Patents

Literature

48results about How to "Avoid Surface Corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

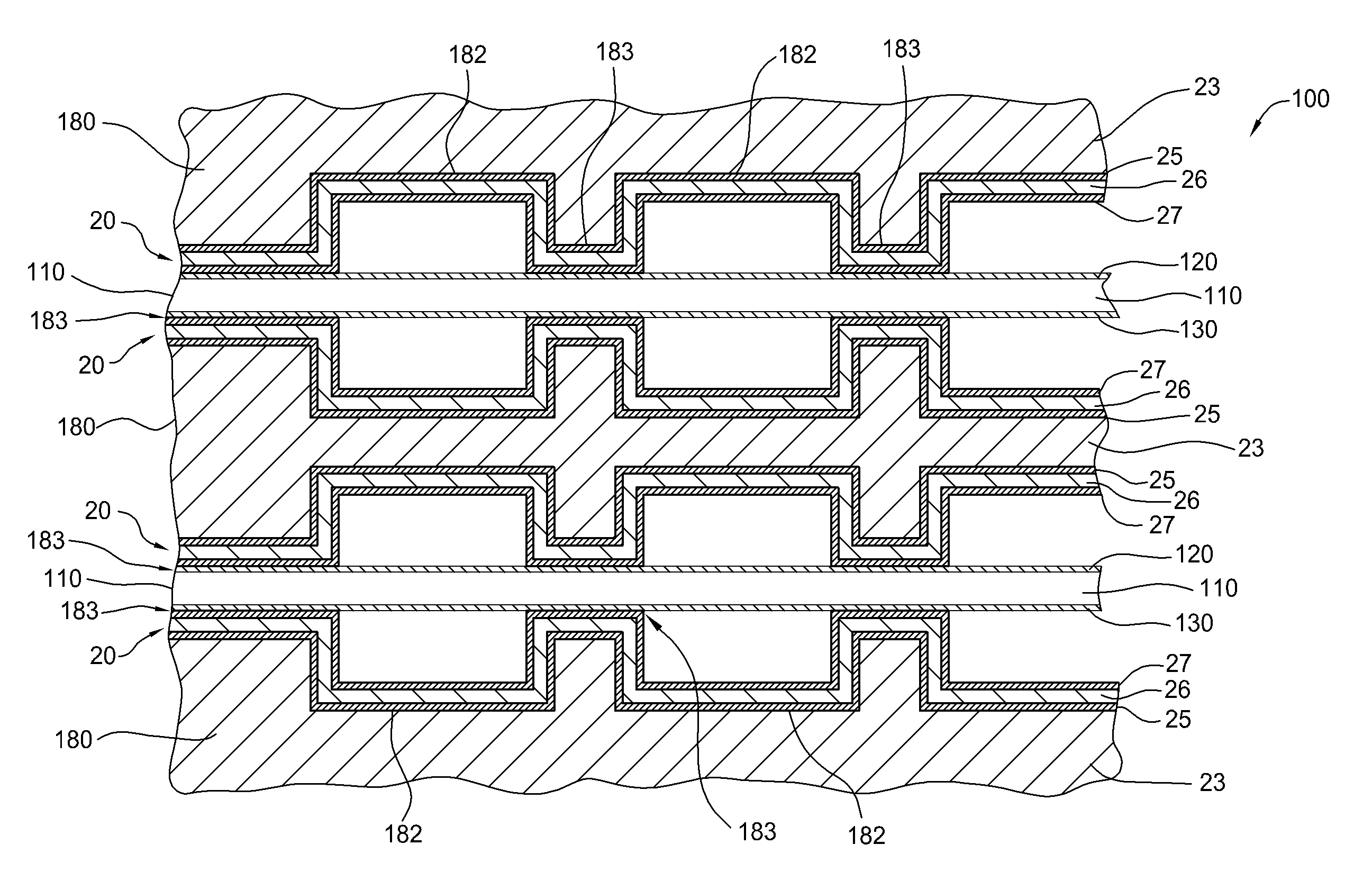

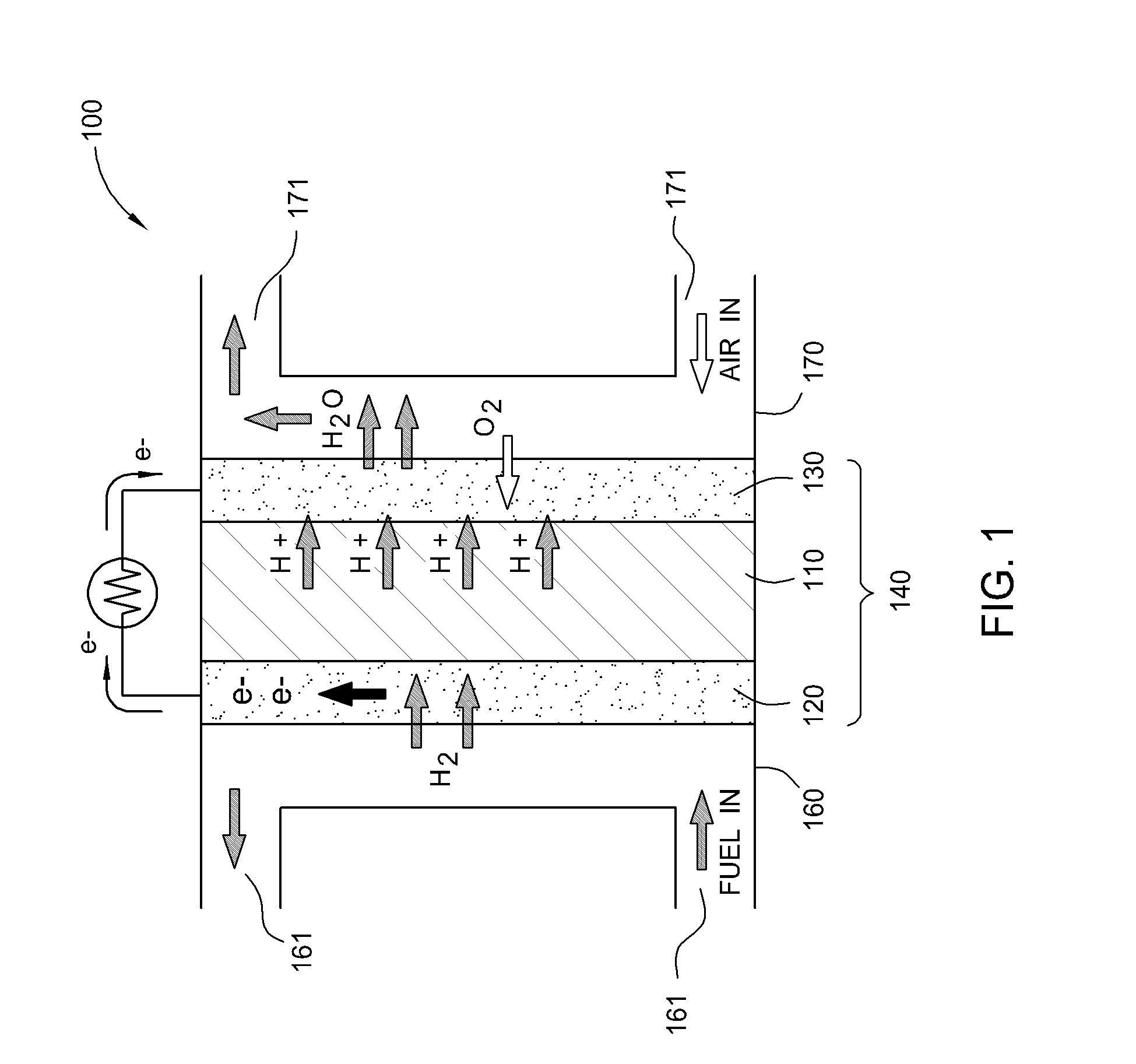

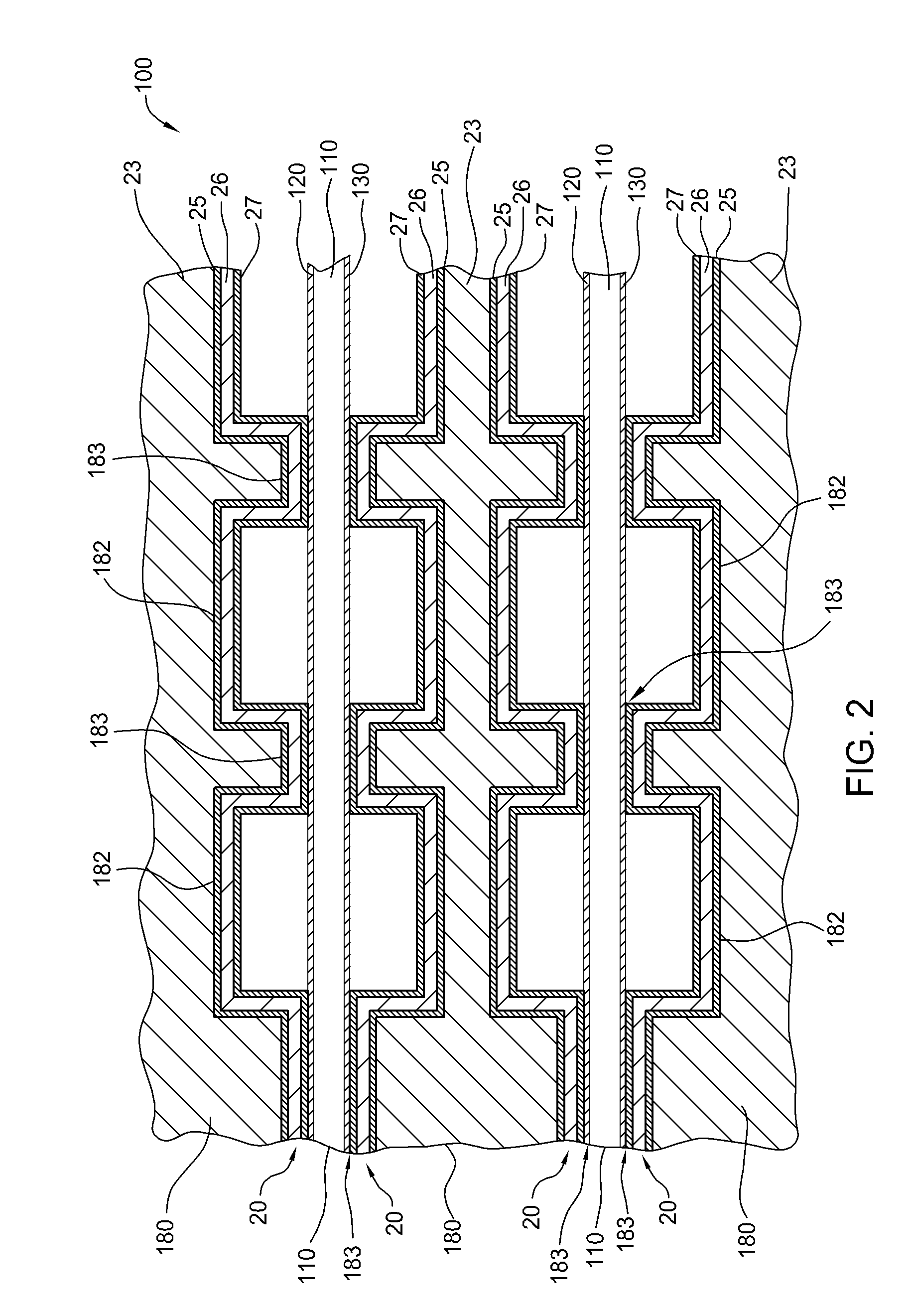

Reliable fuel cell electrode design

InactiveUS20070243452A1Avoid Surface CorrosionAvoid corrosionFinal product manufactureFuel cell auxillariesFuel cellsEngineering

The present invention generally relates to the creation of fuel cell components and the method of forming the various fuel cell components that have an improved lifetime, lower production cost and improved process performance. The invention generally includes treating or conditioning a substrate surface by depositing a material layer, or layers, having good adhesion to the substrate, low electrical resistivity (high conductivity) and has good resistance to chemical attack during the operation of fuel cell. The substrate may be, for example, a fuel cell part, a conductive plate, a separator plate, a bipolar plate or an end plate, among others. In one embodiment, the substrate surface is treated or conditioned by exposing at least a portion of it to a gas or liquid comprising ruthenium tetroxide.

Owner:APPLIED MATERIALS INC

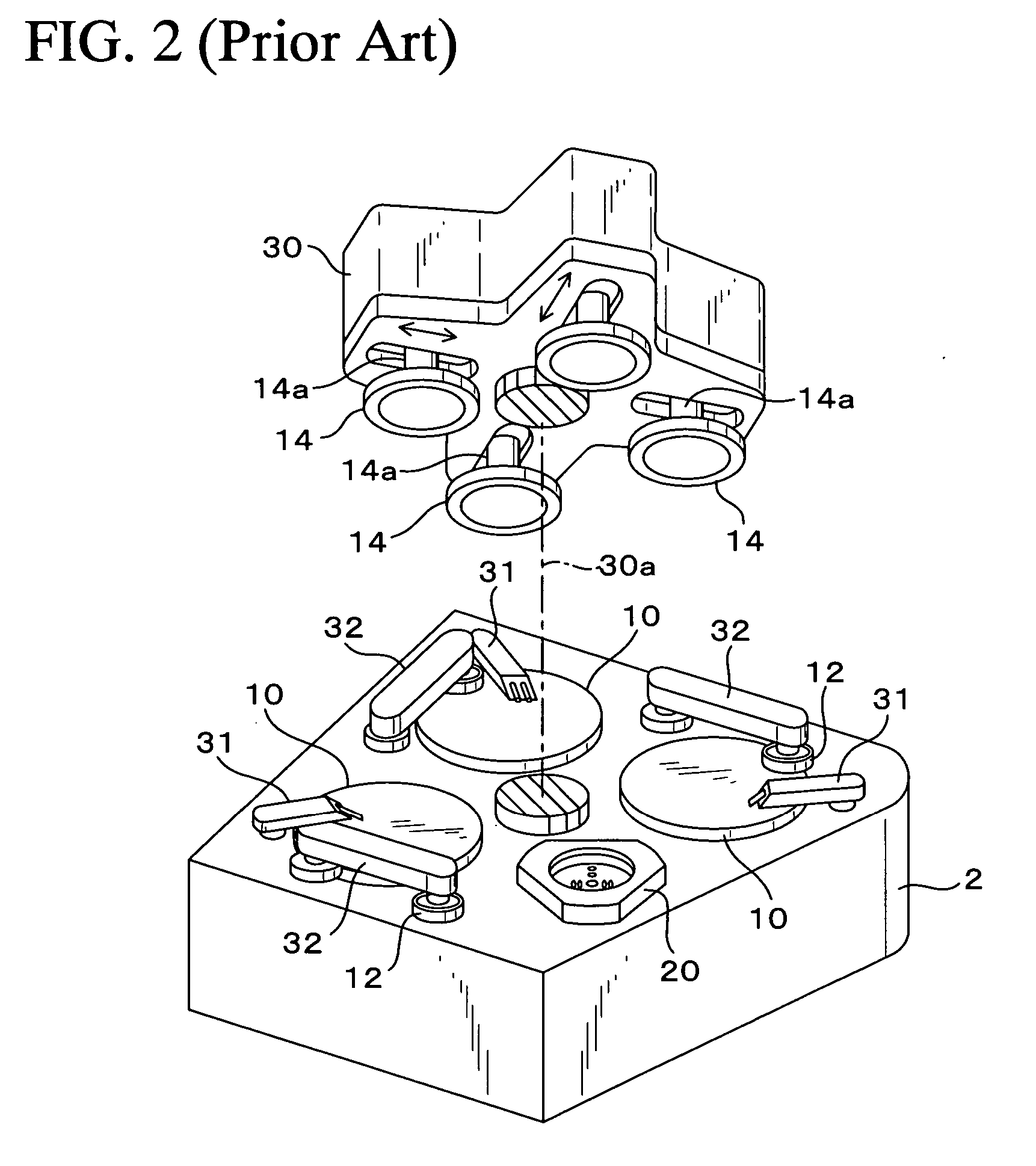

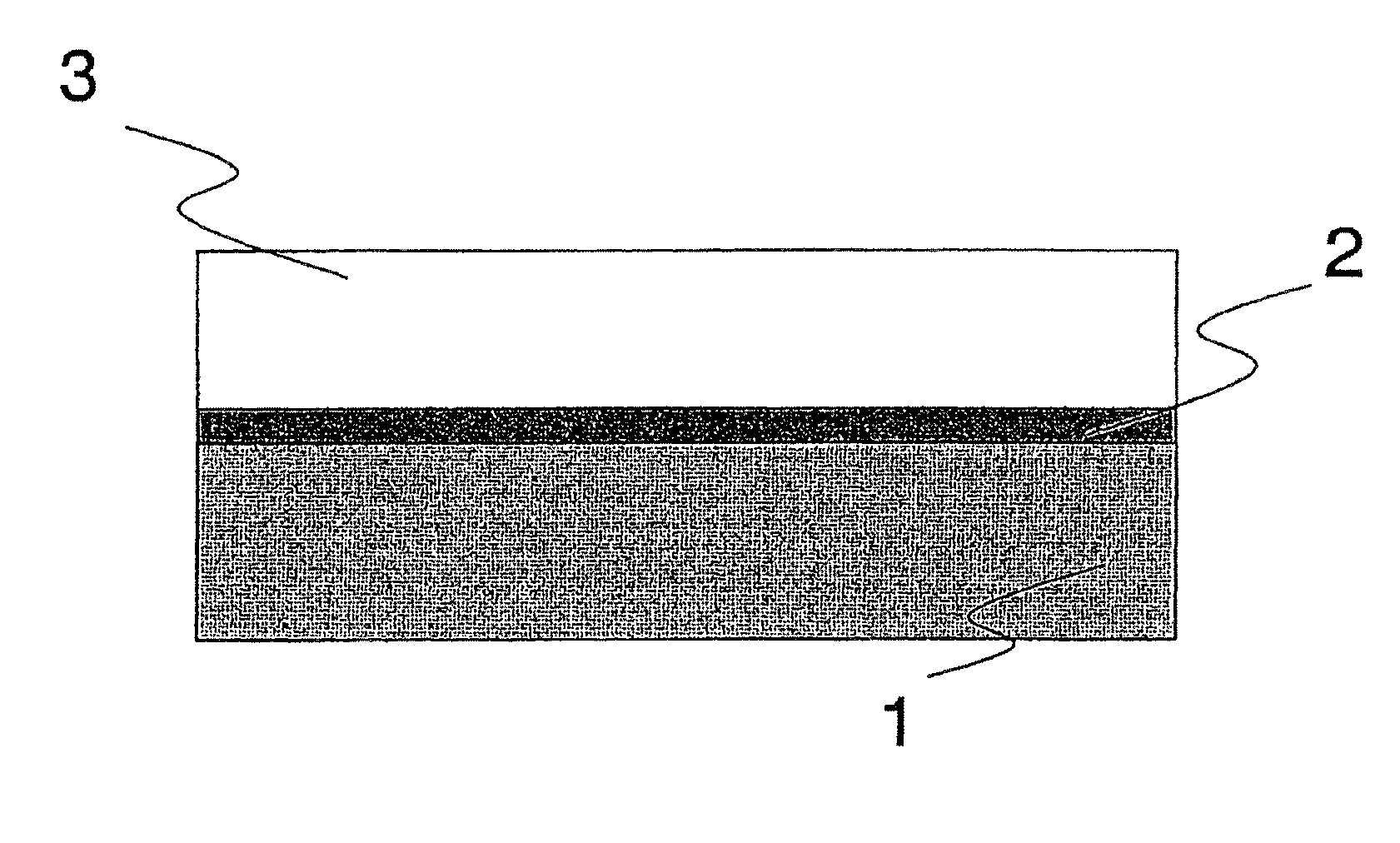

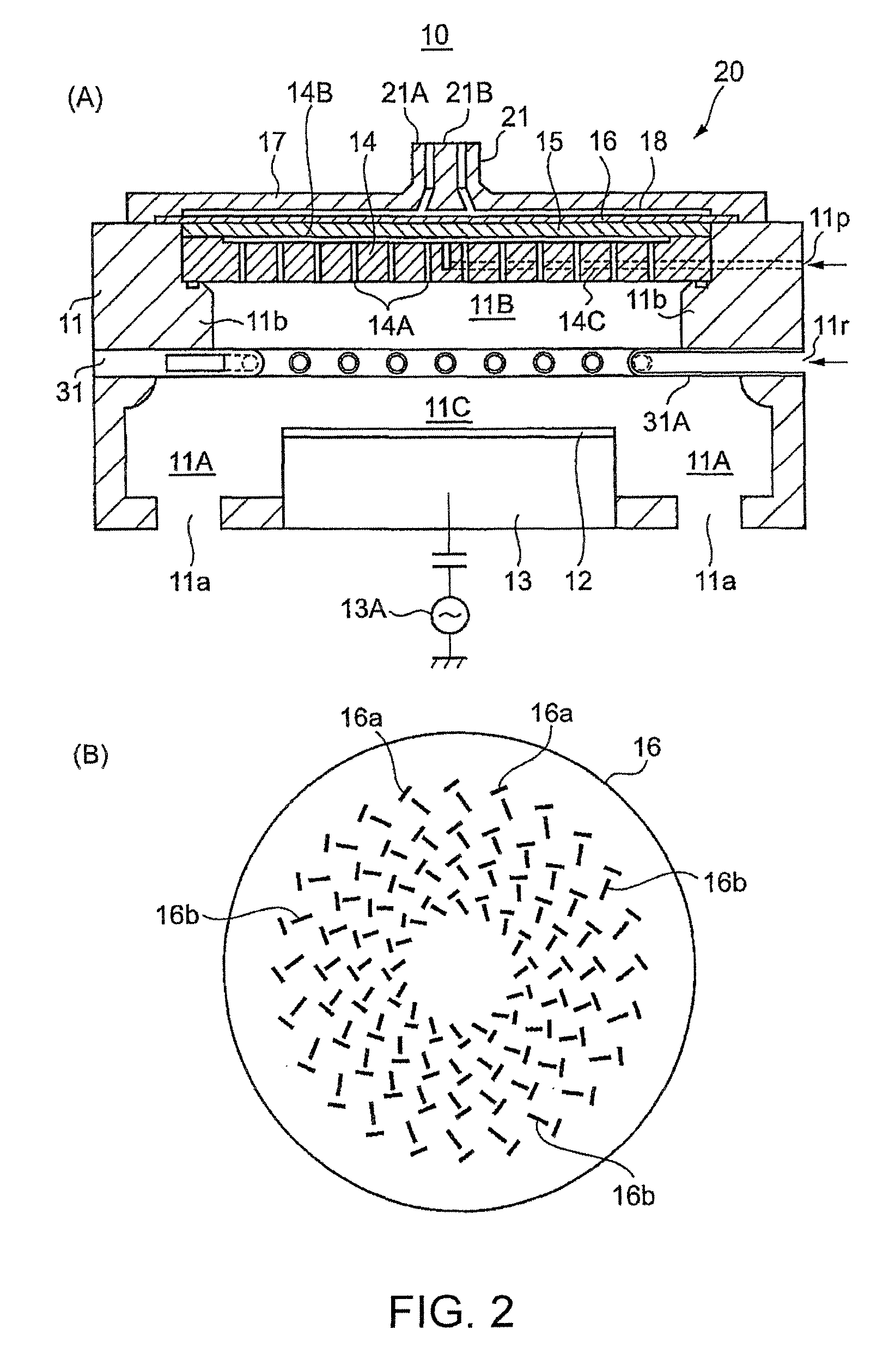

Protective Film Structure of Metal Member, Metal Component Employing Protective Film Structure, and Equipment for Producing Semiconductor or Flat-Plate Display Employing Protective Film Structure

InactiveUS20090142588A1Avoid Surface CorrosionReduce pollutionAnodisationMolten spray coatingTectorial membraneMetallic materials

Multifunction production equipment enabling a plurality of processes in which deposition of reaction products on the inner wall of the processing chamber of equipment for producing a semiconductor or a flat-plate display, metal contamination due to corrosion of the inner wall, or the like, and fluctuation of the process due to discharged gas are suppressed, and a protective film structure for use therein. On the surface of a metal material, a first coating layer having an oxide coating of 1μ thick or less formed as an underlying layer by direct oxidation of a parent material, and a second coating layer of about 200 μm thick are formed. With such an arrangement, corrosion resistance against irradiation with ions or radicals can be imparted to a second layer protective film, and the effect of a protective layer for preventing corrosion of the surface of parent metal caused by diffusing molecules or ions into the second layer protective film can be imparted to the first layer oxide film. Consequently, contamination of the substrate with metals generated from each metal member and the inner surface of the process chamber is reduced, and stripping of the second layer protective film due to lowering in adhesion of the second layer protective film due to corrosion of the interface between the parent material and the second layer protective film can be suppressed.

