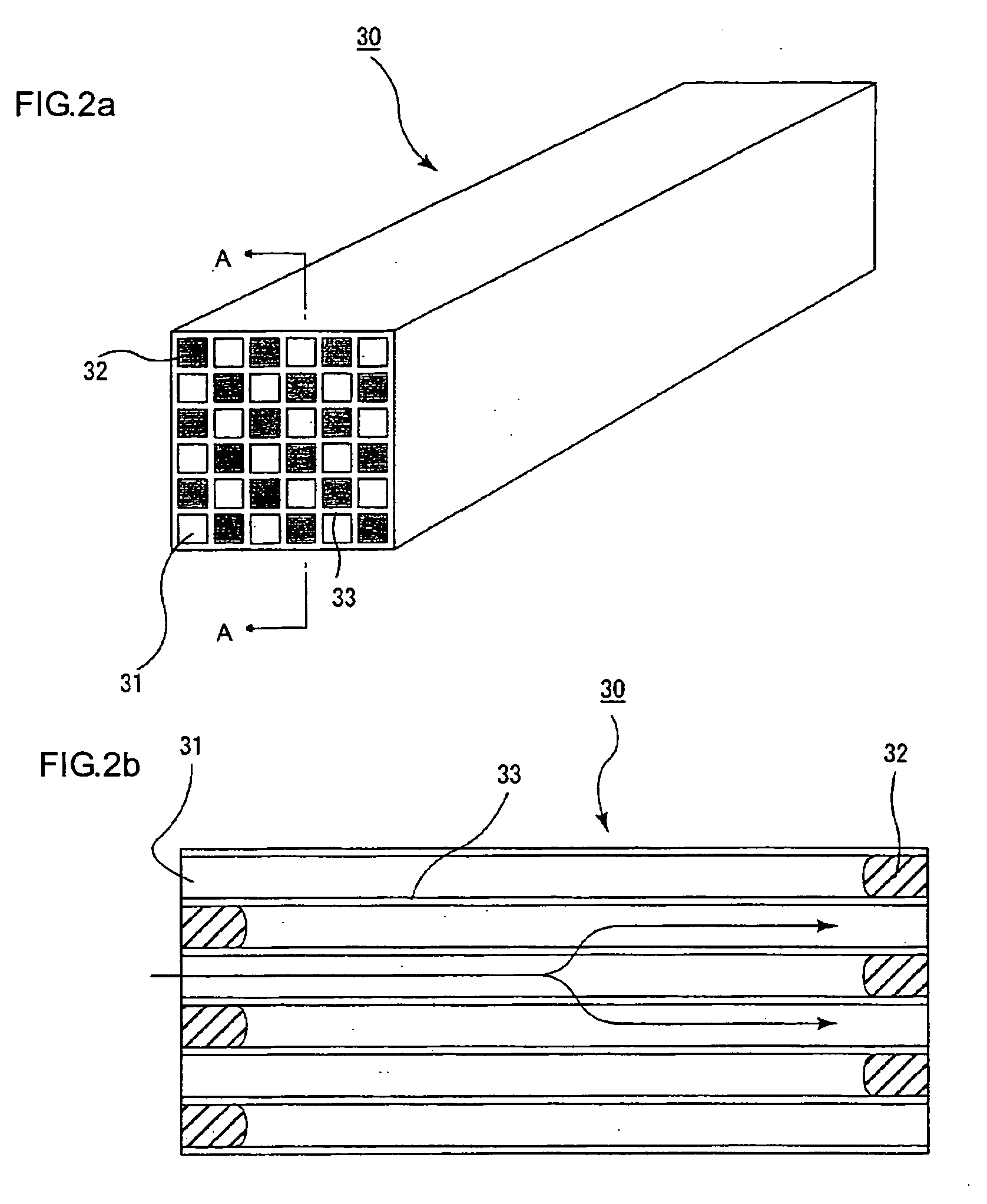

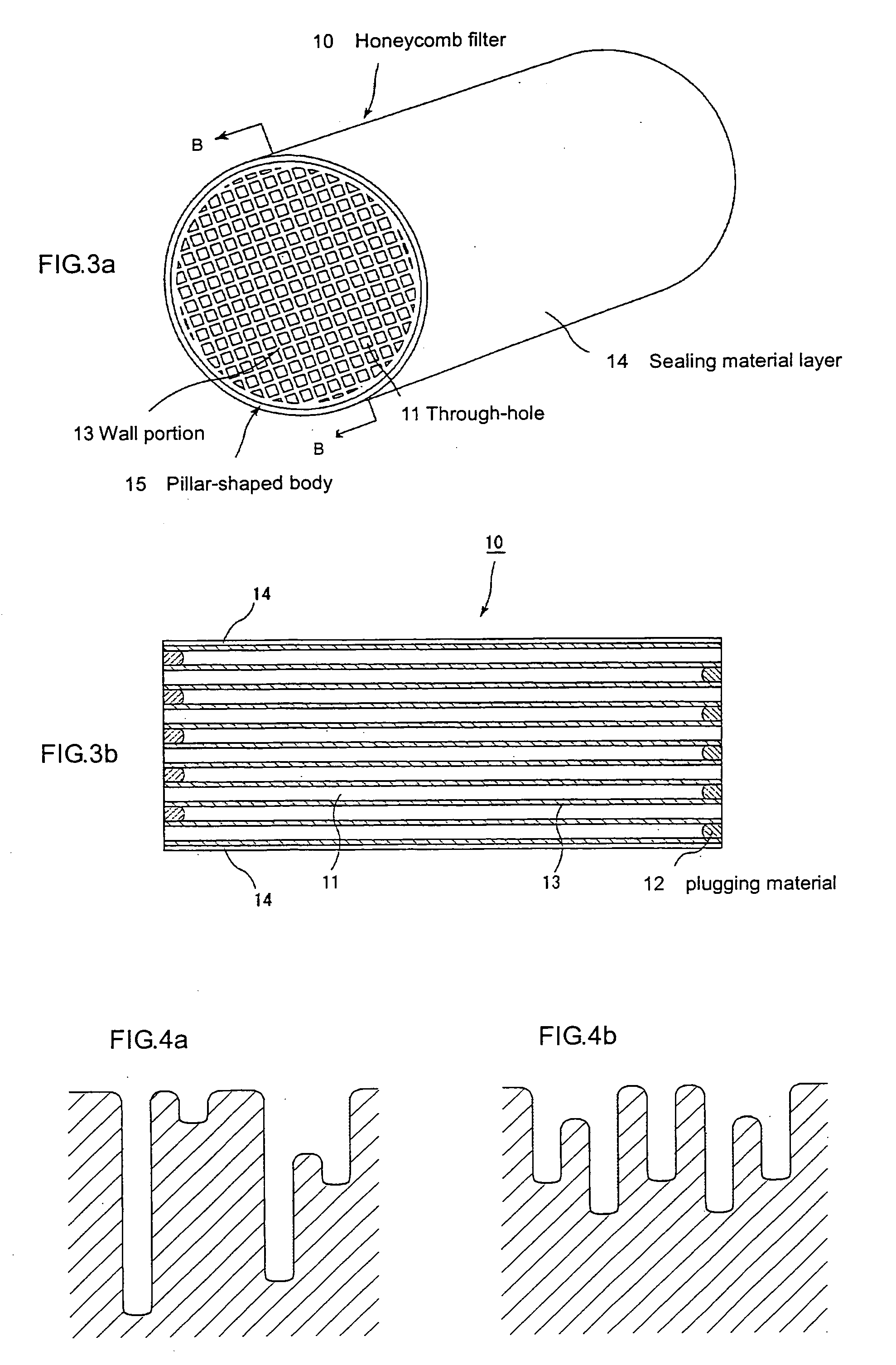

Ceramic honeycomb structure

ActiveUS20060166820A1Excellent in pressure loss and catching efficiencyHigh catalytic activityDispersed particle filtrationExhaust apparatusPore distributionSurface roughness

A honeycomb structural body comprises one or plural pillar-shaped porous ceramic members in which many through-holes are arranged side by side in a longitudinal direction through partition walls and either one end portions of these through-holes are sealed. The partition wall forming the structural body has a surface roughness of not less than 10 μm as a maximum roughness Rz defined in JIS B0601-2001 and an average pore size of 5-100 μm in a pore distribution measured by a mercury pressure method, and satisfies the following relationship: A≧90−B / 20 or A≦100−B / 20 when a ratio pores having a pore size of 0.9-1.1 times the average pore size to total pore volume is A (%) and a thickness of the partition wall is B (μm), and there is proposed an effective honeycomb structural body having excellent pressure loss and catching efficiency and a high catalyst reactivity.

Owner:IBIDEN CO LTD

Polymerization catalysts for producing polymers with low levels of long chain branching

InactiveUS20050288461A1Improve productivityHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationEthylene PolymersPolymerization catalysts

This invention relates to catalyst compositions, methods, and polymers encompassing a Group 4 metallocene with bridging η5-cyclopentadienyl-type ligands, in combination with a cocatalyst and an activator-support. The compositions and methods disclosed herein provide ethylene polymers with low levels of long chain branching.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Polymerization catalysts for producing polymers with low levels of long chain branching

ActiveUS7148298B2High catalytic activityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationEthylene PolymersPolymerization catalysts

This invention relates to catalyst compositions, methods, and polymers encompassing a Group 4 metallocene with bridging η5-cyclopentadienyl-type ligands, in combination with a cocatalyst and an activator-support. The compositions and methods disclosed herein provide ethylene polymers with low levels of long chain branching.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

