Patents

Literature

830results about How to "Low preparation temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing self-sealing silicon carbide ceramic based composite material

The invention relates to a method for manufacturing a self-healing silicon carbide ceramic matrix composite. The method comprises the following steps: preparing fiber preform; filtrating a pyrolytic carbon interface layer by chemical gas phase; carrying out thermal treatment on the interface layer; infiltrating silicon carbide and boron carbide substrate by chemical gas phase alternately; and depositing three silicon carbide coatings by the chemical gas phase. The method has strong designability, simple process and good repeatability. The ceramic matrix composite manufactured by the method has good high temperature resistance and oxidation resistance, has excellent mechanical performance and thermal performance, and can meet the use requirement of a sealing strip / an adjustment sheet, an interior cone and other components of a high thrust-weight ratio aeroengine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

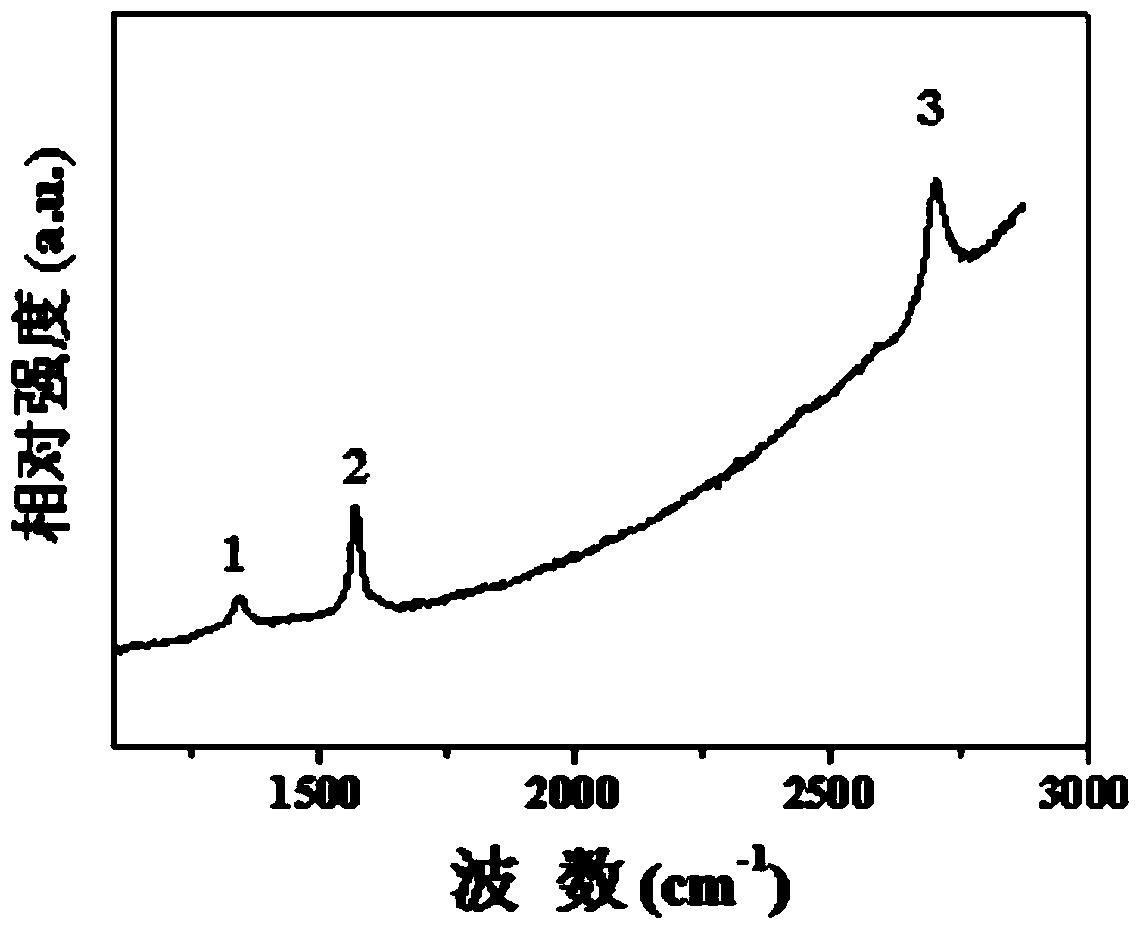

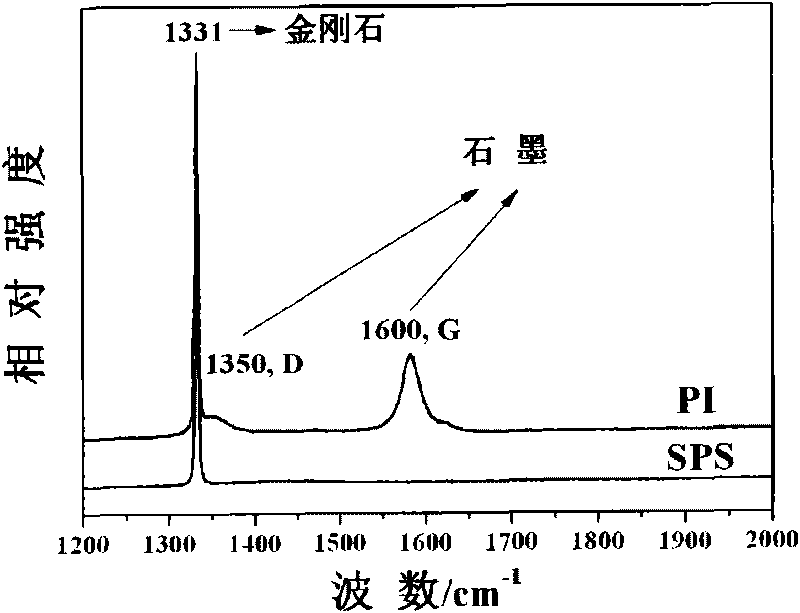

Efficient in-situ preparation method of graphene reinforced copper-based composite material

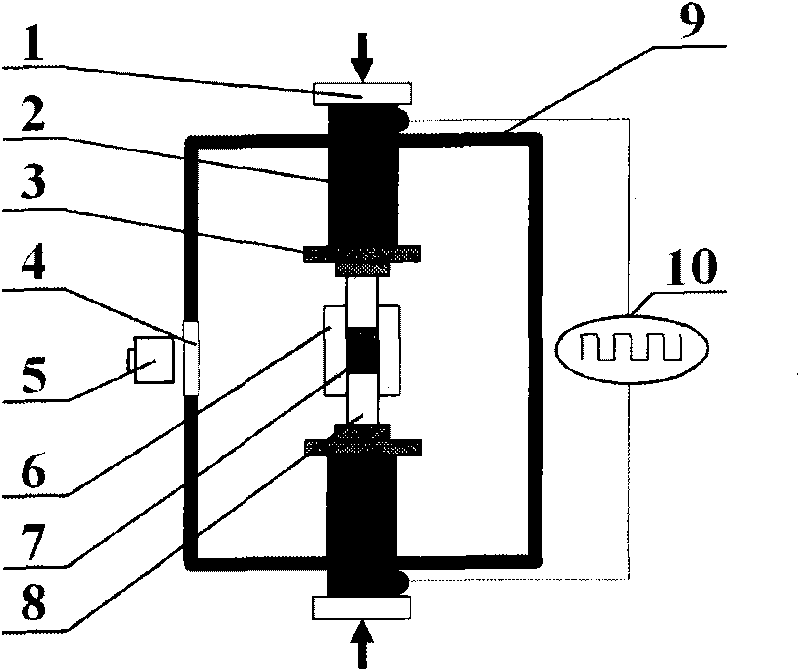

The invention discloses an efficient in-situ preparation method of a graphene reinforced copper-based composite material, and relates to a method for preparing a graphene reinforced copper-based composite material and the method can be used for solving the problems of poor uniform dispersion, poor structure integrity of grapheme and complex process in the existing preparation method of the graphene reinforced copper-based composite material. The efficient in-situ preparation method of the graphene reinforced copper-based composite material comprises the following steps: putting copper powder in a plasma reinforced chemical vapor deposition vacuum device, introducing hydrogen, preserving heat at high temperature, then introducing argon and carbon source gas, depositing, stopping introducing the carbon source gas after ending the deposition, and finally, cooling below the room temperature to obtain grapheme / copper composite powder, and then primarily pressing, sintering and secondarily pressing the grapheme / copper composite powder to obtain the graphene reinforced copper-based composite material. The method is an efficient in-situ preparation method of a graphene reinforced copper-based composite material.

Owner:HARBIN INST OF TECH

Method for preparing superhigh temperature resistant ceramic coat

InactiveCN101306959AImprove anti-ablation performanceImprove antioxidant capacityCeramic coatingSlurry coating

The invention discloses a method for making a super-high temperature resistant ceramic coating. The method adopts organic polymer as adhesive and mixed powder consisting of high melting metal powder, B powder, C powder and Si powder as raw materials; moreover, through adopting processes such as preparing slurry used in a coating, slurry coating, precoating curing, high-temperature reaction sintering, a super-high temperature resistant ceramic coating is finally made on the surface of a ceramic matrix composite material. The coating making process is simple and has low cost; the made coating has ideal bonding performance with a substrate and has excellent ablation resistance and antioxidation, thereby laying the foundation for the application of a ceramic matrix composite material in the super-high temperature resistant and antioxidation fields.

Owner:NAT UNIV OF DEFENSE TECH

Laminated transparent electrode and preparation method thereof

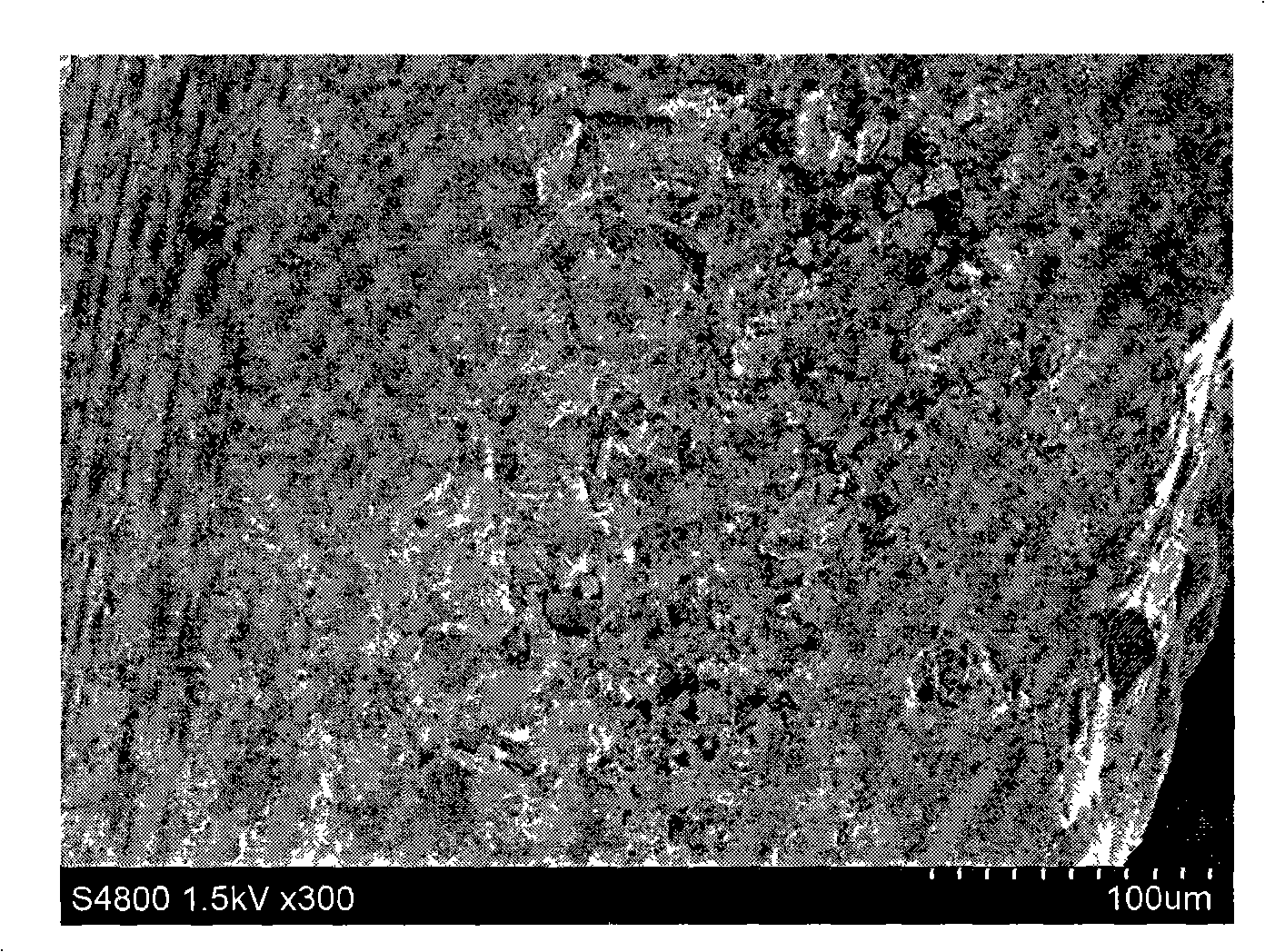

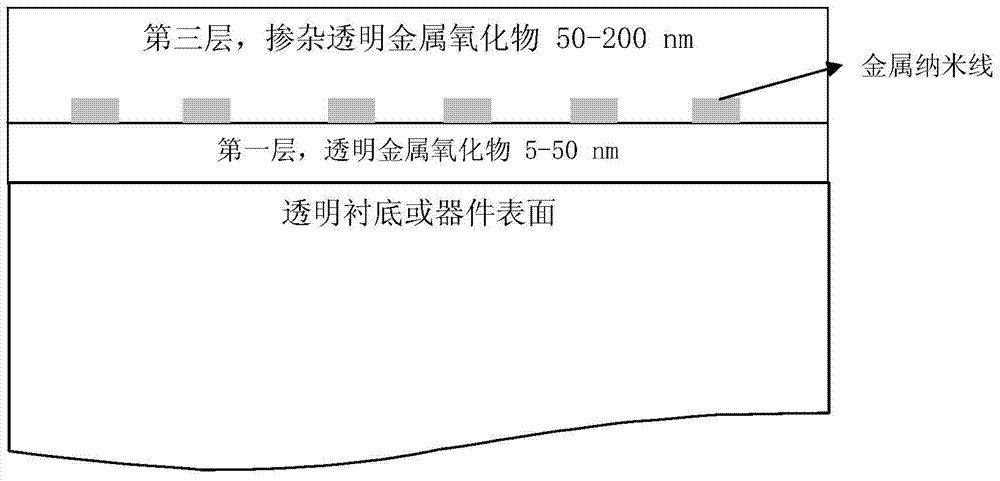

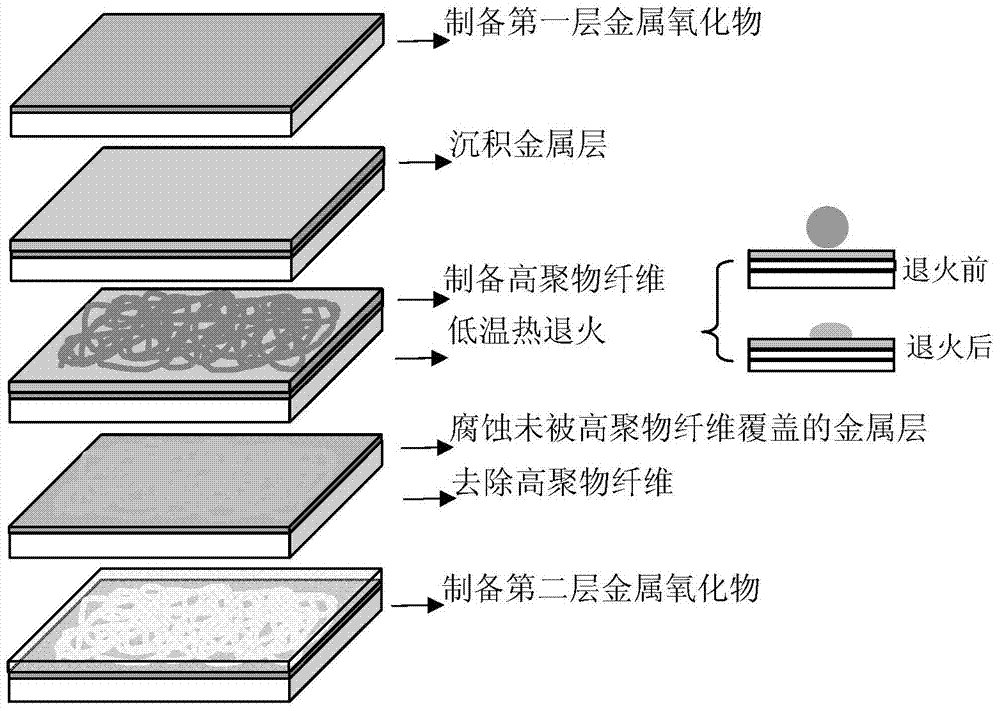

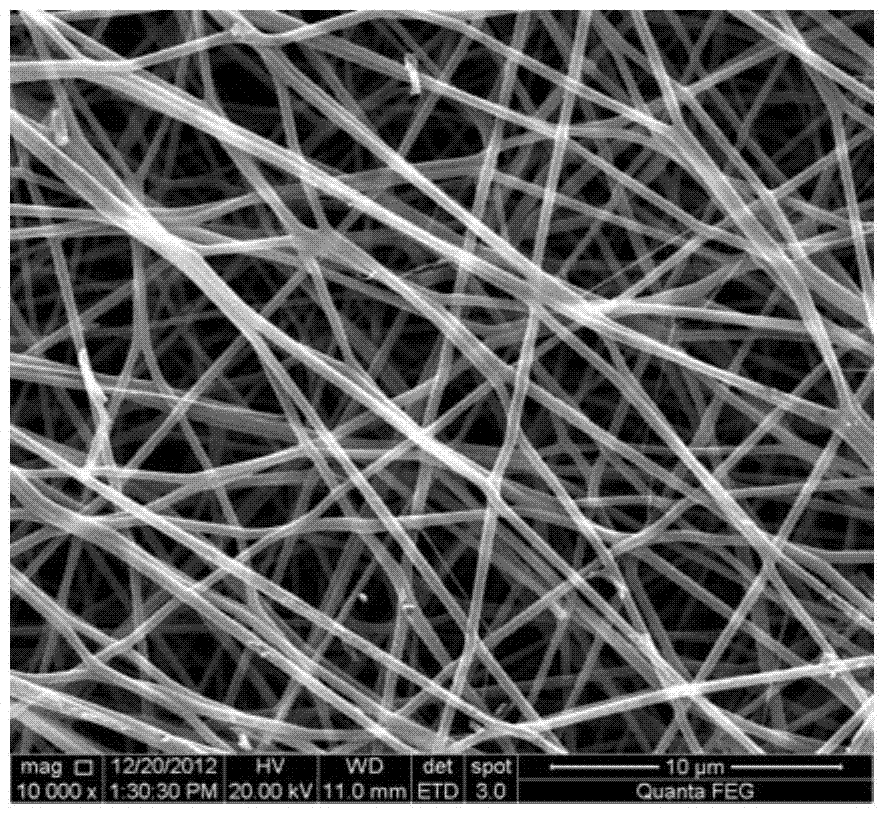

InactiveCN104505149APlay a protective effectReduce surface roughnessConductive layers on insulating-supportsFinal product manufactureElectrospinningNanofiber

The invention provides a laminated transparent electrode and a preparation method thereof. The laminated transparent electrode sequentially comprises a transparent substrate, a first-layer metal oxide film on the transparent substrate, a metal nanowire network layer on the first-layer metal oxide film, and a second-layer metal oxide film covering the metal nanowire network layer and the first-layer metal oxide film not covered by the metal nanowire network layer. A preparation method of the metal nanowire network layer comprises the steps of preparing a metal film layer on the first-layer metal oxide film, preparing a high-polymer nanofiber network on the metal film layer by using an electrostatic spinning technique, removing the metal film that is not covered by the high-polymer nanofiber network through etching by taking high-polymer nanofiber as a mask, and removing the high-polymer nanofiber network. The laminated transparent electrode has the advantages of high light transmissivity, low resistivity, firm contact with the substrate, smooth surface, low preparation and growth temperature, low cost and the like, and can be widely applied to various organic and inorganic photoelectric devices.

