Patents

Literature

183results about How to "Unique performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mobile phone shell and preparation method thereof

ActiveCN103297565AImprove corrosion resistanceAppearance has no effectAnodisationSmall component housingsMobile phoneNanotechnology

The invention provides a mobile phone shell and a preparation method of the mobile phone shell. The mobile phone shell comprises a plastic piece and a metal shell body which is combined with the plastic piece, wherein the surface of a face, combined with the plastic piece, of the metal shell body is provided with an oxidation film layer, corrosion holes are formed in the surface layer of a face, opposite to the plastic piece, of the oxidation film layer, the hole diameter of each corrosion hole is 200 nanometers to 2000 nanometers, nanometer micro holes are formed in the inner layer of the oxidation film layer, the hole diameter of each nanometer micro hole is 10 nanometers to 100 nanometers, and resin compositions of the plastic piece are filled in the nanometer micro holes and the corrosion holes. The prepared mobile phone shell is resistant to abrasion, falling and corrosion.

Owner:BYD CO LTD

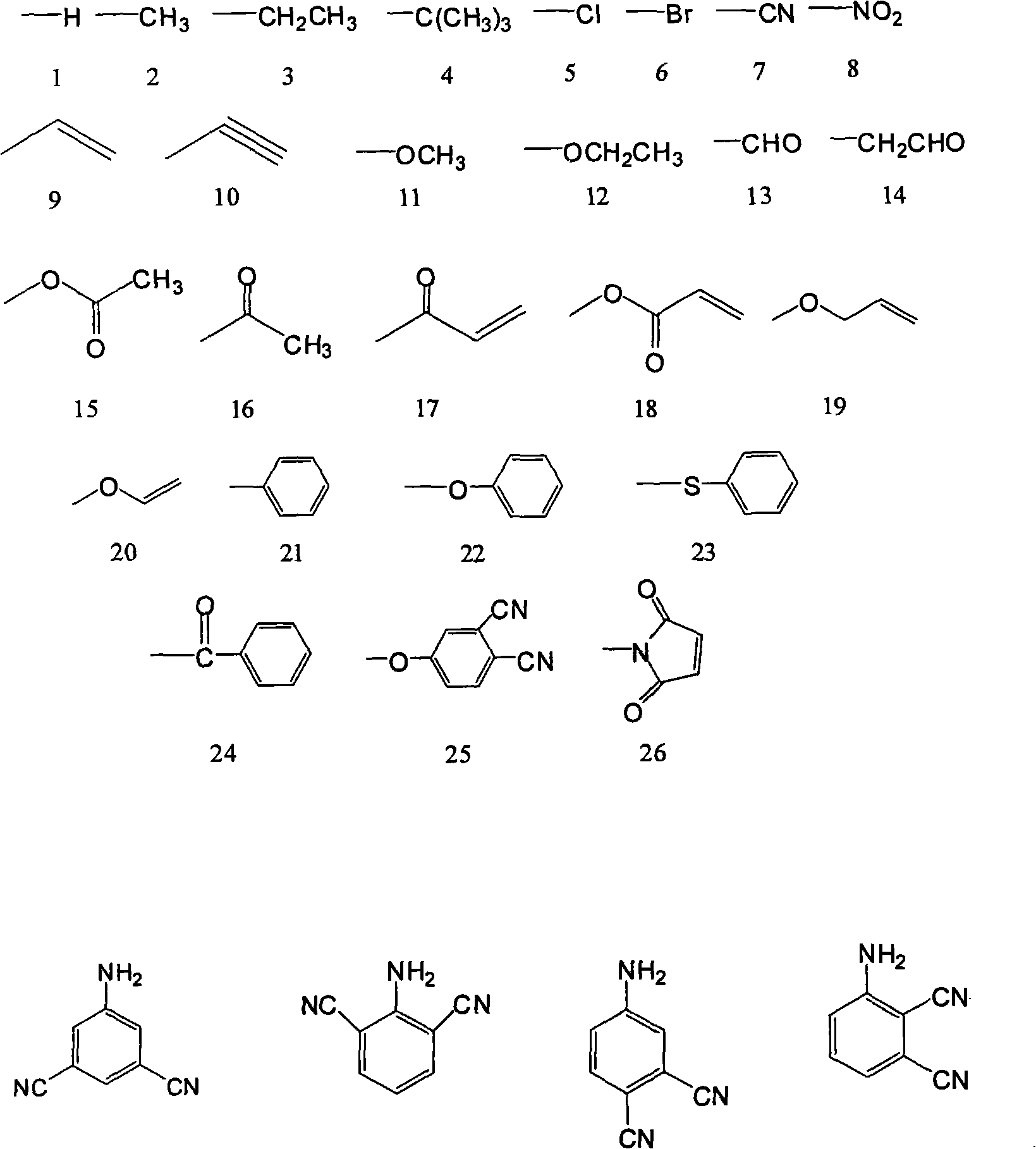

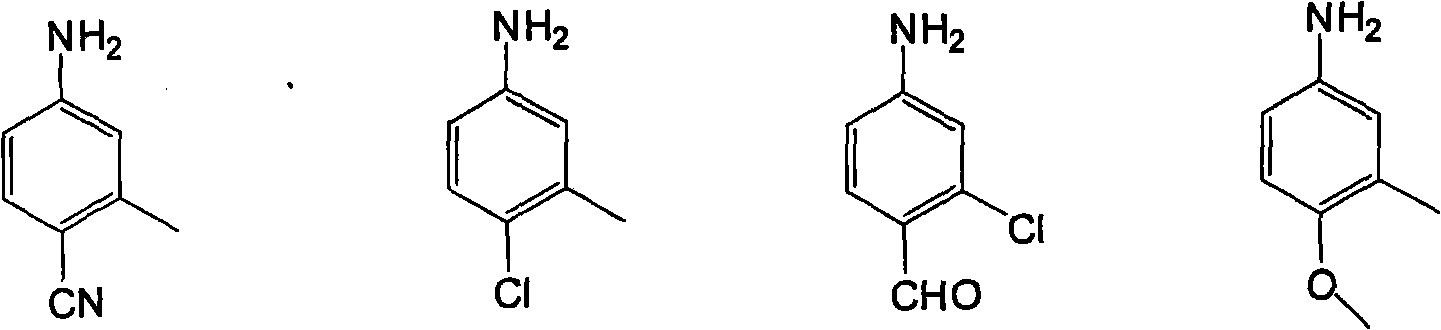

Method for preparing benzoxazine intermediate containing triazine structure

The invention provides a preparation method of triazine structure containing benzoxazine intermediate, which sequentially includes: (1) performing synthetic reaction of aldehyde compound and amine compound at a molar ratio of at least 1:1 which includes adding aldehyde compound and solvent of at least one of clean water, methanol, ethanol, isopropanol, and ethyl acetate into a reactor at the room temperature under the normal pressure to obtain mixed solution with aldehyde mass concentration of no greater than 95%, adding amine compound while stirring, and reacting at 0-100 DEG C under the normal pressure for at least 15 minutes to obtain the reactant liquor; (2) pouring into the cleaning solution, stirring and cleaning, and filtering to collect solid substance, or directly filtering the reactant liquor to collect the solid substance; and (3) drying the solid substance obtained in step (2) at 30-100 DEG C.

Owner:SICHUAN UNIV

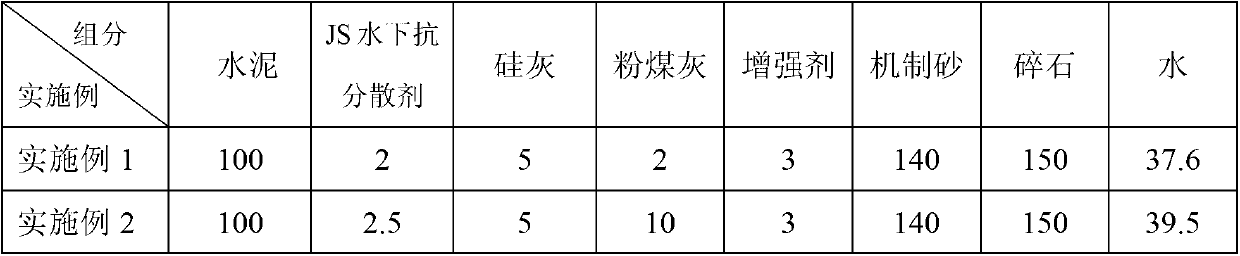

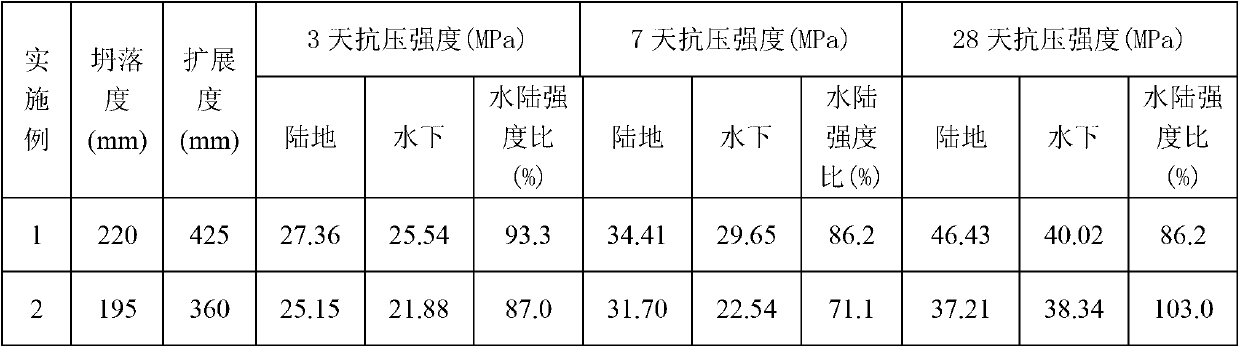

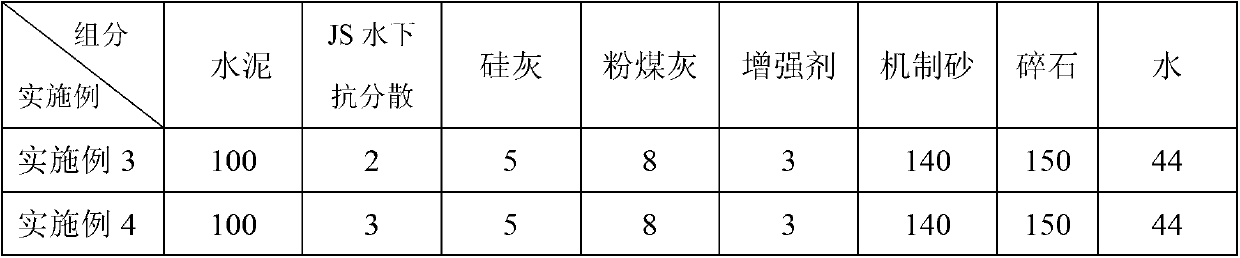

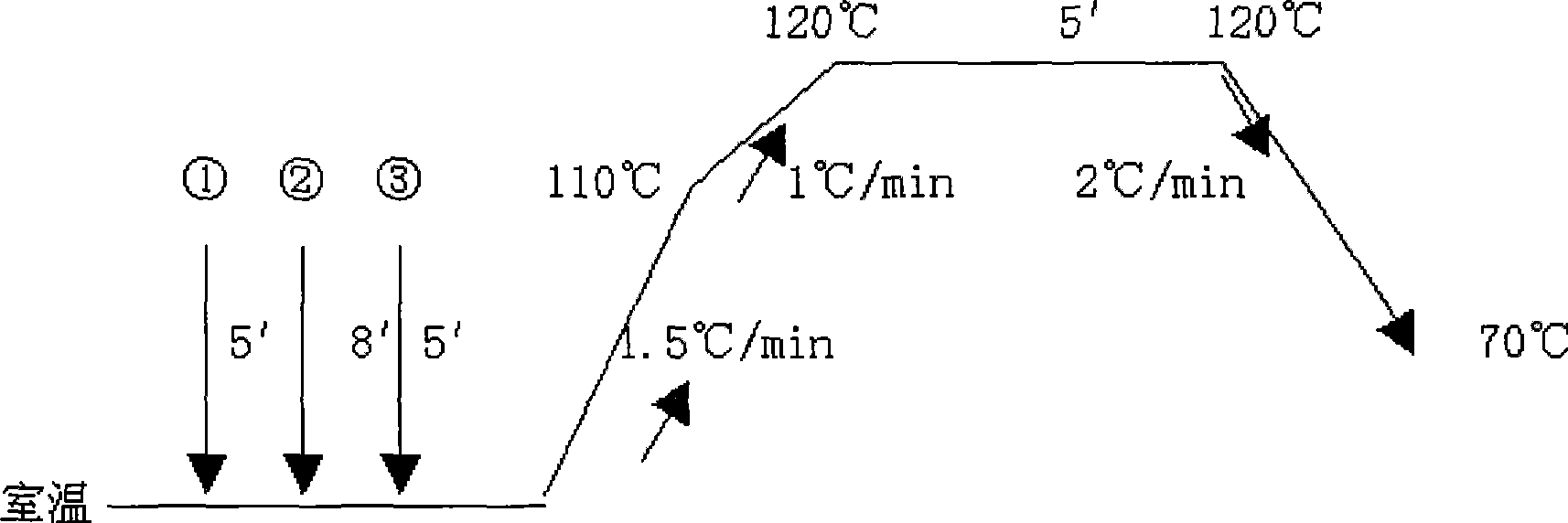

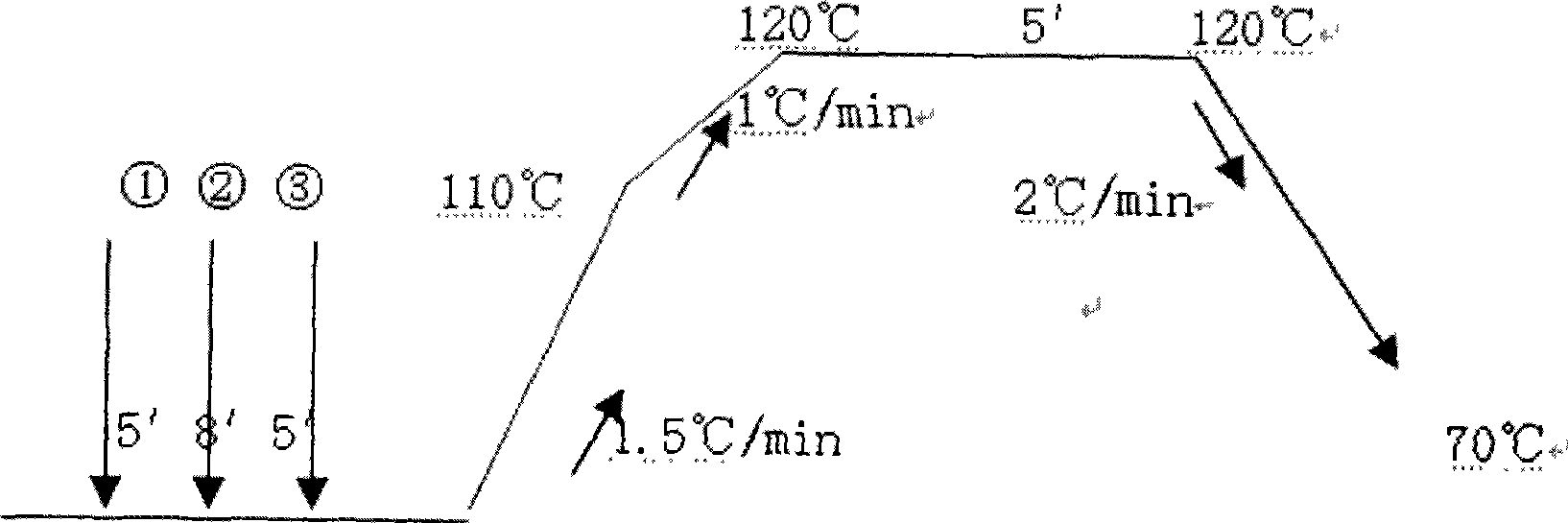

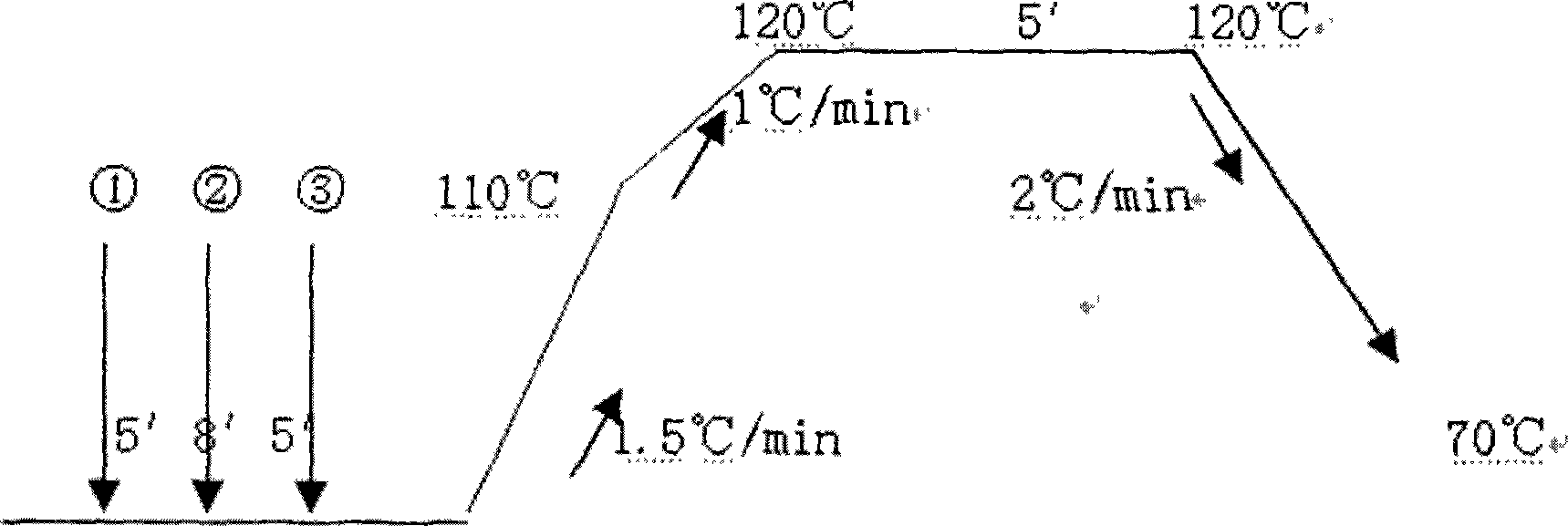

Manufactured sand underwater dispersion resistant concrete and preparation method thereof

The invention relates to a manufactured sand underwater dispersion resistant concrete, which comprises the following components in parts by weight: 100 parts of cement, 1-5 parts of underwater dispersion resistant additive, 2-20 parts of silica fume, 1-20 parts of coal ash, 1-10 parts of an enhancer, 140-200 parts of manufactured sand, 140-200 parts of macadam, and 30-50 parts of water. The preparation method comprises the following steps of firstly putting the manufactured sand, the macadam aggregate, the cement, the enhancer, the coal ash and the silica fume into an agitator, blending through dry mixing, then adding the underwater dispersion resistant additive to further blend through dry mixing, adding water into the material blended through dry mixing previously, stirring for 5-8 minutes, then preparing the manufactured sand underwater dispersion resistant concrete. The manufactured sand underwater dispersion resistant concrete has strong construction mobility, so that the problem of contradiction of mobility and dispersion resistance of the underwater dispersion resistant concrete is better solved, and therefore, the manufactured sand underwater dispersion resistant concrete not only has good dispersion resistance, but also has self-leveling and self-compaction construction mobility.

Owner:江西万年青水泥股份有限公司

Terylene DTY fiber soft cotton velvet and technique for producing the same

InactiveCN101424006AUnique performanceShortening dyeing and finishingWarp knittingDyeing processDyeingFiber

The invention relates to a terylene DTY fibre cotton flannel blanket and a production process thereof, wherein wool silk adopts terylene DTY fibre as a raw material; the specification of the terylene DTY fibre is between 100D / 96F and 300D / 432F; bottom silk adopts two raw materials, namely terylene DTY fibre with specification of between 50D / 24F and 200D / 144F and semi-dull terylene FDY fibre with specification of between 50D / 24F and 200D / 144F; and the production process comprises material ordering, greige cloth weaving, greige cloth inspection, cylinder separation, combing and presetting, dyeing(printing), softening rolling (softening), dewatering, drying, carding, combing and shearing, luster finishing, ring baking, molding, inspection and packaging. The production process has low cost; and the obtained product is light as cocoon silk and warm as eiderdown, and offers unique cordial feeling and full feel in the contact with skin.

