Patents

Literature

742results about How to "Good hydrothermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

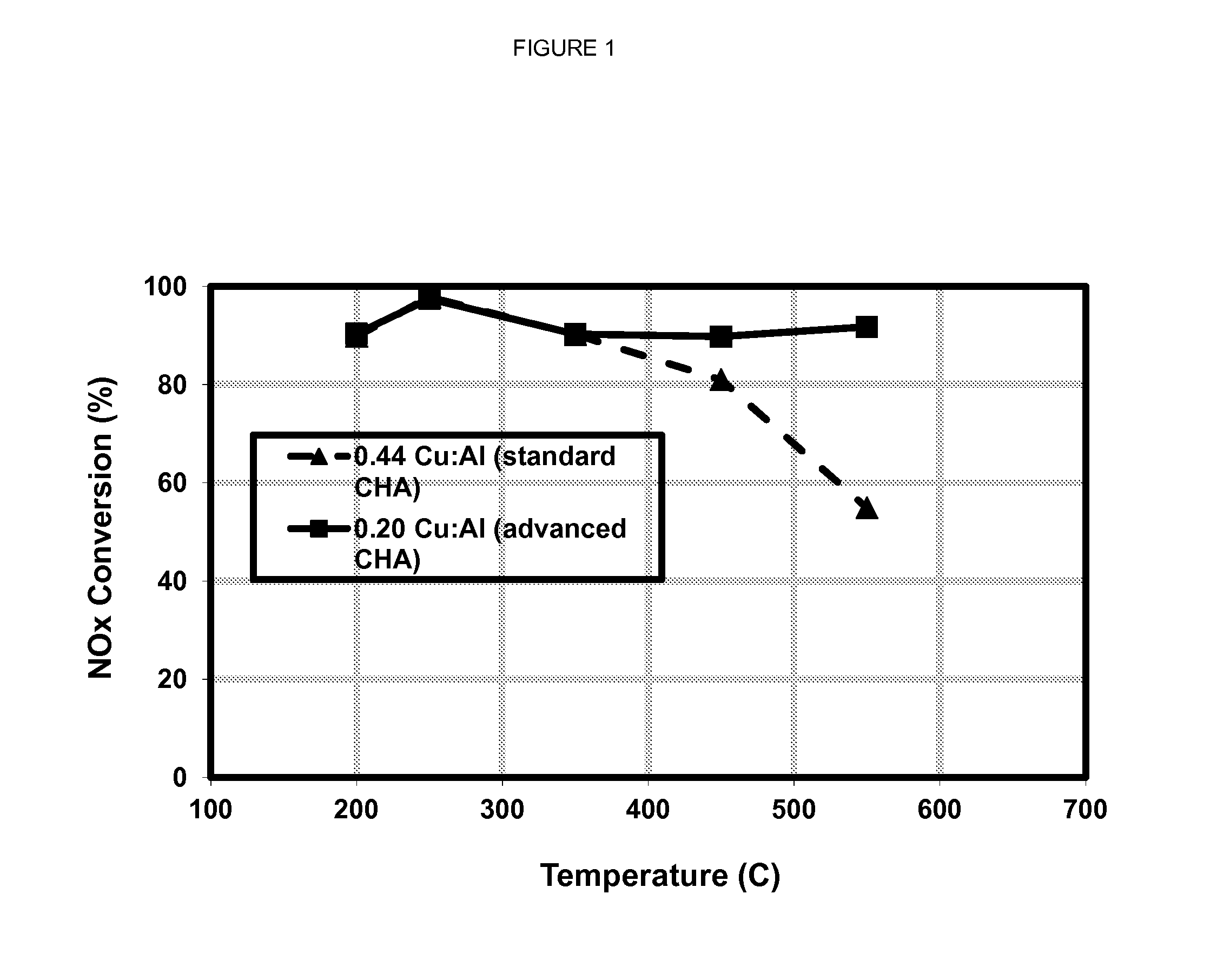

Copper CHA zeolite catalysts

ActiveUS7601662B2Good hydrothermal stabilityHigh catalytic activityCombination devicesAluminium compoundsReaction temperatureCrystal structure

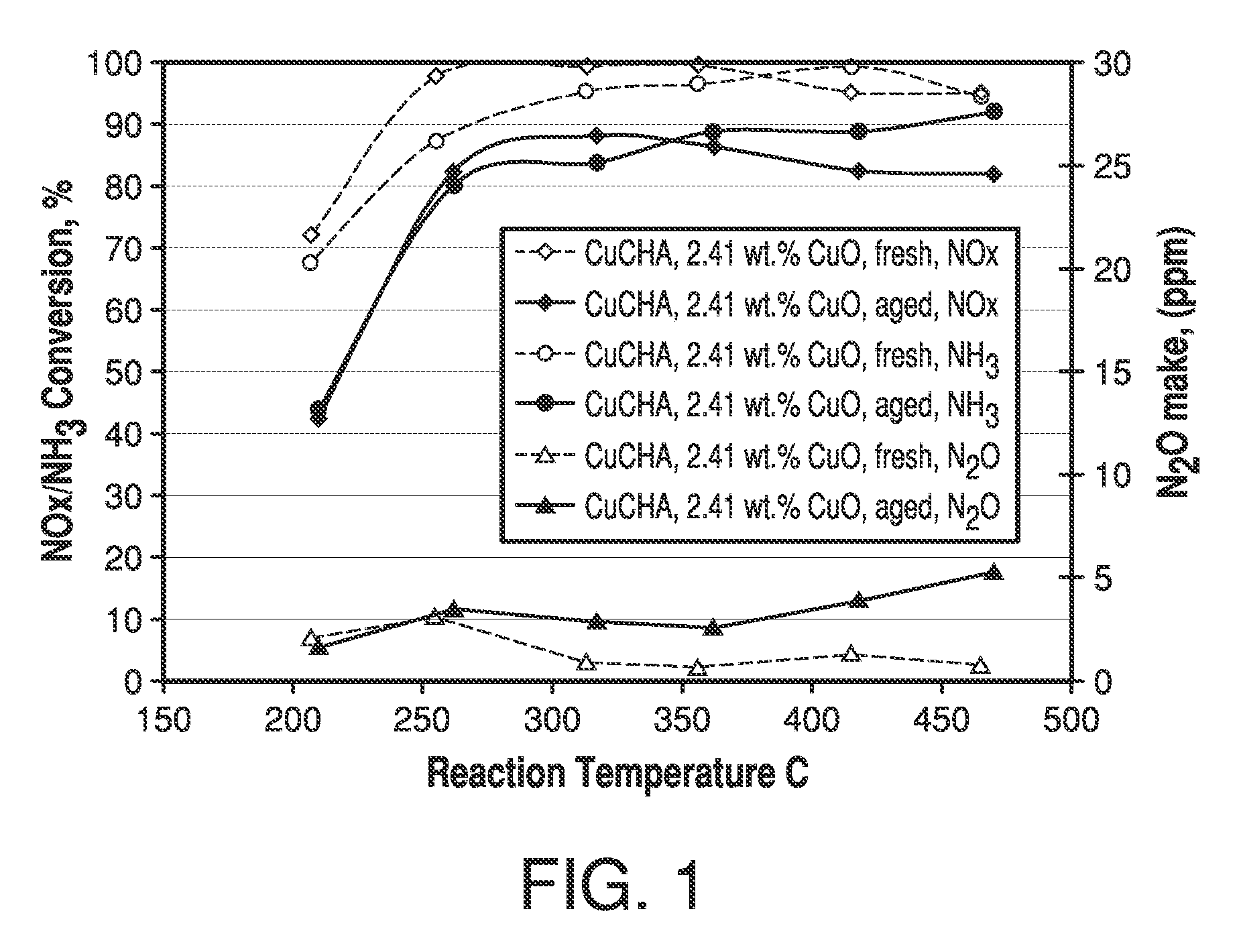

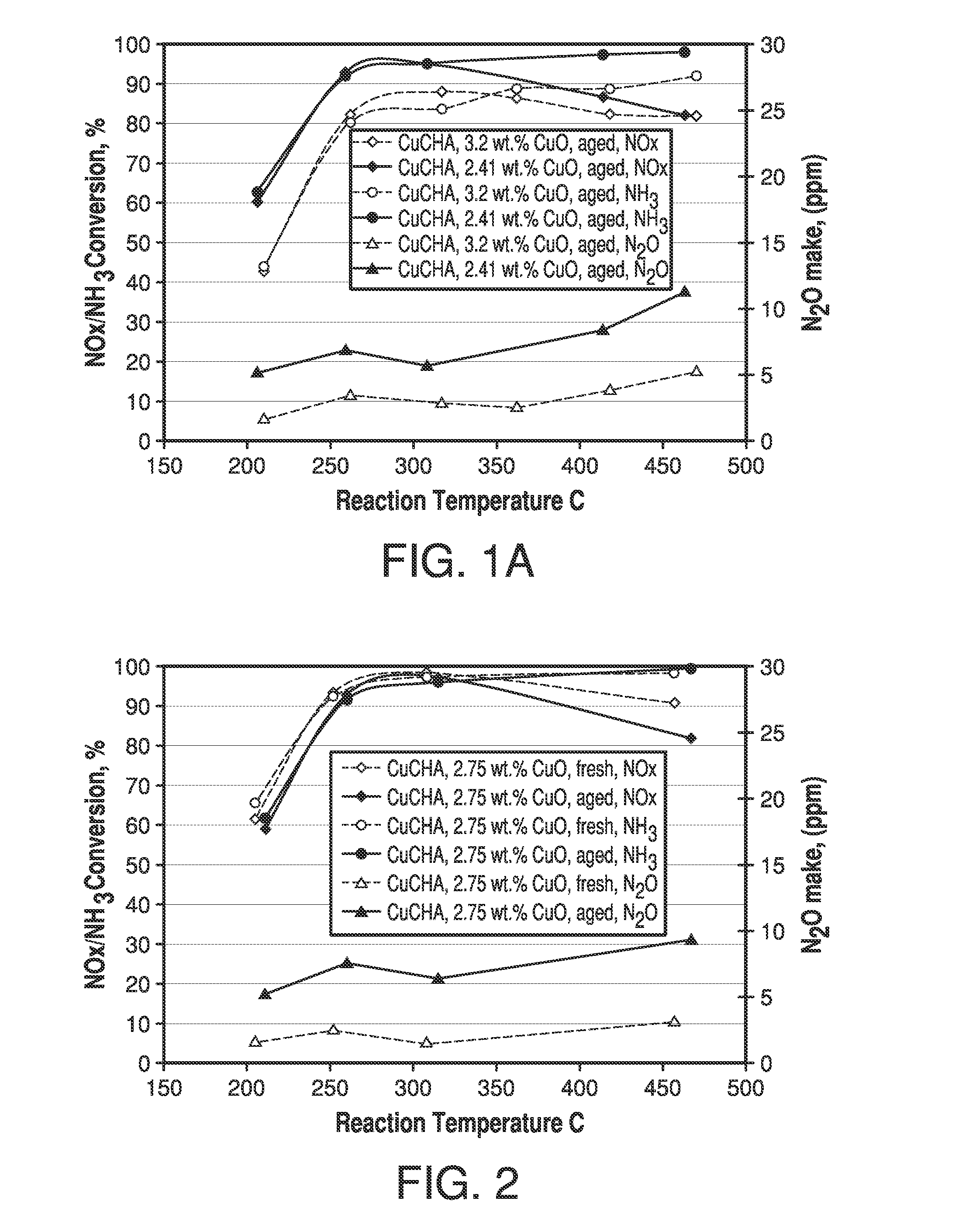

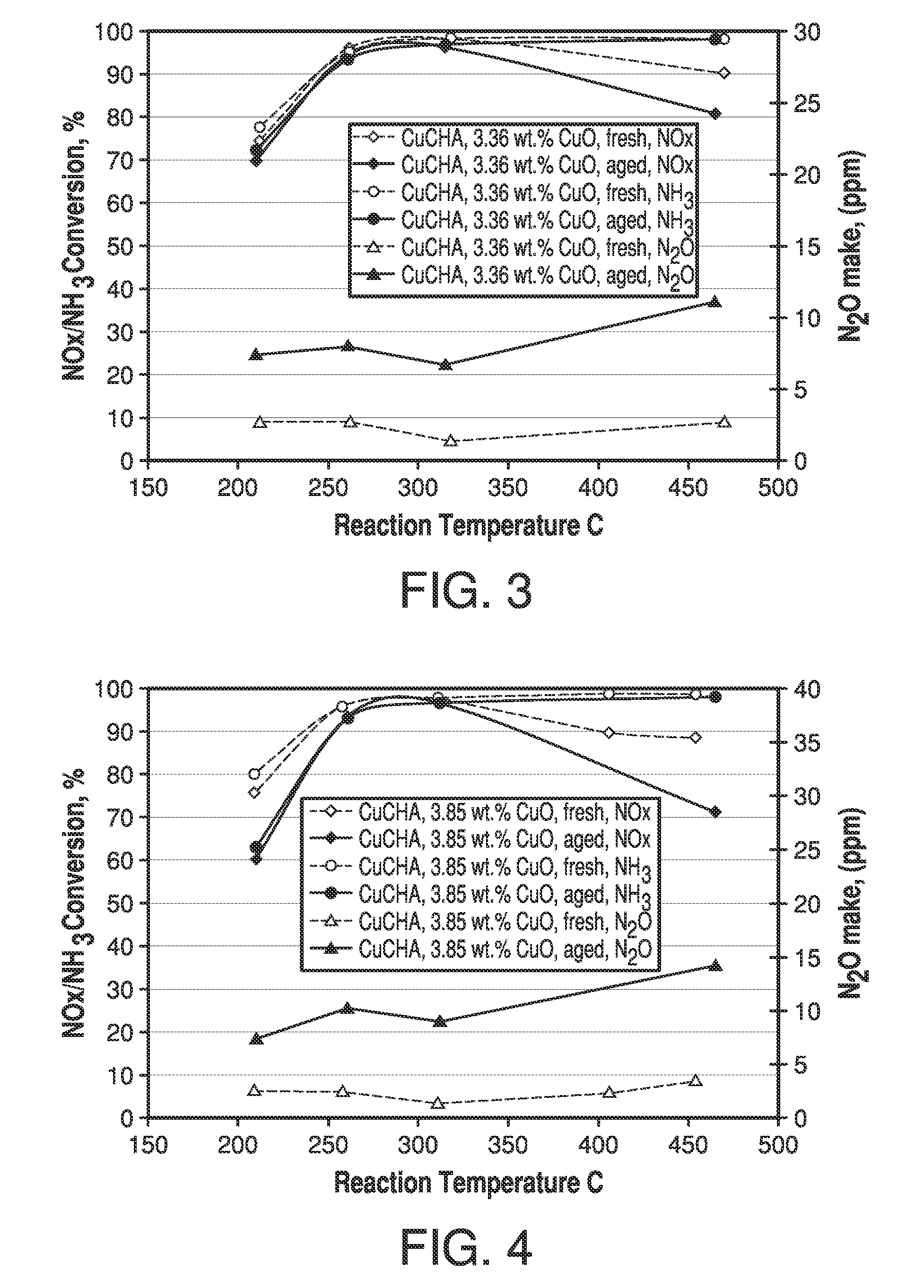

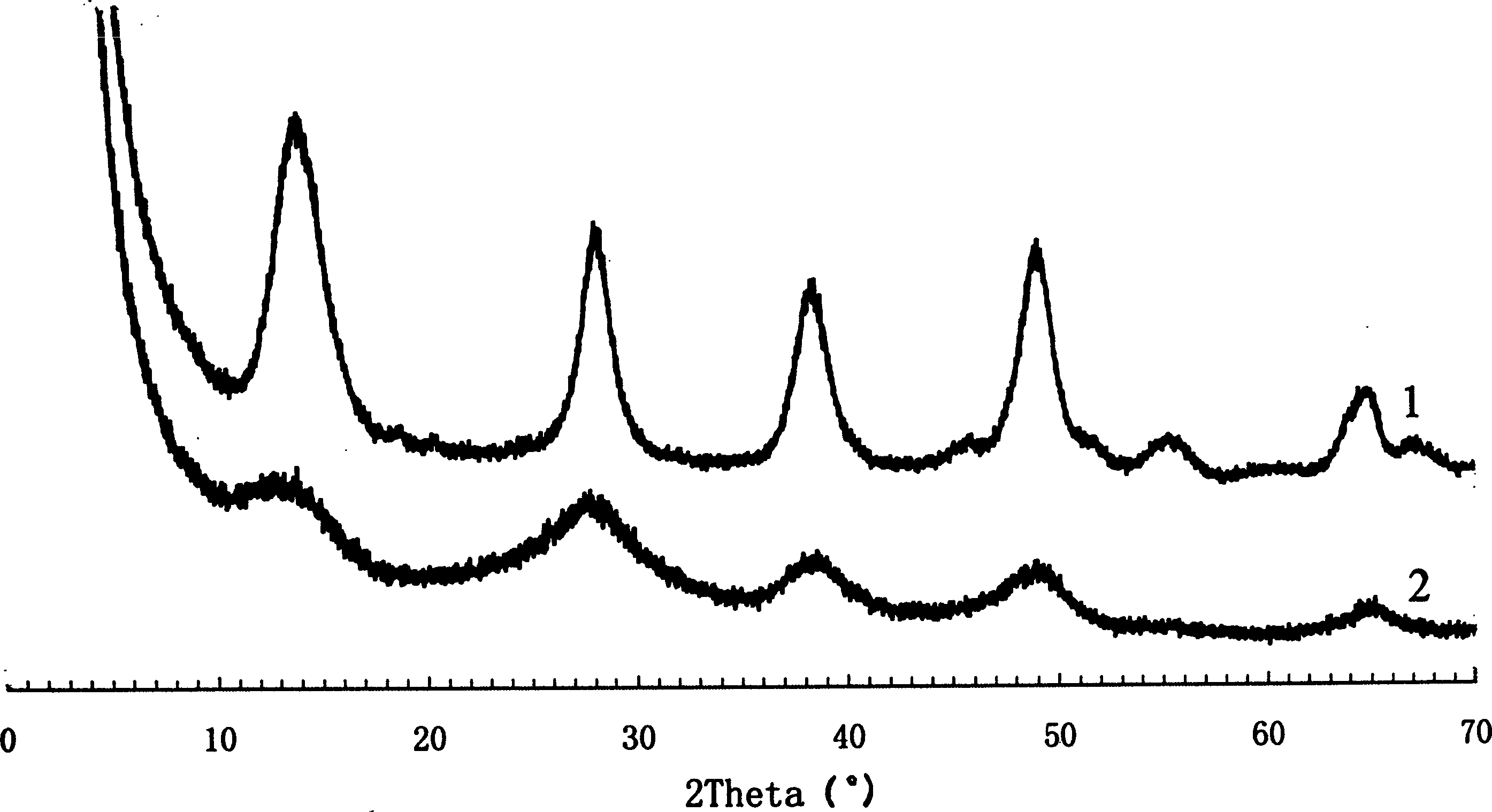

Zeolite catalysts and systems and methods for preparing and using zeolite catalysts having the CHA crystal structure are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stable at high reaction temperatures. The zeolite catalysts include a zeolite carrier having a silica to alumina ratio from about 15:1 to about 256:1 and a copper to alumina ratio from about 0.25:1 to about 1:1.

