Patents

Literature

161results about How to "Reduce interface stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

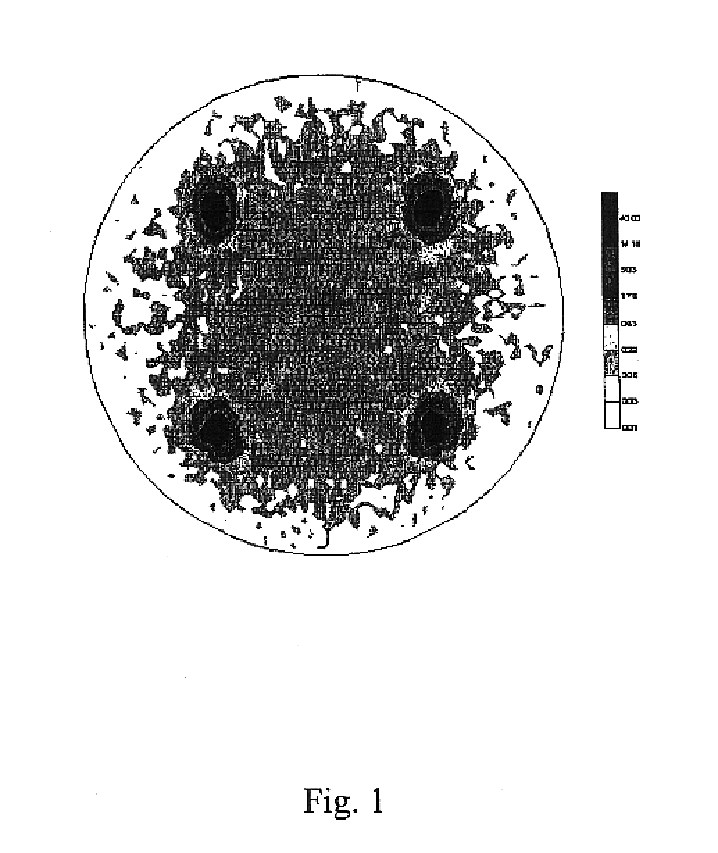

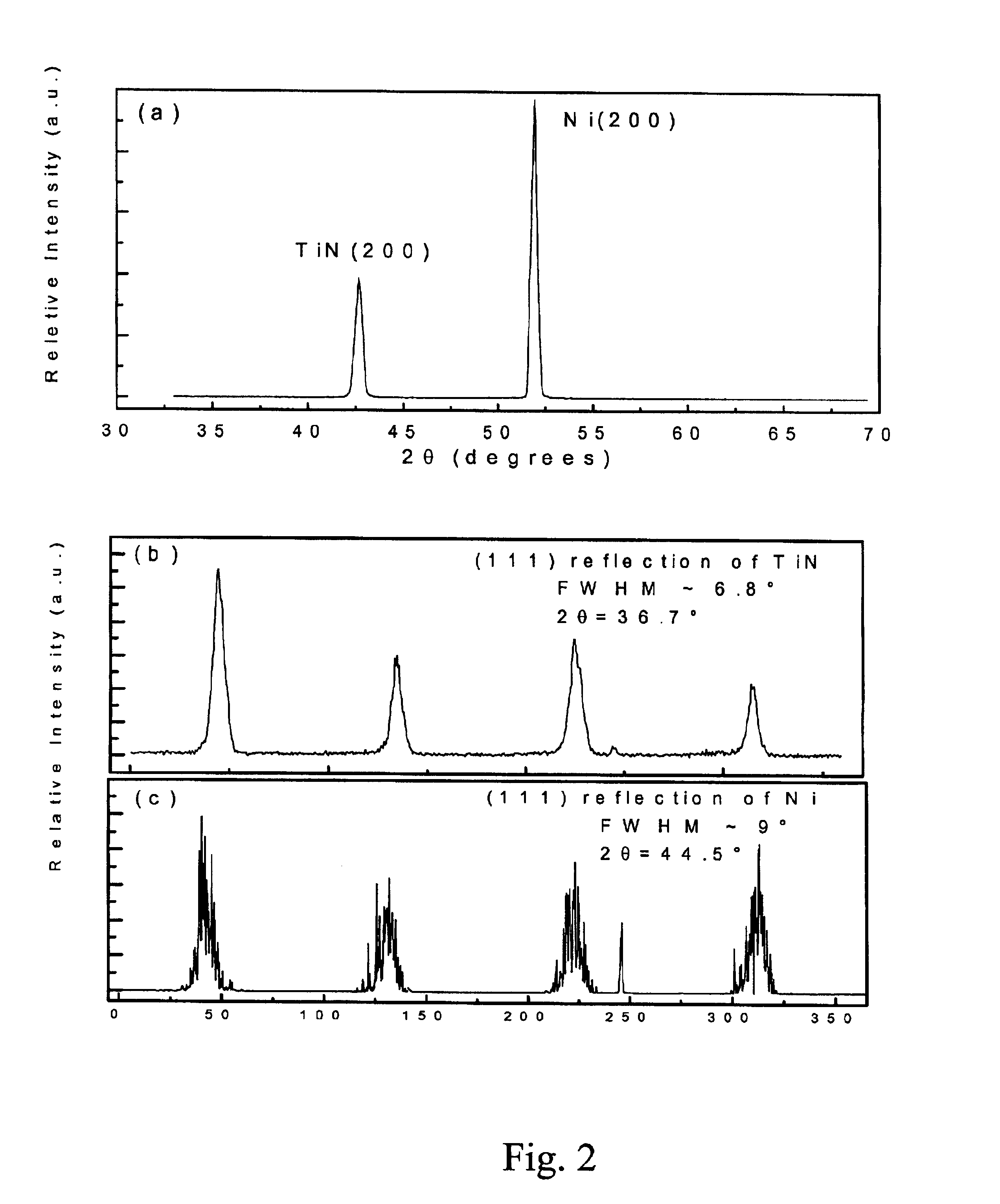

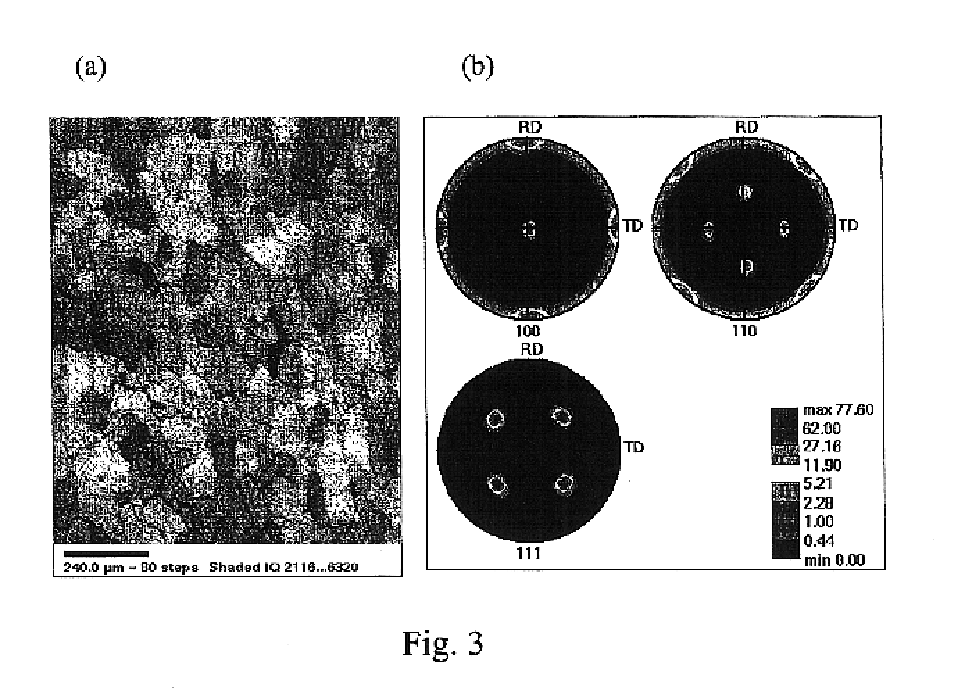

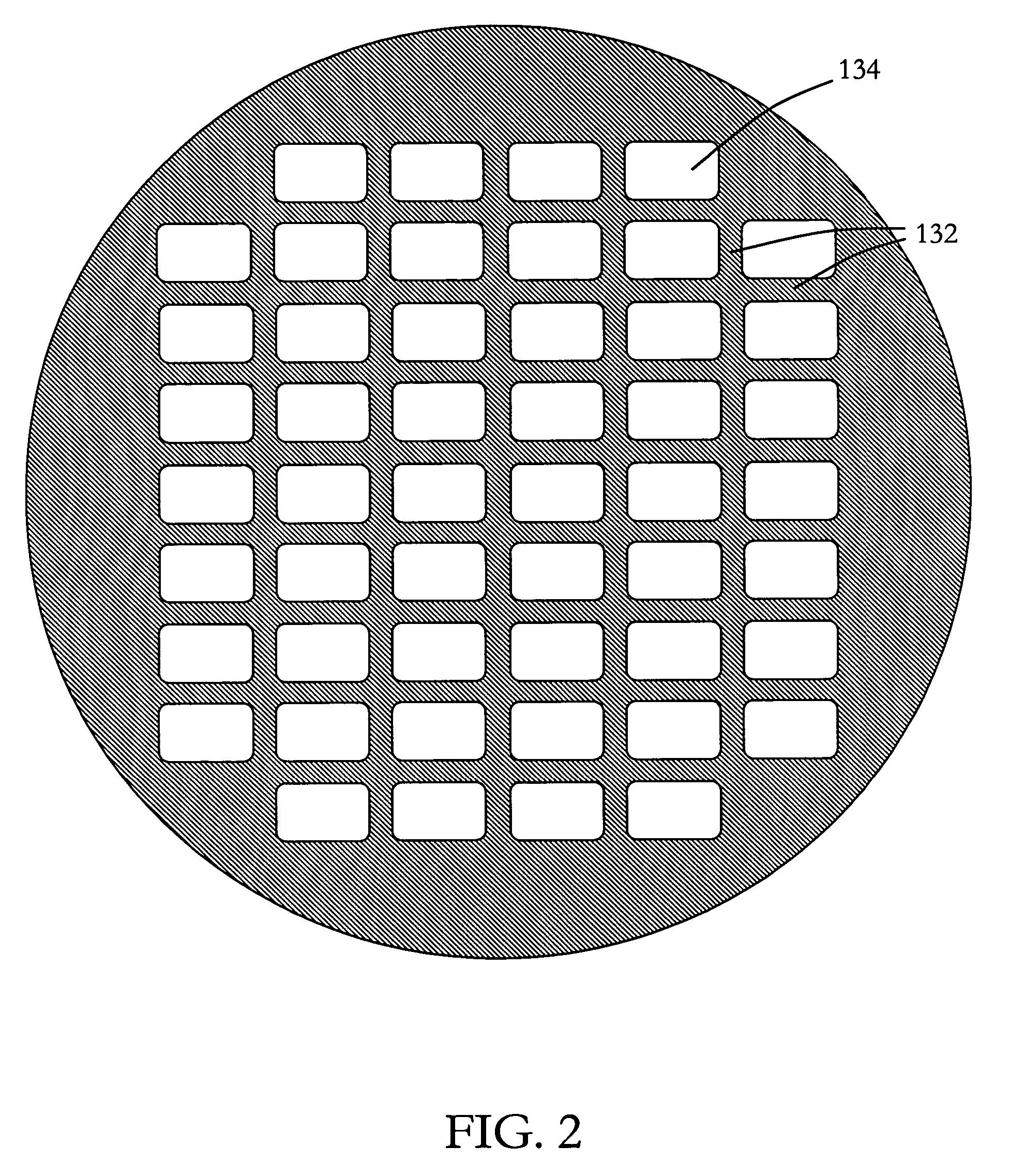

Conductive and robust nitride buffer layers on biaxially textured substrates

InactiveUS6784139B1Wide range of ingredientsReduce interface stressSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentForming gasAlloy

The present invention relates to epitaxial, electrically conducting and mechanically robust, cubic nitride buffer layers deposited epitaxially on biaxially textured substrates such as metals and alloys. The invention comprises of a biaxially textured substrate with epitaxial layers of nitrides. The invention also discloses a method to form such epitaxial layers using a high rate deposition method as well as without the use of forming gases. The invention further comprises epitaxial layers of oxides on the biaxially textured nitride layers. In some embodiments the article further comprises electromagnetic devices which may be super conducting properties.

Owner:APPL THIN FILMS INC +1

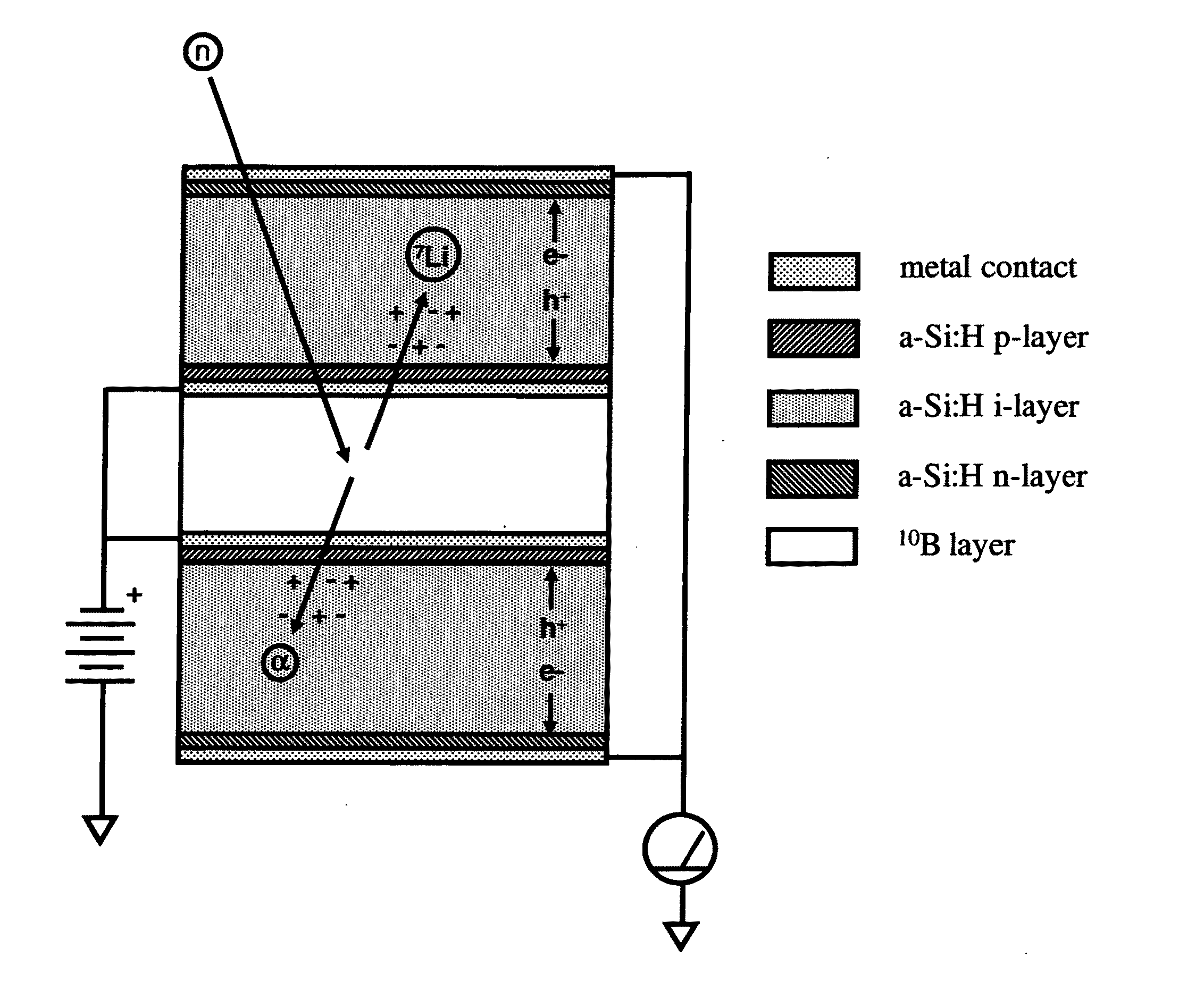

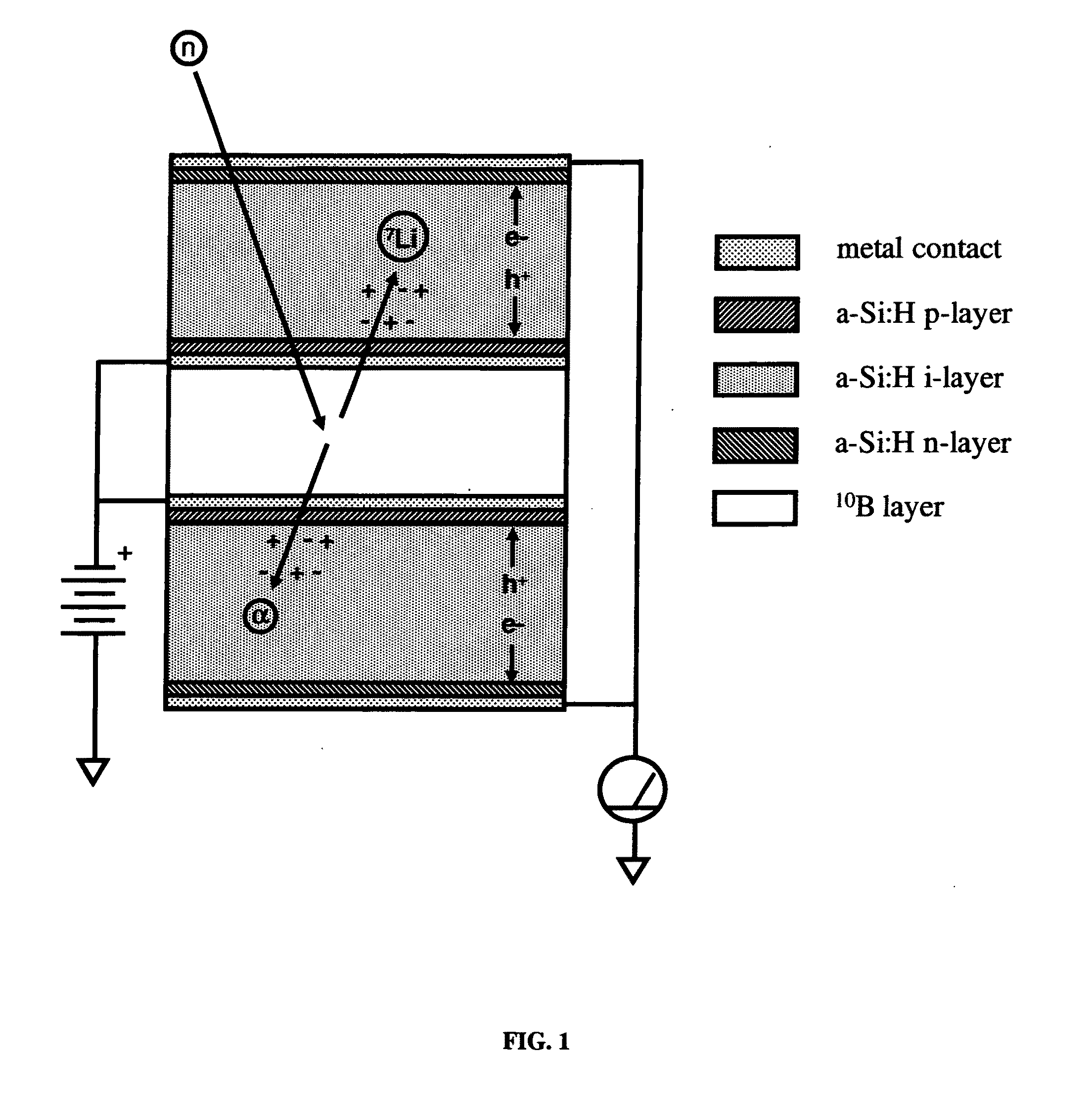

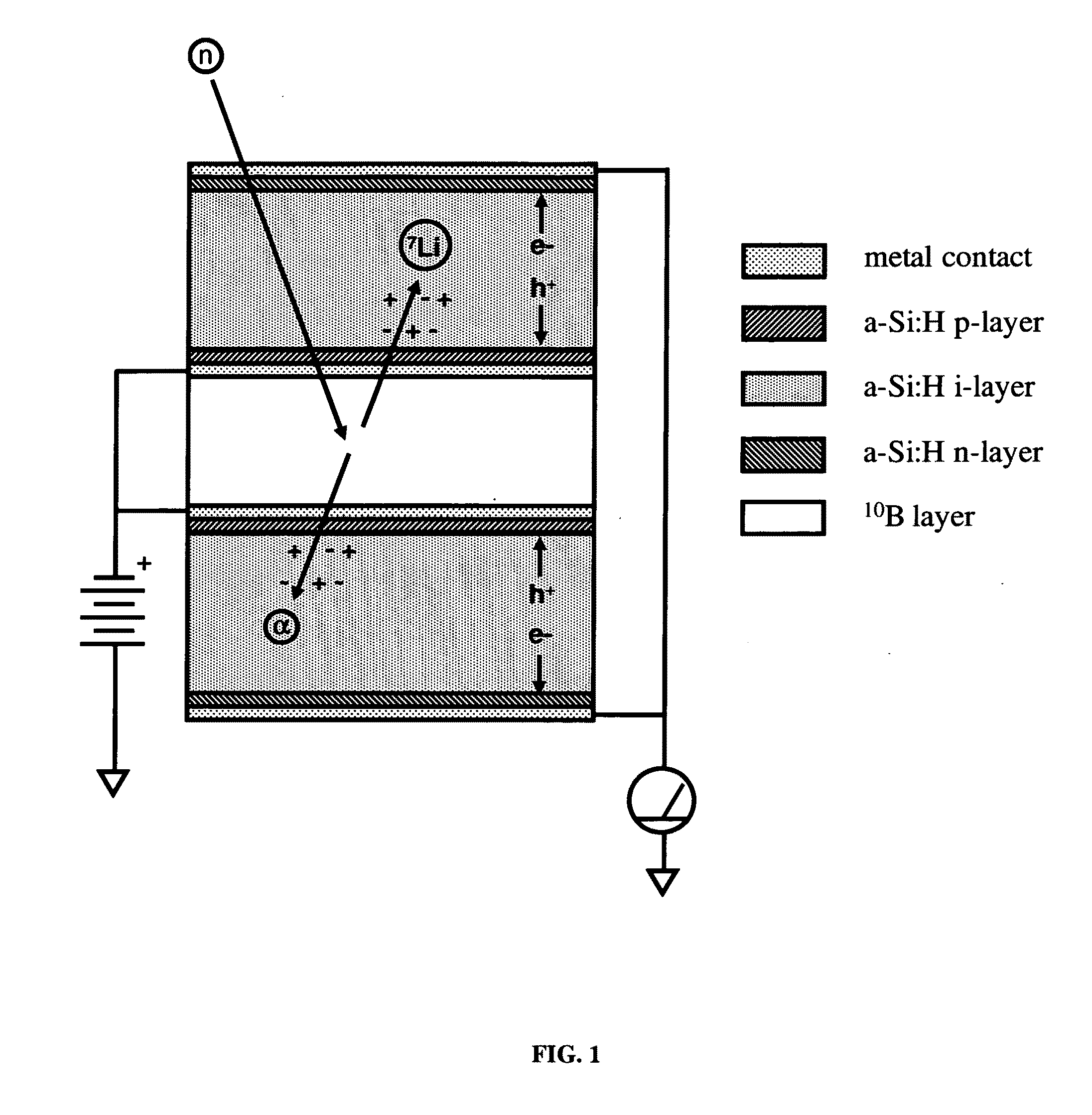

Solid state neutron detector

InactiveUS20110266643A1High neutron capture cross sectionLow costMeasurement with semiconductor devicesSemiconductor devicesElectron holeHigh absorption

A low-cost device for the detection of thermal neutrons. Thin layers of a material chosen for high absorption of neutrons with a corresponding release of ionizing particles are stacked in a multi-layer structure interleaved with thin layers of hydrogenated amorphous silicon PIN diodes. Some of the neutrons passing into the stack are absorbed in the neutron absorbing material producing neutron reactions with the release of high energy ionizing particles. These high-energy ionizing particles pass out of the neutron absorbing layers into the PIN diode layers creating electron-hole pairs in the intrinsic (I) layers of the diode layers; the electrons and holes are detected by the PIN diodes.