Owner:苏州市恒信针织印染有限责任公司

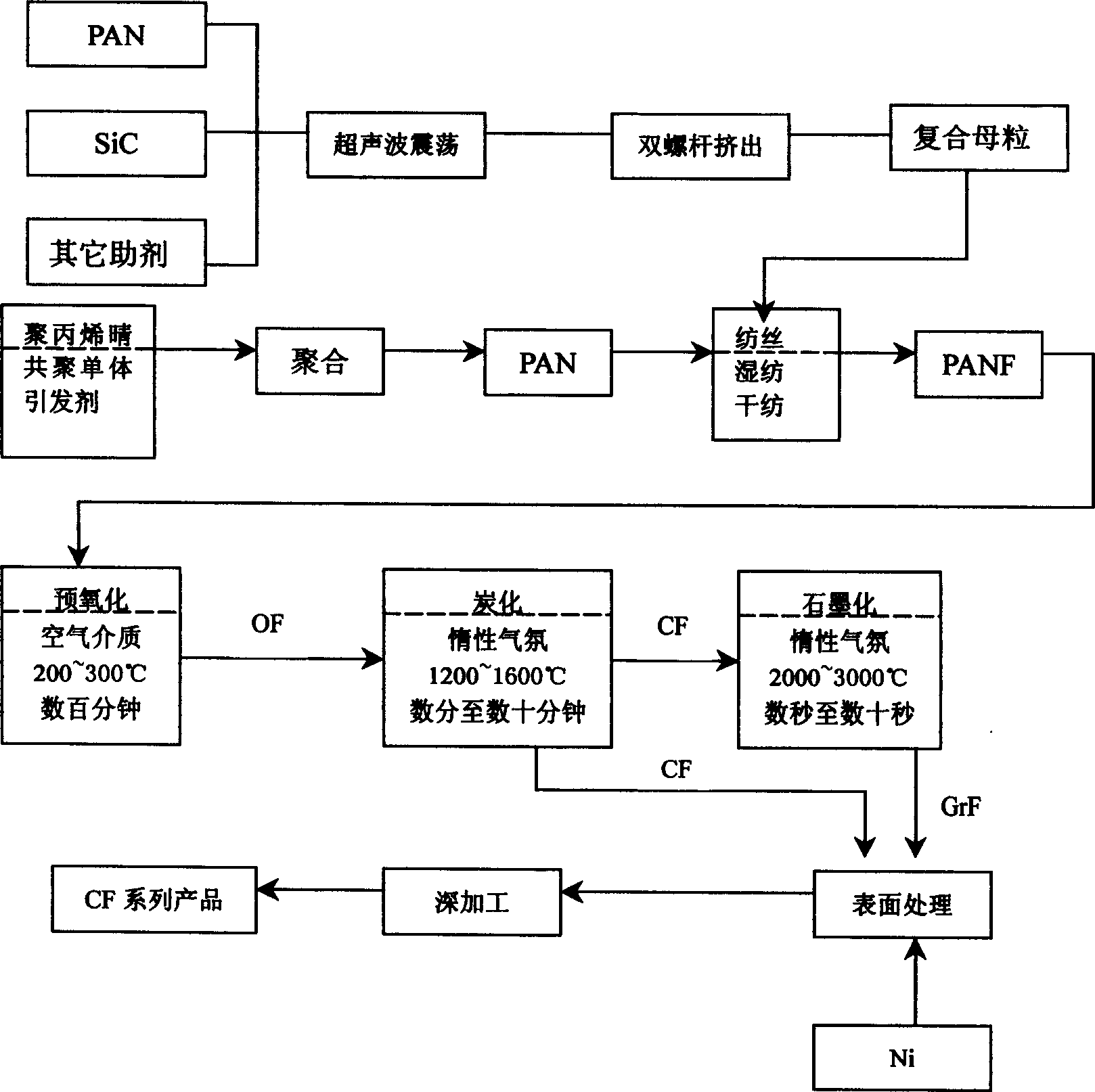

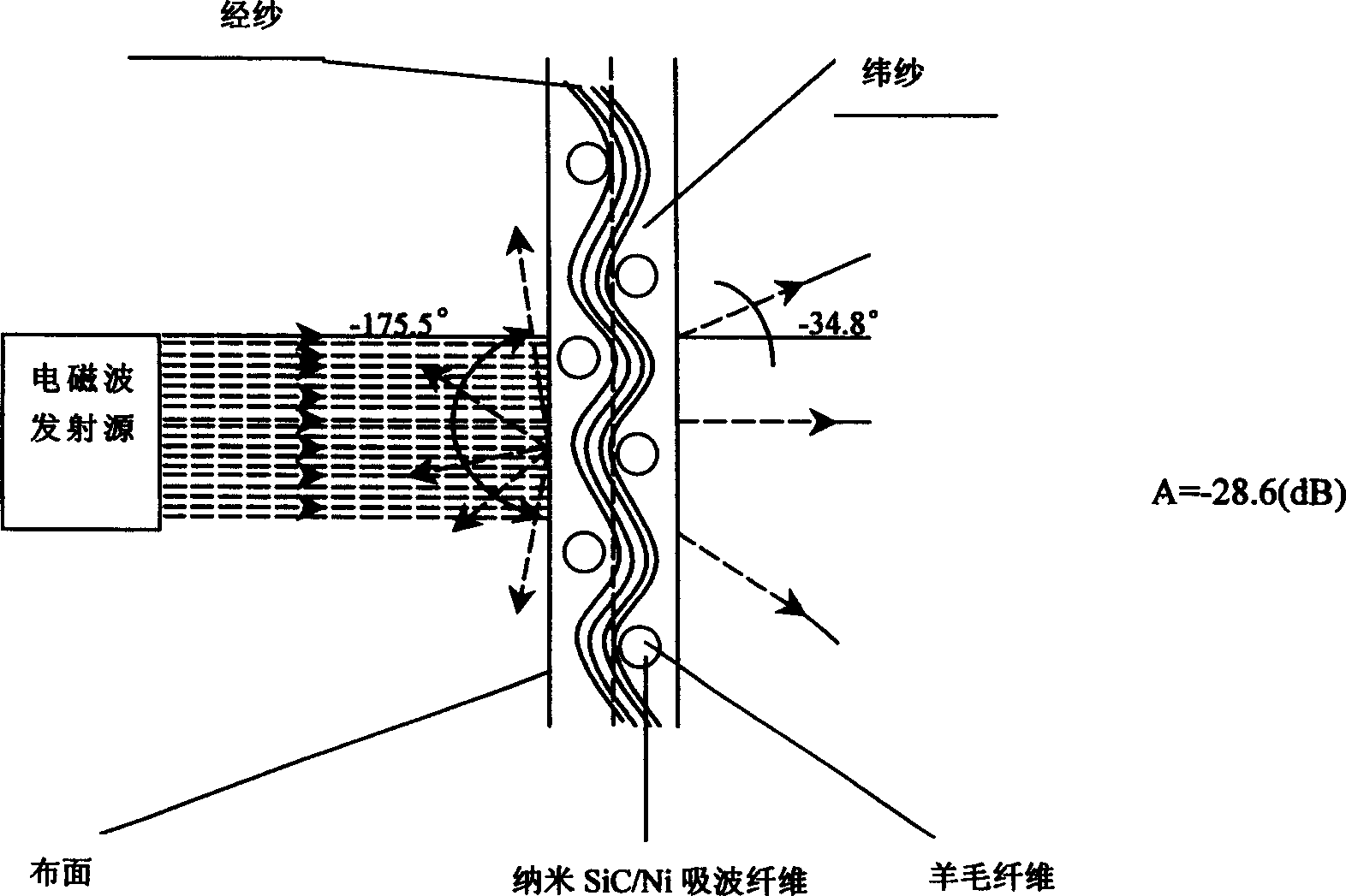

Wave absorbing composite nano-fiber material textile composition and its preparation process

InactiveCN1544723AHigh strengthHigh modulusElectroconductive/antistatic filament manufactureNano siliconComposite nanofibers

The invention relates to a composite fiber material, and the combination contains polyacrylonitrile carbon 80-96, nano silicon carbide 4-20%; nickel powder is 6-20% of the fiber in weight, assistant 5-8%. The steps: making ultrasonic wave vibration, mixing and extrusion on silicon carbide, polyacrylonitrile carbon and assistant to produce compound particles; making copolymerization and commixture on copolymerizable monomer to make polyacrylonitrile carbon wave absorbing fiber; spinning silicon carbide / nickel fiber; making preoxidation, carbonization, graphitization, surface nickel processing and weaving on the spinning to obtain the finished product. It has wide screened wave bands, and high electromagnetic wave absorbing rate, has no secondary pollution. It shortens working procedure, reduces cost, and has the characters of high strength, high modulus, low expansion coefficient, etc.

Owner:西安华捷科技发展有限责任公司

Collation shrink

The invention relates to a film structure combining a metallocene-rich layer and an HDPE-containing layer. A preferred embodiment is a structure having metallocene-rich skin layers and an HDPE-containing core. The structures of the invention are particularly useful for collation shrink.

Owner:EXXONMOBIL CHEM PAT INC

Asphalt waterproof paint for building and preparation method thereof

InactiveCN101921545AUnique performanceImprove performanceUnspecified rubber coatingsBituminous coatingsChemical industryBituminous waterproofing

The invention relates to an asphalt waterproof paint for a building and a preparation method thereof, belonging to the technical field of chemical industry. The asphalt waterproof paint for a building comprises the following raw materials according to parts by weight: 20-25 parts of plasticizer, 6-8 parts of modifier, 25-30 parts of asphalt, 20-30 parts of filler, 4-6 parts of tackifier, 0.2-0.3 parts of crosslink coupling agent, and 0.3-0.5 parts of dispersing agent. The invention has the advantages of reasonable compound design, good intensity, safety, environmental protection and stable product quality, and is capable of adapting the climatic conditions at high and low temperatures.

Owner:嘉兴市博豪家纺有限公司

Pearlescent magic color aluminum powder pigment and preparation method thereof

InactiveCN102260421ASimple processSimple equipmentInorganic pigment treatmentElectrically conductiveTitanium dioxide

The invention discloses an aluminum powder pigment with iridescent pearl luster and a preparation method thereof. The method uses aluminum powder with an average particle size of 10 μm to 150 μm and a surface coated with SiO2 film as the substrate raw material. The SiO2 film is inert, acid-resistant, heat-resistant, and transparent. The pH of the solution is 1.5-2.5 and the temperature is 60 Under the condition of ℃~80℃, deposit a layer of nano-titanium dioxide film on the transparent SiO2 film by chemical liquid phase deposition, wash and dry, and bake the pigment at 500℃~600℃ under the protection of inert gas 0.5~1.0 h, the high-gloss pearlescent aluminum powder pigment with TiO2 / SiO2 / Al-based composite film was obtained. The pigment also has excellent comprehensive properties such as the illusion interference effect of pearlescent pigments and the conductivity, high hiding power, shielding and non-toxic environmental protection of metallic aluminum powder pigments. It has unique decorative effects and can be widely used in high-end automotive topcoats and high-end decorations. Products, surface coating of high-end instruments, ink printing, children's toys, etc. The method of the invention is simple and feasible, and has industrial feasibility.

Owner:SICHUAN UNIV

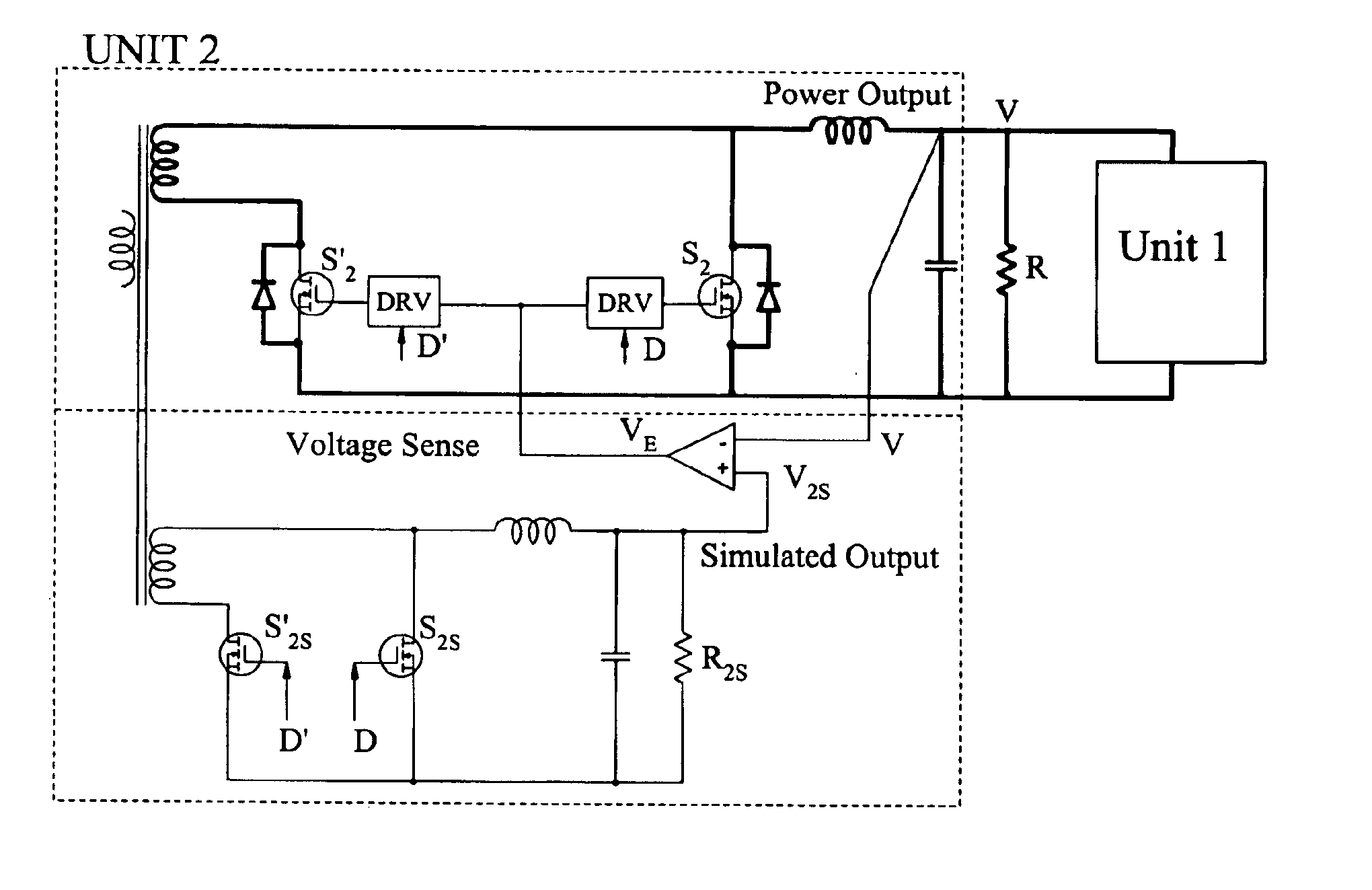

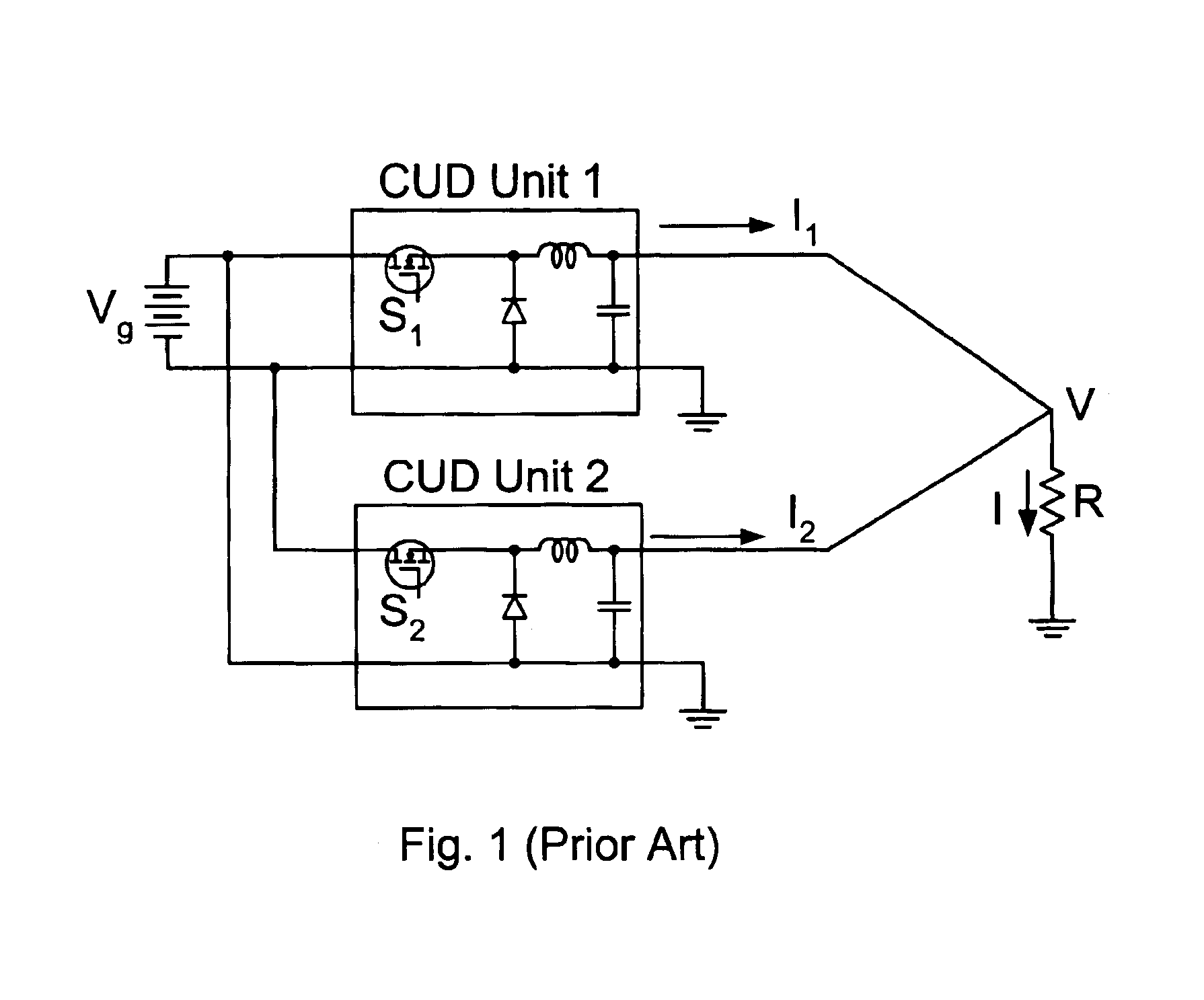

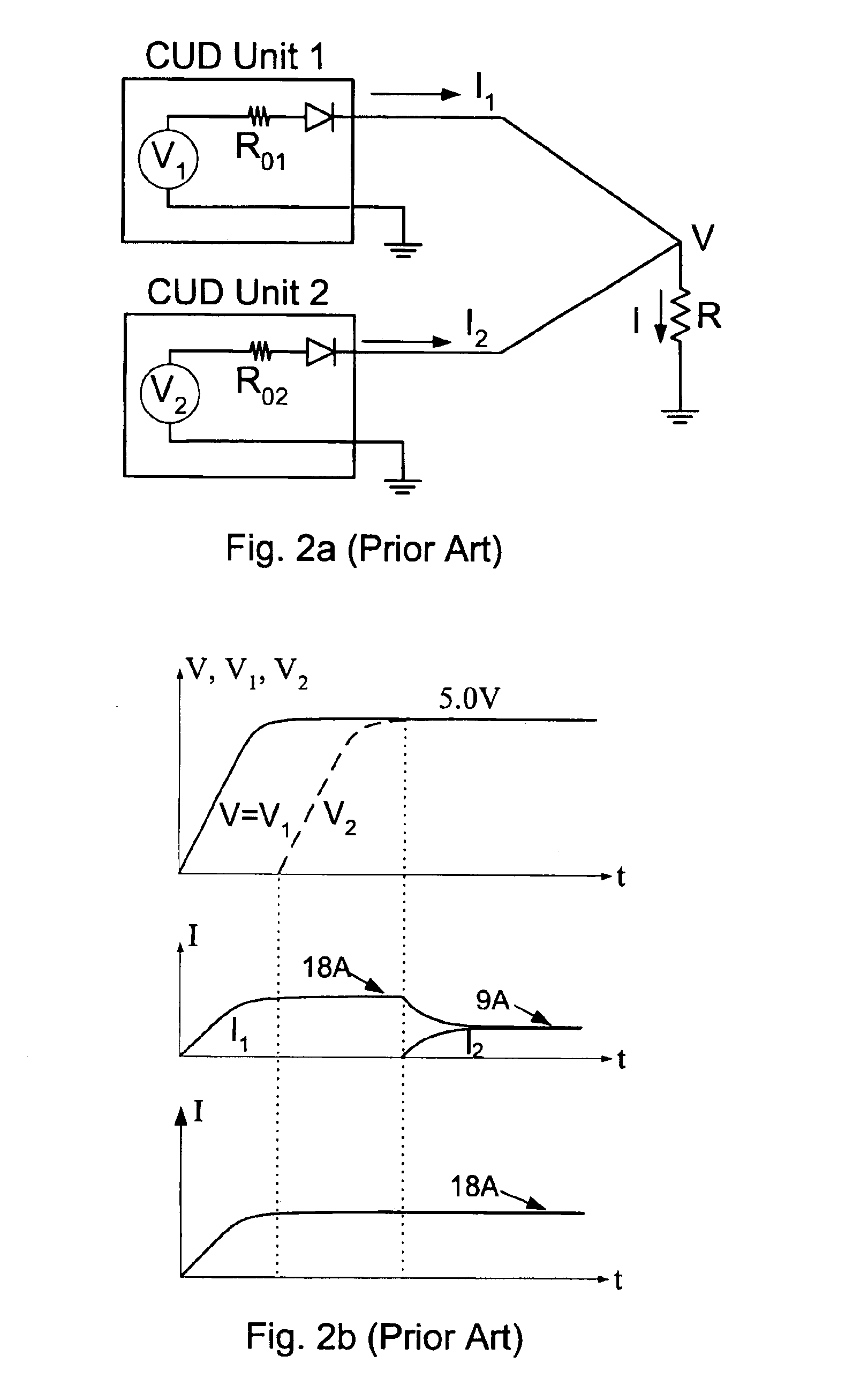

Voltage sense method and circuit which alleviate reverse current flow of current bi-directional converters

InactiveUS6853562B2Eliminate stressHigh pressureEfficient power electronics conversionEmergency protective circuit arrangementsVoltage overshootReverse current

The Voltage Sense Method is introduced and a number of its implementations using Voltage Sense Circuit are demonstrated to solve problems associated with the start-up of parallel switching converters, each converter having output synchronous rectifiers or more general Current Bi-directional Switches: prevention of the excessive reverse current, elimination of the excess voltage stress of the input switches and elimination of the voltage overshoot in the common output voltage. The Voltage Sense circuit added to each converter generates a Simulated Output Voltage, which predicts how would the output voltage of each particular unit rise during the start-up with enabled synchronous rectifiers if that particular unit were to operate alone. When the simulated output voltage of one converter reaches the actual common output voltage, synchronous rectifiers / CBS switches of that particular converter are all enabled so that their body-diodes, used up until that time to prevent reverse current flow, are by-passed eliminating all start-up problems. The introduced Voltage Sense Method and a number of its Voltage Sense Circuitries are also applicable to solve problems associated with the start-up of the current bi-directional converters with a battery load.

Owner:TESLACO

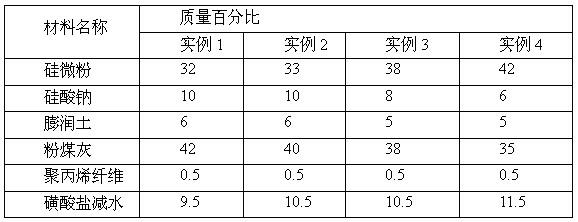

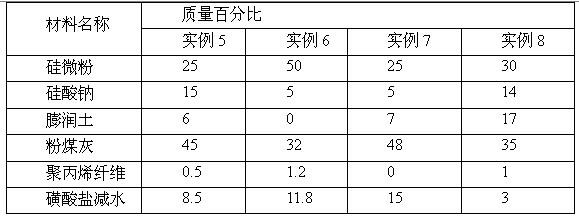

Inorganic cement capillary crystalline waterproofing agent and production process thereof

The invention relates to an inorganic cement capillary crystalline waterproofing agent and a production process thereof. The organic cement capillary crystalline waterproofing agent is prepared from silicon ash, sodium silicate, bentonite, pulverized fuel ash, polypropylene fiber and a sulfonate water reducer by a certain percentage proportion. The production process sequentially comprises the steps of compounding, feeding, mixing, inspecting, packaging and warehousing. The organic cement capillary crystalline waterproofing agent has the advantages of capillary crystalline, waterproofing performance, durability, denseness, leaking stoppage and the like and can be widely used for waterproofing systems comprising building outer walls, basements and the like, especially for negative side waterproofing systems.