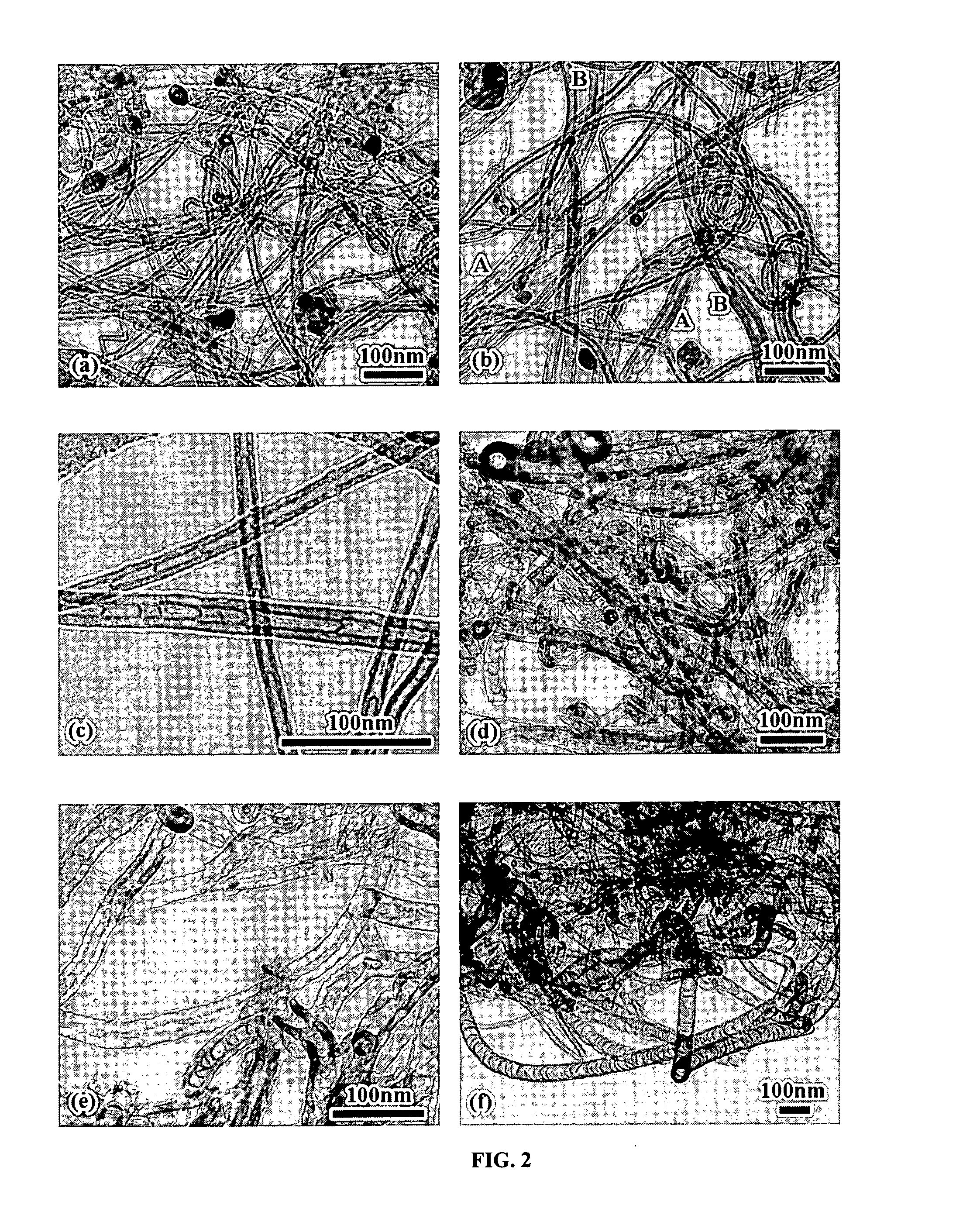

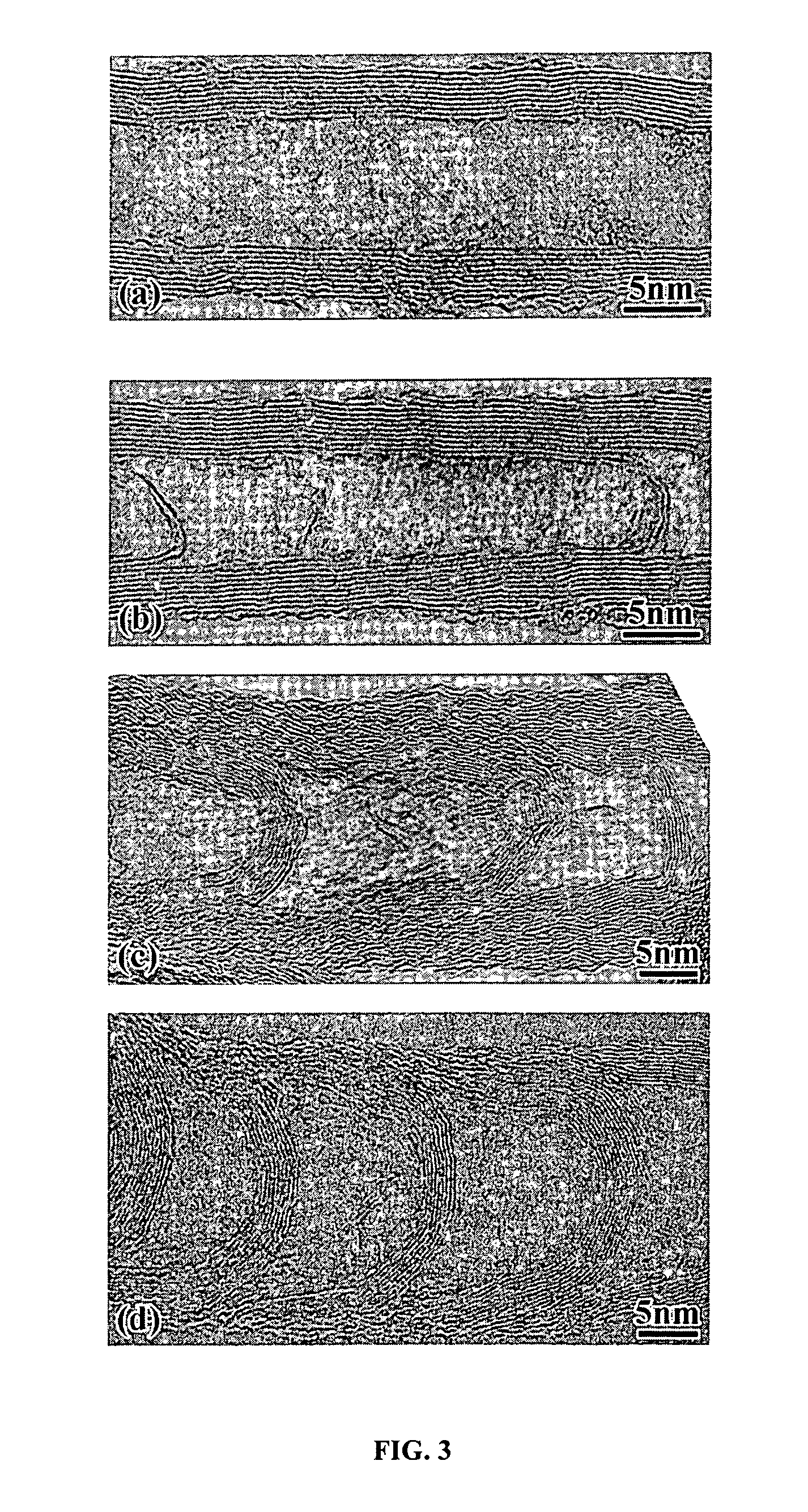

Varied morphology carbon nanotubes and method for their manufacture

InactiveUS7157068B2Increased yieldPromote catalyst activityMaterial nanotechnologyCarbon compoundsCarbon nanotubeMaterials science

Owner:TRUSTEES OF BOSTON COLLEGE THE

Catalysts, activating agents, support media, and related methodologies useful for making catalyst systems especially when the catalyst is deposited onto the support media using physical vapor deposition

InactiveUS7727931B2High catalytic activityTendency increaseMaterial nanotechnologyInternal combustion piston enginesGas phasePhysical chemistry

Use of physical vapor deposition methodologies to deposit nanoscale gold on activating support media makes the use of catalytically active gold dramatically easier and opens the door to significant improvements associated with developing, making, and using gold-based, catalytic systems. The present invention, therefore, relates to novel features, ingredients, and formulations of gold-based, heterogeneous catalyst systems generally comprising nanoscale gold deposited onto a nanoporous support.

Owner:3M INNOVATIVE PROPERTIES CO

Catalyst for preparing propylene through propane catalytic dehydrogenation and preparation method thereof

InactiveCN102389831ALarge specific surface areaHigh catalytic activityMolecular sieve catalystsHydrocarbonsDehydrogenationEconomic benefits

The invention relates to a catalyst for preparing propylene through propane catalytic dehydrogenation, which is a load type platinum-based catalyst and is characterized in that home-made mesoporous molecular sieves MCM-41 are used as carriers, metal Pt is used as an active ingredient, and metals Sn, Sn-Ce or Sn-Ce-Ca are used as auxiliary agents. In a preparation method, an isovolumetric continuous immersion method is adopted for preparation. The catalyst and the preparation method have the advantages that the isovolumetric continuous immersion method is adopted for preparing multi-component catalysts, wherein the content of any one component is easy to control, the prepared catalyst has higher specific surface area (700 to 900m<2> / g) and has high catalytic activity, the propane conversion rate is high, the propylene selectivity is good, the one-path stability is good, in addition, the service life is longer, the preparation method of the catalyst carriers is simple and feasible, the economic benefit is obvious, and good industrial development and application prospects are realized.

Owner:NANKAI UNIV

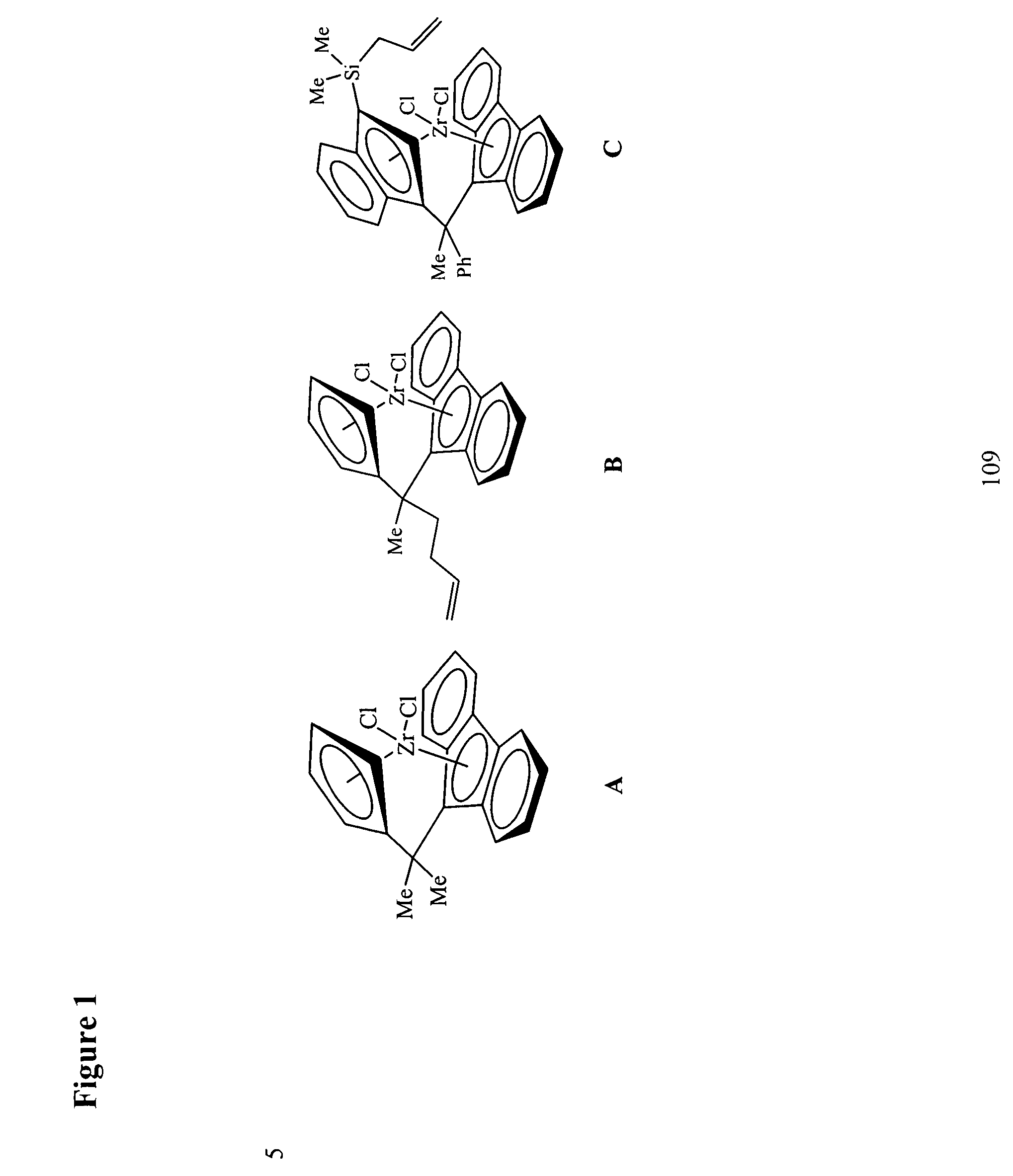

Dual metallocene catalysts for polymerization of bimodal polymers

ActiveUS20070197374A1Good balanceSlow crack growthOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsChemistryMetal

This invention relates to catalyst compositions, methods, and polymers encompassing at least one first Group 4 metallocene compound comprising bridging η5-cyclopentadienyl-type ligands, in combination with at least one second Group 4 metallocene with non-bridging η5-cyclopentadienyl-type ligands, typically in combination with at least one cocatalyst, and at least one activator. The compositions and methods disclosed herein provide ethylene polymers with a bimodal molecular weight distribution.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

