Patents

Literature

93results about How to "Reduce operating rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

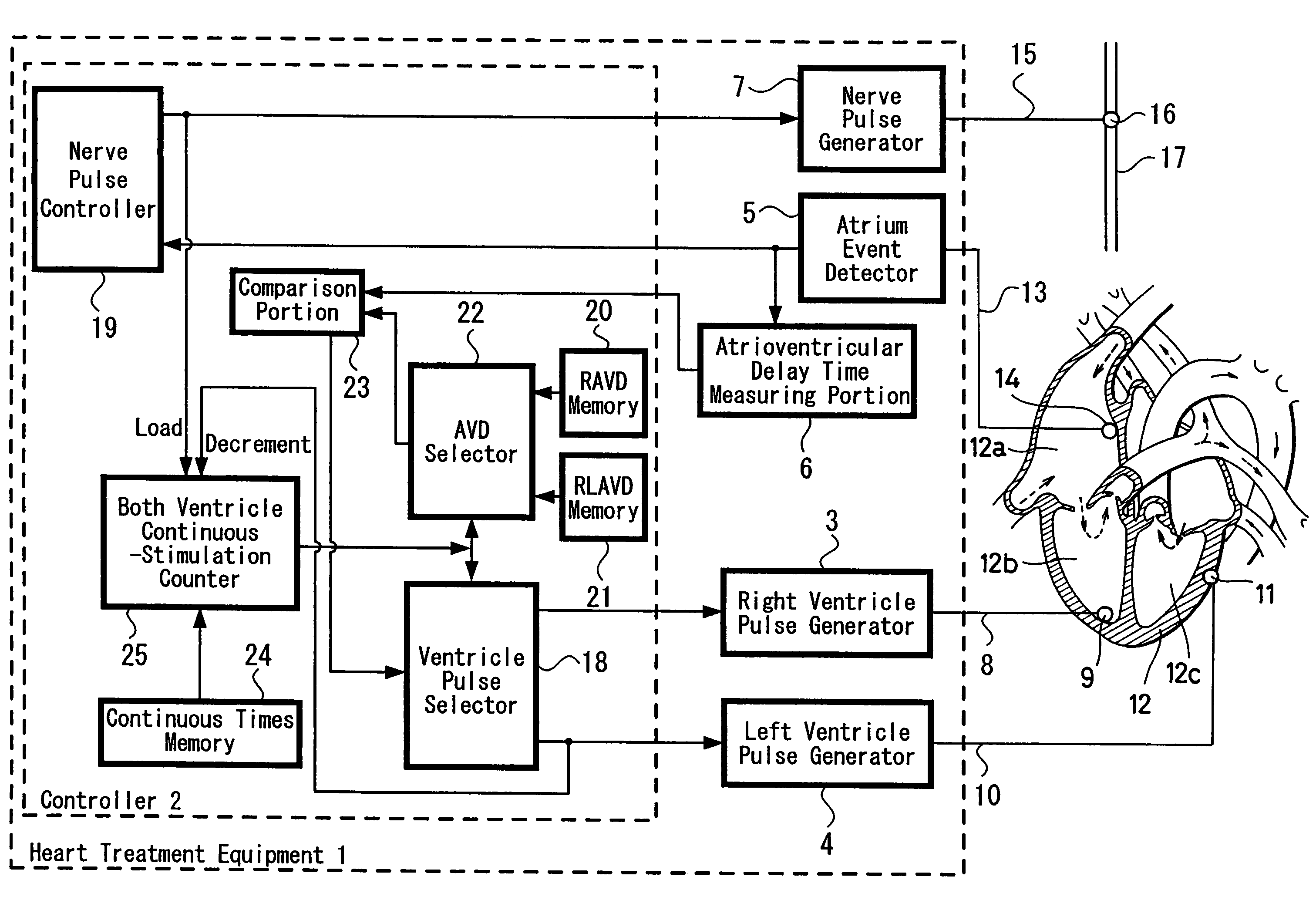

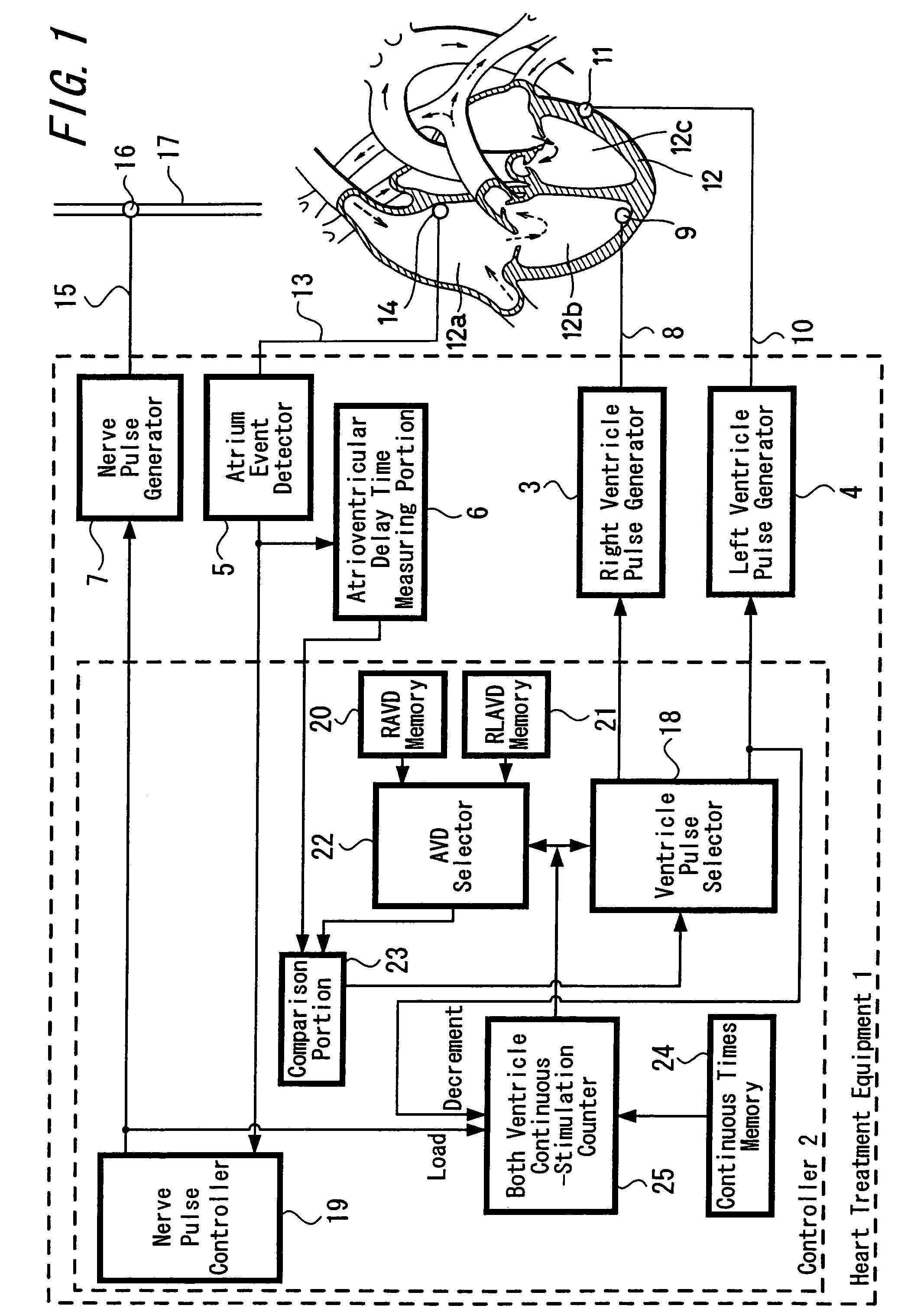

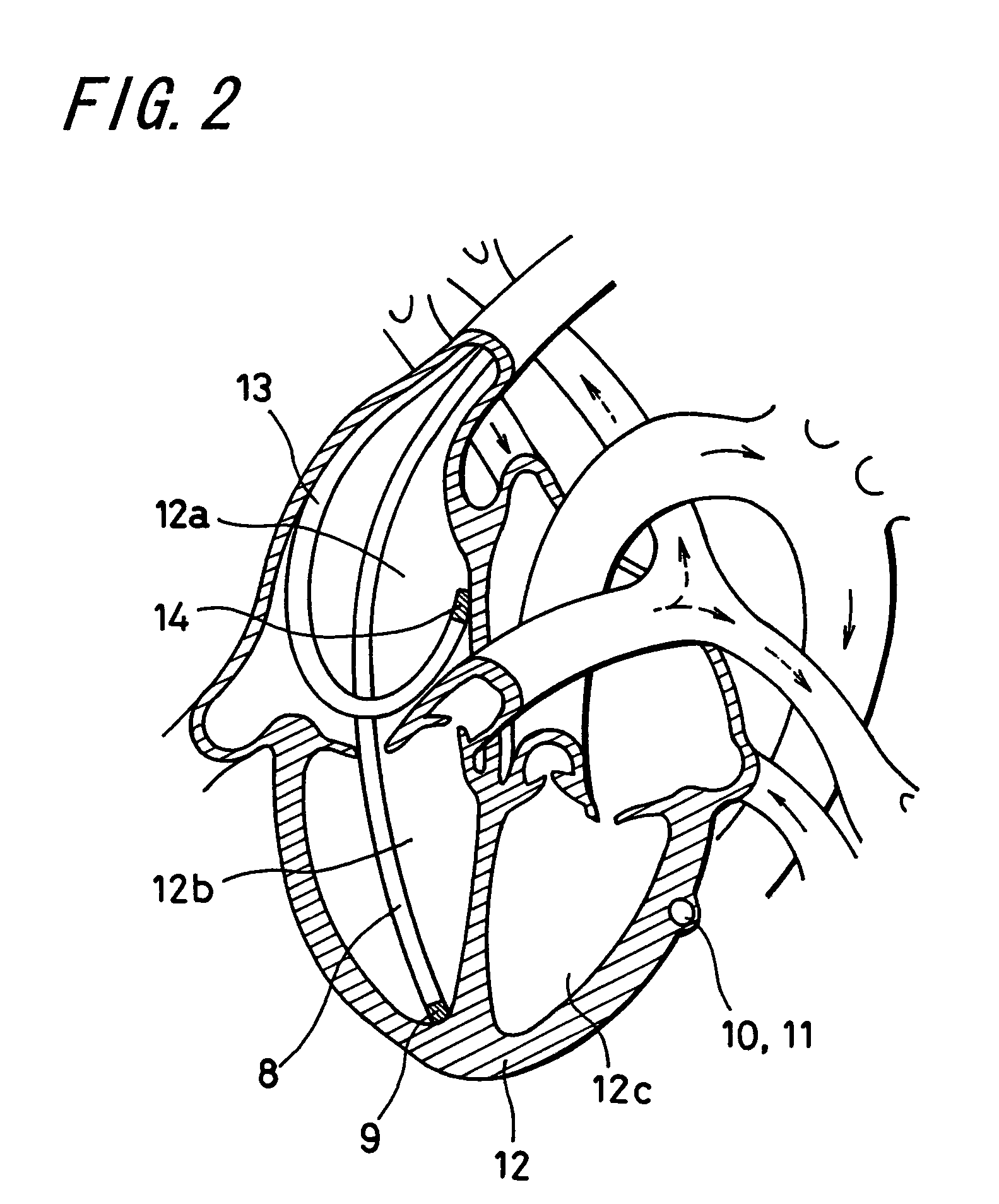

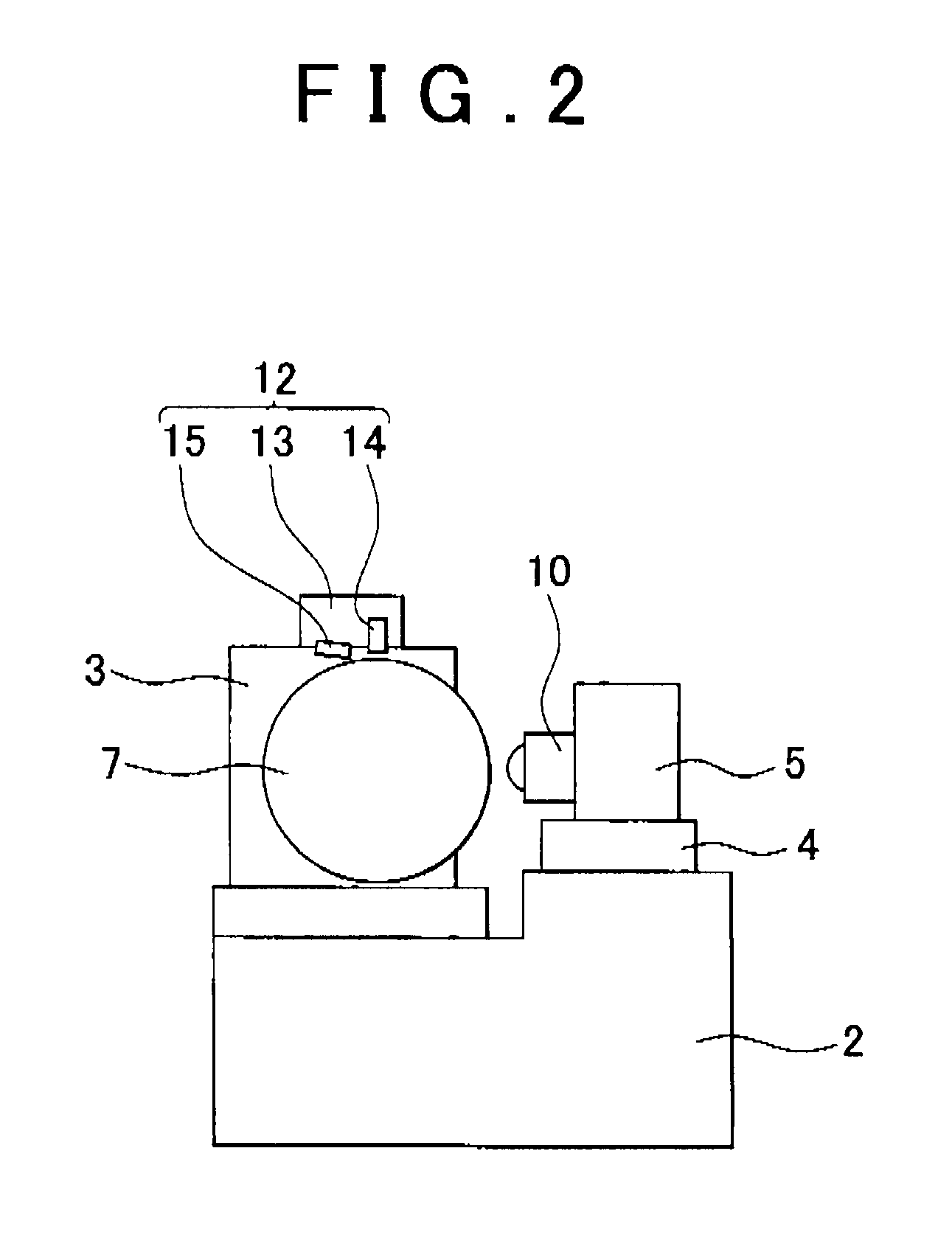

Heart treatment equipment for treating heart failure

InactiveUS7305265B2Reduce power consumptionOperation rate of stimulationHeart stimulatorsArtificial respirationHeart rate deviceLeft ventricle wall

In a heart treatment equipment provided with a stimulating mechanism for both the ventricles, the both ventricle stimulation is made optimized in order to inhibit the decrease of the cardiac output when a heart rate increase or the vagus nerve stimulation is performed and the equipment comprises a right ventricle pulse generator for stimulation the right ventricle, a left ventricle pulse generator for stimulation the left ventricle, wherein the controller for selecting either one of aforesaid right ventricle pulse generator and left ventricle pulse generator or selecting both of them for the ventricle stimulation is constituted such as to select both of the right ventricle pulse generator and the left ventricle pulse generator in response to the vagus nerve stimulation or the heart rate monitor output.

Owner:TERUMO KK

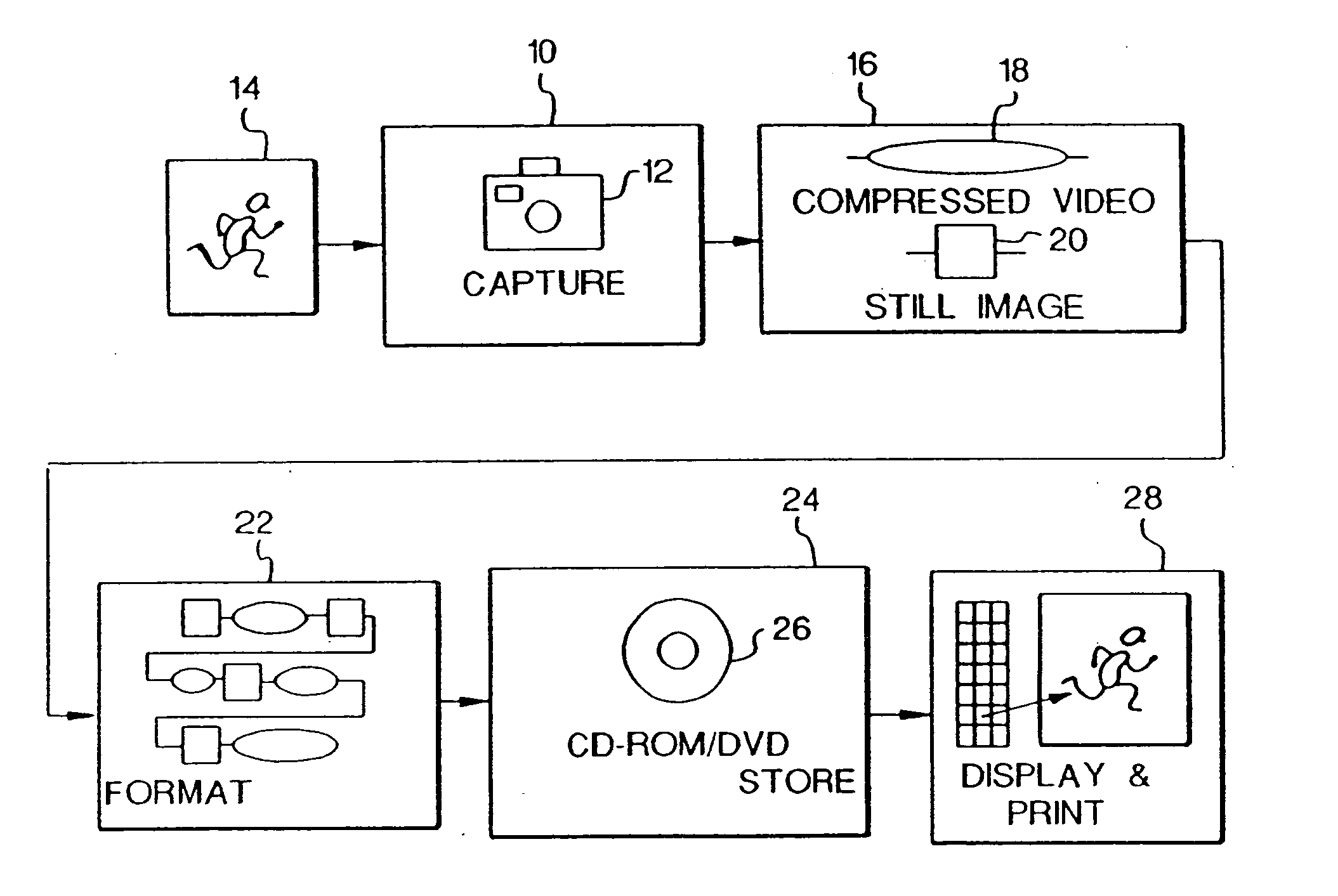

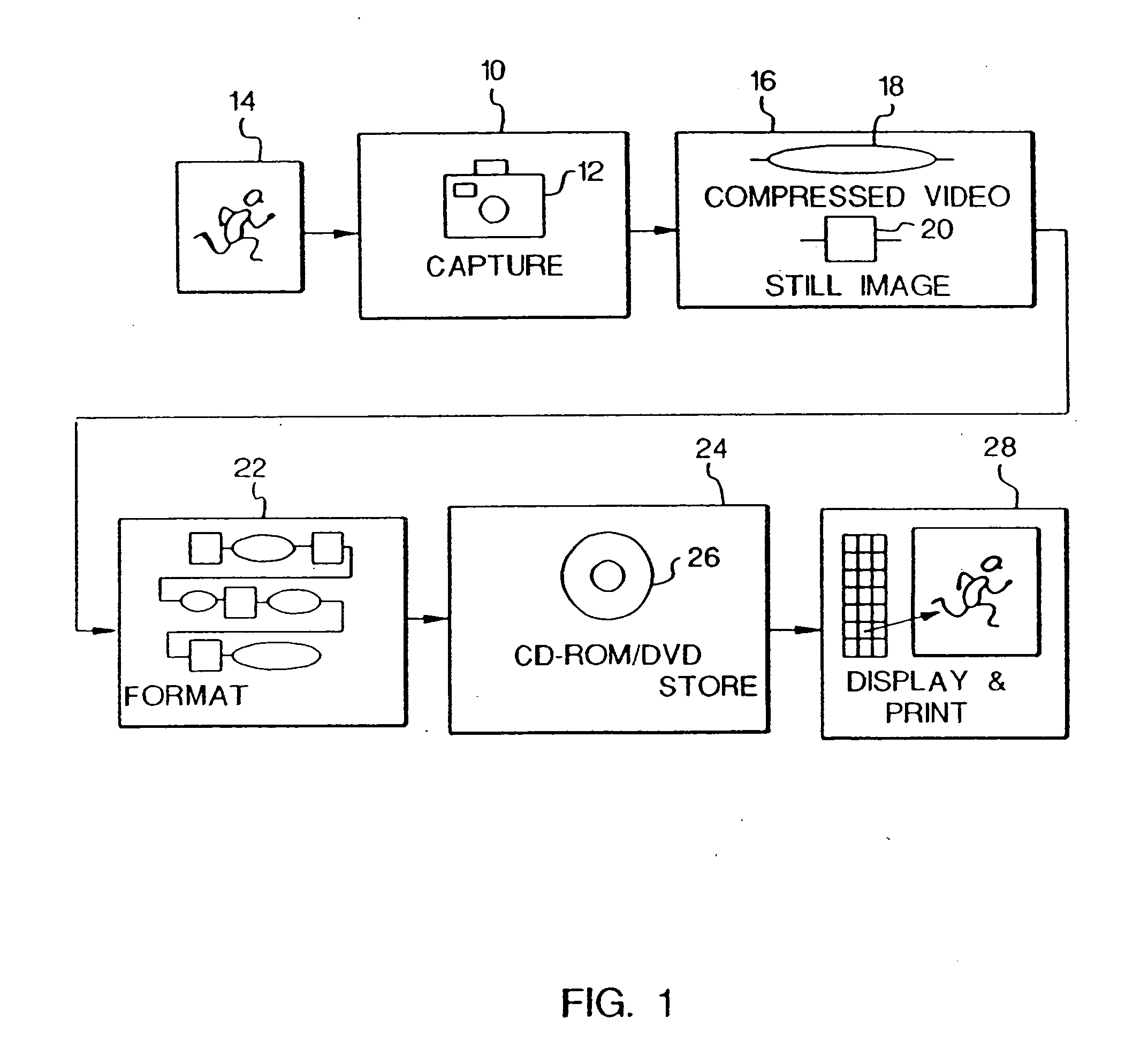

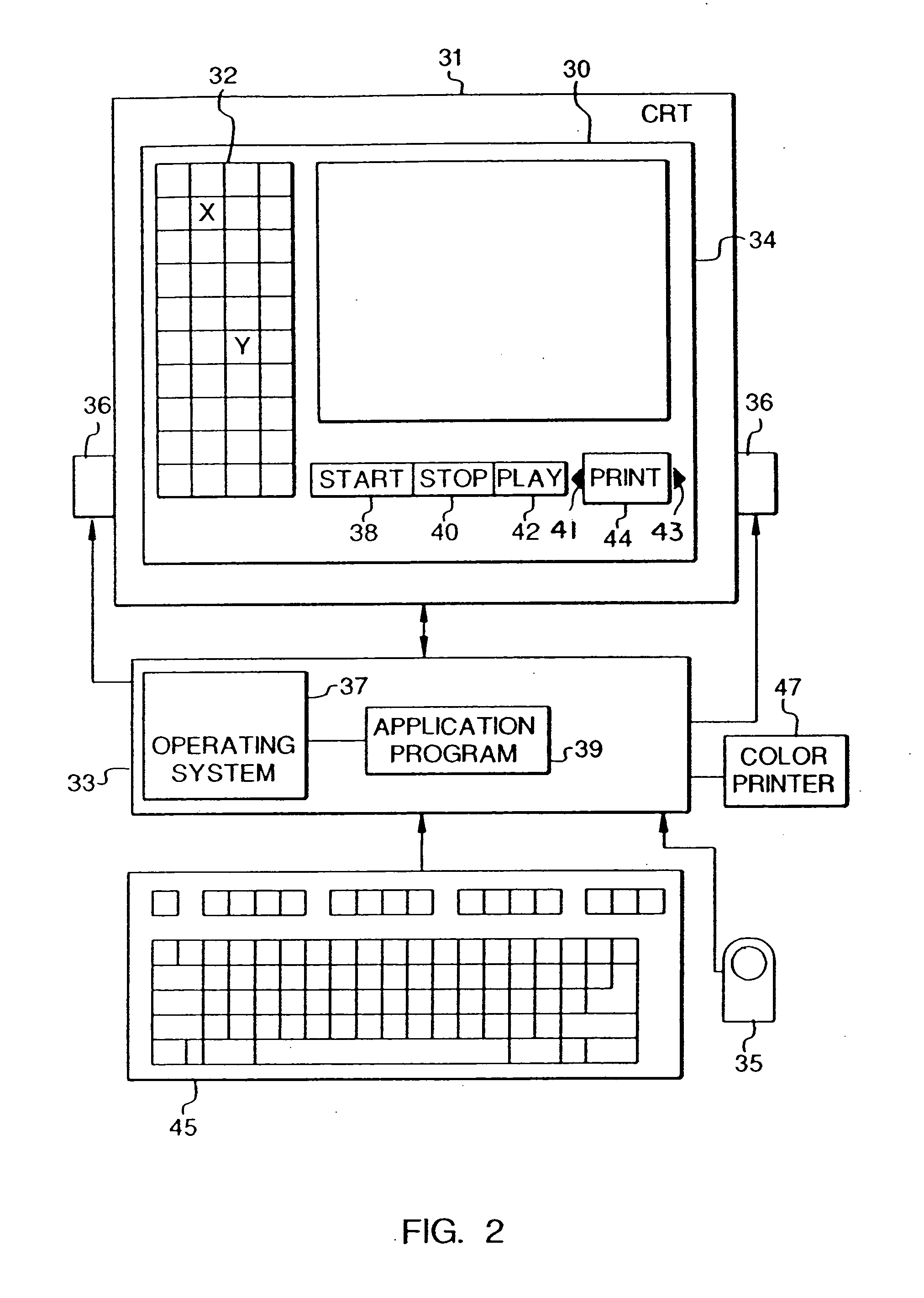

Method for simultaneously recording motion and still images in a digital camera

InactiveUS20060268117A1Reduce operating rateTelevision system detailsColor television detailsDigital videoComputer graphics (images)

A method for simultaneously recording motion and still images, includes the steps of: capturing a motion image sequence and accompanying audio of a scene with a digital video camera adapted to record both motion and higher resolution still images; simultaneously capturing a still image sequence having a higher resolution and lower frame rate than the motion capture sequence; compressing the motion image sequence using interframe compression and the accompanying audio and storing the compressed motion image and audio data; and compressing the still images using intraframe coding and storing the compressed still image data.