Owner:BASF CORP

Process for preparing mesoporous Si-Al material and its preparing process

ActiveCN1565733AImprove accessibilityGood hydrothermal stabilityMolecular sieve catalystsIonIon exchange

A meso-porous silicon aluminum material with thin diaspore-like phase structure is disclosed. The preparing process includes the following steps: aluminum materials and alkali solution are neutralized to glue, and then silicon materials are added, finally the product is given by aging, ion exchange, drying and baking. The meso-porous silicon aluminum materials possess good hydrothermal stability and can be used as catalyst carrier with strong macromolecule cracking capacity, higher raw oil conversion efficiency and lower heavy oil yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pentasil-type molecular sieve containing composition and its preparation method

InactiveUS6080698AGood thermal and hydrothermal stabilityExcellent thermalCatalytic crackingMolecular sieve catalystsMolecular sieveOxide

A molecular sieve containing composition, which can be applied in catalytic cracking reaction for producing more ethylene and propylene, and its preparation method. The composition contains a pentasil-type molecular sieve having a SiO2 / Al2O3 molar ratio of 15-60, prepared by activation and modification with phosphorus, alkaline earth metal and transition metal. The composition essentially includes 85 DIFFERENCE 98% wt of pentasil-type molecular sieve, 1 DIFFERENCE 10% wt of P2O5, 0.3 DIFFERENCE 5% wt of alkaline earth oxide, and 0.3 DIFFERENCE 5% wt of transition metal oxide. The molecular sieve structure and active centers have high thermal and hydrothermal stability. The salient feature of this composition is that when applied as an active component of cracking catalyst for catalytic pyrolysis process, the yield of ethylene is above 18% and the total yield of ethylene and propylene is more than 40%.

Owner:CHINA PETROCHEMICAL CORP +1

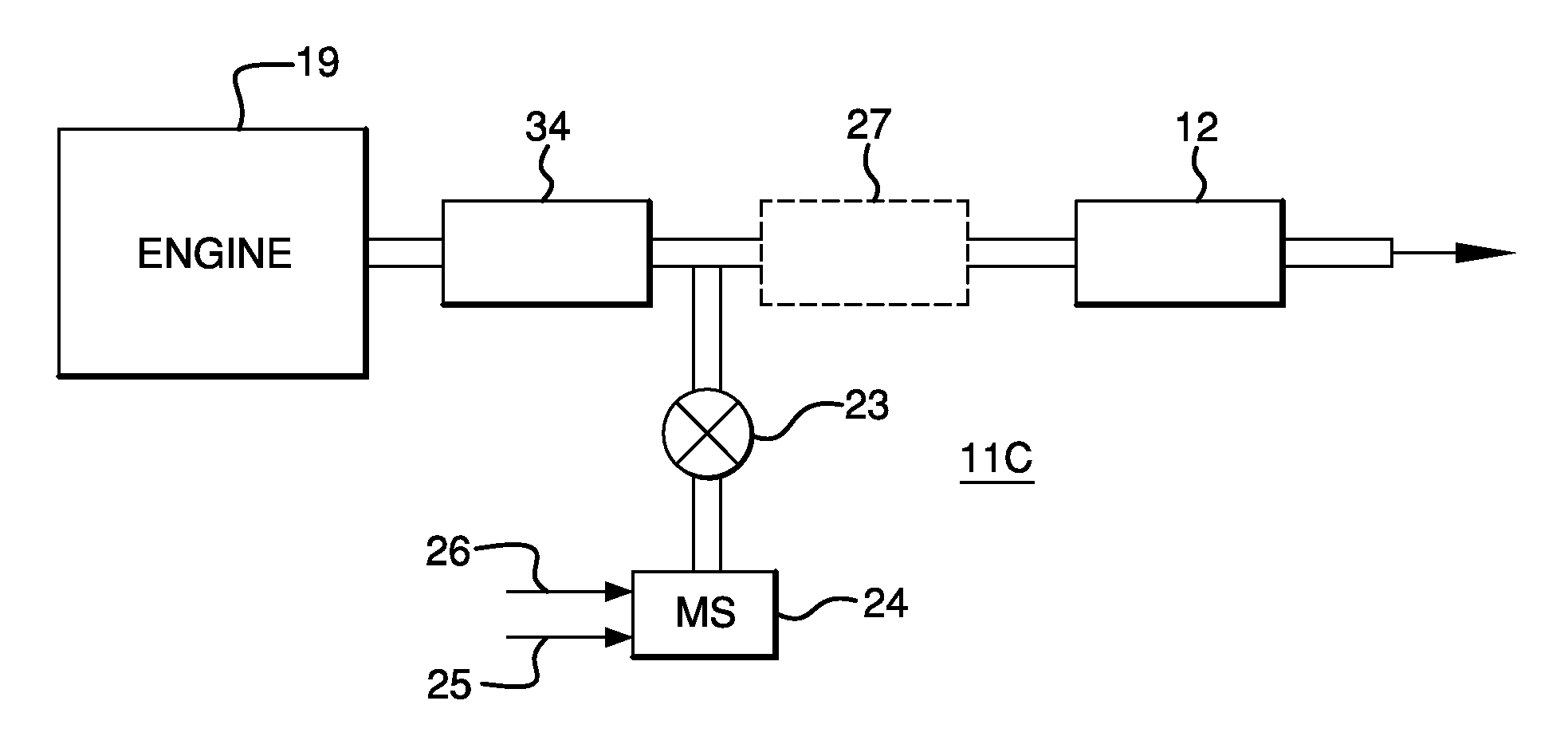

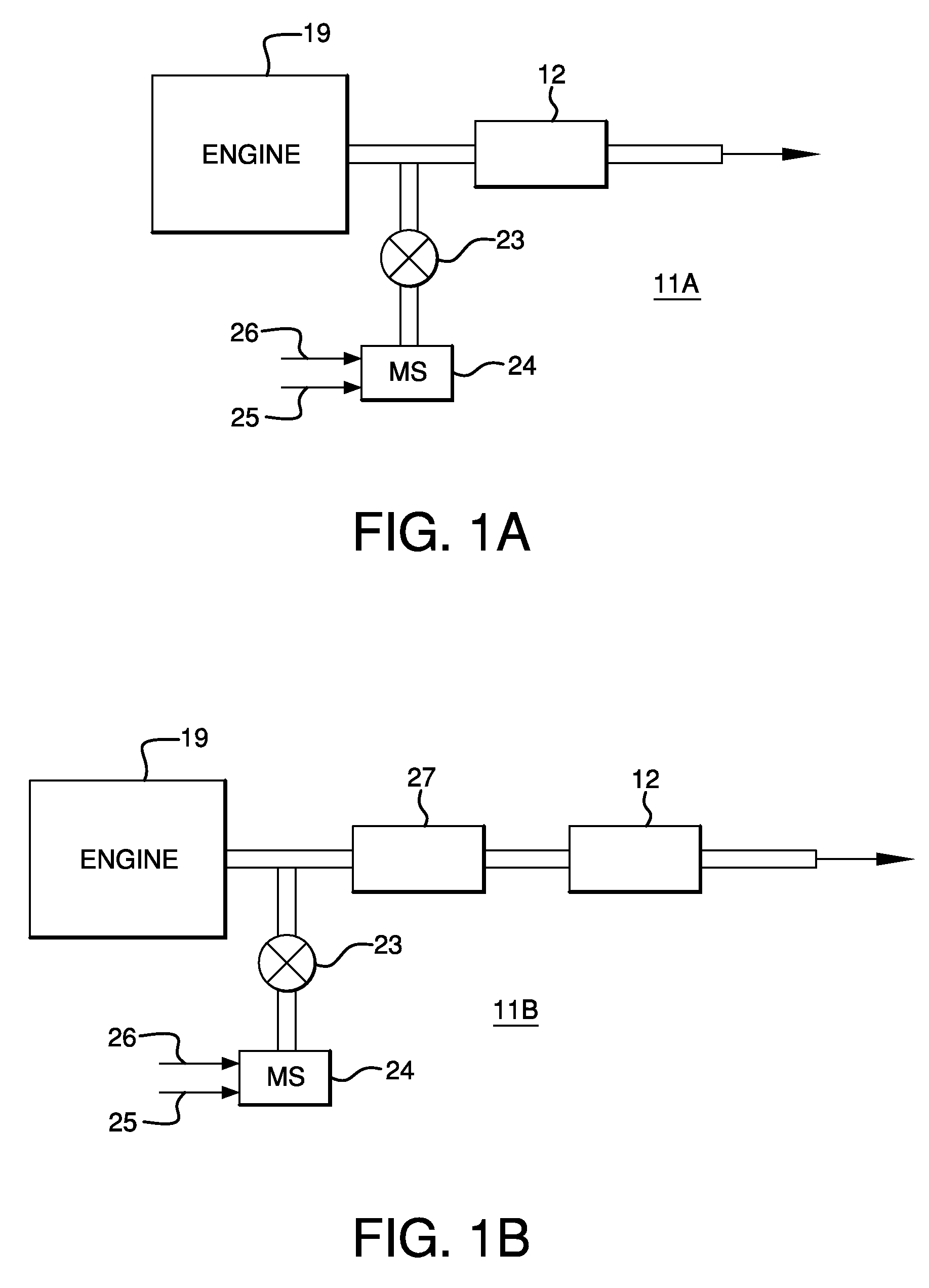

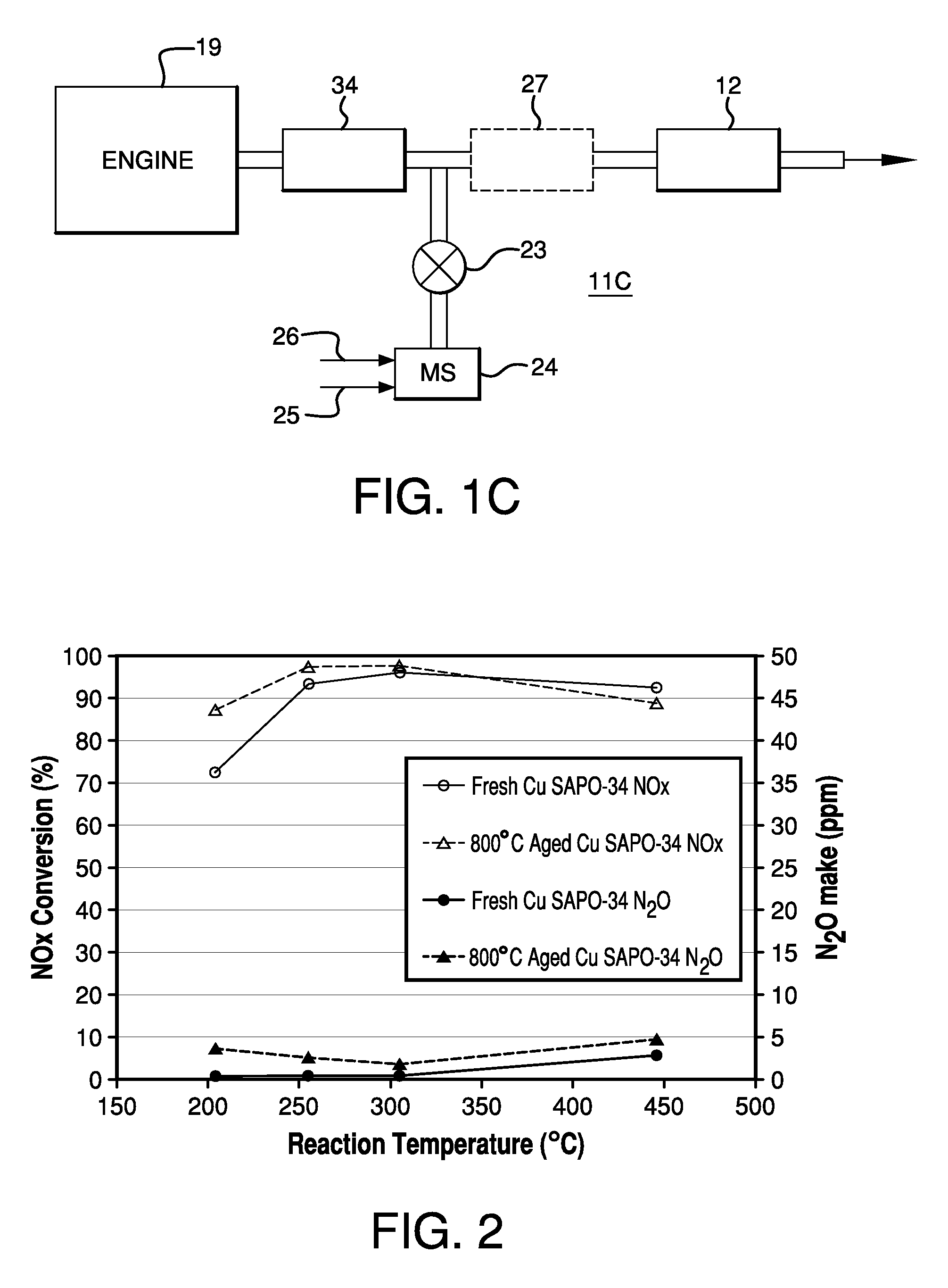

Catalysts, Systems and Methods Utilizing Non-Zeolitic Metal-Containing Molecular Sieves Having the CHA Crystal Structure

InactiveUS20090196812A1Improve nh3 scrExcellent hydrothermal stabilityNitrous oxide captureCombination devicesExhaust gasChemistry

Catalysts comprising metal-loaded non-zeolitic molecular sieves having the CHA crystal structure, including Cu-SAPO-34, methods for preparing such catalysts, and systems and methods for treating exhaust gas incorporating such catalysts are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stability at high reaction temperatures.