Owner:上海英硕聚合材料股份有限公司

Regenerated silicon material as well as preparation method and application thereof

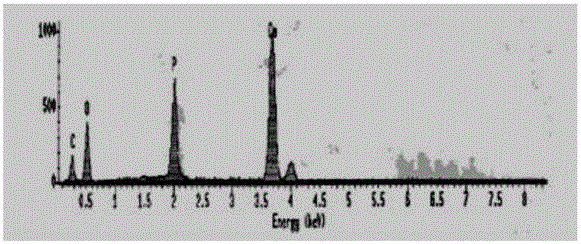

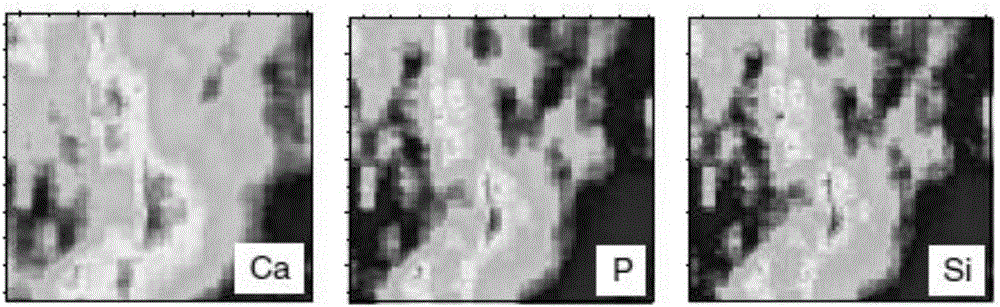

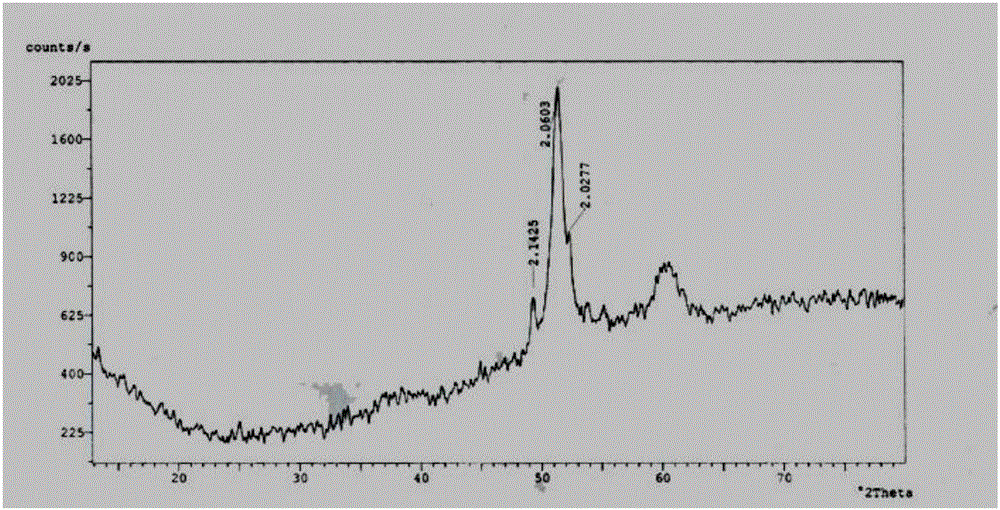

InactiveCN106362214AUnique structureUnique performanceCosmetic preparationsToilet preparationsNMR - Nuclear magnetic resonanceNetwork structure

The invention provides a regenerated silicon material as well as a preparation method and application thereof. The regenerated silicon material is prepared from 40 to 70 weight percent of silicon dioxide and 30 to 60 weight percent of oxide selected from phosphorus, calcium and sodium, wherein the silicon dioxide forms a three-dimensional network structure; calcium ions and phosphorus ions are orderly distributed among three-dimensional reticular silicon atoms, wherein five-valence silicon atoms and / or six-valence silicon atoms account for 1 to 10 mol percent of all silicon atoms; the content of phosphorus oxide is 2 to 5 weight percent; in addition, in an NMR (Nuclear Magnetic Resonance) graph, an absorption peak exists at a position of 200 to 220ppm. The regenerated silicon material rich in five valence coordinate silicon and six valence coordinate silicon can be formed at lower temperature and normal pressure, and has unique structures and performances. Besides, high-coordinate silicon atoms in the regenerated silicon material can make an ultraviolet absorption peak generate red shift.