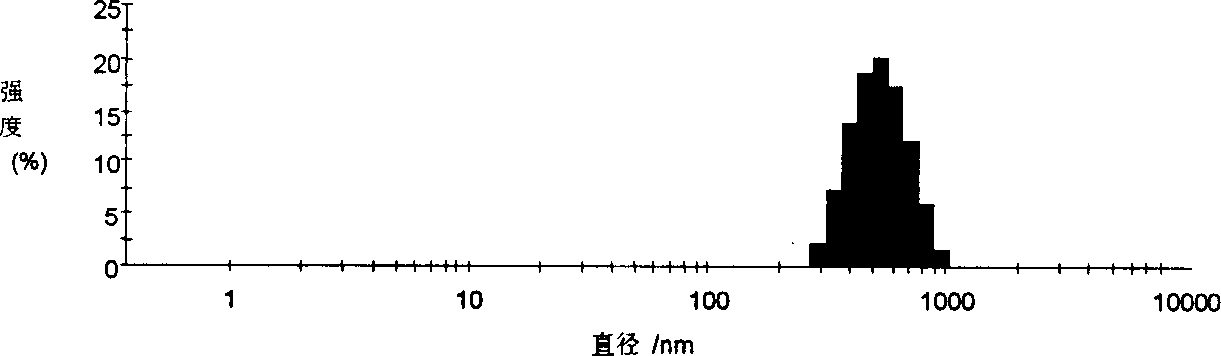

High silicon aluminium ratio small crystal NaY molecular sieve

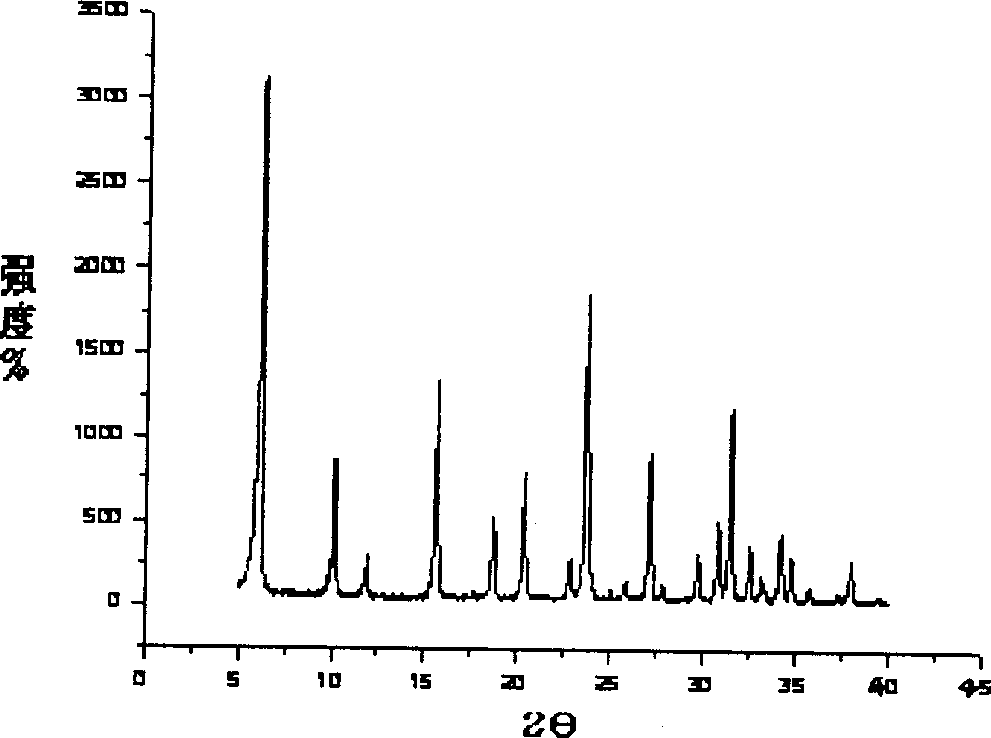

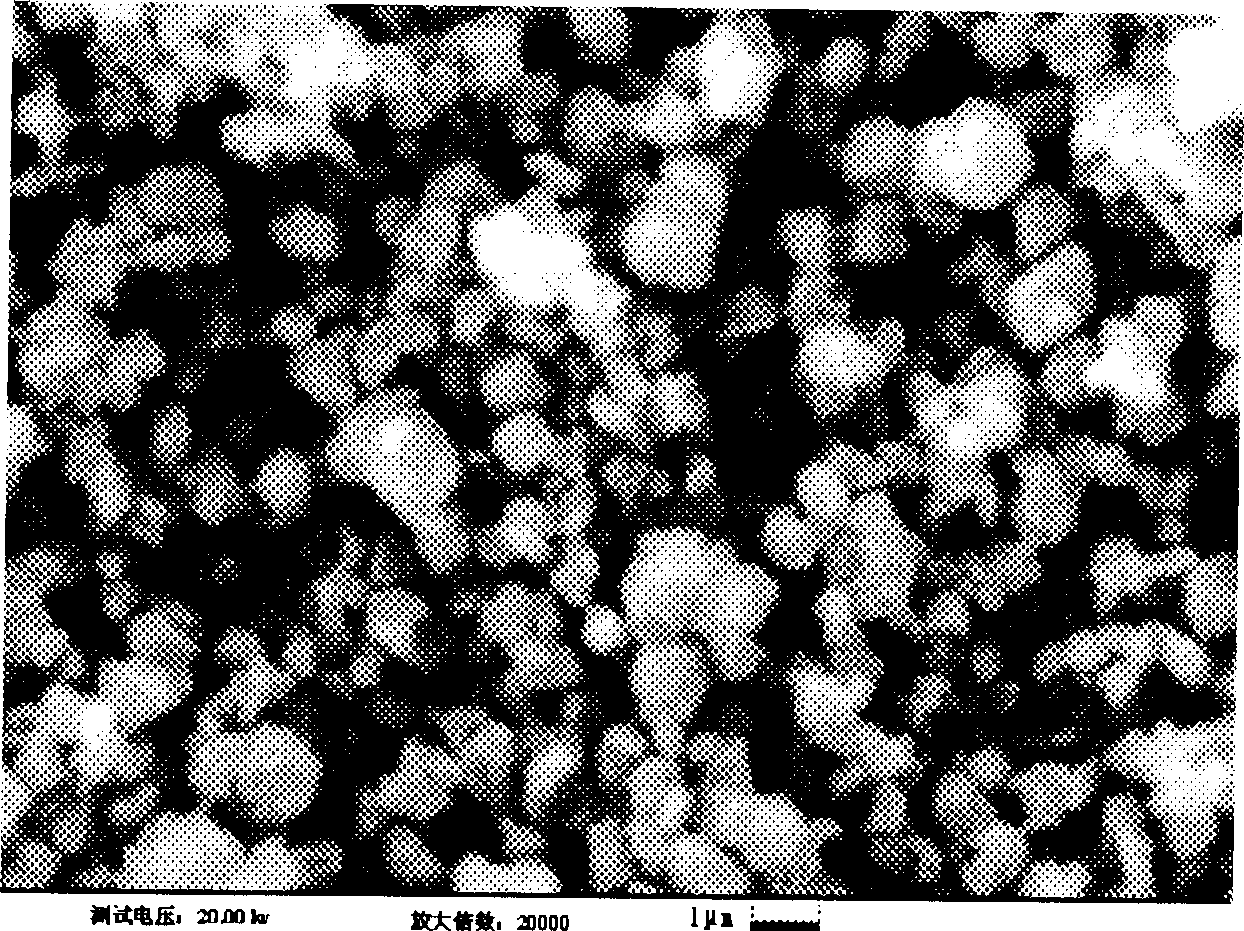

ActiveCN1785807ALow costReduce manufacturing costFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The present invention provides a high silica-alumina ratio small crystal grain NaY molecular sieve. The skeleton silica-alumina ratio of NaY molecular sieve, namely. SiO2 / Al2O3 mole ratio is 6.0-7.0, and the average grain size is 300-800 nm. It can be made up by adopting non-template agent direct synthesis process. Its preparation method includes the following steps: firstly, stirring and ageing for 0.5-48 hr at 15-60deg.C to obtain crystallization guide agent, then mixing said guide agent, water, silicon source and aluminium source to obtain reaction mixture, then crystallizing said mixture at twice, first steps is dynamic crystallization and second step is static crystallization, finally, filtering, washing and drying so as to obtain the invented high silica-alumina ratio small crystal grain NaY molecular sieve whose relative crystallinity is greater than 80%.

