Patents

Literature

234results about How to "Increase capture rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

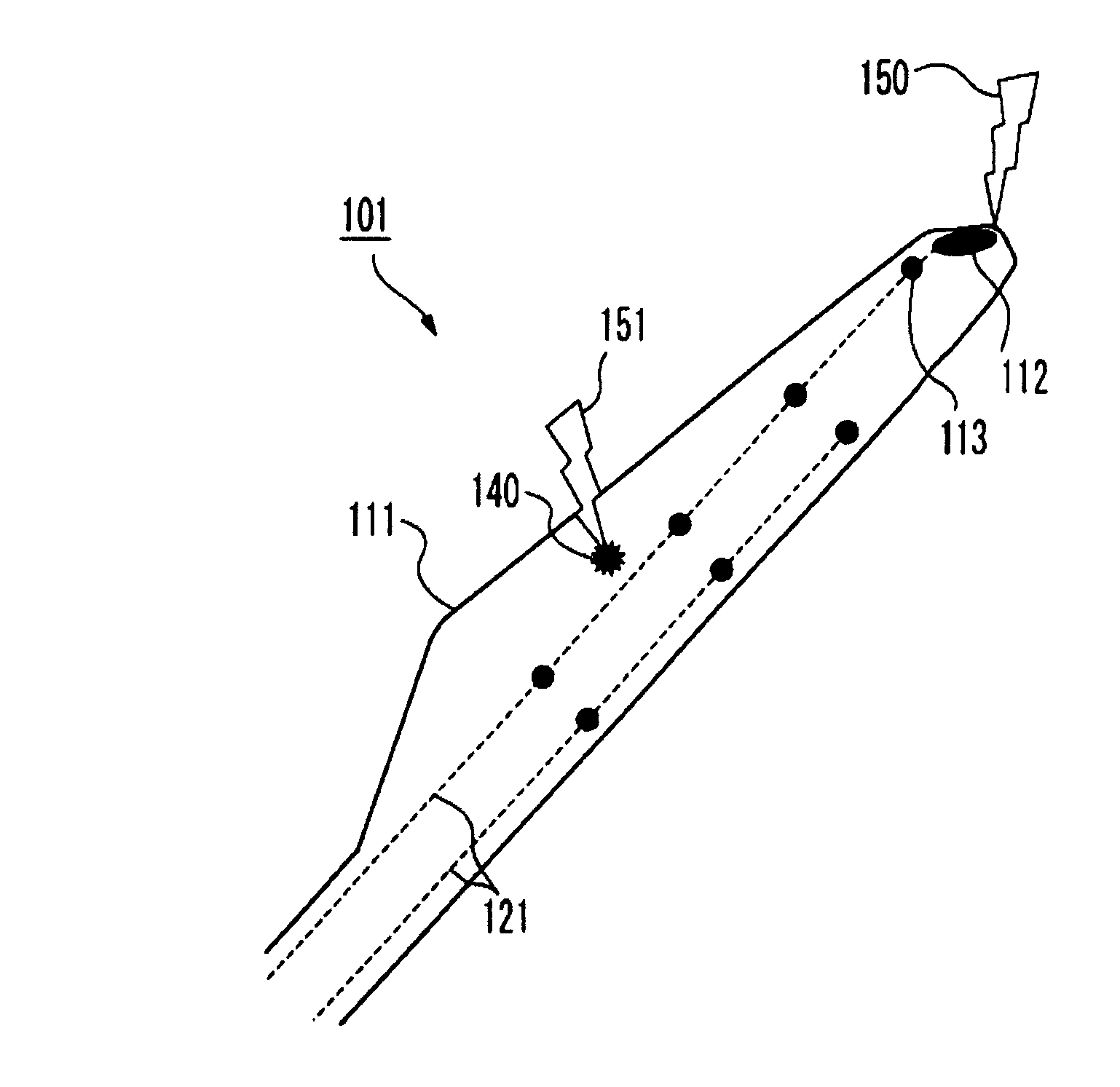

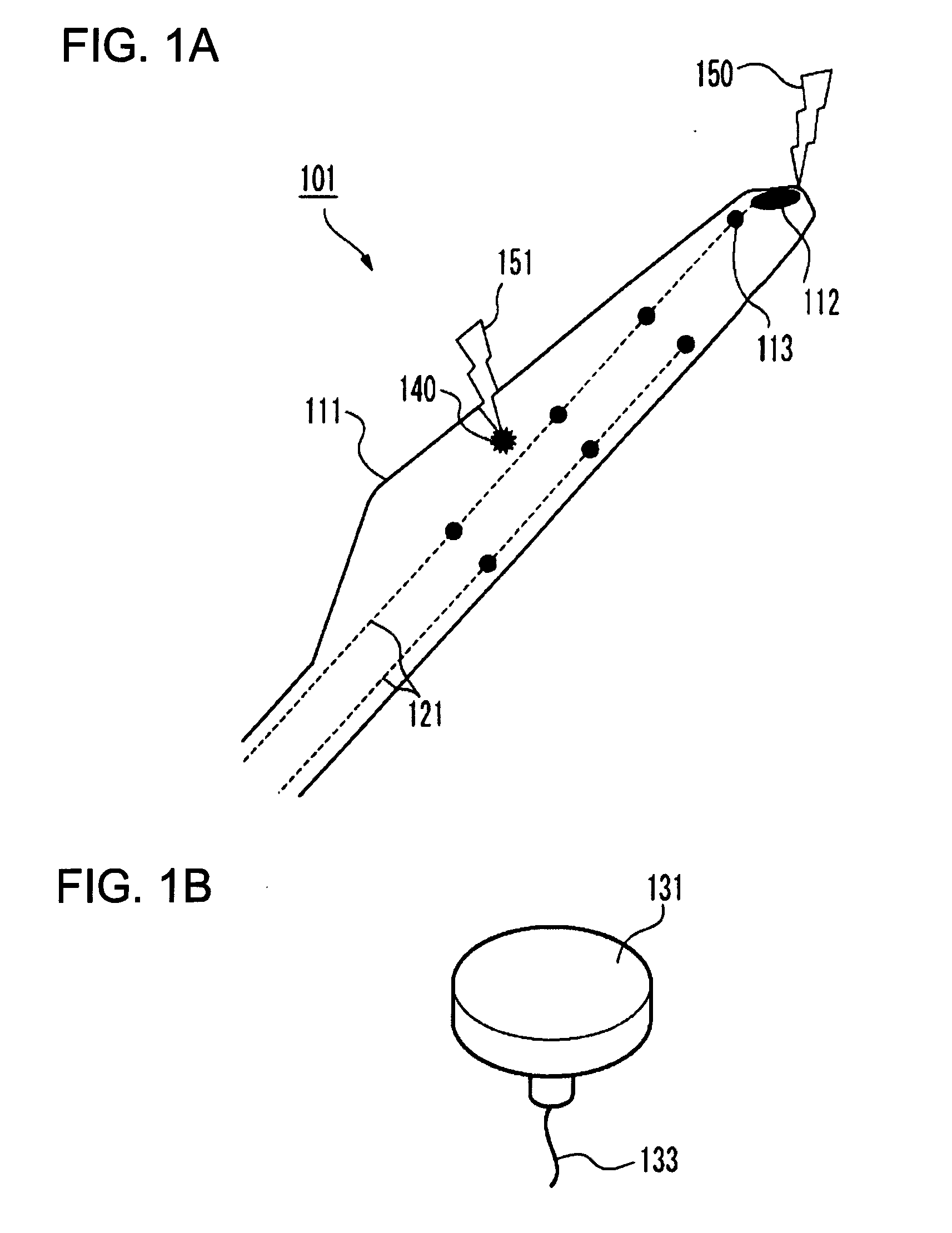

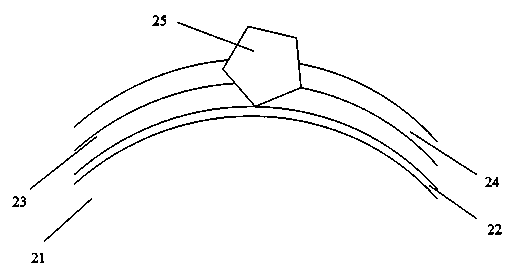

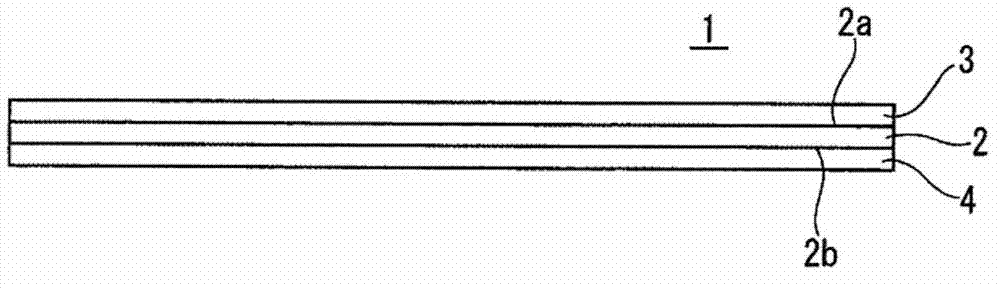

Wind turbine blade and wind turbine generator having the same

ActiveUS20110182731A1Avoid damageIncrease catch ratePropellersInstallation of lighting conductorsTurbine bladeElectrical conductor

A wind turbine blade has a blade body 11, a plurality of receptors 12, 13 embedded in and exposed to the surface of the blade body 11, a conductor layer 14 provided on the surface of the blade body 11 and connecting the receptors 12, 13 with one another and a downconductor 21 connected to the receptors 12, 13 and provided in the blade body 11. The downconductor 21 may be embedded in an insulator.