Owner:BEIJING BEST LIFE REGENERATIVE MEDICINE TECH CO LTD

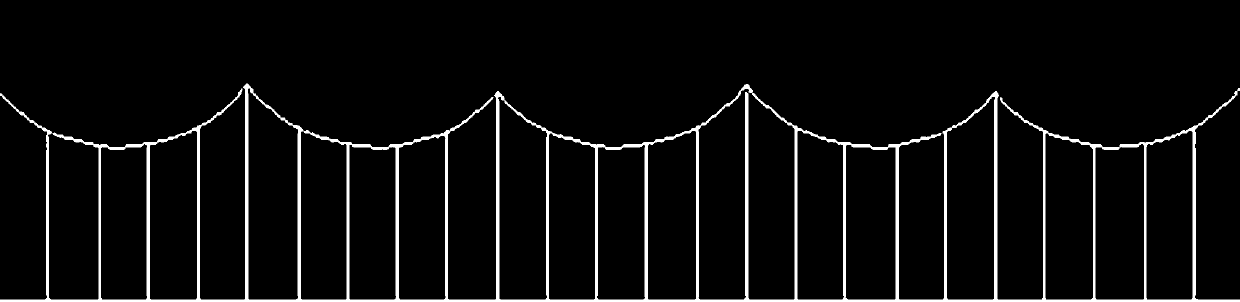

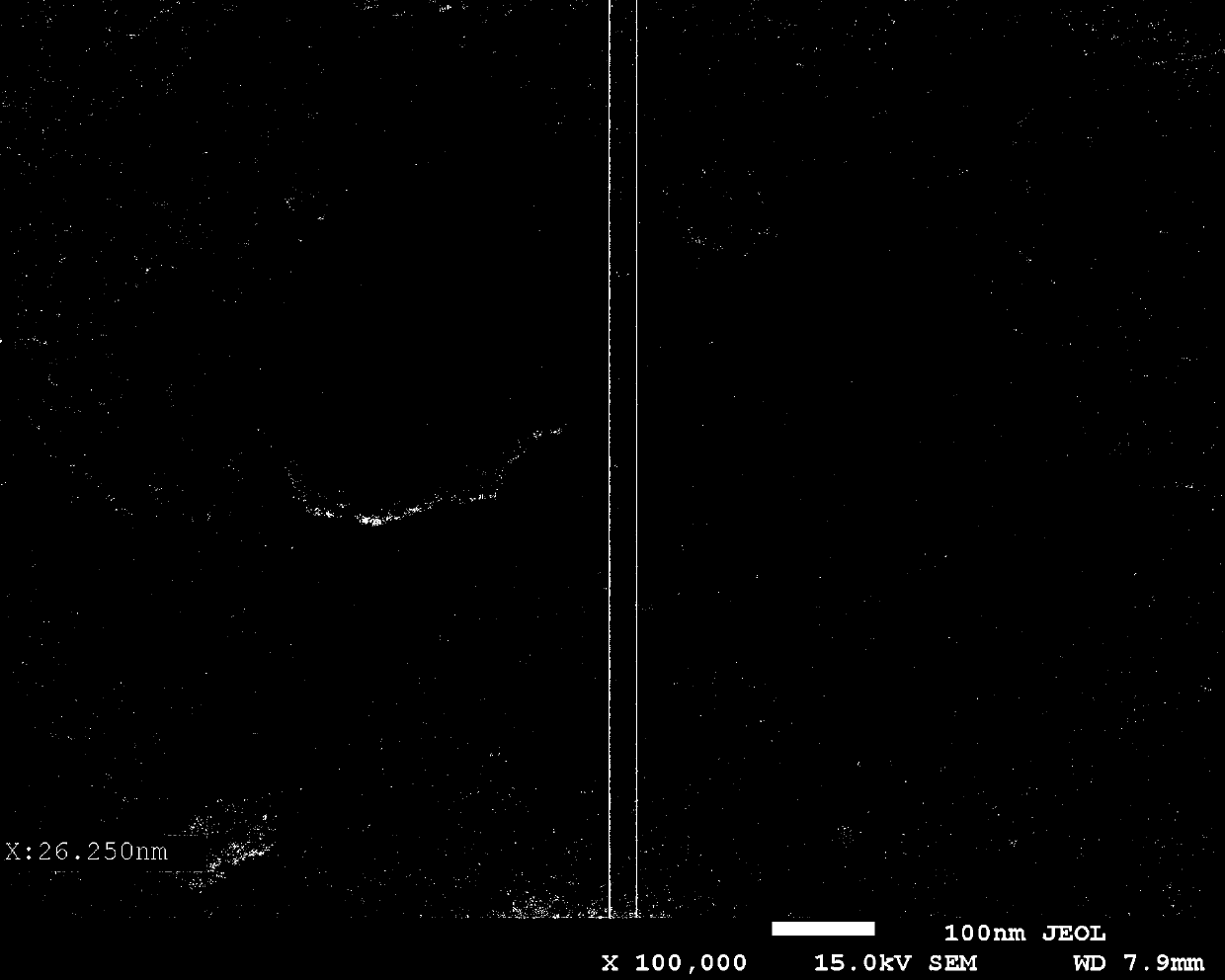

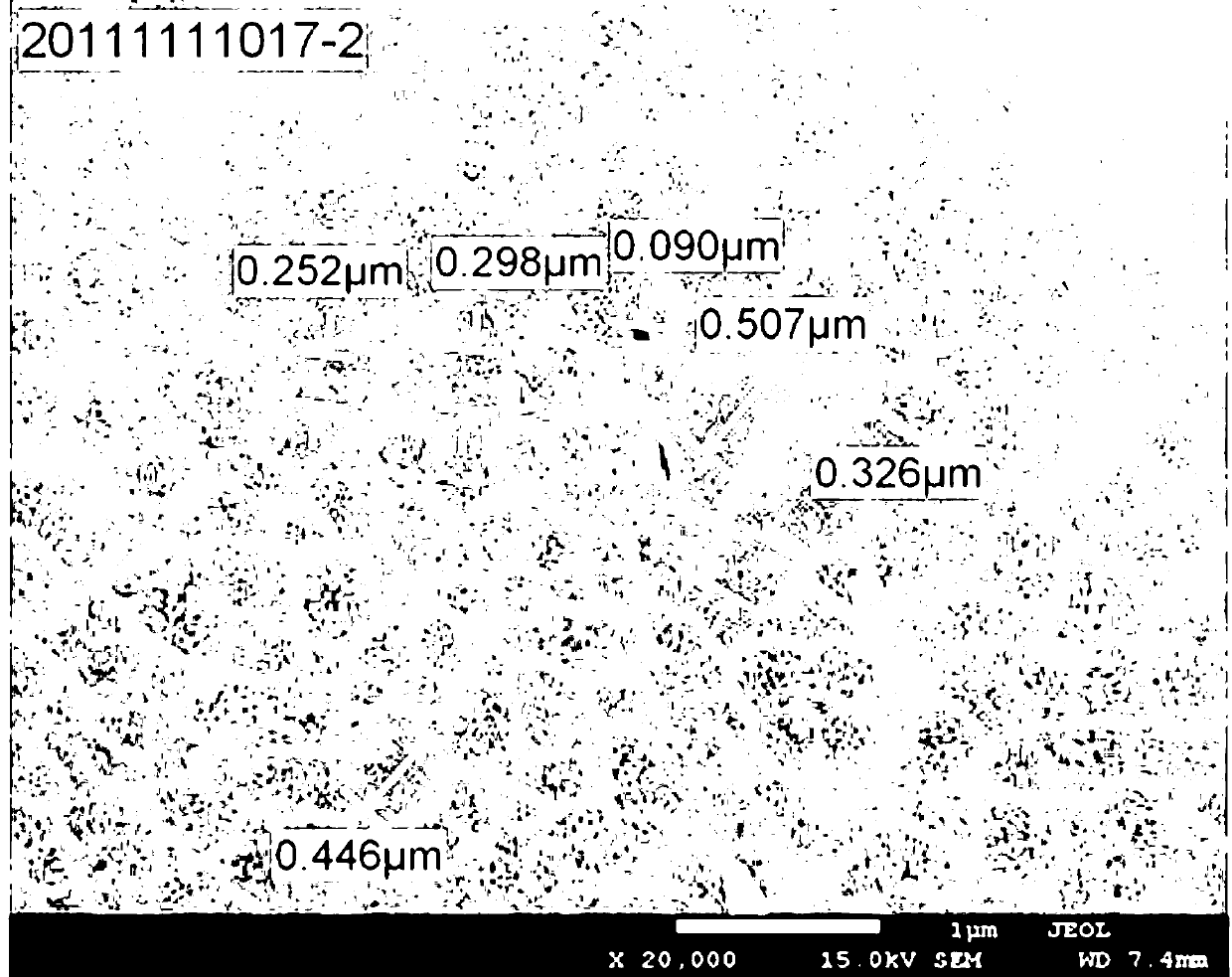

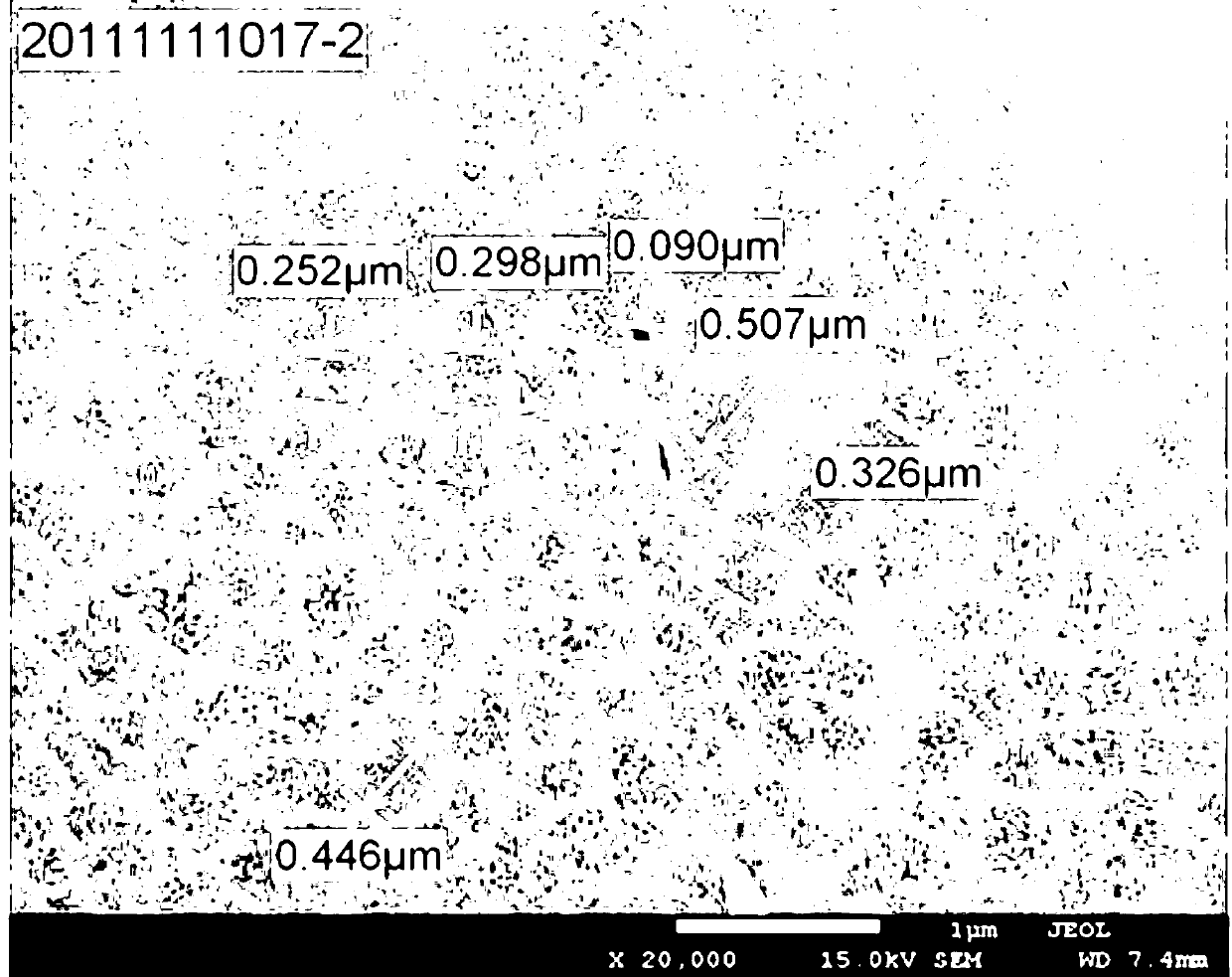

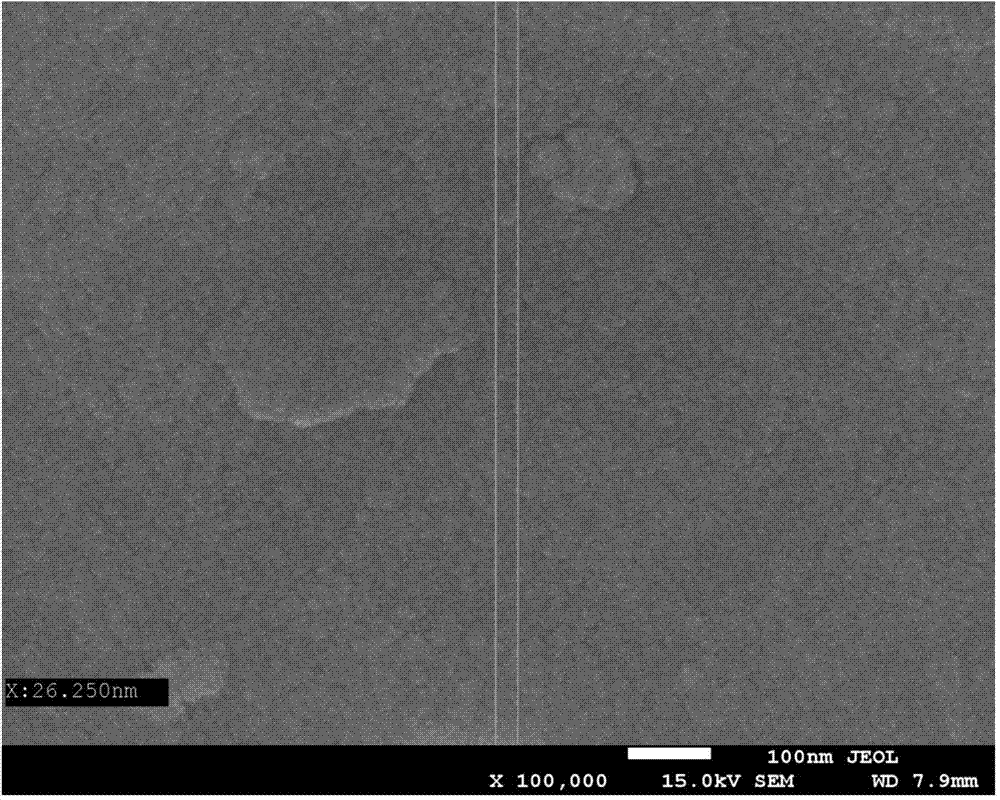

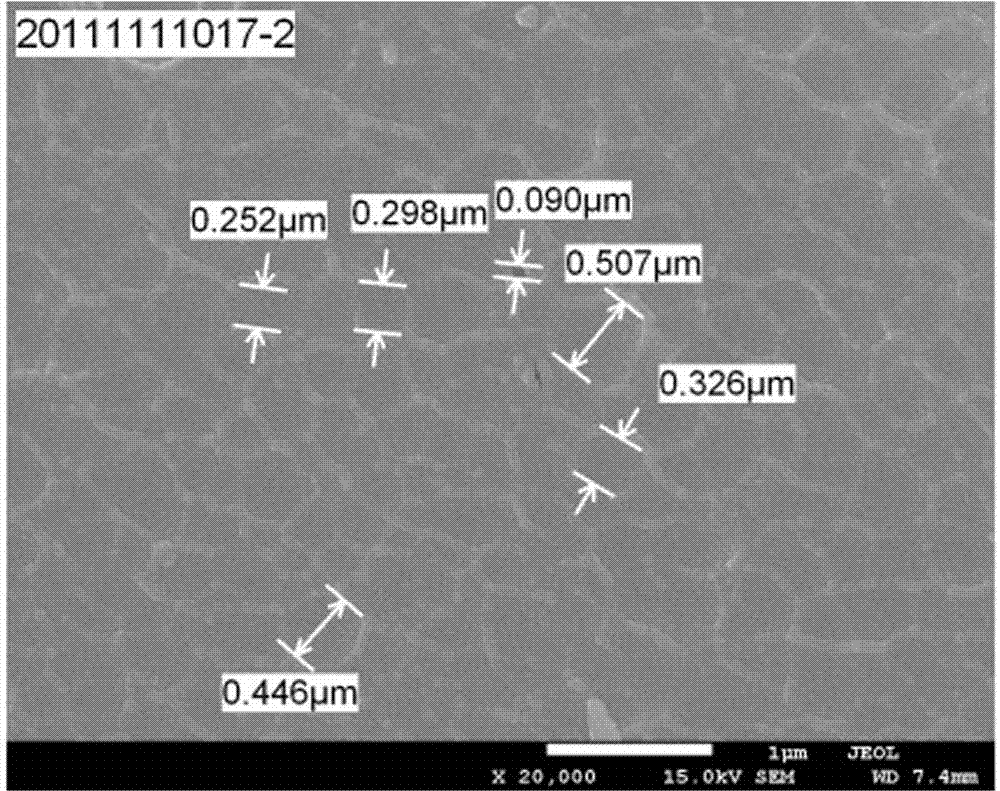

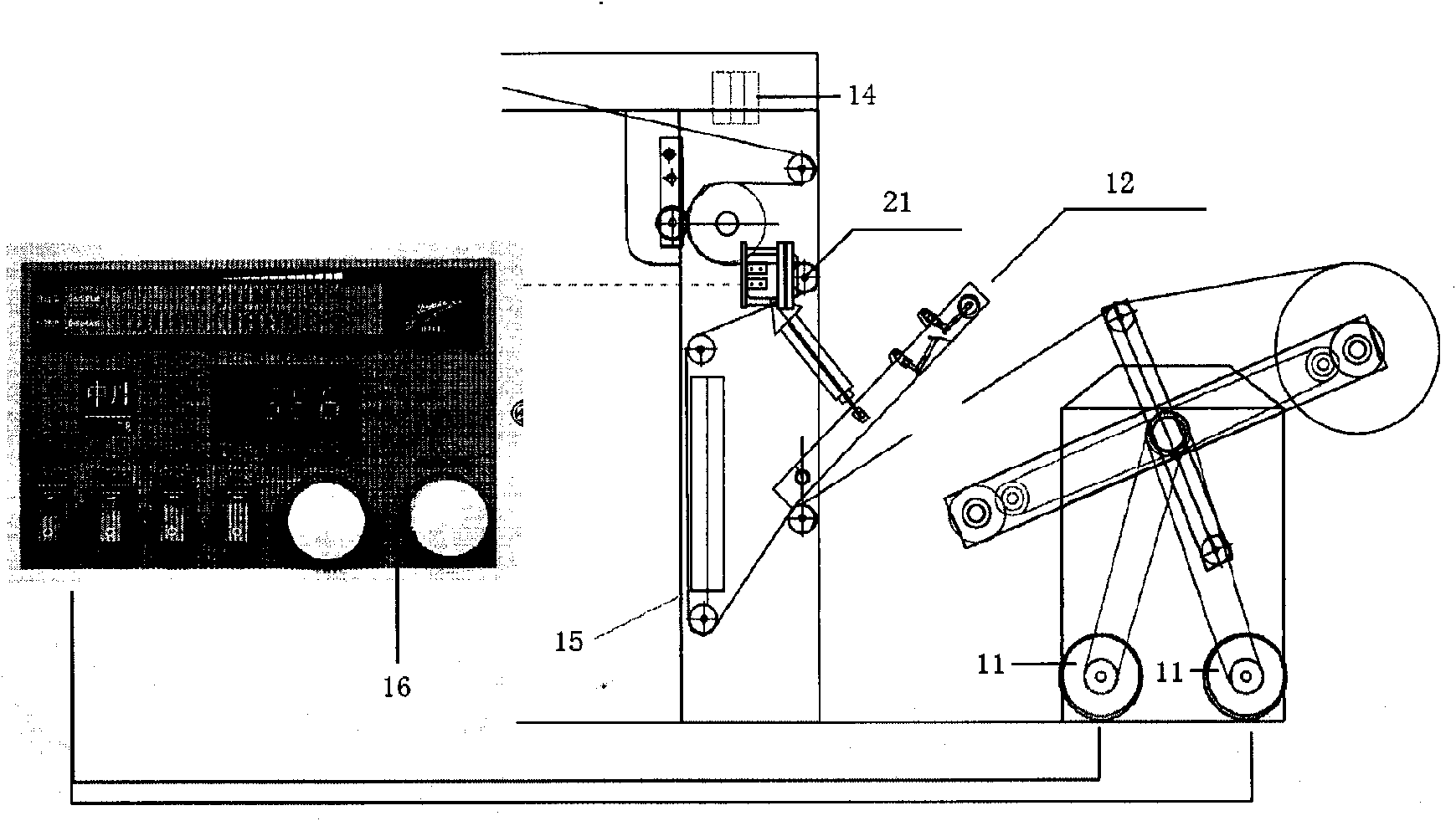

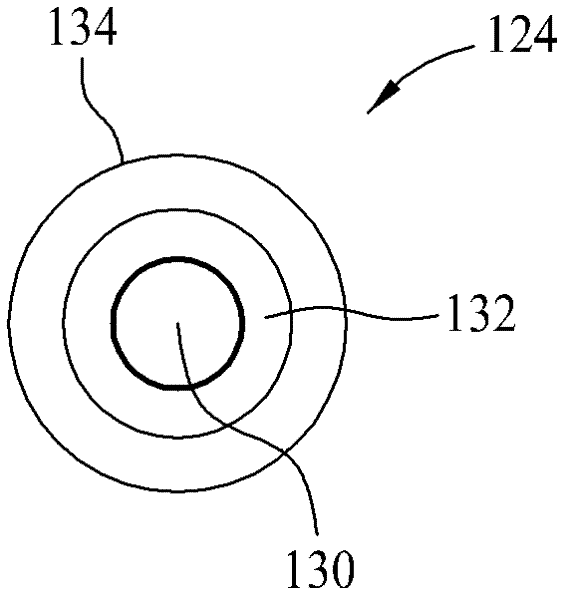

Preparation method of aluminum alloy-resin composite and aluminum alloy-resin composite prepared by using same

ActiveCN103286995AHigh strengthUnique structureAnodisationAutomatic/semiautomatic turning machinesAlloy substrateAnodic oxidation

The invention provides a preparation method of an aluminum alloy-resin composite and an aluminum alloy-resin composite prepared by using the same. The preparation method comprises the following steps: S1. anodizing a pretreated aluminum alloy substrate to obtain an aluminum alloy of which the surface contains a nanoporous oxide film layer; S2. soaking the aluminum alloy containing the nanoporous oxide film layer obtained in the step S1 in an alkaline solution with the pH value of 10-13 to form corrosion pores on the outer surface layer of the oxide film layer, thereby obtaining the surface-treated aluminum alloy substrate; and S3. putting the surface-treated aluminum alloy substrate in a mold, injecting a resin composition into the mold to be combined with the surface-treated aluminum alloy substrate, and forming to obtain the aluminum alloy-resin composite. A unique double-layer stereoscopic porous structure can be formed on the surface of the aluminum alloy to enhance the binding force between the resin and the aluminum alloy; and the invention has the advantages of easier formation, basically no influence on the appearance of the aluminum alloy, wider application range and no environment pollution, and is more suitable for large-scale production.

Owner:BYD CO LTD

Mobile phone case

ActiveCN104780241AImprove corrosion resistanceAppearance has no effectAnodisationSynthetic resin layered productsNanometreNanopore

A shell, a method of preparing the shell and an electronic product comprising the shell are provided. The shell may comprise: a metal shell body, a plastic part made of a resin, and an oxide layer formed between the metal body and the plastic part, joining the plastic part to the metal shell body, wherein the oxide layer contains corrosion pores having an average diameter of about 200 nm to about 2000 nm in the surface contacting the plastic part, and nanopores having a diameter of about 10 to 100 nm in the surface contacting the metal shell body, and a part of the resin is filled in the corrosion pore and corrosion pore.

Owner:BYD CO LTD

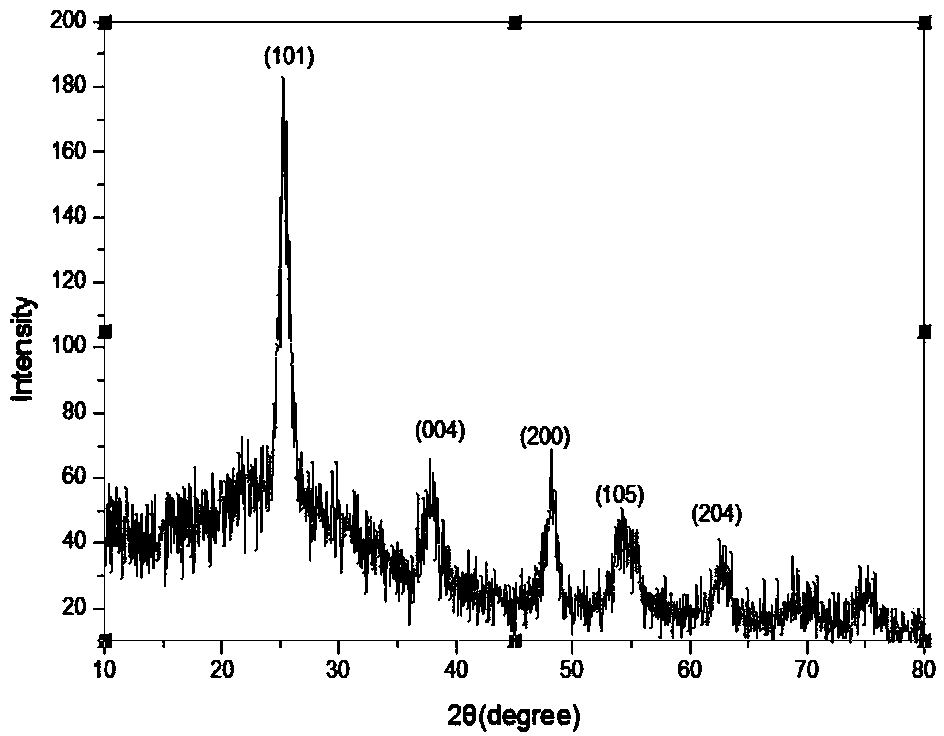

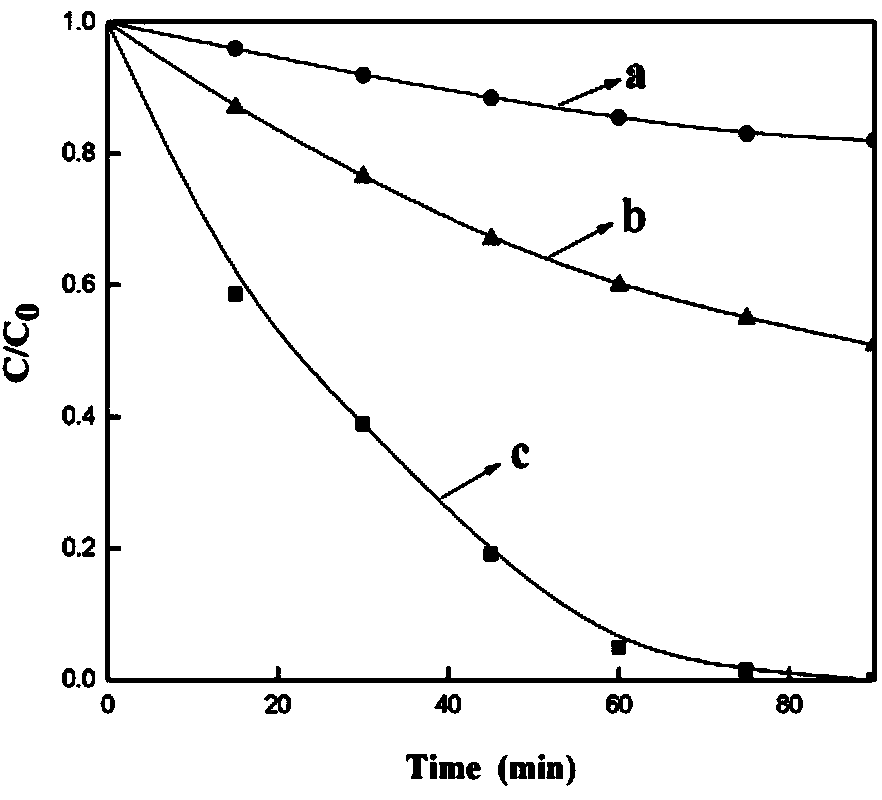

Supported nano TiO2 catalyst and preparation method thereof

InactiveCN103908979AEvenly dispersedLarge specific surface areaOrganic-compounds/hydrides/coordination-complexes catalystsProtonProton exchange membrane fuel cell

The invention discloses a supported nano TiO2 catalyst and a preparation method of the supported nano TiO2 catalyst. The preparation method comprises the following steps: firstly carrying out certain pretreatment on bacterial cellulose prepared by a dynamic fermentation method, by utilizing rich polyhydroxyl groups and a directionally-distributed water molecule layer on the surface of the bacterial cellulose, enabling the titanium dioxide precursor comprising chlorate, sulfate and organic complex and the like to be directionally hydrolyzed on the surface of the bacterial cellulose by a hydrothermal method, and finally preparing the supported nano TiO2 catalyst by dewatering. The supported nano TiO2 catalyst prepared by the invention has the advantages that the preparation process is simple, the cost is low, the reaction condition is mild, the shape of a product is controllable and the specific surface area is large and the like, and can be widely applied in the fields such as photocatalysis, optical devices and proton exchange membrane fuel cells.

Owner:NANJING UNIV OF SCI & TECH

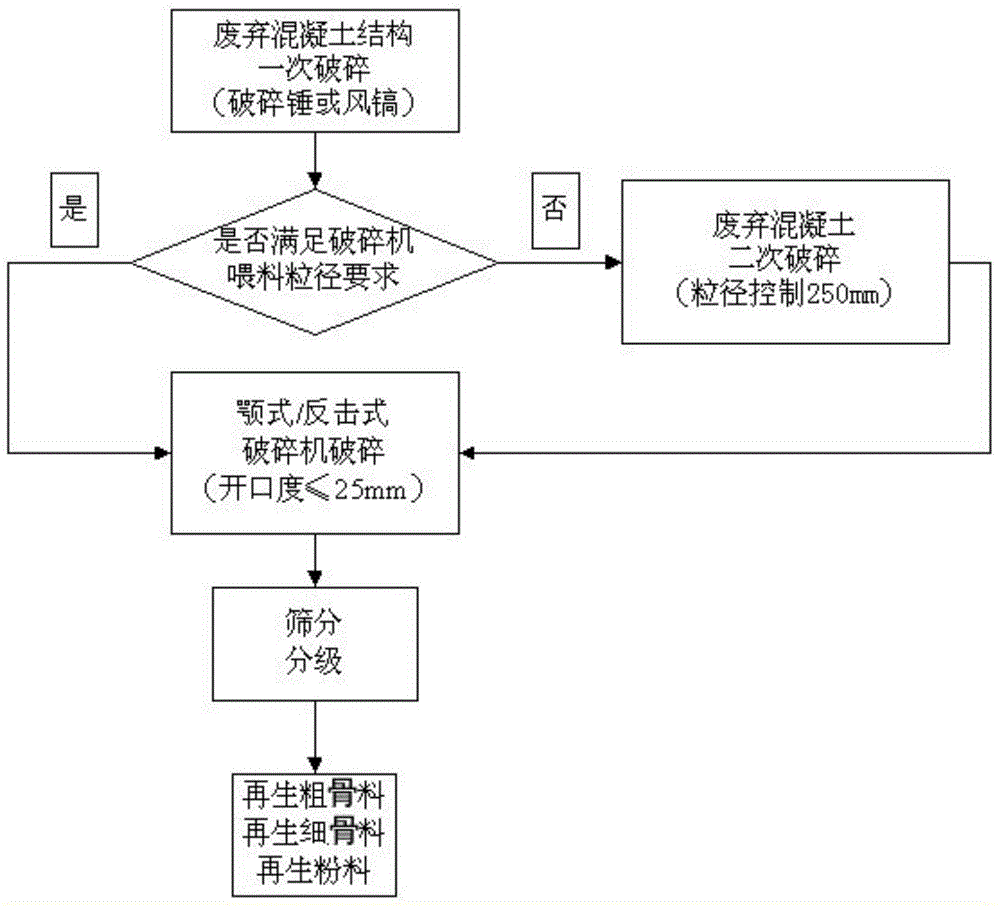

Ecological nanometer photocatalysis completely recycled concrete

ActiveCN104310891AUnique performanceAchieve full utilizationSolid waste managementWater reducerConstruction aggregate

The invention discloses an ecological nanometer photocatalysis completely recycled concrete. The concrete is prepared from following components in parts by weight: 360-480 parts of cement, 1000-1200 parts of loaded photocatalyst coarse aggregate, 500-600 parts of fine aggregate, 40-90 parts of supplementary cementious material, 4-10 parts of efficient water reducing agent, and 150-180 parts of water. The cement has the advantages that regenerated coarse aggregate, regenerated fine aggregate and regenerated concrete powder produced by waste concrete are used for preparing the concrete, so that full utilization of the waste concrete and zero resource waste are really realized, and the ecological environmental protection effect is obvious; the nanometer photocatalysis component is loaded in the regenerated coarse aggregate for the first time, so that the concrete can decompose vehicle exhaust and improve the atmospheric environment.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

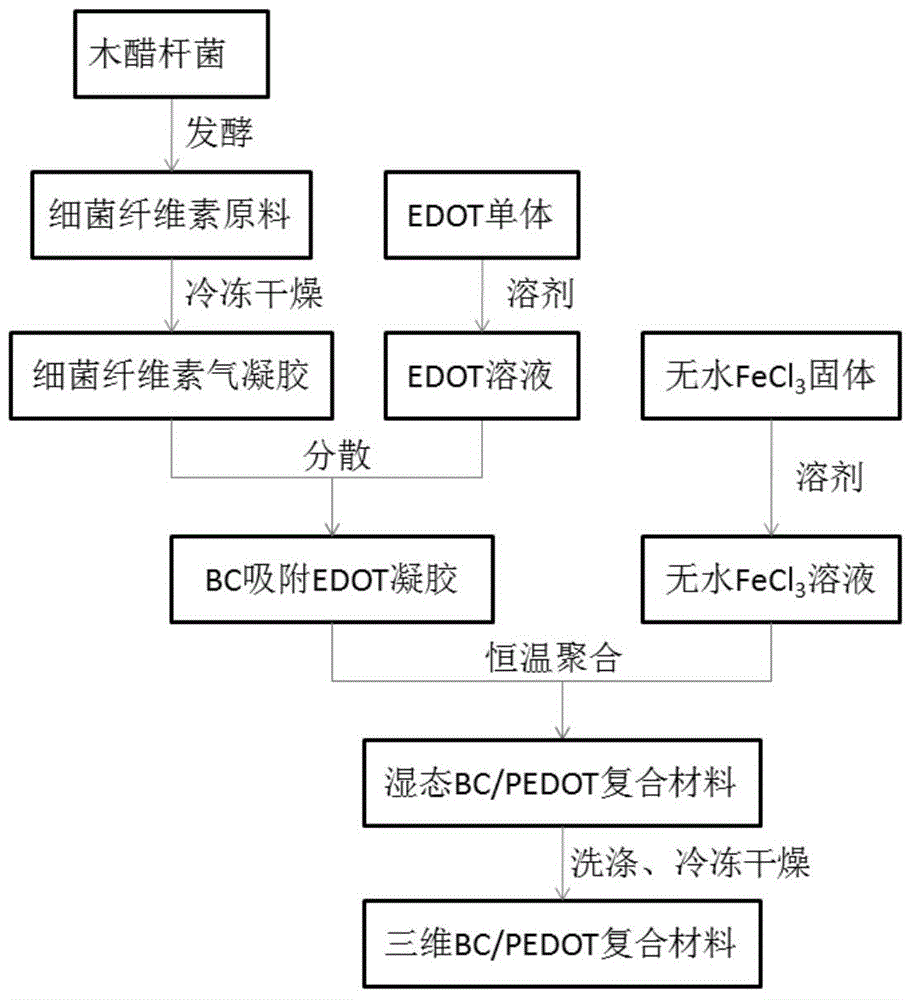

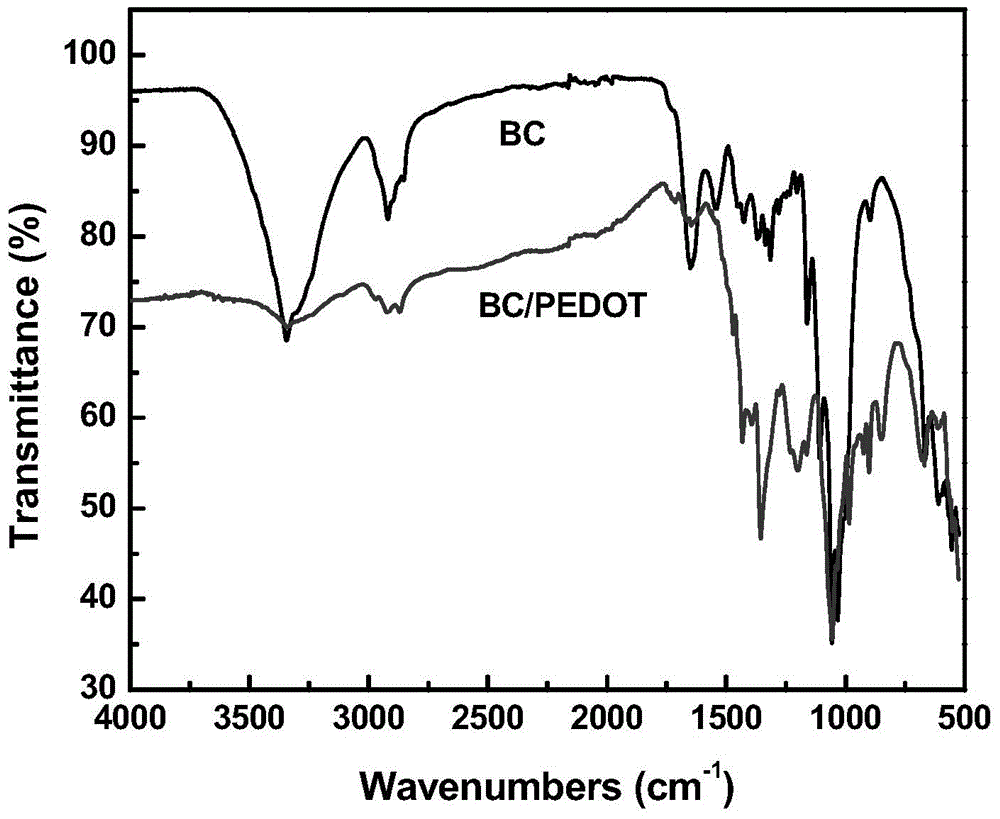

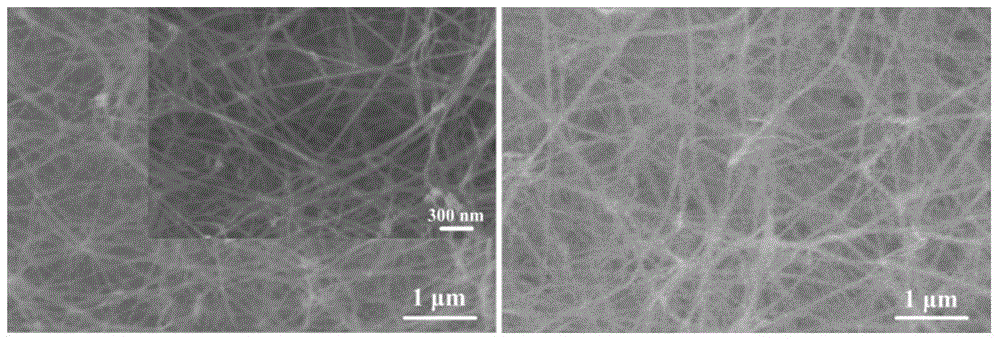

A bacterial cellulose/poly(3,4-ethylenedioxythiophene) nanometer conductive composite material and a preparing method thereof

InactiveCN103980670AUniform chemical structureImprove controllabilityFreeze-dryingBiocompatibility Testing

The invention discloses a bacterial cellulose / poly(3,4-ethylenedioxythiophene) nanometer conductive composite material and a preparing method thereof. The method includes: a step of removing impurities of bacterial cellulose fermented by acetobacter xylinum, pretreating to obtain a clean bacterial cellulose raw material, and performing freeze-drying to obtain bacterial cellulose aerogel; a step of adding the bacterial cellulose aerogel into a 3,4-ethylenedioxythiophene solution, dispersing uniformly, and performing ultrasonic processing so as to allow the ethylenedioxythiophene monomer to be fully adsorbed by the bacterial cellulose; a step of adding a solution of ferric chloride anhydrous with the same volume, performing in-situ oxidation polymerization under ultrasonic constant-temperature conditions, and a step of subjecting the obtained crude product to ultrasonic washing with methanol (or ethanol) and deionized water repeatedly, fully dipping the crude product with deionized water, and performing freeze-drying to obtain the nanometer conductive composite material. The nanometer conductive composite material has advantages of low cost, mild reaction, high speed, good biocompatibility and a three-dimensional net structure.