Owner:PETROCHINA CO LTD +1

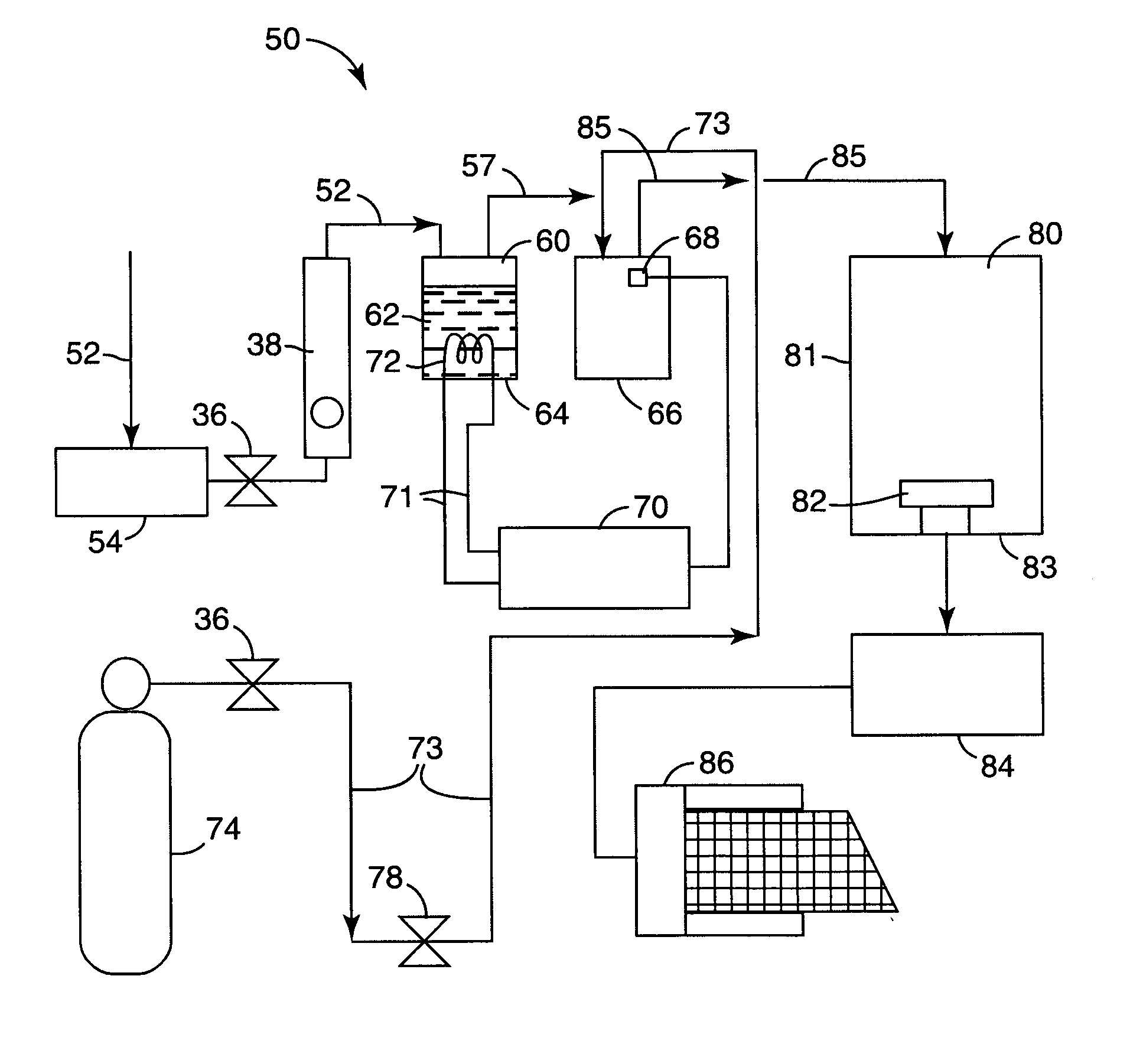

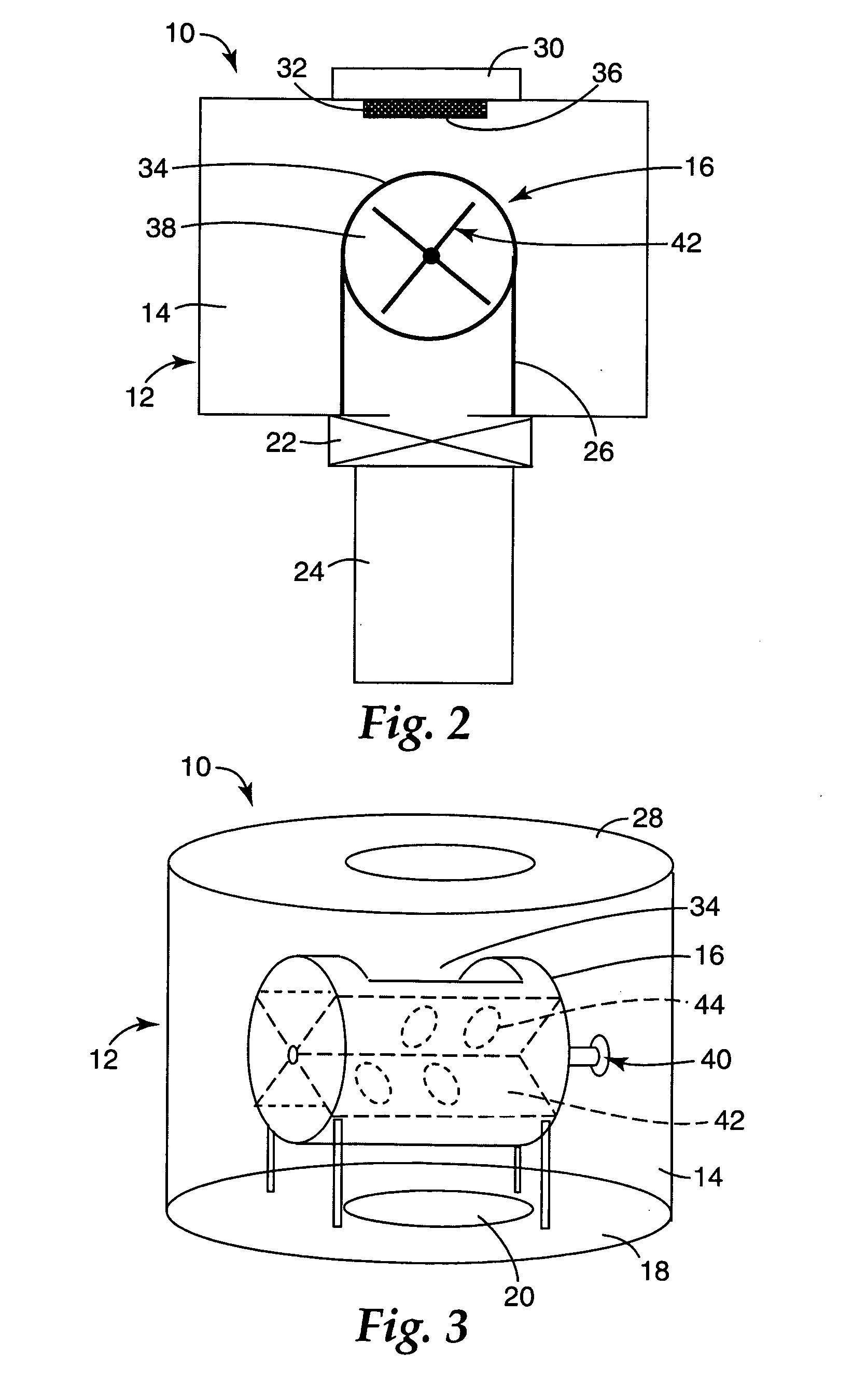

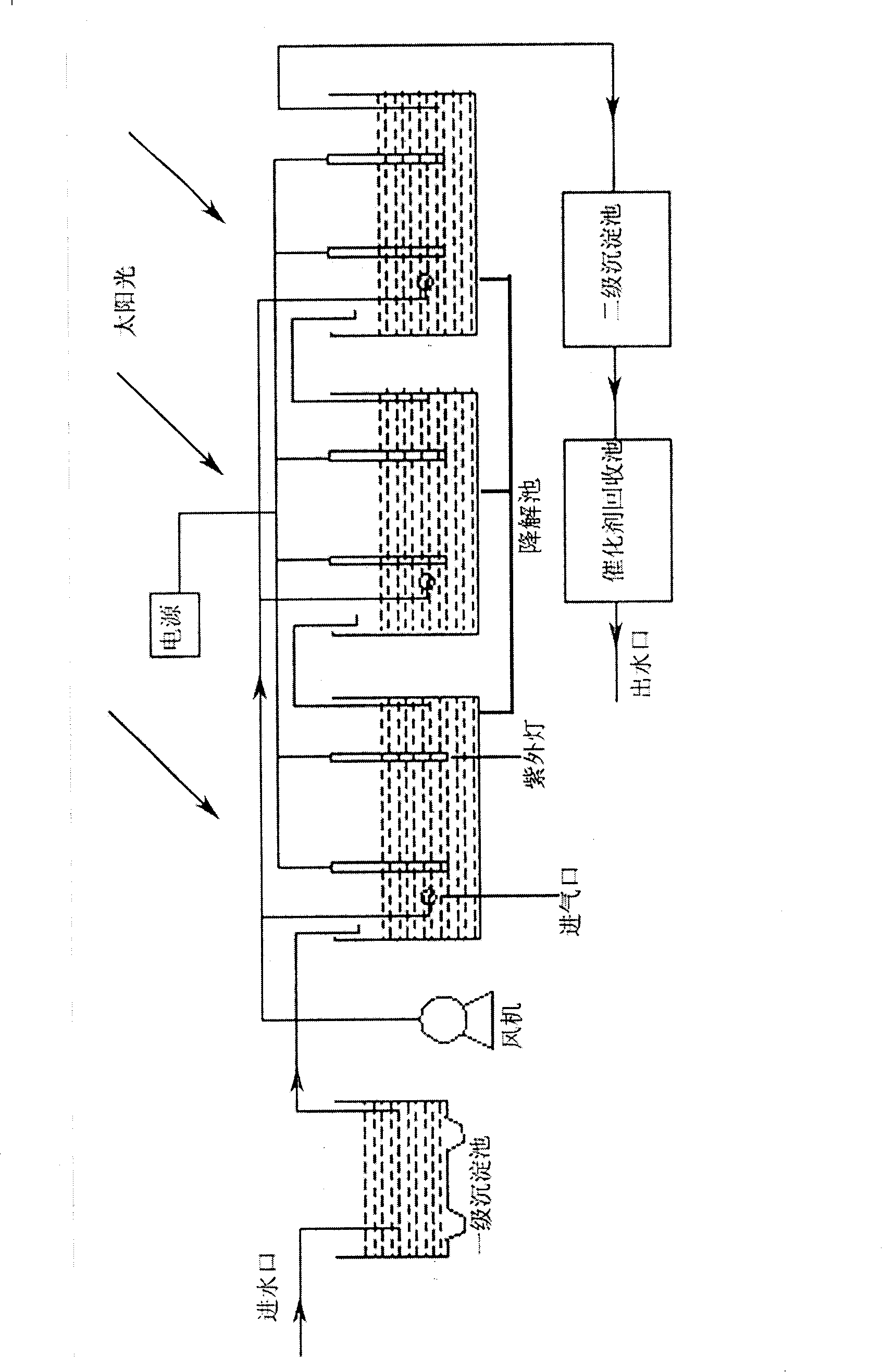

Photocatalysis oxidation treated high concentration organic trade waste

InactiveCN101219371AHigh activityImprove stabilityCatalyst carriersEnergy based wastewater treatmentHigh concentrationEmission standard

The invention relates to a modified loading nano composite photocatalyst which takes titanium dioxide as main part and adopts new reaction technique to degraded the organic industrial wastewater in a water processing system (see attached drawing 1 in Instruction). The main point on preparing the catalyst lies in that titanium dioxide active compounds loaded on different carriers are employed to prepare a loading photocatalyst with grain diameter of 5-40nm; meanwhile, different elements are mixed into the loading photocatalyst to reduce the composition between photoproduciton electron and cavity, which enables the catalyst to move the light absorbing wavelength thereof towards the visible regions, thus effectively improving the degradation rate of organic pollutants as a new environmental-friendly catalyst. As to the new technique of processing the organic industrial wastewater, the invention overcomes the defects that the present photocatalysts are only used for degrading the organic industrial wastewater with low concentration. The catalyst being irradiated respectively or simultaneously under sunbeam and ultraviolet light can decrease COD values of high-concentration organic industrial wastewater from 10000-40000mg / L to less than 100mg / L in short time, thus meeting the national emission standard.

Owner:BEIJING UNIV OF CHEM TECH

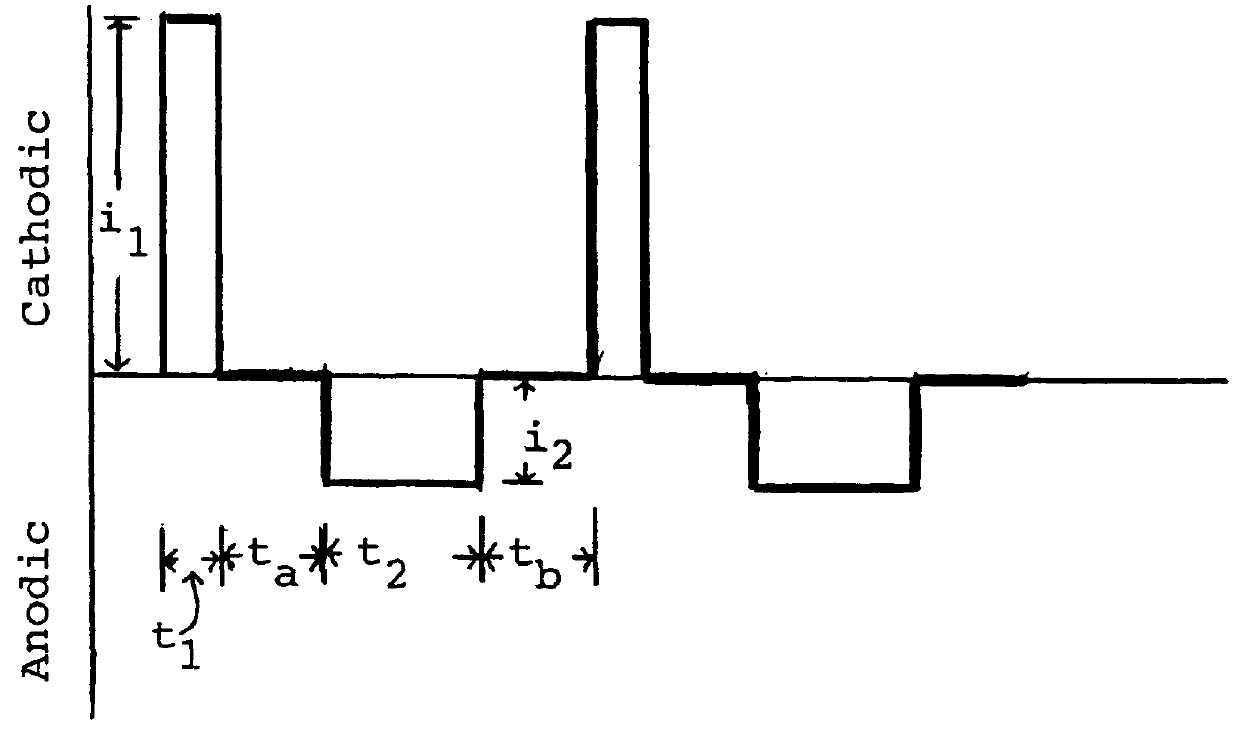

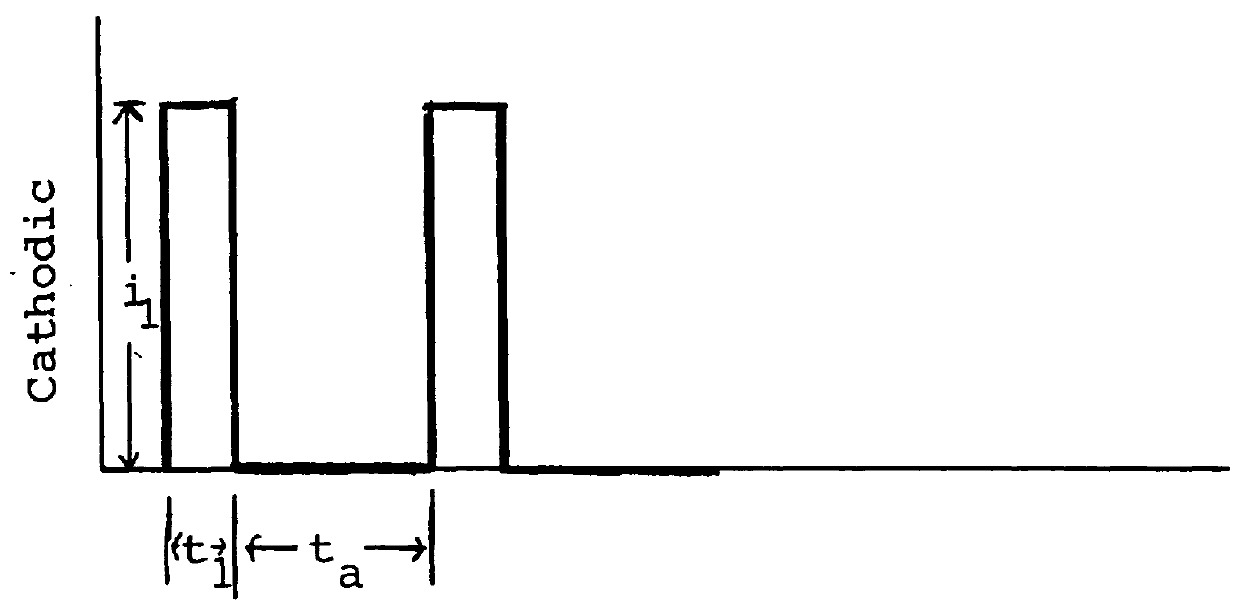

Electrodeposition of catalytic metals using pulsed electric fields

InactiveUS6080504AAdequate power densityEconomical catalyst loadingSolid electrolytesElectrolytic coatingsHertzPulse electric field

A gas diffusion electrode for a proton exchange membrane fuel cell is prepared by electrodeposition of a catalytic metal in nanocrystalline form on a substrate by contacting an electrically conductive substrate and a counterelectrode with a plating bath containing ions of a metal to be deposited on the substrate and passing a pulsed electric current between the substrate and counterelectrode having pulses that are cathodic with respect to the substrate and have a short on-time and / or a short duty cycle with a frequency from about 10 hertz to about 5000 hertz. In a preferred embodiment the electric current is a modulated reversing electric current having pulses that are cathodic with respect to the substrate and pulses that are anodic with respect to the substrate, the cathodic pulses having a short on-time and / or short duty cycle, the charge transfer ratio of the cathodic pulses to the anodic pulses being greater than one, and the frequency of the pulses ranging from about 10 hertz to about 5 kilohertz.