Owner:TREX ENTERPRISES CORP

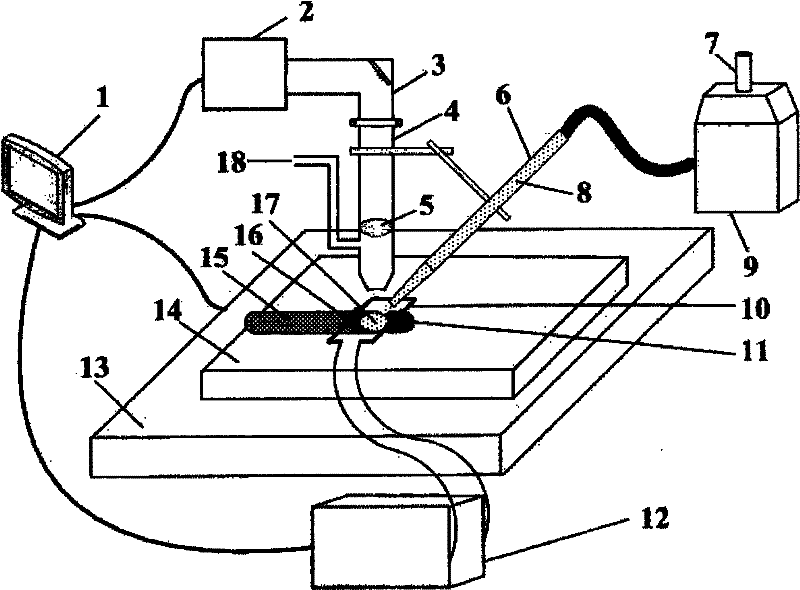

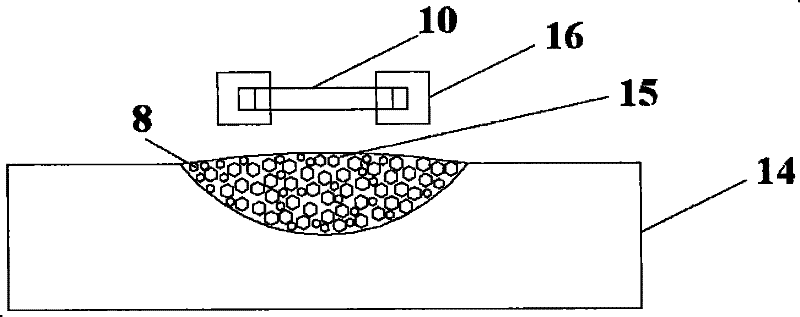

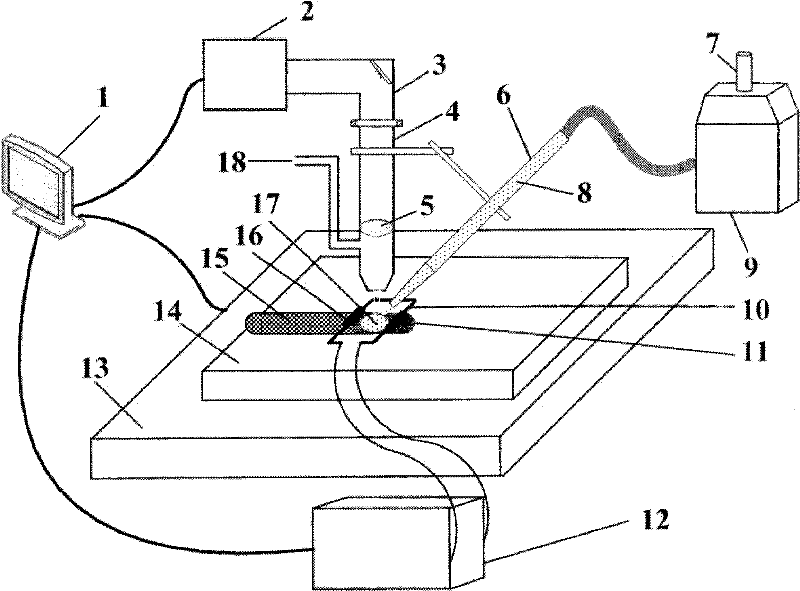

Method for quickly preparing metal ceramic coating through laser induced composite fusioncast

InactiveCN102191495ALarge injection depthHigh volume percentageEfficient propulsion technologiesMetallic material coating processesHardnessMetal

The invention discloses a method for quickly preparing metal ceramic coating through laser induced composite fusioncast. The method comprises the following steps that: (1) a high-melting point and high-hardness ceramic phase is put into a hopper of an automatic powder feeder; (2) the ceramic phase is prevented from being oxidized at a high temperature; (3) a focused laser beam and a powder nozzle of the automatic powder feeder are positioned in an induced heating area to compound a laser heating source and an induced heating source; (4) the moving space is 80 to 20 percent of the diameter of a laser light spot; and (5) the work is finished. The method has the advantages that: the injection depth of the ceramic phase is high in a base material; the volume percent content is high; the chemical components of the metal ceramic coating and the base material are in slow gradient transition; the burning loss of the ceramic phase is low in the process of laser induced composite fusioncast; the obtained metal ceramic coating has a series of excellent properties, such as dense organization, high hardness, high toughness, high wear resistance, no air holes and cracks and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

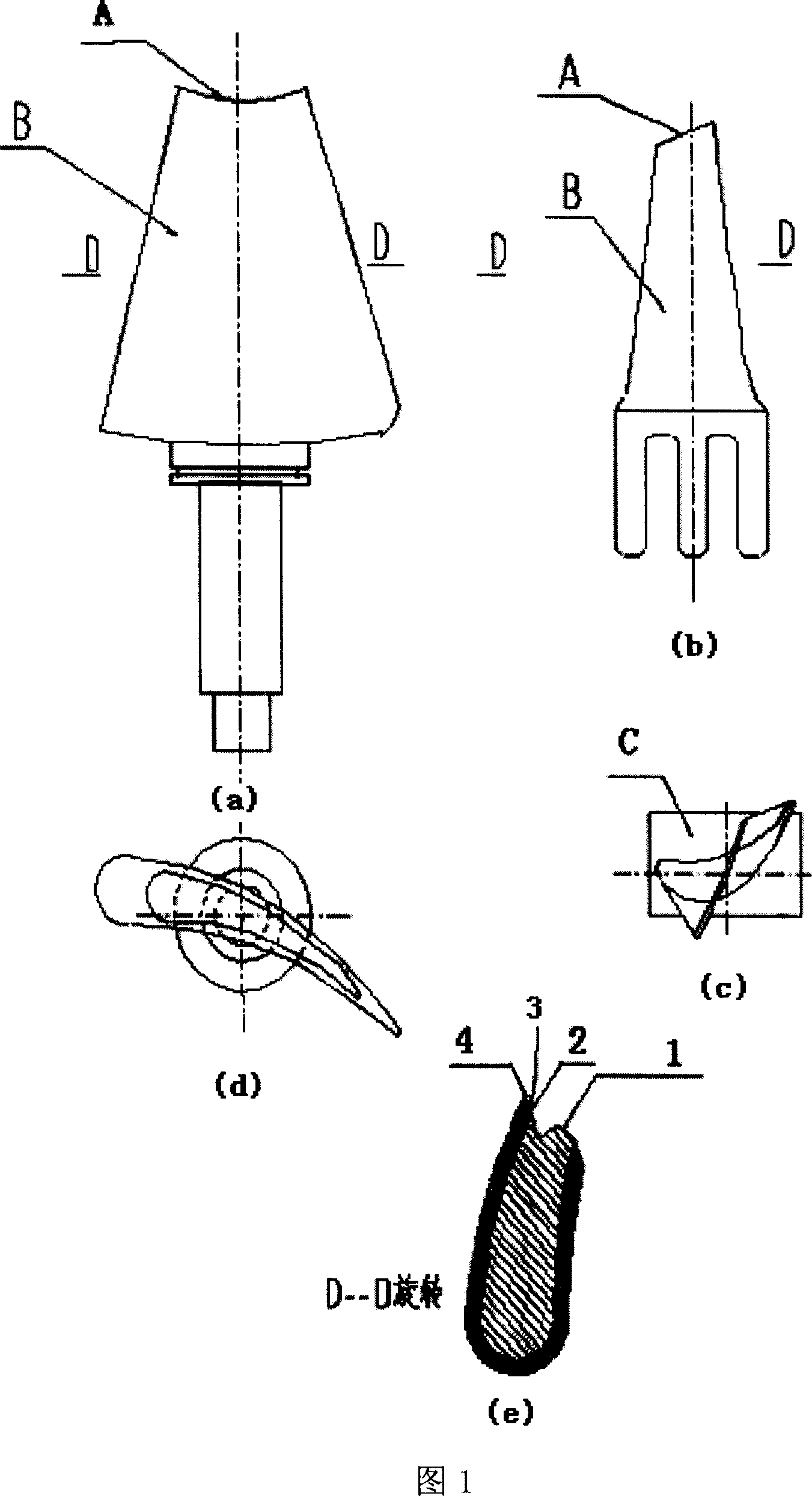

Surface composite coating of turbomachine rotor blade and preparation method thereof

ActiveCN101008324AAlleviate mechanical property mismatchImprove dynamic binding strengthMolten spray coatingBlade accessoriesCorrosion resistant alloyHigh energy

The invention discloses a surface composite coat of the blade on rotor and relative production, wherein, the composite coat is divided into adhesive bottom, middle corrosion-resistance alloy layer and metal ceramic rigid abrasion-resistance layer. The invention utilizes high-energy plasma coater and ultrasonic plasma injector, via ultrasonic plasma coating technique to coat aforementioned three layers on the base of blade; then seal the outer face via macromolecule sealing agent as polyurethane or acrylic acid. The thickness of metal ceramic rigid abrasion-resistance layer is 0.12mm, the thickness of middle corrosion-resistant alloy layer is 0.08mm, and the thickness of bottom adhesive layer is 0.05mm. The invention can improve the corrosion resistance and abrasion resistance of blade.

Owner:XIAN SHAANGU POWER

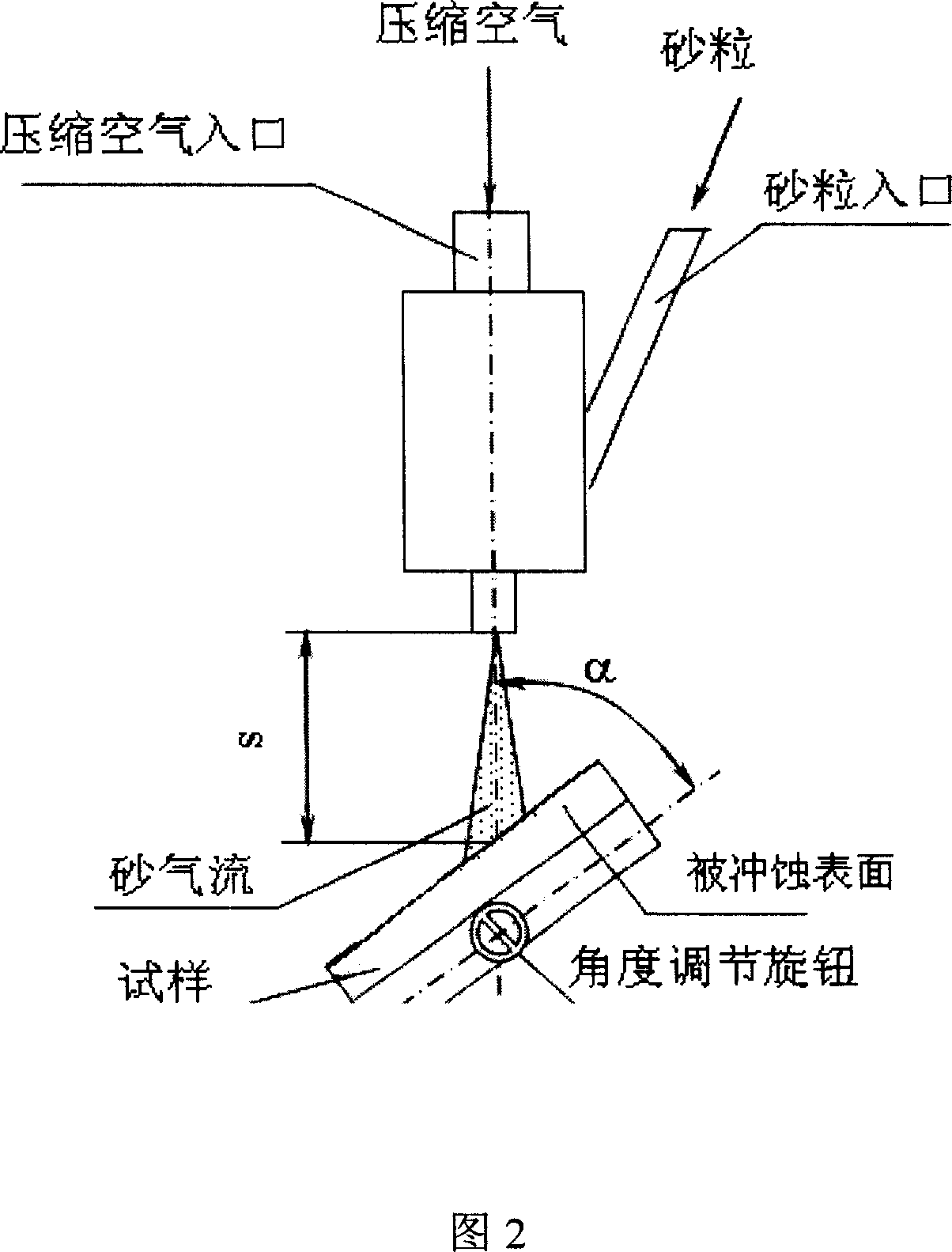

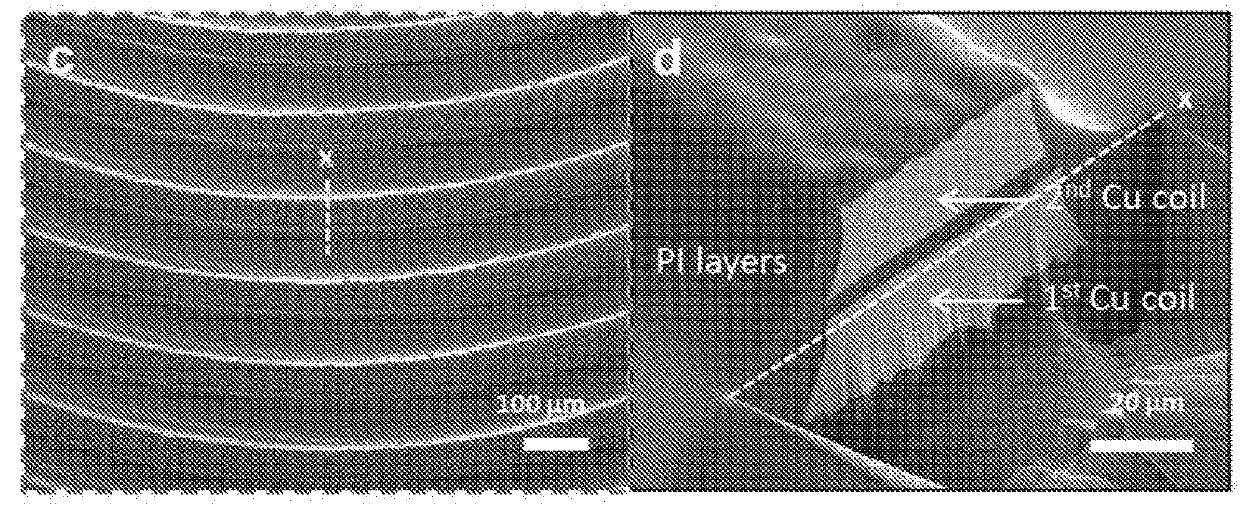

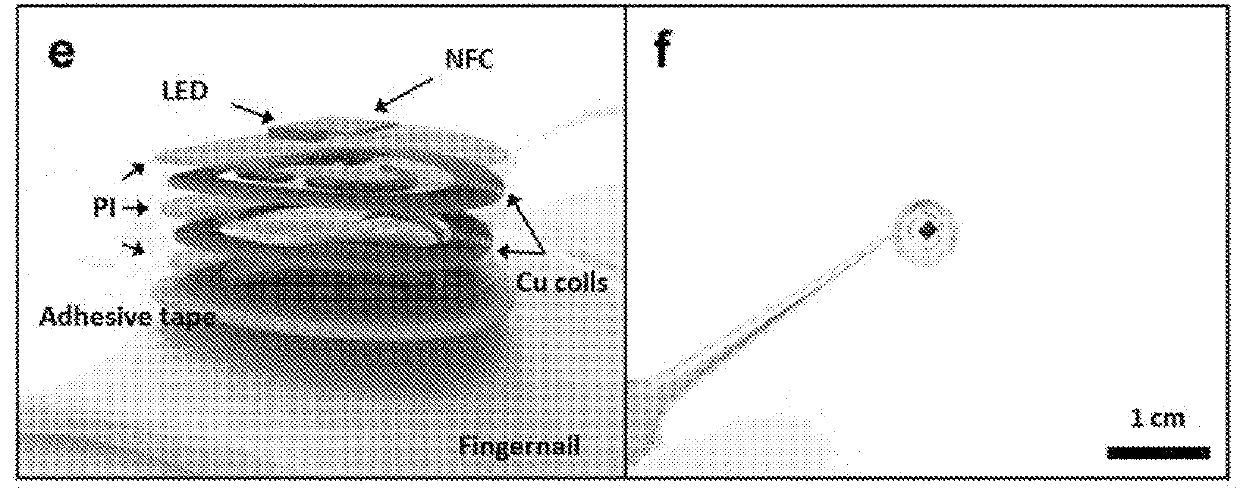

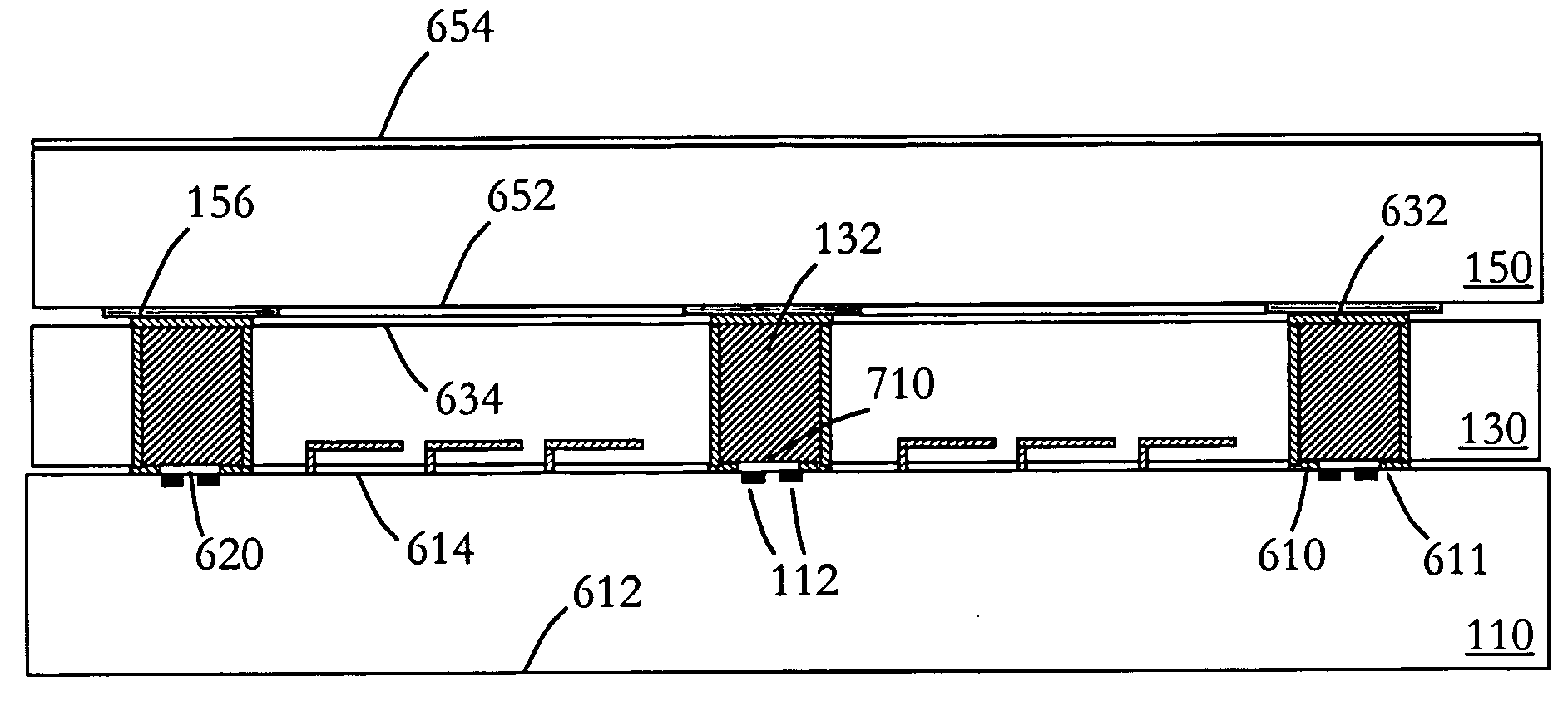

Miniaturized electronic systems with wireless power and near-field communication capabilities

ActiveUS20180165566A1Reduced interfacial stressHigh performanceCircuit arrangementsDiagnostic recording/measuringNear field communicationPhotonics

The invention provides systems and methods for tissue-mounted electronics and photonics. Devices of some embodiments of the invention implement high performance, and optionally flexible, device components having miniaturized formats in device architectures that minimize adverse physical effects to tissue and / or reduce interfacial stresses when mounted on tissue surfaces. In some embodiments, the invention provides complementary tissue mounting strategies providing for mechanically robust and / or long term integration of the present devices, for example, via mounting on tissue surfaces that are not subject to rapid growth or exfoliation processes such as the fingernail, toenail, tooth or earlobe. Devices of the invention are versatile and support a broad range of applications for sensing, actuating and communication including applications for near field communication, for example, for password authentication, electronic transactions and biometric sensing.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