Owner:NANJING UNIV OF SCI & TECH

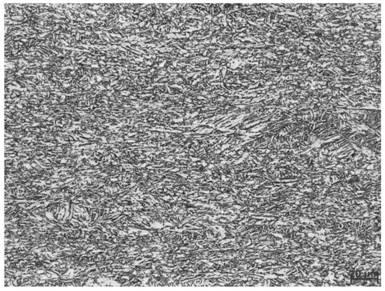

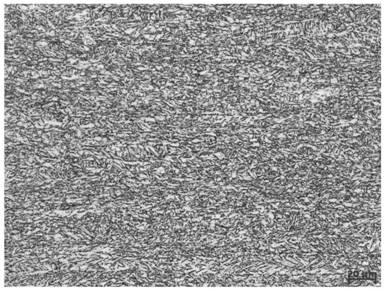

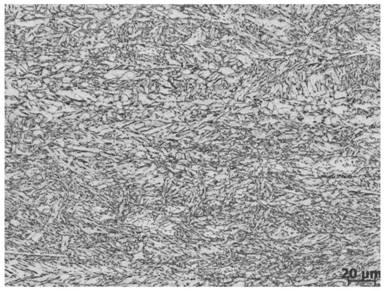

TMCP type high strength and toughness high fatigue resistance weather-proof bridge steel plate, and preparation method thereof

The invention discloses a TMCP type high strength and toughness high fatigue resistance weather-proof bridge steel plate, and a preparation method thereof. The TMCP type high strength and toughness high fatigue resistance weather-proof bridge steel plate comprises, by weight, 0.05 to 0.08% of C, 0.12 to 0.18% of Si, 1.4 to 1.6% of Mn, 0.045 to 0.058% of Nb, 0.01 to 0.02% of Ti, 0.30 to 0.35% of Cu, 0.22 to 0.30% of Cr, 0.45 to 0.55% of Ni, 0.02 to 0.04% of Al, 0.05 to 0.12% of Mo, P<=0.009%, S<=0.005%, and the balance Fe and other unavoidable impurities. The advantages are that: product performance is excellent; the yield strength is larger than 500MPa; -60 DEG C crack-tip opening displacement index is 0.3mm or higher; 10 million time fatigue strength is 170MPa or higher; and corrosion weight loss rate is 3.0g / (m2*h) or lower.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +2

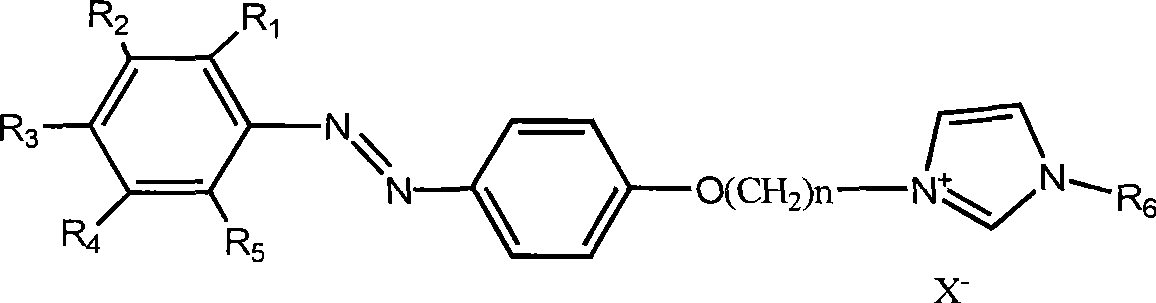

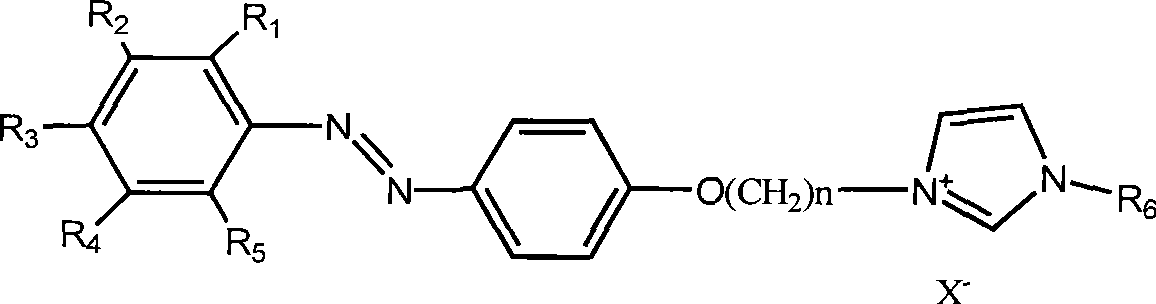

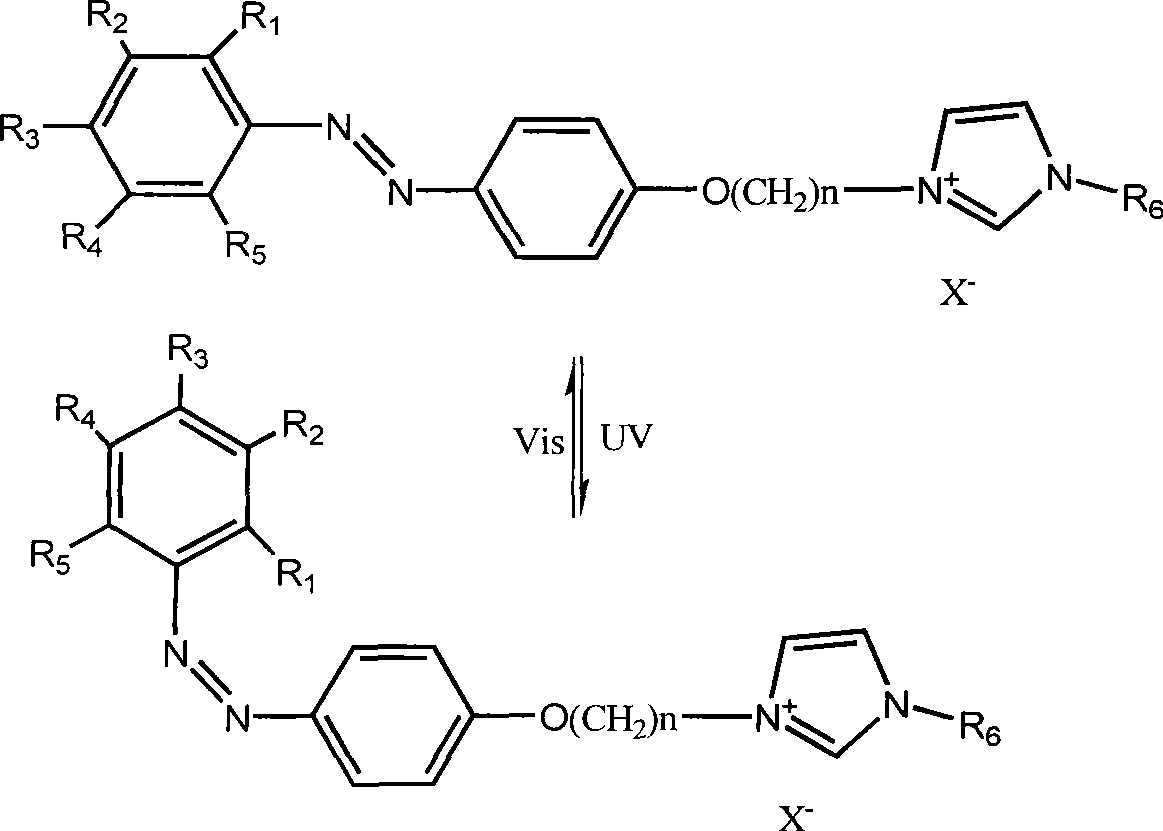

Photoresponse ion liquid and preparation thereof

ActiveCN101468969APhysicochemical property modulationUnique performanceOrganic chemistryDevice materialFluorescence

The invention discloses a photoresponse ionic liquid and a preparation method thereof. The structural formula of the ionic liquid is as follows. The ionic liquid contains photoresponse azobenzene groups, can maintain good photochromic (isomerous) performance under the condition of solution and pure liquid, can realize physiochemical properties of the ionic liquid such as ultraviolet visual absorption spectrum, fluorescence emission spectrum and reversible change of conductivity under the action of light, and can be taken as a superior information storage material, an optical switch molecular device material, an electrically conductive photochromic (isomerous) material and a photosensitive material.

Owner:浙江蓝德能源科技发展有限公司

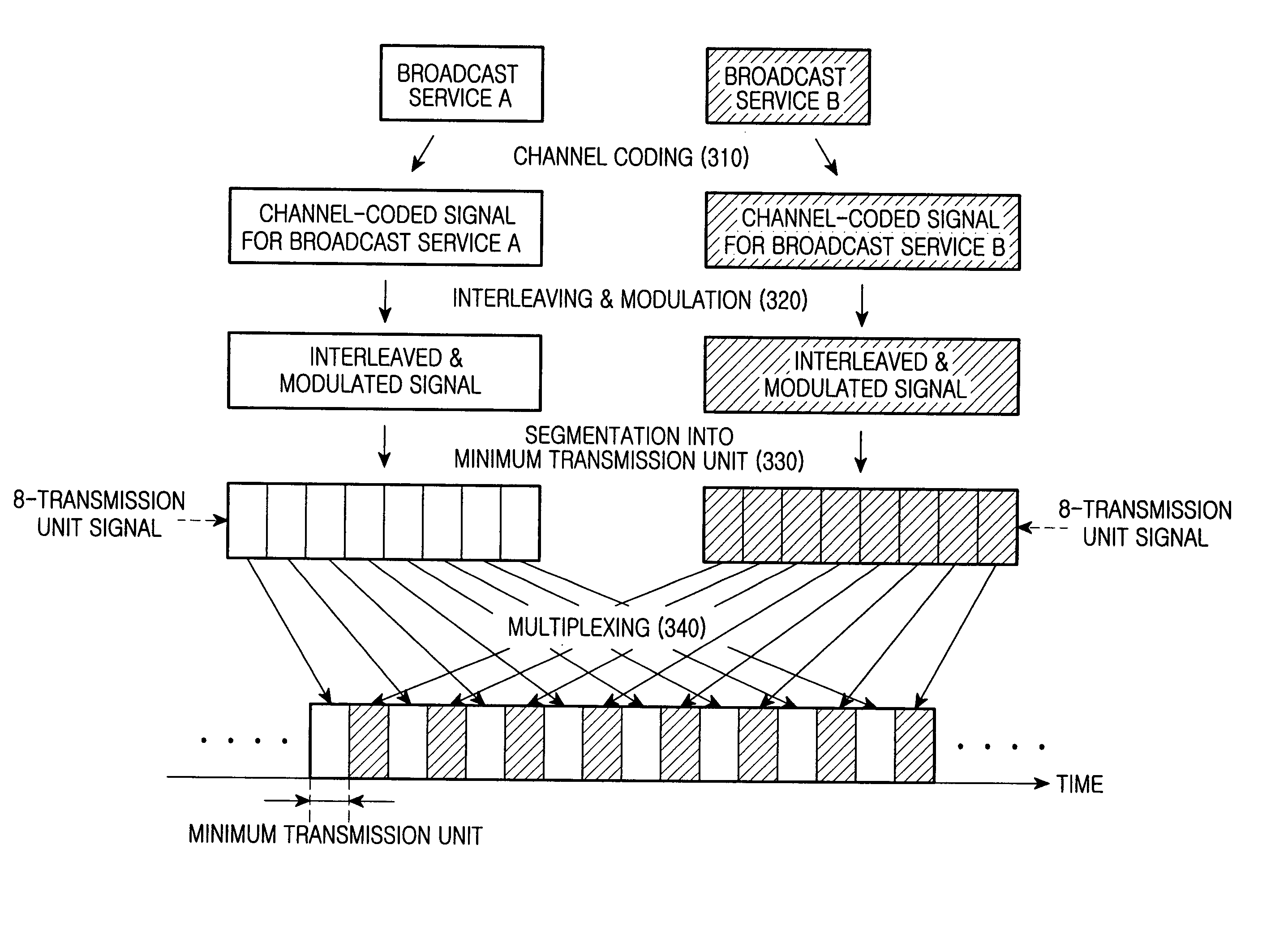

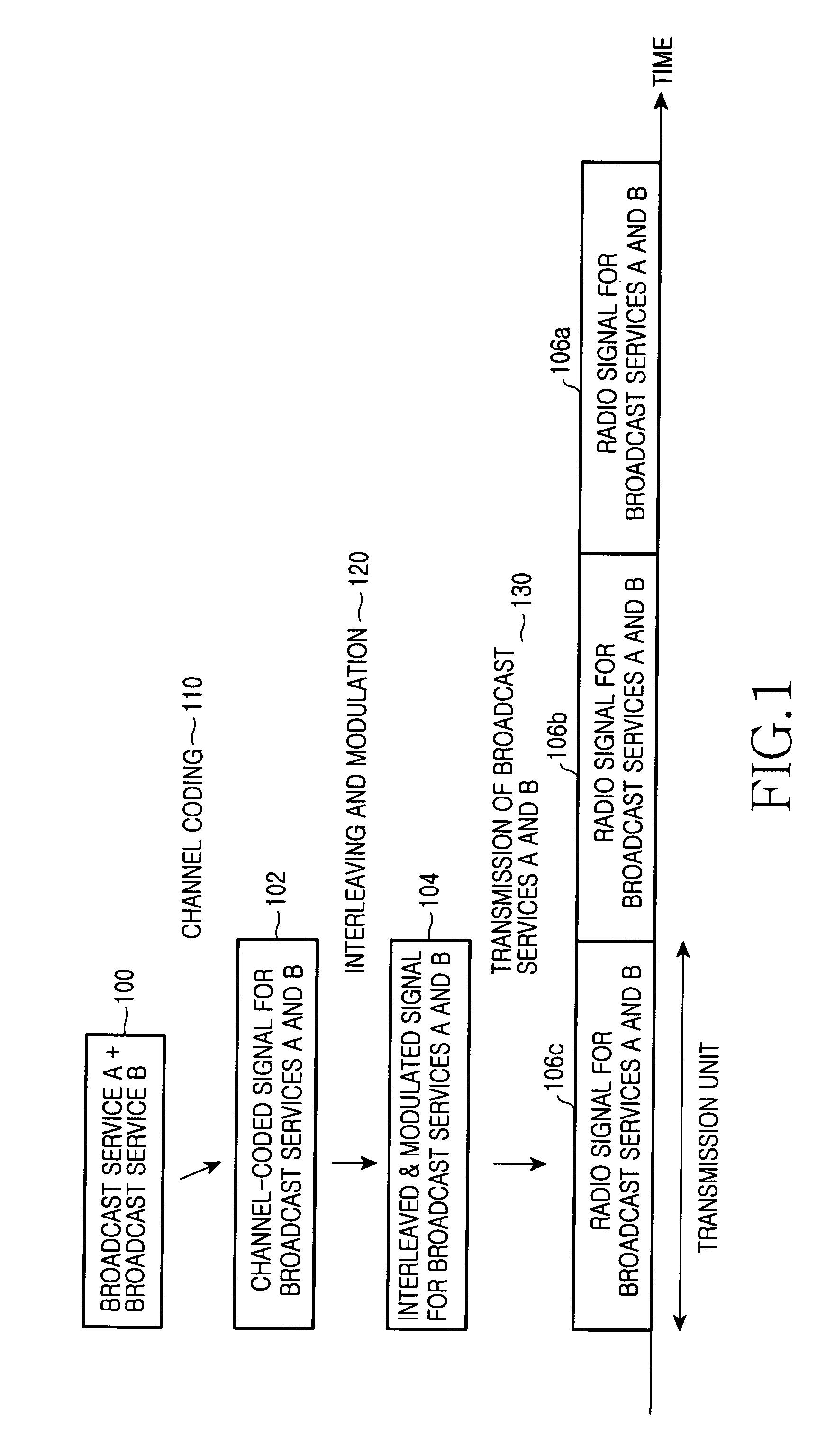

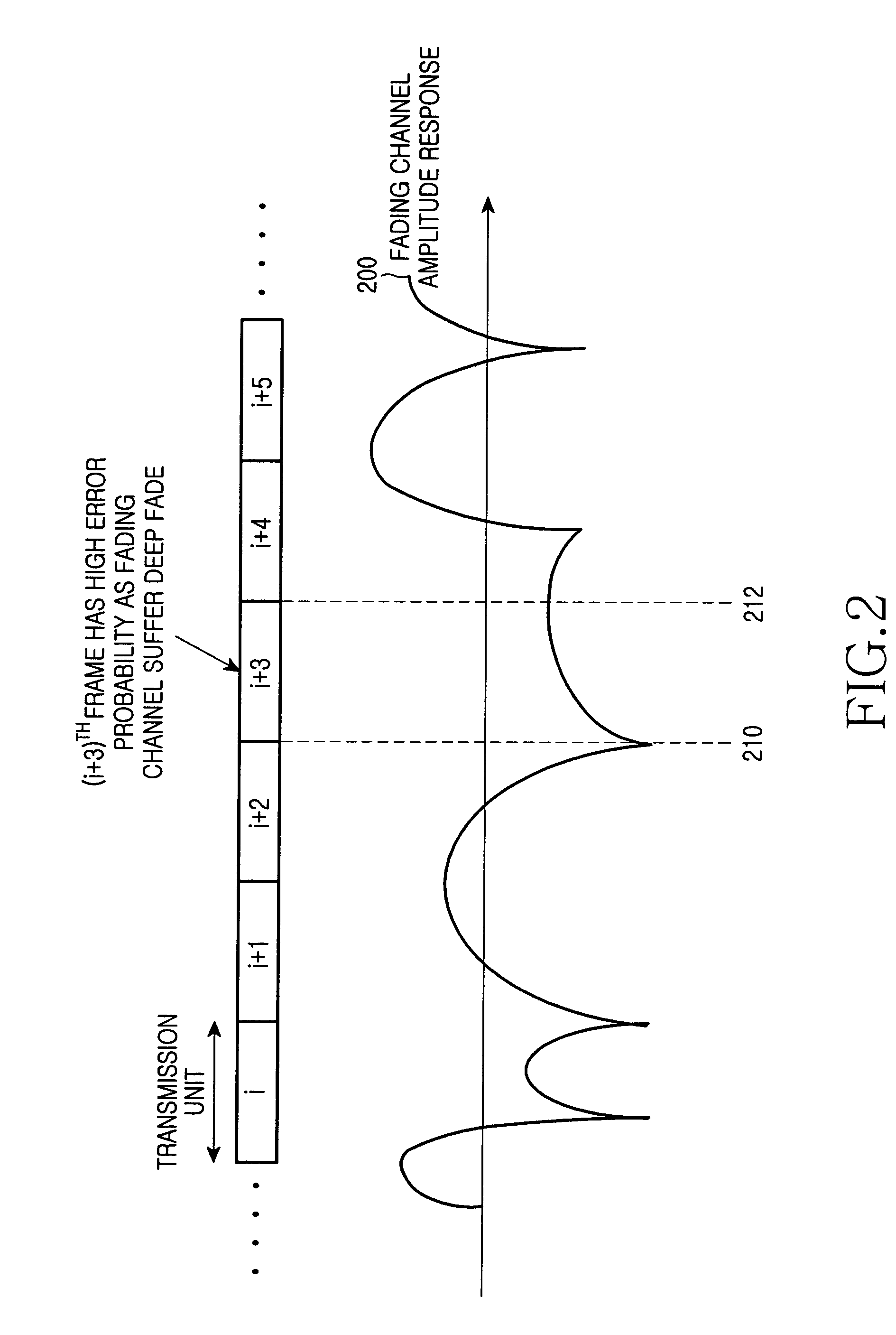

Method for transmitting and receiving broadcast service data in an OFDMA wireless communication system

ActiveUS7751305B2Unique performanceBroadcast-related systemsSpecial service for subscribersCommunications systemPhysical layer

A method for providing two or more broadcast services in an orthogonal frequency division multiple access (OFDMA) wireless communication system. The method comprises the steps of separately receiving broadcast services to be transmitted, and independently performing coding, interleaving and modulation on the broadcast services according to a required quality for each of the broadcast services; segmenting each of the modulated broadcast signals into minimum transmission units; time-division-multiplexing the segmented broadcast service signals; configuring a frame comprising information on the broadcast service in physical layer transmission information transmitted together with the broadcast service; and transmitting the frame.