Owner:FARADAY TECH INC

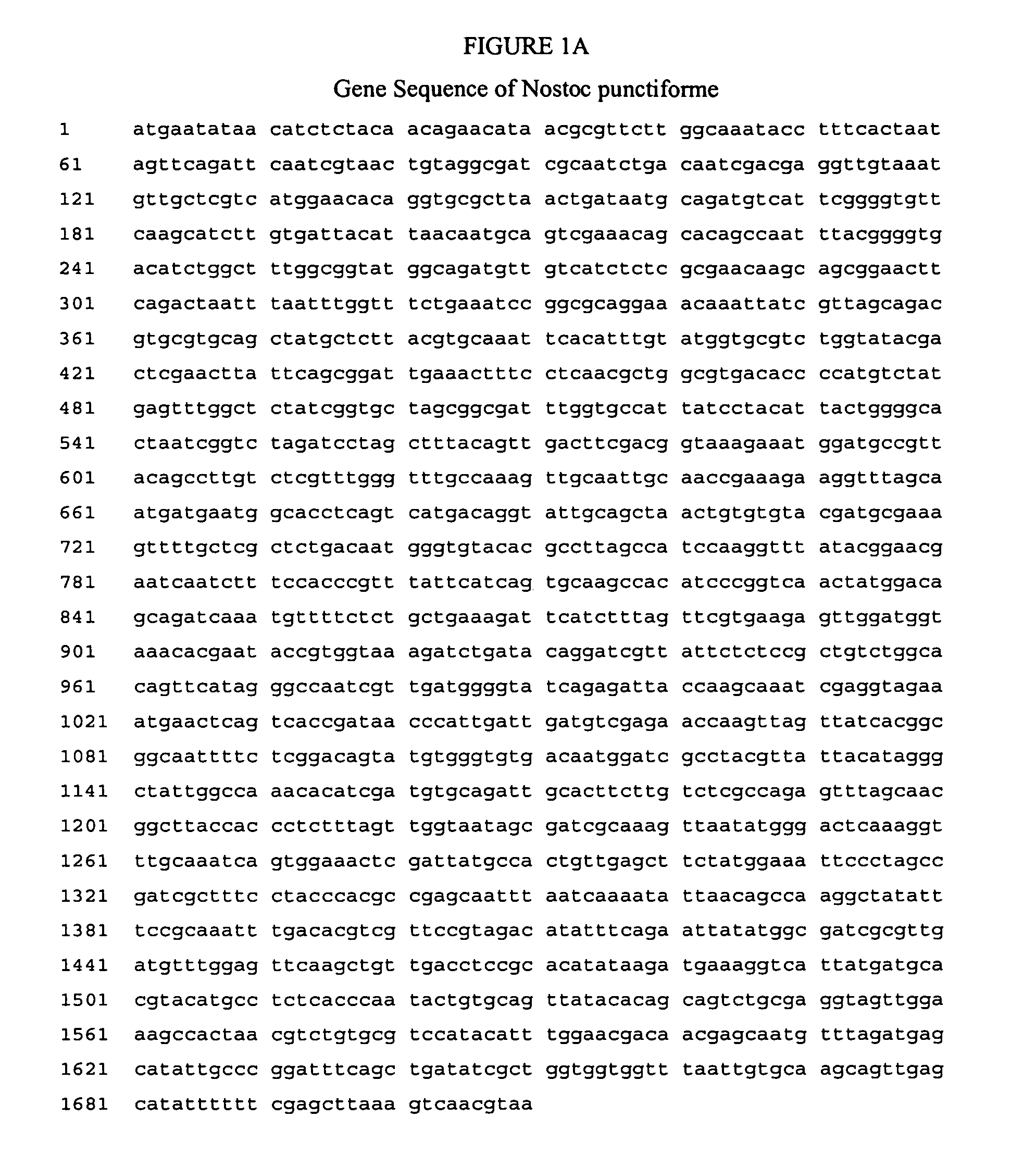

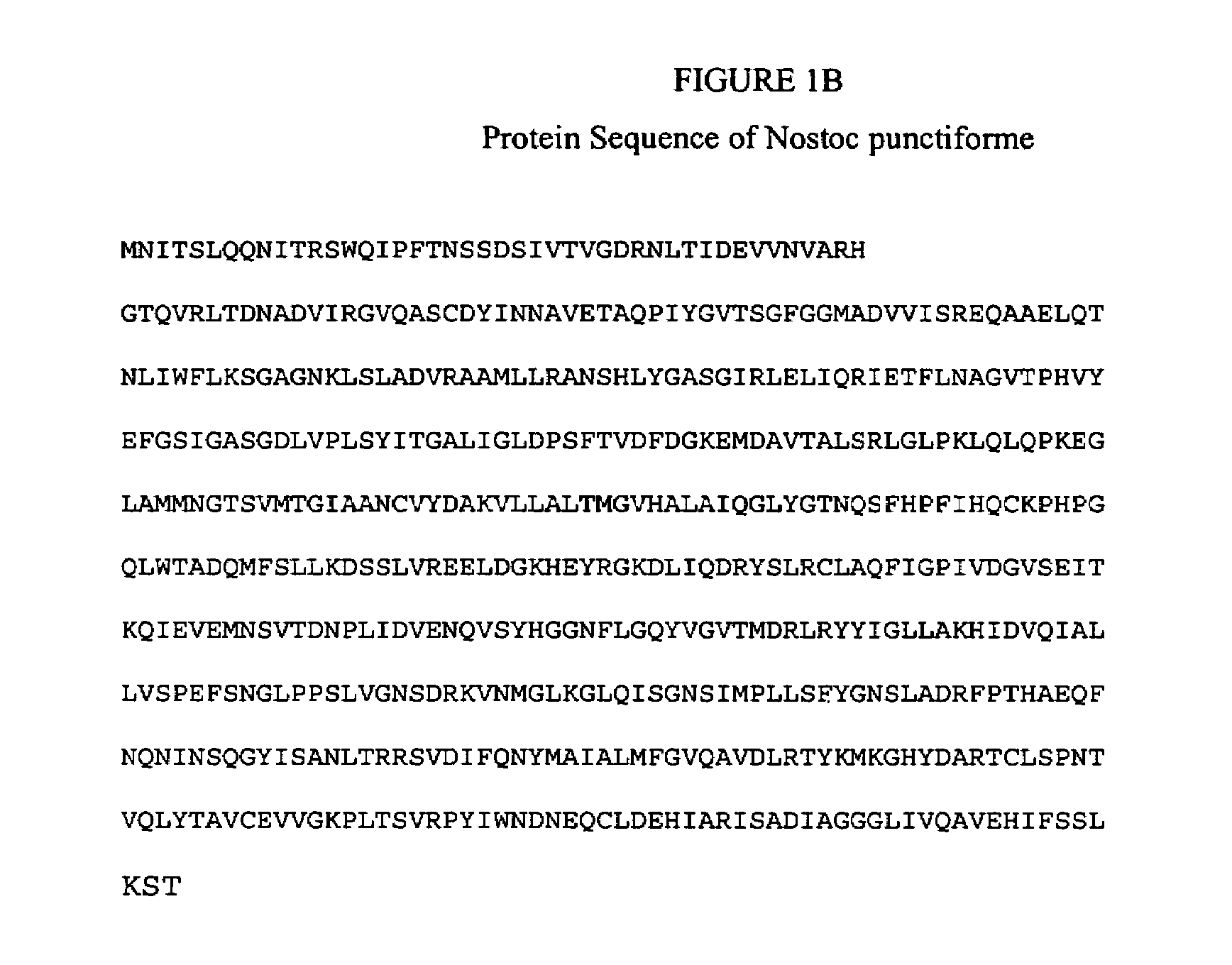

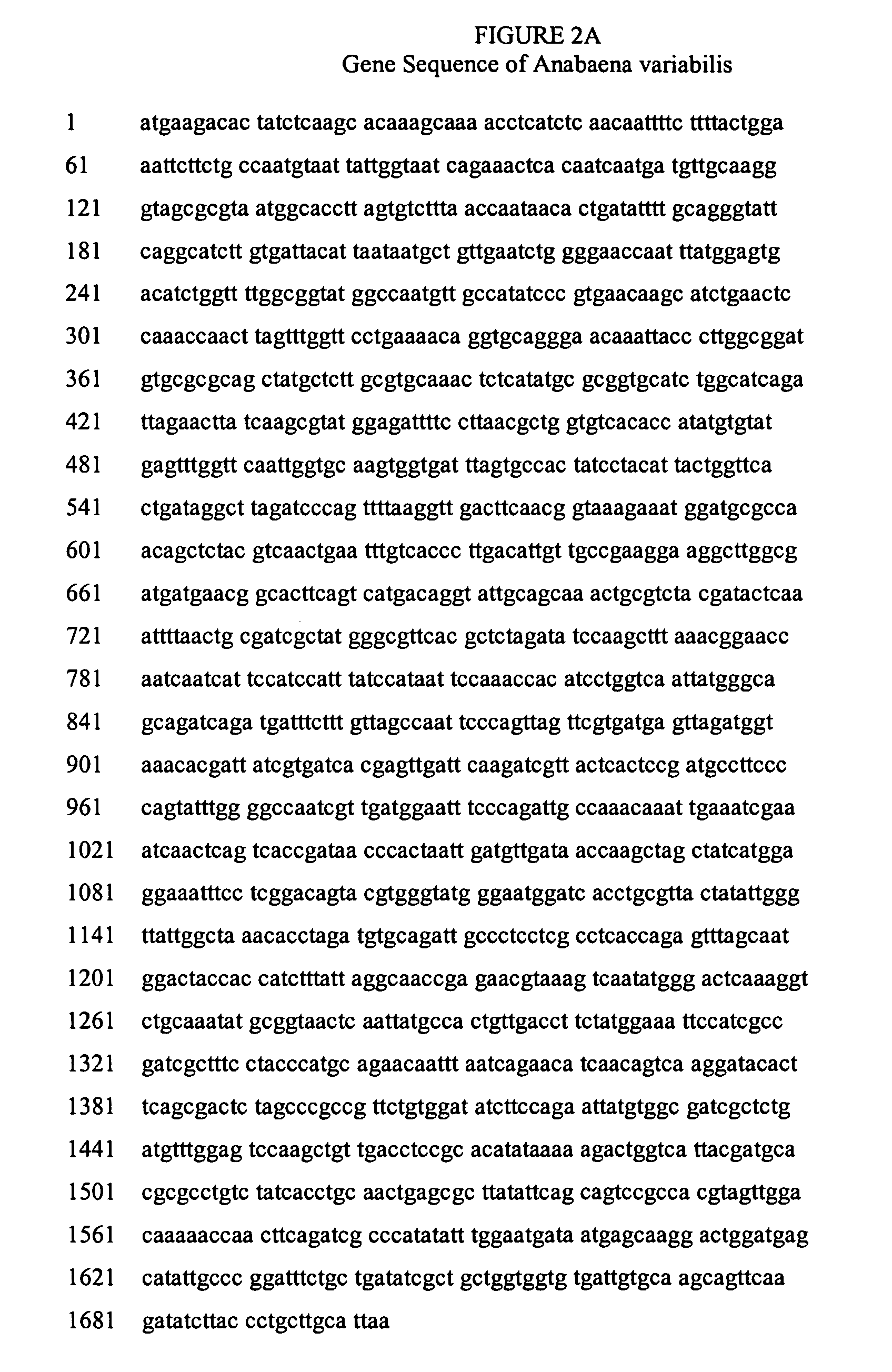

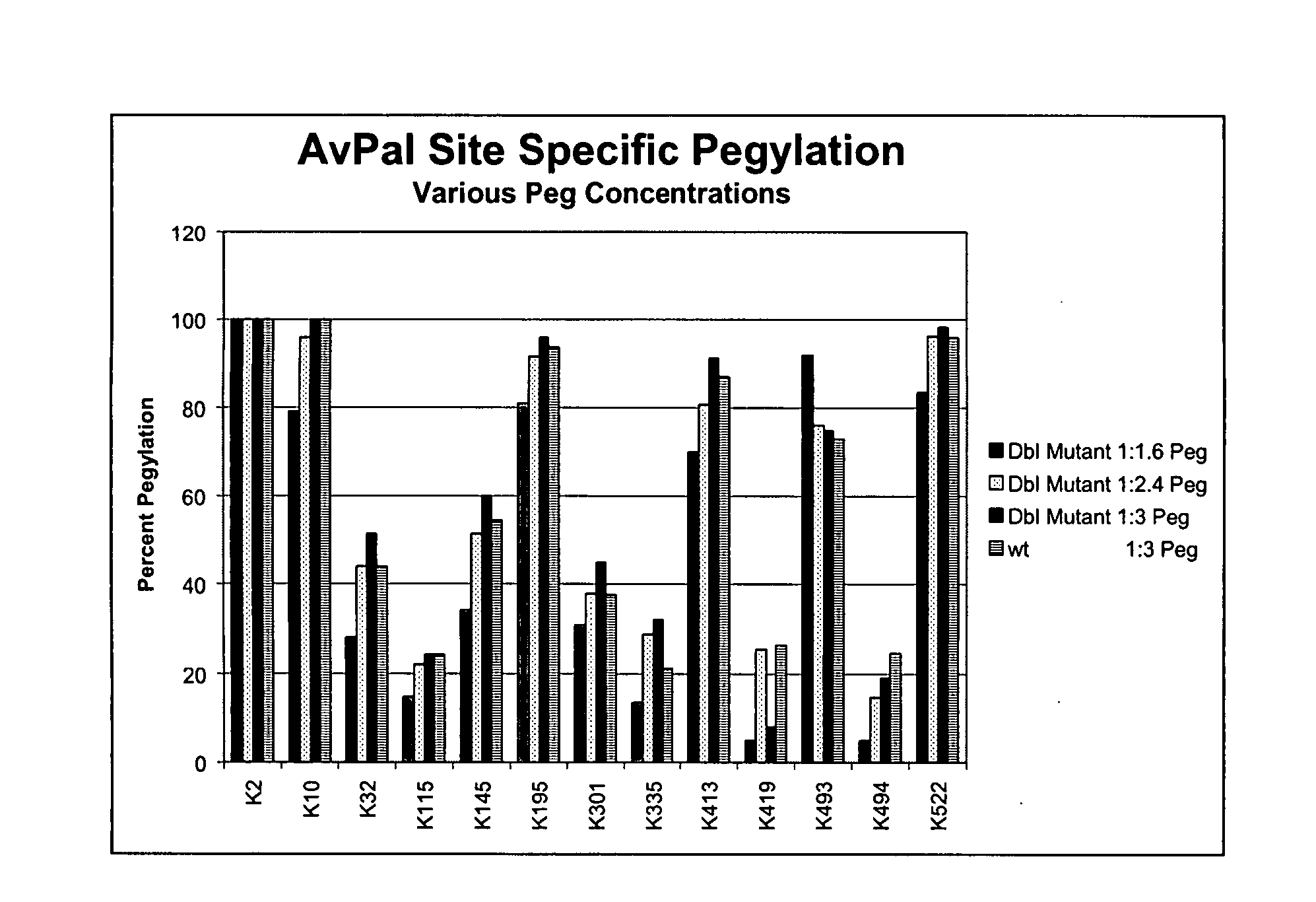

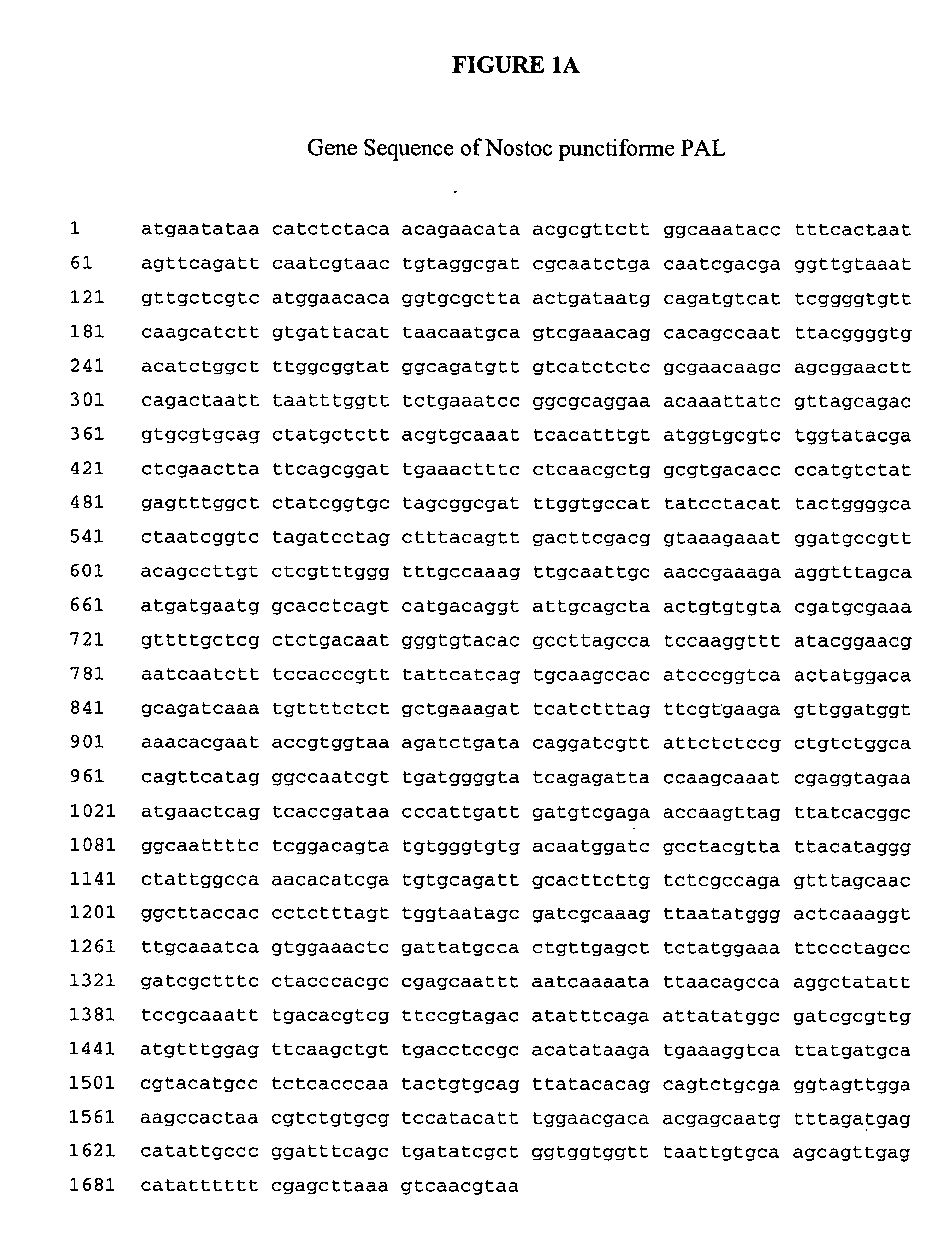

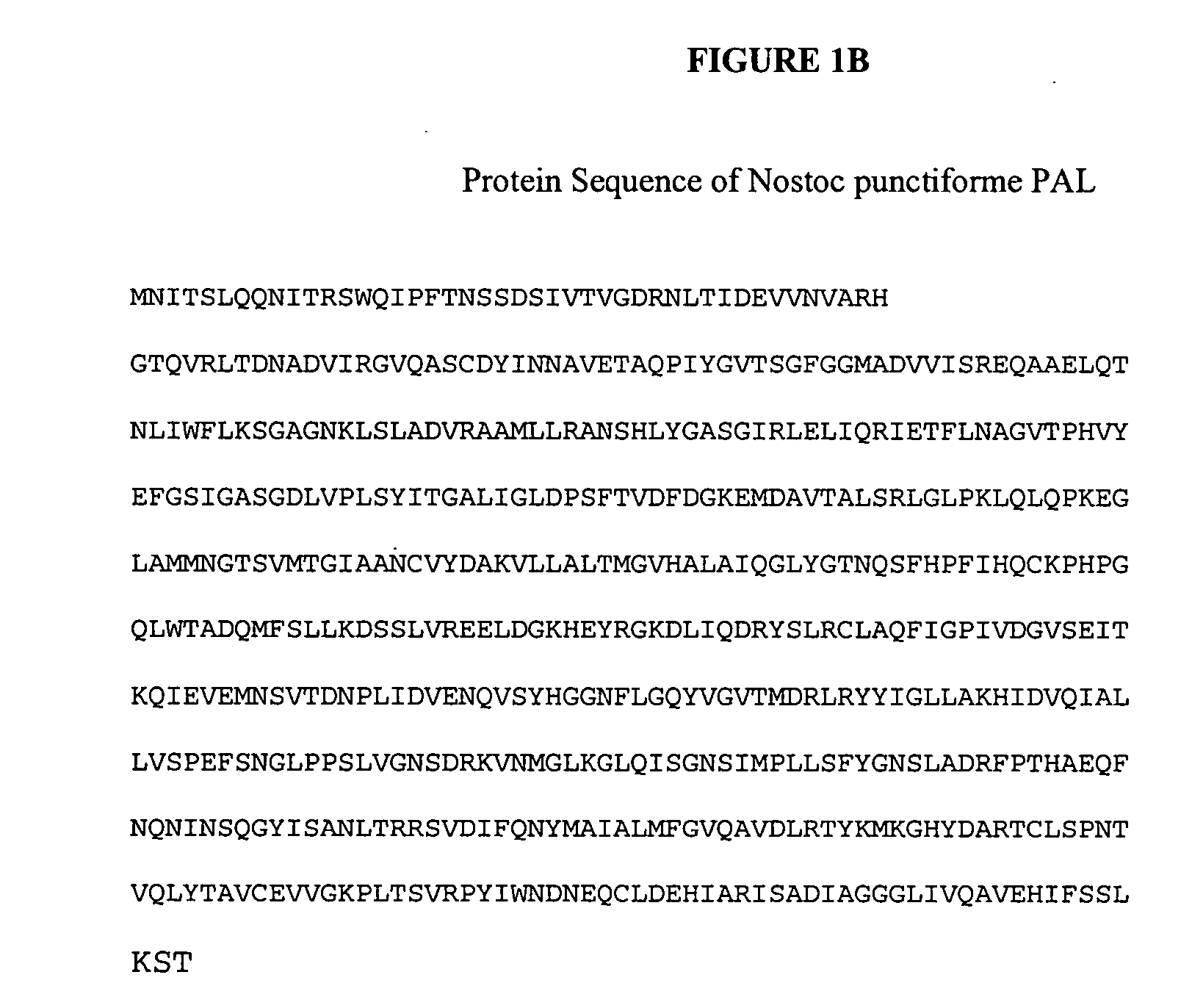

Compositions of prokaryotic phenylalanine ammonia-lyase and methods of using compositions thereof

ActiveUS7531341B1Extended half-lifeLow immunogenicityCarbon-nitrogen lyasesPeptide/protein ingredientsWild typePAL

The present invention is directed to phenylalanine ammonia lyase (PAL) produced by prokaryotes, wherein such prokaryotic PAL wherein the PAL variant has a greater phenylalanine-converting activity as compared to a wild-type PAL. The invention thus provides compositions of bacterial PAL and biologically active fragments, mutants, variants and analogs thereof, as well as methods for the production, purification, and use of such compositions for therapeutic and industrial purposes.

Owner:BIOMARIN PHARMA INC

Polymerization catalysts for producing high molecular weight polymers with low levels of long chain branching

ActiveUS20070179044A1High catalytic activityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsPolymer scienceEthylene Polymers