Owner:EASTMAN KODAK CO +15

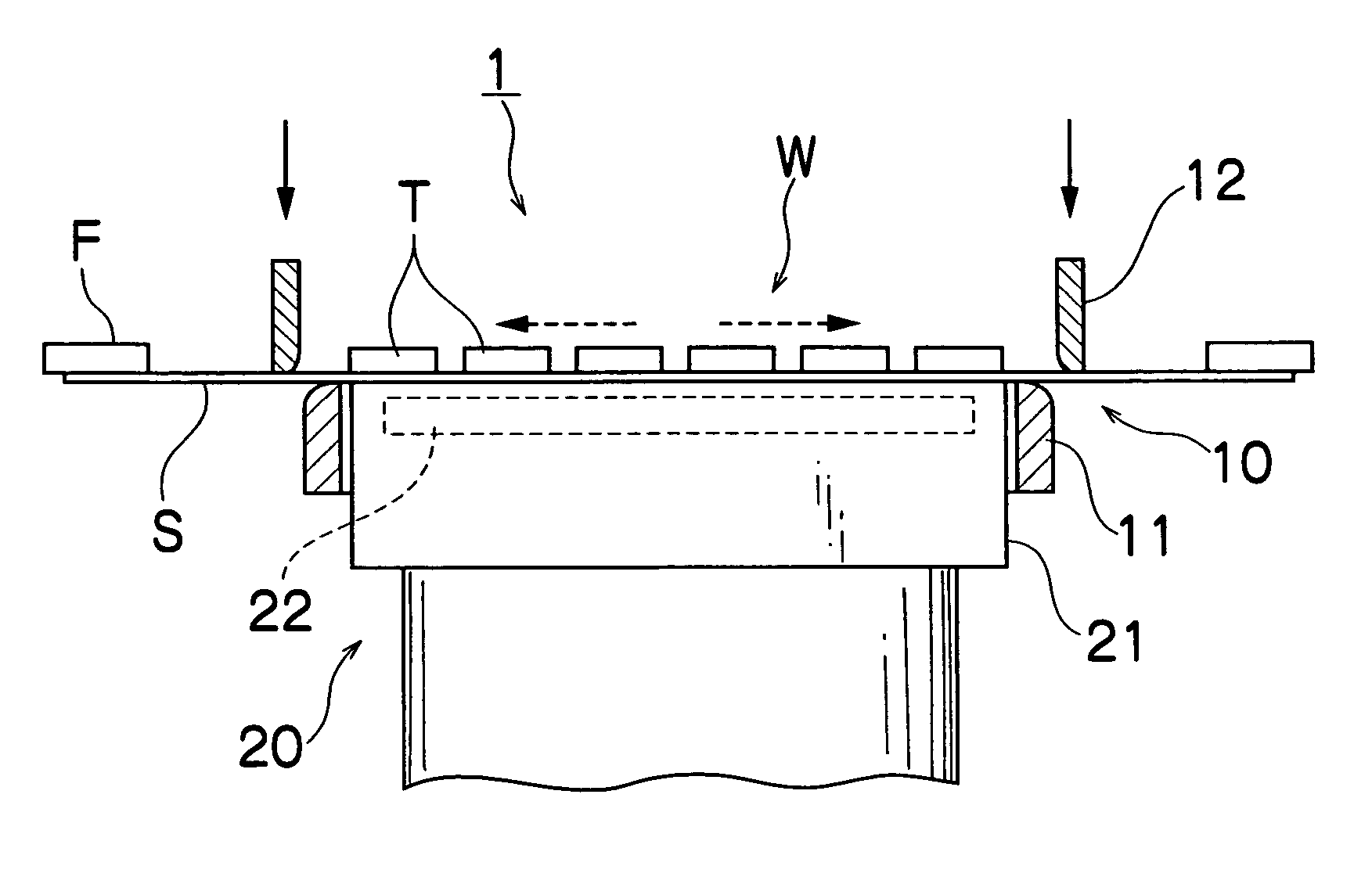

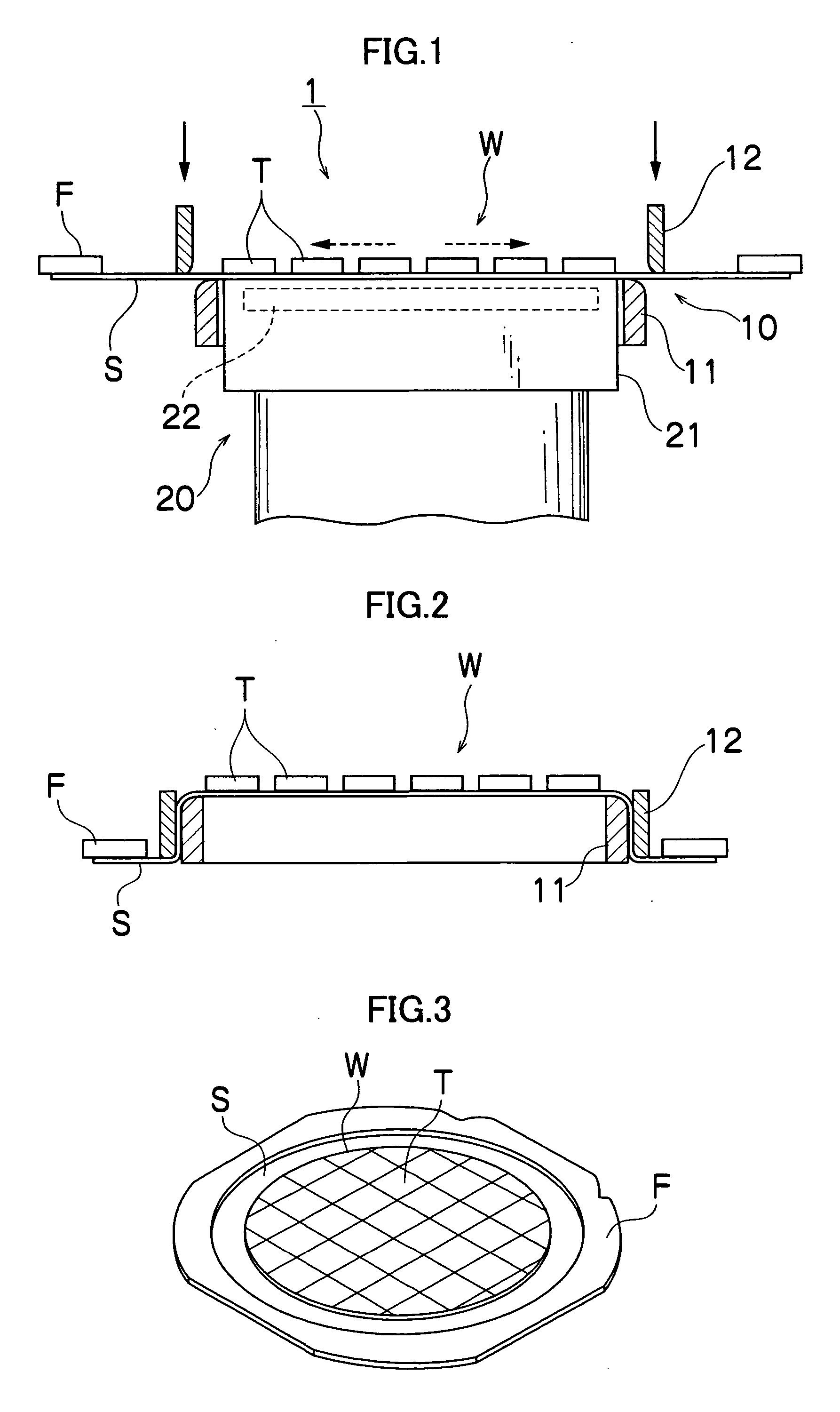

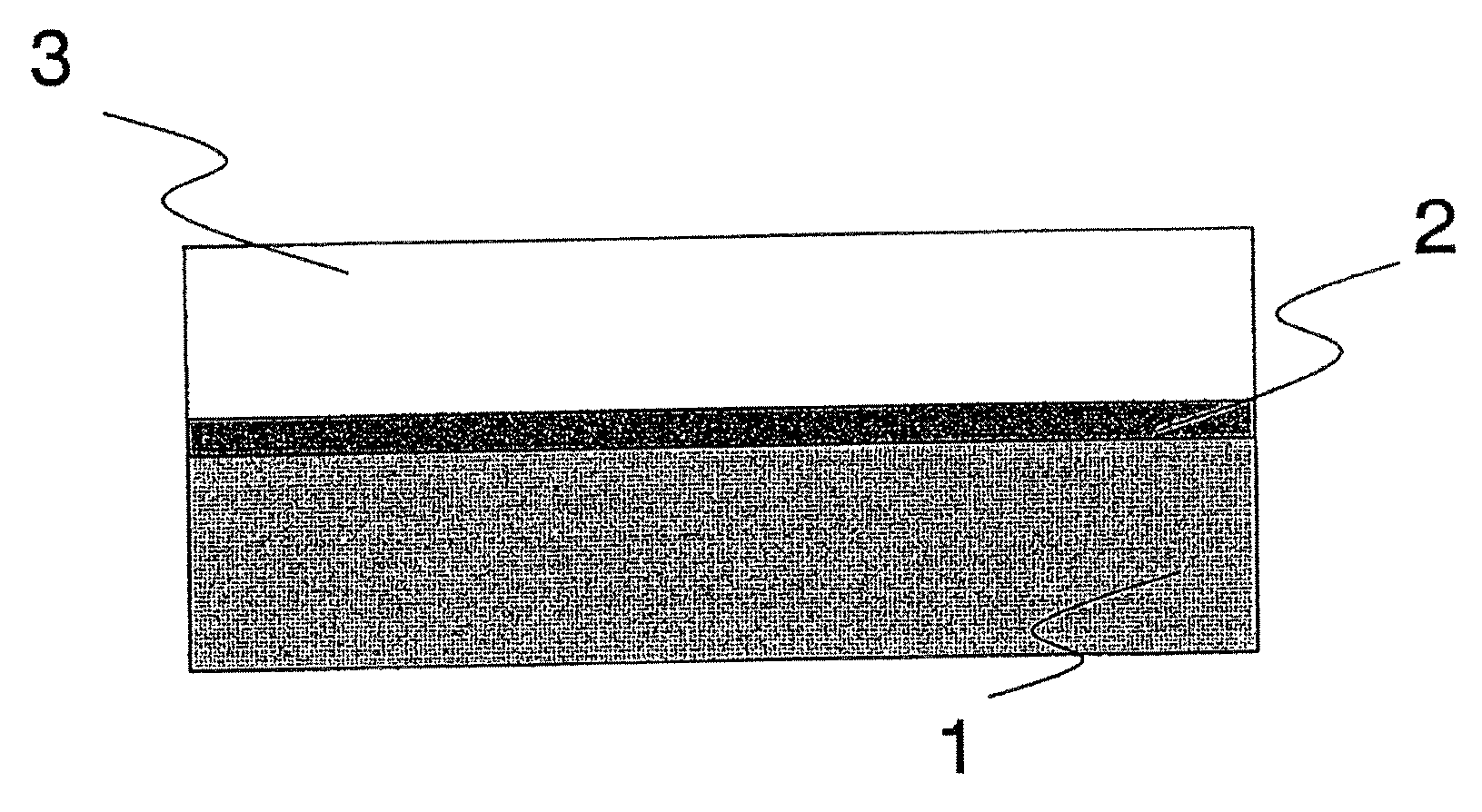

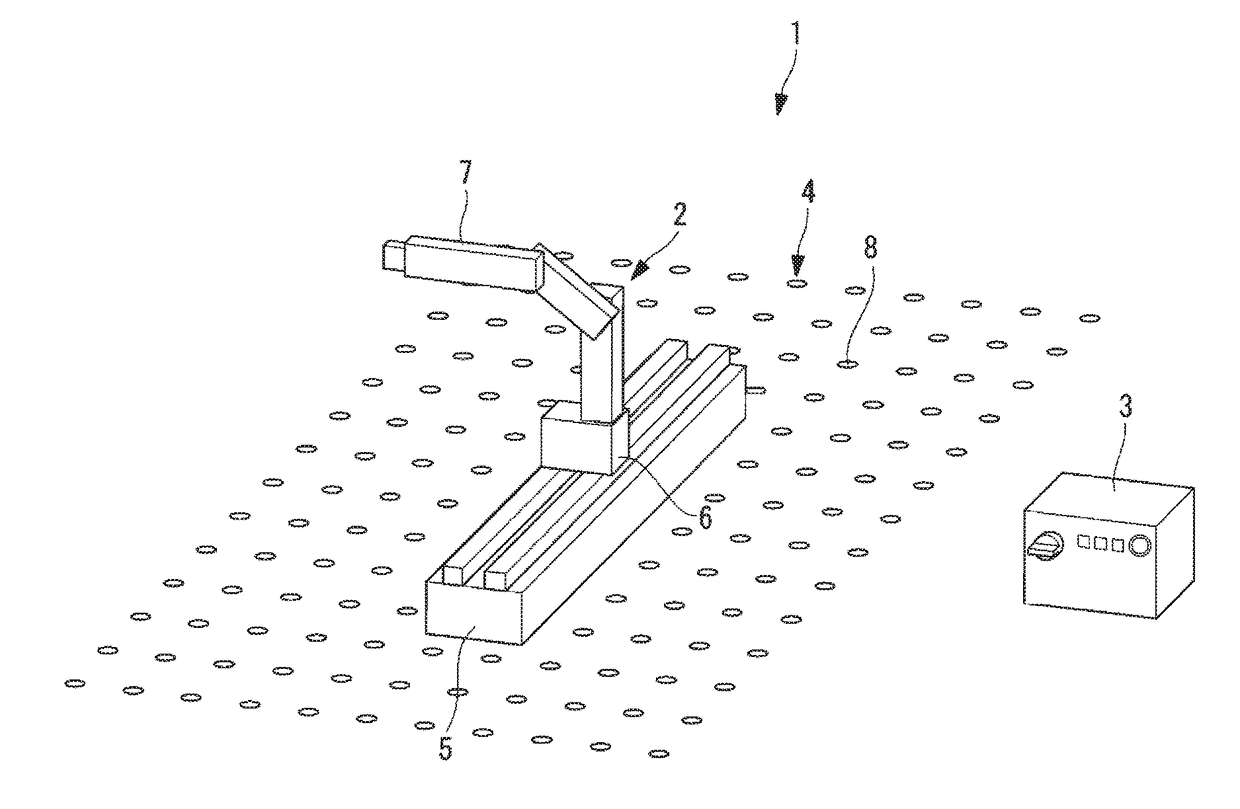

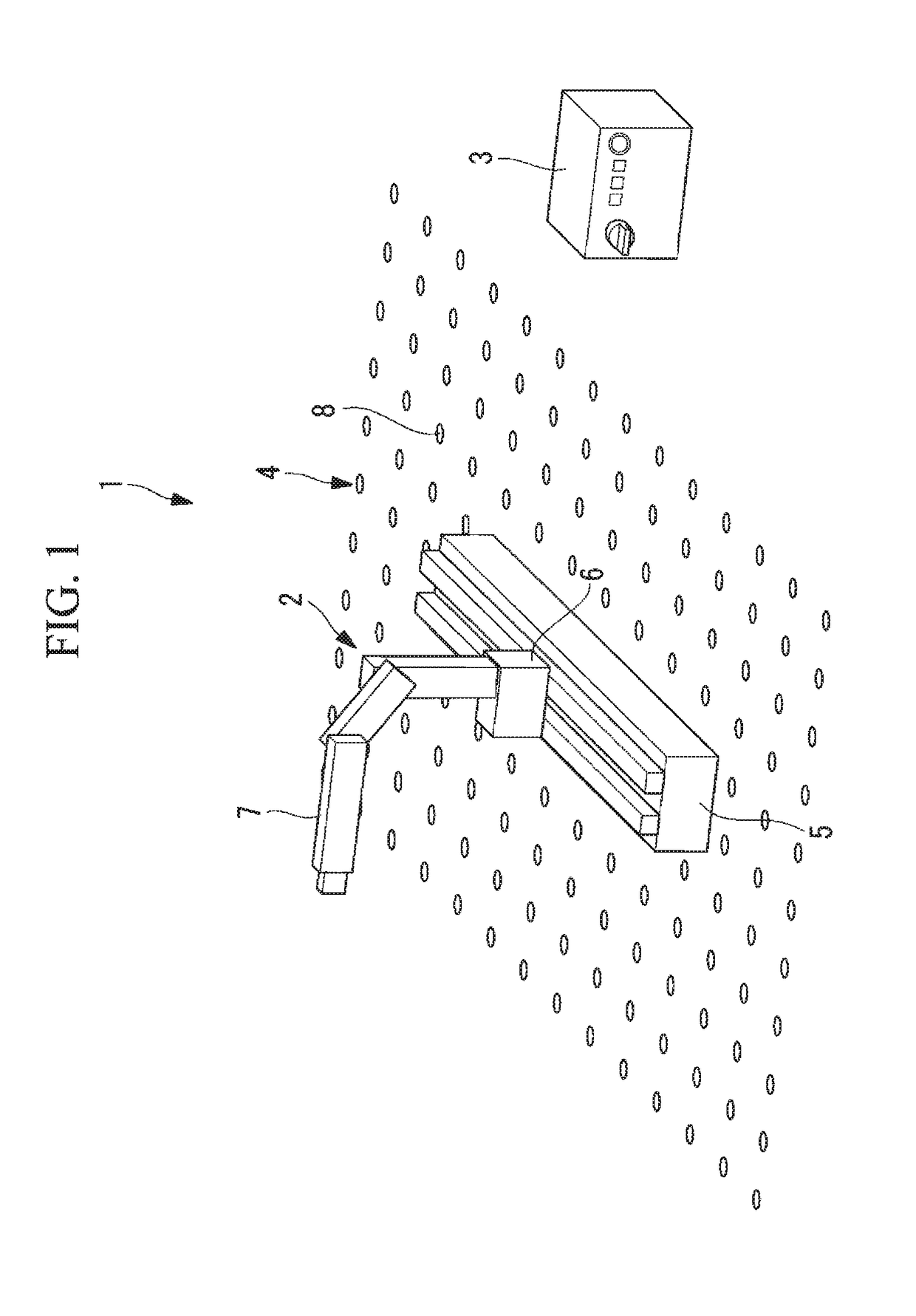

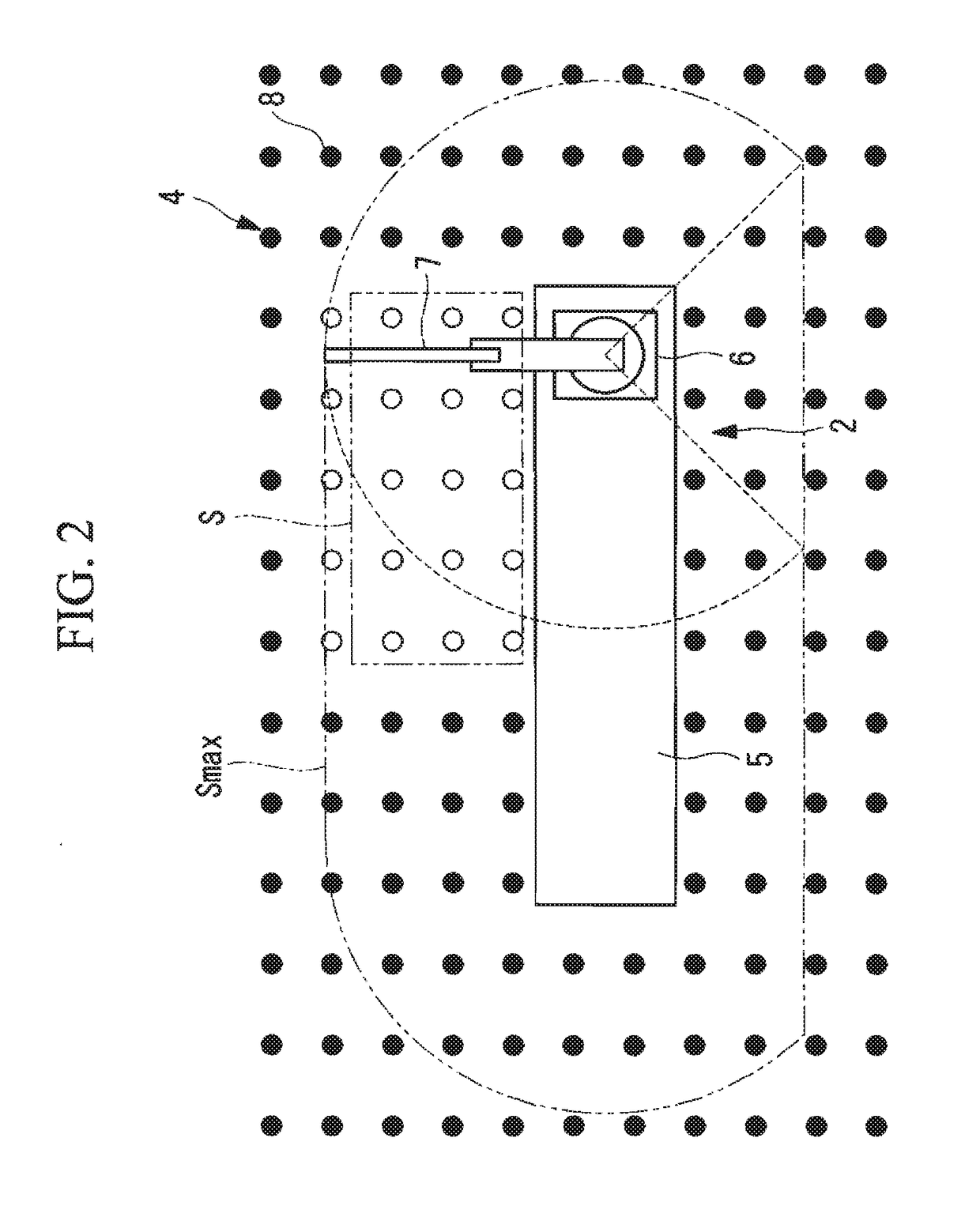

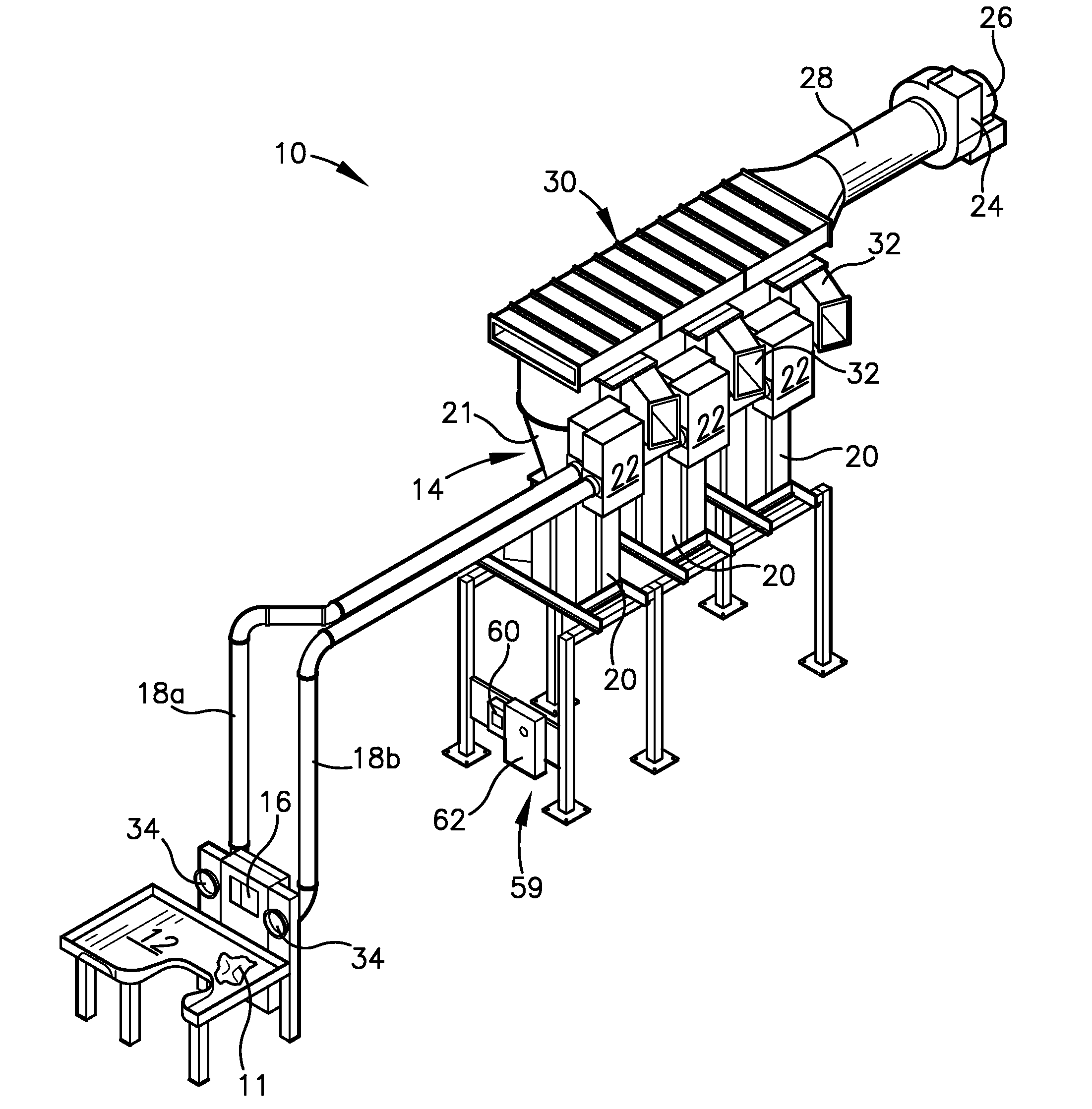

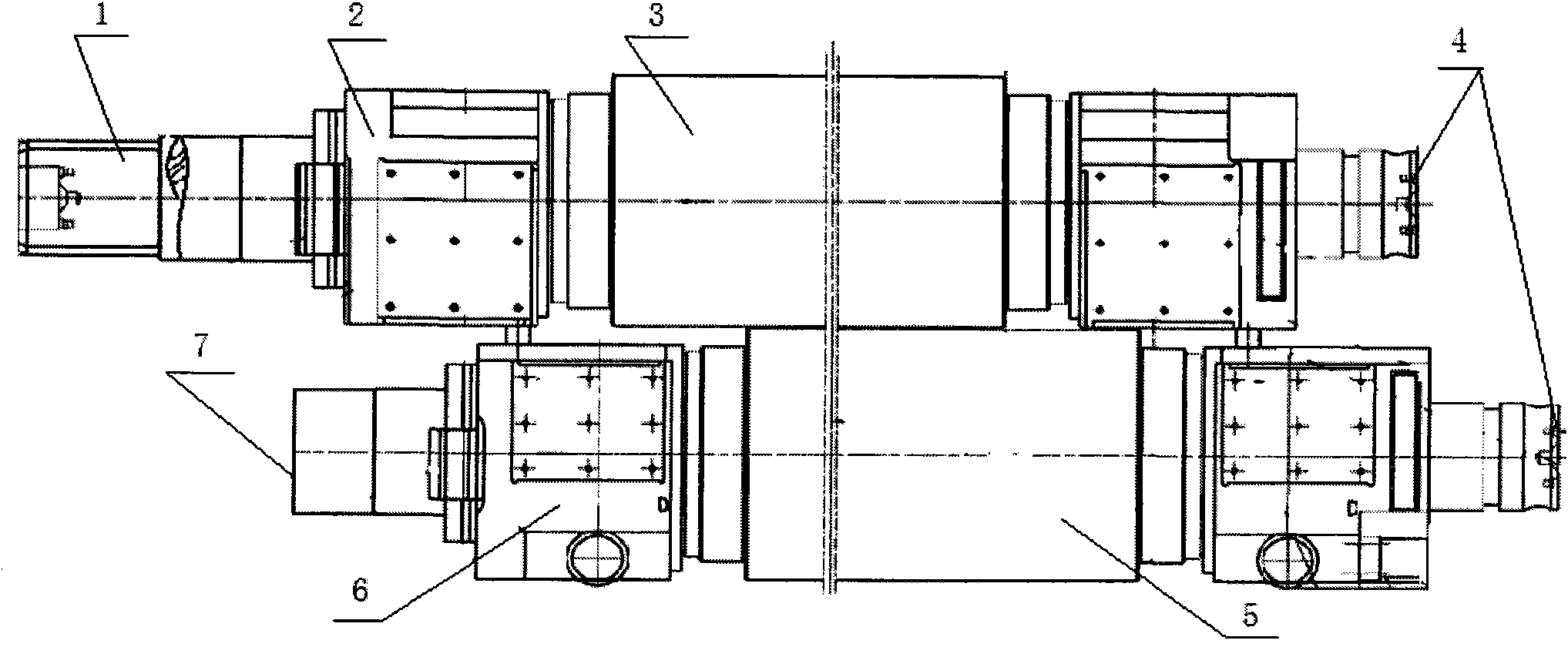

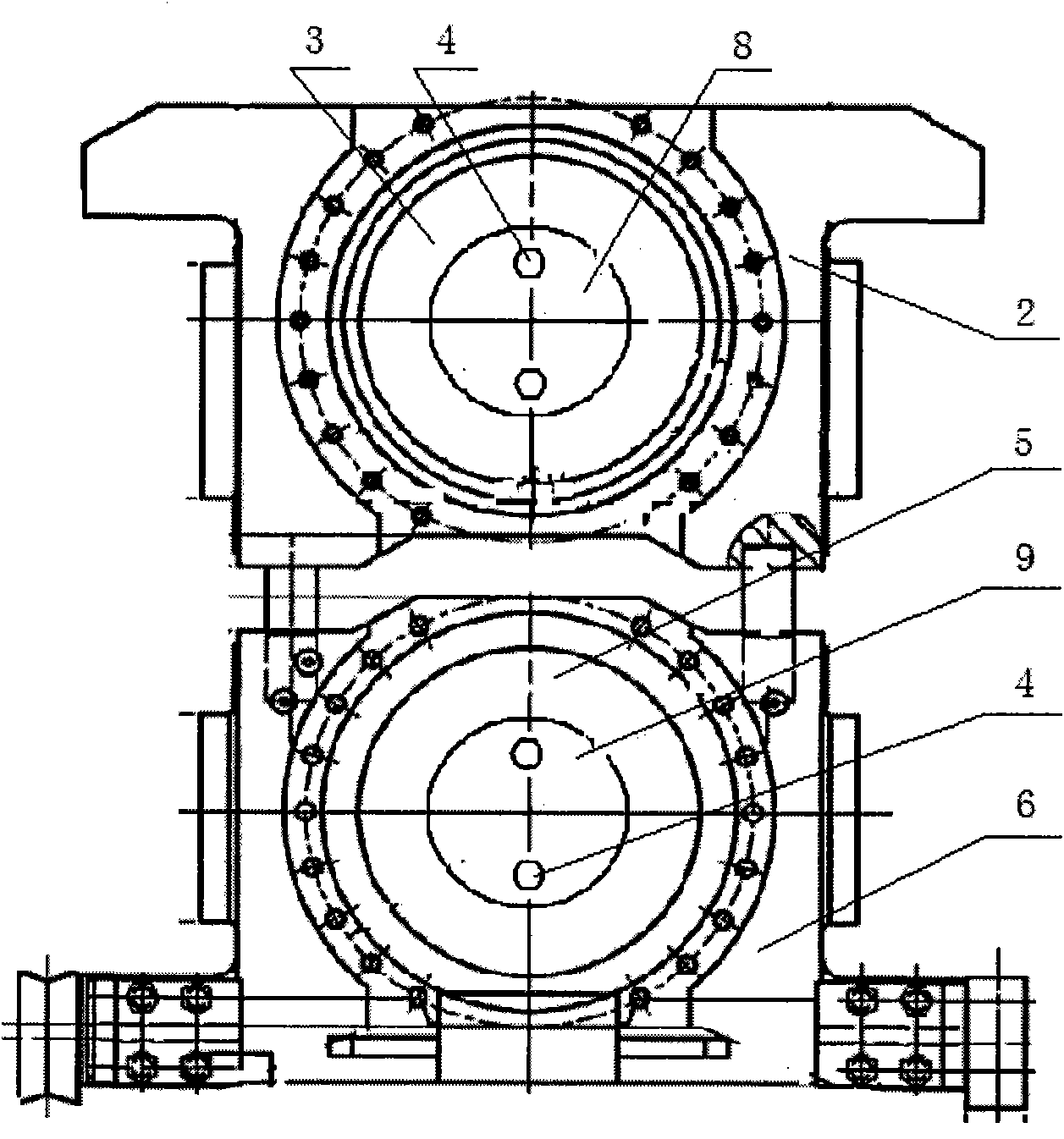

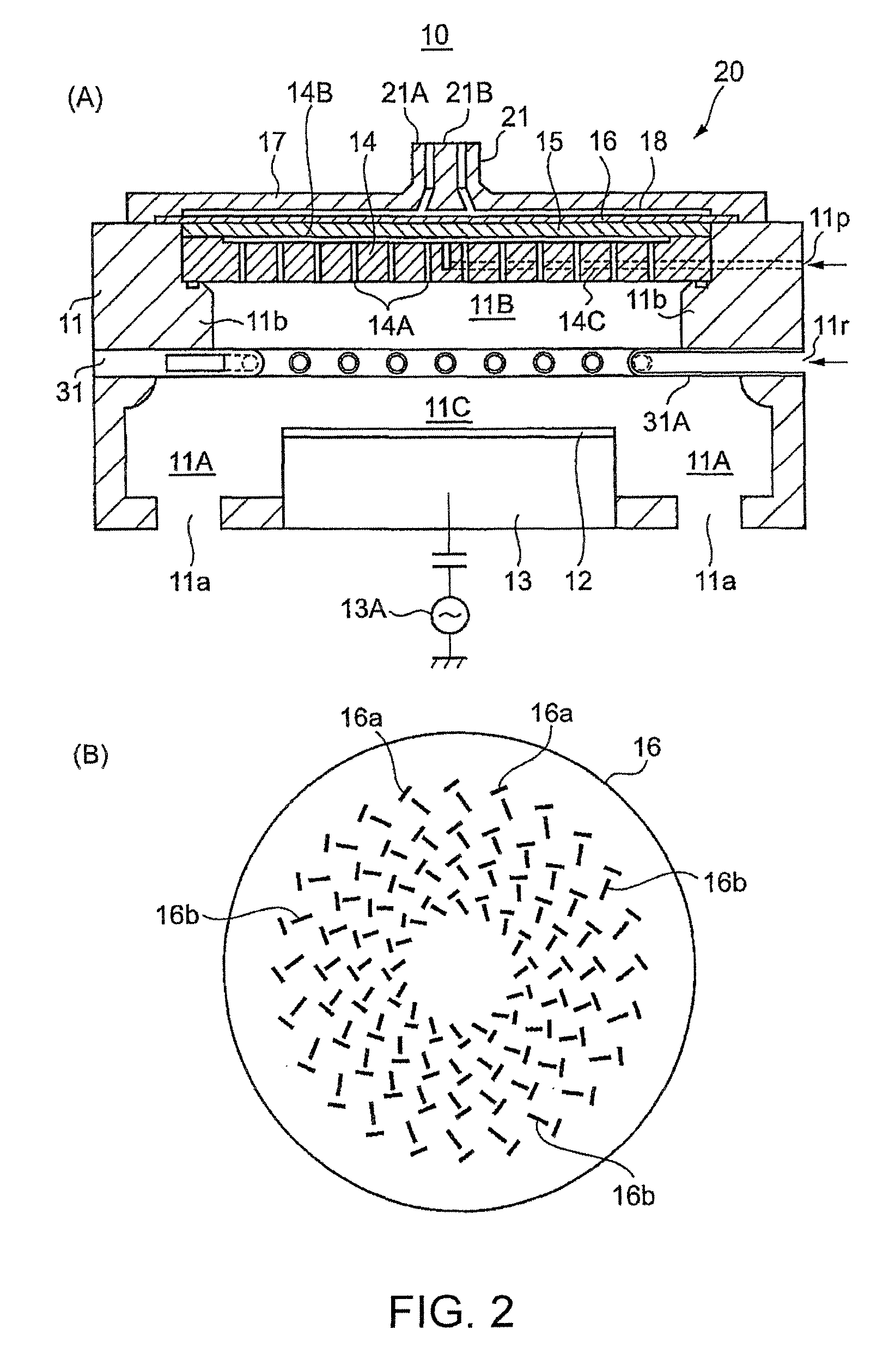

Expanding method and expanding device

ActiveUS20060005911A1Reduce operating ratePrevent edgeLamination ancillary operationsSolid-state devicesEngineeringMechanical engineering

An adhesive sheet (S) is expanded by expanding means (20) with a plate-like article (W) being mounted to a frame (F) after dicing of the plate-like article (W) to increase spacings between individual chips (T), an expanded state of the adhesive sheet (S) is maintained by expansion maintaining means (10), so that the plate-like article (W) is able to be conveyed together with the frame (F) with the spacings between the chips (T) being maintained, thereby preventing adjacent chips (T) from interfering with each other during the conveyance. This allows the plate-like article (W) after the dicing to be conveyed together with the frame (F) without edges of the adjacent chips (T) coming into contact with each other by vibration during the conveyance to cause chipping or microcracks in the edges.

Owner:TOKYO SEIMITSU

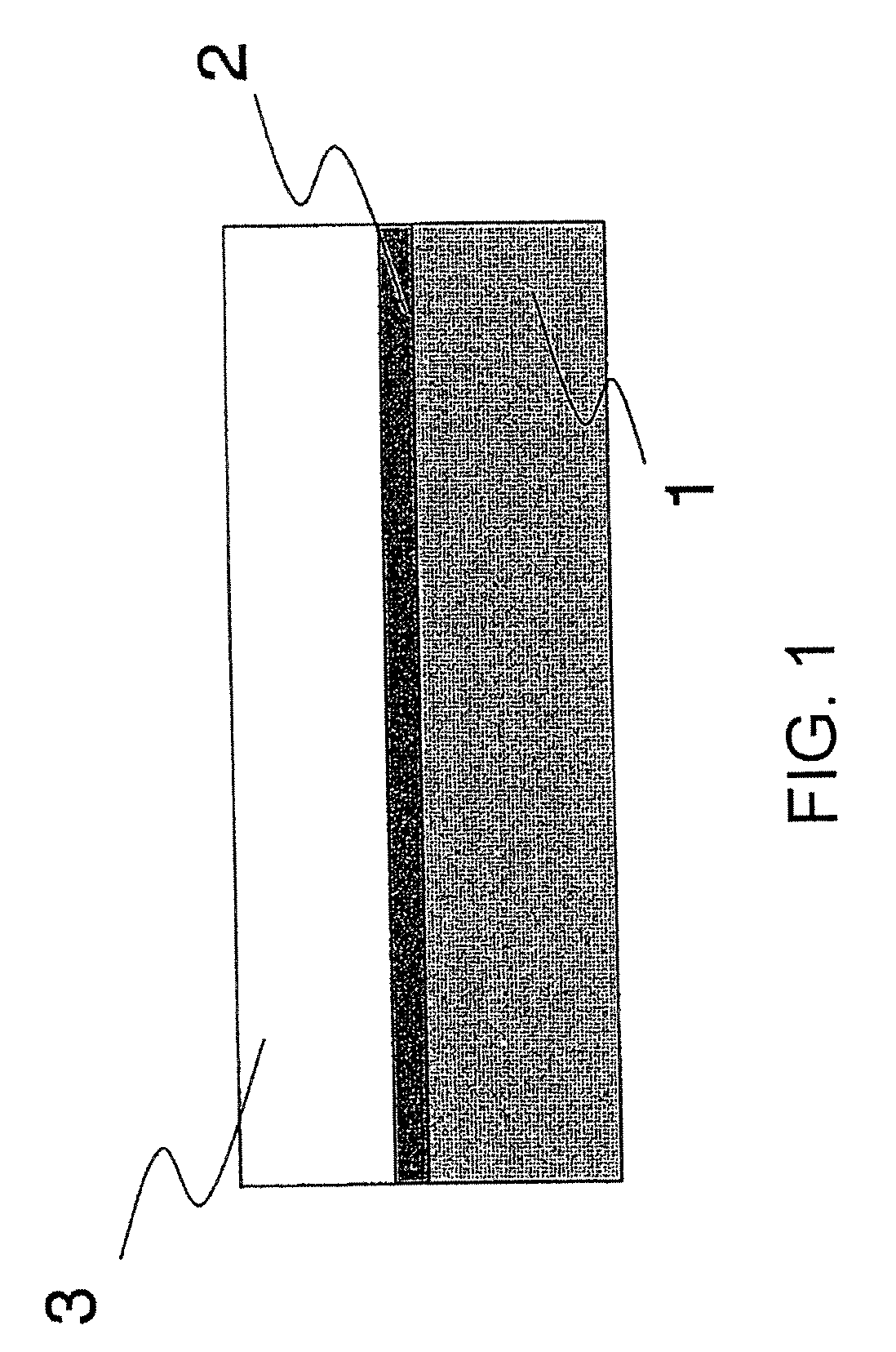

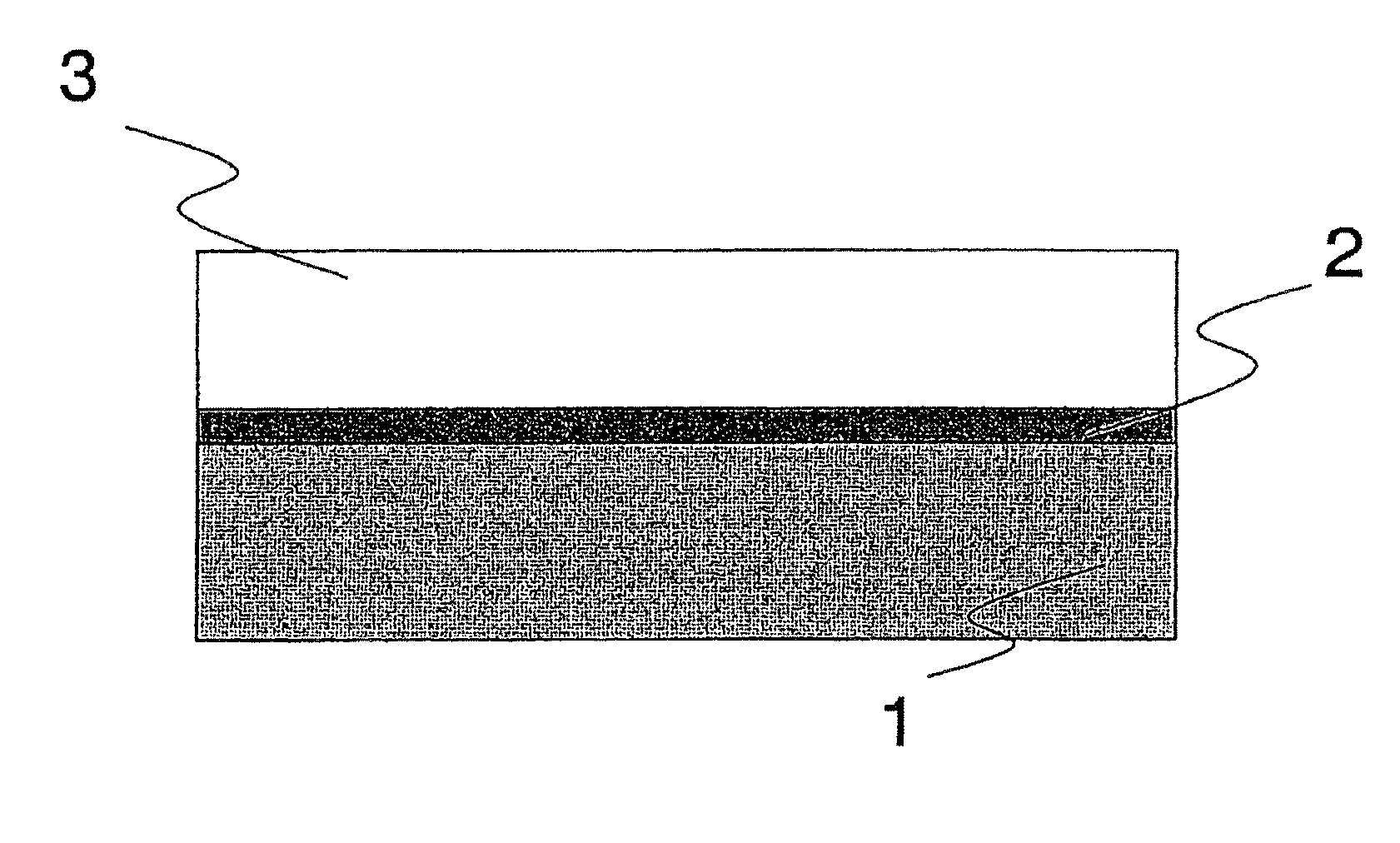

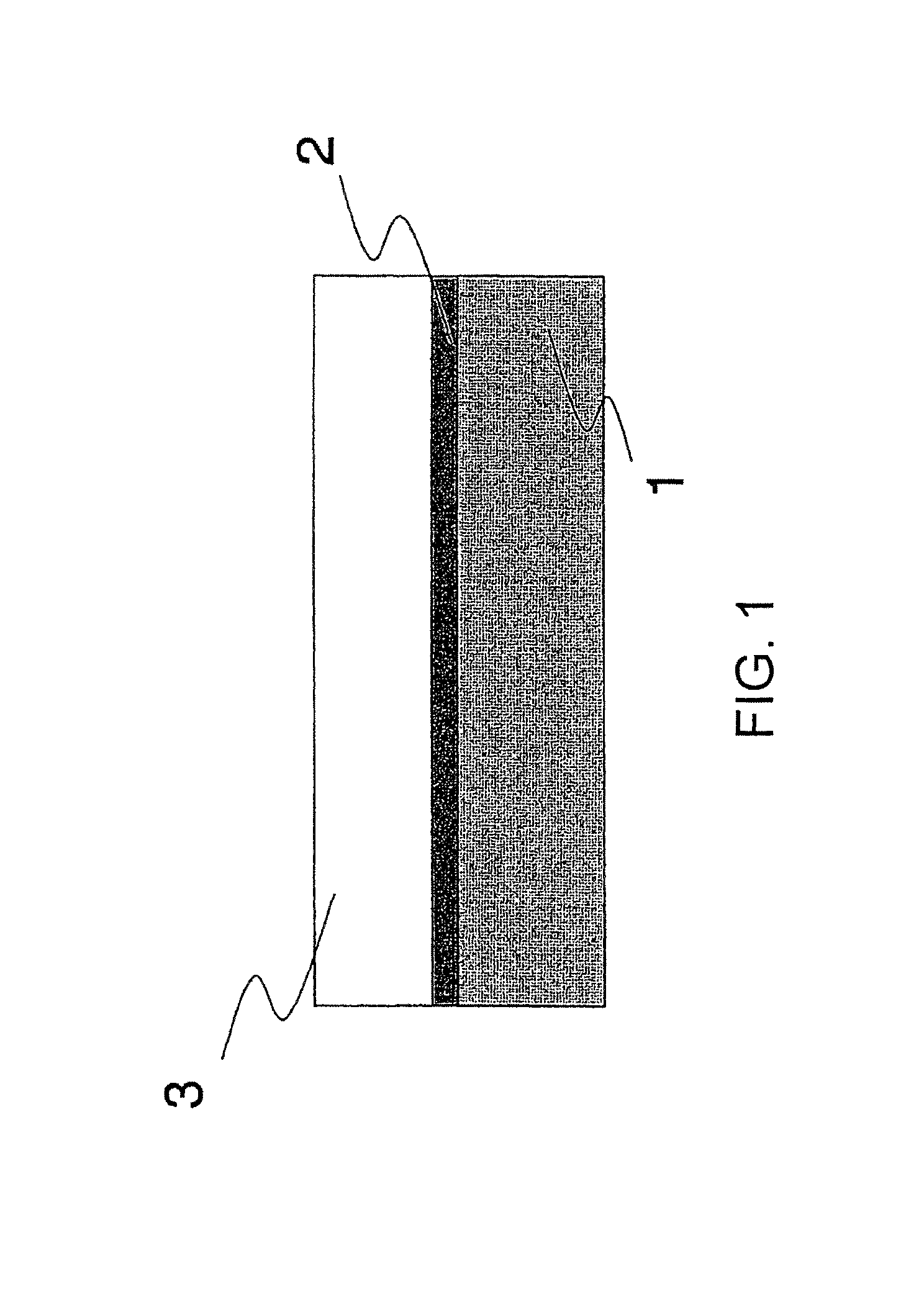

Protective Film Structure of Metal Member, Metal Component Employing Protective Film Structure, and Equipment for Producing Semiconductor or Flat-Plate Display Employing Protective Film Structure

InactiveUS20090142588A1Avoid Surface CorrosionReduce pollutionAnodisationMolten spray coatingTectorial membraneMetallic materials

Multifunction production equipment enabling a plurality of processes in which deposition of reaction products on the inner wall of the processing chamber of equipment for producing a semiconductor or a flat-plate display, metal contamination due to corrosion of the inner wall, or the like, and fluctuation of the process due to discharged gas are suppressed, and a protective film structure for use therein. On the surface of a metal material, a first coating layer having an oxide coating of 1μ thick or less formed as an underlying layer by direct oxidation of a parent material, and a second coating layer of about 200 μm thick are formed. With such an arrangement, corrosion resistance against irradiation with ions or radicals can be imparted to a second layer protective film, and the effect of a protective layer for preventing corrosion of the surface of parent metal caused by diffusing molecules or ions into the second layer protective film can be imparted to the first layer oxide film. Consequently, contamination of the substrate with metals generated from each metal member and the inner surface of the process chamber is reduced, and stripping of the second layer protective film due to lowering in adhesion of the second layer protective film due to corrosion of the interface between the parent material and the second layer protective film can be suppressed.