Owner:SAMSUNG ELECTRONICS CO LTD

Machine-made sand fair-faced concrete mixer

The invention relates to a machine-made sand and clear water concrete mixture, which pertains to the field of novel concrete materials. The clear water concrete mixture is made from 100 parts of cement, 65-150 parts of mineral powder, 0-10 parts of silicon powder, 1.7-2.6 parts of a polycarboxylic acid water reducing agent, 330-530 parts of crushed stone and 250-410 parts of machine-made sand; in order to cause the colors of the fresh mixed concrete and hardened concrete to reach different degrees of light white, the mixture can be further added with 0-6 parts of titanium dioxide. The concrete mixture is entirely made from the machine-made sand, which is helpful to save natural resource, and the concrete has good workability and water retention property.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

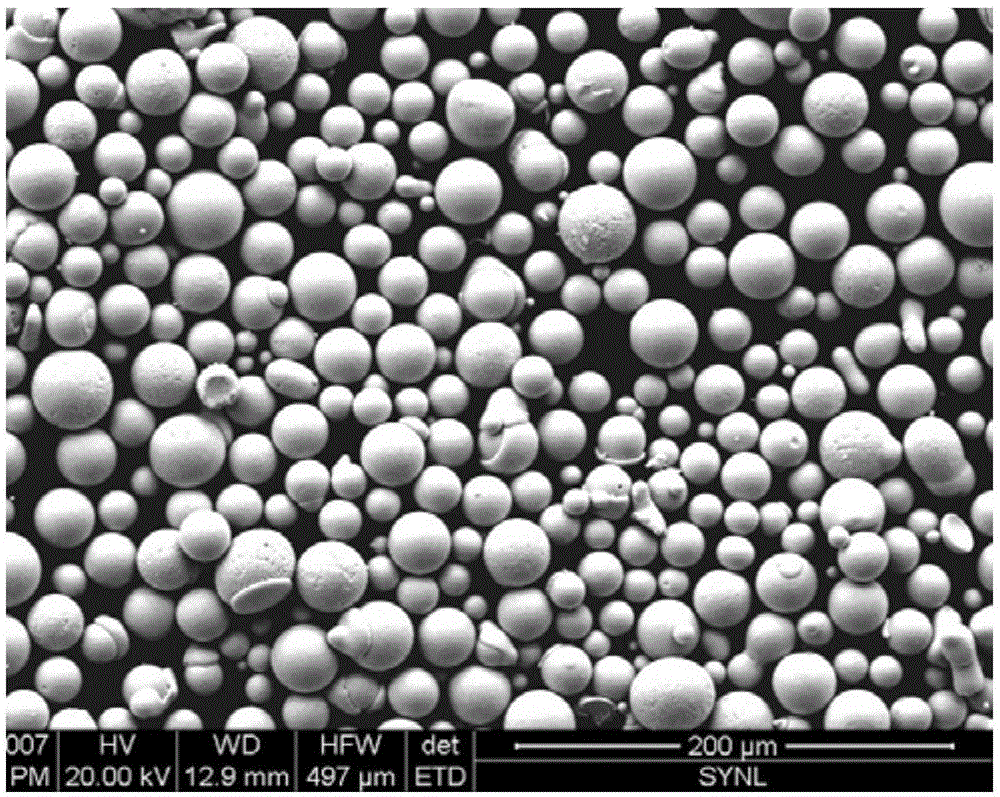

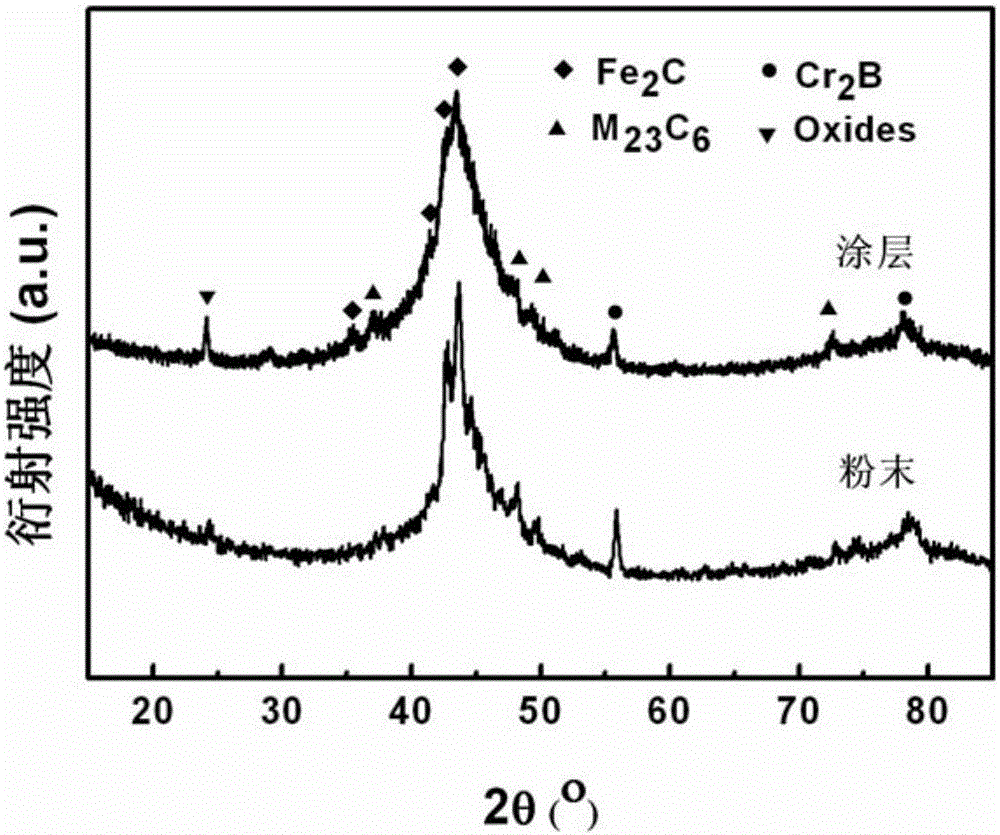

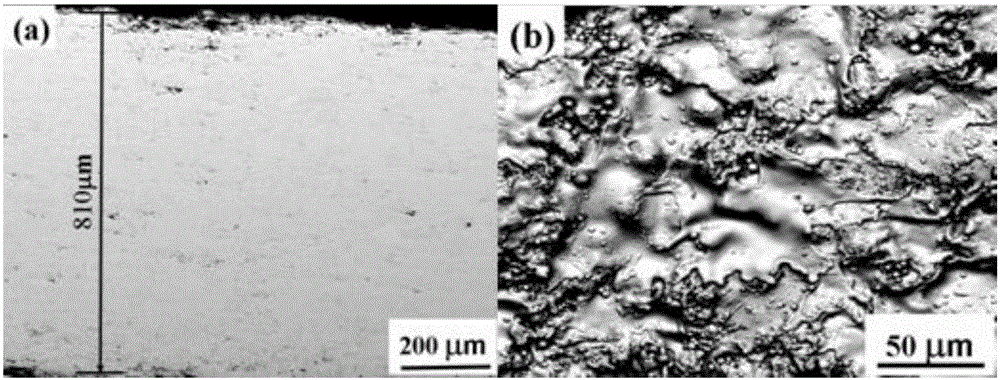

Iron-based amorphous alloy powder and preparing method and application thereof

The invention relates to iron-based amorphous alloy powder and a preparing method thereof. The alloy powder is prepared from, by weight, 40-65% of Fe, 15-25% of Cr, 10-20% of Mo, 2-8% of W, 1-5% of Mn, 1-4% of B, 0-4% of Si, 0-3% of C, 0-2% of Ce, and 0-2% of Y, wherein at least two elements of Si, C, Ce and Y should exist simultaneously, and the total mass percentage is larger than or equal to 1%. The mobility and the filling performance of the iron-based amorphous alloy powder are excellent, the content of an amorphous phase is larger than or equal to 50%, the powder serves a thermal spraying raw material to prepare a coating which is compact and uniform in structure, low in porosity, few in unmelted particles, low in oxygen content, high in amorphous-phase content, free of magnetism, high in substrate-bonding strength, high in Vickers hardness, resistant to corrosion and excellent in friction resistance, and thus the iron-based amorphous alloy powder has multiple purposes.

Owner:CHINA SHIP DEV & DESIGN CENT

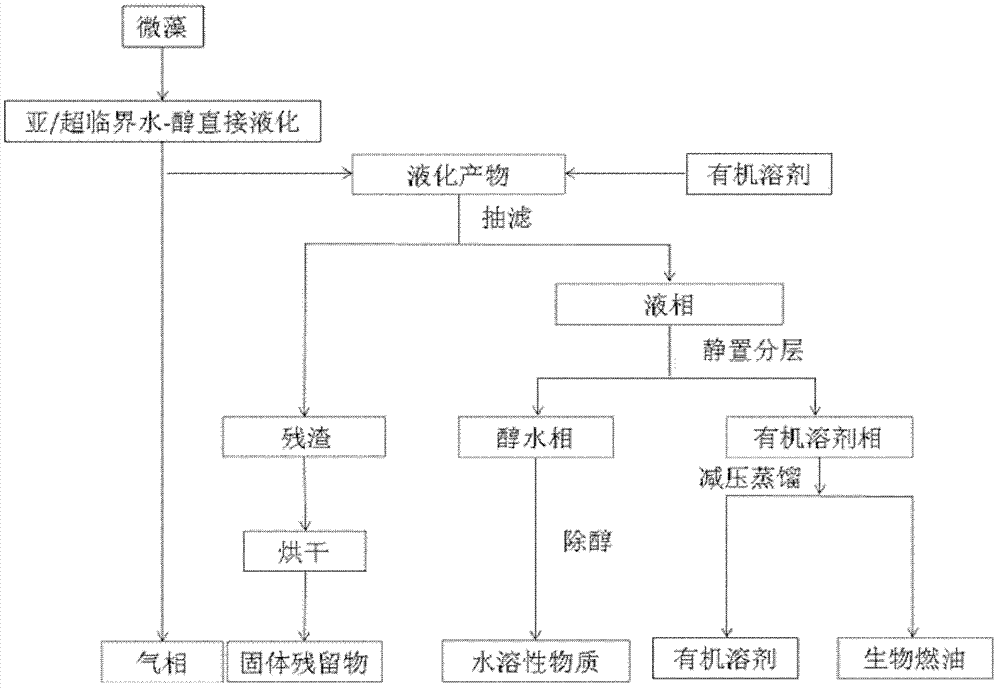

Method for preparing bio-oil from microalgae through direct liquidation

ActiveCN103361166AOvercoming and mitigating pollution problemsReduce energy consumptionLiquid carbonaceous fuelsFatty-oils/fats productionTime rangeOrganic solvent

The invention relates to a method for preparing a bio-oil from microalgae through direct liquidation. The method comprises the following steps of: mixing microalgae with an alcohol-water mixed solution and putting the mixture into a reaction kettle, and heating for reacting, wherein the reaction conditions are as follows: temperature is 260-360 DEG C, and the pressure is 7-22 MPa; the reaction time ranges from 15 to 45 min; the ratio of the microalgae to the alcohol-water mixed solution is 1:(5-20), and the unit of the mixture is g / mL; the volume percentage content of the alcohol in the alcohol-water mixed solution is 20-80%; after the reaction is ended, adding an organic solvent for extracting the reaction liquid, wherein the reaction liquid is divided into an organic solvent phase, an alcohol-water phase and solid residues; after the extraction is finished, separating out the solid residues through suction filtration, and obtaining the organic solvent phase through separation after standing and layering of the liquid phase; removing the organic solvent from the organic solvent phase through reduced pressure distillation, thereby obtaining an oily liquid, namely, the bio-oil product, wherein the conditions of reduced pressure distillation are as follows: the gauge pressure is 0.085-0.095 MPa, and the temperature is 20-40 DEG C. The method provided by the invention is simple in process flow and low in energy consumption; the process of the method is environmentally-friendly.

Owner:PETROCHINA CO LTD +1

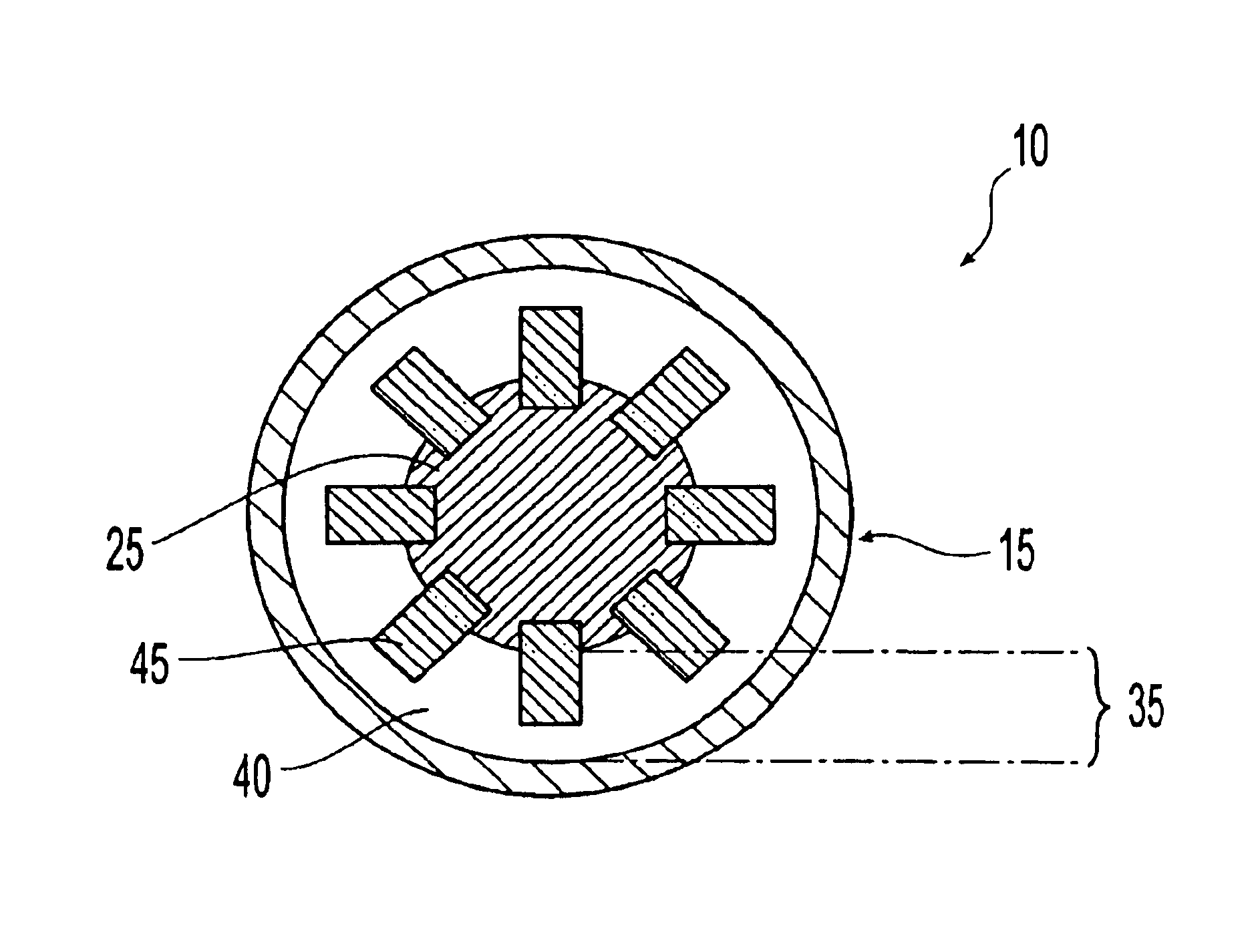

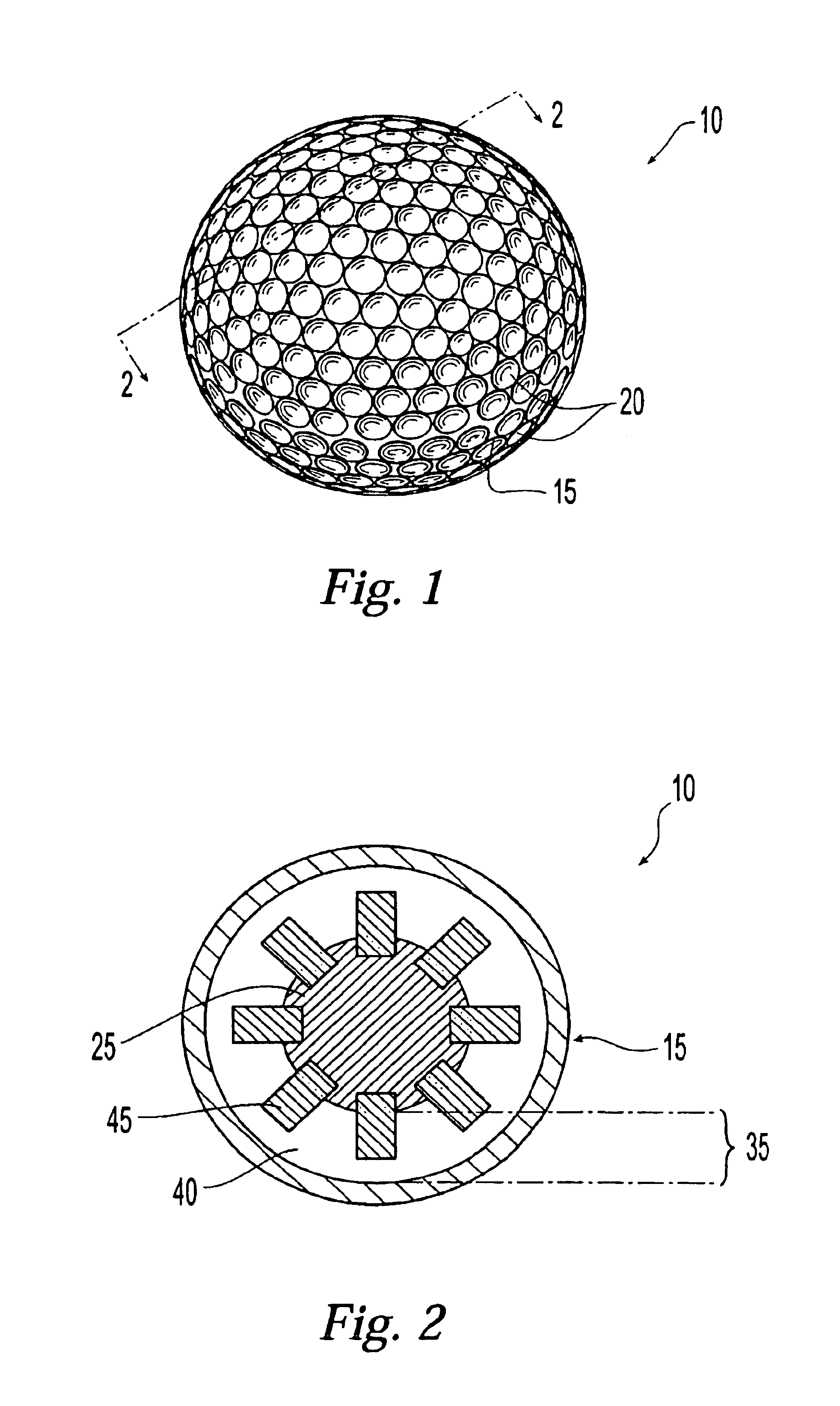

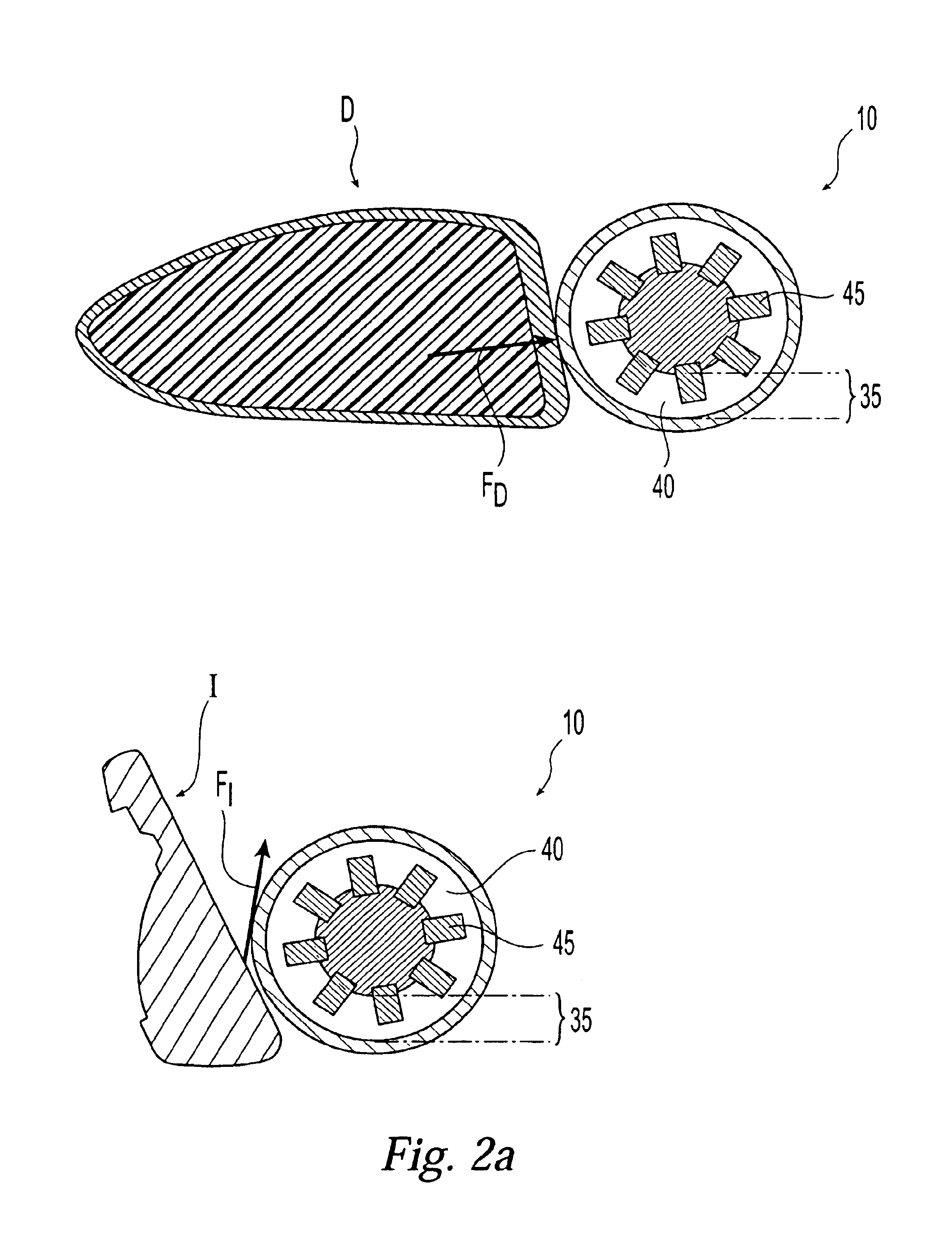

Golf ball with an improved intermediate layer

The present invention is directed towards a golf ball which comprises a core, a cover and at least one improved intermediate layer disposed between core and the cover. The intermediate layer a composite of at least two dissimilar materials that is radially oriented and transversely isotropic so that the layer provides unique performance properties when the ball is struck with different clubs.

