Patents

Literature

695results about How to "Reduce output voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

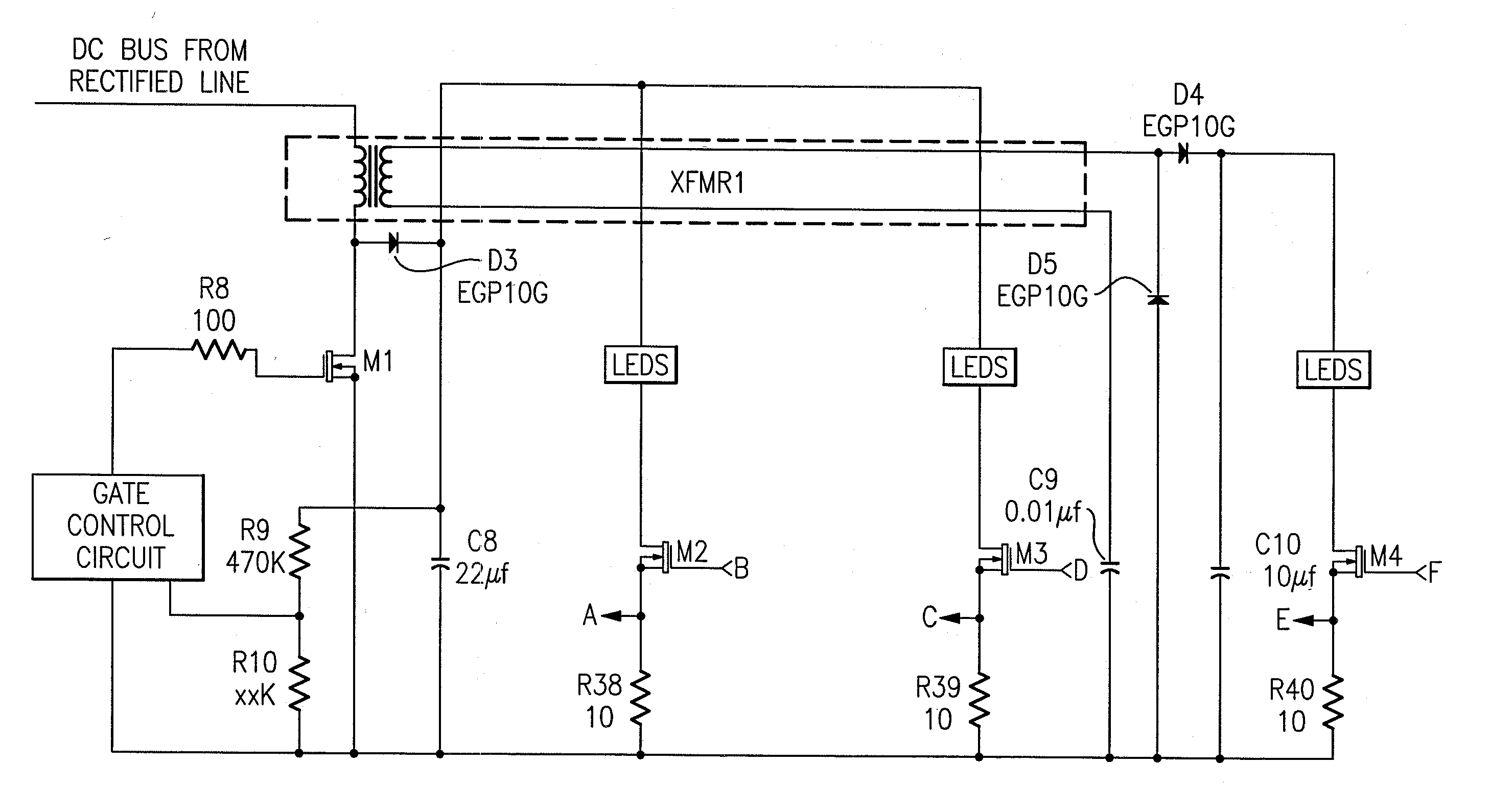

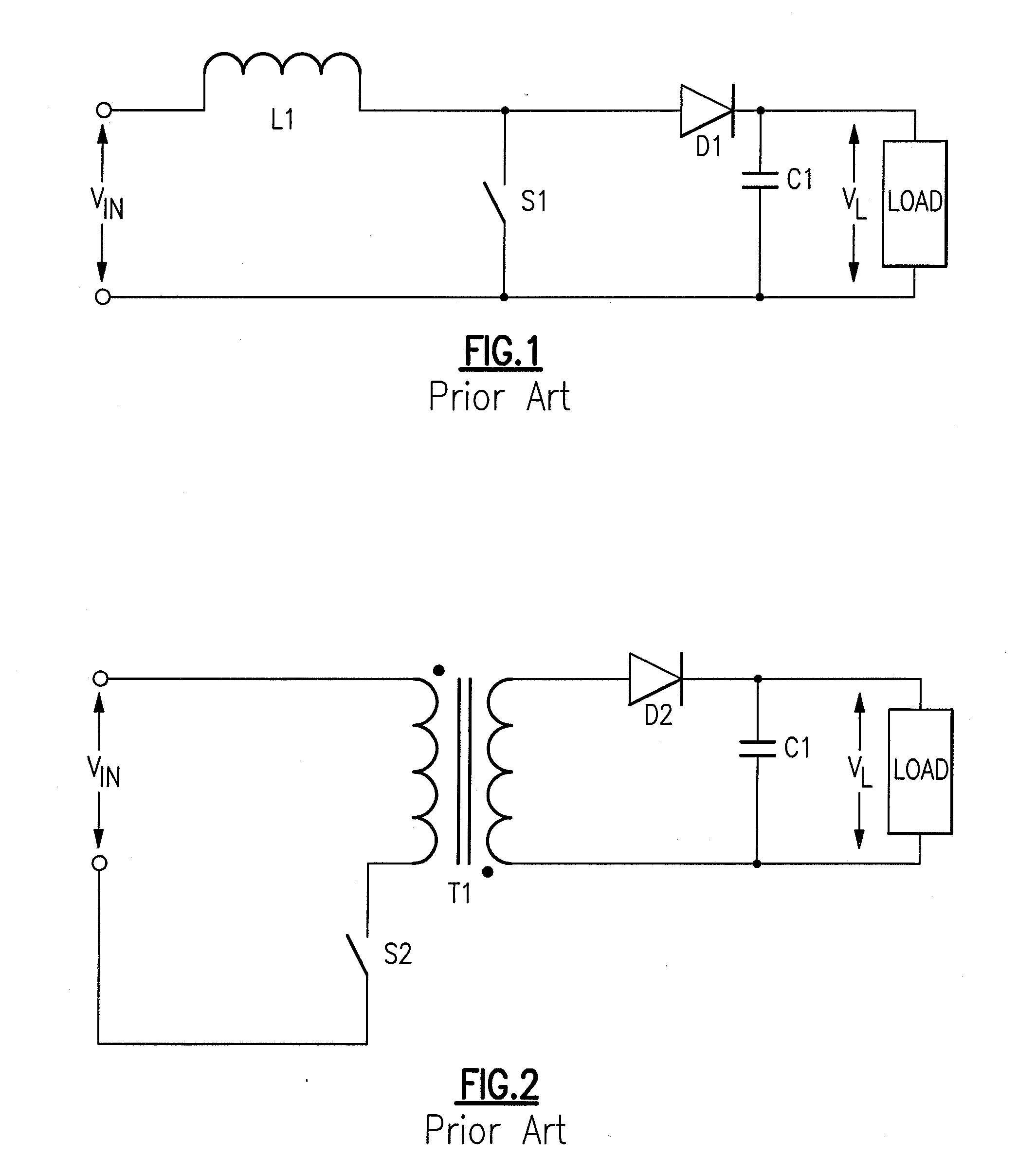

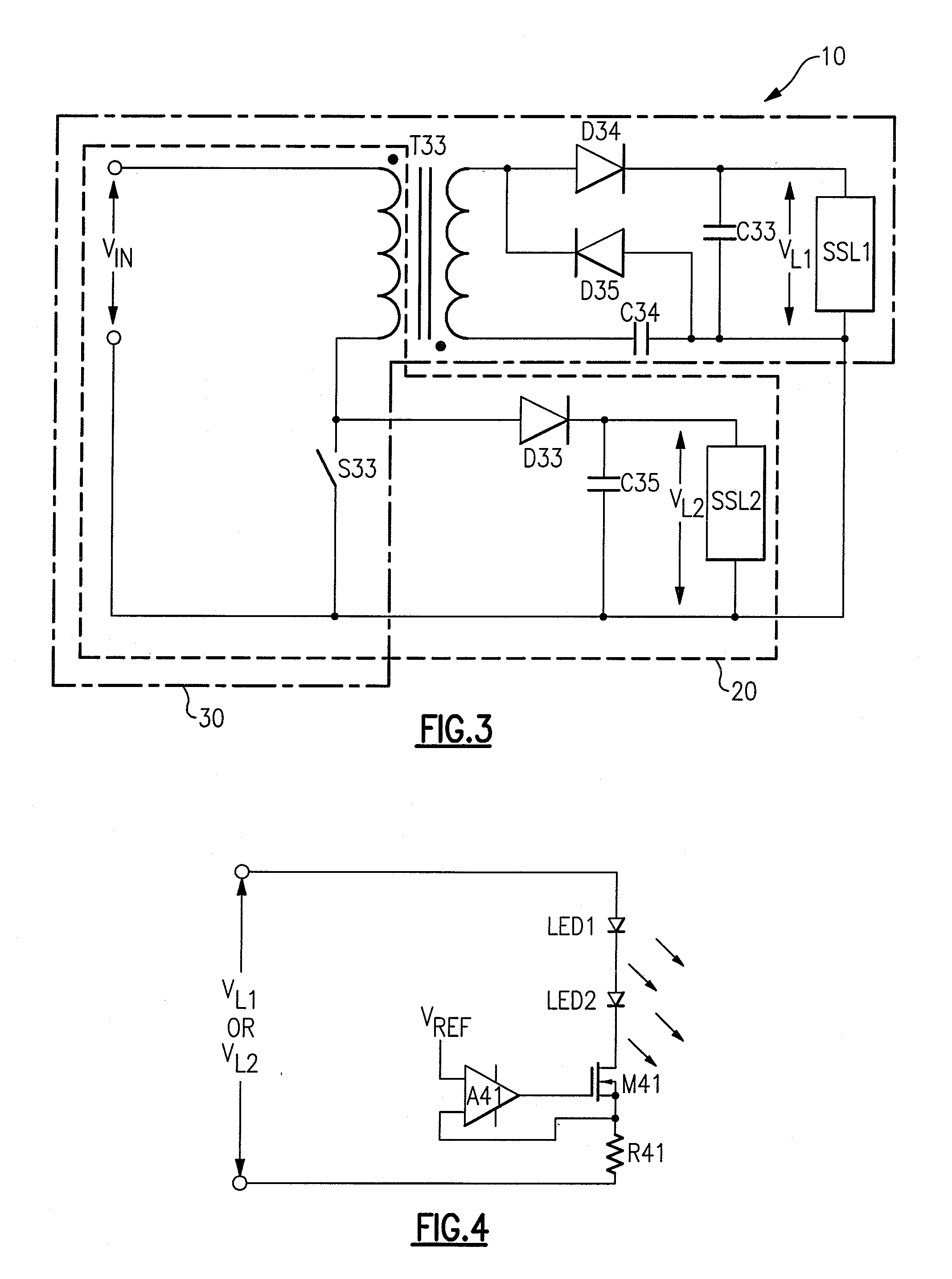

Circuitry for supplying electrical power to loads

ActiveUS20080088248A1Consumes spaceIncrease lossDc network circuit arrangementsDc-dc conversionMOSFETTransformer

A power supply, comprising a boost converter which provides voltage to a first load, and a flyback converter which provides voltage to a second load and which utilizes an inductive element of the boost converter as a primary winding of a transformer of the flyback converter. Also, a power supply comprising a MOSFET which is disposed between solid state elements and a second reference potential and which controls current flowing through the solid state elements. Also, a circuit comprising a transformer, a first circuit portion comprising the primary winding of the transformer and a second circuit portion comprising the secondary winding of the transformer. Also, a power supply comprising means for using a common transformer for providing a boost converter and a flyback converter. Also, a power supply comprising a transformer, means for providing a boost converter utilizing the transformer, and means for providing a flyback converter utilizing the transformer.

Owner:IDEAL IND LIGHTING LLC

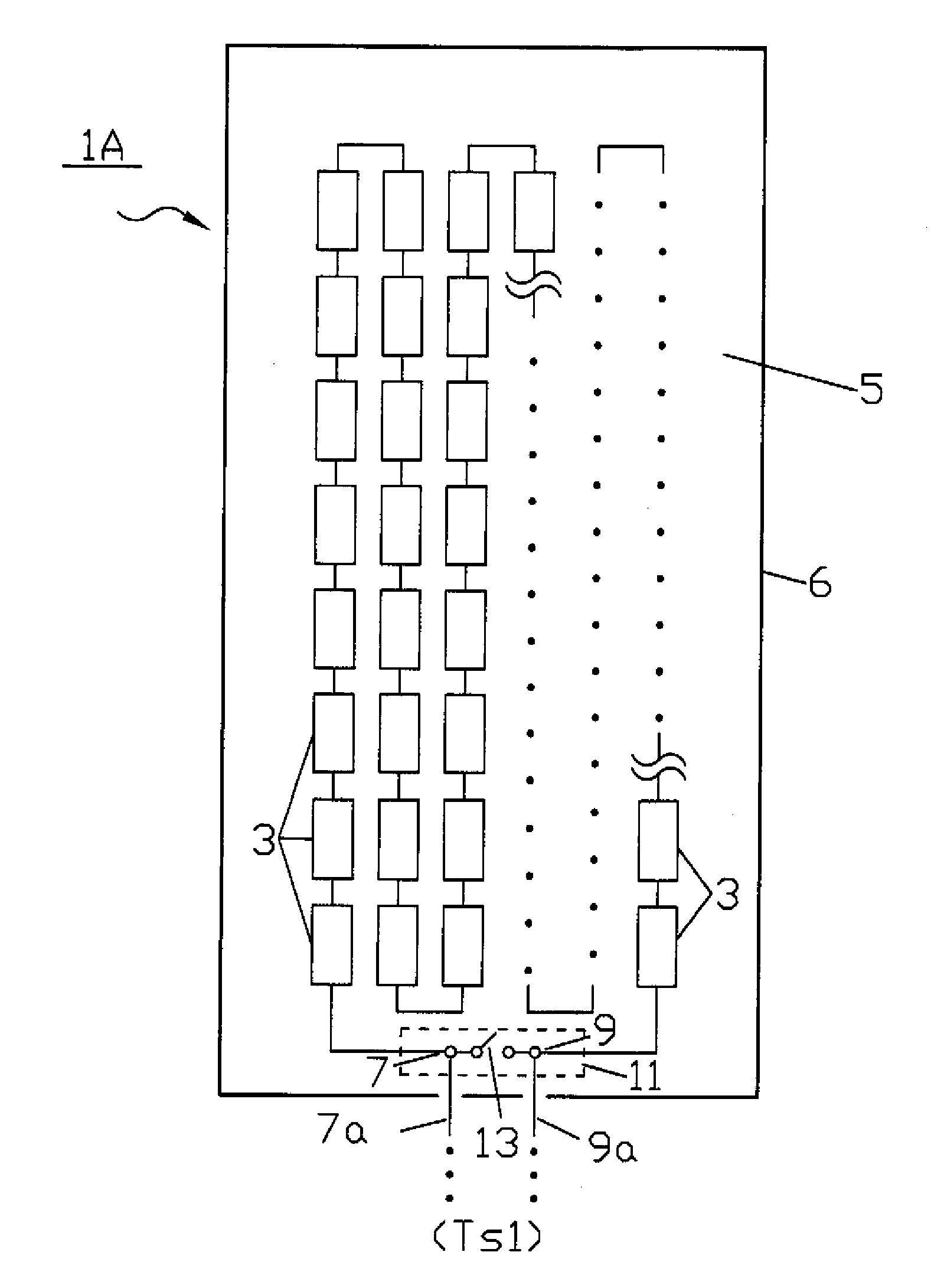

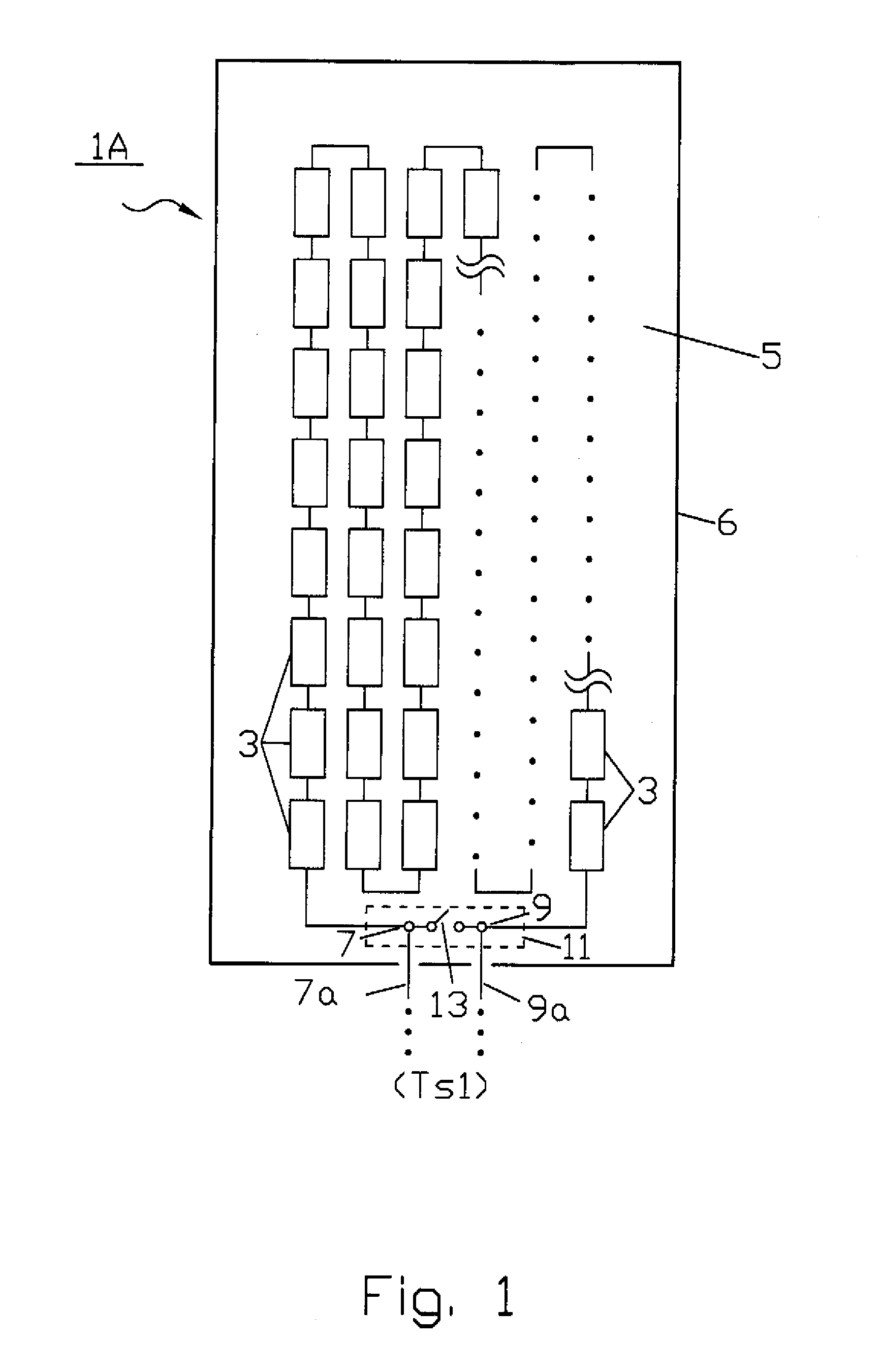

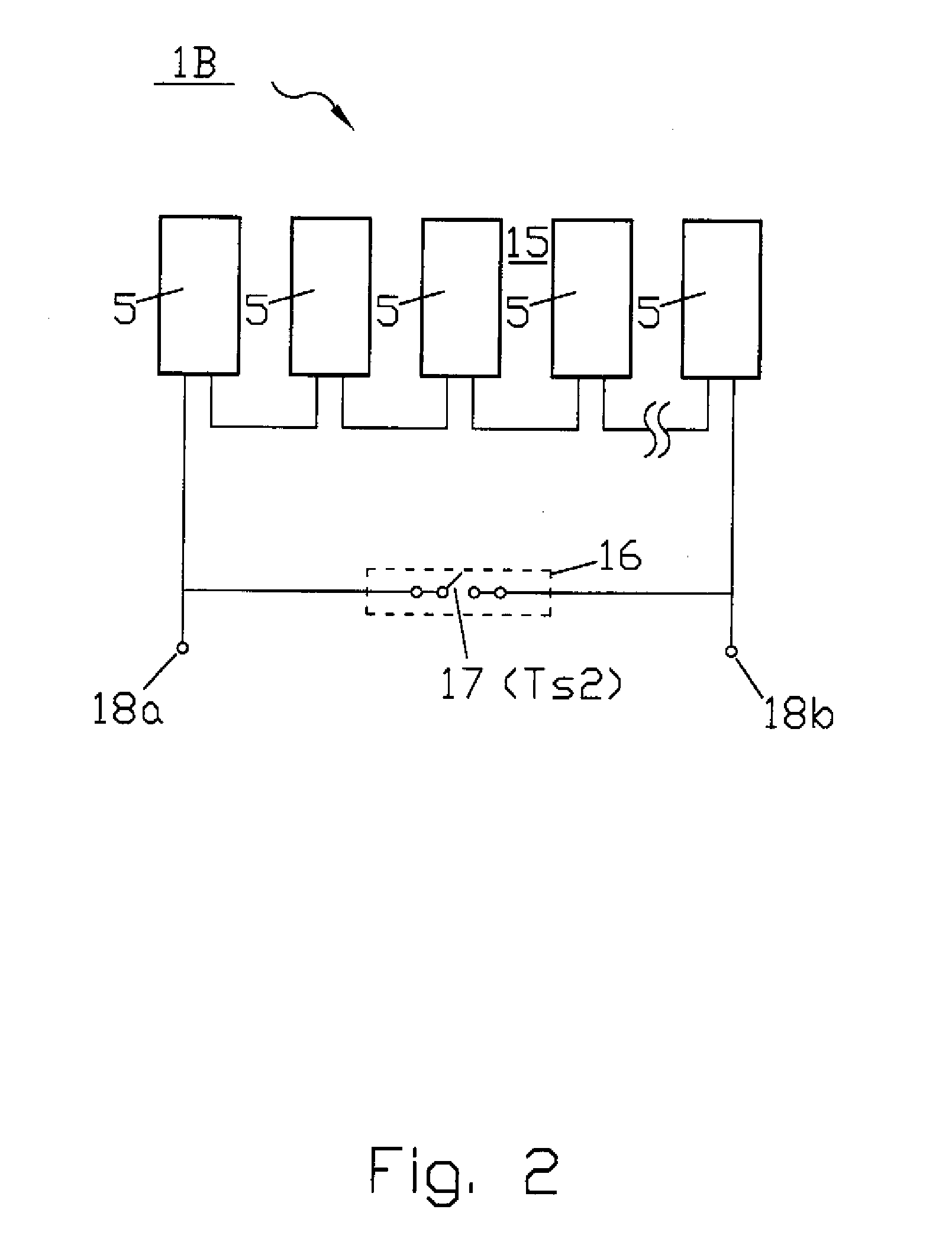

Photovoltaic generator with thermo switch element

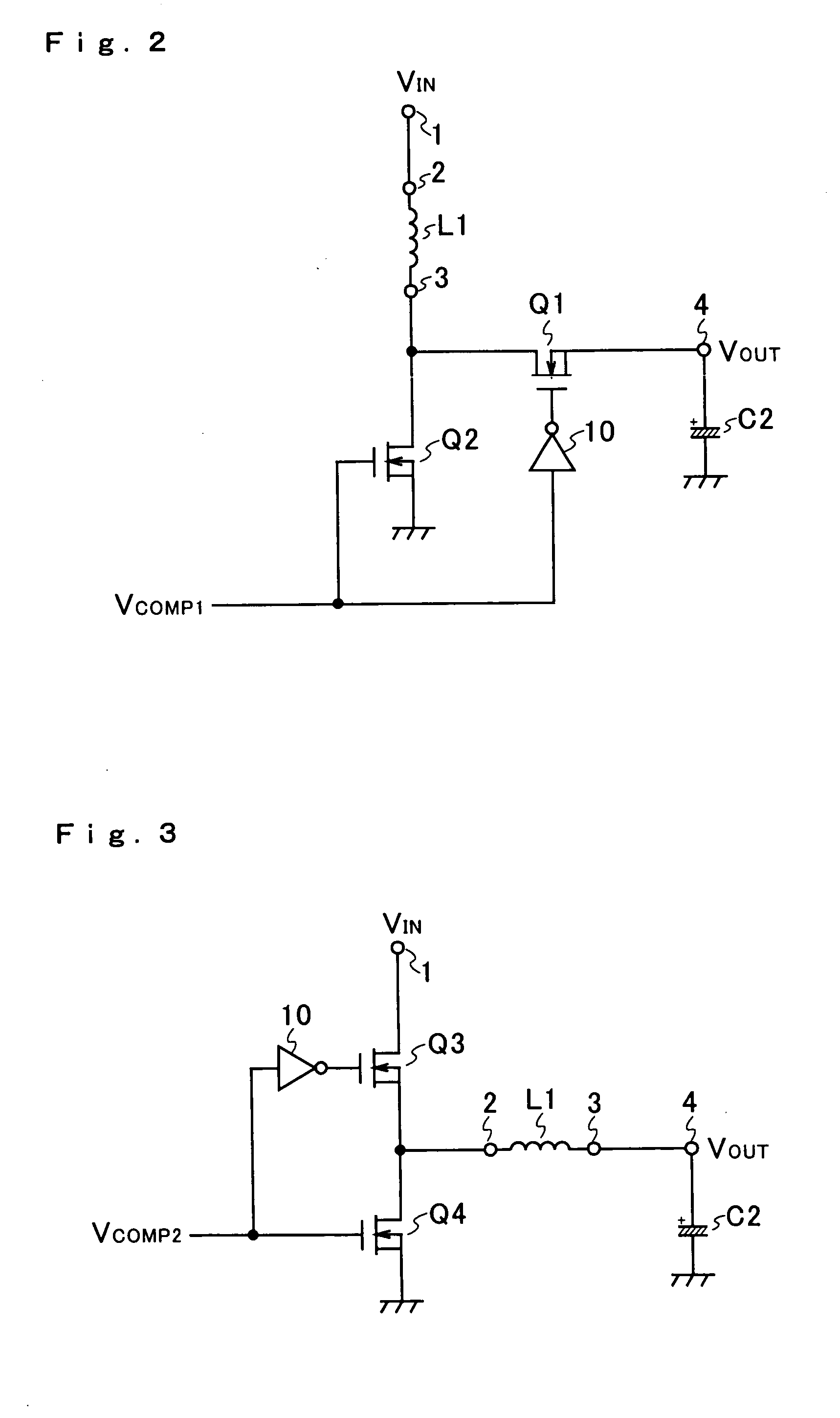

InactiveUS20060231132A1Reduce output voltageReduce riskPV power plantsPhotovoltaic energy generationElectricityPhotovoltaic generator

A photovoltaic system includes a photovoltaic generator, and a thermo switch which reduces an output voltage of the photovoltaic generator in response to a trigger temperature. The photovoltaic generator may include a plurality of photovoltaic cells which are arranged in series to form a photovoltaic module. The module has ends, each of which having an electric module terminal pole, wherein the thermo switch is rendered operative in response to the trigger temperature to short-circuit the module terminal poles and to thereby reduce the output voltage generated by the photovoltaic generator.

Owner:NEUSSNER THOMAS

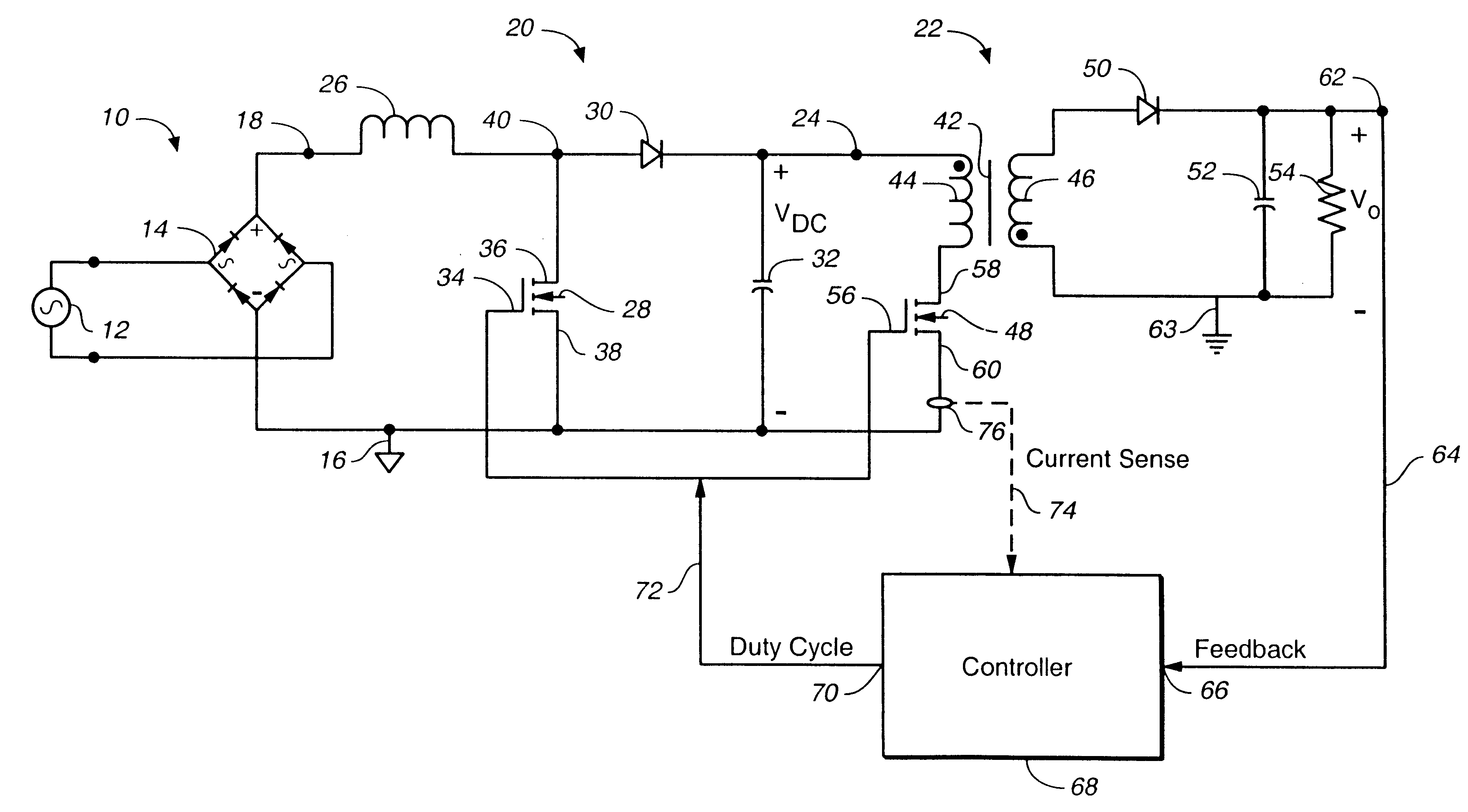

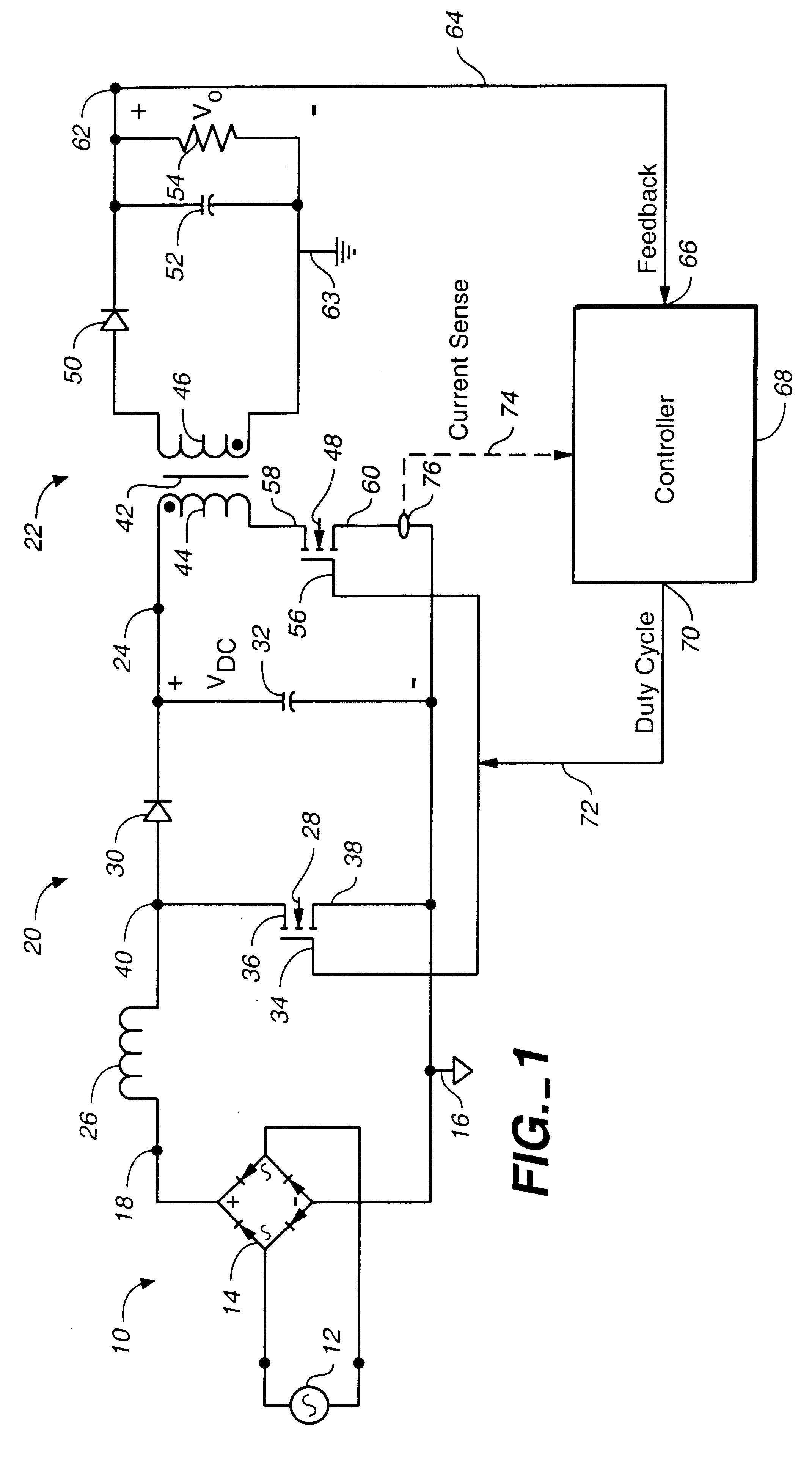

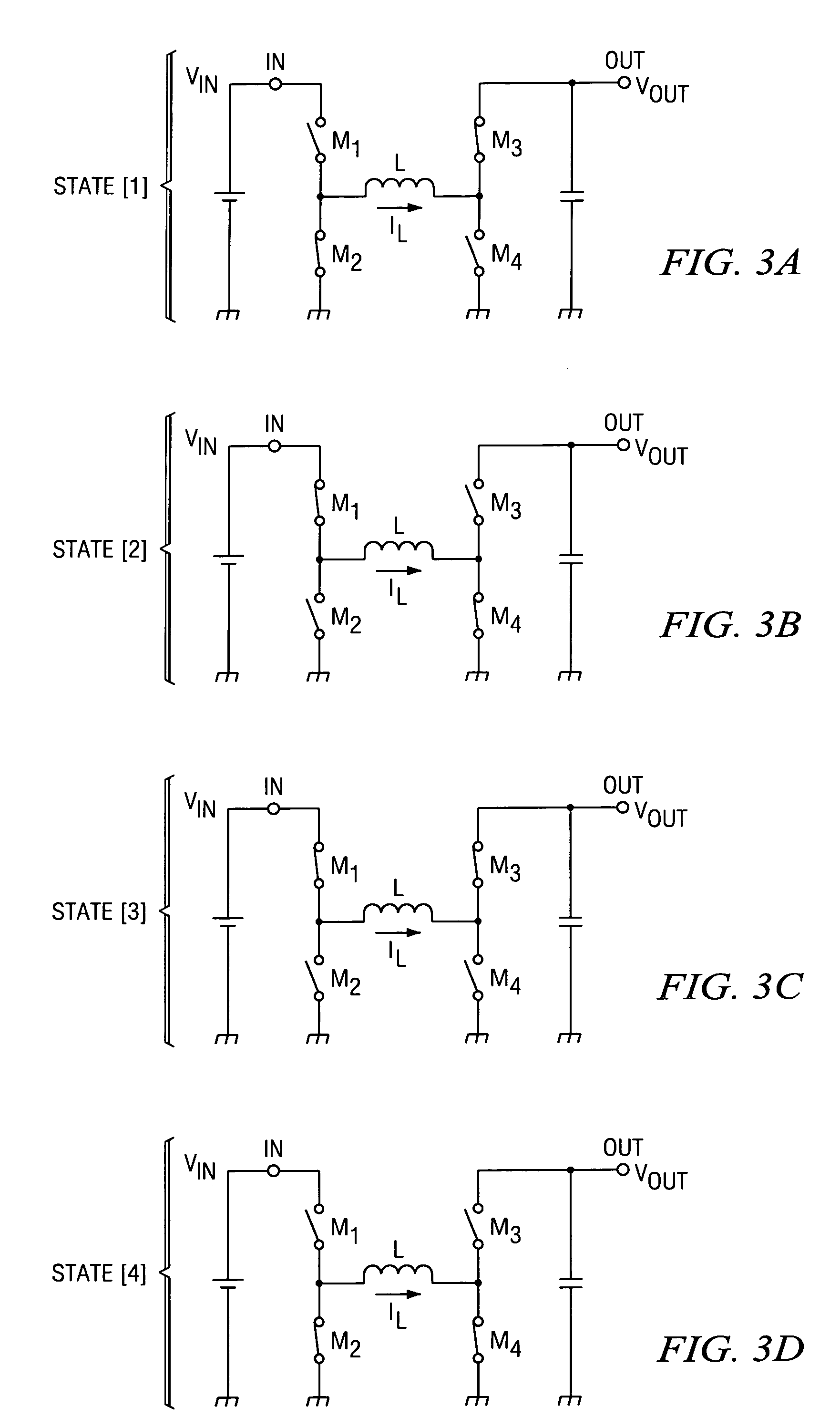

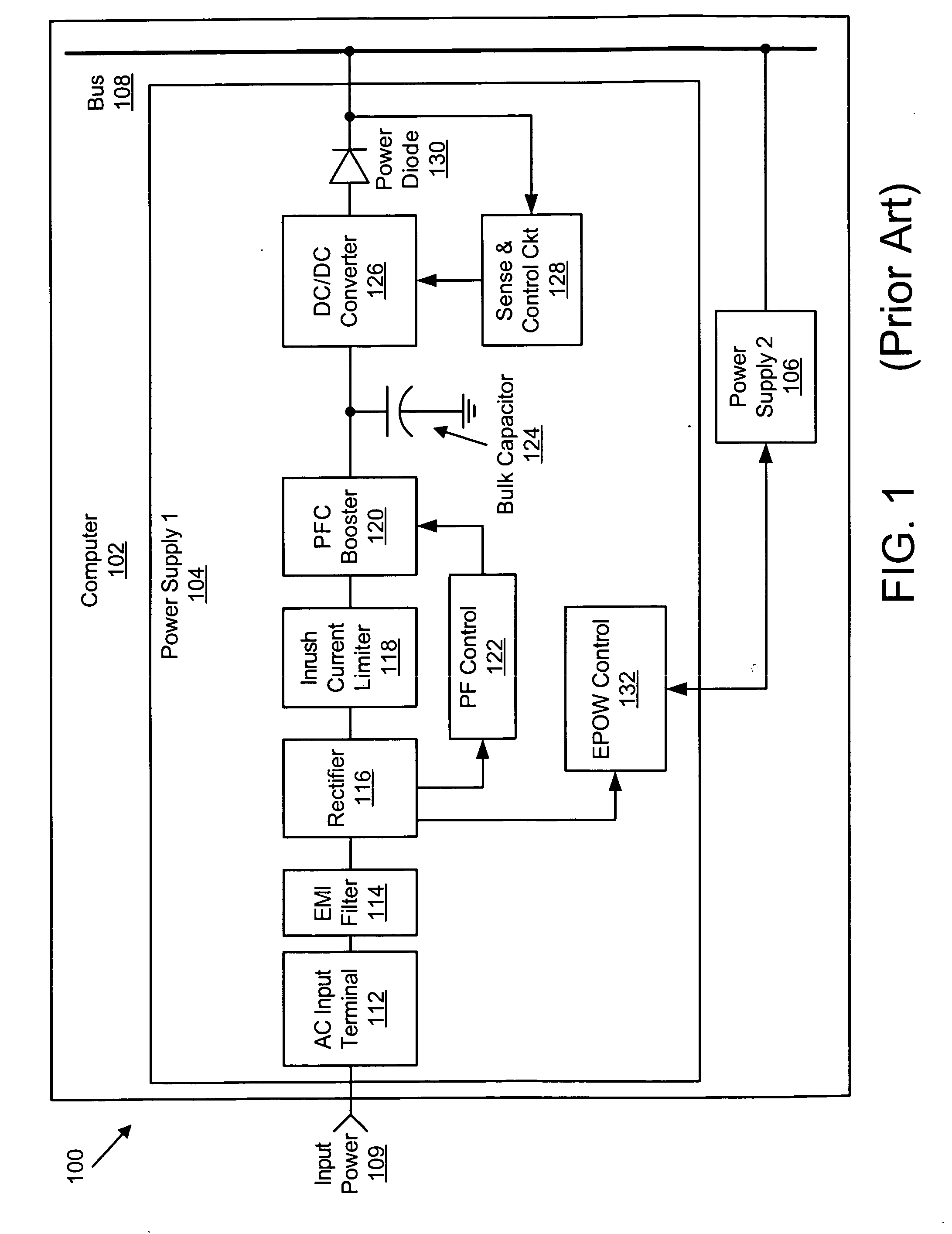

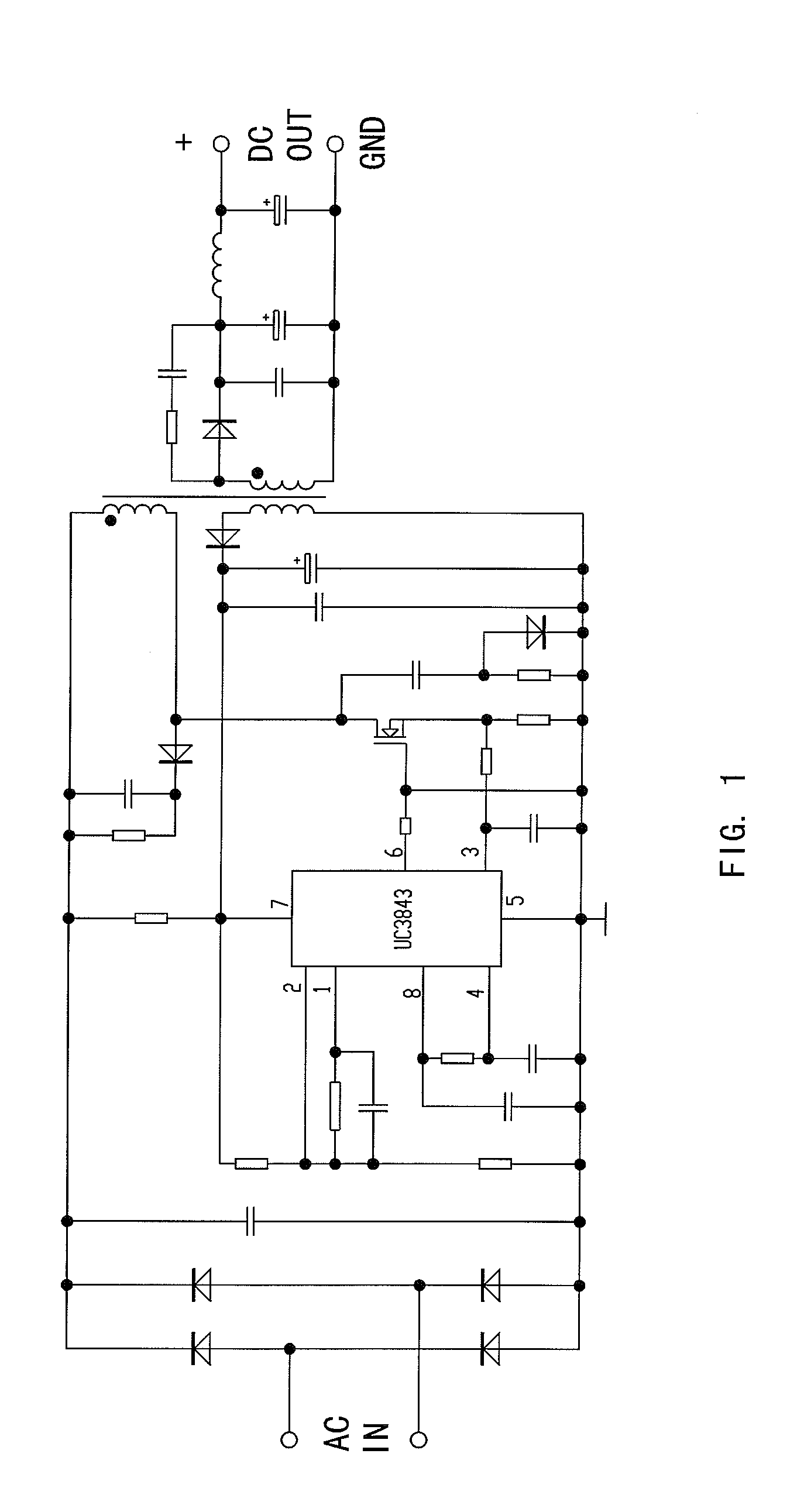

Topology and control method for power factor correction

InactiveUS6344986B1Reduce electromagnetic interferenceReduce output voltageAc-dc conversion without reversalEfficient power electronics conversionTransverterInductor

In a power factor corrected AC-to-DC power supply system, a DC-to-DC power converter is coupled to the output of an AC-to-DC power converter in order to produce a regulated DC output signal from a rectified AC input signal. The AC-to-DC power converter and the DC-to-DC power converter each includes a switch for controlling the operation of their respective power converter. The AC-to-DC converter includes an inductor. The system provides power factor correction for minimizing harmonic distortion by including a controller that receives the regulated DC output voltage as a feedback signal, and in response, produces a series of drive pulses having predetermined constant duty cycle. These pulses are simultaneously fed to each switch, to operate the respective converters alternately between ON and OFF states. When the AC-to-DC converter is driven by a fixed duty cycle of the series of pulses, power factor correction is improved since the current flowing through the inductor is substantially proportional to the waveform of the rectified AC input signal. By preselecting the value of the inductor, the AC-to-DC converter is operable in a discontinuous mode when the instantaneous rectified AC input signal is low and in a continuous mode when the instantaneous rectified AC input signal is high.