This invention relates to catalyst compositions, methods, and polymers encompassing at least one Group 4 metallocene compound comprising bridging η5-cyclopentadienyl-type ligands, typically in combination with at least one cocatalyst, and at least one activator. The compositions and methods disclosed herein provide ethylene polymers with low levels of long chain branching.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

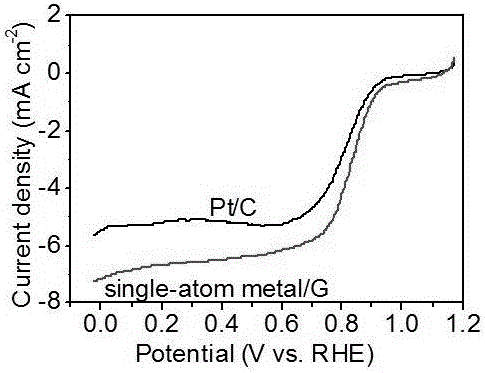

Monodisperse metal atom/graphene composite catalyst and preparation method and application thereof

ActiveCN106694007ALow costSimple stepsCell electrodesCatalyst activation/preparationCvd grapheneChemistry

The invention discloses a monodisperse metal atom / graphene composite catalyst and a preparation method and application thereof. The catalyst is formed by loading monodisperse metal atoms on / in graphene, wherein the content of the monodisperse metal atoms is 0.0001wt%-5.0wt%; the content of heteroatom doped graphene is 95wt%-99.9999wt%; and the content of heteroatom in graphene is 0wt%-90wt%. The monodisperse metal atom / graphene composite catalyst is obtained through an electrochemical method, and the preparation method is simple, easy to operate and control, low in cost, high in efficiency, good in quality, high in security and favorable for industrial production. The composite catalyst has the characteristics of high activity and good stability when being applied to electro-catalytic oxygen reduction, and has better comprehensive performance and good application prospects relative to commercial 20wt% of Pt / C.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