Owner:NGK SPARK PLUG CO LTD +2

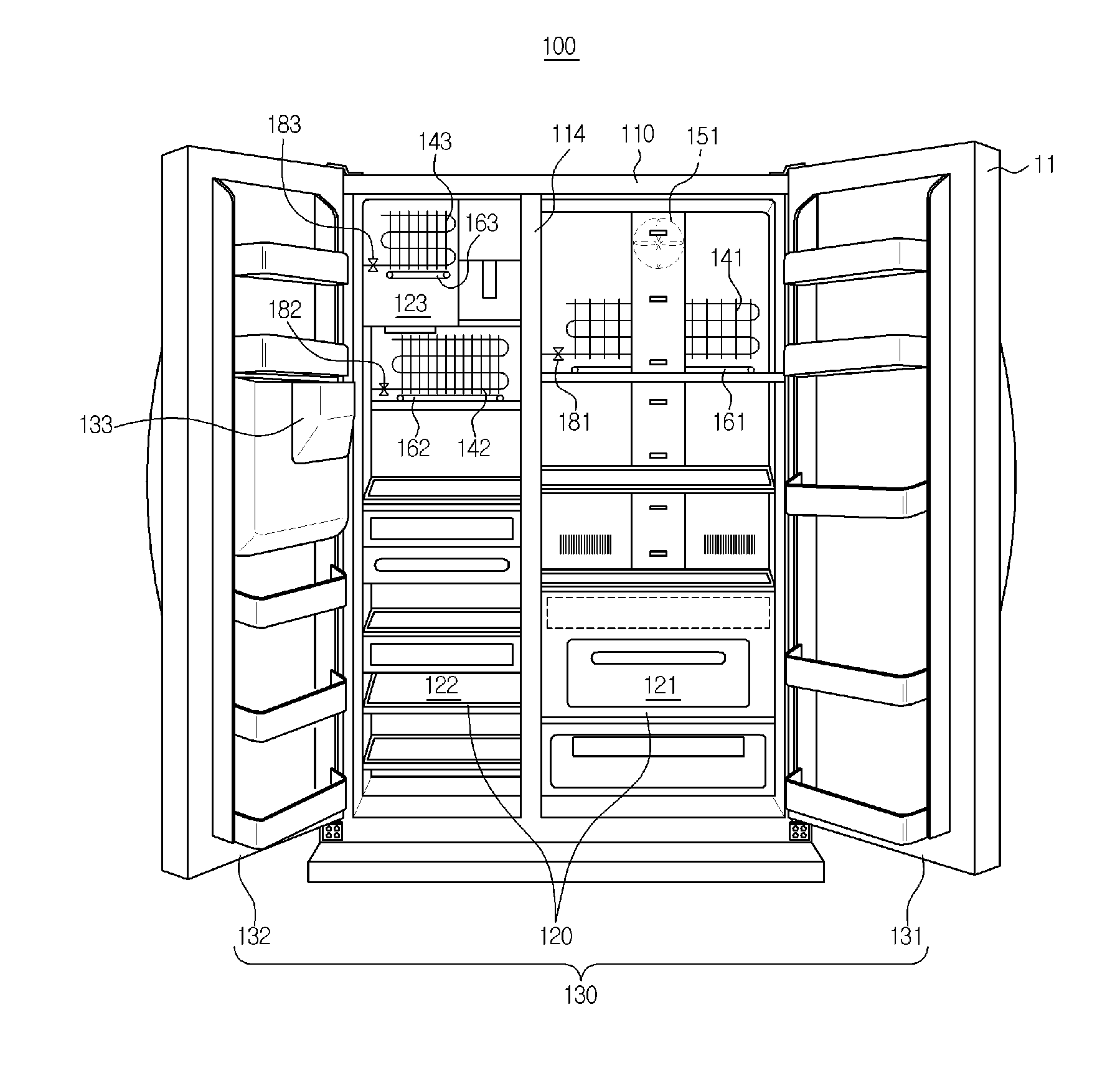

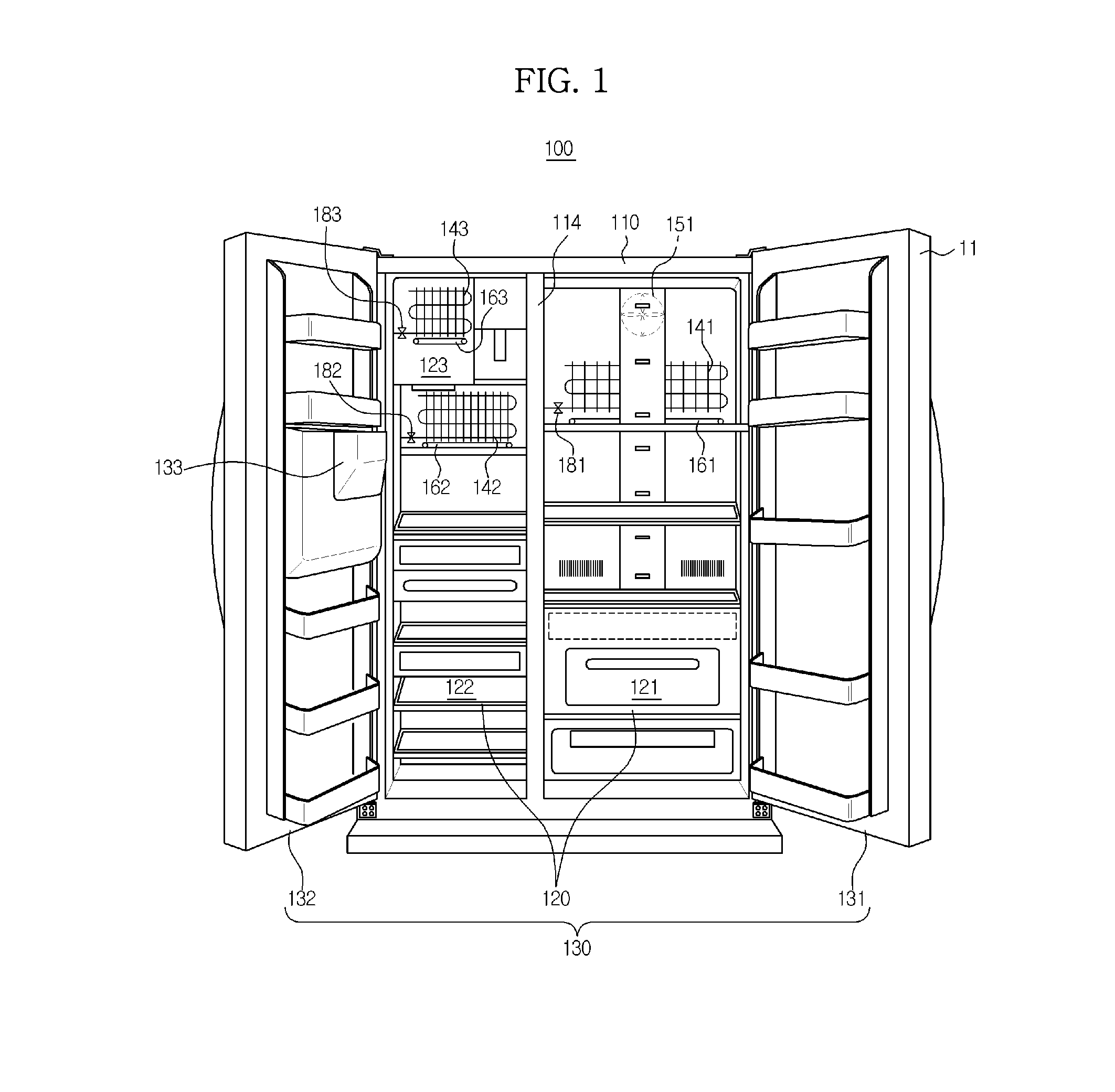

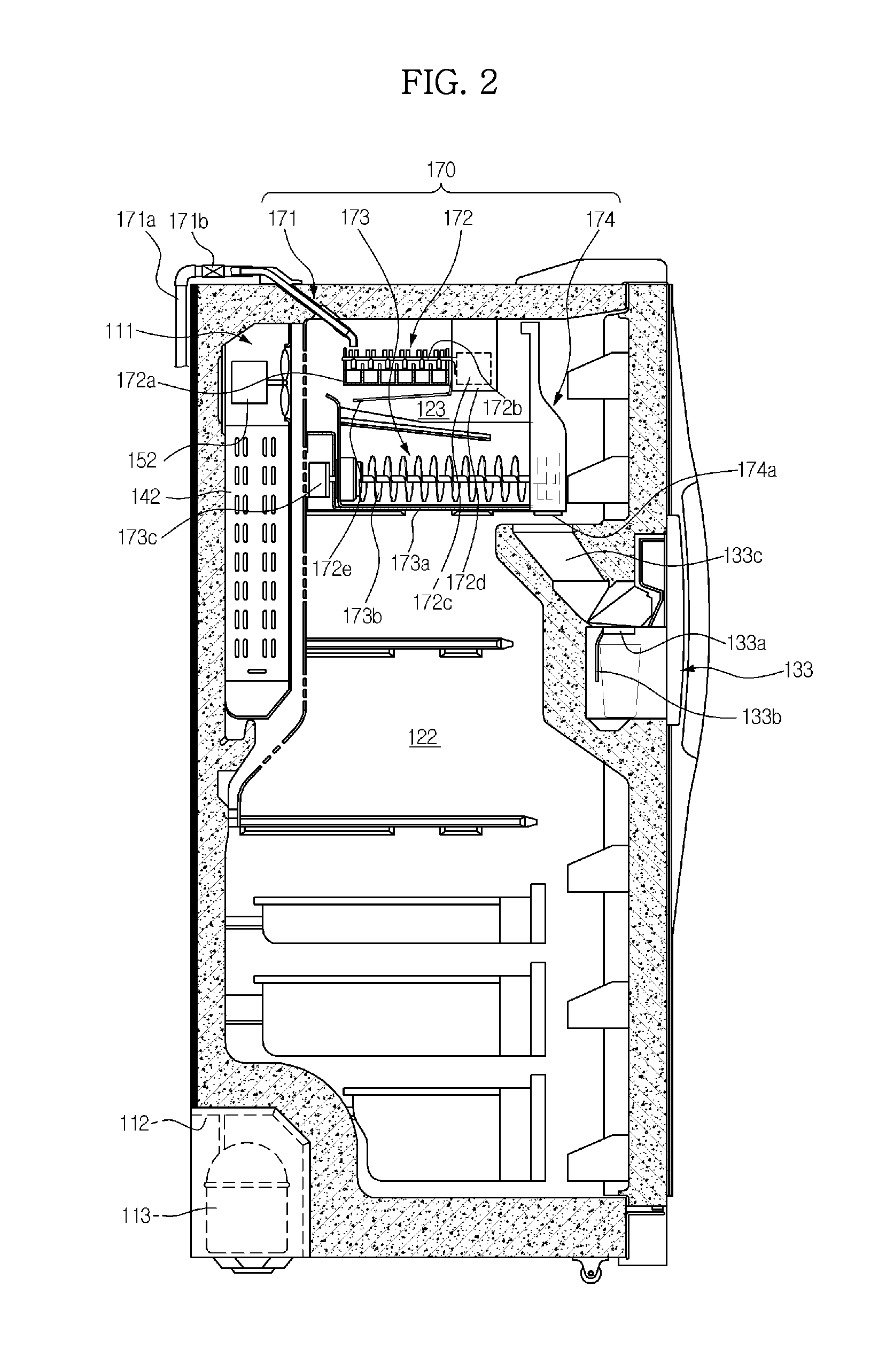

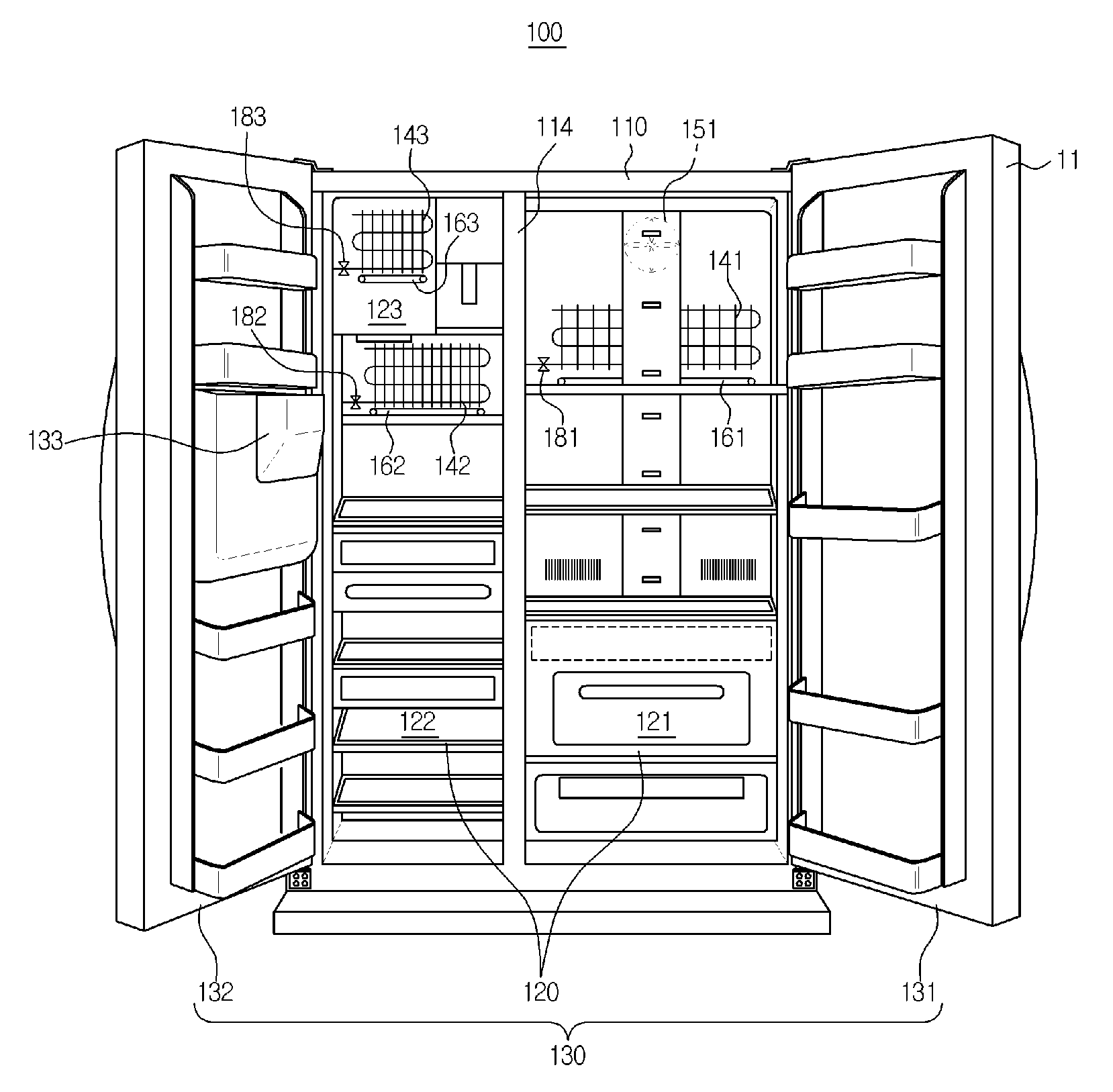

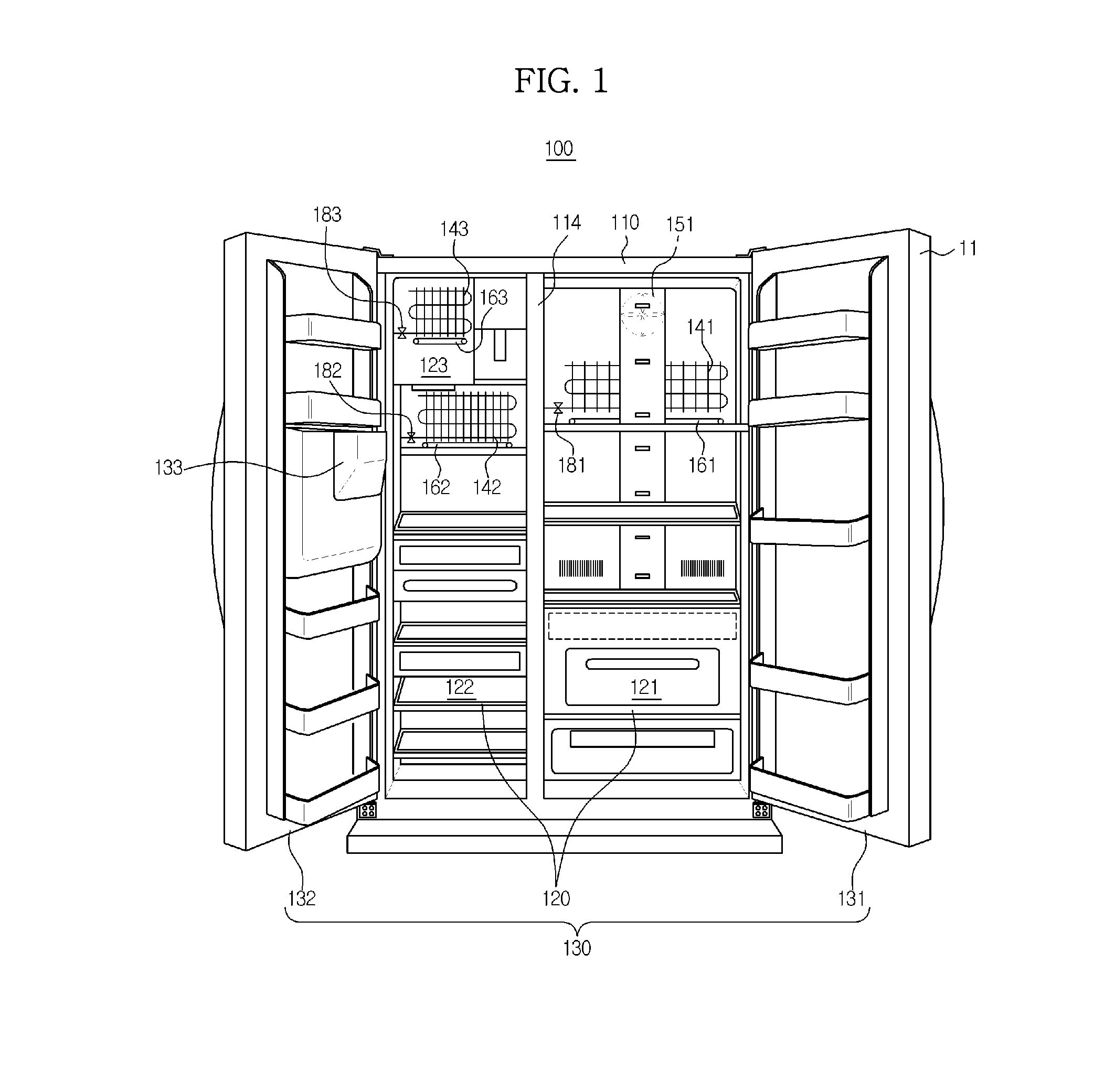

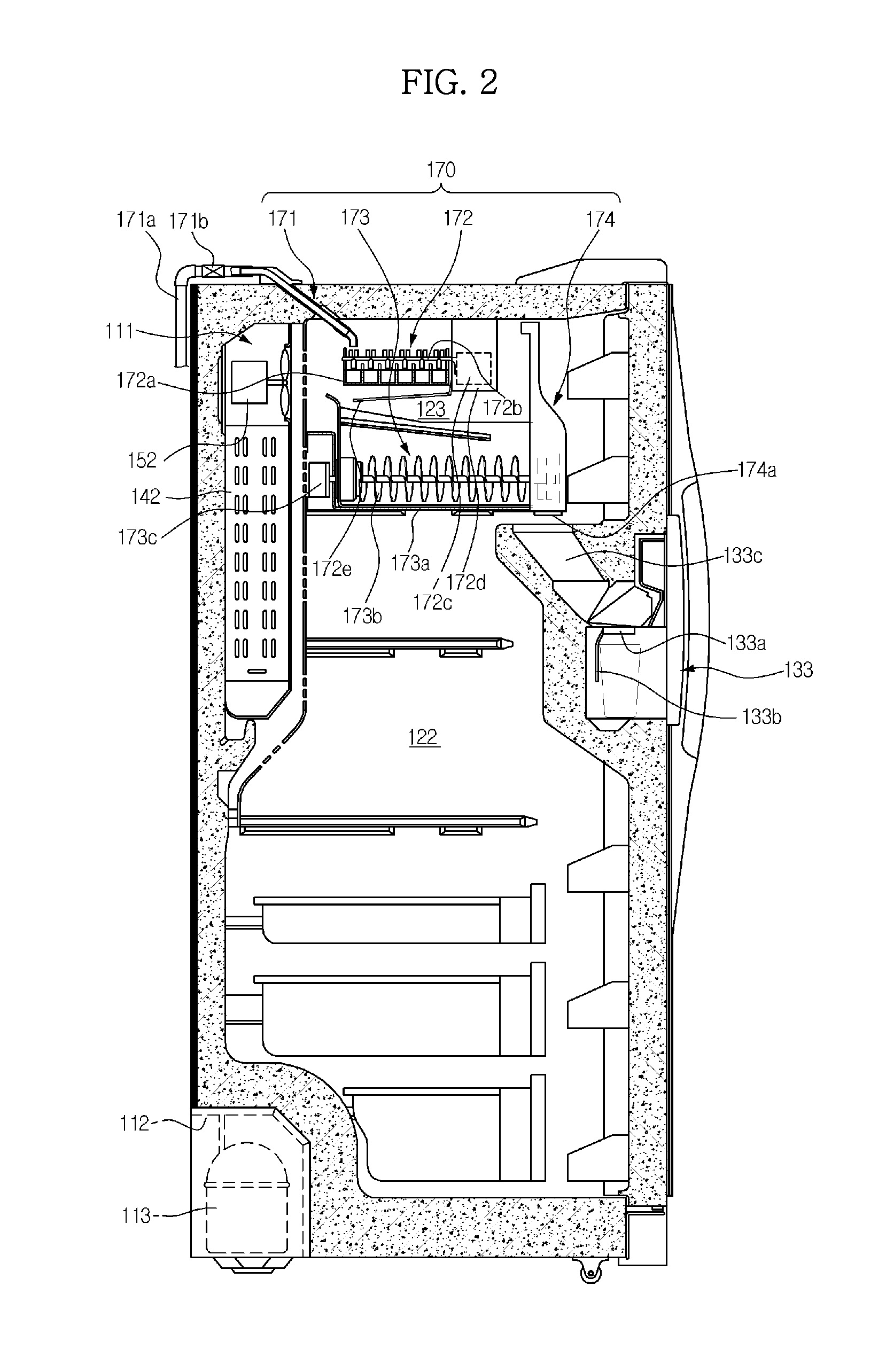

Refrigerator and control method thereof

ActiveUS20130025303A1Avoid concentrationReduce power consumptionFood processingDomestic refrigeratorsEngineeringRefrigerated temperature

A control method of a refrigerator including a compressor to supply refrigerant to an evaporator to cool a storage compartment, a valve to adjust flow of the refrigerant, a fan to blow air heat-exchanged by the evaporator, and a heater to remove frost from the evaporator. The control method includes, upon receiving a power-saving signal, determining whether the received power-saving signal is a first or second power-saving mode signal, upon determining that the power-saving signal is the first power-saving mode signal, performing at least one selected from among resetting of target temperature of the storage compartment, adjustment of an operation rate of the compressor, and adjustment of operation time of the heater to execute a first power-saving mode, and, upon determining that the power-saving signal is the second power-saving mode signal, controlling the compressor, the fan, and the heater to be off to execute a second power-saving mode.

Owner:SAMSUNG ELECTRONICS CO LTD

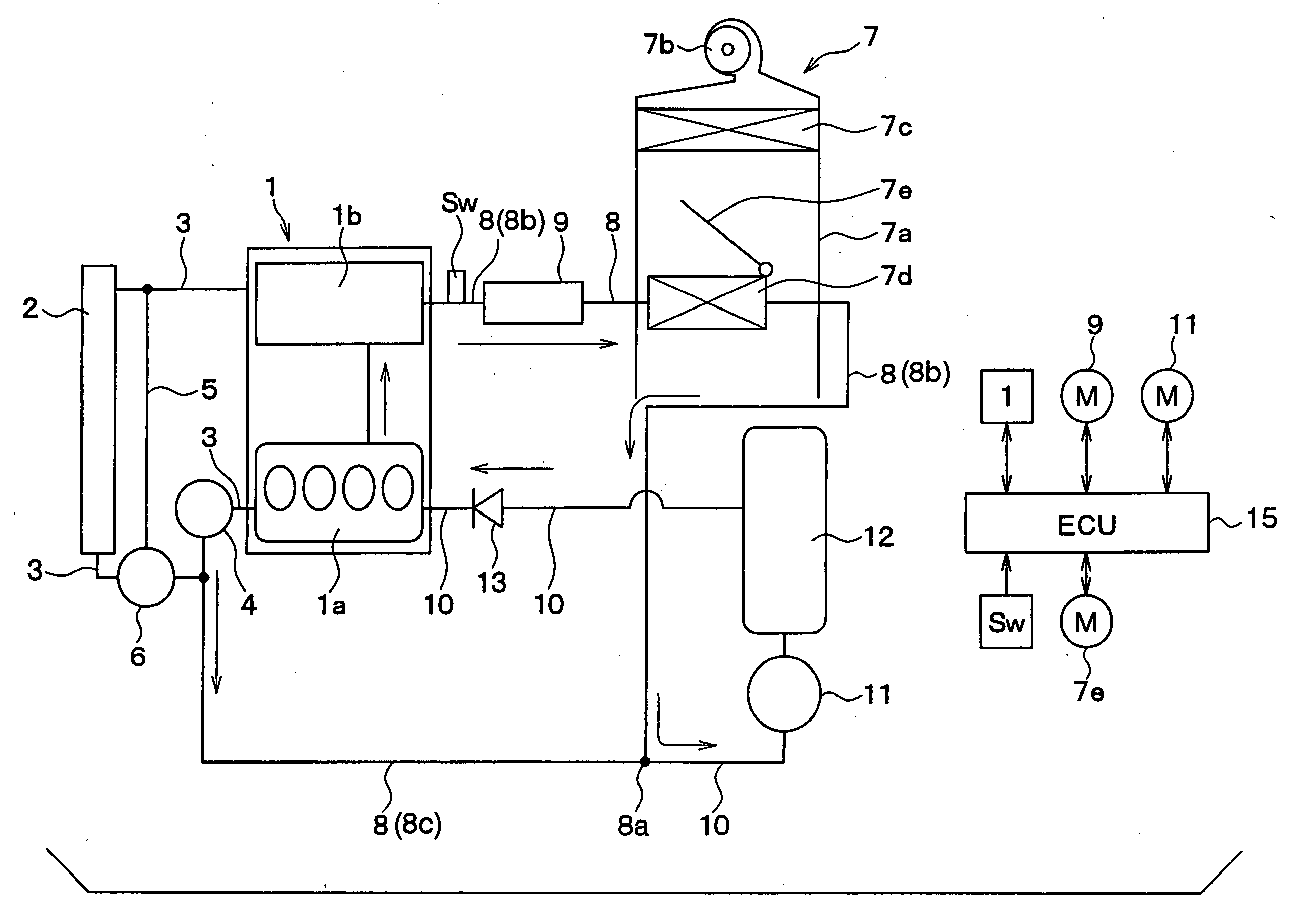

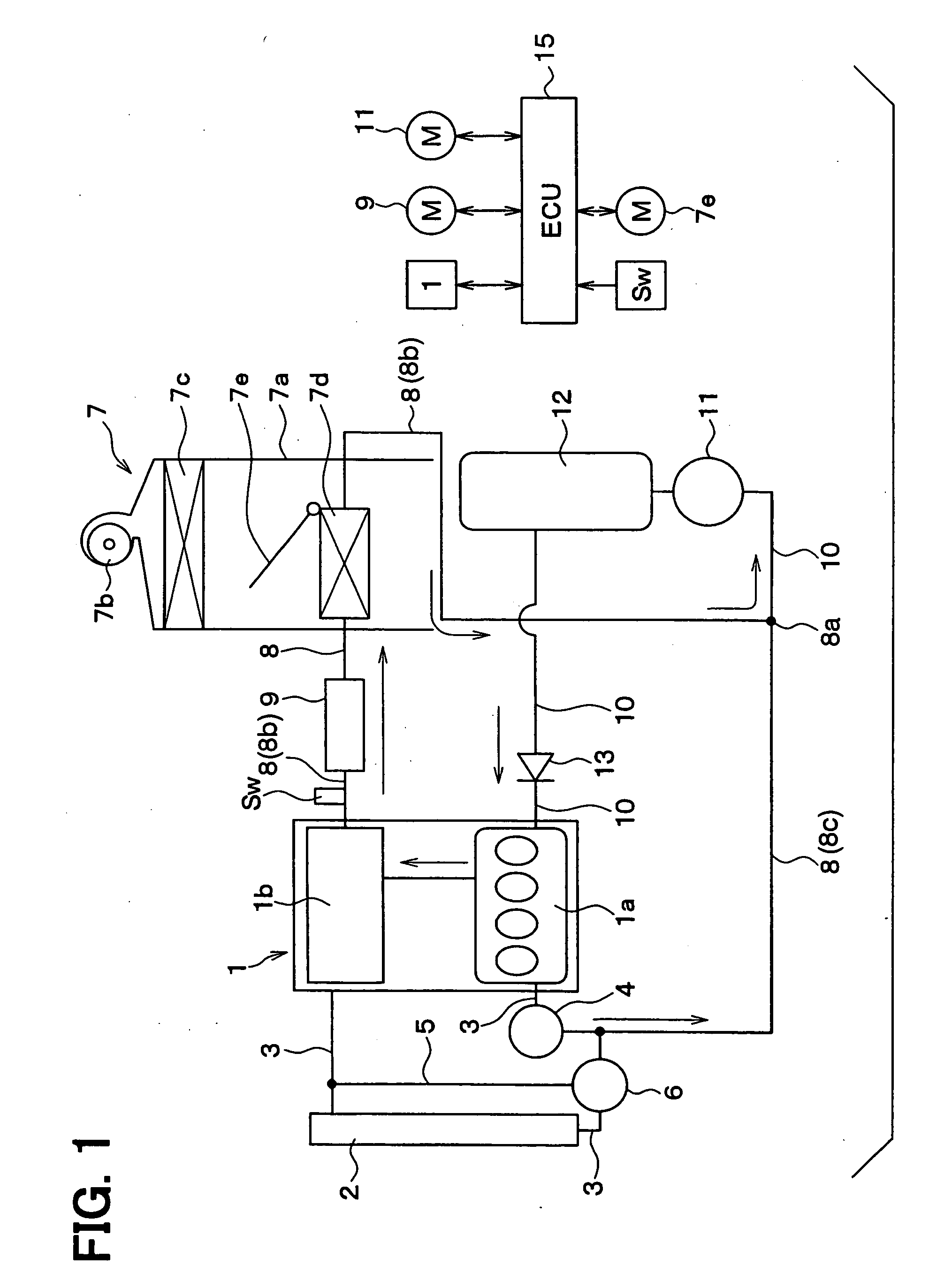

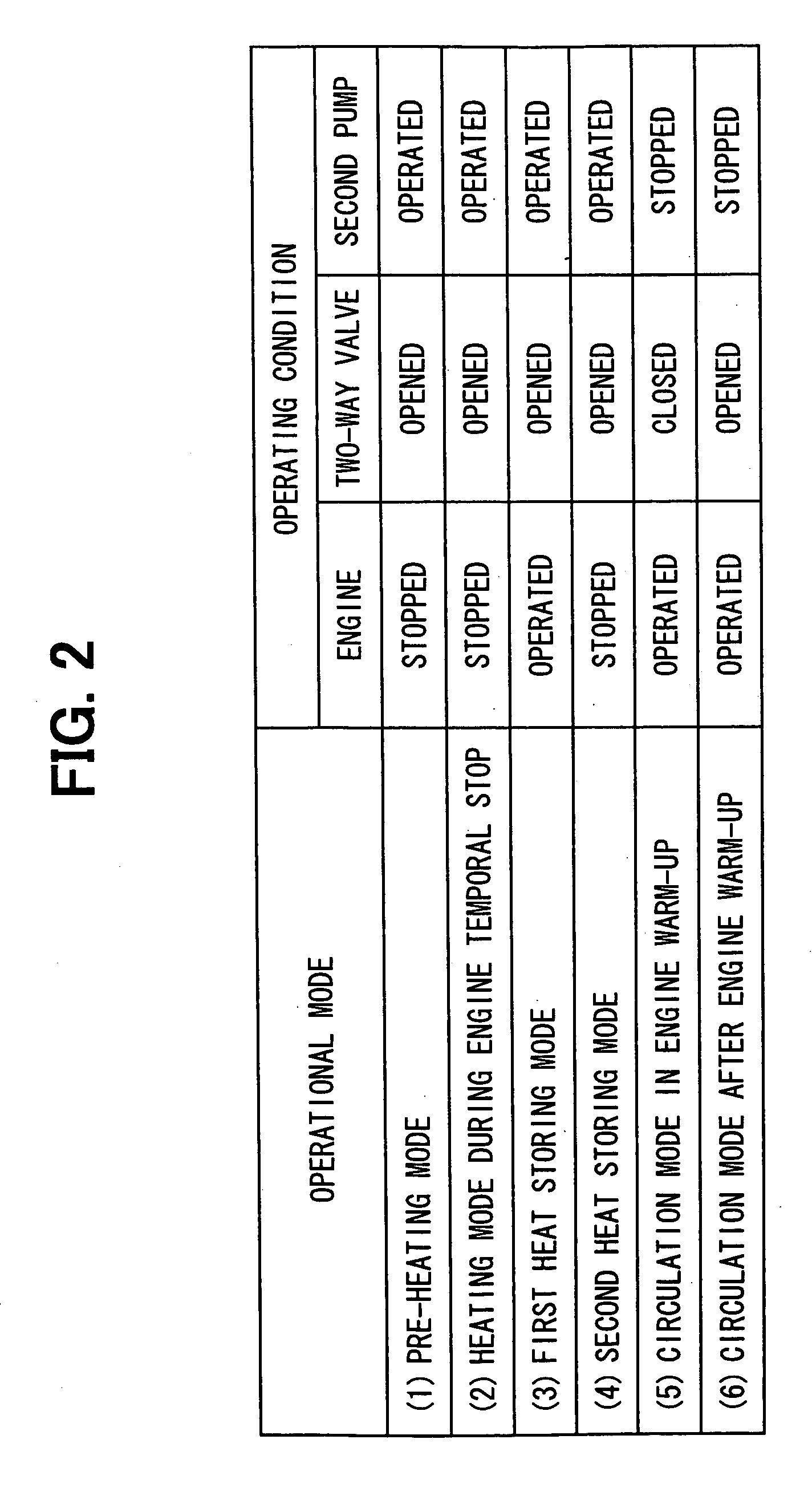

Waste heat utilizing system

InactiveUS20060231640A1Low costReduce power consumptionAir-treating devicesCoolant flow controlEngineeringThermal water

A main cooling circuit is formed by an engine, a radiator and a first pump. A hot water circuit is formed by the engine, a heater core and the first pump. A heat storing water circuit is connected between a bifurcating point of the hot water circuit and the engine, wherein a second pump and a heat storage tank are provided in the heat storing water circuit. Engine cooling water stored in the heat storage tank is circulated by the second pump, so that the hot water is supplied to the engine before the engine operation is started. The engine cooling water is also circulated by the second pump during the engine operation, so that hot water is stored in the heat storage tank.