Owner:BASF CORP

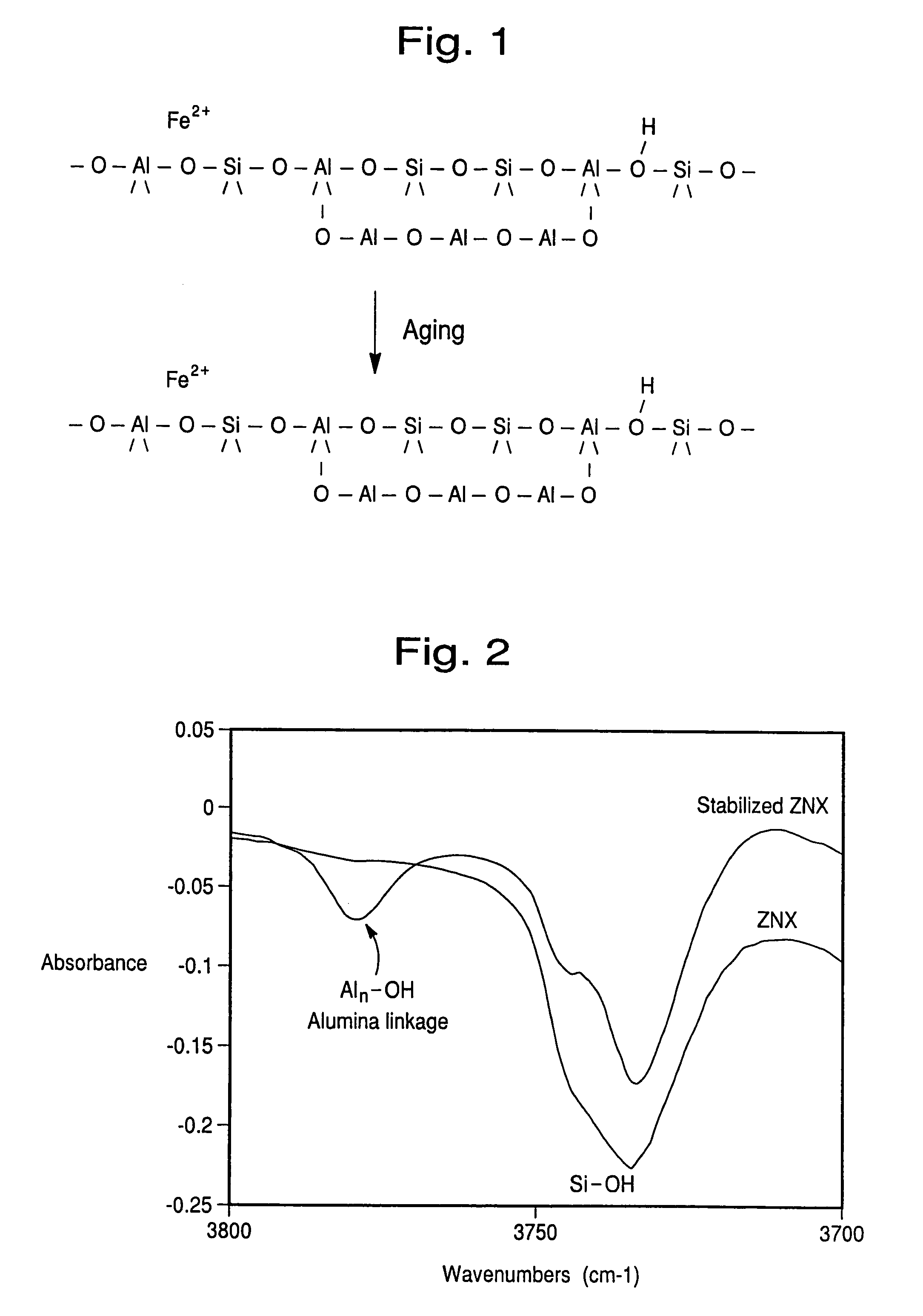

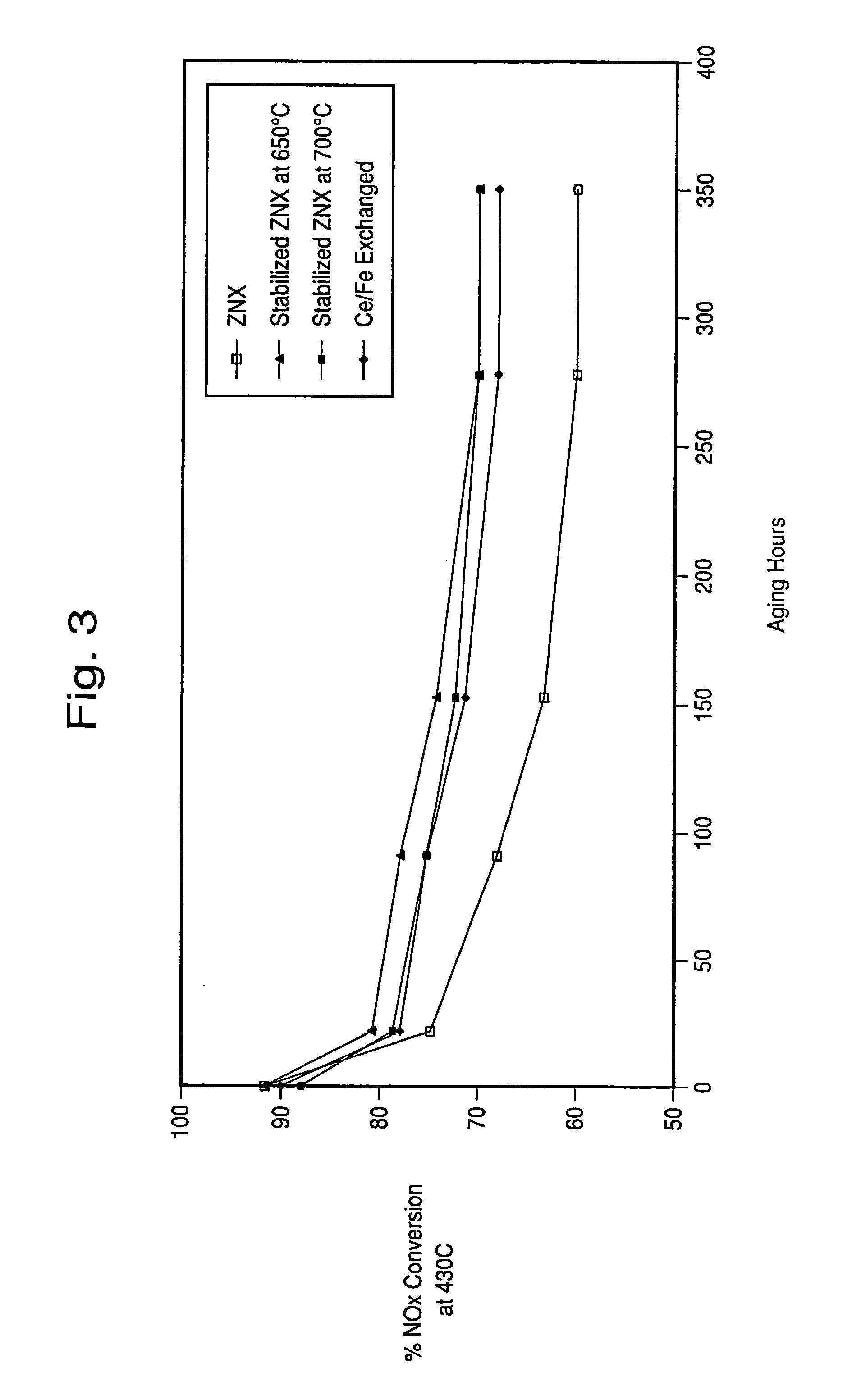

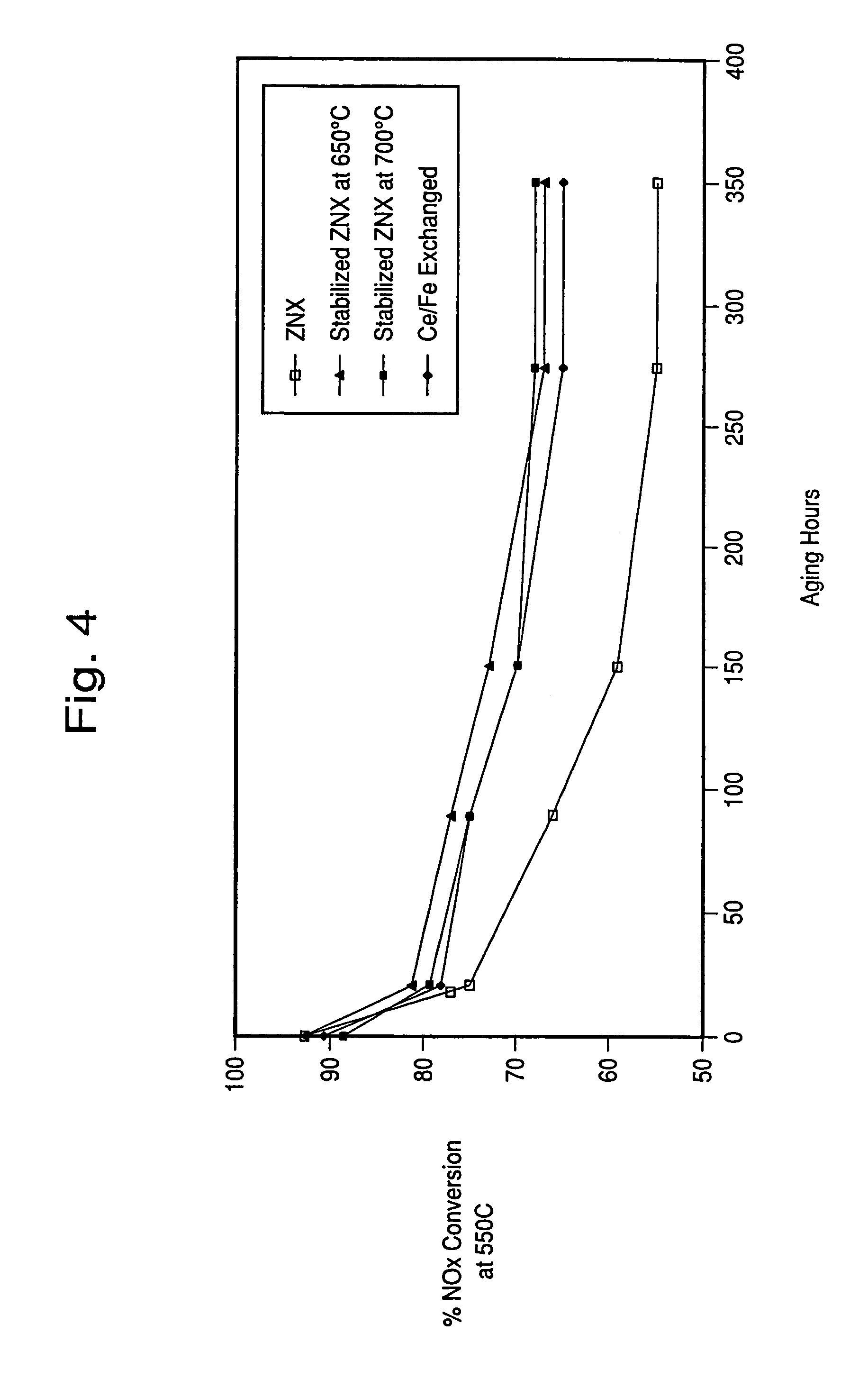

Hydrothermally stable metal promoted zeolite beta for NOx reduction

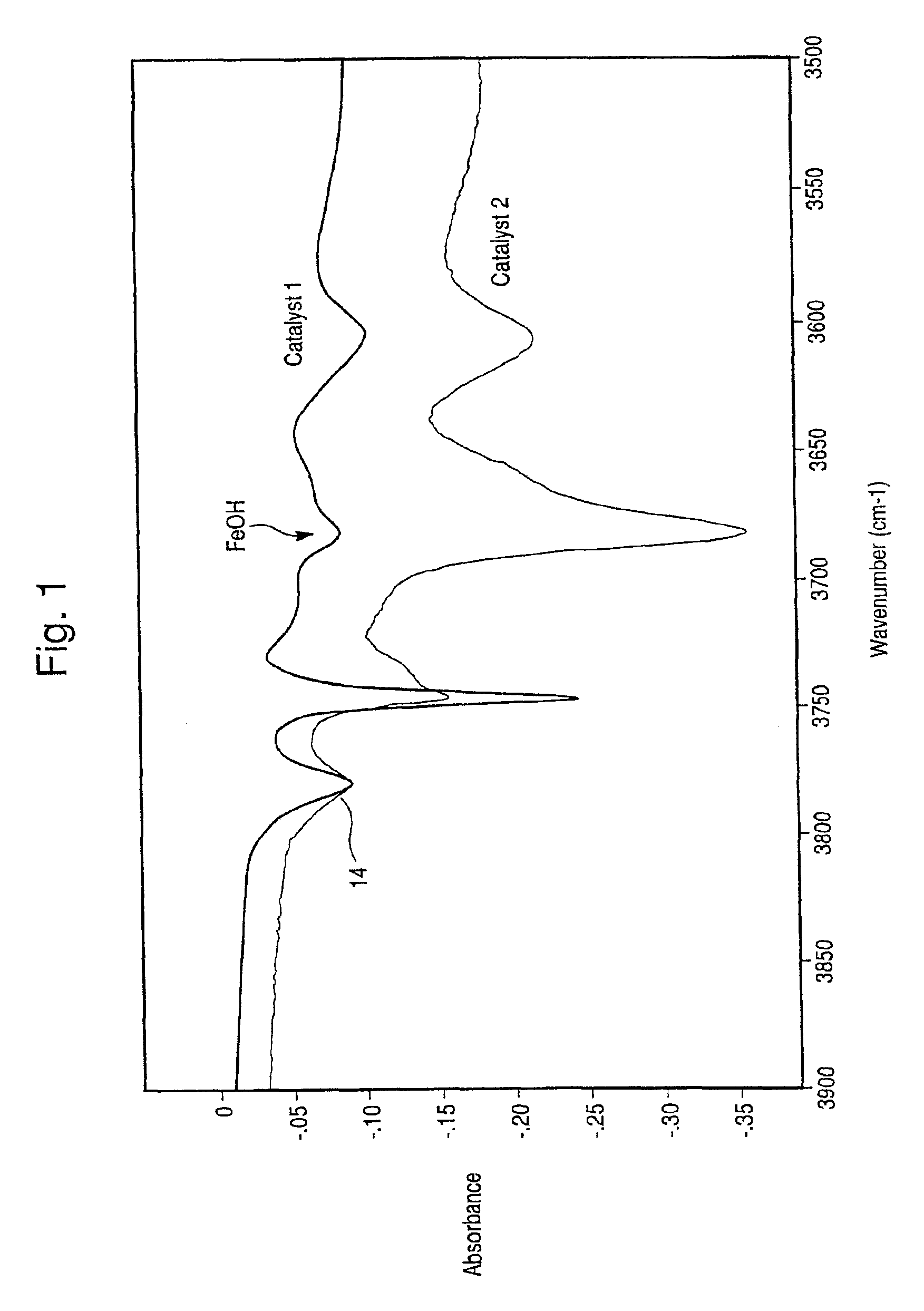

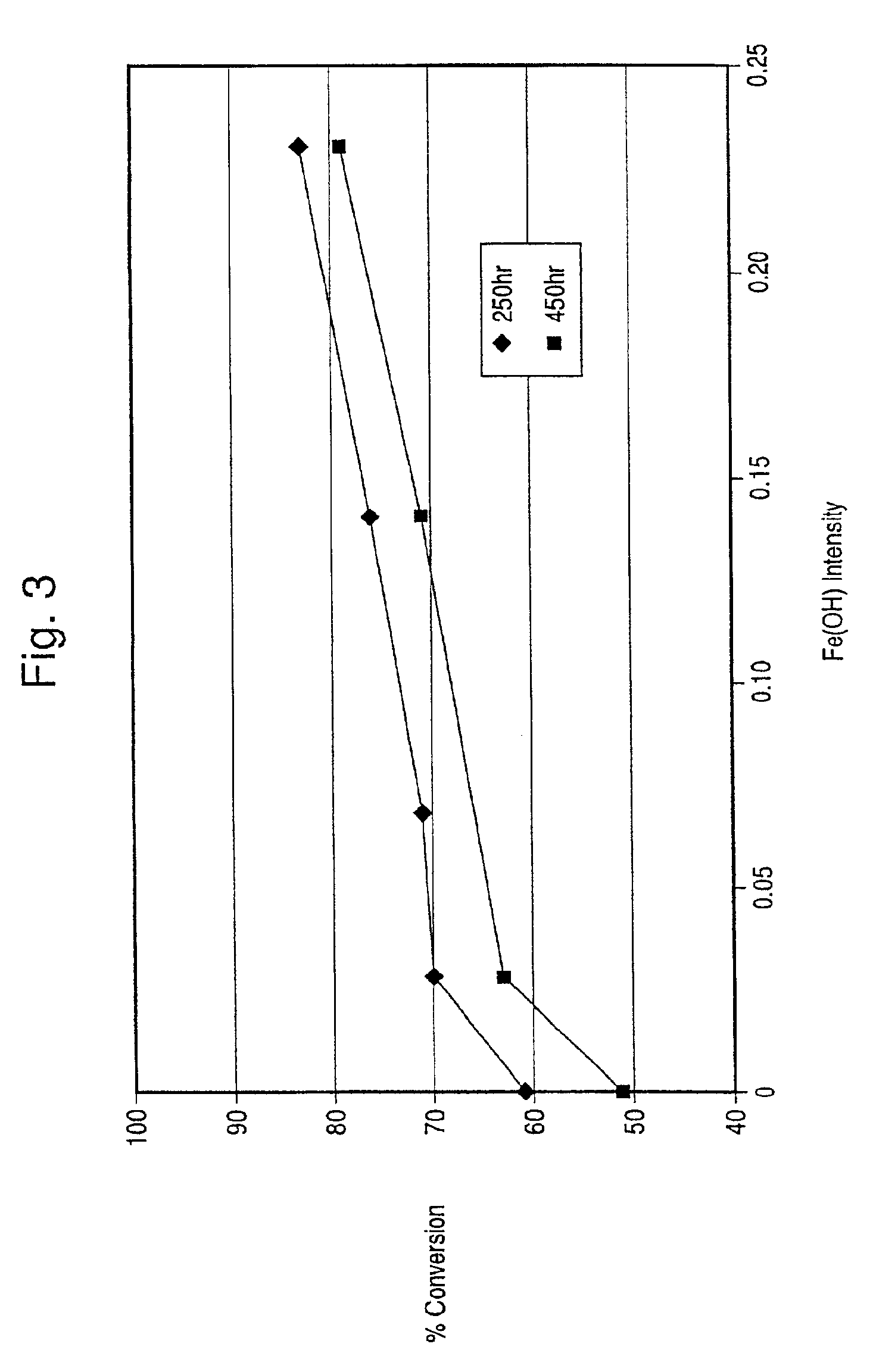

InactiveUS6914026B2Increasing Fe(OH) content of catalystGood hydrothermal stabilityMolecular sieve catalystsDispersed particle separationIron saltsIon exchange

The present invention is directed to an iron-promoted zeolite beta catalyst useful in the selective catalytic reduction of nitrogen oxides with ammonia in which the iron-promoted zeolite beta is treated so as to provide increased amounts of the iron promoter in the form of Fe(OH).The stabilized zeolite is formed by cation exchange of an iron salt into a zeolite beta which has a reduced sodium content such as by exchanging a sodium beta with ammonium or hydrogen cations. A zeolite beta having a reduced carbon content and a Si / Al ratio of no more than 10 also increases the Fe(OH) content of the iron-promoted catalyst. The iron-promoted catalyst which has the iron in the form of Fe(OH) is characterized by a peak at 3680±5 cm−1 in the IR spectra.

Owner:ENGELHARD CORP

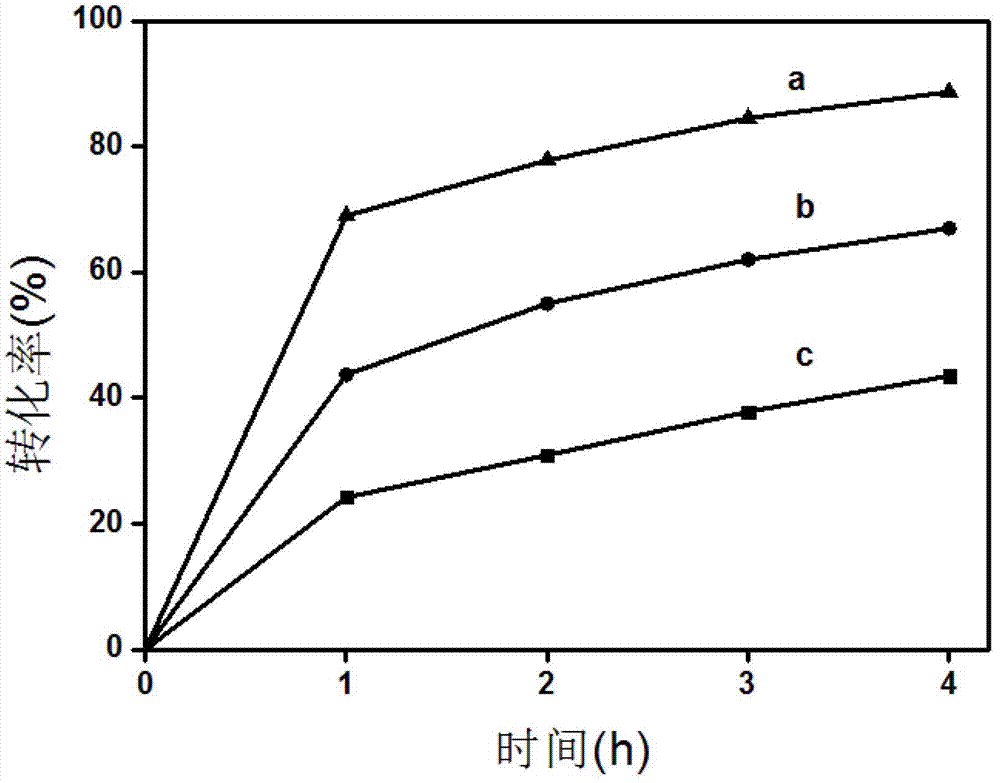

Process for preparing ethandiol by catalyzing epoxyethane hydration

InactiveCN1463960AHigh activityGood choiceBulk chemical productionPreparation by hydrolysisEpoxideEnergy consumption

The present invention relates to process of catalytic hydration of ethylene epoxide to prepare glycol and aims at solving the problems of available corresponding process. The said process is especially suitable for low water ratio operation, and has the features of very low heat energy consumption and power consumption, high activity, selectivity and stability of catalyst, and low production cost. The said process may be used in industrial production of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Stabilized dual zeolite single particle catalyst composition and a process thereof

InactiveUS20030166453A1Good hydrothermal stabilityImprove stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveKaolin clay

The present invention relates to a stabilized dual zeolite catalyst for cracking heavier hydrocarbons into lighter useful products said catalyst comprising two types of zeolites viz., low silica molecular sieve and stabilized high silica zeolite, silica-alumina based binder and kaolin clay and a process for the preparation of the stabilized dual zeolite catalyst.