Owner:MITSUBISHI HEAVY IND LTD

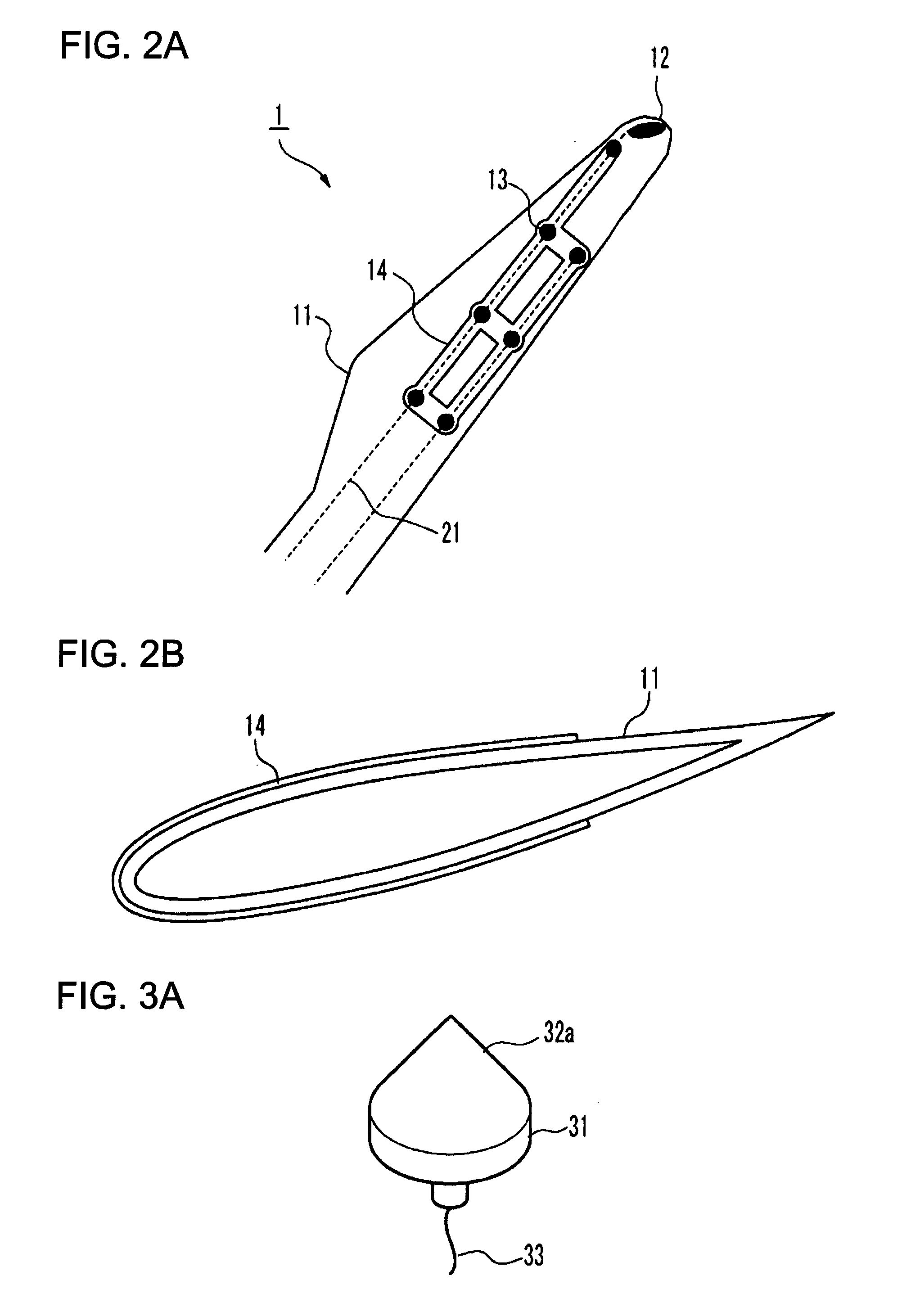

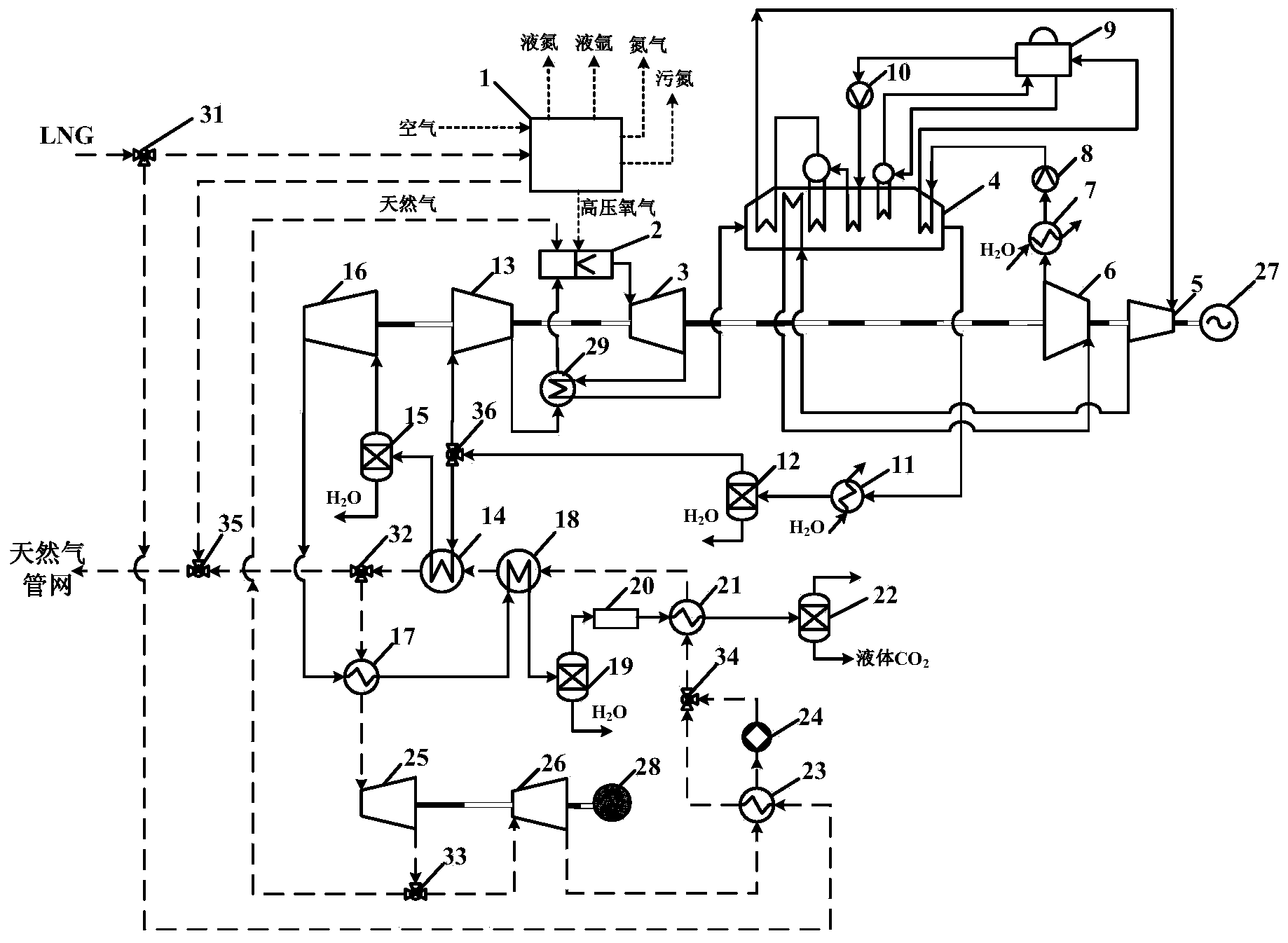

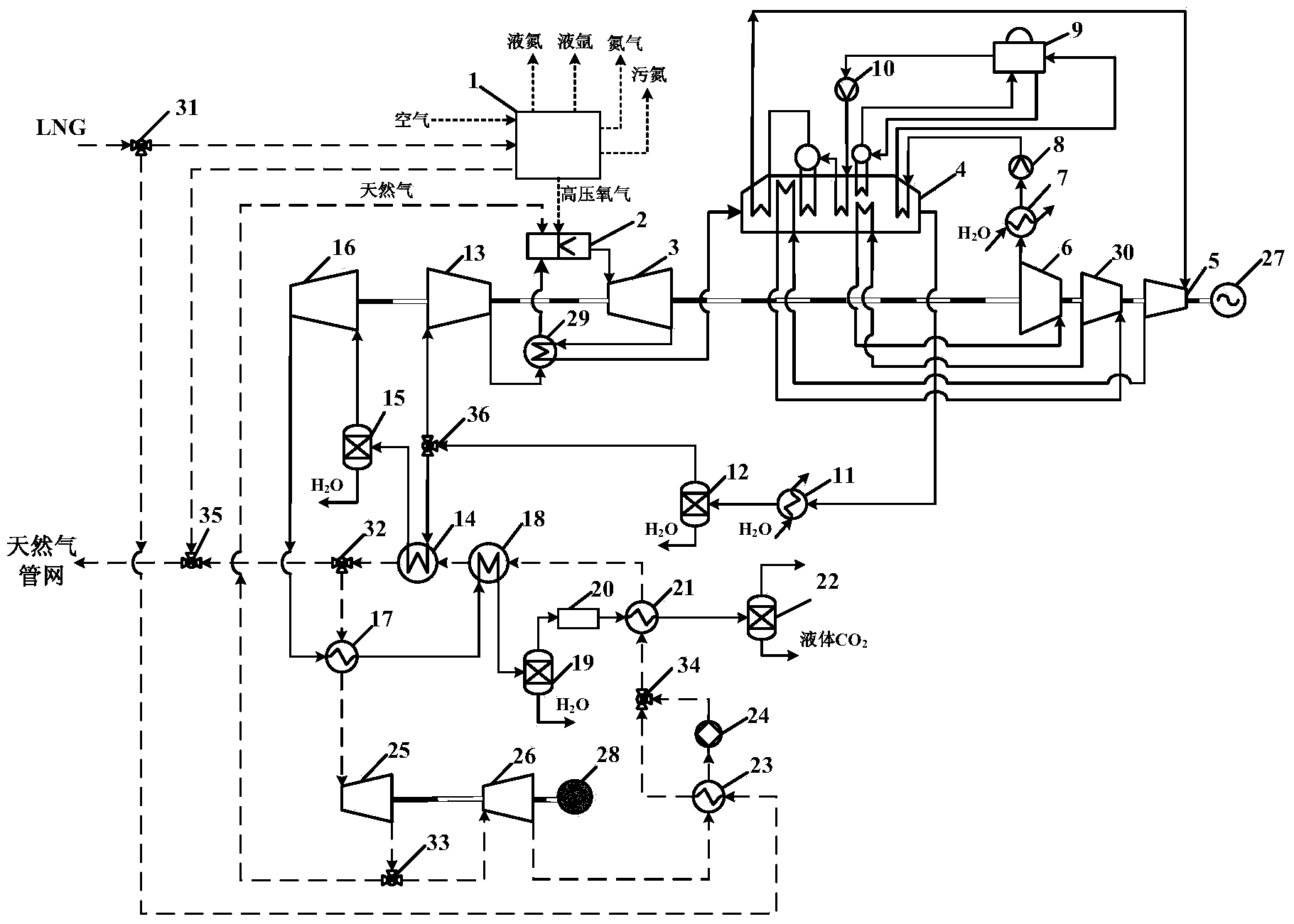

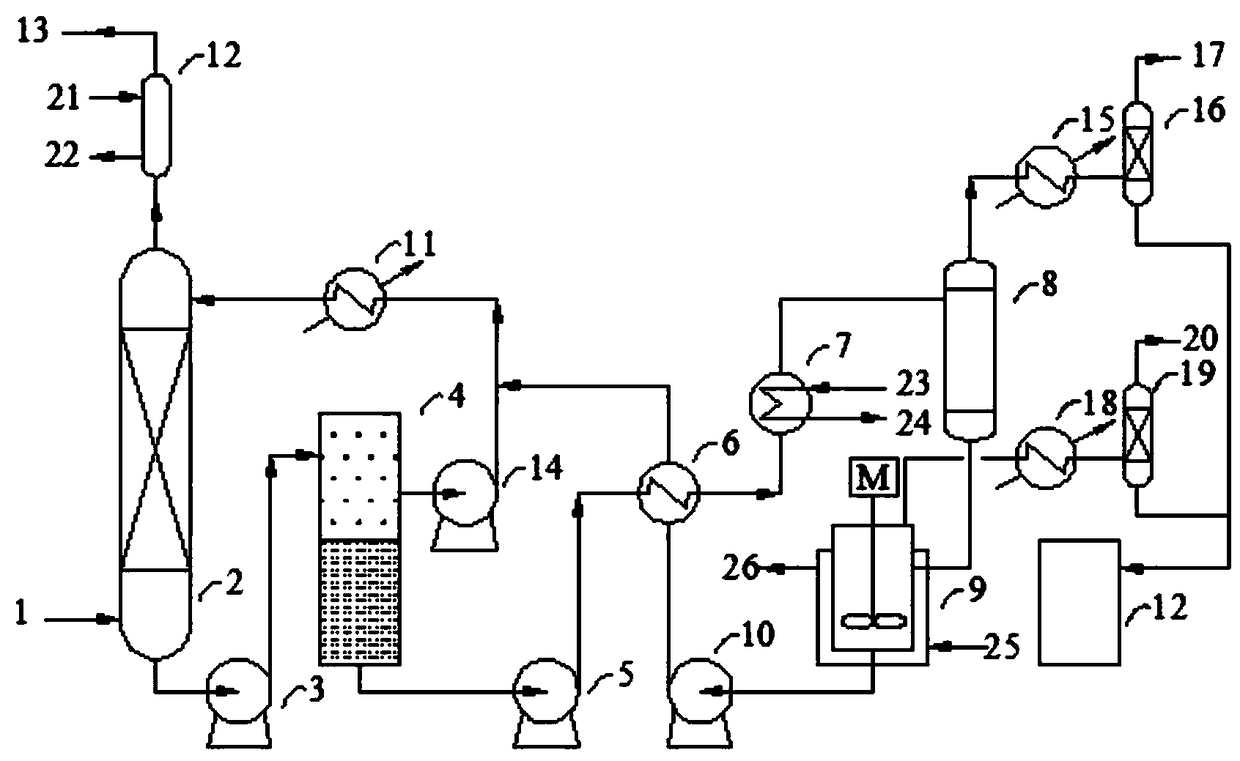

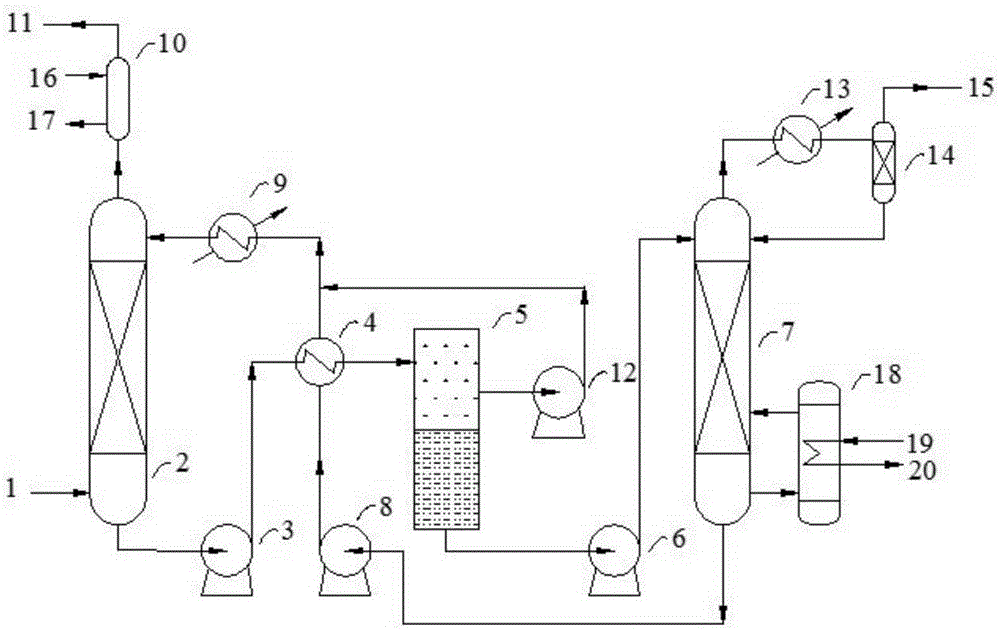

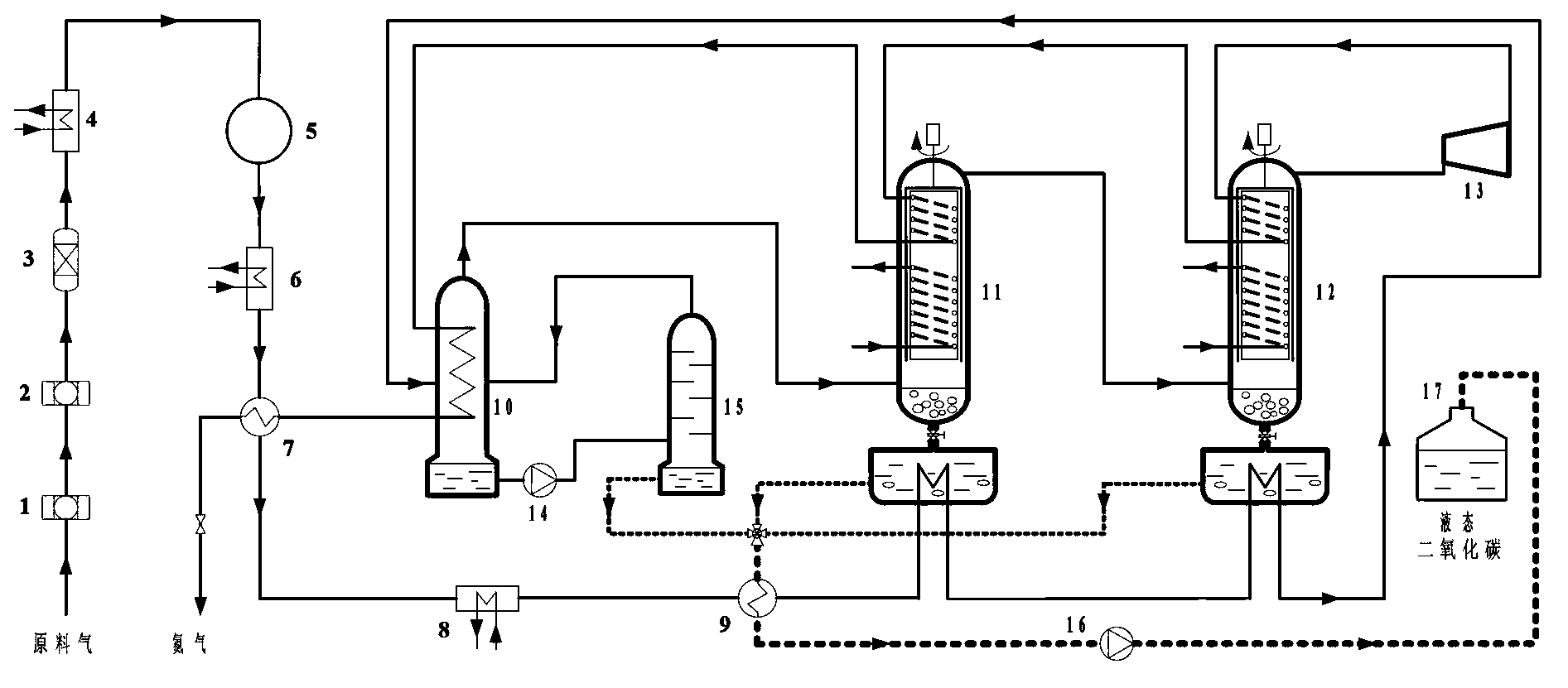

Combined power circulating method capable of catching carbon dioxide (CO2) by using LNG (Liquefied Natural Gas) cold energy and system thereof

ActiveCN103628982AImprove power generation efficiencyIncrease capture rateSolidificationLiquefactionPower cycleHigh pressure

The invention discloses a combined power circulating method capable of catching carbon dioxide (CO2) by using LNG (Liquefied Natural Gas) cold energy and a system thereof. The system comprises an air separation device, an oxygen-enriched-combustion gas turbine circulation device, a high-pressure steam power circulation device, a CO2 separation and liquefaction device and an LNG cold energy power circulation device, wherein the air separation device, the oxygen-enriched-combustion gas turbine circulation device, the high-pressure steam power circulation device, the CO2 separation and liquefaction device and the LNG cold energy power circulation device utilize the LNG cold energy. According to the method and the system, electricity and high-temperature fume which is rich in CO2 and water are generated from LNG through the oxygen-enriched-combustion gas turbine circulation device, and heat is recovered from the fume through the high-pressure steam power circulation device, so as to produce high-temperature and high-pressure steam with the pressure over 18MPa and increase the power generation efficiency of natural gas; moreover, the LNG cold energy is sequentially applied to the air separation device, the LNG cold energy power circulation device and the CO2 separation and liquefaction device, and the energy consumption for CO2 catching is lowered by making full use of the LNG cold energy, so that combined power cycle has relatively high power generation efficiency and relatively high CO2 catching rate, and the efficient utilization of the LNG cold energy is realized.

Owner:JINAN UNIVERSITY

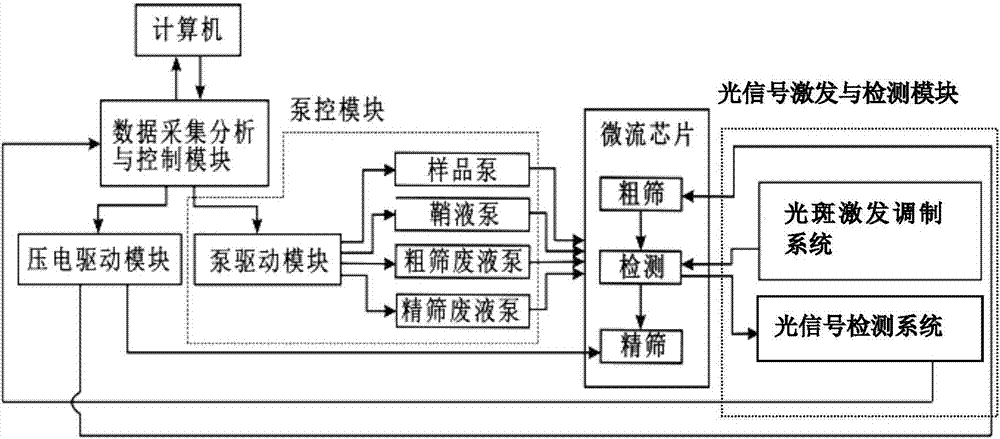

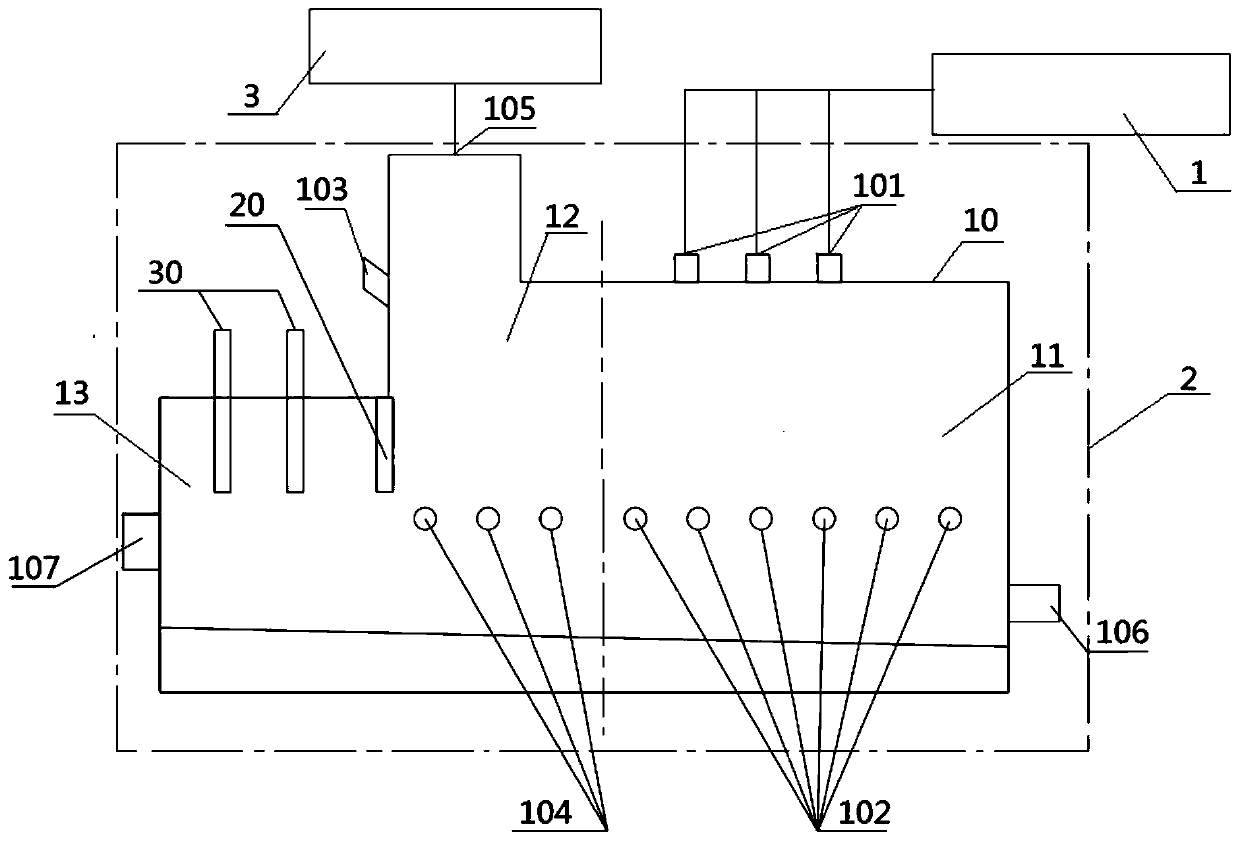

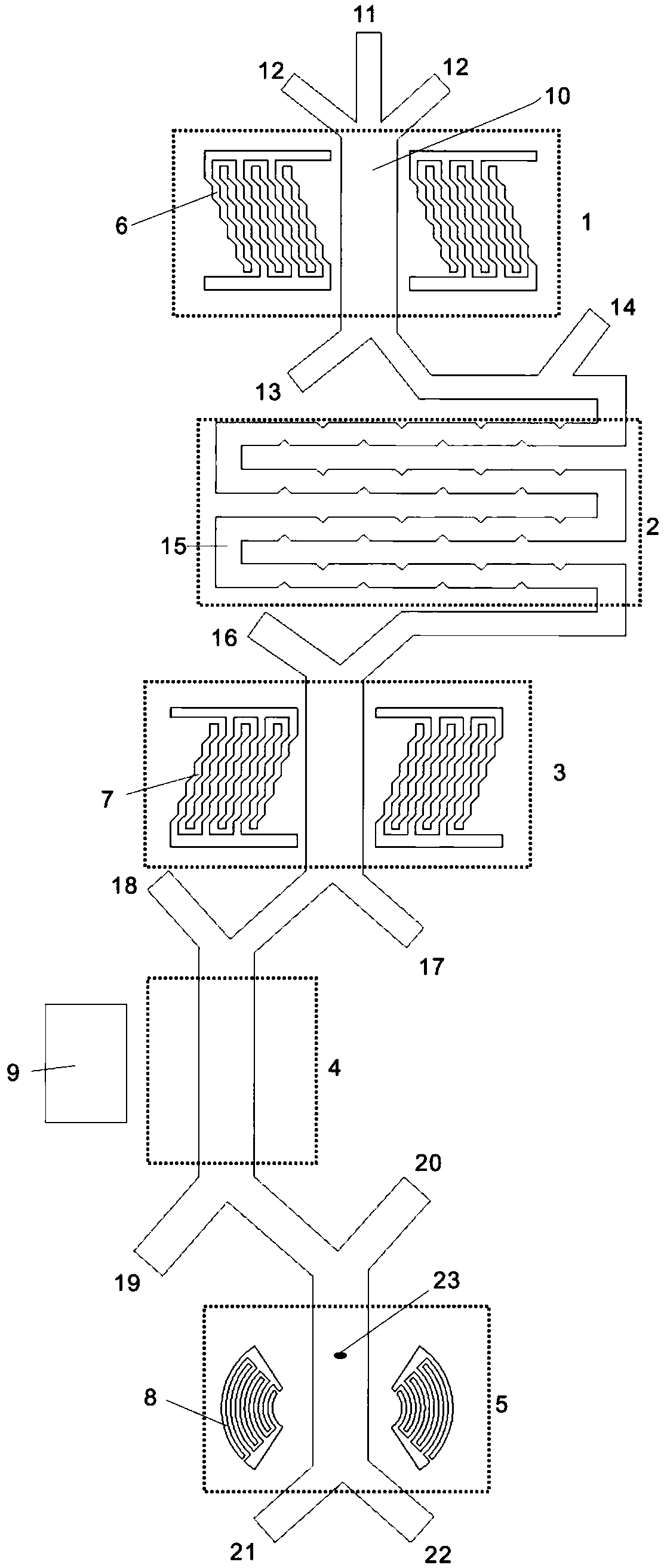

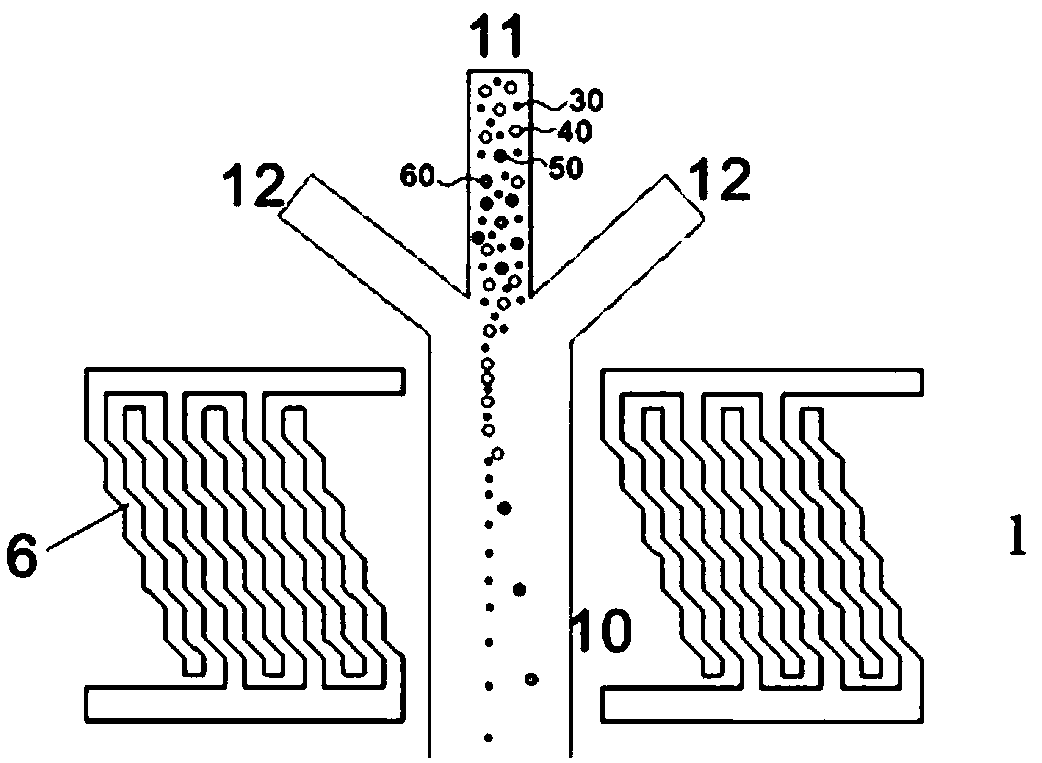

Microfluidic chip system for screening rare cells

PendingCN107505249AHigh purityIncrease capture rateBiological particle analysisIndividual particle analysisFlow cellData acquisition

The invention discloses a microfluidic chip system for screening rare cells. The system comprises a microfluidic chip, an optical signal excitation and detection module, a data acquisition analysis and control module, a piezoelectric driving module and a pump control module. A piezoelectric element is adopted to excite a surface wave sound field, part of non-target substances can be removed by coarse screening on the basis of physical properties of cells, and the purity and the capture rate of fine screening can be improved; meanwhile, effects of cleaning and three-dimensional focusing on a sample can be realized, and the accuracy of subsequent detection and fine screening is improved; the piezoelectric element is used for exciting a surface acoustic wave in a fine screening area, so that the target cells in fluid are driven to deviate from an original path, cell sorting can be realized quickly, and activity of the cells is not affected due to mechanical force acting on the cells. The system has no damage to the cells, can be used for conventional flow cell sorting and rare cell screening, and has great significance in promoting non-invasive prenatal screening and tumor prognosis detection.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