Owner:NORTHEAST NORMAL UNIVERSITY

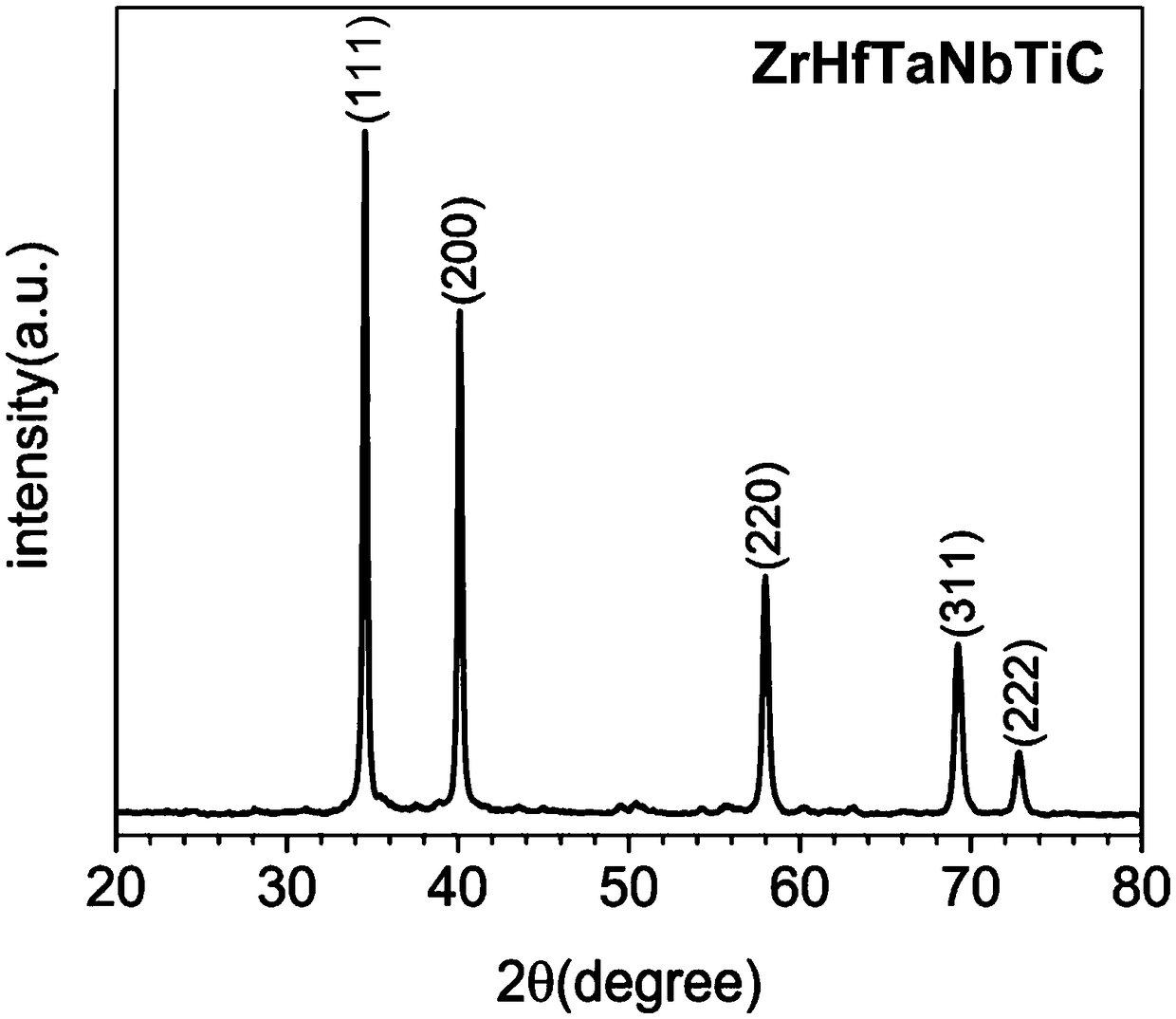

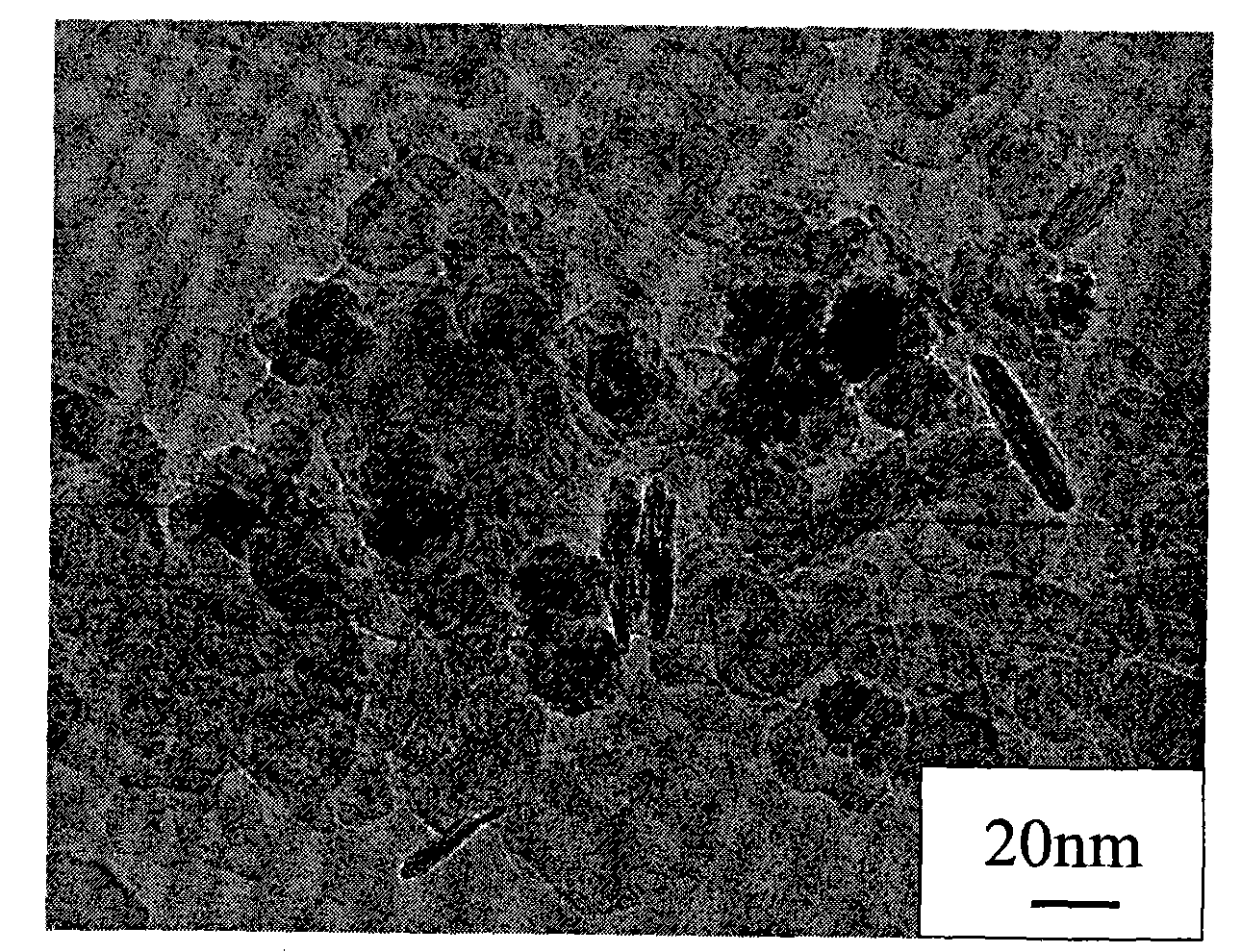

ZrHfTaNbTiC ultrahigh-temperature high-entropy ceramic material as well as preparation method thereof

The invention discloses a ZrHfTaNbTiC ultrahigh-temperature high-entropy ceramic material as well as a preparation method thereof. The ZrHfTaNbTiC ultrahigh-temperature high-entropy ceramic material consists of elements Zr, Hf, Ta, Nb, Ti and C and is a single rock-salt-phase structure. The ZrHfTaNbTiC ultrahigh-temperature high-entropy ceramic material is prepared by adopting a hot pressing and sintering technology. The prepared ZrHfTaNbTiC ultrahigh-temperature high-entropy ceramic material has excellent mechanical properties, and the hardness of the ceramic material reaches up to 38.52 to 41.25 GPa. The preparation method provided by the invention is simple in preparation process, high in efficiency and speed, low in synthetic temperature (1700 to 1900 DEG C), small in impressed pressure (20 to 30 MPa), low in energy consumption, safe, and environmentally friendly, has significant characteristics of repeatability and high reliability and the like, and can be applied to the industrial production.

Owner:SOUTH CHINA UNIV OF TECH

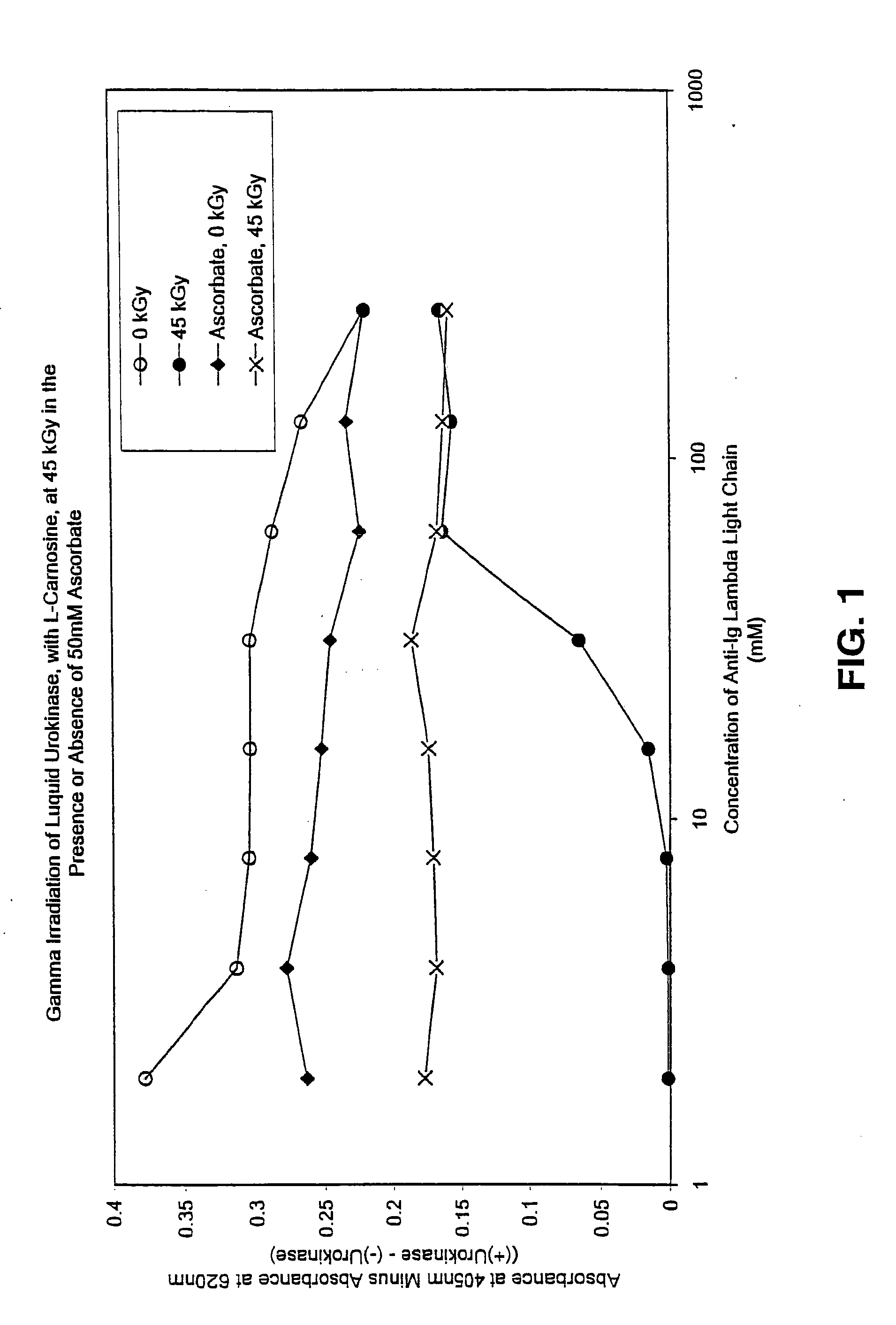

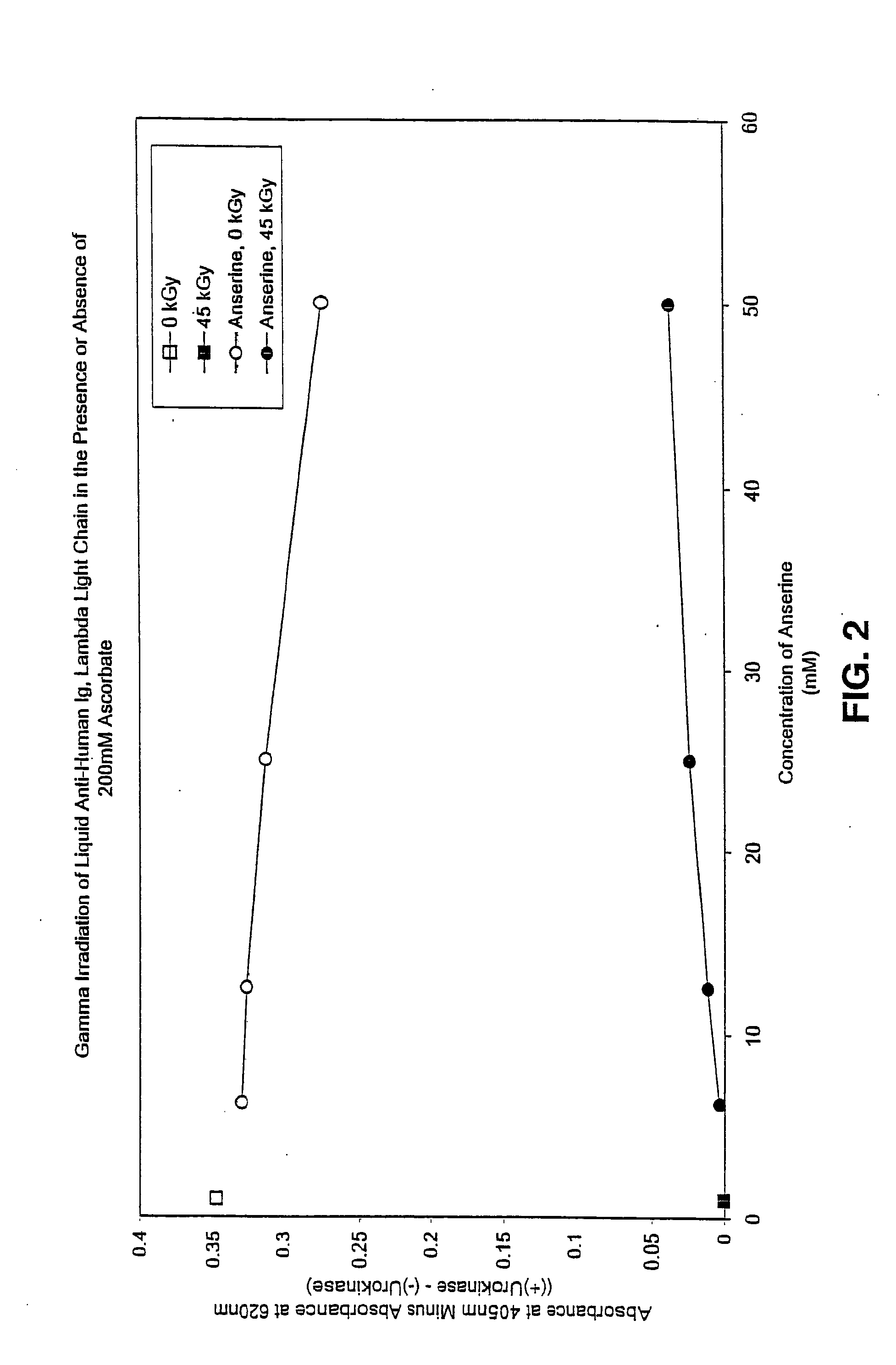

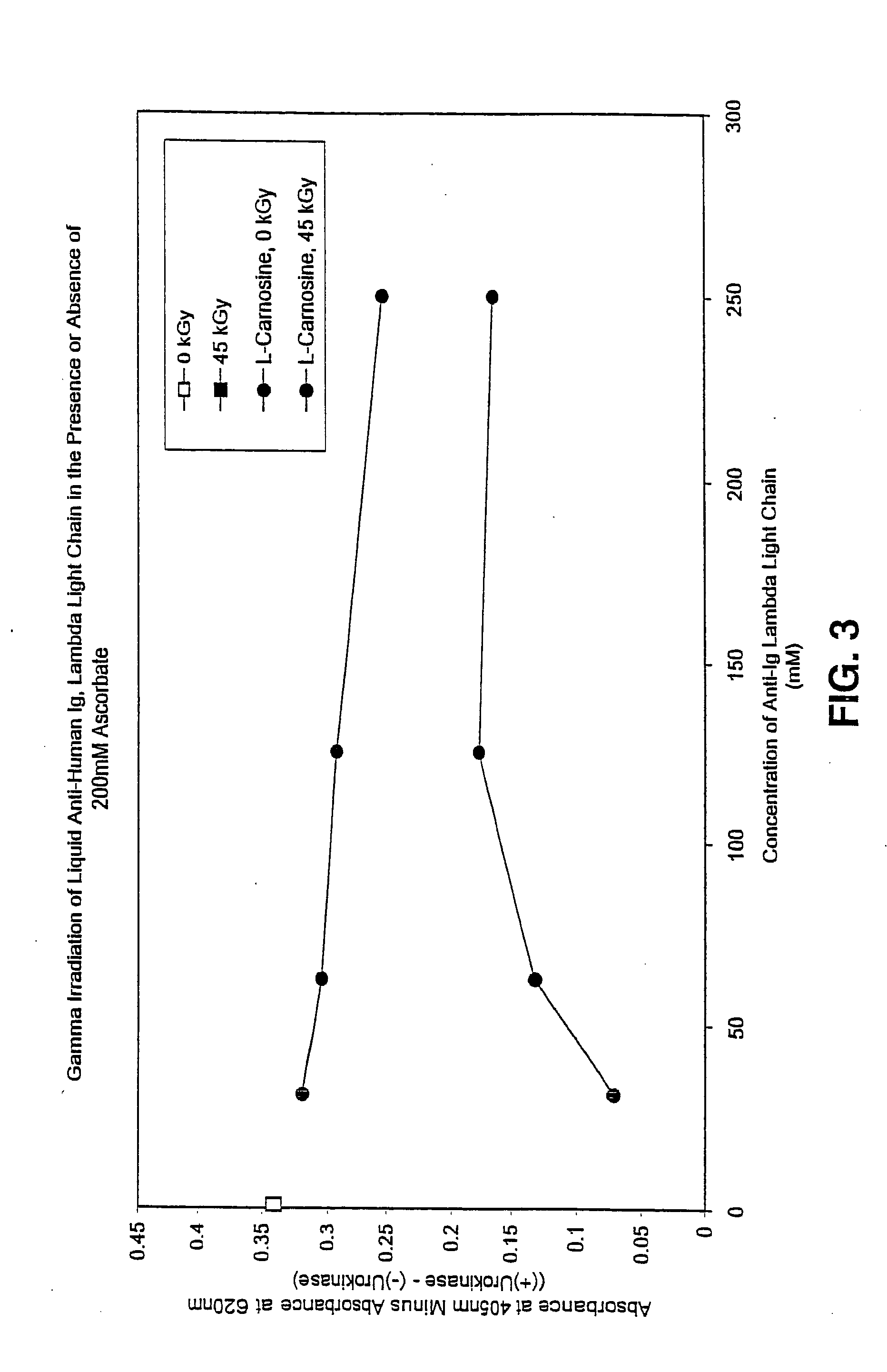

Methods for sterilizing preparations of urokinase

InactiveUS20050069453A1Effective sterilizationAvoid radiationLavatory sanitoryEnzymesUrokinase Plasminogen ActivatorFungal microorganisms

Methods are disclosed for sterilizing preparations of urokinase to reduce the level therein of one or more active biological contaminants or pathogens, such as viruses, bacteria (including inter- and intracellular bacteria, such as mycoplasmas, ureaplasmas, nanobacteria, chlamydia and rickettsias), yeasts, molds, fungi, single or multicellular parasites, and prions or similar agents responsible, alone or in combination, for TSEs. These methods involve sterilizing preparations of urokinase with irradiation.