Owner:ASTEC INT LTD

Ballast circuit for high intensity discharge lamps

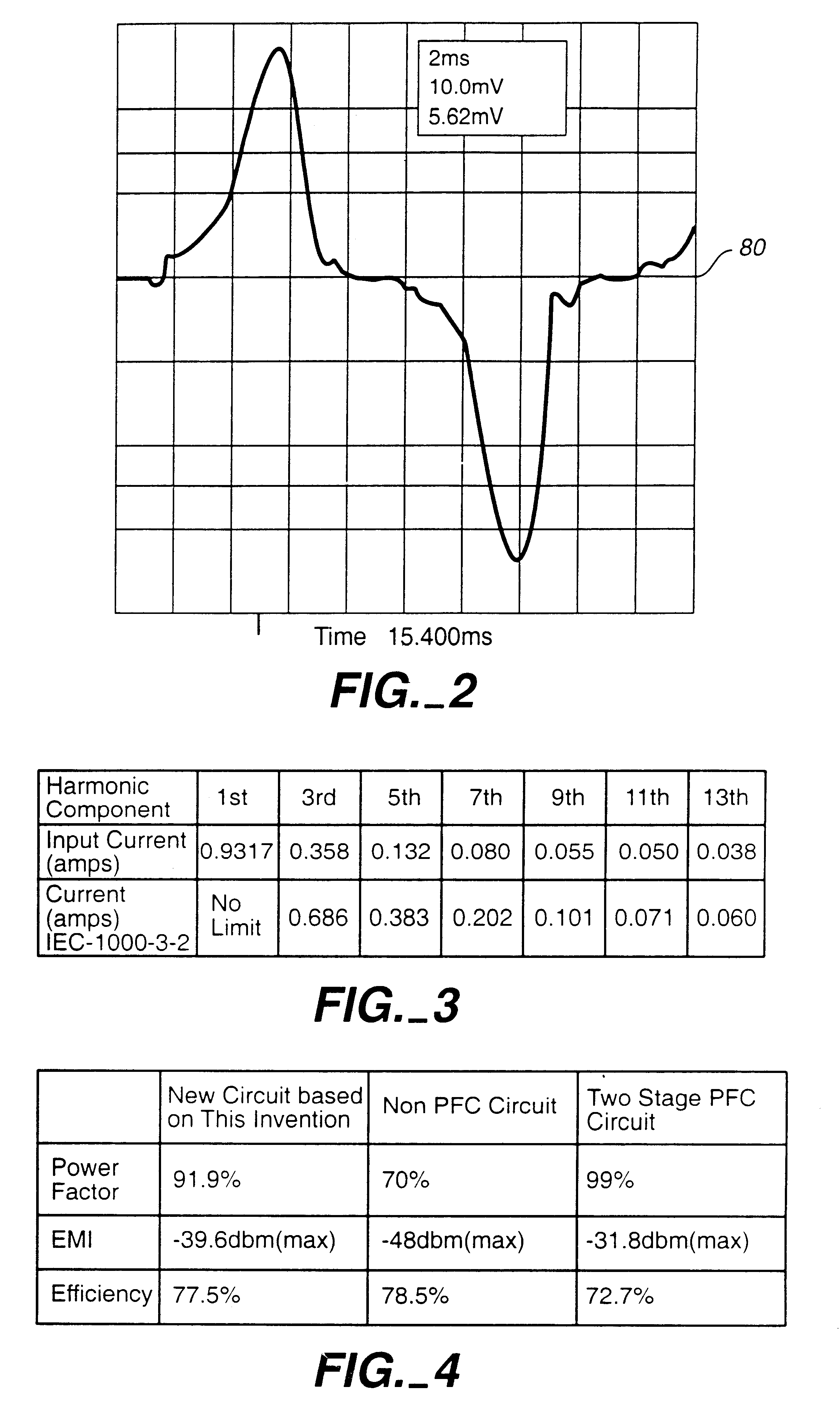

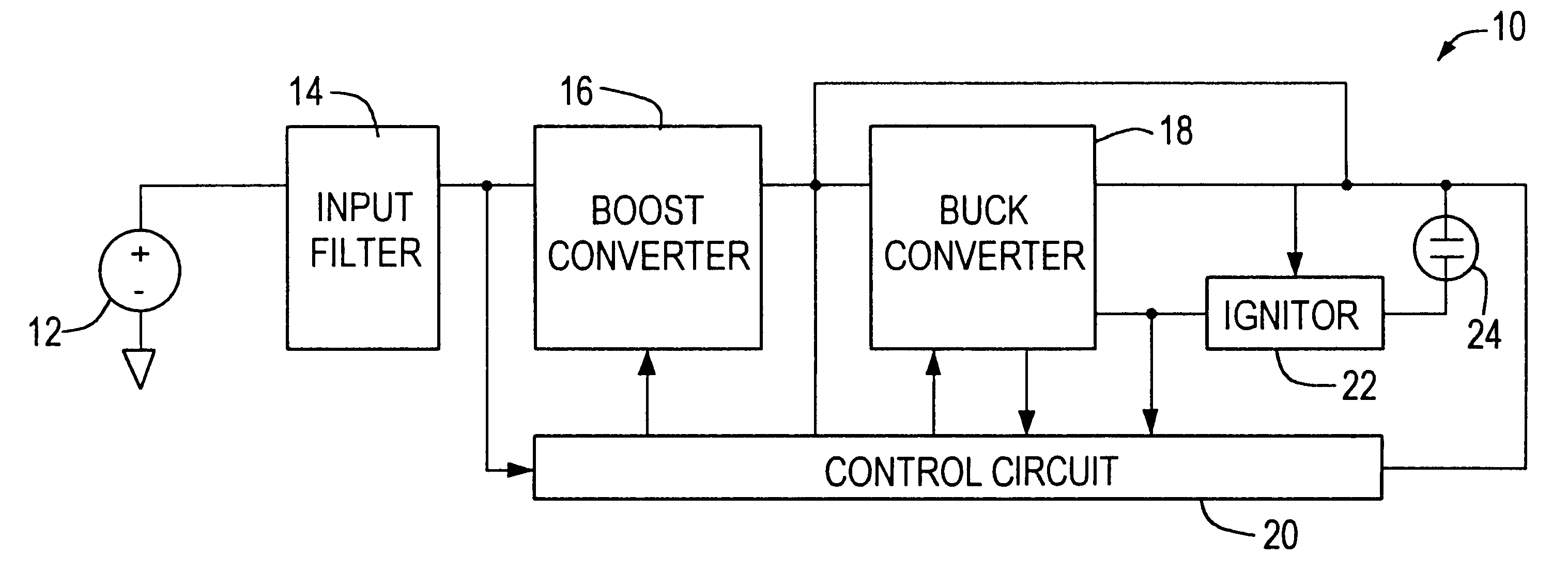

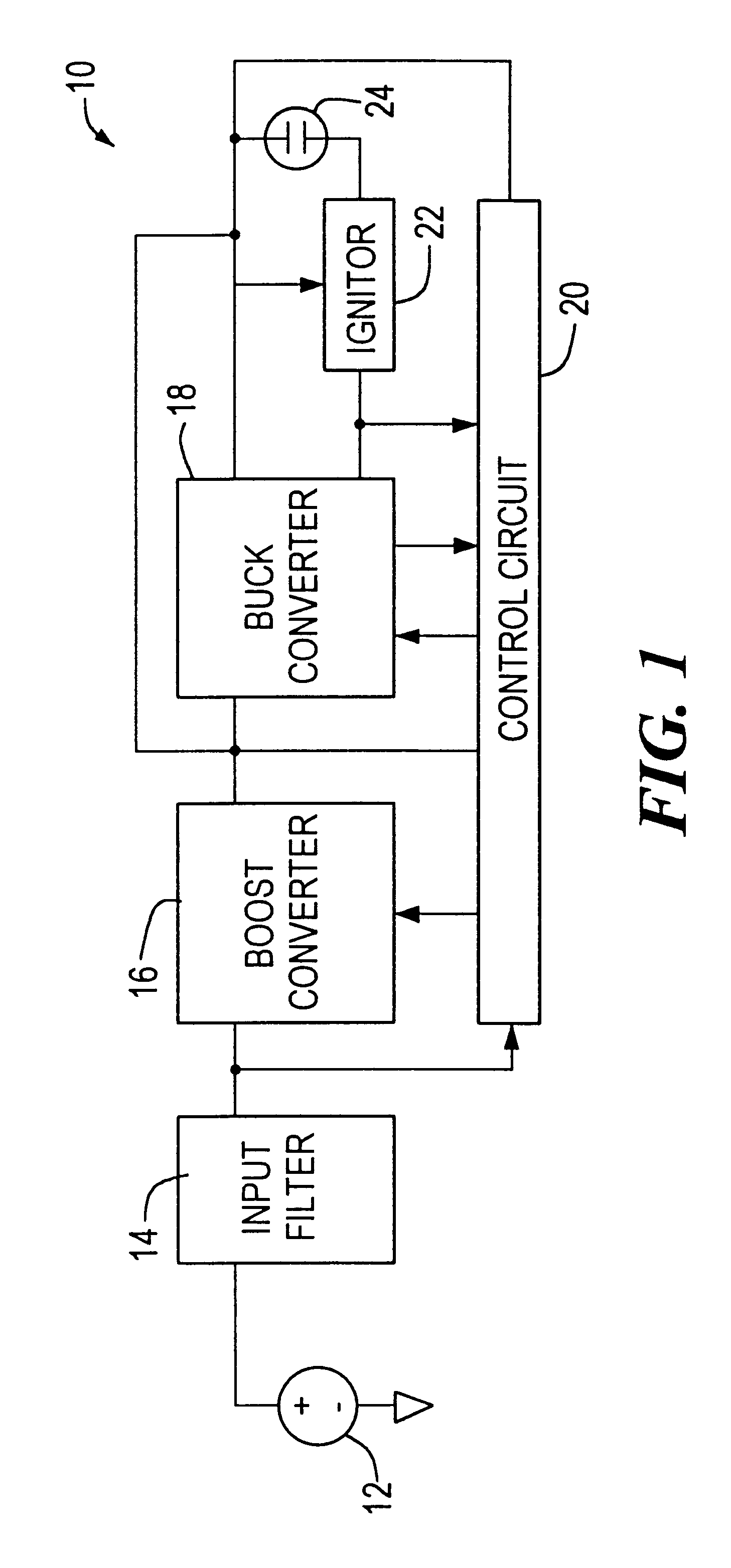

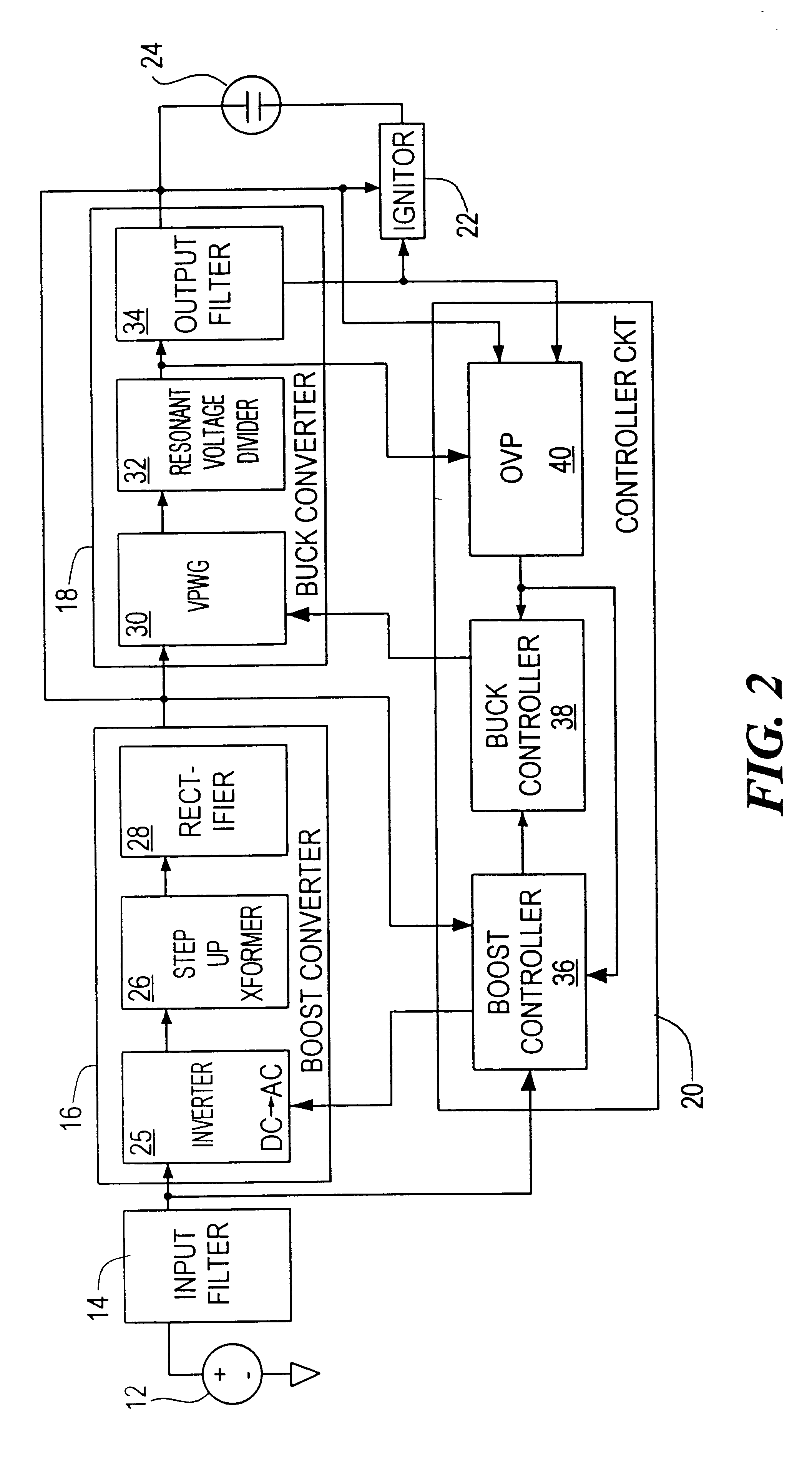

InactiveUS6181084B1Eliminate flickeringMinimises levelAc-dc conversion without reversalConversion with intermediate conversion to dcBuck converterBoost controller

A ballast circuit for a high intensity discharge lamp includes a boost converter, responsive to a dc input voltage, for providing a boosted dc output voltage; a boost controller, responsive to the boosted dc output voltage, for driving the boost converter to maintain the boosted output voltage at a predetermined level; a buck converter, responsive to the boosted dc output voltage, for providing a reduced dc output voltage; and a buck controller, responsive to the reduced output voltage, for driving the buck converter to operate the discharge lamp in a transition mode and maintaining the reduced dc output voltage at a preselected level for operating the discharge lamp in a steady state mode.

Owner:EXCELITAS TECH

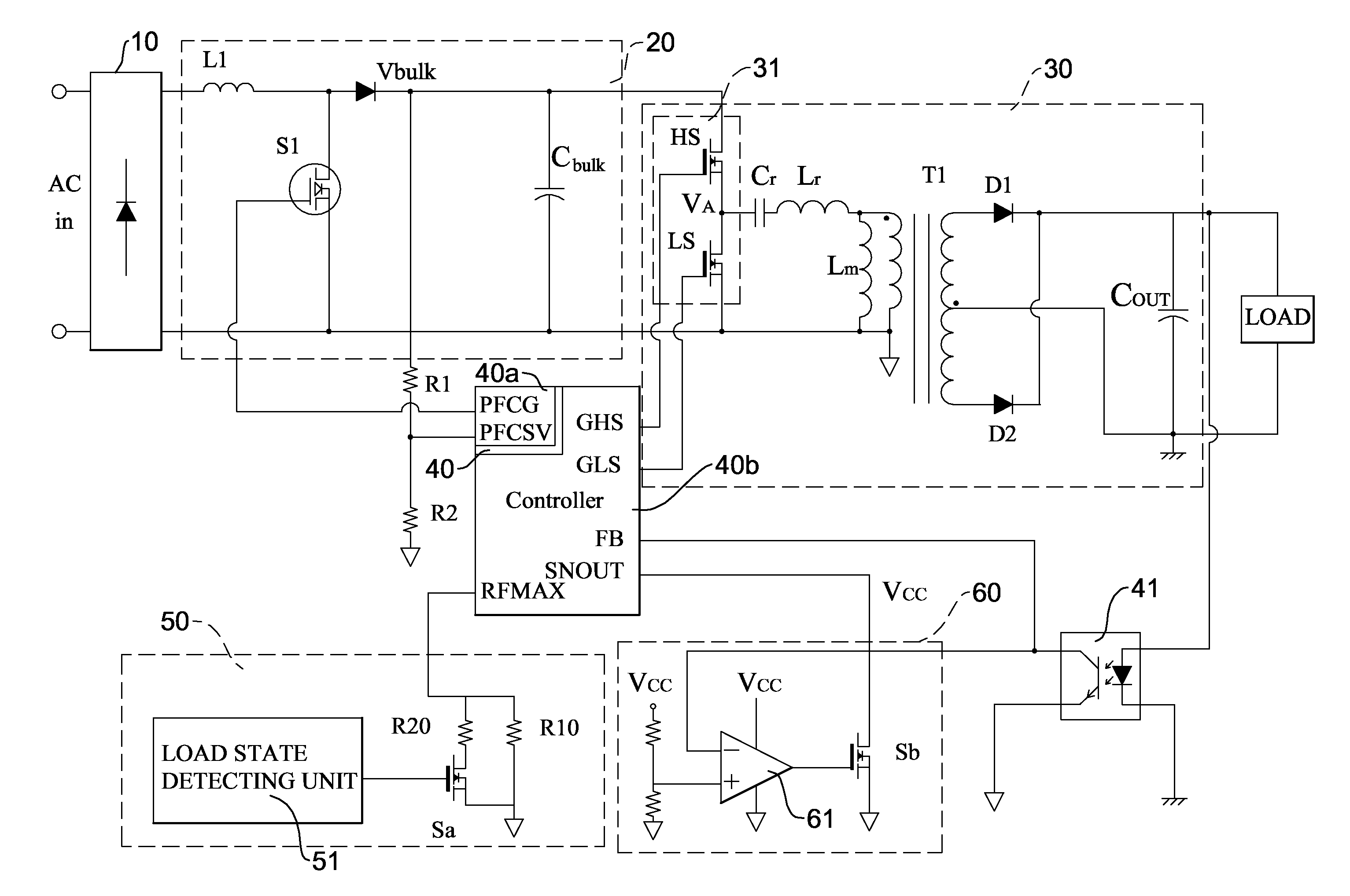

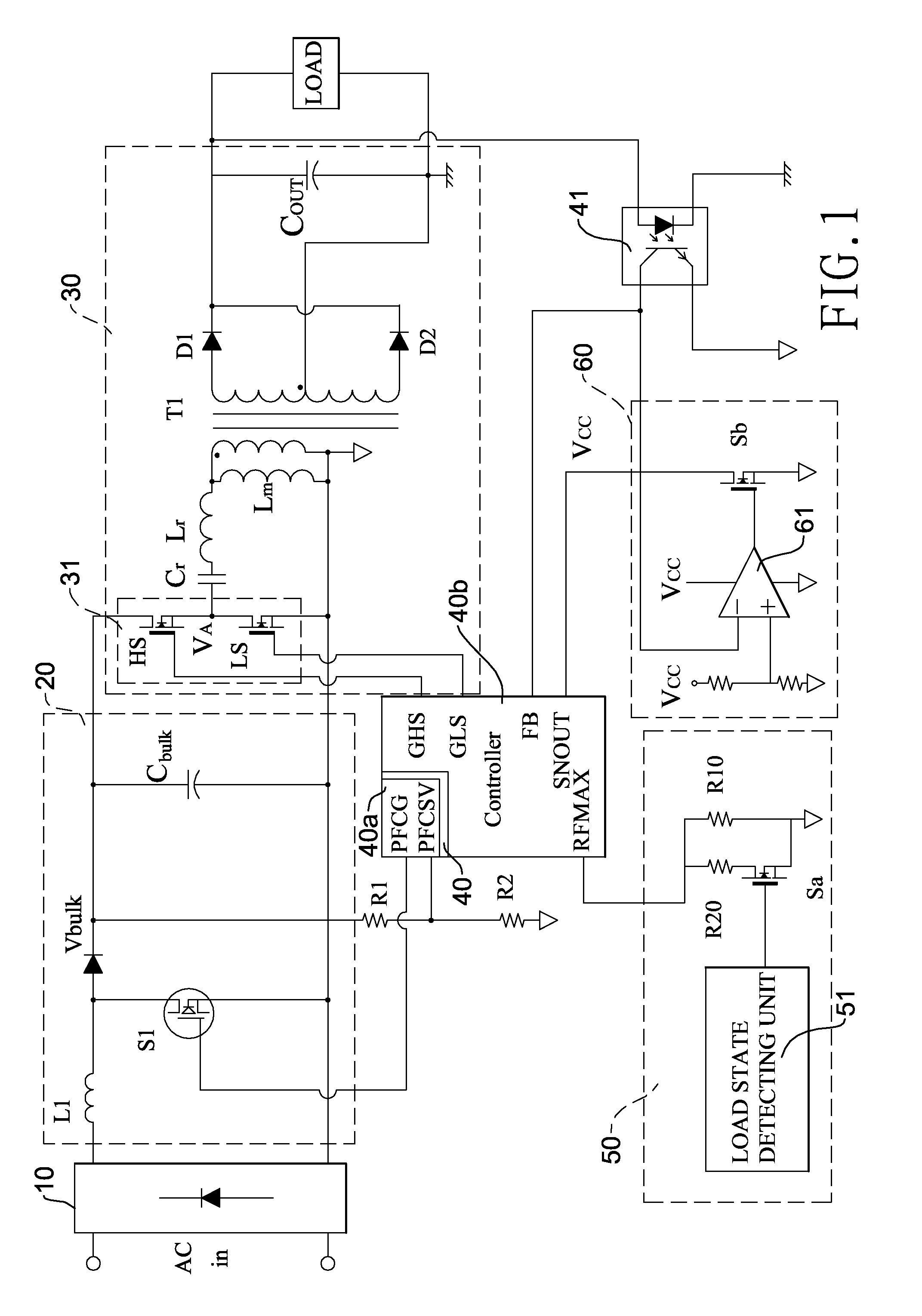

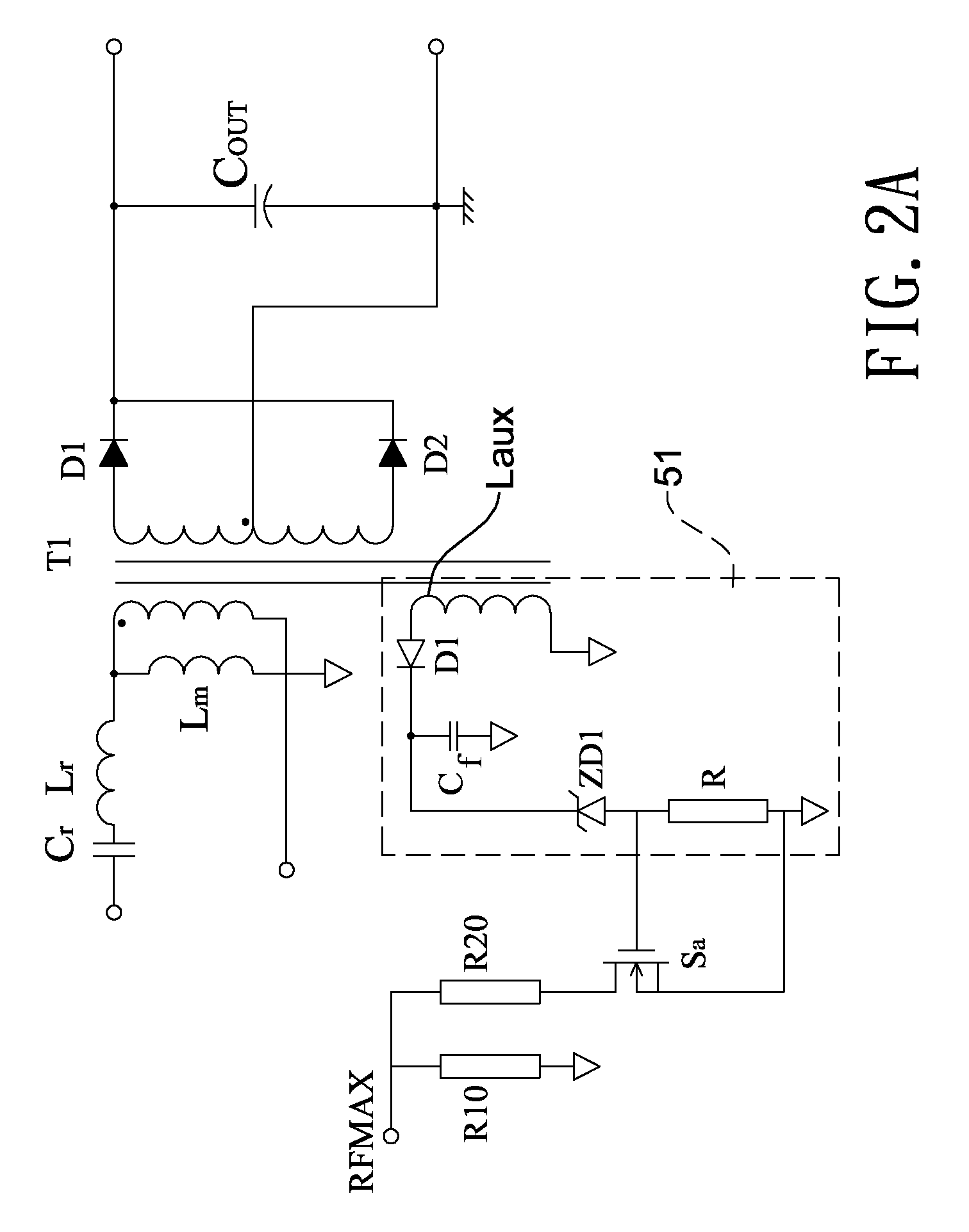

Burst mode resonant power converter with high conversion efficiency

InactiveUS20110085354A1Improve conversion efficiencyLowering maximum switch frequencyEfficient power electronics conversionDc-dc conversionTransformerResonant power converters

A burst mode resonant power converter with high conversion efficiency has a rectifier, a power factor correction circuit, a resonant circuit, a controller, and a burst mode triggering unit. The maximum frequency switching end of the controller is connected to a maximum frequency variable circuit. When the load is medium or heavy, the maximum frequency variable circuit increases the maximum switch frequency of the controller. When the load is in the no-load or the light conditions, it reduces the maximum switch frequency thereof. Therefore, the controller reduces the number of times that the resonant circuit switches the bridge switch circuit. The conduction cycle of the 50% pulse signal output to the bridge switch circuit becomes longer. Larger energy can be transmitted at a time to the secondary coil of the transformer. This increases the overall efficiency.

Owner:ACBEL POLYTECH INC

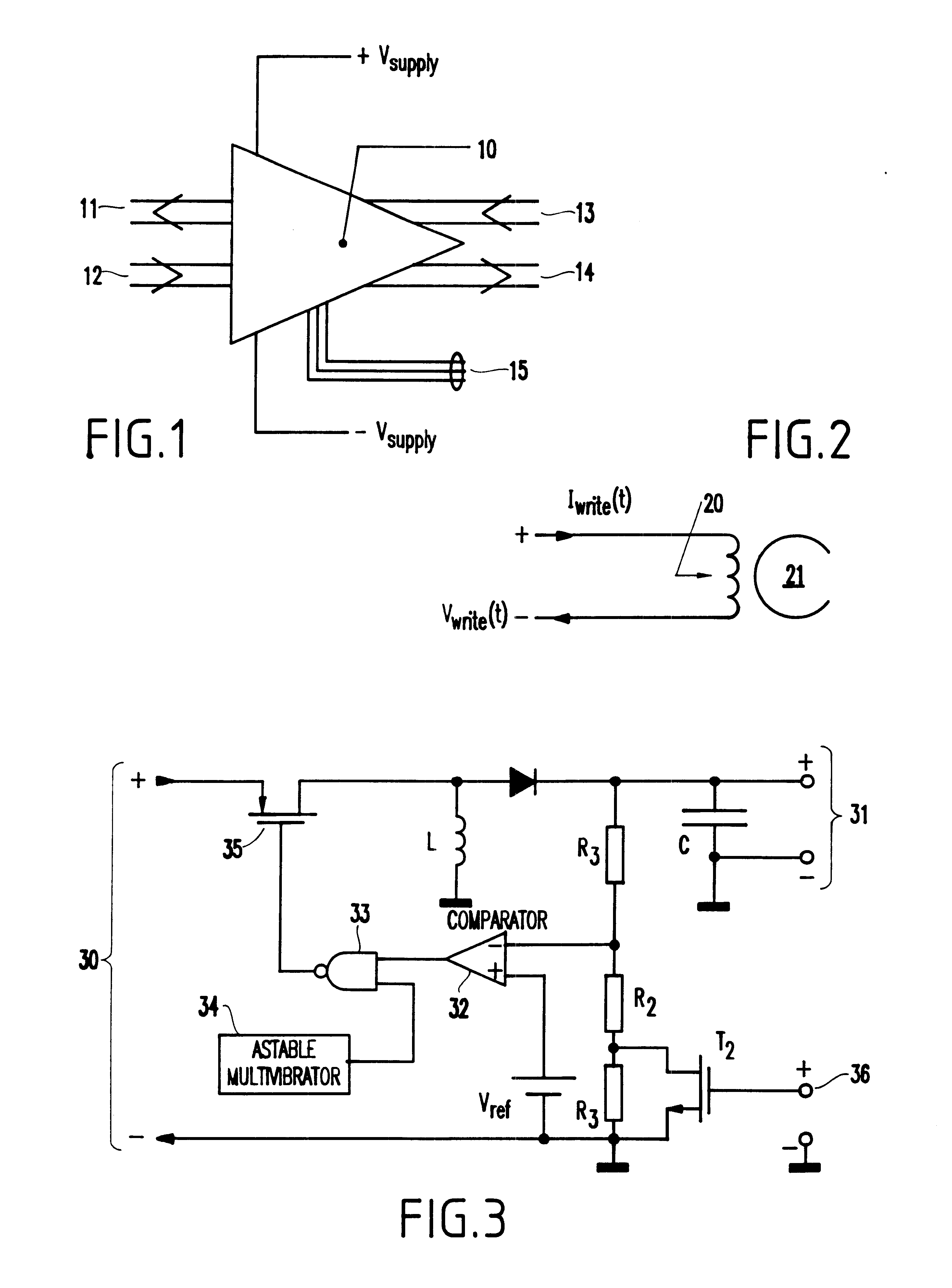

Data storage device having selectable performance modes for use in dual powered portable devices

InactiveUS6622252B1Reduce rateShorten speedEnergy efficient ICTFilamentary/web record carriersAudio power amplifierElectrical battery

A portable computer includes a battery and a connection to an external power source, a two-speed data storage device being supplied power from one or more of the battery and the external power source, and a controller attached to the storage device. With the invention, when the storage device is powered by the internal battery, the controller not only reduces the rotation speed and the clock rate of the storage device, but also reduces the power consumption of the read / write electronics module inside the disk drive by lowering the power supply voltage for the write driver inside said module and lowering the tail currents for the amplifier stages in the readback amplifier inside said module. When the storage device is powered by an external power source, the controller will run the storage device at full speed and highest clock rate, and will provide the write driver inside the read / write electronics module with a power supply voltage high enough to accommodate the resulting higher data rate, and will provide tail currents in the amplifier stages of the readback amplifier high enough to accommodate the higher required bandwidth for the readback amplifier.