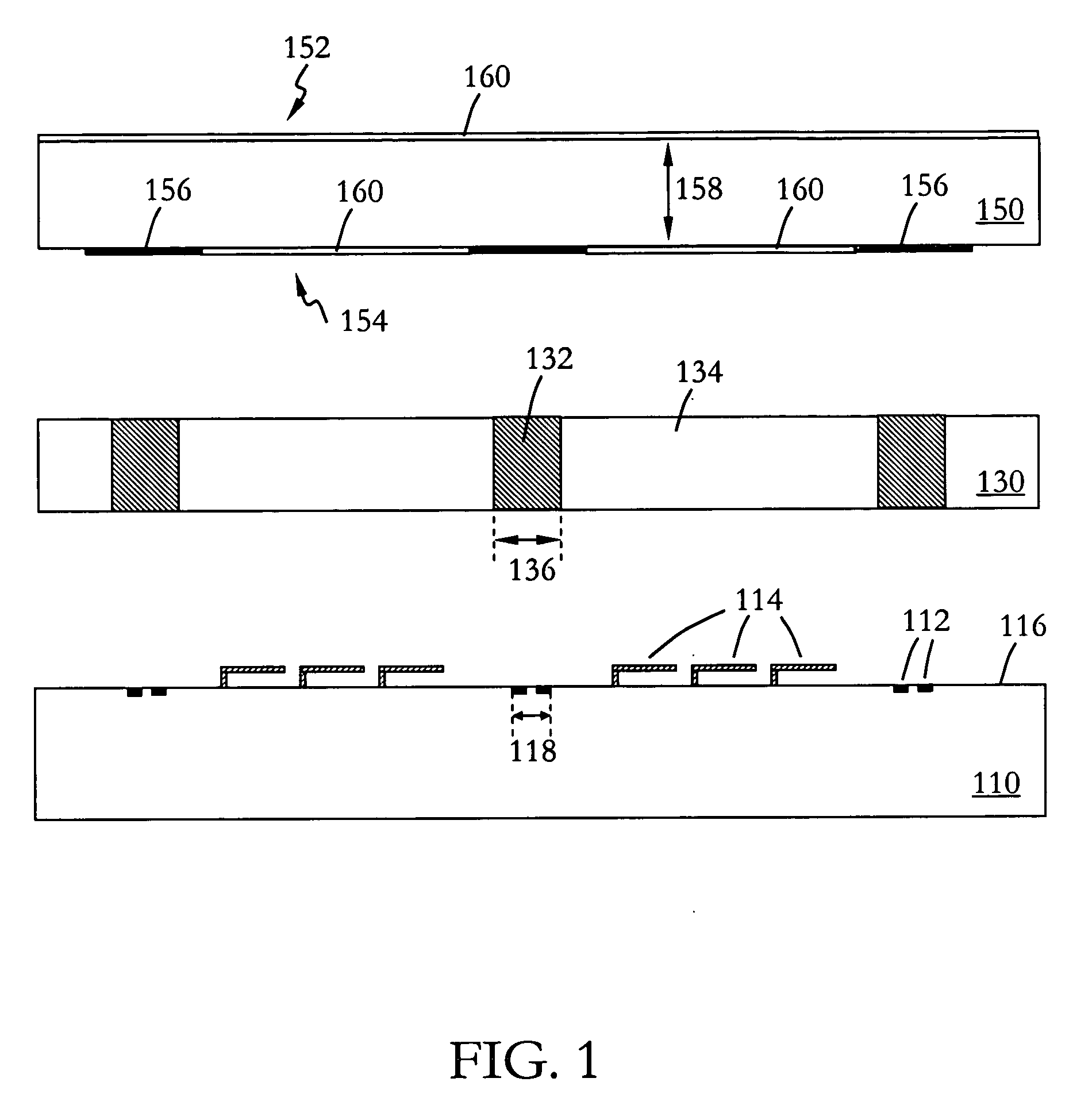

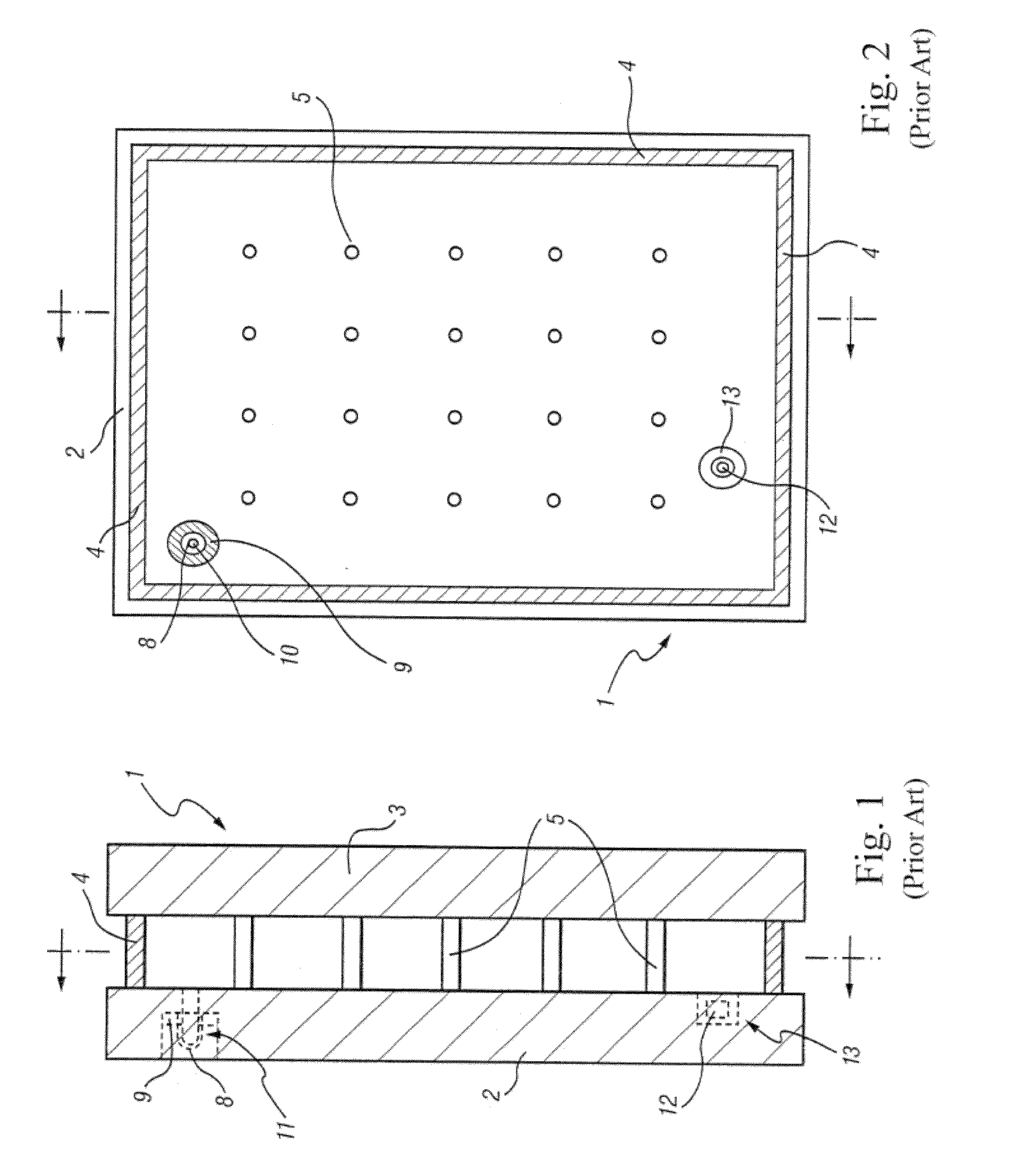

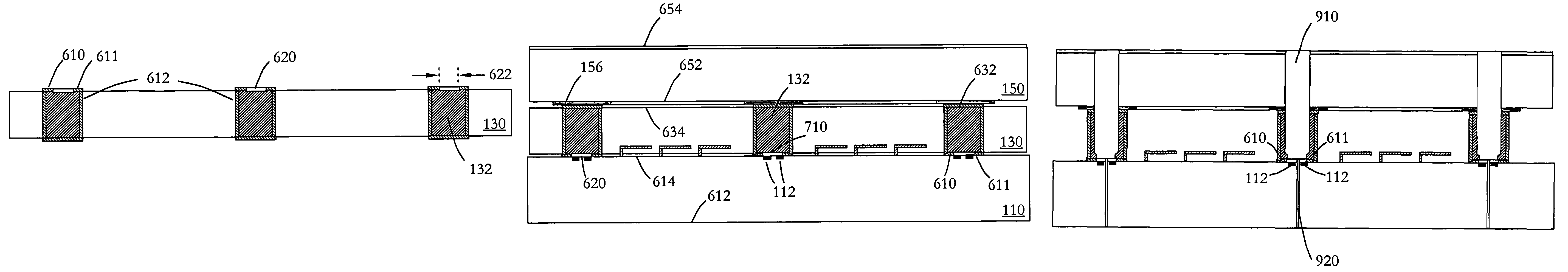

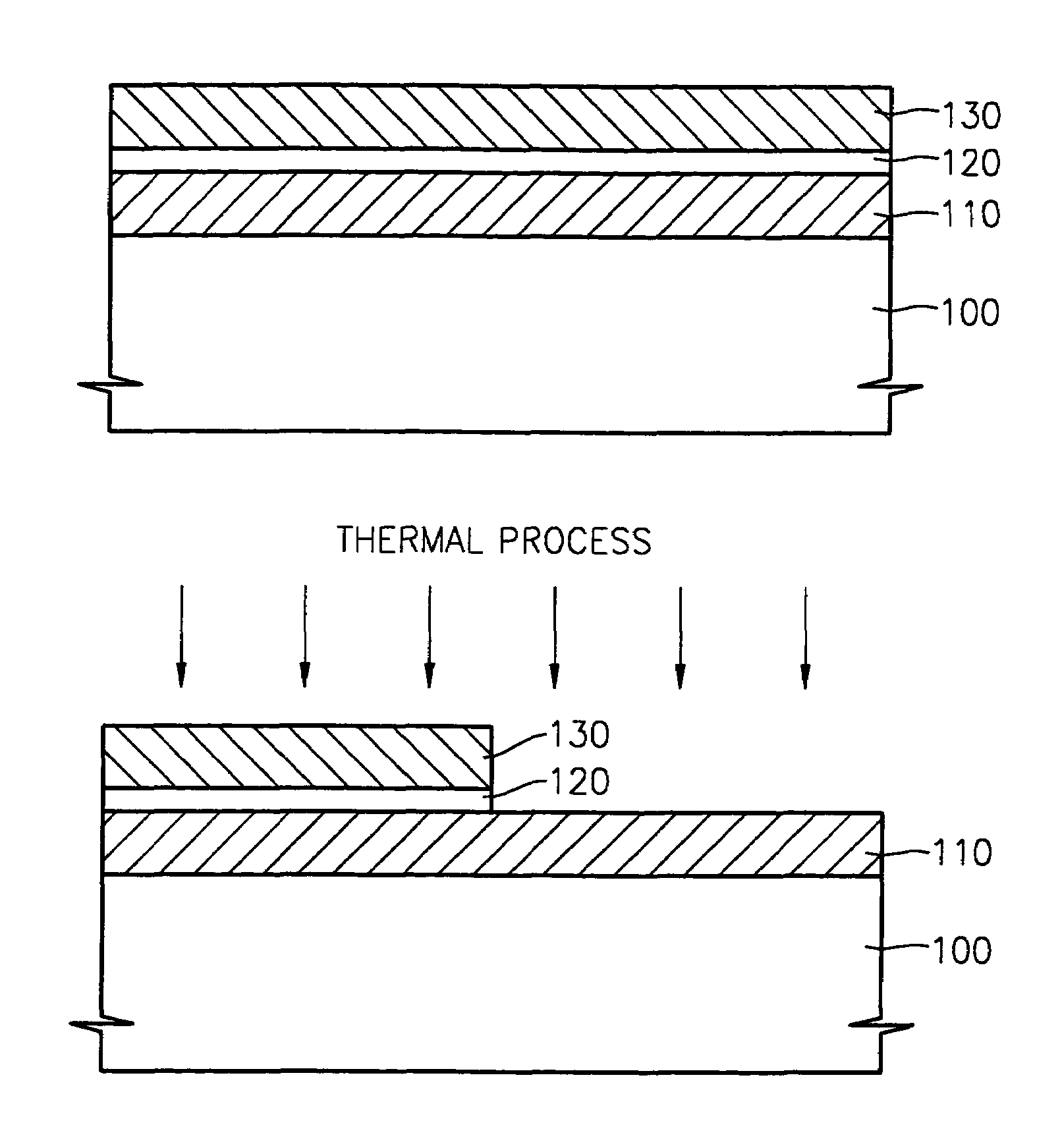

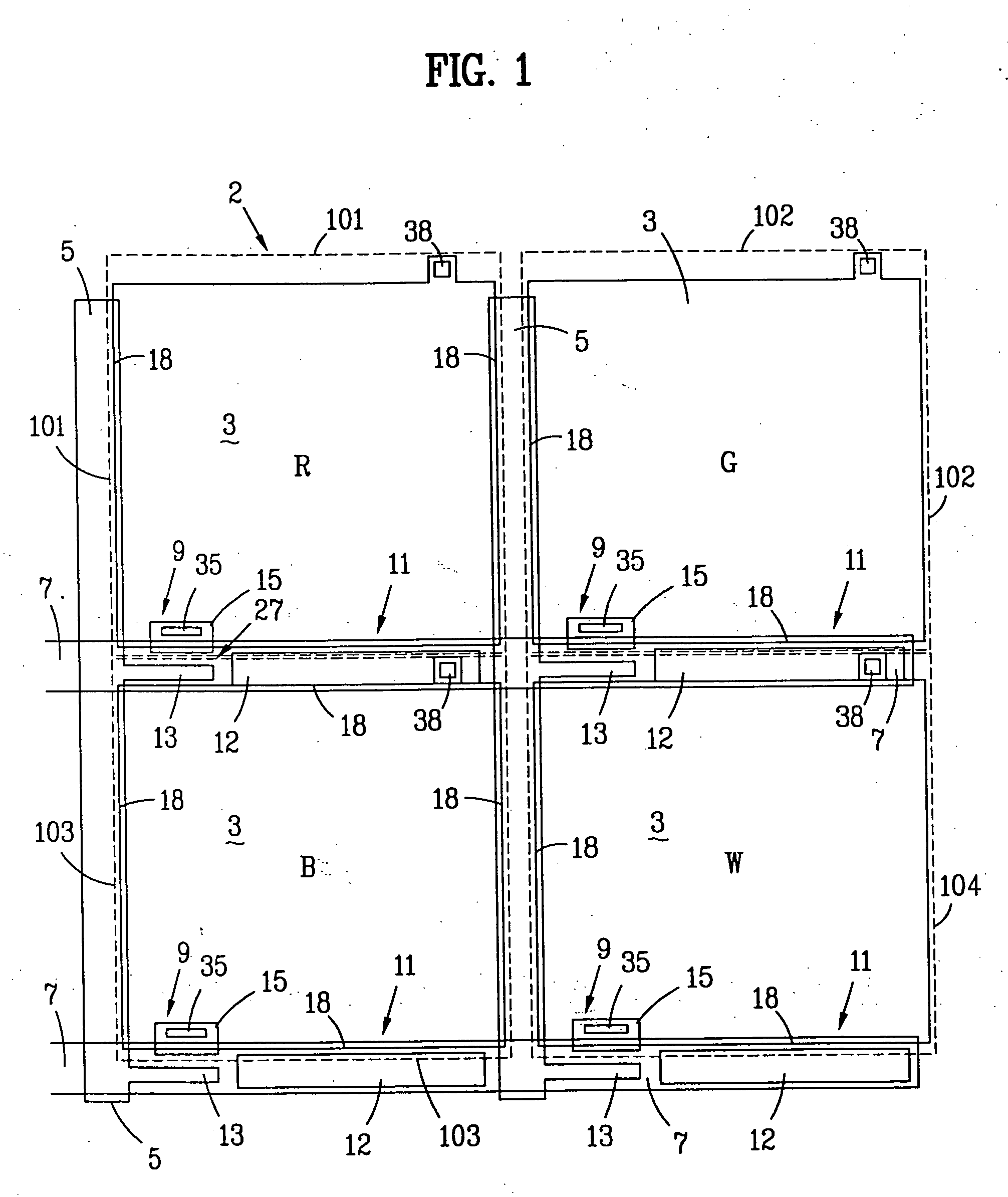

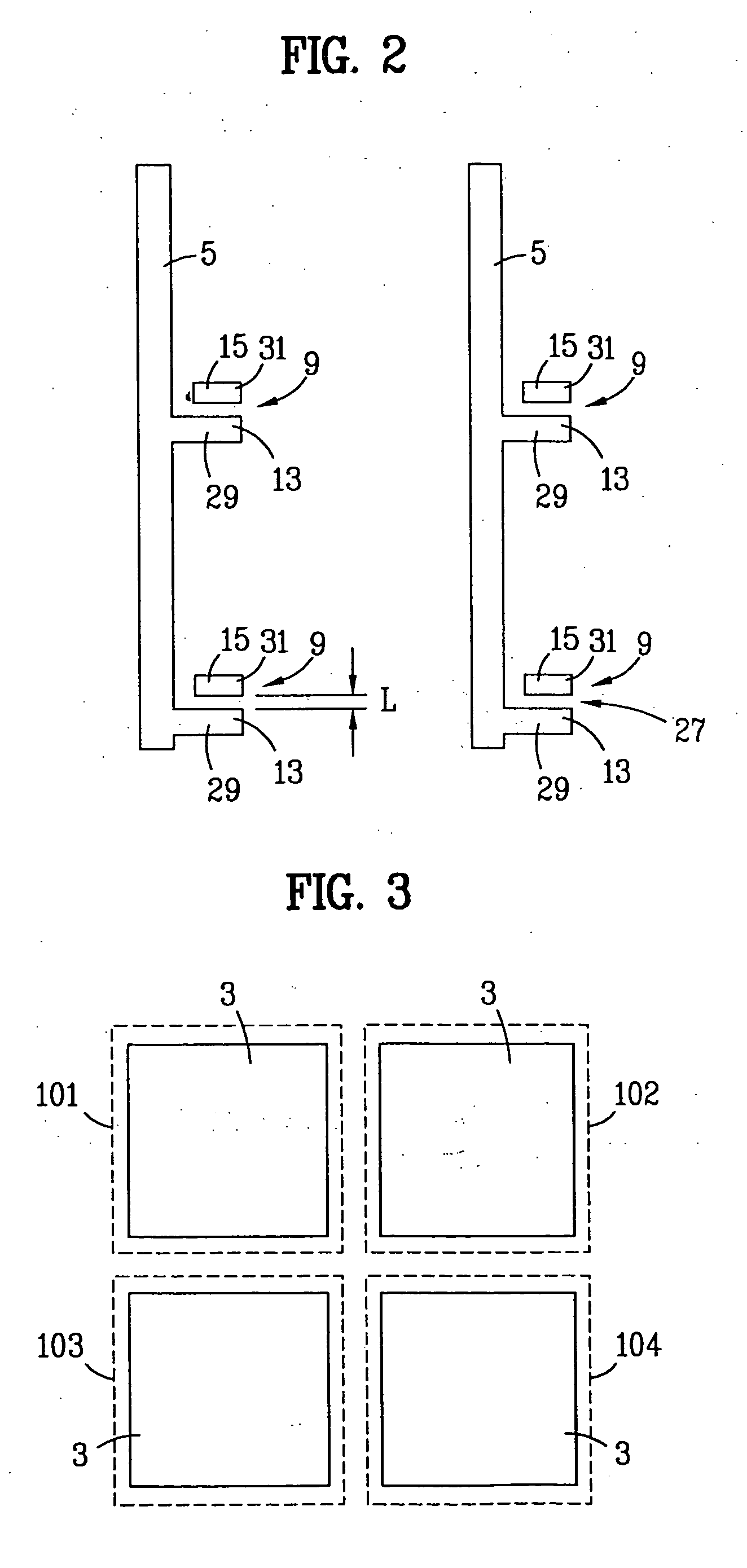

Bond method and structure using selective application of spin on glass

ActiveUS20060281227A1High device yieldHigh throughput and yieldSemiconductor/solid-state device detailsSolid-state devicesEngineeringSpacer device

A method for bonding substrate structures. The method includes providing a transparent substrate structure, the transparent substrate structure comprising a face region and an incident light region, providing a spacer structure, the spacer structure comprising a selected thickness of material, the spacer structure having a spacer face region and a spacer device region, and providing a device substrate structure, the device substrate having a device face region and a device backside region. The method further includes applying a first glue material to the spacer face region and bonding the spacer face region to the face region of the transparent substrate structure. The method also includes applying a second glue material to the spacer device region and bonding the spacer device region to the device face region.