Owner:CLEARANT

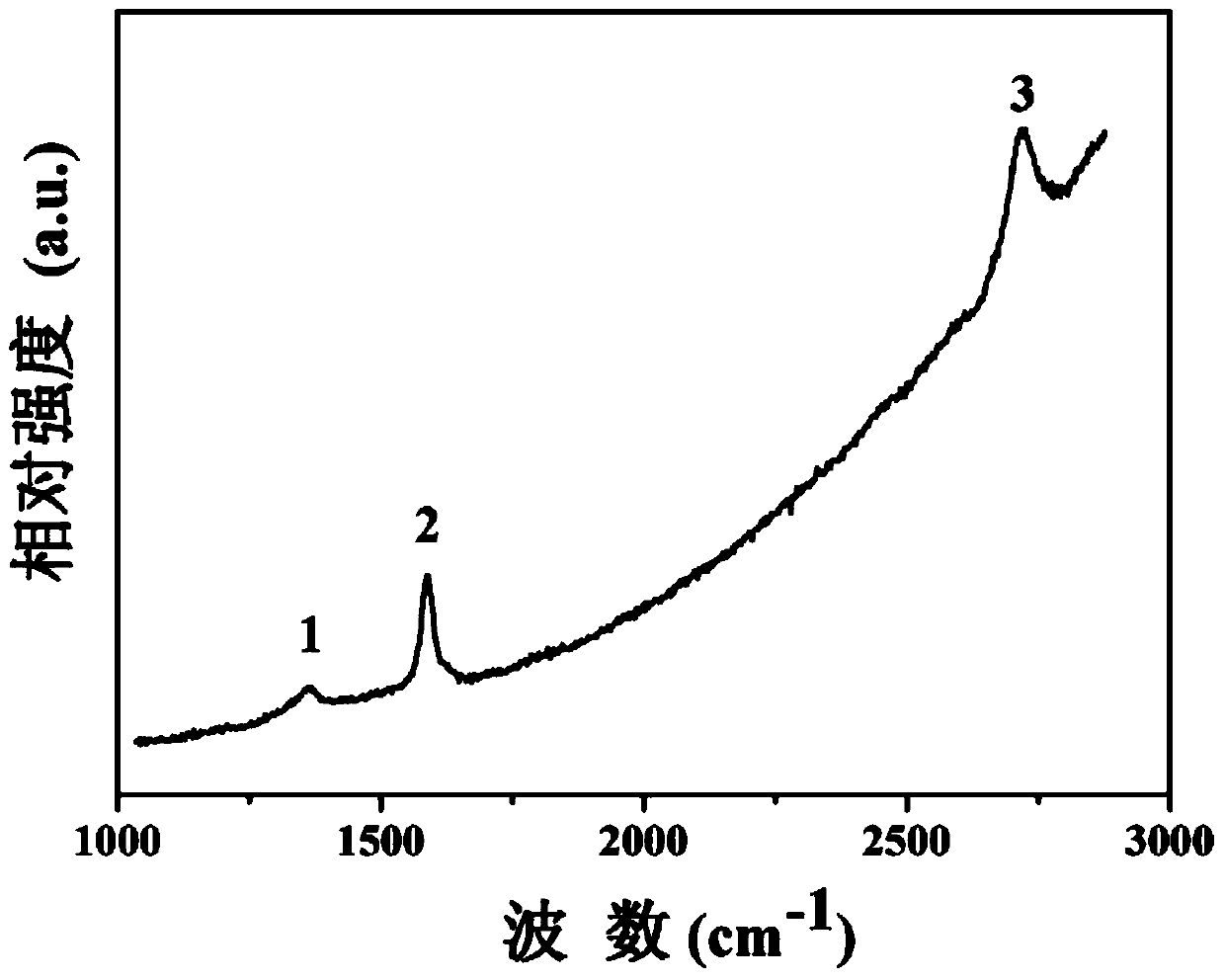

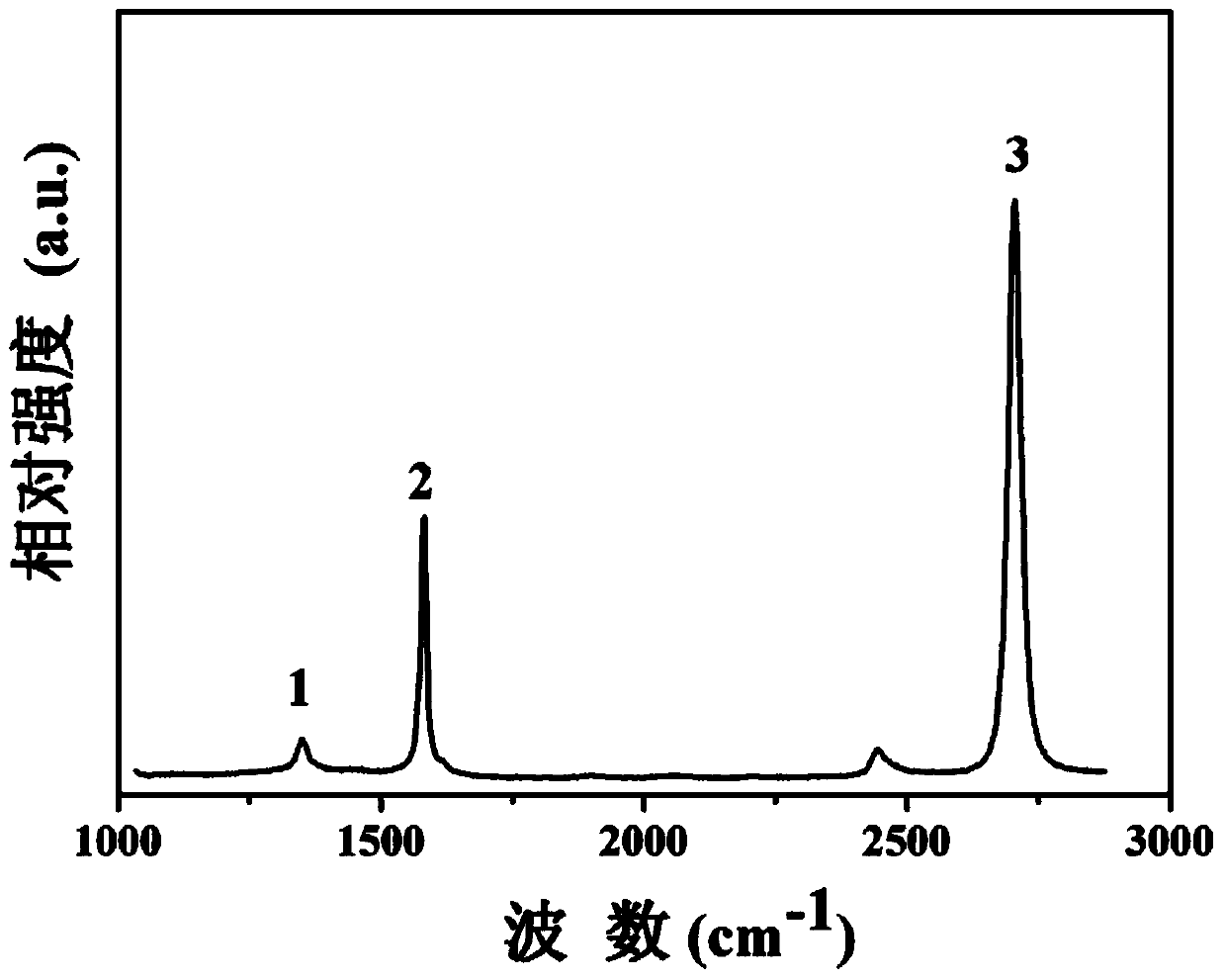

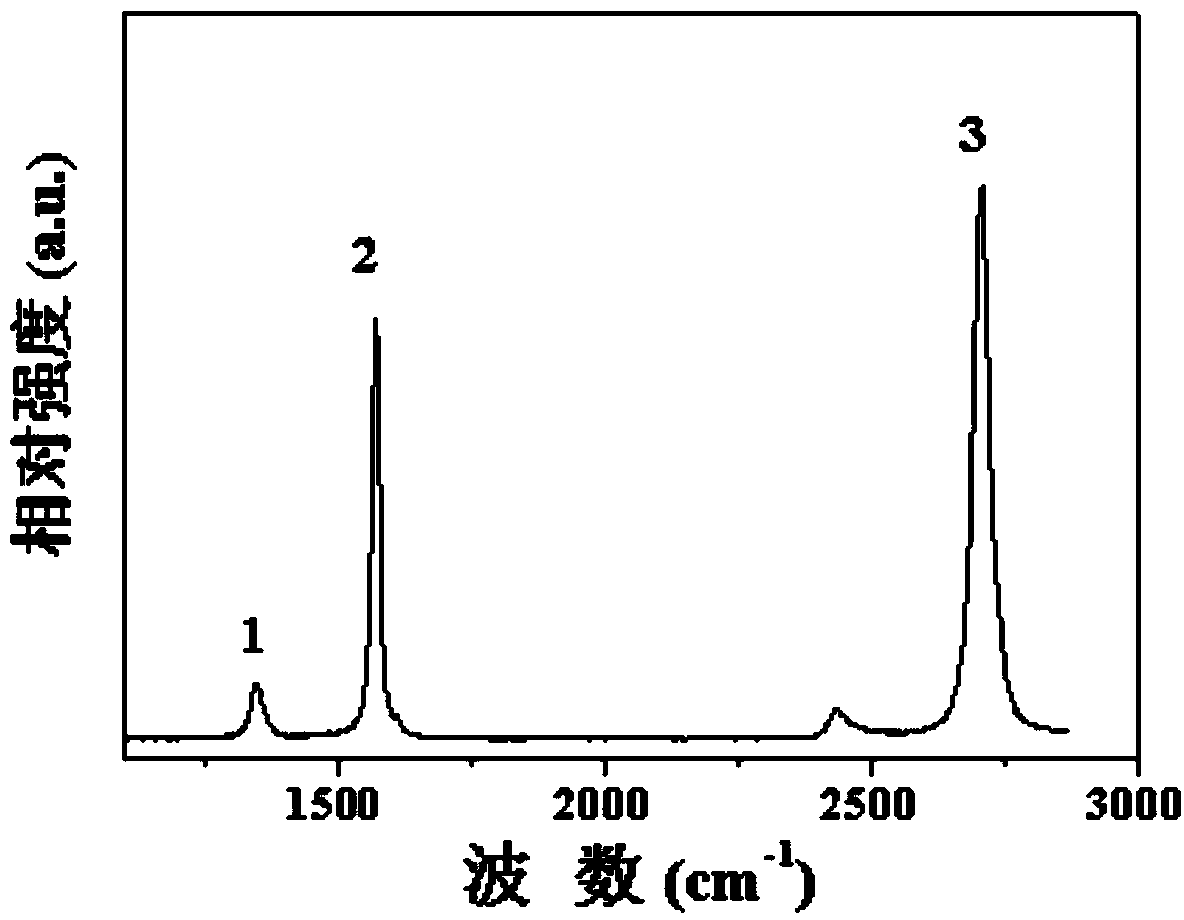

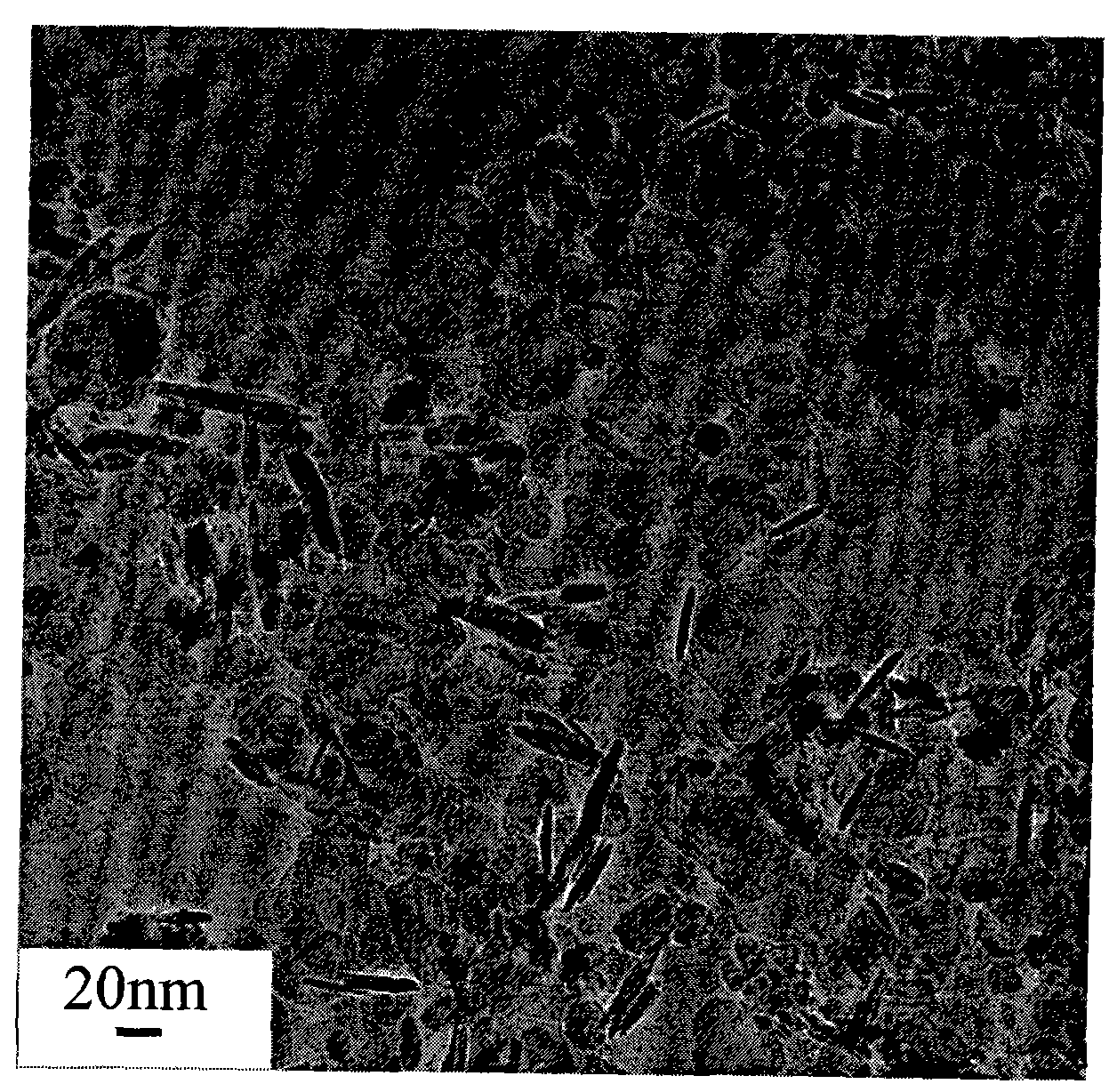

Method for efficiently preparing graphene-reinforcing copper-based composite brazing filler metal at low temperature

ActiveCN103817466AImprove decomposition efficiencyLow preparation temperatureWelding/cutting media/materialsChemical vapor deposition coatingCvd grapheneCarbon source

Owner:HARBIN INST OF TECH

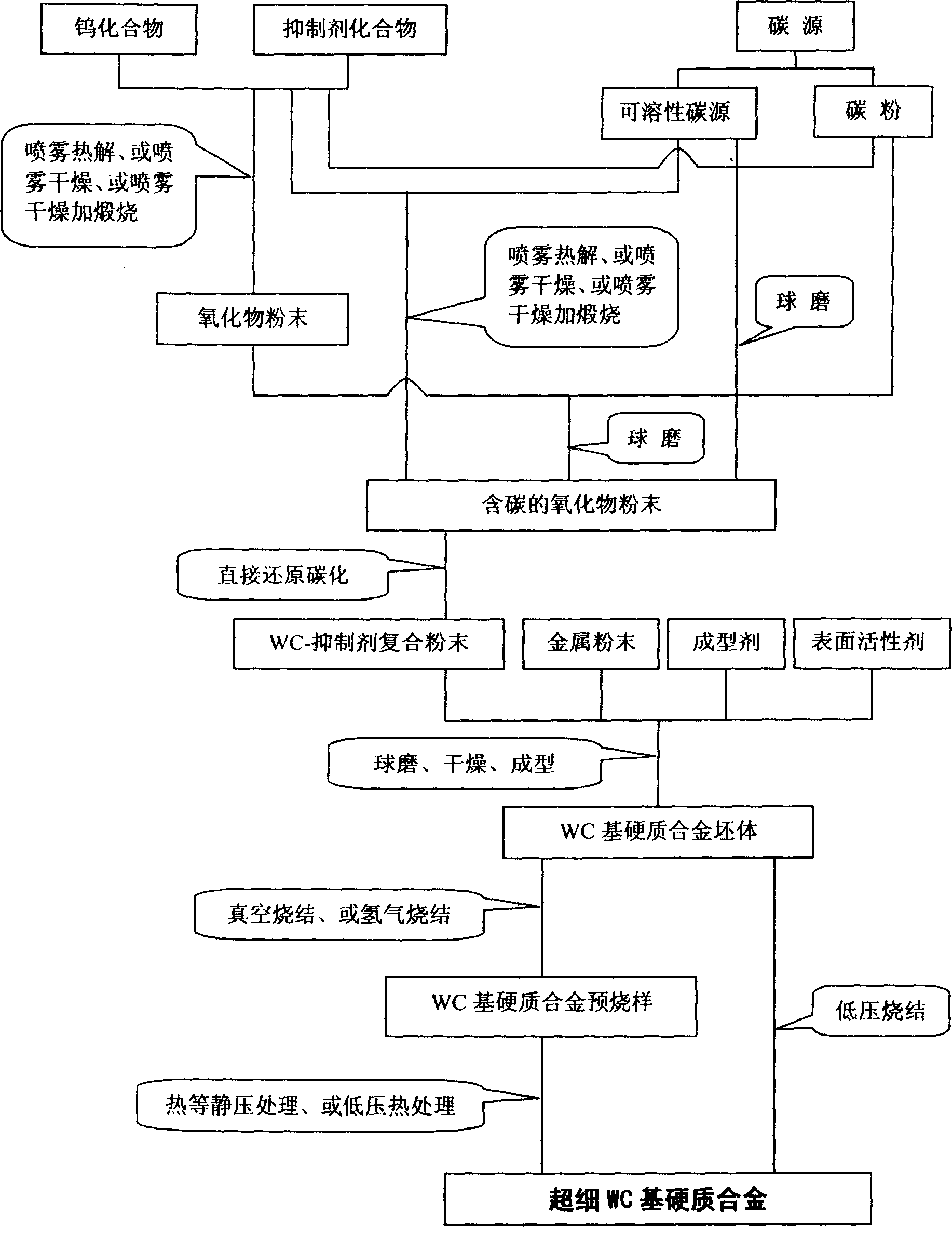

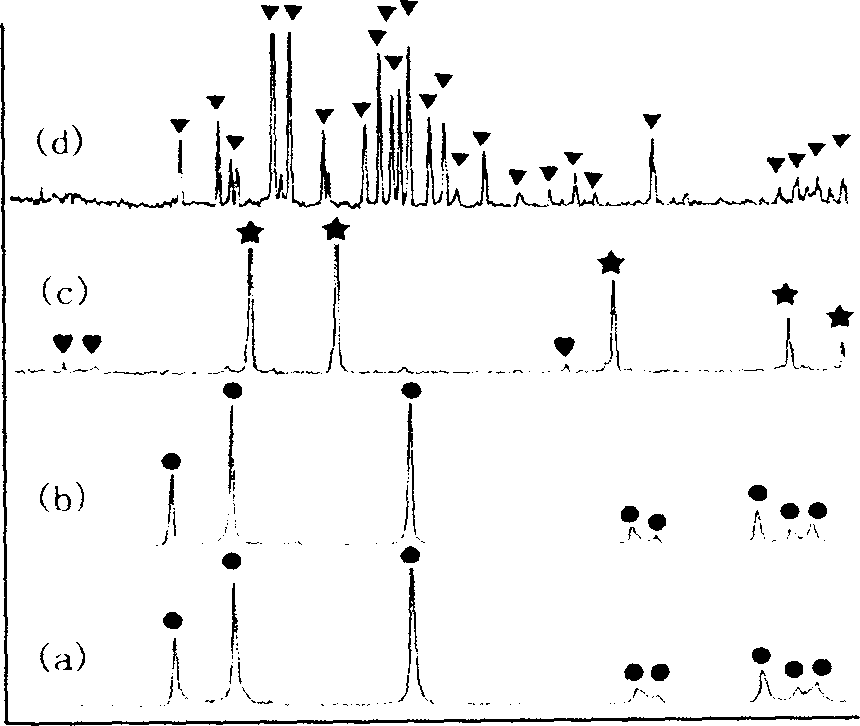

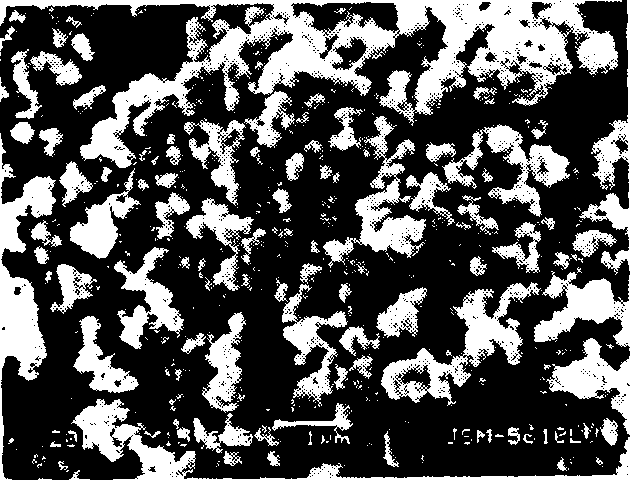

Preparation process of tungsten carbide/inhibitor composite powder and superfine hard alloy thereof

The preparation method for WC-inhibitor composite powder and its ultrafine hard alloy comprises: first, preparing oxide powder with carbon and inhibitor; composing the composite powder with direct reducing carbon method; adding metal powder to grind, dry, form, and vacuum sinter or thermal treat after H2 sintering, or low-pressure sintering directly, and obtaining the ultrafine or nano WC-base hard alloy. This invention introduces multiple inhibitors in early stage to overcome the defect in prior art, selects environment-friendly materials and temperature lower than traditional method, and needs low cost fit to industrialization.

Owner:WUHAN UNIV OF TECH

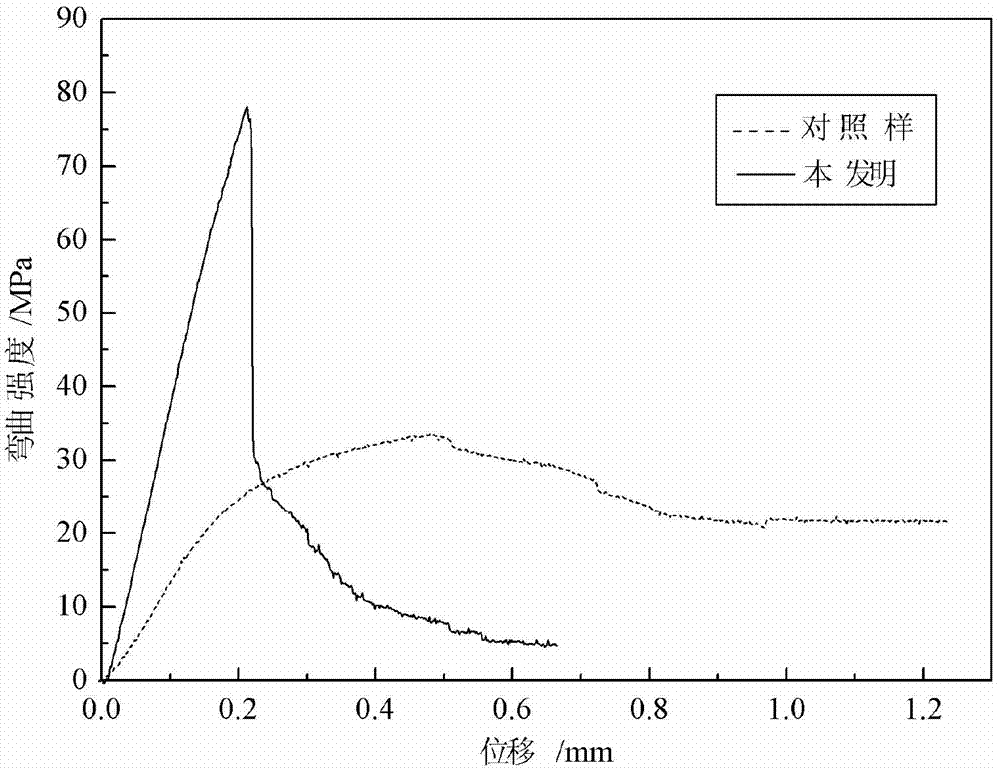

Three-dimensional alumina fiber fabric reinforced oxide ceramic and preparation method thereof

The invention discloses three-dimensional alumina fiber fabric reinforced oxide ceramic. Al2O3, SiO2 and SiOC ceramics are used as a substrate, a three-dimensional alumina fiber fabric is used as a reinforcing body, alumina and silicon dioxide in the substrate are introduced by a sol-gel process, and the SiOC ceramic is obtained by high-temperature cracking of polysiloxane. The preparation method of the three-dimensional alumina fiber fabric reinforced oxide ceramic comprises the following steps: performing vacuum soaking, gelating and high-temperature ceramic treatment on oxide sol serving as a precursor, and repeating for multiple times to obtain an alumina fiber reinforced oxide blank body; soaking the blank body in vacuum by using a polysiloxane-ethanol solution as a precursor, and performing crosslinking and high-temperature ceramic treatment to complete a densifying process; and repeating the steps for multiple times to obtain the oxide ceramic blank body, and oxidizing to prepare the three-dimensional alumina fiber fabric reinforced oxide ceramic. The three-dimensional alumina fiber fabric reinforced oxide ceramic has the advantages of high bending strength, high modulus, good interlaminar shear strength and the like.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing graphene from lignin

ActiveCN105439135ALow preparation temperatureSimple preparation processGrapheneNanotechnologyHigh energyHigh pressure

The invention discloses a method for preparing graphene from lignin. The method comprises steps as follows: a, lignin and aqueous alkali are mixed in a volume ratio of solid to liquid being 1:(5-10), the solution is heated to the temperature of 70-100 DEG C, and the insulation treatment time is 1-3 h; b, a material treated by alkali is filtered and washed, an obtained solid is dried at the temperature of 60-80 DEG C, and pretreated lignin is obtained; c, a catalyst is added to the pretreated lignin obtained in Step b, the mixture is fully mixed by a high-pressure homogenizer, non-homogenous lignin is homogenized and split, and cracked carbon and the catalyst are homogenized to be in a high energy obtaining state; d, the mixture is placed in an autoclave, inert gas is introduced, the pressure is increased at the speed of 0.1-1 MPa / s to 20-50 MPa, the mixture is heated to 500-800 DEG C and cooled to the normal temperature and pressure after being treated, and graphene is obtained. The lignin is decomposed at the high temperature and under the high pressure, high-energy carbon atoms are obtained, graphene grows under the action of the catalyst, with the adoption of the method, the preparation temperature of the graphene is reduced, and the preparation technology is simple, economical, environment-friendly and suitable for industrial production.

