Solar selective absorbing coating and preparation method therefor

An absorbing coating and selective technology, which is applied in solar thermal power generation, coatings, solar thermal devices, etc., can solve problems such as the need to increase the working temperature, the deterioration of coating performance, and the increase in emissivity, so as to improve the absorption and heat dissipation. Effects of stability, reduced interfacial stress, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

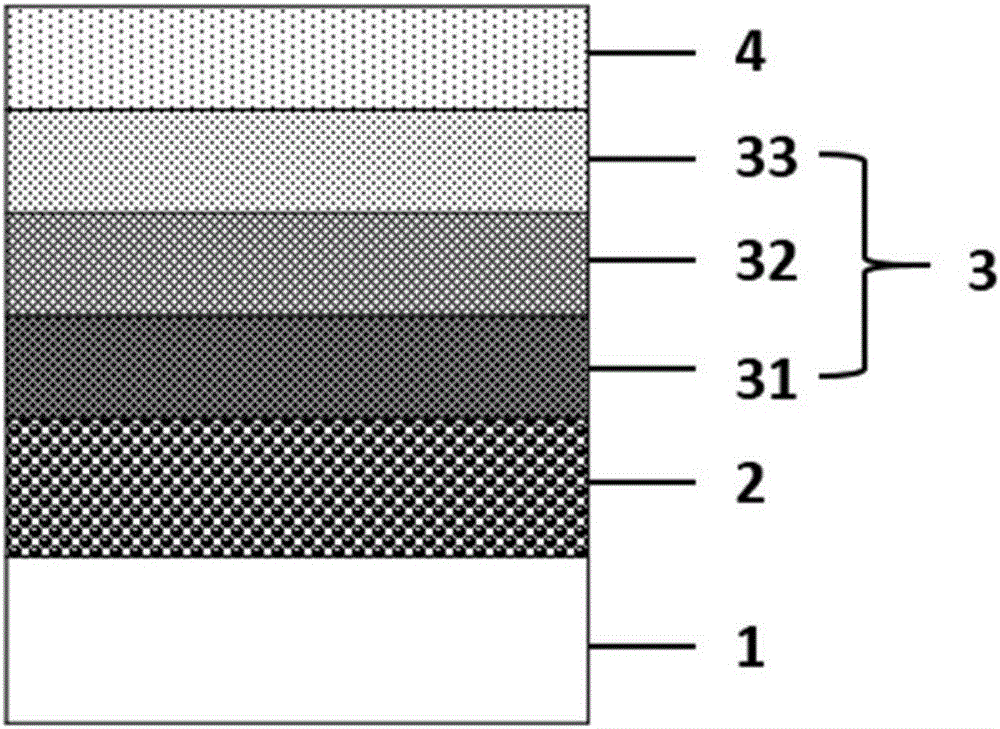

[0035] This embodiment provides a solar selective absorbing coating, the coating includes a substrate, an infrared reflection layer, an absorbing layer and an anti-reflection layer from the bottom layer to the surface in sequence, and the absorbing layer is composed of a first sublayer, a second The second sublayer and the third sublayer are composed of the first sublayer and the second sublayer containing metal nitride, the third sublayer is metal oxynitride, and the first sublayer of the absorption layer is metal nitride , The refractive index and extinction coefficient of the metal nitride of the second sublayer and the metal oxynitride of the third sublayer all decrease successively, the first sublayer is in contact with the infrared reflection layer, and the third sublayer is in contact with the antireflection layer . The first sublayer is incompletely nitrided metal nitride, the second sublayer is metal nitride, and the third sublayer is metal nitride oxide. The incompl...

Embodiment 2

[0038] This embodiment provides a solar selective absorbing coating, its structure is as follows figure 1 As shown, wherein, 1 is the substrate, 2 is the infrared reflection layer, 3 is the absorption layer, 31 is the first sublayer, 32 is the second sublayer, 33 is the third sublayer, and 4 is the antireflection layer.

[0039] Wherein, the substrate is an aluminum substrate with a thickness of 0.5 mm.

[0040] The infrared reflective layer is an Al layer with a thickness of 200nm.

[0041] The absorption layer includes a first sublayer, a second sublayer and a third sublayer from bottom to top, and the first sublayer is CrN x , wherein, 0y , wherein, 1≤y≤1.5, said y is the atomic number ratio of N element to Cr element; said third sublayer is CrN m o n , wherein, 0<m≤1.5, 0<n≤2, the m is the atomic number ratio of the N element to the Cr element, and the n is the atomic number ratio of the O element to the Cr element. The total thickness of the absorption layer is 125nm,...

Embodiment 3

[0059] This embodiment provides a solar selective absorbing coating, its structure is as follows figure 1 As shown, wherein, 1 is the substrate, 2 is the infrared reflection layer, 3 is the absorption layer, 31 is the first sublayer 1, 32 is the second sublayer, 33 is the third sublayer, and 4 is the antireflection layer. Wherein, the substrate is a glass sheet with a thickness of 6 mm. The infrared reflective layer is an Al layer with a thickness of 100 nm.

[0060] The absorption layer includes a first sublayer, a second sublayer and a third sublayer from bottom to top, and the first sublayer is CrN x , wherein, 0y , wherein, 1≤y≤1.5, said y is the atomic number ratio of N element to Cr element; said third sublayer is CrN m o n , wherein, 0<m≤1.5, 0<n≤2, the m is the atomic number ratio of the N element to the Cr element, and the n is the atomic number ratio of the O element to the Cr element. The total thickness of the absorption layer is 120nm, wherein the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com