Efficient photovoltaic power generation system

A photovoltaic power generation system, high-efficiency technology, applied in photovoltaic power generation, photovoltaic modules, control/regulation systems, etc., can solve problems such as reducing system power generation and power generation efficiency, inconsistent pollution and aging degrees, and differences in photovoltaic string characteristics , to achieve the effect of increasing power generation and power generation efficiency, increasing power generation, and fast compensation response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

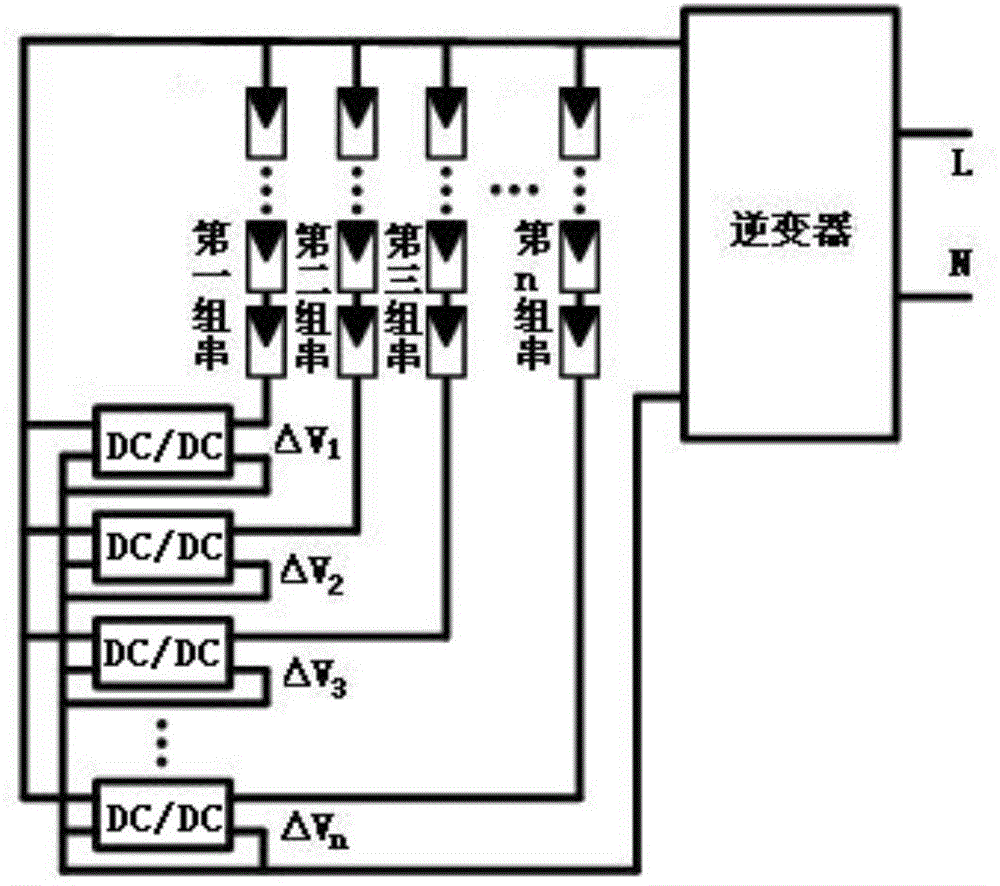

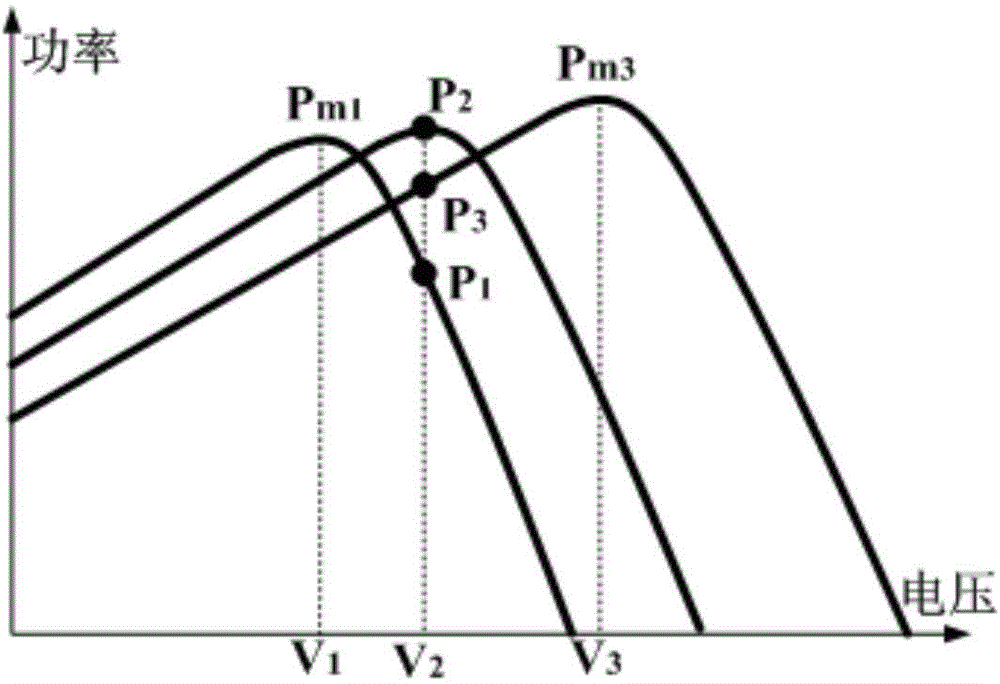

[0035] Such as figure 1 , image 3 and Figure 4 As shown, this example provides a high-efficiency photovoltaic power generation system, including: a DC / DC module, an inverter, and at least two parallel strings, each of which is connected to a DC / DC module; One input terminal of the DC / DC module is connected to the positive pole of the bus bar, and the other input terminal is connected to the negative pole of the bus bar; the two output terminals of the DC / DC module are respectively connected to the bus bar and the group string or are respectively connected to the bus bar through the group string; The positive pole of the busbar and the negative pole of the busbar are respectively connected to the inverter; when the busbar voltage V is equal to the voltage V corresponding to the maximum power point of any string n When inconsistent, the DC / DC module corresponding to the string outputs the compensation voltage ΔV n To the working circuit where the group string is located, so...

Embodiment 2