Owner:DENSO CORP

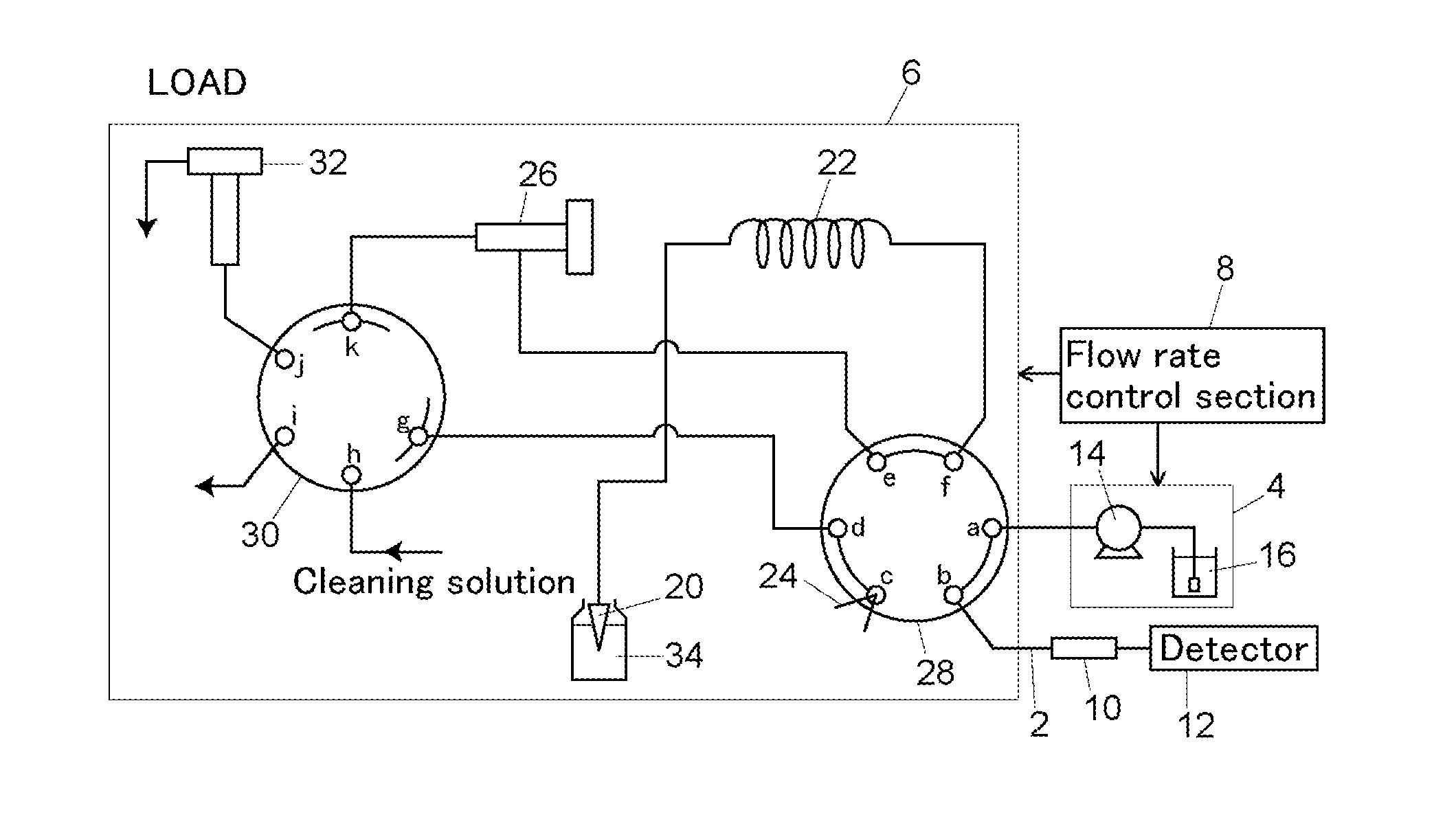

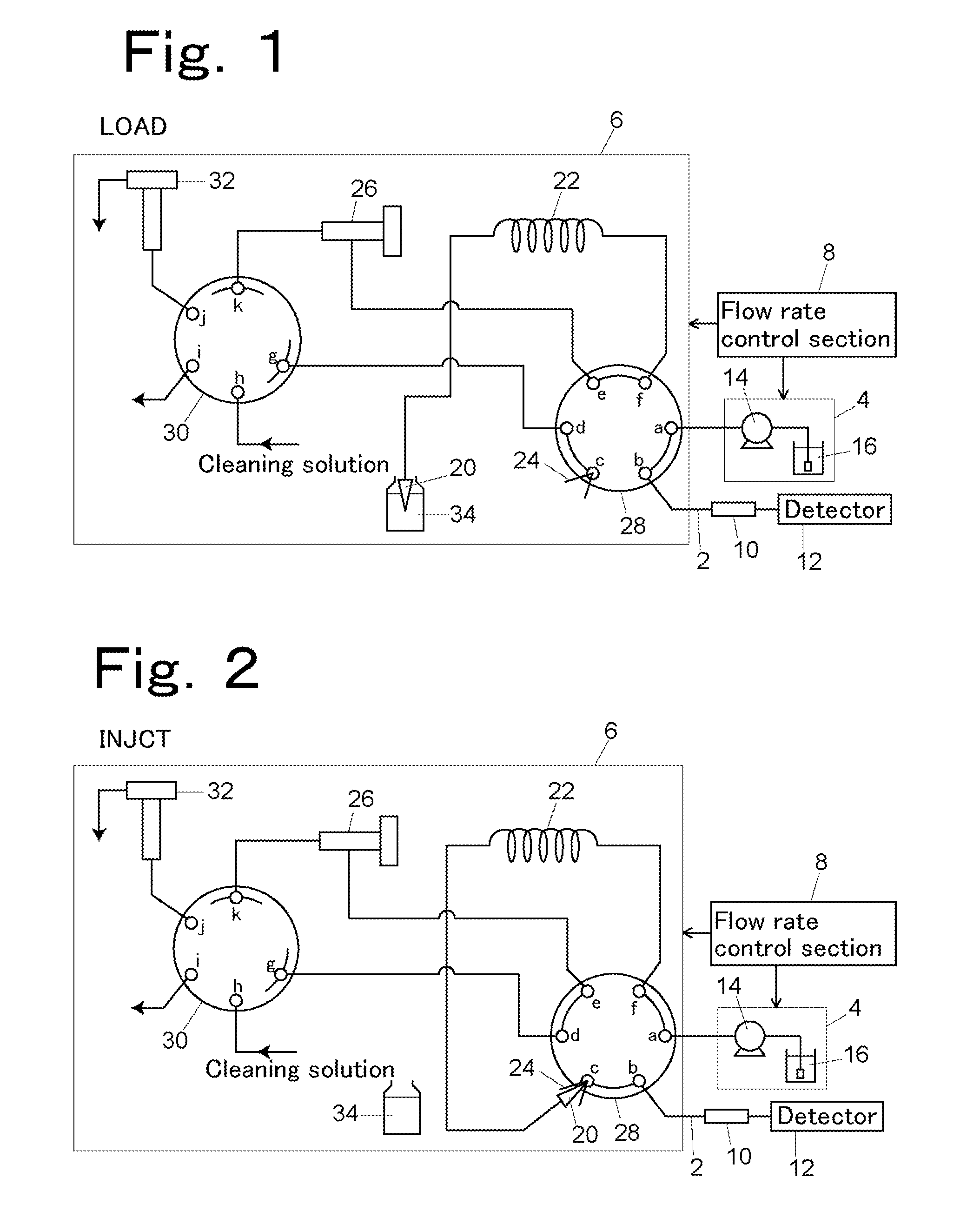

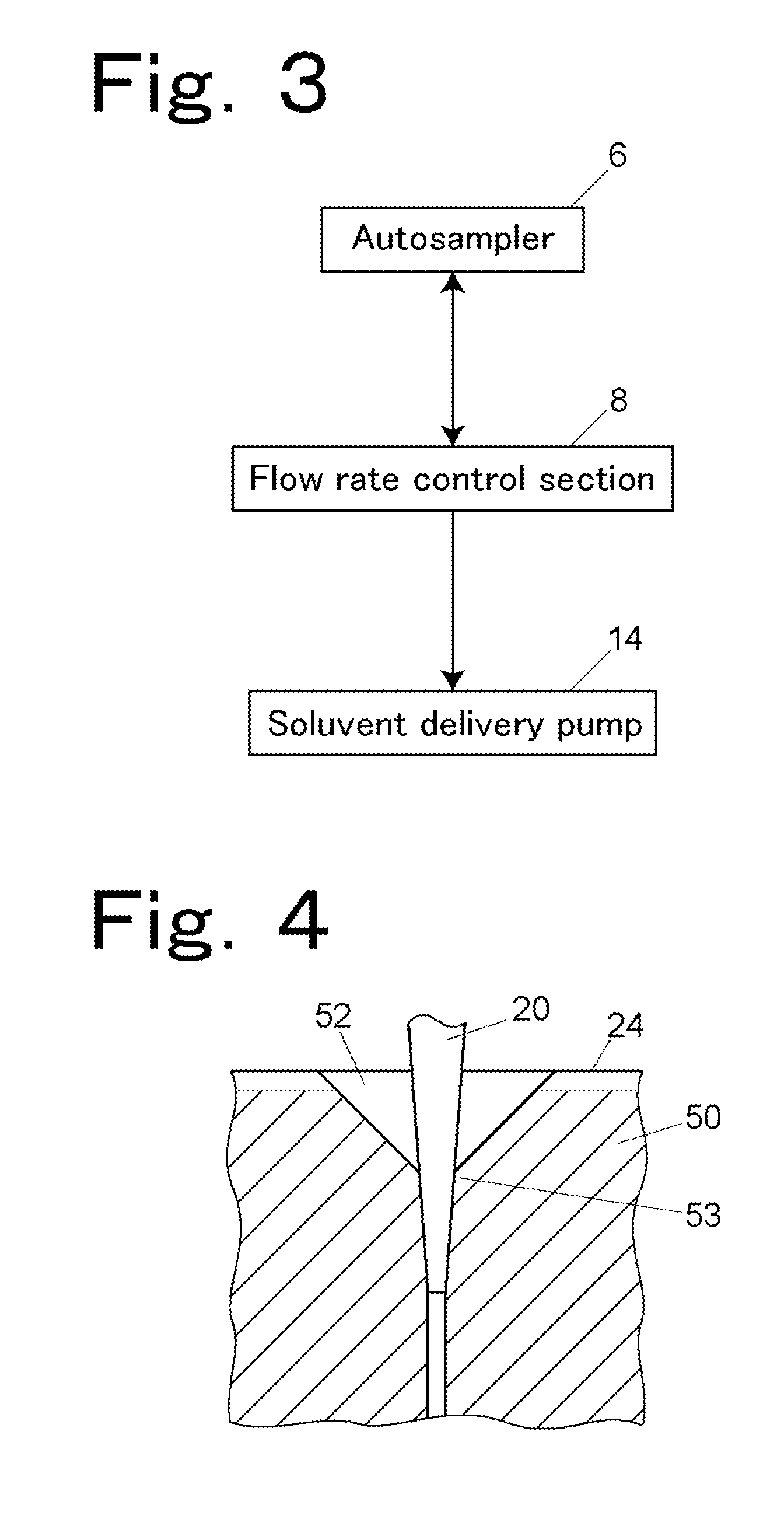

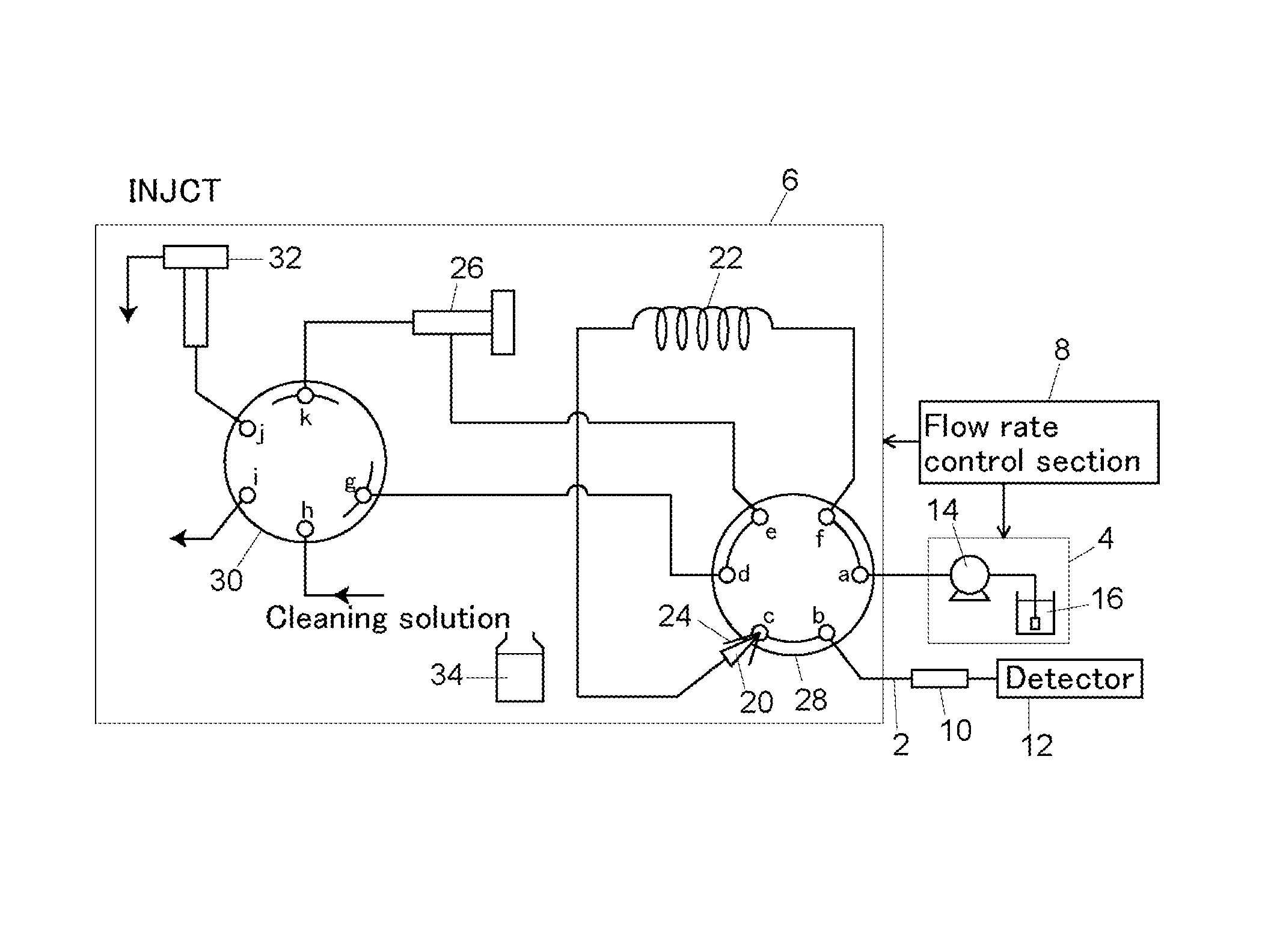

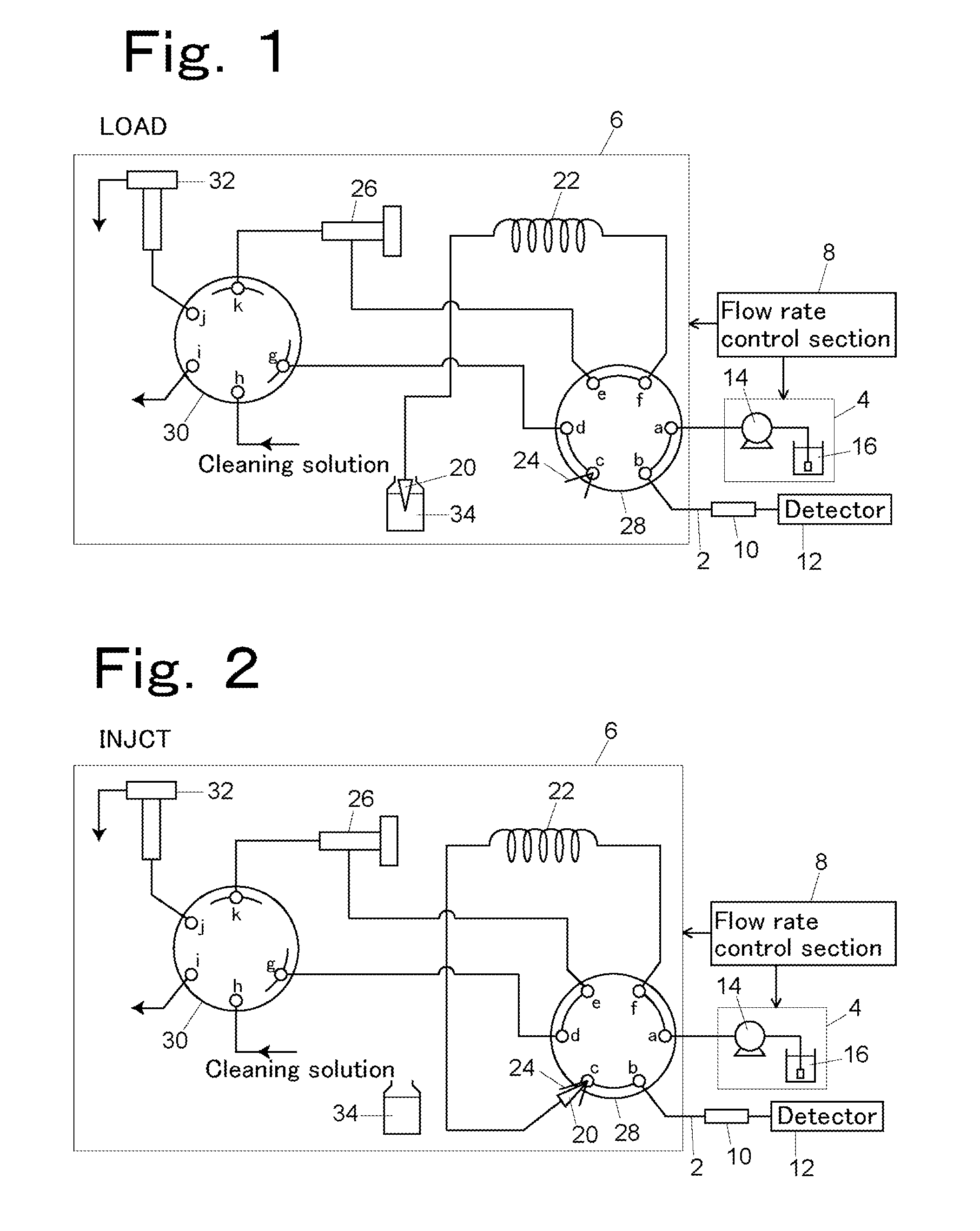

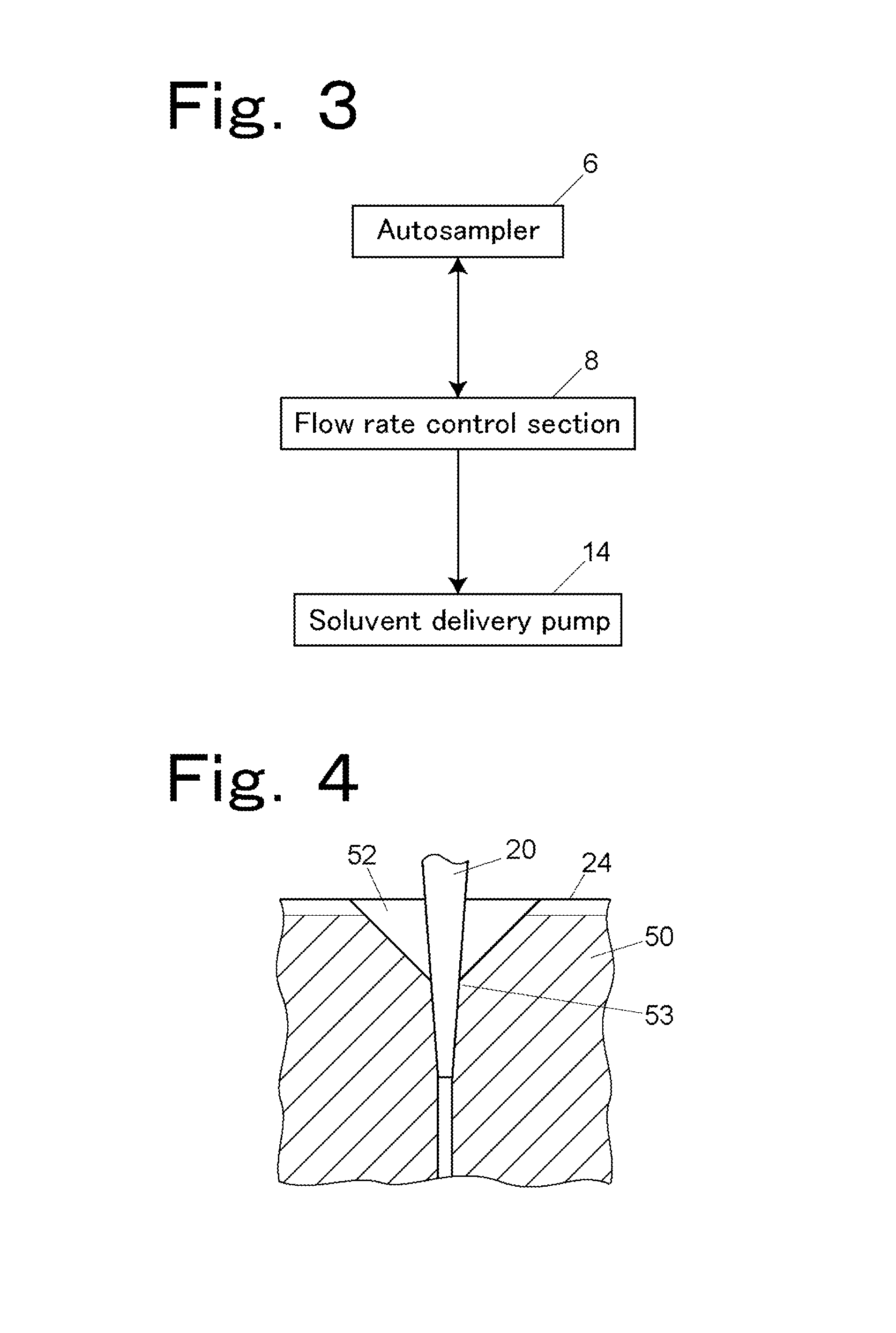

Liquid chromatograph

ActiveUS20120024048A1Reduce pressureReduce injectionComponent separationSurface/boundary effectInjections needleAutosampler

In injecting a sample sucked into a sample loop in an autosampler from an injection needle into an analytical flow path via an injection port by a mobile phase, a sending flow rate of the mobile phase is reduced from a certain flow rate determined in an analysis condition to reduce pressure applied on a joint section between the needle and the injection port to thereby reduce the sample remaining in the injection port.

Owner:SHIMADZU CORP

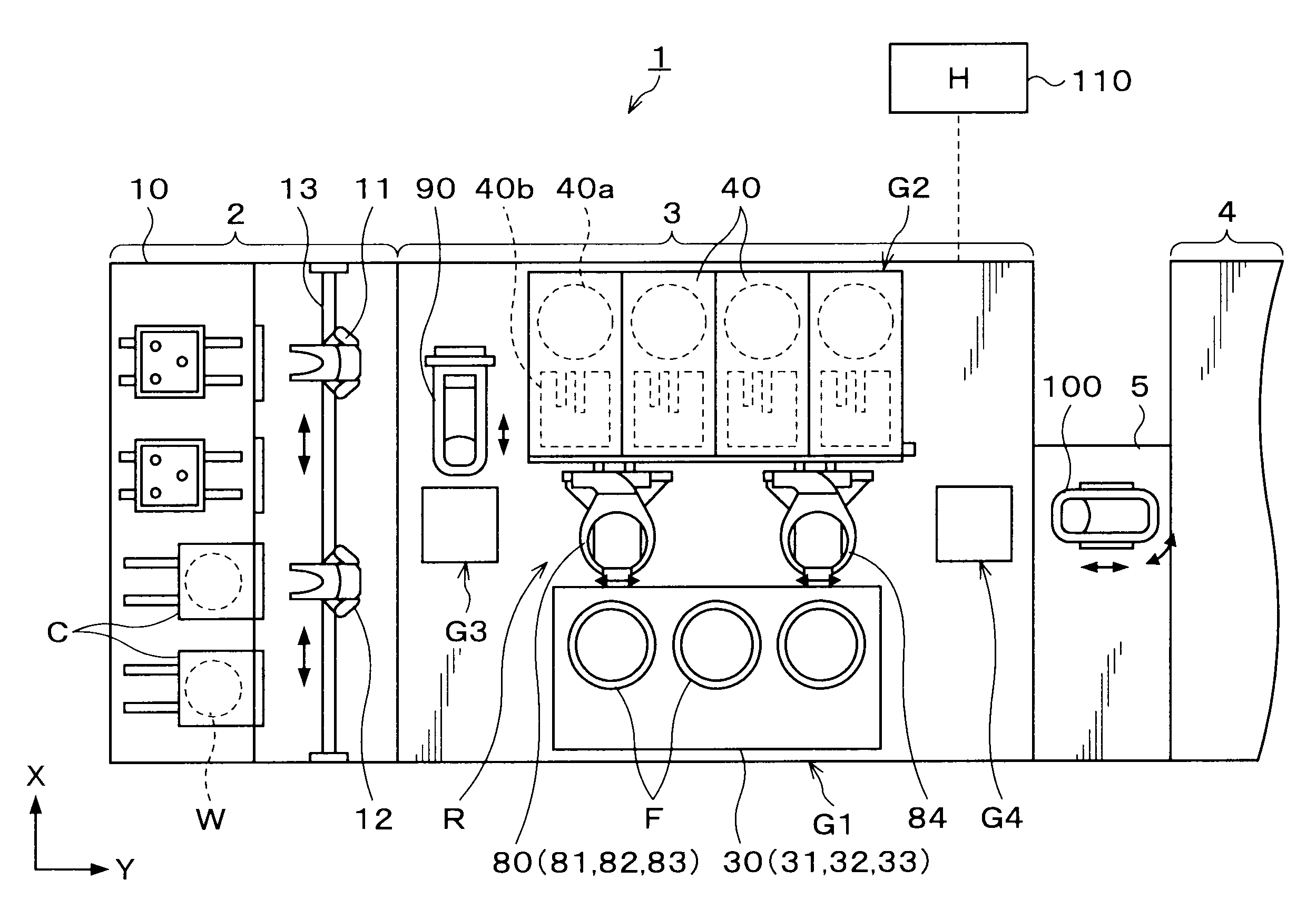

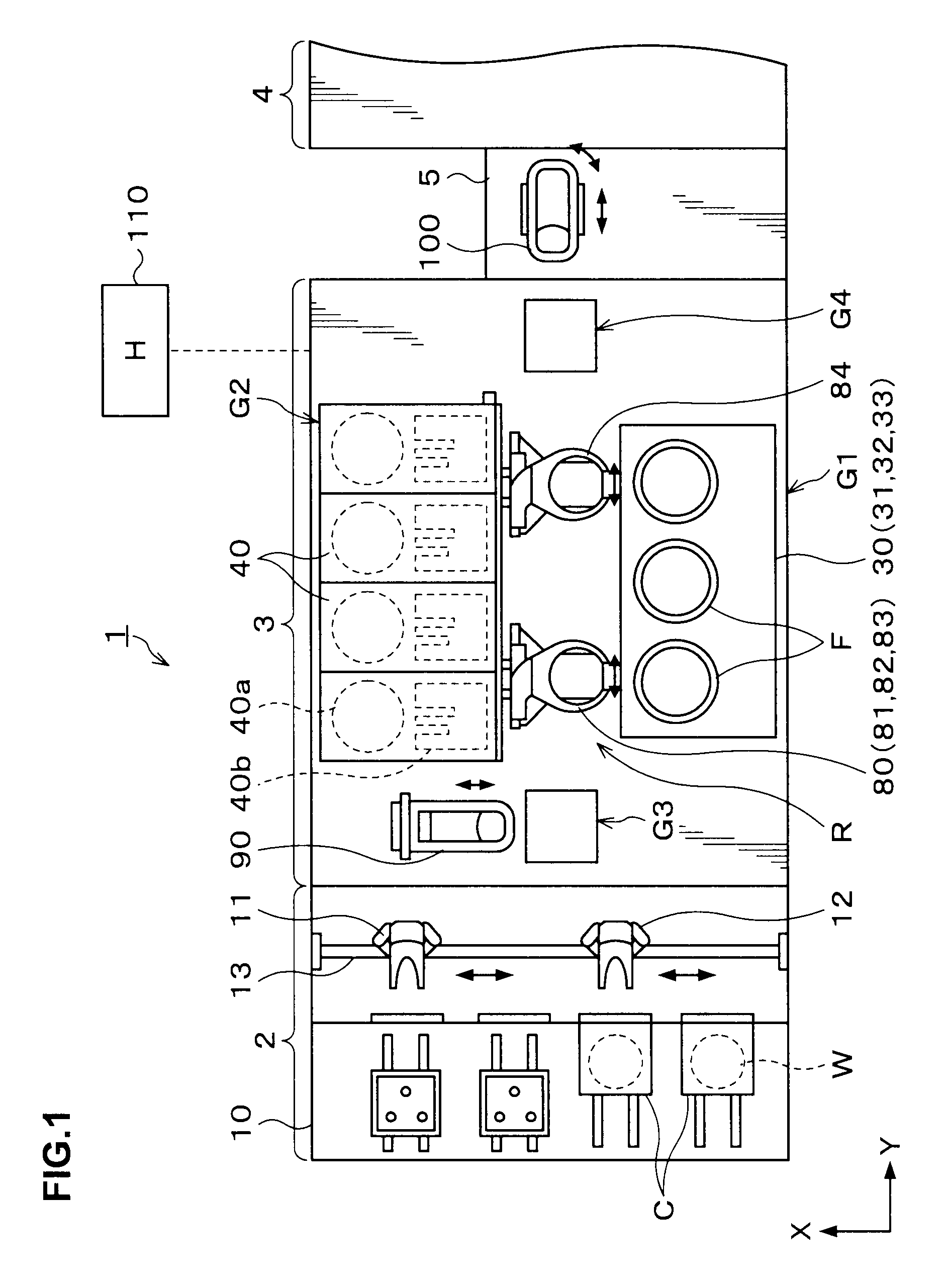

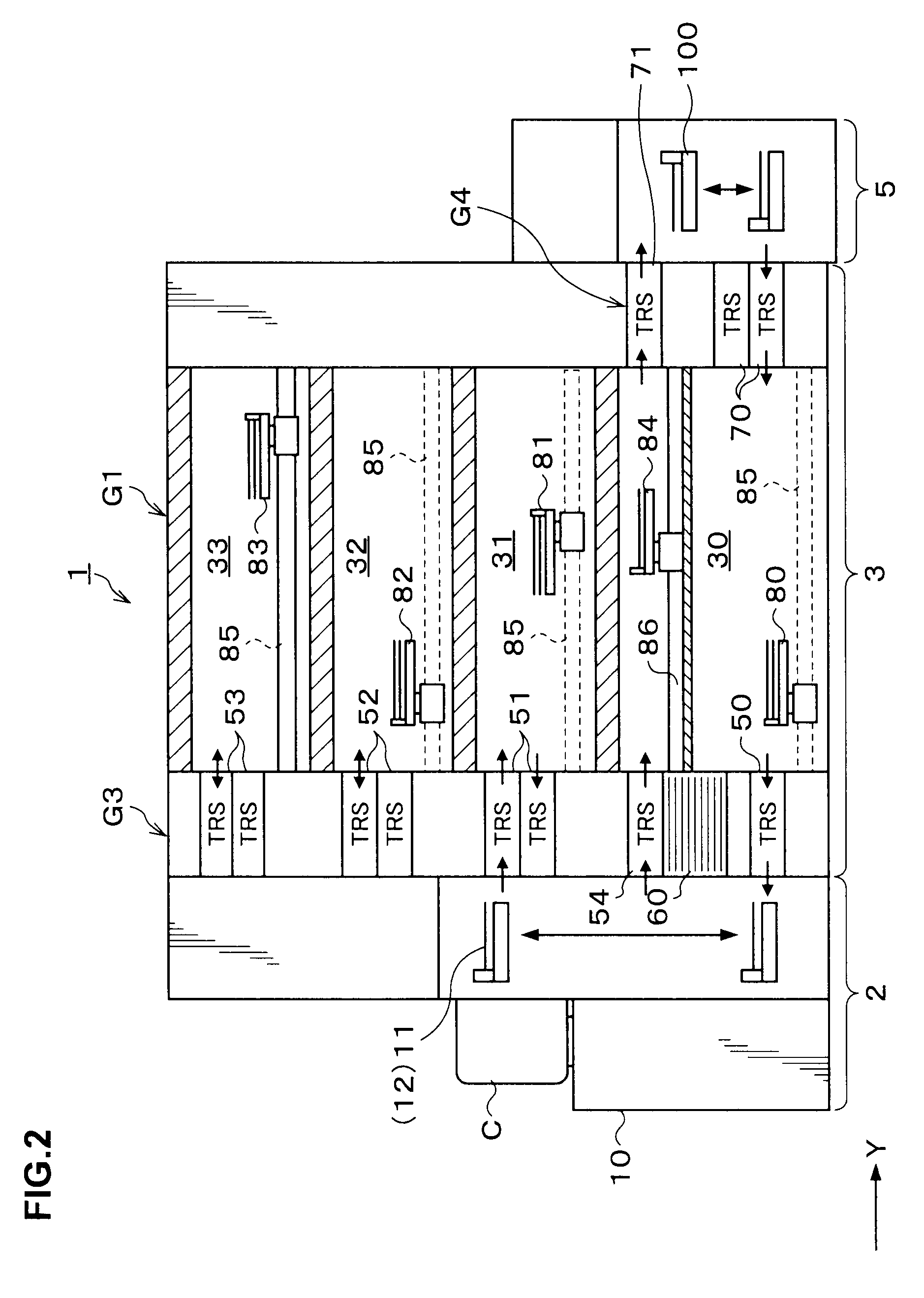

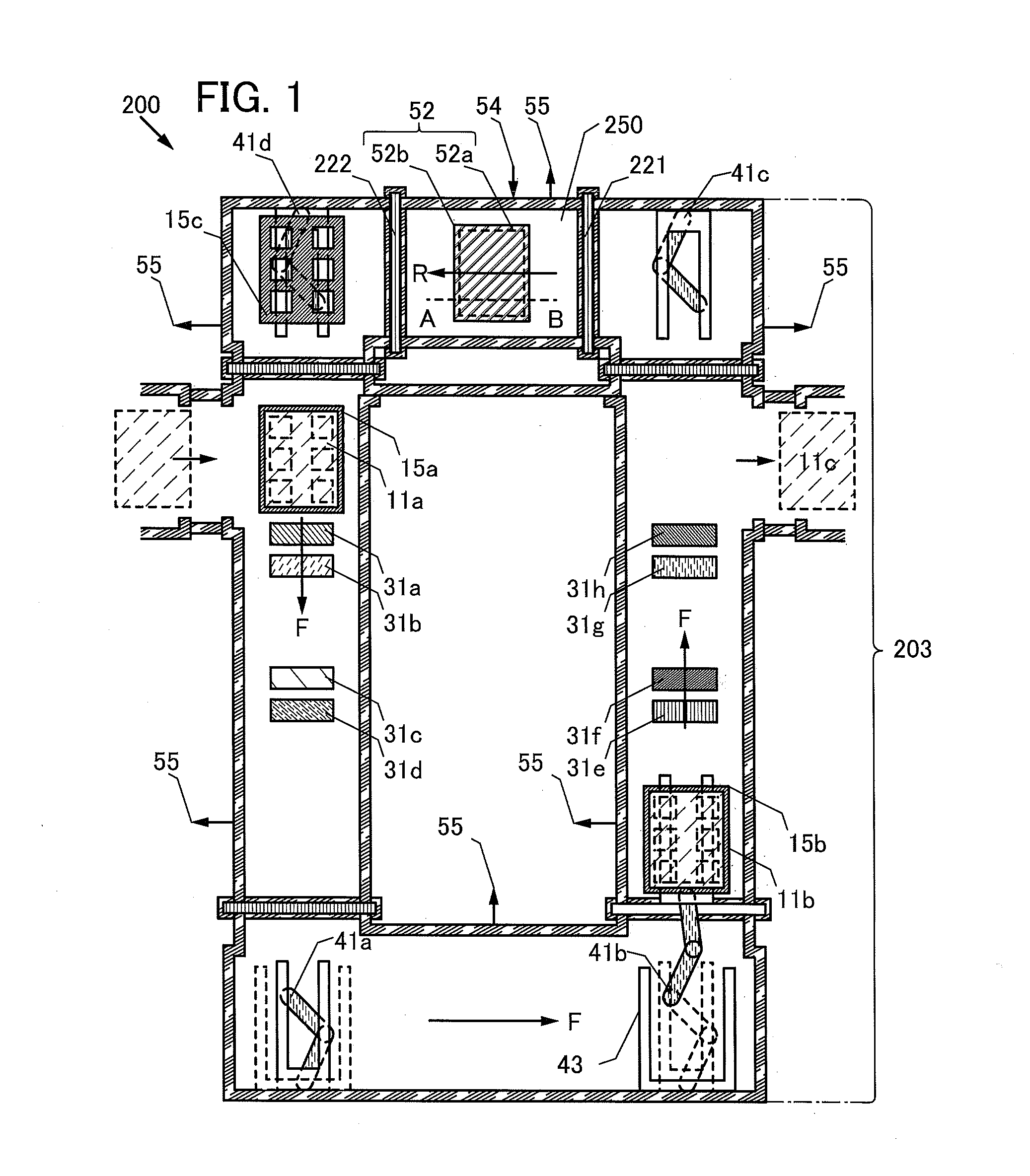

Substrate processing method, substrate processing system, and computer-readable storage medium

ActiveUS20080269937A1Increase productivityReduce operating rateSemiconductor/solid-state device manufacturingThin material handlingProduction rateComputer science

A substrate processing system of the present invention includes a transfer-in / out section for transferring-in / out a substrate and a processing section for performing a plurality of processing and treatments on the substrate, in which a throughput of substrate processing at a pre-stage performed from when the substrate is transferred in from the transfer-in / out section to when the substrate is transferred out to the external apparatus is set higher than a throughput of substrate processing at a post-stage performed from when the substrate is returned from the external apparatus into the processing section to when the substrate is returned into the transfer-in / out section.

Owner:TOKYO ELECTRON LTD

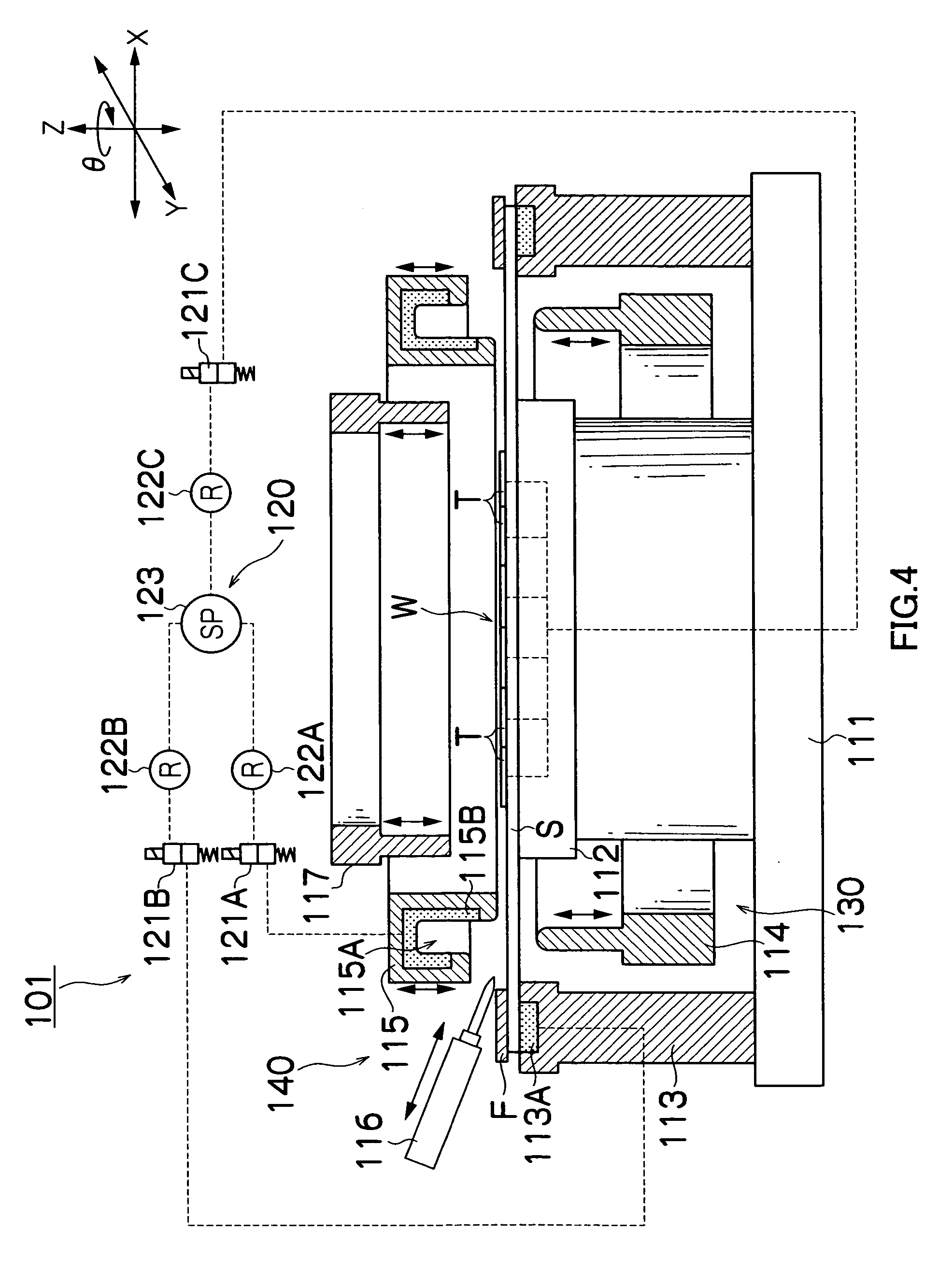

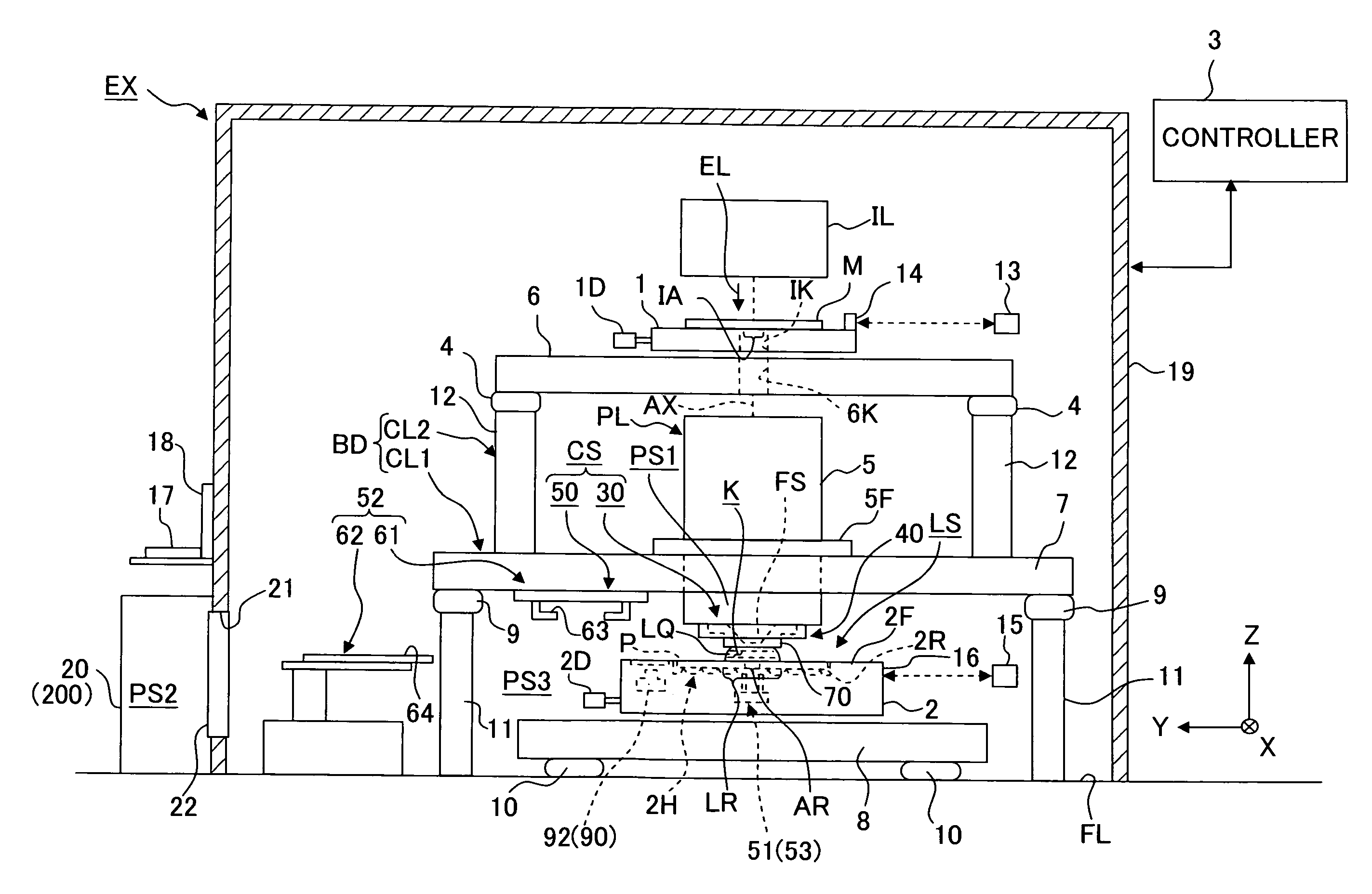

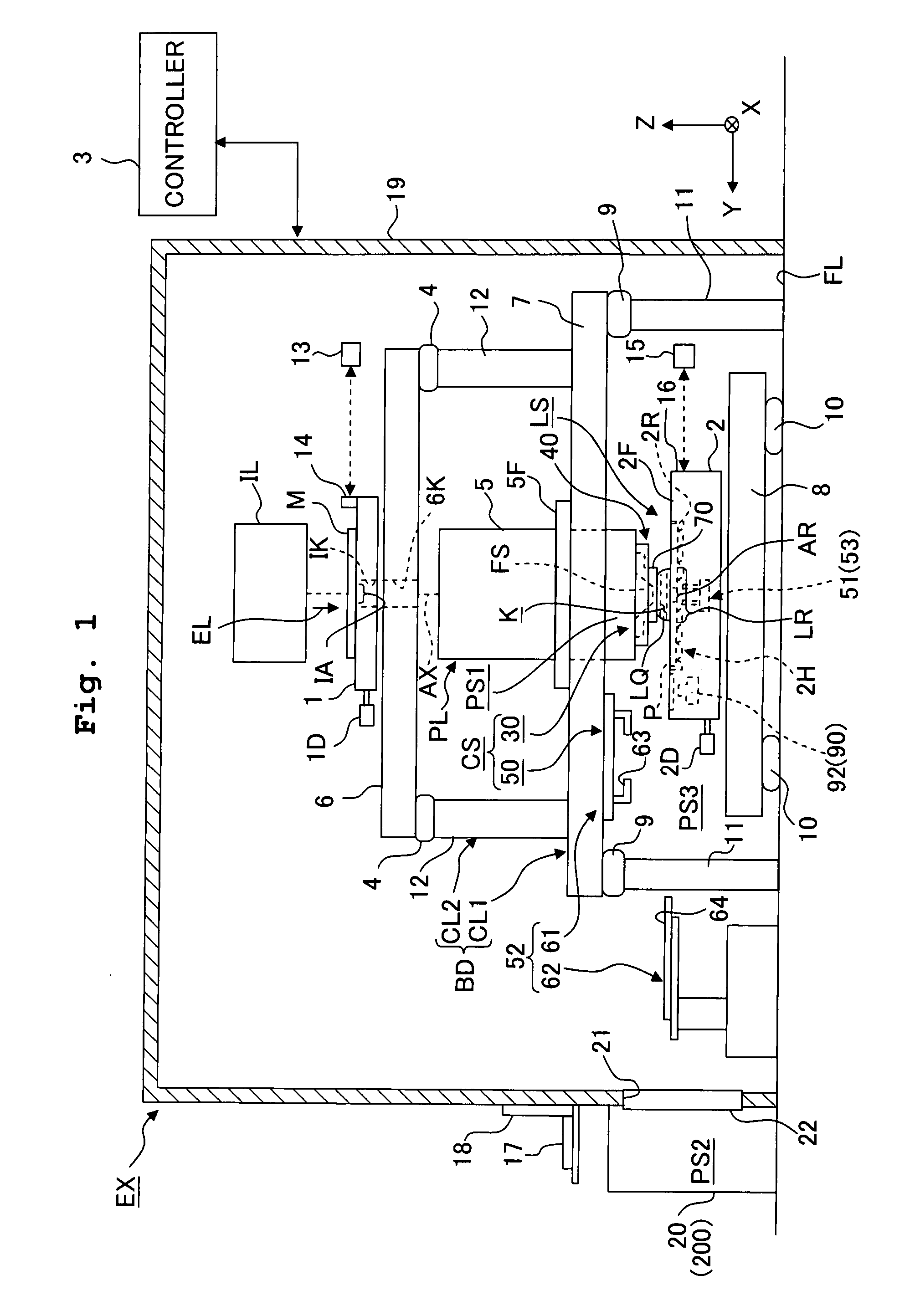

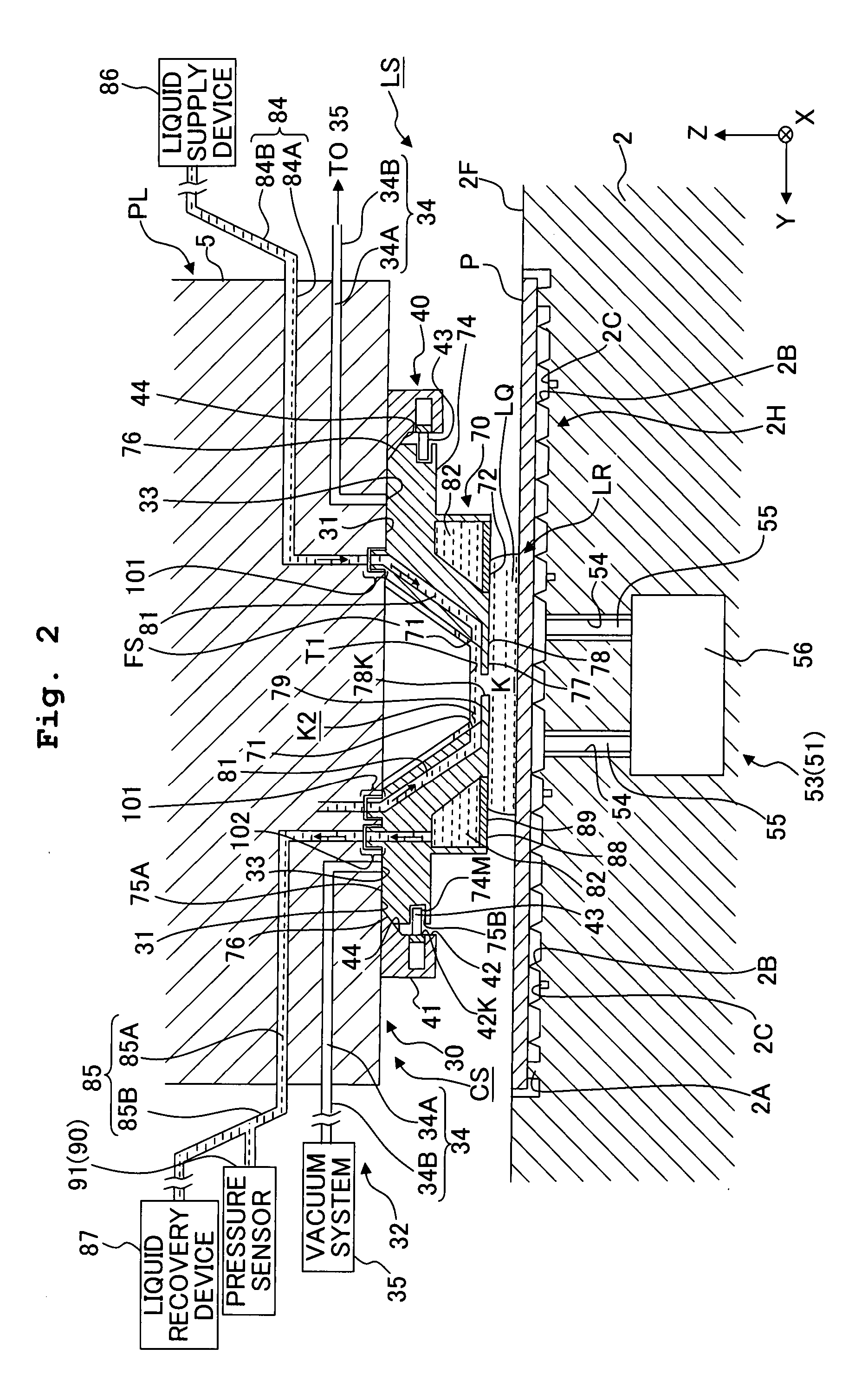

Exposure apparatus, maintenance method, exposure method, and method for producing device

ActiveUS20080013064A1Suppress of operation rateImprove productivityDiffusion transfer processesPhotomechanical apparatusBiomedical engineering

An exposure apparatus EX includes a liquid immersion system and an exchange system which performs exchange of the liquid immersion member. The exchange system has a holding device which holds the liquid immersion member detachably and a transport device. By using the exchange system, it is possible to suppress the lowering in the working rate due to the cleaning or exchange of the liquid immersion member.