Owner:中航装甲科技有限公司

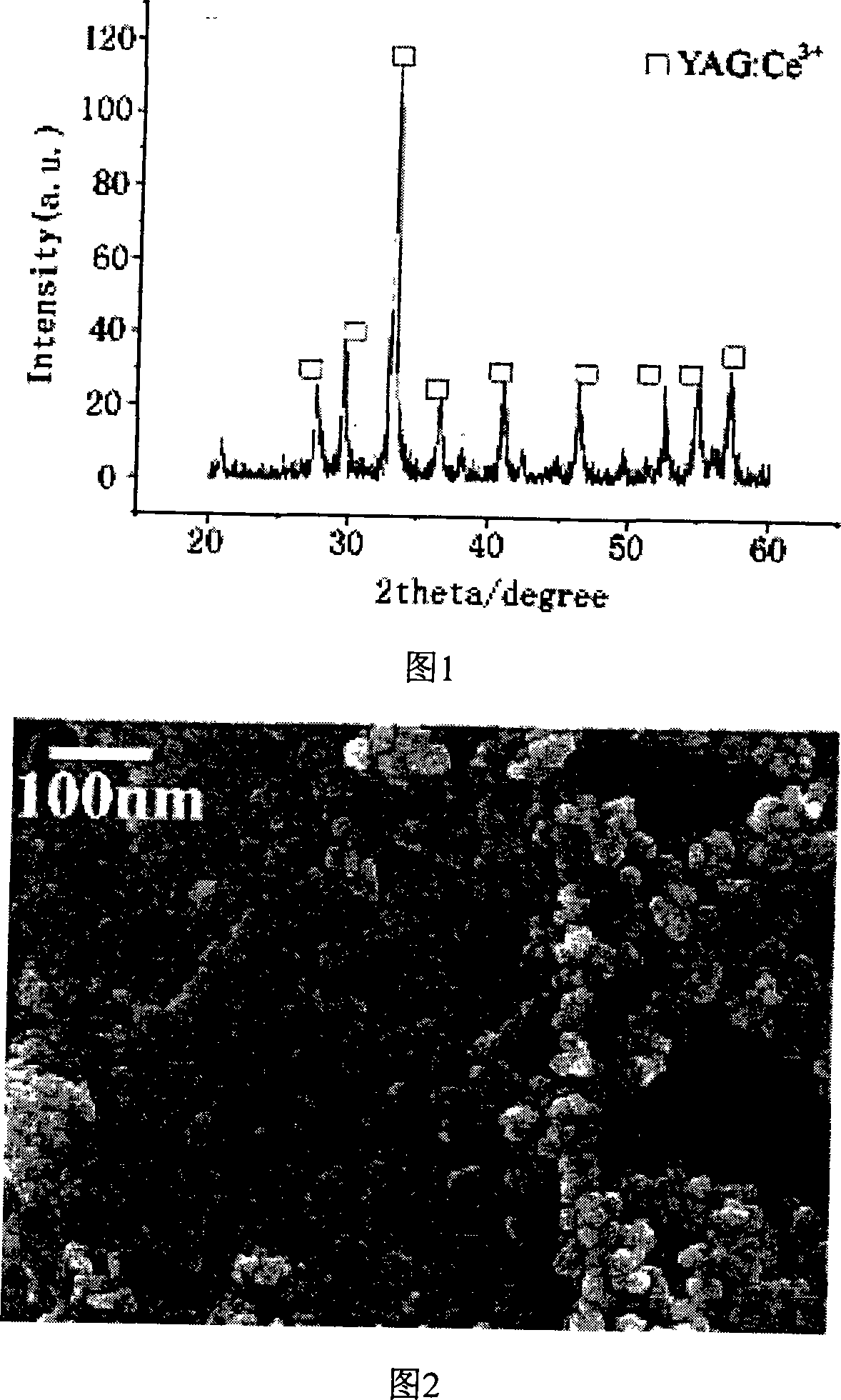

Method for preparing YAG nano powder

InactiveCN101249978ASimple requirementsWell mixedRare earth metal compoundsPolymer sciencePolymer network

Disclosed is a process for preparing YAG nano-powder, which belongs to the inorganic materials and the preparation field. The invention utilizes acrylamide as monomer, employs N, N'-methylene diacrylamide as polymer network agent, utilizes Al(NO3)3Y(NO3)3, Ce(NO3)3*6H2O as raw materials, employs citric acid as regulator, and uses a polymer network gel method and an active carbon adsorption process to prepare the nano-powder of Y3Al5O12(YAG):Ce3+. The method is characterized in that requirements to raw materials are simple and inorganic saline solution can be utilized as the raw materials, the component of the obtained micro powder is mixed evenly, most importantly, the polymer network formed in the gel process and the active carbon decomposed under nitriding atmosphere reduce the contact opportunity of precursor grains, thereby agglomeration is reduced, the nano-powder which is small in grain size and uniform in dispersion can be obtained, thereby largely reducing preparation temperature of materials, and calcination temperature is only 800 DEG C.

Owner:SHANGHAI INST OF TECH

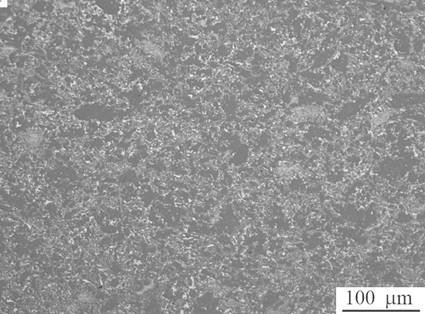

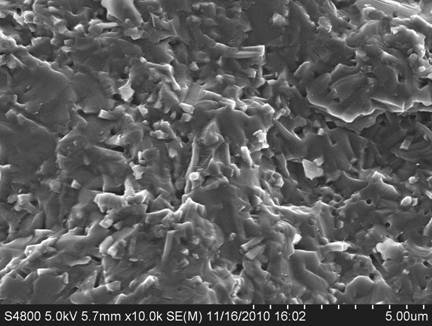

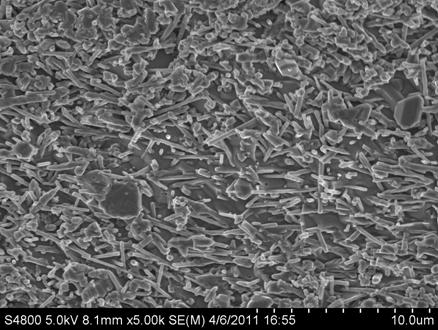

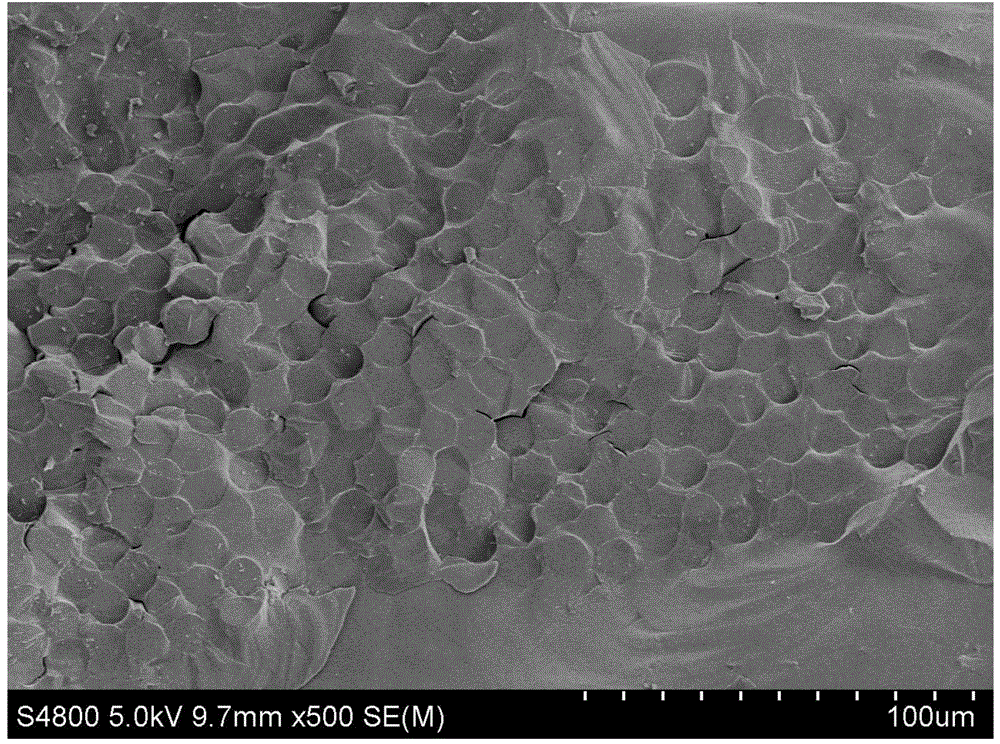

SiC whisker reinforced SiC ceramic matrix composite and preparation method thereof

The invention belongs to the field of the preparation of ceramic matrix composites, and particularly relates to a SiC whisker reinforced SiC ceramic matrix composite and a preparation method thereof. The SiC whisker reinforced SiC ceramic matrix composite is prepared from a preform through a Si or Si alloy infiltration reaction, and the preform is prepared by compressing and molding a raw material comprising a rice hull SiC whiskerized product. By the method, the preparation process is simple, the temperature of the infiltration reaction is low, external pressure is not required, and the preform can be prepared into complicate shapes and can be used for preparing members with complicated shapes. A main composition phase SiC of the composite comes from rice hull, the raw material is rich, the cost is low, the manufacturing cost of the ceramic matrix composite can be remarkably reduced, the resource is saved and the environment is protected. The SiC ceramic matrix composite has good performance, SiC whiskers have the effect of strengthening materials, and the SiC whisker reinforced SiC ceramic matrix composite can be used for applicable occasions of SiC reaction sintering ceramic material products such as sliding bearings, corrosion-resistant and wear-resistant pipelines, valves and fan blades, military and civil body armors and the like.

Owner:ZHEJIANG UNIV

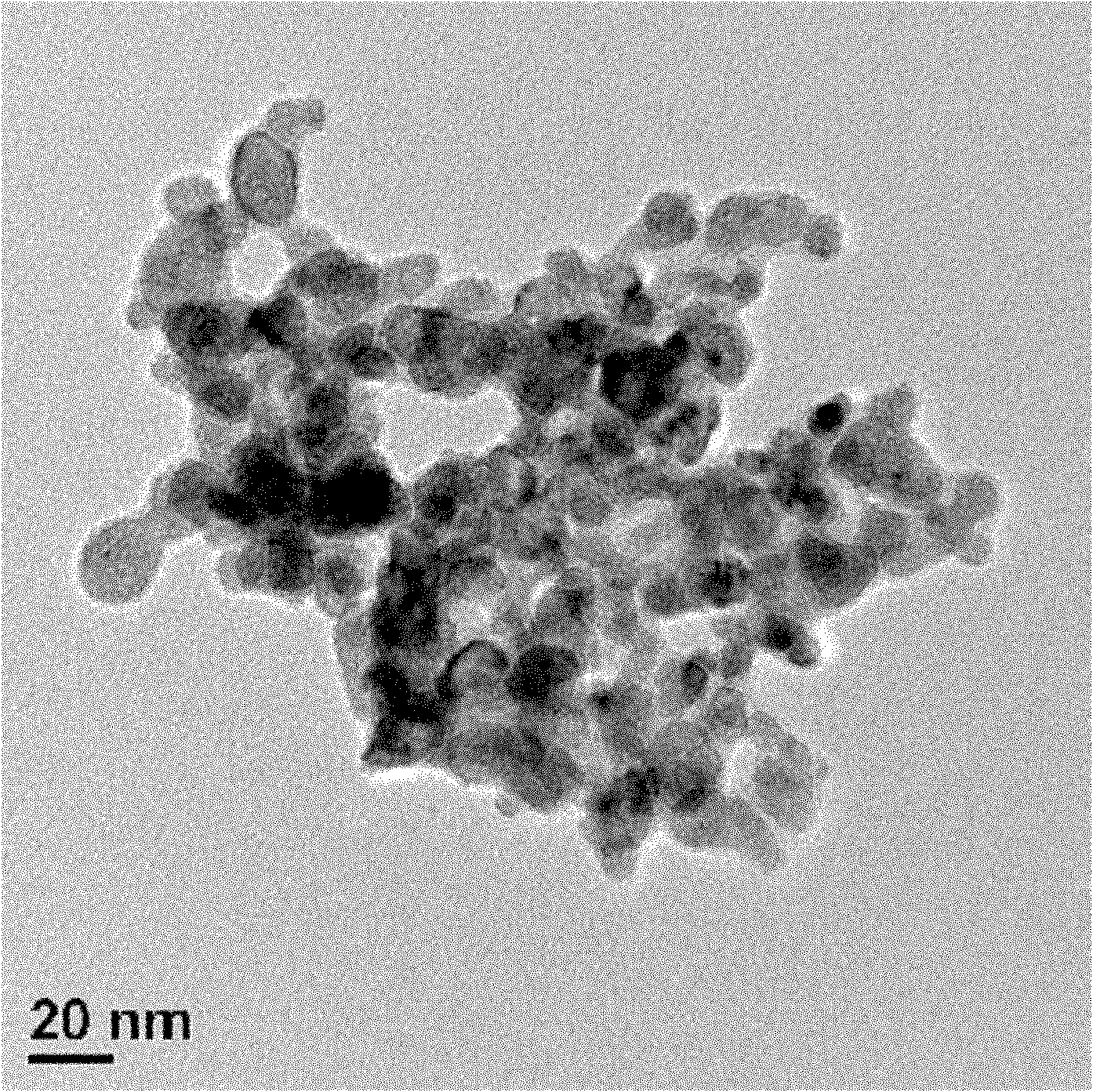

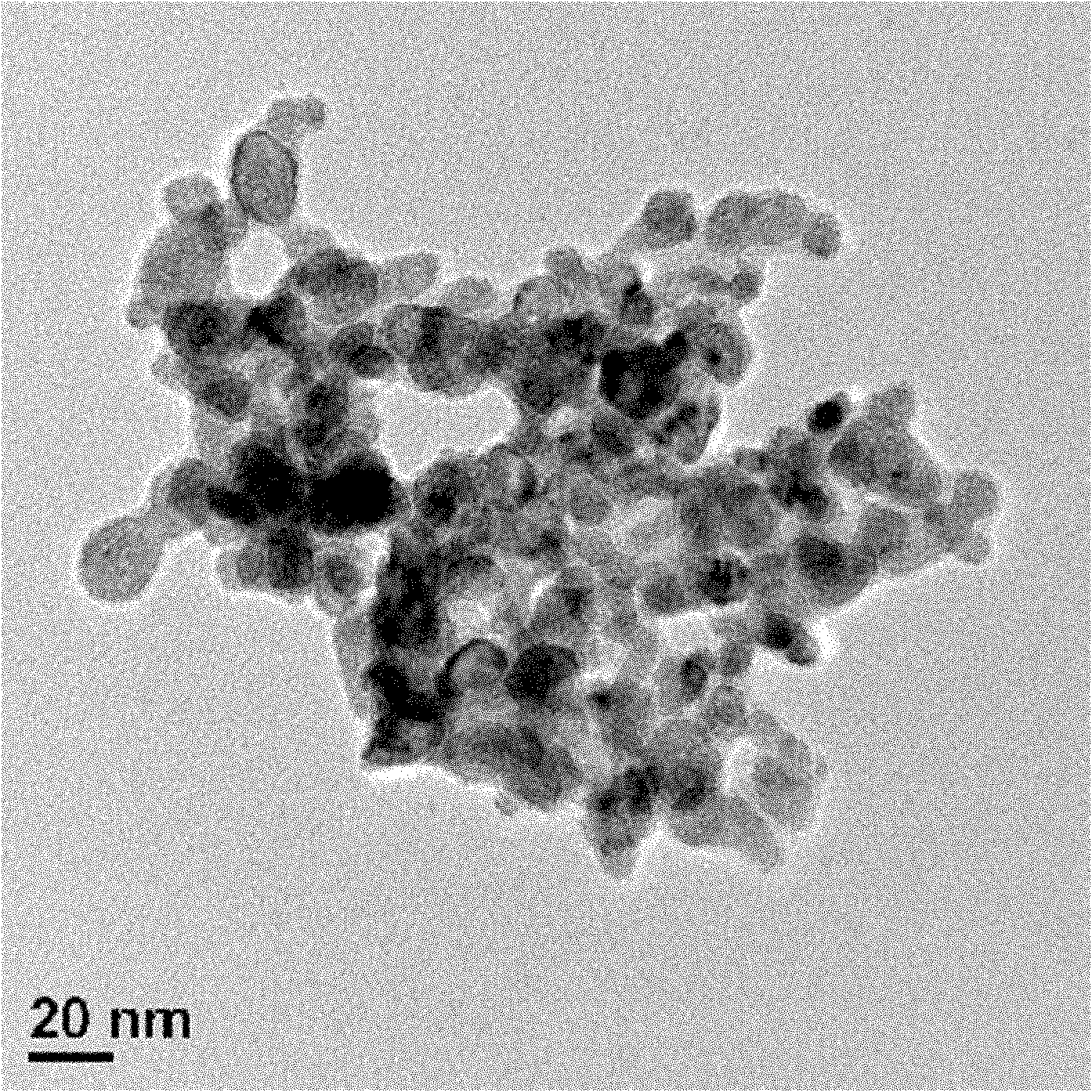

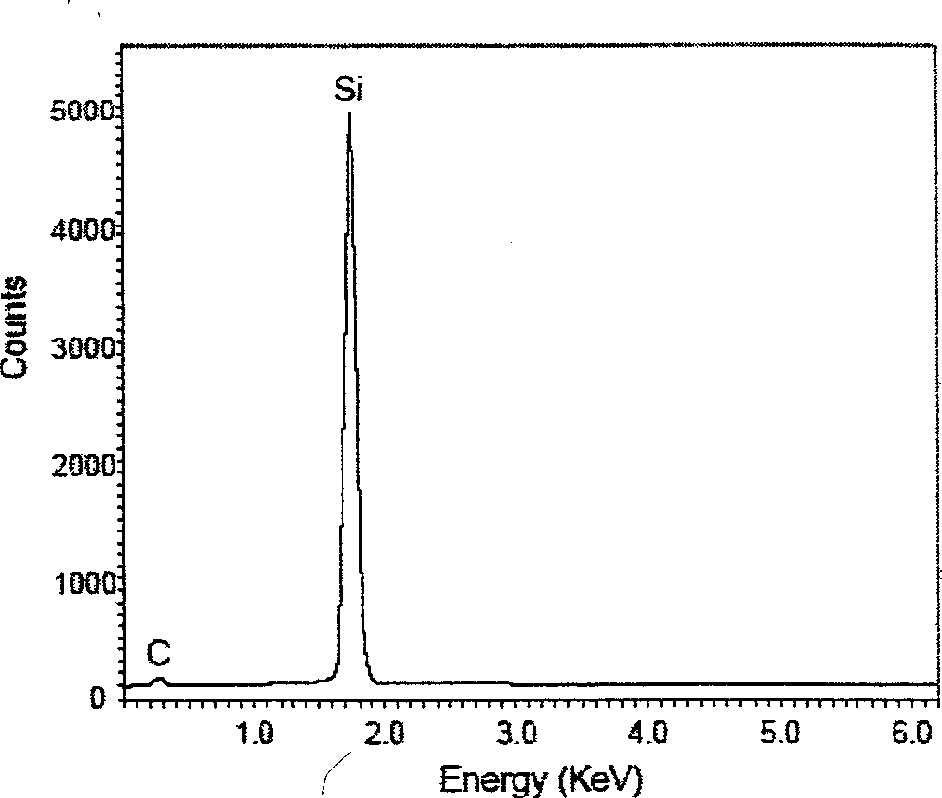

Preparation method of nano-tungsten powder

InactiveCN102019429ASimple preparation processThe preparation process is practicalAir atmosphereAmmonium metatungstate

The invention discloses a preparation method of nano-tungsten powder. The preparation method comprises the following steps: preparing ammonium metatungstate and citric acid into clear mixed aqueous solution; performing complex reaction at the temperature of 60 to 90 DEG C; filtering and drying to obtain the precursor of tungsten oxide; calcining in air to obtain tungsten oxide (WO3) powder; introducing ammonia gas to the tungsten oxide powder for nitridation to obtain tungsten nitride (W2N) powder; and finally performing thermal treatment on the tungsten nitride powder to obtain the nano-tungsten powder. The preparation process disclosed by the invention is simple and practical and has the high operability and is easy in implementation of scale production; the prepared powder has small particle size of which the average particle size is 20-50 nm; the particle size distribution is uniform; and the degree of aggregation is low and high sintering activity is realized. The technology disclosed by the invention can promote the progress of high-quality tungsten material in China and the performance level, and provide means for transforming advantages in tungsten ore resources into industrial and economical advantages.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Chemical vapor deposition process of preparing Sic nanotube

The preparation process of SiC nanotube includes the following steps: 1. cleaning and drying graphite sheet as substrate; 2. soaking the substrate in catalyst solution including catalyst comprising organic compound of Fe, Co, Ni and other metals and co-catalyst comprising organic compound of S; 3. chemically vapor depositing gas source compound comprising organic compound capable of being gasified and containing Si-C bond in the carrier gas comprising N2, H2, NH3 or their mixture and with the molar ratio to the gas source compound of 4.5-7.0 at the temperature of 800-1100 deg.c for 0.8-1.5 hr; and 4. purifying treatment. The present invention has the advantages of: low preparation temperature, easily controlled reaction process, simple technological apparatus, low cost, high yield, high product purity, homogeneous product size distribution and easy use in large scale production.

