Patents

Literature

2627results about How to "Low yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

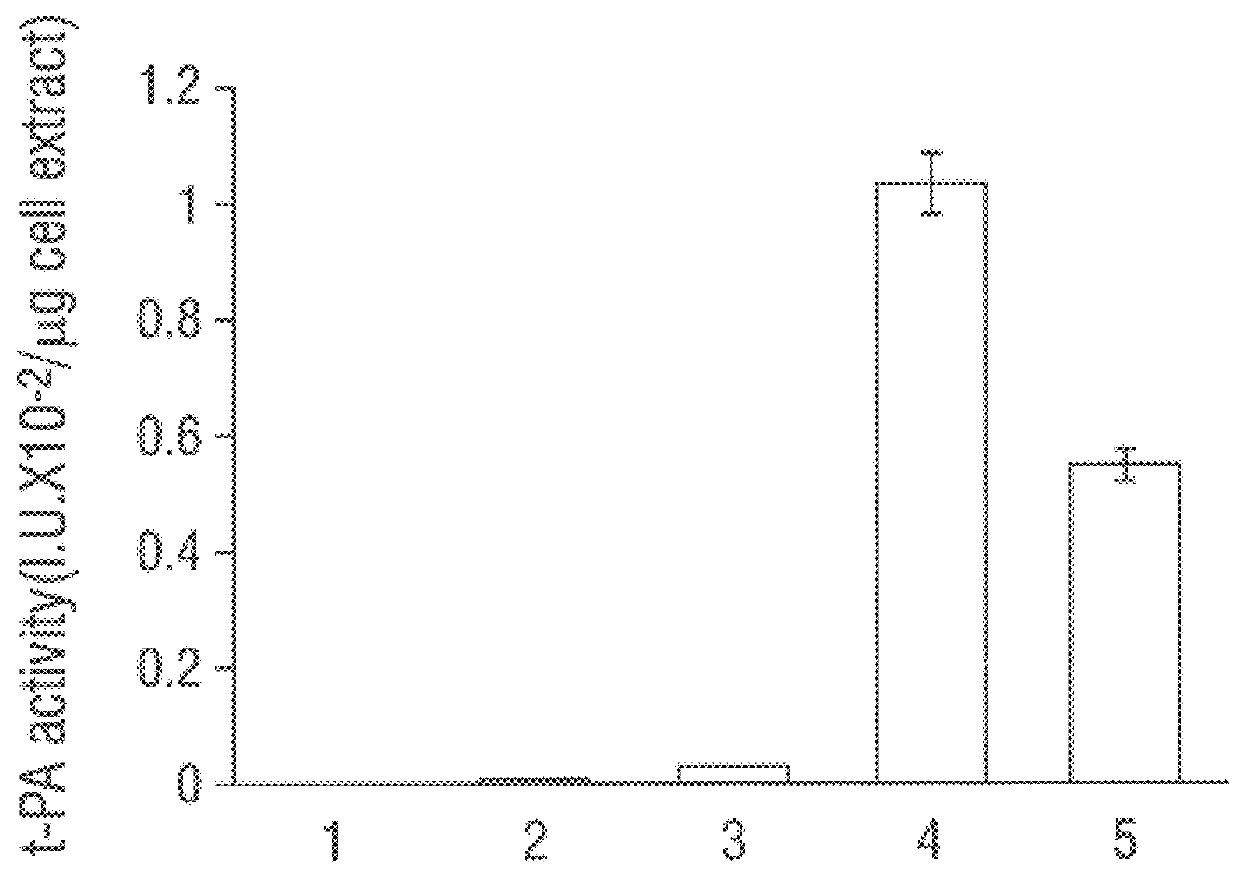

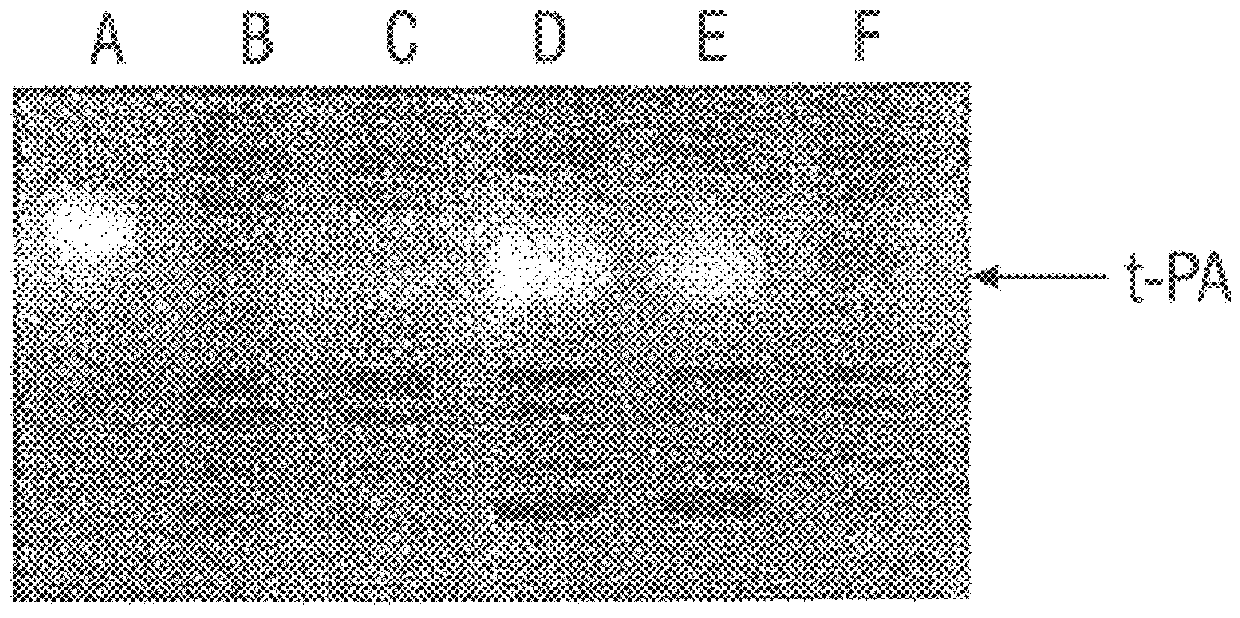

Methods for producing heterologous disulfide bond-containing polypeptides in bacterial cells

InactiveUS6083715AEfficient productionFold preciselyBacteriaUnicellular algaeMolecular biologyDisulfide bond

Disclosed are methods and compositions for producing heterologous disulfide bond containing polypeptides in bacterial cells. In preferred embodiments the methods involve co-expression of a prokaryotic disulfide isomerase, such as DsbC or DsbG and a gene encoding a recombinant eukaryotic polypeptide. Exemplary polypeptides disclosed include tissue plasminogen activator.

Owner:GENENTECH INC +1

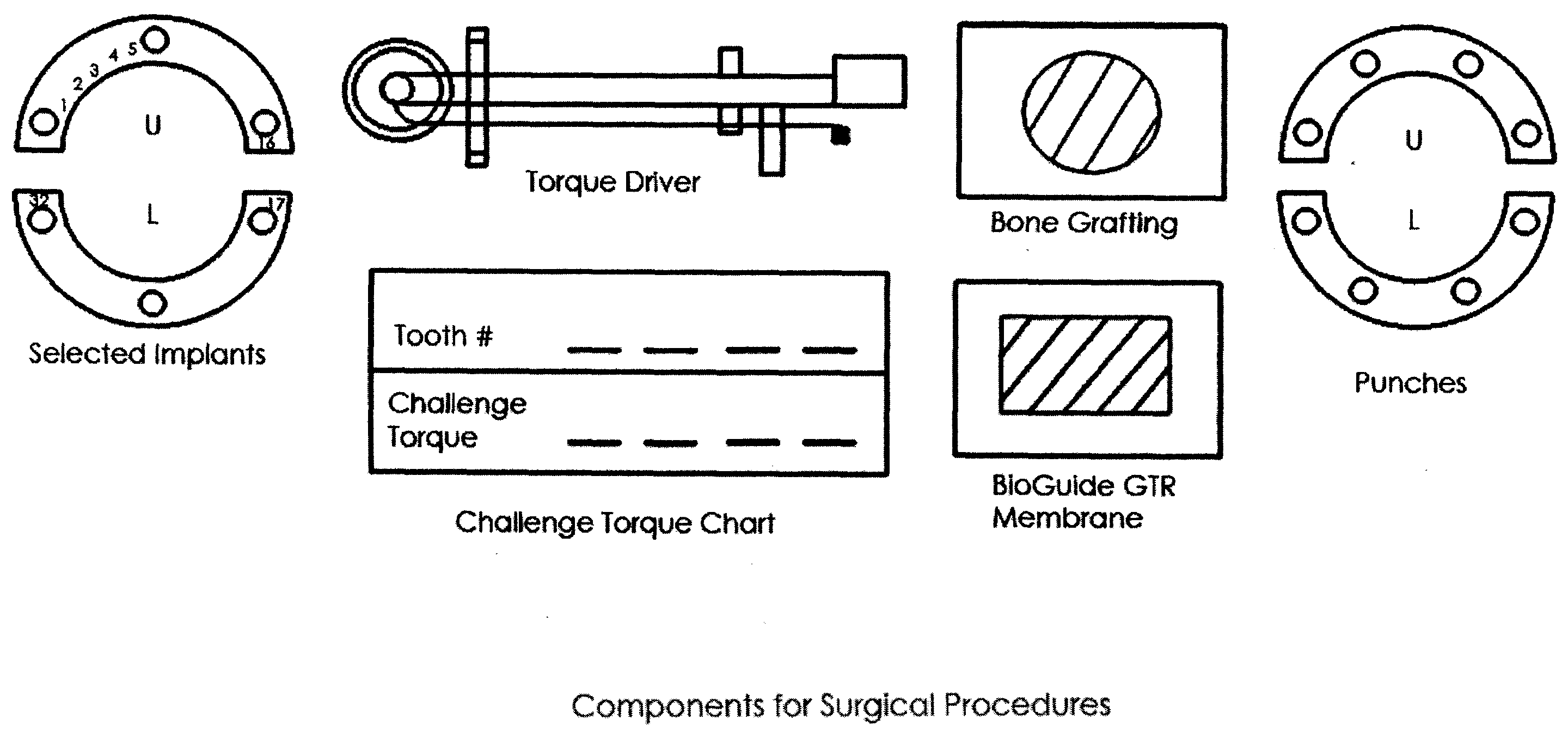

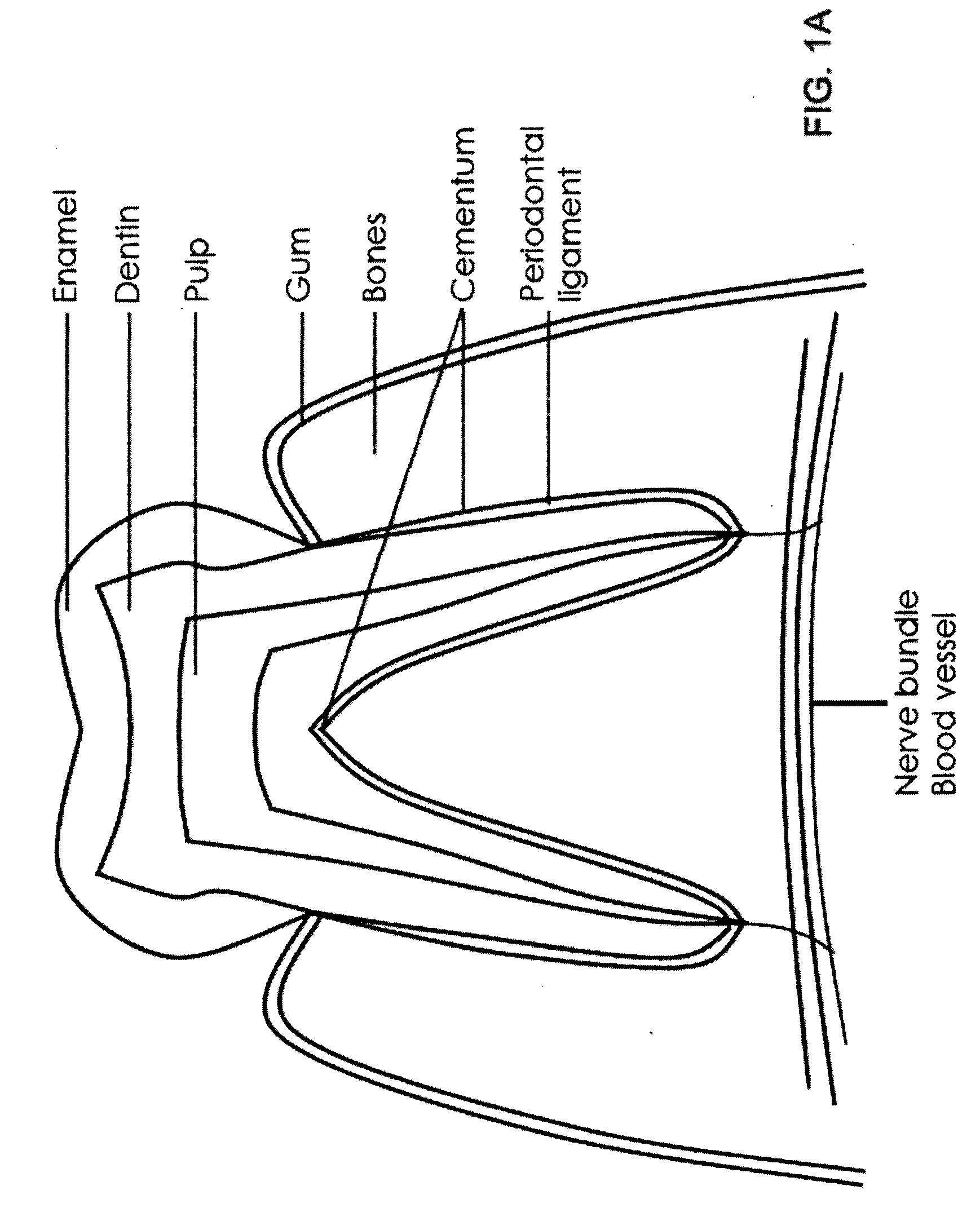

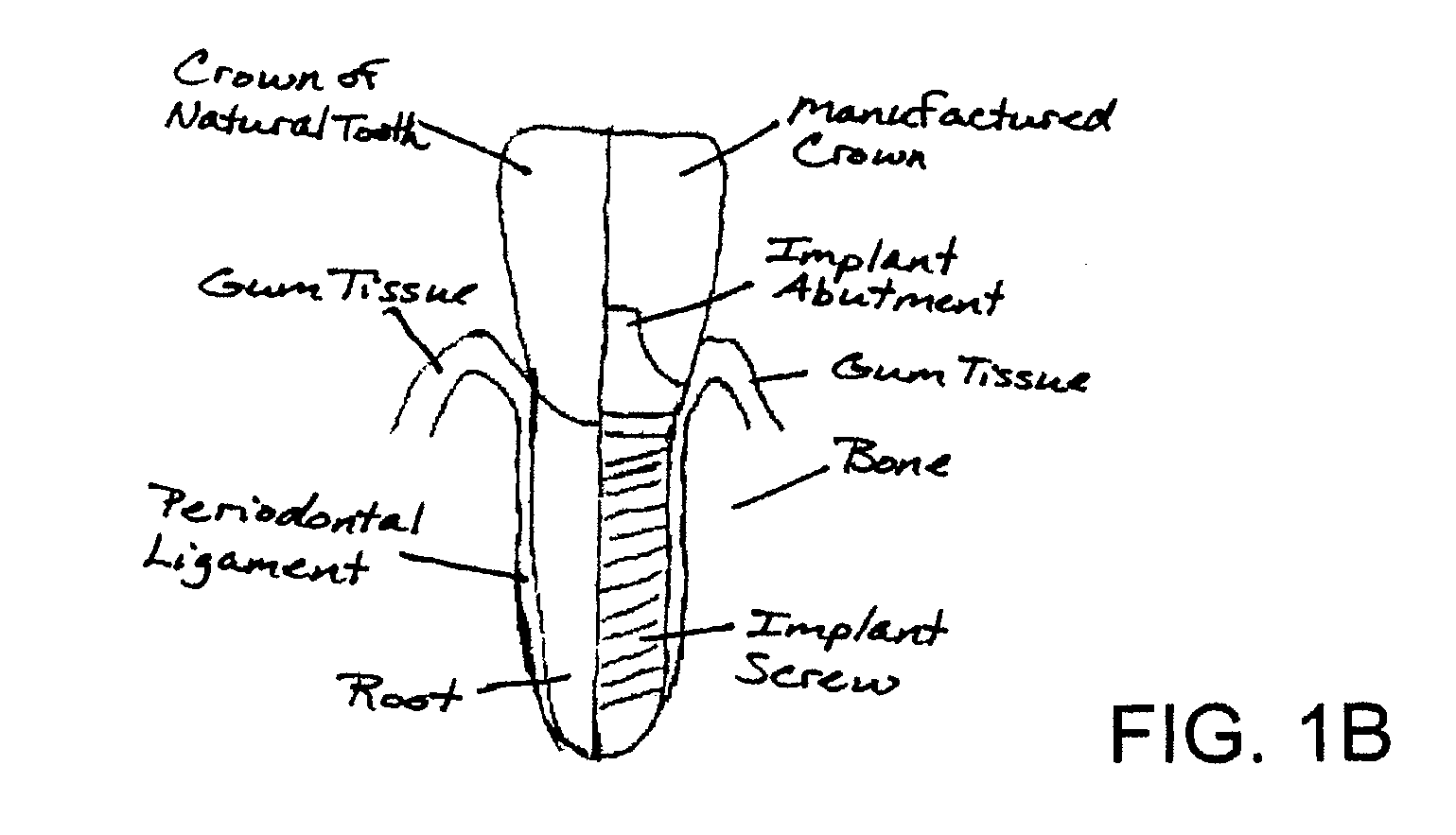

System, Method And Apparatus For Tooth Implant Planning And Tooth Implant Kits

InactiveUS20100105011A1Improve the level ofFacilitate proper fixture placementDental implantsDispensing apparatusPatient dataDental implant

Systems and methods support dental implant patient scheduling and treatment process relating to packaging one or more dental appliances as a kit which is readily used by dental professional during surgery, by communicating manufacturing progress information with a doctor over a network and performing patient scheduling and treatment when the dental appliances reach a certain manufacturing progress. A network-based service may also provide a doctor with a treatment solution including a surgical kit derived from patient data.

Owner:INPRONTO

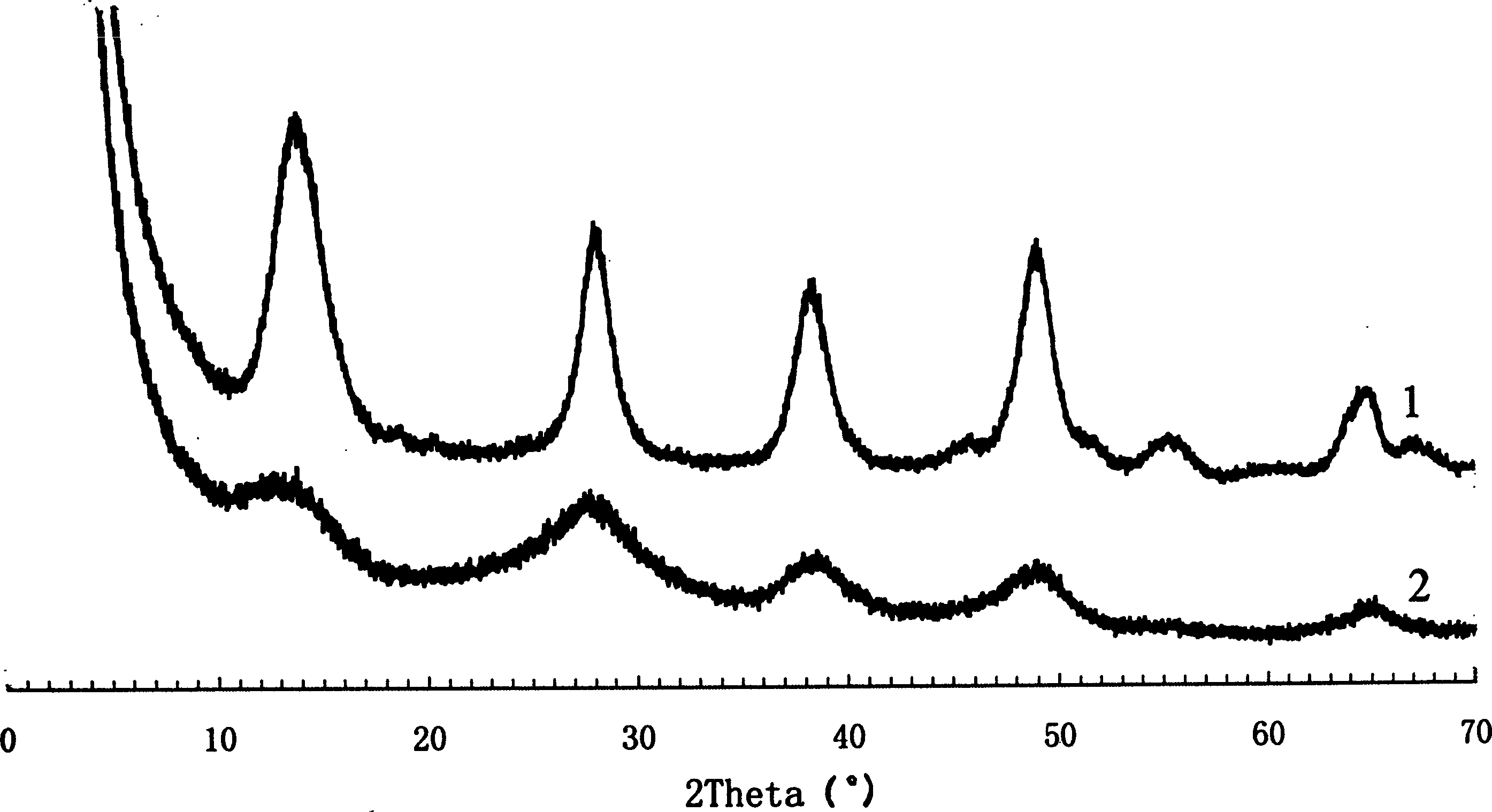

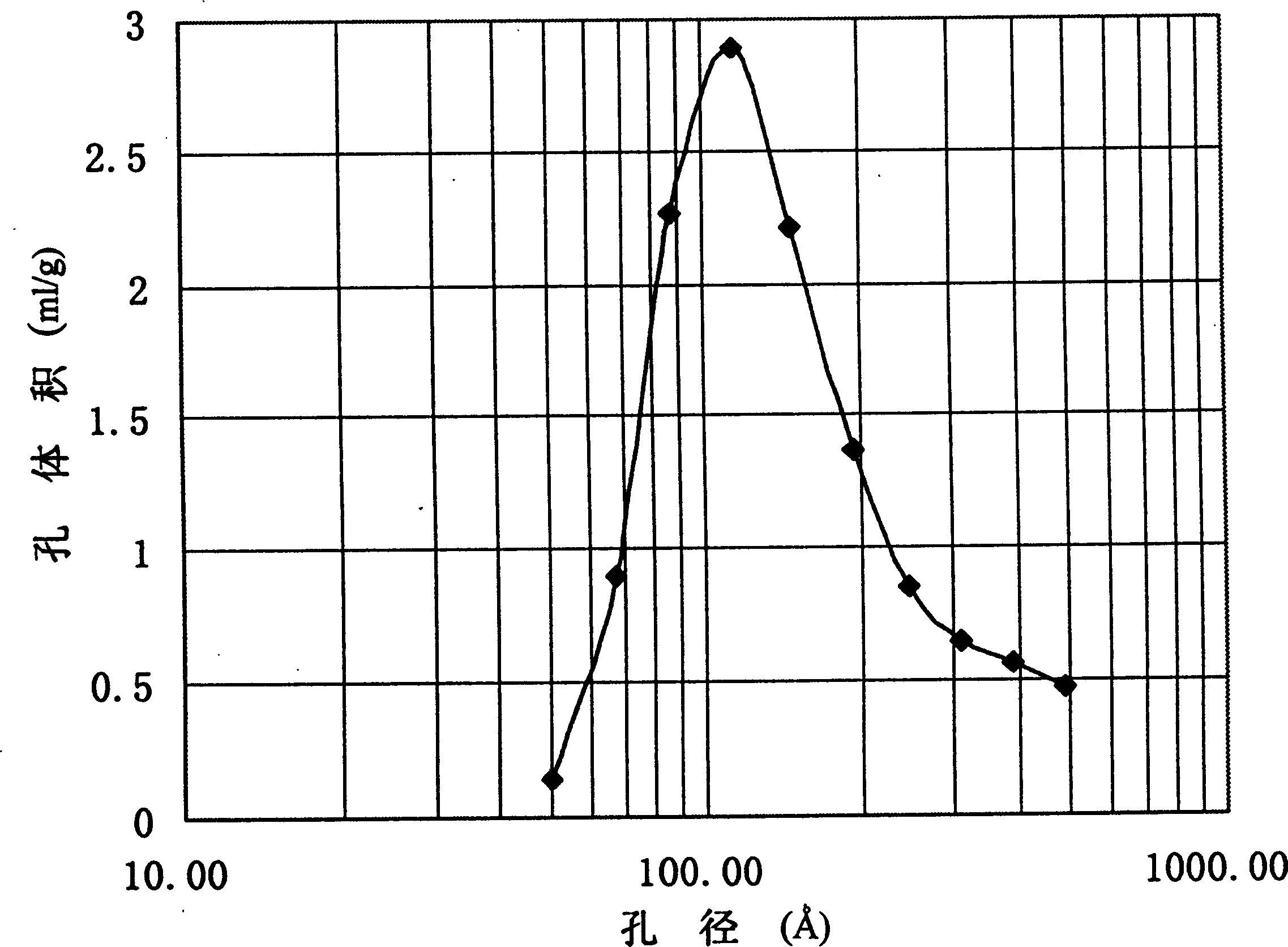

Process for preparing mesoporous Si-Al material and its preparing process

ActiveCN1565733AImprove accessibilityGood hydrothermal stabilityMolecular sieve catalystsIonIon exchange

A meso-porous silicon aluminum material with thin diaspore-like phase structure is disclosed. The preparing process includes the following steps: aluminum materials and alkali solution are neutralized to glue, and then silicon materials are added, finally the product is given by aging, ion exchange, drying and baking. The meso-porous silicon aluminum materials possess good hydrothermal stability and can be used as catalyst carrier with strong macromolecule cracking capacity, higher raw oil conversion efficiency and lower heavy oil yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