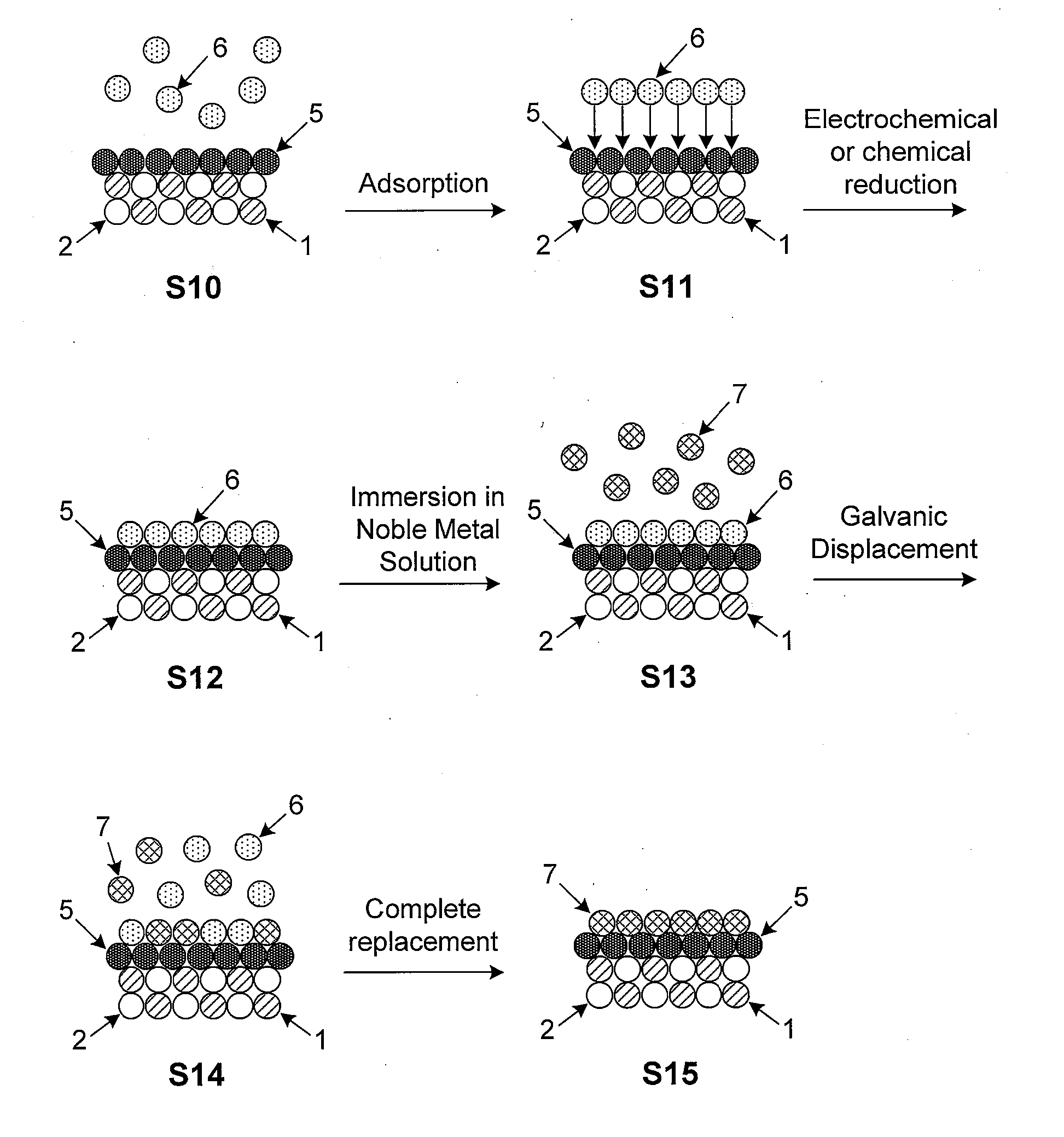

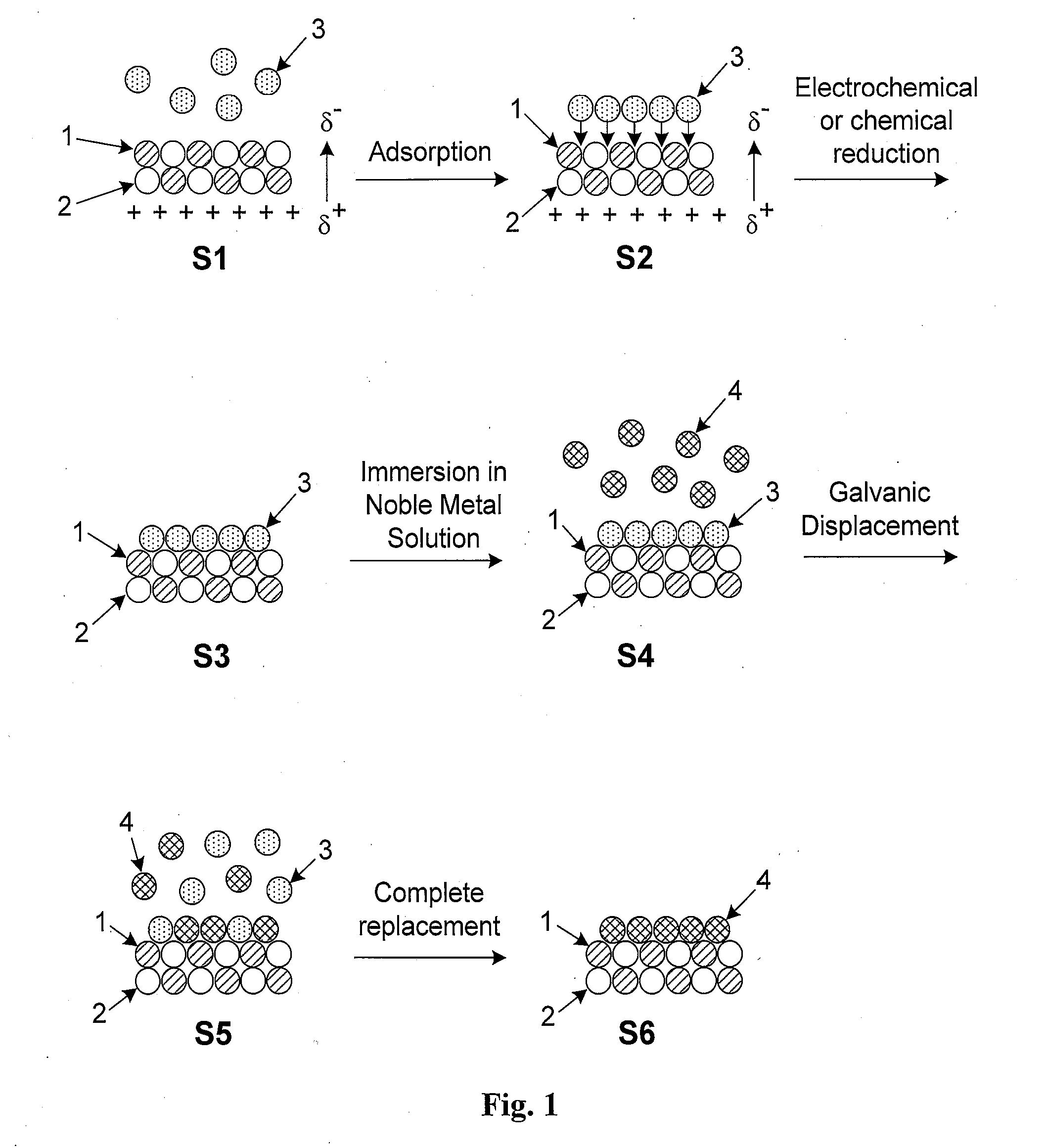

Platinum-Based Electrocatalysts Synthesized by Depositing Contiguous Adlayers on Carbon Nanostructures

InactiveUS20100177462A1High catalytic activityImprove stabilityMaterial nanotechnologyCarbon compoundsNanostructurePt element

High-surface-area carbon nanostructures coated with a smooth and conformal submonolayer-to-multilayer thin metal films and their method of manufacture are described. The preferred manufacturing process involves the initial oxidation of the carbon nanostructures followed by immersion in a solution with the desired pH to create negative surface dipoles. The nanostructures are subsequently immersed in an alkaline solution containing non-noble metal ions which adsorb at surface reaction sites. The metal ions are then reduced via chemical or electrical means and the nanostructures are exposed to a solution containing a salt of one or more noble metals which replace adsorbed non-noble surface metal atoms by galvanic displacement. Subsequent film growth may be performed via the initial quasi-underpotential deposition of a non-noble metal followed by immersion in a solution comprising a more noble metal. The resulting coated nanostructures may be used, for example, as high-performance electrodes in supercapacitors, batteries, or other electric storage devices.

Owner:BROOKHAVEN SCI ASSOCS

Hydrocarbon-Producing Catalyst, Process for Producing the Same, and Process for Producing Hydrocarbons Using the Catalyst

InactiveUS20080064769A1Increase probabilityStably and smoothly promoteHydrocarbon from carbon oxidesOrganic compound preparationRutheniumLiquid hydrocarbons

An object of the present invention is to provide a catalyst which, in the FT process, exhibits a high chain growth probability, and a high catalytic activity, can stably and smoothly promote the reaction, exhibits a high productivity of C5+, and can efficiently produce liquid hydrocarbons, and a process therefor.The invention relates to a hydrocarbon-producing catalyst obtainable by supporting a ruthenium compound on a support composed of a manganese oxide and an aluminum oxide, and which satisfies at least one of characteristics (1) and (2): (1) the catalyst being treated with an aqueous alkaline solution and subsequently subjected to calcination treatment in the air at 150 to 500° C., (2) the aluminum oxide being an aluminum oxide wherein pore volume formed by pores having a pore diameter of 8 nm or more accounts for 50% or more of total pore volume.