Owner:INDIAN OIL CORPORATION

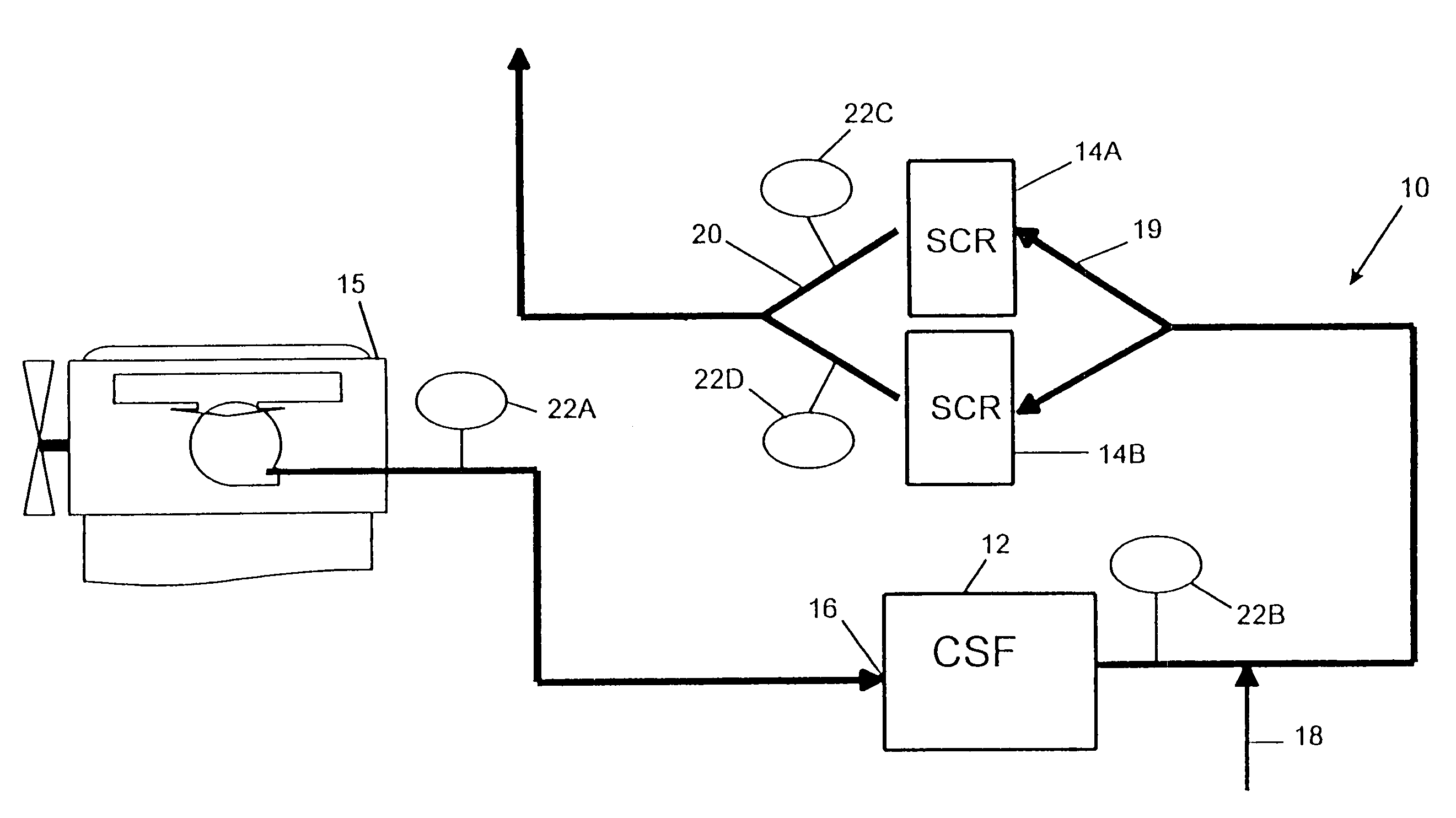

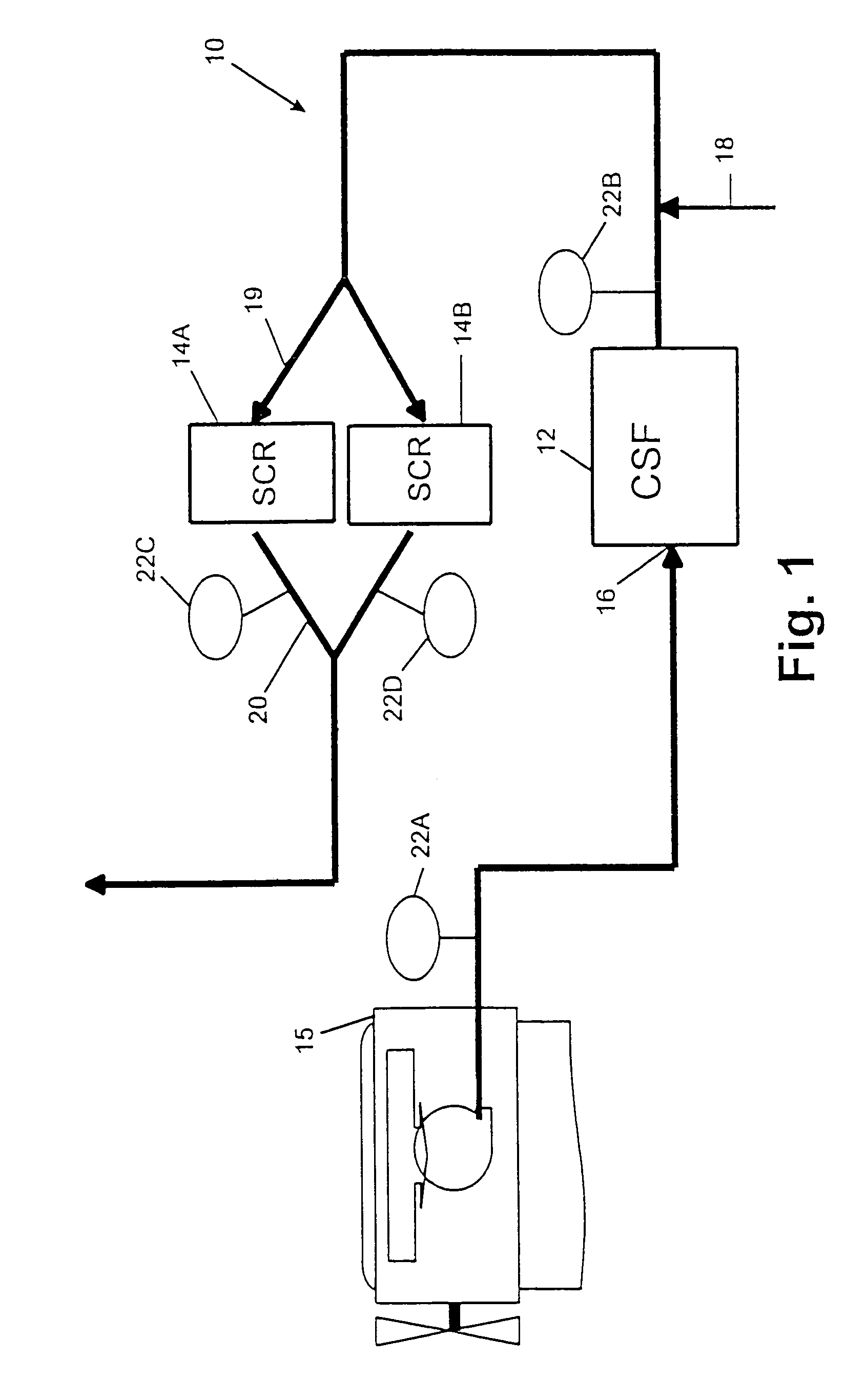

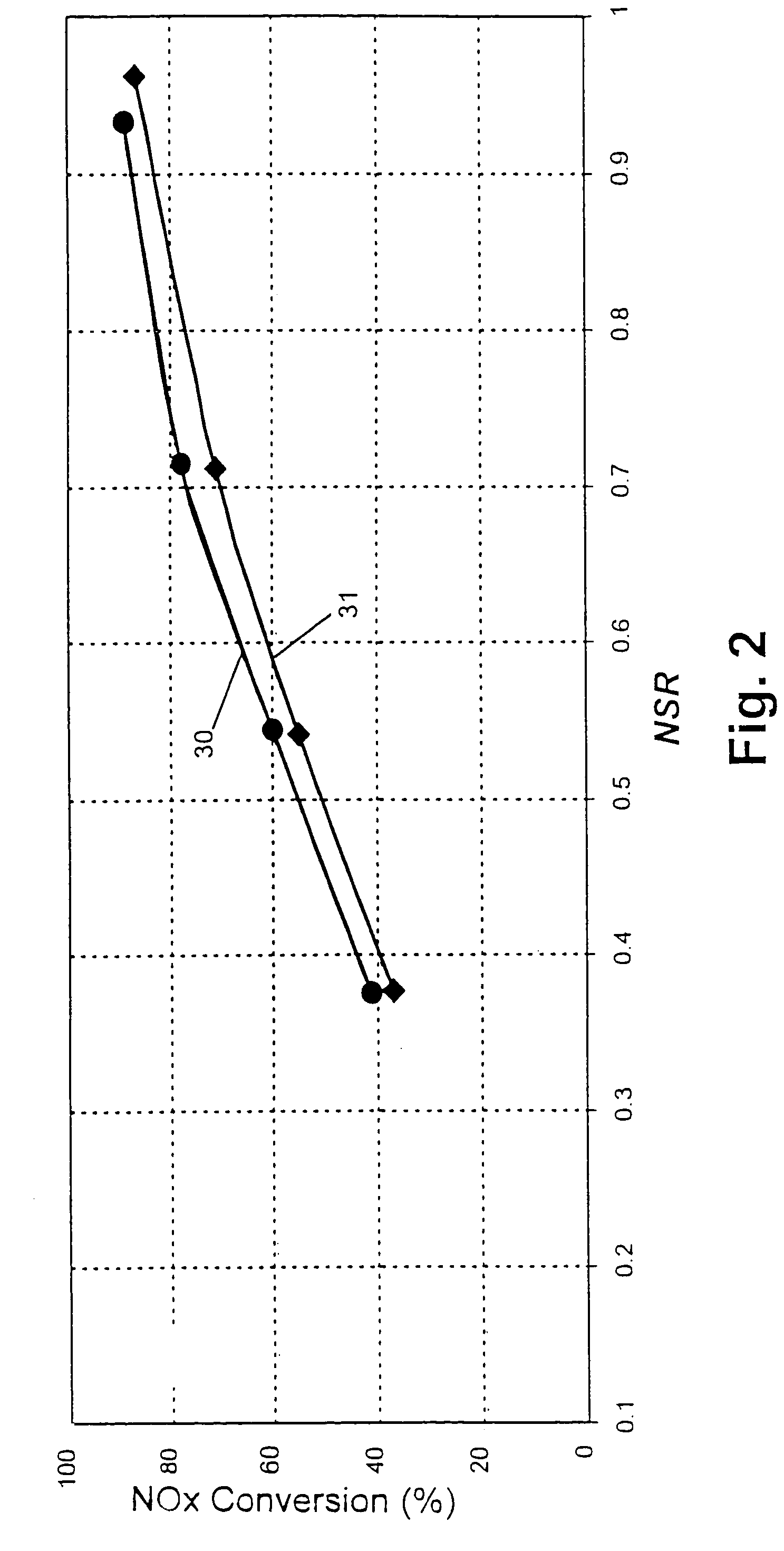

Exhaust system for enhanced reduction of nitrogen oxides and particulates from diesel engines

InactiveUS7143578B2Promote conversionImprove overall utilizationNitrous oxide captureGas treatmentParticulatesNitrogen oxides

A diesel engine aftertreatment exhaust system uses catalyzed soot filters for particulate matter reduction and urea SCR catalysts for NOx reduction on diesel engines in a combined system to lower particulate matter and NOx at the same time. With this integral emission control system, diesel engines are able to meet ultra low emission standards.

Owner:ENGELHARD CORP

Catalyst of catalyzing, cracking for reducing sulfur content in gasoline and preparation process thereof

InactiveCN1597850AGood dispersionGood hydrothermal stabilityCatalytic crackingMolecular sieveIn situ crystallization

The invention is a catalytic cracking catalyst to reduce sulfur content of gasoline and its preparing method, synthesis gama-type molecular sieve by kaoline in-situ crystallization and making exchange sodium reduction or / and rare-earth ion exchange processing to prepare it, and its characteristic: the weight percent of sodium oxide contained in it is less than 0.75%, the ratio of zeolite to silica-alumina is above 4.5, and it adds one or several of the sourish metal elements: Cu, Zn, Fe, Al, Ni, Zr, Sn, Ga, Ti and V in weight percent of 0.1-10%. It has good zeolite dispersivity and excellent hydrothermal stability, good catalytic cracking property, and excellent function of reducing sulfur content of gasoline. It can be used by mixing with routine FCC catalyst and also be singly applied in the catalytic cracking process course.

Owner:PETROCHINA CO LTD

Hydrocarbon cracking catalyst containing modcfied faujasite

InactiveCN1624079AGood hydrothermal stabilityHigh reaction conversion rateCatalytic crackingHigh resistanceRare earth

A hydrocarbon cracking catalyst containing modified octahedra zeolite is prepared from modified octahedra zeolite, one or moke kinds of other modified zeolite, clay and refractory inorganic oxide through proportional mixing, spray shaping, and washing. Its advantages are high activity and stability, high gasoline output rate, low coke output rate, and high resistance to heavy metal pollution.

Owner:PETROCHINA CO LTD

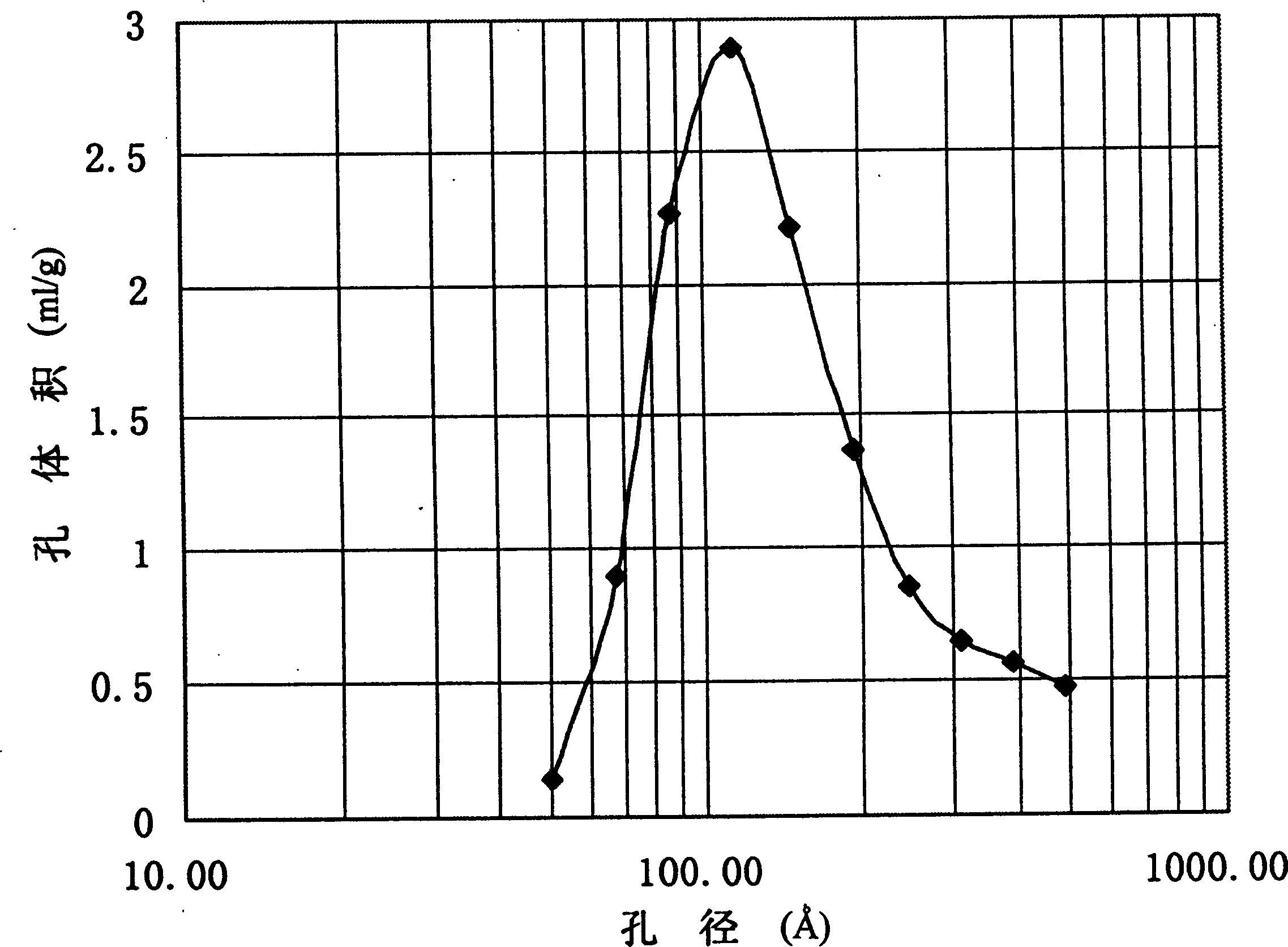

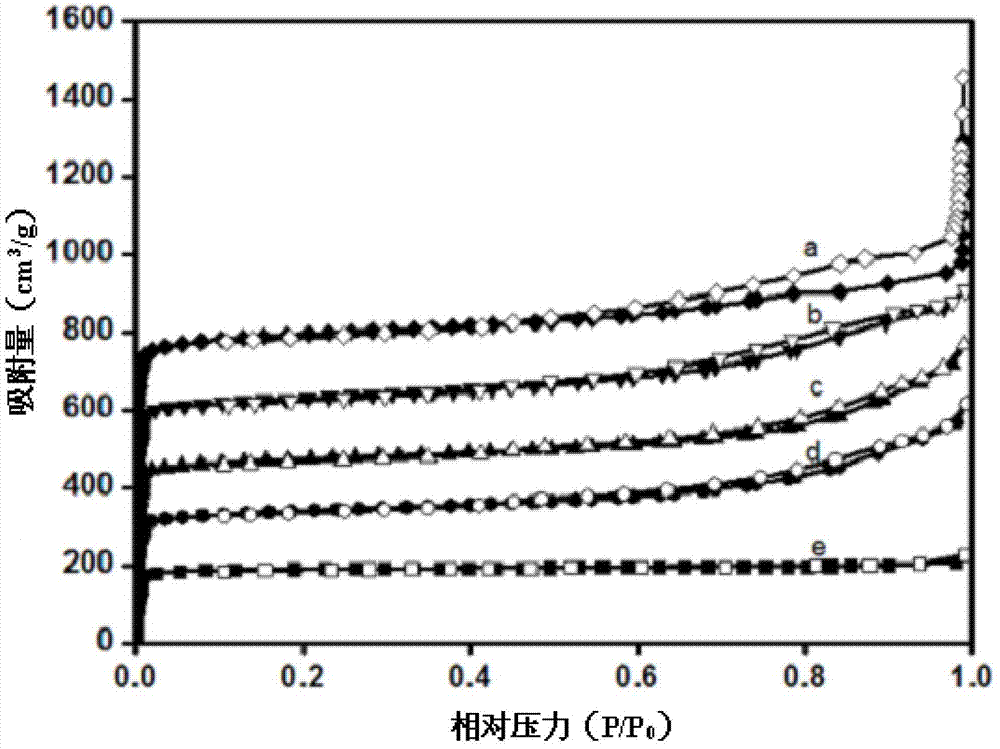

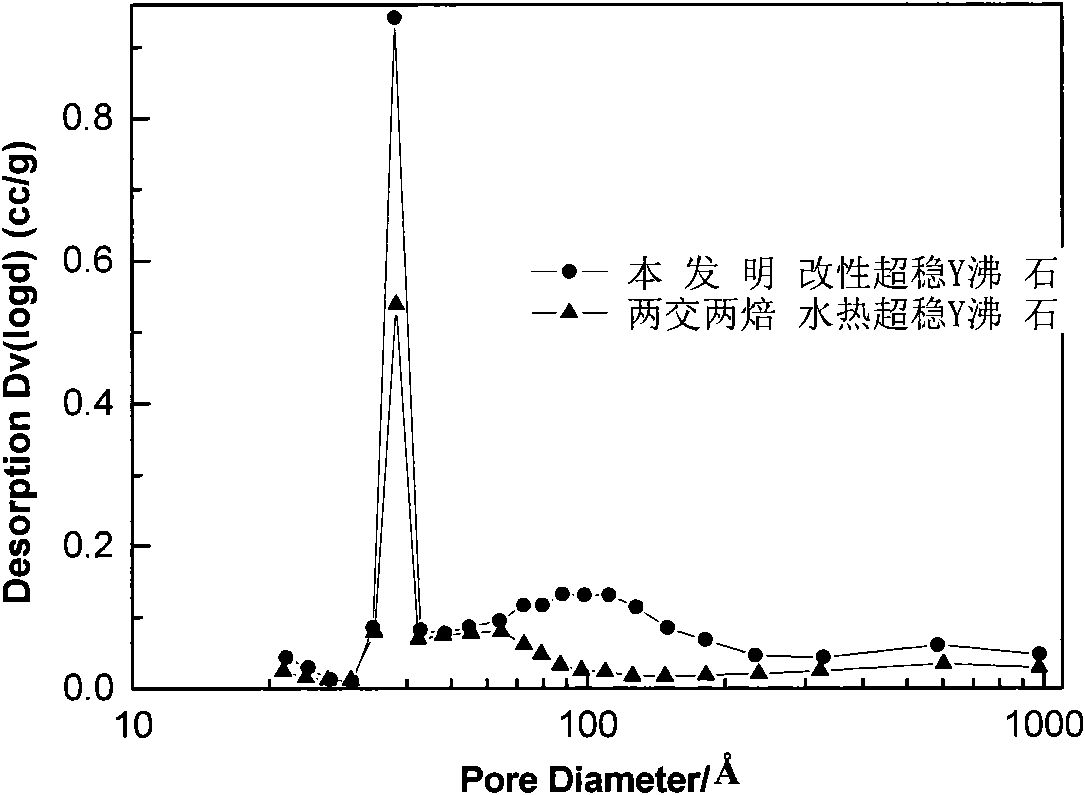

Preparation method of mesoporous-containing Y-shaped molecular sieve

ActiveCN103172082AMicroporosity unchangedGood hydrothermal stabilityFaujasite aluminosilicate zeoliteMolecular sieveOrganic acid

The invention relates to a preparation method of a mesoporous-containing Y-shaped molecular sieve, and relates to a preparation method of a Y-shaped molecular sieve. The preparation method aims to solve the problems of small pore diameter and pore volume of the Y-shaped molecular sieve prepared through the traditional method. The preparation method comprises the following steps of: 1, preparing a sodium type Y-shaped molecular sieve; 2, preparing an ammonium type Y-shaped molecular sieve; 3, processing through an organic acid water solution; 4, processing through NaOH; and 5, processing through an ammonium nitrate water solution so as to obtain the mesoporous-containing Y-shaped molecular sieve. The mesoporous-containing Y-shaped molecular sieve is synthesized through a simple and effective method under a moderate condition, contains abundant mesoporous, is unchanged in microporosity, achieves the volume of the mesoporous at 0.5-1.5 mL / g, greatly promotes the macromolecule to approach a catalytic active center and is favorable for reaction mass transfer through more concentrated pore diameter distribution, has the advantages of adjustable ratio of silicon and aluminum contained in a framework and good hydrothermal stability and can be used as a catalyst carrier or directly used as a catalyst. The preparation method disclosed by the invention can be used for preparing the mesoporous-containing Y-shaped molecular sieve.