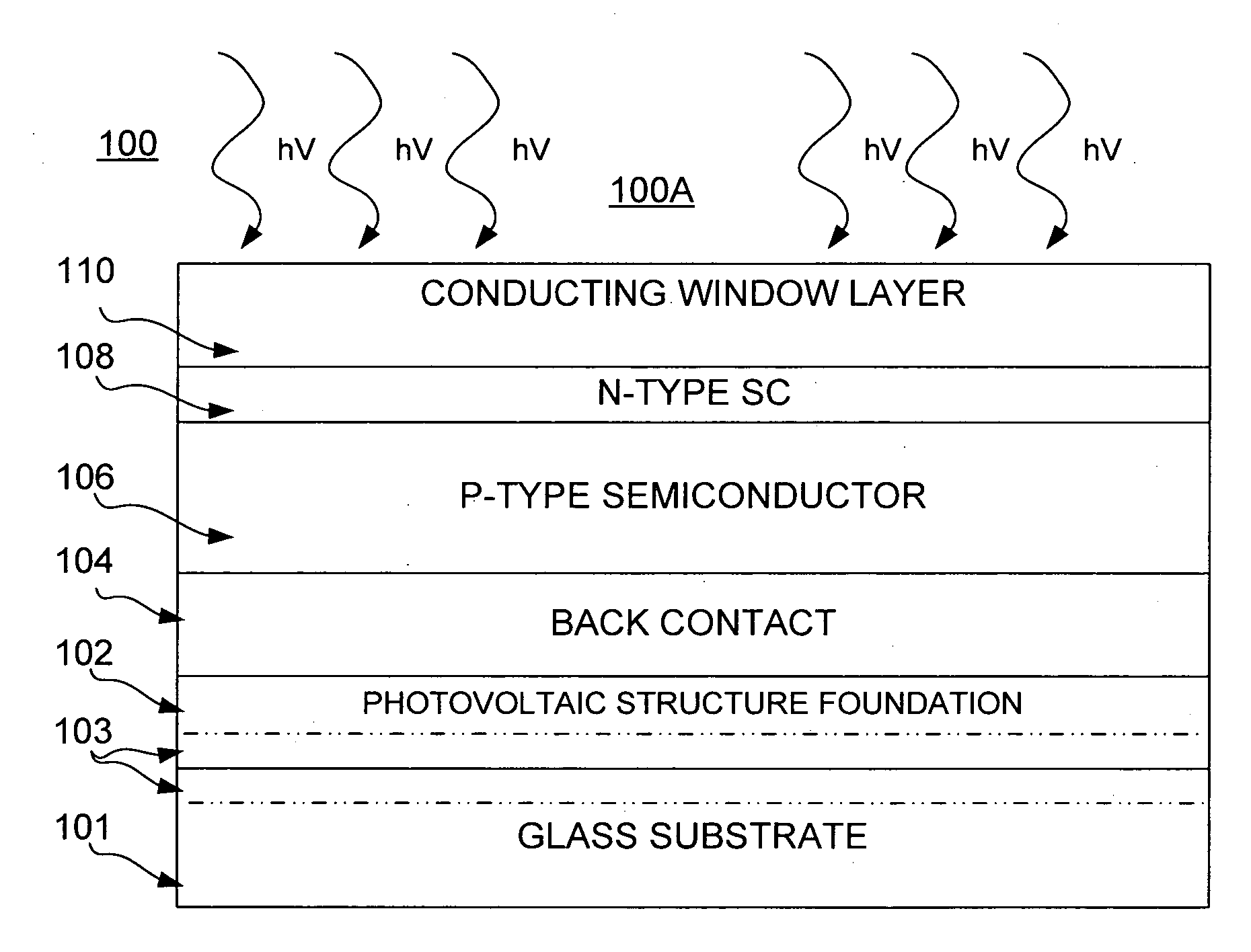

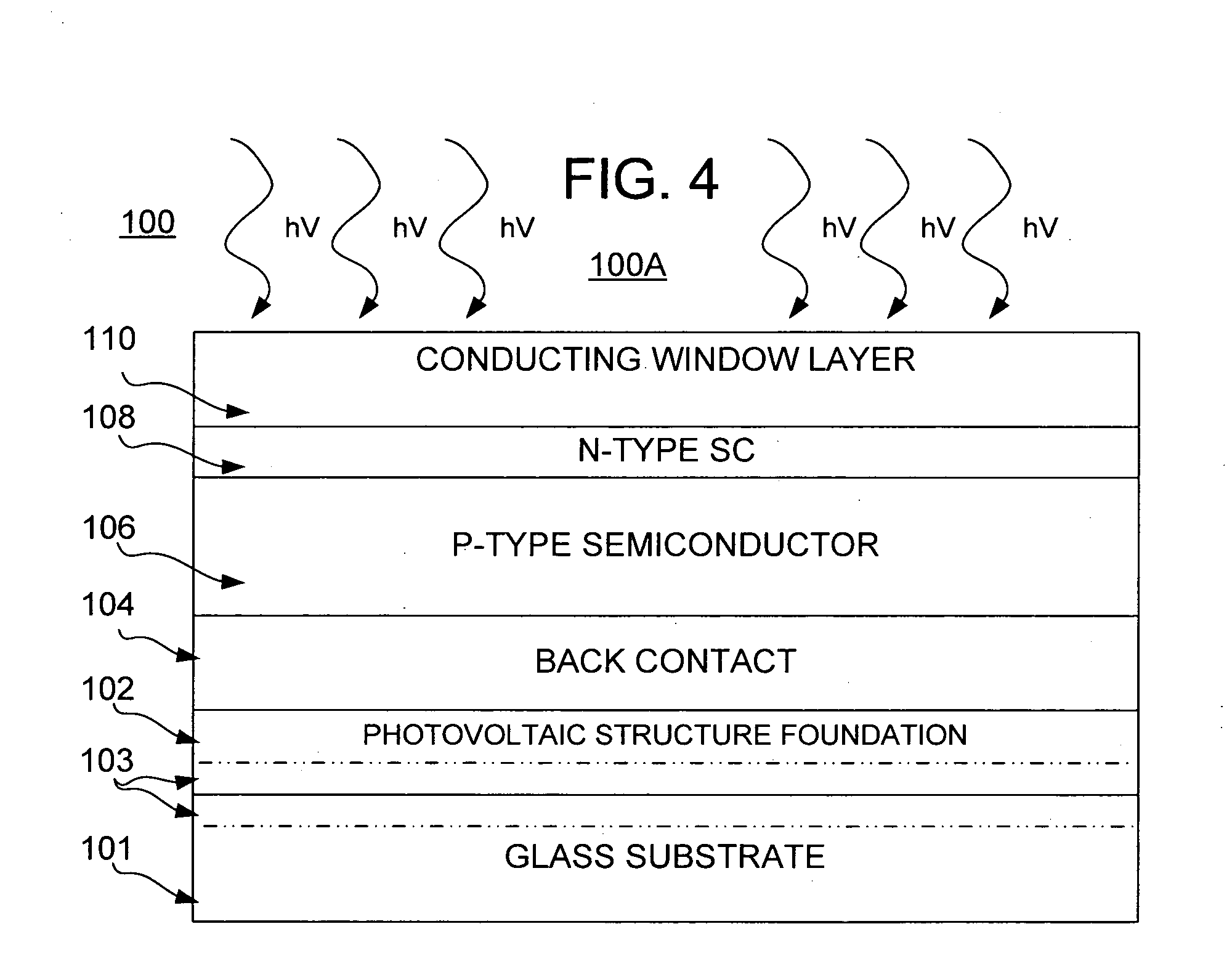

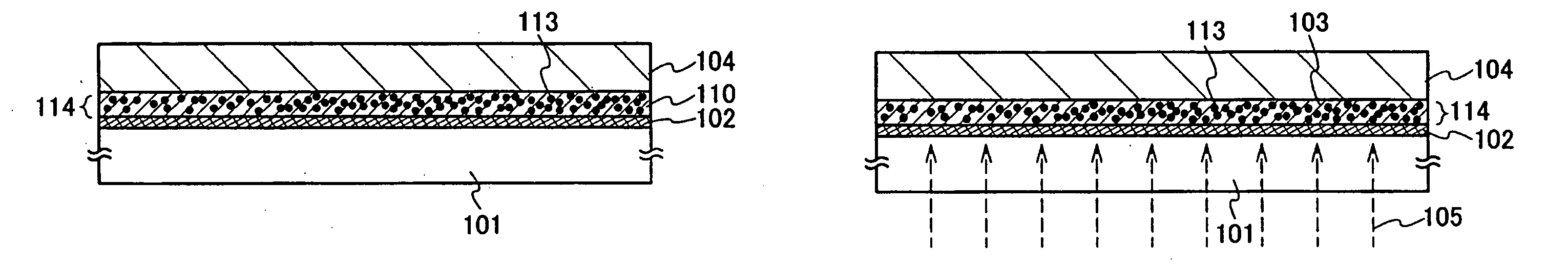

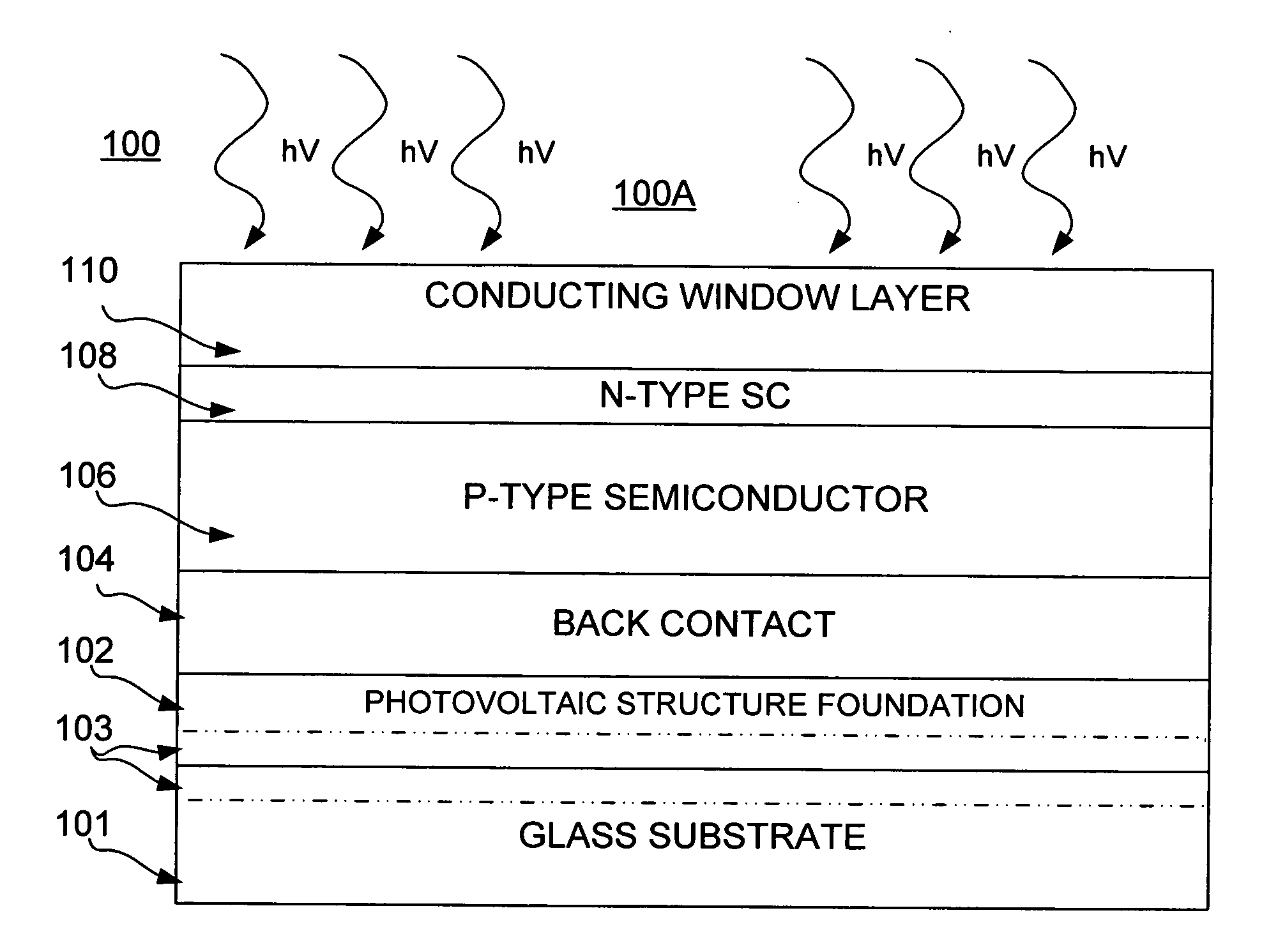

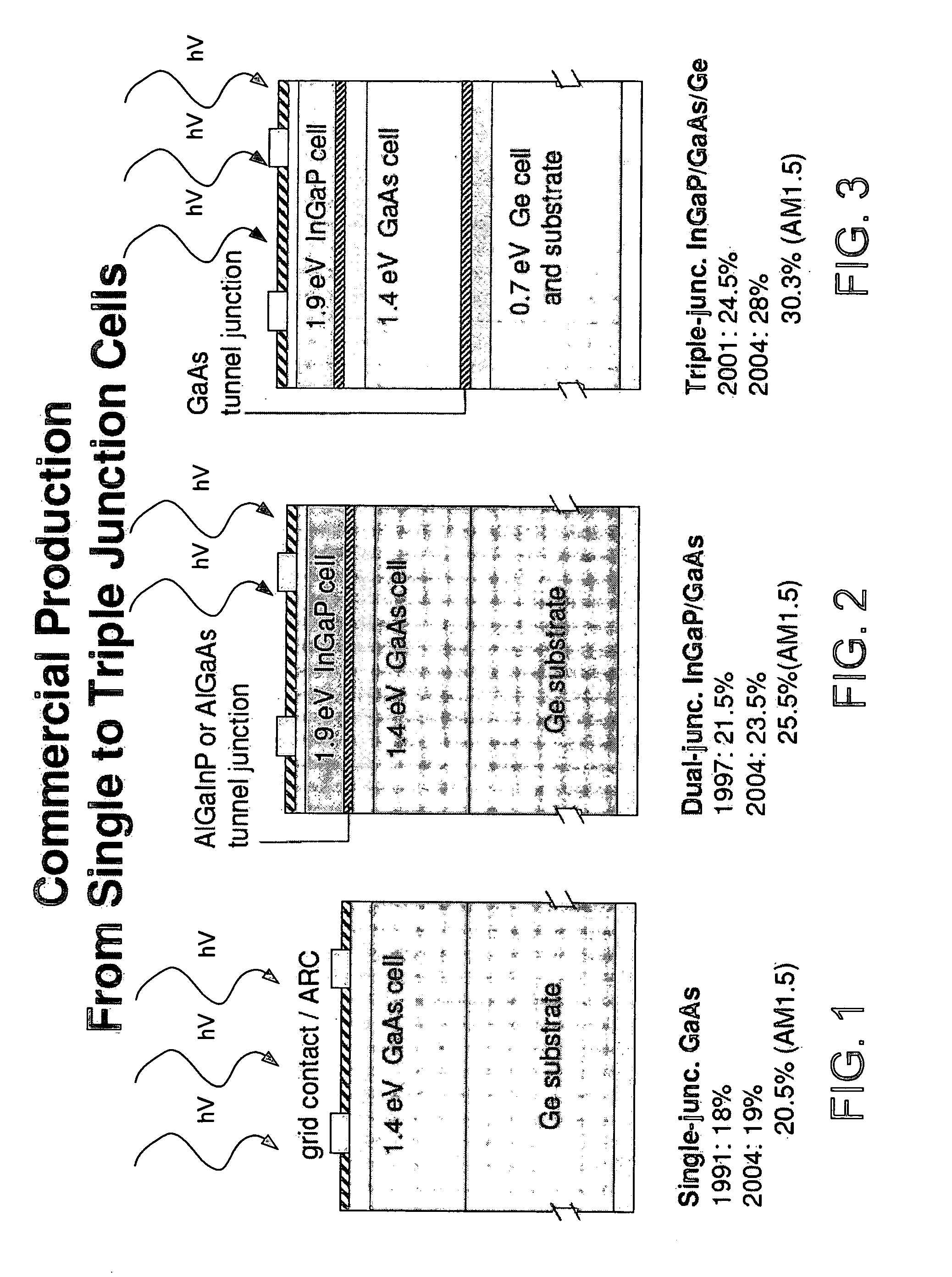

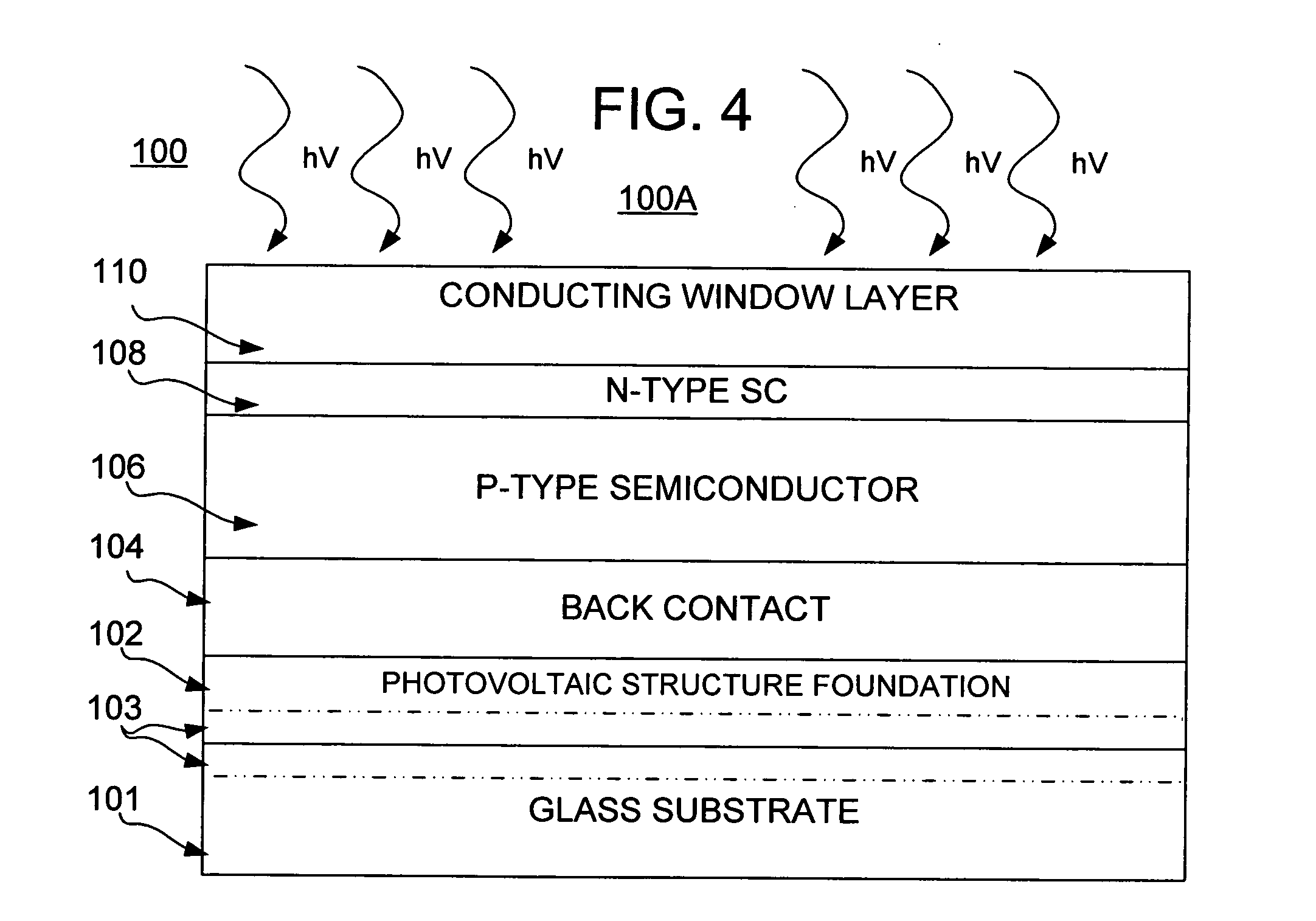

Thin film photovoltaic structure

InactiveUS20070277874A1Faster throughputReduce needSemiconductor/solid-state device manufacturingPhotovoltaic energy generationAnodic bondingVoltage

Systems and methods of production of a photovoltaic device include creating on a donor semiconductor wafer an exfoliation layer and transferring the exfoliation layer to an insulator substrate. One or more finishing processes may be performed before and / or after transferring the exfoliation layer, such as to create a plurality of photovoltaic structure layers. Production of the photovoltaic device further may include subjecting the donor semiconductor wafer to an ion implantation process to create the exfoliation layer, bonding the exfoliation layer to the insulator substrate, and separating the exfoliation layer from the donor semiconductor wafer. Transferring may include forming an anodic bond via electrolysis, such as through the application of heat, pressure and voltage to the exfoliation layer and the insulator structure.

Owner:CORNING INC

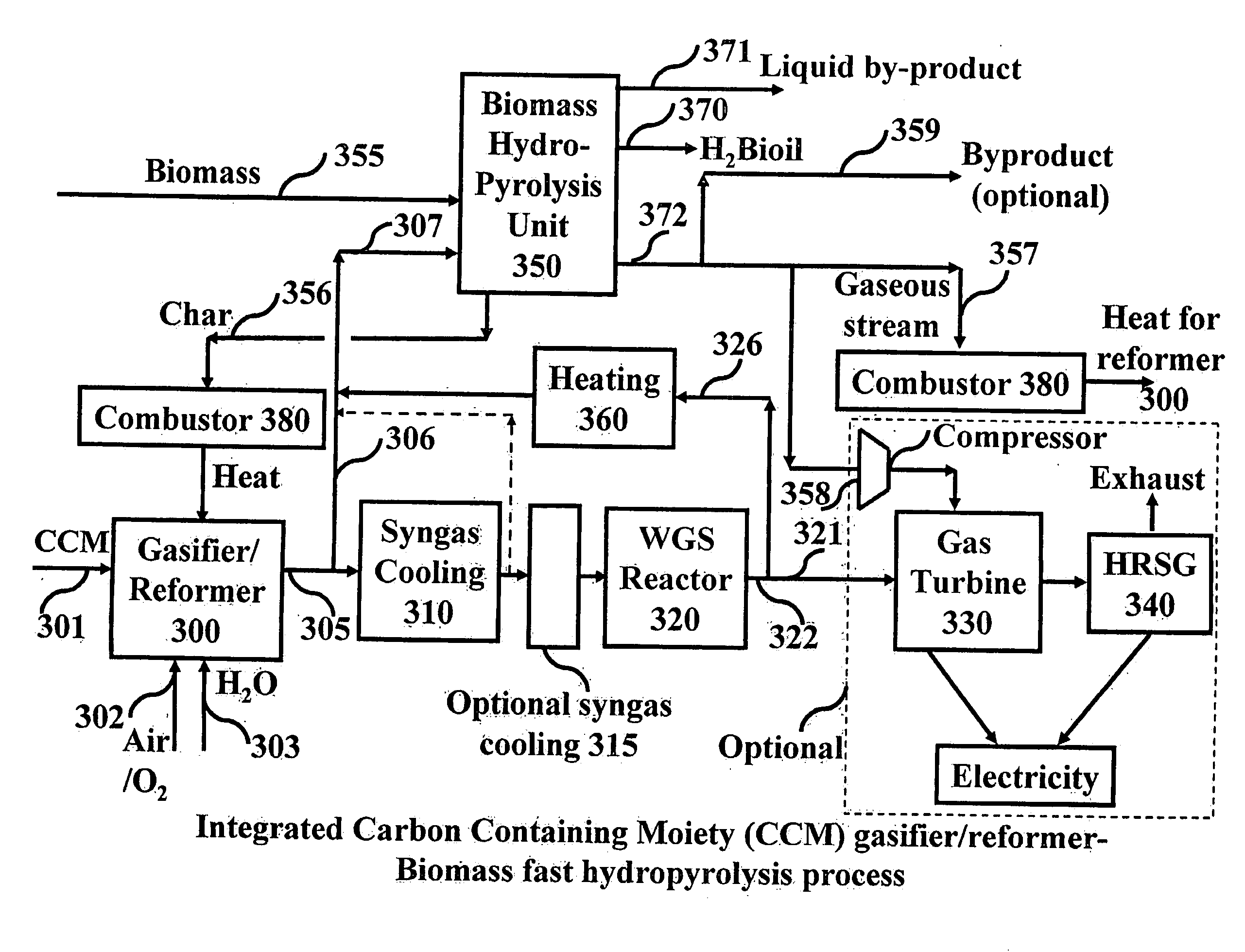

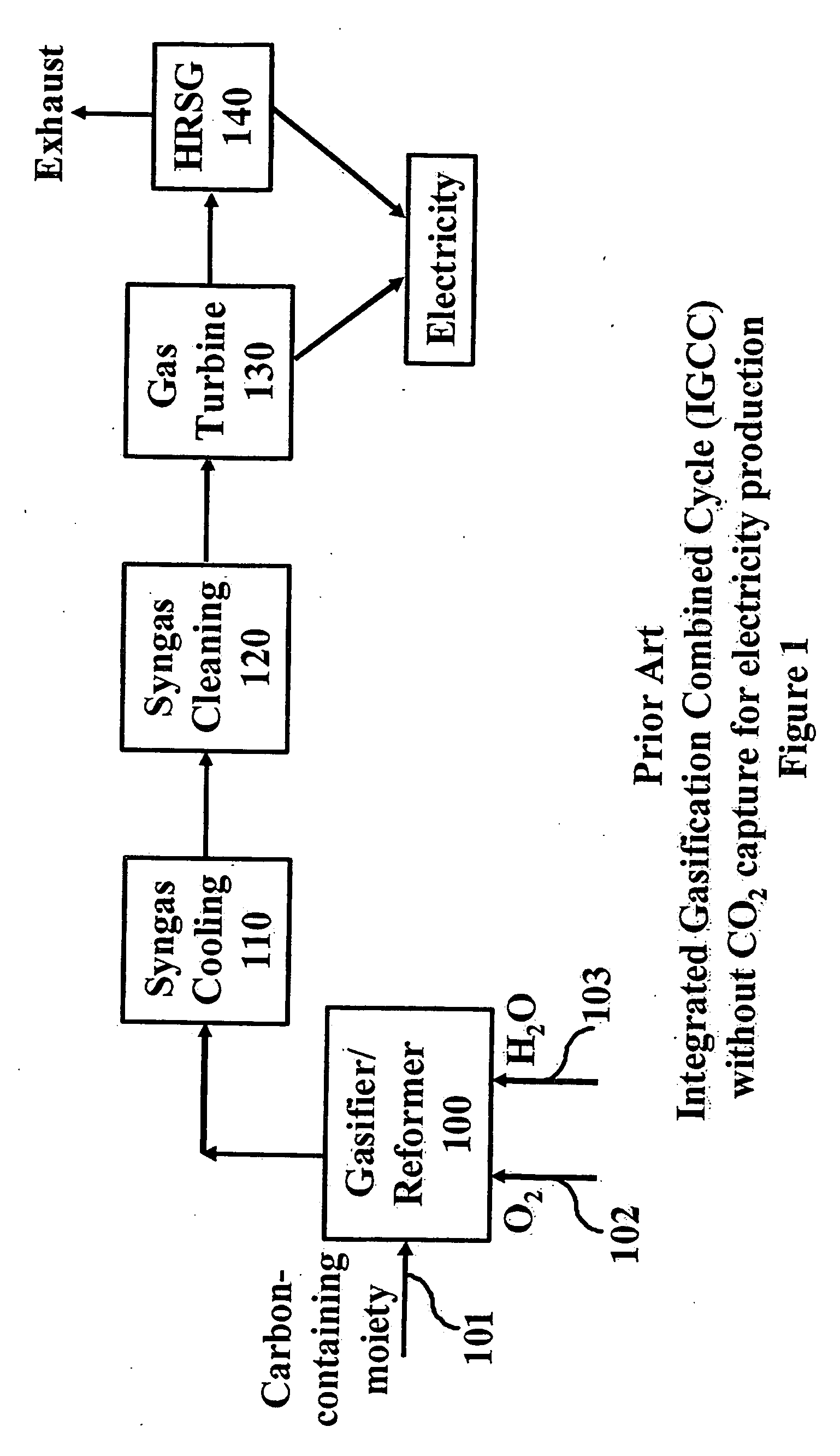

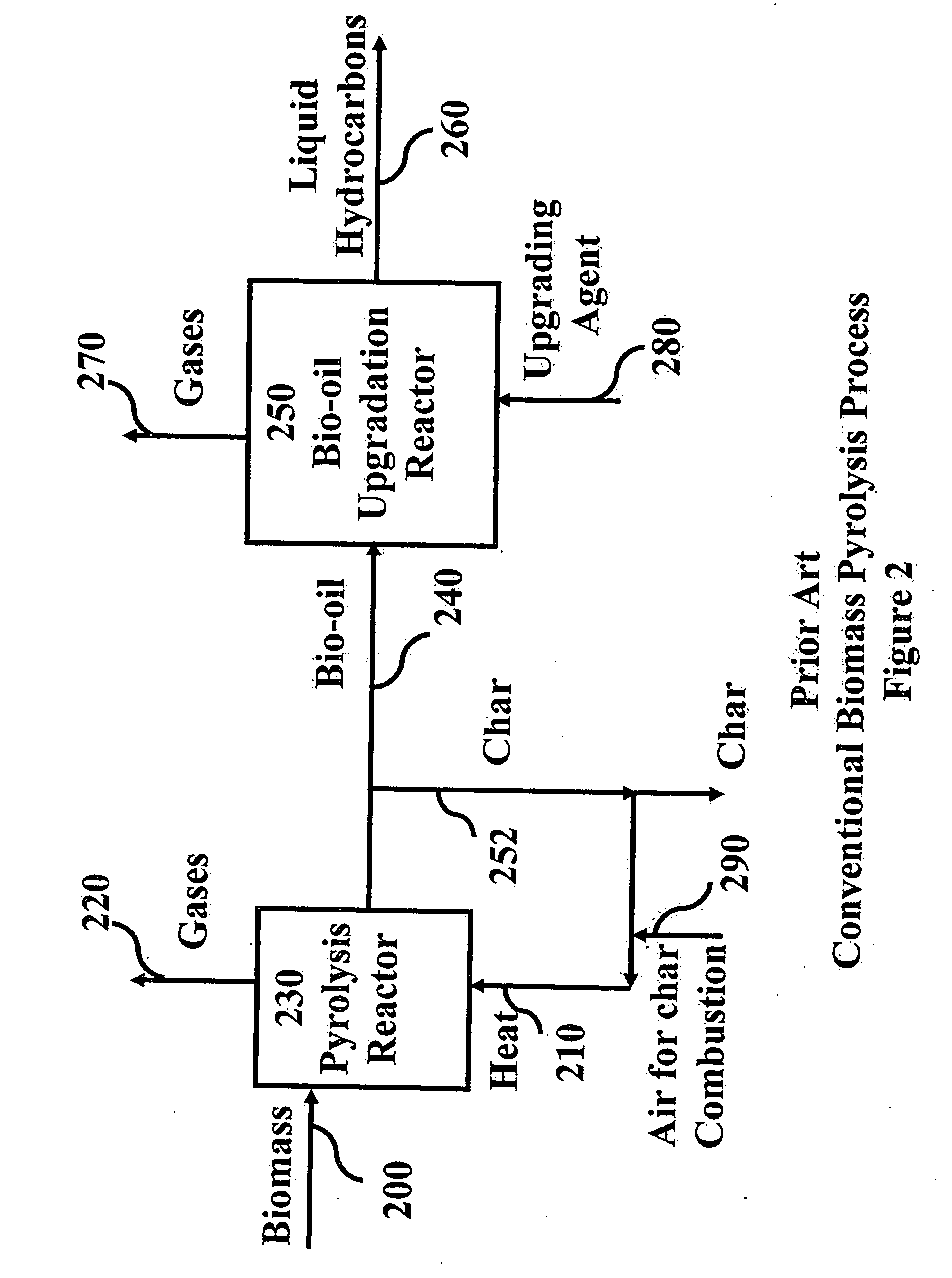

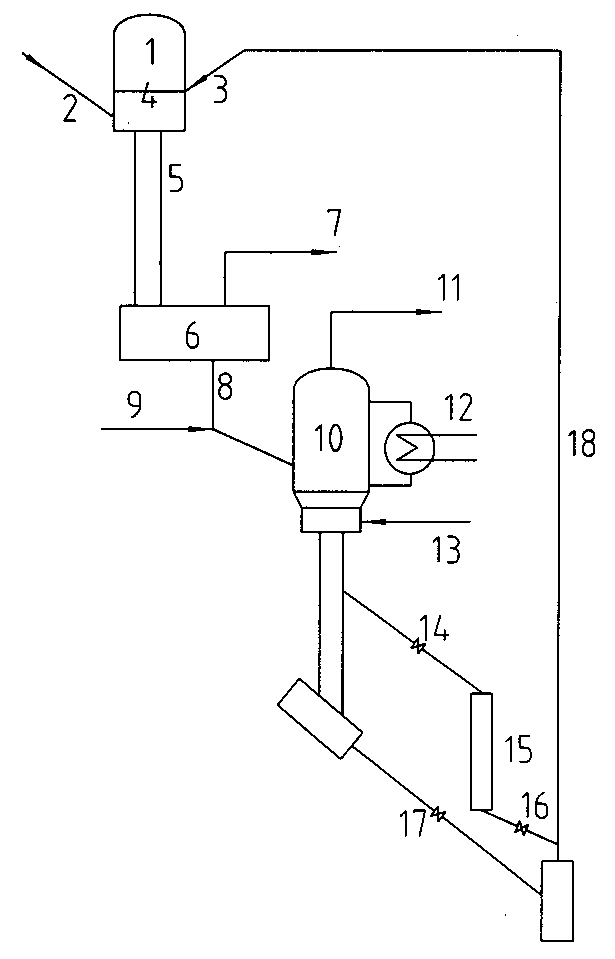

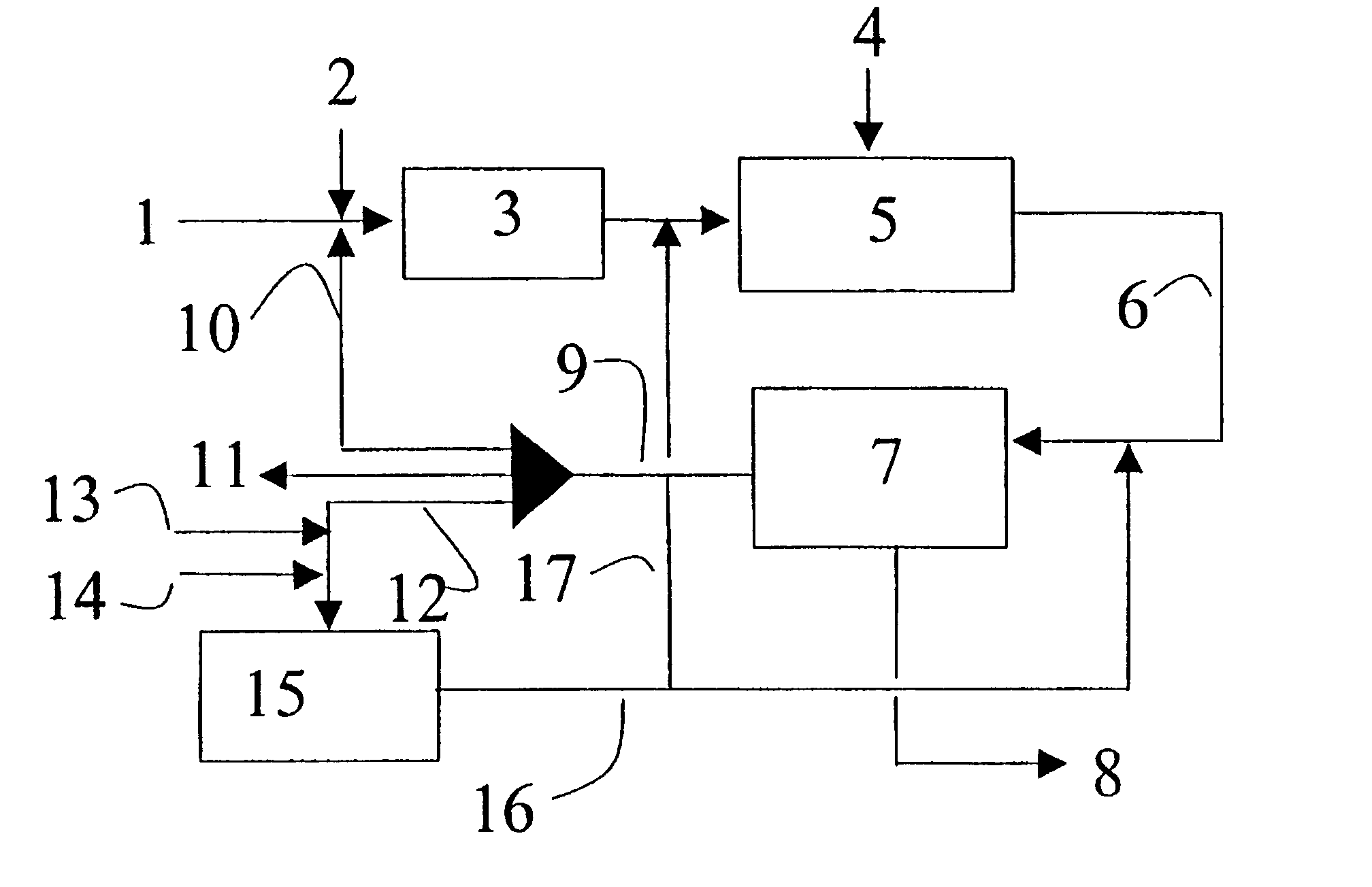

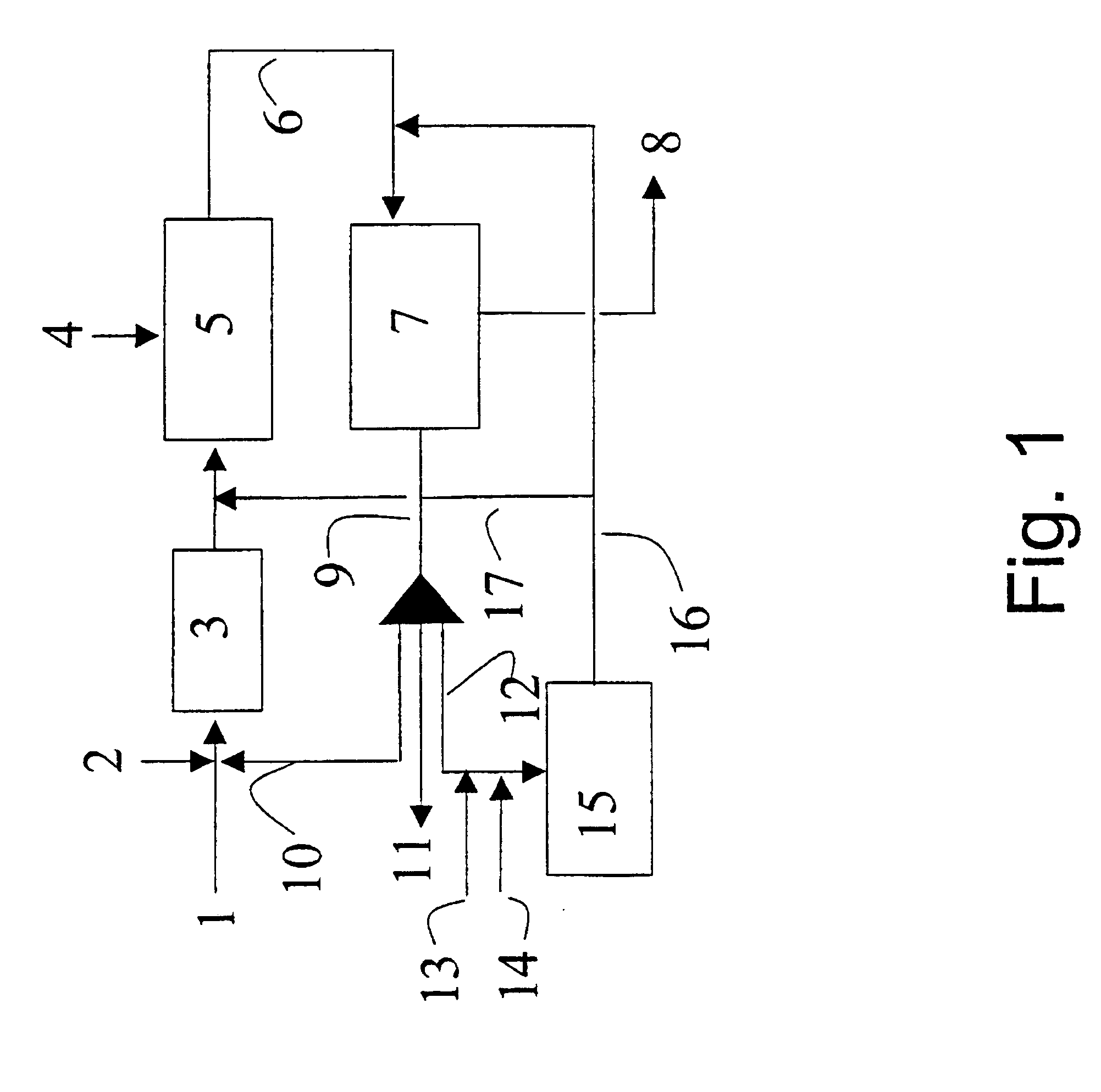

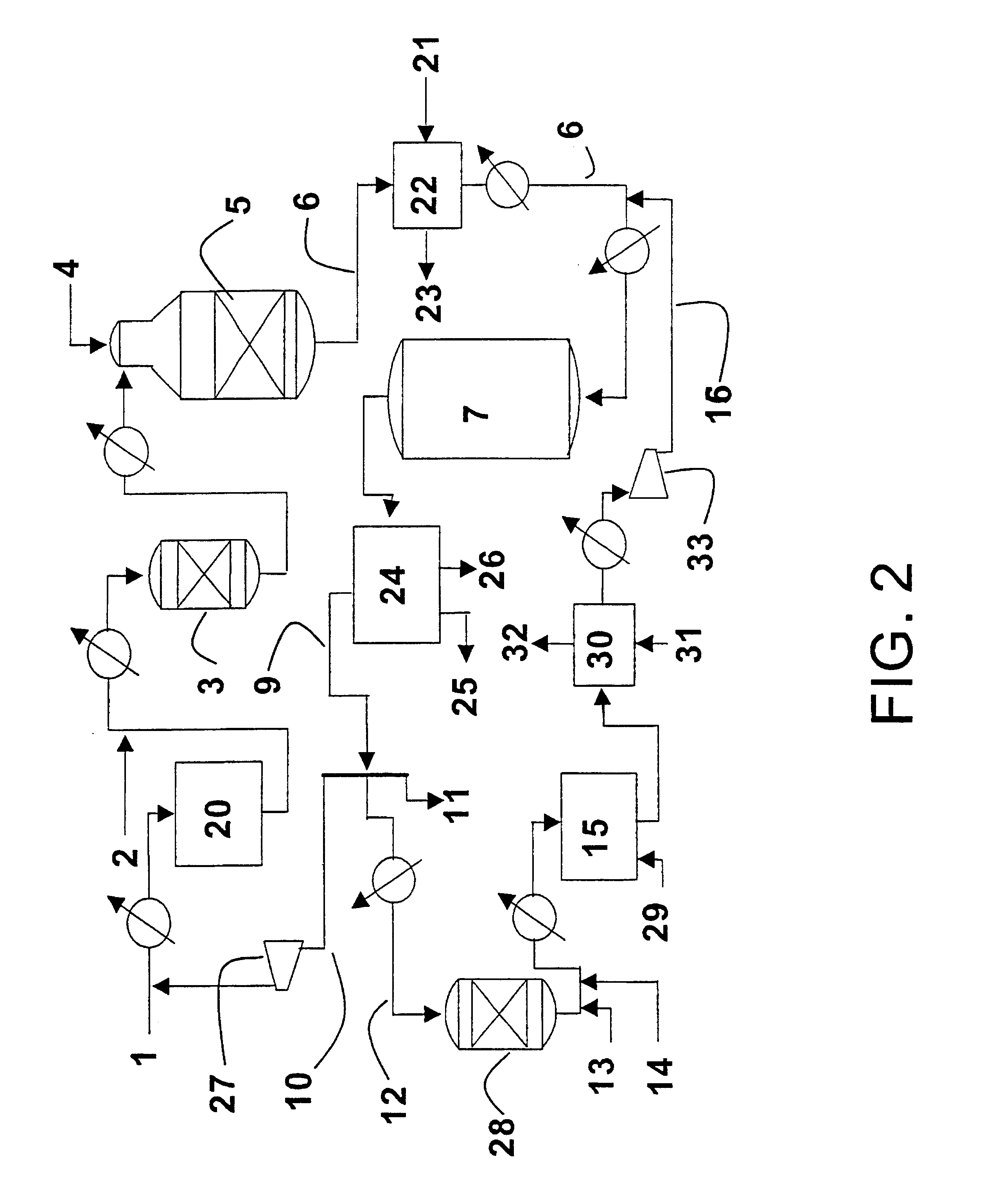

Novel integrated gasification - pyrolysis process

ActiveUS20090084666A1High liquid yieldLow yieldDirect heating destructive distillationCombustible gas catalytic treatmentBiomassChemistry

In at least one embodiment of the present invention, a method for producing liquid hydrocarbons from biomass is provided. The method comprises hydropyrolizing biomass with a gaseous exhaust stream formed from one of gasification and reforming of carbon containing moiety (CCM). The gaseous exhaust stream includes hydrogen (H2) and at least one of carbon monoxide (CO), carbon dioxide (CO2) and water (H2O).