Owner:NGK SPARK PLUG CO LTD +2

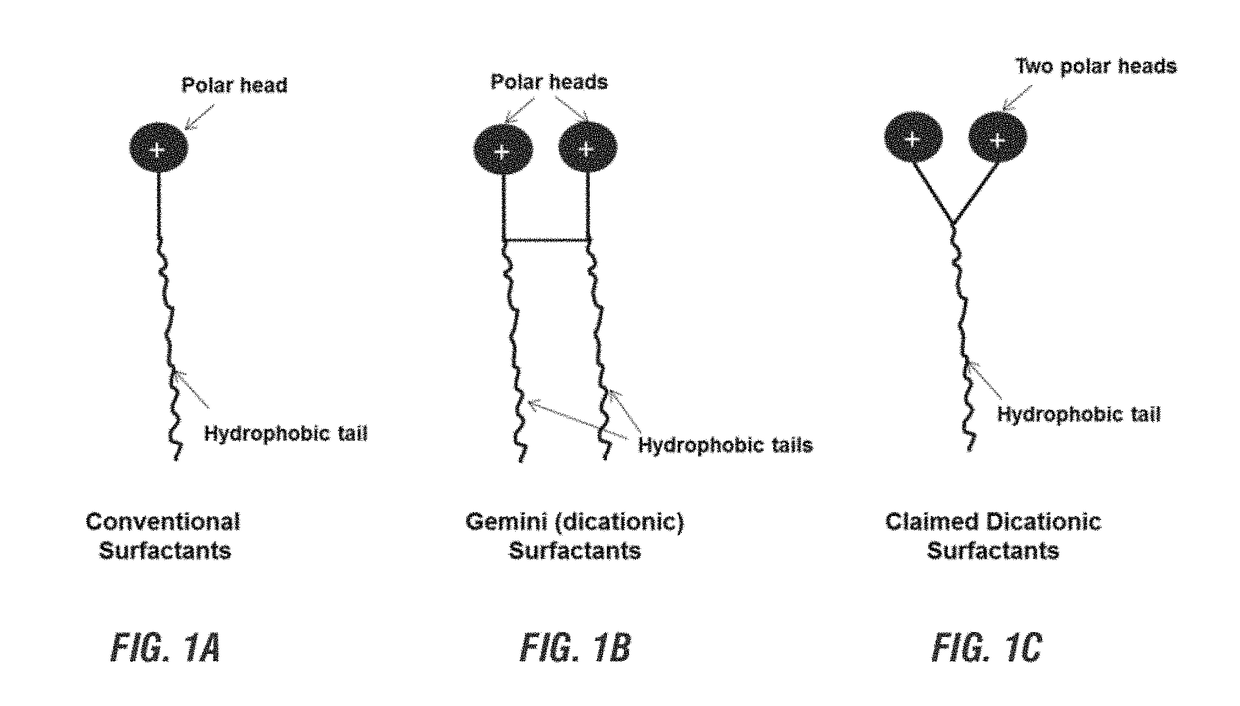

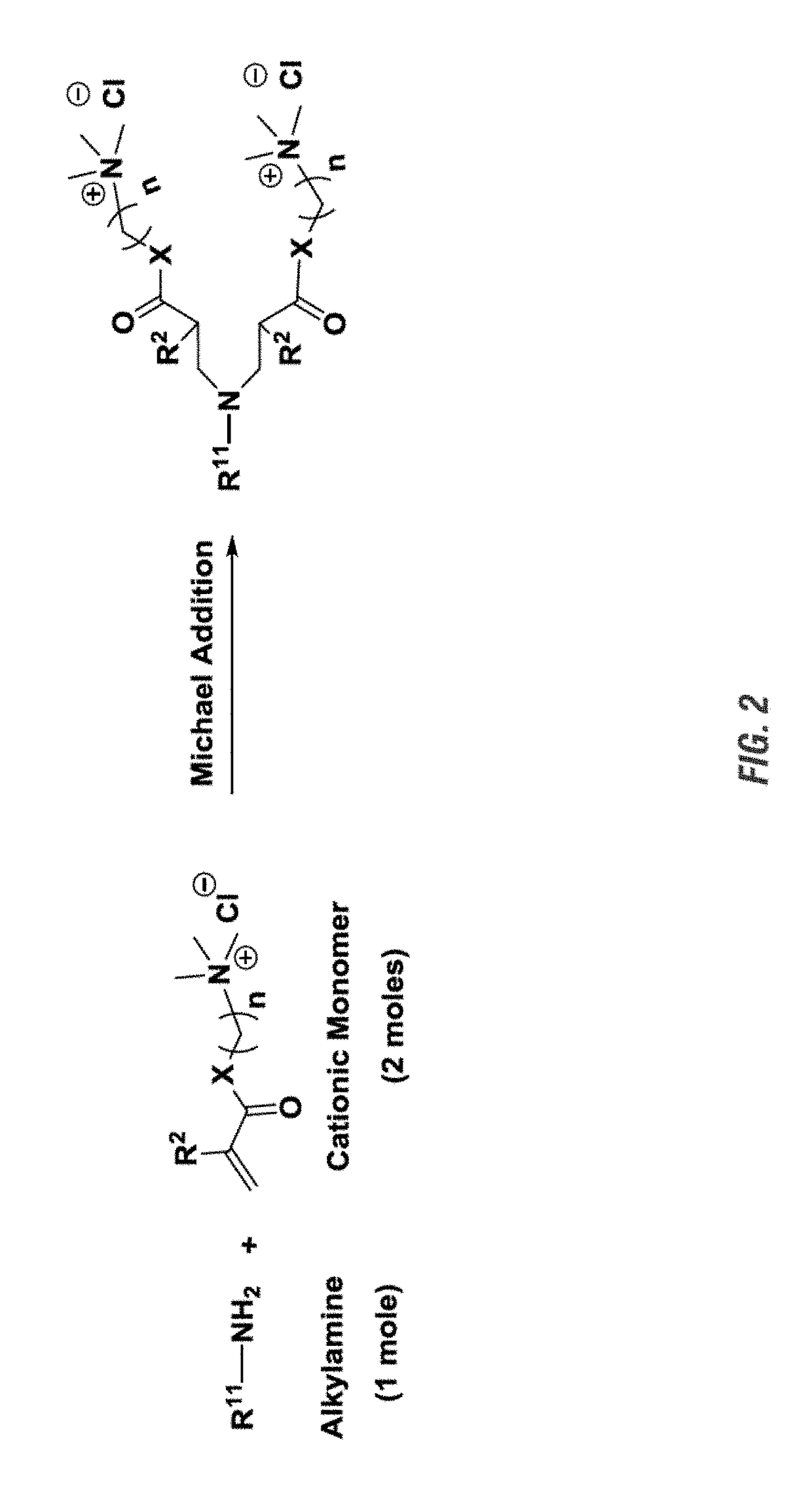

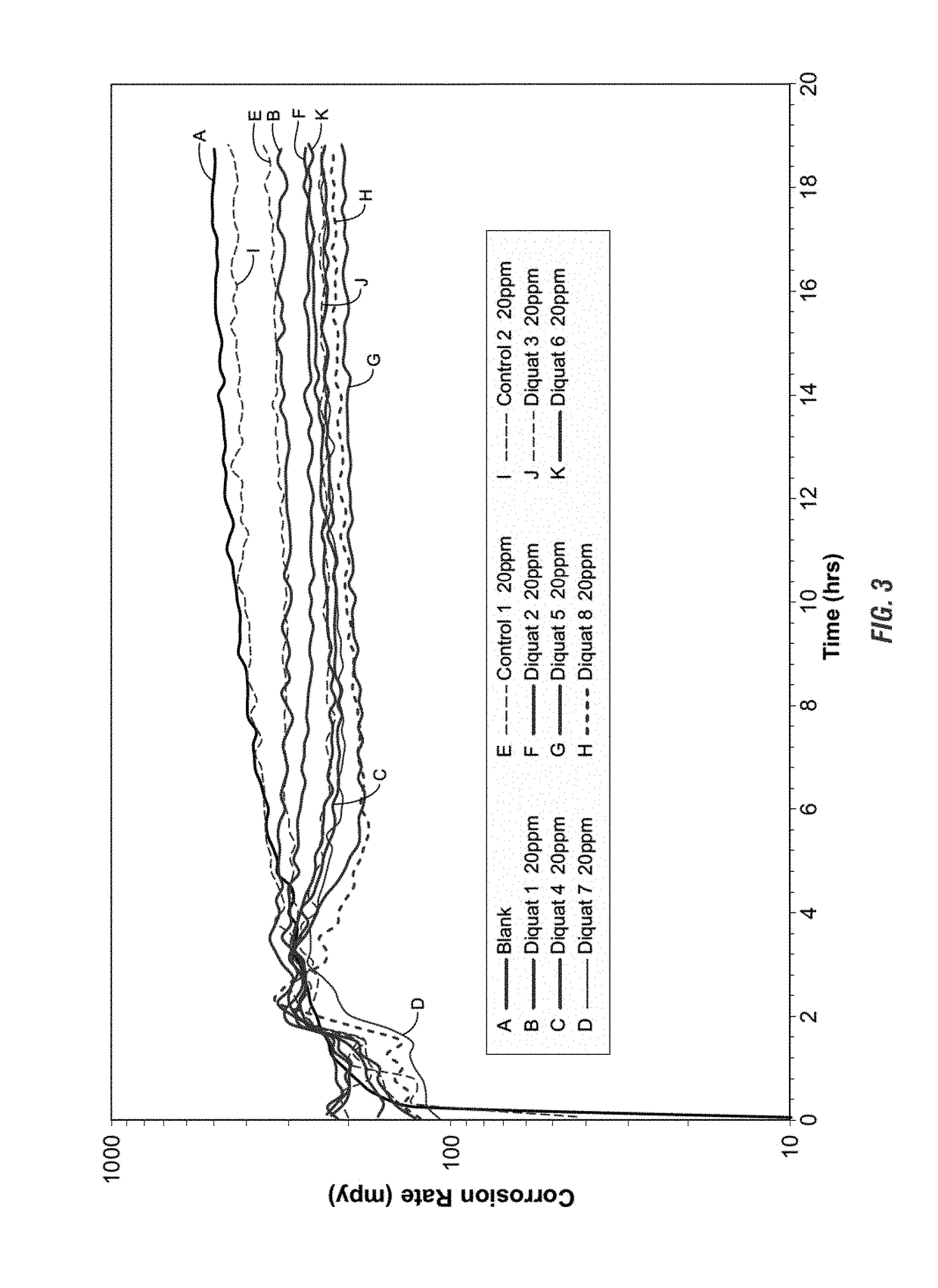

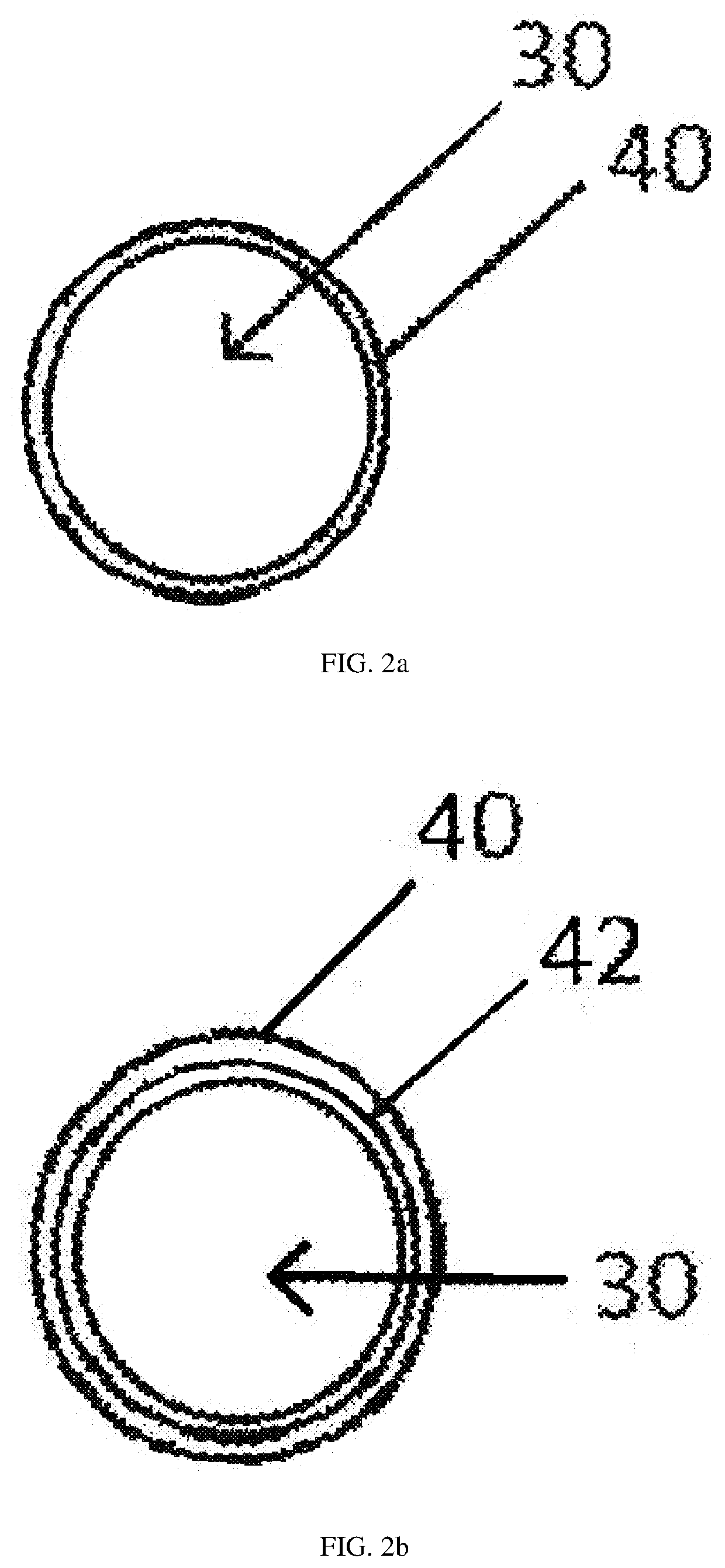

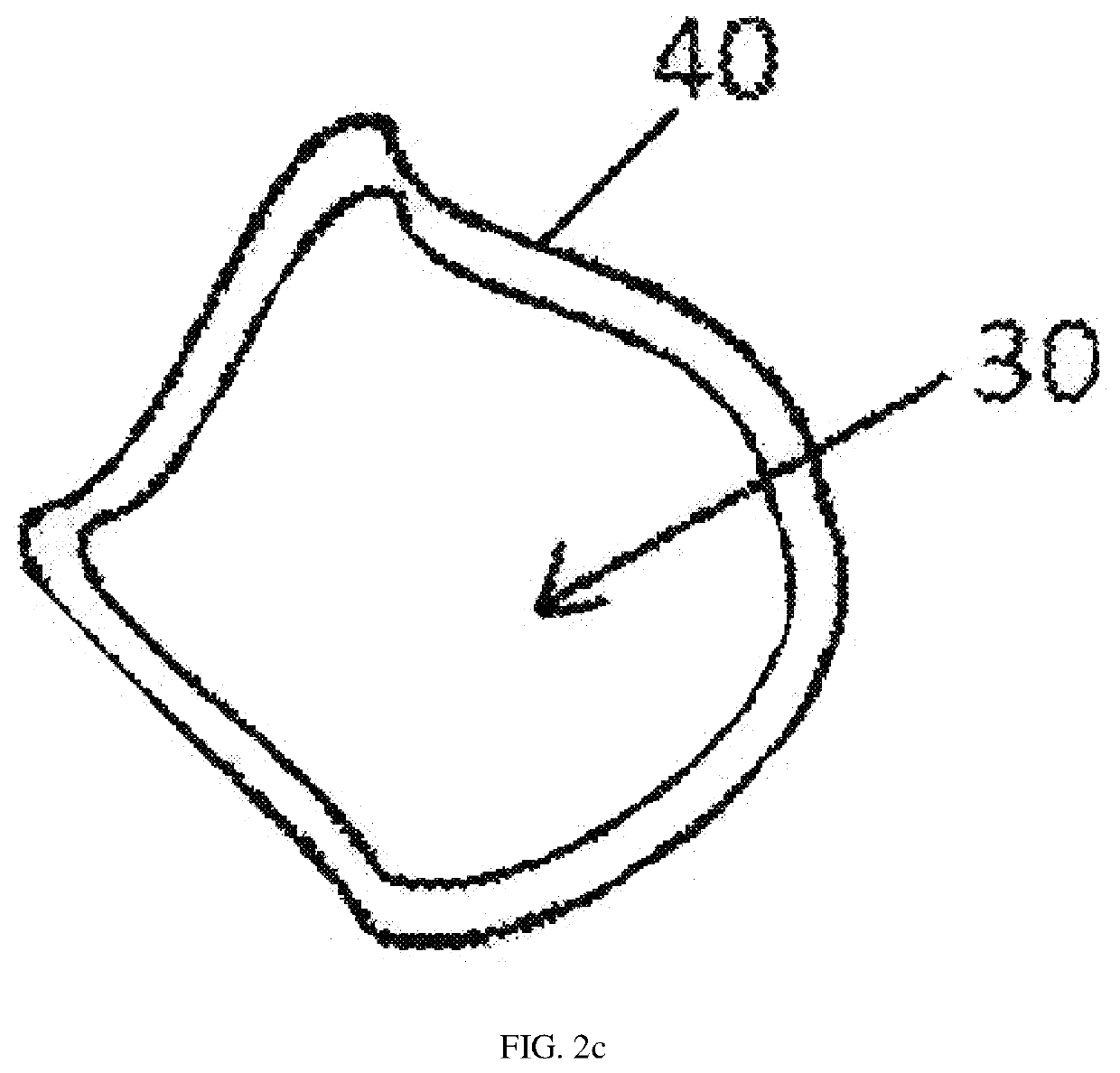

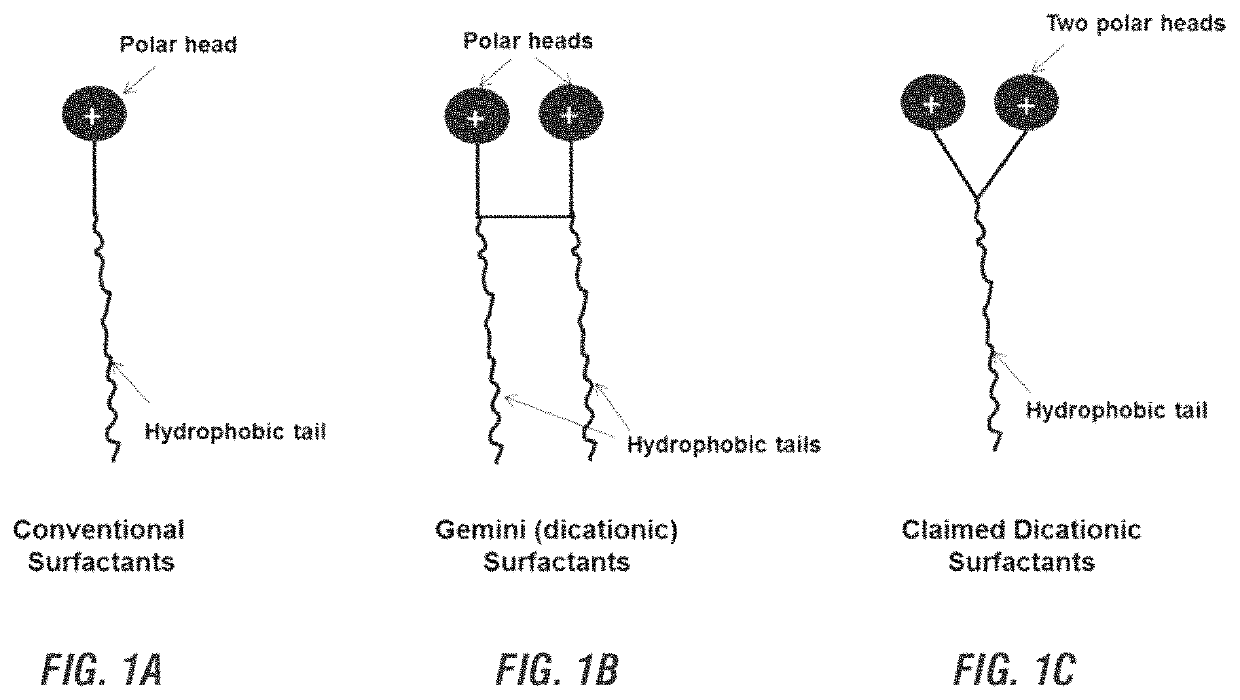

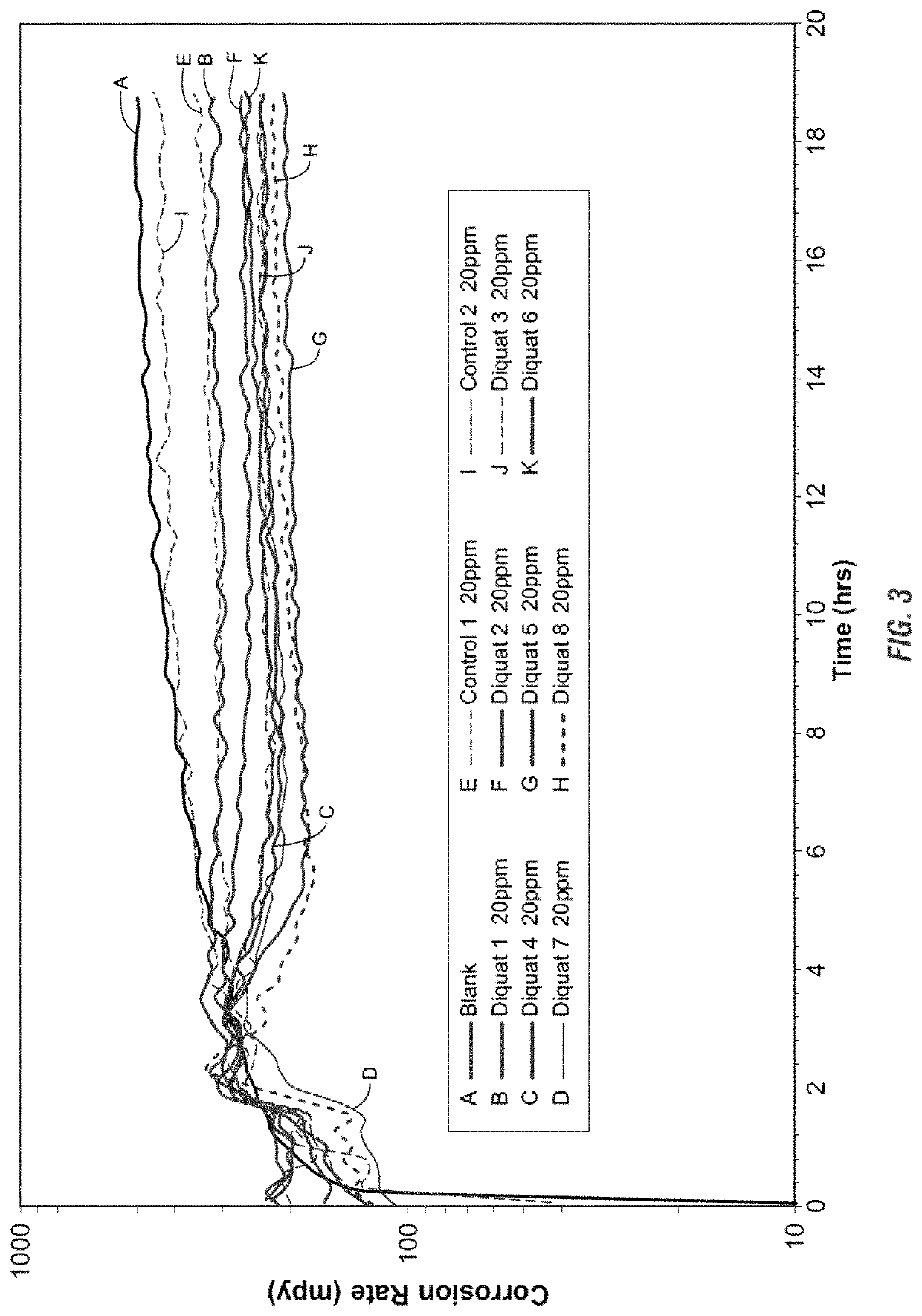

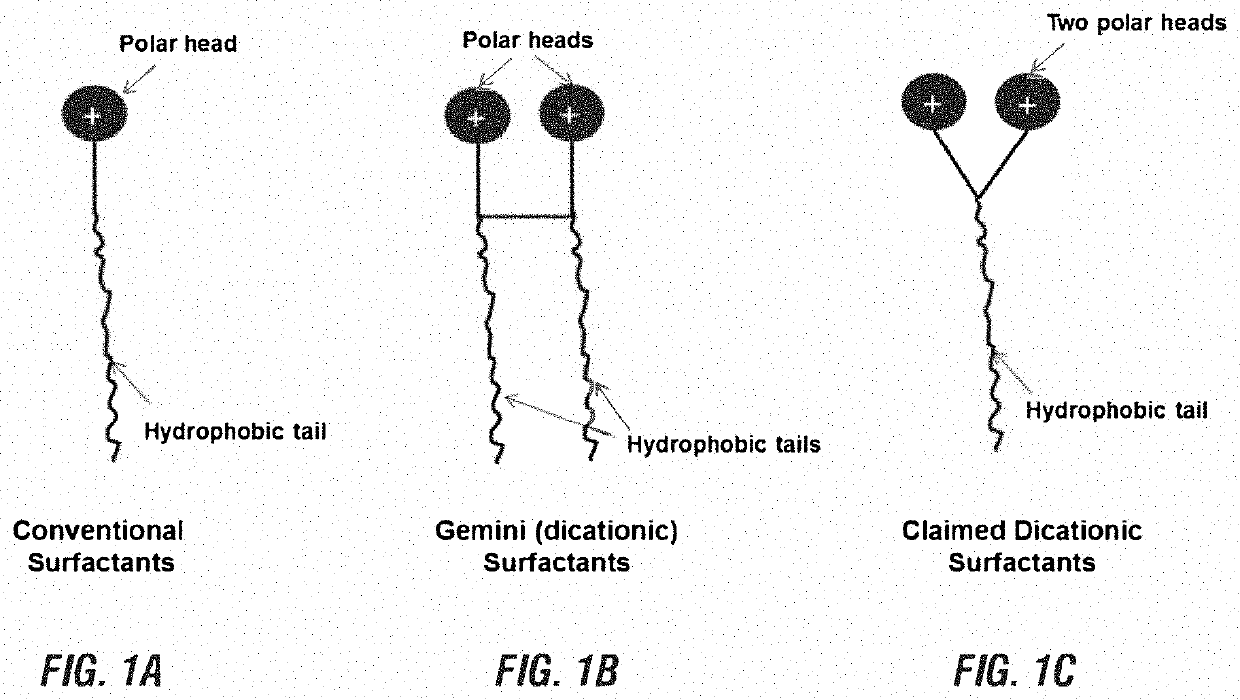

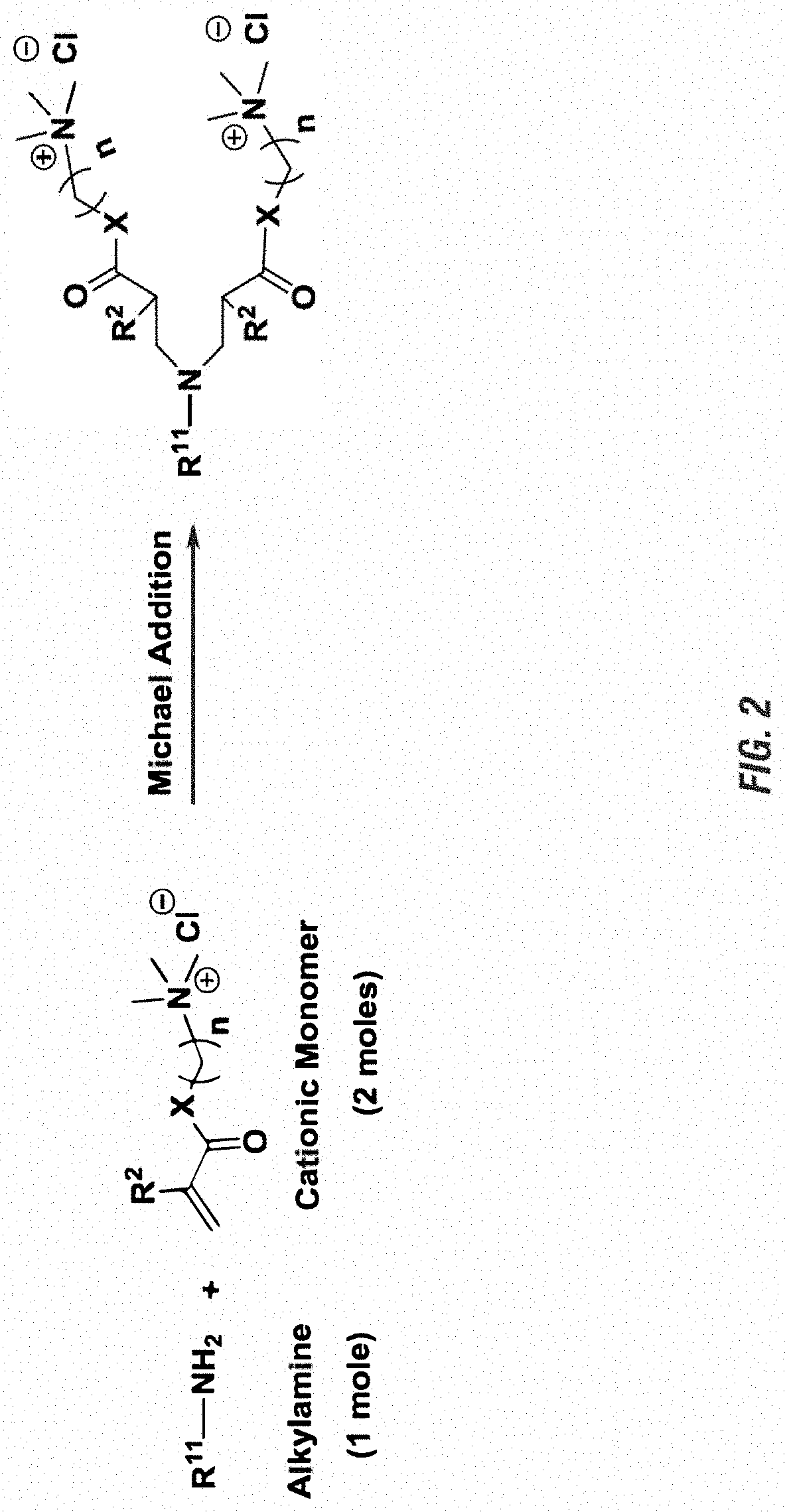

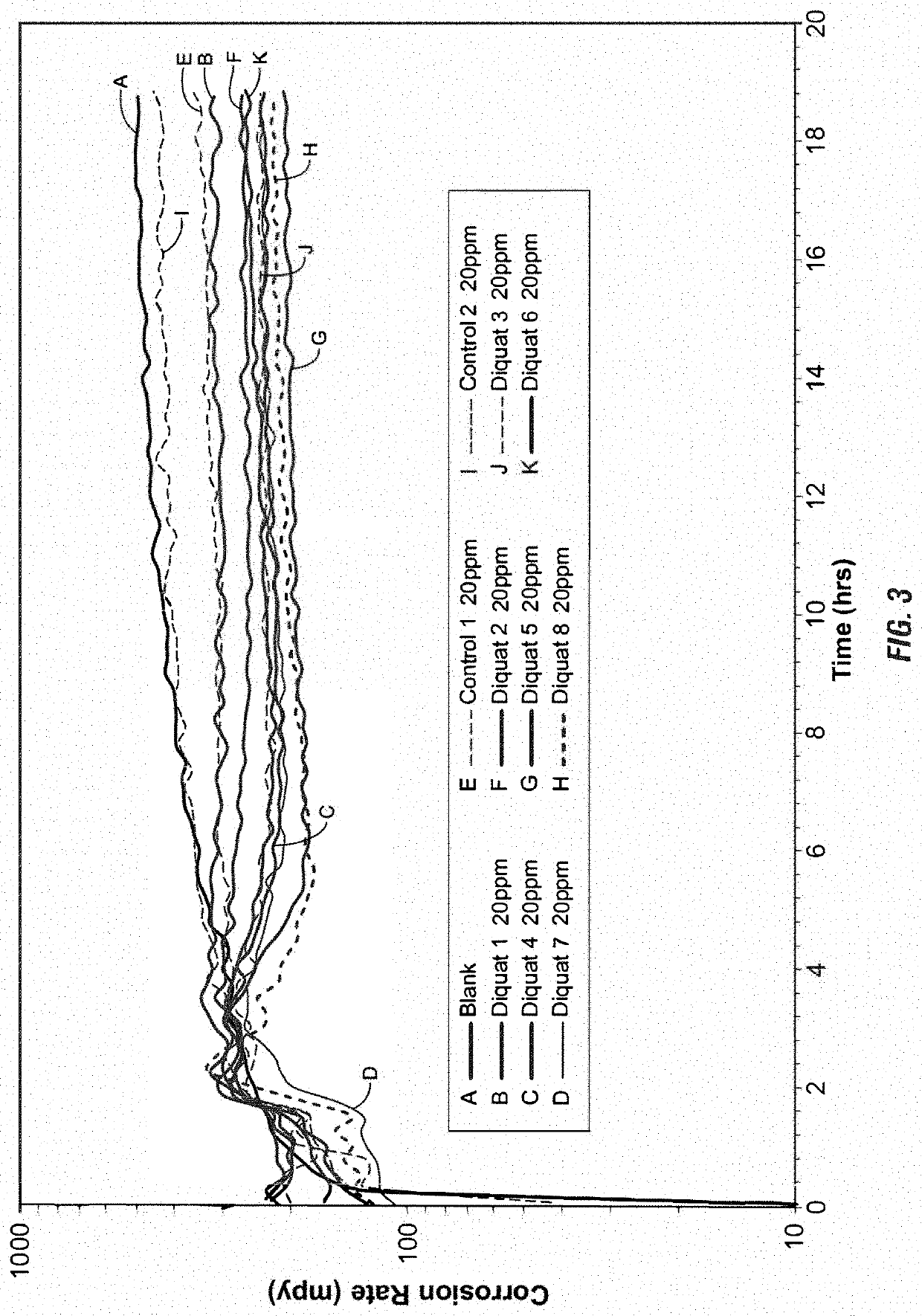

Use of di-ionic compounds as corrosion inhibitors in a water system

ActiveUS20190062187A1Reduce corrosionImprove performanceCationic surface-active compoundsOrganic compound preparationNitrogenQuaternary compound

Disclosed herein are the methods of using di-cationic or di-anionic compounds, which are derived from primary amine through an aza-Michael addition with an activated olefin, in a corrosion control composition to mitigate corrosion of a surface in a water system. The disclosed methods or compositions are found to be more effective than those methods or compositions including commonly used single quaternary compounds for mitigating corrosion for a metal surface in water systems.

Owner:ECOLAB USA INC

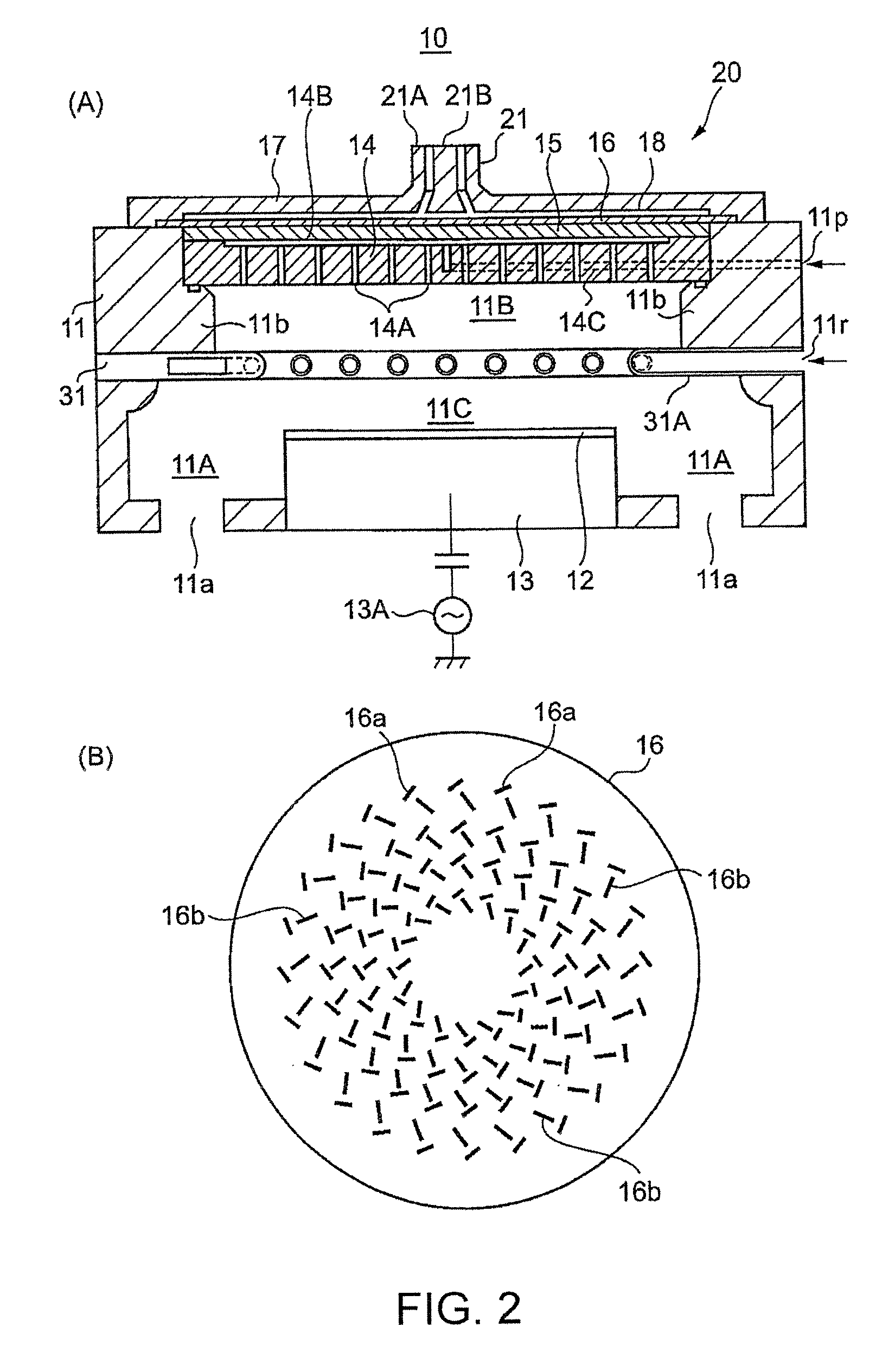

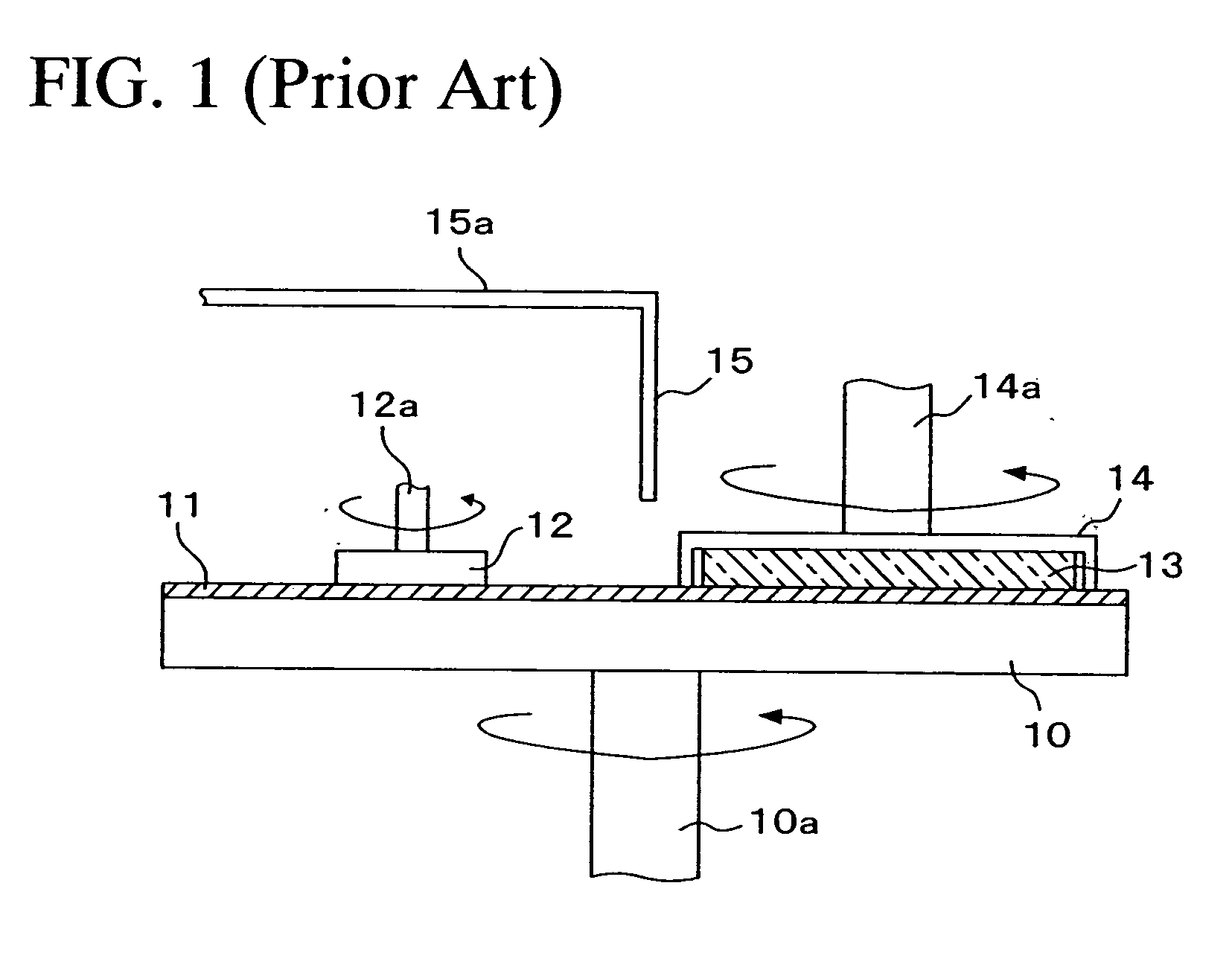

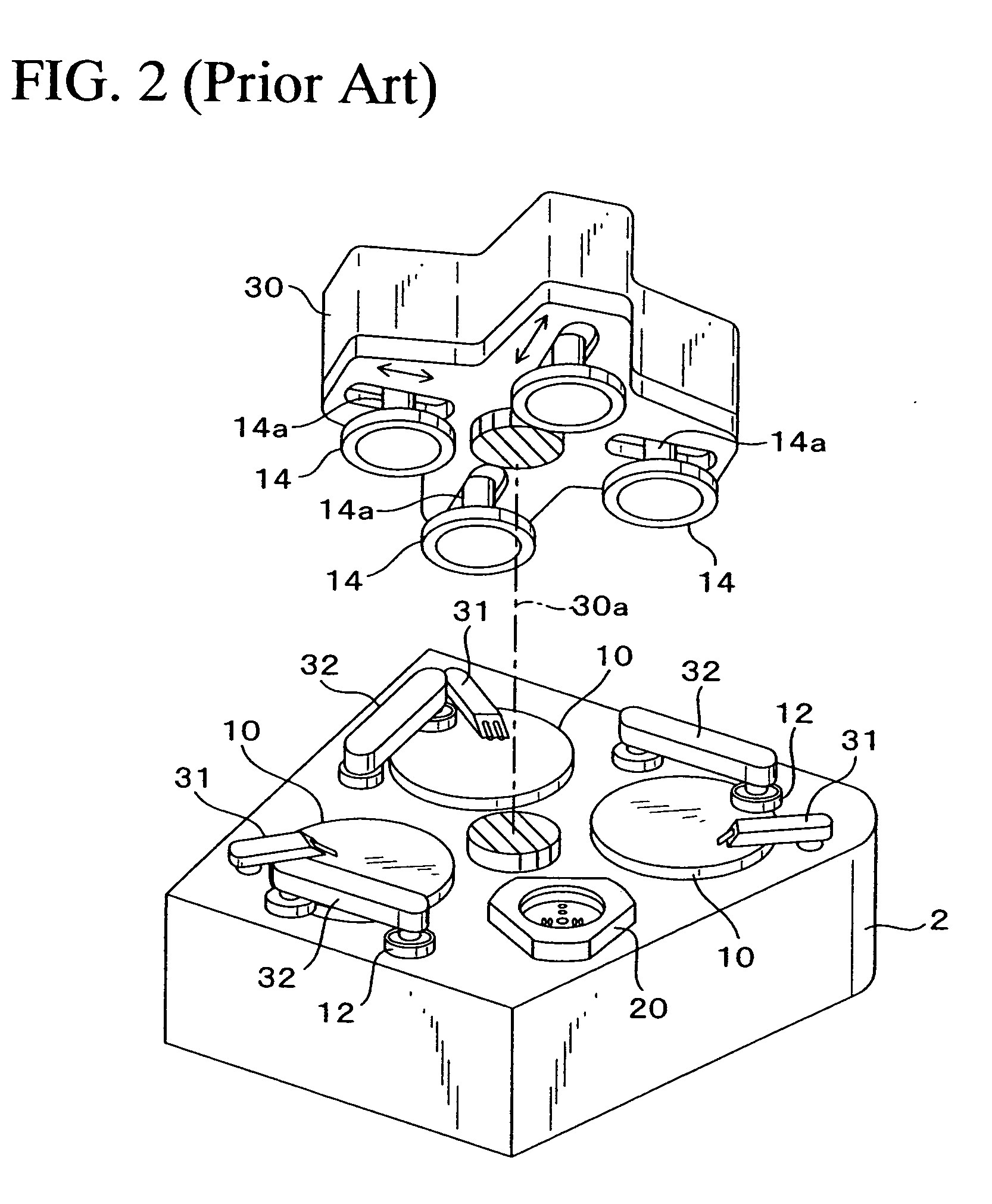

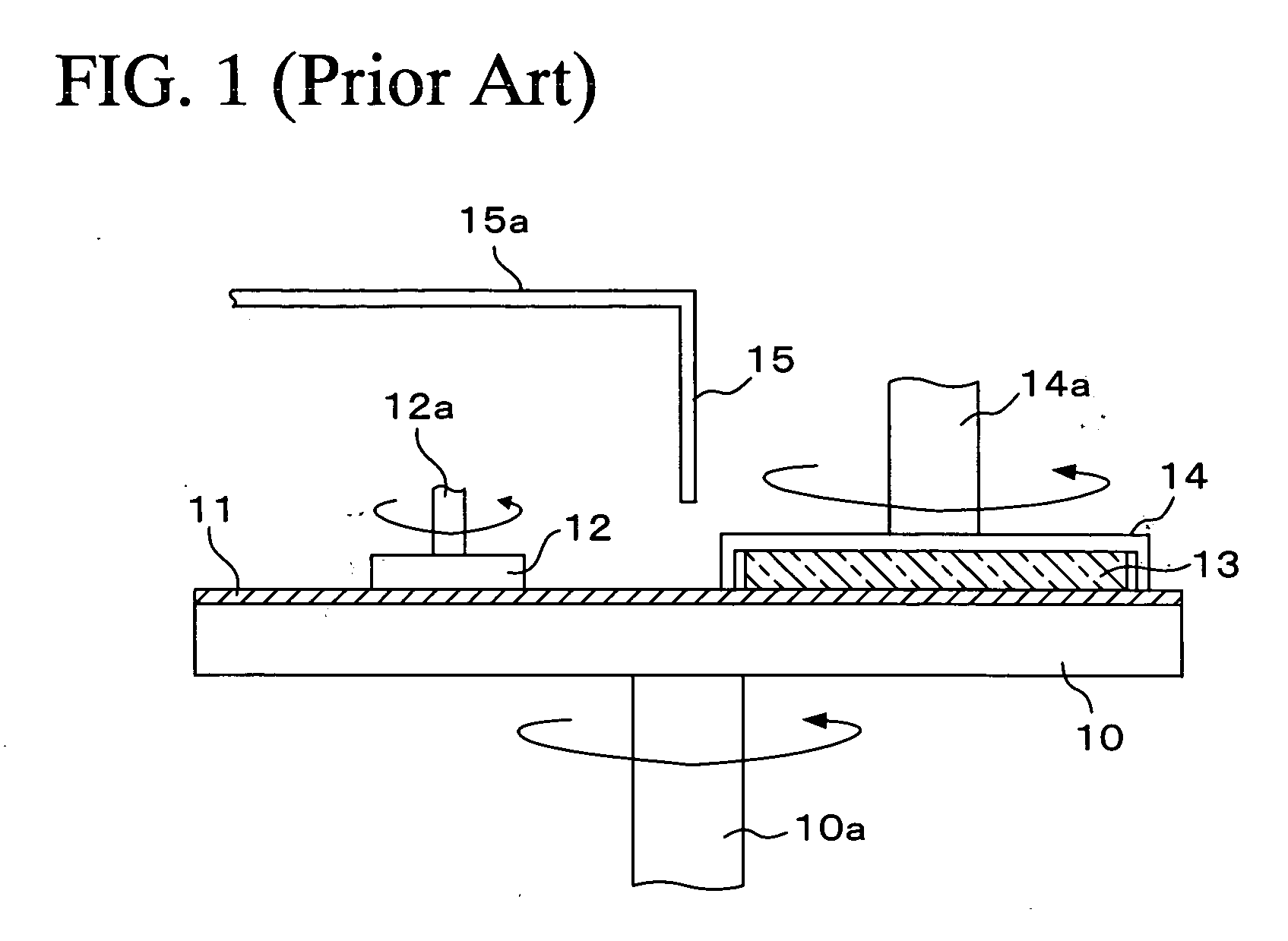

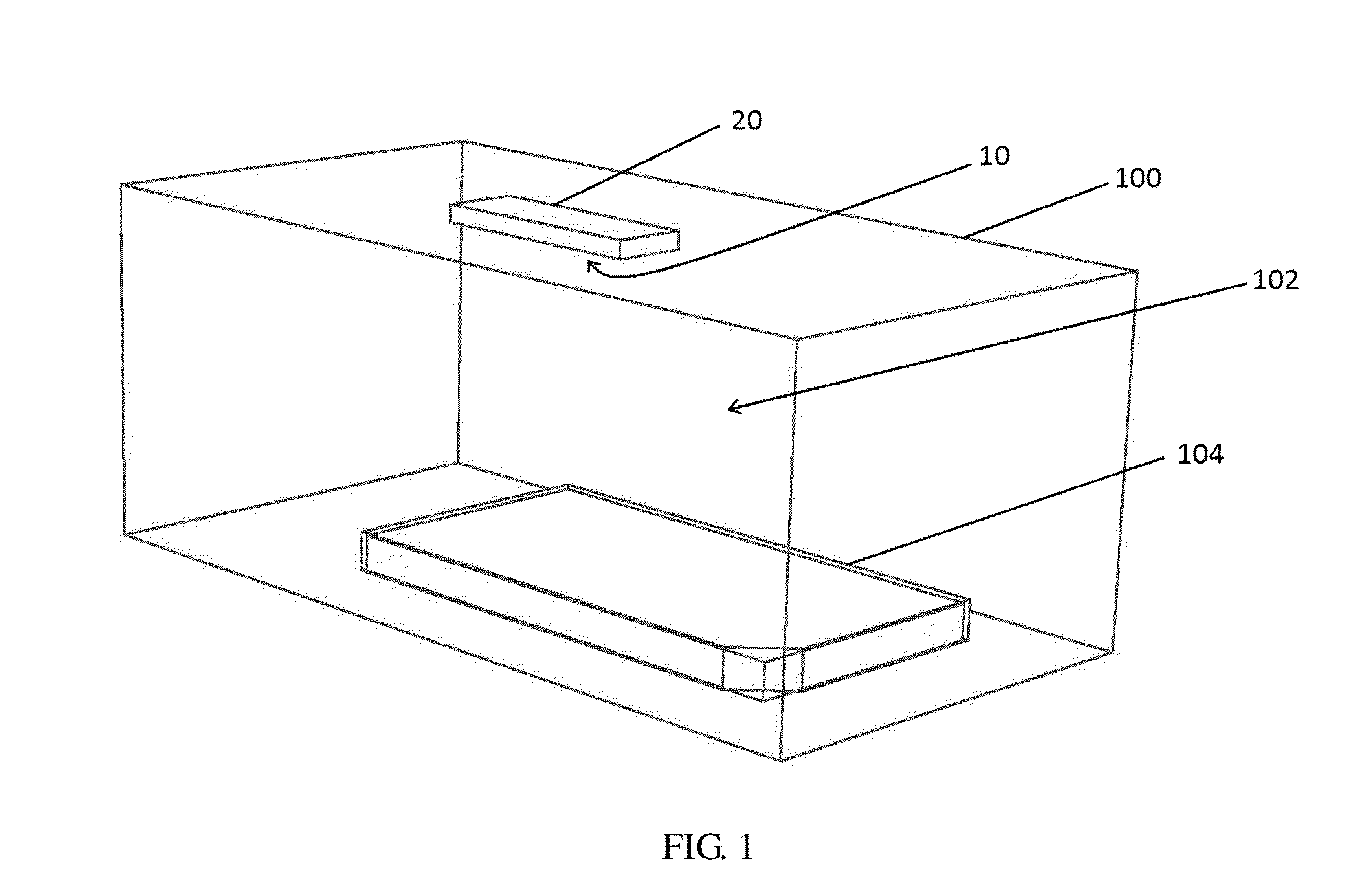

Polishing machine, workpiece supporting table pad, polishing method and manufacturing method of semiconductor device

InactiveUS20070123047A1Avoid Surface CorrosionPrevent oxidation and corrosion and other troubleDecorative surface effectsSemiconductor/solid-state device manufacturingDevice materialSemiconductor

