Heteropolyacid modified alumina ethanol dehydration catalyst and preparation method thereof

A technology of ethanol dehydration and heteropolyacid, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., which can solve the problem of high cost of ethanol dehydration catalyst and low ethylene yield etc. to achieve low cost, improve ethylene selectivity, and inhibit ethylene polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

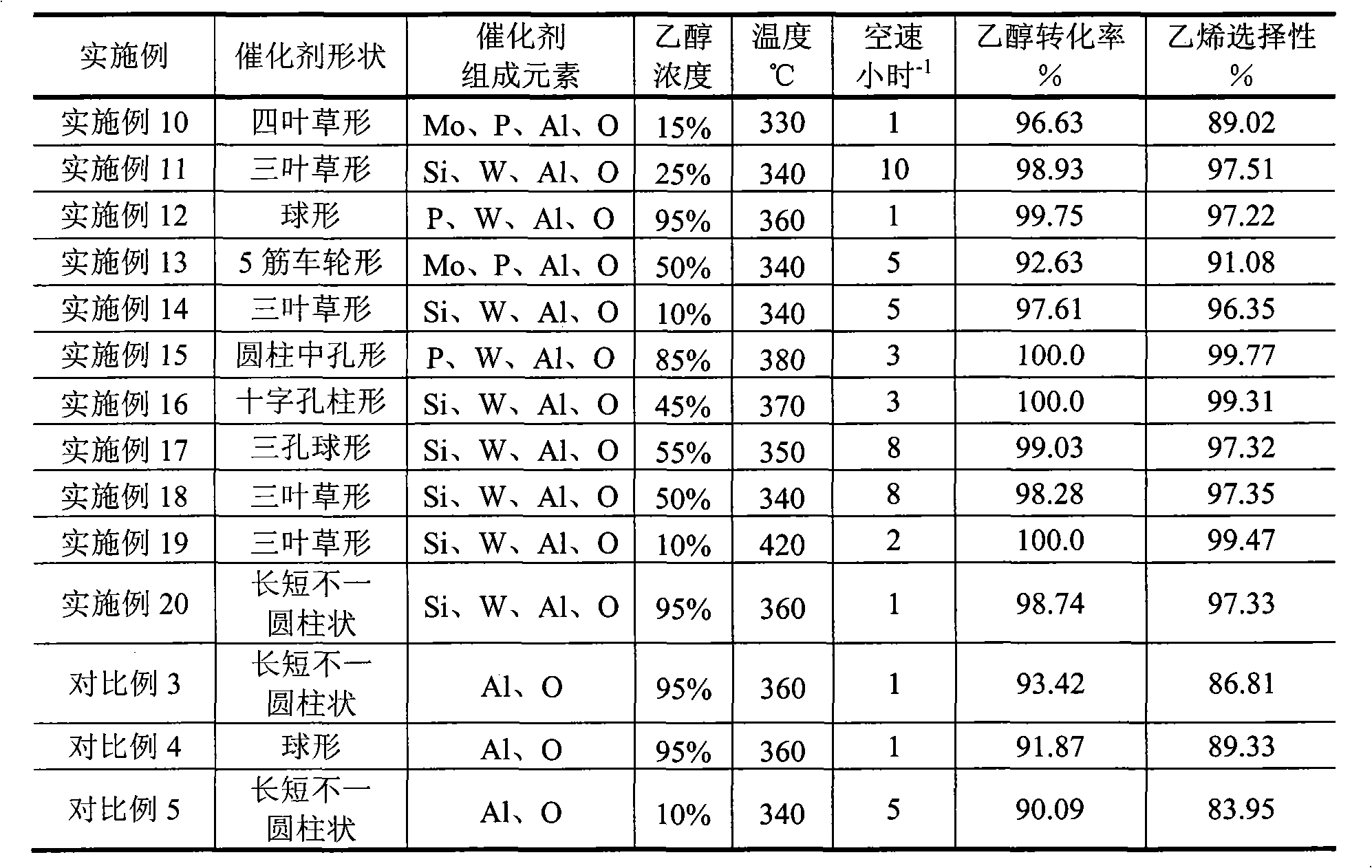

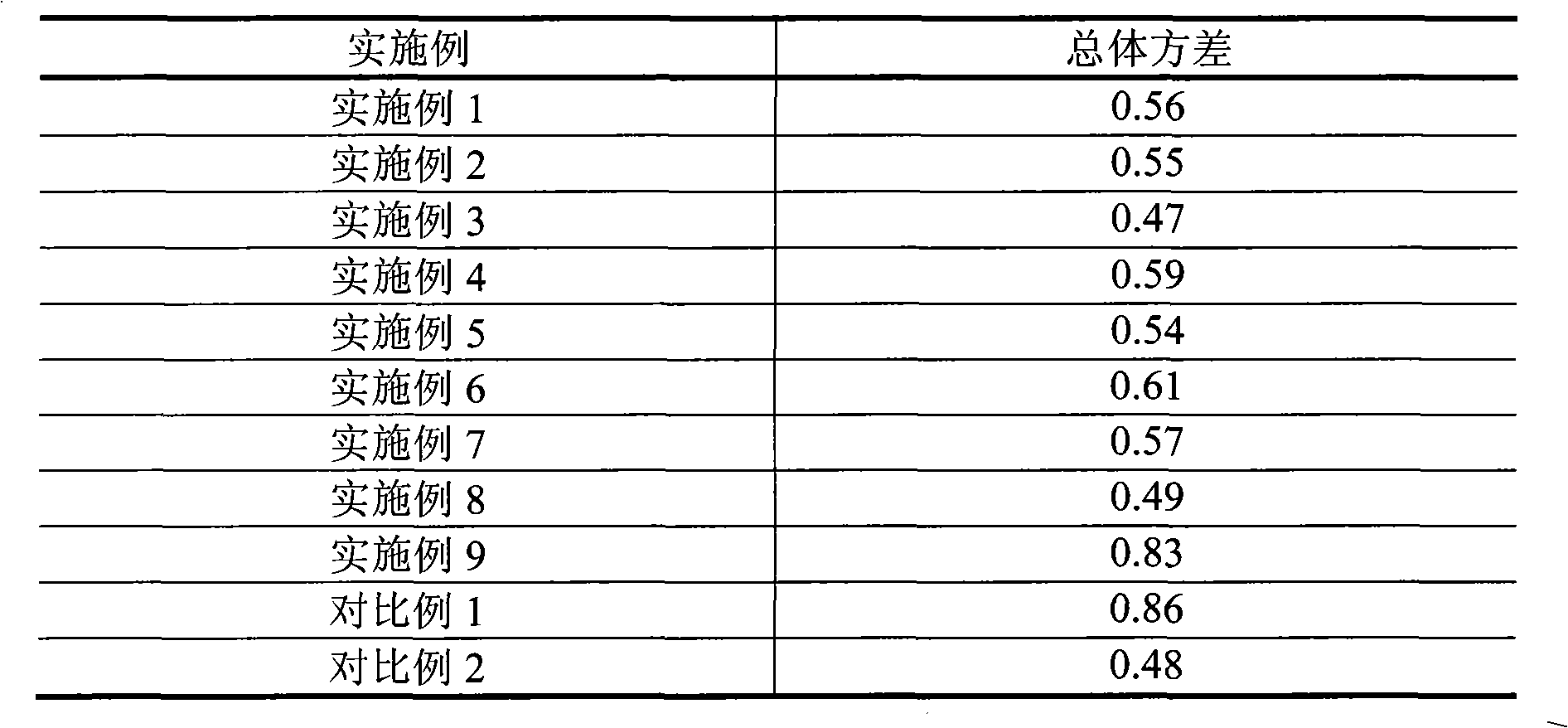

Examples

Embodiment 1

[0021] H 3 Mo 12 o 4 0P·nH 2 O is mixed with boehmite, Tianqing powder, and 0.3 mol / liter nitric acid, and the weight ratio of each raw material is H 3 Mo 12 o 4 0P / Al 2 o 3 / Tian Qing powder = 0.13: 1: 0.1, shaped into a four-leaf clover shape, 4 mm long, 1.1 mm in diameter of the four-leaf circle, dried at 120° C. for 12 hours, and roasted at 550° C. for 10 hours. Al in the catalyst 2 o 3 The parts by weight of is 88 parts, and the parts by weight of heteropolyacid is 12 parts.

Embodiment 2

[0023] Press each step and condition of [embodiment 1], only H 4 o 40 SiW 12 / Al 2 o 3 / Tianqing powder=0.20:1:0.1, the shape is clover-shaped, 5 mm long, and the diameter of the three-leaf circle is 1 mm. Al in the catalyst 2 o 3 The parts by weight of is 83 parts, and the parts by weight of heteropolyacid is 17 parts.

Embodiment 3

[0025] Press each step and condition of [embodiment 1], only H 3 o 4 0PW 12 / Al 2 o 3 / Tianqing powder = 0.20:1:0.1, spherical in shape with a diameter of 3 mm. Al in the catalyst2 o 3 The parts by weight of is 83 parts, and the parts by weight of heteropolyacid is 17 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com