Owner:NAT UNIV OF DEFENSE TECH

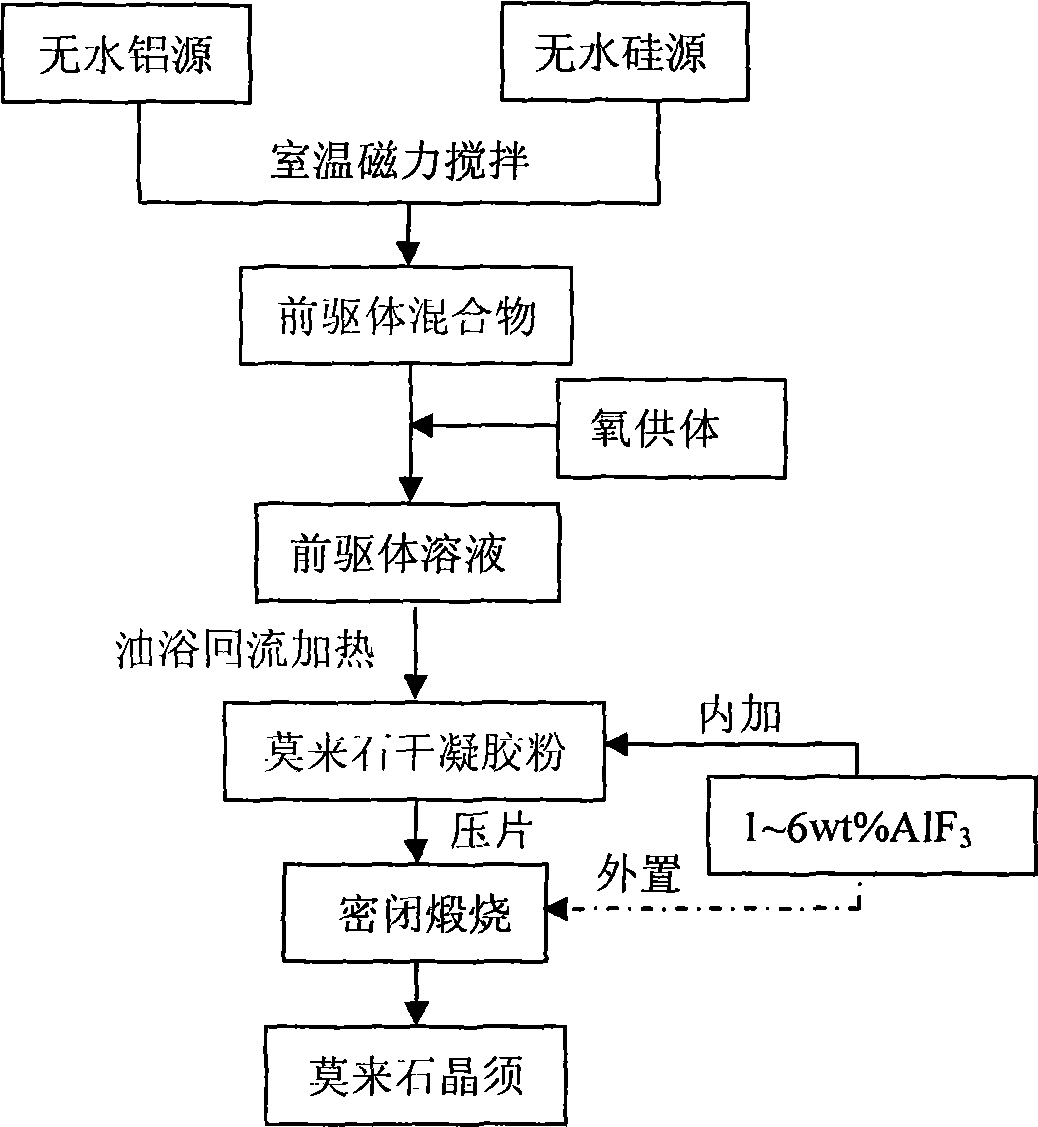

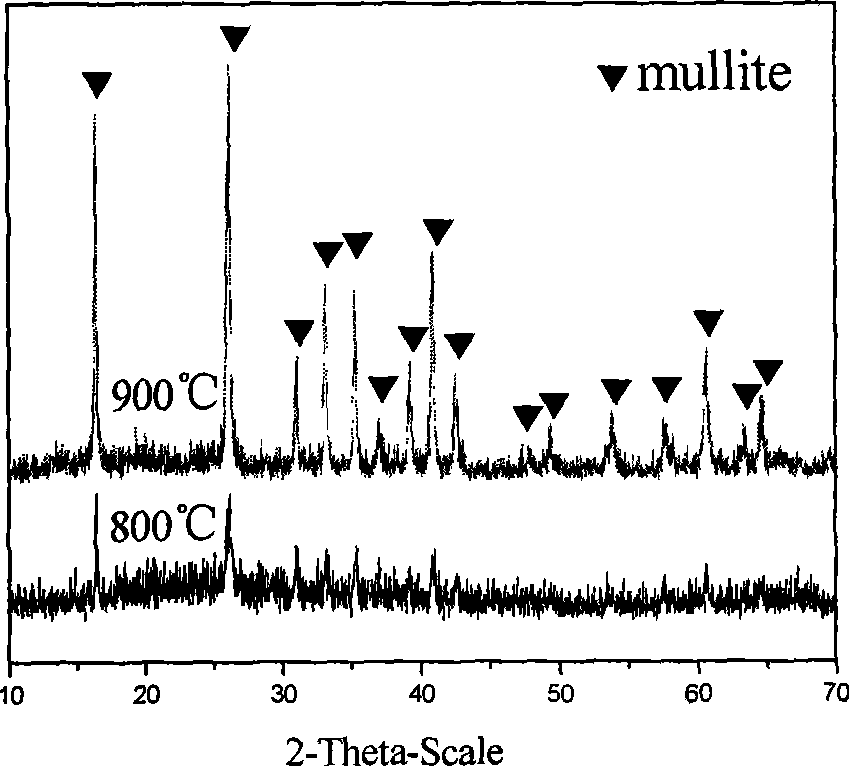

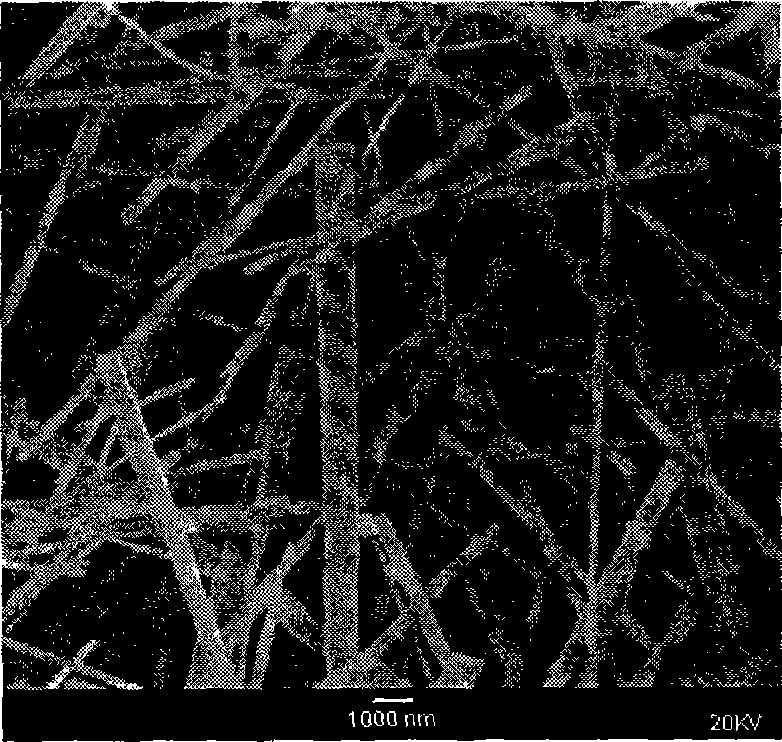

Method for preparing mullite crystal whisker by non-hydrolytic sol-gel process

InactiveCN101498049ALow preparation temperatureQuality improvementPolycrystalline material growthSingle crystal growth detailsOxygen donorSol-gel

The invention discloses a method of preparing porzite whiskers by a non-hydrolyzed sol-gel technology. The method comprises the following steps: using an anhydrous aluminum source and an anhydrous silicon source as precursors and using low-carbon alcohol or ether as an oxygen donor to prepare porzite xerogel powder; then adding a certain amount of fluoride as a whisker catalyst and calcining a closed crucible to prepare the high-purity and white porzite whiskers which have the diameter of 0.2 micron to 2 micron, a slenderness ratio up to 60 to 70 and do not comprise mingled particles. Compared with the prior art, the invention has the advantages of simple technology, convenient operation, low whisker preparation temperature and high whisker yield.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Preparation method of high-performance diamond reinforced Al-matrix electronic packaging composite material

ActiveCN101728279AHigh densityImprove thermal conductivitySemiconductor/solid-state device manufacturingSingle crystalVolumetric Mass Density

The invention relates to a preparation method of a high-performance diamond reinforced Al-matrix electronic packaging composite material, belonging to the field of metal-matrix composite materials. The preparation method is characterized by comprising the following steps: adding alloy elements into a pure Al matrix to prepare elemental mixed powder or Al alloy powder; uniformly mixing the elemental mixed powder or the Al alloy powder and diamond single crystal grains according to the volume percentage ratio of 75:25-40:60; adding the mixture into a graphite mold for carrying out spark plasma sintering, wherein the mixture is added at the heating speed of 50-100 DEG C / min until the sintering temperature is 580-800 DEG C and the sintering pressure is 30-40MPa; keeping the temperature and the pressure for 5-20min; and obtaining the high-performance diamond reinforced Al-matrix electronic packaging composite material after the sintering process finishes. The alloy elements comprise B, Si, Cr, Ti, Nb, Ag, Cu and the like. The material of the invention has the characteristics that the heat conductivity reaches 430W / m.K, the heat expansion coefficient is 6.40ppm / K, the compressive strength is 331MPa, and the density is only 3.13g / cm<3>. The invention effectively solves the problem of graphitization of single crystal diamond grains in the preparation process of the material, and has simple preparation processes and high production efficiency.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Preparation method of titanium dioxide film photocatalyst loaded on surface of flexible base material

InactiveCN1394675AHigh bonding strengthSmall air resistanceDispersed particle separationCatalyst activation/preparationAlcoholSolvent

The preparation method of TiO2 film photocatalyst includes the following steps: firstly, using n-butyl titanate or titanium tetrachloride as precursor, adding pore-forming agent to prepare active layer sol, utilziing pulling-plating process to directly apply the active layer sol on the cleaned flexible base body, centrifugal removing excess sol, then placing the flexible base body with loaded gel into a water hot still, and using water-ethyl alcohol mixed solvent to form nano crystal TiO2 film photocatalyst at low temp.

Owner:TSINGHUA UNIV

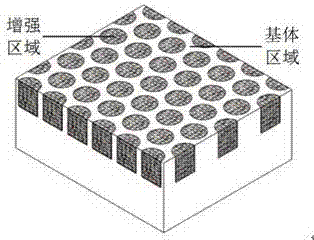

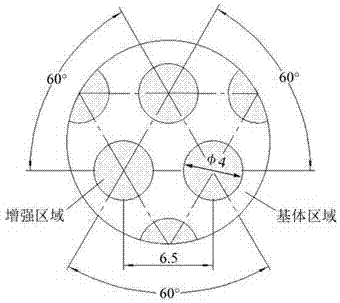

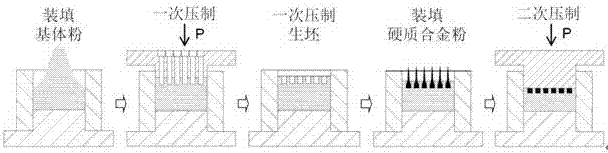

Powder metallurgy preparation method of localization reinforced composite

The invention belongs to the technical field of composite preparation, and particularly relates to a powder metallurgy preparation method of a localization reinforced composite for manufacturing wear-resisting quick-wear parts of mining and building machines. The method comprises the following steps that (1) tungsten carbide powder and titanium carbide powder are used as reinforced particles, reduced iron powder and high-speed steel powder are used as a metal binder, and hard alloy powder is prepared according to a certain proportion; (2) the prepared hard alloy powder is put into a ball mill, and a process control agent is added for ball milling and mixing; and (3) a forming agent is added into the hard alloy powder subjected to uniform ball milling and mixing, and then the steps of mixing, prepressing, smashing, sieving particle making and the like are carried out. In a composite layer of the composite prepared through the method, discontinuous reinforcement areas are uniformly distributed in a continuous matrix area, cracks are not prone to being produced and expanding in the service process of the composite, and strength-toughness matching performance of the composite is achieved well; and the wear resistance of the composite can be obviously improved, and the service life of the composite can be obviously prolonged.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

BiPO4 nanorod and preparation method and application thereof

InactiveCN102872888AGood UV photocatalytic activitySave raw materialsWater/sewage treatment by irradiationCatalyst activation/preparationUltraviolet lightsMonazite

The invention provides a BiPO4 nanorod and a preparation method and application thereof. The preparation method of the BiPO4 nanorod includes the steps: adding Bi(NO3)3 5H2O and NaH2PO4 2H2O into deionized water for reaction so as to obtain precipitate, namely the BiPO4 nanorod. BiPO4 which is prepared by the method and of monoclinic-phase monazite and hexagonal mixed crystal structures has fine ultraviolet light catalytic activity, and MB (methylene blue) liquid phase degradation rate of the BiPO4 reaches degradation activity of BiPO4 prepared by a hydrothermal method; and the whole preparation method is low in raw material cost, simple in process, low in preparation temperature and suitable for industrialized mass production and has extremely high practical value and application prospect, and product cost is effectively reduced.