Owner:HARBIN INST OF TECH

Method for synthesizing silicon aluminum orthophosphate molecular sieve using white bole

InactiveCN101176851AGood hydrothermal stabilityHigh reactivityMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesALUMINUM PHOSPHATEWhite Bole

The invention relates to a method of molecular sieve catalyst synthesis using the kaolin for the synthesis of silicon aluminum phosphate molecular sieve, belonging to the technical field of the preparation of the catalyst materials. The invention is characterized in utilizing the low-cost kaolin as materials. Through (1) roasting the kaolin in the high temperature to gain the crystal aluminum sources and silicon sources; (2) mixing the kaolin with the phosphorus sources and the template agent with the deionized water, processing hydro-thermal crystallization, and roasting and activating the products after washing and drying, the catalyst of the silicon aluminum phosphate molecular sieve can be gained. The structure of the silicon aluminum phosphate molecular sieve is CHA or the intergrowth of CHA and AEI. The invention has the advantages of smaller or lamellar structure molecular sieve gains of the prepared catalyst, which can be used for the process of making olefin from the oxygenic compounds like the limited diffuse alcohol ether to gain the good activity of reaction and the product selectivity, and further the directly application of the catalyst carried by the kaolin micro sphere into fluidized bed reactor.

Owner:CHINA NAT CHEM ENG GRP CORP LTD +1

Catalytic cracking auxiliary agent for reducing sulfur content in gasoline and preparation method thereof

The catalytically cracking assistant capable of lowering the sulfur content in gasoline is composite oxide including aluminum zinc spinel, homogeneously distributed zinc oxide and at least one optional RE oxide. It is prepared through roasting the mixture of laminar aluminum zinc in hdrotalcite structure and optional RE oxide hydrate. The preparation process is simple, and the assistant has the features of high dispersion, high specific surface area, etc. The assistant after being formed is mixed with conventional FCC catalyst and / or active reinforcing assistant for application in catalytically cracking process, and has the function of lowering the sulfur content in gasoline and excellent hydrothermal stability.

Owner:EAST CHINA UNIV OF SCI & TECH +1

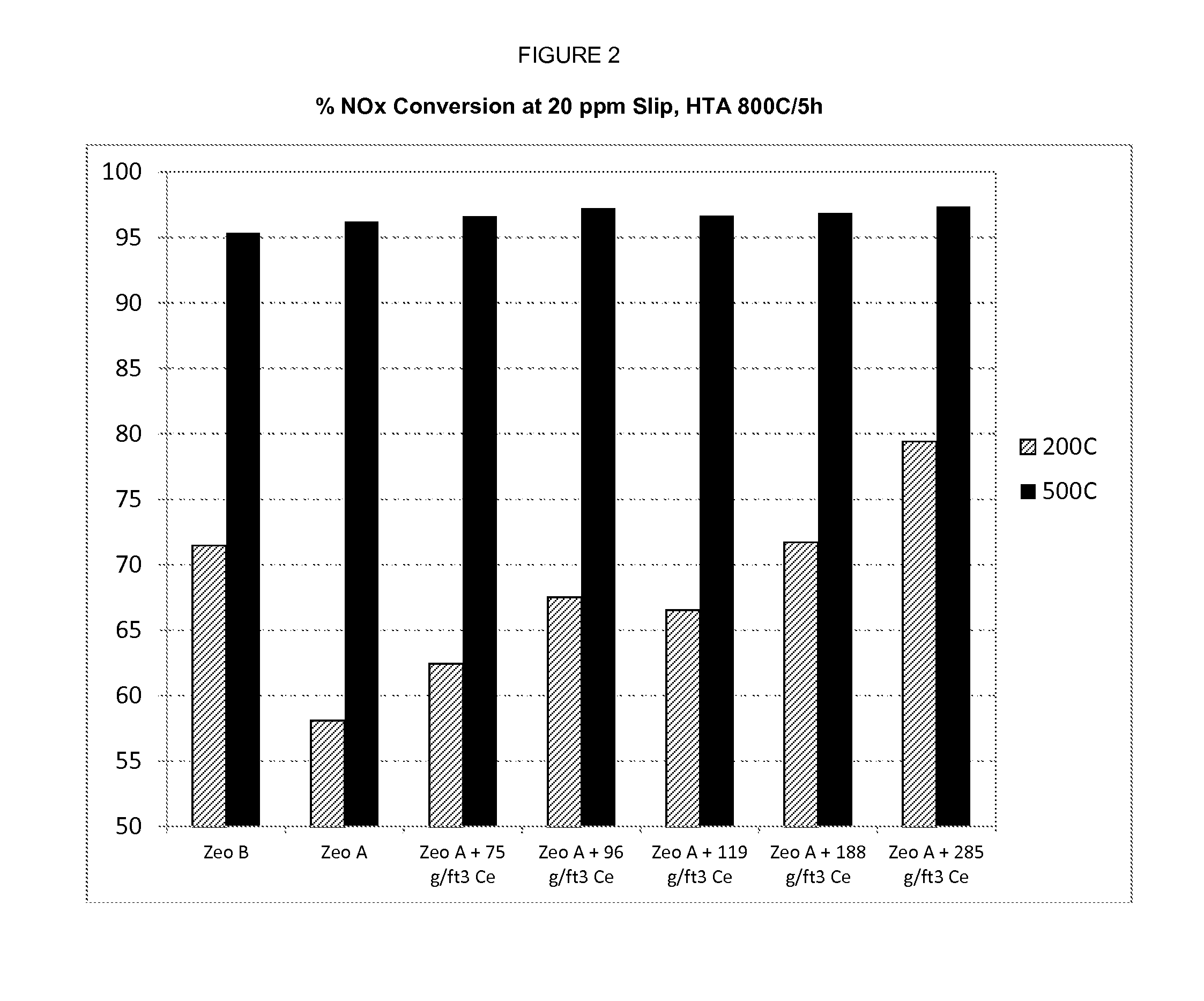

Zeolite catalyst containing metal

ActiveUS20120201731A1Promote conversionGood choiceAluminium compoundsNitrogen compoundsCeriumSilicon dioxide

Provided is a catalyst comprising (a) a zeolite material having a mean crystal size of at least about 0.5 μm, having a CHA framework that contains silicon and aluminum, and having a silica-to-alumina mole ratio (SAR) of about 10 to about 25; and (b) an extra-framework promoter metal (M) disposed in said zeolite material as free and / or exchanged metal, wherein the extra-framework promoter metal is copper, iron, and mixtures thereof, and is present in a promoter metal-to-aluminum atomic ratio (M:Al) of about 0.10 to about 0.24 based on the framework aluminum; and optionally comprising (c) at least about 1 weight percent of cerium in said zeolite material, based on the total weight of the zeolite, wherein said cerium is present in a form selected from exchanged cerium ions, monomeric ceria, oligomeric ceria, and combinations thereof, provided that said oligomeric ceria has a particle size of less than 5 μm.

Owner:JOHNSON MATTHEY PLC

Process for preparing ethandiol by catalytic hydration of epoxyethane

InactiveCN1204103CHigh activityGood choiceBulk chemical productionPreparation by hydrolysisEthylene oxideHigh activity

The present invention relates to process of catalytic hydration of ethylene epoxide to prepare glycol and aims at solving the problems of available corresponding process. The said process is especially suitable for low water ratio operation, and has the features of very low heat energy consumption and power consumption, high activity, selectivity and stability of catalyst, and low production cost. The said process may be used in industrial production of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Super-stable Y zeolite, preparation method and application thereof

ActiveCN102020289AHigh crystallinityIncrease the areaCatalytic crackingMolecular sieve catalystsOrganic acidGasoline

The present invention provides a super-stable Y zeolite and the preparation method thereof. The ratio of silicate to aluminum in the super-stable Y zeolite is 6-11. The lattice constant of the zeolite is 2.446 to 2.458 nanometers. The percentage of non-skeleton aluminum in total aluminum in the zeolite is not higher than 30% by weight. The diameter of secondary pores with diameter of 2 to 100 nanometers in the zeolite shows a double probable distribution. The most probable diameter of the secondary pores with comparatively large diameter is 6-15 nanometers. The proportion of secondary pores with diameter between 8 to 100 nanometers in total secondary pores is 35% to 60%. The preparation method of the zeolite includes the step of making the super-stable Y zeolite come into contact with a solution containing organic acids and inorganic acids in the atmosphere of inert gases and / or nitrogen. The modified super-stable Y zeolite provided in the invention is applied to catalytic cracking; therefore the following effects can be realized: the cracking ability of heavy oil is strong, the selectivity of gasoline is high, and the selectivity of dry gas and carbon coke is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing vanadium-silicon molecular sieve

ActiveCN1840477AReduce manufacturing costMolecular sieve vanadium content adjustableMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveSilicon

The preparation method for V-Si molecular sieve with MFI structure comprises: mixing Si source, V source, the template agent by n-butyl amine and / or triethylamine with mole ratio to SiO2 as 0.04-0.5:1, the inorganic alkali, and water; crystallizing in sealed kettle to obtain the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

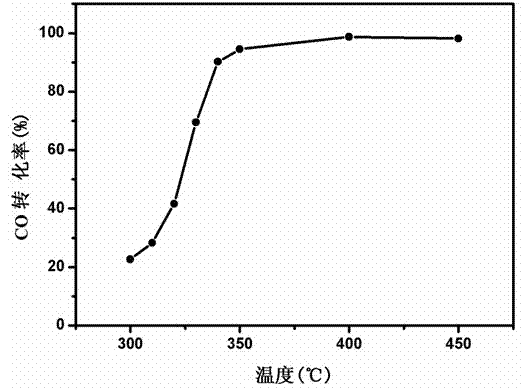

Coal gasification catalyst completely methanated by synthesis gas and preparation and application thereof

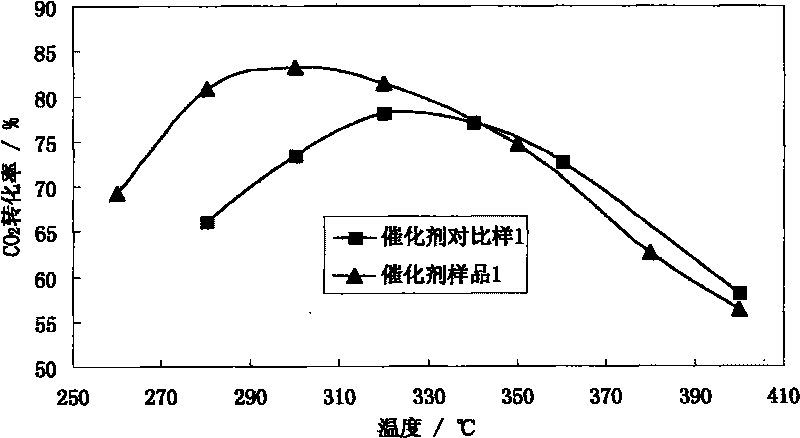

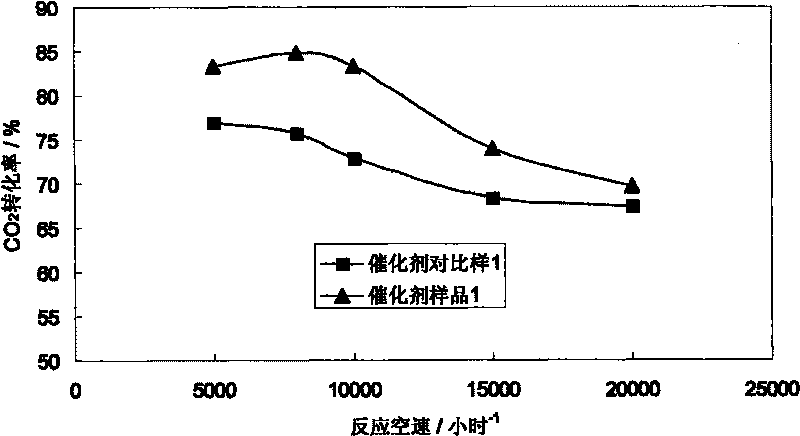

ActiveCN101716513AGood hydrothermal stabilityHigh hydrothermal stabilityHydrocarbon from carbon oxidesGaseous fuelsOxidePrecipitation

The invention relates to a coal gasification catalyzer completely methanated by synthesis gas and a preparation and application thereof. The catalyzer contains an active component, a carrier and an accessory ingredient, wherein the active component is a transition metal oxide NiO, and the content of NiO is 10-75 percent of the total weight of the catalyzer; the carrier is a CeO2-based rare earth metal oxide, and the content of the rare earth metal oxide is 10-19 percent of the total weight of the catalyzer; and the accessory ingredient is La2O3, and the content of La2O3 is 0.1-15 percent of the total weight of the catalyzer; the preparation method adopts a simple homogeneous phase chemical precipitation process. The invention has the advantages of low cost on raw materials and simple preparation method, meets the current increasing needs of clean energies and meanwhile has the irreplaceable important role in the enhancement of international energy sources and resource security.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

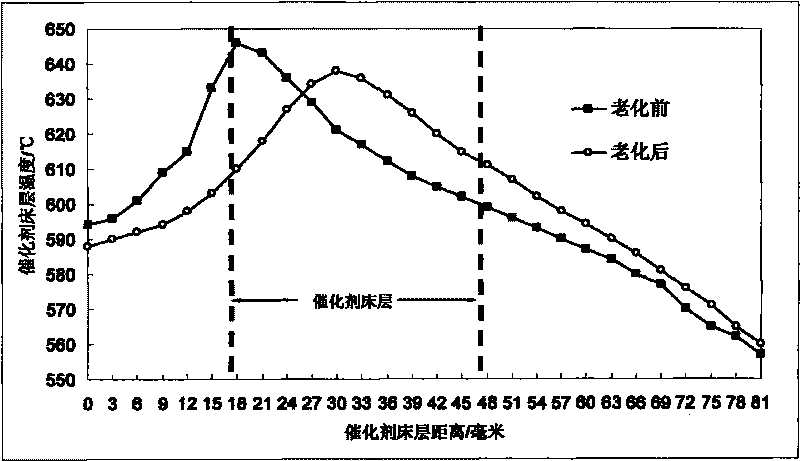

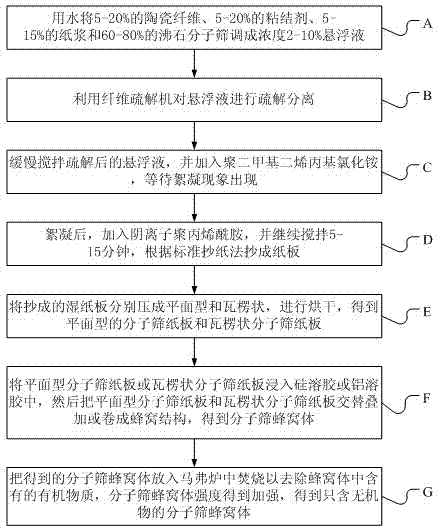

Manufacture method of molecular sieve honeycomb body for absorbing volatile organic compounds

InactiveCN102389773ASmall pressure drop lossLarge specific surface areaOther chemical processesDispersed particle separationFiberMolecular sieve

The invention discloses a manufacture method of a molecular sieve honeycomb body for absorbing volatile organic compounds, which comprises the steps of: regulating 5-20 percent of ceramic fiber, 5-20 percent of adhesion agent, 5-15 percent of paper pulp and 60-80 percent of zeolite molecular sieve with water into a suspension with concentration of 2-10 percent; defibering and separating the suspension; then slowly stirring and adding poly dimethyl diallyl ammonium chloride, after flocculation occurs, adding anionic polyacrylamide and continuously stirring for 5-15 min and then making a paper plate; and making the made wet paper plate into a planar molecular sieve paper plate and a corrugated molecular sieve paper plate, and alternatively overlapping or coiling the planar molecular sieve paper plate and the corrugated molecular sieve paper plate into a honeycomb structure to obtain the molecular sieve honeycomb body. A zeolite molecular sieve provided by the invention is not easy to peel off, and is easy to process into various shapes; and the molecular sieve honeycomb body can absorb organic matters under different temperatures and humidities.