A pedestal pad (workpiece supporting table pad) is arranged on the top of a pedestal (workpiece supporting table) for temporarily placing and holding a pre-polished or post-polished wafer (workpiece). This pedestal pad is formed of resin, and at least a surface of the pedestal pad which comes into contact with the wafer is non-absorbable to a fluid. The tissue of the pedestal pad is dense and smooth, and does not have any cavity, such as fine holes, which holds the fluid.

Owner:FUJITSU SEMICON LTD

Polishing machine, workpiece supporting table pad, polishing method and manufacturing method of semiconductor device

ActiveUS20070060024A1Decrease in manufacturing yieldAvoid Surface CorrosionPolishing machinesRevolution surface grinding machinesDevice materialEngineering

A pedestal pad (workpiece supporting table pad) is arranged on the top of a pedestal (workpiece supporting table) for temporarily placing and holding a pre-polished or post-polished wafer (workpiece). This pedestal pad is formed of resin, and at least a surface of the pedestal pad which comes into contact with the wafer is non-absorbable to a fluid. The tissue of the pedestal pad is dense and smooth, and does not have any cavity, such as fine holes, which holds the fluid.

Owner:FUJITSU SEMICON LTD

Protective film structure of metal member, metal component employing protective film structure, and equipment for producing semiconductor or flat-plate display employing protective film structure

InactiveUS8124240B2Improve corrosion resistanceAvoid Surface CorrosionAnodisationMolten spray coatingTectorial membraneDisplay device

A protective film structure of a metal member for use in an apparatus for manufacturing a semiconductor or the like, the protective film structure including a first coating layer of faultless aluminum oxide formed by direct anodic oxidation of a base-material metal of an aluminum alloy; and a second coating layer formed on the first coating layer and made of yttrium oxide by a plasma spraying method.