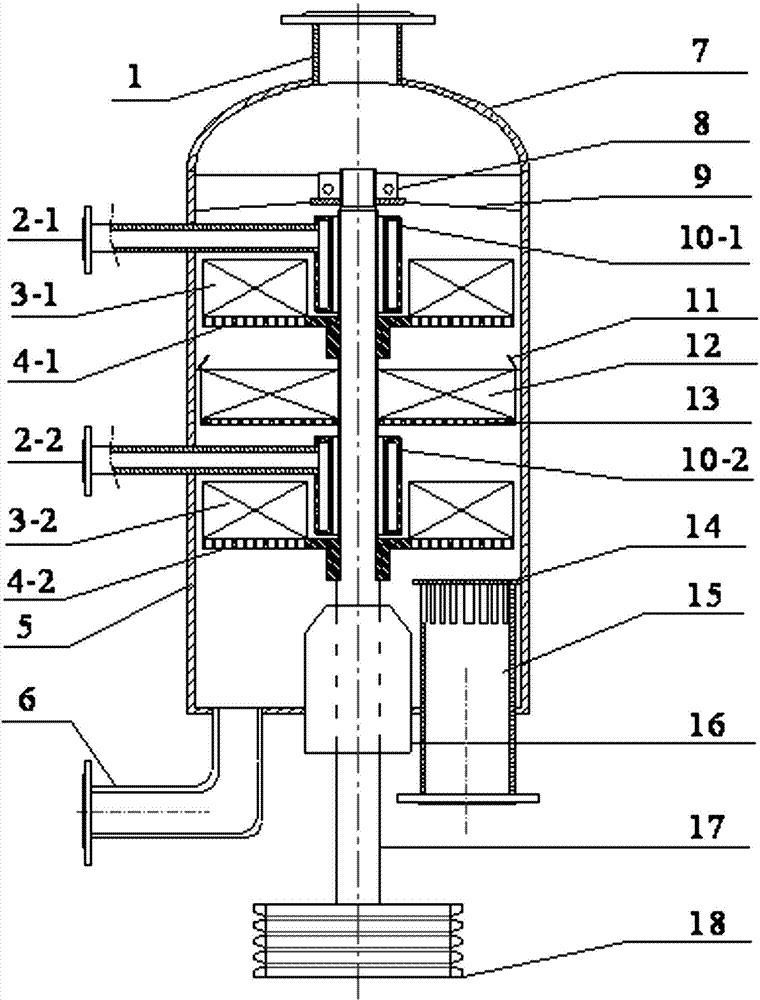

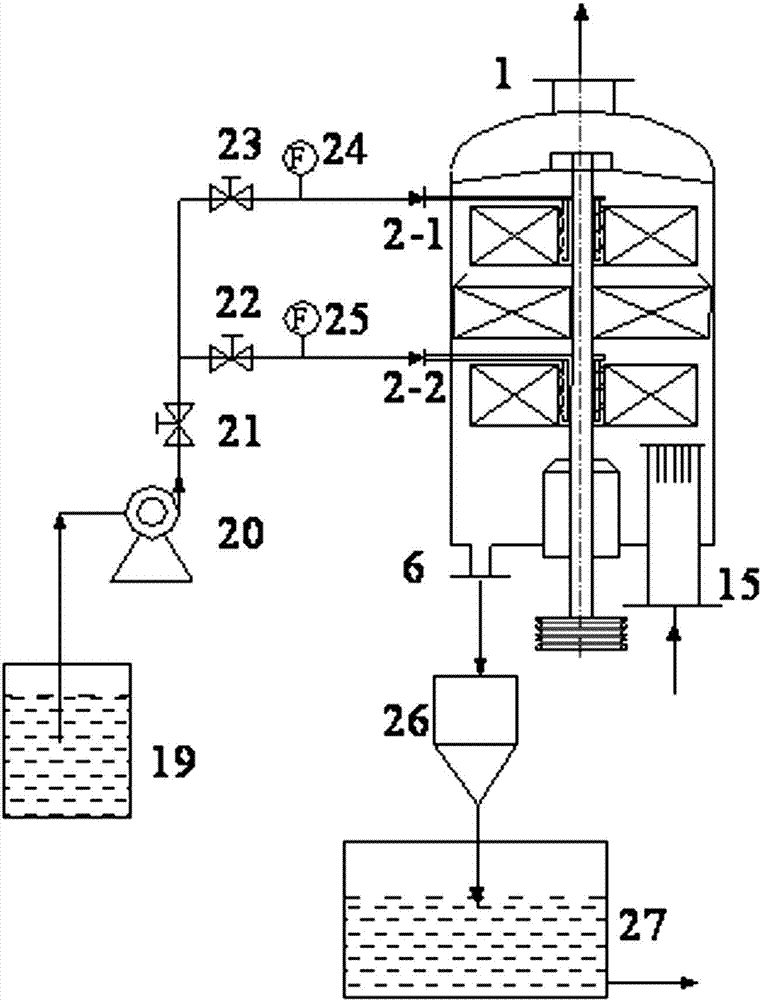

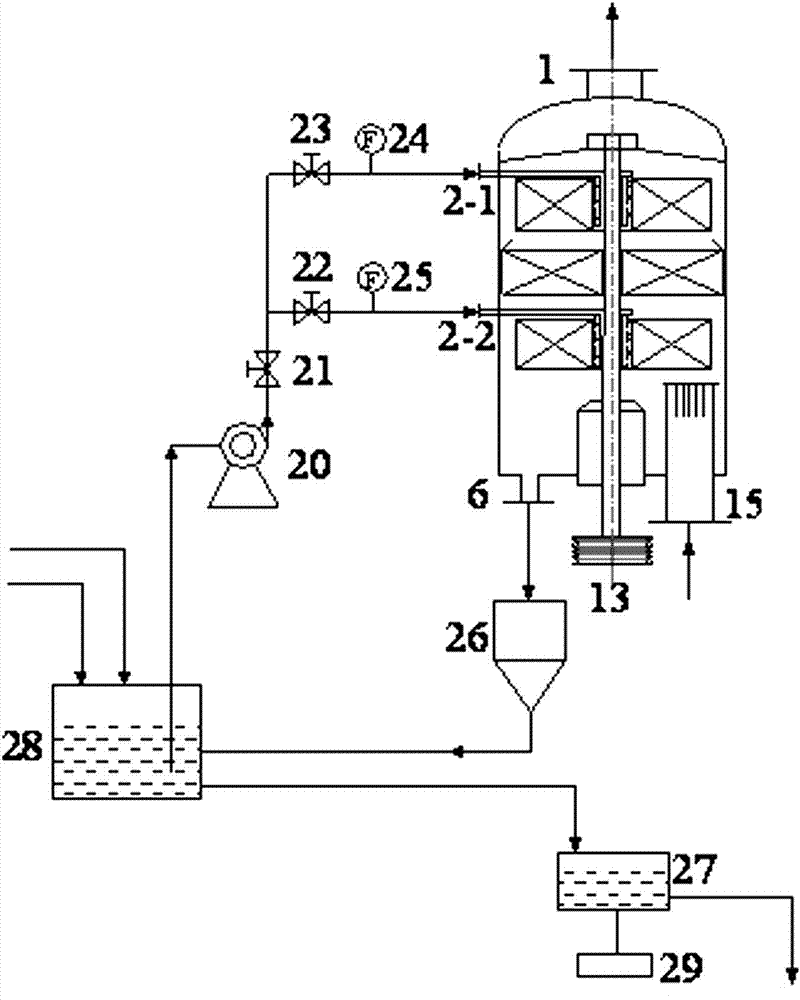

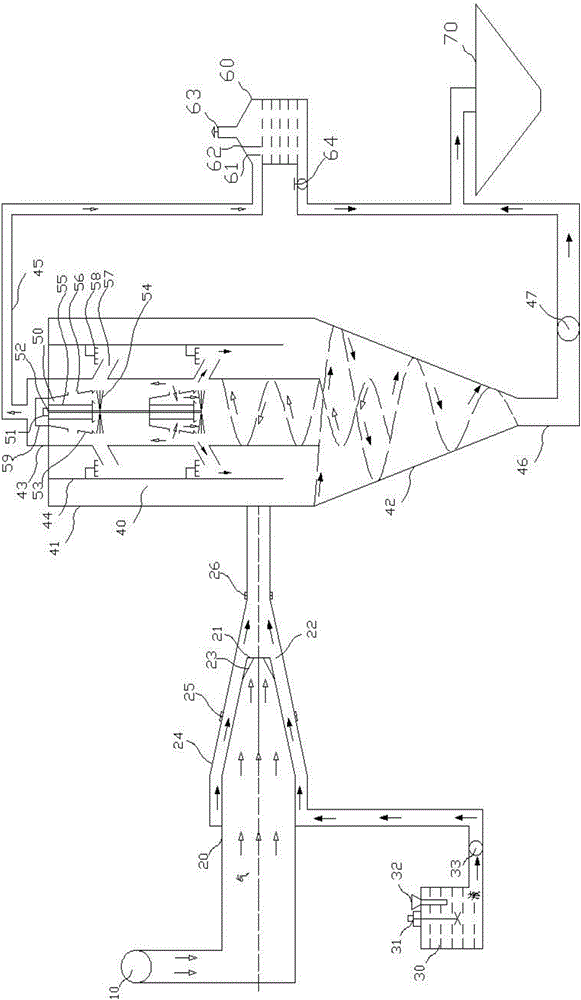

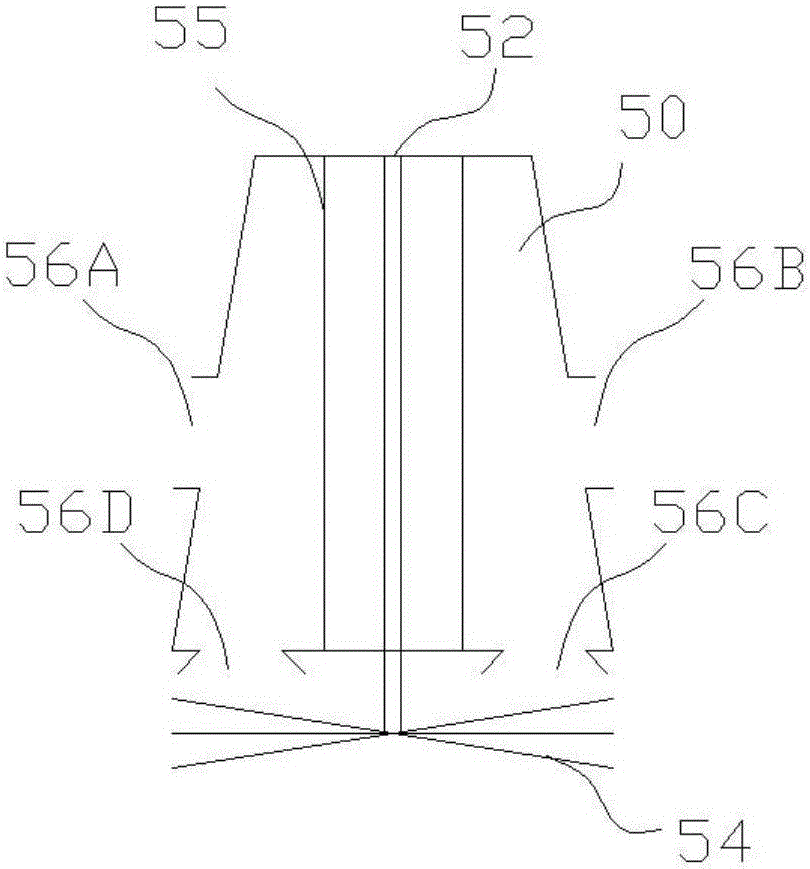

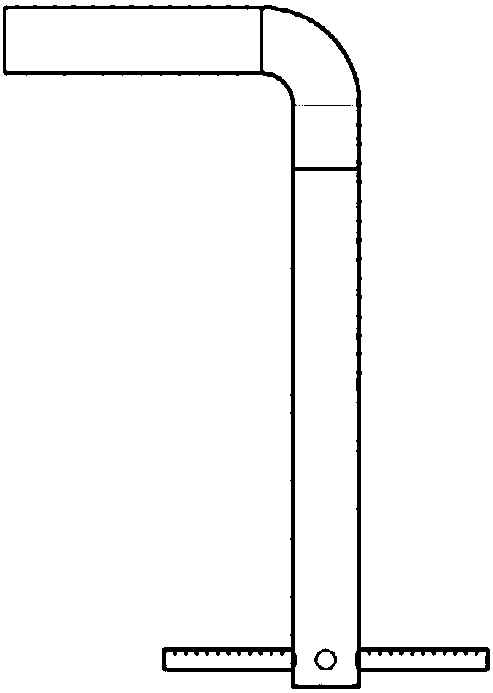

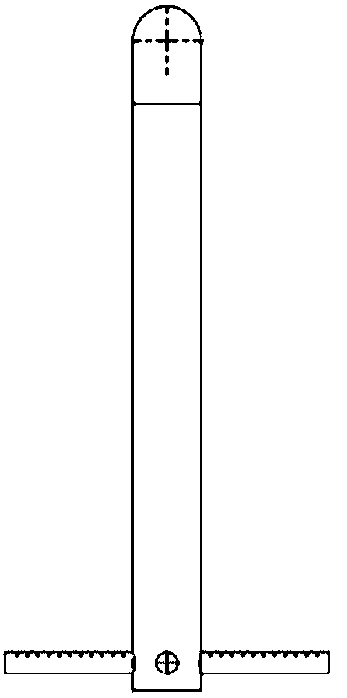

Flue gas desulfurization and dust removal technology and integrated apparatus applicable to ship

ActiveCN104492210AEnhanced mass transferIncrease capture rateCombination devicesGas treatmentFlue gasDust control

The invention belongs to the technology of flue gas desulfurization and dust removal, and in particular relates to a flue gas desulfurization and dust removal technology and an integrated device applicable to ships, and solves the problems in the flue gas desulphurization technology and equipment for ships of the prior art. The flue gas desulfurization and dust removal apparatus includes a multi-stage cross flow rotating packed bed, a barren liquor tank, a barren liquor circulating pump and an aeration tank. The flue gas desulfurization process includes an open seawater method flue gas desulphurization technology and a enclosed alkali method flue gas desulfurization technology. Two technologies can be combined with the rotating packed bed, and the invention has the advantages of high desulfurization efficiency, low energy consumption, simple process, low investment and operation cost, stable operation, convenient startup and shutdown, and integrated desulphurization and dust removal.

Owner:ZHONGBEI UNIV

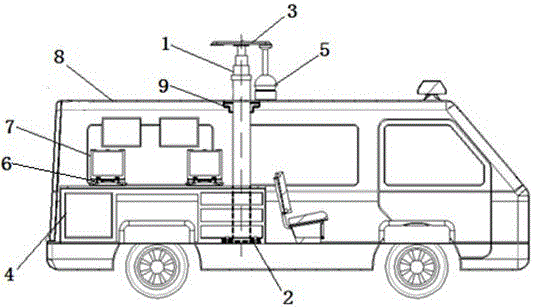

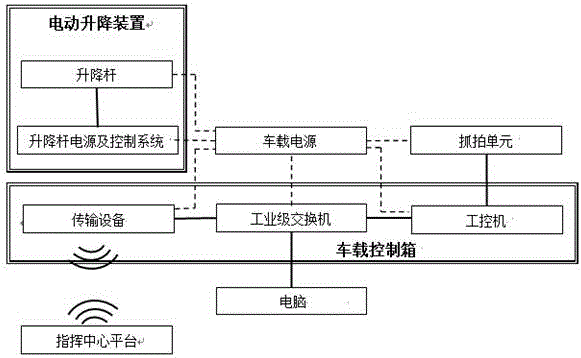

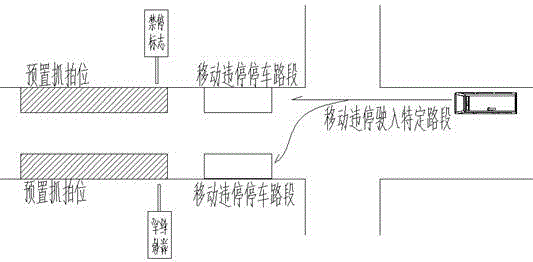

Movable illegal parking snapshot system and implementation method

InactiveCN106327878AFlexible capture methodReduce construction costsRoad vehicles traffic controlClosed circuit television systemsParking areaData information

The invention relates to a movable illegal parking snapshot system and an implementation method. The implementation method includes the steps: parking a movable detection automobile at a detection position; lifting a snapshot unit to a required height; configuring basic parameters and communication parameters of the snapshot unit and an industrial personal computer; drawing an initial model of a detection area, setting illegal parking judgment rules, and drawing adjusting points of the area; adjusting six adjusting points of the area to obtain a detection area A when a detection road section is a linear road section; adjusting six adjusting points of the area to obtain a detection area B when a detection road section is a bent road section, and performing snapshot when an illegal parking behavior is established as total parking time of a vehicle target in an illegal parking area exceeds a time threshold value preset by a system; transmitting illegal parking data information to a command center platform by a transmission device. The movable illegal parking snapshot system performs snapshot for a large number of illegal parking behaviors of fixed illegal parking detection snapshot monitoring ranges, control ranges of roads are widened, control time of the roads is prolonged, law-abiding consciousness of drivers is improved, and road traffic orders can be greatly improved.

Owner:天津市中环系统工程有限责任公司

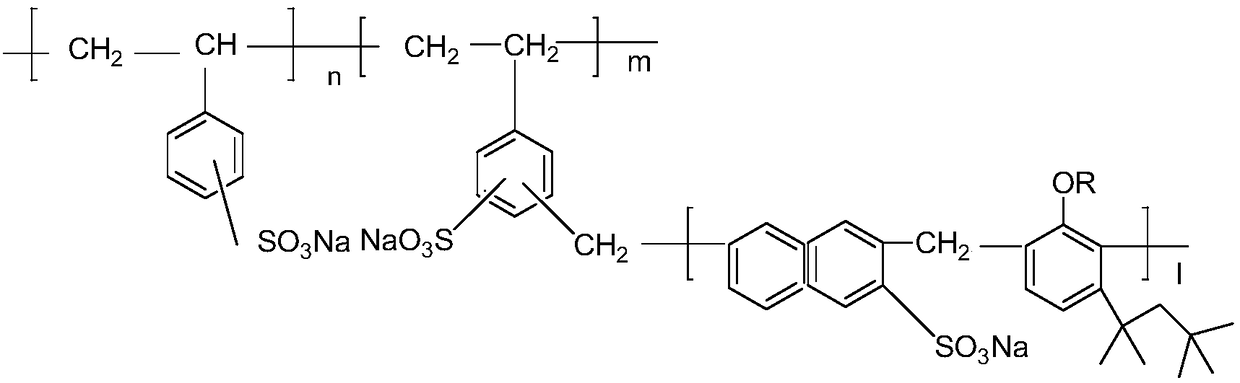

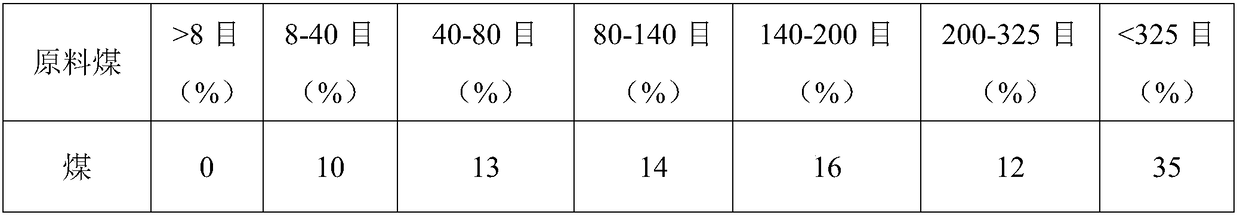

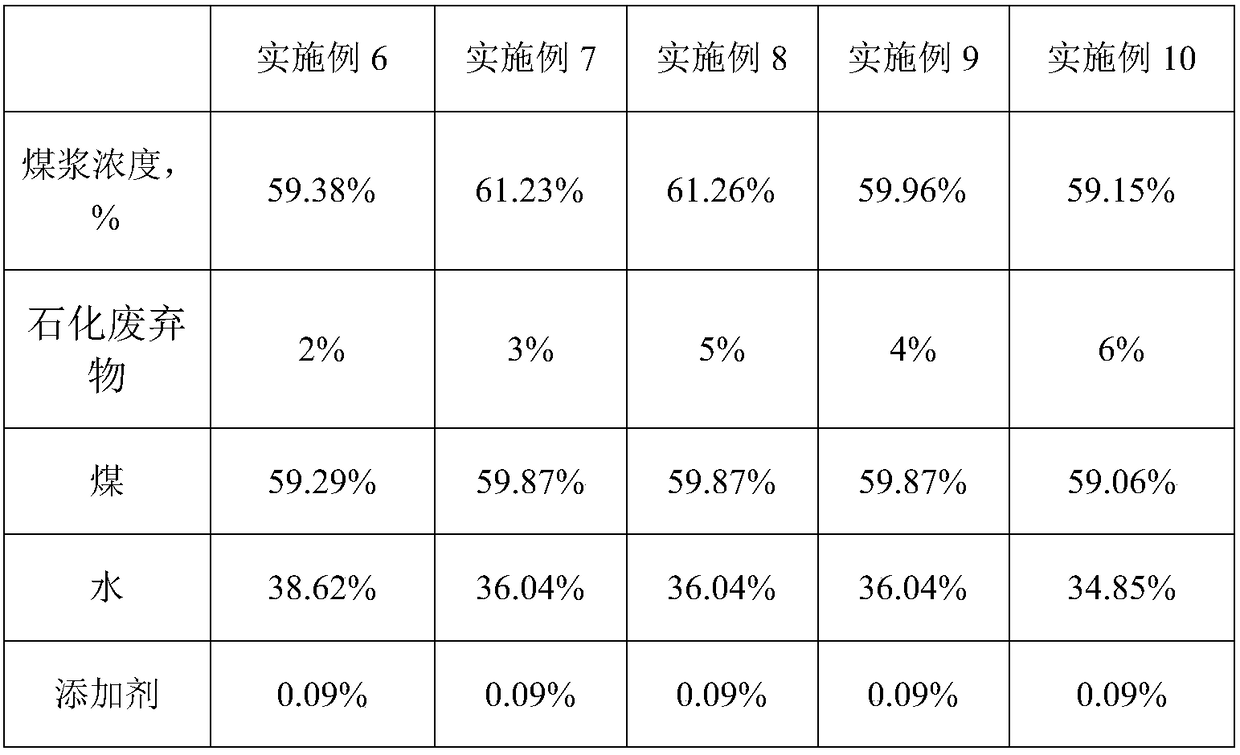

Coal-water slurry mixed with gasified coal and petrochemical waste and its pulping process

The invention discloses coal water slurry prepared by mixing gasified coal with petrochemical wastes. The coal water slurry is prepared from the following components: coal, the petrochemical wastes, additives and water, wherein the mass of the petrochemical wastes accounts for 0-6% of the total mass of the coal water slurry but not zero, and the adding amount of the additives accounts for 0-0.15% of the total mass of the dry coal but not zero. The invention also discloses a slurrying technology of the coal water slurry. The coal water slurry provided by the invention is good in fluidity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