Owner:FOSHAN ENVIRONMENTAL PROTECTION TECH & EQUIP RES DEV PROFESSIONAL CENT +3

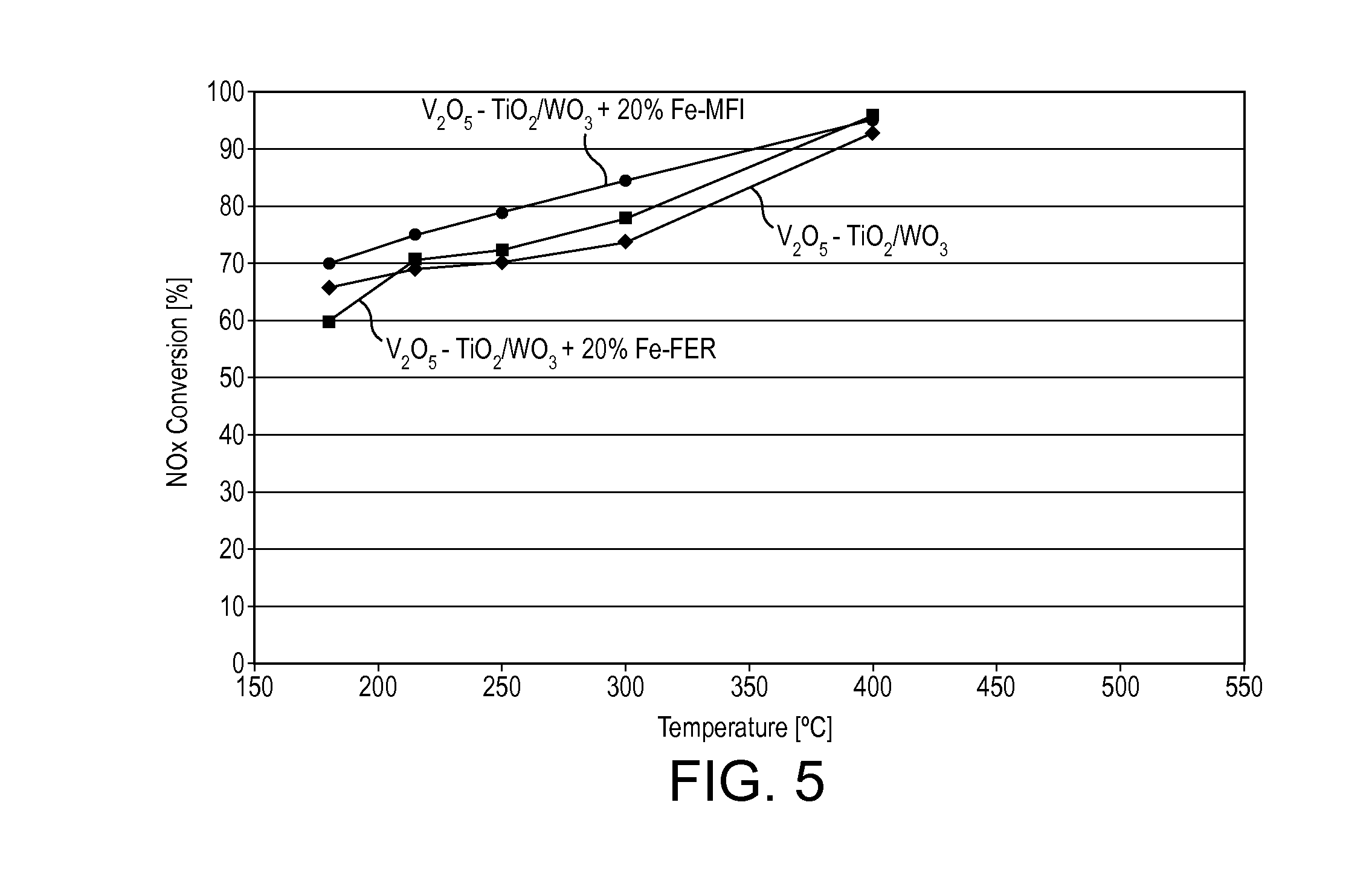

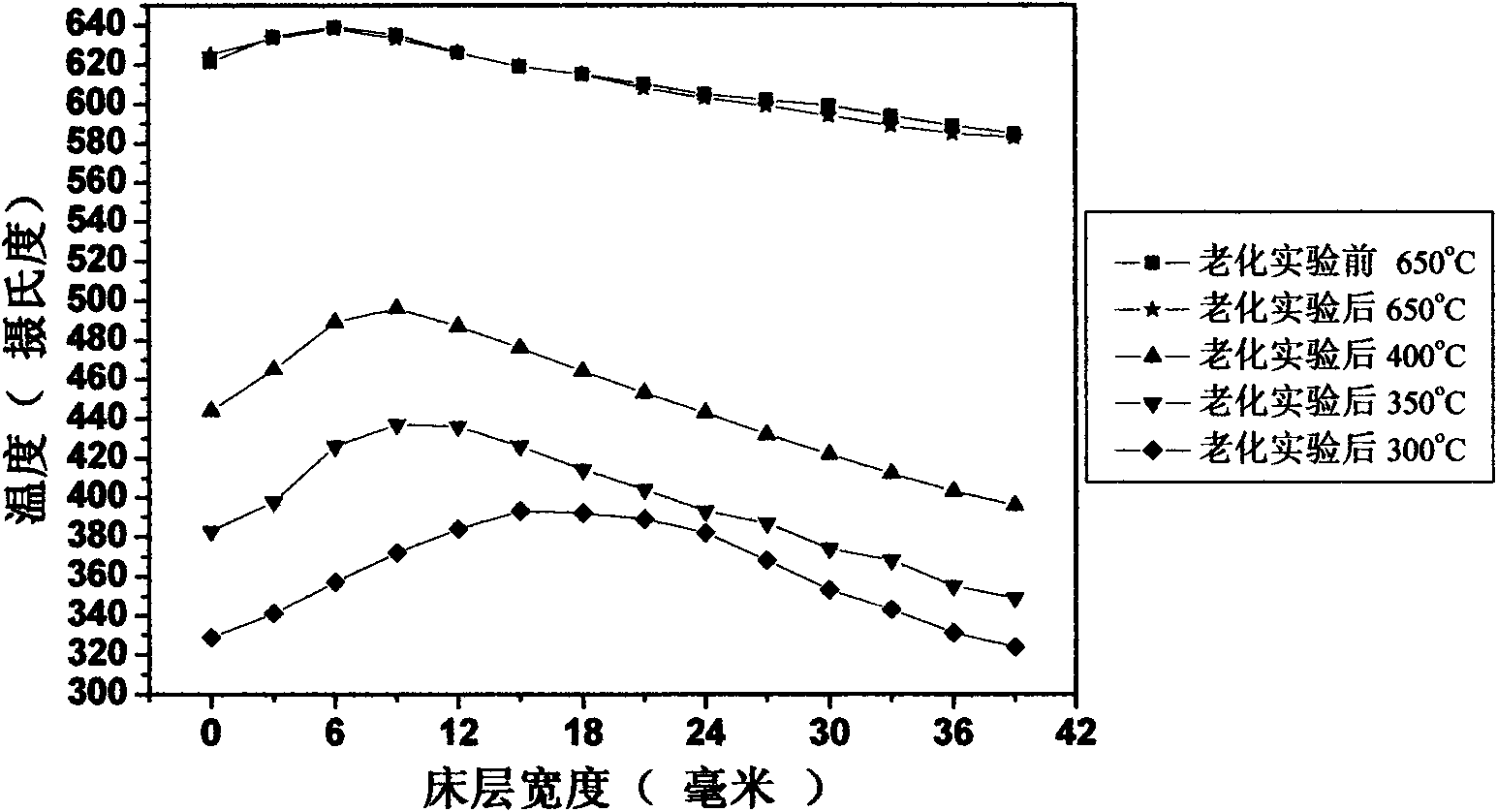

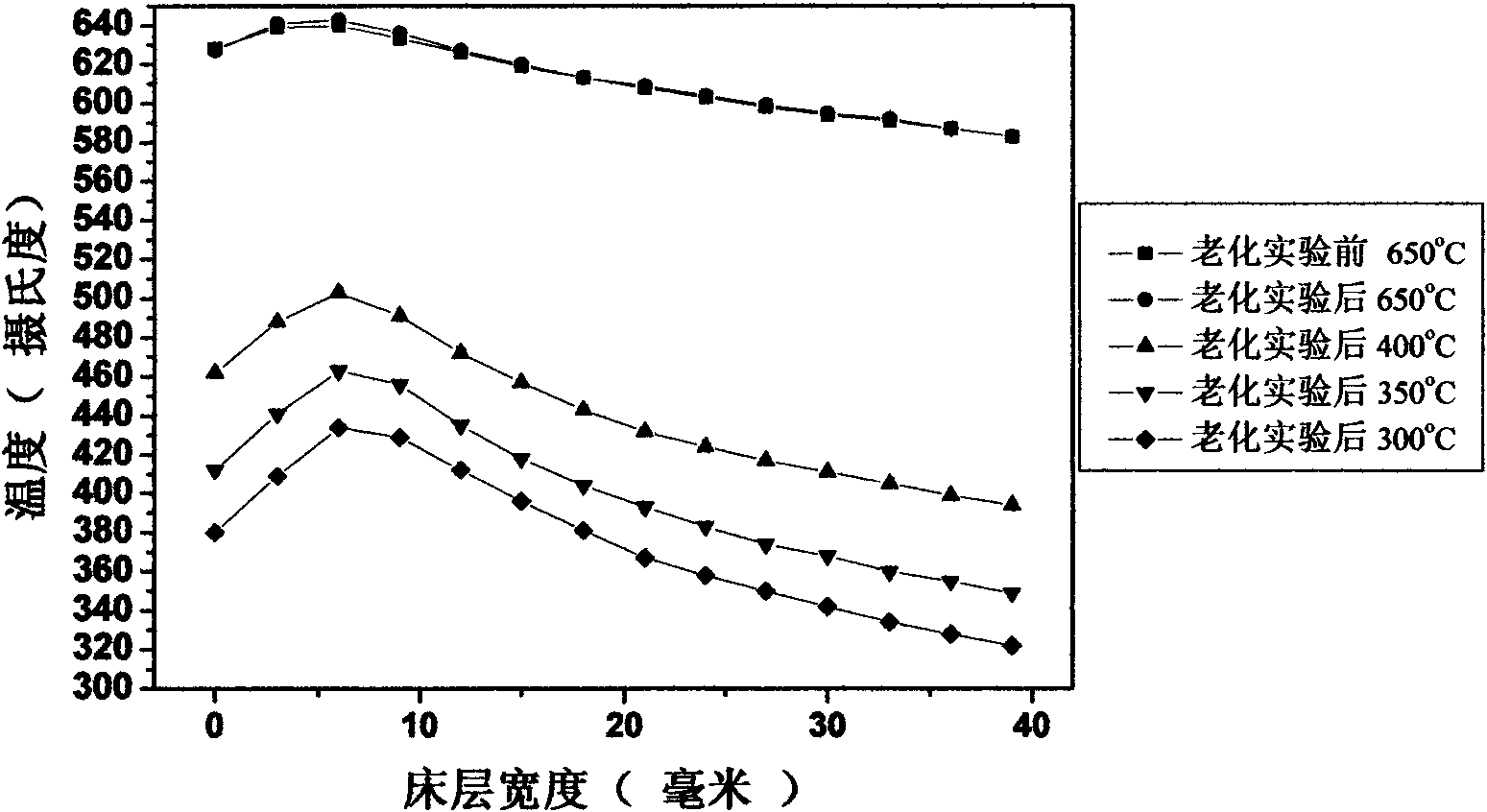

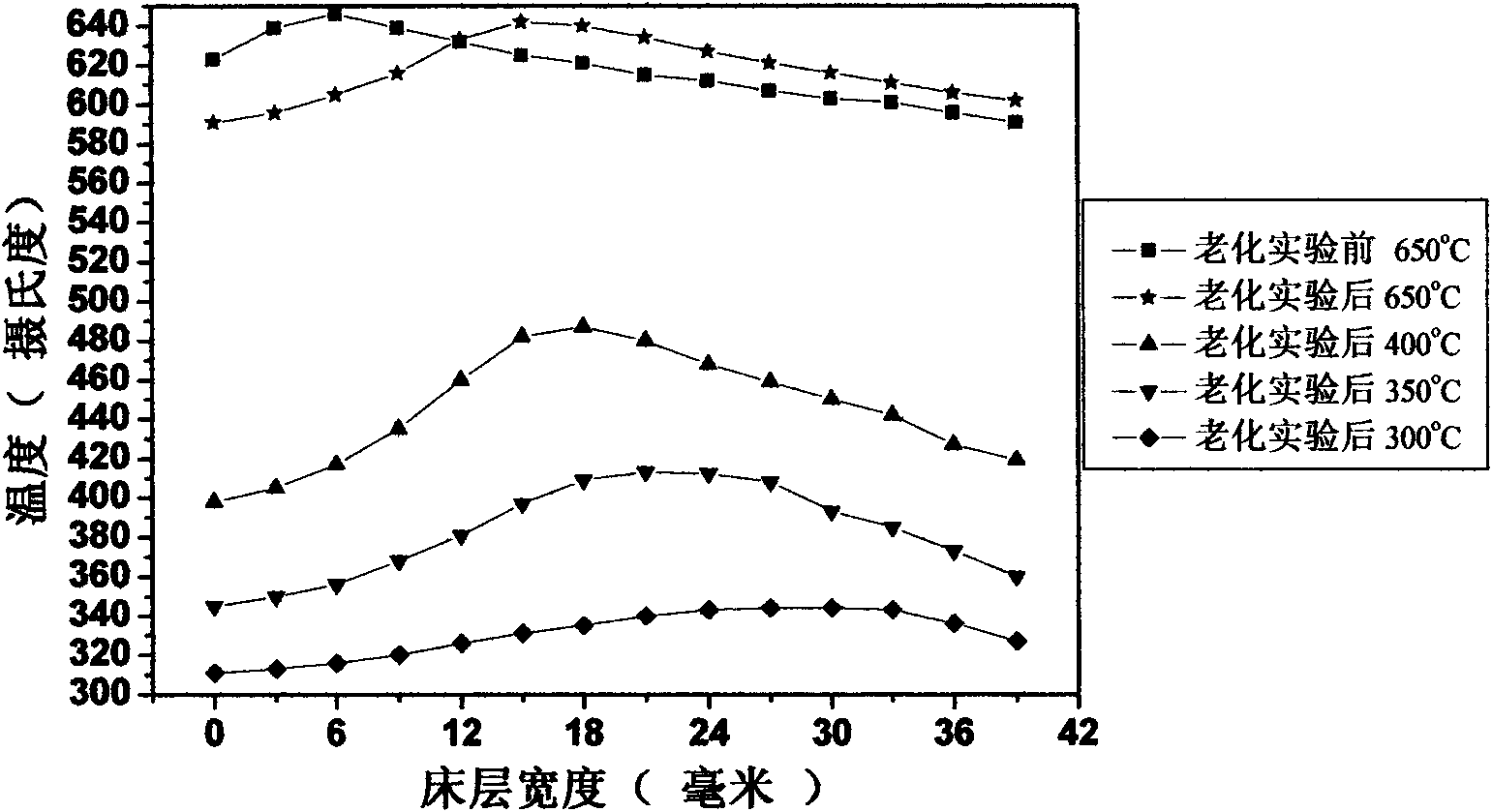

ZEOLITE PROMOTED V/TiW CATALYSTS

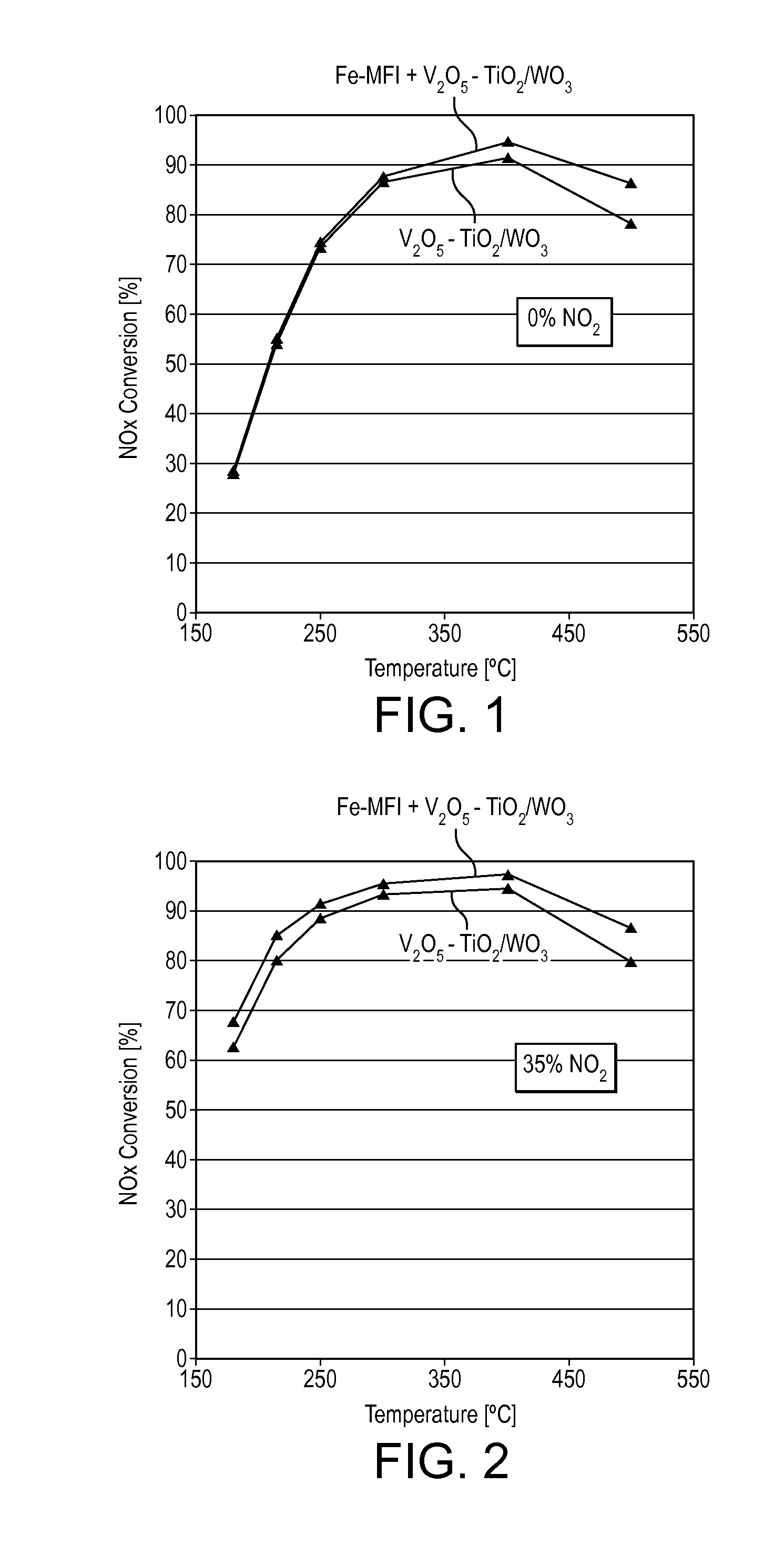

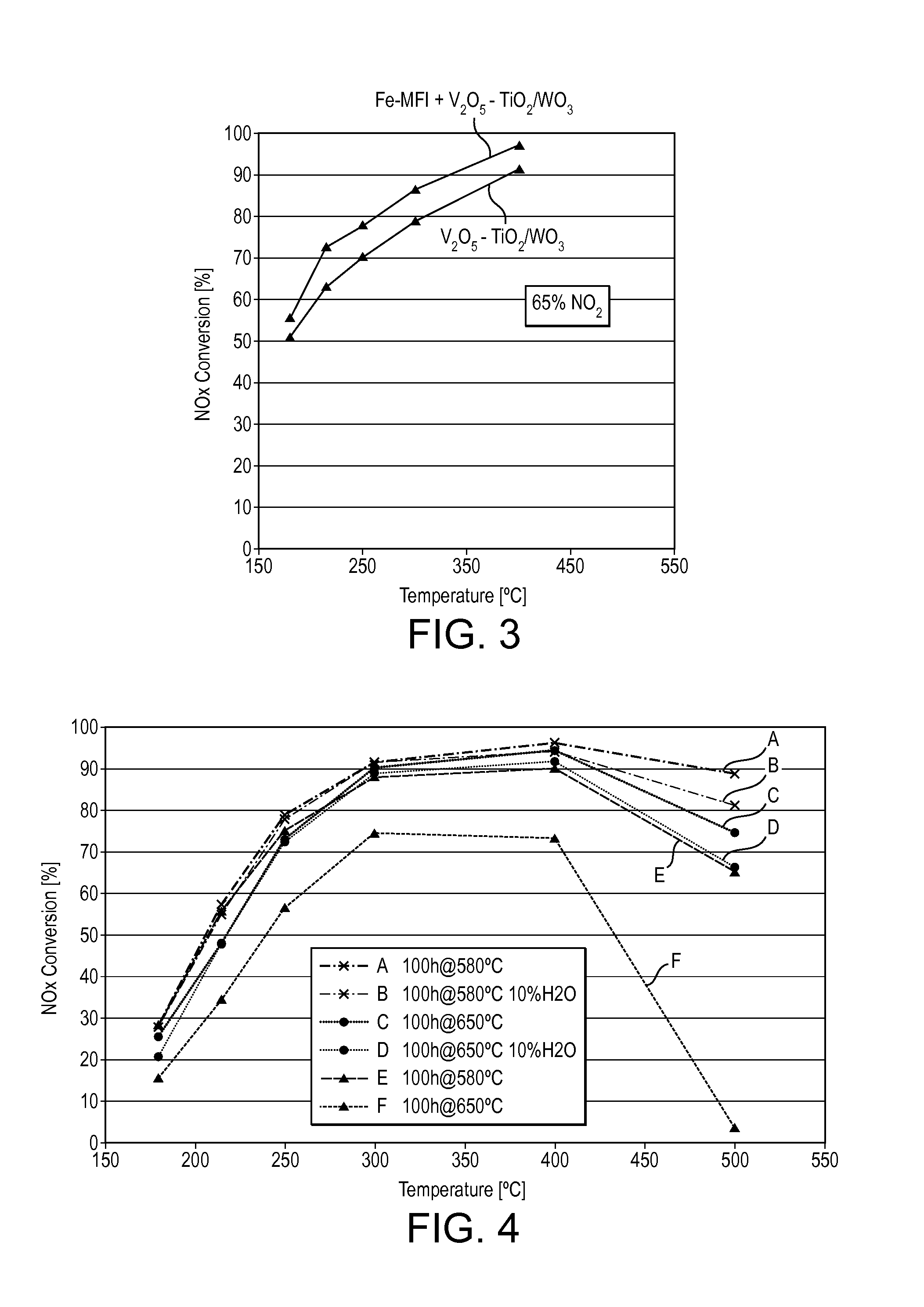

ActiveUS20150224486A1Improve catalytic performanceImprove high temperature performanceNitrogen compoundsInternal combustion piston enginesPtru catalystIon exchange

Provided is a catalyst composition for treating exhaust gas comprising a blend of a first component and second component, wherein the first component is an aluminosilicate or ferrosilicate molecular sieve component wherein the molecular sieve is either in H+ form or is ion exchanged with one or more transition metals, and the second component is a vanadium oxide supported on a metal oxide support selected from alumina, titania, zirconia, cella, silica, and combinations thereof. Also provided are methods, systems, and catalytic articles incorporating or utilizing such catalyst blends.