Owner:NGK SPARK PLUG CO LTD +2

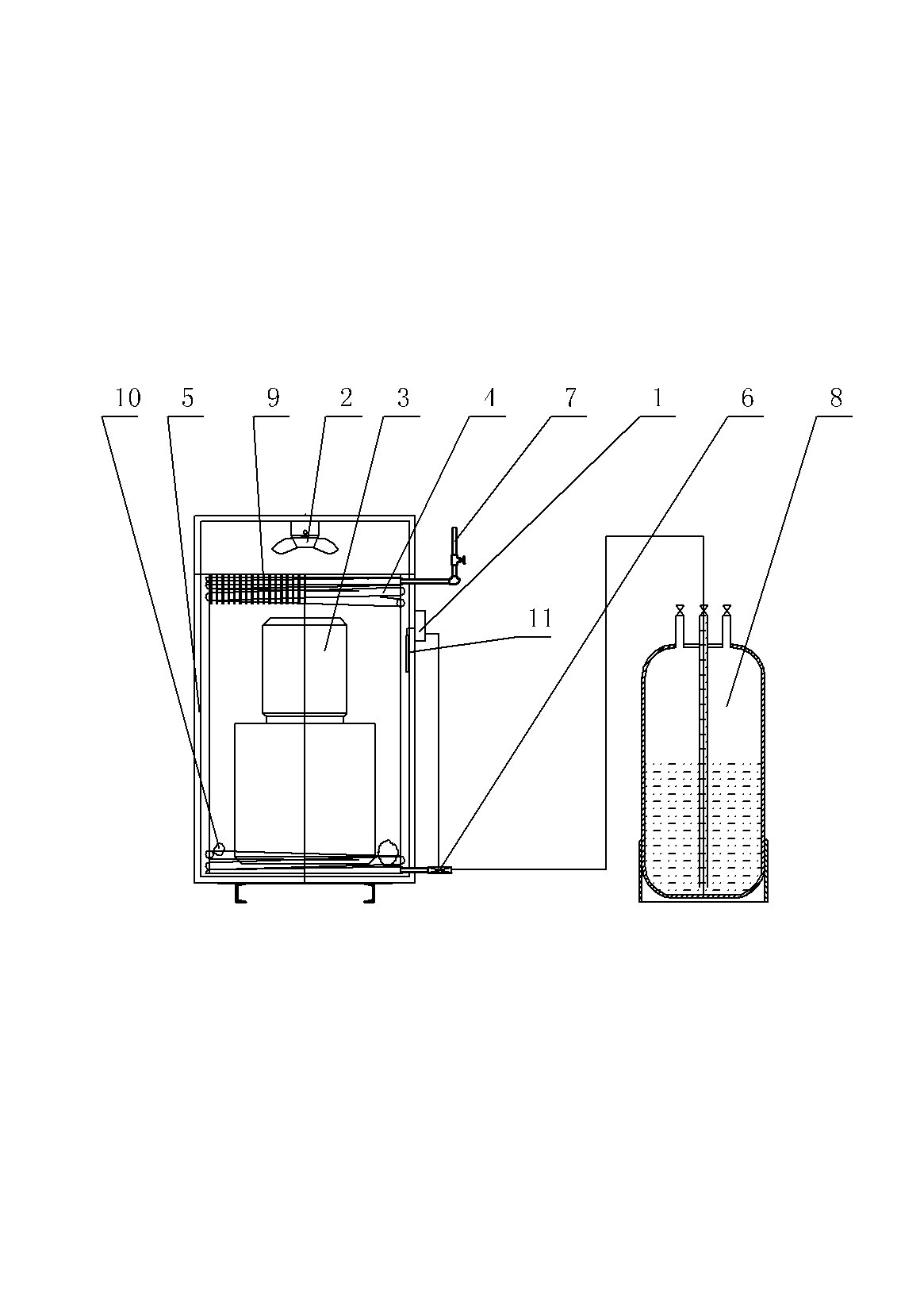

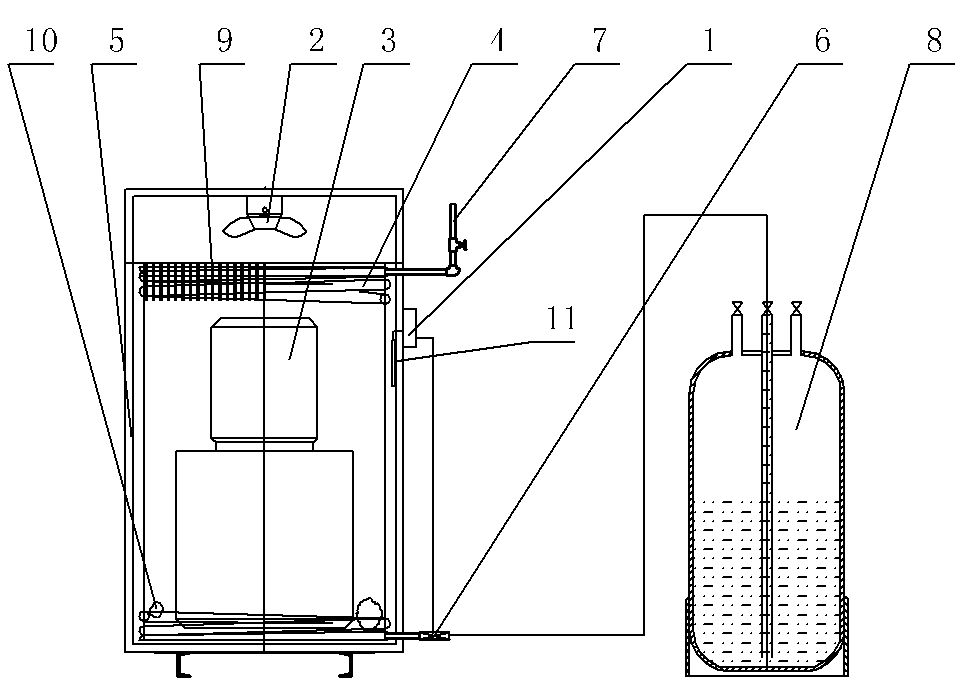

Novel liquid nitrogen cold assembly device

InactiveCN101985198AAvoid Surface CorrosionGuaranteed surface qualityMetal working apparatusInterference fitThermal insulation

The invention provides a novel liquid nitrogen cold assembly device, relating to the technical field of installation equipment for interference fit parts. In the invention, on the premise of ensuring the accurate installation of shafts, superficial corrosion effect of liquid nitrogen on the shafts is effectively reduced so as to avoid frosting, thereby ensuring the cold assembly quality of the interference fit parts. The liquid nitrogen cold assembly device provided by the invention comprises a nitrogen tank and a heat insulation cooling tank, and is characterized in that an evaporator is arranged in the heat insulation cooling tank; and the nitrogen tank is connected with the evaporator through a pipeline.

Owner:WUXI JULI HEAVY IND OFF

Method for inhibiting corrosion

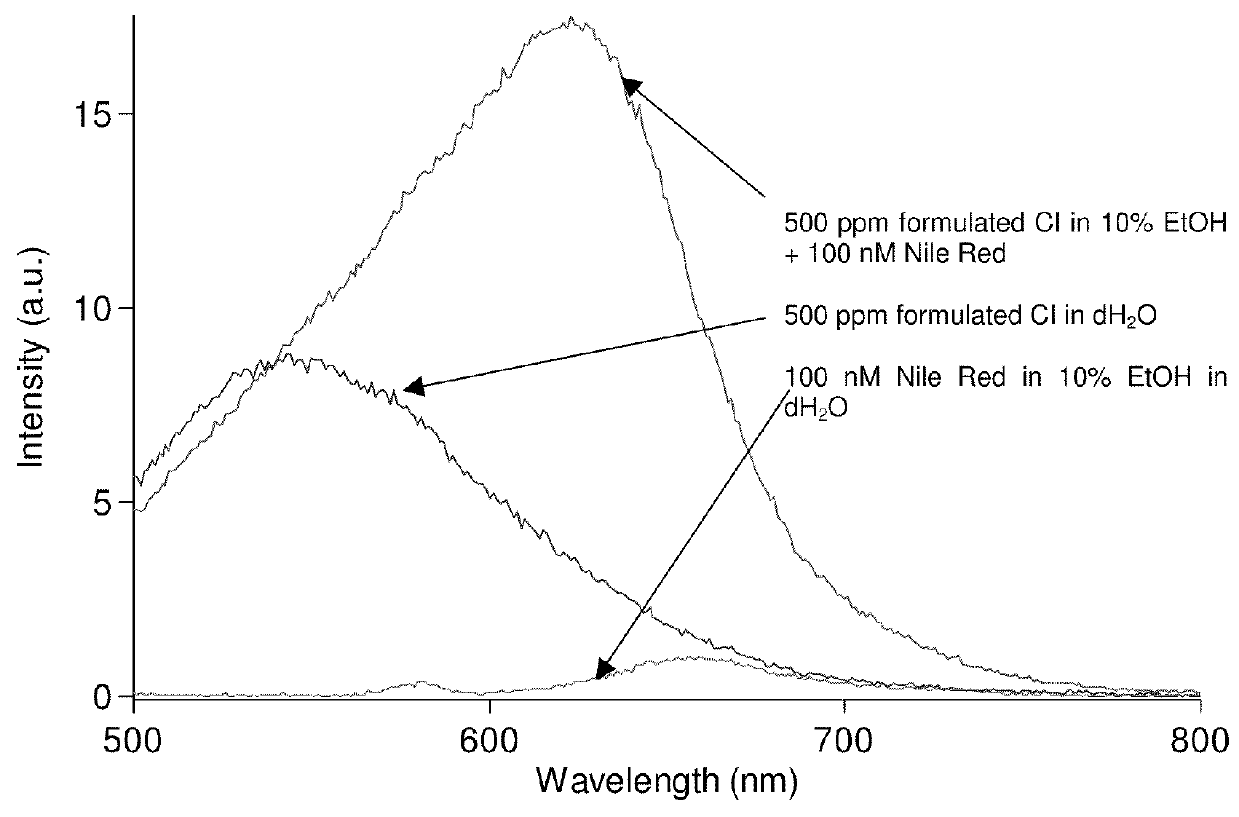

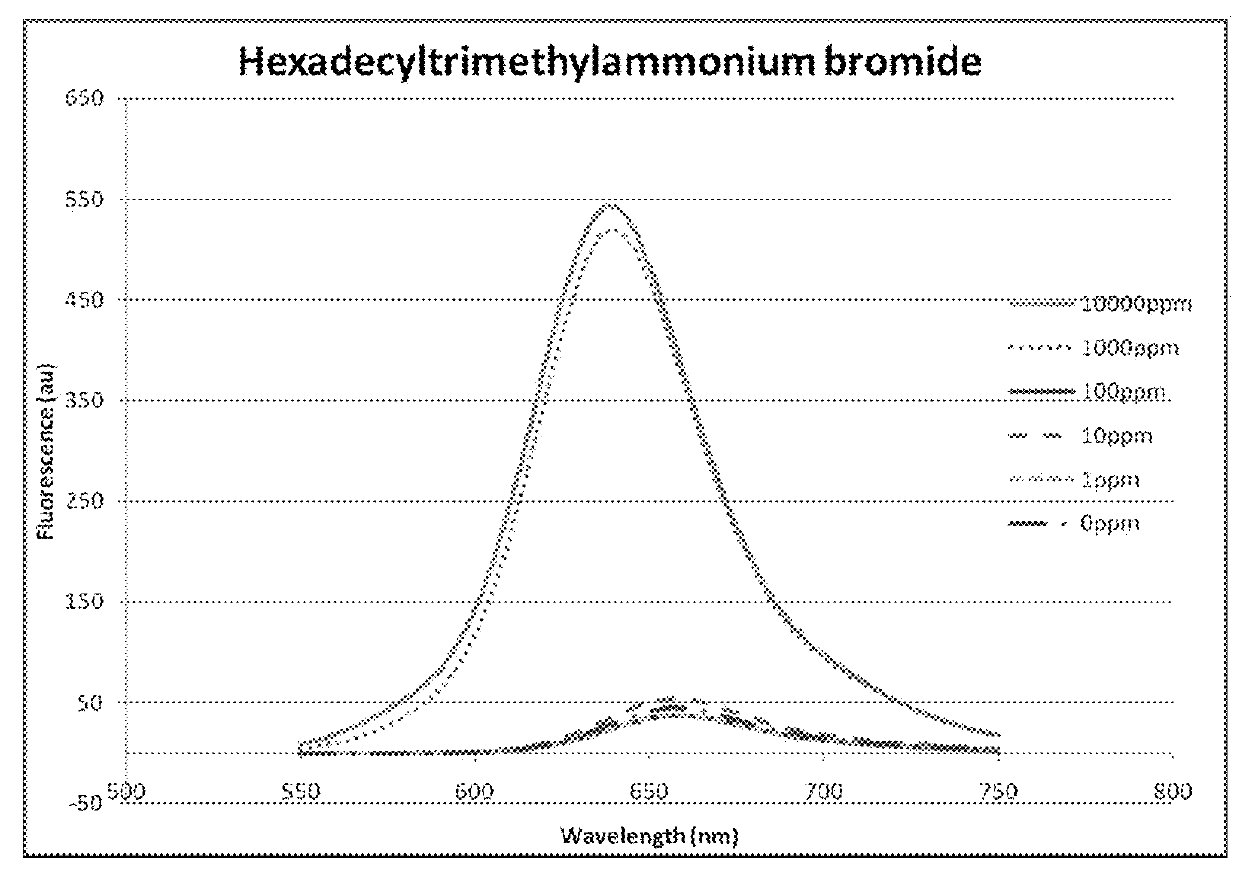

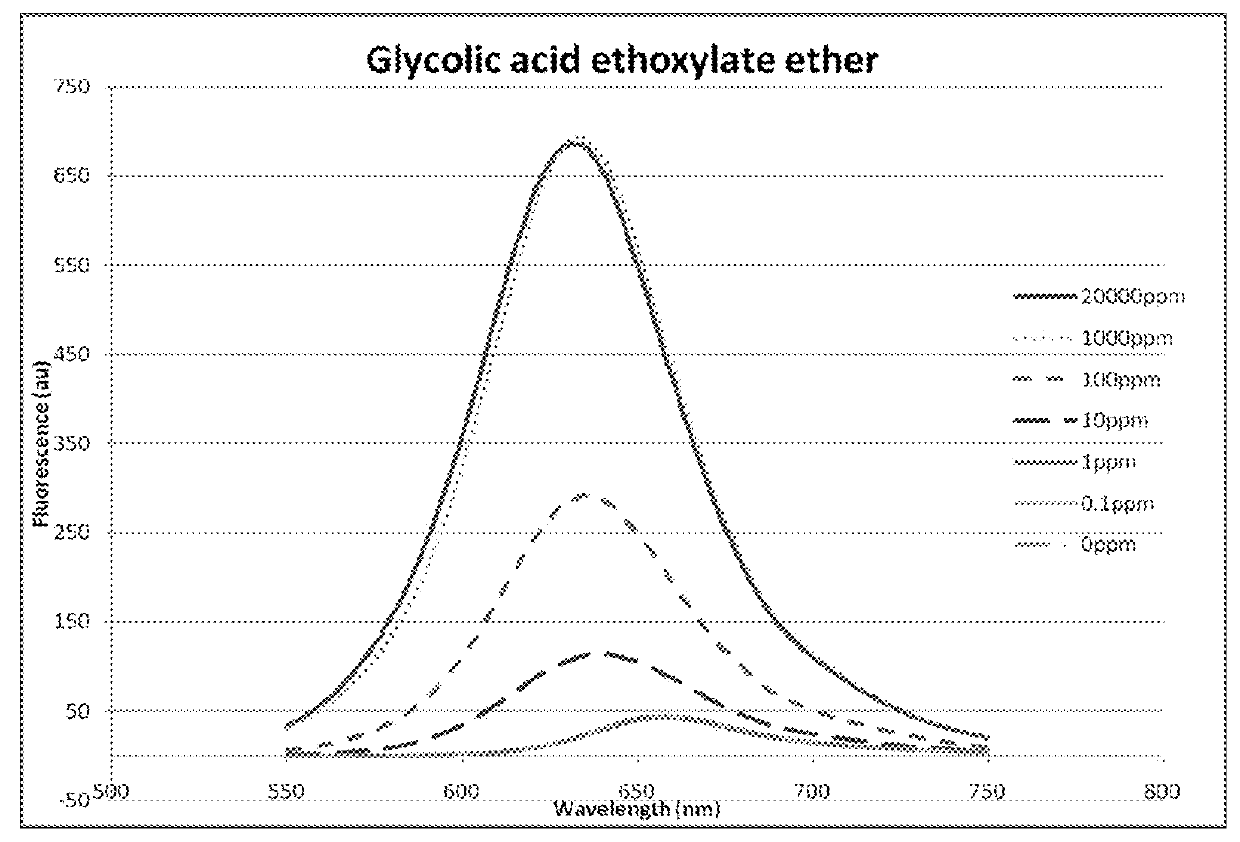

ActiveUS9359677B2Improve accuracyImprove precisionOther chemical processesAnalysis by subjecting material to chemical reactionPhysical chemistryMicelle

A method for inhibiting corrosion comprises the steps of providing a fluid; adding a corrosion inhibitor comprising at least one amphiphilic chemical to the fluid; and monitoring micelles presence in the fluid. A method for determining the amount of corrosion inhibitor that is sufficient to inhibit corrosion, a method for monitoring the activity of an amphiphilic chemical and a system for inhibiting corrosion in a conduit are also disclosed.

Owner:ANPERA TECH LTD

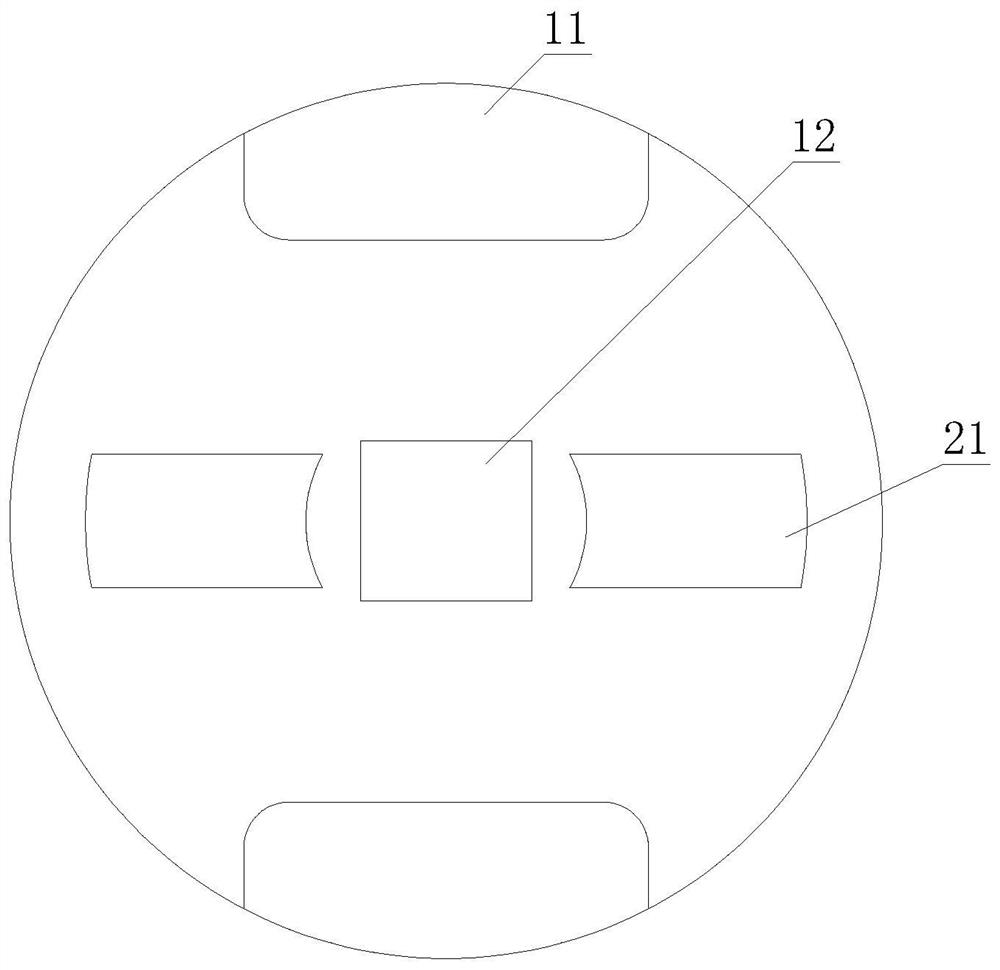

Stacked combined type heavy hammer sheet and manufacturing method thereof

InactiveCN111725762AImprove stabilityImprove securityDevices for damping mechanical oscillationsCoatingsButt jointShock resistance

The invention discloses a stacked combined type heavy hammer sheet and a manufacturing method thereof and belongs to the technical field of hammer manufacturing. The heavy hammer sheet comprises heavyhammer sheet bodies, wherein a square groove is formed in an upper surface of each heavy hammer sheet body, a connecting rod mounting groove is formed in the middle of each heavy hammer sheet body, the multiple heavy hammer sheet bodies are arranged in an overlapped mode, butt joint pieces are symmetrically mounted on two sides of the connecting rod mounting groove in the middle of each heavy hammer sheet body, and the butt joint pieces are symmetrically distributed with the circle center point of each heavy hammer sheet body as the center. The stacked combined type heavy hammer sheet is advantaged in that the whole combined heavy hammer sheet is integrated into a whole, overall stability is improved, after the heavy hammer sheets are combined, the combined heavy hammer sheets are arranged on the cable, the heavy hammer sheet is convenient to assemble and disassemble, high in bonding strength, high in use stability and high in practicability, shock resistance is improved, use safety is improved, compactness and waterproof performance of a coating can be effectively improved, connecting friction force is increased when the square connecting rod mounting groove polished by a file ismounted, and mounting stability is improved.

Owner:安徽省含山县兴建铸造厂

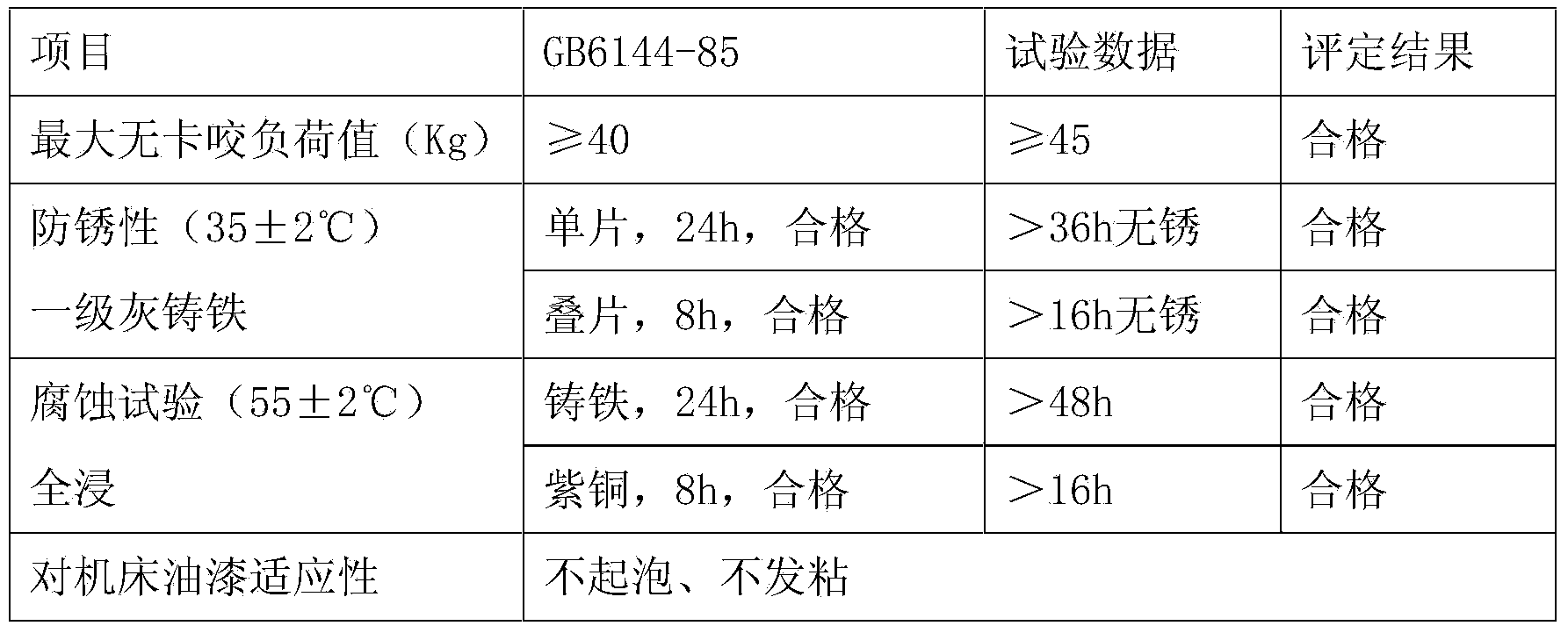

Water-based aluminum alloy cutting fluid and preparation method thereof

InactiveCN103710131AEasy to cleanImprove the lubrication effectLubricant compositionWater basedSulfonate

The invention discloses a water-based aluminum alloy cutting fluid, which is made from the following raw materials in parts by weight: 4-5 parts of octocapric acid, 2-3 parts of boric acid, 10-12 parts of glycerin, 6-9 parts of glycerin monostearate, 2-3 parts of polyisobutene, 10-12 parts of spathulenol, 1-2 parts of diisopropyl naphthalene sulfonate, 1-2 parts of carboxymethylcellulose, 4-5 parts of diethyl carbitol, 6-8 parts of assistant and 200 parts of water. The cutting fluid disclosed by the invention is good in cleaning property, good in lubricating property and capable of overcoming the defects of easy deterioration and smelliness and short service life of the emulsified cutting fluid and greatly prolonging the service lives of machinery and the cutting fluid, and the cooling performance is good, so that the cutting fluid is suitable for processing non-ferrous metals and ferrous metals and is especially suitable for processing aluminum products to prevent the surface corrosion problem of the aluminum products.