Owner:PURDUE RES FOUND INC

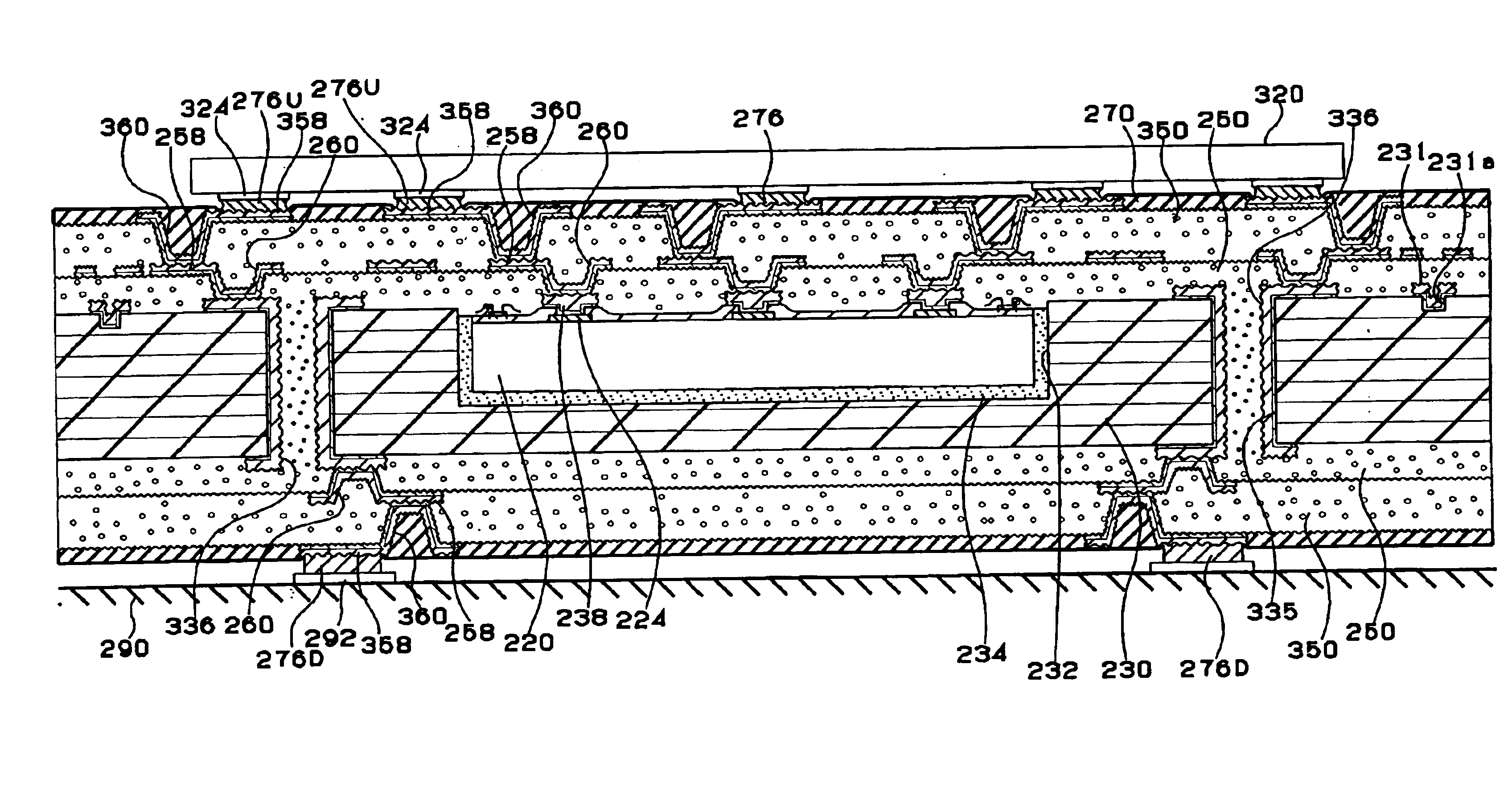

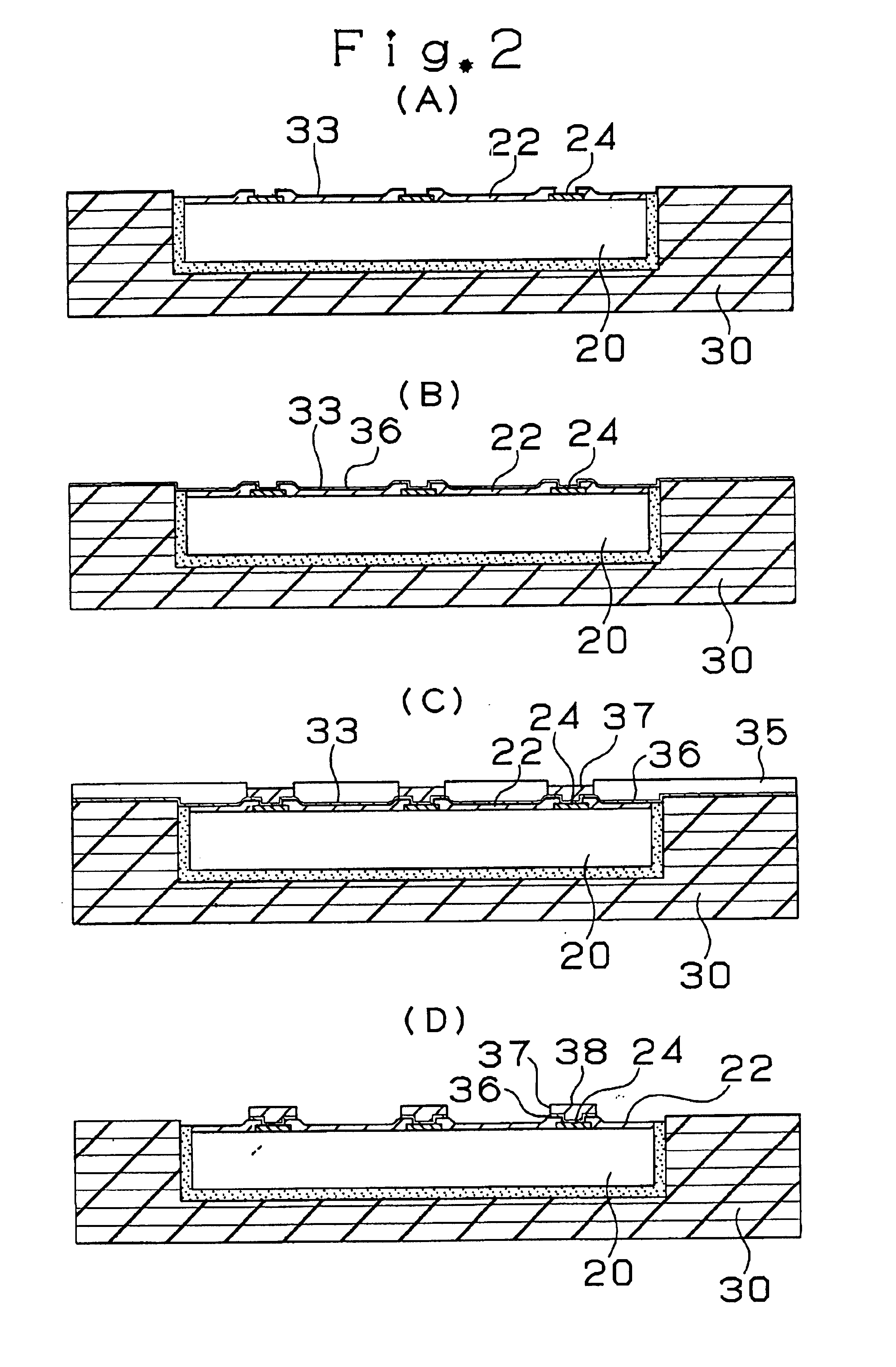

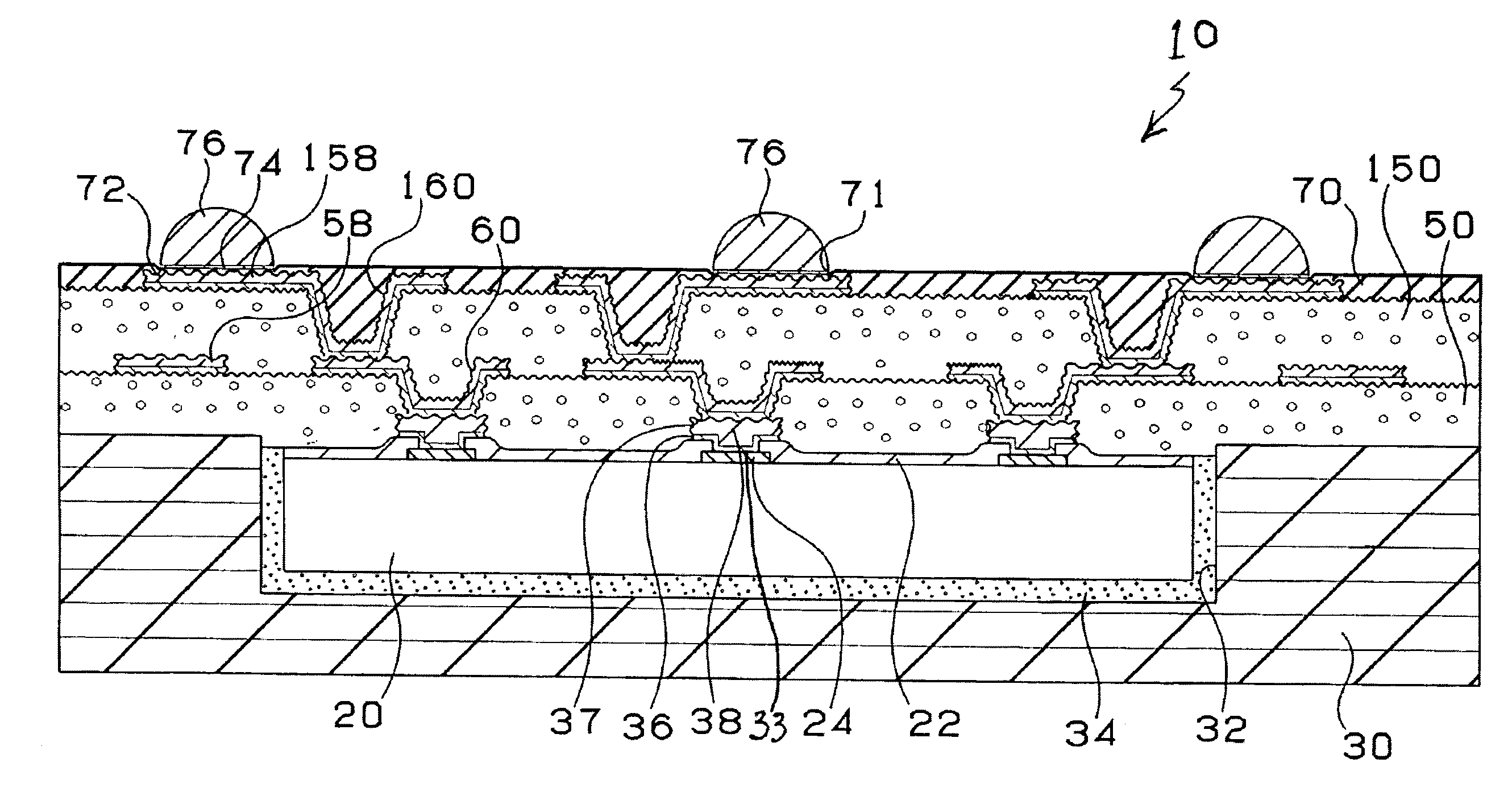

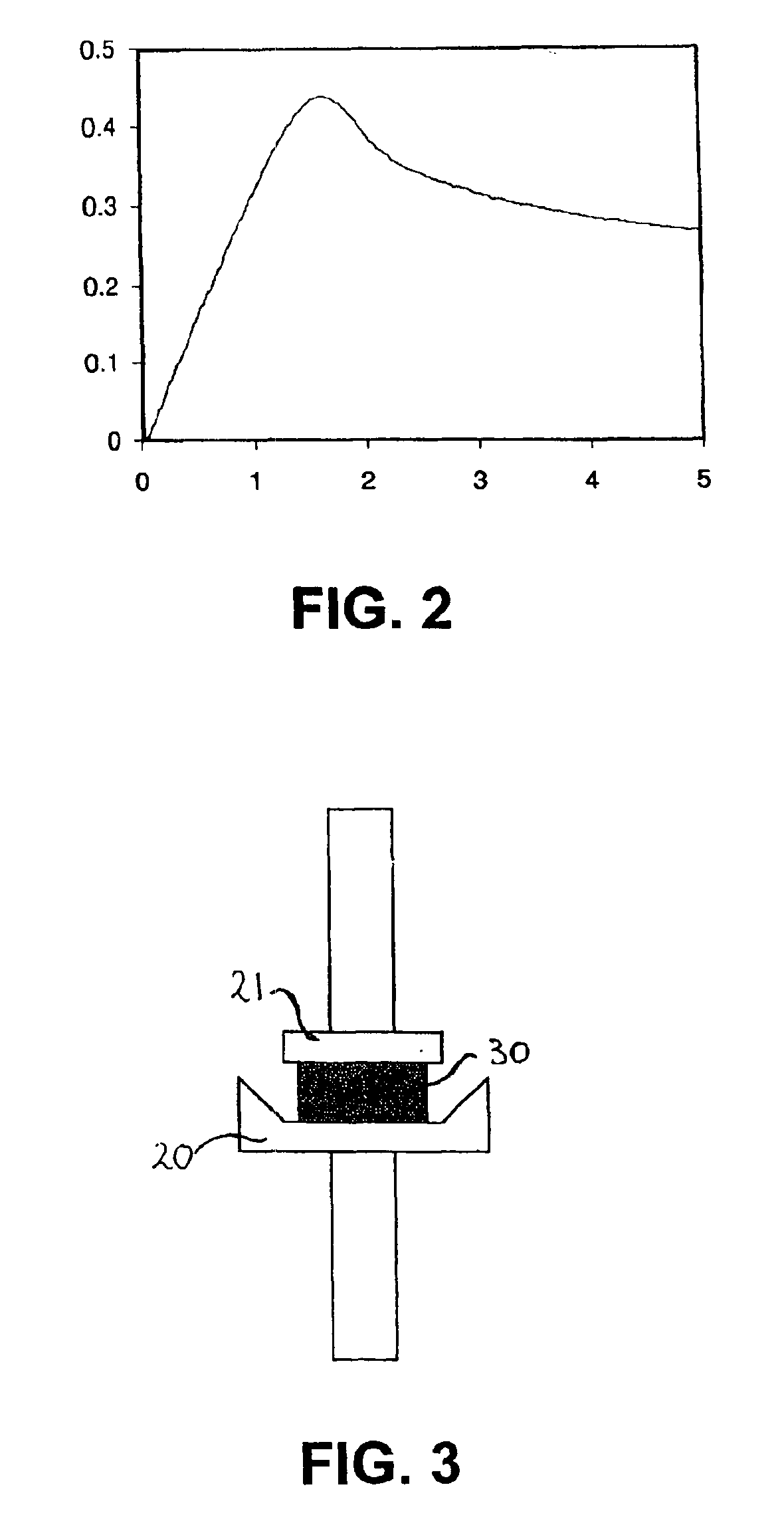

Multilayer printed wiring board and method for producing multilayer printed wiring board

InactiveUS6909054B2Low yieldWithout usingSemiconductor/solid-state device detailsPrinted electric component incorporationCopperPrinted circuit board

A multilayer printed circuit board has an IC chip 20 included in a core substrate 30 in advance and a transition layer 38 provided on a pad 24 of the IC chip 20. Due to this, it is possible to electrically connect the IC chip to the multilayer printed circuit board without using lead members and a sealing resin. Also, by providing the transition layer 38 made of copper on the die pad 24, it is possible to prevent resin residues on the pad 24 and to improve connection characteristics between the pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

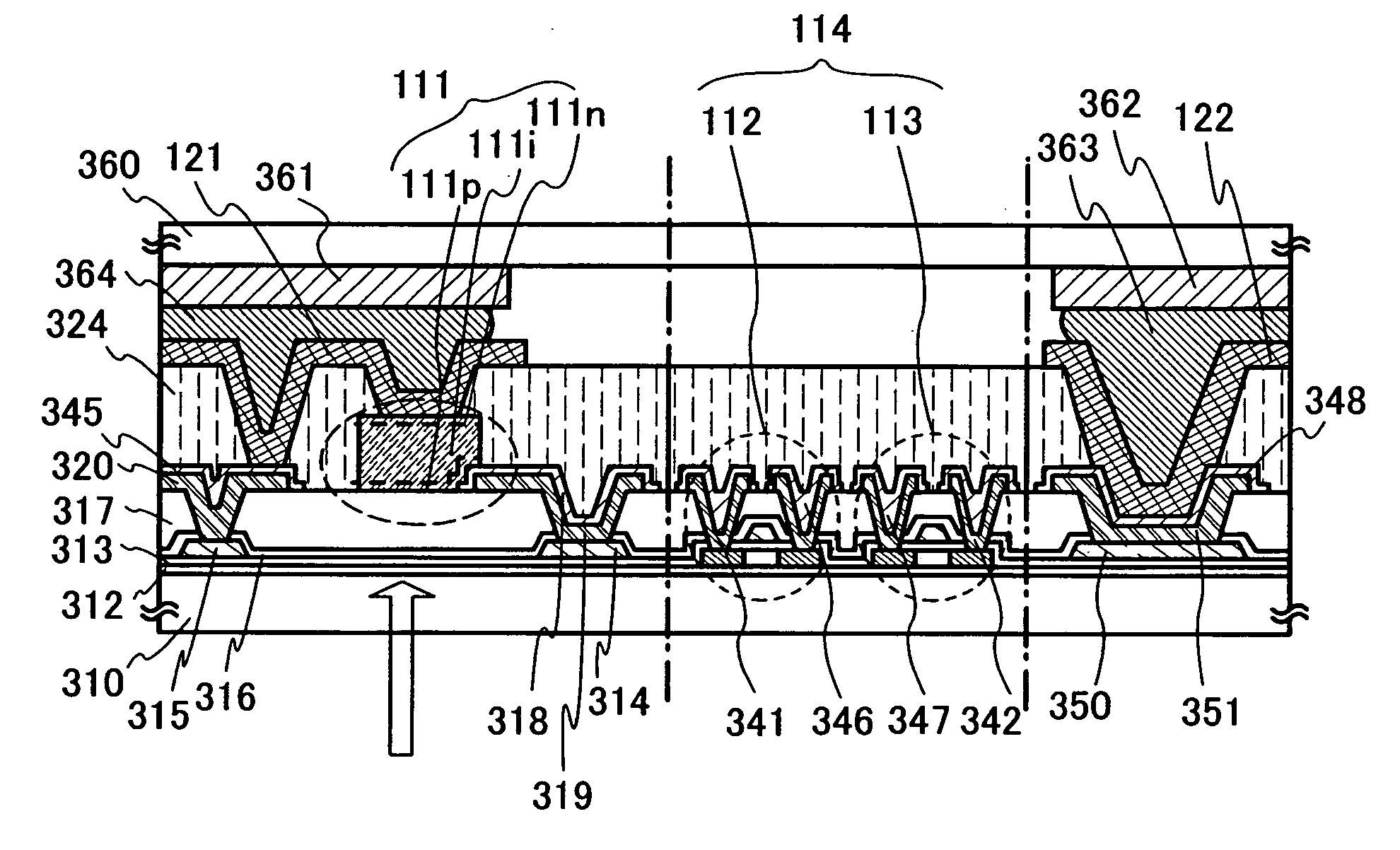

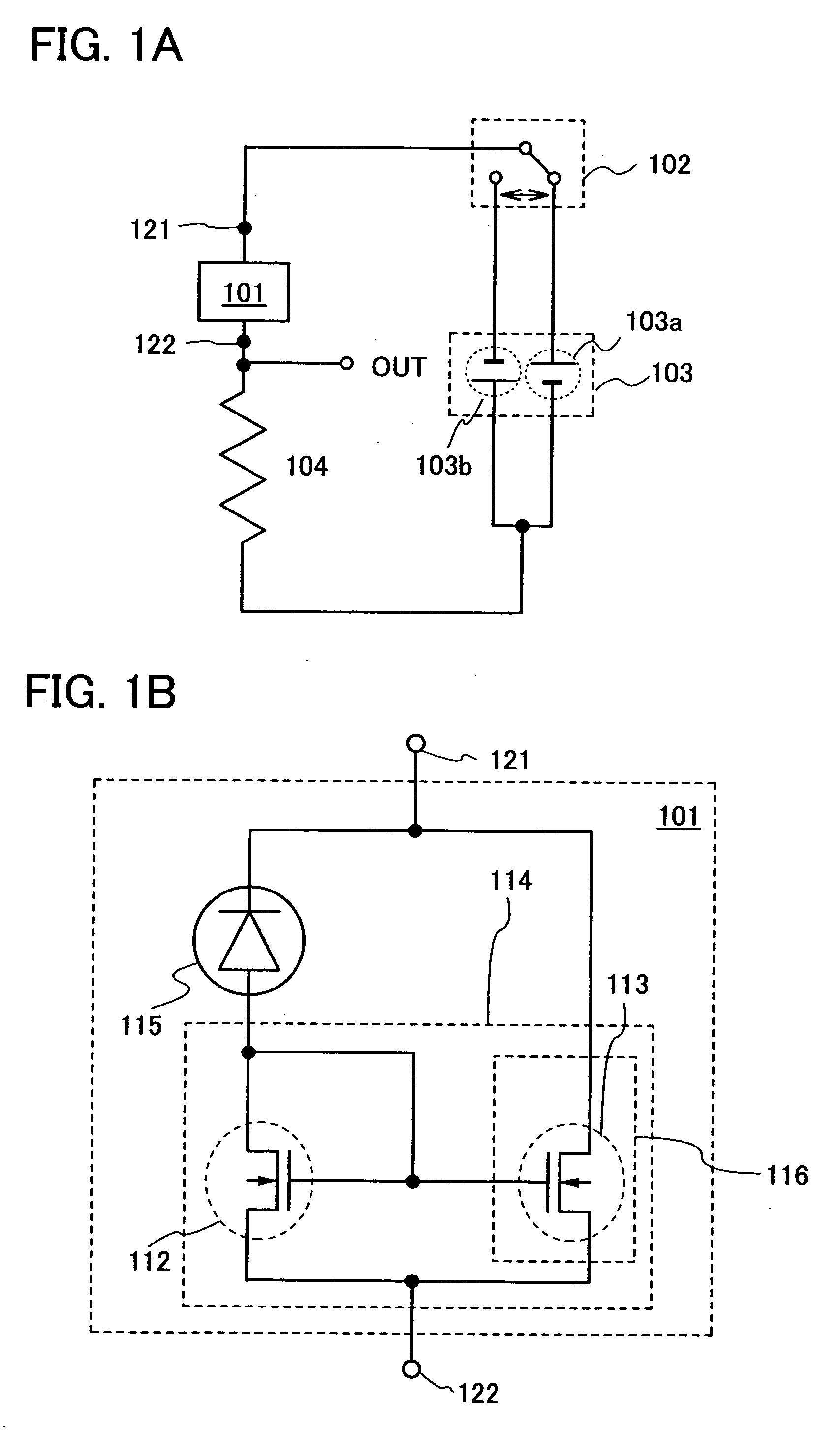

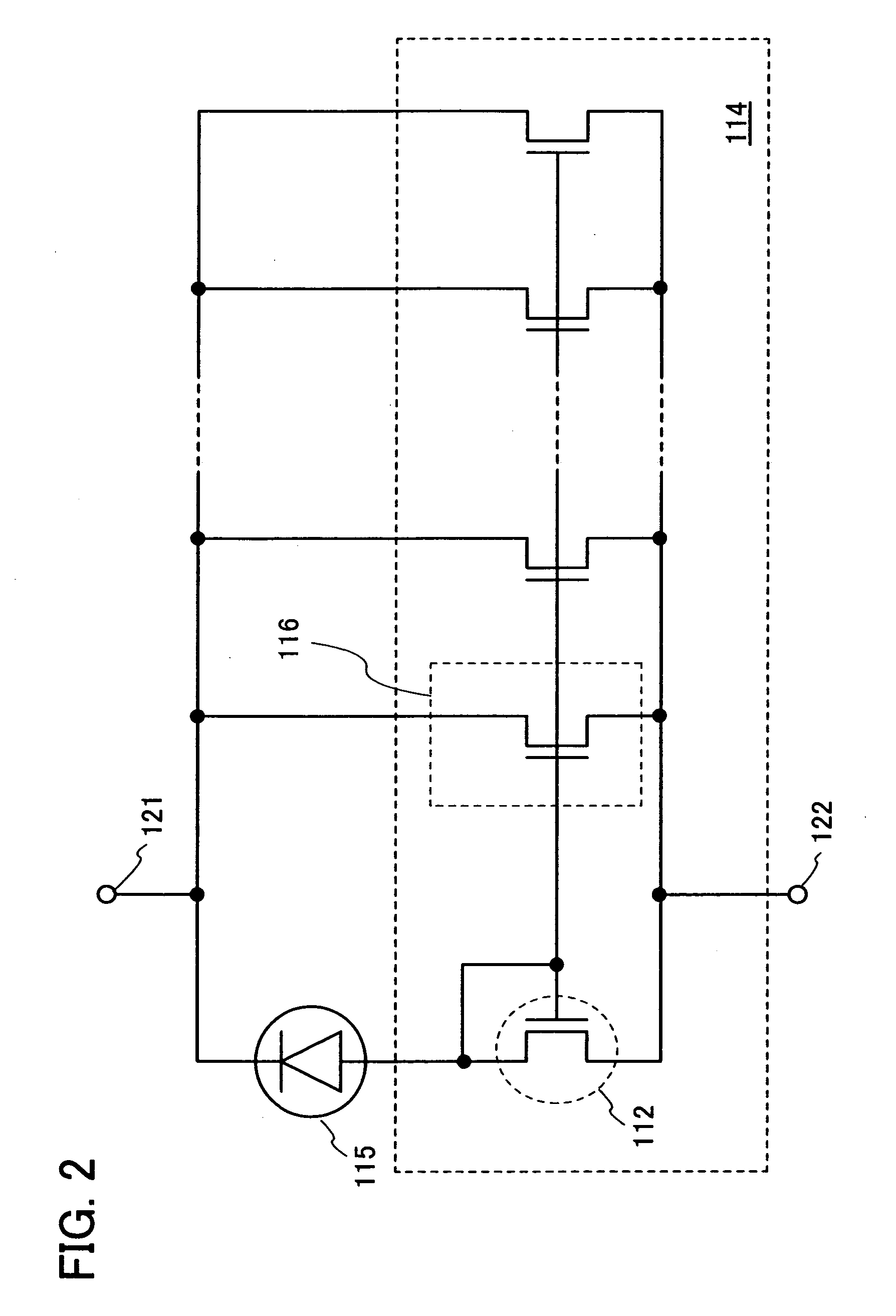

Semiconductor device

ActiveUS20080158137A1Reduce power consumptionHighly convenientStatic indicating devicesMaterial analysis by optical meansIlluminanceAudio power amplifier

A photoelectric conversion device includes a light detection circuit which includes an optical sensor to output a current signal corresponding to illuminance and a current-voltage conversion circuit to convert the current signal output from the optical sensor into a voltage signal; an amplifier to amplify the voltage signal output from the light detection circuit; a comparison circuit to compare voltage output from the amplifier and reference voltage and output the result to a control circuit; and the control circuit to determine an illuminance range to be detected depending on the output from the comparison circuit and output a control signal to the light detection circuit. The current-voltage conversion circuit has a function of changing a resistance value in accordance with the control signal.