Owner:MIRADIA INC

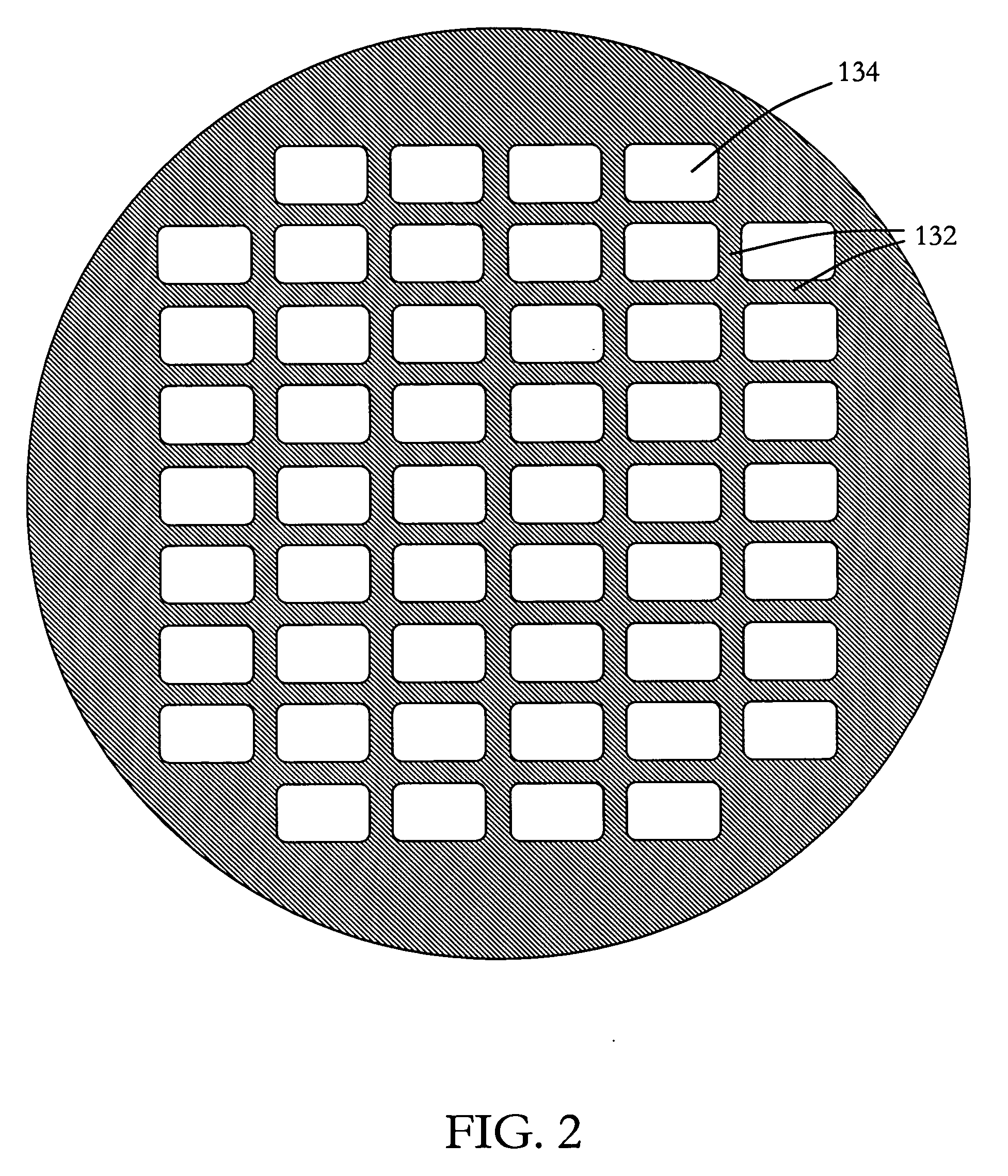

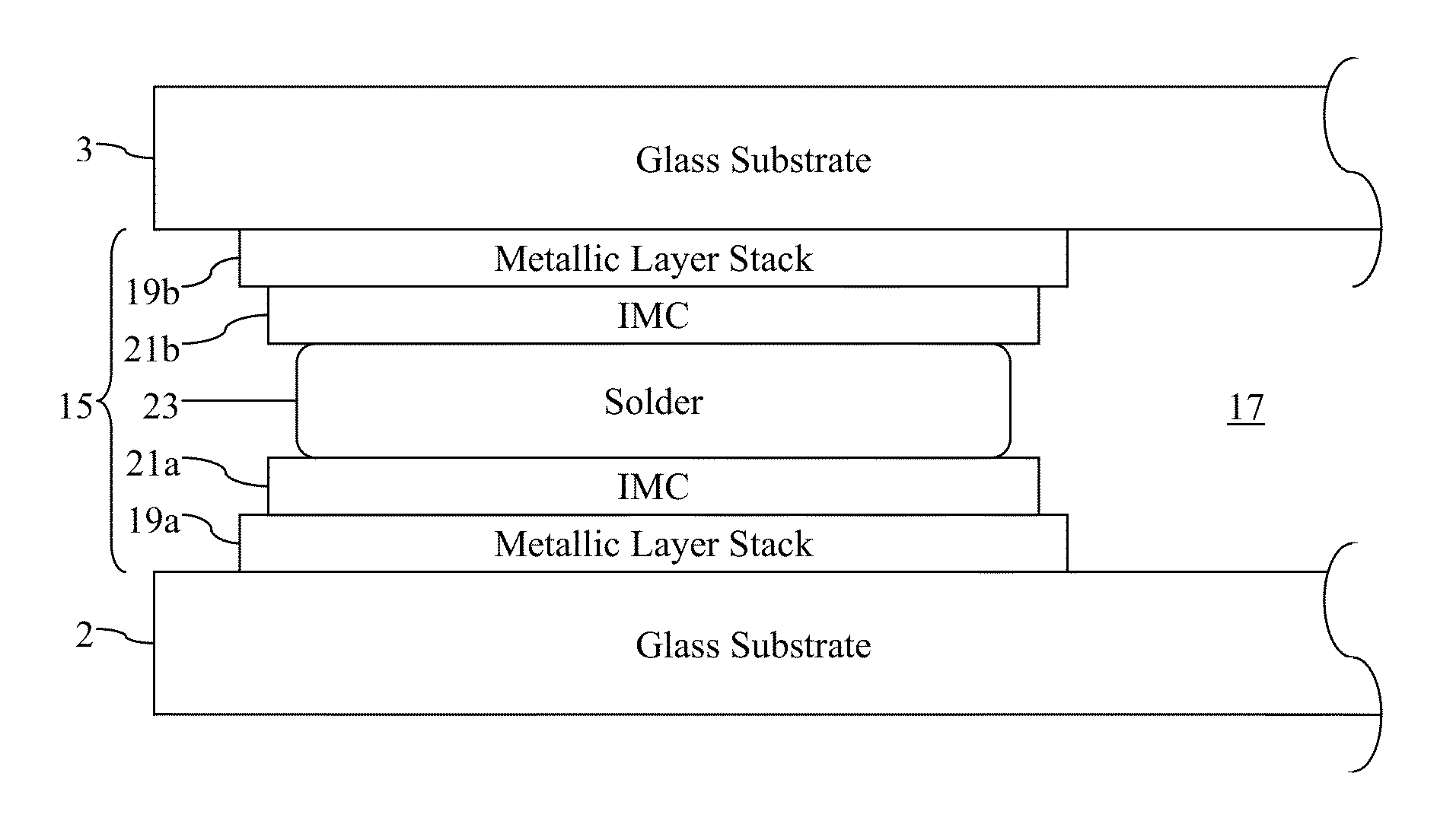

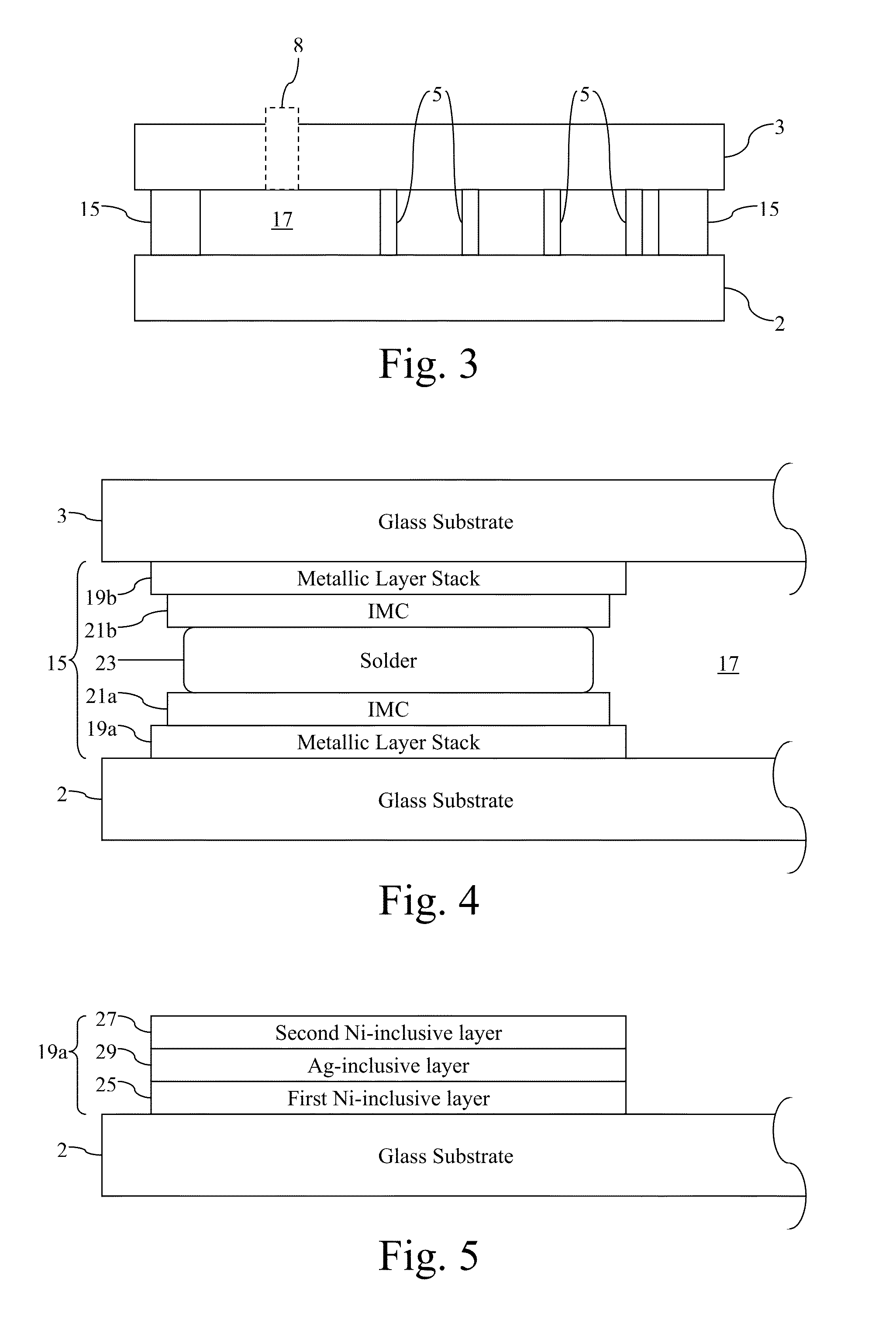

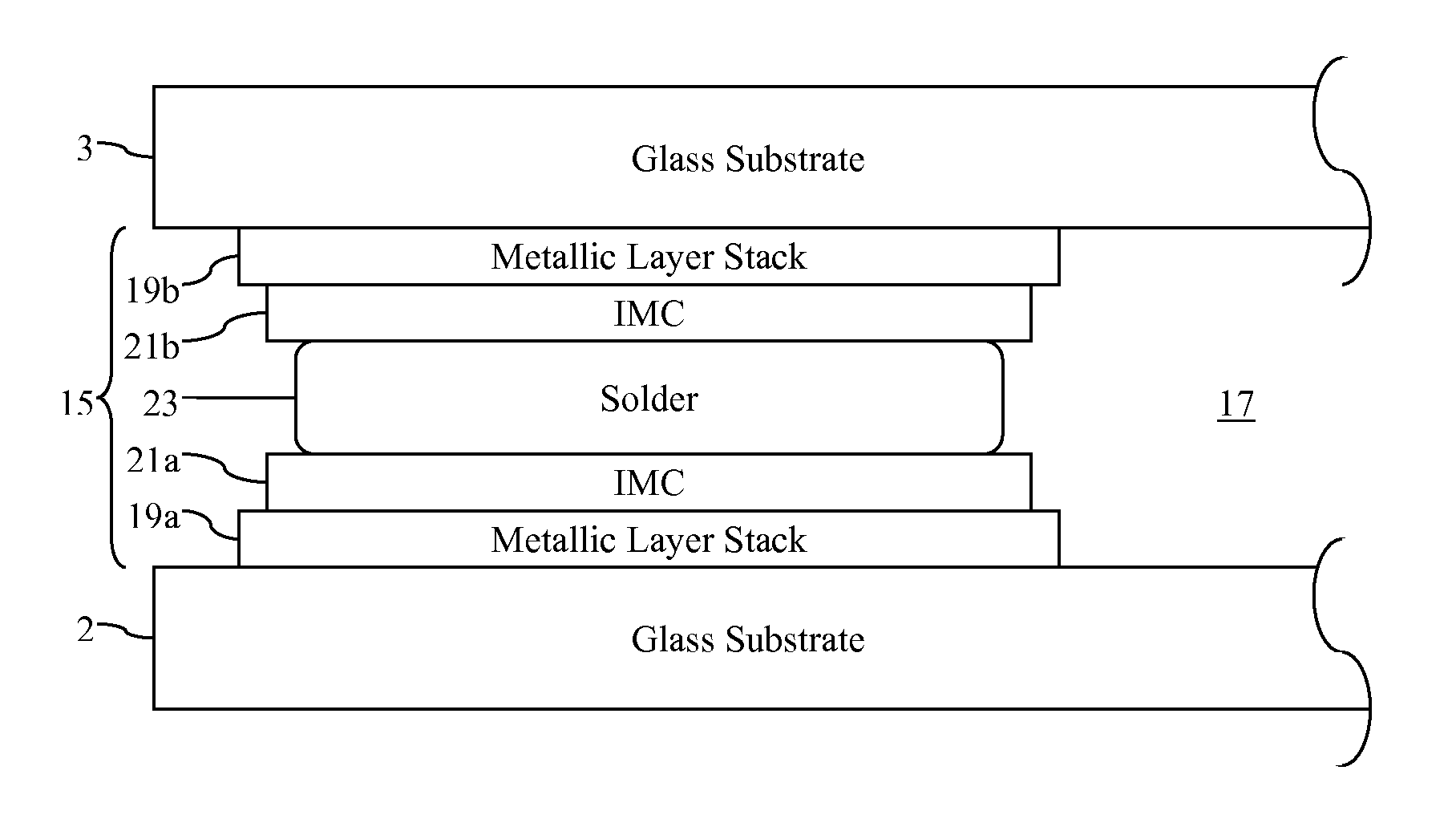

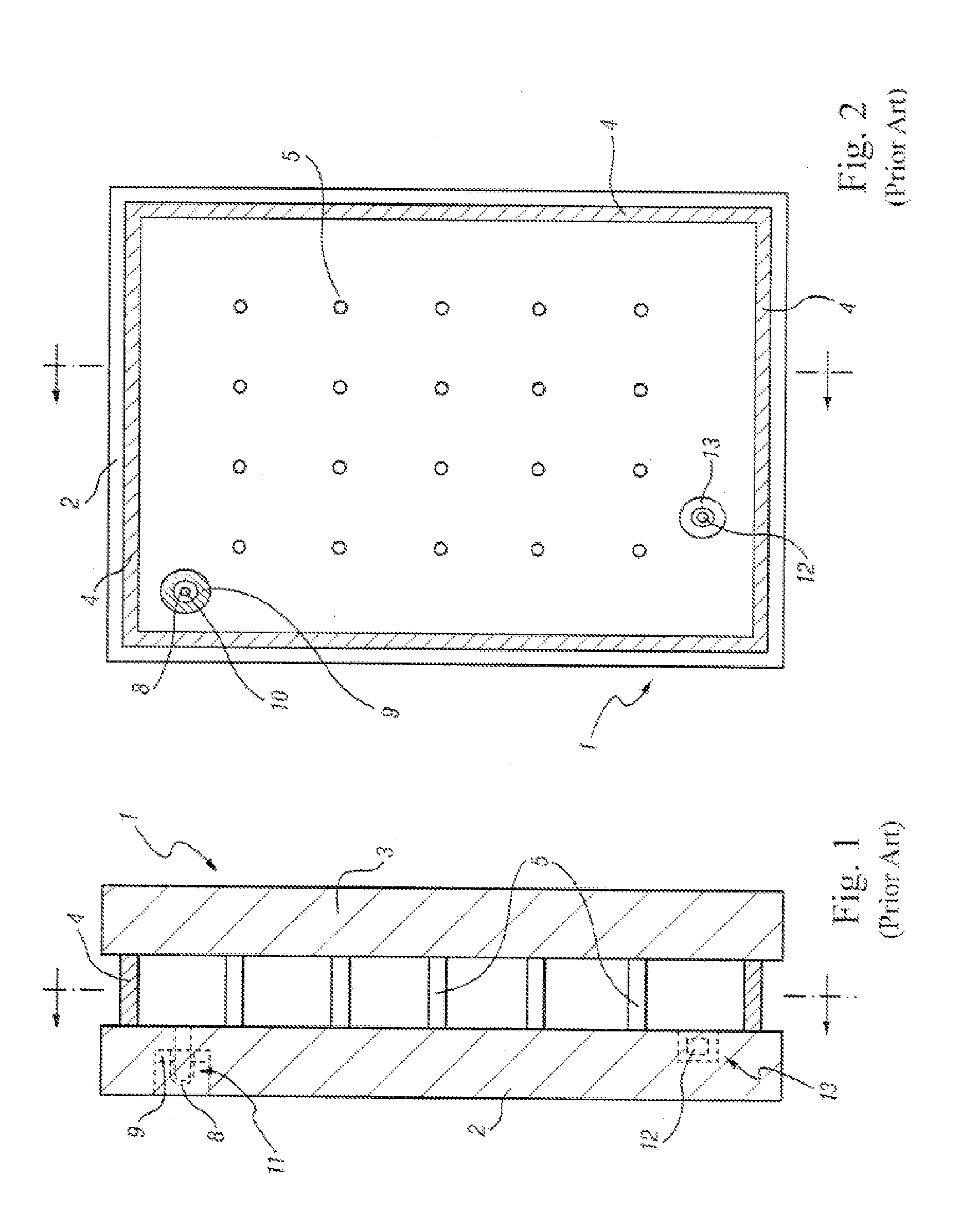

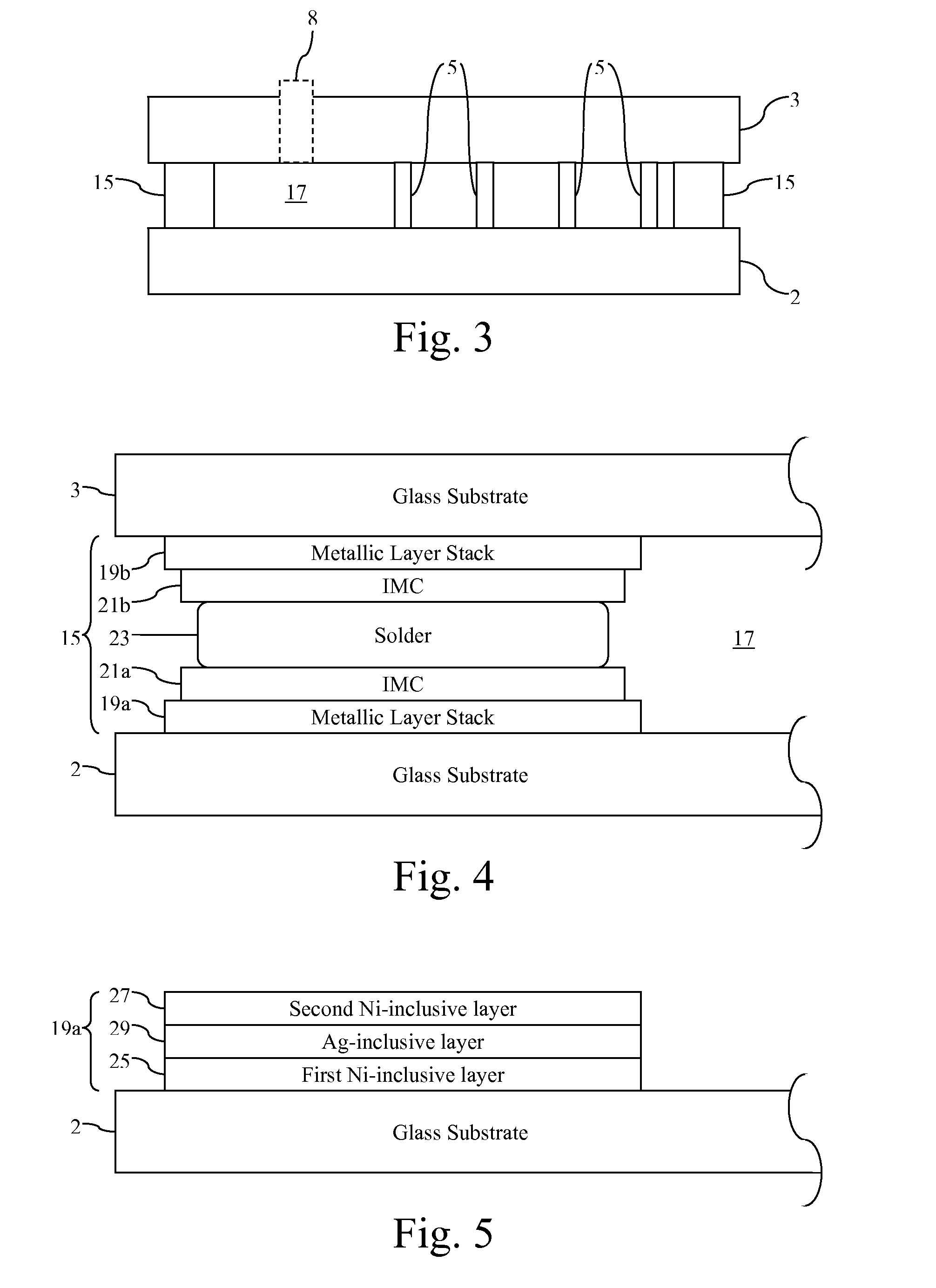

Vacuum insulating glass (VIG) unit with metallic peripheral edge seal and/or methods of making the same

ActiveUS20150184446A1Improve crack resistanceHigh mechanical strengthClimate change adaptationWindows/door improvementMetalloidMetallic coating

Certain example embodiments relate to vacuum insulating glass units having edge seals based on solder alloys that, when reactively reflowed, wet metallic coatings pre-coated on the glass substrates' perimeters, and / or associated methods. The alloys may be based on materials that form a seal at temperatures that will not de-temper glass and / or decompose a laminate, and / or remain hermetic and lack porous structures in their bulks. Example alloys may be based on inter-metallics of Sn and one or more additional materials selected from post-transition metals or metalloids; Zintl anions (e.g., In, Bi, etc.) from Group 13, 14, 15 or 16; and transition metals (e.g., Cu, Ag, Ni, etc.); and excludes Pb. Thin film coatings in certain example embodiments work with the solder material to form robust and durable hermetic interfaces. Because low temperatures are used, certain example embodiments can use compliant and visco-elastic spacer technology based on lamellar structures and / or the like.

Owner:GUARDIAN GLASS LLC

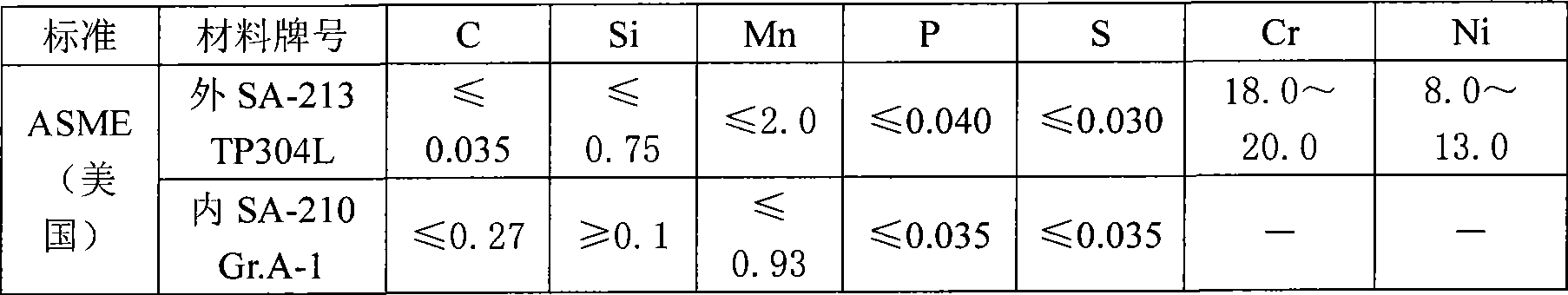

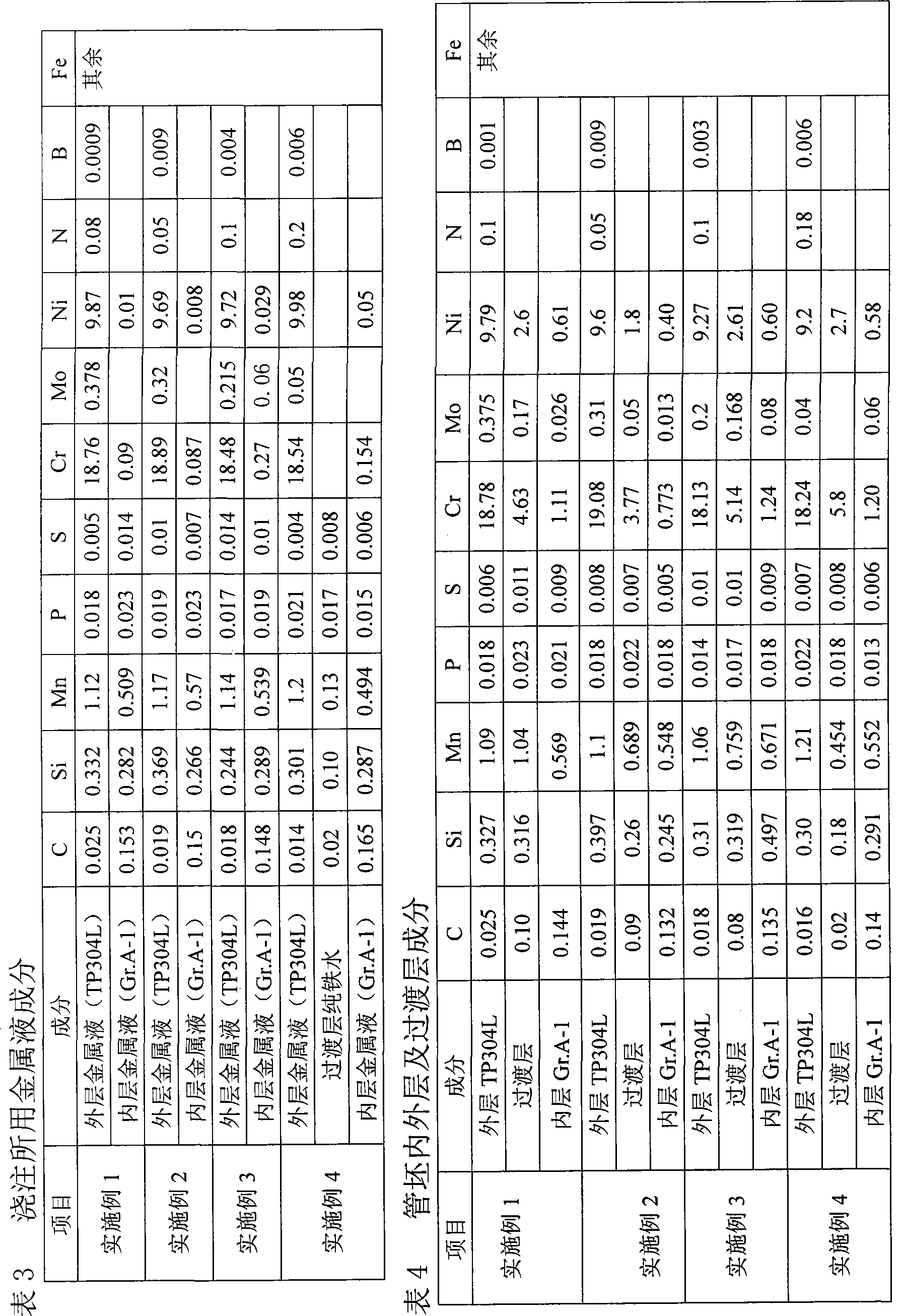

Clad tube blank of dual metal seamless steel tube used for boiler and manufacturing method thereof

InactiveCN101530907ANot easy to layerExtended service lifeRigid pipesMetal layered productsJoint surfaceTransition layer

A clad tube blank of a dual metal seamless steel tube used for a boiler comprises an inner layer and an outer layer; a transition layer is arranged between the inner layer and the outer layer and is respectively bonded with the inner layer and the outer layer completely and metallurgically; the inner layer is cast by a Gr.A-1 material; the transition layer is cast by ferrite or inner layer materials. The transition layer is arranged between the inner layer and the outer layer of the clad tube blank and is respectively bonded with the inner layer and the outer layer completely and metallurgically, therefore, interfacial stress between joint surfaces of the inner layer and the outer layer is reduced, the tube blank is not easy to be layered and the service life of production tubes used for boilers and manufactured by the tube blank is greatly increased.

Owner:XINXING DUCTILE IRON PIPES CO LTD +1

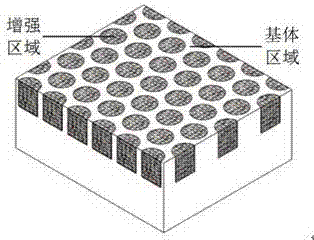

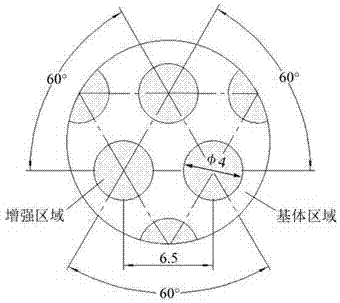

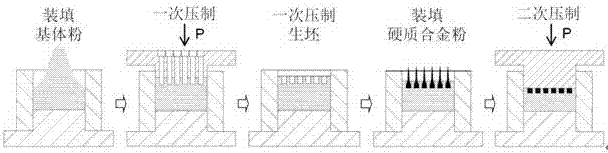

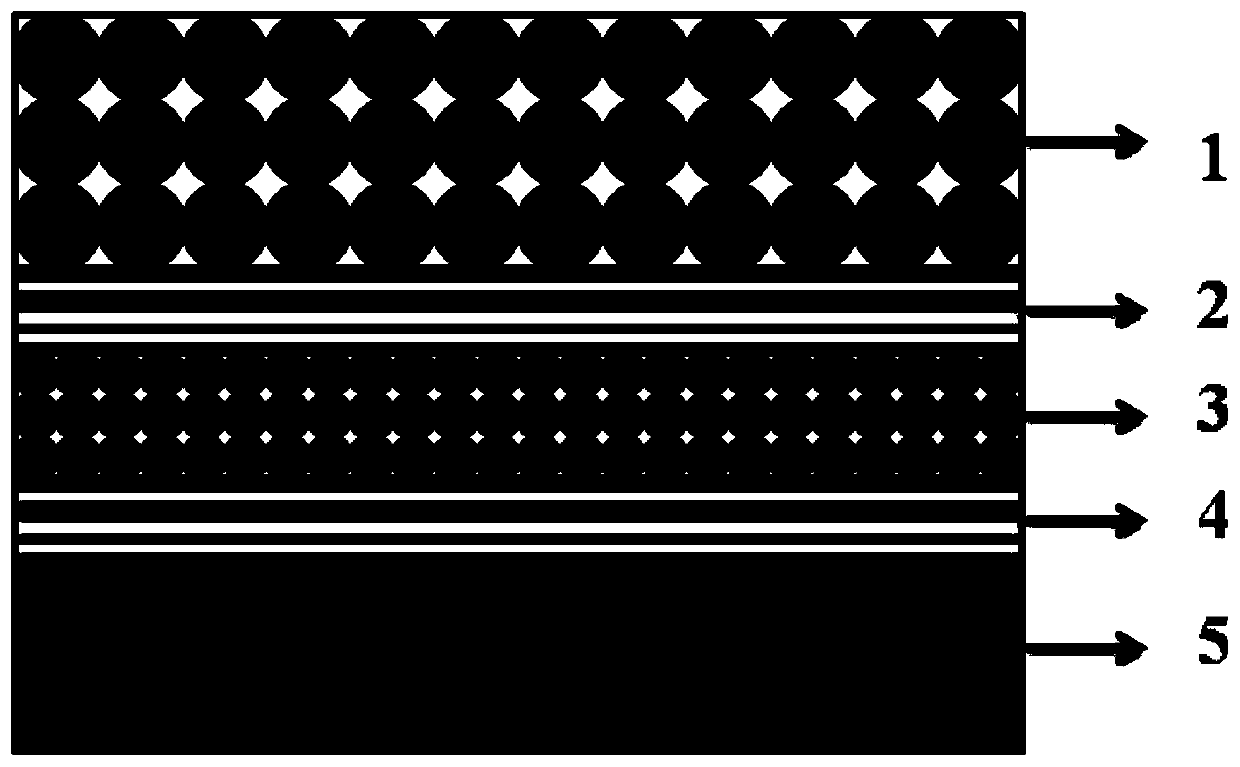

Powder metallurgy preparation method of localization reinforced composite

The invention belongs to the technical field of composite preparation, and particularly relates to a powder metallurgy preparation method of a localization reinforced composite for manufacturing wear-resisting quick-wear parts of mining and building machines. The method comprises the following steps that (1) tungsten carbide powder and titanium carbide powder are used as reinforced particles, reduced iron powder and high-speed steel powder are used as a metal binder, and hard alloy powder is prepared according to a certain proportion; (2) the prepared hard alloy powder is put into a ball mill, and a process control agent is added for ball milling and mixing; and (3) a forming agent is added into the hard alloy powder subjected to uniform ball milling and mixing, and then the steps of mixing, prepressing, smashing, sieving particle making and the like are carried out. In a composite layer of the composite prepared through the method, discontinuous reinforcement areas are uniformly distributed in a continuous matrix area, cracks are not prone to being produced and expanding in the service process of the composite, and strength-toughness matching performance of the composite is achieved well; and the wear resistance of the composite can be obviously improved, and the service life of the composite can be obviously prolonged.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

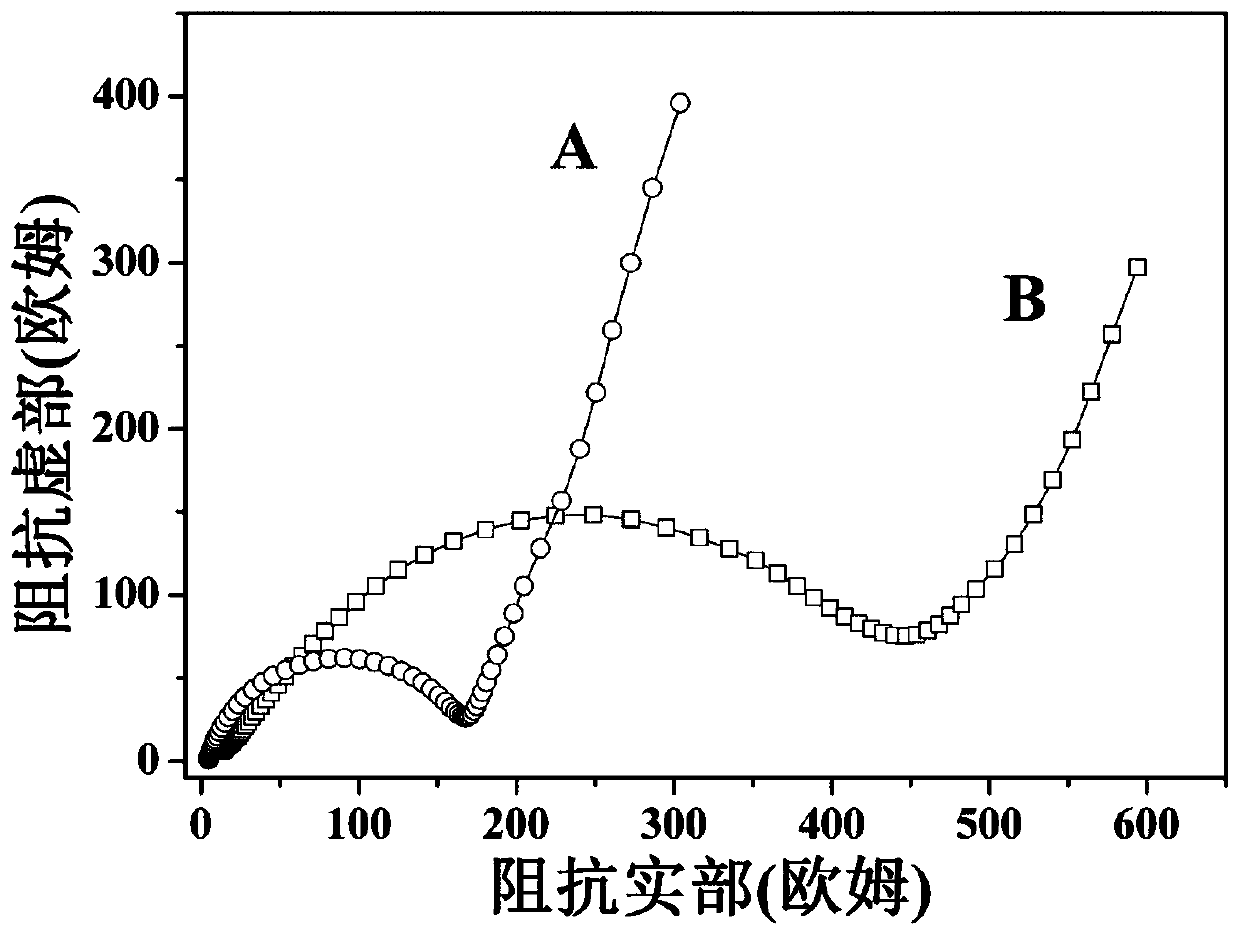

Buffer layer for sulfide solid-state battery, preparation method of buffer layer, and solid-state battery

ActiveCN110034275AFast film formationIncrease relative volatilityFinal product manufactureSecondary cellsSolid state electrolyteElectrical battery

The invention provides a buffer layer for a sulfide solid-state battery. The buffer layer comprises a polymer material and ethylene carbonate, and is formed in situ on an electrode plate through a buffer layer solution; and due to the existence of a polymer, poor physical contact between an electrode and an electrolyte caused by volume deformation of a positive electrode material in a charging / discharging process can be improved. The buffer layer is existent between the positive electrode and the solid electrolyte of the solid-state battery and between the negative electrode and the solid-state electrolyte, so that the solid-solid interface impedance can be reduced; and meanwhile, good ionic conductivity of the buffer layer can improve the lithium ion transmission capacity. The sulfide composite positive electrode in the solid-state battery provided by the invention contains the polymer material, and the existence of the polymer can improve the poor physical contact between the electrode and the electrolyte caused by the volume deformation of the positive electrode material in the charging / discharging process; and meanwhile, the solid-state battery contains the buffer layer, so that the solid-state battery has low interface resistance and high ionic conductivity, and is excellent in capacity and cycling performance.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

In-situ non-crystallizing modification method for surface of metal material

InactiveCN106011847AReduce interface stressIncreasing the thicknessMetallic material coating processesMetallic materialsMetal

The invention belongs to the technical field of modification of surfaces of metal materials, and discloses an in-situ non-crystallizing modification method for the surface of a metal material. The method comprises the steps that amorphous alloy components matched with components of a metal matrix material are selected based on the components of the metal matrix material; then, required simple-substance element powder except main elements of a metal matrix is matched according to the amorphous alloy components; after being mixed, the element powder is preplaced on the surface of the metal matrix; laser is adopted to directly irradiate the mixed powder and the metal matrix to melt the mixed powder and the metal matrix and mix the melts; and an amorphous alloy is generated through the in-situ alloying reaction of the mixed element powder and the main elements of the metal matrix under the condition of quick cooling, and an amorphous alloy surface is prepared. According to the method, the interfacial stress of the amorphous alloy surface and the metal matrix is effectively reduced, the thickness of the amorphous alloy surface is increased, and the surface performance of the metal material is remarkably improved; and the amorphous alloy surface prepared through the method is different from an amorphous alloy coating prepared through a traditional method, the amorphous alloy surface is generated through the in-situ alloying reaction on the surface of the metal matrix, the interface bonding is high, and the performance is excellent.

