Water-circulating-type thermal energy comprehensive utilization thermal management system for electric vehicle

A thermal management system and technology of electric vehicles, applied in the field of thermal management systems for comprehensive utilization of water circulation heat energy, can solve problems such as insufficient heating and cooling capacity, and achieve easy and flexible layout, large air intake, and high system efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

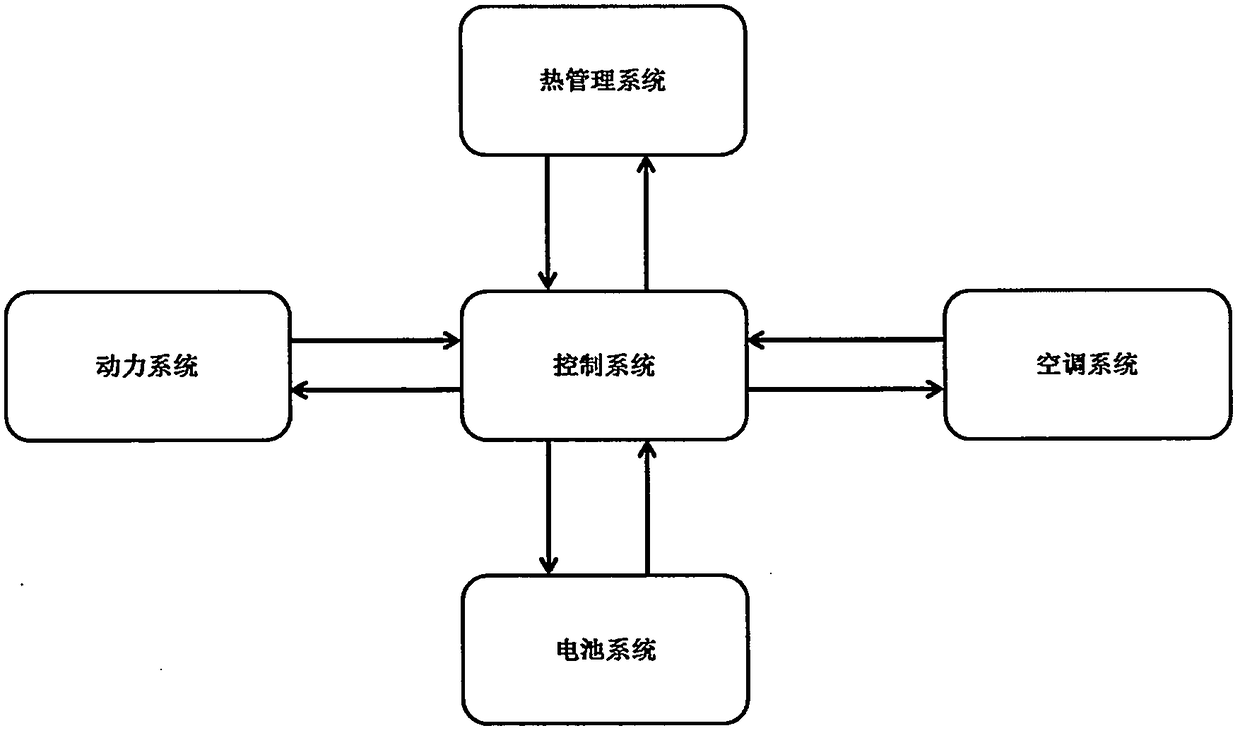

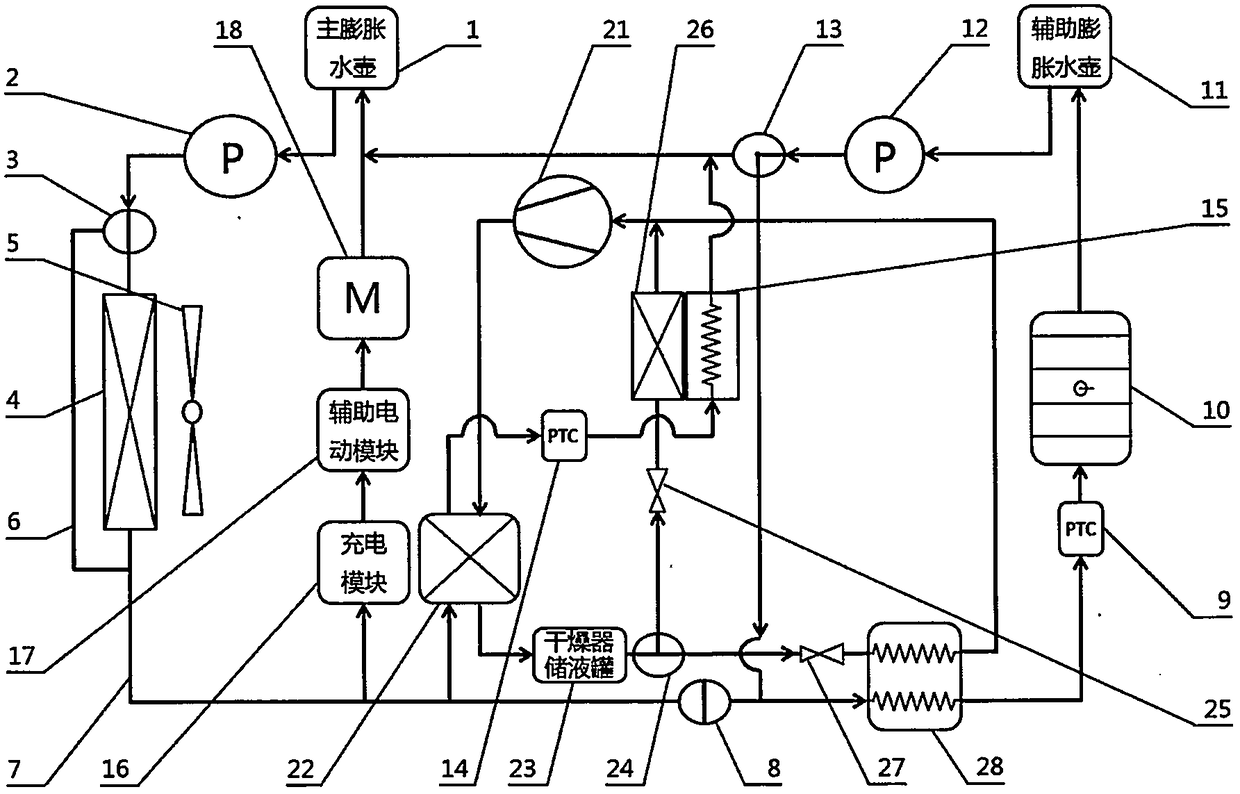

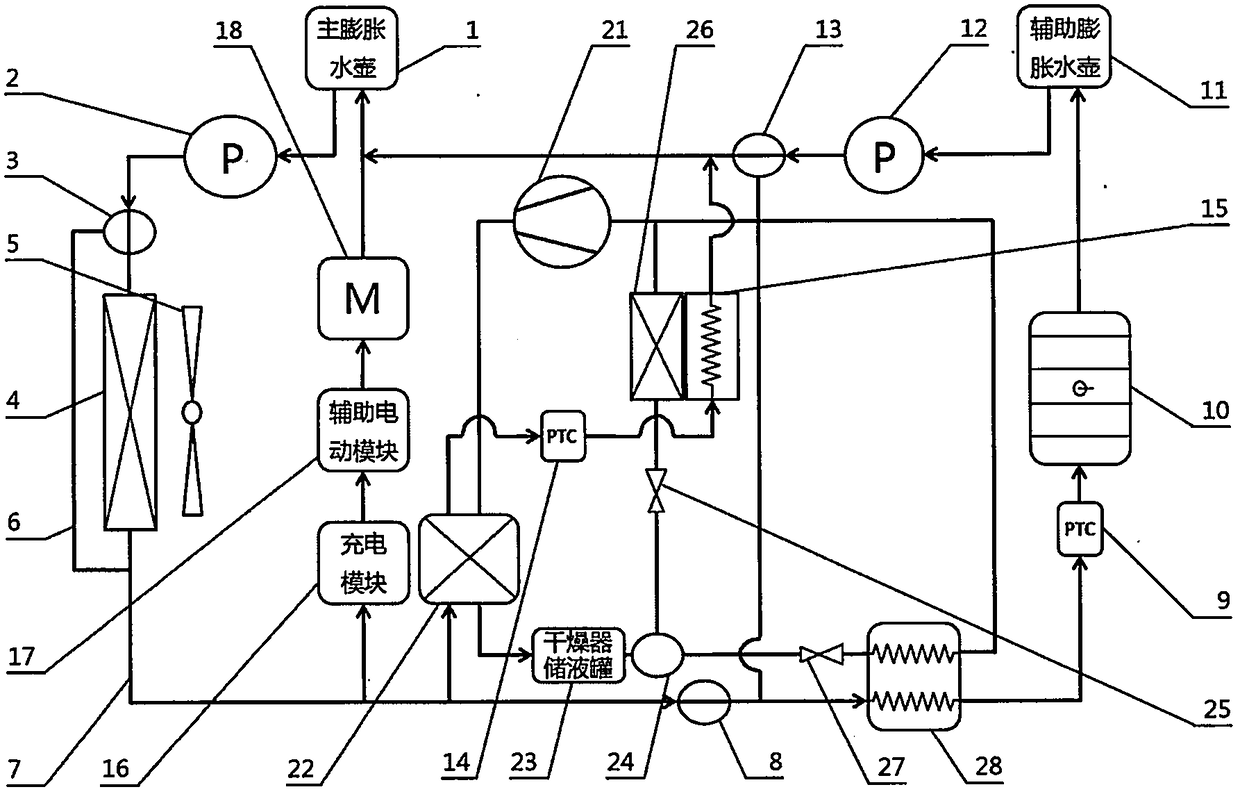

[0046] A water circulation thermal energy comprehensive utilization thermal management system for electric vehicles, which is applied to electric vehicles, to meet the heat dissipation and cooling requirements of electric vehicles under various operating conditions, and to achieve cooling by circulating water in the circulation loop. The heat generated by the various parts of the vehicle is comprehensively utilized. The working mode of the thermal management system is mainly composed of four modes, which are high-temperature cooling mode, medium-temperature cooling mode, medium-low temperature heating and