Owner:SEMICON ENERGY LAB CO LTD

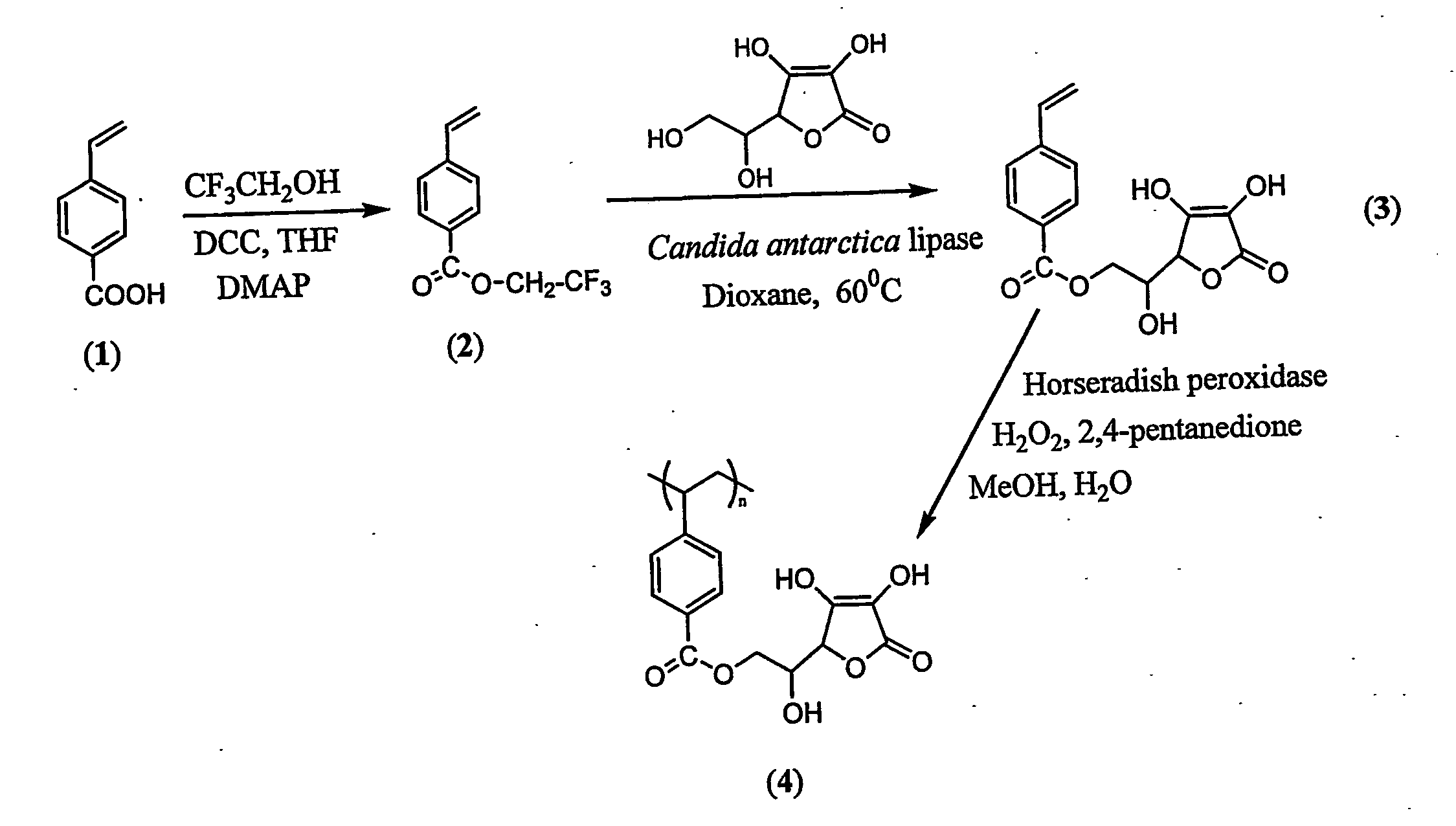

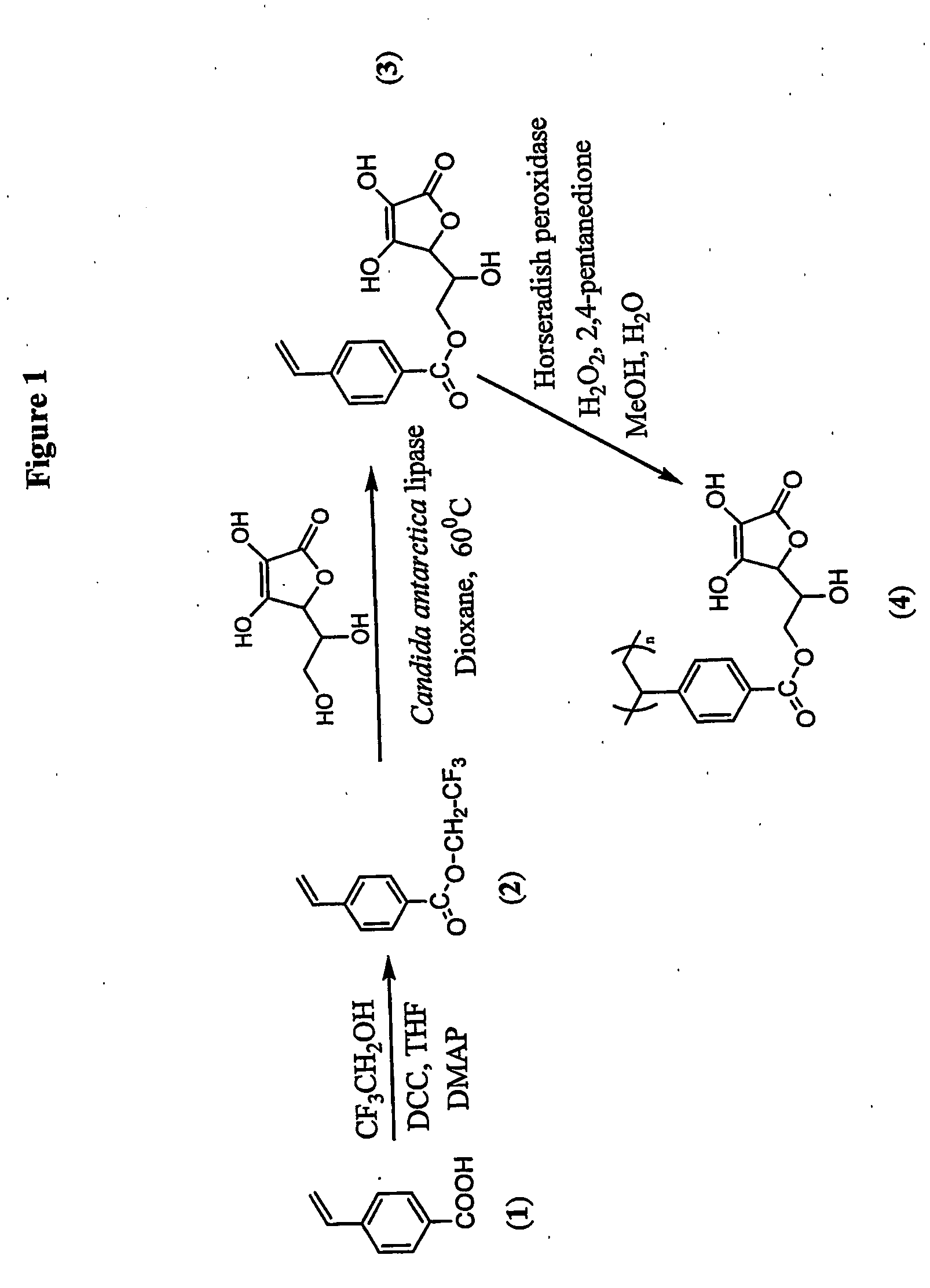

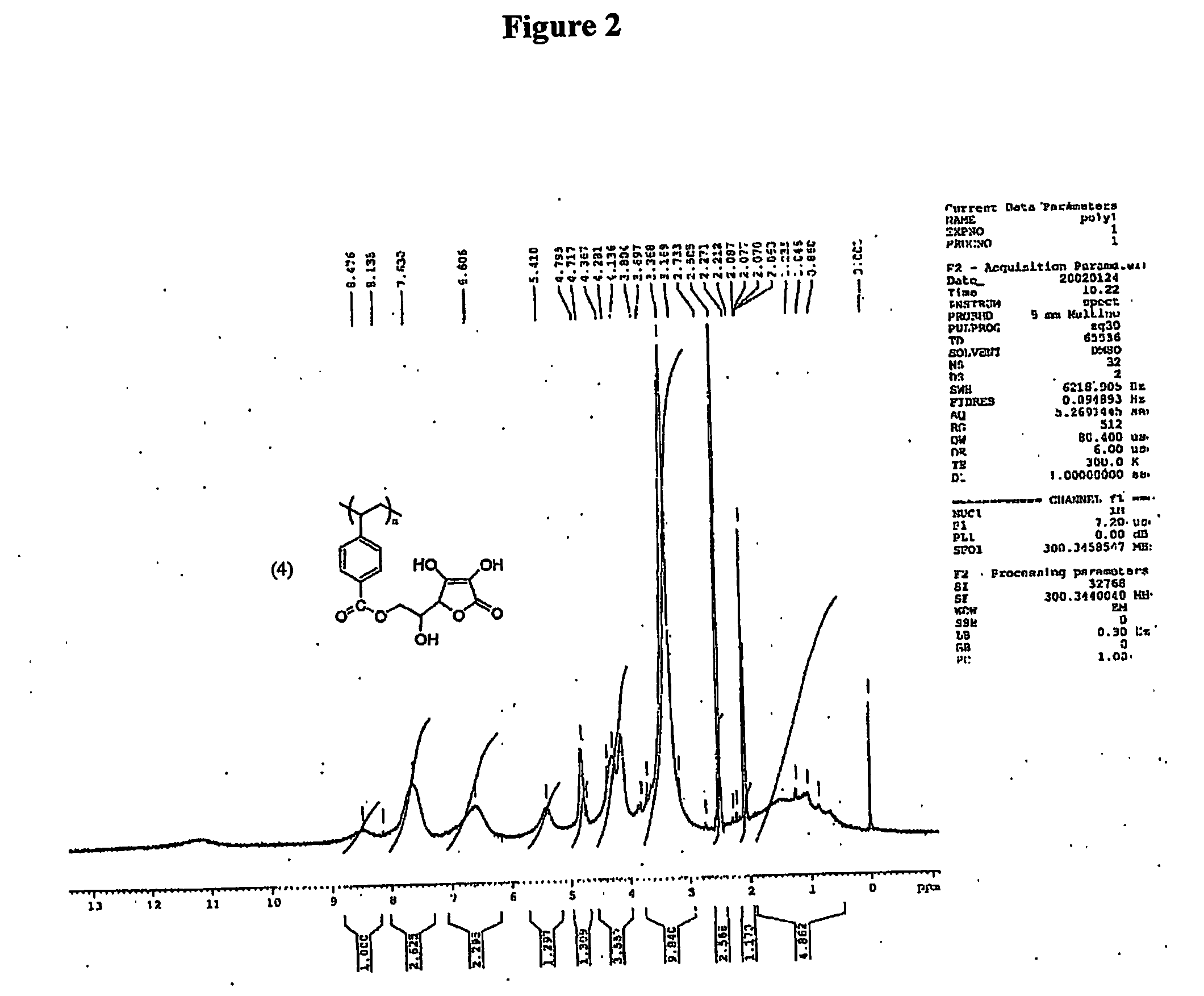

Antioxidant-functionalized polymers

InactiveUS20070010632A1Low yieldReduce sensitivitySuture equipmentsOrganic chemistryAntioxidantOxygen

Methods and compositions are disclosed for the preparation of free radical scavenging polymers and polymer films functionalized with antioxidants. Enzymatic and chemical tailoring of monomers with antioxidants followed by enzymatic polymerization is described. These antioxidant functionalized polymers can increase shelf life and quality of food products, as well as, increase effectiveness of pharmaceutical agents when used as packaging or as coatings on packaging for oxygen sensitive materials. The novel enzymatic covalent coupling of antioxidants to a polymer enhances the free radical scavenging ability of packaging while also inhibiting the escape of the antioxidants, and thus limiting exposure and / or absorption by an individual. In addition to its use in food or pharmaceutical packaging, methods are disclosed for using the antioxidant coupled polymers in a variety of applications including as coatings on the inside of medical devices, such as stents and catheters, which would substantially reduce free radical damage and / or oxygen depletion during medical procedures. Furthermore, through the coupling of antioxidants to biodegradable polymers, controlled delivery and sustained release of an antioxidant to a subject is possible.