Owner:马鞍山市力鑫机械制造有限公司

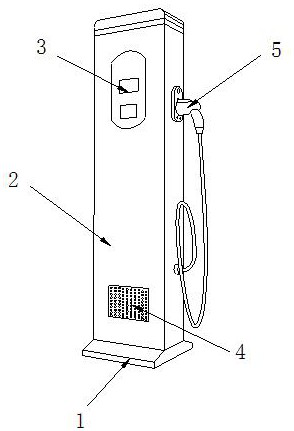

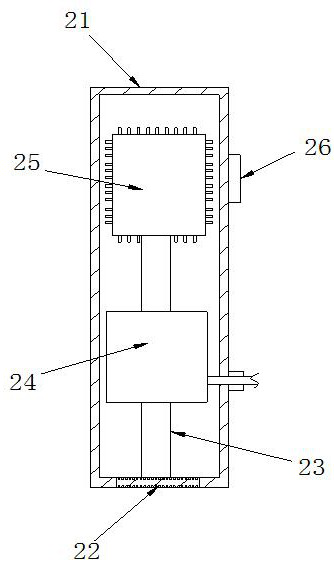

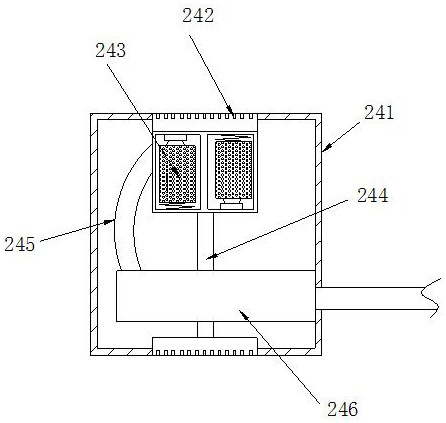

Bidirectional new energy automobile charging pile with charging and discharging functions

InactiveCN112078404AAvoid shockAvoid Surface CorrosionCharging stationsElectric vehicle charging technologyNew energyElectrical battery

The invention discloses a bidirectional new energy automobile charging pile with charging and discharging functions. The charging pile structurally comprises a base, a machine body, an operation table, a heat dissipation opening and a charging head, the top face of the base is welded to the bottom face of the machine body, the back face of the operation table is fixedly installed on the front faceof the machine body, the outer layer of the heat dissipation opening is embedded into the front face of the machine body, and the left side of the charging head and the right side of the machine bodyare overlapped. A cable is pulled out during charging, the cable can be automatically collected into the machine body through a cable winder after the cable is loosened when charging is not needed, surface corrosion caused by wind and rain for a long time is avoided, the short-circuit phenomenon caused by the combined action of corrosion and high temperature is reduced, meanwhile, when short circuit occurs, generated high current can be quickly sensed by a high current circuit breaker, and the circuit is quickly disconnected, so that the generated high current is prevented from impacting a vehicle battery, and the use is safer.

Owner:广州奕极机电科技有限公司

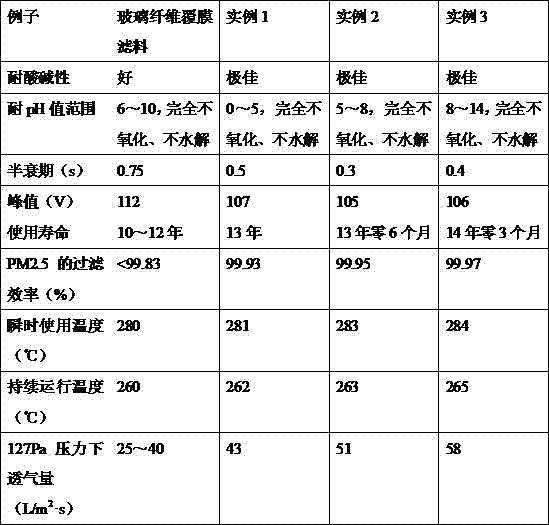

Preparation method of laminated filter material

InactiveCN107213699AAvoid Surface CorrosionImprove the defects that are prone to static electricityMembrane filtersWoven fabricsSlagCarbonization

The invention relates to a preparation method of a laminated filter material, belonging to the technical field of preparation of filter materials. The preparation method comprises the steps of mixing blast furnace slag, sodium carbonate, silica sand and dolomite, preparing molten glass, carrying out water quenching, carrying out wiredrawing, collecting, preparing glass fibers as a matrix, dispersing fluorite powder into peach gum mixed liquid, loading the surface of the glass fiber matrix with the peach gum mixed liquid, calcining, carrying out carbonization, and curing the peach gum mixed liquid to the surfaces of the glass fibers so as to effectively prevent the corrosion of hydrogen fluoride, simultaneously weaving cloth by virtue of the modified glass fibers, and carrying out hot-press film lamination to effectively bond the cloth with a polytetrafluoroethylene film, so as to obtain the polytetrafluoroethylene laminated filter material. The laminated filter material prepared by virtue of the preparation method has excellent mechanical properties and good static electricity resistance and corrosion resistance.

Owner:常州市瑞泰物资有限公司

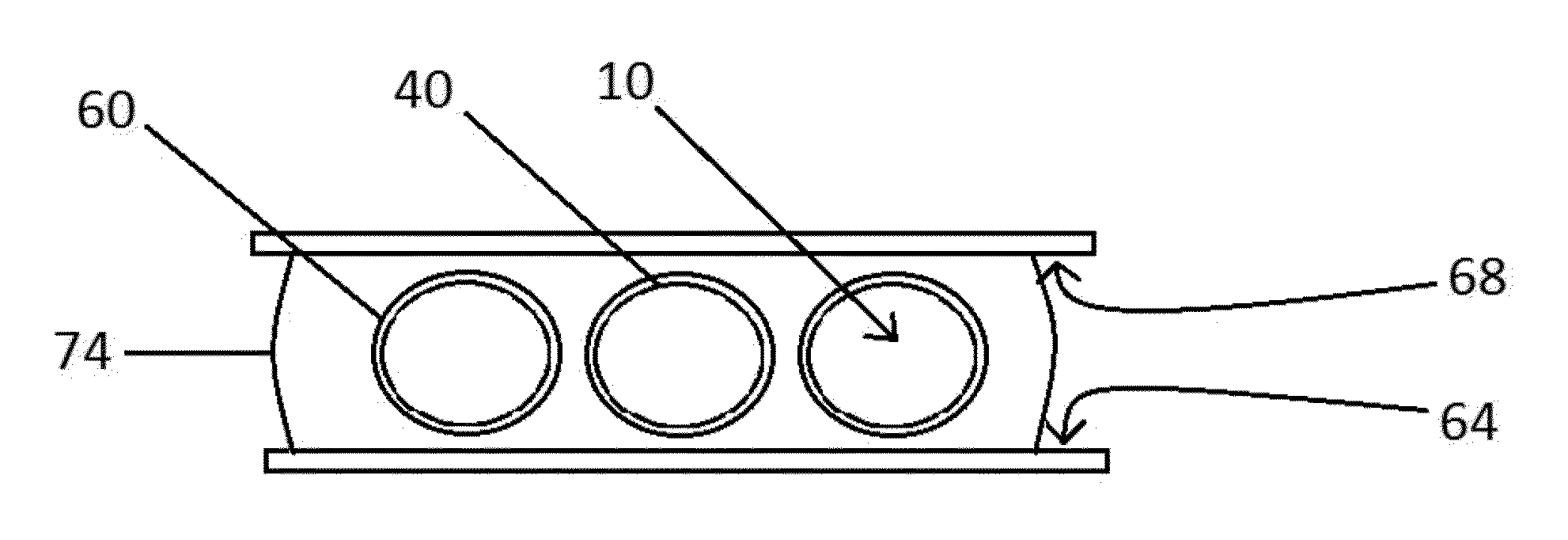

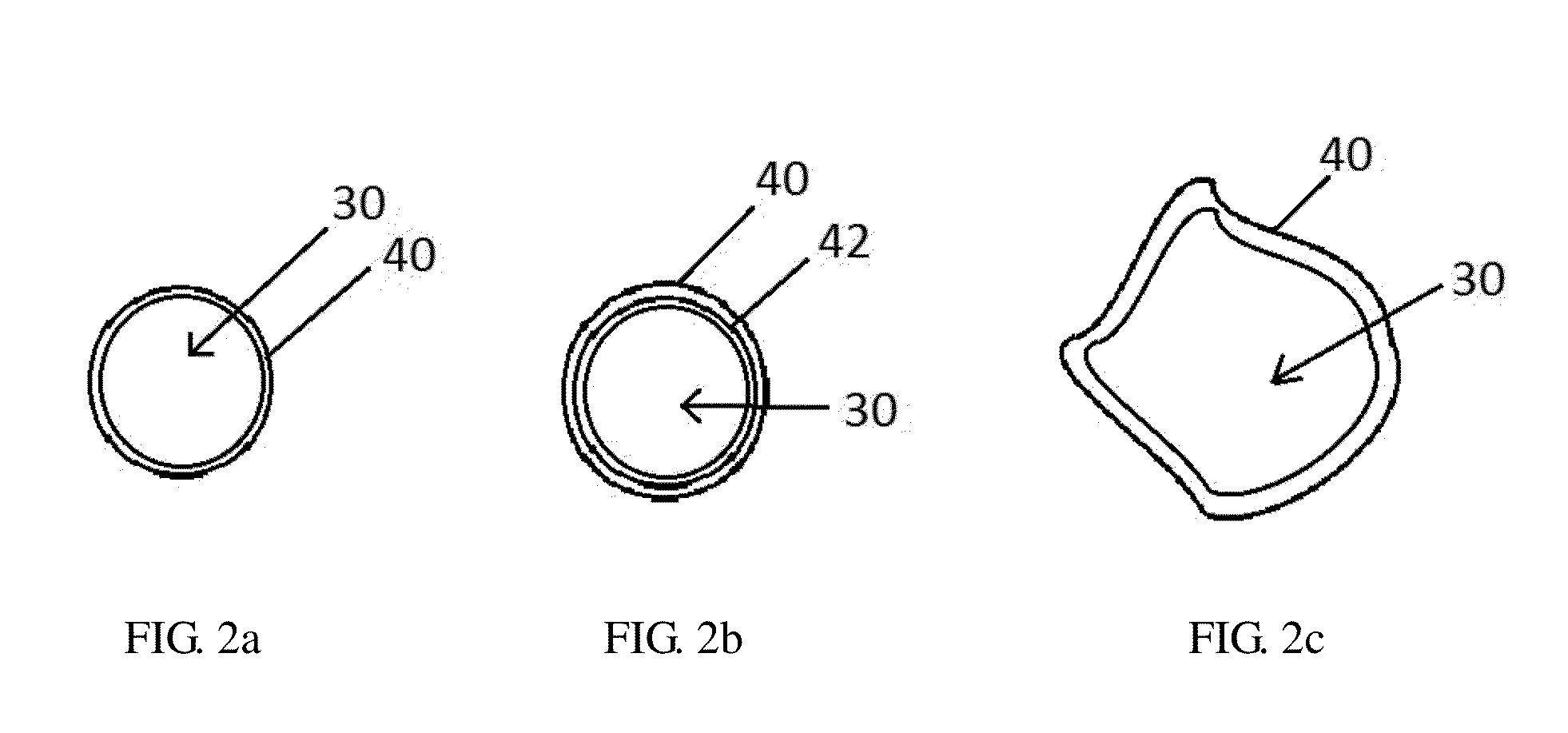

Micro-encapsulated, improved vapor corrosion inhibitor

InactiveUS20200024752A1Control rateAvoid Surface CorrosionThin material handlingChemical inhibitorsPhysical chemistryFluid composition

The current invention relates to a micro-encapsulted, volatile vapor corrosion inhibitor (VCI), and method for the use of same. More particularly, it relates to a fluid composition, and microencapsulation of the fluid composition, that inhibits corrosion and tarnishing and that may be relatively non-toxic. The VCI is intended to be employed in varying concentrations depending on the intended application and deployed via microcapsules. The microcapsules may be adapted to release the VCI over time, or all at once. To effect this, the microcapsules may be adapted to be breached at varying times or at the same time. By adapting the microcapsules, or the method of breaching the microcapsules, the rate at which the VCI is released may be controlled.

Owner:LEE CLIFFORD +1

Use of di-ionic compounds as corrosion inhibitors in a water system

ActiveUS11021383B2Improve performanceAvoid Surface CorrosionCationic surface-active compoundsOrganic compound preparationAmmonium compoundsAlkene

Disclosed herein are the methods of using di-cationic or di-anionic compounds, which are derived from primary amine through an aza-Michael addition with an activated olefin, in a corrosion control composition to mitigate corrosion of a surface in a water system. The disclosed methods or compositions are found to be more effective than those methods or compositions including commonly used single quaternary compounds for mitigating corrosion for a metal surface in water systems.

Owner:ECOLAB USA INC

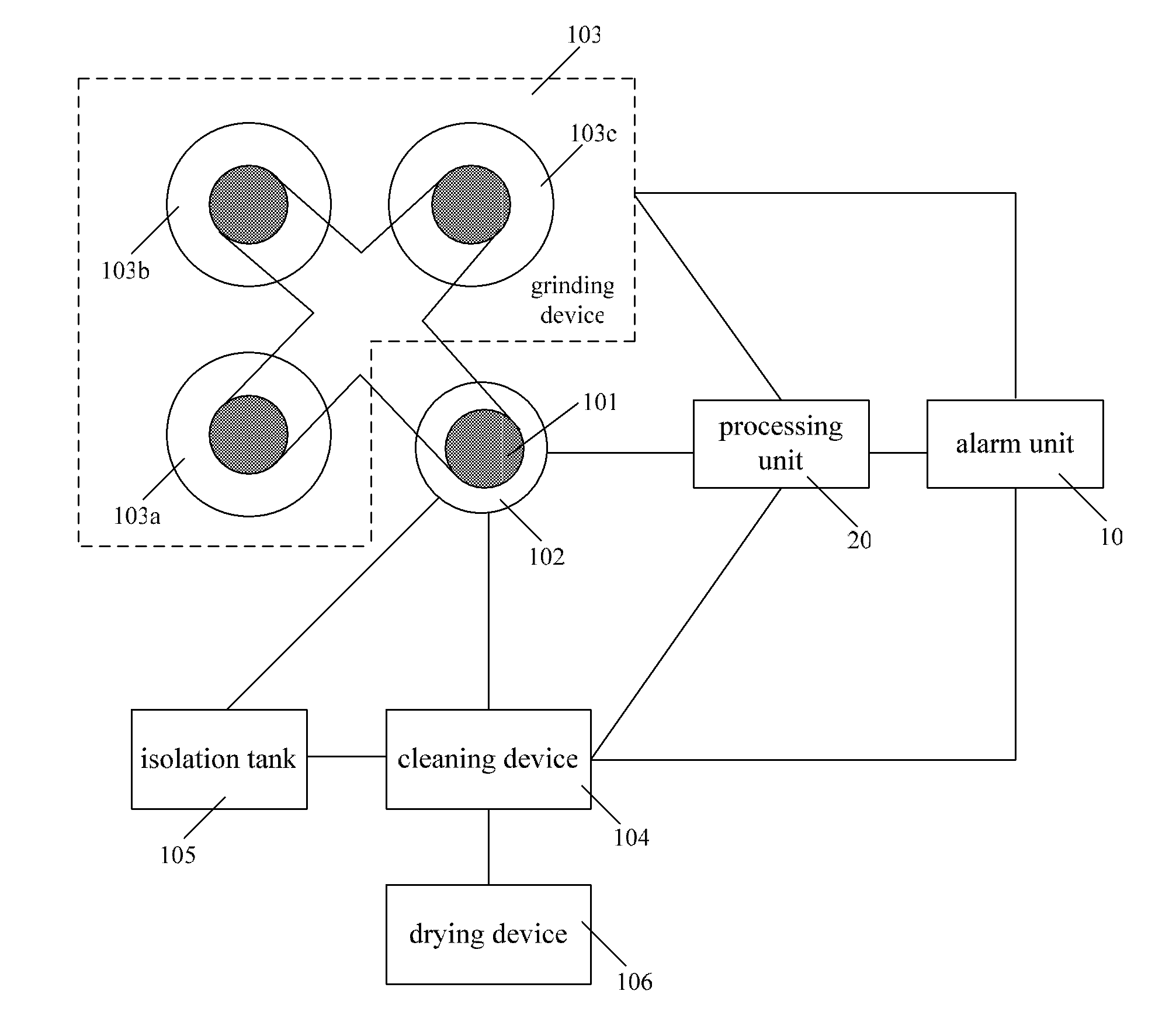

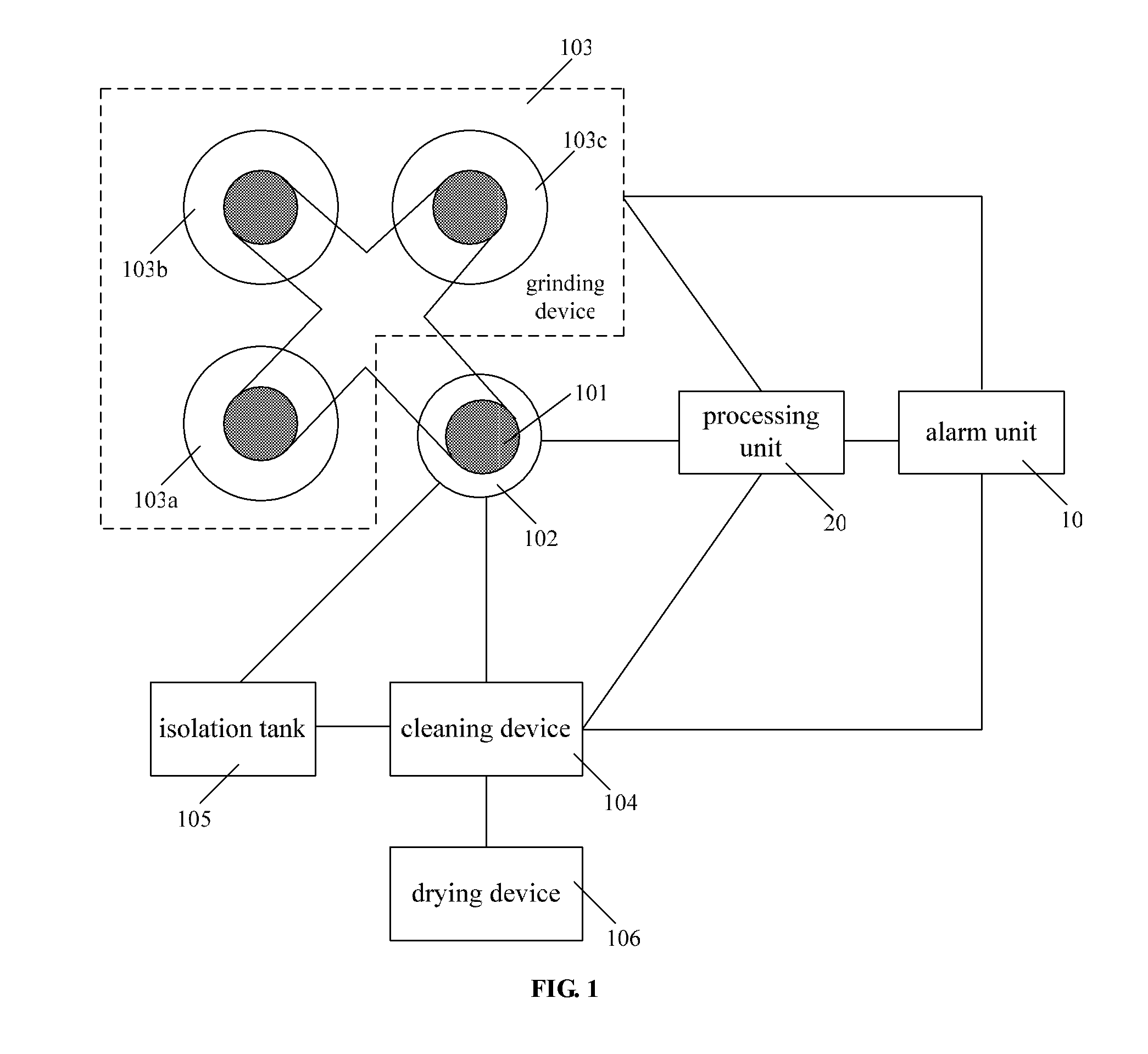

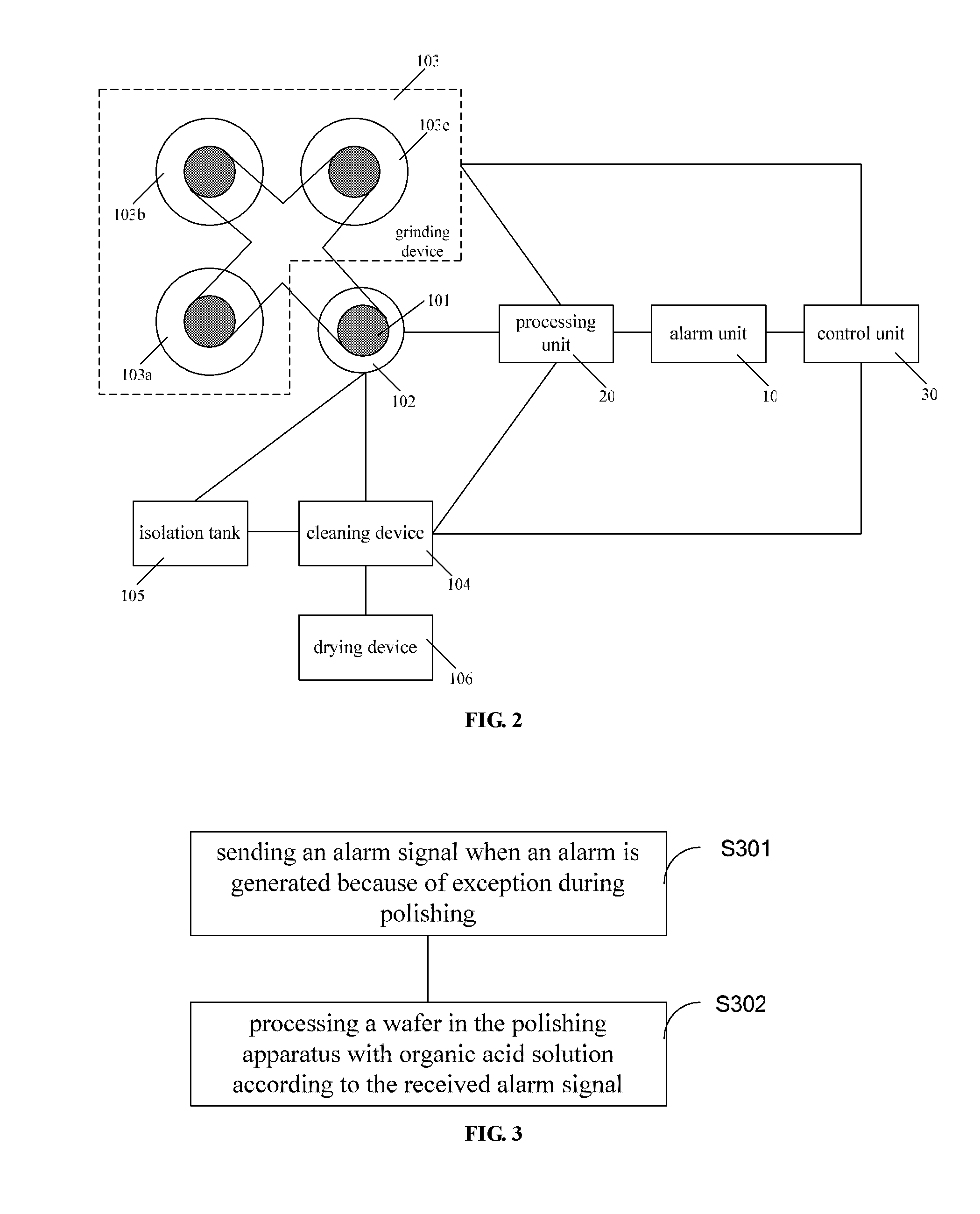

Polishing apparatus and exception handling method thereof

ActiveUS20120142254A1Avoid Surface CorrosionQuality improvementLapping machinesGrinding feed controlOrganic acidMetallic materials

A polishing apparatus and exception handling method thereof is disclosed, the exception handling method of polishing apparatus includes: sending an alarm signal when an alarm is generated because of an exception during polishing; and processing a wafer in the polishing apparatus with organic acid solution according to the received alarm signal. The method and apparatus prevent the metal material from corrosion which causes device failure, when there is an alarm generated because of an exception which stops the apparatus during polishing.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