Owner:IBM CORP

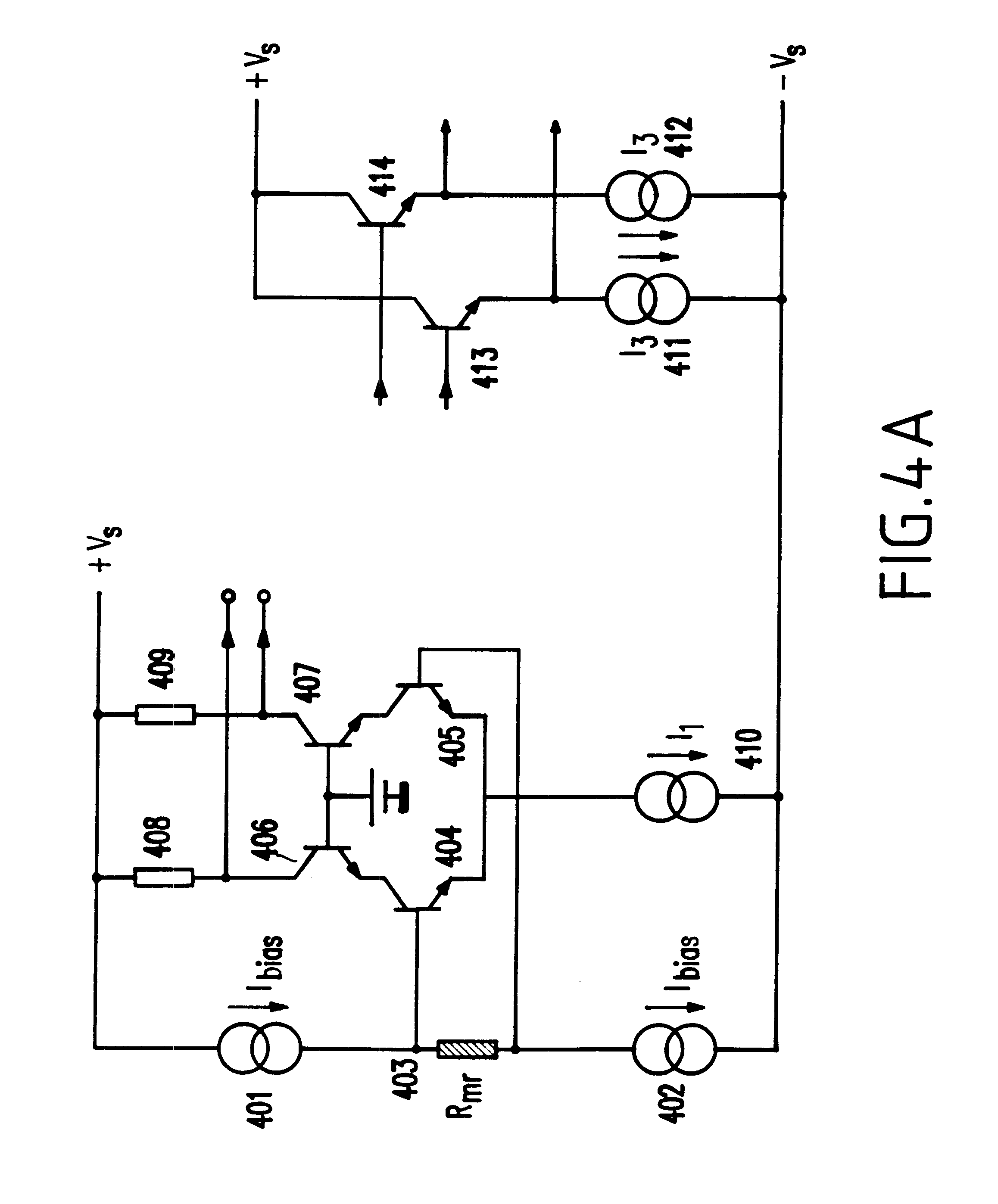

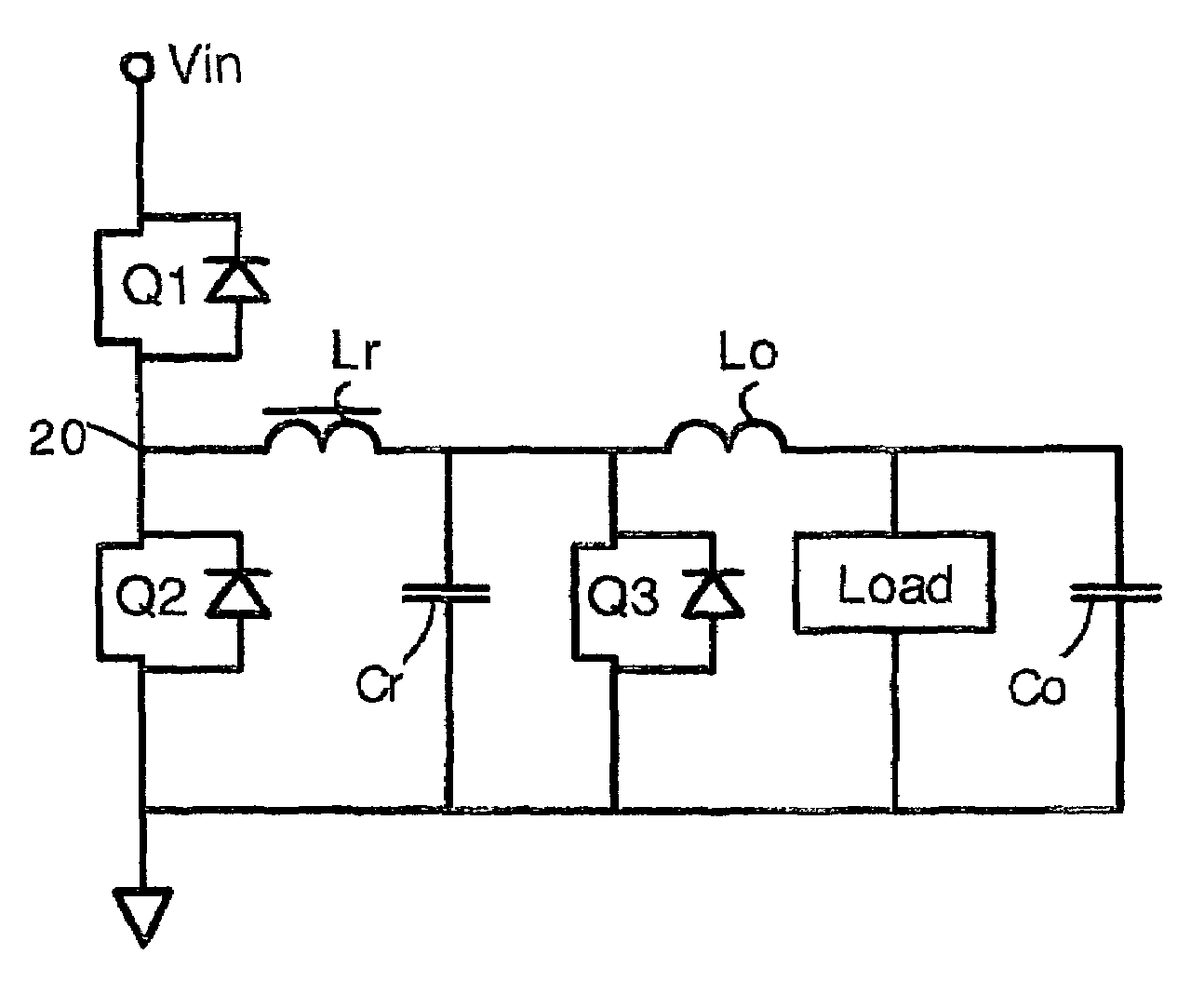

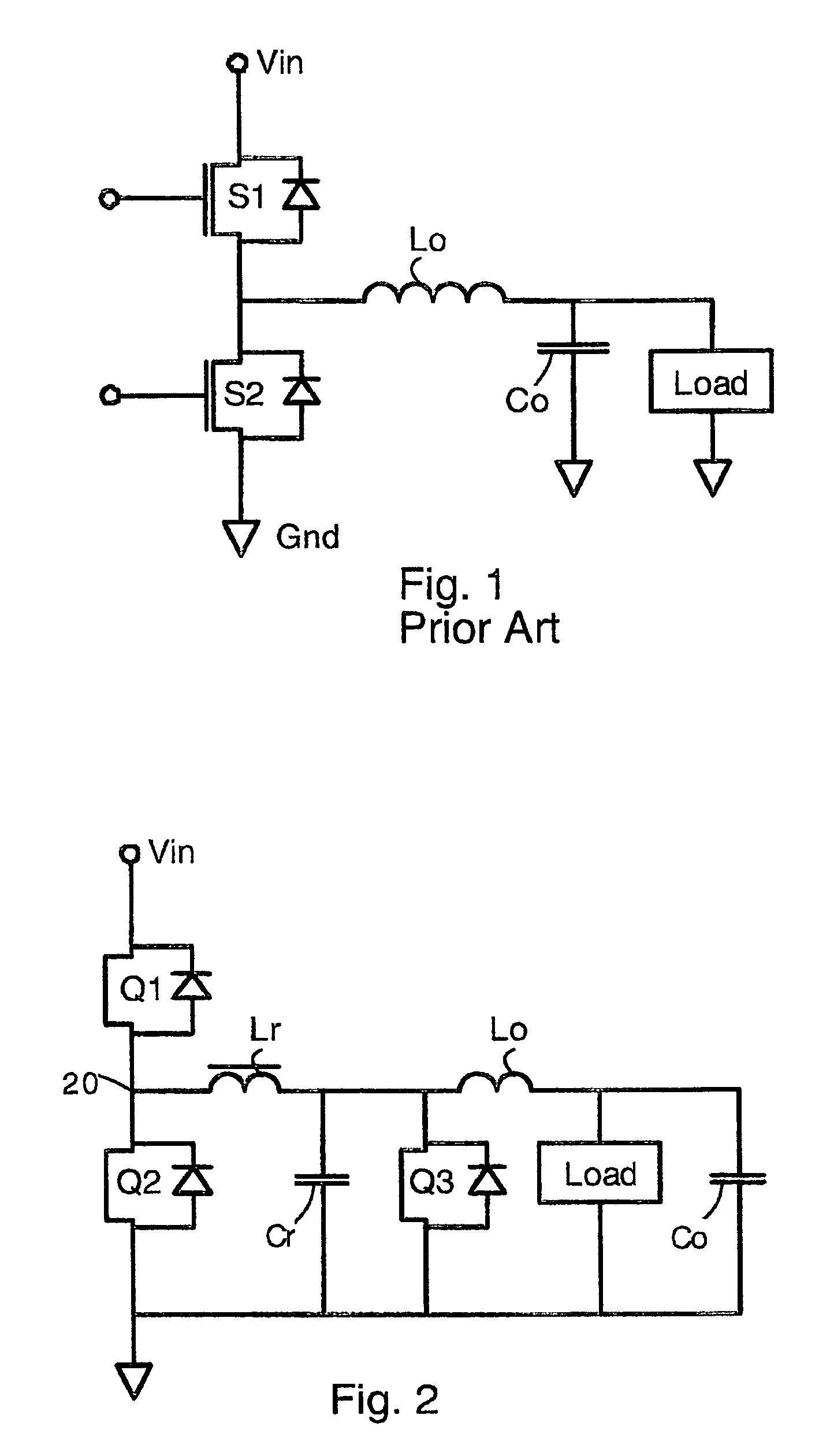

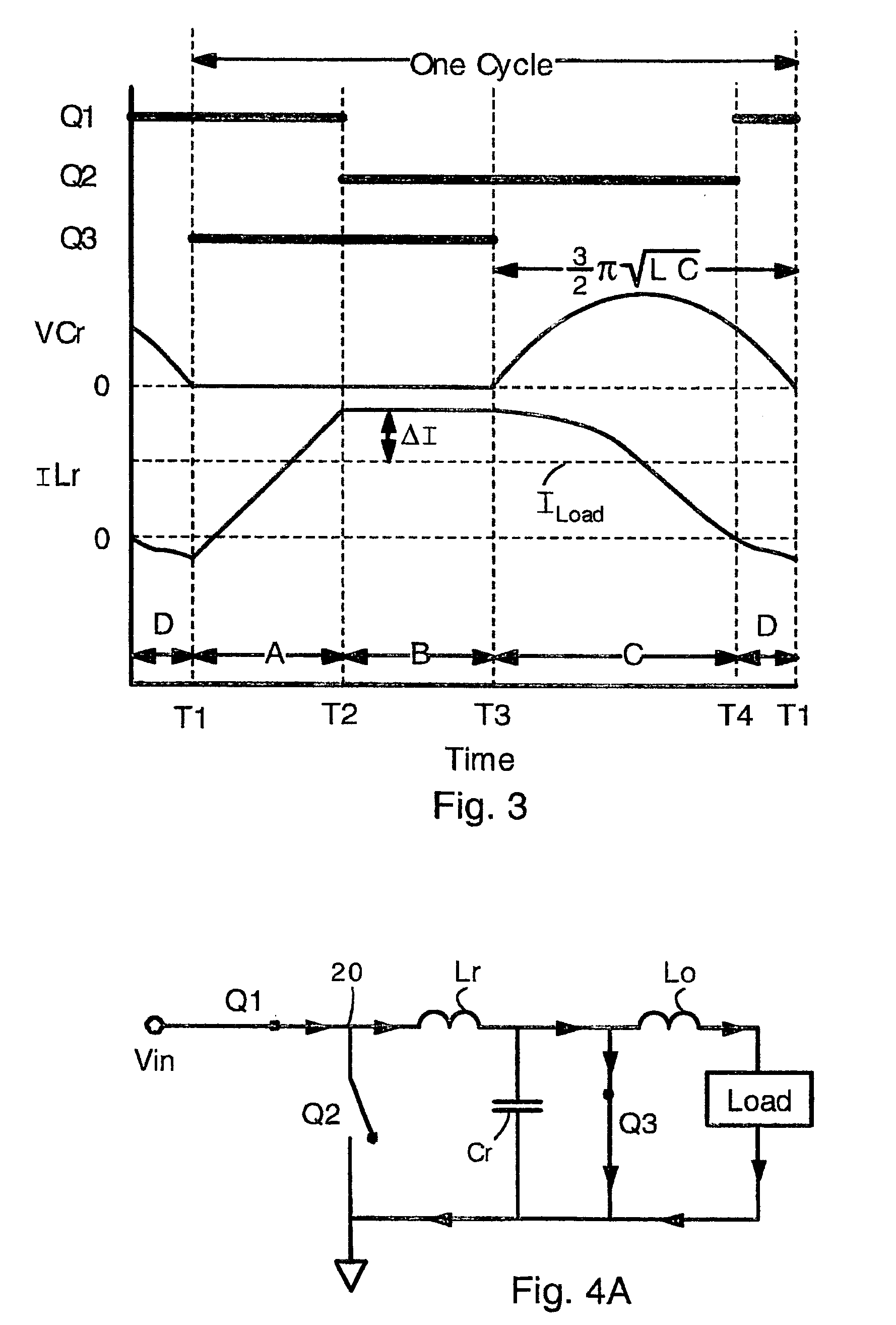

Quasi-resonant DC-DC converters with reduced body diode loss

InactiveUS6989997B2Reduce output voltageGreater duty cycleEfficient power electronics conversionDc-dc conversionSoft switchingDc dc converter

Buck converters having a resonant inductor Lr, resonant capacitor Cr, and synchronous switch Q3 that together provide reduced switching loss and soft switching. In operation, the resonant inductor Lr is charged during a time period A. Then, Lr is freewheeling and provides current to an output inductor Lo. Then, Q3 is turned OFF, and energy from the resonant inductor Lr charges the resonant capacitor Cr. Finally, energy from the resonant capacitor Cr is provided to the output inductor and load. The output power can be adjusted by phase control of the operation of switch Q3. In alternative embodiments, the circuit has a pair of coupled inductors L1 L2 or an isolation transformer 40. The coupled inductors have a polarity selected so that the output voltage is reduced, thereby allowing top switch Q1 to have a greater duty cycle. These circuits feature no body diode loss in the switch Q3.

Owner:VIRGINIA TECH INTPROP INC +1

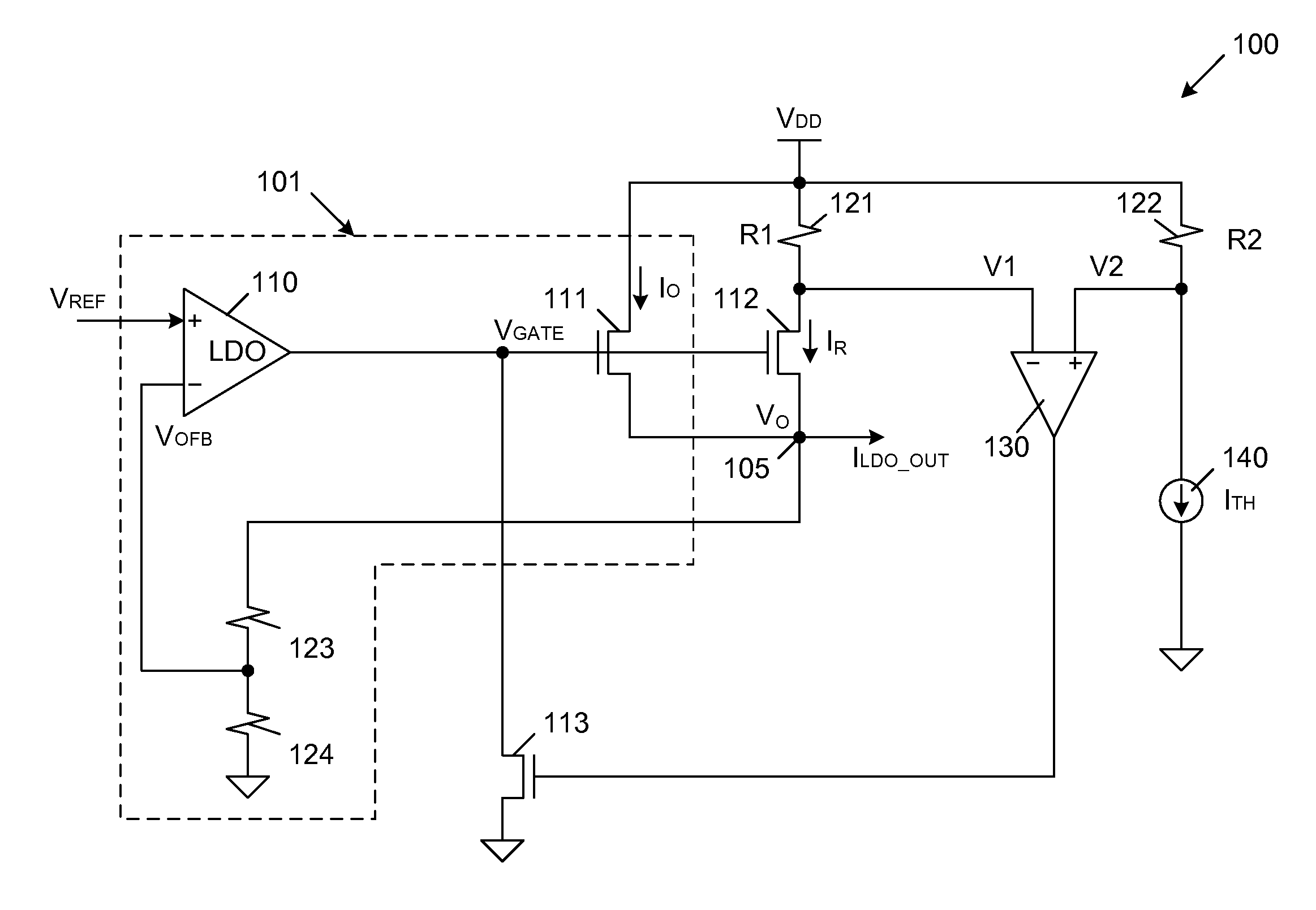

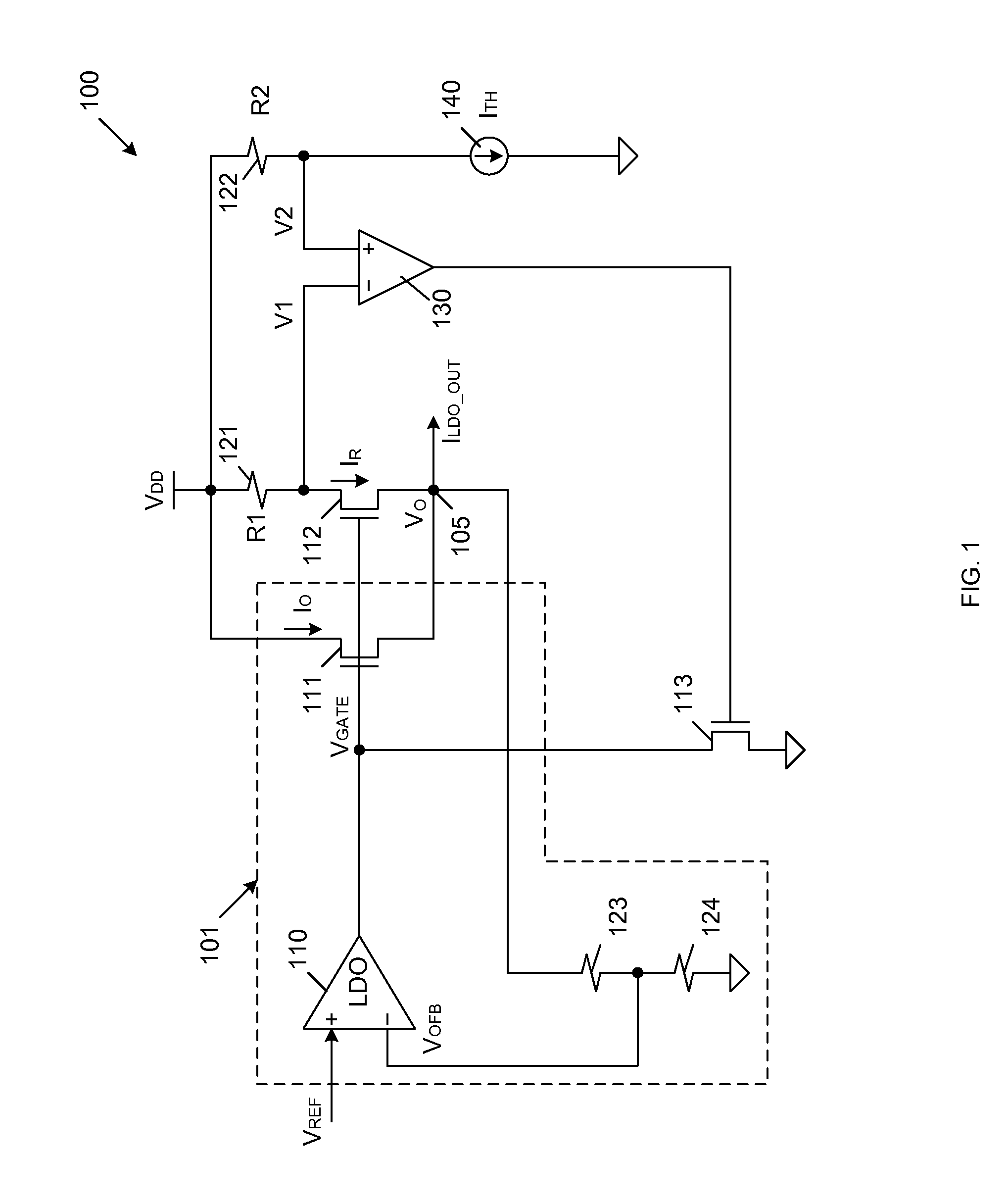

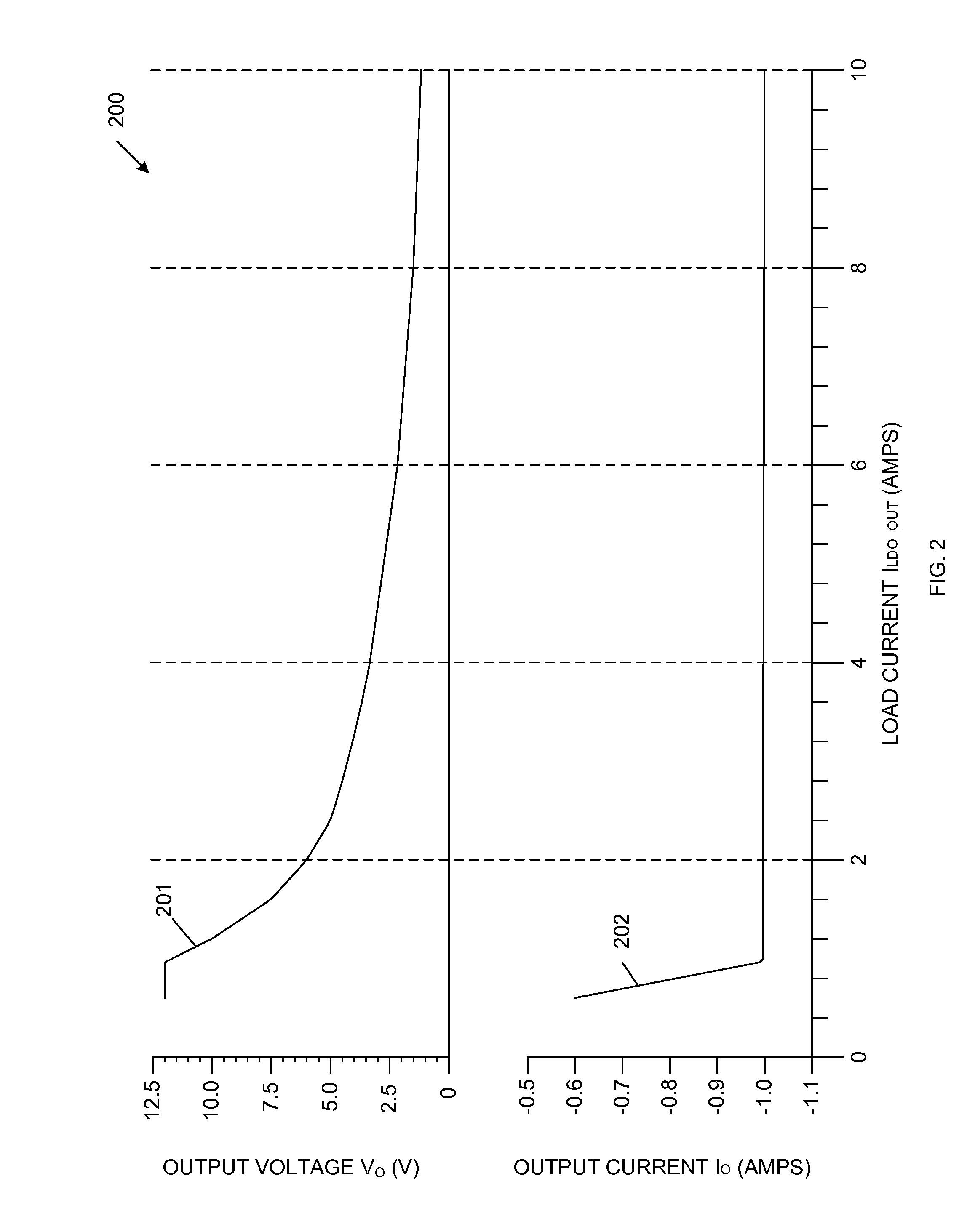

Current Limit Circuit Architecture For Low Drop-Out Voltage Regulators

InactiveUS20130293986A1Reduce output voltageSimple designEmergency protective arrangements for limiting excess voltage/currentElectric variable regulationLinear regulatorEngineering

A current limiting circuit for a linear regulator includes an output stage transistor and a replica transistor, which have gates coupled to receive an output voltage from a linear amplifier and sources coupled to load circuitry. A drain of the output stage transistor is coupled to a VDD supply terminal, while a drain of the replica transistor is coupled to the VDD supply terminal through a first resistor. The output stage transistor and replica transistor are operated in saturation, such that proportional currents flow through these transistors. The voltage drop across the first resistor provides a first voltage, which is applied to a second amplifier. A reference voltage is also applied to the second amplifier. When the first voltage becomes less than the reference voltage, a feedback transistor is enabled to pull down the output voltage of the linear amplifier, thereby limiting the output current supplied to the load circuitry.

Owner:TOWER SEMICONDUCTOR

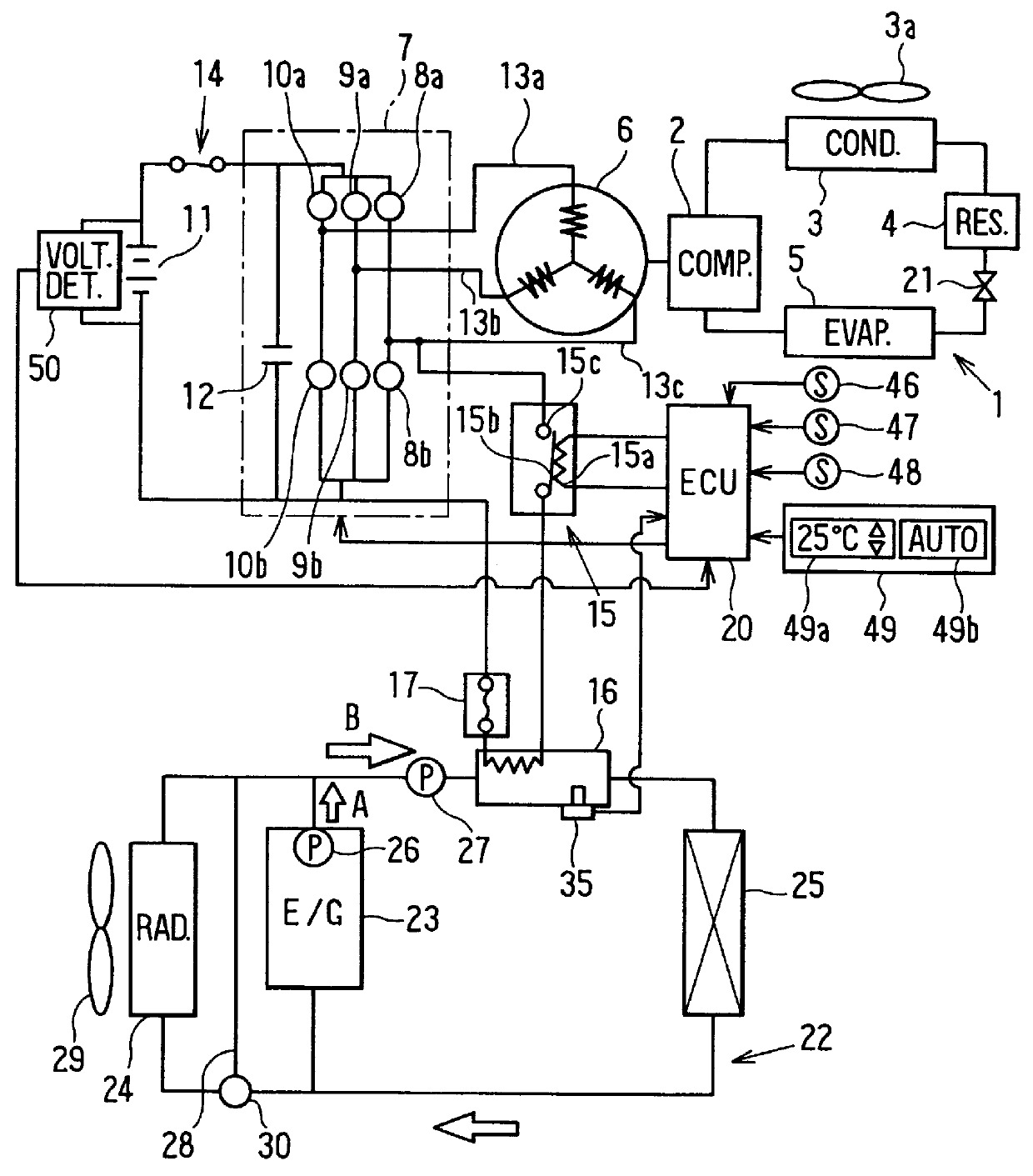

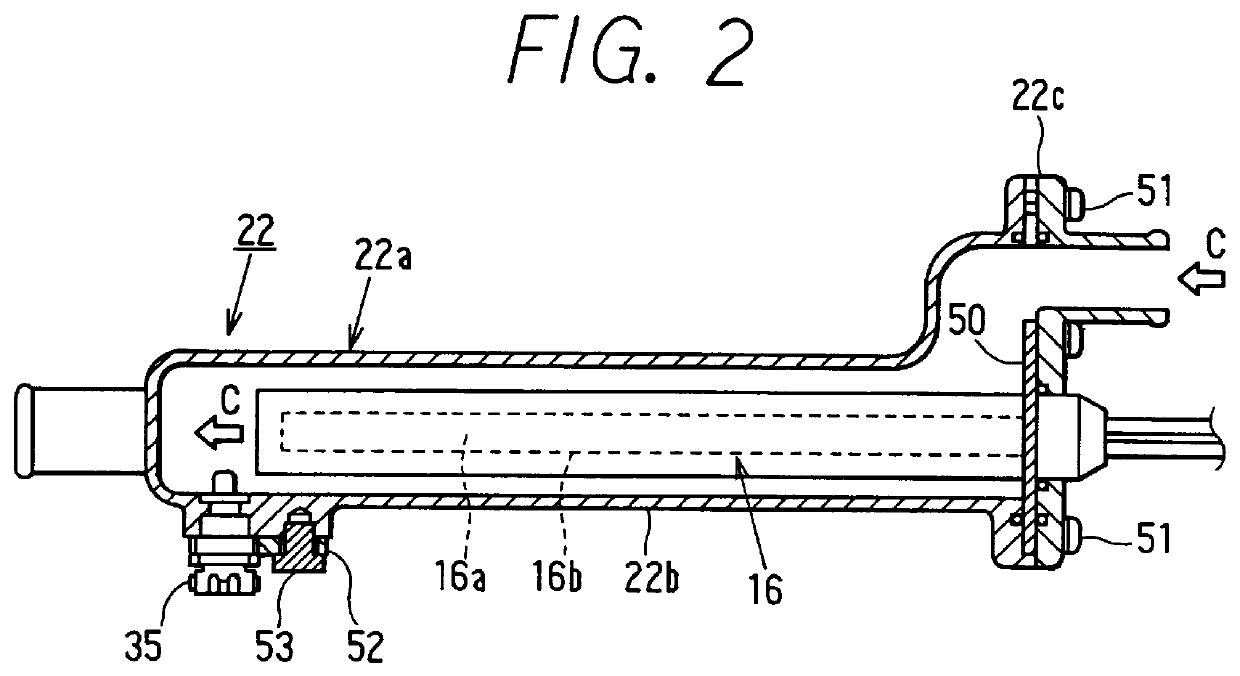

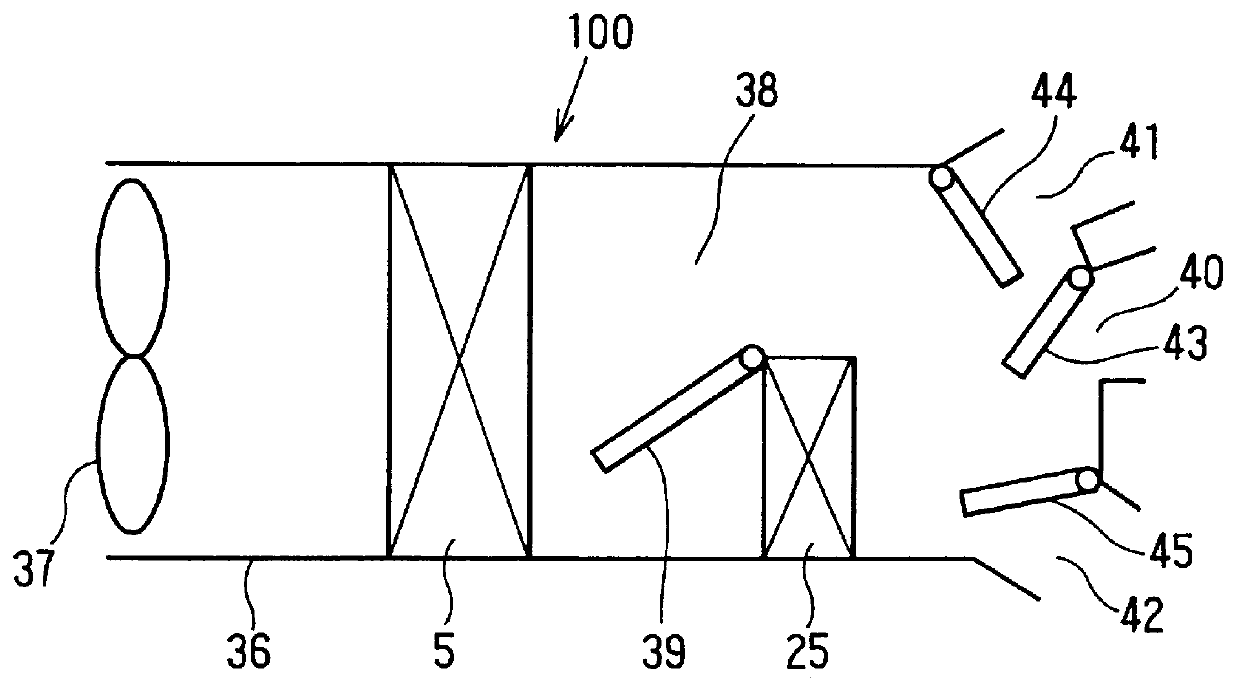

Vehicular air conditioning system

InactiveUS6070650AIncreased durabilityLow costMachines/enginesPower to auxillary motorsFrequency changerEngineering

To provide a vehicular air conditioning system for activating an electric heater with the output coming from an inverter by actuating a relay at a reasonable cost, a relay and an electric heater acting as electric heat source are connected in series between an output line of three output lines of an inverter and the negative side of a vehicular power supply. The electric heater employs a nichrome wire as its heating element and is used for warming the inside of a vehicle compartment. Moreover, the relay is turned ON / OFF after the output voltage of the inverter is set to zero. As a result, the durability of the relay can be improved, and this relay can be implemented by an existing one without newly manufacturing any dedicated relay so that the cost can be lowered.

Owner:DENSO CORP

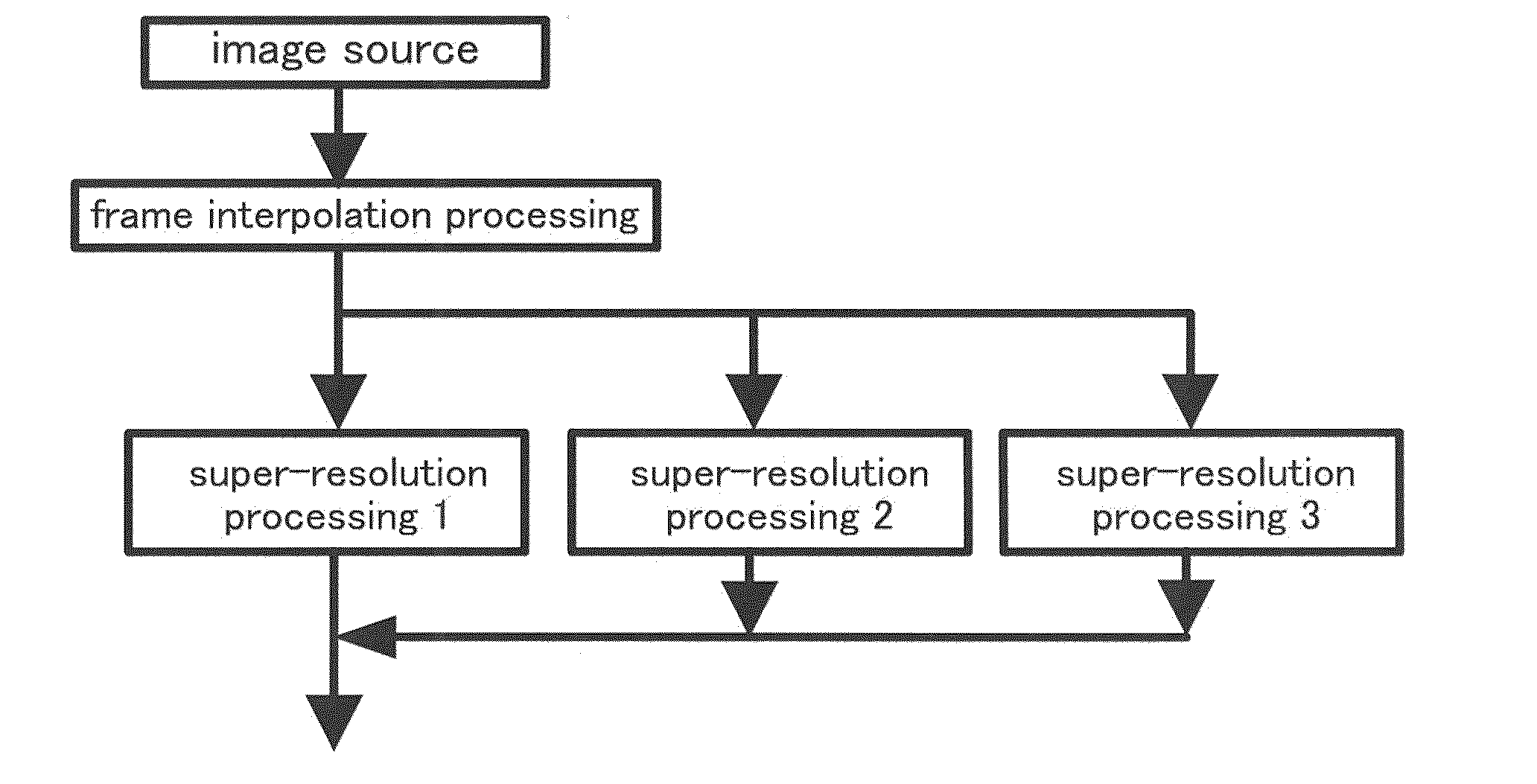

Method for driving display device

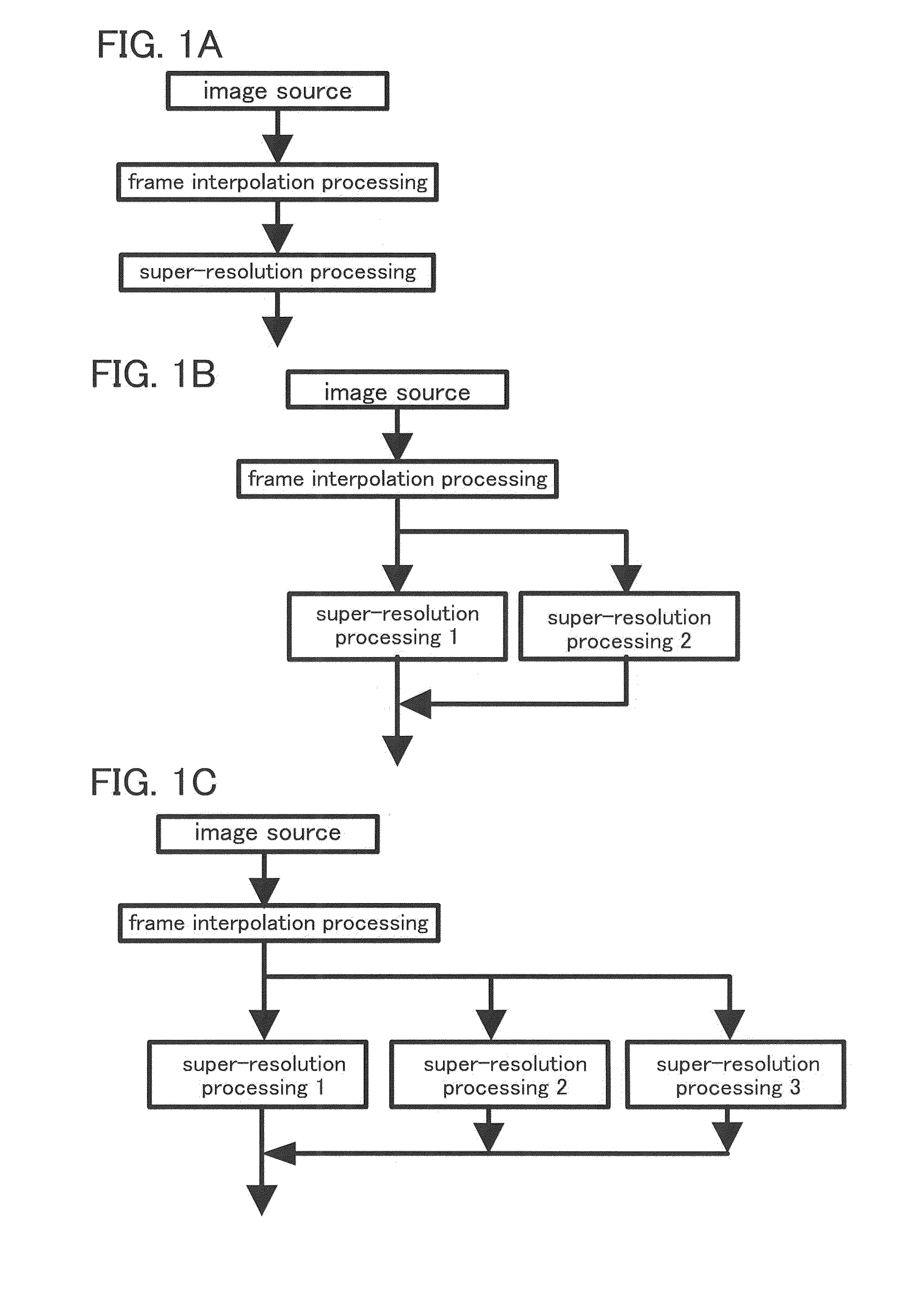

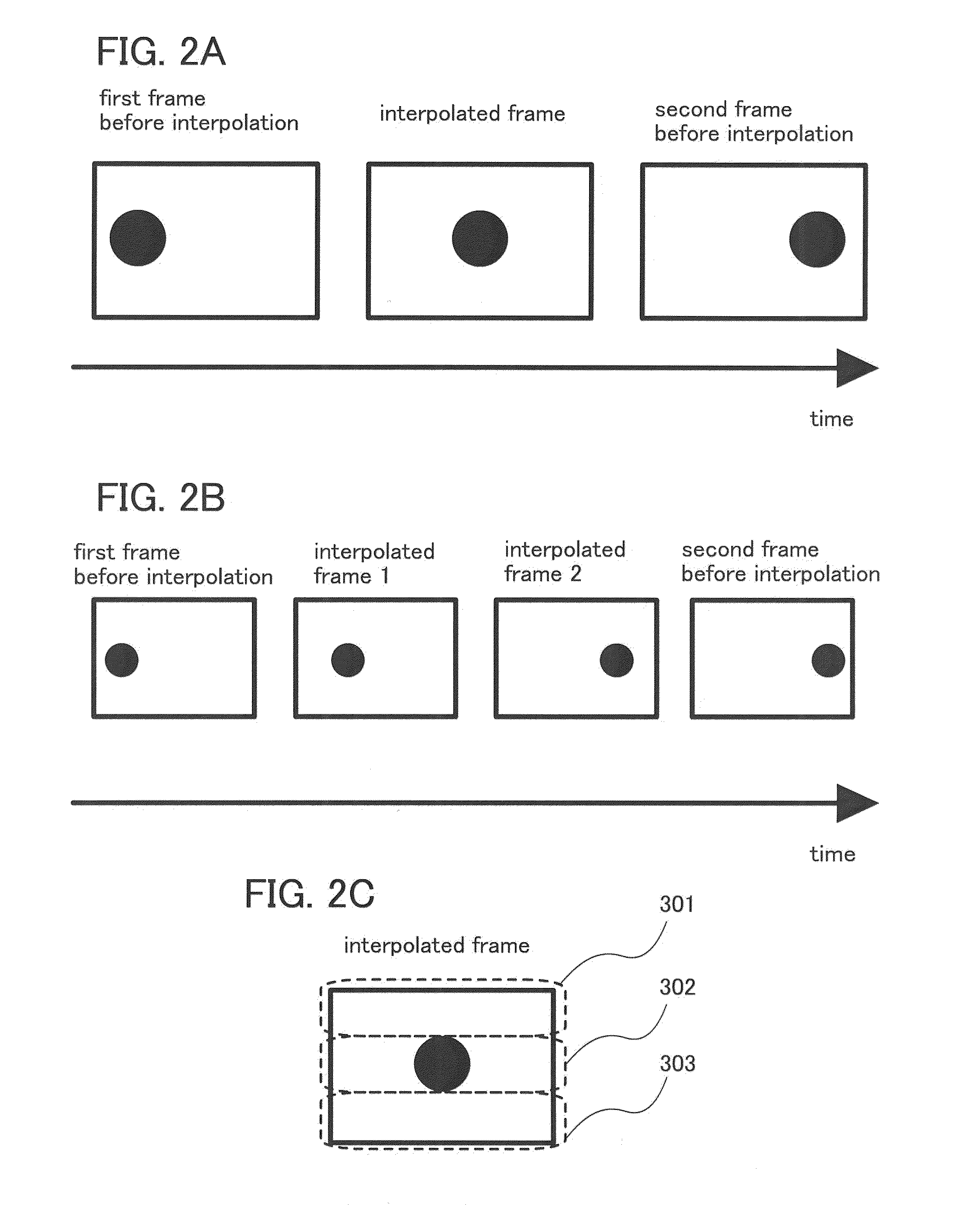

ActiveUS20100201719A1Improve image qualityAccurate operationGeometric image transformationCathode-ray tube indicatorsHigh frame rateComputer graphics (images)