Owner:TRUSTEES OF TUFTS COLLEGE

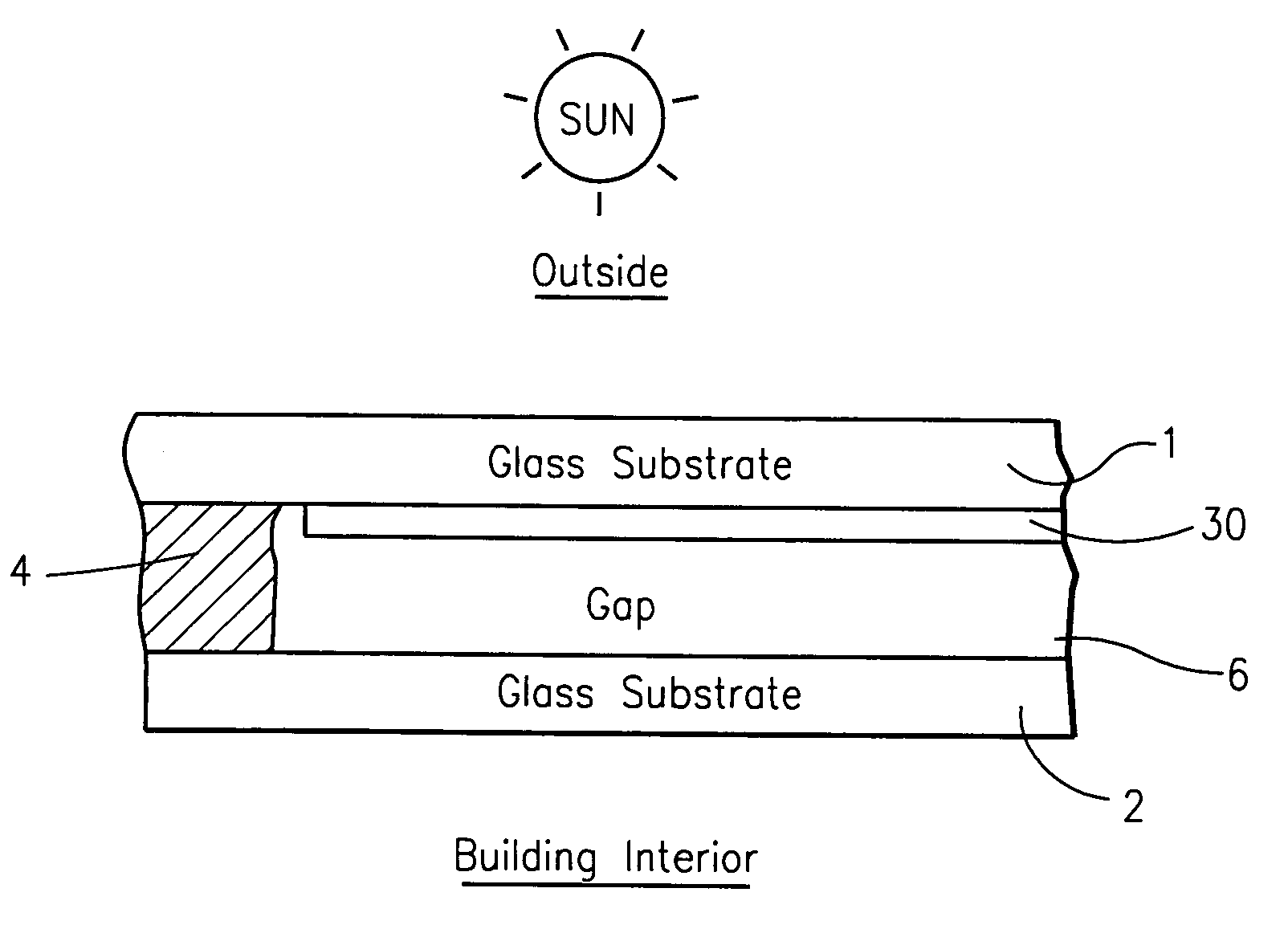

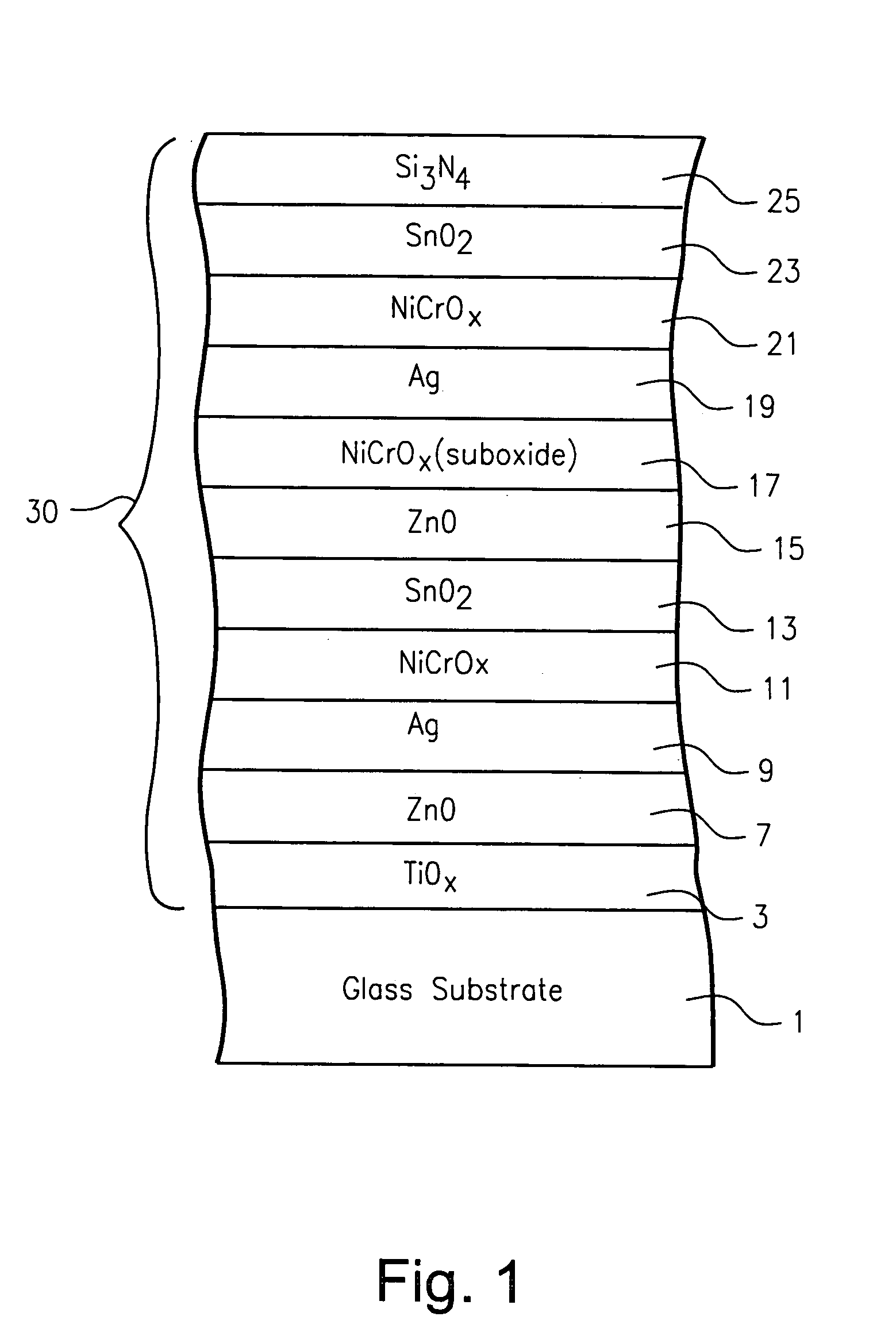

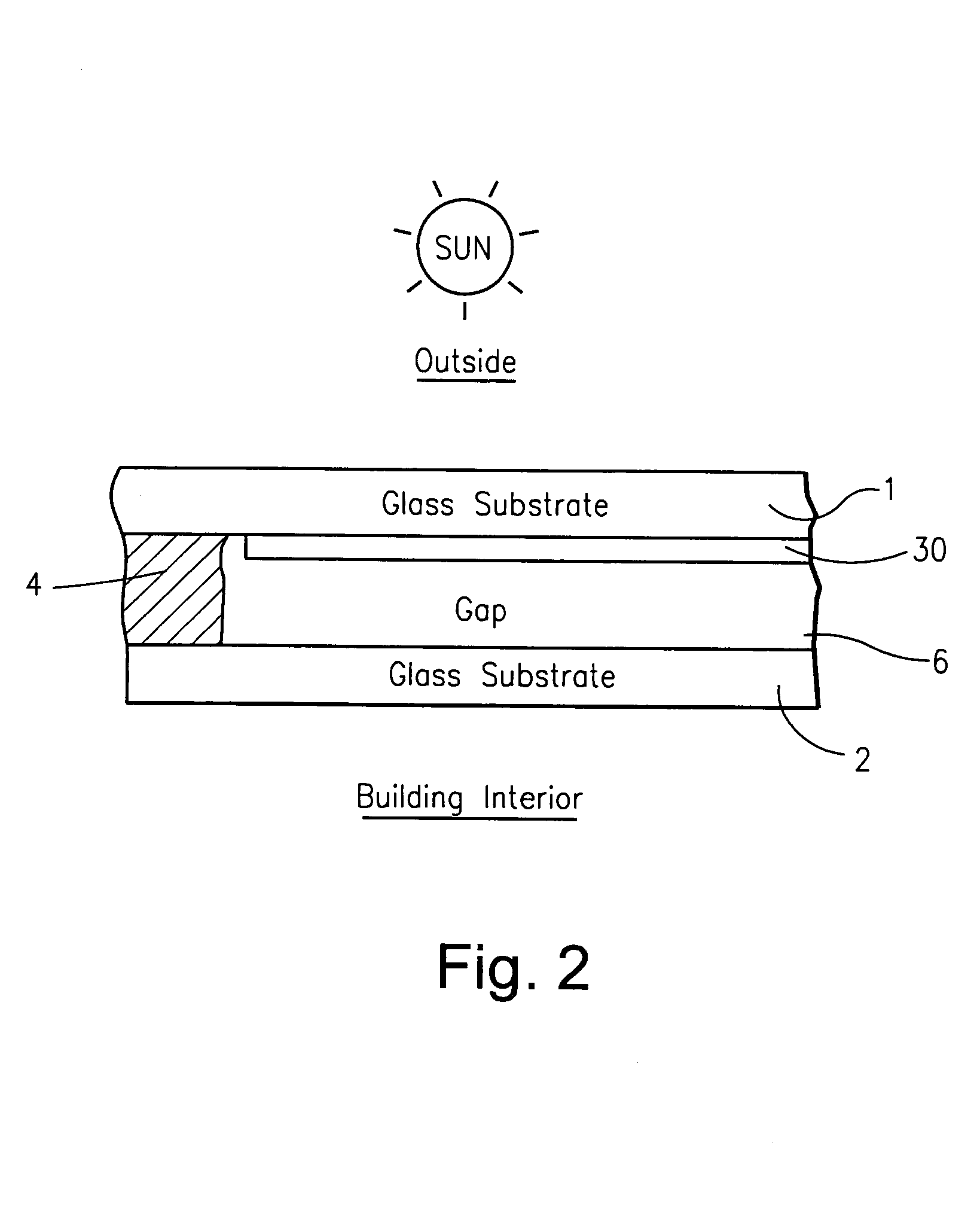

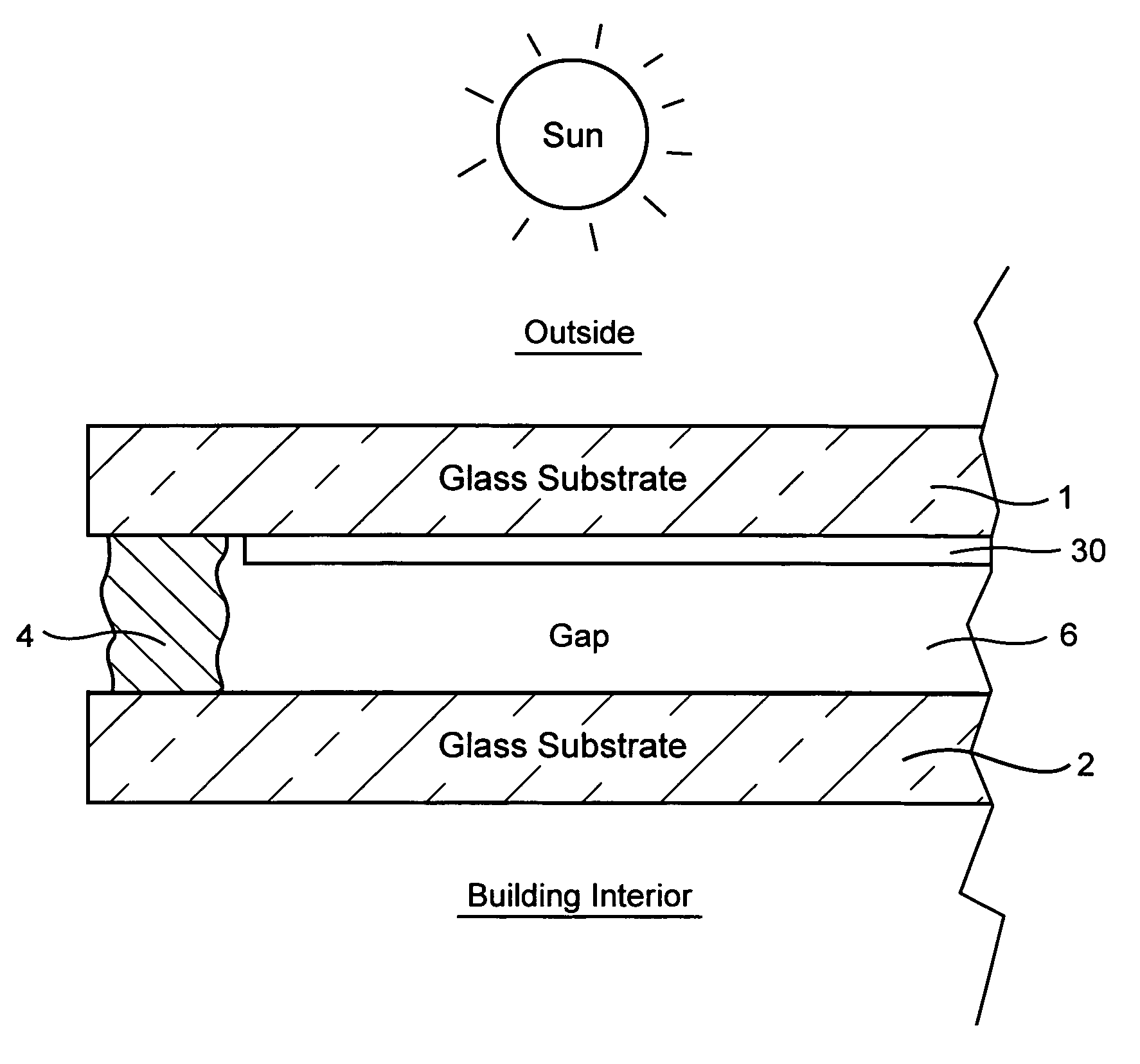

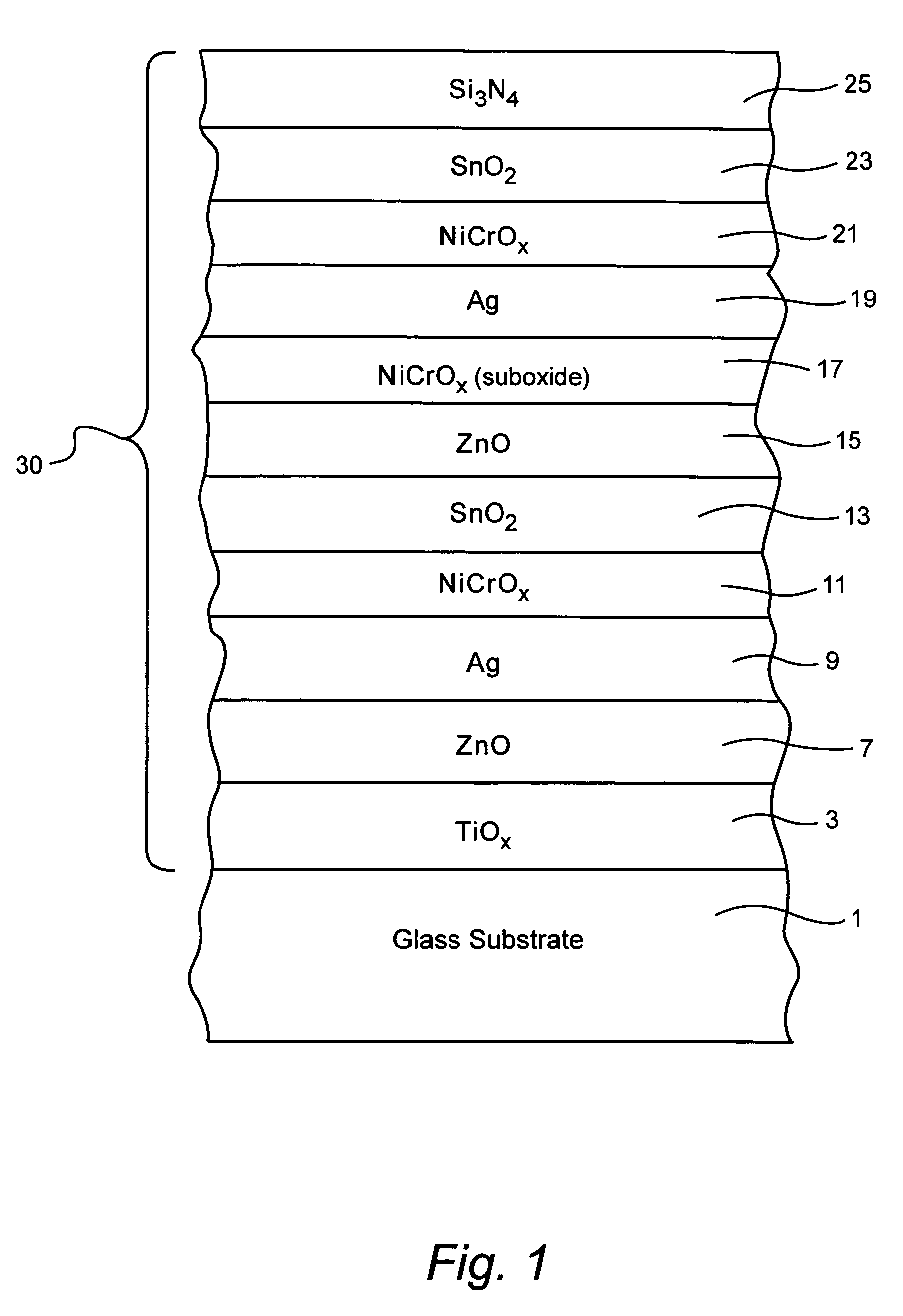

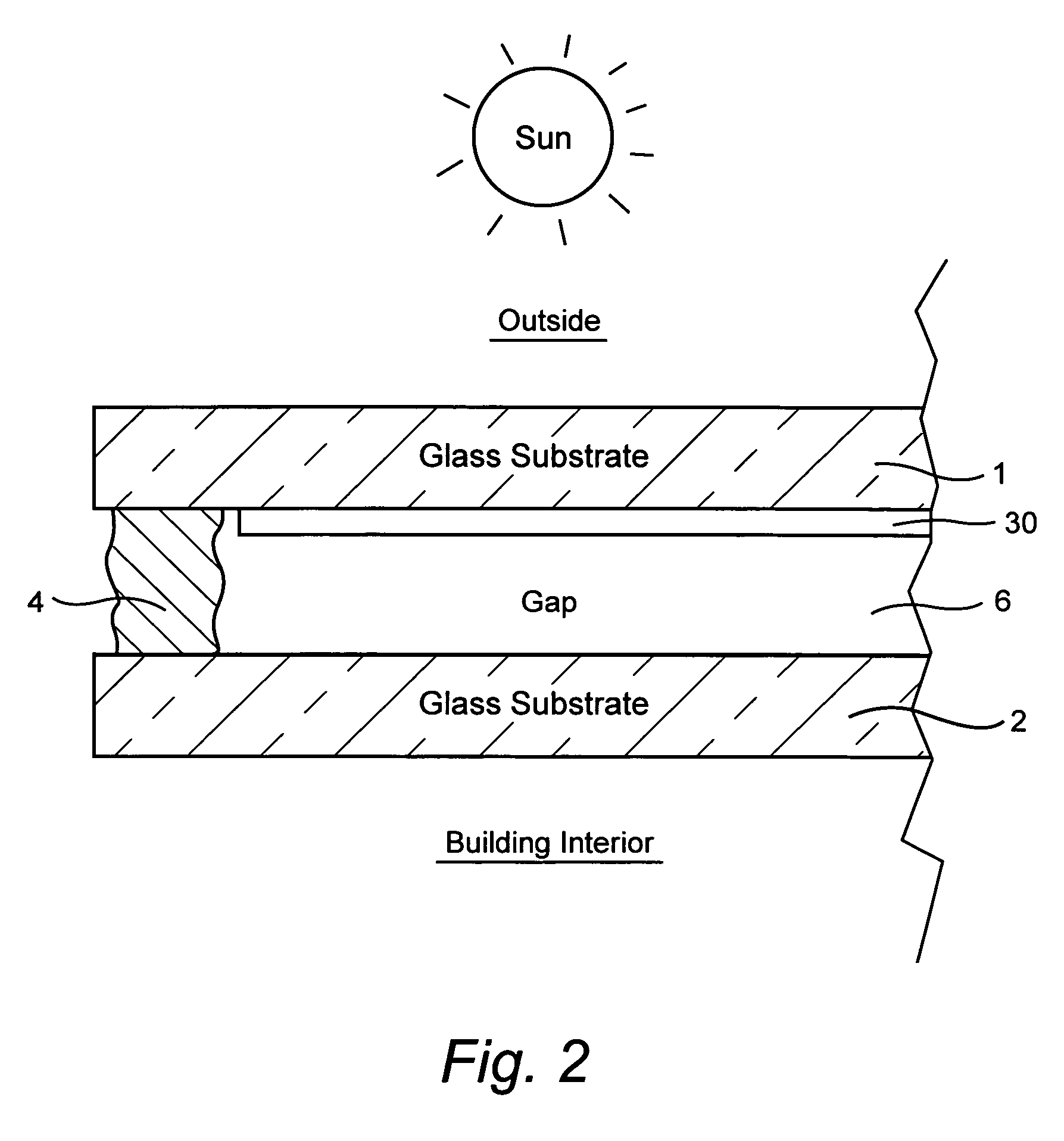

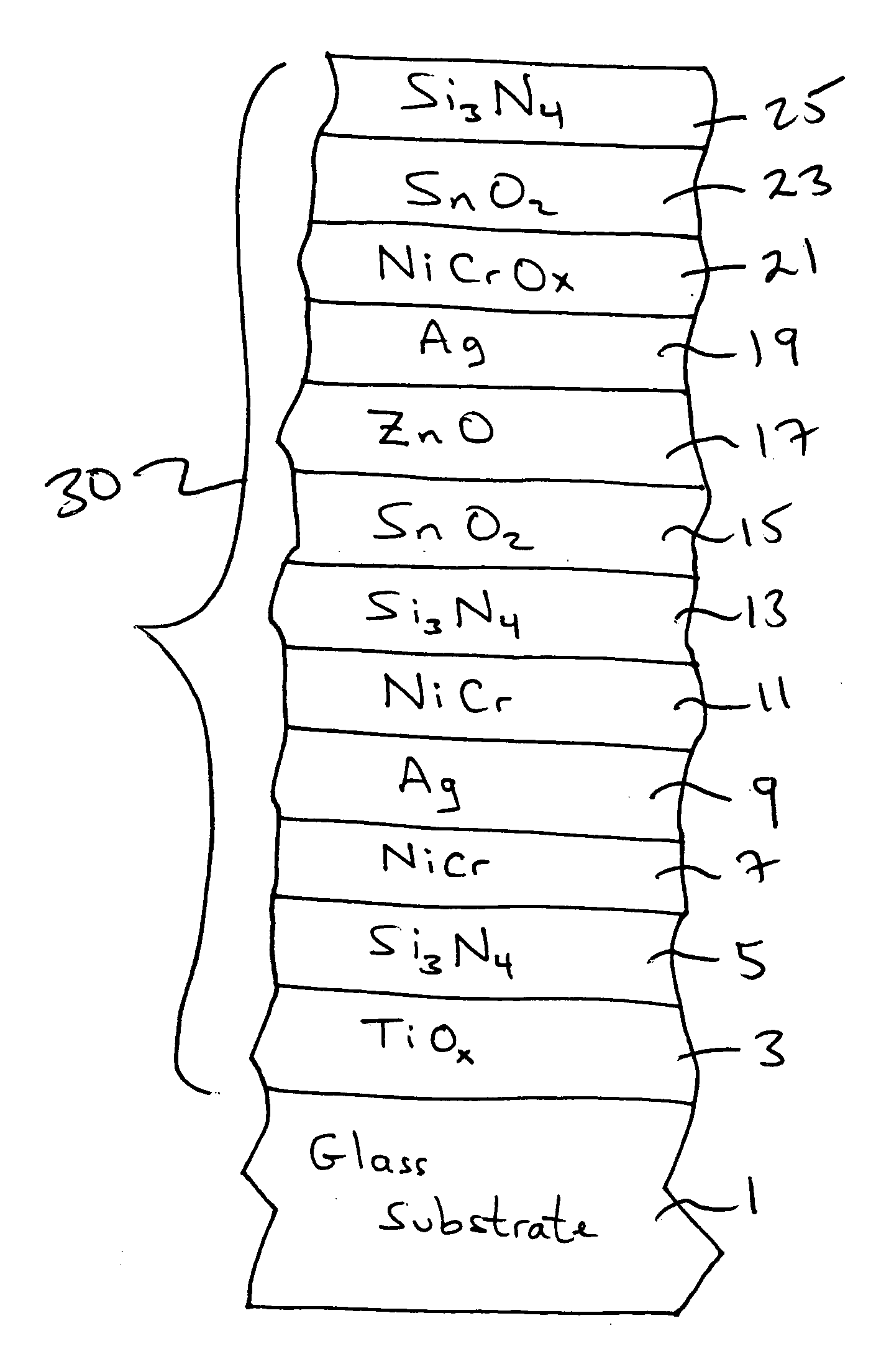

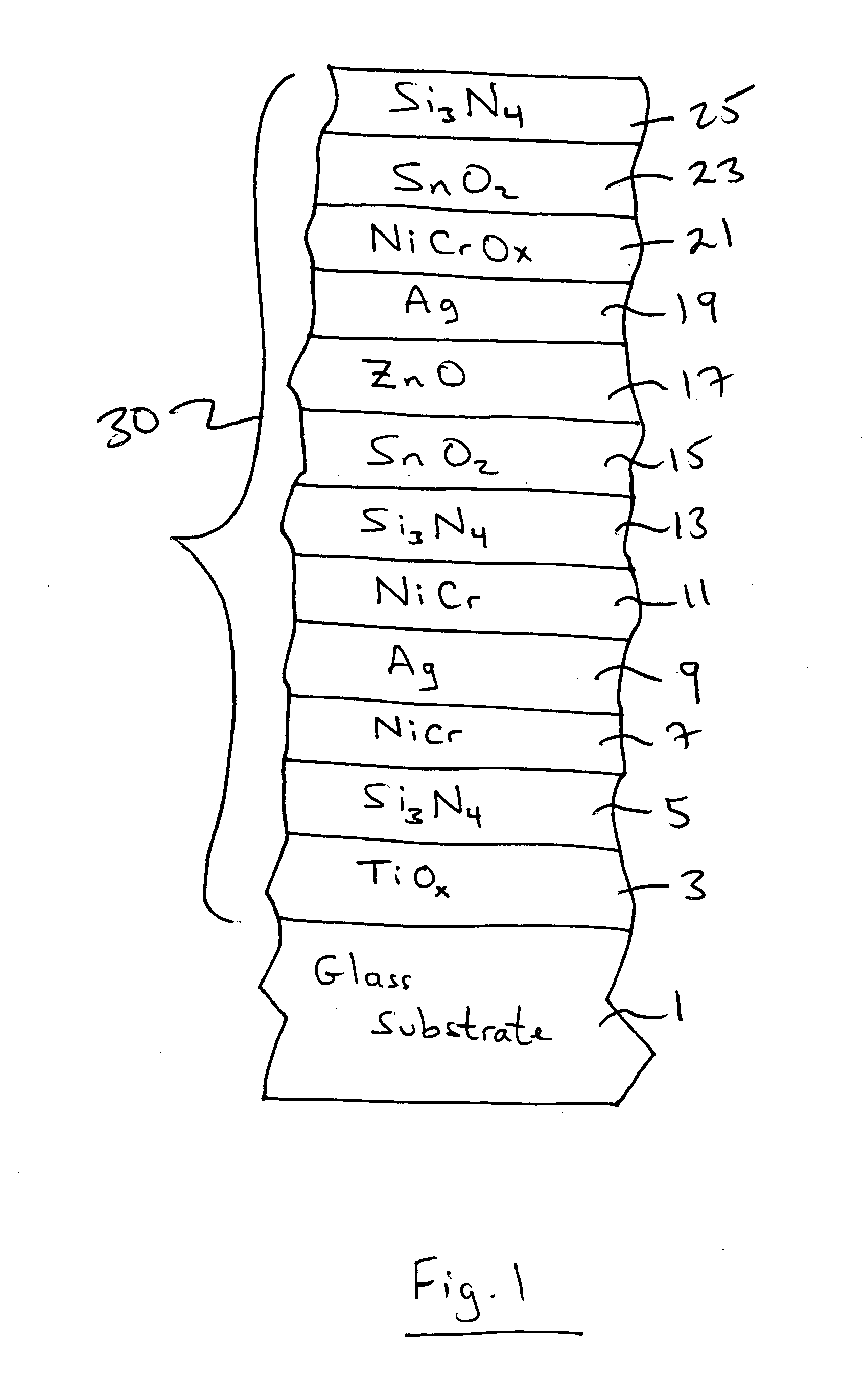

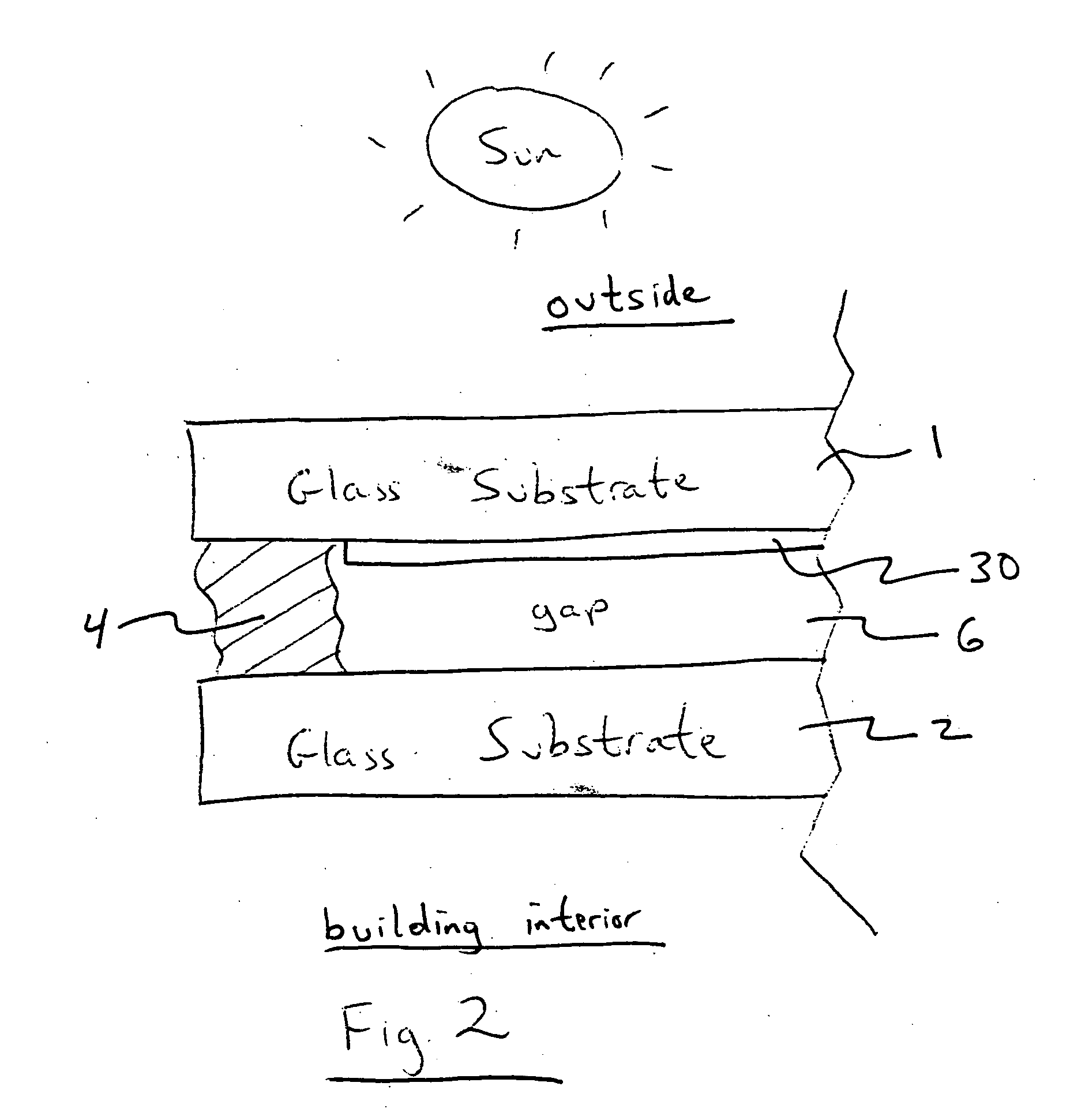

Coated article with low-E coating including IR reflecting layer(s) and corresponding method

ActiveUS7189458B2High selectivitySolution value is not highGlass/slag layered productsCoatingsLow emissivityRadiance

A coated article is provided with a low-emissivity (low-E) layer stack for use in a window unit or the like. The layer stack, or coating, may permit the coated article to achieve one or more of a fairly low solar factor (SF) value, a high selectivity (Tvis / SF) value, substantially neutral color at normal and / or off-axis viewing angles, and / or low emissivity. When high selectivity values are achieved, there is provided a high ratio of visible transmission to SF, which is a desirable feature in certain example instances. In certain example embodiments, a sub-oxide layer (e.g., NiCrOx) may be used as a contact layer under an infrared (IR) reflecting layer in order to permit low SF values, high selectivity, and good coloration to be achieved.

Owner:GUARDIAN GLASS LLC +1

Coated article with low-E coating including IR reflecting layer(s) and corresponding method

InactiveUS7198851B2High selectivityIncrease valueGlass/slag layered productsCoatingsLow emissivityRadiance

A coated article is provided with a low-emissivity (low-E) layer stack for use in a window unit or the like. The layer stack, or coating, may permit the coated article to achieve one or more of a low solar factor (SF) value, a high selectivity (Tvis / SF) value, substantially neutral color at normal and / or off-axis viewing angles, and / or low emissivity. When high selectivity values are achieved, there is provided a high ratio of visible transmission to SF, which is a desirable feature in certain example instances. In certain example embodiments, a sub-oxide layer may be used as a contact layer under an infrared (IR) reflecting layer in order to permit low SF values, high selectivity, and good coloration to be achieved.

Owner:GUARDIAN GLASS LLC +1

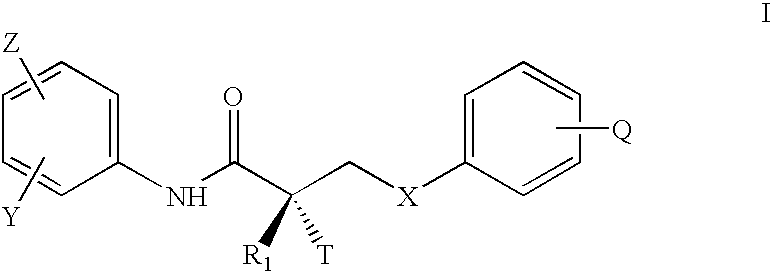

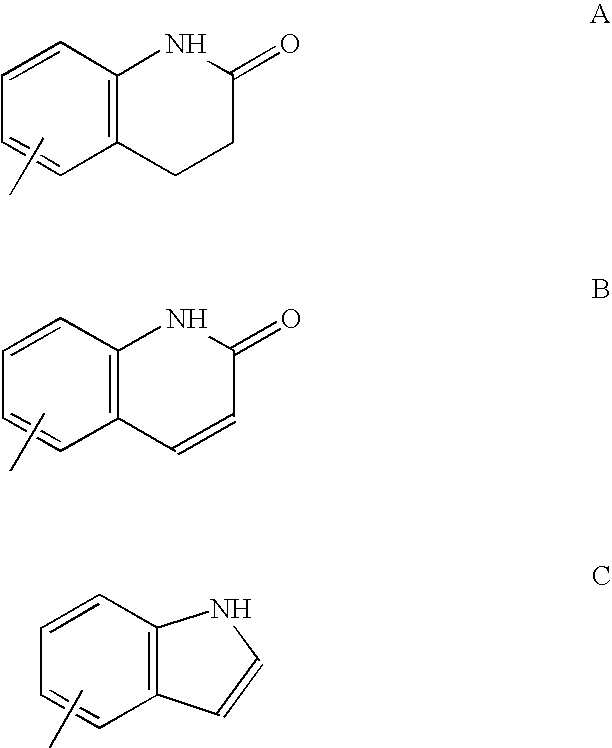

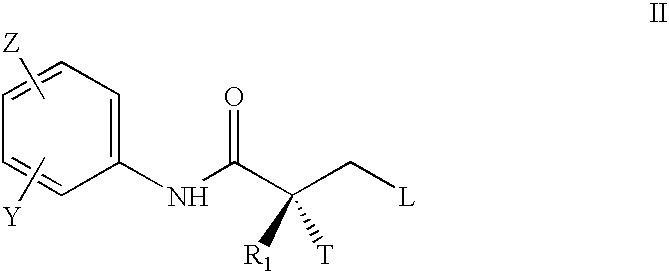

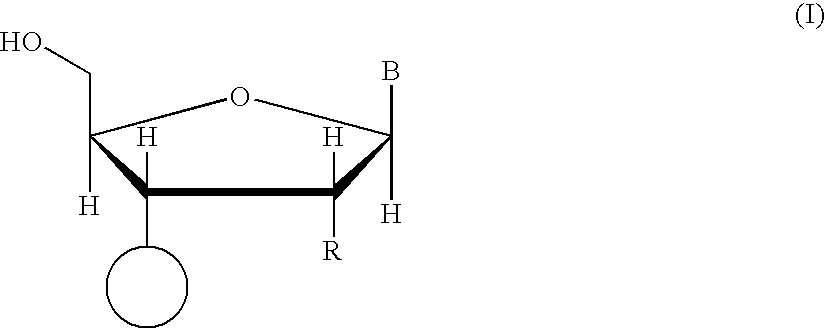

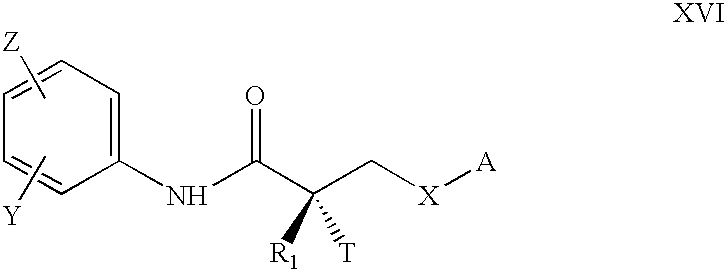

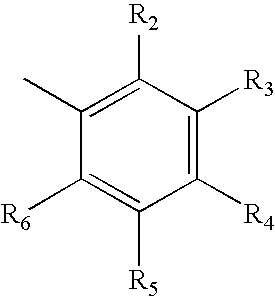

Synthesis of selective androgen receptor modulators

InactiveUS6995284B2Decreased libidoAlteration in mood and cognitionOrganic active ingredientsCarbamic acid derivatives preparationAging maleProstate cancer incidence

The present invention relates to a synthetic process for the preparation of a novel class of androgen receptor targeting agents (ARTA) which demonstrate androgenic and anabolic activity of a nonsteroidal ligand for the androgen receptor. The agents define a new subclass of compounds which are selective androgen receptor modulators (SARM) which are useful for a) male contraception; b) treatment of a variety of hormone-related conditions, for example conditions associated with Androgen Decline in Aging Male (ADAM), such as fatigue, depression, decreased libido, sexual dysfunction, erectile dysfunction, hypogonadism, osteoporosis, hair loss, anemia, obesity, sarcopenia, osteopenia, osteoporosis, benign prostate hyperplasia, alterations in mood and cognition and prostate cancer; c) treatment of conditions associated with Androgen Decline in Female (ADIF), such as sexual dysfunction, decreased sexual libido, hypogonadism, sarcopenia, osteopenia, osteoporosis, alterations in cognition and mood, depression, anemia, hair loss, obesity, endometriosis, breast cancer, uterine cancer and ovarian cancer; d) treatment and / or prevention of chronic muscular wasting; e) decreasing the incidence of, halting or causing a regression of prostate cancer; f) oral androgen relacement and / or other clinical therpauetic and / or diagnostic areas. The process of the present invention is suitable for large-scale preparation, since all of the steps give rise to highly pure compounds, thus avoiding complicated purification procedures which ultimately lower the yield. Thus the present invention provides methods for the synthesis of non-steroidal agonist compounds, that can be used for industrial large-scale synthesis, and that provide highly pure products in high yield.

Owner:UNIV OF TENNESSEE RES FOUND

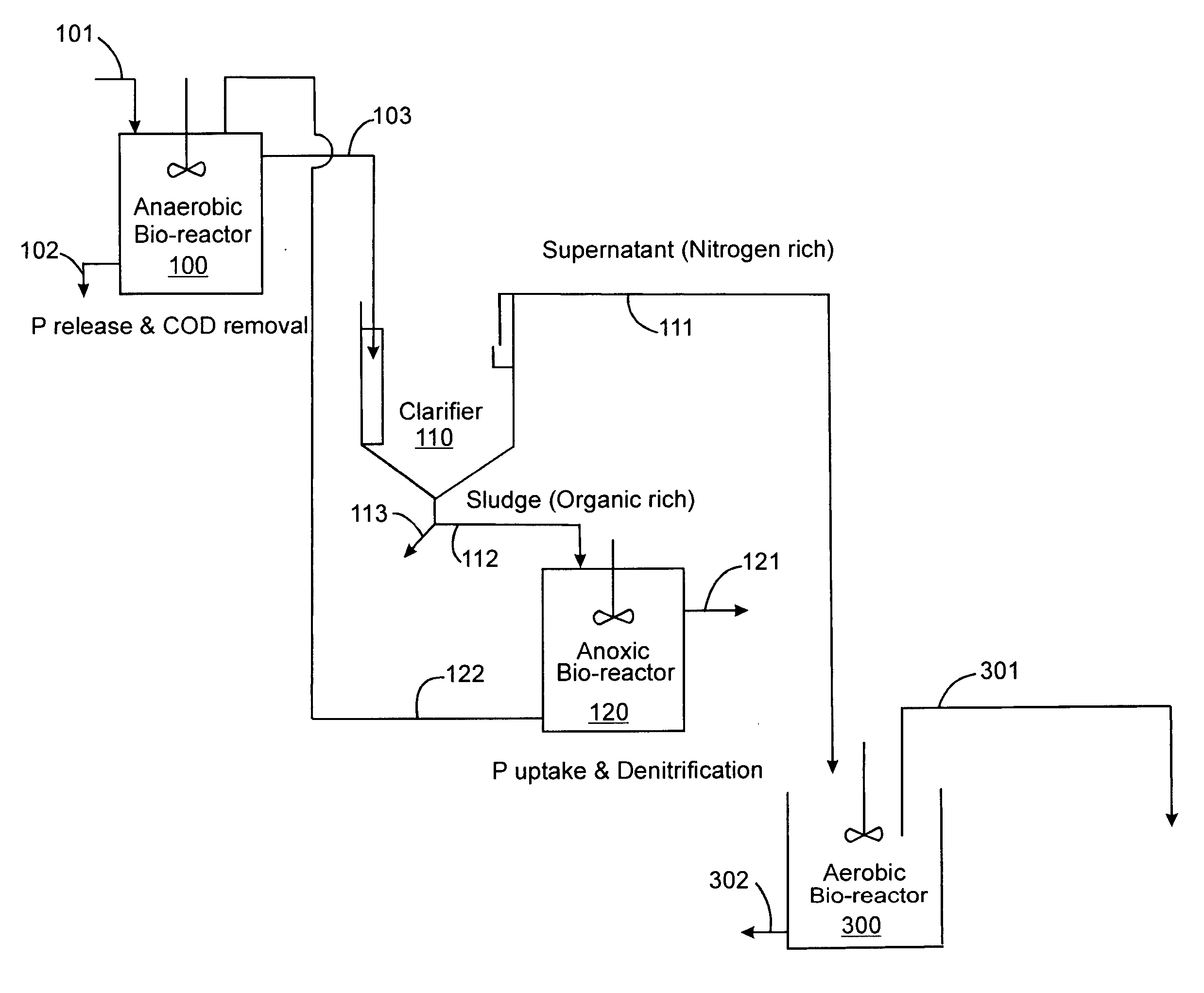

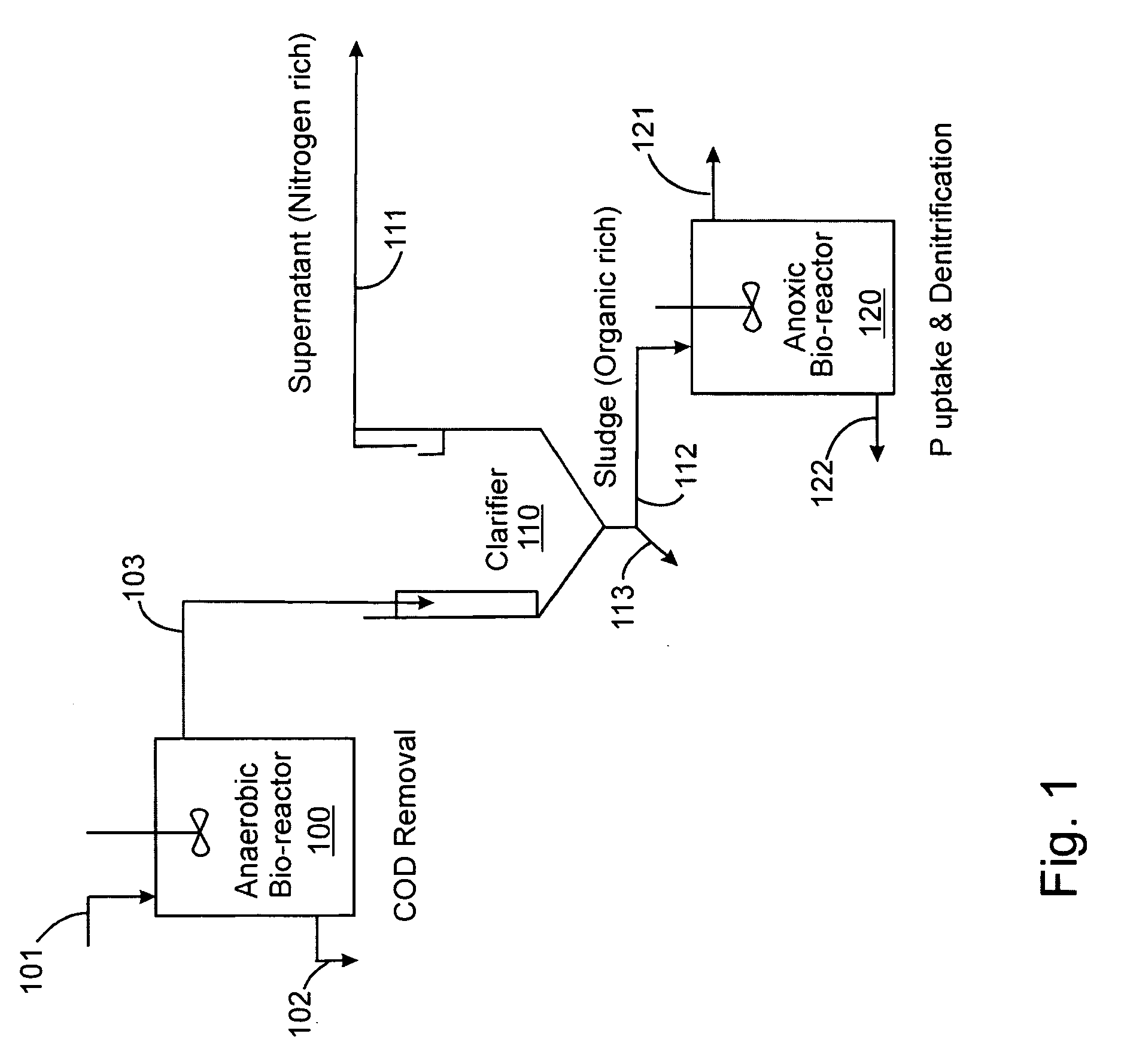

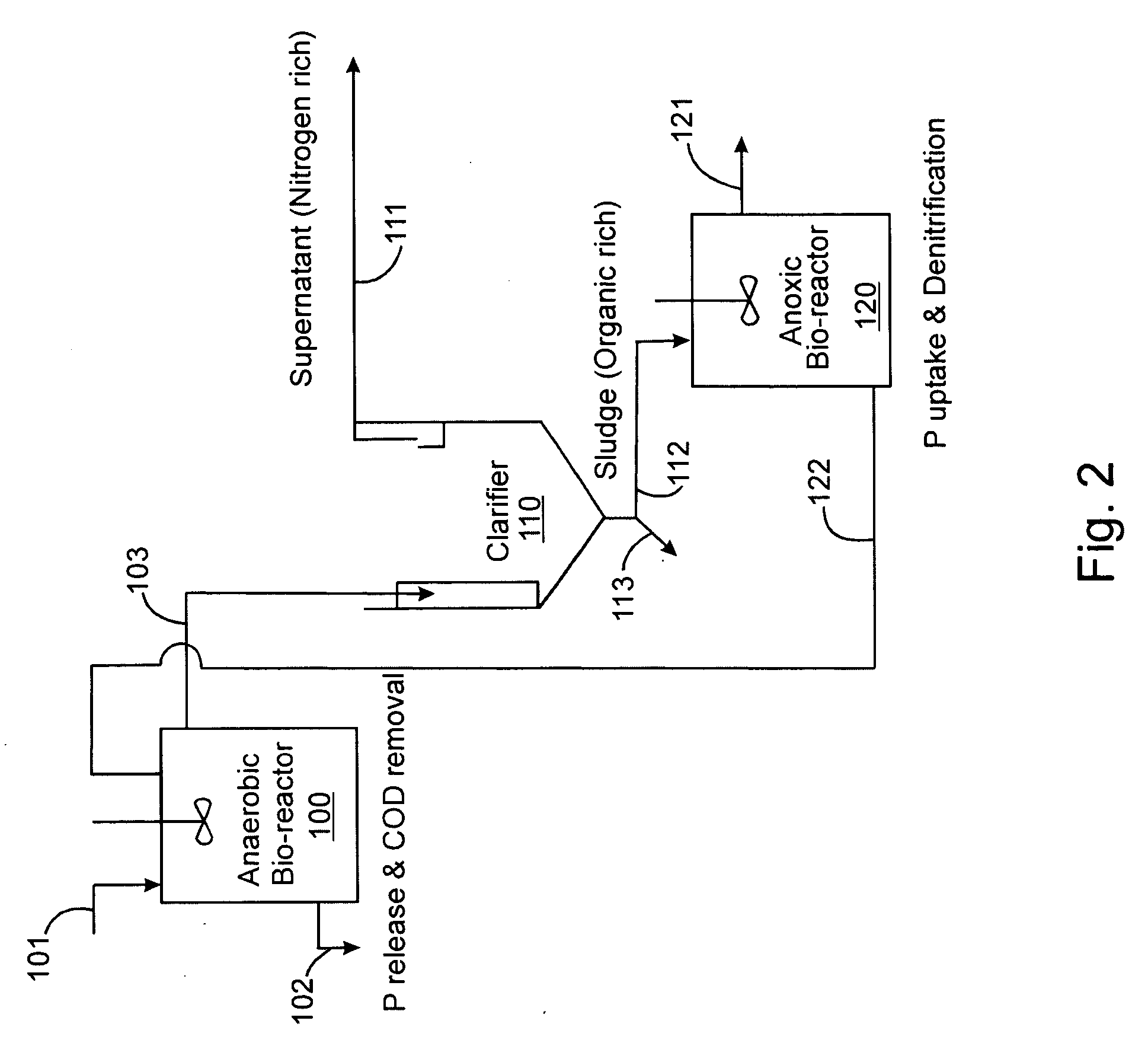

Treatment of wastewater containing phosphorous and nitrogen

InactiveUS20060249449A1Great extent of P releaseHigh P uptakeTreatment using aerobic processesSeparation devicesOxygenClarifier

A method and process for the treatment of wastewater containing phosphorous and nitrogen. The wastewater is first anaerobically treated to produce an anaerobic effluent from which insoluble organic carbon is separated to form a sludge rich in organic carbon that is used as a substrate during anoxic treatment of the wastewater by de-nitrifying phosphorous accumulating organisms (DPAO's) and ordinary de-nitrifying organisms. The separation of insoluble organic carbon is normally conducted using a clarifier located intermediate the anaerobic and anoxic bio-reactors. In one embodiment, the ammonia rich clarifier supernatant is directed to an aerobic reactor for nitrification and the nitrate produced is recycled to the anoxic bio-reactor. The final effluent may be membrane filtered to retain nitrifying biomass within the aerobic bio-reactor. The invention reduces overall hydraulic residence time and sludge volume, which results in a smaller, less expensive wastewater treatment system.

Owner:UNIV OF WESTERN ONTARIO

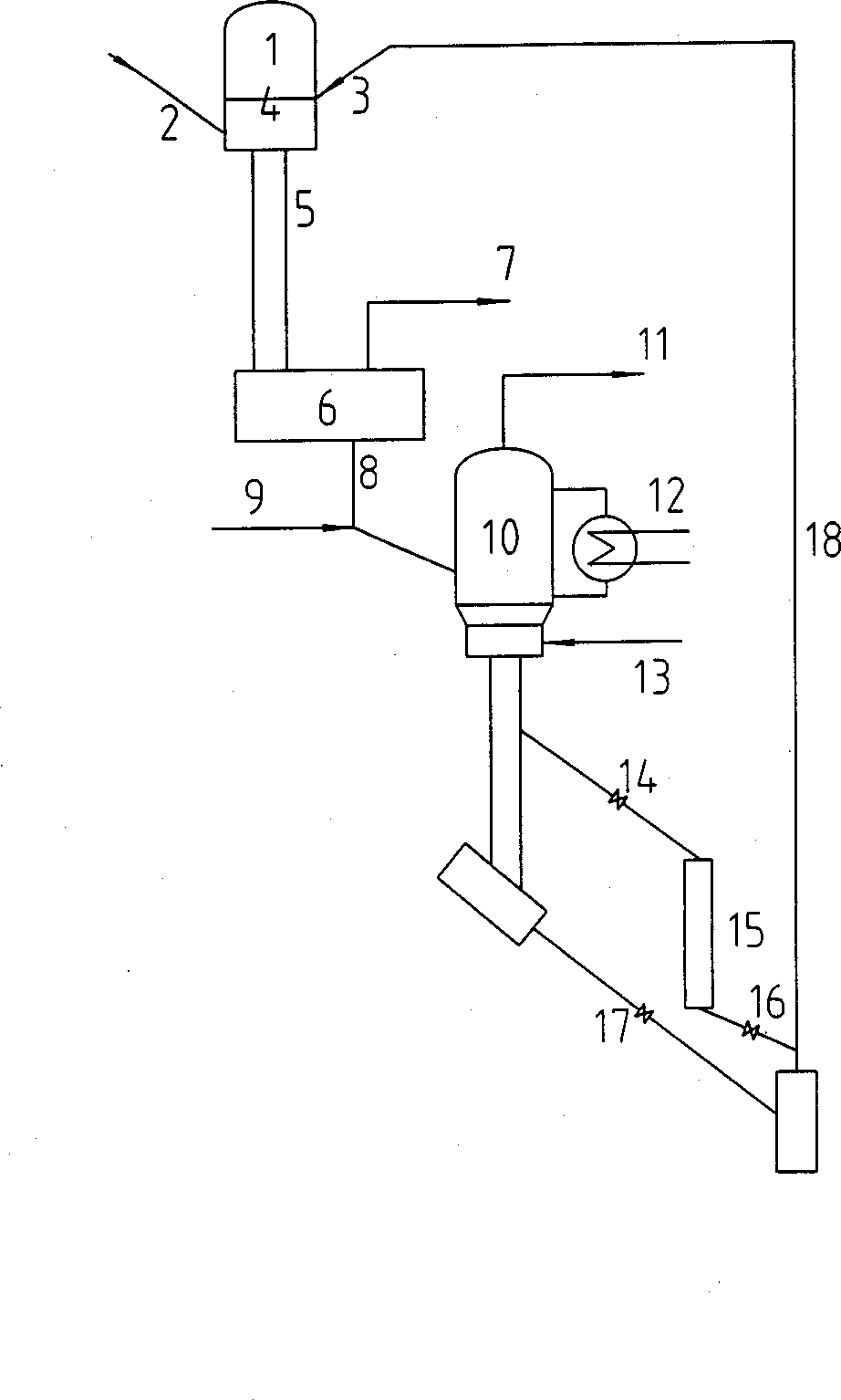

Process and system for preparing low-carbon olefin from methanol or dimethylether

InactiveCN1356299AReduce wearReduce aggregationHydrocarbon from oxygen organic compoundsChemical recyclingAlkaneGas solid

A process for preparing low-carbon olefin from methanol or dimethyl ether includes loading its raw material and silicon aluminium phosphate (SAPO34) molecular sieve as catalyst into gas-solid parallel down-flowing fluidized bed reactor, super-short contact, reaction, fast gas-solid separation to separating resultant from catalyst to prevent secondary reaction, and regerating catalyst for cyclic use. Its advantages include high output rate (93%), high conversion rate of raw material, and less by-product.

Owner:TSINGHUA UNIV

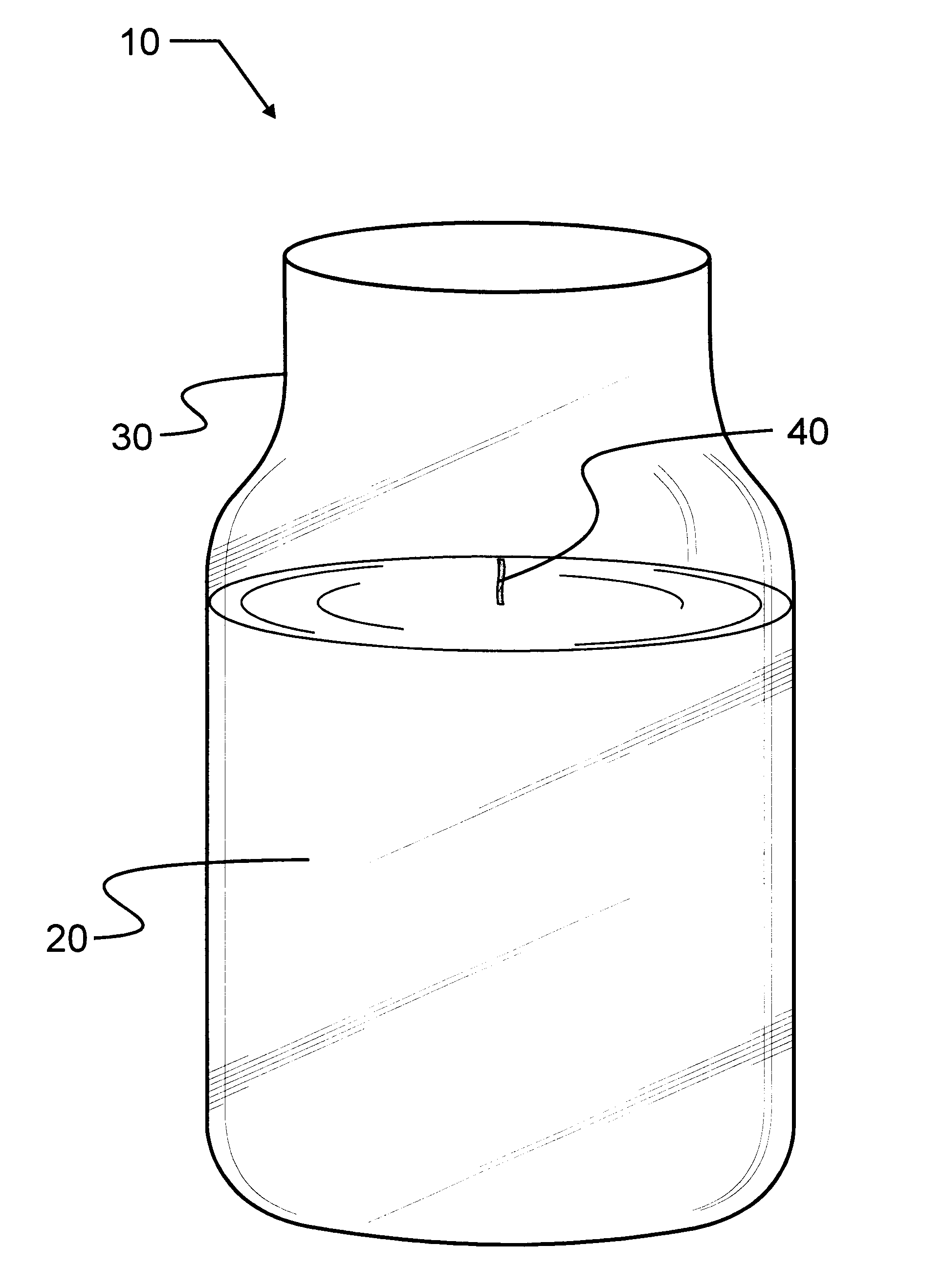

Soybean wax candles

InactiveUS6599334B1Increase profitWithout and crackingSolid fuelsCapillary burnersVegetable oilAlpha-olefin

A solid fuel candle which is highly adapted for use both in a container and also as a free-standing candle includes at least 85 percent hydrogenated soybean oil, approximately 0 to 4 percent synthetic wax composition, approximately 0 to 4 percent of a second hydrogenated vegetable or petroleum oil, approximately 0 to 10 percent fragrance or scent, and approximately 0 to 3 percent dye. The hydrogenated vegetable oil most preferably has an iodine value of approximately 50 and a melting point of approximately 125 degrees Fahrenheit, with a free fatty acid content of less than one-tenth of one percent. The synthetic wax composition is most preferably formed from alpha olefin monomers and oligomers under free radical conditions at relatively low pressures to yield a highly branched polymer wax having congealing and melting points lower than the starting alpha olefin material and a higher molecular weight.