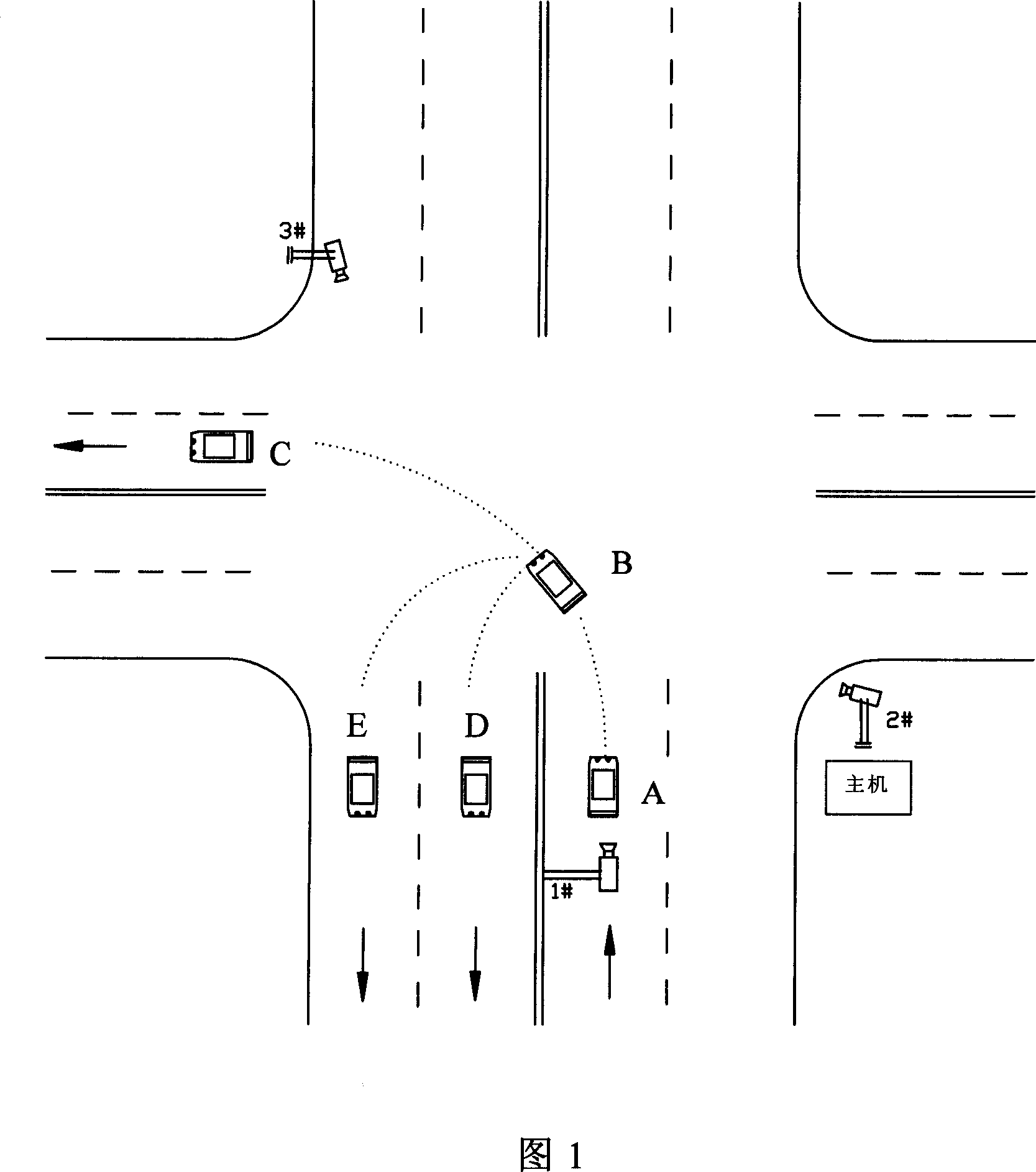

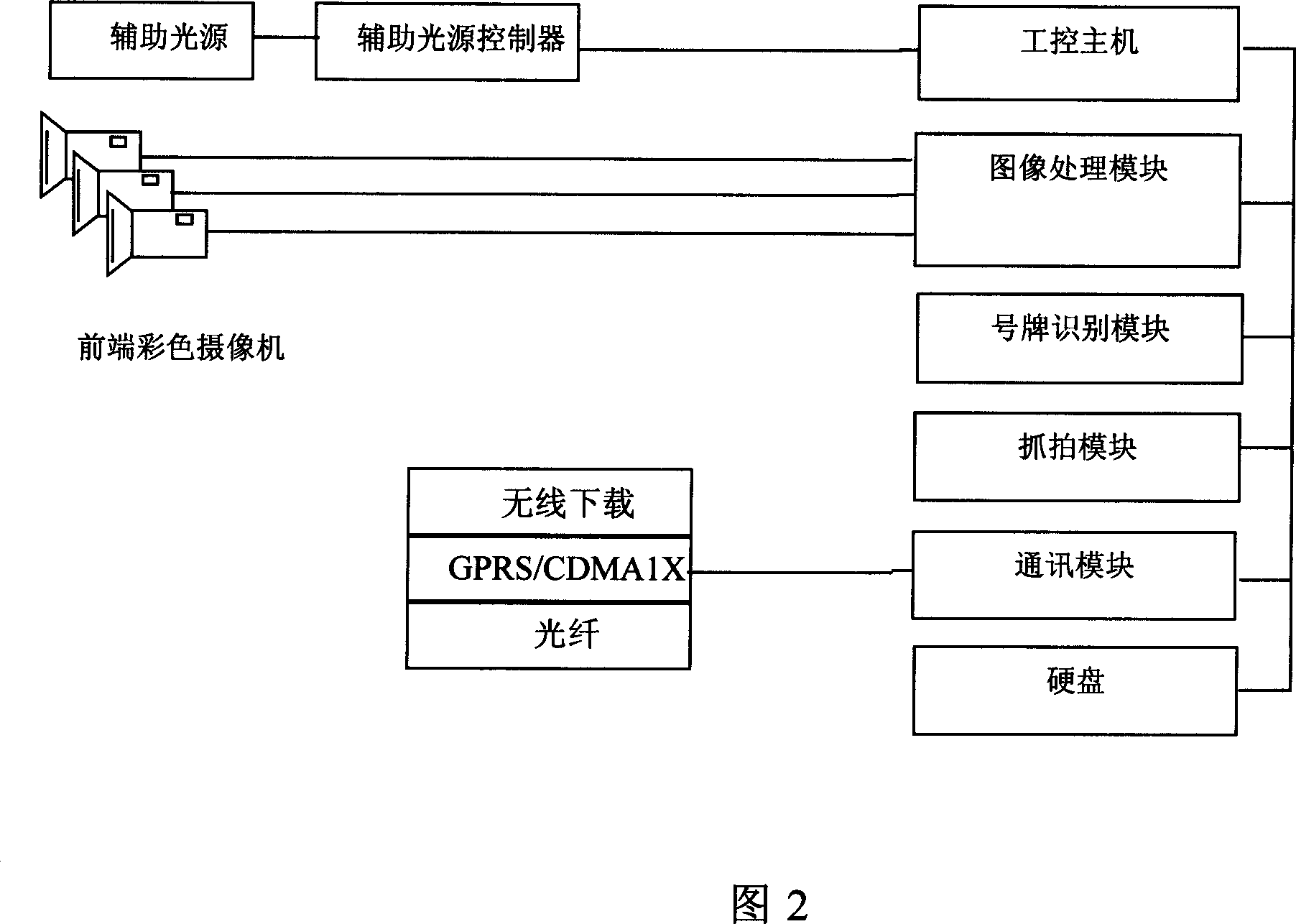

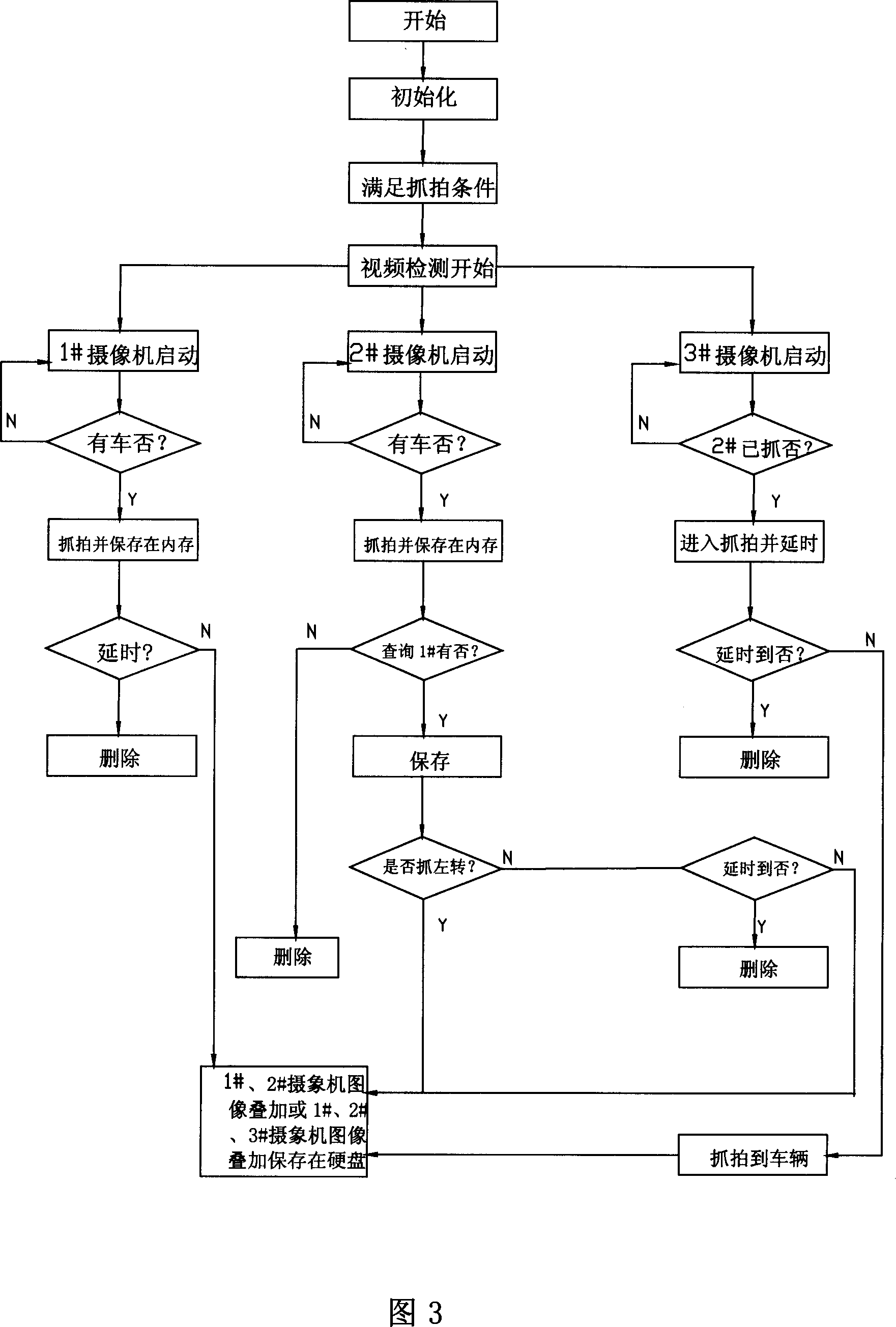

Automatic monitoring system for vehicle illegal turning and left turning

ActiveCN101064062AIncrease capture ratePlay an educational roleRoad vehicles traffic controlCommunication unitMonitoring system

This invention discloses one automobile illegal switch and illegal automatic monitor system, which comprises the following parts: industry control computer, color camera, aid light source, image process unit, communication unit, wherein the industry control computer comprises pad identification module and catch module; the color cameral sets three camera machines with one for automobile car, two for left switch car and three for switch car; the color camera is connected with image process unit and the aid light source, image process unit, communication unit are connected to industry control computer.

Owner:北京市振隆科技股份有限公司

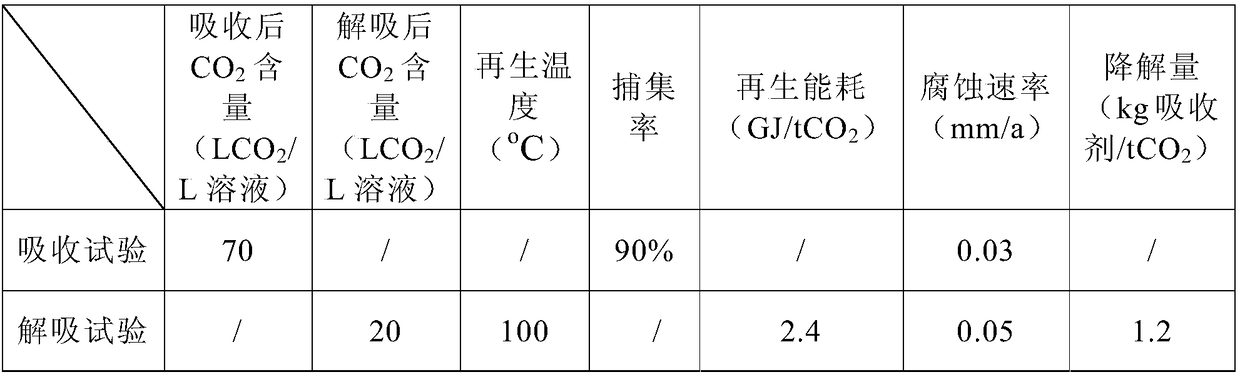

Phase change absorbent for capturing CO2 in waste gas

ActiveCN109331610ALarge absorption capacityIncrease capture rateDispersed particle separationAir quality improvementNanoparticleAntioxidant

The invention provides a phase change absorbent for capturing CO2 in the waste gas. The phase change absorbent for capturing the CO2 in the waste gas comprises an alkylol amine absorbent, an amine absorbent, a nanoparticle, a corrosion inhibitor, an antioxidant, a defoamer and water, the mass ratio of the alkylol amine absorbent to the amine absorbent, to nanoparticles to the corrosion inhibitor to the antioxidant to the defoamer to the water in the phase change absorbent for capturing CO2 in the waste gas is (15%-20%):(5%-10%):(0.01%-0.1%):(0.01%-0.2%):(0.01%-0.2%):(0.01%-0.1%):(70%-80%). Thephase change absorbent for capturing CO2 in the waste gas increases the absorptive capacity of CO2, increases the capturing rate of CO2, reduces the corrosion rate of equipment, improves the self-stability, reduces the regeneration temperature, reduces the energy consumption of regeneration, and improves the degradation effect.

Owner:CHINA PETROCHEMICAL CORP +2

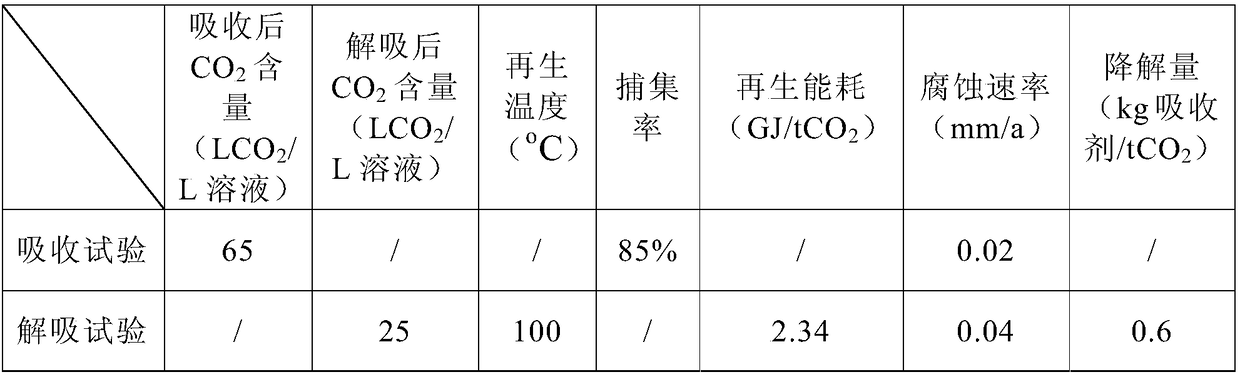

Double phase absorption system for removing CO2 from flue gas

InactiveCN105396447AEffective absorptionEffective implementation of absorptionDispersed particle separationAir quality improvementOrganic solventDouble phase

The invention provides a double phase absorption system for removing CO2 from flue gas. The system is composed of an alkylol amine absorbent, an amine absorbent, an activator, a consumption reduction agent, water and an organic solvent. The double phase absorption system for removing CO2 from flue gas has the advantages of strong absorption capability, fast absorption rate, low regeneration temperature and low energy consumption in the regeneration process.

Owner:SINOPEC ENERGY & ENVIRONMENTAL ENG CO LTD

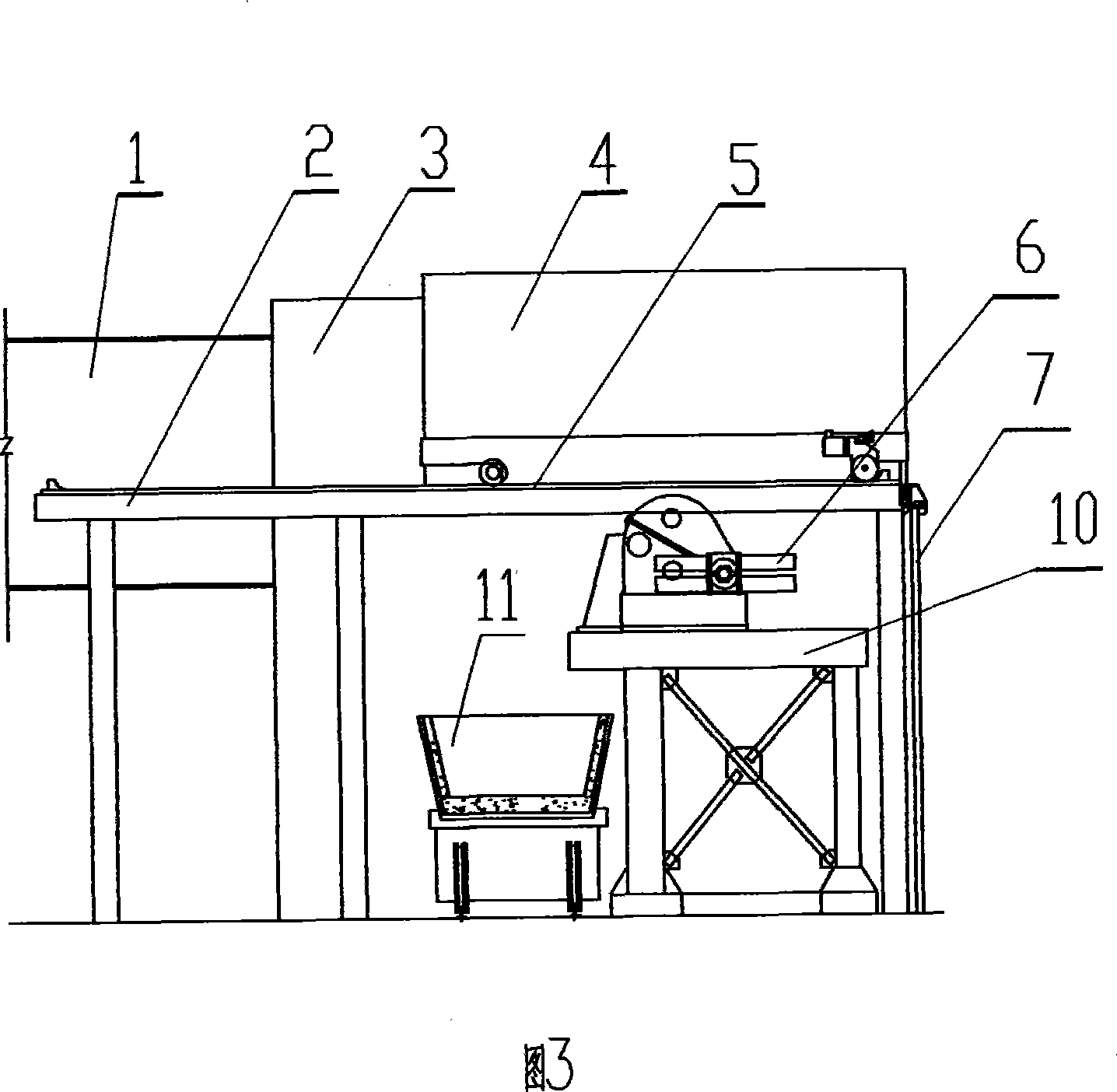

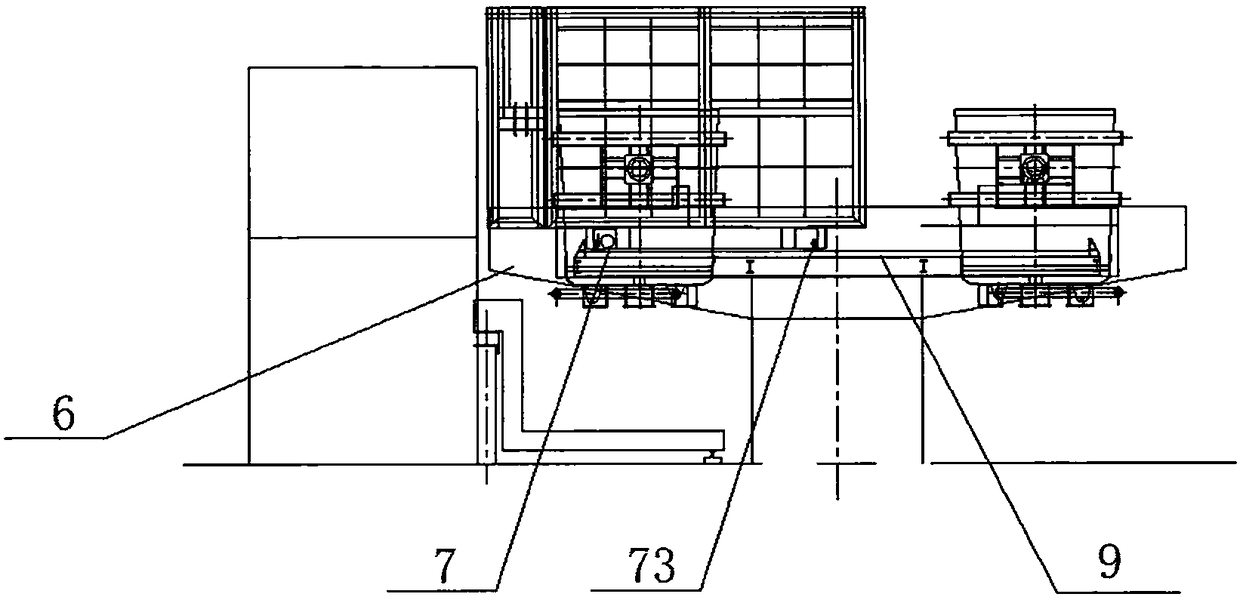

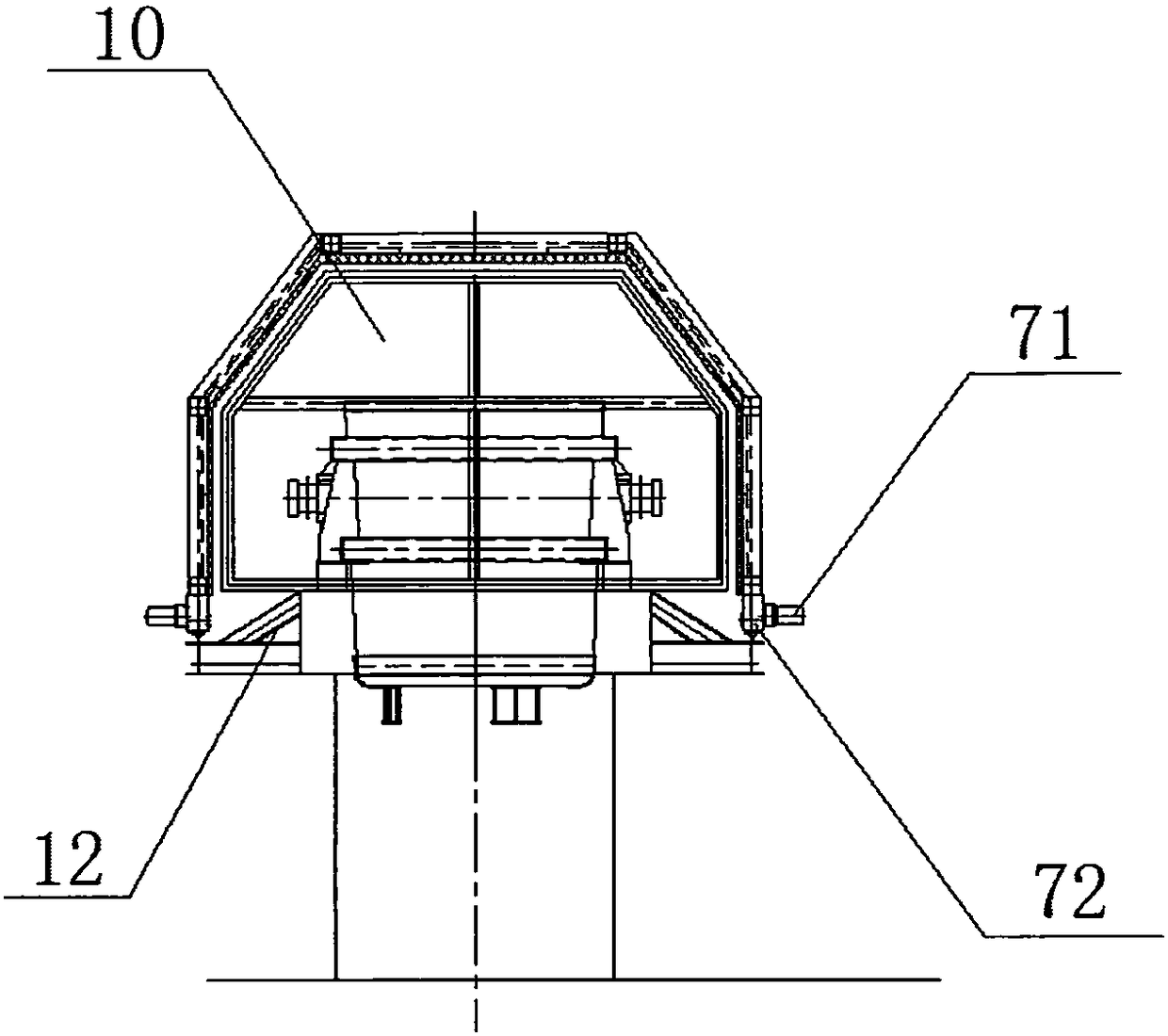

Mobile smoke blast trapping device for furnace mixer

The invention discloses a movable dust arrestment device used for a metal iron mixer, comprising a dedust pipe (1), a support (2), a fixed smoke cover (3) and a movable smoke cover (4). The movable dust arrestment device is characterized in that: the fixed smoke cover (3) and a guide way (5) are arranged on the support (2), and the movable smoke cover (4) can move along the guide way (5), and can be combined with the fixed smoke cover (3) to form a sealed dedust cover; a pig-iron ladle dumping device (6) is arranged on the support (2), and the dedust pipe (1) is arranged on one side of the fixed smoke cover (3). The movable dust arrestment device used for the metal iron mixer has the advantages of convenient usage, ensuring high dust arrestment rate and good dedust effect in the iron receiving process of metal mixer, being energy-saving, reducing running cost, improving the working environment of operating staffs and reducing the operating rate of cranes in workshop.

Owner:HUATIAN ENG & TECH CORP MCC

Diamond wire saw and rapid production method thereof

ActiveCN103388170AIncreased chance of collisionIncrease capture rateElectrolytic coatingsChemical platingHeat treated

The invention discloses a diamond wire saw and a rapid production method thereof. The surfaces of diamond grits are respectively coated with a nickel layer by chemical plating, the nickel layers are fixed on a copper-plated piano wire substrate pre-plated with a nickel layer through electroplating, and then the nickel layers are thickened, so that the diamond grits are solidified more firmly. The rapid production method of the diamond wire saw comprises the following steps of: 1, removing greases and oxides on the surfaces of diamond grits, and carrying out sensitization, activation and chemical nickel plating on the diamond grits; 2, removing greases and oxides on the surface of a metal substrate, and pre-plating nickel layers as buffer layers; and 3, carrying out composite electroplating, thickened electroplating and heat treatment on the diamond wire saw. According to the invention, diamond grits are subjected to chemical nickel plating to achieve an effect of electric conduction, so that the diamond grits carry out sequential movement under the action of an electric field, and chemical consolidation is realized; and in addition, intense agitation is introduced in an electroplating process, so that high-current / density electroplating is realized, and a highly efficient and rapid method is provided for the industrial production of diamond wire saws.

Owner:江西核工业兴中科技有限公司

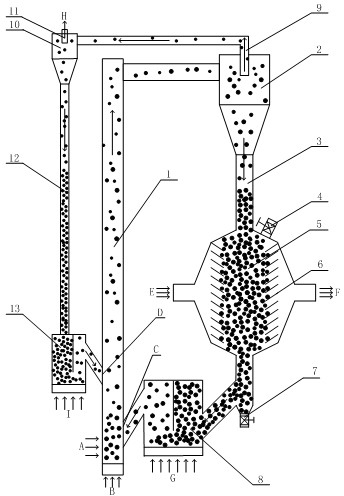

Method for separating CO2 through chemical looping combustion in coal pressure high-density circulating fluidized bed

ActiveCN102183014AIncrease the combustion reaction rateSolving the Response Matching ProblemFluidized bed combustionIndirect carbon-dioxide mitigationCycloneHigh density

The invention provides a method for separating CO2 through chemical looping combustion in a coal pressure high-density circulating fluidized bed, which comprises the following steps: coal particles and a gasifying agent are subjected to gasification reaction in a fuel reactor 1 of the coal pressure high-density circulating fluidized bed, and gasified products and oxygen carriers which return to the fuel reactor are subjected to combustion reaction to produce CO2 and H2O; smoke which is produced during the reaction and carries oxygen-lost oxygen carriers and carbon-containing coal ash enters a primary cyclone separator 2 for separation, and separated oxygen-lost oxygen carriers are in contact with transversely passing air for reaction in an air reactor 5 of a cross flow moving bed to be regenerated and are turned to the combustion reactor through a primary material returning device 8 to continuously participate in the combustion reaction; and separated smoke in the primary cyclone separator 2 further enters a secondary cyclone separator 10 for separation, solid particles secondarily separated are returned to the fuel reactor 1 through a secondary material returning device 13 to continuously participate in the combustion reaction, and H2O is removed from the separated gases through condensation to obtain high-purity CO2.