Owner:TSINGHUA UNIV

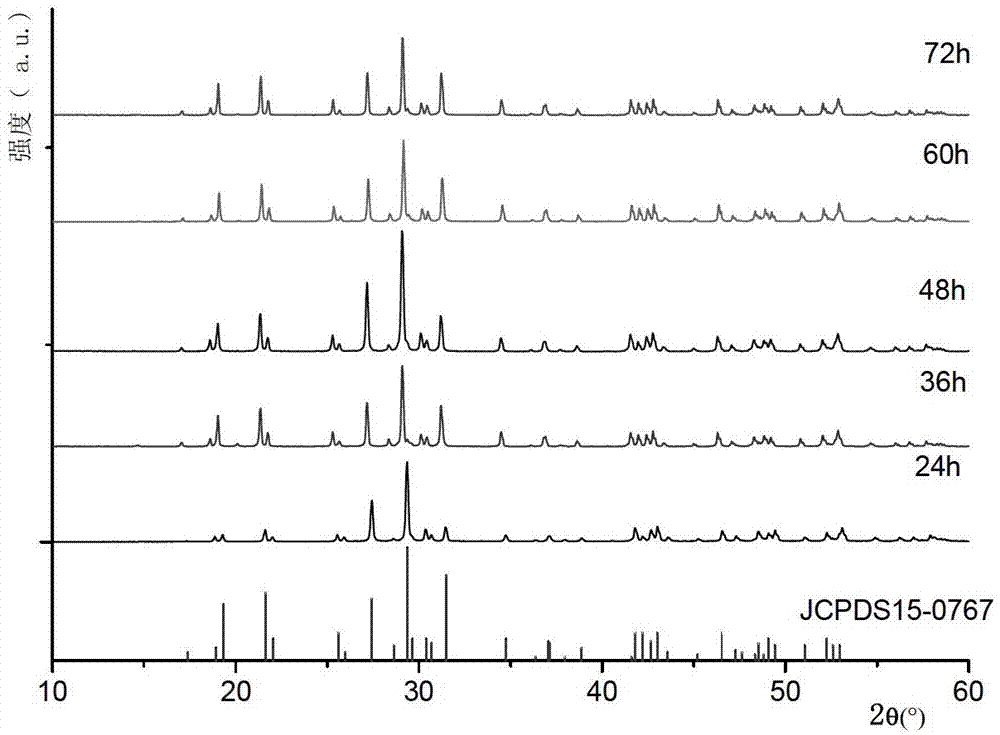

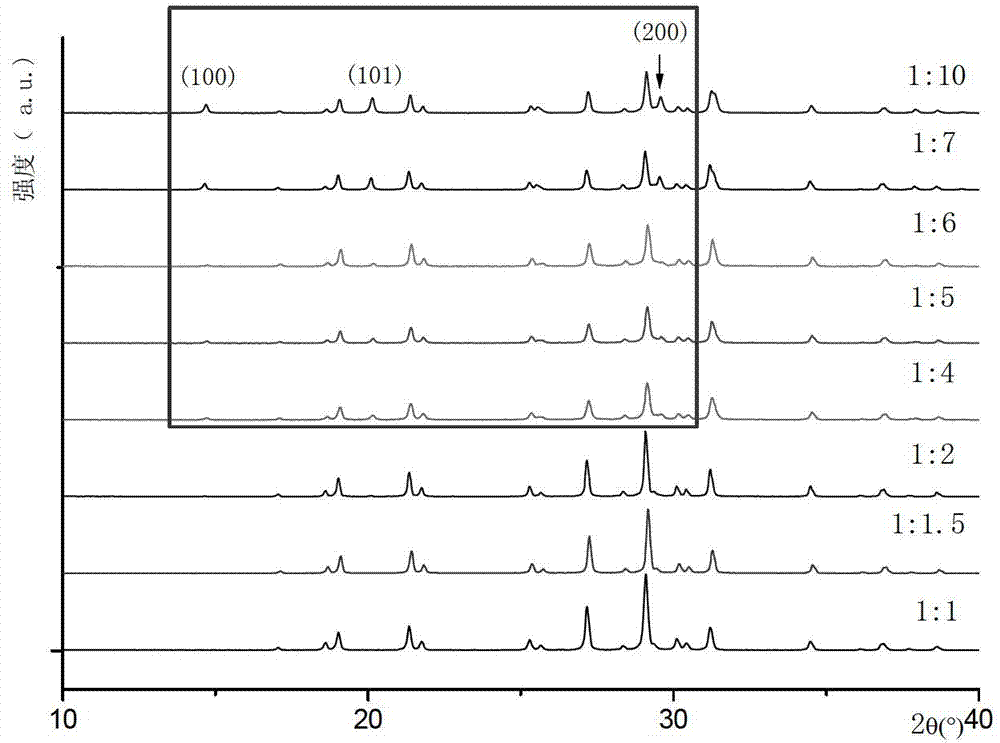

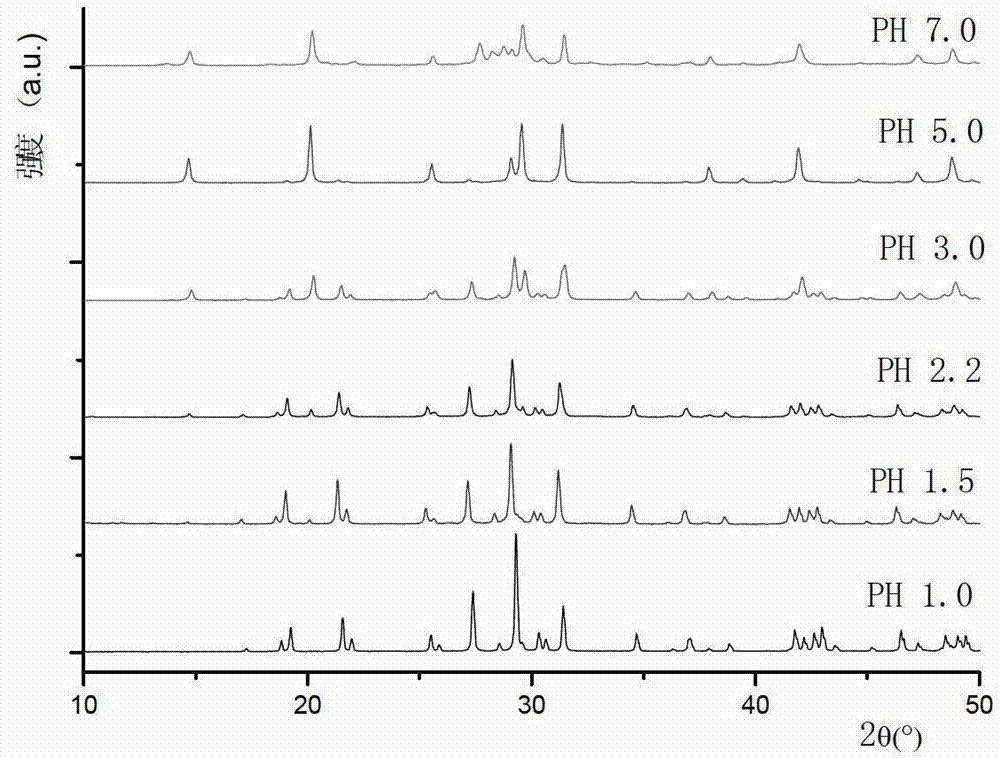

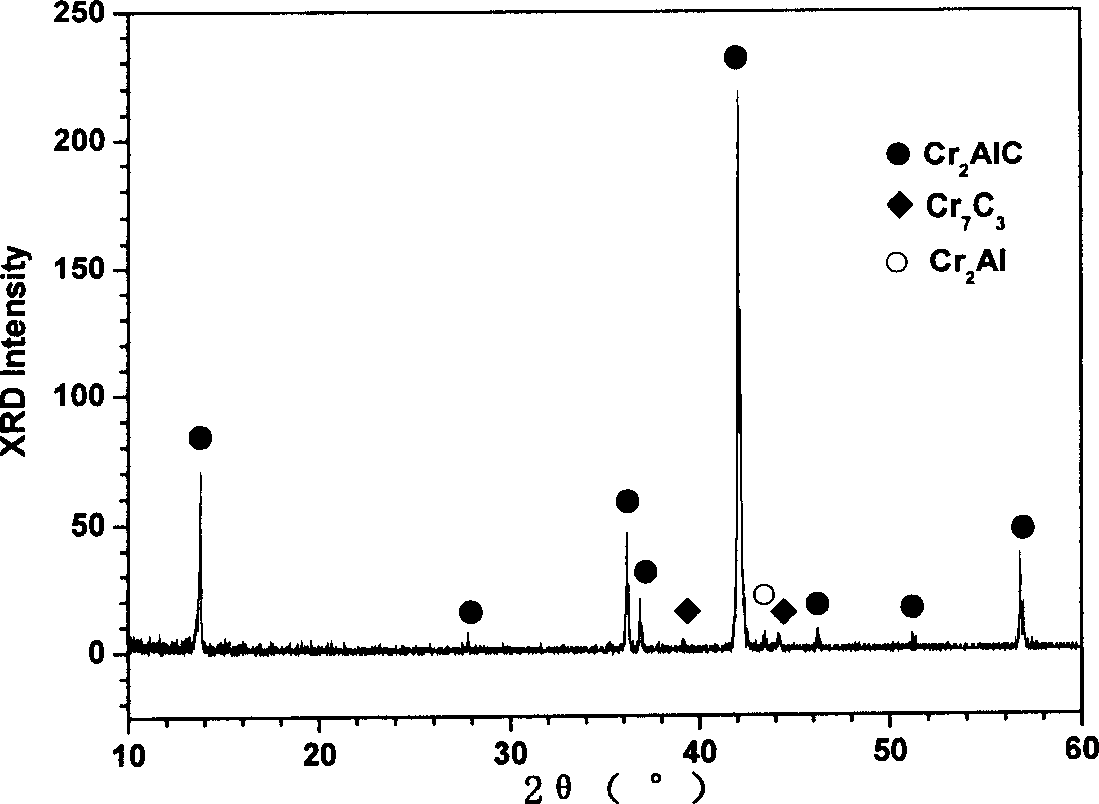

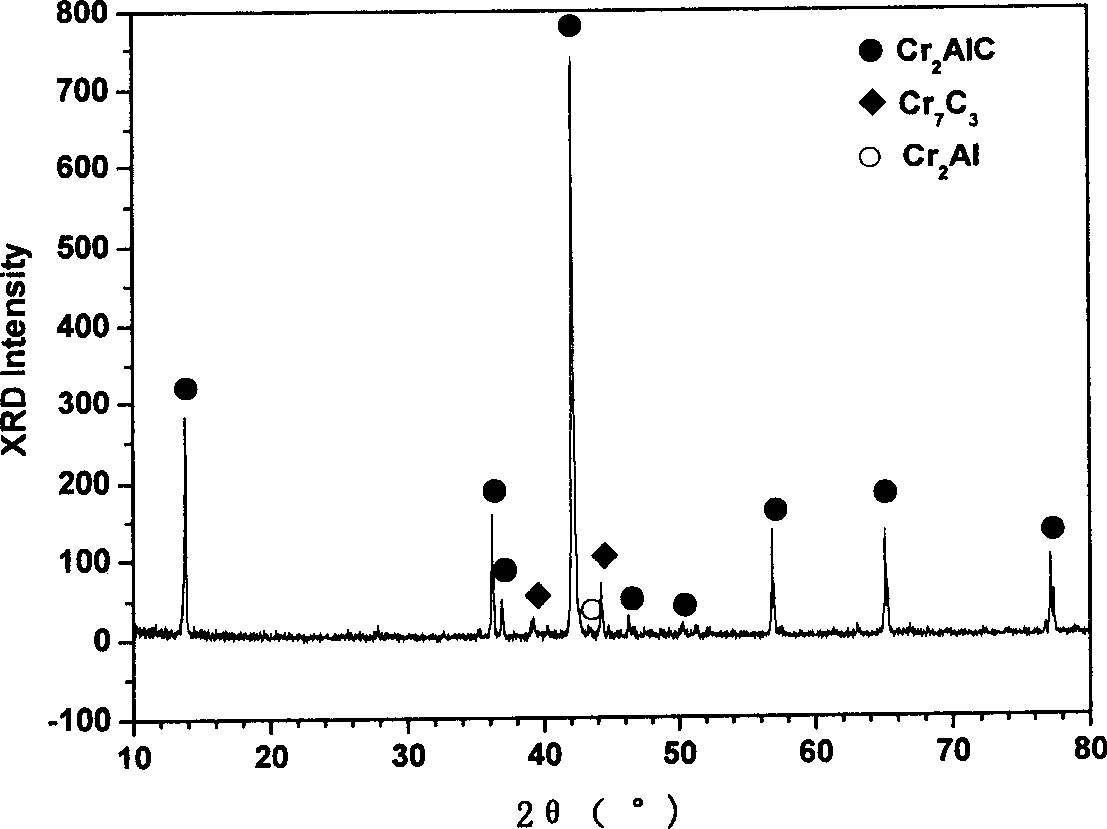

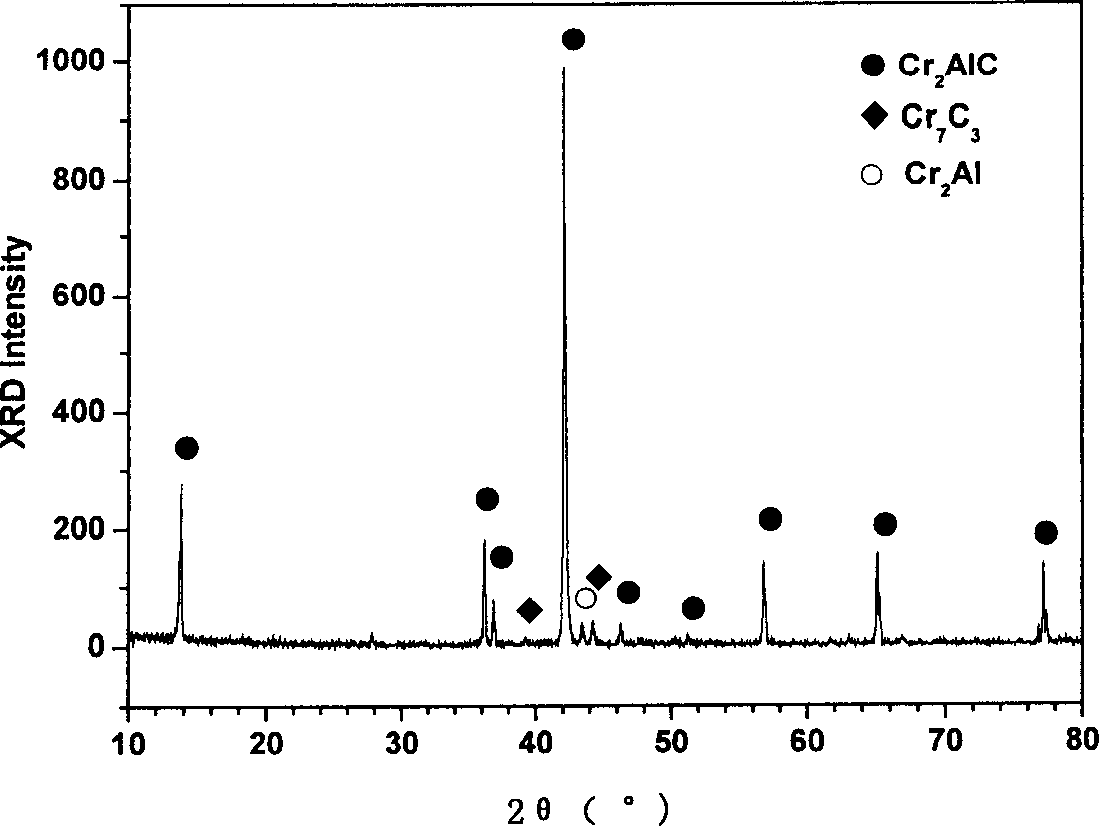

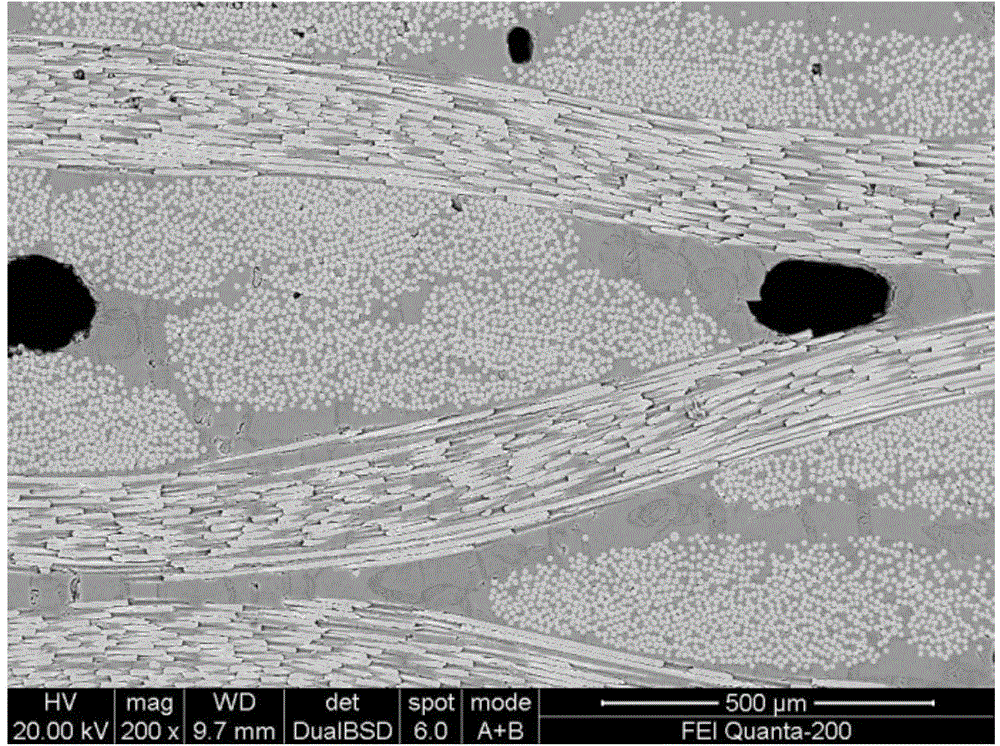

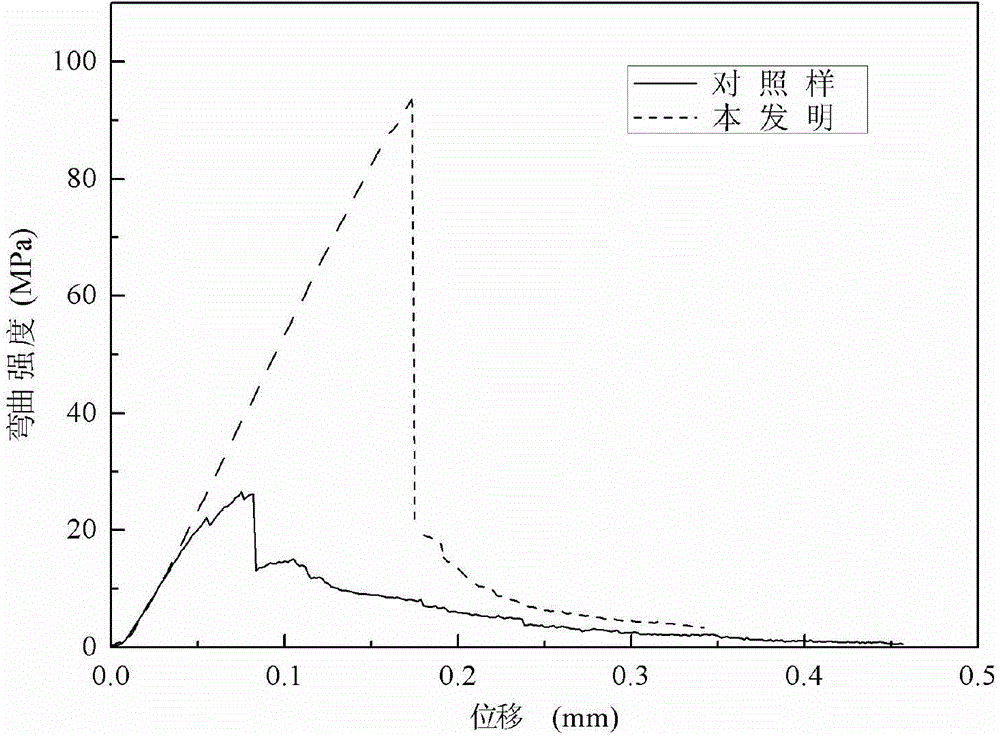

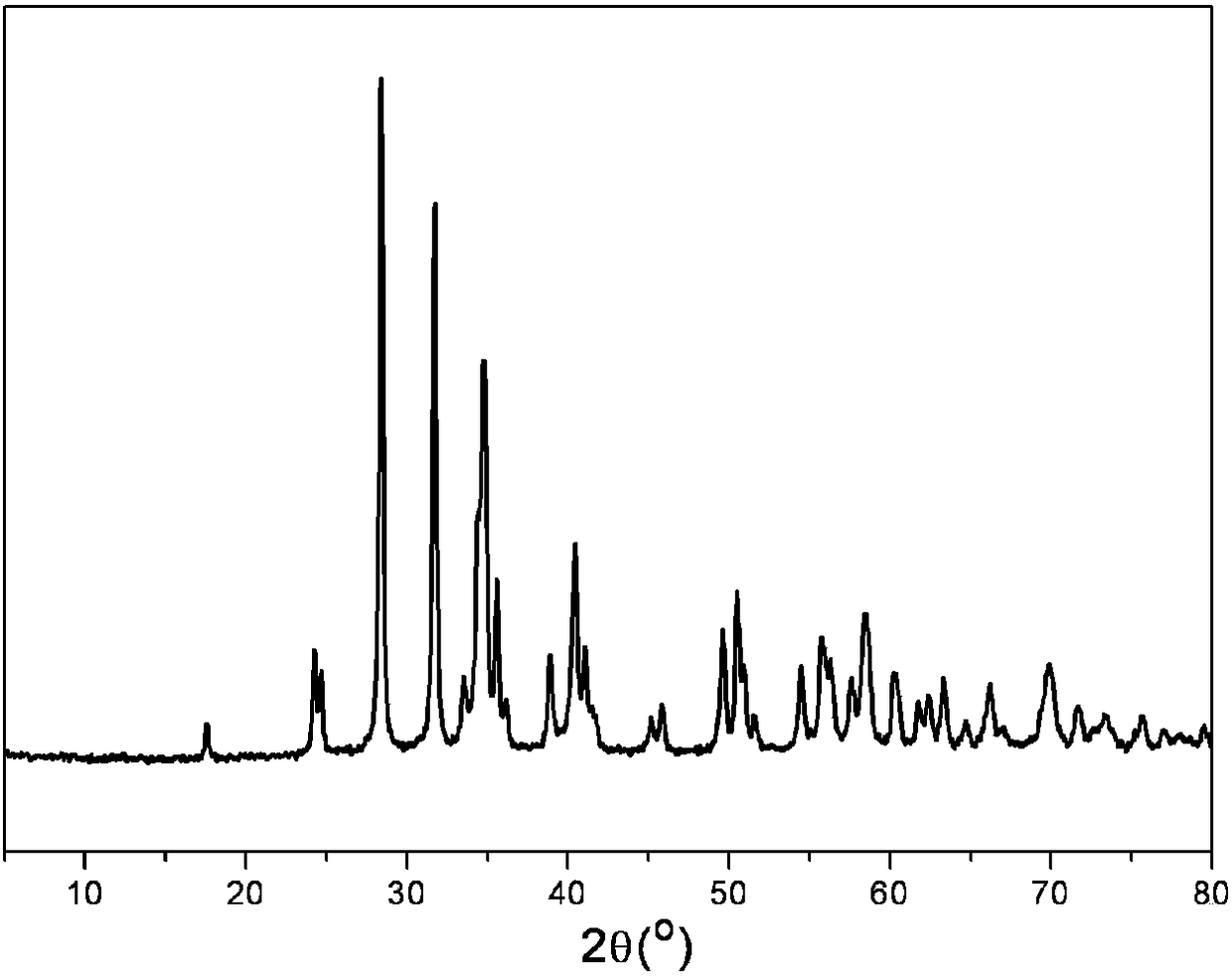

Method for preparing Cr2AlC by molten salt process

The invention discloses a preparing method of Cr2AlC powder through molten salt method, which comprises the following steps: (1) adopting chromium powder, aluminum powder and graphite as raw material; allocating materials according to Cr2AlC chemical gauge with surplus aluminum; (2) heating to 900-1200 deg.c at 10-40 deg.c per min protected by Ar gas; insulating; cooling to prepare Cr2AlC powder. The invention can provide high-purity powder, which is fit for examining study and industrial manufacturing.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

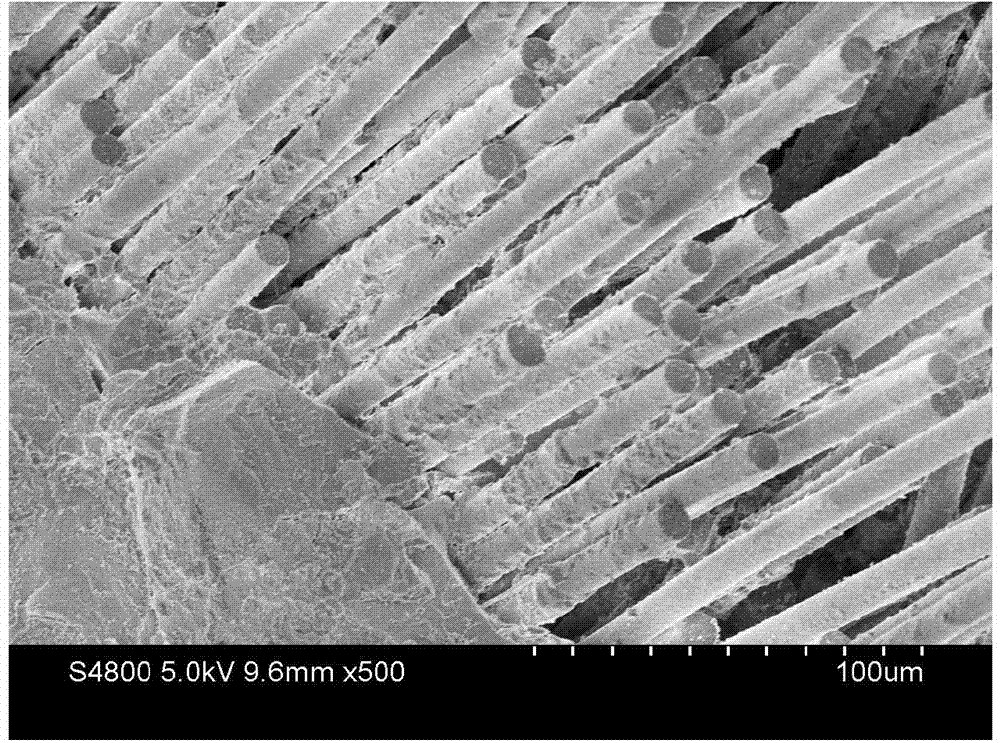

Interface-phase-including alumina fibrous fabric reinforced SiOC (silicon oxycarbide) ceramic and preparation method thereof

The invention discloses an interface-phase-including alumina fibrous fabric reinforced SiOC (silicon oxycarbide) ceramic. The interface-phase-including alumina fibrous fabric reinforced SiOC ceramic uses a SiOC ceramic as a matrix and three-dimensional alumina fibrous fabric as a reinforcement, and a sacrificial carbon interface phase is formed between the matrix and the reinforcement. A preparation method of the interface-phase-including alumina fibrous fabric reinforced SiOC ceramic comprises the following steps of first, putting the alumina fibrous fabric into a muffle furnace for carrying out high-temperature oxidation to remove impurities; afterwards, preparing a cracking carbon coating on the surface of the alumina fibrous fabric by utilizing a chemical vapor deposition technique; preparing a precursor solution, carrying out vacuum impregnation on the alumina fibrous fabric coated with the cracking carbon coating with the precursor solution, taking out the vacuum-impregnated alumina fibrous fabric out for air-drying, carrying out low-temperature crosslinking on the air-dried alumina fibrous fabric, and then completing a one-time compaction process through high-temperature ceramization; repeatedly carrying out compaction for at least five times to prepare a SiOC ceramic intermediate product; finally, carrying out subsequent oxidation to sacrifice cracking carbon, so as to prepare a final product. The product provided by the invention is excellent in room-temperature and high-temperature mechanical properties, high in inoxidizability and low in cost, and can be molded in a near-net-size manner.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing ferroferric oxide nano sheet

InactiveCN101830515ALow costSimple processNanostructure manufactureFerroso-ferric oxidesAlcoholReaction temperature

The invention discloses a method for preparing a ferroferric oxide nano sheet, which comprises the following steps of: dissolving soluble ferrous ion salt in de-ionized water; dissolving strong base in the de-ionized water, and then adding surface active agent; and mixing the two solutions under the ultrasonic condition to react to obtain a suspensoid, extracting the solid phase from the suspensoid, repeatedly washing with distilled water and absolute ethyl alcohol, and then drying in vacuum at 120 DEG C to obtain the Fe3O4 nano sheet. The invention has the characteristics of low reaction temperature, simple process, short production cycle, low cost and high product purity. The obtained nano sheet is a Fe3O4 single-phase two-dimensional sheet, and the thickness is smaller than 5nm on average.