Owner:ANDERSON JILL M

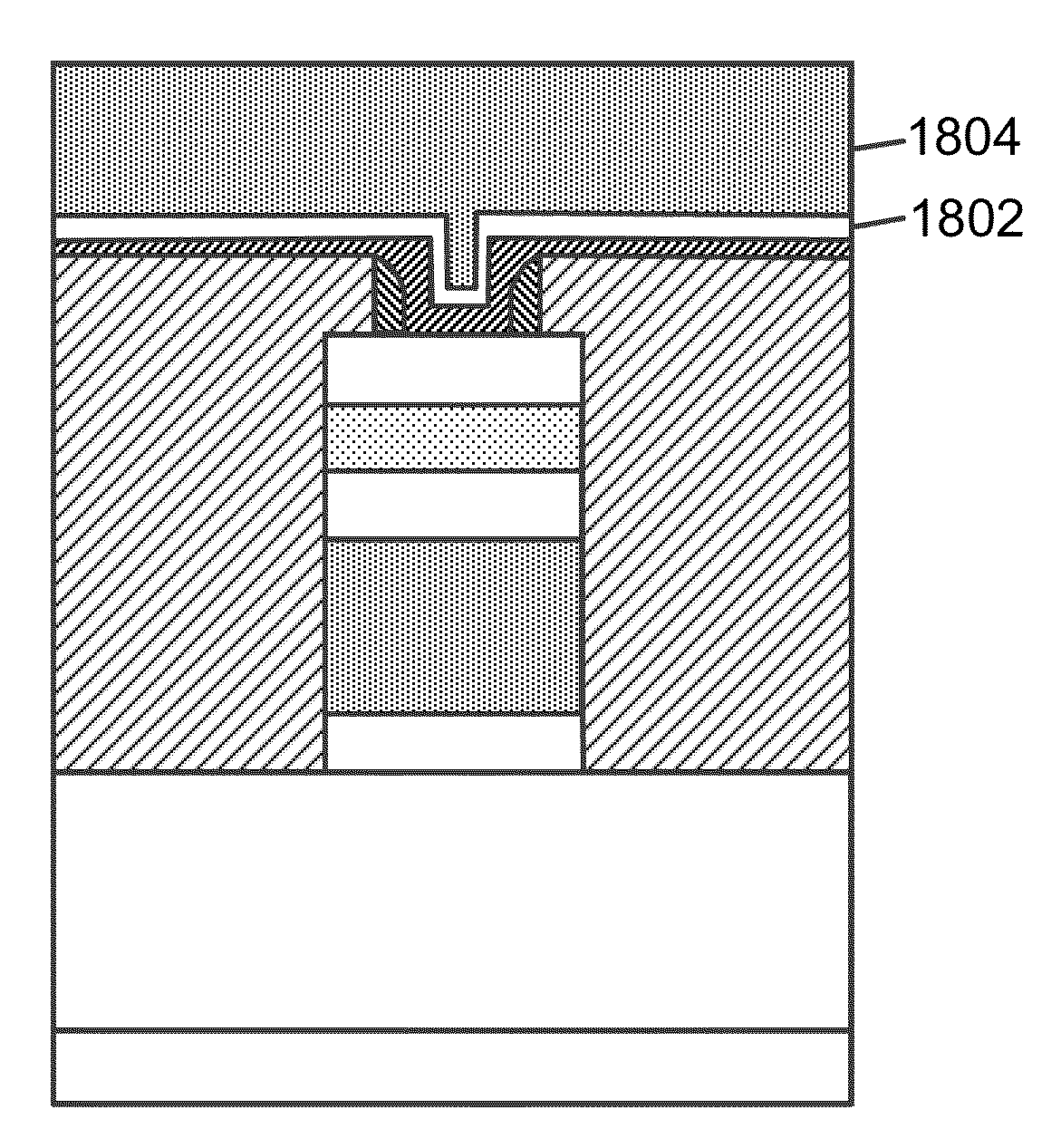

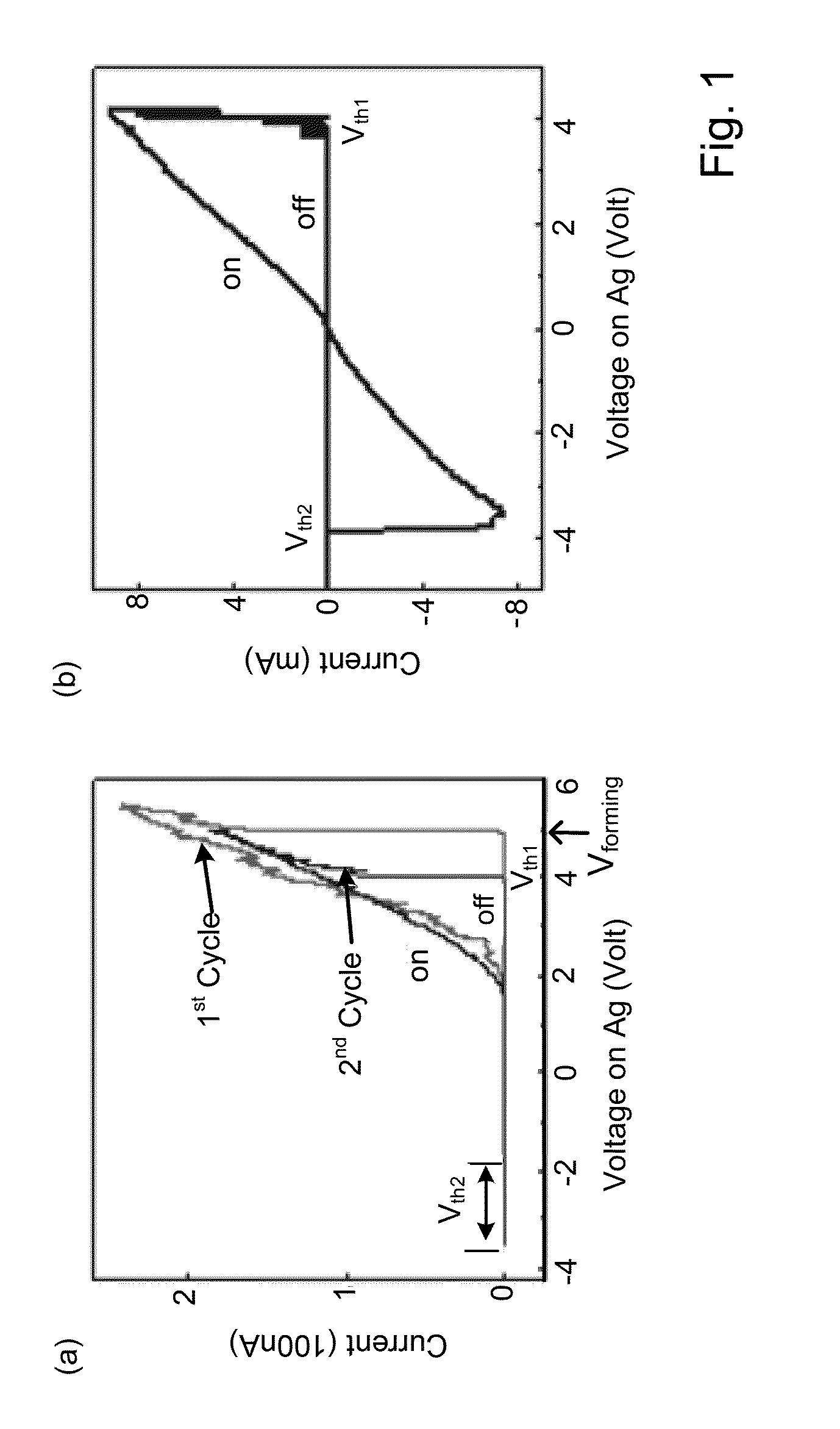

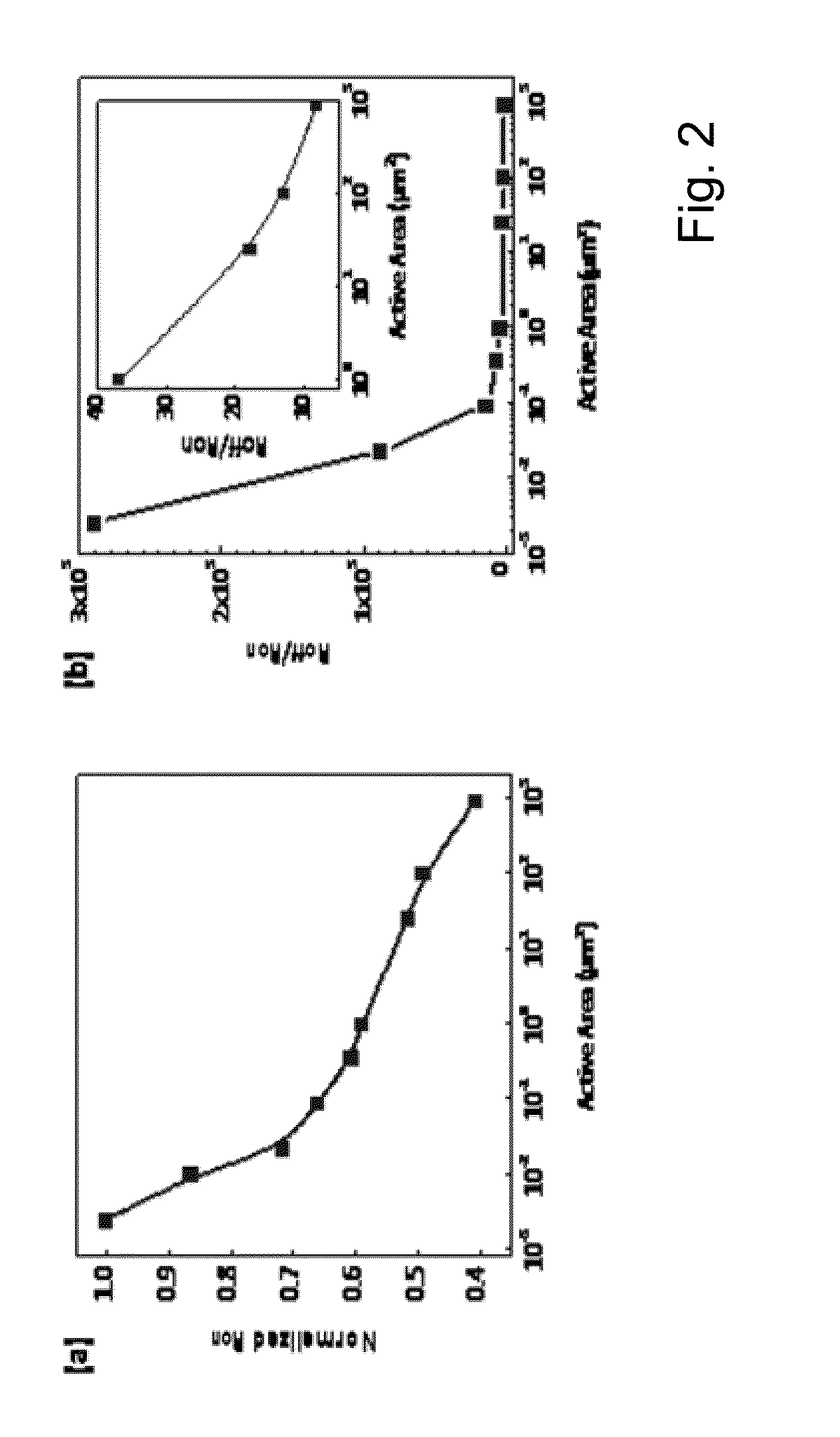

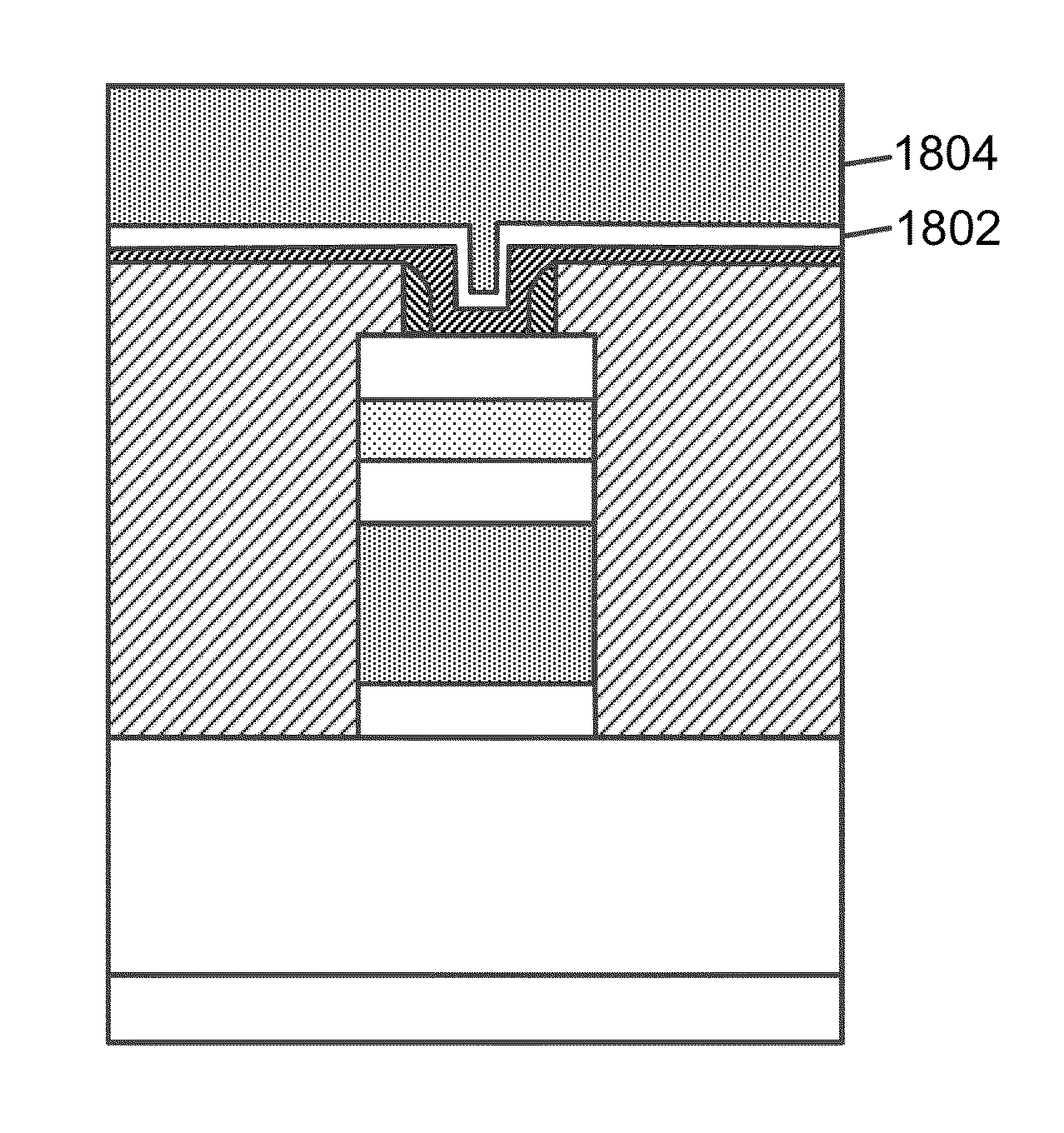

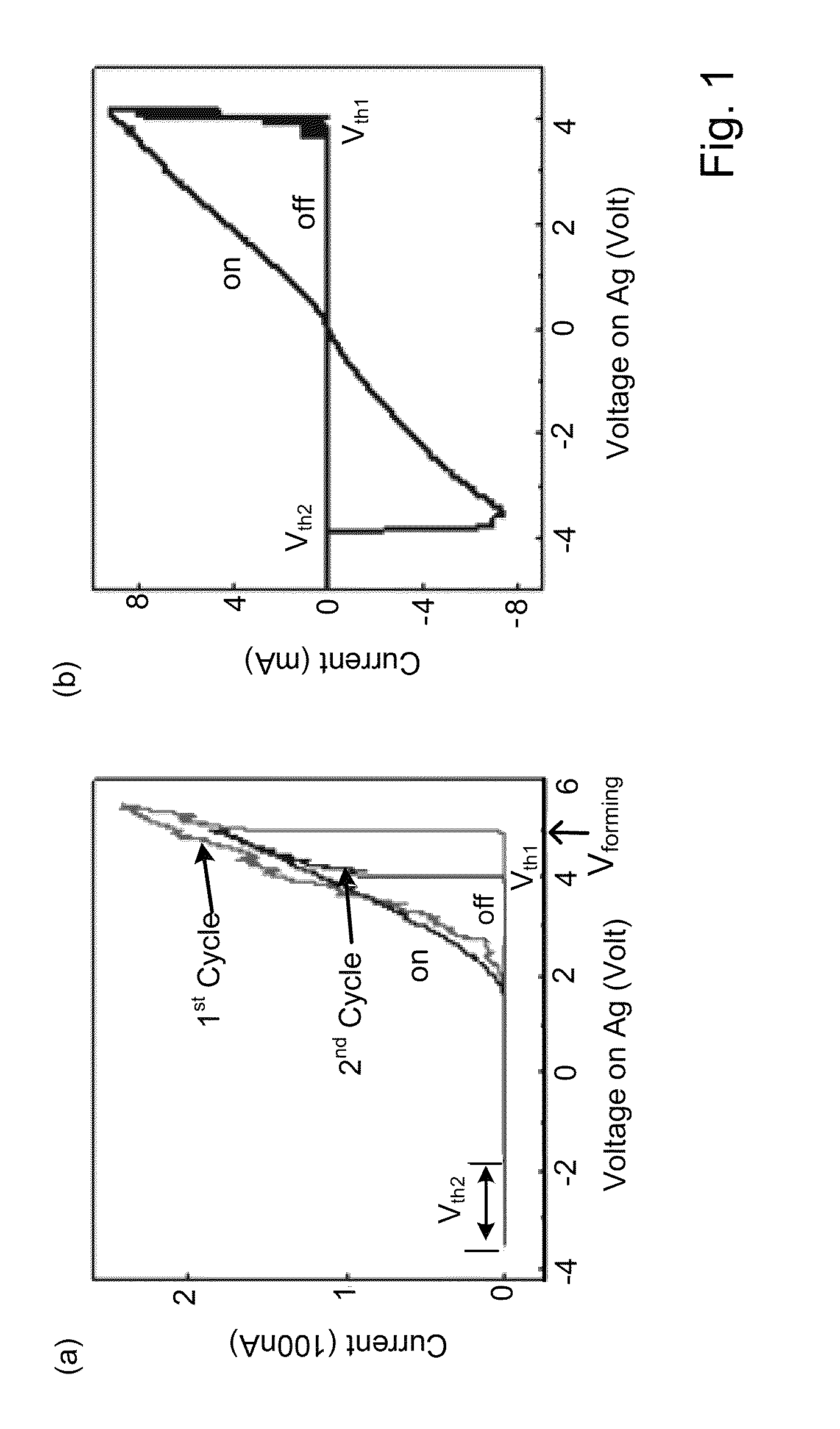

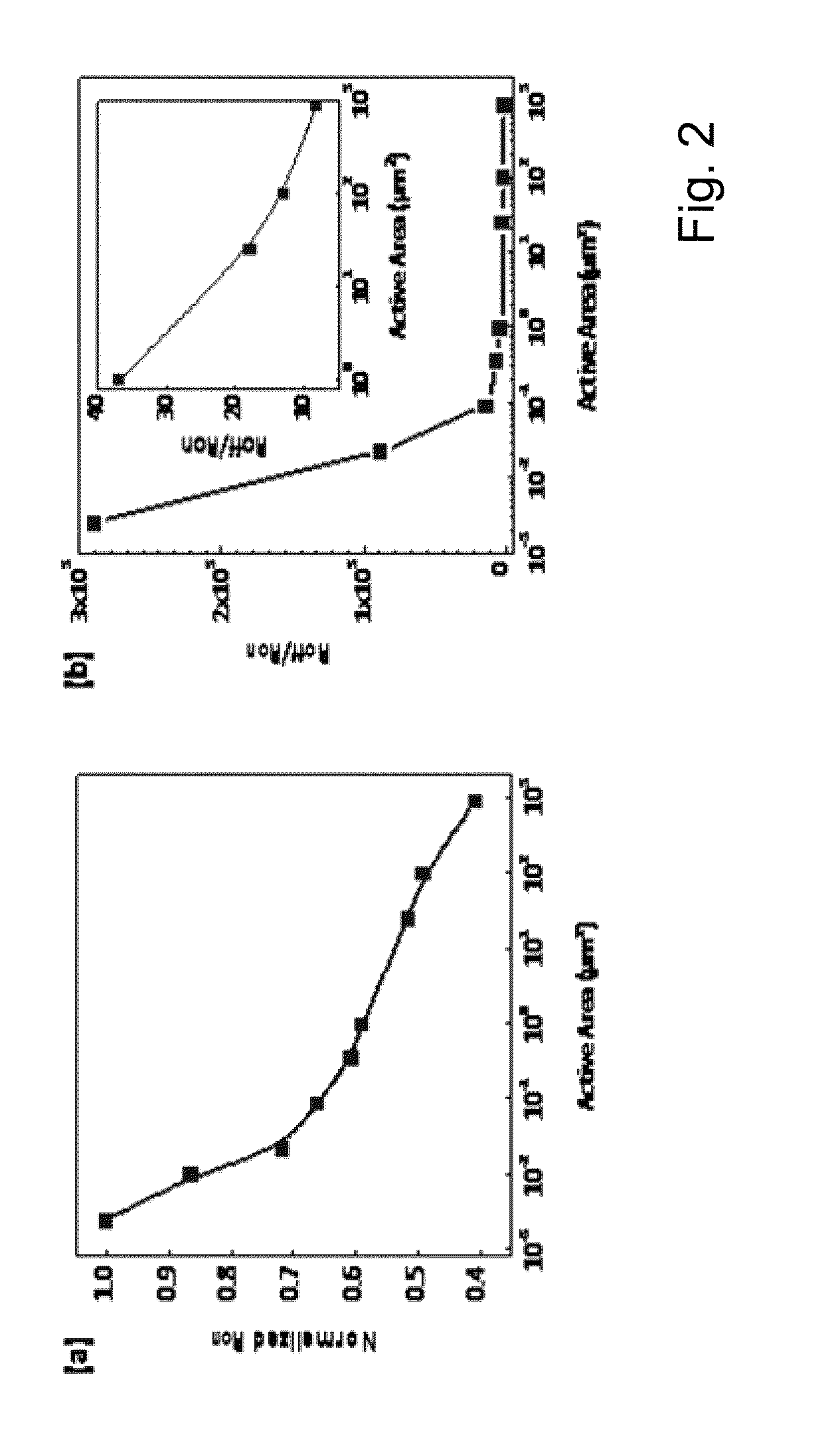

Improved on/off ratio for non-volatile memory device and method

ActiveUS20120012806A1Quick switchWide rangeSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesSwitched currentEngineering

This application describes a method of forming a switching device. The method includes forming a first dielectric material overlying a surface region of a substrate. A bottom wiring material is formed overlying the first dielectric material and a switching material is deposited overlying the bottom wiring material. The bottom wiring material and the switching material is subjected to a first patterning and etching process to form a first structure having a top surface region and a side region. The first structure includes at least a bottom wiring structure and a switching element having a top surface region including an exposed region of the switching element. A second dielectric material is formed overlying at least the first structure including the exposed region of the switching element. The method forms a first opening region in a portion of the second dielectric layer to expose a portion of the top surface region of the switching element. A dielectric side wall structure is formed overlying a side region of the first opening region. A top wiring material including a conductive material is formed overlying at lease the top surface region of the switching element such that the conductive material is in direct contact with the switching element. The side wall spacer reduces a contact area for the switching element and the conductive material and thus a reduced active device area for the switching device. In a specific embodiment, the reduced area provides for an increase in device ON / OFF current ratio.

Owner:CROSSBAR INC

Cracking catalyst

This invention published a fluidization cracking catalyst. The main components of the catalyst are 5~70% (w / w) cracked active component, 5~80%clay and 10~60%agglomerant. Y-type of molecular sieve and 3~20% sialic material which based on catalyst and had been acidized within the cracked active component is the characteristic of the catalyst. The sialic material has a phase structure as thin diaspore. Its formula (calculated by weight of oxidants) is (0-0.3) Na2O . (40-90) Al2O3 . (10-60) SiO2. It has specific area 200~400m2 / g, average aperture 8~20nm, most probable aperture 5~15nm.The acidification treatment mentioned was inorganic acid and sialic material (ratio of the tow: 0.1~0.3) kept contacting for 0.5~3h under room-temperature ~80DEG C.This catalyst has well intensity, high stability of activity, low yield of heavy oil and strong capability of conversion for crude oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

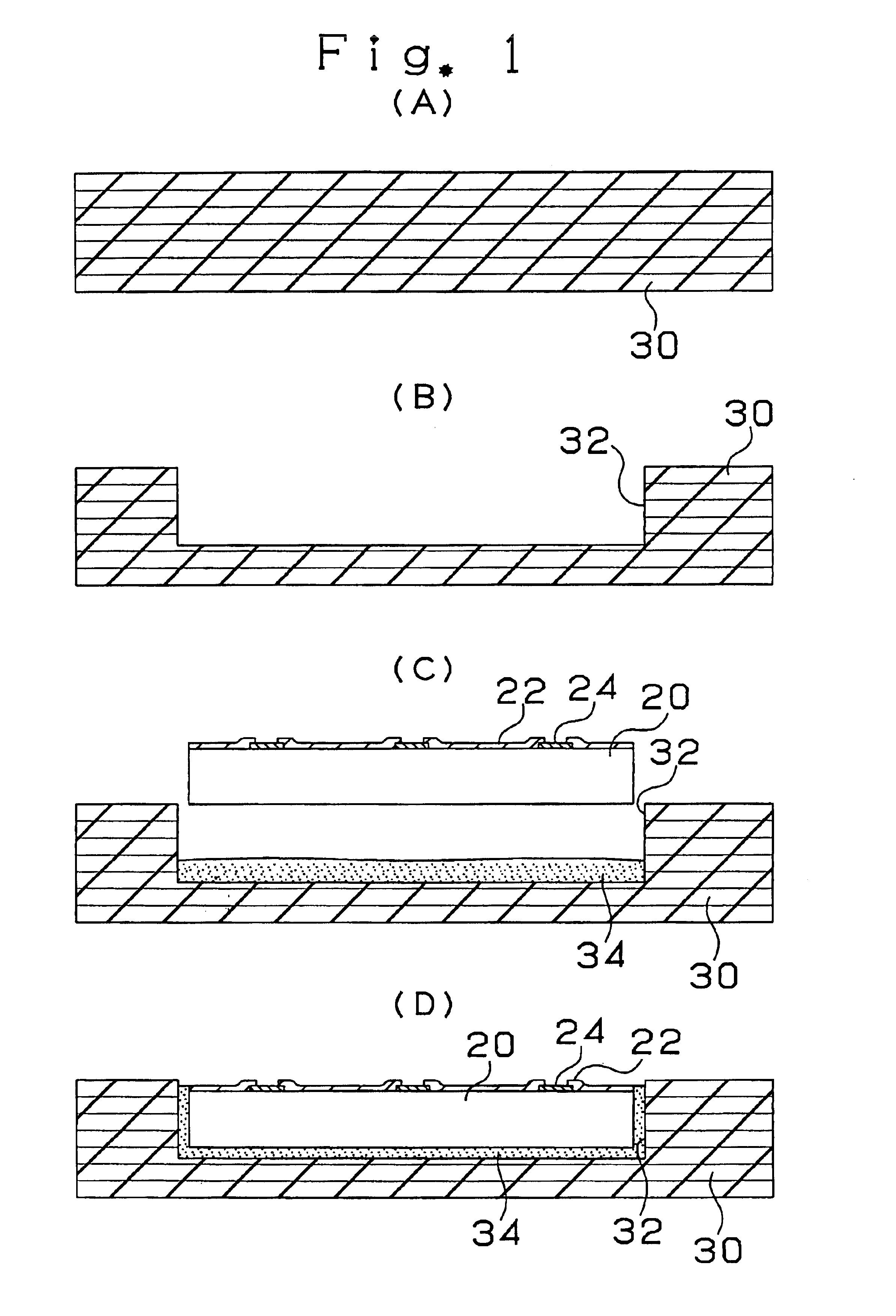

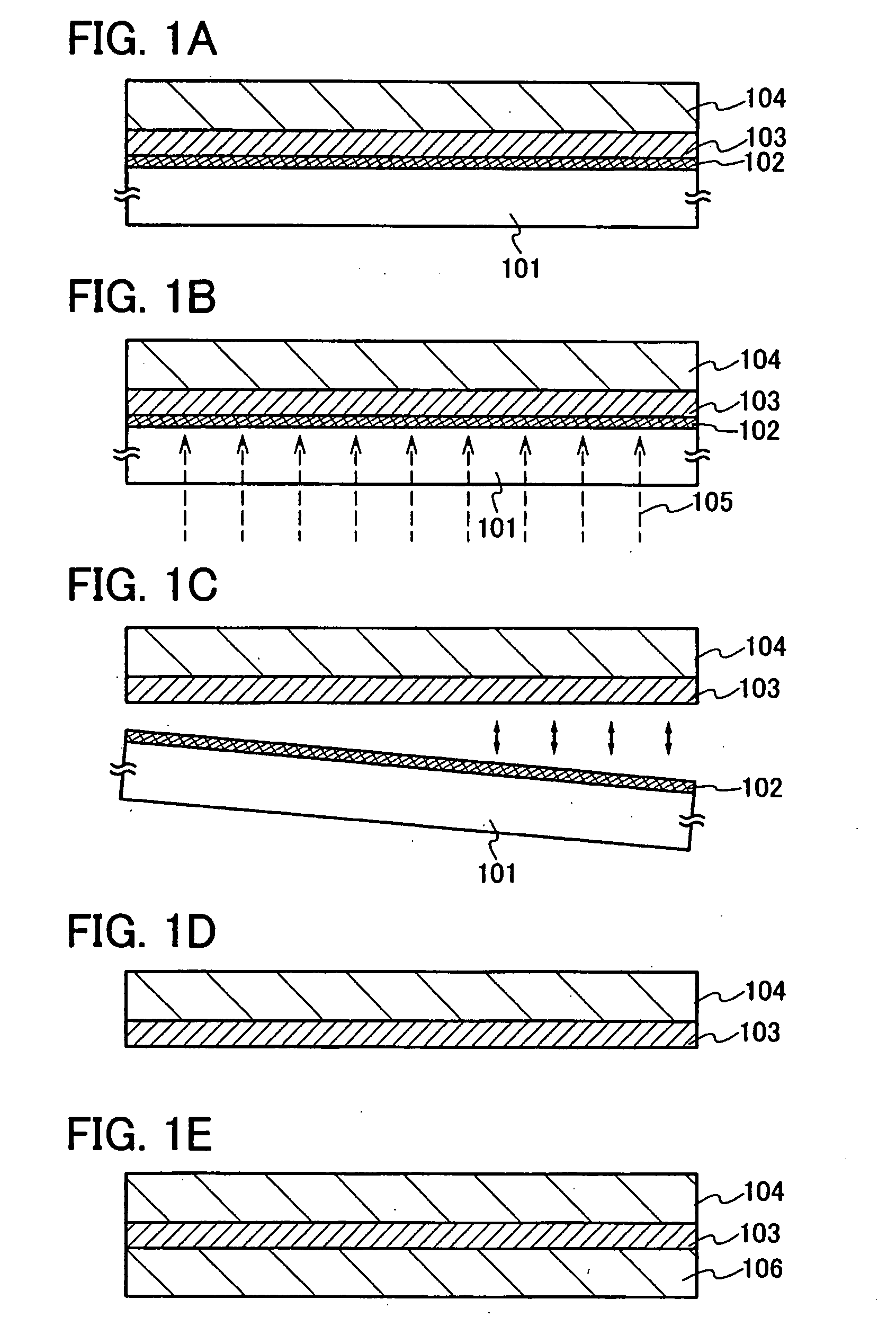

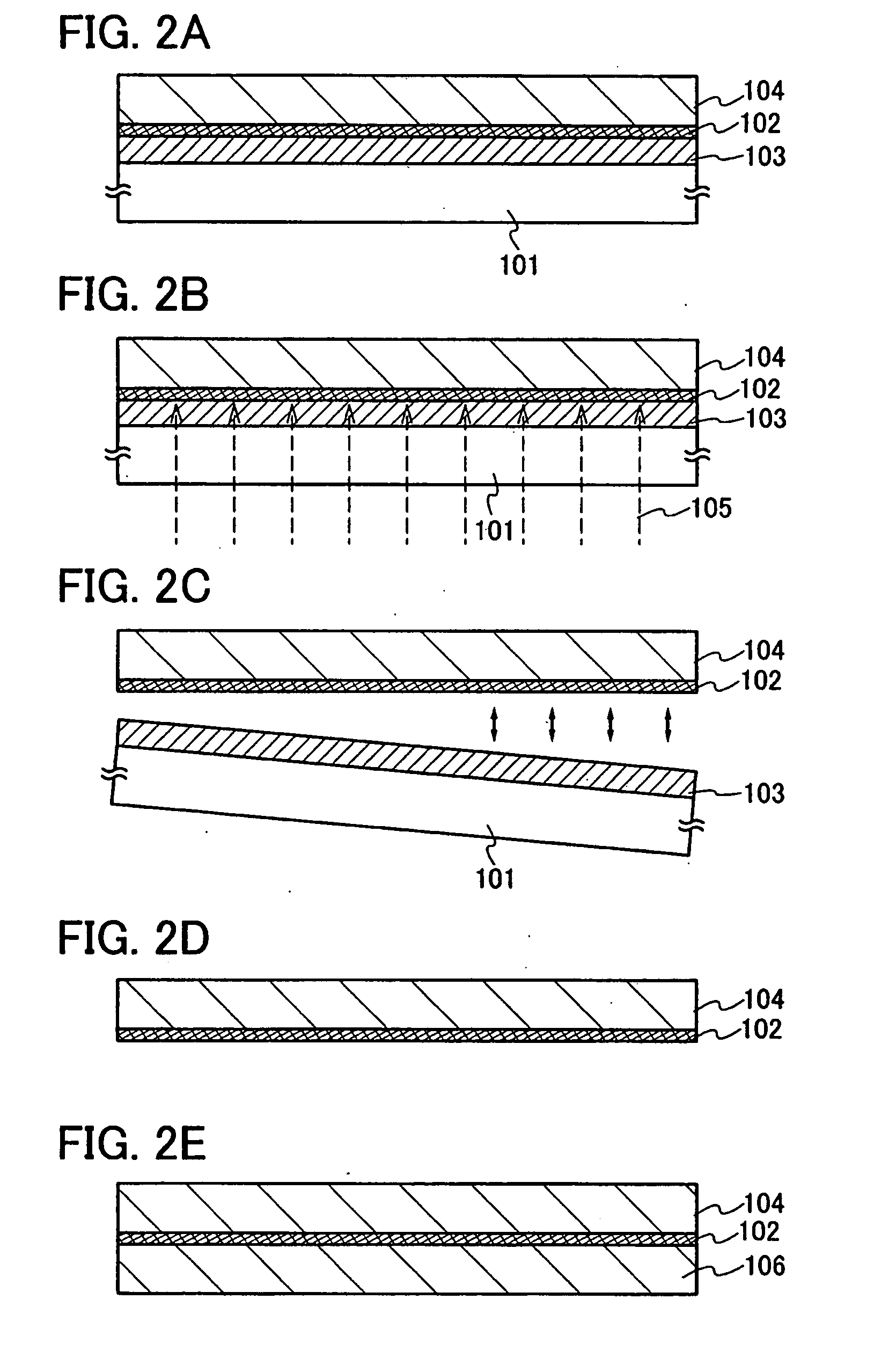

Method for manufacturing semiconductor device

InactiveUS20070207571A1Easy to manufactureHigh energyFinal product manufactureSolid-state devicesOrganic compoundSemiconductor

A method for manufacturing a semiconductor device includes: forming a photocatalytic layer and an organic compound layer in contact with the photocatalytic layer over a substrate having a light transmitting property; forming an element forming layer over the substrate having the light transmitting property with the photocatalytic layer and the organic compound layer in contact with the photocatalytic layer interposed therebetween; and separating the element forming layer from the substrate having the light transmitting property after the photocatalytic layer is irradiated with light through the substrate having the light transmitting property.