Owner:SOUTHEAST UNIV

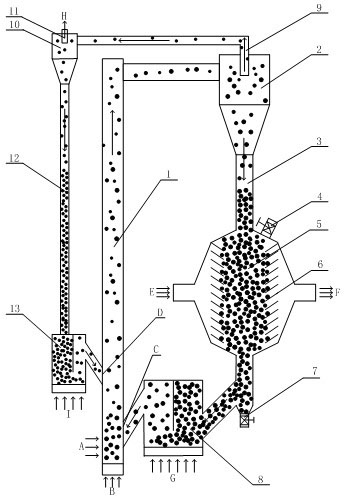

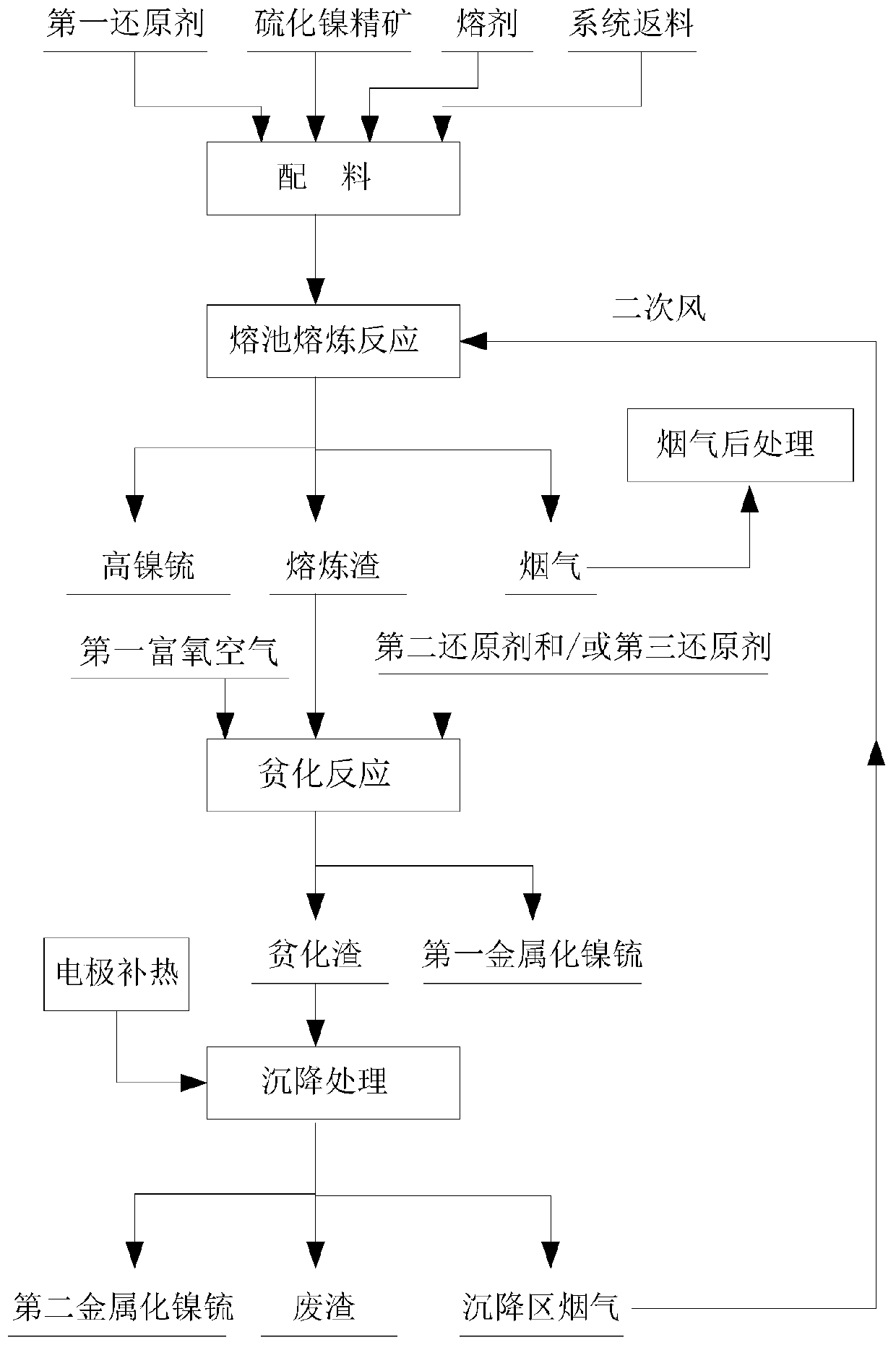

One-step nickel smelting system and one-step nickel smelting method

ActiveCN111101001ASolution conditionsSolve the problem of high nickel content in smelting slagProcess efficiency improvementSlagFlue gas

The invention provides a one-step nickel smelting system and a one-step nickel smelting method. The one-step nickel smelting system comprises a raw material conveying device, a one-step nickel smelting device and a flue gas treatment device; the one-step nickel smelting device is an integrated device and comprises a furnace body, and a molten pool smelting area and a reduction depletion area are sequentially arranged inside the furnace body; a first feeding inlet and a first blower nozzle are formed in the molten pool smelting area, the first feeding inlet is connected with the raw material conveying device, and the molten pool smelting area is used for performing molten pool smelting on nickel sulfide concentrates to produce high nickel matte containing 35-65 wt% nickel, smelting slag andflue gas; the reduction depletion area communicates with the molten pool smelting area, a second feeding inlet, a second blower nozzle and a flue gas outlet are formed in the reduction depletion area, and the reduction depletion area is used for enabling the smelting slag to be subjected to the depletion reaction to produce depleted slag and first metallized nickel matte; the flue gas treatment device is connected with the flue gas outlet. The problems such as high raw material feeding-into-furnace conditions of the DON process, high nickel content in the smelting slag, large load and high energy consumption when an electric furnace separately treats the smelting slag are effectively solved.

Owner:CHINA ENFI ENGINEERING CORPORATION

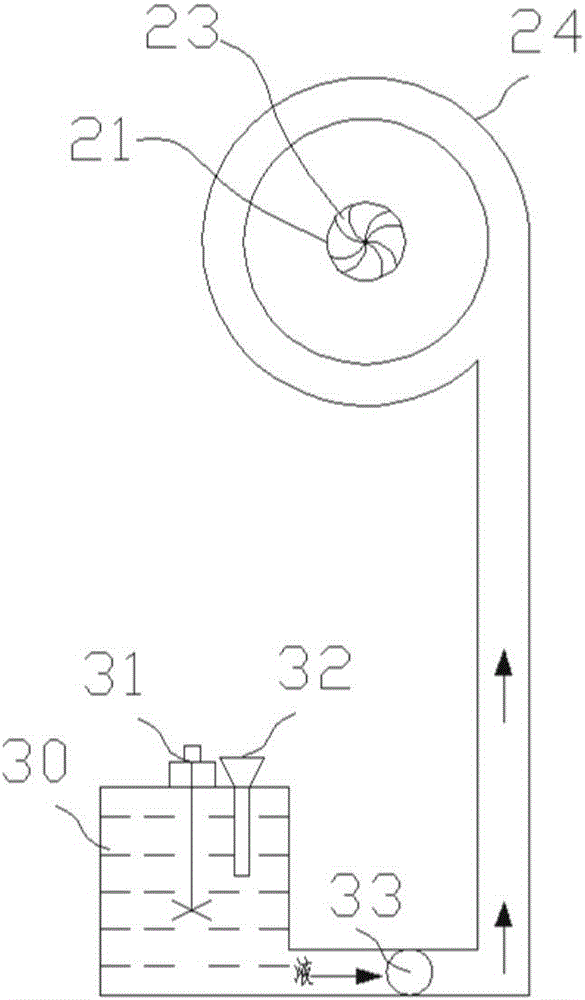

Jet atomization type mining rotational-flow inertial dust remover and application process thereof

ActiveCN106076040AMake sure to remove it completelyReasonable process designCombination devicesImpellerWater storage tank

The invention relates to the technical field of wet dust removal of coal mines, in particular to a jet atomization type mining rotational-flow inertial dust remover and application process thereof. The jet atomization type mining rotational-flow inertial dust remover comprises a dusty gas conveying fan, an annular sleeve jet nozzle, a water storage tank, a rotational-flow dust remover, rotary impeller inertial dust removing devices, a gas-water separator and a concentrator. The jet atomization type mining rotational-flow inertial dust remover has the advantages that dust of various particle sizes can be removed by gradual dust removing and multiple dust removing, and the dust in the dusty gas can be moistened and wrapped by the annular sleeve jet nozzle; large dust and dust-water-mixed wrapped particles can be removed by the rotational-flow dust remover; one or more rotary impeller inertial dust removing devices are arranged in the central overflow channel of the rotational-flow dust remover and used for capturing and discharging fine dust; a front retaining plate and a rear retaining plate are arranged at the inlet of the gas-water separator to guarantee the complete removing of dust. The jet atomization type mining rotational-flow inertial dust remover which uses universal equipment of coal mine enterprises is high in dust removing efficiency, reliable and stable in effect and low in capital construction cost.

Owner:ANHUI UNIV OF SCI & TECH

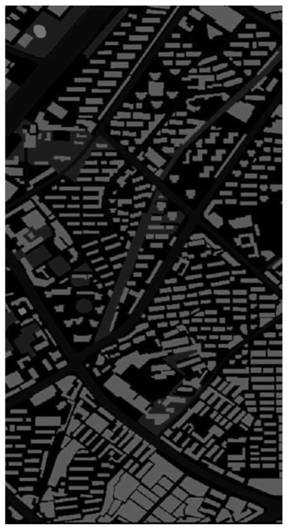

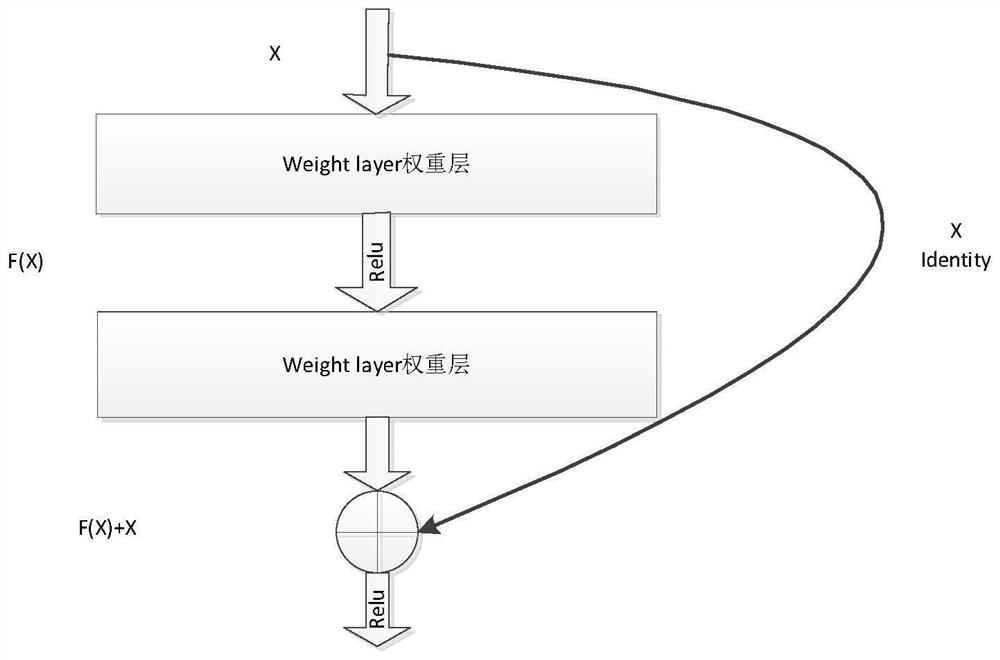

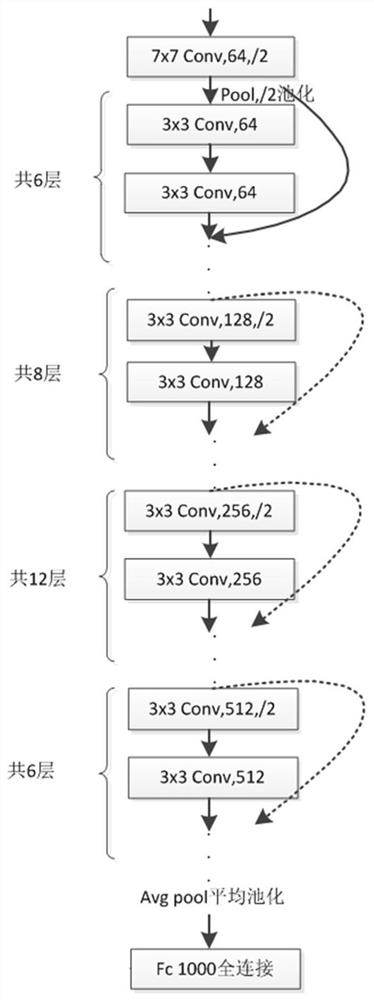

Remote sensing image segmentation algorithm based on convolutional neural network

PendingCN111985274AImprove Segmentation AccuracyClear scene analysis effectScene recognitionNeural architecturesEngineeringConvolution

The invention relates to a remote sensing image segmentation algorithm based on a convolutional neural network, and the algorithm comprises the steps: employing ResNet34 pre-training weight parametersas the depth guarantee of a network layer, so as to solve a problem of gradient disappearance when the network layer is deepened; a pyramid pooling module is adopted to aggregate context informationof different areas in the image so as to improve the capability of obtaining global information; designing a loss function by adopting a method of combining a cross entropy loss function and regularization constraints, wherein the cross entropy is used for judging the closeness degree of actual output and expected output in the multi-classification problem; the regularization term can reduce the complexity of the model so as to prevent overfitting and improve the generalization ability of the model. According to the method, the designed composite convolutional neural network algorithm is applied to semantic segmentation of the remote sensing image, so that the speed of information recognition in the remote sensing image and the capture rate of effective information are greatly improved, and the method is of great significance to information analysis of the remote sensing image.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

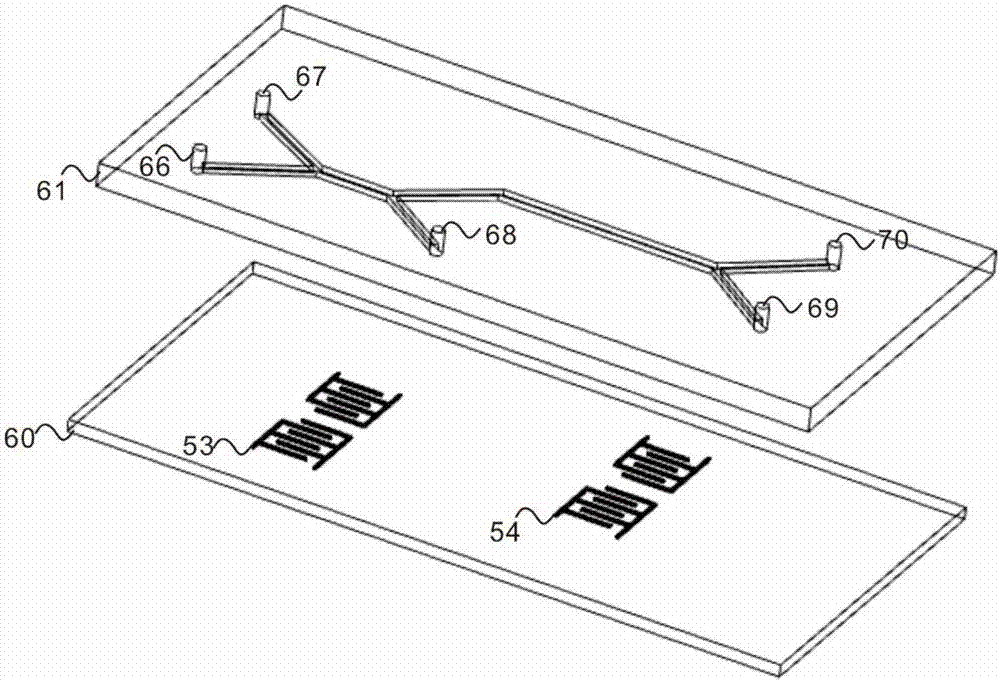

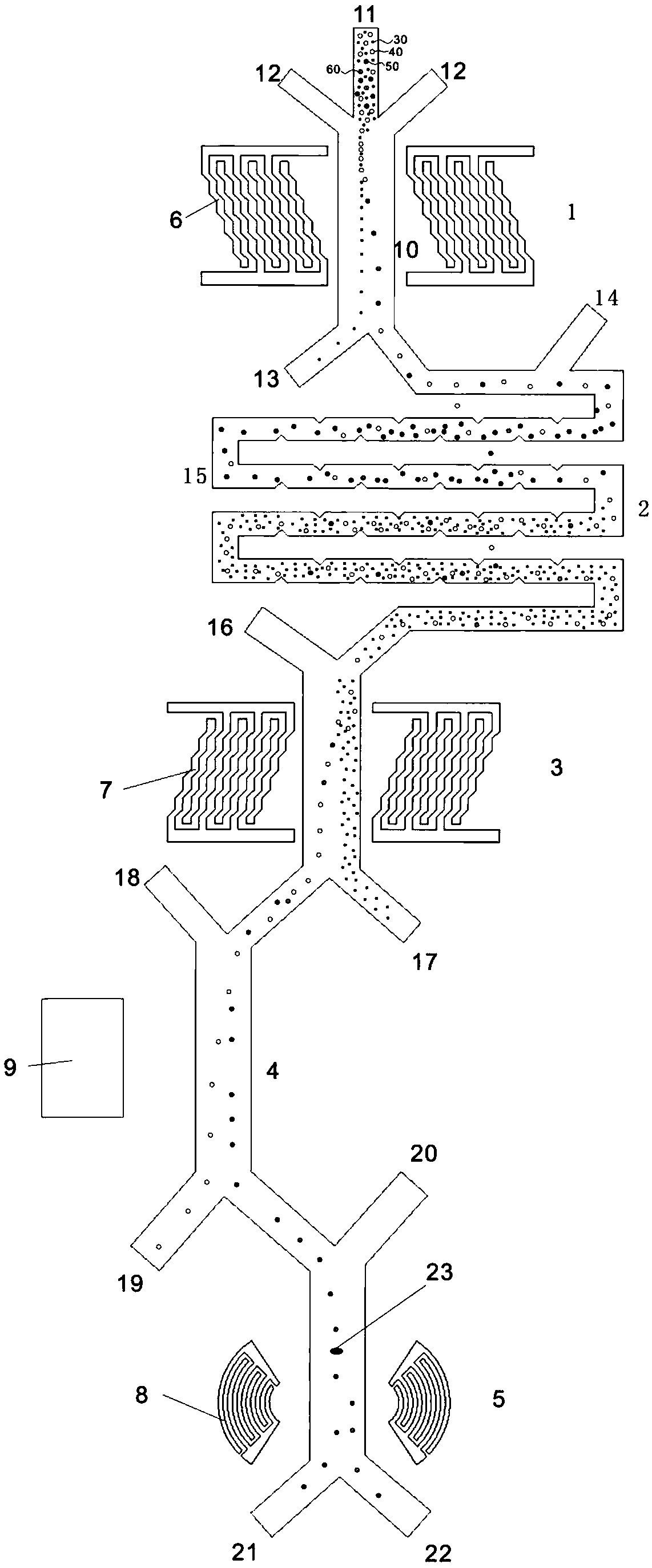

Micro-fluidic chip for screening rare cells in whole blood

PendingCN109439513AHigh purityIncrease capture rateBioreactor/fermenter combinationsBiological substance pretreatmentsRed blood cellMagnetic bead

The invention discloses a micro-fluidic chip for screening rare cells in whole blood. The micro-fluidic chip comprises a microchannel as well as a platelet removing region formed on the microchannel by a first interdigital electrode assembly, a red cell lysis region formed by a lysis pipeline segment on the microchannel, a red cell removing region formed on the microchannel by a second interdigital electrode assembly, a white cell removing region formed on the microchannel by a magnetic field and a target cell extraction region formed on the microchannel through a third interdigital electrodeassembly in sequence. According to the micro-fluidic chip disclosed by the invention, platelets and lysed red cells are removed by using the size difference; white cells are removed by using a specific monoclonal antibody and a magnetic bead mode, and screening purity and capture ratio of target cells are favorably improved; in addition, the micro-fluidic chip can clean samples. The system disclosed by the invention does no harm to cells, can be used for conventional flow cell sorting and screening the rare cells and has important significance for promoting noninvasive prenatal screening and tumor prognosis detection.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Novel carbon dioxide trapping device performing liquefaction and then sublimation

InactiveCN103274406AHigh purityAvoid it happening againCarbon compoundsAir quality improvementSystems designTrapping

The invention discloses a novel carbon dioxide trapping device performing liquefaction and then sublimation. According to the device, research on physical properties of carbon dioxide and related mixtures is combined, and gas-liquid separation is performed firstly through a low temperature mode to obtain a part of liquid carbon dioxide; mixed gas after the liquefaction separating is cooled continuously and passes through two sublimation separating towers, and then carbon dioxide is separated; and dry ice obtained from sublimation separation is collected into a condensation pool, and the pressure is controlled above triple point pressure of carbon dioxide, so that the obtained dry ice can be melted directly into liquid carbon dioxide. The overall system design facilitates sufficient cold quantity recovery. The device improves the carbon dioxide trapping purity effectively, increases the carbon dioxide trapping efficiency, improves the cold quantity recovery rate of the system, and is energy-saving and low in consumption.

Owner:SOUTHEAST UNIV

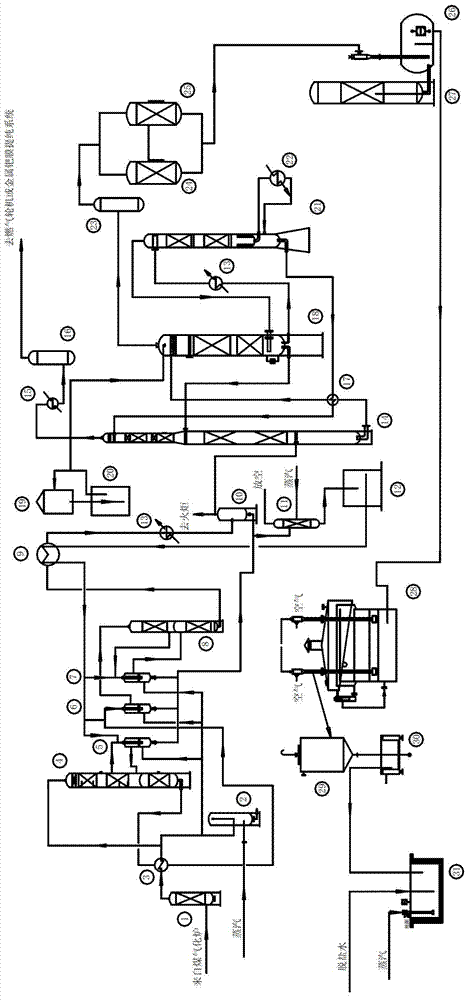

IGCC (Integrated Gasification Combined Cycle) based pre-combustion CO2 capture system

The invention relates to an IGCC (Integrated Gasification Combined Cycle) based pre-combustion CO2 capture system, which comprises a sulfur-resistant conversion device, an MDEA (Methyl Di Ethanol Amine) desulfurization and decarbonization device and a sulfur and carbon separating device, wherein the sulfur-resistant conversion device is used for converting CO in a synthesis gas into a mixed gas consisting mainly of CO2-H2 in a converting furnace, and the MDEA desulfurization and decarbonization device comprises an absorption tower and a desorption tower; the absorption tower is used for receiving the mixed gas in the sulfur-resistant conversion device and for absorbing CO2 and H2S gases, and the desorption tower is used for receiving CO2 and H2S containing rich solution in the absorption tower and for desorbing CO2 and H2S; the sulfur and carbon separating device comprises a desulfurization purifier for receiving the CO2 and H2S gases in the desorption tower; and H2S gas is absorbed by an H2S absorber, and finally the CO2 gas is obtained. According to the IGCC based pre-combustion CO2 capture system, CO2 and H2S are simultaneously removed by a lean solution-half-lean solution MDEA method, so that the absorption rate of CO2 is improved, and the exhaust to air is reduced; and the heat generated by the conversion process of gas is fully utilized to heat MDEA rich solution for regeneration, and the consumption of medium-pressure steam is reduced.