Owner:ACUSHNET CO

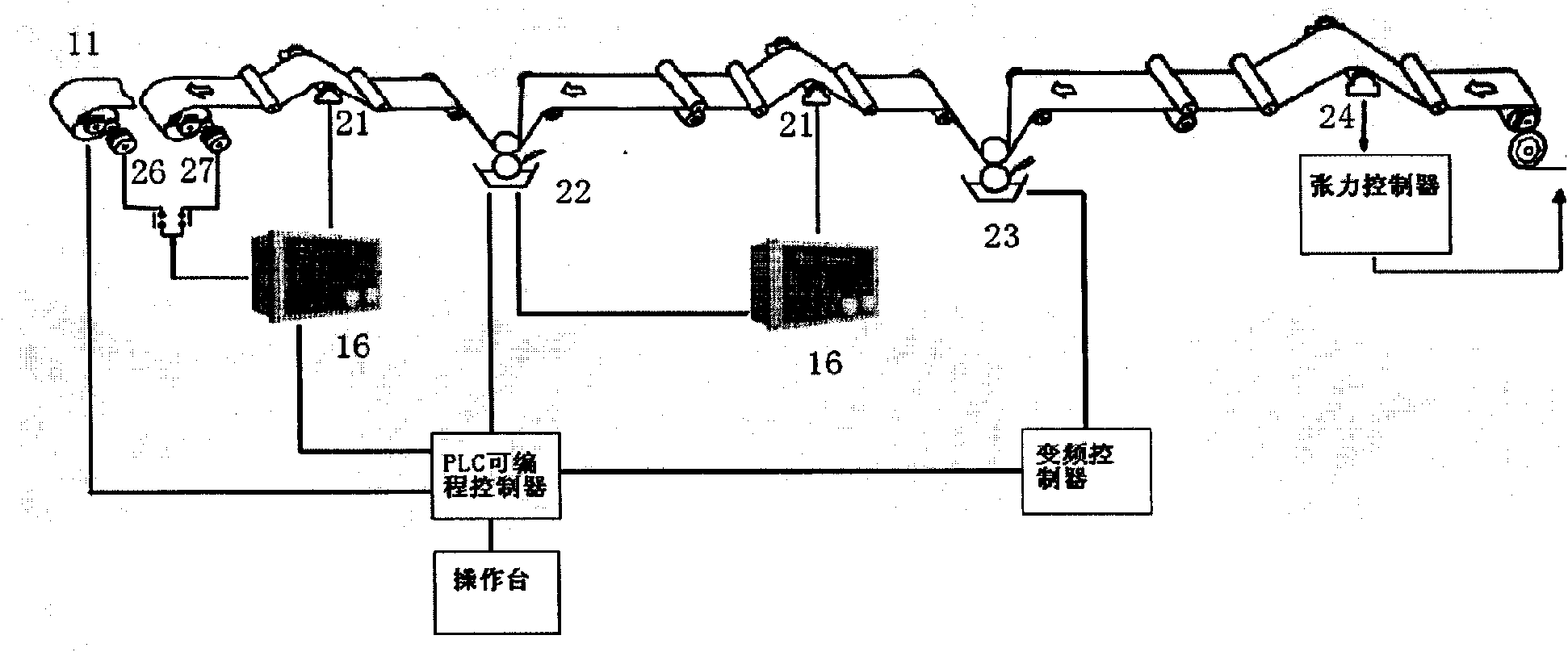

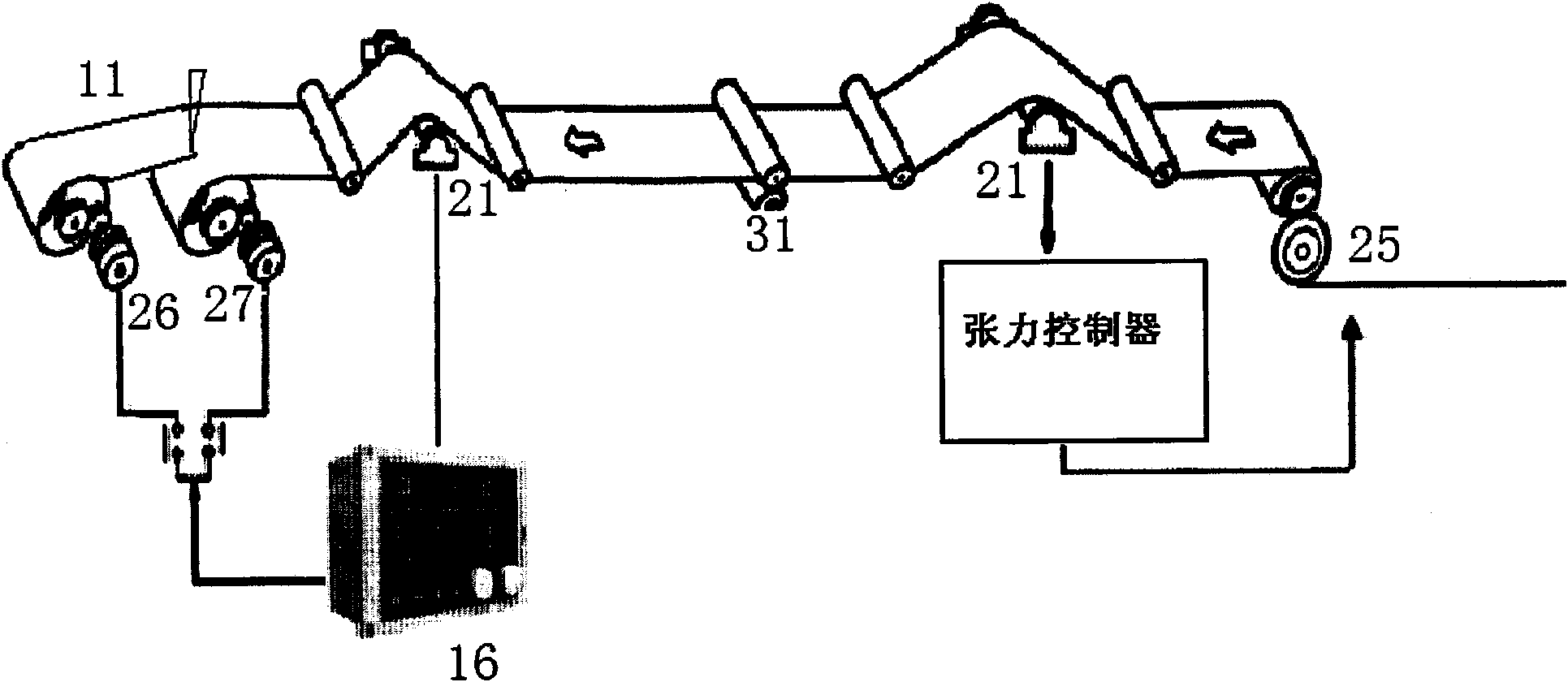

Slip motor automatic control device

InactiveCN101604952ASame torqueSynchronous control is directly effectiveDynamo-electric brake controlAutomatic controlClosed loop

The invention relates to a slip motor automatic control device. The device comprises a slip motor, a tension signal acquisition device and a slip motor controller, wherein the tension signal acquisition device is used for converting the tension expanded when materials are processed into a tension signal; and the slip motor controller is used for comparing the tension signal with the preset normal value and automatically controlling the slip motor according to the comparison result. The device adopts the closed loop tension automatic control mode, and sets the normal value according to the characteristics of the materials; and when a tension senor detects a tension error of the materials, the voltage and the current needed by the slip motor are automatically regulated and outputted after automatic comparison, so that the automatic circulation functions of target determining, automatic detection, automatic comparison and automatic regulation are achieved.

Owner:BEIJING JINPUTE PRINGTING MACHINE

Novel brain tonic health-care beverage

The invention discloses a novel nutritious healthy beverage and making process thereof, which pertains to the field of functional beverage. The invention contains 5-40kg of high fructose syrup, 2-20kg of condensed apple juice, 1-20kg of Chinese date, 0.5-5kg of medlar, 1-20kg of glucose, 0.2-1.5kg of citric acid, 0.1-1.0kg of sodium citrate, 50-500g of vitamin C, 10-100g of lysine, 10-200g of phaseomannite, 0.2-2.0g of vitamin B6, 1-10mg of vitamin B12, 100-1000g of taurine. The making process includes material selecting, cleaning, leaching, slurrying, concocting, filtering, canning, sterilizing, packing and inspecting. The invention is unique in prescription, advanced in process, nutrition abundant in final product, having heath-care functions of brain nutrition compensation, brain power expansion, fatigue relief or the like, especially suitable for students, brain workers, car drivers and night working people.

Owner:BEIJING KEWEIHUA FOOD ENG TECH

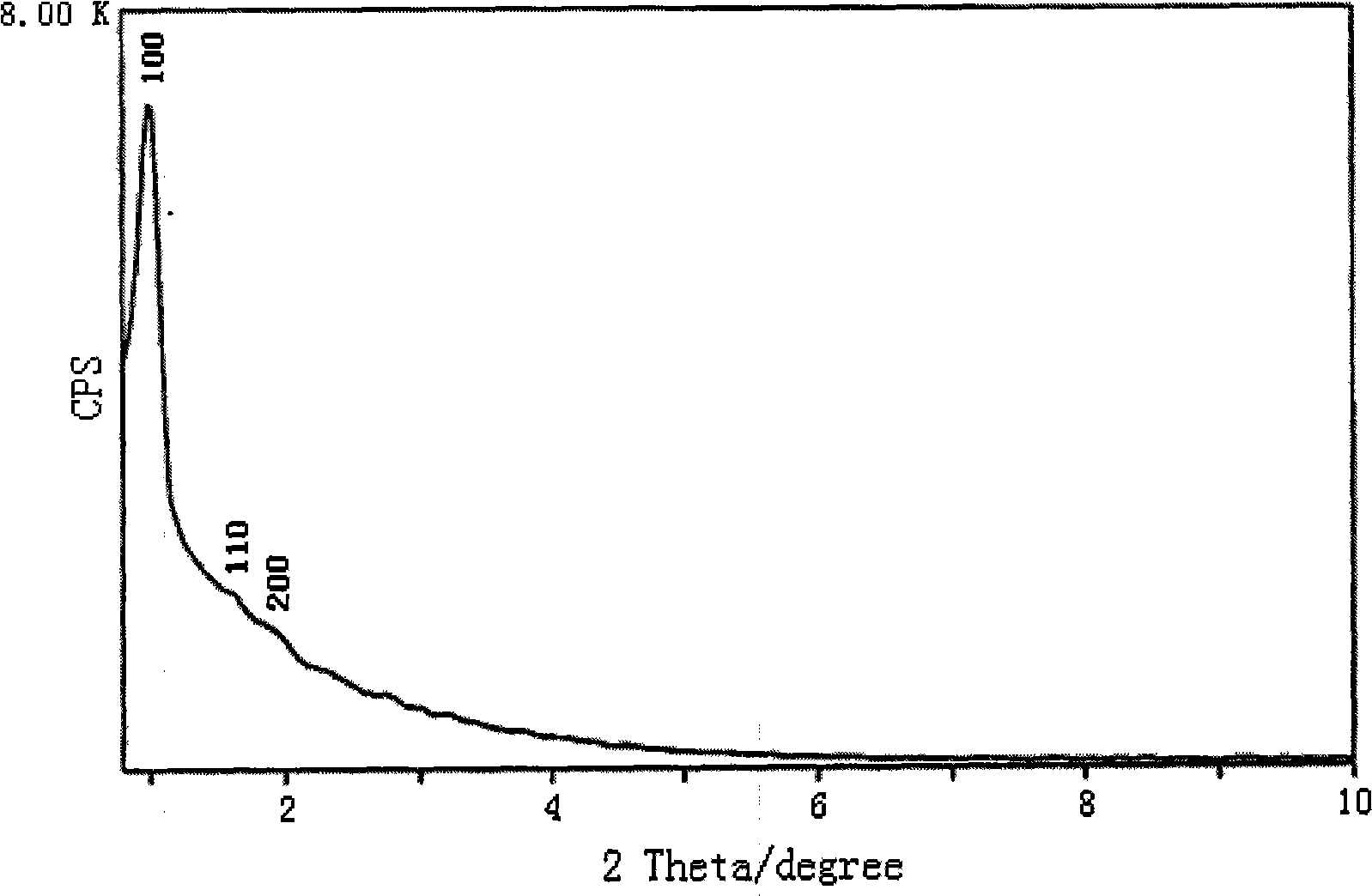

Method for synthesizing bimodal silicon-aluminum mesoporous material

InactiveCN101531375ALower synthesis costUnique performanceCrystalline aluminosilicate zeolitesMuffle furnaceNitrogen adsorption

The invention relates to a method for synthesizing a bimodal silicon-aluminum mesoporous material. The method comprises that: pulverized coal ash / black liquid for papermaking or strong alkali is used as a raw material; firstly, the raw material is evenly mixed in a solution, dried and roasted in a muffle furnace; a roasted product is dissolved by water or acid; an insoluble substance is filtered and removed; and the solution is condensed to obtain a raw material solution for synthesizing the mesoporous material. A surfactant, namely a triblock copolymer (P123) of three block polymers of polyoxyethylene, polyoxypropylene and polyoxyethylene used as a structure guiding agent is dissolved in water, and the mixture is stirred at a constant temperature for more than 1 hour, and slowly dripped with the raw material solution; after the dripping, hydrochloric acid is added into the solution, continuously stirred for more than 24 hours, crystallized at the temperature of 100 DEG C, cooled and filtered to obtain a coarse product; after the coarse product is naturally dried at room temperature, the coarse product can be roasted at the temperature of 550 DEG C or extracted by ethanol to remove the structure guiding agent; and after the coarse product is dried, the mesoporous material of which aperture is in bimodal distribution, namely bimodal SBA-15 is obtained. The mesoporous material contains two kinds of mesopores, wherein the small mesopore is within the range between 3 and 4 nm; the large mesopore is within the range between 5 and 7 nm; an SEM image also shows two different pores; BET nitrogen adsorption proves that the specific surface area of the pore is between 500 and 700m<2> / g; and the size of the pore is between 0.4 and 0.6 cm<3> / g.