Owner:常熟市大地机械铸造厂

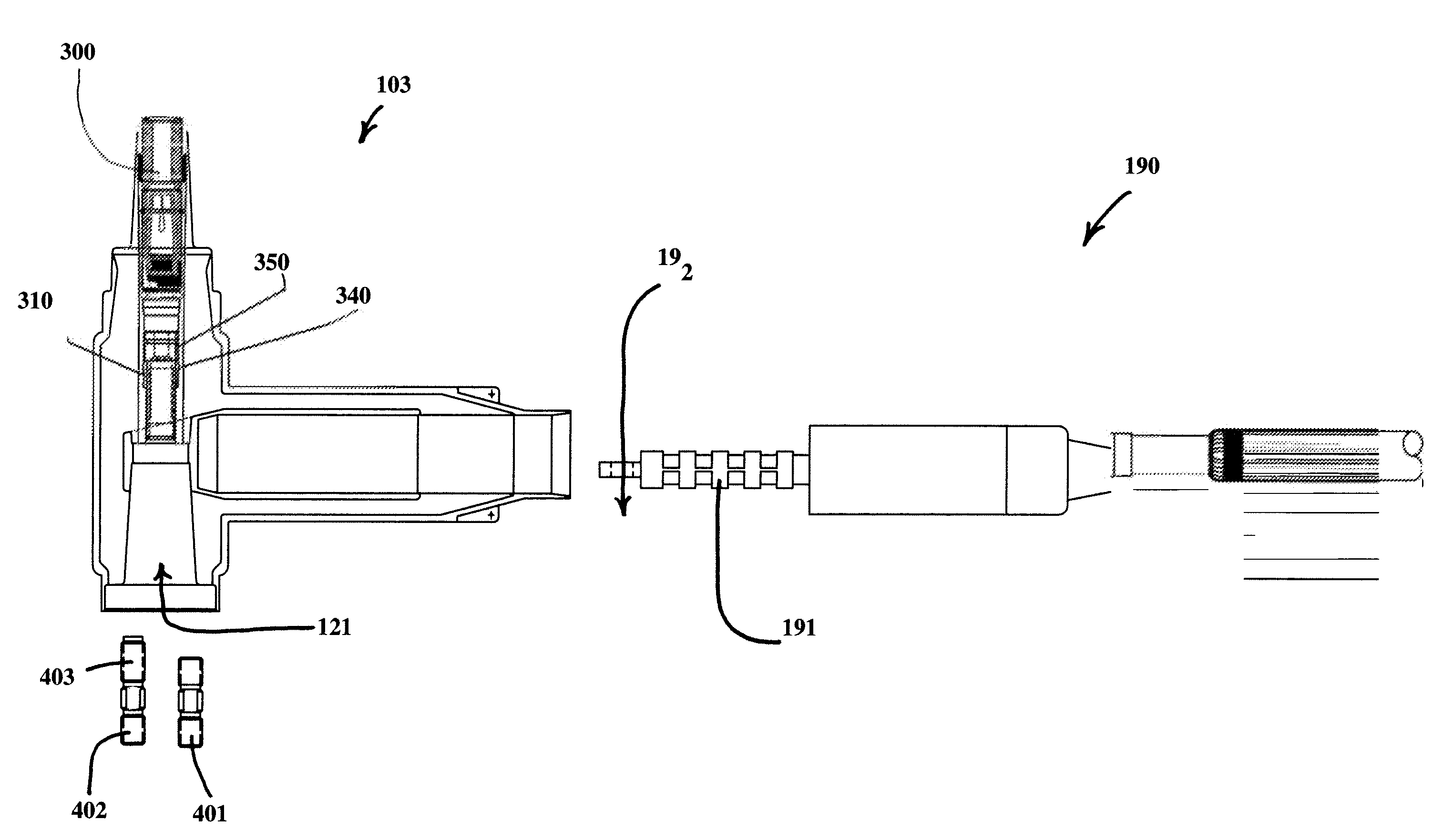

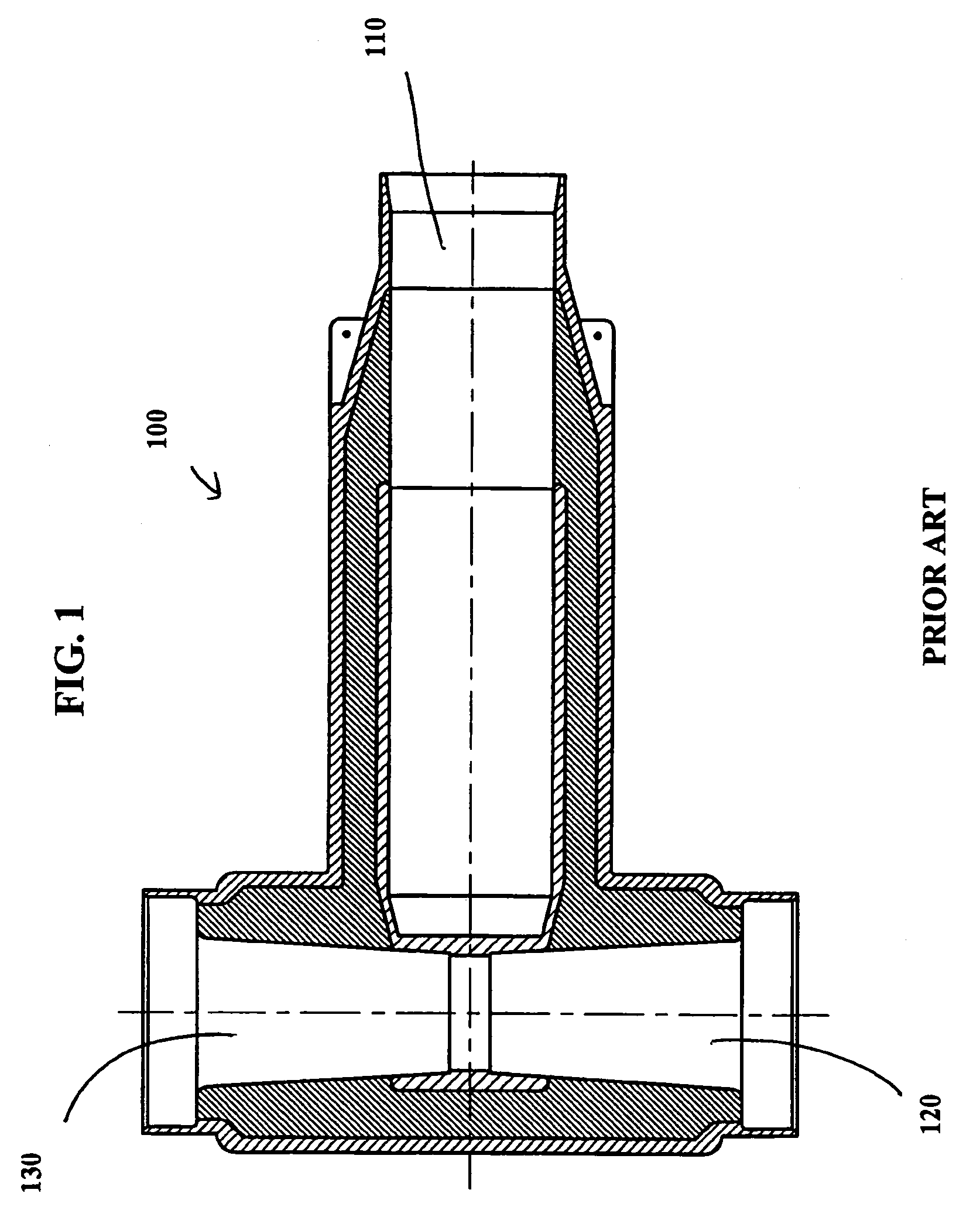

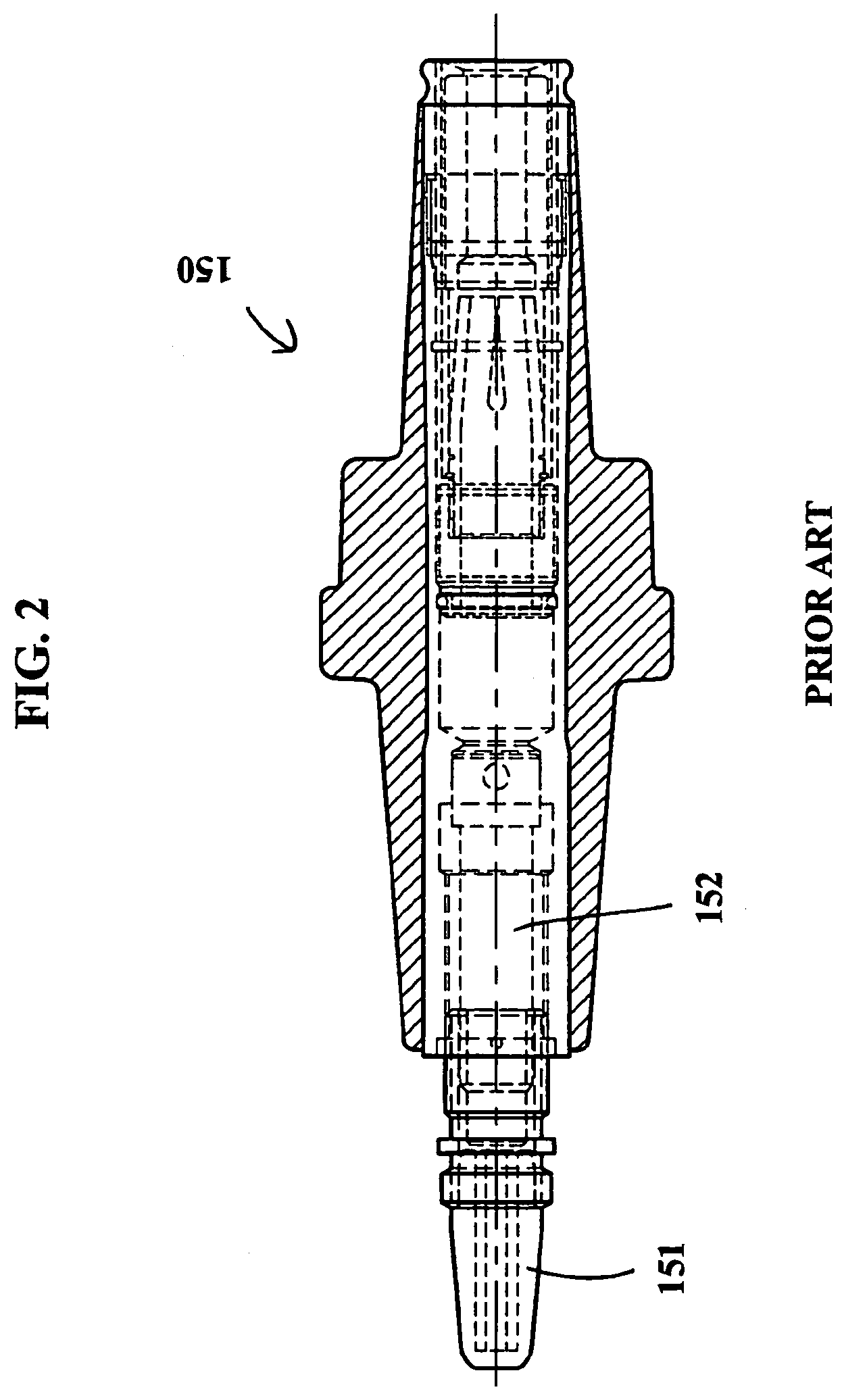

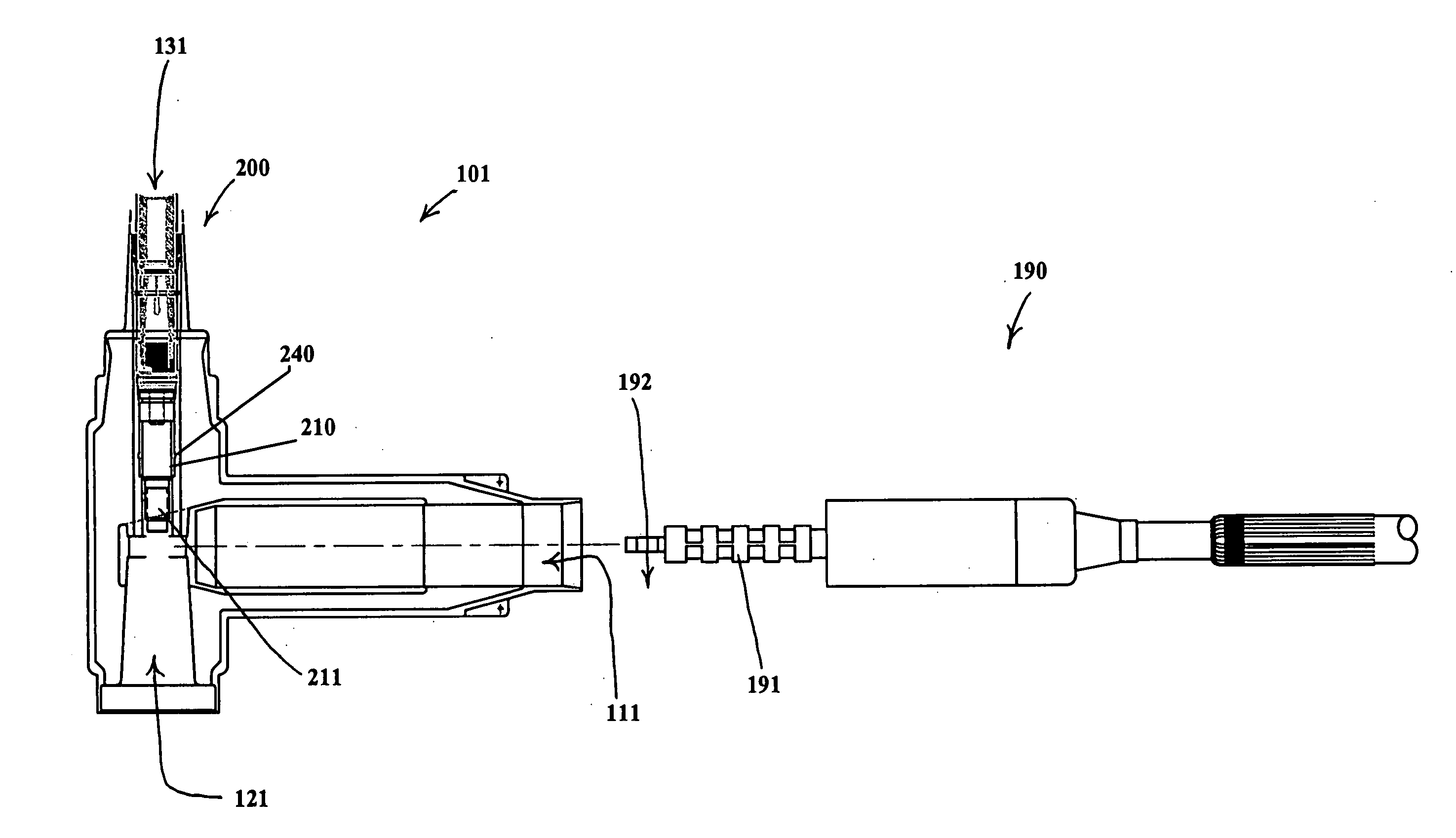

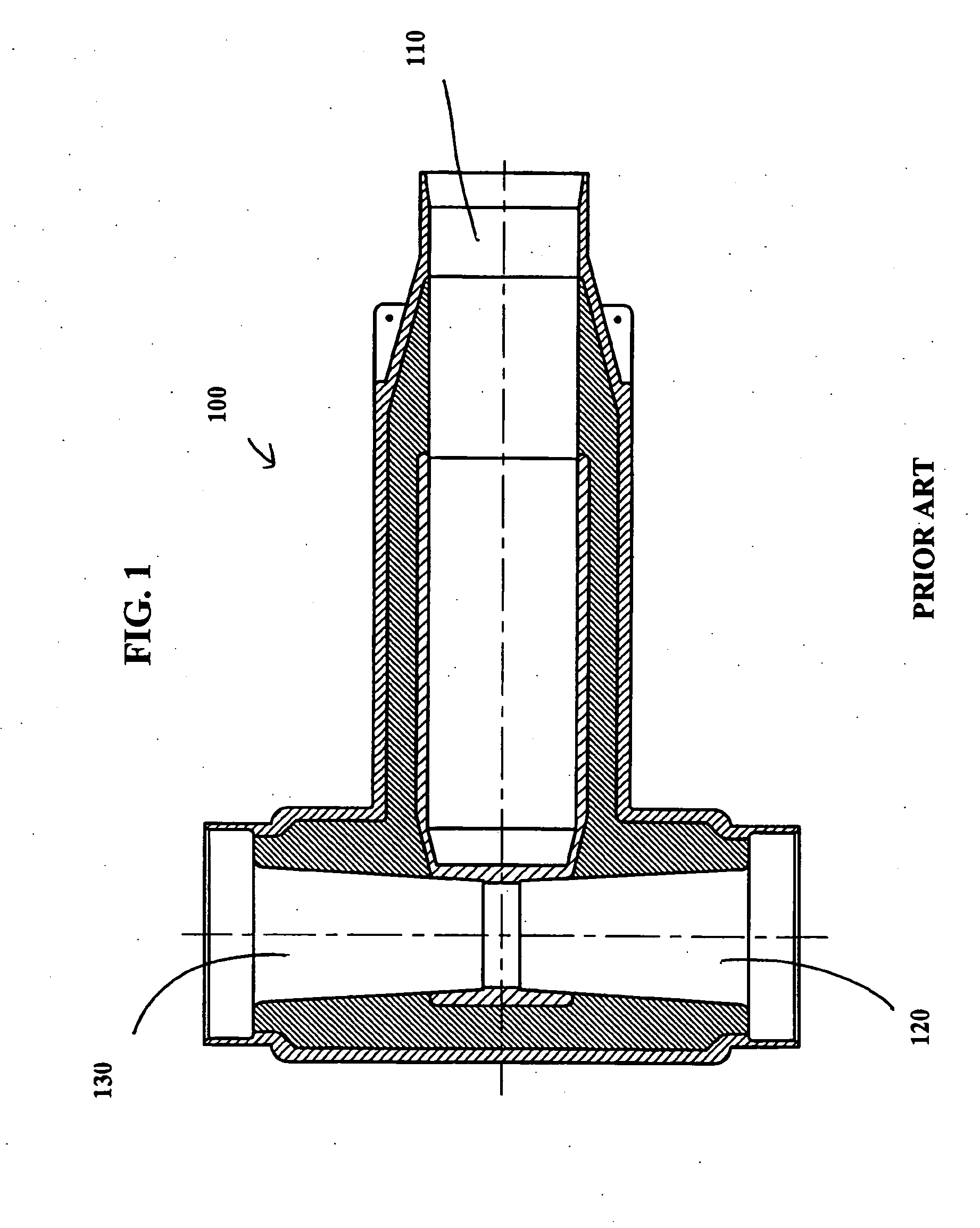

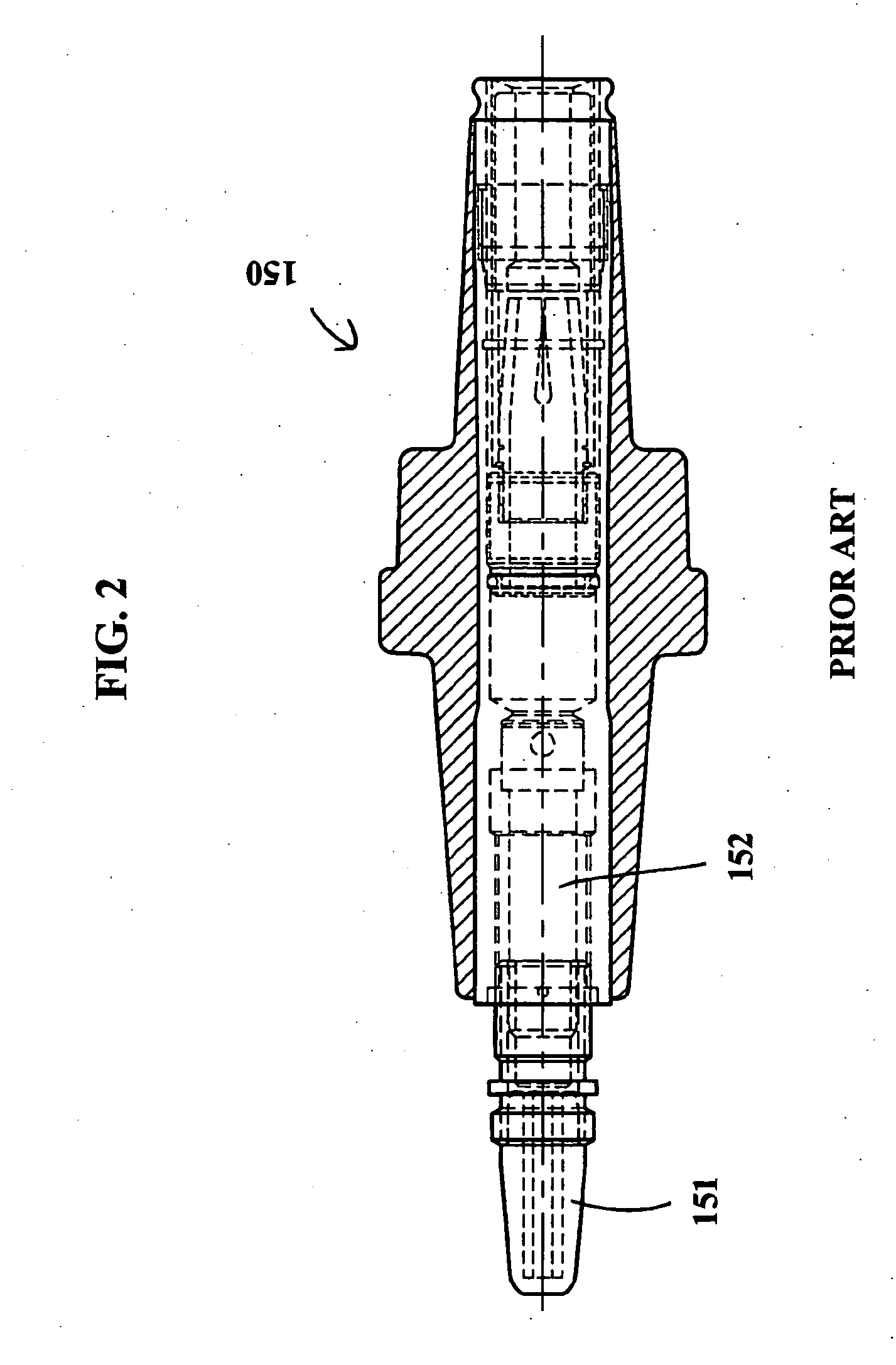

Multiple bore termination system having an integrally formed component

ActiveUS7381103B2Easy to installLess componentsCouplings bases/casesClamped/spring connectionsEngineeringFastener

A cable termination housing for terminating a cable to one or more devices includes a bore for receiving a device mating portion, a component portion integrally formed within the housing, the component portion having a fastener that is slidable between a retracted position wherein fastener does not extend into the lug aperture of the cable assembly and an extended position wherein the fastener extends into the lug aperture. Preferably, the fastener is rotatable while in its extended position so as to couple with the device mating portion.

Owner:RICHARDS MFG CO INC

Vacuum insulating glass (VIG) unit with metallic peripheral edge seal and/or methods of making the same

ActiveUS20150300077A1Improve crack resistanceHigh mechanical strengthClimate change adaptationWindows/door improvementMulti materialMetalloid

Certain example embodiments relate to vacuum insulating glass units having edge seals formed in connection with solder alloys that, when reactively reflowed, wet metallic coatings pre-coated on the glass substrates' perimeters, and / or associated methods. The alloys may be based on materials that form seals at temperatures that will not de-temper glass and / or decompose a laminate, and / or remain hermetic and lack porous structures in their bulks. Example alloys may be based on inter-metallics of Sn and one or more materials selected from post-transition metals or metalloids; Zintl anions (e.g., In, Bi, etc.) from Group 13, 14, 15, or 16; and transition metals (e.g., Cu, Ag, Ni, etc.); and excludes Pb. Thin film coatings in certain example embodiments work with the solder material to form robust and durable hermetic interfaces. Because low temperatures are used, certain example embodiments can use compliant and visco-elastic spacer technology based on lamellar structures and / or the like.

Owner:GUARDIAN GLASS LLC

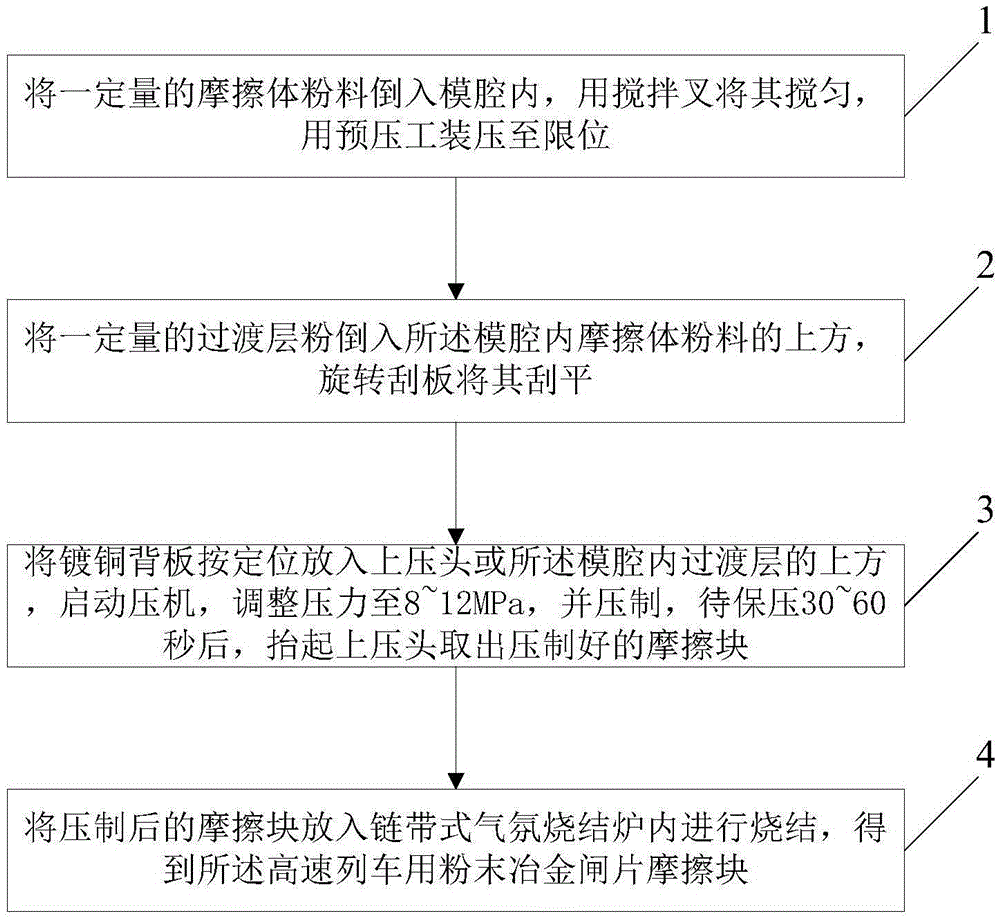

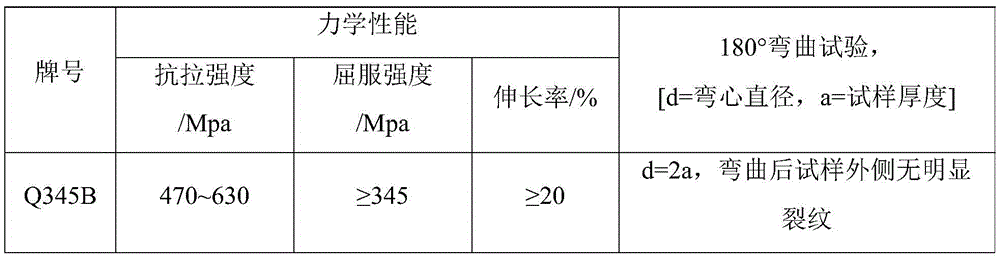

Powder metallurgy brake lining friction block for high-speed train and preparation method thereof

The invention discloses a powder metallurgy brake lining friction block for a high-speed train and a preparation method thereof. The friction block comprises a copper-plated backboard and a friction body. A transition layer is further arranged between the copper-plated backboard and the friction body and metallurgically fused completely with the copper-plated backboard and the friction body. The copper-plated backboard is made from a Q345B material through copper plating. The transition layer is formed by mixing metal powder and copper powder and then sintering the mixed metal powder and copper powder. The copper-plated backboard and the friction body are spliced together through the transition layer during sintering. The friction block prepared through the method can overcome the defect that a backboard and a friction body of an existing friction block are low in splicing strength and consequently the backboard and the friction body are separated and prone to falling, and the service life of a powder metallurgy brake lining made of the friction block is prolonged.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