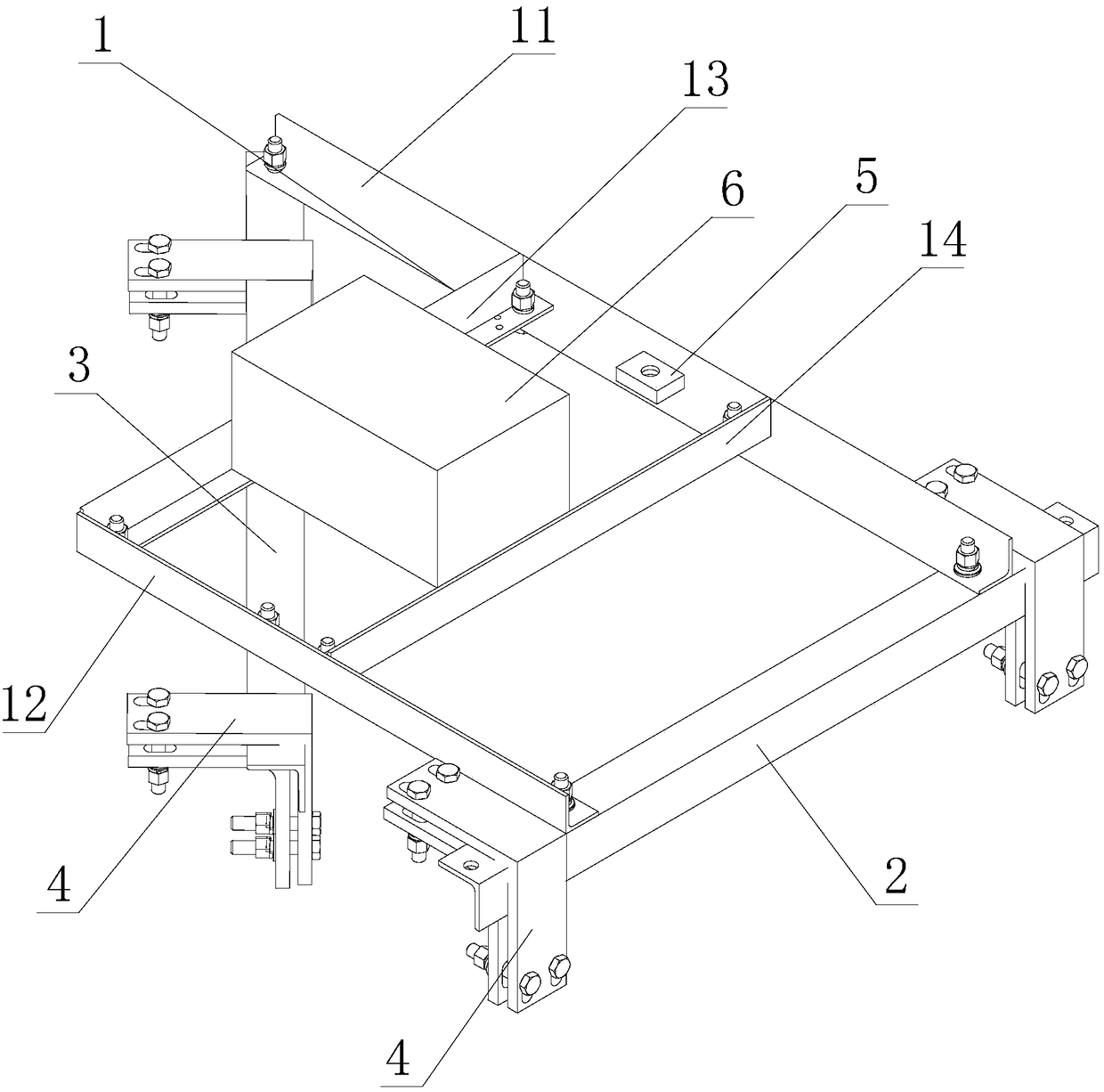

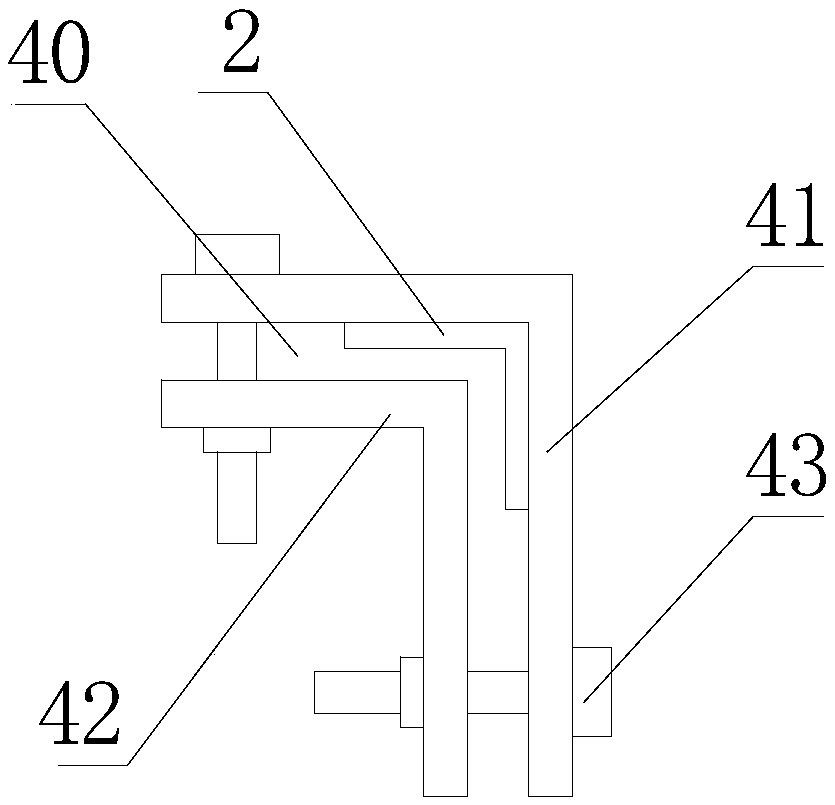

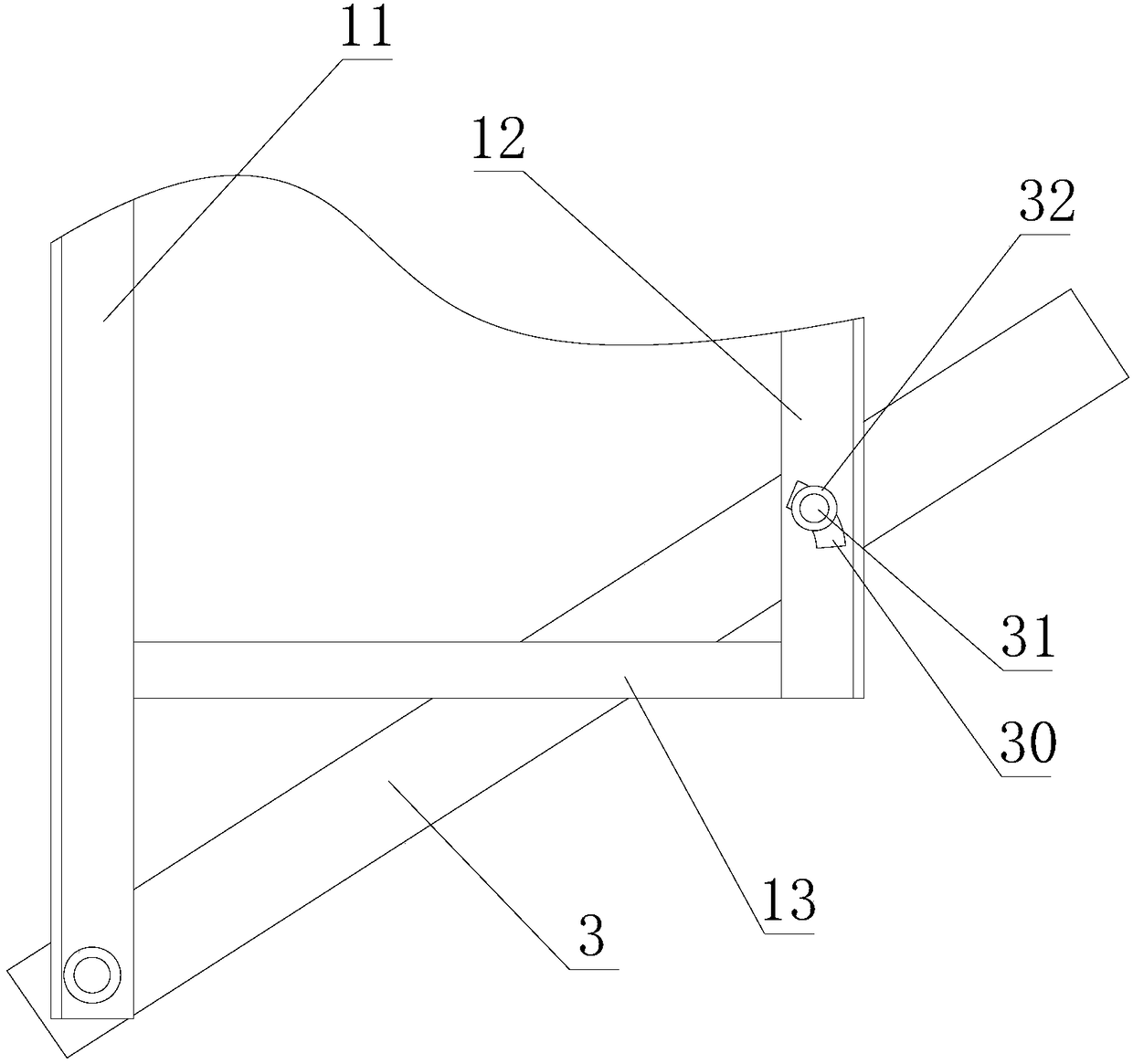

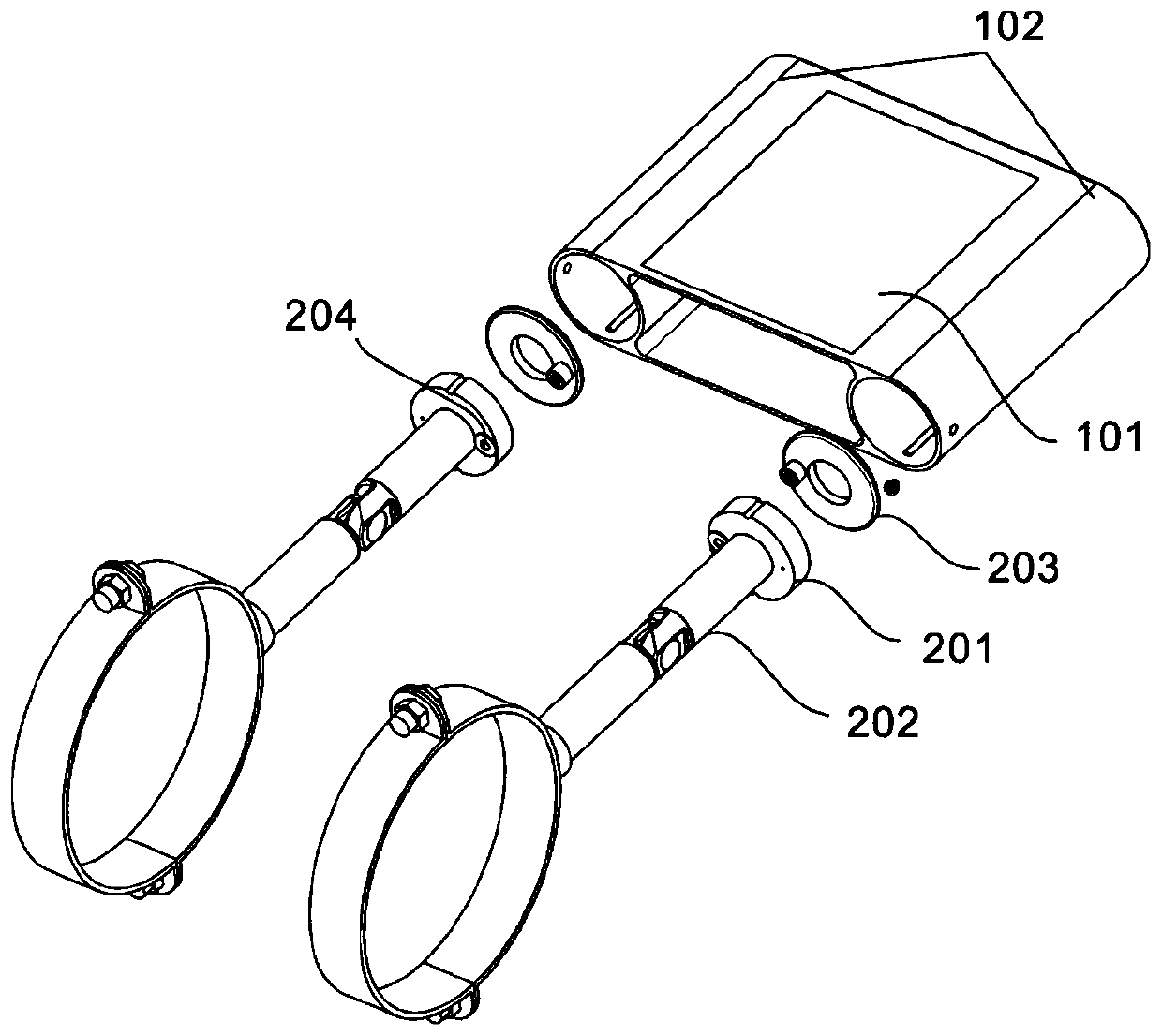

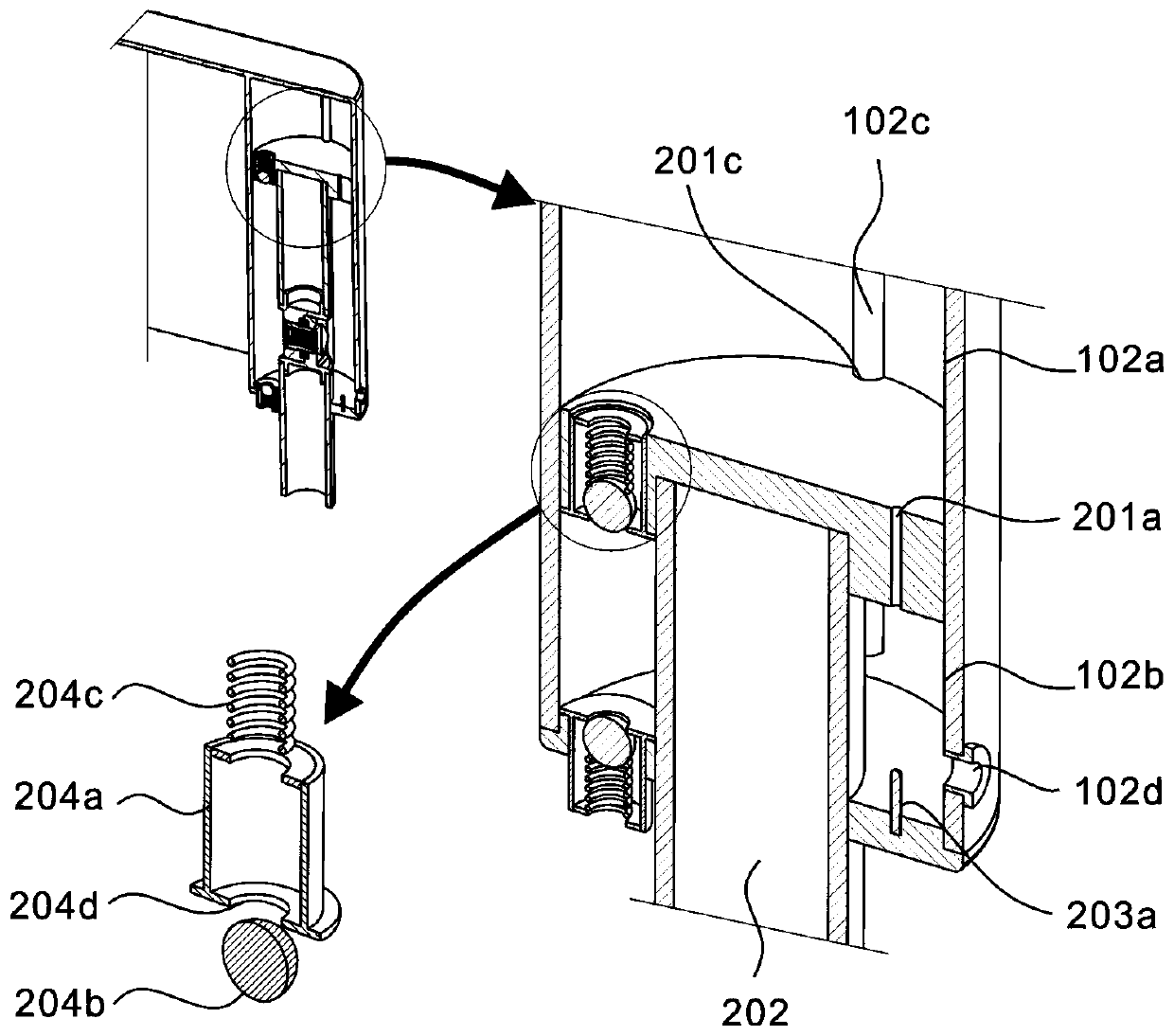

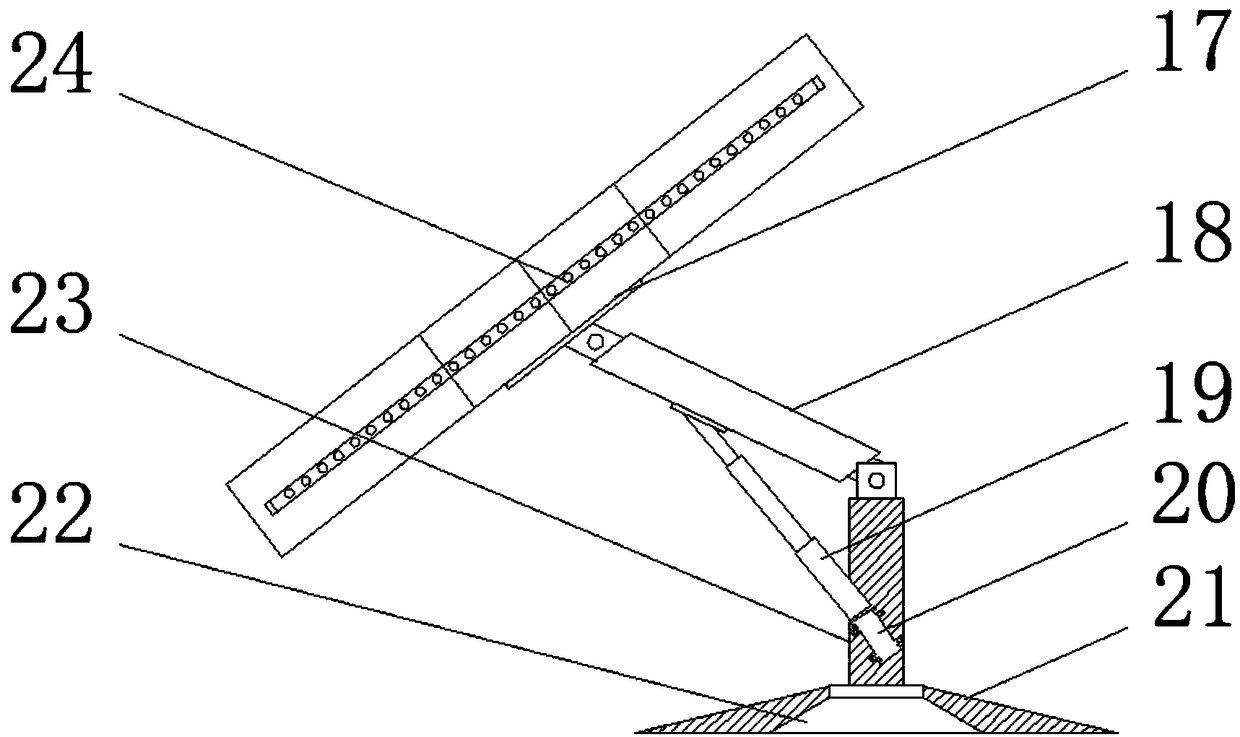

Universal clamp for fixing monitoring device on power transmission tower

PendingCN108072395AGuaranteed stabilityEasy to adjustMeasurement apparatus componentsEngineeringPower transmission

The invention relates to a universal clamp for fixing a monitoring device on a power transmission tower. The universal clamp comprises a base, a fixation rod and a rotation rod. The fixation rod is fixedly connected with one end of the base; the rotation rod is movably connected at the other end of the base; the fixation rod and the rotation rod are respectively provided with locating clips; and the base is mounted on the power transmission tower through the locating clips. The base is provided with an antenna box and a waterproof box. The advantages of the universal clamp are that the base ismounted on the power transmission tower through the locating clips arranged on the fixation rod and the rotation rod, so that the base can be mounted quickly, and mounting stability of the base can be ensured; and by adjusting the position of the rotation rod on the base, the angle between the rotation rod and the fixation rod can be changed, so that the monitoring device can be suitable for positioning installation on power transmission towers in different environments, reliable installation and disassembly is achieved, mounting intensity during installation and fixation is reduced, and workload during installation is small.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST +2

Micro-encapsulated, improved vapor corrosion inhibitor

InactiveUS20150368808A1Control rateAvoid Surface CorrosionOther chemical processesLayered productsFluid compositionCorrosion inhibitor

The current invention relates to a micro-encapsulated, volatile vapor corrosion inhibitor (VCI), and method for the use of same. More particularly, it relates to a fluid composition, and microencapsulation of the fluid composition, that inhibits corrosion and tarnishing and that may be relatively non-toxic. The VCI is intended to be employed in varying concentrations depending on the intended application and deployed via microcapsules. The microcapsules may be adapted to release the VCI over time, or all at once. To effect this, the microcapsules may be adapted to be breached at varying times or at the same time. By adapting the microcapsules, or the method of breaching the microcapsules, the rate at which the VCI is released may be controlled.

Owner:LEE CLIFFORD +1

Multifunctional nontoxic environment-friendly water-based paint and preparation method thereof

ActiveCN103333576ANo pungent smellMeet environmental protection requirementsCoatingsWater basedHydrogen

The invention discloses a multifunctional nontoxic environment-friendly water-based paint and a preparation method thereof. The paint consists of the following compositions in proportion: 20-50 percent of 209 resin, 4-20 percent of phosphoric acid, 0.5-2.0 percent of zinc dihydrogen phosphate, 2-10 percent of tartaric acid, 2-10 percent of azo dyes, 1.5-2.2 percent of ultrafine iron oxide pigment, and the rest amount of water. The preparation process comprises the steps that: 1. a large part of 209 resin and phosphoric acid are stirred for 2.0-2.5 hours at a constant temperature of 28-32 DEG C; 2. the tartaric acid, zinc dihydrogen phosphate and hot water with the temperature of 70-90 DEG C are sufficiently stirred; 3. the azo dyes, ultrafine iron oxide pigment and a small part of 209 resin are stirred sufficiently and uniformly; 4. the two liquids are added to the solution in the first step to be continuously stirred for 1.0-1.2 hours; and 5. the mixed liquid is roll-pressed by a three-roll mill for 2.0-2.5 hours. The water-based paint provided by the invention is nontoxic, free of pungent odor, strong in antirust ability, and short in curing time, cannot cause the rusty phenomenon during the curing process, can prevent strong solvent from dissolving, and has good de-rusting performance and chemical medium resistance.

Owner:山东银箭金属颜料有限公司

Use of di-ionic compounds as corrosion inhibitors in a water system

ActiveUS20210230034A1Improve performanceAvoid Surface CorrosionCationic surface-active compoundsOrganic compound preparationAmmonium compoundsAlkene

Owner:ECOLAB USA INC

Aluminum alloy surface micro-arc oxidation treatment technology

InactiveCN113737246AImprove corrosion resistanceImprove sexual functionAnodisationElectrolytic agentMicro arc oxidation

The invention relates to the technical field of aluminum alloy surface treatment, in particular to an aluminum alloy surface micro-arc oxidation treatment technology. The technology comprises the following steps that surface pretreatment is performed; a micro-arc oxidation electrolyte is prepared; micro-arc oxidation is performed; modification treatment is performed on SiO2 nano particles; and a super-hydrophobic coating is prepared. According to the technology, the surface of the aluminum alloy is treated through micro-arc oxidation, the micro-arc oxidation coating with good stability and functionality is favorably constructed, the modified SiO2 nano particles are soaked in the surface of the aluminum alloy micro-arc oxidation coating, part of air can be sealed in a porous structure of the micro-arc oxidation coating to form an effective air cushion, regular granular bulges are formed outside the aluminum alloy, the surface roughness is increased, the super-hydrophobic coating is formed, and the corrosion resistance of the aluminum alloy is improved.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

Method for preventing corrosion of surface of aluminum-based member

InactiveUS20190078216A1Avoid corrosionSufficient protectionEngine sealsOther chemical processesSURFACTANT BLENDBiomedical engineering

The present disclosure provides a method for preventing corrosion capable of sufficiently protecting a surface of an aluminum-based member (in particular, a contact surface with a gasket) from corrosion, particularly when the surface of the aluminum-based member is sealed by the gasket. The method for preventing corrosion of a surface of an aluminum-based member constituting a structure that sandwiches the gasket together with another member in a press contact state, wherein a surfactant is made to adhere to the surface of the aluminum-based member.