Owner:JOHNSON MATTHEY PLC

Prepn process of REY molecular sieve

ActiveCN101088613AGood hydrothermal stabilityGood cracking reactivityMolecular sieve catalystsMolecular sieveAlkaline water

The present invention discloses preparation process of REY molecular sieve, and features that REY molecular sieve is made to contact first with RE ion containing water solution or contact with RE ion containing water solution and Al ion containing solution or colloid, then with precipitant to precipitate partial RE onto the molecular sieve, and finally with ammonium salt aqua after being hydrothermal treated. The precipitant is water solution of soluble carbonate or alkaline water solution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing complete methanation catalyst for hydrothermal chemical process

ActiveCN102029161AGood activity and stabilityGood hydrothermal stabilityHydrocarbon from carbon oxidesCatalyst activation/preparationChemical synthesisPtru catalyst

The invention provides a method for preparing a complete methanation catalyst for a hydrothermal chemical process. The catalyst comprises the following components: 10 to 75 percent of active nickel ingredient, 10 to 90 percent of high-temperature resistant carrier and 0.1 to 15 percent of rare-earth auxiliary agent, wherein the content is counted on the basis of metal oxide, and the percentage is weight percentage of the total weight of the active ingredient, the carrier and the auxiliary agent. The preparation method comprises the following steps of: (a) forming a catalyst precursor by using the hydrothermal chemical synthesis process; and (b) preparing the obtained catalyst precursor into the complete methanation catalyst by filtering, washing, drying, roasting, forming, re-roasting and reducing. The method is convenient for crystallization and precipitation of catalyst materials, and has simple process and good repeatability. The method provides guarantee for meeting the current increasing clean energy requirement, and has irreplaceable important effect on the enhancement of energy / resource safety at the same time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