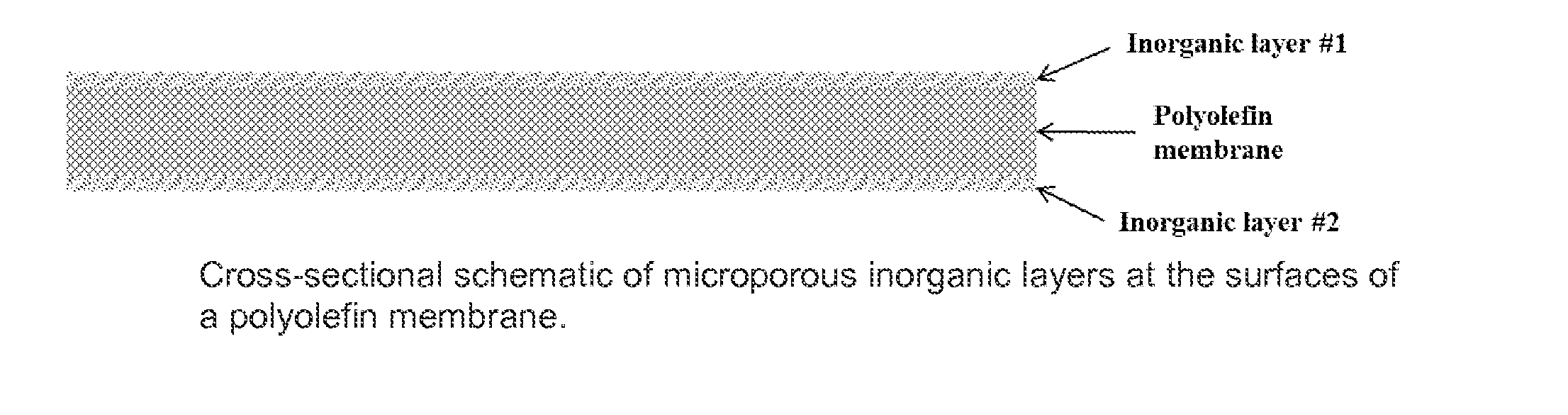

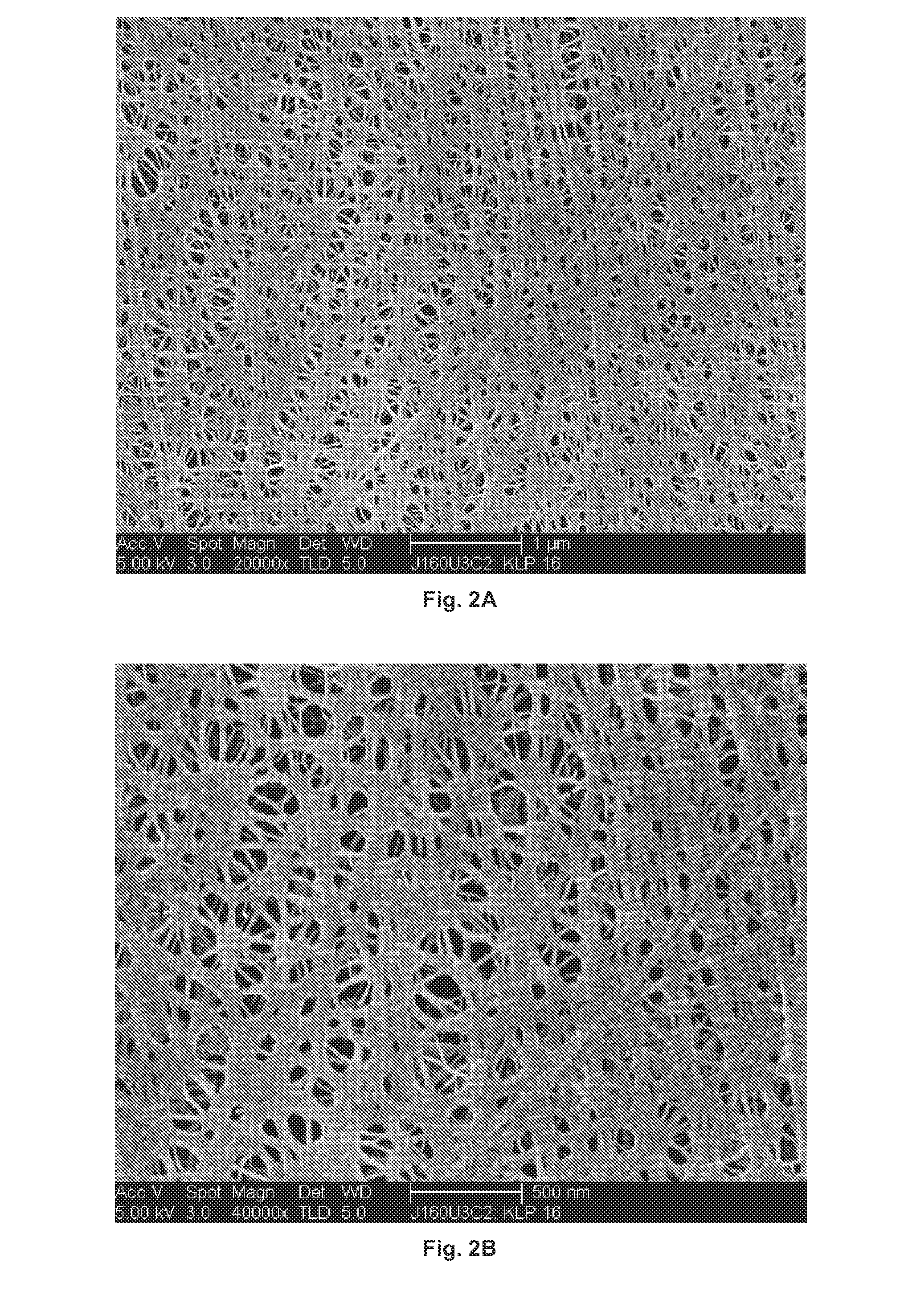

Freestanding, dimensionally stable microporous webs

ActiveUS20160028067A1Good dimensional stabilityMaintain shutdown propertyLamination ancillary operationsLaminationHydrogenSurface layer

A thin, freestanding, microporous polyolefin web with good heat resistance and dimensional stability includes an inorganic surface layer. A first preferred embodiment is a microporous polyolefin base membrane in which colloidal inorganic particles are present in its bulk structure. Each of second and third preferred embodiments is a thin, freestanding microporous polyolefin web that has an inorganic surface layer containing no organic hydrogen bonding component for the inorganic particles. The inorganic surface layer of the second embodiment is achieved by hydrogen bonding with use of an inorganic acid, and the inorganic surface layer of the third embodiment is achieved by one or both of hydrogen bonding and chemical reaction of the surface groups on the inorganic particles.

Owner:AMTEK RES INT

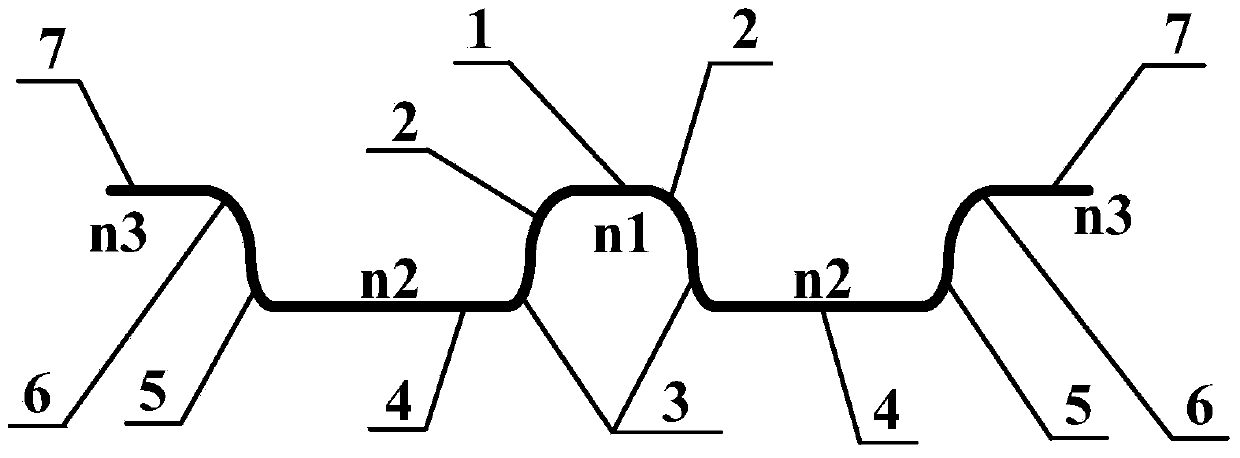

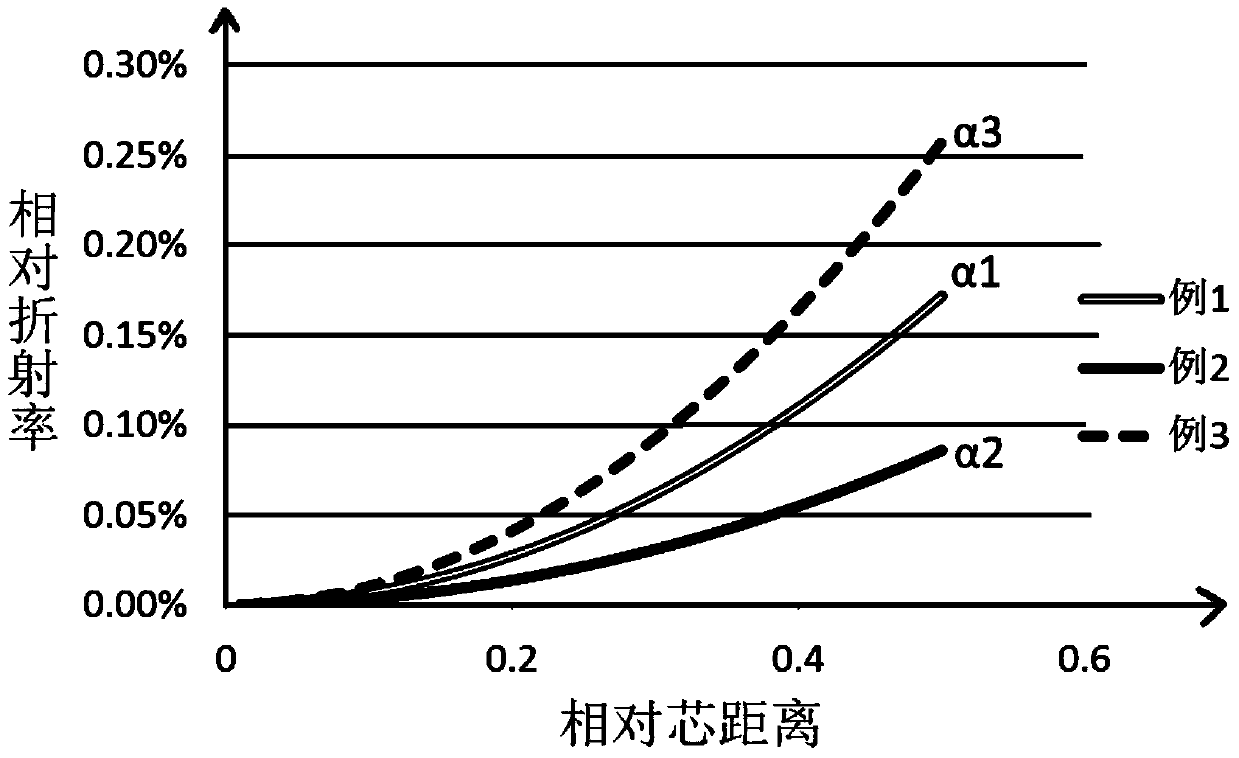

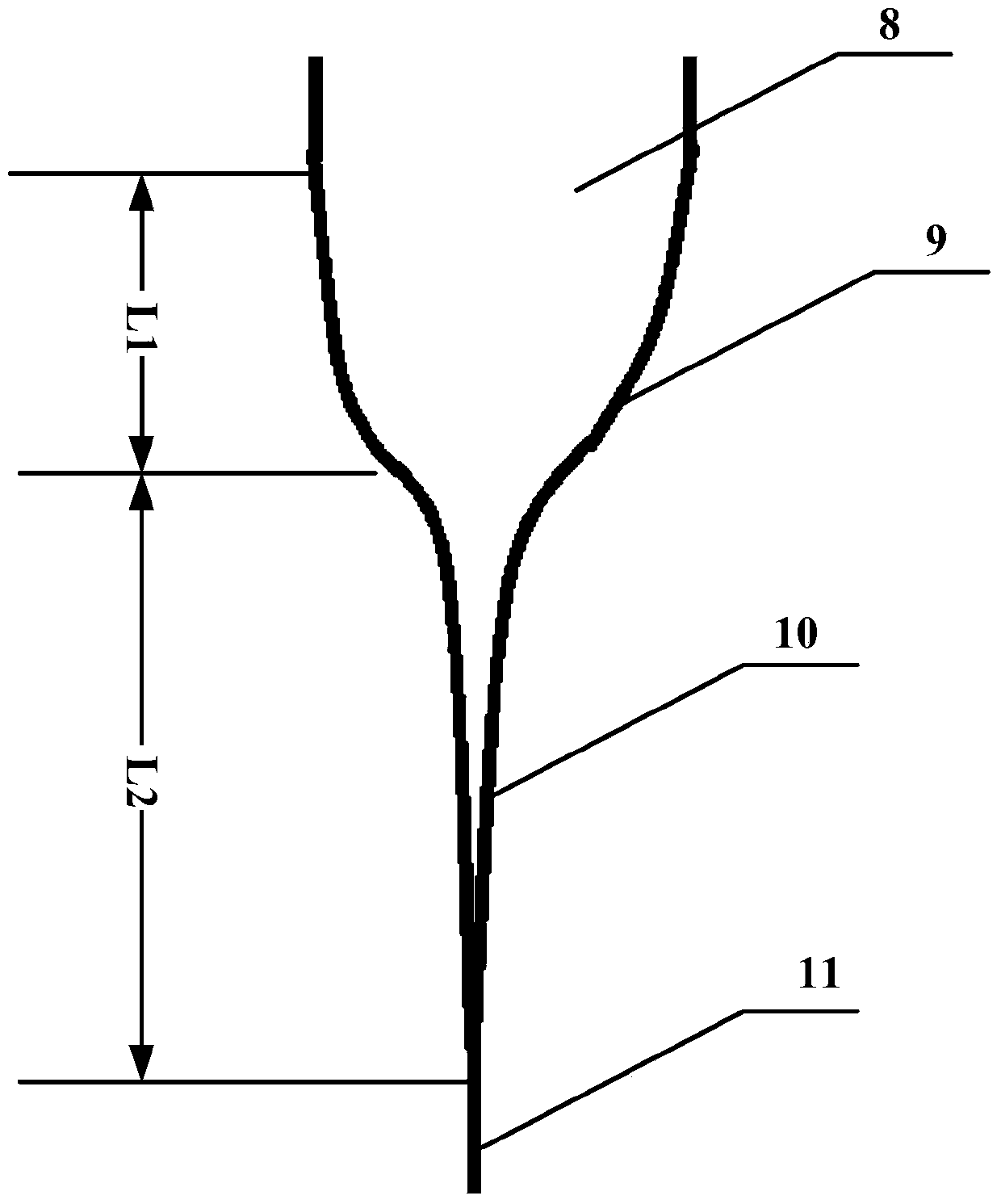

Low-loss optical fiber and manufacturing method thereof

ActiveCN103472529AReduce interface stressGood controlGlass making apparatusOptical fibre with multilayer core/claddingAttenuation coefficientWave band

The invention discloses a low-loss optical fiber and a manufacturing method of the low-loss optical fiber, and relates to the field of optical fibers. The low-loss optical fiber comprises a step change waveguide; the step change waveguide comprises a core layer, a core cladding transition layer, a core cladding interface transition layer, a deep fluorine-doped cladding, a cladding sleeve transition layer, a cladding sleeve interface transition layer and a sleeve layer, wherein the core layer, the core cladding transition layer, the core cladding interface transition layer, the deep fluorine-doped cladding, the cladding sleeve transition layer, the cladding sleeve interface transition layer and the sleeve layer are arranged in sequence from inside to outside; the core layer is made of a pure silicon core slightly doped with fluorine or boron, wherein the relative refringence between the core layer and the pure silicon core is 0-0.1%; the deep fluorine-doped cladding is made of pure silicon dioxide deeply doped with fluorine, wherein the relative refringence between the deep fluorine-doped cladding and the core layer is 0.24%-0.28%; the refractivity in the core cladding transition layer is distributed in a gradient change mode according to a parabola curve, wherein the range of the absolute value of stress coefficients is from 0.005 to 0.015; the base point temperature rises gradually from 900-950 DEG C to 1150-1200 DEG C. The attenuation coefficient of the low-loss optical fiber manufactured according to the manufacturing method can be reduced to less than 0.158 dB / km in a 1550 nm wave band.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

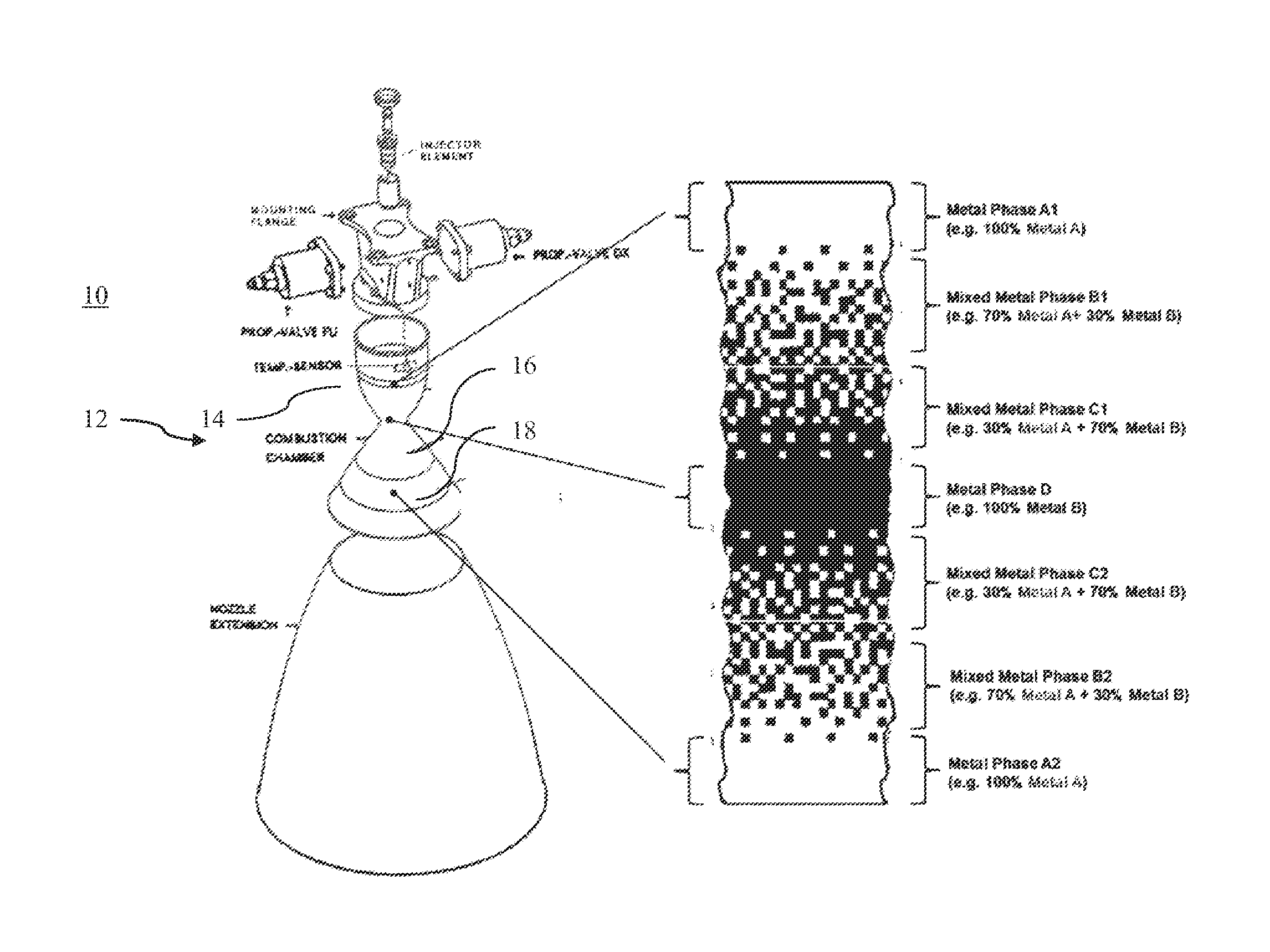

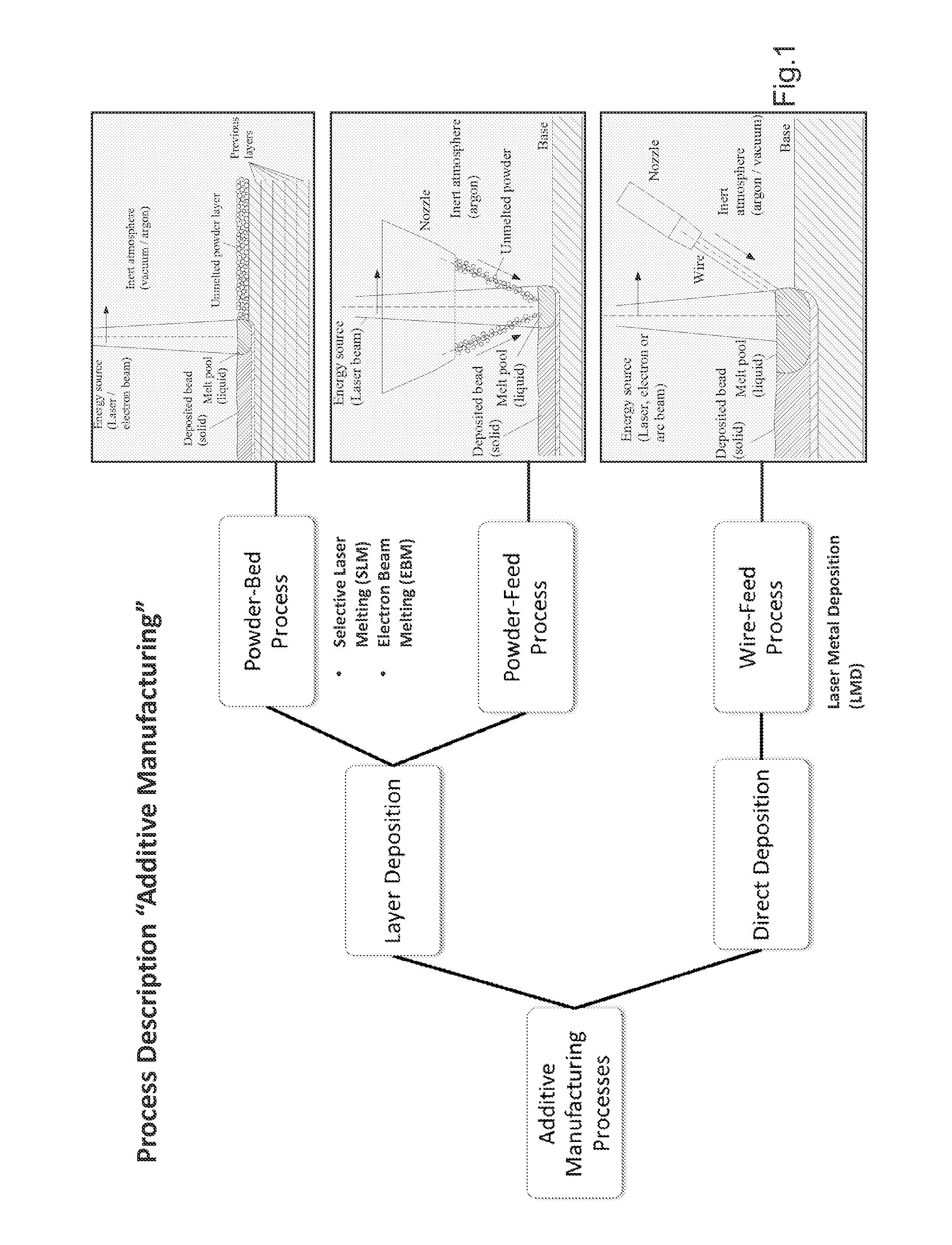

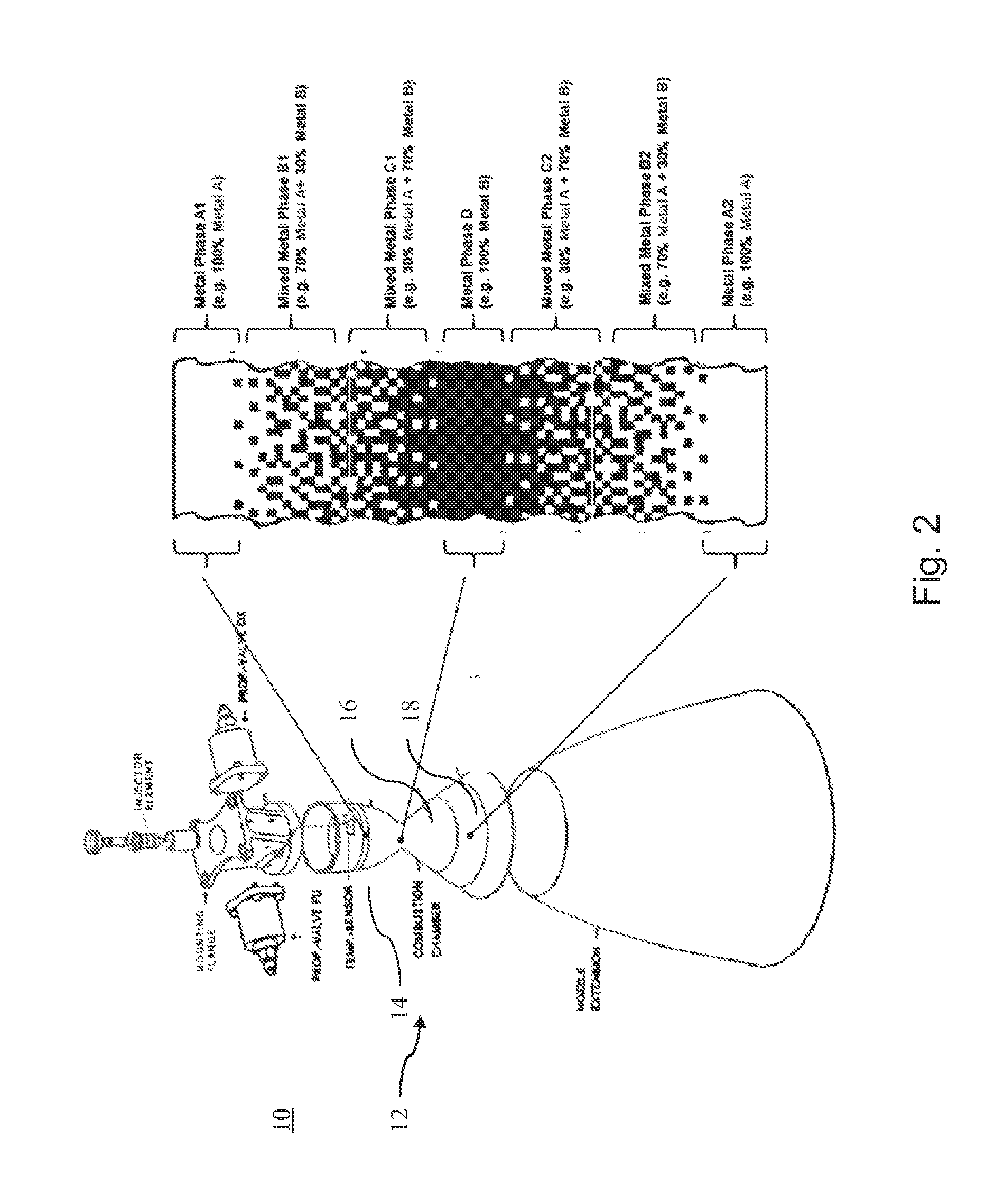

Manufacturing of Components from Parts Made from Different Materials, Particularly of Space Transportation Components Such as Combustion Chambers for Thrusters

InactiveUS20150298213A1Reduce the impactReduce impactAdditive manufacturing apparatusIncreasing energy efficiencyCombustion chamberAdditive layer manufacturing

A method for manufacturing components from parts made from different materials involves producing a transition between one part made from a first material and another part made from a second material by an additive layer manufacturing method. The additive layer manufacturing method involves starting with the first material and then gradually changing the material composition to the second material.

Owner:ARIANEGRP GMBH

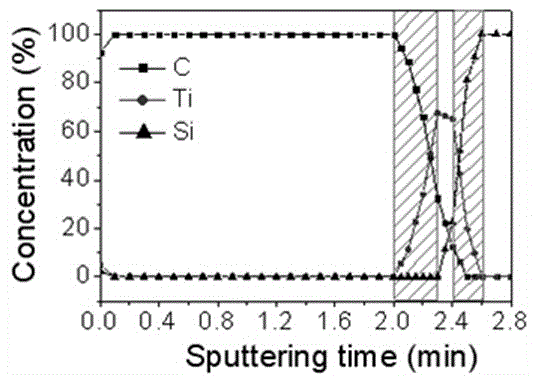

Method for preparing titanium/diamond-like nanometer multilayer film on silicon surface

InactiveCN105132878AHigh bonding strengthReduce interface stressVacuum evaporation coatingSputtering coatingComposite filmVacuum chamber

The invention discloses a method for preparing a titanium / diamond-like nanometer multilayer film on a silicon surface. The method concretely comprises the following steps of: drying a monocrystalline silicon substrate subjected to chemical cleaning in advance; putting the dried monocrystalline silicon substrate onto a rotating sample table of a cathode arcing device; performing vacuum pumping; introducing argon gas into a vacuum chamber; performing sputtering cleaning on the surface of the silicon substrate through an ion source; using high-purity metal titanium and graphite as targets, and using a direct current and pulse double-excitation-source cathode plasma discharge technology for respectively preparing a titanium nanometer function layer and a diamond-like film; and performing later-stage vacuum annealing treatment according to needs. The method has the advantages that the preparing process is simple; and the method can be used for preparing the diamond-like nanometer multilayer composite film with different surface structures. The titanium / diamond-like nanometer multilayer film prepared by the method provided by the invention has the advantages of high hardness, low stress and friction-reduction and abrasion-resistant performance.