Owner:NOK CORP

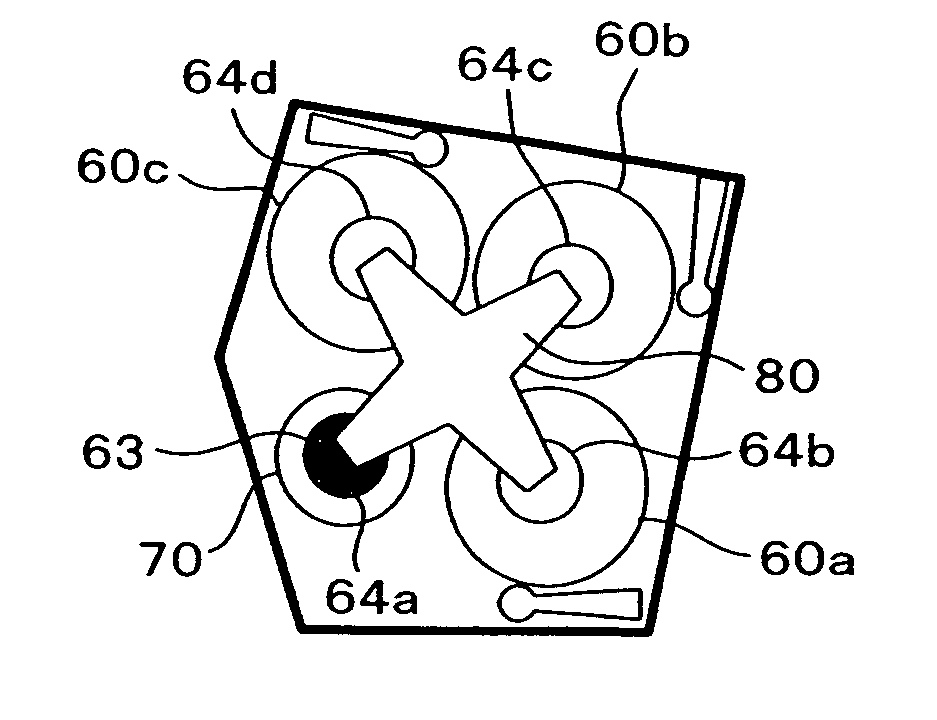

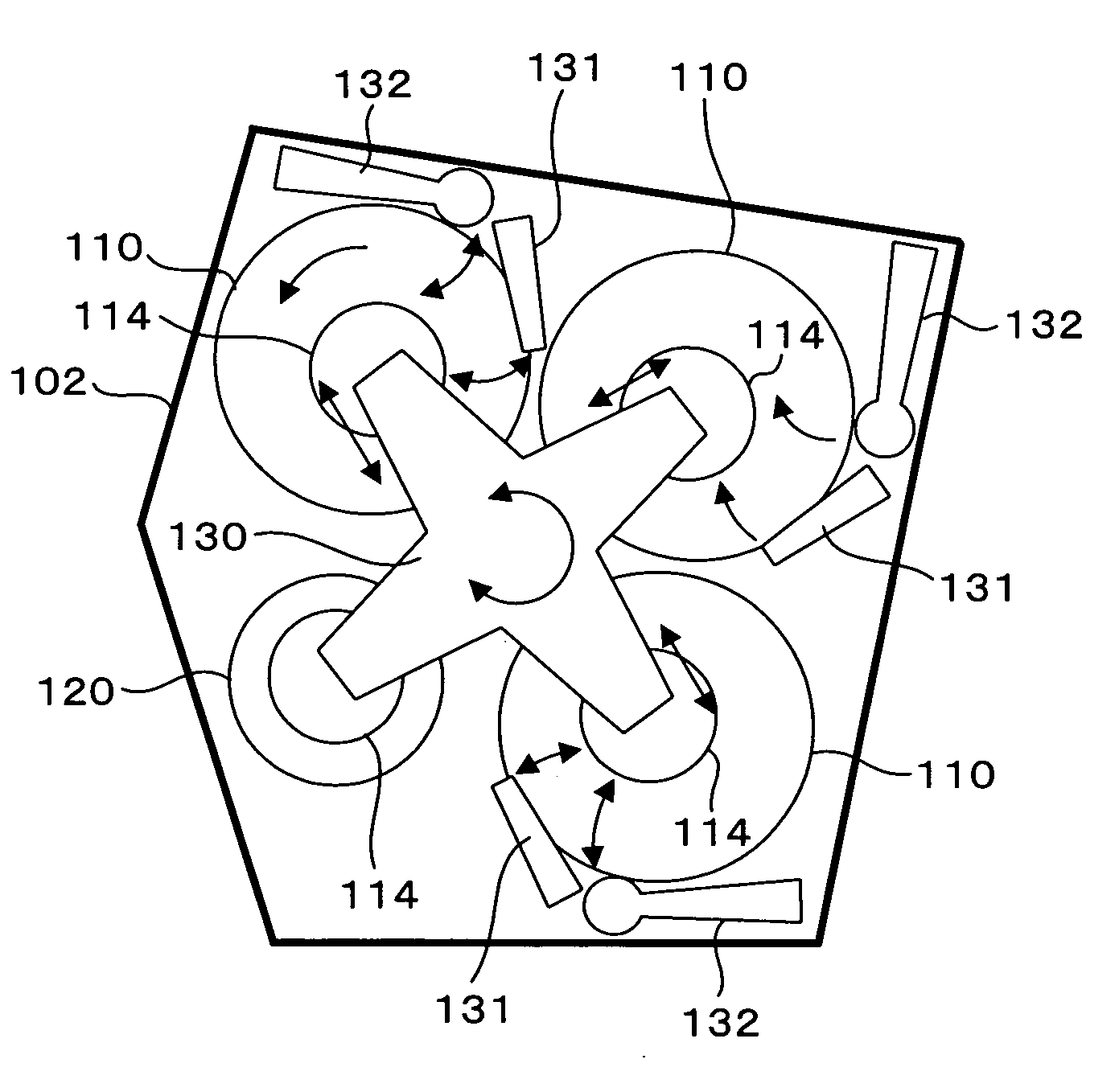

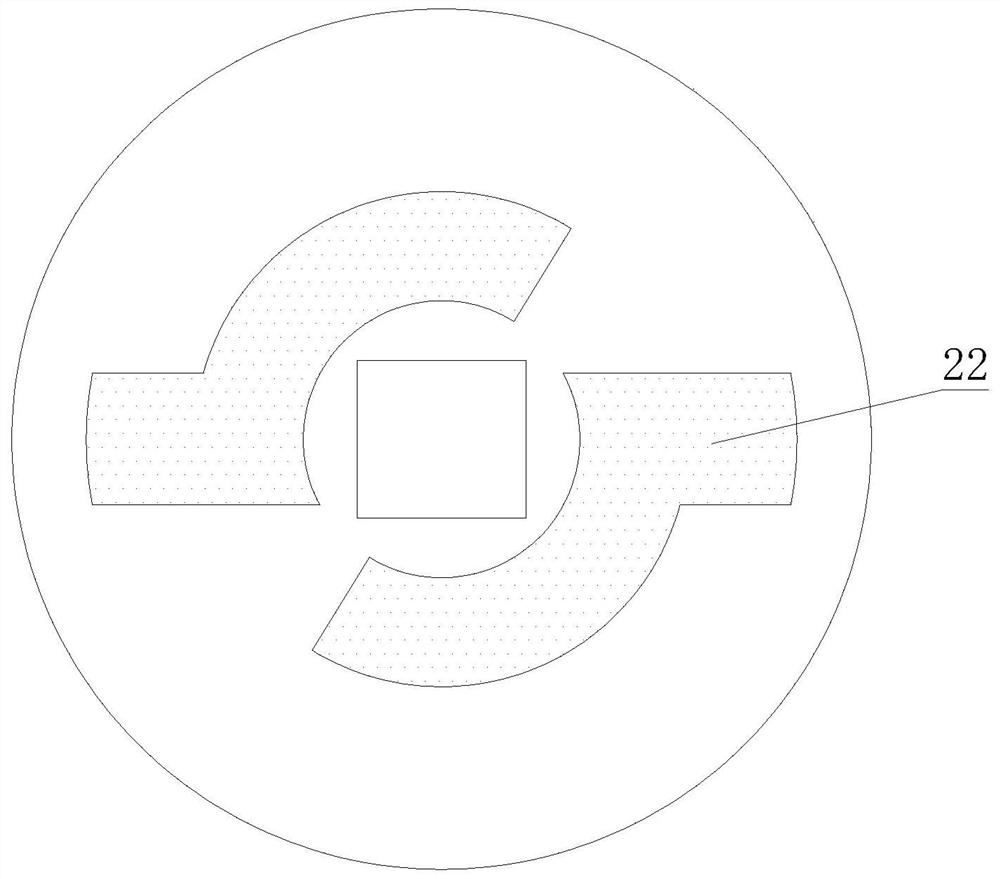

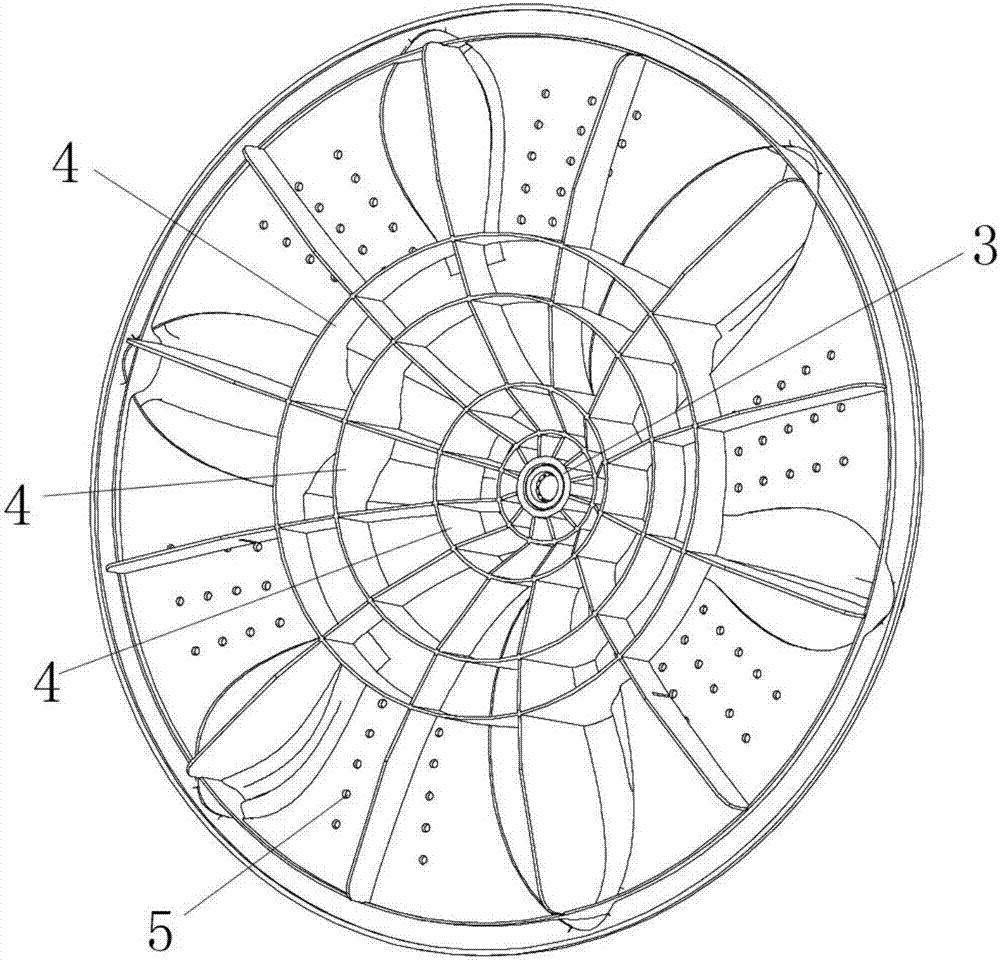

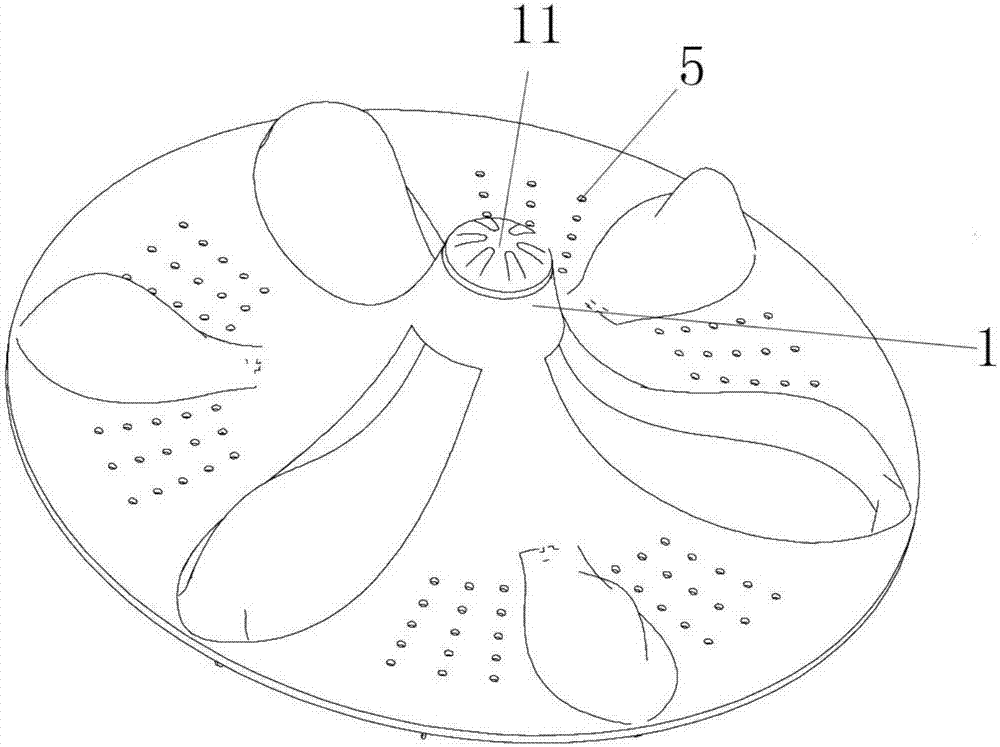

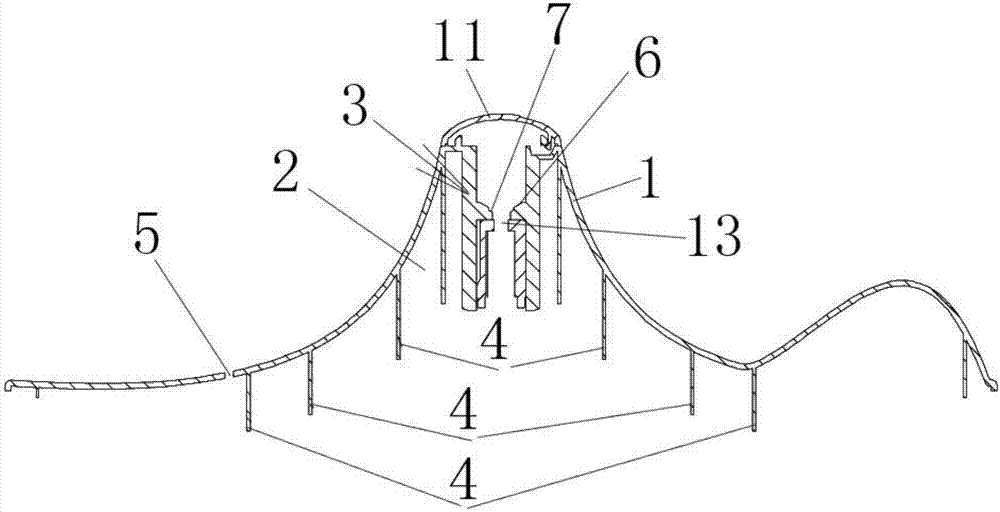

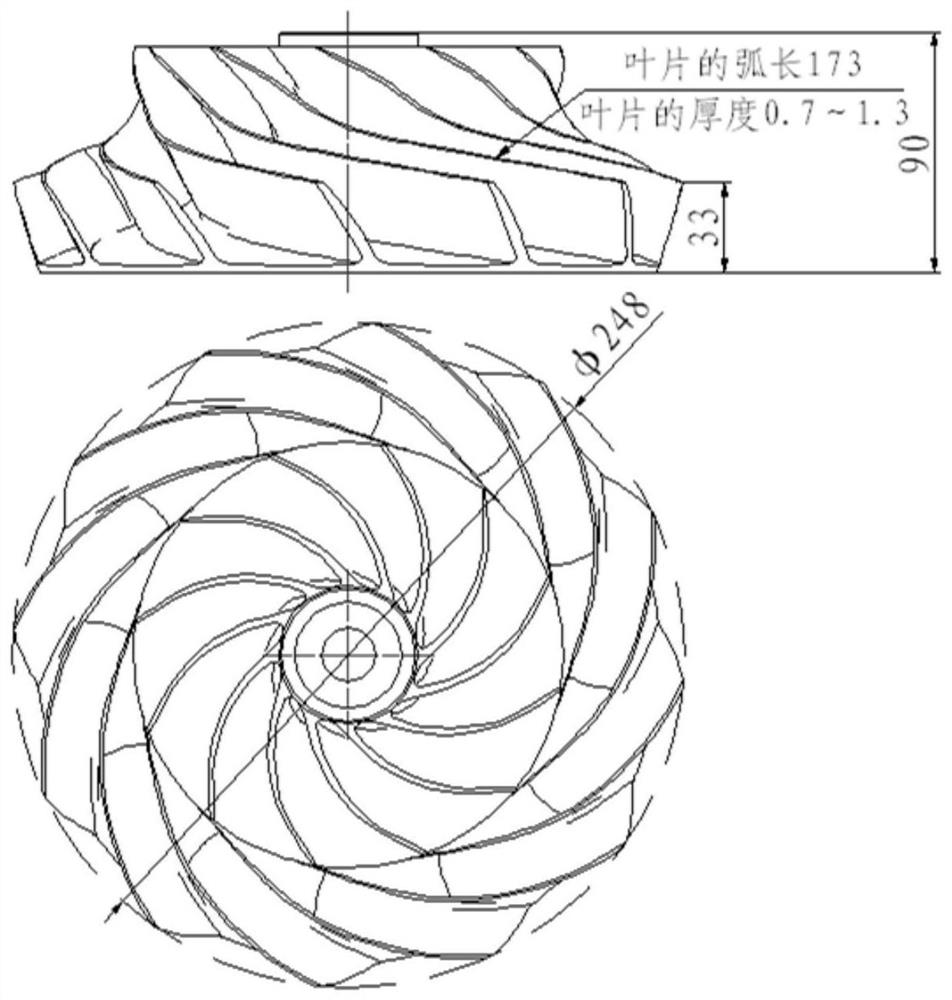

Impeller, impeller assembly and washing machine

ActiveCN107974793AAvoid contactAvoid Surface CorrosionWashing machine with receptaclesTextiles and paperImpellerCavity wall

The invention relates to the technical field of washing machines, and discloses an impeller, an impeller assembly and a washing machine. A protruding part is formed on one side of the impeller, a cavity is formed in the other side of the impeller, and a mounting part is arranged in the cavity; in the height direction of the impeller, a distance between the bottom end surface of the mounting part and the plane where the opening at the lower end of the cavity is located is kept, a water through hole is not formed in the side cavity wall of the cavity, and a sealing structure used for providing aseal for the top end of the cavity is arranged at the top end of the protruding part, so that a sealed pressure air cavity is formed by means of the seal provided by the sealing structure and a waterseal spilling over the opening at the lower end of the cavity after the impeller is mounted; water cannot go into the mounting part and soak the mounting part, so that the situation that the mountingpart is in contact with water and clothing debris is effectively avoided, and the problems are avoided that dirt forms below the impeller and the surface of a metal insert in the mounting part is corroded.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Aluminum alloy surface treatment agent and treatment method

The invention discloses an aluminum alloy surface treatment agent and a treatment method. The aluminum alloy surface treatment agent is prepared from the following components in parts by weight: 40-60 parts of nitric acid, 8-14 parts of coconut fatty acid diethanolamine, 6-9 parts of fatty methyl ester ethoxylate, 1-4 parts of alkyl phenol ethoxylates, 18-25 parts of triethylene glycol, 4-7 parts of urotropine, 2-6 parts of triethanolamine oleic soap, 5-18 parts of gelatin, 9-18 parts of sodium chloride, 6-8 parts of sodium metasilicate, 5-8 parts of an organic acid agent, 1.5-3.5 parts of a preservative and 0.5-1.5 parts of a defoamer. The treatment method mainly comprises the following steps: high pressure washing; deoiling; aluminum alloy surface treatment agent smearing; washing. The aluminum alloy surface treatment agent can be cleaned after being used for once treatment on aluminum alloy, so that the treatment process is greatly simplified, the use of acid liquid is reduced, and the economy and the environment protection performance are improved.

Owner:合肥市旺友门窗有限公司

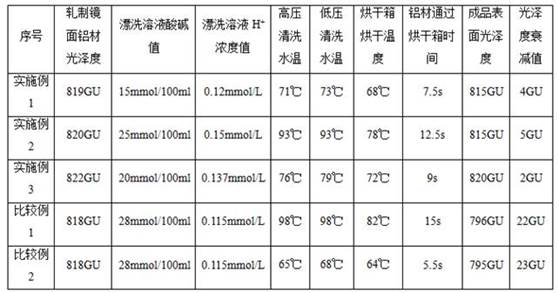

Cleaning method for preventing surface gloss of rolled mirror surface aluminum from being reduced

InactiveCN111940521AAvoid Surface CorrosionSolving Corrosion ProblemsWork cleaning devicesMetal rolling arrangementsHydrogen-Ion ConcentrationsAluminum can

A cleaning method for preventing the surface gloss of rolled mirror surface aluminum from being reduced includes the steps that firstly, a rinsing solution is used for rinsing the rolled mirror surface aluminum, then high-pressure water cleaning is conducted after first-time wringing, second-time wringing is conducted after cleaning, then low-pressure water cleaning is conducted, third-time wringing is conducted after cleaning, then the rolled mirror surface aluminum is dried, cooled and finally coated and rolled, the rinsing solution used in the rinsing process is weakly acidic, the acid value of the rinsing solution is 15-25 mol / L, and the concentration of hydrogen ions in the rinsing solution is 0.12-0.15 mmol / L; and during high-pressure water cleaning and low-pressure water cleaning, the water temperature is 70-95 DEG C, during drying, the drying temperature is 65-80 DEG C, and the time for the rolled mirror surface aluminum to pass through a drying box is 6-13 s. According to themethod, the surface gloss of the rolled mirror surface aluminum can be well kept, the attenuation degree is controlled within 5 GU, the surface gloss of the rolled mirror surface aluminum product is kept, and the special requirements of downstream customers are met.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

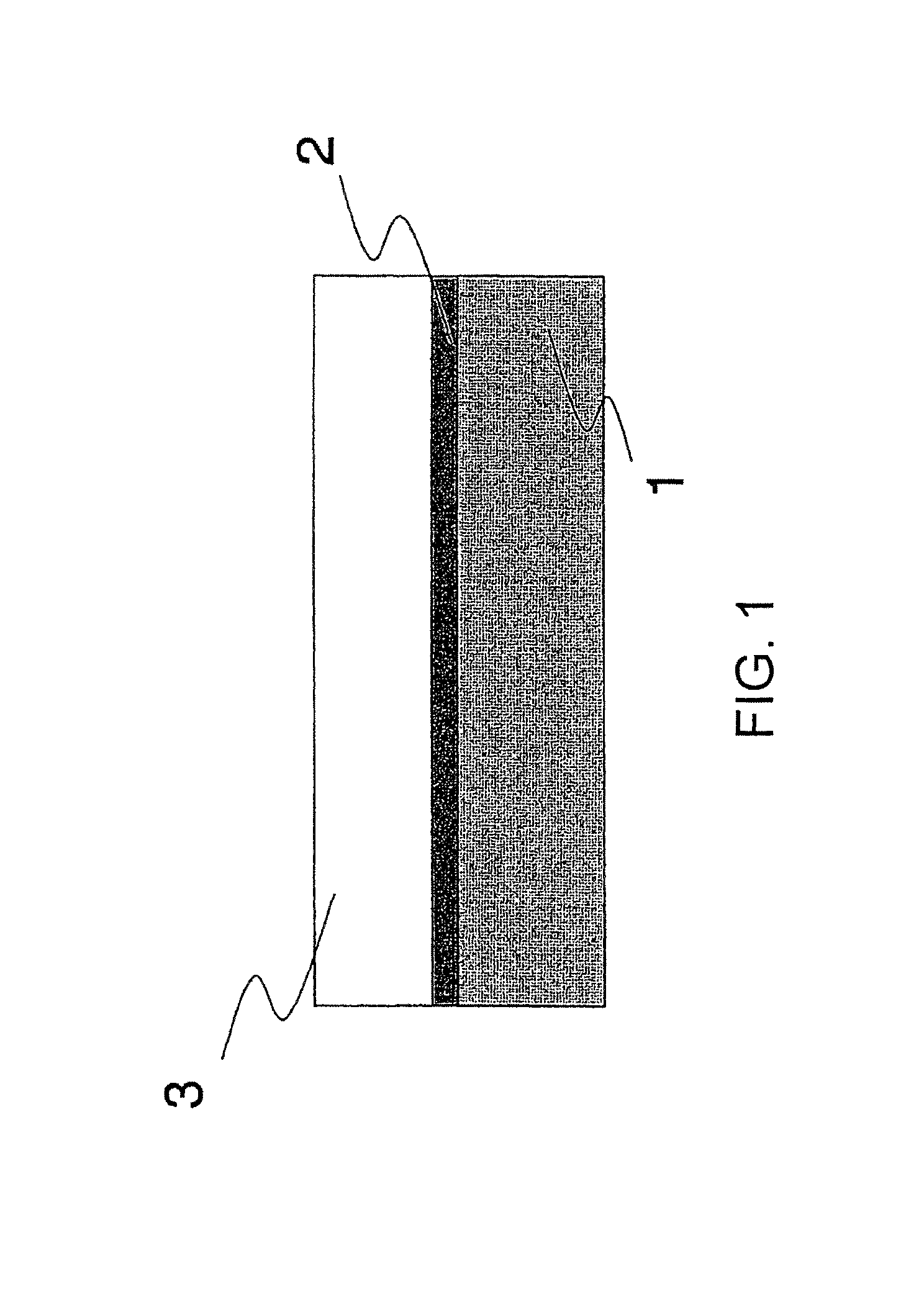

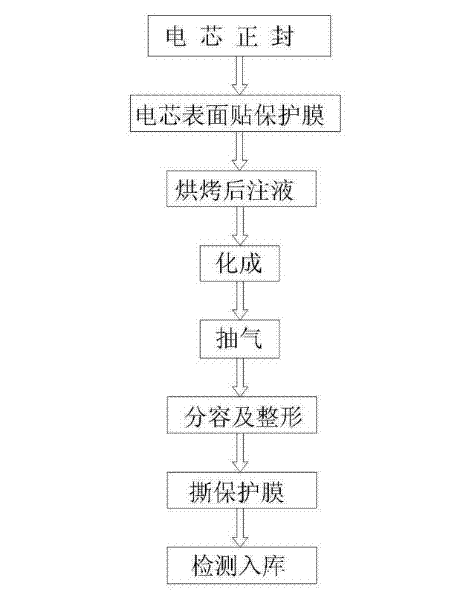

Method for preventing surface of flexible package lithium-ion battery from being corroded

InactiveCN102655242APrevent surface corrosionImprove product qualification rateFinal product manufactureElectrolyte accumulators manufactureElectrical batteryBattery energy

The invention discloses a method for preventing the surface of a flexible package lithium-ion battery from being corroded, and the method can be used for effectively protecting the surface of the flexible package lithium-ion battery, and is good in economic significance. The method comprises the following steps of: when the flexible package lithium-ion battery is assembled, and after a battery core is positively packaged, additionally gluing a protective film on the surface of the battery core; running the lithium-ion battery packaged with the protective film according to a normal operation sequence; tearing up the additionally-glued protective film before the lithium-ion battery is finally detected and put in storage, so that the lithium-ion battery can be produced; and protecting the production process of the battery from the aspect of physical protection, so that the product percent of pass can be effectively improved, and the production cost can be reduced. The method can be widely applicable to the technical field of battery energy sources.

Owner:珠海格力新能源科技有限公司

Anti-corrosion and water-repellent substance and method

ActiveUS9617645B1Improve adhesionAvoid Surface CorrosionLiquid surface applicatorsAnti-corrosive paintsParaffin waxNitromethane

An anti-corrosion and water-repellent substance configured for application to surfaces of materials to prevent corrosion and otherwise protect those materials. The substance consists of 1-bromopropane, nitromethane, ethyloxirane, and highly refined paraffin wax. In a preferred embodiment of a method of treating materials, the anti-corrosion and water-repellent substance is sprayed on a surface. In other embodiments, the substance may be applied with a brush or roller. In yet another embodiment, the substance may be applied by immersing the items being treated for optimal coverage of their exposed surfaces. The substance adheres to various materials and protects them by repelling water, acids, salt brines, and other substances and elements, including corrosives.