Owner:NIKON CORP

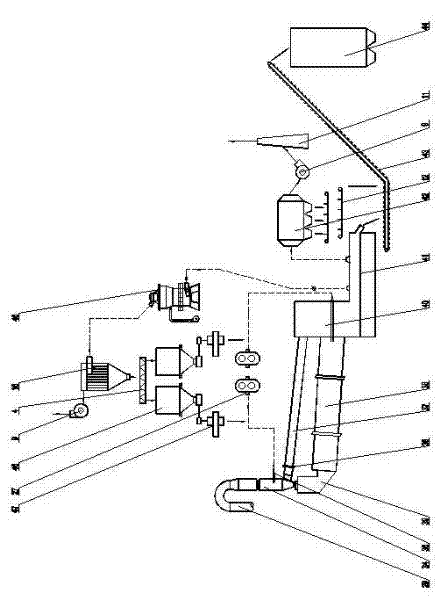

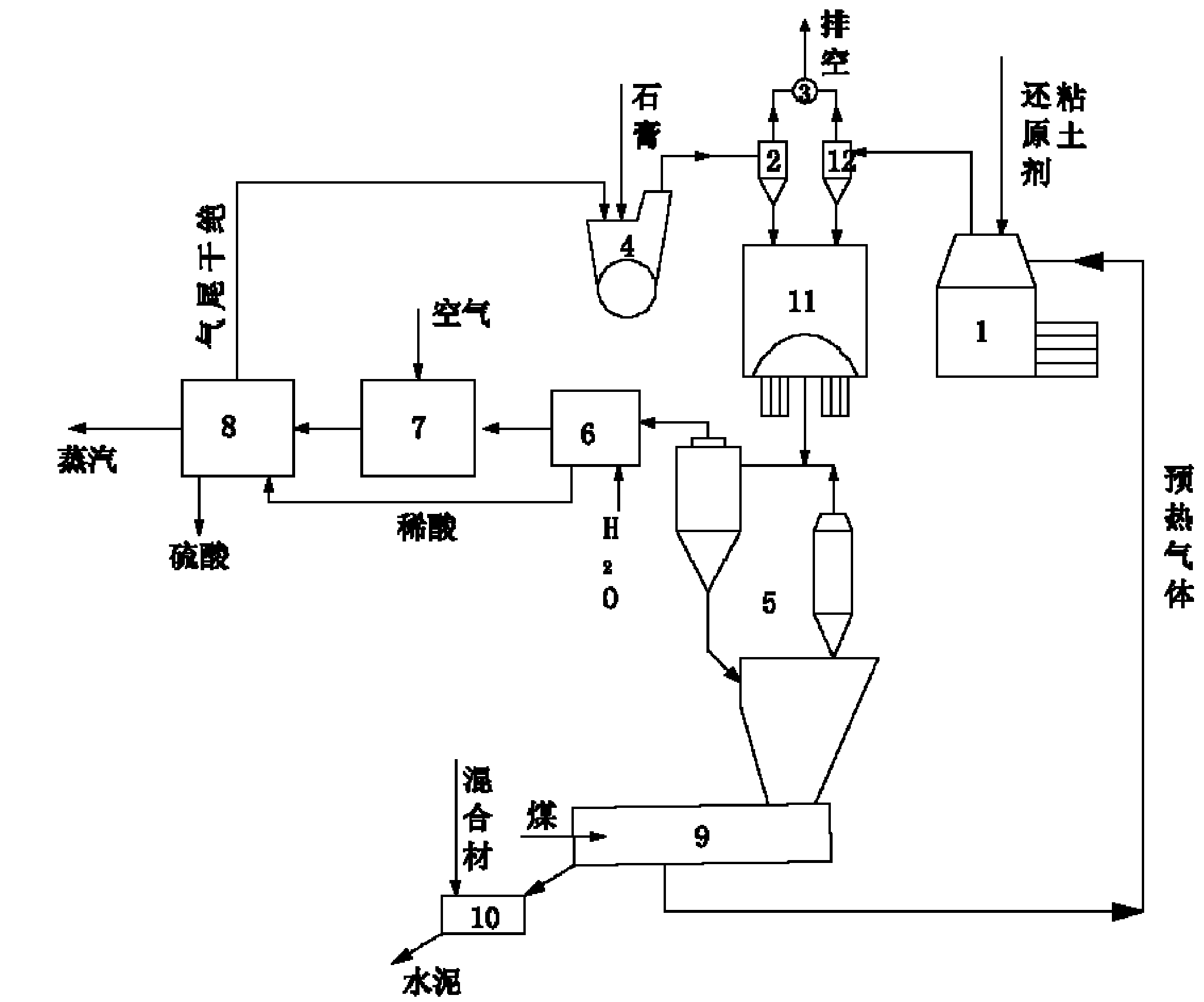

Method for preparing cement clinker from high-proportion carbide slag through decomposition outside kiln of five-stage preheater

The invention relates to a method for preparing cement clinker from high-proportion carbide slag through decomposition outside a kiln of a five-stage preheater. The method is finished by the steps of drying carbide slag, grinding raw materials, and sintering clinker. The step of the drying carbide slag simultaneously comprises the substeps of drying and removing impurities; the step of grinding the raw materials comprises the substeps of grinding, and discharging waste gas; and the step of sintering the clinker comprises the substeps of preheating outside the kiln, decomposing outside the kiln, calcining, and storing the clinker. By implementing the method, the problems of waste residue treatment in the conventional domestic industry for preparing industrial chemicals by an acetylene method are solved, the waste residues such as carbide slag, crushed limestone, limemud and the like can be utilized to the maximum extent, and the problems of environmental pollution caused by waste residue treatment are solved. The carbide slag with water content of less than or equal to 10 percent is directly dried by waste gas of a kiln tail; an additional heat source is saved; waste heat is utilized reasonably; through air separation of the carbide slag in a dryer, ferrosilicon is removed from the carbide slag, the problem that ferrosilicon blocks a grid plate in a mill is solved, the operation of a raw material mill is separated from the operation of a rotary kiln, the operation rate of the raw material mill is reduced, the raw material mill can adapt to various raw materials of carbide slag, and the capacity of the raw material mill is utilized to the maximum extent.

Owner:新疆凯盛建材设计研究院(有限公司)

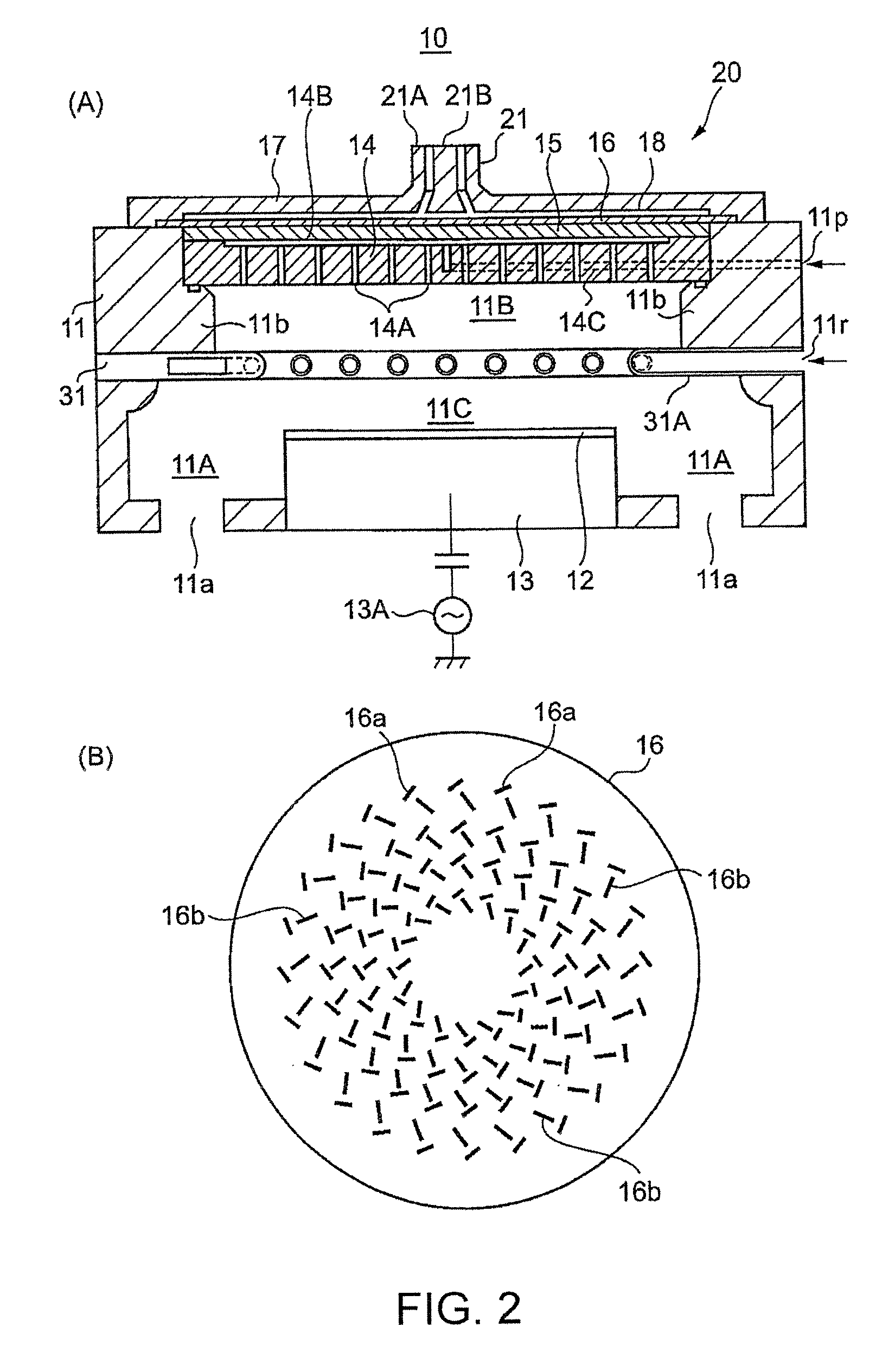

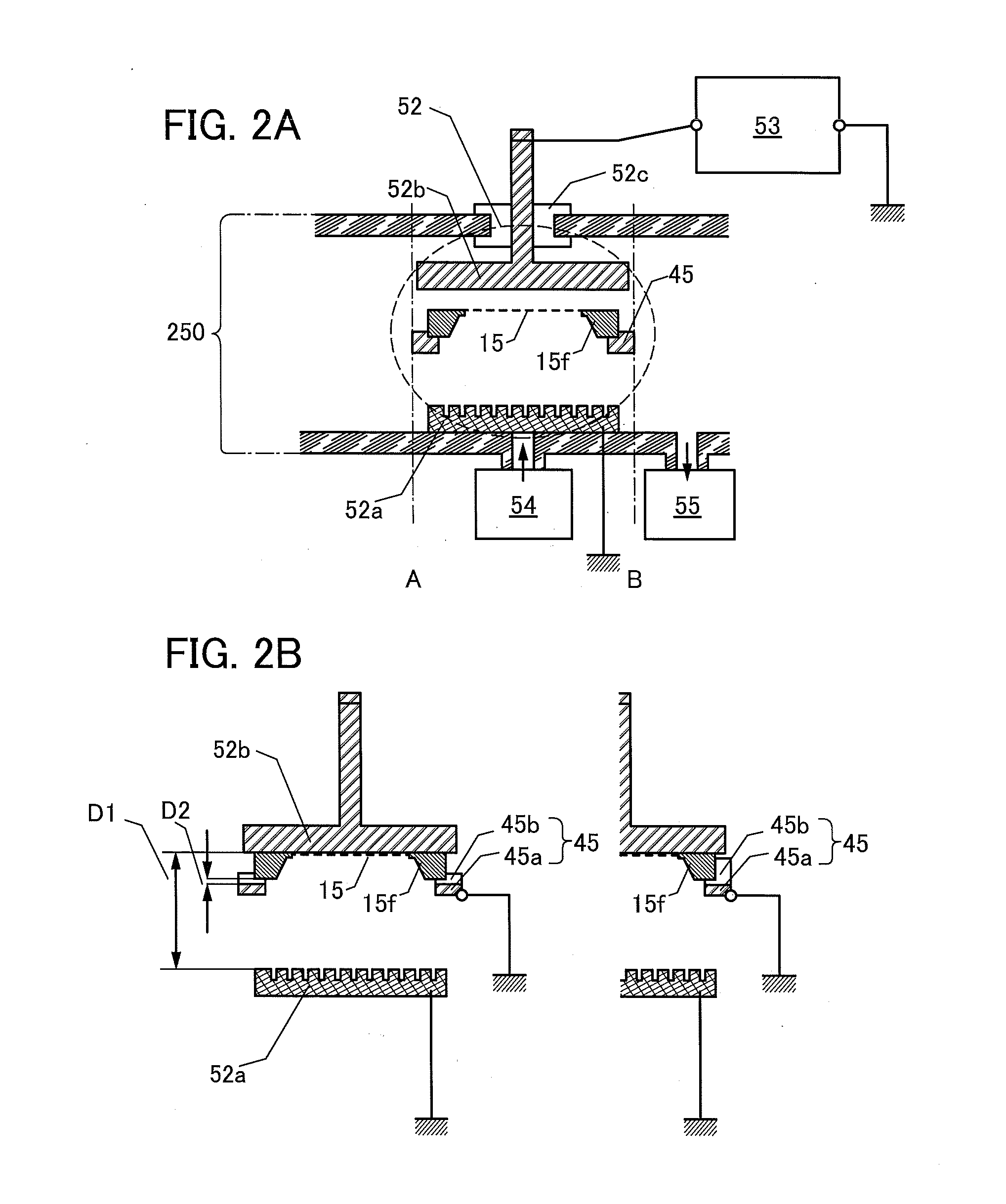

Film Formation Apparatus, Method for Forming Film, Method for Forming Multilayer Film or Light-Emitting Element, and Method for Cleaning Shadow Mask

InactiveUS20130302937A1Reduce operating rateIncrease the number ofElectric discharge tubesSolid-state devicesParallel plateEvaporation

The inventors have reached the idea of a film formation apparatus including a film formation chamber, a removal chamber, two sluice valves provided apart from each other between the film formation chamber and the removal chamber, and a shadow mask transfer mechanism. The film formation chamber includes an evaporation source, and the removal chamber includes a parallel plate plasma source and a shadow mask stage. The film formation apparatus has a film formation mode in which a shadow mask overlapped with an object is transferred by the shadow mask transfer mechanism and a film is formed on the object; and a cleaning mode in which the shadow mask is irradiated with plasma by the plasma source, the shadow mask being held between an upper electrode and a lower electrode by the shadow mask stage.

Owner:SEMICON ENERGY LAB CO LTD

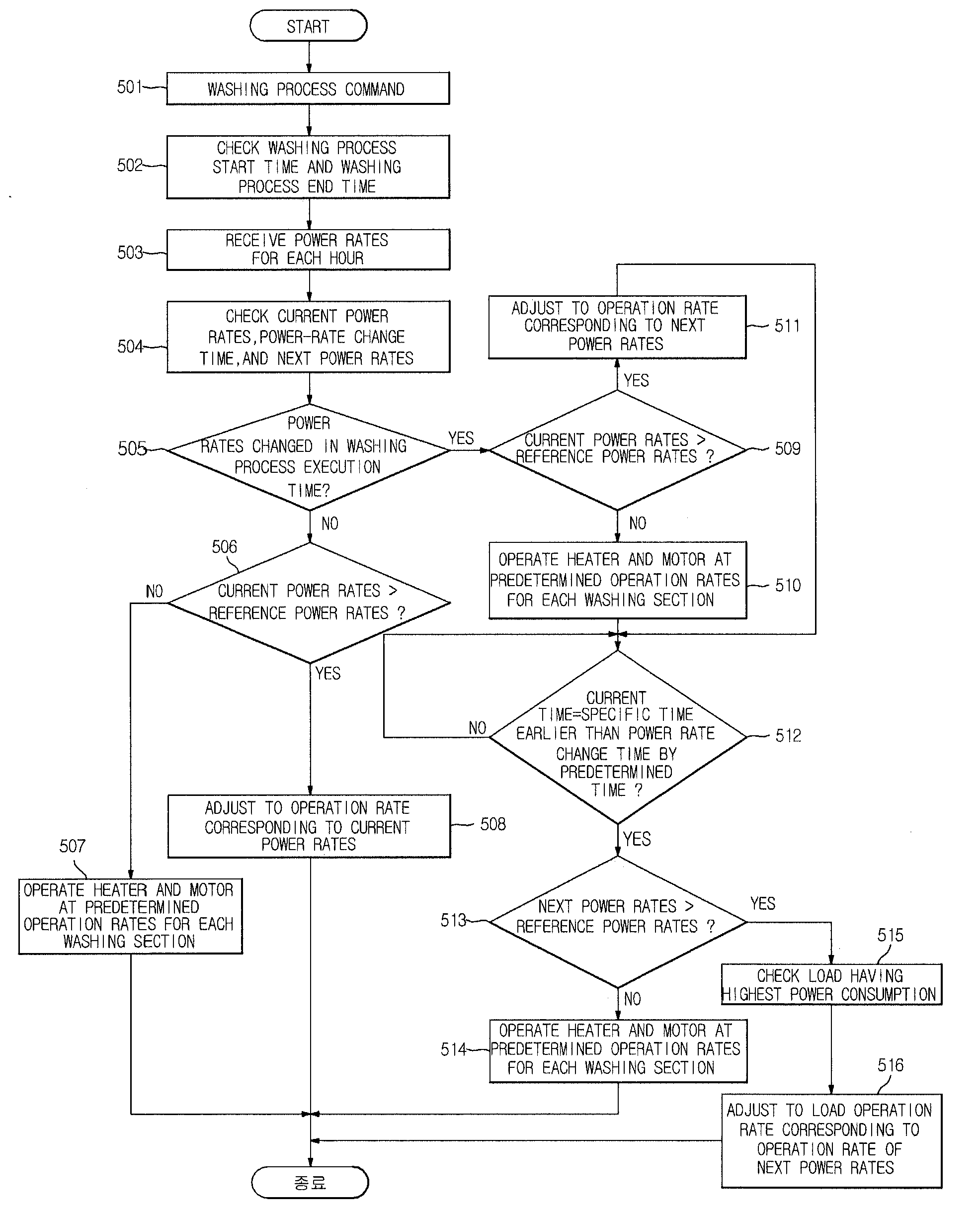

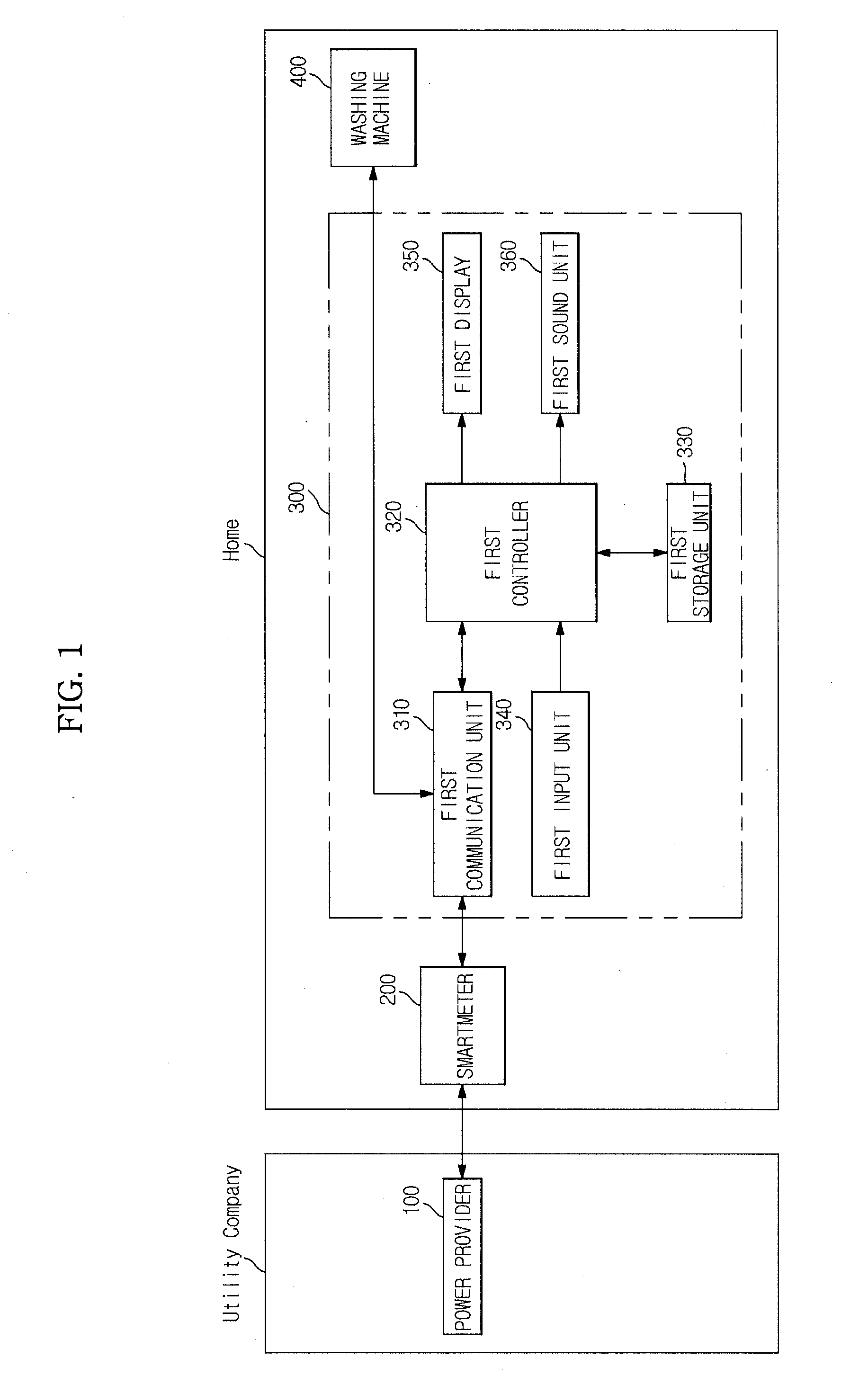

Washing machine and method of controlling the same

InactiveUS20120193985A1Reduce dehydration speedOperation rate be reduceOther washing machinesControl devices for washing apparatusElectricity priceProcess engineering

A washing machine and a method of controlling the same include a motor to rotate a rotary tub including laundry, a heater to heat water contained in the rotary tub, a communication unit to receive an energy saving signal having information regarding an energy saving start time from an energy management system (EMS), and a controller, upon receiving the energy saving signal, to determine which one of the motor and the heater is a load having highest power consumption in a process to be executed at the energy saving start time, and reduce the operation rate of the determined load. Before current power rates exceed reference power rates, the load operation rate of the washing machine is changed so that power consumption is greatly reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

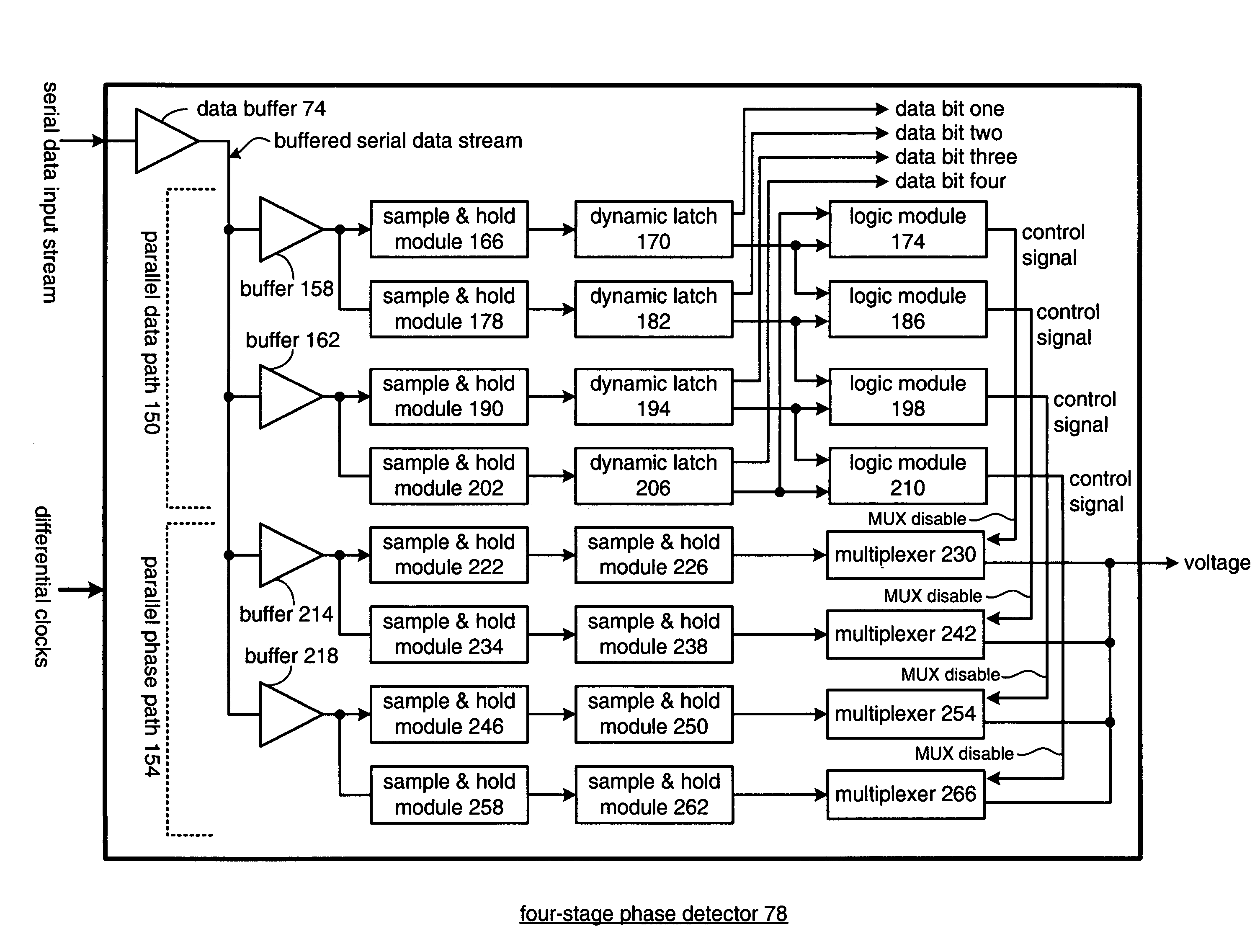

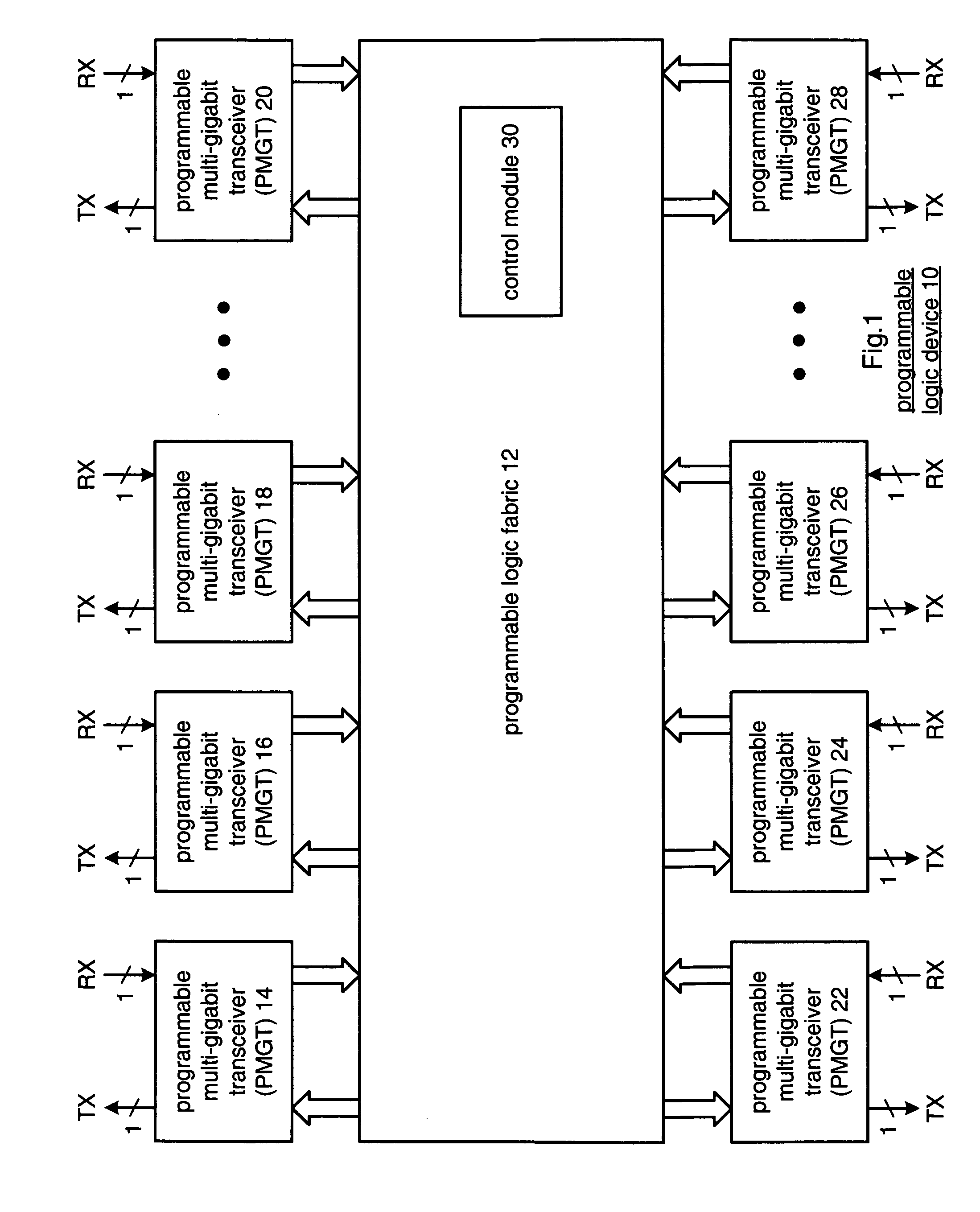

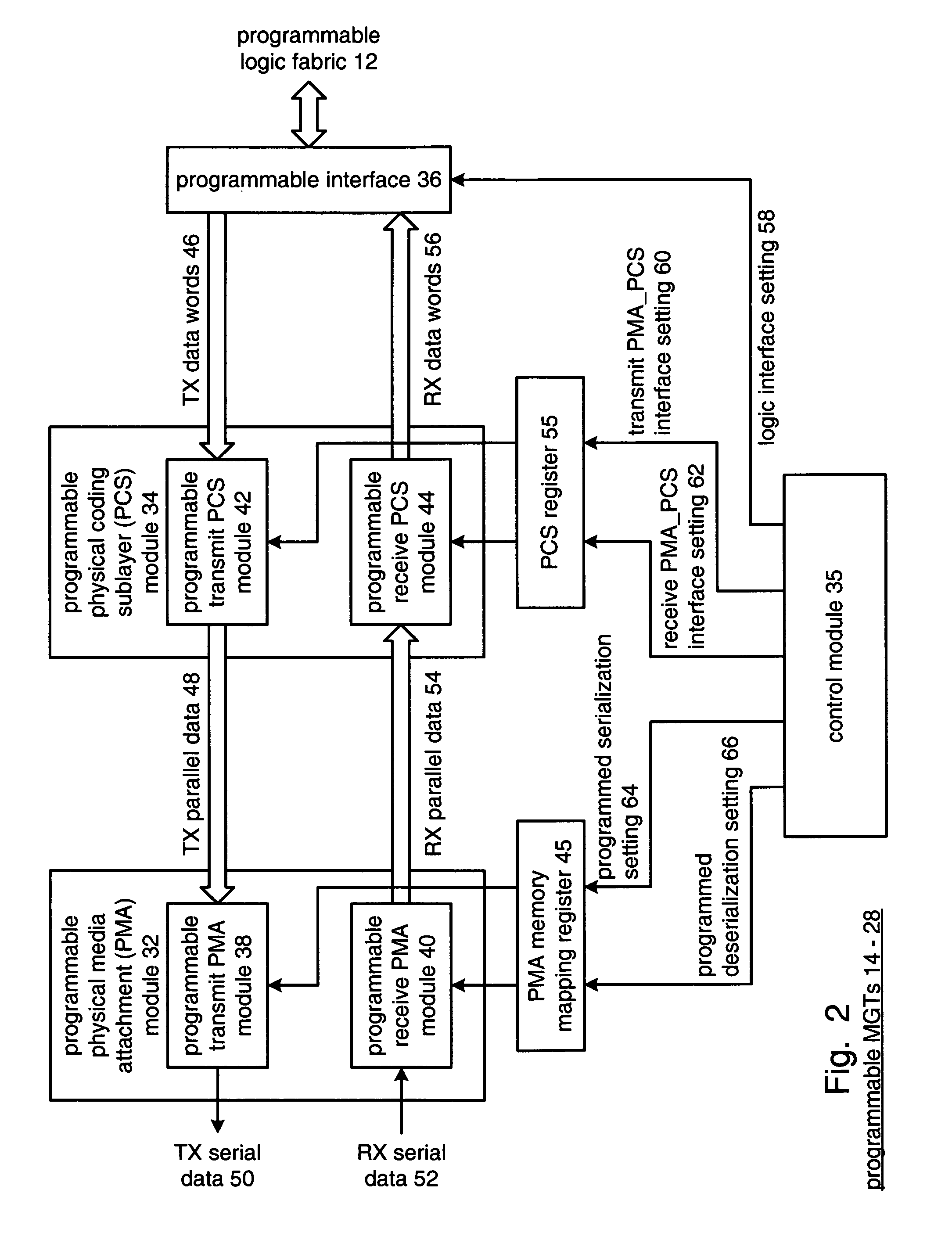

Multi-stage phase detector

ActiveUS7466787B1Reduce operating rateReduce loadPulse automatic controlOscillations comparator circuitsPhase detectorControl signal

A multi-stage phase detector (four stages in one described embodiment) comprises a plurality of data paths and phase paths that are buffered from a received serial data input stream to reduce loading. Each data path recovers a data bit and further functions as a transition detector to detect consecutive data bits having similar logic states. An exclusive NOR gate in the data path produces a control signal to disable a multiplexer in the phase path when two data bits have similar logic states. Each phase path produces a sample of a serial data input stream and produces the sample to a multiplexer for coupling to a transconductance module. The multiplexer output is coupled to or decoupled from the transconductance module by the control signal from the data path to maintain phase-lock.