dehumidification mode, and low-temperature heating mode. That is, when the external temperature is high, the thermal management system can It works in high-temperature cooling mode to cool the passenger compartment and battery system; when the external temperature is moderate, the thermal management system can work in the medium-temperature cooling mode; when the external temp...

Embodiment 2

[0071] This embodiment further adds a refrigerant branch circuit, that is, the third branch circuit, on the basis of the first embodiment above, and transforms the expansion valve conversion three-way valve 24 in the first embodiment into an expansion valve conversion four-way valve 24, The rest of the structure of the thermal management system remains unchanged. The refrigerant in the third branch of the refrigerant returns to the electronic compressor 21 via the heat pump electronic expansion valve 29 and the heat pump evaporator 30 through the self-expansion valve conversion four-way valve 24. The heat pump evaporator 30 is arranged side by side with the radiator 4, and cooling Fan 5 cools it. Among them, the expansion valve switching four-way valve 24 has four passages, the first passage is connected to the liquid storage tank 23 of the dryer, the second passage is connected to the electronic expansion valve 27 of the water-cooled heat exchanger, the third passage is conne...

Embodiment 3

[0086] This embodiment has basically the same structure as Embodiment 1 and Embodiment 2, except that the electronic expansion valve 25 for the evaporator, the electronic expansion valve 27 for the water-cooled heat exchanger and the electronic expansion valve 29 for the heat pump are all electronic expansion valves with a cut-off function. The expansion valve, thus, the expansion valve conversion three-way valve 24 or the expansion valve conversion four-way valve 24 can be omitted, and the cost can be further saved.

[0087] At this time, when the control system controls the thermal management system to switch between high-temperature cooling mode, medium-temperature cooling mode, medium-low temperature heating and dehumidification mode, low-temperature heating mode, and pure heat pump heating mode, the expansion valve will no longer switch The three-way valve 24 or the expansion valve conversion four-way valve 24 controls the pipeline communication between the refrigerant and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com