Owner:ZHEJIANG UNIV

Cf/HfC-TaC-C composite material and preparation method thereof

The invention provides a Cf / HfC-TaC-C composite material and a preparation method thereof, wherein a carbon fiber preform as a skeleton is immersed in a precursor solution containing a hafnium-tantalum precursor copolymer, and curing and cracking are performed to obtain the Cf / HfC-TaC-C composite material. According to the present invention, the process is simple, and the preparation period is short; and the prepared ultra-high temperature ceramic matrix composite material has advantages of excellent high-temperature resistance, excellent oxidation resistance and excellent ablation resistance,can be used as the high temperature thermal structure material of highly-hypersonic aircrafts and rocket propulsion systems, and has wide application prospect.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Preparation method for oxide fiber toughened silicon dioxide ceramic-based composite material gap interface

The invention discloses a preparation method for an oxide fiber toughened silicon dioxide ceramic-based composite material gap interface. The preparation method is characterized by comprising the following steps of: preparing an interface layer of C60 on the surface of an oxide fiber or a fiber prefabricated part, wherein through repeated silica gel steeping thermal treatment process cycles, the interface layer of C60 is still kept between the fiber and a silicon dioxide substrate; performing a sintering process to oxidize the C60 to generate carbon dioxide for volatilizing; thus forming a gap between the fiber and the silicon dioxide substrate, wherein the gap is a weak bonding interface which contributes to crack deviation and fiber extraction. According to the method, the toughness of an oxide fiber toughened silicon dioxide ceramic-based composite material is enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

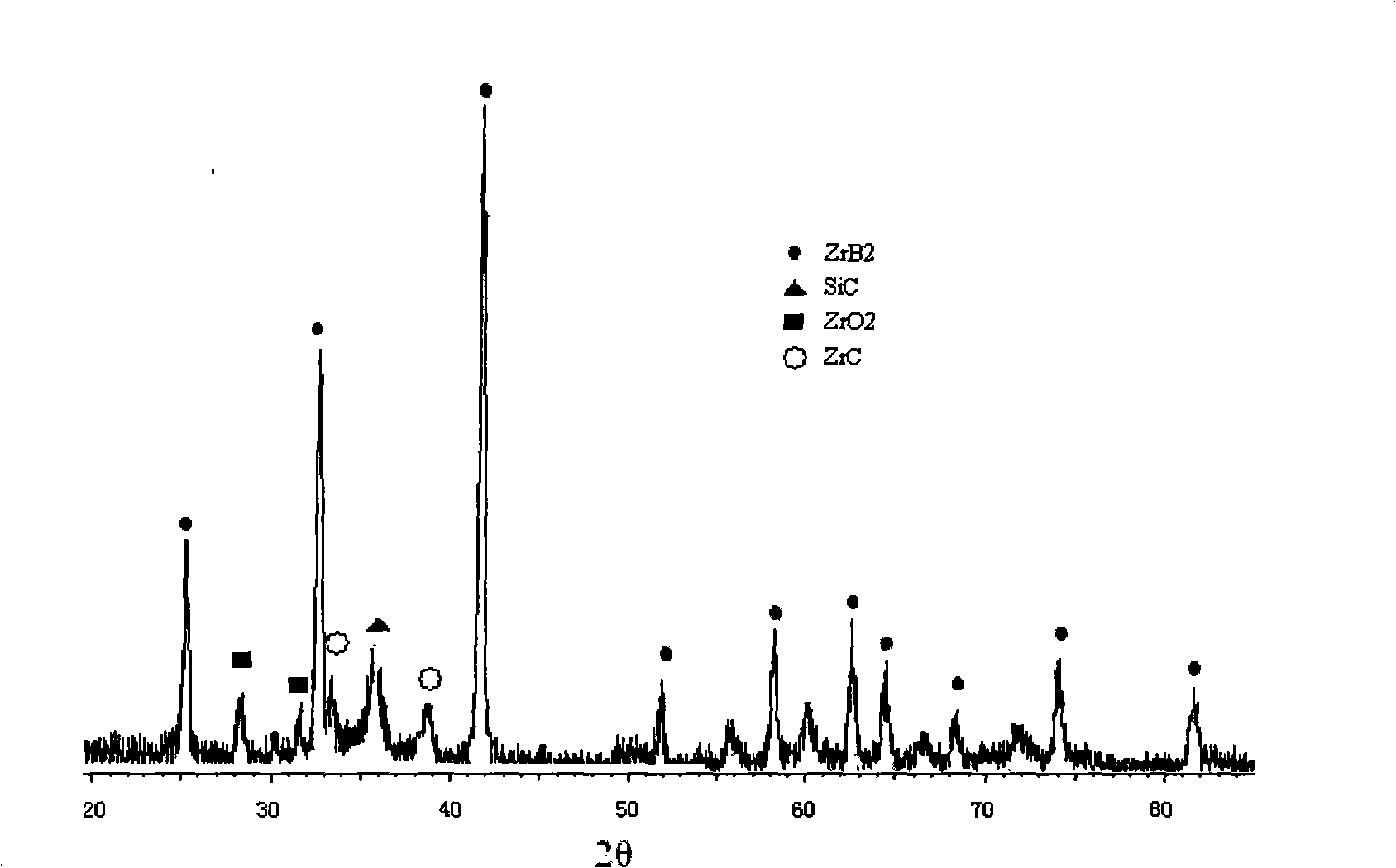

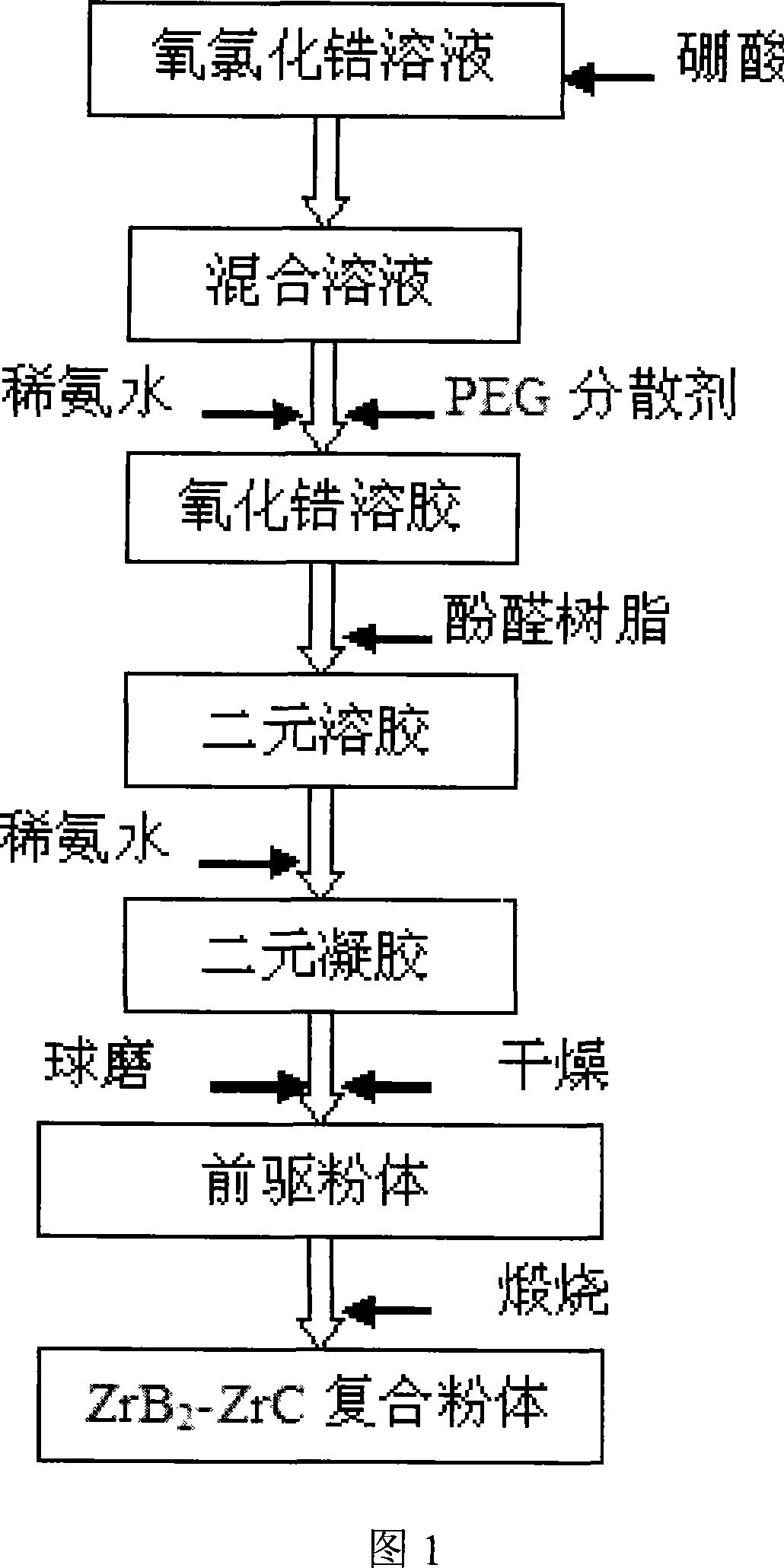

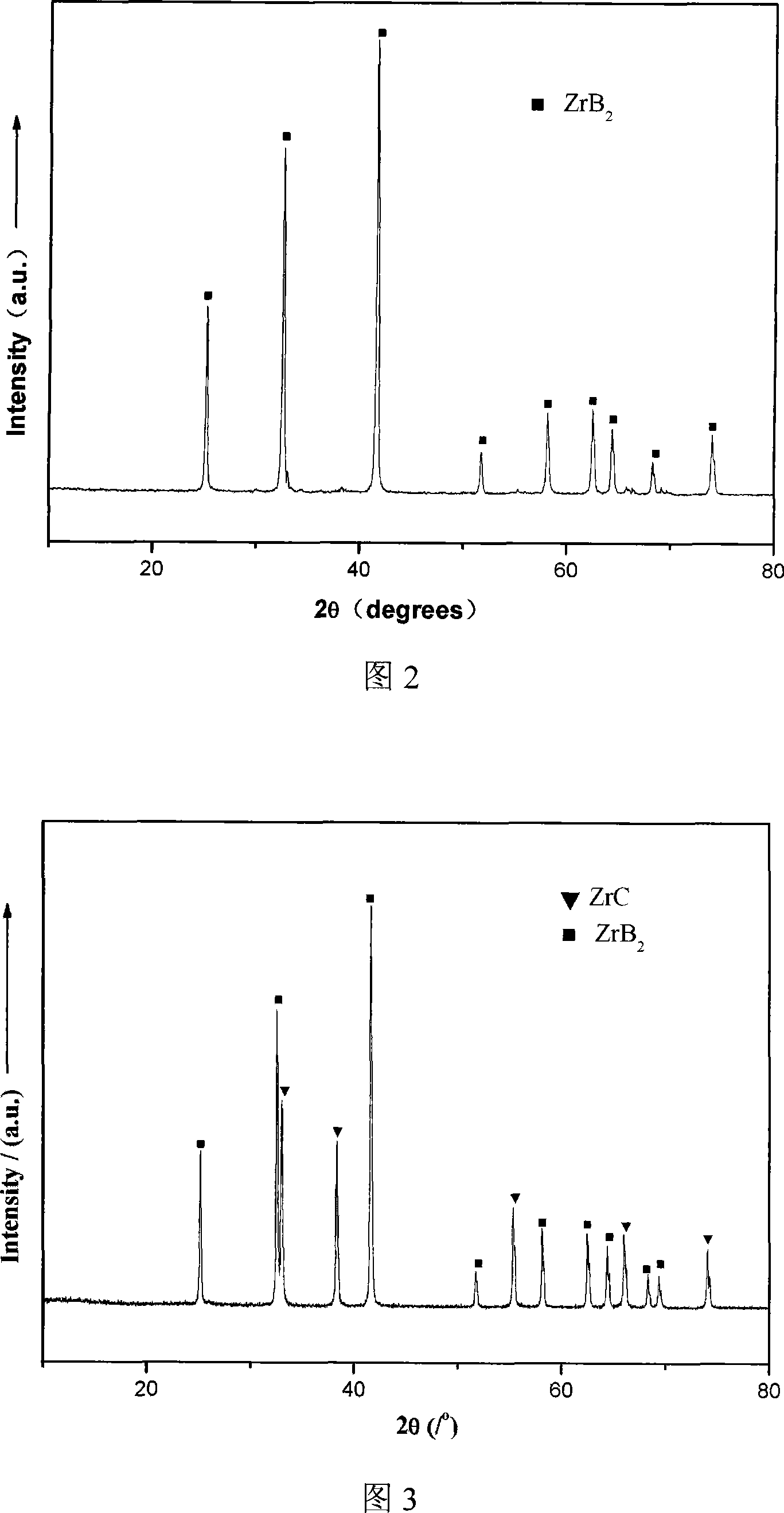

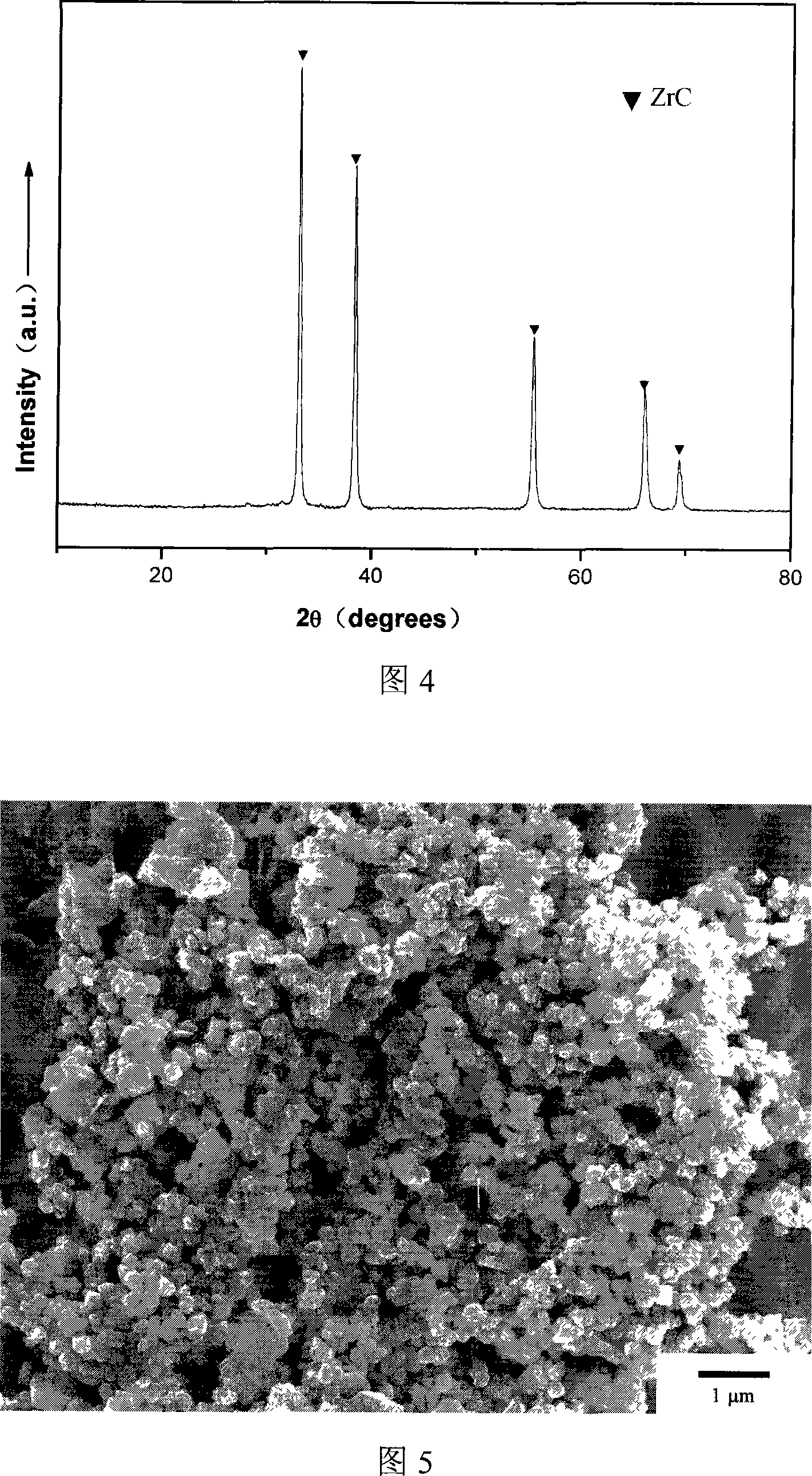

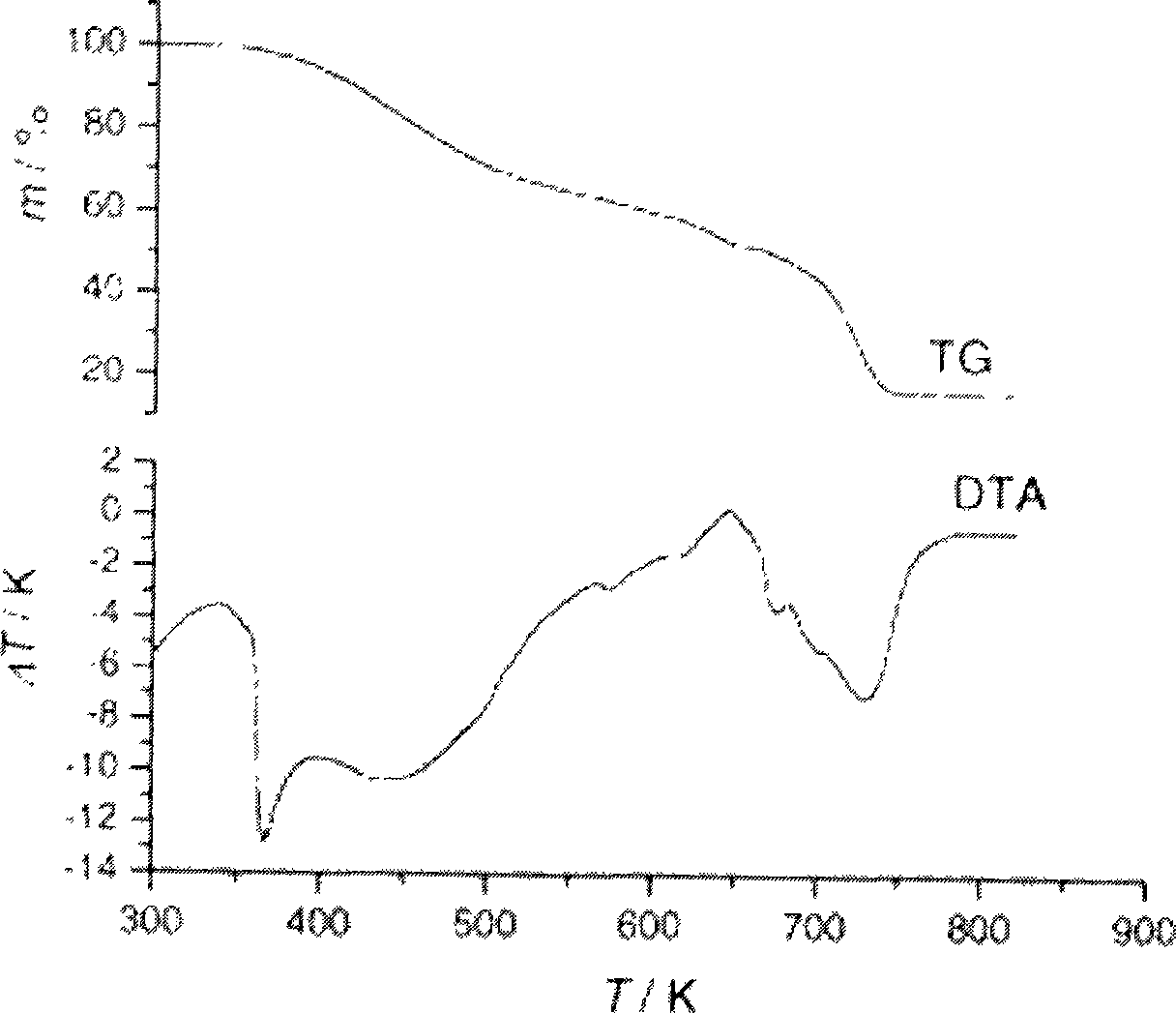

Method for preparing boron-carbon-zirconium material by liquid phase process

InactiveCN101205065AOvercoming is not easy to determine,Overcoming the disadvantages of toxic side effectsCalcium carbideMetal boridesZirconium oxychlorideElectron

The invention relates to a method for preparing boron carbon zirconium materials by liquid phase method, which belongs to the field of structural ceramics. By using carbothermal reduction as the basic principle and adopting zirconium oxychloride, boric acid and phenolic resin as the main materials, the method comprises the steps as follows: the phenolic resin is mixed with zirconia sol which is formed by titration of ammonia; then gel is formed by the titration of the ammonia; finally ball milling is carried out; after drying, screening and heat treatment, the ultrafine boron carbon zirconium materials can be obtained. The boron carbon zirconium materials which are prepared by the invention, with product granularity smaller than 200nm and excellent molding and sintering performance, can be applied to fields such as electron materials and refractory materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

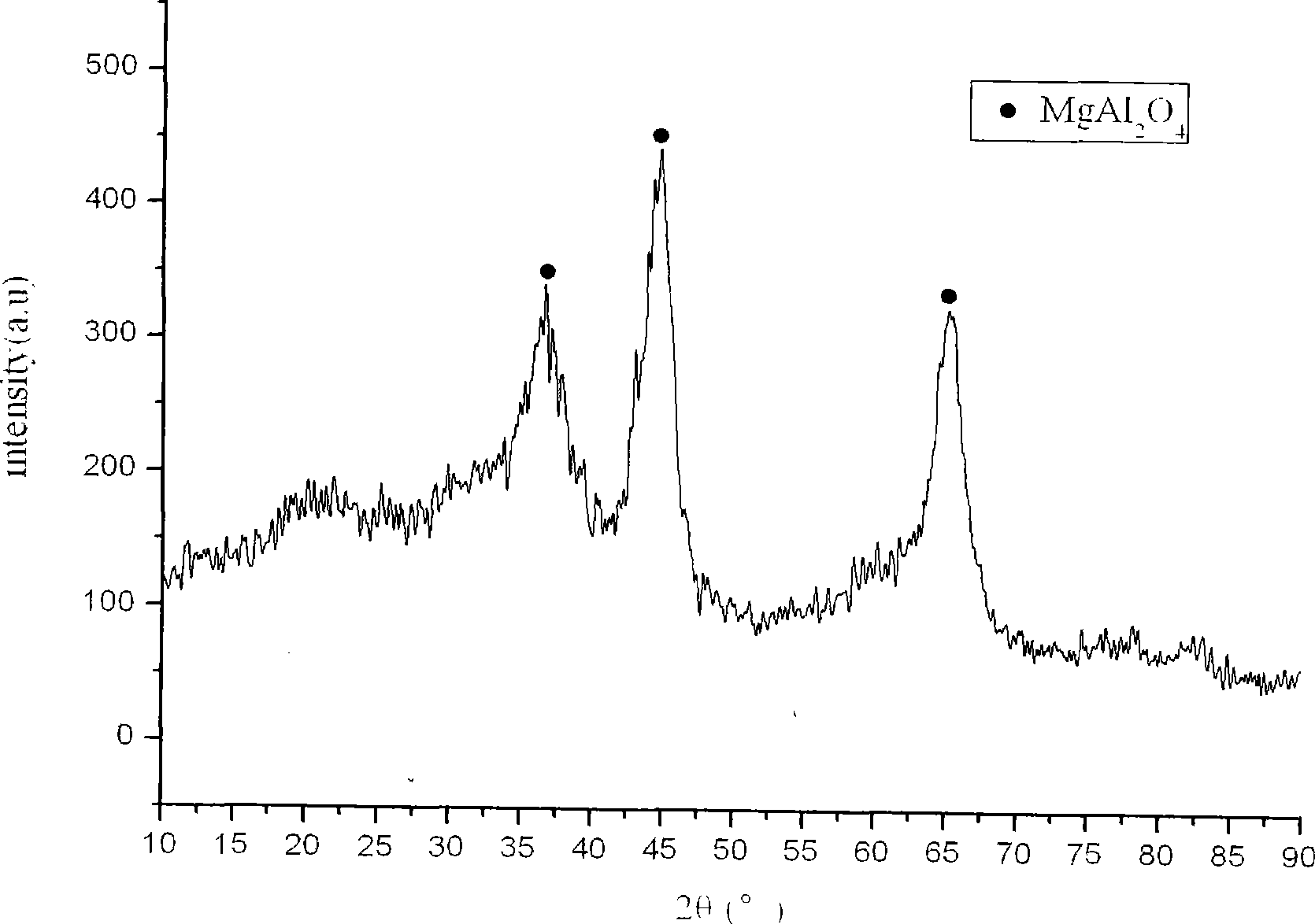

Environment-friendly low-temperature solid-phase synthesis method of magnesia-alumina spinel powder