Owner:TAIYUAN UNIV OF TECH

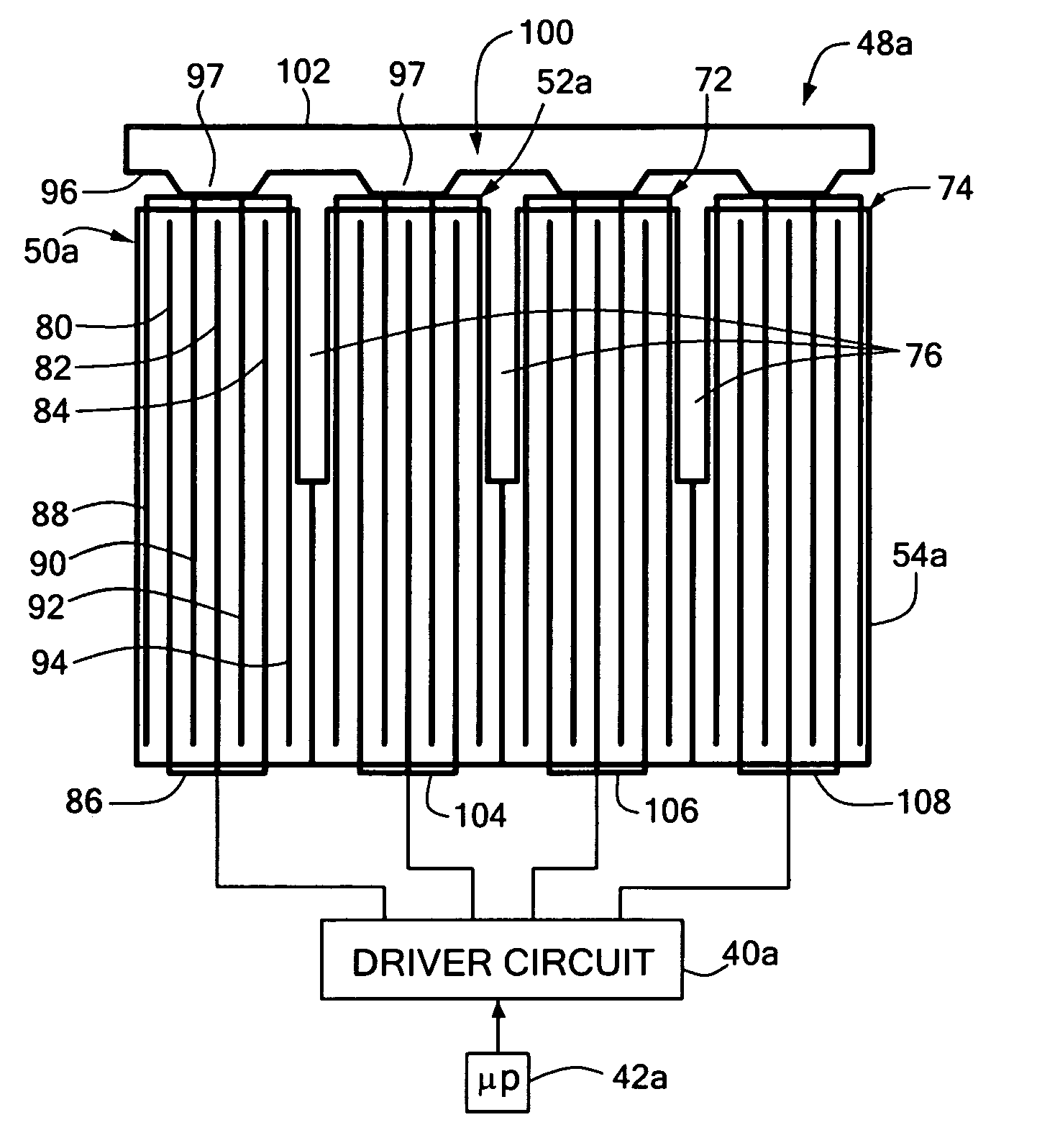

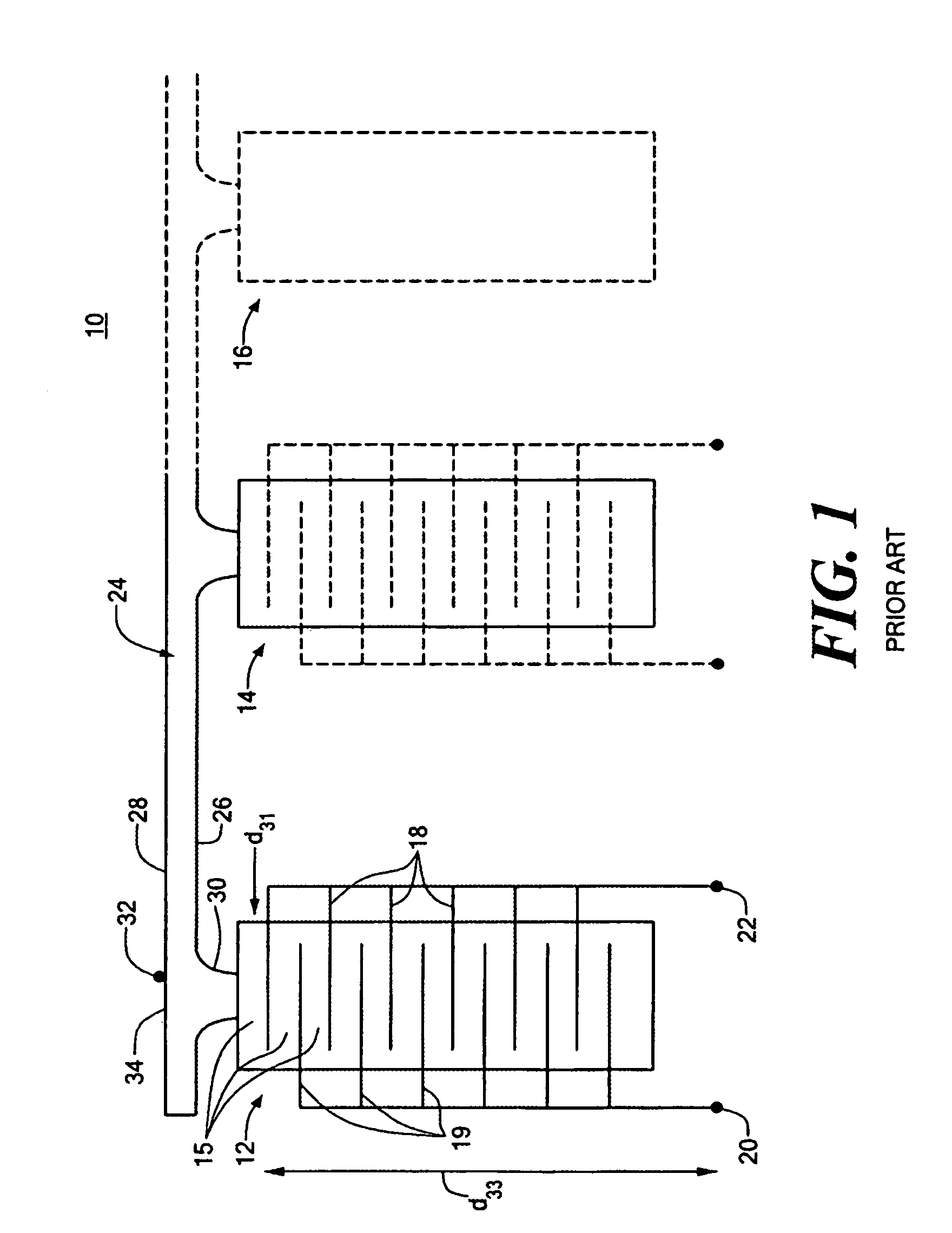

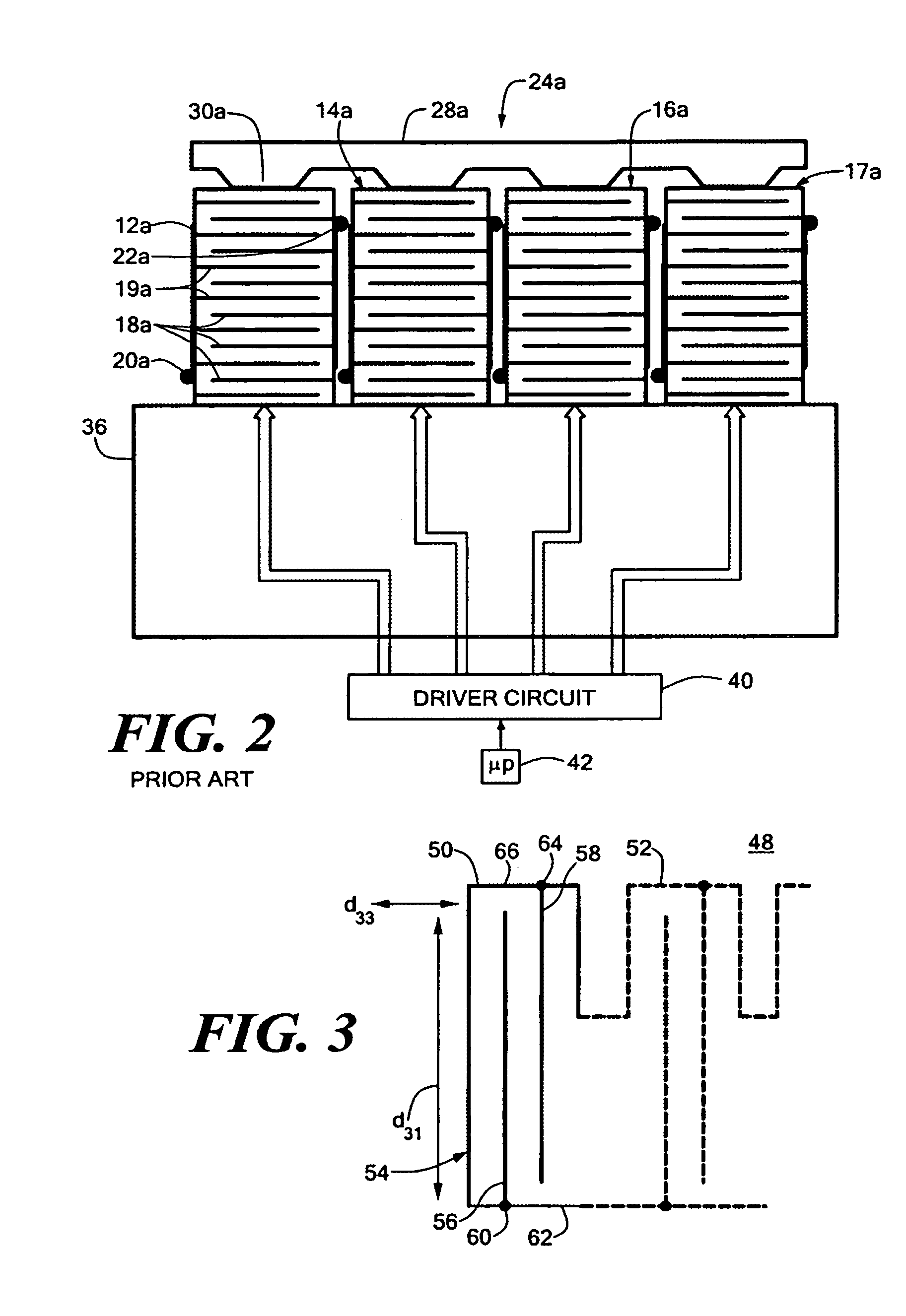

Transverse electrodisplacive actuator array

A transverse electrodisplacive actuator array for controlling the optical phasing of a reflective surface includes a support structure; a plurality of electrodisplacive actuator elements extending from a proximate end at the support structure to a distal end; each actuator element including at least one addressable electrode and one common electrode spaced from the addressable electrode and extending along the direction of said proximate and distal ends along the transverse d31 strain axis; a reflective member having a reflective surface and a mounting surface mounted on the actuator elements; and a plurality of addressable contacts and at least one common contact for applying voltage to the addressable and common electrodes to induce a transverse strain in addressed actuator elements to effect an optical phase change in the reflective surface at the addressed actuator elements.

Owner:NORTHROP GRUMMAN SYST CORP

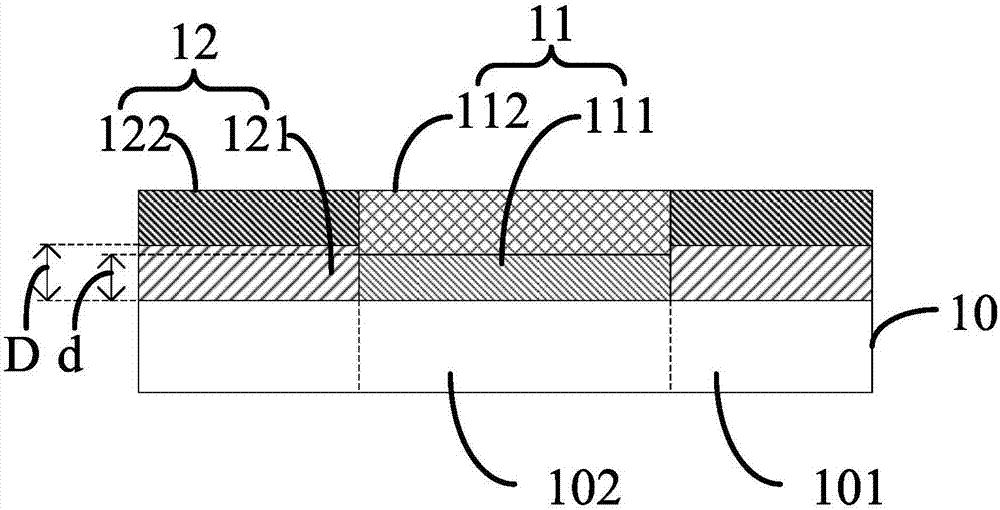

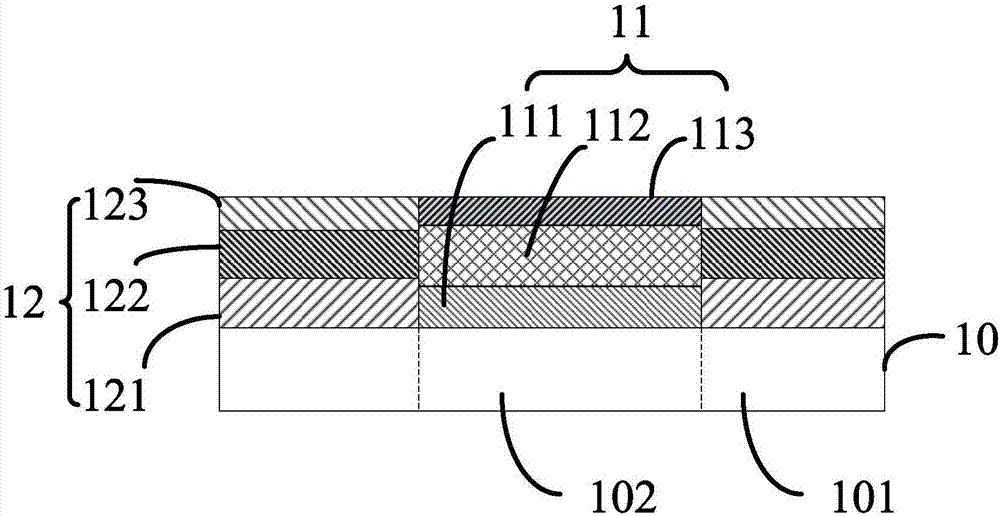

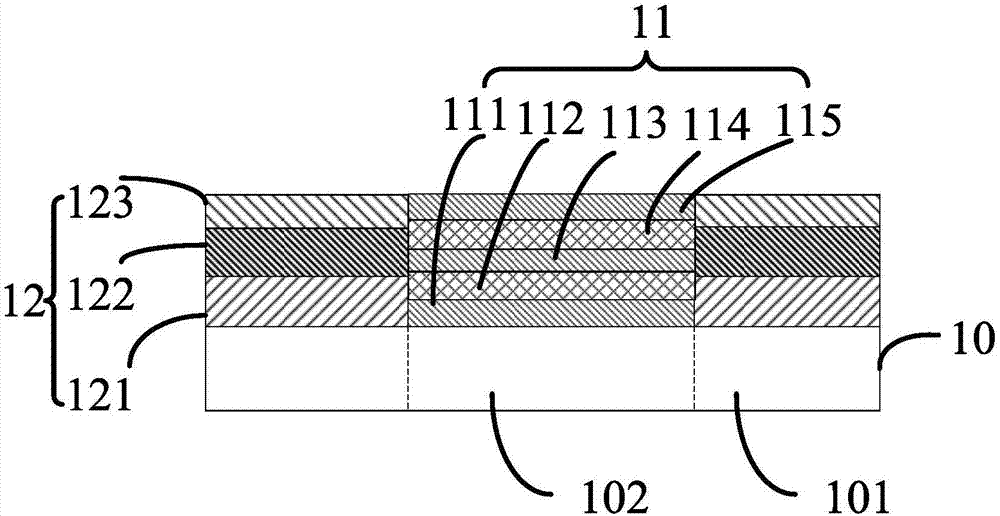

Flexible display assembly, fabrication method thereof and display panel

InactiveCN107968156AImprove crackingImprove bending reliabilityFinal product manufactureSolid-state devicesSurface plateFlexible display

The embodiment of the invention provides a flexible display assembly, a fabrication method of the same and a display panel. The flexible display assembly comprises a display layer, a first thin film layer and a second thin film layer, wherein the display layer comprises a non-bending region and a bending region, the first thin film layer at least comprises a first inorganic layer and a first organic layer, the first inorganic layer and the first organic layer are sequentially formed on the bending region, the second thin film layer at least comprises a second inorganic layer and a second organic layer, the second inorganic layer and the second organic layer are sequentially formed on the non-bending region, the modulus difference between the first inorganic layer and the display layer is smaller than the modulus difference between the second inorganic layer and the display layer, and / or the thickness of the first inorganic layer is smaller than the thickness of the second inorganic layer, and the thickness of the first thin film layer is equal to the thickness of the second thin film layer. By the mode, the bending reliability of the flexible display assembly can be effectively improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

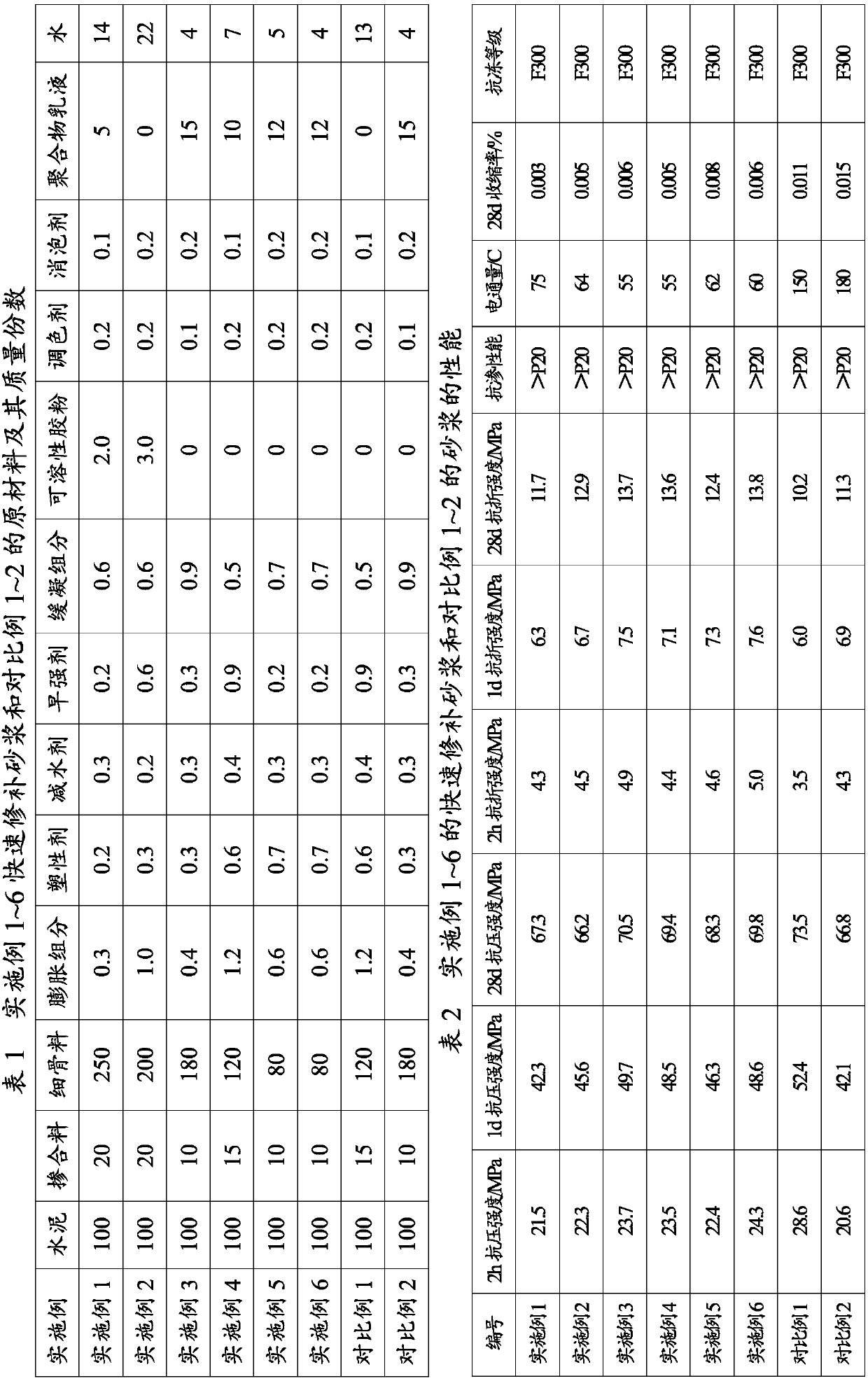

Quick repair mortar for high-speed railway concrete track slab and preparation method thereof

ActiveCN111533517AImprove impermeabilityImprove frost resistanceSolid waste managementPlasticizerLatex rubber

The invention provides quick repair mortar for a high-speed railway concrete track slab. The quick repair mortar comprises, by mass, 100 parts of cement, 50 to 250 parts of fine aggregate, 5 to 25 parts of a mineral admixture, 0 to 8 parts of soluble latex powder, 0 to 20 parts of a polymer emulsion, 0.1 to 1.0 part of a water reducing agent, 0.2 to 2.0 parts of an expansion component, 0.1 to 1.5parts of a plasticizer, 0.1 to 1.2 parts of an early strength agent, 0.2 to 1.5 parts of a retarding component, 0.1 to 0.5 part of a defoaming agent and 0 to 30 parts of water. The mass parts of the soluble latex powder and the polymer emulsion are not 0 at the same time. The invention further provides a preparation method of the quick repair mortar and an application of the quick repair mortar innon-structural damage repair of ballastless high-speed railway concrete track slabs. The quick repair mortar has the characteristics of good workability, early strength, high strength, high volume stability, good durability and the like.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

Bond method and structure using selective application of spin on glass

ActiveUS7265027B2Easy to useHigh device yieldSemiconductor/solid-state device manufacturingMicrostructural devicesEngineeringSpacer device