Owner:HUANENG POWER INTERNATIONAL +1

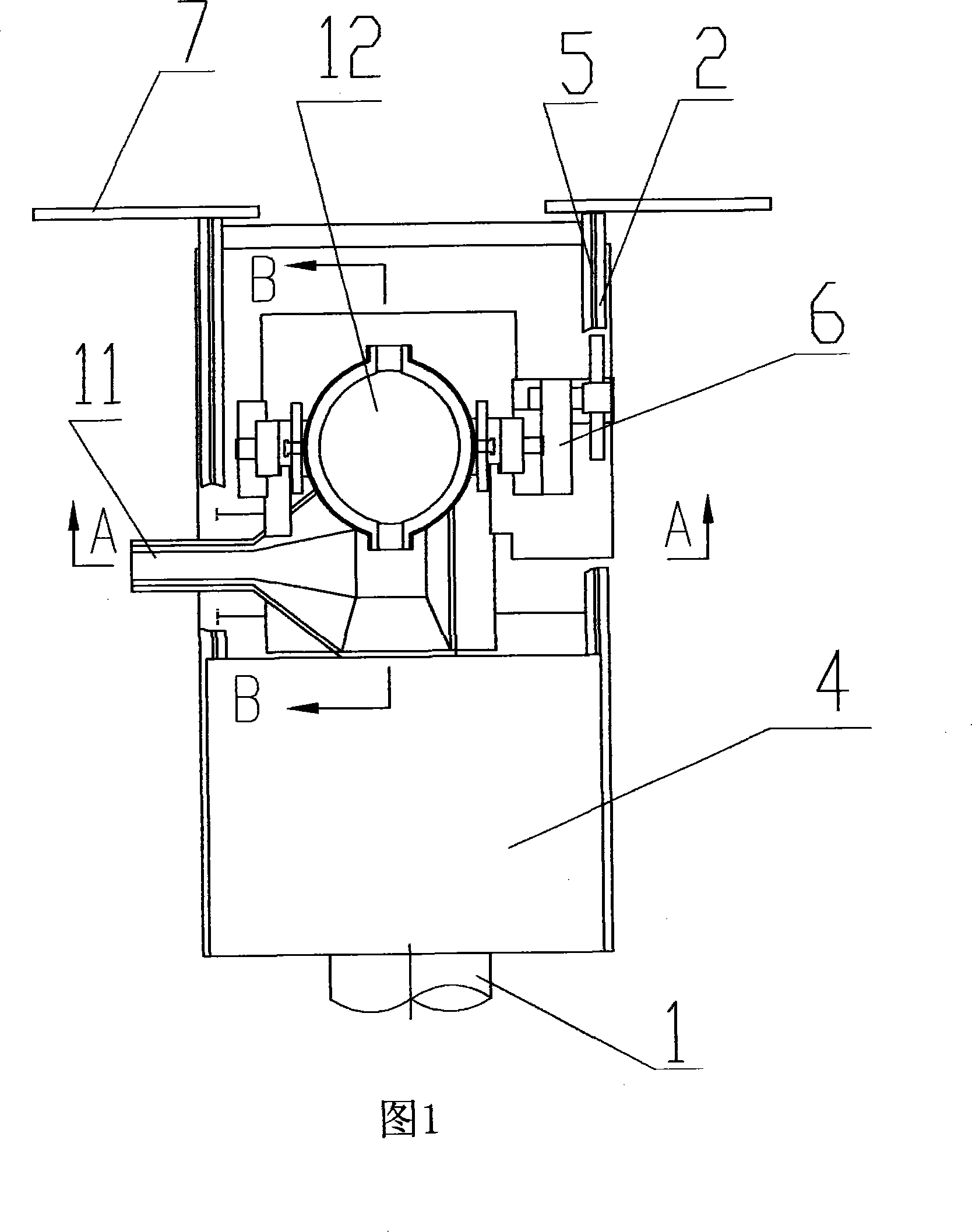

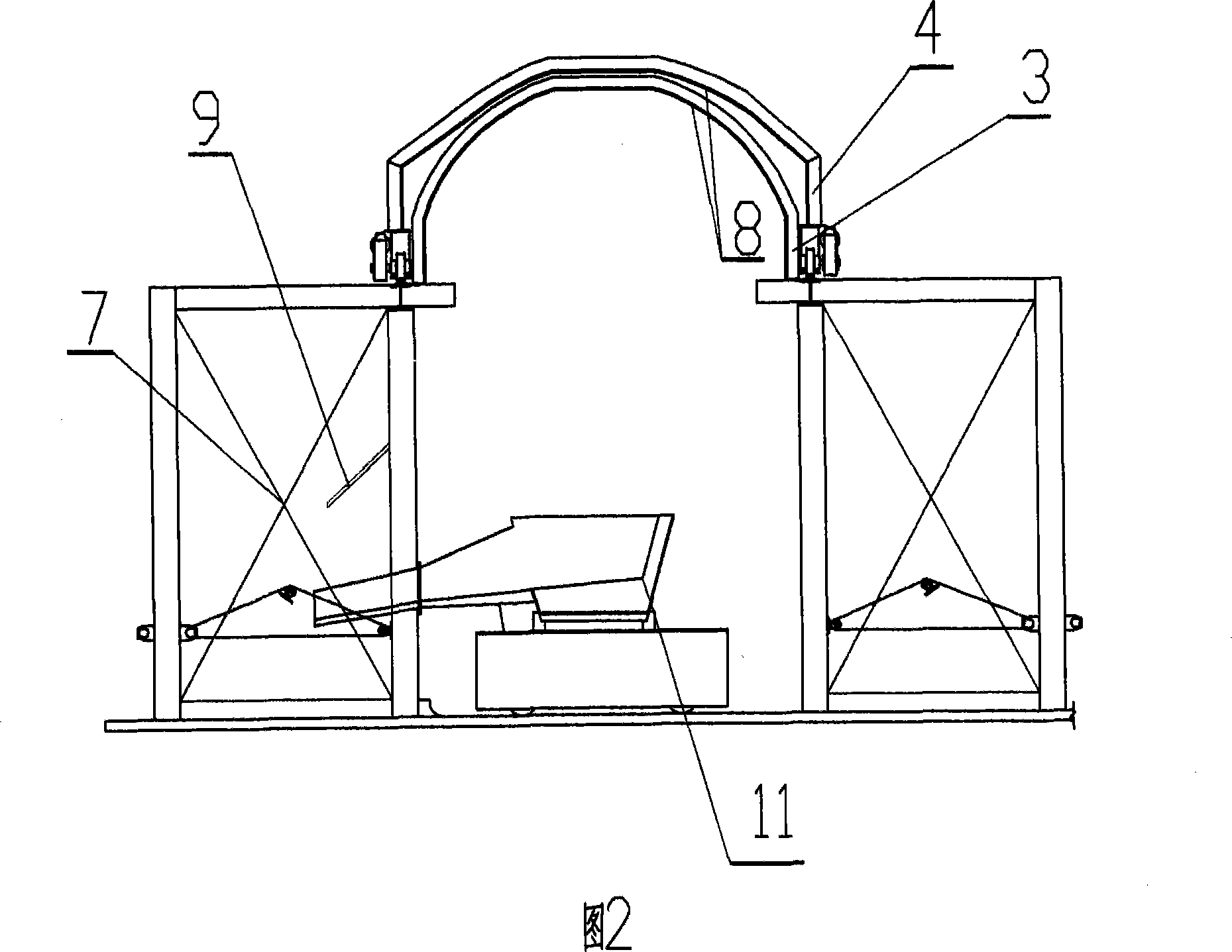

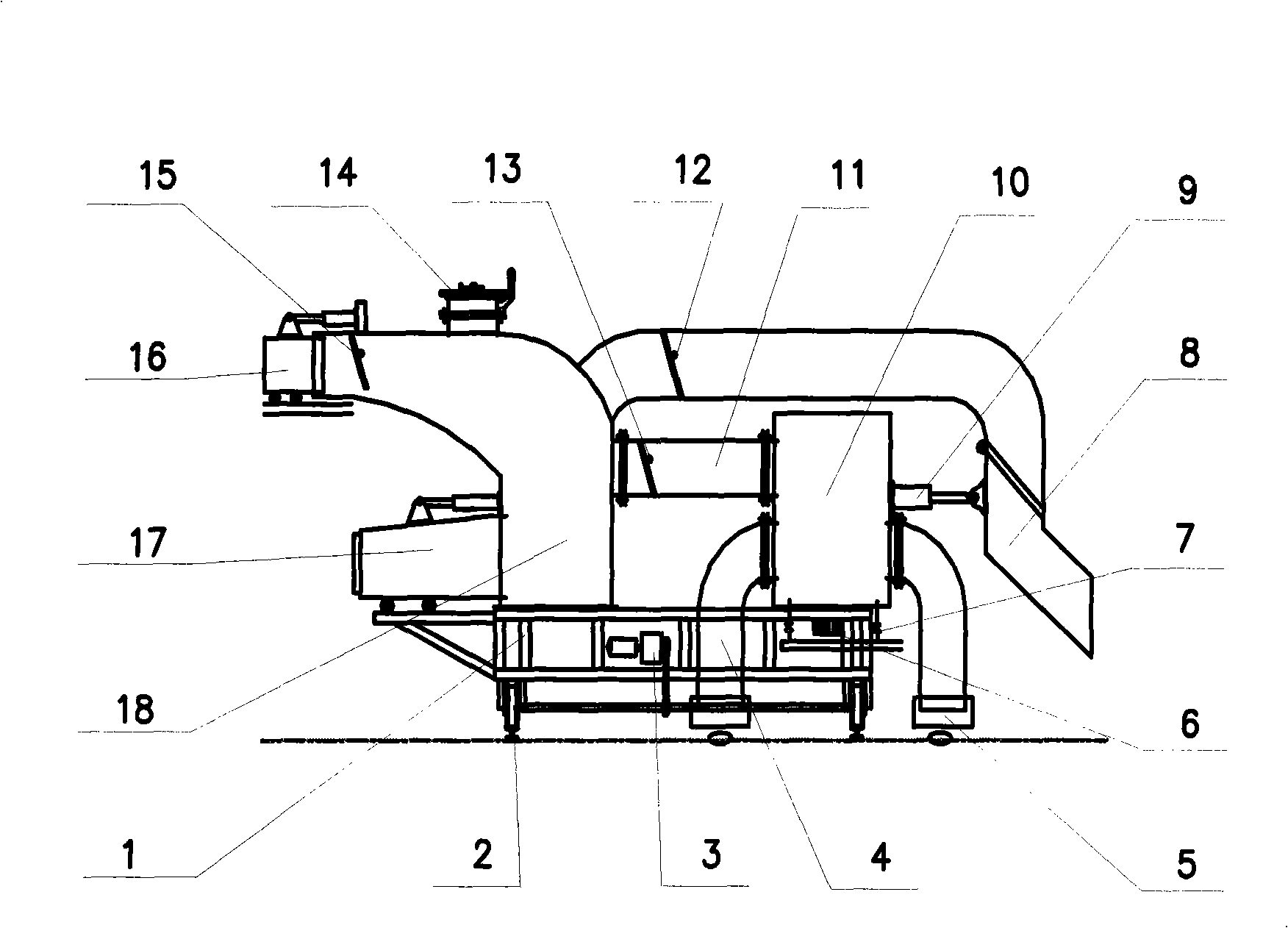

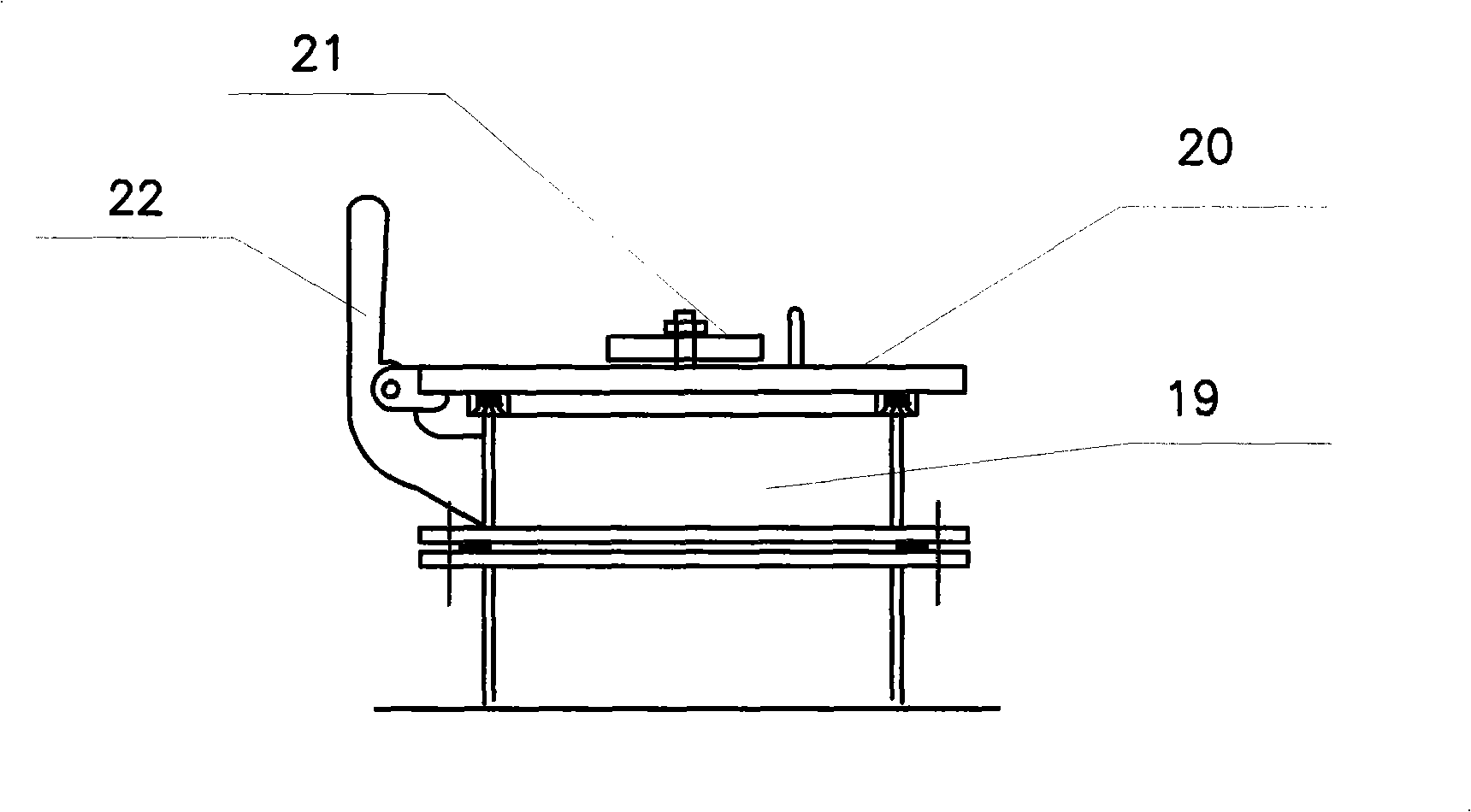

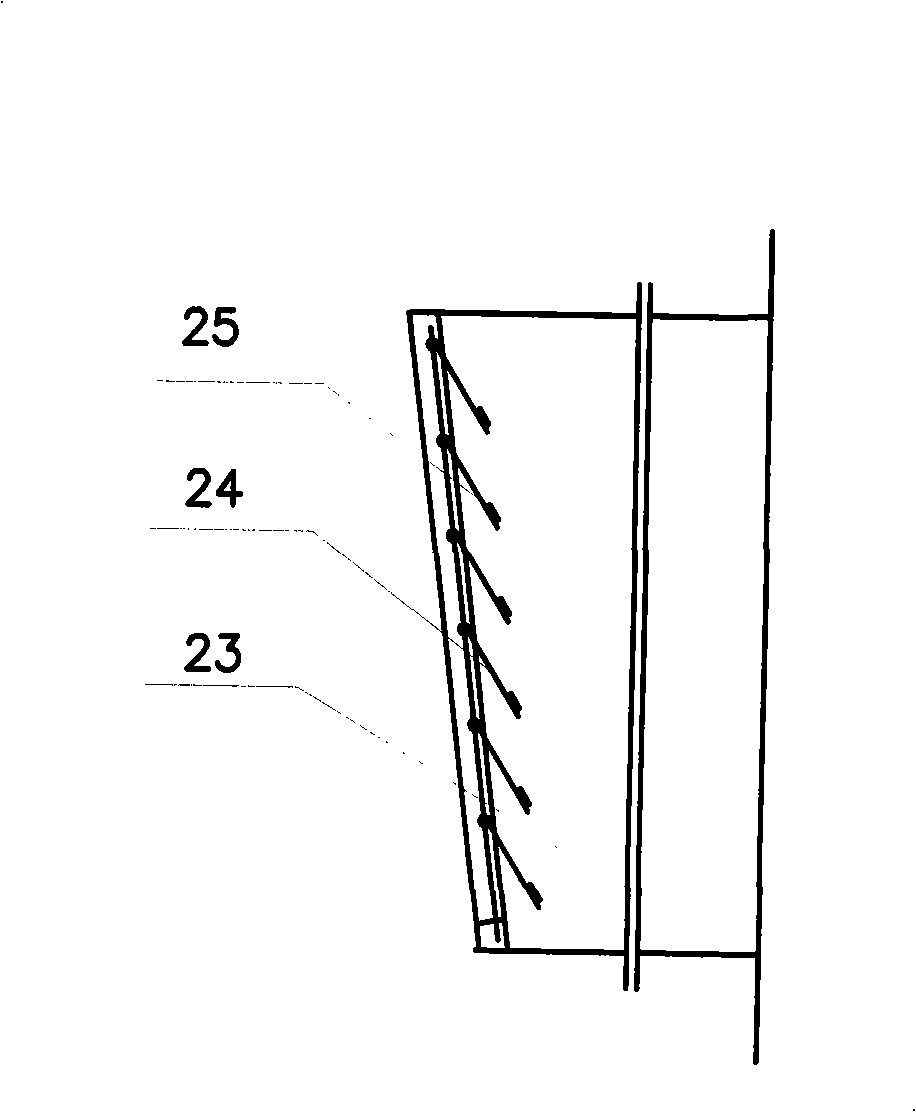

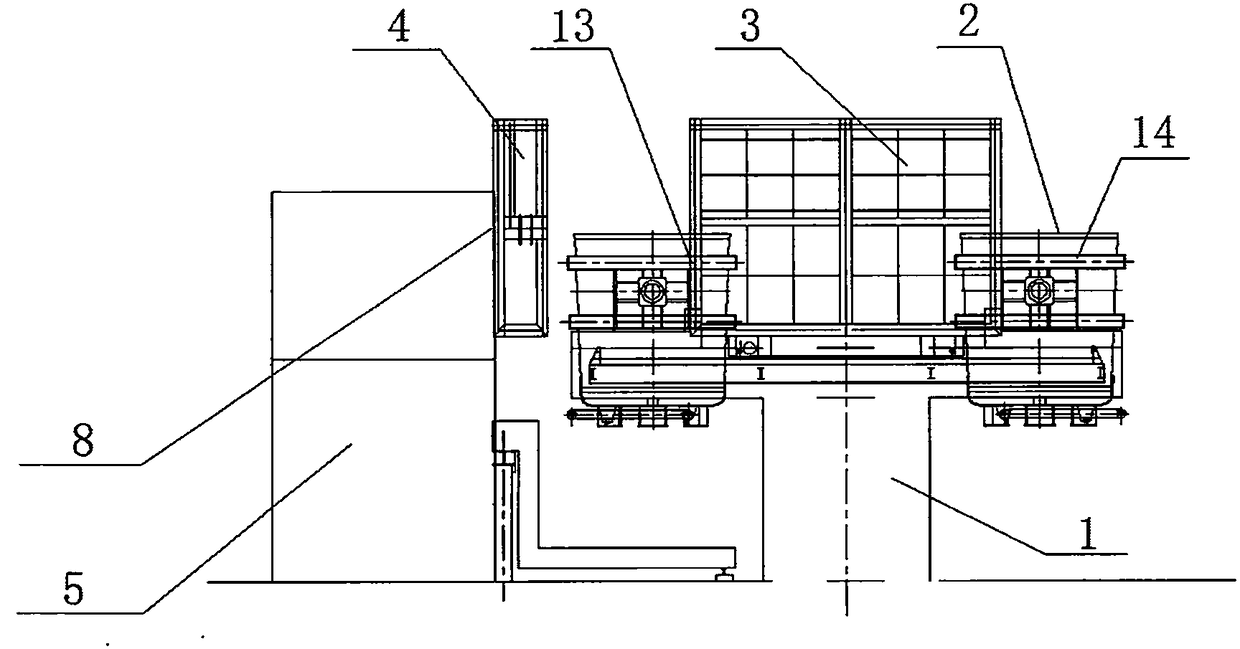

Technique and device for removing dust of coke oven by boiler system

InactiveCN101260304AIncrease capture rateEasy to operateCoke ovensDirt cleaningCombustion chamberCoke oven

The invention relates to a technology and equipment which utilize a boiler system to eliminate fume and dust from a coking oven. A movable dust-collecting vehicle is arranged on the top of the coking oven to collect the fume and dust escaping during the process of coke collecting and coal feeding, and the fume and the dust undergo primary burning in a combustion chamber, the coke foam is separated and then led inside the boiler for sufficient combustion, which not only utilizes the heat energy but also achieves profound dust-elimination and desulfurization for the fume through the configuration facilities of the boiler so as to accomplish the aim of clean discharge. The technology provided by the invention is characterized in simple operation, investment reducing, no occupation of area, and good effect in smoke-removing and dust-elimination, which conforms to national 2nd standard of discharging. The invention can replace the ground dust extract station. In order to implement the fume collection described in the technology, the specific dust-collecting vehicle is designed. The invention is suitable for the factory with an established complete boiler system to carry out the operation of smoke-removing and dust-elimination.

Owner:SHANXI FAXIN GROUP

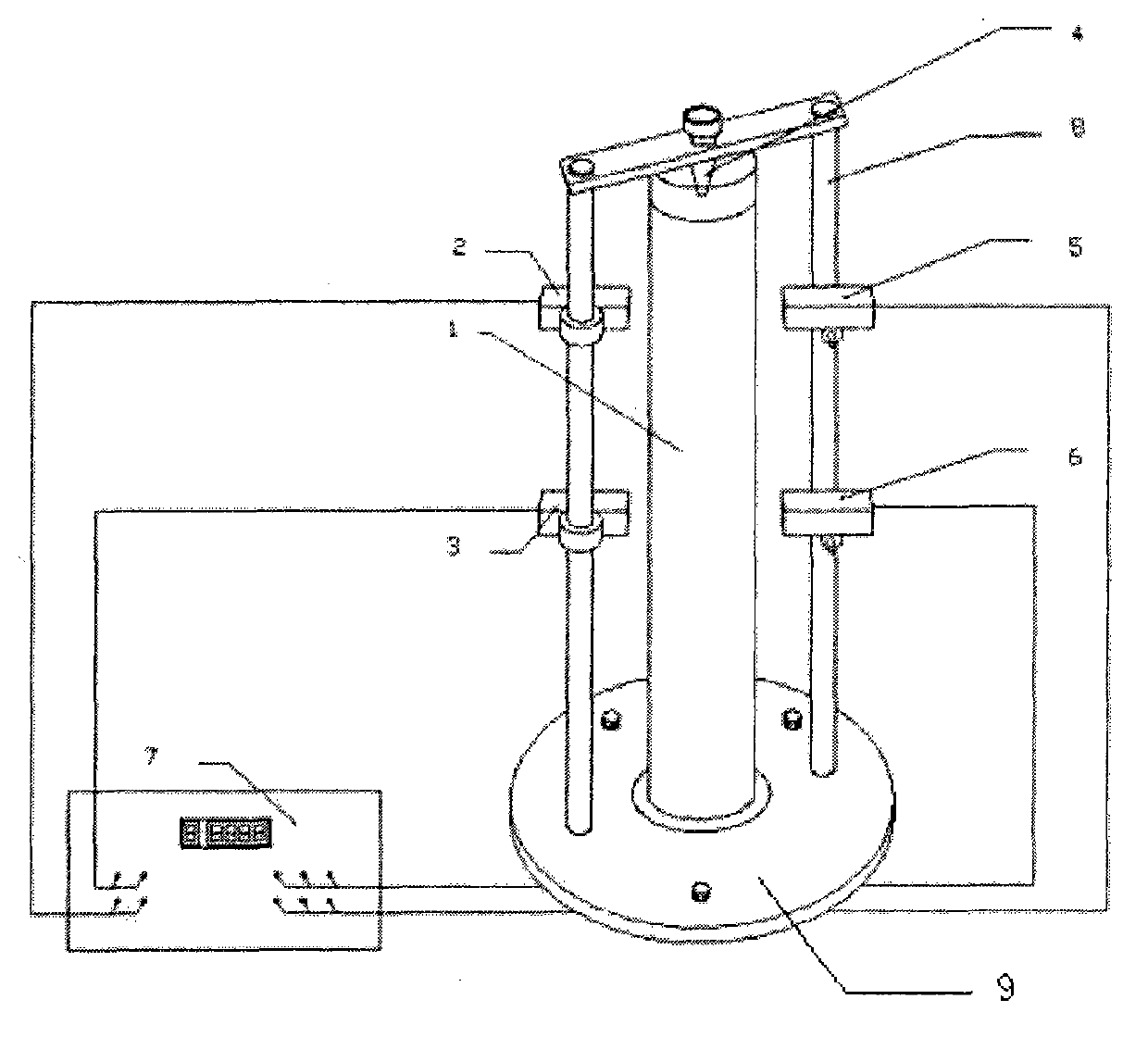

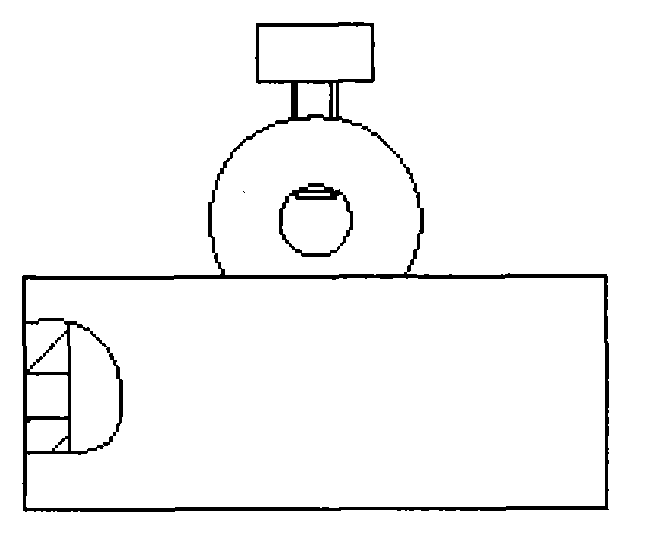

Laser surface capture type measuring apparatus and method for viscosity coefficient

InactiveCN103969158AReduce stray lightImprove signal-to-noise ratioFlow propertiesMicrocomputerLaser transmitter

The invention relates to a viscosity meter, especially to a laser surface capture type measuring apparatus for a viscosity coefficient. The laser surface capture type measuring apparatus comprises a container (1), a first laser transmitter (2), a second laser transmitter (3), a conduit (4), a first laser receiver (5), a second laser receiver (6), a one-chip microcomputer (7), a support (8) and a base (9). The apparatus is characterized in that strip-shaped laser source receivers (10) extending along a horizontal direction are arranged on the first laser receiver (5) and the second laser receiver (6), and laser source transmitting terminals (11) of the first laser transmitter (2) and the second laser transmitter (3) directly transmit laser to the laser source receivers (10) of the first laser receiver (5) and the second laser receiver (6).