Owner:SEMICON ENERGY LAB CO LTD

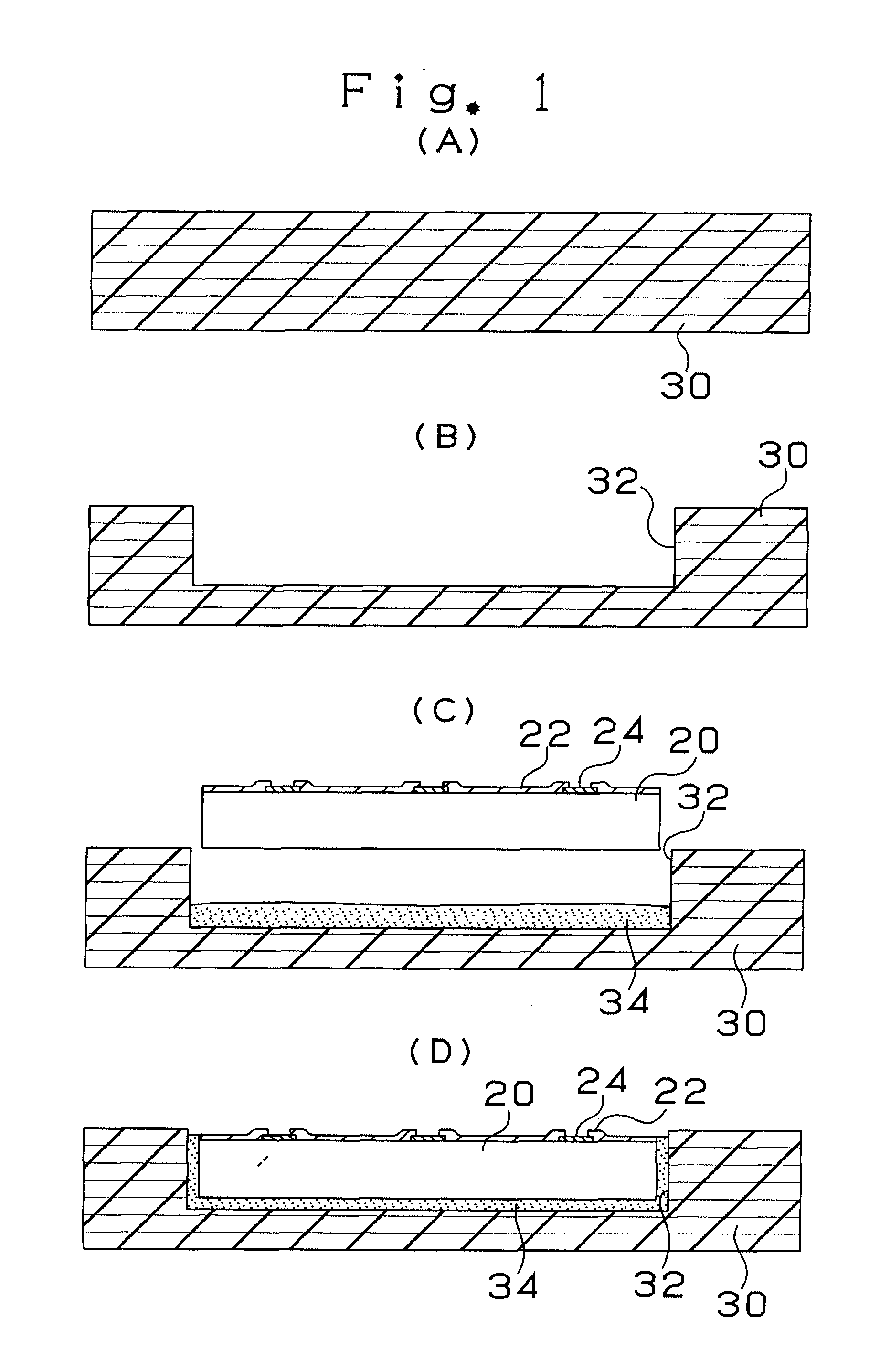

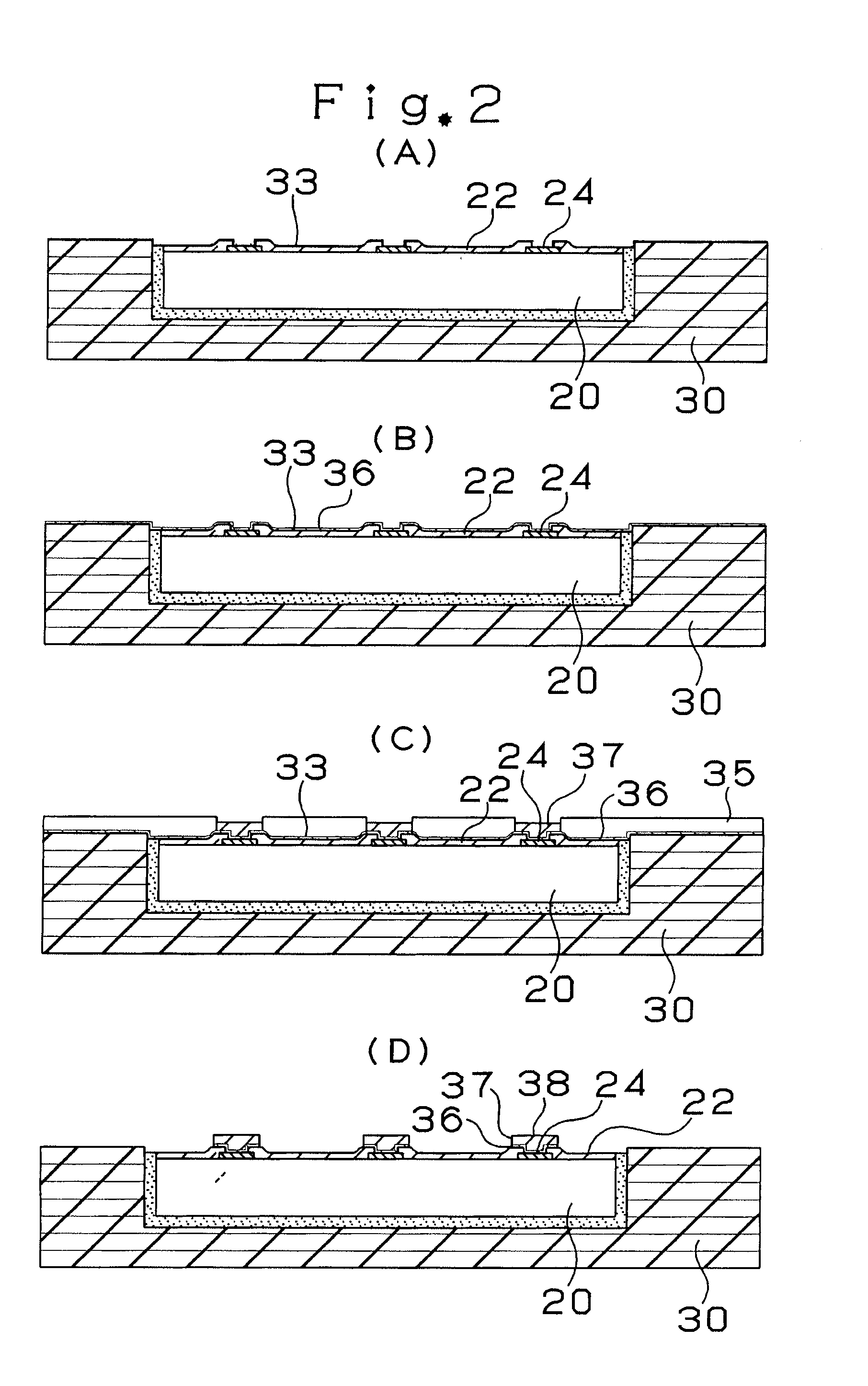

Multilayer printed circuit board and multilayer printed circuit board manufacturing method

InactiveUS20070227765A1Low yieldWithout usingPrinted electric component incorporationSemiconductor/solid-state device detailsCopperPrinted circuit board

A multilayer printed circuit board has an IC chip 20 included in a core substrate 30 in advance and a transition layer 38 provided on a pad 24 of the IC chip 20. Due to this, it is possible to electronically connect the IC chip to the multilayer printed circuit board without using lead members and a sealing resin. Also, by providing the transition layer 38 made of copper on the die pad 24, it is possible to prevent resin residues on the pad 24 and to improve connection characteristics between the pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

On/off ratio for non-volatile memory device and method

ActiveUS8168506B2Improve switching characteristicsLow yieldSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesPower flowConductive materials

This application describes a method of forming a switching device. The method includes forming a first dielectric material overlying a surface region of a substrate. A bottom wiring material is formed overlying the first dielectric material and a switching material is deposited overlying the bottom wiring material. The bottom wiring material and the switching material is subjected to a first patterning and etching process to form a first structure having a top surface region and a side region. The first structure includes at least a bottom wiring structure and a switching element having a top surface region including an exposed region of the switching element. A second dielectric material is formed overlying at least the first structure including the exposed region of the switching element. The method forms a first opening region in a portion of the second dielectric layer to expose a portion of the top surface region of the switching element. A dielectric side wall structure is formed overlying a side region of the first opening region. A top wiring material including a conductive material is formed overlying at lease the top surface region of the switching element such that the conductive material is in direct contact with the switching element. The side wall spacer reduces a contact area for the switching element and the conductive material and thus a reduced active device area for the switching device. In a specific embodiment, the reduced area provides for an increase in device ON / OFF current ratio.

Owner:CROSSBAR INC

Thin film photovoltaic structure

InactiveUS20070277875A1Improve conversion efficiencyWide range of designsPhotovoltaic energy generationSemiconductor devicesSingle crystalEngineering

Photovoltaic devices include an insulator structure bonded to an exfoliation layer, preferably of a substantially single-crystal donor semiconductor wafer, and at least one photovoltaic device layer, such as a conductive layer. In a preferred embodiment, a device may include a conductive layer adjacent to the insulator substrate and integral to the exfoliation layer, near the side that faces the insulator substrate, such as between the insulator substrate and the exfoliation layer. In a further preferred embodiment, a device may include a plurality of photovoltaic device layers distal to the insulator substrate and in or on the exfoliation layer, preferably having been epitaxially grown on the exfoliation layer after the exfoliation layer has been anodically bonded to the insulator substrate by means of electrolysis.

Owner:CORNING INC

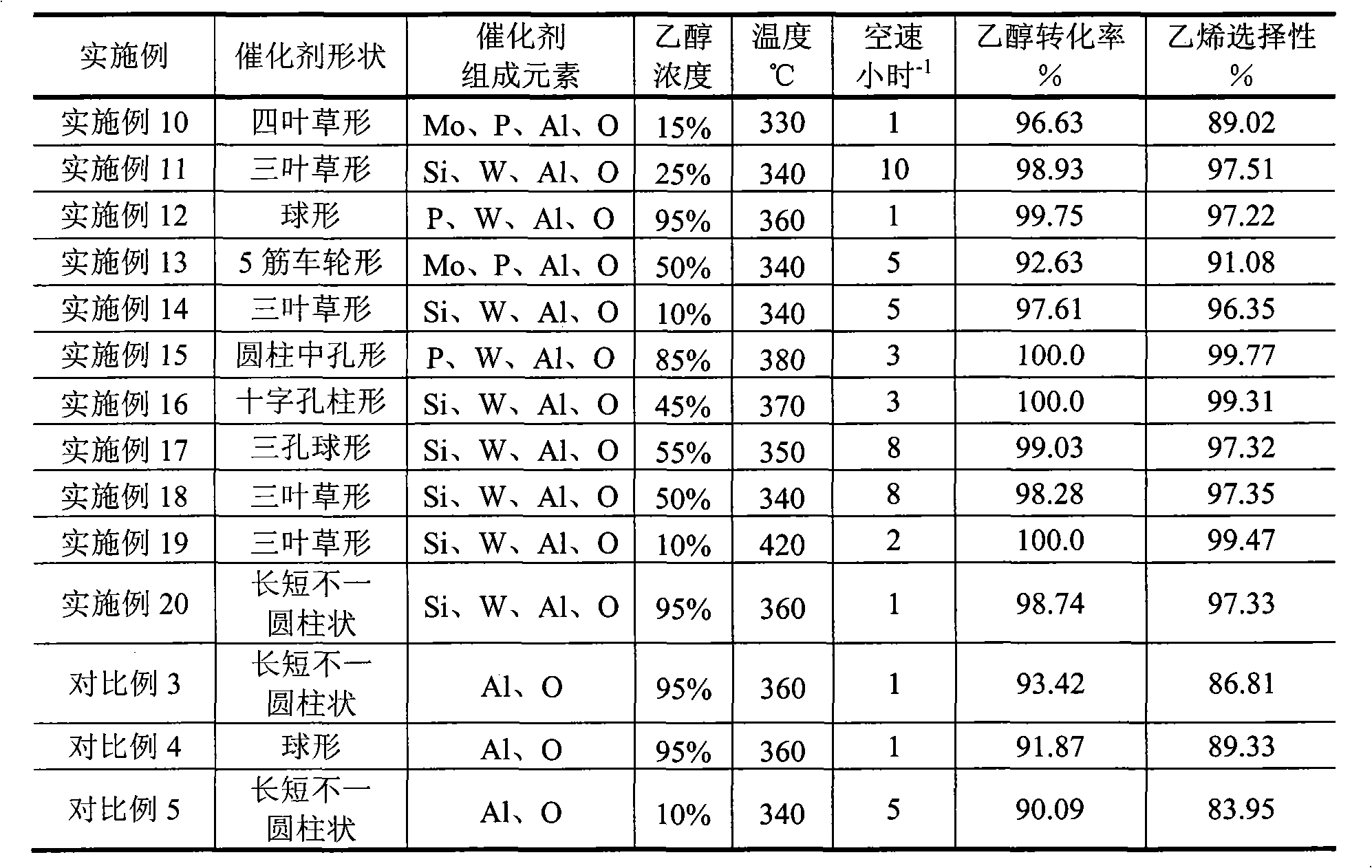

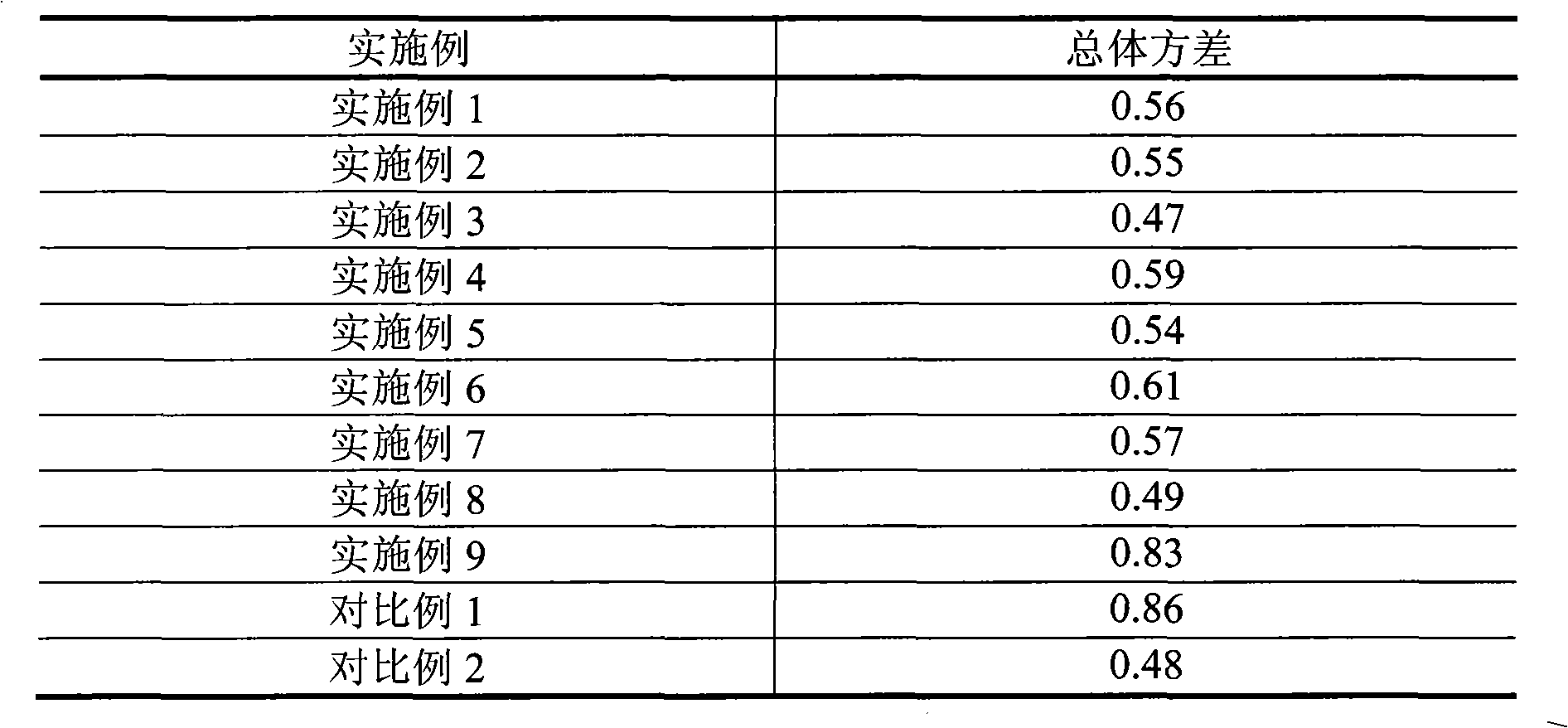

Heteropolyacid modified alumina ethanol dehydration catalyst and preparation method thereof

ActiveCN101940938AIncrease acidityHigh acid strengthCatalyst activation/preparationHydrocarbon from oxygen organic compoundsEthyleneDehydration

The invention relates to a heteropolyacid modified alumina ethanol dehydration catalyst and a preparation method thereof, which mainly solves the problems of high cost of the ethanol dehydration catalyst and low ethylene yield existing in the prior art. The catalyst comprises the following components in part by weight: a) 0.5 to 30 parts of heteropolyacid and b) 70 to 99.5 parts of alumina, wherein the heteropolyacid is at least one selected from HxAB12O40.nH2O or (NH4)mHpAB12O40.nH2O having a keggin structure. The technical scheme solves the problems well and can be used in the industrial production of the preparation of ethylene by ethanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Toner coagulant processes

InactiveUS6416920B1Improve productivityQuality improvementOrganic dyesDevelopersPolymer scienceSilicon oxide

Owner:XEROX CORP

Optimum integration of Fischer-Tropsch synthesis and syngas production

InactiveUS6696501B2High synthetic yieldImprove efficiencyHydrogenHydrocarbon from carbon oxidesSyngasSteam reforming

A method is described for conversion of natural gas or other fossil fuels to higher hydrocarbons, comprising the following steps: a) reaction of natural gas with steam and oxygenic gas in at least one reforming zone in order to produce a synthesis gas consisting primarily of hydrogen and CO, in addition to some carbon dioxide; b) passing said synthesis gas to a Fisher-Tropsch reactor in order to produce a crude synthesis stream consisting of lower hydrocarbons, water and non-converted synthesis gas; c) separation of said crude synthesis stream in a recovery zone, into a crude product stream mainly containing heavier hydrocarbons, a water stream and a tail gas stream mainly containing the remaining constituents; which is charaterized in that the method also comprises the following steps; d) stream reformation of at least part of the tail gas in a separate steam reformer; e) introduction of the reformed tail gas into the gas stream before this is led into the Fischer-Tropsch reactor.

Owner:STATOIL ASA PETRO SA (NO)

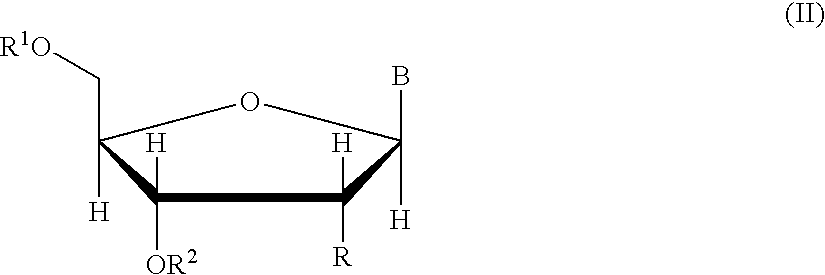

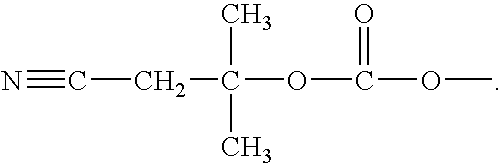

Methods of synthesizing oligonucleotides using carbonate protecting groups and alpha-effect nucleophile deprotection

The invention provides methods for synthesizing oligonucleotides using nucleoside monomers having carbonate protected hydroxyl groups that are deprotected with α-effect nucleophiles. The α-effect nucleophile irreversibly cleave the carbonate protecting groups while simultaneously oxidizing the internucleotide phosphite triester linkage to a phosphodiester linkage. The procedure may be carried out in aqueous solution at neutral to mildly basic pH. The method eliminates the need for separate deprotection and oxidation steps, and, since the use of acid to remove protecting groups is unnecessary, acid-induced depurination is avoided. Fluorescent or other readily detectable carbonate protecting groups can be used, enabling monitoring of individual reaction steps during oligonucleotide synthesis. The invention is particularly useful in the highly parallel, microscale synthesis of oligonucleotides.

Owner:AGILENT TECH INC +1

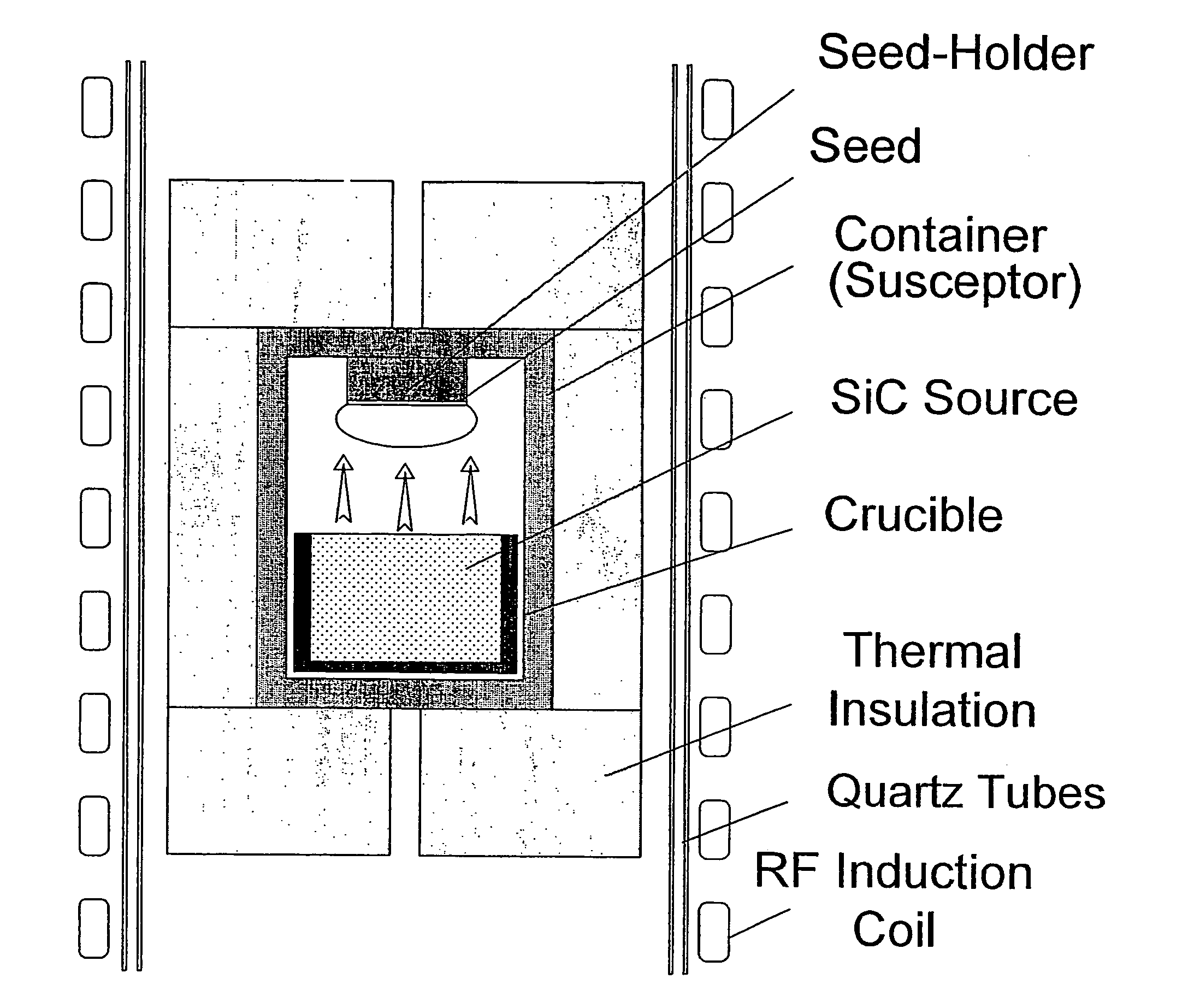

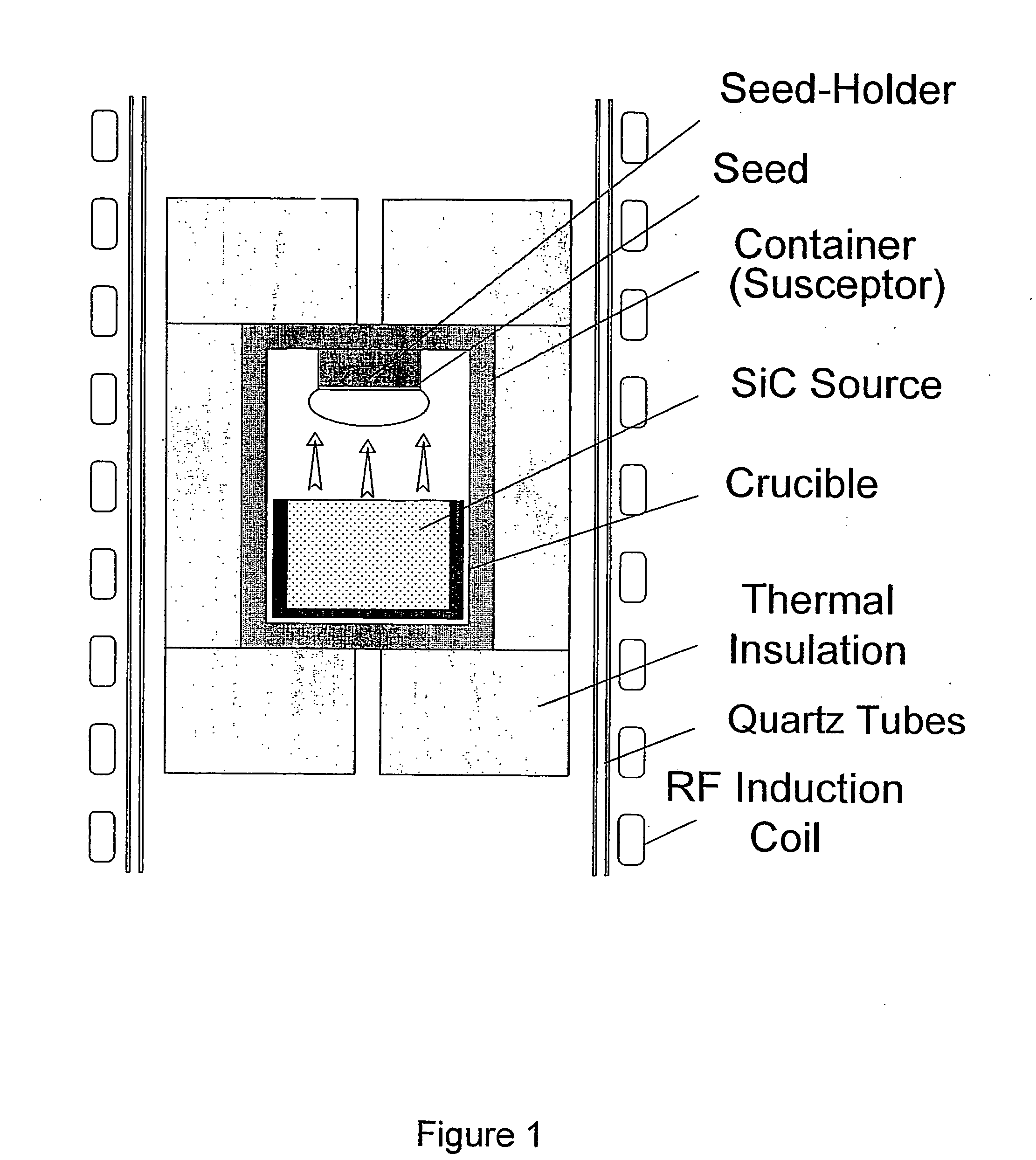

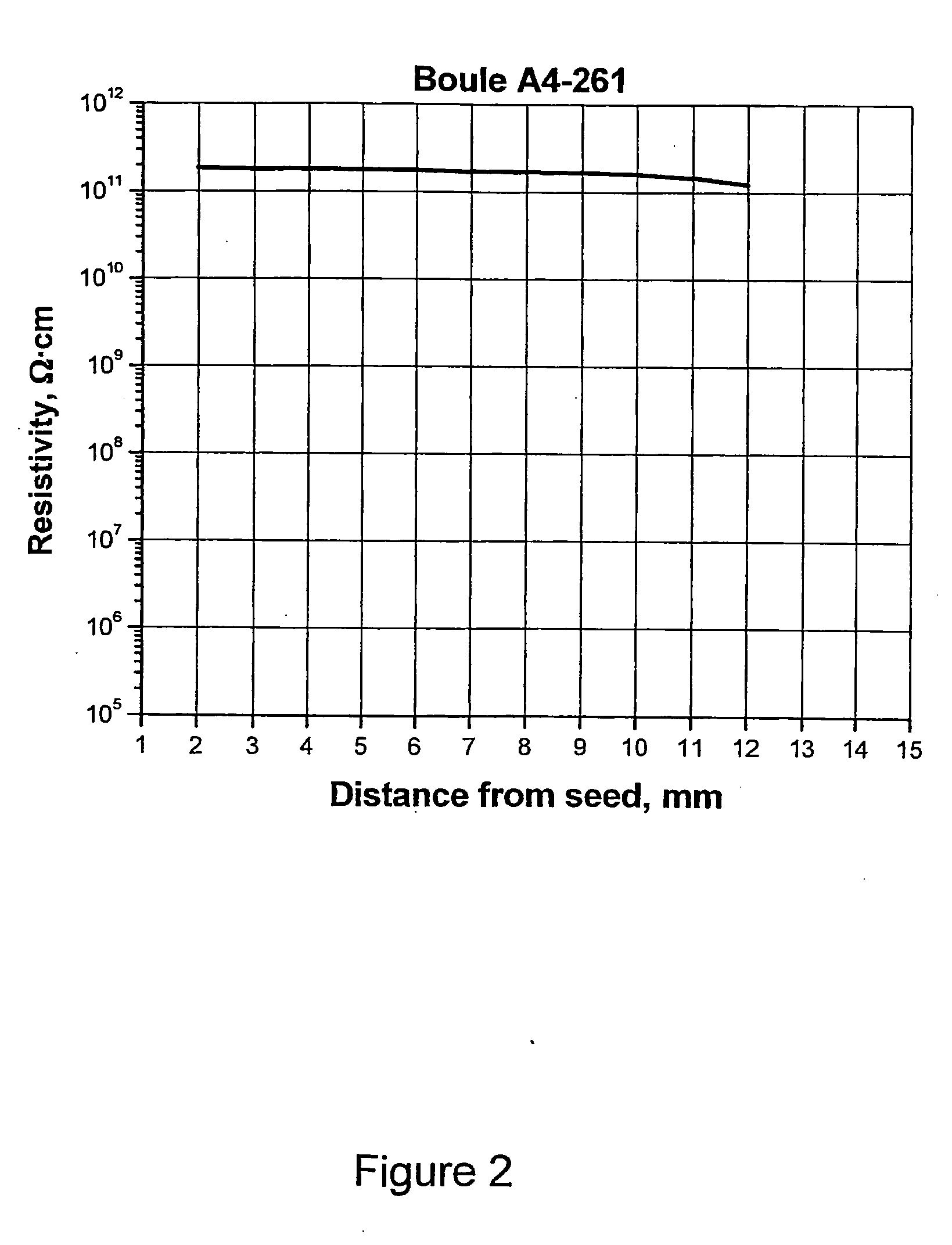

Low-Doped Semi-Insulating Sic Crystals and Method

InactiveUS20080190355A1Overcome disadvantagesIncrease capacitanceNon-metal conductorsPolycrystalline material growthCapacitanceDeep level

The invention relates to substrates of semi-insulating silicon carbide used for semiconductor devices and a method for making the same. The substrates have a resistivity above 106 Ohm-cm, and preferably above 108 Ohm-cm, and most preferably above 109 Ohm-cm, and a capacitance below 5 pF / mm2 and preferably below 1 pF / mm2. The electrical properties of the substrates are controlled by a small amount of added deep level impurity, large enough in concentration to dominate the electrical behavior, but small enough to avoid structural defects. The substrates have concentrations of unintentional background impurities, including shallow donors and acceptors, purposely reduced to below 5·1016 cm−3, and preferably to below 1·1016 cm−3, and the concentration of deep level impurity is higher, and preferably at least two times higher, than the difference between the concentrations of shallow acceptors and shallow donors. The deep level impurity comprises one of selected metals from the periodic groups IB, IIB, IIIB, IVB, VB, VIB, VIIB and VIIIB. Vanadium is a preferred deep level element. In addition to controlling the resistivity and capacitance, a further advantage of the invention is an increase in electrical uniformity over the entire crystal and reduction in the density of crystal defects.