[0044] Such as figure 1 As shown, on the basis of Embodiment 1, one output terminal of the DC / DC module described in this example is connected to the negative pole of the bus bar, and the other output terminal of the DC / DC module is respectively connected to the respective negative poles of the strings, so The positive poles of the strings are respectively connected to the positive poles of the busbars.

[0045] One input end of the DC / DC module is connected to the positive pole of the bus bar, and the other input end is connected to the negative pole of the bus bar; one output end of the DC / DC module is connected to the negative pole of the bus bar, and the other output end is connected to the respective bus bar negative pole. In this way, the DC / DC modules are placed in series at the bottom of the strings. On the basis of improving the power generation, power generation efficiency and cost control of the photovoltaic power generation system, it also makes the wiring simple a...

Embodiment 3

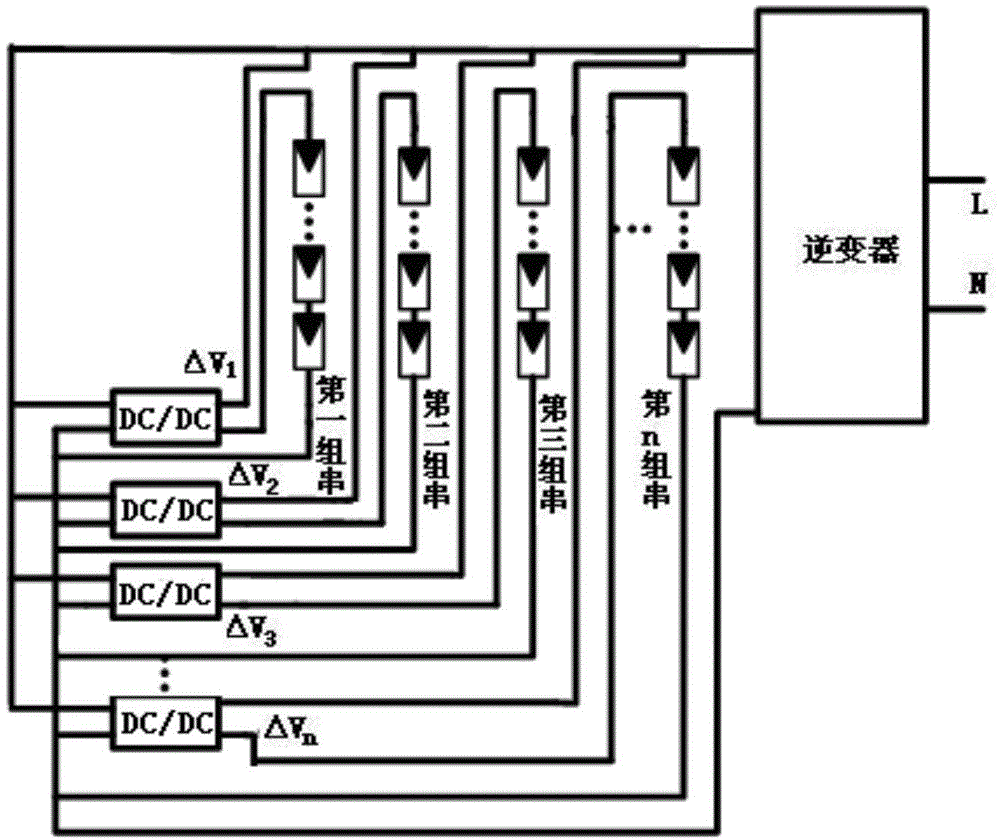

[0048] Such as image 3 As shown, different from Embodiment 1, one output terminal of the DC / DC module described in this example is connected to the positive pole of the bus bar, and the other output terminal of the DC / DC module is respectively connected to the positive pole of the respective strings, so The negative pole of the string is connected to the negative pole of the bus bar.

[0049] That is to say, the DC / DC module is connected in series on the top of the string, one input end of the DC / DC module is connected to the positive pole of the bus bar, and the other input end is connected to the negative pole of the bus bar; the DC / DC module is connected to the negative pole of the bus bar; One output end of the module is connected to the positive pole of the bus bar, and the other output end is connected to the top end of each string. On the basis of improving the power generation capacity, power generation efficiency and control cost of the photovoltaic power generation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com