Owner:XILINX INC

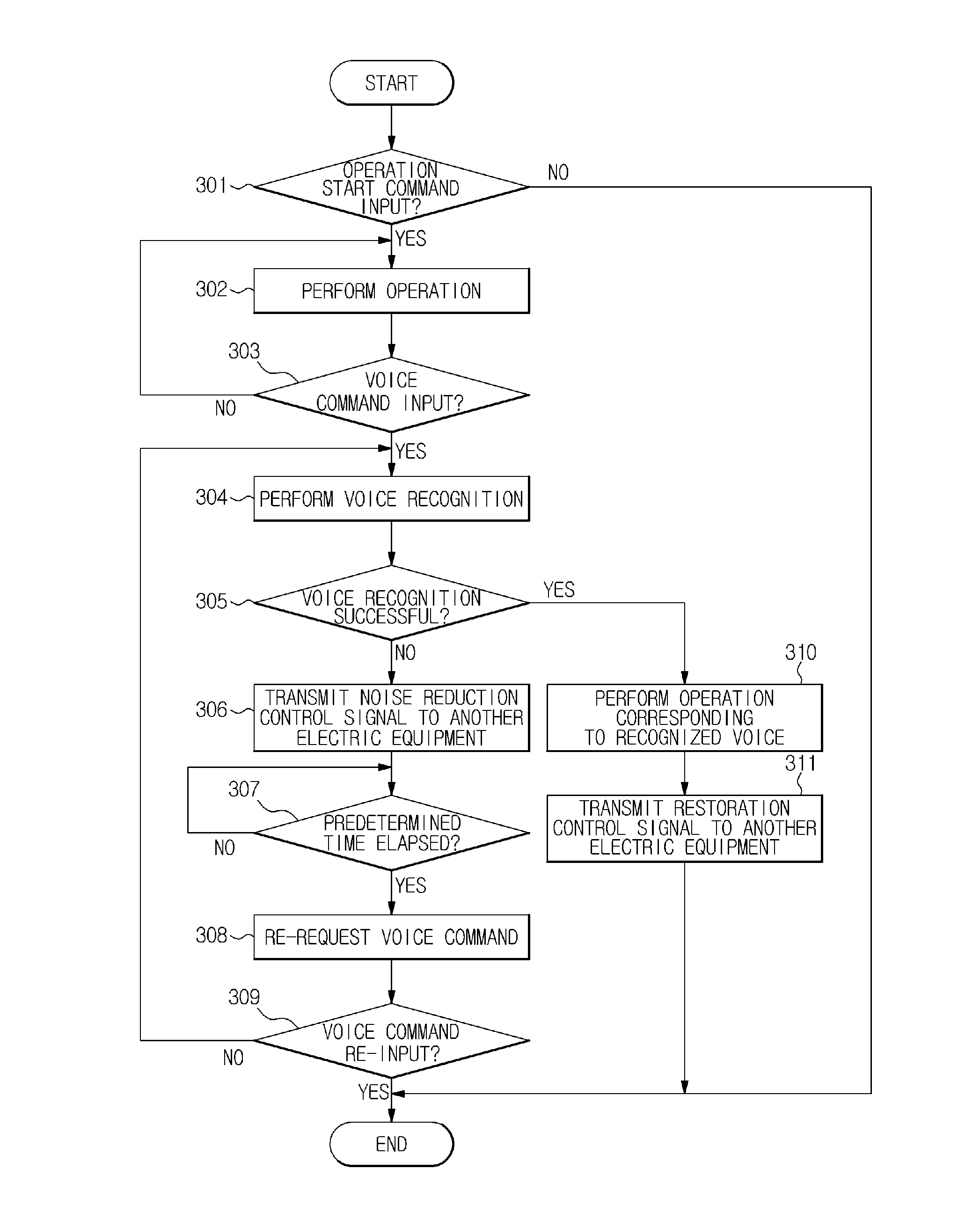

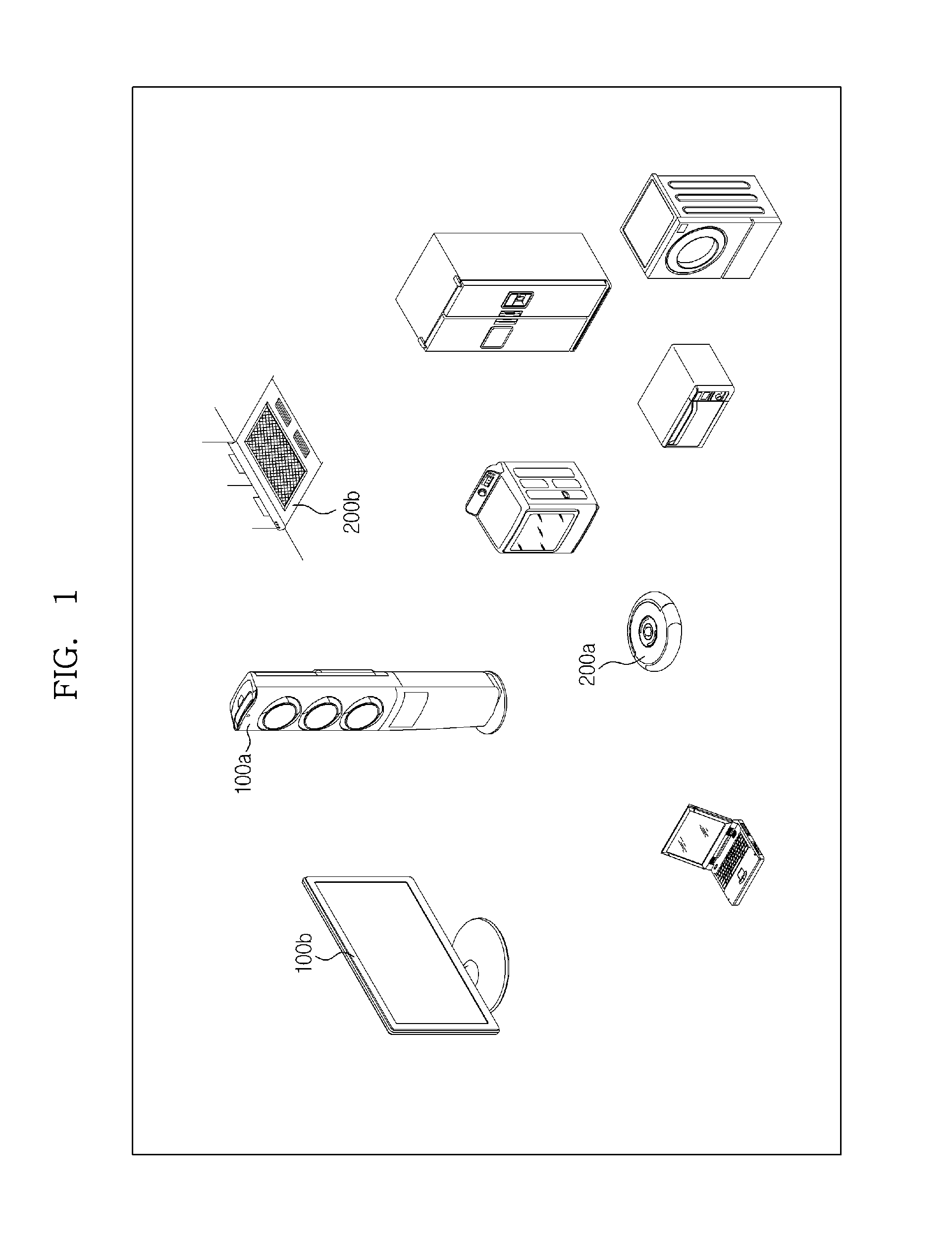

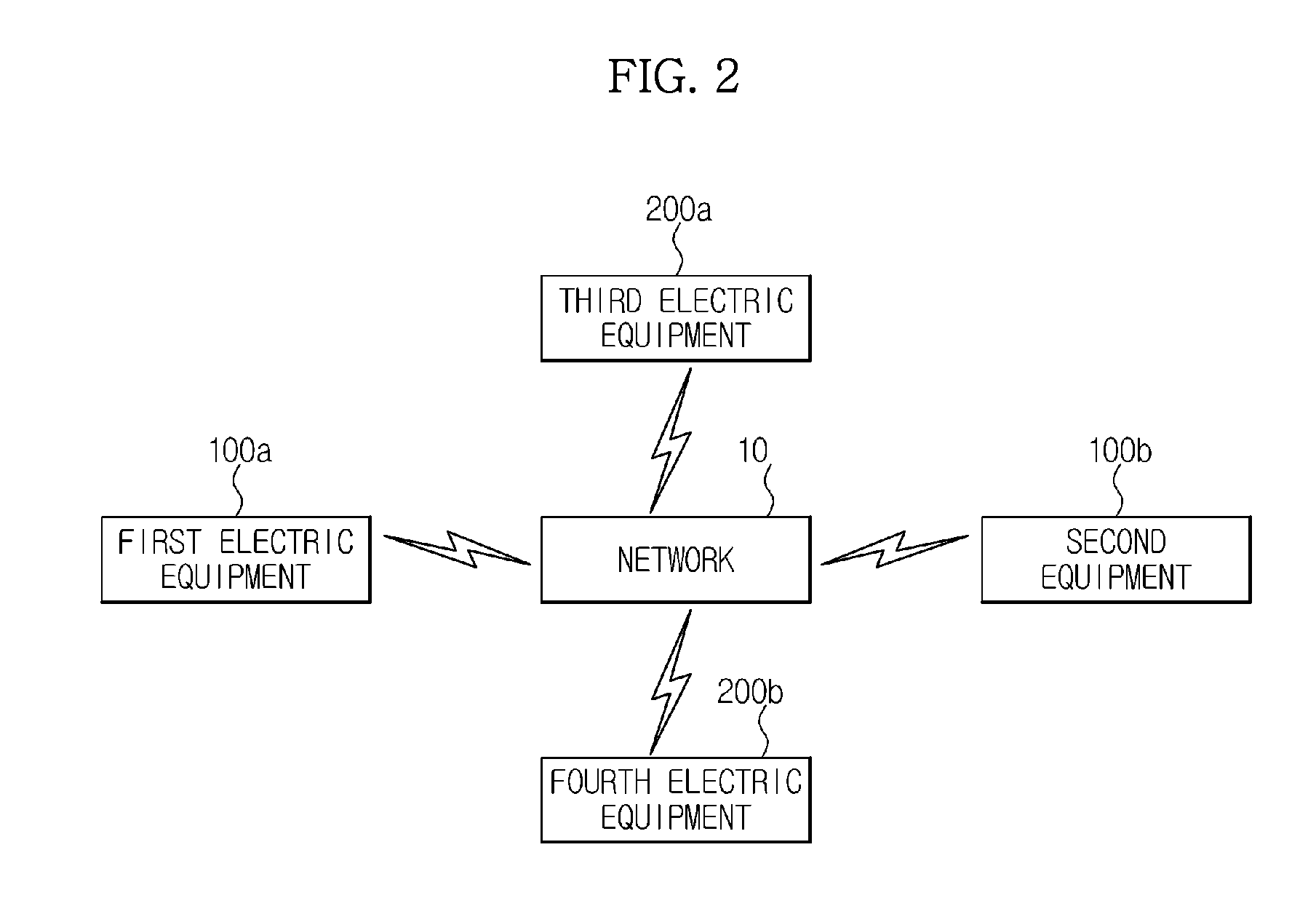

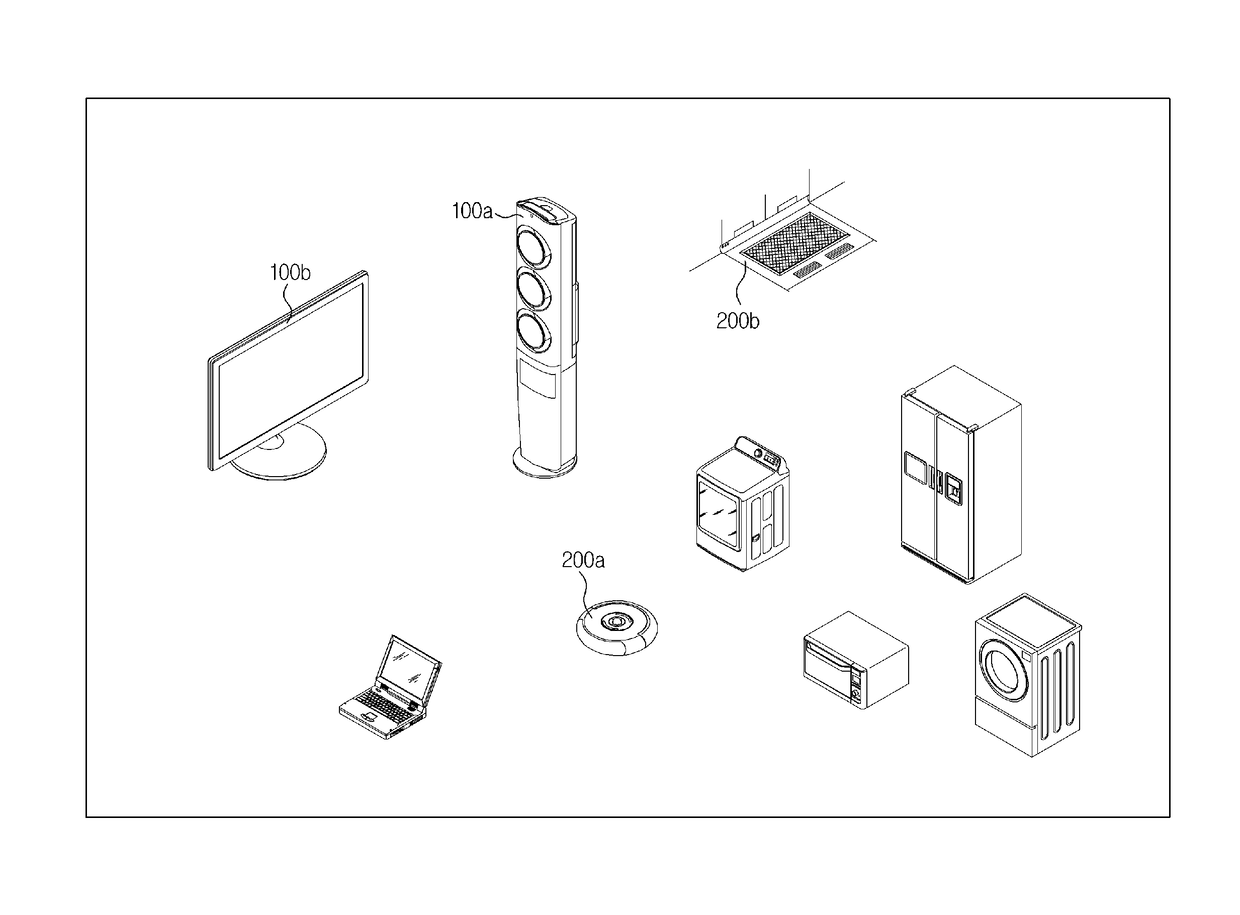

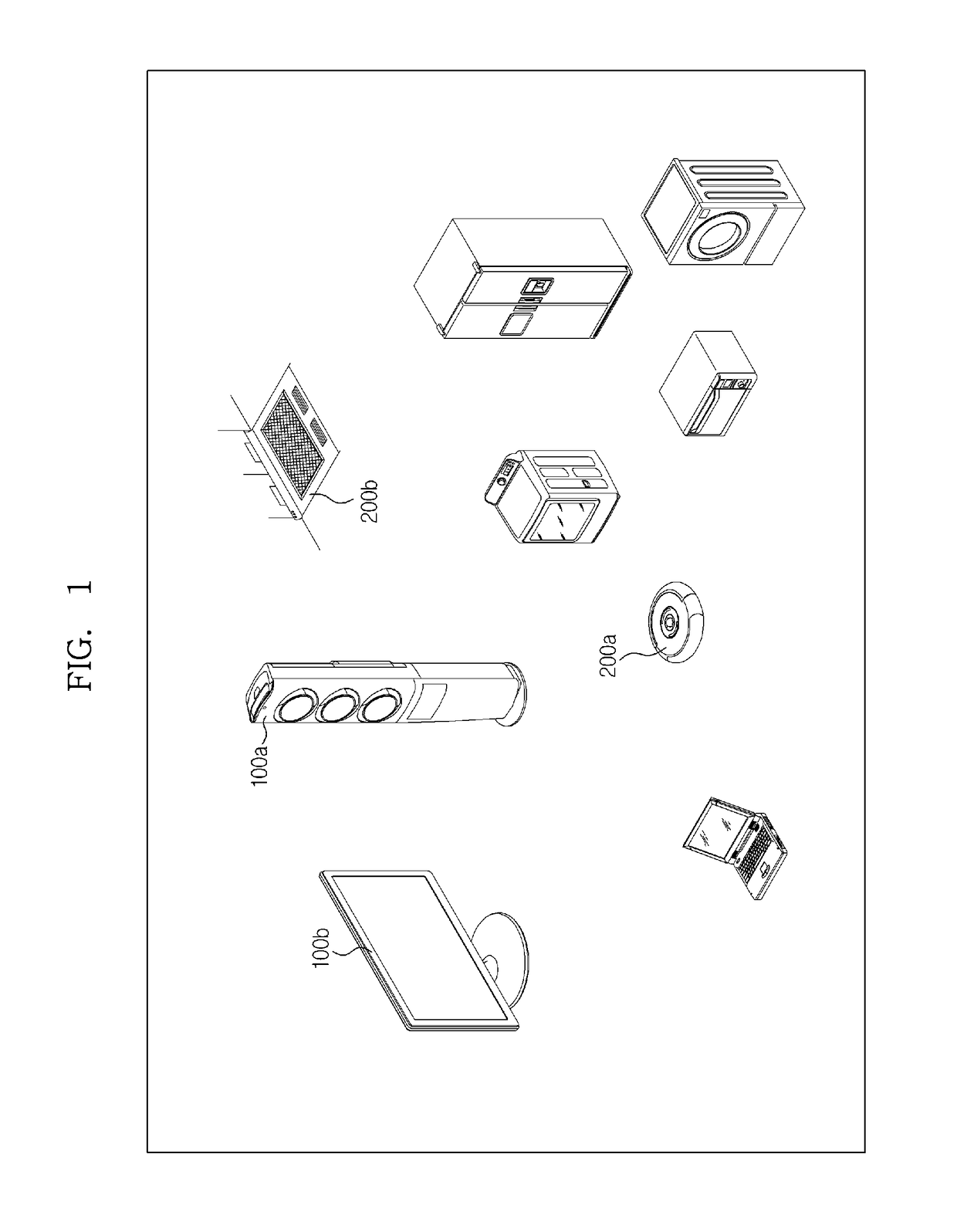

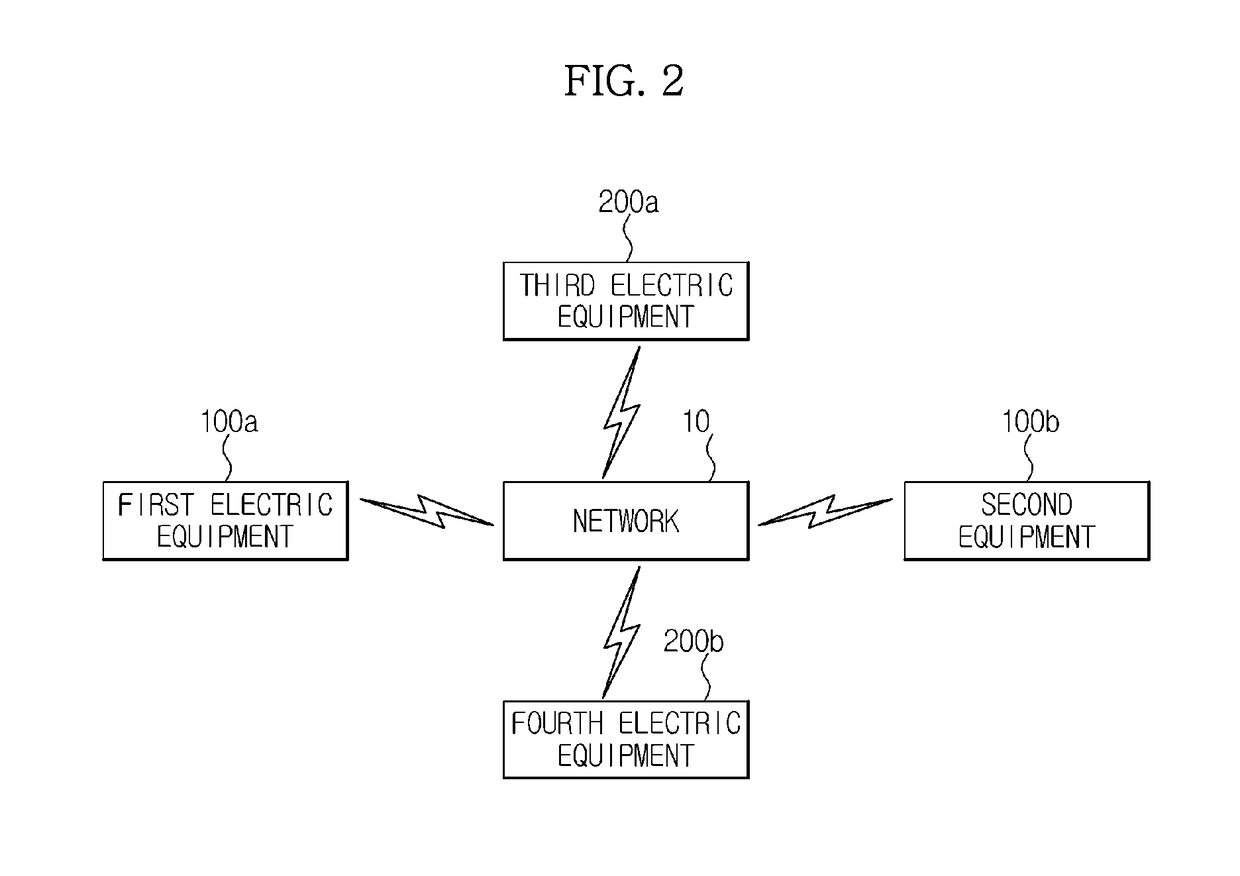

Electric equipment and control method thereof

ActiveUS20150019215A1Reduce noiseReduce operating rateSound input/outputSpeech recognitionCommunication unitControl signal

An electric equipment including a communication unit to communicate with at least one electric equipment in a predetermined space through a network, a sound collection unit to collect sound in the predetermined space, a voice recognition unit to recognize a voice from the collected sound, and a controller to transmit a noise reduction control signal to the at least one electric equipment when the recognized voice is an operation command. Voice recognition is performed in a state in which surrounding noise is reduced, thereby improving performance of the voice recognition and thus improving operational accuracy of an electric equipment. In addition, a voice recognition rate is increased, thereby improving user satisfaction.

Owner:SAMSUNG ELECTRONICS CO LTD

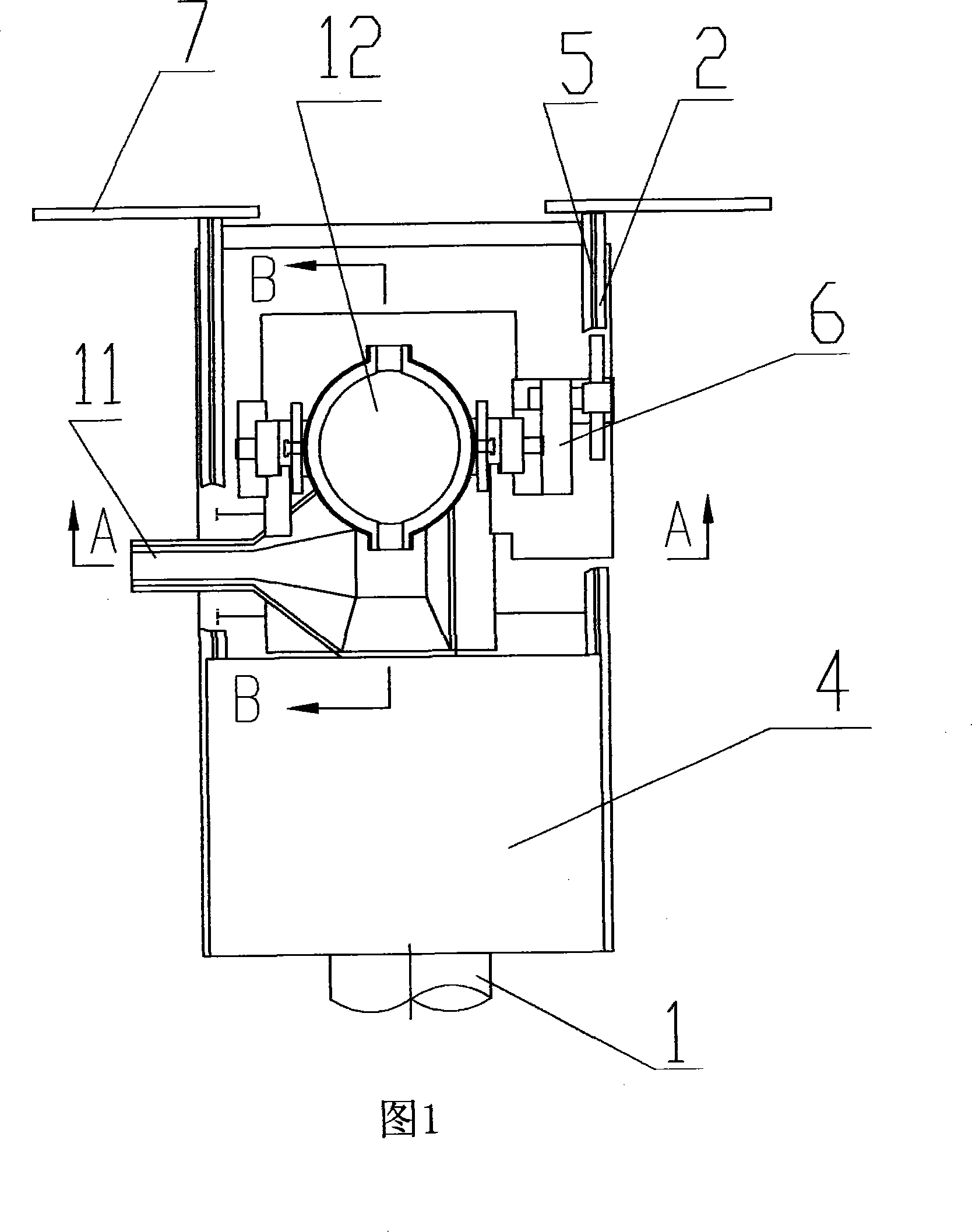

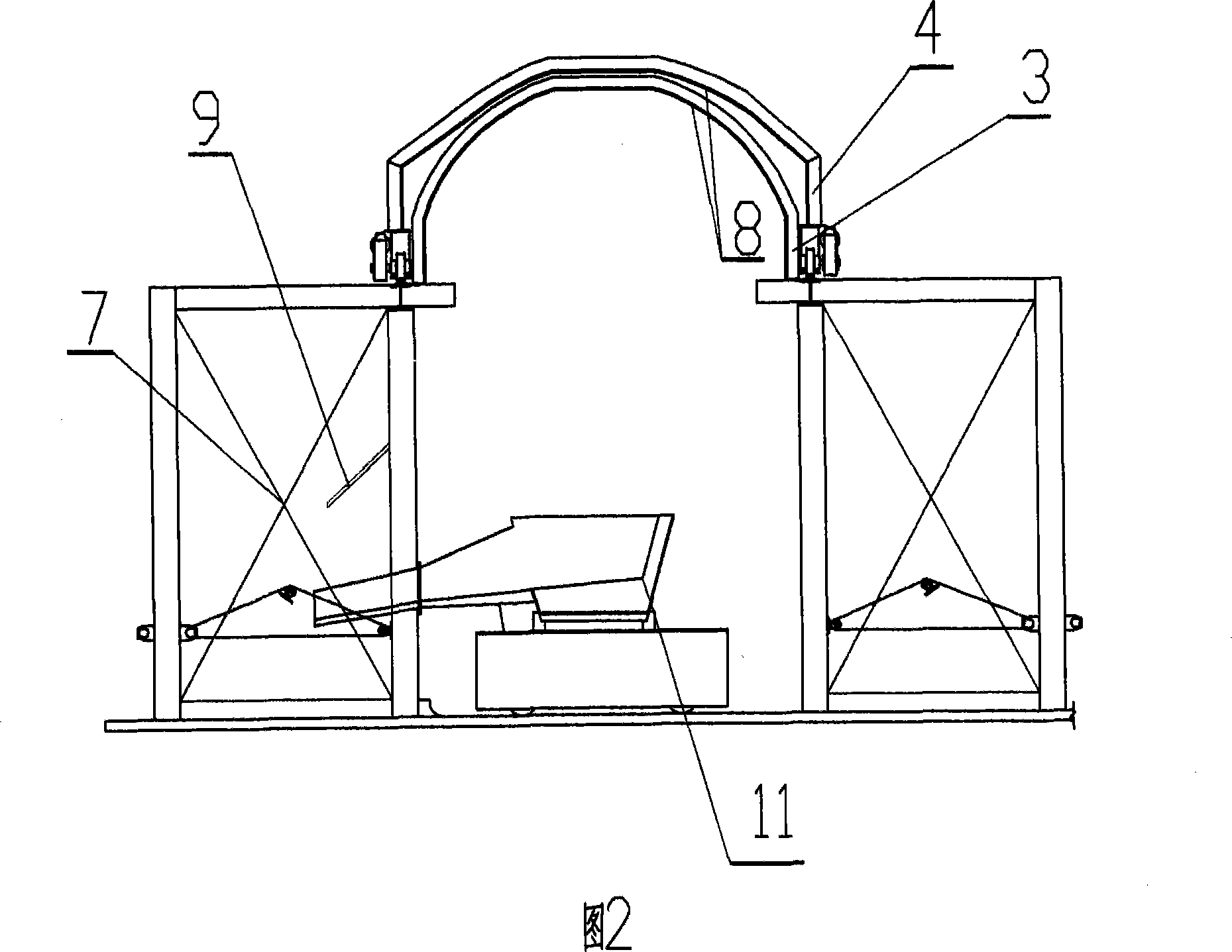

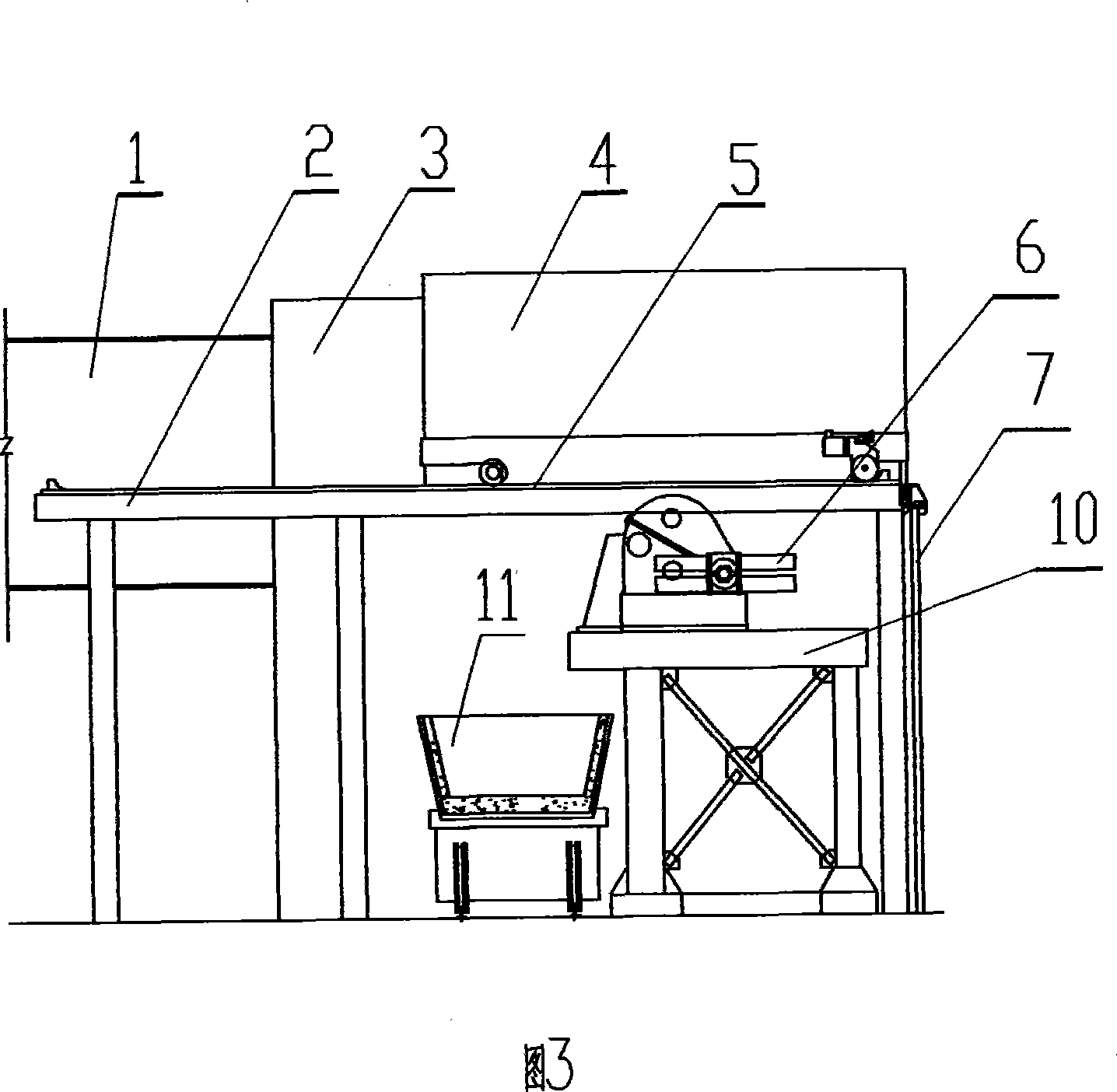

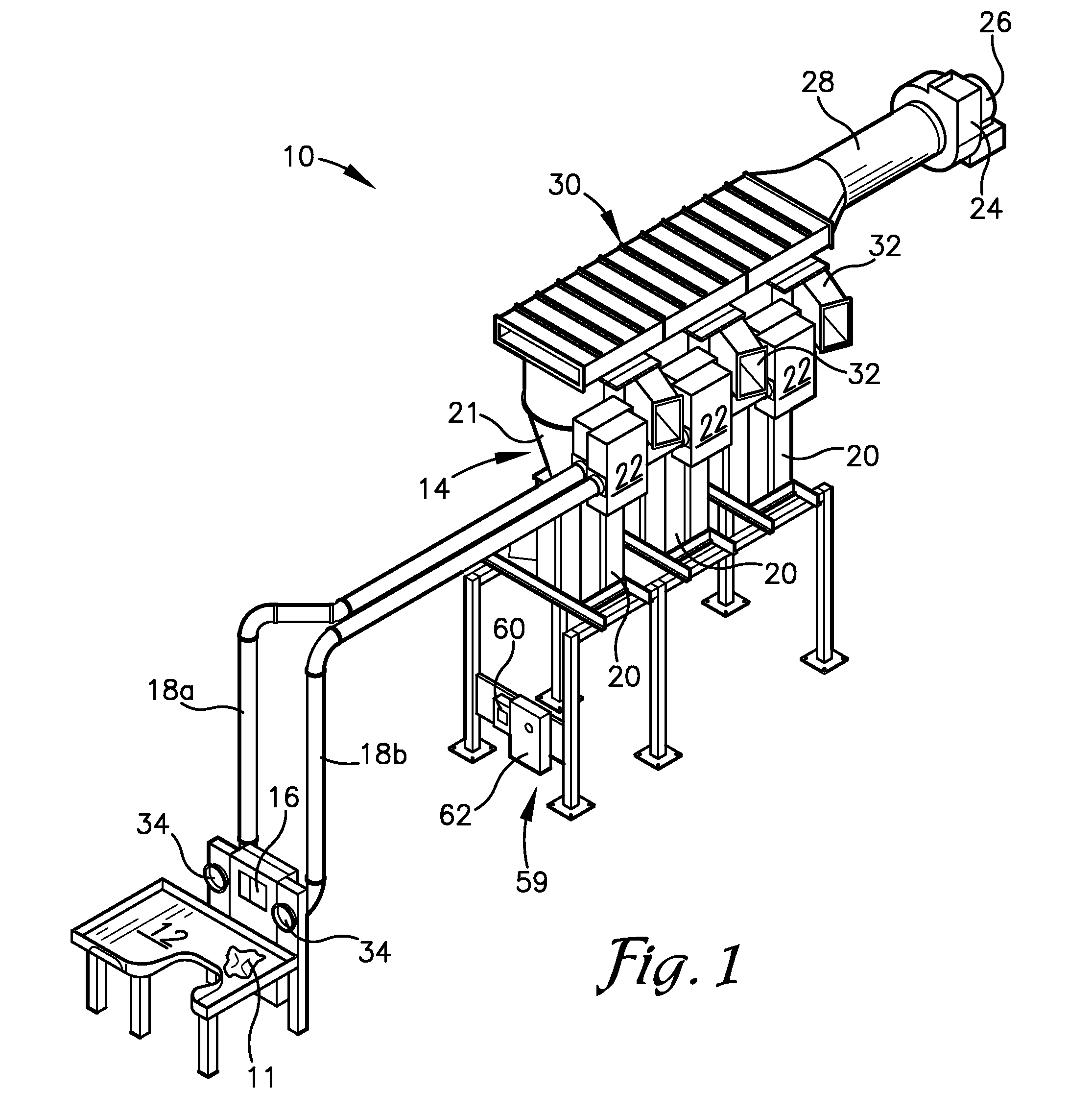

Mobile smoke blast trapping device for furnace mixer

The invention discloses a movable dust arrestment device used for a metal iron mixer, comprising a dedust pipe (1), a support (2), a fixed smoke cover (3) and a movable smoke cover (4). The movable dust arrestment device is characterized in that: the fixed smoke cover (3) and a guide way (5) are arranged on the support (2), and the movable smoke cover (4) can move along the guide way (5), and can be combined with the fixed smoke cover (3) to form a sealed dedust cover; a pig-iron ladle dumping device (6) is arranged on the support (2), and the dedust pipe (1) is arranged on one side of the fixed smoke cover (3). The movable dust arrestment device used for the metal iron mixer has the advantages of convenient usage, ensuring high dust arrestment rate and good dedust effect in the iron receiving process of metal mixer, being energy-saving, reducing running cost, improving the working environment of operating staffs and reducing the operating rate of cranes in workshop.

Owner:HUATIAN ENG & TECH CORP MCC

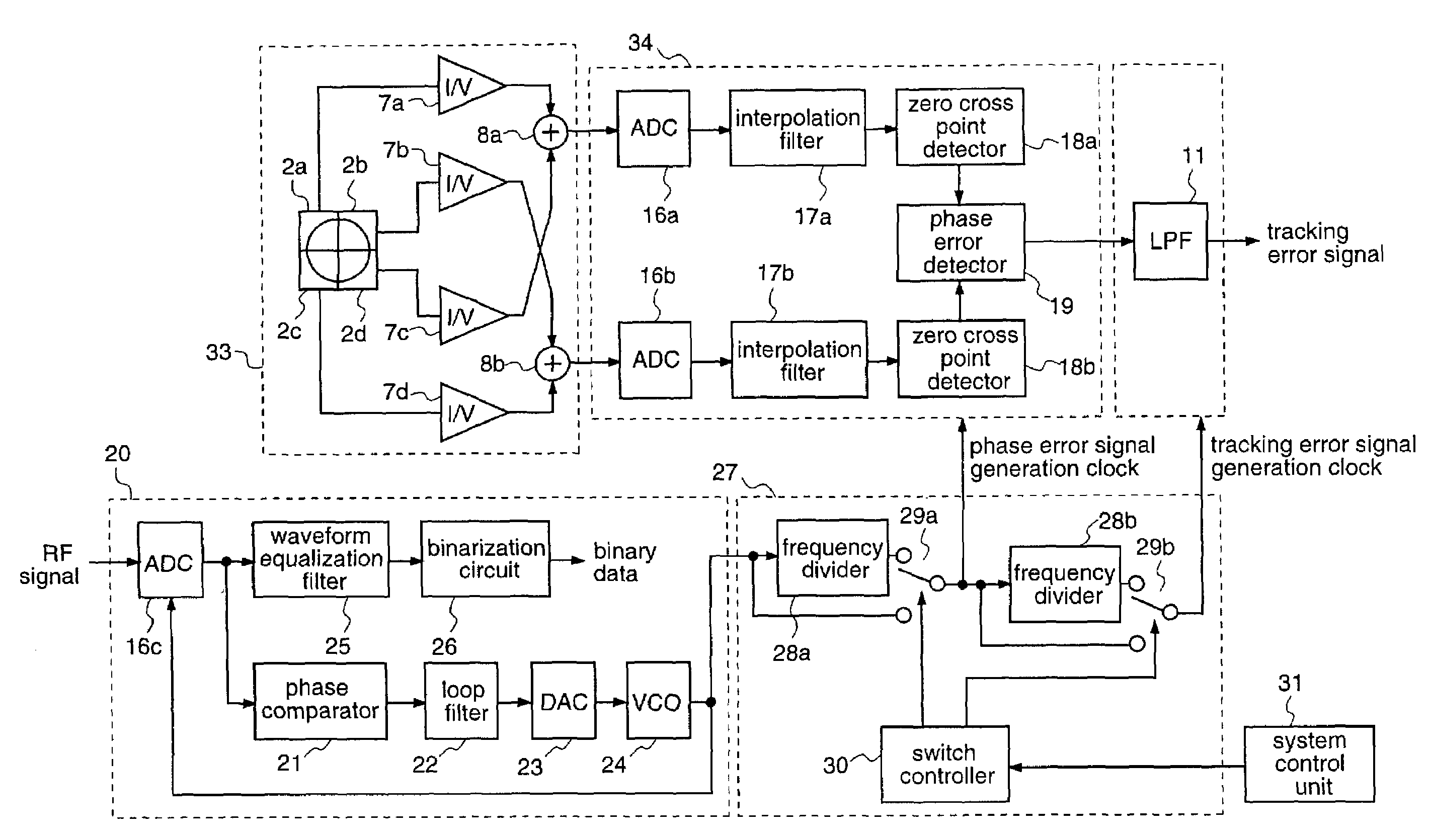

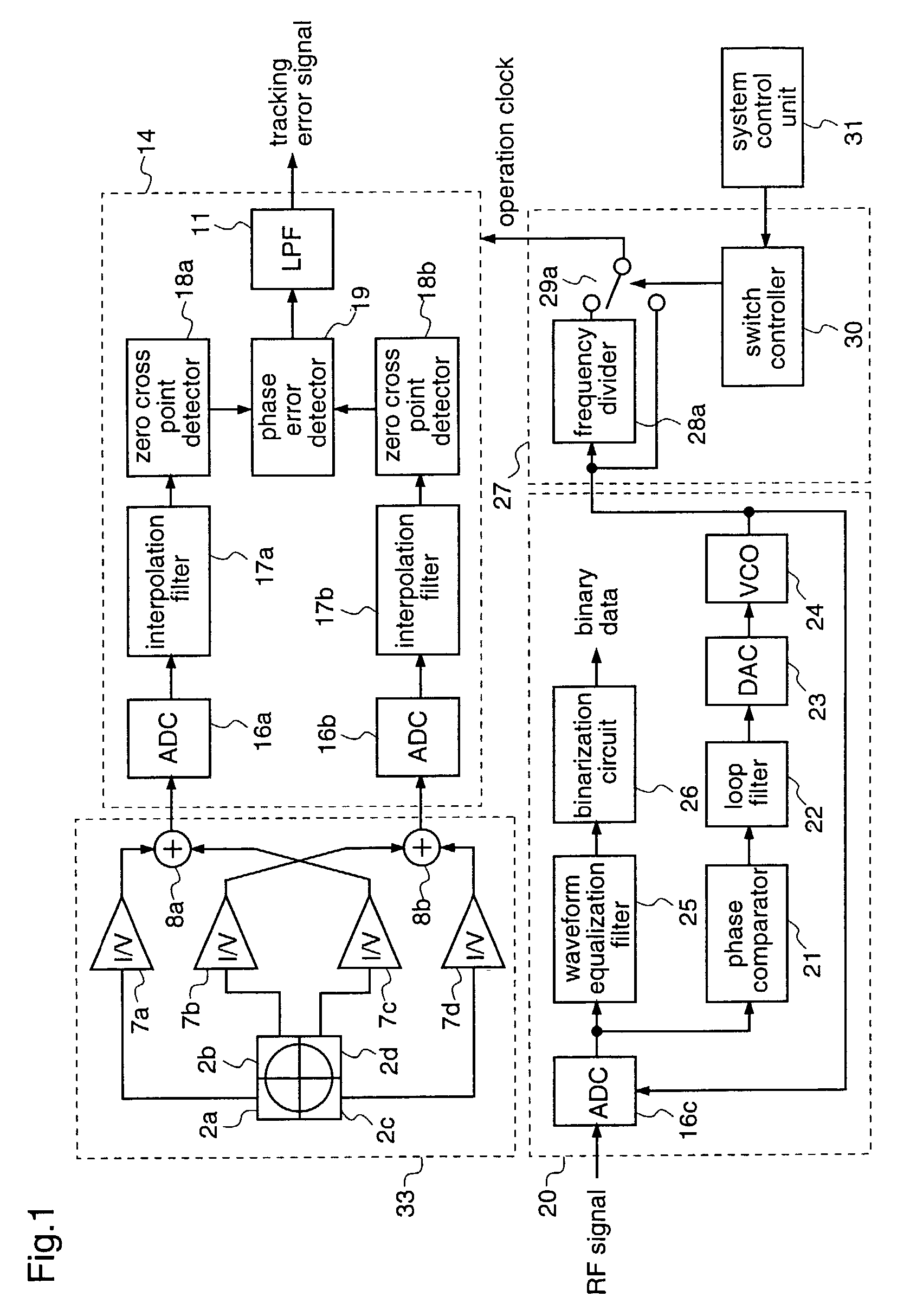

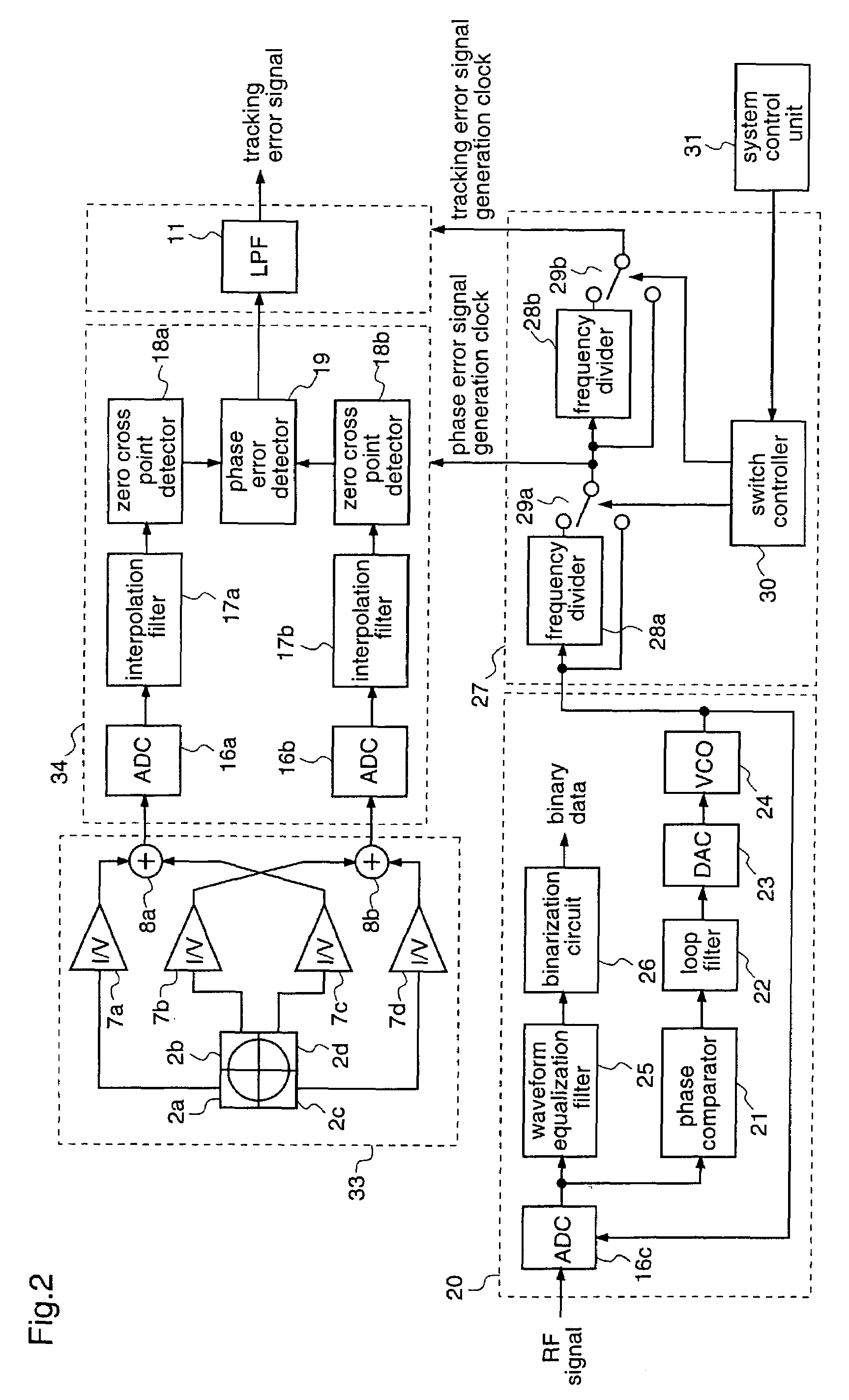

Tracking error detection apparatus

InactiveUS7012862B2Reduce power consumptionReduce operating rateRecord information storageDigital recording/reproducingLight beamBand-pass filter

A tracking error detection apparatus includes a phase error detection unit for detecting a phase error of an output signal according to the amount of reflected light that is obtained when a light beam is applied to an information recording medium and a low-band pass unit for performing band restriction to obtain a tracking error signal from the phase error signal. The tracking error detection apparatus also includes a clock generation unit for generating a clock and a clock control unit having a frequency divider for generating a frequency-divided clock of the clock that is generated by the clock generation unit, wherein the clock control unit uses the frequency-divided clock as an operation clock for the tracking error detection apparatus. Therefore, the operation rate of each unit when generating a tracking error signal can be reduced, whereby a reduction in power consumption is achieved.