Owner:吕勤 +2

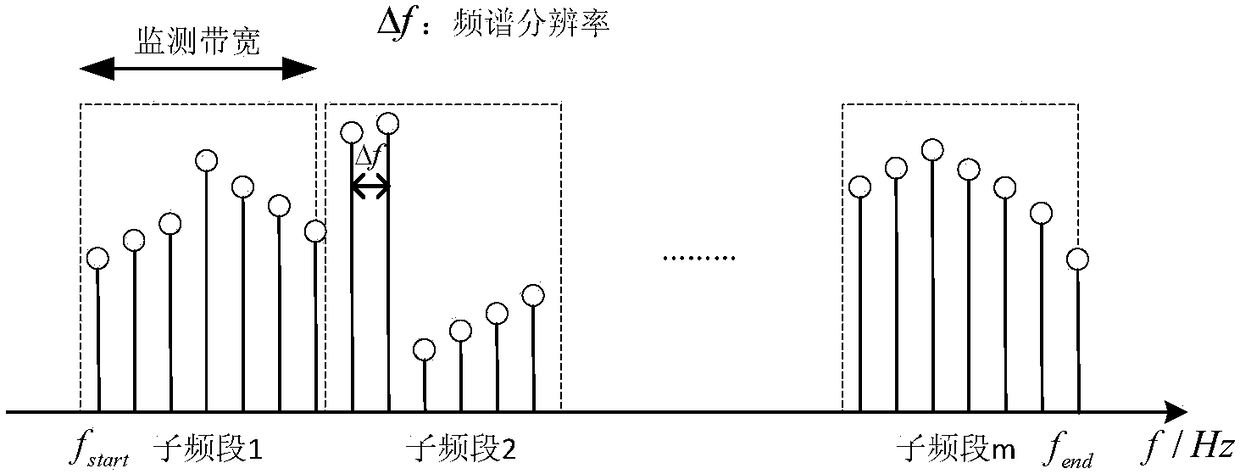

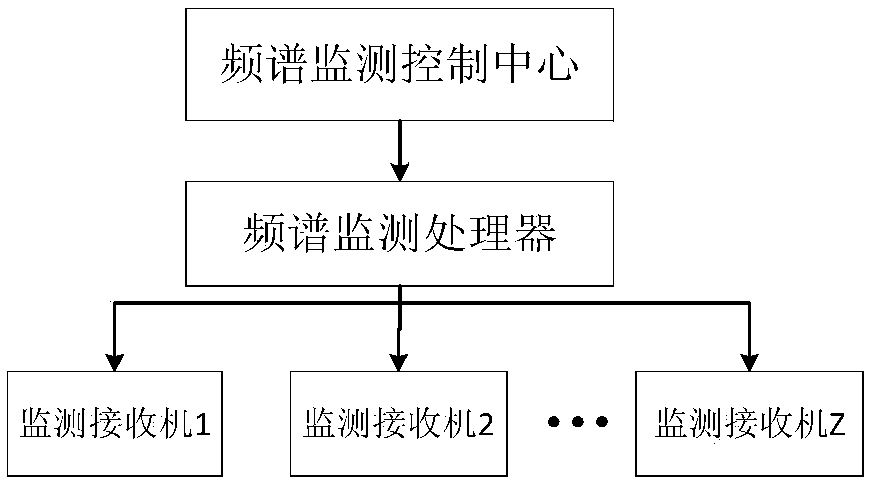

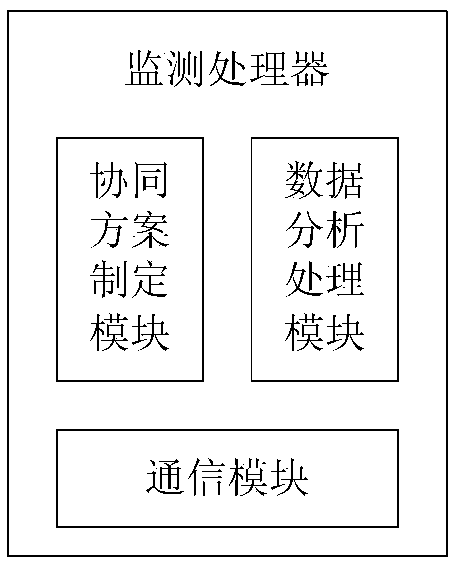

Distributed frequency spectrum monitoring method

ActiveCN108809450AWork lessIncrease capture rateReceivers monitoringFrequency spectrumImage resolution

The invention provides a distributed frequency spectrum monitoring system. The distributed frequency spectrum monitoring system comprises a monitoring control center used for sending a monitoring taskA, and a plurality of monitoring receivers for collecting and transmitting back frequency spectrum data; a monitoring processor is connected between the monitoring control center and the monitoring receivers; the monitoring processor comprises a cooperative scheme formulation module and a data analysis processing module; the cooperative scheme formulation module formulates a scheduling monitoringscheme B and a monitoring command C according to a demand of the monitoring task A, and performs selection, grouping, labeling and synchronization according to the scheduling monitoring scheme B; each of the monitoring receivers collects frequency spectrum data according to the monitoring command C; and the data analysis processing module receives and analyzes the frequency spectrum data transmitted back by each of the monitoring receivers, and transmits analyzed signal data back to the monitoring control center. The invention further provides a frequency spectrum monitoring method based on the system. The frequency spectrum monitoring method provided by the invention simultaneously has good scanning period, spectral resolution and receiving sensitivity.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

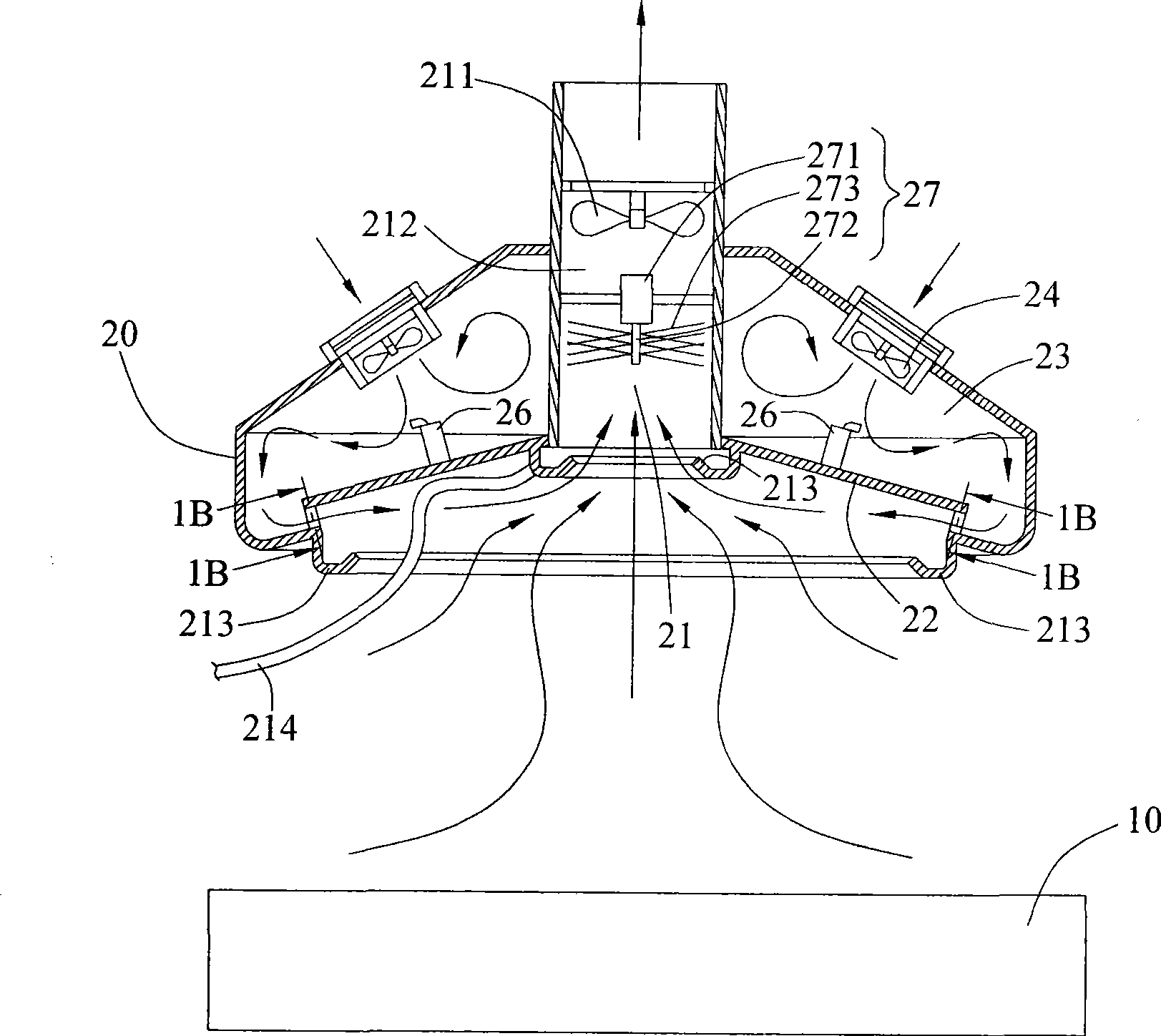

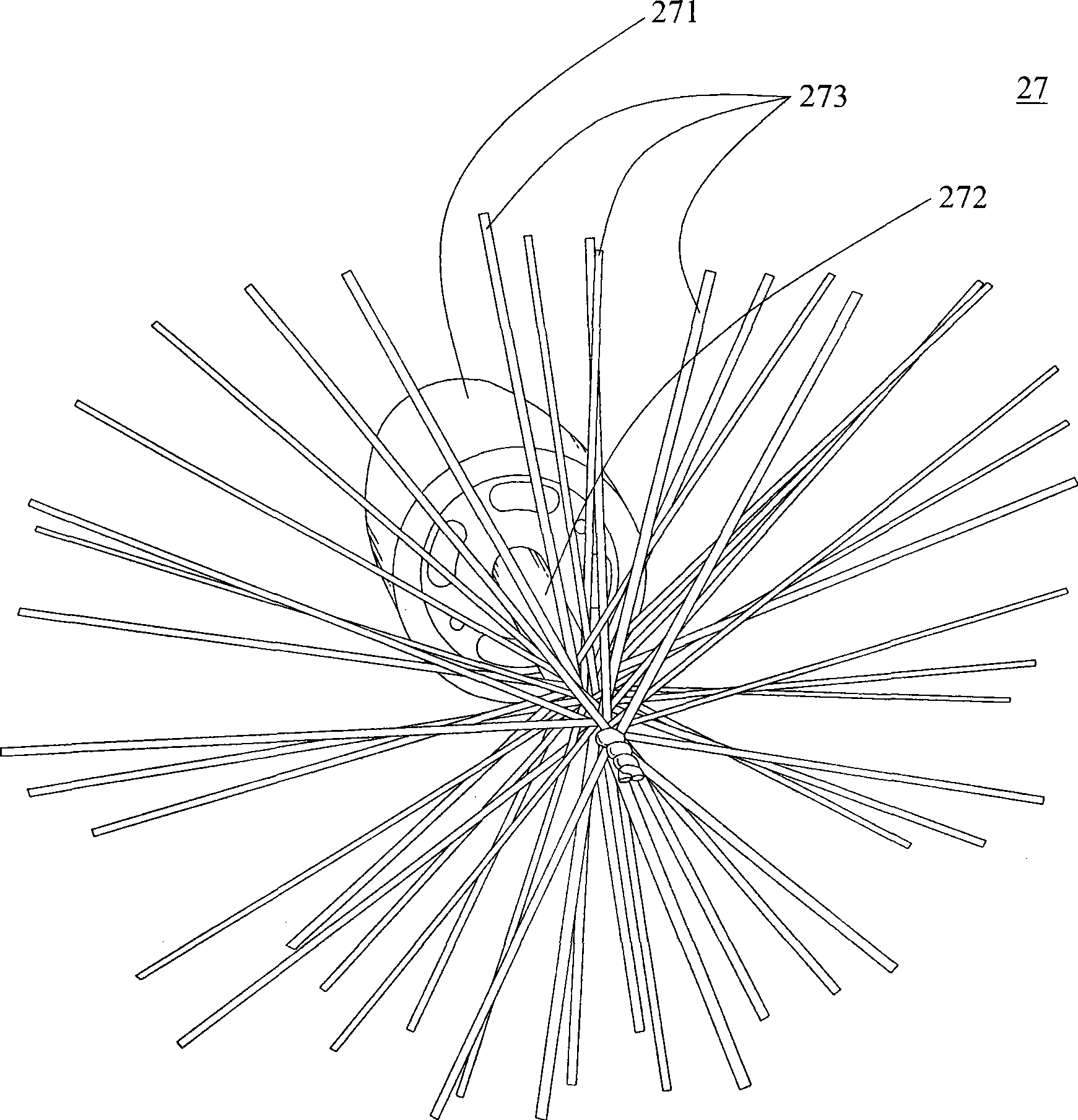

Air particles removing device and method thereof

InactiveCN101455928AIncrease capture ratePrevent escapeDomestic stoves or rangesLighting and heating apparatusAirflowEngineering

The invention discloses a device and a method for discharging air particles. A pollution source is discharged out of a working table by an air pump. The device comprises an exhaust hood, an air feeder, an ultrasound water fog generator and a water fog removing machine. The exhaust hood is arranged corresponding to the working table and provided with an air suction port and an air deflector. The air feeder generates air current flowing along the air deflector towards the air suction port so as to guide the pollution source to flow towards the air suction port and be discharged by the air pump, thereby improving the effect of collecting the pollution source by the exhaust hood. The ultrasound water fog generator generates water fog adsorbing the pollution source on the flowing route of the air current, and the water fog removing machine can remove the water fog and the pollution source in the air current so as to prevent the pollution source from adhering to the exhaust hood.

Owner:ACXING INDAL CO LTD

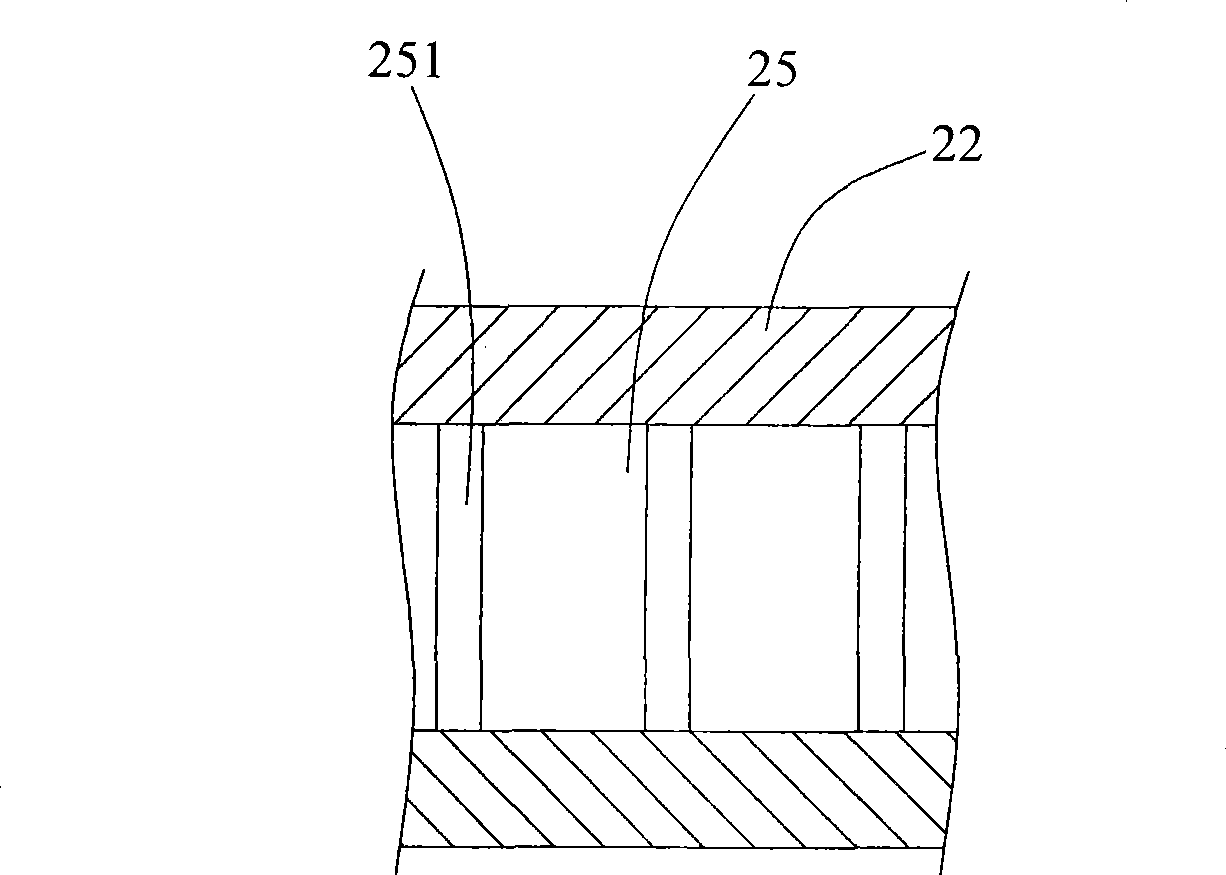

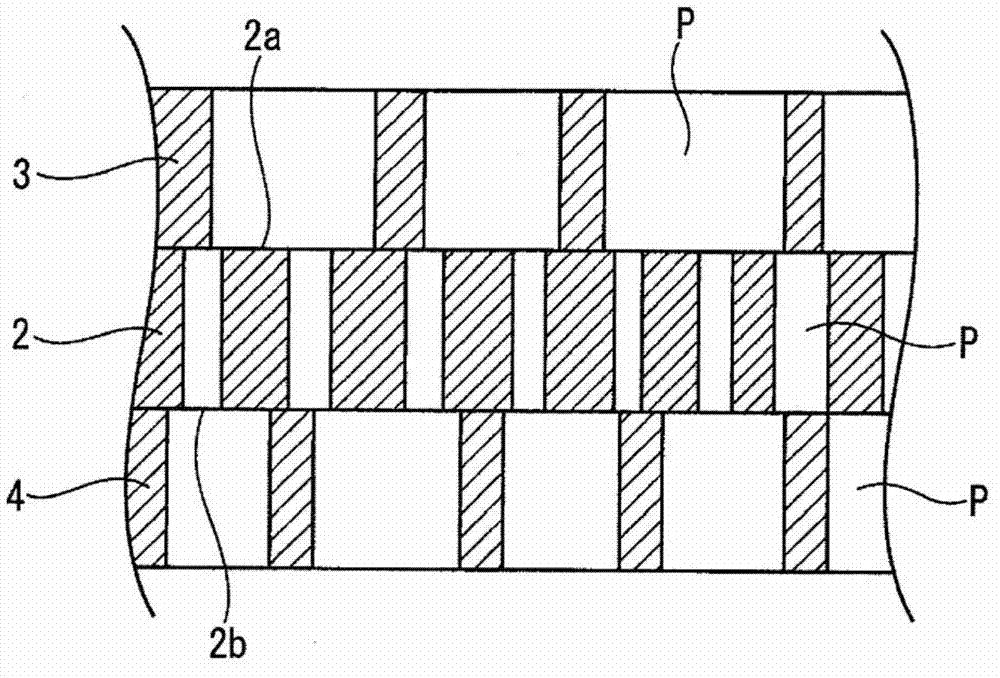

Porous multilayered filter

ActiveCN102958587AImprove filtering effectHigh strengthSemi-permeable membranesMembranesFiltrationEngineering

The purpose of the invention is to protect microfiltration filters so as to prevent damage of the filtration layer. A porous multilayered filter: which is a laminate of three porous drawn PTFE sheets that have been biaxially drawn in the longitudinal and transverse directions; which is obtained from a middle filtration layer, a protective layer that is laminated on the one surface of the filtration layer where the liquid to be processed flows in, and a support layer that is laminated on the other surface of the filtration layer; in which the boundaries between the two surfaces of the filtration layer and the protective layer and the support layer are fused, and the holes of the protective layer and support layer and the holes of the filtration layer communicate with each other three-dimensionally; and in which the mean pore diameter of the holes of the filtration layer is smaller than the mean pore diameters of the holes of the protective layer and the support layer.

Owner:SUMITOMO ELECTRIC FINE POLYMER INC

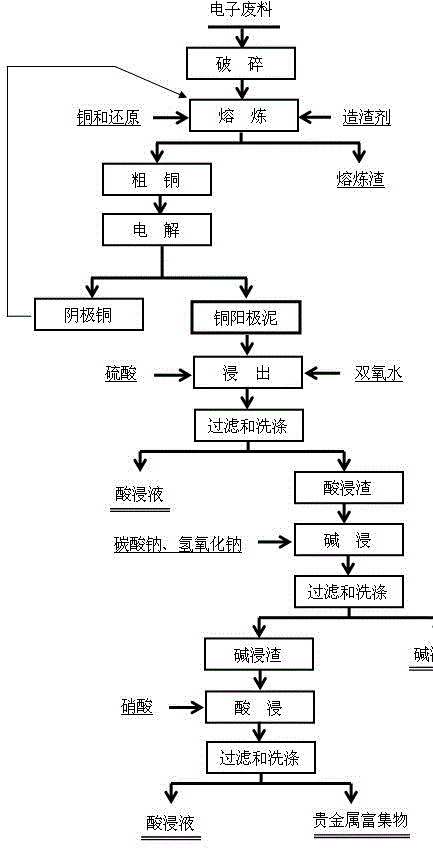

Method for efficiently enriching precious metal from electronic waste

InactiveCN105886768AIncrease capture rateHigh Blister Copper Containing CopperProcess efficiency improvementElectrolysisElectric arc furnace

The invention discloses a method for efficiently enriching precious metal from electronic waste. Particularly, anode slime is obtained from the electronic waste which is subjected to copper smelting capture and then subjected to electrolysis. The method comprises the steps that the electronic waste is crushed, added with copper, a reducing agent and a slag former and placed in an electric arc furnace to be smelted, so that crude copper is obtained, and the precious metal is effectively captured; the crude copper is then subjected to electrolysis, the precious metal enters copper anode slime, and thus preliminary enrichment of the precious metal is achieved; the copper anode slime material is mixed with sulfuric acid and hydrogen peroxide and placed in a reaction kettle to be leached, so that acid leaching residue and acidic leaching liquid are obtained; the acid leaching residue is added with sodium hydroxide and sodium carbonate and subjected to alkali leaching, so that alkali leaching residue and alkali leaching liquid are obtained; and the alkali leaching residue is added with nitric acid to be leached, and lead enters the solution, so that the enriched precious metal is obtained after filtering and washing are conducted. The enriched precious metal is obtained from the electronic waste. The method for efficiently enriching the precious metal from the electronic waste is easy to operate, environmentally friendly, low in production cost, easy to industrialize, high in precious metal yield and good in application prospect.