A low-resolution image is displayed at higher resolution and afterimages are reduced. Resolution is made higher by super-resolution processing. In this case, the super-resolution processing is performed after frame interpolation processing is performed. Further, in that case, the super-resolution processing is performed using a plurality of processing systems. Therefore, even when frame frequency is made higher, the super-resolution processing can be performed at high speed. Further, since frame rate doubling is performed by the frame interpolation processing, afterimages can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

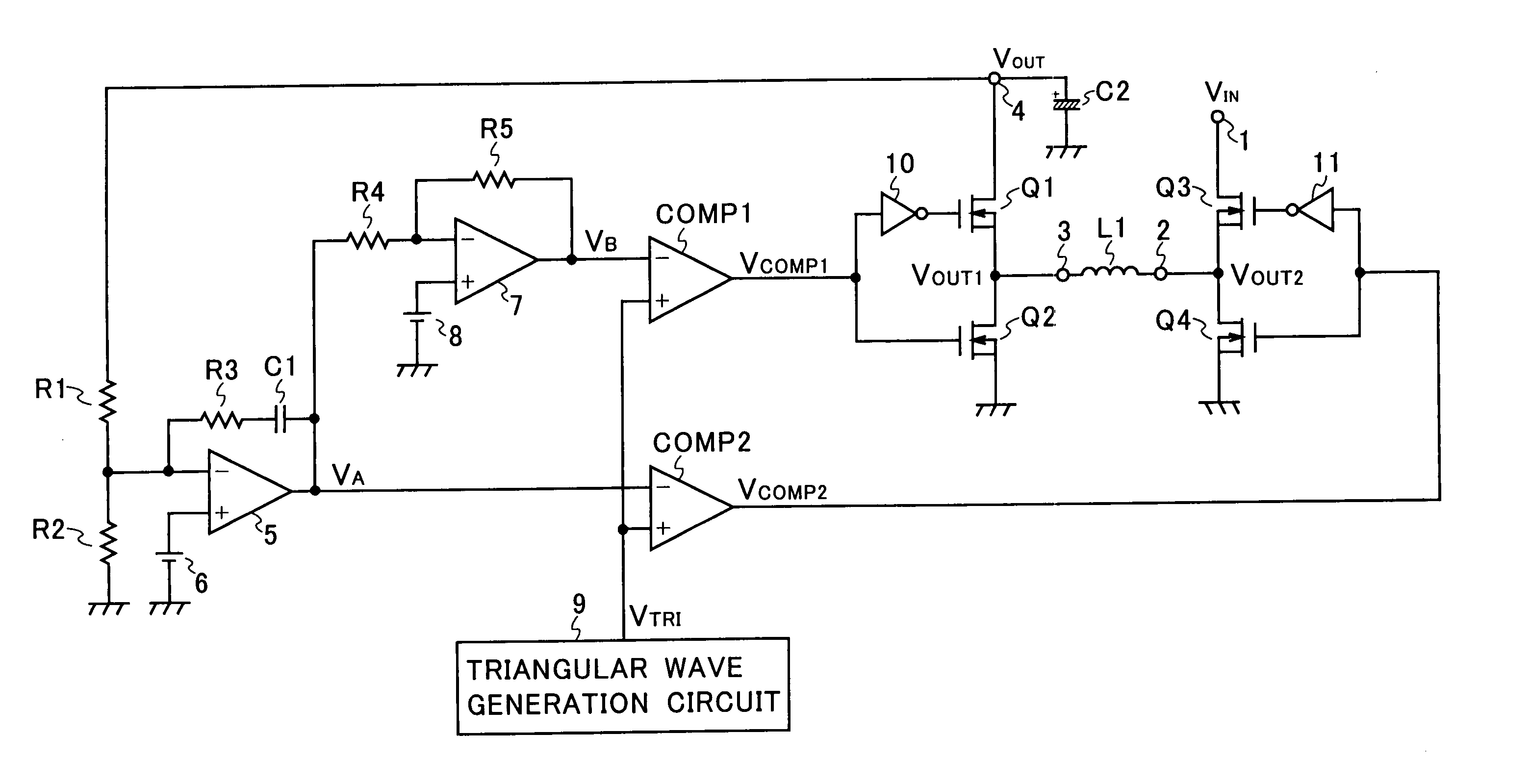

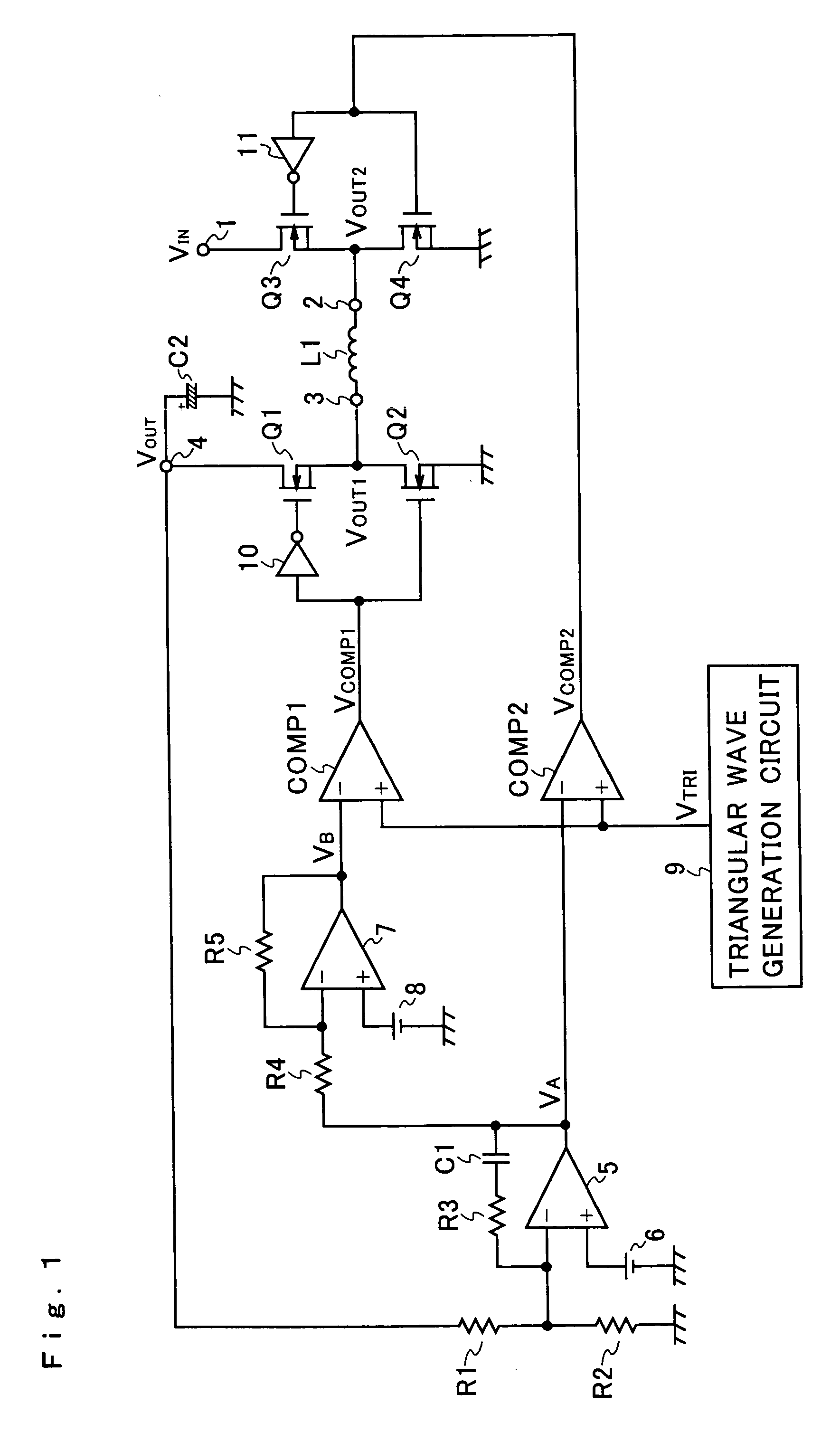

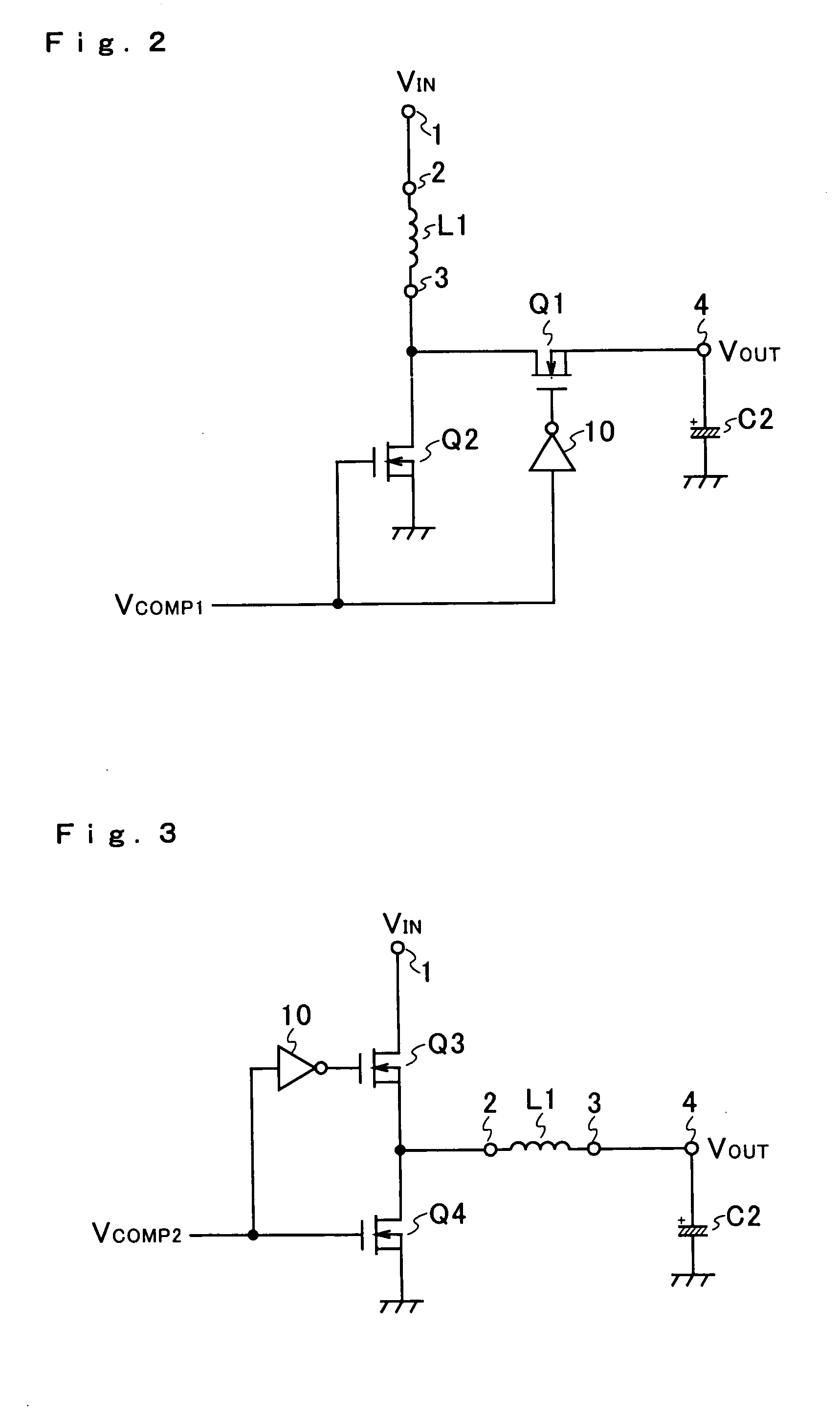

Step-up/step-down DC-DC converter and portable device employing it

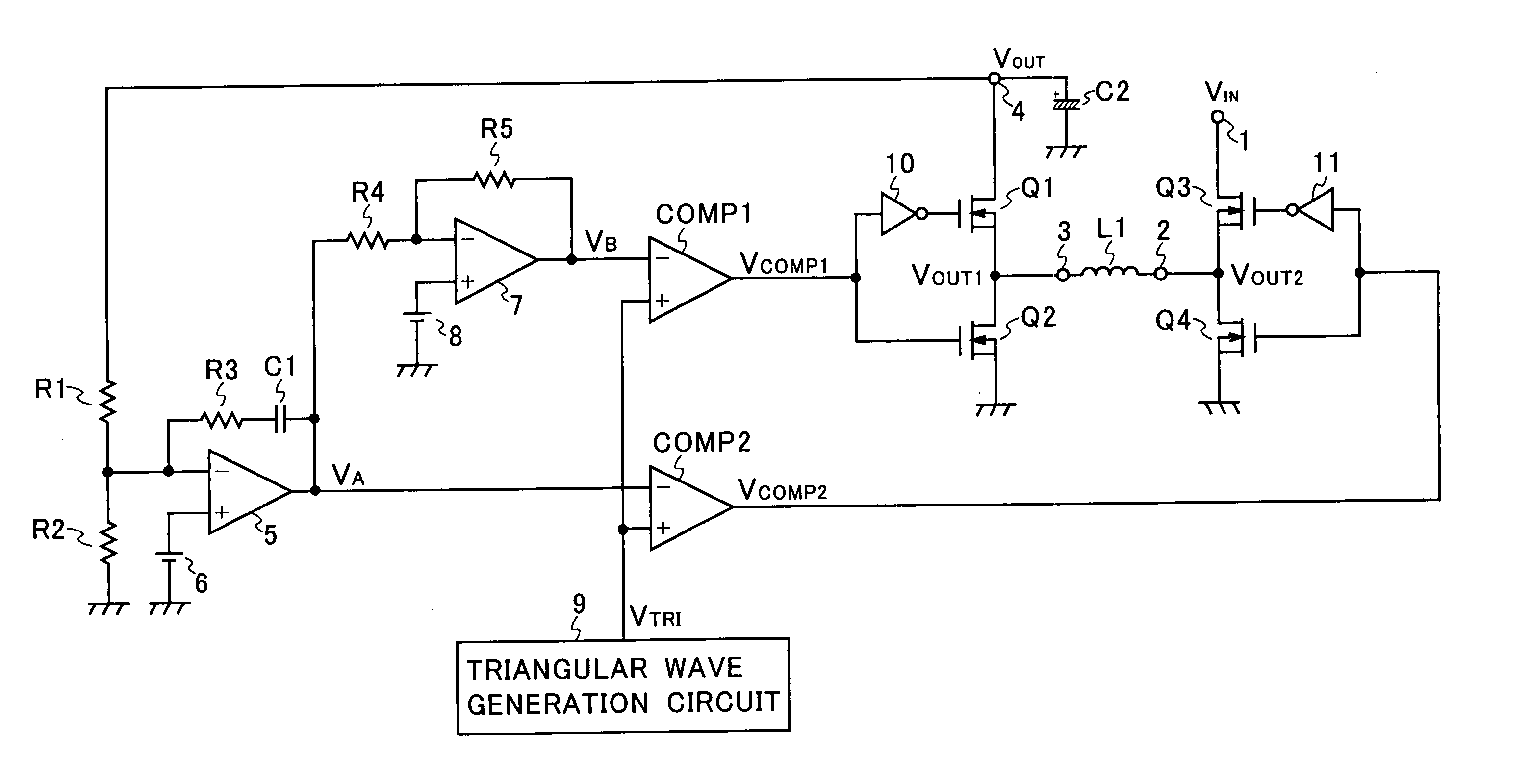

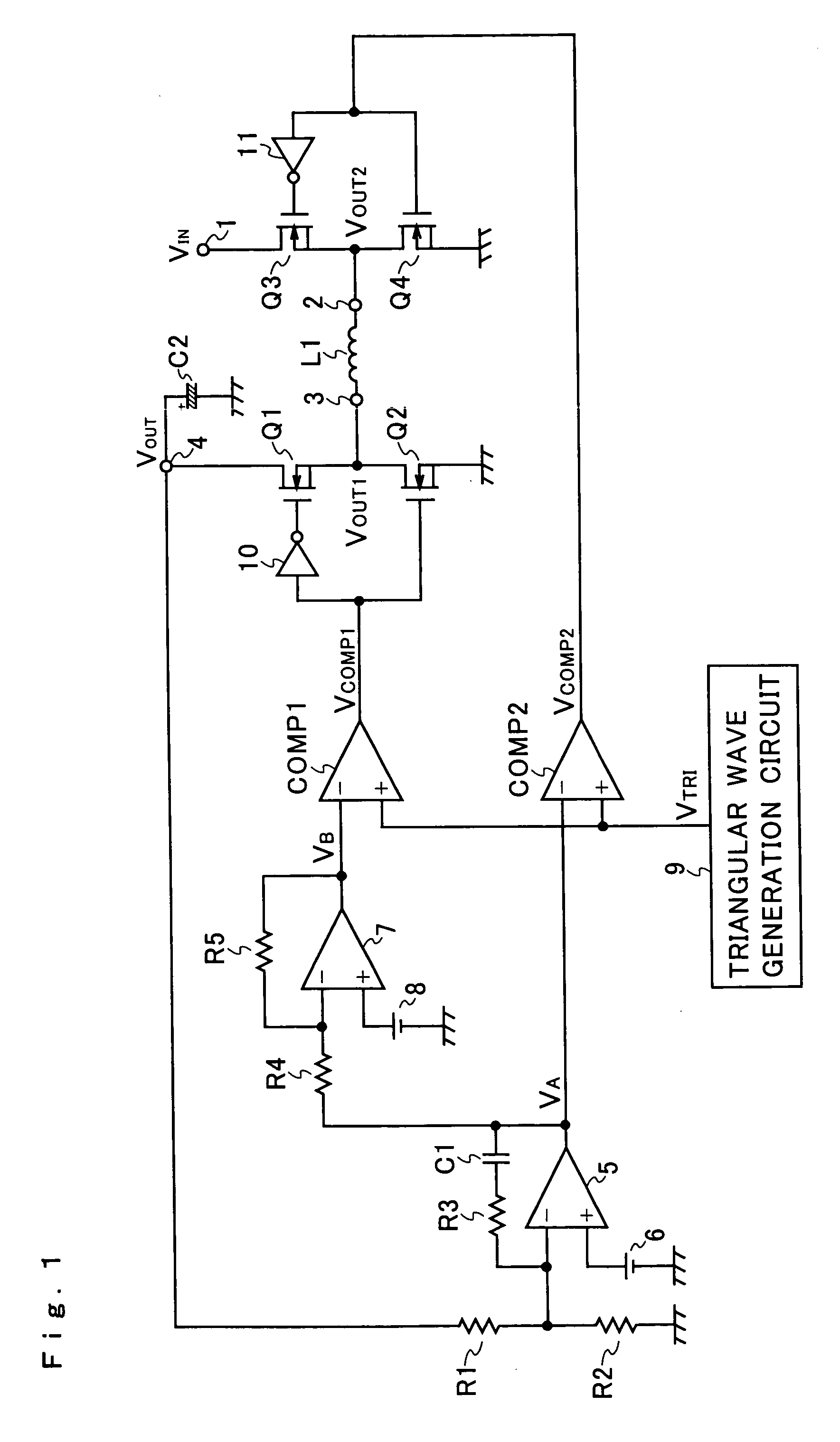

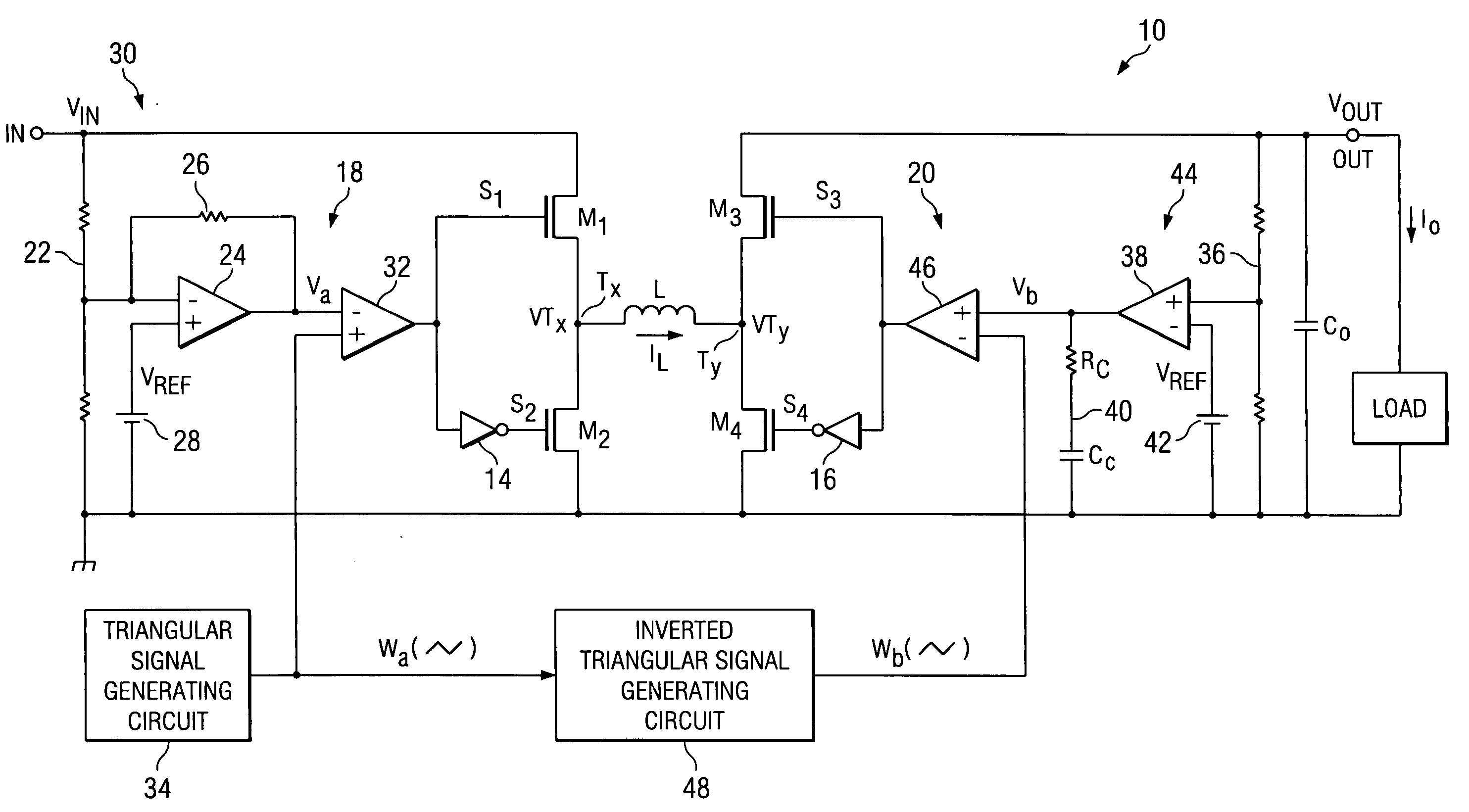

ActiveUS20050007089A1Stable currentStable output voltageDc-dc conversionElectric variable regulationTriangular waveVoltage reference

In a step-up / step-down DC-DC converter, an error signal commensurate with a difference between a voltage commensurate with the output voltage and a predetermined reference voltage and a triangular wave signal are compared by a first comparator, whose output is used to turn on and off a step-up switching circuit. An inverted signal obtained by inverting the error signal and the triangular wave signal are compared by a second comparator, whose output is used to turn on and off a step-down switching circuit. The median level between the outputs of the first and second comparators is set to be lower than the maximum level of the triangular wave signal and higher than the minimum level thereof. Thus, when step-up and step-down modes are switched from one to the other, an overlap period is produced during which the step-up and step-down modes overlap. This makes possible smooth switching between the step-up and step-down modes.

Owner:ROHM CO LTD

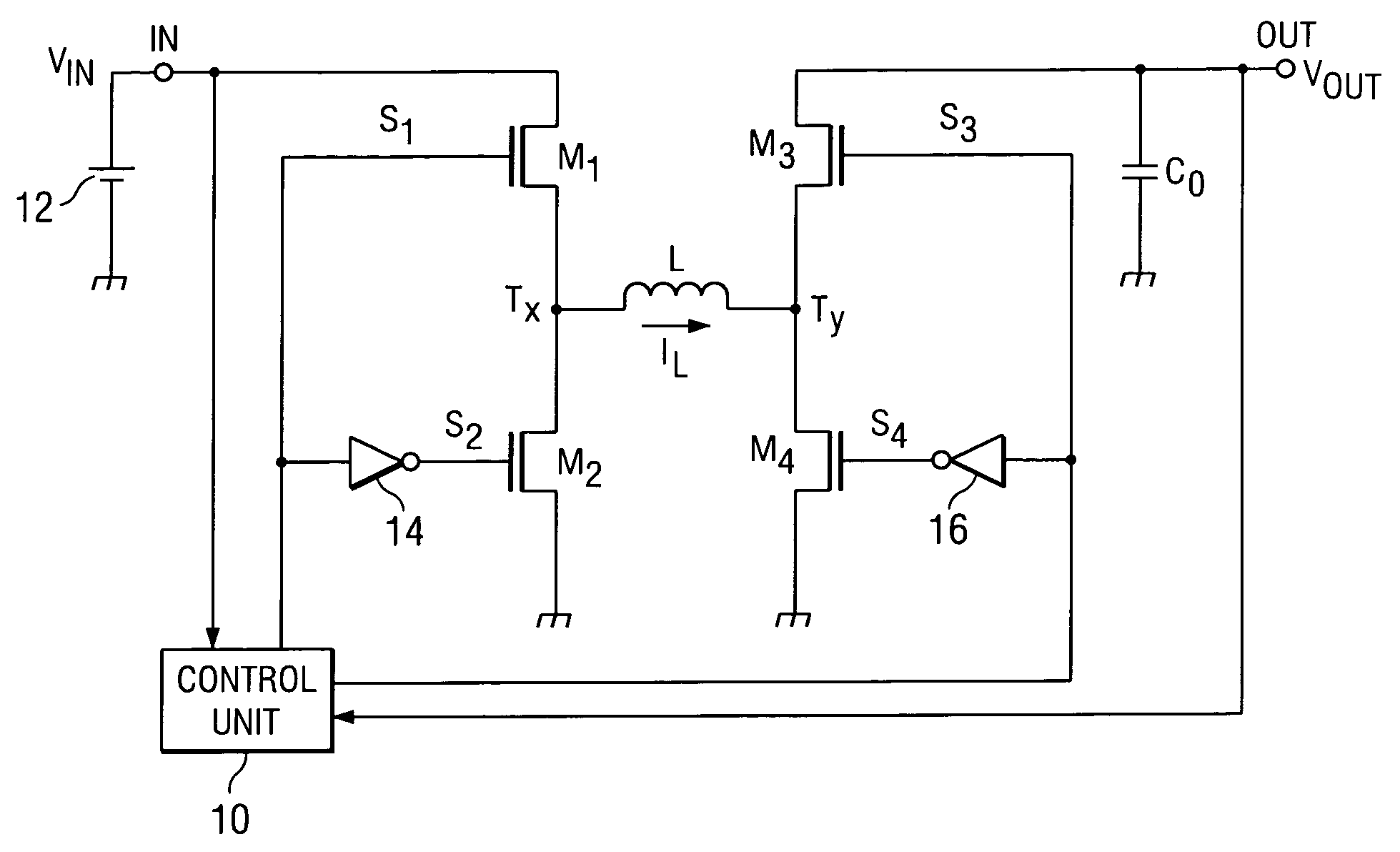

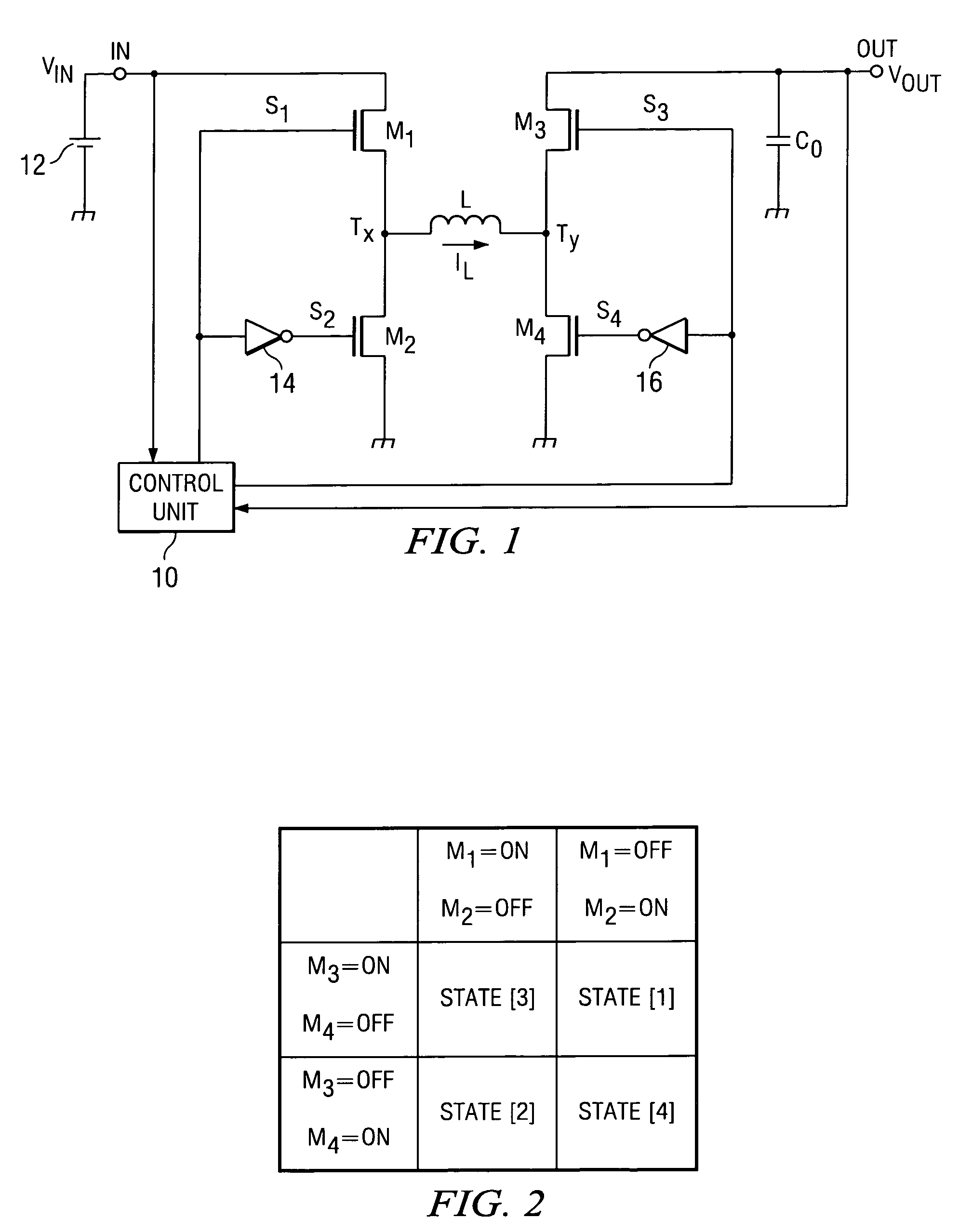

DC-DC converter

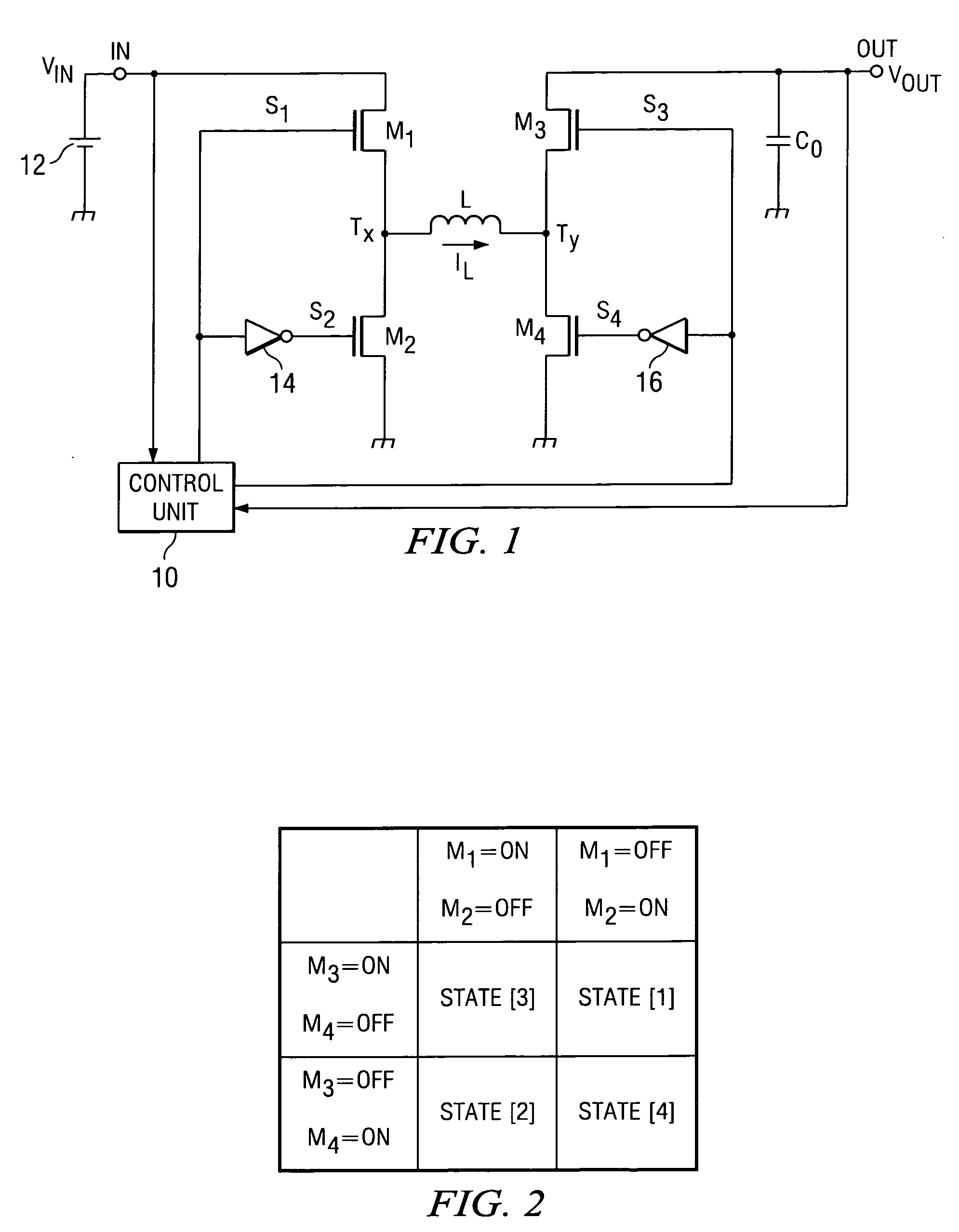

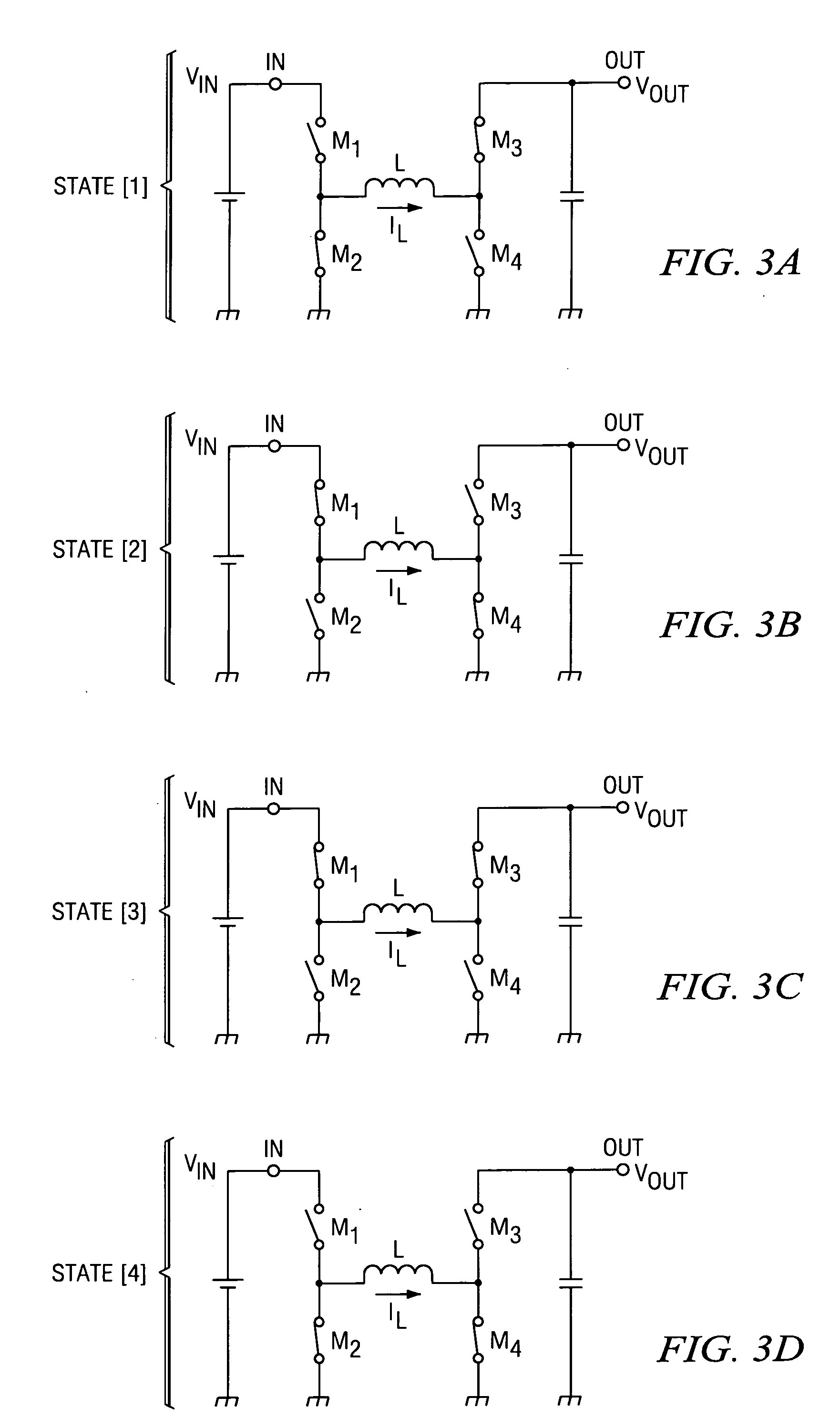

ActiveUS7116085B2Reduce the valueSuppress rippleDc-dc conversionElectric variable regulationDc dc converterPower flow

The objective of this invention is to reduce the current flowing through the inductance element in a step-up / step-down DC—DC converter and to control the ripple in the output voltage. In the DC—DC converter, four states, that is, the first state [1] of (M1, M2)=(off, on) and (M3, M4)=(on, off), the second state [2] of (M1, M2)=(on, off) and (M3, M4)=(off, on), the third state [3] of (M1, M2)=(on, off) and (M3, M4)=(on, off), and the fourth state [4] of (M1, M2)=(off, on) and (M3, M4)=(off, on) are repeated in a prescribed order, preferably in the order . . . [1]→[4]→[2]→[3]→[1] . . . or . . . [1]→[3]→[2]→[4]→[1] . . . .