Owner:PANASONIC CORP

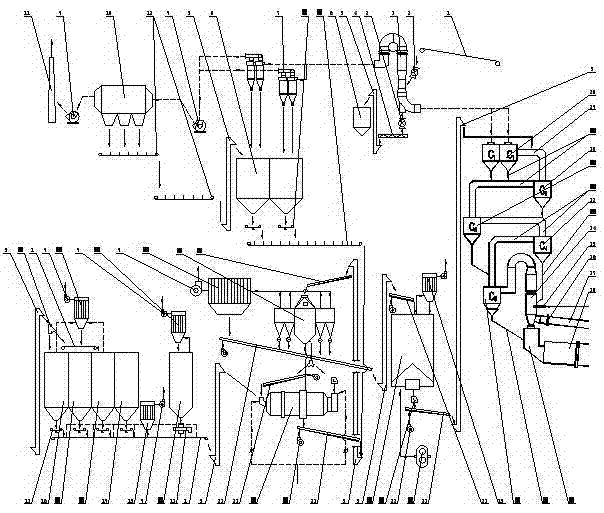

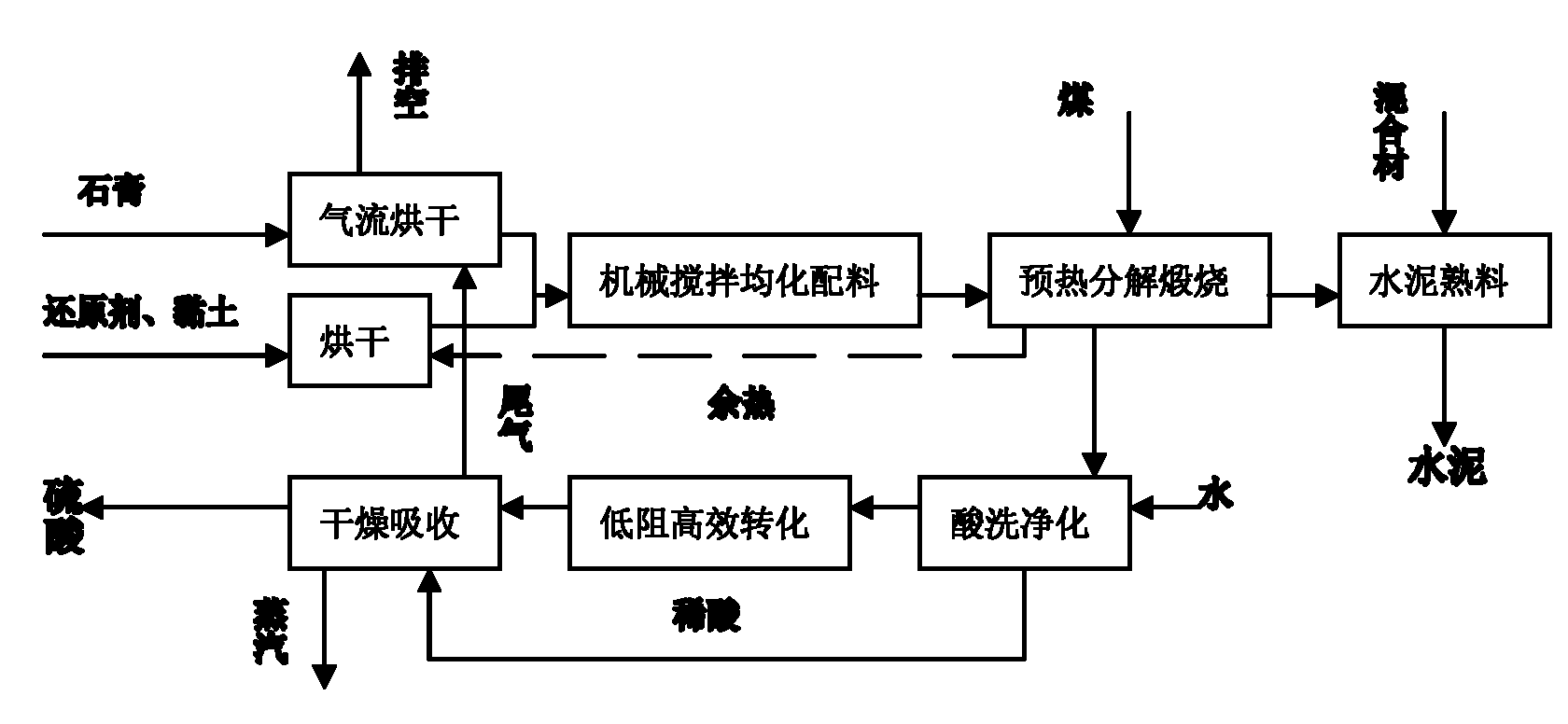

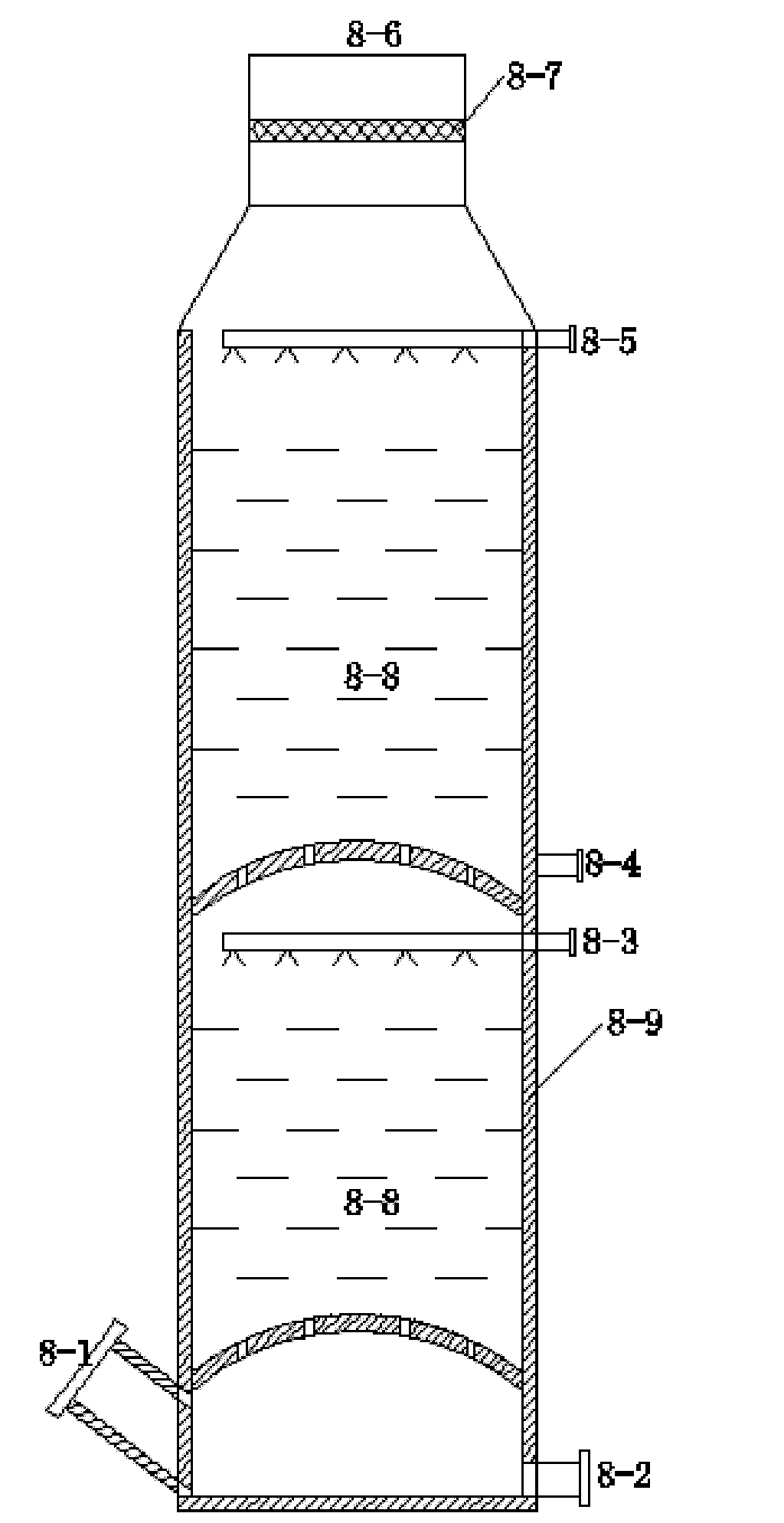

Improved production process for preparing sulfuric acid and cement from gypsum

The invention relates to an improved production process for preparing sulfuric acid and cement from gypsum. Raw materials comprise dihydrate gypsum, clay and a reducing agent. The process comprises the following steps of: drying the raw materials; independently grinding; mechanically stirring and homogenizing; preheating green stock; decomposing and calcining through a rotary kiln; acid-washing and purifying kiln gas; drying through SO2; performing a double-conversion double-absorption process; and grinding the cement to prepare sulfuric acid and cement products, wherein a dihydrate gypsum process is adopted; the raw materials are dried by absolute dry tail gas at the temperature of between 70 and 85 DEG C which is discharged out of a sulfuric acid absorption device to obtain the dihydrate gypsum with free water content of less than 5 weight percent; and the dihydrate gypsum is then directly homogenized with the clay and the reducing agent in the presence of CaCl2 or Na2SO4 to produce the green stock. In the process, the heat consumption is reduced by 30 percent, the power consumption is reduced by 20 percent, the investment is reduced by 25 to 40 percent, and the cost is reduced by 25 to 30 percent. The process overcomes the disadvantages of high power consumption and heat consumption, large investment, low operation ratio and the like in the conventional method, 0.4 to 0.5 tonnage of steam serving as a byproduct is produced by every tonnage of sulfuric acid, and the process has obvious economic benefit.

Owner:南京创能电力科技开发有限公司

Electric equipment and control method thereof

ActiveUS9734827B2Reduce noiseReduce operating rateSpeech recognitionSound input/outputCommunication unitControl signal

Owner:SAMSUNG ELECTRONICS CO LTD

Refrigerator and control method thereof

ActiveUS9534821B2Avoid concentrationReduce power consumptionFood processingDomestic refrigeratorsEngineeringRefrigerated temperature

Owner:SAMSUNG ELECTRONICS CO LTD

Robot system and robot control apparatus

InactiveUS20170248936A1Reduce operating rateAvoid contactProgramme controlProgramme-controlled manipulatorRobotic systemsSimulation

A robot system includes: a robot; an illumination apparatus disposed in or around the robot; and a control apparatus that controls the robot and the illumination apparatus, wherein the control apparatus includes a robot control unit that operates the robot on the basis of a program, an operation area prediction unit that predicts an operation area of the robot on the basis of the program, and an illumination control unit that turns on or off the illumination apparatus on the basis of the operation area predicted by the operation area prediction unit to display the operation area.

Owner:FANUC LTD

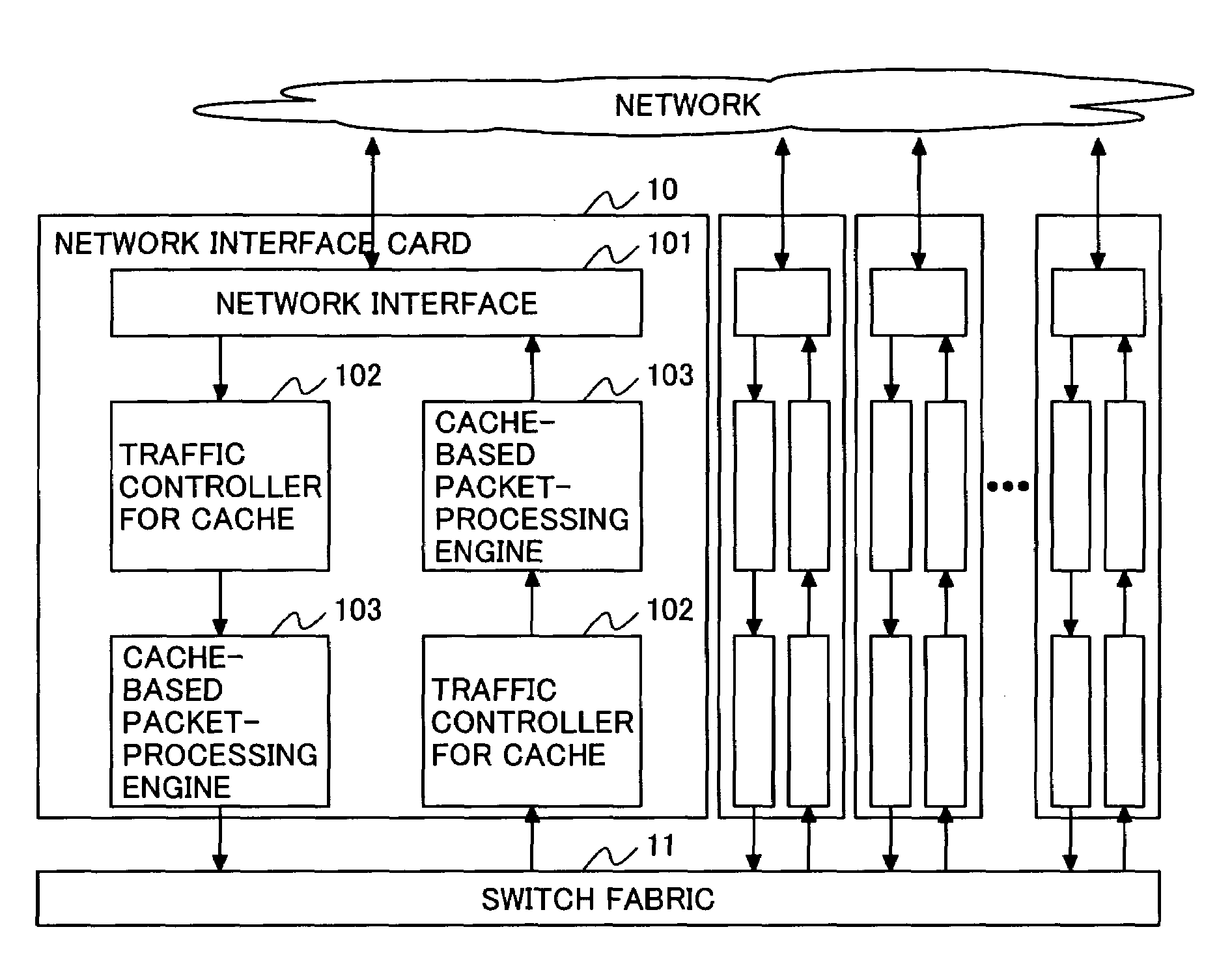

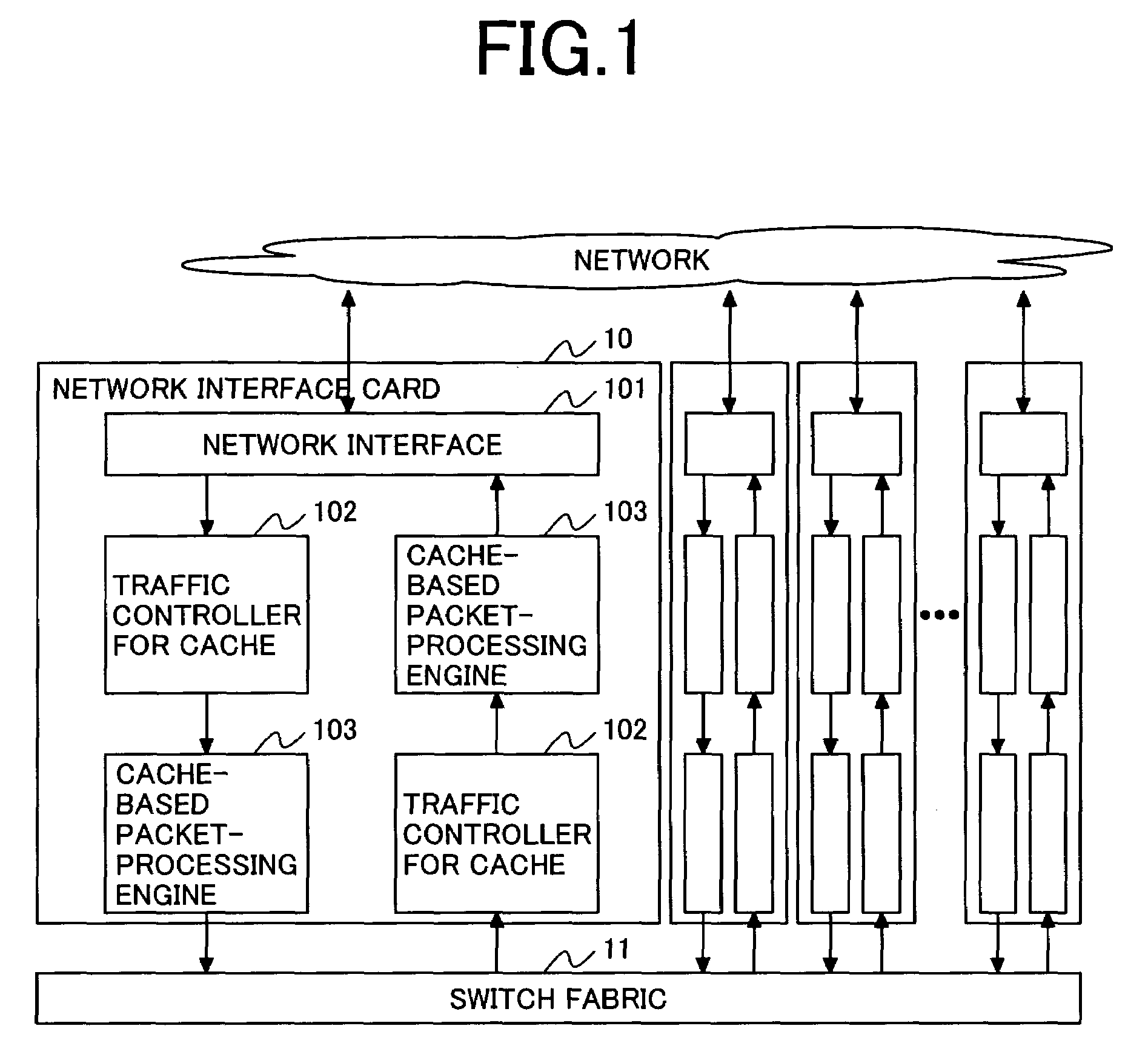

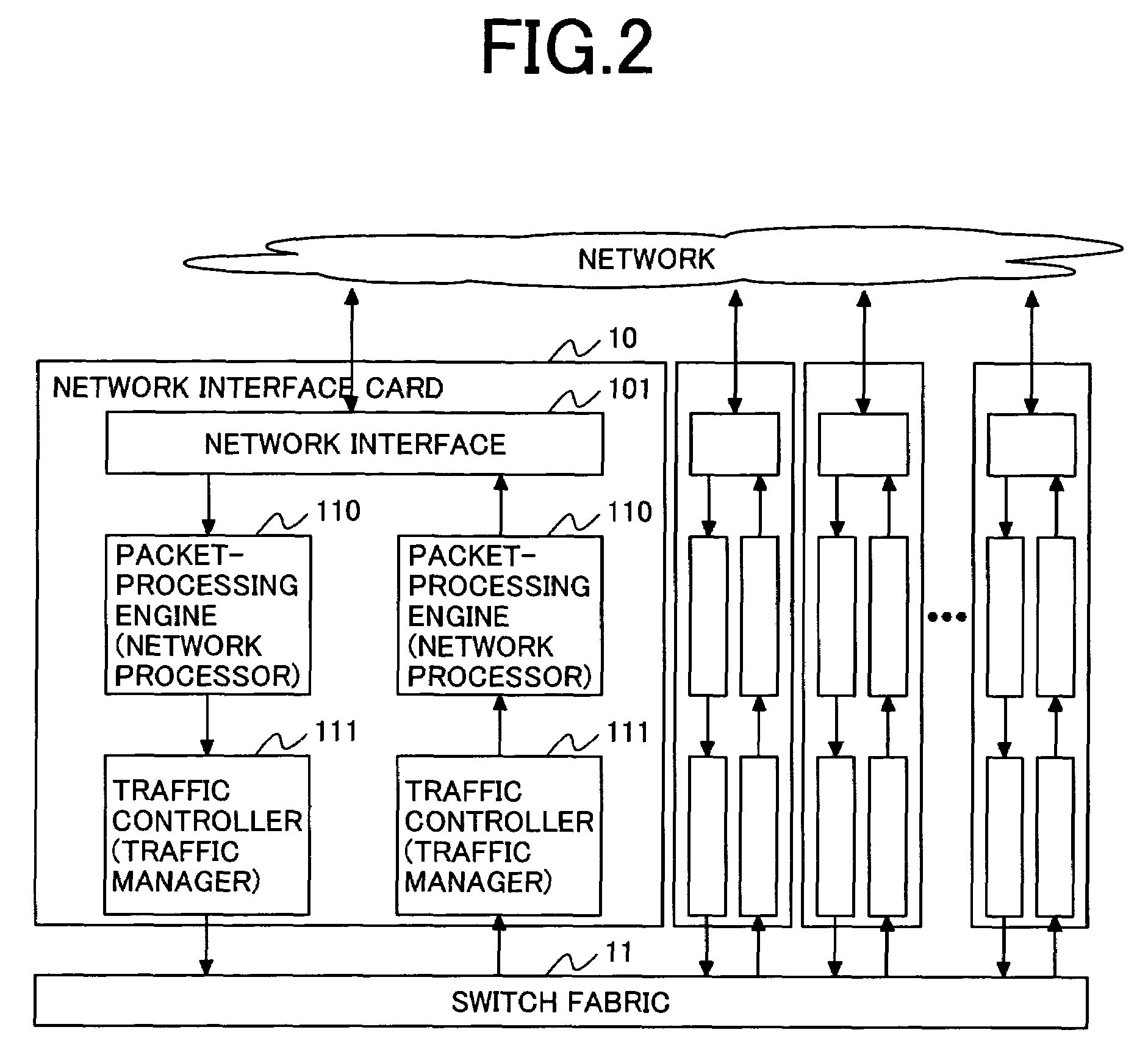

Traffic control method for network equipment

InactiveUS7656887B2Prevent drop in hit rateTransfer processingMemory adressing/allocation/relocationData switching by path configurationRecord statusNetwork packet

A function block containing a process-cache tag for storing process-cache tags in the pre-stage of a process cache and an FIFO queue for each tag entry are installed as a traffic controller. The traffic controller stacks packet groups, identified as being from the same flow, in the same FIFO queue. Each FIFO queue records the logged state of the corresponding process queues, and when a packet arrives at an FIFO queue entry in a non-registered state, only its first packet is conveyed to a function block for processing the process-cache misses, and then it awaits registration in a process cache. Access to the process cache from the FIFO queue is implemented at the time that registration of the second and subsequent packets in the process cache are completed. This allows packets other than the first packet in the flow to always access the process cache for a cache hit.

Owner:HITACHI LTD

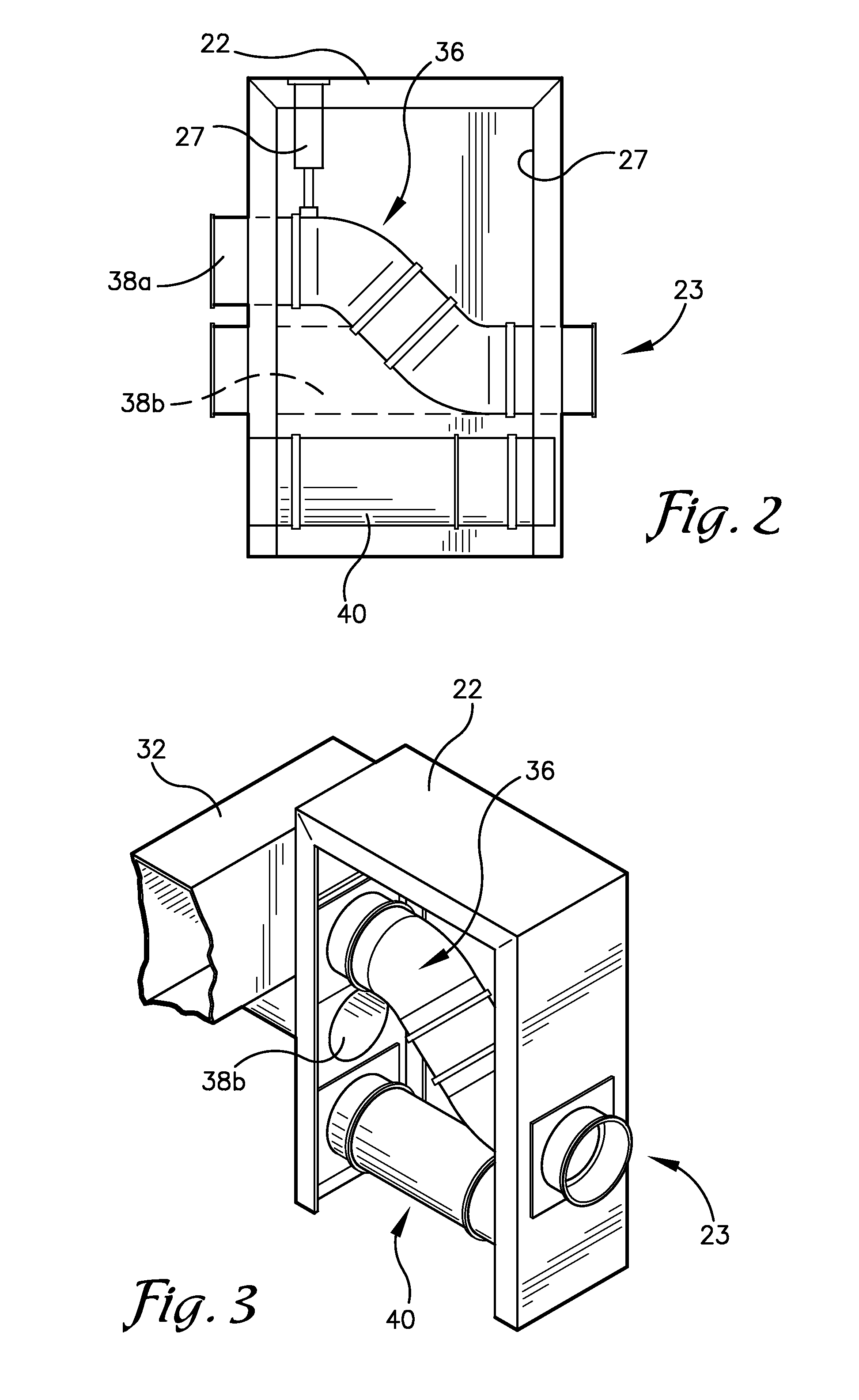

Apparatus for textile counting, sorting and classifying system

InactiveUS20080308472A1Quick start and stopSave electricitySeparation devicesTextiles and paperOff responseProcess engineering

An apparatus is provided for transporting textile items into sorting bins with reduced energy consumption and improved load measuring accuracy and which provides textile item counting and sorting for a commercial laundry using vacuum air systems to move textiles into sorting bins and using a variable frequency drive to increase on / off response time of vacuum in the system.

Owner:COLMAC INDS

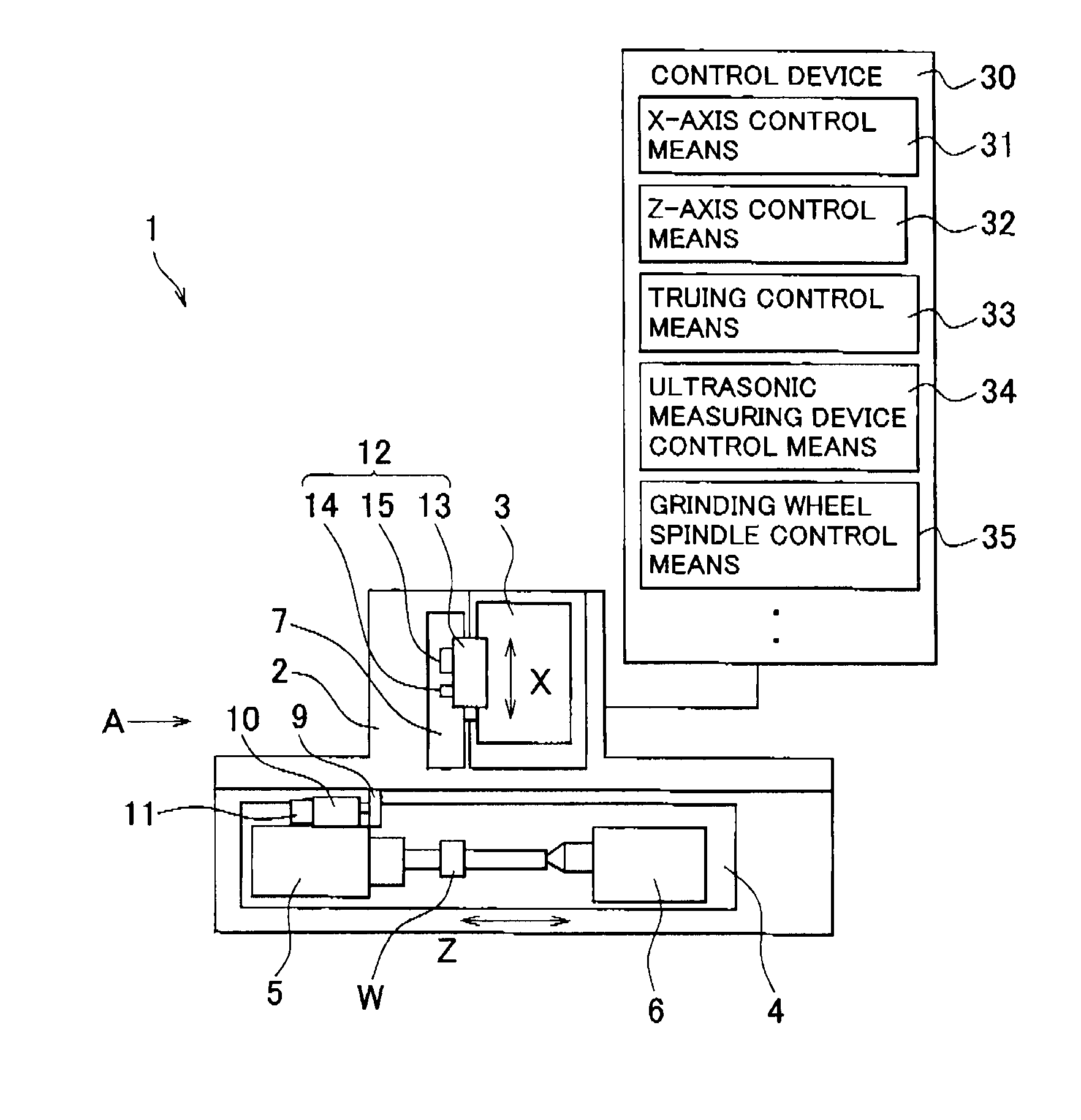

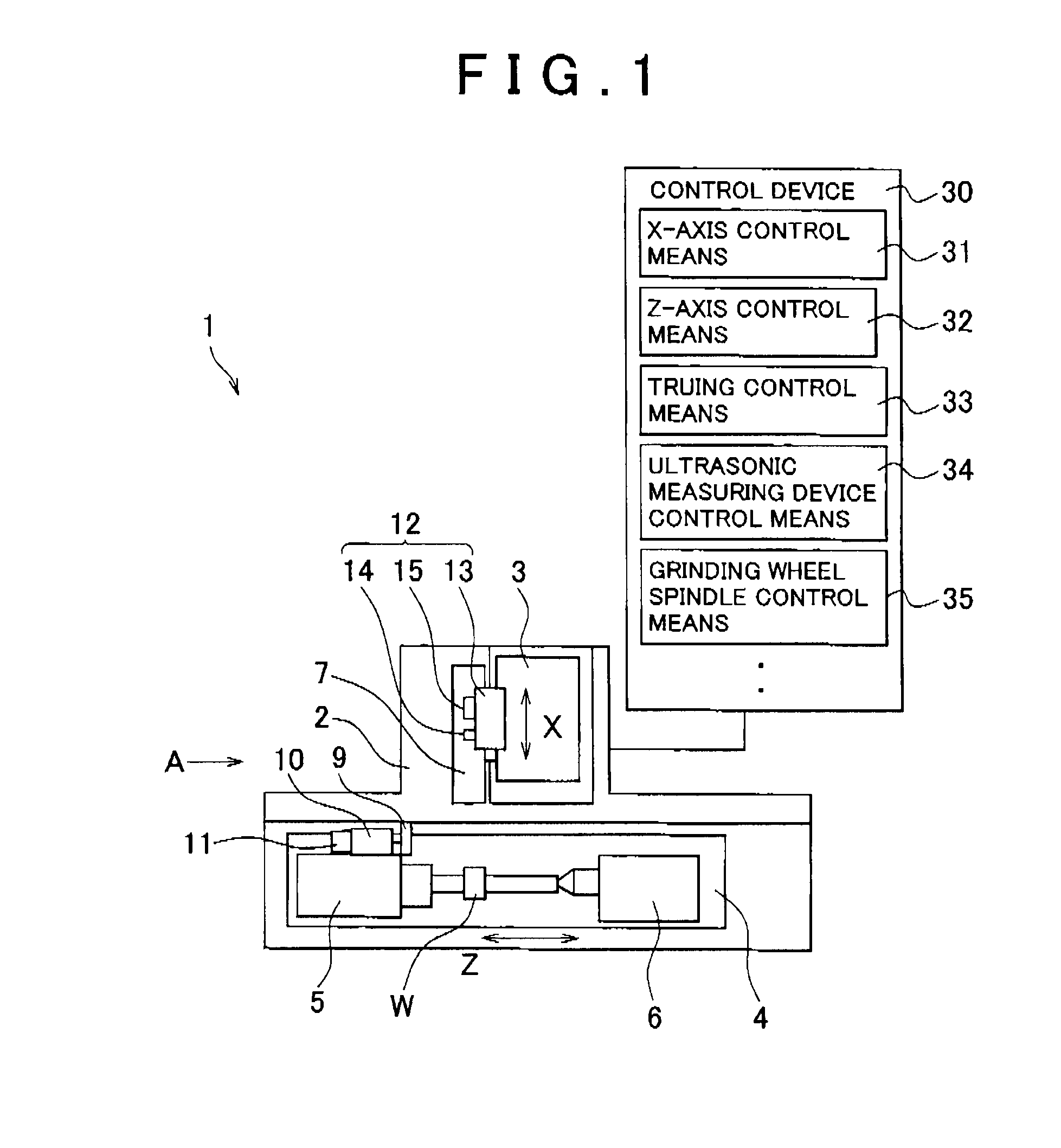

Grinding method and grinding machine

ActiveUS20120028543A1Accurate calculationReduce grinding costsProgramme controlRevolution surface grinding machinesUltrasonic sensorArrival time

A core grinding wheel that has a grinding layer on an outer periphery of a core is used. An ultrasonic wave is output from an ultrasonic sensor to the grinding layer via grinding fluid. An ultrasonic measuring device control unit calculates a thickness of the grinding layer on the basis of a sonic velocity in the grinding layer and an arrival time difference between a reflected wave from a surface of the grinding layer and a reflected wave from a surface of the outer periphery of the core. A grinding process and a truing process are controlled on the basis of an outside diameter of the grinding wheel, which is calculated on the basis of the measured thickness of the grinding layer and an outside diameter of the core.

Owner:JTEKT CORP

Method for allowing hot rolled strip steel to pass through fault rolling mill without being rolled

ActiveCN102397882AReduce operating rateReduce outputRolling safety devicesMetal rolling arrangementsProduction lineStrip mill

The invention provides a method for allowing hot rolled strip steel to pass through a fault rolling mill without being rolled. The method comprises the following steps of: assembling two waste working rolls and a bearing base to form a fault machine frame, and arranging the fault machine frame in the fault rolling mill according to a normal roll replacing process, wherein transmission sides of the two waste working rolls are not provided with flat heads, and torsion holes are drilled on roll heads on working sides of the two waste working rolls; after an upper working roll is lifted by 60 to 70 millimeters, closing a water sealing plate is closed, starting to roll and adding cooling water of the rolling mill; and allowing the strip steel to pass through the fault rolling mill without being rolled for a period of time, and rotating a lower working roll by utilizing a special torsion rod to change a contact position with the strip steel. By the method, any rolling mill can produce the strip steel while performing fault processing under the condition of faults on a strip steel production line, so that the actual rolling stop time due to the faults of a main transmission system is shortened effectively, and the quality of products is ensured while the operating rate and yield of the rolling mill are improved substantially.

Owner:ANGANG STEEL CO LTD

Liquid chromatograph

ActiveUS8794052B2Reduce pressureReduce injectionComponent separationSurface/boundary effectAutosamplerInjection port

In injecting a sample sucked into a sample loop in an autosampler from an injection needle into an analytical flow path via an injection port by a mobile phase, a sending flow rate of the mobile phase is reduced from a certain flow rate determined in an analysis condition to reduce pressure applied on a joint section between the needle and the injection port to thereby reduce the sample remaining in the injection port.

Owner:SHIMADZU CORP

Protective film structure of metal member, metal component employing protective film structure, and equipment for producing semiconductor or flat-plate display employing protective film structure

InactiveUS8124240B2Improve corrosion resistanceAvoid Surface CorrosionAnodisationMolten spray coatingTectorial membraneDisplay device

A protective film structure of a metal member for use in an apparatus for manufacturing a semiconductor or the like, the protective film structure including a first coating layer of faultless aluminum oxide formed by direct anodic oxidation of a base-material metal of an aluminum alloy; and a second coating layer formed on the first coating layer and made of yttrium oxide by a plasma spraying method.

Owner:NGK SPARK PLUG CO LTD +2

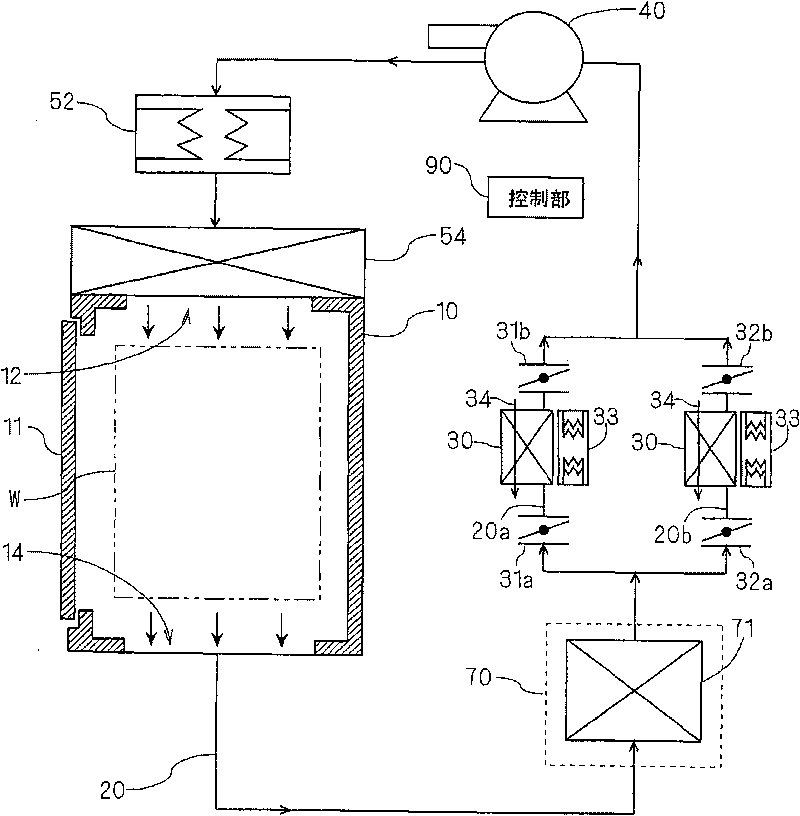

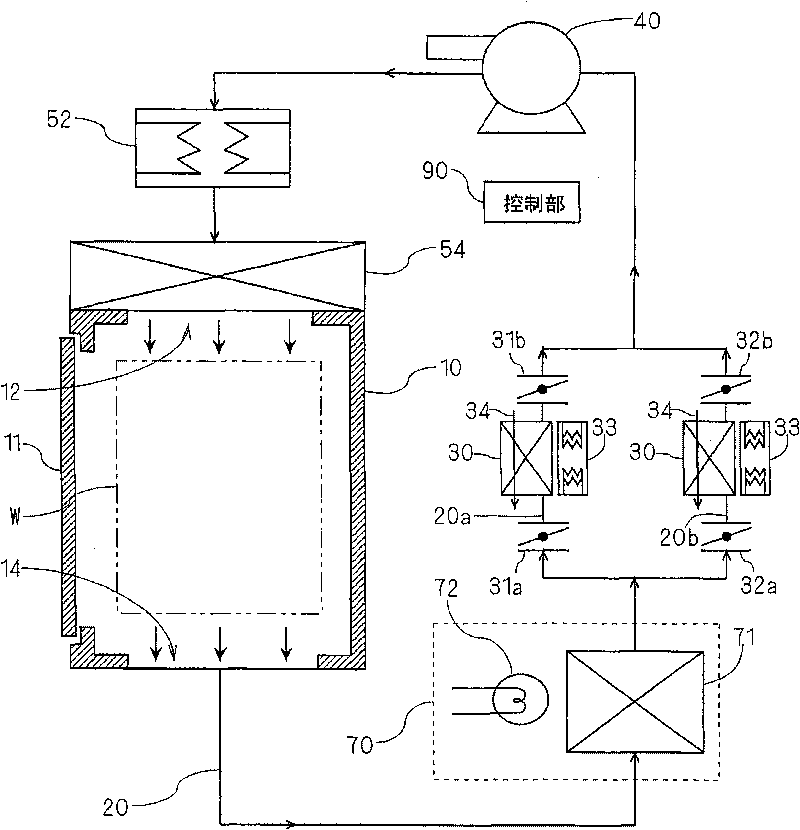

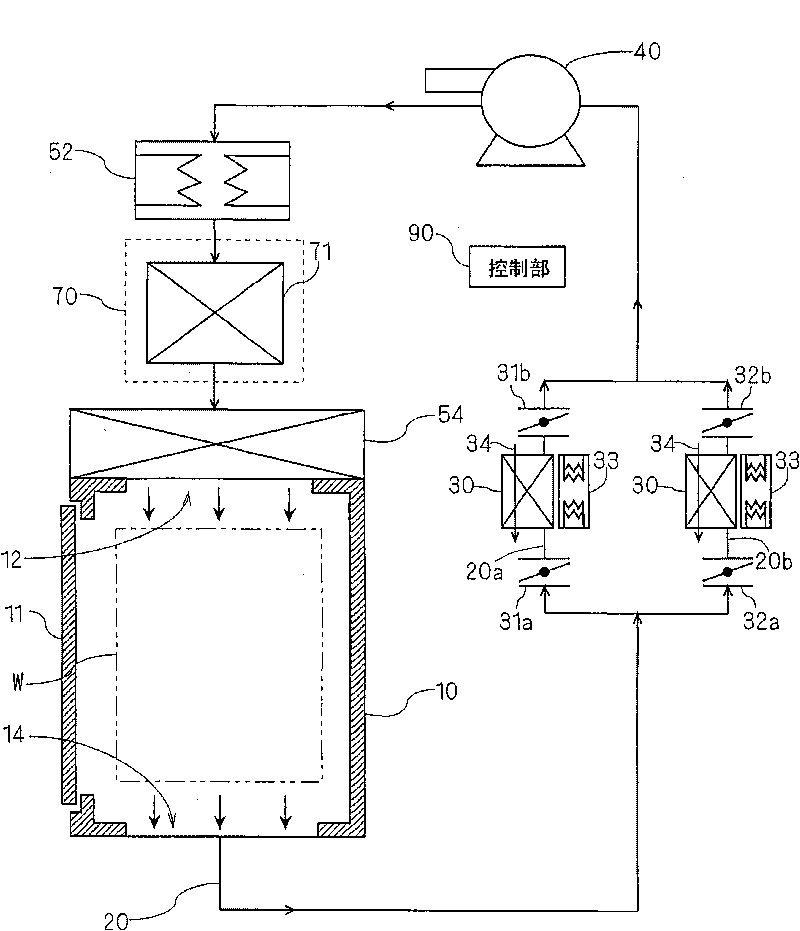

Circle substrate firing furnace

InactiveCN101749949AReduce heat lossEasy to control temperatureSemiconductor/solid-state device manufacturingFurnace typesHot blastOrganic compound

The invention provides a circle substrate firing furnace which can reduce the heat loss and obtain the steady sintering temperature. The sintering treatment of a glass substrate (W) can be performed by blowing out the hot blast from a furnace main body part (10). the hot blast exhausted from the furnace main body part (10) cycles in a circulating path (20) by a circulating fan (40), passes through an adsorption tower (30) for adsorbing and decomposing the resultant from a catalyst filtering part (70) for decomposing the organic compounds, and is heated again in a main heater (52). The hot blast exhausted from the furnace main body part (10) directly flows into the catalyst filtering part (70), thereby the organic compounds contained in the hot blast can be decomposed, thus no additional single heater is needed for heating the catalyst, the heat loss can be reduced. In addition, the sintering temperature in the furnace main body part (10) can be adjusted by controlling the main heater (52), therefore the temperature can be easily controlled to obtain the steady sintering temperature.