Owner:MIRADIA INC

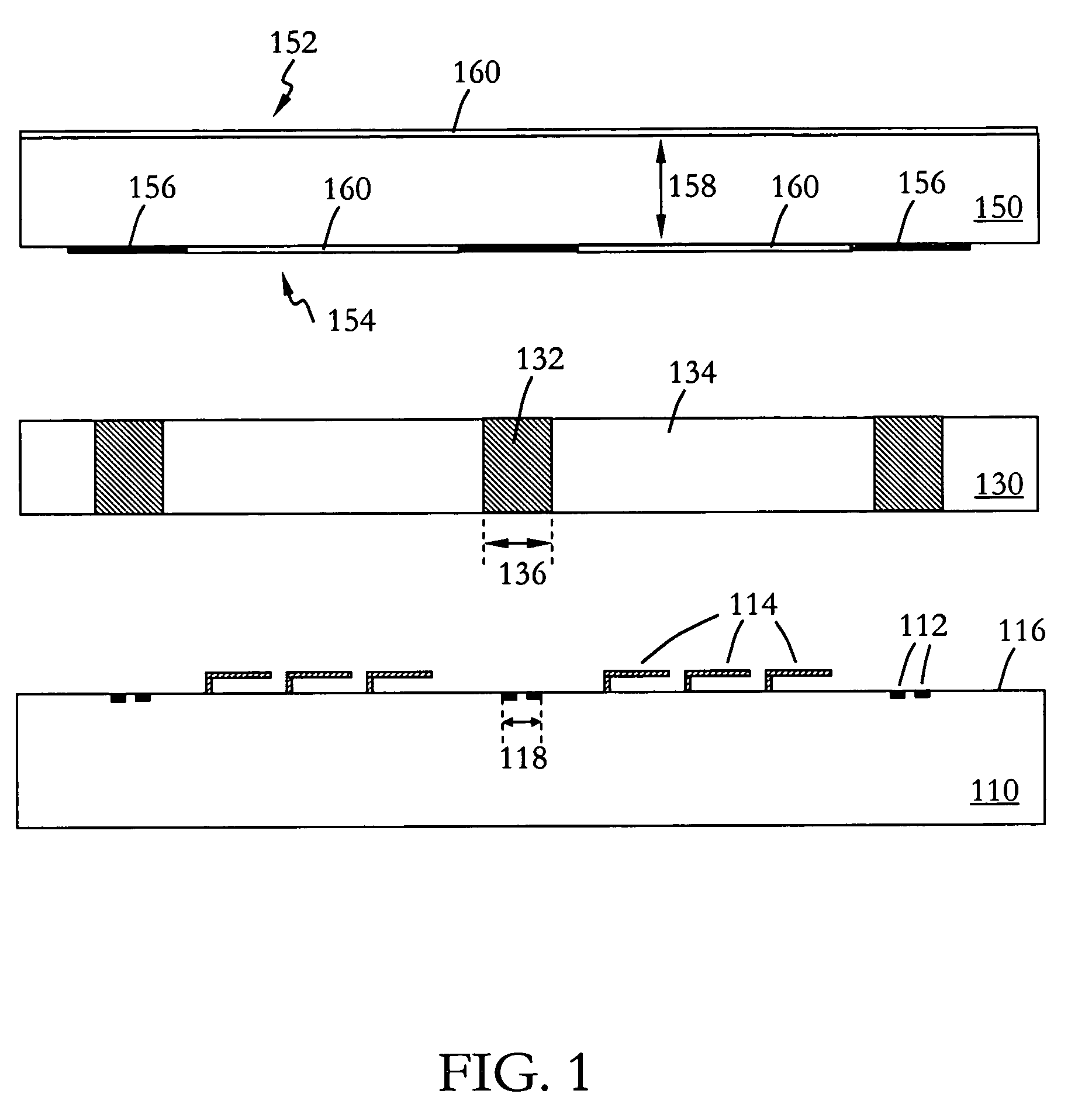

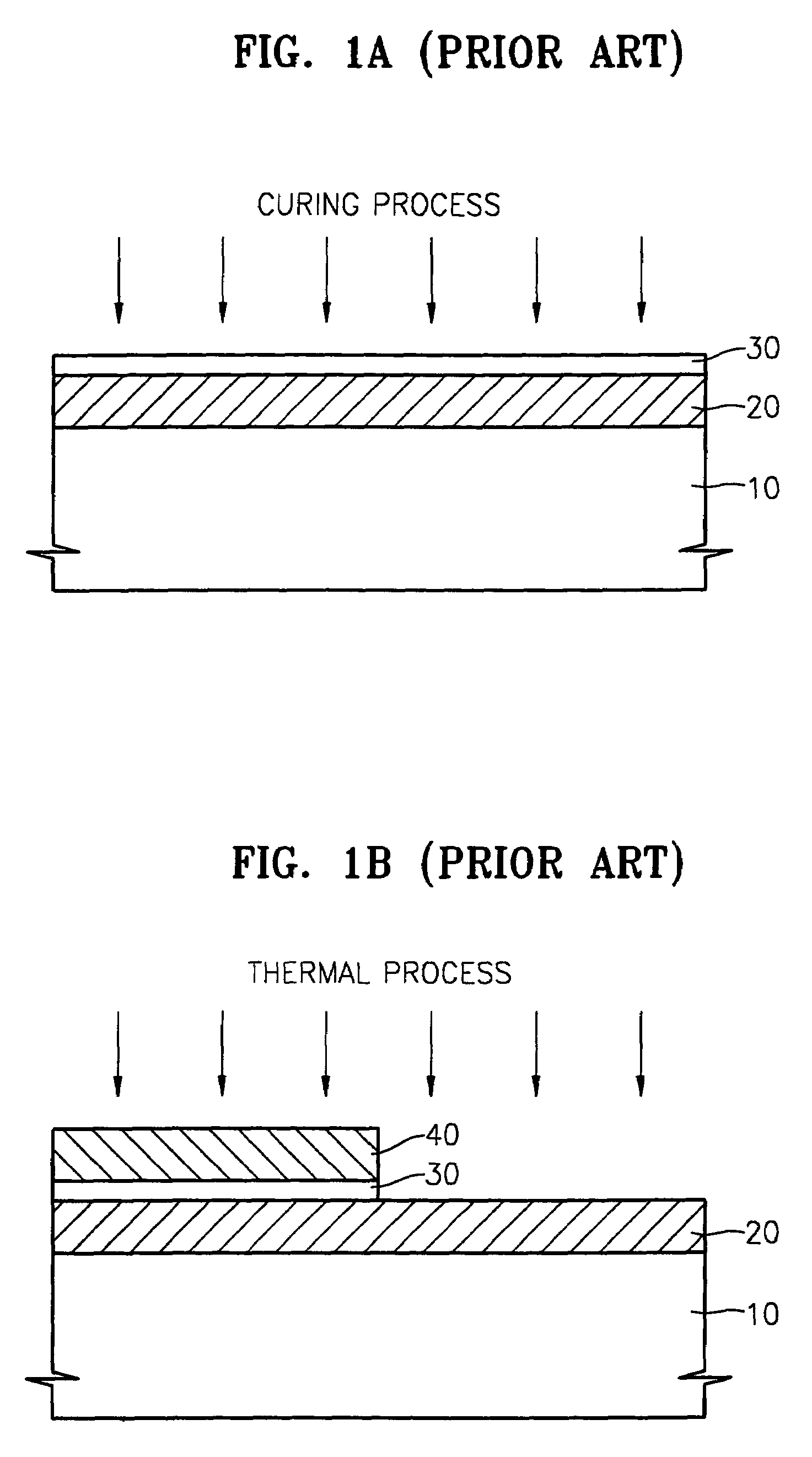

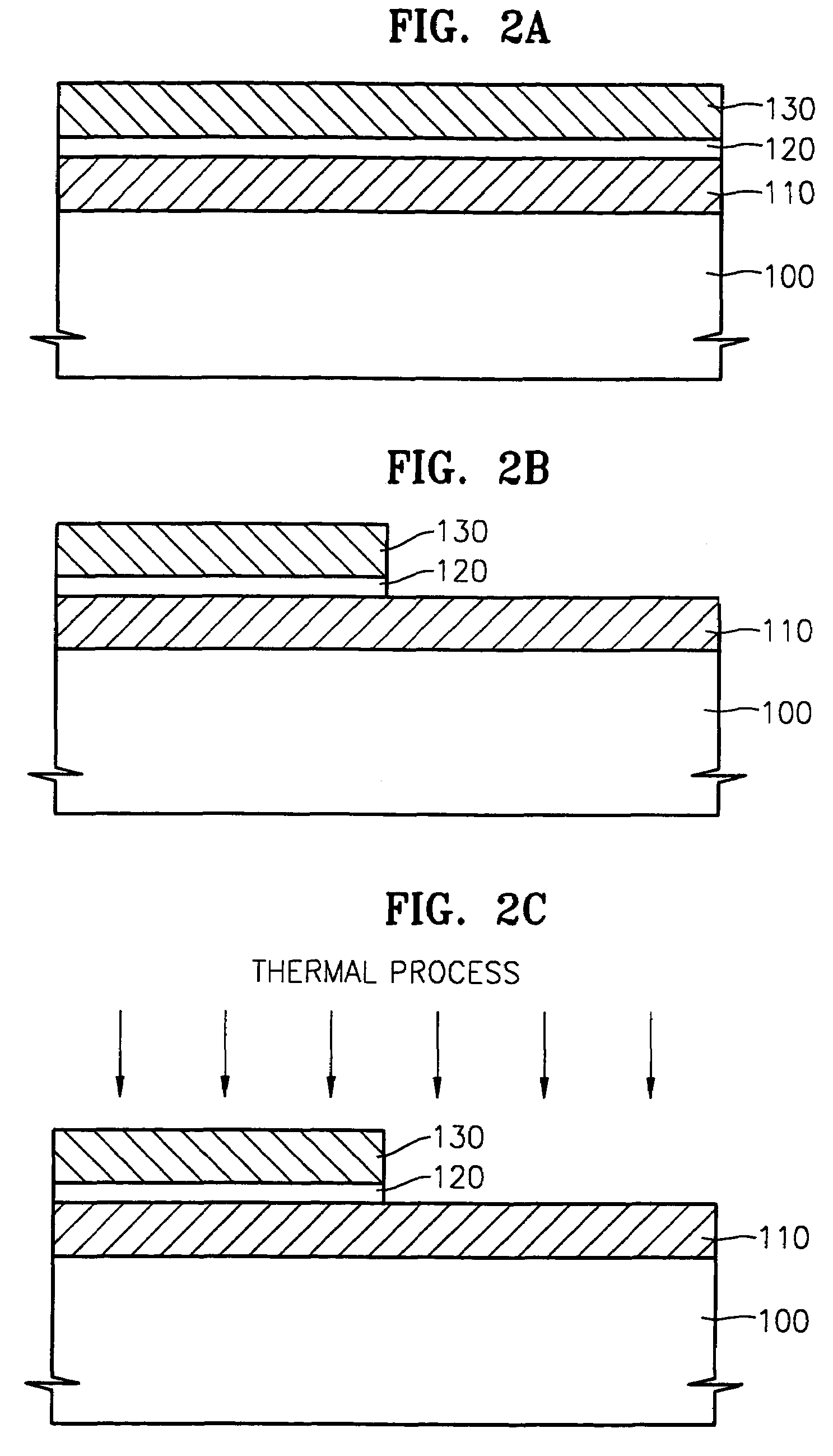

Methods for forming semiconductor devices including thermal processing

InactiveUS7172946B2Reduce interface stressSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsThermal treatment

Methods for fabricating semiconductor memory devices may include forming a first conductive layer for a first electrode on a semiconductor substrate, forming a dielectric layer on the first conductive layer, and forming a second conductive layer for a second electrode on the dielectric layer. Portions of the second conductive layer and the dielectric layer can be removed, and a thermal process can be performed on the second conductive layer and the dielectric layer. The thermal process can reduce interface stress between the second conductive layer and the dielectric layer and / or cure the dielectric layer. In addition, the dielectric layer may be maintained in an amorphous state during and after the thermal process.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for printing combustion chamber lining by using GRCop-42 spherical powder

ActiveCN111515391AImprove conductivityGood thermal expansionAdditive manufacturing apparatusTransportation and packagingCombustion chamberSand blasting

The invention discloses a method for printing a combustion chamber lining by using GRCop-42 spherical powder. The GRCop-42 alloy spherical powder comprises the following chemical components in percentage by weight: 2-4wt% of Cu, 2-4wt% of Cr and Nb. The method comprises the following steps of: 1) heating the spherical powder in vacuum, cooling the spherical powder along with a furnace, then performing ultrasonic vibration, screening the spherical powder and preparing to discharge the spherical powder into the furnace; 2) establishing a process model of a part, and slicing the model in layers to form a laser scanning path of each layer; 3) setting process parameters of powder laying and printing equipment, placing a rear bottom plate substrate, and fully laying the GRCop-42 spherical powderin a powder cylinder; 4) starting the equipment and starting printing and forming; 5) after laser scans one layer, descending a forming cylinder by one layer, then ascending the powder cylinder by one layer, laying a layer of copper powder on the processed layer surface by using the powder in the powder cylinder through a scraper, then descending the powder cylinder, and repeating the steps on each layer until the printing of the structure is finished; 6) performing annealing treatment; and 7) cutting and separating the structure from the substrate, and performing sand blasting on the surfaceof the structure. The method solves the problem of domestic application of advanced materials, and meets the preparation requirement of an aerospace copper alloy structure.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Multiple bore termination system

ActiveUS20060286837A1Economical and simpleEasy to installCouplings bases/casesClamped/spring connectionsFastenerEngineering

A cable termination housing for terminating a cable to one or more devices includes a bore for receiving a device mating portion, a component portion integrally formed within the housing, the component portion having a fastener that is slidable between a retracted position wherein fastener does not extend into the lug aperture of the cable assembly and an extended position wherein the fastener extends into the lug aperture. Preferably, the fastener is rotatable while in its extended position so as to couple with the device mating portion.

Owner:RICHARDS MFG CO INC

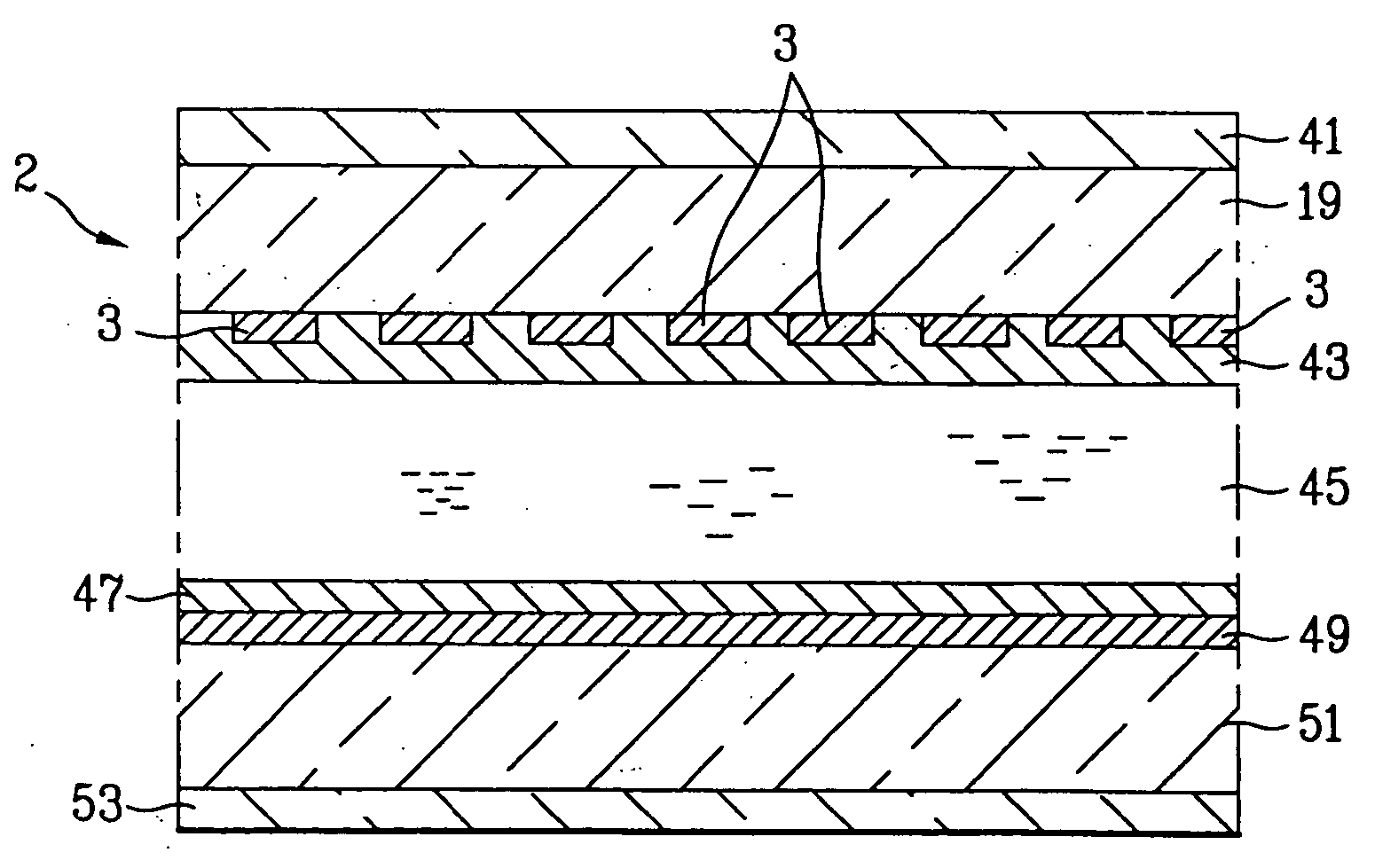

High aperture LCD with insulating color filters overlapping bus lines on active substrate

InactiveUS20050110013A1Reduce interface stressReduce cross-talk and coupling capacitanceTransistorSolid-state devicesActive-matrix liquid-crystal displayCapacitance

A high aperture active matrix liquid crystal display (AMLCD) includes pixel electrodes in respective pixels which overlap adjacent address lines. The color filters are formed on the active substrate in a manner such that the filters also overlap the address lines and function as an insulating layer between the pixel electrodes and address lines in the areas of overlap. Accordingly, line-pixel capacitances are reduced and the resulting AMLCD is easier to manufacture. The total number of process step in manufacturing is reduced, and plate-to-plate (active to passive plate) alignment is much easier and less important.

Owner:LG DISPLAY CO LTD

Solar selective absorbing coating and preparation method therefor

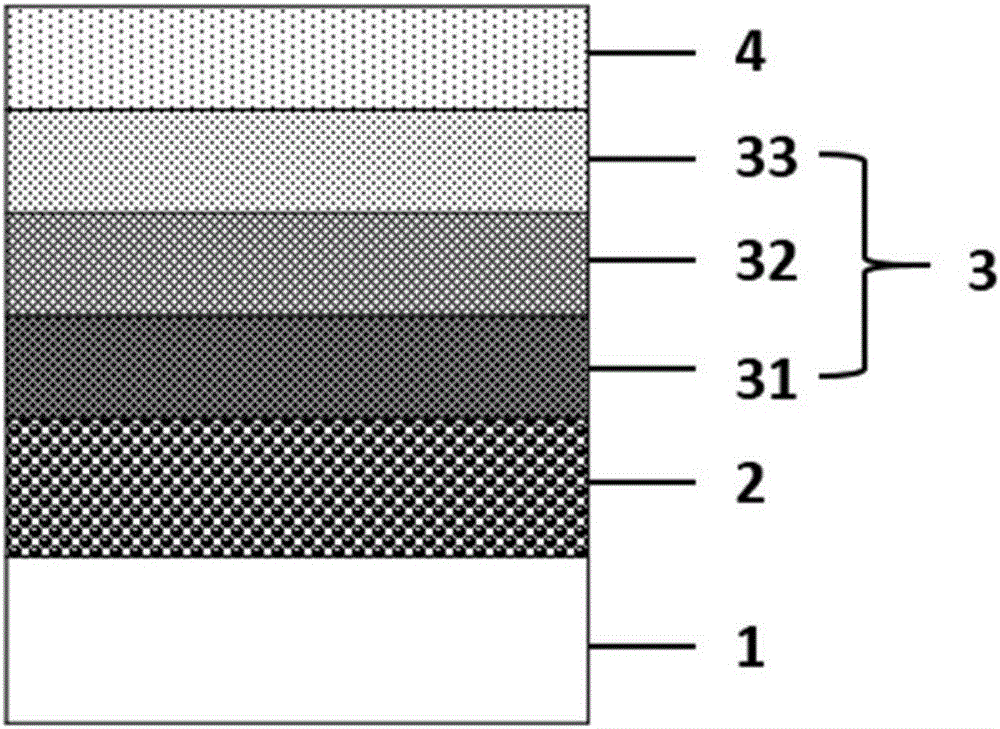

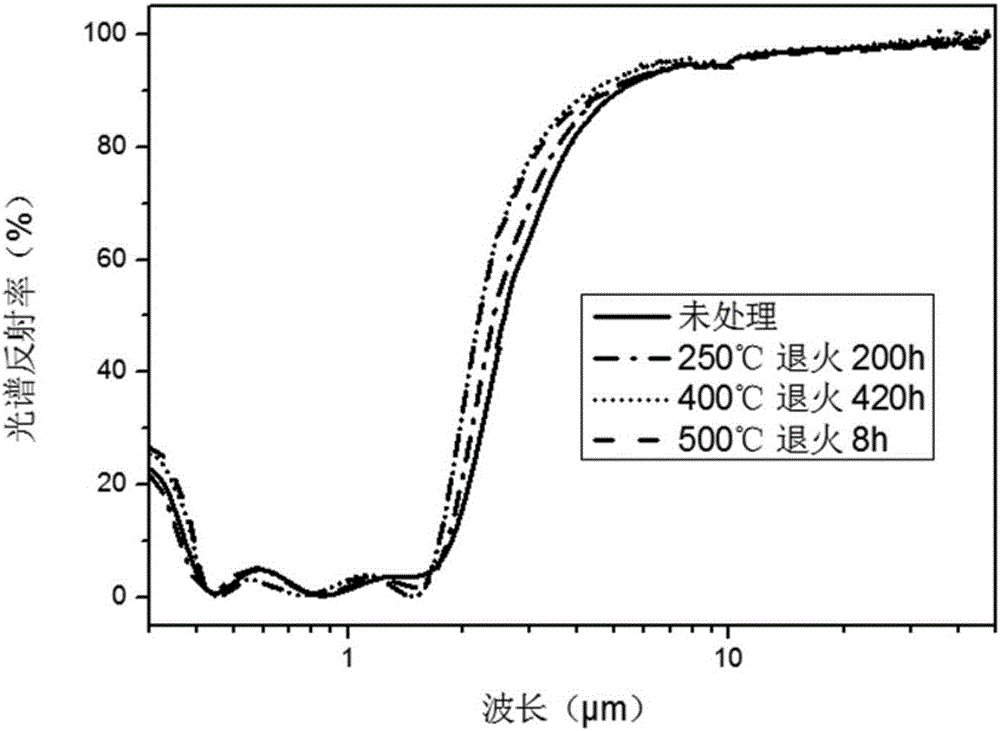

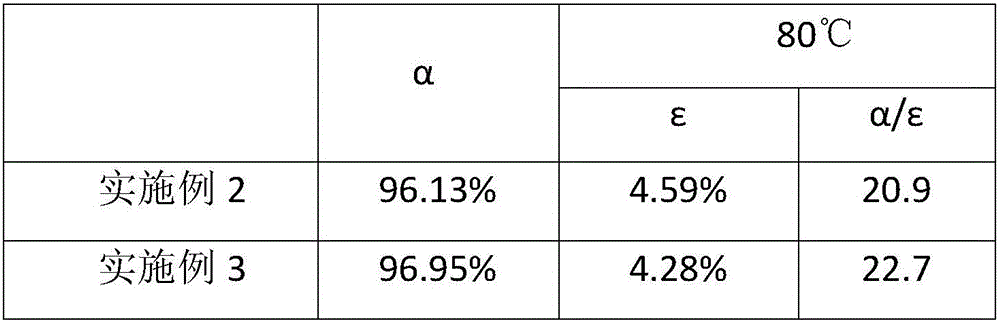

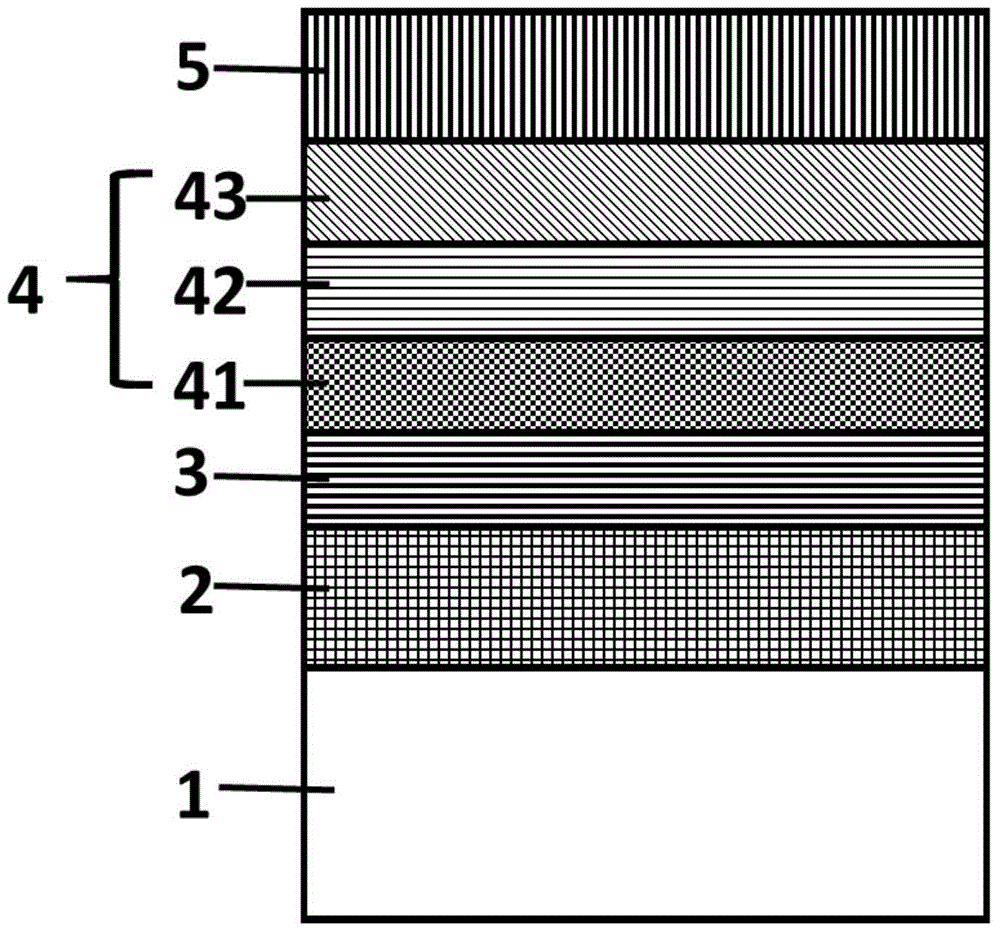

ActiveCN106288462AIncrease working temperatureImprove thermal stabilitySolar heat devicesVacuum evaporation coatingWorking temperatureReflective layer

The invention relates to a solar selective absorbing coating and a preparation method therefor. The coating successively comprises a substrate, an infrared reflective layer, an absorbing layer and an antireflection layer from a bottom layer to the surface, wherein the absorbing layer is composed of a first sub layer, a second sub layer and a third sub layer; the firsts sub layer and the second sub layer contain metal nitrides, the third sub layer is a metal oxynitride, the first sub layer is in contact with the infrared reflective layer, and the third sub layer is in contact with the antireflection layer. The preparation method comprises the following steps: depositing the infrared reflective layer on the substrate; depositing the absorbing layer on the infrared reflective layer; and depositing the antireflection layer on the absorbing layer. According to the metal nitride (oxynitride) solar selective absorbing coating provided by the invention, the working temperature of the metal nitride (oxynitride) solar selective absorbing coating is raised, and the coating is simple to prepare and is more suitable for scaled production.

Owner:CHINA BUILDING MATERIALS ACAD

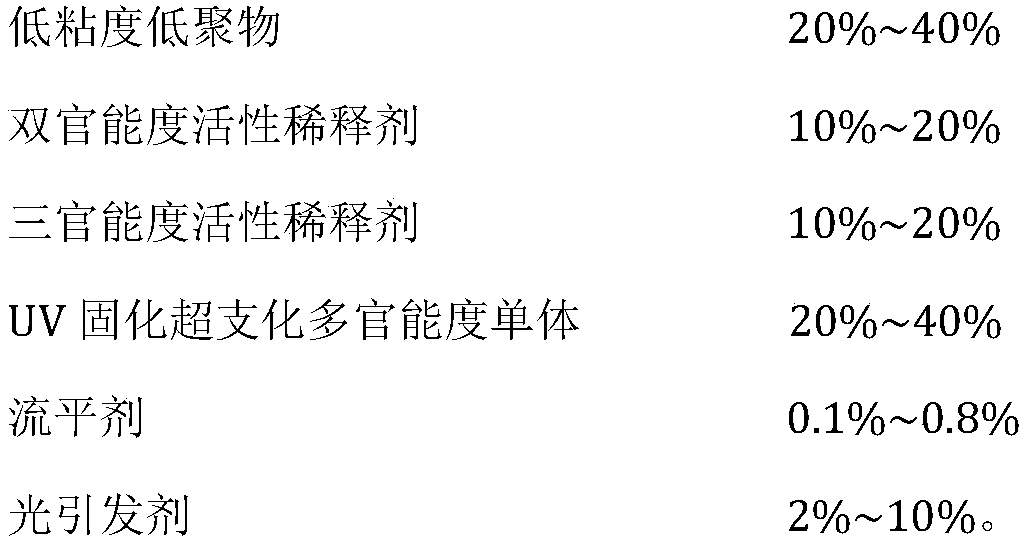

Solvent-free UV (ultraviolet) resin and application thereof

A solvent-free UV resin and application thereof belong to the technical field of environment-friendly paints. The solvent-free UV resin is composed of, by weight percentage, 20-40% low-viscosity oligomer, 10-20% of bifunctional active diluent, 10-20% of trifunctional active diluent, 20-40% of UV curing hyperbranched polyfunctional monomer, 0.1-0.8% of flatting agent and 2-10% of photoinitiator. The solvent-free UV resin can solve the problem VOC (volatile organic compounds) led by toxic organic solvent in UV curing paints.

Owner:TONGGUANG JIANGSU INFORMATION TECH CO LTD +1

Double-face heat-resistant polycrystalline diamond composite sheet and preparing technology thereof

ActiveCN108950560AHigh particle strengthHigh bonding strengthTransportation and packagingMetal-working apparatusPowder mixtureHeat resistance

Owner:ZHONGNAN DIAMOND CO LTD

Solar selective absorbing coating and preparation method thereof

ActiveCN105091377AImprove thermal stabilityImprove absorption rateSolar heat devicesVacuum evaporation coatingRadianceThermal stability

The invention provides a solar selective absorbing coating. The solar selective absorbing coating is sequentially provided with a substrate, an infrared reflection layer, a transition layer, a composite absorbing layer and an antireflection layer from the bottom layer to the surface. Besides, the transition layer is arranged to be made of one or more of CrNx, yCrN*(1-y)Cr2O3, ySi3N4*(1-y)SiO2, yAlN*(1-y)Al2O3 and yTi3N4*(1-y)TiO2, wherein x is larger than 1 and smaller than 1.5, and y is larger than 0 and smaller than 1. Thus, the coating can effectively prevent mutual diffusion between the infrared reflection layer and the absorbing layer, and mutual diffusion among the infrared reflection layer, a diffusion impervious layer and the absorbing layer in the solar selective absorbing coating comprising the diffusion impervious layer The thermal stability of the solar selective absorbing coating is improved, so that the solar selective absorbing coating still has high solar spectral absorptivity and low infrared radiance under the atmospheric condition of 400 DEG C. The solar selective absorbing coating has the good thermal stability and excellent spectral selectivity.

Owner:CHINA BUILDING MATERIALS ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com