Owner:TEXAS INSTR INC +1

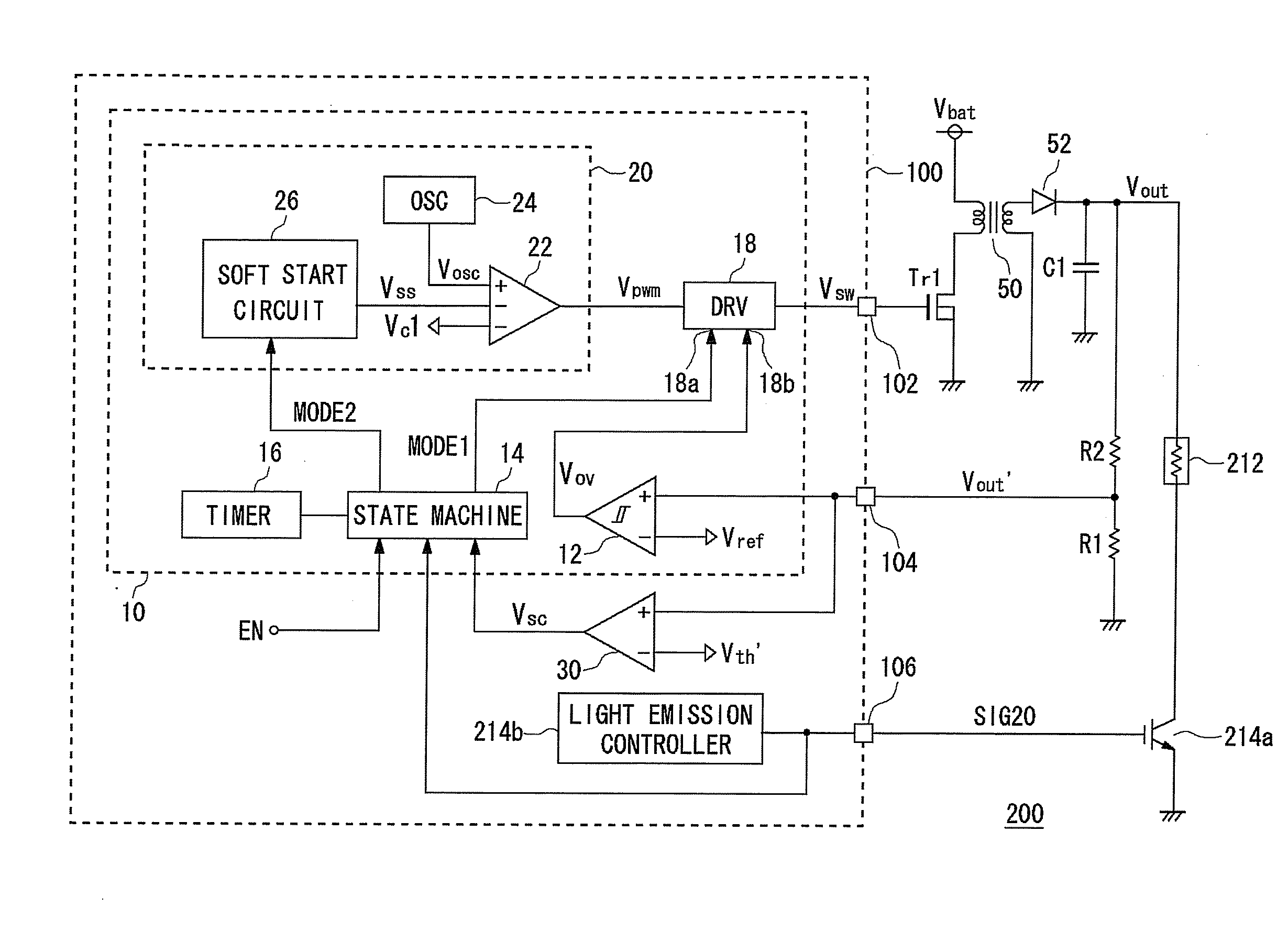

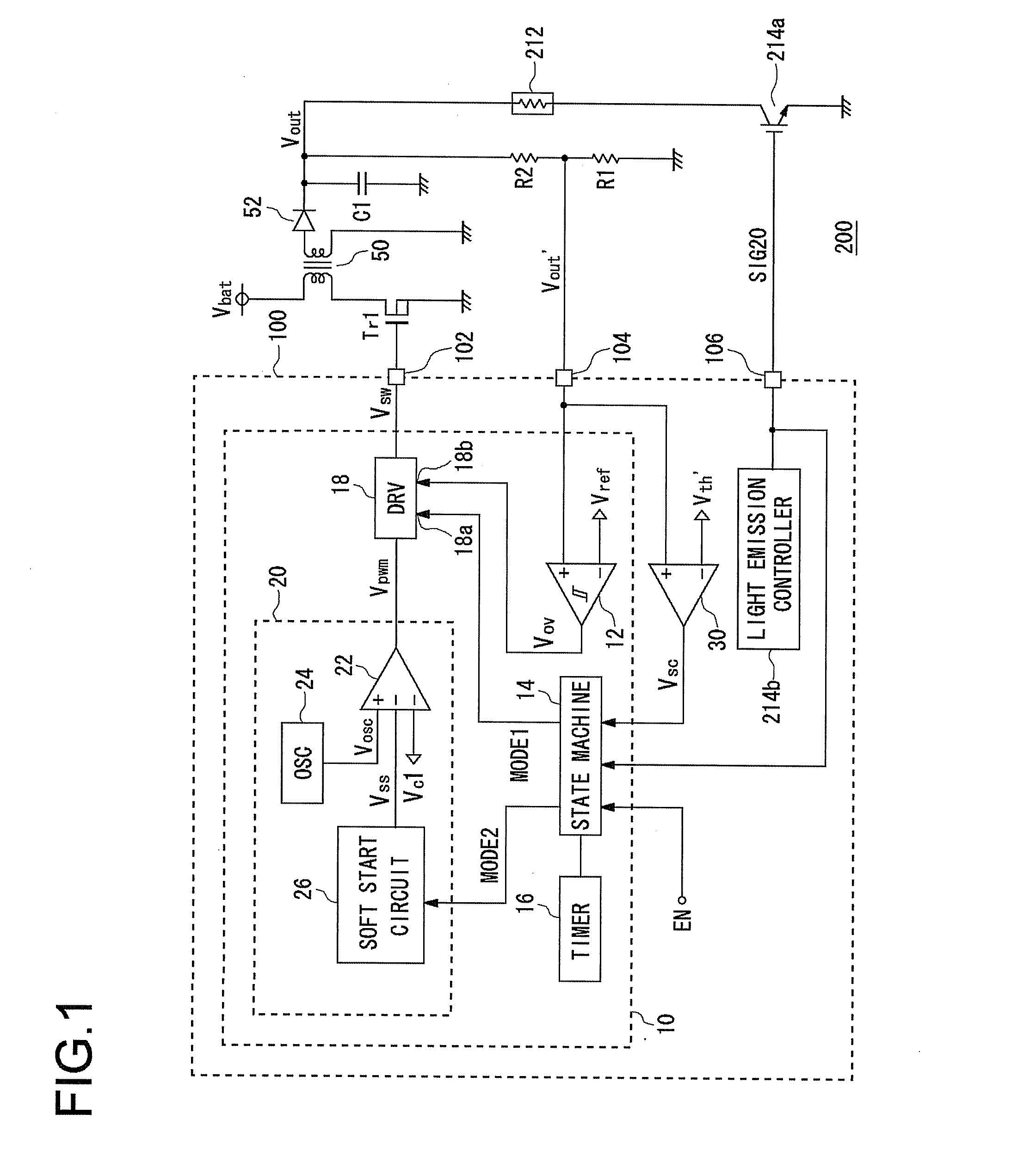

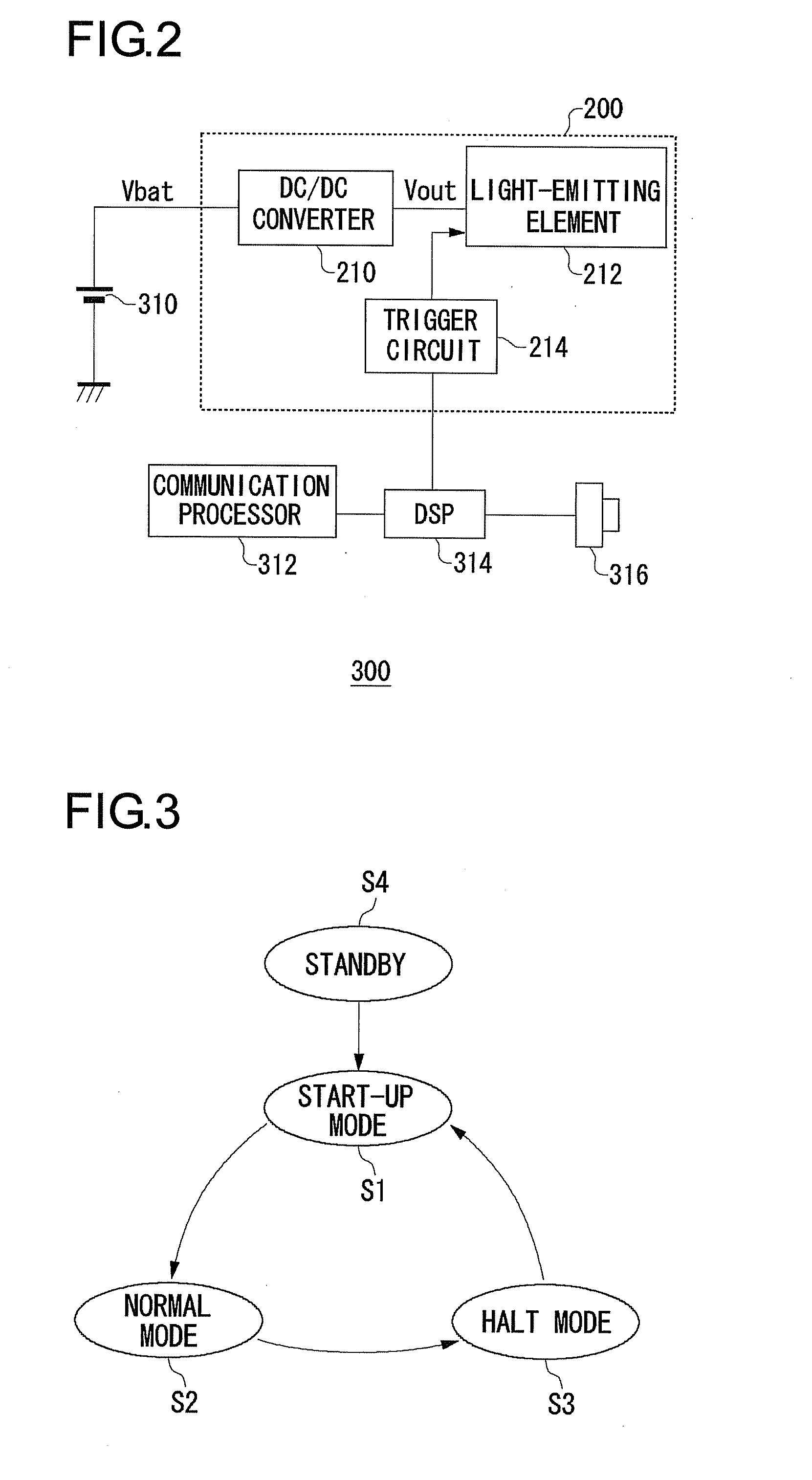

Dc/dc converter control circuit

InactiveUS20080136342A1Increase the output voltageReduce output voltageEmergency protective circuit arrangementsDc-dc conversionStop timeStart up time

A control circuit is provided for a separately excited DC / DC converter which directly monitors output voltage to detect a short-circuit state, and performs overcurrent protection. A switching controller of the control circuit controls a switching operation of a switching transistor of the separately excited DC / DC converter. A voltage comparator compares the output voltage and a threshold voltage, to detect the short-circuit state. After a predetermined start-up time has elapsed after beginning start-up of the separately excited DC / DC converter, when the voltage comparator detects the short-circuit state, the switching controller halts the switching operation of the switching transistor, and makes detection of the short-circuit state by the voltage comparator non-operative before elapse of the start-up time. After detecting the short-circuit state and halting the switching operation of the switching transistor for a predetermined halt time, the switching controller begins start-up of the separately excited DC / DC converter once again.

Owner:ROHM CO LTD

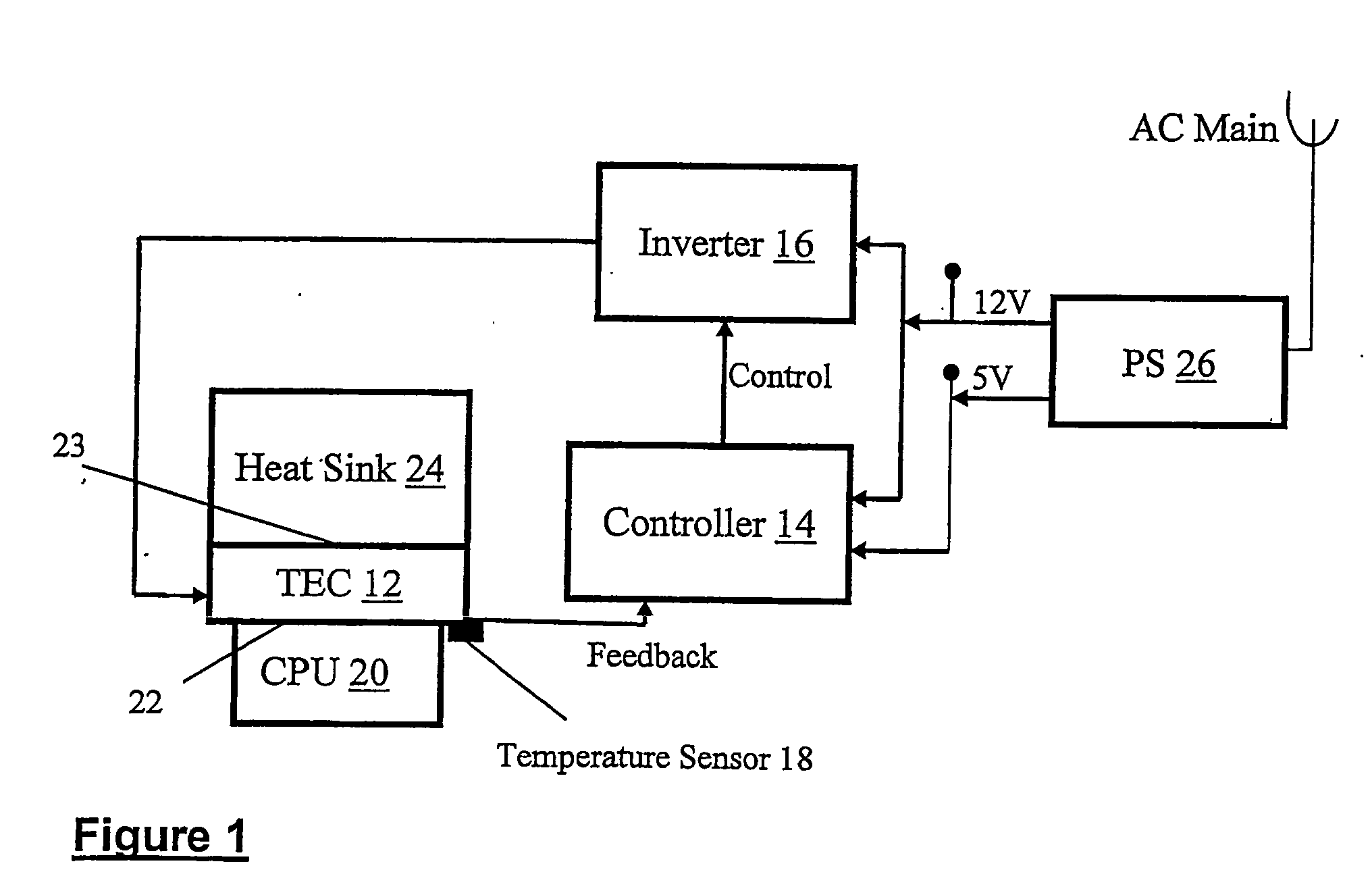

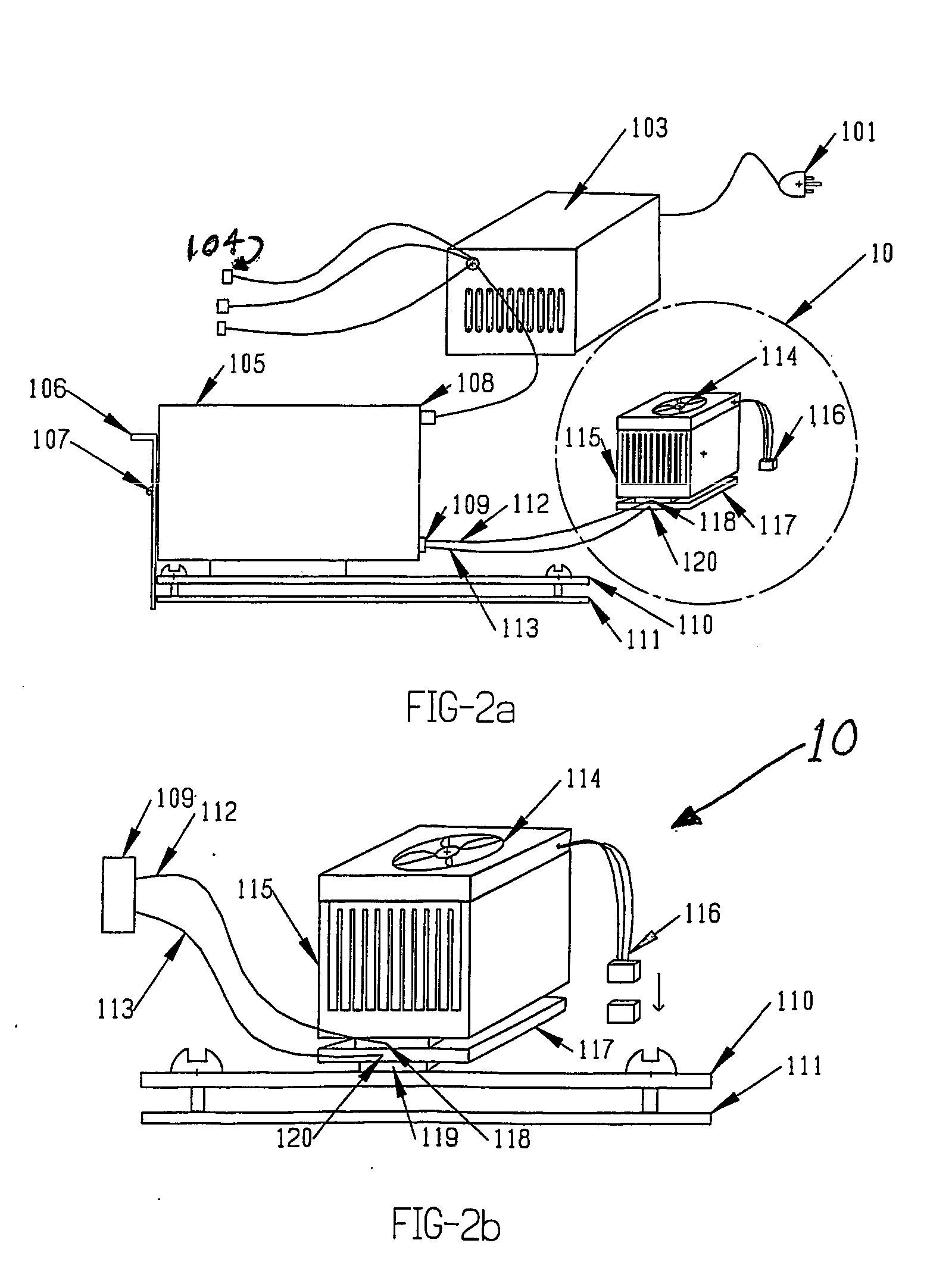

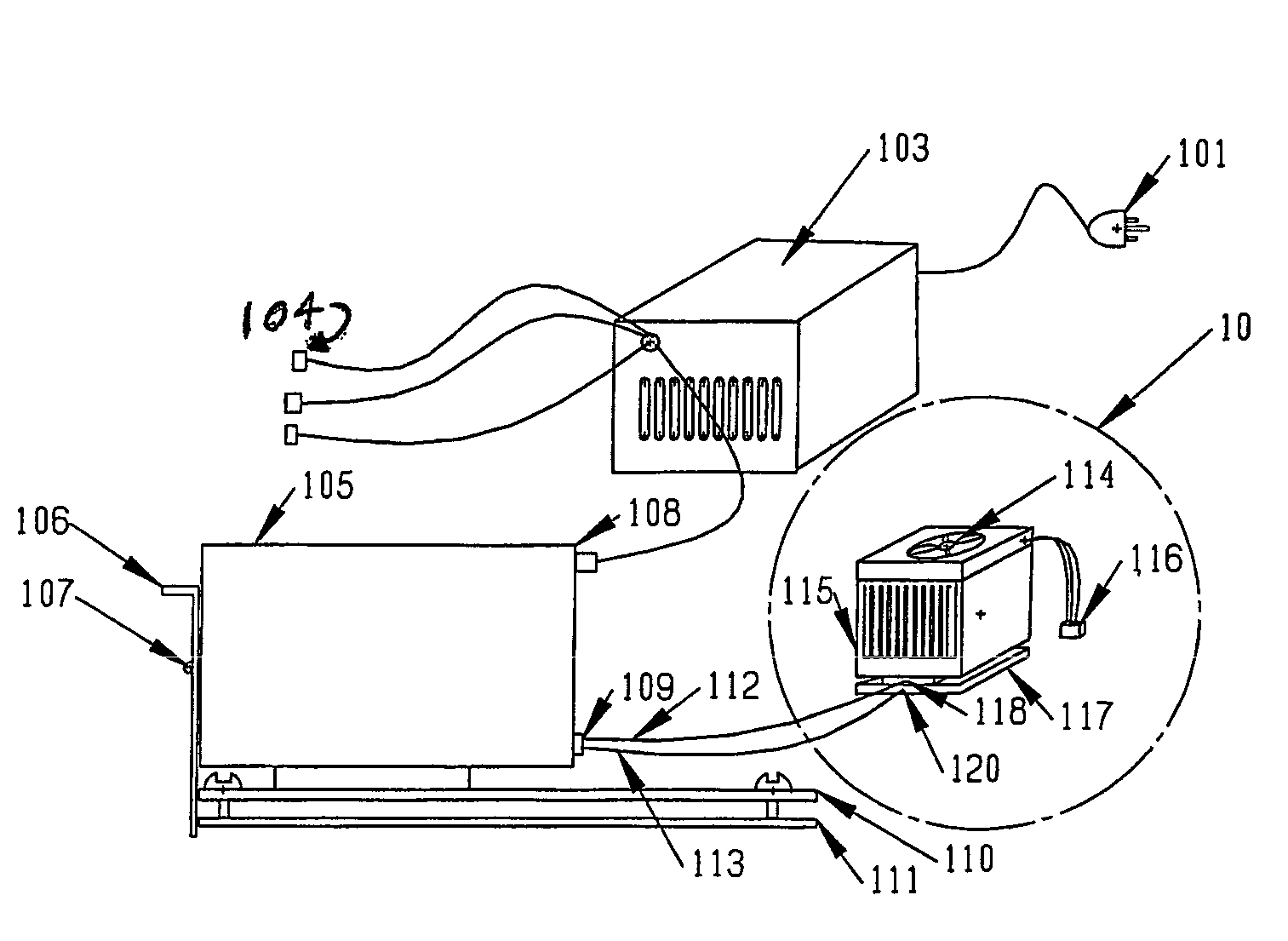

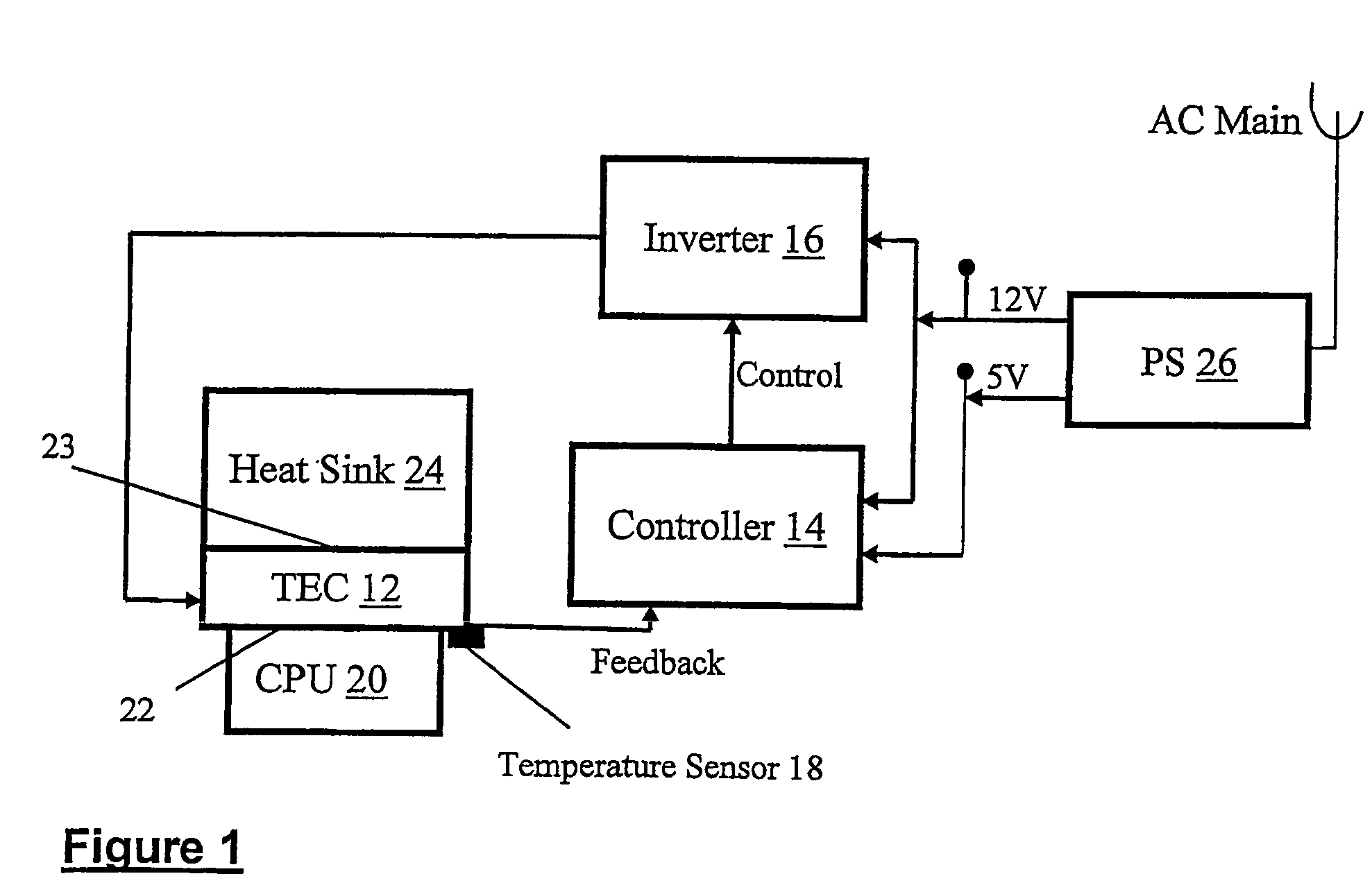

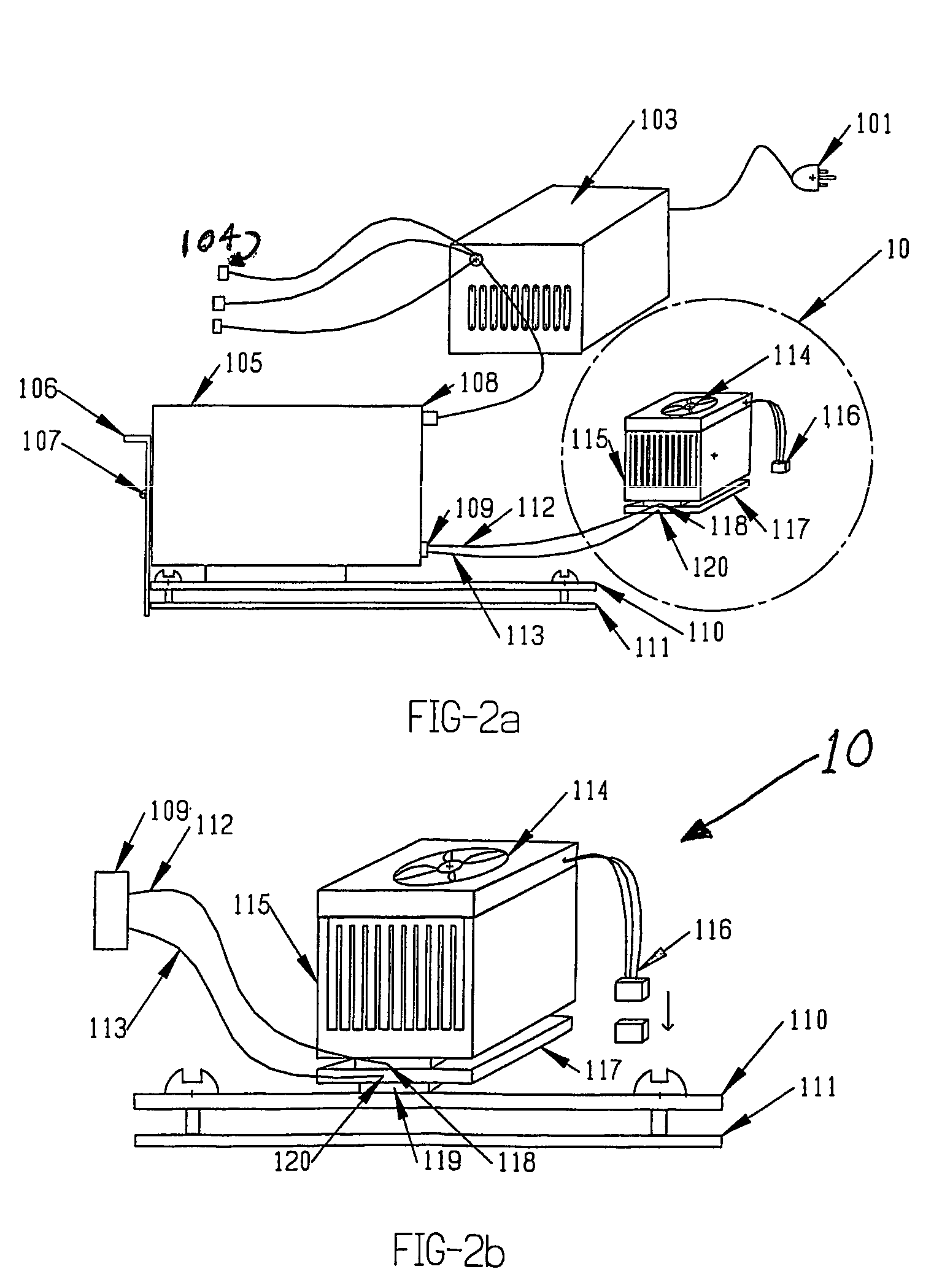

Active cooling system for cpu

InactiveUS20050146850A1Reduce output voltageDomestic cooling apparatusDigital data processing detailsThermoelectric coolingPower inverter

A cooling system for cooling a processor installed within a computer case, the active cooling system comprising: (i) a TEC / heat-sink assembly comprising a thermoelectric cooling module (TEC) having a cold plate and a hot plate, the cold plate being coupleable to a processor, for removing heat from the processor, and the hot plate being coupled to a heat sink ; (ii) a control microprocessor controllingly coupled to a power inverter, said power inverter for provision of high efficiency cooling to the processor by application of an appropriate voltage to the TEC; the control microprocessor being further coupled to (iii) a temperature sensor located on the cold plate of the TEC, for providing information to the microprocessor regarding temperature of the TEC; said cooling system being powered by a standard PC power supply having sufficient power to accommodate power demands of both the PC and the cooling system.

Owner:ACTIVE COOL RES & DEV LTD

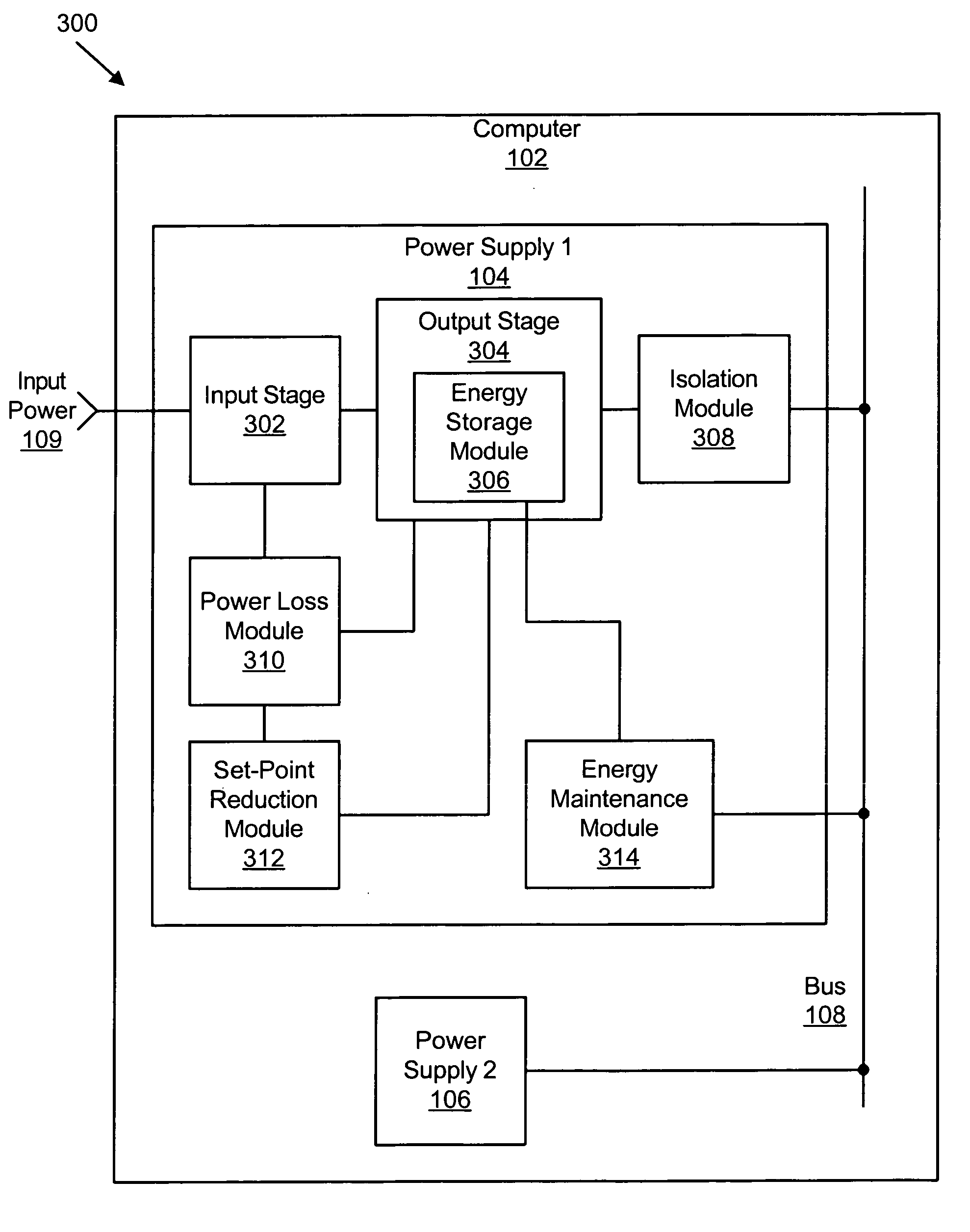

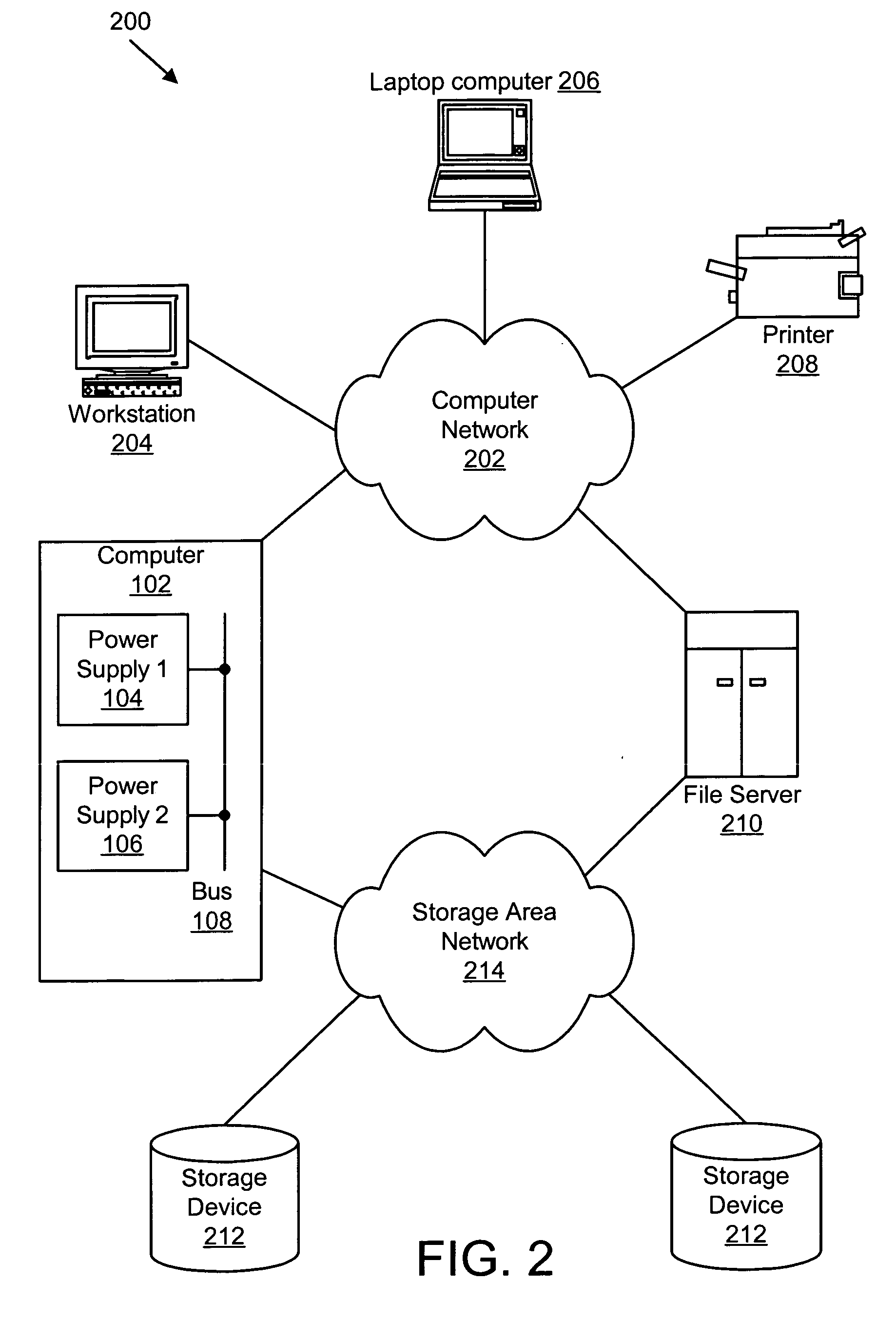

Apparatus, system, and method for maximizing power system holdup time during loss of input power

InactiveUS20060146461A1Maximizing power system holdup timeMaximize power system holdup timeBatteries circuit arrangementsPower supply for data processingElectric power systemEngineering

An apparatus, system, and method are disclosed for maximizing power system holdup time during loss of input power. An energy storage module is included to deliver energy from an output stage of a first power supply to a bus. A power loss module is included to detect loss of power transmitting capability from an input stage of the first power supply to the output stage of the first power supply. A set-point reduction module is included to reduce an output voltage of the first power supply in response to the power loss module detecting loss of power transmitting capability. An isolation module is included to prevent energy flow from the energy storage module to the bus when the output voltage of the first power supply is lower than a voltage on the bus sustained by a second power supply.