Owner:FUTURE VISION

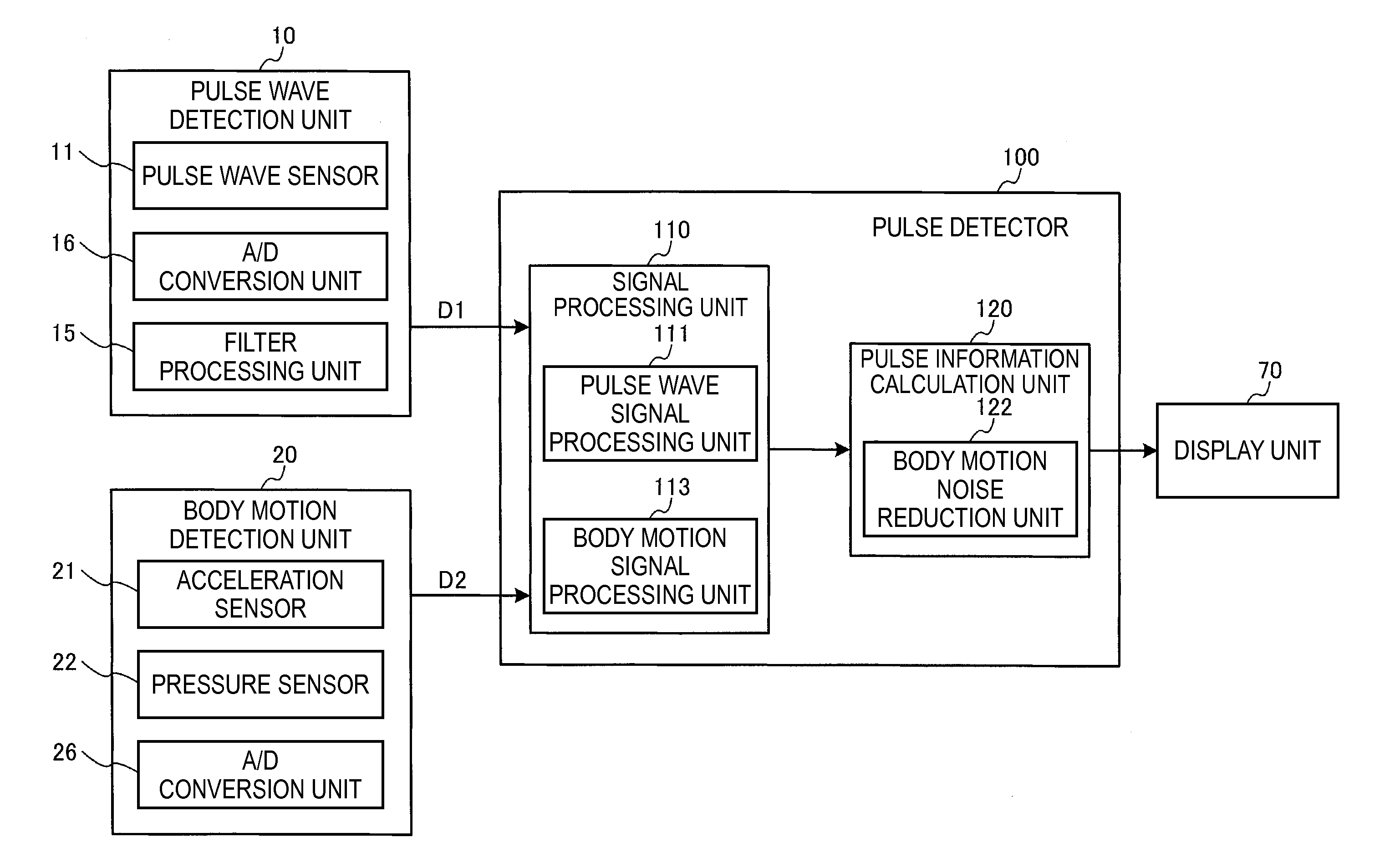

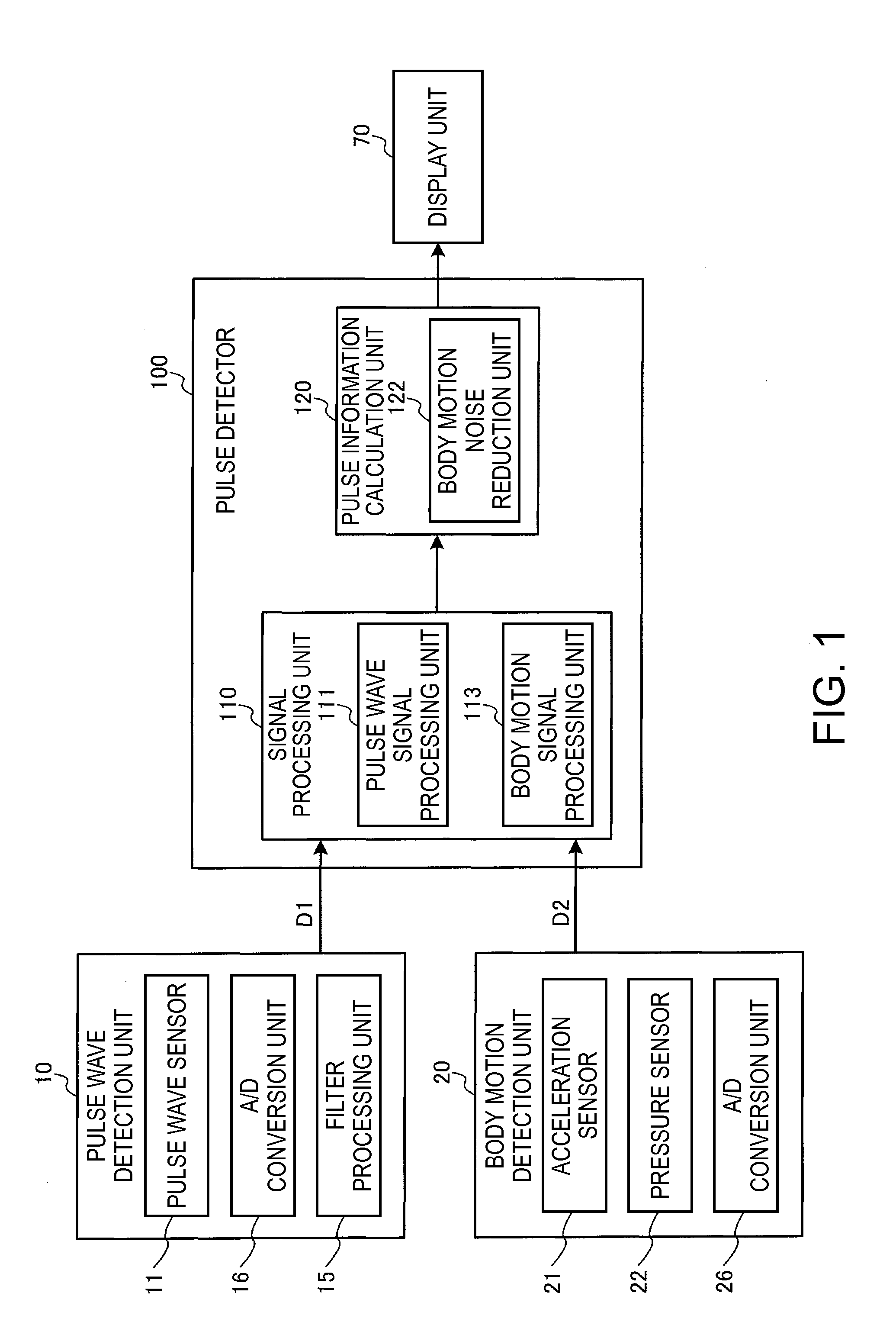

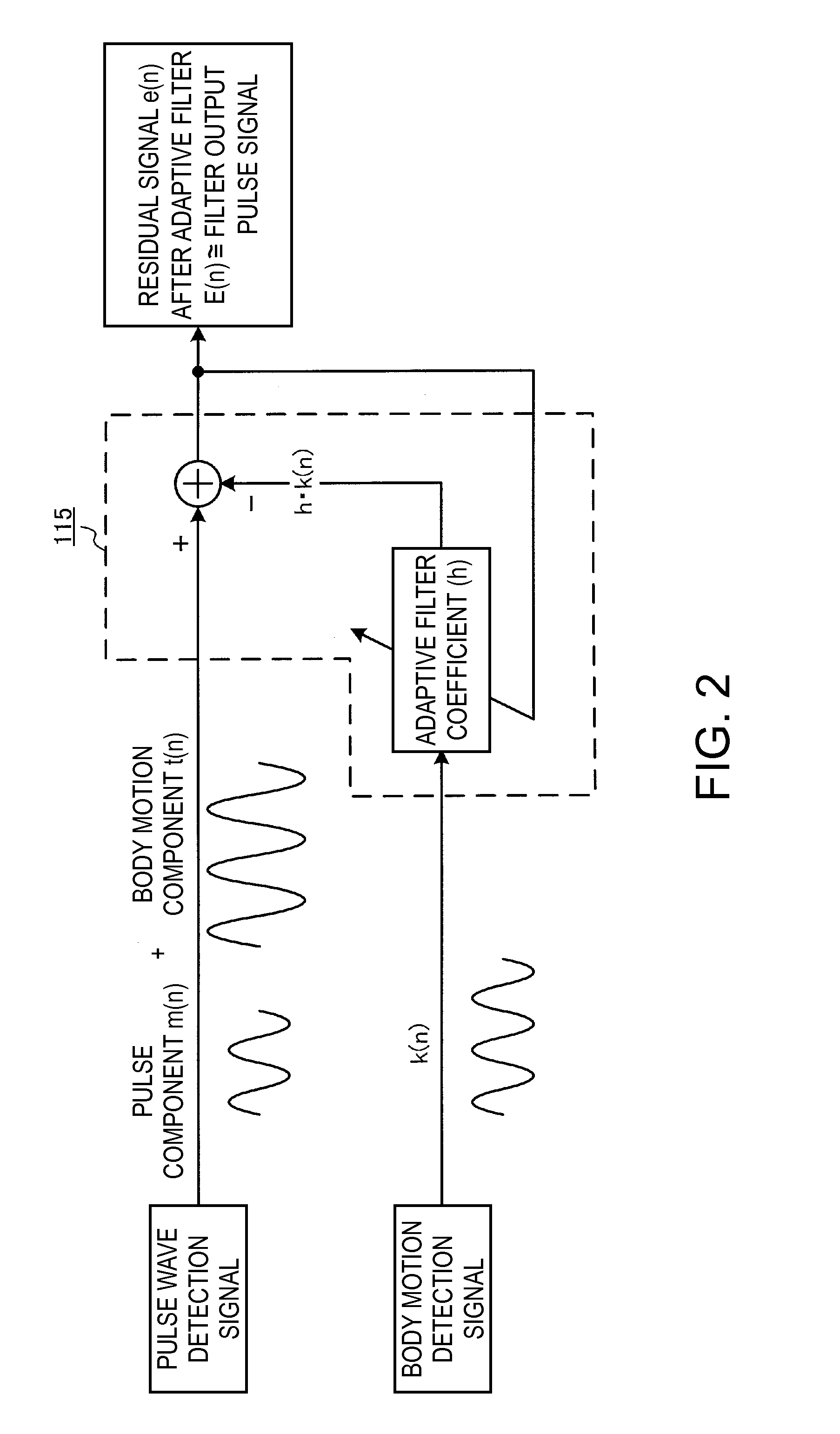

Pulse detector, electronic apparatus, and program

InactiveUS20150088013A1Reduce operating rateReduce processing speedCatheterSensorsClassical mechanicsMotion sensing

A pulse detector 100 includes a pulse information calculation unit 120 which calculates pulse information on the basis of a pulse wave detection signal from a pulse wave detection unit 10 having a pulse wave sensor 11 and a body motion detection signal from a body motion detection unit 20 having a body motion sensor, a determination unit 112 which determines the exercise state of a subject, and a control unit 150 which controls at least one of a pulse wave sensing operation in the pulse wave detection unit 10, a body motion sensing operation in the body motion detection unit 20, and a calculation processing rat in the pulse information calculation unit 120 on the basis of the determination result of the exercise state in the determination unit 112.

Owner:SEIKO EPSON CORP

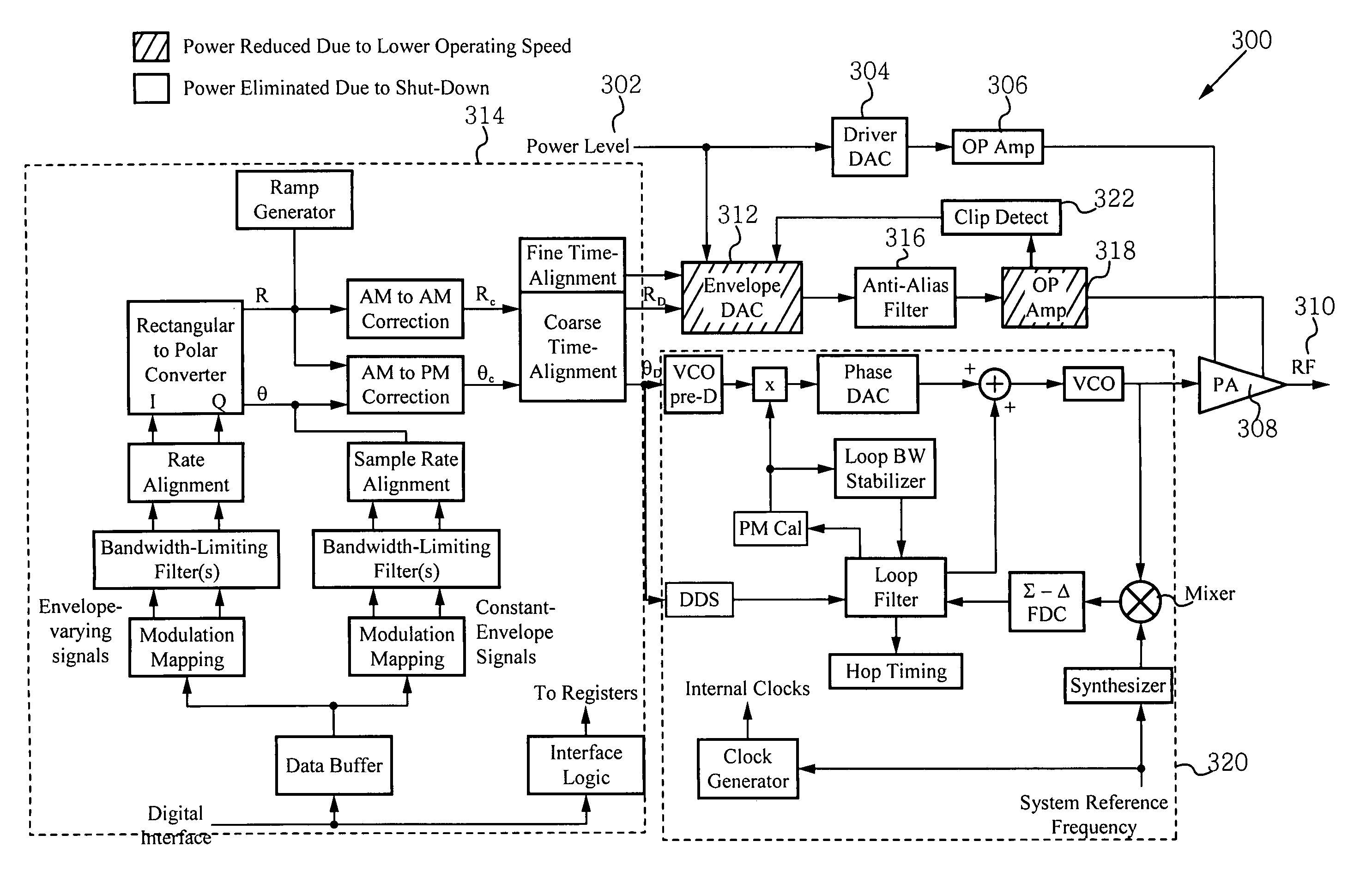

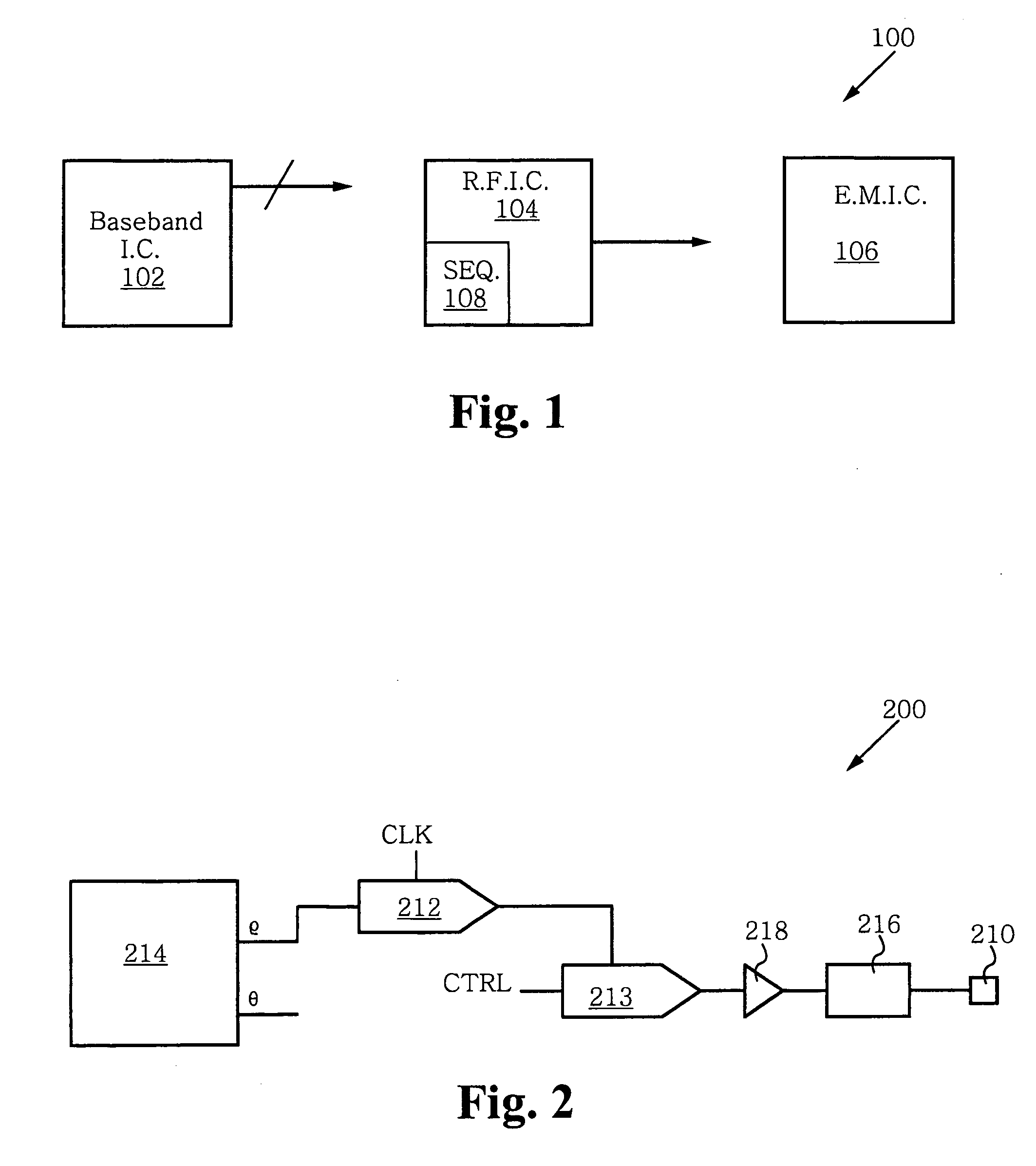

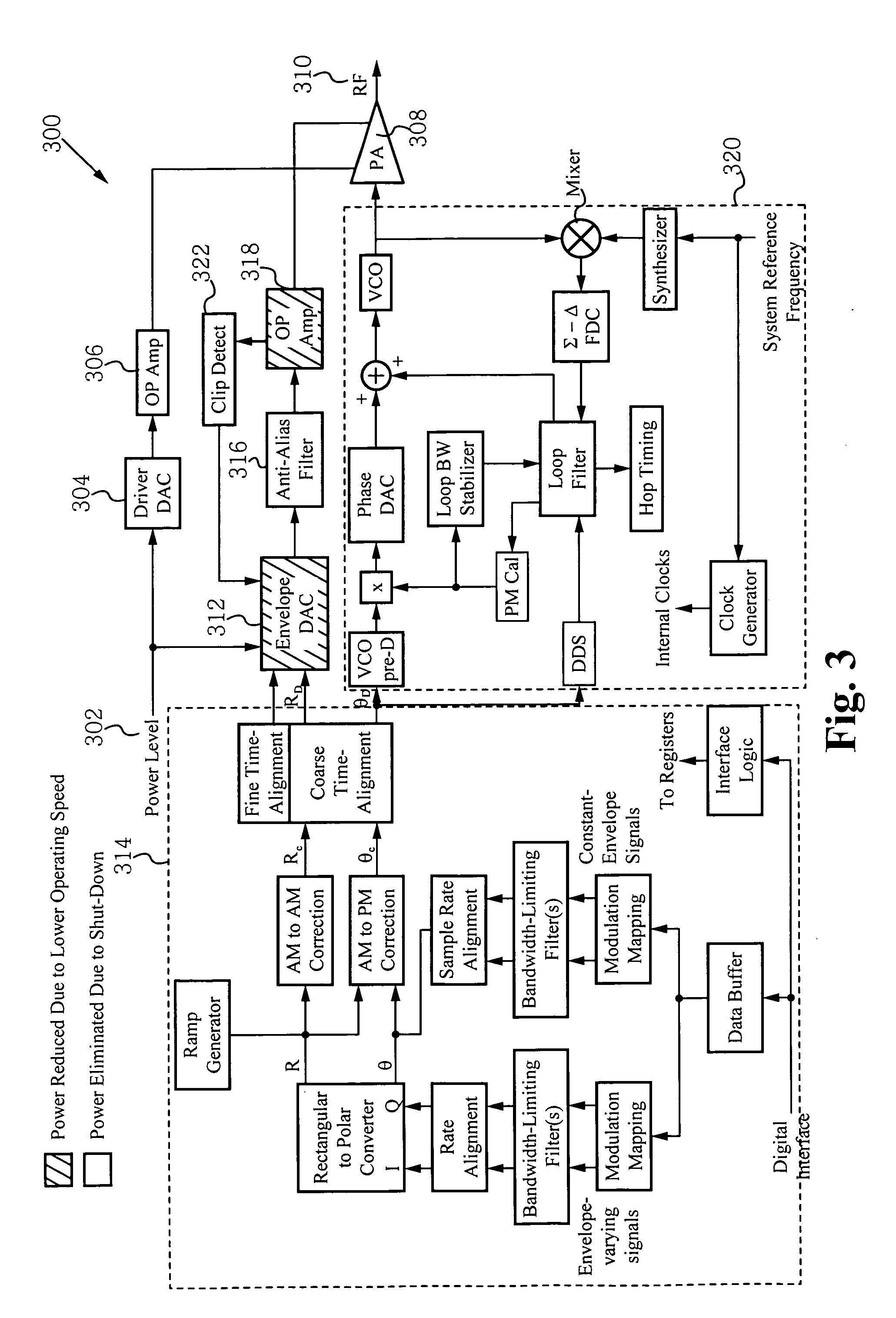

Selective envelope modulation enabling reduced current consumption

ActiveUS20080246550A1Reduce operating rateReduce power consumptionSimultaneous amplitude and angle modulationAngle to amplitude modulation conversionCurrent consumptionPhase modulation

A modulation system includes an amplitude modulation path and a phase modulation path coupled to the amplitude modulation path. One of the amplitude modulation path and the phase modulation path receive a reduced current such that the reduced current reduces power consumption by the system. Preferably, the amplitude modulation path receives the reduced current. The amplitude modulation path has a first set of components and a second set of components. The first set of components consumes less power by using slower operation. The second set of components consumes less power by effectively not operating, or being turned off.

Owner:APPLE INC

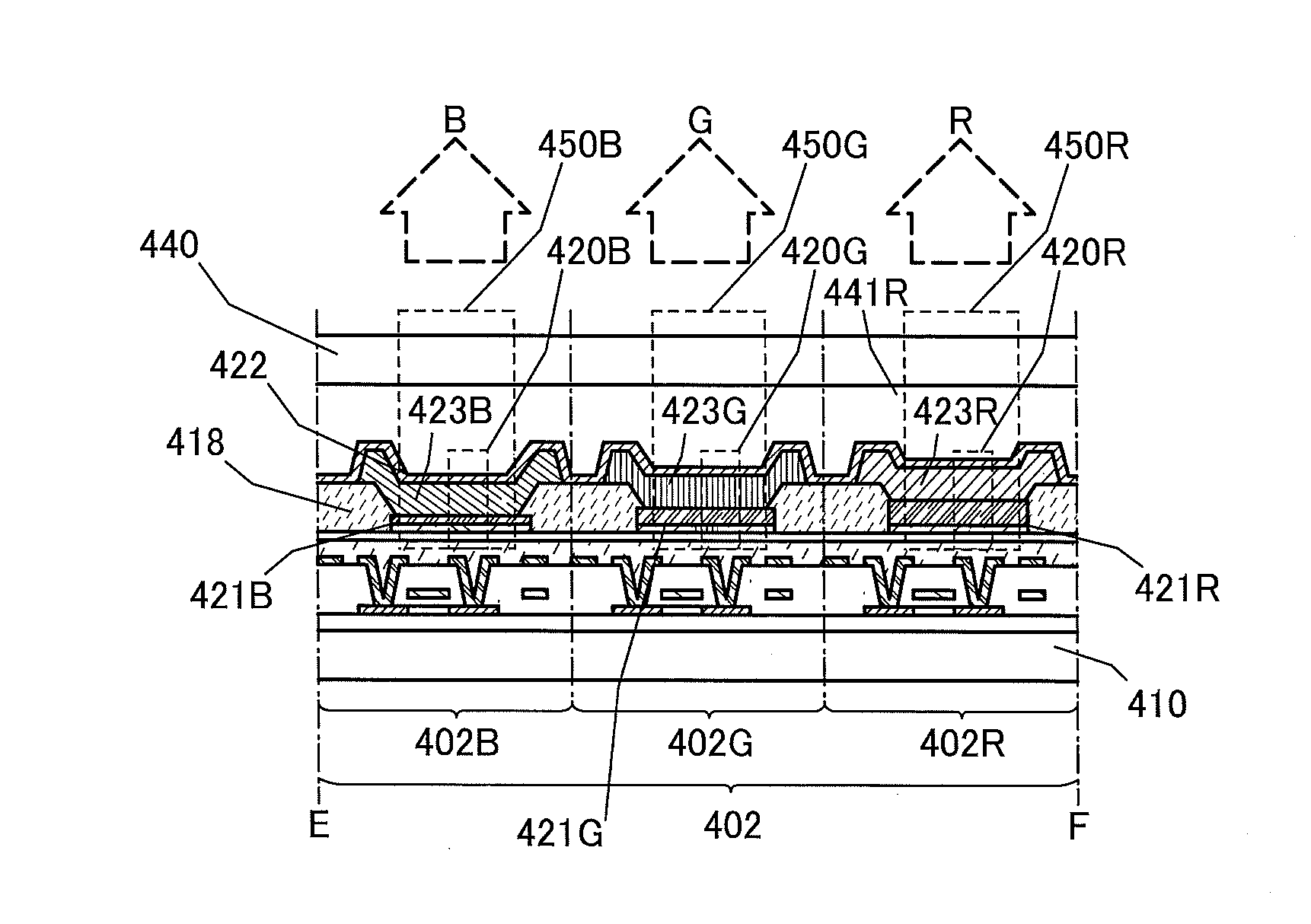

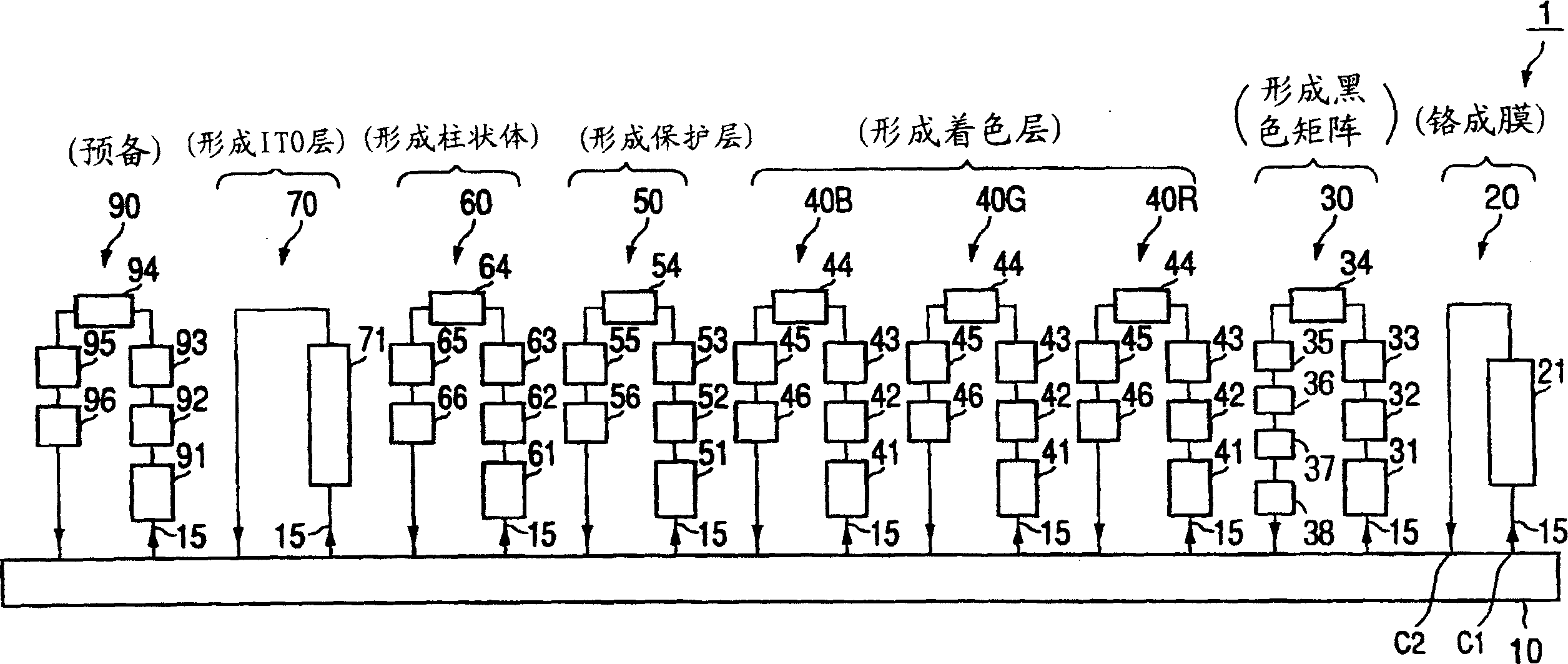

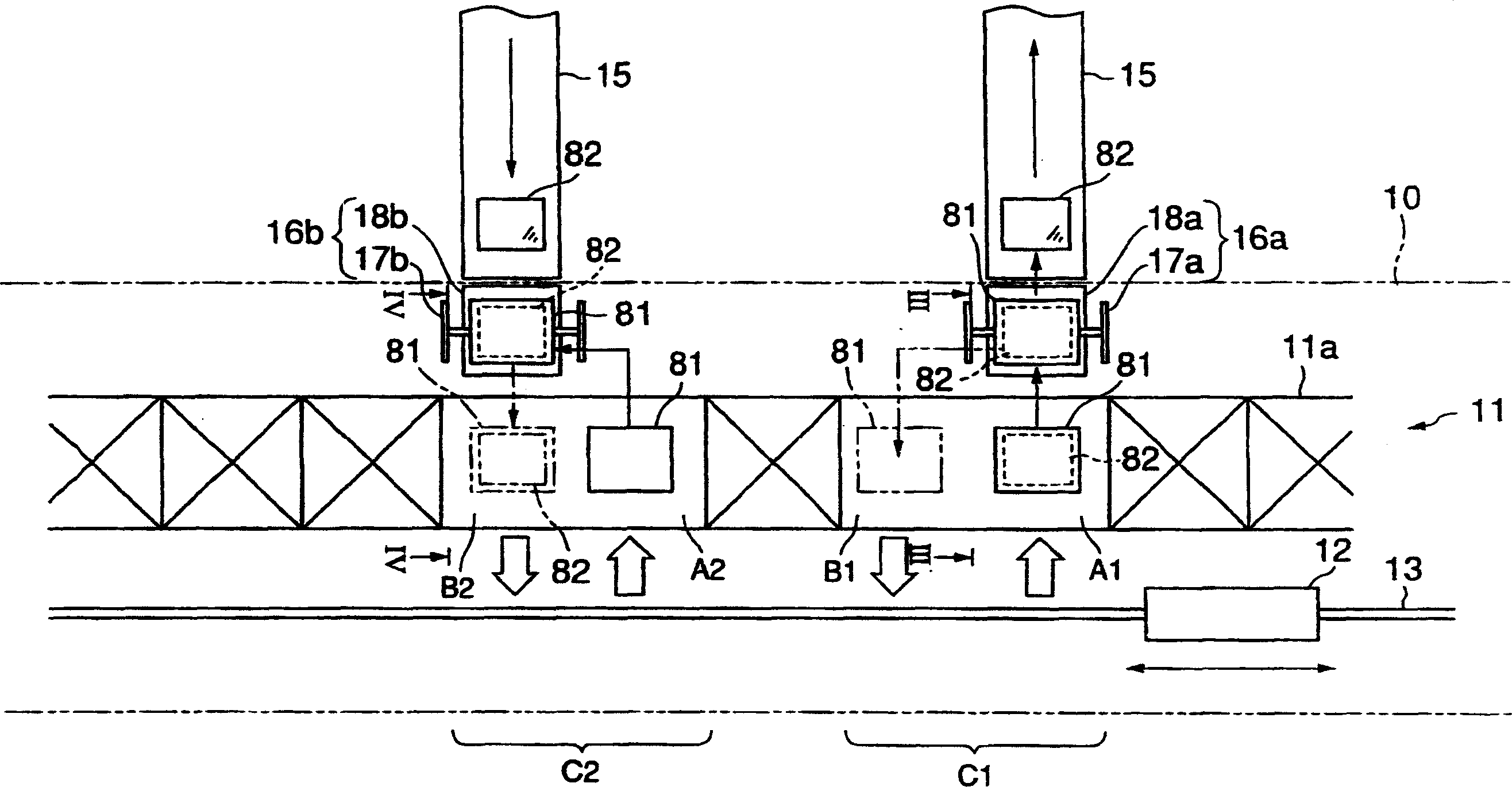

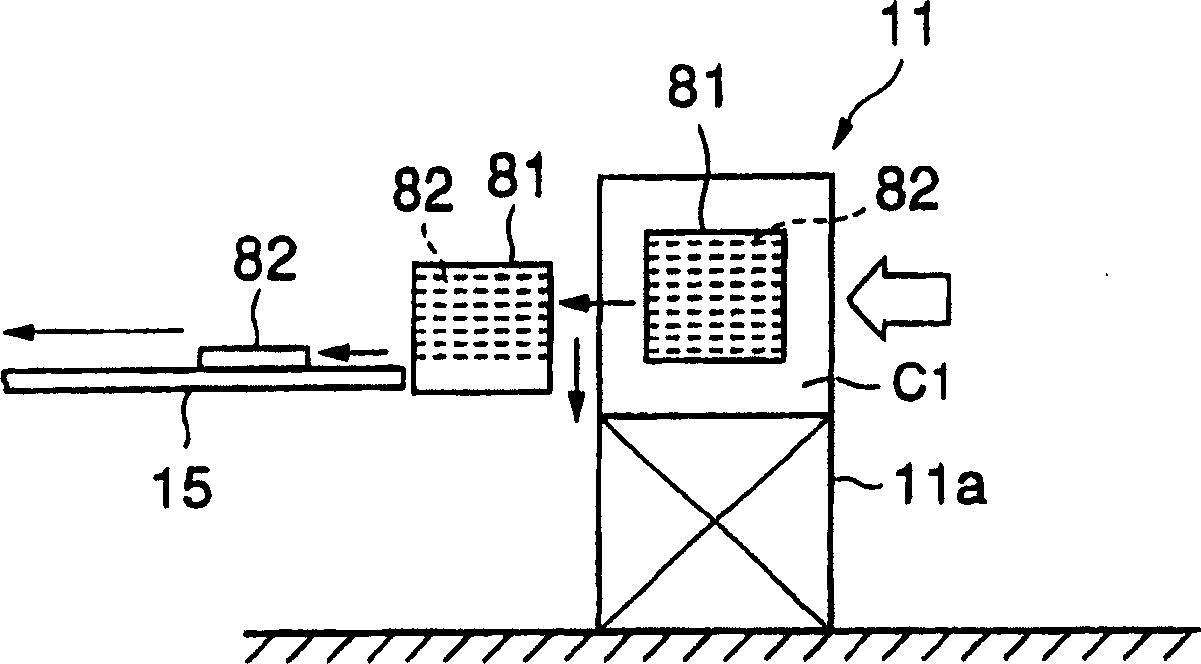

Production line system and automated warehouse used in the system

InactiveCN1672068AEasy to changeReduce operating rateOptical filtersSemiconductor/solid-state device manufacturingProduction lineEngineering

A production line system (1) comprises a core apparatus (10) of a stacker crane form and various processing lines (20, ..., 110) for performing various processes on a glass substrate that is received in a substrate receiving cassette stored in the core apparatus (10) and connected at plural loading / unloading positions (C1, C2) of the core apparatus (10) through a substrate loading / unloading mechanism (16a, 16b). At this time, the processing lines (20, ..., 90) are production lines that are used to perform various process for producing color filters, wherein the processing lines (20, ..., 70) are main screen-making lines for performing the processing steps including photolithography process, while the processing line (90) is a reserve screen-making line for performing the same process. Further, processing line (100) is a substrate inspection line that inspects a processed glass substrate that has been processed in the processing lines (20, ..., 90), and the processing line (110) is a substrate regeneration line that regenerates a glass substrate in which a defect was detected. Further, in a conveying path (15) of the processing lines (30, ..., 70), common defect inspection machines (39-77) are arranged for inspecting a common defect occurring at the same position in a plurality of glass substrates of the processed object. Further, the cassette that is stored and conveyed by the core apparatus (10) is preferably a frame line type cassettes that uses a plurality of frame lines suspending between left and right frames to support the substrate in a horizontal status.

Owner:DAI NIPPON PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com