Owner:SHANDONG UNIV OF SCI & TECH

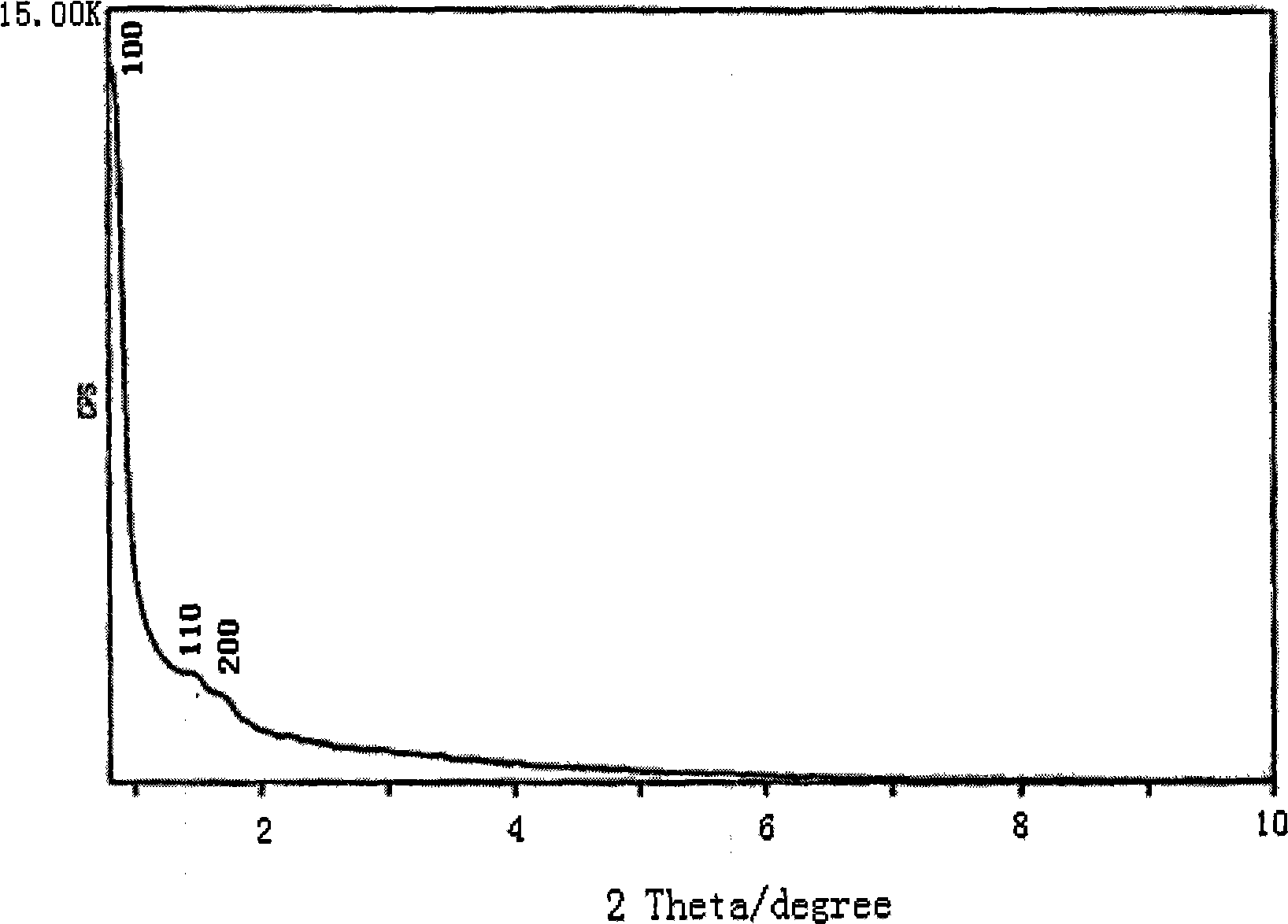

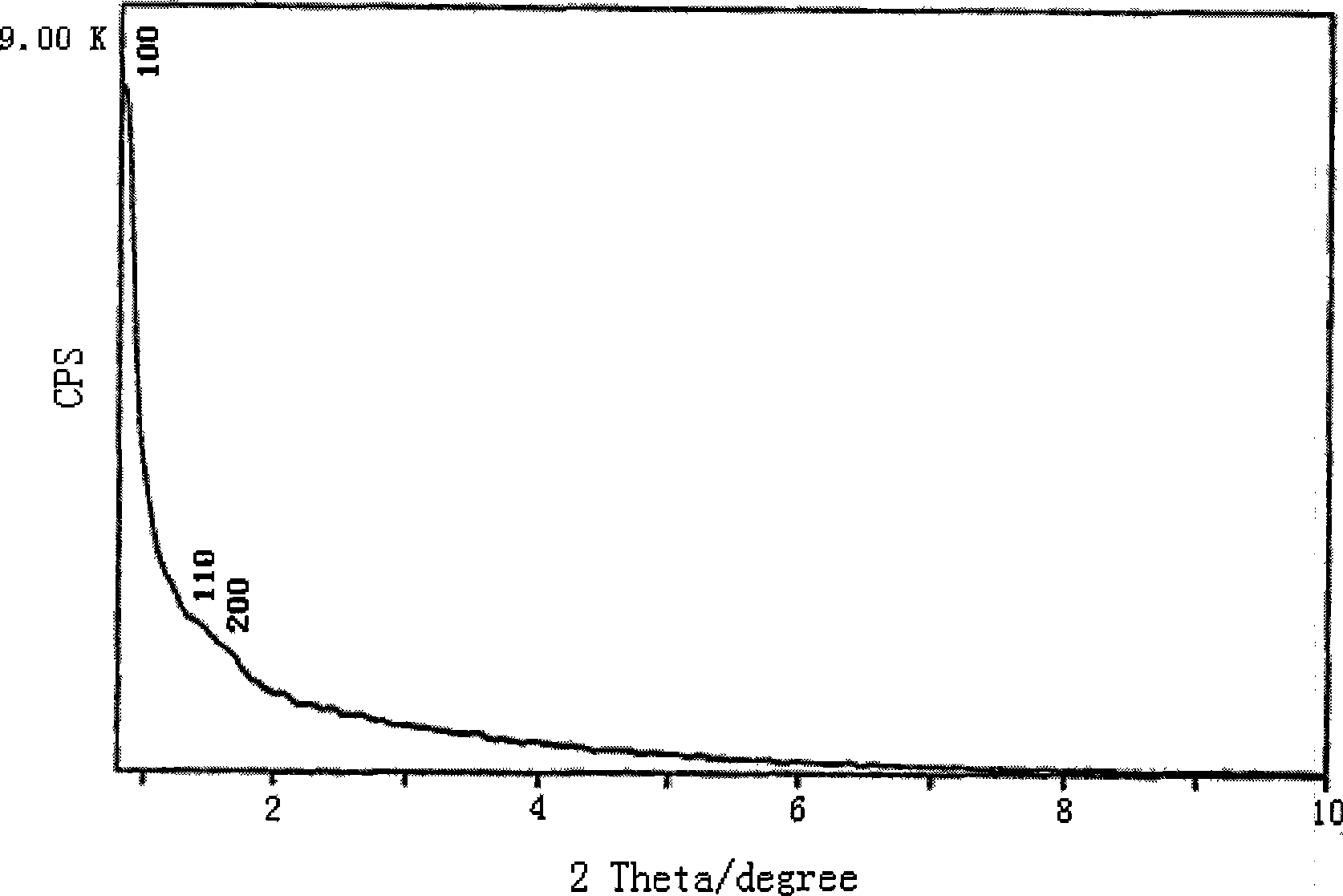

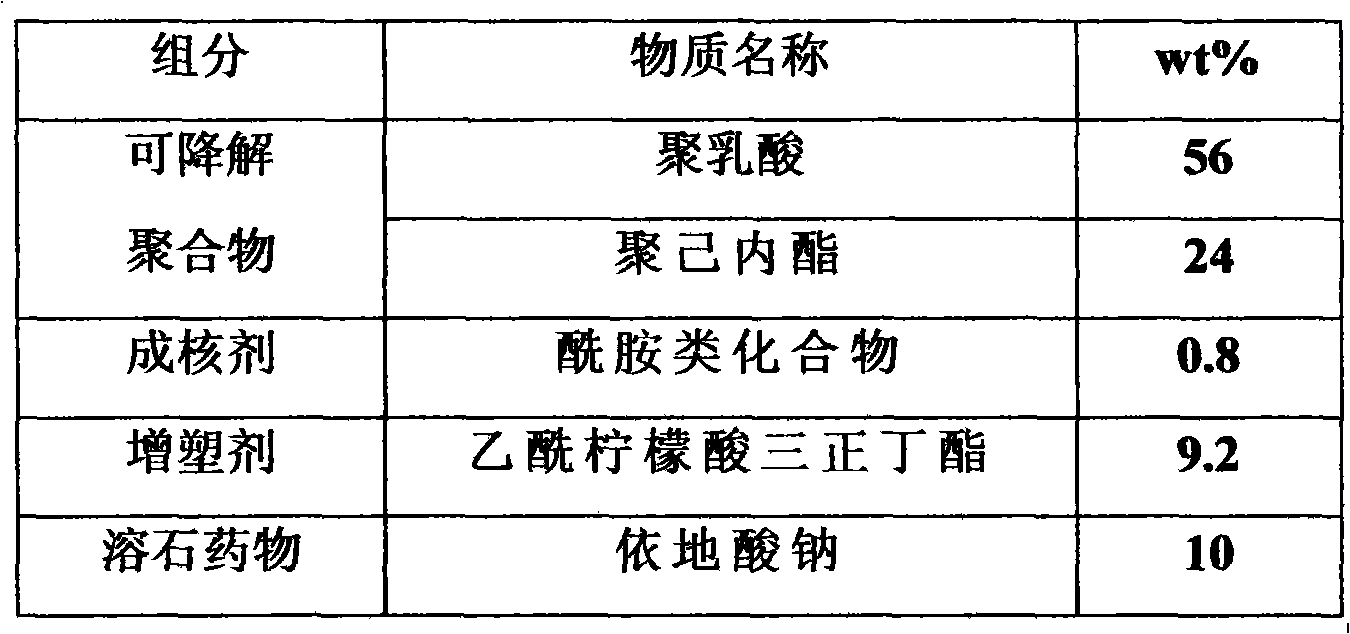

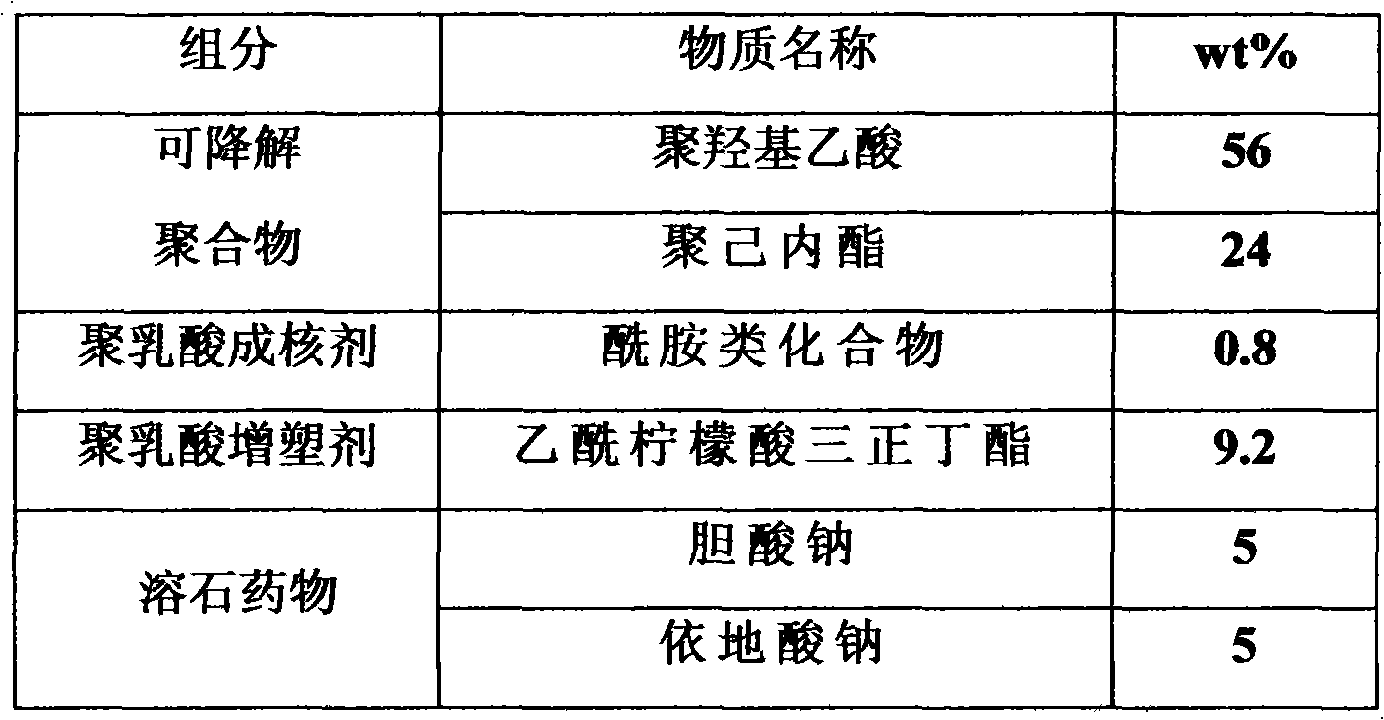

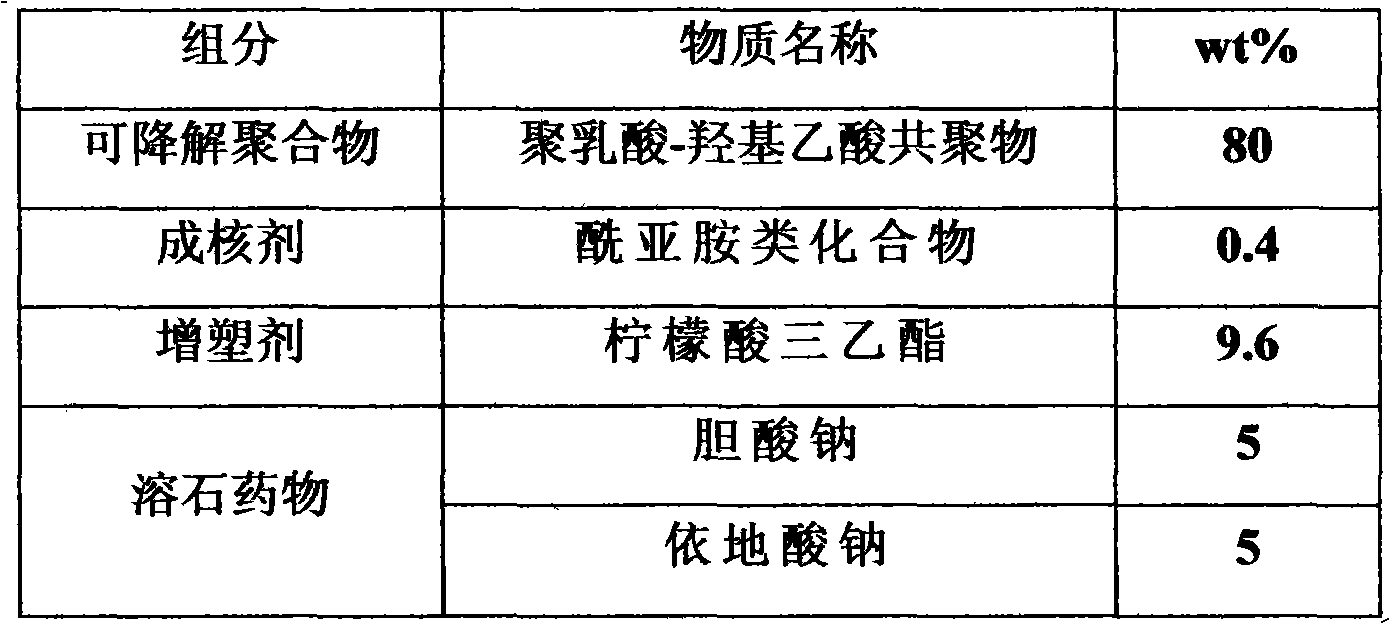

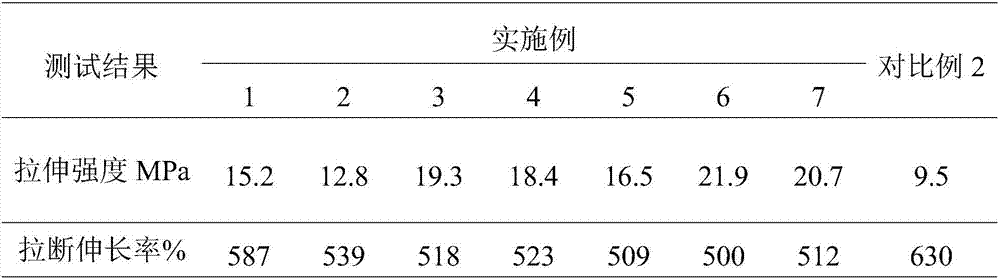

Degradable bile duct bracket with stone dissolution function and preparation method thereof

The invention relates to the technical field of medical instruments, in particular to a degradable bile duct bracket with stone dissolution function and a preparation method thereof. The degradable bile duct bracket is prepared by the following raw materials in proportion: 60-98% by weight (wt) of degradable polymer, 0.1-2.0 % by weight of nucleating agent, 1-15 % by weight of plasticizer, and the balance of stone dissolution drug, wherein the total weight amounts to 100%. The degradable bile duct bracket is obtained by evenly mixing the degradable polymer, the nucleating agent, the plasticizer and the stone dissolution drug, and then fusing and extruding the mixture through a medical catheter precise extruder; by successfully selecting proper degradable polymer, nucleating agent and plasticizer, the defects of the plastic bracket and metal bracket in the bile duct interventional therapy are overcome; moreover, by adding the stone dissolution drug, the curative effective of gall-stone is improved; therefore, the degradable bile duct bracket has wide application prospect.

Owner:苏州同科生物科技有限公司

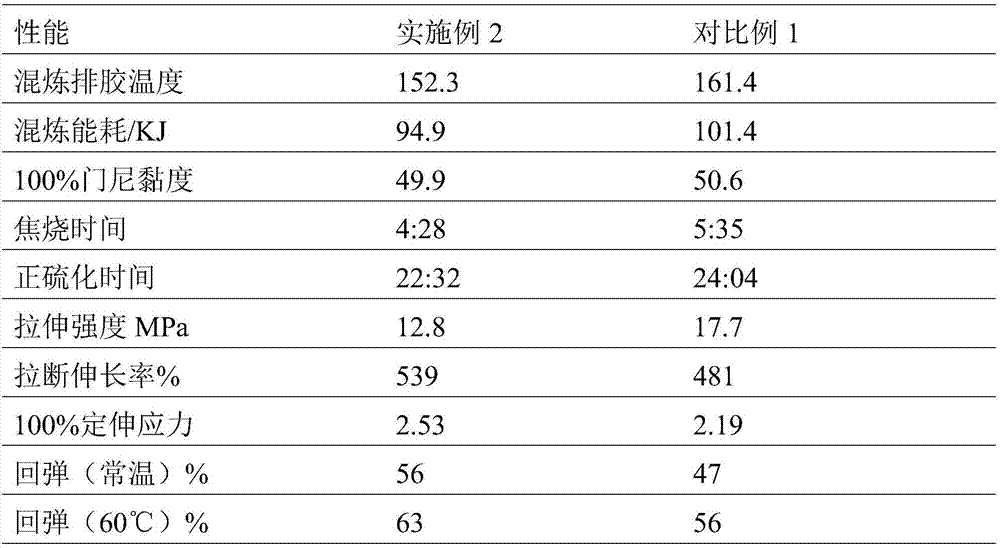

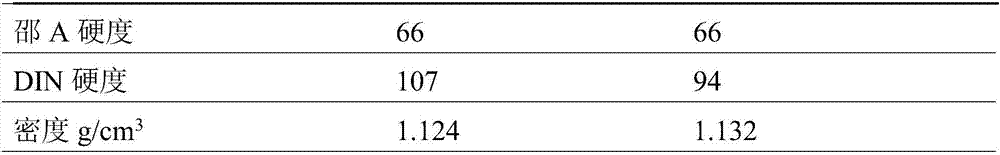

Preparation method of silicon carbon black / natural rubber composite material

ActiveCN107337815ASimple production processMeet the requirements of sustainable developmentSilicon dioxideBall mill

The invention discloses a preparation method of a silicon carbon black / natural rubber composite material, belongs to the technical field of composite materials, and solves the problems of high cost, non renewable resources, complex process, difficult processing and uneven dispersion of use of surface modified silica for filling natural rubber in the prior art. According to the method, first purified rice husks are added into a reaction device for pyrolysis to obtain pyrolysis gas and pyrolytic carbon, and after decoking, cooling and separation, tar-free pyrolysis gas and tar-free pyrolytic carbon are obtained; then tar-free pyrolytic carbon gas flow is pulverized, and ball-milled to the average particle size within 10 mu m to obtain silicon carbon black powder, and the silicon carbon black powder is further processed to obtain the modified silicon carbon black powder and silicon carbon black masterbatch; and finally the silicon carbon black / natural rubber composite material can be obtained by mixing and kneading technology. The preparation method has the advantages of low cost, saving energy, environmental-friendliness, full use of renewable resources, and broad application prospects in the rubber field.

Owner:JILIN UNIV

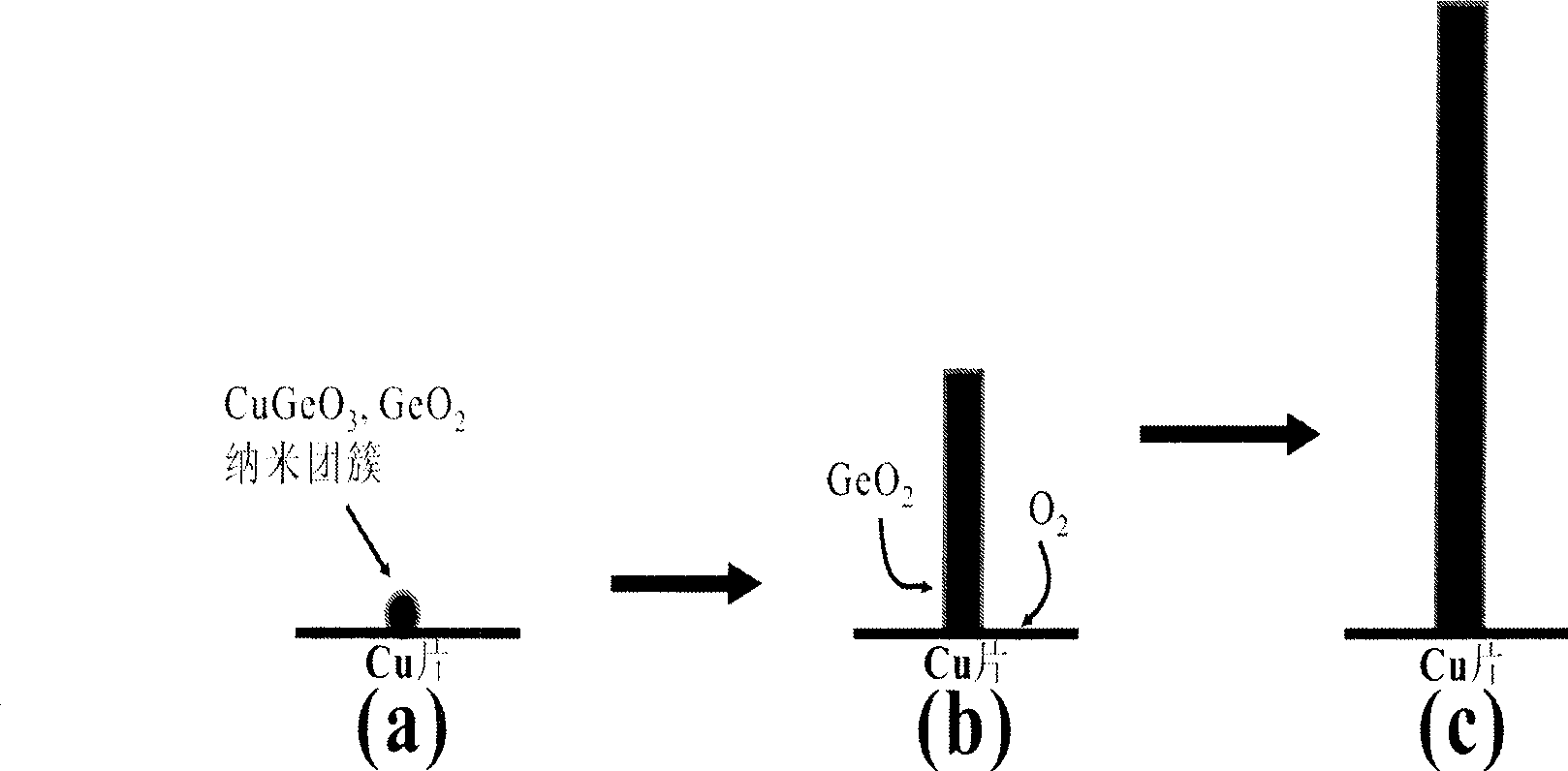

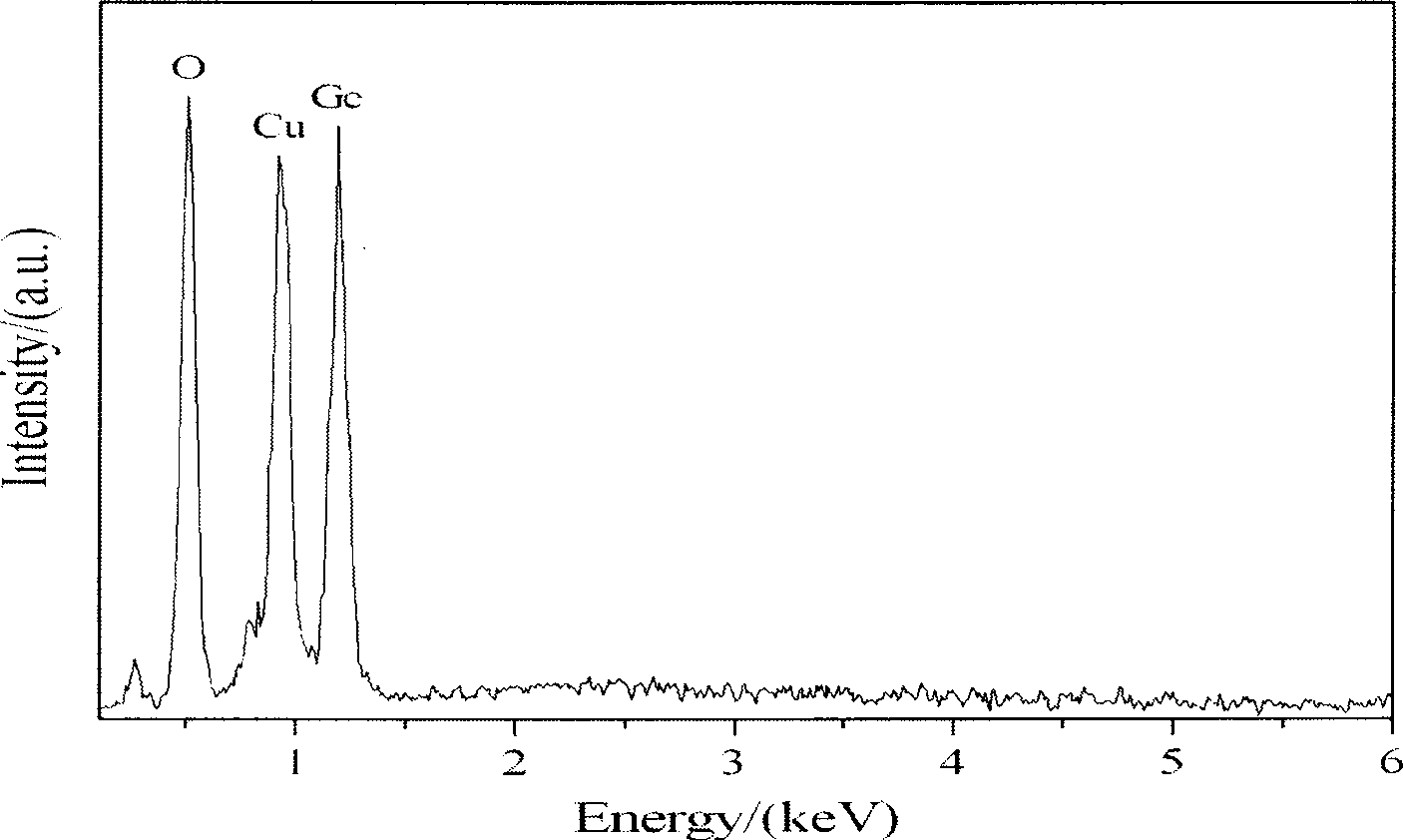

Copper germinate nano-wire and preparation thereof

InactiveCN101434406ALow preparation temperatureEasy to prepareGermanium compoundsSolventSingle crystal

The invention discloses a copper germanic acid nano wire and a preparation method thereof, belonging to the technical field of nano material preparation. The copper germanic acid nano wire consists of single-crystal copper germanic acid core and a very thin amorphous copper germanic acid casing covered on the external layer. The preparation method takes germanium dioxide and sheet copper as raw material and water as a solvent, wherein, the sheet copper is also used as a deposition substrate. The preparation method comprises the steps of: ultrasonically cleaning the sheet copper in distilled water for 10 minutes, fixing the sheet copper in a reaction kettle vessel, uniformly stirring the sheet copper, insulating heat for 0-24 hours under the temperature of 200-500 DEG C and the pressure of 1-15MPa, and finally obtaining the copper germanic acid nano wire on the sheet copper. The preparation method has the advantages of free growth template addition, simple preparation process, easy operation and control, low growth temperature and lower preparation cost. In addition, as the method adopts the processes of innocuous germanium oxide and hydro-deposition, the raw material and the preparation process are harmless to the environment, therefore, the requirement of environmental protection is met. The preparation method can realize the mass preparation of the copper germanic acid nano wire.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

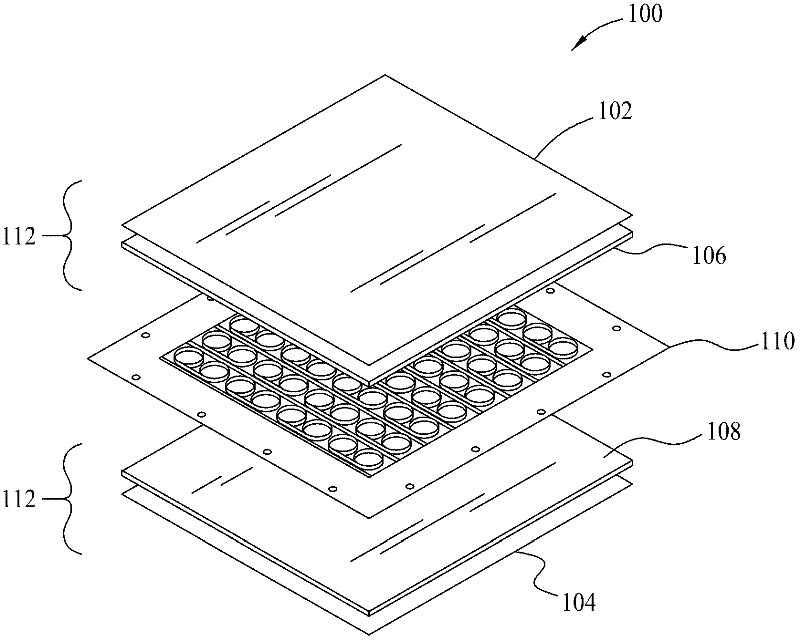

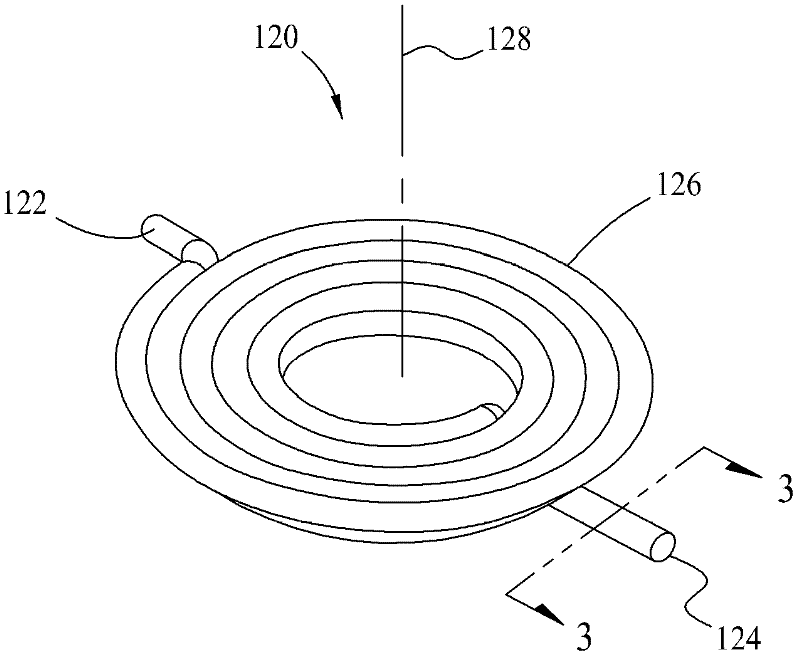

Magnetic component assembly

InactiveCN102460614AEasy to assembleImprove reliabilityTransformers/inductances coils/windings/connectionsInorganic material magnetismSurface mountingTransformer

Magnetic component assemblies including moldable magnetic materials formed into magnetic bodies, at least one conductive coil, and termination features are disclosed that are advantageously utilized in providing surface mount magnetic components such as inductors and transformers.

Owner:COOPER TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com