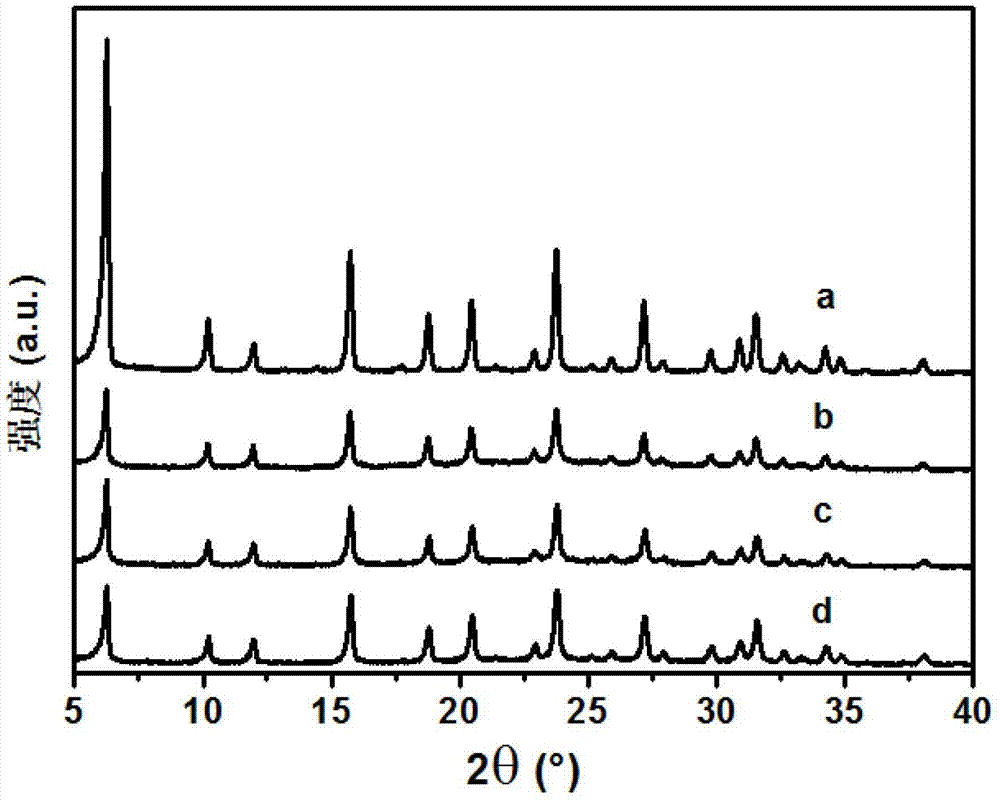

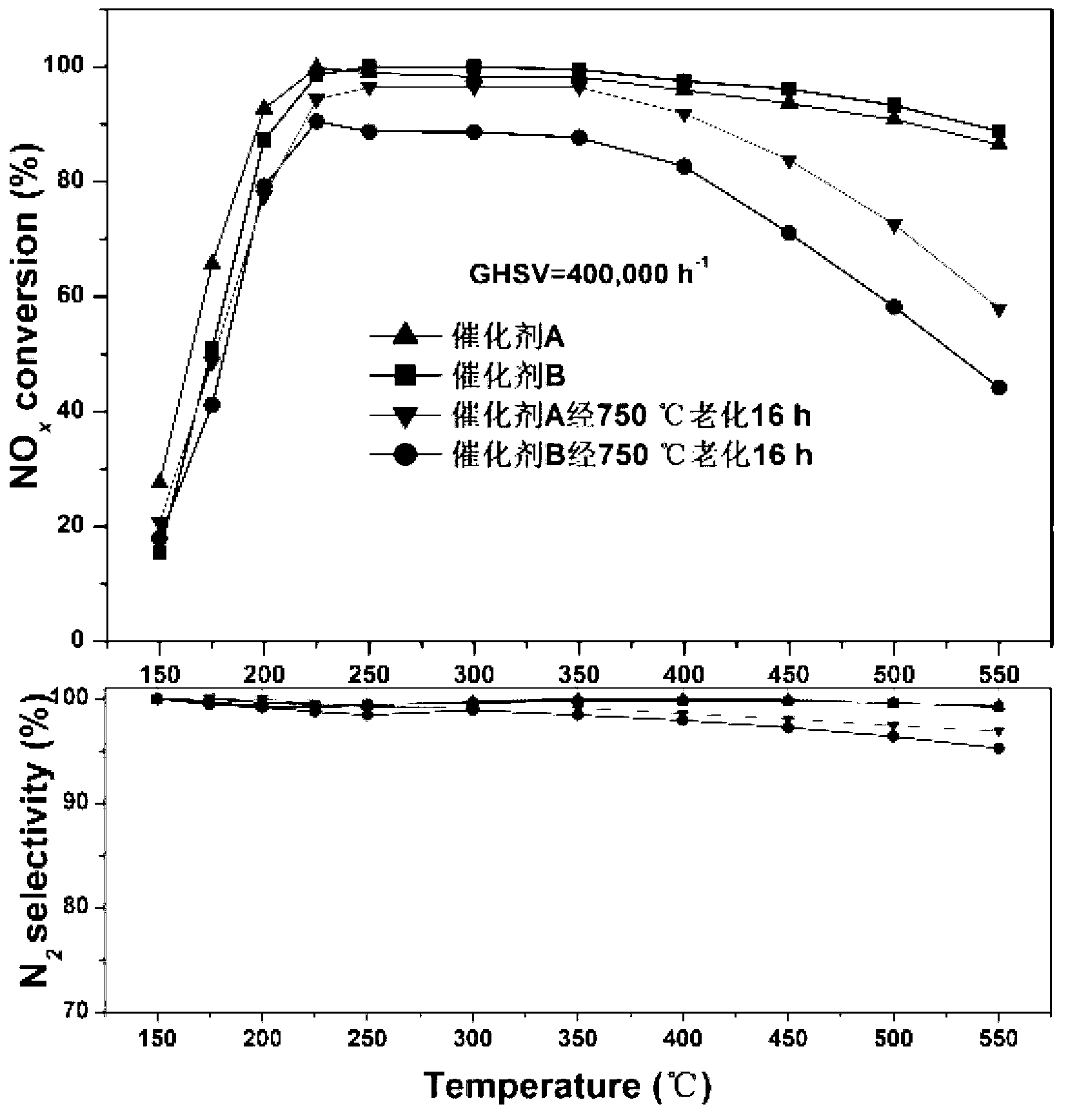

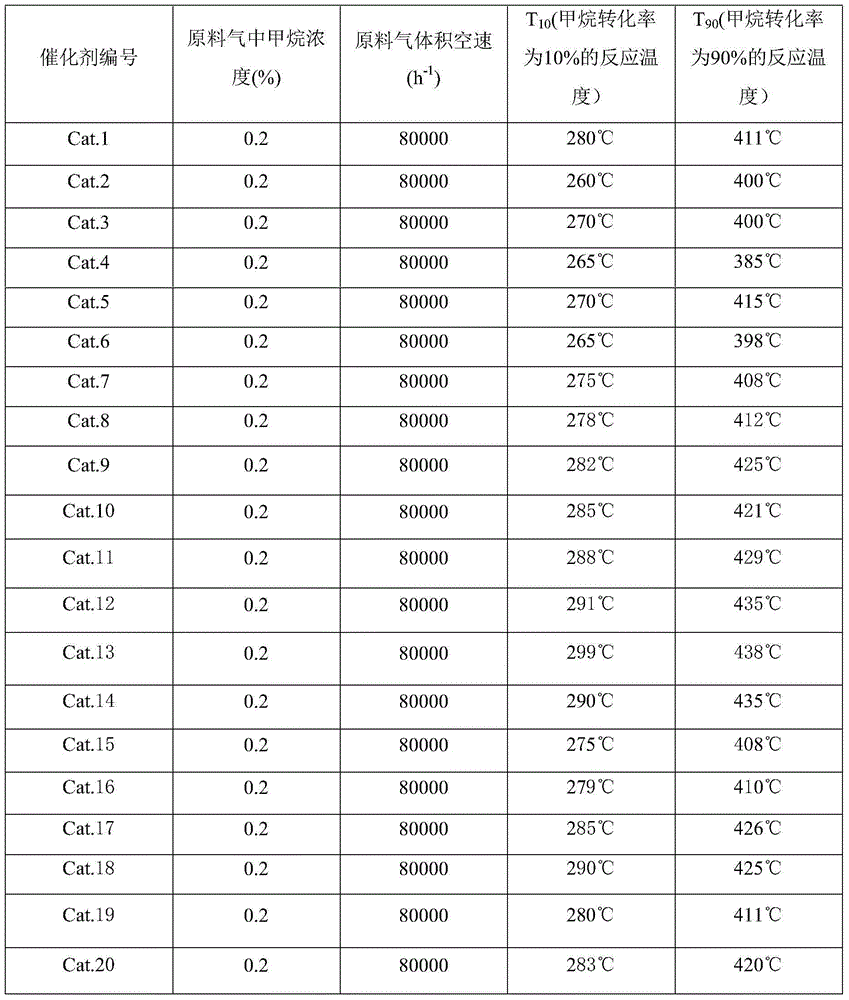

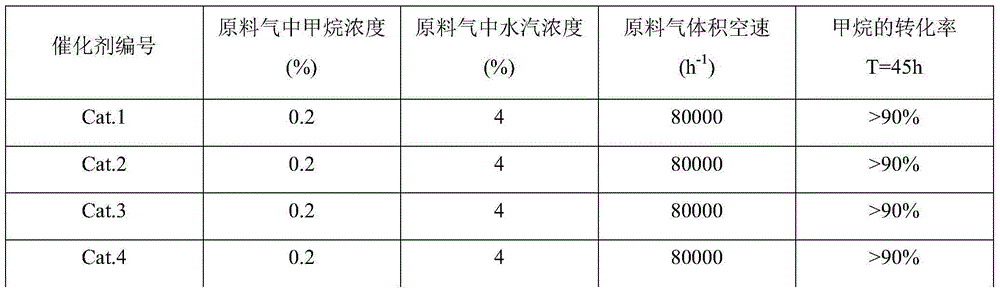

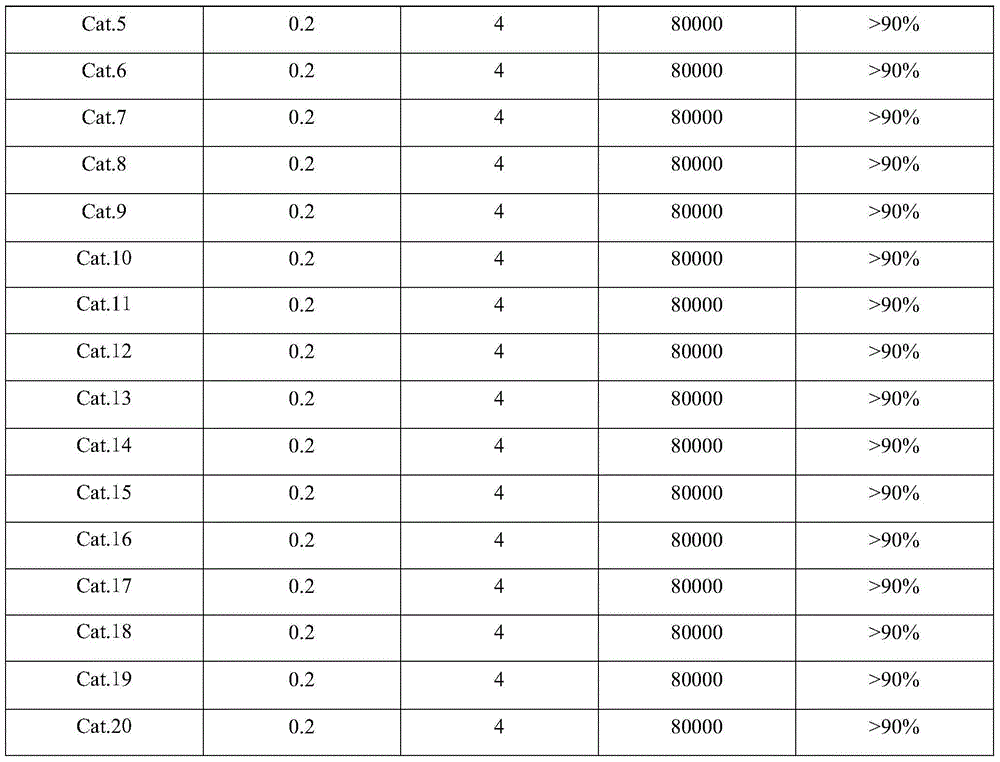

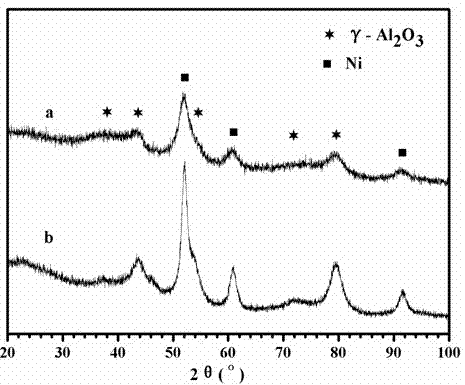

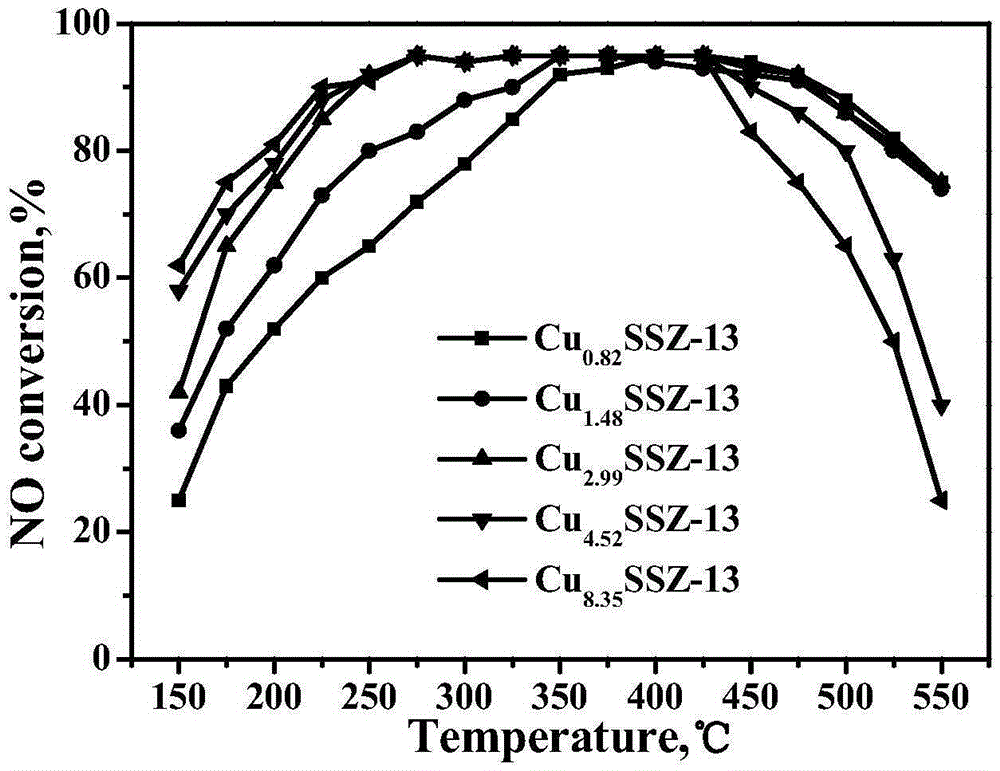

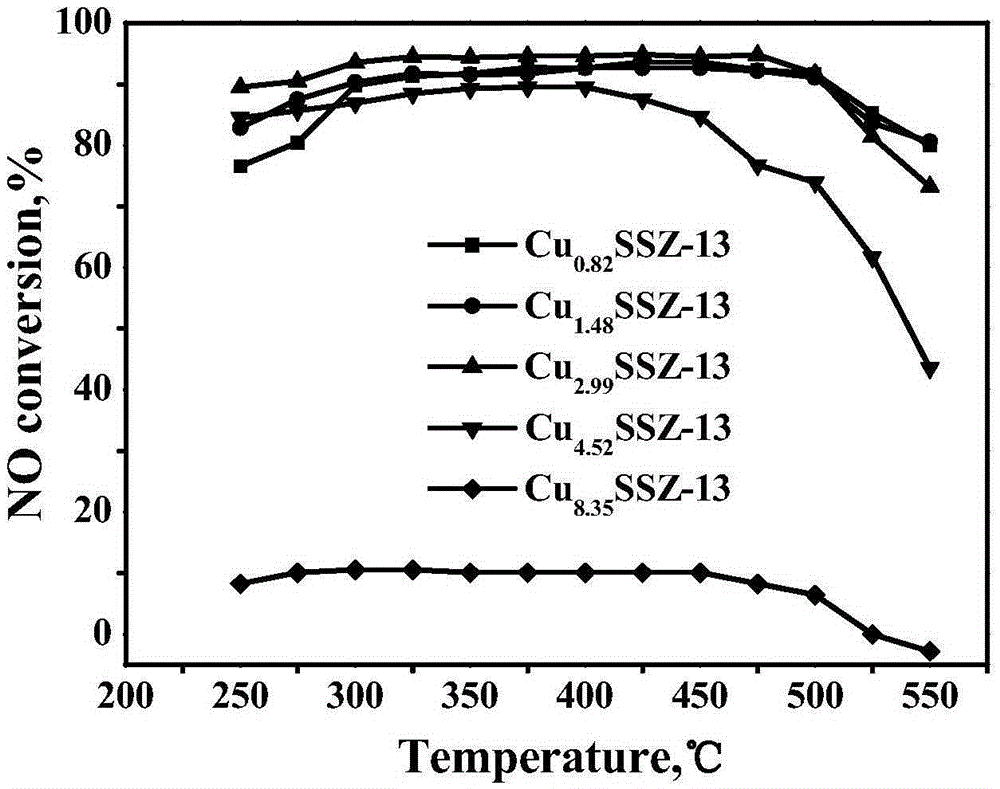

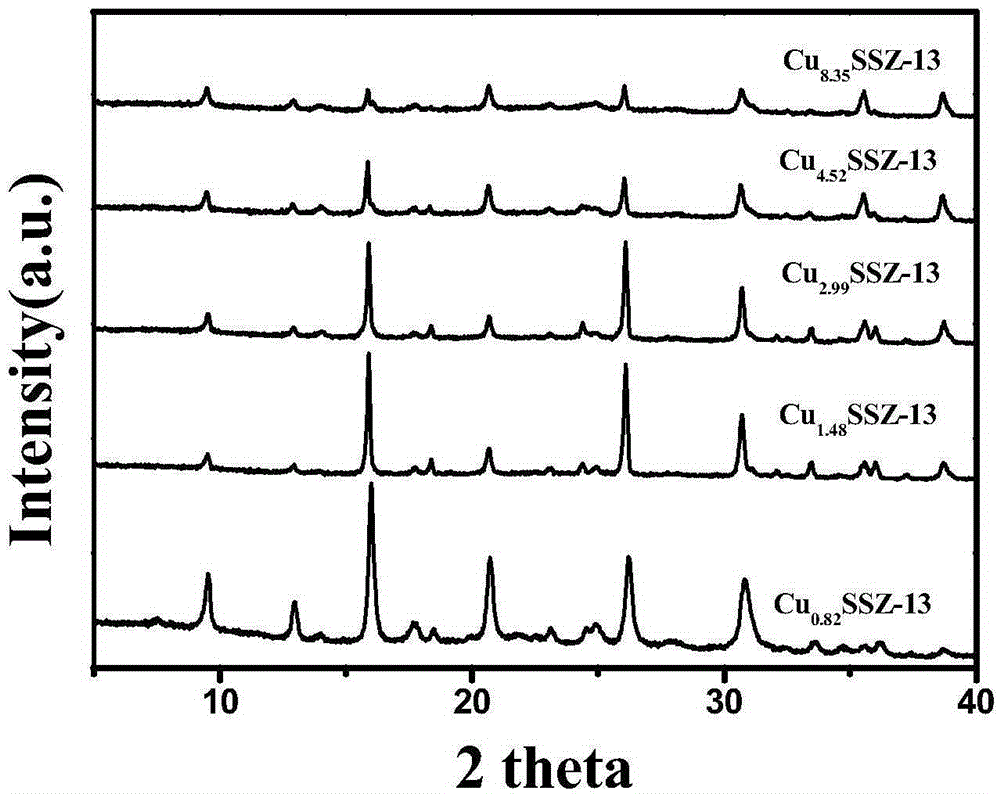

Cu-SSZ-13 catalyst, and preparation method and application thereof

ActiveCN103157505ASolve pollutionImprove activity stabilityMolecular sieve catalystsDispersed particle separationAfter treatmentSynthesis methods

The invention discloses a method for preparing a Cu-SSZ-13 catalyst through an in-situ synthesis method. A Cu-SSZ-13 molecular sieve sample is prepared by taking acid as an exchange reagent and treating through an in-situ synthesis method. Compared with the currently used ammonium nitrate ion exchange method, the after treatment method for the Cu-SSZ-13 molecular sieve prepared through an in-situ synthesis method is more environment-friendly and effective; the activity of the prepared catalyst is higher; and the hydrothermal stability is better. According to the method, the silica-alumina ratio of the molecular sieve structure is increased while the catalyst having high catalytic activity is obtained; and the obtained Cu-SSZ-13 catalyst has excellent hydrothermal stability, wide temperature window and excellent N2 selectivity, and is very applicable to purification of tail gas from diesel cars.

Owner:江西中科鸿虔新材料有限公司

Non-noble metal oxide combustion catalyst, and preparation method and use thereof

InactiveCN105381800AEasy to synthesizeLow costDispersed particle separationCatalyst activation/preparationChemical synthesisCobalt(II,III) oxide

The present invention relates to a non-noble metal oxide combustion catalyst and a preparation method and use thereof, and belongs to the technical field of energy utilization and environment protection. The catalyst is iron oxide, cobaltosic oxide, nickel oxide, cupric oxide, vanadium oxide, chrome oxide, manganese dioxide or cerium dioxide prepared according to the following steps: (1) using hydrothermal chemical synthesis to form a precursor of a catalyst; and (b) washing, filtering, shaping, drying and calcinating the obtained precursor of the catalyst, and finally forming a combustion catalyst or coating the precursor of the catalyst on a carrier to form a combustion catalyst. The catalyst prepared by the method can be used in catalytic combustion of methane and other VOC gas, and has the advantages that the synthesis process is simple, the cost is low, the catalytic activity and hydrothermal stability is high, and the light-off temperature and complete combustion temperature of methane are low.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

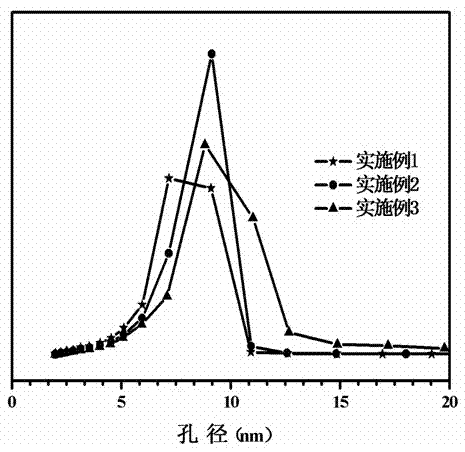

Carbon monoxide methanating catalyst and preparation method thereof

InactiveCN103480375ARaw materials are readily availableLow priceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationFiltration

The invention discloses a carbon monoxide methanating catalyst with high hydrothermal stability and a preparation method thereof, and belongs to the technical field of preparation of catalysts. The carbon monoxide methanating catalyst is prepared mainly by a co-precipitation method according to the following steps: taking alumina (Al2O3) as a carrier and metal nickel as an active component, adding Zr and transition metals as additives, uniformly mixing salt solutions, precipitating, aging, performing suction filtration, washing, drying and calcining the mixture. The preparation method is simple; raw materials are easily available; the cost is low; and the prepared catalyst has the characteristics of high specific surface area, large pore volume and concentrated pore size distribution, is applicable to hydrogenation reactions, in particular to methanation reaction of high-concentration carbon monoxide, and has the advantages of wide using temperature range, high catalytic activity, high hydrothermal stability and the like.

Owner:FUZHOU UNIV

Preparation method and use of Cu-SSZ-13 molecular sieve based catalyst

InactiveCN106179472AHigh crystallinityGood catalytic activityMolecular sieve catalystsInternal combustion piston enginesIon exchangeIon

The invention provides a preparation method of a Cu-SSZ-13 molecular sieve based catalyst. The preparation method comprises the following steps of adding sodium aluminate, sodium hydroxide, a silica solution, copper sulfate, tetraethylenepentamine and an organic template agent to deionized water, and performing stirring so as to obtain gel; and performing a reaction in a reaction kettle, then performing cooling, performing centrifugal filtration, performing washing, performing drying, and performing calcining so as to obtain the Cu-SSZ-13 molecular sieve based catalyst. The method disclosed by the invention is simple in technology, low in cost, energy-saving, and environmentally-friendly. Use of a copper salt solution ion exchange and calcining technology many times is avoided, and the defect that a conventional technology needs performing later-period ion exchange so as to reduce content of active components is overcome. The silica alumina ratio of the Cu-SSZ-13 molecular sieve based catalyst prepared by the method disclosed by the invention is adjustable within the range of 7.9- 26.7, and the percentage by mass of copper is in the range of 0.47 -8.6wt%, excellent NH3-SCR catalytic activity, water thermal stability, alkali metal poisoning resistance and noble metal poisoning resistance can be kept in a wide-temperature window.

Owner:HUAZHONG UNIV OF SCI & TECH

Hydrothermally stable metal promoted zeolite beta for NOx reduction

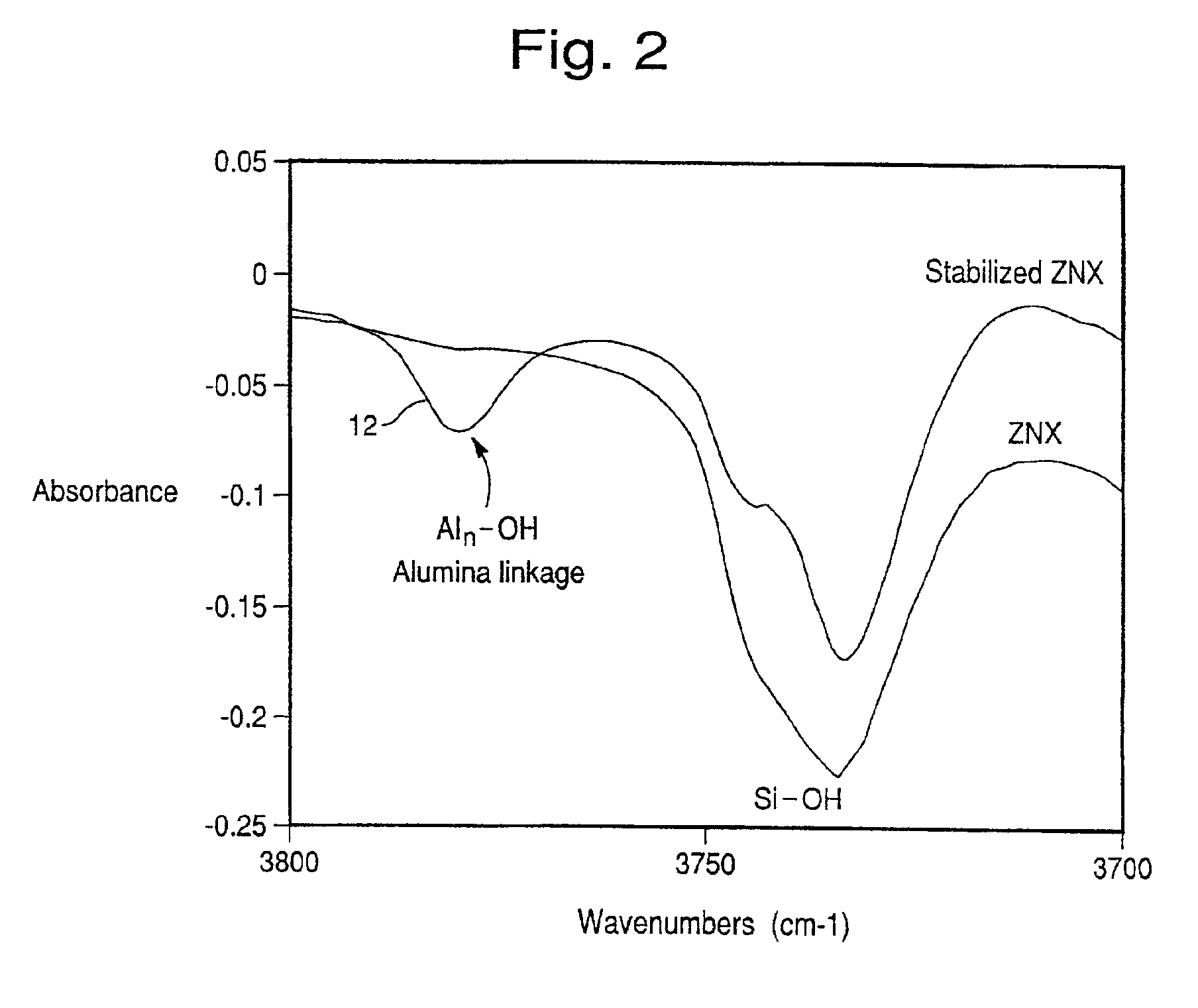

InactiveUS7332148B2Good hydrothermal stabilityImprove stabilityAluminosilicate zeolite type ZSM-12Aluminium compoundsNitrogen oxidesIr absorption

A stabilized metal promoted aluminosilicate zeolite, useful in the selective catalytic reduction of nitrogen oxides with ammonia, having a silica to alumina mole ratio of at least 8 and less than 30 and an FT-IR absorption peak at 3781 plus or minus 2 cm−1 which stabilizes the zeolite against further dealumination such as under oxidizing and harsh hydrothermal conditions.

Owner:ENGELHARD CORP

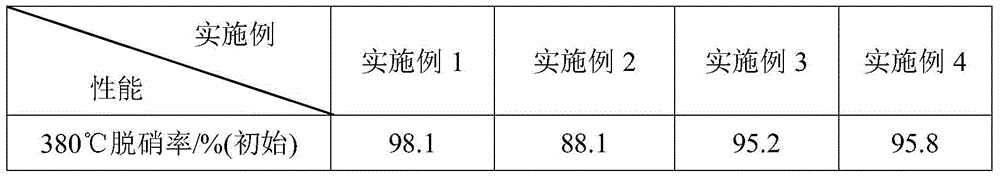

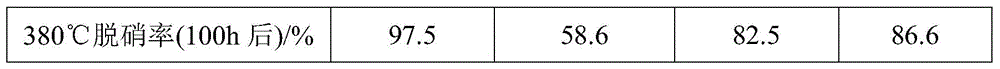

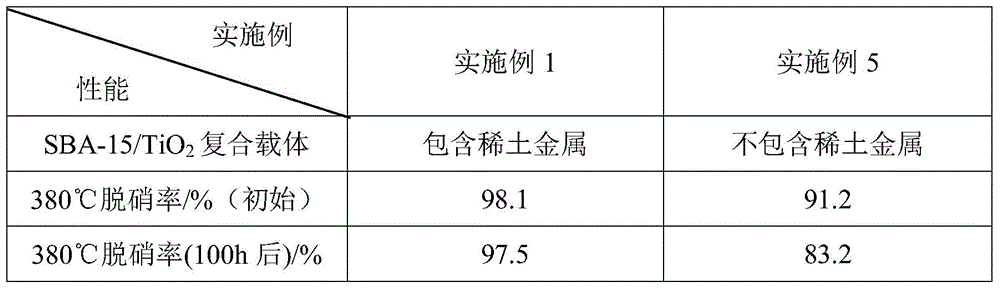

Denitration catalyst with SBA-15/TiO2 serving as carrier and preparing method thereof

ActiveCN105688974ALarge specific surface areaEnhanced mass transferMolecular sieve catalystsGlass fiberMolecular sieve

The invention discloses a denitration catalyst with SBA-15 / TiO2 as a carrier and a preparing method thereof.The denitration catalyst comprises 36wt%-85wt% of SBA-15 molecular sieves, 10wt%-40wt% of TiO2, 0.1wt%-1wt%V2O5, 1wt%-10wt% of active assistant, 1wt%-8wt% of glass fibers and 0.5wt%-5wt% of forming assistant.The preparing method includes the steps that after a titanium salt solution and an electrolyte solution are mixed, SBA-15 molecular sieves with skeletons containing rare-earth metal are added to be soaked, and a series of reactions are carried out to obtained the SBA-15 / TiO2 carrier; the carrier, an ammonium-metavanadate active assistant, glass fibers and a forming assistant are mixed to obtain the denitration catalyst.The denitration catalyst and the preparing method have the advantages that the prepared denitration catalyst is large in specific surface area, high in hydrothermal stability, wide in active temperature window and high in denitration efficiency; meanwhile, the preparing method is simple.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

Hydrodemetalizing catalyst and its prepn

InactiveCN101066530AHigh thermal and hydrothermal stabilityHigh carbon capacity and metal contentPhysical/chemical process catalystsPolymer scienceActive component

The present invention discloses one kind of hydrodemetalizing catalyst and its preparation process. The catalyst has alumina containing P, Mg and K as carrier, VIII and VIB metal element as the active component and optional auxiliary components. It is prepared through a simple preparation process. The catalyst is especially suitable for the hydrodemetalizing process of hydrocarbon with high oxygen content, high metal content and high easy-to-coke component content, such as light coal tar oil fraction, and has the features of high hydrodemetalizing activity, high stability and long service life.

Owner:林方 +4

Synthetic method of mesoporous-microporous molecular sieve by raising hydrothermal stability

ActiveCN102745708AEffective lead generationFully assembledCrystalline aluminosilicate zeolitesMolecular sieveWater vapor

The invention relates to a synthetic method of a mesoporous-microporous molecular sieve, which is characterized in that a microporous molecular sieve precursor solution is synthesized, the precursor is composed of (1-500)Na2O: Al2O3: (1-850)SiO2: (10:800)H2O; a segmented copolymer is used as a main template, a modifier containing trimethoxy silane is used for modifying a polymer, the modified polymer is taken as an assisted template, an dual template is used for assembling the precursor solution of the microporous molecular sieve. According to the invention, the mesoporous-microporous molecular sieve presents great hydro-thermal stability and an adjustable tunnel structure, the specific surface area is between 800-1000m<2> / g, the hydrothermal treatment is carried out by 100% of water vapor with the temperature of 800 DEG C for 8 hours, the retention rate of the specific surface area can reach more than 39%, the hexagonal structure is still obvious, the long-distance ordered nature of the tunnel enables good preservation. The prepared catalyst presents good catalysis performance on the catalytic cracking of the heavy oil.

Owner:PETROCHINA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com