Owner:GOOGLE LLC

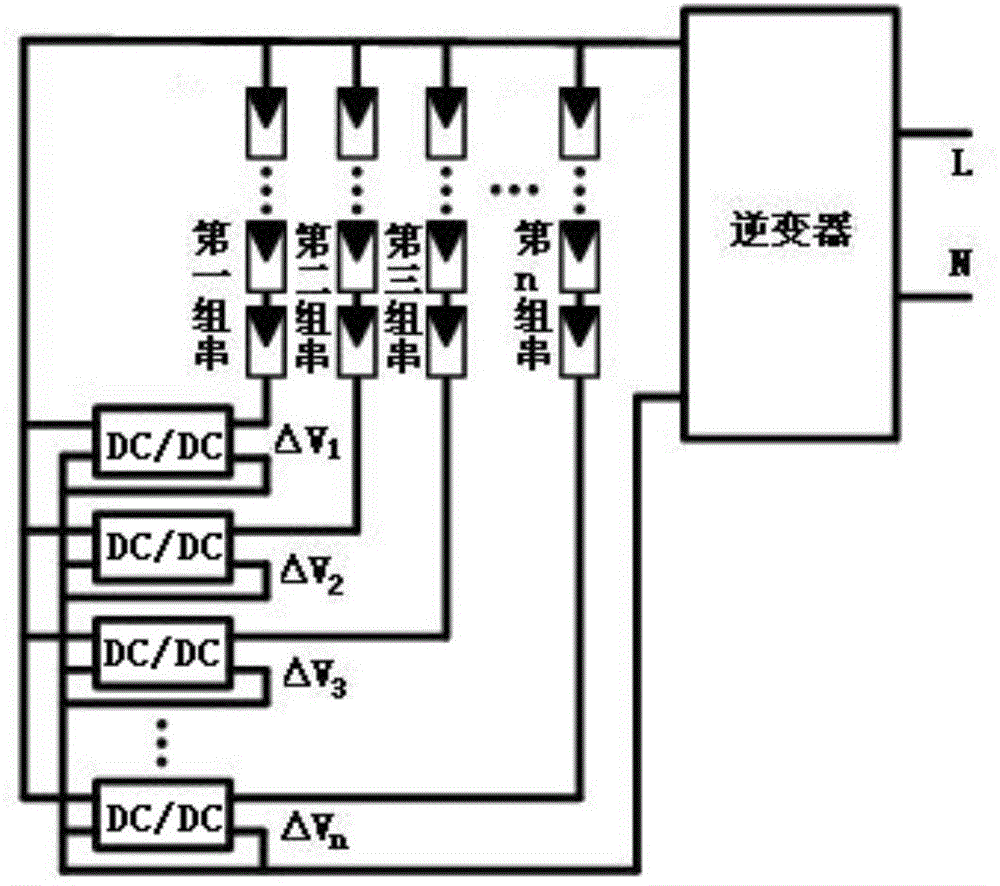

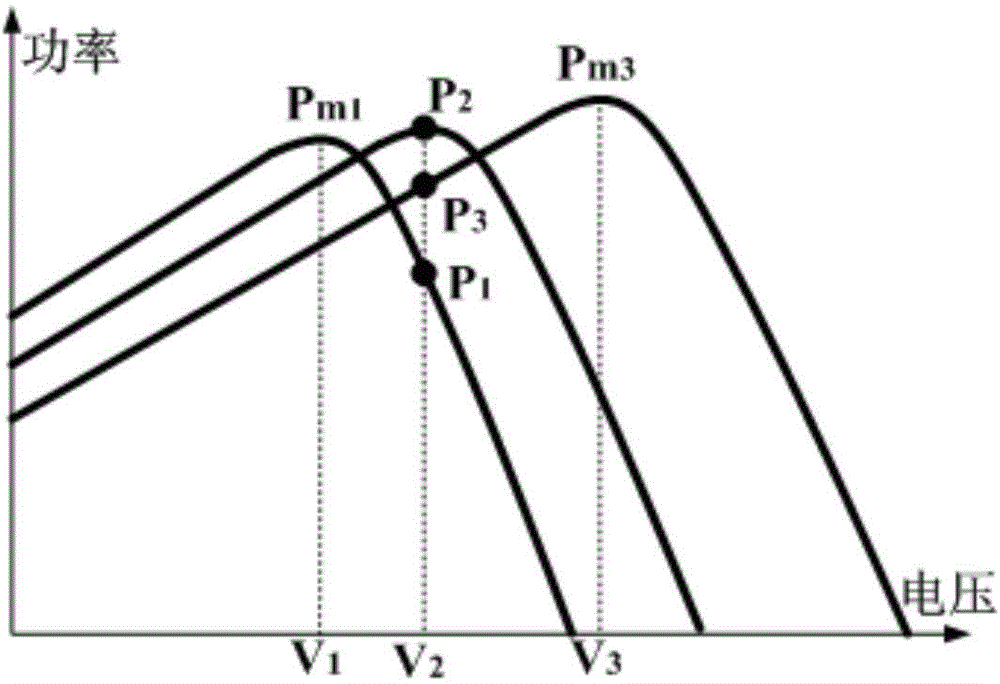

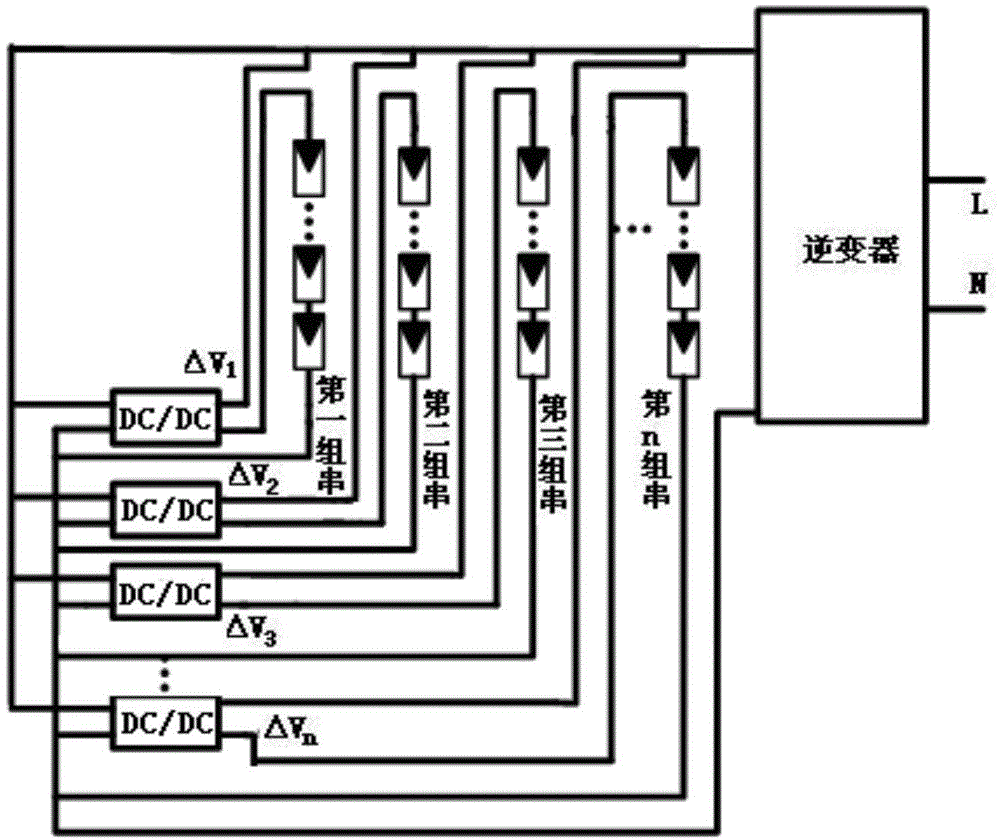

Efficient photovoltaic power generation system

ActiveCN104158482AIncrease power generationImprove power generation efficiencyDc-dc conversionPhotovoltaicsComputer moduleVoltage compensation

The invention provides an efficient photovoltaic power generation system, which comprises DC / DC modules, an inverter and at least two serial strings which are mutually in parallel connection, wherein each serial string is connected with one DC / DC module; the two input ends of each DC / DC module are respectively connected to the positive pole and the negative pole of a bus; the two output ends of each DC / DC module are respectively connected with the bus and the corresponding serial string or are connected with the bus through the corresponding serial string; when the bus voltage V is inconsistent with voltage Vn corresponding to the maximum power point of any of the serial strings, the offset voltage Delta Vn is output by the DC / DC module corresponding to the serial string, so that each serial string works at the maximum power point, wherein the offset voltage Delta Vn equals to the difference value of V and Vn. Through the method that each serial string is in series connection with the corresponding DC / DC module, so that voltage compensation can be performed on each serial string, all the serial strings work at the maximum power points during operation and the gross generation of the photovoltaic power generation system is improved by 3% to 5%.

Owner:SHENZHEN KSTAR NEW ENERGY CO LTD

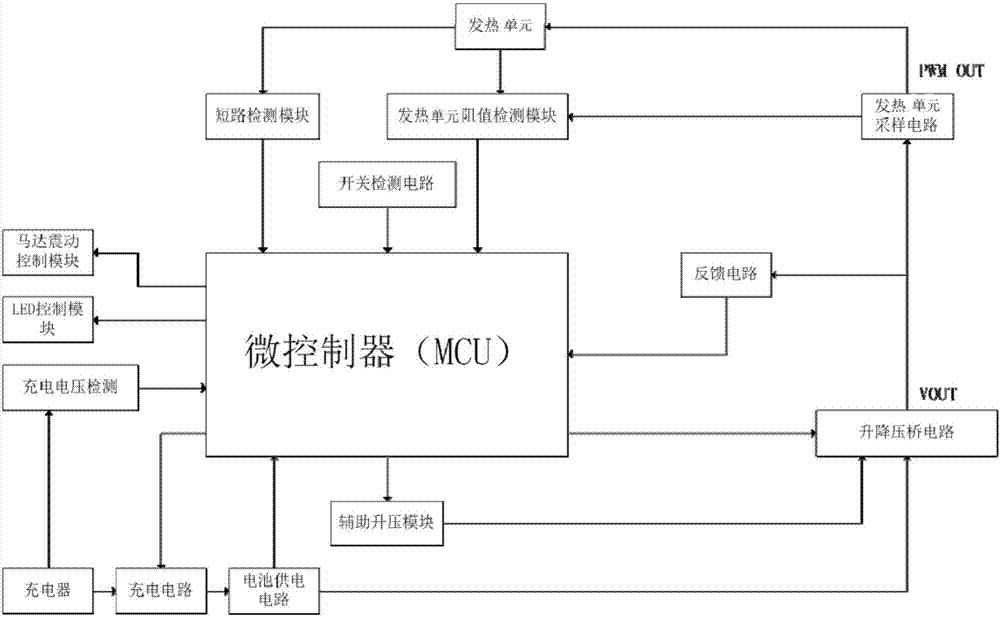

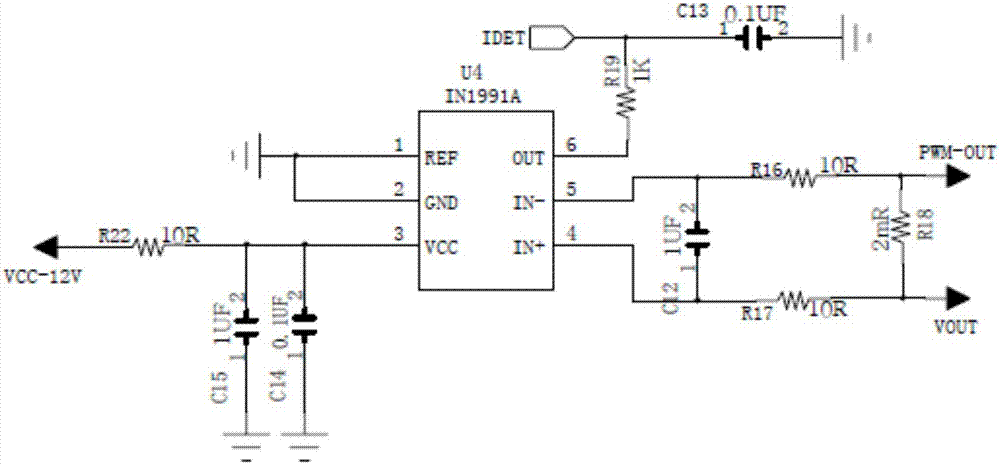

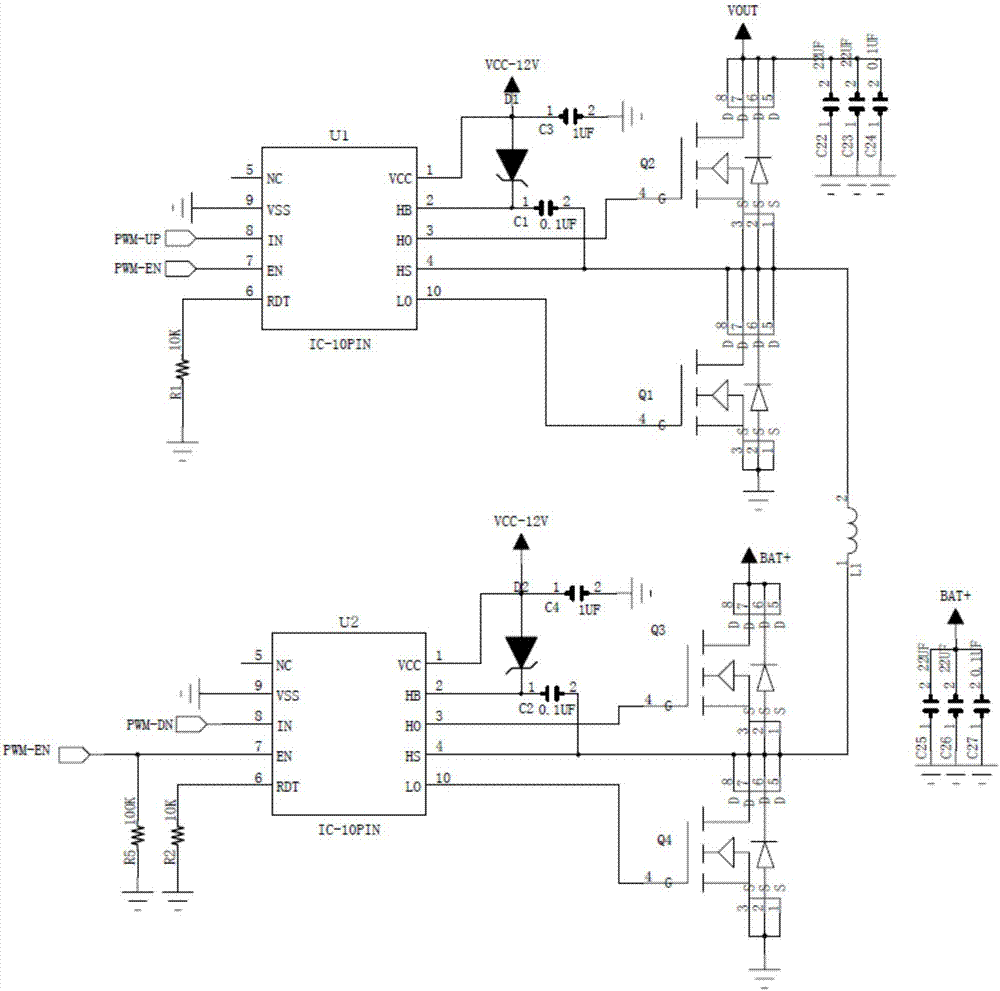

Heating device of electronic smoking set and control method of device

ActiveCN107467718AAdjustable temperatureThe output voltage goes up or downTobacco devicesMicrocontrollerElectricity

The invention relates to a heating device of an electronic smoking set and a control method of the device. A microcontroller of the heating device of the electronic smoking set is electrically connected with a buck-boost bridge circuit, a heating unit resistance value sampling circuit, a heating unit and a heating unit resistance value detection module in sequence and then is connected back to the microcontroller; the heating unit resistance value sampling circuit is connected with the heating unit resistance value detection module, a feedback circuit is connected between the buck-boost bridge circuit and the heating unit, and the feedback circuit is connected back to the microcontroller; when the electronic smoking set is used, the temperature of the heating unit is changed, the resistance value is also changed correspondingly, and the heating unit resistance value detection module detects the resistance value of the heating unit, converts the resistance value into corresponding temperature electric signals, and transmits the signals to the microcontroller; the microcontroller compares the temperature electric signals with a set temperature value and sends control signals to the buck-boost bridge circuit, so that the output voltage of the buck-boost bridge circuit is changed, the power of the heating unit is also changed, and accordingly the temperature of the heating unit is adjusted to be stable.

Owner:HUIZHOU HAPPY VAPING TECH LTD

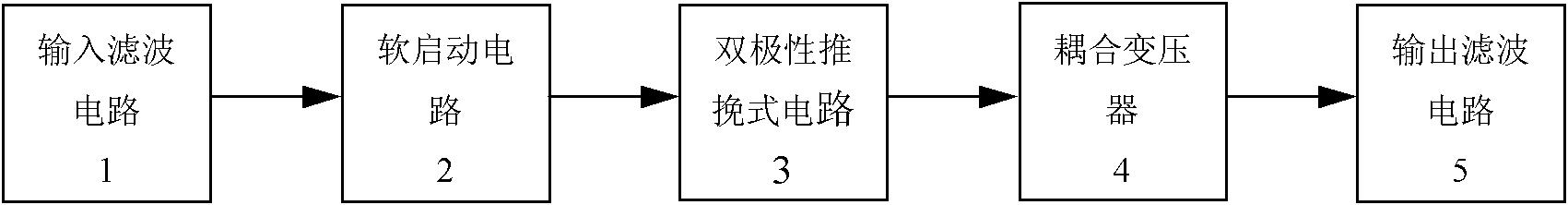

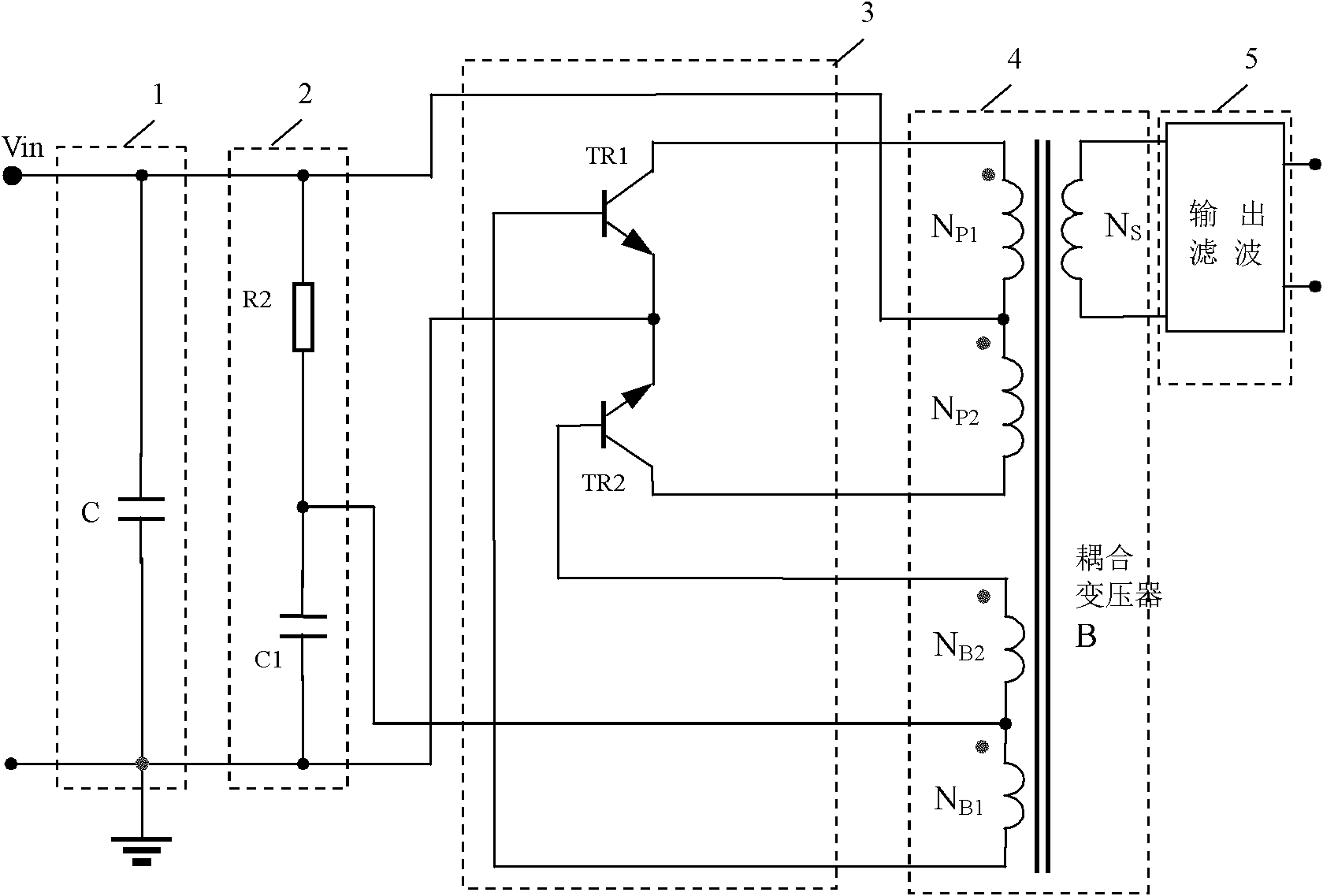

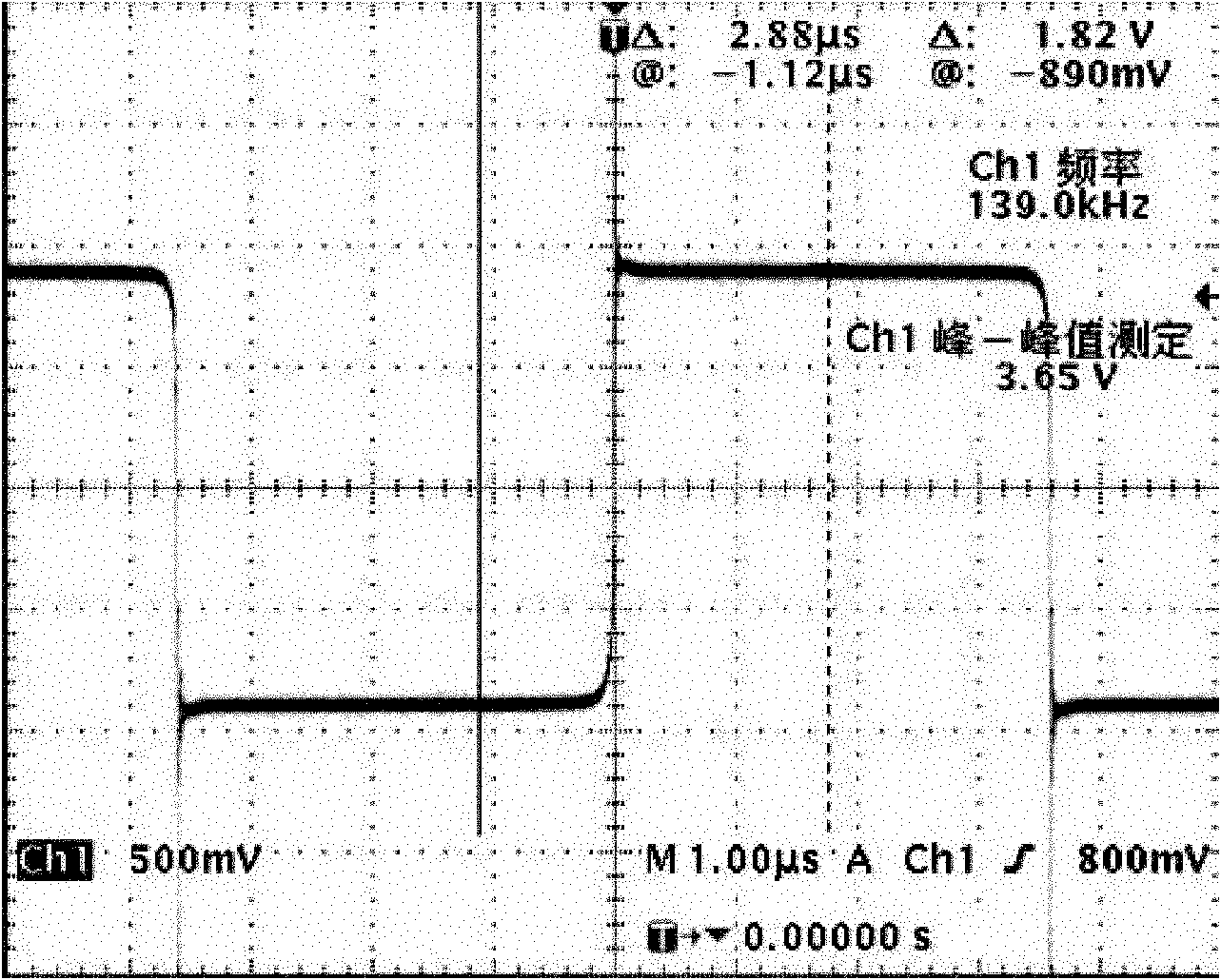

Self-exited push-pull converter

The invention discloses a self-exited push-pull converter, comprising an input soft starting circuit, a bipolar push-pull circuit, a coupling transformer and an output filter circuit, wherein the input soft starting circuit, the bipolar push-pull circuit, the coupling transformer and the output filter circuit are connected in order; the bipolar push-pull circuit comprises two triodes and a high frequency self-exited suppression circuit, wherein the two triodes are in push-pull connection; the emitters of the two triodes are grounded; the bases of the two triodes are respectively connected with two ends of a feedback winding of the coupling transformer; the collectors of the two triodes are connected with two ends of a primary winding of the coupling transformer; the high frequency self-exited suppression circuit is used for removing sine vibration generated due to high characteristic frequency when the triodes are electrified; and the high frequency self-exited suppression circuit is connected in the bipolar push-pull circuit. The self-exited push-pull converter can effectively control high frequency vibration.

Owner:MORNSUN GUANGZHOU SCI & TECH

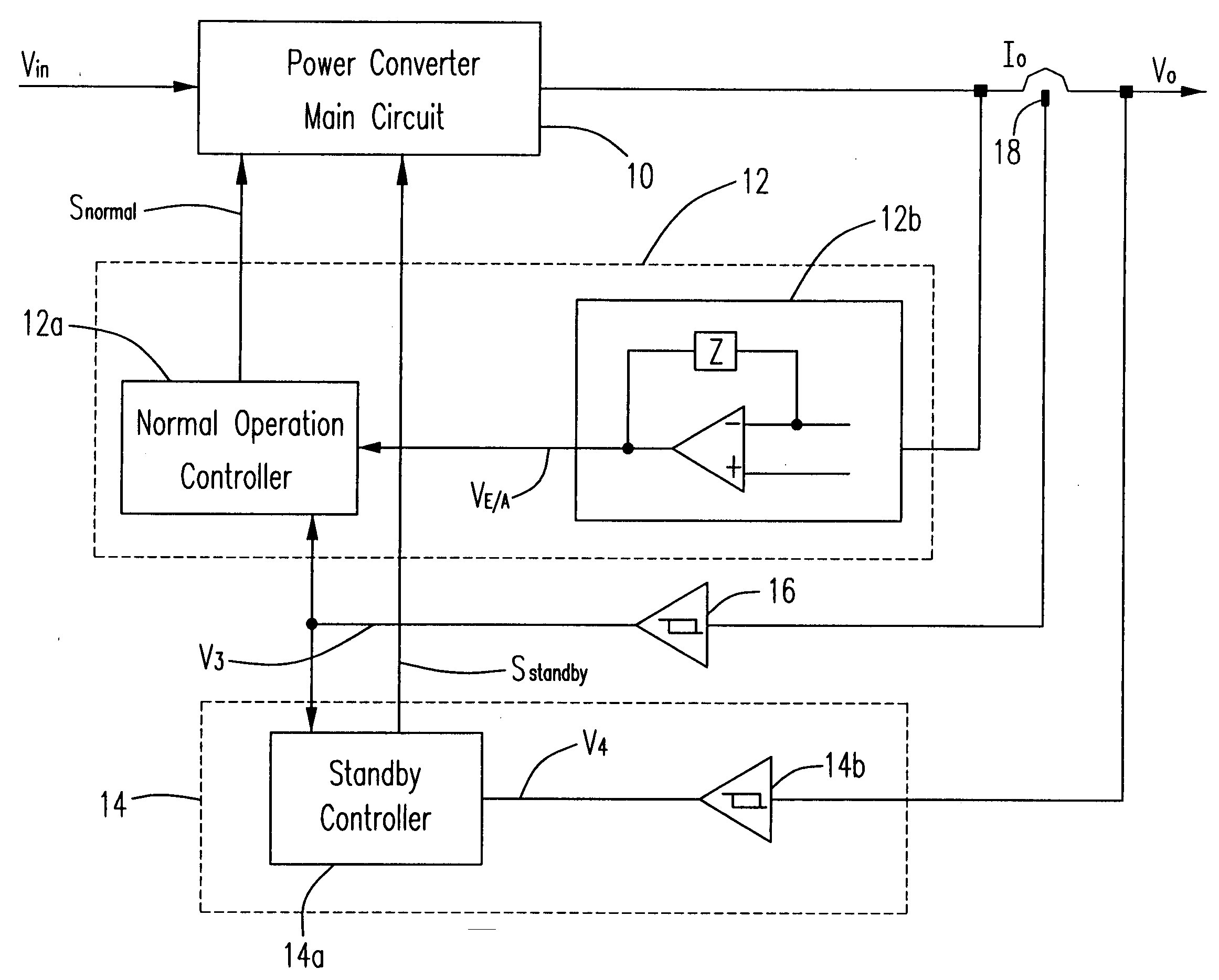

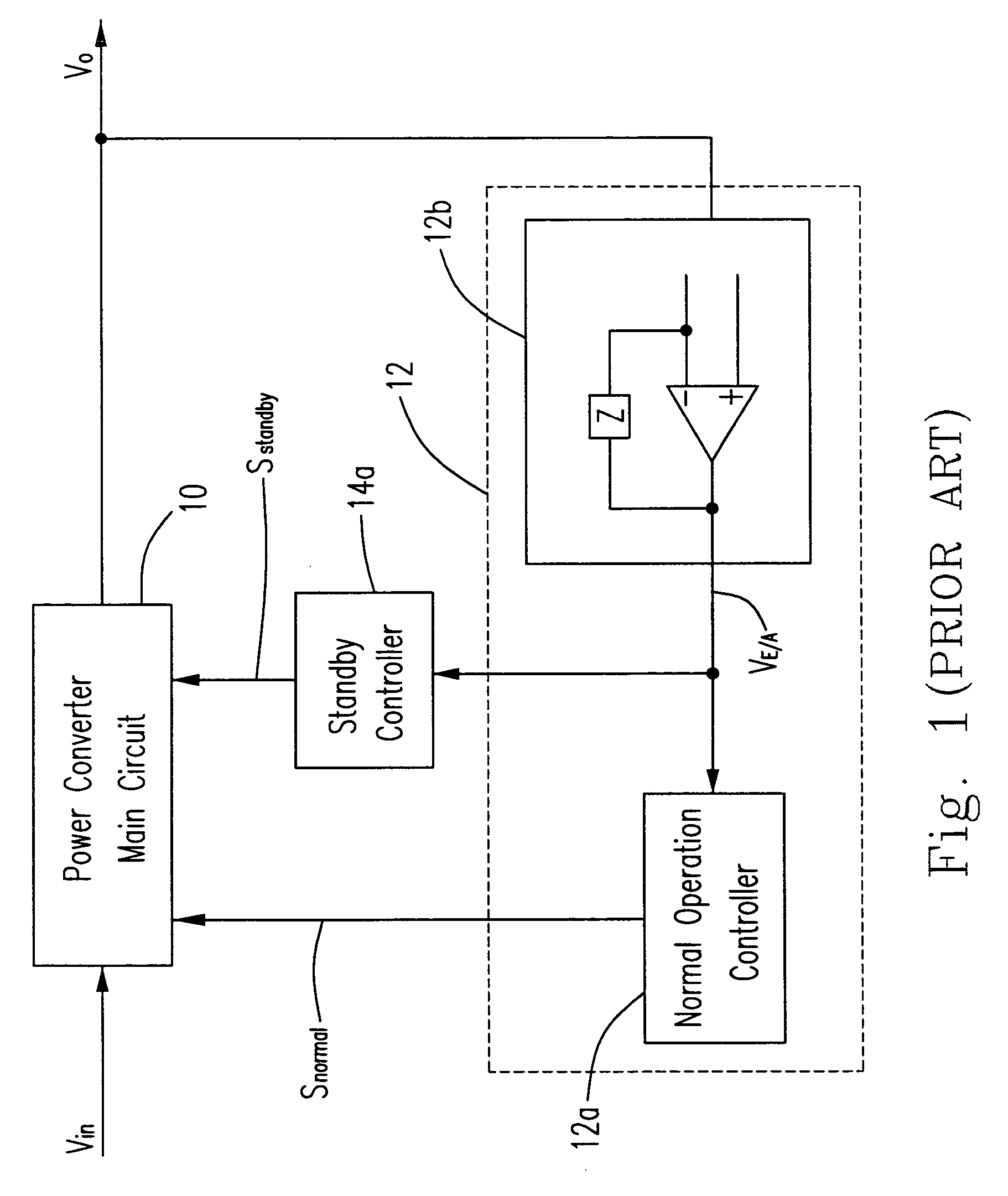

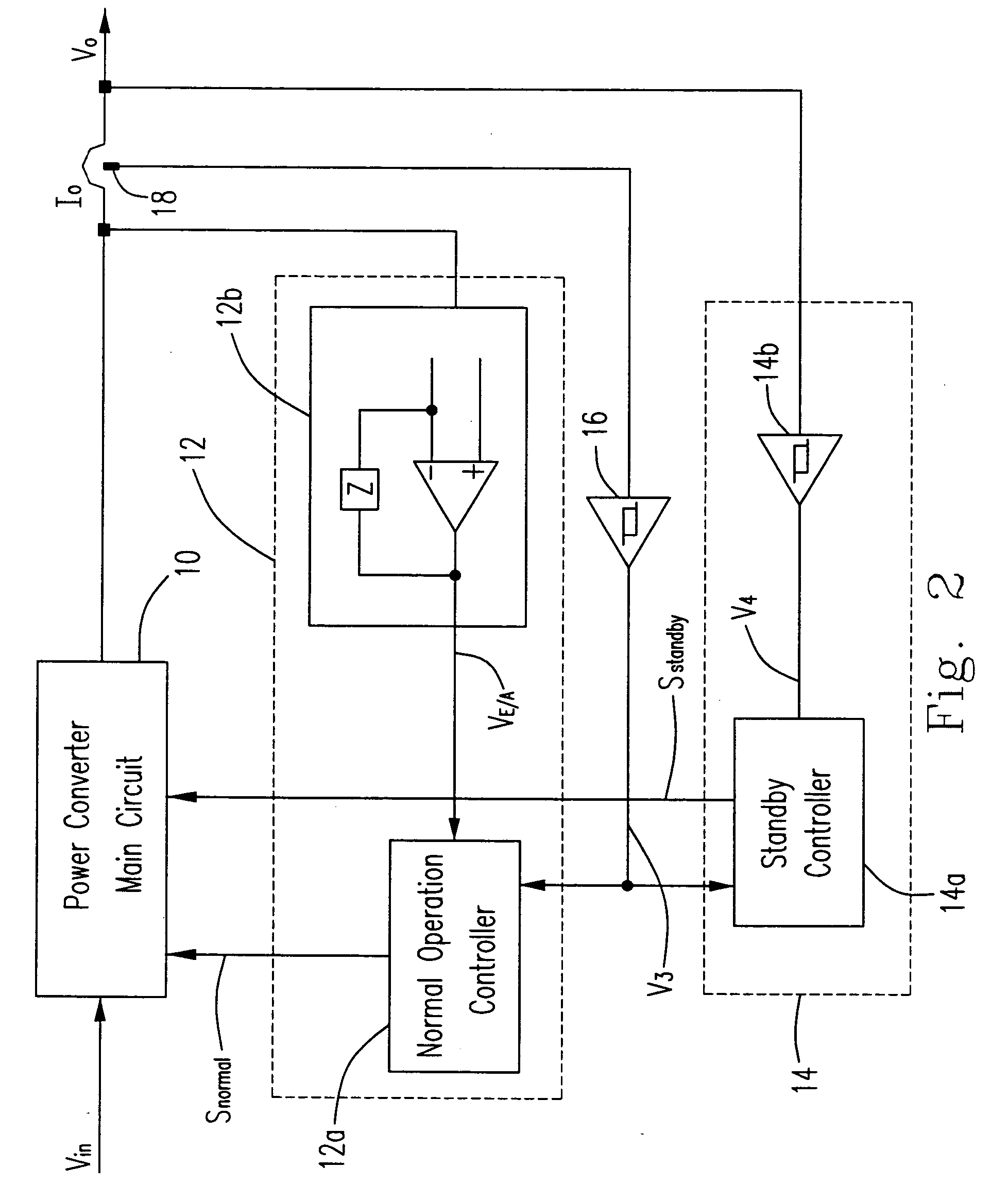

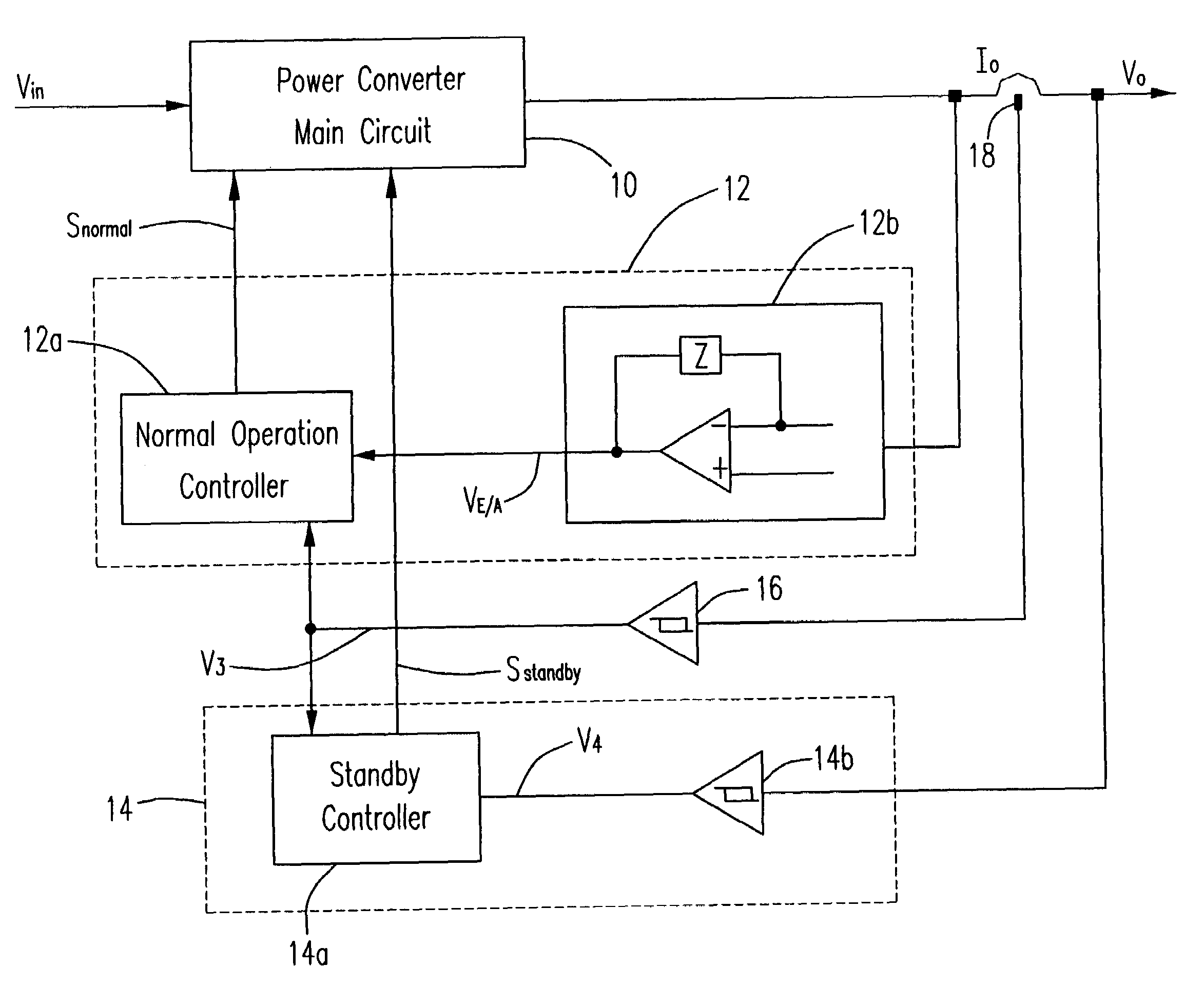

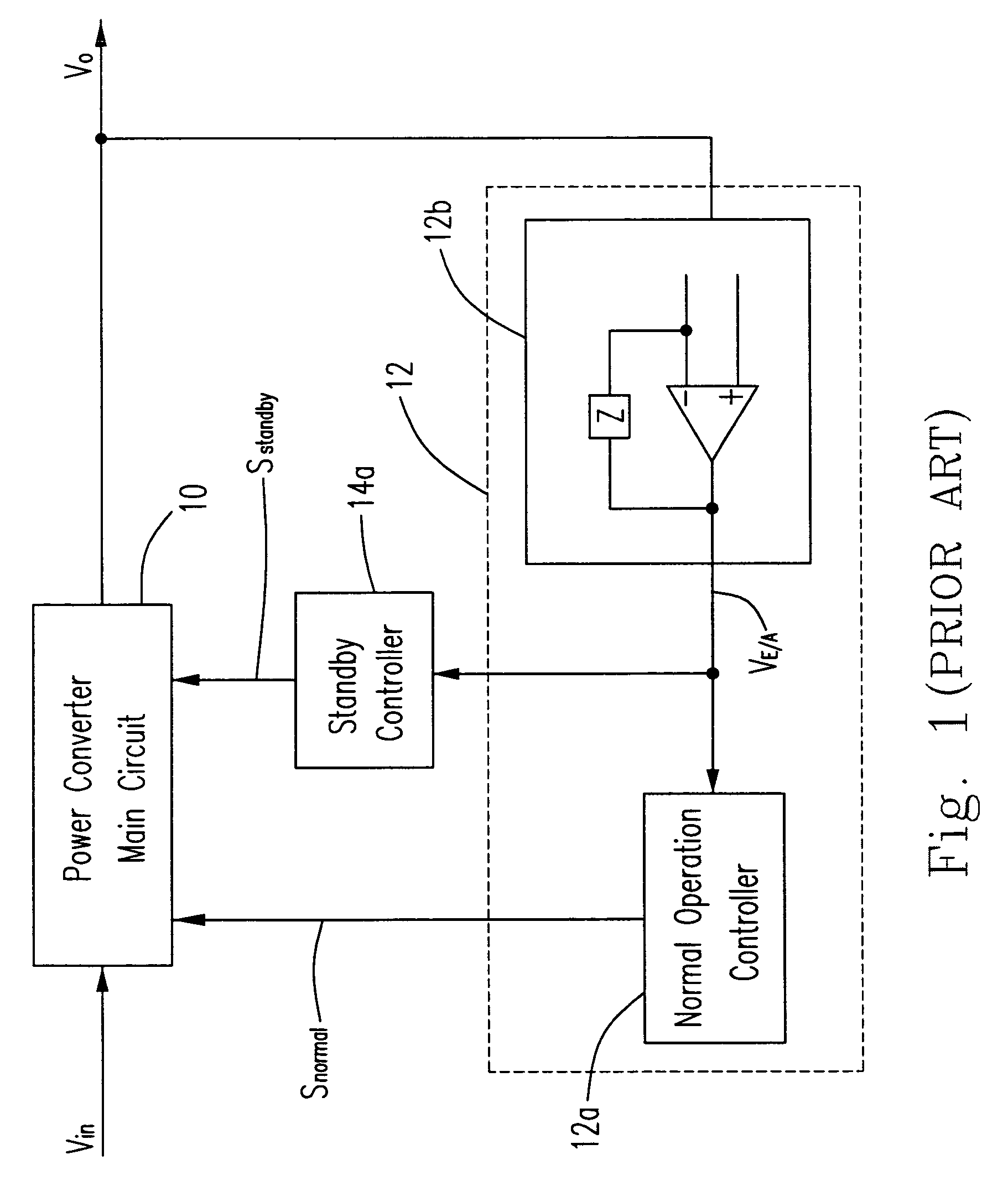

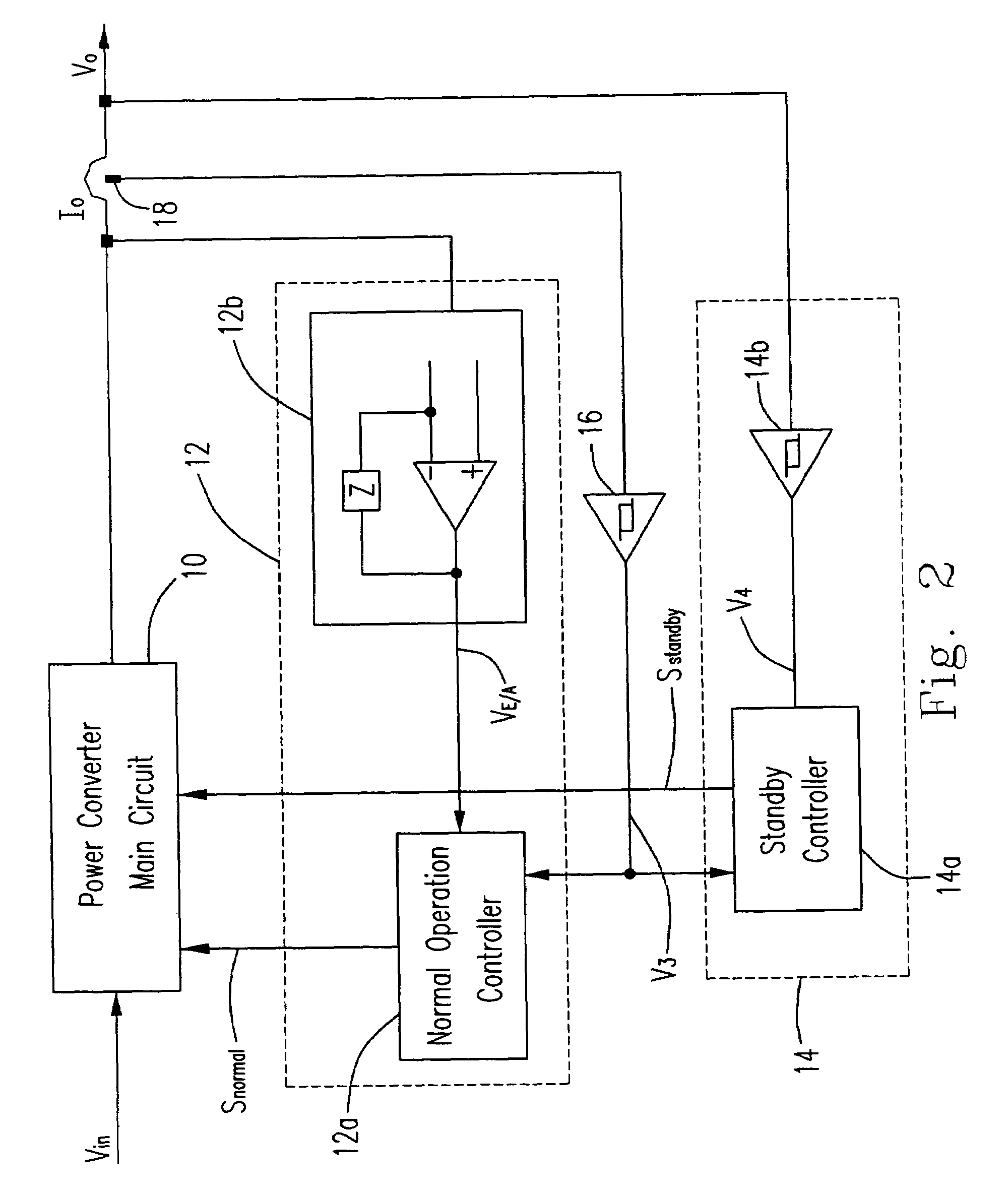

Power supply having efficient low power standby mode

ActiveUS20050046399A1Low standby loss for power converterReduce output voltageEfficient power electronics conversionApparatus with intermediate ac conversionControl signalEngineering