Owner:II VI

Synthesis of selective androgen receptor modulators

InactiveUS20060009529A1Decreased libidoAlteration in mood and cognitionBiocideOrganic active ingredientsDiseaseProstate cancer incidence

The present invention relates to a synthetic process for the preparation of a novel class of androgen receptor targeting agents (ARTA) which demonstrate androgenic and anabolic activity of a nonsteroidal ligand for the androgen receptor. The agents define a new subclass of compounds which are selective androgen receptor modulators (SARM) which are useful for a) male contraception; b) treatment of a variety of hormone-related conditions, for example conditions associated with Androgen Decline in Aging Male (ADAM), such as fatigue, depression, decreased libido, sexual dysfunction, erectile dysfunction, hypogonadism, osteoporosis, hair loss, anemia, obesity, sarcopenia, osteopenia,osteoporosis, benign prostate hyperplasia, alterations in mood and cognition and prostate cancer; c) treatment of conditions associated with Androgen Decline in Female (ADIF), such as sexual dysfunction, decreased sexual libido, hypogonadism, sarcopenia, osteopenia, osteoporosis, alterations in cognition and mood, depression, anemia, hair loss, obesity, endometriosis, breast cancer, uterine cancer and ovarian cancer; d) treatment and / or prevention of chronic muscular wasting; e) decreasing the incidence of, halting or causing a regression of prostate cancer; f) oral androgen relacement and / or other clinical therpauetic and / or diagnostic areas. The process of the present invention is suitable for large-scale preparation, since all of the steps give rise to highly pure compounds, thus avoiding complicated purification procedures which ultimately lower the yield. Thus the present invention provides methods for the synthesis of non-steroidal agonist compounds, that can be used for industrial large-scale synthesis, and that provide highly pure products in high yield.

Owner:UNIV OF TENNESSEE RES FOUND

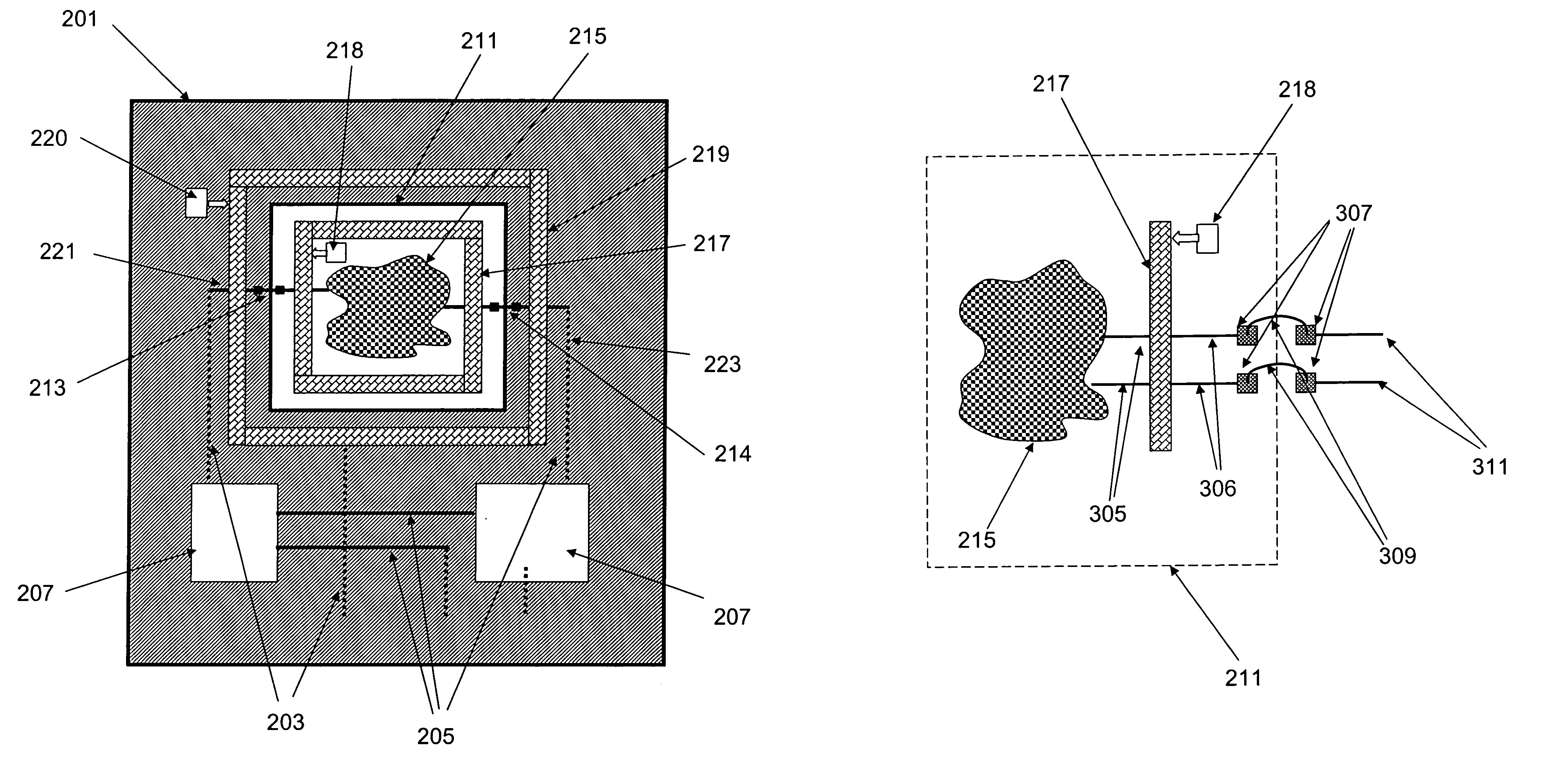

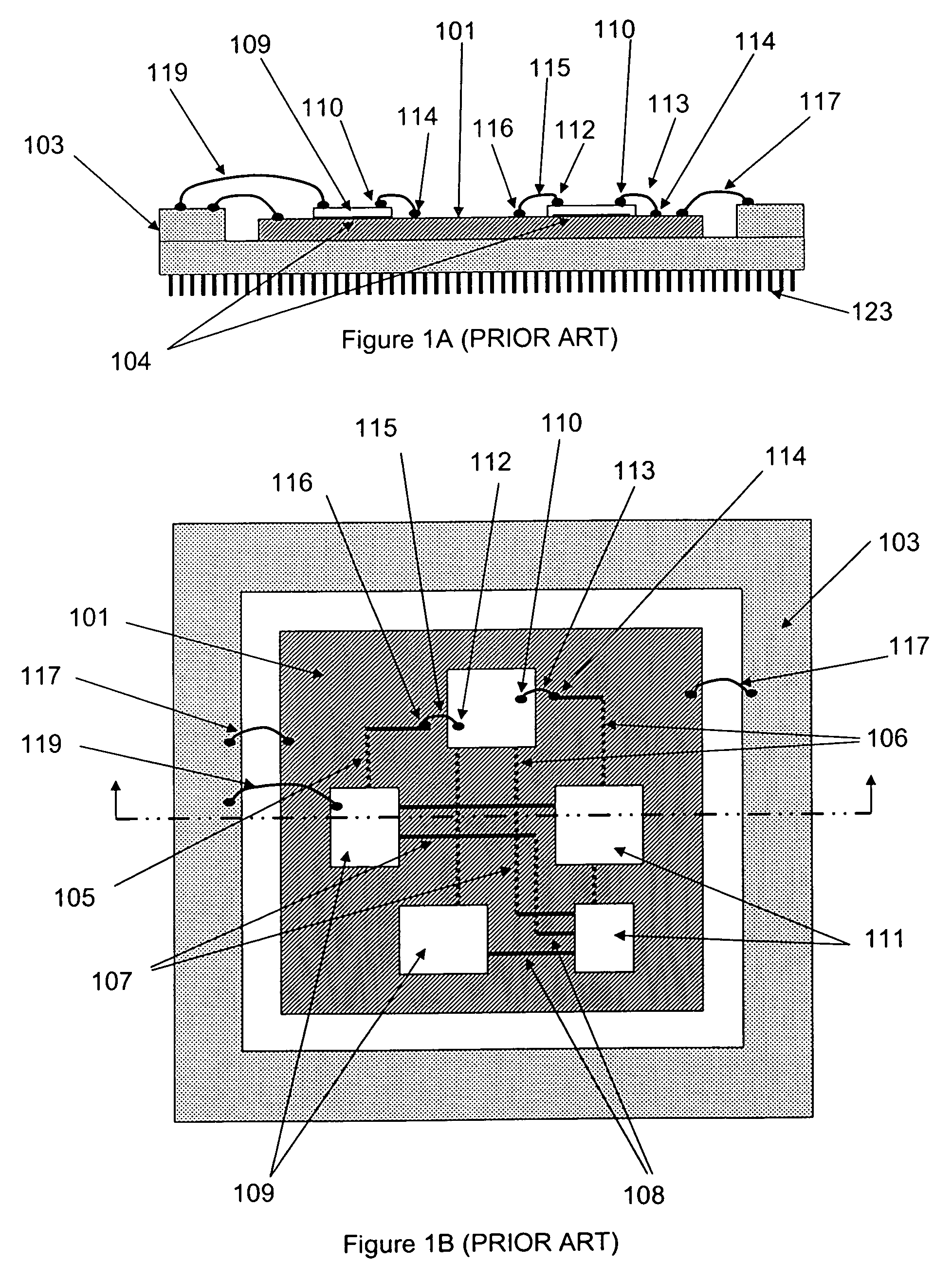

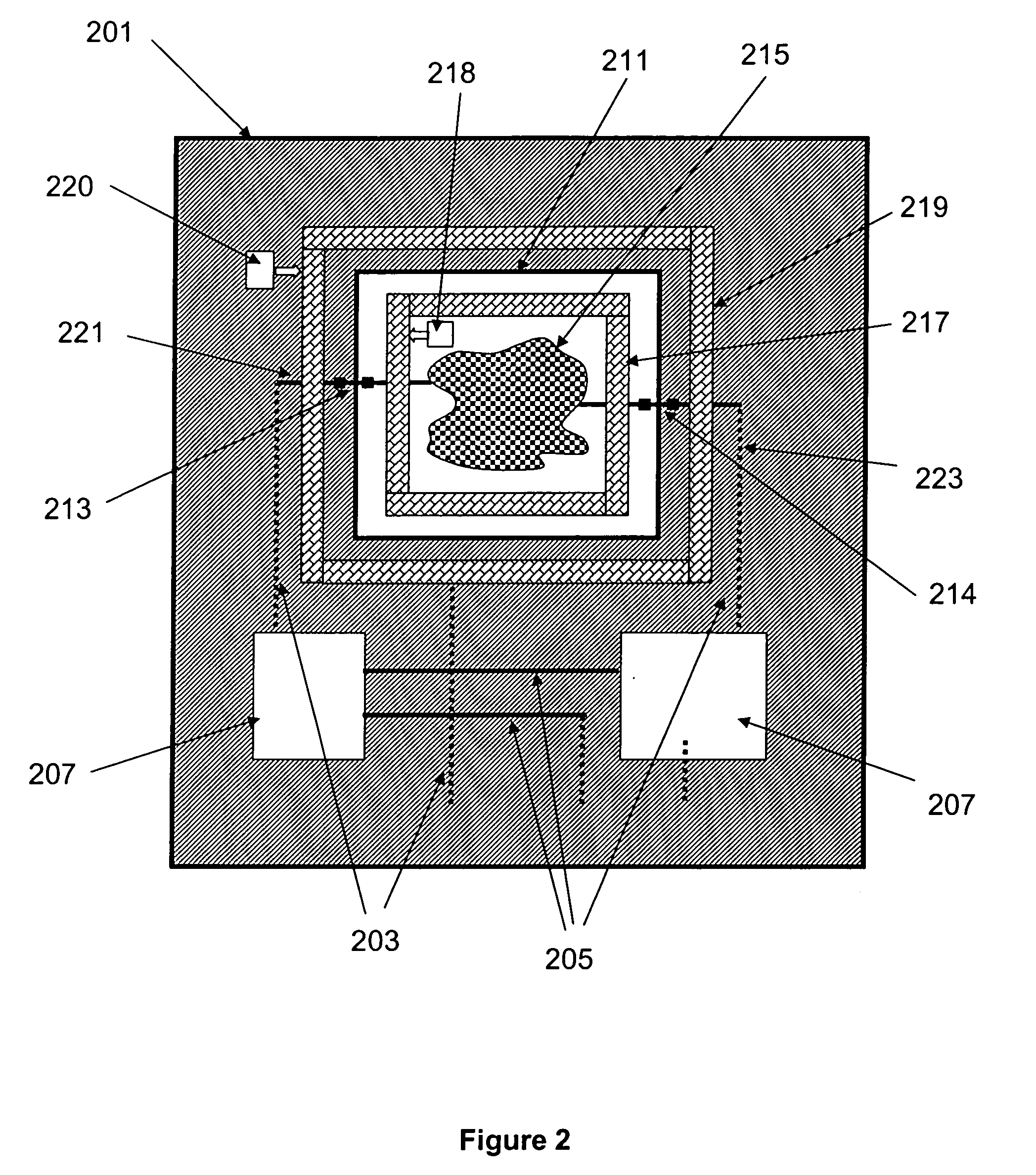

Hybrid semiconductor circuit with programmable intraconnectivity

InactiveUS6991947B1Improve yieldLow manufacturing costSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsProgrammable logic deviceProgrammable circuits

Field programmable circuits and redundant logic are added to the substrate of a hybrid circuit with functionality to bypass and / or repair unusable dies in order to enhance yield and lower costs of manufacture. In a preferred embodiment, a collar of programmable logic is inserted between the functional component on the hybrid die and its I / O terminals. The programmable logic collar can be programmed after hybrid assembly and test in order to correct assembly errors or die failures through one or more of the following actions: switch between redundant functional units and I / Os on the hybrid die; switch between redundant IC dies on the substrate, invert signal polarity; correct crosstalk errors; perform test and fault isolation.

Owner:GHEEWALA TUSHAR

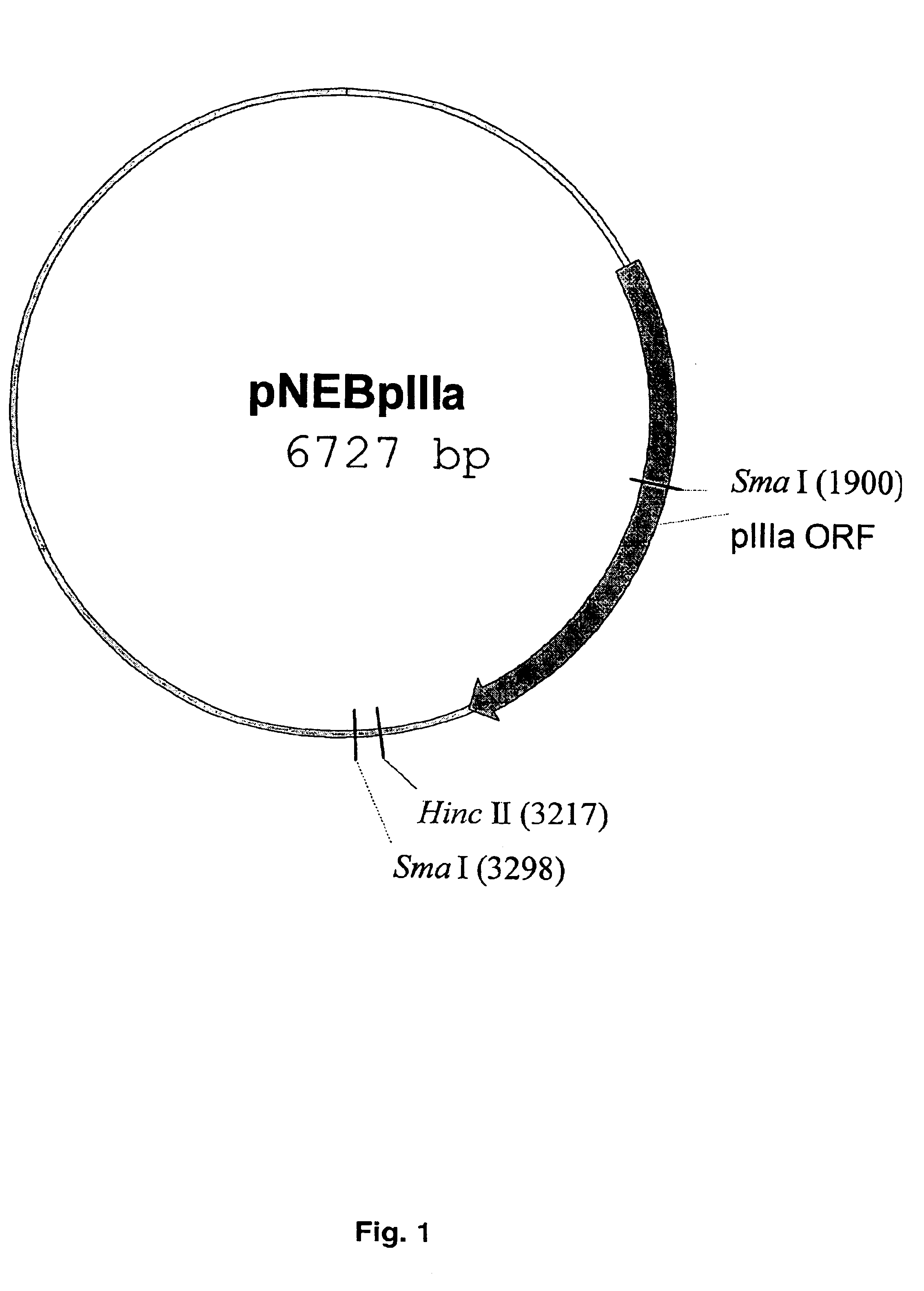

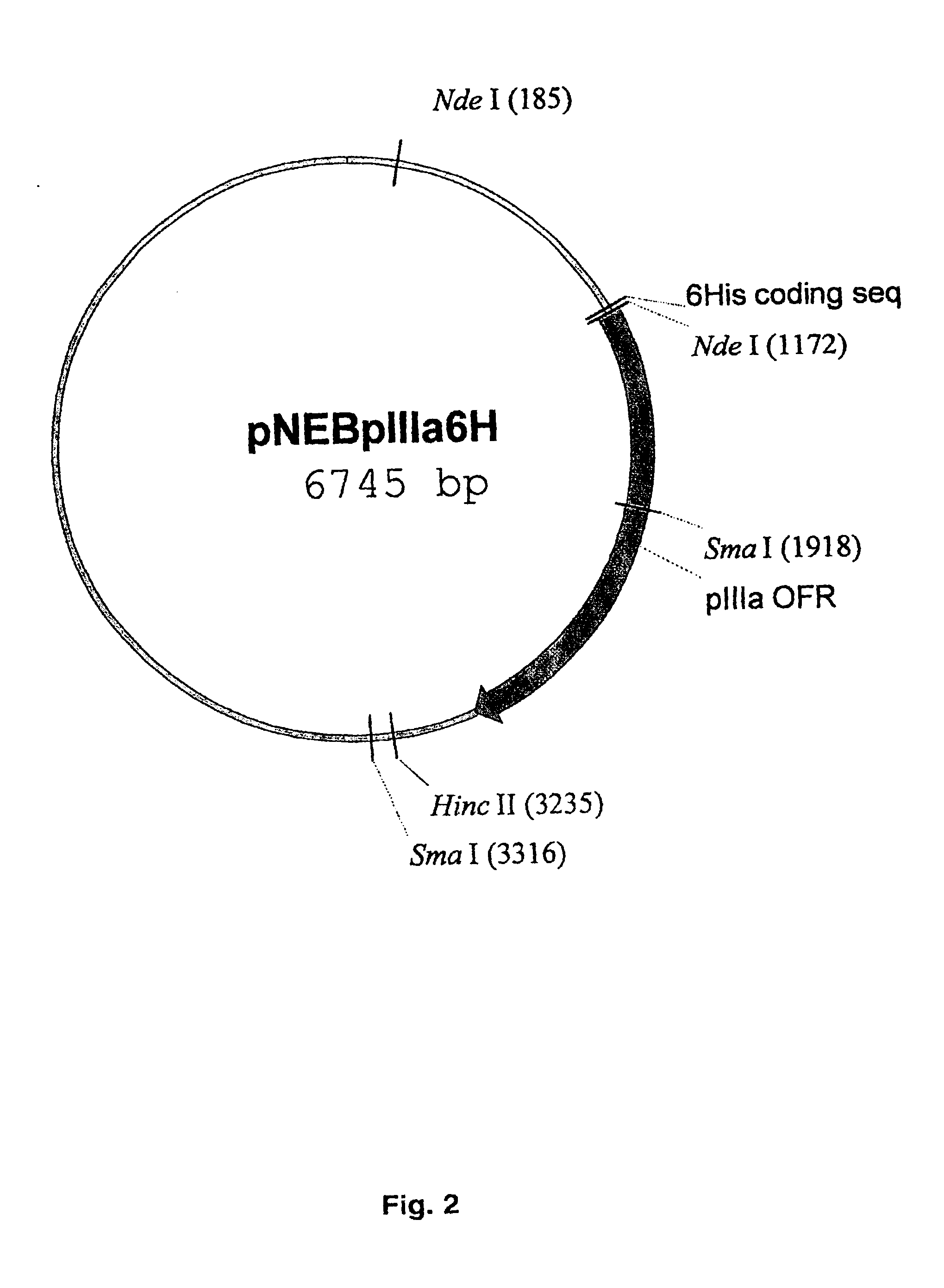

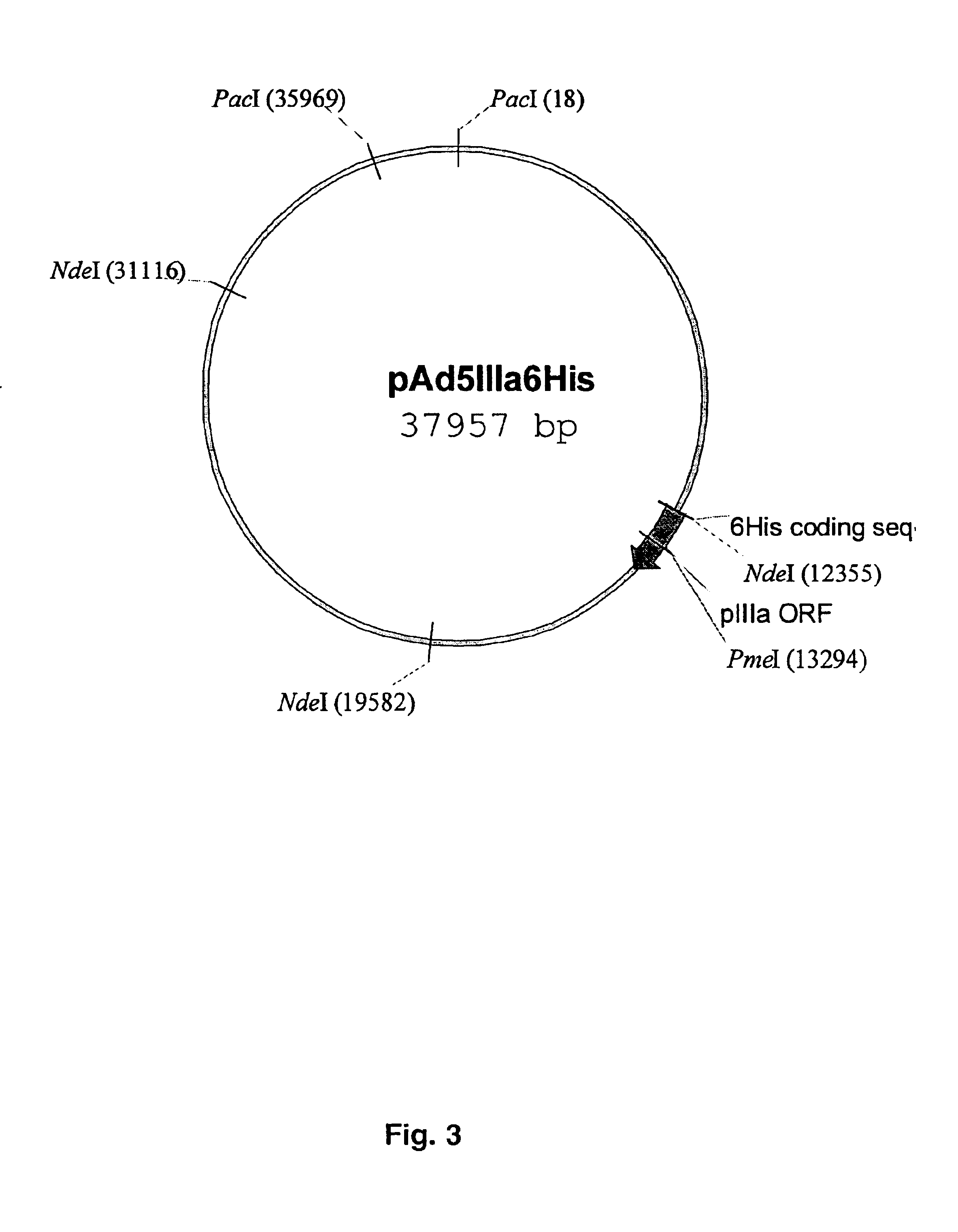

Capsid-modified recombinant adenovirus and methods of use

InactiveUS6955808B2Low yieldEfficiencyBiocideAntibody mimetics/scaffoldsSingle-Chain AntibodiesNoninvasive imaging

The present invention describes recombinant adenoviral vectors modified by incorporating targeting ligands or label into viral capsid or structural proteins. In one embodiment, single-chain antibody was introduced into the minor capsid proteins pIIIa or pIX so that the adenoviral vector can be targeted to a particular cell type. In another embodiment, there is provided a noninvasive imaging strategy useful for monitoring the replication and spread of conditionally replicative adenoviral vectors. Viral structural proteins such as pIX capsid protein, core proteins mu, V and VII were expressed as fusion protein with a fluorescent label. Once incorporated into the virions, detection of the structural fusion protein label would indicate the localization of the disseminated viral progeny. The detected fluorescent signals also closely correlate with the level of viral replication and progeny production.

Owner:UAB RES FOUND

Coated article with low-E coating including IR reflecting layer(s) and corresponding method

ActiveUS20060046073A1Easy and cost-effective to manufactureLess susceptible to yield problemGlass/slag layered productsNatural mineral layered productsLow emissivityContact layer

A coated article is provided with a low-emissivity (low-E) layer stack for use in a window unit or the like. The layer stack, or coating, may permit the coated article to achieve one or more of a low solar factor (SF) value, a high selectivity (Tvis / SF) value, substantially neutral color at normal and / or off-axis viewing angles, and / or low emissivity. When high selectivity values are achieved, there is provided a high ratio of visible transmission to SF, which is a desirable feature in certain example instances. In certain example embodiments, asymmetric IR reflecting layer thicknesses may be used (e.g., bottom IR reflecting layer thicker than the top IR reflecting layer), and / or different contact layers for the top / bottom IR reflecting layers may be used to help achieve a combination of low SF values, high selectivity, and good coloration at normal and / or off-axis viewing angles.

Owner:GUARDIAN GLASS LLC +1

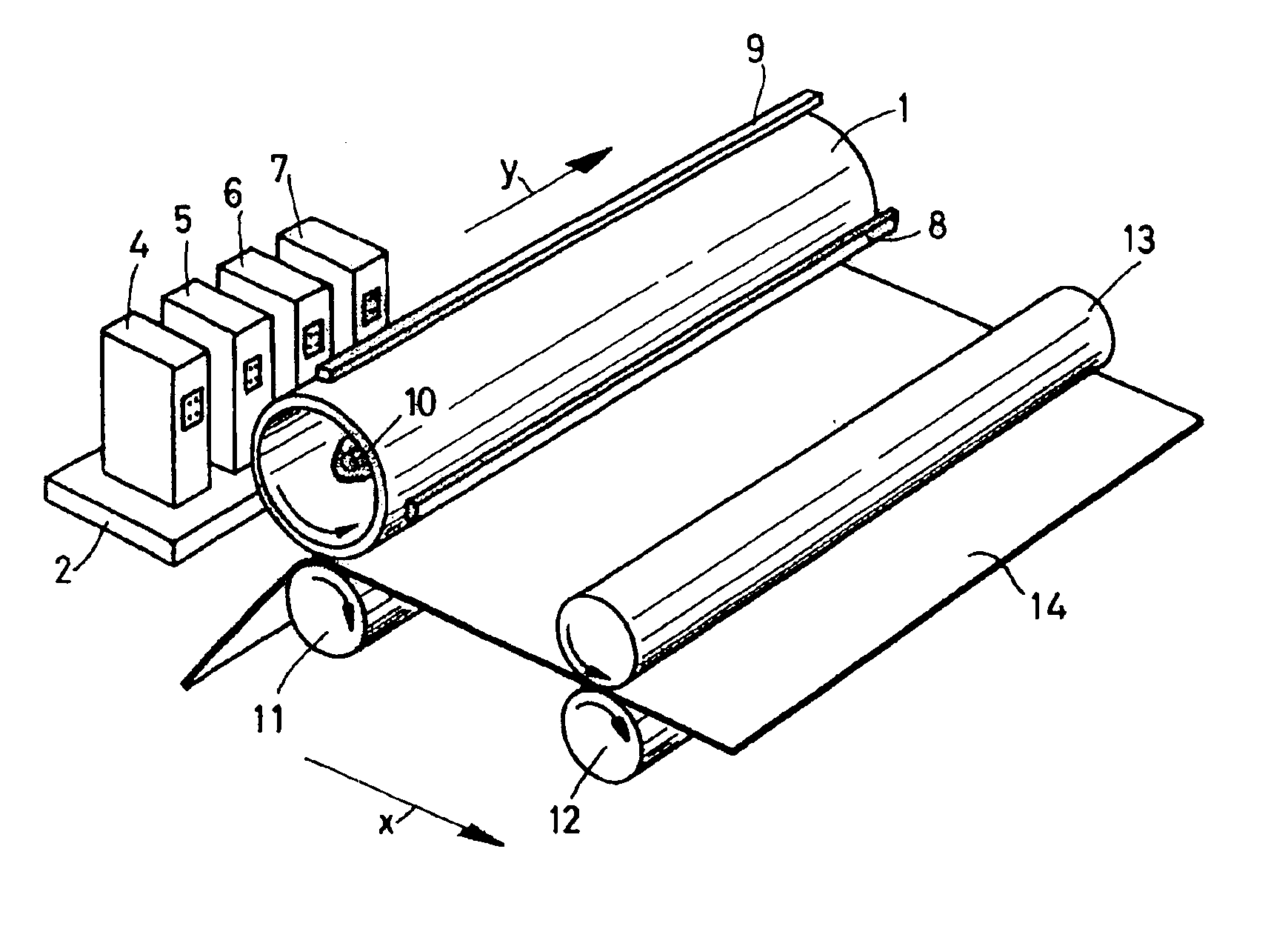

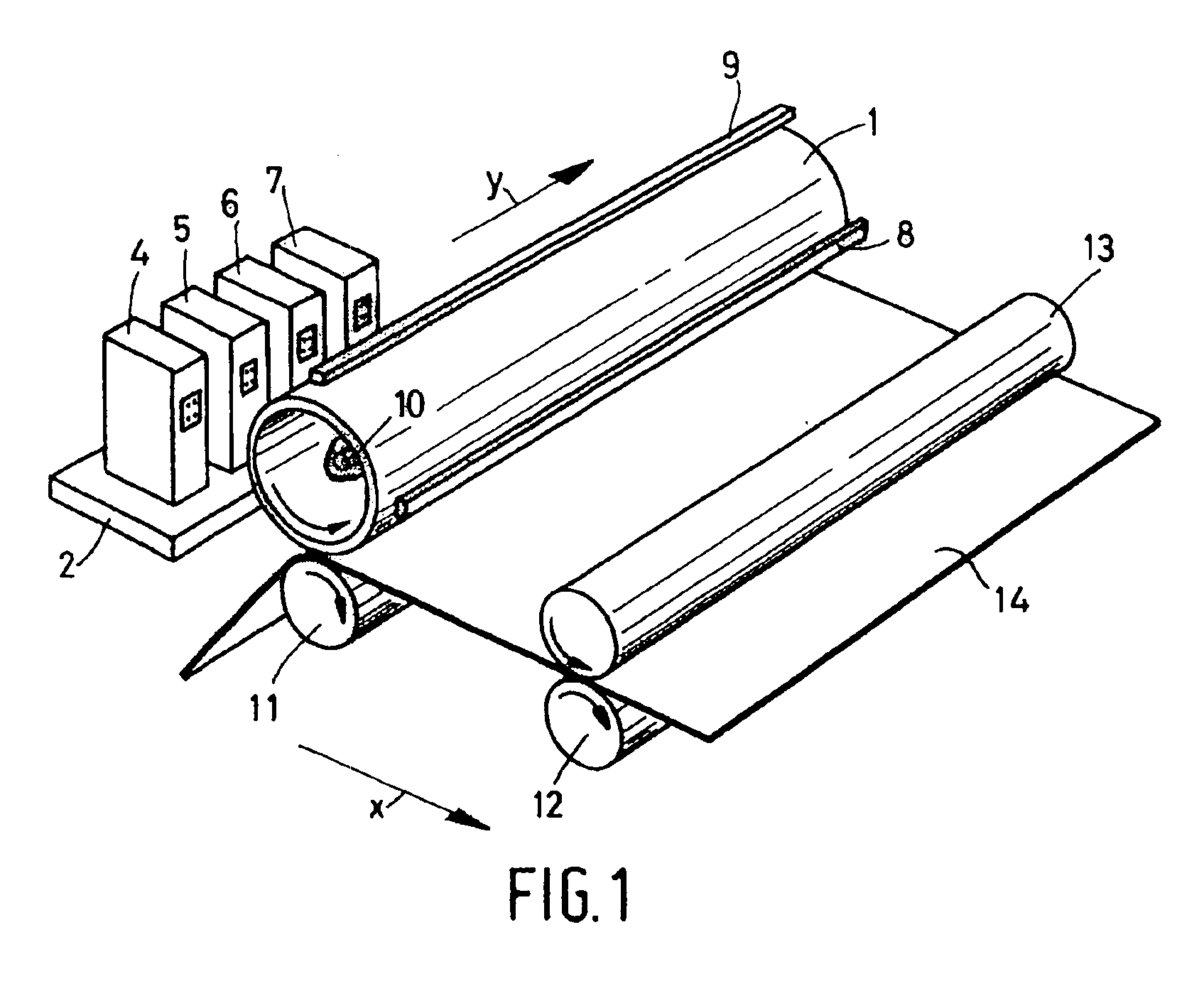

Method of printing a receiving material with hot melt ink and an inkjet printer suitable for applying such a method

InactiveUS6905203B2Reduce hardnessImprove transfer rateMeasurement apparatus componentsPrintingElastomerInk printer

A method of printing a receiving material with hot melt ink using an intermediate element having a surface containing an elastomer with a surface tension in which the polar part thereof is less than or equal to 20 mN / m, wherein the receiving material is brought into contact with the intermediate element in such manner that the ink transfers from the intermediate element to the receiving material, and wherein the elastomer has a hardness of less than 80 Shore A, a thermal conductivity coefficient greater than 0.15 W / mK, and in absorption of less than 10%, and a tanδ of less than 0.3.

Owner:OCE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com