Owner:KUNMING METALLURGY COLLEGE

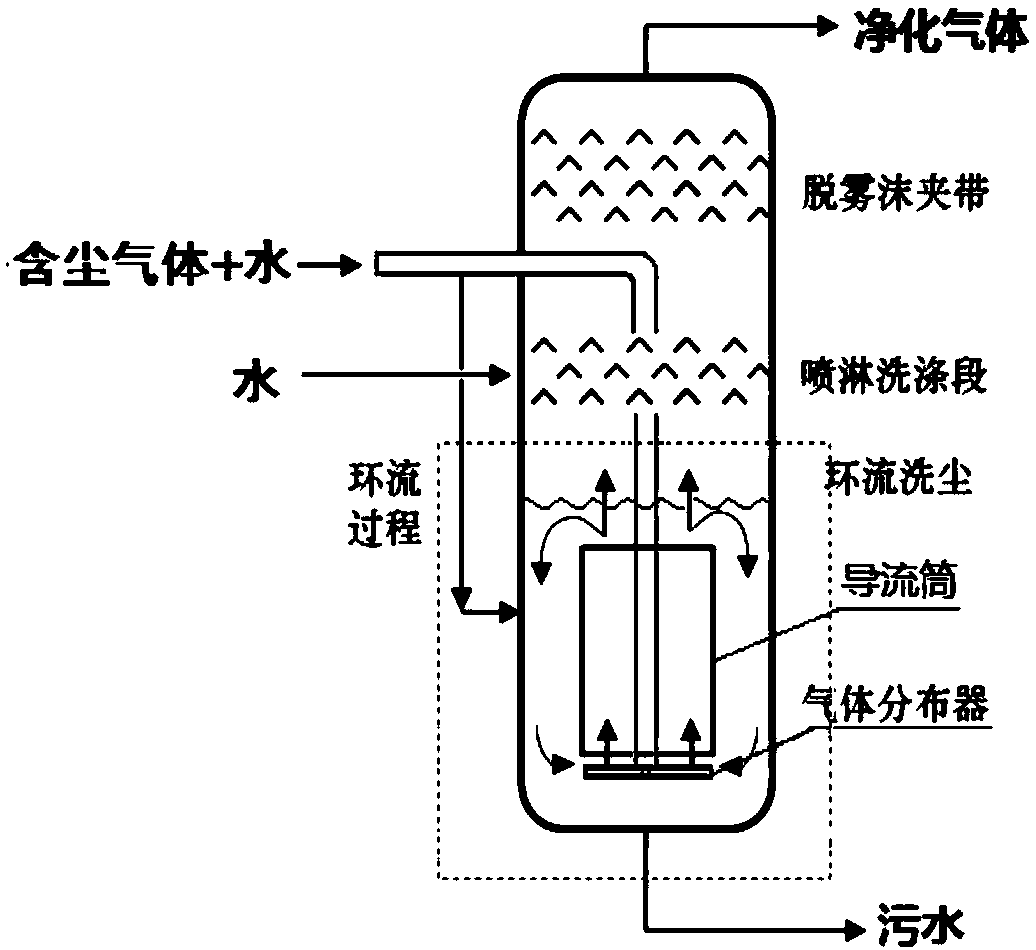

Gas distributor for circulating-flow scrubbing tower and design method of gas distributor

ActiveCN108079708AThe hydraulic index is consistentSimplify the design processUsing liquid separation agentLiquid layerEngineering

The invention provides a gas distributor for a circulating-flow scrubbing tower and a design method of the gas distributor. The gas distributor is of a branch-shaped distributor structure and is provided with a central gas inlet pipe and at least one branch pipe, wherein the branch pipes are connected with the central gas inlet pipe, a blind plate is arranged at the tail end of the central gas inlet pipe, liquid discharging holes are formed in the blind plate at the tail end of the central gas inlet pipe, and liquid discharging holes are also formed near the lowest ends or the tail ends of thebranch pipes; gas spraying holes are formed in the pipe walls of the branch pipes, and blind plate holes are formed in the tail ends of the branch pipes, or Venturi-type spraying nozzles are arrangedin the branch pipes. The pressure drop and the gas velocity of the spraying holes are adopted as the overall design and control indexes of the gas distributor, the design process is simple and easy to implement, and the diameter distribution and phase interface of bubbles can be controlled; a circulating flow can be formed in a flow guiding canister of the scrubbing tower, the standing time of gas at a liquid layer is prolonged, and the humidity of the gas at the liquid layer and the scrubbing efficiency are improved; even distribution of the gas flow is ensured, discharging of liquid and solid sediments is facilitated at the same time, and the gas distributor is applicable to large-scale gas-liquid-solid three-phase separation equipment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

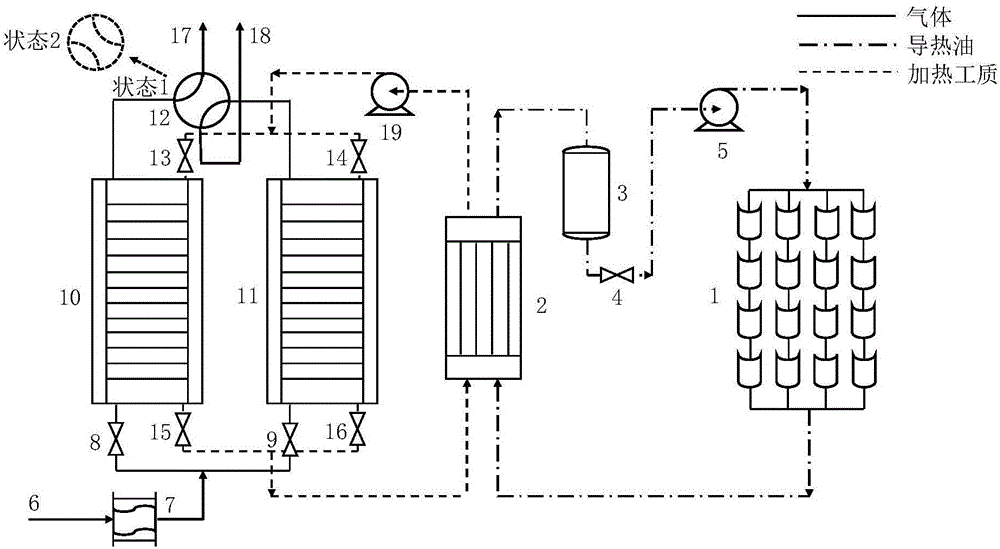

Solar thermal assisted temperature swing adsorption carbon trapping system

InactiveCN106345222AReduce desorption energy consumptionGuaranteed stabilityGas treatmentDispersed particle separationHeat conductingDesorption

The invention discloses a solar thermal assisted temperature swing adsorption carbon trapping system. The solar thermal assisted temperature swing adsorption carbon trapping system comprises a solar heat collecting unit and a temperature swing adsorption carbon trapping unit, wherein the temperature swing adsorption carbon trapping unit comprises a solar heat collector, a heat storage device, an oil storage tank, a heat conducting oil pump and the like; the temperature swing adsorption carbon trapping unit comprises a gas booster pump, an electronic control valve, a four-way reversing valve, a working medium pump, at least one group of double adsorption reaction tower structures and the like. The solar heat collecting unit can provide all heat for a desorption process of the temperature swing adsorption carbon trapping unit; in addition, by adding the heat storage device, the stability of providing the desorption heat can be guaranteed; the temperature swing adsorption carbon trapping unit adopts a circulation mode of double reaction towers, so that the continuity of the temperature swing adsorption carbon trapping process can be guaranteed, and the gas production rate is improved; the desorption energy consumption of temperature swing adsorption carbon trapping is remarkably lower than that of chemical adsorption carbon trapping; the solar thermal assisted temperature swing adsorption carbon trapping system has universality for allocation of solar energy.

Owner:TIANJIN UNIV

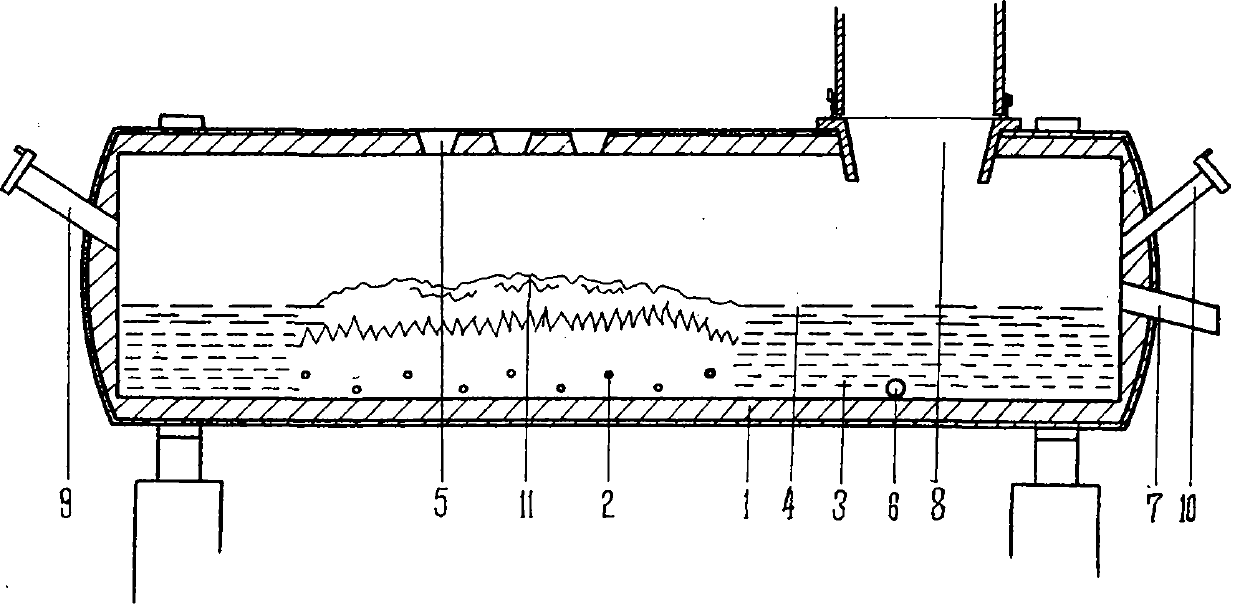

Pouring flue gas dust removal process for continuous casting big ladles

ActiveCN108500224AIncrease capture rateImprove the workshop environmentCasting apparatusFlue gasTuyere

The invention relates to a pouring flue gas dust removal process for continuous casting big ladles. The process comprises the following steps: putting a full pack of steel ladles into a revolving table; rotating the revolving table to a pouring position; moving a movable cover on the upper parts of pouring steel ladles; performing sealing and closure between a fixed cover and the movable cover; beginning to pour the full pack of steel ladles; sucking away flue gas produced in a pouring process by a fan arranged above an operation platform through an air suction hole formed in the fixed cover,and simultaneously, preparing the full pack of steel ladles on a hoisting position; rotating the revolving table to 180 degrees when the pouring is carried out; enabling empty steel ladles to enter into the hoisting position and the full pack of steel lades to enter into the pouring position, and moving the movable cover to the upper part of the pouring position to make room for hoisting; and then repeatedly carrying out the steps. According to the pouring flue gas dust removal process for the continuous casting big ladle disclosed by the invention, through a flue gas collection device with the revolving table for the continuous casting big ladles, dispersion of flue gas is hindered in a process of pouring the big ladles, a flue gas collection ratio is increased, and a workshop environment is improved; and compared with a conventional roofing cover, the pouring flue gas dust removal process disclosed by the invention has the advantages that one-time investment and operation expenses are greatly reduced.

Owner:江苏朗润环保科技有限公司

Method for preparing building material from high-temperature flue gas and alkaline solid waste

ActiveCN114591052AIncrease contactIncrease capture rateSolid waste managementFlue gasProcess engineering

The invention discloses a method for preparing a building material by using high-temperature flue gas and alkaline solid waste, and aims to overcome the defects that CO2 in industrial flue gas with low CO2 concentration cannot be effectively captured, the overall maintenance time of the material is long, and the pressure required by carbonation reaction is large in the existing technology for preparing the building material by using CO2 in the alkaline solid waste and the industrial flue gas. The method is realized on the basis of carbonation reaction of alkaline solid waste and CO2, and comprises the following steps: 1, exciting and activating, and preparing an active green body; 2, performing primary mineralization; 3, crushing the aggregate; 4, preparing a green body containing mineralized aggregate; 5, secondary mineralization; according to the invention, the alkaline solid waste can be effectively utilized to capture CO2 in the high-temperature flue gas with low CO2 concentration; the high-strength mineralized aggregate is obtained through one-time mineralization, the mineralized aggregate is mixed with the alkaline solid waste and the alkali activator, CO2 in high-temperature flue gas is captured again, the capturing rate of CO2 and the reutilization rate of the alkaline solid waste are effectively increased, and the obtained building material is better in durability.

Owner:碳达(深圳)新材料技术有限责任公司

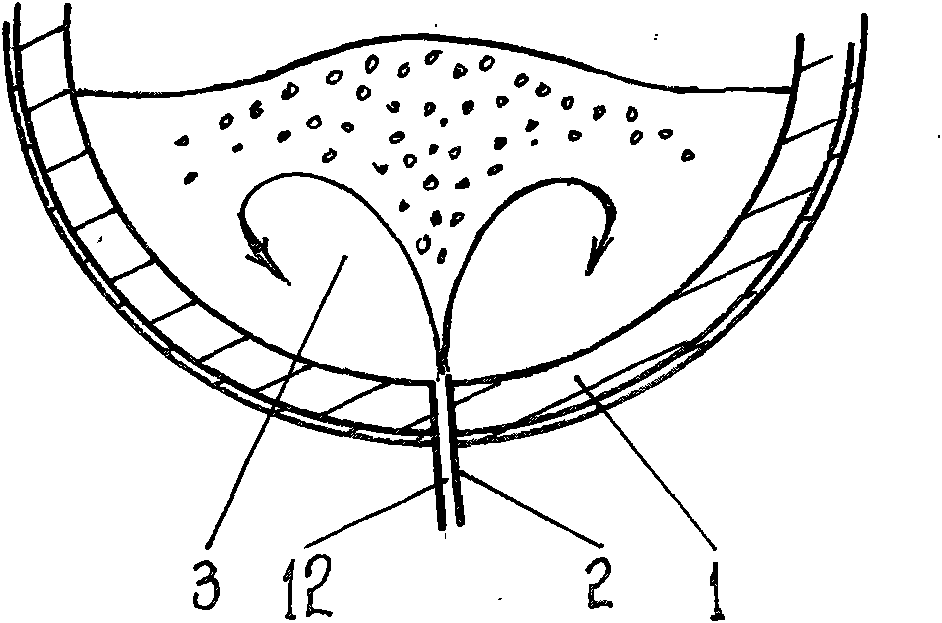

High oxygen-enriched bottom blowing low power consumption molten pool melting technology

InactiveCN101906543AEliminate pollutionReduce lossRotary drum furnacesCrucible furnacesMelting tankHigh energy

The invention provides a high oxygen-enriched bottom blowing low power consumption molten pool melting technology, relating to non-ferrous metallurgy. The invention includes oxygen guns, high oxygen-enriched air, copper matte, slag, mineral aggregate and a flue; wherein the high oxygen-enriched air is ejected into copper matte in a melting pool from bottom to top in a crossing and high-speed way by virtue of a plurality of oxygen guns arranged at the bottom of a furnace body, under the condition of fully mixing and contact, instant vigorous oxidation is taken place, high energy heat is released, and the process that mineral aggregate is melted into matte and slag can be completed without adding any fuel. Compared with the prior art, the invention has the advantages that no fuel is required to be added in the melting process, energy is saved, oxygen is saved, no carbon dioxide is discharged, mineral aggregate extensive manner is adopted, production scale is easy to control, and multi-metal capturing ratio is high, and the service life of oxygen gun is obviously prolonged. Thus the invention has good popularization and use values.

Owner:DONGYING FANGYUAN NONFERROUS METALS

Preparation method for diesel particulate filter with low back pressure and high soot filtration efficiency

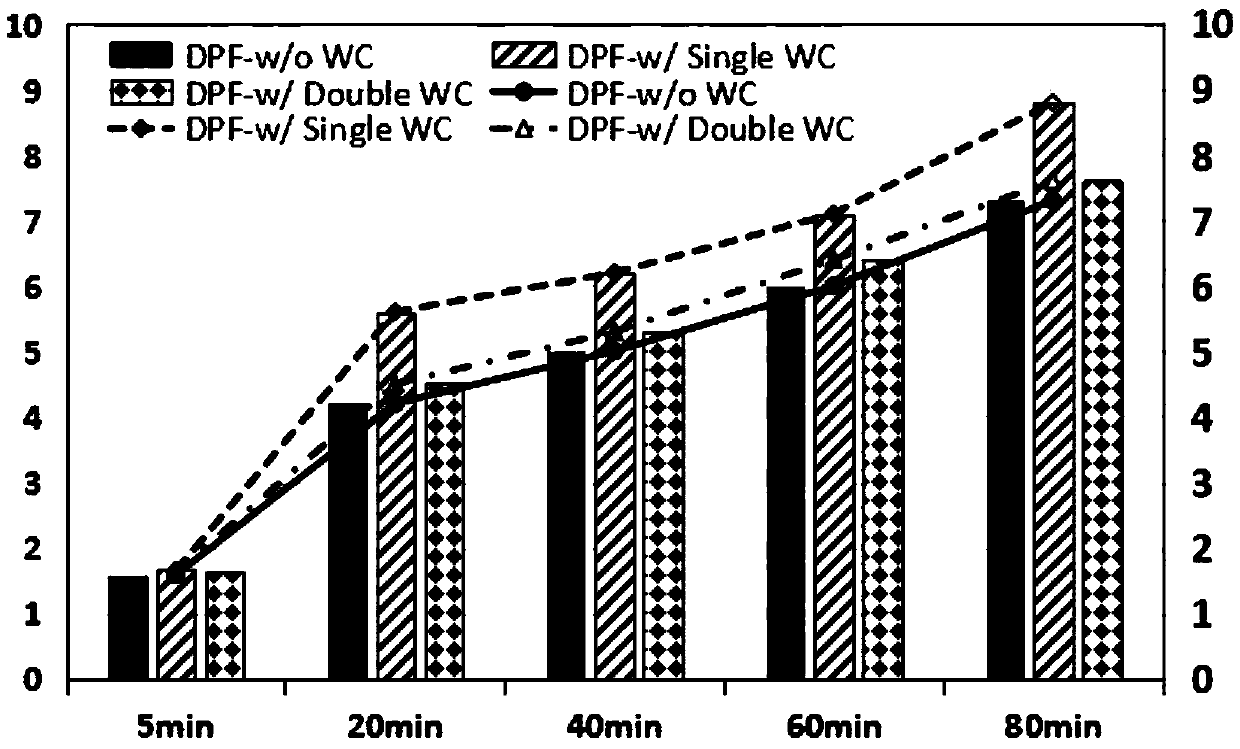

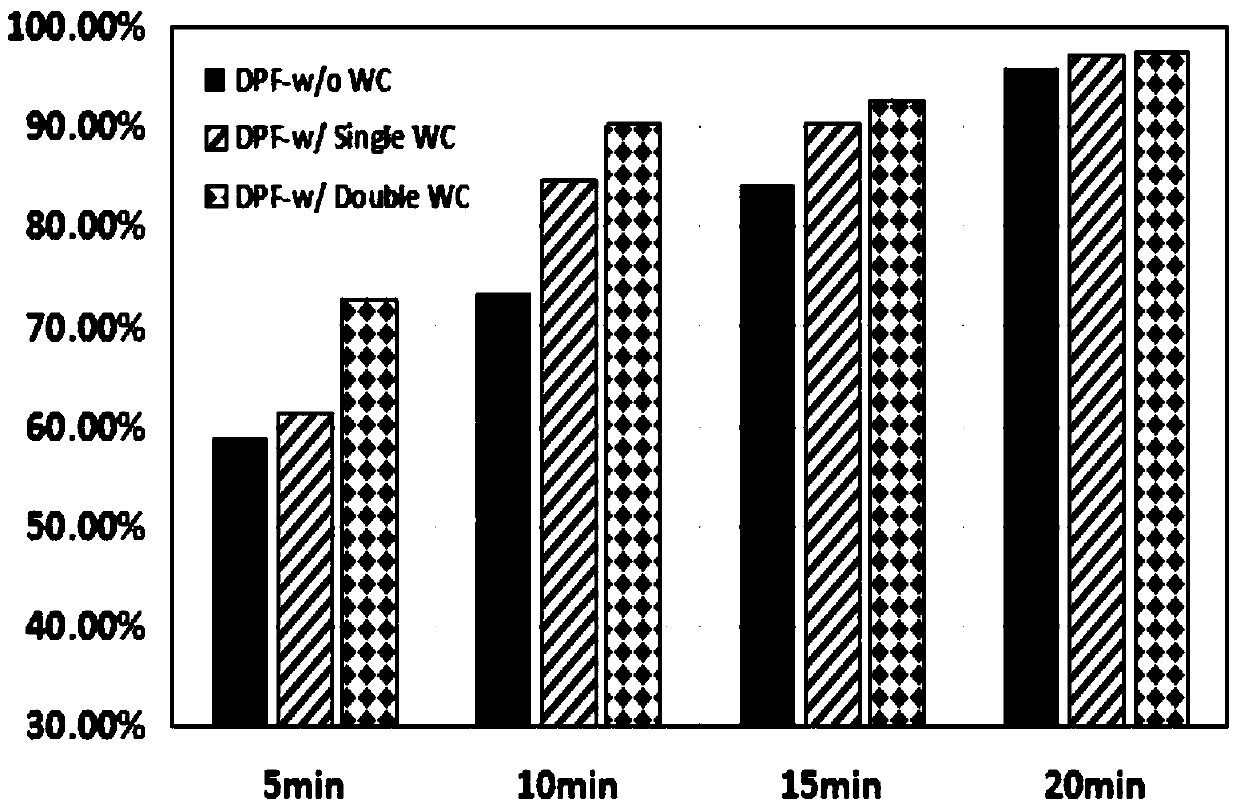

ActiveCN109647088AImprove filtration efficiencyIncrease surface depositionLiquid surface applicatorsGas treatmentMetallurgyFiltration

The invention discloses a preparation method for a diesel particulate filter with low back pressure and high soot filtration efficiency. A diesel particulate filter adopts a honeycomb ceramic wall flow carrier, and a carrier coating is a double layer coating structure; a bottom layer is formed by directly being coated on the carrier and includes high temperature and oxidation resistant ceramic powder particles, so that a porous ceramic film can be formed, wherein the porosity of the bottom layer is greater than that of a filtering wall of the honeycomb ceramic wall flow carrier; and a top layer is coated with a catalytic material which can catalyze and oxidize soot particles, and a formed catalytic layer can be directly in contact with the soot particles. Through the optimization of the porosity and pore sizes of the coating structure of the bottom layer, and the optimization of the catalytic material of the catalytic layer of the top layer and coating loading capacity, the filtering efficiency of the coating on the soot particles can be enhanced, DPF back pressure can be reduced, the surface deposition of the soot particles on the DPF filtering wall can be increased, the contact of the catalytic coating of the top layer with the soot particles can be further increased, and the Catalytic oxidation removal capabilities on the soot particles can be accelerated.

Owner:SINOCAT ENVIRONMENTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com