A power supply has a normal operation mode and a standby operation mode. The power supply includes a main circuit, a first control circuit, a second control circuit, and a switching controller. The main circuit has at least one output port for converting an input voltage into an output voltage at the output port. The first control circuit is used for controlling the main circuit under the normal operation mode. The second control circuit is used for controlling the main circuit under the standby operation mode. And, the switching controller processes a control signal to control the first control circuit and the second control circuit under either of the normal operation mode and the standby operation mode in response to a load status of the output port.

Owner:DELTA ELECTRONICS INC

Active cooling system for CPU

InactiveUS7185500B2Reduce output voltageDomestic cooling apparatusDigital data processing detailsThermoelectric coolingPower inverter

A cooling system for cooling a processor installed within a computer case, the active cooling system comprising: (i) a TEC / heat-sink assembly comprising a thermoelectric cooling module (TEC) having a cold plate and a hot plate, the cold plate being coupleable to a processor, for removing heat from the processor, and the hot plate being coupled to a heat sink; (ii) a control microprocessor controllingly coupled to a power inverter, said power inverter for provision of high efficiency cooling to the processor by application of an appropriate voltage to the TEC; the control microprocessor being further coupled to (iii) a temperature sensor located on the cold plate of the TEC, for providing information to the microprocessor regarding temperature of the TEC; said cooling system being powered by a standard PC power supply having sufficient power to accommodate power demands of both the PC and the cooling system.

Owner:ACTIVE COOL RES & DEV LTD

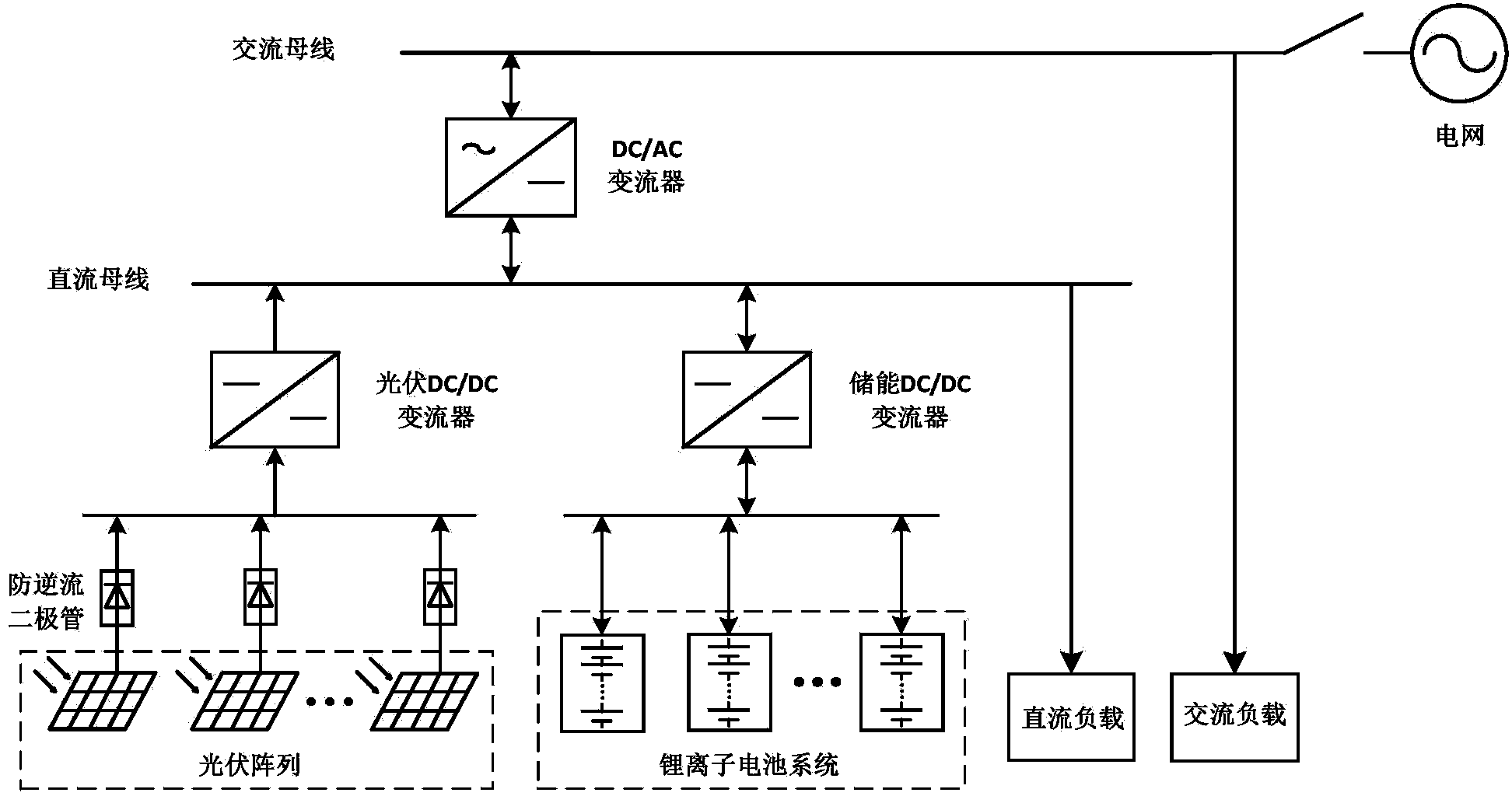

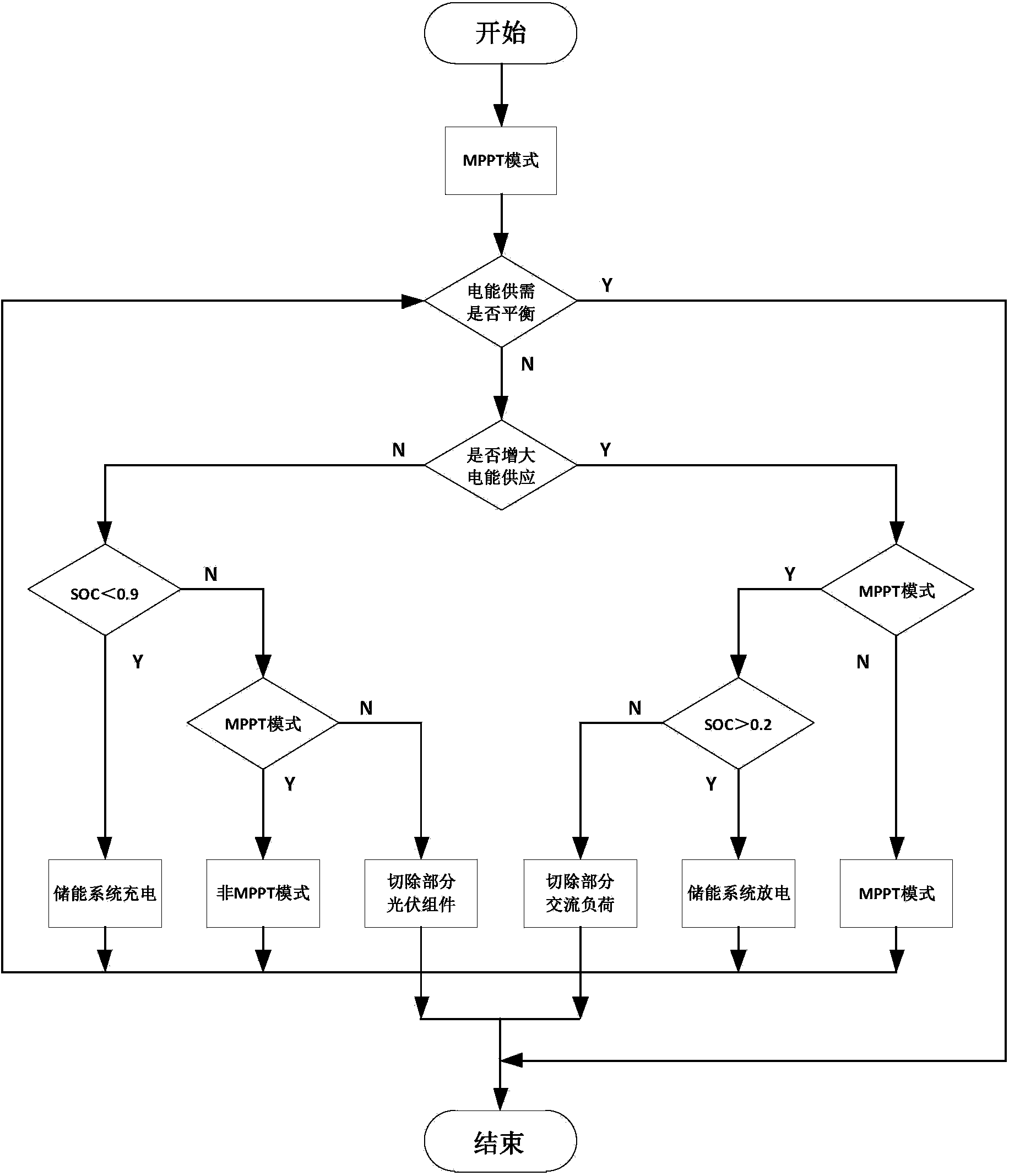

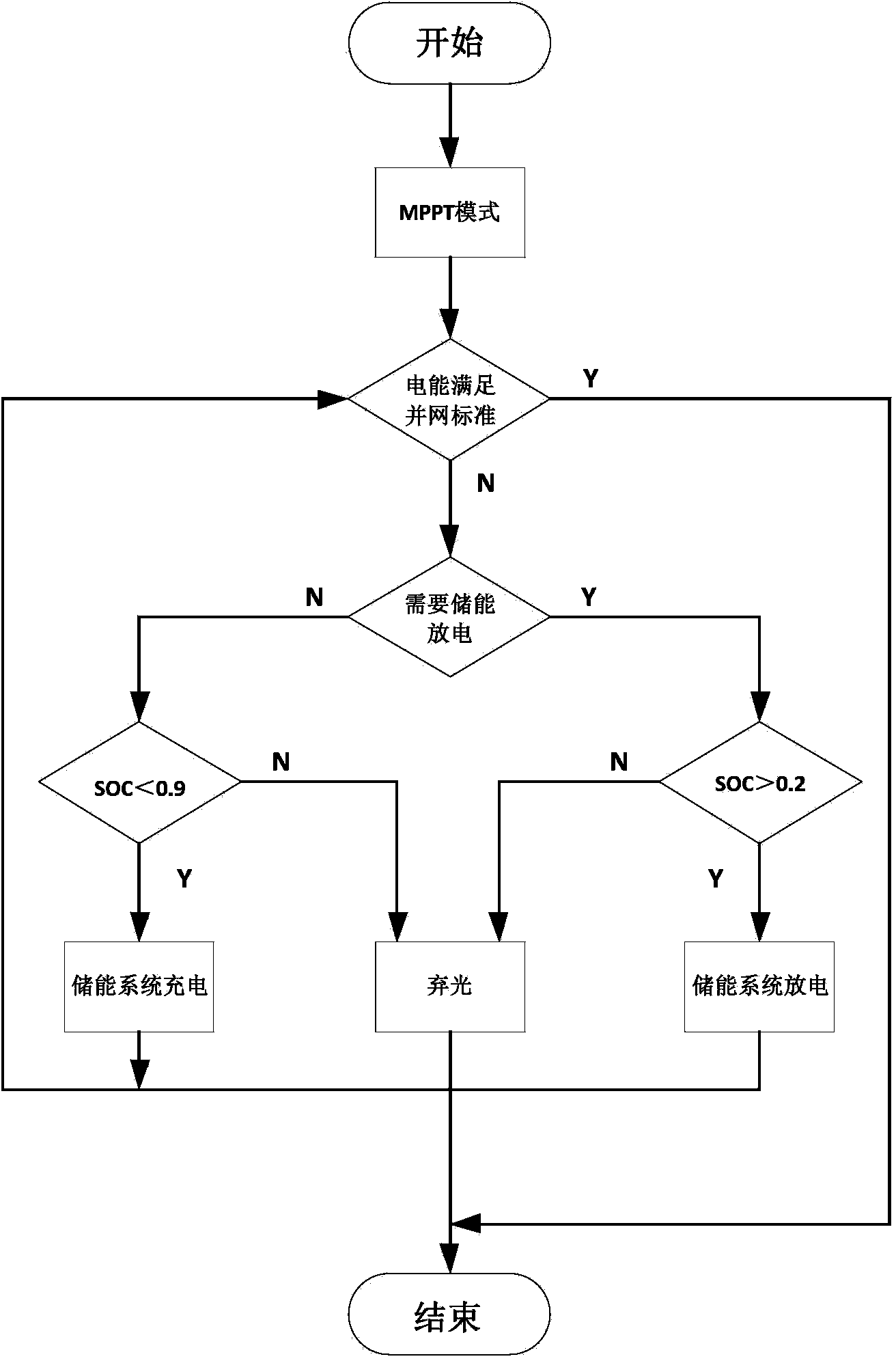

Off-grid and grid-connected operation light and storage joint power supply system

ActiveCN104052082AReduce output voltagePrevent backfeedSingle network parallel feeding arrangementsEnergy storagePower gridOperation mode

The invention provides an off-grid and grid-connected operation light and storage joint power supply system which comprises a DC / AC converter for connecting a direct current bus and an alternating current bus. The alternating current bus is connected with a power grid. The alternating current bus and the direct current bus are connected with an alternating current load and a direct current load respectively. The direct current bus is connected with a photovoltaic array and a battery system through a photovoltaic DC / DC converter and an energy storage DC / DC converter respectively. According to the off-grid and grid-connected operation light and storage joint power supply system, control strategies of the off-grid and grid-connected operation light and storage joint power supply system are provided and include the off-grid state operation control strategy and the grid-connected state operation control strategy. By means of the system and a method, the defects that an existing photovoltaic power supply system is instable in power supply quality, poor in schedulability, single in operation mode, low in energy conversion efficiency and the like are overcome.

Owner:STATE GRID CORP OF CHINA +2

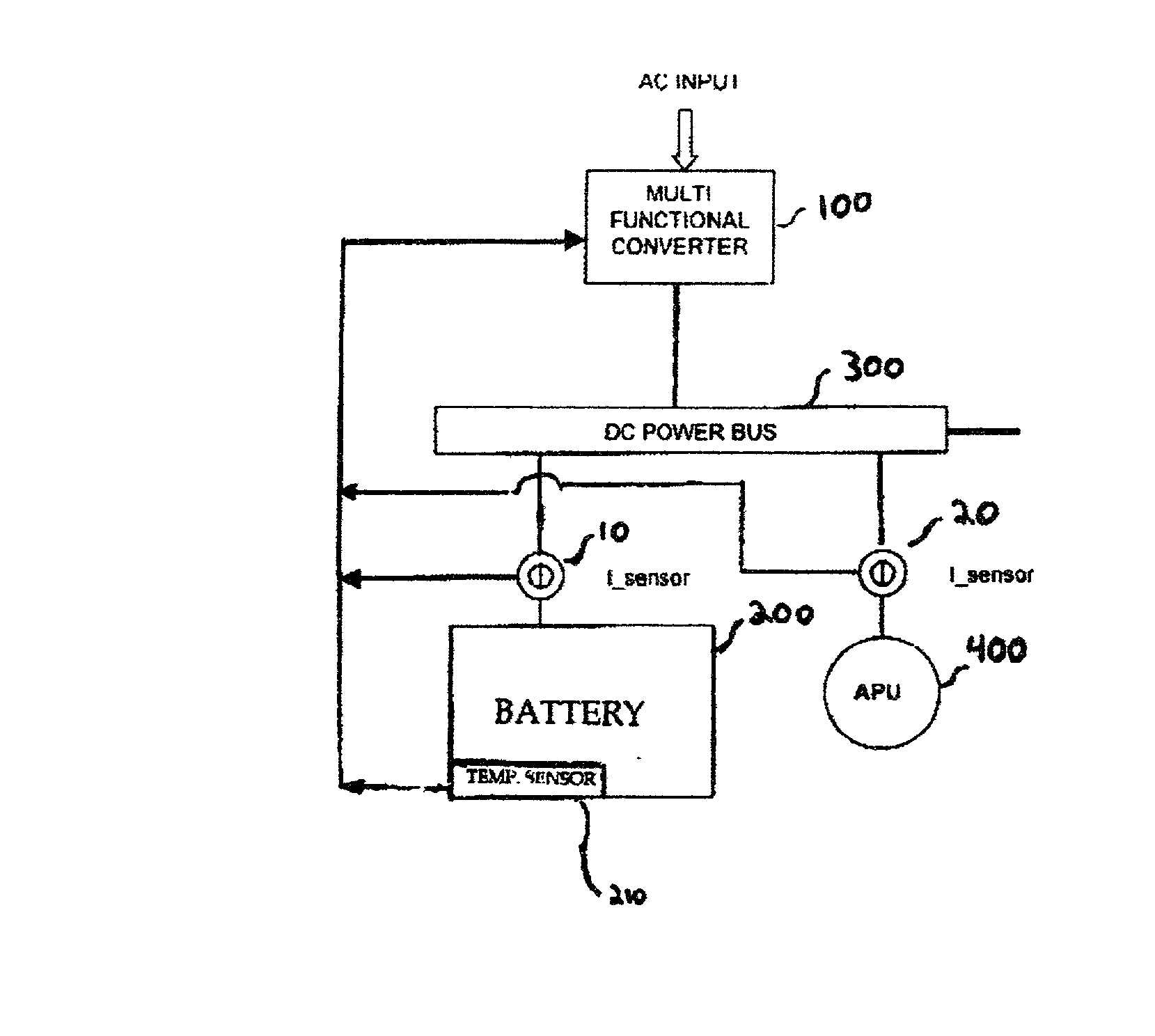

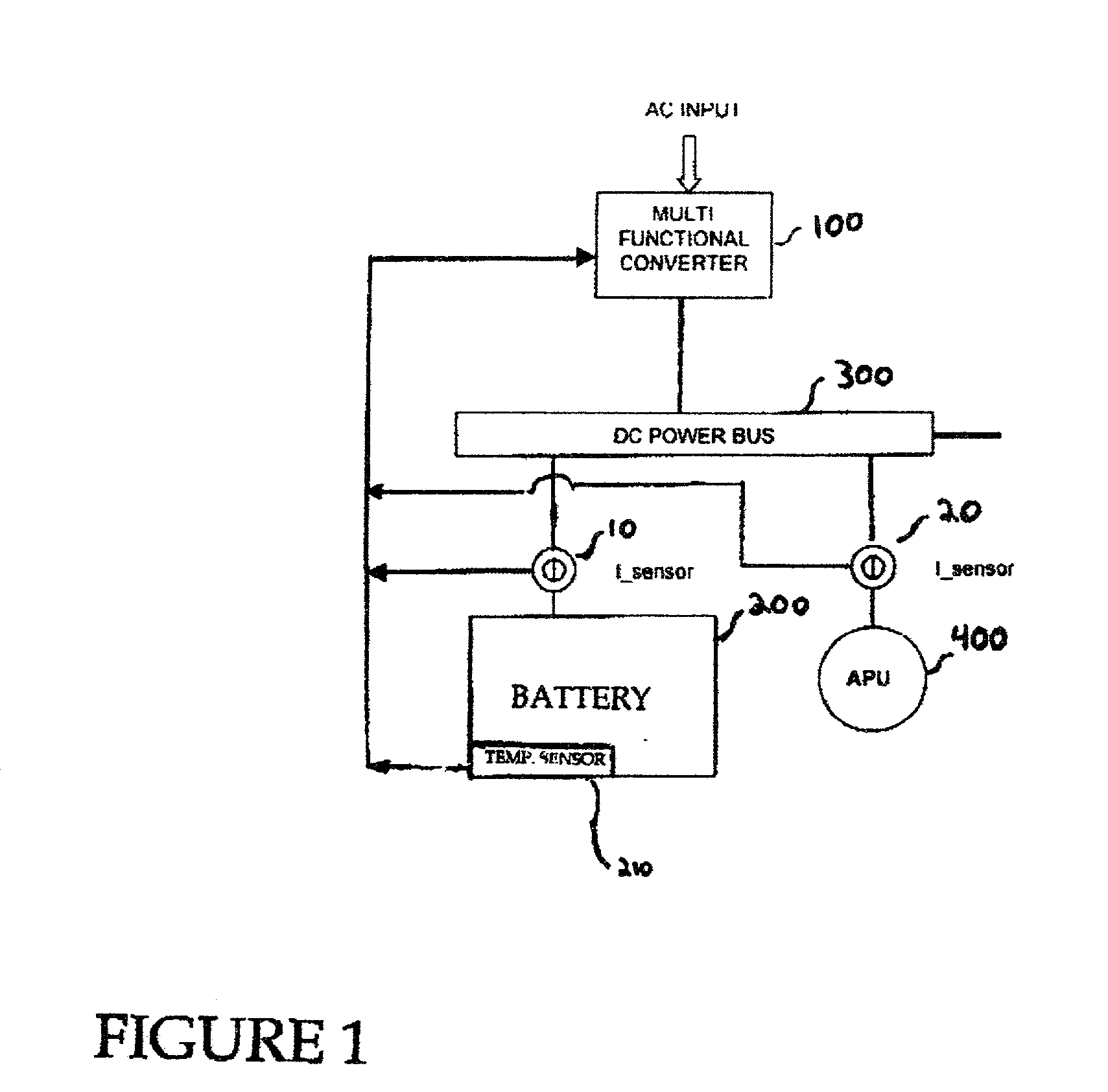

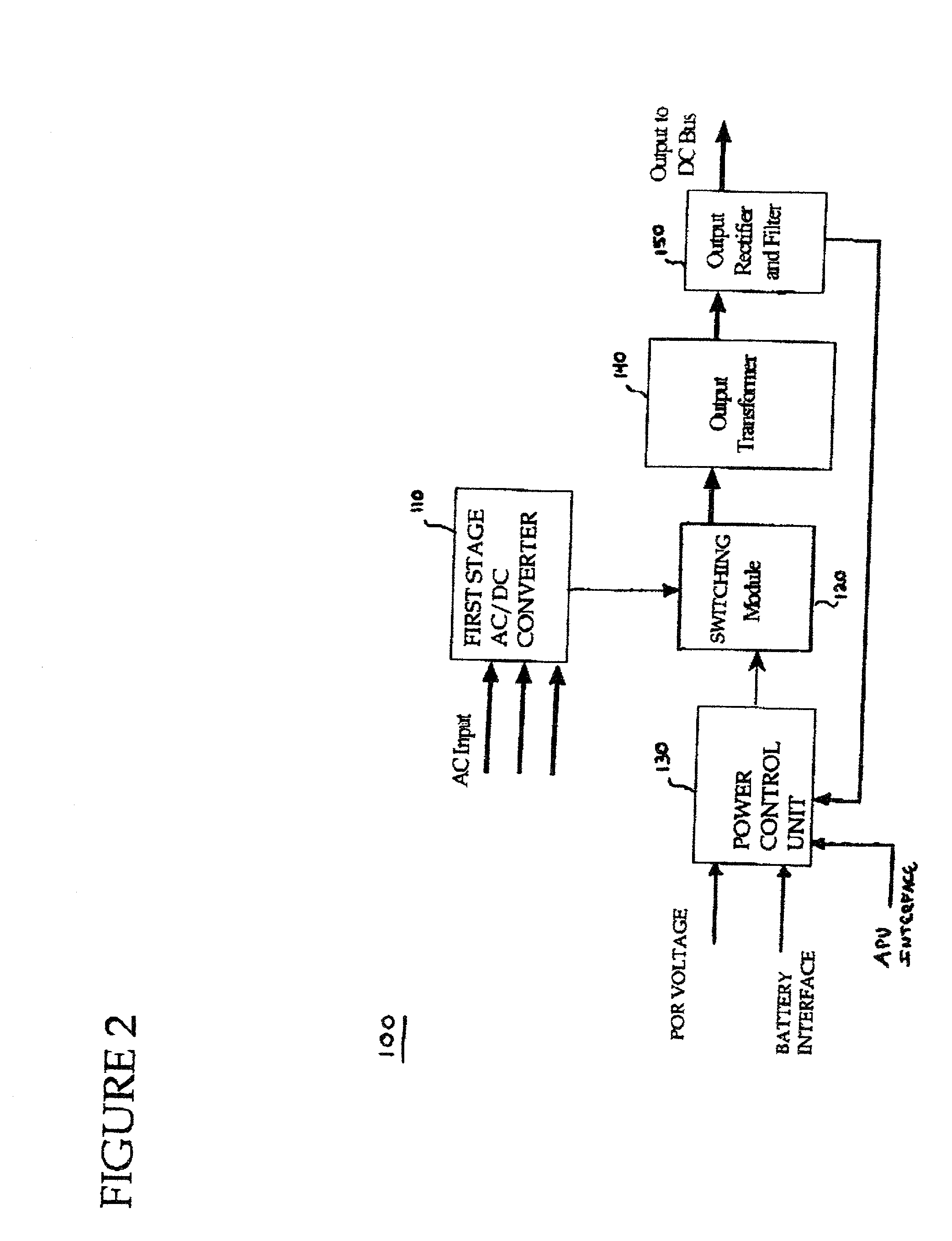

Multi-functional AC/DC converter

InactiveUS20020126518A1Efficient chargingImprove efficiencyAc-dc conversionElectric powerAuxiliary power unitAc to dc converter

A multi-functional AC to DC converter (100) controls AC to DC conversion as a function of at least one characteristic of a battery (200) connected to a DC power bus (300), such that the voltage output by the converter (100) to the DC power bus (300) is varied to efficiently charge the battery (200). In one implementation of the present invention, a multi-functional AC to DC converter (100) also adjusts the voltage output to the DC power bus based on a starting condition of an auxiliary power unit (400) so that the supplied voltage is suitable for starting the APU (400). The present invention is suitable for implementation in an aircraft power system to maintain the voltage output within the compliance range of the DC power bus (e.g., between 27.5 and 29 Vdc) while adjusting the output voltage to efficiently charge a battery (200) connected to the bus (300) and / or start an APU (400) connected to the bus (300).

Owner:HONEYWELL INT INC

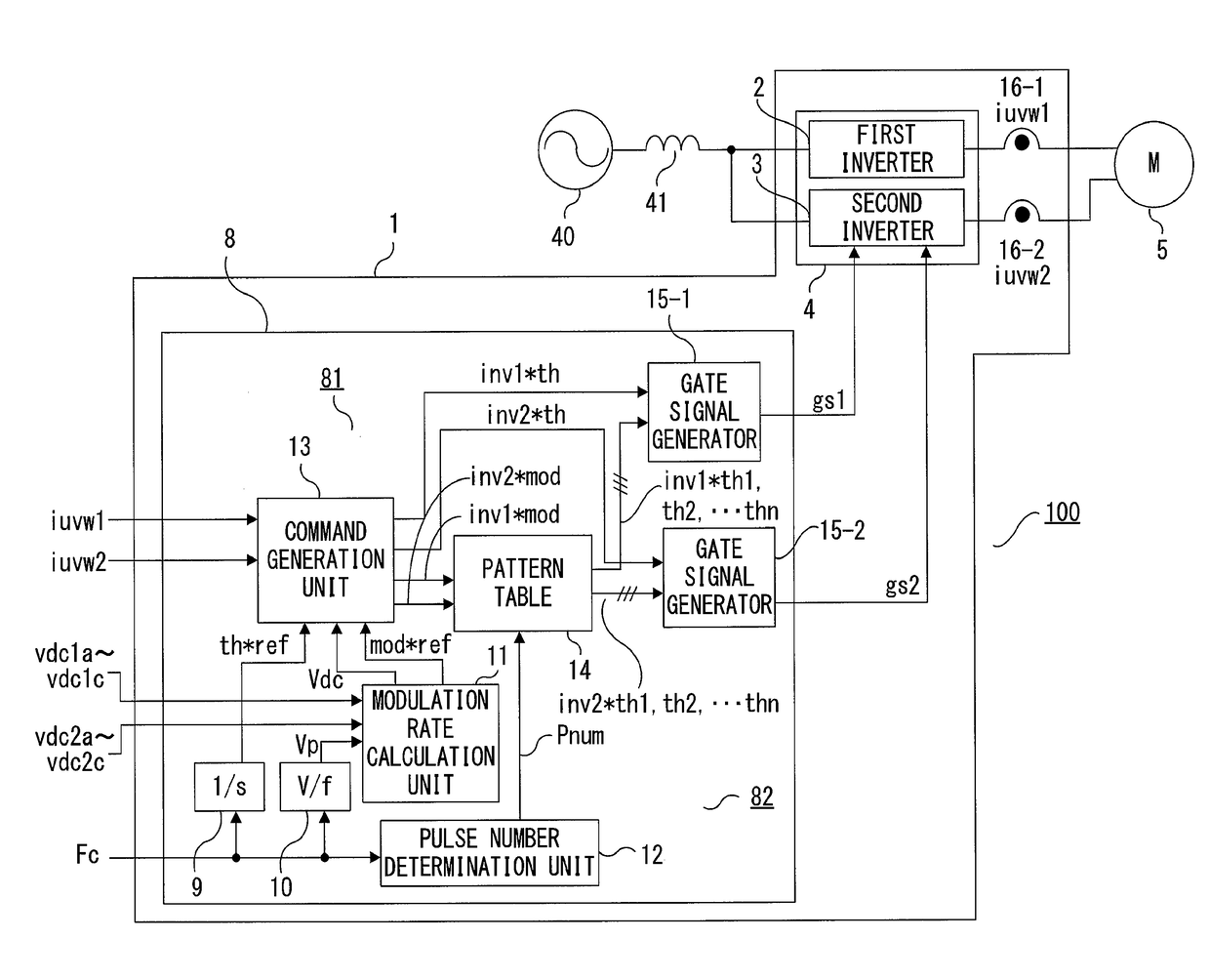

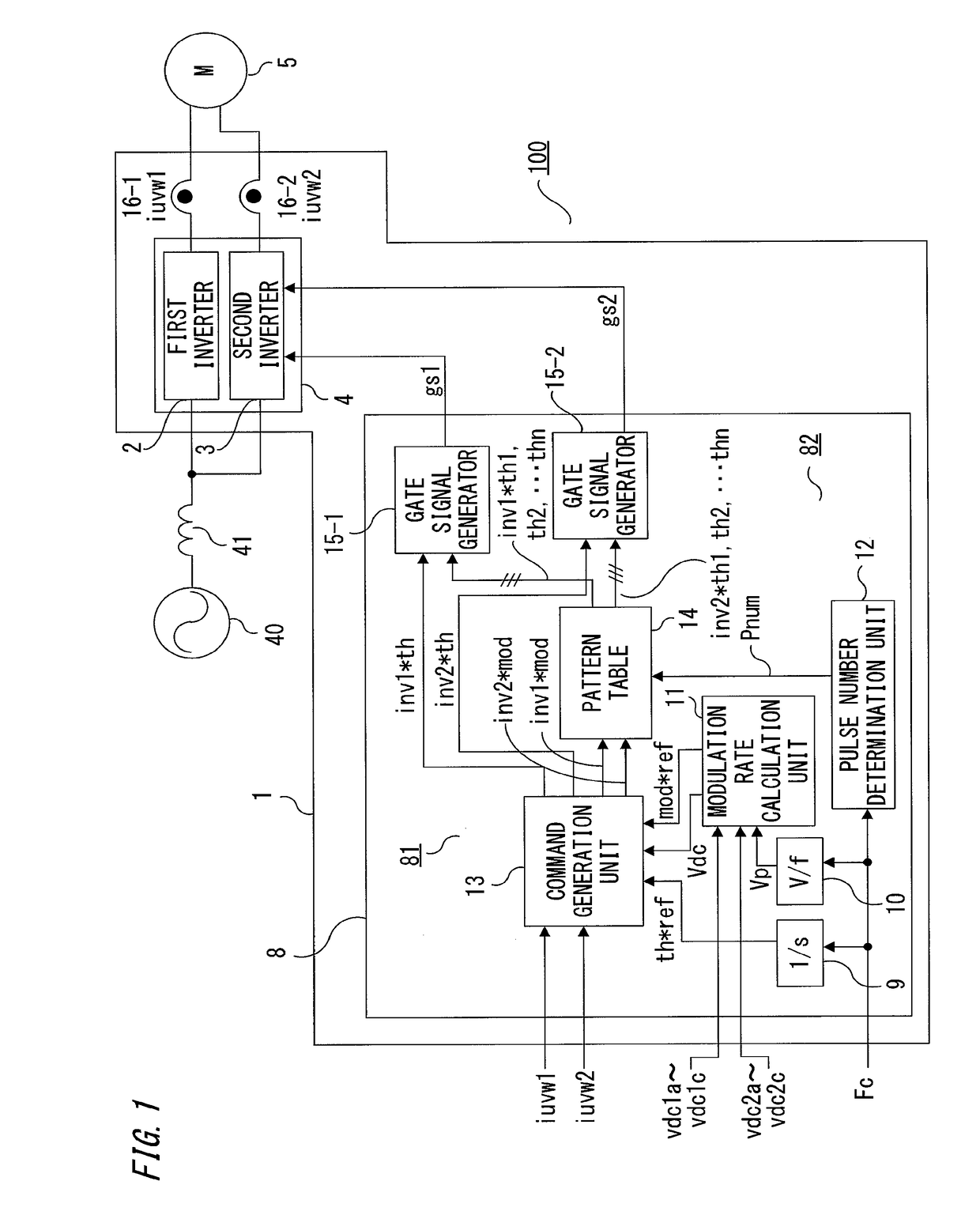

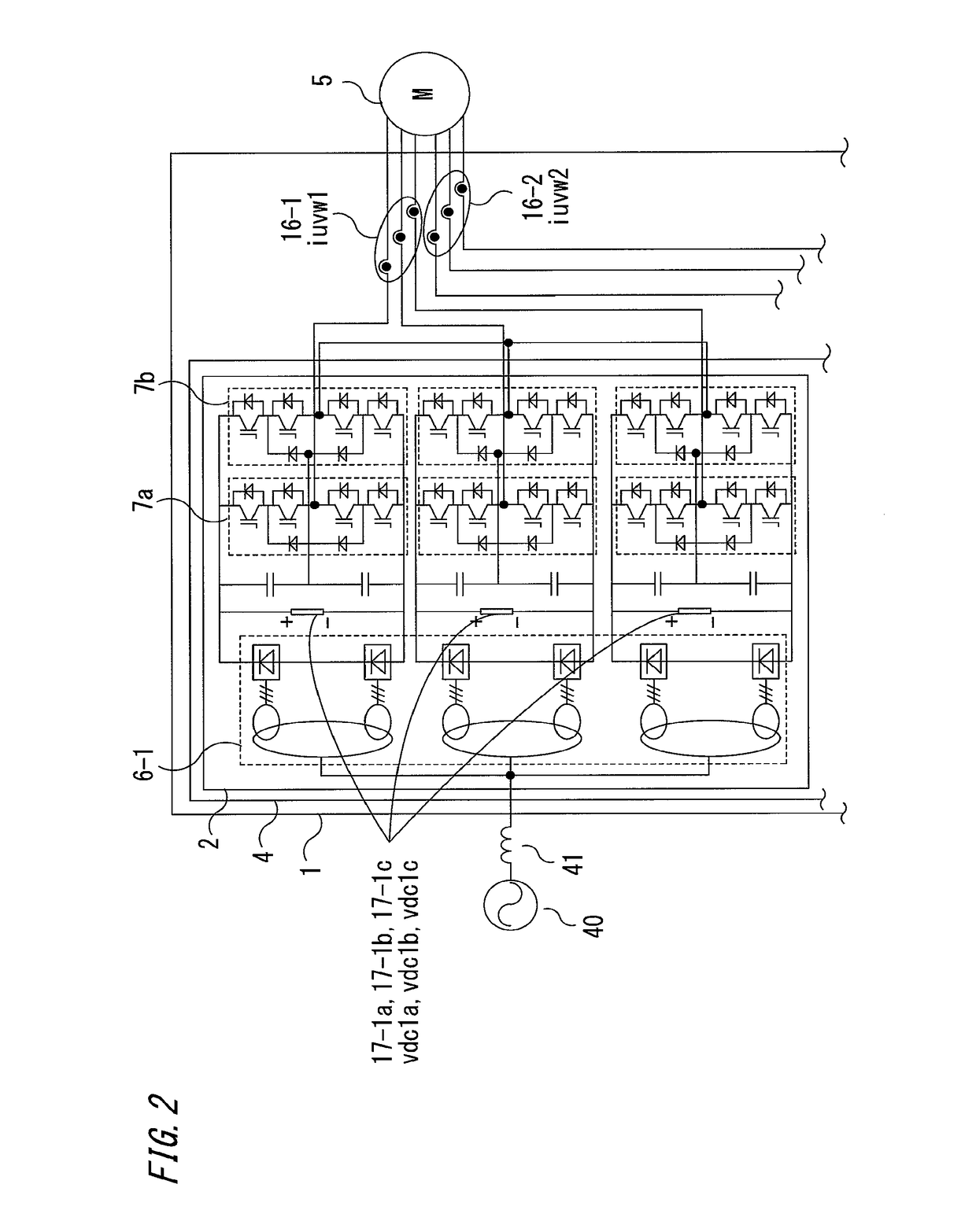

Drive and control apparatus for multiple-winding motor

ActiveUS20170294864A1Reduce low order harmonicHigh precision calibrationAC motor controlElectric motor controlExecution controlHalf cycle