Owner:JAPAN OIL GAS & METALS NAT CORP +1

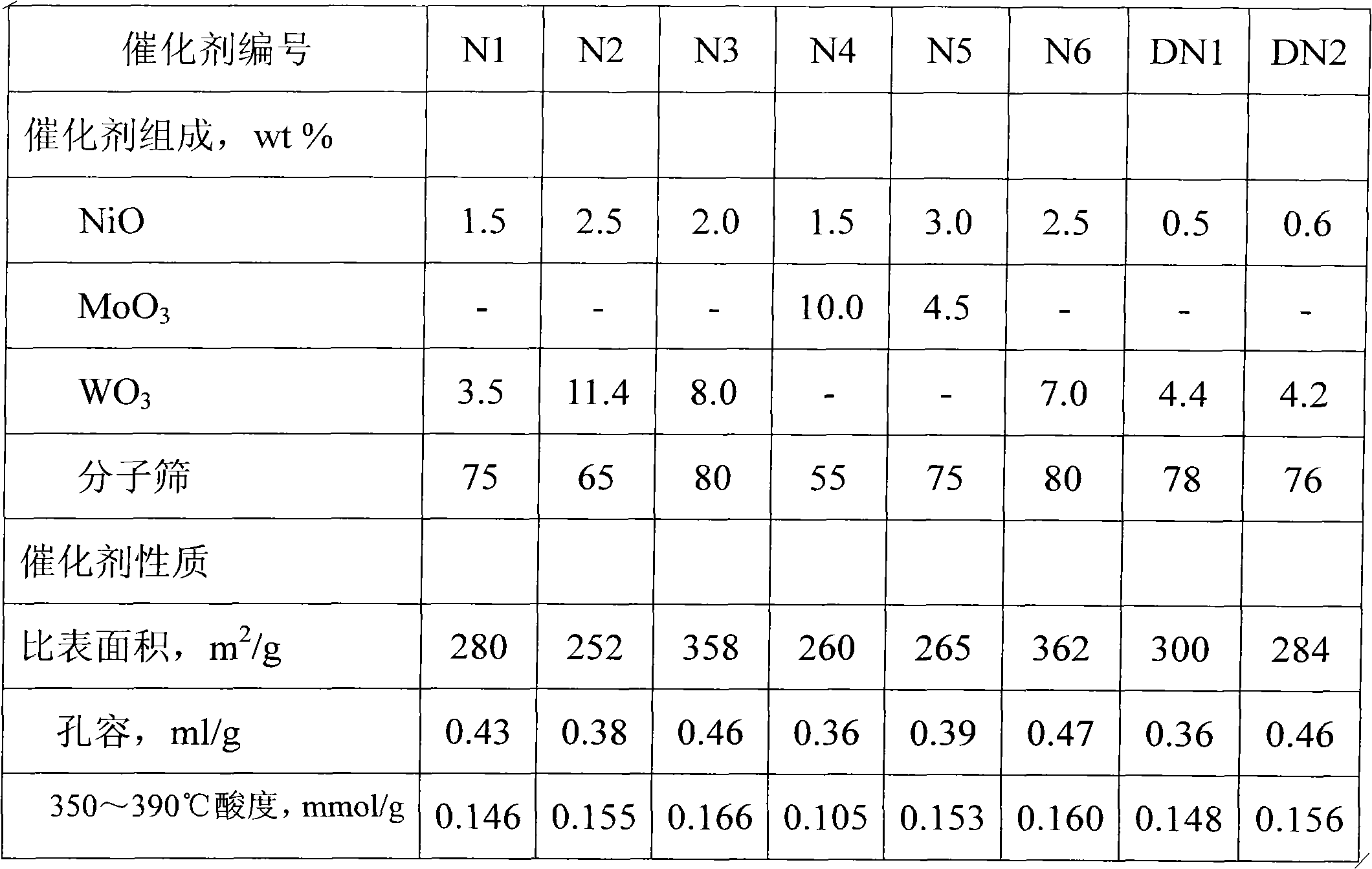

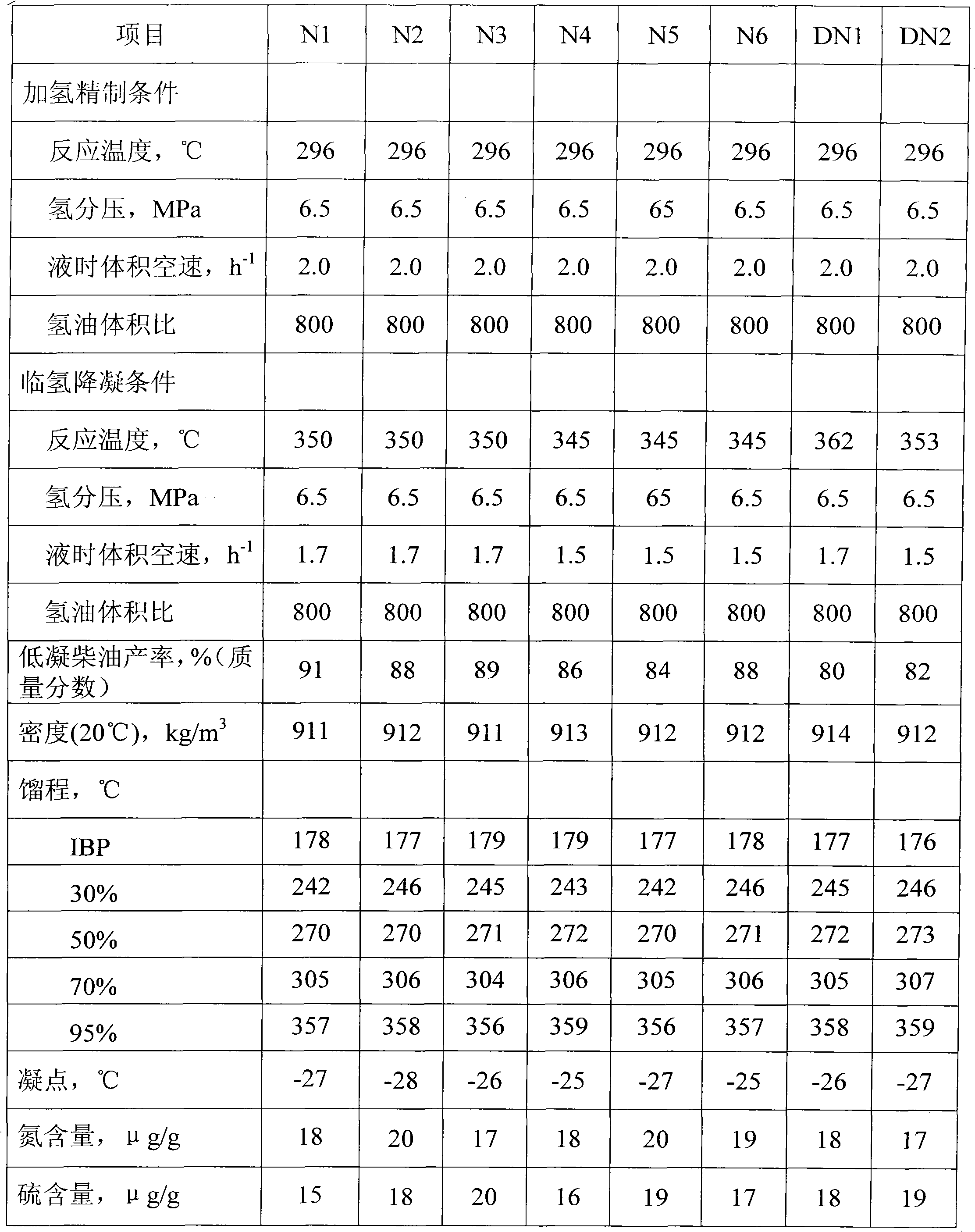

Diesel oil hydrogenation pour point depressing method

ActiveCN102051232ASuitable pore structureAppropriate pore inner surface propertiesCatalyst carriersMolecular sieve catalystsMolecular sieveWax

The invention discloses a diesel oil hydrogenation pour point depressing method. A series flow of hydrofining and hydrogenation pour point depressing is adopted in the method, wherein a hydrogenation pour point depressing catalyst is modified by metal auxiliary agent and silicon, effectively regulates the acidity and orifice shape of the inner surface and the outer surface of a shape-selective cracking molecular sieve, is favorable for dispersing wax molecules in a diesel oil raw material into pore canals of the molecular sieve to perform shape-selective cracking reaction, and has high catalytic activity and selectivity of a target product; and because the acidity of the outer surface of the molecular sieve is weak, side reactions such as secondary cracking and the like are reduced, the pour point depressing effect of the diesel oil is good, and the fraction yield of the diesel oil is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

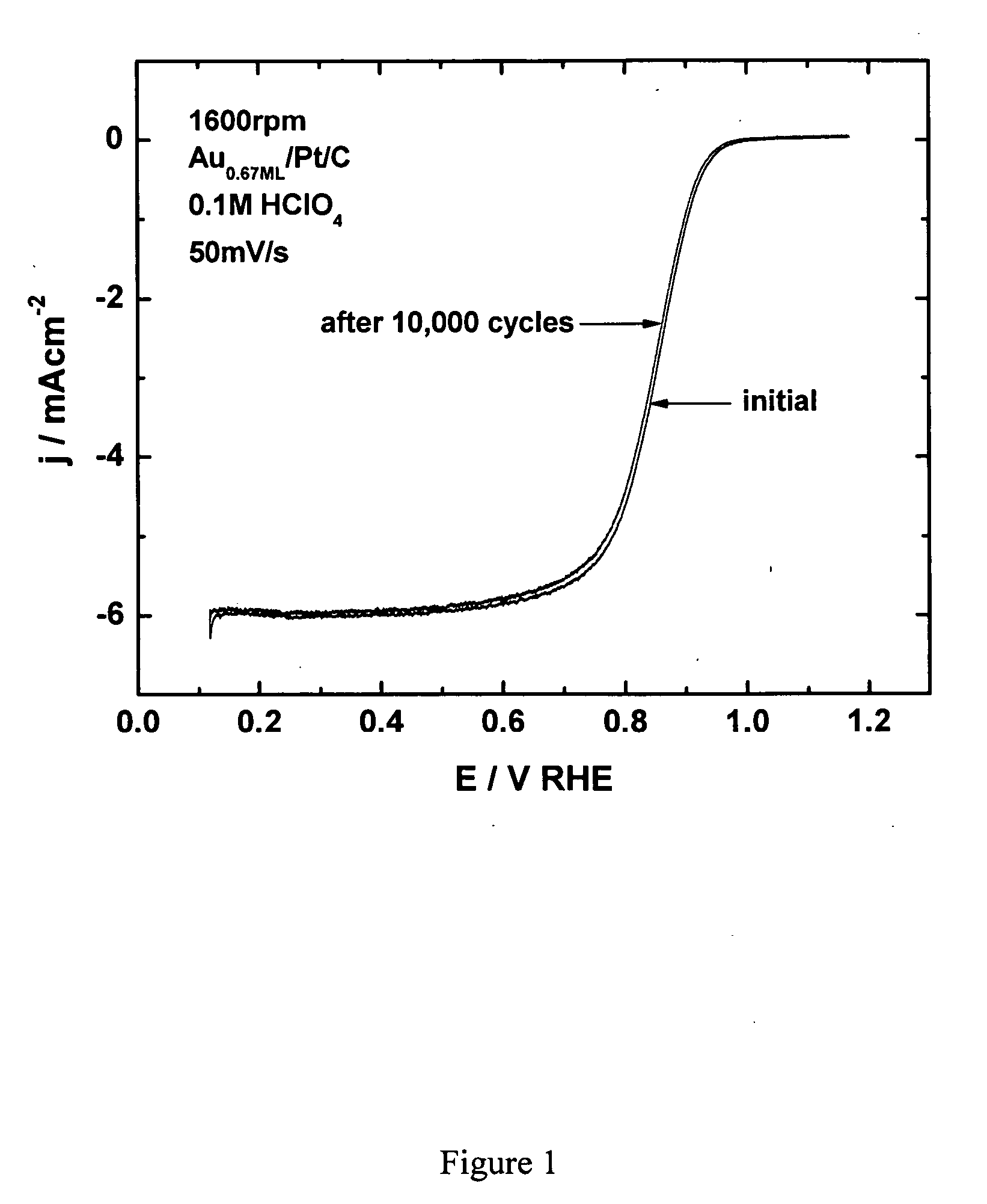

Electrocatalysts having gold monolayers on platinum nanoparticle cores, and uses thereof

InactiveUS20070026292A1Maintain efficiencyReduce loadMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsPlatinumFuel cells

The invention relates to gold-coated particles useful as fuel cell electrocatalysts. The particles are composed of an electrocatalytically active core at least partially encapsulated by an outer shell of gold or gold alloy. The invention more particularly relates to such particles having a noble metal-containing core, and more particularly, a platinum or platinum alloy core. In other embodiments, the invention relates to fuel cells containing these electrocatalysts and methods for generating electrical energy therefrom.

Owner:BROOKHAVEN SCI ASSOCS

Curable composition

InactiveUS20090182099A1Good adhesivenessExcellent curabilityOther chemical processesEster polymer adhesivesNitrogen atomSiloxane

The present invention has its object to provide a curable composition which comprises an amidine compound as a non-organotin catalyst and shows good elongation, flexibility, surface curability, depth curability and adhesiveness; the above object can be achieved by a non-organotin curable composition which comprises: (A) an organic polymer containing a silyl group capable of crosslinking under siloxane bond formation, the silyl group being a group represented by the general formula (1): —SiR1X2; (B) an amidine compound (B-1) as a silanol condensation catalyst; and (C) a carboxylic acid, wherein the ratio between the number of moles (b) of all nitrogen atoms in the (B-1) component of the composition and the number of moles (c) of all carboxyl groups in the (C) component of the composition, namely the ratio (b) / (c), is higher than 2.

Owner:KANEKA CORP

Compositions of prokaryotic phenylalanine ammonia-lyase and methods of using compositions thereof

ActiveUS20080008695A1Reduce protein aggregationReduce enzyme activityNervous disorderPeptide/protein ingredientsWild typeVaccine Immunogenicity

The present invention is directed to phenylalanine ammonia-lyase (PAL) produced by prokaryotes, wherein such prokaryotic PAL wherein the PAL variant has a greater phenylalanine-converting activity and / or a reduced immunogenicity as compared to a wild-type PAL. The invention thus provides compositions of bacterial PAL and biologically active fragments, mutants, variants and analogs thereof, as well as methods for the production, purification, and use of such compositions for therapeutic and industrial purposes.

Owner:BIOMARIN PHARMA INC

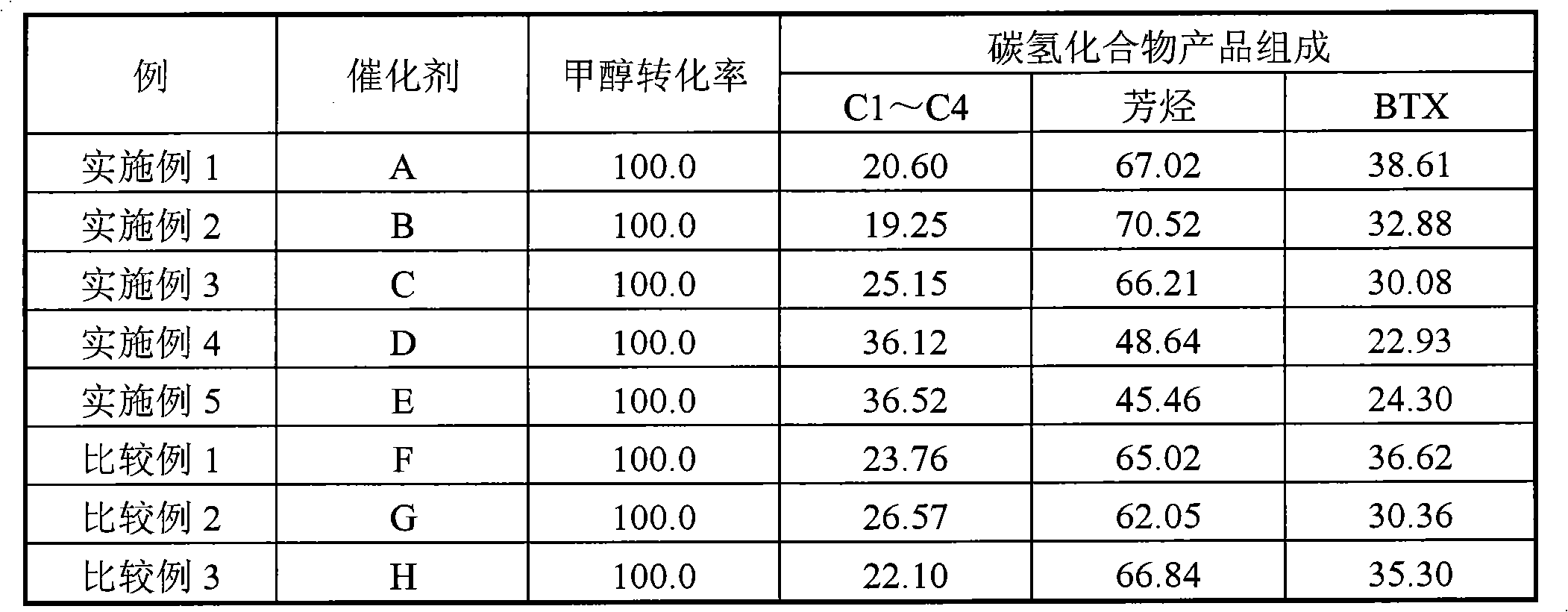

Method for preparing aromatic hydrocarbon through methanol transformation

ActiveCN102372535AHigh selectivityHigh catalytic activityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveReaction temperature

The invention relates to a method for preparing aromatic hydrocarbon through methanol transformation, and mainly solves the problems of complicated process flow and low selectivity of target products existing in the prior art. The problems are better solved by adopting the technical scheme that the method comprises the step of: reacting by taking methanol as a raw material and a mixture of HZSM-5 containing a metal element or oxide thereof and at least one of a HZSM-11 or HMCM-22 molecular sieve as an active main body of a catalyst under the condition that the reaction temperature is 320 to 480 DEG C, the reaction pressure is 0.1 to 3.0MPa and the weight hourly space velocity of the raw material is 0.5 to 6.0 h<-1>; and the method can be used for the industrial production of the aromatic hydrocarbon through methanol transformation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com