Owner:MICROCOR TECH INC

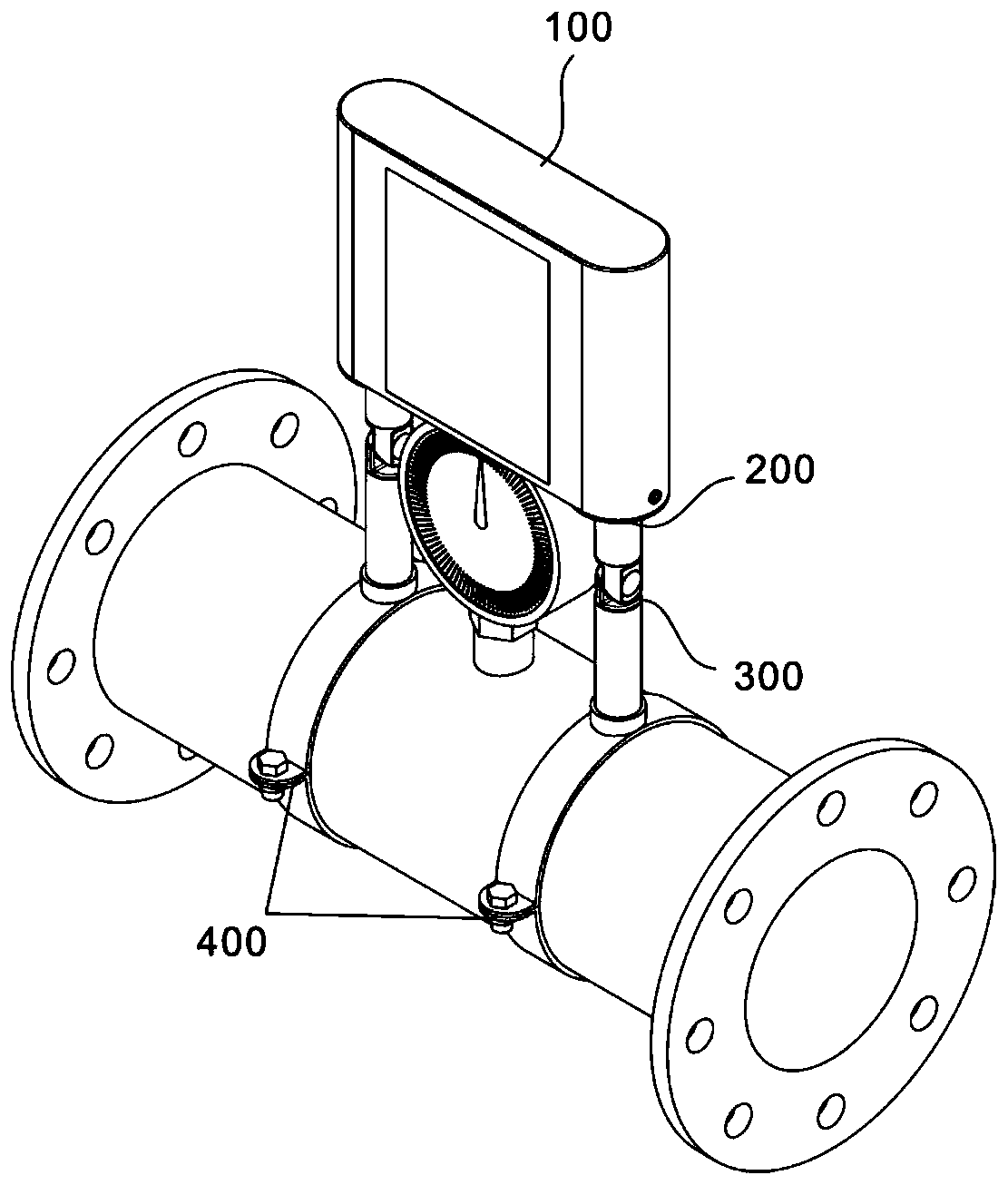

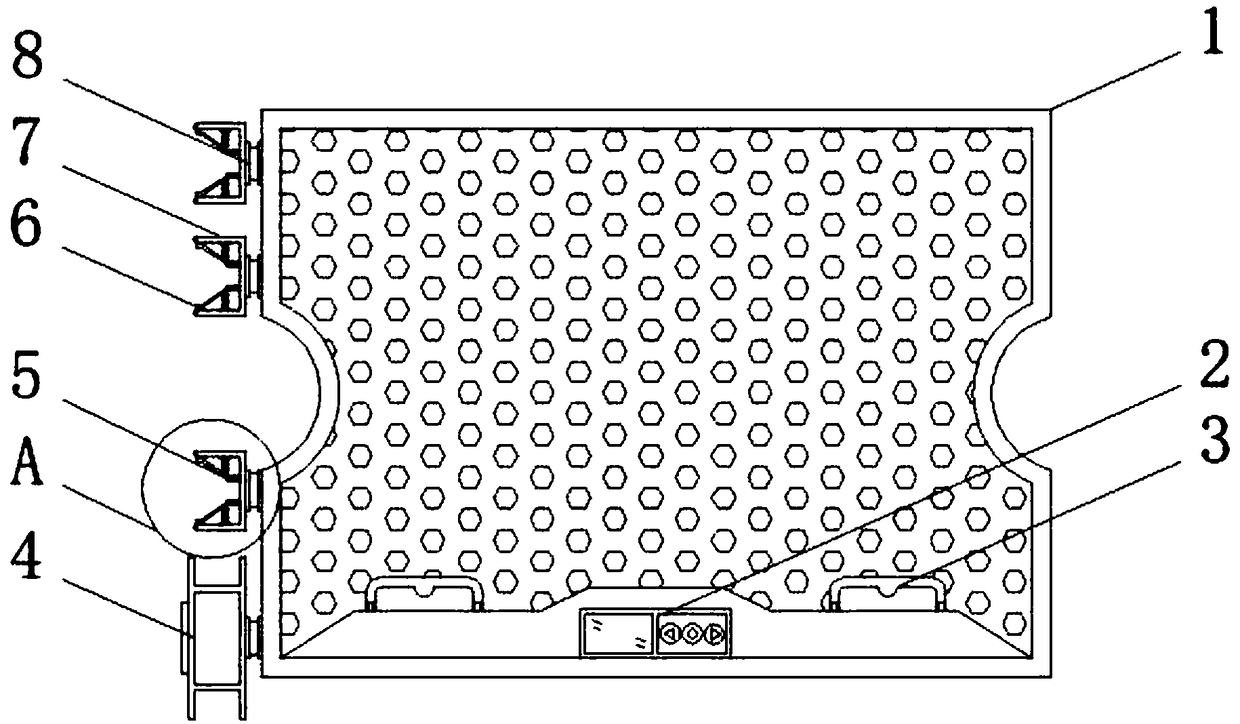

Multifunctional protection device for instrument

PendingCN111289027AAvoid Surface CorrosionExtended service lifeMeasurement apparatus housingsStructural engineeringCylinder block

The invention discloses a multifunctional protection device for an instrument, and the device comprises a housing which comprises an accommodation space and cylinder bodies located at two sides of theaccommodation space; a lifting unit which comprises a piston located in the cylinder body, a piston rod connected with the piston, a cylinder cover for sealing the cylinder body and a first circulating valve penetrating through the piston, the piston is provided with a throttling hole, and the throttling hole penetrates through the piston; a rotating unit which divides the piston rod into two sections, is connected with the piston rod and comprises a first rotating seat and a second rotating seat, wherein the first rotating seat is hinged to the second rotating seat. According to the invention, the protection device can protect the whole instrument panel, prevents appearance corrosion, corrosion and internal water inflow of the instrument in adverse environments such as external rainfall,snowfall and sun exposure, can perform multiple protection modes, and prolongs the service life of the instrument.

Owner:江苏杰创科技有限公司

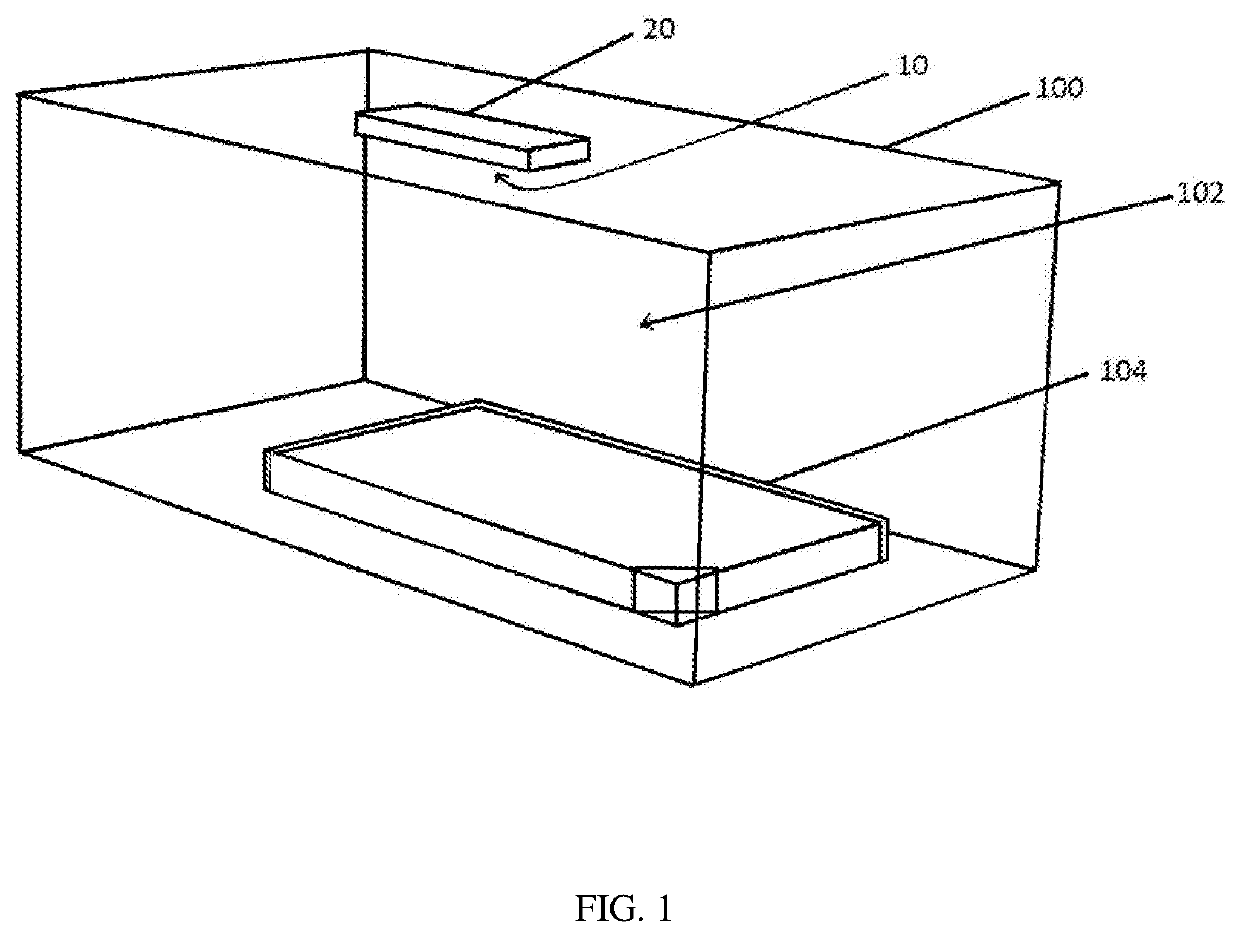

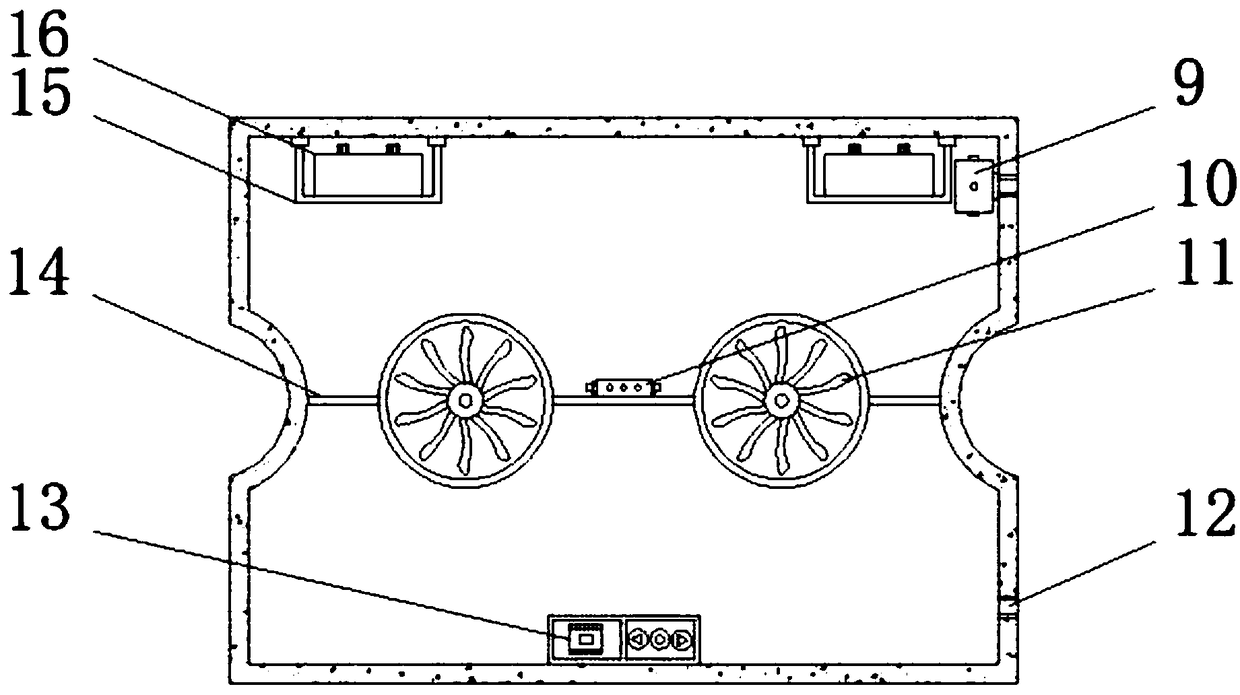

Radiator for notebook computer

The invention discloses a radiator for a notebook computer. The radiator includes a housing, a U-shaped groove, a fixing frame and a single-chip microcomputer. Fixing frames are arranged on the two sides of the top end in the shell. Storage batteries are mounted at the top ends of the fixing frames; a support is arranged in the middle of the interior of the shell. fans are mounted on two sides ofone end of the bracket; a temperature sensor is mounted in the middle of the top end of the bracket; a power adapter is installed at the top end of one side of the interior of the shell, USB interfaces are formed in the two ends of one side of the interior of the shell, supporting plates are arranged on the two sides of the bottom end of the shell, a control panel is installed in the middle of thebottom end of the shell, and a single-chip microcomputer is arranged in the control panel. The suction cups are evenly arranged at the bottom end of the base and adsorb a table top, and therefore thestability of the device is improved.

Owner:兰州巴斯得建筑节能材料科技有限公司

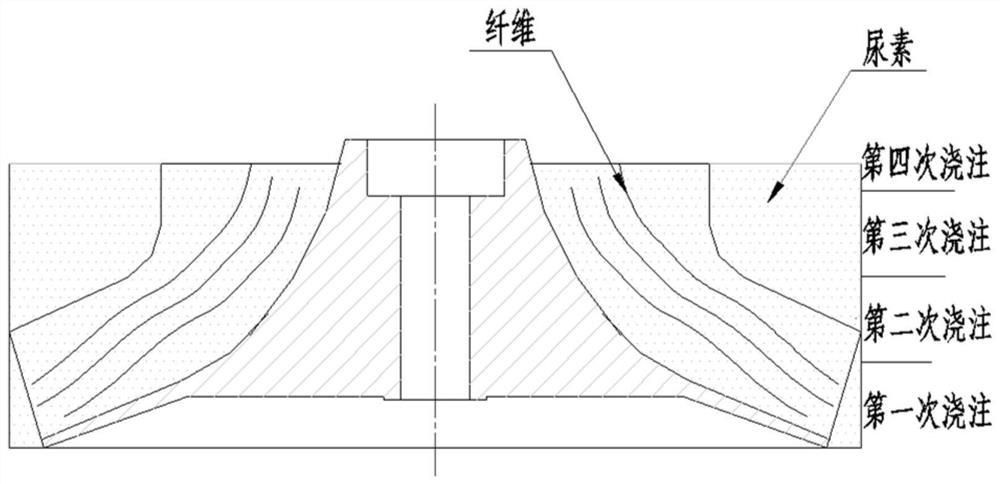

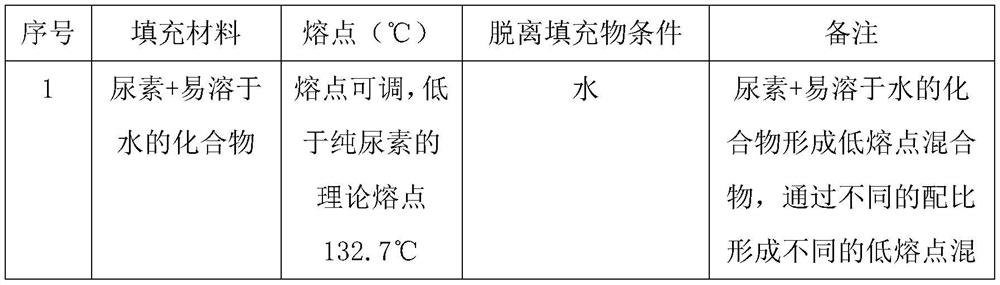

Filling material and filling method

ActiveCN111571291BReduce distortionReduce cutting vibration phenomenonMaintainance and safety accessoriesMachining deformationFilling materials

The invention discloses a filling material and a filling method, which are used to solve the processing deformation and cutting vibration control problems of aluminum alloy thin-walled tubular parts and integral impeller thin-walled blades in the turning process, and then achieve the final part size and surface accuracy Require. The present invention utilizes urea-based binary eutectic filling material to connect the thin-walled sheet and the thin-walled sheet in a thin-walled part into a whole, and also forms the thin-walled and filling material into a similar entity, reducing the thickness of the processing process The cutting vibration phenomenon of the wall is reduced, and the deformation of the part caused by the uneven cutting of the thin wall is reduced, thereby improving the processing accuracy of the thin-walled part.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

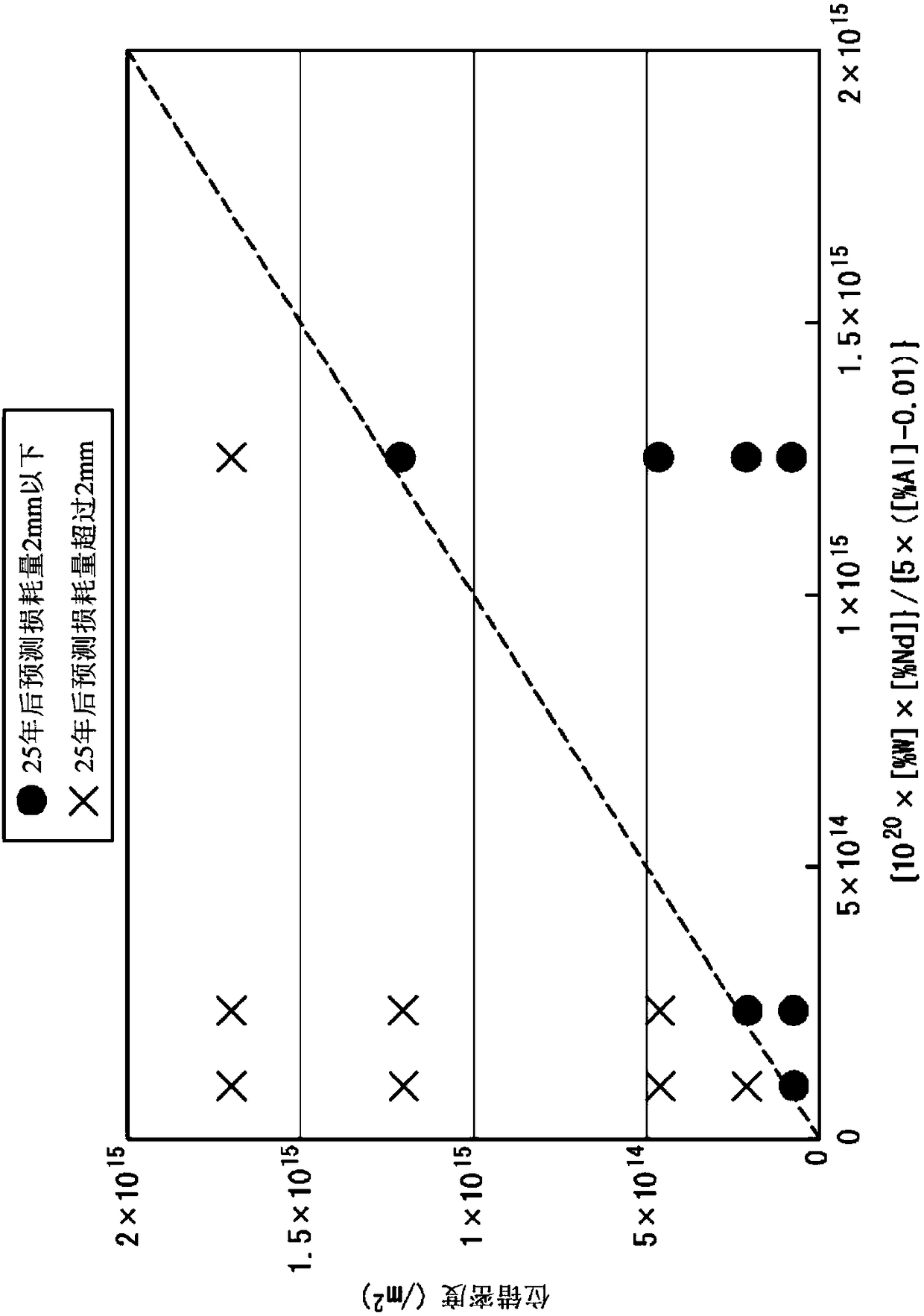

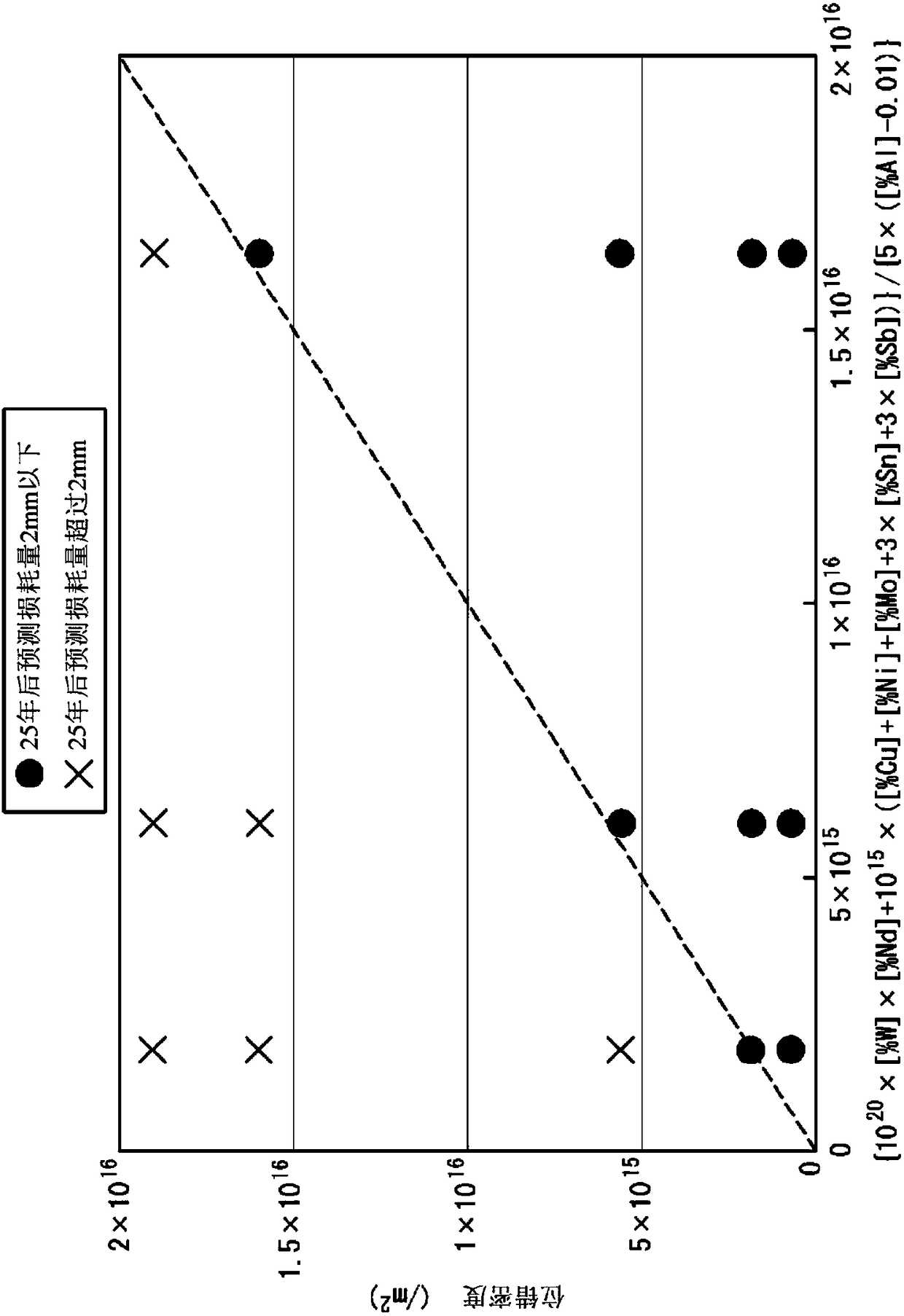

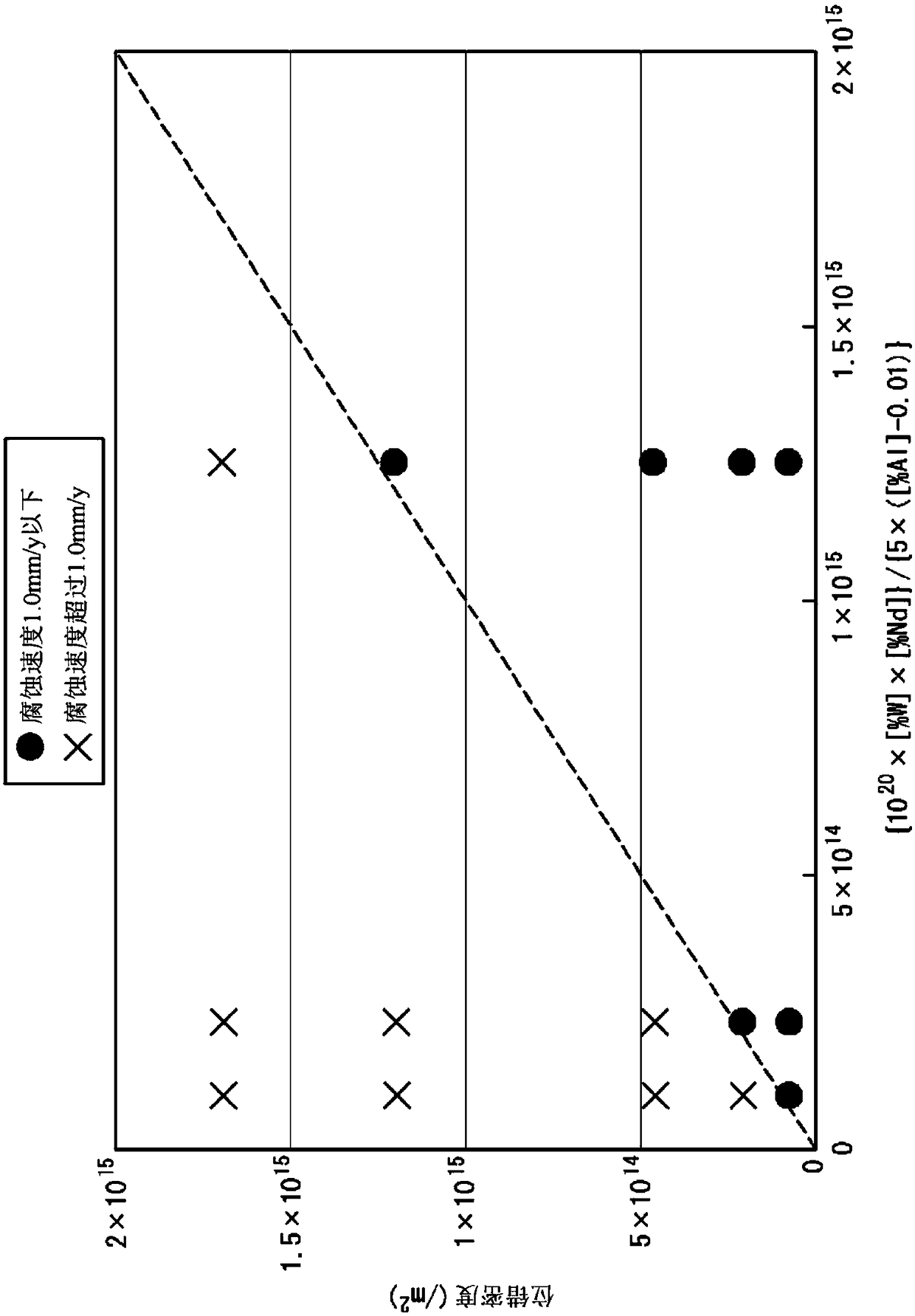

Steel material for crude oil tank with excellent corrosion resistance, and crude oil tank

ActiveCN108368578AInhibit surface corrosionInhibition of localized corrosionLarge containersComponents of crude oilMaterials science

This steel material has a component composition comprising, in mass%, C: 0.03-0.18%, Si: 0.03-1.50%, Mn: 0.1-2.0%, P: 0.025% or less, S: 0.010% or less, Al: 0.015-0.049%, N: 0.008% or less, W: 0.005-0.5%, and Nd: 0.0001-0.010%, with the remainder being Fe and unavoidable impurities, wherein the dislocation density alpha of the steel material is set to within a range that satisfies formula (1), thereby obtaining a steel material for a crude oil tank that has excellent general corrosion resistance in the upper plate of a crude oil tank such as a tanker oil tank unit and that also has excellent local corrosion resistance in the bottom plate of the crude oil tank. Formula (1): alpha( / m2)<={1020*[%W]*[%Nd]} / {5*([%Al]-0.01)}, where [%M] is the content (mass%) of an element M in the steel material.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com