A drive control apparatus for multiple-winding motor includes: a modulation rate phase command generation unit which calculates currents of first and second inverters for driving a multiple-winding three-phase motor and generates a modulation rate command and a phase command for equalizing the currents; a pulse number determination unit which determines the number of pulses per half cycle on the basis of a frequency command; a pattern table for storing switching patterns; and gate signal generators which control the first and second inverters, using an optimal switching pattern based on the number of pulses, wherein the modulation rate phase command generation unit performs control for equalizing currents of the first and second inverters, and the phase or frequency at which the control is performed is changed in accordance with any of the number of pulses, the modulation rate, the frequency command, and the switching pattern.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

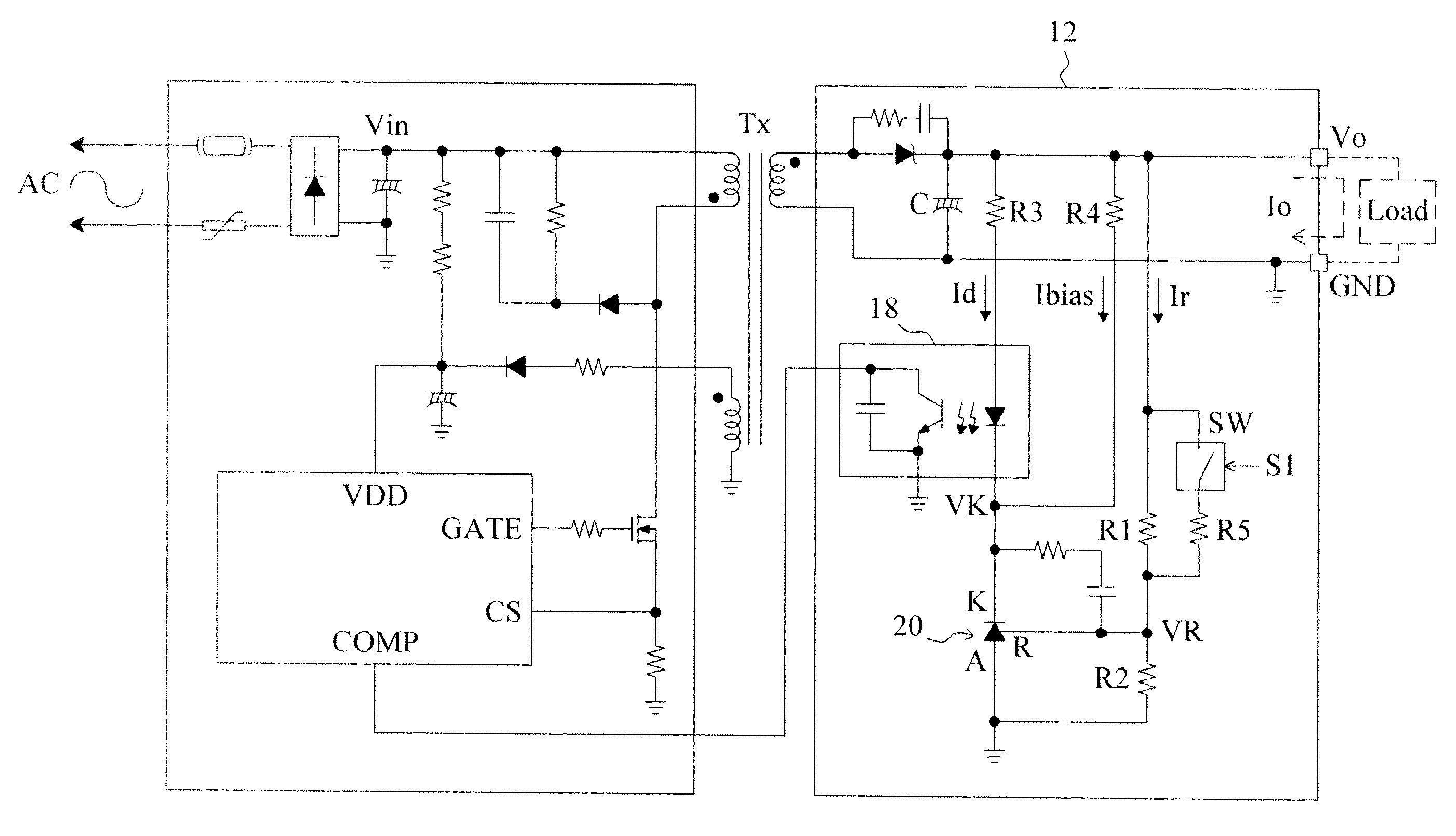

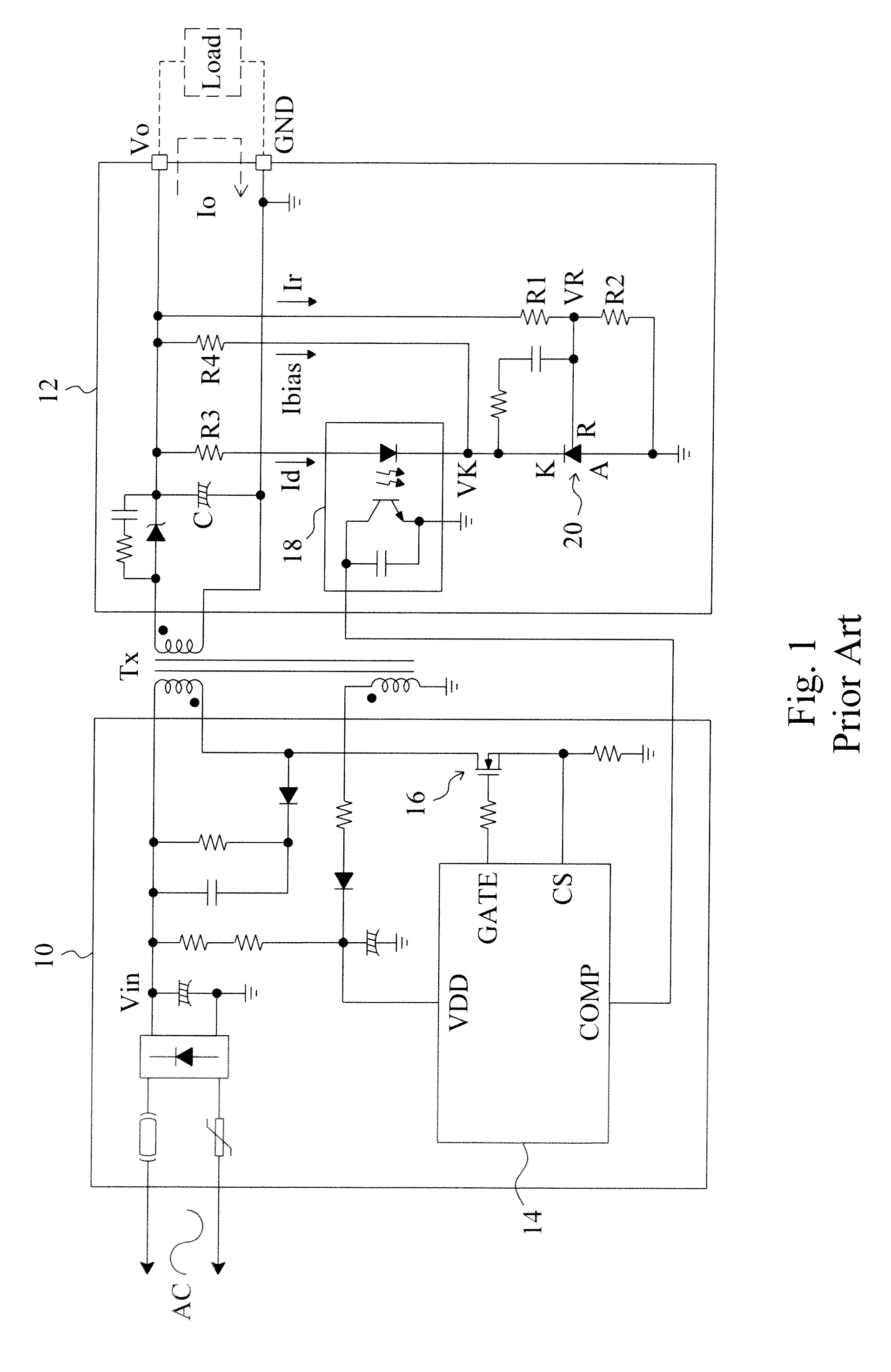

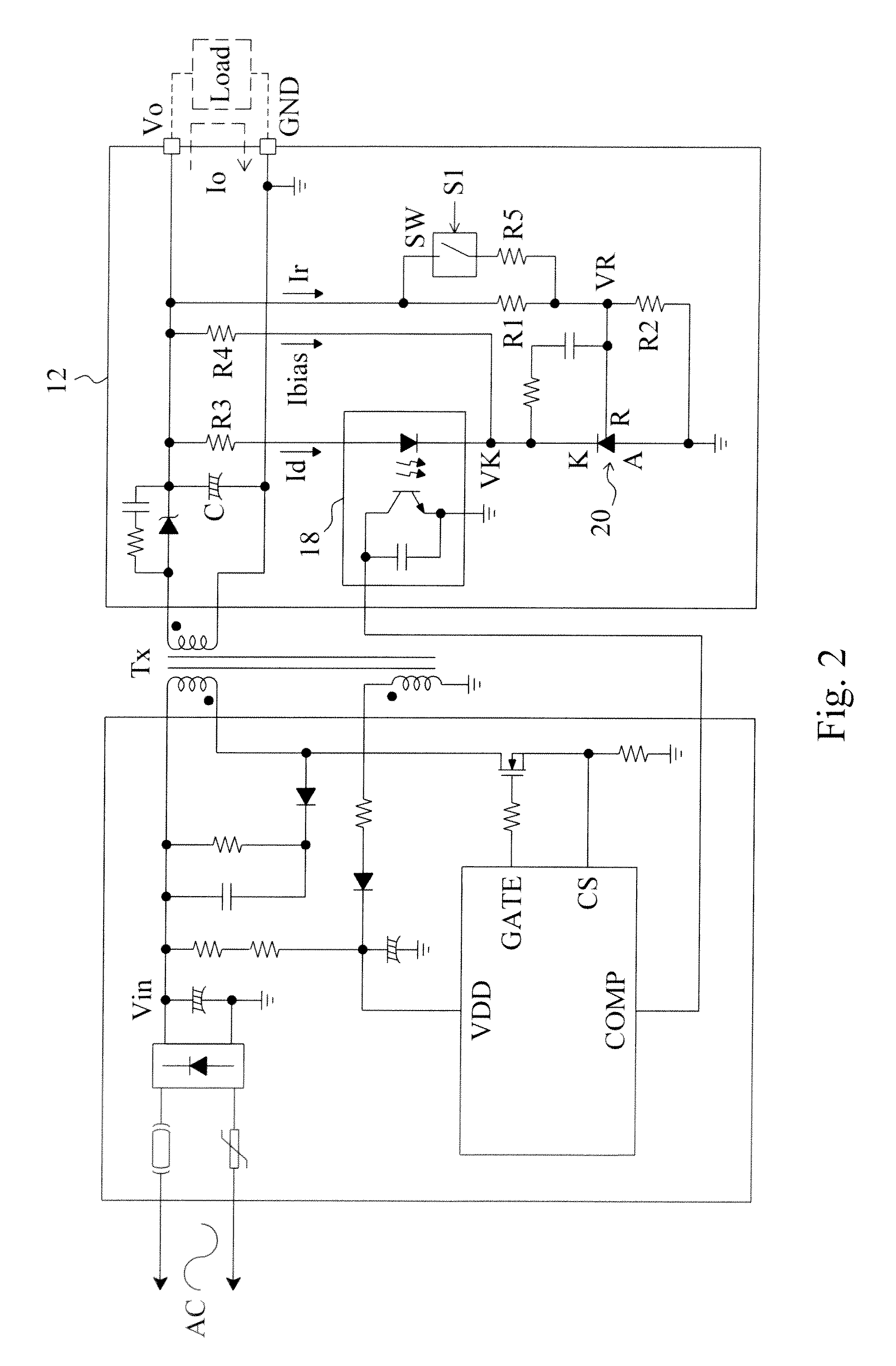

Apparatus and method for standby power reduction of a flyback power converter

ActiveUS20110051463A1Reduce output voltageReduce standby power consumptionEfficient power electronics conversionDc-dc conversionVoltage referenceEngineering

An apparatus and method for a flyback power converter reduce the standby output voltage of the flyback power converter by switching the reference voltage provided by a shunt regulator of the flyback power converter or the ratio of voltage divider resistors of the shunt regulator, to reduce the standby power consumption by an output feedback circuit of the flyback power converter, the shunt regulator, and the voltage divider resistors, and thereby the power loss of the flyback power converter in standby mode.

Owner:RICHTEK TECH

DC-DC converter

ActiveUS20050206354A1Reduce the valueSuppress rippleDc-dc conversionElectric variable regulationDc dc converterEngineering

The objective of this invention is to reduce the current flowing through the inductance element in a step-up / step-down DC-DC converter and to control the ripple in the output voltage. In the DC-DC converter, four states, that is, the first state [1] of (M1, M2)=(off, on) and (M3, M4)=(on, off), the second state [2] of (M1, M2)=(on, off) and (M3, M4)=(off, on), the third state [3] of (M1, M2)=(on, off) and (M3, M4)=(on, off), and the fourth state [4] of (M1, M2)=(off, on) and (M3, M4)=(off, on) are repeated in a prescribed order, preferably in the order . . . [1]→[4]→[2]→[3]→[1] . . . or . . . [1]→[3]→[2]→[4]→[1] . . . .

Owner:TEXAS INSTR INC +1

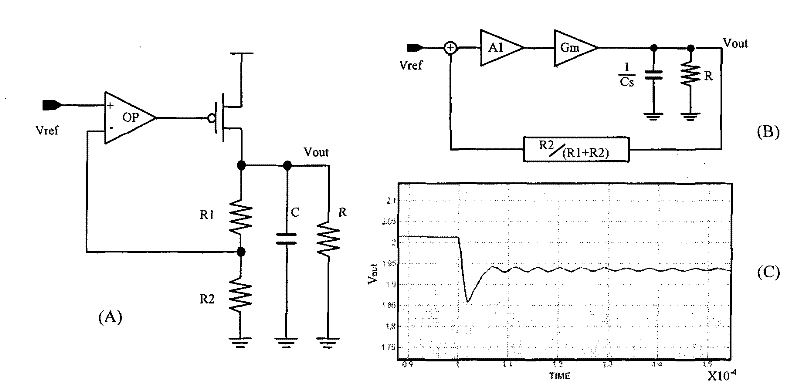

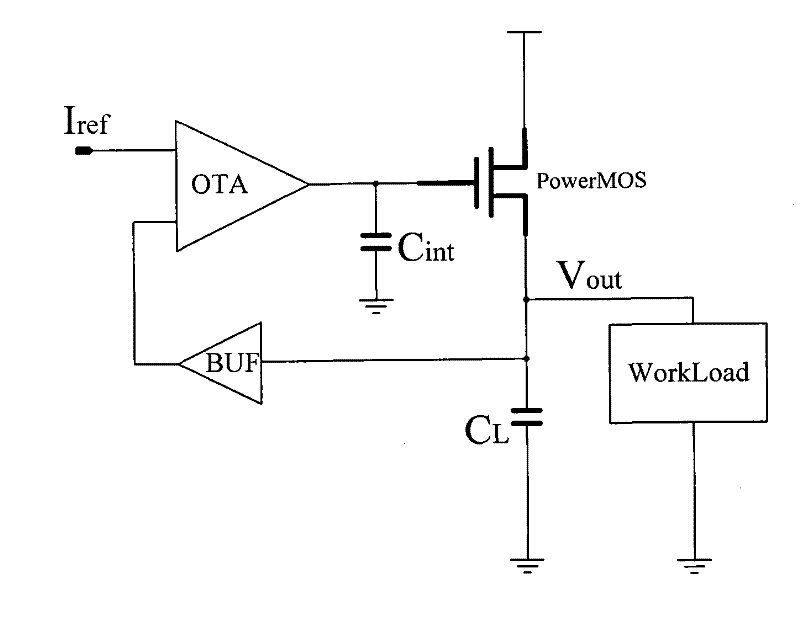

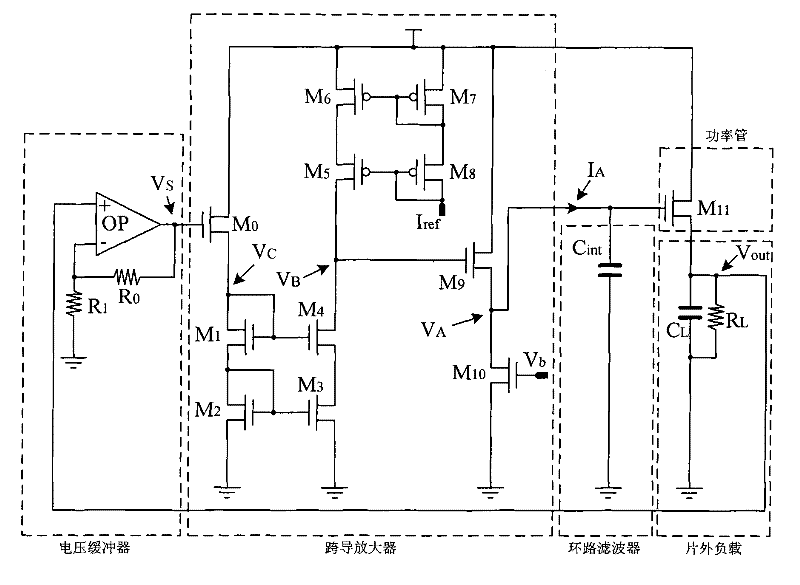

Low Output Voltage Fast Response LDO Circuit Based on Current Control Loop

InactiveCN102298407AGuaranteed response speedImprove stabilityElectric variable regulationElectricityIntegrator

The response ability to the transient change of the load is an important indicator of the LDO performance of the low dropout voltage regulator. The present invention learns from the loop control method of the charge pump type phase-locked loop, discloses a low output voltage fast response LDO structure based on the current control loop, the feedback voltage is converted into current, and the current signal is used as the carrier in the control loop. Operation, the difference current is integrated by the loop filter to form the control voltage of the power tube. Low-dropout regulators based on current control loops respond well to load transients and can produce voltage outputs lower than typical bandgap reference voltages. The fast-response LDO circuit based on the current control loop disclosed by the invention is composed of a voltage buffer, a transconductance amplifier, a loop filter, a power tube and an off-chip load.

Owner:NAT UNIV OF DEFENSE TECH

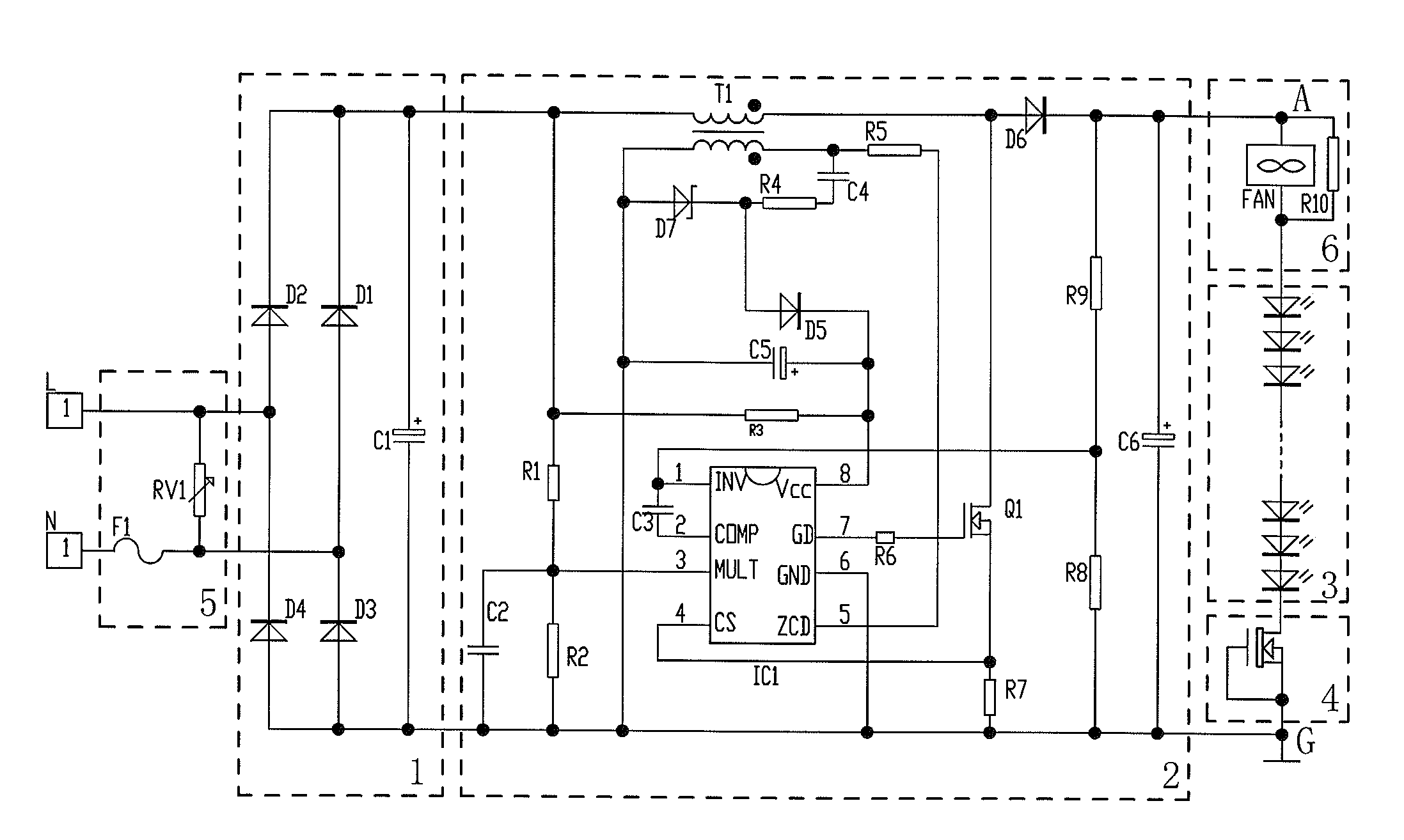

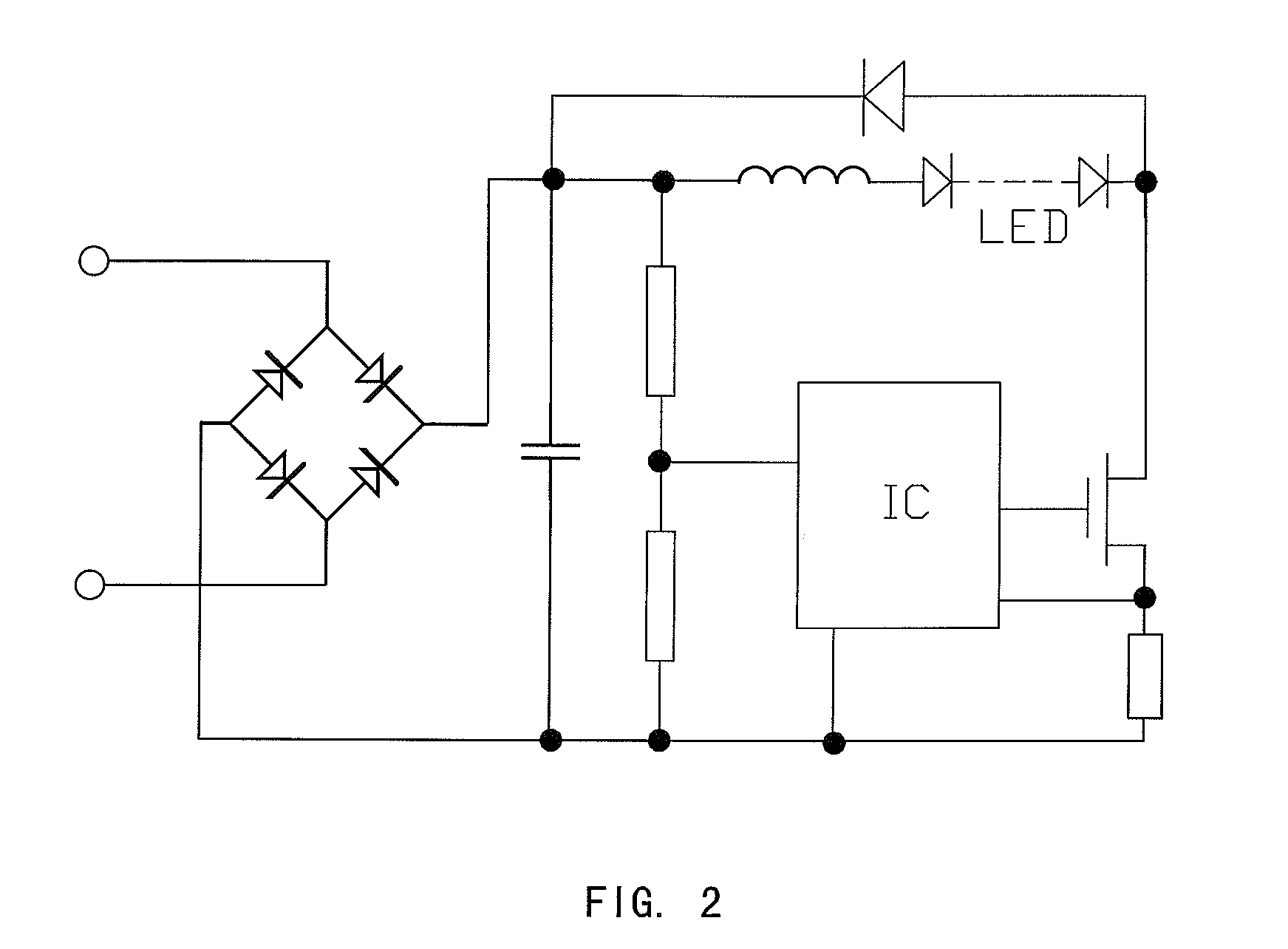

LED Lamp Circuit

InactiveUS20100181833A1Improve cooling effectExtended service lifeDc network circuit arrangementsElectroluminescent light sourcesDriver circuitAC power

The present invention discloses a high power LED lamp circuit with a fan provides advantages such as simple structure, high efficiency, low power consumption, energy saving, and longer lifetime. The LED lamp circuit comprises a rectifying-filtering circuit (1), an LED load (3), an output terminal (A) and a grounding terminal (G) for providing a DC power generated by passing an AC power through the rectifying-filtering circuit (1), the high power LED lamp circuit with a fan further comprises a constant current source (4), a fan driving circuit (6); the lamp circuit is formed by cascading the LED load (3), the constant current source (4) between the output terminal (A) and the grounding terminal (G), the LED lamp circuit is widely applicable in various kinds of LED lamps.

Owner:NANKER GUANGZHOU SEMICON MFG

Step-up/step-down DC-DC converter and portable device employing it

ActiveUS6958595B2Reduce output voltageStable output voltageApparatus without intermediate ac conversionElectric variable regulationMaximum levelDc dc converter

In a step-up / step-down DC-DC converter, an error signal commensurate with a difference between a voltage commensurate with the output voltage and a predetermined reference voltage and a triangular wave signal are compared by a first comparator, whose output is used to turn on and off a step-up switching circuit. An inverted signal obtained by inverting the error signal and the triangular wave signal are compared by a second comparator, whose output is used to turn on and off a step-down switching circuit. The median level between the outputs of the first and second comparators is set to be lower than the maximum level of the triangular wave signal and higher than the minimum level thereof. Thus, when step-up and step-down modes are switched from one to the other, an overlap period is produced during which the step-up and step-down modes overlap. This makes possible smooth switching between the step-up and step-down modes.

Owner:ROHM CO LTD

Method for controlling a dc-to-dc converter

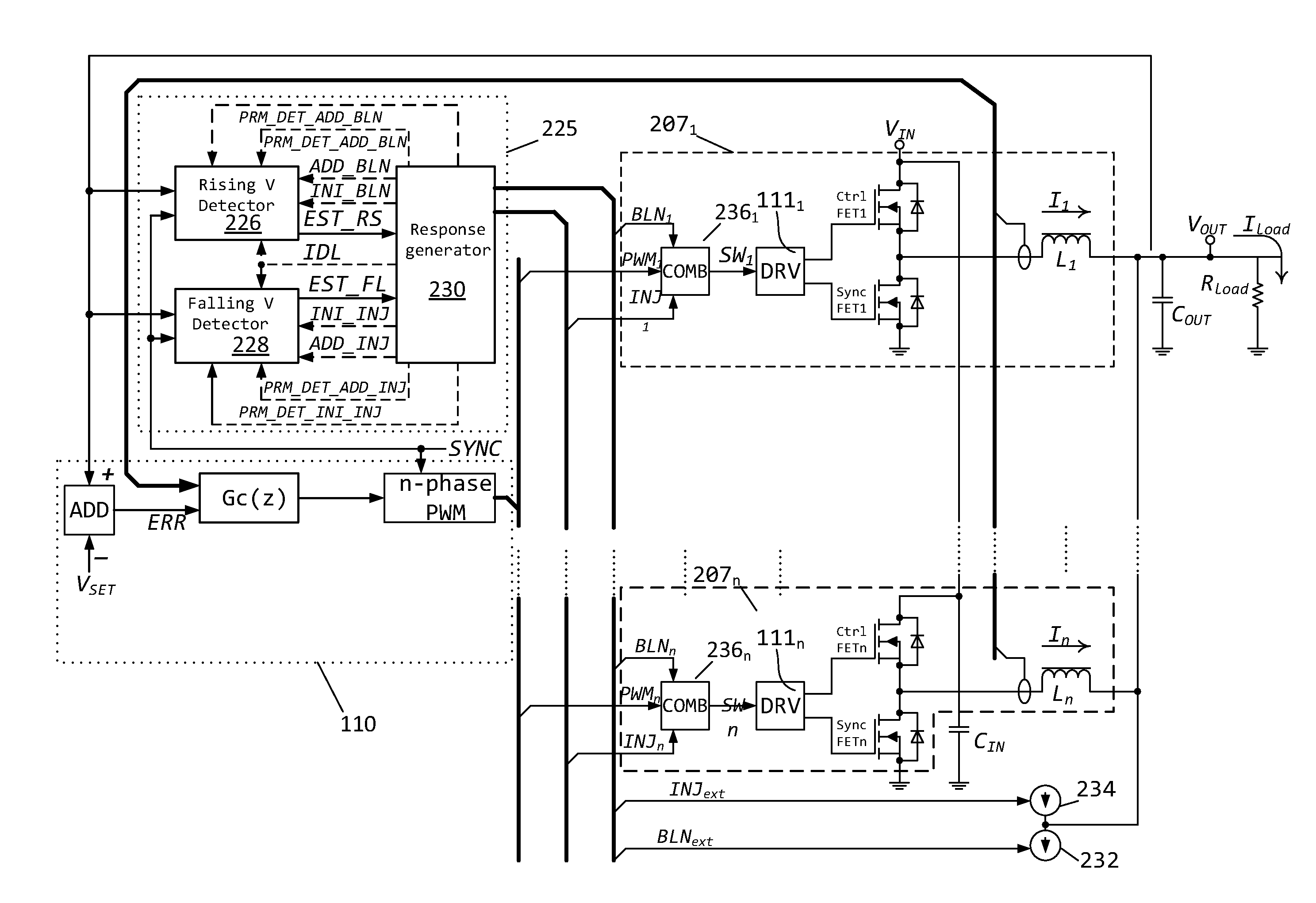

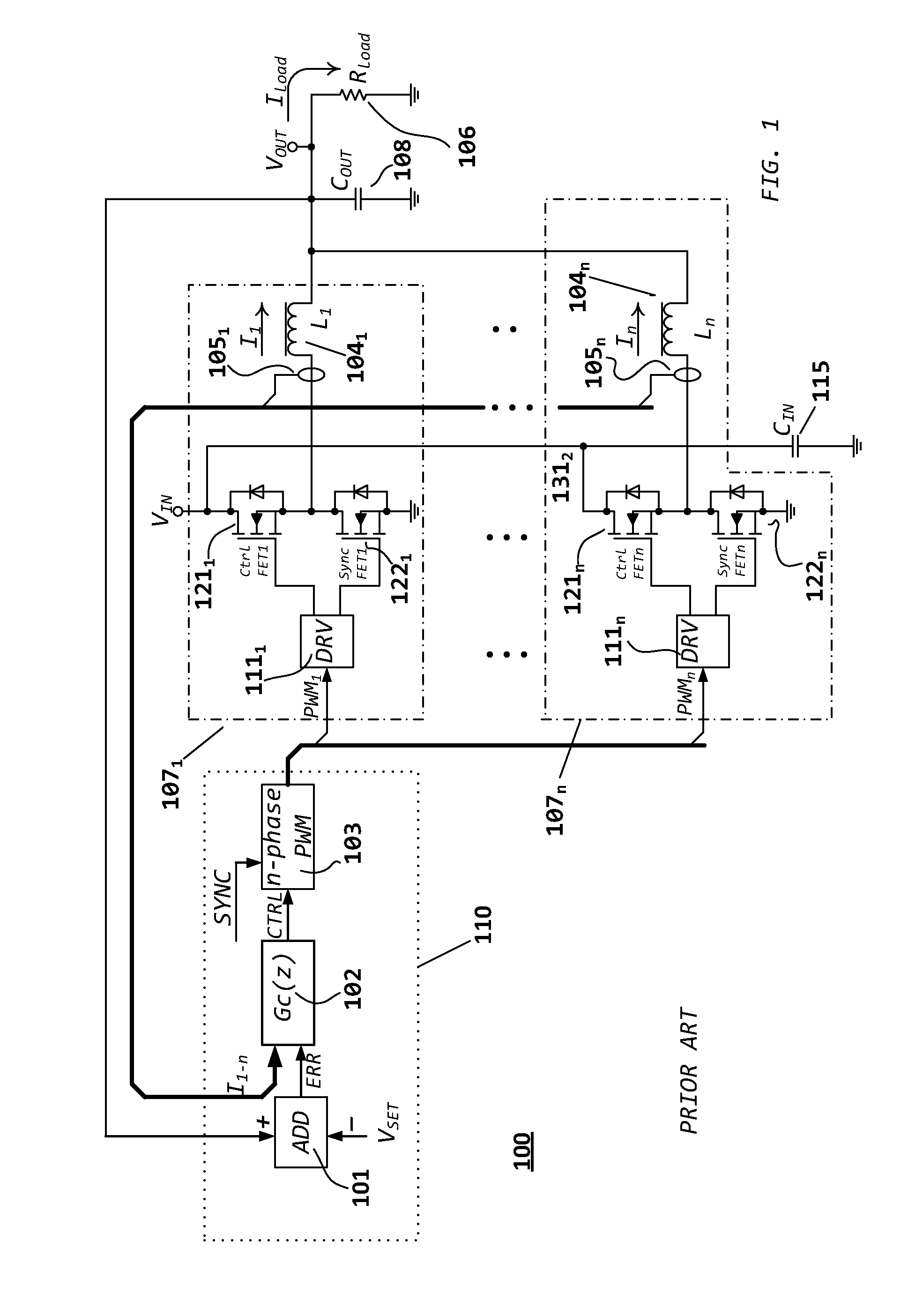

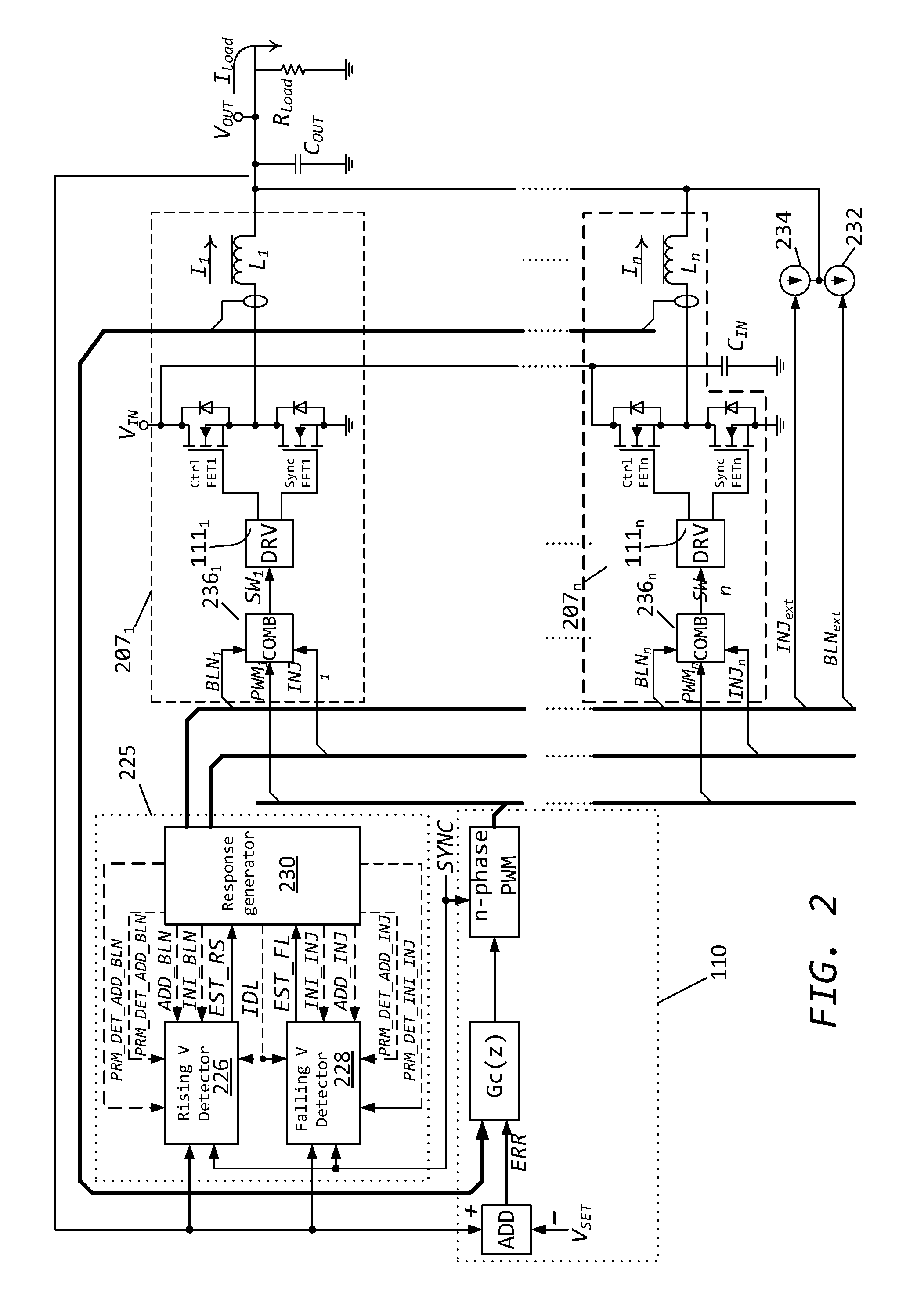

ActiveUS20150326120A1Minimizing voltage deviationShorten total active timeDc-dc conversionElectric variable regulationFull bridgePush pull

Methods and circuits for power supply arrangement and control are disclosed herein. More specifically the application relates to a control method and a controller for a DC-to-DC converter, such as a synchronous Buck converter, which implements a transient detection scheme together with response generation to allow the converter to recover from a positive and / or negative load current step in the robust way, with low undershoot / overshoot at the output voltage. The control method may be implemented by either an analog or a digital circuit. The controller may be integrated with existing controller schemes (such as voltage-mode controllers) to provide superior dynamic performance during large-signal transient conditions while providing stable operation during steady state conditions. The methods and circuits provided herein are applicable to Buck converters and Buck-derived converters such as forward, push-pull, half-bridge, and full-bridge converters.

Owner:ROHM CO LTD

Power supply having efficient low power standby mode

InactiveUS7034513B2Low standby loss for power converterReduce output voltageEfficient power electronics conversionApparatus with intermediate ac conversionControl signalOperation mode

A power supply has a normal operation mode and a standby operation mode. The power supply includes a main circuit, a first control circuit, a second control circuit, and a switching controller. The main circuit has at least one output port for converting an input voltage into an output voltage at the output port. The first control circuit is used for controlling the main circuit under the normal operation mode. The second control circuit is used for controlling the main circuit under the standby operation mode. And, the switching controller processes a control signal to control the first control circuit and the second control circuit under either of the normal operation mode and the standby operation mode in response to a load status of the output port.

Owner:DELTA ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com