InactiveCN101445261ALow priceAvoid emissionsAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSynthesis methodsOxygen

An environment-friendly low-temperature solid-phase synthesis method of magnesia-alumina spinel powder belongs to the solid-phase low-temperature synthesis method of complex oxide powder. The method comprises the following steps: selecting magnesium nitrate powder or other crystalline hydrate powder with purity more than 95% and alumina powder or various alumina precursor powders as the raw materials; decomposing magnesium nitrate at low temperature by conventional milling, mixing and low-temperature solid-phase co-firing process to obtain high-activity magnesium oxide and oxygen; and synthesizing the magnesia-alumina spinel powder from the high-activity magnesium oxide and oxygen at 350 to 600 DEG C. Compared with the prior solid-phase synthesis method, the calcination temperature is reduced by 500 to 700 DEG C, thereby greatly reducing the energy consumption and obviating emission of greenhouse gas CO2. Compared with liquid-phase synthesis and sol-gel process, the calcination temperature is reduced by hundreds of centigrade, the unavoidable environment pollution of the liquid-phase process is obviated, and the method can achieve low material cost, simple facility and short production flow. The method can be used for synthesizing high-temperature ceramics, high-temperature electric-insulation refractory materials, catalyst carriers and transparent materials.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

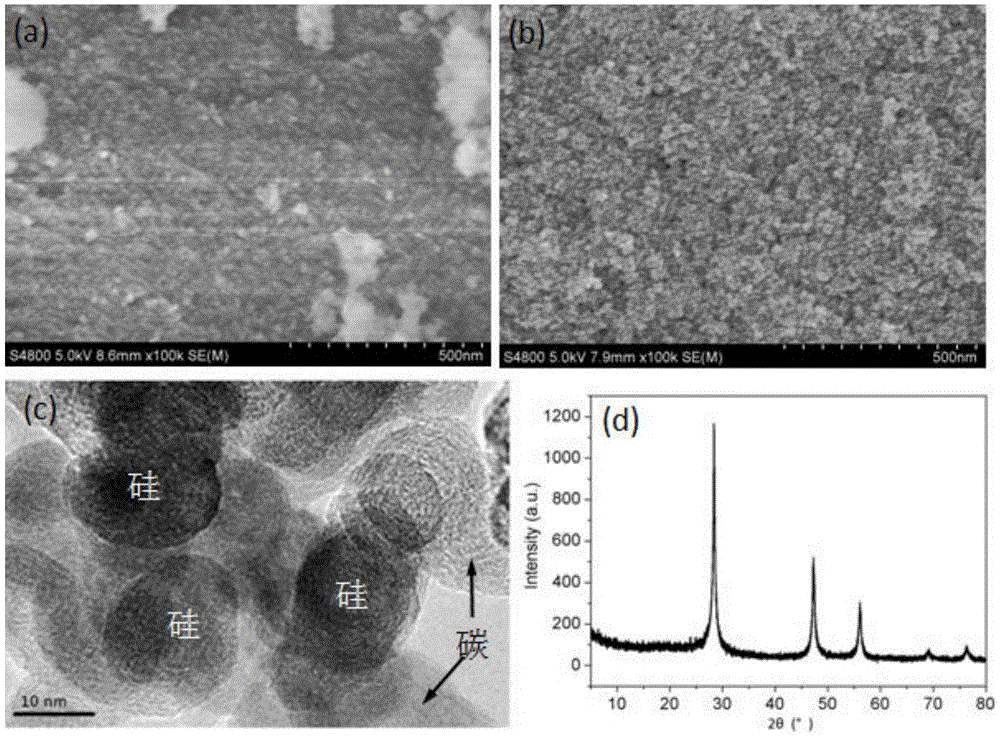

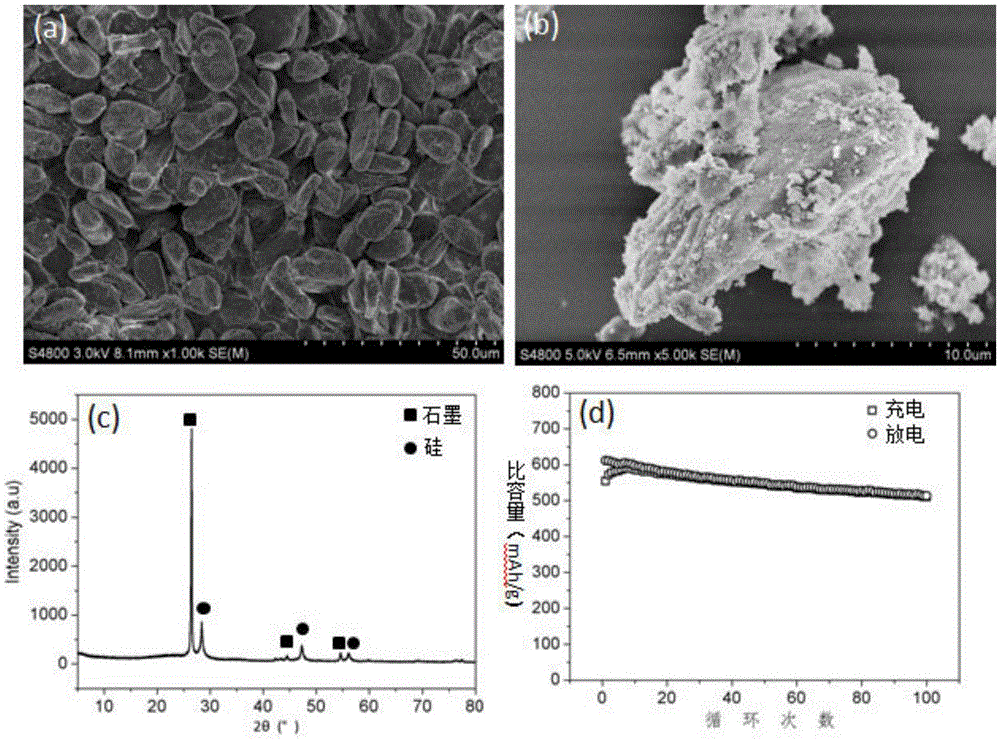

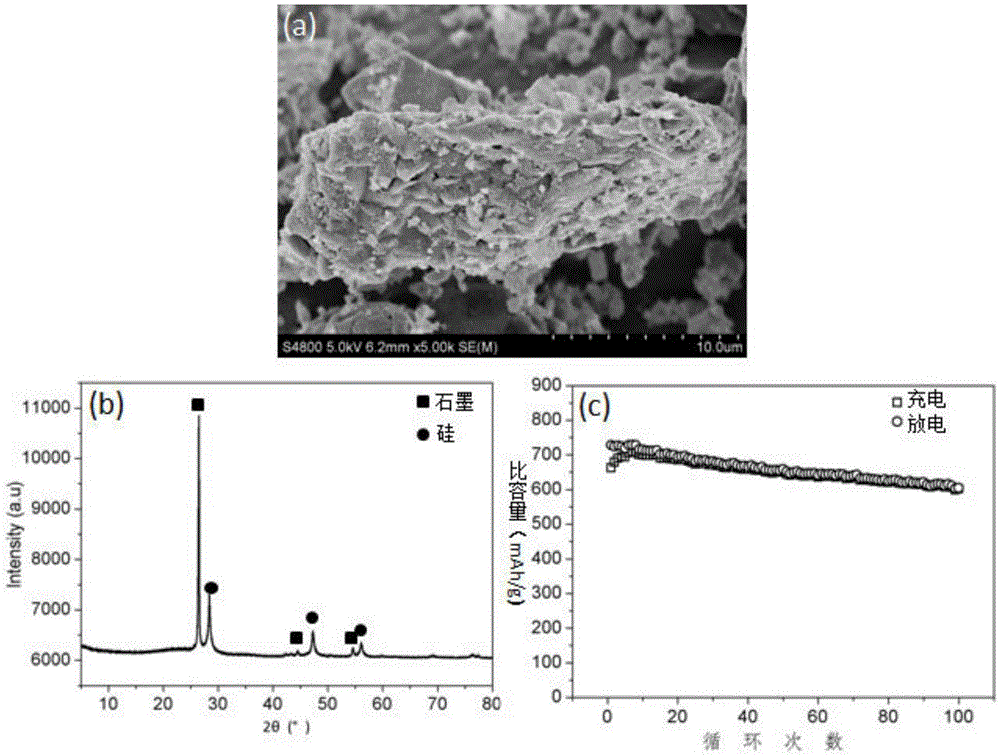

Preparation method of silicon-carbon-graphite composite anode material

InactiveCN105633374ALow preparation temperatureLow equipment requirementsMaterial nanotechnologyCell electrodesCarbon coatingMagnesium

The invention relates to a preparation method of a silicon-carbon-graphite composite anode material. The method comprises the following steps of carrying out carbon coating on nanosilicon dioxide powder; with magnesium powder as a reducing agent, reducing carbon-coated nanosilicon dioxide into carbon-coated nanosilicon through magnesiothermic reduction; and with the carbon-coated nanosilicon as a raw material, fully mixing the carbon-coated nanosilicon with graphite powder at a certain mass ratio to prepare the silicon-carbon-graphite composite anode material. The required reduction temperature is low; the preparation technology is simple; mass production is easy to achieve; and the prepared composite material has excellent cycle performance and relatively high first cycle columbic efficiency when applied to a positive electrode of a lithium-ion battery.

Owner:HUNAN UNIV

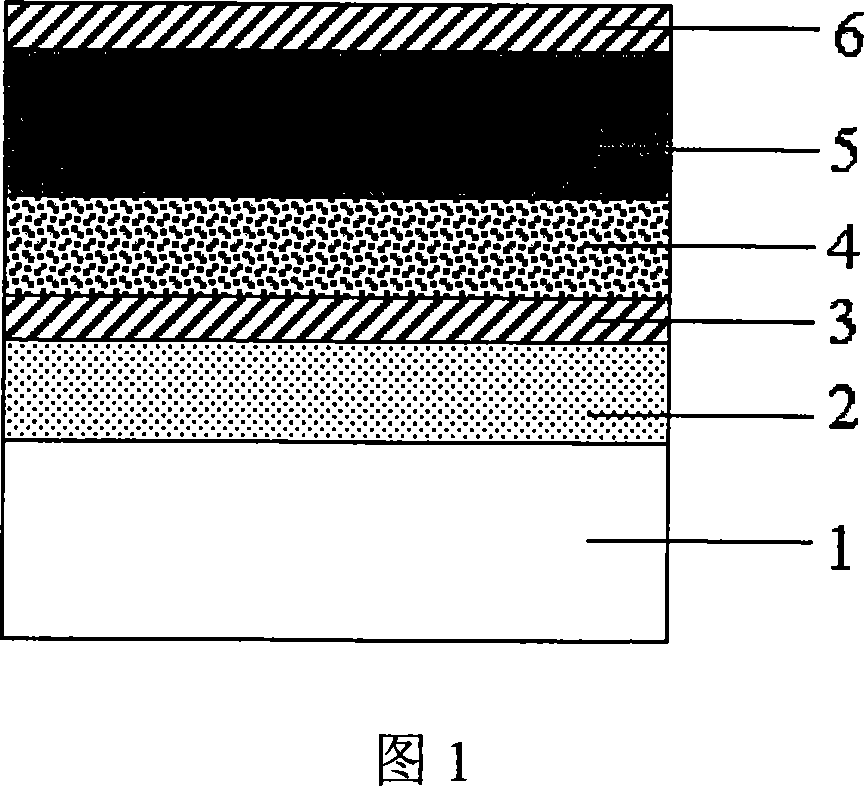

Bismuth ferric/bismuth titanate laminated construction electric capacity and method for preparing the same

InactiveCN101136404AMaximum polarizationGood anti-fatigue propertiesSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceFerroelectric capacitor

This invention relates to a BFO / BXT laminated capacitor and its preparing method, in which, the capacitor includes: a substrate made of silicon and orderly combined with an oxidation layer, a lower electrode metal layer, a BFO film and an upper metal layer, in which, a BXT induction film is set between the lower electrode metal layer and the BFO film. The method includes: preparation of sol of RFO and BXT precursors and preparation of the capacitor of its laminated structure and the ferroelectric capacitor prepared with this method includes excellent property of anti-fatigue, high residual polarized intensity, low operational voltage and better dielectric property.

Owner:TSINGHUA UNIV

Method for preparing porzite powder by fly ash

The invention relates to a method for preparing porzite powder by fly ash. The method comprises the following steps: putting the raw materials of the fly ash and bauxite into a ball mill respectivelyand removing iron after dry milling; taking the fly ash and the bauxite after being processed by iron removing, putting into an alumina crucible respectively, putting the alumina crucible into a silicon-carbon rod resistance furnace, heating and taking out after natural cooling; and stirring the fly ash and the bauxite after being naturally cooled evenly, putting into the silicon-carbon rod resistance furnace, heating and taking out after natural cooling so as to obtain the porzite powder with different granularities and alumina contents. In the invention, the fly ash of a solid waste discharged by a coal-fired power plant is used for synthesizing porzite, which is not only beneficial to saving natural resources and lowering the production cost but also beneficial to environmental protection; the preparation temperature is low, high-temperature calcination is avoided and mineral resources and energy resources are saved; and by controlling the adding quantity of the bauxite and regulating the mixture ratio of the raw materials, porzite aggregates with different alumina contents can be synthesized.

Owner:SHAANXI UNIV OF SCI & TECH

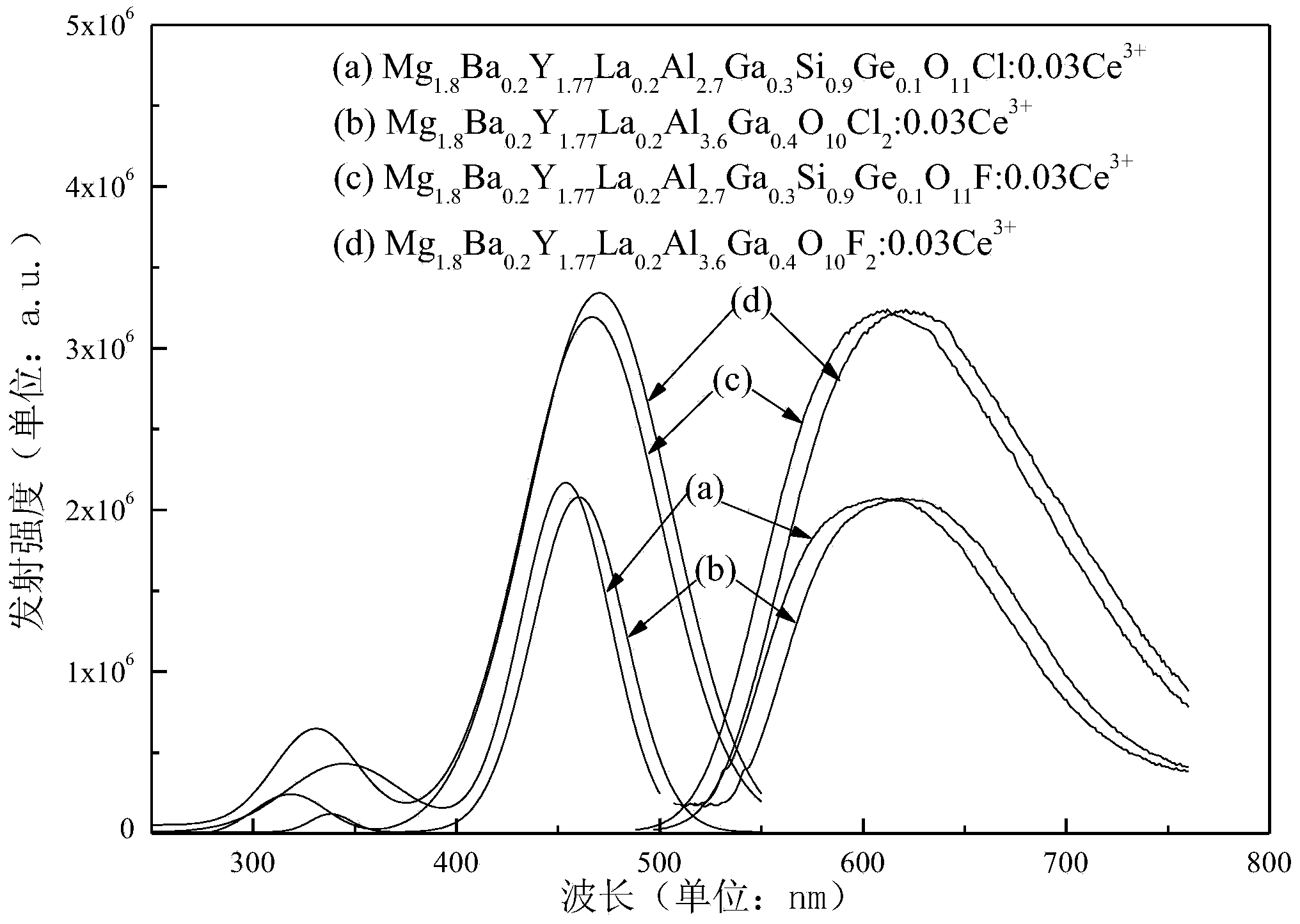

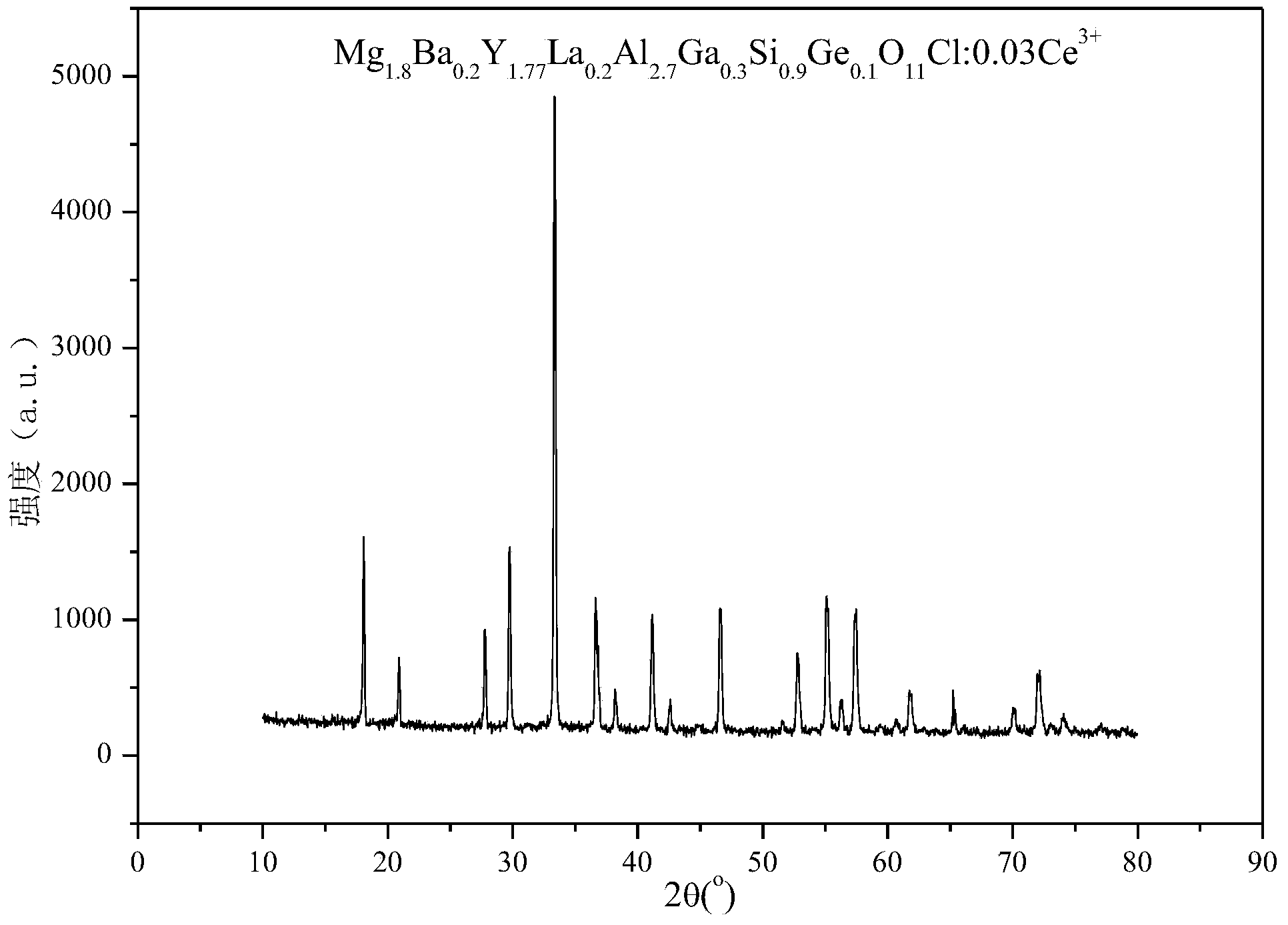

Red and orange light fluorescent powder with garnet structure and preparation method thereof

ActiveCN104212458ALow preparation temperatureGood chemical stabilityLuminescent compositionsSemiconductor devicesChemistryWavelength range

The invention discloses a red and orange light fluorescent powder with garnet structure. The fluorescent powder has a chemical expression of Mg2-xAxY2-y-cByAl2+z-aCaSi2-z-bDbO12-zEz:cCe<3+>, wherein A represents one or more than two selected from Ba, Sr and Ca in arbitrary proportion, B represents one or more than two selected from Gd, La and Sc in arbitrary proportion, C represents Ga, D represents Ge, E represents F or Cl, x, y,z, a, b and c represent corresponding mole fractions and satisfy the relations of: 0<=x<0.35, 0<=y<0.35, 0<z<=2, 0<=a<0.5, 0<=b<0.35, 0<c<0.2, and 2-z-b>=0. Under the excitation of blue light in wavelength of 455nm, the red and orange light fluorescent powder has emission wavelength range of 500-750 nm, wherein the main emission wavelength range is 600-621 nm, the emission spectra shows obvious redshift compared with YAG (delta S=60-80nm), and the preparation temperature is low.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com